Patents

Literature

106results about How to "Improve casting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cylinder block made from wearable aluminum alloy and manufacturing technique

InactiveCN1563456ADense internal organizationImprove air tightnessCylindersManufacturing technologyChemical composition

This invention discloses an abrasion Al arroy cylinder and its manufacture technology, which chemical composition in weights is Si 7.6-8.3% Cu2.5-3.5% 0.3-0.5%Mg, Mn 0.2-0.4%, rest is Al. The technology is that the Al alloy raw material matched in terms of the above mentioned proportion is smelted in a thermal insulation furnace, refined, gas cleaned-up and modificated with dust refinery agent and the solution temperature is monitored by a dogmatic thermometer via a thermal coupler, then an alloy iron cast cylindrical jacket is put on the position of its mold to pour the solution onto the mold cavity to be casted with low pressure casting so as to integrate the jacket with the solution finally it is finished by the process center.

Owner:WENZHOU RUIMING IND

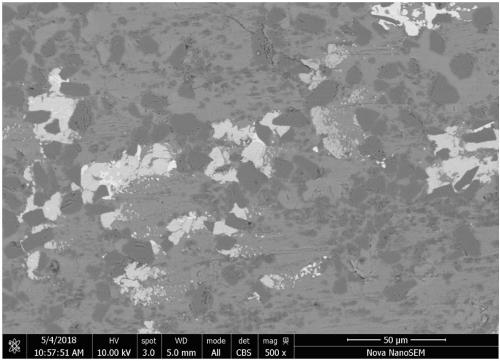

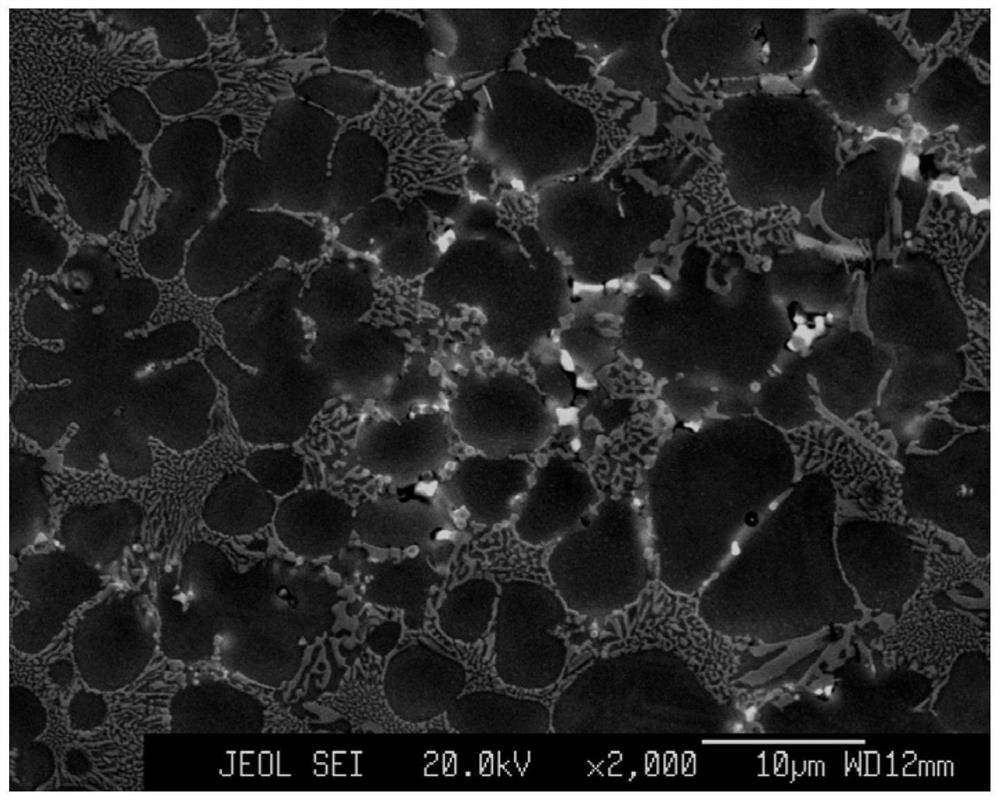

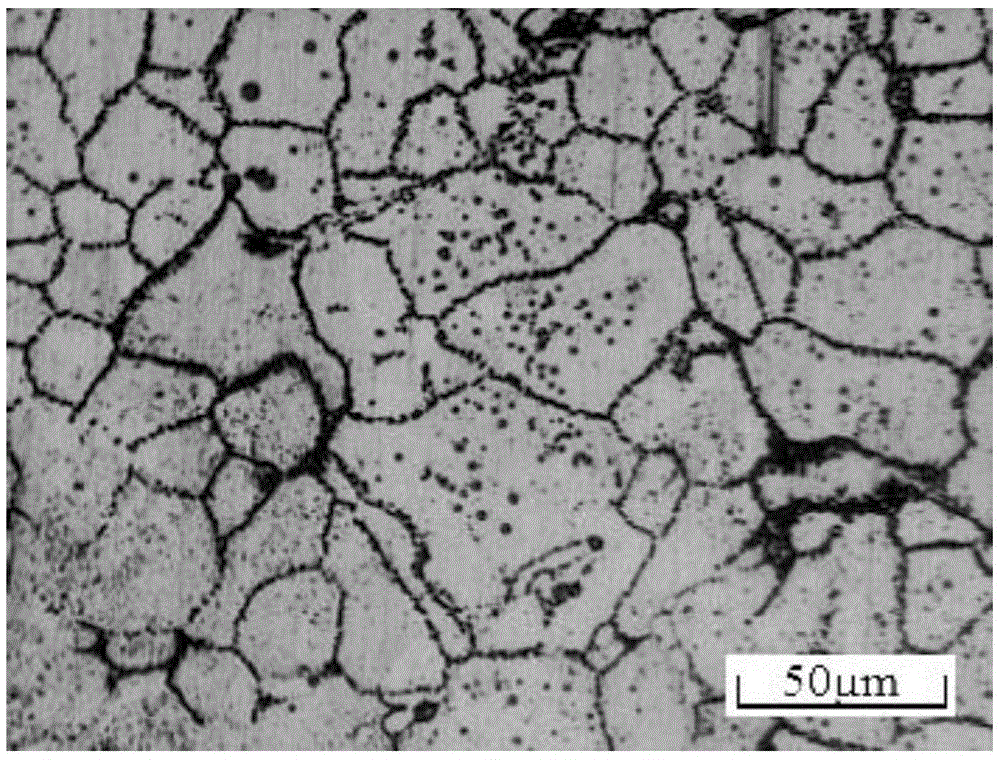

SiC particle-enhanced aluminum based composite with high-temperature wear resistance and preparation method of SiC particle-enhanced aluminum based composite

The invention provides a SiC particle-enhanced aluminum based composite with high-temperature wear resistance and a preparation method of the SiC particle-enhanced aluminum based composite and belongsto the field of aluminum alloy materials. The preparation method comprises the following steps of smelting industrial pure aluminum, aluminum-silicon alloy, aluminum-copper alloy, pure magnesium, thealuminum-copper alloy, aluminum-nickel alloy, aluminum-zinc alloy, aluminum-titanium alloy and aluminum-magnesium alloy at 700-800 DEG C according to a mass ratio; performing degassing refining; performing casting at 700-750 DEG C; using vacuum smelting, stirring and casting equipment to smelt a substrate at 700-800 DEG C; adding micron-size SiC particles; performing semi-solid state stirring at550-570 DEG C; performing casting at 700-750 DEG C; and performing T6 heat treatment. For the SiC particle-enhanced aluminum based composite with the high-temperature wear resistance and the preparation method, the substrate alloy components are designed self according to an alloy phase diagram, and a proper element content is selected, so that a high temperature resistant hard phase occurs aftersubstrate alloy heat treatment, and the substrate hardness at high temperature is ensured; and meanwhile, by adding an SiC-enhanced phase, the high temperature resistance of the composite is further improved.

Owner:TONGJI UNIV

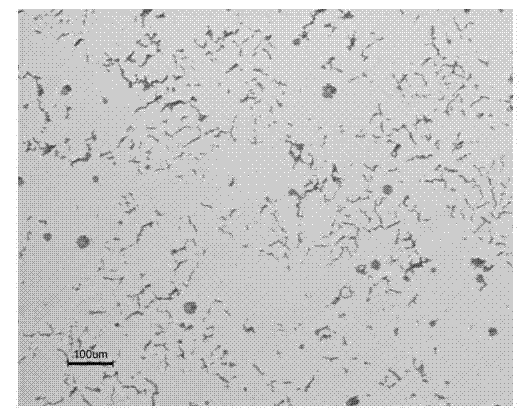

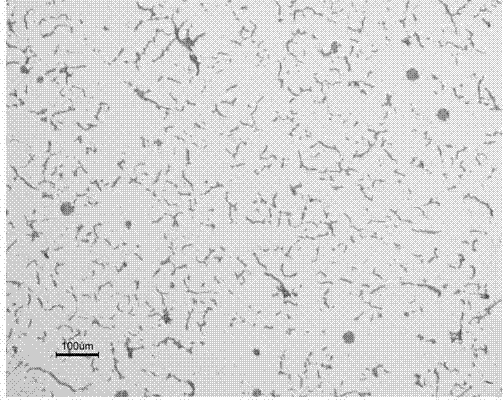

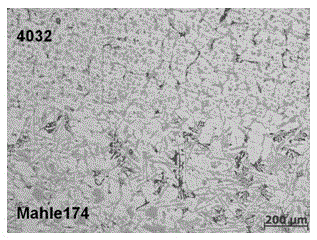

High-strength vermicular cast iron and preparation method thereof

The invention provides high-strength vermicular cast iron and a preparation method thereof. The high-strength vermicular cast iron consists of the following components in percentage by weight: 3.4-3.8 percent of C, 2.1-2.6 percent of Si, 0.2-0.6 percent of Cu, 0.2-0.5 percent of Mo, 0.2-0.8 percent of Mn, 0.02-0.04 percent of Sn, 0.004-0.032 percent of Sb and the balance of iron and inevitable impurities. The microscopic structure of the vermicular cast iron provided by the invention consists of a substrate and vermicular graphite, and the vermicular rate surpasses 85 percent. The vermicular cast iron can be prepared into vermicular cast iron with excellent comprehensive performance by preserving heat at the temperature 900-950 DEG C for 1.5-3 hours, preserving heat in a saline solution at the temperature 320-360 DEG C for 1.5-3 hours and performing air cooling. The vermicular cast iron provided by the invention has the characteristics of high strength, high plasticity, heat resistance, impact resistance, fatigue resistance, high casting forming performance, and the like. The tensile strength of the high-strength vermicular cast iron at the room temperature is 780-950 MPa, and theelongation percentage is more than or equal to 3 percent, so that the requirements of a high-power diesel engine on the materials of key parts are met. The preparation method of the high-strength vermicular cast iron provided by the invention has a stable vermiculation process, a high vermicular rate and a simple process, and is convenient to operate.

Owner:XIAN KANGBO NEW MATERIAL TECH

Plain bearing alloy consisting of a tin-based white metal

The invention relates to a plain bearing alloy consisting of a tin-based white metal and containing antimony as the primary alloy element and between 1 and 10 % by weight copper. The aim of the invention is to achieve excellent strength characteristics coupled with a high degree of ecofriendliness without impairing the tribological characteristics. To achieve this, the white metal, which except for inevitable impurities is devoid of cadmium, lead, arsenic and chrome, contains between 4 and 30 % by weight antimony as the primary alloy element, at least one element from an element group containing cobalt, manganese, scandium and germanium, in a total concentration relating to the elements from said group that are used, of between 0.2 and 2.6 % by weight, in addition to at least one element from an element group containing magnesium, nickel, zircon and titanium, in a total concentration relating to the elements from said group that are used, of between 0.05 and 1.7 % by weight, the maximum total proportion of antimony and copper being 35 % by weight for an antimony content that corresponds to three times the copper content.

Owner:MIBA GLEITLAGER GMBH

Aluminium front cover and manufacturing process thereof

The invention discloses an engine aluminum alloy front cover and its manufacturing engineering, in which the chemical composition consists of (mass%): 7.8-8.2% silicon, 2.6-3.0% copper,0.25-0.35% magnesium,0.28-0.38% manganese and the other is aluminum. The manufacturing engineering includes: first preparing die for the front cover and water circulating channel core for inactivity; smelting the aluminum alloy raw material with a perfect allocation according to the said proportion in die-casting furnace and performing aftertreatment deaeration, metamorphic conditioning and temperature administration; when pouring, accurately placing water circulating channel core into front cover die cavity, then pouring the acceptable aluminum alloy liquor into pouring cup on the said die, performing gravity roll-over casting with metallic gravity casting machine to make the aluminum alloy liquor enter die cavity smoothly and steadily; after casting, obtaining the product by cold-setting, impact cleaning and central handling. The said aluminum alloy front cover is of smooth surface, dense internal organization, good air impermeability and fewer holes, which can effectively improve the engine service behavior.

