Patents

Literature

97results about How to "Convenient smelting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extrusion casting method for wrought aluminum alloy lampshade

The invention provides an extrusion casting method for a wrought aluminum alloy lampshade. The extrusion casting method comprises the following steps of S1, preparing an aluminum alloy precursor; S2, adding the aluminum alloy precursor into a smelting furnace, and heating to 690-710 DEG C until the aluminum alloy precursor is completely molten to obtain molten aluminum, introducing nitrogen or mixed inert gas to the molten aluminum by rotary blowing equipment for refining, purifying and skimming; S3, regulating the smelting temperature to 710-730 DEG C, and adding an AlSr alterant to react for 10-30 minutes; and then, regulating the smelting temperature to 700-720 DEG C again, adding an AlTiB grain refiner, uniformly stirring for 5-10 minutes, and next, adding a hexachloroethane refining agent to react, and skimming after ending to obtain refined molten aluminum; S4, pouring the refined molten aluminum into a die cavity, and carrying out extrusion casting to obtain a cast-state casting; and S5, carrying out thermal treatment on the cast-state casting to obtain the wrought aluminum alloy lampshade. The wrought aluminum alloy lampshade prepared by using the extrusion casting method is compact in tissue and high in corrosion resistance, tensile strength and elongation percentage.

Owner:东台城东科技创业园管理有限公司

Aluminum profile and heating processing technology thereof

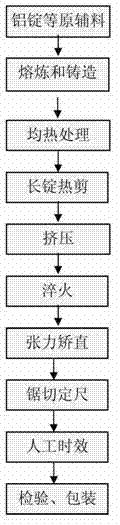

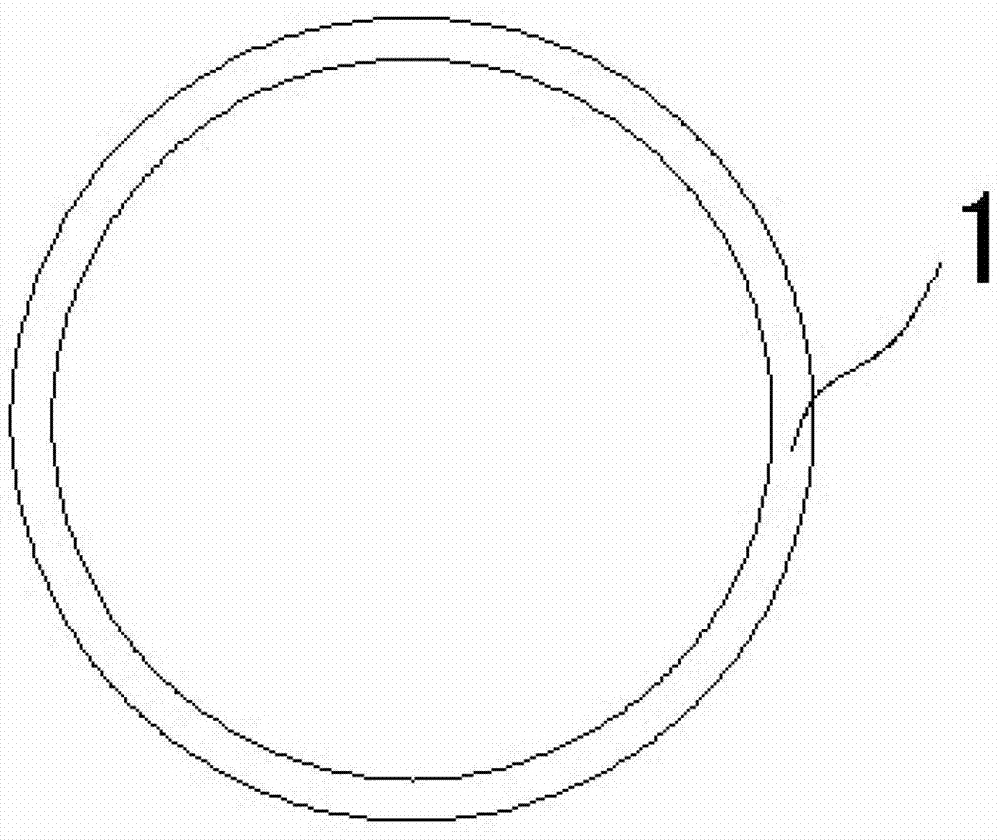

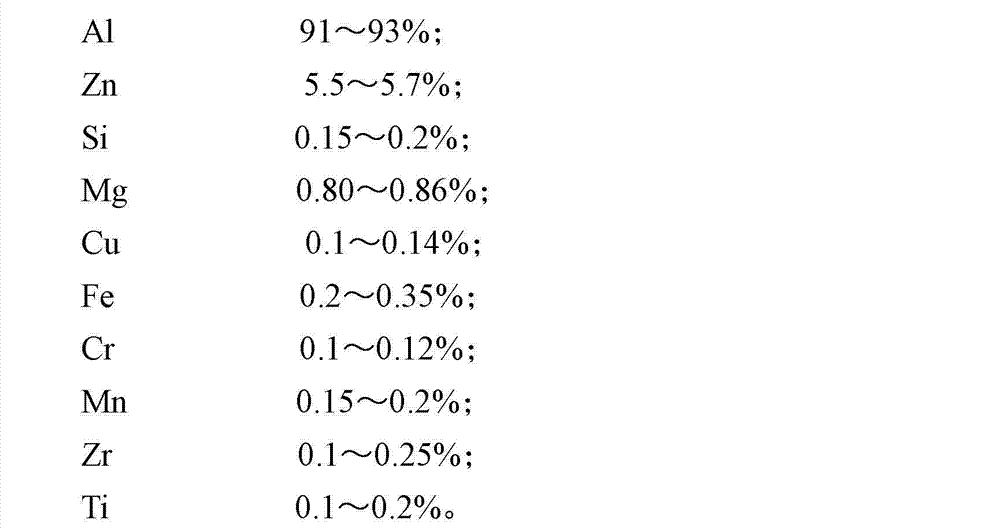

An aluminum profile is annular and is prepared by components in percentage by weight: 91-93% of Al, 5.5-5.7% of Zn, 0.15-0.2% of Si, 0.80-0.86% of Mg, 0.1-0.14% of Cu, 0.2-0.35% of Fe, 0.1-0.12% of Cr, 0.15-0.2% of Mn, 0.1-0.25% of Zr and 0.1-0.2% of Ti. A heating processing technology comprises following steps of: (1) smelting and casting raw material aluminum ingots, enabling a casting speed to be 85-95mm / min, enabling a pouring temperature to be 715-730 DEG C, and enabling cooling water pressure to be 0.04-0.08MPa; (2) extruding, enabling an extruding temperature to be 440-460DEG C, and enabling an extruding speed to be 3-6M / min; (3) conducting stretcher strengthening, and enabling strengthening deformation quantity to be 0.5%-1.5%; (4) conducting aging furnace heating, enabling a furnace temperature of an aging furnace at a first section of aging to be 100 DEG C, enabling heat preservation time to be 3h, enabling the furnace temperature of the aging furnace at a second section of aging to be 160 DEG C, and enabling heat preservation time to be 5h; and (5) testing and packaging. The aluminum profile mainly solves the problem that the aluminum profile in the prior art is not high in strength, poor in breakage toughness and poor in fatigue performance.

