Patents

Literature

263results about How to "Reduce high temperature viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

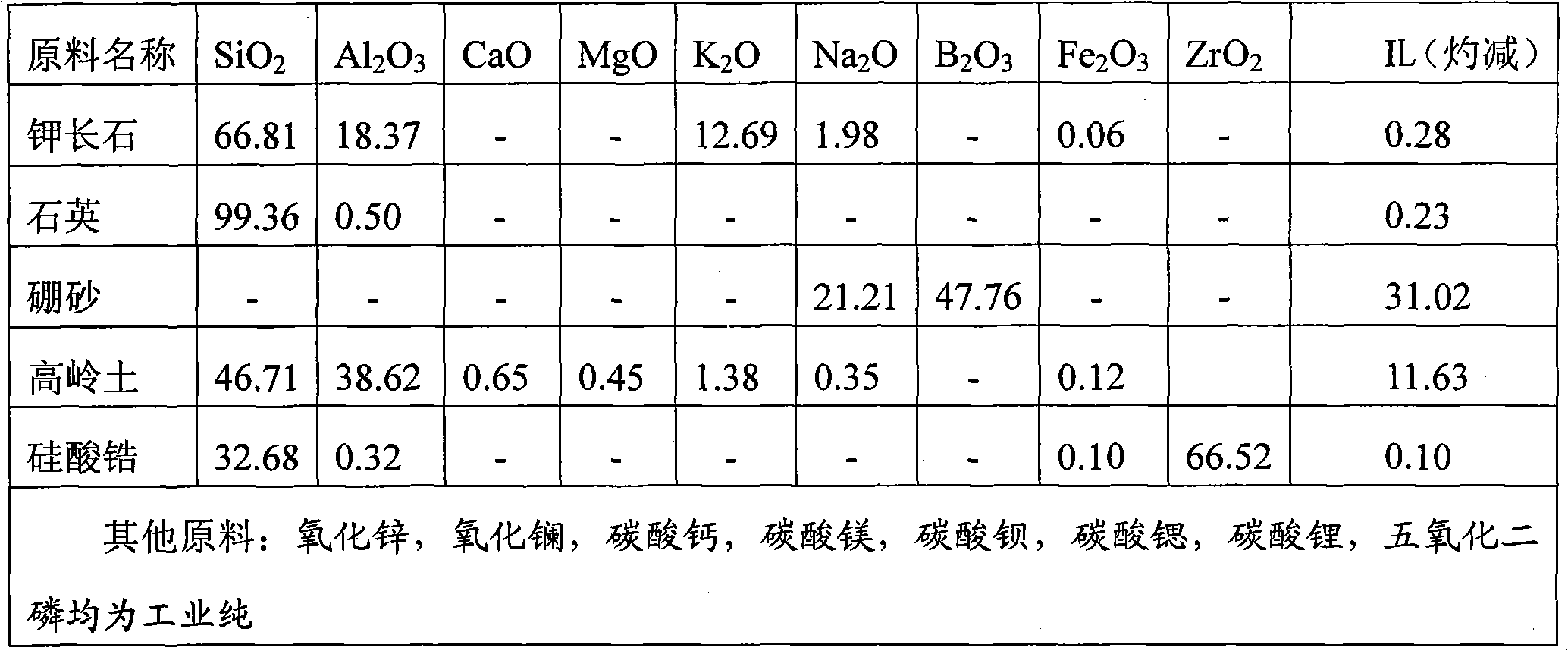

Multicolor furnace transmutation glaze ground coat and manufacturing method thereof

The invention relates to a multicolor furnace transmutation glaze ground coat and a manufacturing method thereof. The manufacturing method comprises the step of adding a part of chromogenic oxides into feldspar, quartz, calcite, talc and kaolin which are selected as ground coat raw materials. Moreover, the ratio of silicate to aluminium of the ground coat must be over six, so that solution can be decomposed at high temperature to release gas to form a plurality of fine and dense small bubbles and defects are formed on the surface of a glaze layer; and then suitable cover glazes are matched to generate various furnace transmutation effects. According to a process formula of the glaze of the ground coat, the multicolor furnace transmutation glaze ground coat comprises the following components in part by weight: 45 parts of feldspar, 18 to 25 parts of quartz, 12 to 18 parts of calcite, 2 to 5 parts of talc, 5 to 12 parts of kaolin, 10 to 14 parts of iron oxide red and 2 to 5 parts of manganese carbonate. The ground coat prepared according to the process formula comprises the following chemical compositions: 58 to 64 percent of SiO2, 8 to 11 percent of Al2O3, 7 to 9.8 percent of CaO, 0.4 to 1.6 percent of MgO, 4 to 5.8 percent of K2O, 0.9 to 1.2 percent of Na2O, 9 to 13 percent of Fe2O3 and 0.9 to 2.3 percent of MnO.

Owner:HUNAN LILING HONGGUANYAO CERAMICS

Lead-free and cadmium-free bone china glaze and preparation process thereof

The invention discloses a lead-free and cadmium -free bone china glaze and a preparation process thereof. The lead-free and cadmium-free bone china glaze comprises the following compositions in percentage by weight: 50.0 to 62.0 percent of SiO2, 6.0 to 10.0 percent of Al2O3, 6.0 to 10.0 percent of CaO, 0.5 to 4 percent of MgO, 0.0 to 2.0 percent of BaO, 0.5 to 3.0 percent of SrO, 6.0 to 10.0 percent of ZnO, 2.0 to 6.5 percent of K2O, 1.0 to 5.0 percent of Na2O, 0.2 to 3.0 percent of Li2O, 1.0 to 3.0 percent of B2O3, 1.0 to 3.5 percent of ZrO2, 0.2 to 1.0 percent of La2O3, and 0.1 to 2.0 percent of P2O5. By optimizing the glaze formula, the glaze has no lead and cadmium, so the glaze is non-toxic and environment-friendly. The lead-free and cadmium-free bone china glaze and the preparation process thereof have the advantages of reducing the consumption of zinc oxide, overcoming the defects of soft glaze, easy scratching and color disadvantage caused by high zinc oxide content, and improving the hardness of the glaze by optimizing the chemical compositions of the glaze.

Owner:SHENZHEN YONG FENG YUAN IND

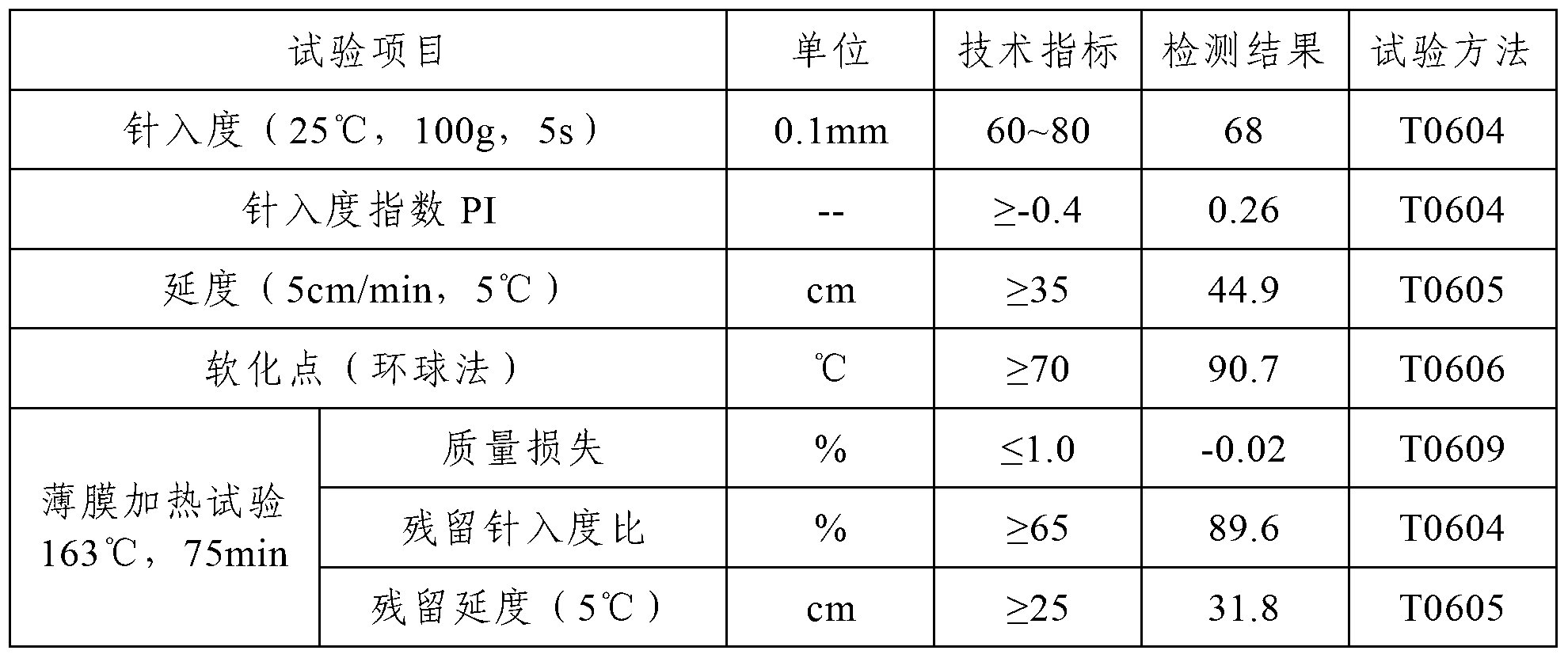

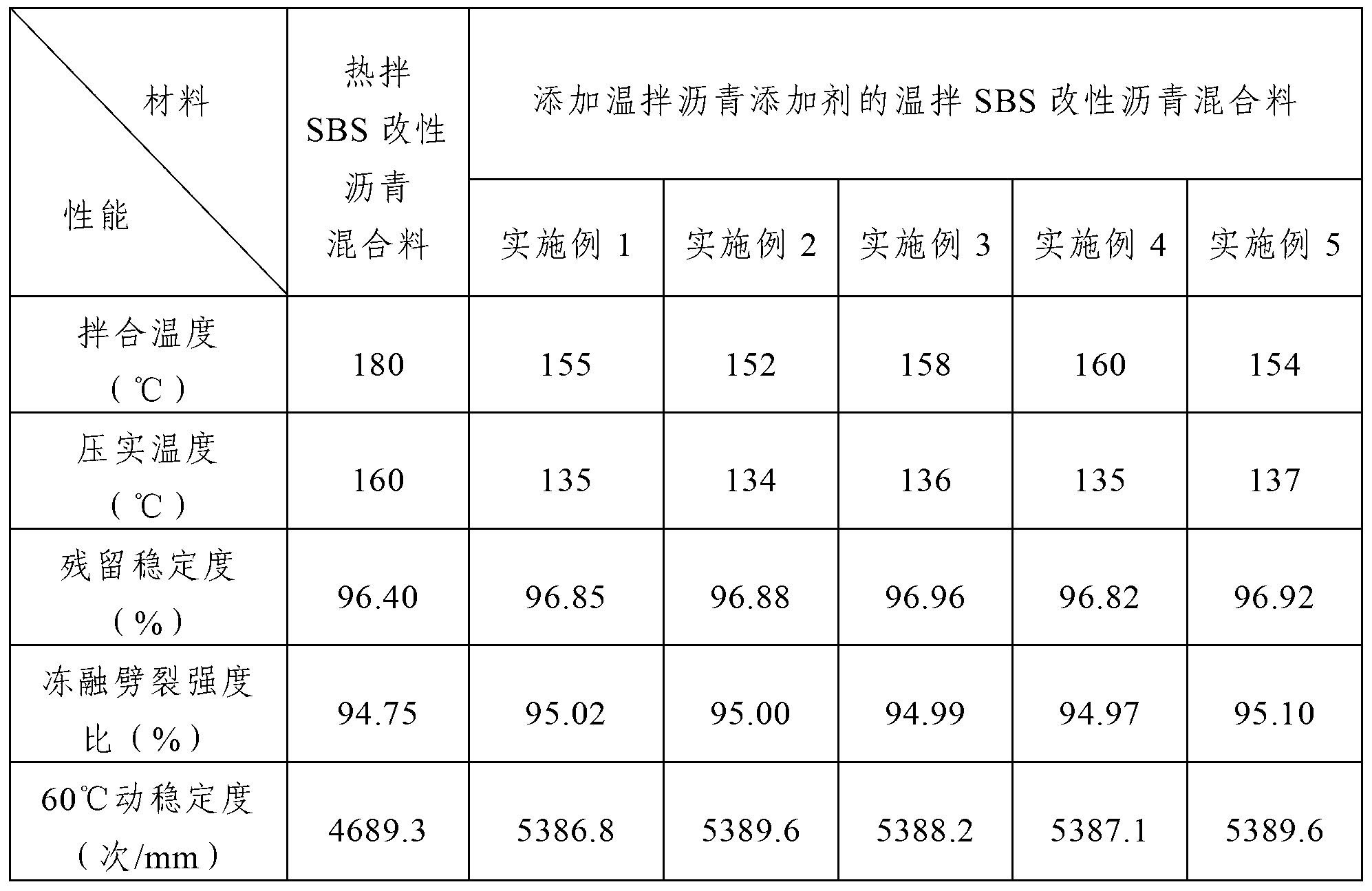

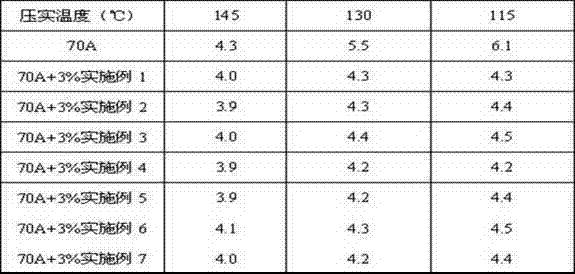

Warm mix asphalt additive and preparation method thereof

ActiveCN103242666AReduce high temperature viscosityReduce the temperatureClimate change adaptationBuilding insulationsChlorinated paraffinsBall mill