Owner:WENZHOU RUIMING IND

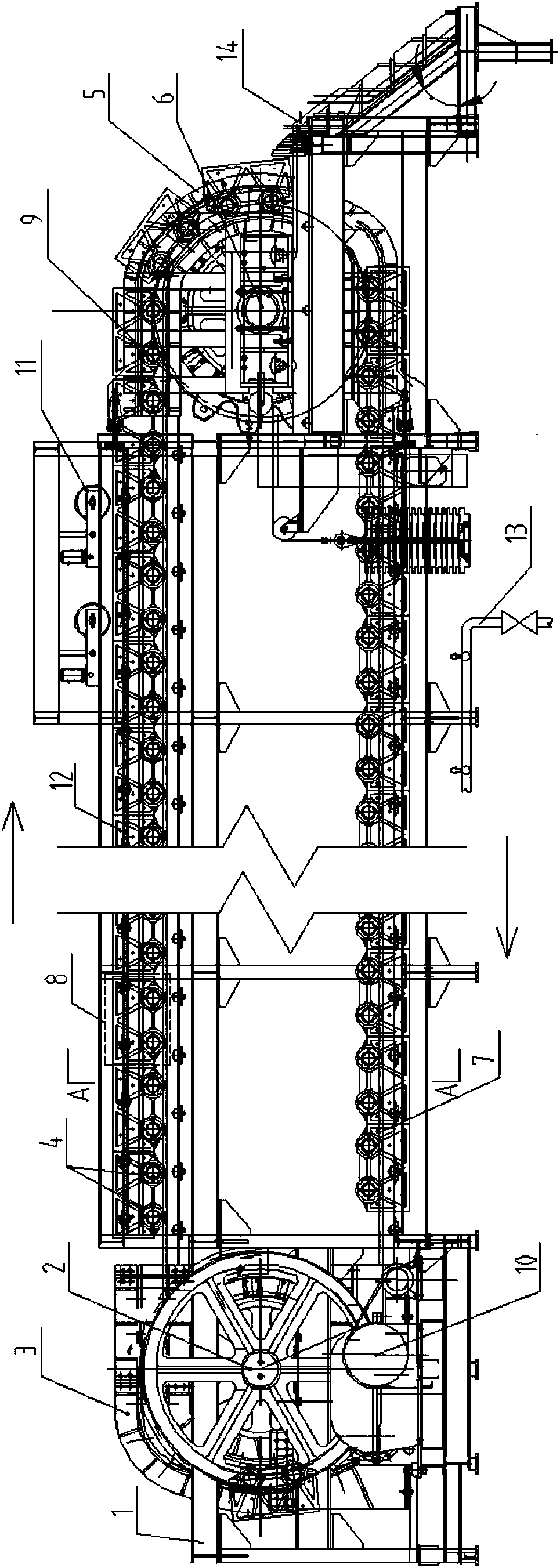

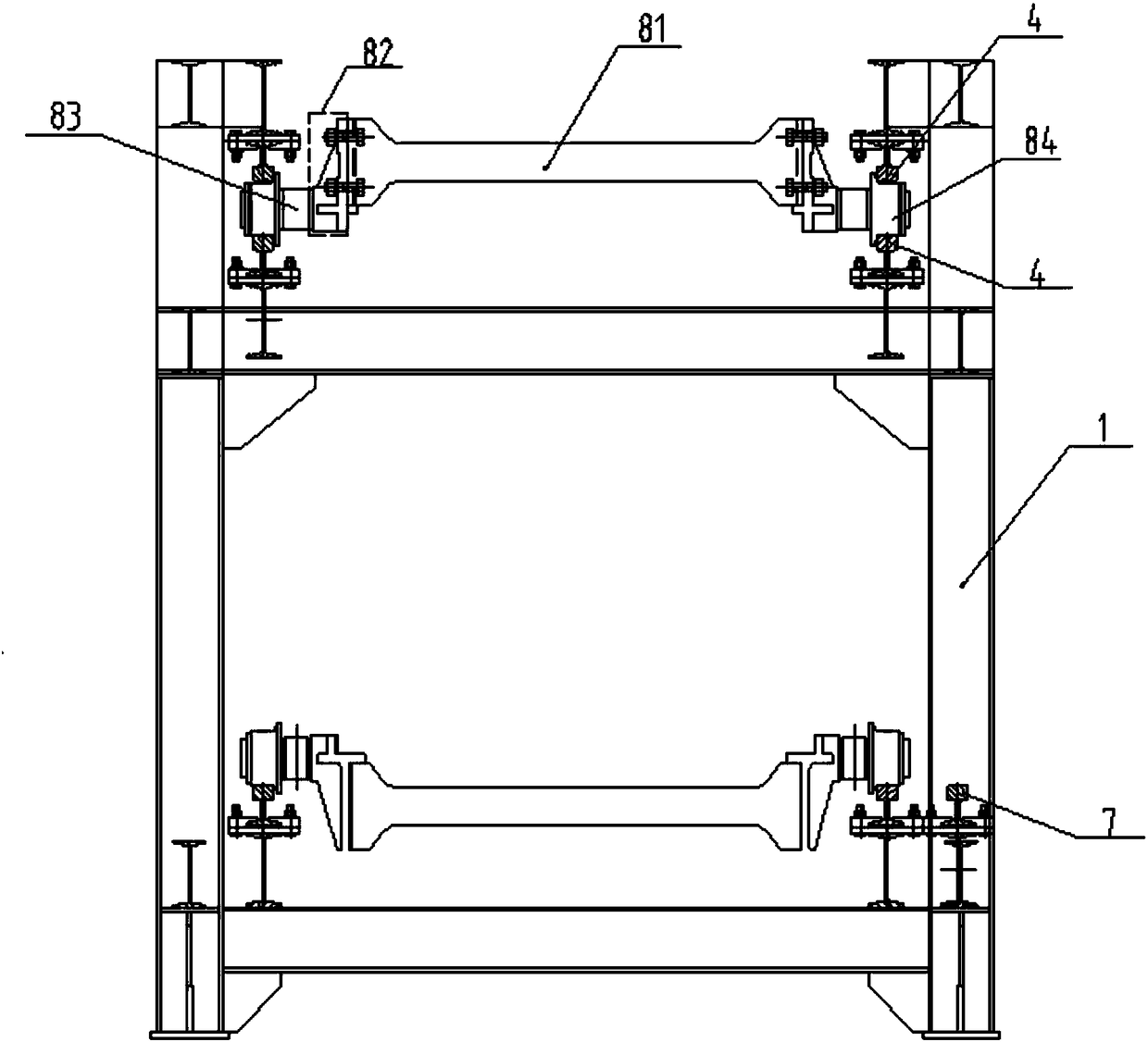

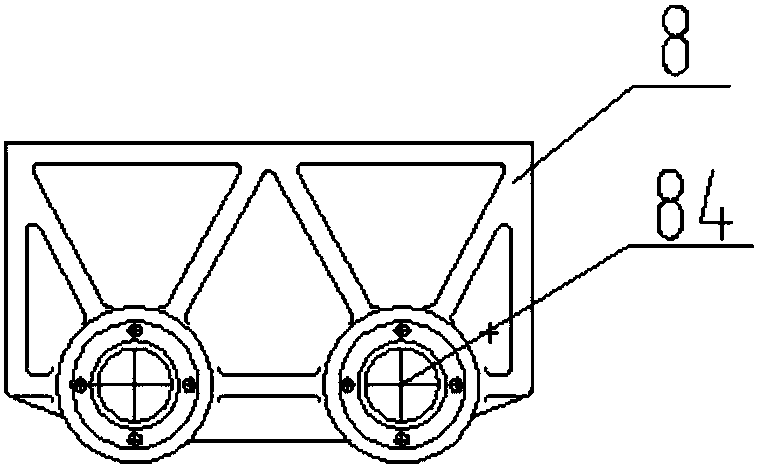

Novel ferroalloy continuous casting machine

PendingCN108247027ANot easy to burnConvenient for centralized processingIngot casting plantsMolten metal conveying equipmentsIngotSmall footprint

The invention discloses a novel ferroalloy continuous casting machine, and is applied to the field of ferroalloy production facilities. The novel ferroalloy continuous casting machine includes a rack,a head star wheel, a heat bent rail, an upper rail, a tail rail, a tail star wheel and a lower guide rail, wherein the head star wheel, the heat bent rail, the upper rail, the tail rail, the tail star wheel and the lower guide rail are sequentially arranged on the rack in a circular sealing mode; a plurality of freestanding trolley bodies are arranged on the guide rail; each trolley body includesa panel ingot mould, a transition part, a shaft sleeve and wheels, wherein the upper and lower faces of the panel ingot mould are symmetrically sunken inwards. The invention aims at eliminating the disadvantages of traditional shaping modes of pit casting, cast iron ingot mould casting and plate-chain pig machines and having the advantages of the better technical scheme. Particularly, compared with the traditional modes, the casting performance of the novel ferroalloy continuous casting machine is improved at all aspects; the novel ferroalloy continuous casting machine has the significant advantages that the yield and the quality are high, the labor strength is low, multispecies casting is achieved, centralized treatment is conveniently conducted on fume and gas, the occupied area is small, maintenance is convenient, the mould-iron ratio is large, and the ingot mould is not easily damaged by fire.

Owner:乌兰察布市旭峰新创实业有限公司

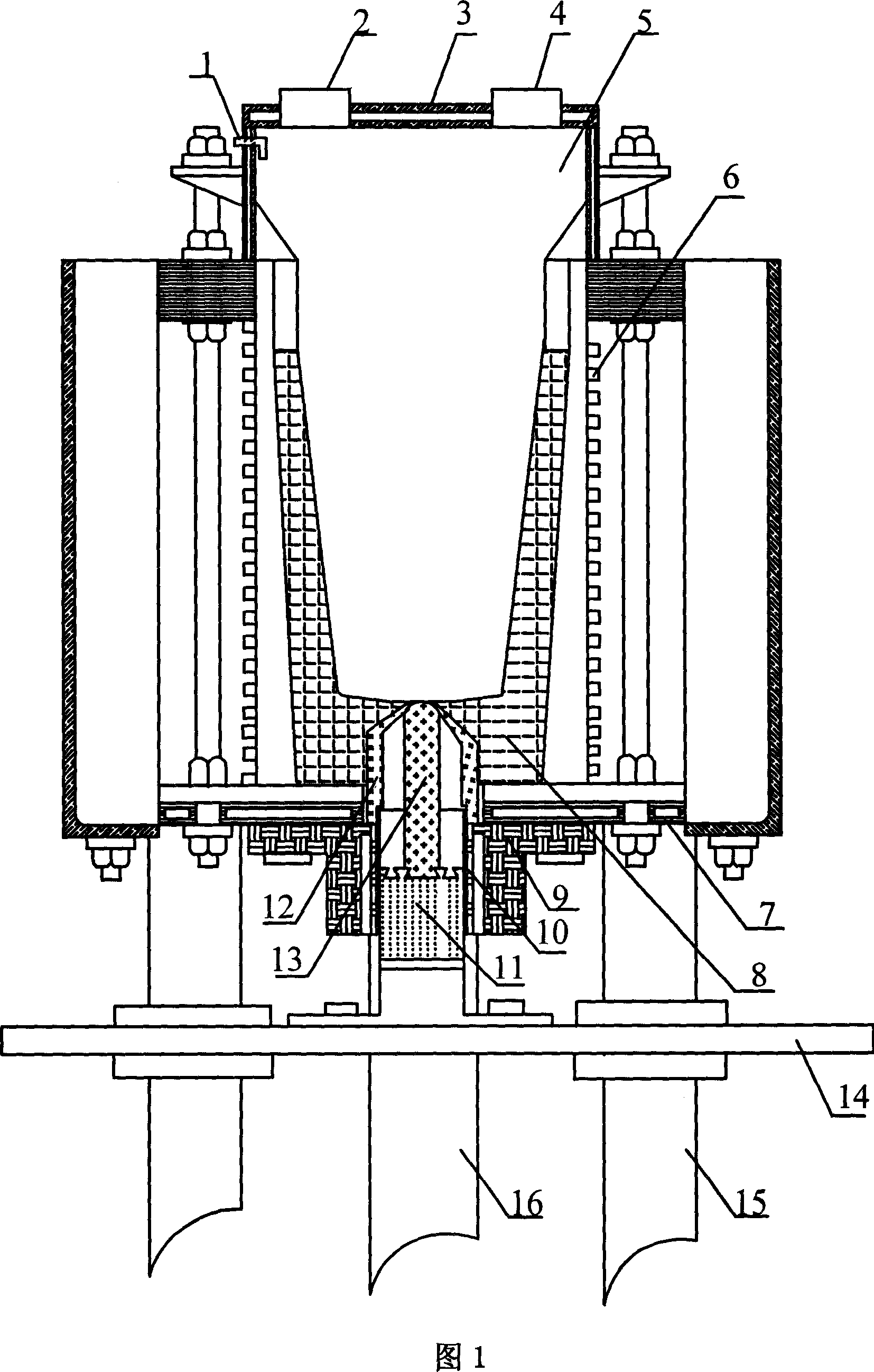

Equipment for nonvacuum melting and casting readily oxidizable metal and alloy

The invention relates to a device used in non-vacuum smelt casting oxidizable metal and alloy. Wherein, the furnace has heater and pot; the furnace cover has gas inlet and material inlet; and it has cooler; the bottom of furnace has lower irrigator; the bottom of pot has bottom bowl; the irrigator of bottom bowl contacts the plug rod vertically; the bottom plug rod is connected to the dummy ingot head; the dummy ingot head adjusts the position of plug rod; the bottom bowl is connected to crystallizer connected to the cooler; the crystallizer has graphite sheath and cooling water groove, to reduce the casting ingot temperature; the dummy ingot head has dovetail groove to solidify the fusion as drawing function; the dummy ingot head is connected to adjuster. The invention processes the whole process under protective gas, with low hurt rate and improved quality.

Owner:苏州有色金属研究院有限公司

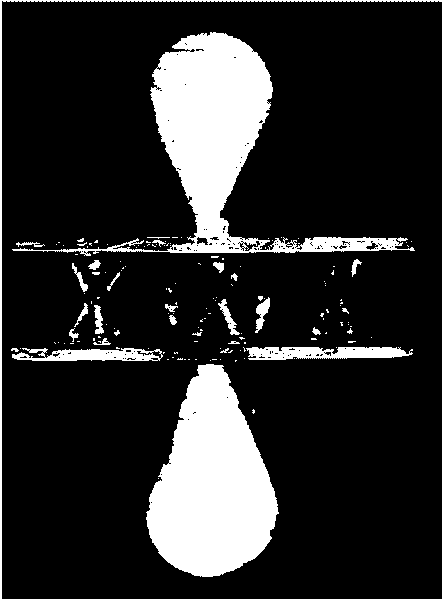

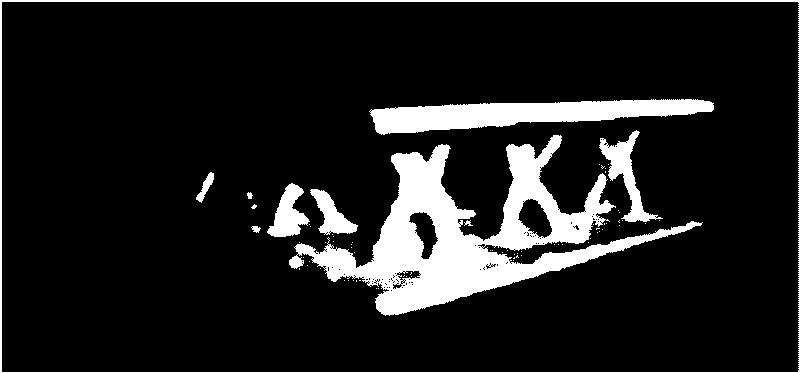

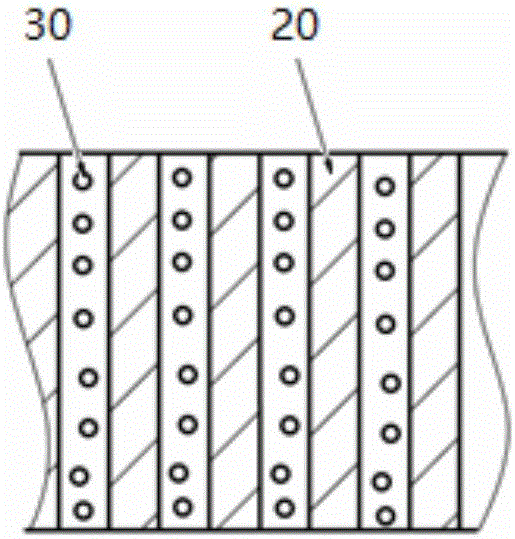

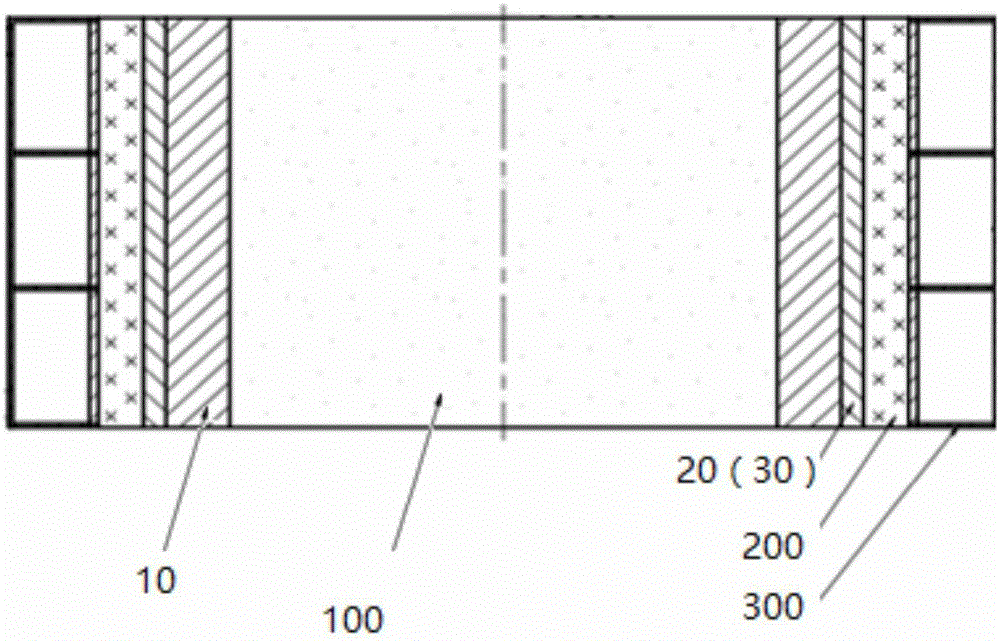

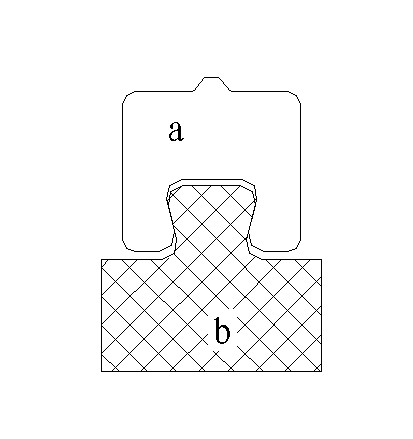

Low pressure casting method for lattice sandwich plate

InactiveCN101700568AAchieve preparationHigh bonding strengthFoundry mouldsFoundry coresWaxPressure casting