Owner:张家港市金邦铝业股份有限公司

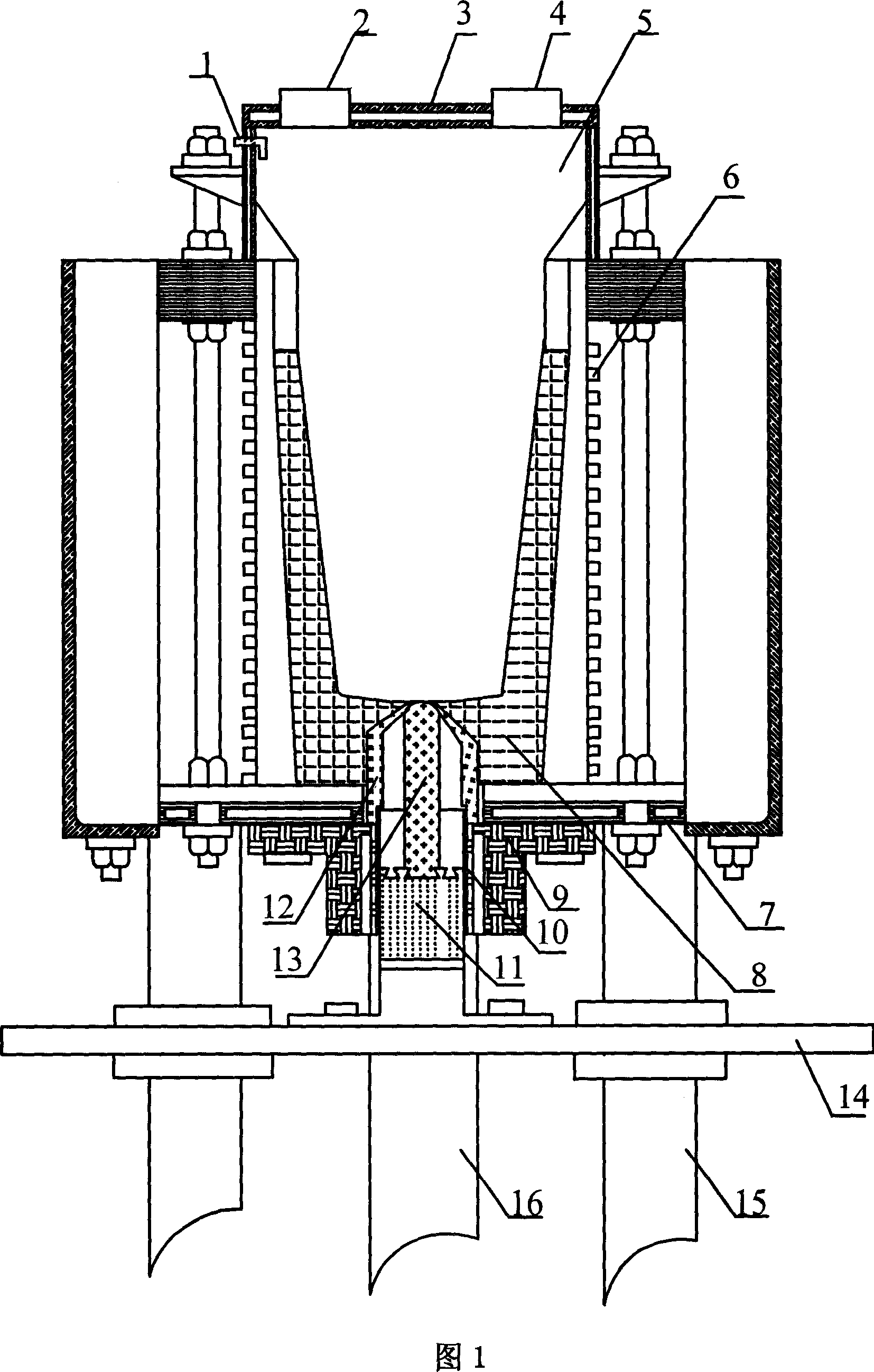

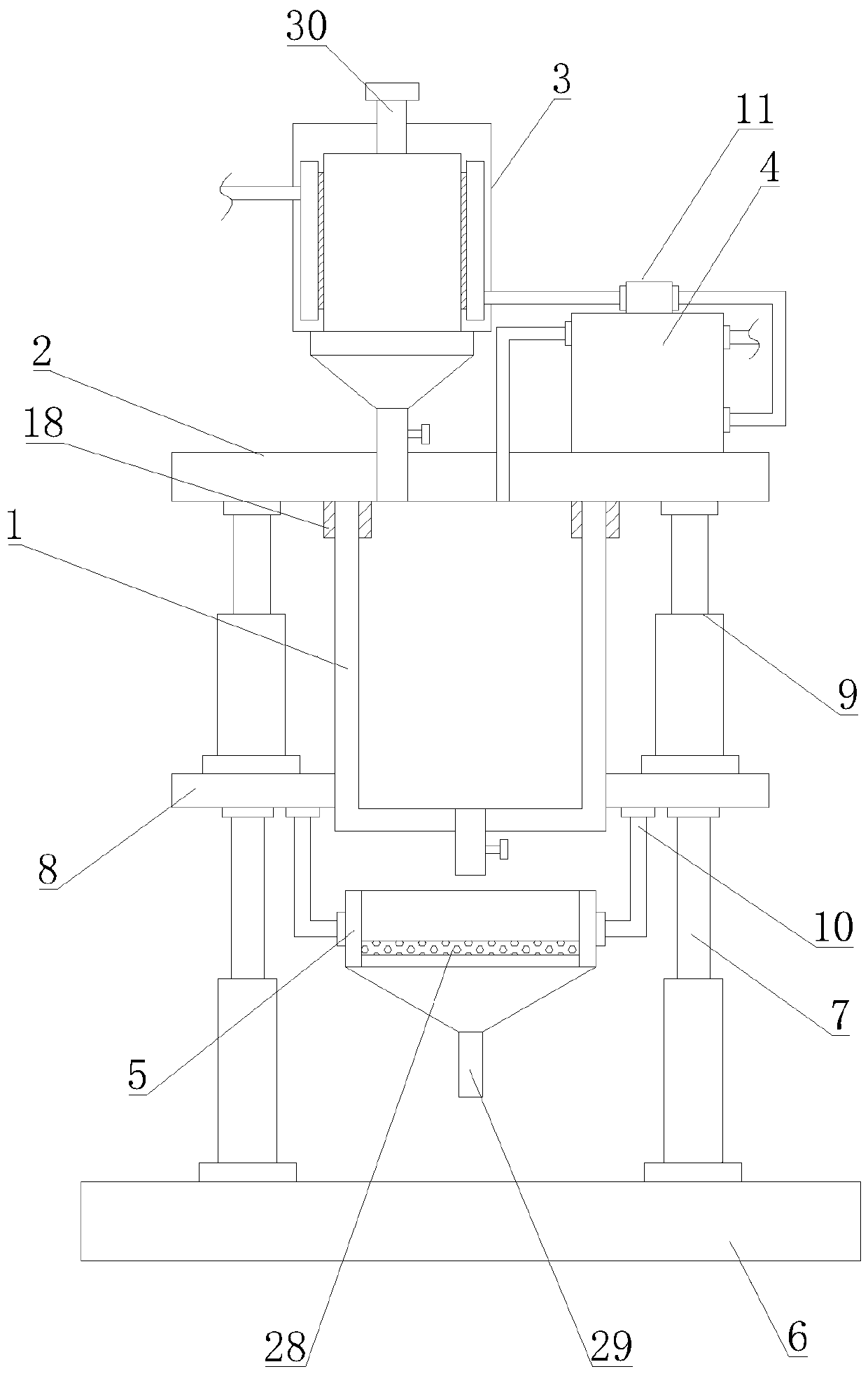

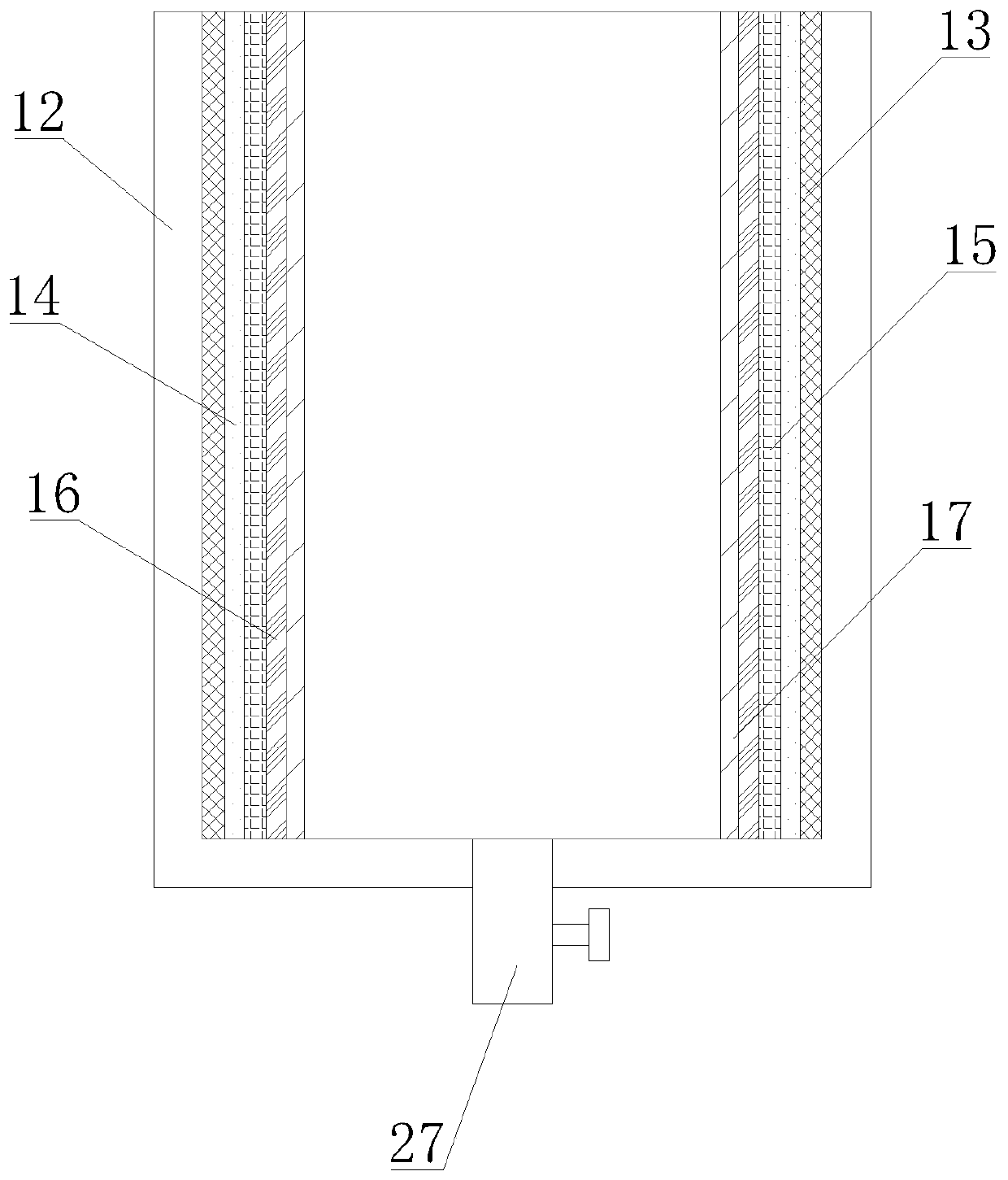

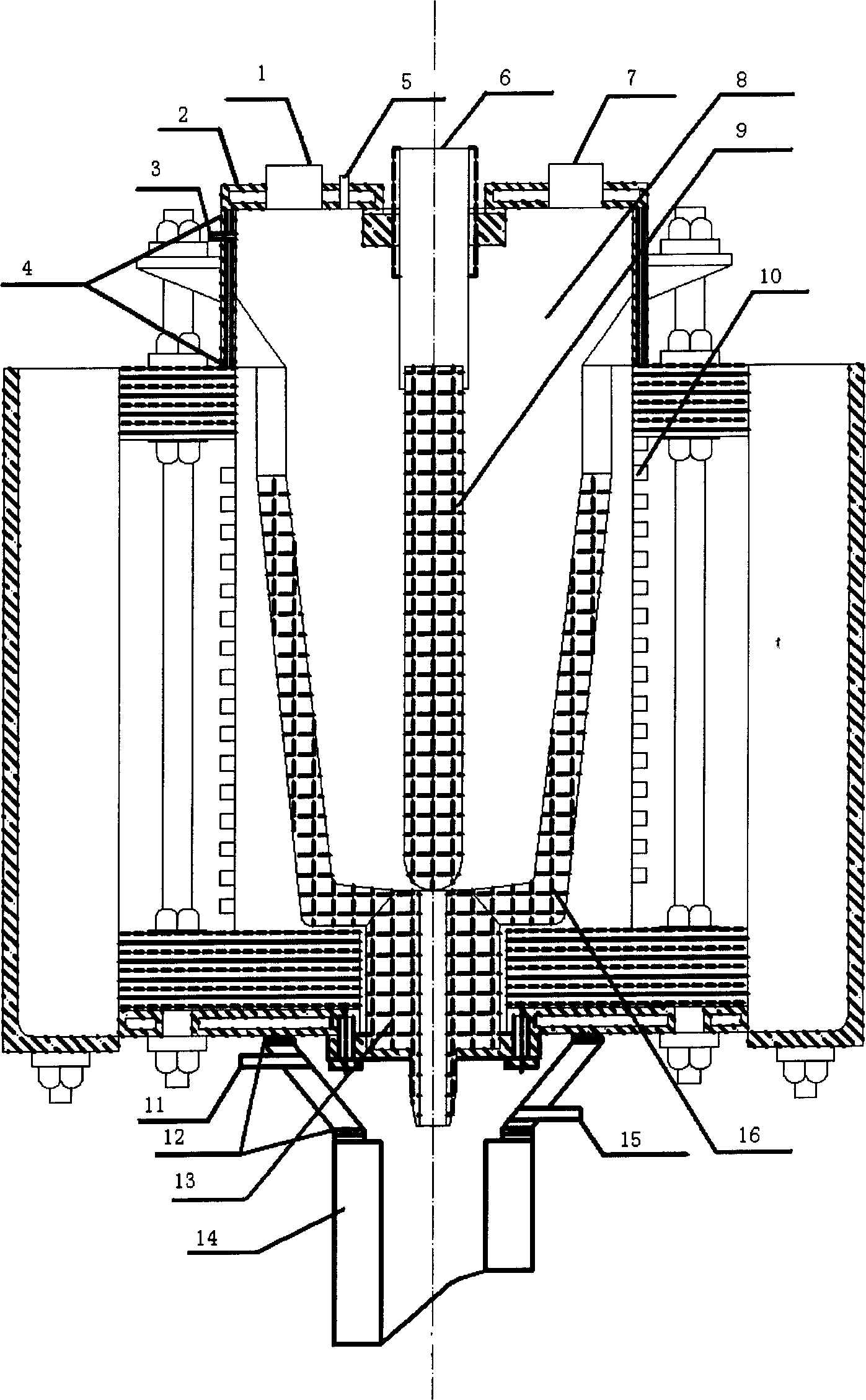

Equipment for nonvacuum melting and casting readily oxidizable metal and alloy

The invention relates to a device used in non-vacuum smelt casting oxidizable metal and alloy. Wherein, the furnace has heater and pot; the furnace cover has gas inlet and material inlet; and it has cooler; the bottom of furnace has lower irrigator; the bottom of pot has bottom bowl; the irrigator of bottom bowl contacts the plug rod vertically; the bottom plug rod is connected to the dummy ingot head; the dummy ingot head adjusts the position of plug rod; the bottom bowl is connected to crystallizer connected to the cooler; the crystallizer has graphite sheath and cooling water groove, to reduce the casting ingot temperature; the dummy ingot head has dovetail groove to solidify the fusion as drawing function; the dummy ingot head is connected to adjuster. The invention processes the whole process under protective gas, with low hurt rate and improved quality.

Owner:苏州有色金属研究院有限公司

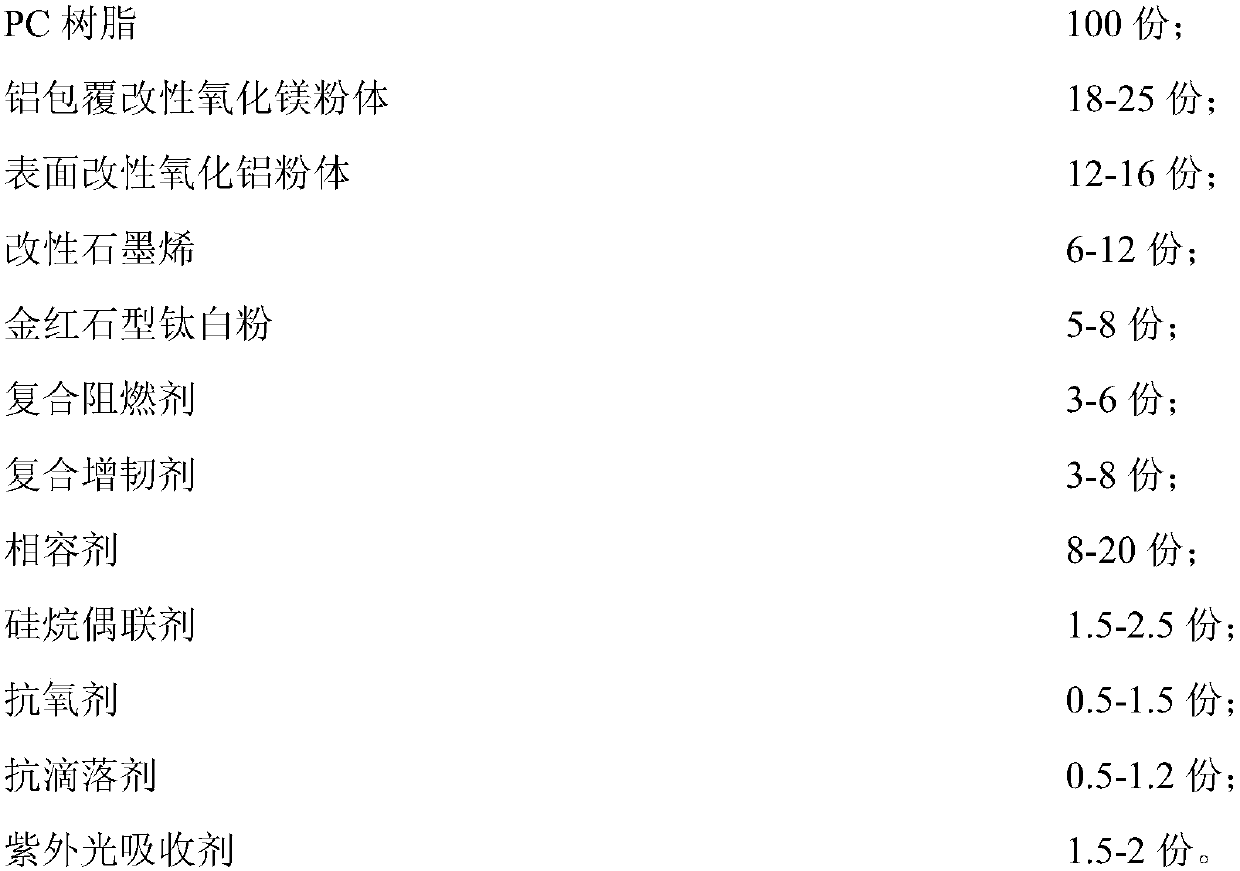

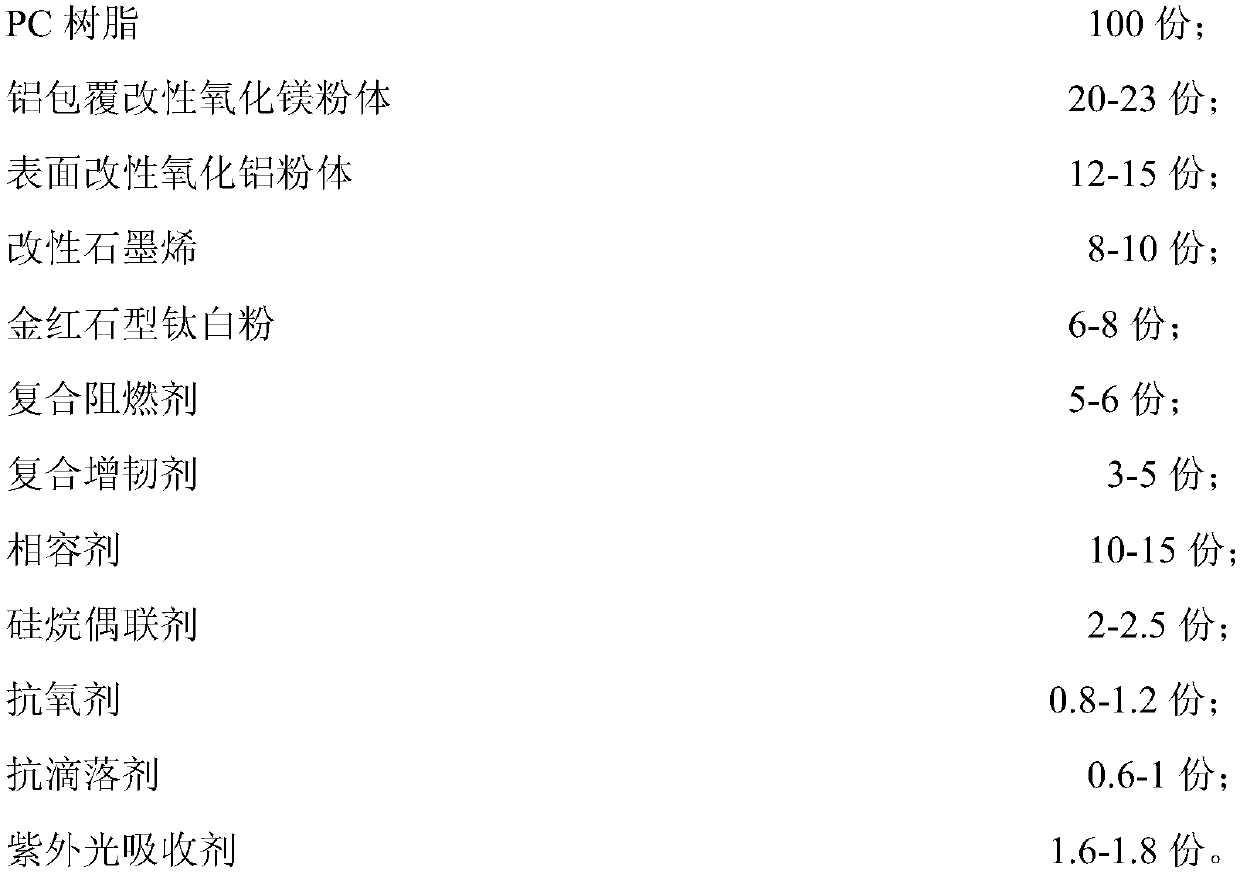

PC alloy material and preparation method thereof

The invention provides a PC alloy material and a preparation method thereof. The PC alloy material is prepared by mixing the following components in parts by weight: 100 parts of PC resin, 18-25 parts of aluminium coated modified magnesium oxide powder, 12-16 parts of surface modified aluminum oxide powder, 5-8 parts of rutile type titanium dioxide, 6-12 parts of modified graphene, 3-8 parts of a composite toughing agent, 3-6 parts of a composite flame-retardant agent, 8-20 parts of a compatilizer, 1.5-2.5 parts of a silane coupling agent, 0.5-1.5 parts of an oxidation inhibitor, 0.5-1.2 parts of an anti-dripping agent and 1.5-2 parts of an ultraviolet absorber. According to the PC alloy material, the PC resin and the various kinds of powder are fused; the powder is modified so that the powder can be fused in the PC resin fused body well; and the composite flame-retardant agent and the composite toughing agent are innovated, so that the prepared PC alloy material has good mechanical property, thermal property, optical property and electrical property, belongs to a brand-new PC alloy material, and has wide market popularization and application prospects.

Owner:东莞市亚仑塑料原料有限公司

Manufacturing method for medical bone fixing device

The invention discloses a manufacturing method for a medical bone fixing device. The medical bone fixing device comprises, 4%-6% of Nb, 2%-3% of Cu, 6.5%-7.5% of Fe, 3%-4% of Mo, 1%-2% of Mn, 5%-7% of Zr, 0.6%-0.7% of Ge, 2.5%-3.5% of Cr, 1.5%-2.5% of Ca, 0.15%-0.25% of Mg, less than 0.1% of C and the balance Ti. After element powder or alloy powder of all elements with appropriate granularities are selected and mixed, injection molding sintering is carried out, and the bone fixing device is obtained; the strength of the bone fixing device is far larger than that of a medical pure titanium material, the bone fixing device is friendly to the environment of the kinterior of the human body, the density is low, the bone fixing device has the good smelting and sintering machining performance, the mechanical property is similar to that of human bone, and the fatigue resistance and the decay resistance are good.

