Patents

Literature

3305results about "Sewing-machine control devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

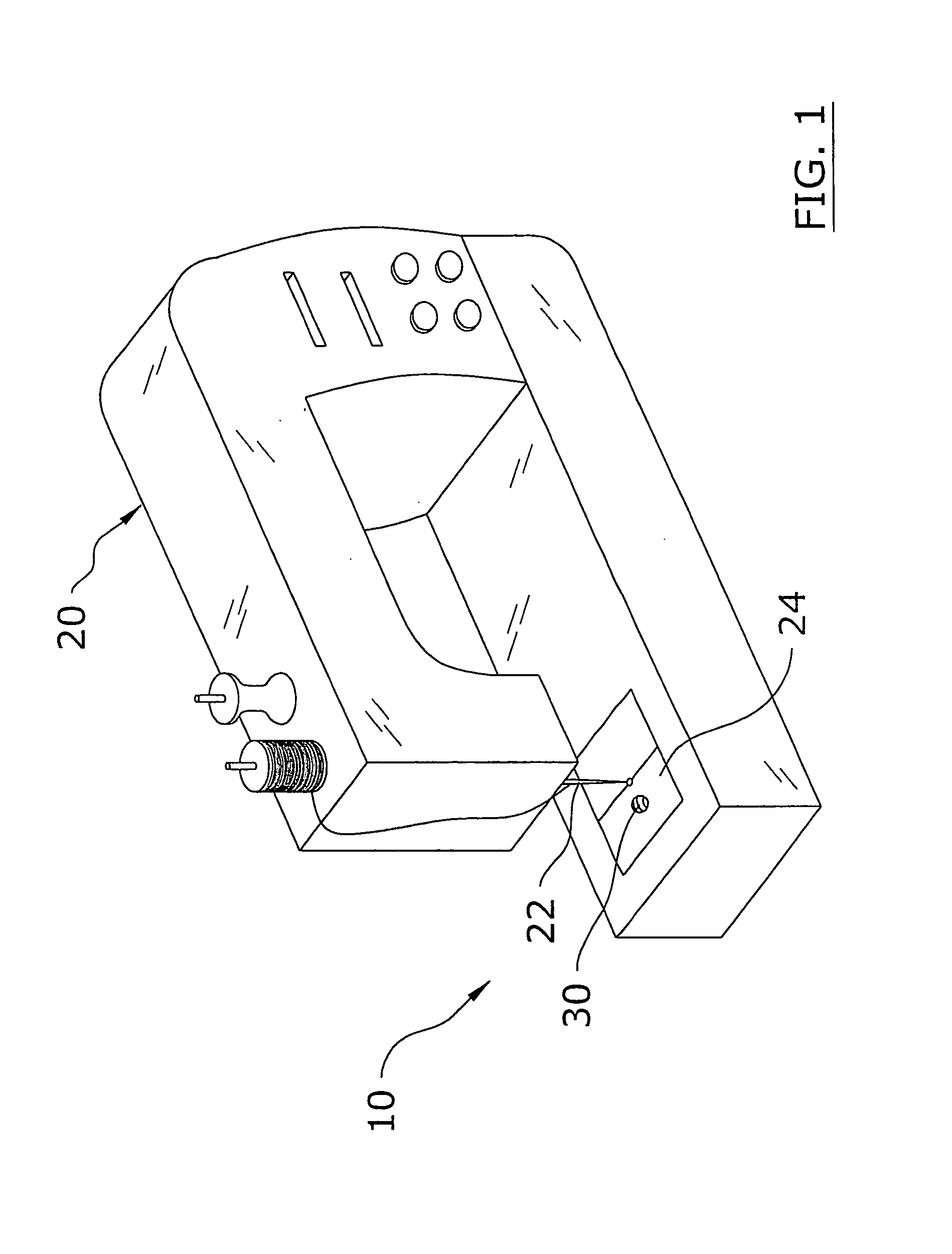

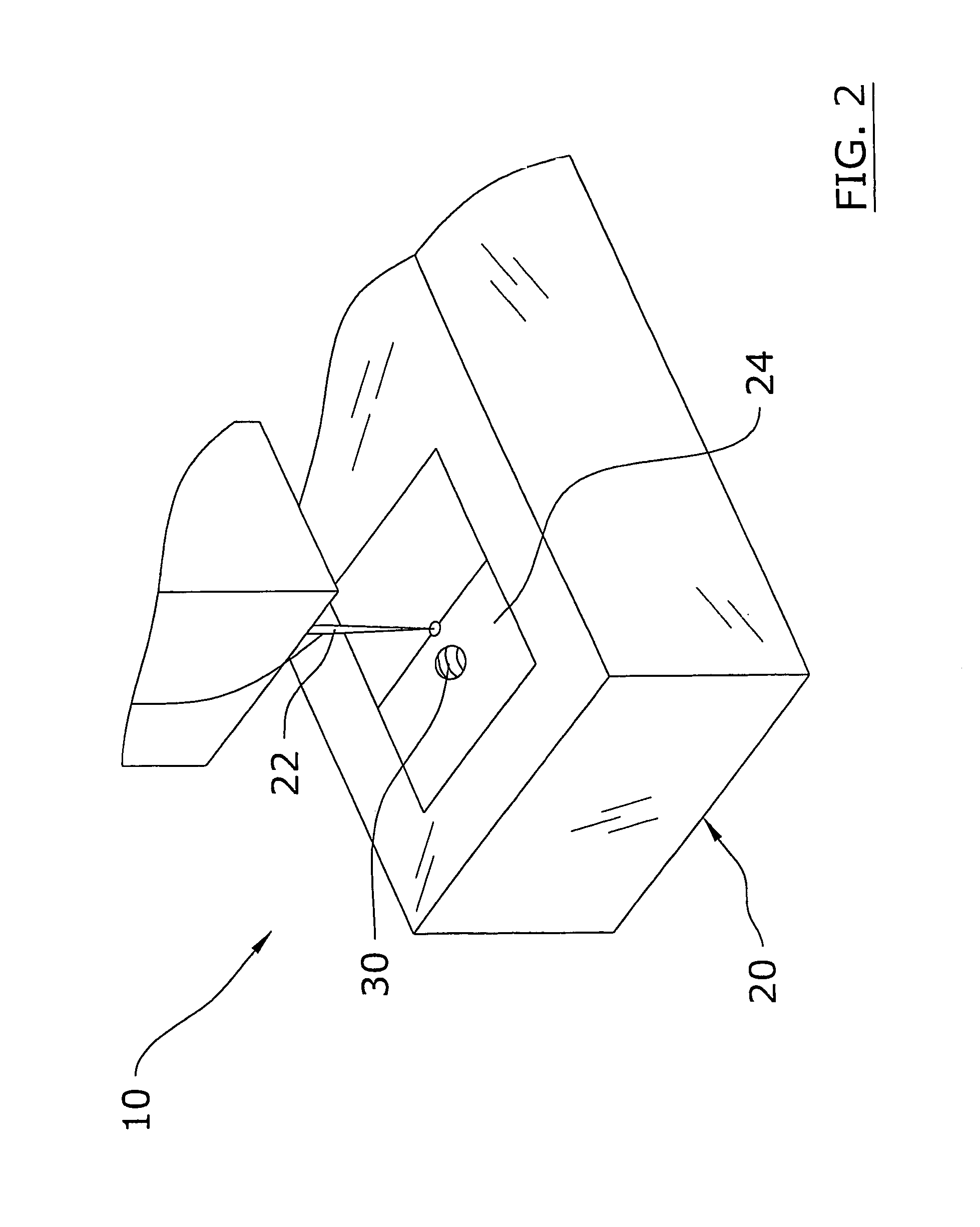

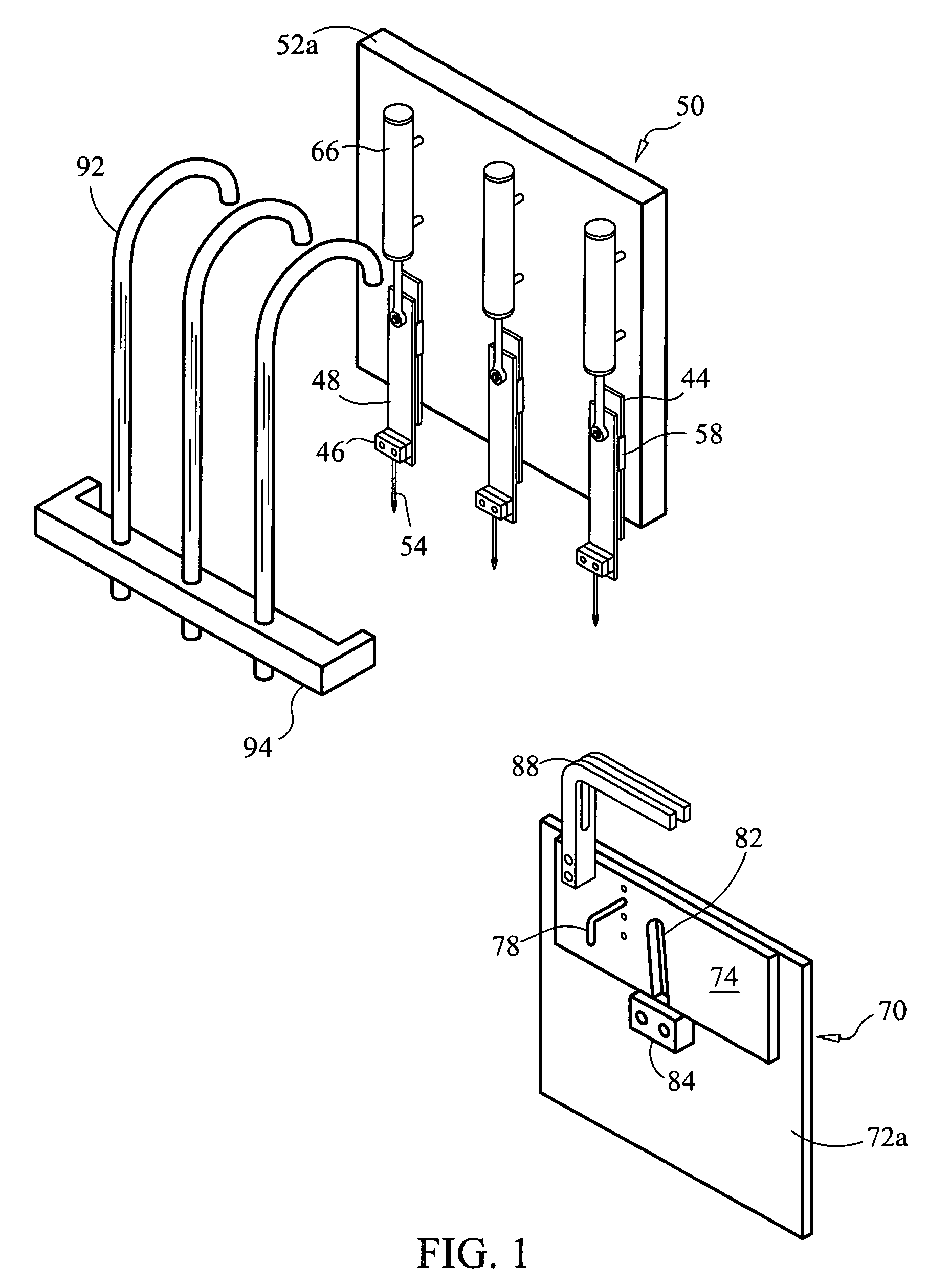