The invention discloses a low pressure casting method for a lattice sandwich plate and relates to a method for manufacturing the lattice sandwich plate. The invention solves the problems, such as difficult complete formation and high defect rate of the lattice sandwich plate resulted from the current manufacturing methods. The method according to the invention comprises the steps: producing a wax pattern, pasting and drying the surface, the adjacent surface and the back of the wax pattern; heating and demoulding the wax pattern to obtain the profile shell of the lattice sandwich plate; and in the end, obtaining the lattice sandwich plate by lifting, filling and pressure maintaining with a low pressure casting machine. The method combines investment pattern precision casing technique, rapid prototyping manufacturing technique with low pressure casing technique so as to result in the lattice sandwich plate with complete formation and low defect rate.

Owner:HARBIN INST OF TECH

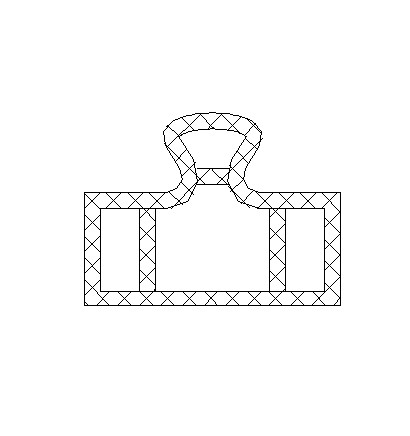

Squeezing roller sleeve and manufacturing method thereof

ActiveCN106040347AImprove toughnessImprove wear resistanceGrain treatmentsEngineeringPulp and paper industry

The invention relates to a squeezing roller sleeve and a manufacturing method thereof. The squeezing roller sleeve comprises a roller sleeve base body and an insert, wherein the roller sleeve base body and the insert are combined in an imbedding manner; the strength of the roller sleeve base body is lower than that of the insert; the toughness of the roller sleeve base body is higher than that of the insert; the roller sleeve base body is in a cylindrical shape; and the insert is arranged on the outer circumferential face of the roller sleeve base body. The manufacturing method of the squeezing roller sleeve includes the following steps that the insert is prefabricated, the casting mold of the squeezing roller sleeve is manufactured, the squeezing roller sleeve is formed through an imbedding process, and heat treatment is performed on the squeezing roller sleeve. The abrasion resistance and the anti-fatigue performance of the squeezing roller sleeve are good, the service life is long, and the production cost is low.

Owner:北京奥邦新材料有限公司

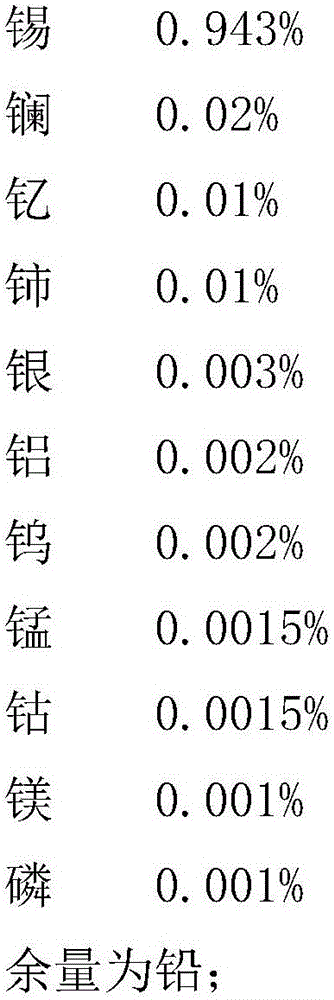

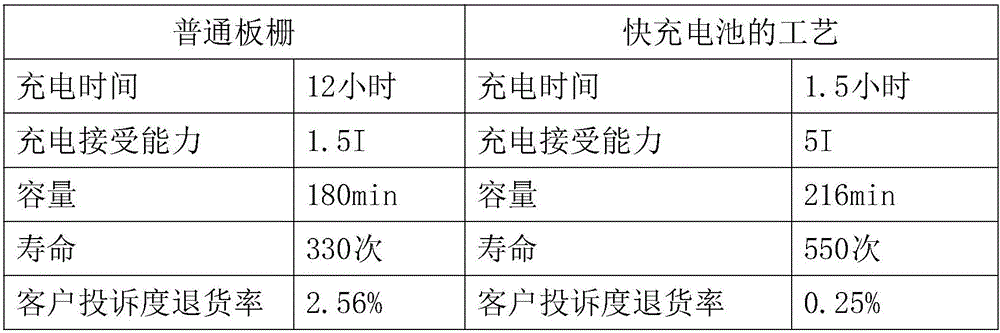

Plate grid alloy for positive plate of lead-acid storage battery

ActiveCN106099118AHigh mechanical strengthDelay Linear DeformationElectrode carriers/collectorsCeriumManganese

The invention discloses a plate grid alloy for a positive plate of a lead-acid storage battery, and relates to the technical field of processing of lead-acid storage batteries. The plate grid alloy is prepared from the following components in percentage by weight: 0.943% of tin, 0.02% of lanthanum, 0.01% of yttrium, 0.01% of cerium, 0.003% of silver, 0.002% of aluminum, 0.002% of tungsten, 0.0015% of manganese, 0.0015% of cobalt, 0.001% of magnesium, 0.001% of phosphorus and the balance of lead. The prepared plate grid alloy is a rare-earth alloy; and the mechanical strength of a plate grid can be improved through addition of the tin, rare earth and the silver, so that linear deformation of the plate grid is delayed. Meanwhile, the oxygen-evolution potential of a positive electrode can be regulated and controlled through addition of the tungsten, the manganese and the cobalt; and corrosion of the plate grid is reduced, so that the service lifetime of the plate grid is prolonged. The casting property can be improved through addition of the aluminum, the magnesium and the phosphorus; the molten alloy liquid has good mobility; a mold cavity can be easily filled with the alloy liquid; and the plate grid alloy is easy to mold during casting.

Owner:JIESHOU HUAYU POWER SUPPLY

Lead-acid accumulator grid alloy additive and preparation method thereof

InactiveCN103805809AExtended service lifeImprove casting effectElectrode carriers/collectorsCollocationSulfur

The invention discloses a lead-acid accumulator grid alloy additive and a preparation method thereof. The lead-acid accumulator grid alloy additive comprises the following raw materials in parts by weight: 940-960 parts of lead, 20-40 parts of antimony, 5-12 parts of tin, 0.55-0.65 part of selenium, 0.7-0.9 part of copper and 0.1-0.2 part of sulfur. The preparation method of the lead-acid accumulator grid alloy additive comprises the steps of preparing an alloy which contains selenium, copper and sulfur elements and lead into a lead-selenium-copper-sulfur alloy for later use; then placing the lead into a high-temperature furnace for heating and melting, and then adding all additives in batches; carrying out stirring treatment, then removing residues, and casting an ingot to obtain a lead-acid accumulator grid alloy; melting to obtain the lead-acid accumulator grid alloy additive. The lead-acid accumulator grid alloy additive disclosed by the invention has the advantages of good flowability and uniformity, convenience for accumulator grid casting and reasonability in alloy component collocation; an accumulator grid poured by using the lead-acid accumulator grid alloy additive has good corrosion resistance and tensile strength and prolongs the service life of a grid in the charge and discharge circulation of the accumulator.

Owner:GUANGXI SHAHU STORAGE BATTERY

Process for preparing Pb-base mixed rare earth slab lattice alloy

InactiveCN1721561ANo pollution in the processMeet the requirements of mechanized productionElectrode carriers/collectorsPolymer scienceGrating

The present invention is the preparation process of Pb-base mixed RE sheet grating alloy, and features that the alloy contains RE mixture in 0.03-0.04 wt% and the RE mixture consists of La 62.4-64.43 wt%, Ce 25.62-25.69 wt%, Pr 2.3-2.36 wt%, Nd 9.02-9.18 wt% and impurity not more than 0.5 wt%. The preparation process includes the following steps: heating reduced Pb or pure Pb to 560-600 deg.c, adding sodium hydroxide in 0.2 % for reduced Pb, maintaining for 30 min, stirring, letting stand to fish slag, adding RE mixture, Sn, As and S, maintaining at 560-600 deg.c, stirring for complete dissolving, fishing slag, and casting sheet grating at 450-480 deg.c. The sheet grating is used in accumulator.

Owner:XINXIANG CITY ZHUOWEI POWER SUPPLY

Preparation method for high-viscosity resin casting body

The invention belongs to a macromolecular material evaluation technology. A resin matrix and / or a curing agent are / is dissolved or diluted through the dilution of a low-boiling-point solvent to resin and the characteristic that the low-boiling-point solvent is easy to discharge; the viscosity of a resin system at normal temperature is reduced; then heating is executed to remove the solvent and air bubbles in vacuum, including determination of initial curing temperature, dissolving and mixing, viscosity adjustment, bubble removal and curing processes. According to the method, the air bubbles formed in a high-viscosity resin casting forming process can be effectively eliminated; the non uniformity of the performance of the resin casting body, which is caused by deposition in the curing process, is prevented; the preparation method is suitable for resin systems which are liquid, semisolid and solid at the room temperature and also suitable for resin systems in which the curing agent, an accelerant and the like cannot be dissolved in main resin; the preparation method is particularly suitable for resin systems which are solid or semisolid under the room temperature and are still extremely high in viscosity after being heated to the initial curing temperature.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

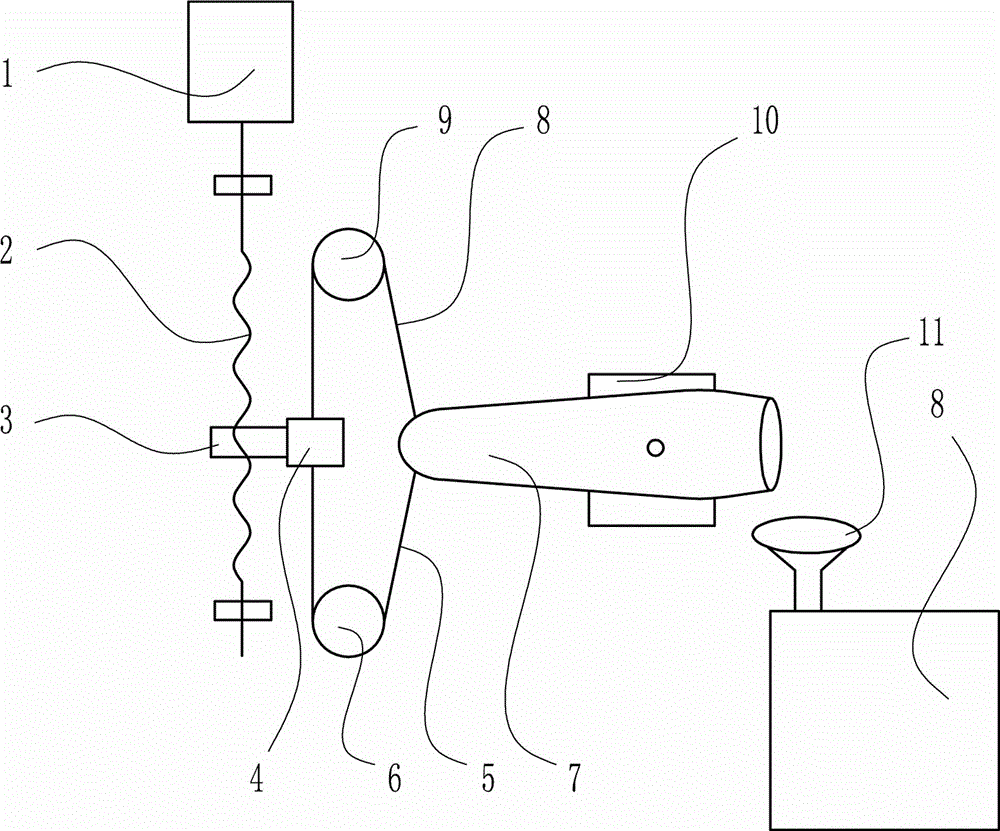

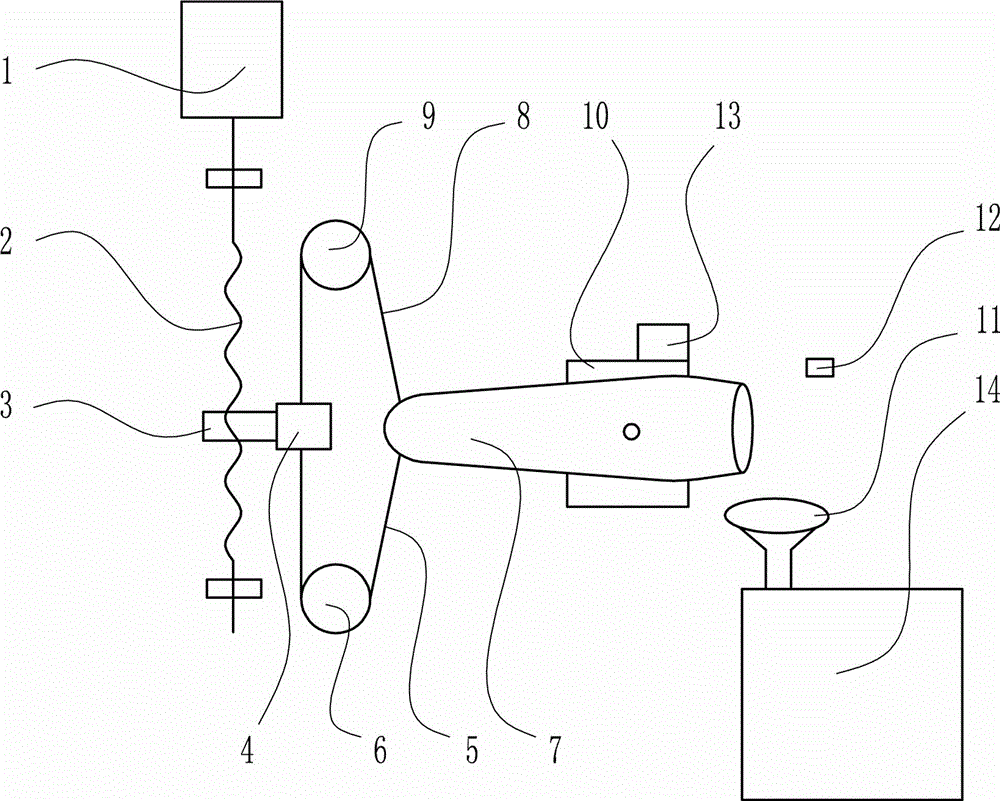

Quick pouring device of mold molten iron

InactiveCN105397073APrevent overflowImprove casting effectMolten metal conveying equipmentsManufacturing engineeringMetallurgy