Owner:赵丽

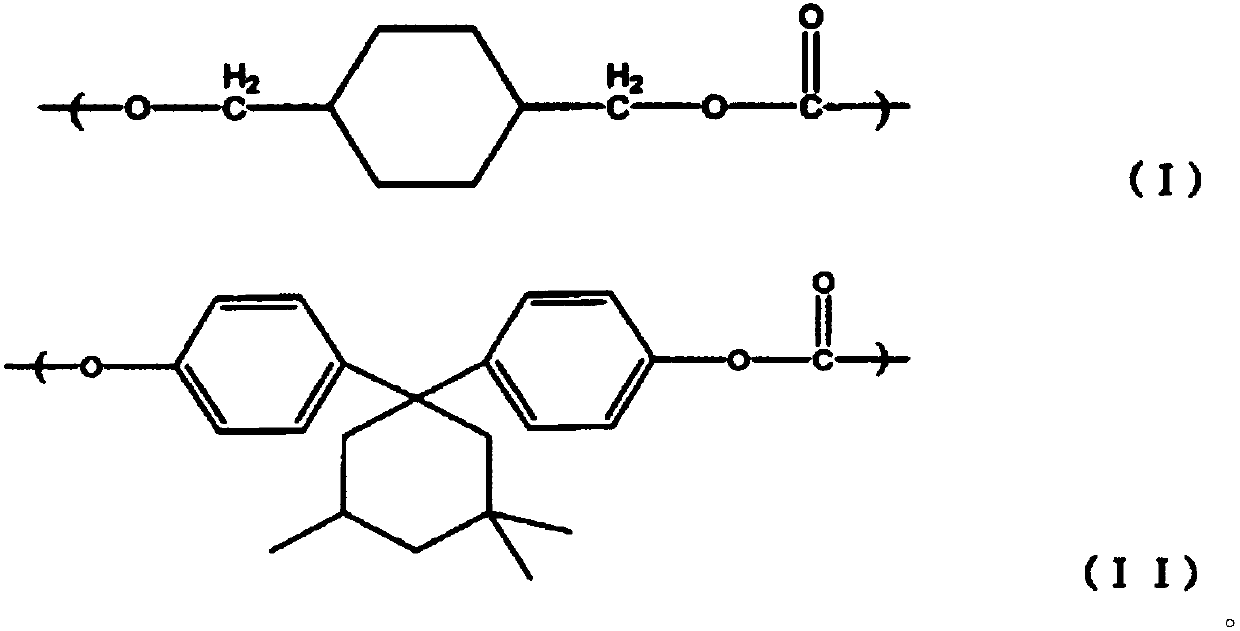

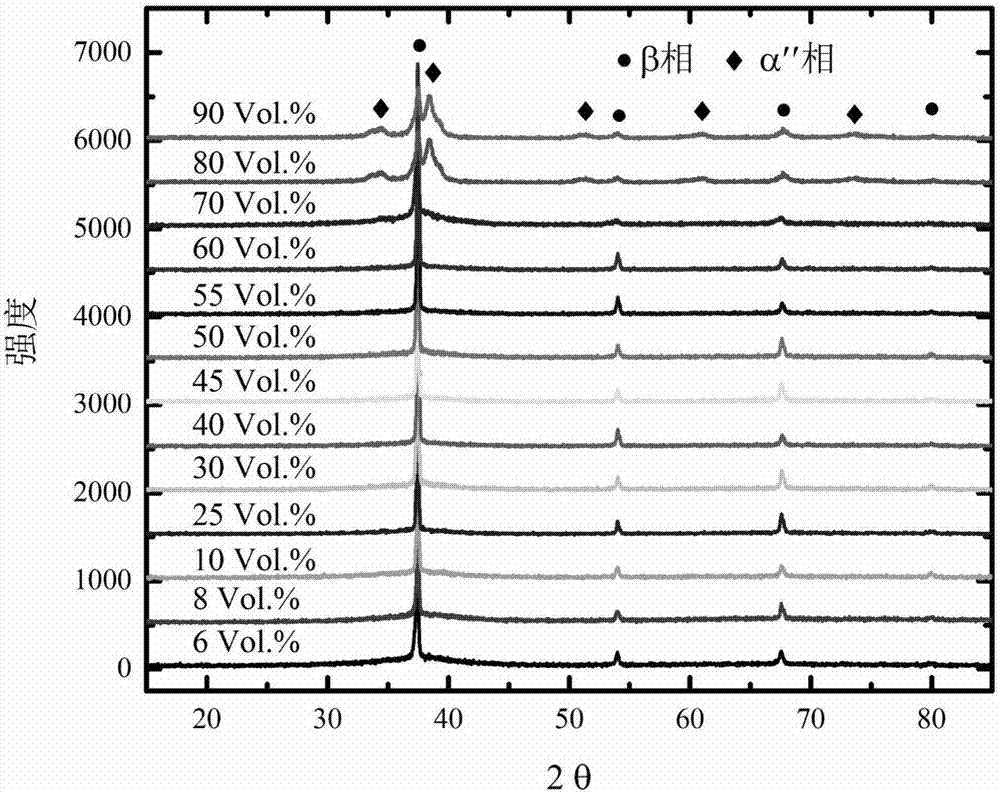

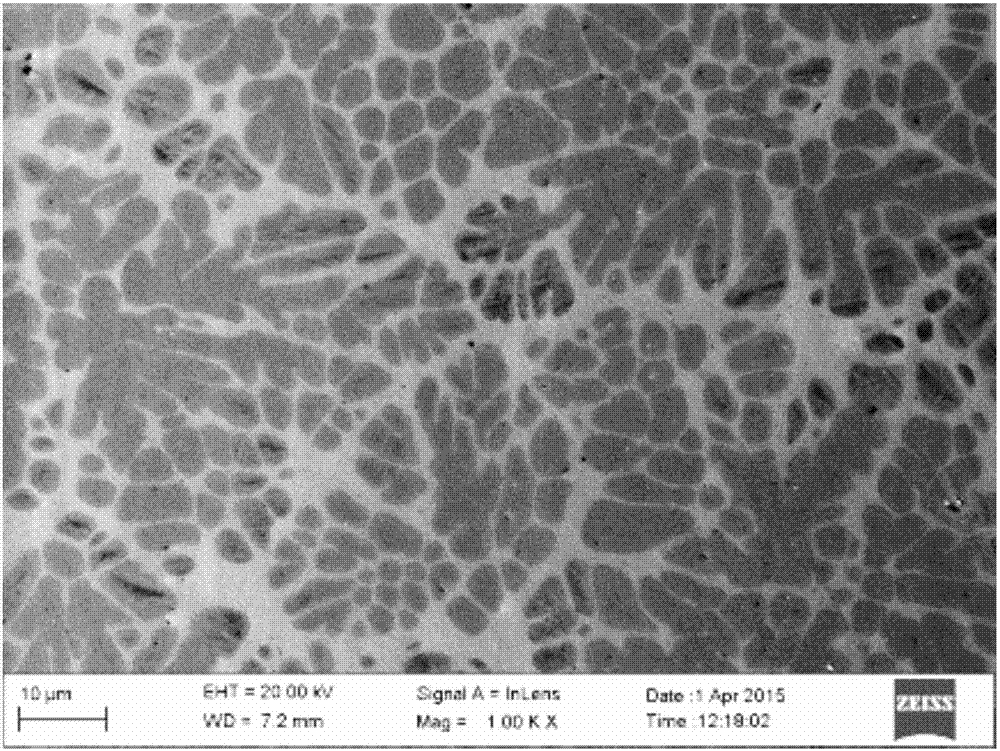

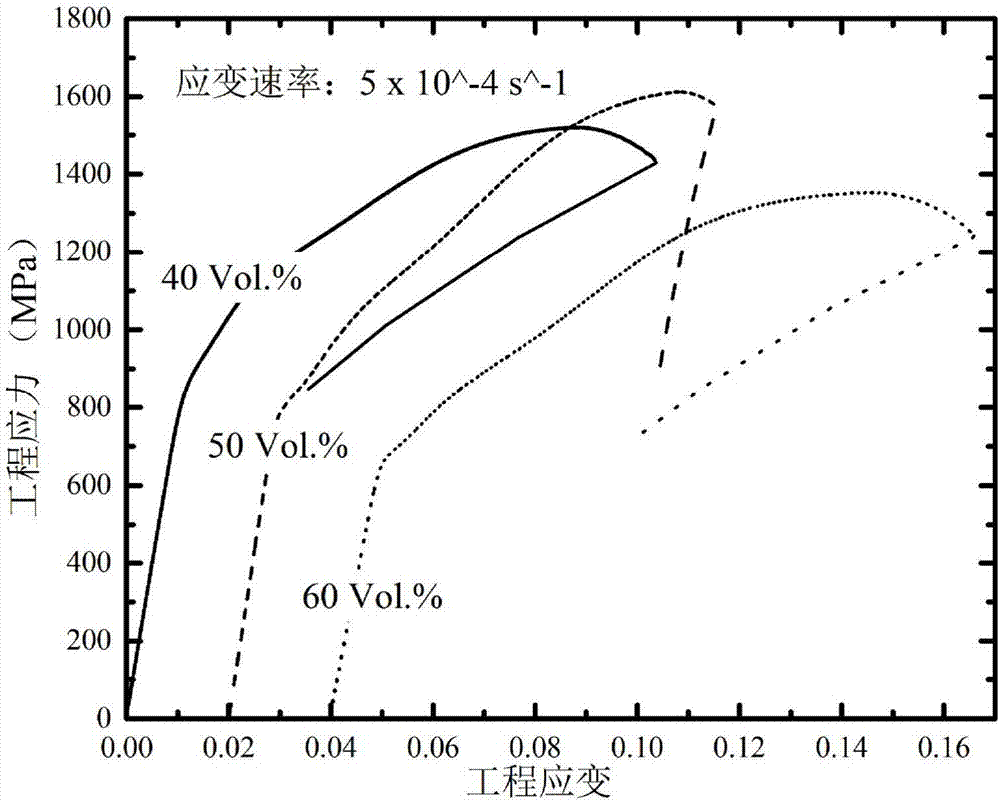

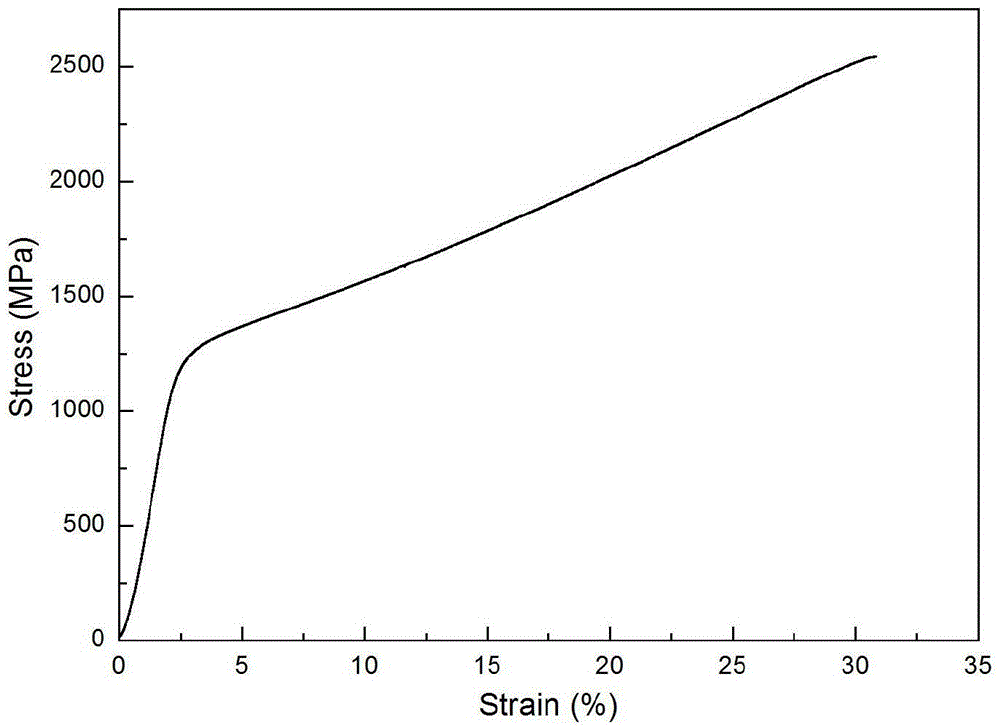

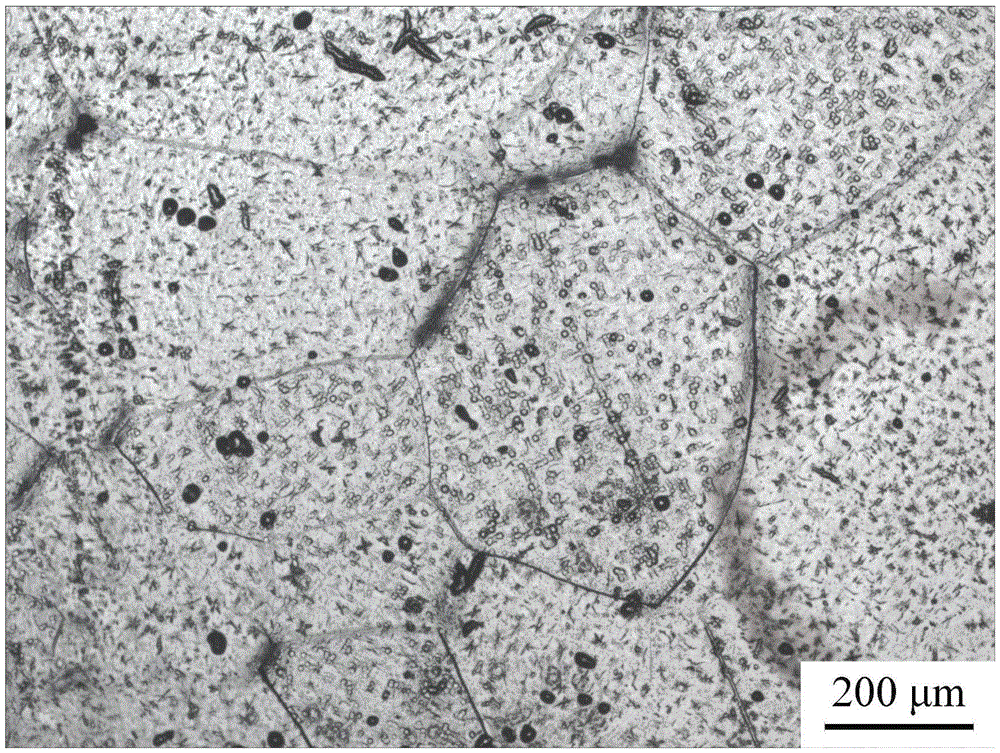

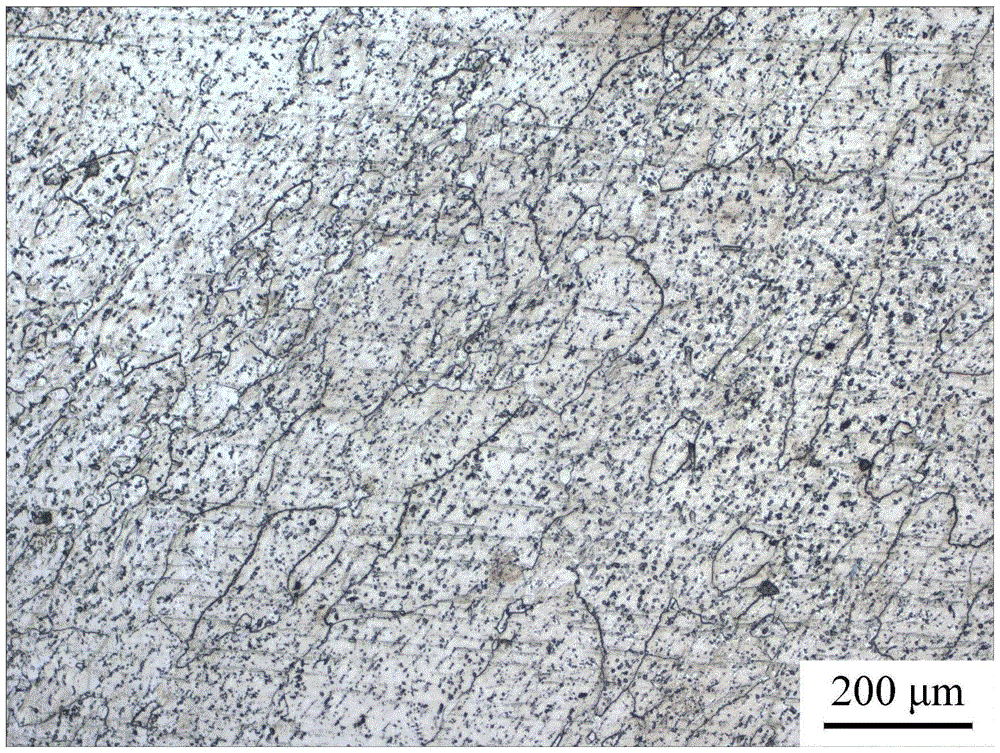

Ti-Zr-Cu-Be four-element amorphous composite with processing hardening capacity and preparation method thereof

ActiveCN107385365ASimple ingredientsImprove the ability to formMartensite transformationChemical composition

The invention discloses a Ti-Zr-Cu-Be four-element amorphous composite with the processing hardening capacity and a preparation method thereof. The composite is a type of amorphous alloy composite containing a dendritic crystal phase, wherein the dendritic crystal phase is prepared from the chemical components of 59-60 parts of Ti, 38-39 parts of Zr and 1-3 parts of Cu, the volume fraction of the dendritic crystal phase is 5-95%, and an amorphous matrix is prepared from the chemical components of 33-34 parts of Ti, 35-36 parts of Zr, 8-9 parts of Cu and 21-24 parts of Be. The dendritic crystal phase has the deformation-induced Martensite phase transformation characteristic, the composite shows excellent comprehensive mechanical properties of high strength, high plasticity, processing hardening and the like under the actions of tension and compression loads, for example, under the tension load, the processing hardening behavior is remarkable, the plastic deformation capacity is 6-15%, and the strength is 1100-1900 MPa. Meanwhile, by means of Martensite phase transformation, the composite has the super-elastic characteristic under the tension load through cyclic loading, for example, elastic deformation can be 2.7-3%. As for the composite, the chemical composition is simple, the chemical components of the second phase are relatively stable, and structural design and controllable preparation of the composite are facilitated.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

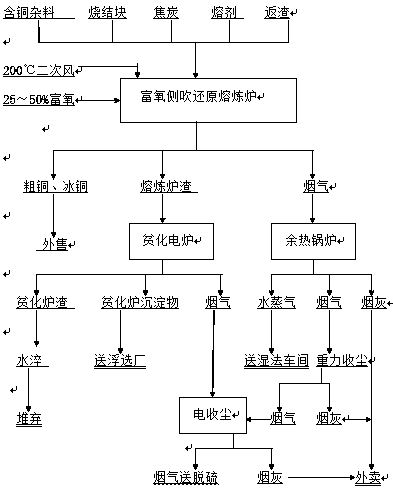

Sintering combined oxygen-enriched side-blown smelting process of vertical drying kiln

InactiveCN108998661AHigh recovery rateGood sealingProcess efficiency improvementSludgeNon-ferrous extractive metallurgy

The invention discloses a sintering combined oxygen-enriched side-blown smelting process of a vertical drying kiln in the technical field of environmental protection systems. The smelting process comprises the following steps of adding little lime and fine anthracite to copper and nickel-contained sludge, mixing the lime, the fine anthracite and the copper and nickel-contained sludge proportionally and stirring evenly to obtain a mixture; pelletizing the mixture by a pelletizer to obtain pellets, and adding the pellets evenly into the vertical drying kiln from a kiln crown by a feeding device,wherein the pellets move down by dead weight; adding obtained agglomerated cakes from the furnace top of an oxygen-enriched side-blown smelting furnace continuously together with inorganic hazardouswastes, such as waste anode scraps, quartz stone, limestone, non-ferrous metal smelting waste and incineration disposal residues; making obtained slag enter an electric slag cleaning furnace after theobtained slag is discharged from the oxygen-enriched side-blown smelting furnace, reheating and clarifying and separating the slag by the electric slag cleaning furnace, thereby clarifying and separating copper and nickel mechanically entrained in the slag once again, and discharging the slag from the electric slag cleaning furnace and performing water quenching to make the slag become water-quenched slag; and disposing generated flue gas by processes of waste heat recovery, shock chilling, bag dust collection, sulfur removal, denitration, fluorine and chlorine removal and the like, thereby realizing up-to-standard discharge.

