Patents

Literature

1272results about How to "Improve refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Search system with query refinement and search method

ActiveUS20070282811A1Easy to refineImprove refinementWeb data indexingSpecial data processing applicationsElectronic documentDocumentation

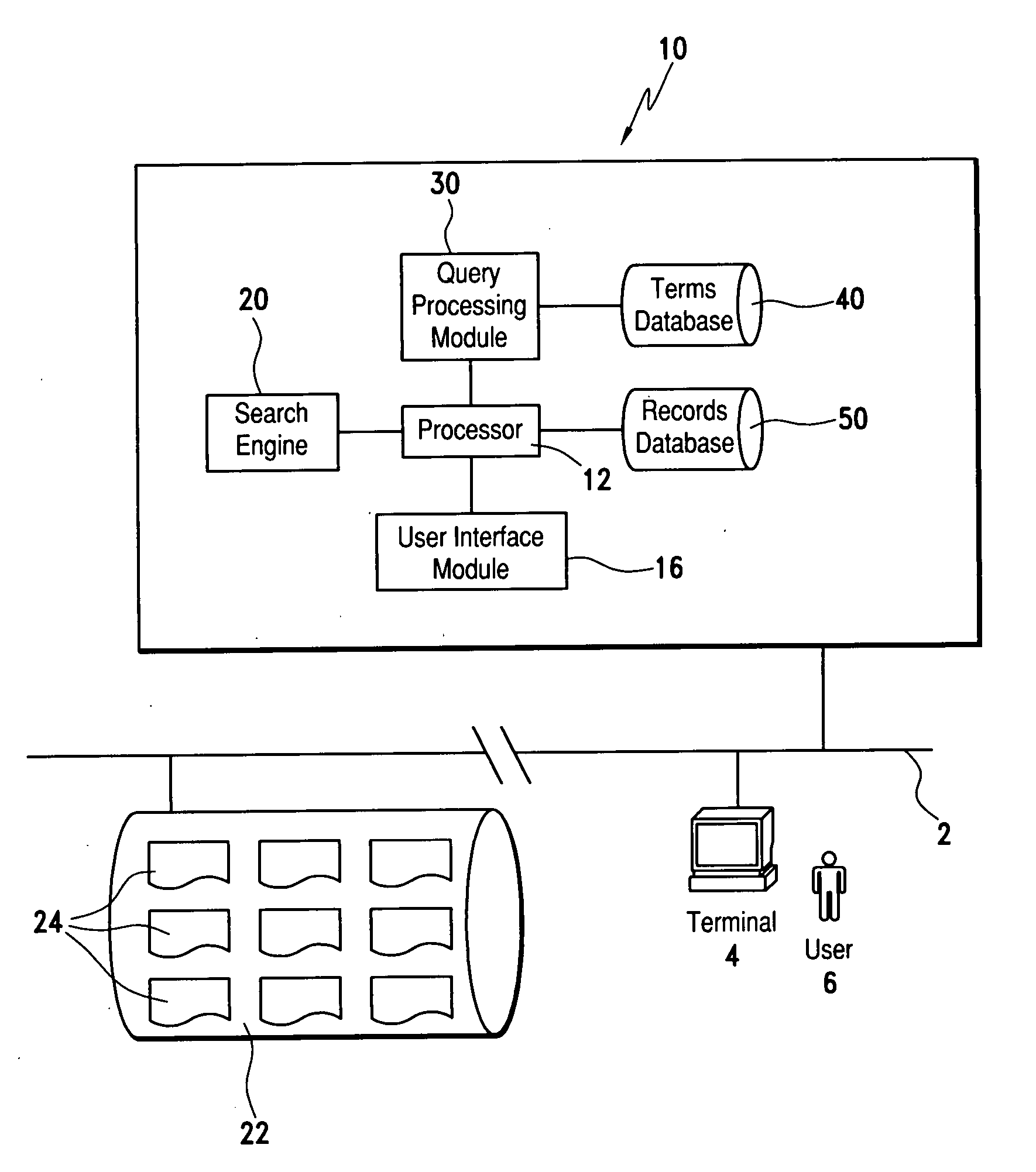

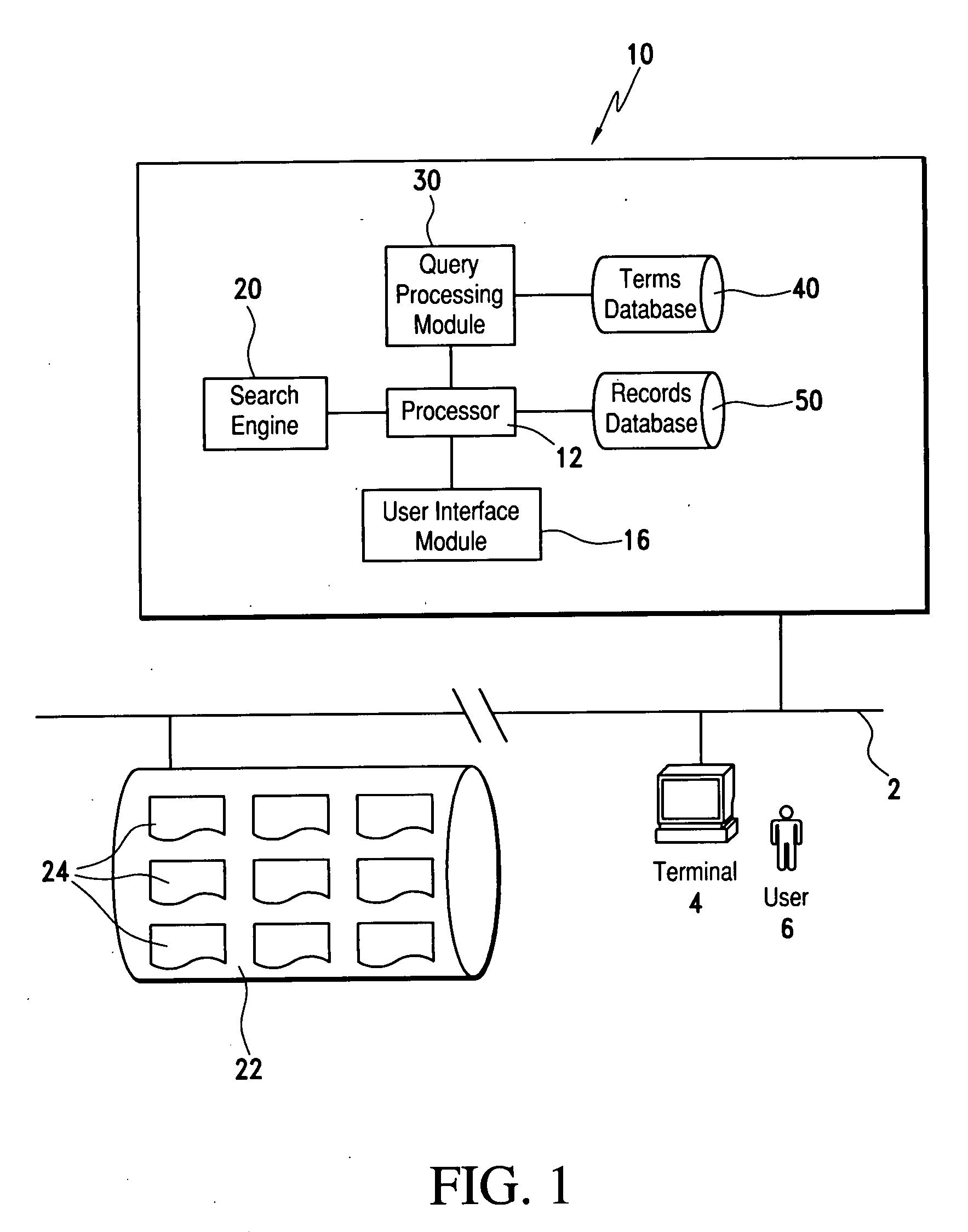

A search system and method for searching for electronic documents, and providing a search result in response to a search query. In one embodiment, the search system includes a processor, a user interface module adapted to receive a search query from a user that includes a search query term, a search engine that electronically searches for electronic documents that satisfy the search query term, and a query processing module that identifies at least one alternative term for the search query term, and provides the alternative term to the user interface module for display to the user, and also provides the alternative term to the search engine to search for electronic documents that satisfy the alternative term.

Owner:TEXTDIGGER

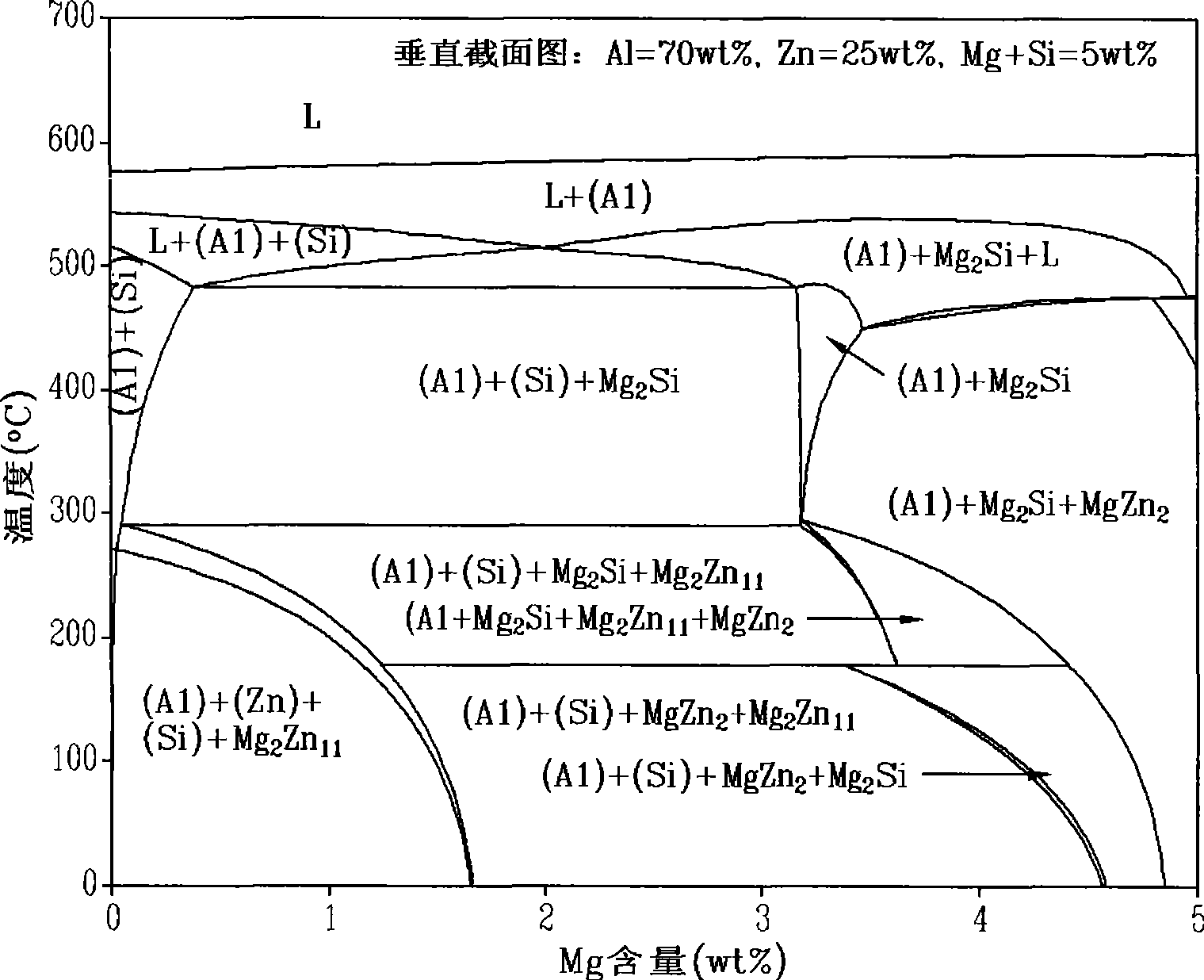

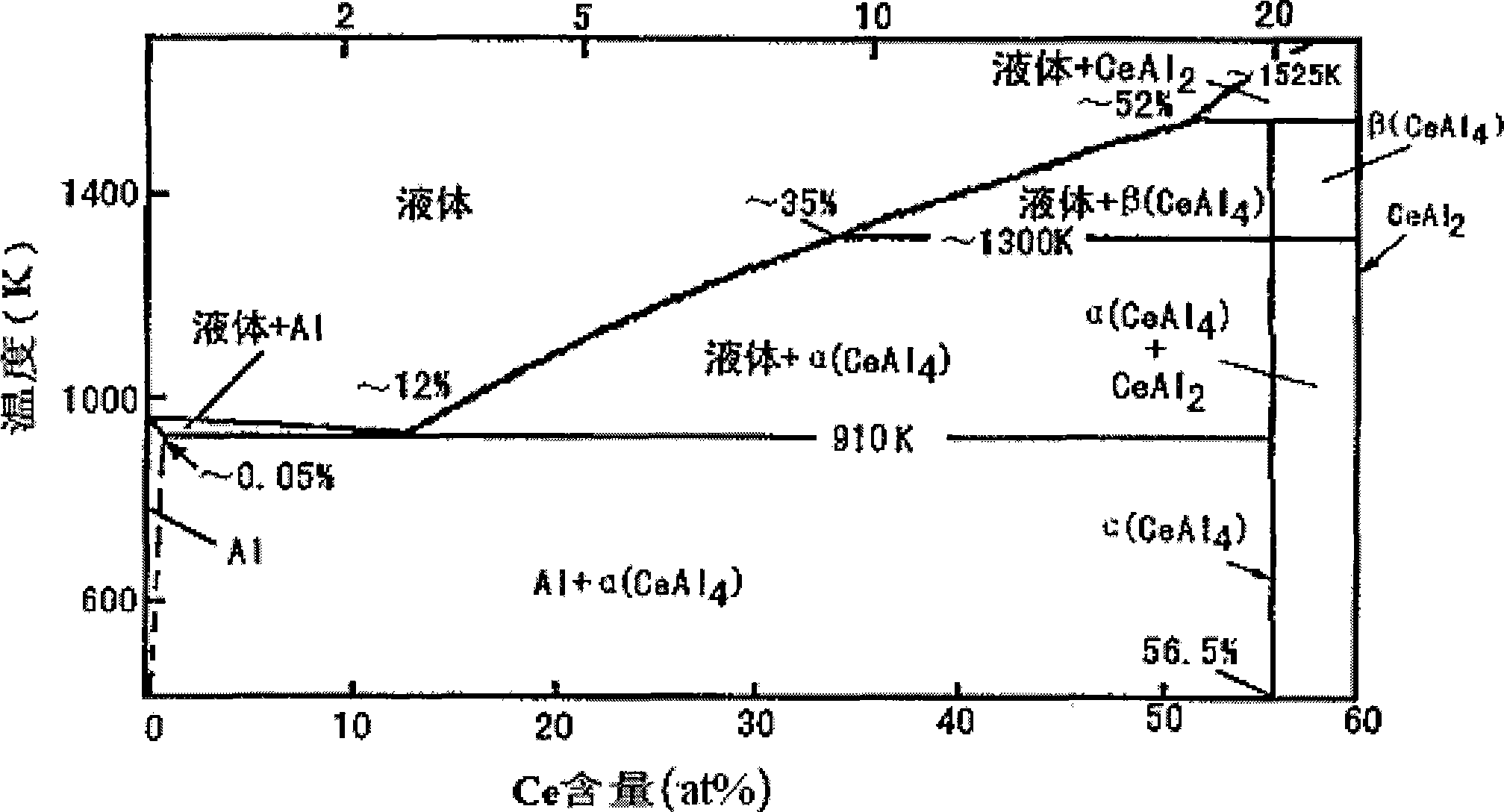

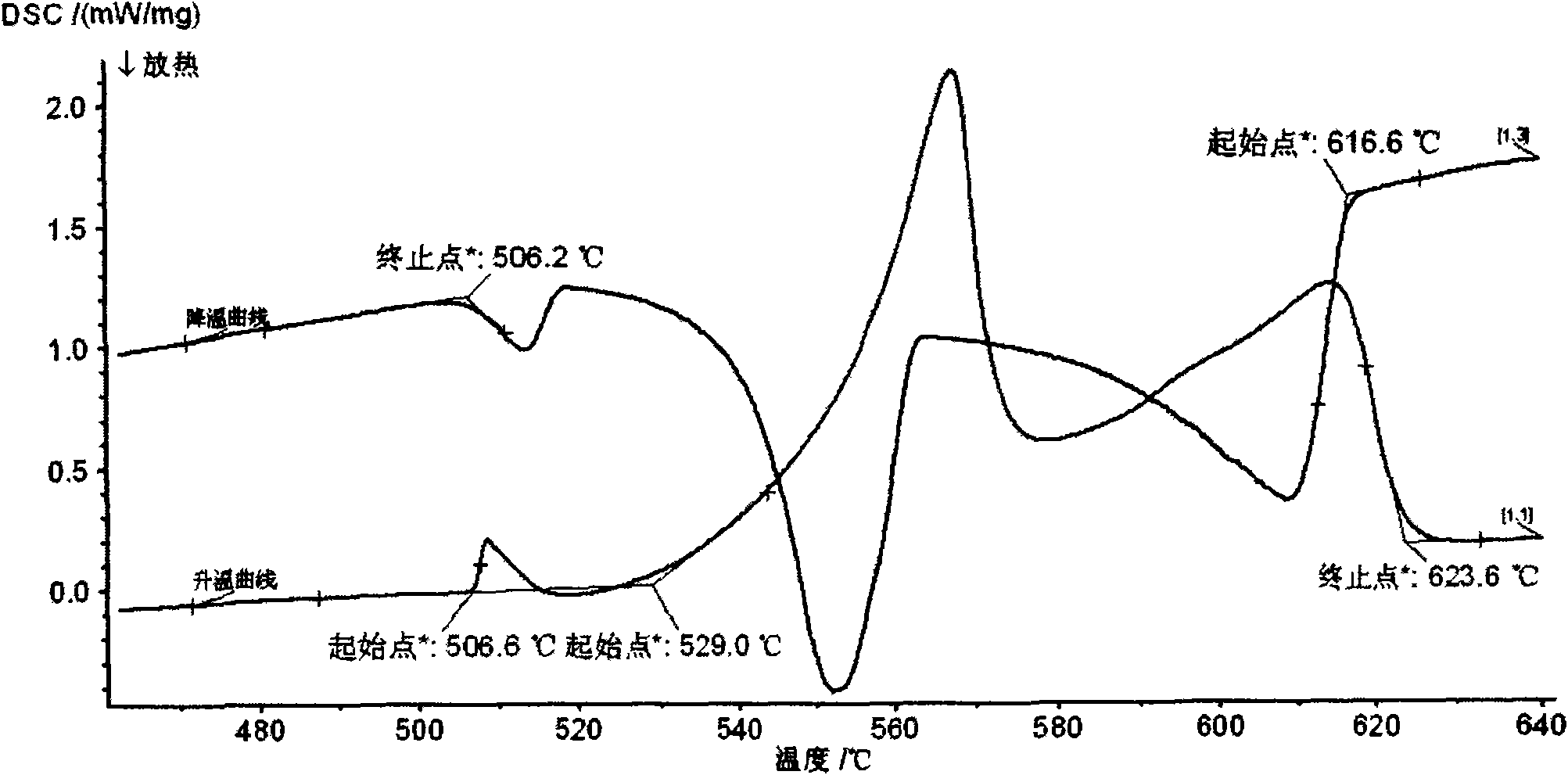

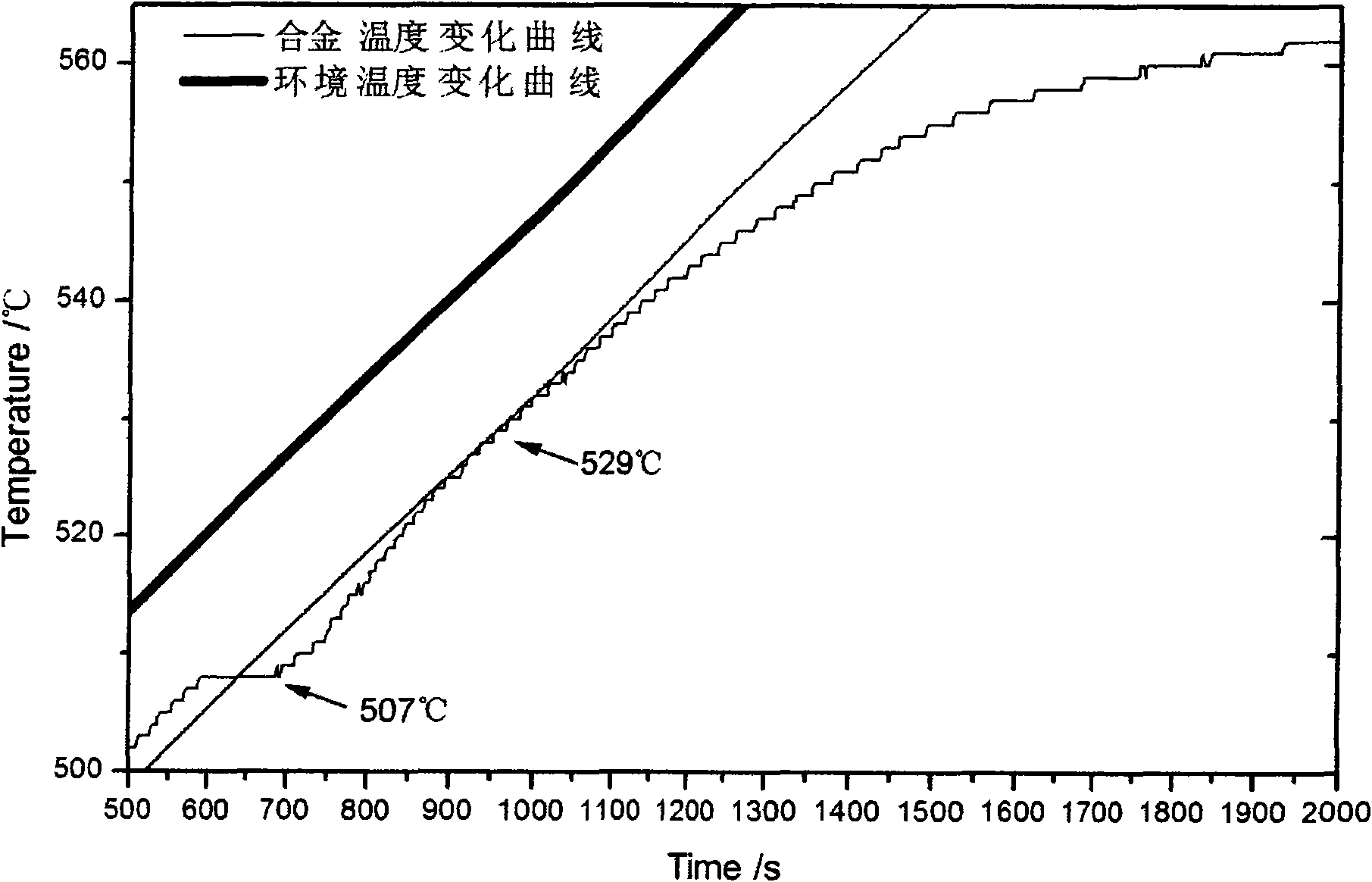

Al-Zn-Mg-Si alloy for hot dipping steel

InactiveCN101457320AAvoid gatheringDeterioration of surface propertiesHot-dipping/immersion processesRare earthZinc alloys

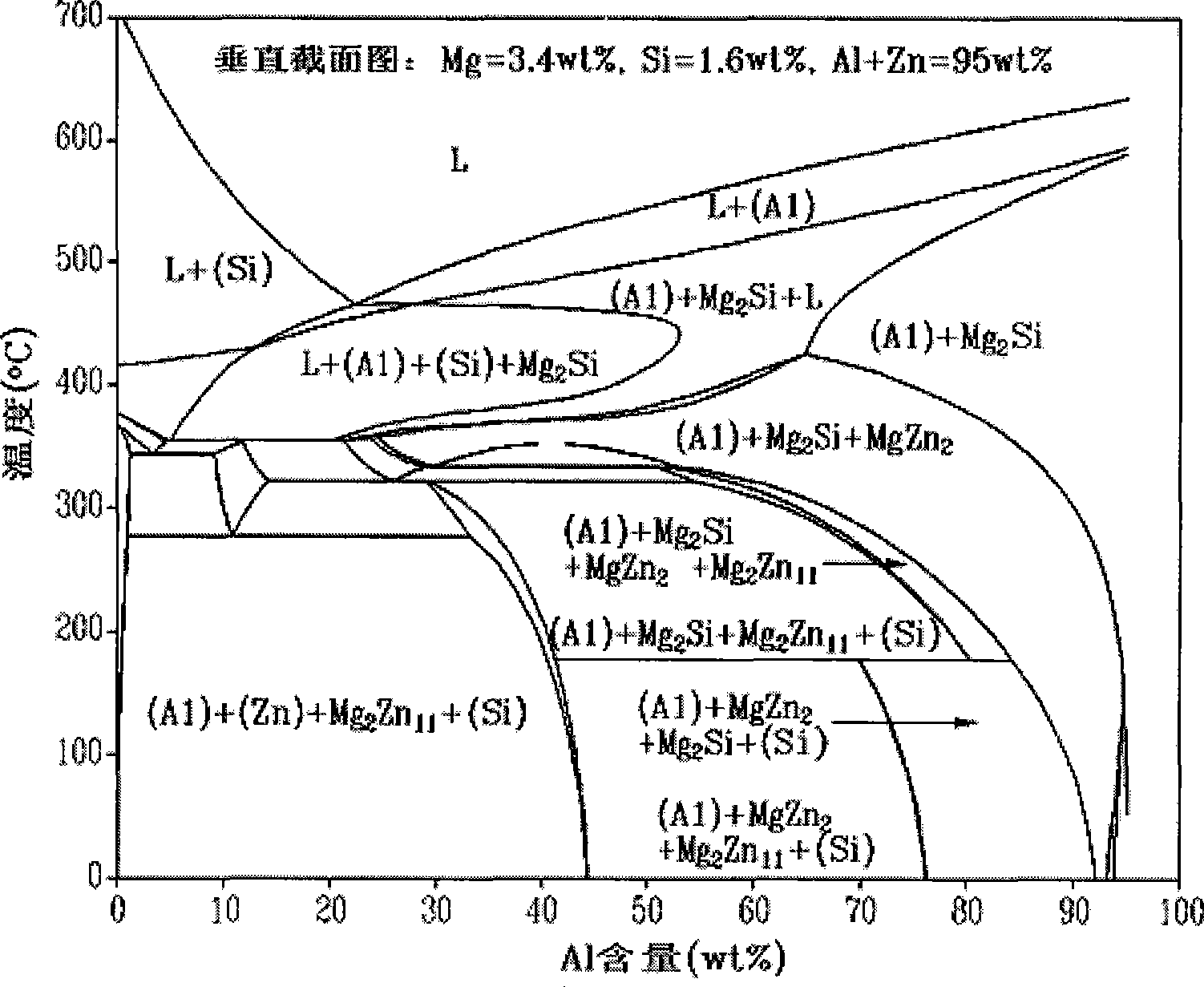

The invention provides a rare earth-containing Al-Zn-Mg-Si alloy with high aluminum content for hot-dipping steel products, comprising the following compositions by weight percent as follows; Al: 50-75%, Mg: 1-5%, Si: 0.5-2.5%, the addition of 0.002-0.1% of Ti, 0.001-0.045% of B and 0.05-1% of rare earth (La or Ce), and the balance of Zn and unavoidable impurities. The invention utilizes corrosion resistance of Mg2Si and grain-refining effect of the rare earth, the Ti and the Bi elements to improve quality of plating solution and obtain a high aluminum content aluminum-zinc alloy cladding with ,a bright and smooth surface and great corrosion resistance property. In addition, the content of aluminum in the alloy is up to 50-75%, thereby lowering production cost.

