Preparation method of high-strength fireproof glass

A technology of fireproof glass and manufacturing method, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of high cost of molten salt method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

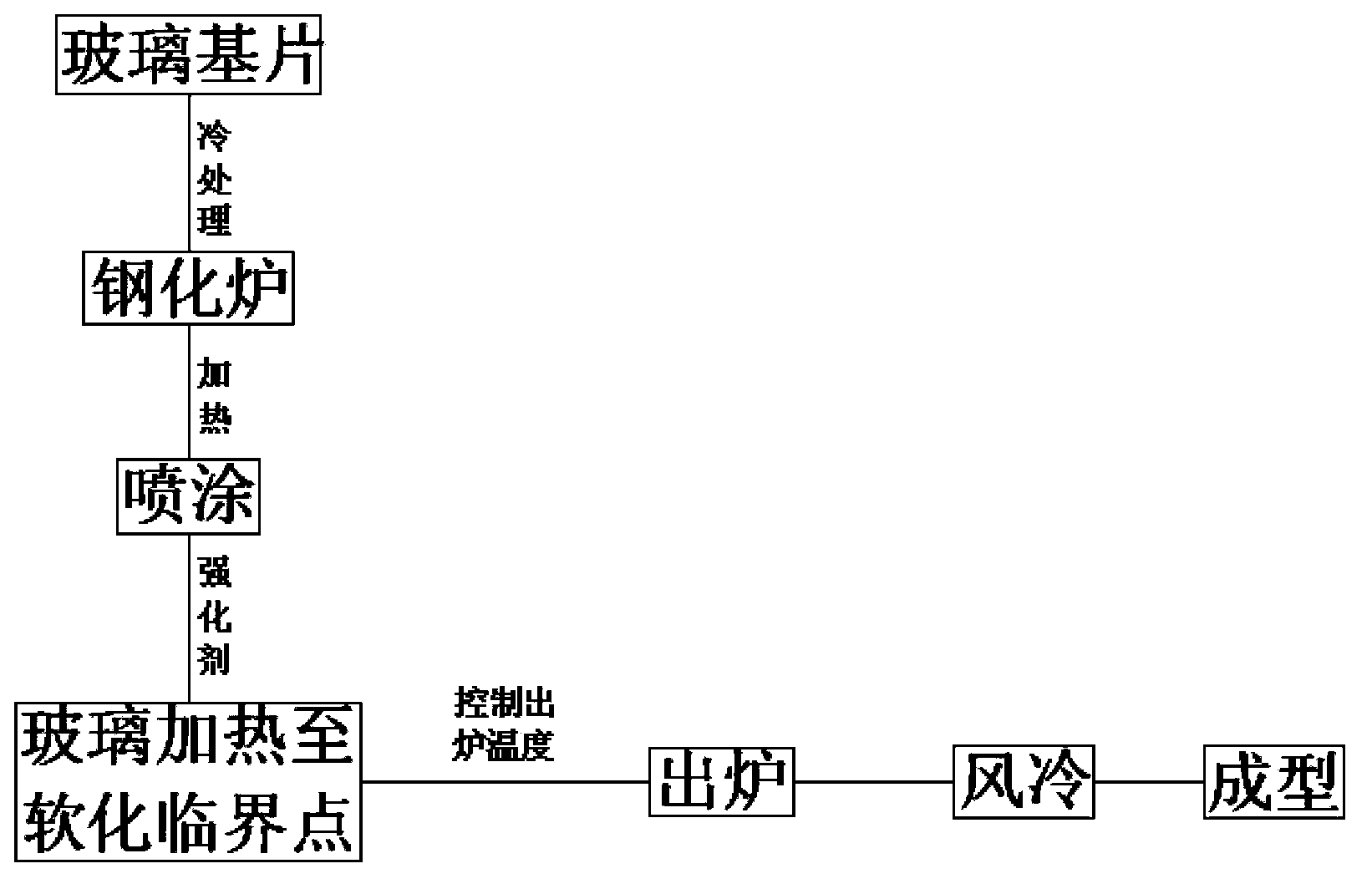

[0025] Embodiment 1 of the present invention: as figure 1 Shown, a kind of manufacture method of high-strength fireproof glass is characterized in that:

[0026] In step a, the float glass is used as a substrate, and the cold treatment of edge grinding, filleting and cleaning is carried out;

[0027] Step b, send the cold-treated float glass into a tempering furnace for heat treatment, heat it to 700°C, and heat it for 50 S / mm. During the heating process, spray a strengthening agent, and the proportion of the strengthening agent by weight is: K 3 PO 4 : 40 parts, Na 3 PO 4 : 3 parts, Na: 0.5 parts, coating liquid thickener: 0.2 parts, SnCl 4 : 5 servings, ROSO 3 Na: 0.2 parts, water: 25 parts, heat the glass to the softening critical state;

[0028] Step c, setting a temperature sensor to control the furnace temperature at 700°C;

[0029] In step d, the glass heated and softened to a critical state is sent to the air cooling at a speed of 200 mm / s. The upper wind press...

Embodiment 2

[0032] Embodiment 2 of the present invention: as figure 1 Shown, a kind of manufacture method of high-strength fireproof glass is characterized in that:

[0033] In step a, the float glass is used as a substrate, and the cold treatment of edge grinding, filleting and cleaning is carried out;

[0034] Step b, sending the cold-treated float glass into a tempering furnace for heat treatment, heating to 710°C, heating time 50S / mm, spraying a strengthening agent during the heating process, and the proportion of the strengthening agent by weight is: K 3 PO 4 : 50 parts, Na 3 PO 4 : 4 parts, Na: 1.3 parts, coating liquid thickener: 5 parts, SnCl 4 : 7 servings, ROSO 3 Na: 0.7 parts, water: 31 parts, heat the glass to the softening critical state;

[0035] Step c, setting the temperature sensor to control the furnace temperature at 705°C;

[0036]In step d, the glass heated and softened to a critical state is sent to the air cooling at a speed of 250 mm / s. The upper wind press...

Embodiment 3

[0039] Embodiment 3 of the present invention: as figure 1 Shown, a kind of manufacture method of high-strength fireproof glass is characterized in that:

[0040] In step a, the float glass is used as a substrate, and the cold treatment of edge grinding, filleting and cleaning is carried out;

[0041] Step b, send the cold-treated float glass into a tempering furnace for heat treatment, heat it to 720°C, and heat it for 50 S / mm. During the heating process, spray a strengthening agent, and the proportion of the strengthening agent by weight is: K 3 PO 4 : 60 parts, Na 3 PO 4 : 5 parts, Na: 4 parts, coating solution thickener: 10 parts, SnCl 4 : 10 servings, ROSO 3 Na: 1.2 parts, water: 40 parts, heat the glass to the softening critical state;

[0042] Step c, setting the temperature sensor to control the furnace temperature at 710°C;

[0043] In step d, the glass heated and softened to a critical state is sent to the air cooling at a speed of 300 mm / s. The upper wind pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com