Owner:广州叶林环保科技有限公司

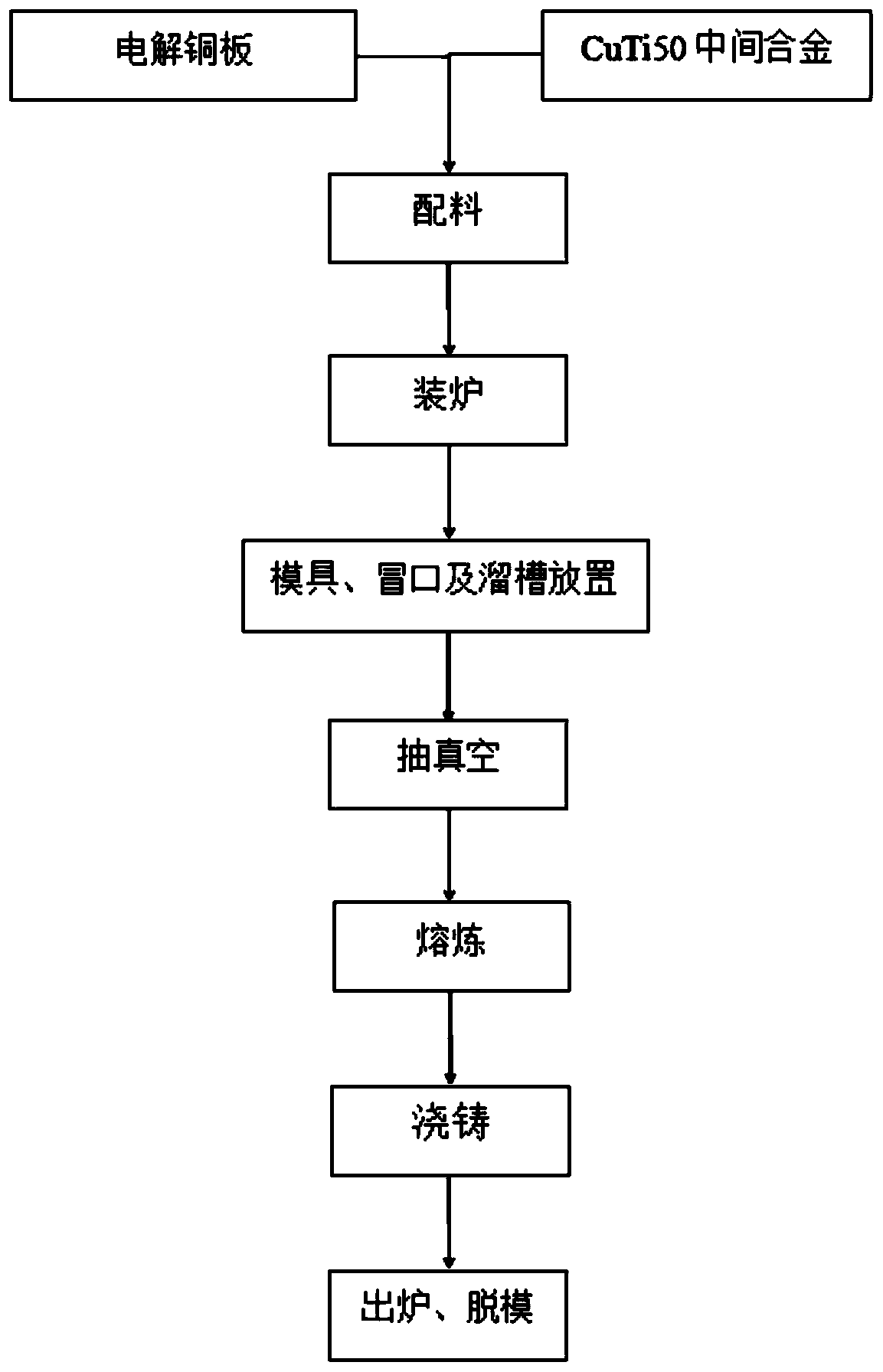

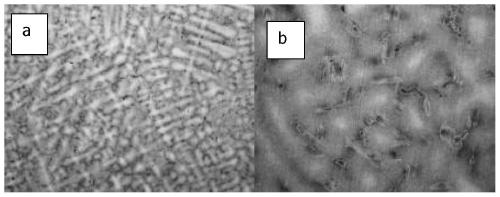

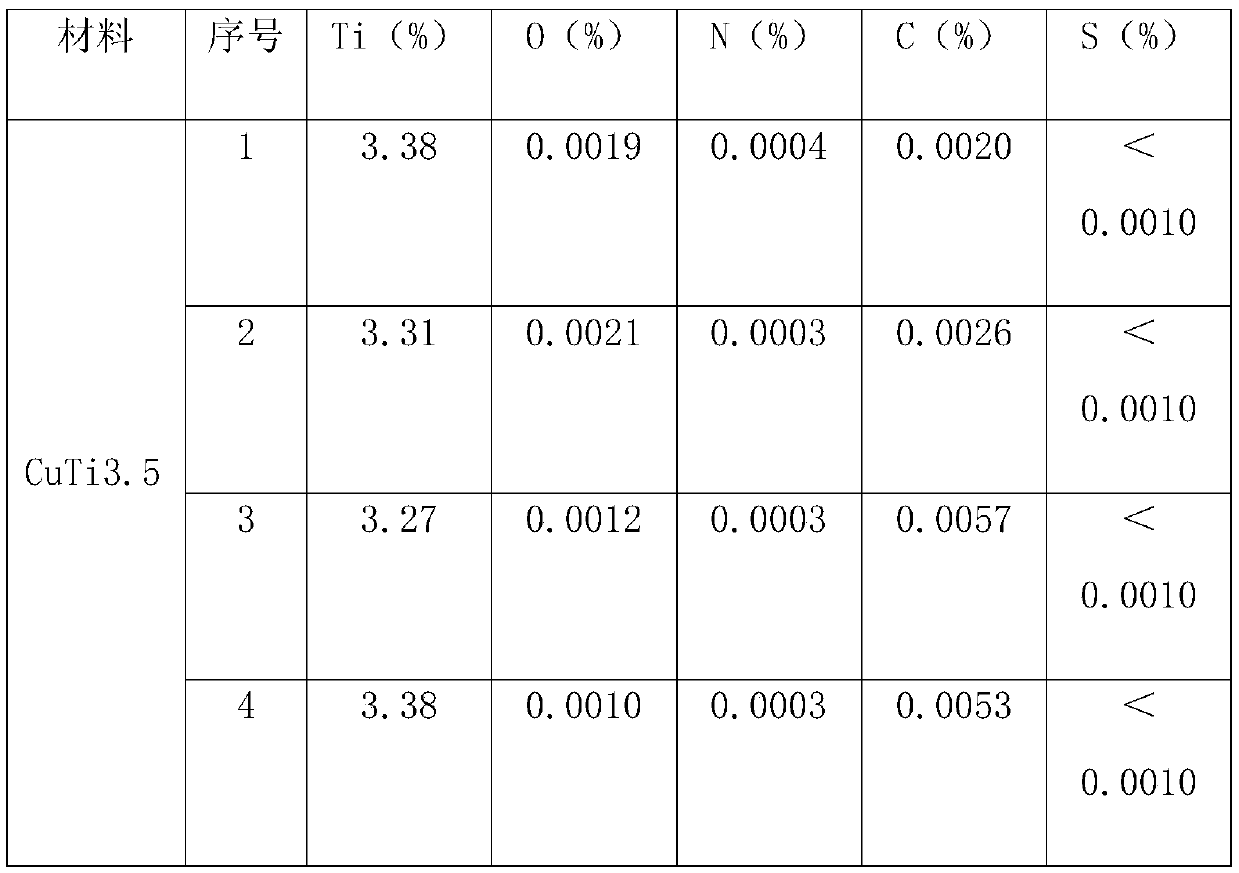

Method for preparing CuTi alloy material by vacuum induction melting

ActiveCN111041256ASmall fluctuations in compositionConvenient smeltingPotentiometerVacuum induction melting

The invention discloses a method for preparing a CuTi alloy material by vacuum induction melting. The method specifically comprises the following steps: matching 3.6% of Ti and 96.4% of Cu in percentage by weight, adding Ti in the form of an intermediate alloy, arranging an insulated riser at the upper part of a steel die during loading, wrapping the upper edge of the outer wall of the steel die with insulation cotton, mounting an electrolytic copper plate first, inserting the intermediate alloy at the upper part of the electrolytic copper plate, closing a furnace cover, starting a Roots pumpwhen P is smaller than or equal to -0.1 MPa by a vacuum gauge, switching on a composite vacuum gauge, and making preparation for heating when low vacuum is 10 Pa; performing melting according to powergradient, carrying out casting first slowly, then quickly and then slowly, rotating a potentiometer to a 0 position after casting, and carrying out discharging, cooling and demolding. The method forpreparing a CuTi alloy material by vacuum induction melting is more efficient, more environmentally friendly, lower in cost and suitable for wide promotion.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

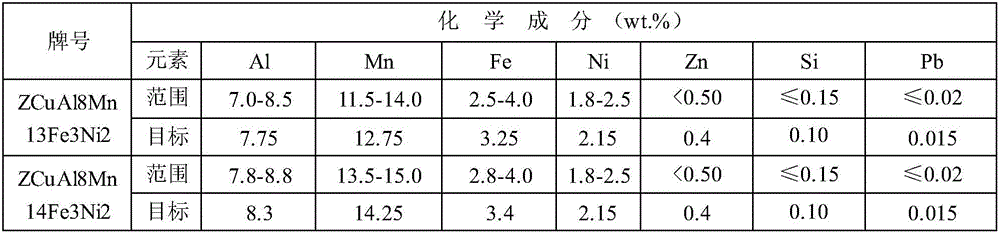

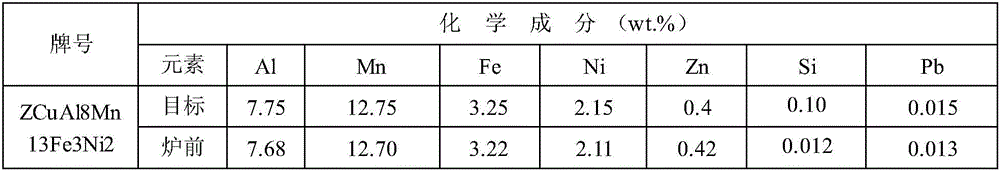

Smelting method for high-manganese aluminum bronze alloy

ActiveCN106399728APrecise control and guaranteed contentReliable and easy smelting methodSmelting processMedium frequency

The invention discloses a smelting method for high-manganese aluminum bronze alloy. The smelting method for the high-manganese aluminum bronze alloy comprises the main steps that a furnace body of a medium-frequency induction furnace is treated, and a gas diffusion device is mounted on the furnace body of the medium-frequency induction furnace; alloy components are designed; raw materials and tools used in the smelting process are prepared; the raw materials are fed in the furnace; the temperature of the materials in the furnace is increased, so that the materials in the furnace are melted; argon is introduced to the bottom of the furnace; cooling and charging are conducted; the components are checked preliminarily; and the quality of molten liquid is detected, and the alloy is discharged out of the furnace. The smelting method for high-manganese aluminum bronze alloy can be used for smelting high-manganese aluminum bronze ZCuAl8Mn13Fe3Ni2 alloy and high-manganese aluminum bronze ZCuAl8Mn14Fe3Ni2 alloy, can be used for preparation of standard high-manganese aluminum bronze substances, and can also be used for production of products with high component and casting quality requirements.

Owner:CSIC NO 12 RES INST

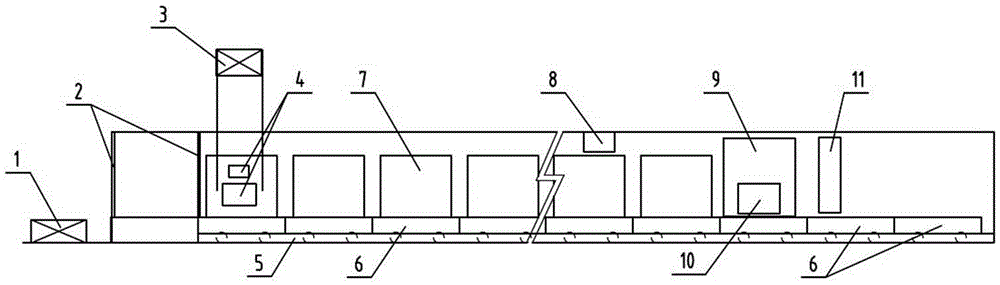

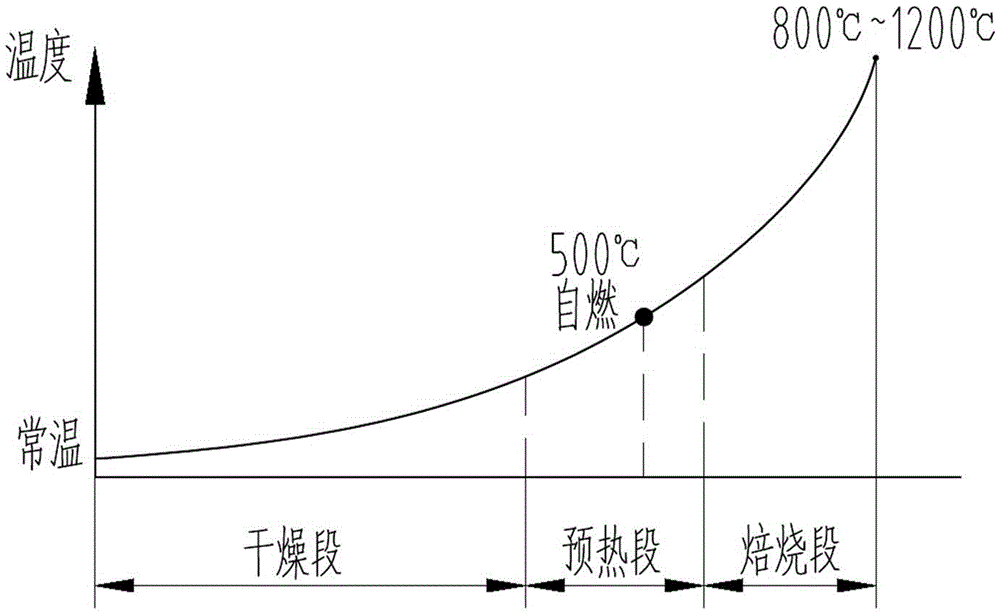

Tunnel kiln used for smelting

ActiveCN105352314AConvenient smeltingAchieve energy saving and emission reductionFurnace typesTunnel kilnWorking temperature

The invention belongs to the technical field of metallurgical equipment and discloses a tunnel kiln device suitable for the iron smelting technology. The tunnel kiln comprises a kiln body, a rail penetrating the kiln body and kiln cars arranged on the rail. The tunnel kiln comprises a drying section, a preheating section and a roasting section in the length direction of the kiln body. The working temperature of the drying section ranges from the normal temperature to 80 DEG C. The working temperature of the preheating section ranges from 80 DEG C to 600 DEG C. The working temperature of the roasting section ranges from 600 DEG C to 1500 DEG C. The tunnel kiln device is used for drying, preheating and roasting furnace burden briquettes, so that the requirement for smelting is met, energy consumption is low, and environment friendliness is achieved.

Owner:HENGNAN YANGGANG METALLURGICAL TECH CO LTD

Medical suture material and preparation method

InactiveCN105624495AGood tensile strength and hardnessGood corrosion resistance strength and biocompatibilitySuture equipmentsCorrosionMagnesium

The invention discloses a medical suture material and a preparation method. The medical suture material comprises components in parts by weight as follows: 110-140 parts of magnesium, 1-2 parts of zinc, 0.1-0.4 parts of aluminum, 3-5 parts of molybdenum, 2-2.5 parts of calcium, 0.1 parts of carbon, 4-6 parts of niobium, 0.5-1 part of iron, 1-2 parts of manganese, 0.5-1 part of germanium, 1-2 parts of zirconium and 0.05-0.1 parts of titanium. The medical suture material has very high strength and elongation at break, is easily degradable and has good corrosion resistance and biocompatibility.

Owner:青岛博泰美联化工技术有限公司

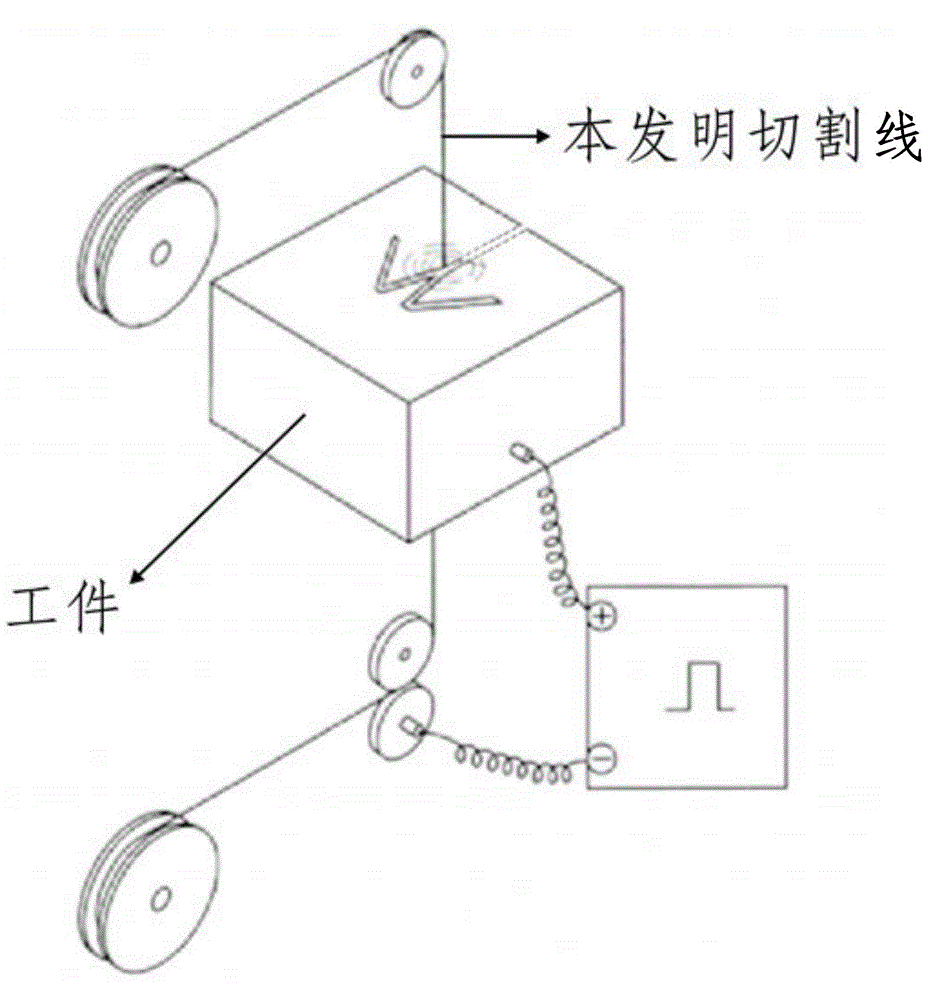

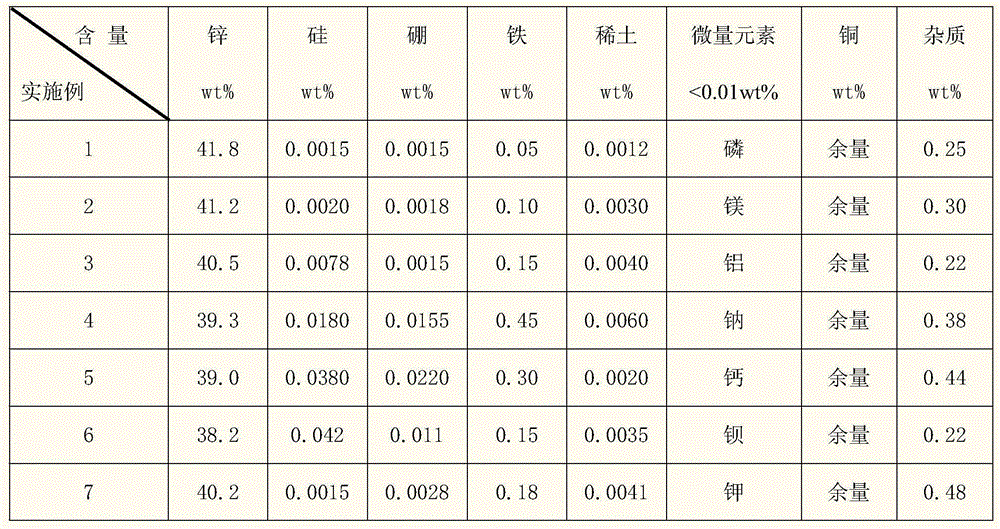

High zinc-silicon-boron-ferro copper alloy

The invention discloses a high zinc-silicon-boron-ferro-copper alloy. The copper alloy is characterized by comprising the components in percentage by weight: 38.0-44.0 percent of zinc, 0.001-0.5 percent of silicon, 0.001-0.025 percent of boron, 0.005-0.5 percent of ferro, 0.001-0.01 percent of rare earth, 0.0005-0.1 percent of other element including at least one of phosphorus, magnesium, potassium, calcium, sodium, aluminum and barium, and the balance of copper and inevitable impurity elements. The copper alloy is used for manufacturing a cutting line for one-way wiring; compared with the prior art, the copper alloy has the advantages that the manufactured cutting line for one-way wiring is high in mechanical performance, stable in discharging performance and high in cutting speed; the cutting line is simple in processing procedures, wide in application and low in cost and has wide market prospect.