Owner:SHANGHAI UNIV

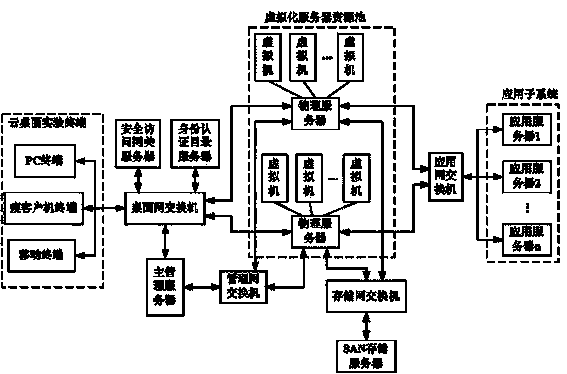

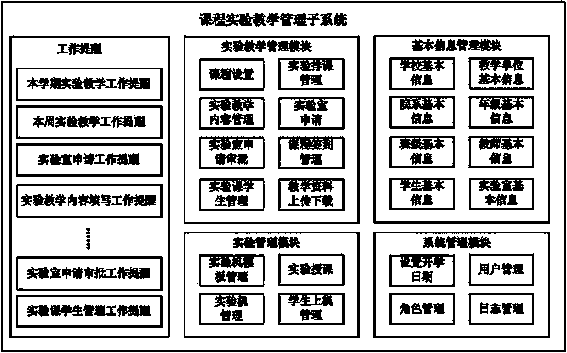

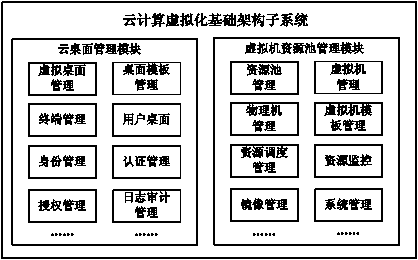

Experiment teaching system based on cloud desktop

ActiveCN103888530AReduce hardware construction and maintenance costsReduce overall energy consumptionUser identity/authority verificationElectrical appliancesVirtualizationApplication server

The invention discloses an experiment teaching system based on a cloud desktop. The experiment teaching system based on the cloud desktop comprises a virtualized server resource pool, wherein a plurality of physical servers are arranged inside the virtualized server resource pool; each physical server is provided with a plurality of virtual machines; a cloud desktop experimental terminal is connected with the physical servers in the virtualized server resource pool through a desktop net interchanger; a main management server is connected with the physical servers through a management net interchanger and is further connected with the desktop net interchanger; a storage server is connected with the physical servers through a storage net interchanger; the physical servers is connected with at least one application server through an application net interchanger. The cloud desktop remote access and the virtual machine technology are utilized, hardware cost and maintenance cost are effectively lowered, and the resource utilization rate is improved. The cloud desktop experimental terminal is low in configuration demand and high in universality and flexibility. The standardization and refinement of the experiment teaching process are improved, safety is high, and the supervision and administration capacity of experiment teaching is enhanced.

Owner:HAIYU SCI & TECH DEV GUIZHOU PROV +1

Fine grained aluminium alloy and its preparing method

InactiveCN1936050AGive full play to the refinement effectLow costPhotography auxillary processesOxideTitanium oxide

The invention relates to a refined crystal grain aluminum alloy and the manufacturing method. It is made up from Si 0.2-7.5wt%, Mn 0.05-1.5wt%, Mg 0,05-6.0wt%, Zn 0.03-8.5wt%, Cu 0.05-7.0wt%, Ni 0.1-2.5wt%, Ti 0.01-0.15wt%, RE 0.01-0.3wt%, B 0.0001-0.10wt%, and the rest is Al. The technology feature is that it adds silicon titanium alumina, borax and or rare earth oxide or rare earth carbonate, or titanium oxide, borax and / or rare earth oxide or rare earth carbonate into aluminum cell. Add the manganese oxide, compound of copper or Ni would be also added. Comparing to traditional technology, the refiner is not added, and the refining effect is enhanced and the perdurability is prolonged. It could be used to produce wire, band, tube, panel, aluminum foil, etc.

Owner:DONGHUA UNIV

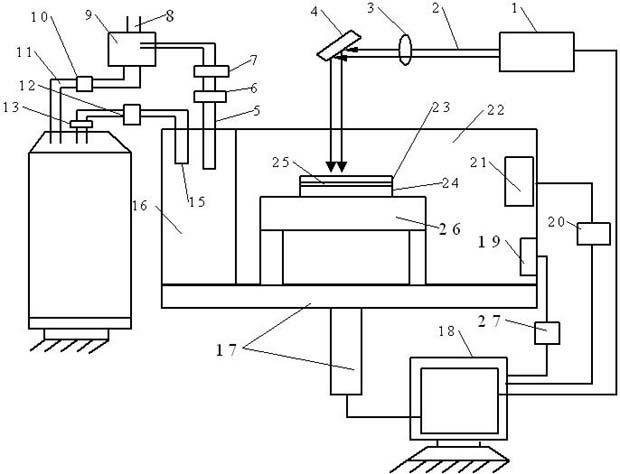

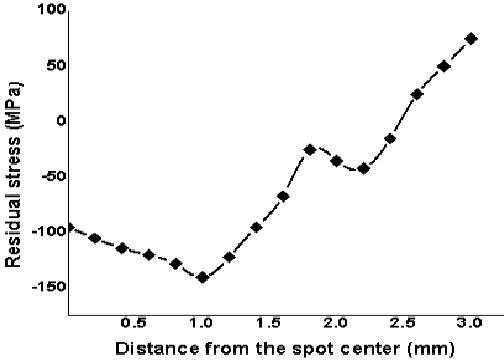

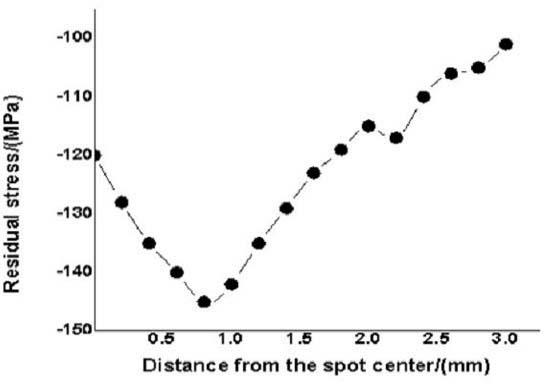

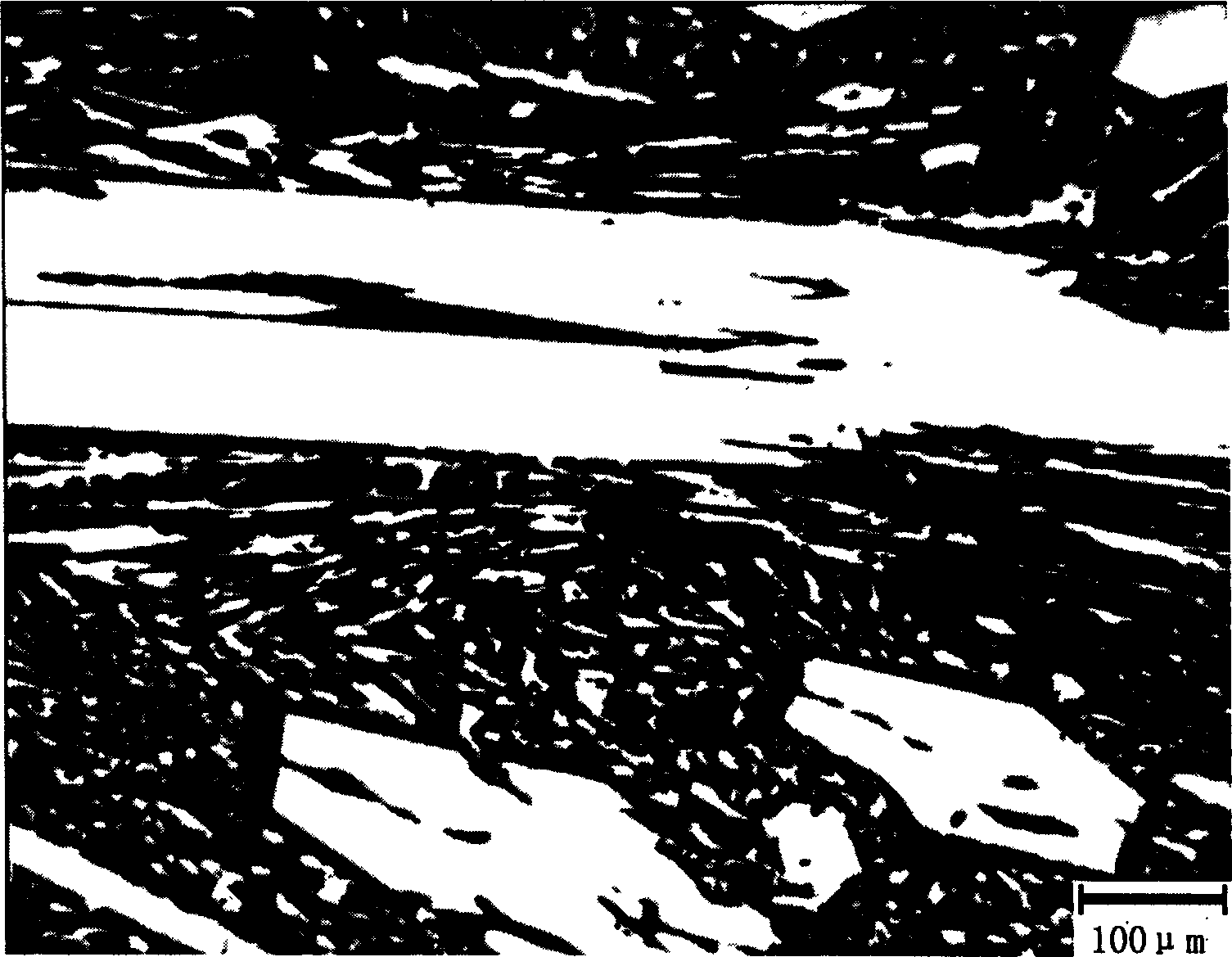

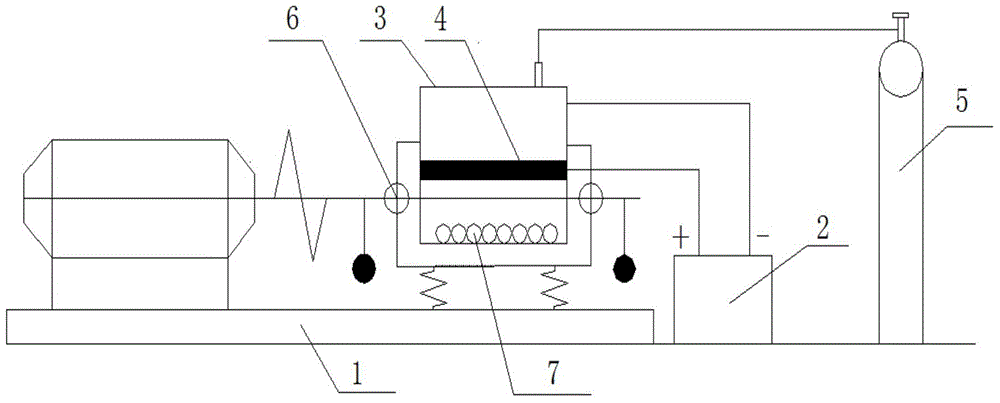

Method and device for processing metal materials with cryogenic laser shock

A method and a device for processing metal materials with cryogenic laser shock belong to the fields of laser processing and subzero treatment. The device comprises a cryogenic treatment cavity, a laser, a liquid nitrogen tank, a temperature sensor and the like. The method is used for strengthening the materials in an ultra-low temperature environment by adopting the laser shock processing technology, insulating the materials for a period after the strengthening process, and heating the materials to be as hot as the ambient temperature. In the ultra-low temperature environment, the metal materials shrink, and a large quantity of dislocation is generated in the materials; due to the instant impact effect of the laser shock processing technology, the high-density dislocation in the materials moves at a high speed, so as to induce high-density nano twin crystal, which ensures that the materials have superior tenacity as well as high intensity, and brittle failure of the metal materials in the low-temperature environment can be avoided effectively; and a large quantity of nano educt is dissolved out from the materials, and the conversion of residual austenite as well as the thinning of martensite and crystal can be promoted effectively, which remarkably improves the mechanical properties and the mechanical properties of the materials.

Owner:JIANGSU UNIV

Low cost, high-wearability hypereutectic high chromium cast iron and its production method

This invention provides a hypereutectic high chromium cast iron cast iron and its making method, the main components of the cast iron as follows: Cú‘3.5í½4.5úÑú¼Mnú‘1.0í½3.0úÑú¼Crú‘17í½30úÑú¼Siú‘0.5í½1.5 úÑú¼Cuú‘1.0í½2.0úÑú¼Pú‘íœ0.06úÑú¼Sú‘íœ0.06úÑú¼Niú‘íœ1úÑú¼the rest is iron. The making method is to use twice gestation transformation dealing method to thin the early produced calcium carbide, wherein the grain such as TiN and NbNin in the alloy of the inoculant can increase the uncleus quantum of the early produced calcium carbide. The rare earth, magnesium and kallium congregate on the surface of the early produced calcium carbide to make them thin and spheric. The inoculant can speed the solidification of the alloy to prohibit the early produced calcium carbide from growing to reach the aim of thinning the early produced calcium carbide. Wherein, the sediment pump overcurrent piece made by the hypereutectic high chromium cast iron cast iron has a better casting charater, resistance, and high using longevity.

Owner:XI AN JIAOTONG UNIV

High-hardness hypereutectic high chromium, manganese, molybdenum and tungsten alloy wear resistant steel material and use thereof

The invention discloses a high-hardness hypereutectic high Cr-Mn-Mo-tungsten alloy abrasion-resistant steel and iron material which adopts multivariant alloying and has the advantages of good hardenability, high hardness, better abrasion-resistance and wear resistance, and the like compared with the prior high-chromium cast iron especially the addition of C, Cr, Mn, Mo and tungsten, thereby enlarging the application range of materials. The invention is suitable for preparing wearing and corrosive wearing parts, in particular to parts used for impacting corrosive wearing working conditions.

Owner:JINAN UNIVERSITY

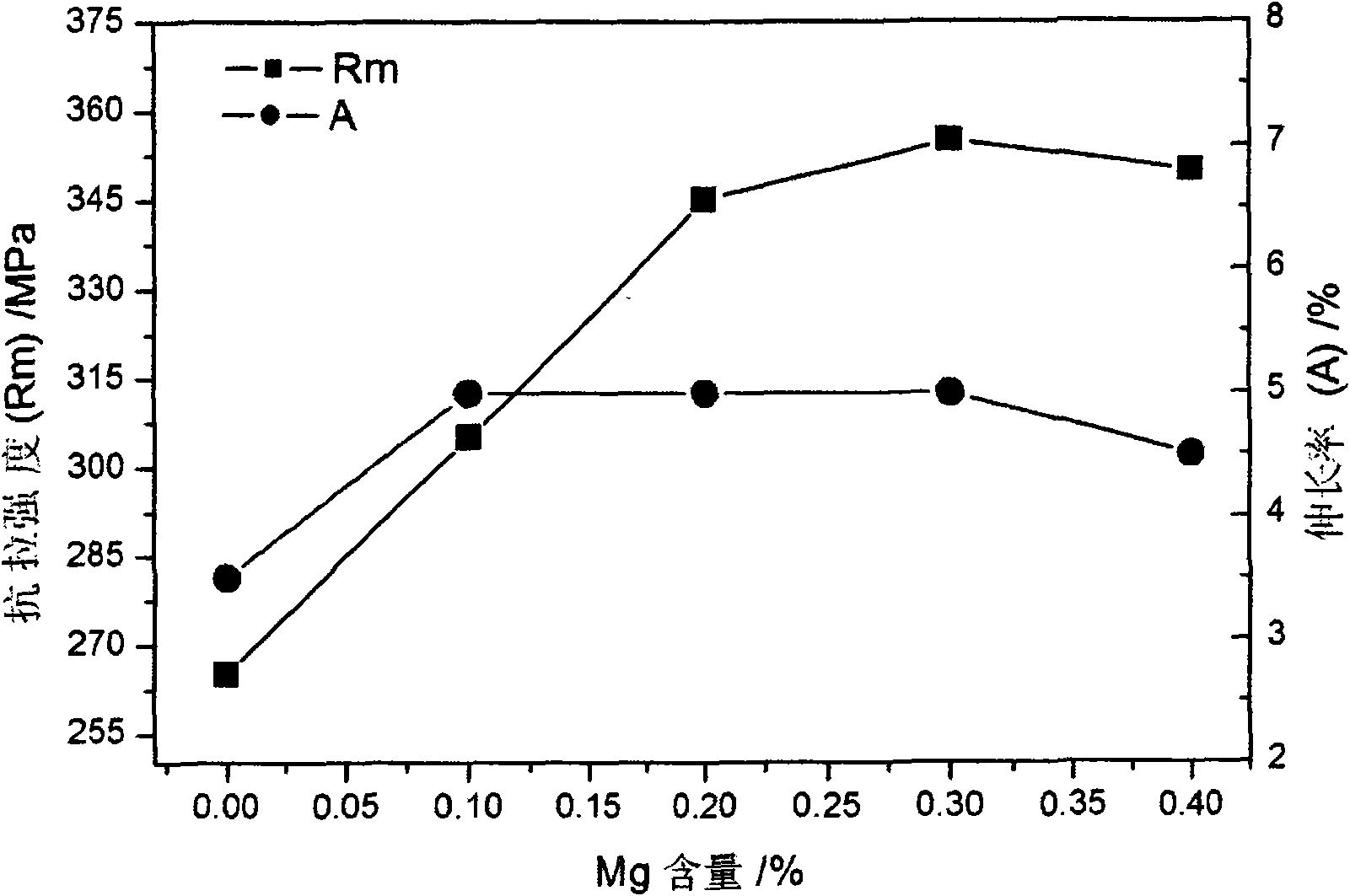

Cast aluminum-silicon alloy for engine cylinder head and heat treatment process

InactiveCN102071341AImprove room temperature performanceHigh tensile strengthChemical compositionSilicon alloy

The invention relates to a cast aluminum-silicon alloy for an engine cylinder head and a heat treatment process. The alloy comprises the following chemical ingredients in percentage by weight: 5.0 to 7.0 percent of Si, 3.0 to 4.0 percent of Cu, 0.2 to 0.4 percent of Mg, 0.1 to 0.3 percent of Mn, 0.10 to 0.20 percent of Zr, 0.15 to 0.25 percent of Ti, 0.01 to 0.05 percent of B, 0.02 to 0.09 percent of Sr, 0.1 to 0.3 percent of rare earth (RE), less then 0.3 percent of Fe and the balance Al, wherein the rare earth (RE) adopts mixed rare earth. The heat treatment process comprises the following steps: carrying out primary solution at a temperature between 490 DEG C and 505 DEG C, and carrying out heat insulation for 4 to 6h; carrying out secondary solution at a temperature between 510 DEG C and 525 DEG C, carrying out heat insulation for 6 to 10h, and carrying out quenching by hot water of 60 to 80 DEG C; and carrying out aging treatment with parameters of the aging temperature being 155to 165 DEG C and the heat insulation time being 5 to 9h, and carrying out cooling in the air. All alloy elements of the cast aluminum-silicon alloy provided by the invention are reasonably matched, good mechanical performance is realized, at a normal temperature, the tensile strength reaches 325 to 355MPa, the tensile stretch is 2.5 to 5.5 percent, at a high temperature of 250 DEG C, the tensile strength reaches 240 to 270MPa, and the tensile stretch is 3.0 to 5.5 percent, after the heating processing technology, the heat resistance performance of the alloy is improved, and the casting defect is reduced.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

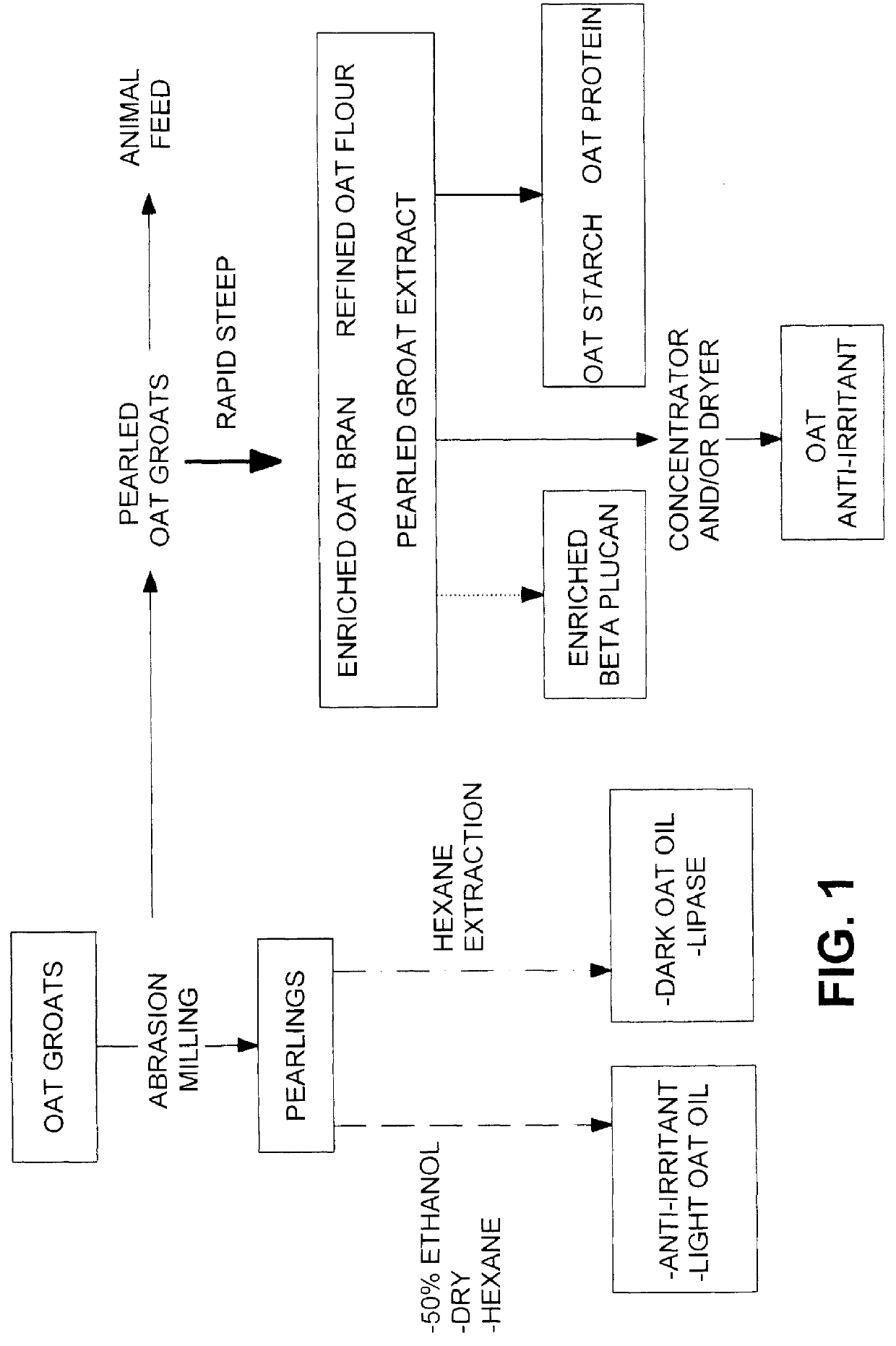

Methods for processing oat groats and products thereof

InactiveUS6113908AEffective alcohol concentrationHandling characteristics of the process mass are not negatively affectedCosmetic preparationsBiocideBeta-glucanAqueous medium

Methods of treating dehulled or hull-less oat, i.e. oat groats, to produce oat pearlings, oat flour and oat bran products are described. Oat groats are abrasion milled to remove up to 15% by weight and produce pearled oat groats and pearlings. The pearlings are extracted sequentially with aqueous ethanol and hexane to produce an anti-irritant and a light oat oil, or with hexane to produce a dark oat oil and lipase. The pearled oat groats are steeped in an aqueous medium for up to 4 hours and then macerated to produce an enriched oat bran, from which an enriched beta glucan may be extracted; a refined oat flour, from which oat starch and oat protein may be extracted; and a pearled oat groat extract from which further products, such as an oat anti-irritant can be recovered.

