Patents

Literature

158results about How to "Construction environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

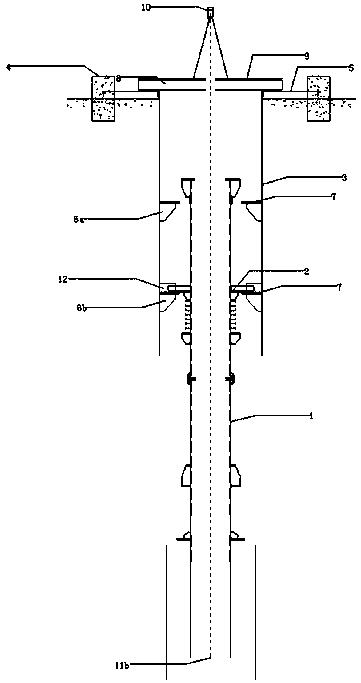

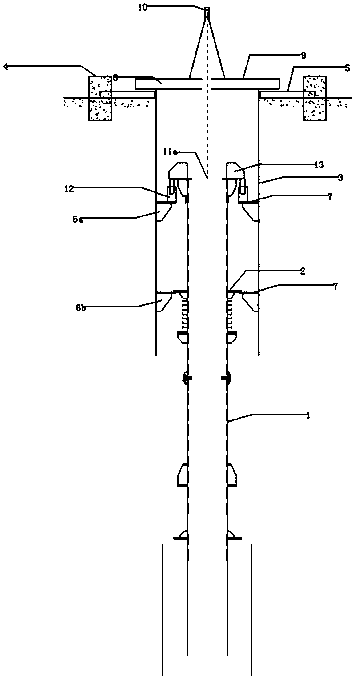

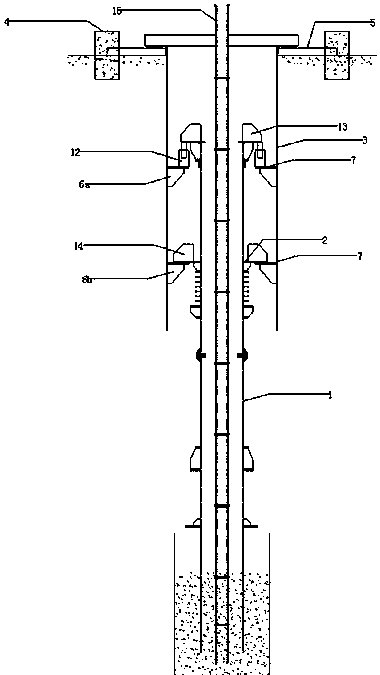

Method for treating soft foundation

ActiveCN101831903AReduced bound waterSolve the problem that the water content is difficult to be lower than the critical point of 35%Soil preservationThermal energyVacuum pumping

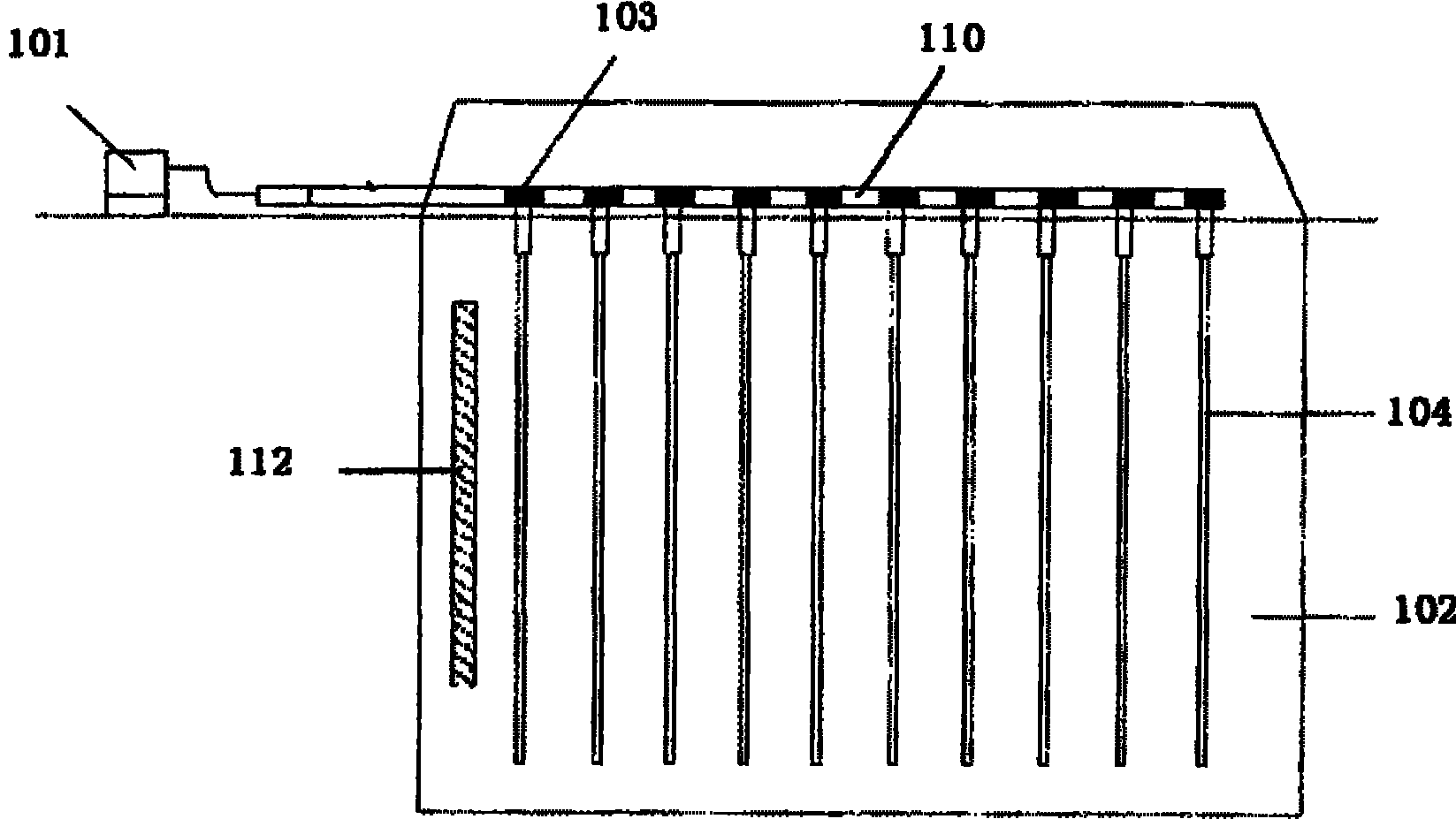

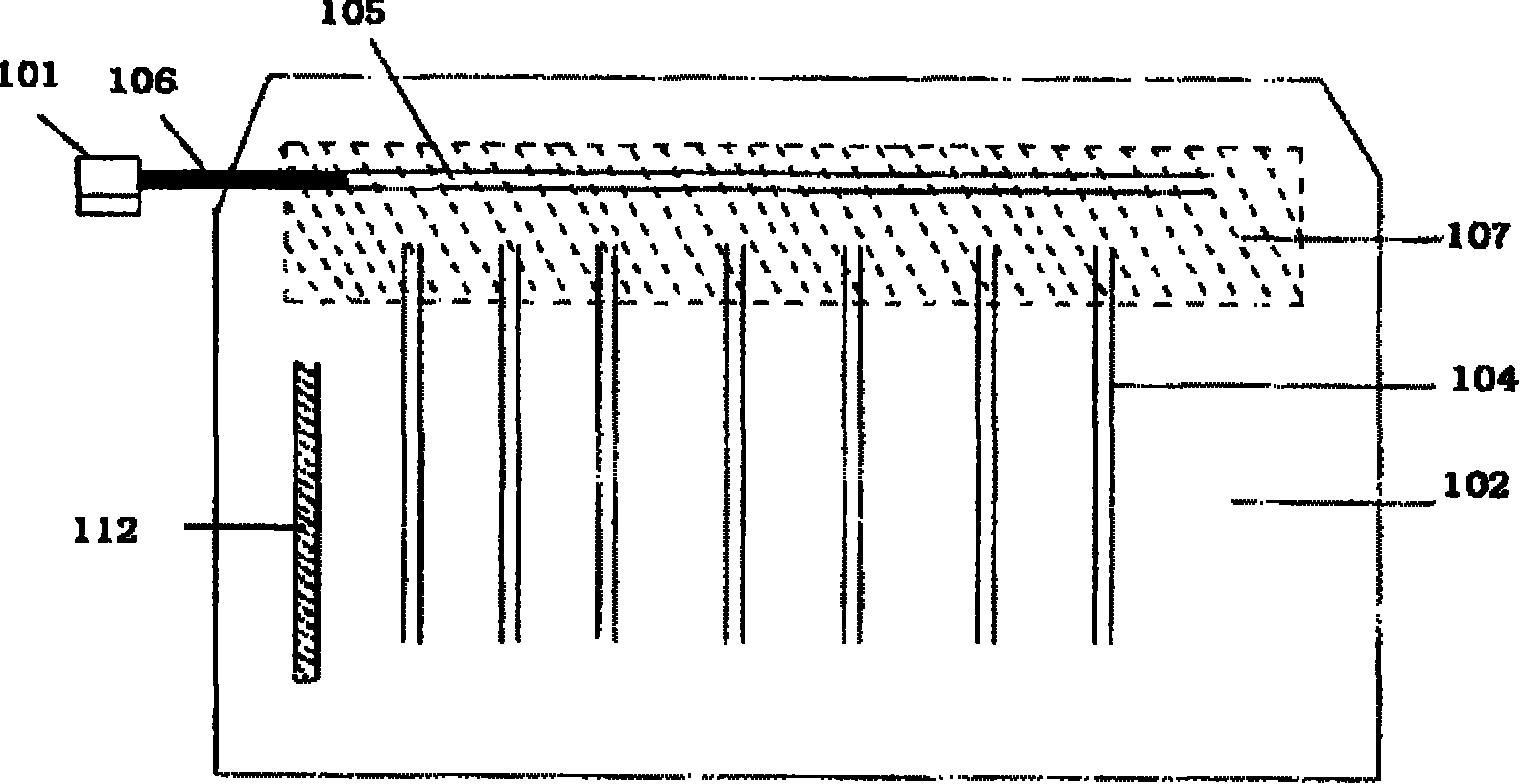

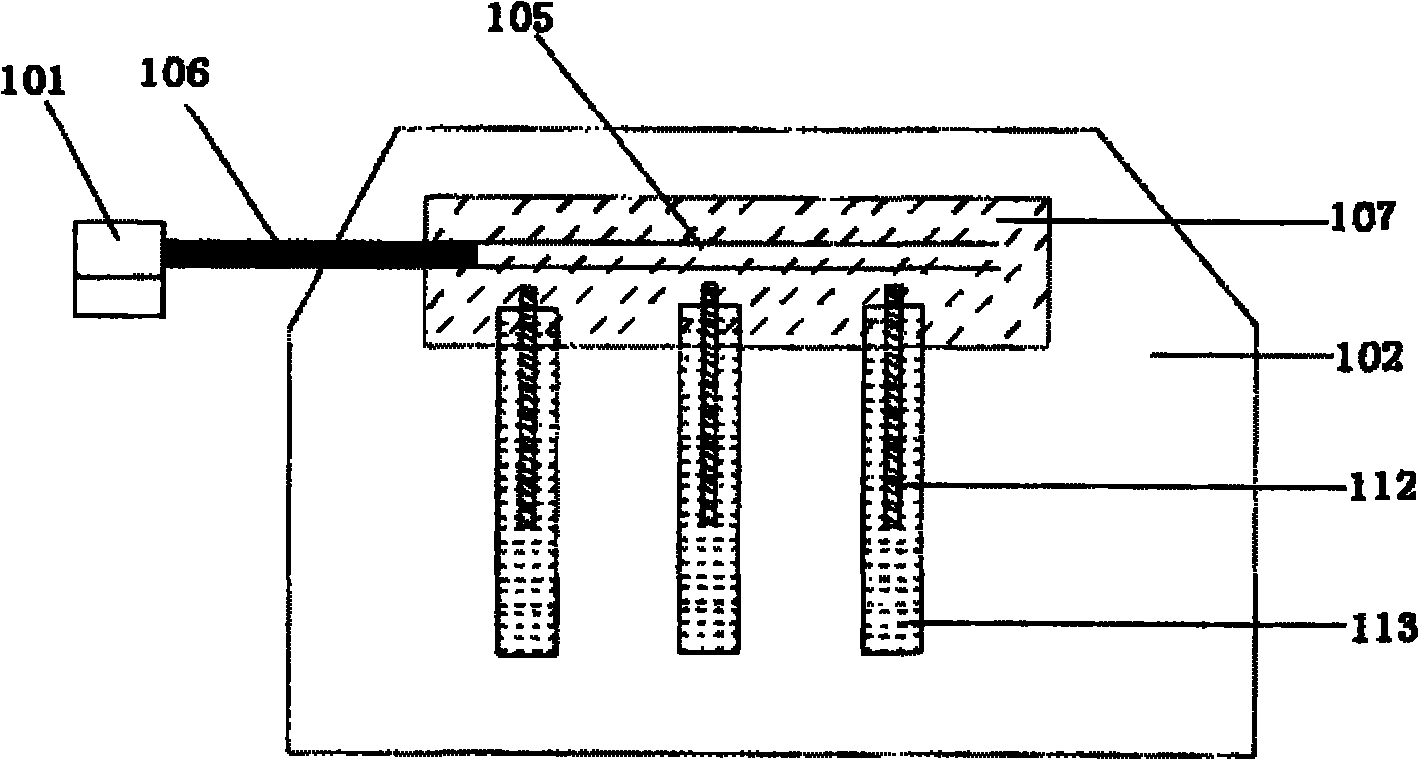

The invention relates to a method for treating a soft foundation. The method comprises the following steps of: 1, inserting electrical bars into treated soft soil; 2, reserving vertical drainage channels in the treated soft soil and communicating the vertical drainage channels with vacuum-pumping equipment; and 3, starting up the electrical bars to heat the treated soft soil and simultaneously starting up the vacuum-pumping equipment to vacuumize for quickening the drainage of bound water of the treated soft soil. The invention also relates to another method for treating the soft foundation. The method is implemented by arranging the electrical bars in sand drains. Due to the adoption of the method, the bound water in the soft soil can be gasified so that the bound water is quickly drained out of the soft soil, and the difficult problem that the water content of the soft soil is difficult to be lower than the critical point of 35 percent is solved. The method effectively reduces the bound water of the soft soil, realizes controllable improvement of mechanical properties of the soft soil, and meets the requirements of engineering construction by controlling heat energy and heating time. Due to the adoption of the technical scheme of the method, the time limit for a project can be shortened by over 50 percent, the construction cost can be saved by over 30 percent, the quality can be greatly improved, and the construction is environmentally protective.

Owner:SHANGHAI HARBOUR SOFT SOIL TREATMENT ENG CO LTD

A construction method for the communication channel of the broken stratum in the shield tunnel crossing the river

ActiveCN102287198AEnsure normal excavationMake sure the excavation is completeUnderground chambersBlastingEnvironmental resistanceGround contact

The invention relates to a construction method for an underground tunnel, in particular to a construction method for a river-crossing shield tunnel crushed stratum communication channel, which is used for solving the problems of failure of stratum reinforcement, long working period, high cost, poor quality and the like existing in the construction process of the conventional river-crossing shieldtunnel crushed stratum communication channel. The method comprises the following steps of: determining the position of the communication channel; before opening, performing pre-grouting to integrallyconsolidate broken rock outside the excavation outline of the communication channel; forming a high-strength waterproof curtain; before excavation, performing stress conversion; drilling and partitioning to remove a left line pipe sheet, brushing the top, performing tunnel excavation with a combined damping burst technology, and timbering; and drilling and partitioning to remove a right line pipesheet, brushing the top, and performing second lining construction by adopting a combination template. Due to the adoption of the construction method, water seepage is avoided after excavation, the technology is advanced, the blank of a communication channel pre-grouting technology is fulfilled, the working period is short, the mechanical degree is high, the process is simple, construction is environmentally-friendly, collapse is avoided, and over-excavation is greatly lowered; and the method has a wide application range.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

