Rectangular aqueduct construction steel mould trolley

A steel formwork trolley and trolley technology, applied in water conservancy projects, artificial waterways, buildings, etc., can solve the problems of long equipment manufacturing cycle, high construction cost, low construction efficiency, etc., to save turnover materials, improve appearance quality, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

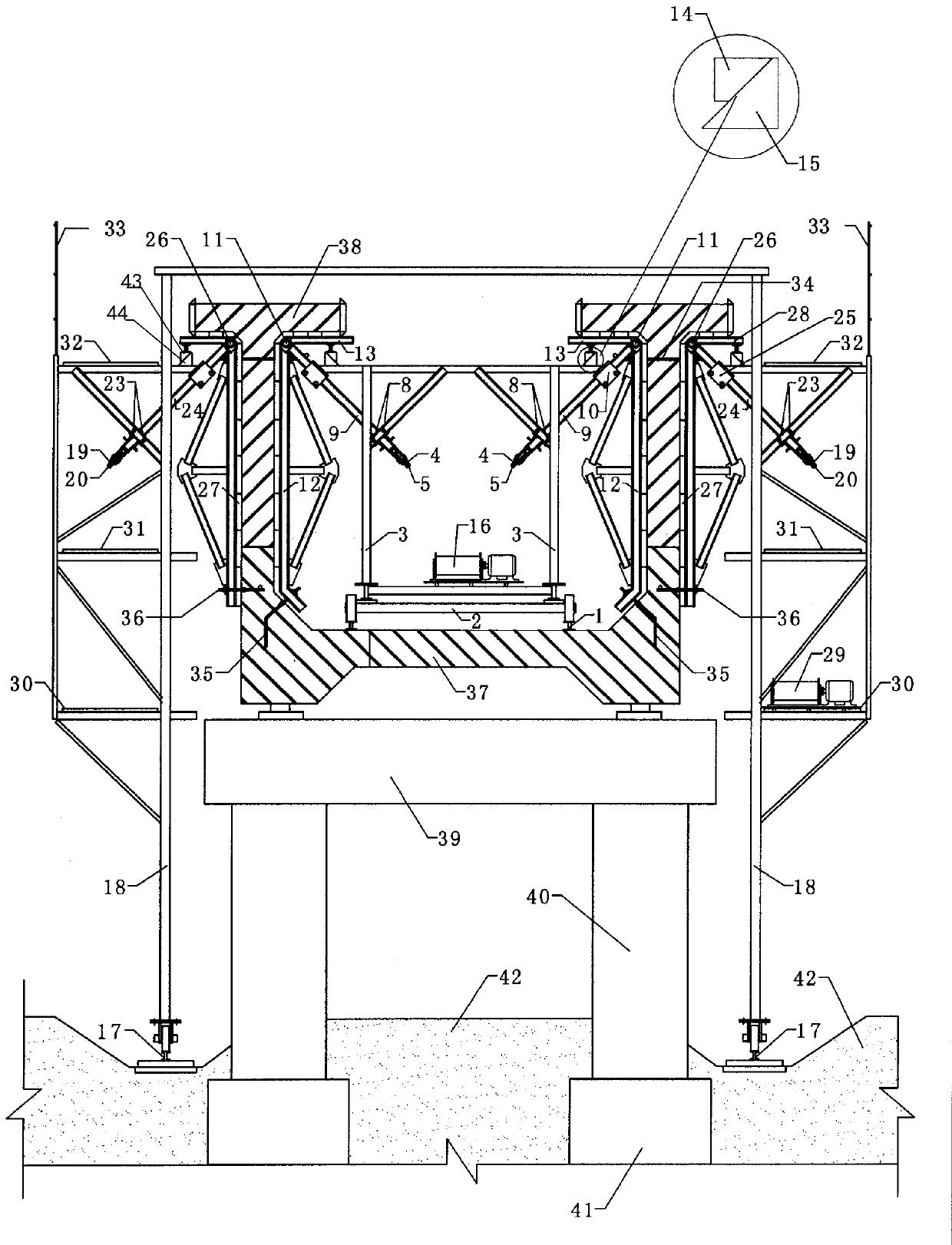

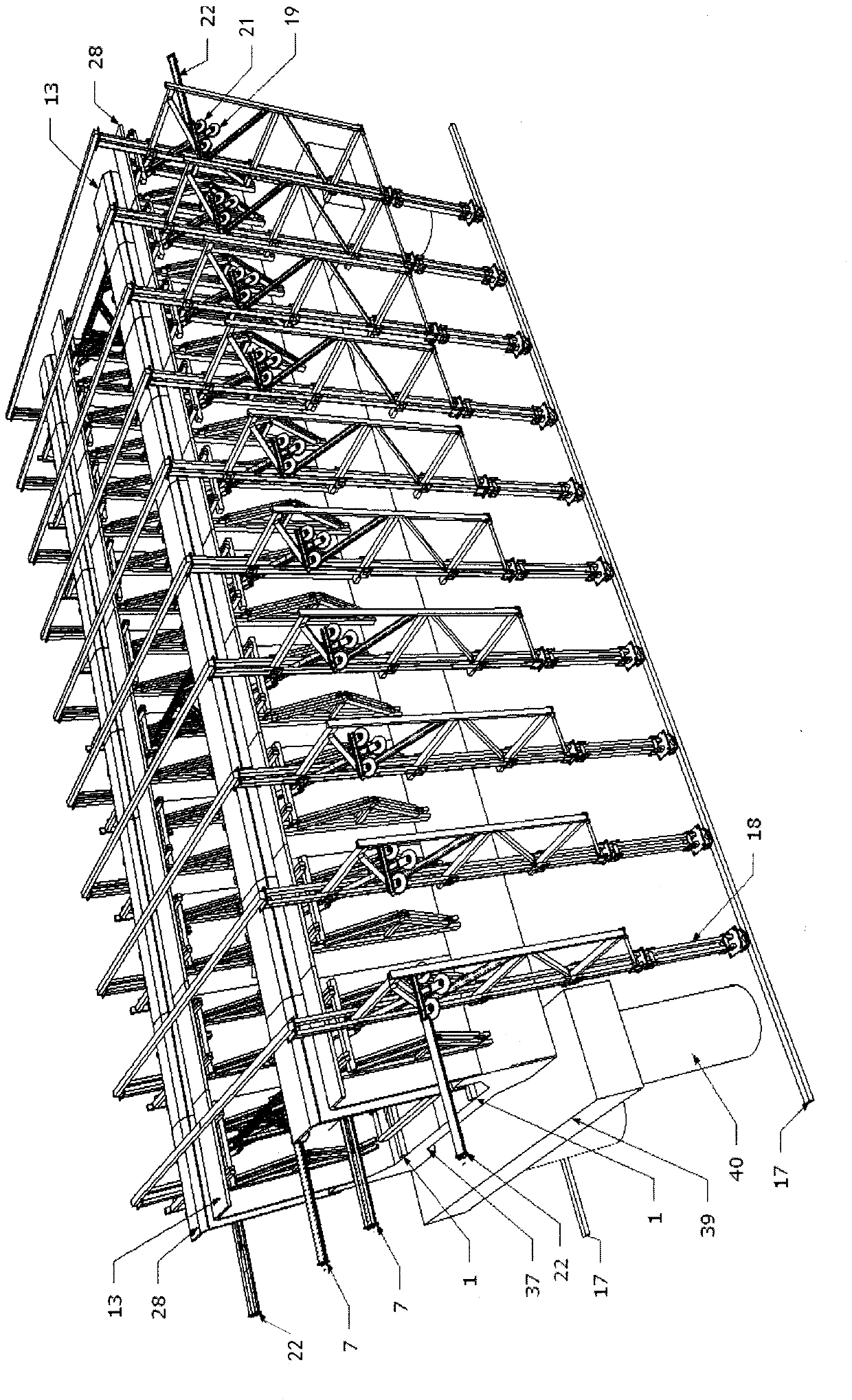