Owner:AGRI & AGRI FOOD

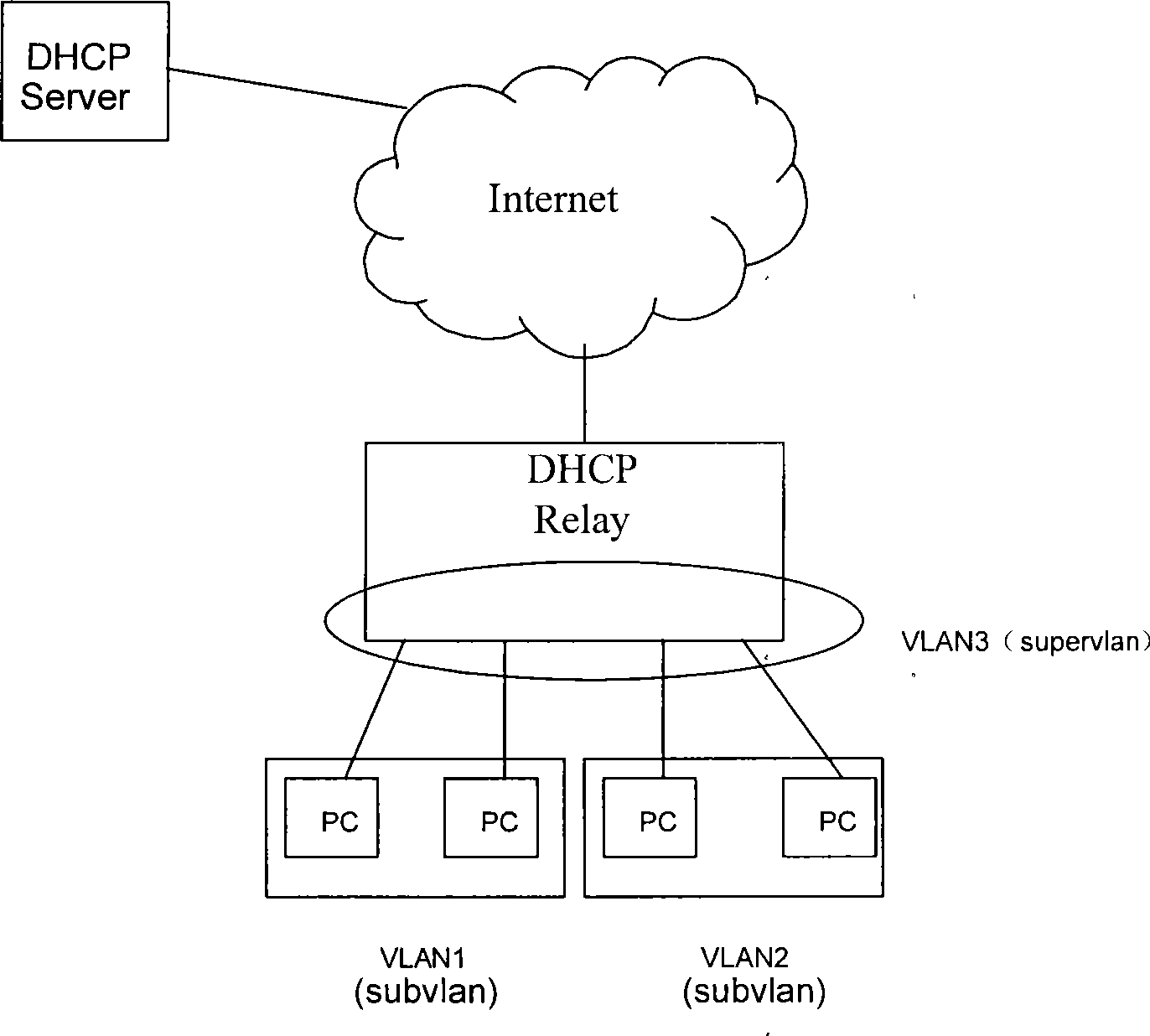

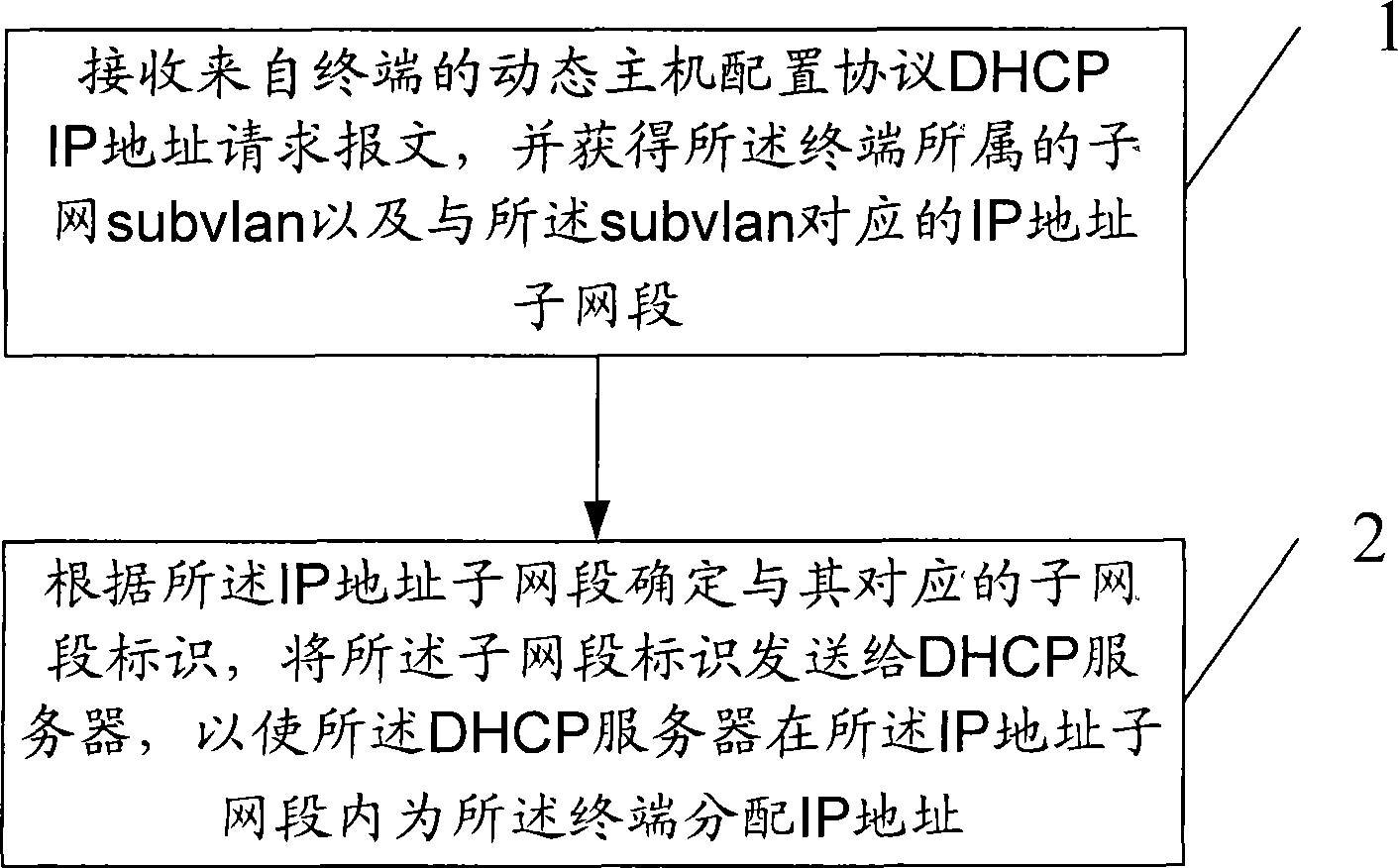

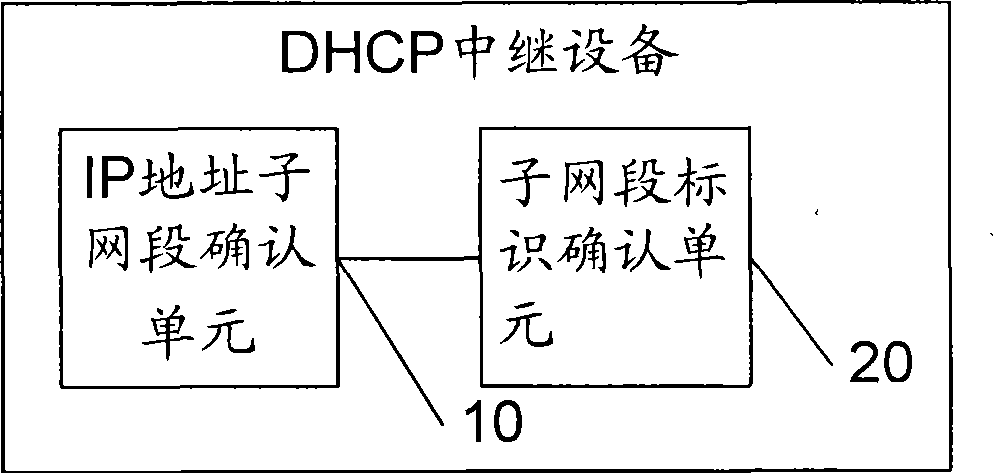

IP address assignment method and system

InactiveCN101534329AImprove refinementGood management relationshipTransmissionIP address managementNetwork segment

The embodiment of the invention provides an IP address assignment method, DHCP truck equipment, a DHCP server and an IP address assignment system; wherein, an IP address assignment method comprises: receiving an IP address request message from the dynamic host configuration protocol (DHCP) of the terminal, and obtaining the subvlan to which the terminal belongs and the IP address subnet section corresponding to the subvlan; according to the IP address subnet section, determining the subnet section mark corresponding to the same, transmitting the subnet section mark to the DHCP server so that the DHCP server can assign the IP addresses in the IP address subnet section for the terminal. The IP address of the terminal and the subvlan to which the terminal belongs have good management relation which facilitates the identification of the subvlan to which the terminal belongs by the IP address of the terminal, thus improving the elaboration of the IP address management.

Owner:HUAWEI TECH CO LTD

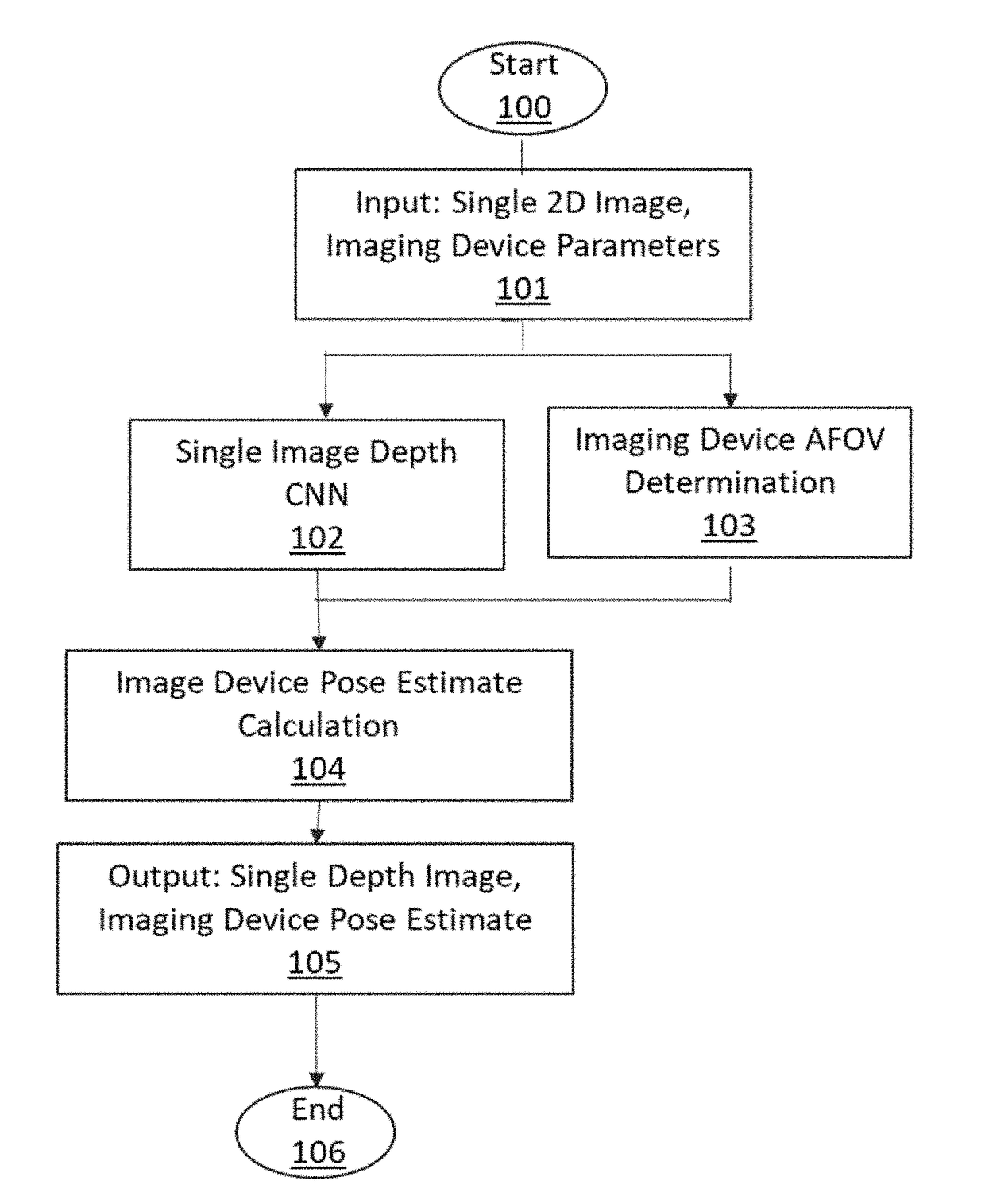

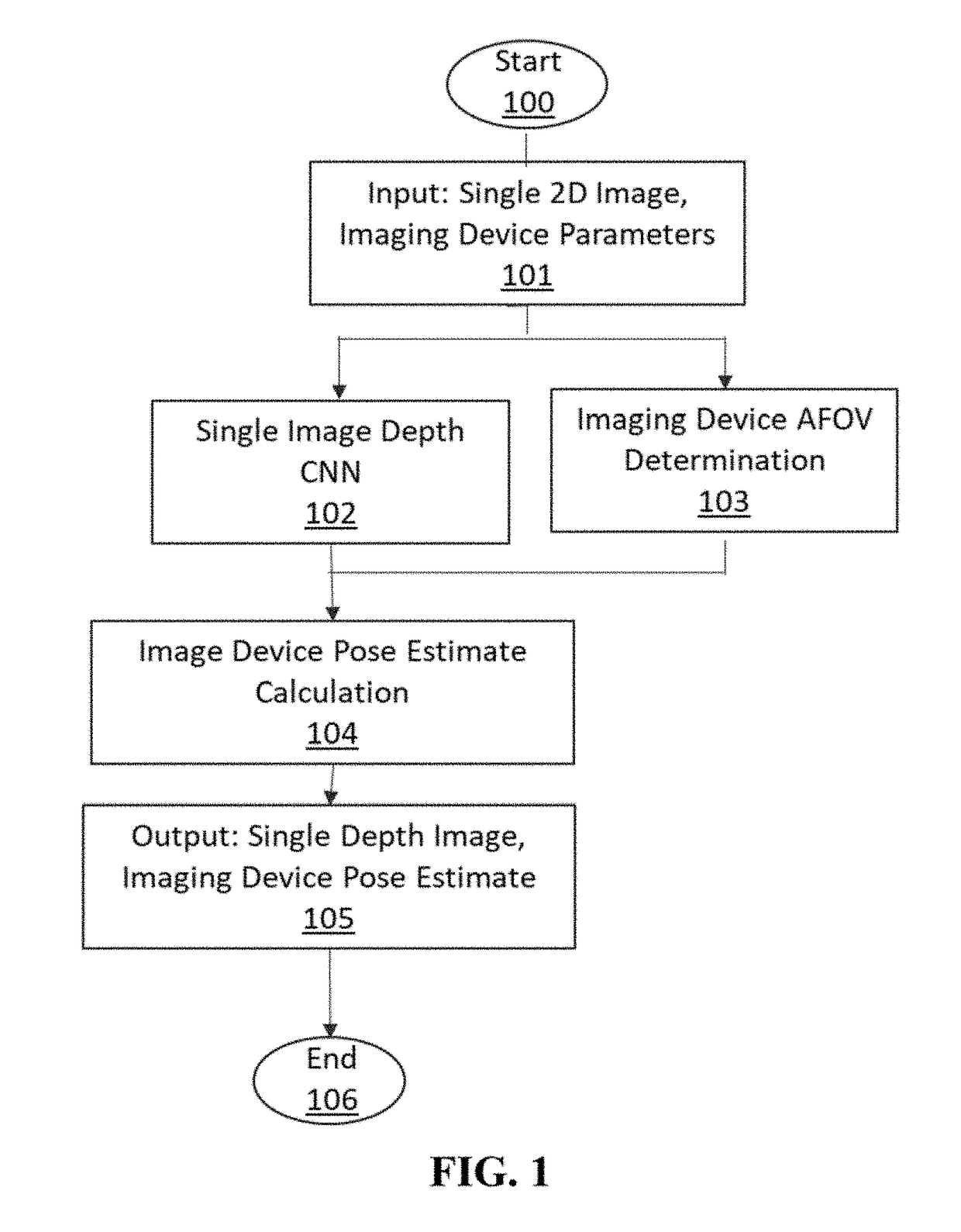

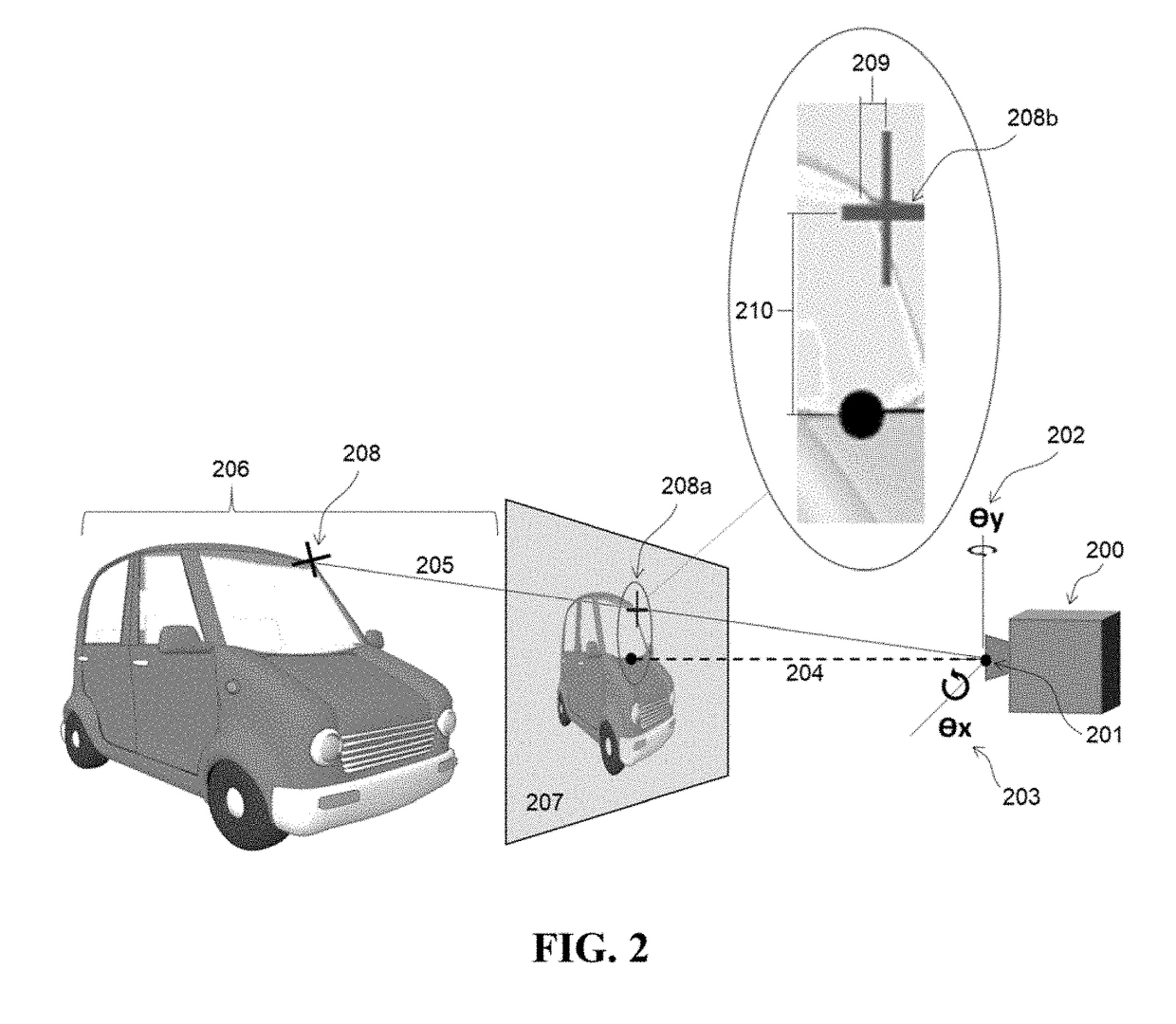

Machine learning based model localization system

ActiveUS20180189974A1Improve refinementEfficient reconstructionImage enhancementImage analysisImage sensor3d image

A method for deriving an image sensor's 3D pose estimate from a 2D scene image input includes at least one Machine Learning algorithm trained a priori to generate a 3D depth map estimate from the 2D image input, which is used in conjunction with physical attributes of the source imaging device to make an accurate estimate of the imaging device 3D location and orientation relative to the 3D content of the imaged scene. The system may optionally employ additional Machine Learning algorithms to recognize objects within the scene to further infer contextual information about the scene, such as the image sensor pose estimate relative to the floor plane or the gravity vector. The resultant refined imaging device localization data can be applied to static (picture) or dynamic (video), 2D or 3D images, and is useful in many applications, most specifically for the purposes of improving the realism and accuracy of primarily static, but also dynamic Augmented Reality (AR) applications.

Owner:MANOR FINANCIAL INC

High-strength high-toughness low temperature steel for ship and manufacture method thereof

ActiveCN102851591AAchieve sex changeImprove purityRoll mill control devicesProcess efficiency improvementCrack resistanceHeat-affected zone

The invention discloses high-strength high-toughness low temperature steel for ship and manufacture method thereof. The steel is composed of (by wt%) C 0.04-0.12, Si 0.20-0.55, Mn 0.8-1.4, P 0.005-0.015, S less than or equal to 0.005, Als 0.02-0.07, N less than or equal to 0.005, Cu 0.05-0.40, Ni 0.05-0.50, and Fe and unavoidable impurity in balance, with Ni / Cu of 1.2-1.5; and one or more than two of Nb 0.005-0.03, Ti 0.005-0.02, Ca 0.001-0.006, and Mg 0.0005-0.002. The steel has advantages of low compression ratio, high strength, good low temperature impact energy, good texture uniformity, and good elongation, to ensure low hardenability and cold crack resistance of repair welding heat-affected zone even if under polar climate condition.

Owner:ANGANG STEEL CO LTD

Aluminium alloy for vehicle hub and preparation method thereof

The invention provides an aluminium alloy for a vehicle hub and a preparation method thereof. The alloy comprises the following components by weight percent: 4.5-6.3% of Zn, 1.4-2.5% of Mg, 0.5-0.9% of Cu, 0.12-0.3% of Zr, 0.05-0.15% of Ti, 0.05-0.2% of Cr, 0.1-0.3% of Sc and the balance of Al. The preparation method of the aluminium alloy comprises the following steps: weighting raw materials, melting the raw materials except for magnesium blocks, adding a covering agent, then adding the preheated magnesium blocks, stirring, injecting nitrogen or argon to degas, filtering with a ported ceramic plate, reducing the temperature, standing for 20 minutes, and adopting a liquid forging mould and a liquid forging forming method to prepare the hub. The prepared vehicle hub has high strength, impact toughness and corrosion resistance; and the mechanical properties of the aluminium alloy hub can be ensured, the production cost can be reduced and the large-scale production of the hub is easy to perform.

Owner:ZHEJIANG GKO ALUMINUM

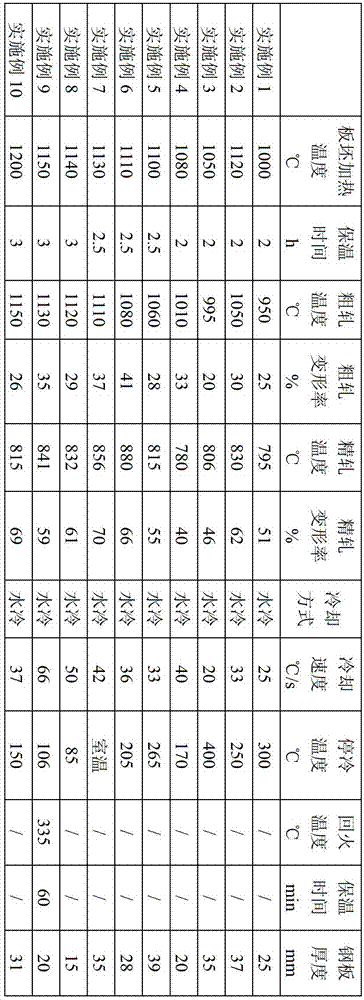

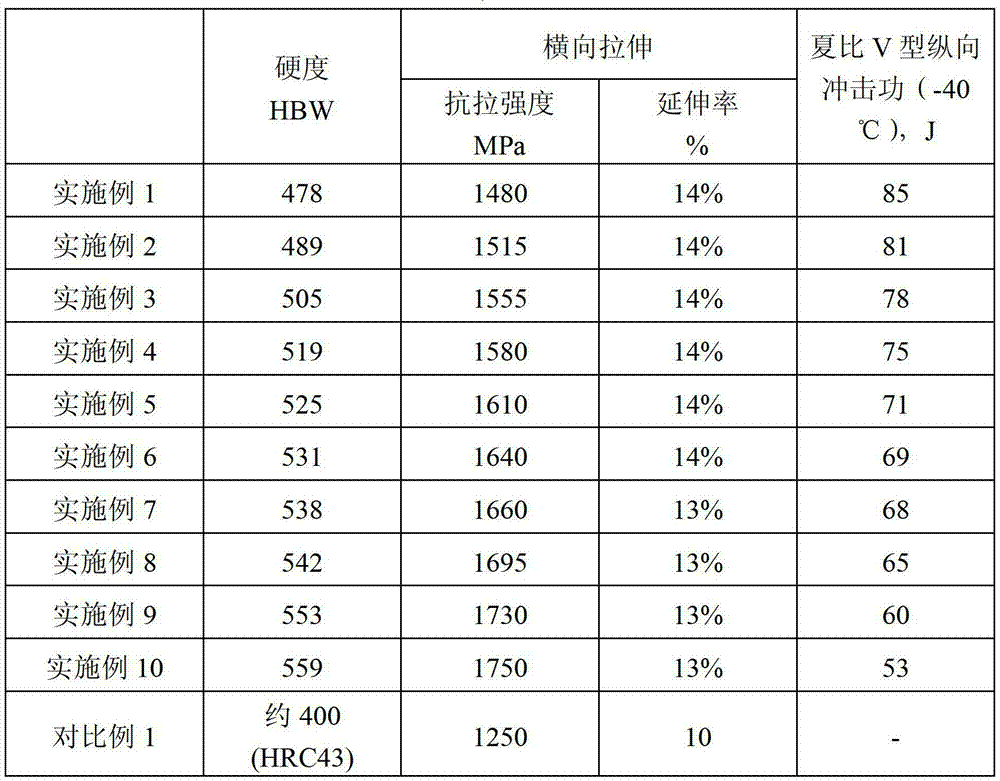

Low-alloy high-performance wear-resistant steel plate and manufacturing method thereof

ActiveCN103205627AImprove performanceHigh hardnessFurnace typesQuenching agentsChemical compositionWear resistant

The present invention provides a low-alloy high-performance wear-resistant steel plate and a manufacturing method thereof. The steel plate comprises the following chemical compositions (wt%) of 0.21-0.32% of C, 0.10-0.50% of Si, 0.60-1.60% of Mn, 0.0005-0.0040% of B, 0-1.50% of Cr, 0-0.80% of Mo, 0-1.50% of Ni, 0-0.080% of Nb, 0-0.080% of V, 0-0.060% of Ti, 0.010-0.080% of Al, 0.0010-0.0080% of Ca, 0-0.0080% of N, 0-0.0080% of O, 0-0.0004% of H, 0-0.015% of P, and 0-0.010% of S, wherein the following relationships are satisfied: 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, 0.01%<=(Al+Ti)<=0.13%, and the balance is Fe and inevitable impurities. The low-alloy high-performance wear-resistant steel plate manufactured by the above compositions and through a TMCP process has high strength and hardness, good toughness and excellent wear resistance, and is suitable for easy-to-wear parts in various mechanical equipments.