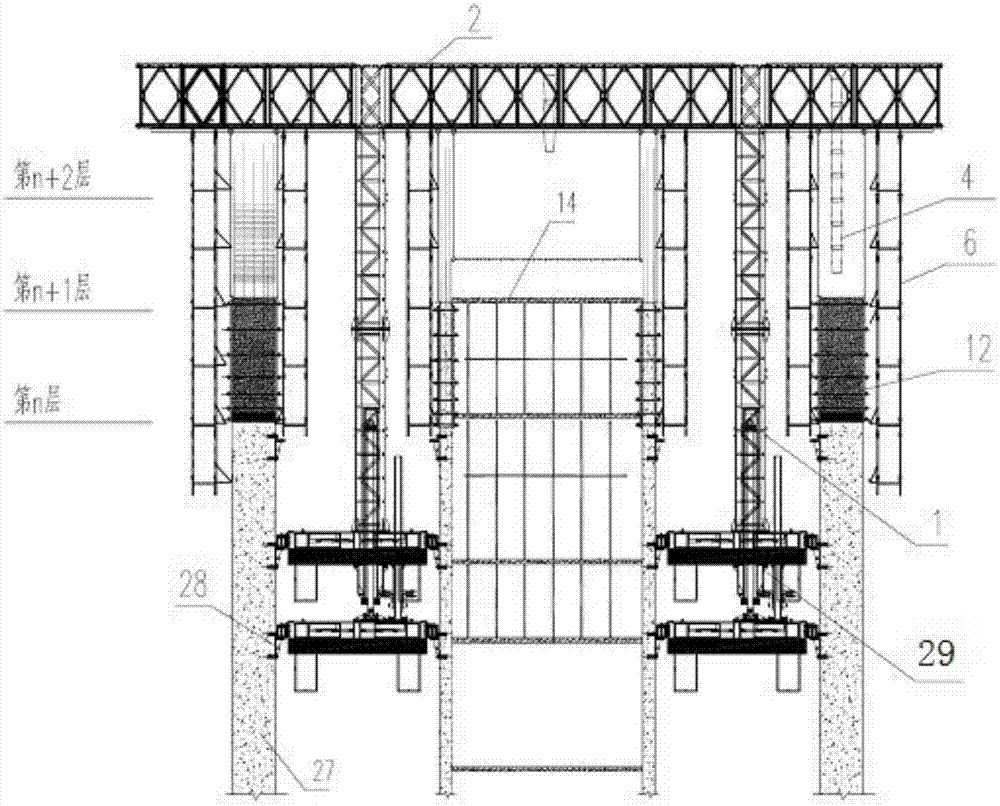

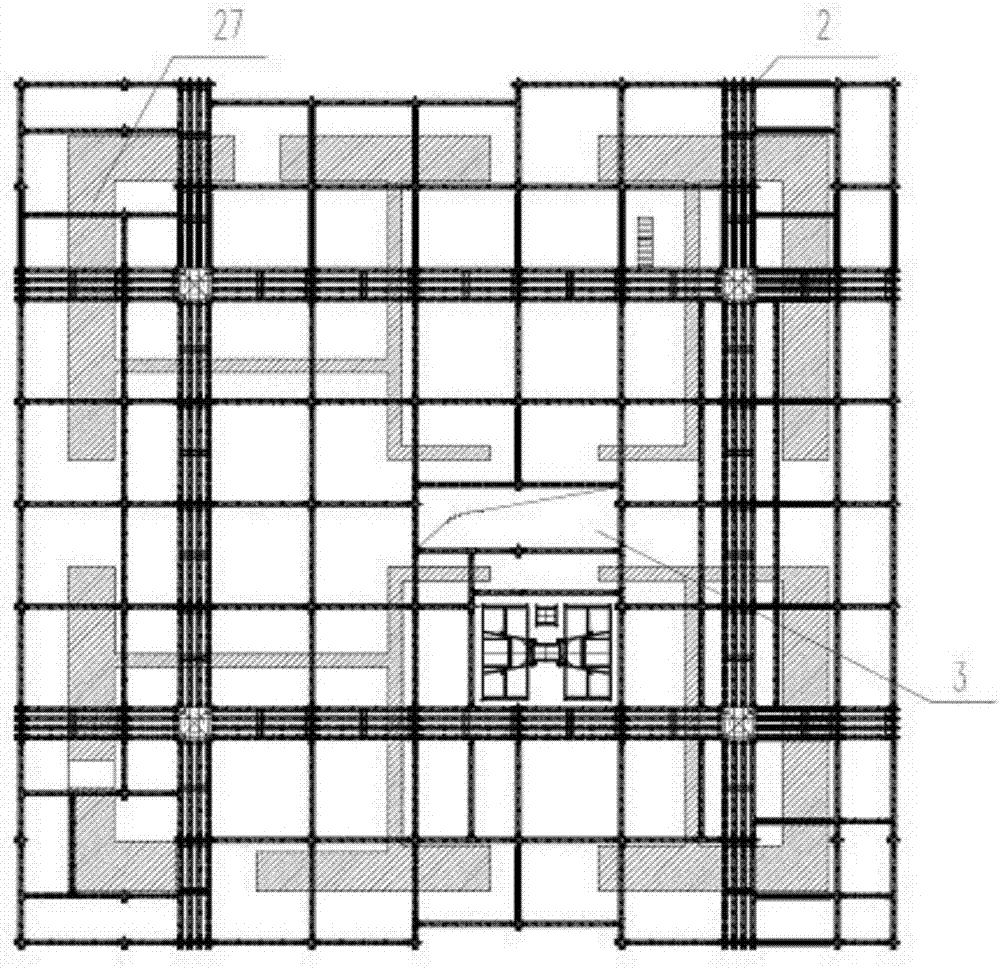

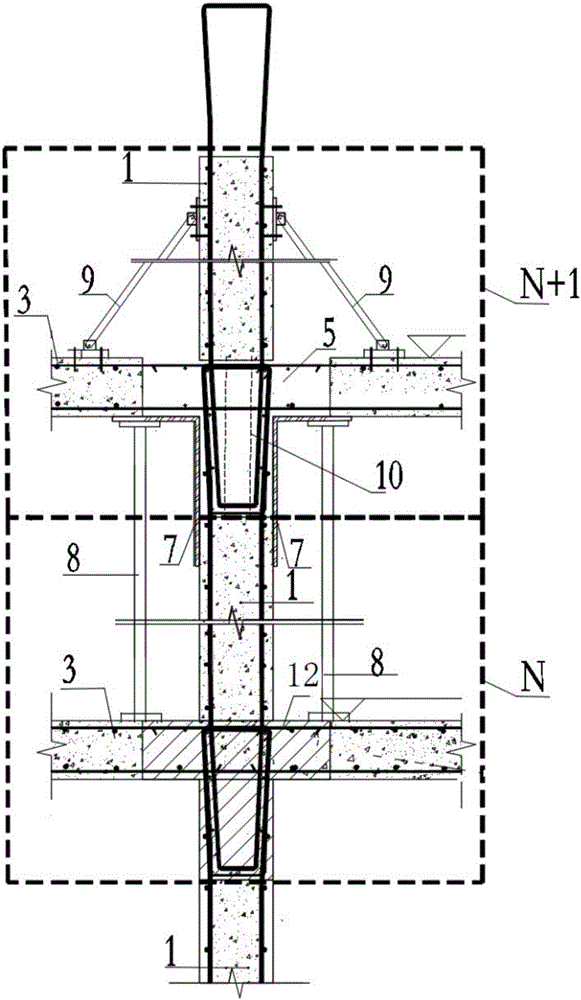

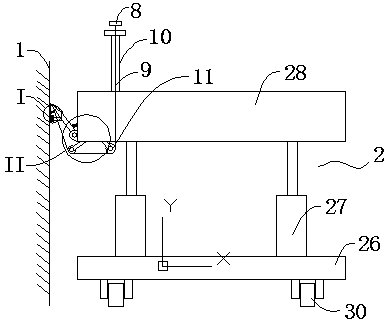

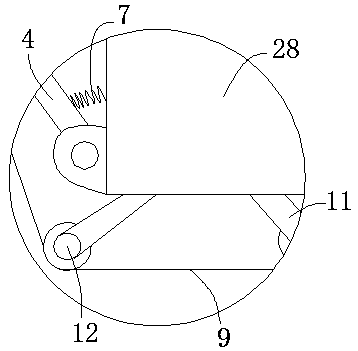

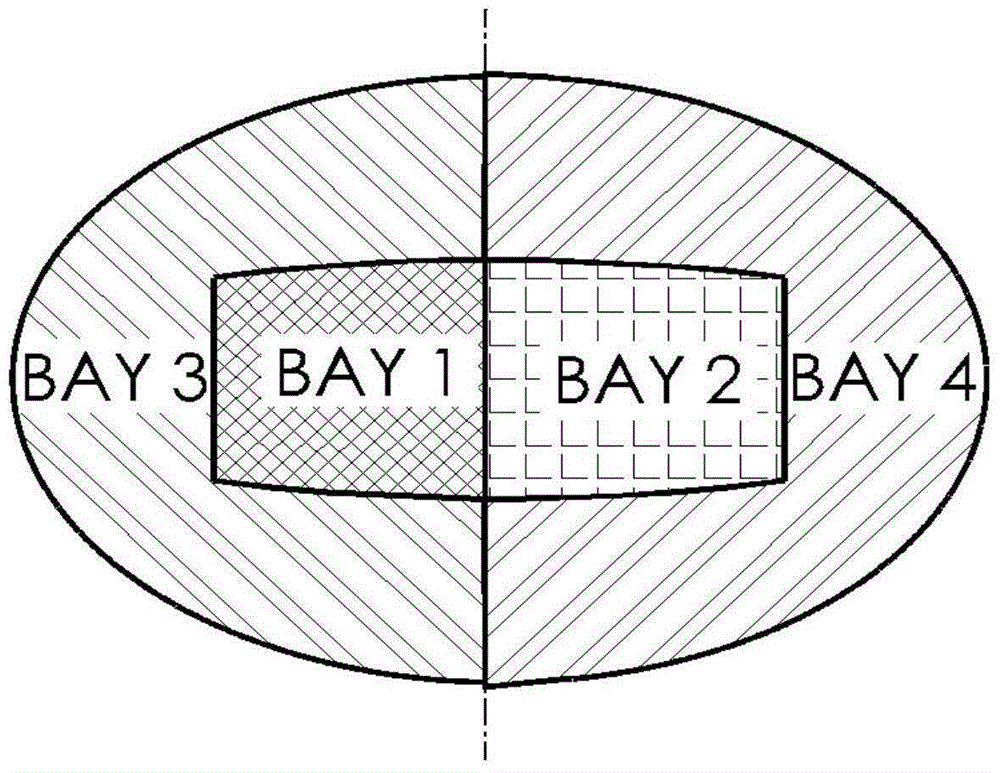

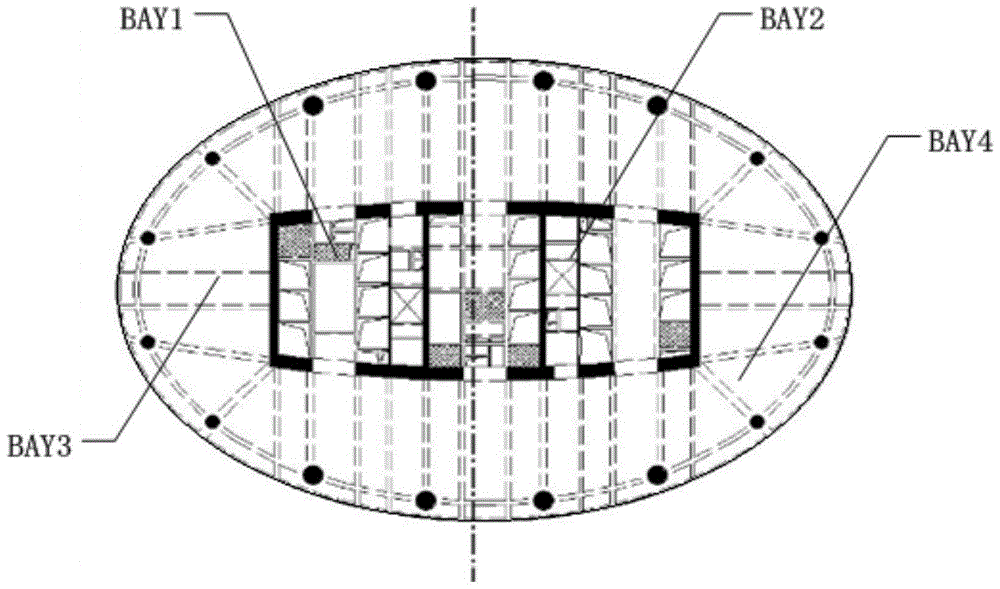

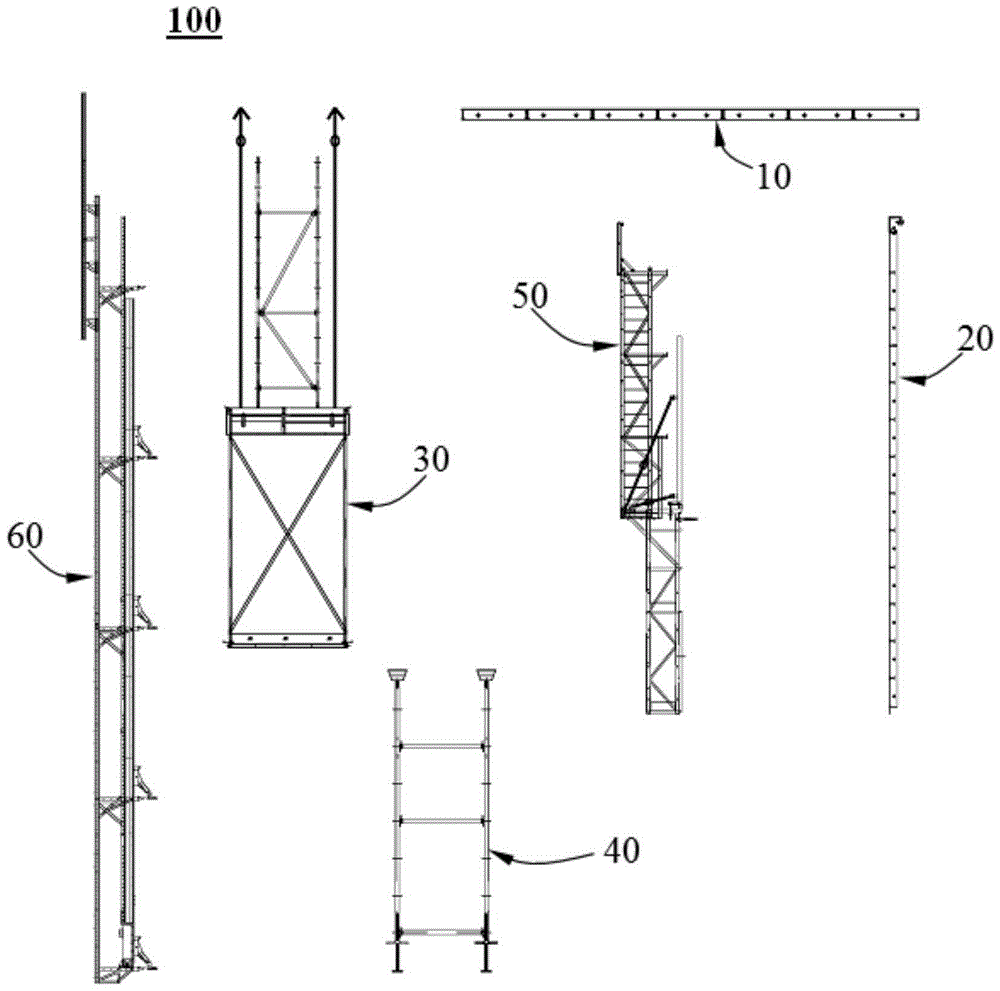

Super high-rise core tube horizontal direction and vertical direction synchronous construction top formwork system and construction method

InactiveCN106869489AReduce productionReduce consumptionForms/shuttering/falseworksForm treatmentSupporting systemControl system

The invention discloses a super high-rise core tube horizontal direction and vertical direction synchronous construction top formwork system which comprises a truss platform system, a hanger enclosure system, a supporting system, a formwork system and a hydraulic control system. The formwork system is an aluminum alloy formwork system. The aluminum alloy formwork system comprises vertical wall formworks and horizontal formworks. Each vertical wall formwork comprises a plurality of aluminum alloy standard unit plates spliced transversely, and C-shaped aluminum alloy grooves located in the aluminum alloy standard unit plates. Each horizontal formwork is formed by splicing a plurality of aluminum alloy bulk slicing plates. The horizontal formworks on the different layers are formed by splicing the aluminum alloy bulk slicing plates different in quantity. The horizontal formworks are connected with the vertical wall formworks through the C-shaped aluminum alloy grooves. According to the super high-rise core tube horizontal direction and vertical direction synchronous construction top formwork system provided by the invention, synchronous construction of horizontal structures and vertical structures of a core tube is achieved.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

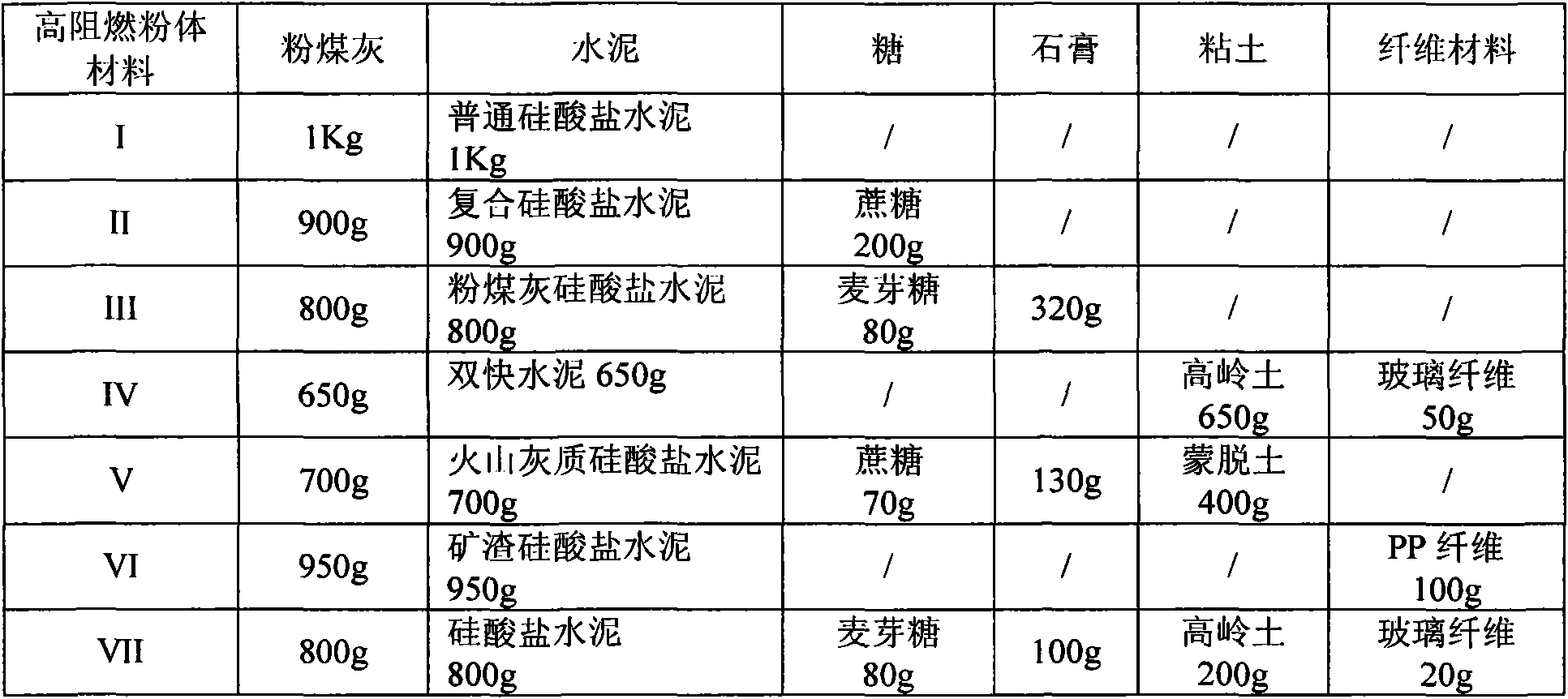

Spray-coating sealing material for coal rock mass

The invention provides a spray-coating sealing material for coal rock mass, belonging to the technical field of organic / inorganic compound materials. The spray-coating sealing material for the coal rock mass is a complex of high-molecular emulsion and high-flame-retardant powder materials, without any toxic and harmful substances, free of springback for construction, safe and environmental protective. When sprayed at vertical surfaces and top surfaces, the material does not flow and sag, and is good in overall effect. After curing, the coating has advantages of strong adhesion stress, high tensile strength, large tensile deformation, and excellent sealing performance. The material can be used for surface protection of the coal rock mass, air leakage prevention, gas leakage prevention, and rapid surface protection and moistureproof treatment after tunneling of swelling rock.