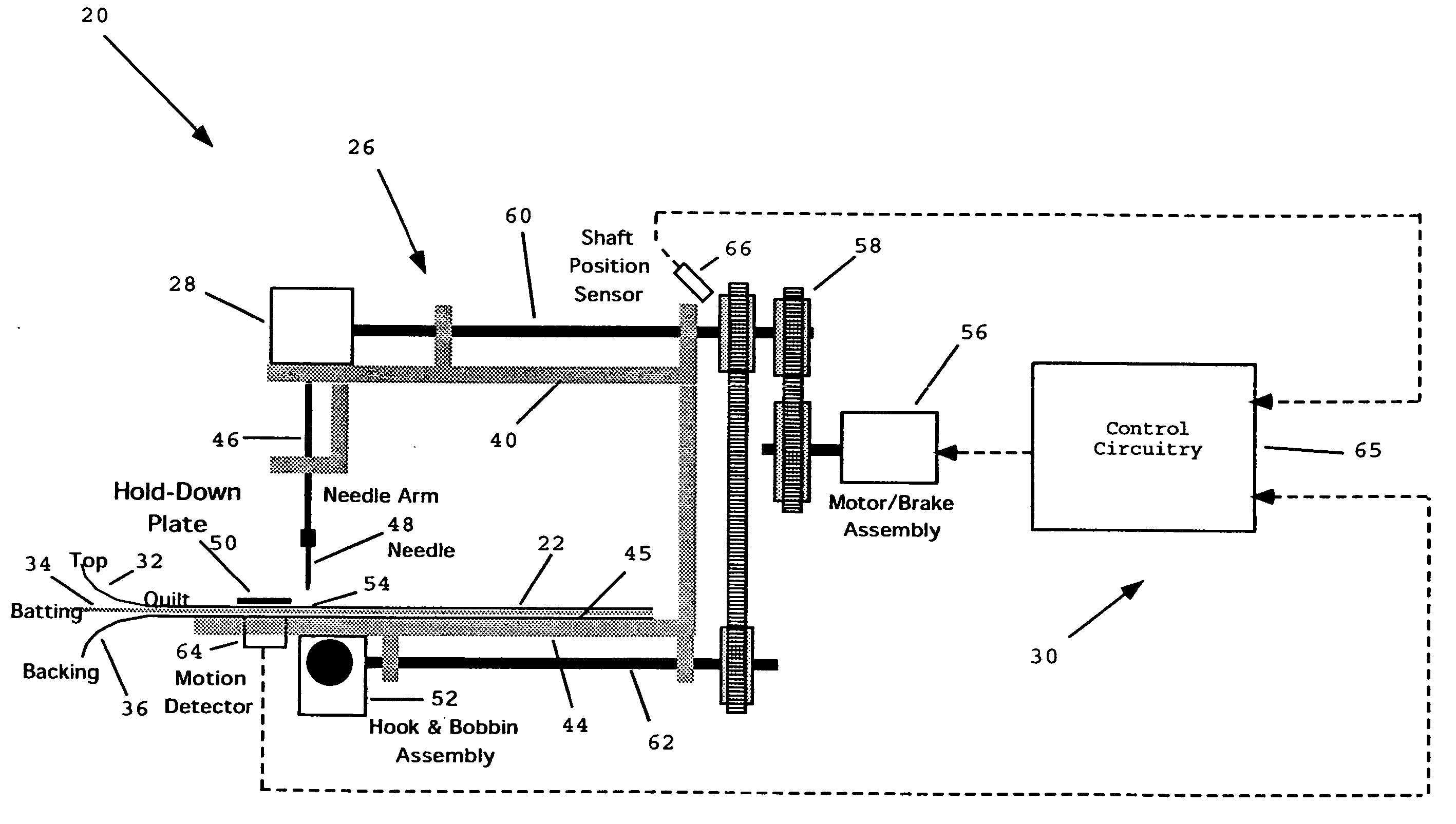

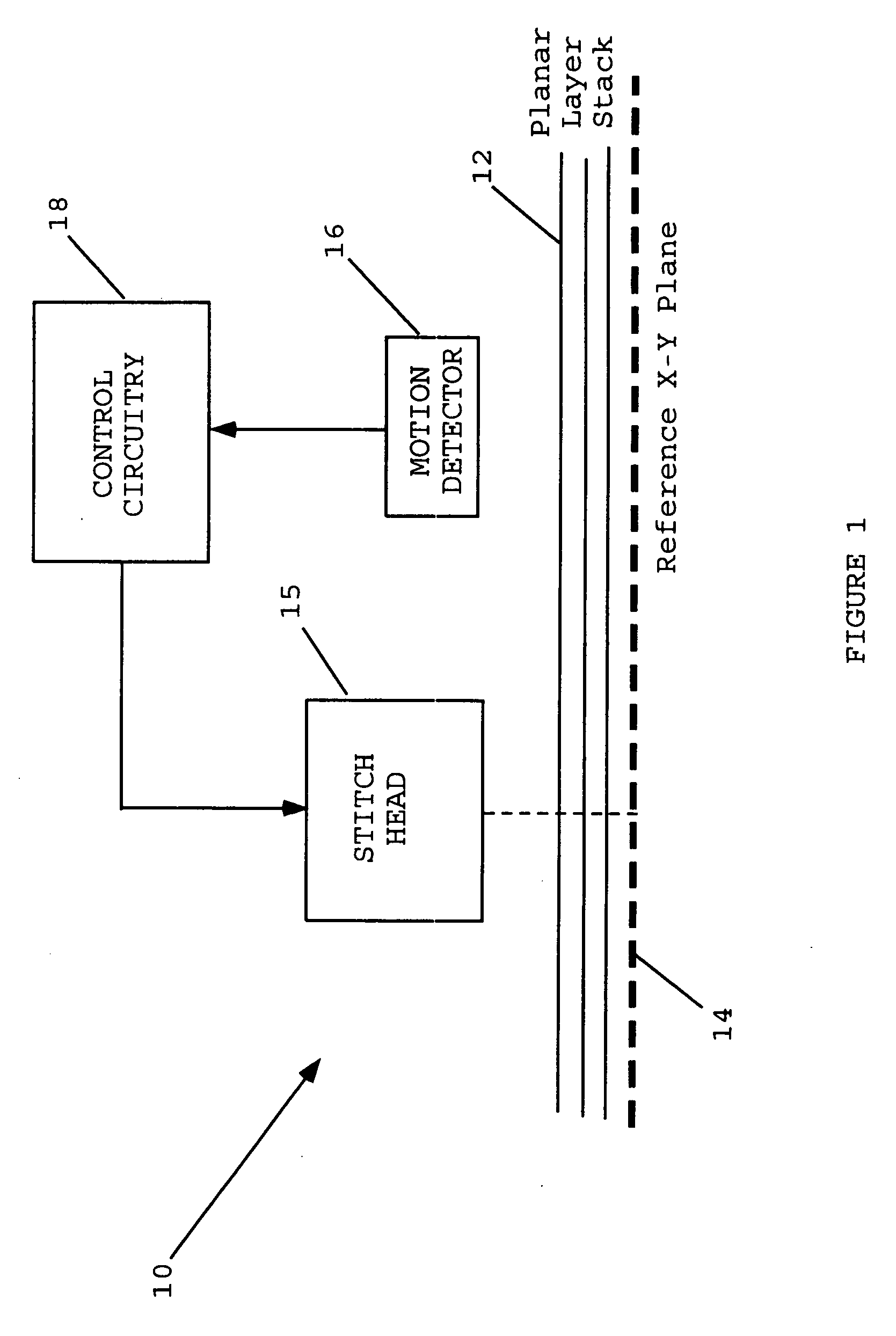

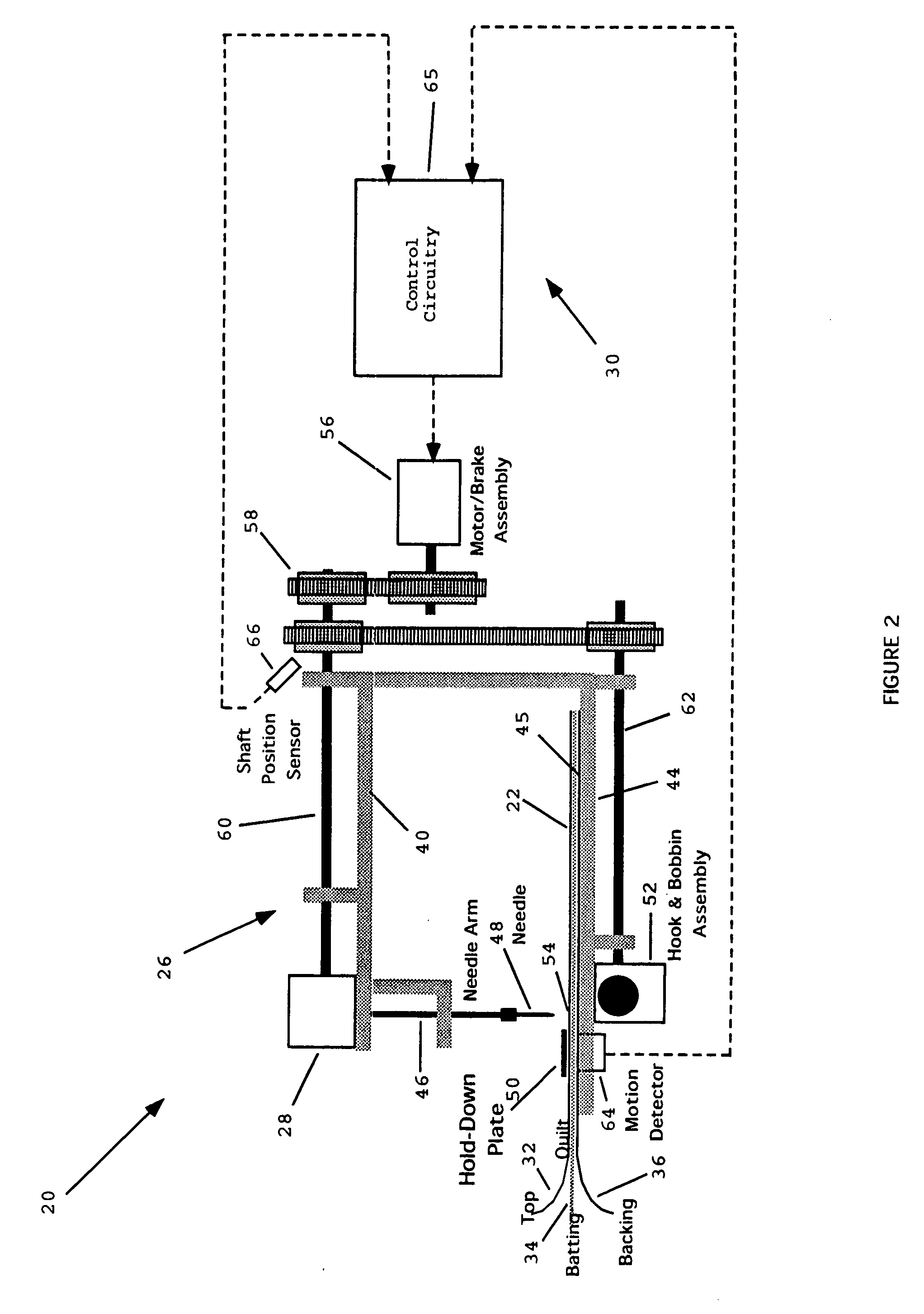

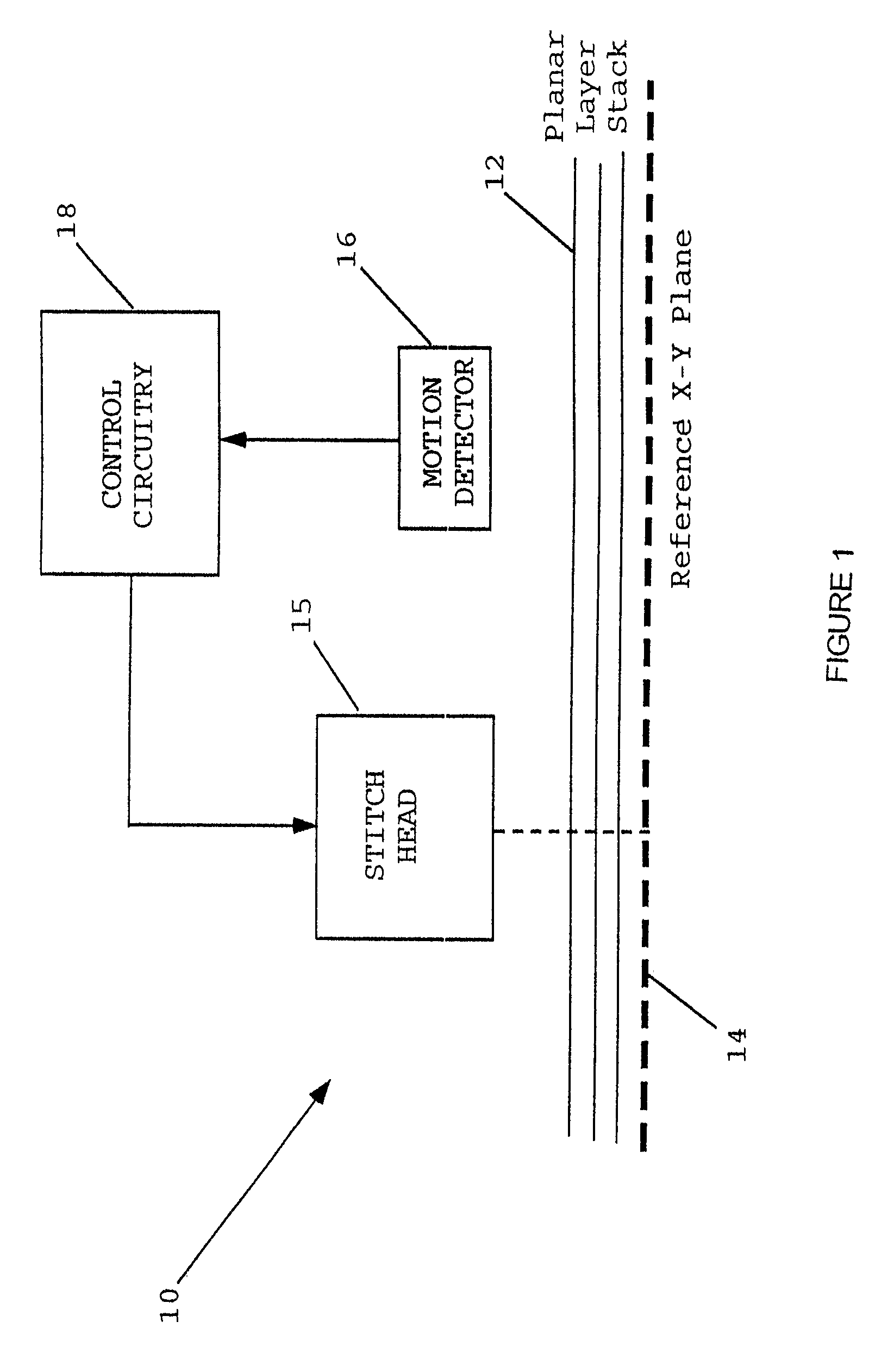

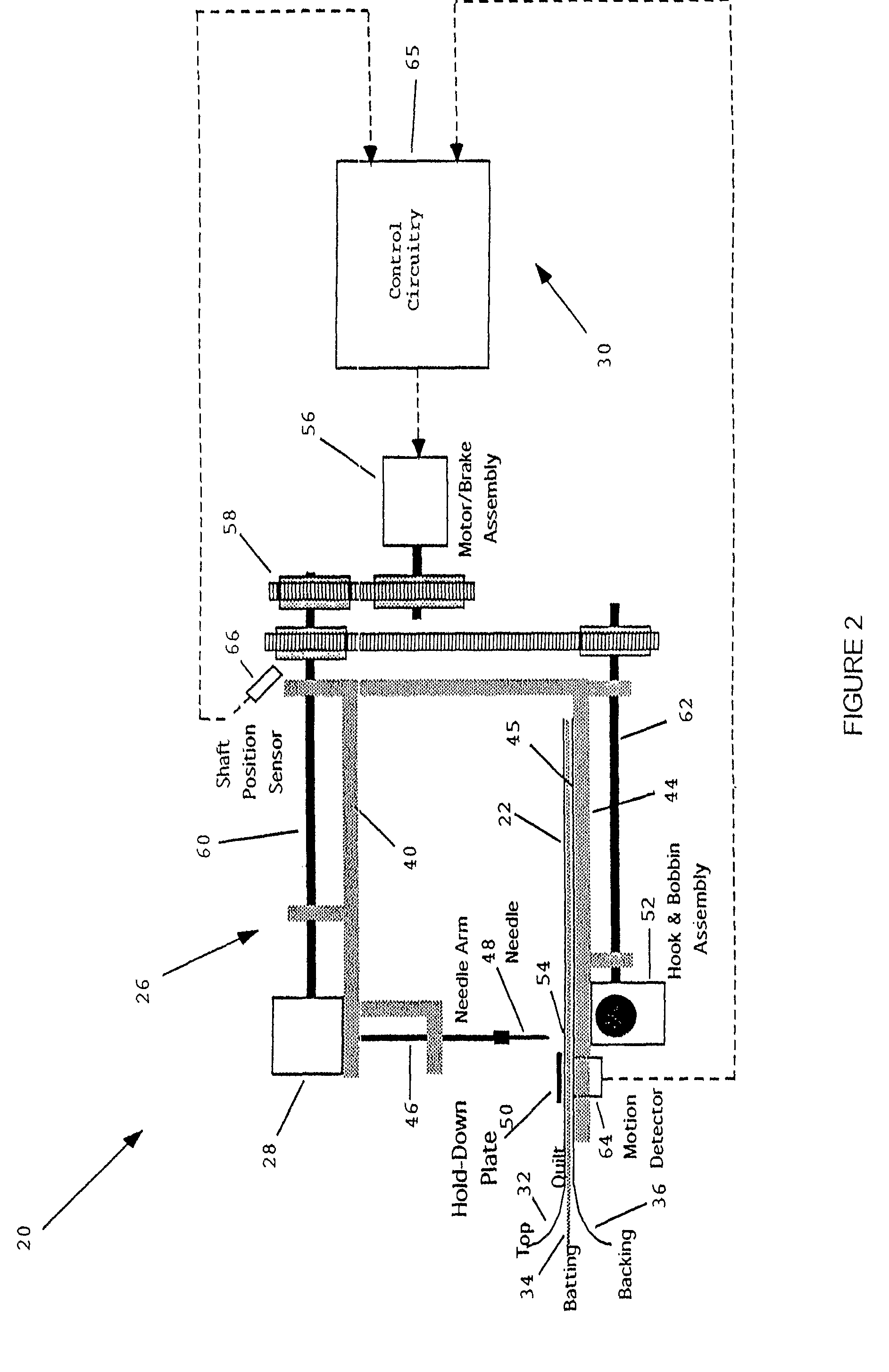

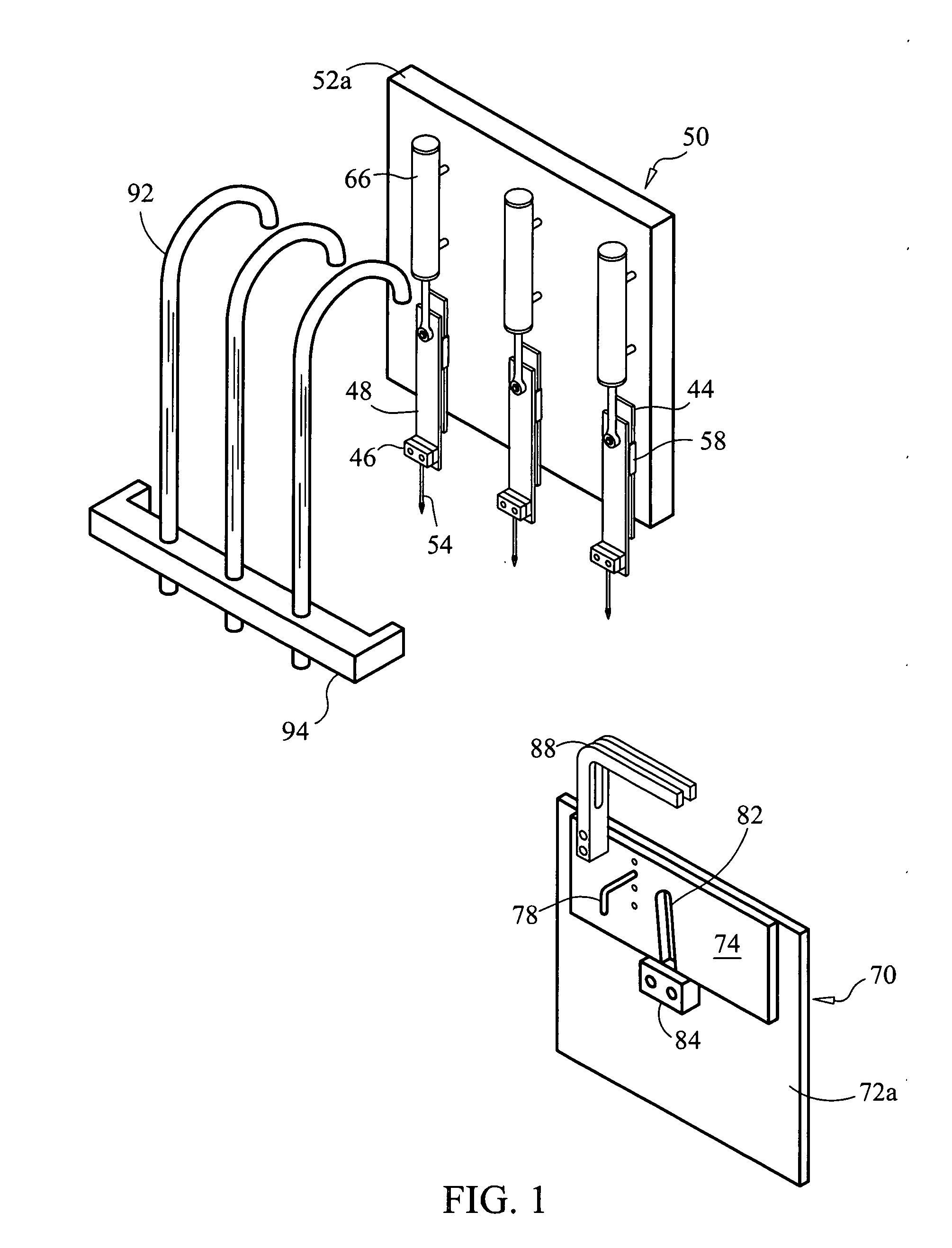

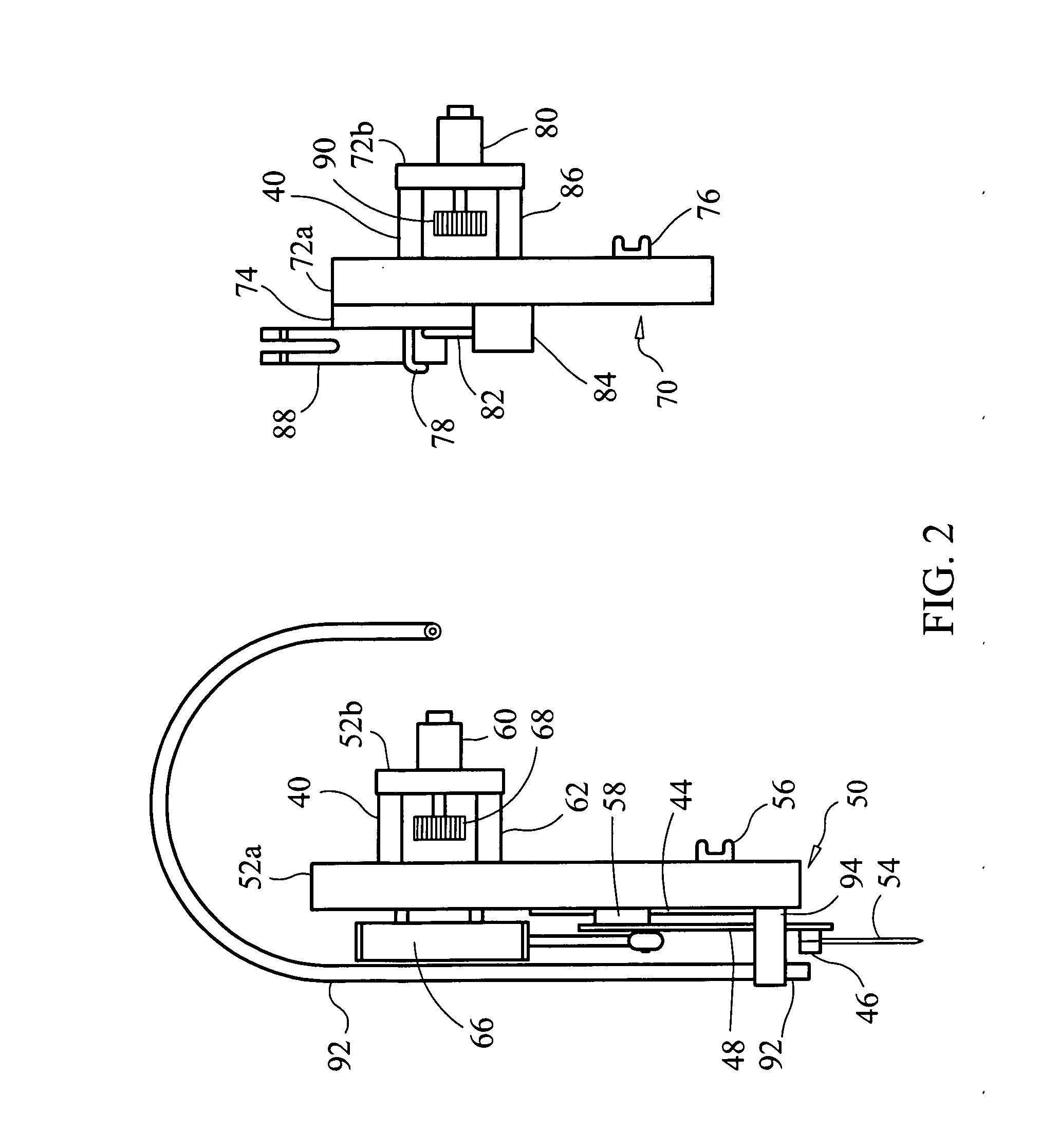

