Patents

Literature

1557 results about "Pig iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pig iron is an intermediate product of the iron industry, also known as crude iron, which is obtained by smelting iron ore in a blast furnace. Pig iron has a very high carbon content, typically 3.8–4.7%, along with silica and other constituents of dross, which makes it very brittle and not useful directly as a material except for limited applications.

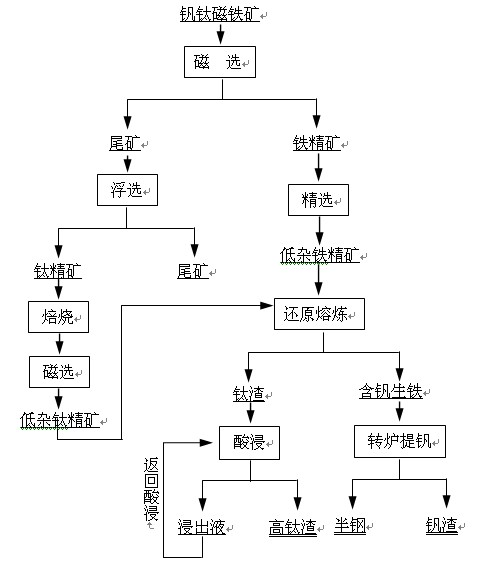

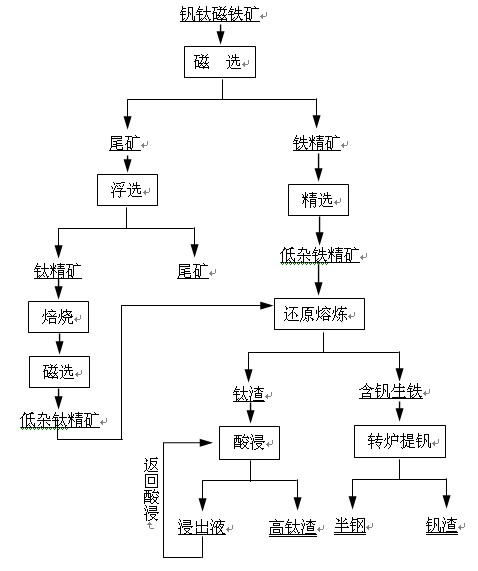

Method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium

InactiveCN102179292AHigh technical difficultyIncrease processing costWet separationSmelting processMagnetite

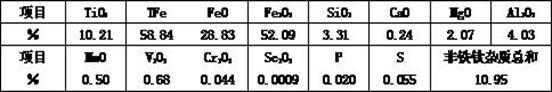

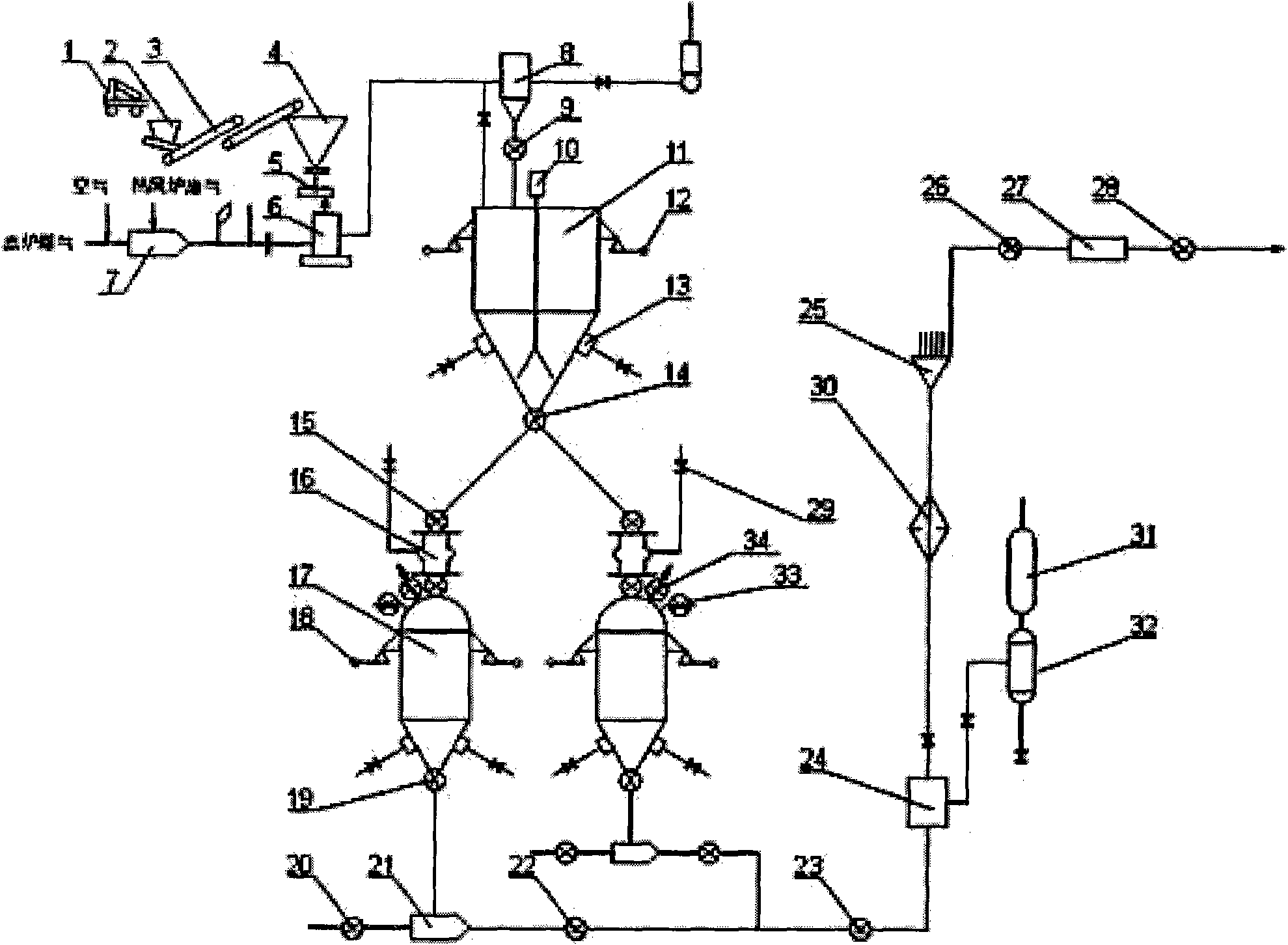

The invention discloses a method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium, comprising the following steps of: magnetically selecting raw magnetite, that is, acquiring iron-vanadium concentrate and tail magnetite after performing magnetic selection on the vanadium-titanium magnetite; sorting titanium concentrate from the tail magnetite, that is, acquiring the titanium concentrate after performing floating selection on the obtained tail magnetite; roasting and magnetically selecting the titanium concentrate, that is, performing enriched-titanium impurity-removing magnetic selection after roasting the titanium concentrate; finely selecting the iron-vanadium concentrate, that is, performing the magnetic selection and fine section again on the iron-vanadium concentrate obtained from magnetic selection; reducing and smelting, that is, mixing the titanium concentrate obtained from the impurity-removing process with the iron concentrate according to the beneficiation yield, adding in a reducer and soda ash to perform reduced iron and vanadium smelting process; purifying vanadium slag, that is, removing the impurity of the vanadium slag obtained by reducing and smelting by using the acidic dipping to obtain the high-quality titanium slag product with the content of TiO2 larger than 92%; and extracting vanadium from pig iron, that is, performing vanadium extraction by converter blowing on the vanadium-containing pig iron obtained by reducing and smelting to obtain the semi-steel and vanadium slag. The method not only improves the utilization ratio of titanium, iron and vanadium but also obtains the high-titanium slag product with the content of TiO2 larger than 92% so as to widen the application field of titanium.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Synthetic cast iron for production of hydraulic piece and preparation method thereof

The invention discloses a synthetic cast iron for hydraulic member production, the mass percentage of the compositions is as follows: 1.8 percent to 3.3 percent of C, 1.8 percent to 2.0 percent of Si, 0.4 percent to 0.7 percent of Mn, 0 percent to 0.3 percent Cr, 0 percent to 0.5 percent of Cu and the rest is Fe. The percentage of the compositions of the charging is as follows: 50 percent to 75 percent of scrap steel, 10 percent to 30 percent of foundry returns, pig iron of 10 percent to 20 percent of pig iron and 1.5 percent to 2.6 percent of recarbonizer. The molten iron is added carbon at low temperature and compensated carbon at high temperature to reach the required ingredients during smelting. The invention can effectively remove the fault of shrinkage porosity inside the high strength gray cast iron; therefore the body strength is greatly improved. The invention has petty microscopic constitution and the casting has compact texture.

Owner:CSIC NO 12 RES INST

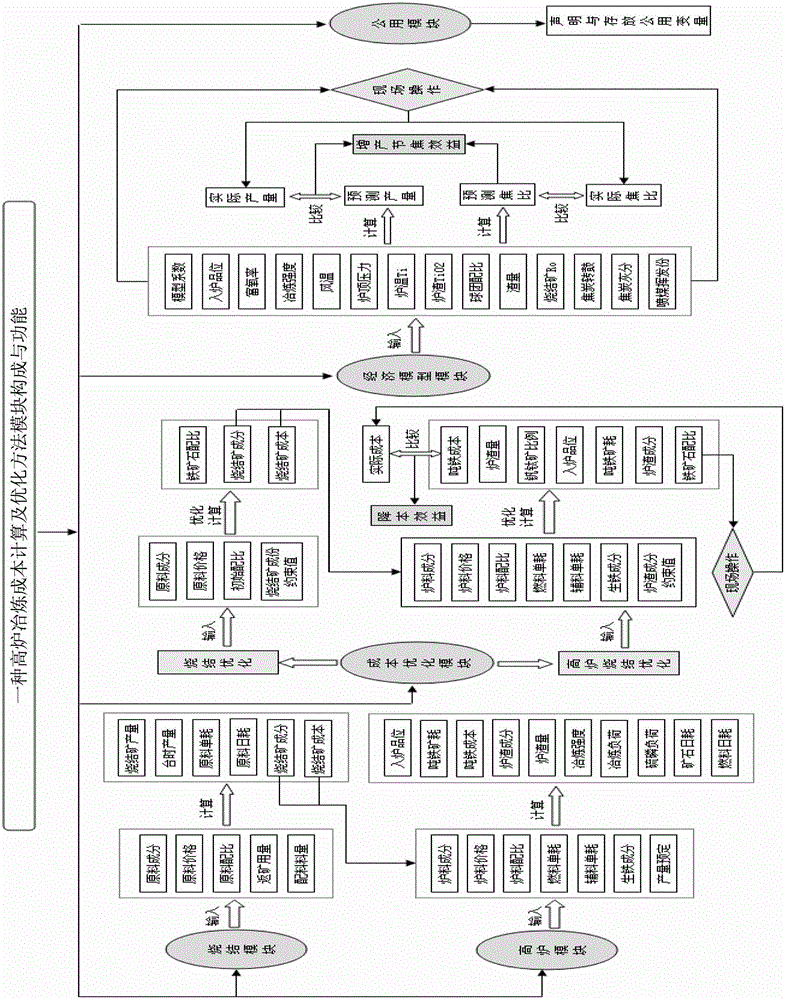

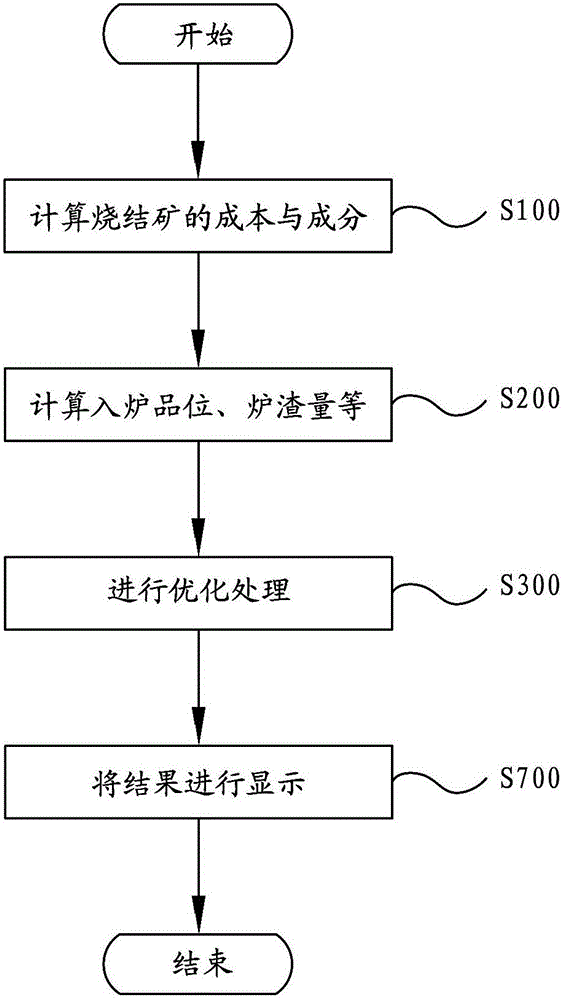

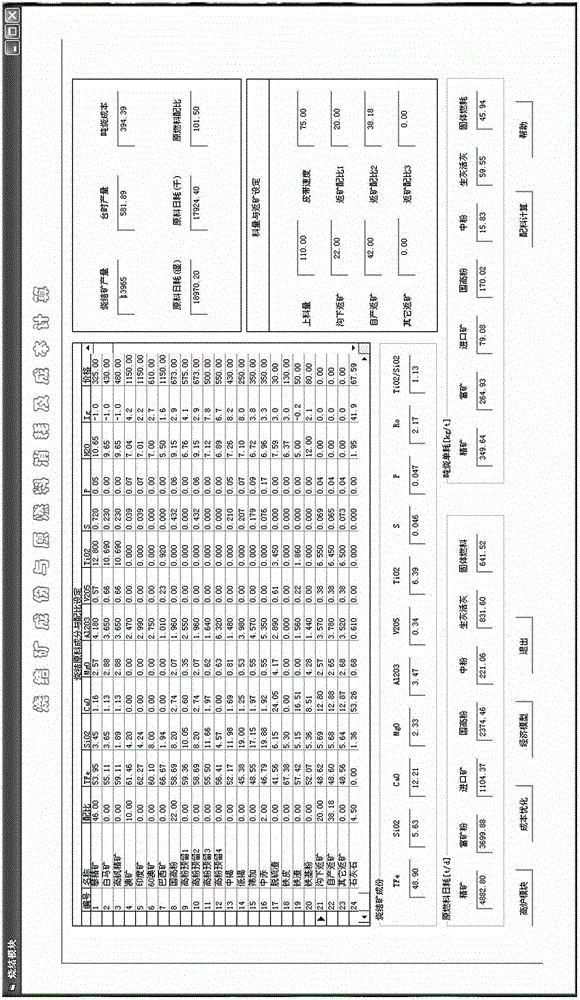

Blast furnace smelting cost calculating and optimizing method

InactiveCN102722652ARaise the ratioReduce smelting costBlast furnace detailsSpecial data processing applicationsAlkalinityBlast furnace smelting