Owner:山东固安特新材料科技股份有限公司

Manufacturing method of rubber and chemical fiber synthetic waterproof sheet and product thereof

ActiveCN102182253AHigh strengthImprove toughnessUnderground chambersRoof covering using flexible materialsChemical fiber clothMacromolecule synthesis

The invention relates to a manufacturing method of a rubber and chemical fiber synthetic waterproof sheet and a product thereof, and the rubber and chemical fiber synthetic waterproof sheet is formed by compounding three layers of material, wherein the middle layer is a chemical fiber cloth or felt composite layer, and the chemical fiber cloth or felt composite layer is a waterproof layer enabling polymer synthetic rubber composite material and chemical fiber cloth or felt to infiltrate and adhere mutually; when in manufacturing, the chemical fiber cloth or felt of the middle layer is firstlyplaced in a dip coating groove for enabling the chemical fiber cloth or felt to soak polymer synthetic rubber waterproof rubber material, and the middle sheet layer is further manufactured; and two layers of the chemical fiber cloth or felt are stuck on two surfaces of the middle sheet layer respectively, thereby forming the three-layer compound synthetic waterproof sheet. The polymer synthetic rubber waterproof rubber material takes rubber as main material, and a high polymer and other auxiliary materials are added for manufacturing the waterproof rubber material; the auxiliary materials comprise an accelerant, filling material, a softener, a cross-linking agent or an anti-aging agent; and the middle sheet layer can be manufactured by one of three forms respectively, namely the cold working method, the hot working method and the rolling method.

Owner:杨太龙

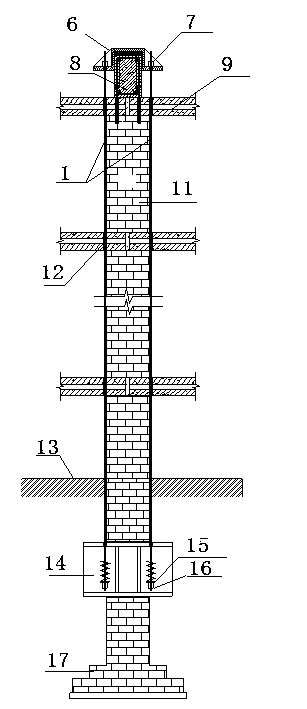

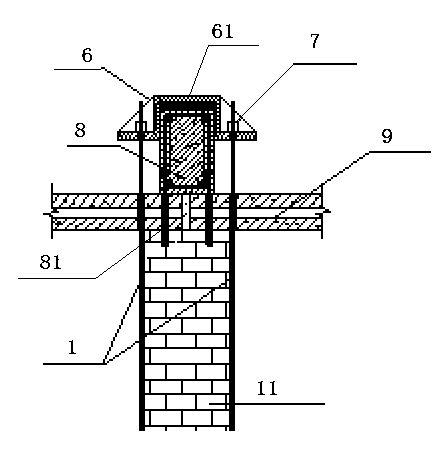

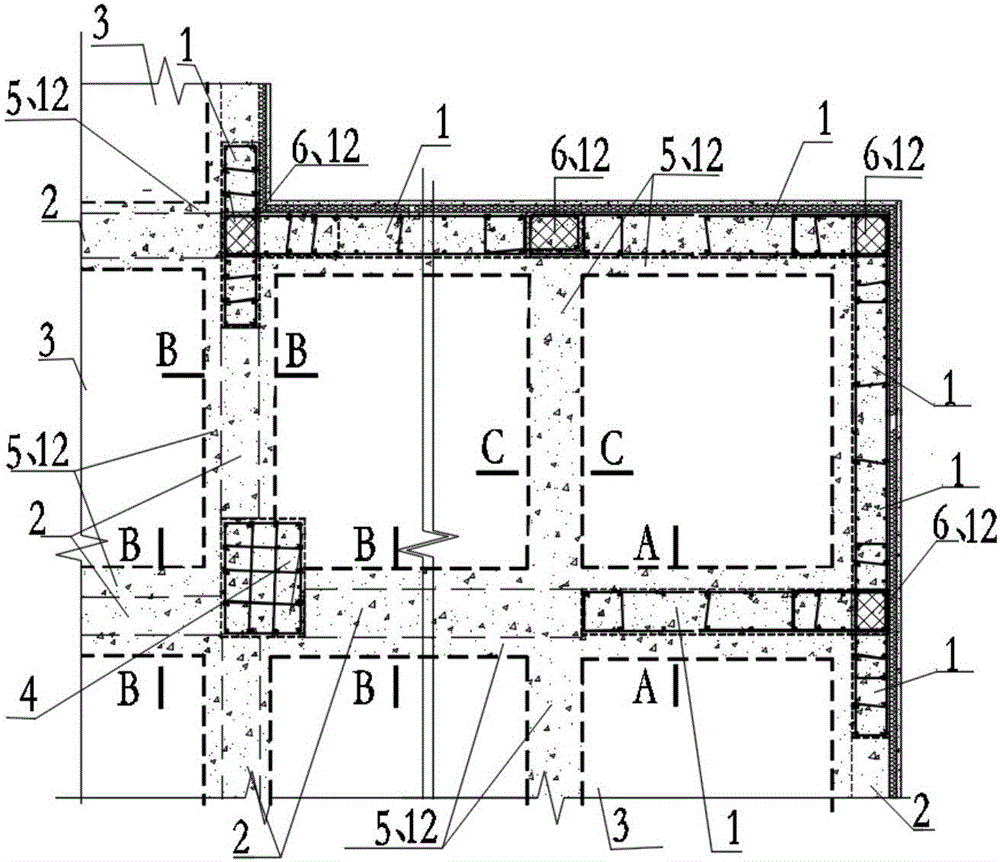

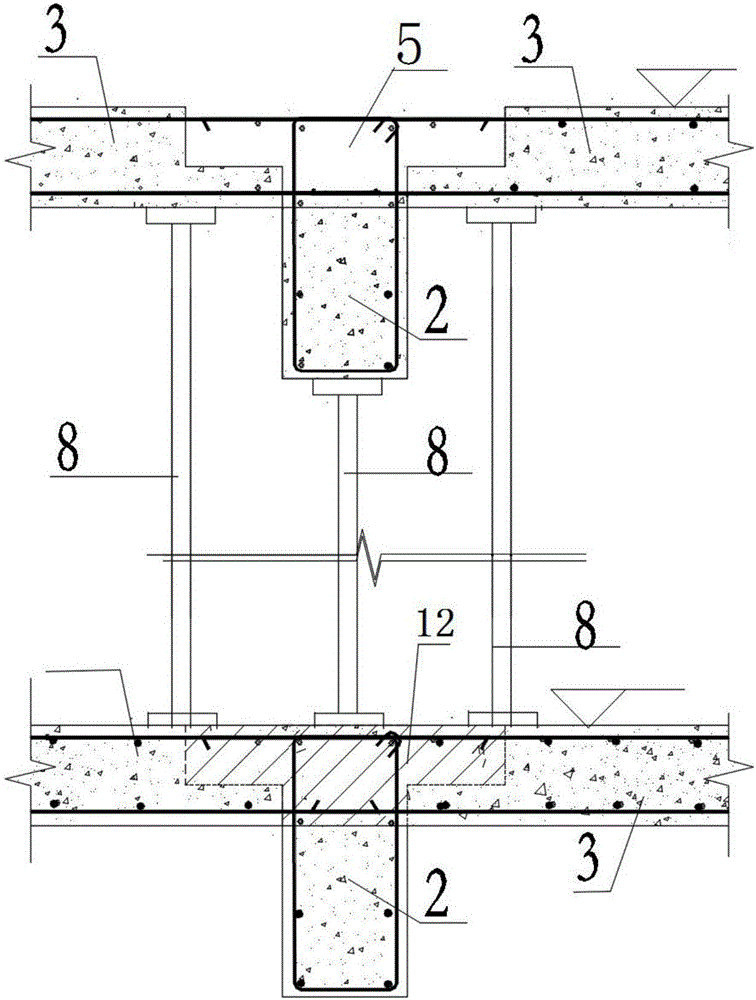

Vertical un-bonded prestressed anti-seismic strengthening structure of masonry building

InactiveCN102704704AImprove the seismic bearing capacityImprove integrityBuilding repairsShock proofingPre stressPre stressing

The invention relates to a vertical un-bonded prestressed anti-seismic strengthening structure of a masonry building. The structure is characterized in that un-bonded prestressed ribs are vertically arranged on each of two sides of a strengthened wall, a coping beam or a wall top force transfer shim block is arranged on the top of the strengthened wall, and the tension ends of the un-bonded prestressed ribs are anchored on the coping beam or the wall top force transfer shim block; a foundation force transfer shim block is arranged on the foundation part of the strengthened wall, and the fixed ends of the un-bonded prestressed ribs are anchored on the foundation force transfer shim block; and by applying a pre-stressing force, the anti-seismic capability of the strengthened wall is greatly improved. The vertical un-bonded prestressed anti-seismic strengthening structure of the masonry building can effectively improve the anti-seismic bearing capacity of the masonry wall and enhance the integrity and the energy dissipation capability of the masonry structure, is beneficial to deformation recovery after seism, is easy and convenient to construct, low in influence and low in manufacturing cost, and belongs to a novel anti-seismic strengthening technology of masonry structures which are worthy of vigorous promotion.

Owner:BEIJING ACAD OF BUILDING ENG

Method for constructing anti-pollution durable colored thin anti-skid road surfaces

ActiveCN102776816AImprove adhesionImprove crack resistanceIn situ pavingsPaving detailsEpoxyBasement

The invention provides a method for constructing anti-pollution durable colored thin anti-skid road surfaces, comprising the following steps: (1) preparing cementing materials and aggregates, wherein the cementing materials adopt wet-mixing modified epoxy resin adhesives; the aggregates adopt colored pottery particle aggregates; the modified epoxy resin adhesives are used for painting prior to the use of the aggregates; and the thickness of the coating is 0.1 to 0.3mm; (2) treating basements of the constructed road surfaces; (3) scraping and paving modified epoxy resin cementing materials; (4) spreading the colored pottery particle aggregates; and (5) blocking the dead corners of the colored road surfaces with fog seals. The wet-mixing modified epoxy resin adhesives are used for color matching; with the utilization of a small spraying mechanical device, the locations of the dead corners of the non-traffic colored road surfaces are effectively blocked by the fog seal method in advance; and the covering thicknesses of the colored fog seals are 0.1 to 0.3mm. The method for constructing the anti-pollution durable colored thin anti-skid road surfaces can improve the adhesion, the crazing resistance property, and the anti-skid property of the colored road surfaces, and moreover, the colors can be fresh for a long time.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

