Patents

Literature

161results about How to "No flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

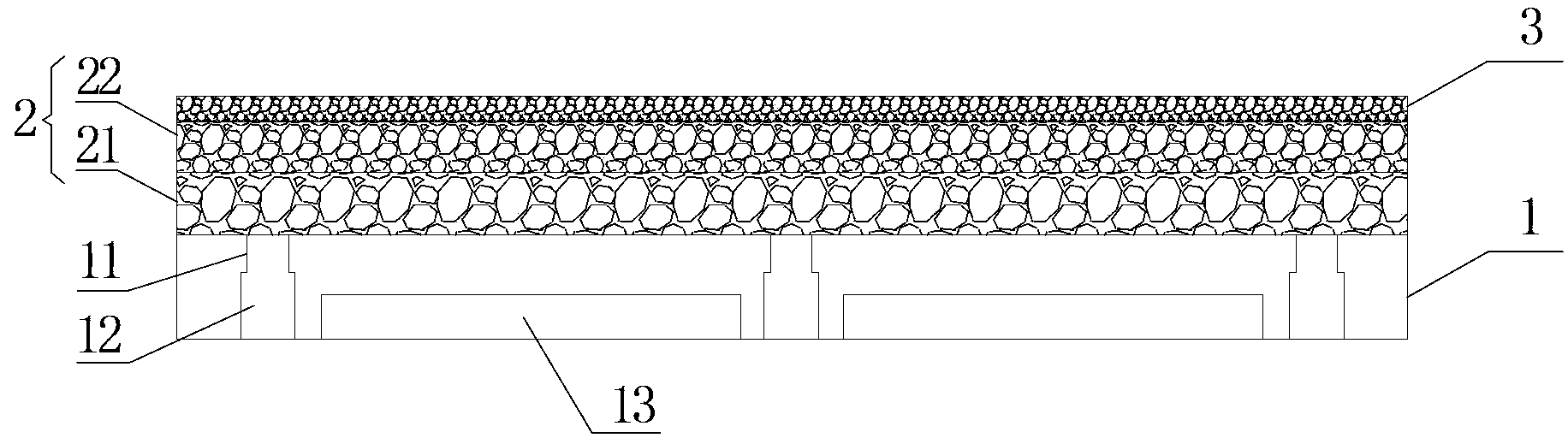

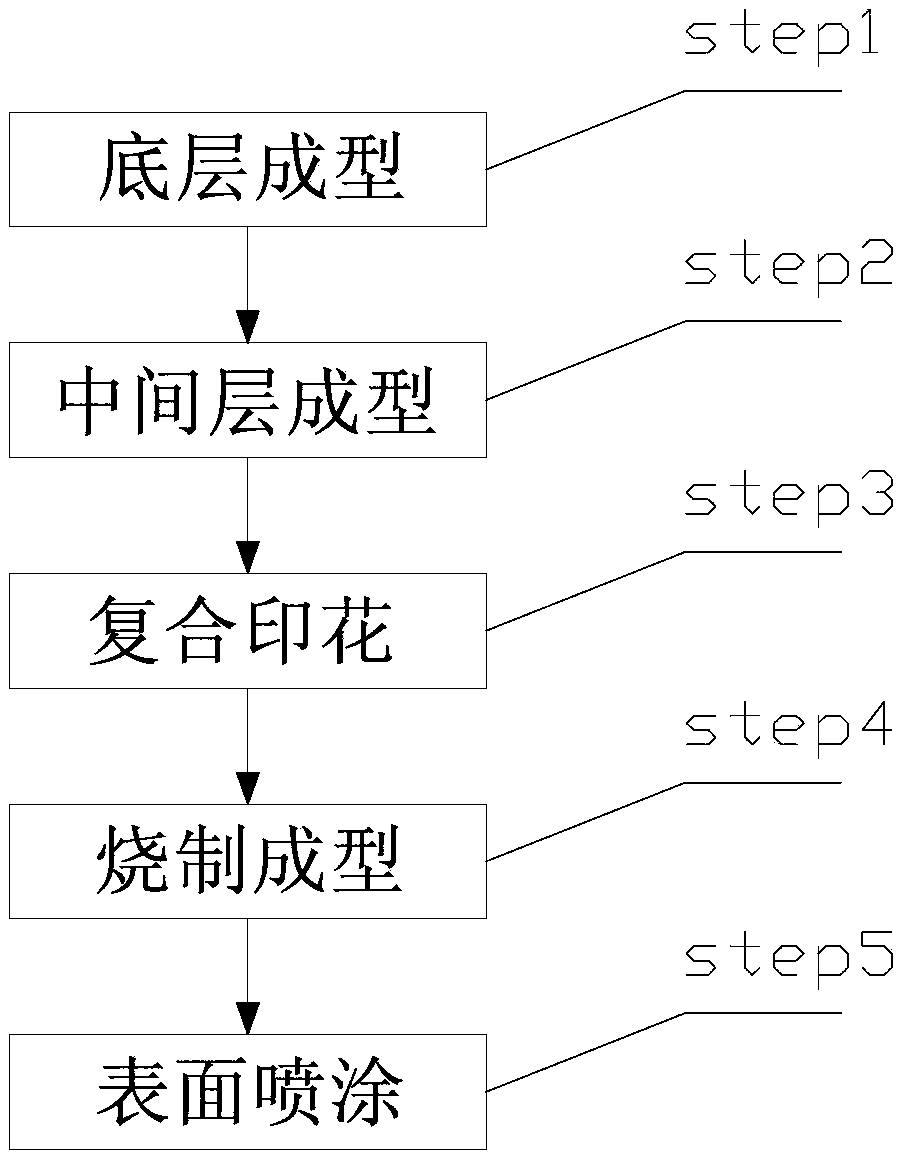

Water permeating and anti-skidding floor tile and manufacturing method thereof

ActiveCN103397767AFill technology gapsImprove the decorative effectLayered productsFlooringSurface layerPorous ceramics

The invention discloses a water permeating and anti-skidding floor tile. The water permeating and anti-skidding floor tile comprises a bottom layer, middle layers and a surface layer all of which are combined together. The bottom layer is a dense ceramic layer, and a water removing hole penetrating through the upper surface and the lower surface of the bottom layer is formed in the bottom layer. The middle layers are porous ceramic layers which are provided with a plurality of through holes, and the effective aperture of each through hole is not larger than that of the water removing hole. The surface layer is a decoration glaze layer, and a plurality of micropores are formed in the decoration glaze layer, and the effective aperture of each micropore is not larger than that of the through holes. Preferably, the middle layers comprise at least two layers, and the effective apertures of the through holes in each layer are reduced gradually from bottom to top. Compared with the prior art, the water permeating and anti-skidding floor tile has the advantages of being good in water permeating performance, anti-skidding effect, mold proofing effect, anti-pollution effect and decorative effect. The invention further provides a manufacturing method of the water permeating and anti-skidding floor tile.

Owner:江显异

Micro slag gas protection flux-cored wire suitable for electric arc additive manufacturing of die

ActiveCN106077992ANo flowWell formedArc welding apparatusWelding/cutting media/materialsLiquid metalMagnesite

The invention relates to a micro slag gas protection flux-cored wire suitable for electric arc additive manufacturing of a die. The flux-cored wire is formed by wrapping a powder core with a steel strip and comprises a component A, a component B and a component C. The component A comprises, by weight, 30-45% of rutile, 4-7% of cryolite, 8-14% of fluorite, 10-20% of marble, 8-14% of magnesite, 8-14% of potassium titanate and 10-22% of albite. The component B comprises, by weight, 5-20% of aluminum magnesium alloy, 5-15% of ferrotitanium, 26-40% of nickel, 8-20% of molybdenum, 12-24% of chrome, 10-18% of 45# silicon iron and 10-28% of manganese. The component C is composed of iron powder and impurities. After the flux-cored wire is welded, a micro amount of molten slag is formed and thinly and uniformly covers the surface of deposited metal, the molten slag cocks and falls off automatically after cooling, and multilayer welding can be achieved without slag removing; and in addition, weld spatter hardly appears, electric arcs are stable, molten metal does not flow, the appearance is attractive, excellent welding technological performance is achieved, and the deposited metal has good comprehensive mechanical performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

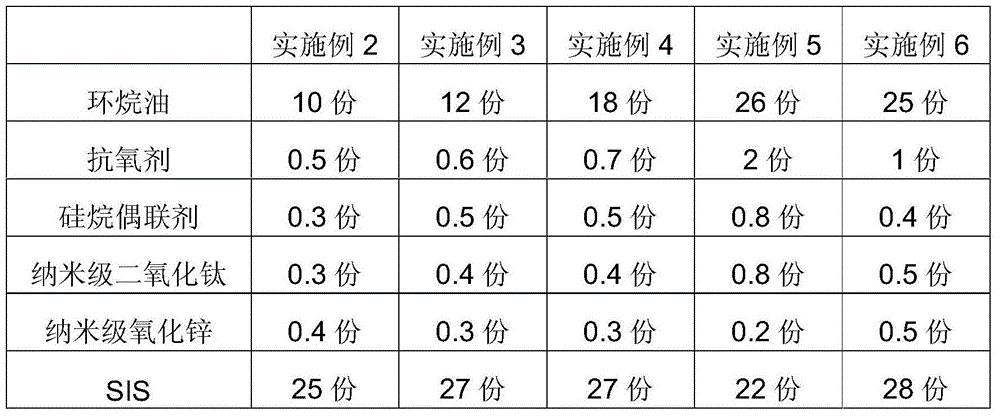

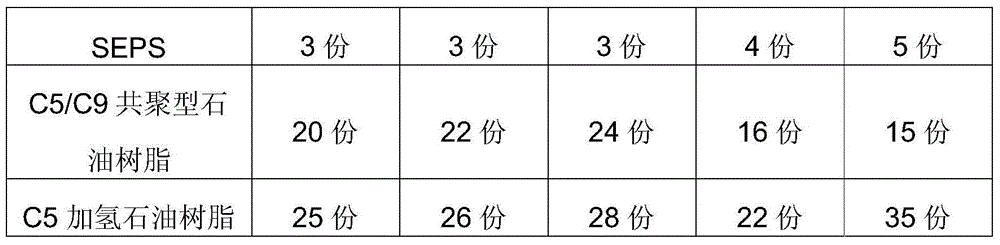

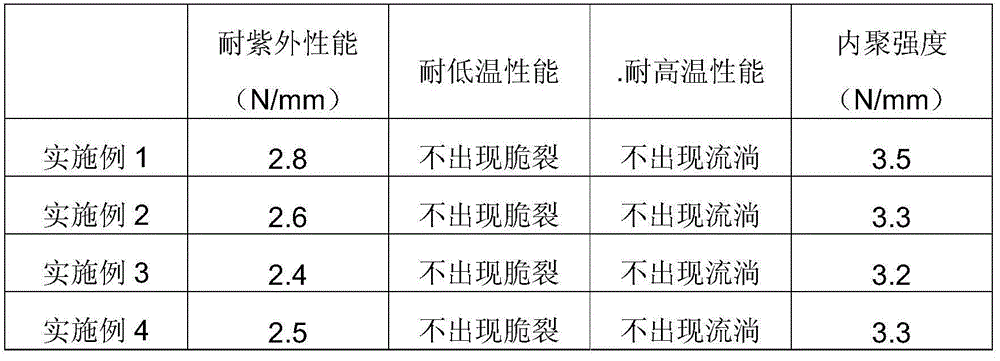

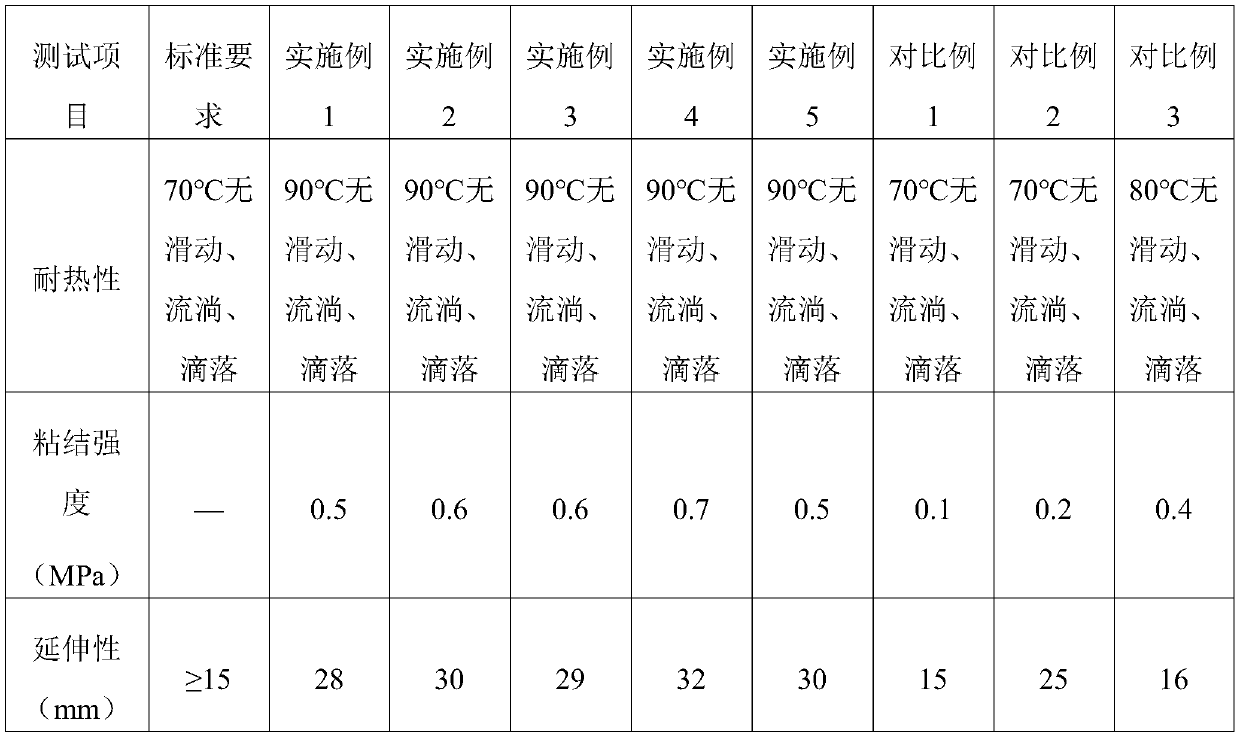

Hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls, and preparation method thereof

ActiveCN105086895AImproves UV resistanceImprove low temperature resistanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantTemperature resistance

The invention provides a hot melt adhesive for hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls. The The hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls comprises 10-30 parts of naphthenic oil, 0.1-3 parts of an antioxidant, 0.1-1 part of a silane coupling agent, 0.1-1 part of nanometer titanium dioxide, 0.1-1 part of nanometer zinc oxide, 20-32 parts of a styrene-isoprene-styrene copolymer, 1-5 parts of a styrene-hydrogenated isoprene-diblock copolymer, 15-30 parts of C5 / C9 copolymerized petroleum resin and 20-35 parts of C5 hydrogenated petroleum resin. The invention also provides a preparation method of the hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls. The hot melt adhesive has the advantages of excellent ultraviolet resistance, good low temperature resistance, good high temperature resistance, and appropriate cohesion strength, initial adhesion and peel strength, can be firmly pasted to a base material, can be firmly pasted to reaction sand particles spread on the surface of the base material, and has good weatherability.

Owner:HUIZHOU NENGHUI CHEM CO LTD

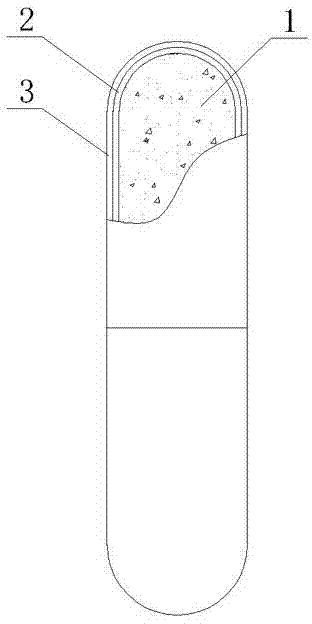

Photochromic double-shell microcapsule and preparation method and application thereof

InactiveCN102886233AHas thermosetting propertiesImprove processing resistanceTenebresent compositionsMicroballoon preparationIn situ polymerizationWear resistant

The invention relates to a photochromic double-shell microcapsule and a preparation method and application thereof. The microcapsule comprises a core, an internal shell and an external shell, wherein the core is manufactured by a photochromic material; the internal shell adopts vinyl monomer as polymerizing monomer, and wraps the core in an interfacial polymerization way; and the external shell adopts etherifying melamine resin prepolymer as polymerizing monomer, and wraps the internal shell in an in-situ polymerization way. The photochromic double-shell microcapsule provided by the invention is simple in preparation technology, and is non-toxic and innocuous; the wall of the microcapsule is high in toughness, is wear-resistant, heat-proof and water-proof, is good in processability, and is capable of permanently implementing a photochromic function; and the photochromic double-shell microcapsule can be applied to the field of textile and printing, and meets the demands on personalization and counterfeiting prevention.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