Owner:NINGBO BODE HIGHTECH CO LTD

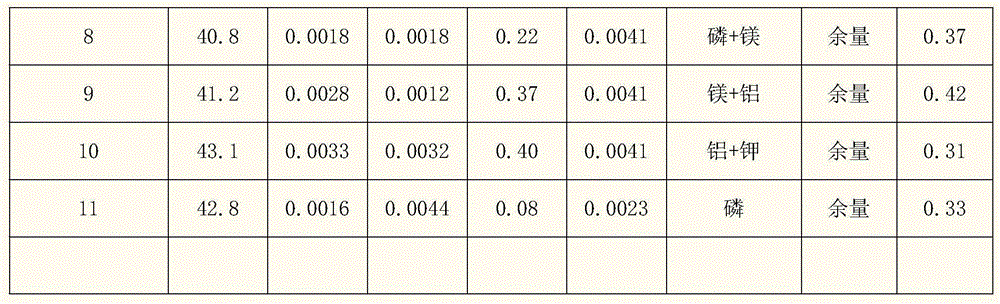

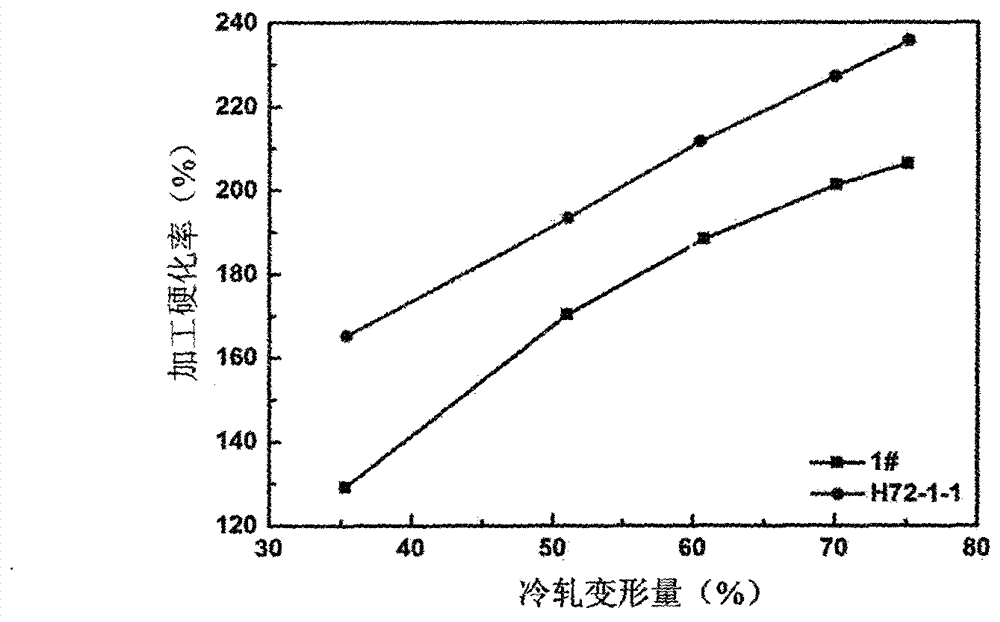

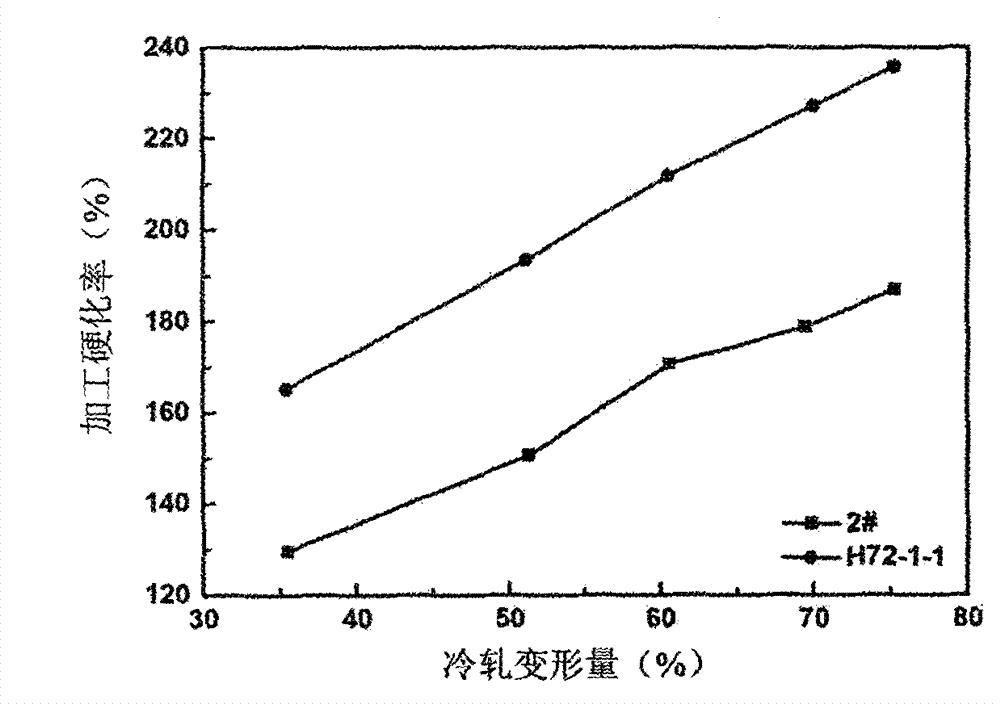

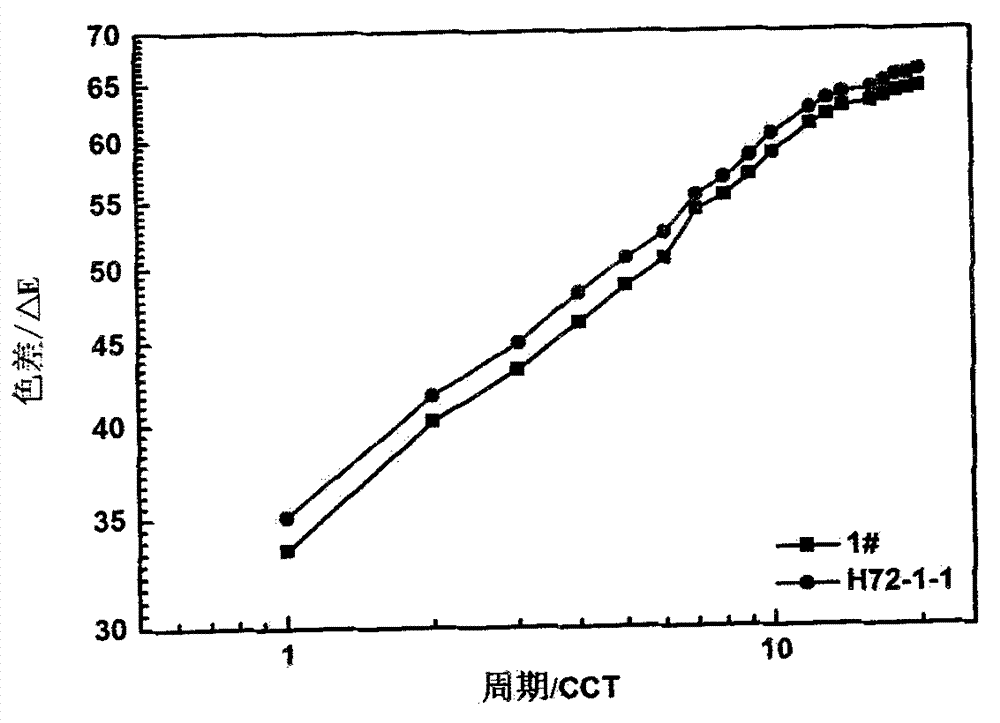

Coinage-used golden yellow copper alloy material and preparation method thereof

The present invention discloses a yellow copper alloy, and particularly relates to a coinage-used golden yellow copper alloy material having high resistance to discoloration and good cold processability. The material is mainly applied to coinage billets and various decorative materials. The coinage-used golden yellow copper alloy material is composed of the following components by weight: 75.0-77.0 wt% of Cu, 1.8-2.4 wt% of Al, 0.2-0.8 wt% of Ni, 0.003-0.01 wt% of B, 0.10-0.20 wt% of Si, no more than 0.1 wt% of Ce, no more than 0.06 wt% of Fe, no more than 0.05 wt% of Pb, and the balance being Zn. Compared with the conventional coinage material of HSn 72-1-1 alloy, the alloy produced by the invention has higher golden color and excellent discoloration resistance under the condition of high humidity, artificial sweat, salt spray, SO2, H2S and other hot and humid environments. At the same time, the alloy is excellent in cold processing performance, the cold processing amount per pass is up to 60%, the processing hardening rate and rigidity both satisfy the requirements of coinage technology, and the alloy has the characteristics of golden color and low cost of raw materials and manufacturing.

Owner:CHINA BANKNOTE PRINTING & MINTING +1

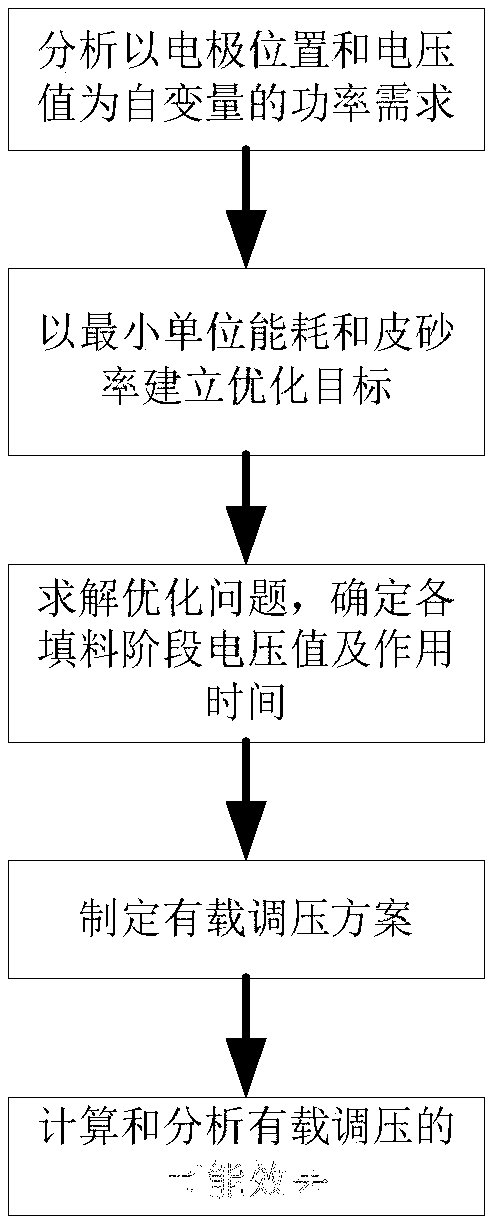

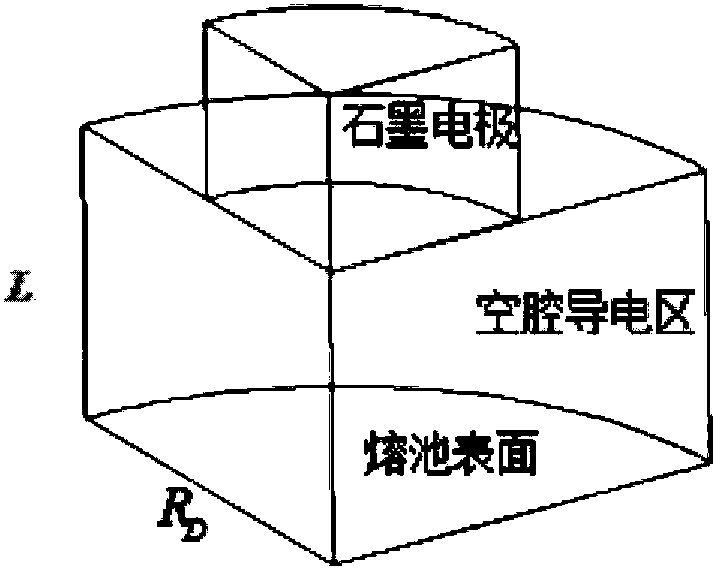

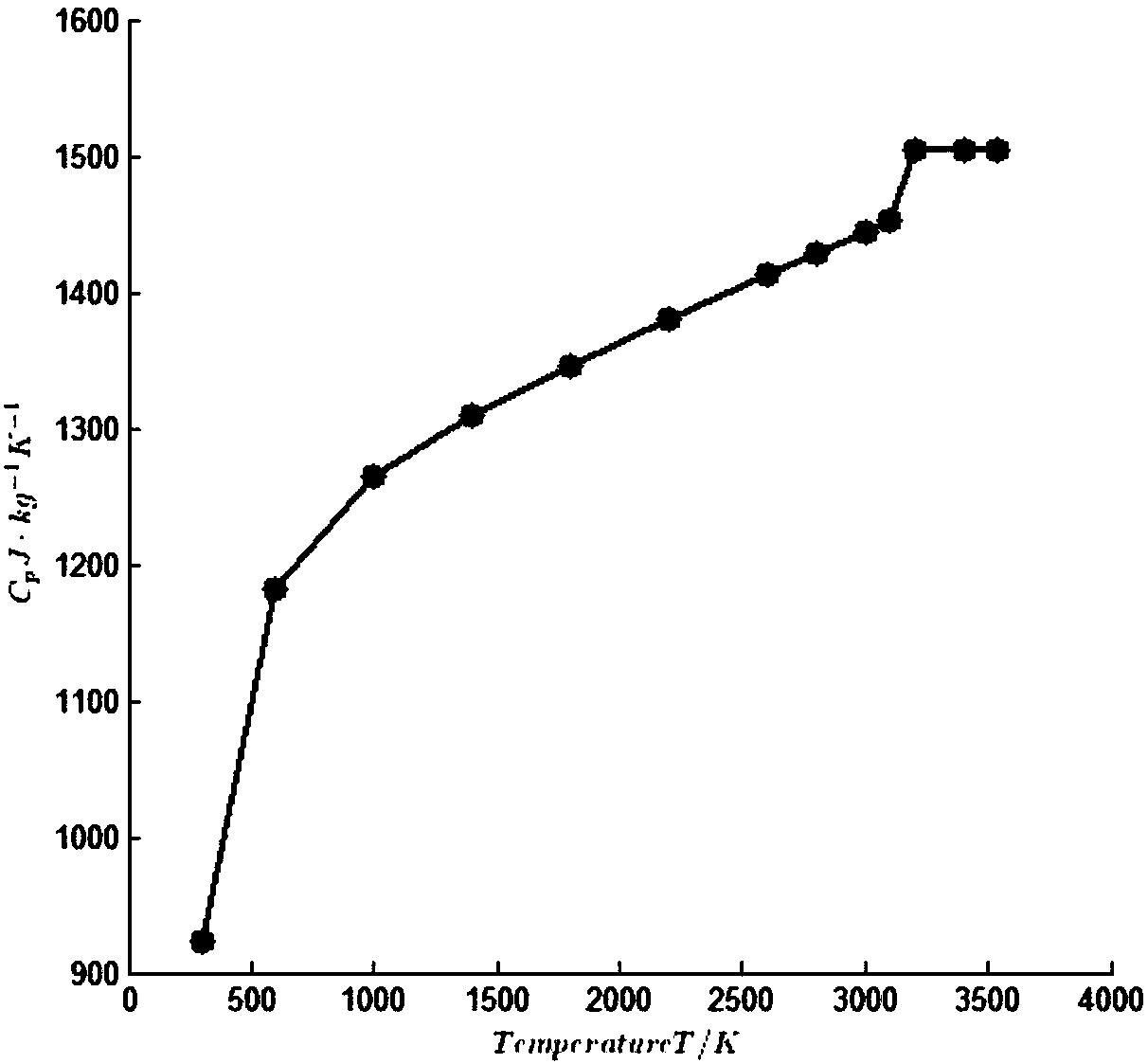

Transformer on-load voltage regulation construction method based on electrical smelting furnace for magnesium

The invention discloses a transformer on-load voltage regulation construction method based on an electrical smelting furnace for magnesium. The transformer on-load voltage regulation construction method comprises the steps of: analyzing power requirement taking electrode positions and voltage values as independent variables; establishing an optimization object based on minimum unit energy consumption and a hull sand rate according to the power requirement; solving an optimization problem, and determining voltage values and action time at filling stages; and planning an on-load voltage regulation scheme according to the voltage values and action time at the filling stages. The step of analyzing power requirement taking the electrode positions and the voltage values as the independent variables is implemented by: taking arc heat as an internal heat source of an temperature field model of the electrical smelting furnace for magnesium, and establishing an internal heat source arc and gas cavity conduction region model; and carrying out data fitting on a relation of magnesium oxide specific heat capacity c to temperature as well as a relation of density rho to temperature separately, so as to obtain action relations between temperature variation and the voltage at the stages, the voltage action time and electrode lifting height. The transformer on-load voltage regulation construction method can make two indexes including fused magnesite unit energy consumption and melting lump hull sand rate superior to that of the existing constant-current control strategy, and is of great guiding significance to the production process of the electrical smelting furnace for magnesium.

Owner:NORTHEASTERN UNIV

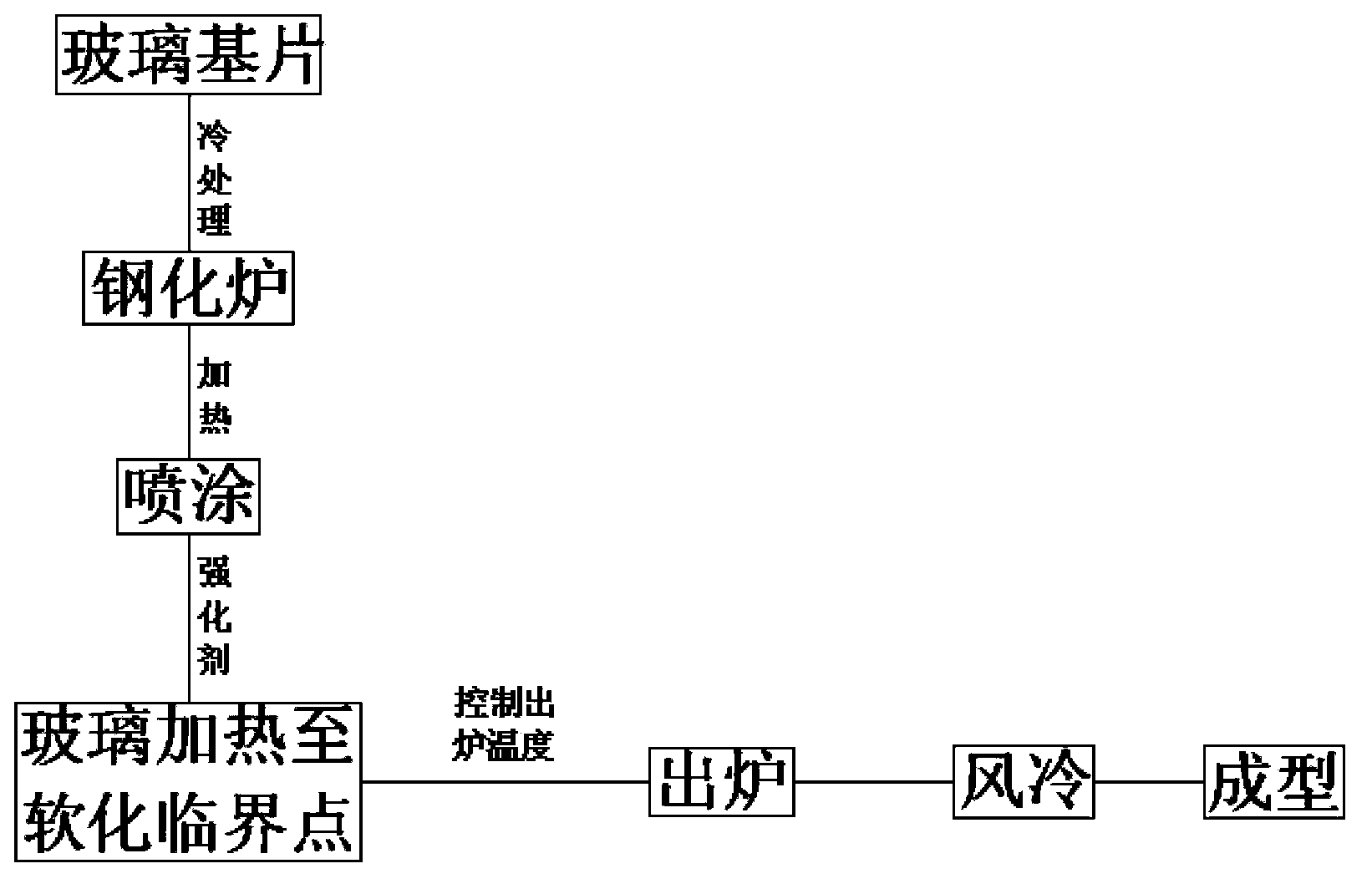

Preparation method of high-strength fireproof glass

InactiveCN103833200AHigh melting temperatureGood chemical stabilityGlass tempering apparatusCold treatmentHeating time

The invention discloses a preparation method of high-strength fireproof glass. The preparation method comprises following steps: float glass is taken as a substrate, and is subjected to cold treatment including edge polishing, circular corner polishing, and cleaning; the treated float glass is delivered into a toughening furnace for heat treatment, wherein the treated float glass is heated to 700 to 720 DEG C, heating time is 50S / mm, spraying of a reinforce is carried in the heating process, and the treated float glass is heated to softening critical states; a temperature sensor is used for controlling a discharging temperature to be 700 to 710 DEG C; the glass which is heated to the softening critical states is delivered into an air cooling device with a speed of 200mm / s-300mm / s, upper air pressure of the air cooling device is controlled to be 680 to 700kPa, and lower air pressure is controlled to be 640 to 660kPa. According to the preparation method, spraying of the reinforce in the high-temperature heating process is adopted, so that the obtained glass possesses fire resistance, and strength of the glass is more than 5 times of original strength of the glass; the preparation method is simple and convenient; production cost is reduced; and pollution on the environment is reduced.