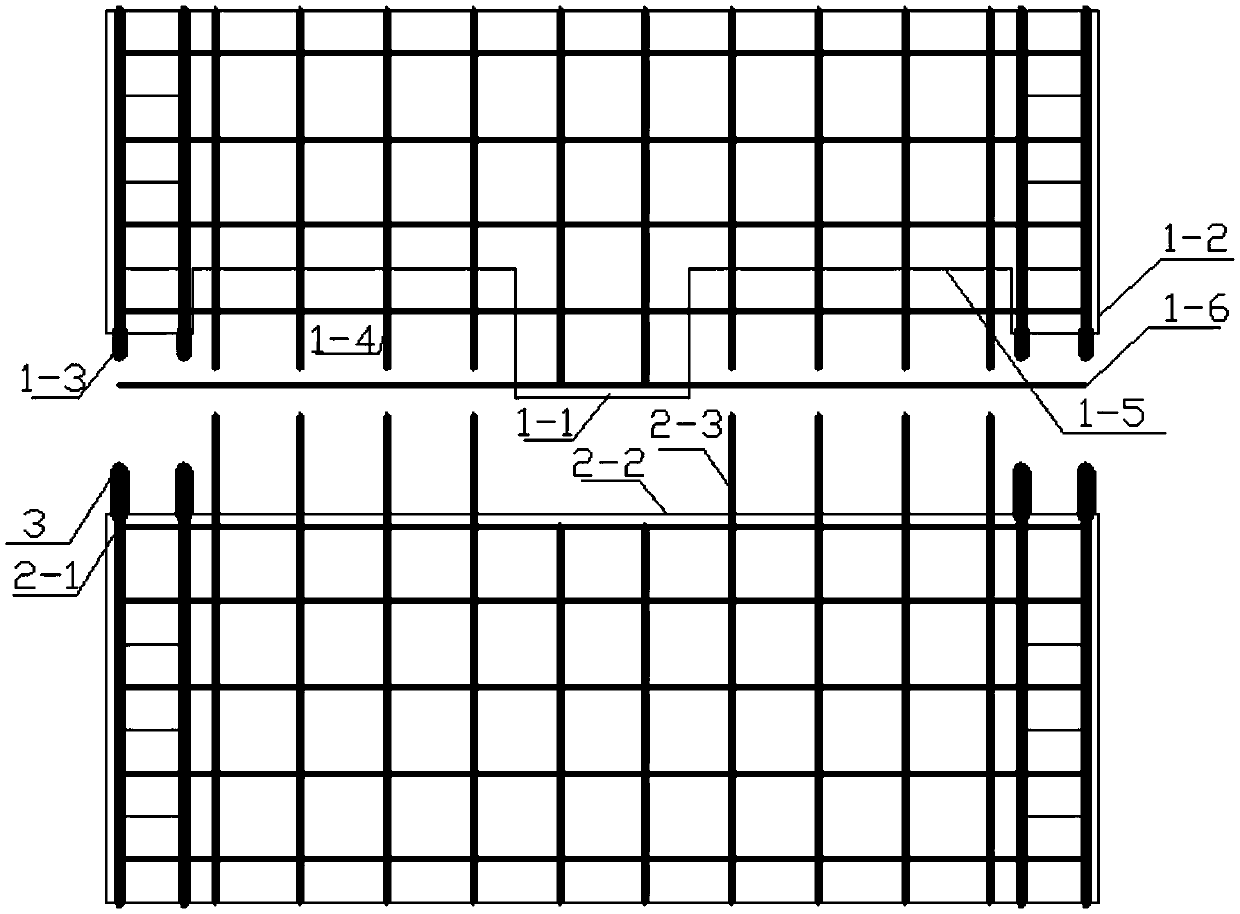

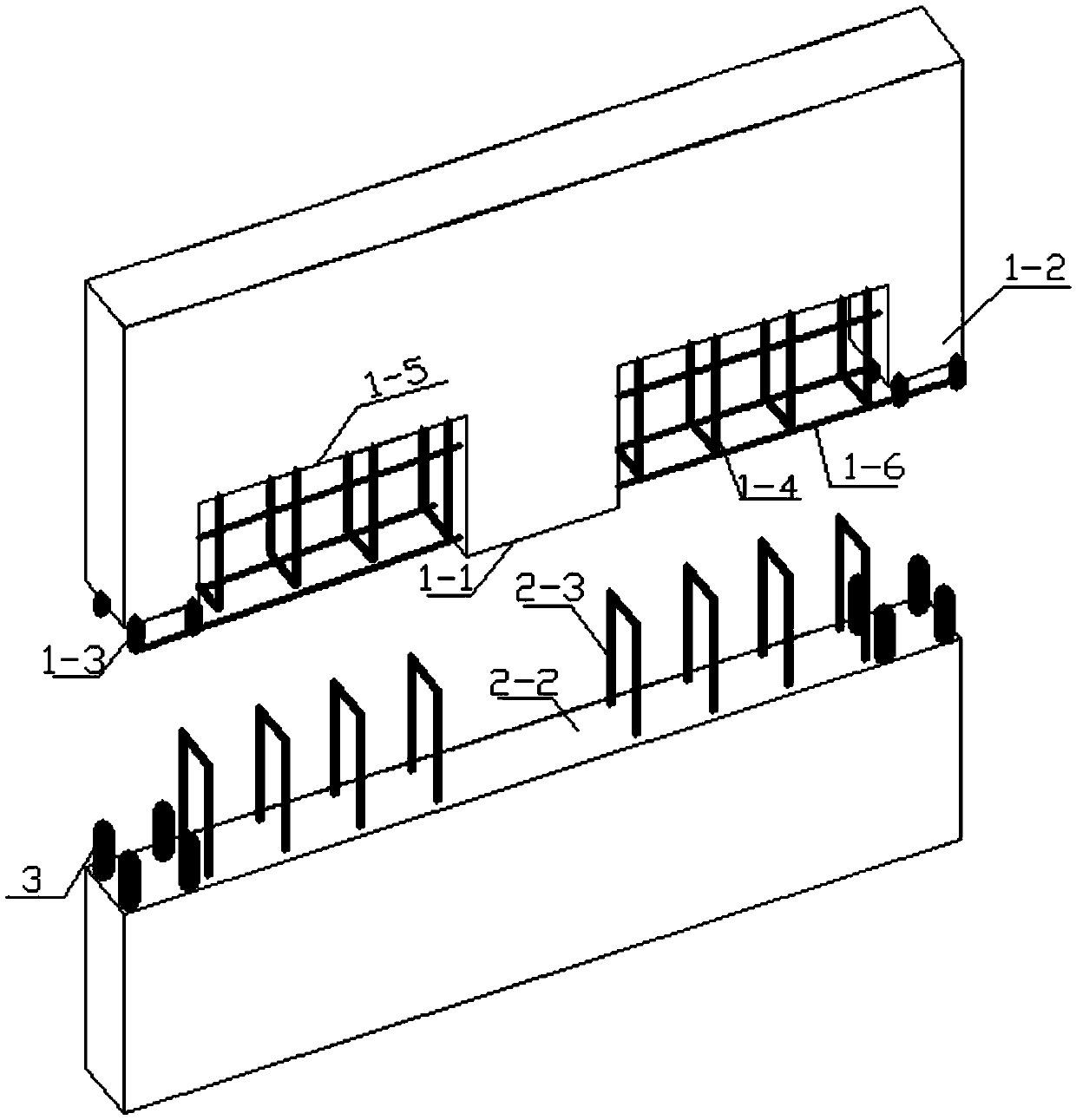

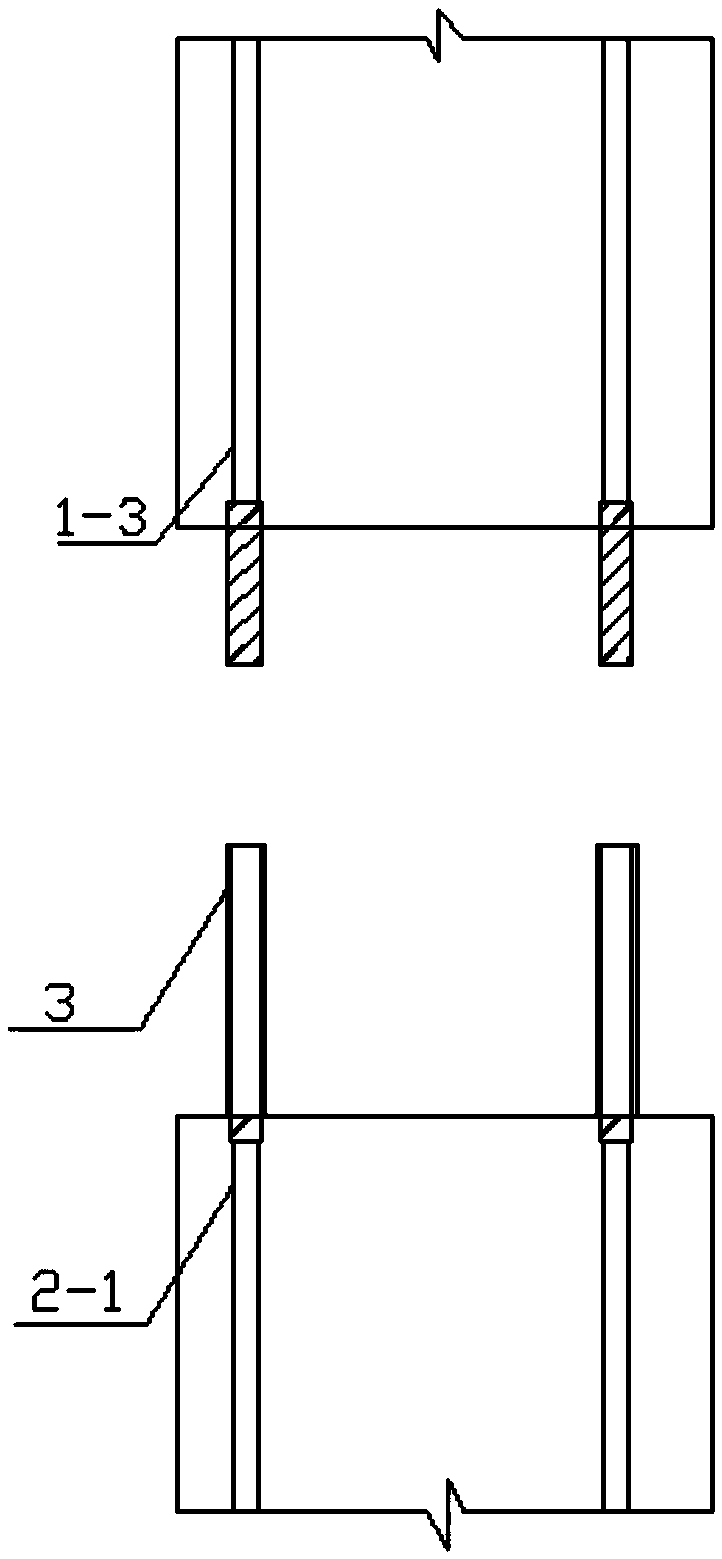

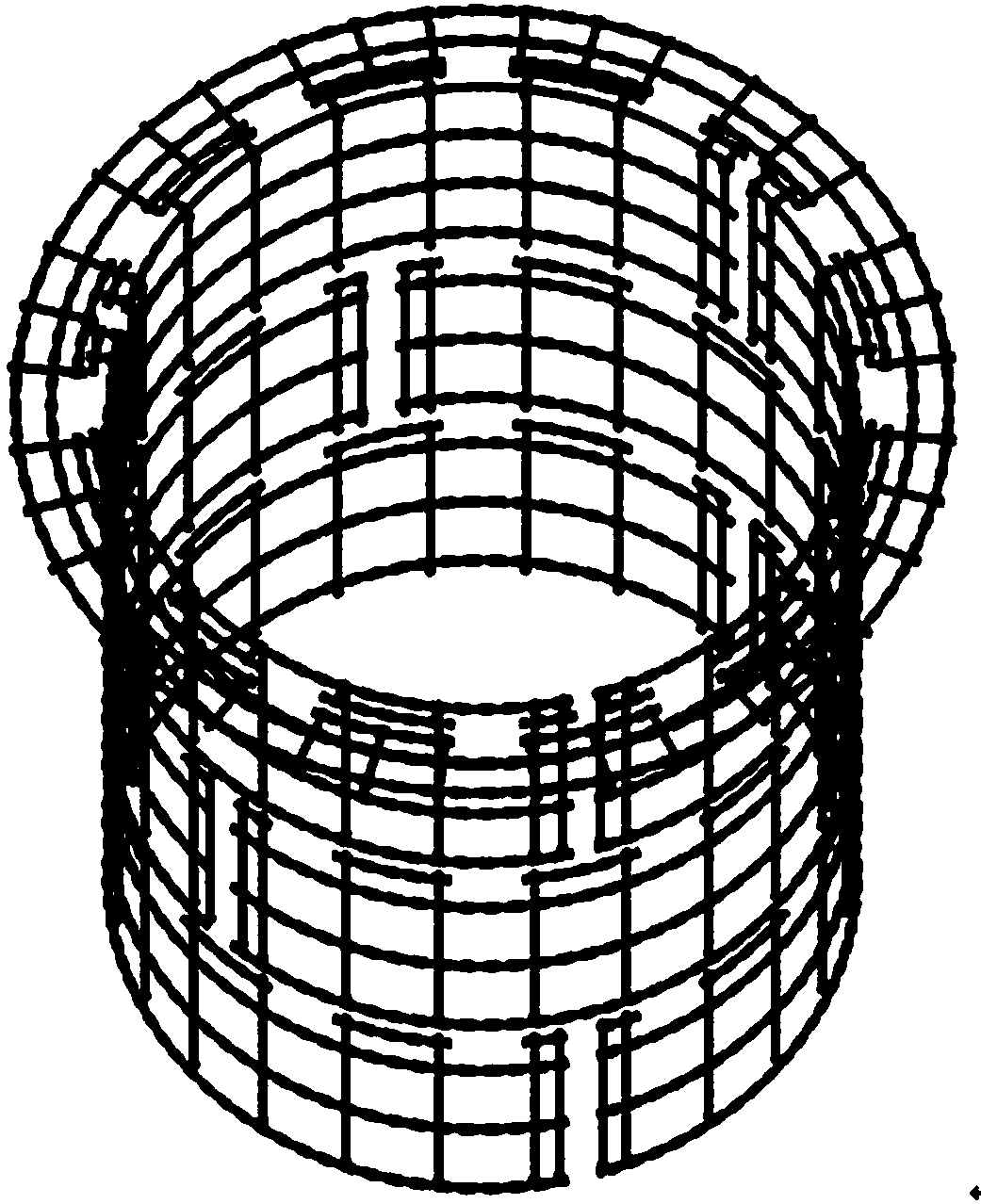

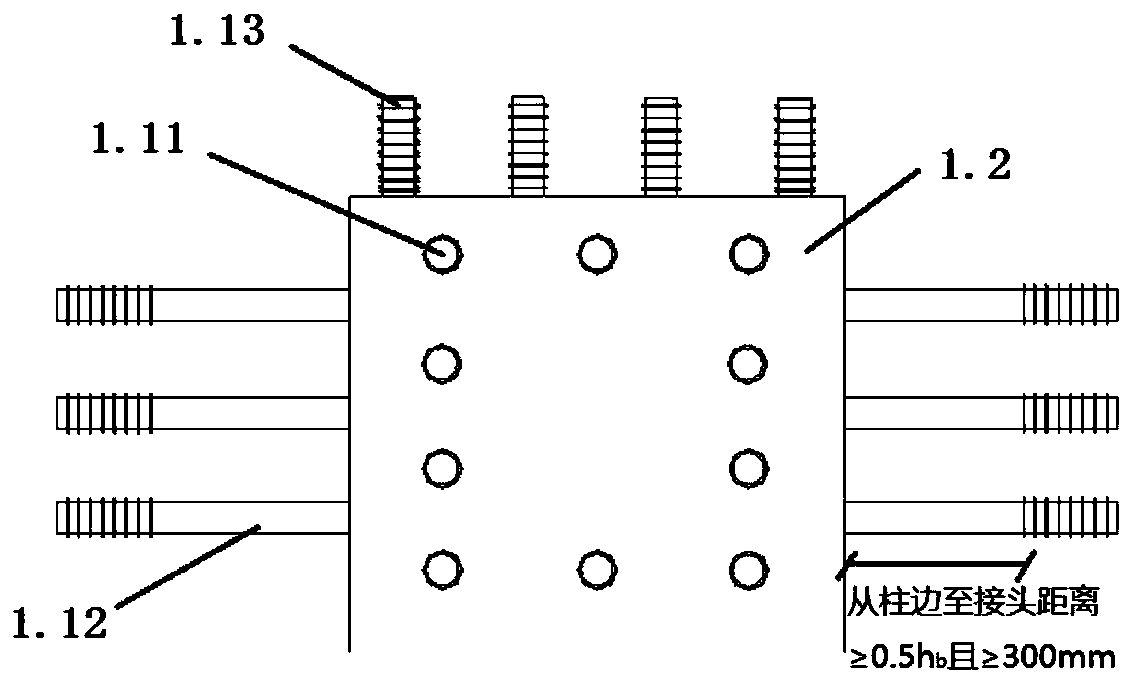

Assembled type shear wall upper-layer and lower-layer combined connection structure

The invention discloses an assembled type shear wall upper-layer and lower-layer combined connection structure which comprises an upper-layer prefabricated wall and a lower-layer prefabricated wall which are connected in a butted mode. When the upper-layer prefabricated wall and the lower-layer prefabricated wall are connected in the butted mode, a downward-protruding supporting structure of the upper-layer prefabricated wall is supported on the lower-layer prefabricated wall, structural longitudinal ribs of an embedded column of the upper-layer prefabricated wall and structural longitudinal ribs of an embedded column of the lower-layer prefabricated wall are opposite in a one-to-one mode and are connected mechanically, the structural longitudinal ribs I of the upper-layer prefabricated wall and the structural longitudinal ribs II of the lower-layer prefabricated wall are connected in an overlapped mode, and the upper-layer prefabricated wall and the lower-layer prefabricated wall are connected at the joint through a cast-in-place concrete structure. The combined connection way combined with the cast-in-place concrete structure is formed through mechanical connection, steel bar splicing and concrete spraying, the wall prefabrication technology is simpler, on-site construction is more convenient and rapider, and the workpiece manufacturing cost and the construction cost can be reduced.

Owner:TIANJIN UNIV

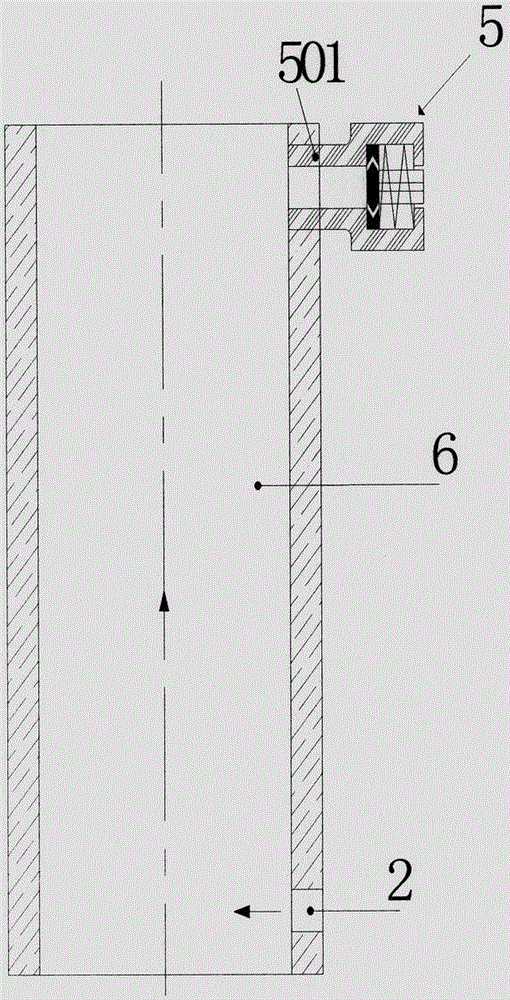

Green alkali-free liquid concrete setting accelerator and preparation method thereof

The invention relates to a green alkali-free liquid concrete setting accelerator and a preparation method thereof, and belongs to the technical field of concrete processing. According to the method, aluminum sulphate, calcium hydroxide, organic acid and deionized water are taken and are charged into a three-opening flask; stirring is performed under the condition of constant-temperature water bath; setting accelerator mother liquid is obtained; sodium fluoroaluminate is taken and is added into the deionized water; heating and stirring are performed; then, organic alcohol amine is added; continuous stirring is performed; then, the setting accelerator mother liquid is dripped; after the dripping is completed, ethylene diamine tetraacetic acid is added; heat insulation stirring is performed;after the materials are cooled to the room temperature, stabilizing agents are added; stirring is performed; the green alkali-free liquid concrete setting accelerator is obtained. The setting accelerator provided by the invention has the advantages of no alkali, non-toxicity, no smell and no corrosion; the environment is protected in the construction process; almost no harm is caused on the body health of construction personnel and ecological environment in the spraying process; the production process is simple; the preparation is easy; the storage is easy; the stability in the storage processis high.

Owner:常州琨瑶纺织品有限公司

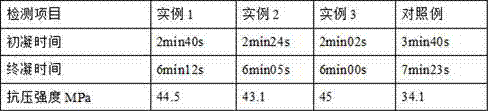

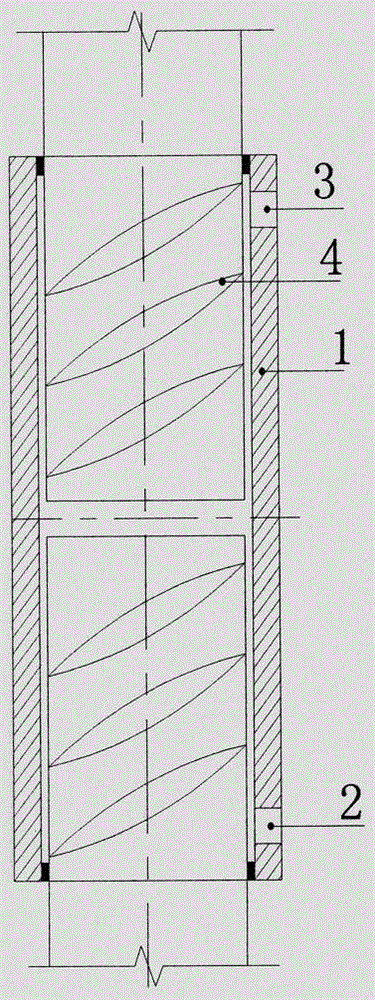

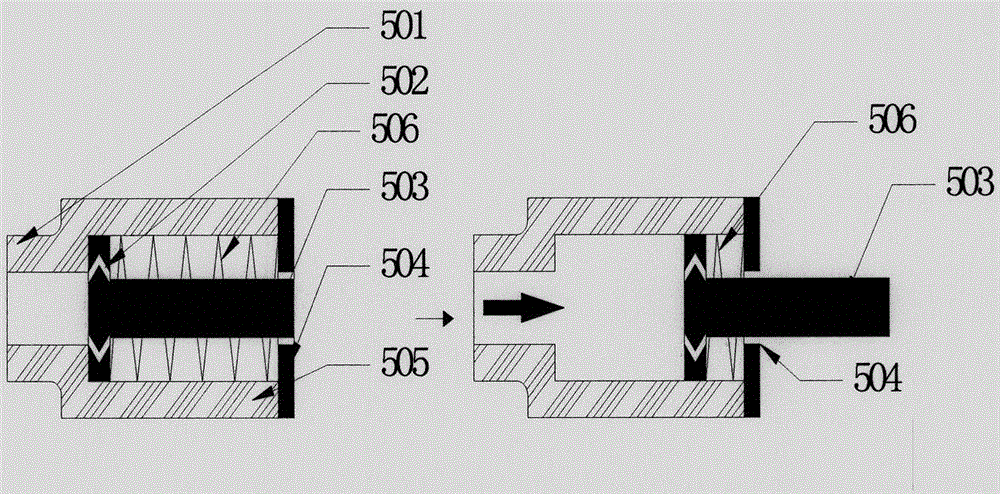

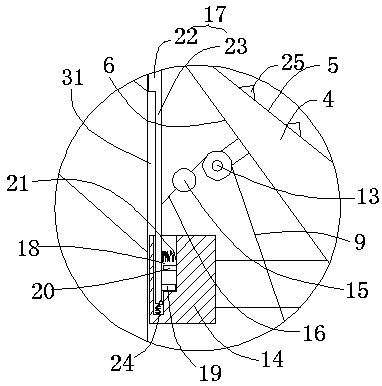

Blocking valve, grouting sleeve and prefabricated component connecting method

PendingCN105781022AImprove grout qualityHigh strengthBuilding reinforcementsLift valveAgricultural engineeringBlocked valves

The invention provides a blocking valve, a grouting sleeve and a prefabricated component connecting method. The steel bar connection grouting sleeve has a sealed space, and can be automatically sealed after grouting, and the grouting degree can be observed in a grouting process. Compared with an existing open sleeve, the grouting sleeve has the advantages that higher pressure can be born in the grouting process, the grouting sleeve can be automatically sealed after grouting, and the grout fullness of the sealed space can be observed in the grouting process, thereby monitoring the grouting quality of the grouting sleeve. The blocking valve, the grouting sleeve and the prefabricated component connecting method can be widely applied to a grouting sleeve connection process in the technical field of building construction.