The invention relates to the field of the pig iron smelting, and particularly relates to a blast furnace smelting cost calculating and optimizing method. The blast furnace smelting cost calculating and optimizing method provided by the invention comprises the following steps: calculating the component content, the alkalinity and the unit price of a sinter according to the ratio of sintering materials; calculating the furnace charging grade, the slag amount and the slag component content by using the component content and the unit price of the sinter according to the proportion of blast furnace burdens; and optimizing the component content, the alkalinity and the unit price of the sinter as well as the furnace charging grade, and the slag amount and the slag component content of the blast furnace. The above process is an inverse process of calculating components of the sinter or the slug components and the slug cost. The blast furnace smelting cost calculating and optimizing method provided by the invention can calculate the proportion of low cost iron ore in an inverse mode, and the blast furnace smelting cost calculating and optimizing method is used to guide the production. Moreover, the blast furnace smelting cost calculating and optimizing method can meet the production requirements of a blast furnace and achieve the favorable smelting cost.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

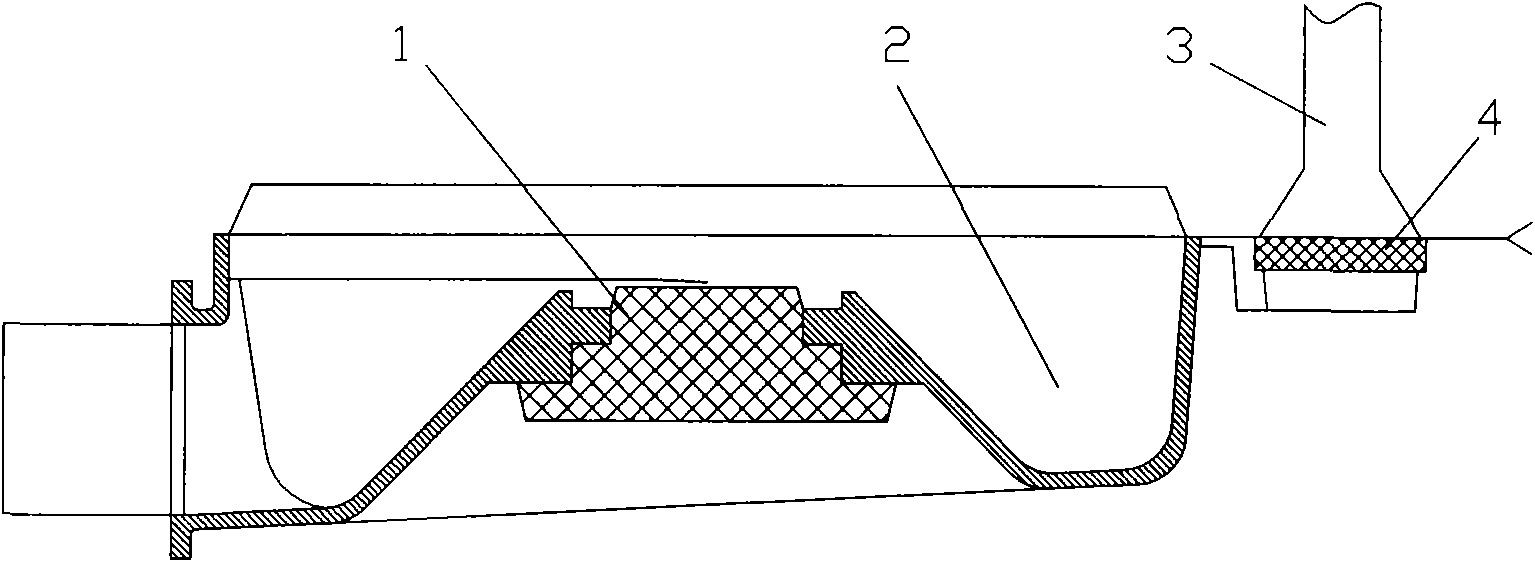

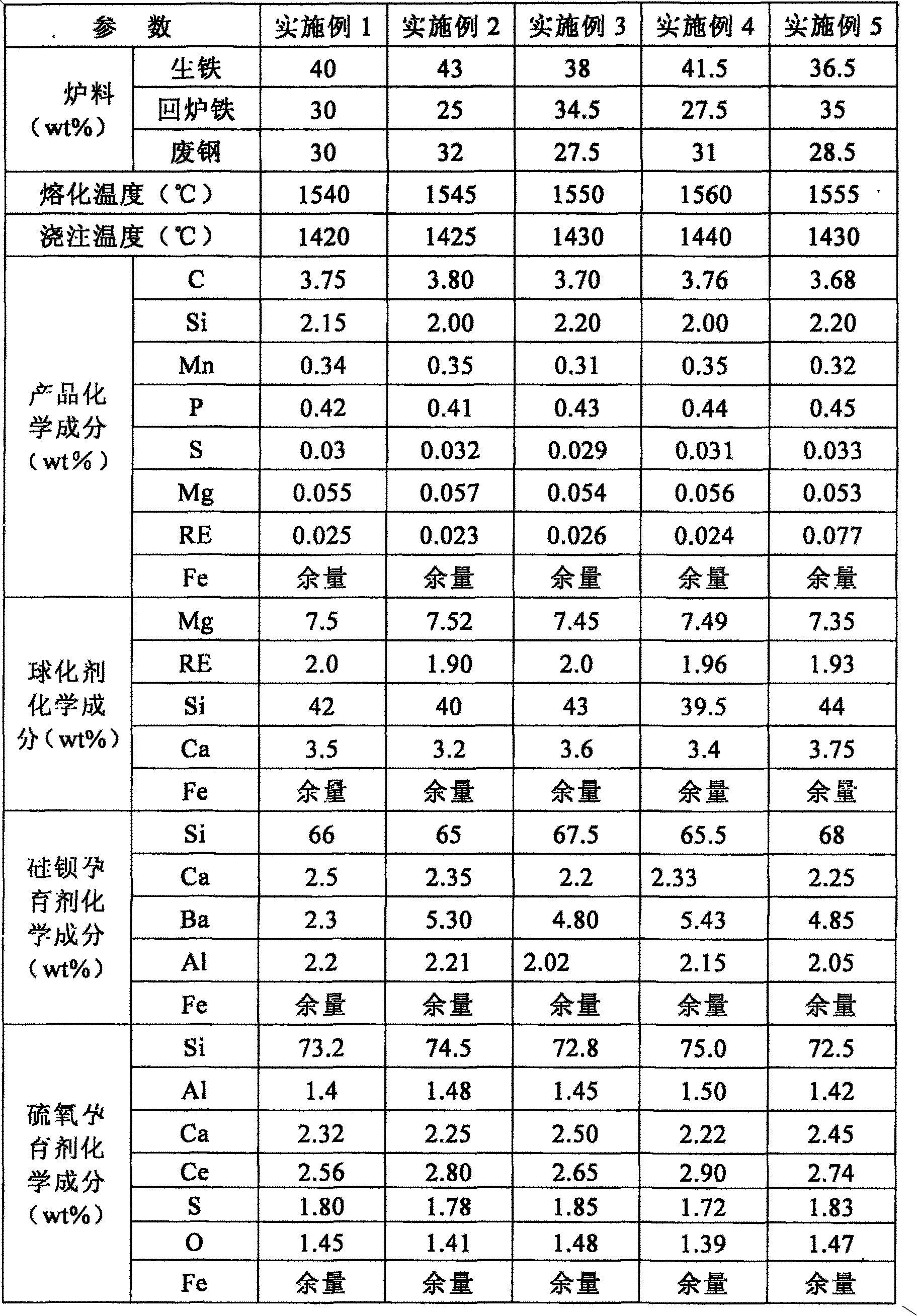

Method for casting as-cast high-tenacity cast iron bearing cover of locomotive

The invention relates to a method for casting an as-cast high-tenacity cast iron bearing cover of a locomotive. The method comprises the following steps: sand mulling, molding, core making, mould assembly, charging smelting, tapping spheroidization inoculation treatment, casting, cooling, unboxing and casting cleaning. The step of charging smelting comprises charging arrangement and smelting, as well as the smelting of a medium-frequency induction furnace, wherein the charging comprises 35-45 percent of pig iron, 25-35 percent of returning iron and 25-35 percent of waste steel according to weight percentage. The tapping spheroidization inoculation treatment comprises spheroidization treatment and secondary silicon-barium inoculation. Stream inoculation of tertiary sulfur-oxygen nucleating agent is conducted during the casting. The bearing cover of the locomotive produced by the method has a tensile strength higher than or equal to 400 MPa, a specific elongation more than or equal to 18 percent, a hardness HBS ranging from 130 to 180 and a low temperature (-20 DEG C) impact value higher than or equal to 12 J / cm; the spheroidization rate the metallurgical structure of casting body is higher than or equal to 85 percent, and the ferrite content is higher than or equal to 95 percent; the thickness difference of casting walls is less than or equal to + / - 1 mm; and the detection result of the casting ultrasonic and magnetic powder inspection reaches the second grade standard of the state.

Owner:上海华新合金有限公司

Method for directly restoring and recovering copper iron from smelting copper slag

ActiveCN102952952AMeet the requirements of energy saving and emission reductionEfficient recyclingProcess efficiency improvementGas emission reductionMolten stateOxygen

The invention belongs to the field of metallurgy, and particularly relates to a method for directly restoring and recovering copper iron from smelting copper slag. The method comprises the following steps of: transferring high-temperature molten state copper slag to a high-temperature reducing furnace by a tundish, jetting oxygen to previously desulfurize, adding slagging constituent to keep temperature, jetting natural gas to carry out smelting reduction, slowly cooling to 1096 DEG C at the speed of 1.5-2 DEG C / min, and keeping the temperature for 1h to obtain 7.3at% Cu-Fe copper alloy melt and gamma pig iron, or slowly cooling to 850 DEG C at the speed of 1.5-2 DEG C / min, and keeping the temperature for 1h to obtain 2.7at% Cu-Fe copper alloy melt and gamma pig iron. According to the method provided by the invention, the total recovery use of valuable components, i.e. copper, iron and the like, can be realized, and the alloy melt obtained by the reduction smelting is slowly cooled and separated to obtain copper-rich alloy and low-sulfur gamma pig iron, so that separation of copper and iron is realized and the additional values of products can be improved.

Owner:NORTHEASTERN UNIV

Reduction and utilization method of dedusting ash of stainless steel

InactiveCN101705333AReduce pollutionHigh recovery rateRotary drum furnacesProcess efficiency improvementMixed materialsMolten steel

The invention relates to a reduction and utilization method of dedusting ash of stainless steel, comprising the following steps of: (1) preparing materials: uniformly stirring and mixing raw materials into a mixed material according to following proportions: 90-95 dedusting ash, 2-4 reducing agent and 3-6 bonding agent; (2) extrusion formation: pressing the mixed material into dedusting ash pressure balls; (3) maintaining: naturally drying and maintaining the dedusting ash pressure balls, wherein the measured intensity of the pressure balls is 2420N / each ball-2820N / each ball; (4) sintering: adding the dedusting ash pressure balls into a rotary kiln, sintering at 650+ / -50 DEG C for no less than 20 minutes, and discharging; (5) preparing materials for an electric furnace according to the following proportions: 70-80 stainless steel waste steel, 35-40 high-carbonferrochrome, 40-45 pig iron containing chromium and nickel, 3-5 dedusting ash pressure balls, 6-8 slag former and 0.3-0.5 reducing agent; and (6) melting: adding the prepared materials into the electric furnace for melting, and tapping when the temperature and the components of the molten steel meet the requirement. The reduction and utilization method of the dedusting ash of stainless steel has the advantages of low cost and little pollution to the environment.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

