Spray-coating sealing material for coal rock mass

A coal rock mass and sealing material technology, applied in the field of organic/inorganic composite materials, can solve problems such as unsatisfactory curing speed and poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] According to the amount of polyvinyl acetate emulsion, acrylic emulsion (using pure acrylic emulsion, styrene-acrylic emulsion or vinegar-acrylic emulsion respectively), ethylene-vinyl acetate (VAE) emulsion, and styrene-butadiene emulsion listed in the following table 1, after mixing, 4Kg of polymer emulsions A-Q were prepared respectively for subsequent use.

[0100] polymer emulsion

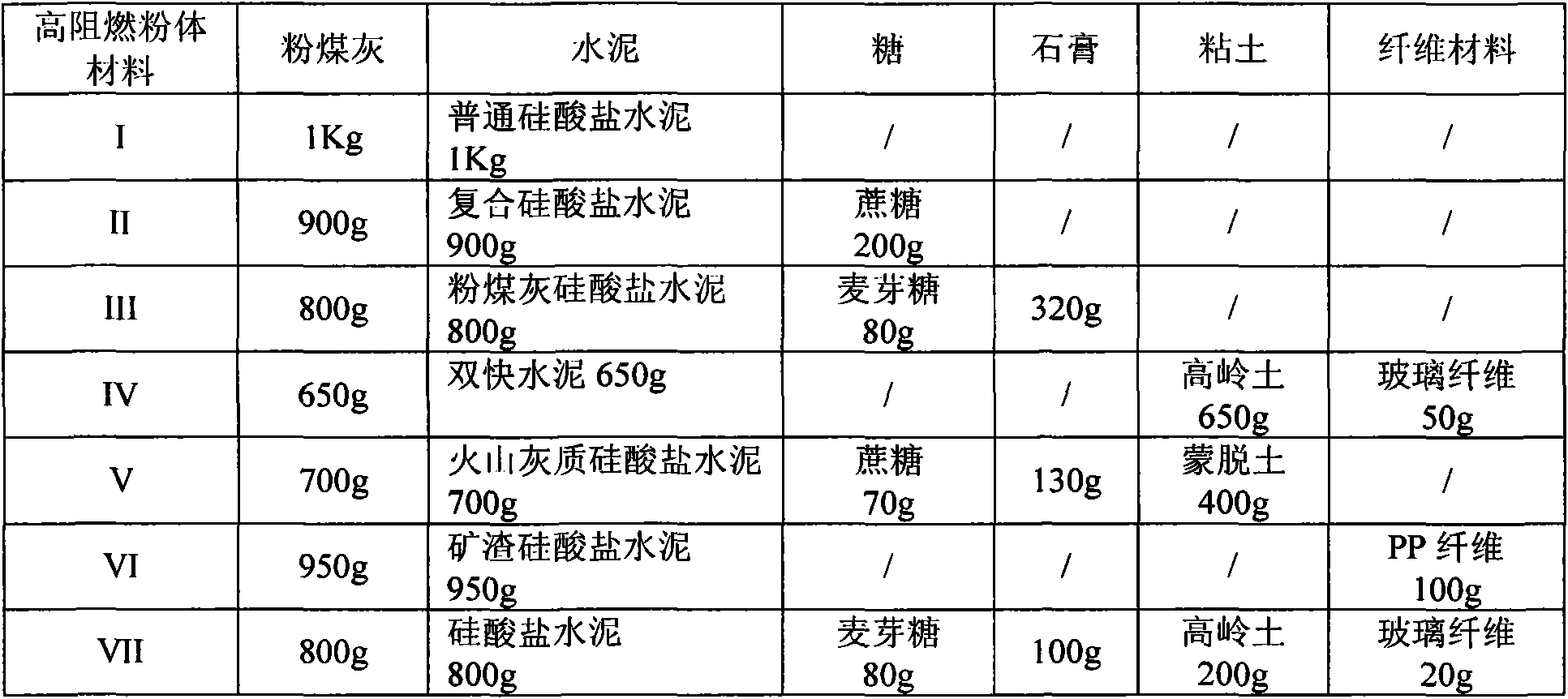

[0101] According to the dosages listed in Table 2 below, mix the involved fly ash, cement, sugar, gypsum, clay, and fiber materials evenly to prepare 2Kg of high flame-retardant powder materials for later use.

[0102]

[0103] Randomly select one group from the 17 kinds of polymer emulsions in Table 1, and mix them one by one with any group of the 7 kinds of high flame-retardant powder materials in Table 2 according to the ratio of 2:1 to prepare 119 A kind of coal and rock mass spraying sealing material.

[0104] These coal and rock mass spray sealing materials all meet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com