Owner:虞建忠

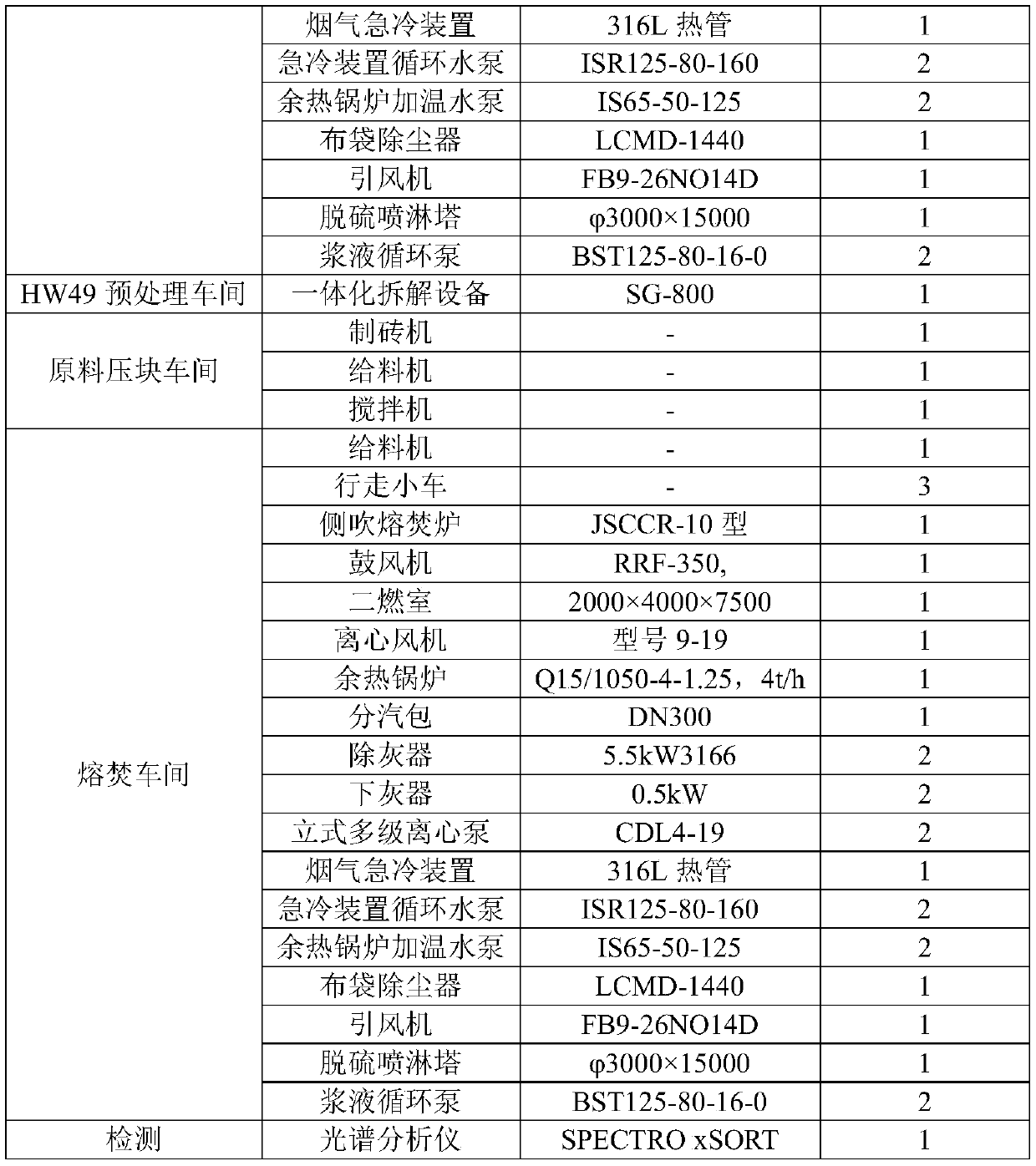

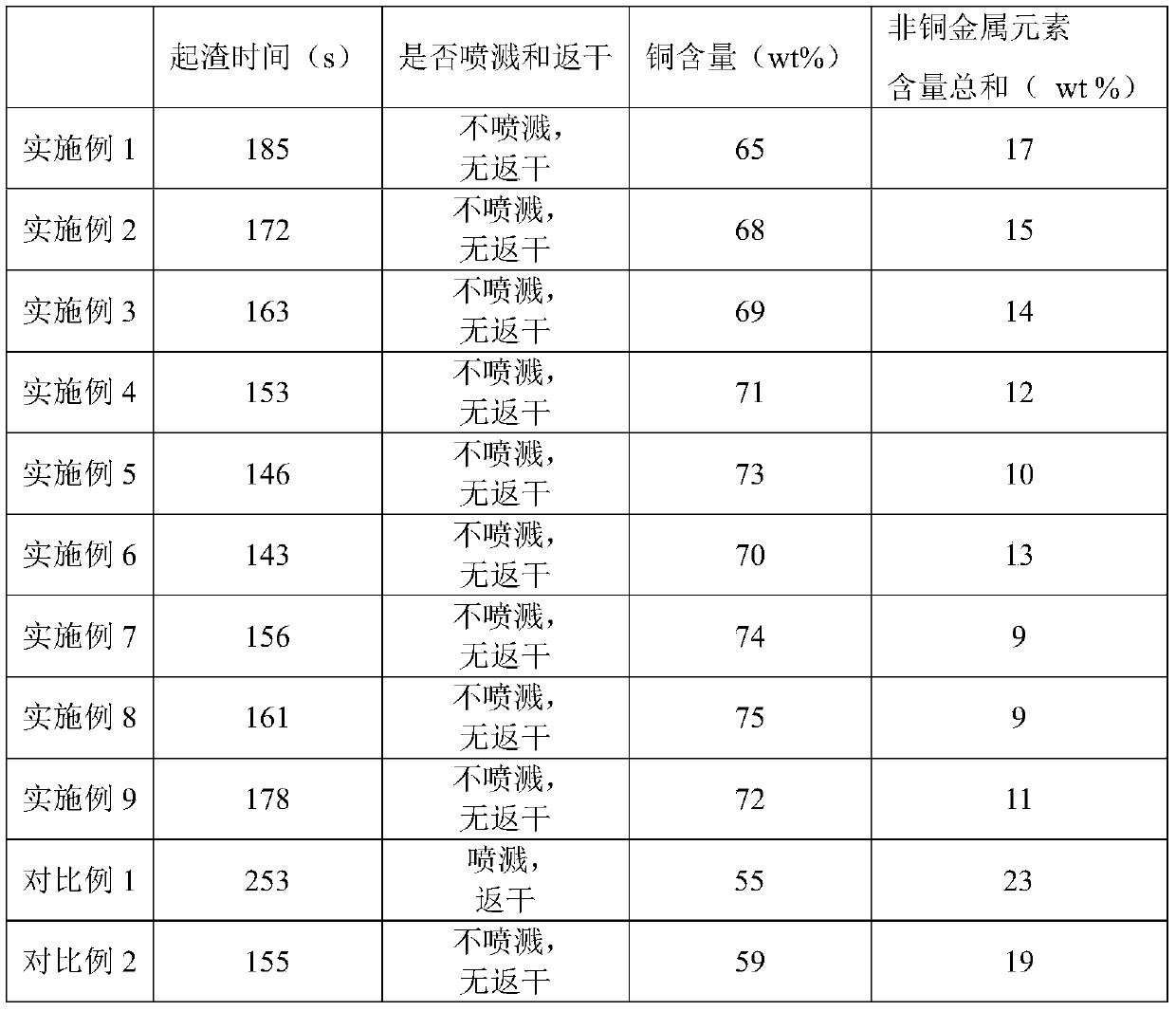

Copper-contained waste metal copper recycling process

ActiveCN111020212AIncreased copper contentSpeed up meltingProcess efficiency improvementCopper metalWaste material

The invention discloses a copper-contained waste metal copper recycling process. The process comprises the following steps of firstly, preparing copper-contained clinker; secondly, preparing copper-contained powder; thirdly, brick making, wherein the copper-contained clinker prepared in the first step, and the copper-contained powder made in the second step are burdened until the copper containingamount reaches above 25wt%, and then enter a brick making system, and a solidifying agent is prepared for preparing a copper brick block; fourthly, smelting; and fifthly, smelting furnace smoke treatment. According to the copper-contained waste metal copper recycling process, metal copper in the copper-contained waste can be recycled, meanwhile, non-copper metal elements in the recycled copper alloy can be reduced, and a raw material can be provided for subsequent preparing of refined copper.

Owner:洛南环亚源铜业有限公司

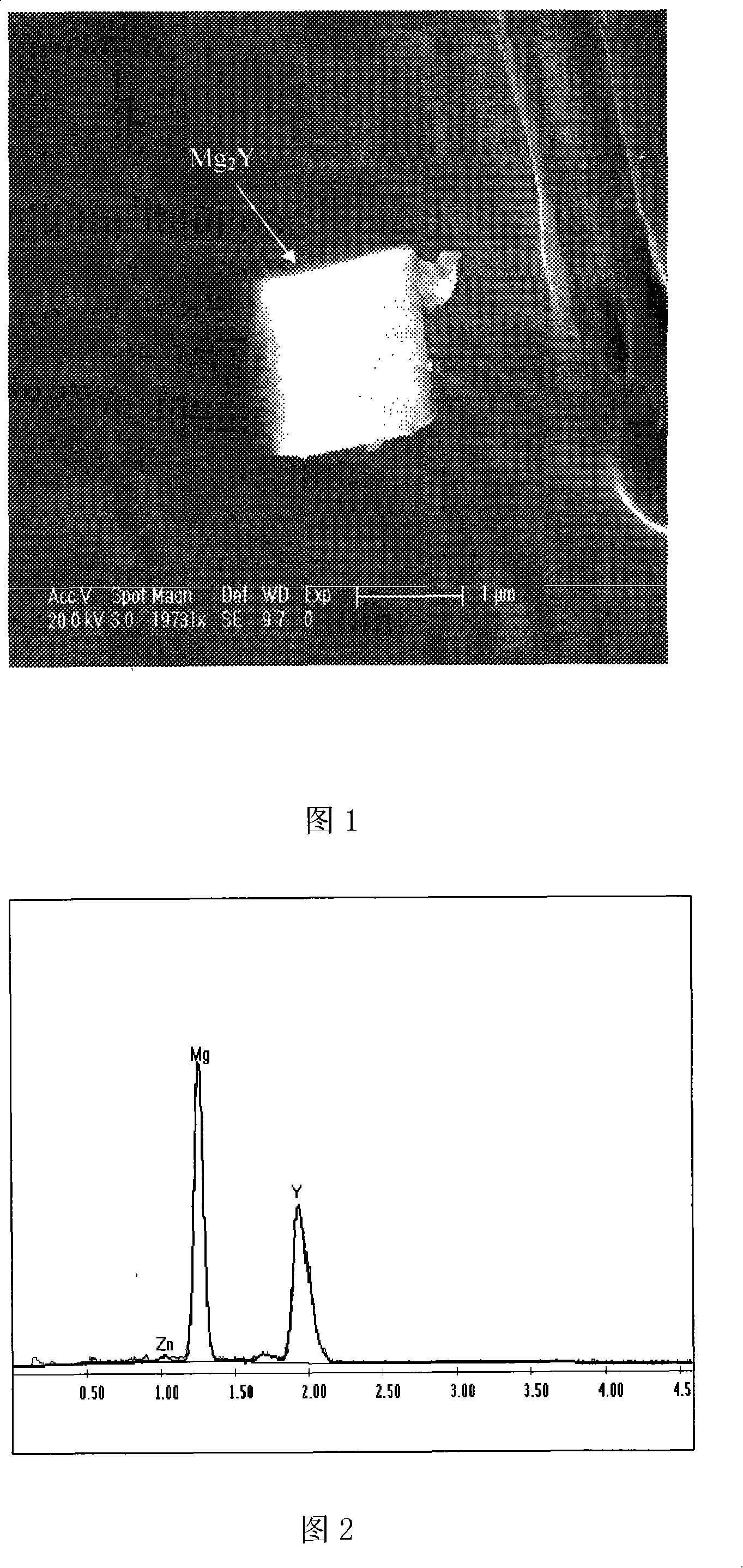

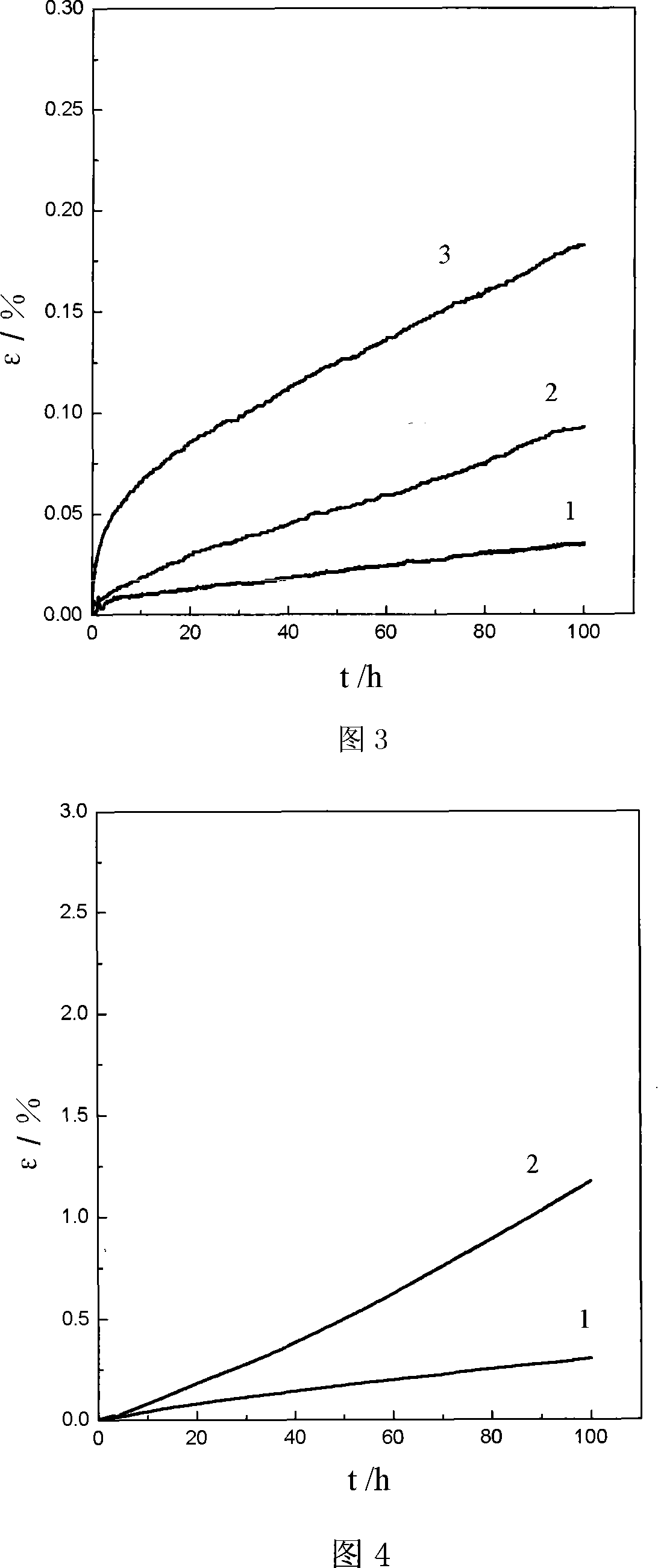

Aluminum-free heat-resistant die-casting rare earth magnesium alloy

The heat resistant no-aluminum die cast Mg-RE alloy consists of Y 2-4 wt%, Gd 0.2-0.6 wt%, Zn 0.3-0.6 wt%, Mn 0.1-0.3 wt%, and Mg for the rest. Y as the excellent additive for raising the performance of Mg alloy can refine the dendrite crystal in the alloy, increase the rate of fiber structures in alloy fracture and raise the plasticity of the alloy; and Gd and Zn serve as the alloy reinforcing elements too. The heat resistant no-aluminum die cast Mg-RE alloy has excellent room temperature mechanical performance, high temperature mechanical performance superior to that of AE44 alloy, and excellent creep resistance in the conditions up to 250 deg.c and 30 MPa.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

