Patents

Literature

59results about How to "Save turnover materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-altitude long-span overhanging corridor type reinforced concrete structure and construction method

InactiveCN102444203ASave turnover materialsReduce construction costsBuilding material handlingSteel platesReinforced concrete

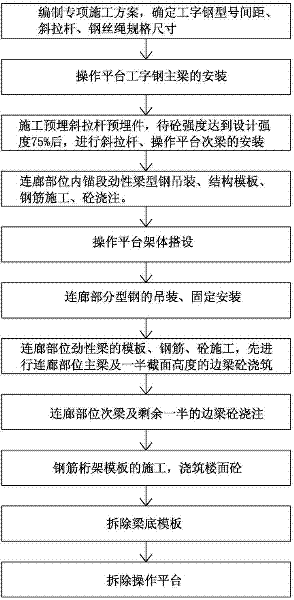

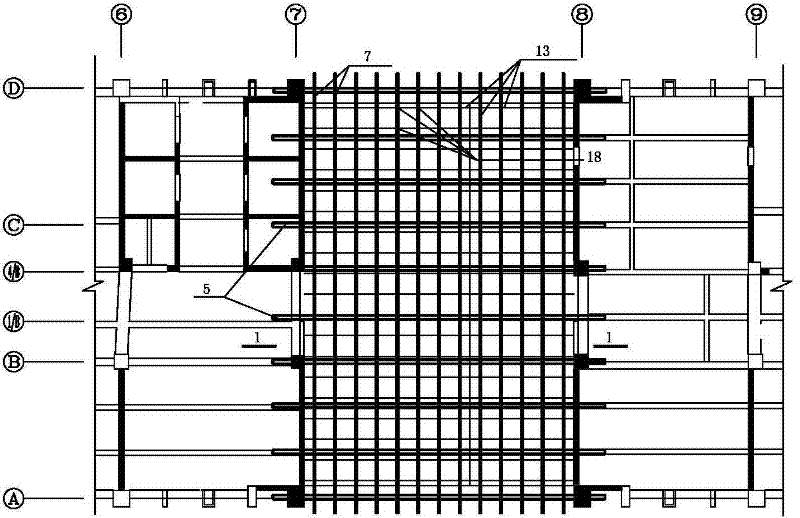

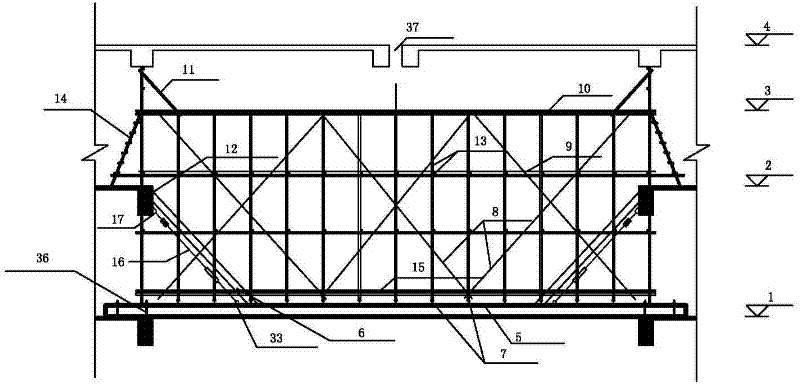

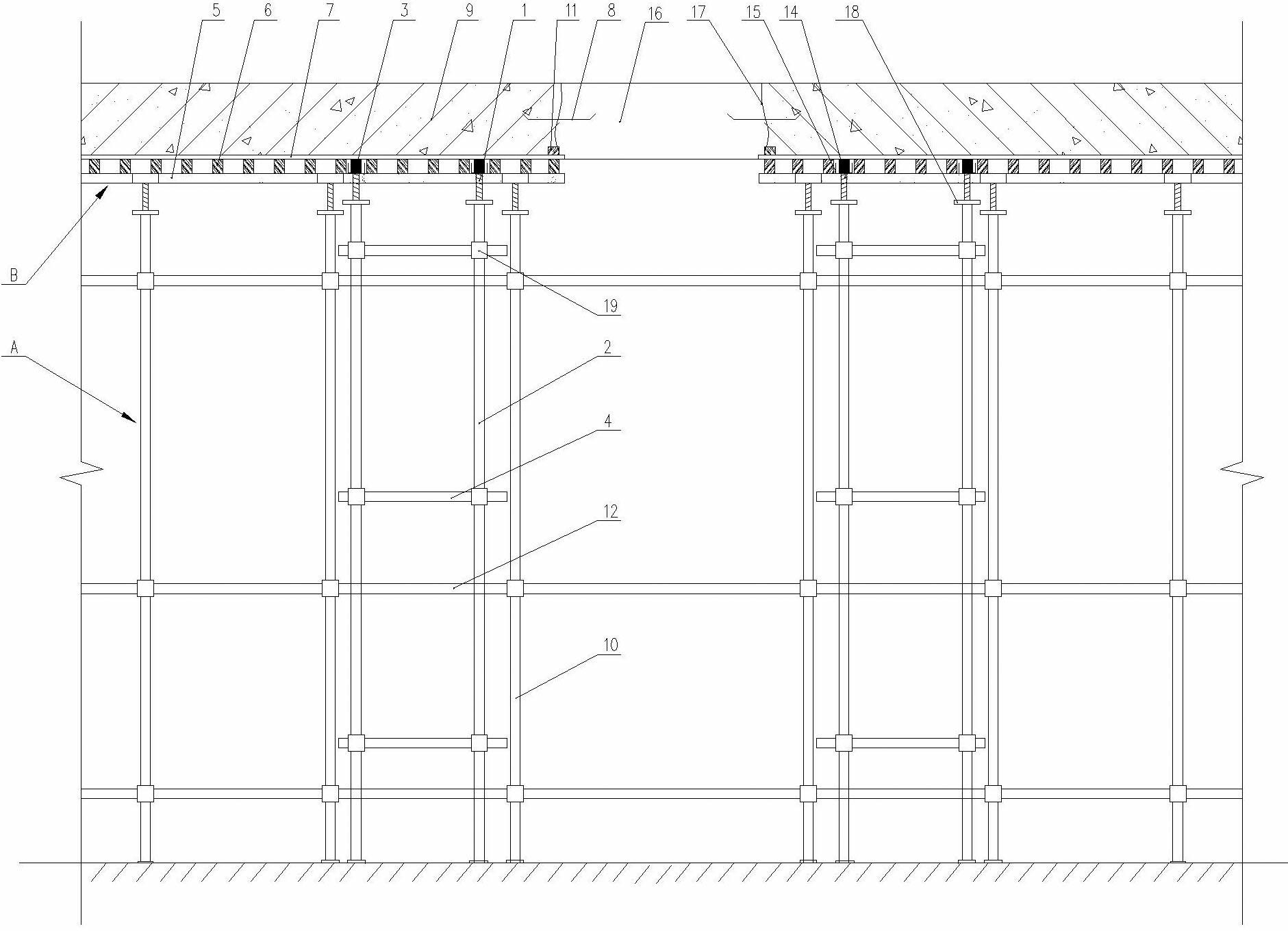

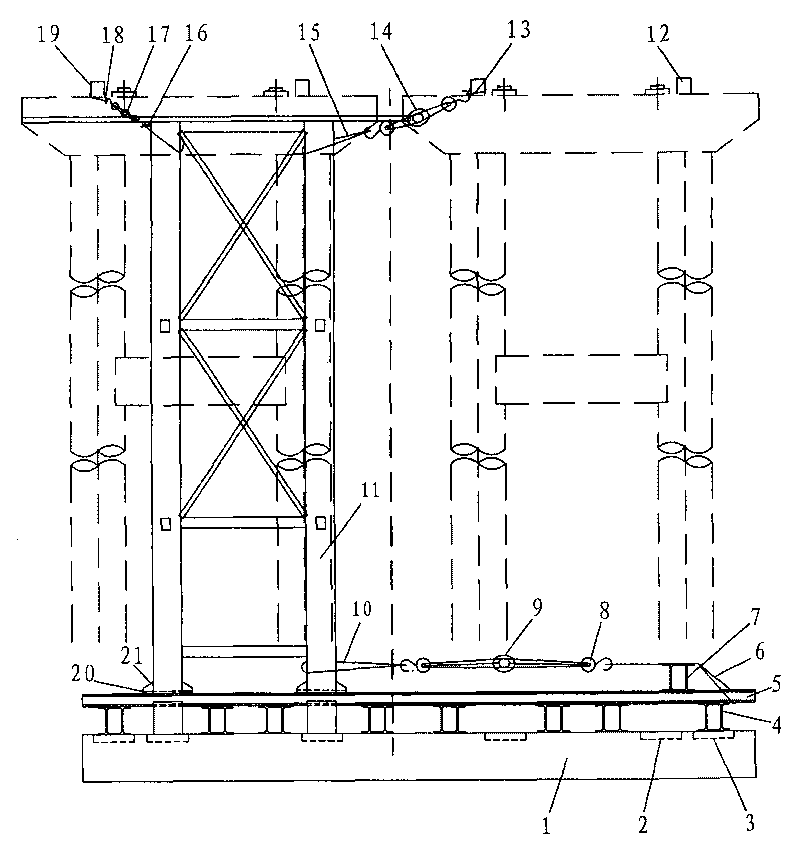

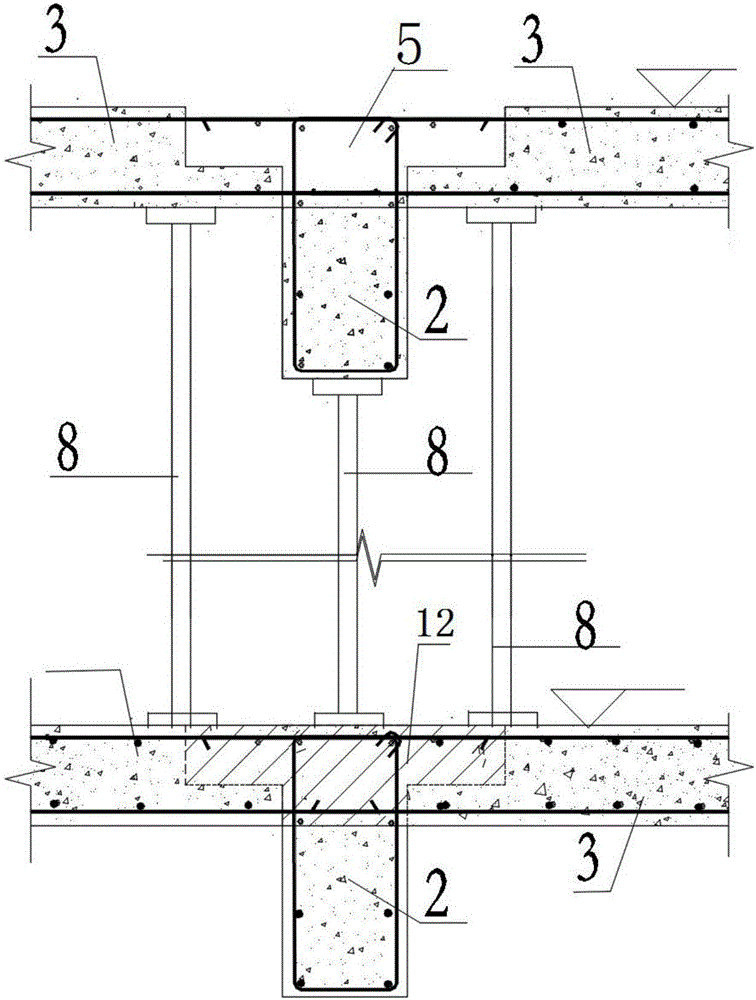

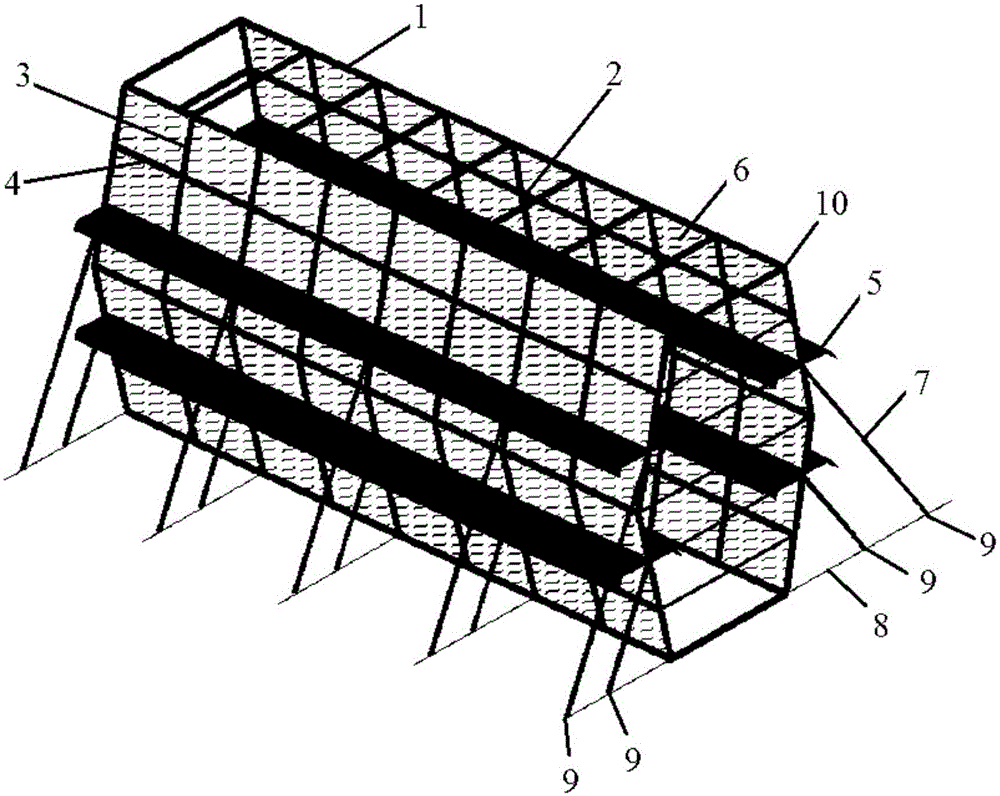

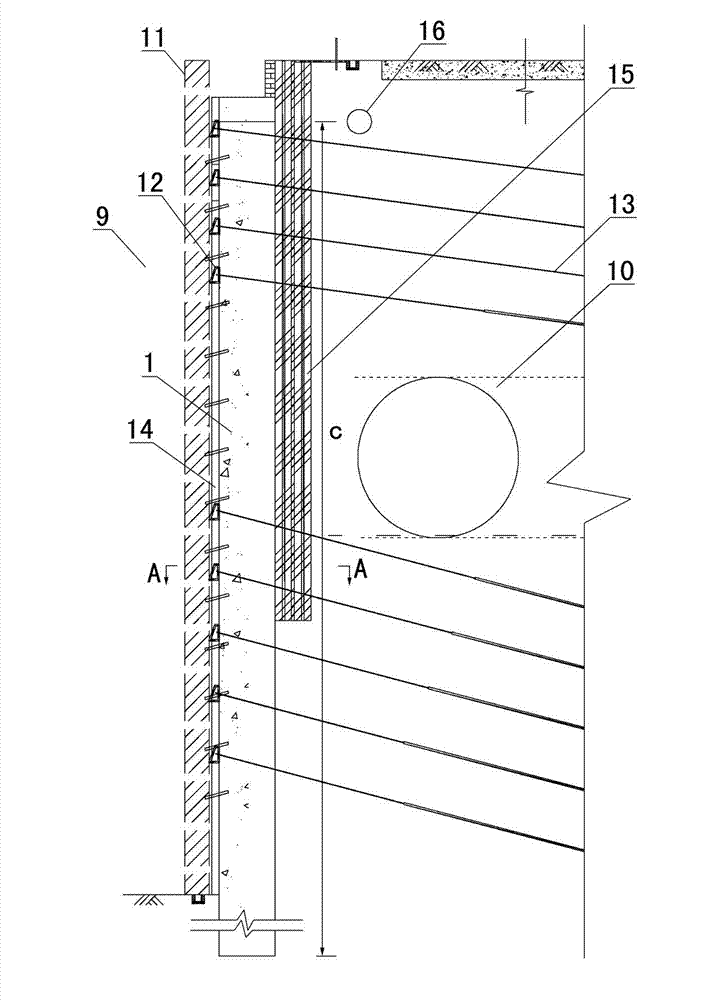

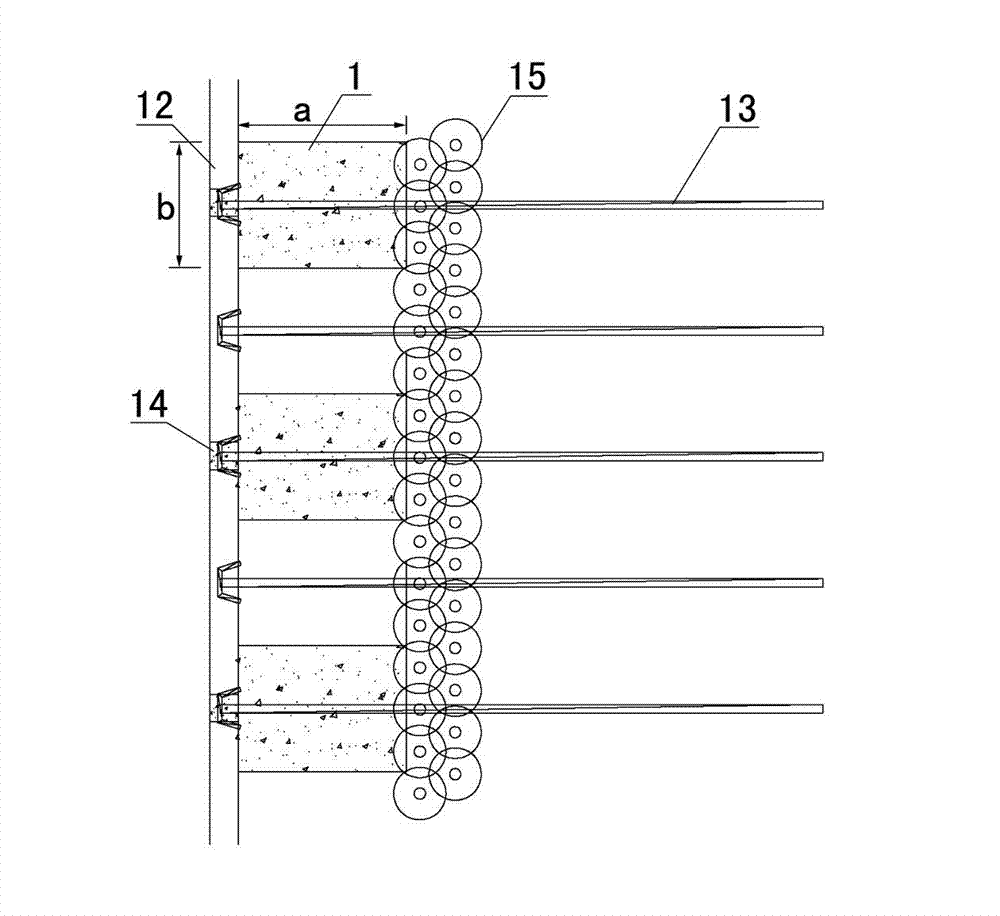

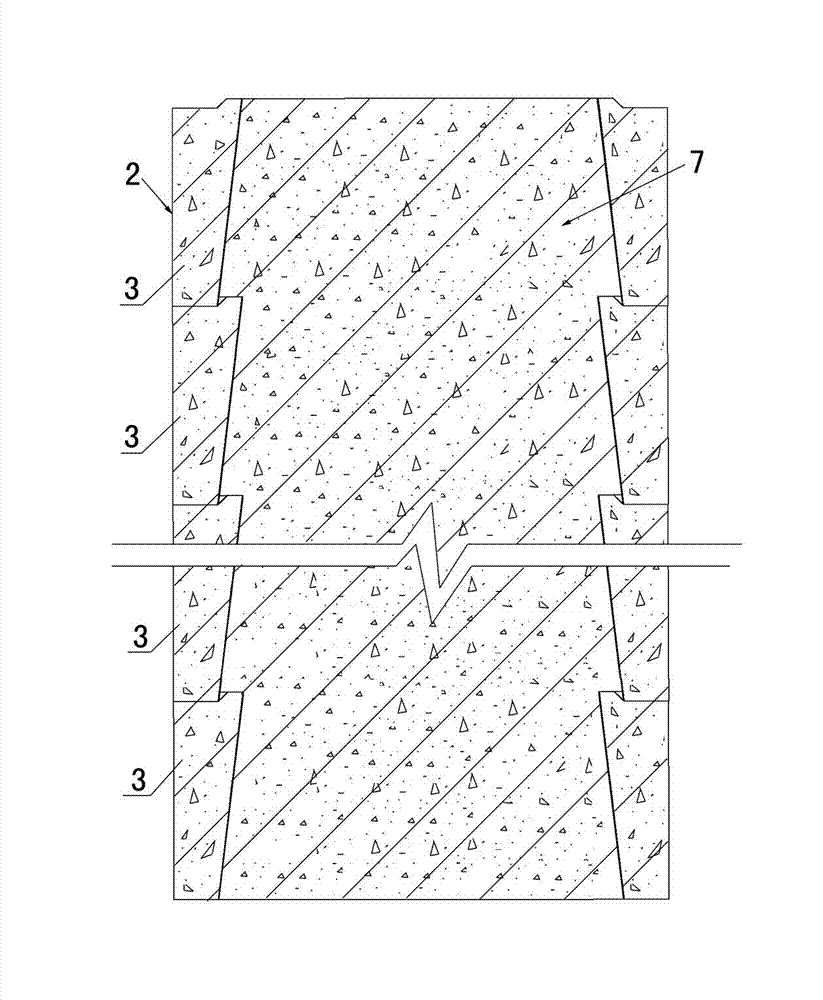

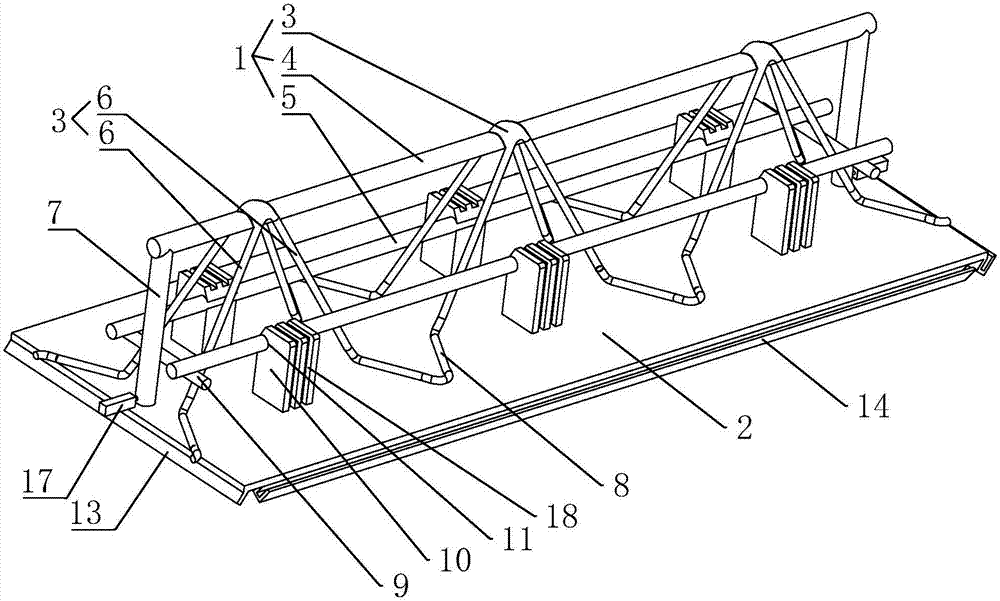

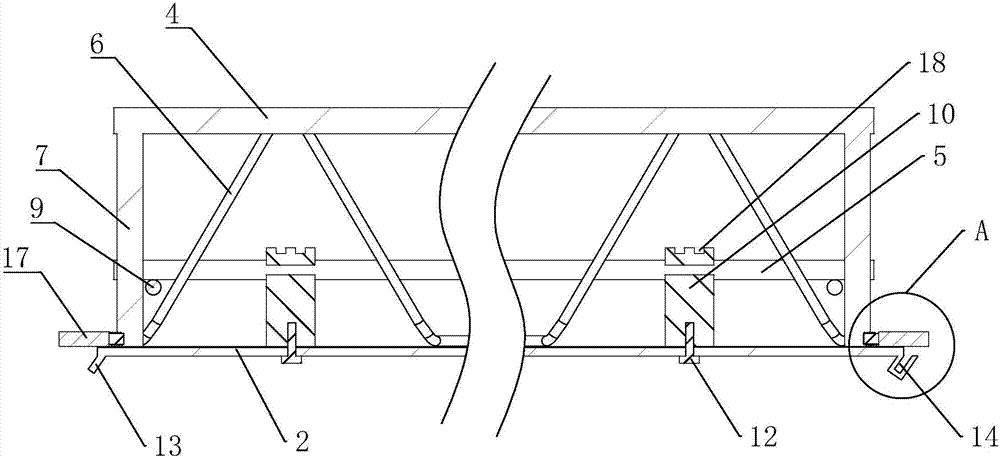

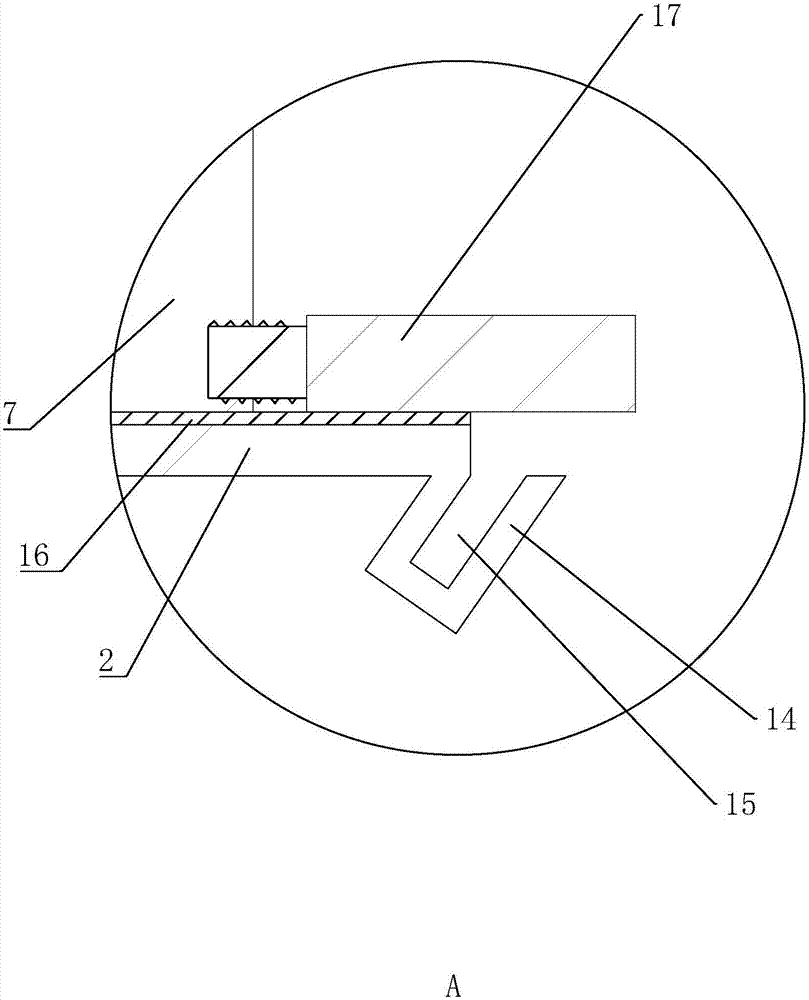

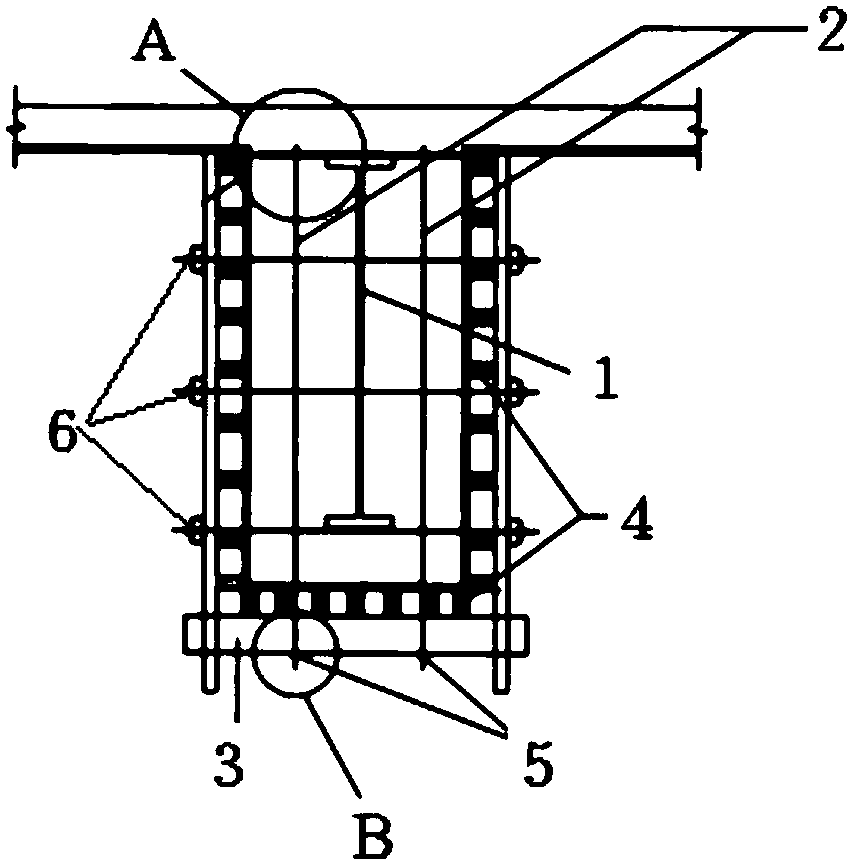

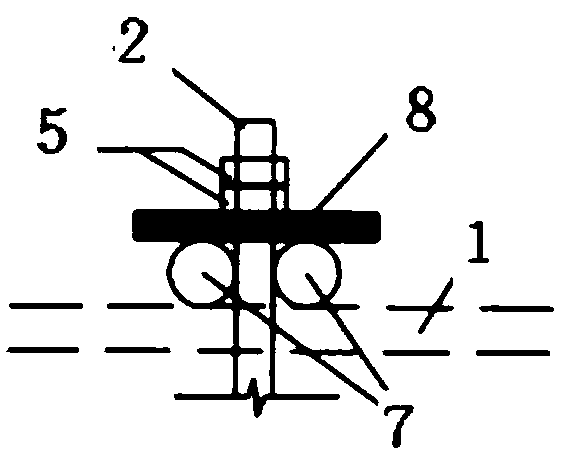

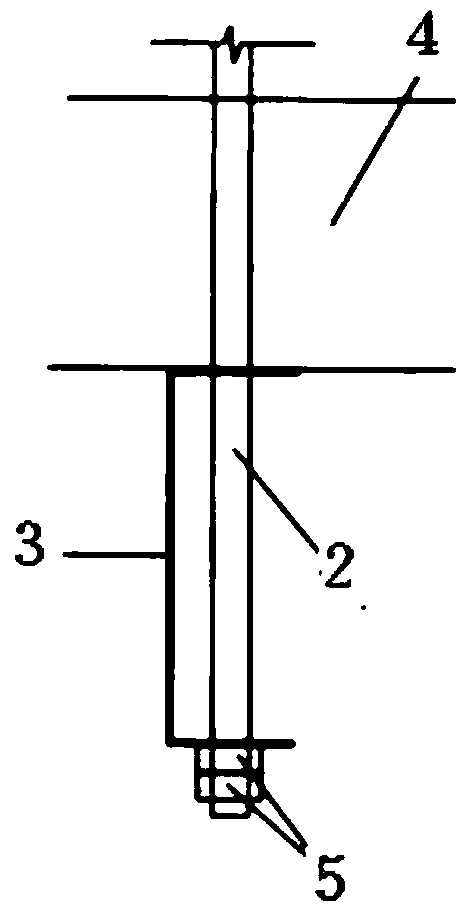

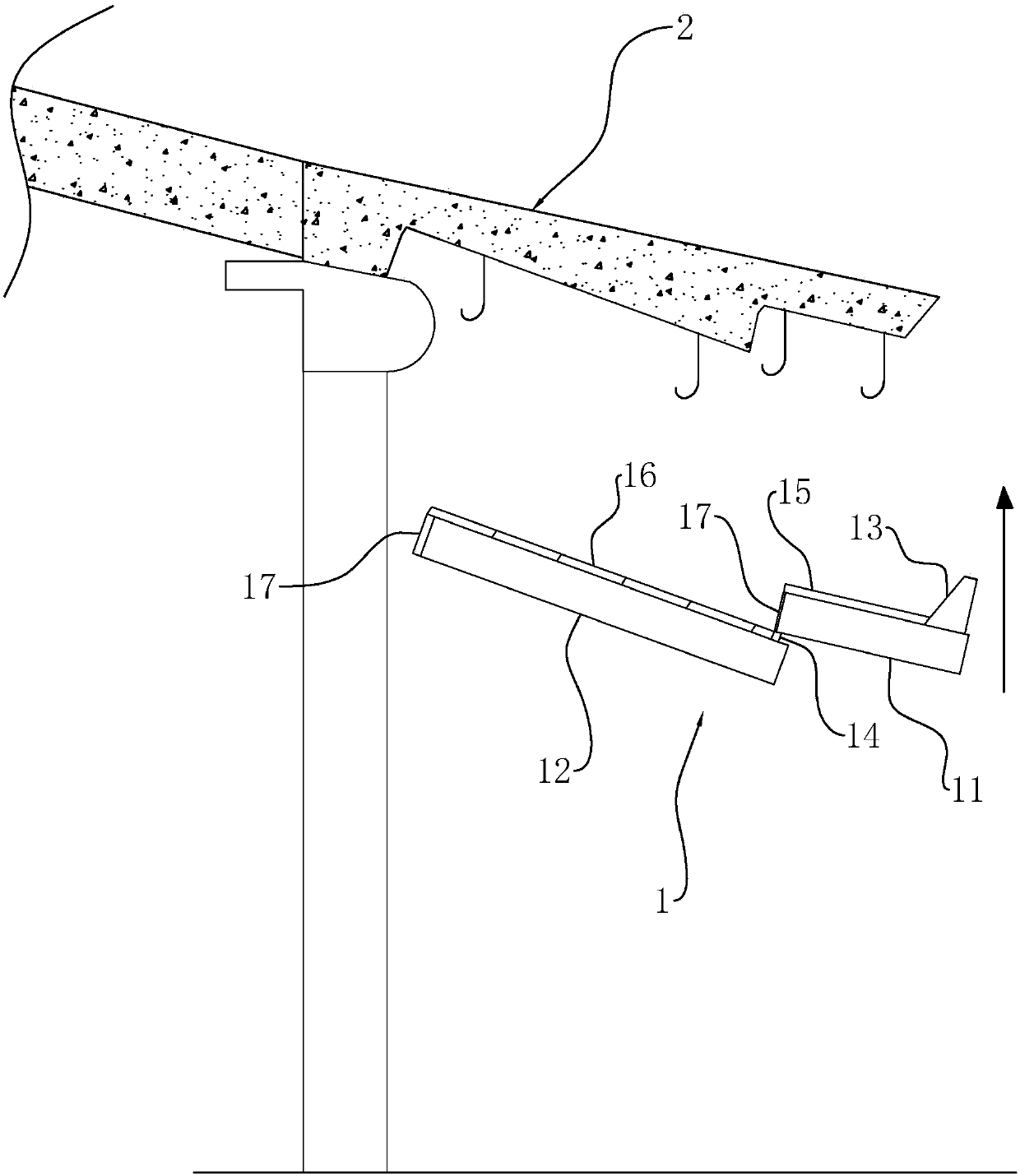

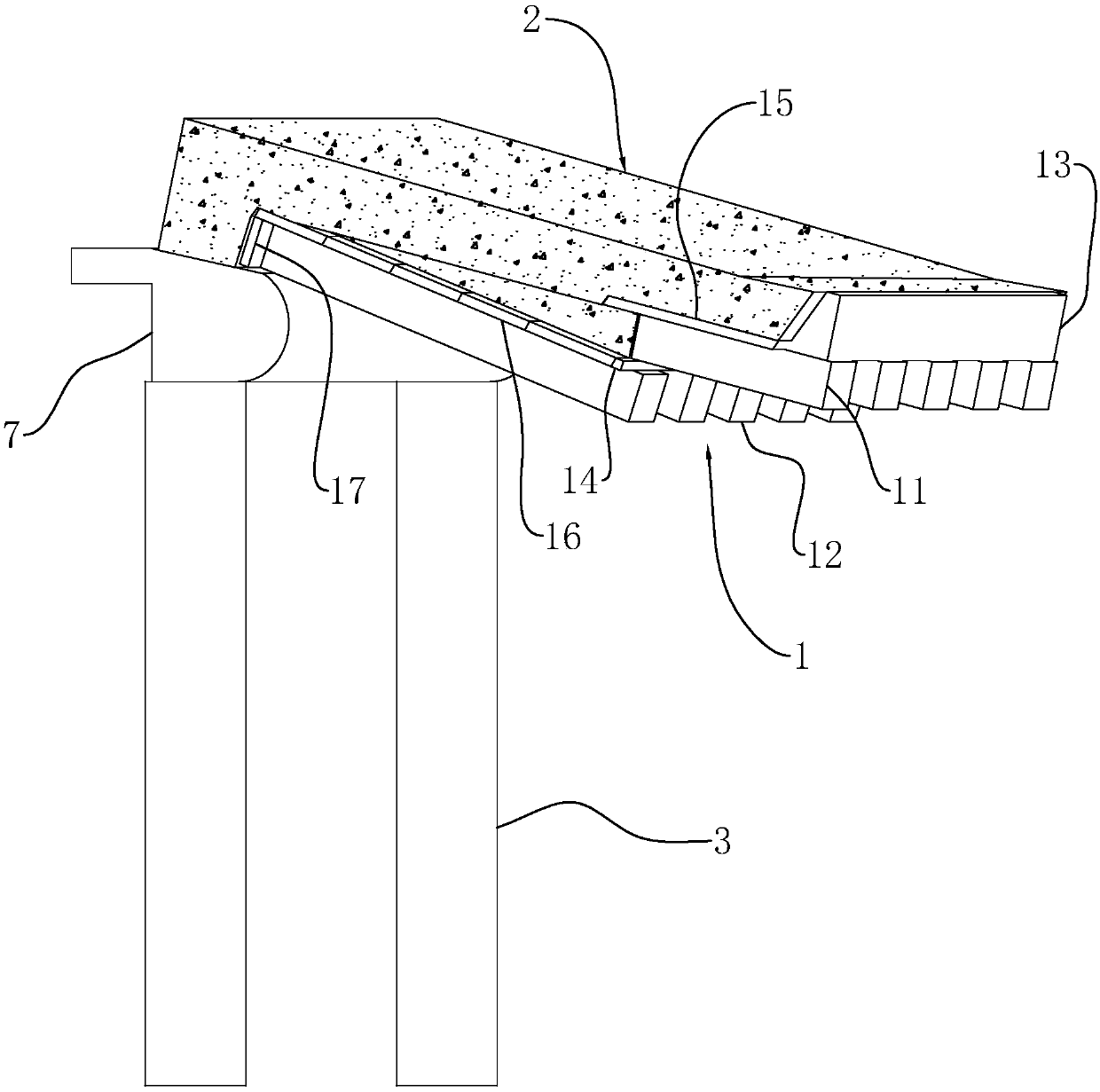

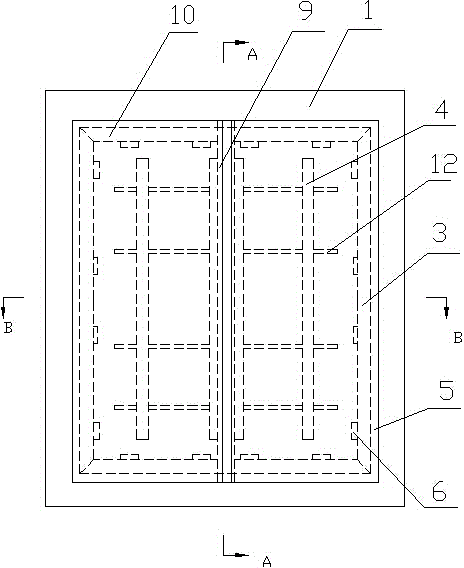