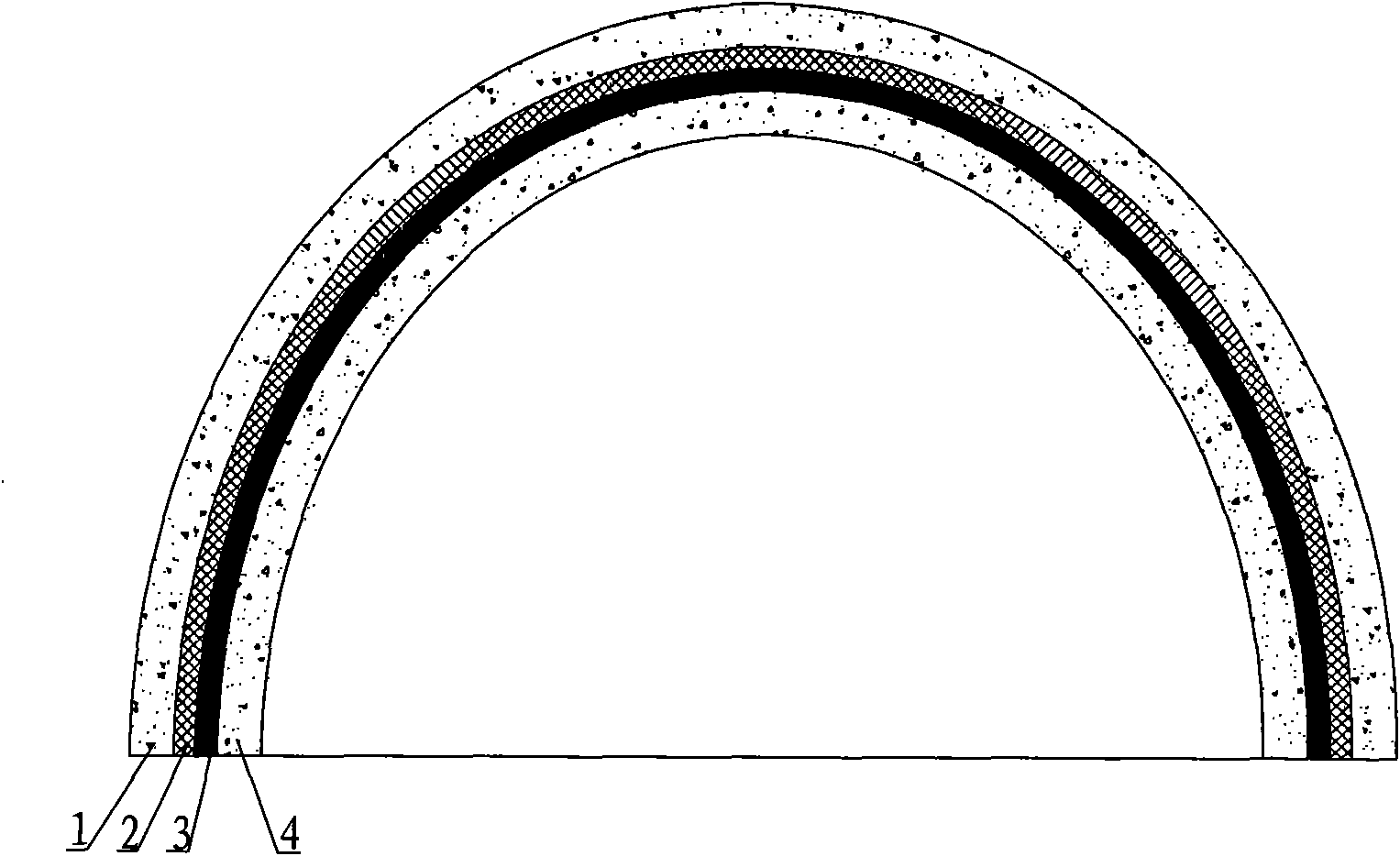

Construction method of tunnel waterproof and water drainage system

InactiveCN101614129AWill not harmWill not sputterUnderground chambersDrainageStructural deformationGeomorphology

The invention discloses a construction method of a tunnel waterproof and water drainage system, comprising the following steps: (1) preparing raw materials on a drainage layer; (2) injecting the drainage layer; (3) injecting a waterproof layer. The drainage layer and the waterproof layer of the invention all adopt the construction technology of injection. On the basis of water conductivity function, the drainage layer also has the functions of leveling and adapting to structural deformation, the waterproof layer adopts the construction mode of instantaneous film forming by ultraspeed curing and injecting, and the formed film is an integral structure, thus realizing that the integral structure is seamless and waterproof, the injection surface is free of flow, the film surface is smooth without bubbles and the construction produces no volatile organic compounds, simultaneously greatly improving the construction efficiency and reducing the labor intensity of workers.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

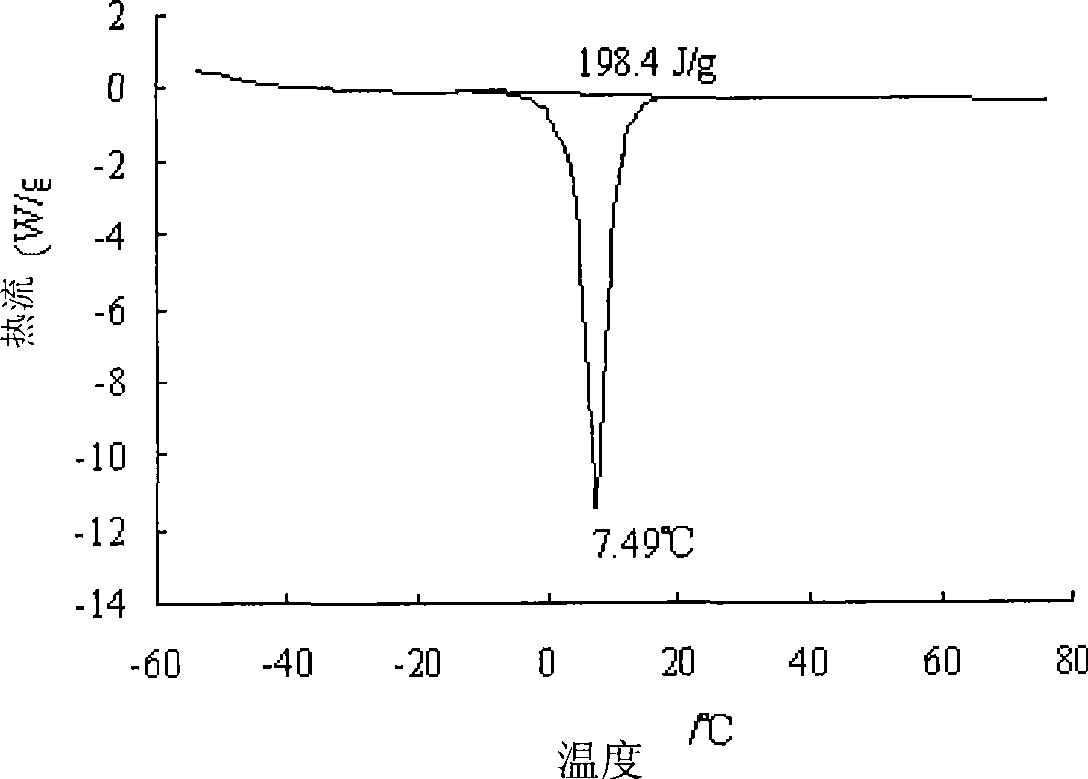

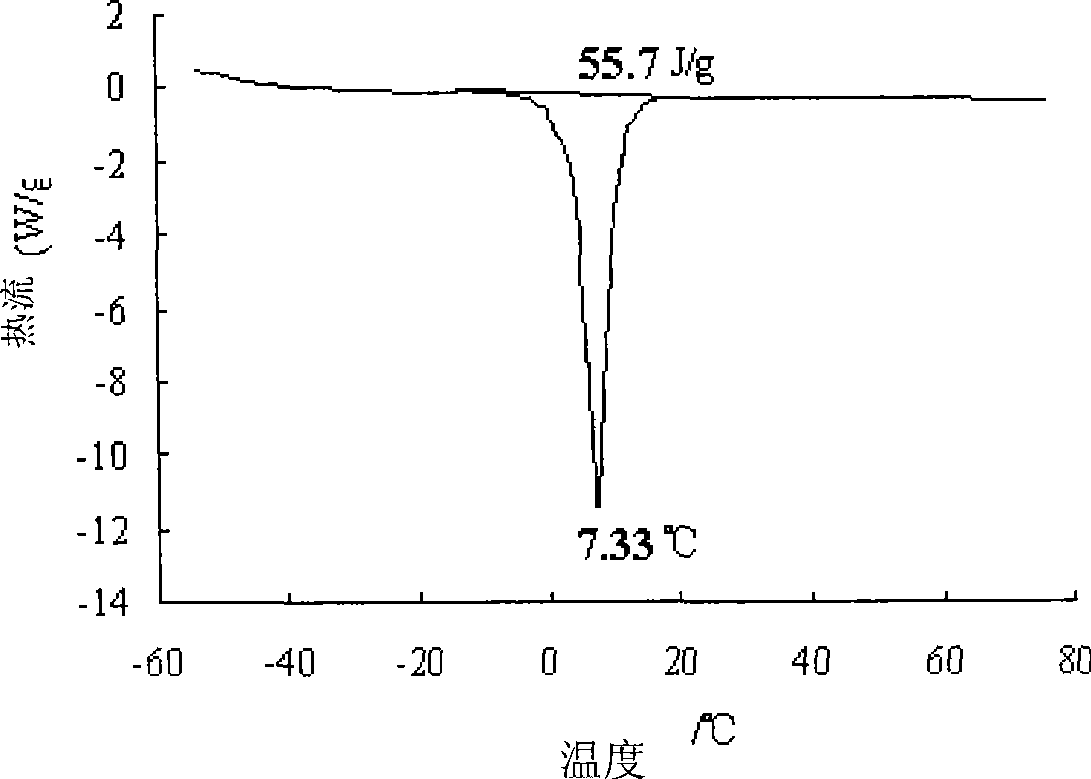

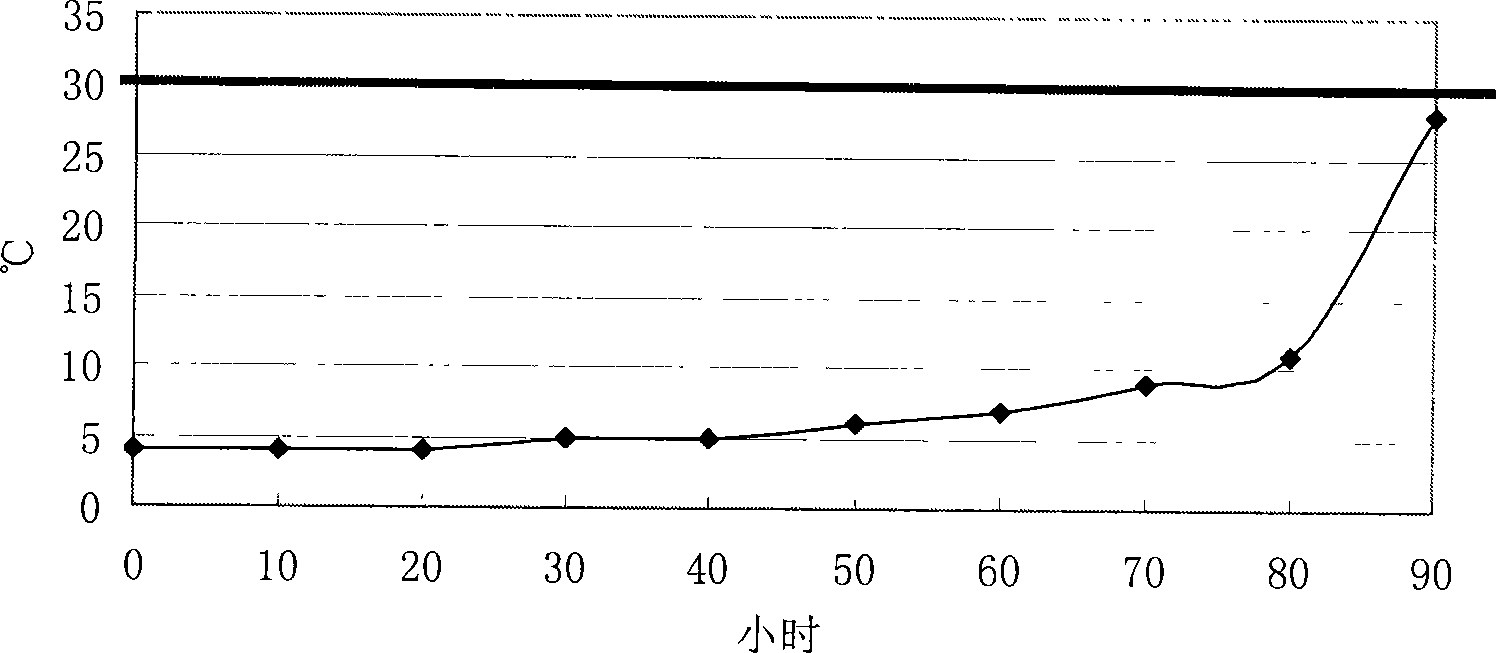

Fixed shape phase-change material based on tetradecane and method for producing the same

ActiveCN101423749AKeep shapeMaintain strengthHeat-exchange elementsPolymer scienceWorking temperature

The invention discloses a figuration phase change material based on tetradecane. The figuration phase change material is formed by mixing and processing the tetradecane with the mass percentage between 30 and 80 percent and the balance being a polymer framework material, wherein the polymer framework material is one or a combination of polyethylene (PE), styrene-butadiene-styrene copolymer (SBS) or styrene-isoprene-styrene copolymer (SIS). The invention has the tetradecane absorbed and / or wrapped in the specific polymer material as a framework. Because the polymer material as the framework can not be deformed in the working temperature range (20 below zero to 40 DEG C for example) of the tetradecane, the shape of the material can be kept, and the problems about collapse or flowing and leakage can not occur. Therefore, the obtained figuration phase change material can be widely applied to the low-temperature preservation and transportation of medicines, foods and the like.

Owner:FIELD OPERATION BLOOD TRANSFUSION INST OF PLA SCI ACAD OF MILITARY

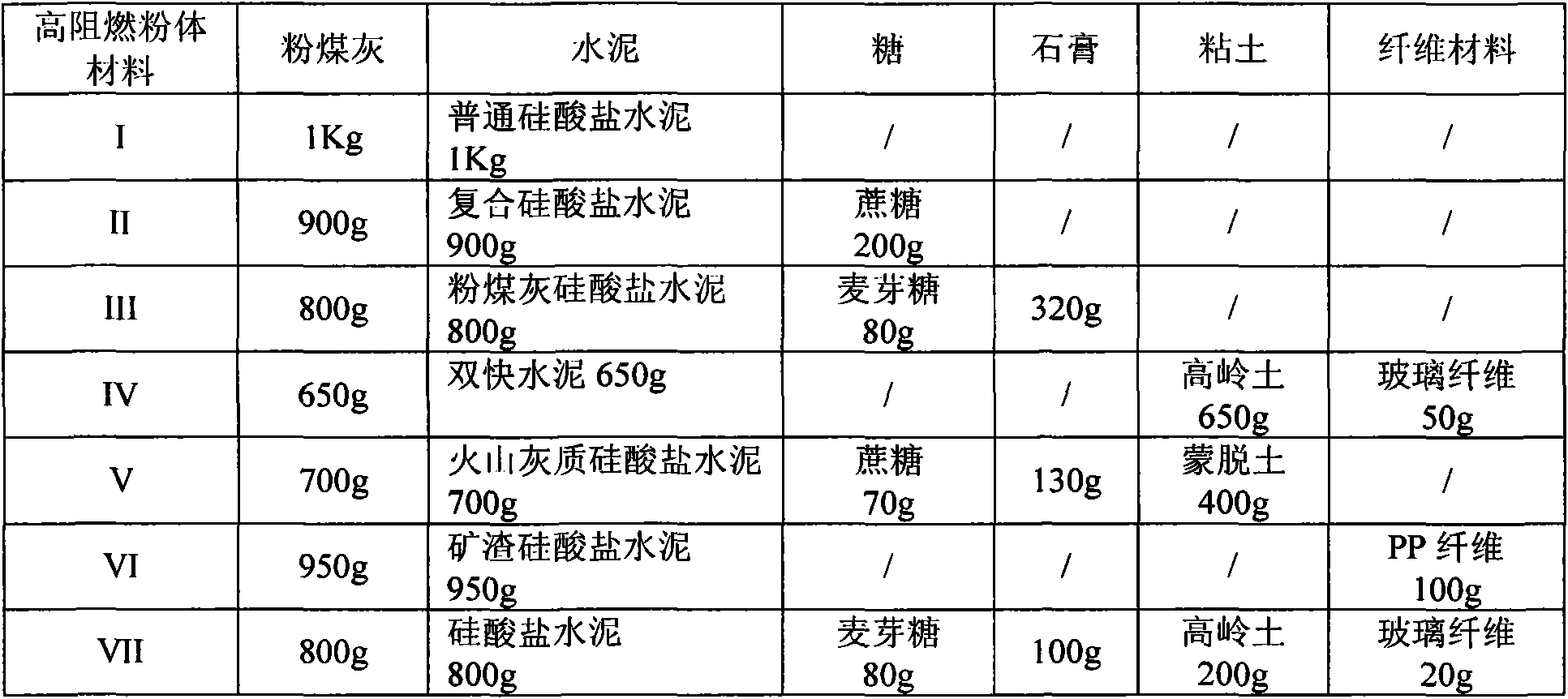

Spray-coating sealing material for coal rock mass

The invention provides a spray-coating sealing material for coal rock mass, belonging to the technical field of organic / inorganic compound materials. The spray-coating sealing material for the coal rock mass is a complex of high-molecular emulsion and high-flame-retardant powder materials, without any toxic and harmful substances, free of springback for construction, safe and environmental protective. When sprayed at vertical surfaces and top surfaces, the material does not flow and sag, and is good in overall effect. After curing, the coating has advantages of strong adhesion stress, high tensile strength, large tensile deformation, and excellent sealing performance. The material can be used for surface protection of the coal rock mass, air leakage prevention, gas leakage prevention, and rapid surface protection and moistureproof treatment after tunneling of swelling rock.