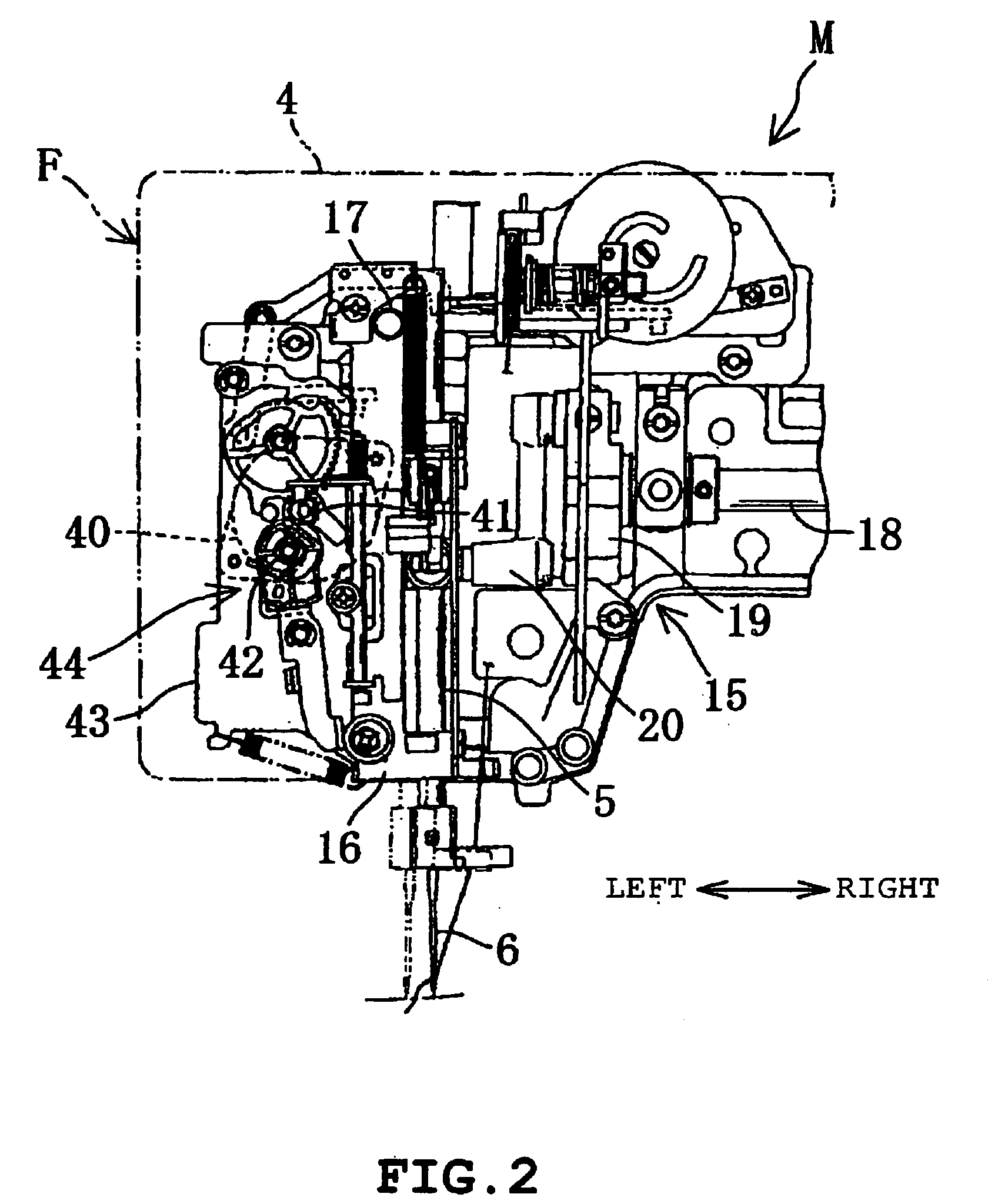

Quilting method and apparatus

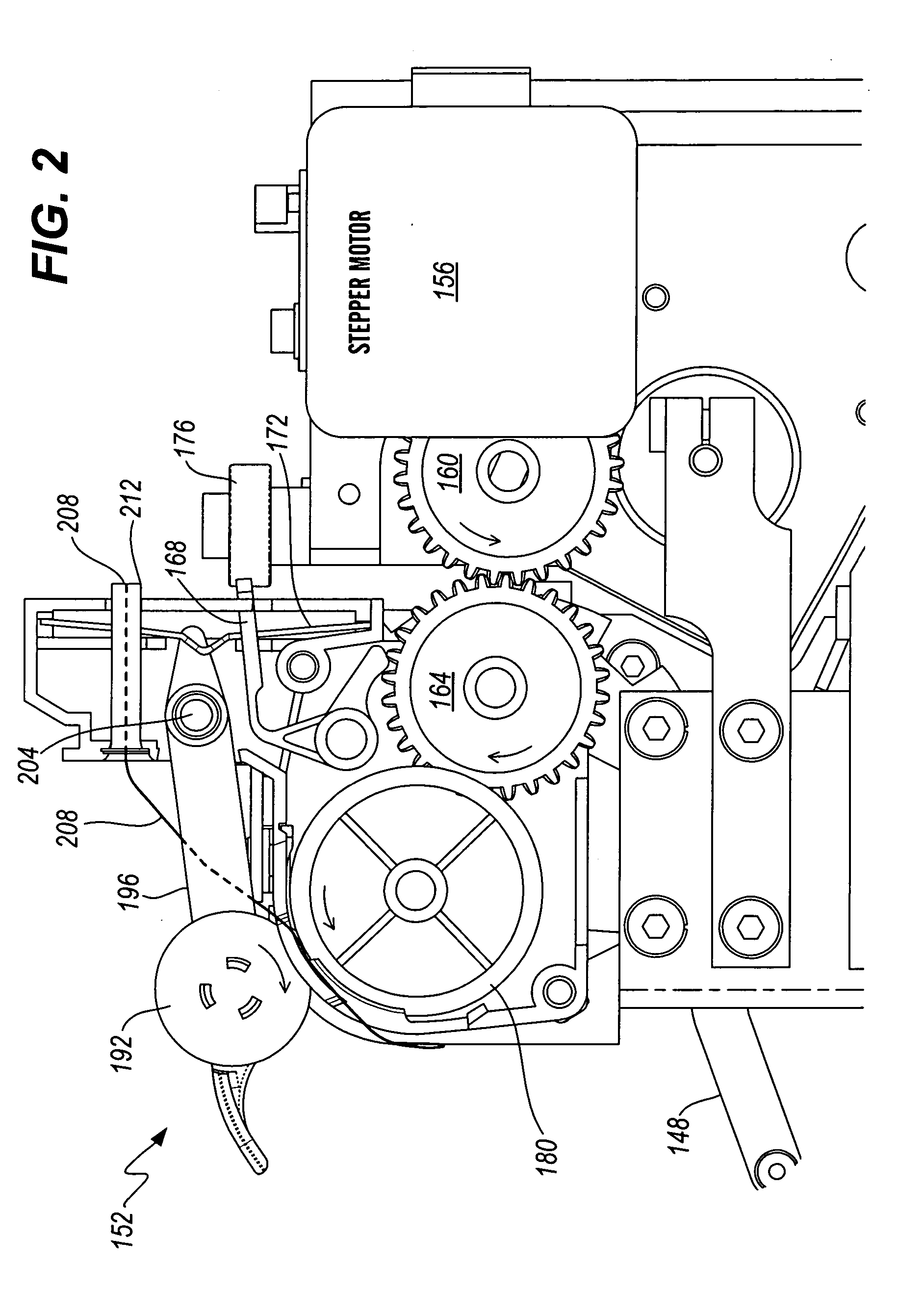

ActiveUS6883446B2Easy to produceProgramme-controlled sewing machinesSewing-machine control devicesMotion detectorEngineering