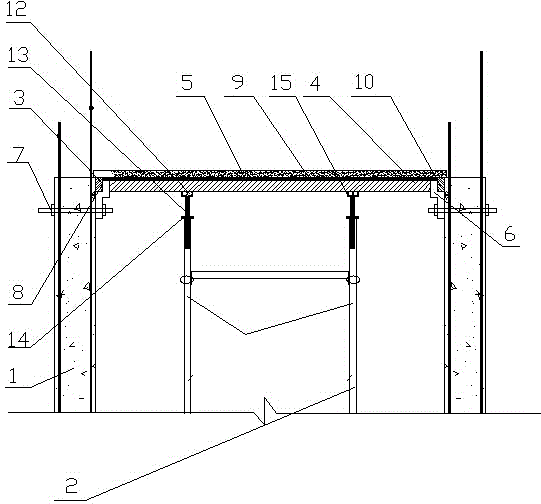

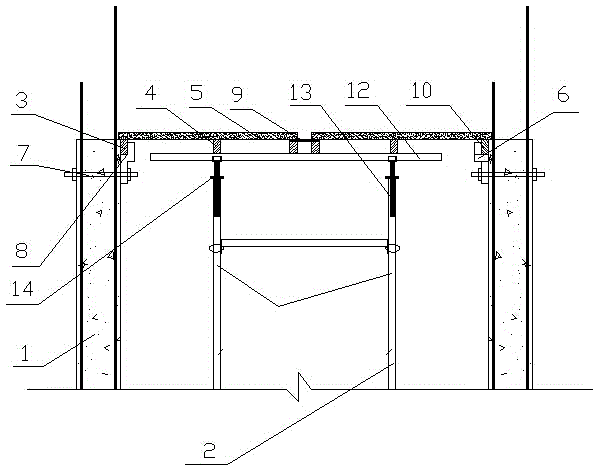

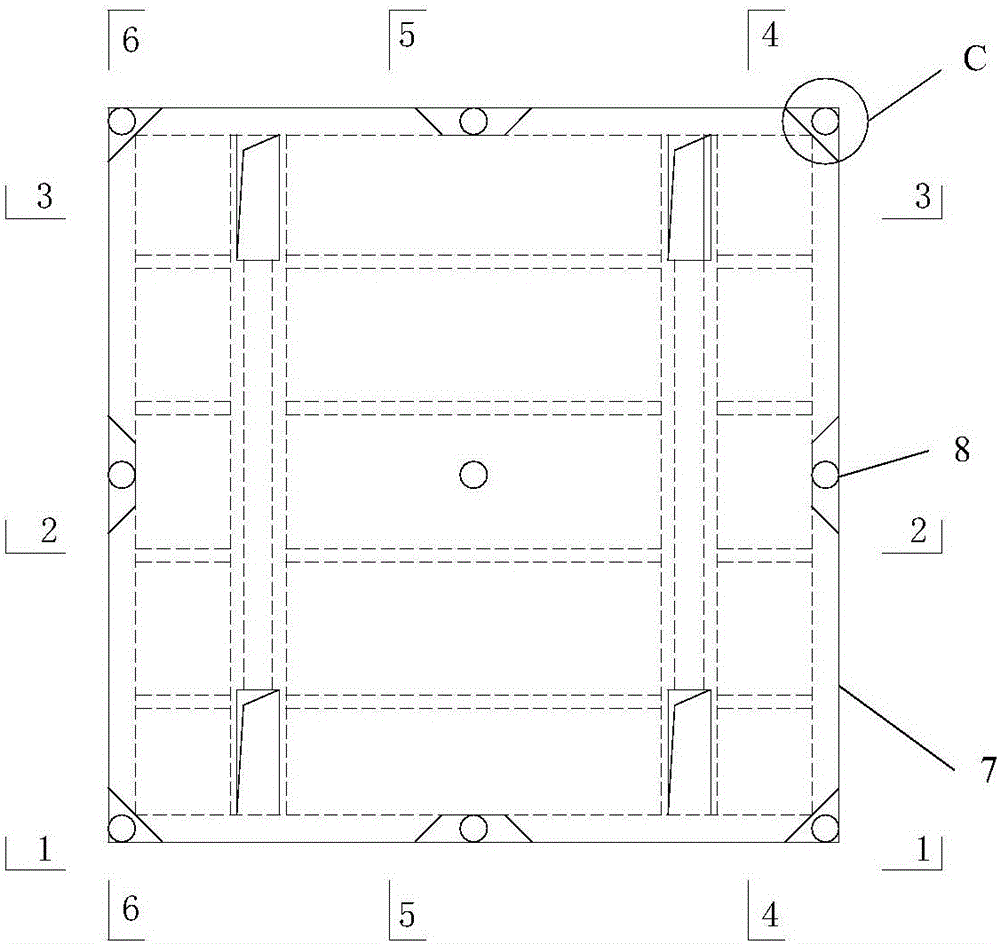

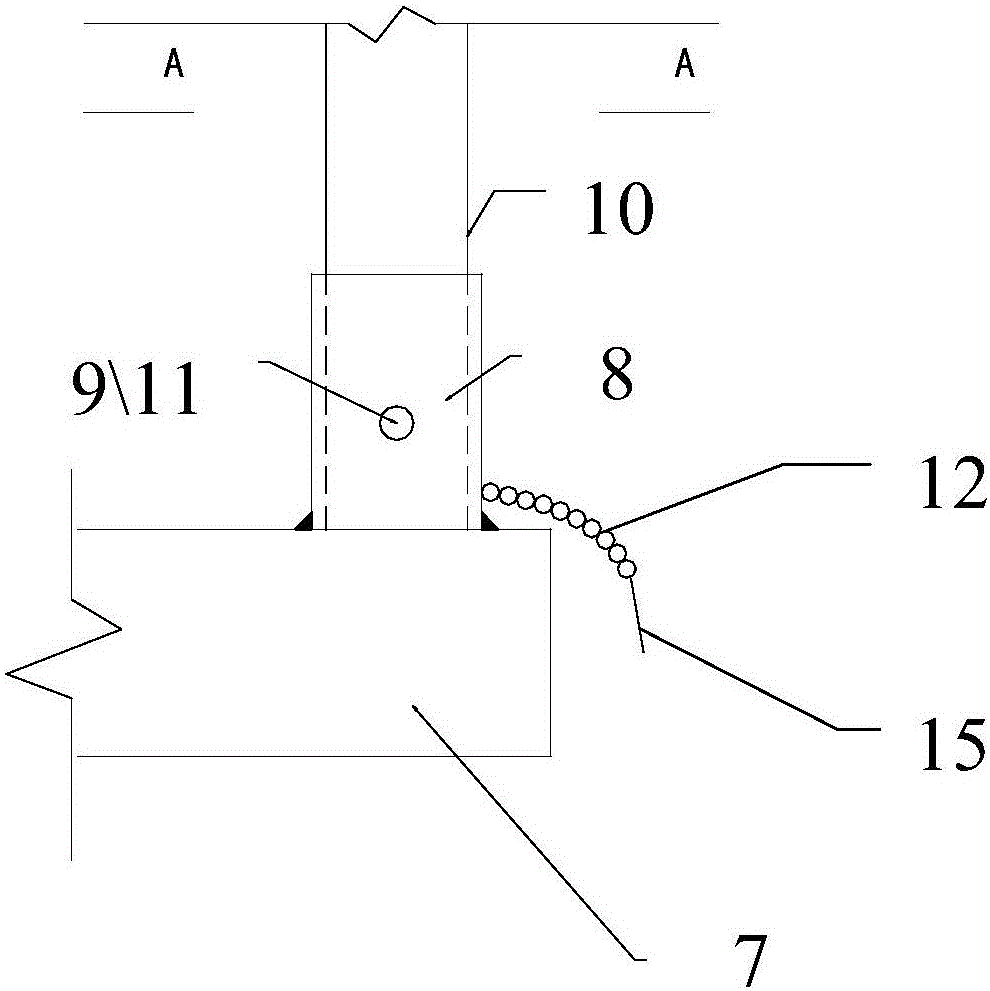

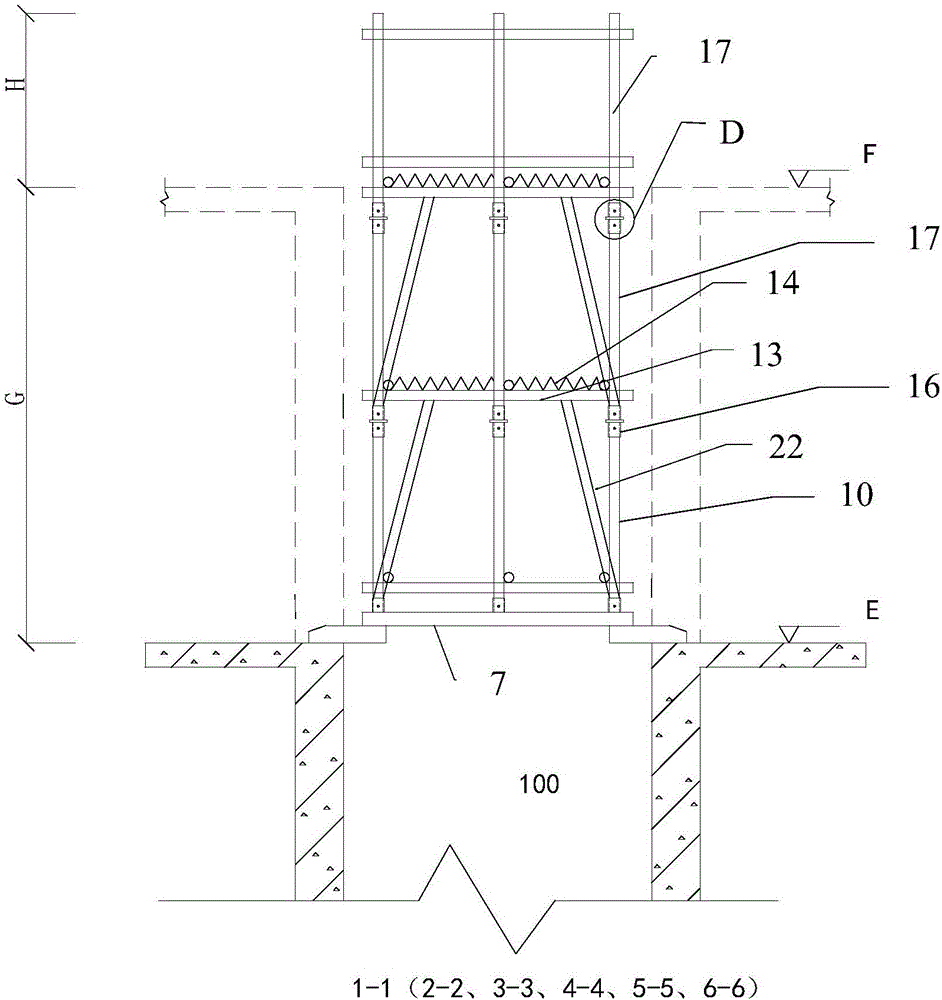

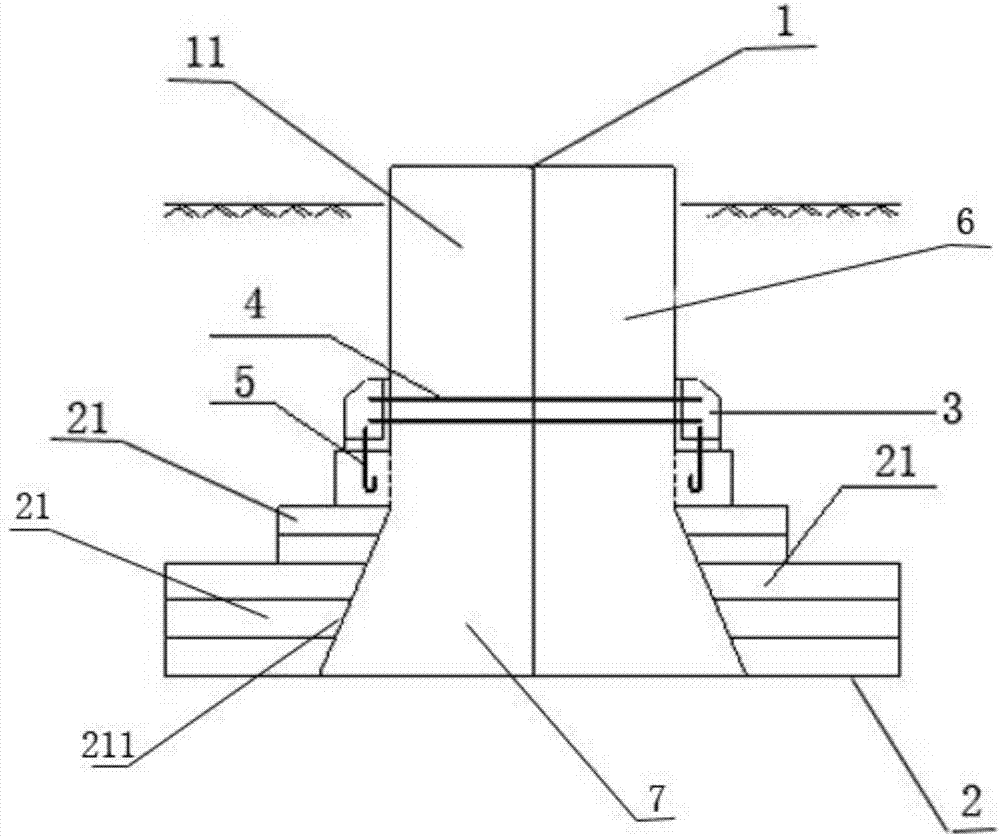

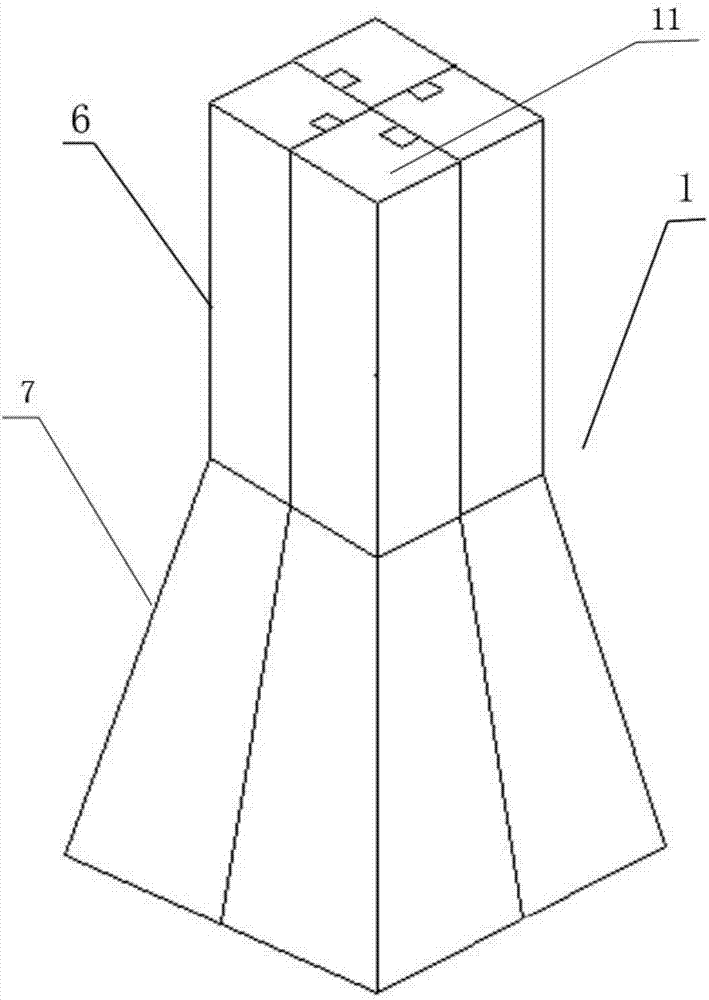

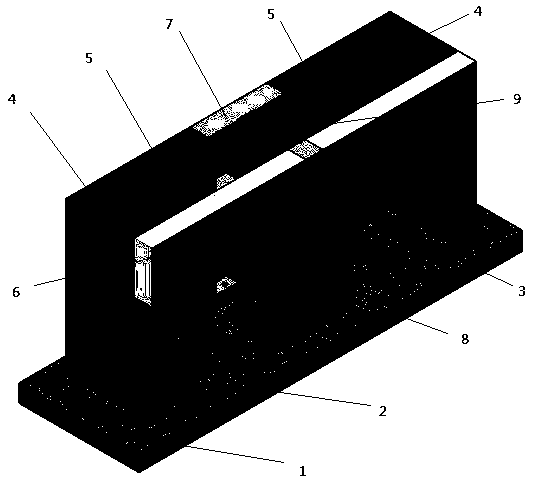

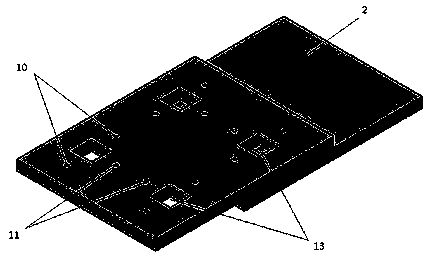

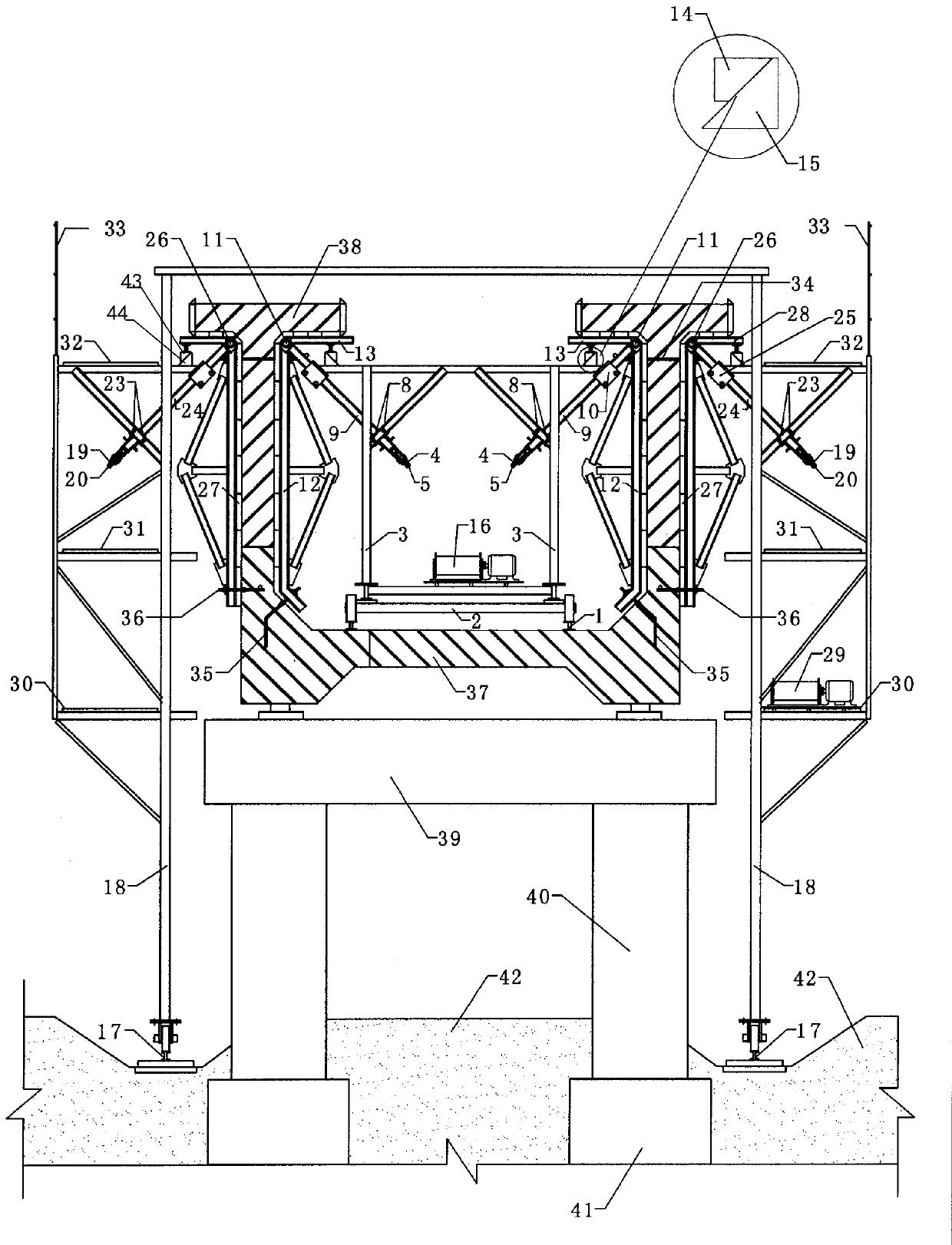

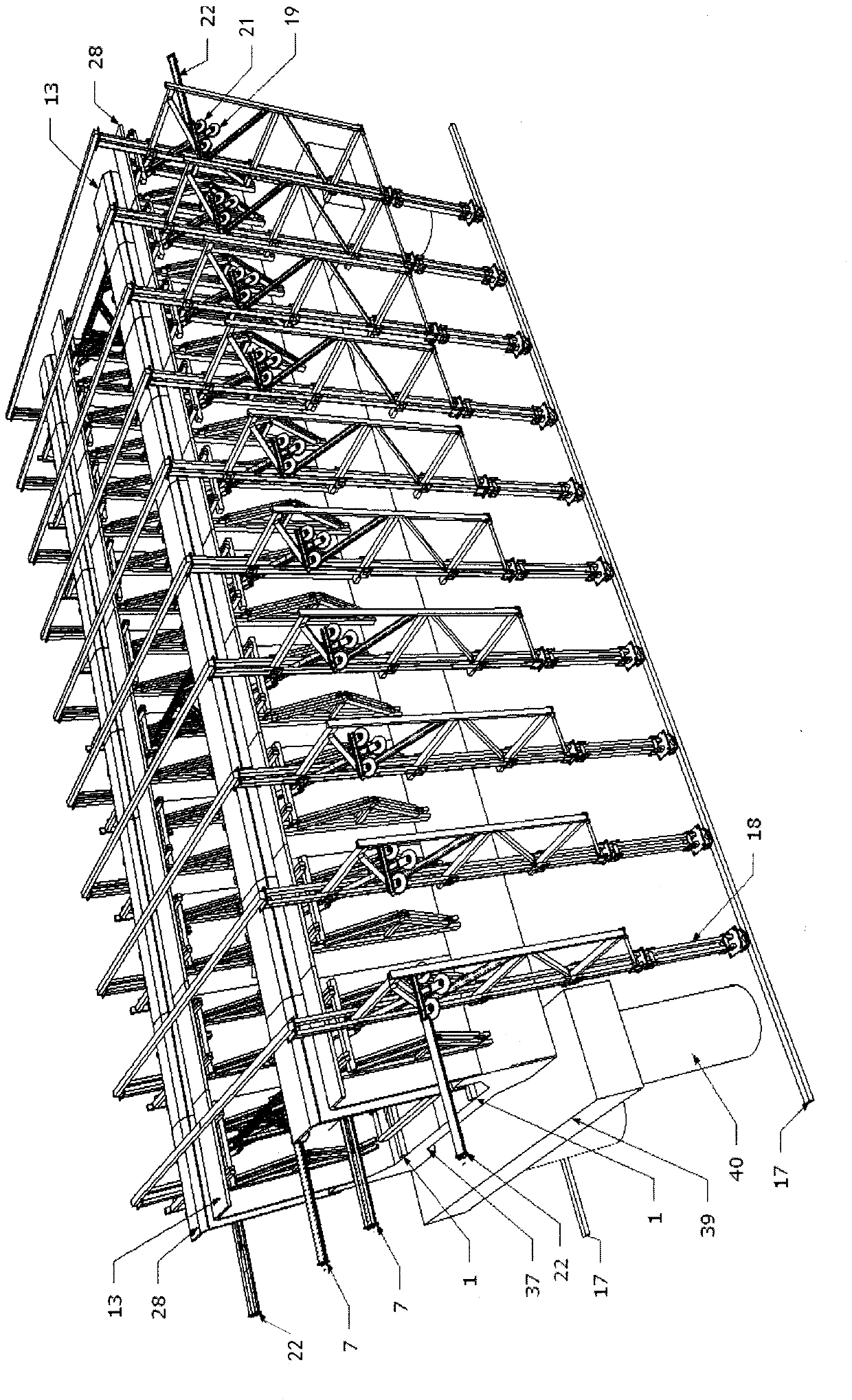

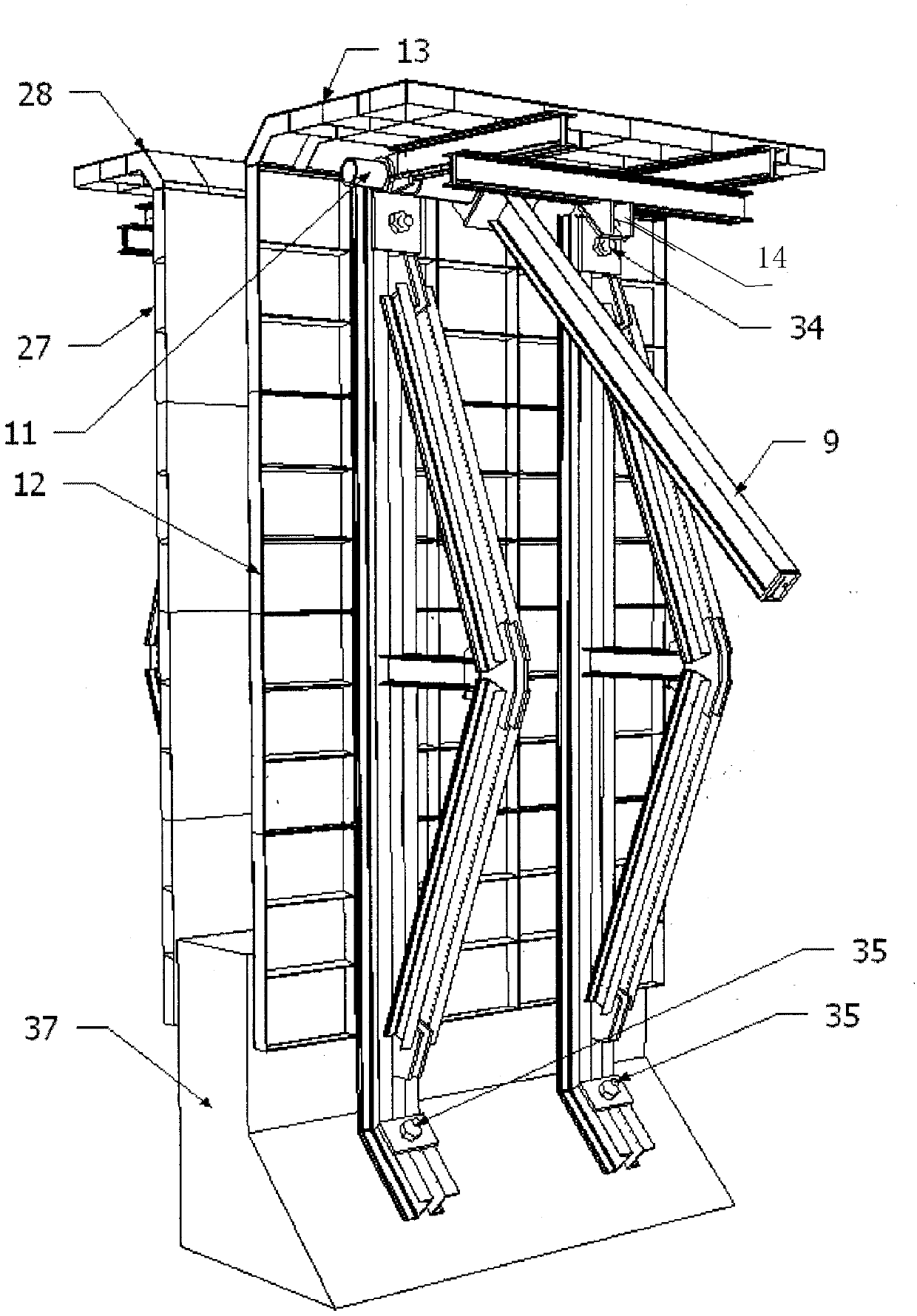

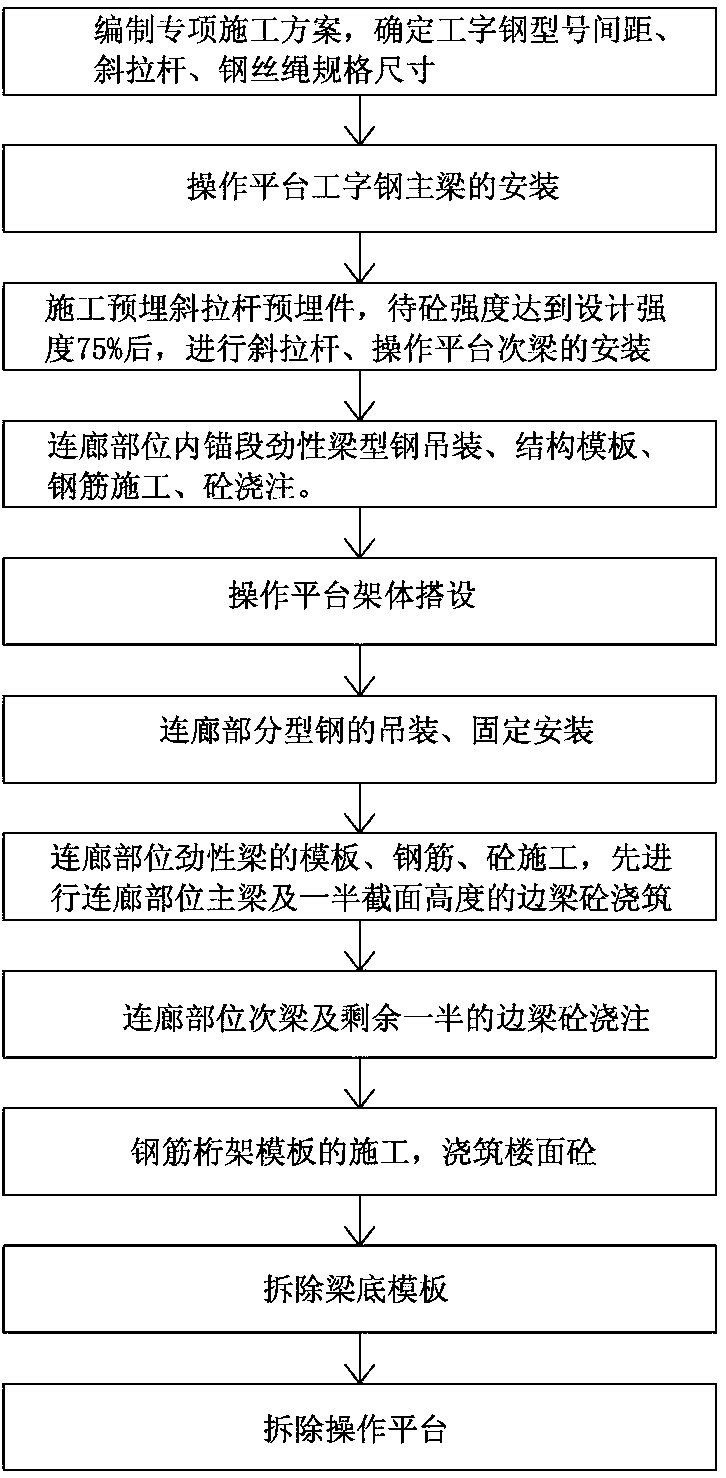

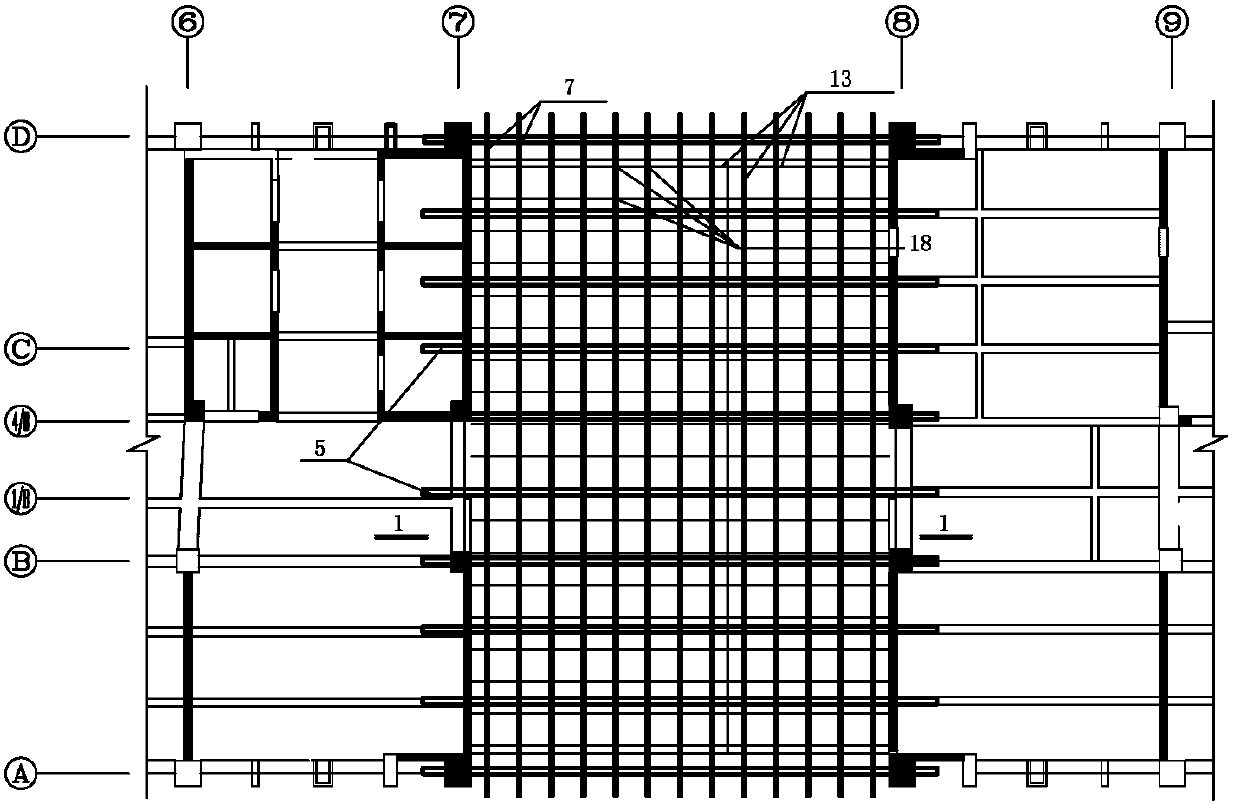

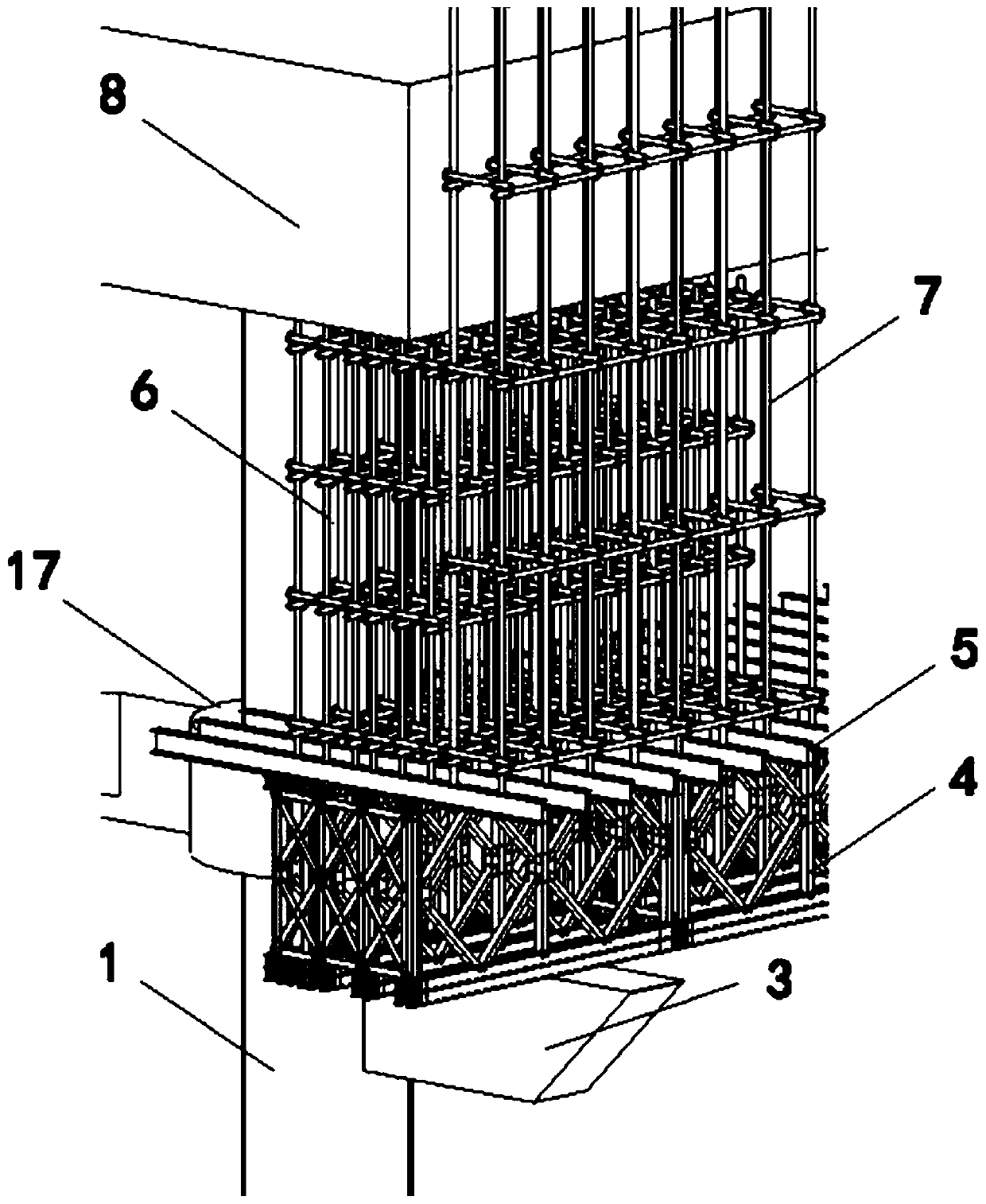

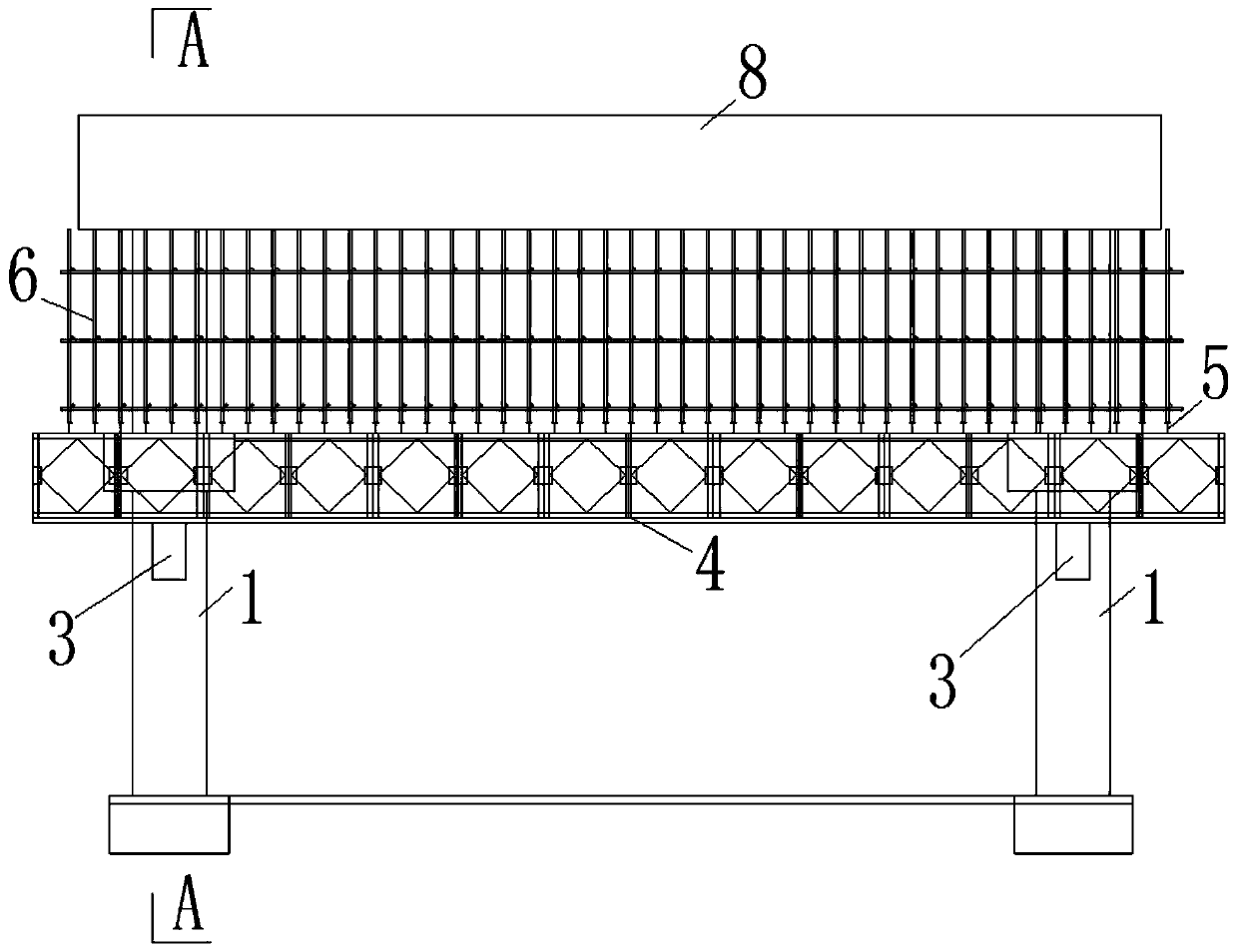

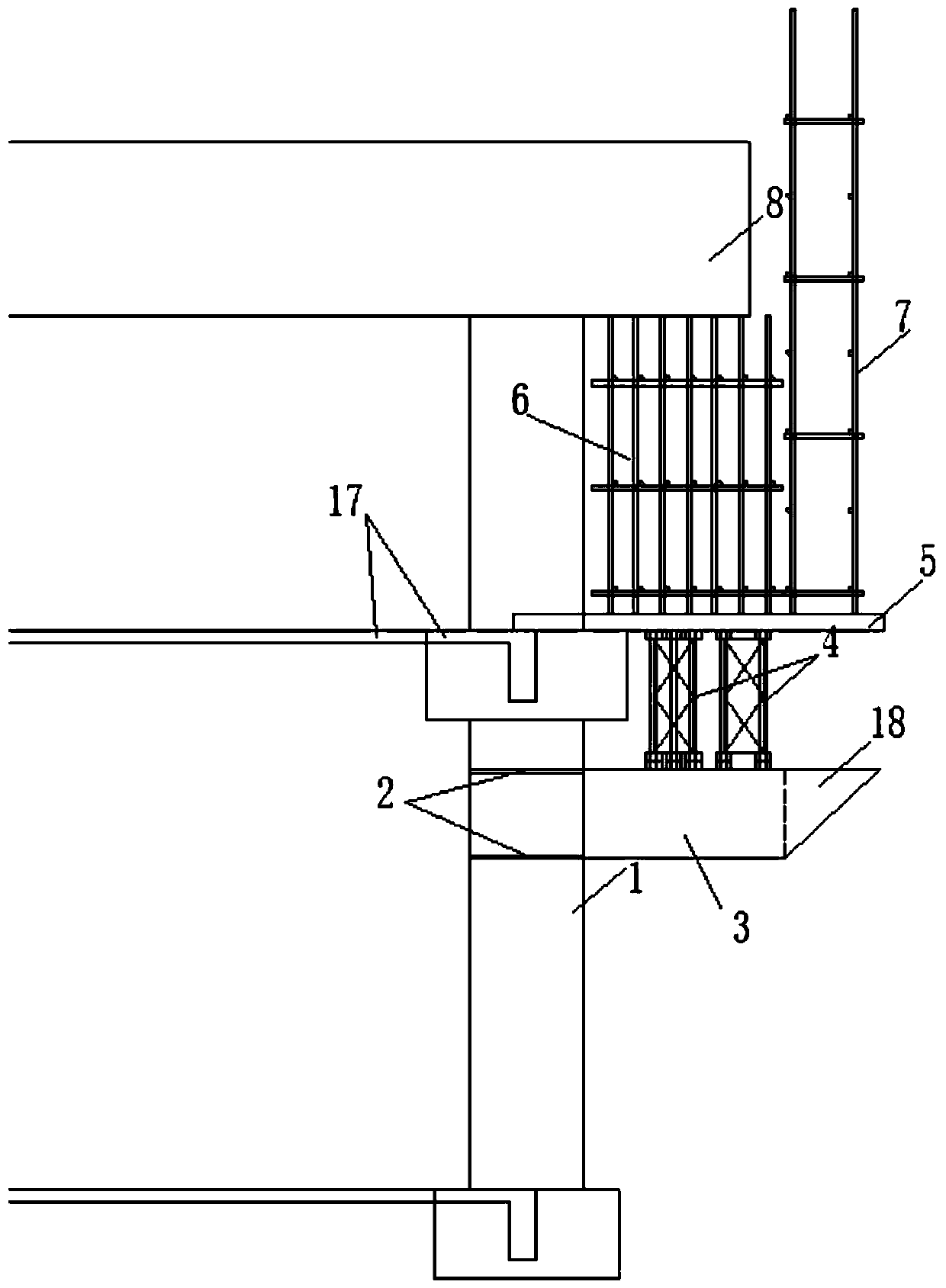

The invention relates to a high-altitude long-span overhanging corridor type reinforced concrete structure and a construction method, wherein the corridor part is a stiff beam structure; with own bearing capacity of a profile steel, a beam template supporting system is a hung template supporting system in such a manner of fixing a square steel by means of a U-shaped screw and a nut; a floorslab is a self-supporting steel bar truss template which is welded to a pre-embedded steel plate on the stiff beam by means of a pin; and a steel platform is arranged on a corresponding floor at the lower part of the corridor as an operating and safety protection platform for template support construction. The high-altitude long-span overhanging corridor type reinforced concrete structure and the construction method have the advantages that: the template supporting construction method, according to which the operating platform is built from H-steel or profile steel beams, the stiff beam is hung and is self-supported and the floorslab is self-supported, is employed, so that the problem of difficult template supporting of the high-altitude long-span overhanging corridor structure, the revolving materials are greatly saved, the construction cost is reduced, the construction progress is accelerated and the safety is ensured; and the steel plate is pre-embedded on the stiff beam, so that the floor bearing plate is effectively connected with the stiff beam and the floor bearing plate and the stiff beam are capable of acting together to ensure the safety of the structure.