Owner:山东固安特新材料科技股份有限公司

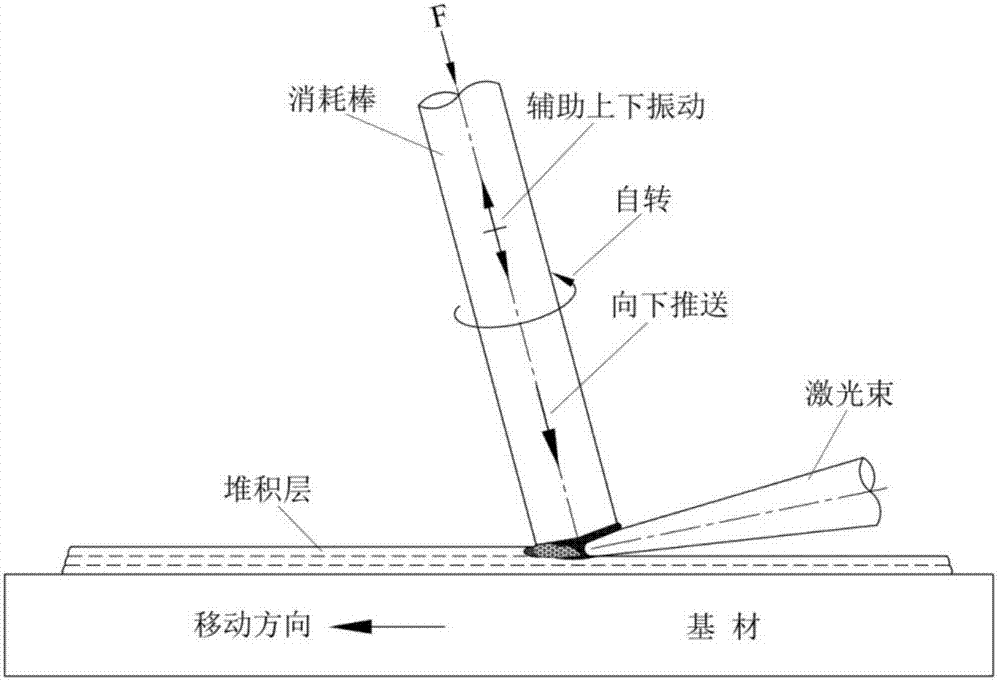

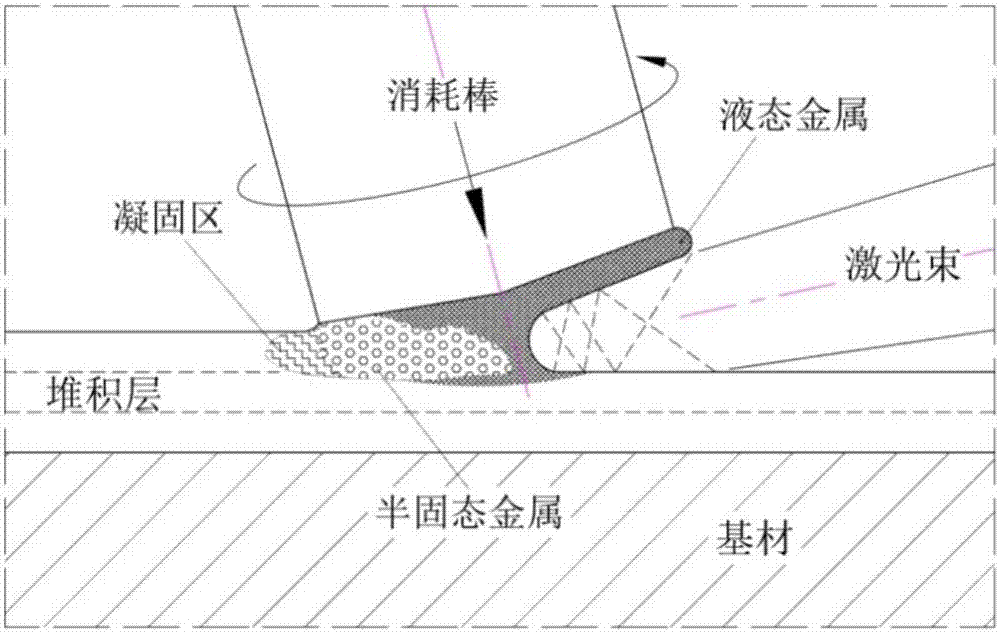

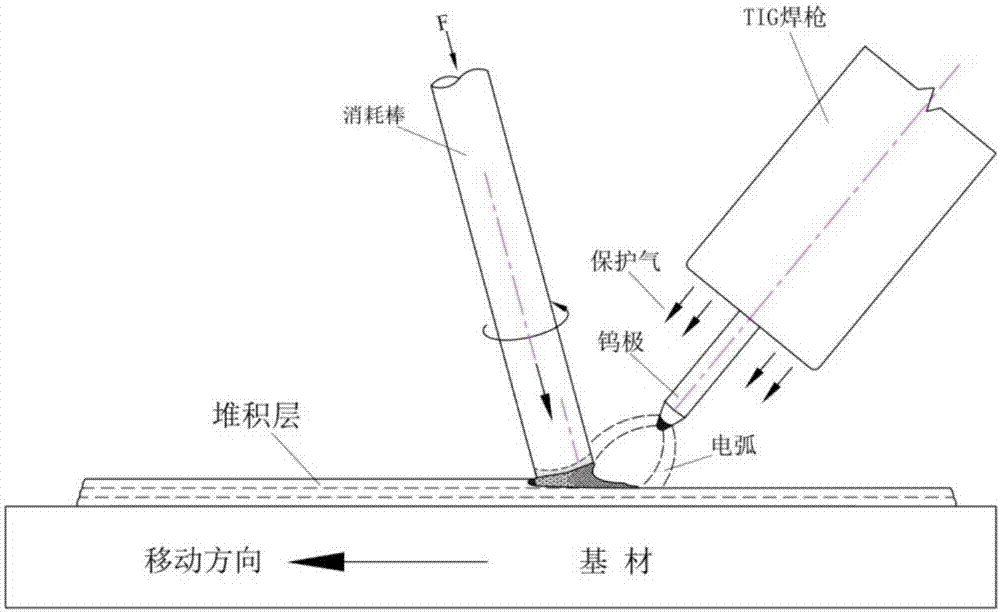

Micro-domain semi-solid state additive manufacturing method

ActiveCN107414325AReduce distortionReduced tendency to crackAdditive manufacturing apparatusArc welding apparatusMaterials preparationHigh energy

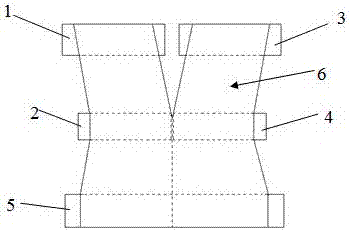

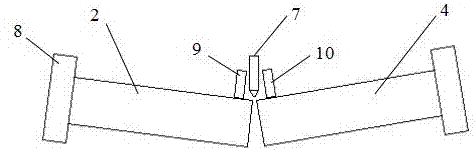

The invention provides a micro-domain semi-solid state additive manufacturing method. The problems about structure homogeneity, performance reliability, stress and deformation, air holes and cracks and the like of a molding piece are mainly solved. A stick-shaped material serves as a consumable item, and heating manners such as high energy beams, electric arcs and resistance heat are adopted for acting on the front end of the consumable item to enable the front end to be in a solid-liquid two-phase coexistence semi-solid state; and meanwhile, rotating twisting force and axial thrust are applied to the consumable item to conduct powerful effects such as shearing, stirring and extruding on semi-solid state metal, and in other words, mold-free semi-solid state flowing deformation molding is carried out. The consumable item is transited to bottom layer metal continuously in the manner to form metallurgical bonding, the stacking process is repeated according to a planned route obtained after discretization slicing treatment, and then a solid piece or a stacking layer in a special shape can be formed. The micro-domain semi-solid state additive manufacturing method is simple in operation process, the part performance is excellent, many defects in traditional additive manufacturing are overcome, and the prospects in the aspects of large structure shaping, damaged part repairing and composite material preparation are wide.

Owner:BEIJING UNIV OF TECH

Novel high-temperature-resistant non-curing waterproof coating and preparation method thereof

InactiveCN110016291AImprove high temperature resistanceImprove adhesionFireproof paintsOther rubber coatingsPolymer sciencePolyamide

The invention belongs to the technical field of building materials, and provides a novel high-temperature-resistant non-curing waterproof coating. The coating is composed of the following components in percentage by weight: 25-35% of asphalt, 15-30% of rubber oil, 10-20% of waste tire rubber powder, 5-10% of styrene-butadiene rubber, 1-3% of styrene-butadiene-styrene (SBS), 4-10% of tackifying resin, 10-20% of fly ash, 2-5% of a high-temperature modifier and 2-5% of a viscosity reducer, wherein the high-temperature modifier is a BL modifier or polyamide wax. The preparation method is carried out by adopting a three-section-type feeding method and comprises the following steps: adding asphalt and rubber oil, carrying out heating to 150 DEG C, then adding the SBS, the styrene-butadiene rubber, the tackifying resin and the viscosity reducer, carrying out heating to 180 DEG C, then adding the fly ash and a high-temperature modifier, mixing the components at 180 DEG C to form a uniform liquid, and carrying out cooling and discharging to obtain the novel high-temperature-resistant non-curing waterproof coating. The invention solves the problem that a non-curing rubber asphalt waterproofcoating is poor in heat resistance.

Owner:河南驼峰防水科技有限公司

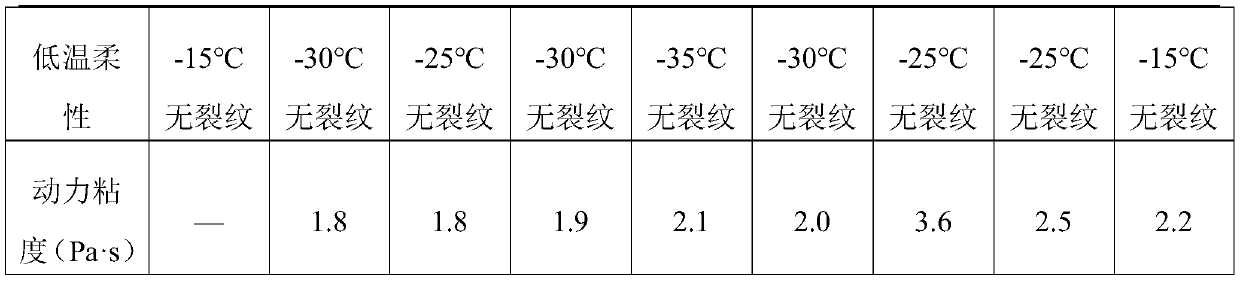

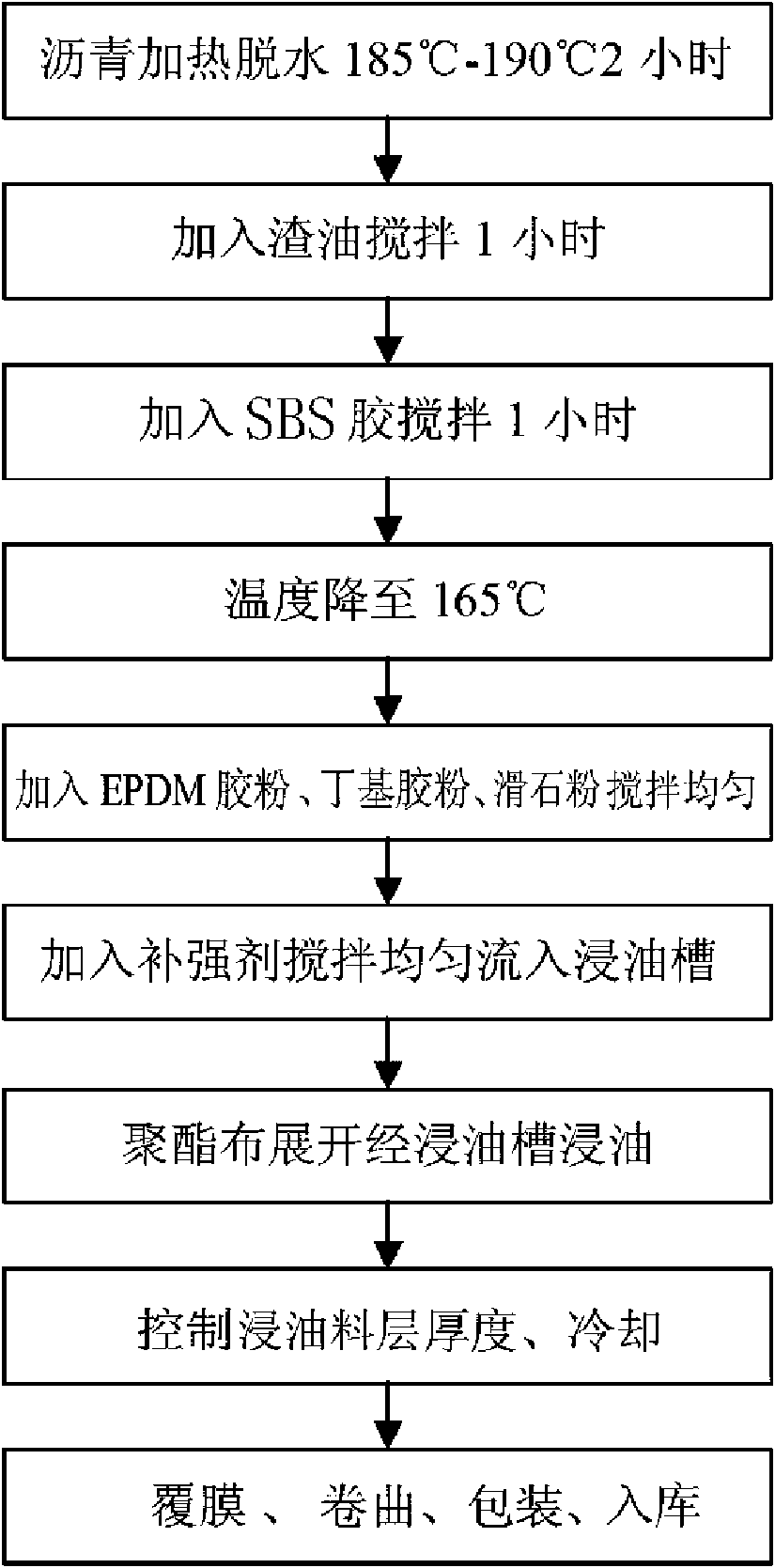

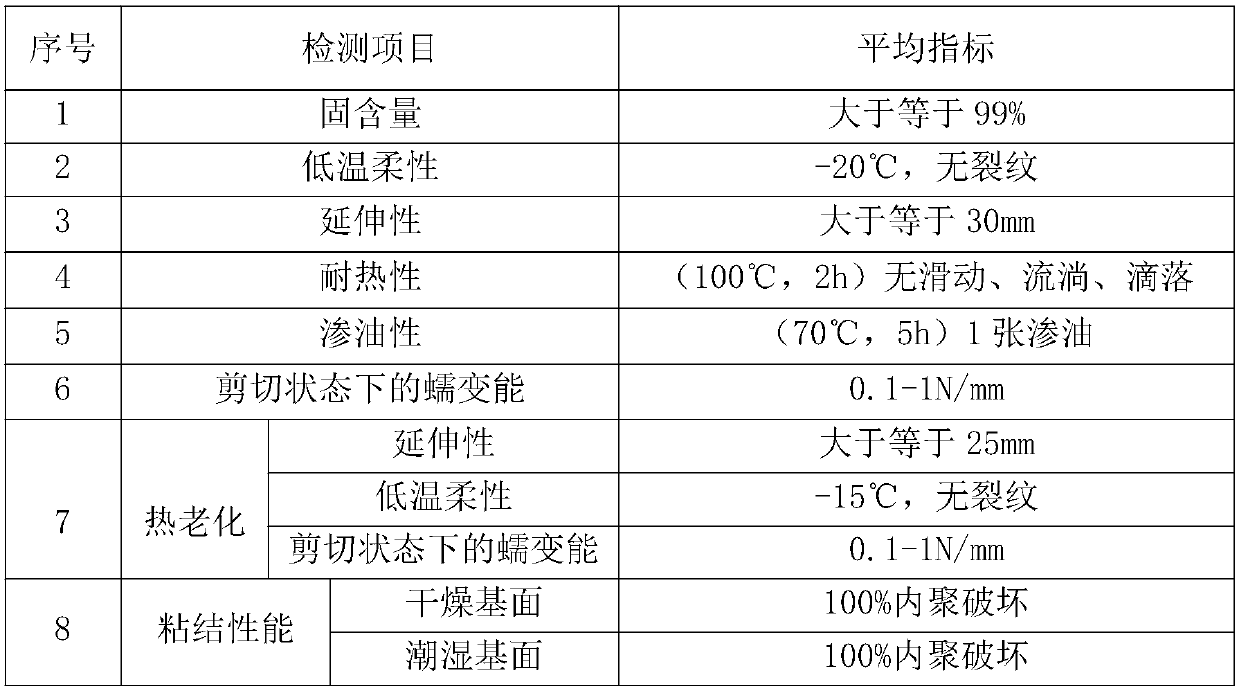

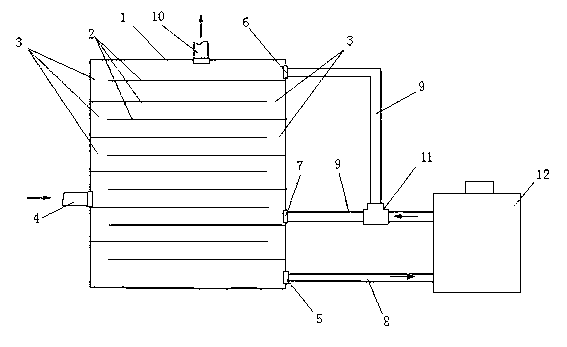

Styrene butadiene styrene (SBS) modified bituminous waterproof sheet material and preparation technology thereof

InactiveCN101644095AIncrease elasticityBright appearanceRoadwaysUnderground chambersBituminous waterproofingPolyester

The invention provides a styrene butadiene styrene (SBS) modified bituminous waterproof sheet material and preparation technology thereof. The waterproof sheet material comprises polyester cloths, animmersion oil coating layer and a film-mulching layer. The immersion oil coating layer comprises the following materials in parts by mass: 32-52 parts of bitumen, 12-22 parts of residual oil, 9-19 parts of EPDM rubber powder, 2-7 parts of butyl rubber powder, 11-21 parts of talc powder and 5.6-10.6 parts of SBS rubber. The bitumen is the mixture of 9-19 parts of 10# bitumen and 23-33 parts of 60#bitumen. The invention is characterized by wide high temperature and low temperature resistance range, good elasticity and good hardness, is not easy to deform and is suitable for various levels of waterproofing works of roofing of industrial and civil buildings, underground, bridges, highways, swimming pools and the like in the south and in the north.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD

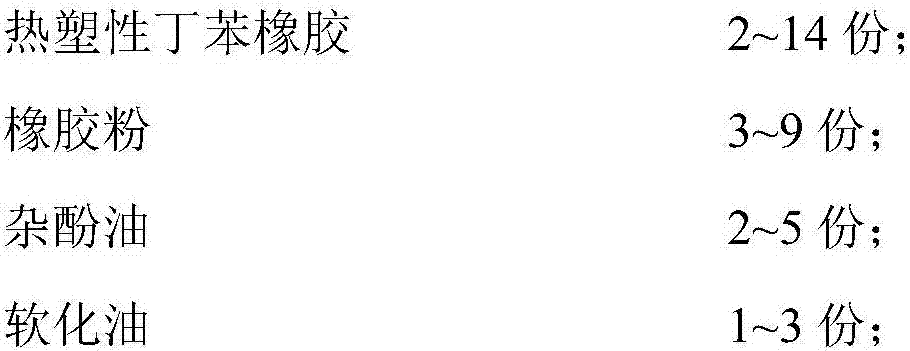

Novel hot-melt pressure-sensitive adhesive for waterproof materials and preparation method thereof

InactiveCN104946178ANo crackNo flowMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesThermoplastic elastomerHot melt

The present invention relates to the technical field of hot melt adhesives, specifically, to a hot-melt pressure sensitive adhesive used in a waterproof material and a preparation method therefor. By a weight percentage, the hot-melt pressure sensitive adhesive comprises the following components: a thermoplastic elastomer of 30-40%, tackifying resin of 30-50%, rubber softening oil of 15-30% and an auxiliary agent of 0.3-1%. The preparation method comprises: adding the thermoplastic elastomer, the tackifying resin, the rubber softening oil and the auxiliary agent respectively into a closed container, heating and stirring in a condition of 180 degrees centigrade until even, and standing to obtain the hot-melt pressure sensitive adhesive. A purpose of the present invention is to provide the hot-melt pressure sensitive adhesive used in the waterproof material and the preparation method therefor. The hot-melt pressure sensitive adhesive has good low-temperature resistance and good adhesion performance, is safe and environmentally-friendly, and has very good utility value.