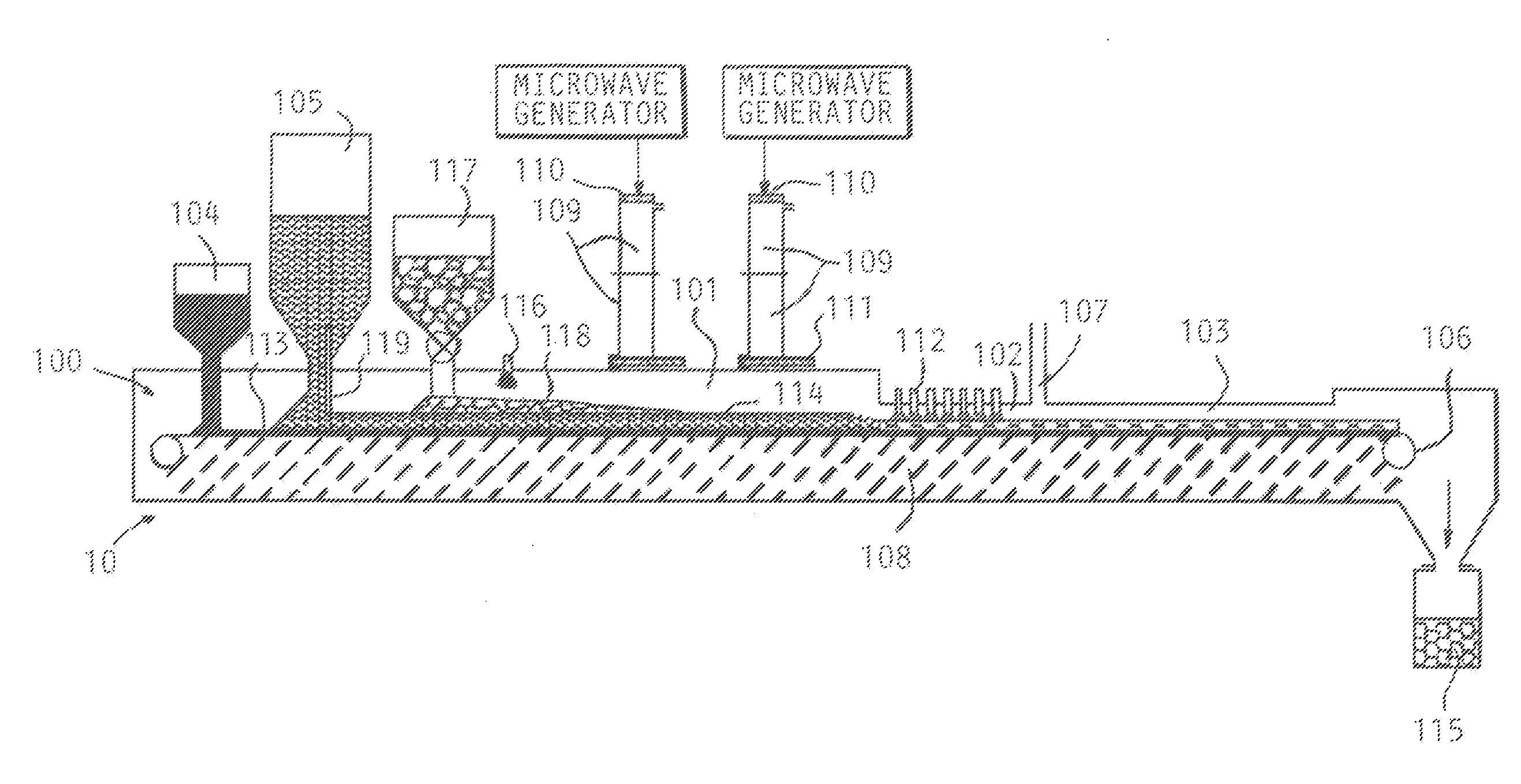

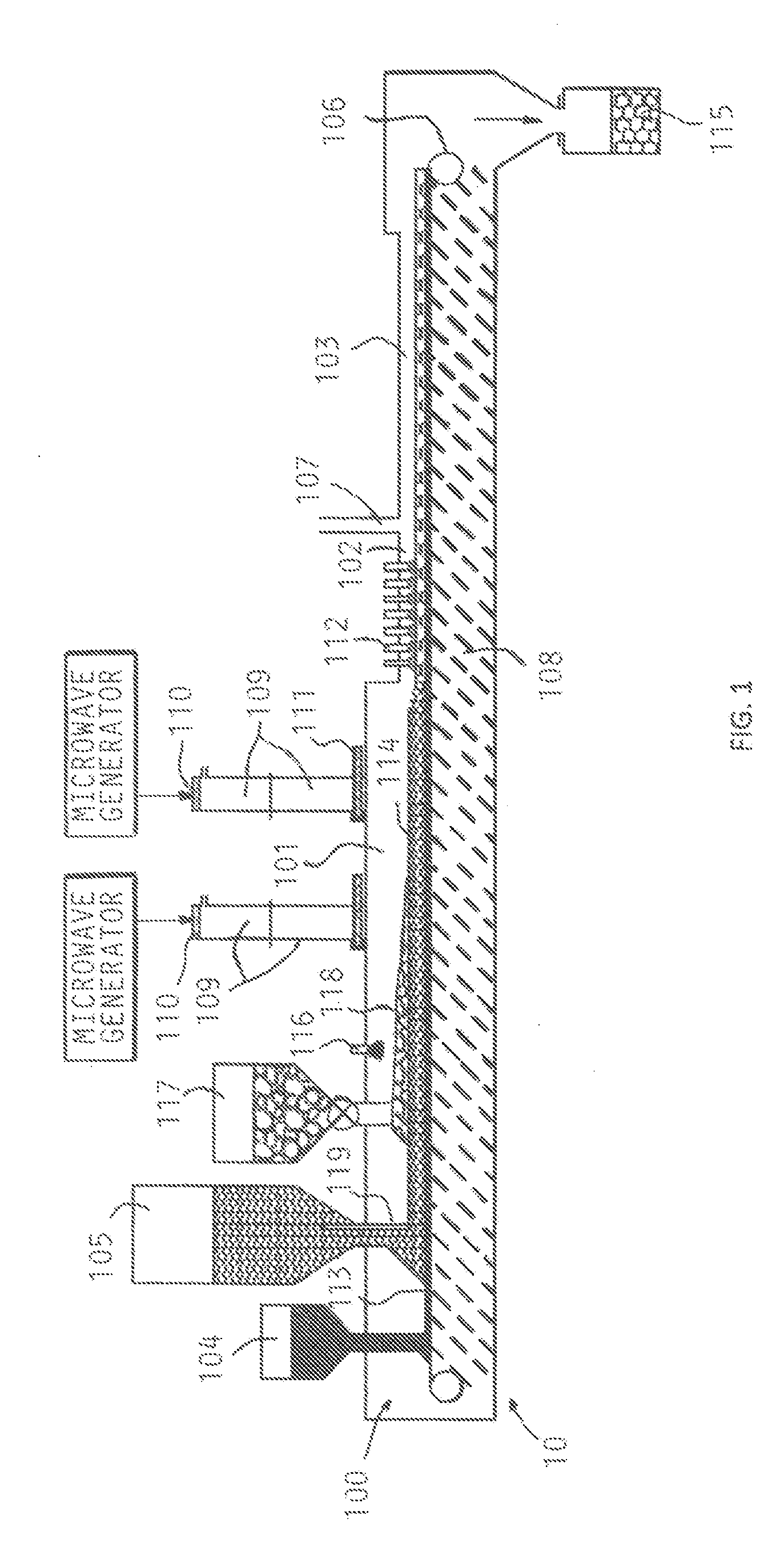

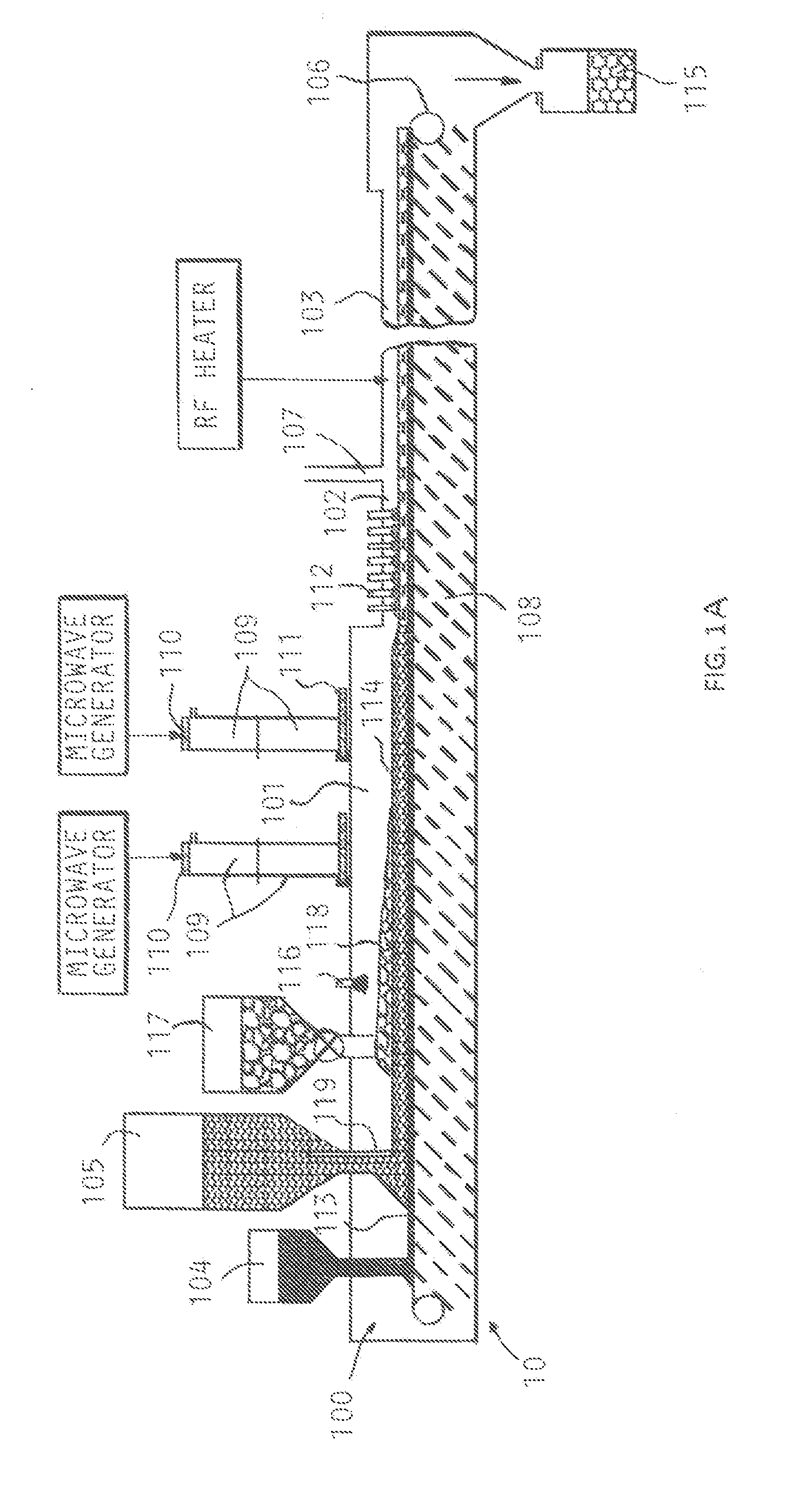

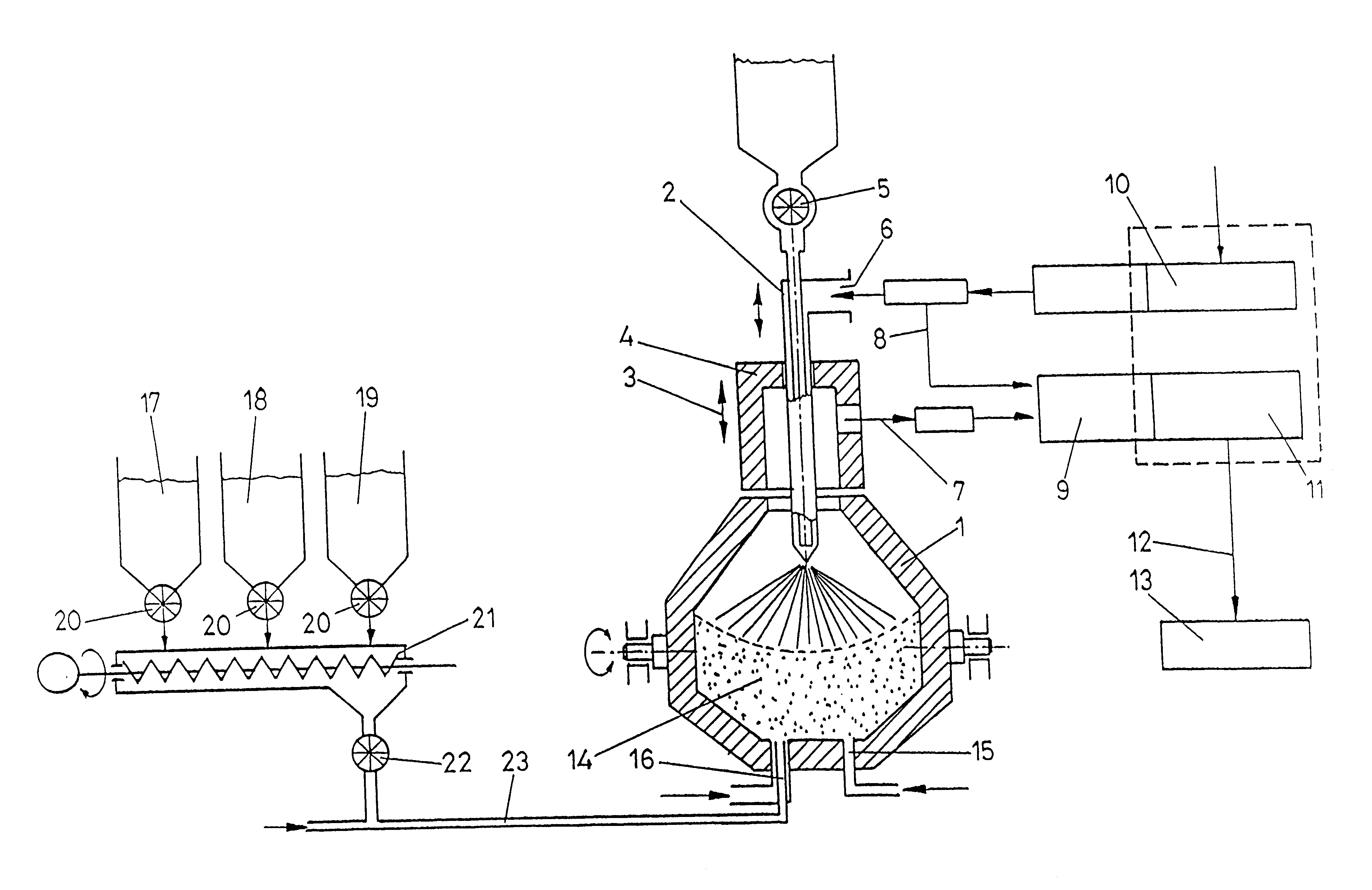

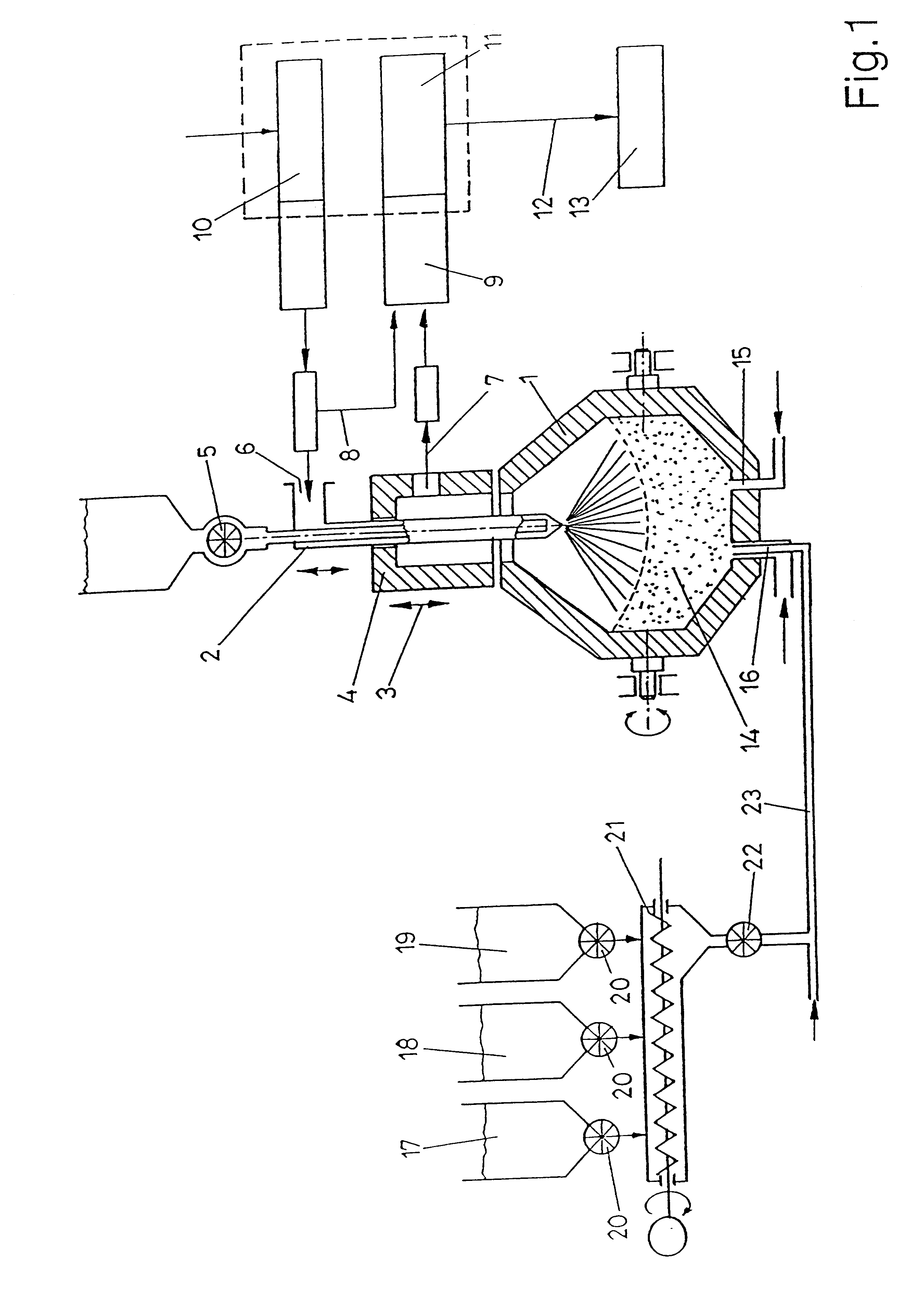

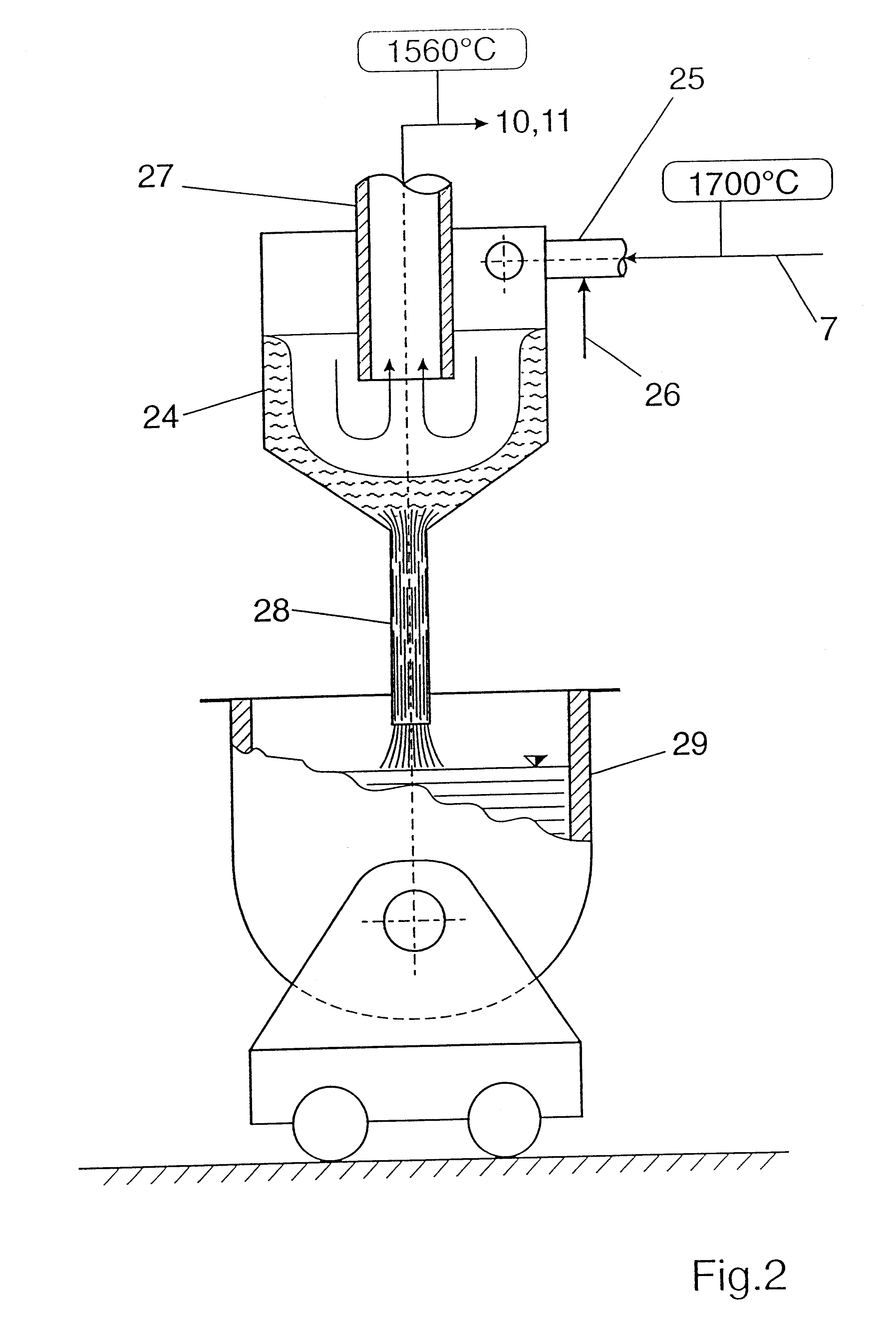

Method and Apparatus For Coproduction of Pig Iron and High Quality Syngas

ActiveUS20120031232A1Improve microwave absorption performanceHeating up fastBlast furnace detailsCharge manipulationSludgeLiquid fuel

Combined microwave heating and plasma / electric arc heating is utilized in several processes and apparatus which involve co-production of pig iron and high quality syngas, biomass to liquid fuel production, coal to liquid fuel production, co-gasification of biomass and coal, municipal solid waste