Owner:浙江城建建设集团有限公司

Method for high altitude installation of large span steel truss

InactiveCN101255768ASolve quality problemsSolve many disadvantages such as long construction periodBuilding material handlingSUSPENDING VEHICLEFalsework

The present invention relates to a method for installing a large span steel truss on high altitude. The method comprises the steps of arranging embedded part on the structure girder at two sides of the designed position of the steel truss, then installing extensible guide on the embedded part, and at last assembling a specialized steel structure tackle. Firstly, a large tonnage hoisting machine is used for hanging the steel truss which is wholly assembled underground to two tackles that are arranged on station. Afterwards, the steel trust is parallelly moved to the installation position through the synchronous slippage of two tackles on the extensible guide. Lastly, the two-end capitals of the designing position of the steel truss are installed with an independent holding pole, a chain block and a pulley assembly. These hoisting apparatuses are used for hanging the longeron from the tackle. The longeron of the lengthened part is cut and the steel truss is installed to the position according to the design requirement. Compared with the traditional high altitude dispersed splitting method for building whole surface of scaffold, the installing method provided by the invention subtly settles many abuses of difficulty for controlling the construction quality, long construction period and the like in the traditional method. The manpower and considerable material transportation are saved and the construction quality can be effectively guaranteed. Various requirements of the designing and constructing are excellently and rapidly satisfied.

Owner:NINGBO CONSTR +1

Beam plate post-cast strip template support system and construction method thereof

InactiveCN102691411AImprove construction qualityFast constructionForms/shuttering/falseworksBuilding material handlingArchitectural engineeringSupport system

The invention discloses a beam plate post-cast strip template support system and a construction method, wherein a main template support body supports all beam plates arranged at two sides of a post-cast strip, and support latticed columns are independently supported at two sides of the post-cast strip. After the main template support body is built, and when bottom templates of the beam plates are paved, the post-cast strip is unavailable without installation. When the main template support body is built, the bottom templates can be wholly paved, or the support latticed columns can be independently paved, so that the construction speed can be accelerated; the independent latticed column is convenient to uniformly set and wholly distribute; the whole template of a main template support system can be disassembled, and only the latticed columns can be remained to support, so that the mass of revolving materials can be saved, and the inconvenient material transportation traffic caused by the isolation and division of a post-cast strip-supported mould base in a basement can not be avoided; and before the concrete arranged at two sides of the post-cast strip is cast, the region is convenient and thorough to clean, and the construction quality of the post-cast strip can be preferably guaranteed.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

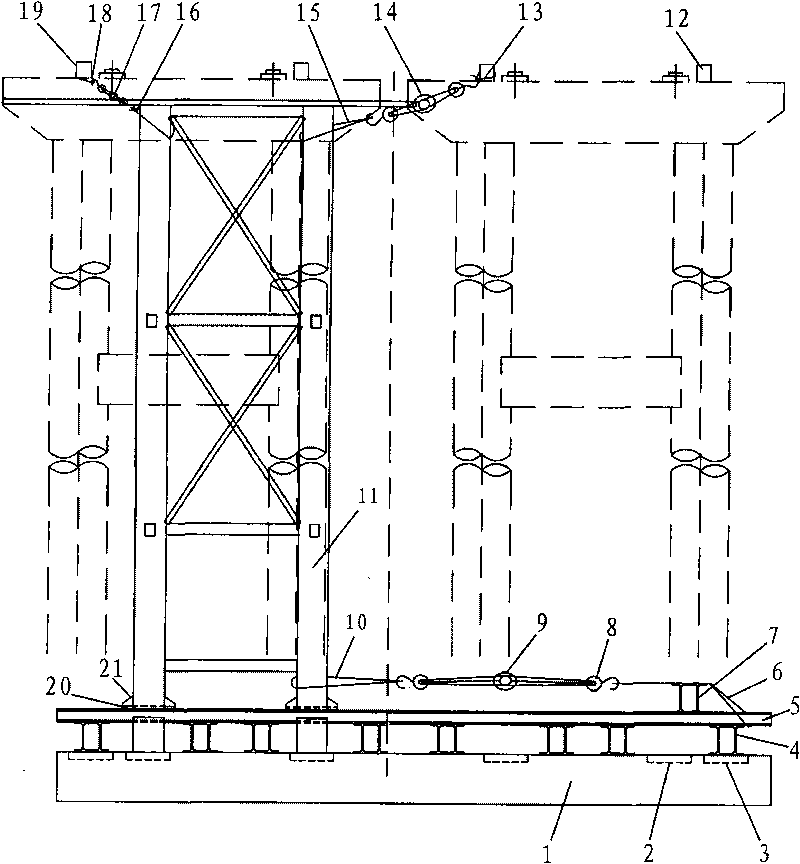

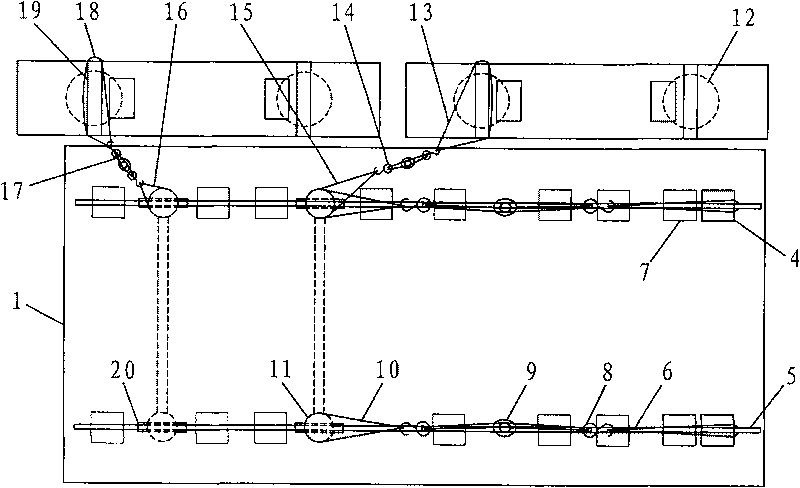

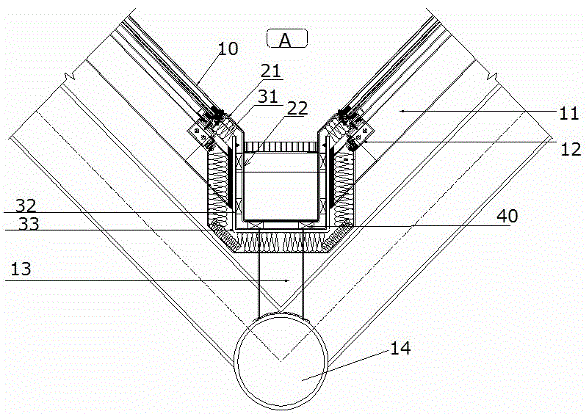

Integral slide device and method of floor steel pipe column bracket of bridge end bay closure section construction

InactiveCN101713170AReduce investmentSave turnover materialsBridge erection/assemblySheet steelMechanical equipment

The invention relates to integral slip device and method of a floor steel pipe column bracket of a bridge end bay closure section construction. The device comprises a floorstand, a drawing mechanism and two slip tracks (5) symmetrically arranged on an expanded foundation (1), wherein two slip steel plates (20) are arranged on each slip track, and the slip steel plates move on the slip tracks under the action of the drawing mechanism; the lower parts of the slip tracks are supported on the expanded foundation (1) through a plurality of track leveling supporting seats (4); and the supporting seats have the effect of leveling and ensures that the whole tracks are horizontally arranged on the expanded foundation (1). The method comprises the following steps of: doing preparation works, measuring an elevation, mounting the floorstand and the drawing mechanism, implementing integral slip, and the like. The invention can effectively solve the problem of displacement of the whole bracket system in construction environments of large height and difficult going in and out of mechanical equipment and has the advantages of simple move mode, bracket dismounting procedure saving, turnover material loss reduction, construction period shortening, and the like.

Owner:CHINA FIRST METALLURGICAL GROUP

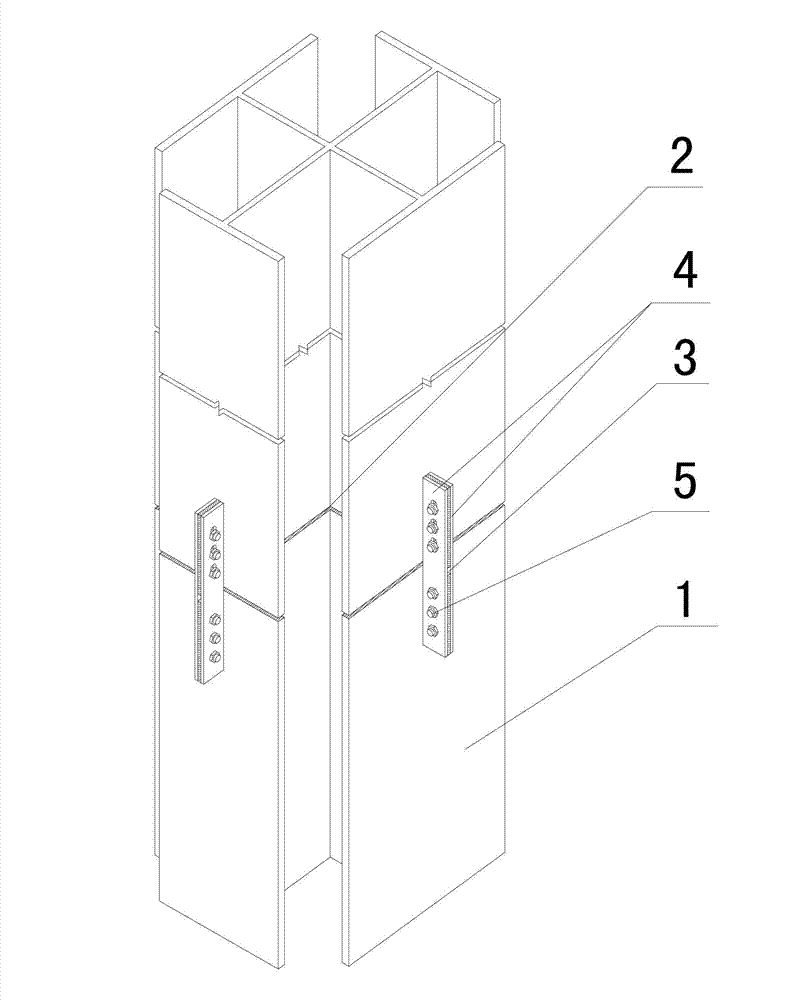

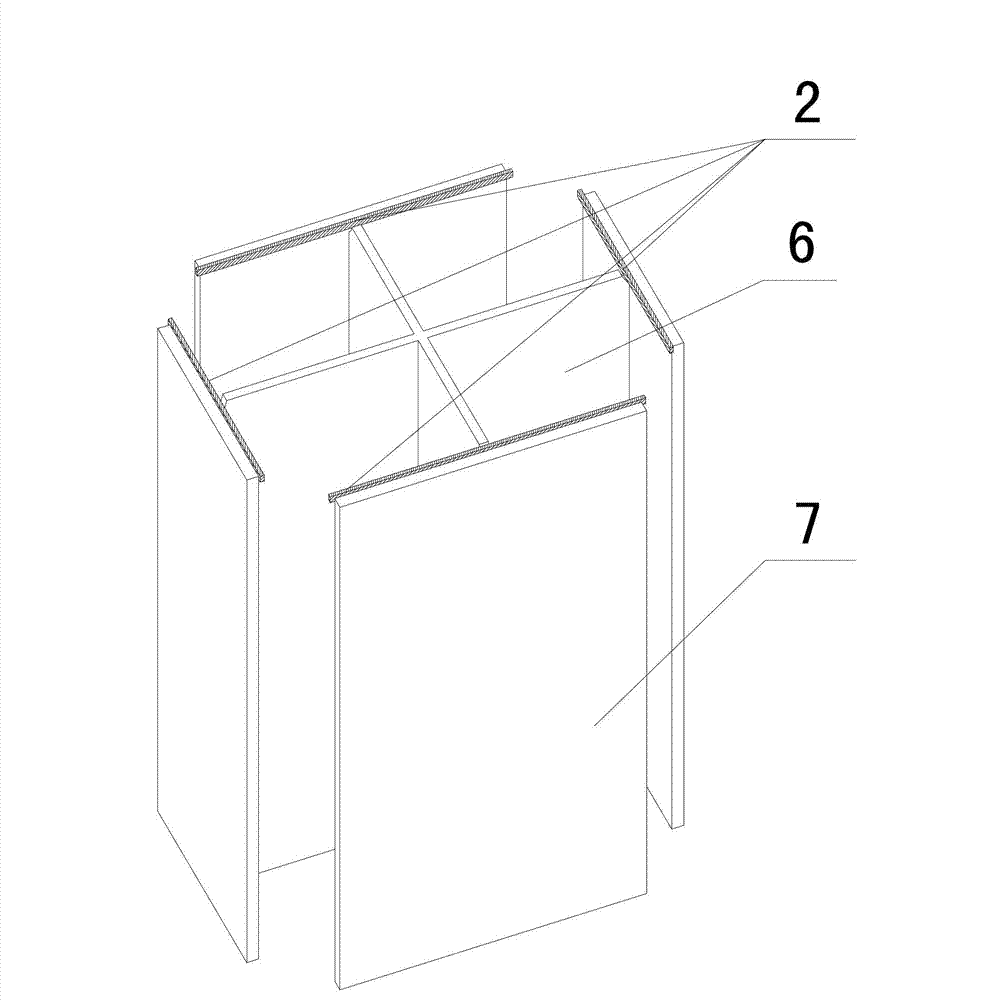

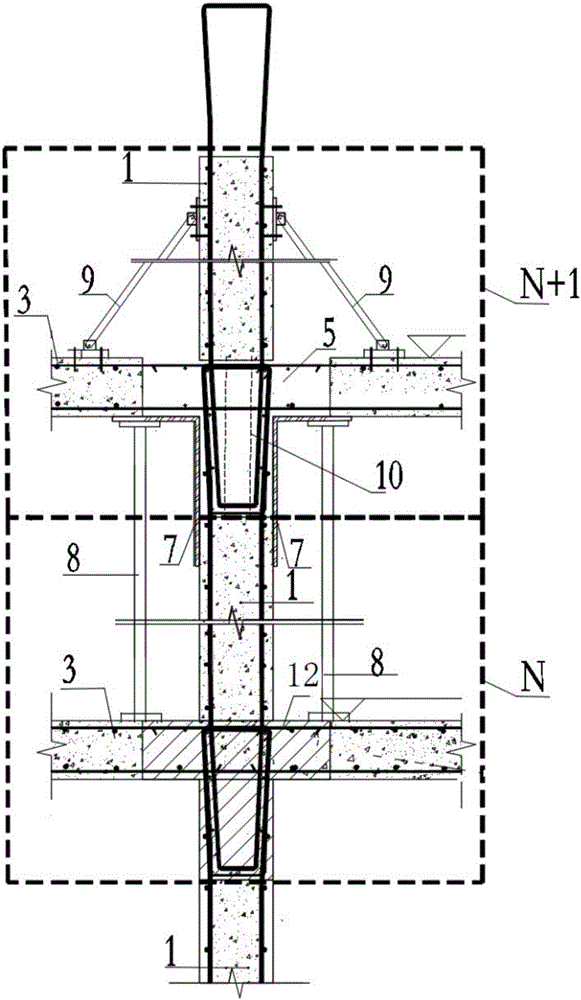

Section steel column for high-rise building section steel concrete combination structure, and construction method thereof

ActiveCN102733545AGuaranteed section sizeGuaranteed lengthStrutsBuilding material handlingConnection typeEngineering

The present invention discloses a section steel column for a high-rise building section steel concrete combination structure, and a construction method thereof. The section steel column comprises a plurality of column sections, wherein the column sections are sequentially connected from bottom to top, an interface position of two optionally adjacent column sections is provided with an inner sleeve interface, and an outer side wall of a connection position of the two adjacent column sections is provided with a buckle fixation type assembly. The construction method comprises that: the insert-connection type initial positioning of the two adjacent column sections is achieved through the inner sleeve interface; the cross extending line and the buckle fixation type assembly are combined to carry out positioning correction on the column; a scale measurement method is adopted to carry out column scale height adjustment; and the cross extending line and the buckle fixation type assembly are combined to carry out verticality correction on the full length of the column sections. With the section steel column of the present invention, the model of one construction interface in each floor of the traditional section steel column can be increased to the model of one construction interface in every two floors or three floors, such that more than half of the construction interfaces of the section steel column can be saved, the probability of deviation error due to construction interface operation can be greatly reduced, and the guarantee degree of installation quality can be improved.

Owner:广东中城建设集团有限公司 +1

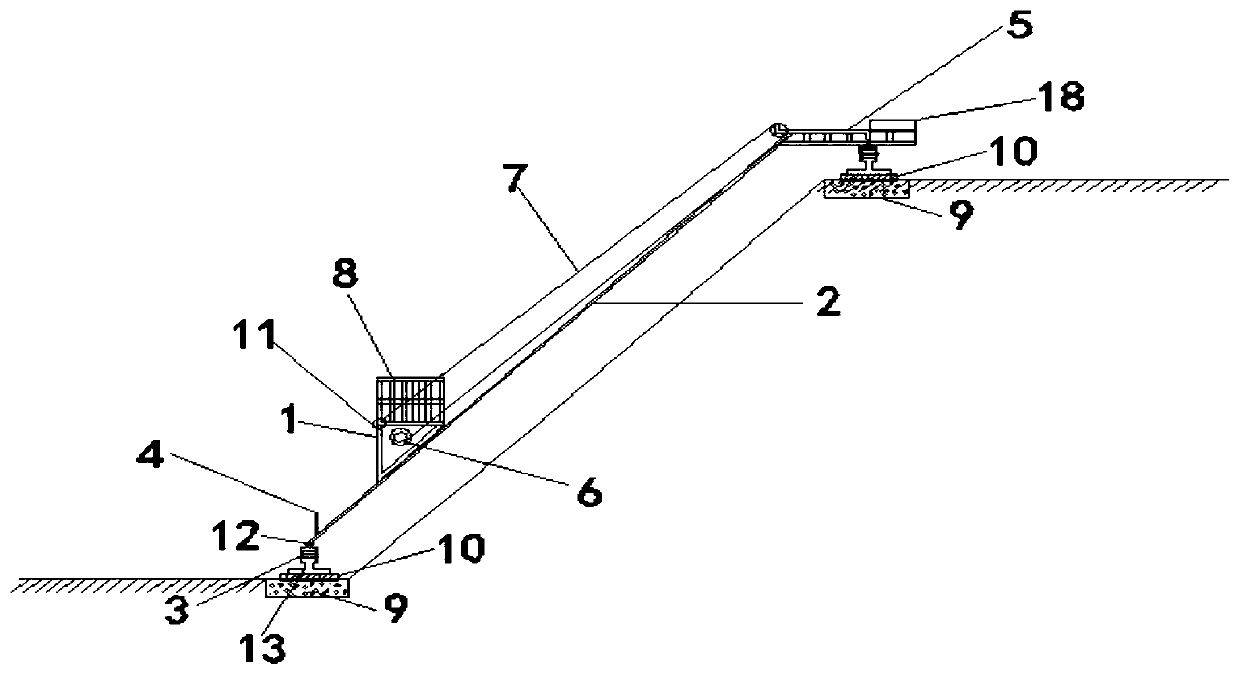

Movable operation platform for slope construction

InactiveCN110723692ASave turnover materialsEasy to moveSafety devices for lifting equipmentsWindlassHydraulic pressure

The invention provides a movable operation platform for slope construction. The movable operation platform comprises two sets of guide rails, an operation platform body and an electric device, and ischaracterized in that the two sets of guide rails comprise large guide rails arranged on slopes up and down in the horizontal direction and small guide rails arranged perpendicular to the up and downguide rail direction along the slopes; large guide rail frames are arranged on the large guide rails; the small guide rails are arranged on the large guide rail frames; two pulleys in contact with thelarge guide rails are respectively arranged on the slopes up and down; hydraulic devices are arranged on the pulleys; the operation platform body moves up and down parallel to the slopes through small guide rail frames arranged on the small guide rails; the electric device is arranged on the operation platform body; and through button box operation instructions, a windlass is controlled to operate, and the stop, the startup and the moving directions of the guide rails and the operation platform body are controlled. The operation platform solves the problems of difficult slope construction operation and danger, is simple in operation, safe and convenient, and improves the production efficiency.

