Equipment for nonvacuum melting and casting readily oxidizable metal and alloy

A non-vacuum smelting technology for easily oxidized metals, which is applied in the smelting and casting equipment of easily oxidized metals and alloys, and in the field of equipment combining smelting and continuous casting of easily oxidized metals and alloys under non-vacuum conditions. Issues such as discontinuity and limiting industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

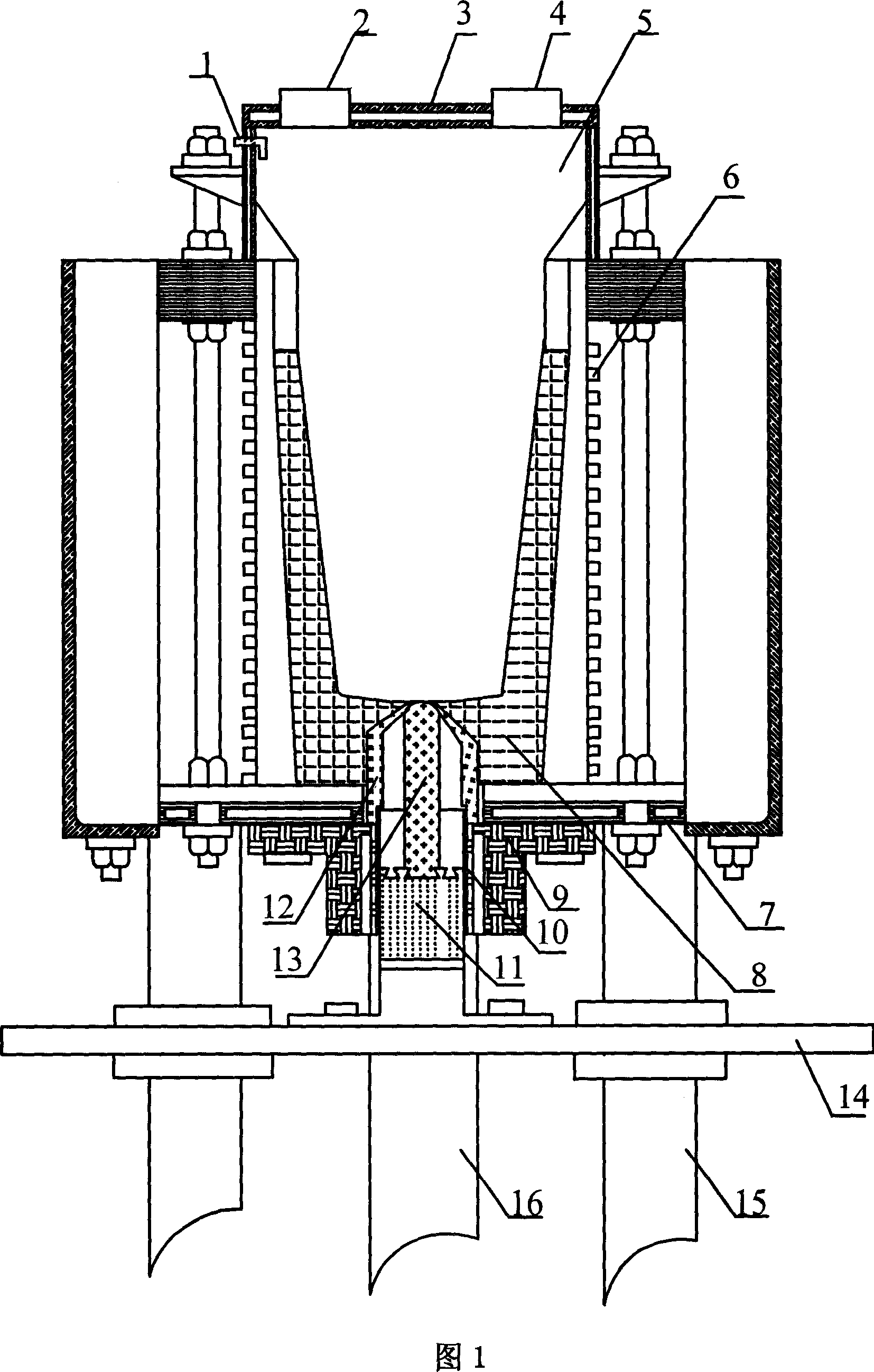

[0019] Take the raw materials electrolytic copper, copper-chromium intermediate alloy and zinc respectively, and the amount of materials taken is shown in Table 1, and put into the furnace 5 from the feeding port 4, so that it is filled in the middle of the crucible 8, and the furnace cover 3 can also be opened to directly add the raw materials; cover the cover and Observe the window 2, open the protective gas valve, and pass argon gas from the upper air inlet 1 until the air is discharged from the upper feeding port 4, the protective gas is filled with the furnace 5, and the match will be extinguished immediately when the match is lit at the upper feeding port 4. Turn on the induction heating device 6 to heat the induction furnace body, the power is 10KW, the time is 10 minutes, the power adjustment is 50KW, and it is heated to melting. The whole heating process can be observed through the observation window 2. Add copper clad zirconium and magnesium from feeding port 4, and s...

Embodiment 2

[0023] Using electrolytic copper and titanium sponge as raw materials, the present invention is carried out under the same conditions as in Example 1. The chemical contents of raw materials and ingots are shown in Table 2. The loss rates of each metal during the smelting process are: Cu: ≤1.0%, Ti: 3.4%. The surface of the ingot is smooth, without cracks, with few internal pores and inclusions, and the grain size of the ingot is about 0.1um.

[0024] raw material

[0025] The above examples show that the present invention adopts non-vacuum method to smelt and semi-continuously cast easily oxidizable metals and alloys in a protective gas atmosphere. In the protective gas layer, the partial pressure of oxygen and hydrogen is very small, which accelerates the melting process Diffusion of oxygen and hydrogen in the middle, the density of oxygen and hydrogen is small, it floats up to the upper gas outlet of the furnace and is discharged in time, and the effect of deoxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com