treatment, waste-to-energy (agriculture waste, ASR and PEF), EAF dust and BOF sludge treatment to recover zinc and iron, hazardous bottom ash vitrification, and bromine, chlorine and sulfur removal / recycling.

Owner:HUANG XIAODI +1

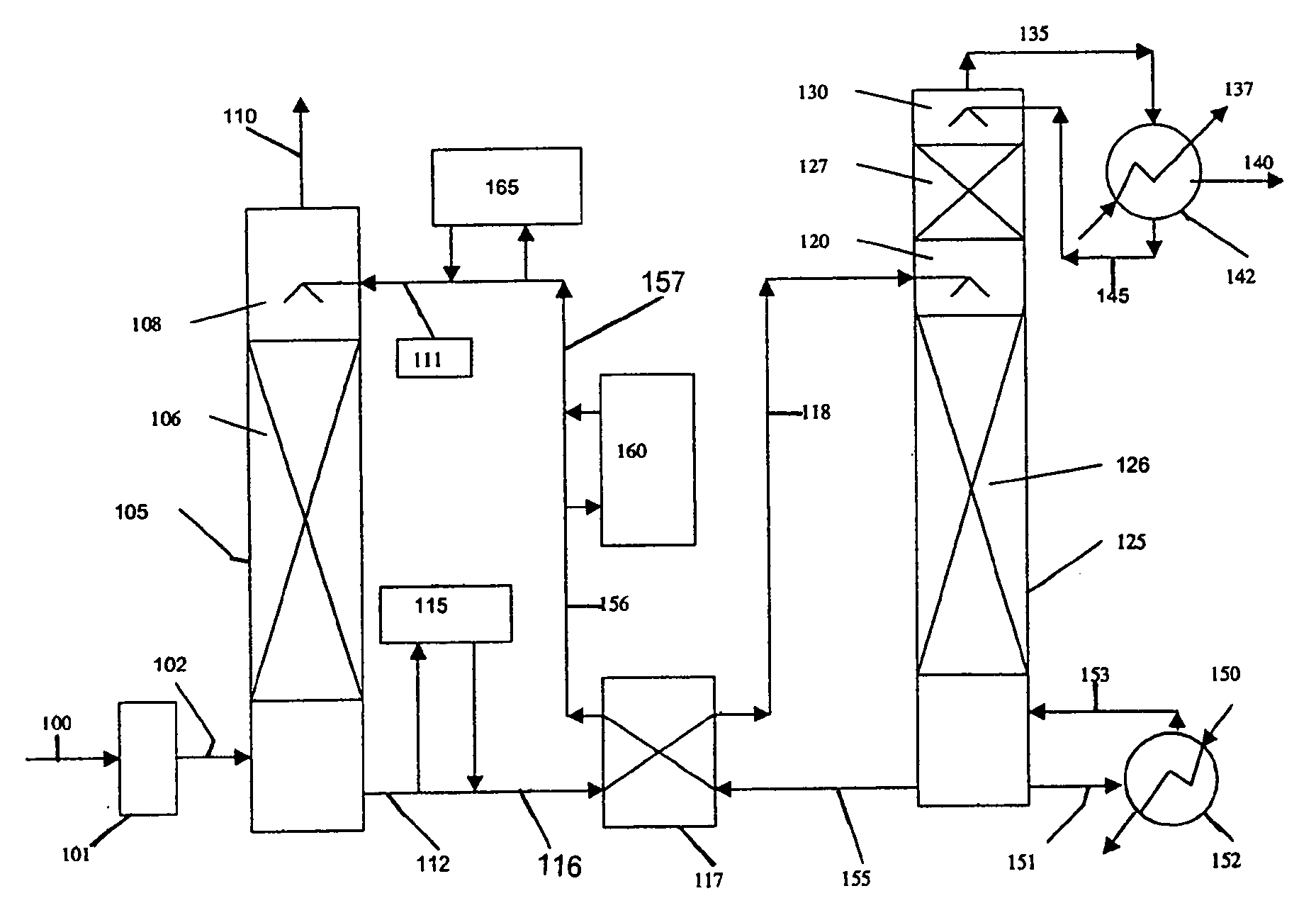

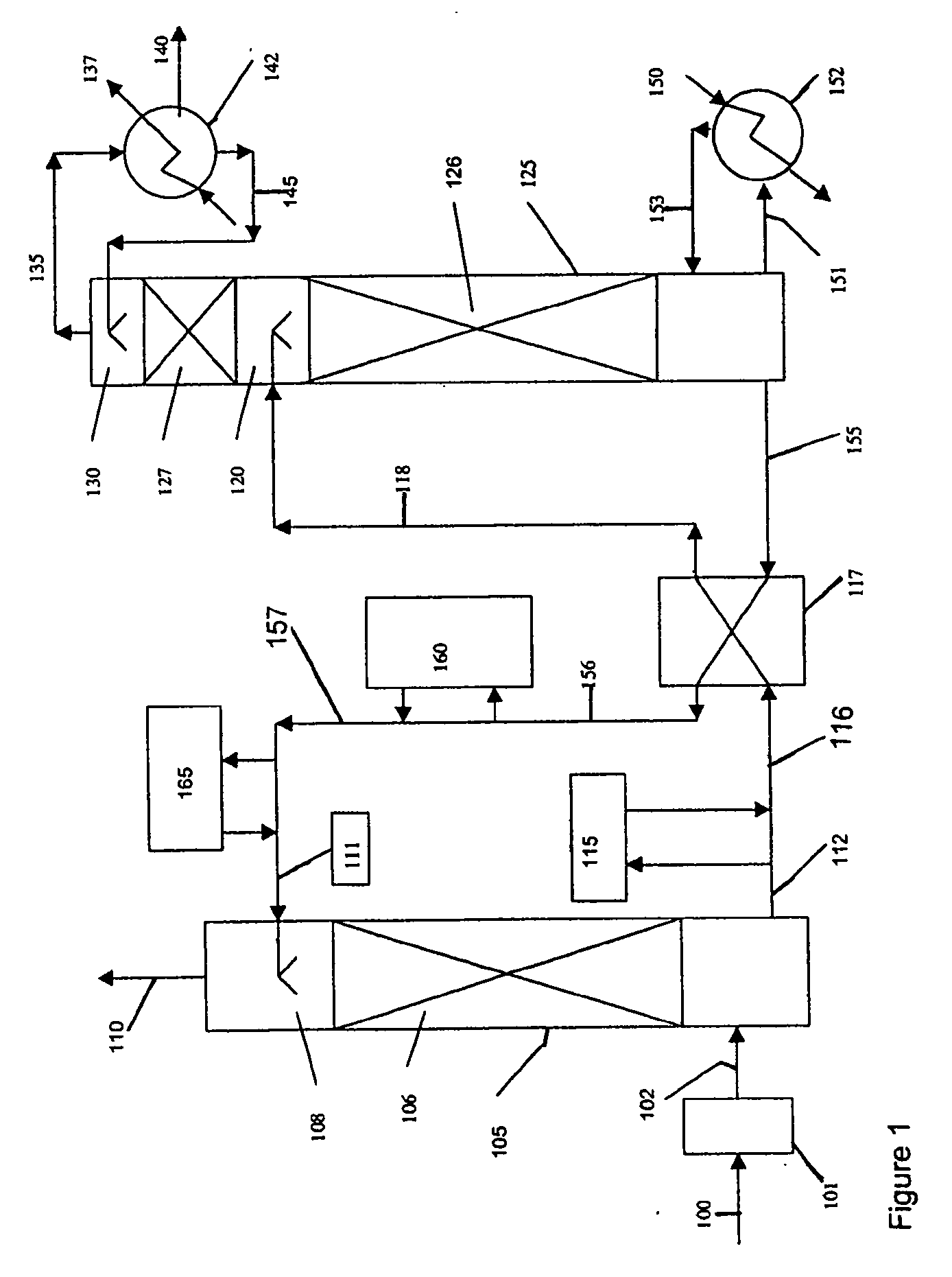

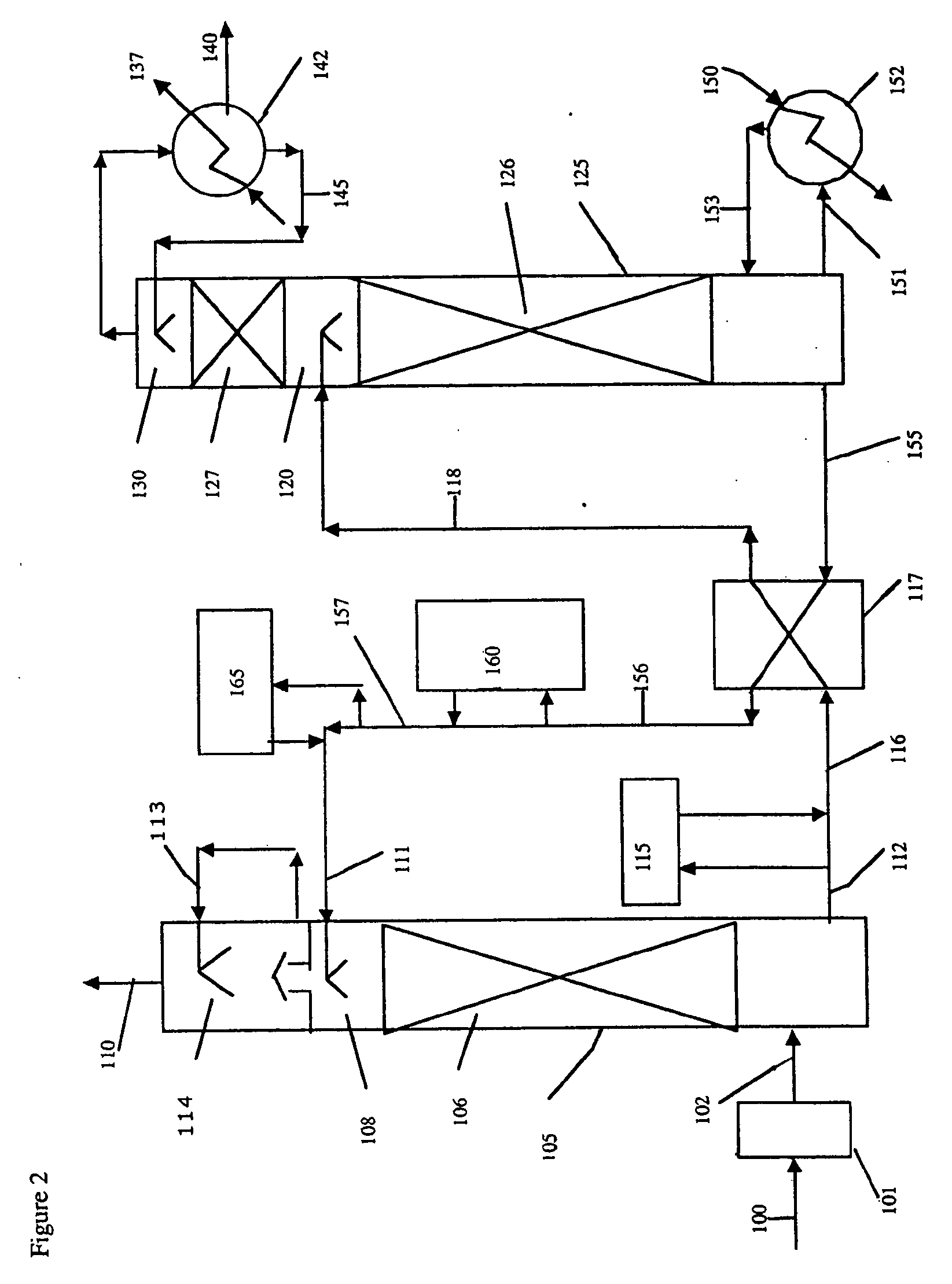

Method and apparatus for NOx and Hg removal

InactiveUS20060021506A1Prevent buildupReduce probabilityNitrogen compoundsUsing liquid separation agentCyclic processMercury vapour

A cyclic process for the removal of NOx from a NOx containing feed gas, and optionally removal mercury vapour and / or sulfur dioxide is provided. A process is also provided by which an iron chelate absorbent may be thermally regenerated.