Owner:CHINA FIRST METALLURGICAL GROUP

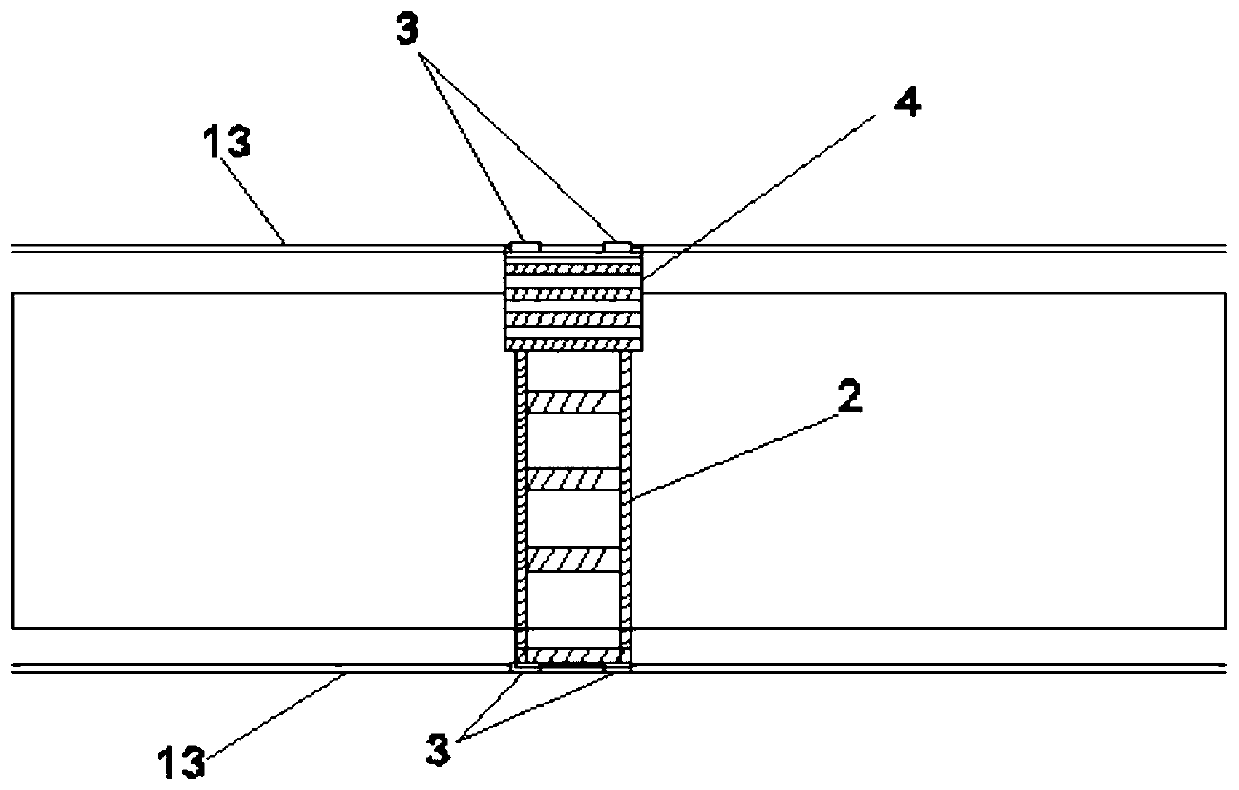

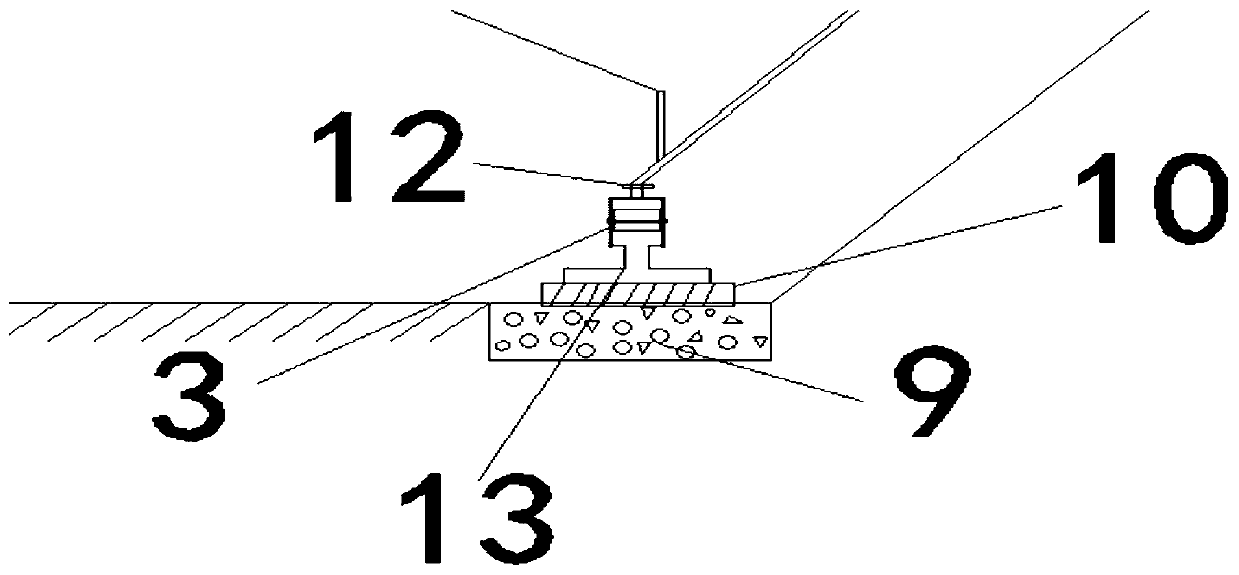

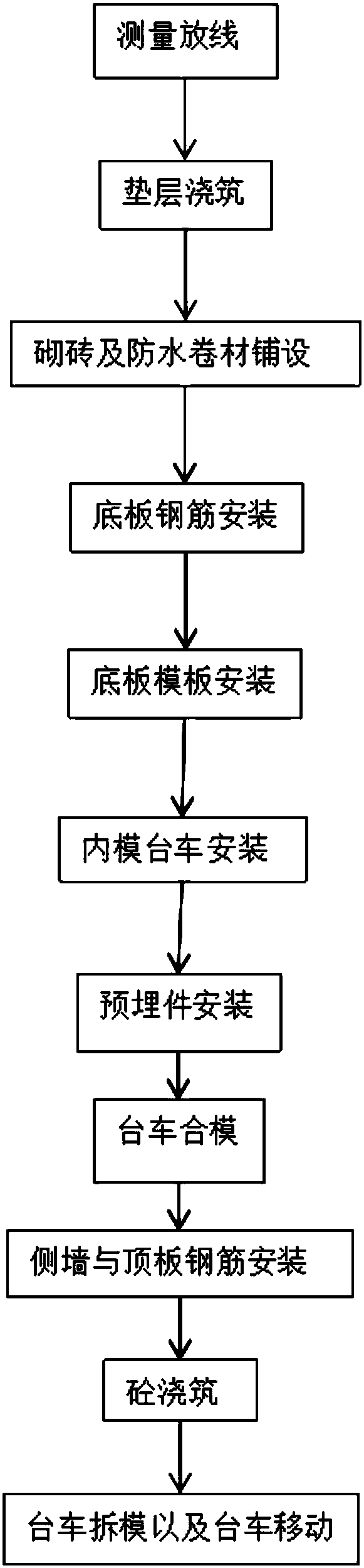

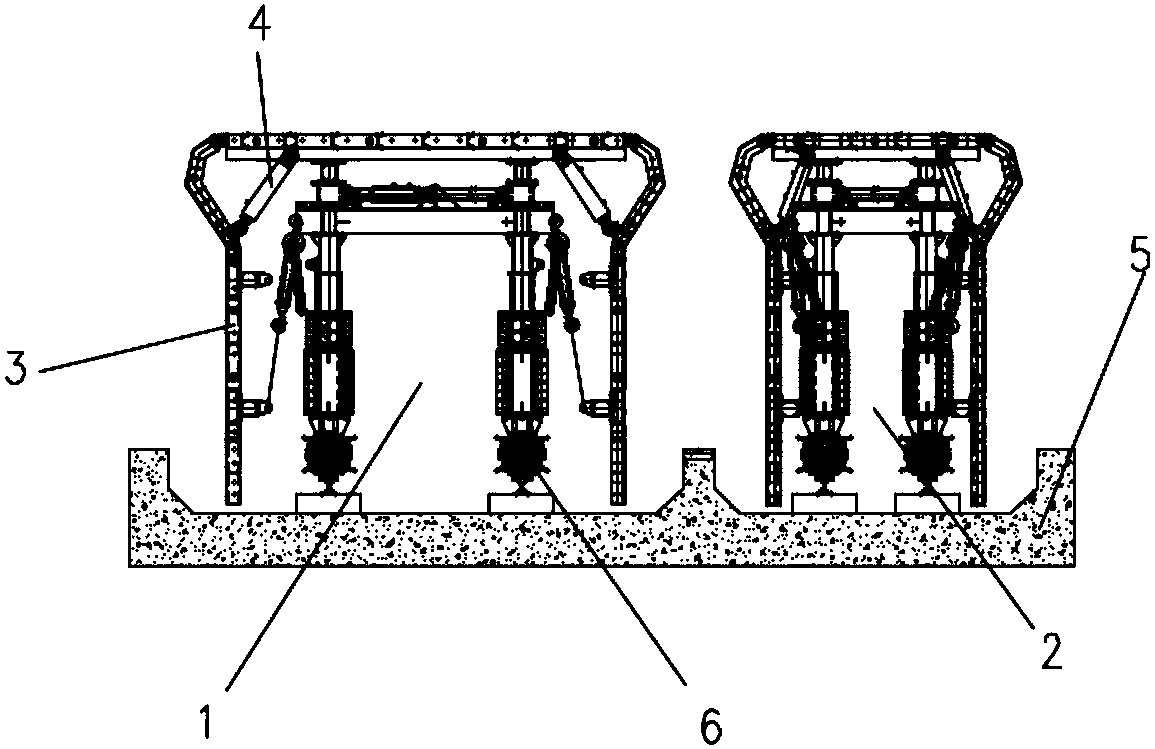

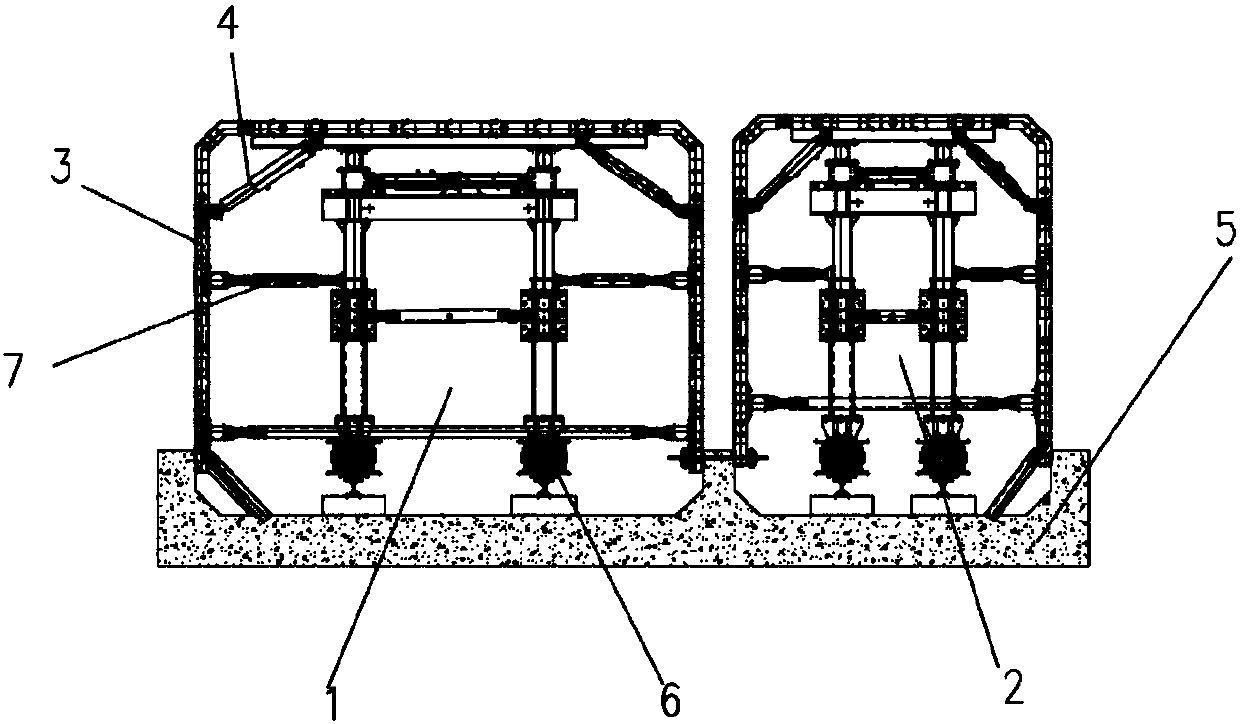

Construction method for support formwork integrated hydraulic inner formwork trolley of comprehensive pipe gallery

ActiveCN107905254AImprove flatnessLess labor requiredArtificial islandsUnderwater structuresSocial benefitsVehicle frame

The invention provides a construction method for a support formwork integrated hydraulic inner formwork trolley of a comprehensive pipe gallery. The construction method comprises the following steps of surveying and setting out, pouring of a cushion layer, bricking and waterproof roll laying, mounting of base plate rebars, mounting of base plate formwork plates, mounting of the inner formwork trolley, mounting of embedded parts, formwork closing of the trolley, mounting of side wall and top plate rebars, concrete pouring, formwork removal of the trolley and moving of the trolley. According tothe construction method, dimensions of the support formwork integrated hydraulic inner formwork trolley are customized according to internal space dimensions of the pipe gallery; the support formworkintegrated hydraulic inner formwork trolley is composed of a walking system, a trolley frame, steel formwork plates, a formwork plate vertical and side-direction extending-and-contracting system, a hydraulic system and an electrical control system; the formwork plates are rapidly combined through rapid locating of the trolley and removed rapidly after pouring is completed; after pouring of a pipegallery main body is completed, locating of a subsequent pipe gallery main body can be completed by moving the trolley through the walking system; and after concrete pouring is completed, the surfaceis good in flatness and appearance quality, and good social benefits are achieved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

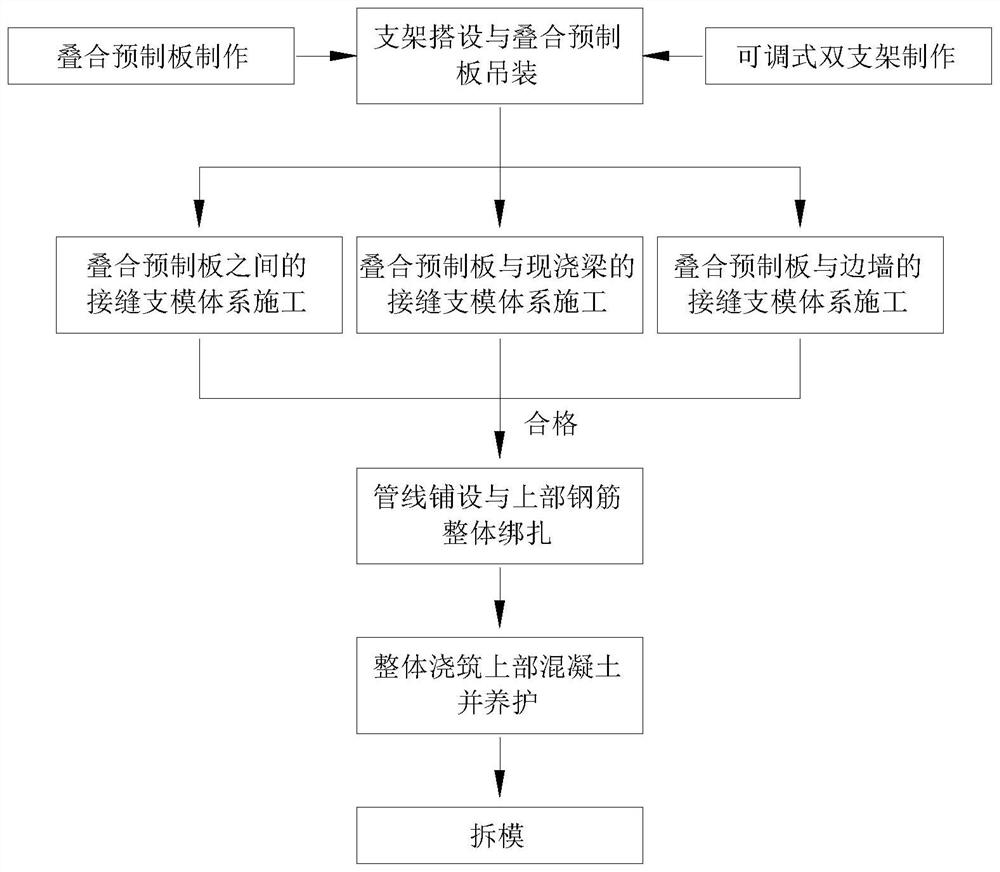

Assembled concrete structure construction method

ActiveCN106193623AIncrease stiffnessReduce supportBuilding material handlingEngineeringStructure system

The invention discloses an assembled concrete structure construction method. According to the construction method, a reversed construction procedure is adopted for installation of a vertical component of a currently constructed floor, that is, before connection assembly of a horizontal component of the currently constructed floor, the vertical component connected to the upper portion of the horizontal component is hoisted firstly, and finally connection concrete is poured at a time to connect the horizontal component with the vertical component of the currently constructed floor into a whole. The construction method adopts the reversed construction procedure, so that construction links are reduced, and the construction period is shortened; the method is suitable for assembled concrete building construction for structure systems such as precast shear walls, composite wallboards and frameworks, and has the advantages of convenient construction, time saving, economy, environment friendliness and the like; and meanwhile, the requirement for identical performance as a cast-in-place structure is met.

Owner:刘祥锦

Application of plain concrete columns to later-poured strip supporting

ActiveCN104389430AGuarantee the construction qualitySave turnover materialsBuilding material handlingEngineeringSteel tube

The invention discloses the application of plain concrete columns to later-poured strip supporting and belongs to the technical field of construction. The application of the plain concrete columns to later-poured strip supporting sequentially includes the steps of selection of bellows, hole forming of beam base plates, mounting and reinforcing of the bellows, the pouring of plain concrete columns, removal of formwork supports, building of later-poured strip formwork supports and pouring of concrete and removal of the plain concrete columns. According to the application of the plain concrete columns to later-poured strip supporting, the formwork supports previously arranged in a full span mode can be replaced with the plain concrete columns, so that a lot of revolving materials such as steel tubes and fasteners are saved in the long wait in the construction of a main structure, a certain effect of the civilization construction in a construction site is obtained, the construction site after the completion of later-poured strip construction is cleaned, the risk of construction in the site is reduced for workers, the quality of later-poured strip construction is ensured, and a lot of benefits are achieved at the same time.

Owner:CHINA ZHONGSHE CONSTR ENG GROUP +2

Post-cast strip device and construction method thereof

InactiveCN105133663AReduce wasteAvoid safety hazardsArtificial islandsUnderwater structuresSupporting systemWater leakage

The invention discloses a post-cast strip device which comprises a foundation base plate. A reinforcement cage is welded inside the foundation base plate. The reinforcement cage comprises a main rib framework composed of a plurality of main ribs, and waist ribs are arranged between the main ribs of the main rib framework and comprise vertical waist ribs and longitudinal waist ribs, wherein the vertical waist ribs and the longitudinal waist ribs are connected between the main ribs. A plurality of symmetrical water stopping steel plates are further longitudinally arranged on the two sides of the reinforcement cage, and the outer surface of the reinforcement cage is further provided with a closing net. The two sides of the reinforcement cage are fixed at the position of a welding point of a lower base plate of the foundation base plate through a plurality of symmetrical fixing tie bars. The post-cast strip device has the advantages that the step of dismantling formworks and a supporting system on the two sides of a post-cast strip after the construction of the base plate is omitted, the hidden danger of water leakage of the post-cast strip is avoided, wood and revolving materials are saved, steel bar processing leftovers are fully utilized, and the steel bar waste is reduced. The hidden safety danger of operation in a narrow space by constructors is avoided, and the construction quality of the post-cast strip is enhanced.

Owner:中铁十六局集团城市建设发展有限公司

Ultra-deep large-section square supporting pile and construction method thereof

InactiveCN102828506AImprove skid resistanceShorten the construction periodExcavationsBulkheads/pilesReinforced concreteSlurry

The invention relates to an ultra-deep large-section square supporting pile and a construction method thereof. The ultra-deep large-section square supporting pile is arranged on one side of a foundation pit close to a metro shield area and comprises a pile hole retaining wall and a pile core, wherein the pile hole retaining wall and the pile core both have cast-in-place reinforced concrete structures; the pile hole retaining wall is formed by splicing sections of square protecting cylinders; inner lateral surfaces of the square protecting cylinders are inclined planes which are inclined to the pile core from bottom to top; a lug boss is arranged at a seam of upper and lower two sections of square protecting cylinders and on one side of the upper end face of the lower square protecting cylinder close to the pile core; and double-slurry liquid composed of sodium silicate and cement paste is filled in a gap between the lug boss and the square protecting cylinders. The anti-skidding capacity of the ultra-deep large-section square supporting pile is strong, so that the foundation pit support construction and the metro shield construction are no longer conflicted after the supporting pile is adopted; the foundation pit support construction and the metro shield construction can be performed alternately; and the construction period of the foundation pit support is greatly shortened.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

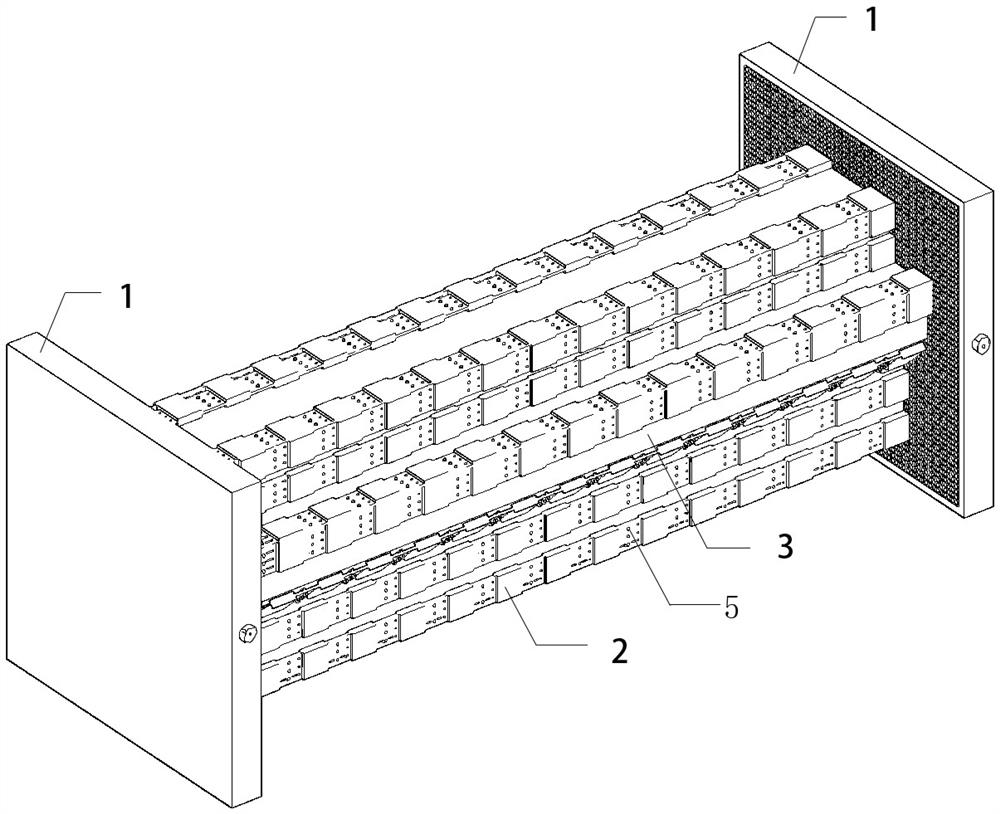

Truss plate

ActiveCN107201796AImprove seismic performanceImprove construction efficiencyFloorsArchitectural engineeringRebar

The invention discloses a truss plate which a steel bar truss and a bottom mold. The steel bar truss comprises a plurality of web rod groups, upper chord steel bars and two lower chord steel bars, wherein the web rod groups are arranged in the length direction of the bottom mold, two ends at open positions of the web rod steels of the adjacent web rod groups are fixedly connected, the upper chord steel bars are arranged in the length direction of the bottom mold and are fixedly connected to the tip ends of all web rod groups, the two lower chord steel bars are arranged in the length direction of the bottom mold and are fixedly connected to the two ends at the open positions of all the web rod groups respectively, fasteners are arranged on two sides of each lower chord steel bar and are provided with circular-arc clamping grooves for clamping the lower chord steel bars in the sides with respect to the lower chord steel bars, and fixing bolts for fixedly connecting the fasteners and the bottom mold are arranged on the fasteners. The truss plate can be processed in a factory in a unified mode, laying can be directly performed in a site after machining is completed, field welding is decreased, and accordingly the construction speed is improved.

Owner:浙江之江工程项目管理有限公司 +1

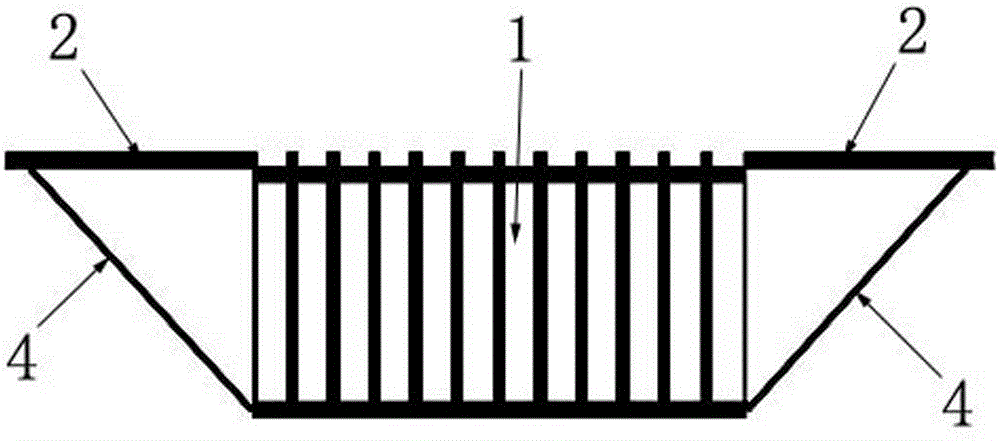

Steel reinforced concrete beam pouring and tamping support-free suspension molding plate structure and method

InactiveCN108374555AObvious advantagesSave turnover materialsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksPurlinReinforced concrete

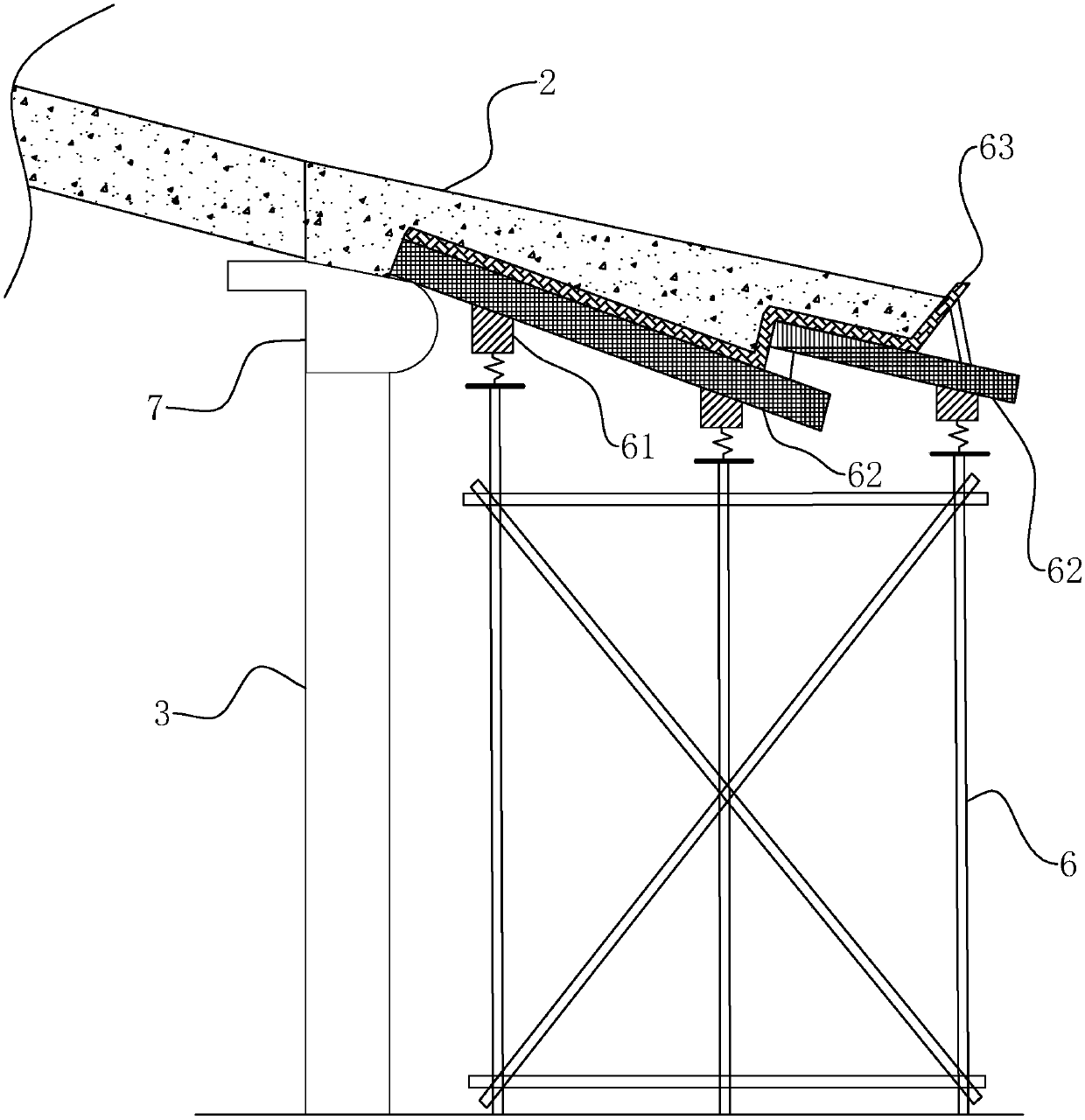

The invention relates to a steel reinforced concrete beam pouring and tamping support-free suspension molding plate structure and a construction method. Two sides of a steel beam of the structure arerespectively provided with a suspension rod, the upper portion of the suspension rod is fixed on an upper wing of the steel beam, the lower portion of the suspension rod is fixed on a channel steel purlin of a beam bottom mold, and the distance of the channel steel purlin along the beam is 1000mm; the bottom of channel steel is fixedly connected with the suspension rod by virtue of two nuts; and abeam molding plate is fixed on two side surfaces of the beam by using a split bolt along the height direction. The construction method comprises the following steps: (1) installing a section steel column; (2) installing a section steel beam; (3) arranging a beam molding plate system; (4) installing a beam molding plate support-free suspension system; and (5) pouring the steel reinforced concrete.By sufficiently utilizing the bearing capability of the section steel, the beam molding plate is suspended on the section steel beam, before the concrete is hardened, a section steel skeleton is usedas a bearing stress system, no support is arranged below the molding plate, the circulation material is saved, and the construction speed is increased. The steel reinforced concrete beam pouring andtamping support-free suspension molding plate structure is more apparent in advantage in the construction process of the large-sectional and high altitude section steel beam concrete.

Owner:SHUNJIE CONSTR GROUP

Integral construction method of pseudo-classic architecture wood eave rafter and cast-in-place reinforced concrete eaves board

The invention discloses an integral construction method of a pseudo-classic architecture wood eave rafter and a cast-in-place reinforced concrete eaves board. The technical scheme of the method is characterized by comprising the following construction steps: wood eave rafter components are processed and all components are assembled into a whole board on the ground and connection pieces are mounted; a support frame is set up; the assembled whole board is hoisted on the support frame; eaves board body rebar is mounted and the connection pieces are connected with the body rebar and a constructedbody structure; finally eaves board concrete is poured. According to the method, the wood eave rafter and the eaves board are combined into a whole, the connection is more firm and safer, the construction is simple and convenient, the construction period can be shortened, and at the same time, the revolving material is saved.