The invention provides a warm mix asphalt additive which is prepared from the following raw materials in parts by weight: 15-20 parts of polyethylene wax, 15-20 parts of chlorinated paraffin-70, 30-50 parts of kieselguhr, 1-3 parts of stearamide and 1-4 parts of solid anti-striping agent. The invention further provides a method for preparing the warm mix asphalt additive. The method comprises the following steps of: both grinding the polyethylene wax and stearamide into micro-powder, and subsequently putting the chlorinated paraffin-70, kieselguhr, the solid anti-striping agent and the grinded polyethylene wax and stearamide into a high-speed ball mill to be milled so as to obtain the warm mix asphalt additive. By utilizing the warm mix asphalt additive, the mixing and compressing temperature of an asphalt mixing material can be decreased by more than 20 DEG C on the premise that the property of the asphalt mixing material is not affected, so that the warm mix asphalt additive can be widely applied to asphalt mixing material construction in areas of different climates.

Owner:辽宁奥鹏交通科技集团股份有限公司

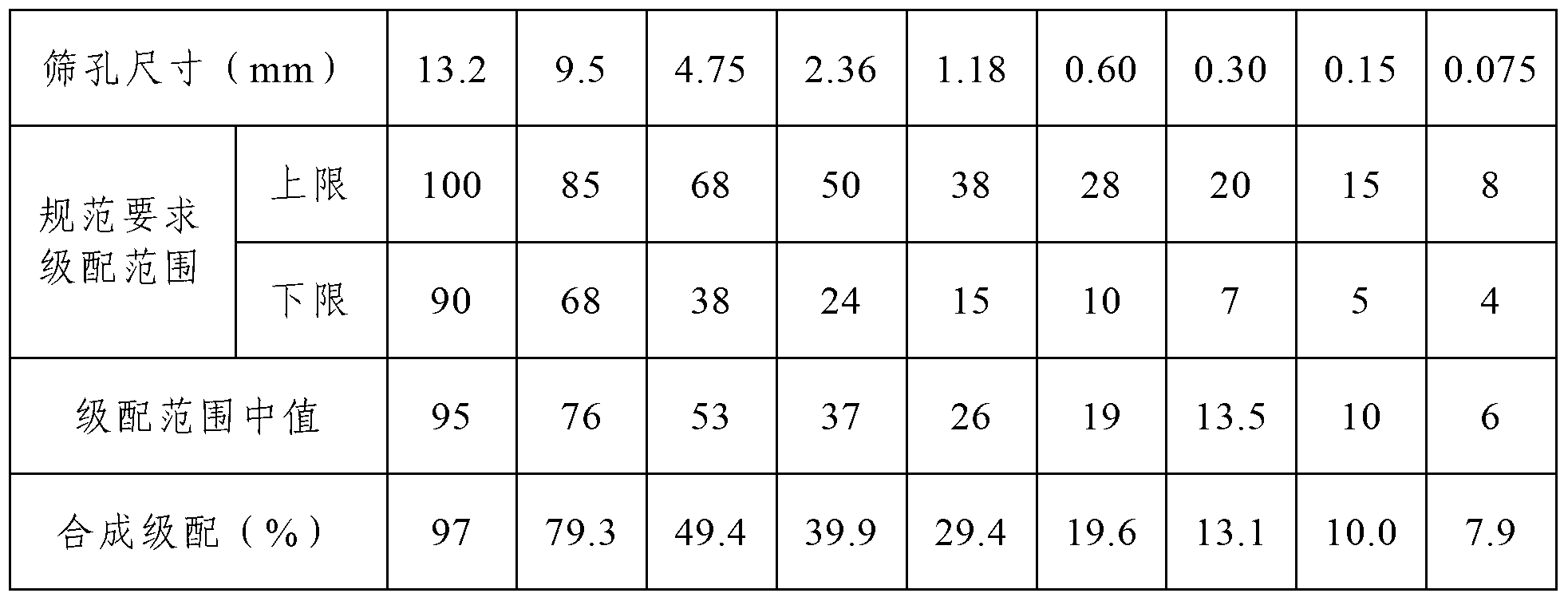

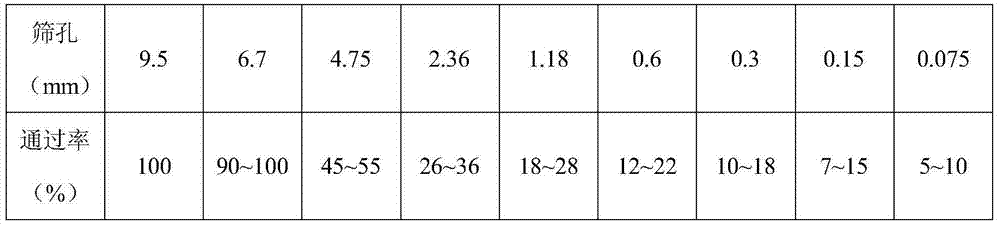

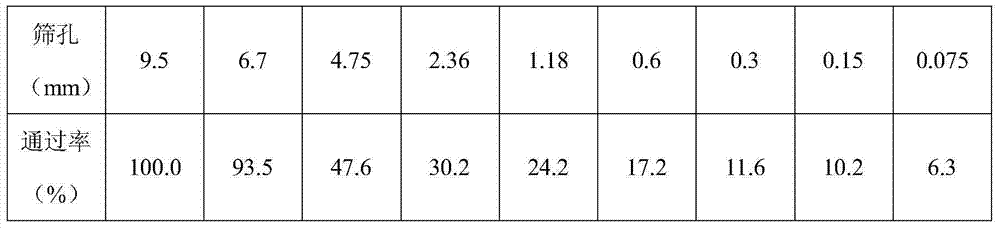

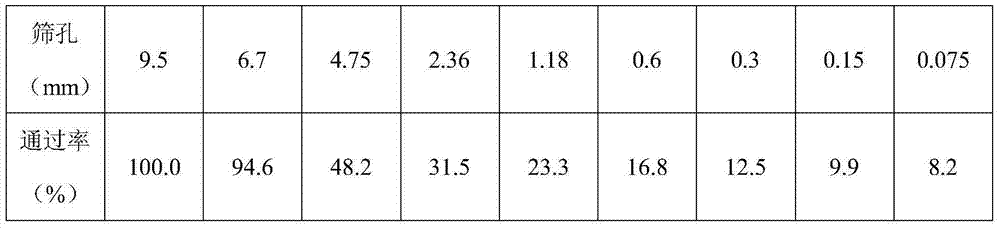

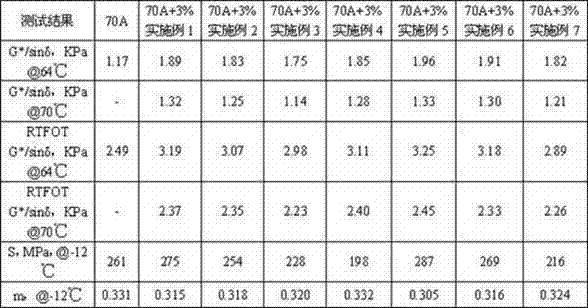

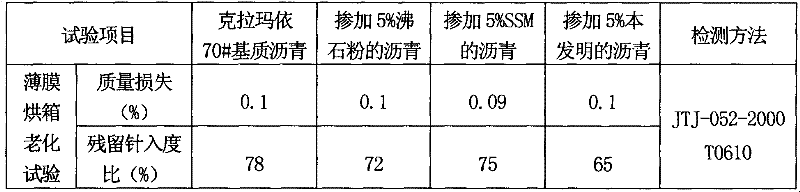

Bituminous mixture used for thin layer overlay of cement concrete pavement and preparation and construction methods of bituminous mixture

The invention discloses a bituminous mixture used for a thin layer overlay of cement concrete pavement and preparation and construction methods of the bituminous mixture. The bituminous mixture comprises mineral aggregate, bitumen, a fiber stabilizer and an additive, wherein filler in the mineral aggregate is copper tailing power. The bituminous mixture has the advantages that the copper tailing power is used as the filler in the bituminous mixture, thus copper tailing is comprehensively recycled. Besides, the bituminous mixture is superior in performances, is easily compacted, and can be paved on the cement concrete pavement for 1.5-2.5cm; the damaged pavement can be quickly repaired after construction; the smoothness and the skid resistance of the pavement are restored; the quality of the pavement is improved; the service life of the pavement is prolonged; driving comfort and safety are improved; the pavement can also be precured; the construction cost is lowered; energy and resources are saved; influences on environment and facilities are reduced; and the like. Moreover, the preparation method and the construction method of the bituminous mixture are simple and practicable, easy to operate and high in practicability.

Owner:江苏航卓建设股份有限公司

Preparation method of stone-pattern-simulating glazed brick

The invention discloses a preparation method of a stone-pattern-simulating glazed brick. The preparation method comprises the following steps of: 1) laying and accumulating colored dry particles on the surface of a blank body according to the pattern requirement with the thickness being 1-3mm; 2) after drying the blank body laid with the dry particles, burning the blank body for 90-150 minutes in a kiln at the temperature of 1150-1230 DEG C; and 3) edging and polishing the burnt brick body to obtain the stone-pattern-simulating glazed brick. The preparation method is simple in process and low in production cost; and the obtained glazed brick is strong in stereoscopic impression and vivid in stone-simulating effect, and meets the requirements of consumers better.

Owner:广东道氏陶瓷材料有限公司

Antique matte glaze with delicate texture and using method thereof

The invention discloses an antique matte glaze with delicate texture. The antique matte glaze with the delicate texture consists of a frit and raw materials, wherein the mass ratio of the frit to the raw materials is 1-1.5: 1. The invention also discloses a preparation method of the antique matte glaze with the delicate texture. The preparation method comprises the following steps of: applying a layer of base glaze on the surface of a brick blank, and applying a layer of the matte glaze; and sintering the brick blank at the temperature of 1150-1250 degrees centigrade to obtain a final product. The matte glaze provided by the invention consists of the frit with good high temperature fluidity and part of the raw materials, so that the glaze surface can flow levelly at high temperature quickly; through matching of different materials, the matte, smooth and delicate effects of the glaze surface are ensured; through the composition design of half raw material and half frit, the compositionis more stable and is applicable to different technical conditions and furnace temperatures; and the sintering temperature and the matte degree of the matte glaze are regulated by regulating the adding amount of aluminum oxide.