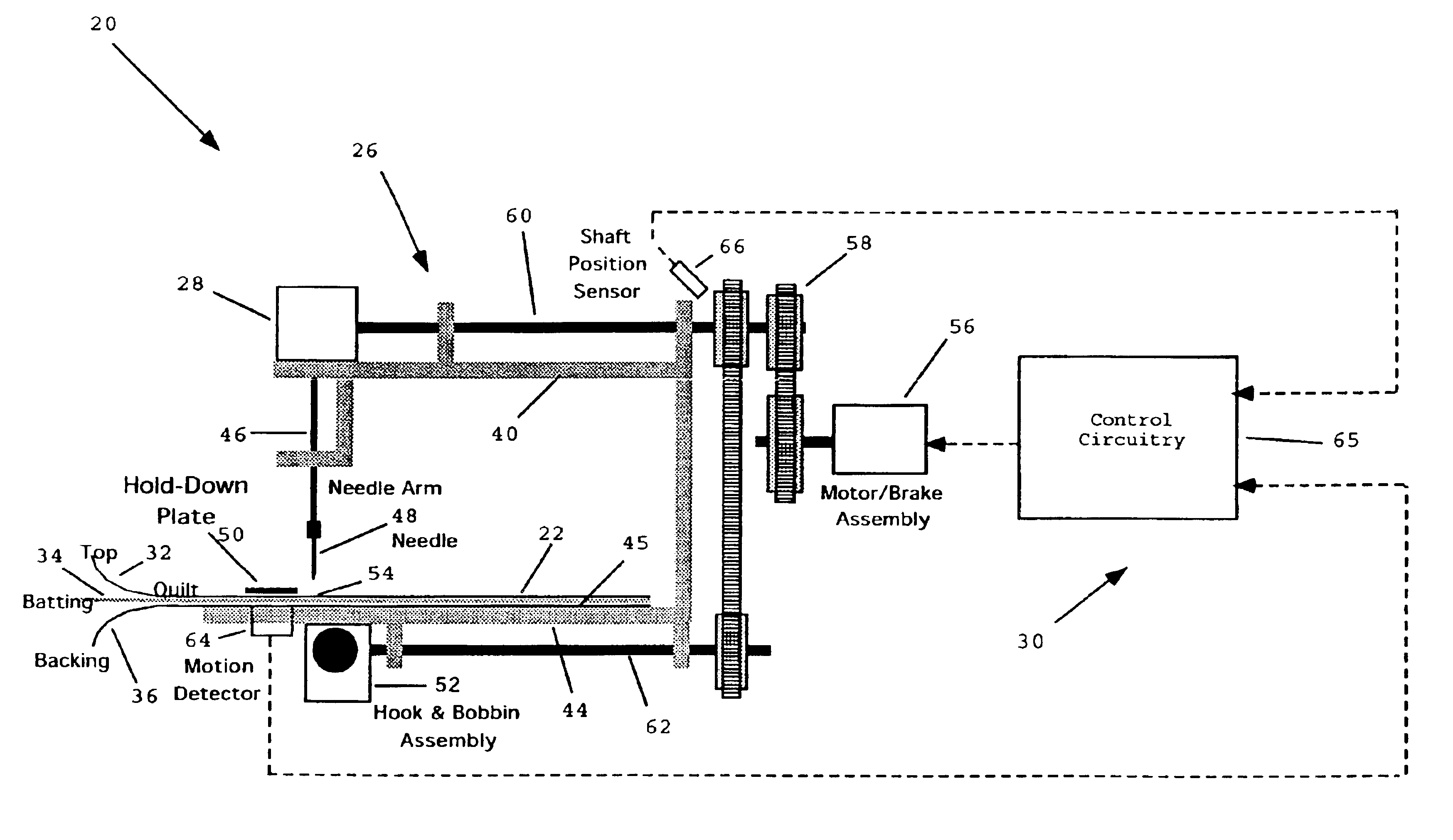

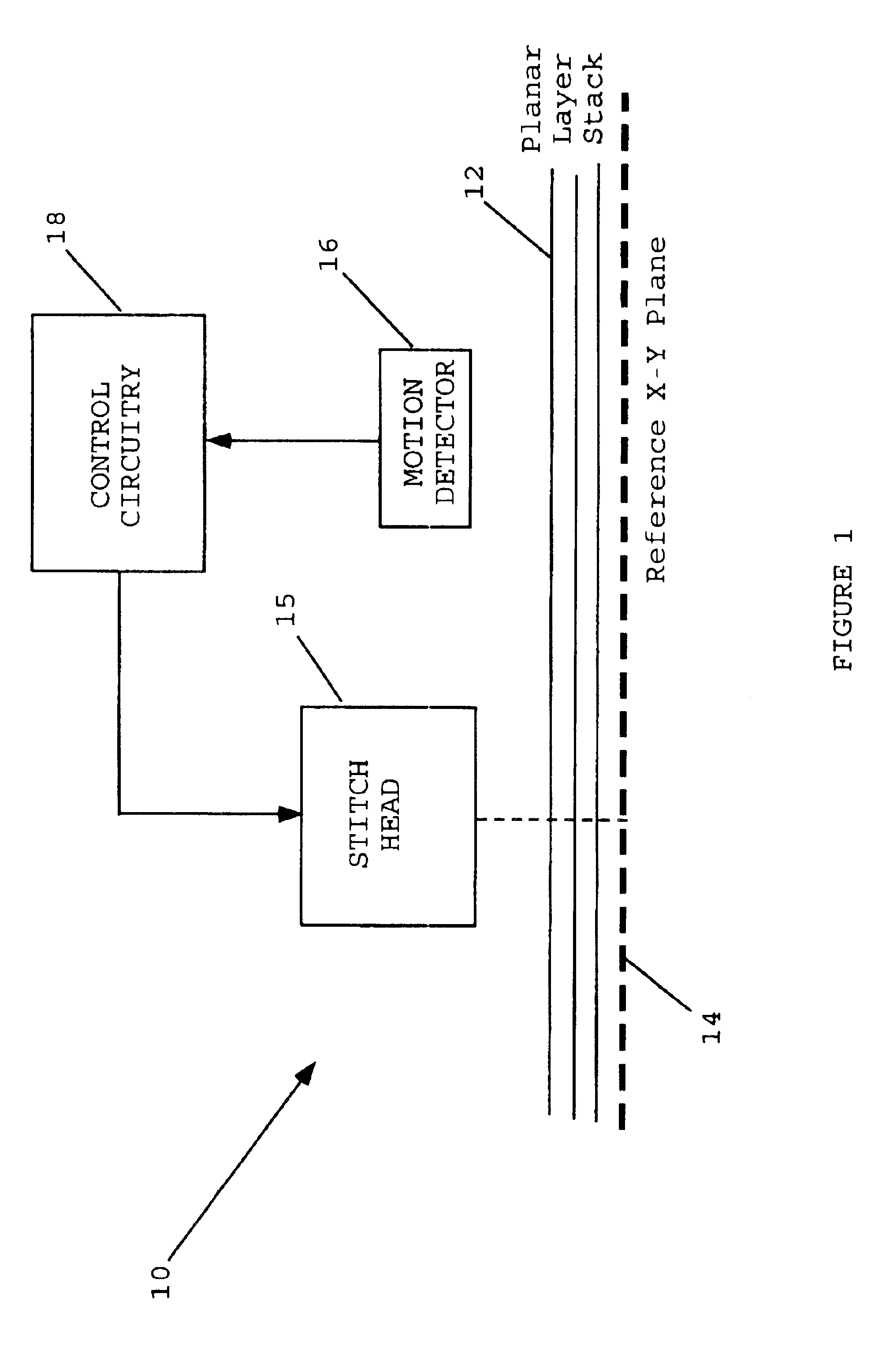

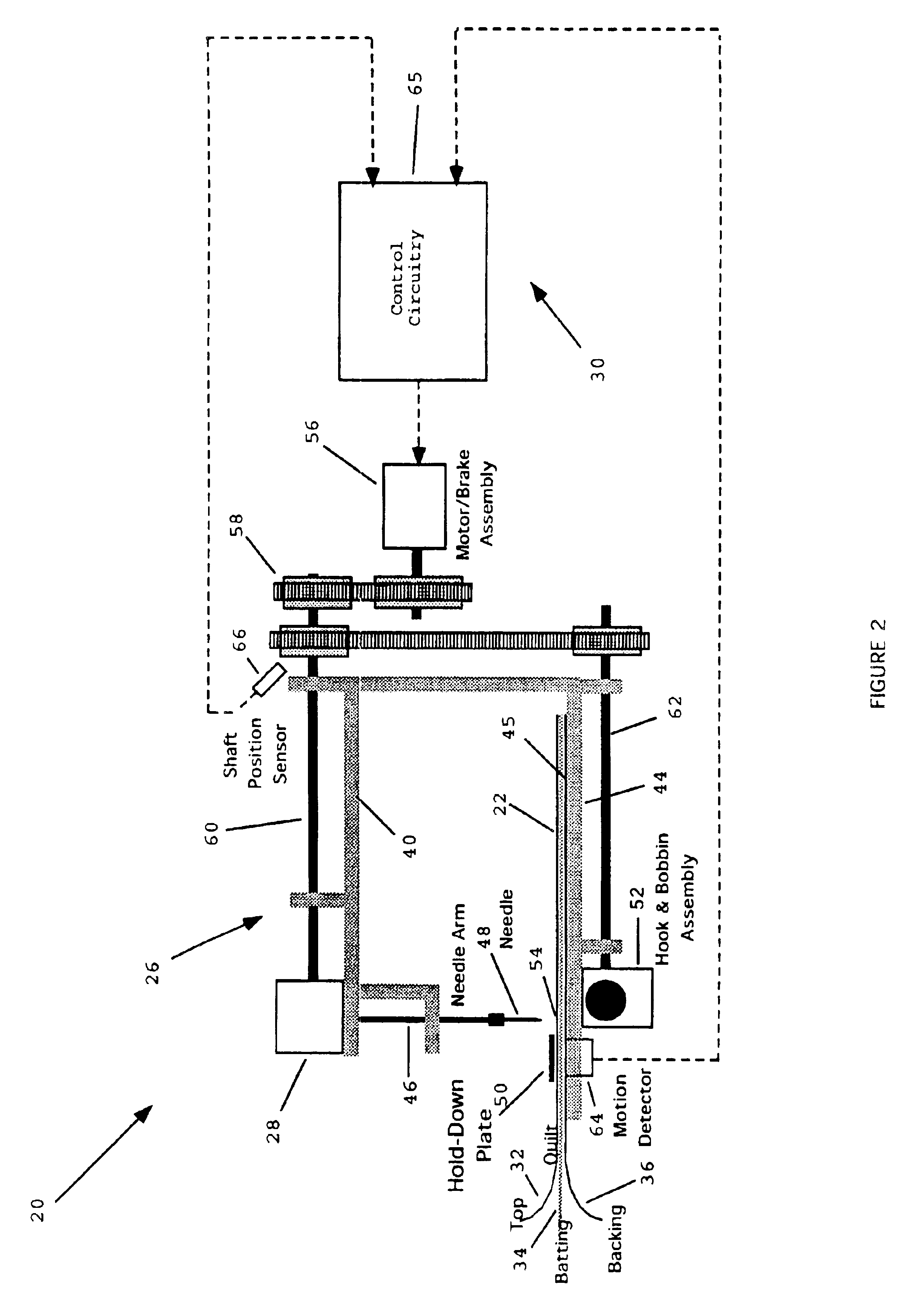

A quilting apparatus for enabling a user to freely move a stack of fabric layers across a planar bed relative to an actuatable stitch head. The apparatus includes a motion detector which detects the movement of the stack and controls the actuation of the stitch head. Consequently, the apparatus functions to synchronize the delivery of stitch strokes by the head with the manually controlled movement of the quilt material stack. This frees the user to move the stack over a wide range of speeds, to start or stop movement at will, and to guide the stack in any direction across the planar bed.

Owner:BERNINA SEWING MACHINE

Optical stitch regulator system

InactiveUS6959657B1Effective supervisionProgramme-controlled sewing machinesSewing-machine casingsEngineeringControl unit

An optical stitch regulator system for efficiently regulating the stitch length and stitch frequency of a sewing machine. The optical stitch regulator system includes at least one optical sensor within or external of the sewing platform of a sewing machine for sensing the motion of the fabric being sewn. The motion data is communicated to a control unit which communicates with the sewing machine for controlling the stitch length and frequency.