The invention relates to a pouring device, in particular to a quick pouring device of mold molten iron. The technical problem to be solved by the invention is to provide the quick pouring device of mold molten iron. In order to solve the technical problem, the invention provides the quick pouring device of mold molten iron; and the quick pouring device of mold molten iron comprises a motor I, a lead screw, a nut, a connecting block, a lower pull rope, a lower pulley, a molten iron holding device, an upper pull rope, an upper pulley, a motor II and a funnel. The quick pouring device of mold molten iron overcomes the defects of molten iron waste, casualties and bad influence on people production and life caused by overflow from the funnel in quick pouring of molten iron in a traditional pouring device.

Owner:CHONGQING YUXI STEEL GRP CO LTD

Method for controlling content of oxygen in steel

The invention discloses a method for controlling the content of oxygen in steel. The method comprises the following steps: primarily smelting molten steel; adding an aluminiferous deoxidizer in a ladle in the tapping process for pre-deoxidation, and stirring by using an argon bottom blowing mode; carrying out ladle furnace refining, heating and slagging, and then adding a diffusion deoxidizer forenhanced deoxidation so as to rapidly form white slag; carrying out calcium line feeding treatment on molten steel; carrying out vacuum treatment, and then softly blowing argon; and stopping blowing the argon on the molten steel for killing treatment, purifying the molten steel and then carrying out continuous casting. According to the method, the re-pollution of the molten steel can be avoided, the probability of forming fine Al2O3 inclusions can be lowered, and the pouring property of the molten steel can be improved.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

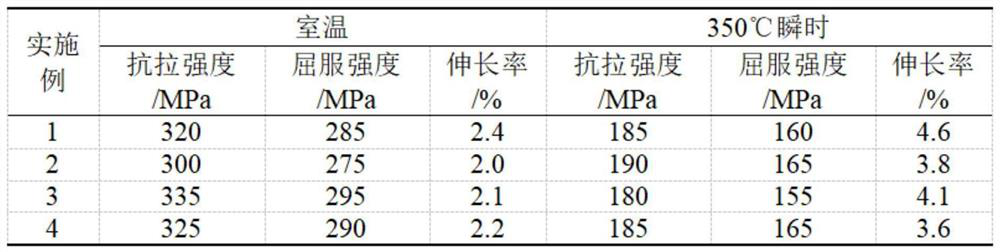

Heat-resistant regeneration die-cast aluminum alloy and preparation method thereof

The invention discloses a heat-resistant regeneration die-cast aluminum alloy and a preparation method thereof, and belongs to the field of regeneration die-cast aluminum alloy preparation. The invention provides the heat-resistant regeneration die-cast aluminum alloy capable of reducing the preparation cost and the preparation method of the heat-resistant regeneration die-cast aluminum alloy. Chemical components of the heat-resistant regeneration die-cast aluminum alloy include 10.0%-12.0% of Si, 0.50%-0.75% of Ni, 0.95%-1.35% of Mg, 0.9%-1.4% of Fe, 0.20%-0.30% of Mn, 0.08%-0.12% of Cr, 0.015%-0.03% of B, smaller than or equal to 0.15% of an impurity element and the balance Al. The preparation method includes the steps that smelting is conducted; sampling is conducted to adjust the alloycomponents; refining is conducted after low-melting-point alloy addition; slag removal is conducted; and casting is conducted. According to the heat-resistant regeneration die-cast aluminum alloy andthe preparation method, Ni and Cu are replaced with the low-cost impurity element Fe, and the alloy cost is effectively reduced; and by means of the compound modification technology of the Mn, the Cr, the B and the like, the size of the iron-rich phase is refined, and the high-temperature strength of the alloy is ensured.

Owner:肇庆南都再生铝业有限公司 +2

Ultralow-temperature high-toughness special nodular cast iron metal material and preparation method thereof

InactiveCN104451359AGood structural performanceImprove wear resistanceProcess efficiency improvementScrapFerrosilicon

The invention discloses an ultralow-temperature high-toughness special nodular cast iron metal material and a preparation method thereof. The ultralow-temperature high-toughness special nodular cast iron metal material comprises the following raw materials in parts by weight: 92-95 parts of pig iron, 5-8 parts of scrap steel, 1-2 parts of silicon iron, 2-3 parts of ferromanganese, 0.5-1 part of bismuth iron, 1.6-1.8 parts of a nodulizing agent and 0.5-0.8 part of an inoculant. The ultralow-temperature high-toughness special nodular cast iron metal material is prepared by smelting the pig iron, the scrap steel, the silicon iron, the ferromanganese, the bismuth iron and the inoculant in an electric furnace, performing metamorphic inoculation before furnace, casting forming and cooling. The ultralow-temperature high-toughness special nodular cast iron metal material has good structural performance, casting forming performance and machinability, can be applicable to workplaces with high requirements on high toughness, high strength, high wear resistance, cold resistance, corrosion resistance, shock absorption and safety performance, can be applied to high-speed trains, a wind power industry, vehicles, petroleum, a petrochemical industry and other industries, has relatively cheap raw materials, and has a very high practical value, a very high promotional significance and a wide market prospect.

Owner:SHANDONG YUANTONG MASCH CO LTD

Corner piece manufacturing method

InactiveCN103286268AOptimize structureReduce in quantityFoundry mouldsFoundry coresMagnetEngineering

The invention discloses a corner piece manufacturing method. The manufacturing method includes the steps: performing a three-dimensional modeling by the aid of three-dimensional modeling software, drawing a solid model of a corner piece, and manufacturing a wood pattern with the corner piece and meeting size requirements by the aid of a corner piece model manufactured and arranged by a machining center; performing sandbox modeling by the wood pattern, arranging a magnet in a sand body of a sand mould at a dead corner of the corner piece when in modeling, and painting parting agents on a parting section; and opening a sandbox, trimming defective portions, closing the sandbox, pouring molten iron into the sandbox after the temperature of the molten iron is cooled to the casting temperature, and cooling the molten iron at the indoor temperature. By the aid of the manufacturing method, the corner piece structure can be effectively optimized by the aid of a solid of the corner piece manufactured by three-dimensional modeling, so that the corner piece is more suitable for molten iron casting, the number of casting dead corners is decreased, formability of the corner piece is improved, the molten iron can more rapidly flow to the dead corner as the magnet is arranged at the dead corner, incomplete casting of the dead corner is avoided, the finished product ratio is increased, production efficiency is improved, and production cost is reduced.

Owner:YANGZHOU TONGYING MACHINERY MFR

Production method of fused AZS hanging wall brick

The invention discloses a production method of a fused AZS (Al2O3-ZrO2-SiO2) hanging wall brick. By shifting a lost foam technology used for the metallurgy industry to the fusion-cast refractory industry, the invention realizes a production method of a fused AZS special-shaped product. The method comprises the steps of: (1) foam model making; (2) cartonning of the model and sand filling; (3) batching; (4) electric furnace casting; (5) insulation and annealing; and (6) cold working. The inside of the model is a ribbed hollow structure, which ensures the strength and dimension of the model and simultaneously reduces model volume, thus enhancing the casting effect. The fused AZS hanging wall brick produced in the invention is free of crack in the whole body, has regularity up to the standard requirement, and has a tolerance at the neck of -0.3-0.5mm, thus being in line with the profile requirement of mother brick equipment and acceptance criteria. Characterized by high internal densification degree, obviously reduced crack generation probability, good regularity, accurately controlled dimension, less unnecessary processing loss, reduced processing, cutting, polishing and production cost, and all physical and chemical indexes kept within a standard control scope, the fused AZS hanging wall brick produced in the invention can be applied in the glass industry.

Owner:郑州东方安彩耐火材料有限公司

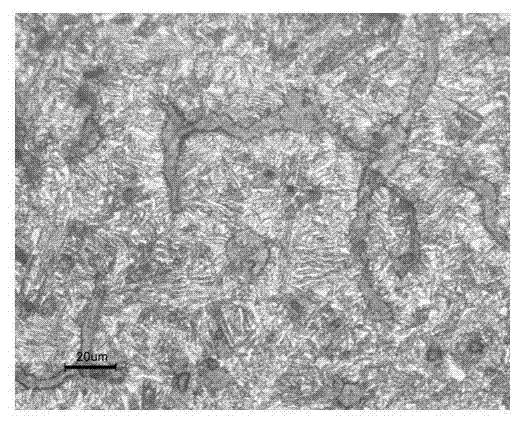

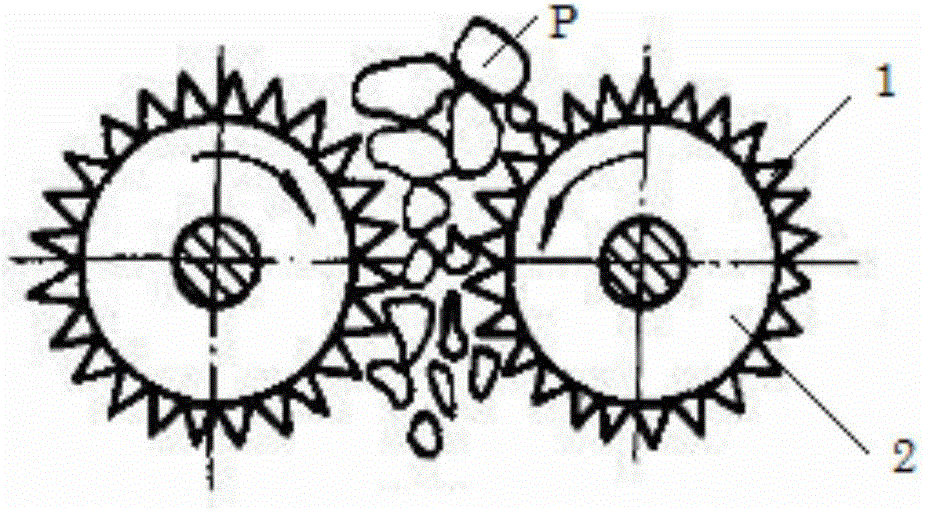

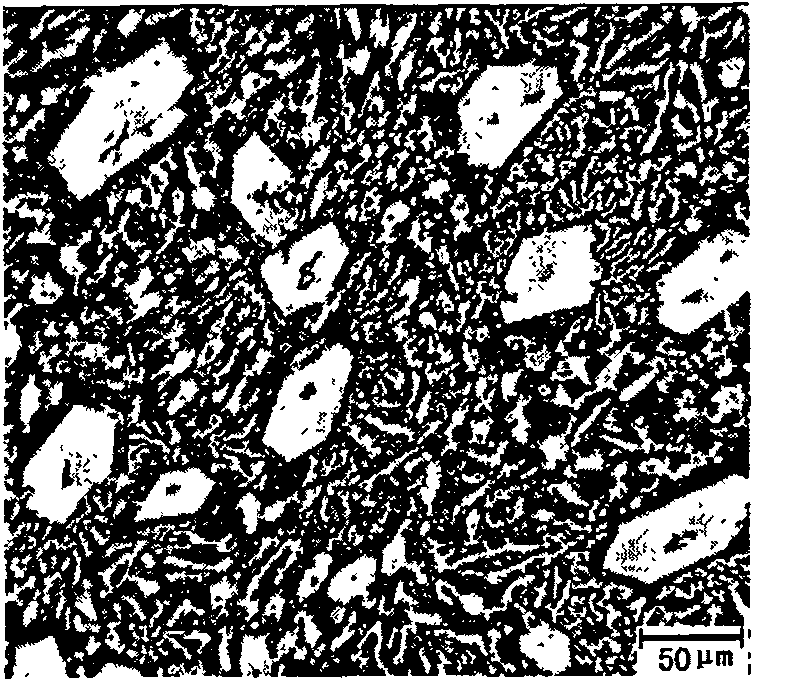

Hypereutectic high-chromium white cast iron preparation method

InactiveCN101302597BLow priceIncrease the number ofProcess efficiency improvementWear resistantHigh carbon

The invention relates to wear-resistant white cast iron and a method for preparing the same, in particular to hypereutectic high-chromium white cast iron and a method for preparing the same. The castiron is suitable for preparing an overflow part (such as an impeller, a guard board, a shell and so on) of a slurry pump or a Yellow River water pump for conveying eroding and abrading slurry. The compositions by weight percentage of the hypereutectic high chromium white cast iron are: 3.0 to 4.5 percent of C, 15 to 35 percent of Cr, 0.5 to 1.5 percent of Ti, 0.5 to 2.5 percent of Mn, 0.001 to 0.5percent of B, 0.5 to 1.5 percent of Si, less than 0.06 percent of P, less than 0.06 percent of S, and the balance being Fe. The method comprises the following steps of: determining a proportion relation of the compositions, according to the compositions of the hypereutectic high-chromium white cast iron, and compositions of scrap steel, pig iron, high-carbon ferrochromium, ferromanganese, ferroboron and ferrotitanium; batching, melting, casting and heat treating to acquire a hypereutectic high chromium white cast iron material with a hardness between HRC 65 and HRC 68 and an impact ductilitybetween 5.0 and 6.5 J / cm2.