Owner:广东道氏陶瓷材料有限公司

Ultrahigh-alkalinity crystallizer mould flux special for high-pulling-rate peritectic steel

The invention discloses an ultrahigh-alkalinity crystallizer mould flux special for high-pulling-rate peritectic steel. 38%-42% of CaO, 25%-29% of SiO2 and 7%-10% of F- are adopted to improve the crystallization capacity of the mould flux, reduce stress concentration and improve lubrication; 2%-5% of MgO and 2%-5% of Al2O3 are adopted to improve the fluidity of a flux film and reduce cracks; an excellent heat transfer coordination and heat transfer control effect is achieved by adopting the mould flux with the alkalinity ranging from 1.35 to 1.52, 25%-29% of SiO2, 2%-5% of Al2O3 and 2%-5% of MgO; the effects of effectively controlling the melting rate to guarantee melt flux feeding and preventing subsurface blowholes can be achieved with the carbon proportioning range of 4%-7%. Raw materials for preparing the ultrahigh-alkalinity crystallizer mould flux can be easily obtained, the flux consumption ranges from 0.32 kg per ton of steel to 0.38 kg per ton of steel, and cost of per ton of steel is low; on-spot practical application indicates that the mould flux can be well spread in a crystallizer and be evenly and stably melt and is high in casting percent of pass.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Floride-free low-boron and alkaline-free glass fiber prescription and preparation method

The invention relates to a glass fiber production prescription, in particular to an environment-friendly alkaline-free glass fiber prescription emitting less toxic gas. The prescription is characterized in that the components include SiO2, Al2O3, B2O3, CaO, MgO, K2O and Na2O2. Compared with the E glass fiber widely applied presently, the glass fiber prepared with the prescription of the invention is improved as follows: the raw material containing floride which is most harmful is completely abandoned and the raw material containing volatile boron is largely reduced, but the glass fiber of the invention still remains similar electric performance and mechanical performance. The invention is characterized in that an alkaline-free glass fiber using blast furnace slag as one of the main raw materials, realizing reduction of operation difficulty and great reduction of exhaust emission is preferential and can be produced directly in large scale in a tank furnace including an electric boosting structure. The use of an industrial raw material easy for melting and clearing, namely, the blast furnace slag, ensures the glass fiber to have similar operating performance as the E glass fiber and to adapt to large-scale production under the existing E glass fiber tank furnace production technology.

Owner:TAISHAN FIBERGLASS INC

Ultralow-expansion-coefficient high-transparency microcrystalline glass and preparation method thereof

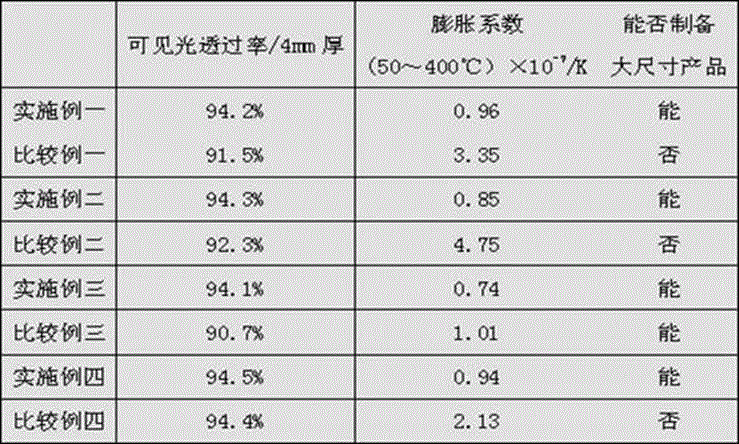

The invention discloses an ultralow-expansion-coefficient high-transparency microcrystalline glass which comprises the following components in percentage by weight: 65-69% of SiO2, 19-20% of Al2O3, 3.1-4.2% of Li2O, 3-4.5% of B2O3, 0.1-0.4% of Na2O, 0.1-0.4% of K2O, 0.3-0.5% of MgO, 0.6-1.4% of BaO, 0.6-1.4% of ZnO, 1.0-1.7% of TiO2, 1.0-1.3% of ZrO2, 0.4-0.8% of P2O5, 0.3-0.8% of F and 0.02-0.3% of CeO2. The preparation method comprises the following steps: melting glass raw materials, cooling, molding, annealing, crystallizing, and carrying out after treatment to obtain the microcrystalline glass finished product. The microcrystalline glass has the advantages of high transparency and ultralow expansion coefficient, and can be used for manufacturing large-size or complex-structure products.

Owner:虎石新材料(宜兴)有限公司

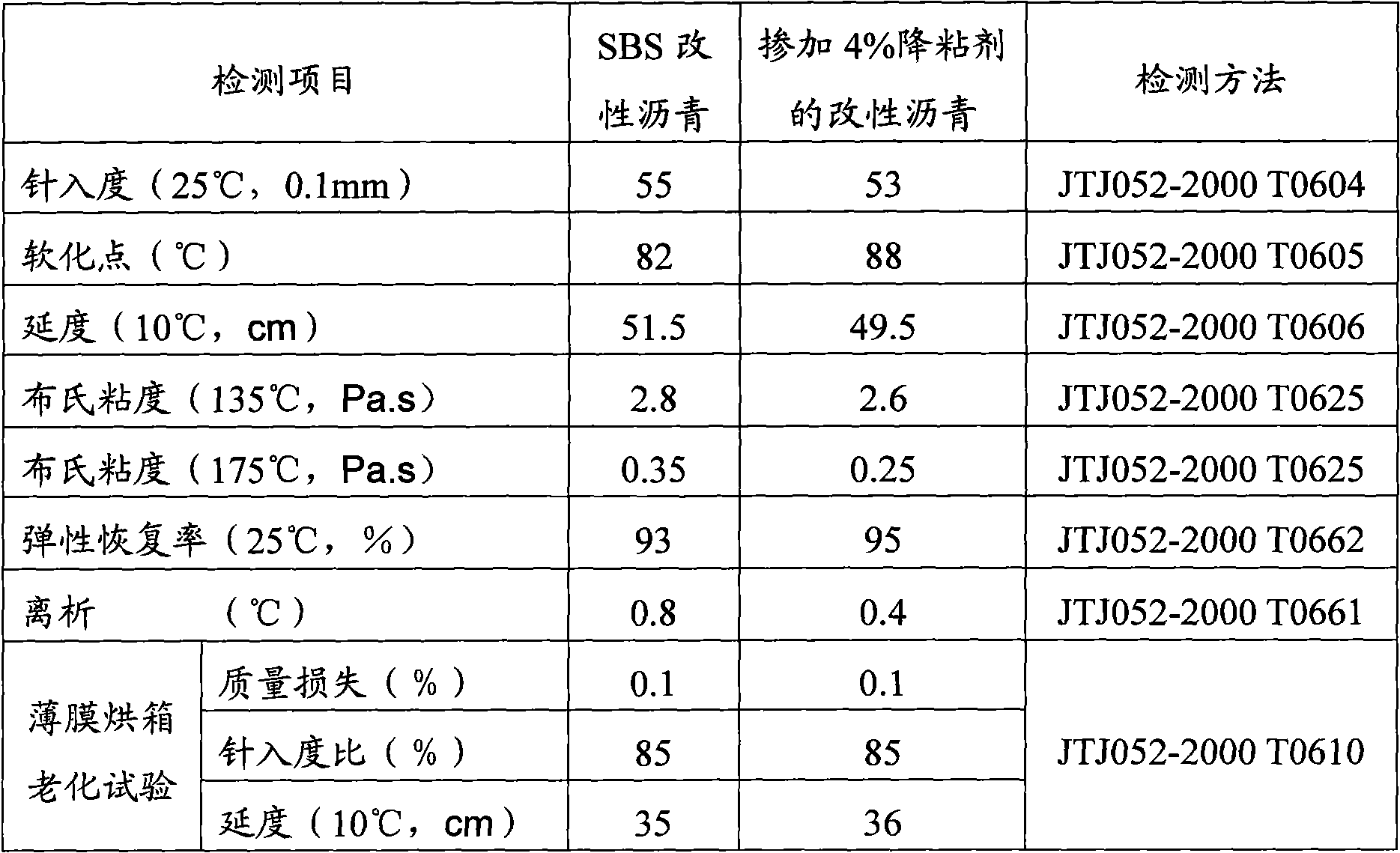

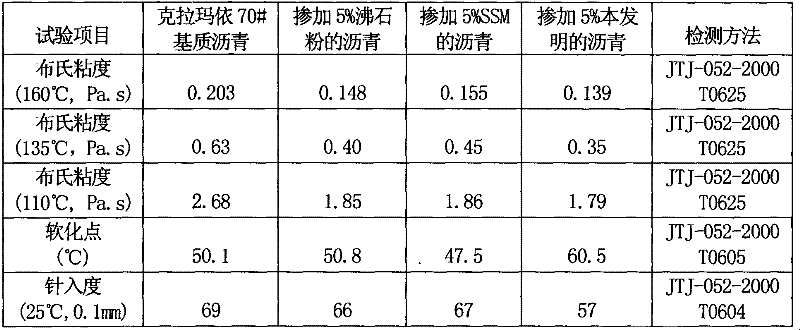

Modified asphalt viscosity decreasing agent

ActiveCN101781468AReduce high temperature viscosityImprove low temperature crack resistanceBuilding insulationsCasting typesEngineering

The invention provides a modified asphalt viscosity decreasing agent which relates to a paving material for roads, bridges and tunnels. The viscosity decreasing agent is prepared from the following components in parts by weight: 4-20 parts of organic acid, 1-30 parts of surface active agent, 5-80 parts of synthesis paraffin, and 1-30 parts of compatilizer. After the viscosity decreasing agent is doped, the high-temperature viscosity of the modified asphalt is greatly decreased, while other various indexes are not changed. Simultaneously, compared with the common modified asphalt, after the viscosity decreasing agent is doped, the concrete stirring temperature, low-temperature property and fatigue property of the casting type asphalt are greatly improved. The invention is mainly used for road petroleum asphalt and SBS modified asphalt.