Owner:CANSOLV TECH INC

Melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing

ActiveCN101649369AReduce dosageImprove toughnessProcess efficiency improvementGranularityFerrosilicon

The invention discloses a melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing, which produces the synthetic cast iron by taking scrap steel, pig iron and cast iron returns or scrap steel and cast iron returns as the main raw materials in an induction furnace by utilizing SiC as an carburizing siliconizing agent, wherein the addition of SiC is 0.5-3%, and thegranularity is 6-20mm; SiC is added to a hearth before melting or is added during the melting process, or the two modes cooperate to be used. The invention utilizes SiC to replace the pig iron and silicon iron carburizing siliconizing to reduce the pig iron and silicon iron so as to reduce the cost, and meanwhile, the tendency of the molten iron chill and the reverse chill of the produced synthetic cast iron is small; the dimensions of graphite pebbles in produced nodular cast iron are small, the sphericity or roundness is high, the content of ferrite is high, and the roughness of the nodularcast iron is improved; the organization of produced grey cast iron is refined, and the mechanical property and the abrasion resistance are obviously improved. The invention can be used for producingvarious trademarks of grey cast iron, nodular cast iron and alloy cast iron.

Owner:河南省金太阳精密铸业股份有限公司

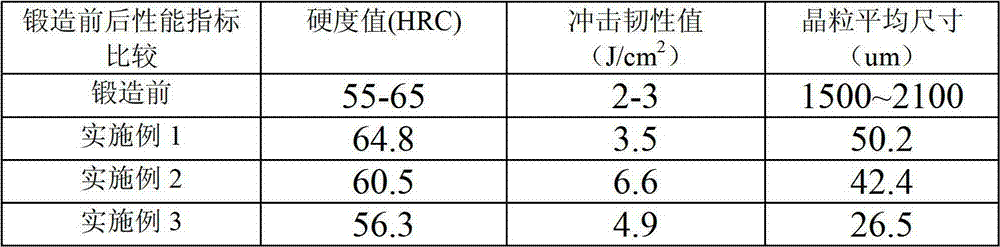

High-strength casted air-colled bainite wear-resisting steel and preparing method

InactiveCN1775983AImprove mechanical propertiesImprove toughnessMolten metal pouring equipmentsFoundryWear resistant

The invention relates to a high strength foundry air cooling bainite wear resistant steel that the chemical constituents is 0.32-0.65 C, 0.8-3.0 Si, 1.2-3.0 Mn, 0.5-0.8 Cr, 0.3-0.8 Cu, 0.001-0.008 B, 0.18-0.35 Al, 0.05-0.15 Y, 0.05-0.20 Ti, 0-0.12 Mg, 0-0.12 Ca, 0-0.15 Zn, and 0.10<Mg+Ca+Zn<0.25, the else is Fe and trace impurities. The process includes the following steps: smelting waste steel, pig iron, ferrochrome iron and copper board, adding ferrosilicon and ferromanganese preliminary deoxidation into melting down and alloying; heating to 1600-1660 degree centigrade after adjusting the constituents adding aluminum deoxidatioin and alloying and blast furnace tapping; putting the compounding modification particle of Yt, boron, titanium, magnesium, calcium, and zinc on the bottom of pouring ladle, taking modification process to the molten steel; molding the molten steel after modification process into normal matrix for casting. The invention could prolong the useful life of antifriction component, improve working efficiency, and have good economic benefit.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

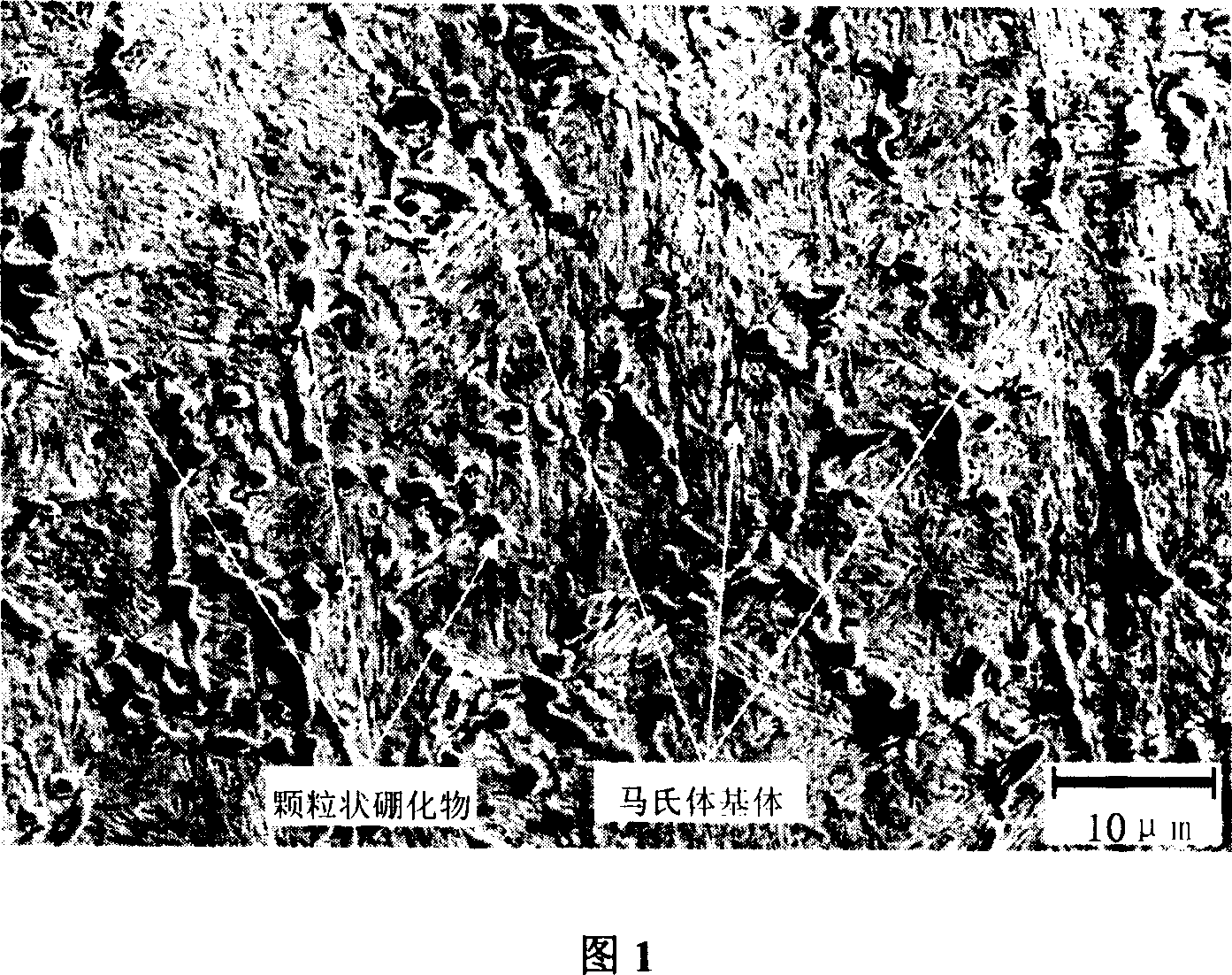

High-boron cast steel containing granular boride and preparing method thereof

The invention discloses a preparing method of granular boride high-boron cast steel, which comprises the following steps: allocating 0.15%-0.45% C,0.75%-2.70% B, 0.34 %-1.50% Ti, 0.80%-1.20% Cr, 0.50%-1.50% Si, 0.50%-1.50% Mn, 0.04%-0.12% Ce, 0.08%-0.20% Al, 0.03%-0.10% Ca, 0.01%-0.06 N, P<0.05%, S<0.05% and Fe; setting B / C=5.0-6.0, B / Ti=1.8-2.2; adopting electric stove to melt; mixing common scrap steel, pig iron and chromium iron; heating to melt; adding into silicon iron and manganese iron; adding into ferroboron and ferrotitanium before tapping; adjusting furnace-front element to be quality; heating-up; adding into silicon-calcium alloy; pre-deoxidizing; end-deoxidizing with aluminum; micro-alloying; proceeding composite deteriorating process outside of the furnace with cerium and nitrogen; keeping the temperature; proceeding oil-cooling quenching; tempering under the low temperature; getting the product. This invention possesses merits of high hardness and strength and good tenacity and resistance, which can increase the durability of wear resisting part.

Owner:XI AN JIAOTONG UNIV

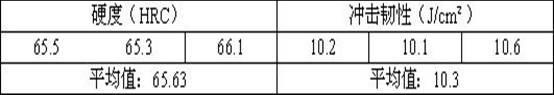

Hypoeutectic high-chromium white cast iron and preparation method thereof

The invention discloses a hypoeutectic high-chromium white cast iron, which comprises the following components calculated according to mass fraction: 1.9-2.4 of C, 16-22 of Cr, less than or equal to 0.8 of Si, less than or equal to 0.7 of Mn, 0.5-1.0 of Ni, 1.0-1.7 of Mo, less than 0.04 of S, less than 0.06 of P, 0.05-0.4 of RE, 0.5-1.0 of Cu, 0.05-0.15 of Zn, 0.1-0.3 of V and the balance of Fe. The preparation method comprises the following steps of: defining the mixture ratio according to the requirement of mass fraction and mixing; mixing scrap steel and pig iron in an intermediate-frequency induction furnace and heating the mixture to be melt; after molten iron is smelt, sequentially adding high carbon ferro-chrome, manganese iron, nickel and molybdenum and smelting again; feeding a zinc ingot with small granularity and rare earth or vanadium at the bottom of a casting ladle, covering a steel sheet or scrap iron and compacting; pouring the molten iron into the casting ladle and carrying out metamorphism and deslagging treatment; casting the molten iron and forming to obtain a hypoeutectic high-chromium white cast iron piece; then placing the hypoeutectic high-chromium white cast iron piece into a heat treatment furnace for thermally treating; and quenching and tempering to obtain a hypoeutectic high-chromium white cast iron material with the hardness of 60-66HRC (Hardness Rockwell) and the impact ductility of 10-14J / cm<2>. The hypoeutectic high-chromium white cast iron has the advantages of low cost, high wear resistance and reliable use safety. In addition, the preparation method of the hypoeutectic high-chromium white cast iron is simpler, and is easy in operation and strong in practicability.

Owner:云南化铸科技有限责任公司

Converter vanadium-extracting method of molten iron containing vanadium

The invention provides a converter vanadium-extracting method of molten iron containing vanadium. The converter vanadium-extracting method comprises the following steps of after the molten iron containing the vanadium enters a converter, adding 5-10kg / t Fe of pig iron; controlling the oxygen supplying intensity of an oxygen gun in the oxygen-blowing smelting stage to be 2.0-3.0m<3> / (min.tFe); at the non-oxygen-blowing smelting stage, introducing air with the flow being less than 0.002m<3> / (min.tFe) into the converter as bottom-blowing gas, introducing air with the flow being 0.1-0.5m<3> / (min.tFe) into the converter as the bottom-blowing gas at the time interval from starting of blowing to 1-1.5 minutes before the end of blowing in the oxygen-blowing smelting stage, and introducing inert gas into the converter as the bottom-blowing gas at the stage beyond the time interval in the oxygen-blowing stage; and adding a vanadium-extracting cooling agent into the converter at the time interval from starting of blowing to 3 minutes after smelting in the oxygen-blowing smelting stage so as to control the temperature of the molten iron in the converter to be lower than 1370 DEG C. The converter vanadium-extracting method provided by the invention has the advantages that the used amount (for example below 5-10kg / t Fe) of the cooling agent can be reduced, the oxidation rate of vanadium is increased (for example, more than 90%), and the purposes of utilizing the resources and reducing the vanadium-extracting cost are easily achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