Owner:DUVAL RICHARD J

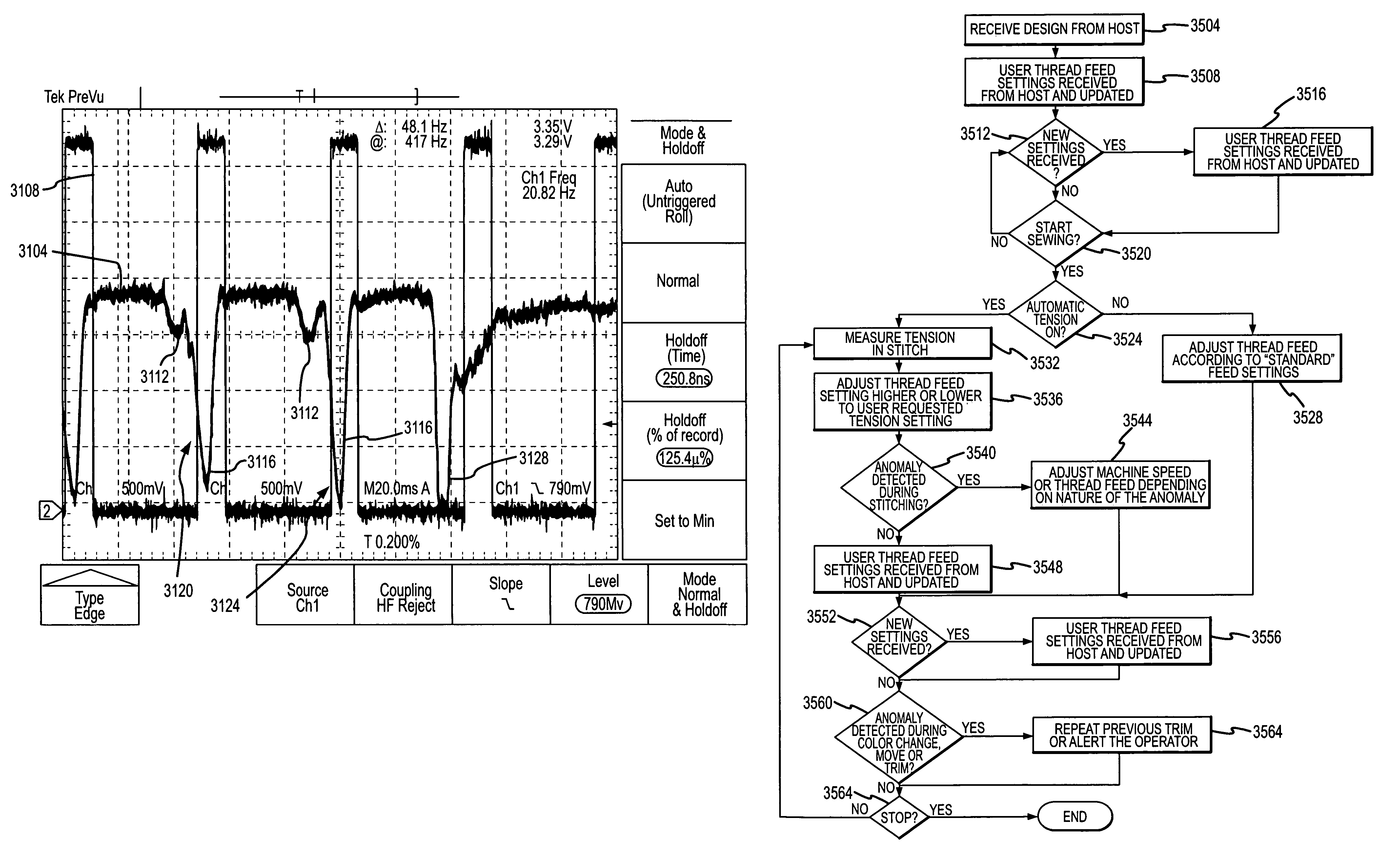

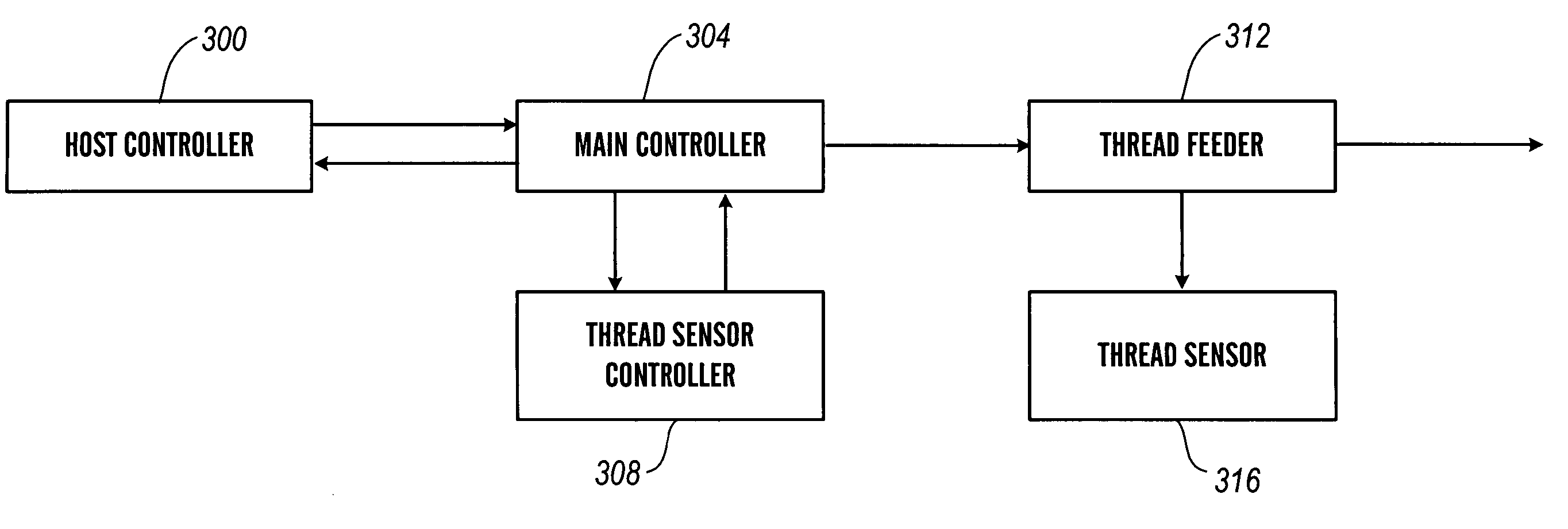

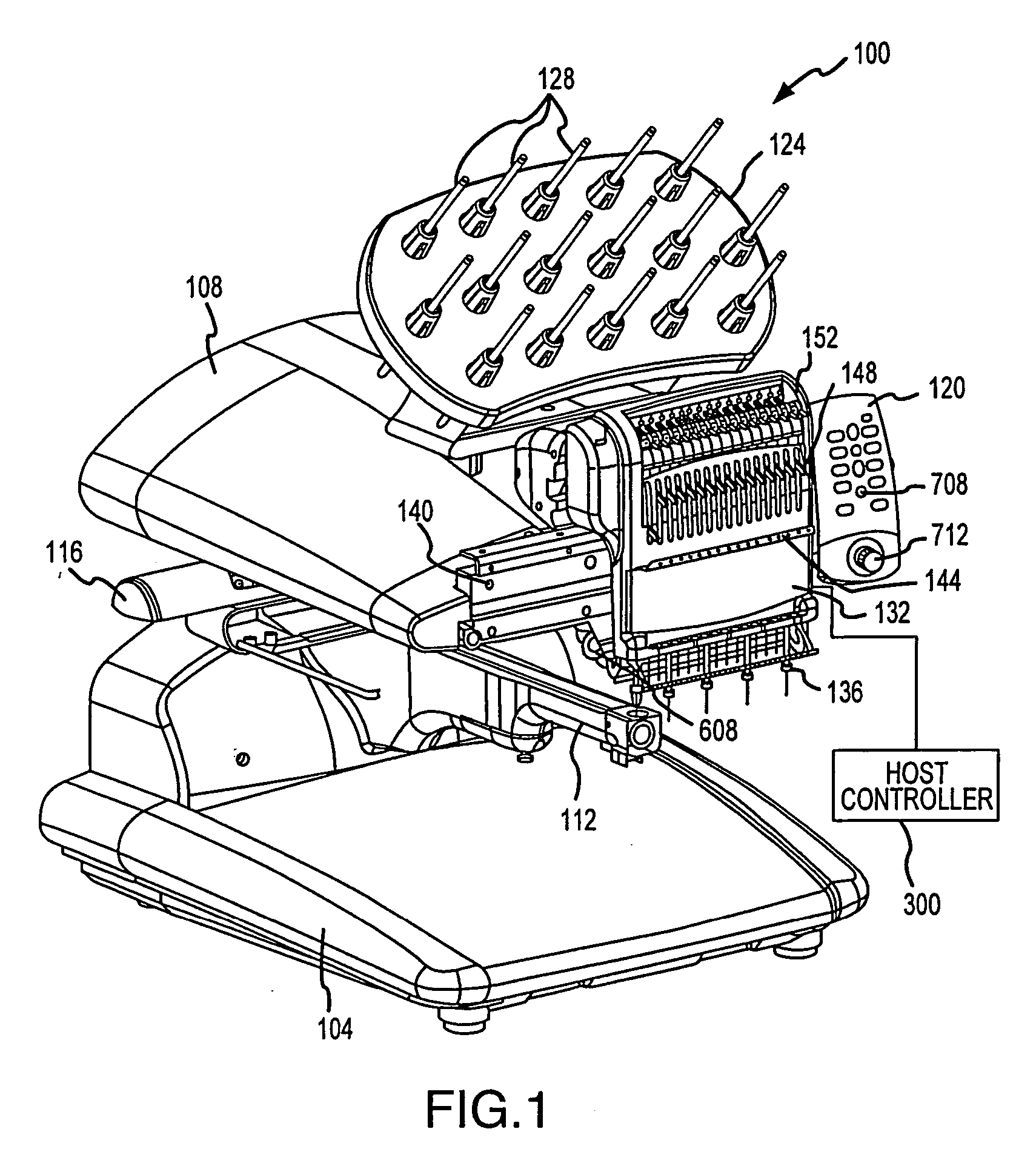

Computerized stitching including embroidering

InactiveUS7308333B2Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

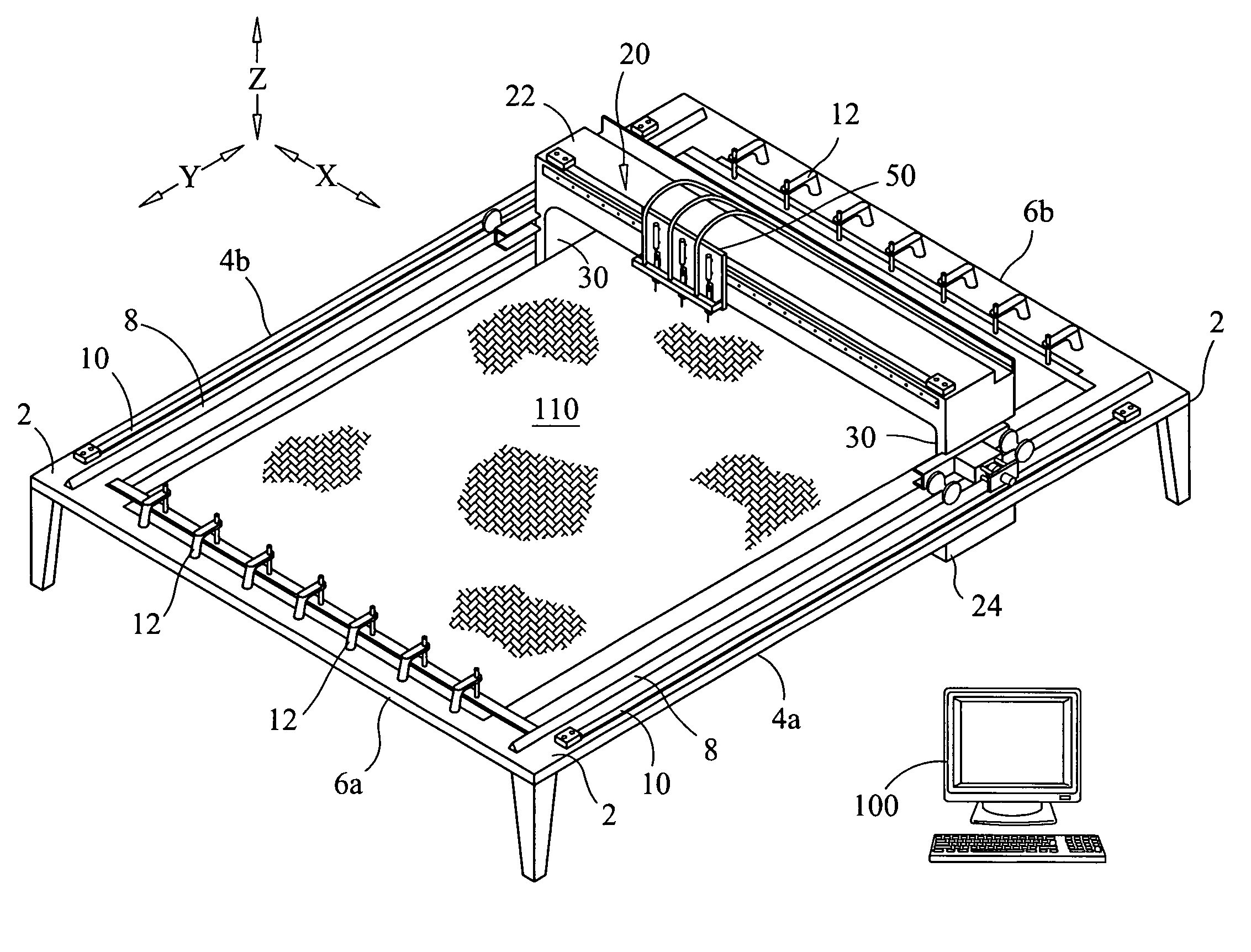

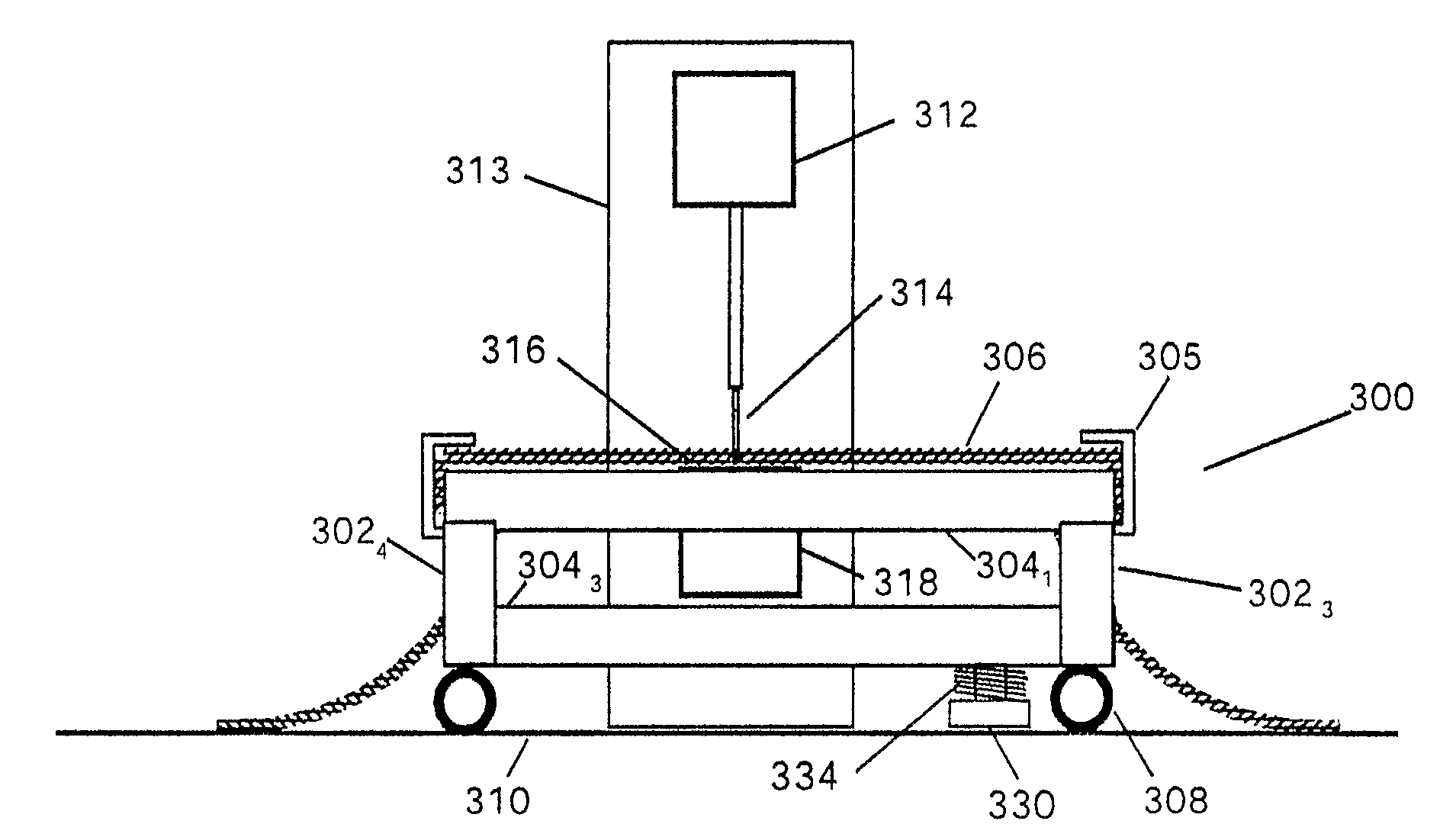

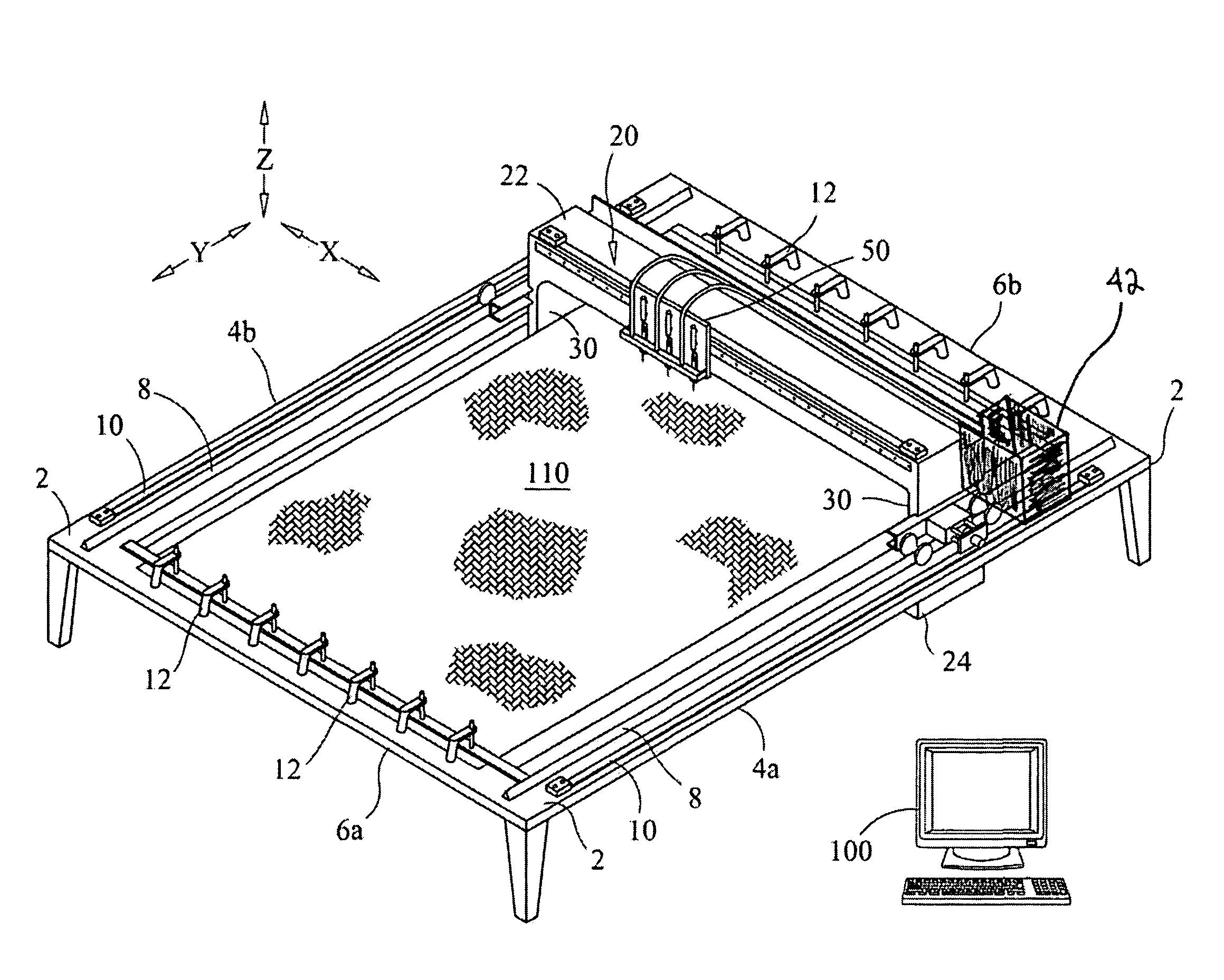

Tufting machine for producing athletic turf having a graphic design

ActiveUS7814850B2Reduce positioning accuracyEfficient constructionTufting apparatusSewing-machine control devicesGraphicsYarn

A tufting machine capable of producing individual articles of athletic turf bearing precise graphic patterns is disclosed. The machine includes a support frame to which a backing material is statically held, a tufting frame that spans above and below the backing and is computer-controlled to travel along the support frame, a yarn-inserting needle carriage disposed above the backing along the tufting frame and a yarn-catching looper carriage disposed below the backing along the tufting frame. The carriages are computer-controlled to asynchronously shift relative to each other as may be necessary for their individual yarn-inserting components and yarn-catching components to cooperate.