Owner:BAOSHAN IRON & STEEL CO LTD

Application method of cold field plasma discharge assisted high energy ball milled powder and plasma assisted high energy ball milling device

The invention provides an application method of cold field plasma discharge assisted high energy ball milled powder and a plasma assisted high energy ball milling device using the cold field plasma discharge assisted high energy ball milling method. The method comprises the following steps: utilizing dielectric barrier discharge to generate plasmas, introducing a dielectric barrier discharge electrode bar into a high-speed vibrating ball-milling tank, on one hand, requiring a solid insulating medium on the outer layer of the electrode bar to simultaneously bear high-voltage discharge and mechanical shock failure of the grinding ball, and on the other hand, requiring the high-speed vibrating ball milling device to uniformly process the powder. The method is based on the ordinary ball milling technology; the processing efficiency and the effect of the ball mill can be greatly improved by the following steps: under a non-heat-balance discharge condition of the pressure that the discharge space pressure is set to be about 102-106 Pa, introducing the discharge plasmas to input another effective energy to the processed powder, promoting the powder to be processed to be subjected to combined action of the mechanical stress effect and the heat effect of the external electric field, and further accelerating refining of the powder and promoting the alloying progress.

Owner:SOUTH CHINA UNIV OF TECH

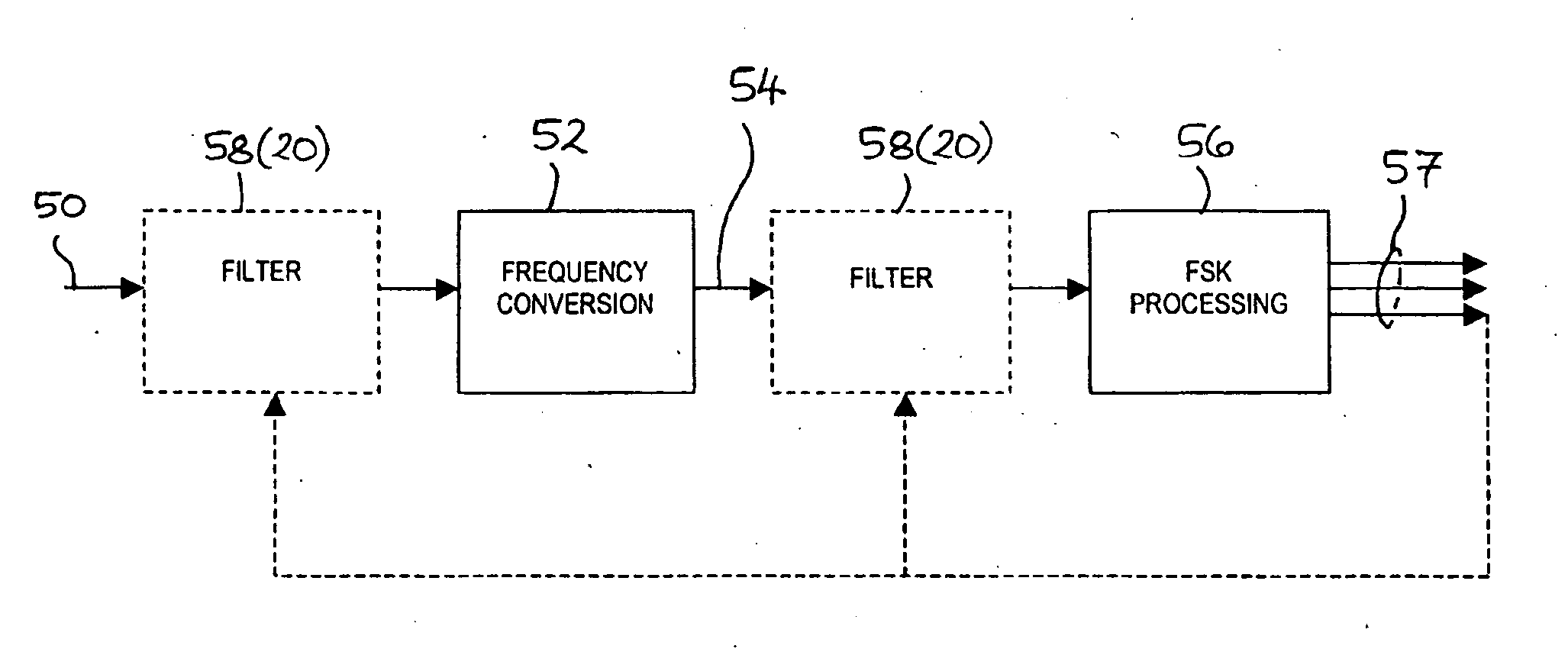

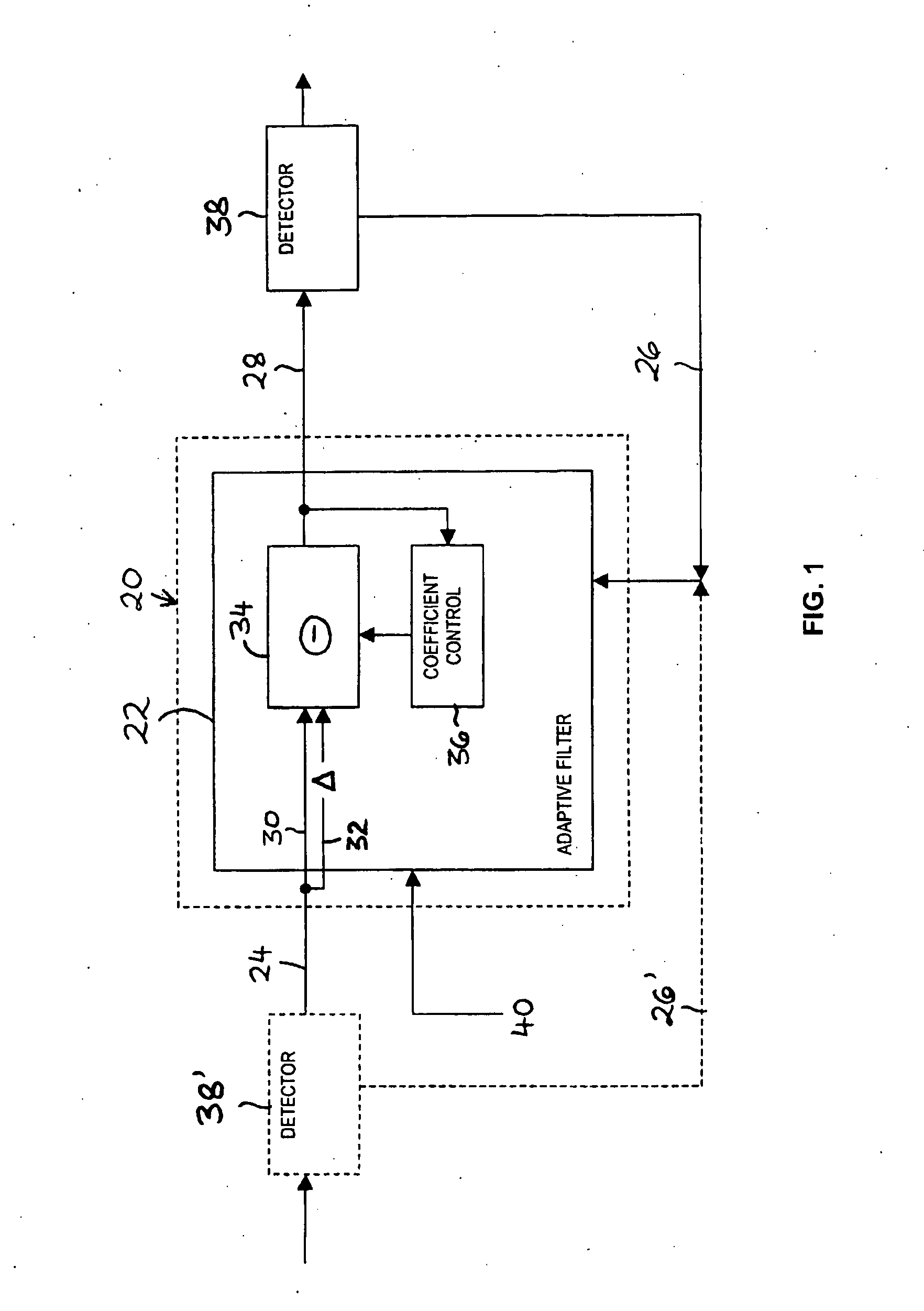

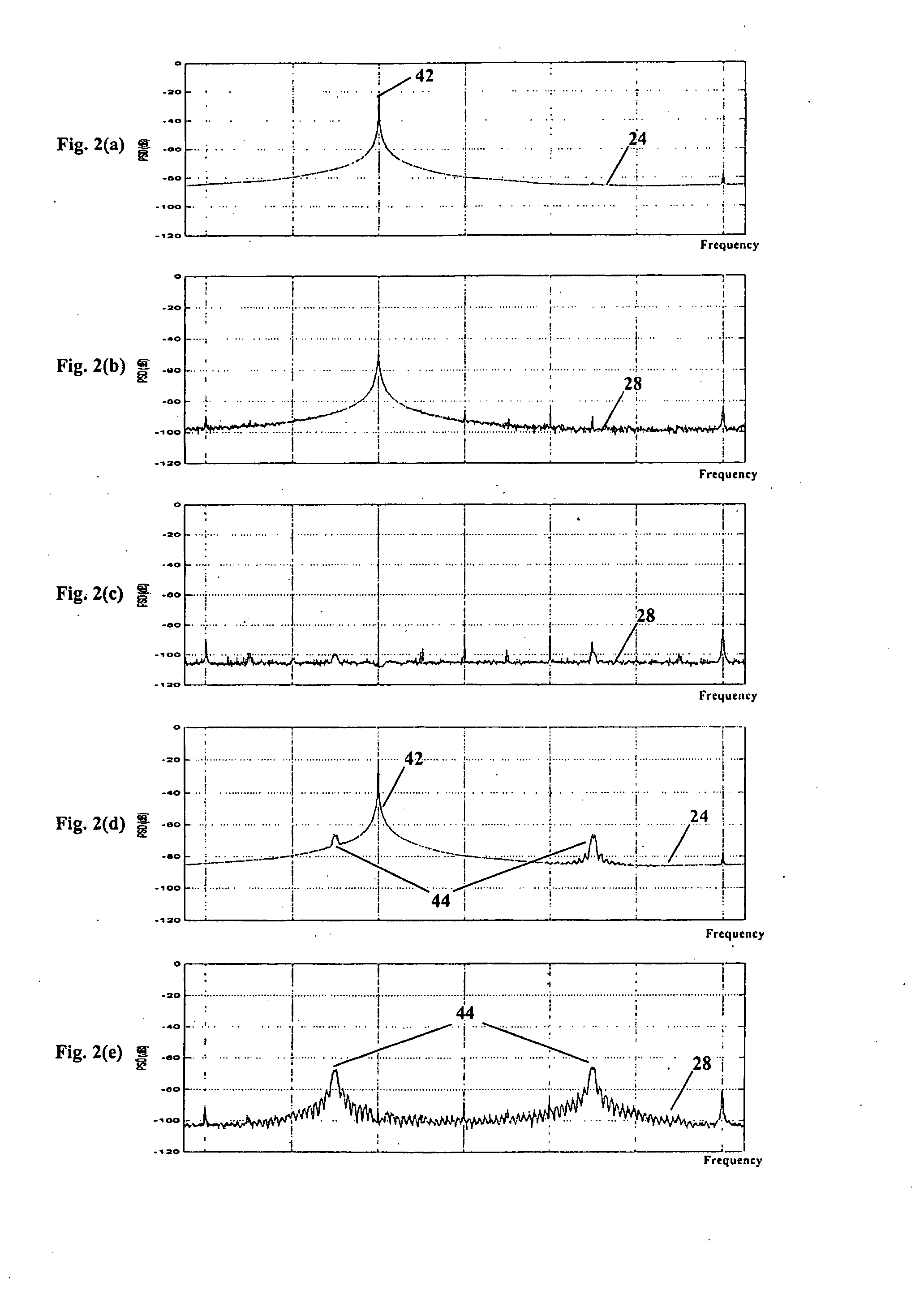

Supressing interference for wireless reception and improvements relating to processing a frequency shift keyed signal

InactiveUS20070201588A1Rapid responseSlow responseError preventionFrequency/rate-modulated pulse demodulationHysteresisAdaptive filter

A communications receiver may include an adaptive filter unit for removing coherent interference components from a received signal. In the absence of a signal of interest, the filter may adapt dynamically to remove current interference components. When a signal of interest is detected, the filter may be controlled to stop (or at least reduce) its adaptation, to prevent removal of the signal of interest. The received signal may be down-converted to a complex baseband by conditioning circuitry. A detector may detect the signal of interest, and control the filter. Autocorrelation may be used to estimate a characteristic of the signal of interest in the complex baseband. The detector may include hysteresis to react quickly to the start of signal of interest, and more slowly to an end of the signal of interest. The signal of interest may be a frequency shift keyed (FSK) signal. A demodulator may demodulate FSK components based on the autocorrelation result. The characteristic of the signal of interest used for detection and / or demodulation may be a directional characteristic of a vector representing the complex baseband signal in complex space.

Owner:IMRA EURO

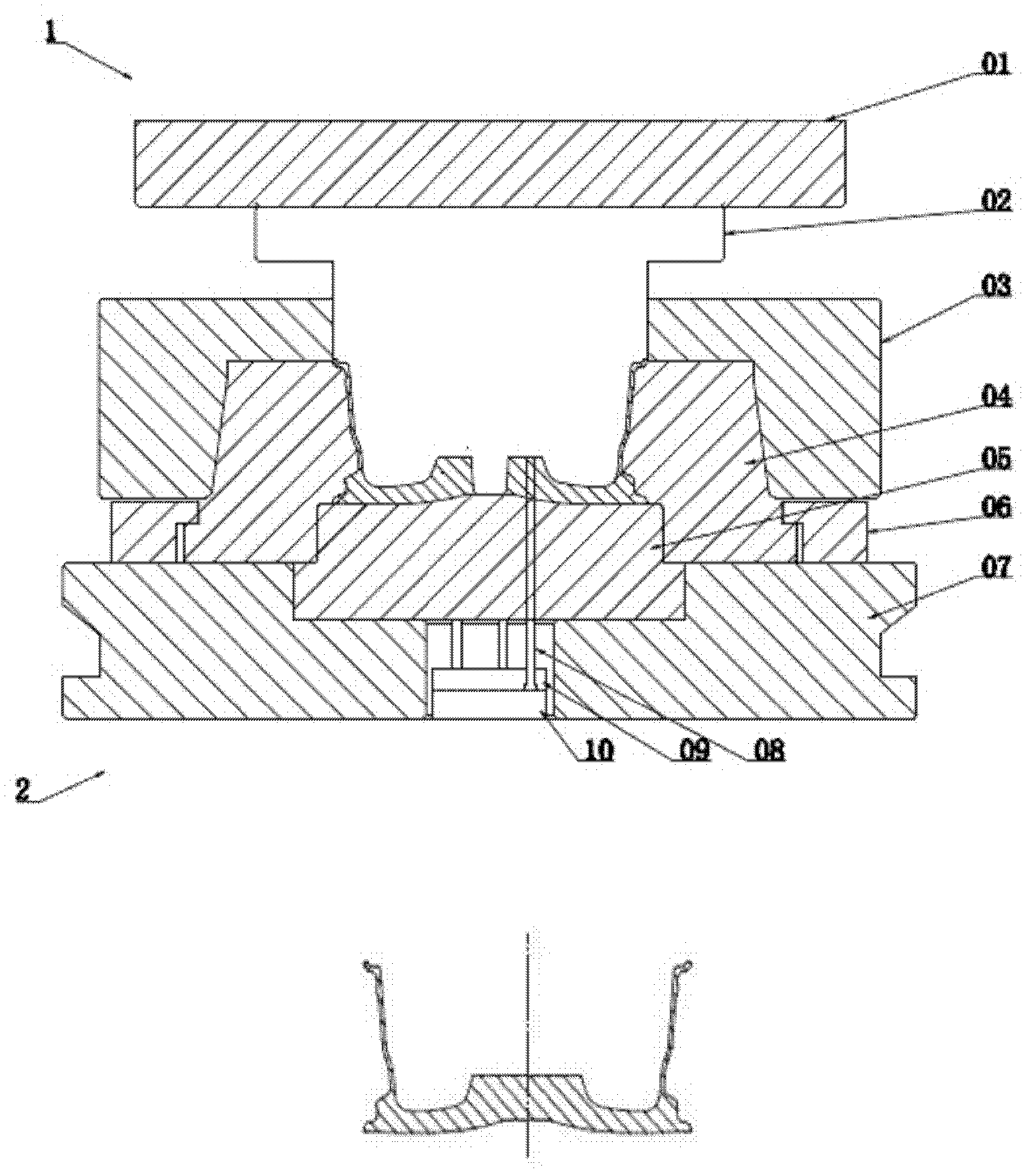

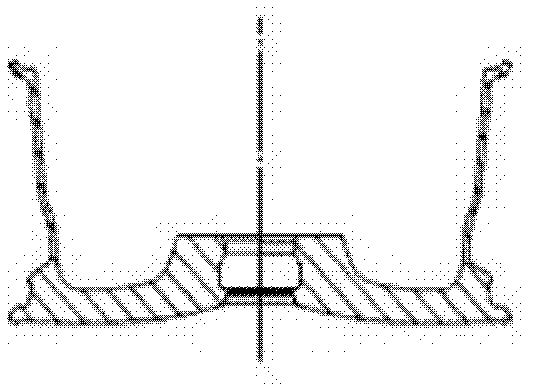

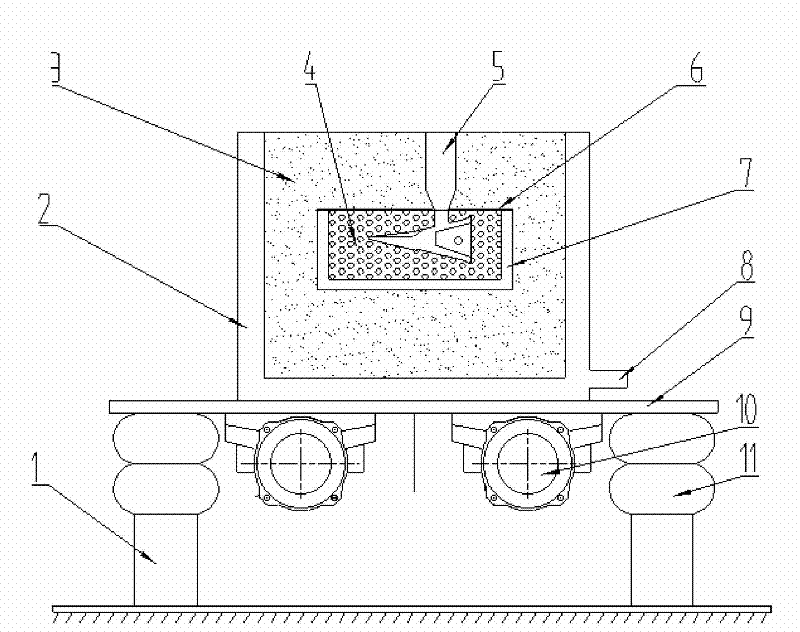

Lost wax shell-based negative pressure dry sand and iron shot chilling vibrational casting process method

InactiveCN102240778AHigh strengthReduce the number of hanging coatsFoundry mouldsFoundry coresWaxHigh density

The invention discloses a lost wax shell-based negative pressure dry sand and iron shot chilling vibrational composite casting process method. The method is characterized by comprising the following steps of: feeding a shell manufactured by a lost wax process into a chilling sand box; loading steel shots in the gap between the shell and the chilling sand box; feeding the chilling sand box into a sand box with a vacuumized negative pressure model; fully filling dry sand between the chilling sand box and the sand box with the vacuumized negative pressure model; paving a plastic film; placing a pouring cup; and pouring under the simultaneous vacuumizing and vibrating condition. By the method, the strength of molding sand is high, a chilling effect is good, the process characteristics of lost foam casting and hot investment casting are combined, the defect of foam-gasified carbon special for the lost foam casting is overcome, the chilling effect of the iron shots is fully exerted, the pouring is performed under the vibration condition, and alloy grains are refined, so that wear-resisting castings have higher density, hardness and wear resistance.

Owner:HUBEI GENGLIAN WEAR RESISTANT MATERIALS TECH

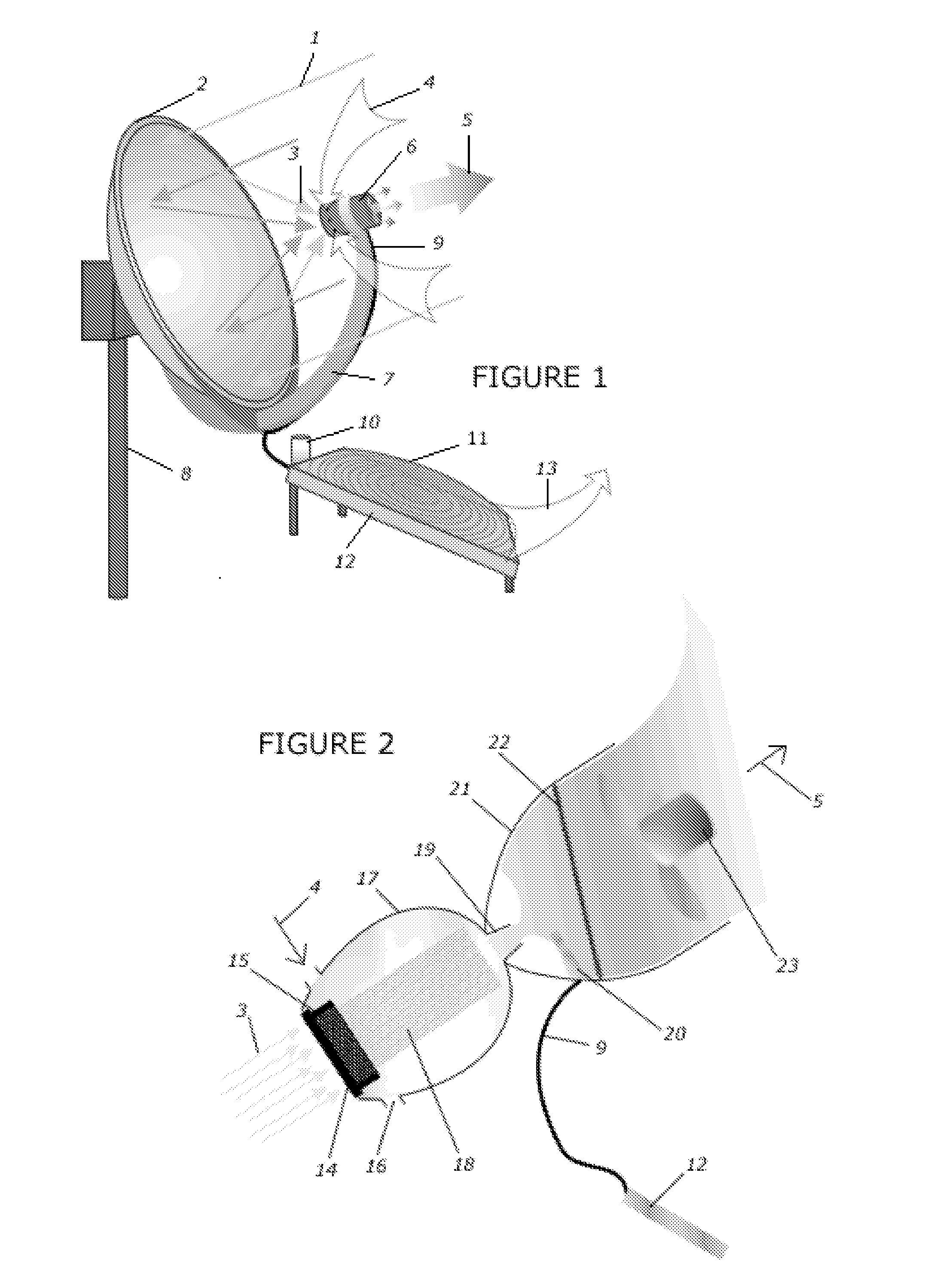

Solar Atmospheric CO2 Cleaner

InactiveUS20080196581A1High value by-productStabilize increasing CO concentrationSolar heating energyGas treatmentAtmospheric airAtmosphere of Earth

An increasing level of carbon dioxide gas in the earth's atmosphere has been determined and is generally accepted by the scientific community. The human contribution to increases in the percentage of carbon dioxide in the atmosphere has been identified as a driving force of global climate change.The impact of global climate change might be mitigated by means to reduce or stabilize the percentage of carbon dioxide in the atmosphere.The invention provides a means for cleaning the atmosphere of carbon dioxide molecules by dissociation and refining the by-products into valuable fuels and other substances. It is taught that solar energy can be used to energize a photonic crystal producing the power and specific frequency required for localized excitation of CO2 molecules in a specific vibration mode and to the majority exclusion molecular structures comprising atmospheric gases sufficient to break covalent bonds of CO2, thereby producing reactant by-product that can be collected and refined into valuable substances and fuel.