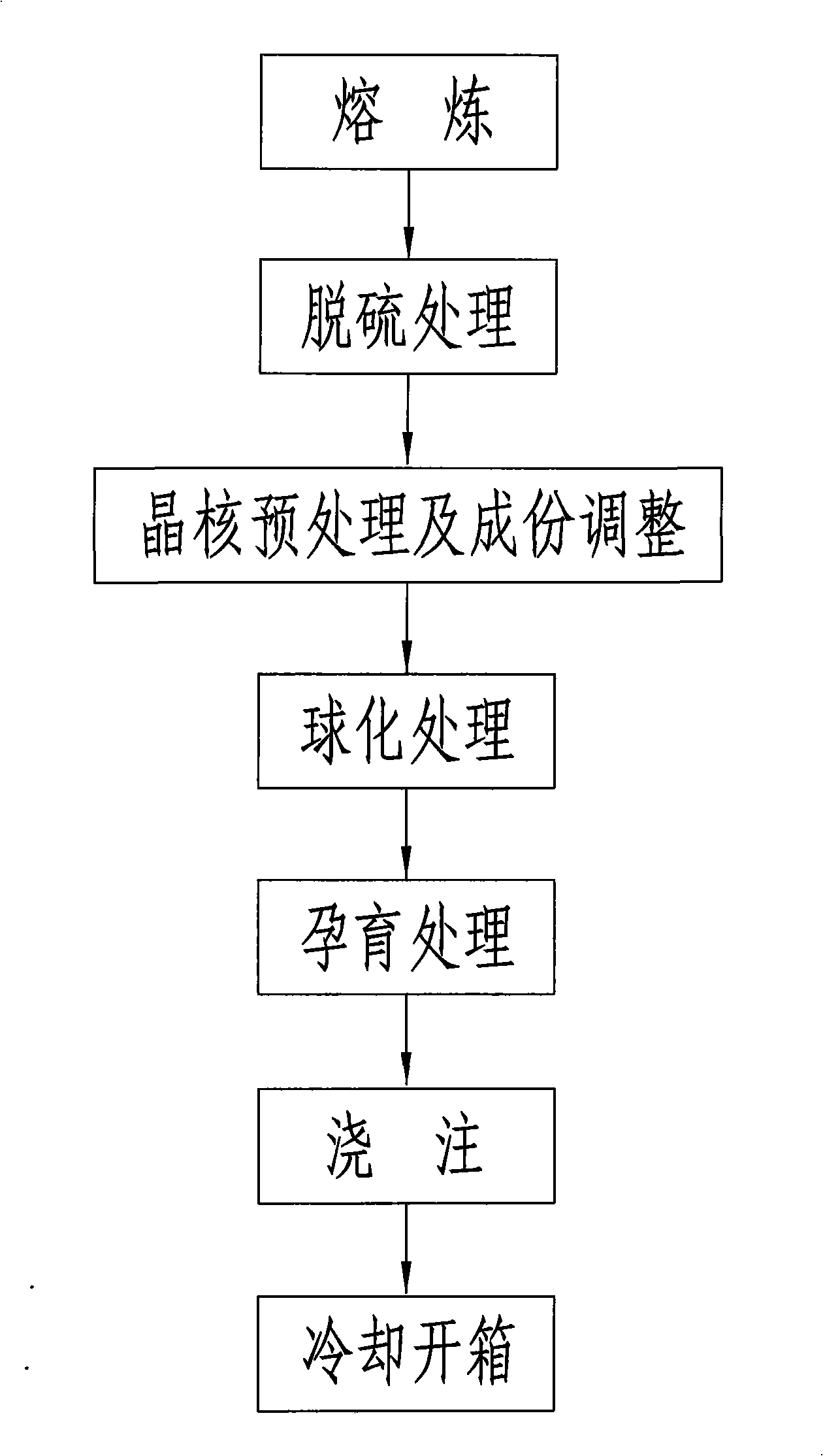

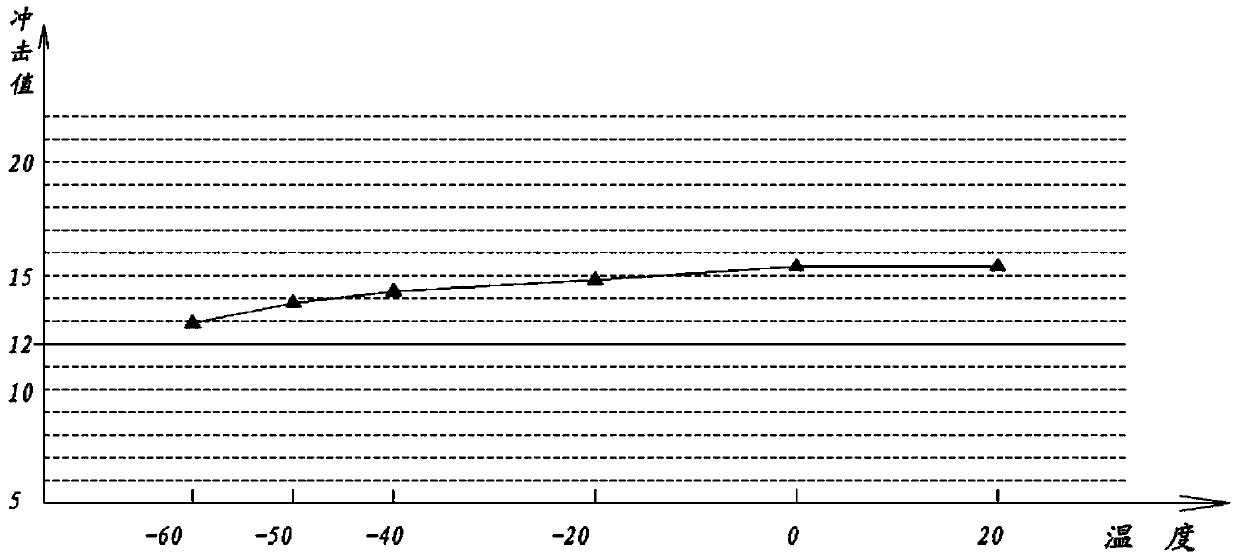

Smelting technique for cast of wind energy apparatus

InactiveCN101407884AHigh nodularityMeet mechanical performance requirementsSmelting processLiquid iron

The invention discloses a smelting process of castings of wind energy equipment, which is suitable for the smelting production of castings of wind energy equipment with the wall thickness of 60 to 200mm and includes the following steps: a. new pig iron, scrap steel and carburants with special requirements are sent into a melting electric furnace for smelting; b. high temperature liquid iron is subjected to desulfurization treatment by a desulfurization agent; c. the desulfurized liquid iron is returned into a heat insulation electric furnace for component adjustment, and the carburant is added for carrying out pre-treatment of crystal nucleus to graphite in the liquid iron; d. spheroidization treatment is carried out to the liquid iron; e. an inoculant is added into the liquid iron for inoculation; f. the liquid iron is poured to casting sand mold; and g. the castings are naturally cooled to 500 to 550 DEG C for unpacking after finishing pouring. The smelting process of castings of wind energy equipment can increase the spheroidization efficiency of ductile iron castings used by the wind energy equipment, which causes the castings to have good intensity of tension, extensibility and high impact ductility in low temperature environments, thus meeting the requirements on the castings used by the wind energy equipment.

Owner:CHANGZHOU ZHUORUN WIND POWER EQUIP

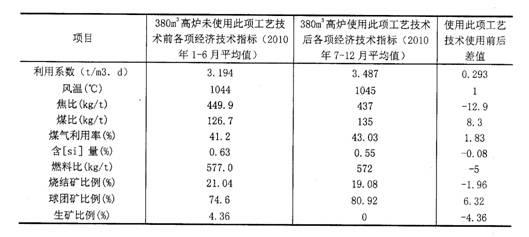

Method for smelting bell-less top blast furnace high proportion pellet ore burden structure

InactiveCN102010920AAvoid thickeningImprove utilization factorBlast furnace detailsAlkalinityCombustion

The invention discloses a method for smelting a bell-less top blast furnace high proportion pellet ore burden structure. Alkalinity of sintering ore is improved to be 2.5-3.5 times or flux with high CaO content is added, the technology that bulk coke is charged at the center and coke is mixed in ore is adopted, a charging method of split charging, ore coke unequal stockline and chute feeder feeding from small angle to high angle is adopted, a tank is reversed regularly, and batch weight of ore is expanded, so that a blast furnace stock column can maintain stable and uniform edge gas flow and strong center gas flow when gas flow passes through; the tuyere theoretical combustion temperature is controlled to be 2200-2300 DEG C; and the operation policy of low silicon and low slag basicity is adopted to smelt. The utilization factor of the blast furnace can be improved by 8-10%; the fuel ratio of the blast furnace can be reduced by 2-3%; and the Si content of pig iron is reduced, the desulphuration capacity is improved, the pig iron quality is improved, the furnace body service life is prolonged to more than eight years, and the blast furnace production stability and the economic benefit are improved. The invention is applicable to the bell-less top blast furnace under the condition that pellet ore in the blast furnace burden structure accounts for 60-100% of the total burden quantity.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Oxide dispersion strengthening low activity ferrite/martensite steel and smelting method thereof

ActiveCN106756434ASufficient oxygen contentLow viscosityIncreasing energy efficiencyRare earthManganese

The invention discloses oxide dispersion strengthening low activity ferrite / martensite steel and a smelting technology and a smelting method of the oxide dispersion strengthening low activity ferrite / martensite steel, and belongs to the technical field of special steel metallurgy. The oxide dispersion strengthening low activity ferrite / martensite steel comprises raw materials including, by mass percent, 8.9%-9.1% of electrolytic chromium, 0.4%-0.5% of electrolytic manganese, 0.05%-0.08% of high-purity silicon, 0.08%-0.12% of high-purity graphite, 1.4%-1.6% of metal tungsten, 0.1% of metal tantalum, 0.18%-0.22% of metal vanadium, 0.1%-0.25% of sponge titanium, 0.2%-0.5% of high-purity rare earth yttrium, 1% of oxide scales and the balance high-purity low-sulfur low-phosphorus pig iron. A preparing method of the oxide dispersion strengthening low activity ferrite / martensite steel comprises material preparing, vacuum induction smelting, casting, forging and electroslag remelting processes, ODS-RAFM is prepared, and the large-specification ODS steel high in density, uniform in component, little in energy consumption, high in purity, stable in smelting method and capable of meeting the need of large nuclear power equipment is achieved.

Owner:NORTHEASTERN UNIV

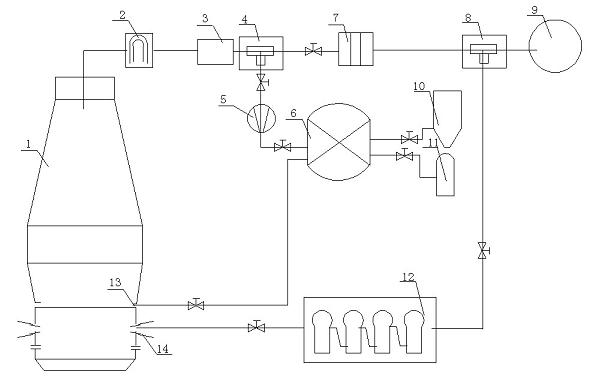

Device and method for top gas enrichment utilization of blast furnace

InactiveCN102220443AReduce cloggingAvoid damageBlast furnace detailsIncreasing energy efficiencyReduction rateEngineering

The invention relates to a device and method for top gas enrichment utilization of a blast furnace, in particular to a device and method for using top gas in a blast furnace production process, belonging to the field of smelting pig iron with the blast furnace. The device is characterized in that: a tee joint is arranged on a pipeline between a gas purifying and de-dusting system and an excess pressure power generation device; a gas pressurization device, a gasification furnace and a gas back-eject hole which is formed on the blast furnace are connected through the pipeline and a valve to form one way of the tee joint; the gasification furnace is provided with an oxygen supply pipeline and a coal blending device; the enriched gas, after being pressurized, enters the gasification furnace and is subjected to gasification reaction with oxygen and powder coal in the pressurized gasification furnace; a reaction product is ejected into the blast furnace for smelting iron through the back-eject hole which is formed on the blast furnace; the excess pressure power generation device is respectively connected with a hot blast heater, a power plant boiler pipeline and a valve through a gas distributor to form another way of the tee joint; and the generated hot air is fed into the blast furnace through a nozzle. The device has the advantages of novel conception, simple process flow, easiness in implementation, safety and reliability in operation and capabilities of increasing the calorific value of gas, ejecting back to smelt iron, increasing the indirect reduction rate, reducing the coal ratio, reducing blast furnace slag and CO2 emission, regulating and controlling the width of a cohesive zone of the blast furnace, ensuring long-term smooth running of the blast furnace, avoiding diffusion of the top gas, saving energy and contributing to environment friendliness.

Owner:MAANSHAN IRON & STEEL CO LTD

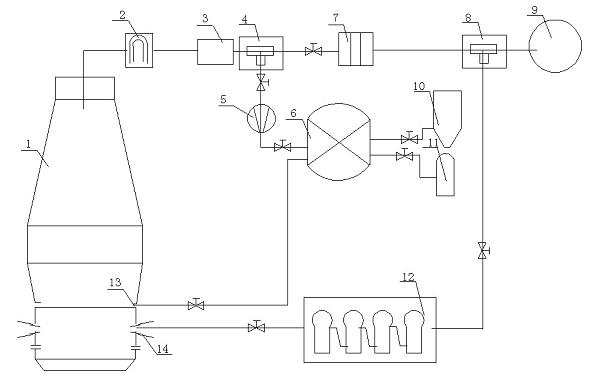

Mixed slag smelting reduction production and thermal refining method

ActiveCN106191344AEasy to removeTake advantage ofRecycling and recovery technologiesProcess efficiency improvementMolten stateReducing agent

The invention discloses a mixed slag smelting reduction production and thermal refining method, and belongs to the field of non-blast furnace iron smelting and comprehensive utilization of resources. The method comprises the following steps: 1) an iron-contained material and a reducing agent are added in mixed slag of blast furnace slag and molten steel slag for heating to reach a molten state; and oxide gas is sprayed for iron smelting by smelting reduction to treat most iron-contained material; and 2) an iron component, a calcium silicon component and a phosphorus component in the mixed slag are separated and recovered according to a reaction device. After smelting reduction, the reduced slag can serve as a cement additive, a cement regulator, a cement clinker or a cement clinker with high production additional value, so that the method realizes efficient comprehensive utilization of the resources, and is a new smelting reduction iron making method. The method uses smelting reduction of the mixed slag for production of pig iron or steel and phosphorus-enriched phases and thermal refining, is short in reaction time, high in metal recovery rate, low in production cost, high in raw material adaptability, high in handling quantity, environment-friendly and high in economic benefit, and can effectively achieve the goal of efficient recycling of metallurgic resources and heat energy.

Owner:NORTHEASTERN UNIV

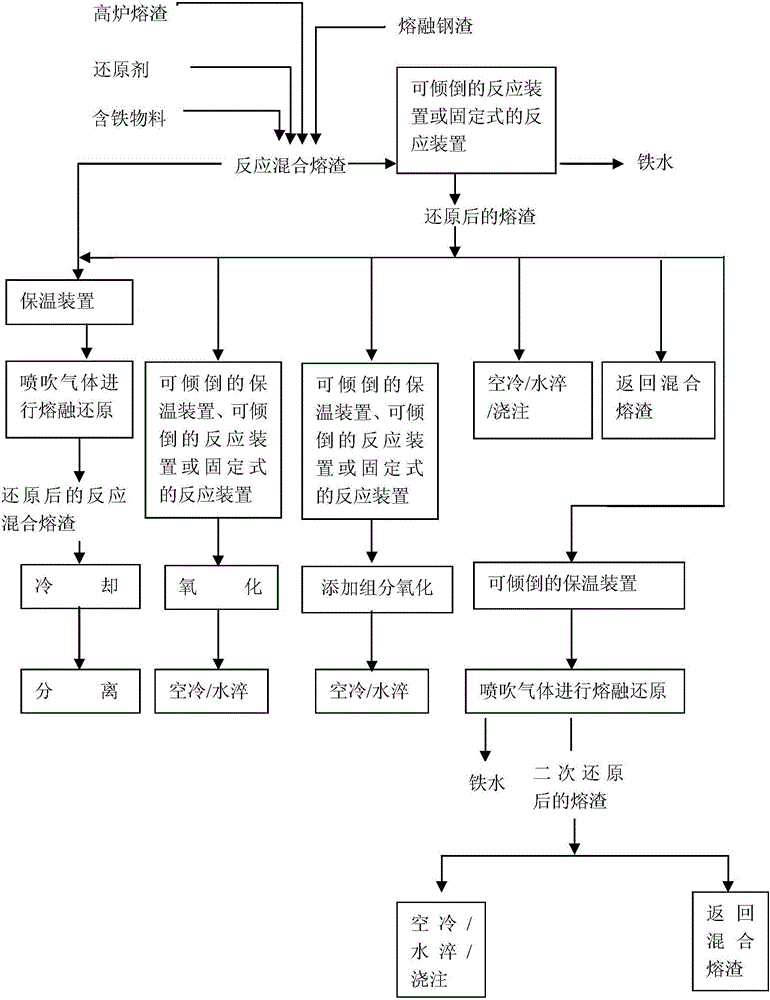

Low-temperature tough ferrite nodular cast iron of 60 DEG C below zero and preparation method thereof

The invention provides a low-temperature tough ferrite nodular cast iron of 60 DEG C below zero and a preparation method thereof. The low-temperature tough ferrite nodular cast iron of 60 DEG C below zero comprises the following components in percentage by weight: 3.60-3.80 percent of C, 1.80-2.1 percent of Si, less than 0.08 percent of Mn, less than 0.025 percent of P, less than 0.01 percent of S, less than 0.02 percent of Ti, 0.3-0.7 percent of Ni, 0.03-0.05 percent of Mg residue, less than 0.01 percent of Re residue and the balance of Fe. The preparation method of the low-temperature tough ferrite nodular cast iron of 60 DEG C below zero comprises the following steps: 1, smelting, spheroidizing and inoculating pig iron, waste steel and spheroidized alloy in sequence; 2, pouring molten iron into a cavity from a spheroidizing bag, wherein the pouring temperature is 1,440-1,380 DEG C within 6 minutes from the end time of the spheroidizing treatment to the pouring end time; 3, performing annealing heat treatment on the low-temperature ductile iron of cast iron. The low-temperature ductile iron meanwhile has good toughness at the temperature of 60 DEG C below zero under the condition that high strength is kept, and the standard requirements corresponding to QT400-18AL are met.

