Low cost, high-wearability hypereutectic high chromium cast iron and its production method

A high-chromium cast iron, high wear resistance technology, applied in manufacturing tools, heat treatment process control, heat treatment equipment, etc., can solve the problems of unfavorable material toughness, poor fluidity of alloy liquid, unstable quality, etc., and achieve a remarkable inoculation effect. , Remarkable refinement effect, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

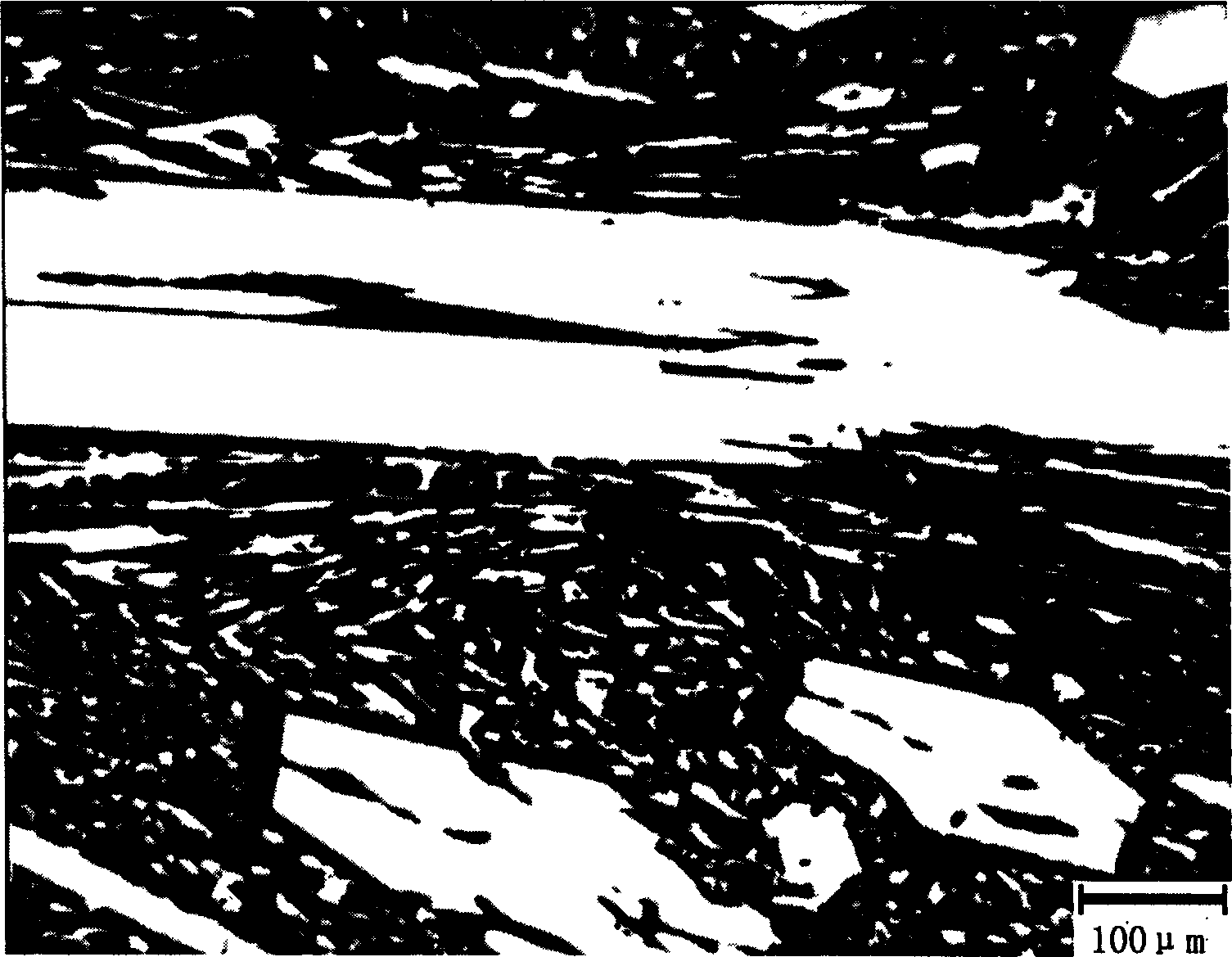

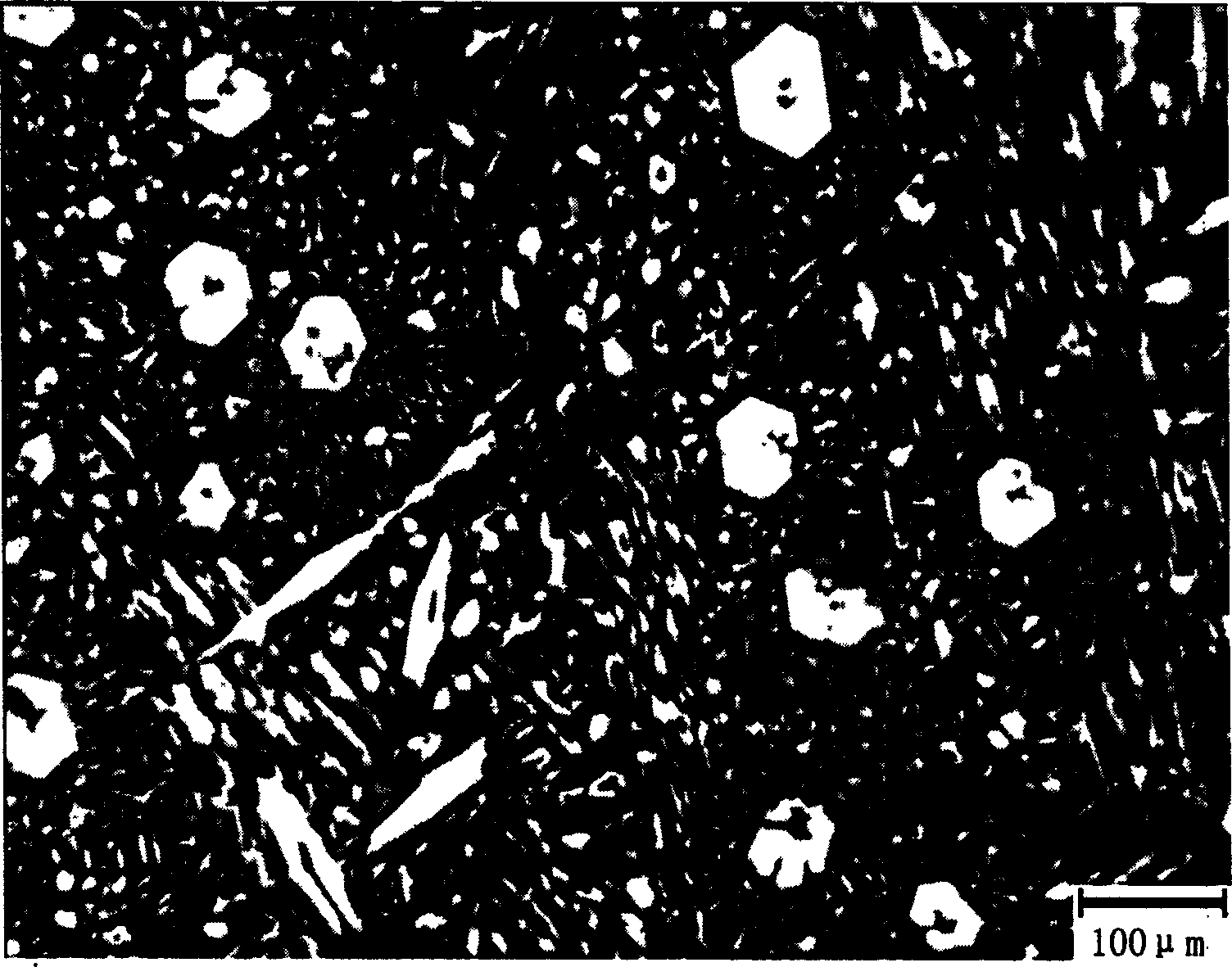

Image

Examples

Embodiment

[0056] Adopt high-carbon ferrochrome, common steel scrap, pig iron, ferromanganese, scrap copper, nickel plate according to the technical scheme batching (wt%) of the present invention; Smelting in 500kg acid medium frequency induction furnace. When the temperature rises to 1650°C, aluminum is added as a deoxidizer, and the molten iron is poured into the ladle immediately after deoxidation;

[0057] The roasted and dried intermediate alloy, potassium salt (potassium permanganate), and cerium rare earth magnesium alloy with a particle size of 10mm to 13mm are placed in the ladle in advance (protective measures should be taken when handling in the ladle);

[0058] The composition of the inoculant in the ladle is (accounting for the wt% of the treatment alloy solution): 0.5-2.0% master alloy + 1.0-3.0% potassium salt + 0.5-3.0% cerium rare earth magnesium alloy.

[0059] The composition of the master alloy is: C: 1.0-4.0%, Mn: 1-5%, Cr: 2-4, Nb: 0.5-4%, V: 0.2-1%, Si: 05-1.0%, N:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com