Owner:XI AN JIAOTONG UNIV

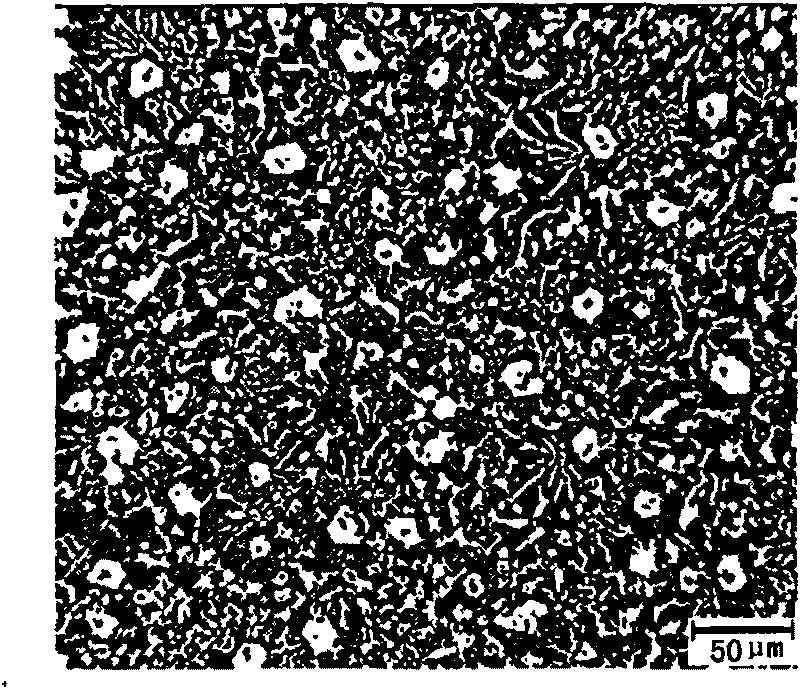

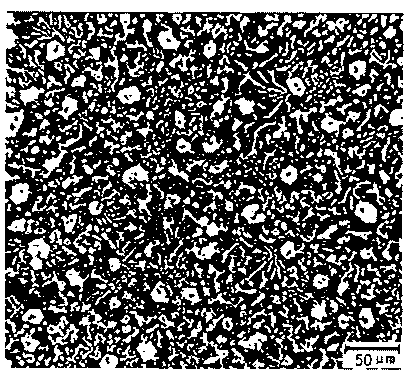

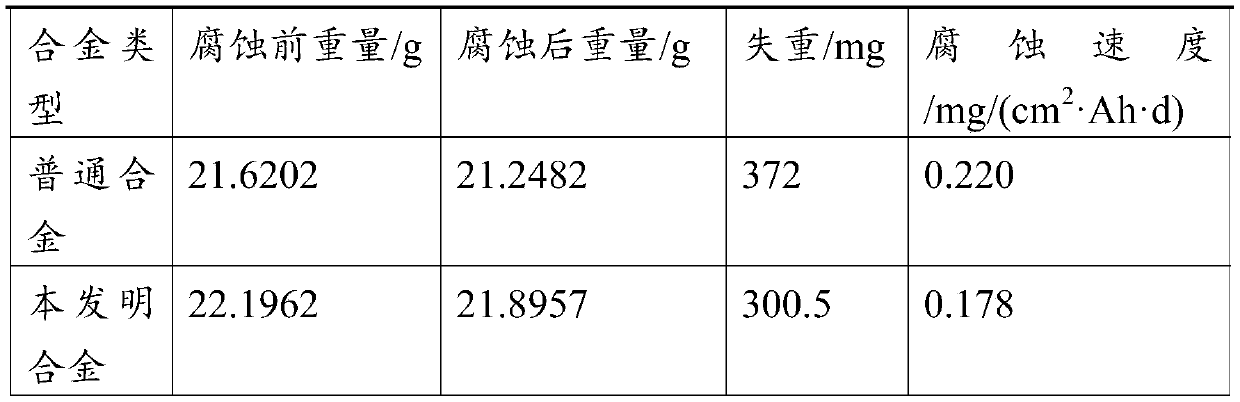

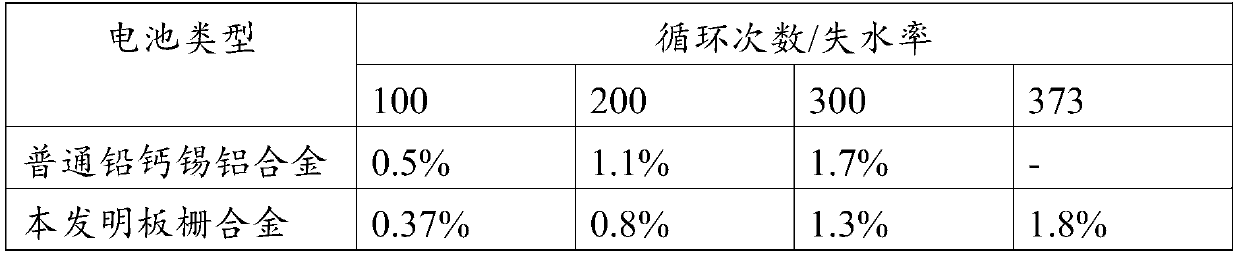

Novel grid alloy, positive plate grid containing novel grid alloy and lead-acid storage battery

The invention relates to a grid alloy. The grid alloy is prepared from the components in percentage by weight: 0.08-0.09% of calcium, 0.4-0.8% of tin, 0.015-0.025% of aluminum, 0.02-0.03% of cerium, 0.025-0.035% of copper, 0.015-0.025% of sodium and the balance of lead. The invention further relates to a positive plate grid comprising the grid alloy, a preparation method of the grid alloy, a preparation method of the positive plate grid and a lead-acid storage battery provided with the positive plate grid. Through constant current corrosion tests and water loss rate tests, it is found that thecorrosion resistance of the lead-acid storage battery provided with the positive plate grid made of the novel grid alloy is greatly improved, and the water loss rate is further greatly reduced.

Owner:ANHUI LEOCH BATTERY TECH

Gravity casting mold for end cover of new energy water cooling motor shell and casting process thereof

InactiveCN112387931AGuarantee product qualityShorten the flow distanceFoundry mouldsFurnace typesNew energyElectric machinery

The invention belongs to the technical field of new energy automobiles, in particular to a gravity casting mold for an end cover of a new energy water cooling motor shell and a casting process thereof. The mold comprises an upper mold and a lower mold. The upper mold and the lower mold are assembled to form mold cavity, a sprue is arranged at the center of the upper mold, sprue covers are arrangedaround the sprue, an ejecting system is arranged below the lower mold and comprises an ejector pin plate, an ejector pin panel, an ejector pin and a reset rod, a dividing cone is arranged at the center of the lower mold, the dividing cone and the sprue covers on the upper mold form a pouring gate with a slag avoiding function, a hydraulic pulling core is arranged on one side of the lower mold, and heating pipes are arranged on the upper and lower molds. The upper and lower molds are opened, the hydraulic pulling core is assembled in position to assemble the mold, and molten aluminum is castedin the mold cavity by a sprue casting mold. The mold is simple in structure, reasonable in design and high in yield. By additionally arranging the dividing cone, a product produced with the slag avoiding function is free of casting defects such as slag inclusion and pores. The mold is high in production efficiency and easy to operate and the labor intensity of staff can be ensured low.

Owner:SHANDONG HONGYUAN NEW MATERIALS CO LTD

High-strength and high-toughness cast steel resistant to abrasion and corrosion in high temperature and used for incinerator fire grate and preparation method thereof

ActiveCN105648345AImprove mechanical propertiesHigh hardnessProcess efficiency improvementRare earthToughness

The invention discloses a high-strength and high-toughness cast steel resistant to abrasion and corrosion in high temperature and used for an incinerator fire grate and a preparation method thereof. The high-strength and high-toughness cast steel resistant to abrasion and corrosion in high temperature and used for the incinerator fire grate comprises, by weight percentage, 0.18%-0.42% of C, 0.8%-2.0% of Si, 0.5%-1.2% of Mn, 15%-25% of Cr, 0-0.015% of P, 0-0.01% of S, 1.5%-3.5% of Al and 0.005%-0.02% of RE. When C is smaller than 0.25% and Cr is smaller than 20%, the high-strength and high-toughness cast steel further comprises 0.05%-0.25% of Nb and 0.05%-0.25% of Ti. The high-strength and high-toughness cast steel is prepared by the steps of sorting, smelting, refining, deoxidation, modification fining, casting and the like. The cast steel has the good casting molding performance and machining performance, high strength, good ductility and toughness, superior abrasion and corrosion resistance in high temperature, low production cost and long service life, and is especially suitable for large mechanical reciprocating grates of municipal refuse incinerators in China.