Owner:CHANGZHOU HUADE MACHINERY

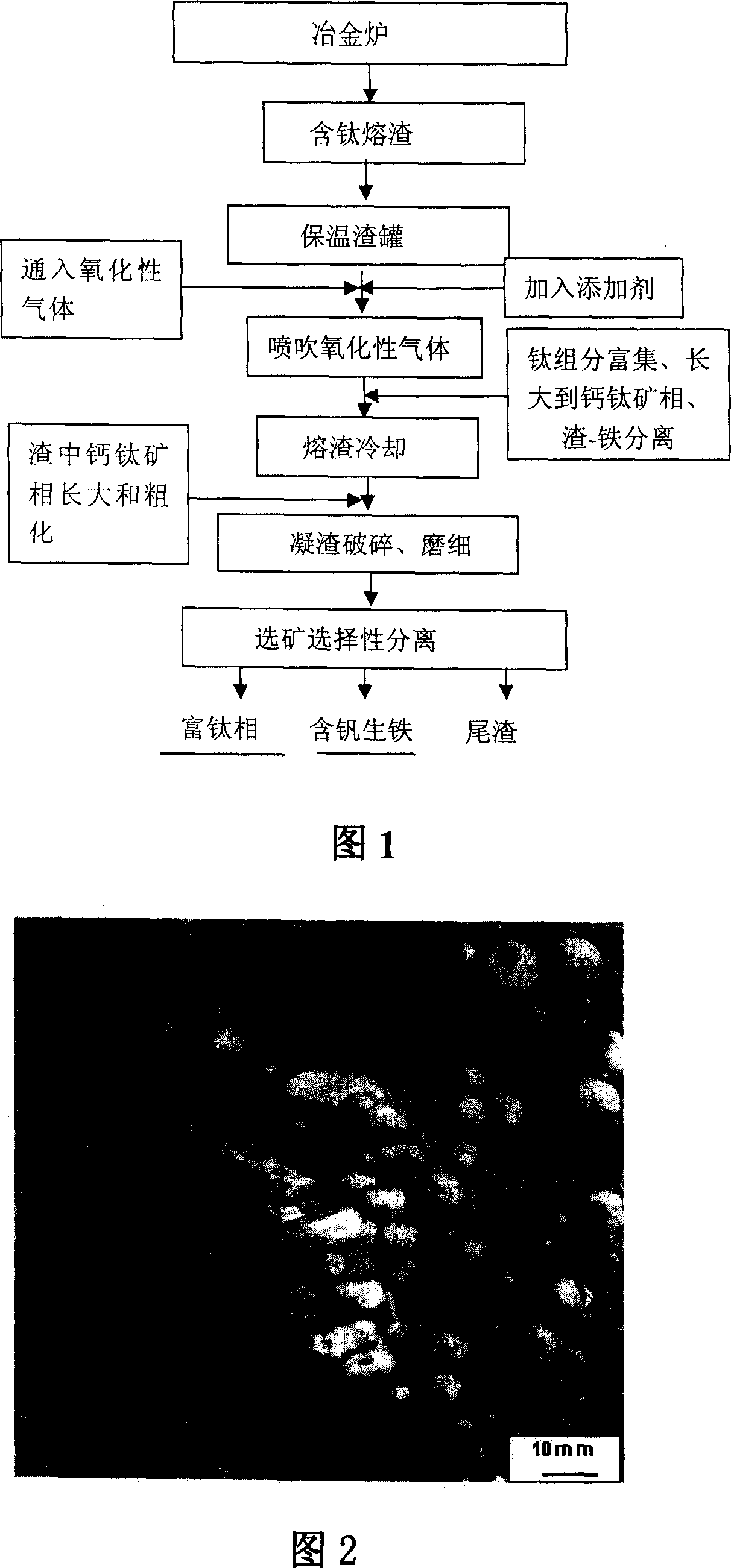

Process for separation and production of titanium-rich materials from titanium-containing blast furnace slag

InactiveCN1952188AFacilitate the realization of comprehensive utilizationRealize comprehensive utilizationProcess efficiency improvementMagnetic beadRoom temperature

A method for separating titanium from the slag containing titanium component, contains the following three steps: heating the slag in the slag tank, adding additives at the same time or after that, blowing oxidizing gases into the tank, stirring the slag constantly, causing titanium components selectively to enrich in perovskite phase, then controlling cooling rate for the slag cooling to room temperature, perovskite phase selectively growing up, finally, crushing the cooling condensate residue grinding and ore dressing perovskite to obtain titanium-rich material, magnetic-separating iron magnetic beads deposited on the metal slag to obtain vanadiferous iron. The process is reasonably designed with practical equipment easy to operate and can make use of the own energy of the slag to regulate the slag temperature, promote oxidation reaction in the slag, has high thermal efficiency, facilitate the promotion of selective enrichment of various titanium scattered in the phase of titanium for the deposition of ironic beads entrained in the slag, and is profit to the realization of comprehensive utilization of titanium, vanadium resources, and is easy for industrial production, is energy-saving and pollution-free.

Owner:隋智通

Boron contg. multi-element low alloyed wearable cast steel and prepn. thereof

InactiveCN1834279AHigh strengthImprove wear resistanceHeat treatment process controlRare earthPotassium

This invention discloses a multi-element low alloy abrasion-resisting cast steel, which is composed of C 0.20-0.45 wt.%, Mn 1.1-1.8 wt.%, Si 0.8-1.5 wt.%, Cr 0.3-1.2 wt.%, B 0.05-0.20 wt.%, Ti 0.08-0.30 wt.%, N 0.03-0.20 wt.%, Ca 0.05-0.15 wt.%, K 0.04-0.15 wt.%, and the rest is Fe and inavoidable impurities. The cast steel is manufactured by: (1) mixing scrapped steel, silicon iron, chromium iron and manganese iron, (2) carrying out carburization by using scrapped graphite electrode or pig iron, (3) melting to obtain liquid steel and adjusting the components until being qualified, (4) heating the liquid steel to 1620-1660 deg.C, (5) adding Si-Ca alloy, boron iron, titanium iron and nitrogen-containing chromium iron, and then pouring out of the furnace, (6) pulverizing Y-based rare earth magnesium alloy and potassium-containing substances to granules whose sizes are less than 15 mm, (7) drying at 130-180 deg.C, (8) placing at the bottom of the ladle, (9) carrying out modification treatment by pour-over process, and casting at 1480-1520 deg.C, (10) austenitizing at 830-1050 deg.C for 0.5-4 h, (11) rapidly cooling, (12) keeping the temperature at 150-300 deg.C, and (13) cooling in a furnace or in the air.

Owner:XI AN JIAOTONG UNIV

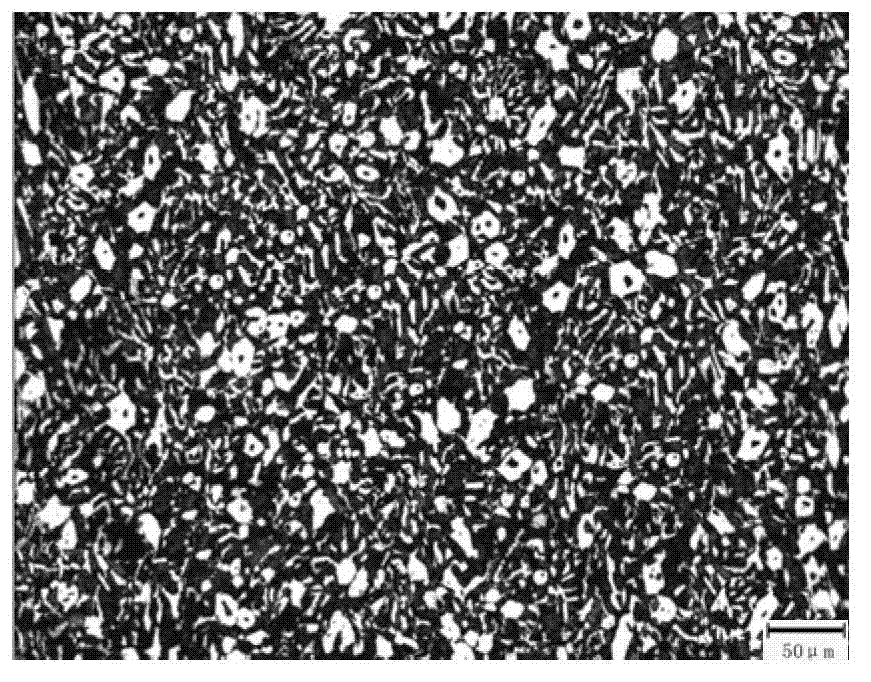

Method for preparing hypereutectic high chromium white cast iron

InactiveCN102925783ALow costDense tissueMetal-working apparatusProcess efficiency improvementChemical compositionHigh carbon

The invention discloses a method for preparing hypereutectic high chromium white cast iron. According to the method, steel scrap, pig iron, high carbon ferro-chrome, ferromanganese and ferrosilicon are taken as smelting raw materials. The method comprises the following steps of: preparing the following chemical compositions in percentage by weight: 3.0 to 4.5 percent of C, 15 to 35 percent of Cr, 0.5 to 1.5 percent of Mn, 0.5 to 1.5 percent of Si, less than 0.06 percent of P, less than 0.06 percent of S and the balance of Fe; melting the raw materials in an electric furnace, deoxidizing, quickly pouring a casting fluid in the furnace into a casting ladle; when the temperature is reduced to 1,300-1,350DEG C, pouring the casting fluid into a sand mould for forming; heating a cast in the electric furnace to the temperature of between 700 and 1,000DEG C, keeping the temperature, quickly taking out of the furnace, and forging on a forging machine for forging deformation treatment; and tempering the forged piece to obtain the hypereutectic high chromium cast iron.

Owner:XI AN JIAOTONG UNIV

Vanadium titanium cast iron brake drum and preparation method thereof

The invention relates to a manufacturing technique of an automotive vanadium titanium cast iron brake drum with high strength and high abrasive resistance, and particularly relates to a preparation method of a vanadium titanium cast iron brake drum. The preparation method comprises the following steps: melting base iron, namely b y taking vanadium titanium pig iron, steel scrap, foundry returns, a carburant, ferrosilicon, ferromanganese and ferrochrome as furnace charge, adding the carburant to the furnace bottom; smelting the furnace charges by using a medium-frequency induction furnace to prepare the base iron; heating and purifying molten iron in an overheating manner after the molten iron is molten down, and then carrying out heat preservation at 1520-1530 DEG C; and carrying out drossing, adding a slag conglomeration agent to the surface to carry out heat preservation after drossing, and then adding a little of furnace charge, and adjusting the ingredients and the like of the molten iron. A little of furnace charge is added at the later smelting stage to increase the heterogeneous core technology, so that the chilling tendency of the molten iron is relieved, the graphitization ability of the molten iron is improved, and the inoculation effect is improved. A secondary inoculation treatment process of a launder and a pouring cup is adopted, so that the inoculation effect is improved, the graphite form is improved, carbide and ferrite are removed, and the content of pearlite is improved.

Owner:陈国

Method for manufacturing high chromium white wear-resistant cast iron

InactiveCN101104196AHigh hardnessImprove impact toughnessHeat treatment bathsIntermediate frequencyWear resistant

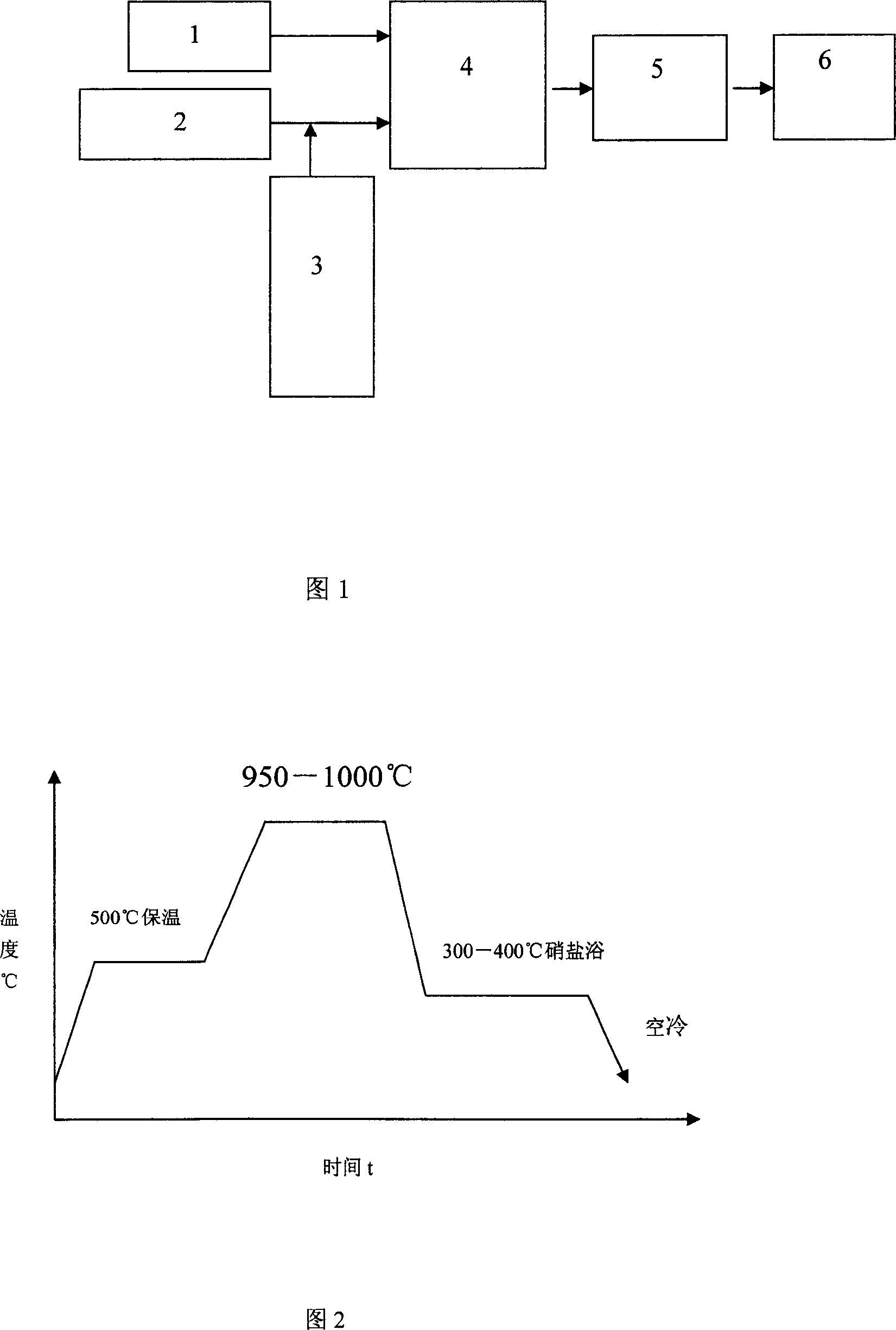

The invention discloses a manufacturing method of high chromium white mouth wear resistance cast iron, which adopts a wet casting; pig iron, scrap steel and partial ferroalloy are added in an intermediate frequency induction electric furnace in proportion to smelt qualified liquid iron; and then re modification is carried out; the modified processed liquid iron is cast into a sand mould to be cast and molded; finally isothermal salt bathing heat treatment is carried out. The stiffness, the impacting toughness and the wear resistance of the cast iron manufactured by the method are obviously improved with lower cost , and thus the invention is convenient for the industrial production.