Owner:BEIJING JIEYANTE ENG TECH

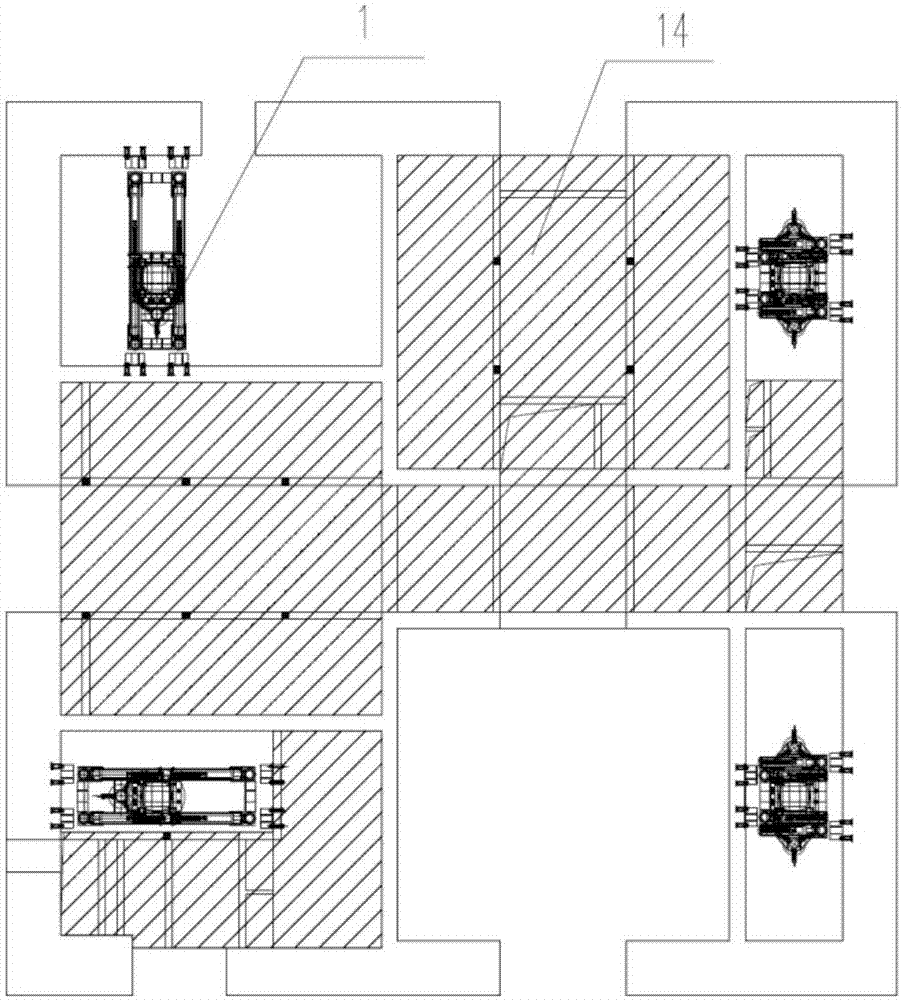

Construction technology for precisely positioning and quickly installing steel pipe column in covered top-down excavation method

PendingCN108374418AImprove installation accuracyShorten the construction periodBulkheads/pilesSteel platesRebar

The invention discloses a construction technology for precisely positioning and quickly installing a steel pipe column in a covered top-down excavation method. The construction technology comprises the following steps of after a reinforcement cage of a pile foundation is lifted, casting a concrete pier and installing channel steel along the cross direction of a steel casing, measuring the elevation and coordinates of the steel casing, determining the relative elevation and coordinates of the steel pipe column, and welding two support steel plates on the steel casing; lifting the steel pipe column into a lifting hole, and completing the primary installation of the steel pipe column by using the steel casing as a reference object; building a platform by channel steel and steel sheets on a hole opening, setting out the coordinates in the steel pipe column, and marking; arranging a laser plumb aligner, trimming the steel pipe column by a jack, and coinciding the center of target and the light sport; welding the steel pipe column and the steel casing by steel sheets to form a whole. The construction technology has the advantages that by arranging the two support steel plates in the steel casing, the steel pipe column can be suspended in air during lowering; the center coordinates and verticality of the steel pipe column are adjusted by the laser plumb aligner and the jack, and the concrete casting is not needed before the positioning of the steel pipe column is completed.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

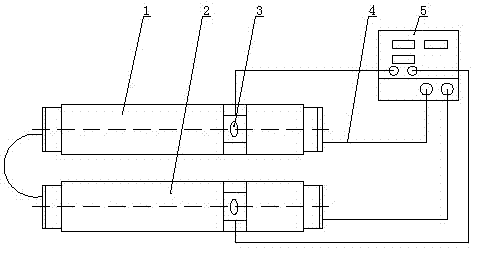

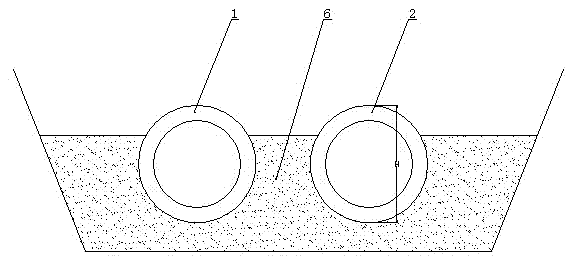

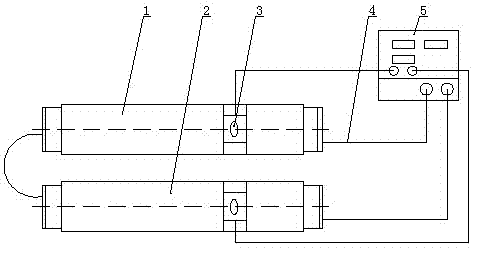

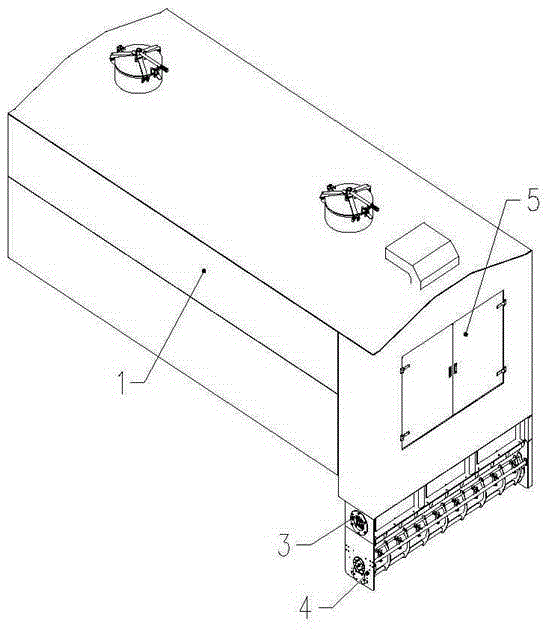

Construction method for prefabricating directly-buried uncompensated centralized heat supply pipeline by electrically preheating

InactiveCN102444750AImprove running stabilityGuaranteed elongationPipe laying and repairElectricityEngineering

The invention relates to a construction method for prefabricating a directly-buried uncompensated centralized heat supply pipeline by electrically preheating. The method comprises the following steps of: (1) grooving, adjusting the coordinate and scale height of the heat supply pipeline, and computing the preheating temperature and the designed elongation of the heat supply pipeline; (2) controlling the sand refilling height at a half to three quarters of the pipeline height H; (3) connecting the same-side end of the heat supply pipeline with preheating equipment through a cable respectively, and short-circuiting the other side of the heat supply pipeline through a cable; (4) arranging temperature sensors on the heat supply pipeline respectively; (5) recording the initial temperature of the heat supply pipeline and the initial position of a measuring point, starting temperature raising, controlling the temperature raising gradient within 1 DEG C per hour, and preserving heat after a preheating temperature is reached; (6) refilling sand into both sides of the heat supply pipeline, tamping, and controlling the preheating temperature within the range of + / -2 DEG C; (7) after the designed elongation is reached, shutting down the preheating equipment; and (8) performing subsequent construction according to the steps (1)-(7). The construction method disclosed by the invention is safe, reliable, easy and practical, is easy for accurately controlling construction equipment, and is consistent with the national policy of energy saving and emission reduction.

Owner:MCC TIANGONG GROUP

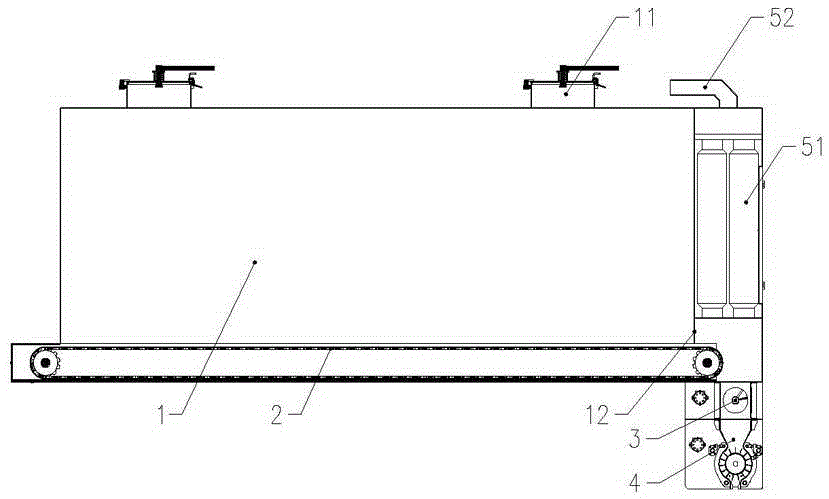

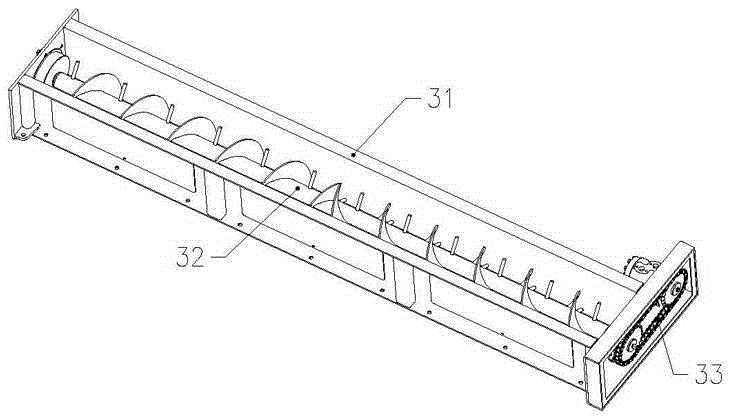

Vehicular spreader of solid road binder

A vehicular spreader of a solid road binder comprises a storage bin, a material conveying mechanism, a material distributing mechanism, a spreading mechanism and a dust removal device, wherein the storage bin is of a square sealed box structure, openable and closable charging holes are formed in the top of the storage bin, the material conveying mechanism is in seal connection with the low part of the storage bin, and is corresponding to a discharge hole in the lower part of rear end of the storage bin; the rear end of the storage bin is in seal connection with the dust removal device additionally; the lower end of the dust removal device is in seal connection with the material distributing mechanism, the position of the material distributing mechanism directly faces an output end of the material conveying mechanism, and the spreading mechanism is in seal connection with the lower end of the material distributing mechanism; the vehicular spreader has the characteristics of being reliable in performance, reasonable in structure, easy to operate and maintain, environment friendly in construction and the like.

Owner:ZHEJIANG MEITONG ROAD CONSTR MACHINERY

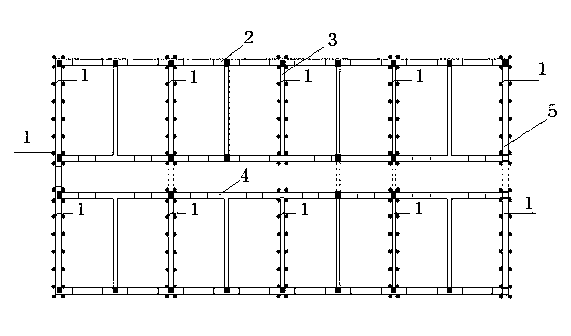

Assembled concrete structure construction method

ActiveCN106193623AIncrease stiffnessReduce supportBuilding material handlingEngineeringStructure system

The invention discloses an assembled concrete structure construction method. According to the construction method, a reversed construction procedure is adopted for installation of a vertical component of a currently constructed floor, that is, before connection assembly of a horizontal component of the currently constructed floor, the vertical component connected to the upper portion of the horizontal component is hoisted firstly, and finally connection concrete is poured at a time to connect the horizontal component with the vertical component of the currently constructed floor into a whole. The construction method adopts the reversed construction procedure, so that construction links are reduced, and the construction period is shortened; the method is suitable for assembled concrete building construction for structure systems such as precast shear walls, composite wallboards and frameworks, and has the advantages of convenient construction, time saving, economy, environment friendliness and the like; and meanwhile, the requirement for identical performance as a cast-in-place structure is met.

Owner:刘祥锦

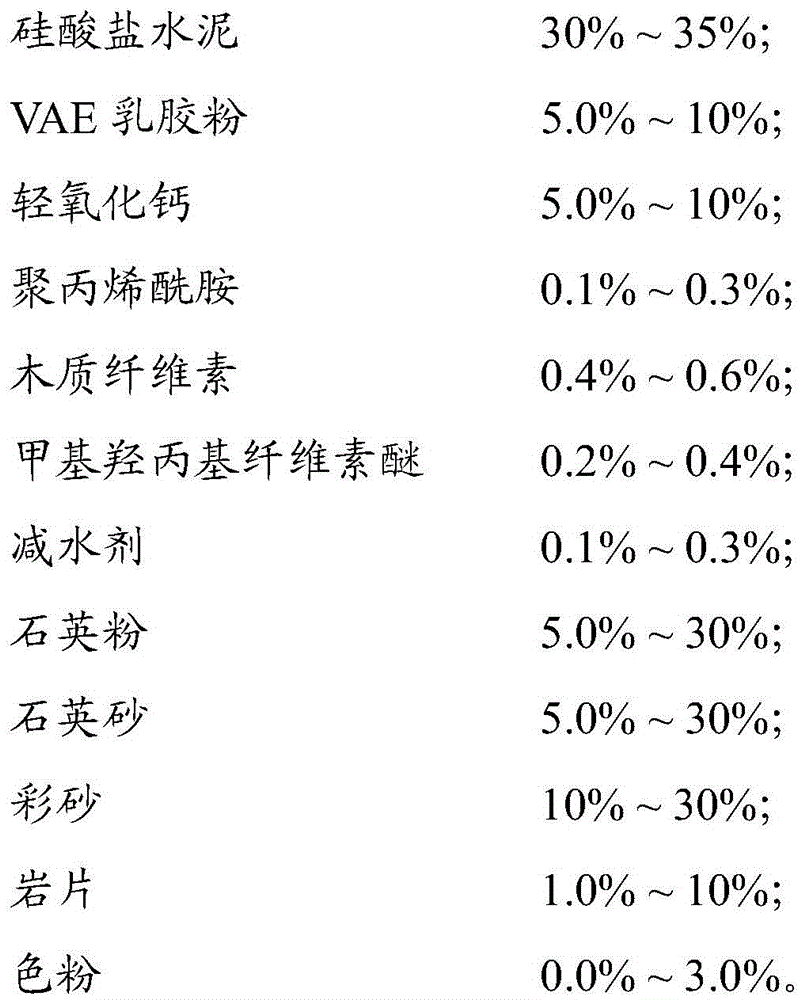

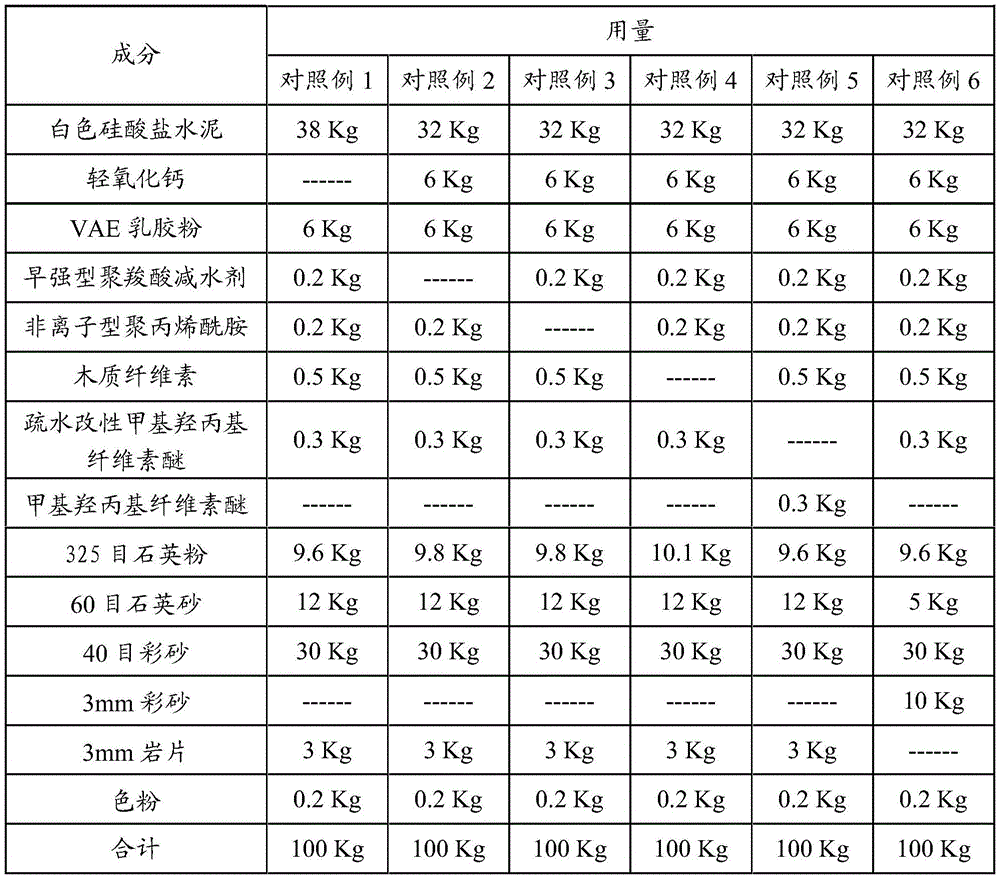

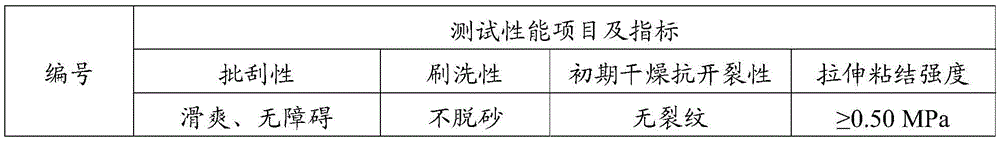

Simulated stone dry powder coating and construction method thereof

ActiveCN105541230AProduce visual effectsProduce texture effectBuilding material handlingCelluloseWater reducer

The invention discloses a simulated stone dry powder coating and a construction method thereof. The simulated stone dry powder coating is prepared from the following raw materials in percentage by weight: 30-35% of Portland cement, 5.0-10% of VAE emulsion powder, 5.0-10% of light calcium oxide, 0.1-0.3% of polyacrylamide, 0.4-0.6% of lignocellulose, 0.2-0.4% of hydroxypropyl methyl cellulose ether, 0.1-0.3% of water reducer, 5.0-30% of quartz powder, 5.0-30% of quartz sand, 10-30% of color sand, 1.0-10% of rock slice and 0.0-3.0% of color powder. The simulated stone dry powder coating can generate a visual effect of a stone, can generate a texture effect of the stone, can be directly constructed in a dry powder manner and is simple in construction and environmentally friendly.