Owner:COOLEY WARREN LYNN

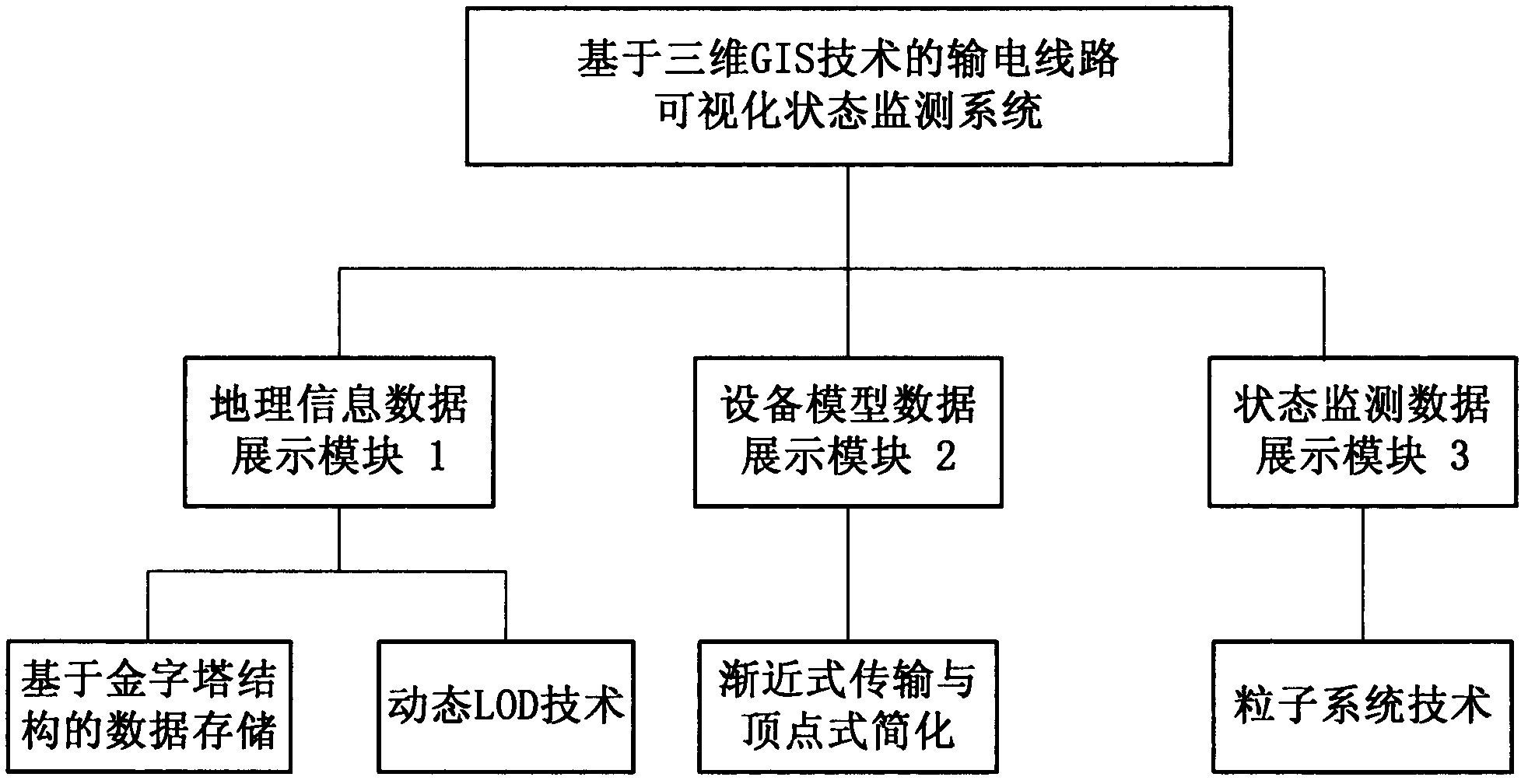

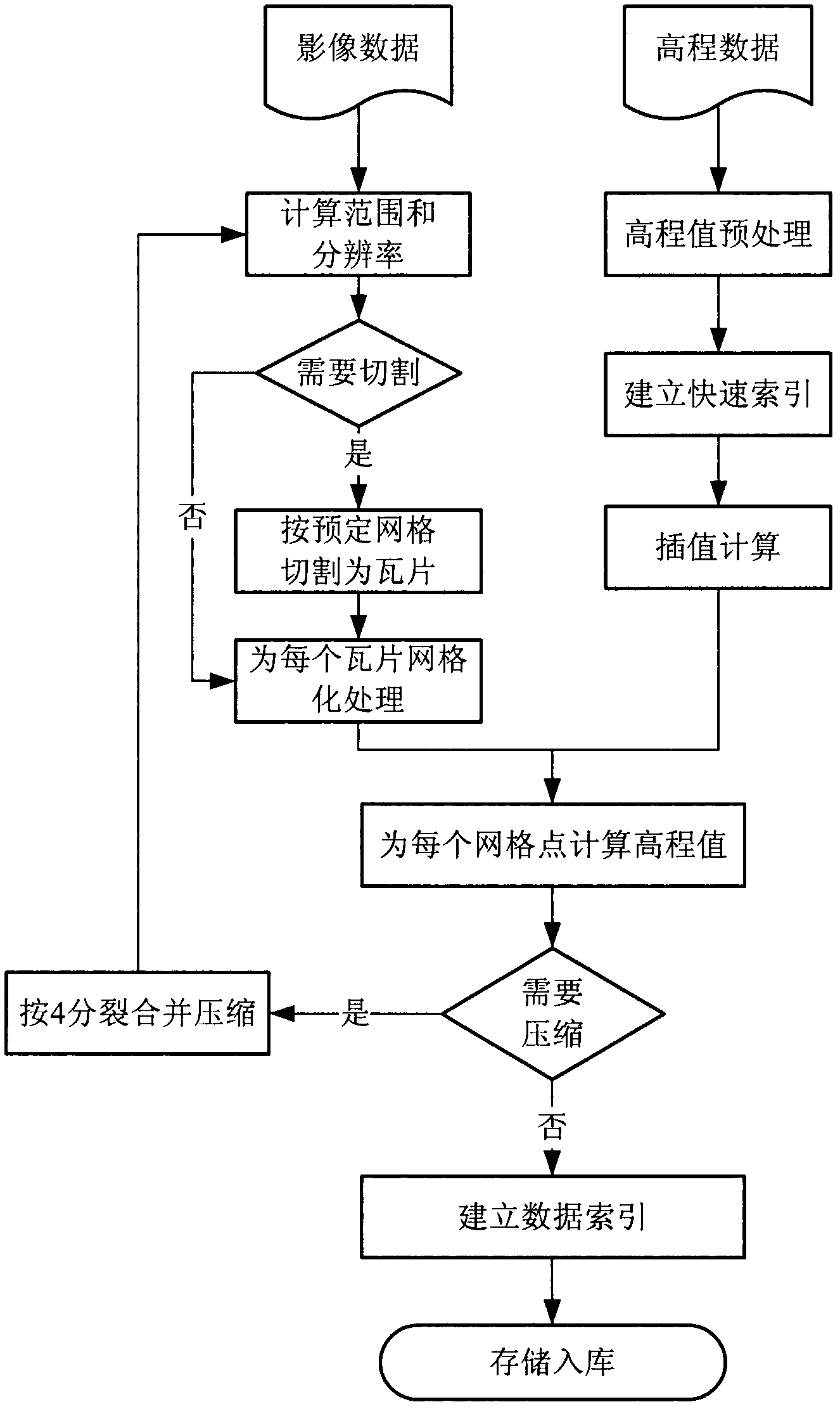

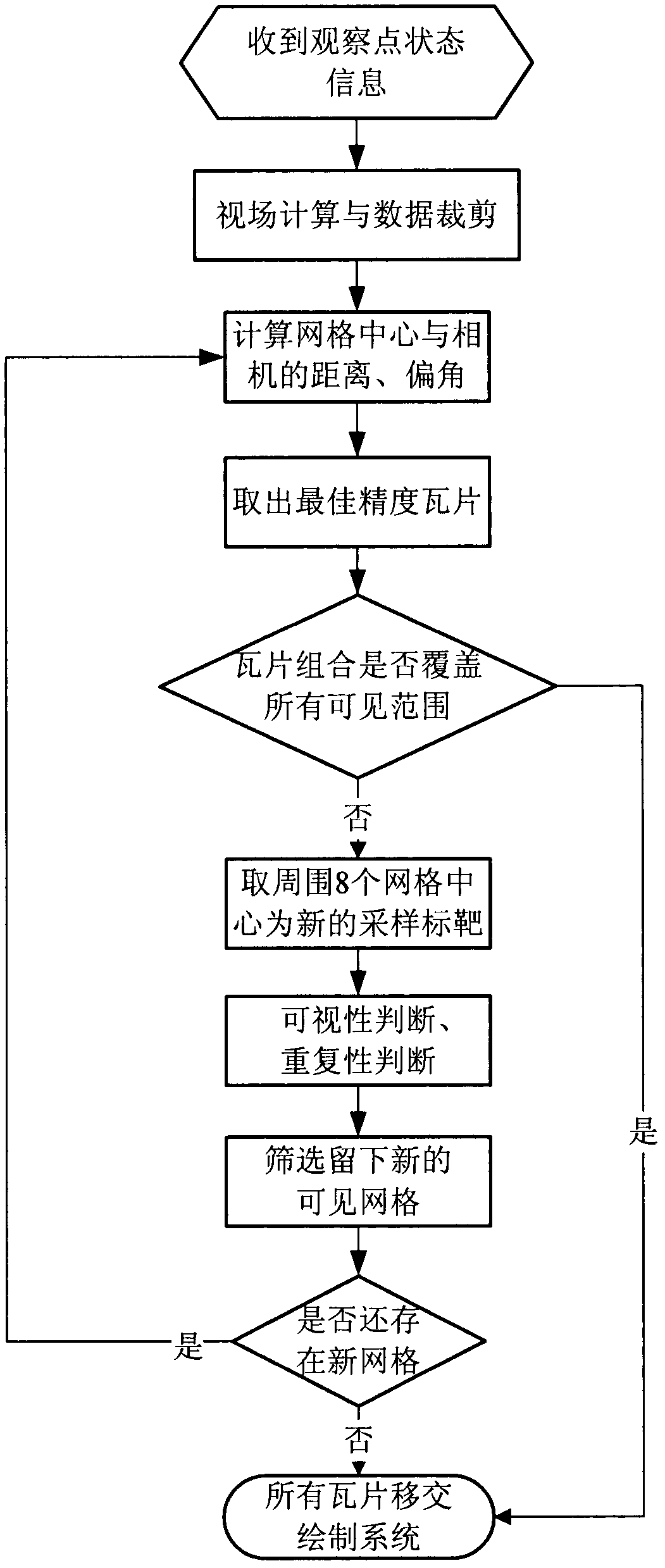

Three-dimensional GIS (Geographic Information System) technology based visual state monitoring system for power transmission lines

ActiveCN102323996ARealize 3D landscape simulationRealize 3D displaySpecial data processing applicationsData displayPower equipment

The invention discloses a three-dimensional GIS (Geographic Information System) technology based visual state monitoring system for a power transmission line. The visual state monitoring system comprises a geographic information data display module, an equipment model data display module and a state monitoring data display module. In the system, on the basis of the three-dimensional GIS technology, the three-dimensional landscape simulation of a power transmission line corridor and the three-dimensional display of a power transmission equipment state are realized by presenting mass spatial information in a multi-angle and ominibearing manner, so that information support is provided for promoting the fineness, scientization and intelligent levels of power equipment running management.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD +2

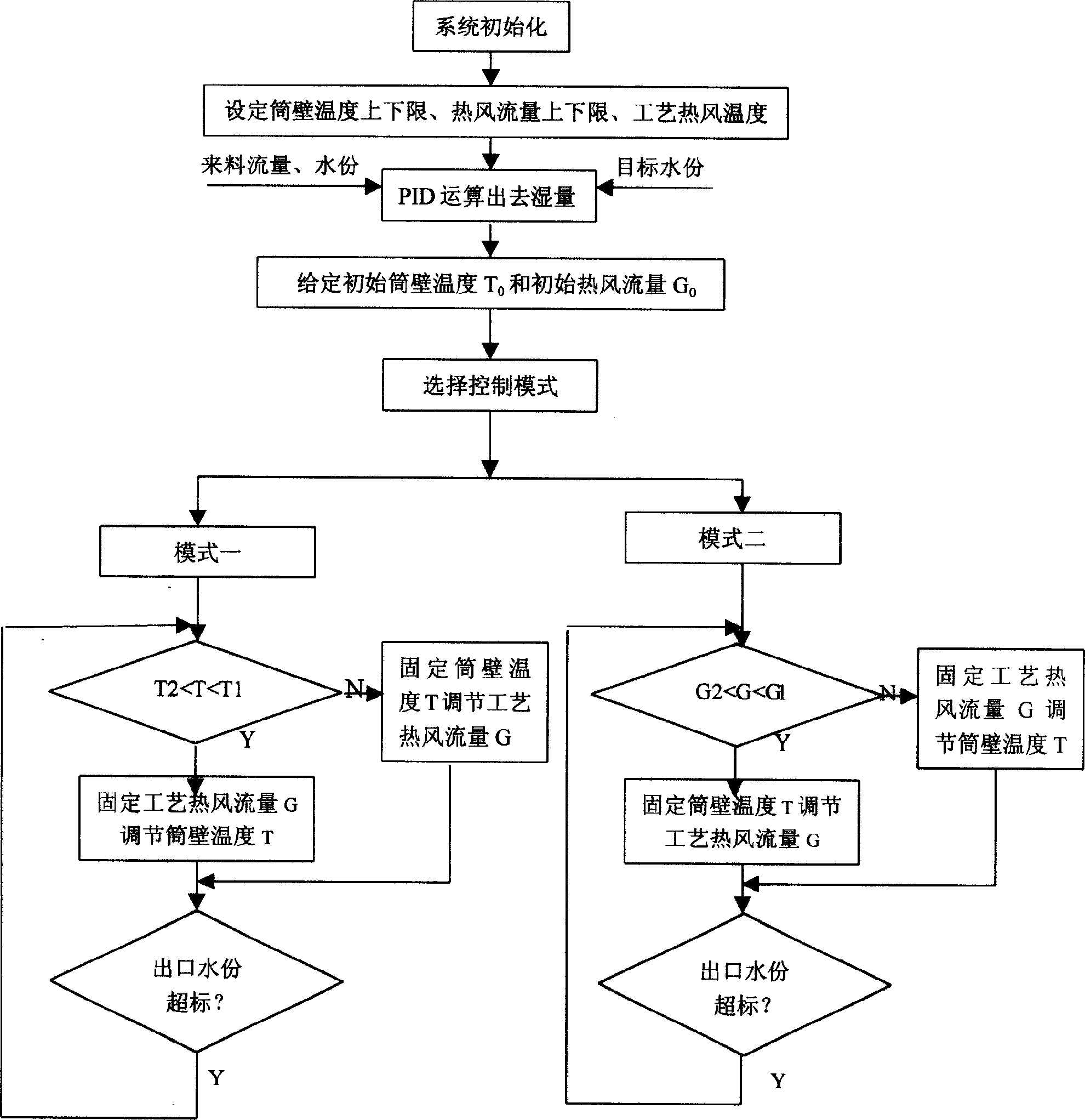

Tobacco shreds drying and moisture moving control method

InactiveCN1656946AImprove flexibilityImprove refinementTobacco preparationAutomatic controlLoop control

A control method for drying tobacco shreds features use of dual-loop control and two control modes. After the upper and lower temp limitations of cylinder wall are set up by system, the temp of cylinder wall is regulated for automatically controlling the content of water in tobacco shreds. After the temp of cylinder wall is fixed, the flow of hot-air is regulated to control the content of water in tobacco shreds. Otherwise, after the upper and lower limitations of the flow of hot air ar set up, the flow of hot air is regulated to control the content of water in tobacco shreds or after the flow of hot-air is fixed, the temp of cylinder wall is regulated to control the content of water in tobacco shreds.

Owner:LONGYAN CIGARETTE FACTORY

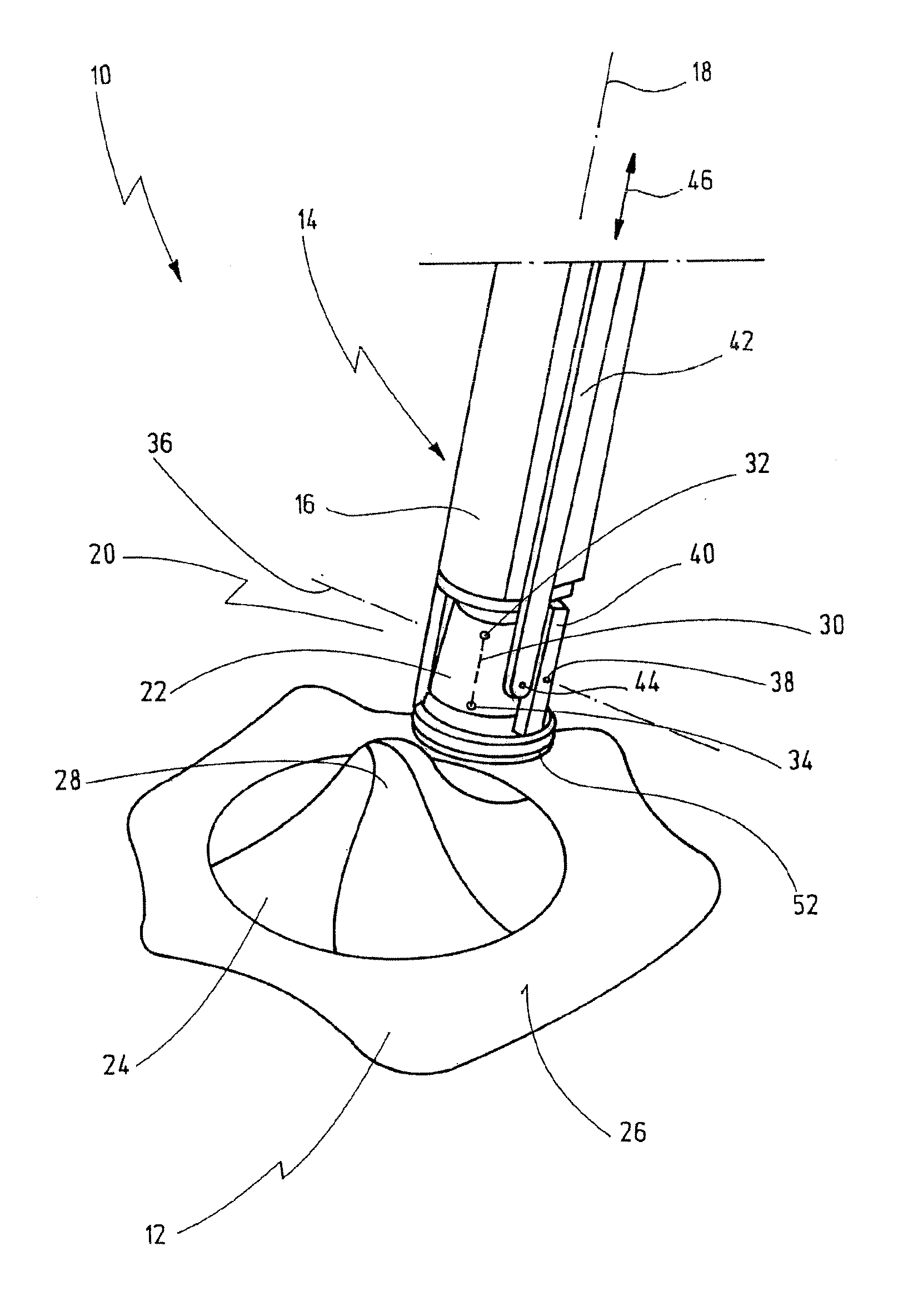

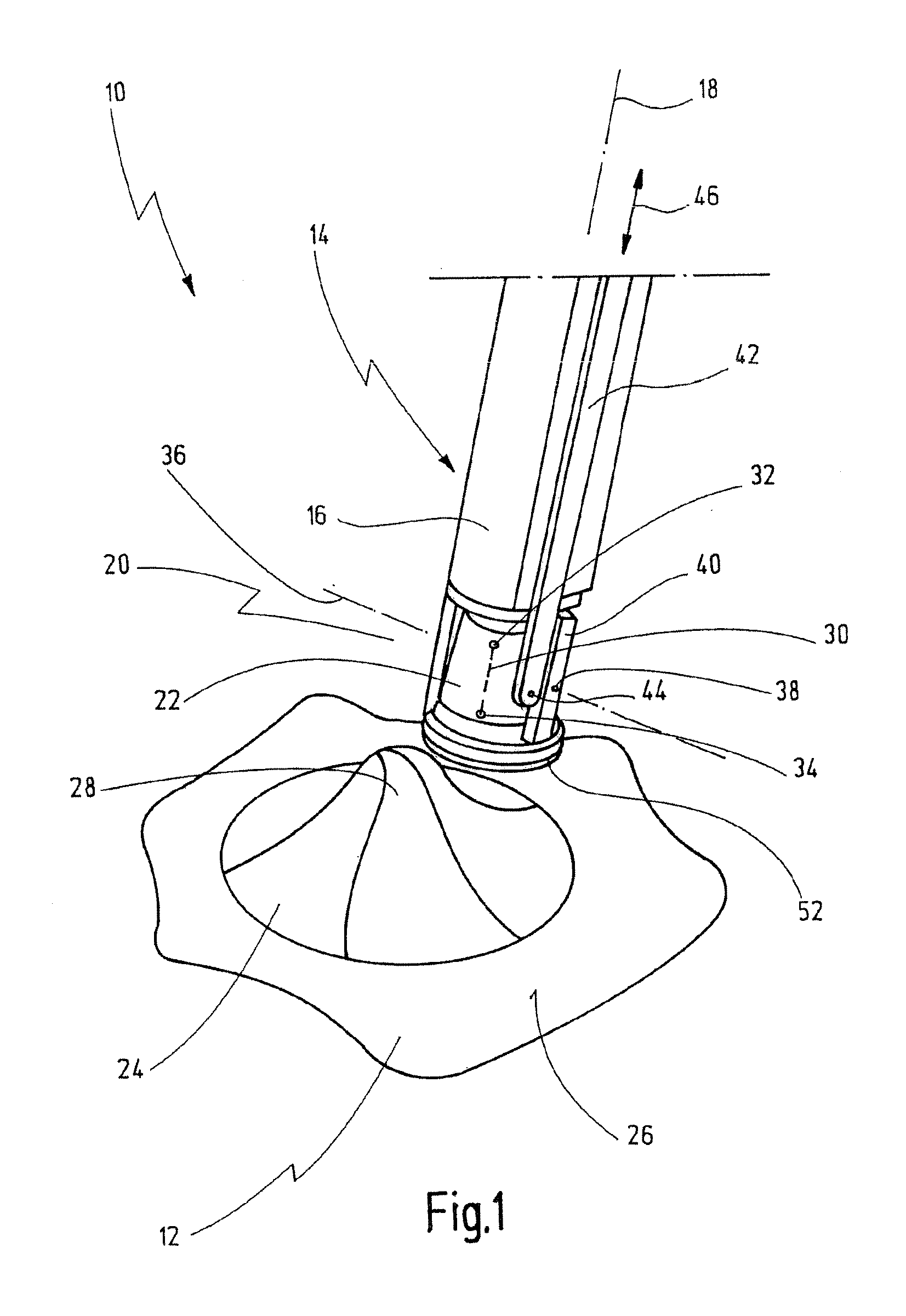

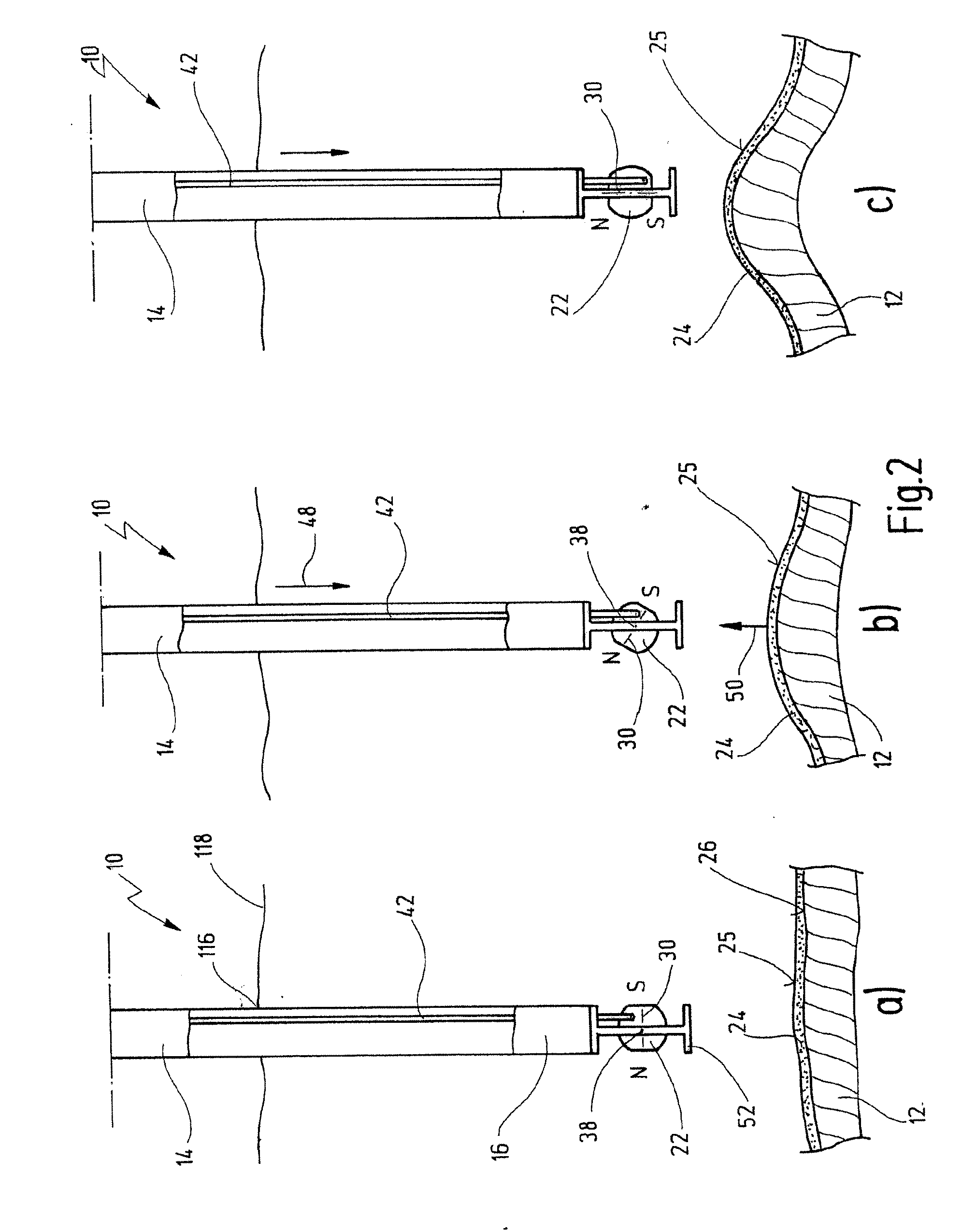

Medical Instrument And Method For Manipulating, In Particular Retracting Tissue Or An Organ

ActiveUS20070135685A1Reduce magnetic forceImprove refinementDiagnosticsSurgical manipulatorsDistal portionSurgery

A medical instrument for manipulating, in particular retracting tissue or an organ in the human or animal body, comprises an elongated shaft having a distal portion introducible into the body, and at least one working element arranged at a distal end portion of the shaft for manipulating the tissue or organ. The at least one working element comprises at least one magnetically acting element producing a magnetic field for manipulating the tissue or organ. A method for manipulating, in particular retracting tissue or an organ uses the instrument.

Owner:DUNDEE UNIV OF

Mesophase-pitch-based carbon fiber and preparation method thereof

The invention discloses a mesophase-pitch-based carbon fiber and a preparation method thereof. The preparation method comprises the steps of conducting mesophase pitch polymerization, modification and visbreaking, conducting centrifugal spinning, conducting hot jetting drafting, conducting oxidation, carbonization and graphitization, and obtaining the mesophase-pitch-based carbon fiber. The diameter of the mesophase-pitch-based carbon fiber ranges from 120 nm to 2000 nm, the draw ratio is 500-20000: 1, the tensile strength is 1.5-4.0 GPa, the tensile modulus is 300-600 GPa, the electrical resistivity is less than 0.2 * 10 <-4> omega.cm, the thermal conductivity is 500-800 W / m.k, and the mesophase-pitch-based carbon fiber is low in fabrication cost and can be applied to fields such as static electricity resistance, heat dissipation, electromagnetic shielding and heat shielding.