Owner:JIANGSU CANLON BUILDING MATERIALS

Epoxy non-cured rubber asphalt waterproof coating and preparation method thereof

InactiveCN107739575ASolve the problem of heating to constructionEnsure safetyFireproof paintsOther rubber coatingsSelf-healingEpoxy

The invention discloses an epoxy non-cured rubber asphalt waterproof coating and a preparation method thereof and belongs to the field of coatings. The coating comprises a component A and a componentB, wherein the component A is prepared from asphalt, plasticizers, polymer modifiers and epoxy resin; the component B is prepared from epoxy curing agents. The problem that the non-cured rubber asphalt waterproof coating can be constructed after the coating is heated can be solved; the coating is energy-saving and environmentally friendly; the safety of constructors is ensured; the construction operation is simplified; the application range of the product is expanded; the coating is excellent in construction performance, does not need to be heated in the whole construction process, is excellent in high-temperature performance, can achieve obstacle-free construction under high temperature and low temperature, and is high in flexibility, high in elongation rate, excellent in creep property,high in self-healing capability, high in water channeling resistance and high in adhesion performance.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

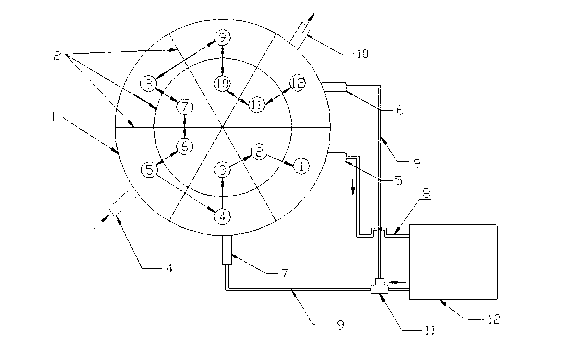

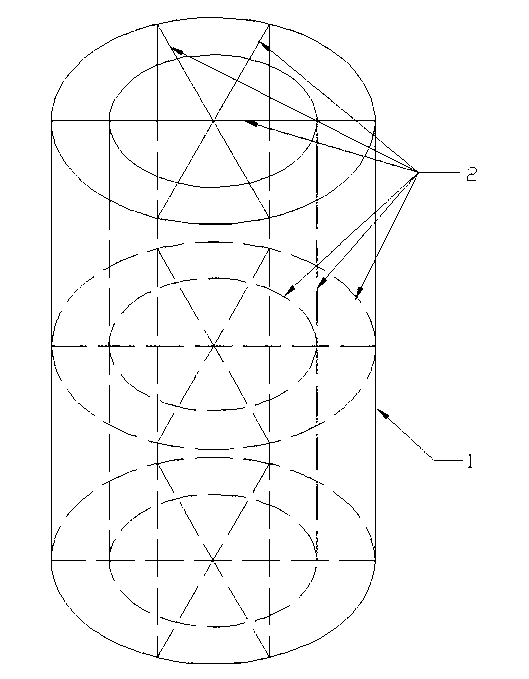

Multiple-cavity heat preservation water tank free of water mixing

ActiveCN103134186AReduce muddy waterLow thermal conductivityFluid heatersBusiness efficiencyEngineering

The invention relates to a multiple-cavity heat preservation water tank free of water mixing. The multiple-cavity heat preservation water tank free of water mixing is characterized in that the inside of a tank body is divided by a plurality of separation plates or separation films into N hollow cavities, each hollow cavity is provided with water passing holes, the water passing holes of the first hollow cavity are communicated with the second hollow cavity, the Nth hollow cavity is provided with a hot water supply port, the water passing holes of the Nth hollow cavity are only communicated with the (N-1)th hollow cavity, the water passing holes of the other hollow cavities are respectively communicated with a former hollow cavity and a later hollow cavity, the inside of the water tank forms a through path, and in the through path, series connection is formed from the first hollow cavity to the Nth hollow cavity, and all the hollow cavities are communicated. The first hollow cavity is provided with a water outlet which is communicated with a water outlet of an external water pump through a water outlet pipe, the water tank is provided with at least one water return port which is communicated with the water outlet of the external water pump through a water return pipe, the Nth hollow cavity is provided with a water return port, one hollow cavity in the middle of the water tank is provided with a cold water supplementing port. The multiple-cavity heat preservation water tank free of water mixing can basically avoid the phenomenon of mixing of cold water and hot water, improves the energy efficiency ratio and the heating capacity of a system, guarantees the hot water supply and the stability of outlet water temperature, adopts a sectional heating method, reaches a required temperature rapidly, and reduces power of equipment configuration and the size of the water tank.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

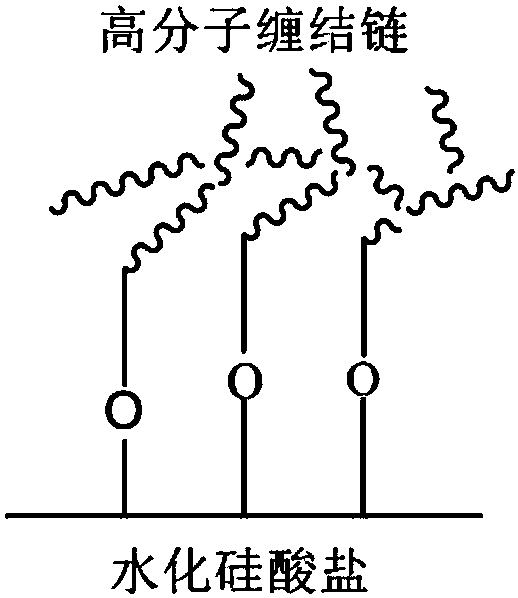

Butyl rubber reactive bonding layer used for pre-paving reactive-bonding waterproofing coiled material, preparation method thereof, and the pre-paving reactive-bonding waterproofing coiled material

ActiveCN107603519AHigh strengthHigh hardnessNon-macromolecular adhesive additivesLayered productsInsulation layerSilicon dioxide

The invention discloses a butyl rubber reactive bonding layer used for a pre-paving reactive-bonding waterproofing coiled material, a preparation method thereof, and the pre-paving reactive-bonding waterproofing coiled material, and relates to the technical field of high-molecular pre-pavement materials. The butyl rubber reactive bonding layer is mainly produced from: 100 parts of raw rubber, 9.5-15.5 parts of a linear tackifying resin containing terminal hydroxyl group structure, and 12.5-19.5 parts of active filler comprising active silicon dioxide and aluminum oxide. The reactive bonding layer solves the defects that a bonding layer of a waterproofing coiled material in the prior art is liable to flow, deform and wrinkle when being heated, is brittle at low temperature, is free of sticking feet only if a single anti-sticking layer or insulation layer exists, and is poor in stripping strength with post-poured concreted. The butyl rubber reactive bonding layer can form permanent chemical bonds with concrete, so that a real skin-type water-proofing structure is formed between the pre-paved high-molecular waterproofing coiled material and the concrete, and the bonding layer is freeof sticking feet and allows people to walk thereon without coverage by sand and coating layers. In addition, the reactive bonding layer has good low temperature resistance and thermal stability.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

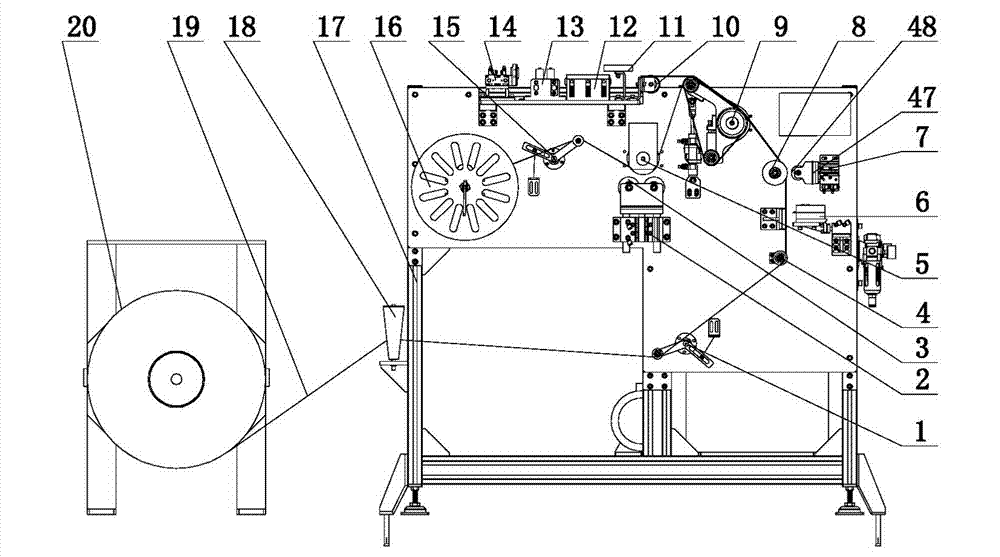

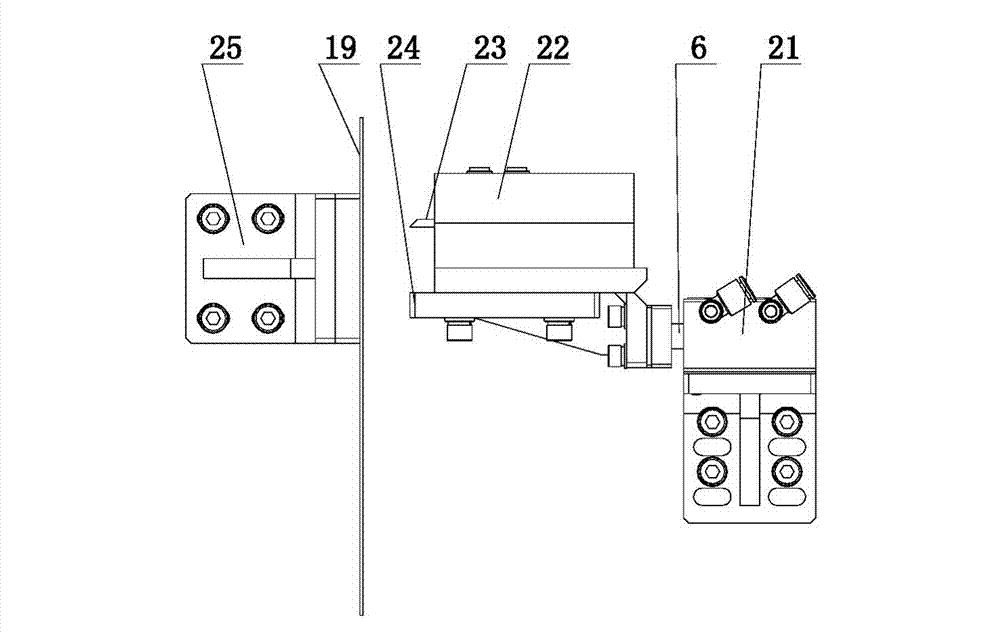

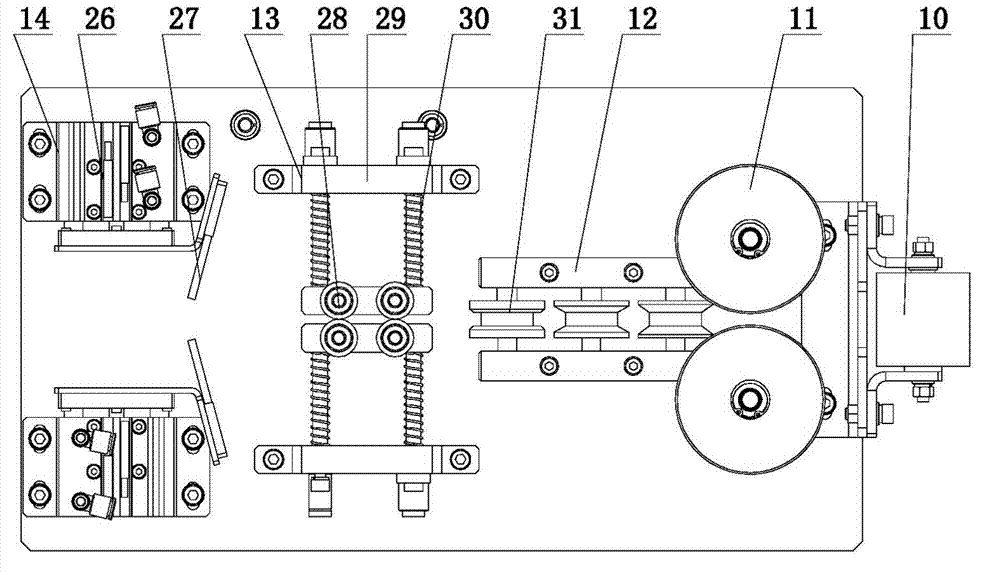

Solar cell assembly substrate automatic sealing-tape machine

The invention provides a device capable of wrapping sealing tape on the periphery of a cell substrate and relates to automatic production devices in the field of photovoltaic, in particular to a solar cell assembly substrate automatic sealing-tape machine. The solar cell assembly substrate automatic sealing-tape machine comprises an unwinding device and an edge wrapping device corresponding to the unwinding device and is characterized in that the edge wrapping device comprises a frame. A guiding device corresponding to the unwinding device is arranged on the frame, and a shearing device corresponding to the guiding device is arranged on the frame. An edge wrapping component is arranged at the upper end of the frame, and an active sealing tape pulling device is arranged on the frame below the edge wrapping component.

Owner:YINGKOU JINCHEN MACHINERY

Straw biological matrix seedling-raising disk and preparation method thereof

The invention provides a straw biological matrix seedling-raising disk and a preparation method thereof. The straw biological matrix seedling-raising disk includes a seedling-raising disk and a bottom film arranged thereunder. A matrix is filled between the seedling-raising disk and the bottom film. The seedling-raising disk includes waste paper pulp, bamboo pulp, straw powder, bio-gum, a composite micro-fertilizer and water. The matrix includes plant straw, a straw fermentation agent, an additive, a seedling strengthening agent and water. The bottom film is a bast fiber mulching film. The seedling-raising disk is simple and scientific in preparation method and is free of addition of any other chemical raw materials or fertilizers, so that the seedling-raising disk keeps the characters of the raw materials and has a certain effect. The technical scheme replaces soil and a plastic seedling-raising disk by the straw biological matrix, which reduces the damage of white pollution. By means of the straw biomass for culturing seedlings of paddy rice for replacing the technology of seedling cultivation in nutrient soil in production over the years, the seedling-raising disk solves the problem that cultivated land is damaged and soil is difficult to obtain by farmers during a paddy rice seedling-raising process. The seedling-raising disk fully utilizes straw regenerated resources, thereby reducing environment-pollution due to straw incineration and achieving energy saving and emission reduction.

Owner:HUBEI NIXIMI TECH CO LTD

Welding method for stainless steel plates with thickness being smaller than 0.3 mm

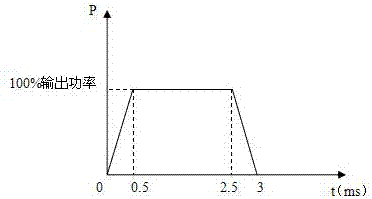

ActiveCN106938384AReduce wasteNo missing weldingLaser beam welding apparatusBreaking strengthHeat-affected zone

The invention provides a welding method for stainless steel plates with the thickness being smaller than 0.3 mm. The welding method for the stainless steel plates with the thickness being smaller than 0.3 mm comprises the following steps that the stainless steel plates are cut according to requirements, cut openings are made smooth, and burrs are removed; and the two to-be-welded plates are fixedly mounted on clamps correspondingly, and weld openings of the two to-be-welded plates are aligned; a YAG pulse laser welding machine is adopted, laser beams are kept irradiating the corresponding weld openings of the two plates, and energy is output in the trapezoidal pulse form; and the moving speed of the plates is kept being matched with the frequency and pulse width of laser pulses, so that two adjacent welding spots are made to be in lap joint. By adoption of the welding method for the stainless steel plates with the thickness being smaller than 0.3 mm, small-width stainless steel plates with the same thickness can be combined through laser welding, welding omission, seams, holes, flow and burning damage of a heat affected zone are avoided; the welding spots are continuous, the edges of the welding spots are in lap joint, the overlapping degree of the welding spots is not smaller than half of the diameter of the welding spots, airtightness is guaranteed, and holes are voided; and the strength of welding lines is higher than that of base metal, and high yield strength and tensile breaking strength are achieved.

Owner:天津滨海雷克斯激光科技发展有限公司

High-temperature-resistant modified asphalt waterproof coiled material and preparation method thereof

ActiveCN108081698AImprove thermal stabilityGood low temperature flexibilityFibre typesSynthetic resin layered productsThermal ageingFiber

The invention provides a high-temperature-resistant modified asphalt waterproof coiled material and a preparation method thereof. The modified asphalt waterproof coiled material comprises a tread baselayer, prepreg, a coating material and an isolating material; the tread base layer of the modified asphalt waterproof coiled material is fiberglass mesh cloth and polyester fiber composite tread base; and the prepreg is prepared from the following raw material components: 130# asphalt, chlorinated rubber, ethylene-vinyl acetate glyceride, elm tree wood powder and an anti-ageing agent. The modified asphalt waterproof coiled material has excellent thermal stability, thermal ageing resistance and low-temperature flexible performances.