Owner:重庆市智翔铺道技术工程有限公司

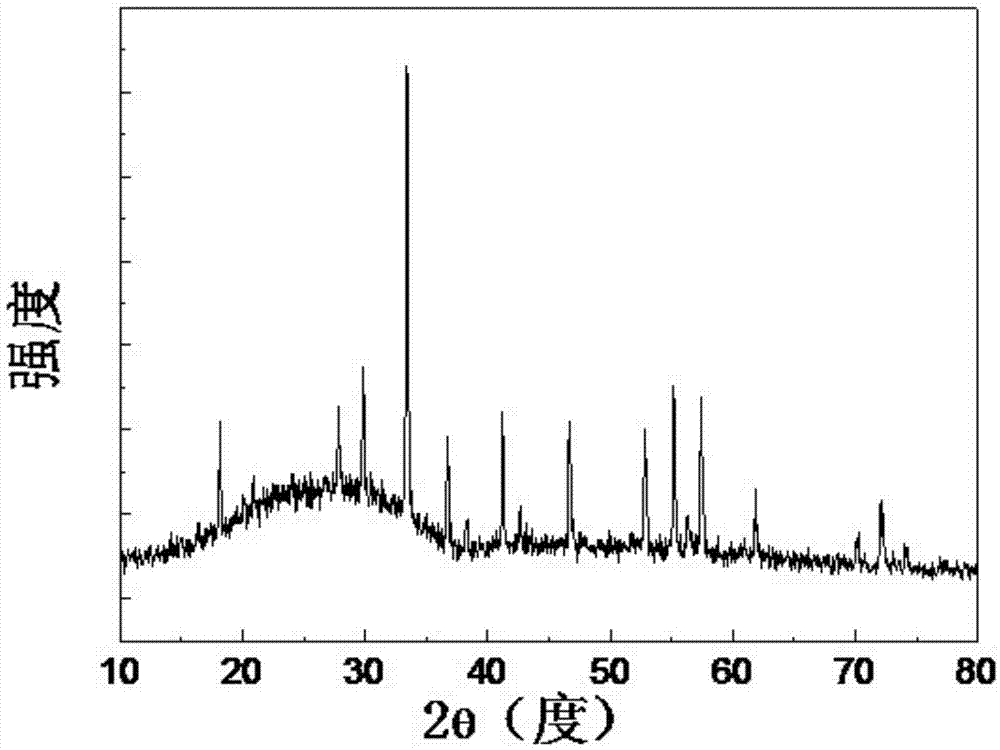

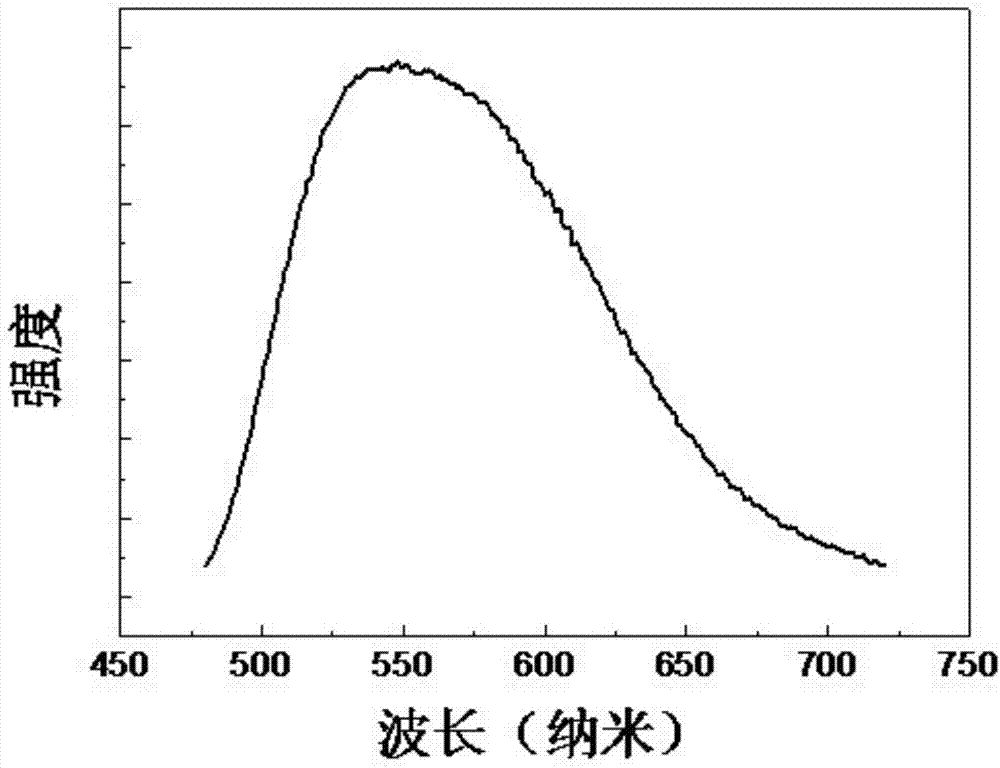

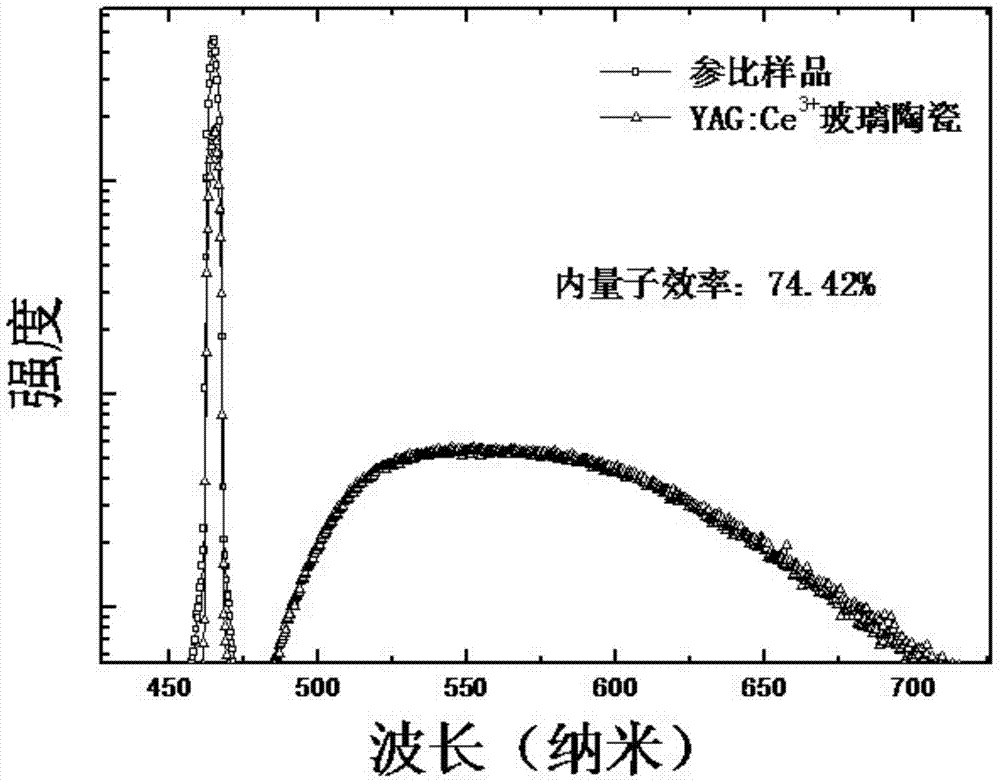

Glass ceramic for blue light-excited white-light LED (Light-Emitting Diode), and preparation method thereof

The invention discloses a glass ceramic for a blue light-excited white-light LED (Light-Emitting Diode), and a preparation method thereof. The glass ceramic is structurally characterized in that R3M5O12:Ce, R' micrometer crystallized phase is inlaid in an oxide glass substrate, wherein R is one of Y, Gd, Lu, Sc and La; M is one of Al, Ga and In; R' is one of Eu, Sm, Pr and Mn; the content of the micrometer crystallized phase accounts for 10-50wt% of the glass ceramic. The glass ceramic is prepared by adopting a melt quenching method or combining the melt quenching method with follow-up thermal treatment. The glass ceramic can be used as a fluorescent material for manufacturing a novel blue light-excited white-light LED device.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

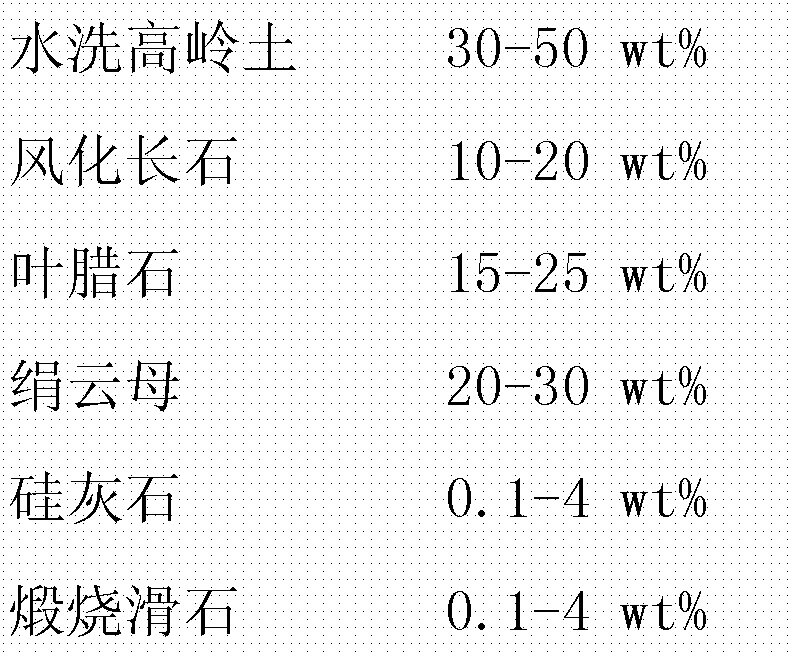

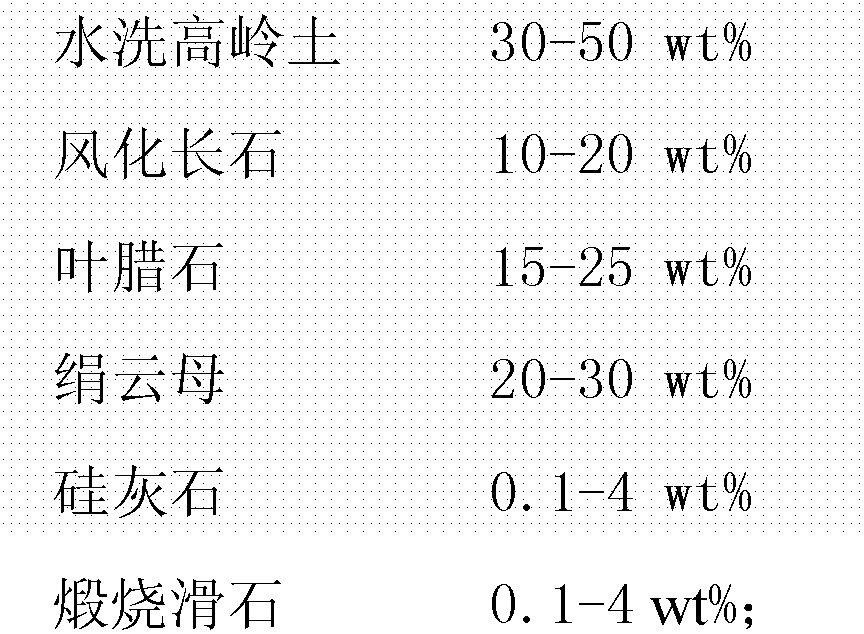

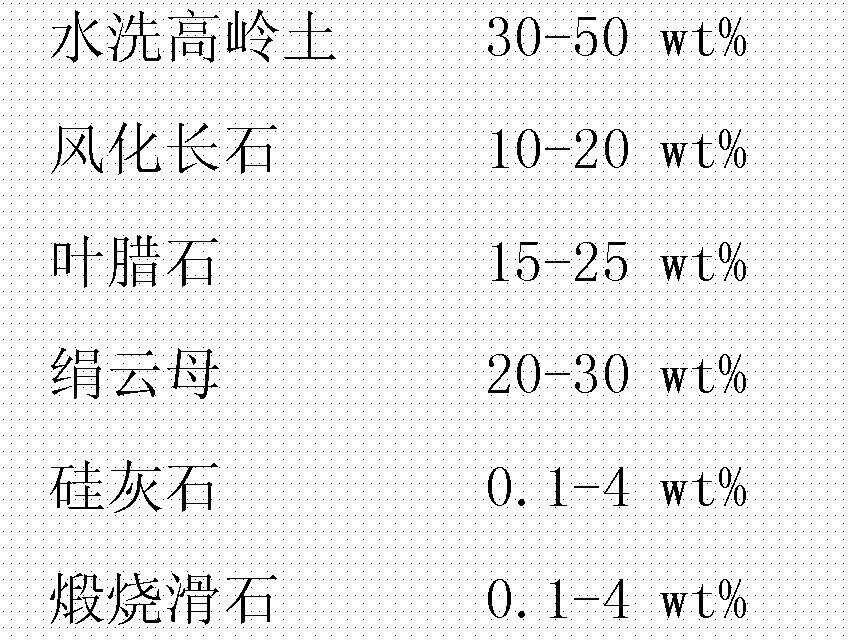

Mud for sanitary ceramics and mud preparation process

InactiveCN102603268ASmall coefficient of thermal expansionLess free quartz contentClaywaresPyrophylliteGranularity

The invention discloses mud for sanitary ceramics and a mud preparation process. The mud is mainly made of multiple raw materials and water by means of mixing and ball milling. The raw materials include 30-50wt% of water washed kaolin, 10-20wt% of weathered feldspar, 15-25wt% of pyrophyllite, 20-30wt% of sericite, 0.1-4wt% of wollastonite and 0.1-4wt% of calcined talc, and usage of water is 40-45wt% of the amount of the raw materials. The pyrophyllite, the water washed kaolin, the wollastonite and the calcined talc which have low-temperature sintering characteristics and the sericite and the weathered feldspar which have high high-temperatuare fusibility are used as the raw materials, and by means of the reasonable proportion, high-temperature components SiO2+Al2O3 of mud can be controlled within a low range, MgO, CaO,K2O and Na2O which are high in fusibility are increased, and the components with granularity smaller than 10um in the mud account for 65wt%-70wt%, so that the mud can be easily sintered. Compared with the prior art, the mud has the advantages that the mud can be formed by sintering at a low temperature (1150 DEG C), so that energy saving and consumption reduction are realized.