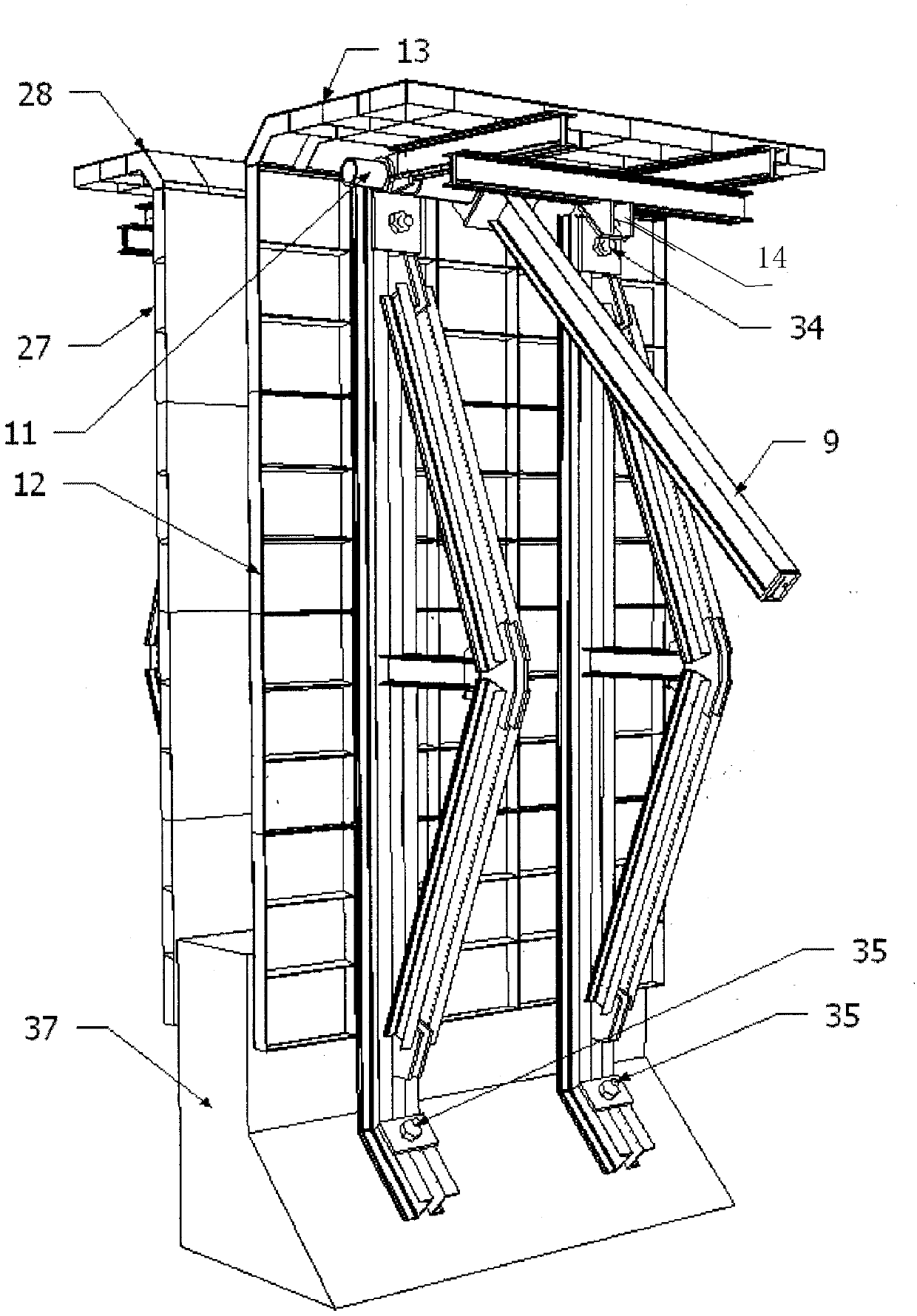

[0023] Figure 1 to Figure 5 Middle, 1. Inner trolley track; 2. Inner trolley chassis; 3. Inner trolley door frame; 4. Inner push rod movable pulley; 5. Inner trolley wire rope; 6. Fixed pulley; 7. Inner trolley formwork lifting Booster; 8. Inner trolley push-pull rod lower guide roller; 9. Inner trolley template push-pull rod; 10. Inner trolley push-pull rod upper guide roller; 11. Inner trolley formwork hinge shaft; 12. Inner trolley vertical Oriented formwork (truss type); 13. Horizontal formwork of inner trolley (steel stiffener type); 14. Inner movable slider; 15. Internal fixed slider; 16. Hoist of inner trolley; 17. Outer trolley track; 18. 19. Movable pulley of the outer trolley; 20. Steel wire rope of the outer trolley; 21. Lifting fixed pulley of the outer trolley template; 22. Lifting booster of the outer trolley template; 23. Lower guide of the outer trolley pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com