Owner:富华防水科技股份有限公司

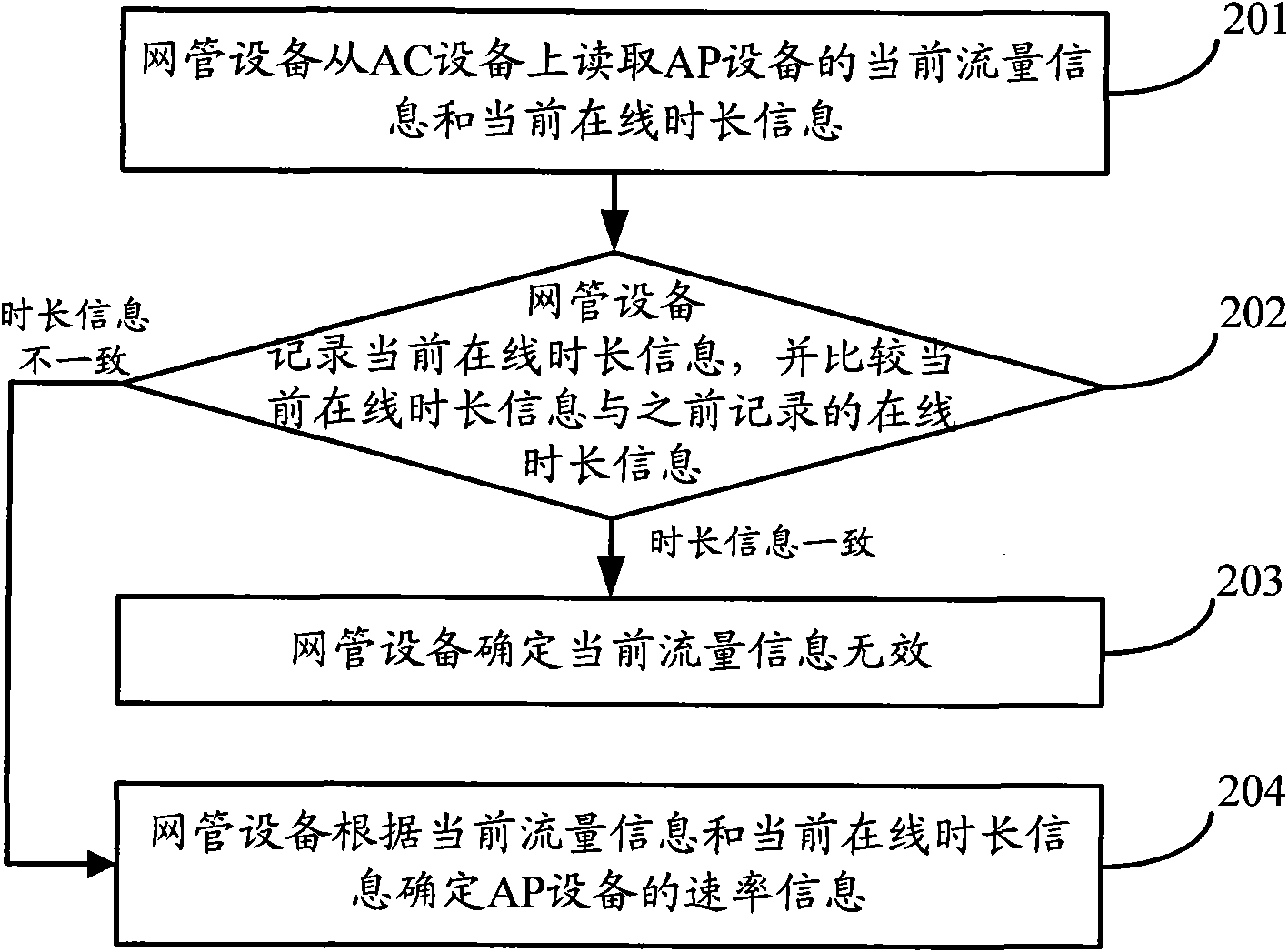

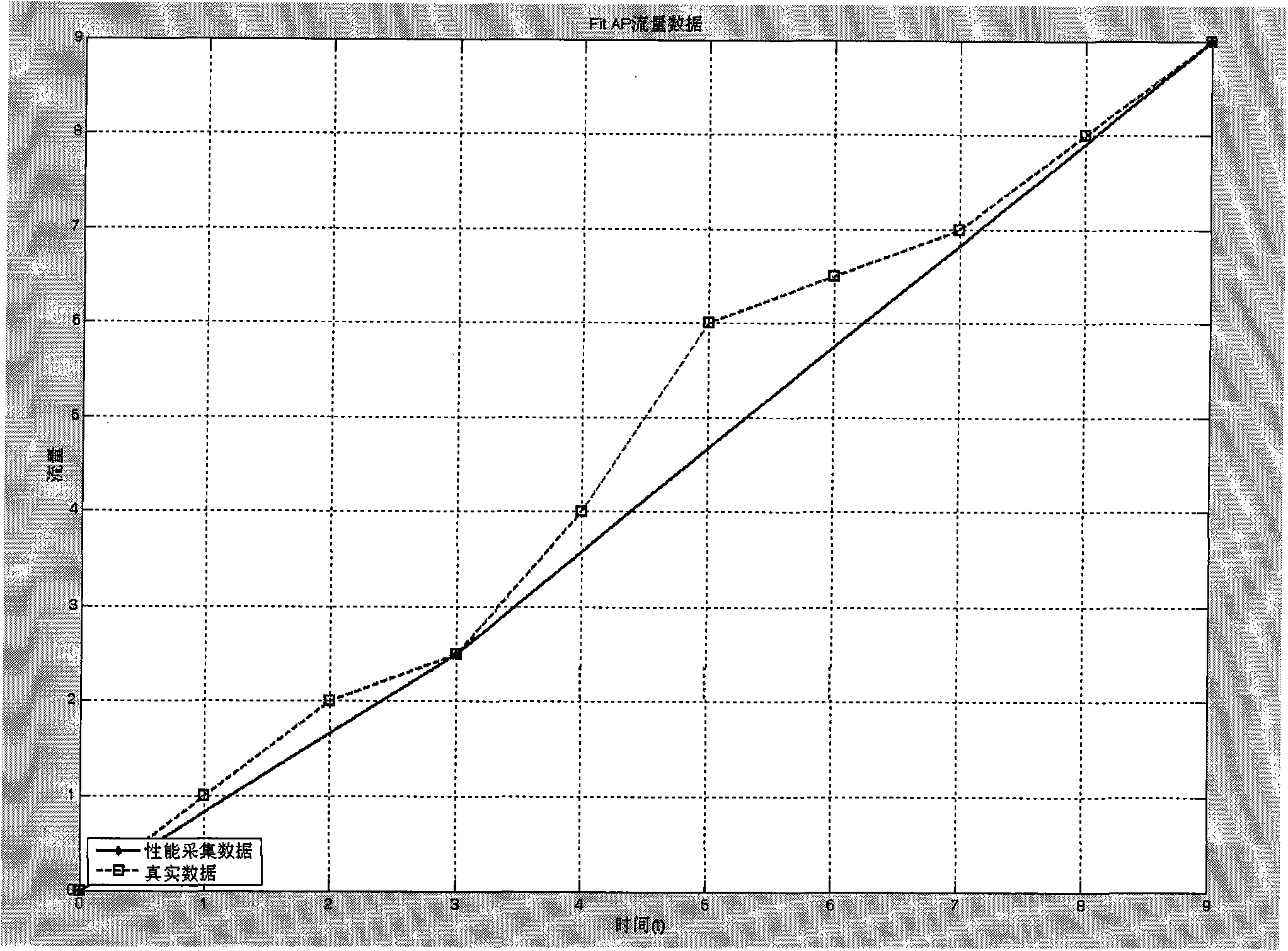

Method and device for counting rate

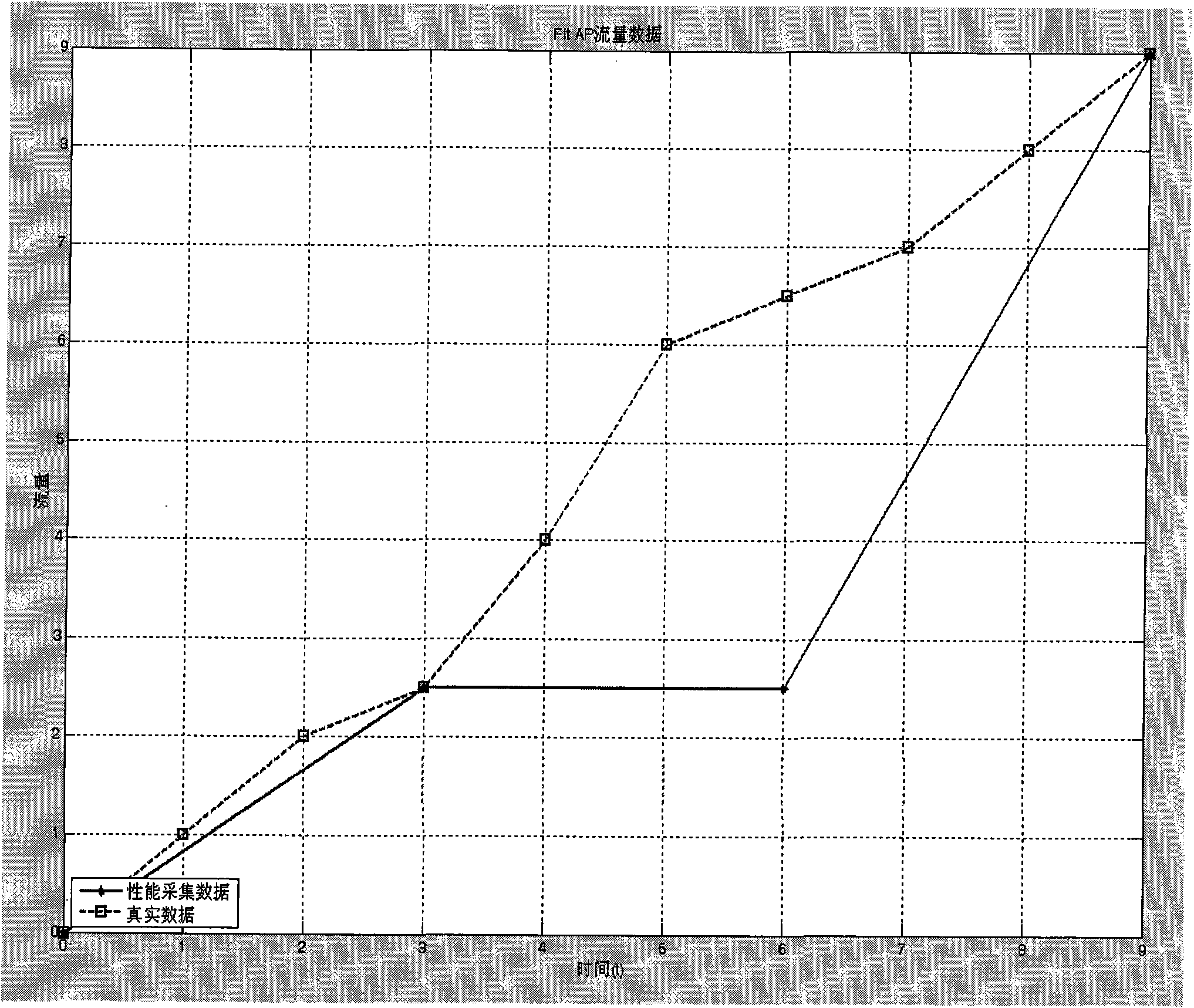

InactiveCN101945014ASolve traffic statisticsResolve accuracyData switching networksWireless communicationCounting rateNetwork management

The invention discloses a method and a device for counting rate. The method comprises the following steps that: network management equipment reads current flow information and current online time length information of AP equipment from AC equipment; the network management equipment compares the current online time length information with previously recorded online time length information; when the current online time length information is consistent with the previously recorded online time length information, the network management equipment determines that the current flow information is invalid; and when the current online time length information is inconsistent with the previously recorded online time length information, the network management equipment determines the rate information of the AP equipment according to the current flow information and the current online time length information. In the method and the device, the flow and the rate of the AP equipment can be accurately determined.

Owner:NEW H3C TECH CO LTD

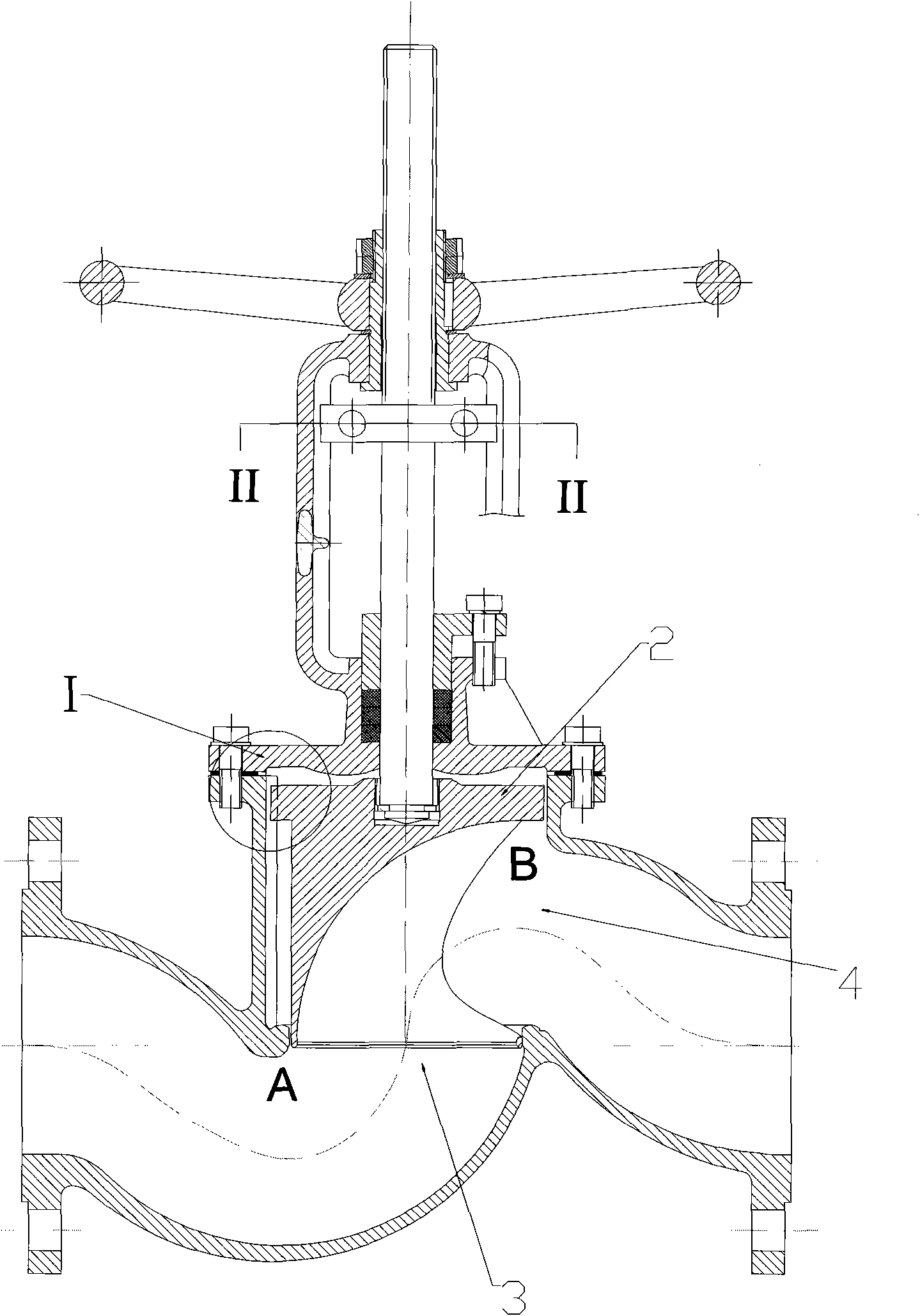

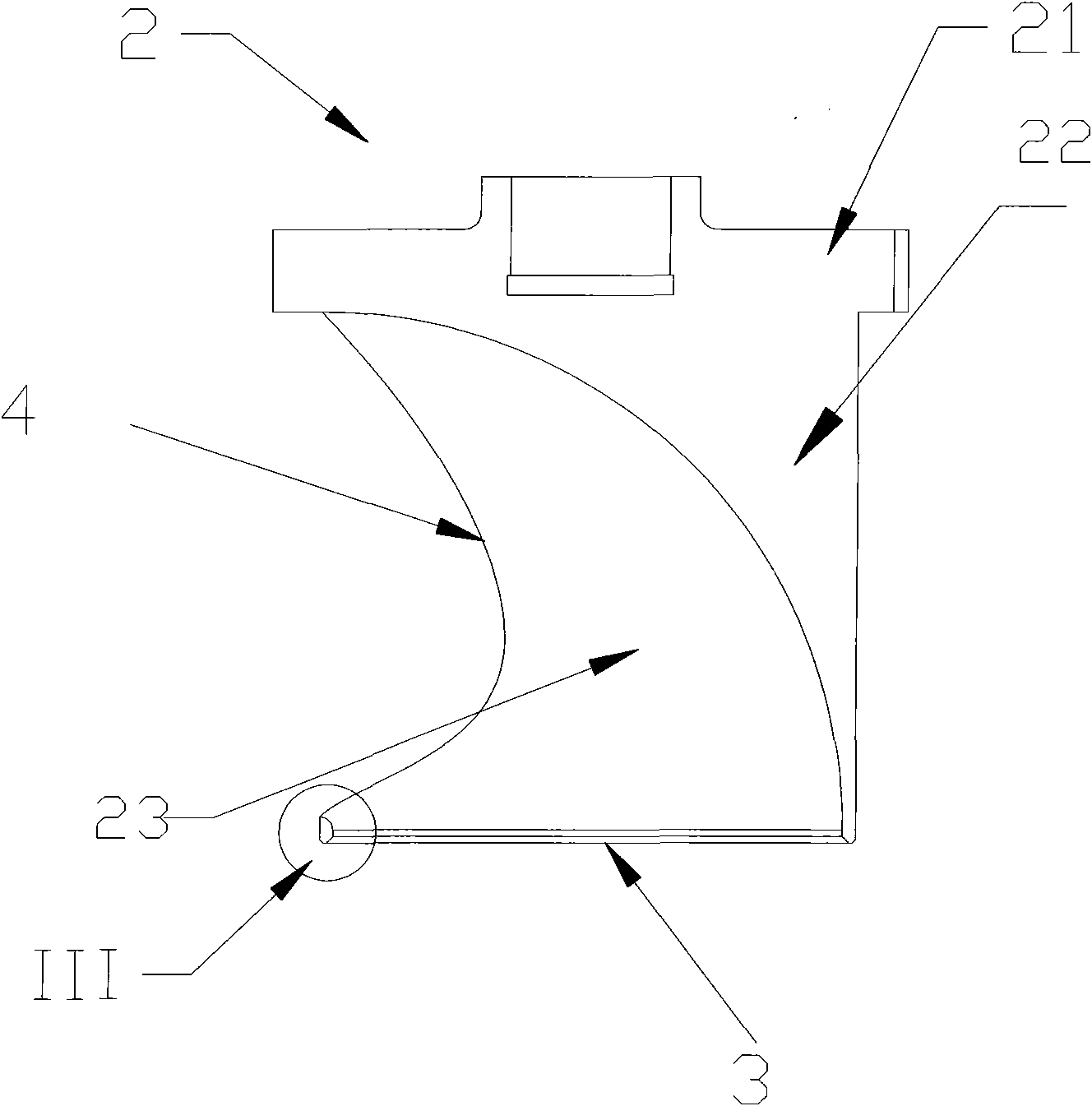

Stop valve of pipeline

The invention discloses a stop valve of a pipeline, which comprises a valve clack, wherein the valve clack comprises a sealed valve plate and a lower cylindrical body which is vertical to the valve plate; the internal surface of the lower cylindrical body of the valve clack is a cylindrical ring surface, the cylindrical ring surface is vertical to the sealed surface of a valve seat at a fluid inlet, and an outlet is tangential to an inlet of a valve body, i.e. the tangential line of the center line of the cylindrical ring surface at the outlet is superposed with the tangential line of the center line of the section at the inlet of the valve body. The cylindrical ring surface can be a cylindrical ring with equal diameter and can be also a cylindrical ring with variable diameter. The valve clack of the stop valve structure can lower the local resistance of the valve obviously, lower the pressure of a medium on a valve rod because the structure of the valve clack enables the medium to smoothly flow from an inlet of a valve cavity to an outlet, reduce the energy loss of the pipeline valve greatly, save the running cost of the pipeline and play an indispensable positive role in the aspects of environmental protection and energy saving.