Owner:SIGNATURE BANK OF GEORGIA +1

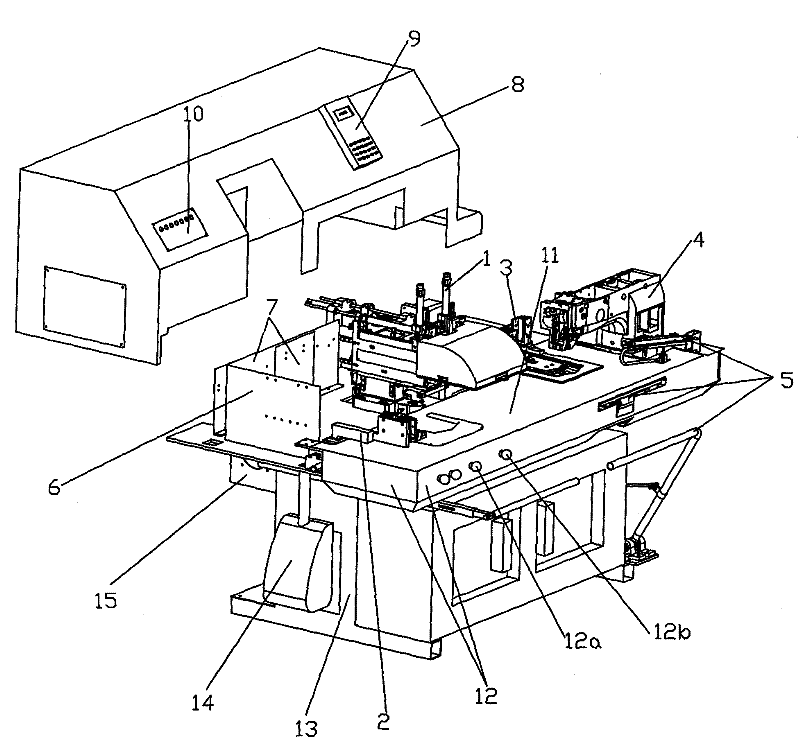

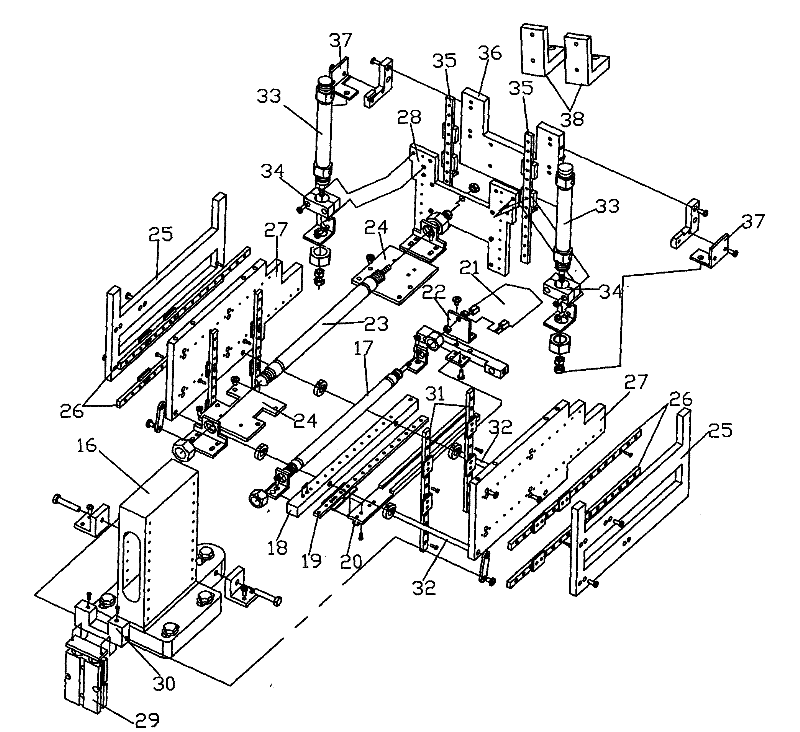

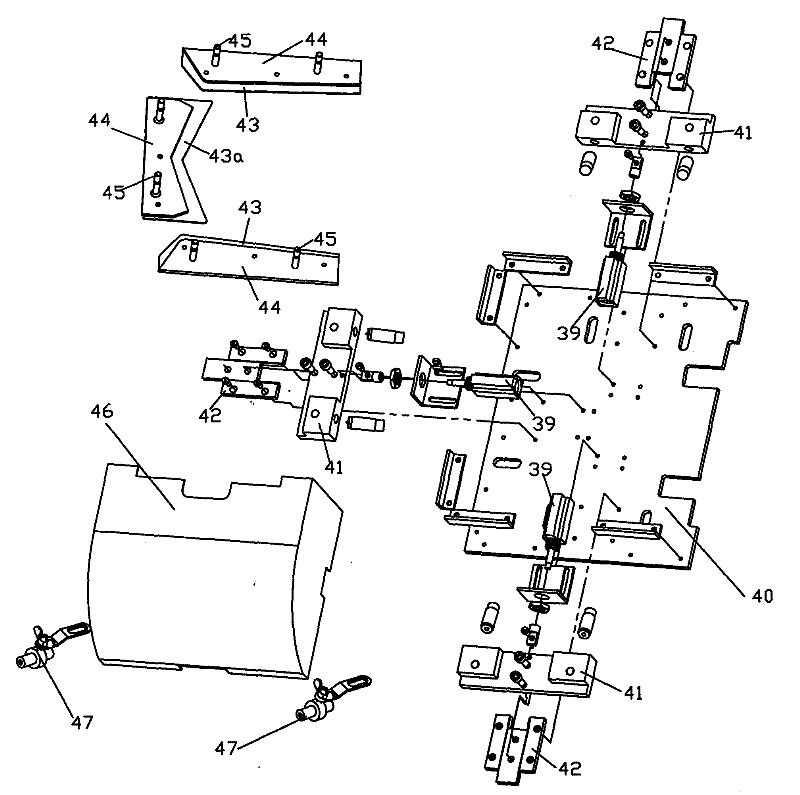

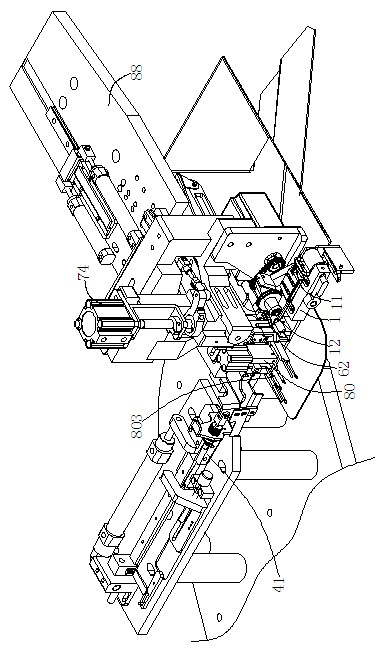

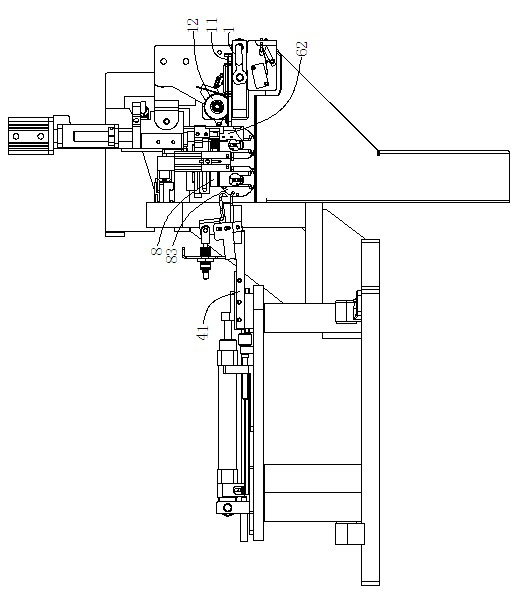

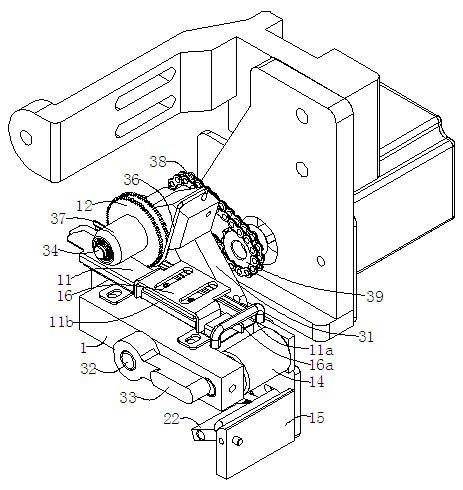

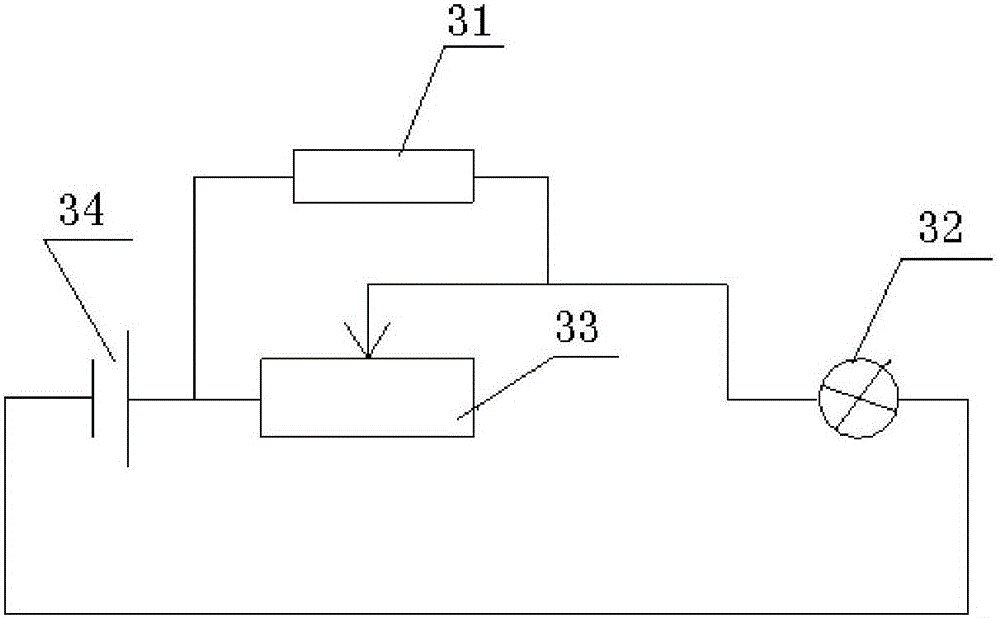

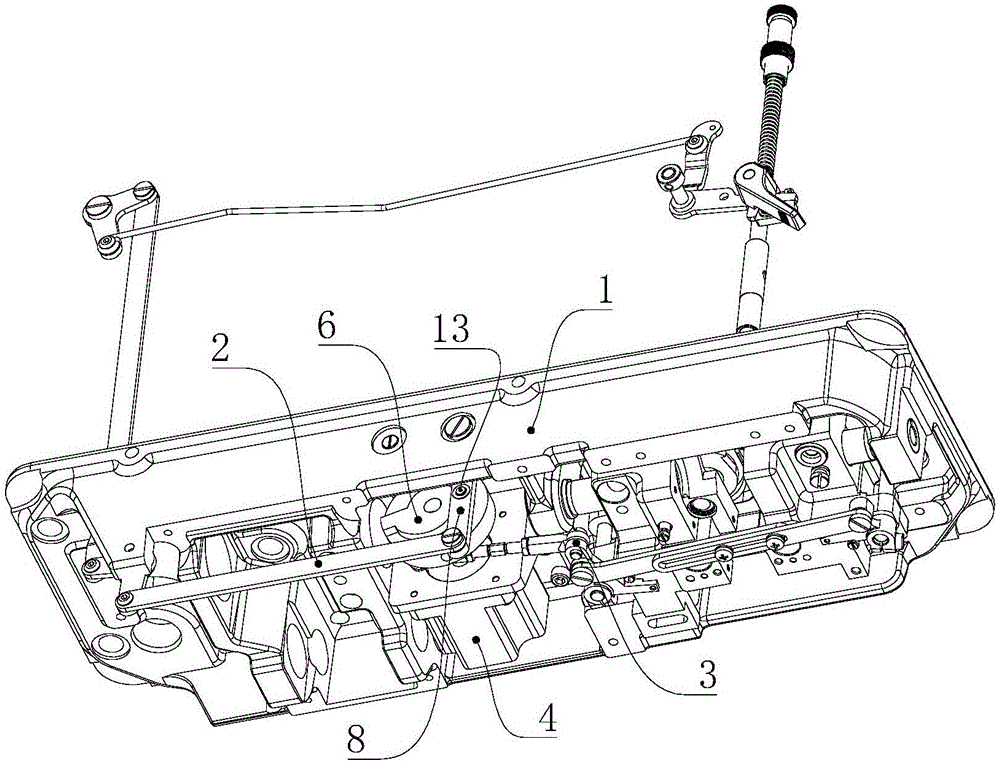

Pneumatic full-automatic pocket patching machine

InactiveCN102191633AReasonable structureEasy to operateWork-feeding meansSewing-machine control devicesManufacturing cost reductionSolenoid valve

The invention discloses a pneumatic full-automatic pocket patching machine. The machine comprises a rack steel plate, a pneumatic automatic non-ironing and folding mechanism and the like, wherein the pneumatic automatic non-ironing and folding mechanism is arranged above the rear part of the rack steel plate; a pneumatic automatic feeding mechanism is transversely arranged in front of the pneumatic automatic non-ironing and folding mechanism; a coordinate pattern transmission mechanism is arranged on the left of the pneumatic automatic non-ironing and folding mechanism; a rotating shuttle type pattern sewing machine sewing head is arranged in front of the rack steel plate on the right and is transversely arranged; an air pressure adjusting mounting plate is arranged at the left rear end of the rack steel plate; solenoid valve mounting plates are arranged on the right of the air pressure adjusting mounting plate; a shield is arranged on the rear half part of the whole rack steel plate; stainless steel coamings are arranged below a stainless steel working table; a first starting switch and a second starting switch are arranged above one stainless steel coaming; a dust collector is arranged on the left of a rack; and an electrical appliance control box is arranged behind the rack and on the lower part of the rack steel plate. The machine has the effects of lowering the manufacturing cost and realizing automatic programs such as non-ironing programs and the like.