Owner:ANHUI HONGCHANG NEW MATERIAL CO LTD

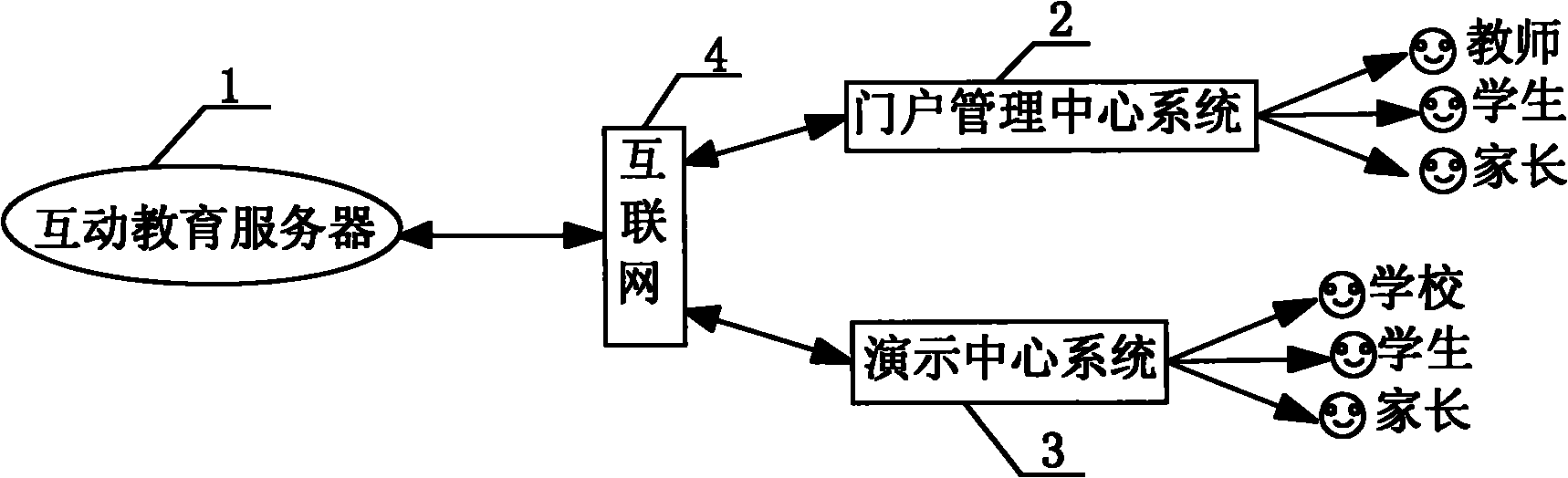

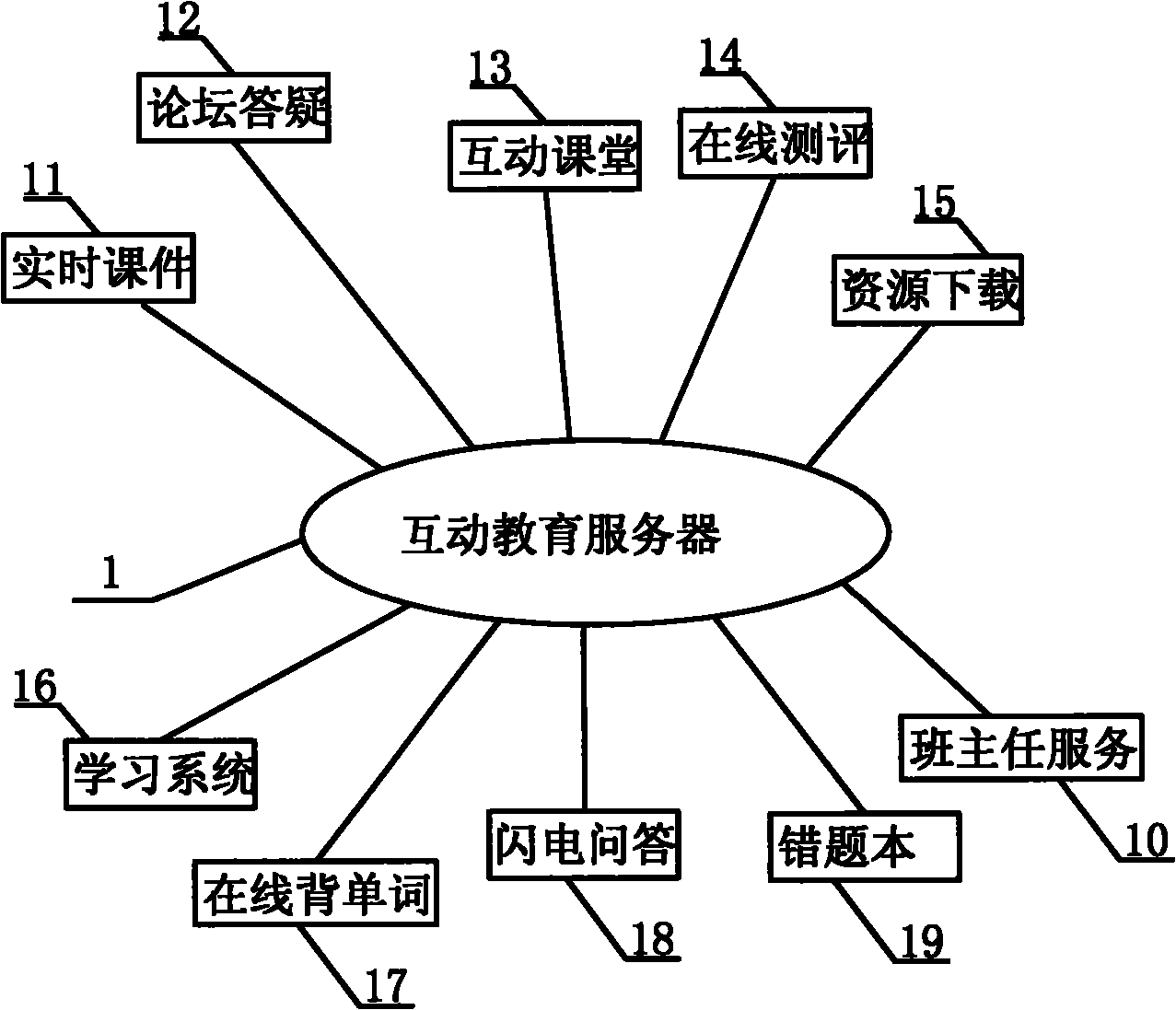

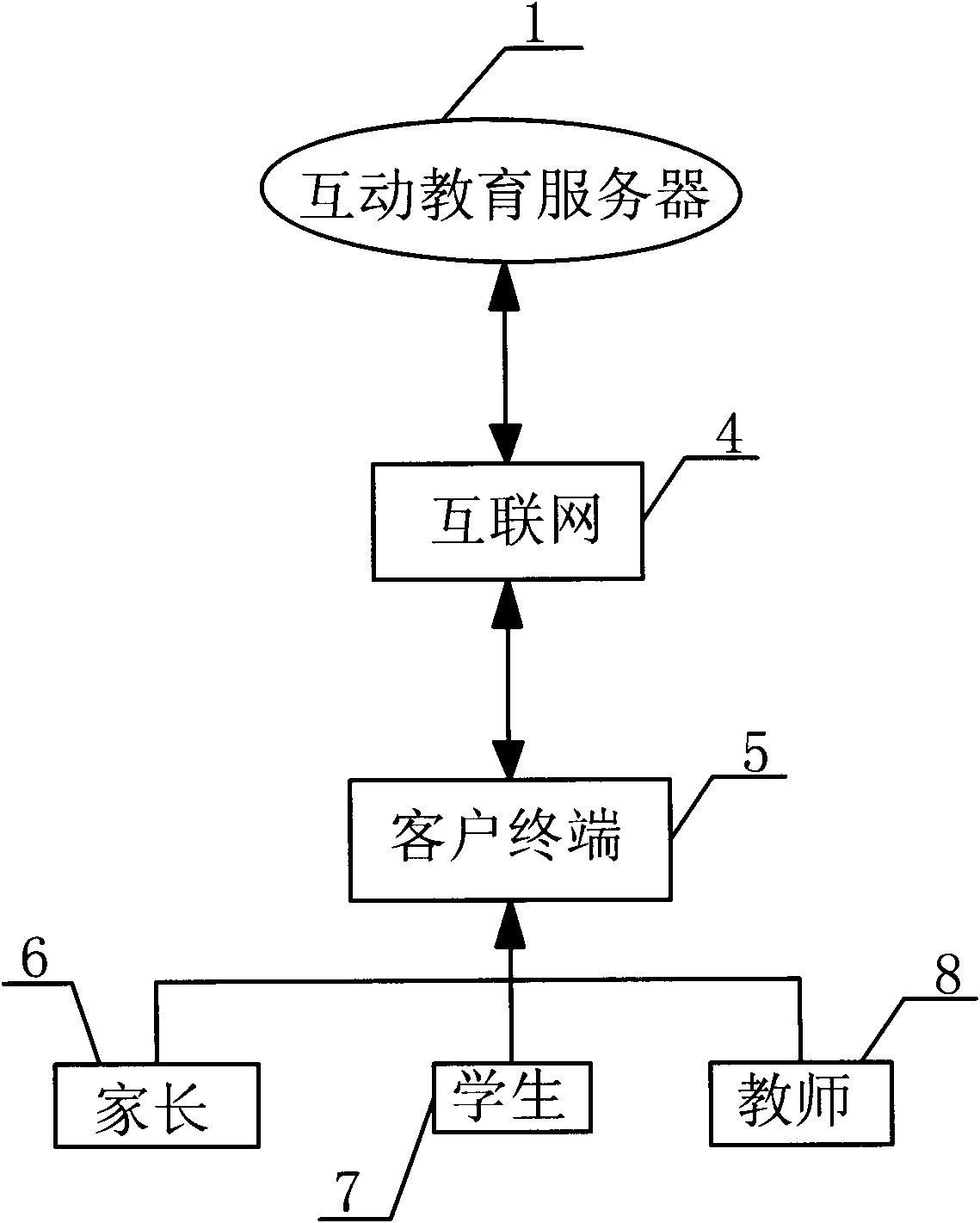

Novel-class standard online education platform

InactiveCN102185886AShorten the timeCounseling is goodTransmissionElectrical appliancesPersonalizationTerminal server

The invention discloses a novel-standard sign online education platform. The online education platform realizes local or foreign dissemination of teaching information by the Internet, and comprises an interactive education server, a portal management center system and a demonstration center system, wherein the portal management center system and the demonstration center system are both connected with the interactive education server by the Internet; the Internet is also connected with a client terminal system; the client terminal system comprises a terminal server, a teacher terminal, student terminals and parent terminals, and is connected with the teacher terminal, the student terminals and the parent terminals respectively; the portal management center system comprises built-in functional modules for online providing related statistical analytical information and personalized information for a teacher, students and parents; and the demonstration center system controls the normal running of each piece of projection display equipment and demonstrates information shared by the education platform. The novel-class sign online education platform maximally utilizes high-quality educational resources, and effectively improves the teaching efficiency by an Internet technology.

Owner:SHANGHAI XUEZHOU INFORMATION TECH

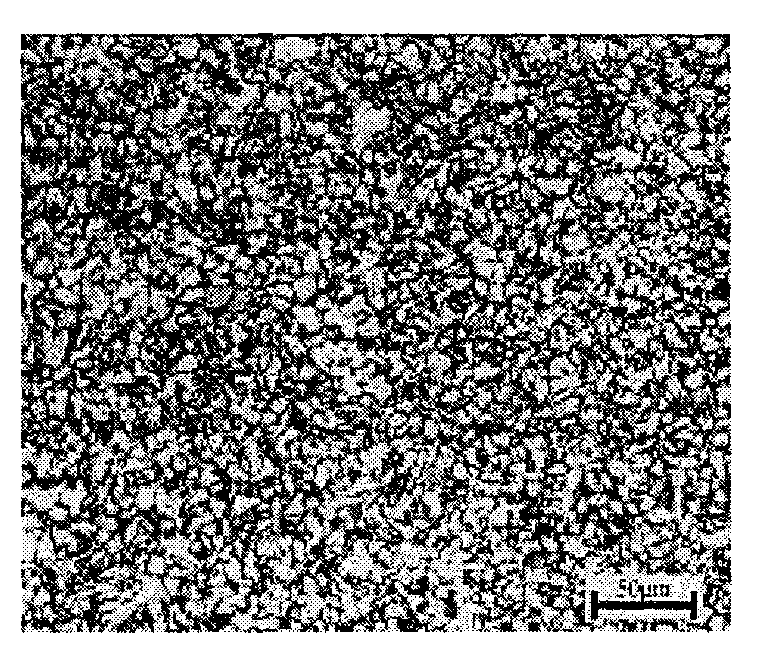

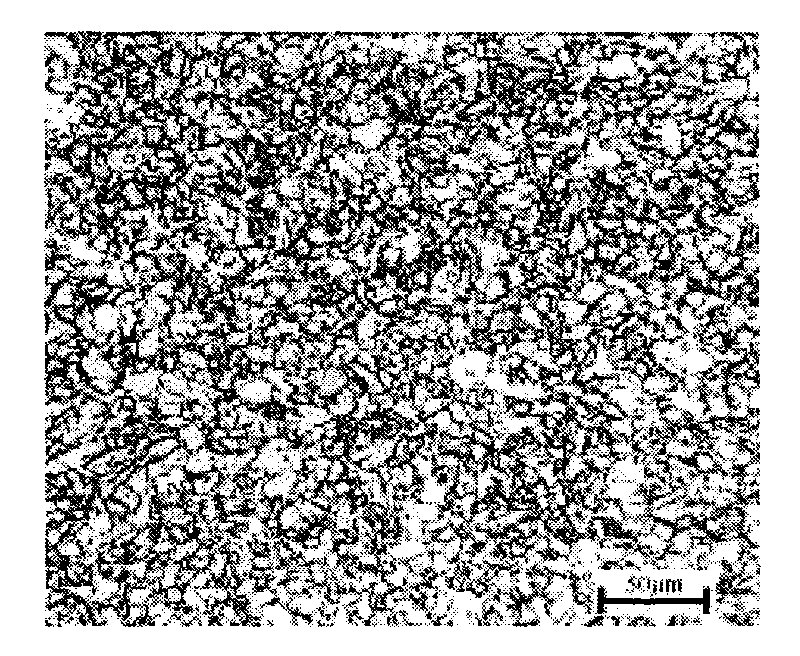

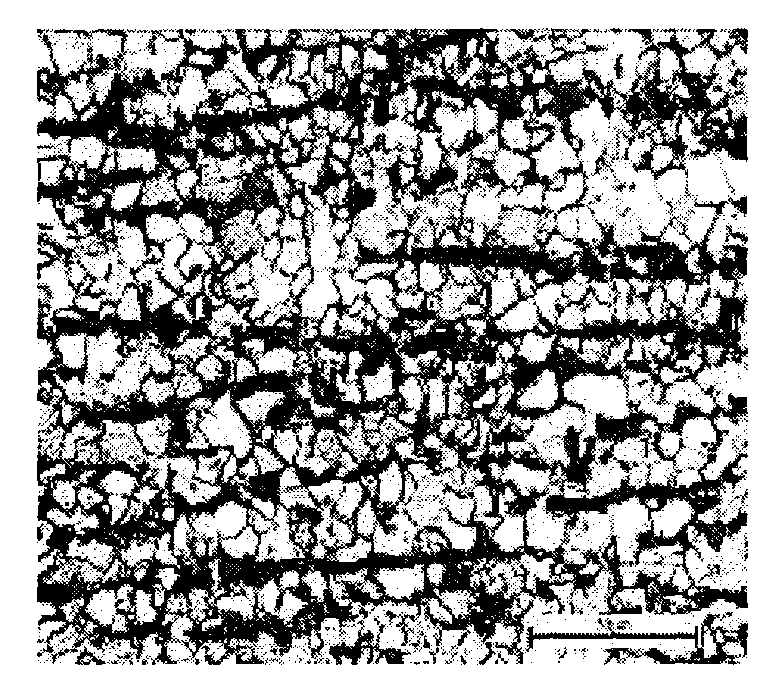

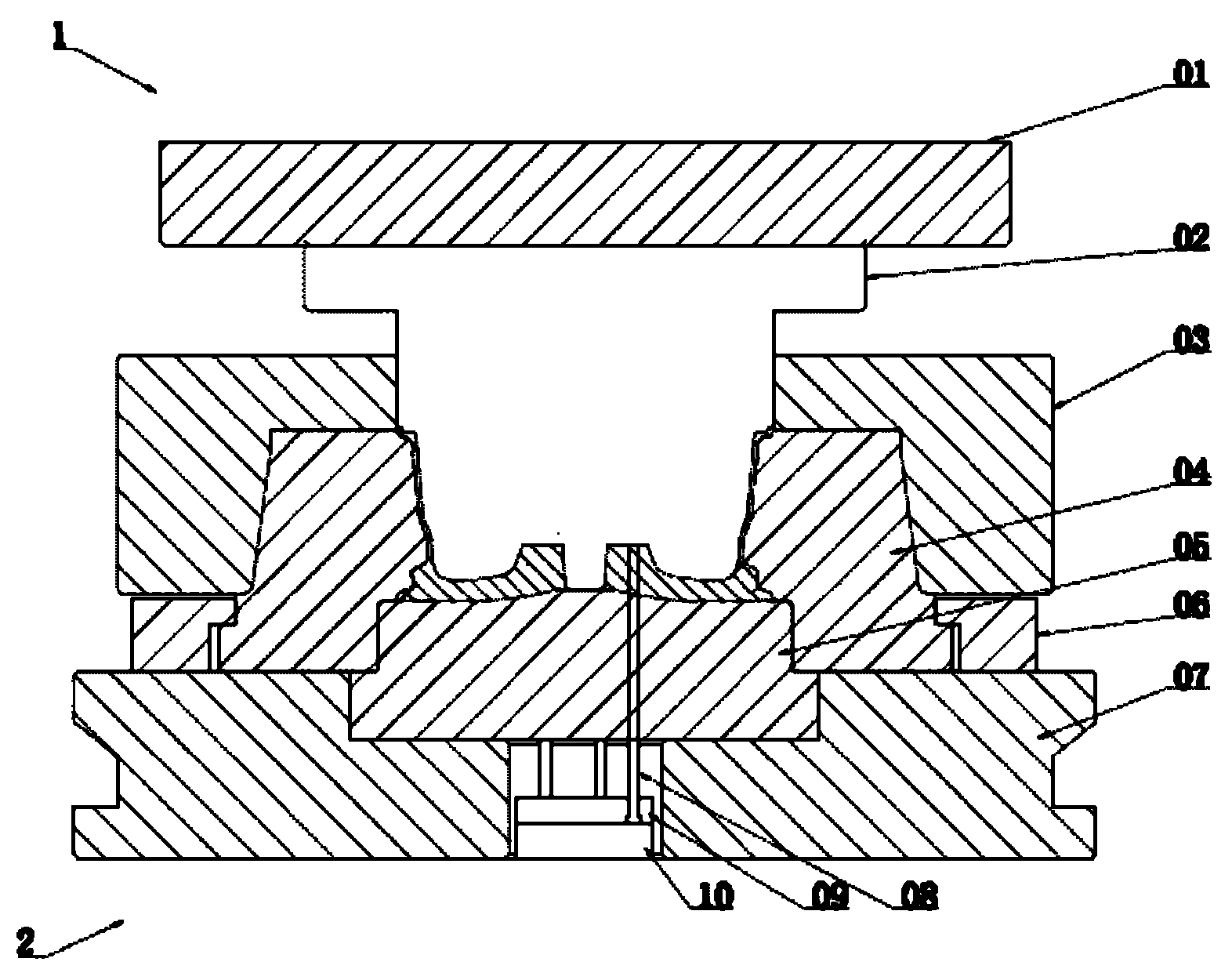

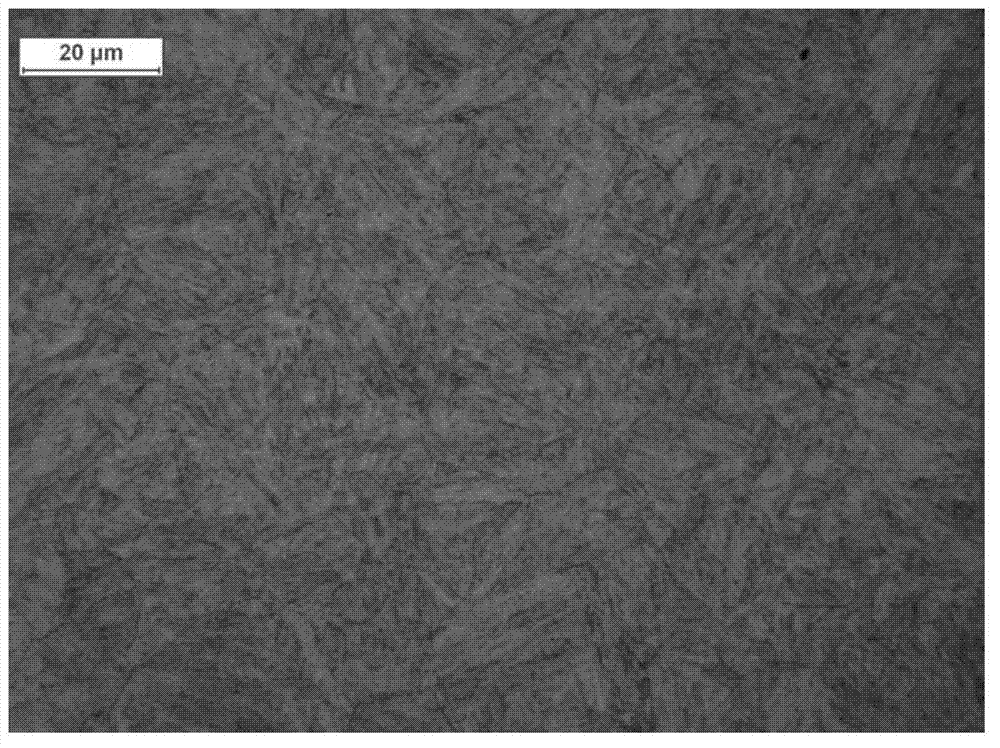

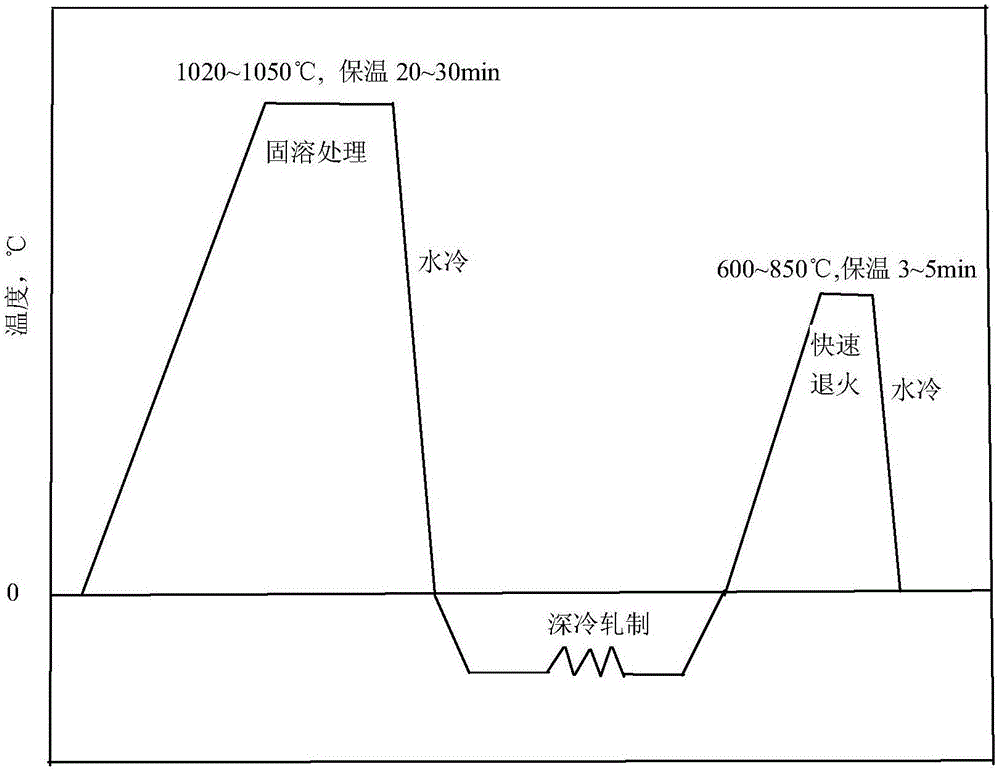

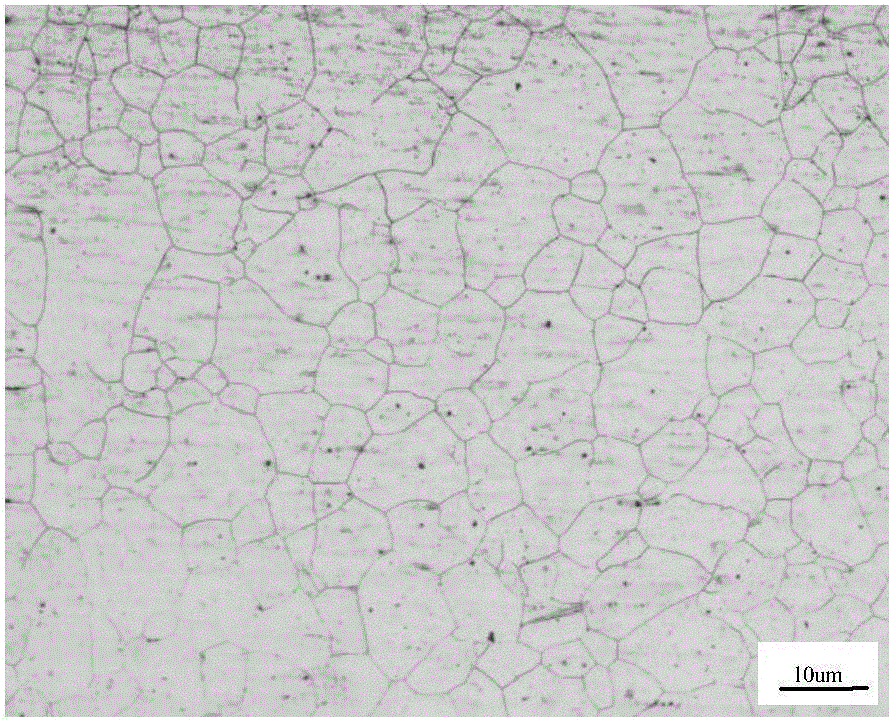

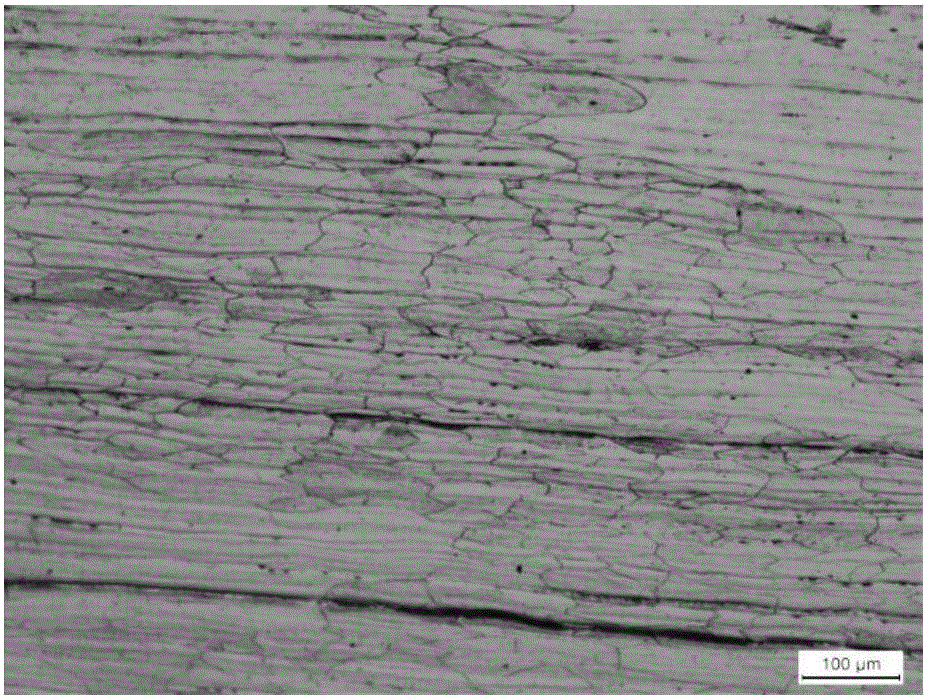

Method for preparing nanocrystalline austenitic stainless steel plate through deep cooling rolling-rapid annealing

ActiveCN106435131ARemarkable grain refinement effectIncreased strength and plasticitySteel platesAustenitic stainless steel

The invention provides a method for preparing a nanocrystalline austenitic stainless steel plate through deep cooling rolling-rapid annealing and belongs to the field of stainless steel manufacturing. The method comprises the steps that (1) an austenitic stainless steel blank is hot-rolled after being subjected to heat preservation at the temperature of 1150 DEG C-1250 DEG C and then is air-cooled to the room temperature after being water-cooled to 150 DEG C-200 DEG C, and a hot-rolled plate is prepared; (2) deep cooling rolling is conducted, specifically, the hot-rolled plate is subjected to solid solution treatment, after an oxide layer on the surface is removed, deep cooling rolling is conducted, the steel plate is subjected to liquid nitrogen treatment before cold rolling per pass, and a deep cooling rolled stainless steel plate is prepared; and (3) the deep cooling rolled stainless steel plate is air-cooled to the room temperature after being subjected to heat preservation at the temperature of 600 DEG C-850 DEG C, so that the nanocrystalline austenitic stainless steel plate is prepared. The yield strength of the stainless steel plate prepared by the method is 956-1170 MPa, the tensile strength is 1130-1380 MPa, the percentage elongation after fracture is 18%-52%, and the product of strength and elongation is 55000-58080 MPa.%. According to the method for preparing the nanocrystalline austenitic stainless steel plate through deep cooling rolling-rapid annealing, the time is short; the efficiency is high; energy sources are saved; the cost is low; and a sample piece large in section size is easy to produce.