Owner:北京房修一建筑工程有限公司

Supporting system of pre-stressed concrete laminated slab of shear wall structure

InactiveCN105275202AInstallation quality is easy to controlClear forceForms/shuttering/falseworksSupporting systemPre stress

A supporting system of a pre-stressed concrete laminated slab of a shear wall structure belongs to the field of building construction and comprises a quadruple shear wall body, a first wood brace, a second wood brace and a laminated slab, wherein Z-shaped fixation parts are arranged uniformly on the upper annular circumference on the inner wall of the quadruple shear wall body, the lower part of the Z-shaped fixation part is fixed on the shear wall body, an U-shaped groove is formed between the upper part of the Z-shaped fixation part and the wall part, and the first wood brace is respectively clamped in the U-shaped groove of the row of Z-shaped fixation parts on the upper part of each shear wall body. The supporting system of the pre-stressed concrete laminated slab of the shear wall structure provided by the invention is beneficial in that (1) construction operations of this invention are simple and convenient and can guarantee a construction period; (2) installation quality of the laminated slab can be controlled easily, and evenness can be guaranteed; and (3) the laminated slab provided by the invention is definite in load carrying, safe and reliable, and eliminates safety hidden dangers of template frame collapse with a traditional manner.

Owner:JIANGSU HUAJIANG CONSTR GROUP

Liftway combined type lifting operation frame

InactiveCN105908961AEasy to manufactureSimple manufacturing methodScaffold connectionsBuilding support scaffoldsEngineeringSteel tube

The invention provides a liftway combined type lifting operation frame comprising the following elements: a liftable steel platform; a platform sleeve welded on the liftable steel platform and provided with a first plug pin hole; a platform plug tube, wherein at least one end of the platform plug tube is provided with a second plug pin hole, and one end of the platform plug tube inserts into the platform sleeve; platform plug pins, wherein the platform plug tube and the platform sleeve are connected and fixed through the first plug pin hole, the second plug pin hole, and the platform plug pins; a horizontal lever connected with the platform plug tube. A floor or overhang steel tube scaffold normally erected in the liftway is not needed, and the steel tube scaffold can be repeatedly erected on the liftable platform; the liftway combined type lifting operation frame is simple in making, can be repeatedly cycled in usage, can be customized according to liftway sizes of projects and items, thus reducing steel equipment material mass input, reducing item cost, effectively preventing operation level high altitude falling conditions, and providing safety protection effect in the liftway.

Owner:SHANGHAI NO 7 CONSTR

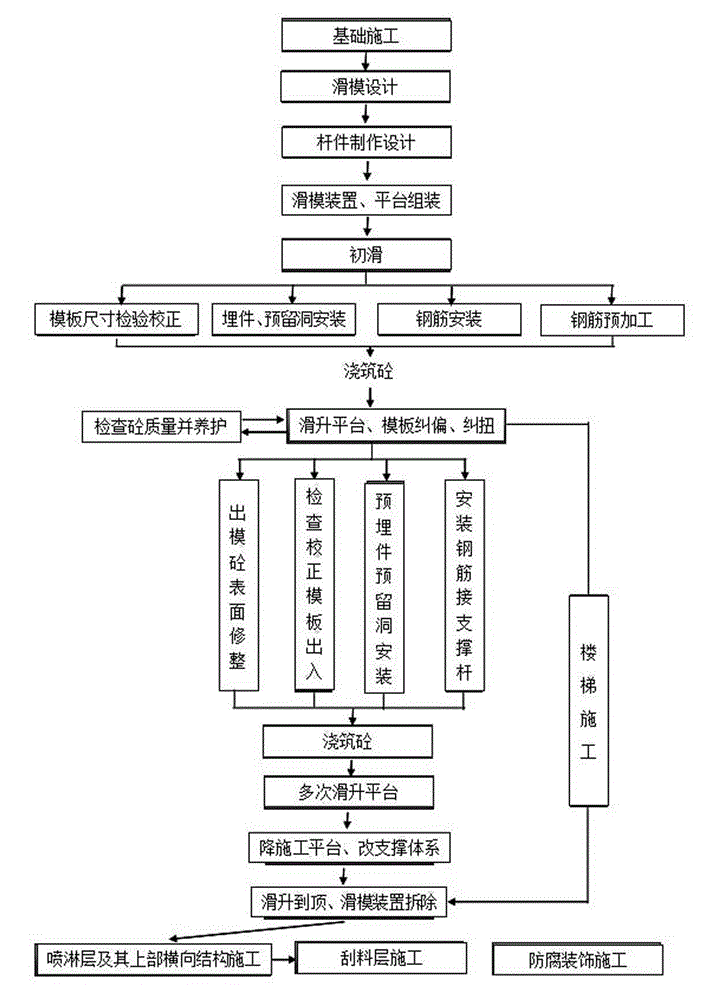

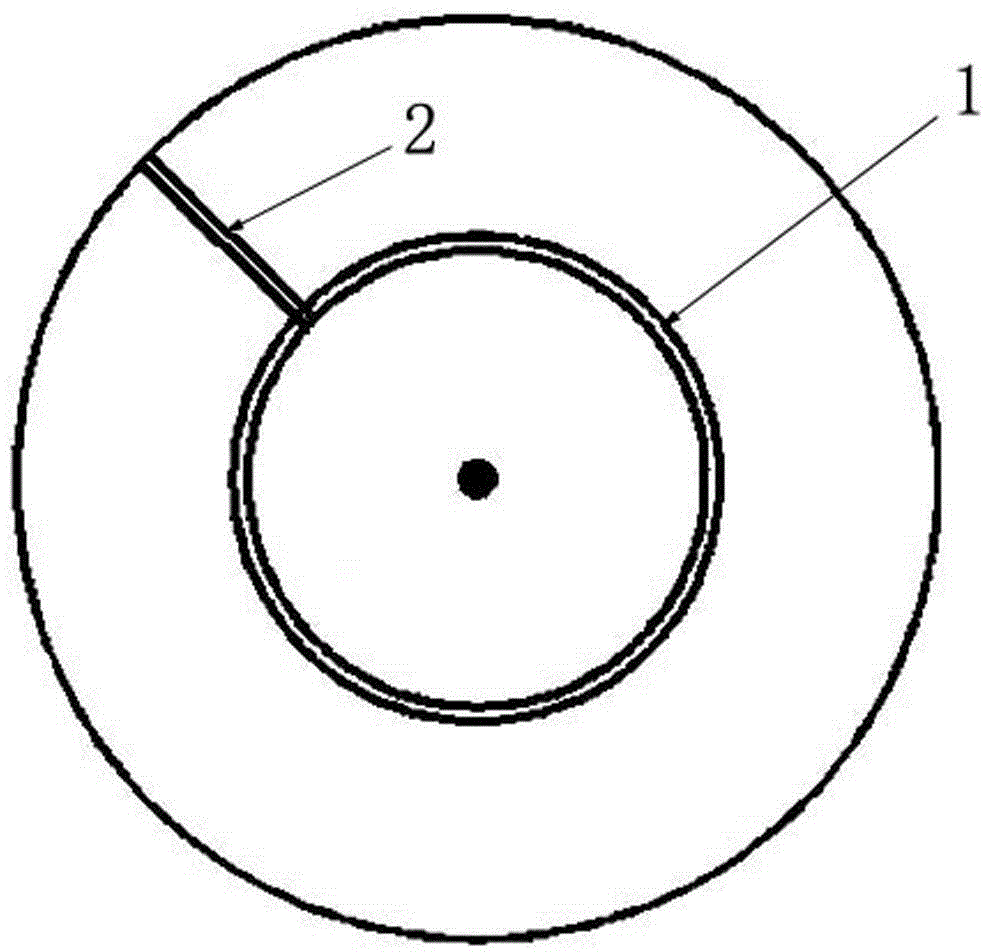

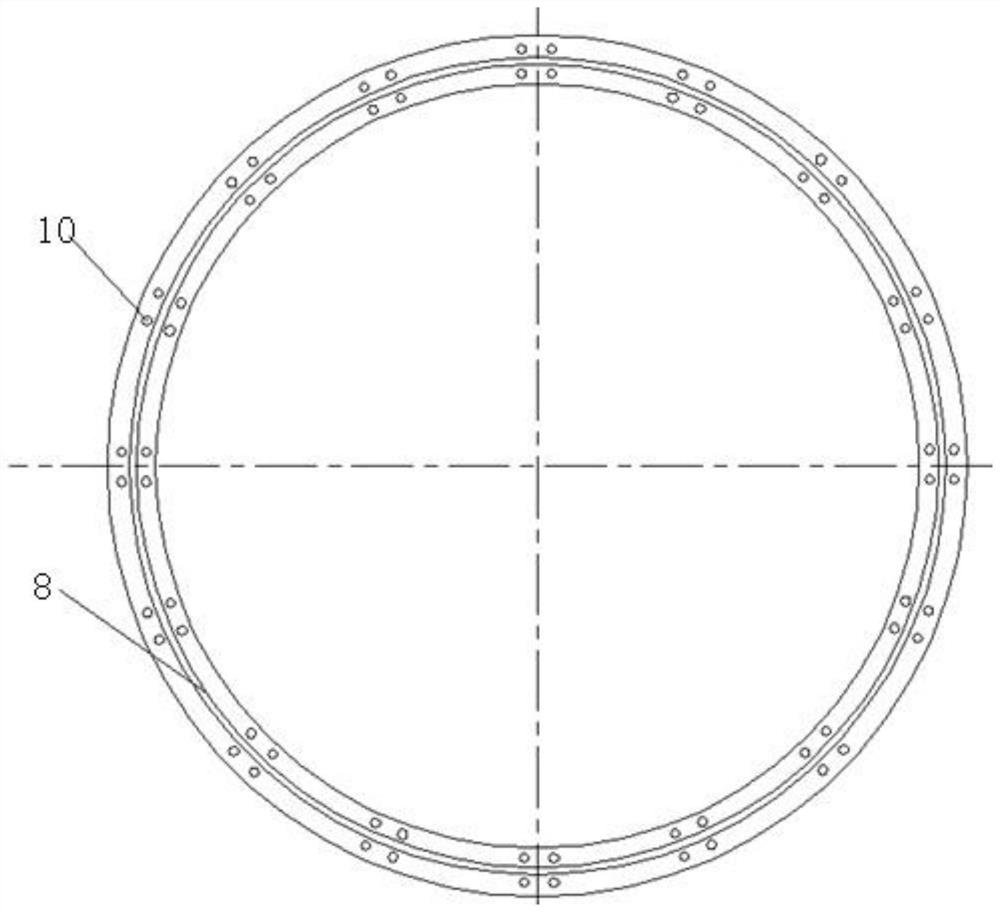

Construction process for constructing prilling tower spraying layer by slide mold device dragging construction platform

ActiveCN104594631AEasy constructionSave turnover materialsTowersBuilding material handlingSUSPENDING VEHICLEArchitectural engineering

The invention provides a construction process for constructing a prilling tower spraying layer by a slide mold device dragging a construction platform. The construction process solves the problem of construction difficulty of a prilling tower spraying layer. According to the method, a slide mold device for tube wall construction of a prilling tower is used for carrying the construction platform to realize the synchronous sliding ascending, after the construction platform slides and ascends to a position under the prilling tower spraying layer, the construction platform is disengaged from the slide mold device for constructing the tube wall of the prilling tower spraying layer, in addition, the construction platform is fixed to a corbel pre-buried in the tube wall, then, the slide mold device of the tube wall continuously and upwards slides and ascends for completing the construction of the tube wall, after the tube wall construction is completed, the construction platform is used, and in addition, a tower crane is matched for vertically conveying and constructing the spraying layer. When being used for constructing the prilling tower spraying layer, the method has the advantages that the construction is simple and convenient, a great amount of turnover materials are saved, the use of a large-scale crane and a large-scale hoisting machine is avoided, the cost is reduced, the economic benefits are good, and the operation platform is adopted, so that the high-altitude construction safety is well ensured. The method also obtains a good effect in practical application, and in addition, the method wins good reputation from owners.

Owner:CHINA CHEM ENG SECOND CONSTR

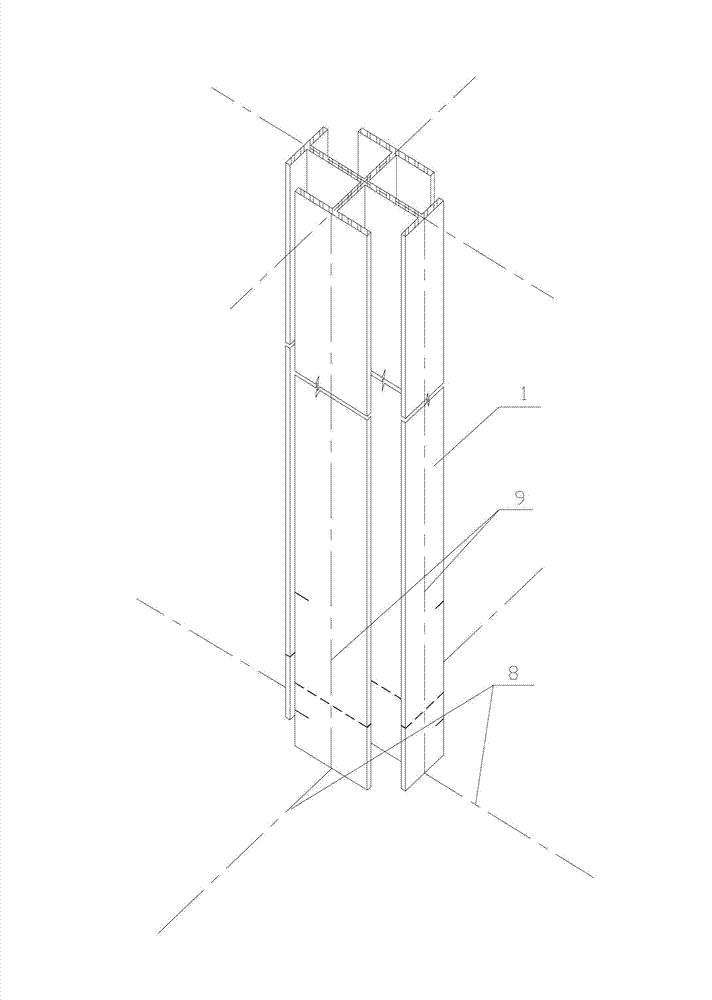

Pole tower prefabricated assembly type concrete stepped foundation and assembling method thereof

ActiveCN108005099AIngenious structural designImprove work efficiencyFoundation engineeringWind energy generationTowerTransmission equipment

The invention relates to a pole tower prefabricated assembly type concrete stepped foundation and belongs to the technical field of power communication transmission equipment. The pole tower prefabricated assembly type concrete stepped foundation comprises a core column, a stepped hoop and steel plate connecting keys. The core column comprises a plurality of splicing columns. The splicing columnsare of the same structure and are sequentially spliced into the core column through splicing grooves and splicing strips. The core column comprises an upper column body and a lower prismoid body fixedto the lower end of the upper column body. The stepped hoop comprises a plurality of annular sleeves with different outer diameters and inner diameters. The multiple steel plate connecting keys are mounted on the outer side of the core column and the periphery of the upper end of the stepped hoop. The steel plate connecting keys are fixed to the upper end of the stepped hoop through embedded anchors. The steel plate connecting keys are fixed to the core column through through anchor bars. The pole tower prefabricated assembly type concrete stepped foundation is ingenious in structure design,all construction projects are changed into all prefabricated modules, by splicing all the modules, the operation efficiency is improved, the construction period is shortened, and an assembling methodof the pole tower prefabricated assembly type concrete stepped foundation is simple and convenient to operate.

Owner:JIANGSU ELECTRIC POWER CO +2

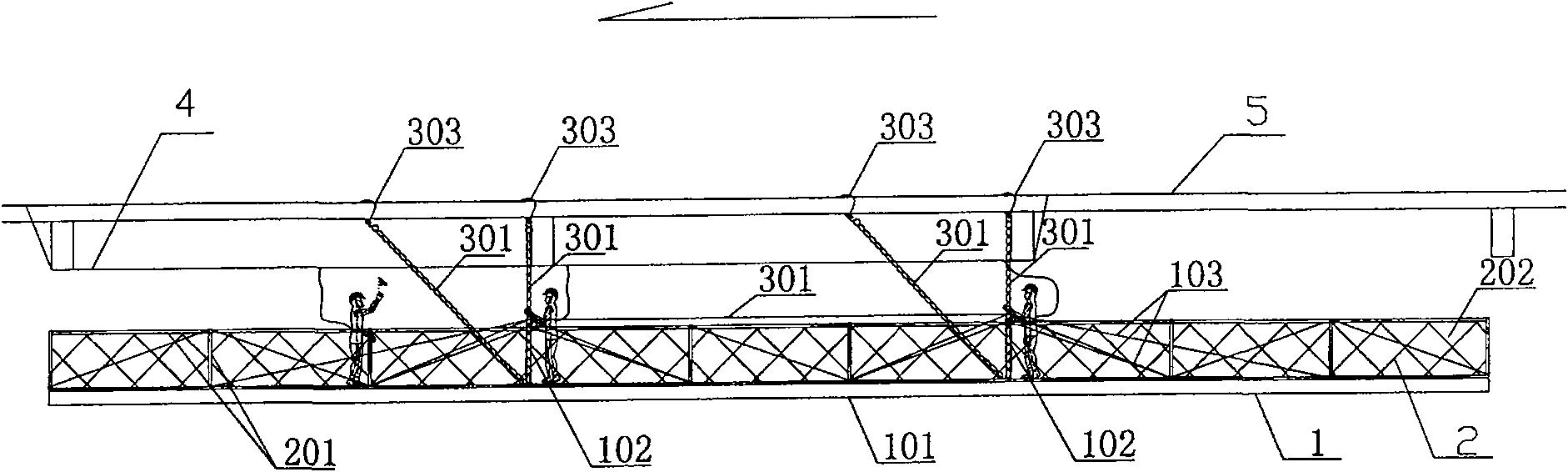

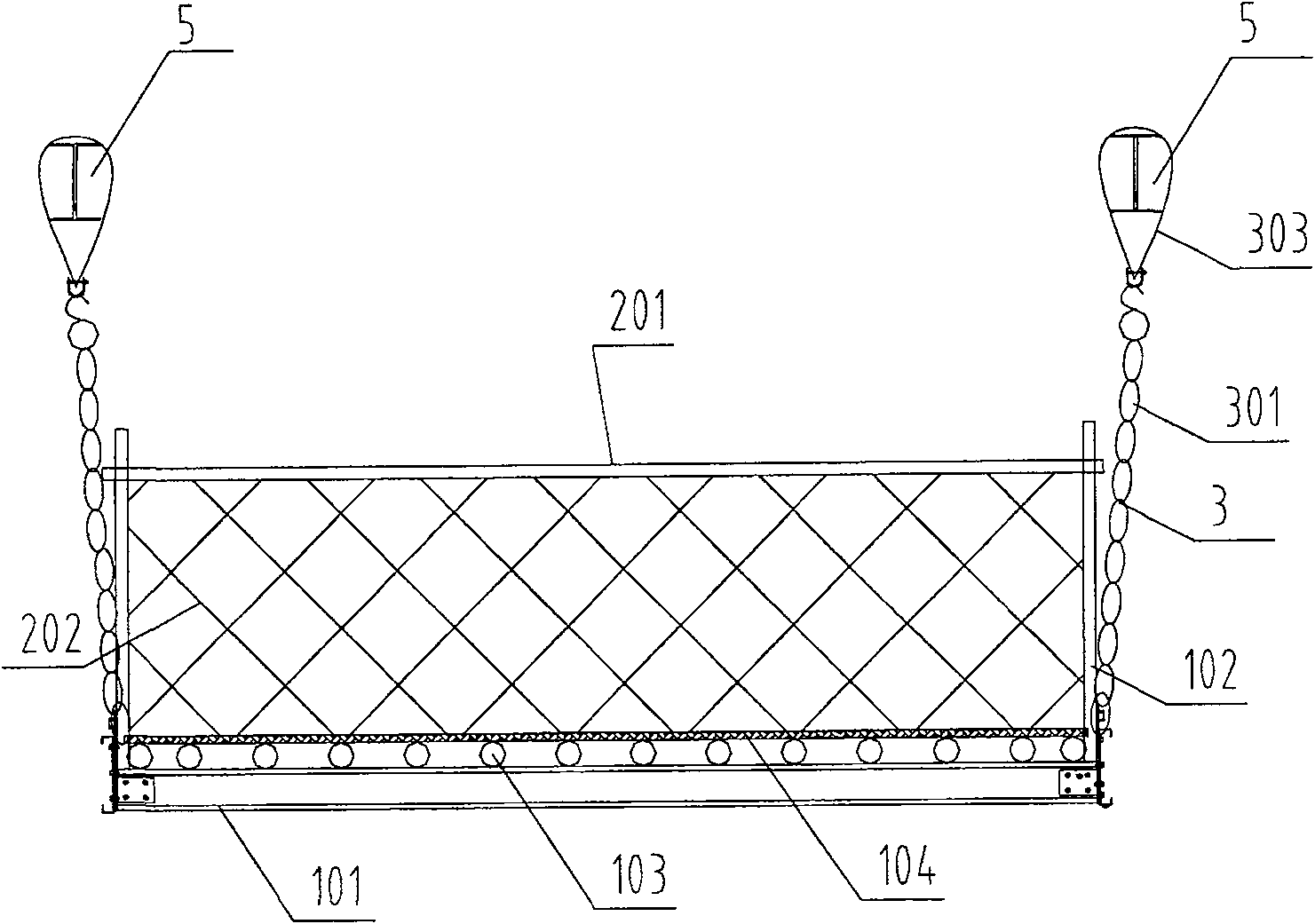

High-altitude bridge type cantilever scaffold

The invention discloses a high level bridge type suspended falsework with the top terminal suspended on the steel beam of the construction structure, consisting of a falsework frame, a fence, and a hanger. The falsework consists of a bottom frame, the upright columns of the fence at the two sides, and slanting steel wires; each fence consists of horizontal and vertical steel fence pipes and closely-knitted safety net, wherein the horizontal and vertical steel fence pipes are clamped with the upright columns of the fence to form a truss; the closely-knitted safety net is hung on the frame of the fence. One end of the slanting steel wire is connected with the top end of the upright columns of the fence, while the other end is connected with the bottom frame and the part of the connecting nodes of the vertical fence pipes. The bottom frame, the upright columns of the fence, and the steel fence pipes are connected by the slanting steel wires to form the truss. The hanger consists of a pulling wire and a pulling tool, wherein the two ends of the pulling wire are connected respectively with the beam and the falsework frame; one end of the pulling tool is connected fixedly with the steelbeam of the construction structure. The invention is convenient for high altitude construction, and has the advantages of highly reliable safety, light weight, convenient assembly and disassembly, etc.

Owner:TONGZHOU CONSTR GENERAL CONTRACTING GROUP +1

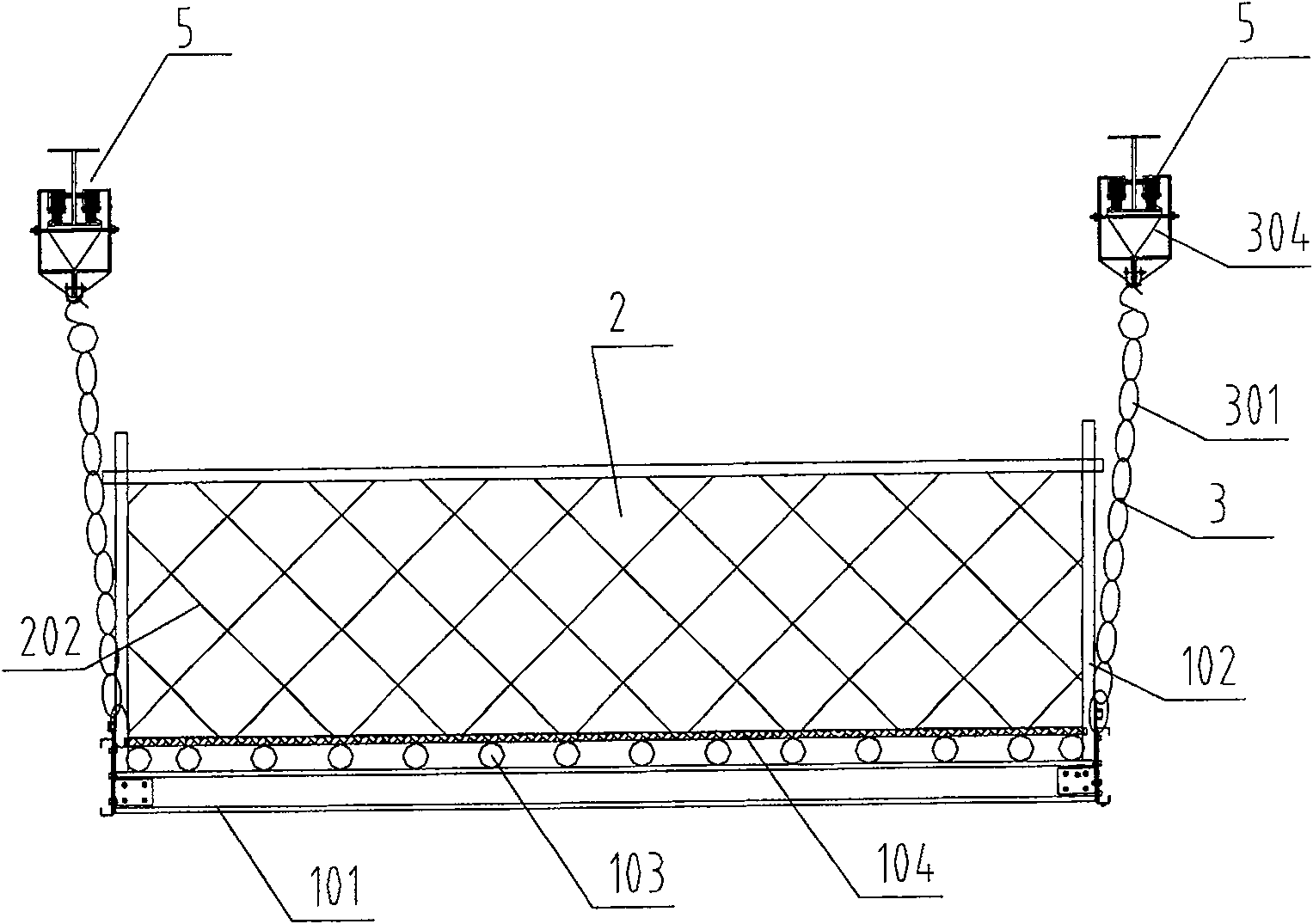

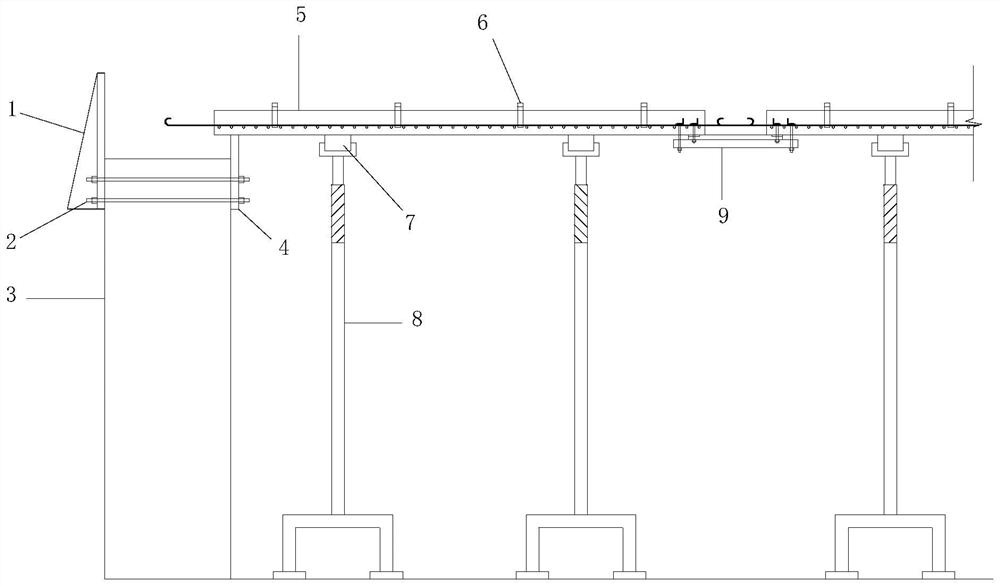

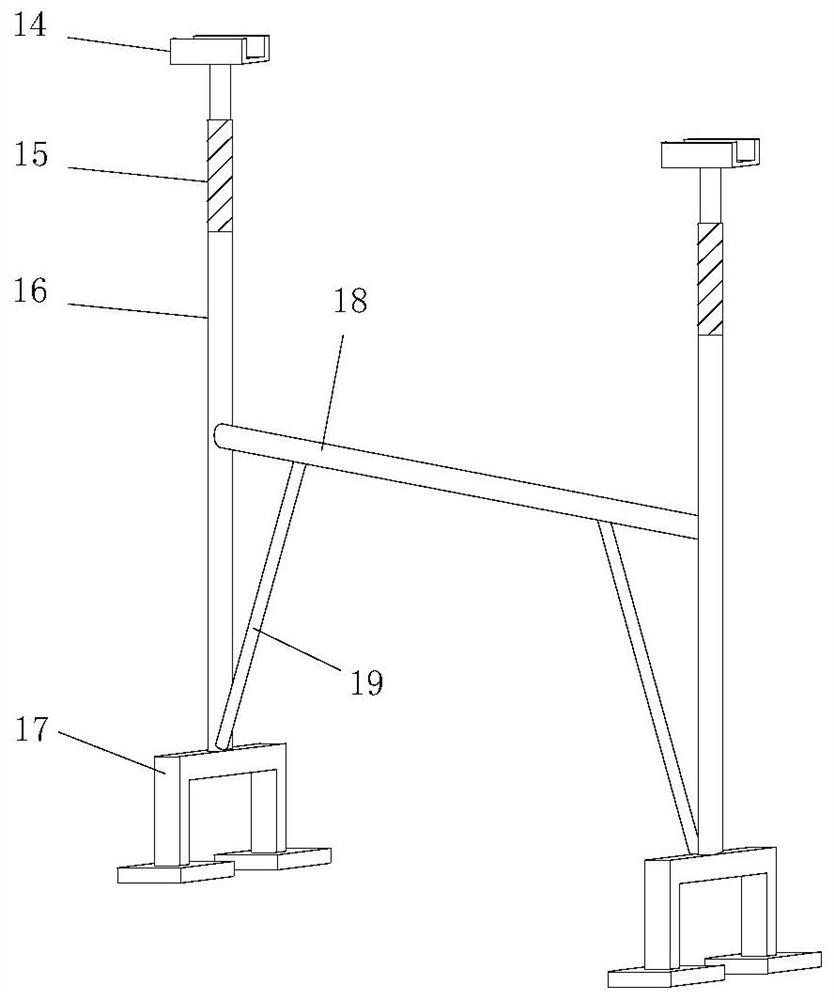

Integral joint type reinforced concrete laminated slab and construction method

ActiveCN114482375AQuick installationEnsure safetyFloorsCeramic shaping apparatusReinforced concreteArchitectural engineering

The invention provides an integral joint type reinforced concrete laminated slab and a construction method. The integral joint type reinforced concrete laminated slab comprises adjustable double supports used for supporting a laminated prefabricated slab and a slab wall joint formwork system of the laminated prefabricated slab and an existing unreinforced side wall. The plate seam joint formwork system is used for superposing the prefabricated plates; the plate beam joint formwork system is used for superposing the prefabricated plates and the middle cast-in-place beams; according to the integral joint type reinforced concrete laminated slab, when a prefabricated laminated slab is manufactured, the integral lifting rib plates are used for replacing traditional truss steel bars, the lifting safety and stability are guaranteed, meanwhile, the perforated angle steel is pre-buried in the edge of the joint, a row of short bolts and a row of long bolts are embedded in the edge of the joint and are arranged in a staggered mode, and the overall joint type reinforced concrete laminated slab is formed. Under the condition that a prefabricated slab is not perforated, rapid installation of a joint formwork system can be achieved at the same time, meanwhile, the problems of slurry leakage, formwork expansion and the like during concrete vibrating and pouring are avoided, and the construction quality and attractiveness of post-cast strip concrete at the joint are improved.