Owner:SHANGHAI GUIYI SEWING EQUIP MFG

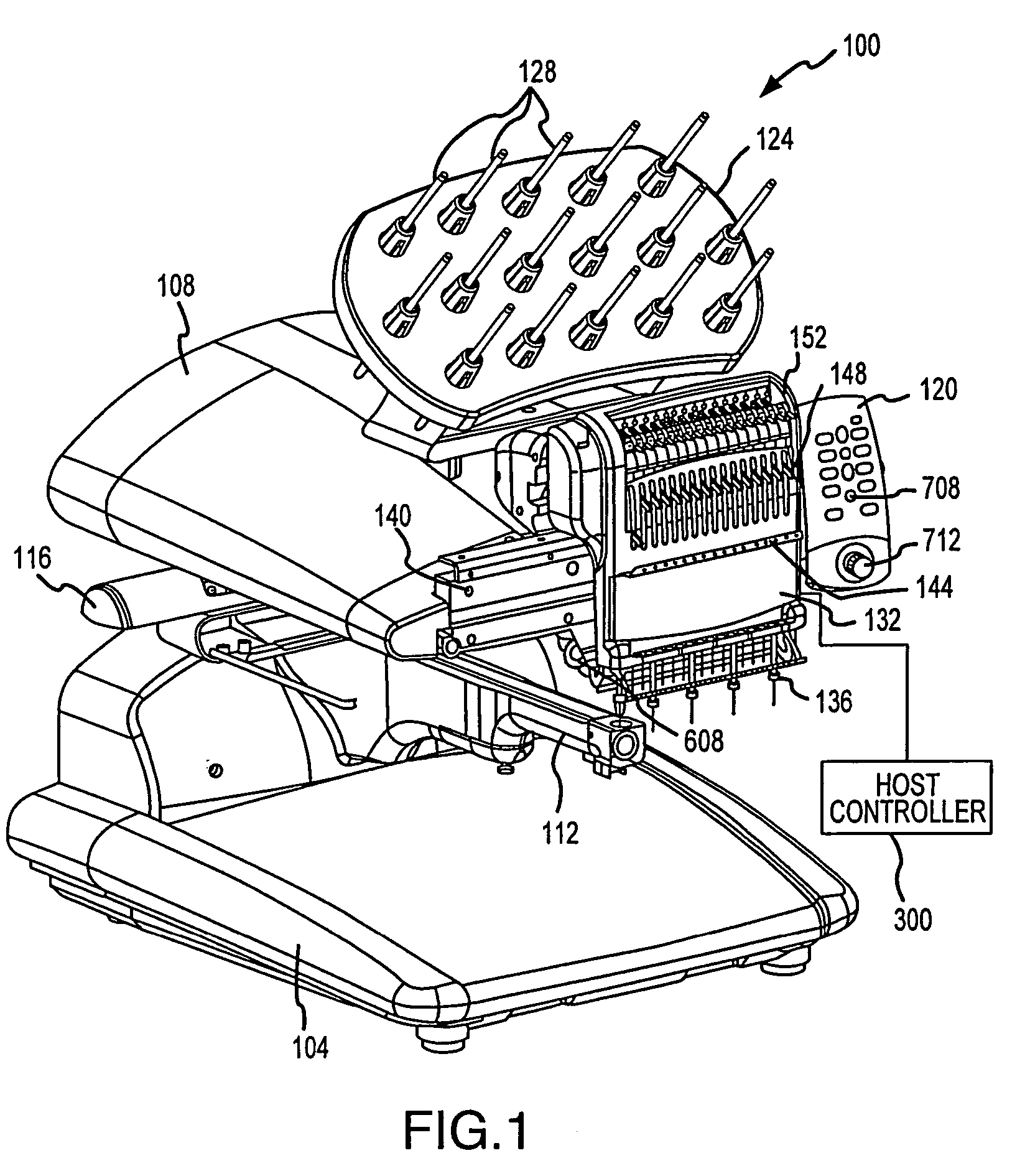

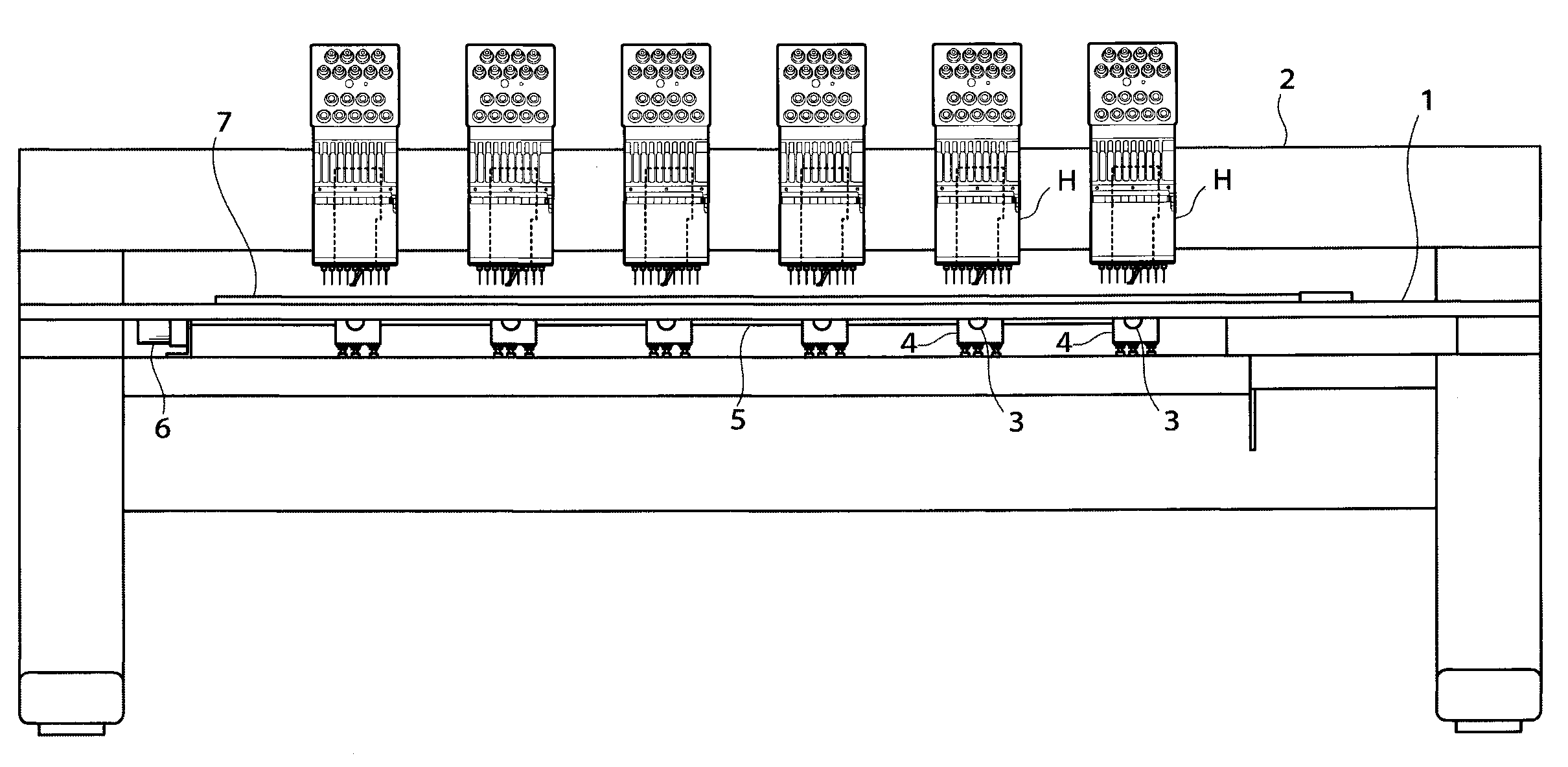

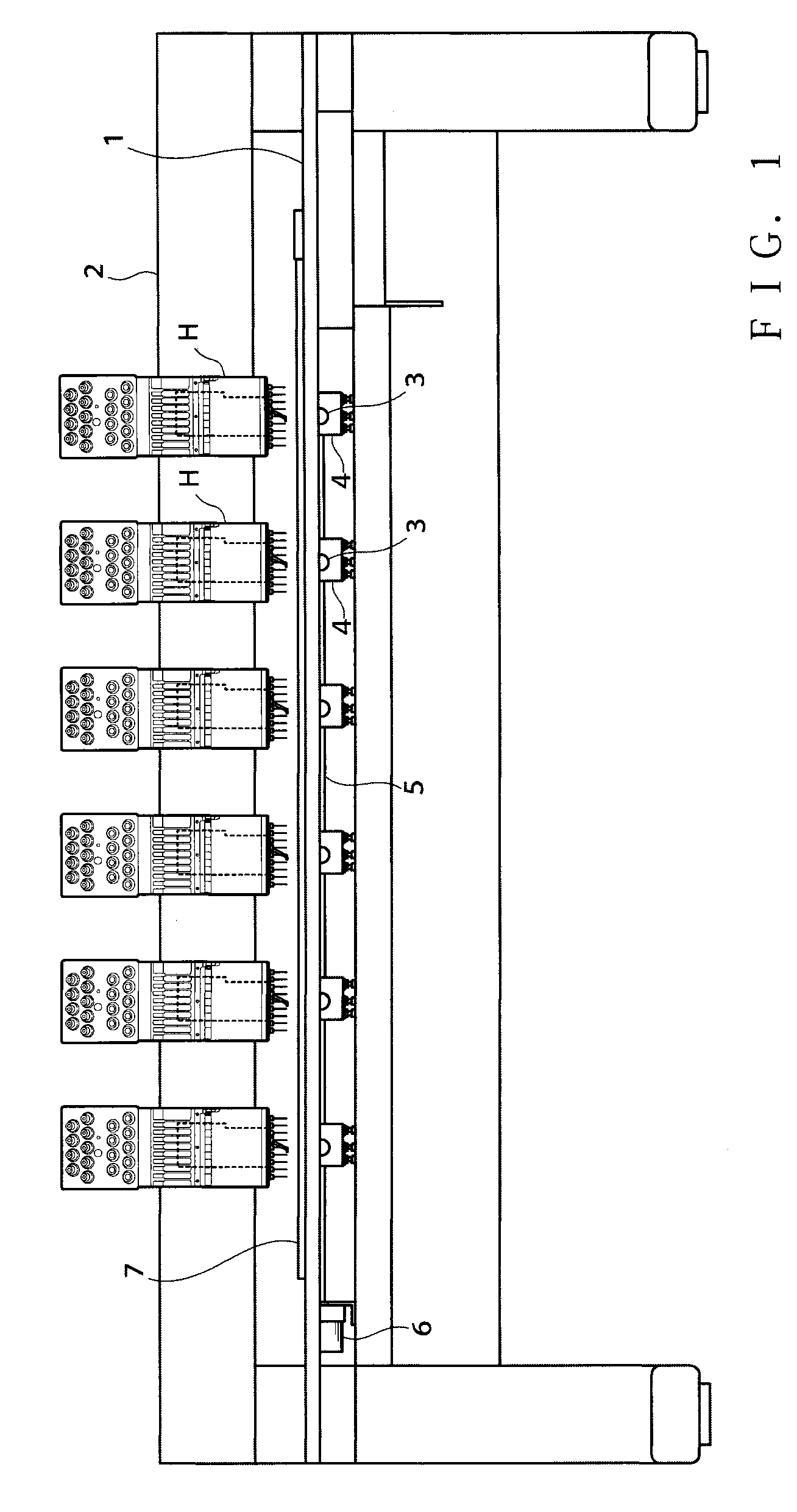

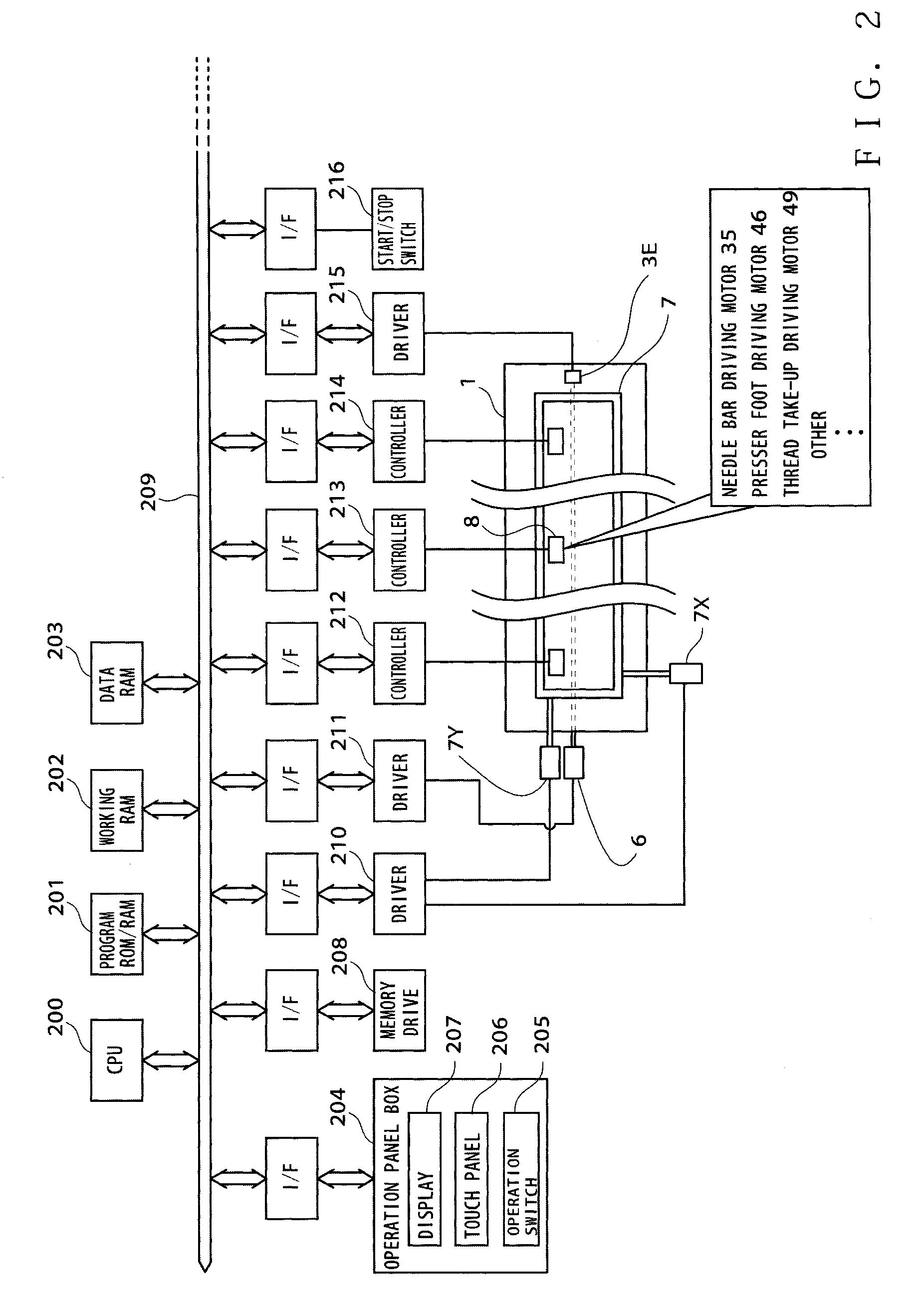

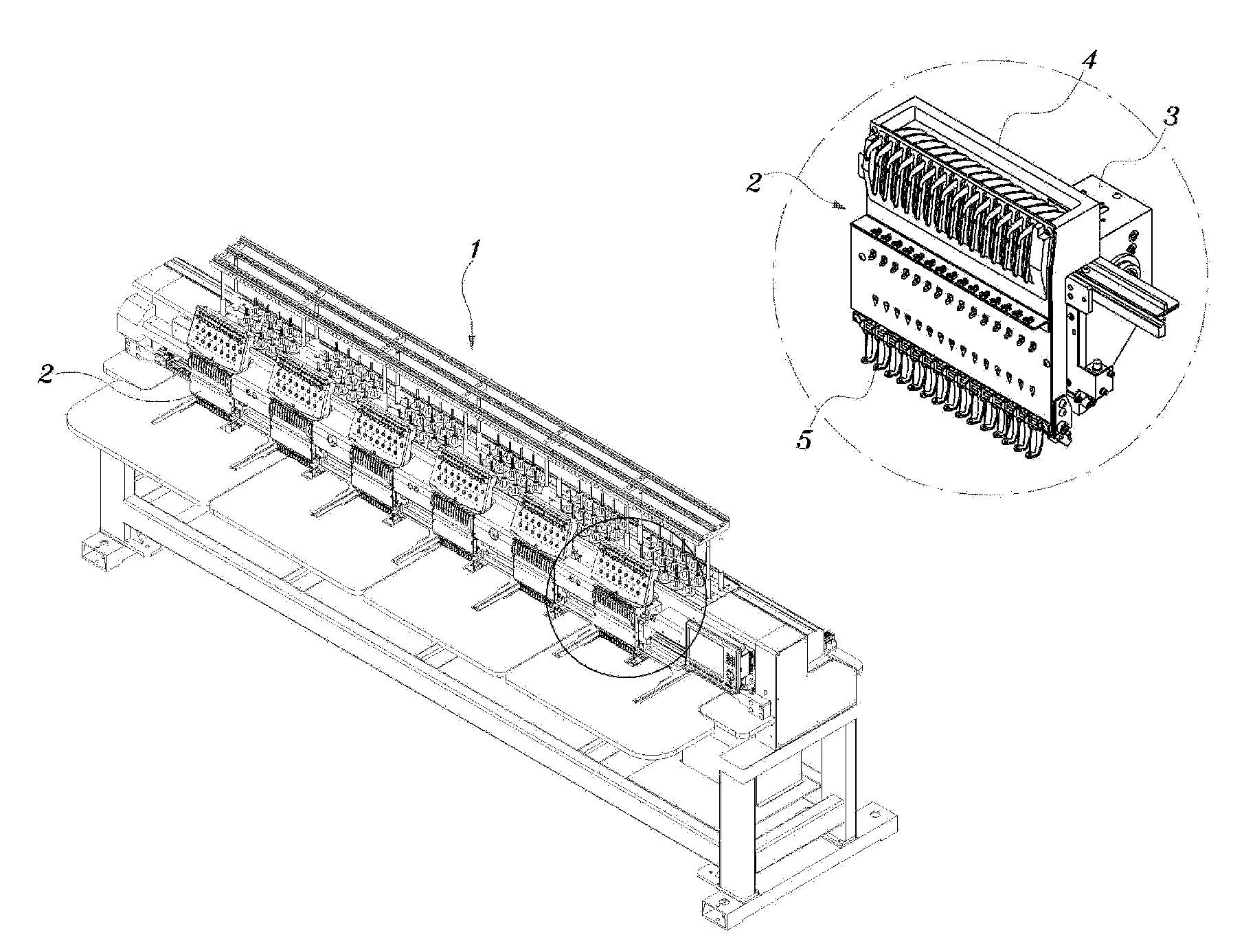

Multi-head embroidery sewing machine

InactiveUS20070261621A1Avoid unevennessEasy to switchPressersSewing-machine control devicesMechanical componentsEngineering

Individual motors in a sewing machine of the invention are provided, for each of a plurality of machine heads, for individually driving respective mechanical components, such as a needle bar driving mechanism, thread take-up lever and presser foot mechanism. A plurality of rotary hooks are driven by a common motor. Even in a case where embroidering workpieces set on the individual machine heads differ in material between the heads and upper threads used for the machine heads differ in characteristic between the heads, the sewing machine can make, in a concurrent, parallel fashion, embroidery products of different texture suited for the respective materials, characteristics, etc., by setting independent stitch formation per machine head.