Owner:GUANGDONG NATURAL COATING CHEM CO LTD

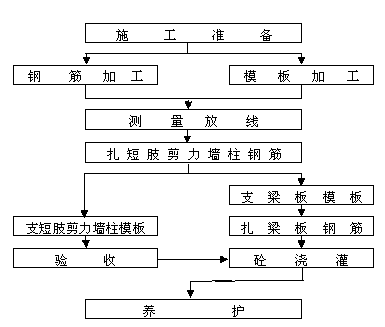

Main structure construction method by sequentially processing beam slab frameworks, short-leg shear wall and column frameworks

InactiveCN103266766AConstruction duration shortenedShorten the time intervalBuilding material handlingFloor slabConcrete beams

The invention relates to a main structure construction method by sequentially processing beam slab frameworks, short-leg shear wall and column frameworks. The method includes the following steps: a, strapping short-leg shear wall and column rebars; b, mounting the beam slab frameworks; c, calibrating the shear wall and column rebars before strapping beam rebars, immediately performing inspection after strapping the beam rebars, and then strapping floor slab rebars; d, mounting the short-leg shear wall and column frameworks when strapping the floor slab rebars; and e, simultaneously pouring concrete to beam slabs, floor slabs and short-leg shear walls and columns. In the method, mounting of the short-leg shear wall and column frameworks and strapping of the beam slab rebars and the floor slab rebars which are completely not in the same working face can be performed simultaneously, and the mounting of the short-leg shear wall and column frameworks becomes a non-critical work from a critical work and does not occupy construction periods, so that main engineering construction duration of the whole frame shear structure is reduced, and a main structure construction period and time intervals in shutdown and waiting of labor force are greatly shortened.

Owner:JIANGNAN CONSTR CO LTD DONGYANG ZHEJIANG

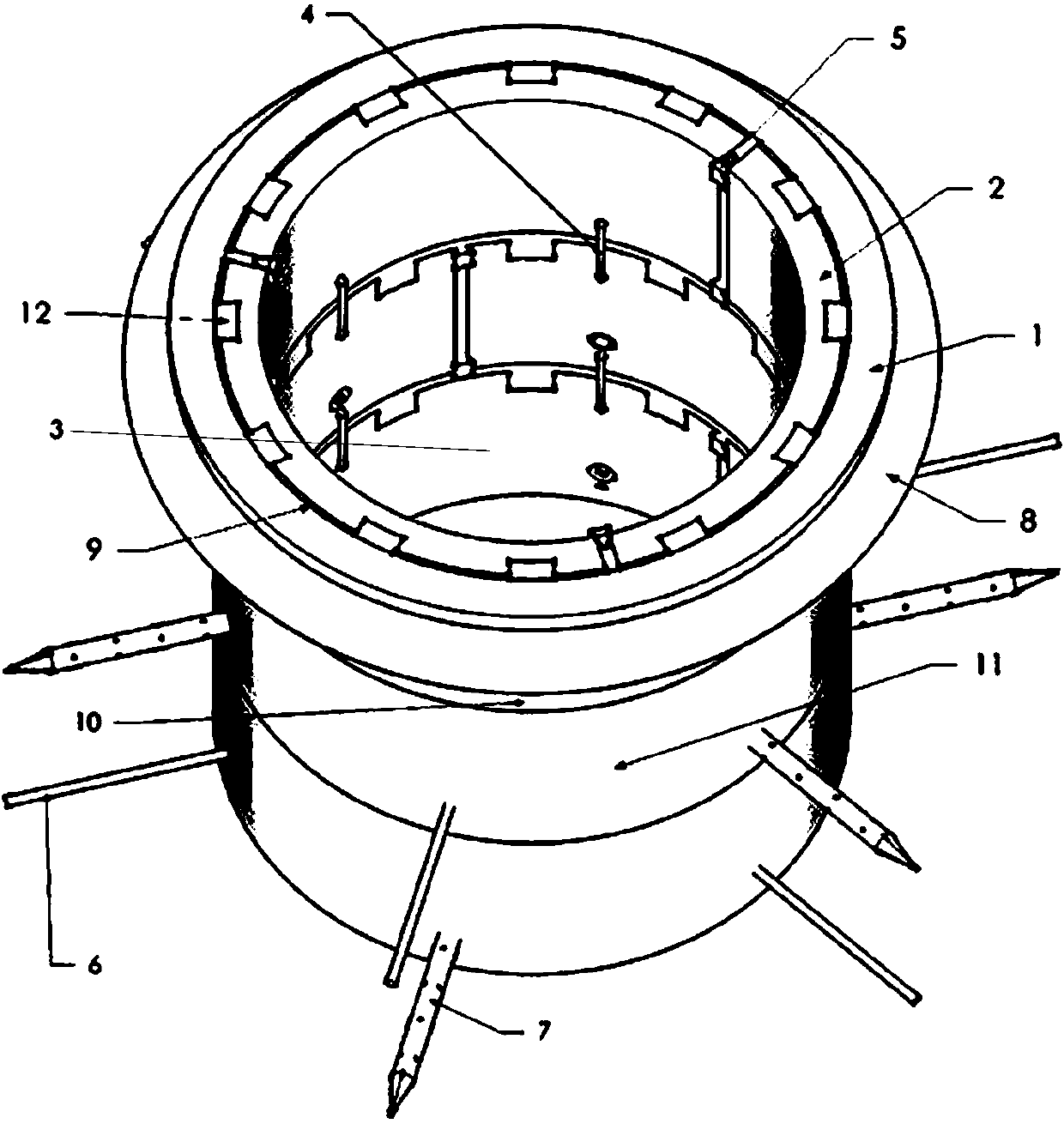

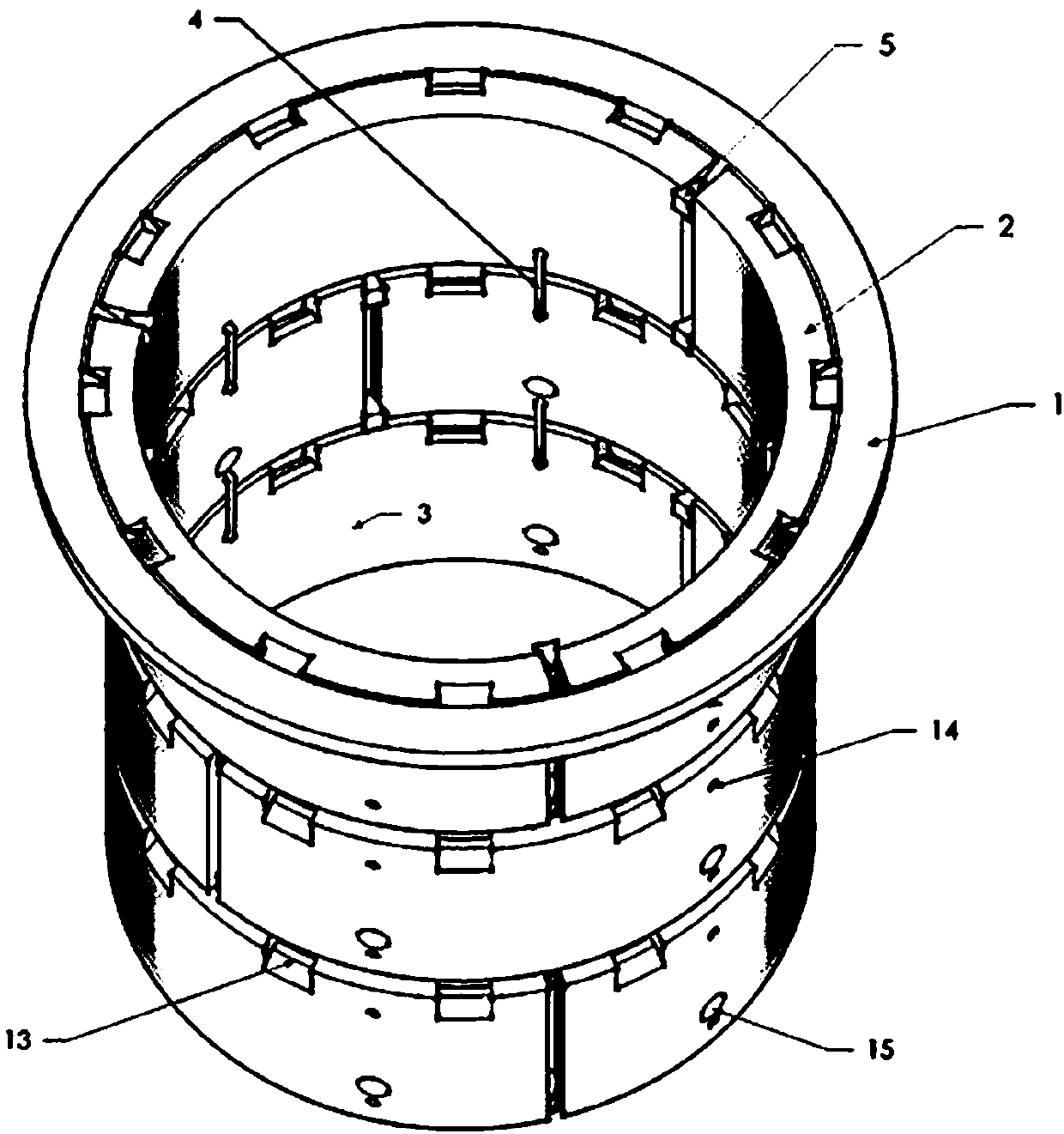

Manual hole digging pile assembly type protection wall and construction technology thereof

PendingCN107675704ARealize factory productionFast progressBulkheads/pilesArchitectural engineeringSprue

The invention discloses a manual hole digging pile assembly type protection wall which is composed of a prefabricated component, an auxiliary part and cast-in-place concrete. The prefabricated component comprises a well ring, a well opening and a standard joint. An inverted circular truncated cone opening is formed in the inner side of the well ring. The well ring is connected with the well opening. The well opening is formed by splicing three arc plates, and multiple sprue gates A evenly distributed are formed in the upper portion of the well opening. The standard joint is formed by splicingthree arc plates, and multiple sprue gates B are evenly formed in the upper portion of the standard joint. Connecting holes and reserved holes are reserved in the well opening and the standard joint.The auxiliary part comprises wooden wedges, vertical connecting hooks, horizontal nails and grouting floral tubes. The diameter of the protection wall is adjusted in a fine manner among the arc plates, and the well opening and the standard joint are connected through the vertical connecting hooks via the connecting holes. The cast-in-place concrete comprises a well ring cushion layer, well openingsit grout (mortar), prefabricated component (well opening and standard joint) connectors and fat groove (well opening and standard joint) packing. The manual hole digging pile assembly type protection wall is fast in construction progress, and the hole forming quality is more reliable.

Owner:GUIZHOU CONSTRAL ENG GROUP

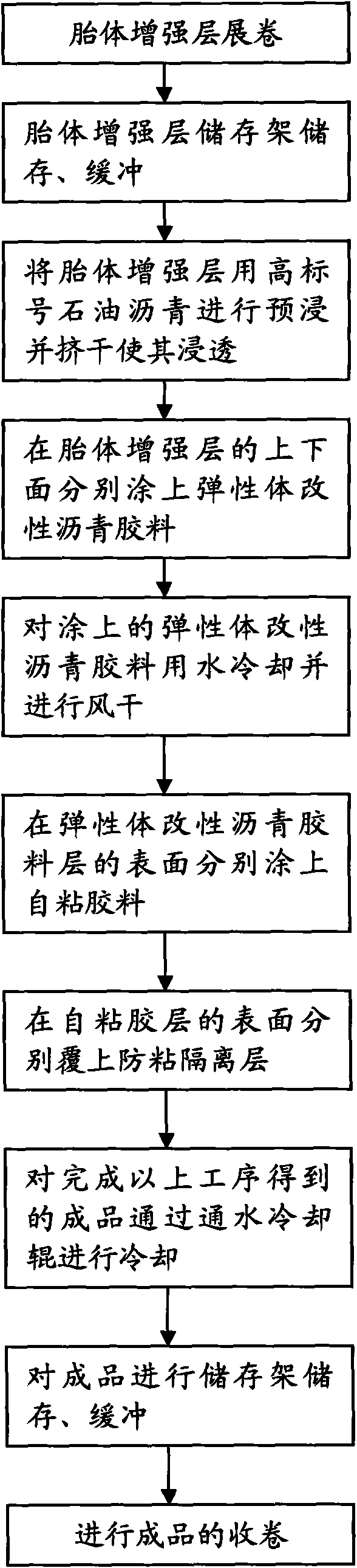

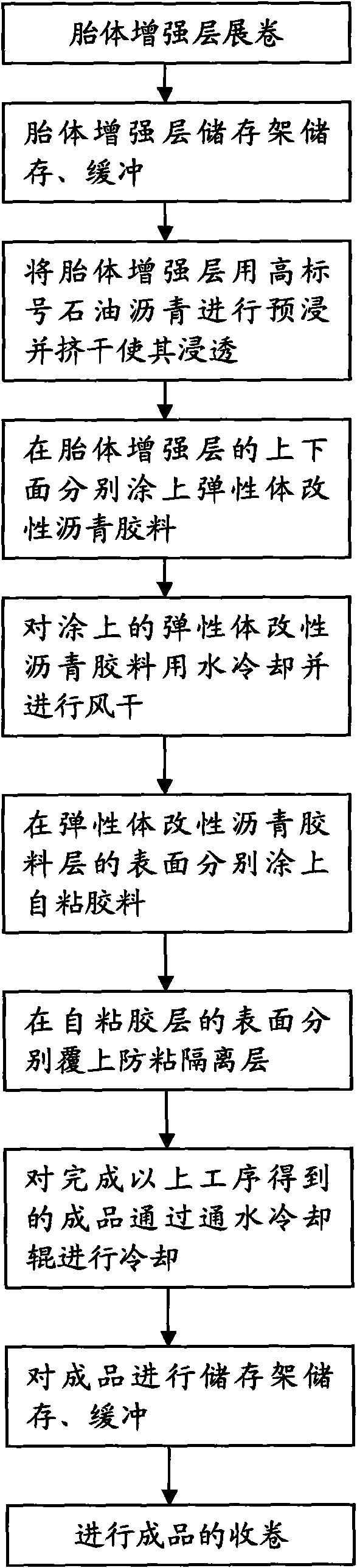

Preparation method of elastomer modified asphalt waterproof roll capable of being placed in wet

InactiveCN101769046AConstruction safetyConstruction environmental protectionLamination ancillary operationsRoof covering using flexible materialsElastomerBituminous waterproofing

The present invention discloses a preparation method of elastomer modified asphalt waterproof roll capable of being placed in wet, comprising the following steps: uncoiling a carcass reinforcement layer, storing the carcass reinforcement layer on a store frame, buffering, pre-impregnating the carcass reinforcement layer by high-grade petroleum asphalt and squeezing to dry for complete impregnation, coating an elastomer modified asphalt glue stock on the upper and the lower surfaces of the carcass reinforcement layer, cooling the elastomer modified asphalt glue stock by water and performing air drying, coating a self-adhesive glue stock respectively on the surface of the elastomer modified asphalt glue stock layer, covering a conglutination resistant isolation layer respectively on the surface of the self-adhesive glue stock layer, cooling the product after the processes above by a flow-through cooling roll, storing the product on a store frame, buffering and finally coiling the product. The roll of the invention has low preparation cost, good stability of structure and thermal expansivity, security construction, environmental protection and reliable adhesion. The adhesion between the self-adhesive glue stock and the elastomer modified asphalt glue stock is strong and the roll prepared has reliable waterproof effect.

Owner:浙江天信建材有限公司

Epoxy resin terrazzo mixing proportion

The invention relates to an epoxy resin terrazzo which is characterized by being prepared by evenly blending the following raw materials according to the specific weight: 6.0-6.5 kg / m<3> of epoxy resin, 1.2-1.3 kg / m<3> of curing agent, 0.5-1.0 kg / m<3> of flour, 100-160 kg / m<3> of industrial salt, 1320-1640 kg / m<3> of stones, 10-30 kg / m<3> quartz sand, 450-670 kg / m<3> glass, and 10-30 kg / m<3> of luminous powder. Compared with the prior art, the epoxy resin terrazzo has the advantages that the quality of terrace is obviously improved, and the construction process is more environment-friendly. The epoxy resin terrazzo has good application prospects at the places of supermarkets and the like which lay emphasis on the decoration effect.