Owner:HANGZHOU JIANGRUN TECH LIMITED

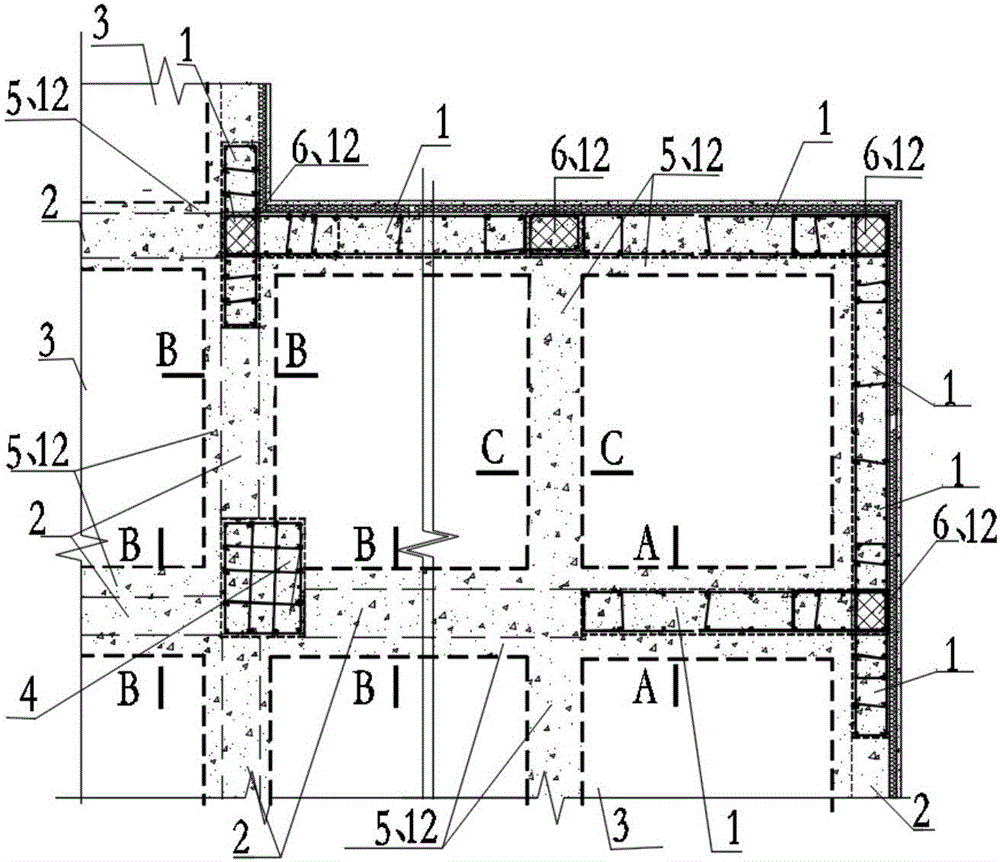

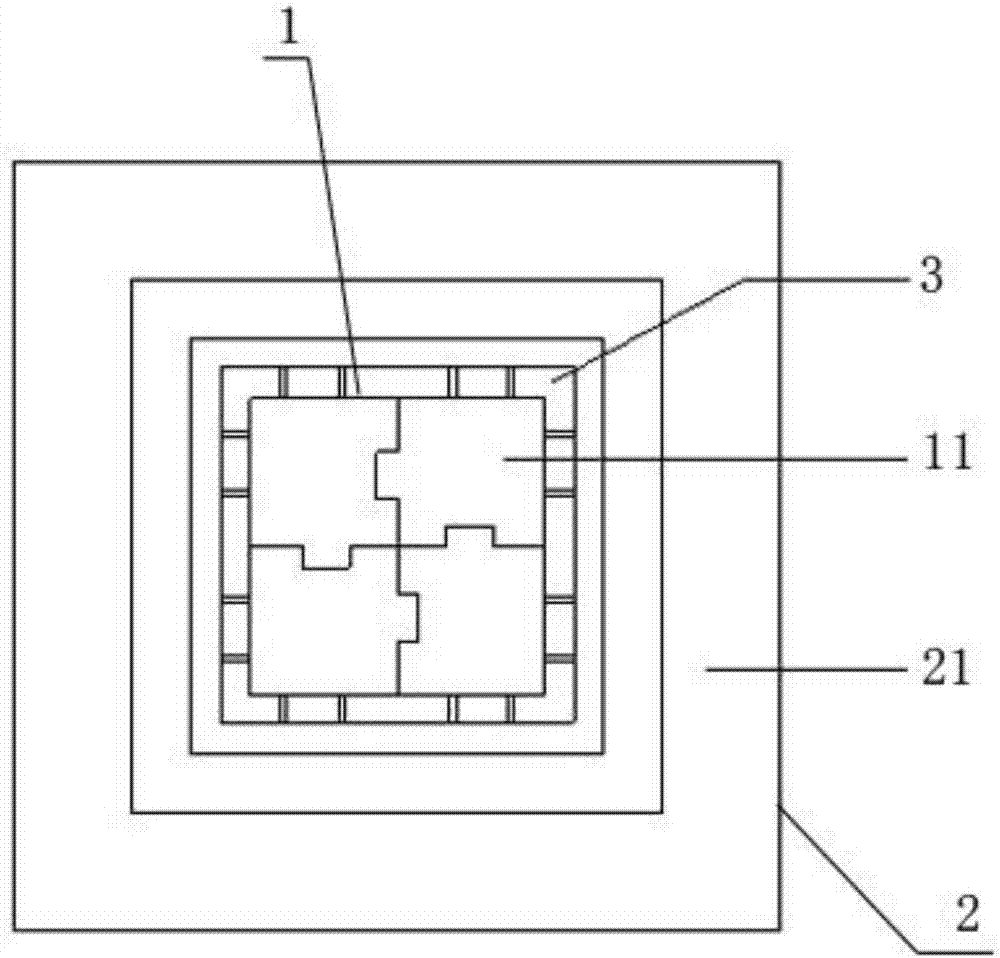

Segmentation method for prefabricated basic module of ring main unit and mounting and connection method for prefabricated basic module of ring main unit

ActiveCN110565682AShorten the construction periodReduce social impact and environmental impactFoundation engineeringSite managementWorkload

The invention discloses a segmentation method for a prefabricated basic module of a ring main unit. The segmentation method comprises the following steps of dividing the prefabricated basic module ofthe ring main unit into a first plate module, a second plate module, a third plate module, a fourth wall module, a fifth wall module, a sixth beam module, a seventh wall module, an eighth wall moduleand a ninth beam module. The modules are mutually connected through self-compacting grouting or bolts and screw rods, so that construction is simple, wet operation at a construction site is basicallyavoided, the site management and control workload is reduced, and the safety civilization construction degree is increased; and meanwhile, by saving turnover materials, such as templates and scaffolds, the labor cost is greatly saved, the site construction cost, the labor cost and the management cost are greatly lowered, and the construction safety risk caused by long-time operation in a foundation pit is reduced at the same time.

Owner:南京电力设计研究院有限公司

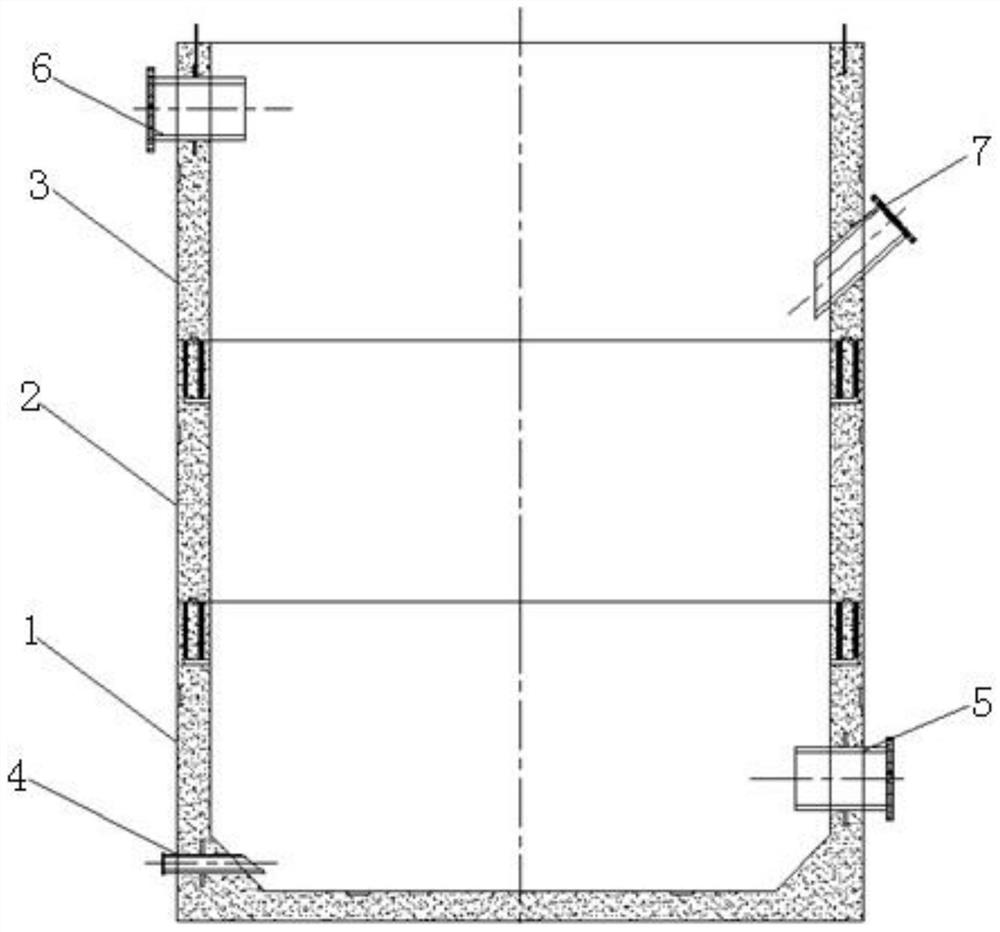

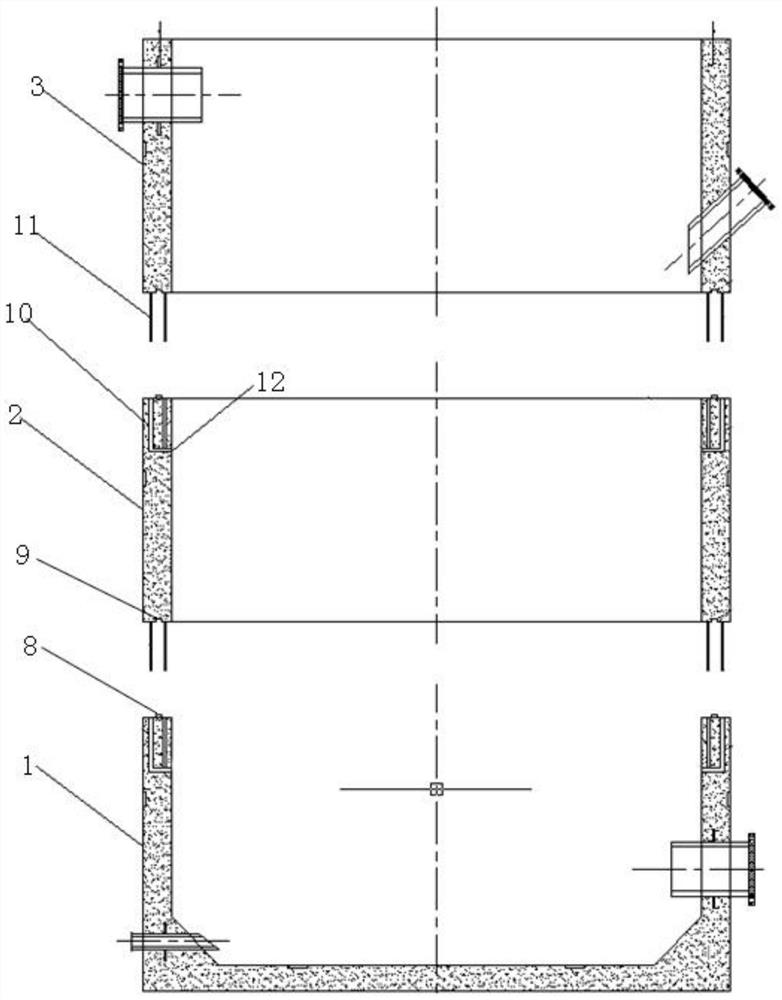

Rectangular aqueduct construction steel mould trolley

ActiveCN107829408AImprove construction efficiencyImprove appearance qualityHydro energy generationArtificial water canalsArchitectural engineeringUltimate tensile strength

A rectangular aqueduct construction steel mould trolley is composed of an inner trolley and an outer trolley; the inner trolley is composed of an inner trolley track (1), an inner trolley chassis (2),and a plurality of inner trolley template structure units composed of inner trolley portal frames (3), inner trolley templates and inner template lifting devices; the outer trolley is composed of anouter trolley track (17), and a plurality of outer trolley template structure units composed of outer trolley portal frames (18), outer trolley templates and outer trolley template lifting devices; the both sides of the outer trolley portal frames (18) are provided with three layers of construction platforms separately; inner and outer trolley traction devices are provided with a hoist separately.After the wall of an aqueduct and flange plates are cast to reach a certain strength, the inner and outer trolley templates are removed, and then the steel mould trolley can move forward to a next station under the traction of a hoist, so that hoisting equipment and manual handling are not required; the construction efficiency is increased by three times or so, and labor force is saved greatly; and revolving materials are saved, and the appearance quality is improved.

Owner:内蒙古辽河工程局股份有限公司

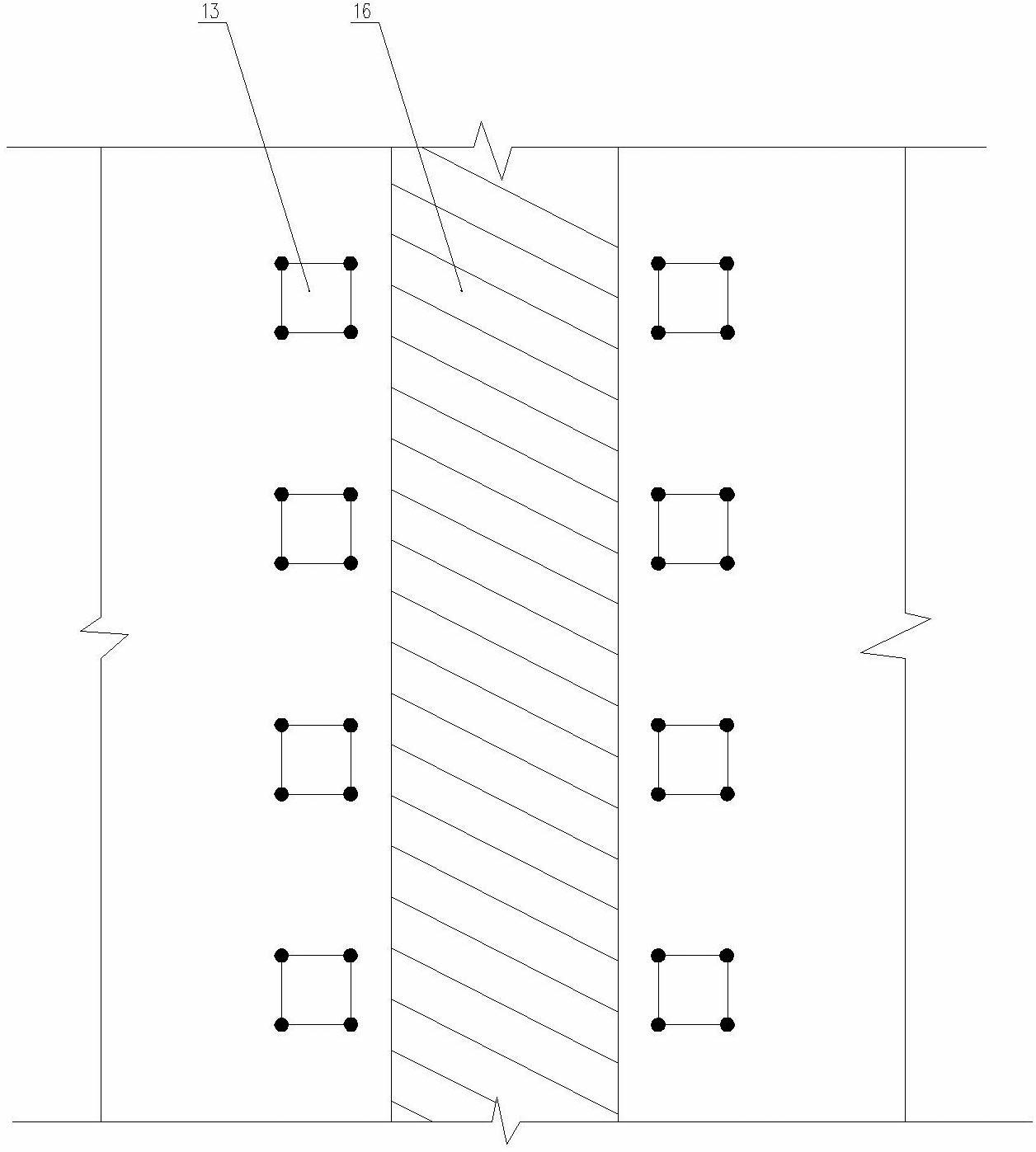

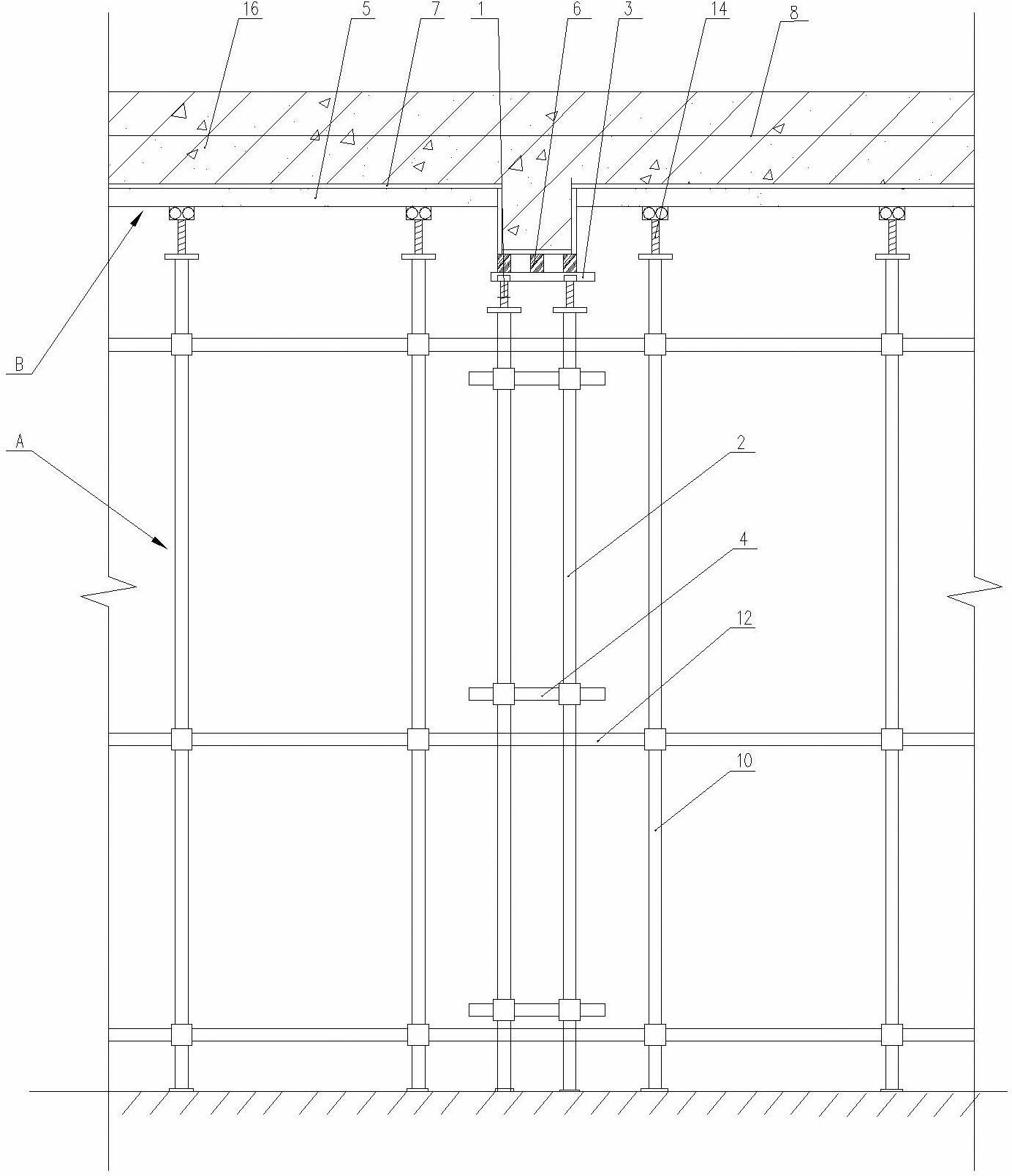

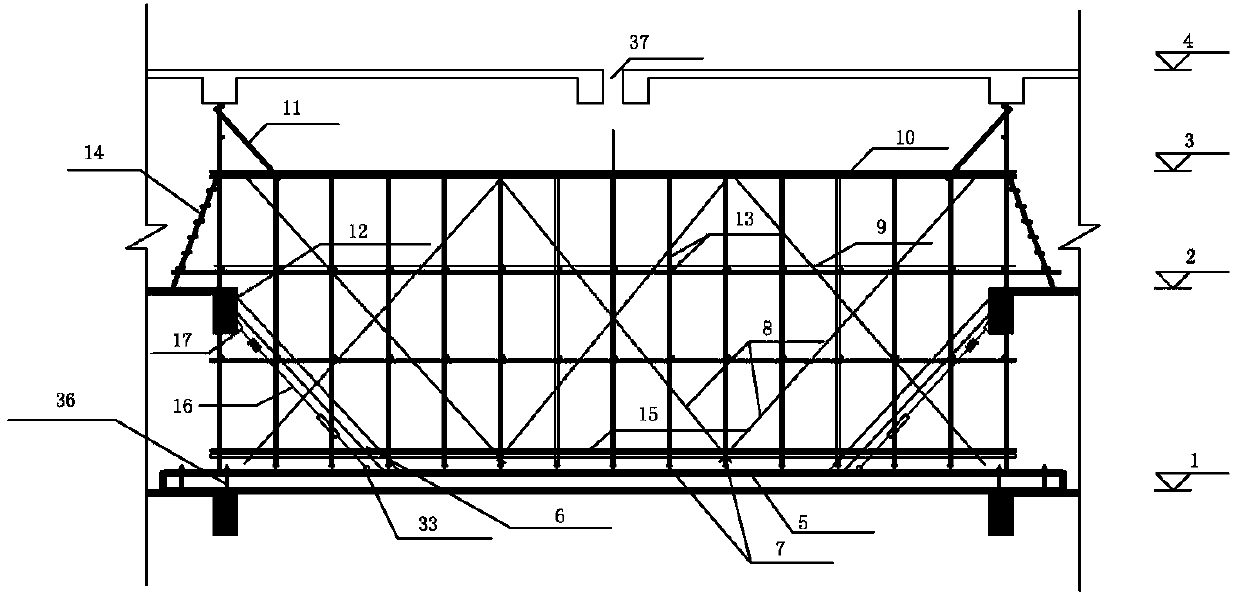

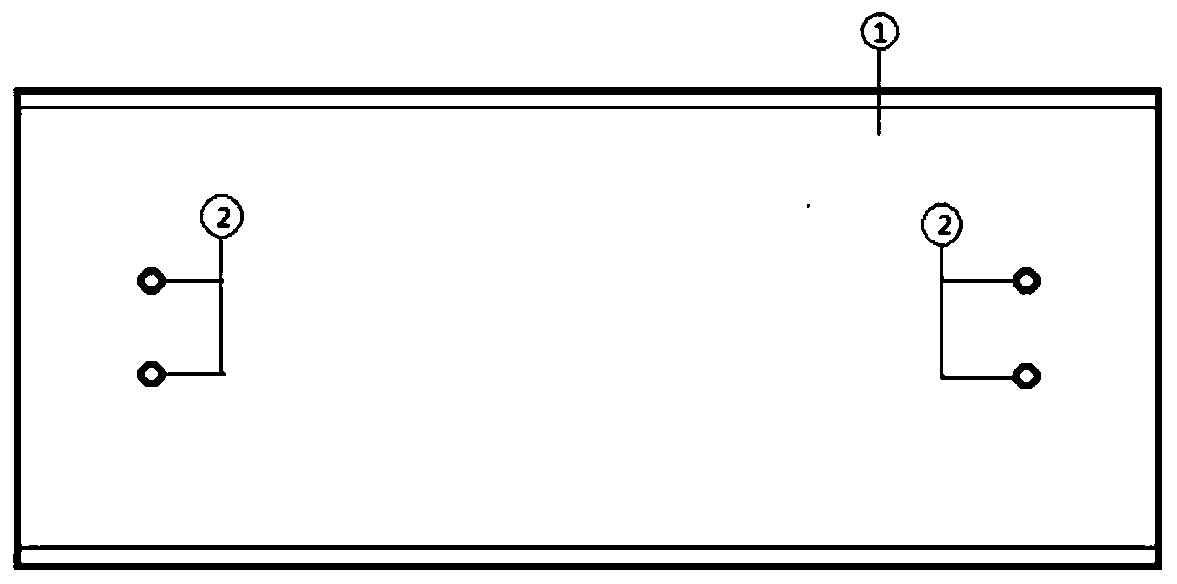

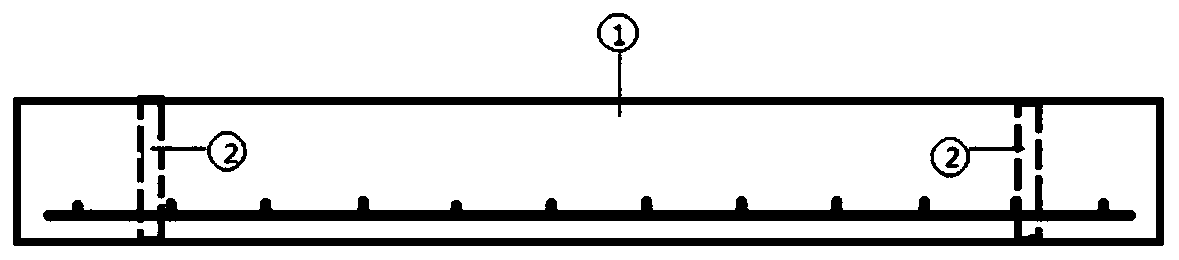

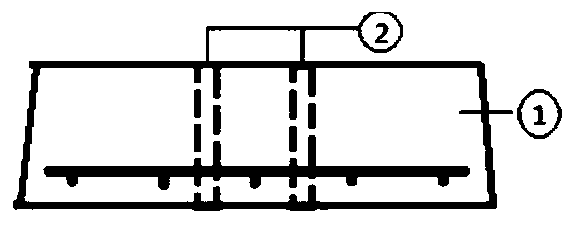

High-altitude long-span overhanging corridor type reinforced concrete structure and construction method

InactiveCN102444203BSave turnover materialsReduce construction costsBuilding material handlingSupporting systemFloor slab

The invention relates to a high-altitude long-span overhanging corridor type reinforced concrete structure and a construction method, wherein the corridor part is a stiff beam structure; with own bearing capacity of a profile steel, a beam template supporting system is a hung template supporting system in such a manner of fixing a square steel by means of a U-shaped screw and a nut; a floorslab is a self-supporting steel bar truss template which is welded to a pre-embedded steel plate on the stiff beam by means of a pin; and a steel platform is arranged on a corresponding floor at the lower part of the corridor as an operating and safety protection platform for template support construction. The high-altitude long-span overhanging corridor type reinforced concrete structure and the construction method have the advantages that: the template supporting construction method, according to which the operating platform is built from H-steel or profile steel beams, the stiff beam is hung and is self-supported and the floorslab is self-supported, is employed, so that the problem of difficult template supporting of the high-altitude long-span overhanging corridor structure, the revolving materials are greatly saved, the construction cost is reduced, the construction progress is accelerated and the safety is ensured; and the steel plate is pre-embedded on the stiff beam, so that the floor bearing plate is effectively connected with the stiff beam and the floor bearing plate and the stiff beam are capable of acting together to ensure the safety of the structure.