Owner:GUANGDONG LIANSU TECH INDAL

Solvent-free high-impact normal temperature-cured epoxy anti-corrosion paint

InactiveCN102108240AIncreasing the thicknessNo pollution in the processAnti-corrosive paintsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to solvent-free high-impact normal temperature-cured epoxy anti-corrosion paint which comprises the following raw materials by weight percent: 30-50% of epoxy resin, 10-30% of cardanol curing agent, 2-10% of toughening agent, 0.1-1% of modified polysiloxane leveling agent, 0.01-0.1% of polysiloxane defoaming agent, 4-8% of polyacrylic ester dispersing agent, 3-11% of zinc phosphate, 3-8% of aluminum triphosphate, 6-15% of barite powder, 3-8% of titanium dioxide, 0.01-0.1% of carbon black, 3-8% of mica powder and 3-8% of talcum powder. The solvent-free high-impact normal temperature-cured epoxy anti-corrosion paint has the benefits as follows: the solvent-free high-impact normal temperature-cured epoxy anti-corrosion paint is an environment-friendly paint, the solid content is high, the thickness of a once formed film is large, the phenomenon of trickling is avoided, the paint film is non-toxic, and no pollutions can be caused to the environment; and the solvent-free high-impact normal temperature-cured epoxy anti-corrosion paint is strong in adhesive force and extremely strong in impact resistance, and can be used as the anti-corrosion paint for drinking water pipelines, sewage, brine and ore slurry conveying pipelines and inner walls of storage tanks.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

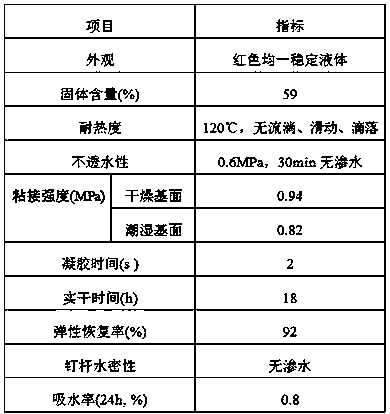

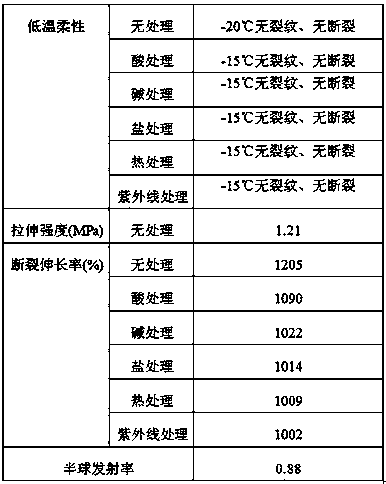

Heat reflection type colored spray-quick-setting rubber-asphalt waterproof coating material and preparation method therefor

ActiveCN109280452AHigh solid contentWater-based environmental protectionRosin coatingsConjugated diene hydrocarbon coatingsNano zinc oxideAsphalt

The invention provides a heat reflection type colored spray-quick-setting rubber-asphalt waterproof coating material. The waterproof coating material is characterized by comprising a component A and acomponent B, wherein the component A comprises the following ingredients: emulsified modified asphalt, fillers, an infrared reflection pigment, nano zinc oxide, a dispersant, latex, a bactericide, water and color paste. The component B is prepared through mixing calcium chloride, sodium chloride and water according to the mass ratio of 7.8: 0.2: 92. The waterproof coating material is aqueous andenvironmentally friendly and is high in adhesion and high in bonding strength.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL +3

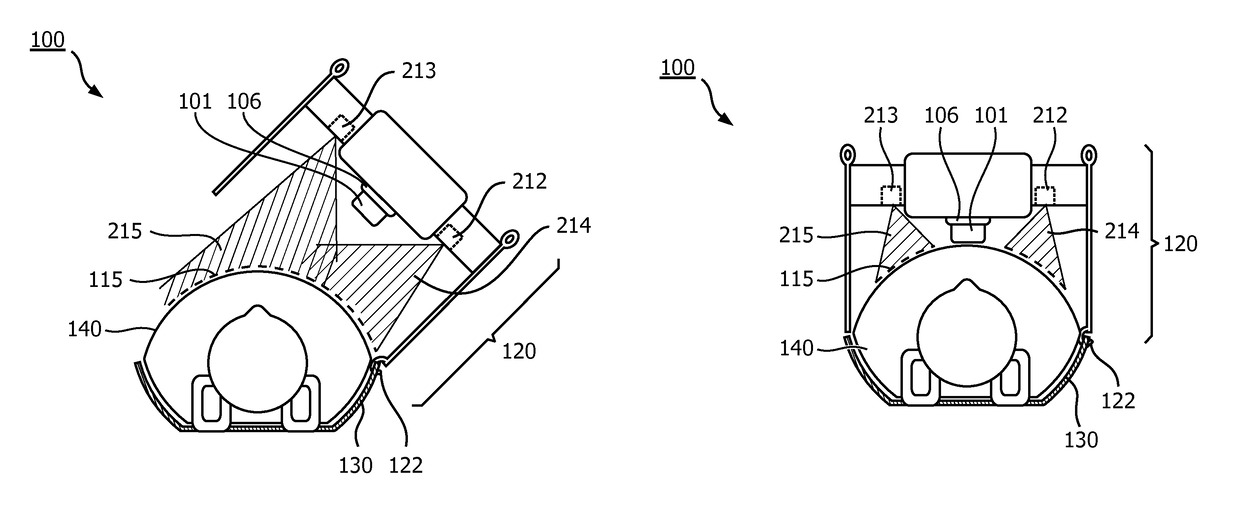

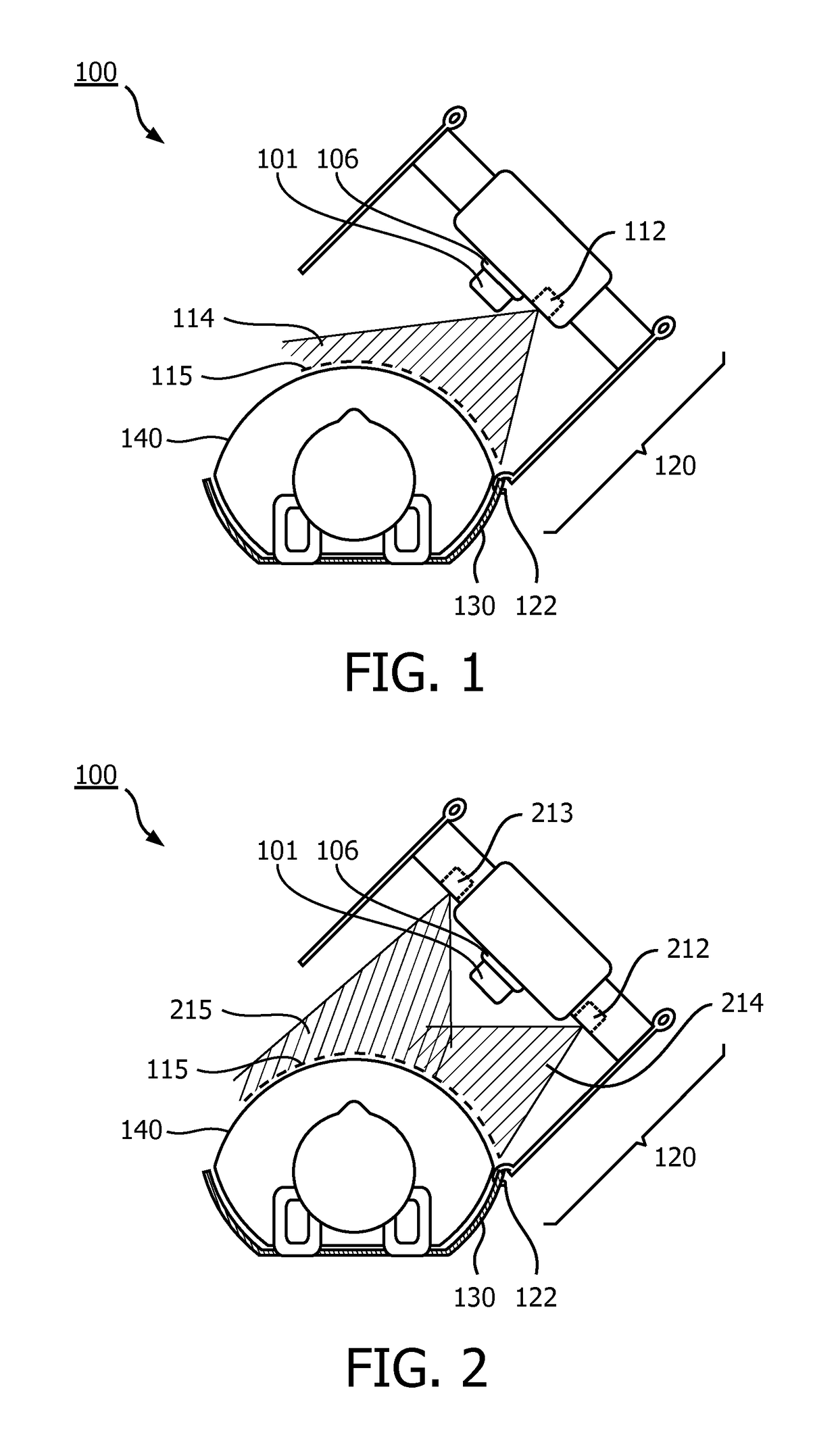

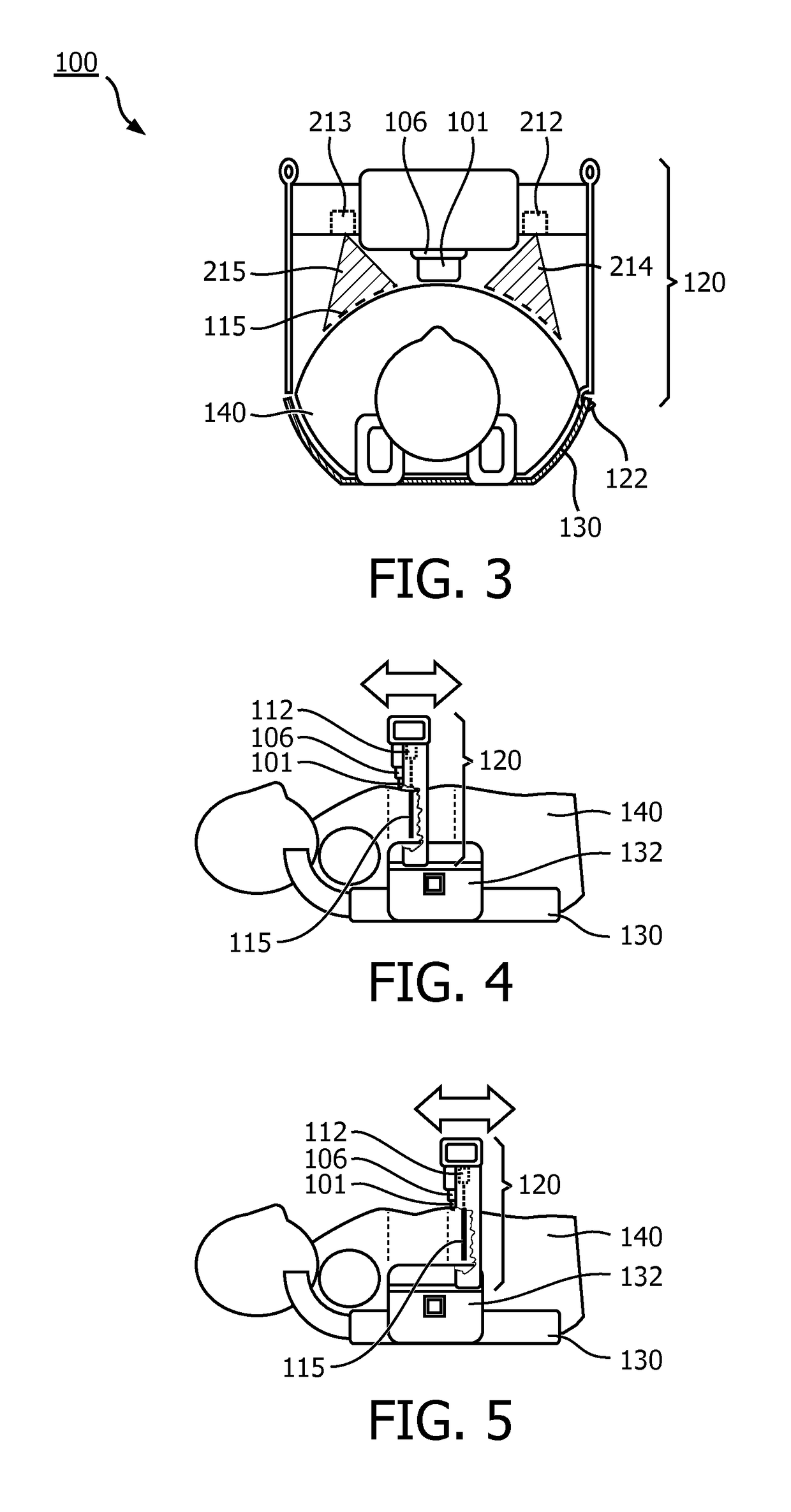

Laser alignment for automated CPR device

ActiveUS9707151B2Timely controlReduce in quantityElectrotherapyIron-lungsComputer scienceOptical alignment

An automated cardiopulmonary resuscitation (ACPR) device includes a compression element for acting on a compression location on a chest of a patient, and an optical alignment aid configured and arranged for projecting, at least temporarily, a light pattern on the patient's chest. The light pattern projected by the optical alignment aid guides the user during the placement procedure of the ACPR device. The light pattern projected by the optical alignment aid allows the user to monitor whether the position of the automated cardiopulmonary resuscitation device has moved during the administration of CPR.

Owner:KONINK PHILIPS ELECTRONICS NV

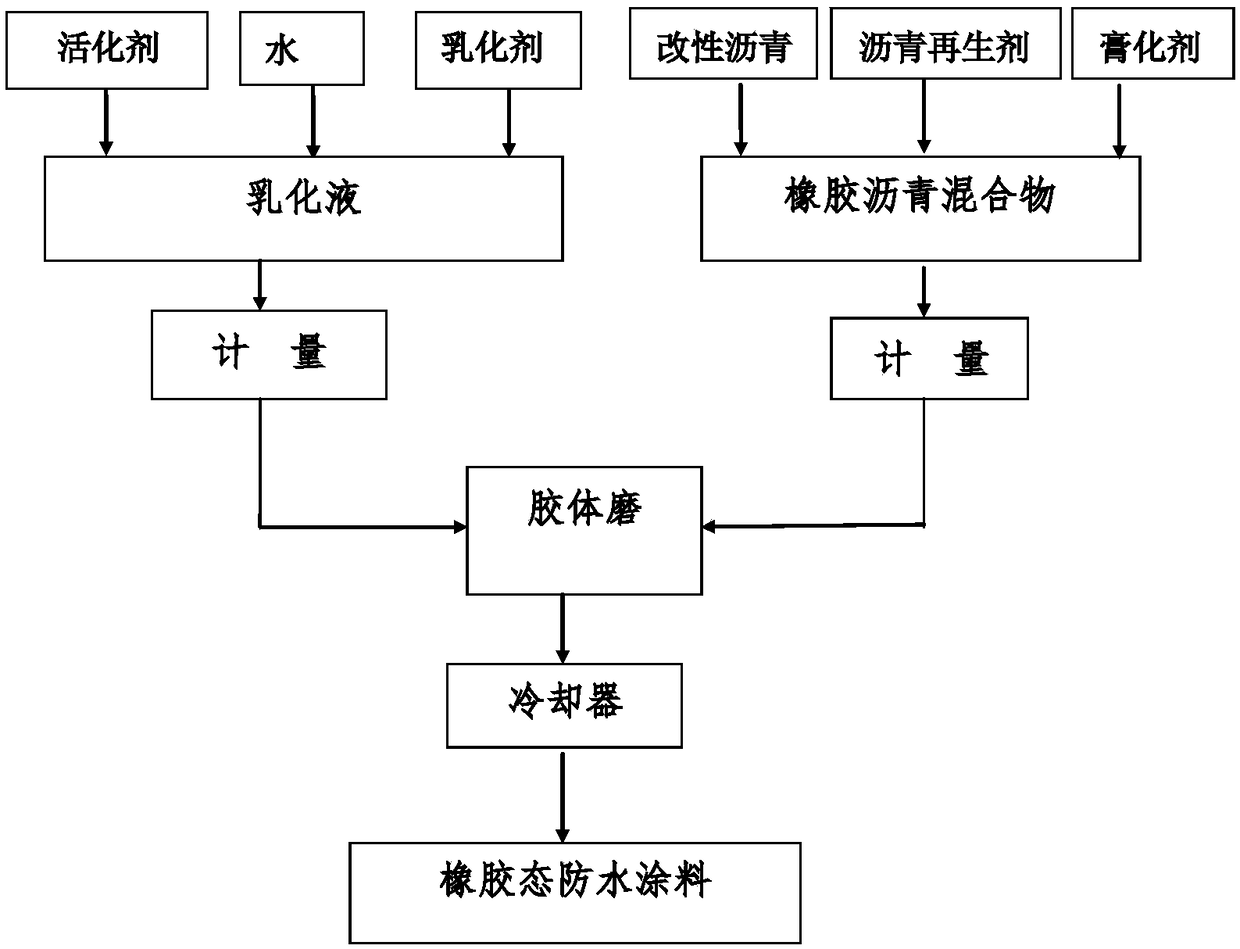

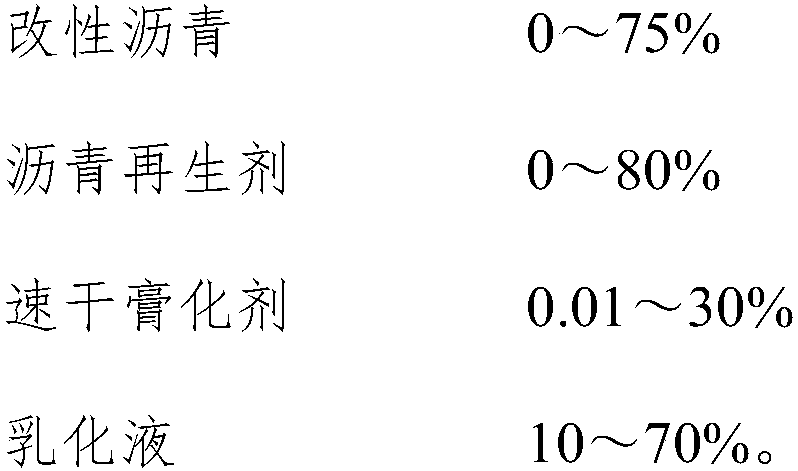

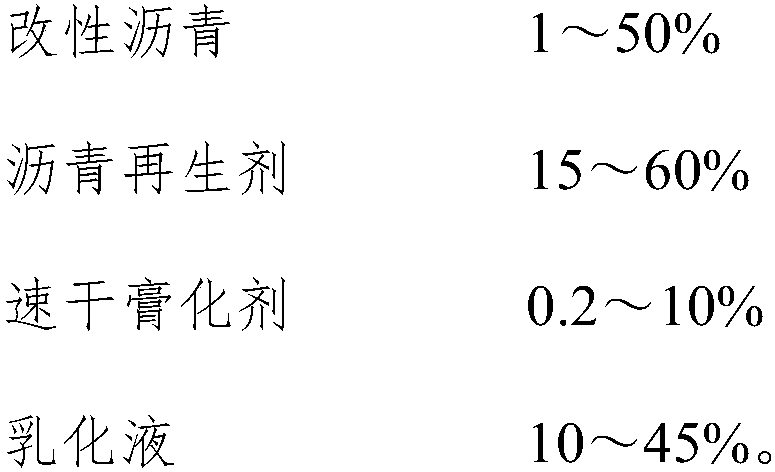

Multi-path thick coating and one-step molded rubber-state waterproof coating and preparation method thereof