Owner:ZHONGTIAN CONSTR GROUP

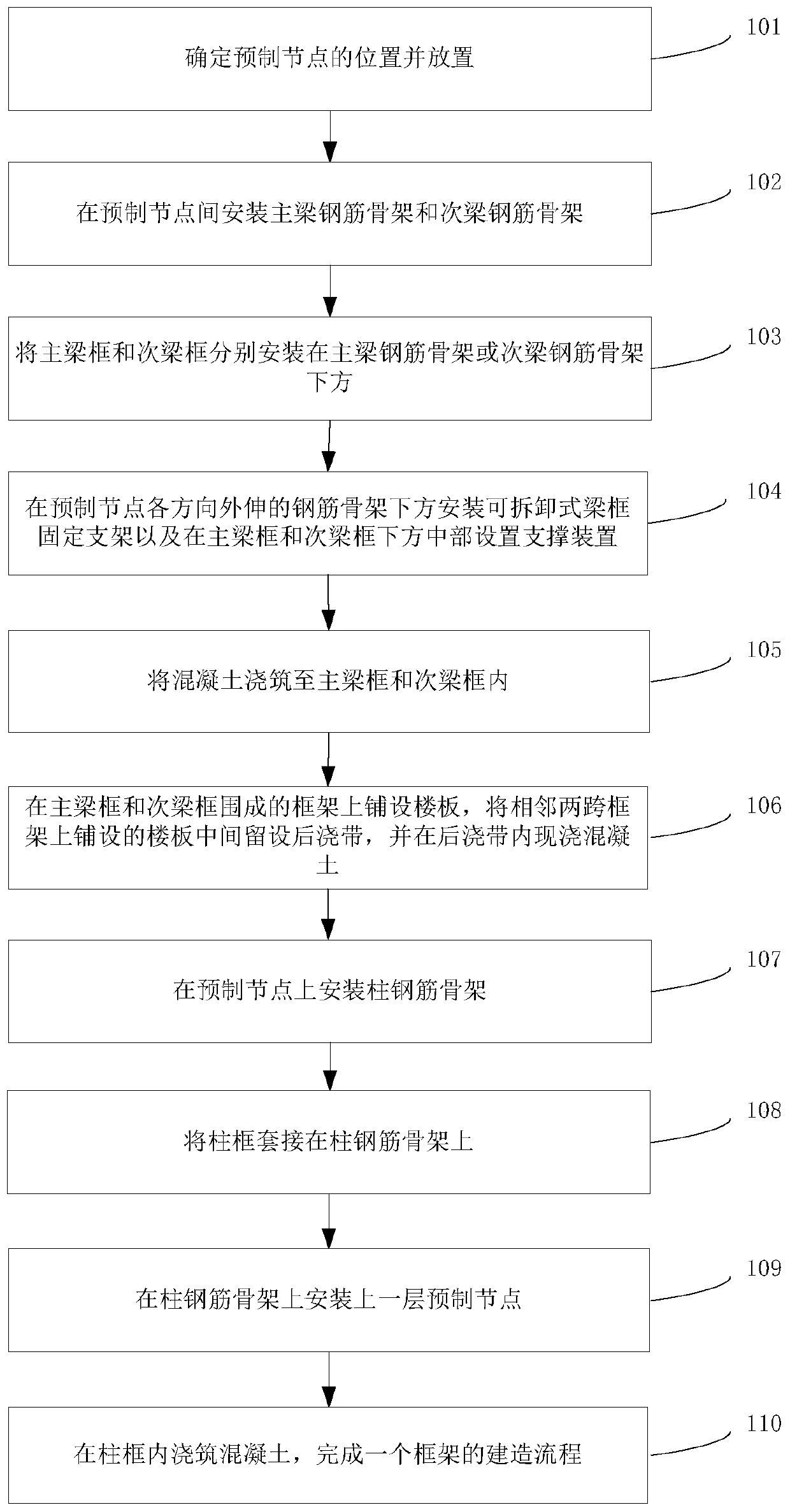

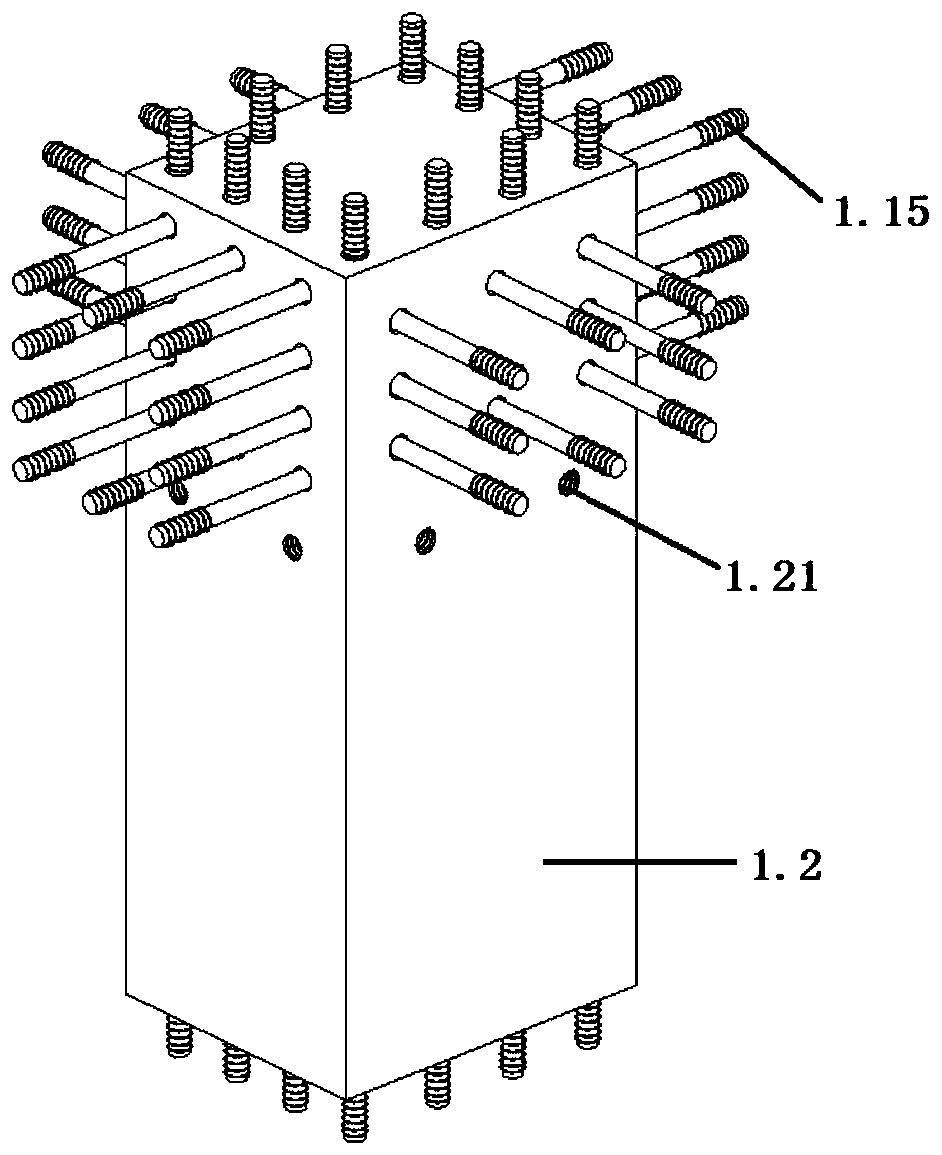

Independent node fabricated frame structure and construction method

PendingCN110905074AEasy to processAvoid the problem of uneven forceBuilding reinforcementsFloor slabArchitectural engineering

Owner:LONGXIN CONSTR GRP

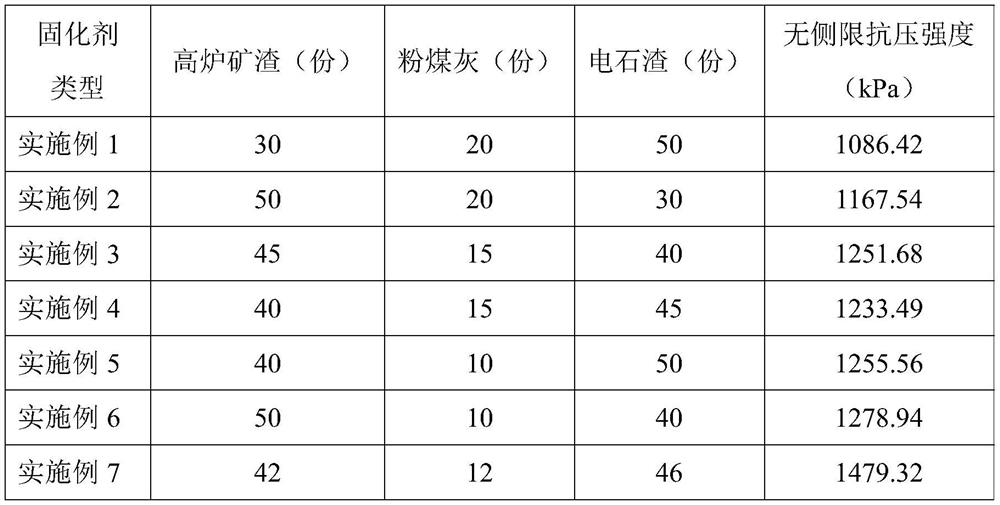

Soil stabilizer for roadbed filling

InactiveCN113214835AWide variety of sourcesLow costRoadwaysBuilding constructionsSlagToxic industrial waste

The invention discloses a soil stabilizer for roadbed filling, which is characterized in that three industrial wastes of granulated blast furnace slag, fly ash and carbide slag are used as raw materials, and Taizhou mucky soil with the water content not less than 50% and the organic matter content not less than 3% is subjected to reinforcement treatment, so that the strength and stability requirements of roadbed filling are met. The invention discloses a construction method for solidifying mucky soil with the soil stabilizer. According to the soil stabilizerdisclosed by the invention, three industrial wastes are combined together according to a proper proportion, and the strength and stability of the soil stabilizer are exerted through a pozzolanic reaction. The soil stabilizer not only can solve the problem that a large amount of mucky soil in Taizhou has no place to stack, but also can solve the problem that industrial waste polluting soil, air and water cannot be directly utilized in industrial production, and meanwhile, roadbed earthwork is saved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +2

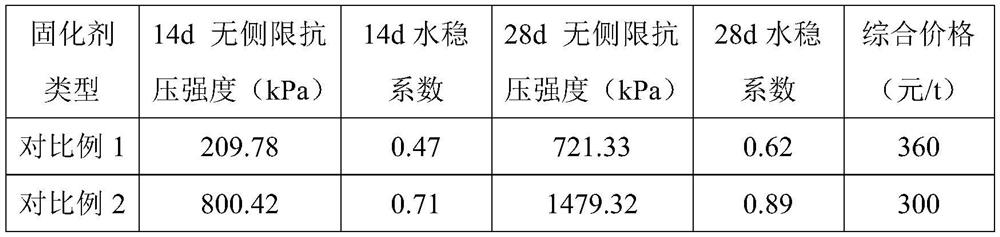

Inflation anchor bar

InactiveCN101476320ASimple materialReduce engineering costsExcavationsBulkheads/pilesEngineeringSteel tube

The invention discloses an inflatable anchor rod. One end of a steel tube (1) is an open end, while the other end is a closed end; the upper end and the lower end of a rubber film (4) with rough appearance are fastened and sleeved outside the closed end of the steel tube (1); and a part of the steel tube (1), which is corresponding to the rubber film (4), is drilled with air holes (3). The thickness of the rubber film (4) is between 2 and 4 mm. The invention is an inflatable anchor rod which can be directly used in soft soil regions without reinforcing soft soil, can provide all anchored force after the construction is finished, shorten the construction period, and has no pollution.

Owner:CENT SOUTH UNIV

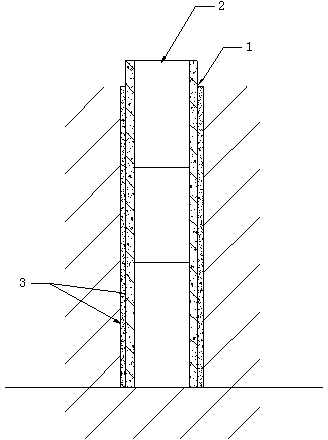

Construction structure of building external wall

ActiveCN110195510AConstruction environmental protectionProcess to reduce accumulation of materialsScaffold accessoriesButt jointArchitectural engineering

The embodiment of the invention provides a construction structure of a building external wall. The construction structure comprises a movable rack and a carrying assembly. The carrying assembly comprises a carrying plate. The carrying plate is connected to the movable rack, and is used for butt joint to a to-be-operated wall space for carrying a material falling from the to-be-operated wall space.The construction structure of the building external wall can carry a fallen material, prevent the material from polluting the ground and the wall space, and is environmental-friendly and reliable toconstruct.

Owner:河南置诚建筑工程有限公司

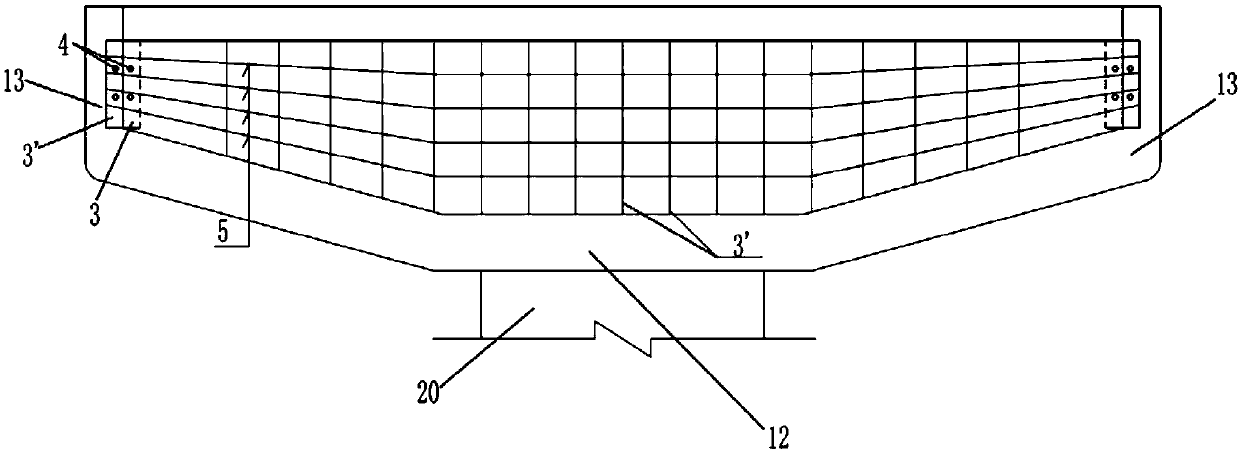

Bent cap of prefabricated assembled pier, pier, bridge and bridge assembling construction method

PendingCN108677687AEasy to buildConstruction and environmental protectionBridge structural detailsBridge erection/assemblyEngineeringOpen hole

The invention discloses a bent cap of a prefabricated assembled pier. The bent cap is characterized in that the bent cap comprises a prefabricated bent cap component and an inner mold, wherein the prefabricated bent cap component is provided with an equal-height section and variable-height sections located on the sides of the equal-height section, and an open hole where the top of a pier body of the pier is embedded is formed in the bottom; and the inner mold is arranged in the prefabricated bent cap component. On the premise that force bearing reliability and durability of the connecting portion are guaranteed, a monorail bridge assembling requirement and an installation support moderately-adjustable requirement can be met, construction is convenient and quick, and cost reduction and application and popularization are facilitated.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