Owner:浙江城建建设集团有限公司

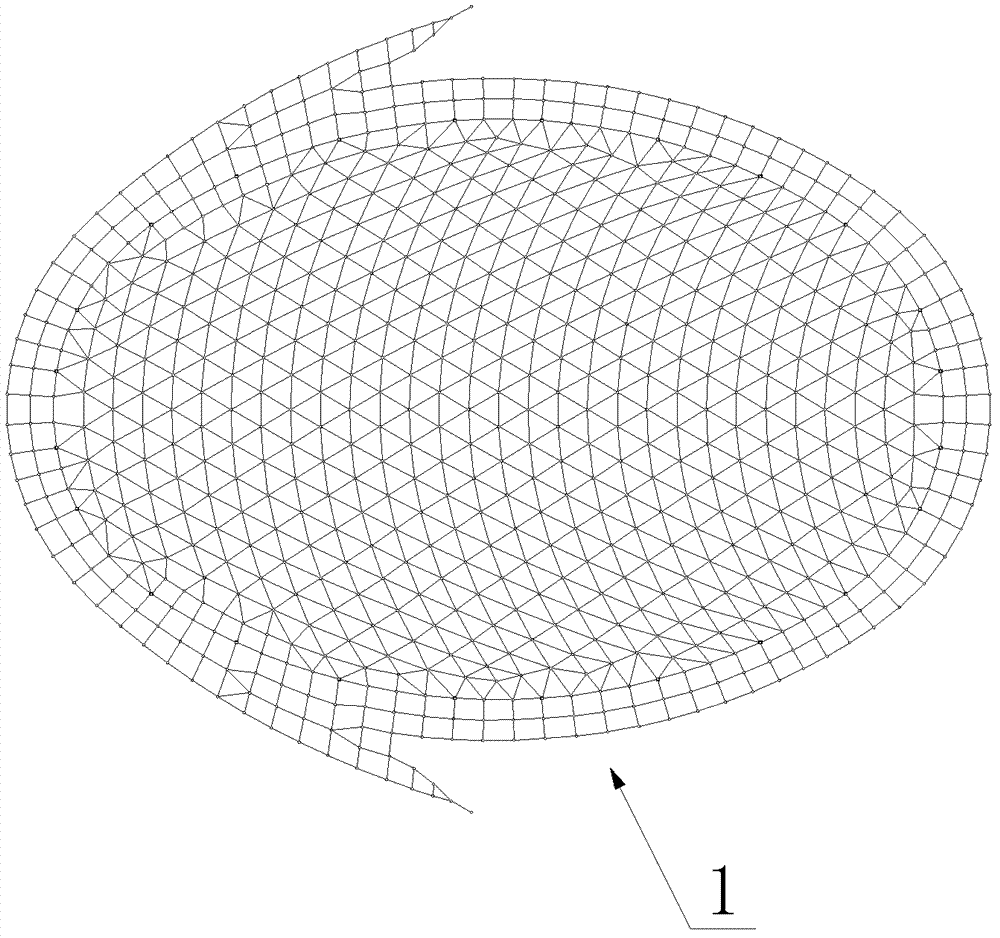

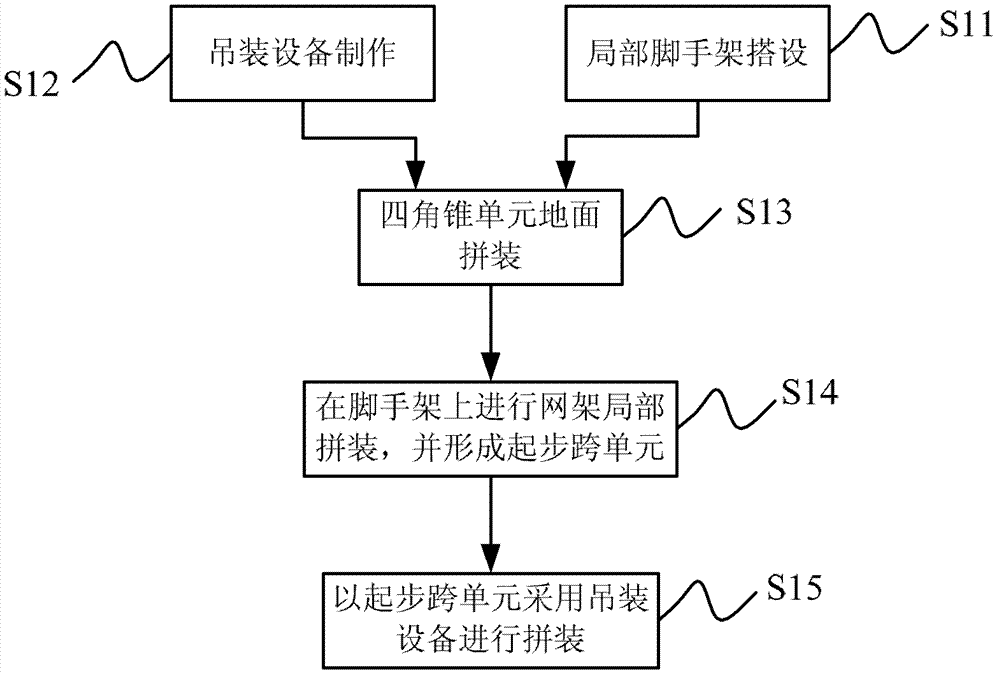

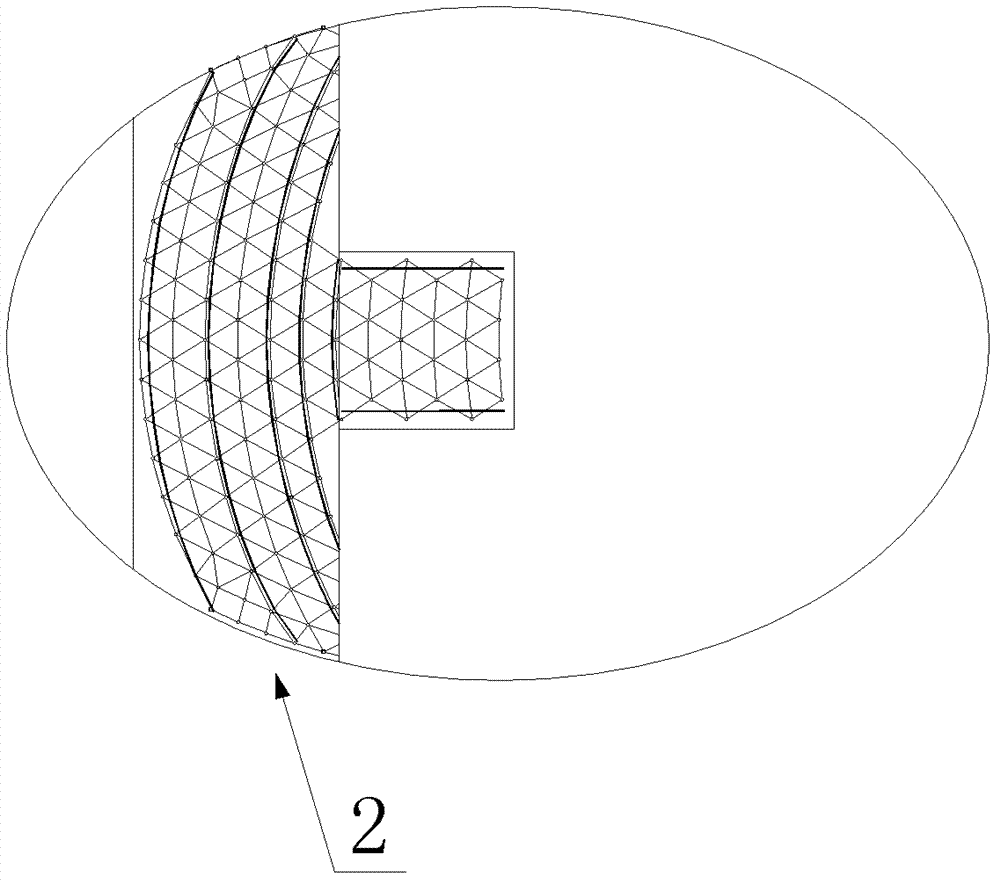

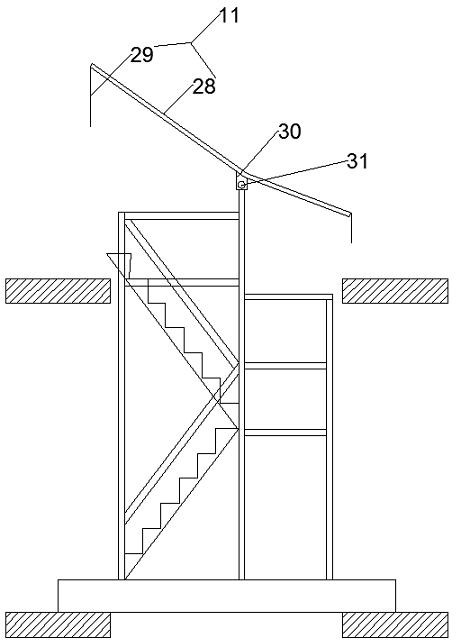

High-altitude bulk process of bolt ball net frame

ActiveCN102345393BSave turnover materialsSimple and fast operationBuilding material handlingEngineeringUltimate tensile strength

The invention discloses a high-altitude bulk process of a bolt ball net frame, comprising the steps: 1) erecting local scaffolds; 2) assembling square pyramidal units on the ground; 3) carrying out local assembly of the net frame on the local scaffolds and forming a net-frame start crossing unit; and 4) assembling the start crossing unit by adopting lifting equipment, wherein the lifting equipment is fixed to the start crossing unit; the square pyramidal units are lifted to high altitude by the lifting equipment and are symmetrically overhung, expanded and assembled from the middle of the net-frame start crossing unit to the two sides thereof till the assembly of the whole bolt ball net frame is finished. The high-altitude bulk process provided by the invention is applicable to installation and construction of various large-span bolt ball net frame roof structure systems; and according to the high-altitude bulk process, large construction machines are not needed, the operation is simpler, and only few supporting scaffolds need to be erected, thus greatly improving the labor efficiency and reducing the labor intensity.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

Super-heavy overhanging suspension member supporting system of super high-rise residential building conversion layer and construction method of super-heavy overhanging suspension member supporting system

PendingCN111593874AReduce the impact of constructionAvoid wastingScaffold accessoriesBuilding support scaffoldsSupporting systemArchitectural engineering

The invention discloses a super-heavy overhanging suspension member supporting system of a super high-rise residential building conversion layer and a construction method of the super-heavy overhanging suspension member supporting system. According to the method, a reinforced load-bearing steel pipe column, a steel box beam bracket, a bailey frame, an I-beam distribution beam and a dense type steel pipe fastener type supporting frame constitute the suspension member supporting system. The member load is evenly transmitted to a cantilevered steel platform through the dense type steel pipe fastener type supporting frame, and the size of the steel platform can be flexibly designed to meet the requirements according to the actual load, span and overhanging length on site. Fewer materials are used and can be used in a recycling mode, no requirement for the bearing capacity of a lower horizontal structure exists, and the impact on construction of surrounding podium buildings and undergroundstructure areas is reduced. The construction process is safe and reliable, green and environmentally friendly, the popularization rate is high, and the super-heavy external overhanging suspension member supporting system is very suitable for construction tasks similar to super-heavy external overhanging suspension members.

Owner:CHINA CONSTR FOURTH ENG DIV

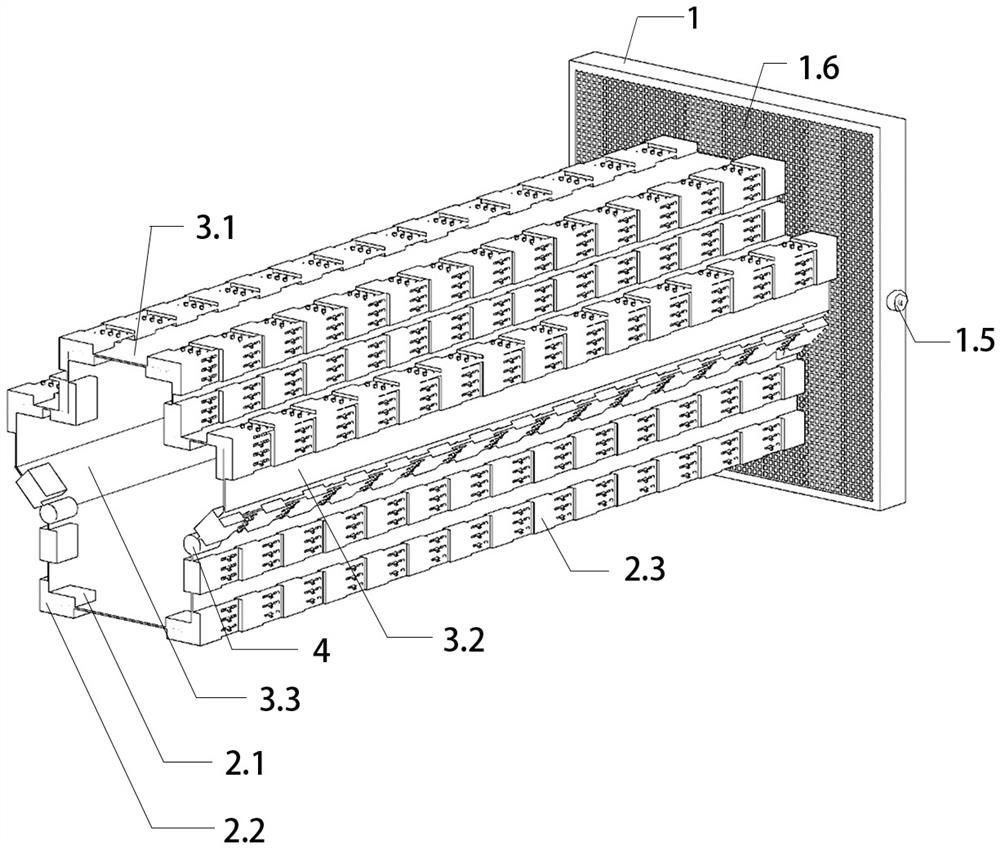

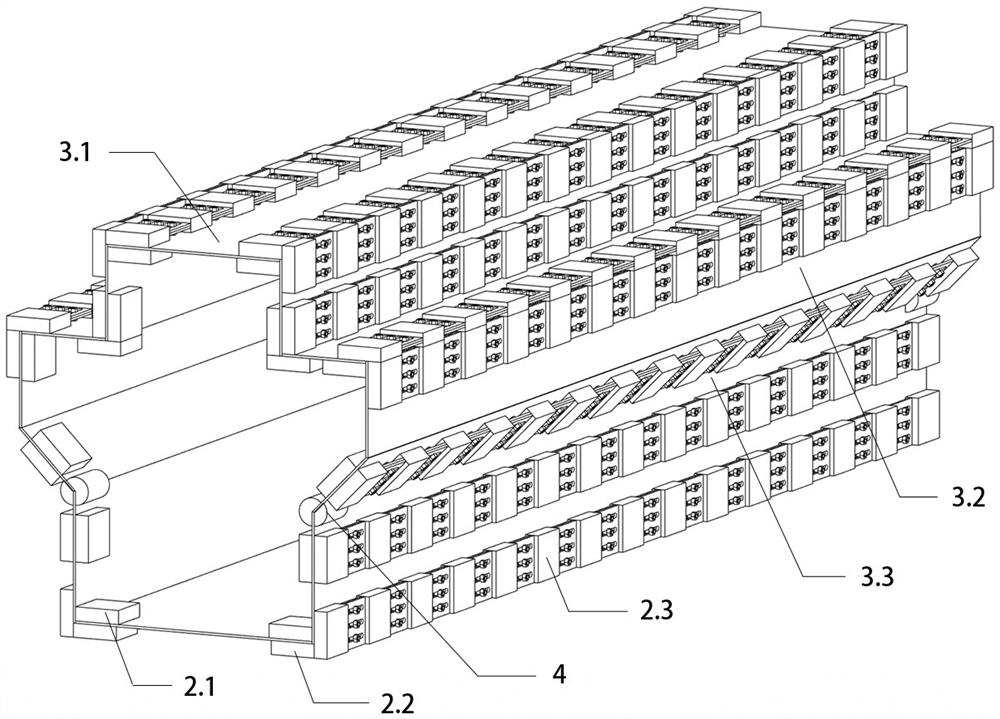

Special-shaped beam formwork quick mounting and dismounting structure using electromagnetic force and mounting and dismounting method thereof

ActiveCN112814375AQuick fixQuick installationForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksShaped beamControl theory

The invention relates to the field of building construction, in particular to a special-shaped beam formwork quick mounting and dismounting structure utilizing electromagnetic force and a mounting and dismounting method thereof. The special-shaped beam formwork quick mounting and dismounting structure comprises a pair of fixing plates 1, a shaping block 2, an angle-variable fixing block 4 and a formwork 3, wherein the shaping block 2 and the angle-variable fixing block 4 are magnetically attracted between the pair of fixing plates 1 along the cross section shape of a special-shaped beam, and the formwork 3 is clamped between the shaping block 2 and the angle-variable fixing block 4. The fixing plates 1 comprise flat rectangular shells 1.1, horseshoe-shaped iron cores 1.2 arranged in the shells 1.1, coils 1.3 wound on the horseshoe-shaped iron cores 1.2, controllers 1.4 connected with the coils 1.3 and current stepless regulating switches 1.5 arranged on the controllers 1.4. After the shells 1.1 are electrified, a magnetizer plate 1.6 is formed, and rectangular grids are drawn on the magnetizer plate 1.6. The shaping block 2 comprises an internal shaping block 2.1, an external end part shaping block 2.2 and an external standard shaping block 2.3; and a magnetizer block is formed after the shaping block 2 passes through. The problem that material waste is caused due to the fact that when the special-shaped beam formwork is fixed, a large number of turnover materials need to be cut to erect a fixed scaffold is solved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

A pre-assembled leaching tank and assembly method

ActiveCN109811124BShort construction periodFast constructionProcess efficiency improvementEnvironmental engineeringMechanical engineering

The invention provides a pre-assembled leaching tank and an assembling method thereof. The pre-assembled leaching tank comprises a bottom plate section, a middle section and an upper part groove bodywhich are sequentially connected from bottom to top; the bottom plate section is of a cylindrical barrel structure with an opening formed in the top; a barrel wall is provided with a discharge hole pre-buried sleeve and a maintenance manhole pre-buried sleeve; a placing position of the discharge hole pre-buried sleeve is lower than a placing position of the maintenance manhole pre-buried sleeve; the middle section and the upper part groove body are both of a cylindrical barrel structure with openings formed in the top and bottom respectively; the barrel wall of the upper part groove body is provided with an overflow hole pre-buried sleeve and a feeding hole pre-buried sleeve; and a placing position of the overflow hole pre-buried sleeve is higher than a placing position of the feeding holepre-buried sleeve. The pre-assembled leaching tank is small in amount of required turnover material and rapid in construction period.

Owner:CHINA FIRST METALLURGICAL GROUP

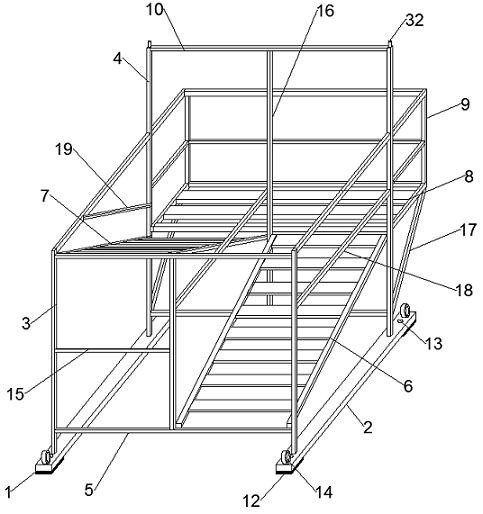

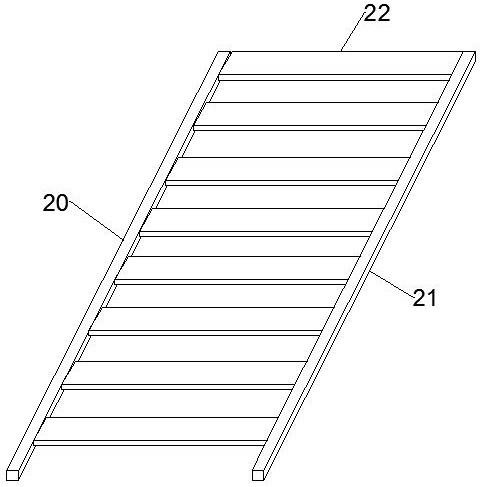

Fabricated building shaping protective stair and construction method thereof

PendingCN114319751AReduce security risks of weak connectionsEasy to operateTreadsConstruction engineeringArchitectural engineering

The fabricated building shaping protective stair comprises a first supporting bottom beam and a second supporting bottom beam, first supporting stand columns and second supporting stand columns are arranged at the tops of the first supporting bottom beam and the second supporting bottom beam, and a plurality of supporting cross beams are arranged between the first supporting stand columns and between the second supporting stand columns. A first stair unit assembly is arranged on one side of the top end of the supporting cross beam, a second stair unit assembly is arranged on the top of one side of the first stair unit assembly, a corner platform is arranged in the middle of one side of the second supporting stand column, and a top supporting beam is arranged on one side of the top end of the corner platform. The tower crane has the beneficial effects that the tower crane is convenient to integrally lift, use and operate, saves working hours, does not need to be assembled and disassembled and improves construction efficiency; after construction is finished, recycling can be achieved, turnover materials are saved, and the cost is effectively saved; the problem of insufficient edge protection in a traditional method is solved through shaped protection; the fastener is not connected with the outer frame, and the safety risk that fastener connection is not firm is reduced.

Owner:QINGDAO BOHAI CONSTR GROUP

Device for precisely embedding concrete movable cover plate in reserved hole and installing and using method thereof

InactiveCN110561612APrecise positioningControl spacingCeramic shaping apparatusStructural engineeringModel Number

The invention provides a device for precisely embedding a concrete movable cover plate in a reserved hole and an installing and using method thereof. The precise embedding device comprises embedding device bodies and a connector. The embedding device bodies are used for being inserted into concrete before the concrete is primarily set. The connector is used for connecting the embedding device bodies so that the distance between every two embedding device bodies can be controlled and the reserved hole can be accurately located. The size, specification and model number of the embedding device bodies can be adjusted according to the actual situation, the precise embedding device is embedded and pulled out as a whole before the concrete is primarily set, and the locating precision of the reserved hole can be effectively improved. The pipe diameter of the connector is one specification larger than the diameter of the embedding device bodies, and inserting and pulling are facilitated. The length of the connector can be freely adjusted according to the actual locating size of the reserved hole. The diameter of the embedding device bodies and the diameter of the connector can be flexibly changed according to the design requirement of the cover plate, and the distance of the reserved hole can be freely changed. The embedding device bodies and the connector are detached before the concrete is finally set, the precise embedding device can be recycled, and recycling materials are saved.

Owner:中国人民解放军63926部队

The method of installing the steel truss and curtain wall of the daylighting roof in the air

ActiveCN103615047BSave turnover materialsShorten the construction periodWallsBuilding material handlingSafety netBuilding construction

The invention relates to a method for installing a daylighting roof steel truss and a curtain wall in the air. The installed daylighting roof steel truss comprises a plurality of unit steel trusses, and every unit steel truss comprises a lower chord, an upper chord, a cross rod and a web member. The method comprises a first step of lifting the daylighting roof steel truss and hanging a safety net; a second step of utilizing the steel truss lower chords to serve as a supporting structure to erect a safety walkway and a construction operation platform; a third step of performing the first step and the second step in a line production mode; a fourth step of arranging double safety ropes or guardrails at the position of the safety walkway close to the edge, and installing the safety net; a fifth step of laying skirting boards on two sides of the safety walkway; a sixth step of installing a curtain wall glass frame; a seventh step of installing curtain wall glass; an eighth step of installing a drainage channel between the unit steel trusses where the curtain wall glass is installed well, enabling the drainage channel to have a certain gradient, arranging a water collecting tank at the tail end of the drainage channel, and enabling the water collecting tank to be communicated with a building drainage pipe.

Owner:GUANGZHOU CONSTR ENG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com