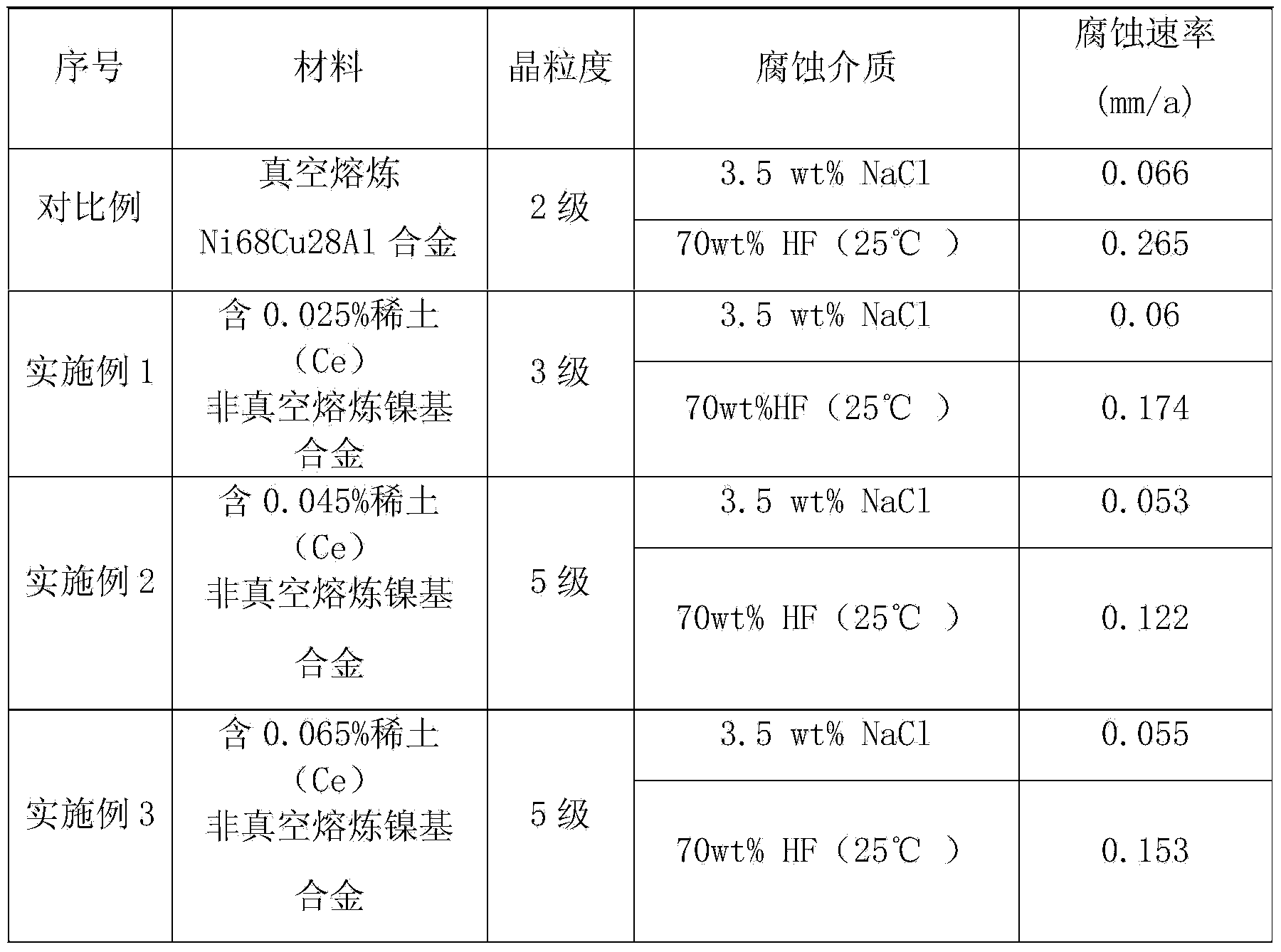

Nickel-based alloy and preparation method thereof

ActiveCN104388756AGood casting performanceImprove corrosion resistanceFoundry mouldsFoundry coresMaterials preparationRare earth

The invention belongs to the technical field of material preparation and in particular relates to a nickel-based alloy and a preparation method thereof. The nickel-based alloy comprises the following components in percentage by weight: 25-35% of Cu, 0.5-1.5% of Mn, 0-2.5% of Fe, 2.5-3.5% of Al, 0.5-0.9% of Ti, 0.025-0.065% of rare earth Ce and the balance of Ni and inevitable impurity elements, wherein the sum of the percents by weight of the components is 100%. The preparation method of the nickel-based alloy comprises the following steps: smelting the components, carrying out oxygen content treatment on an alloy liquid, carrying out modification treatment on the alloy liquid, and finally casting and cooling. The nickel-based alloy can have smaller grain size, corrosion resistance is stronger compared with that of the traditional casting nickel-based alloy, and the nickel-based alloy is also extremely simple and easy to prepare.

Owner:HEFEI UNIV OF TECH +1

Production method of high-strength and high-toughness aluminum bar

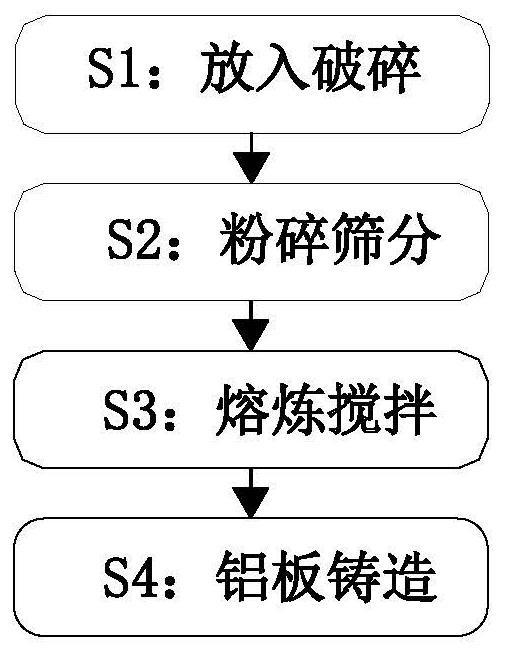

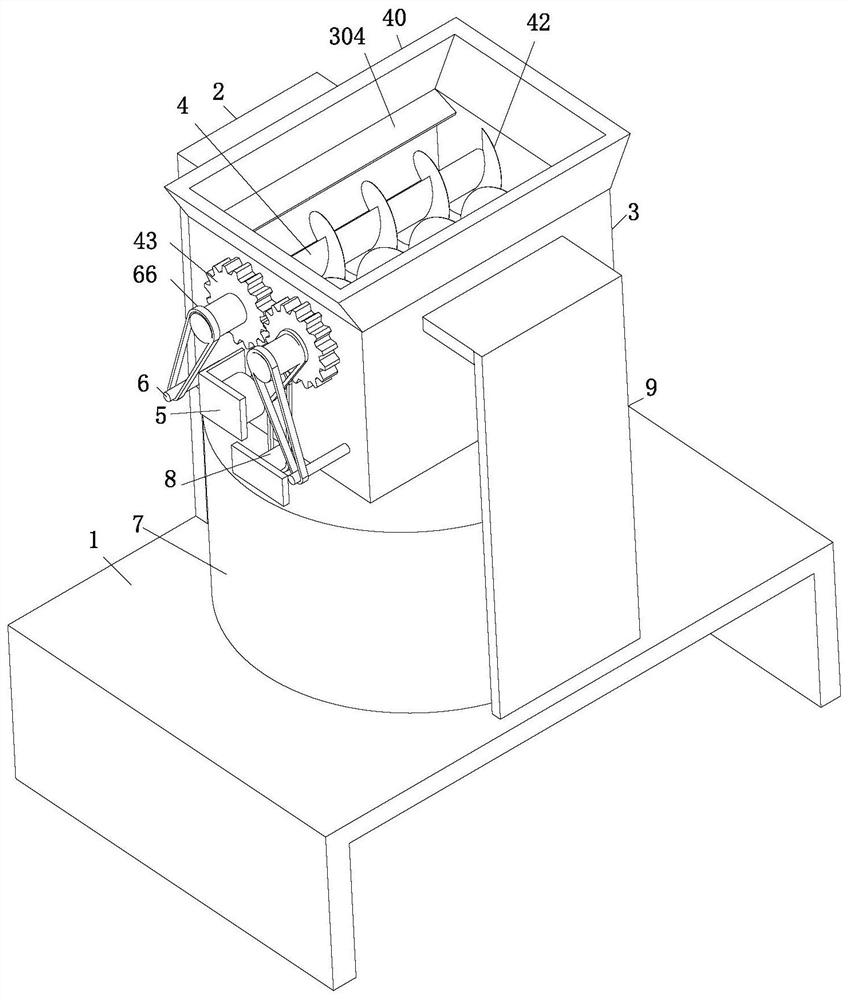

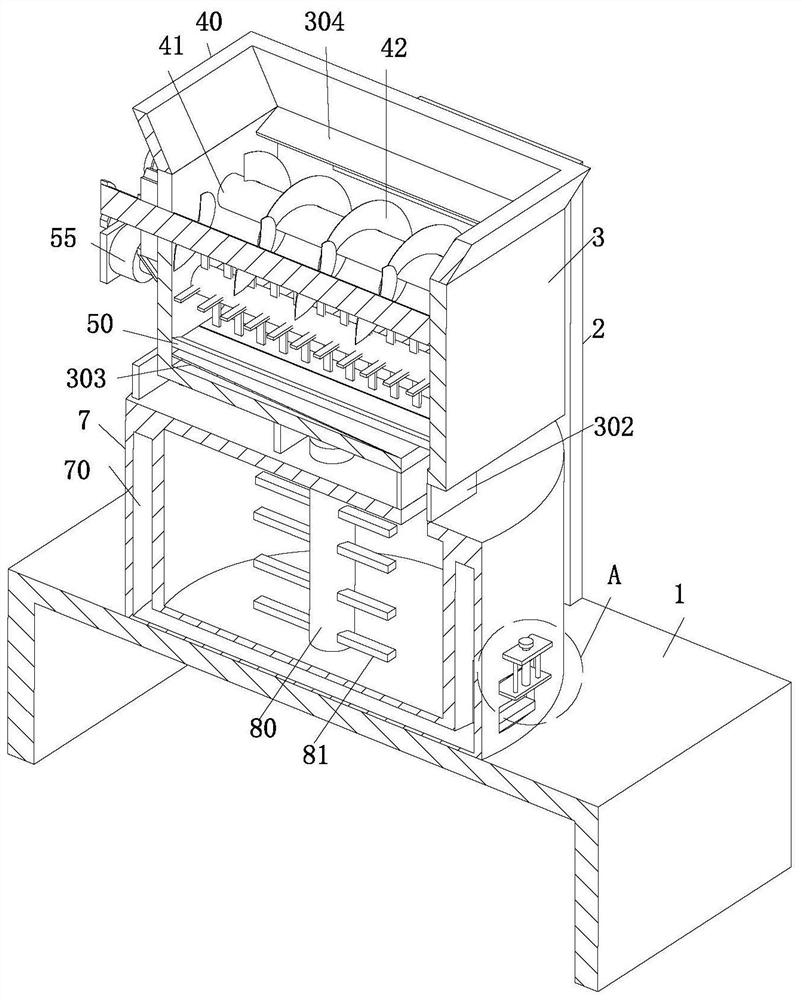

ActiveCN113215422AReduce volumeEasy to transportMolten metal pouring equipmentsGrain treatmentsRaw materialAluminium alloy

The invention relates to a production method of a high-strength and high-toughness aluminum bar. The production method comprises a workbench, an L-shaped frame plate, a crushing box, a crushing mechanism, a smashing mechanism, a screening mechanism, a smelting barrel, a stirring mechanism and an adjusting mechanism. The crushing mechanism, the smashing mechanism and the screening mechanism are combined, so that the size of fed aluminum alloy raw materials is reduced, and the aluminum alloy raw materials are conveniently conveyed and smelted. The small-size aluminum alloy raw materials are conveniently smelted, so that the smelting speed of the aluminum alloy raw materials is increased, and meanwhile the aluminum alloy raw materials are completely smelted. Therefore, the production efficiency of the aluminum bar is improved, and the situation that the production efficiency of the aluminum bar is low is avoided, Meanwhile, the size of a discharge chute is adjusted through the adjusting mechanism, therefore the amount of aluminum alloy raw material liquid injected into an aluminum bar casting cavity mold can be effectively controlled, the raw materials are prevented from spreading out of the aluminum bar mold, and resource waste can be effectively avoided.

Owner:安徽佳晟金属科技有限公司

Metal additive for aluminum alloy smelting and using method thereof

The invention discloses a metal additive for aluminum alloy smelting and a using method thereof. 1.0-1.5% of -325-mesh titanium hydride powder is added into the metal additive; experiments find that when the metal additive is added under a condition that temperature of smelted aluminum is 680-700 DEG C, the titanium hydride powder occurs decomposition reaction similar to little explosion in the smelted aluminum, metal elements are uniformly dispersed in the smelted aluminum, and segregation of metal components of aluminum alloy is eliminated completely; a lot of heat is released during decomposition reaction, local temperature of the smelted aluminum is increased, and smelting of the metal elements is facilitated; adding temperature is low, energy consumption is low, burning up of the metal elements is reduced, and actual yield is increased; temperature of the smelted aluminum is increased to 730-750 DEG C, and alloying reaction rate is increased.

Owner:KUNMING METALLURGY INST

Burner of reverberatory furnace

ActiveCN103994438AWide flame coverageUniform melting temperatureGaseous fuel burnerCombustion chamberEngineering

A burner of a reverberatory furnace comprises a natural gas main pipe. The front end of the natural gas main pipe is connected with a spray head with a throat. The spray head with the throat comprises a spray head body and the throat. The pray head body is a hollow diffusion-type semi-closed structure with the sectional area of the end face A larger than the sectional area of the end face B, the end face A is fully open, a connecting port connected with the front end of the natural gas main pipe is formed in the end face B, the cross section of the throat is rectangular, and the throat is fixedly connected with the end face A of the spray head body. The spray head with the throat is located in an oxygen distribution chamber, the oxygen distribution chamber is a closed cavity connected with a combustion chamber, a partition plate is arranged between the oxygen distribution chamber and the combustion chamber, oxygen spray holes are distributed in the surface of the partition plate, an installing hole matched with the spray head with the throat is formed in the partition plate, the upper edge of an outlet of the spray head with the throat is fixedly connected with the upper edge of the installing hole in a sealed mode, and gap is reserved between the lower edge and the two side edges of the outlet and the partition plate. The burner is wide in flame coverage, high in fuel utilization rate and little in damage to a vault of the combustion chamber.

Owner:CINF ENG CO LTD

Slag-forming constituents used for lead and lead-base alloy fusion casting

The invention relates to a slag-forming constituent in casting lead and lead-base alloy, which comprises 35-70wt% of CaF2, 3-5wt% of Na3AlF6, 3-8wt% of KCl, 8-10wt% of NaCl, 2-5wt% of ZnCl2, 20-50wt% of C powder and 3-5wt% of NH4Cl. The invention makes use of the principle that inorganic salt can improve interfacial force and boundary tension between lead fondant and oxidate so as to de-slag in casting and using of lead-base product, improve quality of casting and using, ensure slag to carry on powder, and recovery metal efficiently. The invention the properties of simple preparation, low input of apparatus and capital and extensive usages such as lead ingot casting, lead-base alloy product casting and lead-base product later usage.

Owner:株洲冶炼集团有限责任公司

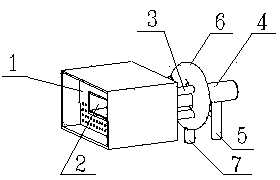

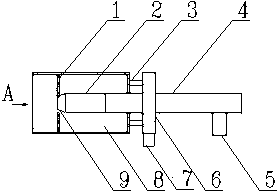

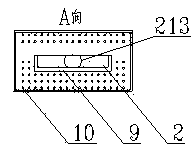

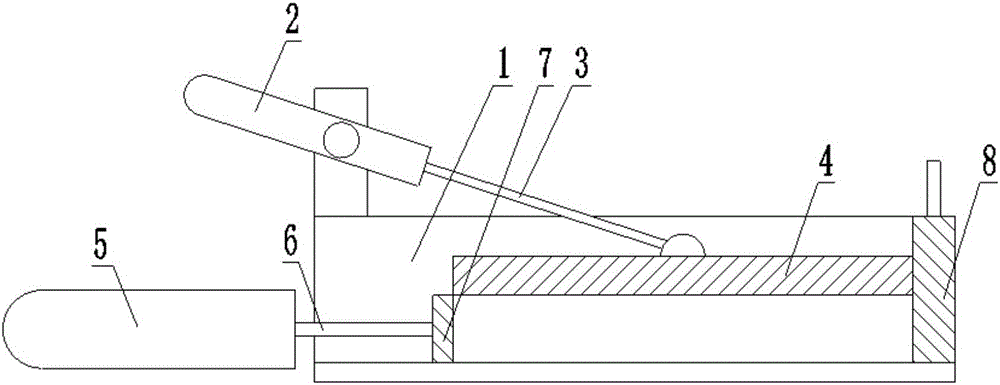

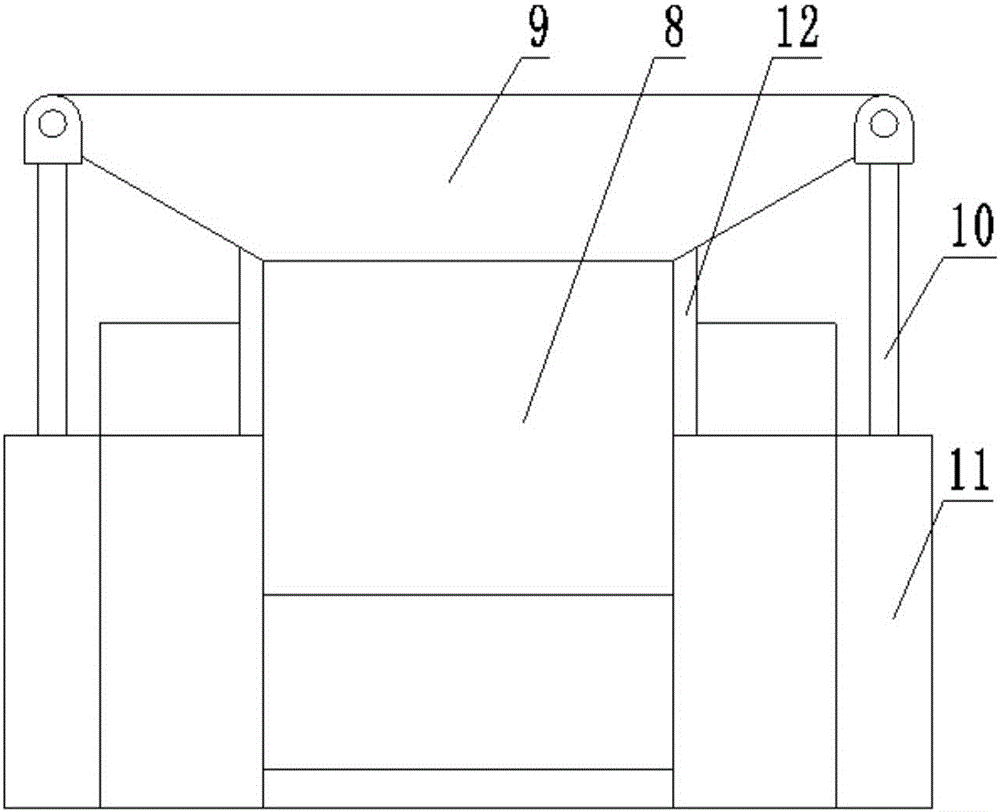

Efficient compressing and packaging device for aluminum product machining

The invention discloses a high-efficiency compression packing device for processing aluminum materials, which comprises a frame (1), the top of the frame (1) is rotatably connected with an inclined hydraulic cylinder (2), and one end of the inclined hydraulic cylinder (2) pushes The rod (3) is connected with a pressure plate (4); the horizontal hydraulic cylinder (5) is arranged below the inclined hydraulic cylinder (2), and one end of the horizontal hydraulic cylinder (5) is connected with a push plate (7) through a horizontal push rod (6); One end of the frame (1) is connected with a switch knife (8), the top of the switch knife (8) is connected with a crossbar (9), and the two ends of the crossbar (9) are connected with a vertical push rod (10). Vertical hydraulic cylinder (11). The invention can not only improve the compression packing efficiency and compression packing effect, but also can be conveniently used in smelting.