InactiveCN108395844AReduce wax contentImprove performanceRoof covering using flexible materialsProtective foundationColloidAsphalt

The invention relates to multi-path thick coating and one-step molded rubber-state waterproof coating and a preparation method thereof and belongs to the technical field of sealing water prevention. The rubber-state waterproof coating provided by the invention is mainly prepared from the following raw materials in percentage by mass: 0 to 75 percent of modified asphalt, 0 to 80 percent of asphaltregeneration agent, 0.01 to 30 percent of quick-drying creaming agent and 10 to 70 percent of emulsified liquid; the rubber-state waterproof coating is prepared through steps of preparing a rubber asphalt mixture, preparing the emulsified liquid, emulsifying and creaming and de-foaming. According to the rubber-state waterproof coating, an inorganic creaming agent is used as the quick-drying creaming agent and the emulsified liquid is used for emulsifying and creaming the rubber asphalt mixture through a colloid mill by adopting a one-pot method and the prepared rubber-state waterproof coatingis uniform, fine and smooth and has high quality; the rubber-state waterproof coating has very good thixotropic performance, rapid dehydration and drying properties and excellent construction and application performance; the production efficiency is improved by applying the one-pot method and quality stability of a product and environment protection are facilitated.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

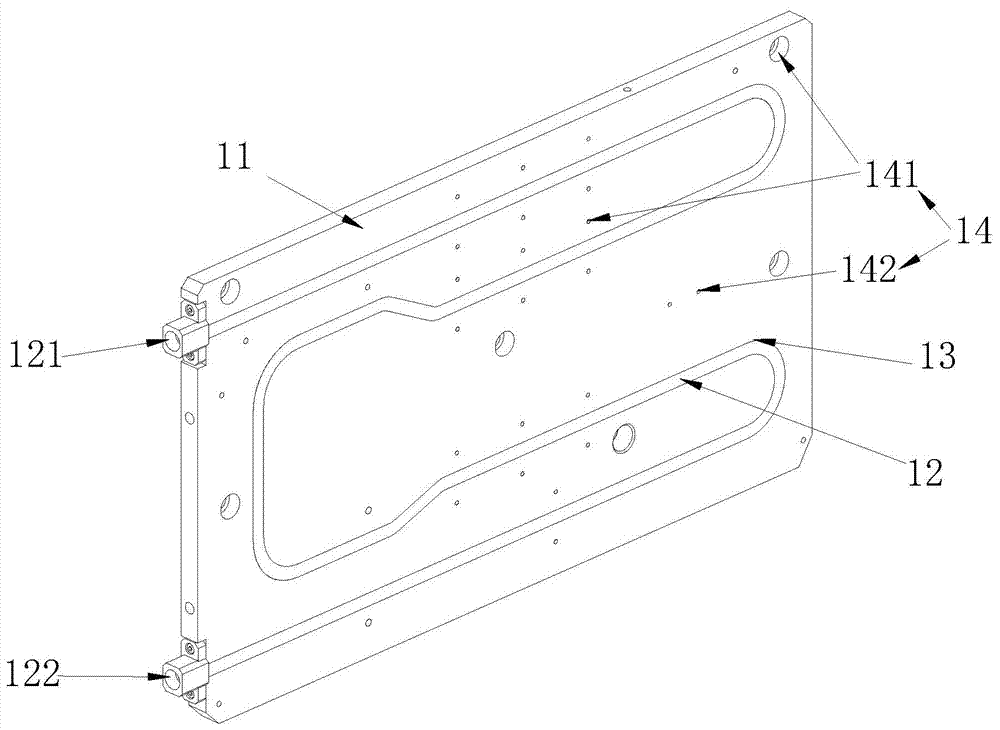

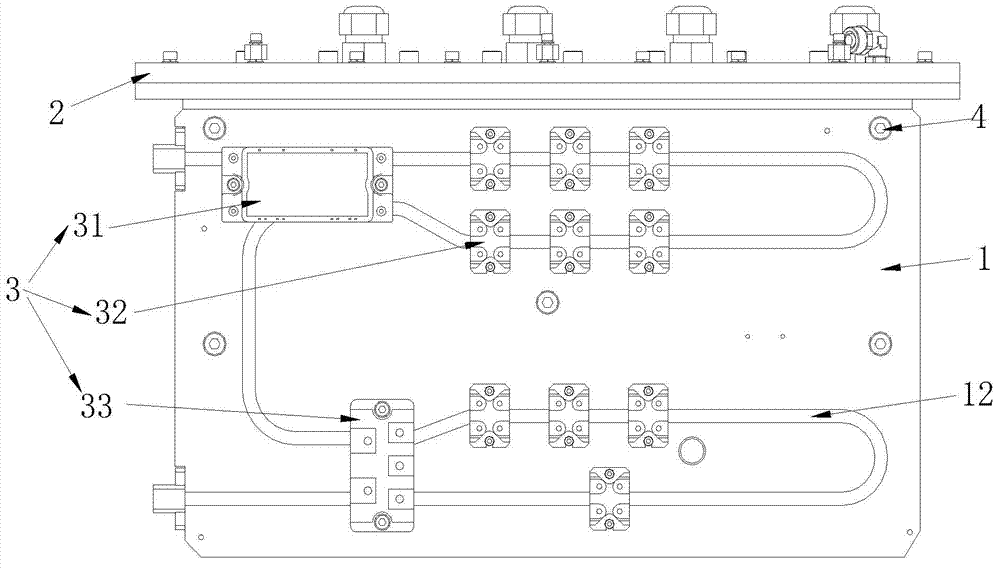

Radiator for high-voltage transformer oil tank and power module

InactiveCN103500627AImprove heat transfer efficiencyPrevent liquid leakageTransformers/inductances coolingBurning outThermal conductivity

The invention relates to the technical field of heat dissipation, in particular to a radiator for a high-voltage transformer oil tank and a power module. The radiator comprises a base plate and a copper pipe. The surface of the base plate is provided with a bent groove. The copper pipe is embedded in the groove. The gap where the groove makes contact with the copper pipe is filled with high thermal conductivity materials. The surface, opposite to the surface provided with the groove, of the radiator is tightly attached to the transformer oil tank. The power module is mounted on the copper pipe. Since the high-voltage transformer oil tank and the power module adopt the same radiator for heat dissipation, only one liquid path is needed for being connected with a cooling liquid, liquid path connection connectors are reduced, and the situation that the liquid is leaked from the liquid path to burn out a power supply is prevented. No water flows in the oil tank, and therefore the situation that water enters the high-voltage transformer oil tank to burn out a high-voltage transformer is prevented.

Owner:HANS LASER TECH IND GRP CO LTD

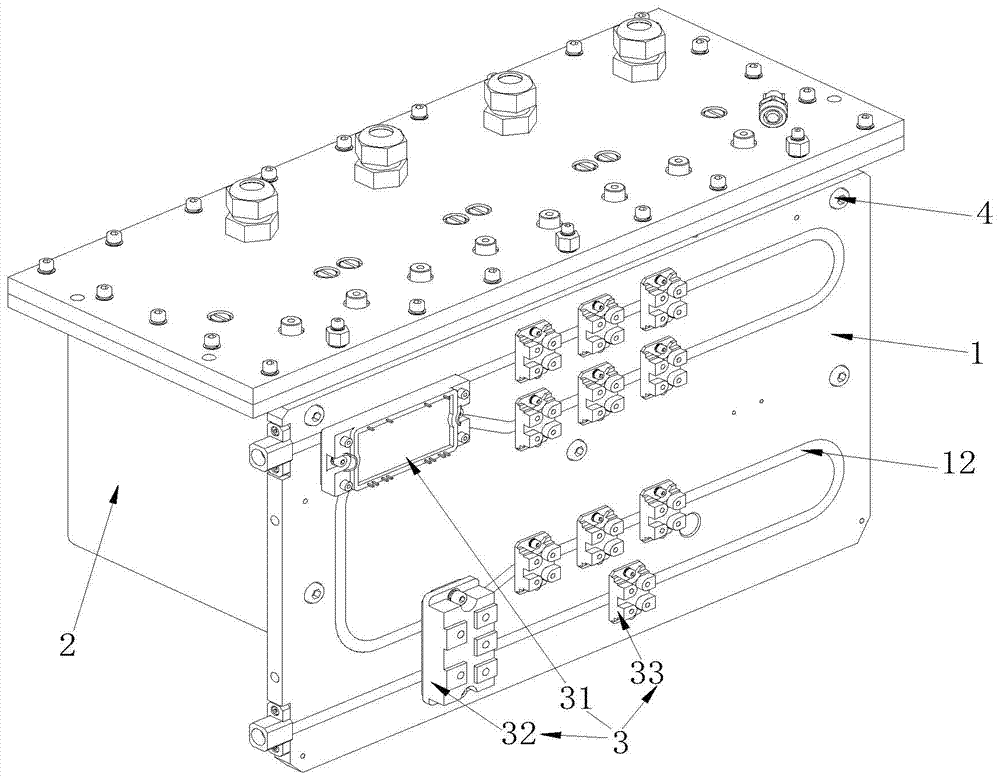

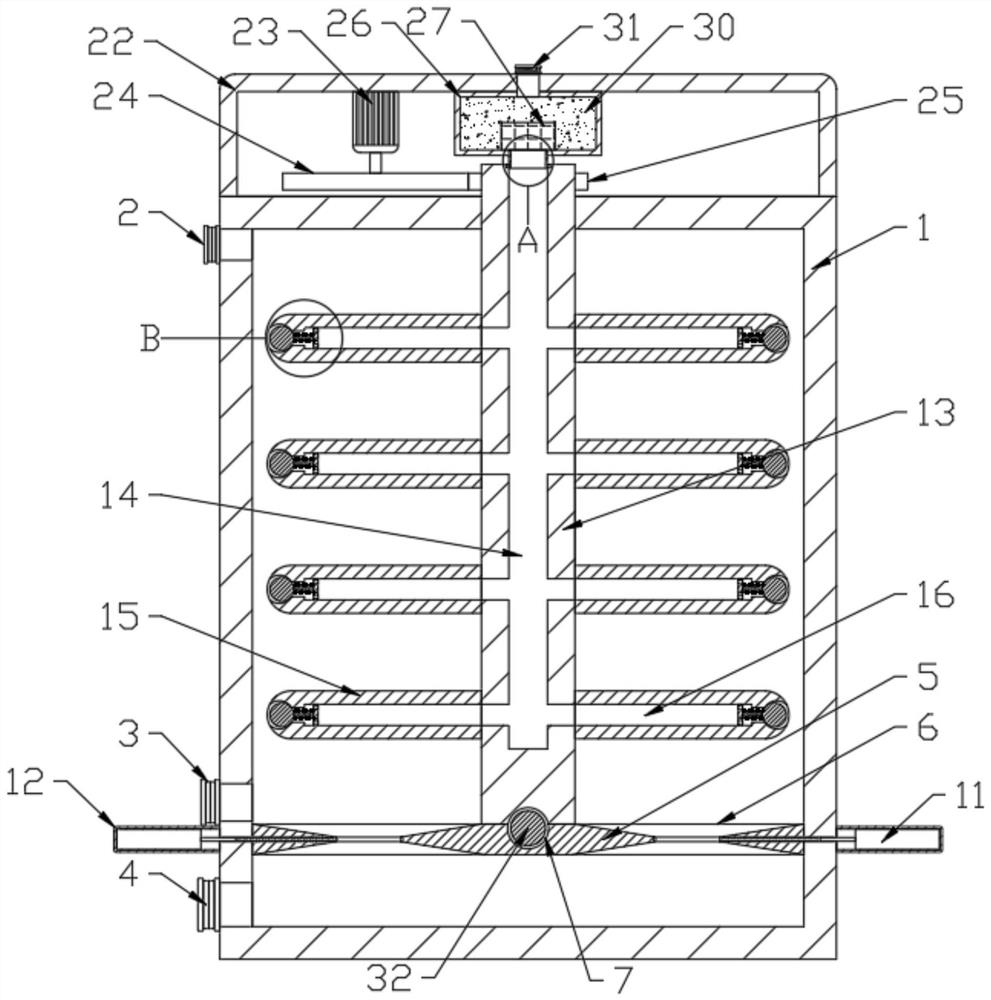

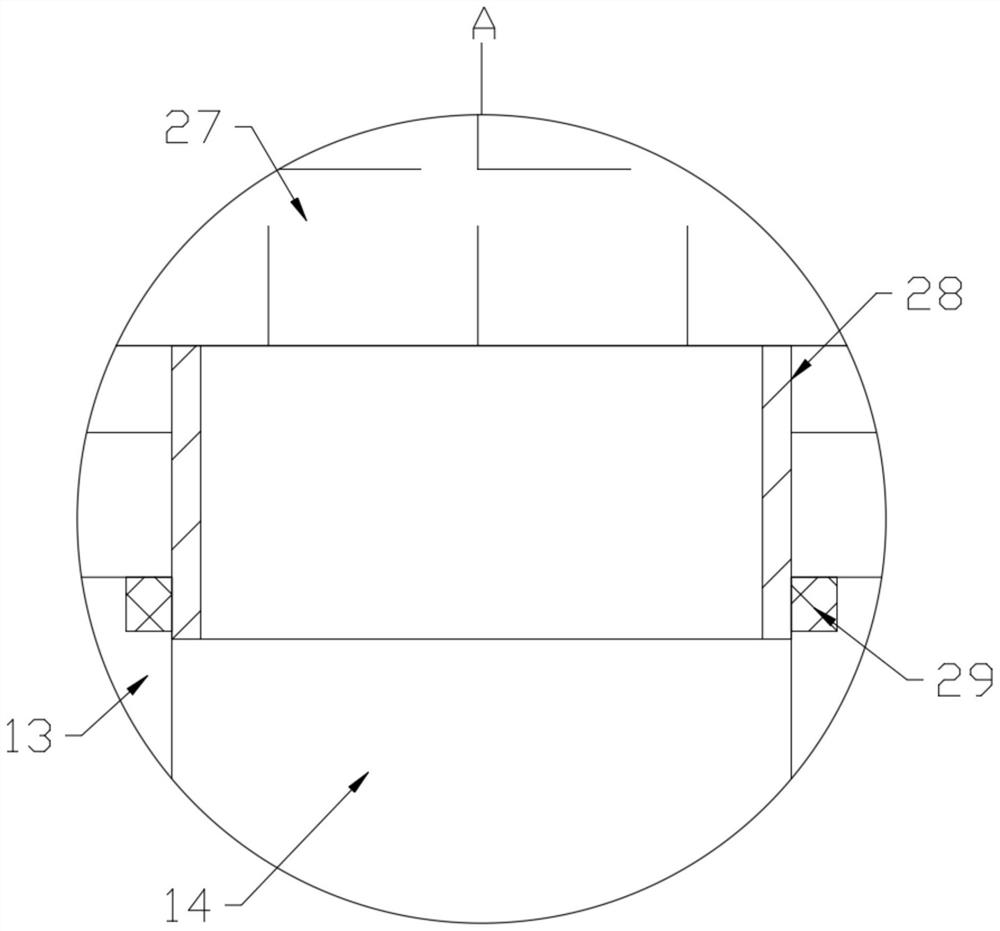

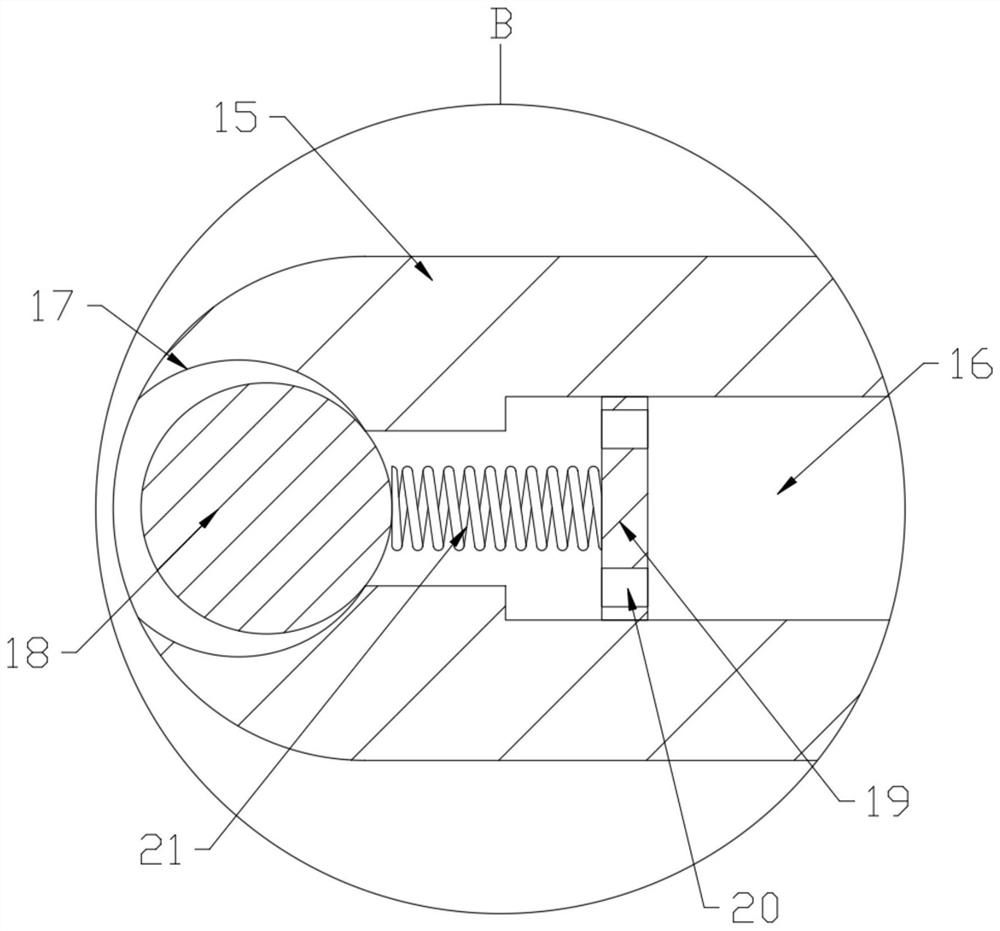

Engineering sewage disposal device

InactiveCN111977765ANo flowGood finished productRotary stirring mixersTransportation and packagingElectric machinerySewage

The invention discloses an engineering sewage disposal device. The engineering sewage disposal device comprises a box body, a water inlet, a water outlet and a sewage outlet, wherein the water inlet,the water outlet and the sewage outlet are formed in the side face of the box body; a fixing plate with two falling grooves and a rotary drum are arranged in the box body; a sealing assembly is arranged on the side face of the box body; a cavity is formed in the rotary drum, and a plurality of stirring rods are arranged on the rotary drum; a transverse cavity which communicates with the cavity isarranged in each stirring rod; a control assembly for controlling whether the transverse cavity communicates with the interior of the box body or not is arranged in each stirring rod; a case is fixedly connected to the upper end of the box body; a driving assembly is arranged in the case; and a conveying assembly for conveying flocculation liquid to the cavity in the rotary drum is arranged in thecase. A motor drives the rotary drum in the box body to rotate, the stirring rods on the rotary drum are driven to stir sewage in the box body, in the stirring process, self-adding of flocculating liquid is achieved through elasticity of a first spring, work of a liquid conveying pump in a liquid storage box and rotation speed adjustment of the rotary drum, and the flocculating liquid is added while stirring is conducted; and the flocculation liquid can be effectively mixed with the sewage for reaction, and impurities in the sewage are removed.