Owner:HUIHUANG PLUMBING GROUP

Method for manufacturing Buddhist master Jun porcelain artware

InactiveCN107586107ALower melting temperatureReduce high temperature viscosityOrnamental structuresSpecial ornamental structuresGypsumKiln

The invention discloses a method for manufacturing Buddhist master Jun porcelain artware. The method comprises the following steps: 1, sculpturing a model; 2, manufacturing molds, namely respectivelymanufacturing plaster molds of a plurality of parts sculptured in the step 1; 3, selecting clay; 4, performing pulping, namely, firstly and roughly crushing the clay selected in the step 3 into sand or powder, grinding till the fineness is 230-250 meshes, mixing with water, and performing ball milling so as to obtain a sizing agent; 5, performing slip casting; 6, drying the biscuiting; 7, performing biscuiting, namely putting a blank into a biscuiting kiln, and burning for 5-6 hours at 900-1000 DEG C; 8, performing glazing; 9, performing burning, namely putting the glazed and dried blank intoa kiln, and burning for 12-15 hours at 1280-1300 DEG C. By adopting the method, a good blank and glaze combination effect is achieved, a high finished product rate of the Jun porcelain is achieved, and the shape and the color of the Jun porcelain can relatively well embody the creative and artistic effect of the artware.

Owner:李德汉

Calcium phosphate opaque glass and method for making same

InactiveCN101182117AThe process steps are simpleReduce manufacturing costCalcium biphosphateBoron oxide

The invention discloses a manufacturing method for calcium phosphate opaque glass, which includes following steps: firstly, 70-75 portions of silicon dioxide, 0.5-2.0 portions of alumina, 8.0-12.0 portions of calcium oxide, 2.0-5.0 portions of magnesium oxide, 9.8-15.0 portions of sodium oxide, 1-3 portions of phosphorus pentoxide, 0.1-0.2 portions of boron oxide and 0.1-0.5 portions of calcium nitrate are evenly mixed into raw material; secondly, the raw material is melted and clarified and is stretched into forming through squeezing to obtain raw glass; thirdly, the heat treatment of opacifying is implemented on the raw glass, whish is then cooled to be at the normal temperature, and the polishing and the cutting forming are implemented successively to obtain the calcium phosphate opaque glass. The invention also provides the calcium phosphate opaque glass, which is made according to the preparation method. The calcium phosphate opaque glass of the invention has the advantage of perfect opaque effect.

Owner:ZHEJIANG UNIV

Environment-friendly asphalt mixture warm mix modifier and preparation method thereof

InactiveCN103923473AGood effectReduce the temperatureClimate change adaptationBuilding insulationsPlasticizerSURFACTANT BLEND

Belonging to the field of road materials, the invention in particular relates to an environment-friendly asphalt mixture warm mix modifier and a preparation method thereof. The modifier comprises the following components by weight: 100 parts of polyethylene wax, 20-40 parts of an organic lubricant, 10-30 parts of a lubricating surfactant, and 3-10 parts of a plasticizer. The preparation method includes: subjecting the polyethylene wax, the organic lubricant, the lubricating surfactant and the plasticizer to heating melting at 130-150DEG C, mixing them evenly, conducting extrusion by a screw extruder, carrying out cooling under normal temperature, and cutting the product into particles. The warm mix modifier provided by the invention is environment-friendly, energy-saving and emission reducing, can effectively lower the mixing temperature of the asphalt mixture by 20-40DEG C, enhance the adhesion performance between asphalt cement and aggregate, improve the anti-water damage performance of the warm mix asphalt mixture, and strengthen the rutting resistance and low temperature resistance of the warm mix asphalt mixture.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

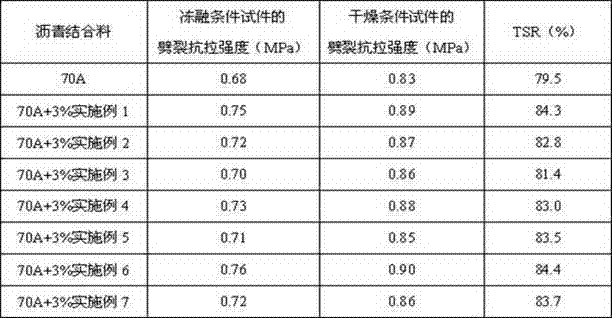

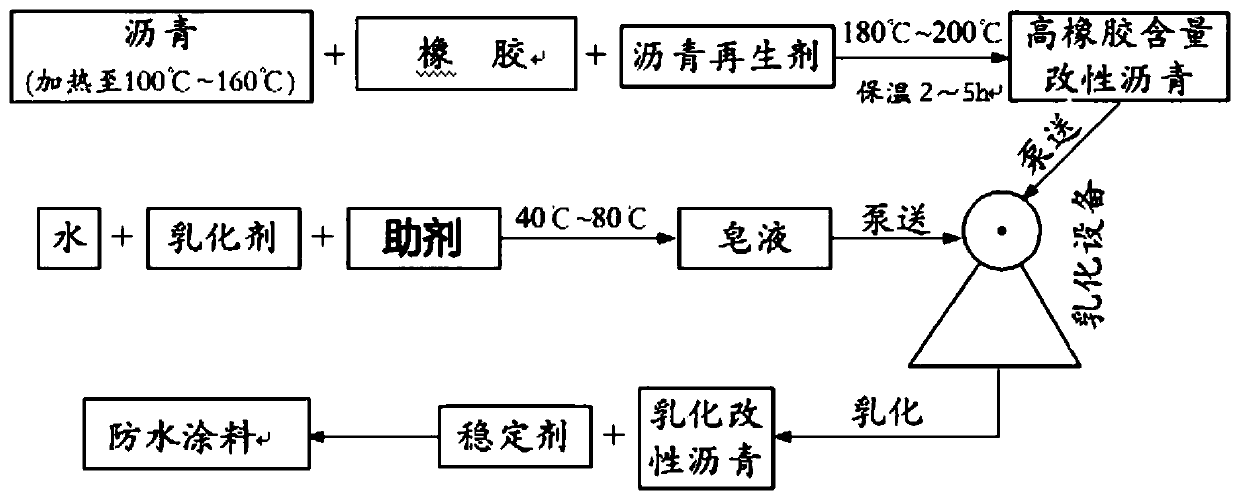

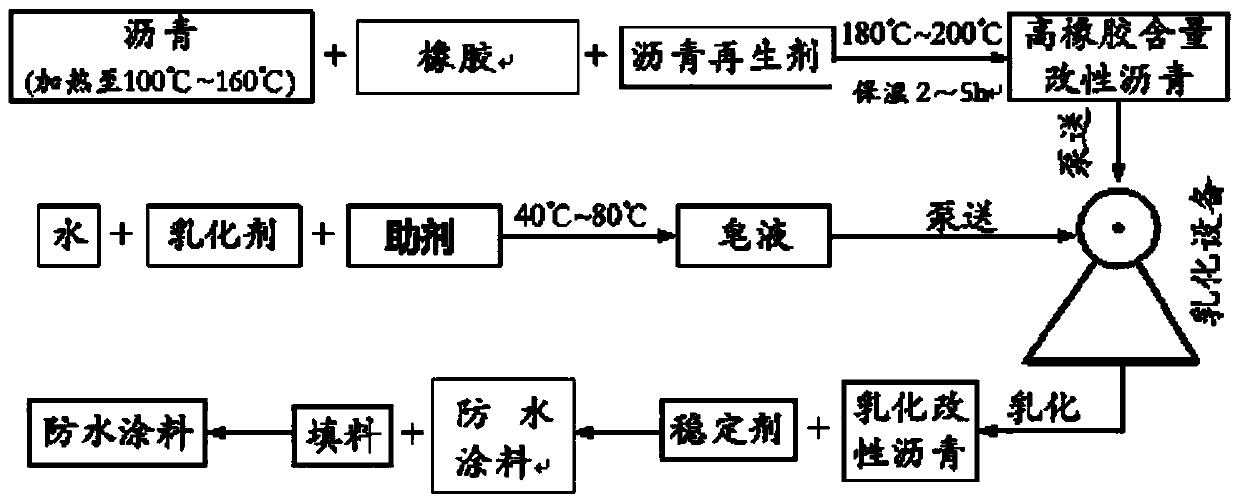

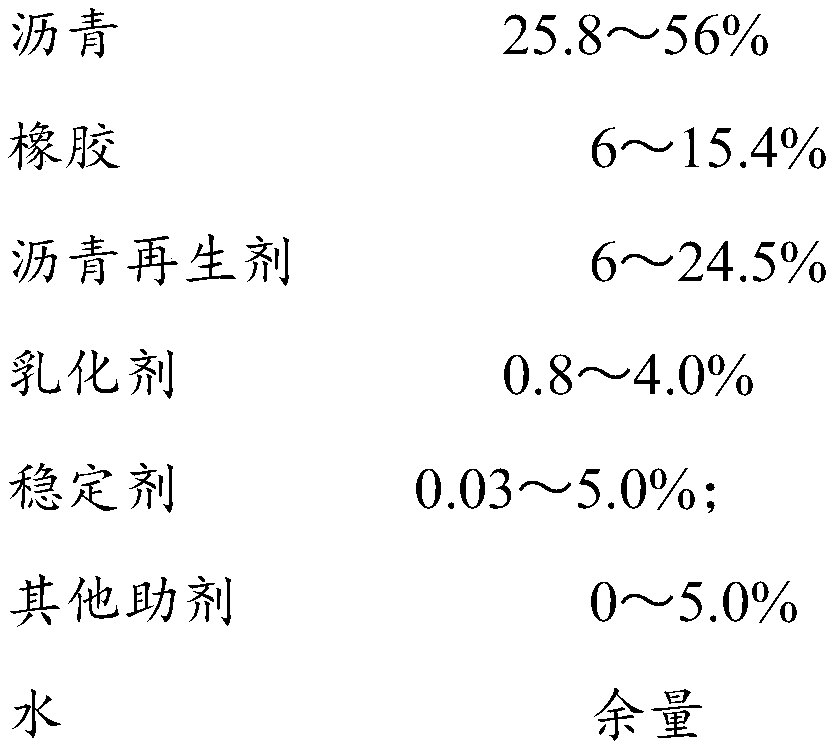

Rubber modified asphalt waterproof coating material, preparation method and uses thereof

InactiveCN110128945AReduce high temperature viscosityReduce the difficulty of emulsificationRoof covering using flexible materialsProtective foundationMaterials preparationPolymer science

The invention discloses a rubber modified asphalt waterproof coating material, which is prepared by mixing the following components: asphalt, rubber, an asphalt regenerant, an emulsifier, a stabilizer, water and other auxiliary agents. The invention further discloses a preparation method and applications of the rubber modified asphalt waterproof coating material. According to the present invention, in the rubber modified asphalt waterproof coating material preparation process, by using the asphalt regenerant, the added rubber can be fully fused with the asphalt, such that the modified asphaltwith high rubber content cannot segregate, and the asphalt regenerant can greatly reduce the high-temperature viscosity of the modified asphalt so as to reduce the emulsification difficulty of the modified asphalt with high rubber content; by using the preparation process comprising secondary pH value adjustment, the high solid content emulsified product can be prepared in the case of the low emulsifier adding amount; and by adding the stabilizer to the product of the invention, the occurrence of demulsification can be avoided so as to ensure the storage stability of the product at a later stage.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Medium-temperature high-white zirconium-lithium slurry opaque glaze and production method thereof

The invention relates to a medium-temperature high-white-zirconium-lithium raw opalescent glaze and a production method thereof. The invention belongs to an opalescent glaze used for a ceramic product and a production method thereof. The invention mainly solves the technical difficulties of the prior opalescent glaze that the price is price; the cost is high; the fault of raw glaze surface can be easily produced; the color of the glaze surface is easily changed. A technical proposal adopted by the invention is the medium-temperature high-white-zirconium-lithium raw opalescent glaze which consists of feldspar, quartz, calcite, lithia porcelain, zircon powder, fluorite, talc, kaolin, trimeric sodium phosphate and additive, wherein, the weight percentages are 35 percent to 40 percent of feldspar, 10 percent to 15 percent of quartz, 5 percent to 10 percent of calcite, 12 percent to 15 percent of lithia porcelain, 10 percent to 15 percent of zircon powder, 1 percent to 2 percent of fluorite, 5 percent to 10 percent of the talc, 5 percent to 10 percent of kaolin, 0.1 percent to 0.2 percent of the trimeric sodium phosphate and 0.1 percent to 0.25 percent of additive. The production method of the invention consists of the steps as follows: firstly, the raw materials are washed and picked; secondly, the glaze materials are proportioned according to the weight percentages; thirdly, the glaze materials are processed for wet ball milling; fourthly, when the glaze materials is out from a mill, the glaze materials are processed for removing iron and sieving by strong magnet.