Owner:安徽省安工机械制造有限公司

High strength and toughness wear-resistant ductile iron rocking arm and production method thereof

ActiveCN104775065AReduce manufacturing costHigh strengthFoundry mouldsFoundry coresFerroniobiumNiobium

The invention discloses a high strength and toughness wear-resistant ductile iron rocking arm and a production method thereof, and belongs to the technical field of casting. The method comprises the following steps: carrying out mixing and heating fusion on common scrap steel, pig iron for nodular cast iron, a carburant, ferrosilicon, sheet copper and ferroniobium to obtain base molten iron, wherein the base molten iron comprises, by mass, 3.45-3.70% of C, 1.30-1.45% of Si, 0.20% or less of Mn, 0.15-0.25% of Cu, 0.03-0.06% of Nb, below 0.04% of S, below 0.04% of P, and the balance of Fe and inevitable impurity elements; and carrying out composite inoculation, spheroidization and multi-microalloying modification to obtain the ductile iron rocking arm. The obtained ductile iron rocking arm has the characteristics of fine graphite nodules, uniform distribution, good strength and toughness and good wear resistance, and has good use effects in automobile engines.

Owner:HANDAN LIANCHENG MACHINERY MFG CO LTD

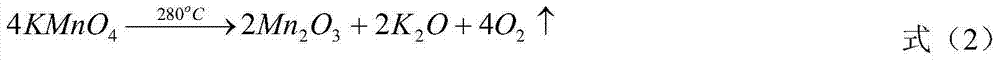

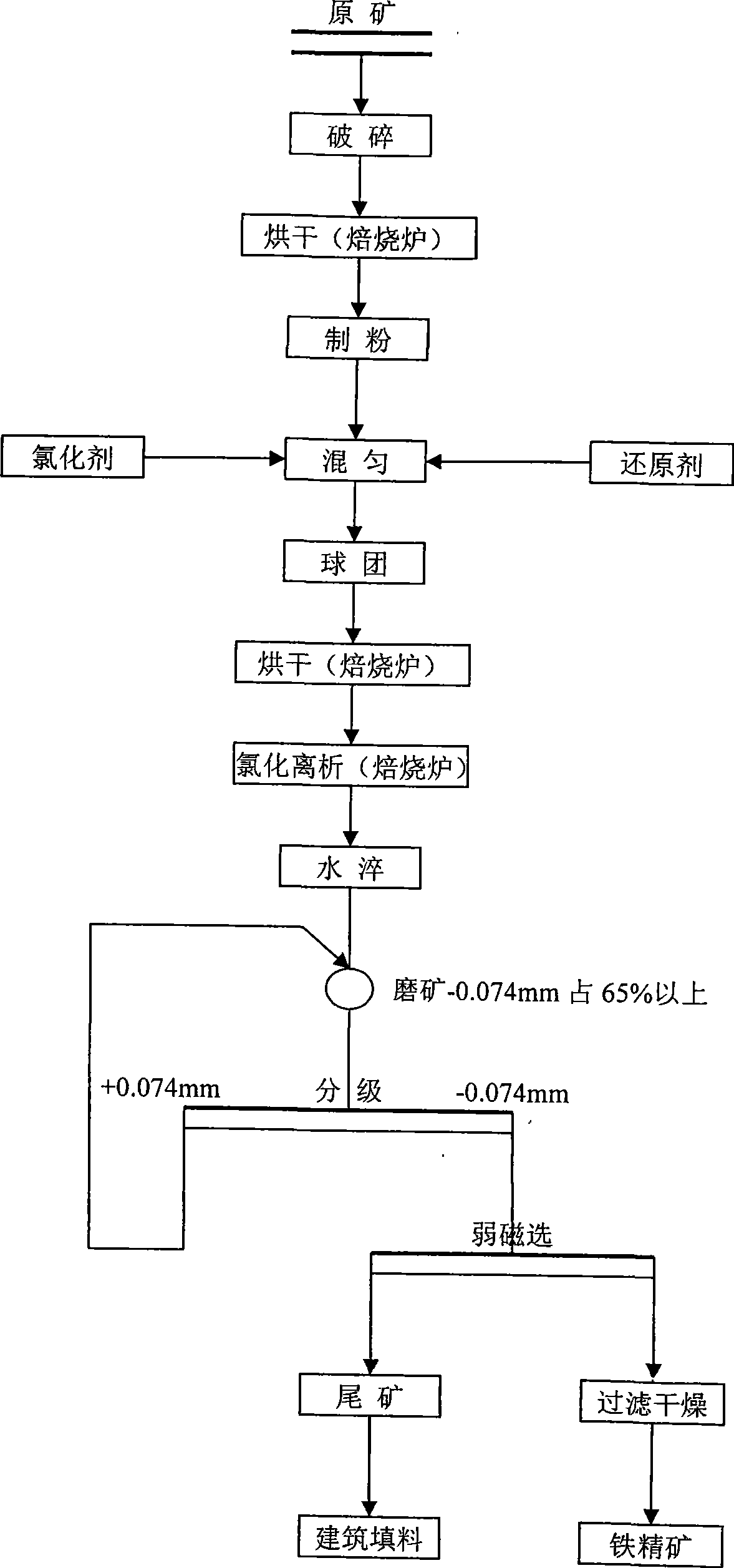

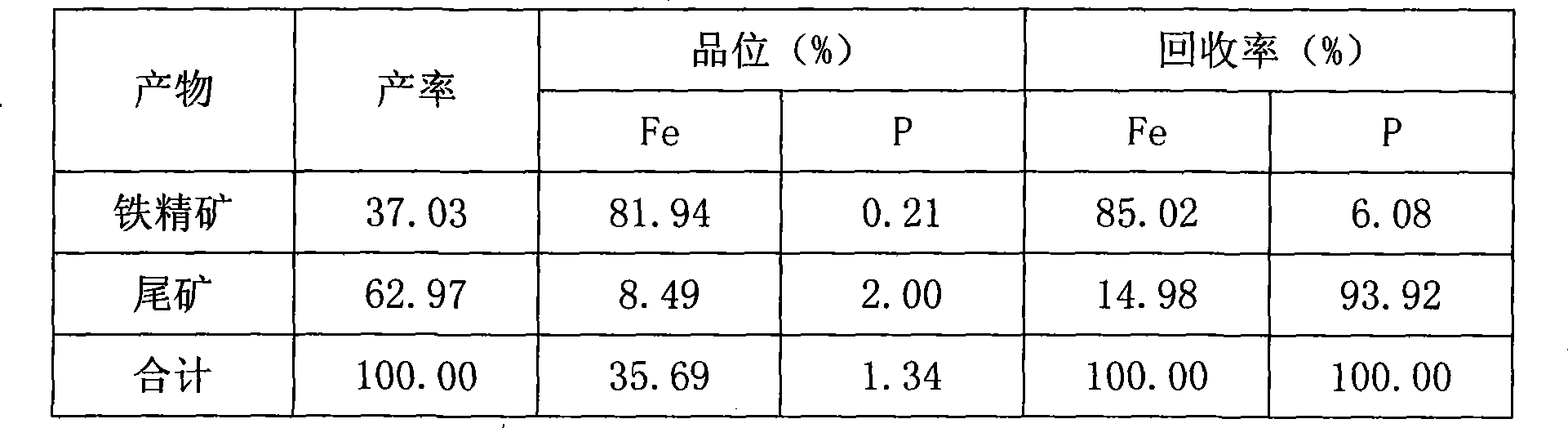

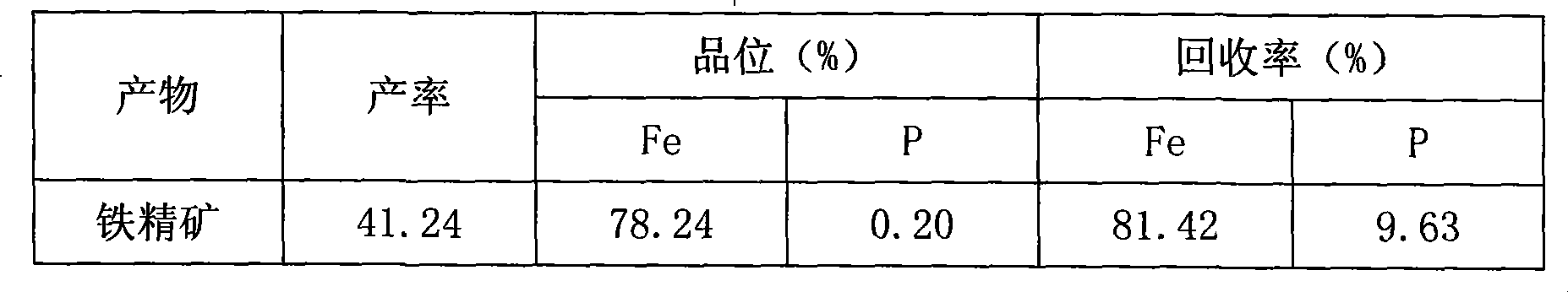

Method for reducing phosphorus by chloridization separation-weak of high phosphor iron ore

InactiveCN101457288AReduce phosphorus contentGood beneficiation indexMagnetic separationWet separationIronstoneIron increased

The invention relates to a chloridizing segregation-low-intensity magnetic separation method for reducing phosphorus of a high phosphorus iron ore. A chloridizing segregation-low intensity magnetic separation process is adopted to realize iron increase and phosphorous reduction in the method. A chlorinating agent and a reducing agent coke are added to the high phosphorus iron ore and mixed evenly, then chloridizing segregation roasting is carried out in a roasting furnace; the roasted product is water quenched and ball milled, and then separated by a low-intensity magnetic field magnetic separator, thus being capable of obtaining an iron ore concentrate with the iron grade more than 80%, the iron recovery rate more than 85% and the phosphorous content less than 0.20%. The iron ore concentrate powder can be taken as a raw material for smelting pig iron after being pelletized. Additionally, with regard to high phosphorus iron ores which contain sulfur or contain sulfur and arsenic at the same time, such as hematite, hematite-limonite ore, oolitic hematite-limonite ore, hematite, siderite and the like, the product iron ore concentrate with the sulfur content less than 0.20% and the arsenic content less than 0.04% can also be obtained.

Owner:昆明晶石矿冶有限公司

Process for working up steel slags and iron carriers for obtaining pig iron and environmentally safe slags

InactiveUS6332910B1Improve heat transfer performanceExtended service lifeManufacturing convertersProcess efficiency improvementAlkalinityNitrogen

In a process for working up steel slags and iron carriers such as, e.g., electric furnace slags, converter slags, fine ores, dusts from steel production, mill scales for obtaining pig iron and environmentally safe slags, the volume ratio of molten slag to iron bath is chosen to be larger than 0.5 to 1 and, preferably, 0.8:1 to 1.5:1 and the slags are supplemented with SiO2 carriers such as, e.g., foundry sands, metallurgical sands and / or fine ores so as to adjust a slag basicity (CaO / SiO2) of between 1.0 and 1.8 and, preferably, 1.2 and 1.8 at an Al2O3 content of between 10 and 25% by weight, based on the slag. In doing so, hot blast is top-blown and coal, optionally along with an inert gas and, in particular, nitrogen and, furthermore, optionally oxygen or hot air is blown through the iron bath.

Owner:HOLCIM

Harmless regeneration recycling method of trash fly ash by using blast furnace

ActiveCN101554632ALow construction costLow running costSolid waste disposalHazardous substanceLitter

The invention discloses a harmless regeneration recycling method of trash fly ash by using a blast furnace. The method has steps as follows: the blast furnace is used as processing equipment; trash fly ash is mixed into pulverized coal before the blast furnace injects coal, the mixture of pulverized coal and trash fly ash is delivered into the hearth of the blast furnace through the process of coal injection; or trash fly ash is mixed into the regenerative balls which are used by the blast furnace, and the regenerative balls mixing with trash fly ash are delivered into the blast furnace and used as common raw materials-pellet ore for ironmaking process in the blast furnace; the pellet ore is normally smelted, the high temperature and reducing atmosphere in the hearth area is used for processing and regenerating the fly ash. The invention can process mass trash fly ash, and does not need more special equipments. Not only the method can effectively process harmful material without new harmful products, but also calcium and other metal materials in the fly ash can be used for ironmaking process in the blast furnace, and then brought into pig iron or furnace cinder to be regenerated and utilized.

Owner:CHONGQING ANGRUIYUE SCI & TECH

Method for producing vermicular cast iron brake drum

The invention discloses a method for producing a vermicular cast iron brake drum, which solves the problems of too heavy weight, low strength and short service life in the traditional vehicle brake drum. The method comprises the following steps of: weighing 84 portions by weight of pig iron, 16 portions by weight of steel, 0.7 portion by weight of manganese iron and 0.68 portion by weight of ferrosilicon accounting for 100 portions by weight, and smelting in an electric furnace; taking a vermiculated iron ladle, and arranging a dike on the bottom of the vermiculated iron ladle to separate the bottom of the vermiculated iron ladle into a region A and a region B, wherein the height of the dike is 100-250mm;preparing a vermiculizer, an inoculant and metallic tin; pouring the base iron into the region B separated on the bottom of the vermiculated iron ladle; and after the vermiculated iron ladle is filled up, holding the emulsification time for 1-1.5 minutes to obtain the liquid vermicular cast iron, and pouring the liquid vermicular cast iron into a brake drum casting die to obtain the vermicular cast iron brake drum. The vehicle brake drum has the advantages of high strength, light weight, favorable thermal conductivity and long service life.

Owner:山西汤荣机械制造股份有限公司

Gas-based shaft-furnace direct-reduction smelting method for high-chromium-content vanadium-titanium magnetite

The invention discloses a gas-based shaft-furnace direct-reduction smelting method for high-chromium-content vanadium-titanium magnetite. According to the method, a shaft furnace serves as main equipment, and 100% high-chromium-content vanadium-titanium magnetite serves as a raw material. The method is characterized by comprising the steps of preparing oxidized pellets through grinding the magnetite, palletizing, oxidizing and roasting, putting the oxidized pellets in the shaft furnace, carrying out direct reduction by using reducing gas, and then, carrying out smelting separation in a high-frequency induction furnace, thereby obtaining vanadium-chromium contained pig iron and high-titanium-content slag. According to the method disclosed by the invention, the grade and yield of iron in the obtained pig iron are higher than 90%, the yield of both vanadium and chromium is higher than 85%, the grade of TiO2 in the high-titanium-content slag is about 40%, and the yield reaches 85-90%.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com