Two-side-connection combined steel plate shearing force wall

A steel plate shear wall and steel plate technology, applied to walls, building components, insulation, etc., can solve the problems of increasing construction volume and cost, reducing the application range of steel plate walls, and not being able to use steel plate walls, etc., achieving high construction efficiency, The effect of small amount of construction and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

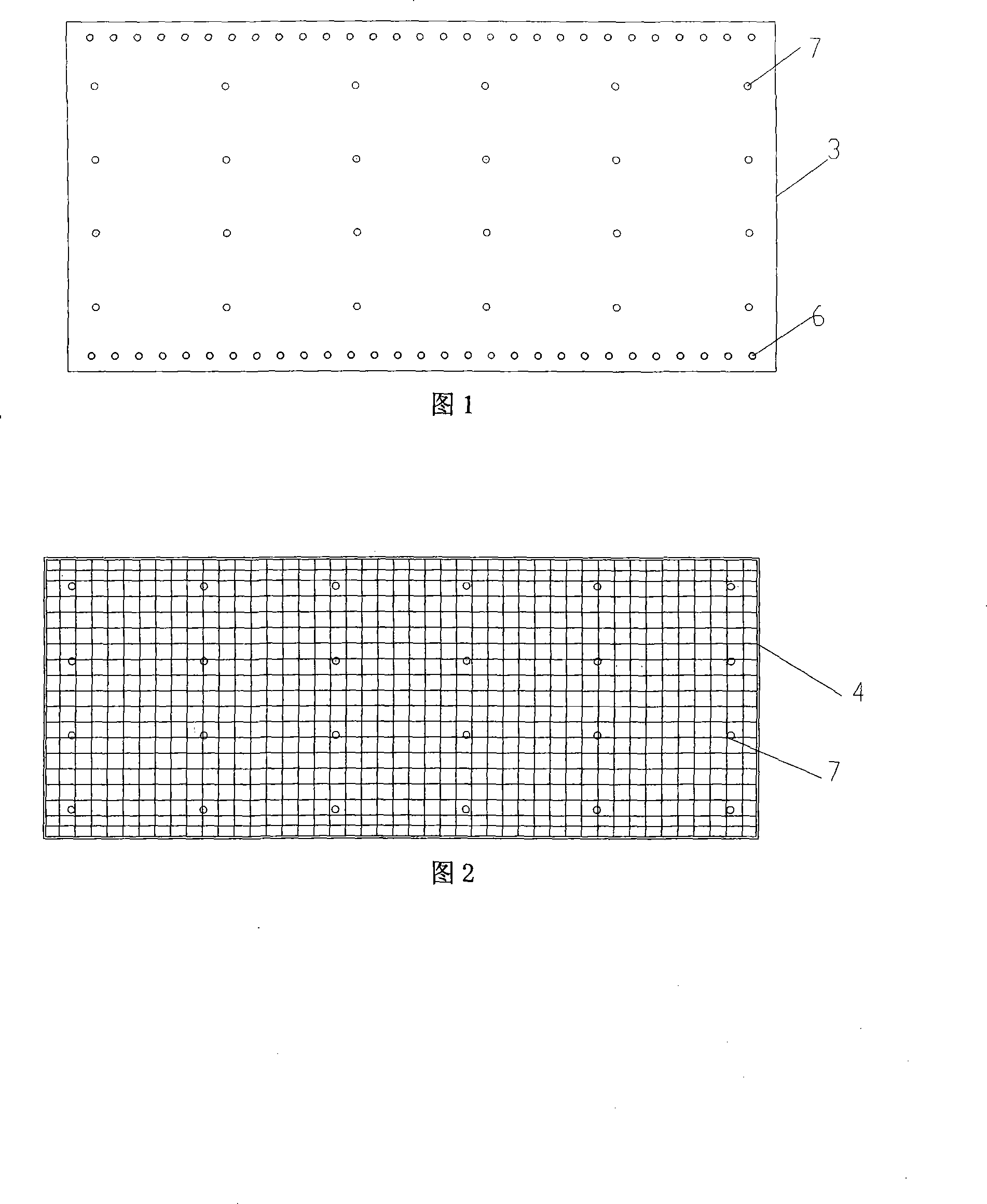

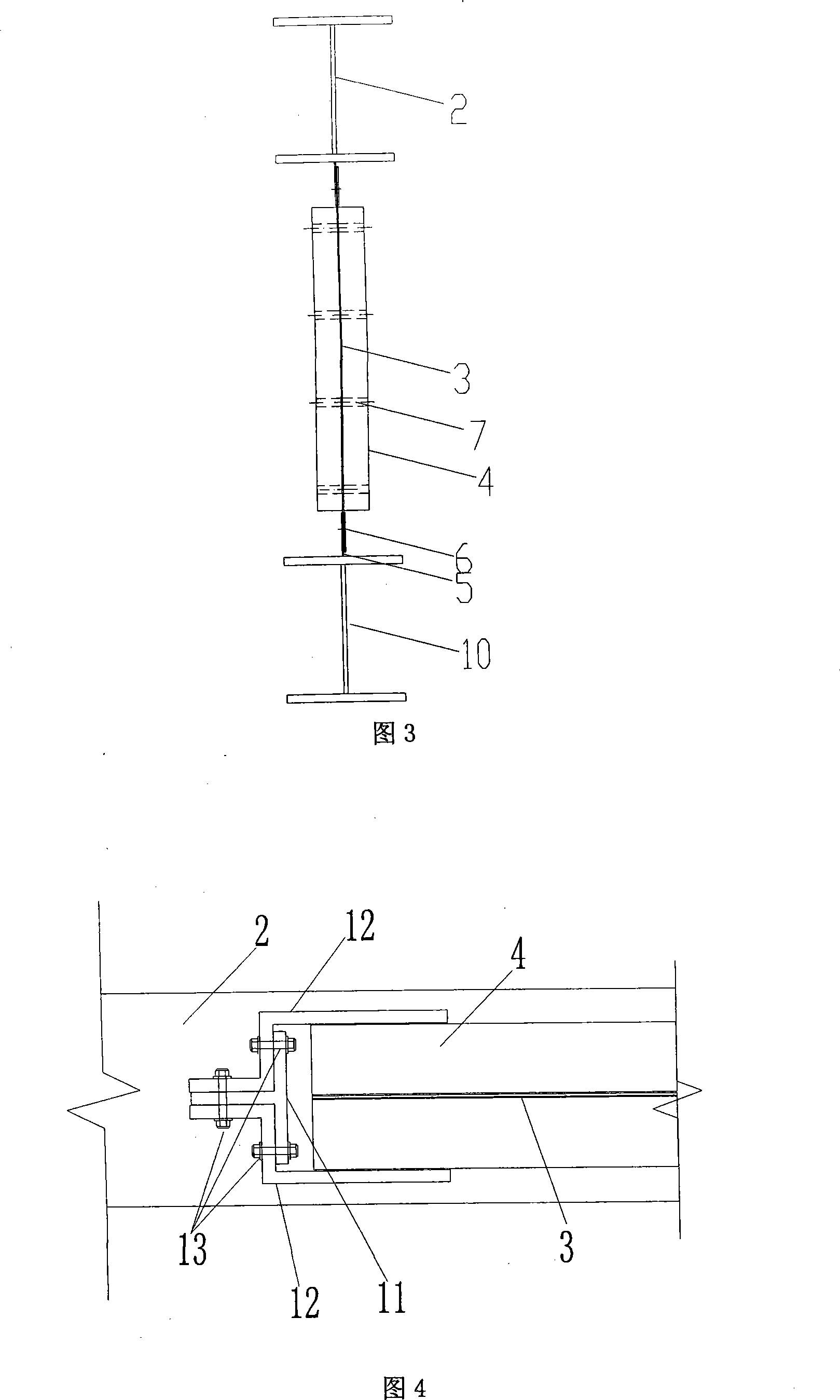