Owner:阳城县侨枫瓷业有限公司

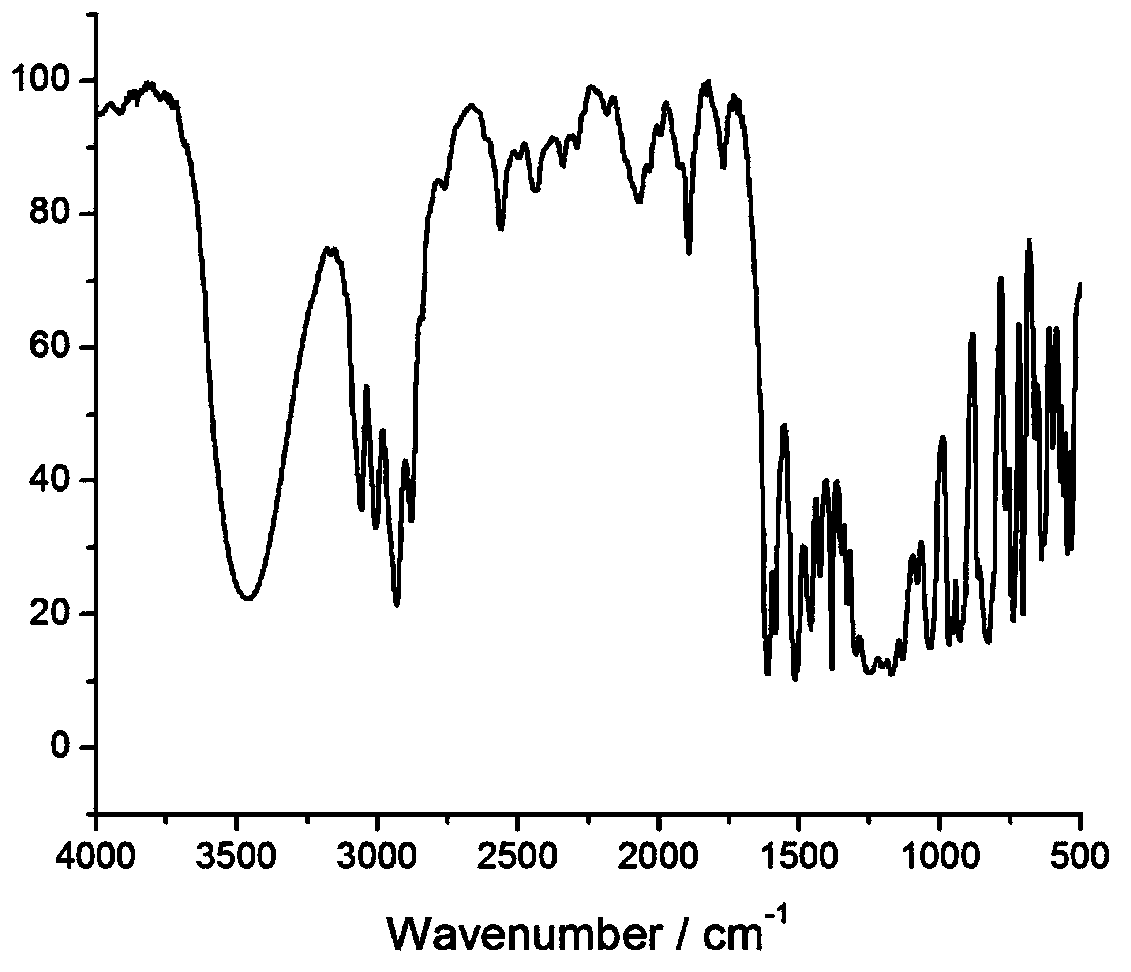

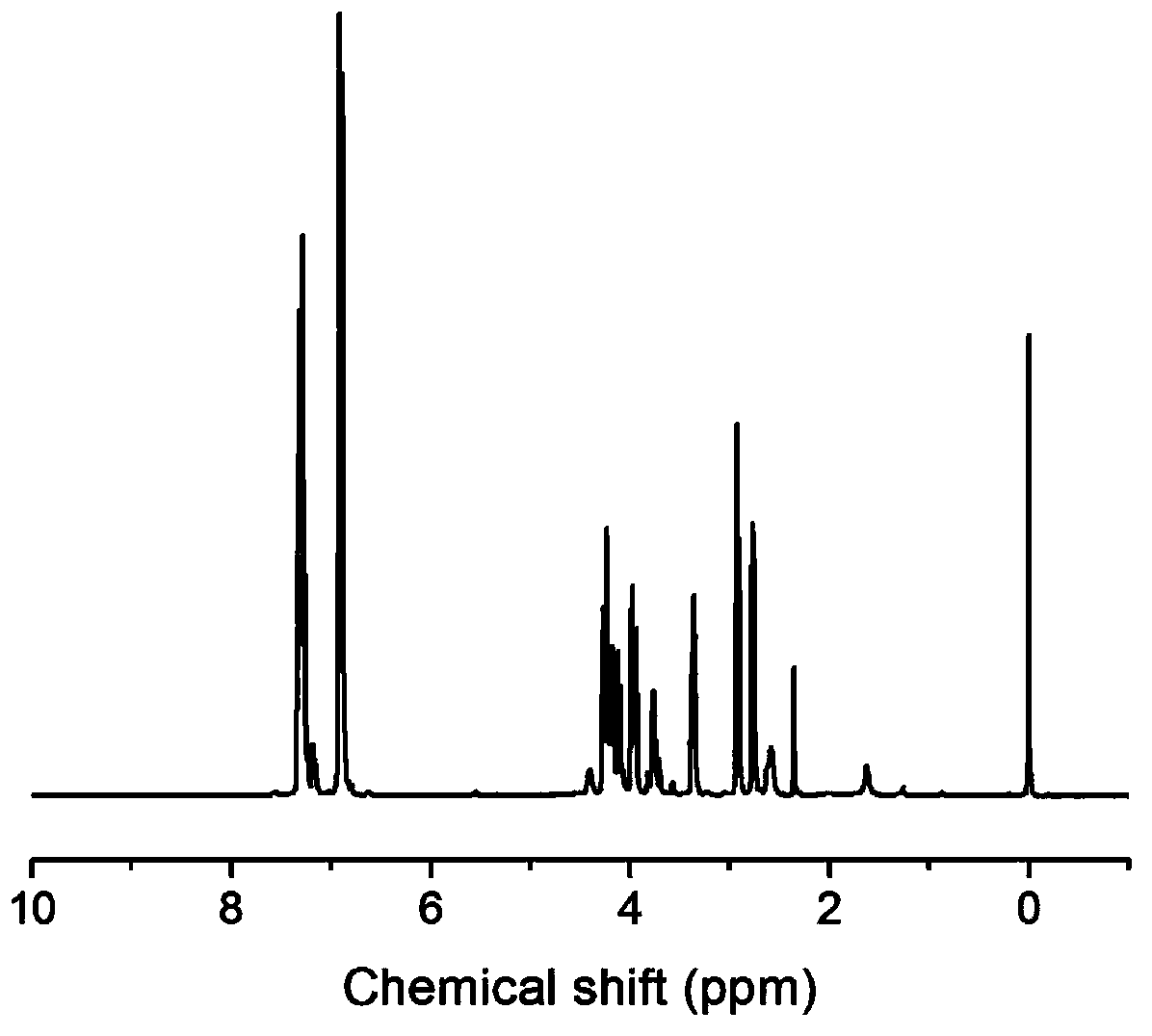

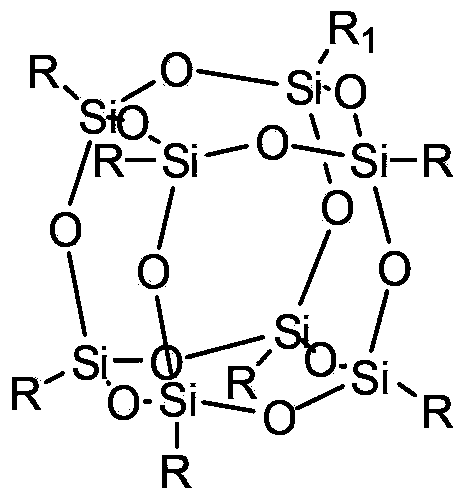

Environment-friendly fluorine/silicon-containing heavy anticorrosive epoxy resin paint and preparation method thereof

ActiveCN103450725AImprove amphiphobiaImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsWeather resistanceReactive diluent

The invention relates to an anticorrosive paint and a preparation method thereof, particularly an environment-friendly fluorine / silicon-containing heavy anticorrosive epoxy resin paint and a preparation method thereof. The paint is composed of 30-70g of fluorine-containing epoxy resin, 10-40g of curing agent, 0.1-5g of POSS (polyhedral oligomeric silsesquioxane), 0.5-5g of silane coupling agent, 10-30g of reactive diluent, 0.5-3g of dispersant and 0.1-3g of photostabilizer. The paint provided by the invention has the advantages of high fluorine content, favorable adhesion to the substrate, simple construction technique, excellent corrosion resistance and excellent weather resistance, and is especially suitable for an anticorrosive coating under harsh conditions. The paint uses the reactive diluent capable of participating in curing reaction as the solvent instead of the organic volatile solvent component, and thus, has an environment-friendly function, thereby having great popularization and application value.

Owner:XIAMEN UNIV

Glass protection lubricant powder used for titanium alloy die forging forming and paint

InactiveCN105132103AWide temperature rangeNo flowCoatingsLubricant compositionCelluloseWater soluble

The invention belongs to the technical field of paint, and relates to glass protection lubricant powder used for titanium alloy die forging forming and paint. The glass protection lubricant powder comprises silicon dioxide (SiO2), sodium oxide (Na2O), calcium oxide (CaO) and boric oxide (B2O3). Brush coating is conducted through suspension prepared from heat-resistant type water-soluble cellulose and water, wherein the grain size of glass powder is 200 meshes or below. The use temperature range of the glass protection lubricant is wide and is between 700 DEG C and 1000 DEG C, melting begins at the temperature of 700 DEG C, and no flowing happens at the temperature of 1000 DEG C. the forging process temperature of titanium alloy is 945+ / -15 DEG C. The high temperature viscosity change range of the glass protection lubricant is narrow, and melting coverage can be achieved within the short time of 8 minutes or less. The flowing and protection deficiency phenomena do not happen within the heat preservation time of 8 hours. In addition, the high-temperature contact angle of the prepared glass protection lubricant on the surface of TC4 titanium alloy is small, the temperature is 40 degrees lower than the temperature of 945+ / -15 DEG C, and in other words, the titanium alloy surface wettability is good. The friction coefficient measured through a circular ring test is lower than 0.01.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