Owner:SHANGHAI ENVIRONMENTAL ENG DESIGN & RES INST CO LTD +1

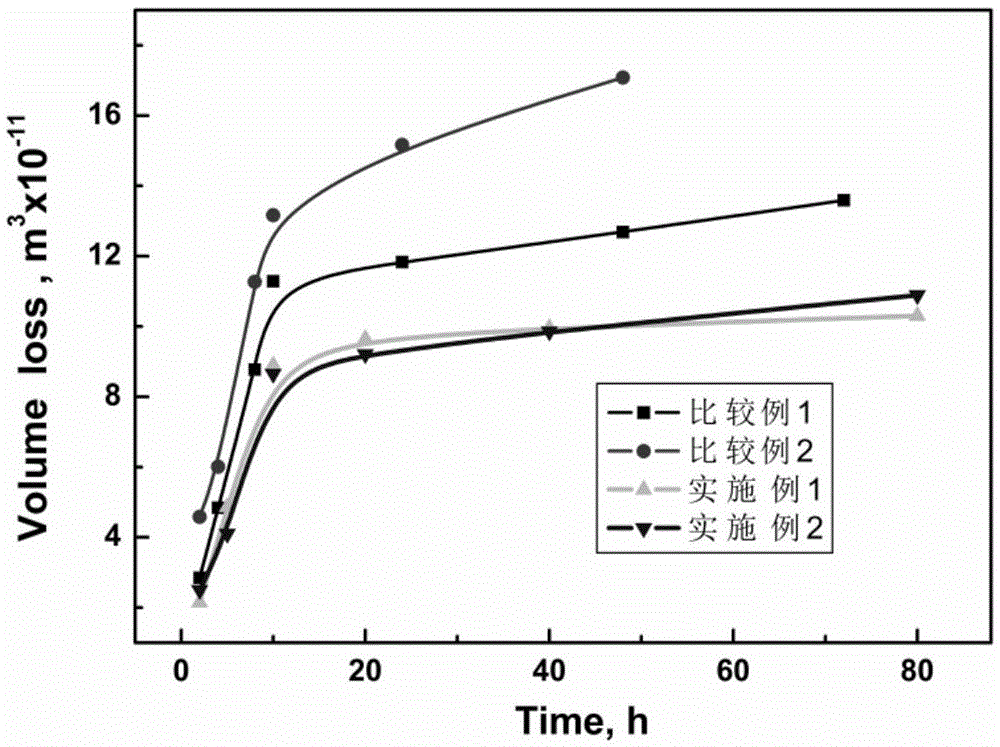

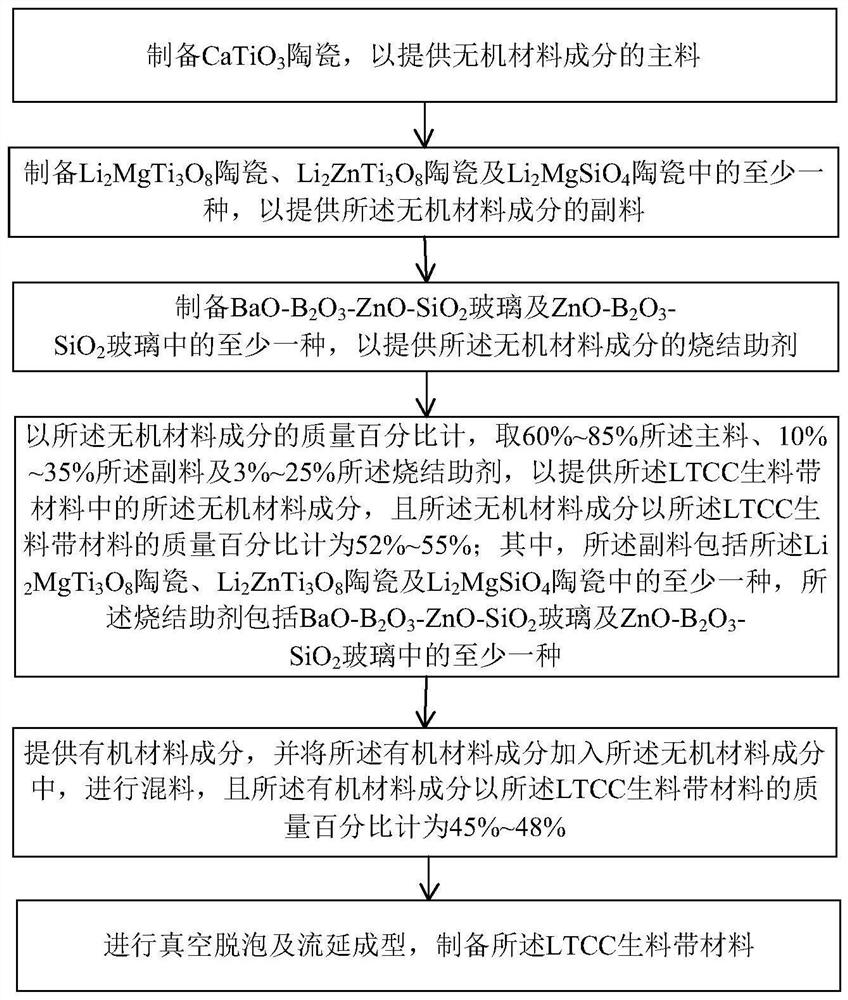

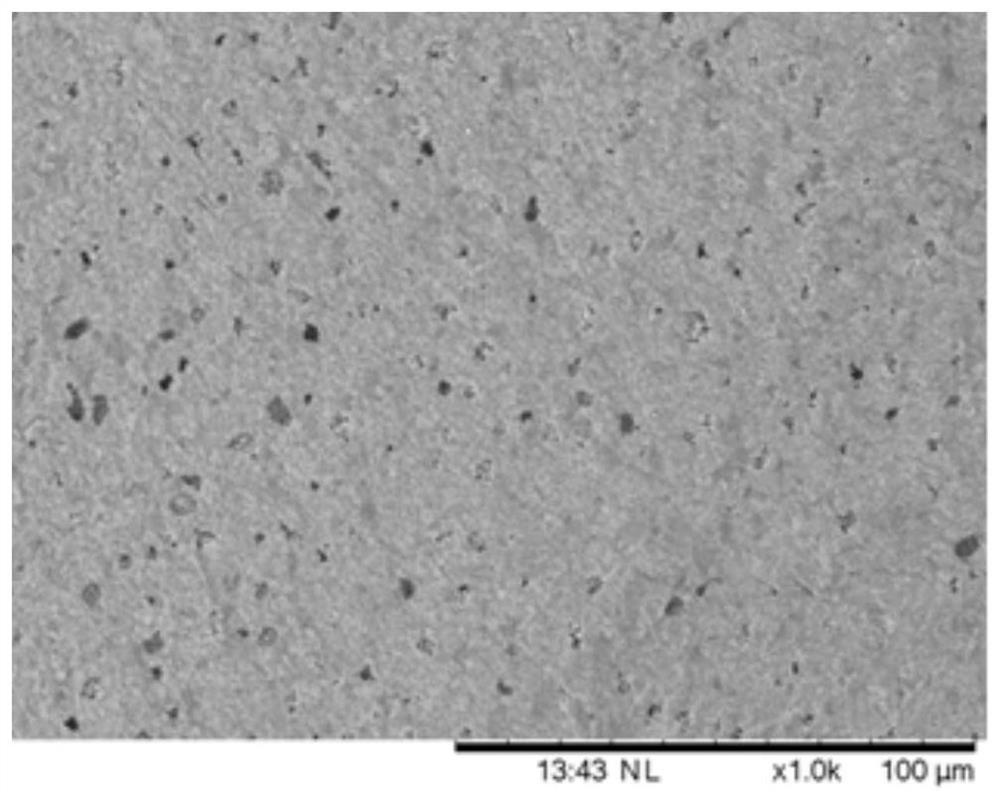

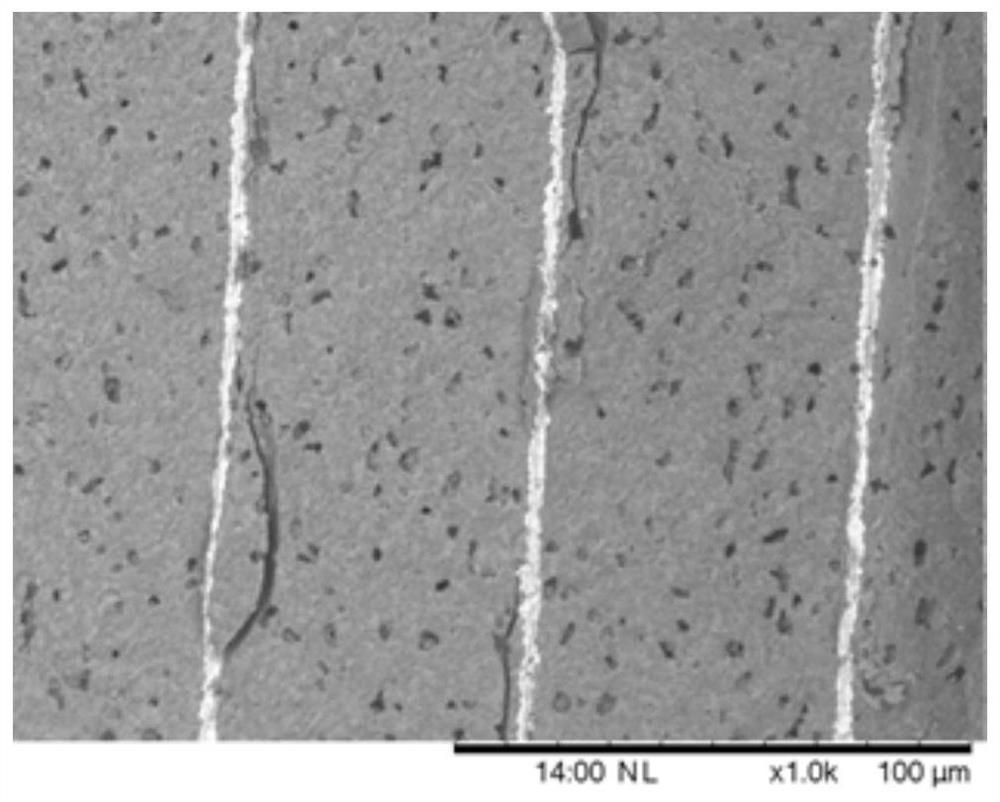

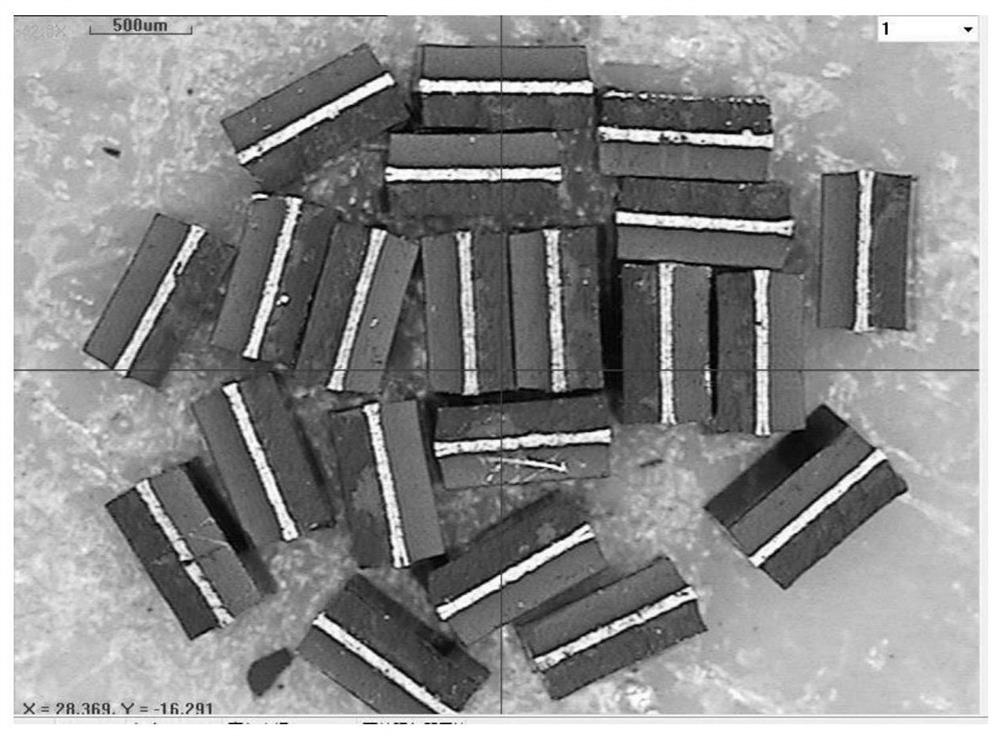

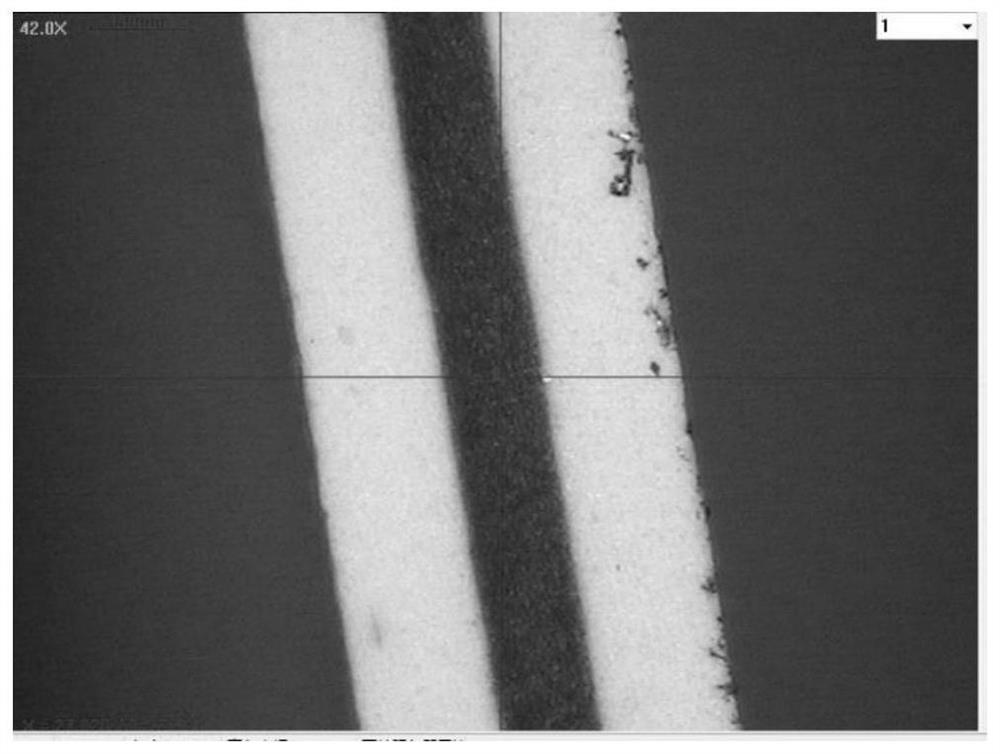

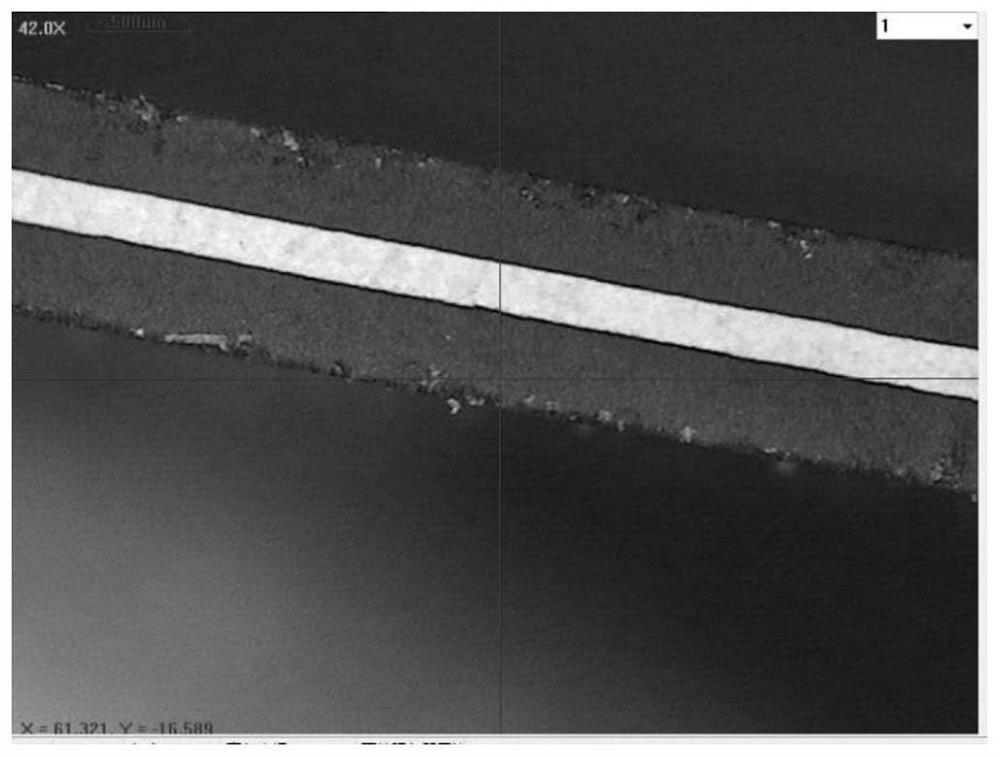

LTCC raw material tape material, substrate and preparation method

The invention provides an LTCC raw material tape material, a substrate and a preparation method. Li-based ceramic with relatively low sintering temperature is adopted in inorganic material components, so that the dielectric constant of a mixture can be effectively adjusted in the sintering process, and the sintering assisting effect can be achieved. In organic material components, a solvent is selected from an alcohol-ketone mixed solvent which is low in boiling point, easy to volatilize and good in solubility with the binder, so that the tape casting effect is good, and the LTCC raw material tape material which is smooth in surface and uniform in thickness is formed. The medium-high dielectric constant LTCC teflon tape material and the LTCC substrate which have the dielectric constant of 40-80, the dielectric loss of 1.0*10<-3> to 2*10<-3> and good cofiring performance with low-melting-point metal slurry can be prepared.

Owner:上海晶材新材料科技有限公司 +1

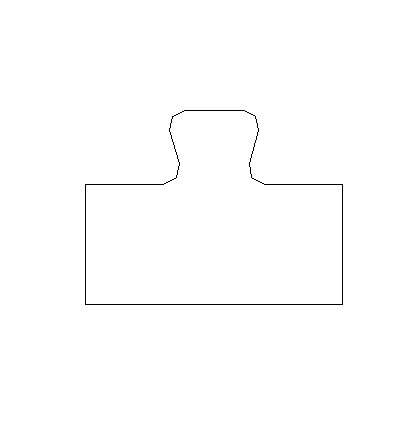

Aluminizing and inlay casting technology for Al-based material

The invention discloses an aluminizing and inlay casting technology for an Al-based material. The aluminizing and inlay casting technology comprises selection of an aluminizing material and surface active treatment on the Al-based material, and further comprises aluminizing and inlay casting, wherein the selection step means selecting the aluminizing material according to the Al-based material; the surface active treatment step means putting the Al-based material in an alkaline solution for soaking, taking out the soaked Al-based material, and carrying out cleaning and drying; and aluminizing and inlay casting are carried out after the selection step and the surface active treatment step, and particularly comprise the steps of melting the selected aluminizing material, carrying out heat preservation, heating the Al-based material subjected to surface active treatment, then putting the heated Al-based material into the molten aluminizing material, shaking to ensure that the heated Al-based material vibrates up and down, taking out the vibrated Al-based material, putting the vibrated Al-based material in a mold, casting the molten aluminizing material to obtain a cast, and allowing the cast to solidify, so that a metallurgical bonding surface is formed between the Al-based material and the aluminizing material. The aluminizing and inlay casting technology has the advantages that the operation is simple and convenient; the cost is low; the popularization and the use are easy; and the metallurgical bonding surface is formed between the Al-based material and the aluminizing material.