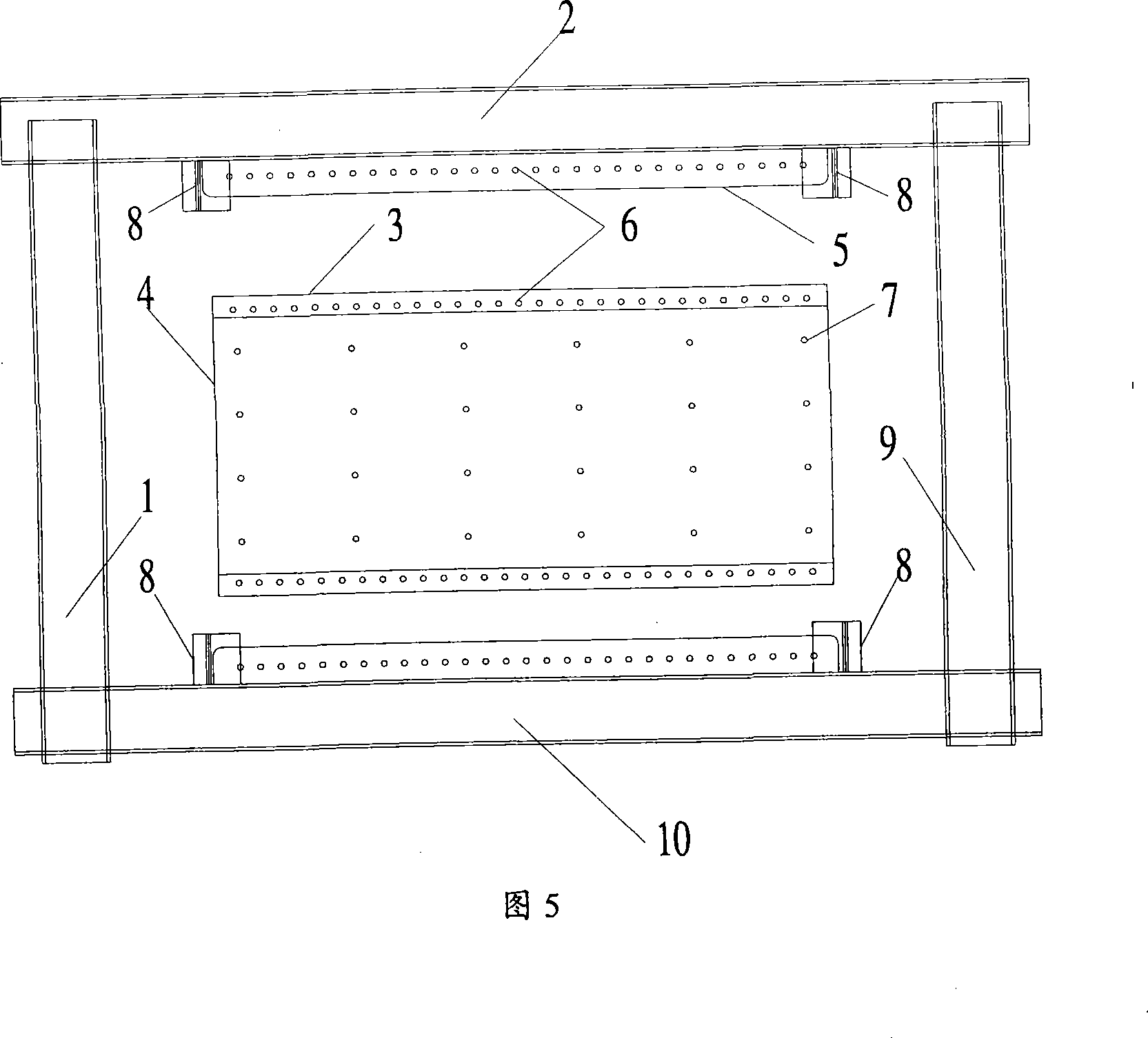

[0027] Embodiment 1: The combined steel plate shear wall connected on both sides of the present invention is composed of a steel plate 3 filled in, a concrete steel plate 4 hung outside, and edge members; the edge members are composed of upper edge frame beams 2, lower edge frame beams 10, and left edge frame columns 1. The frame column 9 on the right edge is composed, the steel plate 3 for inner filling can be made of ordinary structural steel, the concrete slab 4 for external hanging is made of prefabricated concrete slab, the fishplate 5 is welded with the upper and lower edge frame beams, and the steel plate 3 for inner filling is passed through The high-strength friction bolts 6 are connected to the fishplate 5, the external concrete slab 4 is connected to the inner filling steel plate 3 through common bolts 7, and the support frame 8 is used to prevent out-of-plane deformation of the wall. Out-of-plane support 8 is formed by connecting T-shaped steel plates 11 and Z-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com