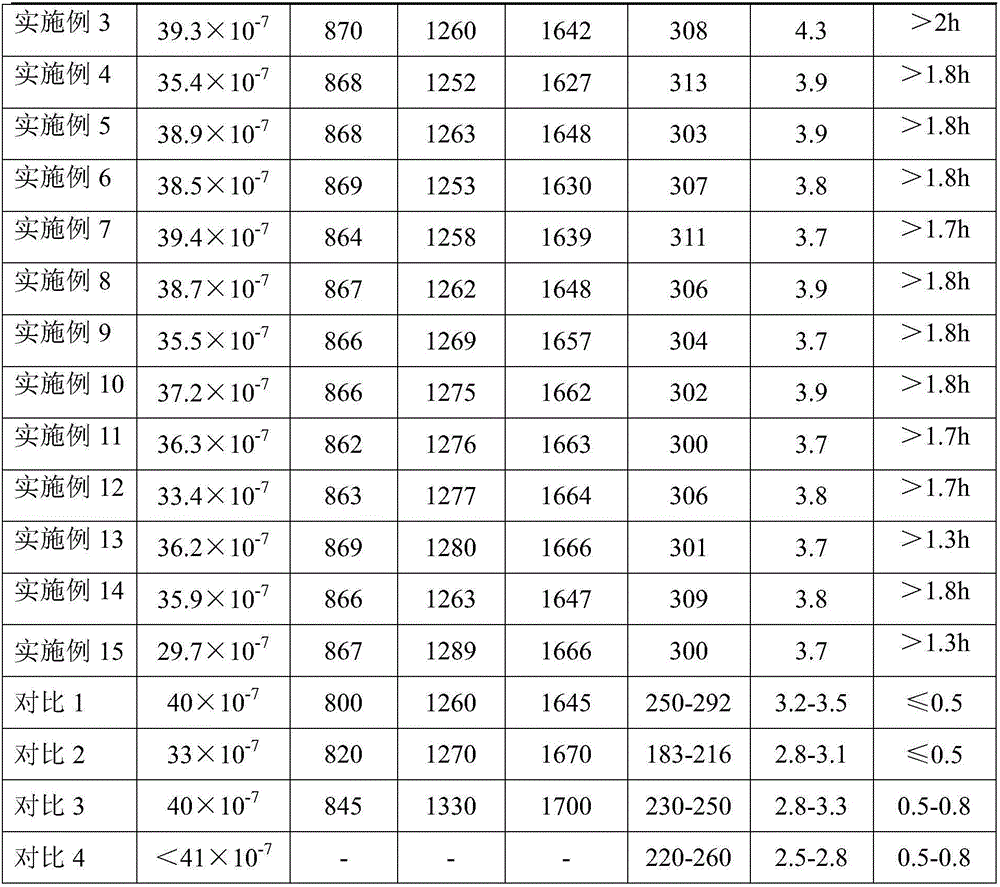

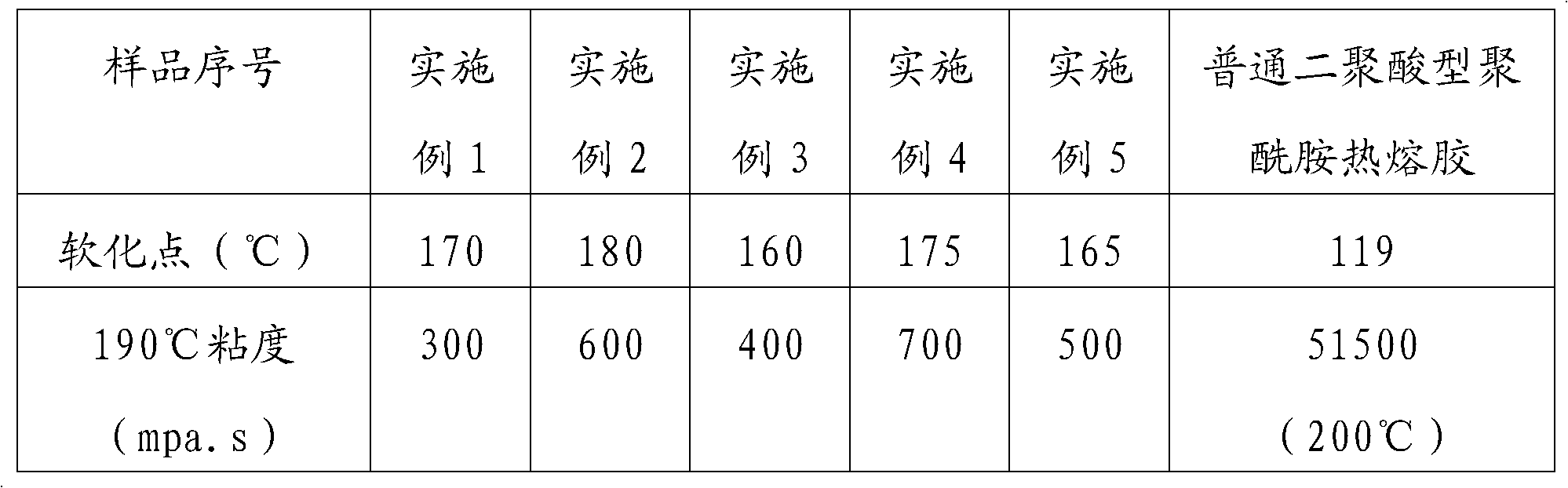

Preparation method for polyester amide hot melt adhesive

InactiveCN106750330AReduce high temperature viscosityEasy to shapeAdhesivesPolymer scienceAntioxidant

The invention relates to a preparation method for a polyester amide hot melt adhesive. The preparation method includes the steps of: 1) adding a binary acid, a binary amine, a catalyst, and an antioxidant into a reactor, and stirring and heating the mixture under protection of nitrogen gas; 2) slowly increasing the temperature to 220-280 DEG C, and meanwhile continuously evaporating water generated in a reaction during the temperature increase, and performing the reaction for 1-3 h to obtain a polyamide prepolymer; and 3) adding polyether glycol or polyester glycol and performing a reaction for 1-5 h, vacuum-dehydrating the products for 1-3 h, and discharging the products under protection of nitrogen gas to prepare the polyester amide hot melt adhesive. The polyester amide hot melt adhesive has excellent high- and low-temperature resistance and mechanical performance, has high adhesion force on various substrates, is environment-friendly and solvent-free, and can be widely applied in the fields of automobiles and electronics.

Owner:YANTAI DARBOND TECH

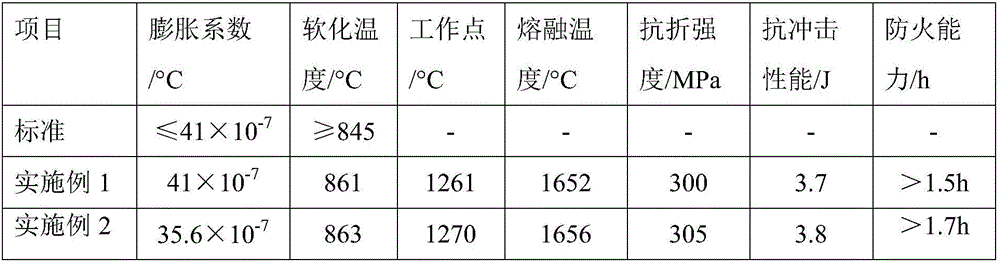

Heat-resistant borosilicate flat glass and preparation method thereof

ActiveCN106587604AEffective control of air bubblesEffective control of striaeFlat glassFire protection

The invention provides heat-resistant borosilicate flat glass and belongs to the technical field of fireproof glass. The heat-resistant borosilicate flat glass is prepared from, by weight, 78.1-82% of SiO2, 1-5% of Al2O3, 9-14% of B2O3, 3-6% of Na2O, 1-5% of CaO, 0.5-2% of K2O, 0.1-3% of ZrO2 and 0.01-2% of GeO2, wherein the total content of SiO2 and B2O3 accounts for 87.1-92% of the total content of all the materials, and the weight ratio of SiO2 to B2O3 is 5.5 to 8.6. The invention further provides a preparation method of the heat-resistant borosilicate flat glass; compared with current borosilicate flat glass in the market, the heat-resistant borosilicate flat glass has a higher glass softening point and a lower linear expansion coefficient, at the same time, the melting temperature and the molding temperature are relatively low; the glass is easy to manufacture and can serve as the fireproof glass applied in the fire protection field after being tempered.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

Copolyamide hot melt adhesive and its preparation method

ActiveCN102443374AReduce high temperature viscosityEasy to shapeNon-macromolecular adhesive additivesDiamineSolvent

The invention relates to a copolyamide hot melt adhesive and its preparation method. The copolyamide hot melt adhesive is composed of diacid, aliphatic diamine and an antioxidant. The preparation method comprises the following concrete steps of: (1) adding dimeric acid, aliphatic dibasic acid and the antioxidant into a reactor, stirring and heating under the protection of nitrogen, adding aliphatic diamine with continuously stirring, and reacting for 1-5 hours; (2) slowly heating up to the temperature of 220-280 DEG C while continuously steaming out water generated from the reaction, insulating, reacting for 1-3 hours and maintaining for 1-5 hours, and finally discharging under the protection of nitrogen to obtain the copolyamide hot melt adhesive. The copolyamide hot melt adhesive has low high-temperature viscosity, is easy to mold, has good high and low temperature resistance and mechanical properties, has low water absorption, is environmentally friendly and solvent-free, and can be widely applied in automobile electronic industry.

Owner:YANTAI DARBOND TECH

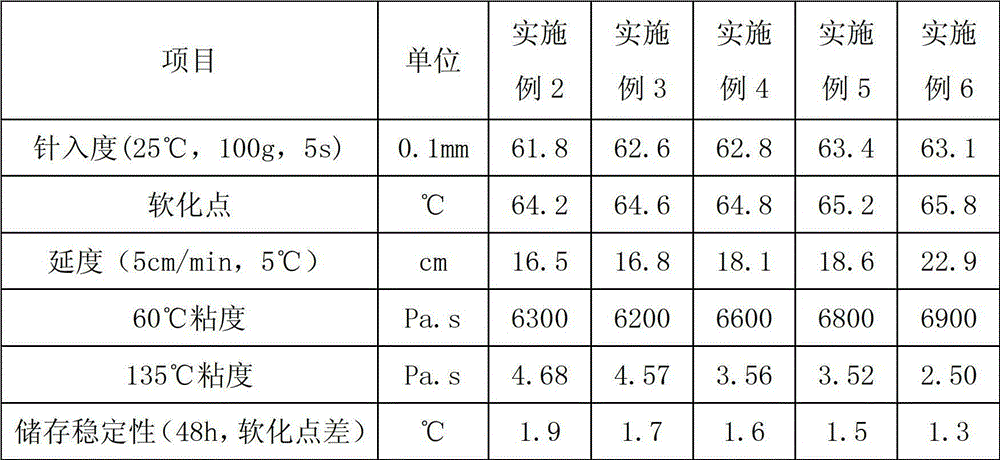

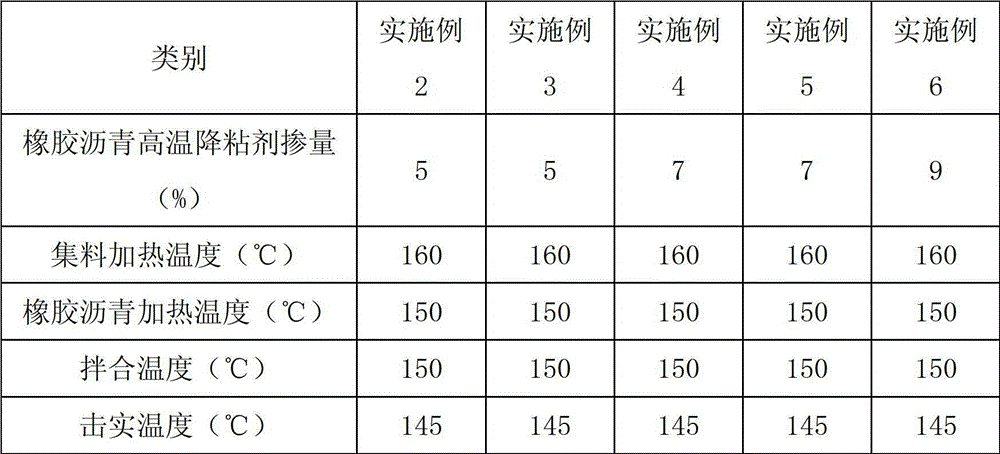

Rubber asphalt high temperature viscosity reducer, preparation method and application thereof

ActiveCN102942794AGood storage stabilityDelay agingClimate change adaptationBuilding insulationsWaxPolymer science

The invention discloses a rubber asphalt high temperature viscosity reducer, a preparation method and an application thereof. The rubber asphalt high temperature viscosity reducer is prepared by raw materials of, by mass, 100 parts of oxidized polyethlene wax, 5-40 parts of higher fatty acid and 10-50 parts of metal hydroxide. The rubber asphalt high temperature viscosity reducer is simple in preparation process, convenient to use and capable of reducing high temperature viscosities of ordinary rubber asphalt and modified rubber asphalt and reducing rubber asphalt intermolecular surface tension so that mixing temperatures of rubber asphalt mixtures are reduced, and purposes of reducing energy consumption and protecting environment are achieved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Modified asphalt viscosity reducer and preparation method thereof

InactiveCN105062102AHigh softening pointHigh strengthBuilding insulationsPolymer sciencePolyvinyl alcohol

The invention provides a modified asphalt viscosity reducer and a preparation method thereof. The modified asphalt viscosity reducer is prepared by: subjecting, by weight part, 10-30 parts of aliphatic amide, 5-15 parts of zeolite powder, 3-20 parts of a high polymer additive, and 18-40 parts of a low molecular weight additive to mechanical stirring at 60-100DEG C for 20-30min. Specifically, the aliphatic amide is octadecanamide with a melting point of 96-101DEG C, the high polymer additive is polypropylene oxide, phenolic resin or polyvinyl alcohol, and the low molecular weight additive is Tween 80, Span 80 or fatty alcohol-polyoxyethylene ether. The viscosity reducer can reduce the high temperature viscosity of asphalt, improve the asphalt softening point, prevent modified asphalt aging, and can save the energy for heating mixing of asphalt and reduce harmful gas emission.