Owner:DONGFENG COMML VEHICLE CO LTD

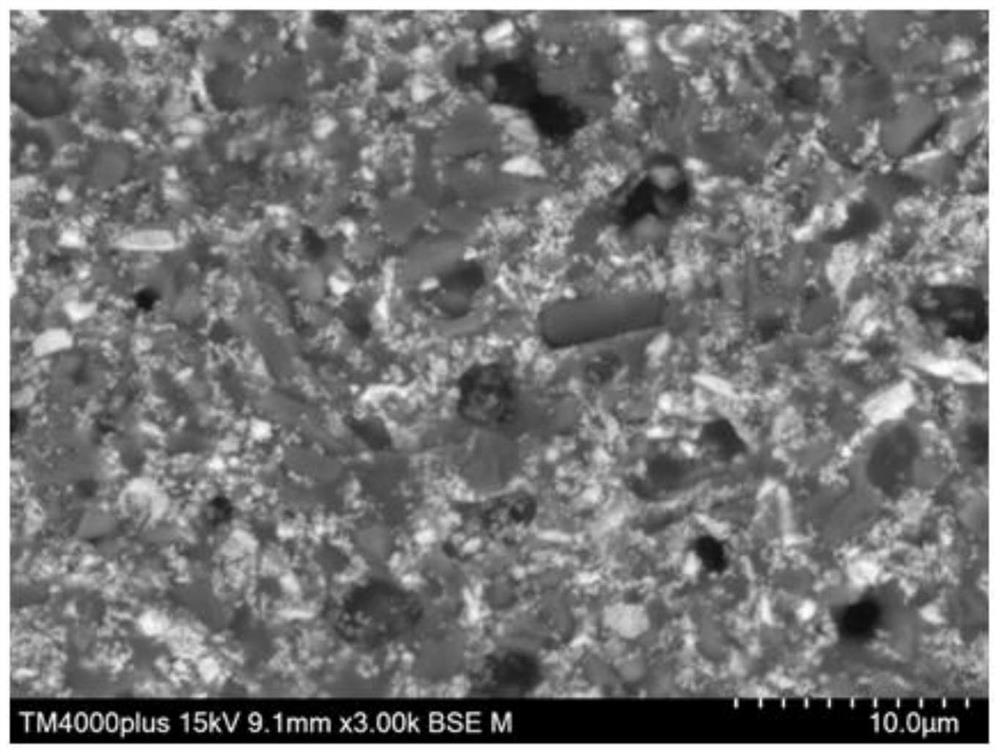

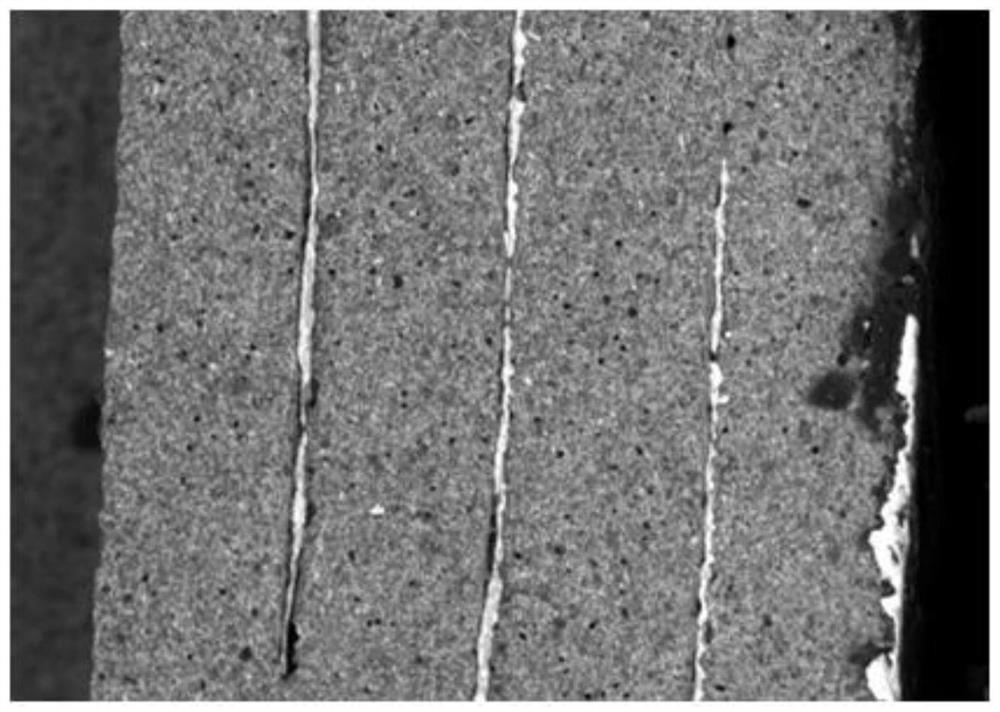

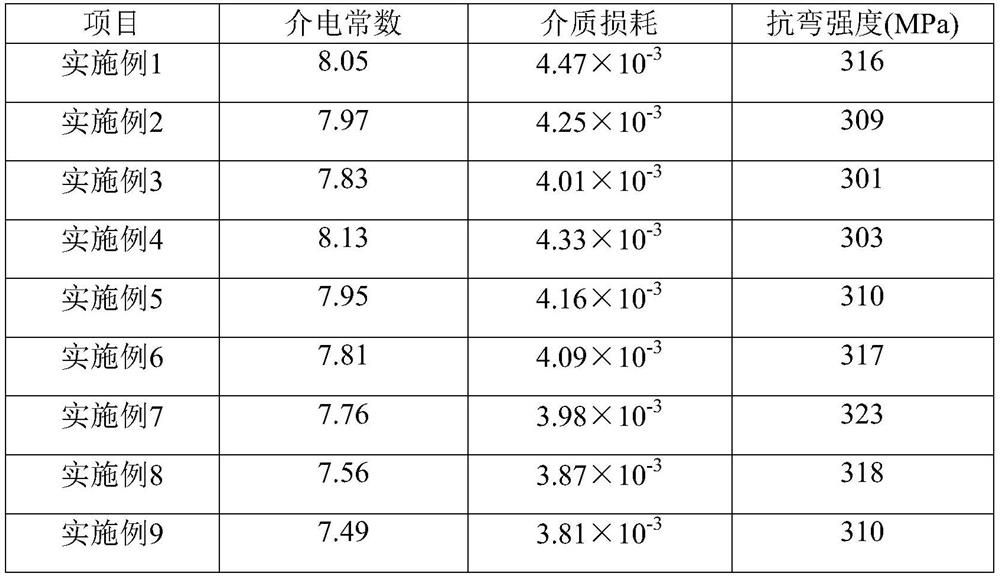

LTCC raw material tape material, LTCC substrate and preparation method

The invention provides an LTCC raw material tape material, an LTCC substrate and a preparation method, and the LTCC raw material tape material comprises the following components in percentage by mass: 40-50 wt% of an inorganic material and 50-60 wt% of an organic material, the inorganic material comprises the following components in percentage by mass: 20 to 60 weight percent of Al2O3 ceramic, 10 to 50 weight percent of ZrO2 ceramic, 25 to 38 weight percent of CaAlSi microcrystalline glass and 0 to 3 weight percent of sintering aid; the organic material comprises an alcohol-ester mixed solvent, a dispersing agent, a binder and a plasticizer. Mixing the raw materials according to the mass ratio, and casting to obtain an LTCC raw material tape material; and after being subjected to overlying forming, the substrate is put into a sintering furnace to be roasted, and the LTCC substrate is obtained. The dielectric constant of the LTCC substrate is 7.0-8.3, the dielectric loss of the LTCC substrate is 0.003-0.005, the bending strength of the LTCC substrate is 300 MPa or above, and the LTCC substrate is good in cofiring matching performance with silver and gold electrode slurry.

