Assembled concrete structure construction method

A technology of concrete structure and construction method, which is applied in the construction of buildings, construction, and the processing of building materials, etc., can solve the problems of high technical precision of sleeve connecting steel bars, inability to assemble the structure, and troublesome hoisting of steel bars, etc. The effect of saving turnover materials, reducing vertical temporary supports and formwork, and simplifying construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

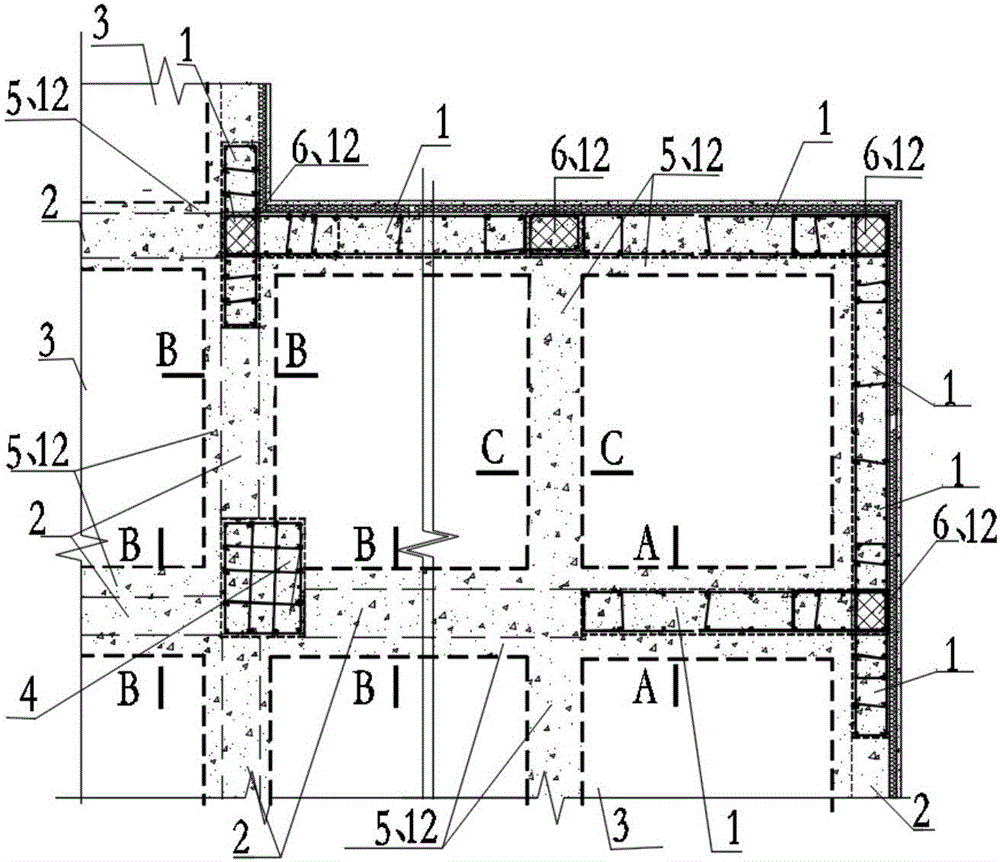

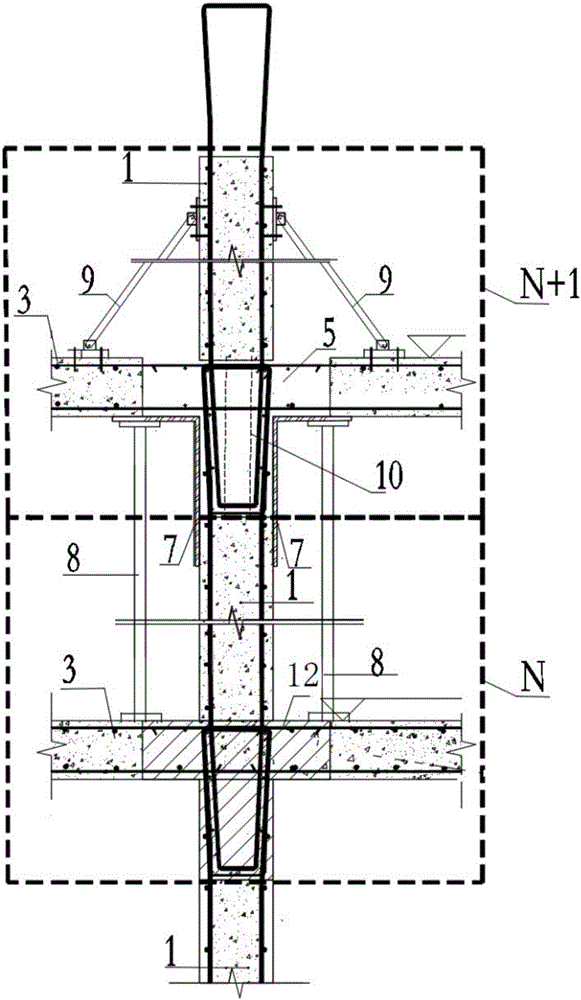

[0060] Such as Figure 1-4 As shown, the prefabricated prefabricated concrete structure construction method of this embodiment does not include the construction of prefabricated building wall panels, and the specific steps are:

[0061] a. Design general assembly drawings and prefabricated components to make construction drawings, produce prefabricated structural components according to the requirements of the design drawings and transport them to the site;

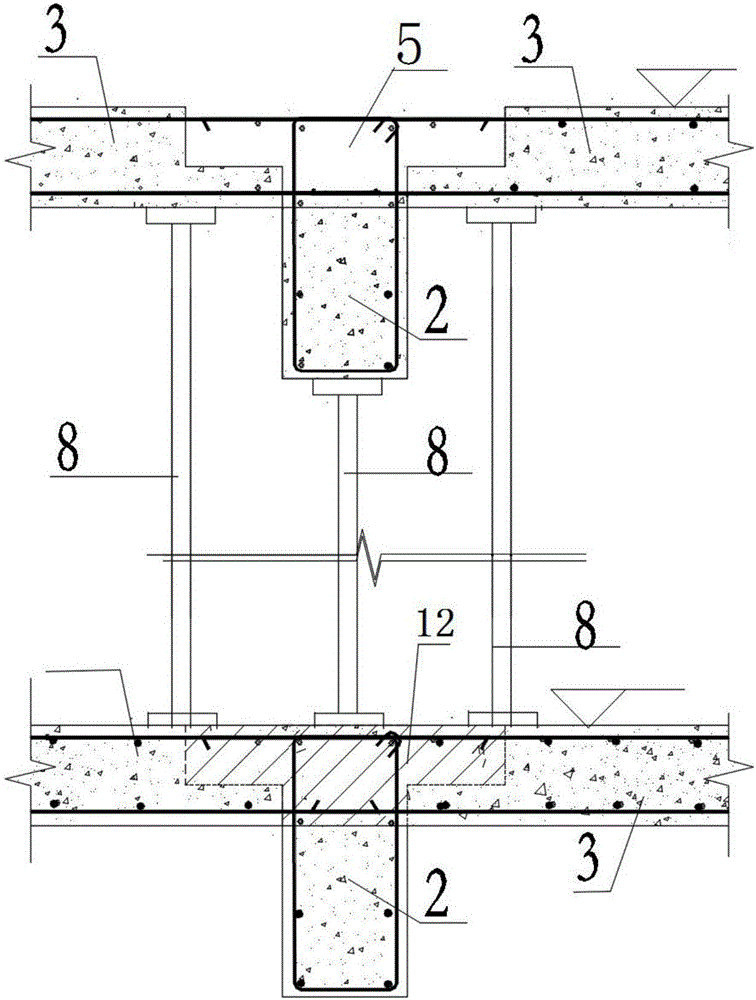

[0062] b. (this is the operation of entering the next construction layer N+1 after the last assembly construction layer N is completed), install the vertical support 8 and the required formwork 7 for supporting the horizontal member. The installed support 8 and formwork 7 are required to meet the precise elevation requirements, and the loads of the connected vertical members on the installed horizontal members are required to be considered;

[0063] c, hoisting the prefabricated composite beam 2 and the prefabricated flo...

Embodiment 2

[0072] Such as Figure 2-6 As shown, the prefabricated building wall panel 11 is also assembled and constructed during the structure construction and assembly stage of the prefabricated concrete structure construction method of this embodiment, and the specific steps are:

[0073] a. Design general assembly drawings and prefabricated components to make construction drawings, produce prefabricated structural components and prefabricated building wall panels 11 according to the requirements of the design drawings and transport them to the site;

[0074]b. (this is the operation of entering the next construction layer N+1 after the last assembly construction layer N is completed), install the vertical support 8 and the required formwork 7 for supporting the horizontal member. The installed support 8 and formwork 7 are required to meet the precise elevation requirements, and the loads of the connected vertical members on the installed horizontal members are required to be consider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com