Owner:天津天合建岭路桥工程科技有限公司

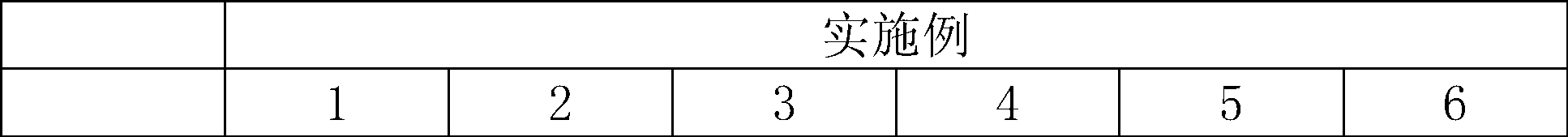

Energy-saving and environment-friendly glass

The invention discloses energy-saving and environment-friendly glass. The energy-saving and environment-friendly glass is manufactured by the following components of, by weight, 50-70% of SiO2, 5-12% of Na2O, 2-8% of K2O, 4-10% of CaO, 5-16% of B2O3, 0.1-1% of Al2O3, 0.1-1% of Fe2O3, 0.5-1.5% of CeO2 and 0.3-1.5% of SnCl2. In a formula of the glass, Na2O and K2O are used as co-solvents, so that high temperature viscosity of the glass is reduced; and the produced glass has high quality. In the formula of the glass, a proper amount of Fe2O3 and SnCl2 is added, so that the glass has very good effects of absorbing ultraviolet rays and infrared rays and preventing radiation. Components of B2O3 and Al2O3 in the formula can well improve stability of the glass structure and realize high transmittance of the glass.

Owner:潘慧敏

Sintered flux for submerged-arc welding of steel structure U-shaped rib plate

ActiveCN105945453AImprove bindingNo crackArc welding apparatusWelding/cutting media/materialsSubmerged arc weldingMetallurgy

The invention discloses sintered flux for submerged-arc welding of a steel structure U-shaped rib plate. The sintered flux comprises, by mass percent, 15%-25% of MgO, 3%-8% of CaO, 15%-25% of CaF2, 2%-5% of MnO, 25%-35% of Al2O3, 10%-20% of SiO2, 3%-7% of TiO2 and 1%-3% of SiFe. According to the sintered flux, the welding speed can be increased, the stable fusion depth can be provided in the high-speed welding state, and welding forming is attractive.

Owner:武汉天高熔接股份有限公司

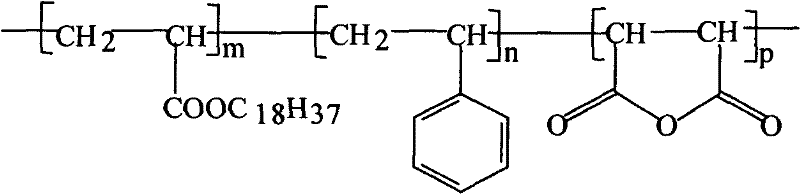

Warm mix asphalt viscosity breaking agent

InactiveCN102408733AReduce high temperature viscosityHigh softening pointClimate change adaptationBuilding insulationsStyrene-maleic anhydride copolymerViscosity

A warm mix asphalt viscosity breaking agent is prepared by mixing an octadecyl acrylate-styrene-maleic anhydride copolymer with zeolite powder in a mass ratio of 1: 0.5-3. The warm mix asphalt viscosity breaking agent provided in the invention is capable of reducing the high temperature viscosity of asphalt, increasing the softening point of asphalt, reducing the ageing of an asphalt mixture and effectively improving the cold cracking and long-term fatigue properties of the asphalt material; and the warm mix asphalt is capable of saving the energy source for warm mixing of asphalt and reducing the mission of harmful gases.

Owner:CHANGAN UNIV

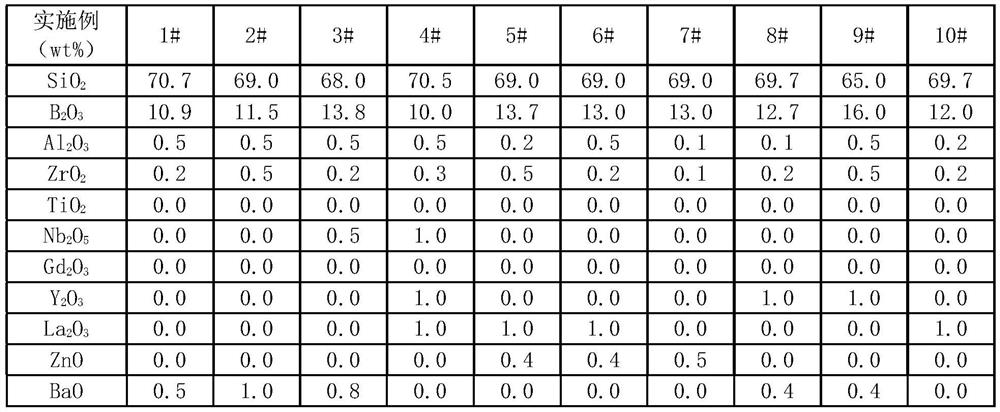

Optical glass and optical element

ActiveCN112028475AReduce high temperature viscosityImprove inner qualityNitrogen oxidesRefractive index

The invention provides optical glass with a refractive index of 1.50-1.56, an Abbe number of 57-67 and low high-temperature viscosity. The optical glass comprises the following components in percentage by weight: 50-80% of SiO2, 3-20% of B2O3, 5-25% of Li2O, Na2O and K2O, and 0.05-5% of Al2O3 and ZrO2, and the ratio of (Li2O+Na2O+ K2O+ B2O3) / (SiO2+Al2O3) ranges from 0.2 to 0.8. Through reasonablecomponent design, the obtained optical glass has the advantages of expected refractive index and Abbe number, low high-temperature viscosity, excellent internal quality and light transmittance, low raw material cost, low production energy consumption, low unit nitrogen oxide emission and good process performance, and can meet the requirements of a one-time dropping molding process; and the opticalglass can be applied to the fields of high-precision imaging-level vehicle-mounted headlamp lens manufacturing and the like.

Owner:CDGM OPTICAL GLASS

Jun-porcelain wood burning glaze

The invention relates to a jun-porcelain wood burning glaze. The glaze is prepared from, by weight, 28-35 parts of quartz, 19-23 parts of potassium feldspar, 7-12 parts of albite, 15-18 parts of plant ash, 10-15 parts of limestone, 3-4 parts of talc and 1-2 parts of ferric oxide. The purposes of making the glaze surface of prepared jun porcelain cyan, making the glaze color uniform and mild and making the glaze surface slightly yellow can be achieved, and the jun-porcelain wood burning glaze has the advantages of being low in cost and high in rate of finished products.

Owner:温书强

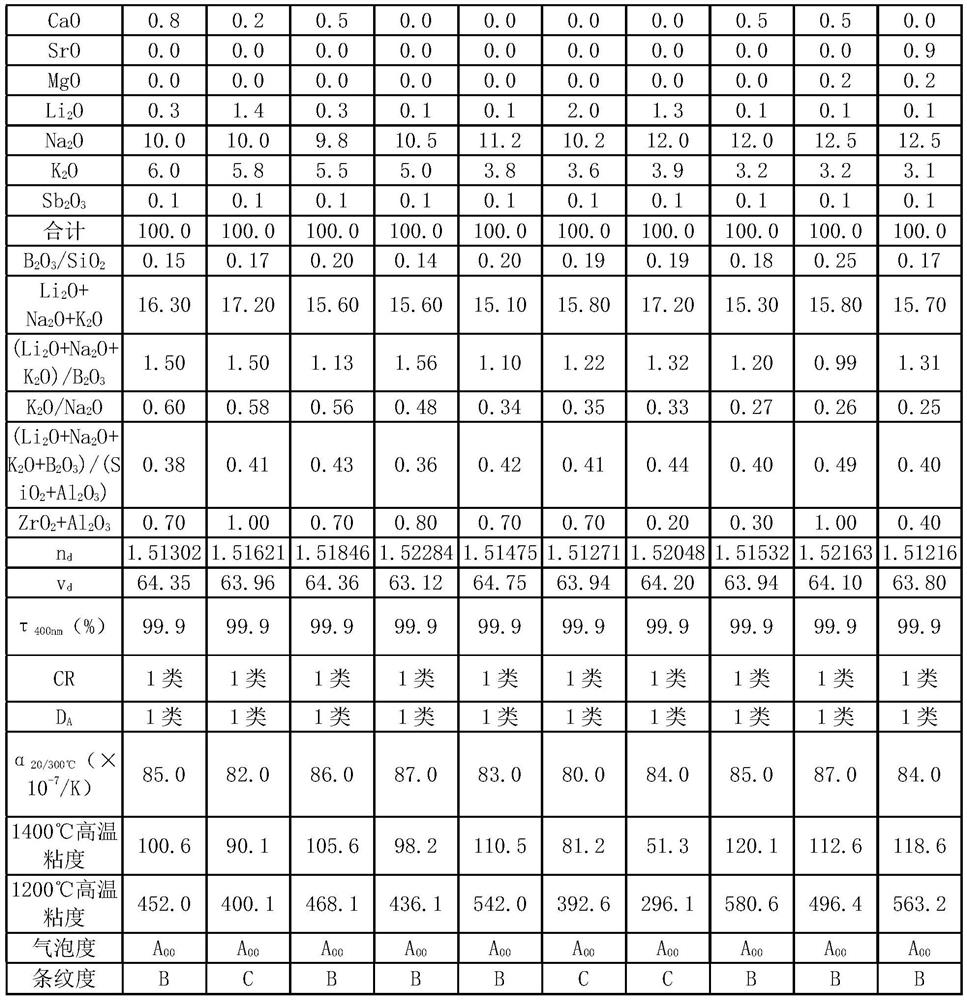

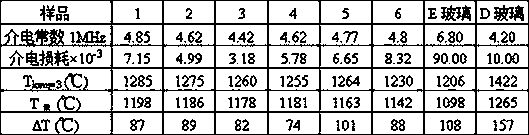

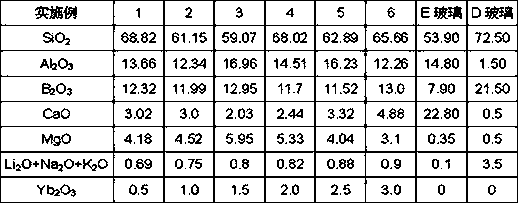

Yb2O3-doped fluorine-free low-dielectric constant glass fiber and preparation method thereof

InactiveCN110451811AExcellent dielectric propertiesReduce high temperature viscosityGlass furnace apparatusGlass fiberFiber

The invention provides Yb2O3-doped fluorine-free low-dielectric constant glass fiber and a preparation method thereof. The dielectric constant and dielectric loss of glass fiber are reduced through addition of rare earth oxide Yb2O3. The glass fiber composition does not contain the fluorine element at all, so that the environment is protected to a large extent. The glass fiber comprises the components: in percent by mole, 55-75% of SiO2, 5-20% of Al2O3, 7-15% of B2O3, 0-8% of CaO + MgO, 0.1-1% of Li2O + Na2O + K2O and 0.1-7% of Yb2O3. The dielectric constant and dielectric loss of the preparedglass fiber can reach a good level, the dielectric constant and dielectric loss at room temperature and 1 MHz are 4.4-4.97 and 3.1x10<-3)-8.45x10<-3> separately, and the glass fiber has excellent lowdielectric properties, good thermal stability and a wide molding temperature range at the same time, and is suitable for a reinforcing material for substrates for printed circuit boards.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com