Owner:苏州和必尔斯电子科技有限公司

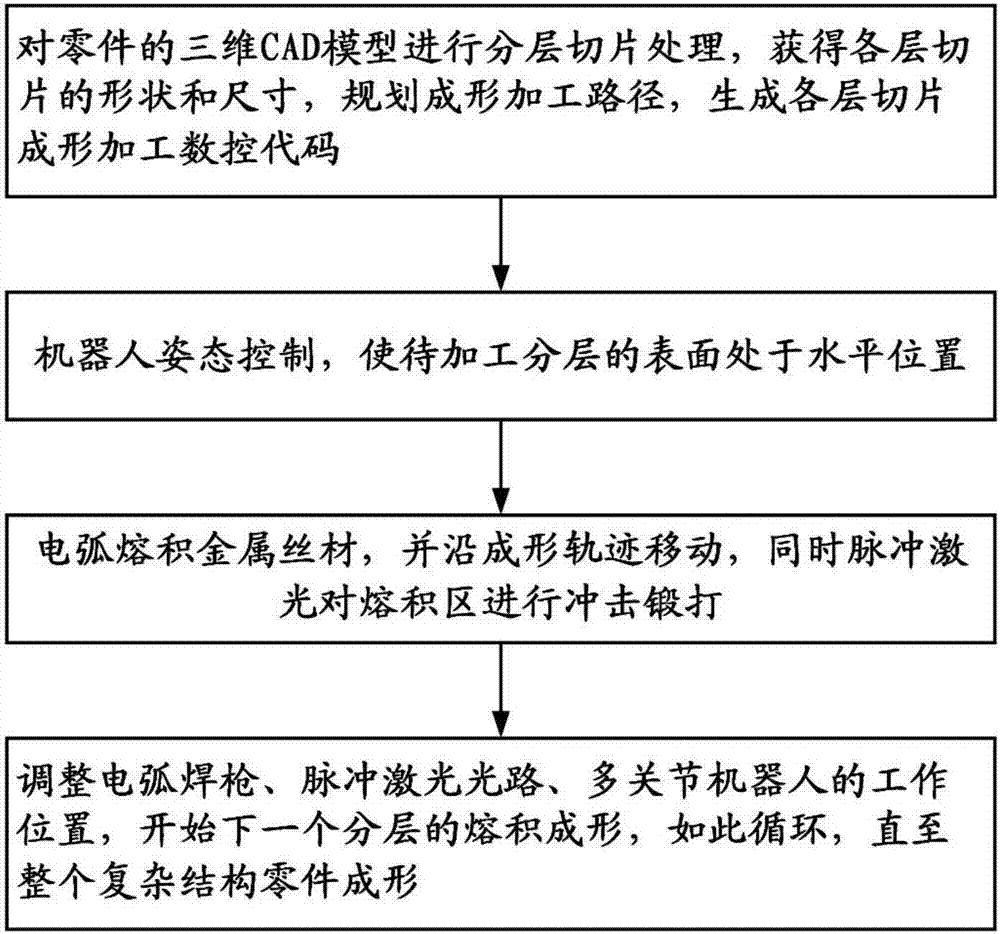

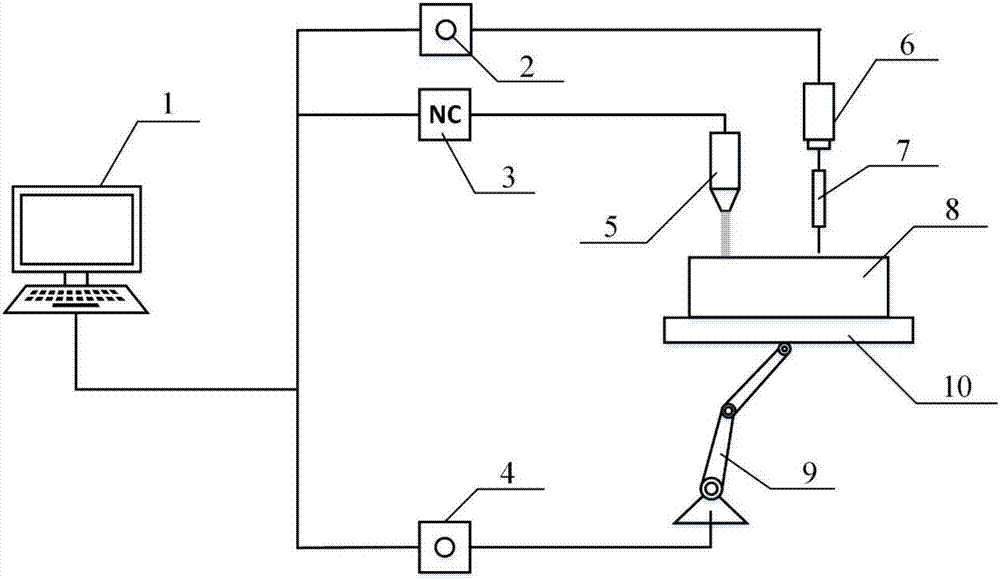

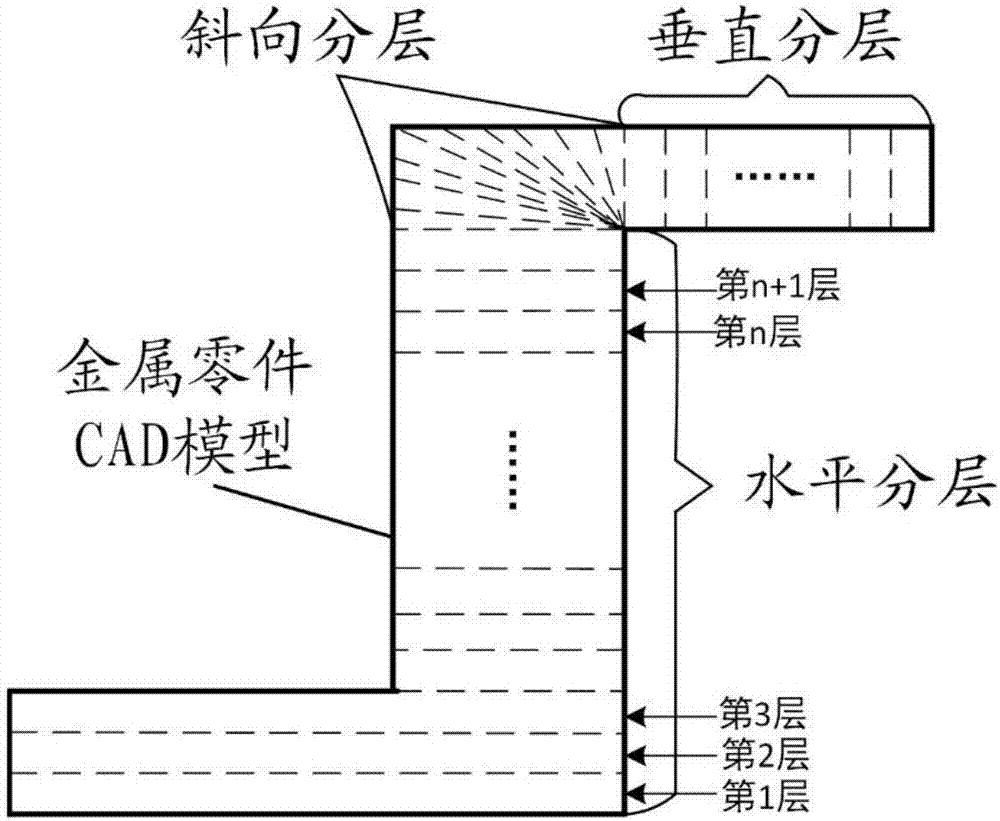

Robot posture controlled electric arc deposition laser forging additive manufacturing method and equipment

ActiveCN107234239AGrain refinementNo flowAdditive manufacturing apparatusIncreasing energy efficiencyShock waveElectric arc

The invention discloses a robot posture controlled electric arc deposition laser forging additive manufacturing method and equipment for complex structural components. By adopting a robot posture control scheme, the space position of a melt forming part on a machining region can be freely adjusted, and the melting material flowing, falling and collapsing problems caused by the gravity action are solved. Meanwhile, the force effect of shock waves induced by pulse laser is used for reducing or eliminating internal defects and residual stress of a melting region and refining grains of the melting region, and the mechanical performance of the formed metal parts is improved. By means of the robot posture controlled electric arc deposition laser forging additive manufacturing method and equipment, the complex structural metal parts can be directly and rapidly formed, the efficiency is high, and the quality of the formed metal parts is relatively high.

Owner:GUANGDONG UNIV OF TECH

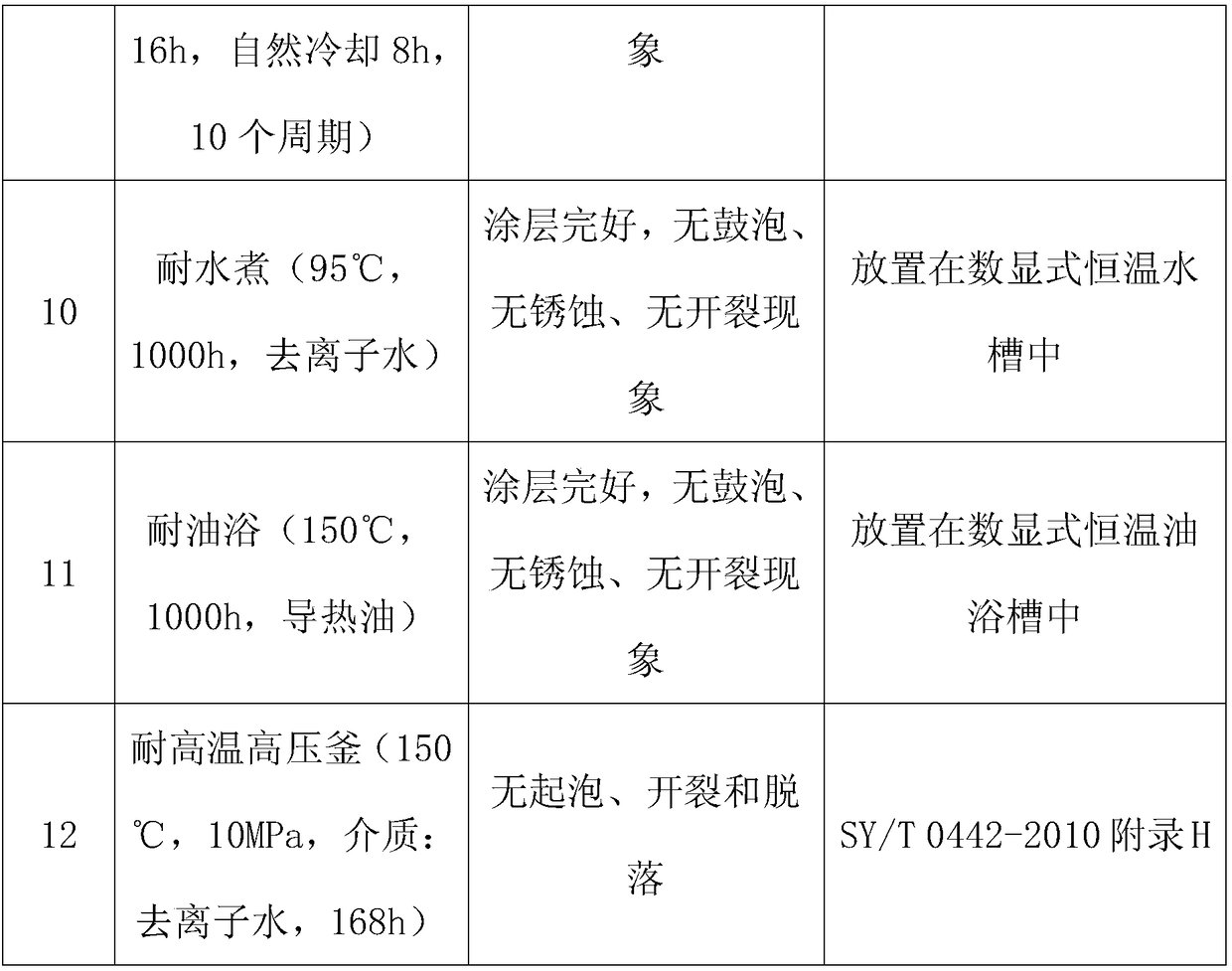

High-temperature-resisting anticorrosion coating for inner wall of steel thermal pipeline and construction technology

InactiveCN108864791AAchieving Pipeline OperationsMeet the standard requirementsFireproof paintsAnti-corrosive paintsProduction lineTemperature resistance

The invention discloses a high-temperature-resisting anticorrosion coating for an inner wall of a steel thermal pipeline. The high-temperature-resisting anticorrosion coating is prepared from the following raw materials according to the ratio: 50 to 75 percent of a base material and 25 to 50 percent of a curing agent; the high-temperature-resisting anticorrosion coating is smooth and uniform and has relatively strong high temperature resistance and relatively strong corrosion resistance; the standard requirements of the inner wall of the steel thermal pipeline on the anticorrosion coating aremet. The invention further discloses a construction method of the high-temperature-resisting anticorrosion coating for the inner wall of the steel thermal pipeline; the construction method comprises the following four steps: preparing the high-temperature-resisting anticorrosion coating; pre-treating the inner surface of a steel pipe; carrying out spraying treatment on the inner surface of the steel pipe; checking the quality. According to the construction method, the production line work the construction of the anticorrosion coating is realized and the construction efficiency is extremely improved; meanwhile, a construction finished product has the characteristics of smooth and uniform coating, no flowing, no orange skin, no leakage points and the like and can meet the standard requirements of the inner wall of the steel thermal pipeline on the anticorrosion coating.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Method of impregnating graphite electrode by using vinylit resin

The invention relates to a graphite electrode, in particular to a method of impregnating the graphite electrode by using vinylit resin, which comprises the following steps: finished graphite electrode product is placed into an impregnation container and then is sealed, the first vacuumizing is performed, the vinylit resin is sucked from a pipe at one side of the impregnation container to impregnate the working surface of the graphite electrode, the second vacuumizing is performed, the first pressurizing is performed, the third vacuumizing is performed, the second pressurizing is performed, a valve of a pressure meter is opened for relieving pressure, an impregnation basket is gripped, the impregnated graphite electrode is taken out, the resin on the surface of the impregnated graphite electrode is removed by using solvent, and the graphite electrode is placed at normal temperature until no liquid flows down on the surface for polymerizing. Air in the clearance of the graphite electrode treated by the method is thoroughly discharged so that the resin is fully impregnated into the inner walls of fine holes of graphite and the inner walls of the fine holes of the graphite are filled with the resin, the polymerization is complete, the surface of the graphite has no phenomenon of bubble flowing, and no overflowing and scaring, and is not easy to oxidize to cause the shedding, therefore, the graphite has good corrosion resistance and long service life. The method has low cost, and better solves the penetration problem.

Owner:殷志军

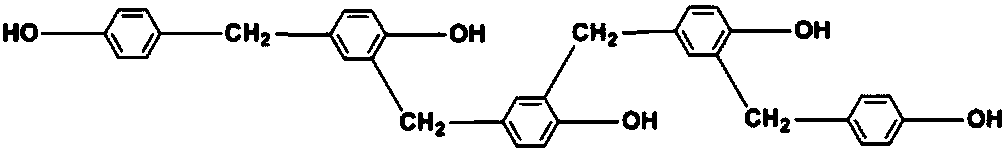

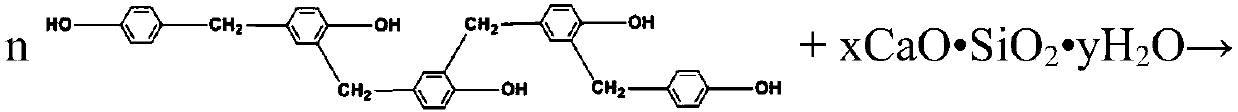

Hyperbranched structure-containing asphalt pavement joint sealant and preparation method thereof

InactiveCN106854452AGood high and low temperature resistanceHigh elastic recovery rateNon-macromolecular adhesive additivesBituminous material adhesivesReducerRoad surface

The invention discloses a hyperbranched structure-containing asphalt pavement joint sealant and a preparation method thereof. The joint sealant is prepared from, by weight, 44-52 parts of matrix asphalt, 5-9 parts of a hyperbranched monomer, 10-20 parts of an auxiliary additive, 1-7 parts of a viscosity reducer, 2-10 parts of a composite modifier and 12-18 parts of a filler. The preparation method comprises the following steps: heating the matrix asphalt to 130-150 DEG C, conveying the heated matrix asphalt to a stirring tank, adding the auxiliary additive, stirring the matrix asphalt and the auxiliary additive for 30 min, heating the obtained mixture to 150-170 DEG C, sending the heated mixture to a colloid mill, heating the mixture to 190 DEG C, adding the composite modifier, stirring the mixture and the composite modifier for 1 h, cooling the obtained material to 160-170 DEG C, adding the hyperbranched monomer, stirring the material and the hyperbranched monomer for 1 h, adding the filler and the viscosity reducer, and stirring all above materials for 1 h to obtain the joint sealant. The hyperbranched structure-containing asphalt pavement joint sealant has high elasticity recovery rate and excellent high and low temperature resistance, is suitable for asphalt pavement cracks under different climate conditions; and the preparation method has the advantages of simplicity, simplicity in operation, and suitableness for industrial application.

Owner:江苏超力建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com