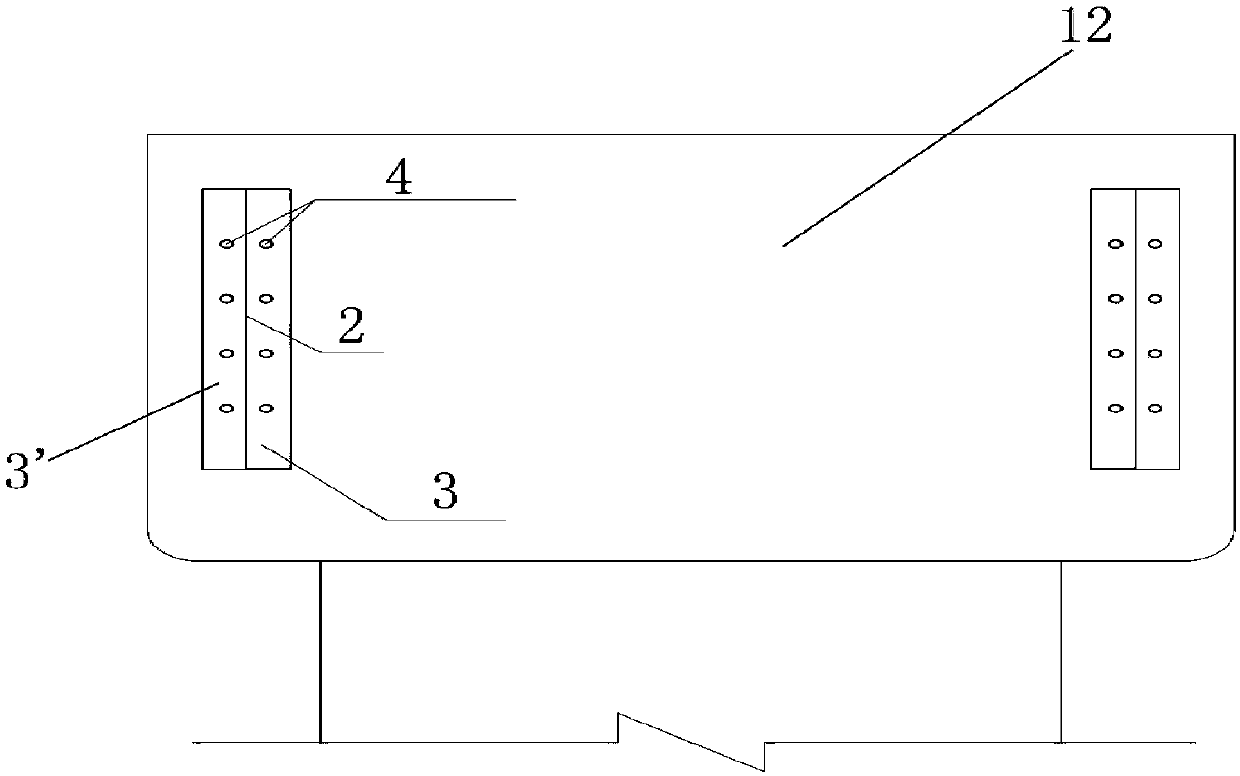

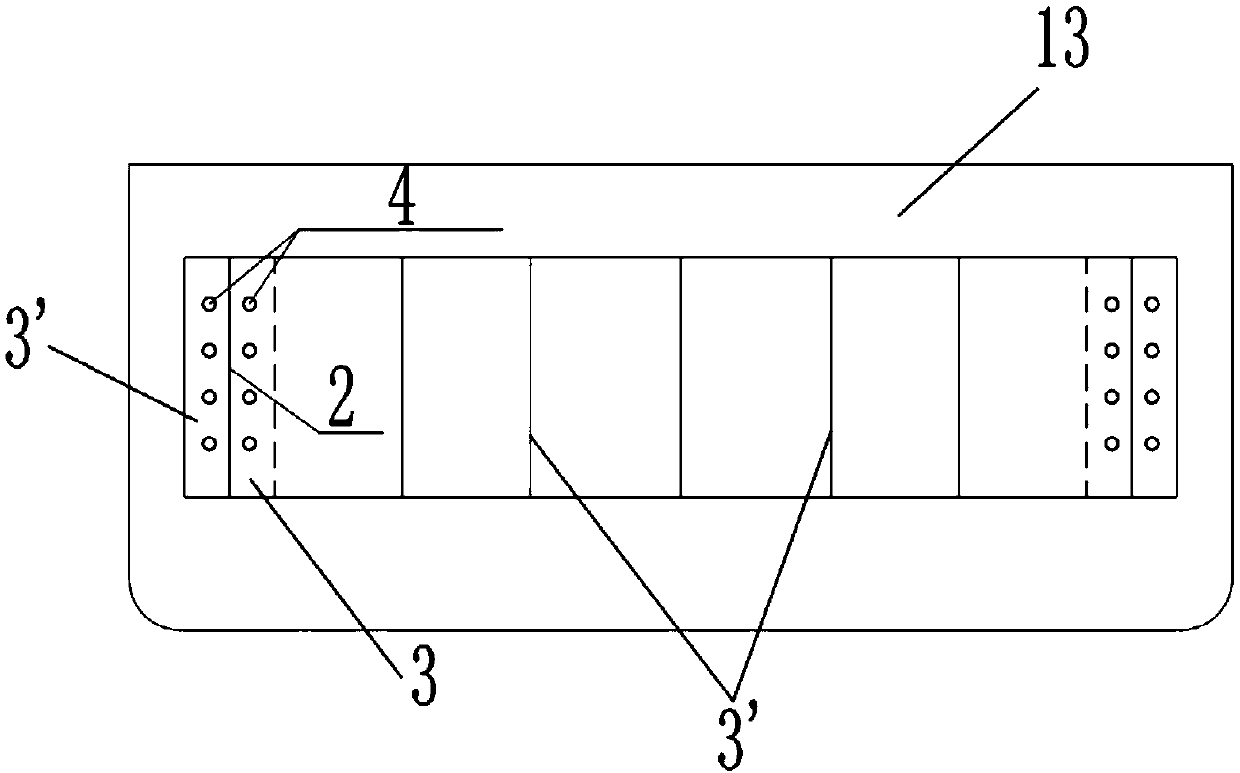

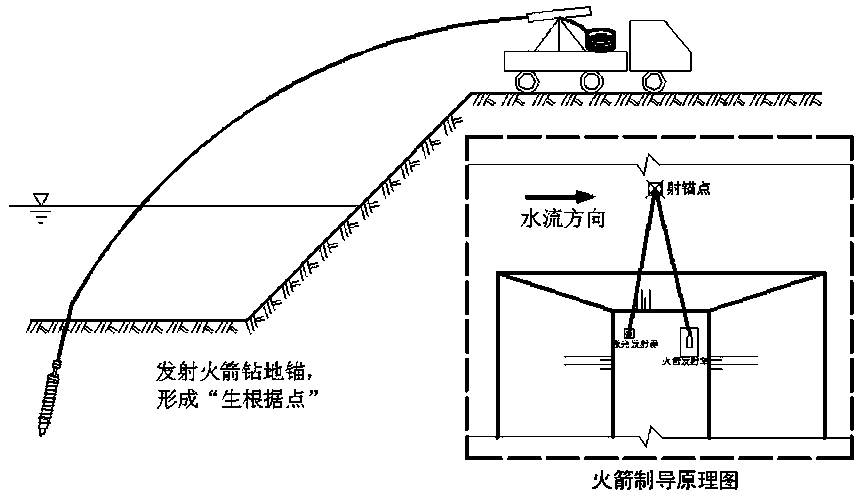

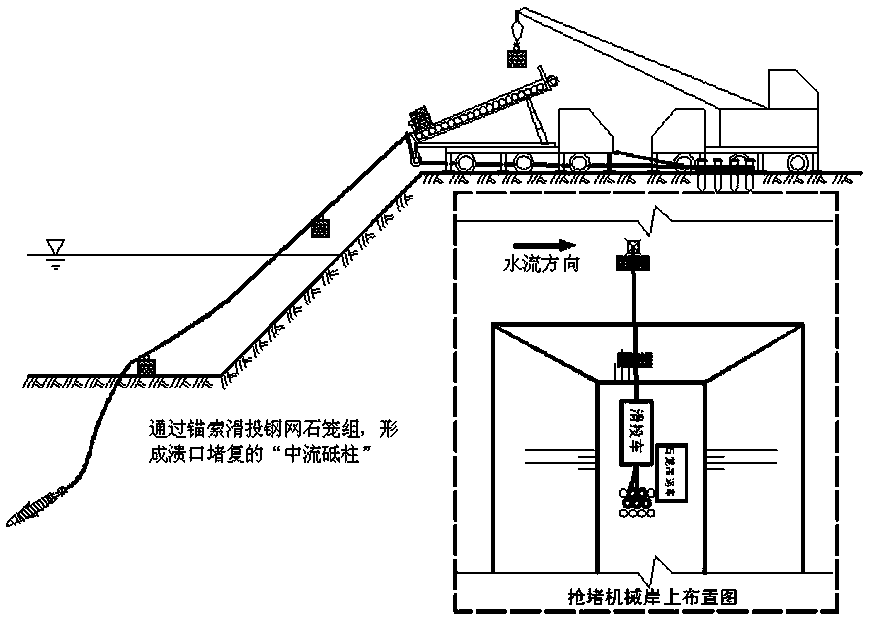

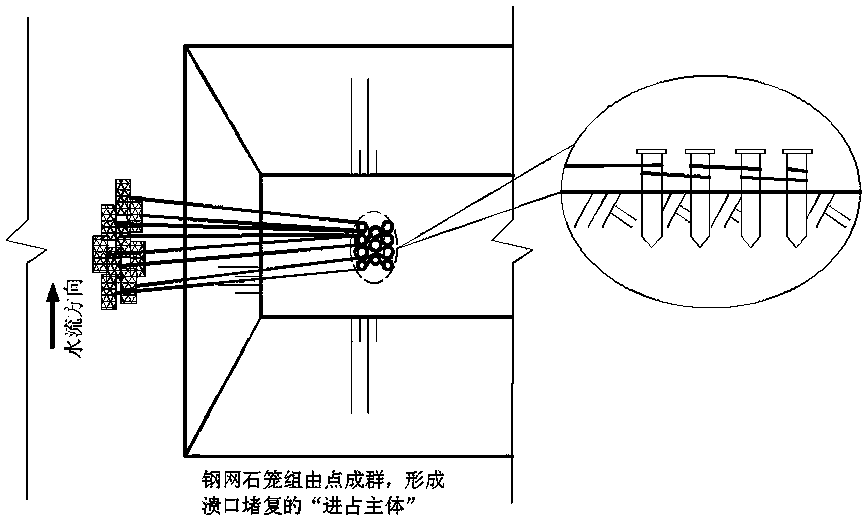

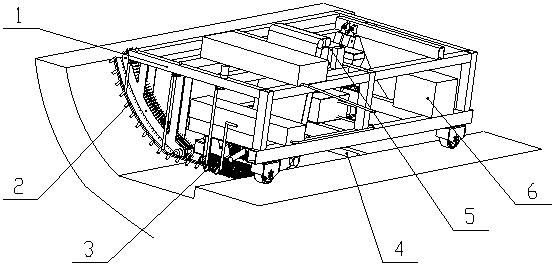

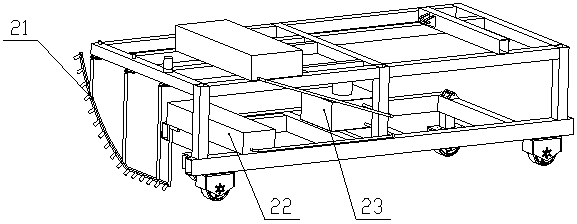

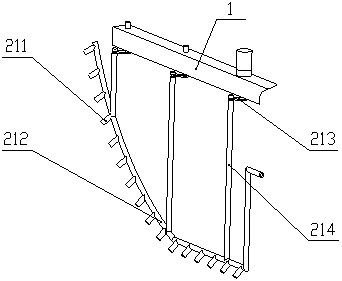

A method of blocking river breaches based on array rocket drilled ground anchors

ActiveCN107447728BImplement fixed-point rootingImplement extensionsMarine site engineeringMarine engineeringEconomic benefits

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Tunnel side wall chiseling sweeper

InactiveCN111101969AHigh degree of mechanizationAchieve mechanical propertiesMining devicesUnderground chambersSewageControl system

The invention relates to a tunnel side wall chiseling sweeper which comprises a frame, a chiseling system, a sweeping system, a water removal system, a hopper and a power and control system. The chiseling system comprises a spray head device, a high-pressure water pump and a water storage device and is used for generating high-pressure water to chisel concrete, and the sweeping system is used forcollecting sundries and sending the sundries to the hopper; the water removal system is used for collecting sewage and sending the sewage to the hopper, the hopper is used for storing sundries and filtering the sewage and sending the filtered water to the water storage device, the power and control system provides power and controls each system, and the chiseling system, the sweeping system, the water removal system, the hopper and the power and control system are installed on the frame and move along with the frame. The mechanical chiseling construction and cleaning of side wall and base concrete can be realized.

Owner:长沙仪秀兴智能科技有限公司

Building construction system

InactiveCN105178602AGood stabilityImprove bearing capacityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFloor slabArchitectural engineering

The invention provides a building construction system. The building construction system comprises a core tube part and a peripheral part; plenty of aluminum formwork systems are adopted for the core tube part at such positions as the wall of an elevator shaft, a floor slab, a wall column, a beam and stairs and for the peripheral part at such positions as a pillar and stairs; an elevator shaft steel formwork worktable is arranged in the elevator shaft; bench formworks are adopted for the peripheral part at such positions as the floor slab and the beam; compared with a traditional wood formwork, the aluminum formwork is good in stability, high in bearing capacity, and simple and easy to mount, and the construction process of the aluminum formwork is more environmentally friendly; after construction, the concrete is highly flat; besides, the overall construction period of a building can be effectively shortened and the overall building quality can be improved, and therefore, the construction cost can be reduced; in addition, a protective screen of the peripheral part is also capable of improving the safety of construction.

Owner:GENUINE TREASURE CONSTR TECH COMPANY

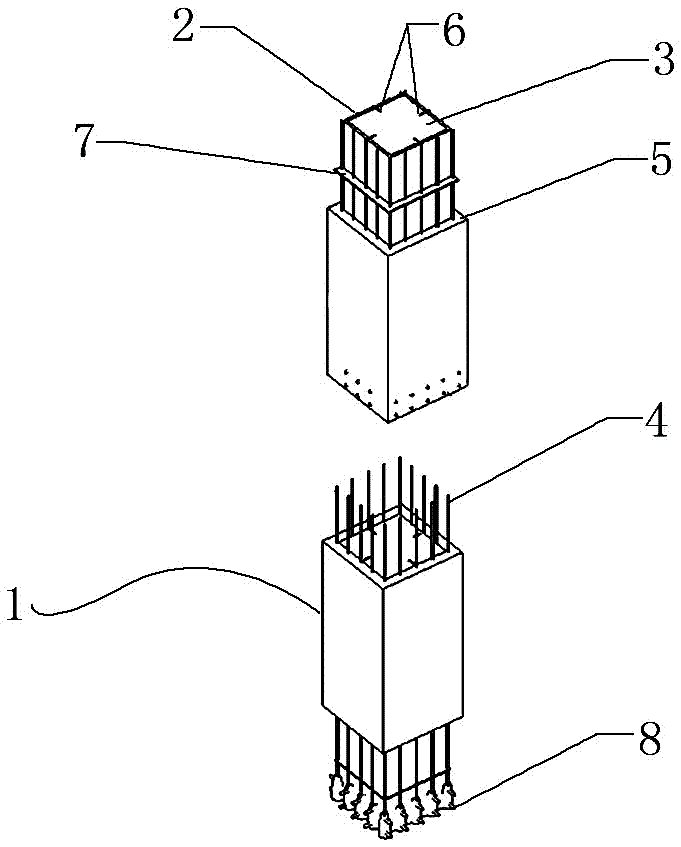

Drilling and concrete injected root composite pile implanting pile structure and construction method

The invention discloses a drilling and concrete injected root composite pile implanting pile structure. The drilling and concrete injected root composite pile implanting pile structure comprises a pile hole, a pipe pile which is implanted into the pile hole and concrete layers between the pipe pile and the pile hole and inside the pipe pile walls. The implanting pile structure construction method comprises the following steps of (1) drilling the pile hole with the diameter larger than that of the pipe pile in a required pile position in the foundation through drilling machinery; (2) pouring concrete into the pile hole root through a grouting pipe; (3) inserting a prepared pipe pile into the pile hole which is poured with concrete, enabling the concrete to move upward along the pipe wall of the pipe pile and a gap between the pipe pile and the pile hole and performing concrete consolidation forming after pile implanting is achieved. The composite pile implanting pile structure has a high bearing capacity as a drilling pipe and is superior to the drilling pipe in cost. The implanting pile structure construction method needs no mud retaining wall, is environmental friendly in construction progress and shortens the construction days.

Owner:国鼎(南通)管桩有限公司 +1

Novel plant shaping technology

InactiveCN110731186ATo achieve a variety of landscape effectsChange the cultivation mediumGrowth substratesCulture mediaProcess engineeringBiology

The invention relates to a novel plant shaping technology. The novel plant shaping technology includes: selecting plant materials and performing early-stage preprocessing; selecting plant shaping frames, (containers) and culture medium materials and manufacturing; performing plant material cuttage, fixation and later maintenance and the like.

Owner:高仁丽

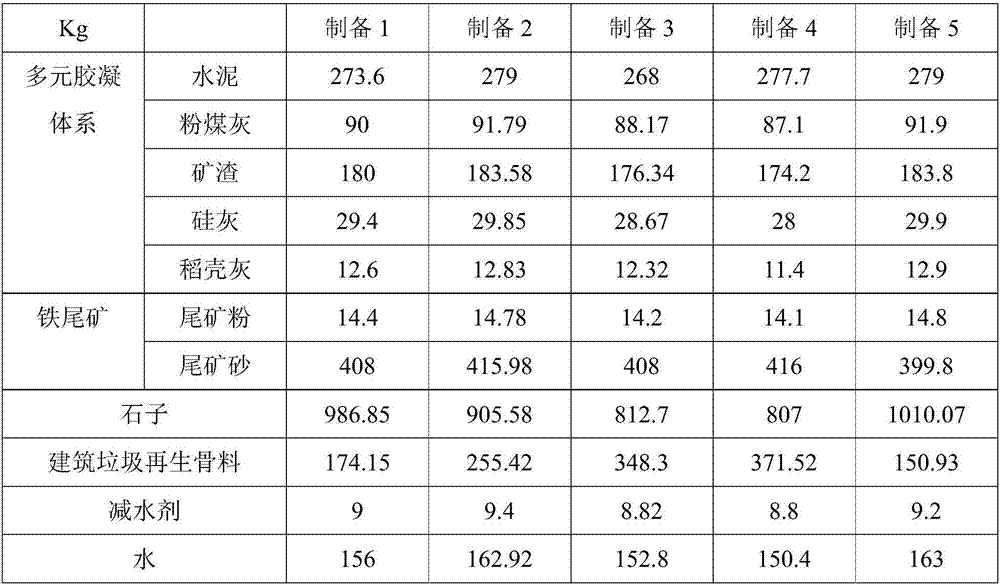

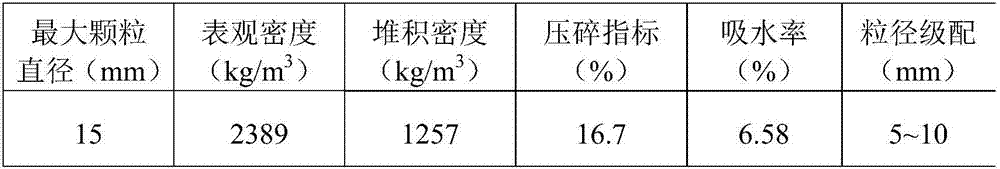

Assembled steel tube high-strength concrete columns and construction method thereof

ActiveCN107460994AIncreased durabilityImprove fire performanceStrutsSolid waste managementHigh strength concreteSteel tube

The invention relates to the technical field of assembled steel tube high-strength concrete columns, and discloses the assembled steel tube high-strength concrete columns and a construction method thereof. The assembled steel tube high-strength concrete columns are formed by sequential connecting of prefabricated standard column joints, and the standard column joints comprise steel tubes, high-strength concrete, stiffening ribs and ordinary concrete, wherein the high-strength concrete is poured in the steel tubes; the stiffening ribs are arranged on the outer side of the steel tubes in a surrounding mode, and the ordinary concrete is poured at the outside of the steel tubes; the high-strength concrete is high-strength concrete with added iron tailings and construction waste; vertical rib groups are fixed to the inner walls of the steel tubes in a welded mode; horizontal end plates are arranged on the outer circumferences of the steel tubes along the section direction in a surrounding mode; through holes are evenly formed in the horizontal end plates at intervals; the stiffening ribs penetrate through the through holes and are arranged in the length directions of the steel tubes in a full-length mode; one ends of the stiffening ribs extend out of the standard column joints, and the other ends of the stiffening ribs are provided with half grouting sleeves which are connected with the stiffening ribs extending out of the adjacent standard column joints. The assembled steel tube high-strength concrete columns are fireproofing, corrosion resisting, high in bearing capacity, and excellent in durability.

Owner:江苏悦港新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com