Owner:上海晶材新材料科技有限公司

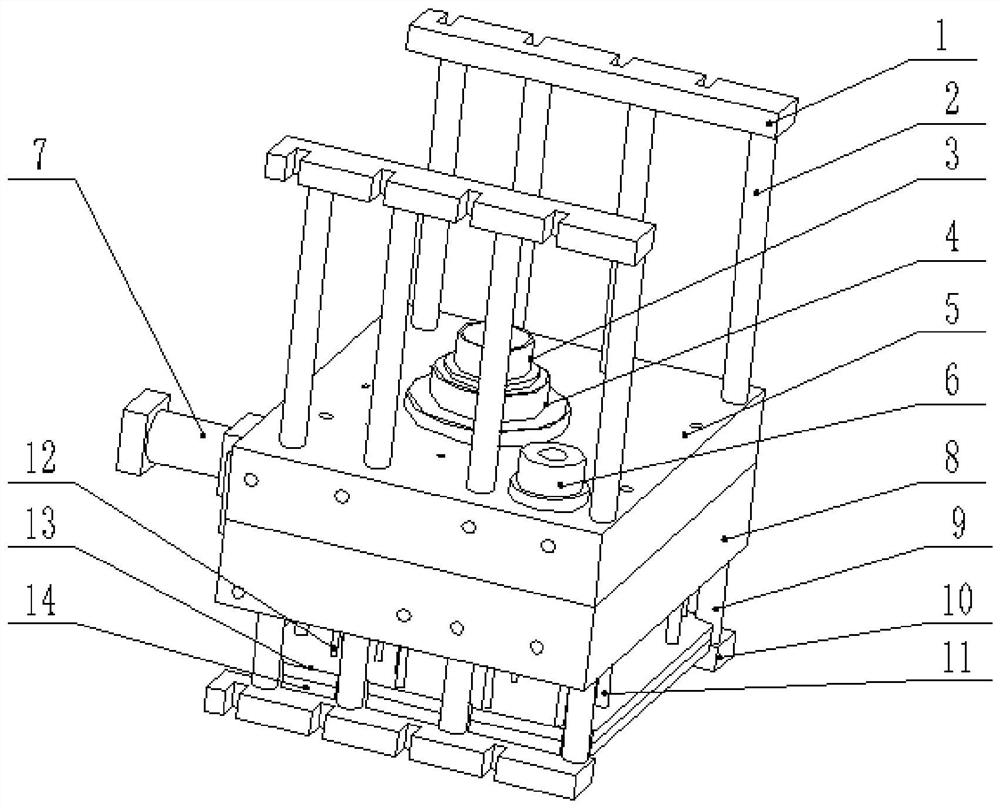

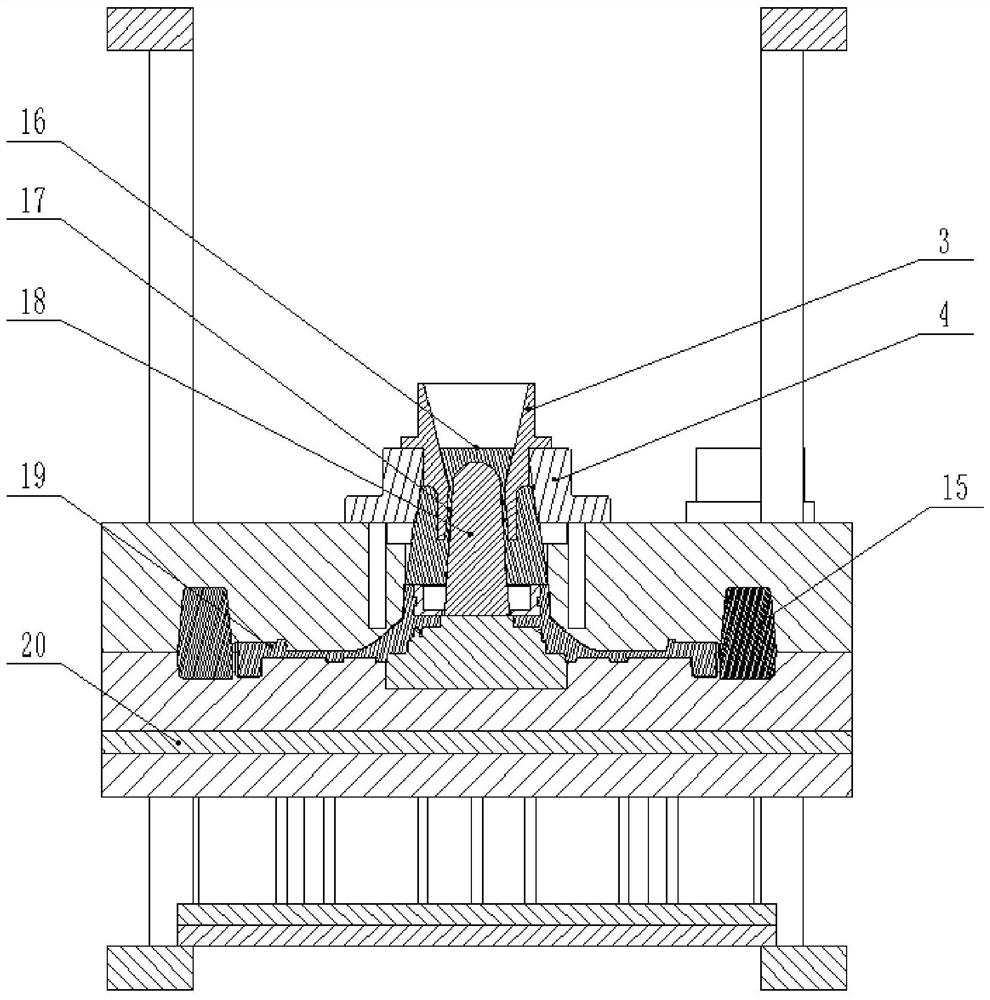

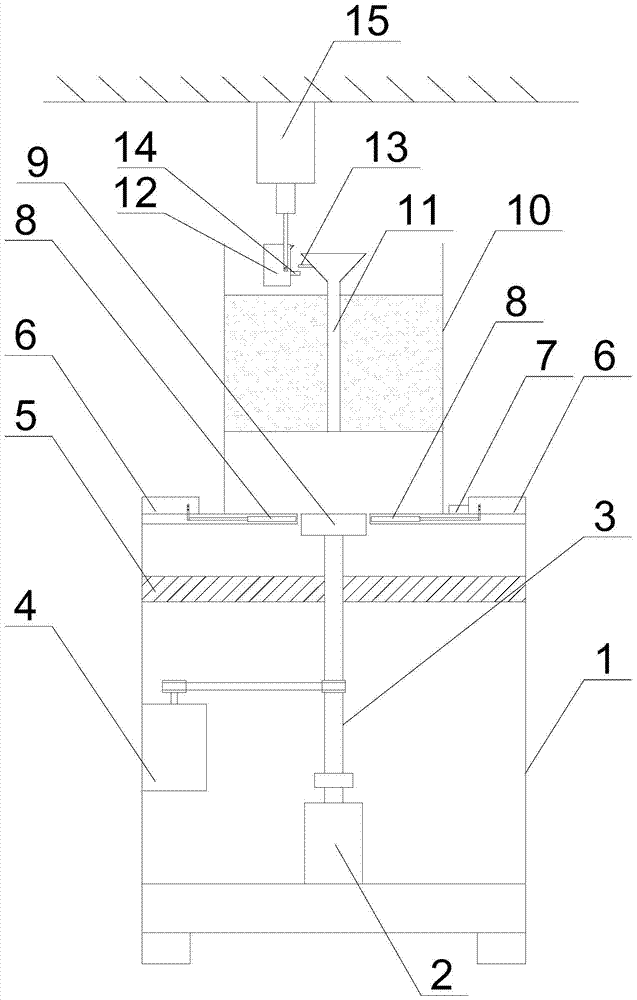

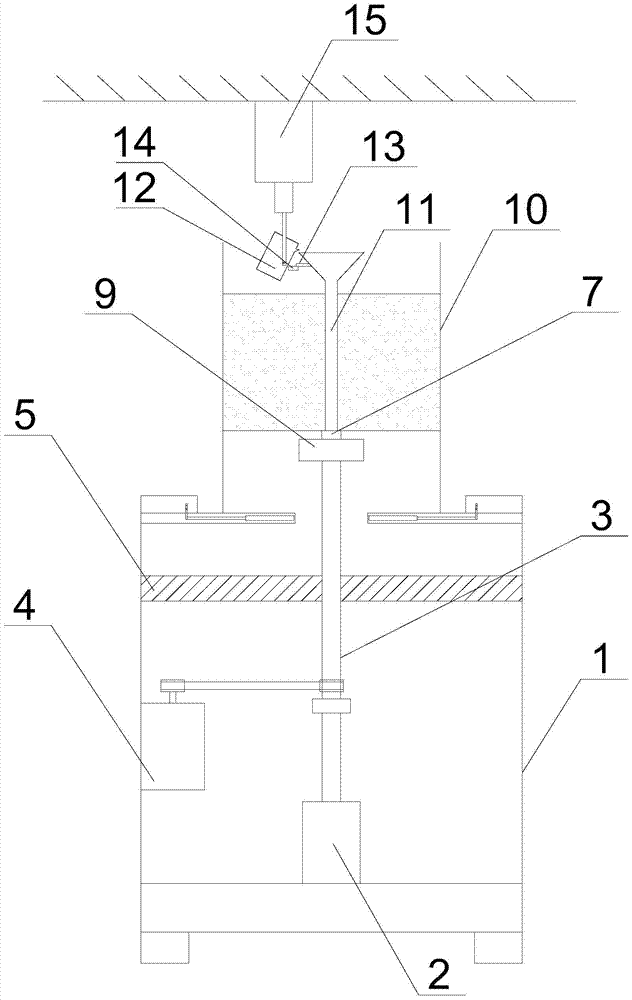

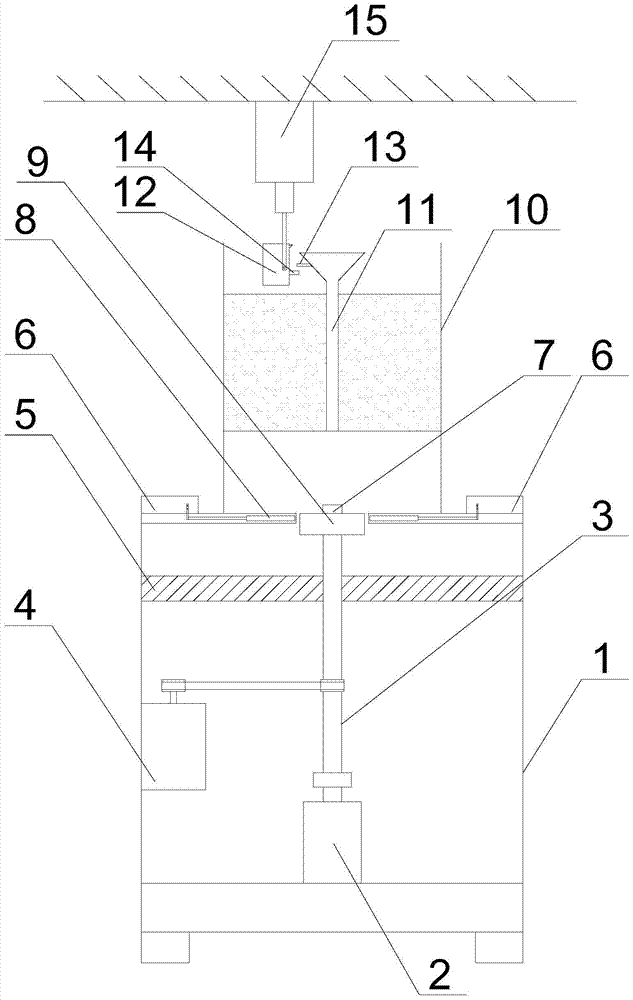

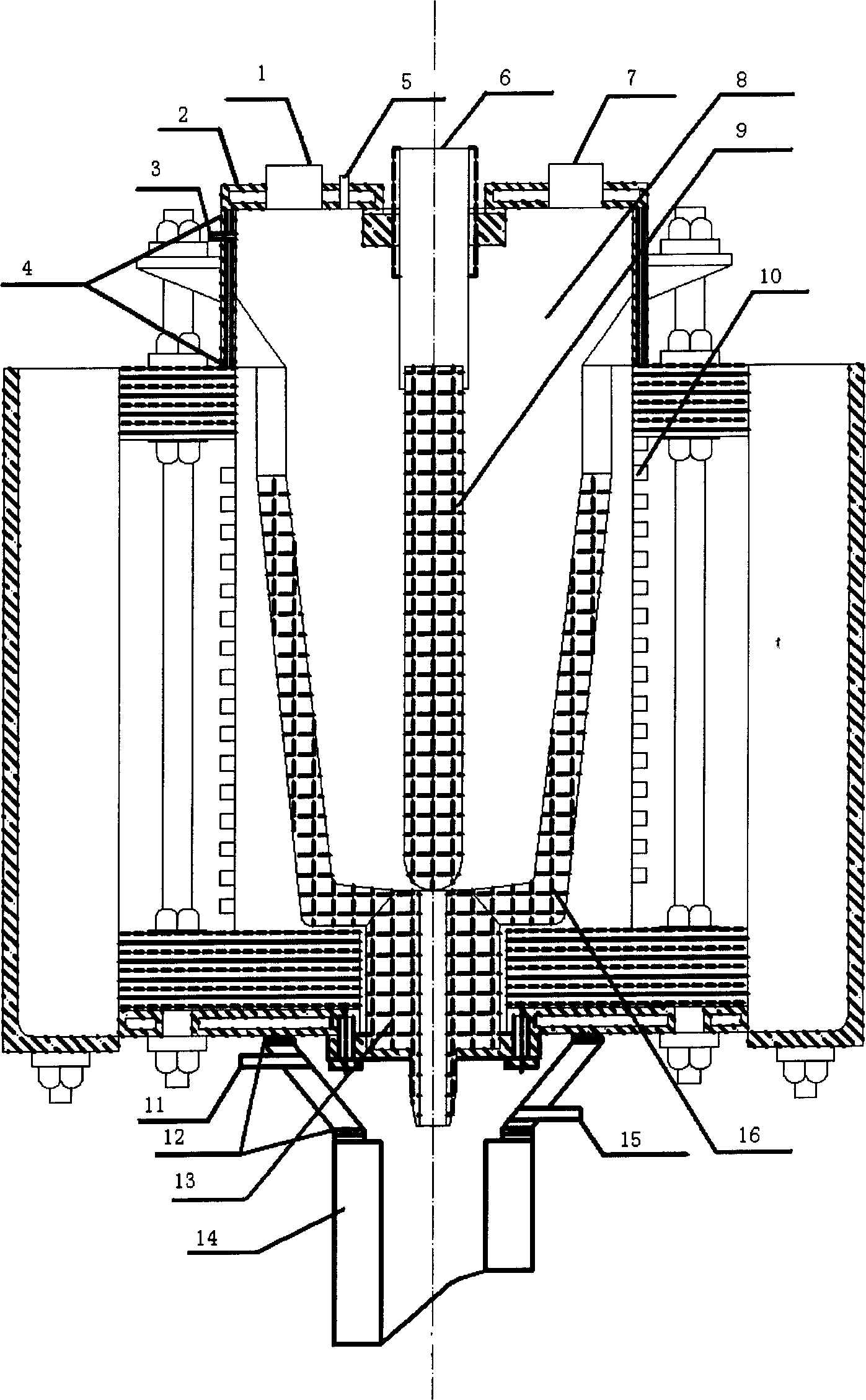

a casting equipment

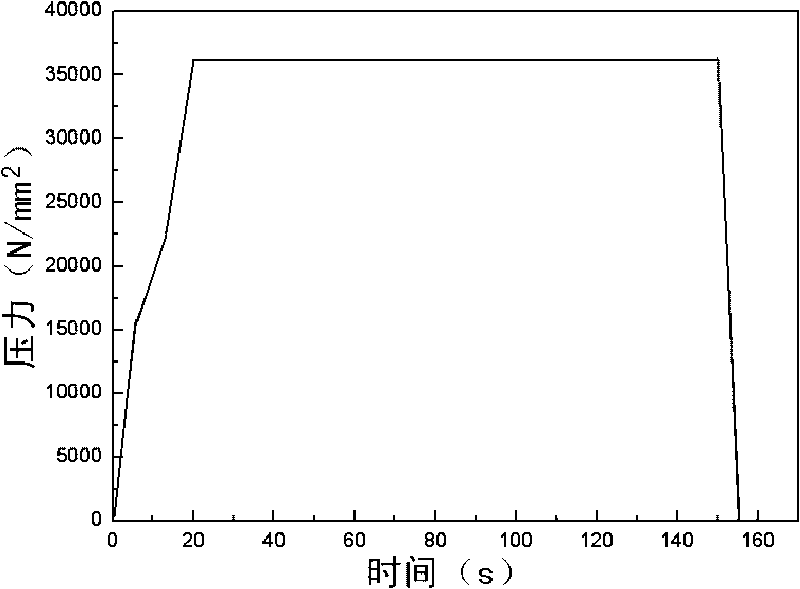

ActiveCN104588626BImprove casting effectImprove operational flexibilityMolten metal conveying equipmentsCastingInertia

The invention discloses a casting method and casting equipment for implementing the casting method. The method comprises the steps of S1, pouring casting liquid into a mold through a pouring gate arranged on the mold; S2, enabling the casting liquid to fully fill a casting cavity of the mold through movement of the mold; S3, cooling and solidifying the casting liquid to form a casting blank. The equipment comprises a mold, a pouring device and a movement device, wherein the mold is provided with a casting cavity and a pouring gate and the casting cavity is communicated with the pouring gate; the pouring device is used for preparing casting liquid and pouring the casting liquid into the pouring gate; the mold is installed on the movement device, the movement device is driven by a movement drive mechanism to drive the mold to move, and the casting liquid in the casting cavity fully fills the casting cavity through inertia thereof. The casting method and the casting equipment for implementing the casting method have the beneficial effects that the casting liquid in the casting cavity fully fills the entire casting cavity under the effect of inertial force through the movement of the mold under the drive of the movement device and the casting effect is good.

Owner:山西建邦集团铸造有限公司

Equipment of non-vacuum smelting easy oxidation metal and alloy

InactiveCN1869564AReduce partial pressureFacilitated DiffusionCasting plantsCrucible furnacesLoss rateCunife

The invention provides a device for non-vacuum smelting easy- to-oxidize metals and alloys, and its main parts comprise furnace body and furnace cover, where the furnace body is equipped with a heater, and a pot is placed inside the furnace body; and the furnace cover has an gas inlet, an gas outlet and a feed inlet and is equipped with a cooling mechanism; the bottom of the hearth is equipped with a bottom pouring orifice, a vertical stopper is arranged inside the furnace body, the lower end of the stopper is connected with the bottom pouring orifice, the upper end of the stopper is equipped with an adjustment mechanism which adjusts the vertical position of the stopper to prevent metal melt from flowing down in the smelting course; the lower side of the furnace body is directly connected with a crystallizer or iron mold, it adopts a down-pouring mode and the connecting channel is made with an gas inlet and an gas outlet. And its whole smelting and casting course is performed in the industrial pure protective gas, having low melting loss rate and good deoxidizing and dehydrogenating effects, easy to implement large-scale continuous operation and obviously improving the pouring quality.

Owner:苏州有色金属研究院有限公司

LTCC raw material tape material, LTCC substrate, LTCF-LTCC heterogeneous substrate and corresponding preparation method

The invention provides an LTCC raw material tape material, an LTCC substrate, an LTCF-LTCC heterogeneous substrate and a corresponding preparation method, and the LTCC raw material tape material comprises 45-55 wt% of an inorganic material component and 45-55 wt% of an organic material component based on the mass percentage of the LTCC raw material tape material; the inorganic material comprises the following components in percentage by mass: 50-70 wt% of a ceramic material and 30-50 wt% of a glass material; the organic materials comprise a solvent, a dispersing agent, a binder and a plasticizer. The tape casting slurry is good in forming effect, the prepared LTCC raw material tape and LTCF are good in cofiring matching performance and compact in sintering, the dielectric constant of the LTCC raw material tape material is 4.5-7.0, and the dielectric loss is 2.3 * 10 <-3 >-4.5 * 10 <-3 >; and the LTCF-LTCC heterogeneous substrate is tightly bonded in a co-firing manner, and the shear surface has no collapse opening, so that the condition that the LTCC layer is diffused by the LTCF layer can be effectively avoided.

Owner:上海晶材新材料科技有限公司

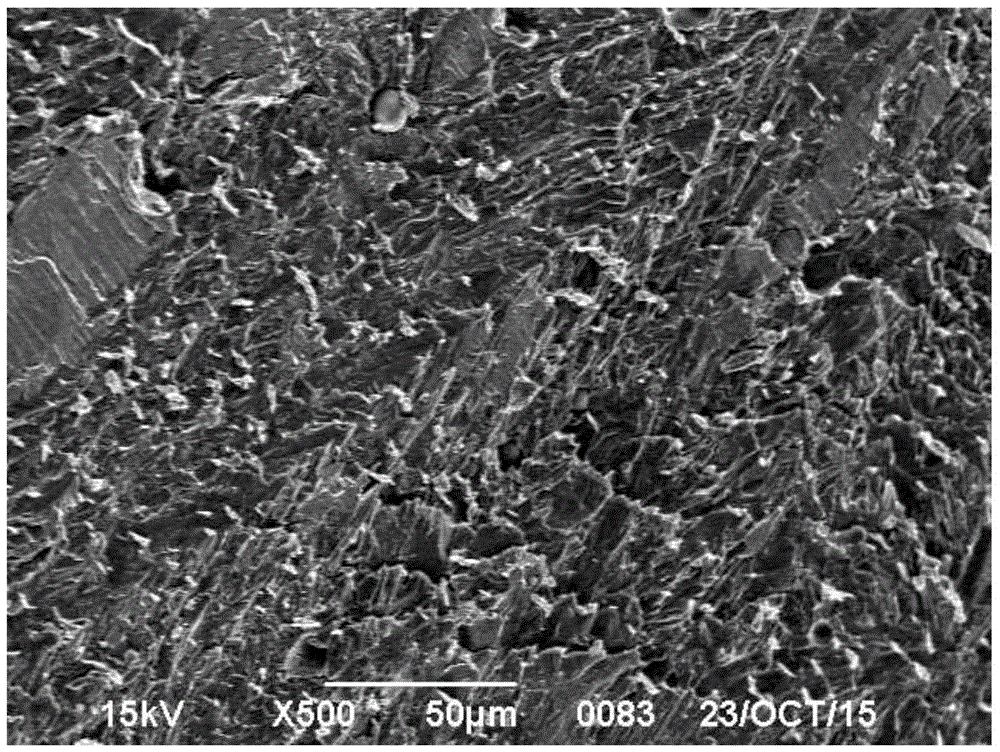

Preparation method for Si-Mn alloyed wear-resistant cast steel

InactiveCN106521294AReduce manufacturing costSimple production processProcess efficiency improvementAlloy elementScrap

The invention provides a preparation method for Si-Mn alloyed wear-resistant cast steel. The preparation method comprises the steps of: firstly mixing, heating and melting Q235 steel scrap, carbon ferrochrome and a high manganese steel waste material; when the molten iron temperature reaches 1520-1550 DEG C, adding a silicon steel sheet waste material; after fully melting the materials, adding metallic aluminum to deoxidize; then performing external treatment on the molten iron and performing moulding by casting; and quenching and tempering a casting to obtain the Si-Mn alloyed wear-resistant cast steel. According to the preparation method provided by the invention, by taking cheap high manganese steel waste material and silicon steel sheet waste material as main raw materials and adding a proper amount of high carbon ferrochrome without expensive alloy elements such as molybdenum, nickel and copper, the production cost is greatly reduced; the obtained cast steel is excellent in mechanical property, the hardness reaches 55-57HRC, the hardness is uniformly distributed, the impact toughness reaches 138-148 J / cm<2>, and the tensile strength reaches 1650MPa above, and the cast steel reaches requirements of ultra-high strength wear-resistant steel and has good economical and social benefits in popularization and application.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com