Owner:NORTHEASTERN UNIV

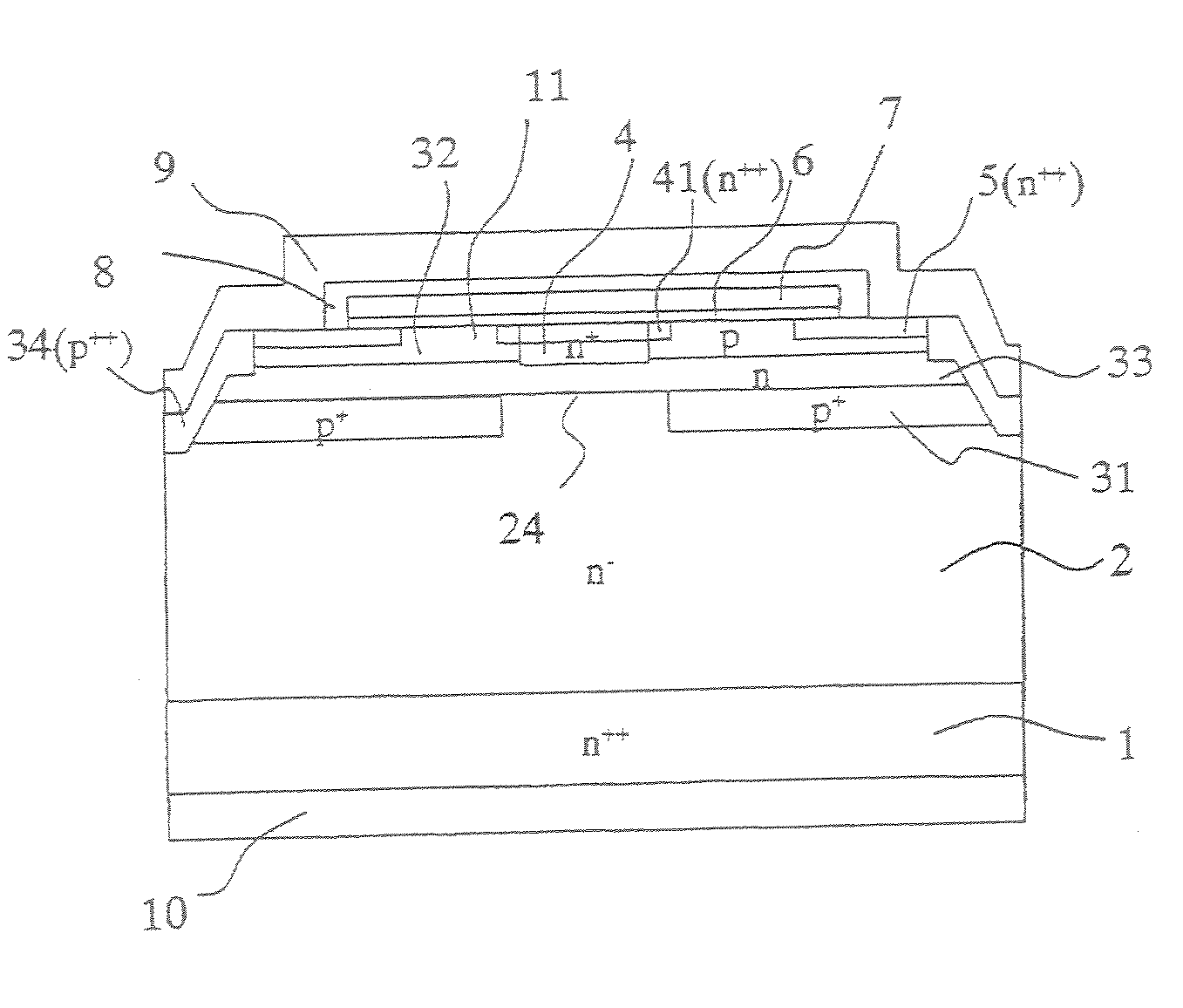

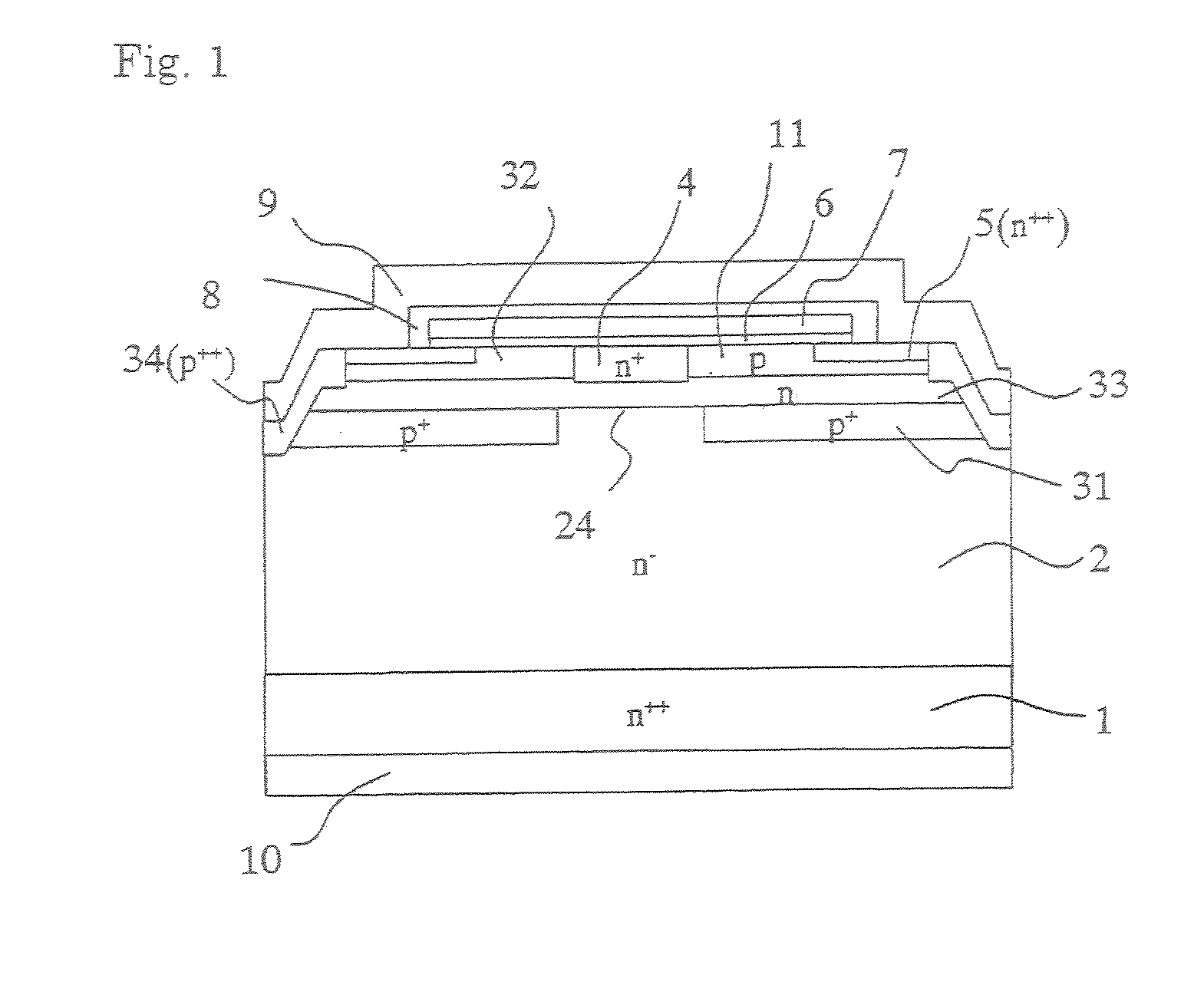

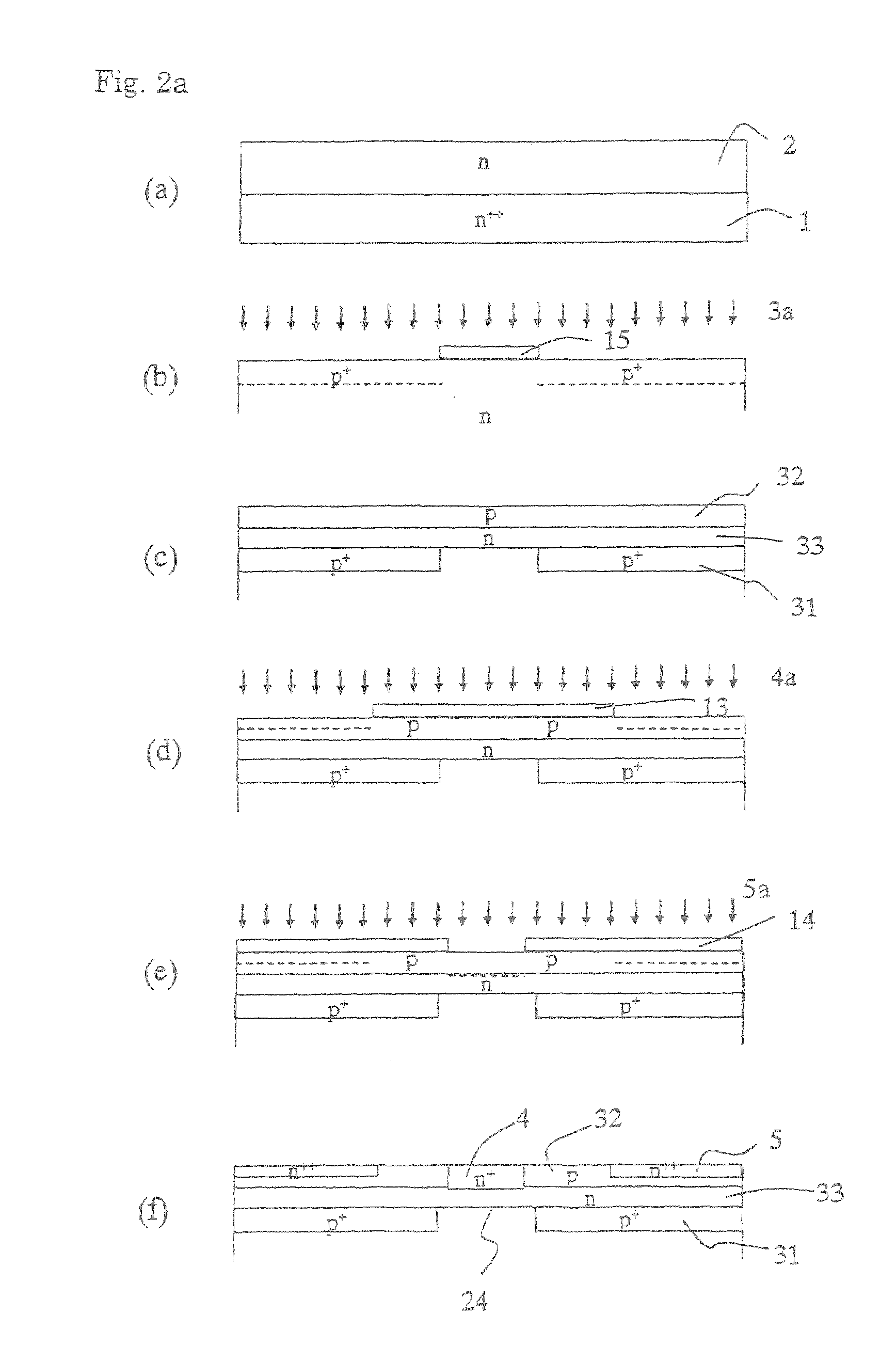

Silicon carbide mos field-effect transistor and process for producing the same

InactiveUS20090134402A1Lower on-resistanceHigh blocking voltageSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETHigh concentration

In the SiC vertical MOSFET having a low-concentration p-type deposition film provided therein with a channel region and a base region resulting from reverse-implantation to n-type through ion implantation, dielectric breakdown of gate oxide film used to occur at the time of off, thereby preventing a further blocking voltage enhancement. This problem has been resolved by interposing of a low-concentration n-type deposition film between a low-concentration p-type deposition film and a high-concentration gate layer and selectively forming of a base region resulting from reverse-implantation to n-type through ion implantation in the low-concentration p-type deposition film so that the thickness of deposition film between the high-concentration gate layer and each of channel region and gate oxide layer is increased.

Owner:NAT INST OF ADVANCED IND SCI & TECH

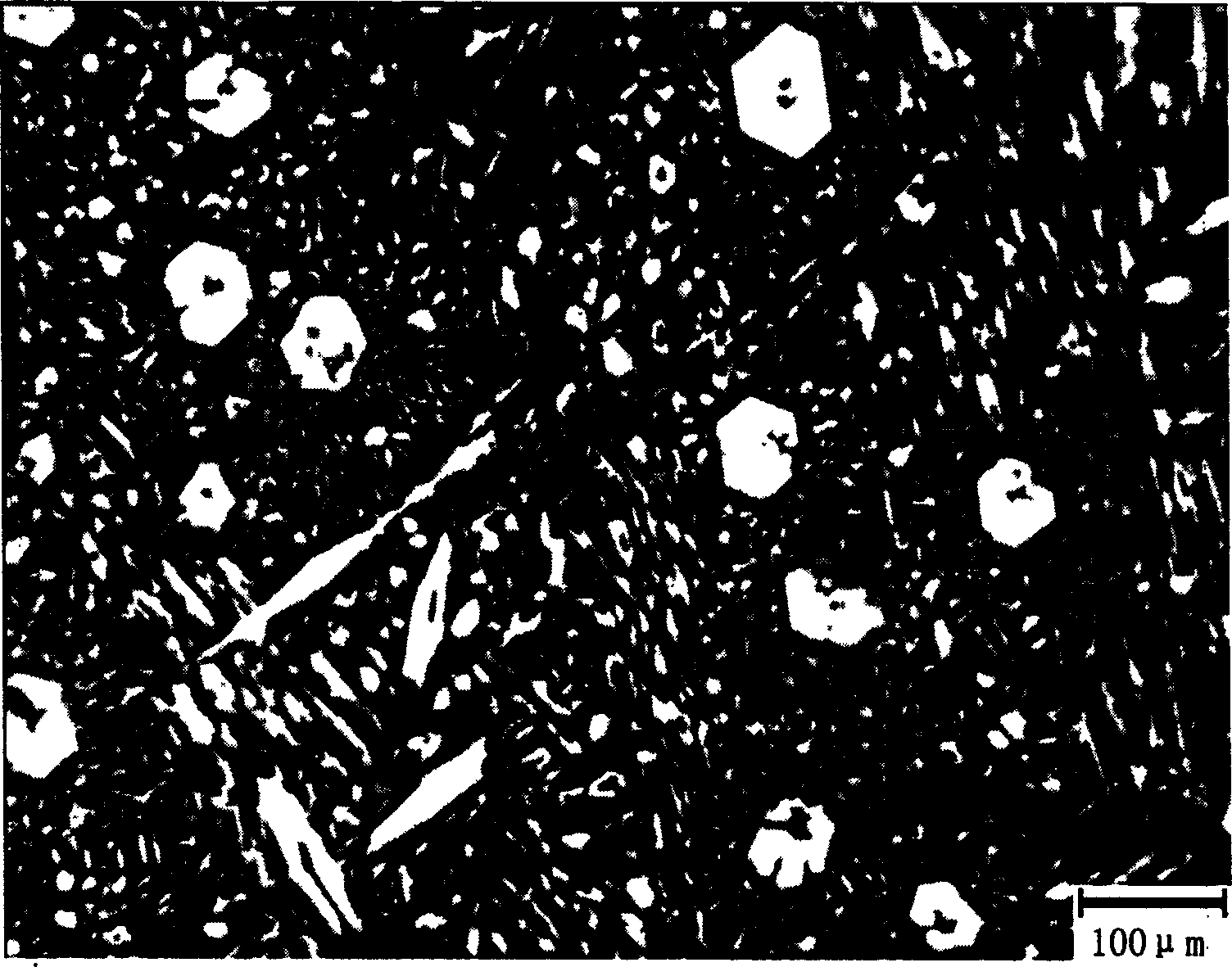

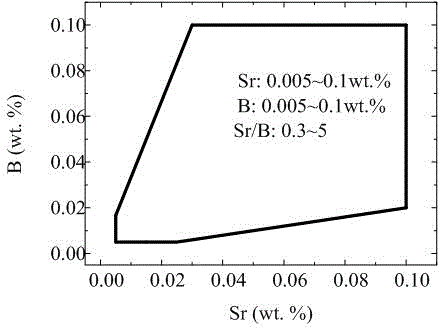

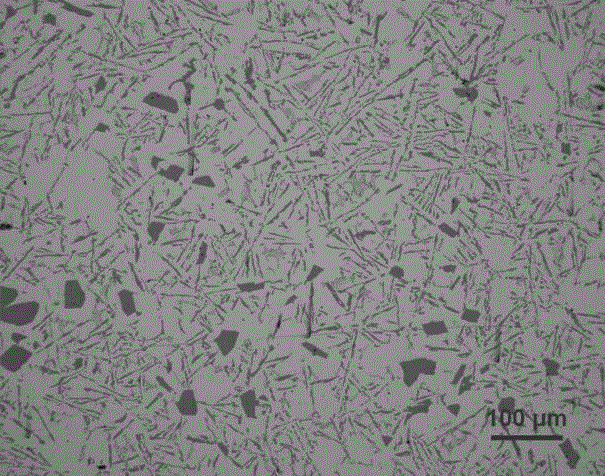

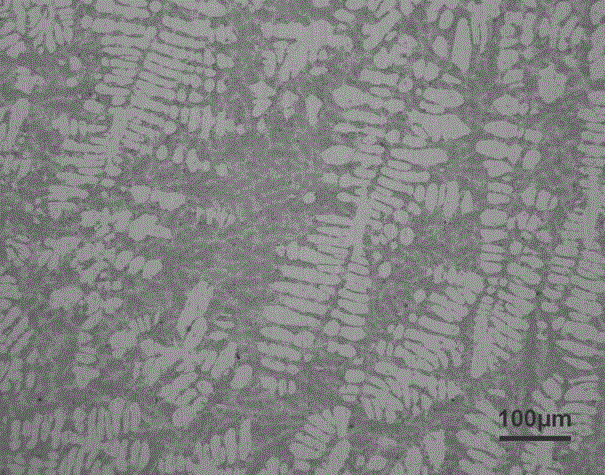

Method for modification and refinement of hypoeutectic and eutectic Al-Si alloy

The invention relates to a method for modification and refinement of a hypoeutectic and eutectic Al-Si alloy. The hypoeutectic and eutectic Al-Si alloy with the Si content of 2-13.5 wt.% is subjected to modification and refinement treatment with Sr and B; after treatment, the Sr content in an alloy melt is 0.005-0.1%, the B content is 0.005-0.1%, and the mass ratio of Sr to B is 0.3-5. An Al-B intermediate alloy is used as a refiner, and has excellent grain refining effect on the Al-Si alloy; an Al-Sr intermediate alloy is used as a modifier, can effectively modify eutectic Si in the Al-Si alloy. By controlling melting, modification and refinement treatment processes, the grain refiner also has good refinement effect on alpha-Al while the added modifier has good modification effect on the eutectic Si, so that an ingot microstructure is simultaneously modified and refined, and a mutual poisoning effect between Sr and B can be effectively avoided.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

