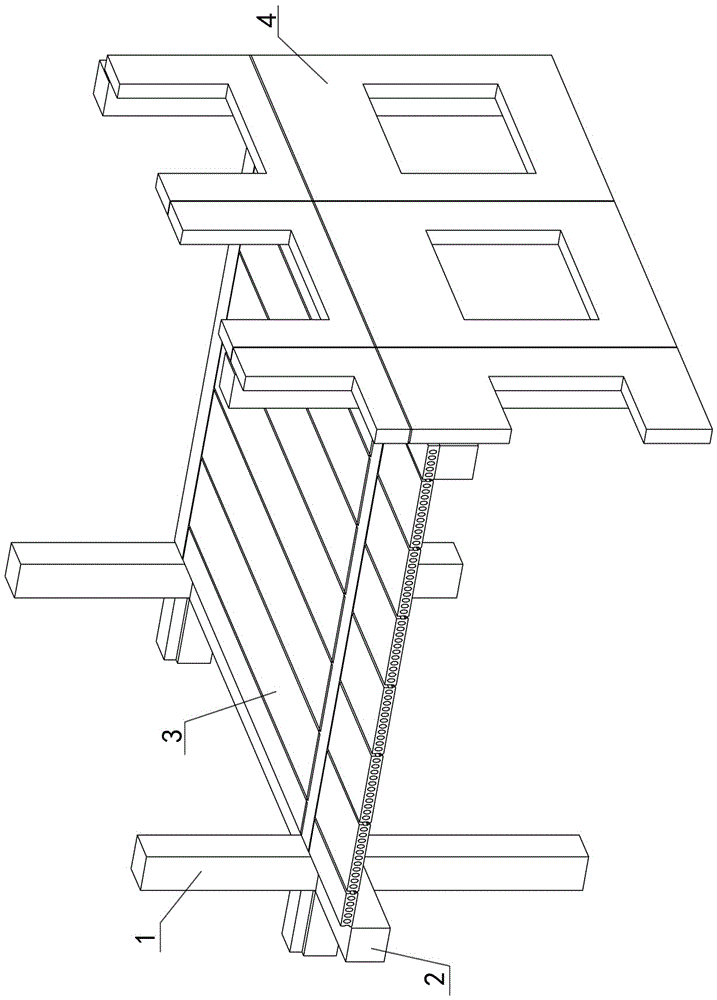

Column-through assembled prestressed concrete frame system and construction method thereof

A frame system and prestressing technology, which is applied in the direction of architecture and building construction, can solve problems such as unsatisfactory seismic performance, easy damage to column feet, and complicated construction, so as to improve the level of green construction, improve the seismic resistance of structures, and improve construction efficiency. The effect of build speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