Owner:HUZHOU RONGYAO ALUMINUM IND CO LTD

Slag-forming constituents used for lead and lead-base alloy fusion casting

The invention relates to a slagging agent for melting and casting of lead and lead-based alloys. Its composition and weight percentage are: CaF245%~70%, Na3AlF63%~4%, KCl 3%~5%, NaCl 8%~10%, ZnCl22%~3%, C powder 12%~35%, NH4Cl 2 %; The present invention utilizes some inorganic salts to improve the surface tension and interfacial tension principle between the lead melt and the oxide, and adopts a reasonable proportion to make lead ingots and lead-based alloys fully Slag removal and purification can improve the quality of smelting and use, and ensure that the slag body is powdery after salvaging slag, with very little metal entrainment, and the entrained metal can flow out effectively, further recovering metal, and at the same time ensuring good environmental protection and safety. The preparation of the invention is simple, and the input equipment and capital are less. It can be used for melting and casting of lead ingots, melting and casting of lead-based alloy products and later use of lead-based products.

Owner:株洲冶炼集团有限责任公司

Titanium-iron-carbon alloy with low cost and high strength

Disclosed is titanium-iron-carbon alloy with low cost and high strength. The titanium-iron-carbon alloy is characterized by comprising, by mass, 11%-12% of Fe, 0.03%-0.07% of C, the balance Ti and inevitable impurities. According to the titanium-iron-carbon alloy, a titanium alloy system serves as an object; the two elements of titanium and iron serve as a main alloy body; the titanium alloy with high strength and ductility is obtained by adding trace carbon element. The titanium alloy adopting the matching ratio is not only easy to smelt, but also low in cost.

Owner:YANSHAN UNIV

Environment-friendly smelting furnace for nickel-based alloy powder coating

InactiveCN110411208AIncrease temperatureExtended service lifeCharge manipulationIncreasing energy efficiencySmelting processAlloy

The invention belongs to the technical field of smelting furnaces, and particularly relates to an environment-friendly smelting furnace for a nickel-based alloy powder coating. The furnace aims to solve the problem that an existing smelting furnace is not energy-saving and environment-friendly. According to the technical scheme, the furnace comprises a smelting furnace body, a smelting furnace cover body, a material storage tank and a purification heat absorption tank, wherein the smelting furnace cover body is arranged on the smelting furnace body, the material storage tank is arranged on thesmelting furnace cover body, a material conveying pipe is arranged on the material storage tank, a liquid storage cavity is formed in the material storage tank, a connecting pipe communicates the liquid storage cavity and the purification heat absorption tank, a water pump is arranged on the connection pipe, a liquid discharge pipe is arranged on the material storage tank and communicates with the liquid storage cavity, the purification heat absorption tank is arranged on the smelting furnace cover body, one end of an air inlet pipe extends into the smelting furnace body, the other end of theair inlet pipe extends into the purification heat absorption tank, and a gas exhaust pipe is arranged on the purification heat absorption tank. According to the furnace, the operation is convenient,the safety performance is good, the heat preservation effect is good, the energy consumption is reduced, waste gas in the smelting process can be purified, the heat in the waste gas can be absorbed and utilized, and the energy-saving and environment-friendly effects are realized.

Owner:扬州安泰威合金硬面科技有限公司

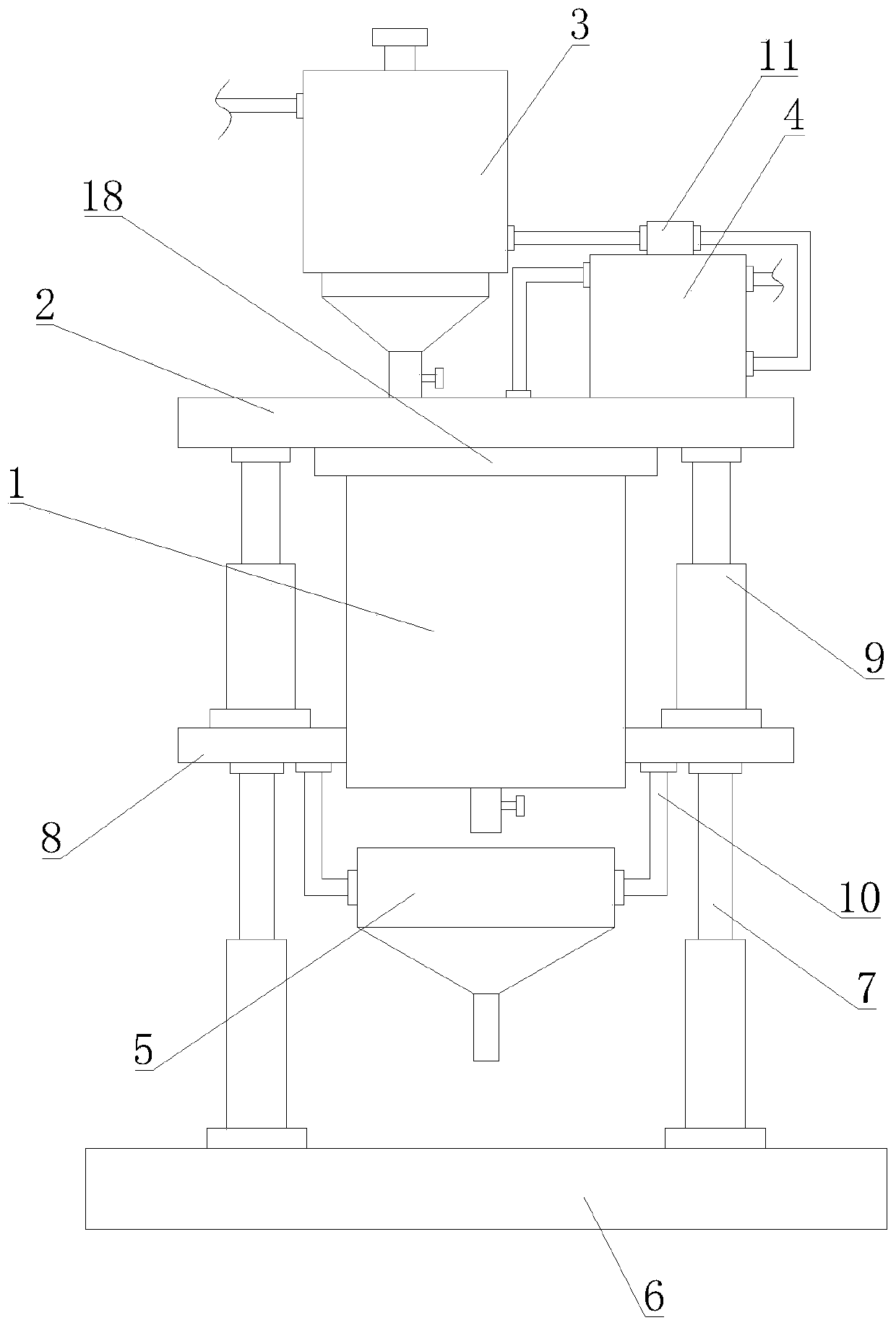

Equipment of non-vacuum smelting easy oxidation metal and alloy

InactiveCN1869564AReduce partial pressureFacilitated DiffusionCasting plantsCrucible furnacesLoss rateCunife

The invention provides a device for non-vacuum smelting easy- to-oxidize metals and alloys, and its main parts comprise furnace body and furnace cover, where the furnace body is equipped with a heater, and a pot is placed inside the furnace body; and the furnace cover has an gas inlet, an gas outlet and a feed inlet and is equipped with a cooling mechanism; the bottom of the hearth is equipped with a bottom pouring orifice, a vertical stopper is arranged inside the furnace body, the lower end of the stopper is connected with the bottom pouring orifice, the upper end of the stopper is equipped with an adjustment mechanism which adjusts the vertical position of the stopper to prevent metal melt from flowing down in the smelting course; the lower side of the furnace body is directly connected with a crystallizer or iron mold, it adopts a down-pouring mode and the connecting channel is made with an gas inlet and an gas outlet. And its whole smelting and casting course is performed in the industrial pure protective gas, having low melting loss rate and good deoxidizing and dehydrogenating effects, easy to implement large-scale continuous operation and obviously improving the pouring quality.

Owner:苏州有色金属研究院有限公司

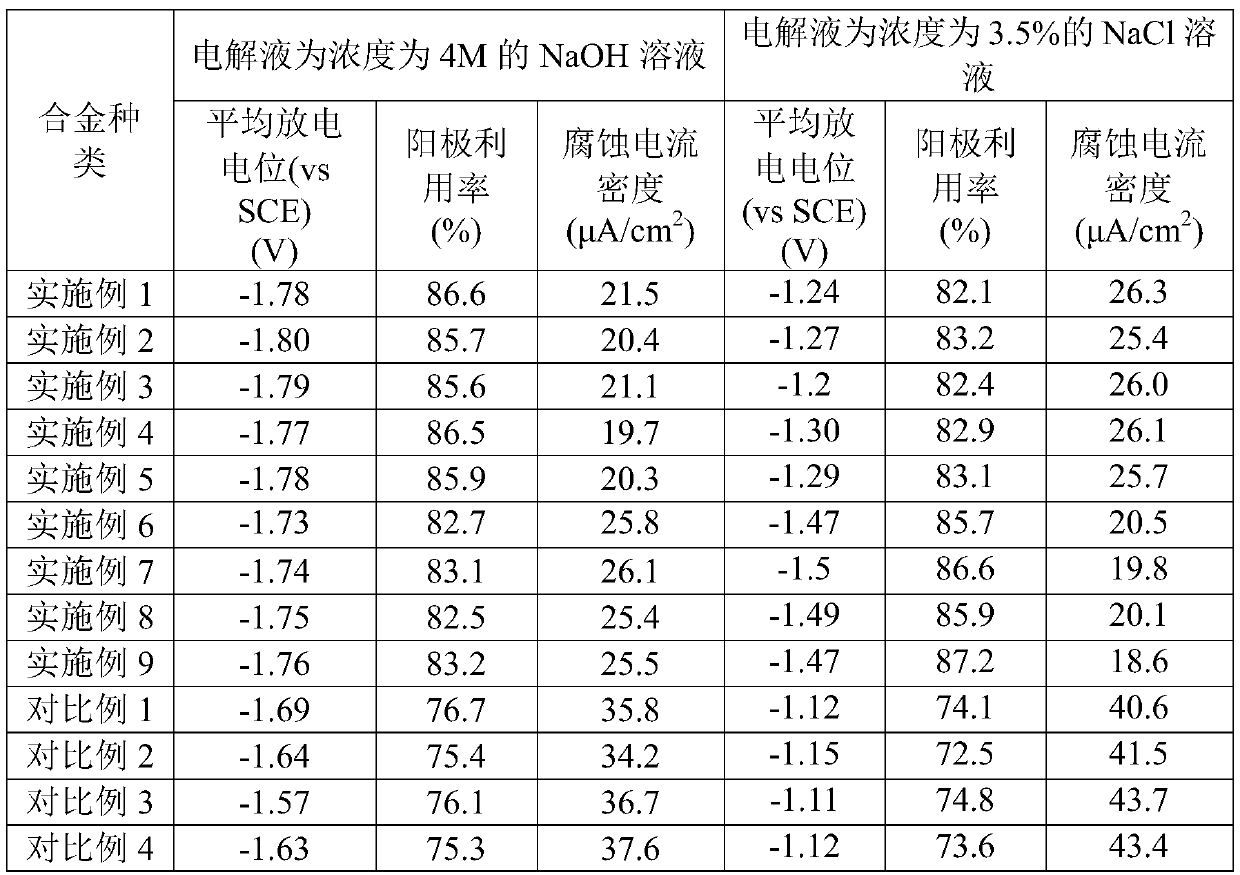

Amorphous-nanocrystalline Fe-based composite soft magnetic alloy and preparation method thereof

ActiveCN108447641AMagneticReasonable formulaInductances/transformers/magnets manufactureMagnetic materialsCompound aMischmetal

The invention discloses an amorphous-nanocrystalline Fe-based composite soft magnetic alloy and a preparation method thereof. The amorphous-nanocrystalline Fe-based composite soft magnetic alloy is formed by compounding a Fe-based soft magnetic alloy A and a Fe-based soft magnetic alloy B, wherein the Fe-based soft magnetic alloy A is prepared from the following raw materials of Al, Si, B, Fe andunavoidable impurities; the Fe-based soft magnetic alloy B is prepared from the following raw materials of Al, Si, Ni, Co, Cr, Ti, Mo, Sm, B, composite rare-earth metal, Fe and unavoidable impurities;and the preparation method comprises the following steps of (S1) preparing powder of the Fe-based soft magnetic alloy A; (S2) preparing the powder of the Fe-based soft magnetic alloy B; (S3) preparing the powder of a Fe-based composite soft magnet; and (S4) smelting and rapidly quenching the powder of the Fe-based composite soft magnet to obtain the amorphous-nanocrystalline Fe-based composite soft magnetic alloy. The composite soft magnetic alloy disclosed by the invention is reasonable in formula, low in coercivity, simple in preparation method and suitable for industrial production.

Owner:ZHEJIANG HENGJI YONGXIN NEW MATERIALS CO LTD

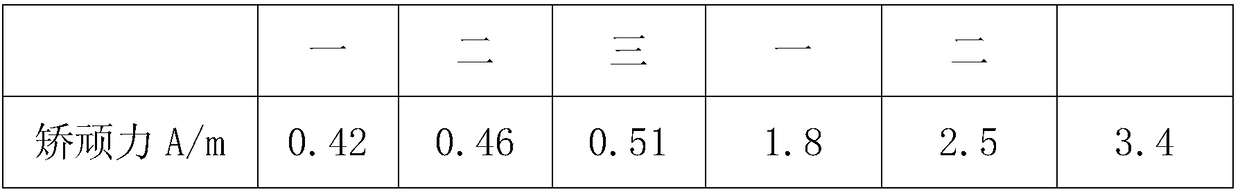

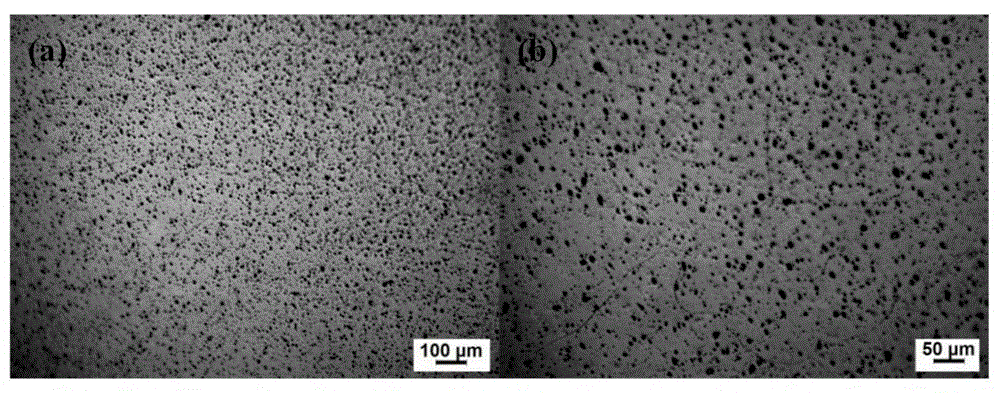

Anode alloy material, preparation method thereof, anode for aluminum-air battery and aluminum-air battery

ActiveCN111057914AInhibition of hydrogen evolution reactionIncrease profitFuel and secondary cellsCell electrodesMetallurgyBattery cell

The invention discloses an anode alloy material, a preparation method thereof, an anode for an aluminum-air battery and the aluminum-air battery, and relates to the field of anode materials for air batteries. The anode alloy material comprises aluminum and alloy elements added into the aluminum, wherein the alloy elements comprise, by mass, 0.01%-5.5% of Mg, 0.01%-3.0% of Sn, 0.01%-2.5% of Ce, 0.0001%-0.0010% of B and 0.01%-2.0% of Ti. The preparation method comprises the steps of preparing the anode alloy material from the raw materials according to the component matching ratio. The components of the anode alloy material are limited, the dosage of each component of the anode alloy material is adjusted, the optimal component dosage ratio is obtained, the hydrogen evolution reaction of thealuminum alloy anode material can be effectively inhibited, and the anode alloy material with negative average discharge potential and high anode utilization rate is developed.

Owner:GUANGDONG INST OF NEW MATERIALS

High-strength cast magnesium alloy and preparation method thereof

ActiveCN105112751AGood aging precipitation strengthening effectImprove mechanical propertiesUltimate tensile strengthAluminium element

The invention relates to a high-strength cast magnesium alloy. The high-strength cast magnesium alloy is an Mg-Bi-Al-Zn-Sr alloy and comprises components in percentage by weight as follows: 3wt%-8.0wt% of Bi, 0.5wt%-4.0wt% of Al, 0.1wt%-1.0wt% of Zn, 0.05wt%-0.15wt% of Sr and the balance of Mg. The Bi element is used as a main alloy element, a large quantity of Mg3Bi2 phases are formed through simple alloying means, a small quantity of aluminum and zinc elements are used for improving the strength of the alloy, so that the high-strength cast magnesium alloy is developed from the alloy series, and the alloy has the tensile strength of 276-296 MPa, the yield strength of 155-170 MPa and the elongation of 5.3%-7.3% and has mechanical properties comparable with those of rear earth magnesium alloys.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com