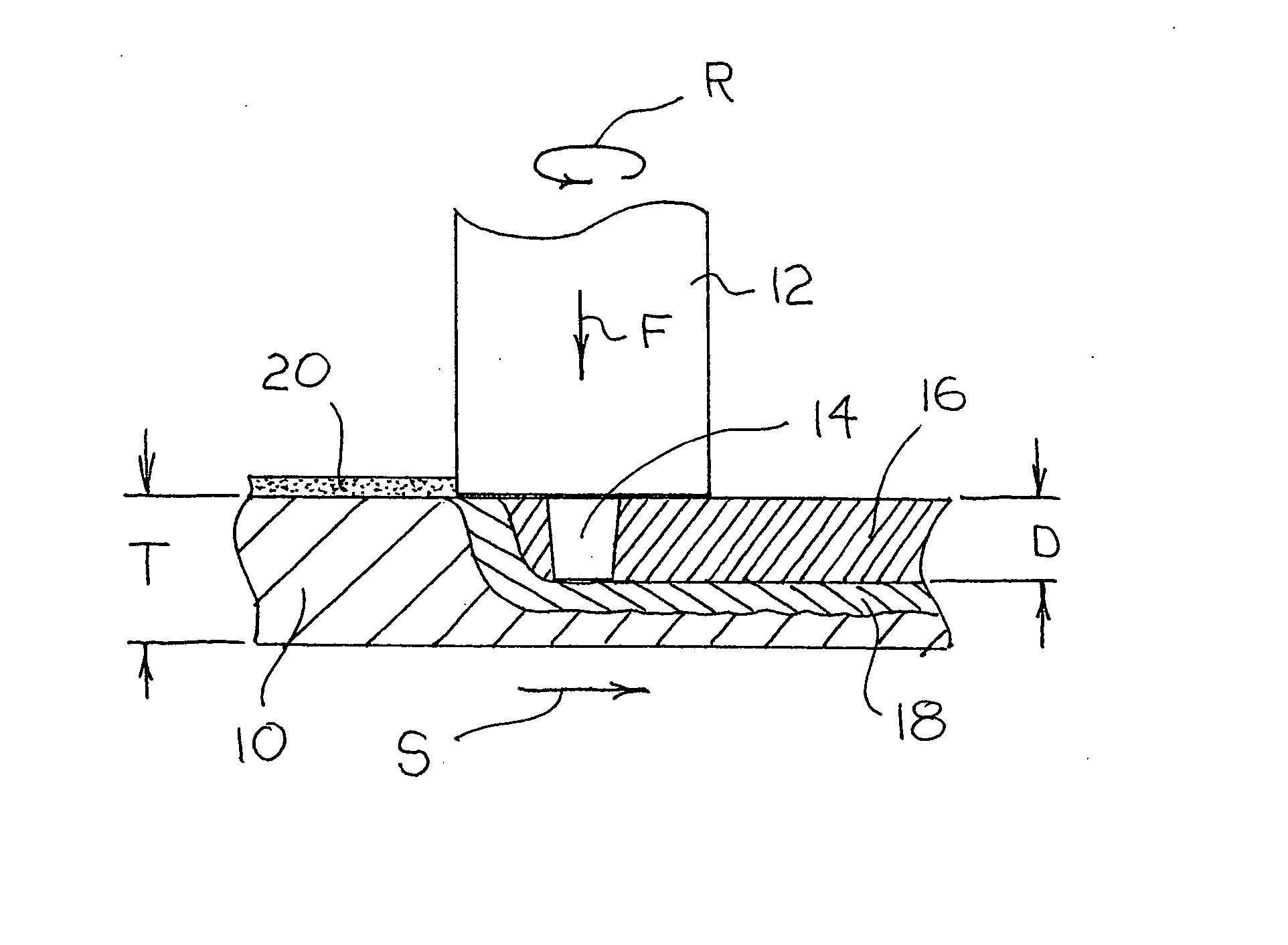

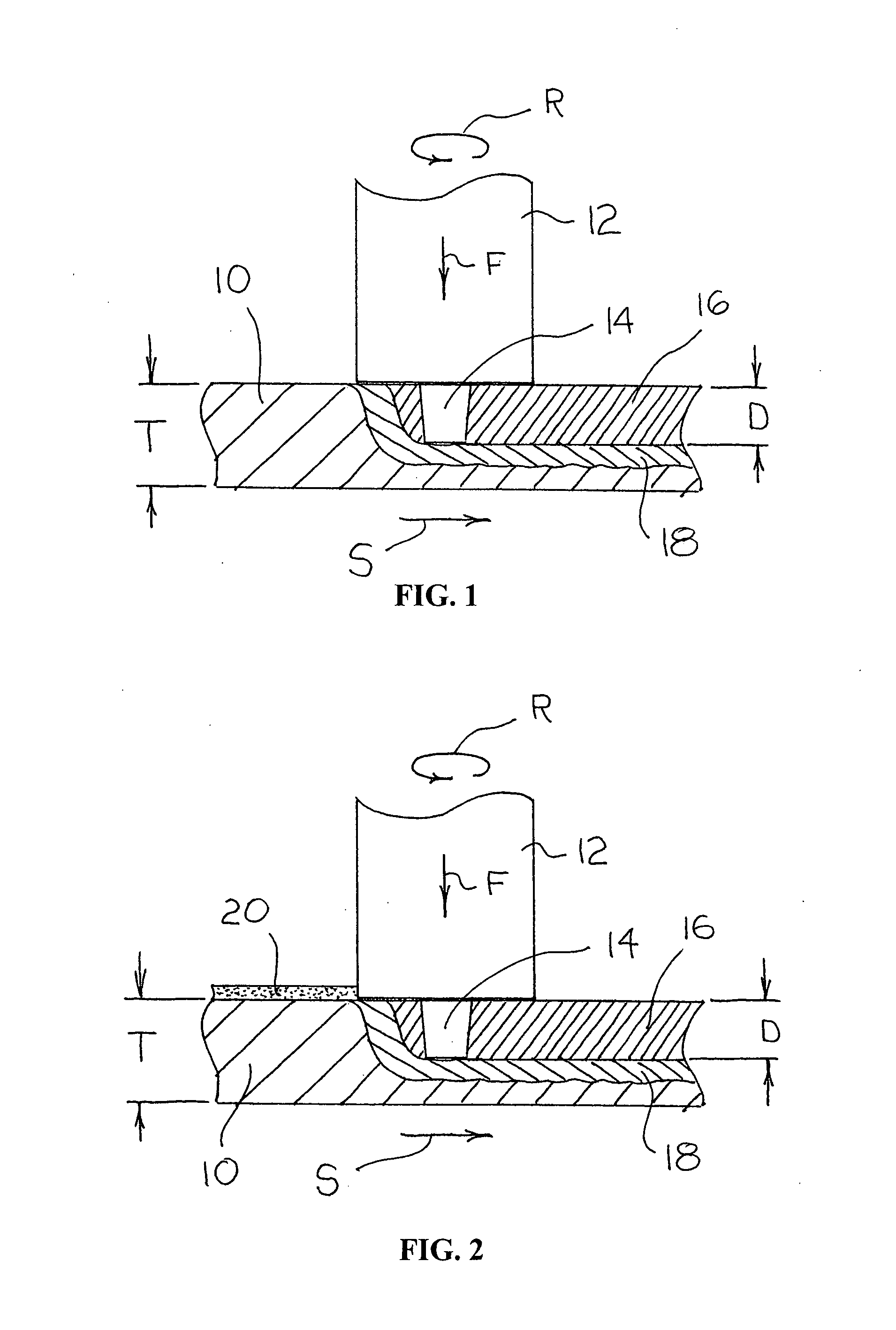

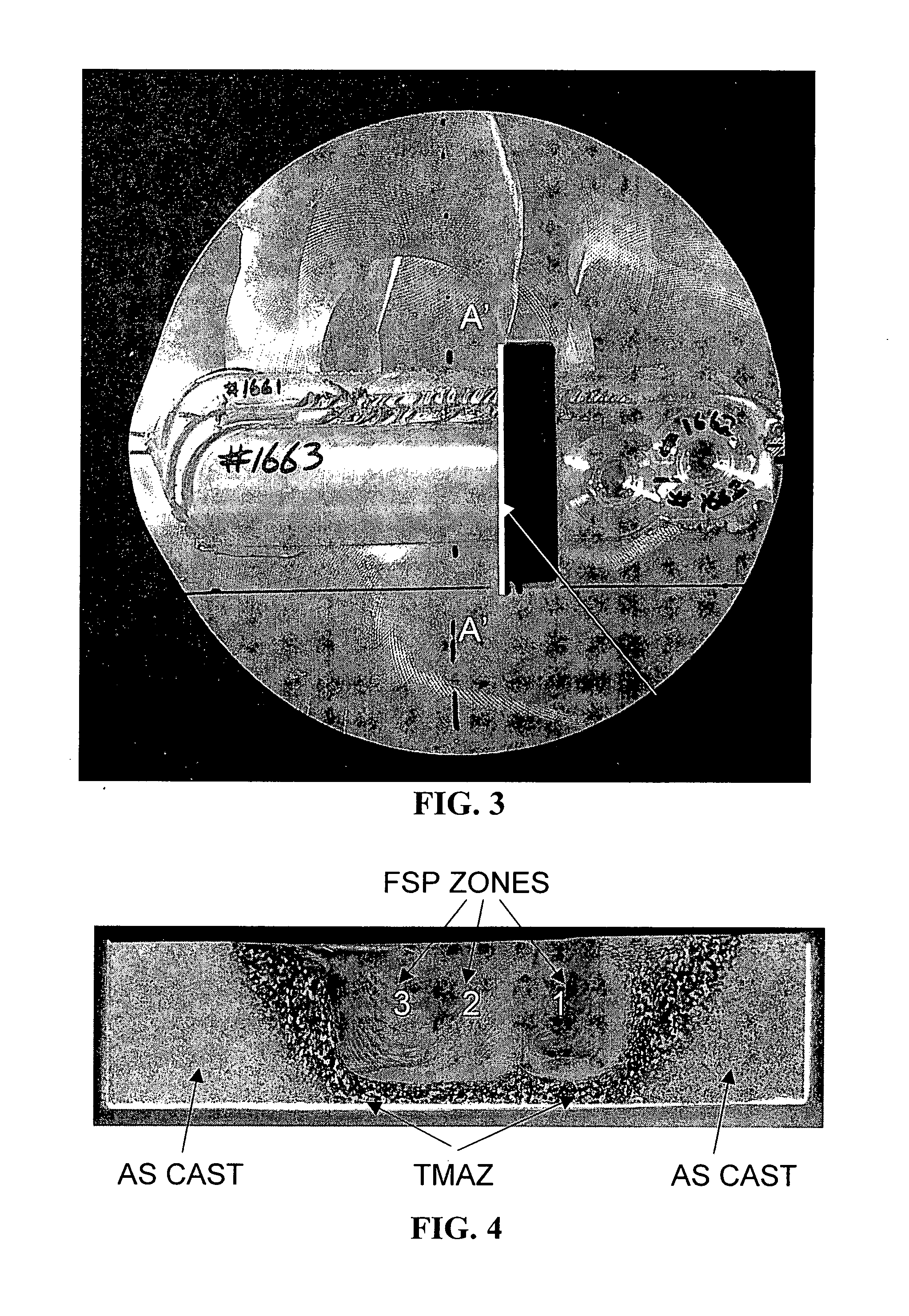

Stir processed cast aluminum-scandium structures and methods of making the same

InactiveUS20070297935A1Improve mechanical propertiesImprove corrosion resistanceAluminium compoundsGallium/indium/thallium compoundsFriction stir processingScandium

Friction stir processing is applied to an aluminum-scandium alloy workpiece in either a wrought or cast state including scandium-containing precipitates. The process selectively modifies the microstructure of the aluminum-scandium workpiece, for example, by reducing grain size and recrystallization of the substrate. Benefits include increased physical properties of the aluminum-scandium alloys as well as the ability to form unique alloy structures.

Owner:LANGAN TIMOTHY +2

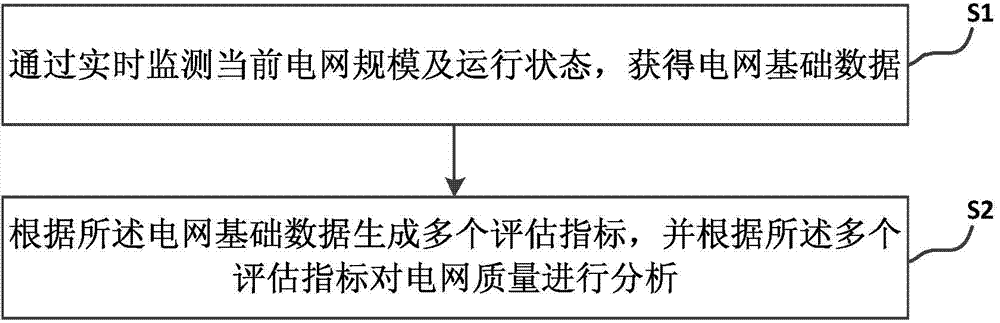

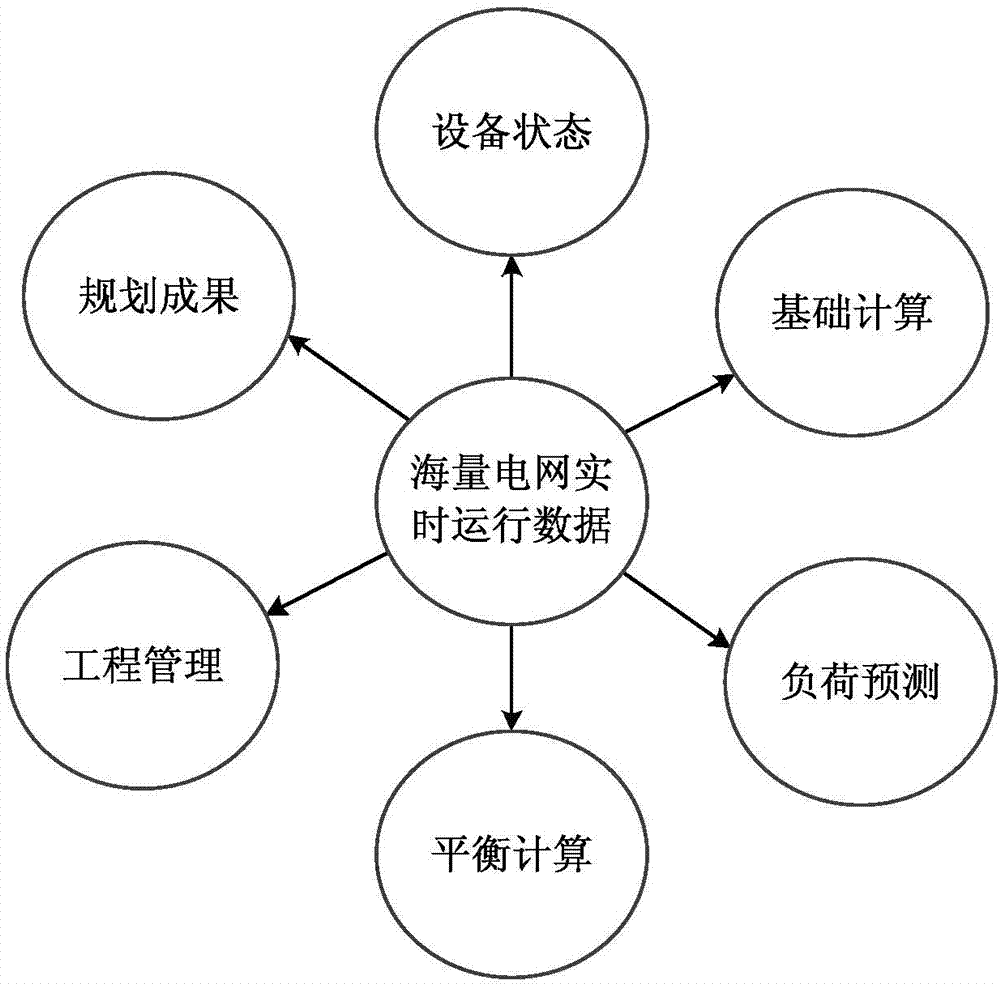

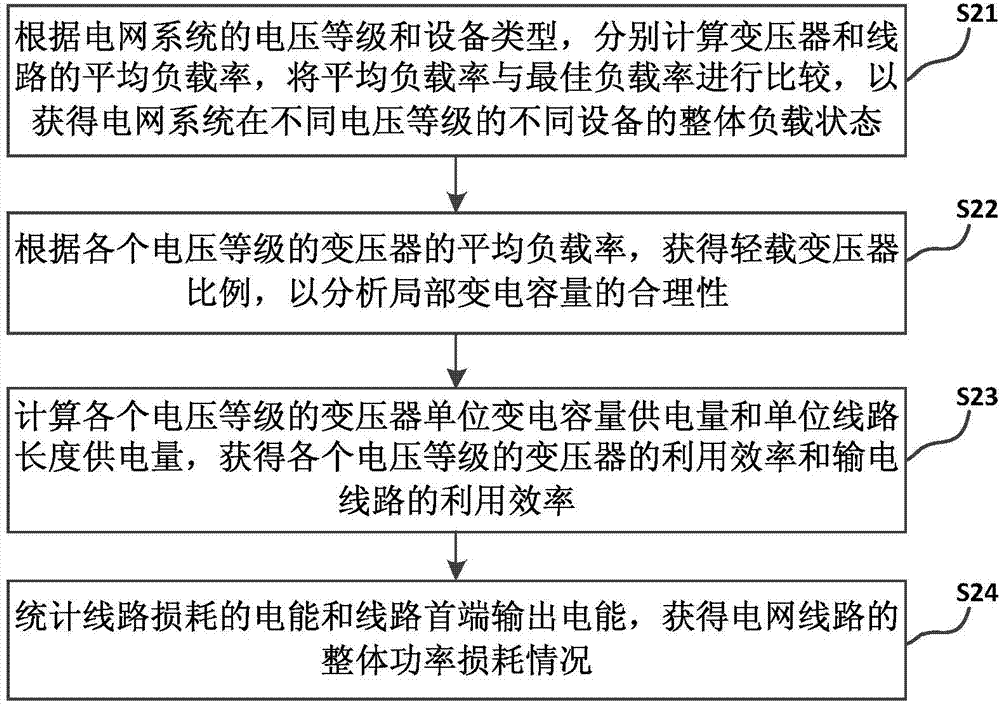

Power network quality analysis method based on real-time operating data

InactiveCN104778550APromote standardization and refinementAuxiliary Grid Planning Decision AnalysisResourcesPower gridReal-time computing

The invention discloses a power network quality analysis method based on real-time operating data. The power network quality analysis method comprises the following steps: obtaining basic data of a power network through real-time monitoring of the current scale and operating status of the power network; generating a plurality of evaluation indicators according to the basic data of the power network, and carrying out power network quality analysis according to the evaluation indicators. The power network quality analysis method provided by invention has the advantages that through effective usage of the data generated in a real-time manner during operation of the power network, a comprehensive evaluation indicator system can be established for power network quality analysis and evaluation, so that reasonable power network planning and objective evaluation of the power network planning can be achieved.

Owner:STATE GRID HUNAN ELECTRIC POWER

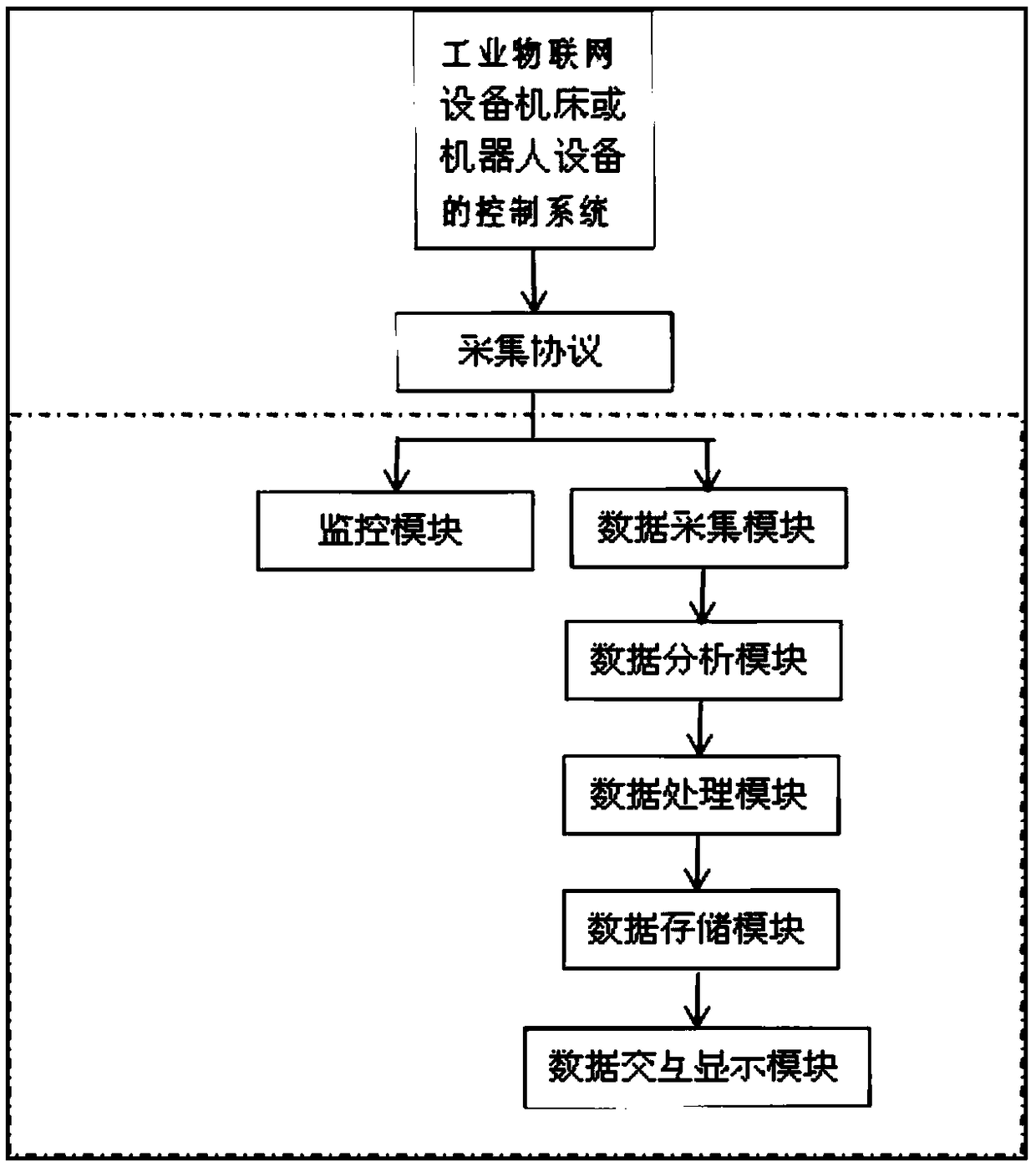

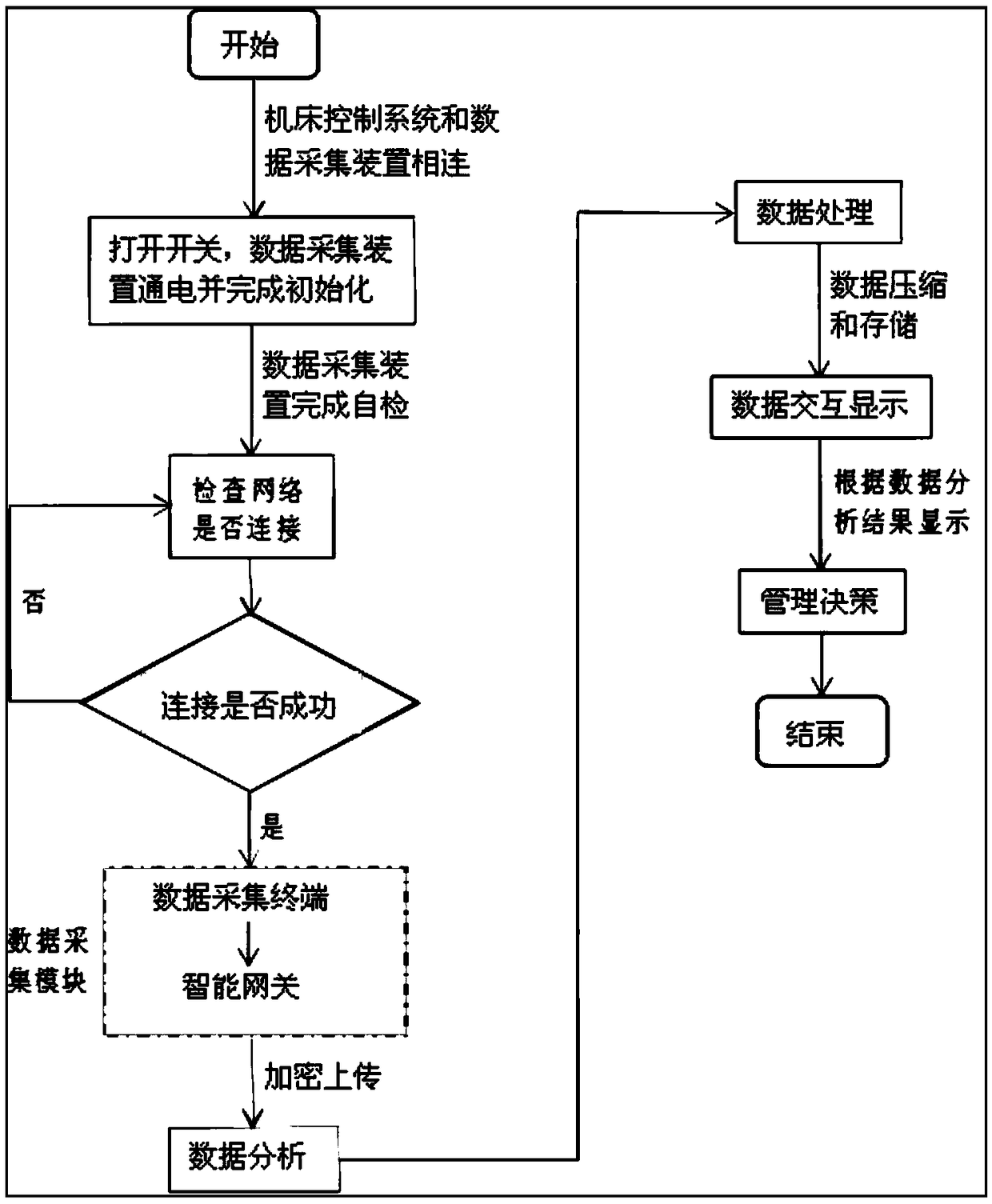

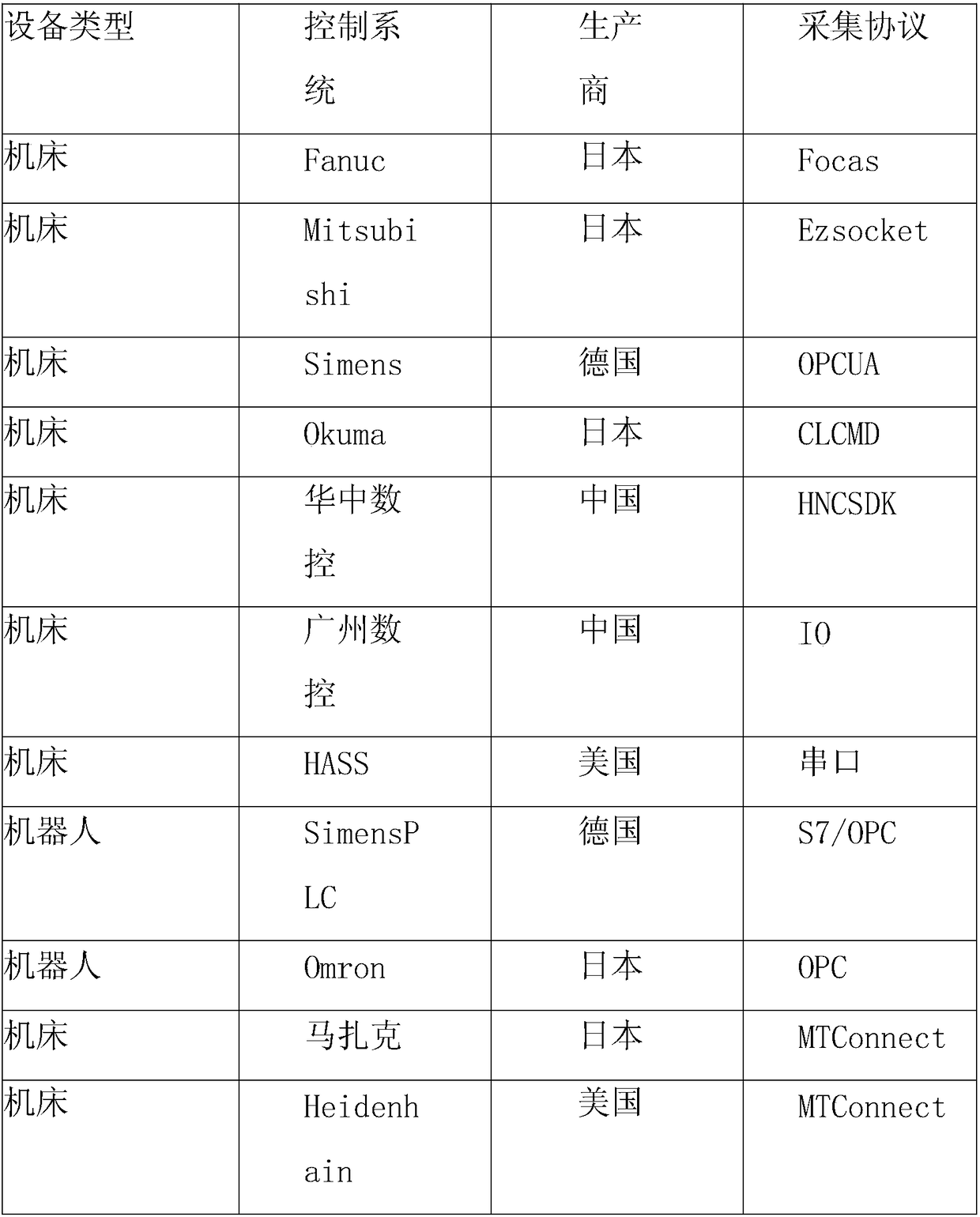

Industrial intelligent manufacturing data acquisition apparatus and method based on Internet of Things

PendingCN108762210AEasy to exportRefined production managementTotal factory controlProgramme total factory controlIndustrial equipmentThe Internet

The invention discloses an industrial intelligent manufacturing data acquisition apparatus and method based on the Internet of Things. The apparatus comprises a data acquisition module, a data transmission module, a data analysis module, a data processing module, a data storage module, a data interaction display module and a monitoring module, the data acquisition module is connected with a control system of an industrial Internet of Things equipment machine tool through an acquisition protocol, the data acquisition module, the data transmission module, the data analysis module, the data processing module, the data storage module and the data interaction display module are connected in sequence, and the monitoring module is connected with the control system of the industrial Internet of Things equipment machine tool through the acquisition protocol. According to the method and apparatus, data acquisition, analysis, transmission, storage and monitoring are performed for industrial Internet of Things factory equipment machine tools and robot equipment etc., the work efficiency is improved, the production cost is reduced, the information interaction between industrial equipment and production management personnel is enhanced, the efficiency of the equipment is improved, and intelligent and datamation management of factory processing equipment can be realized.

Owner:银川华信智信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com