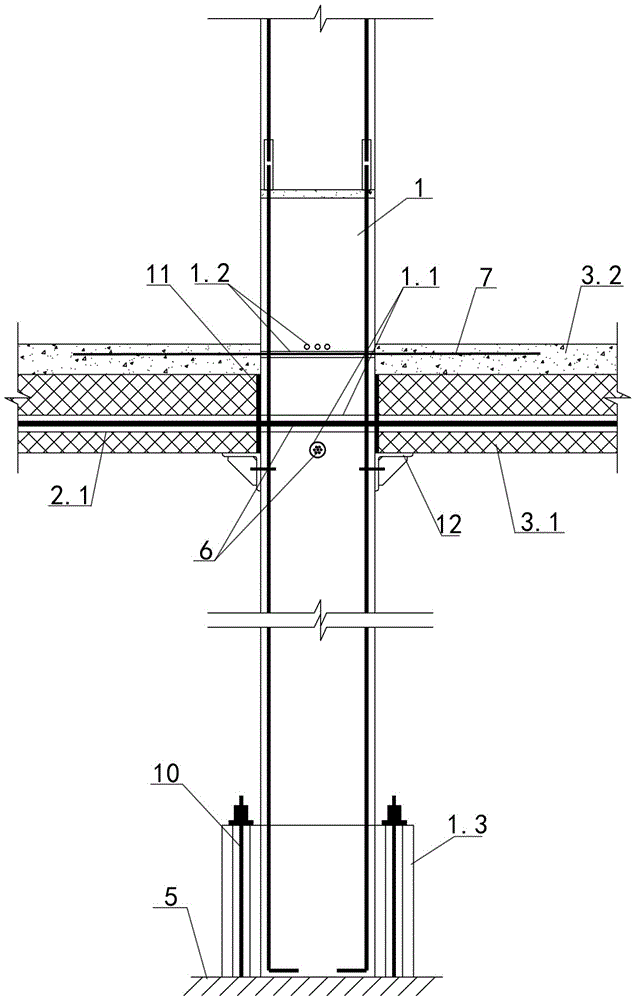

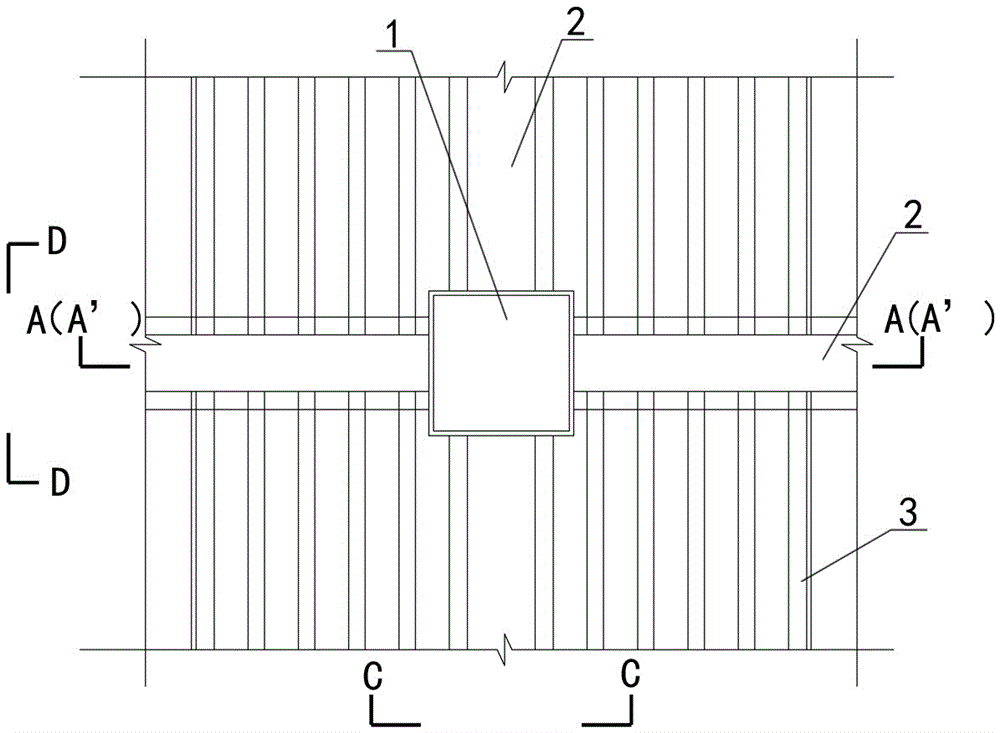

Embodiment 1

[0085] Example as image 3 and Figure 4 As shown, the energy-dissipating steel bars are unbonded steel bars 7.1 in the column, and the prefabricated reinforced concrete column 1 and the top cast-in-place laminated reinforced concrete layer 3.2 are connected within the column body with a prestressed channel 1.1 Column energy-dissipating reinforcement tunnels 1.2 parallel to and through the column body, the column energy-dissipating reinforcement tunnels 1.2 are intersected and staggered along the height direction of the column to form two vertical layers of space, and the energy-dissipating reinforcement bars 7 penetrate the column energy-dissipating Inside the steel bar channel 1.2, along the column height direction of the prefabricated reinforced concrete column 1, the intersecting and staggered arrangement is two vertical floors. The energy-dissipating steel bar partly runs through the energy-dissipating steel bar channel 1.2 of the column, while the other part is anchored ...

Embodiment 2

[0087] Example two such as image 3 and Figure 5 As shown, the energy-dissipating steel bar is an unbonded steel bar 7.2 outside the column, including an anchor section 7.2a inside the column, an unbonded section 7.2b outside the column, and a bonded section 7.2c outside the column. The prefabricated reinforced concrete column 1 On the column body, within the height range of the connection with the top cast-in-place laminated reinforced concrete layer 3.2, an energy-dissipating steel bar taper thread connection joint 8 is embedded in the side of the column body, and the anchor section 7.2a inside the column is not bonded to the outside of the column The segment 7.2b is mechanically connected and lengthened at the column edge through the energy-dissipating steel bar taper thread connection joint 8, and the non-bonded segment 7.2b outside the column and the bonded segment 7.2c outside the column are continuous steel bars. The column of the prefabricated reinforced concrete col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com