Owner:TOKAI IND SEWING MACH CO LTD

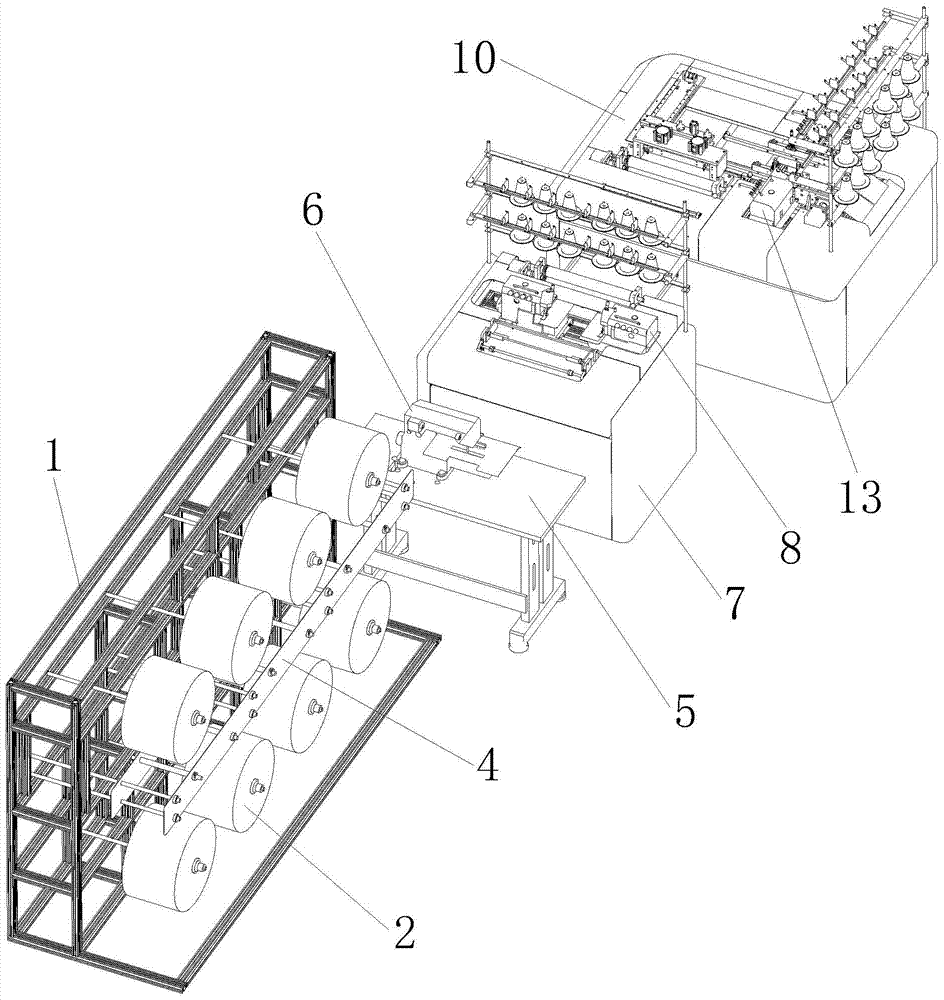

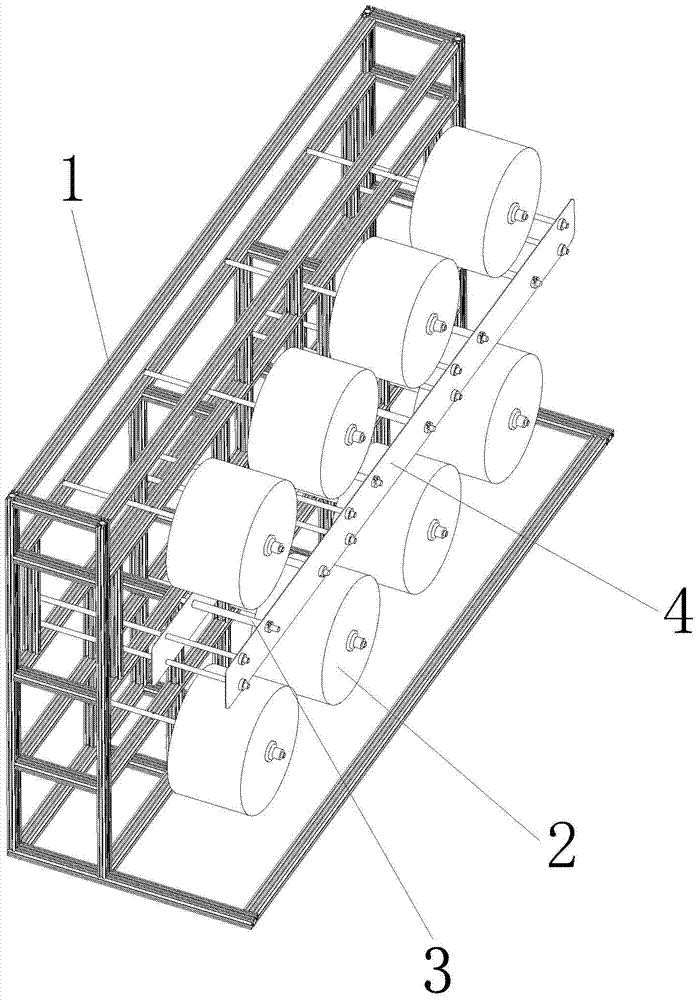

Towel machine

ActiveCN103498291AReduce manufacturing costIncrease productivityWorkpiece carriersWork-feeding meansIndustrial engineering

The invention discloses a towel machine. The towel machine comprises a feeding device, a first processing device and a second processing device. The feeding device, the first processing device and the second processing device are oppositely and fixedly placed in sequence. The feeding device is used for feeding cloth to the first processing device; the first processing device is used for binding off the two edges of the cloth fed by the feeding device for the first time; the second processing device is used for cutting off the cloth fed by the first processing device and then binding off the two edges of the cloth for the second time. According to the towel machine, original manual operation is replaced by mechanical automatic operation for towel production, so that labor intensity is greatly reduced for workers, the production mode that a single worker operates multiple machines can be realized in production, production efficiency of the product is improved, production cost is lowered, effective production management is facilitated, and the production value of the product is maximized.

Owner:SUZHOU TRANSPARENT TECH CO LTD

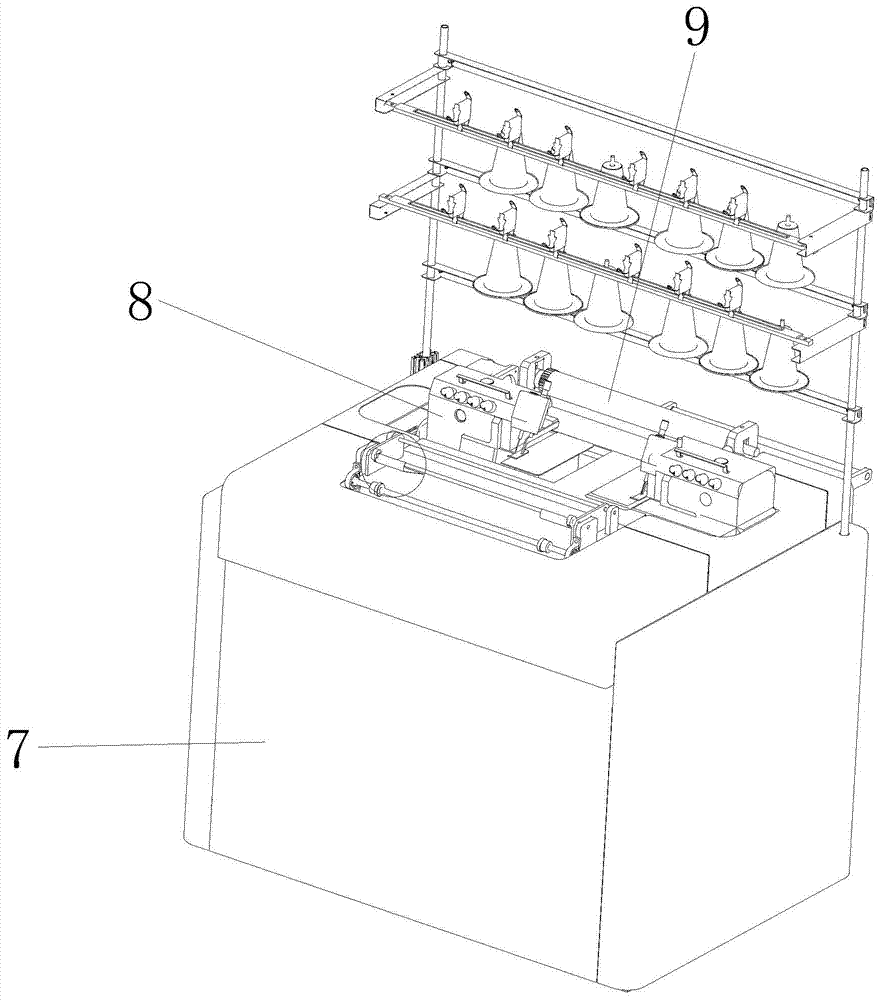

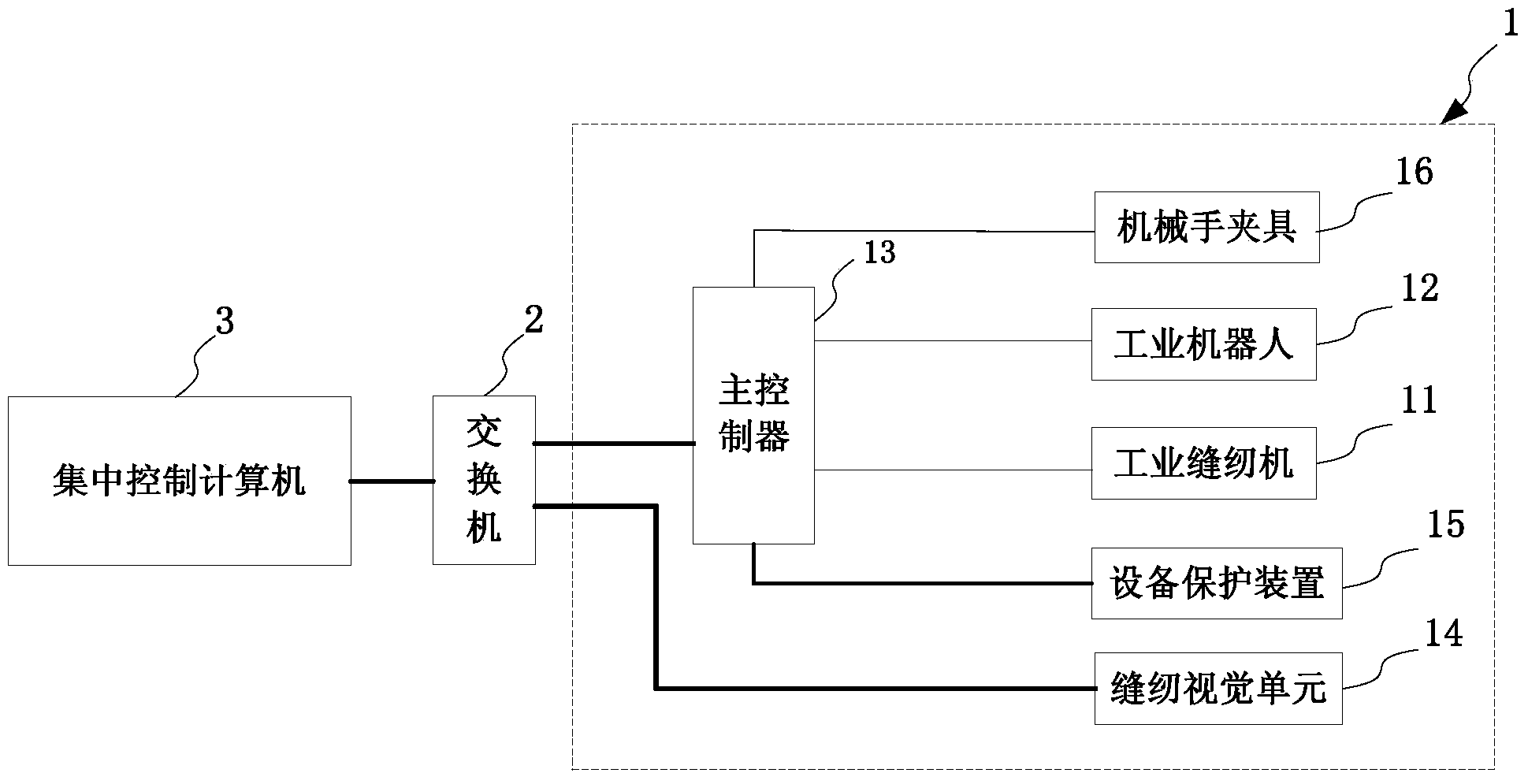

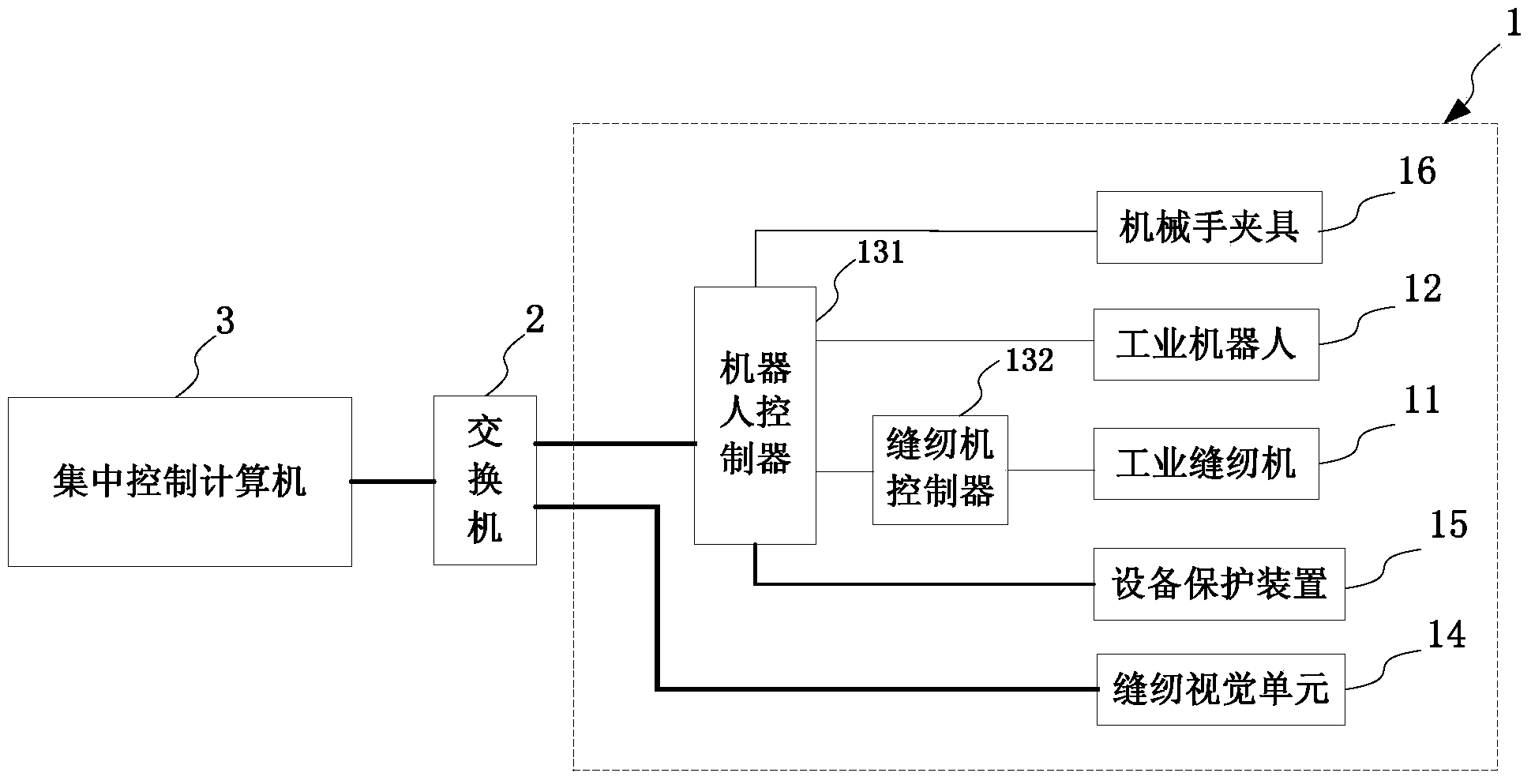

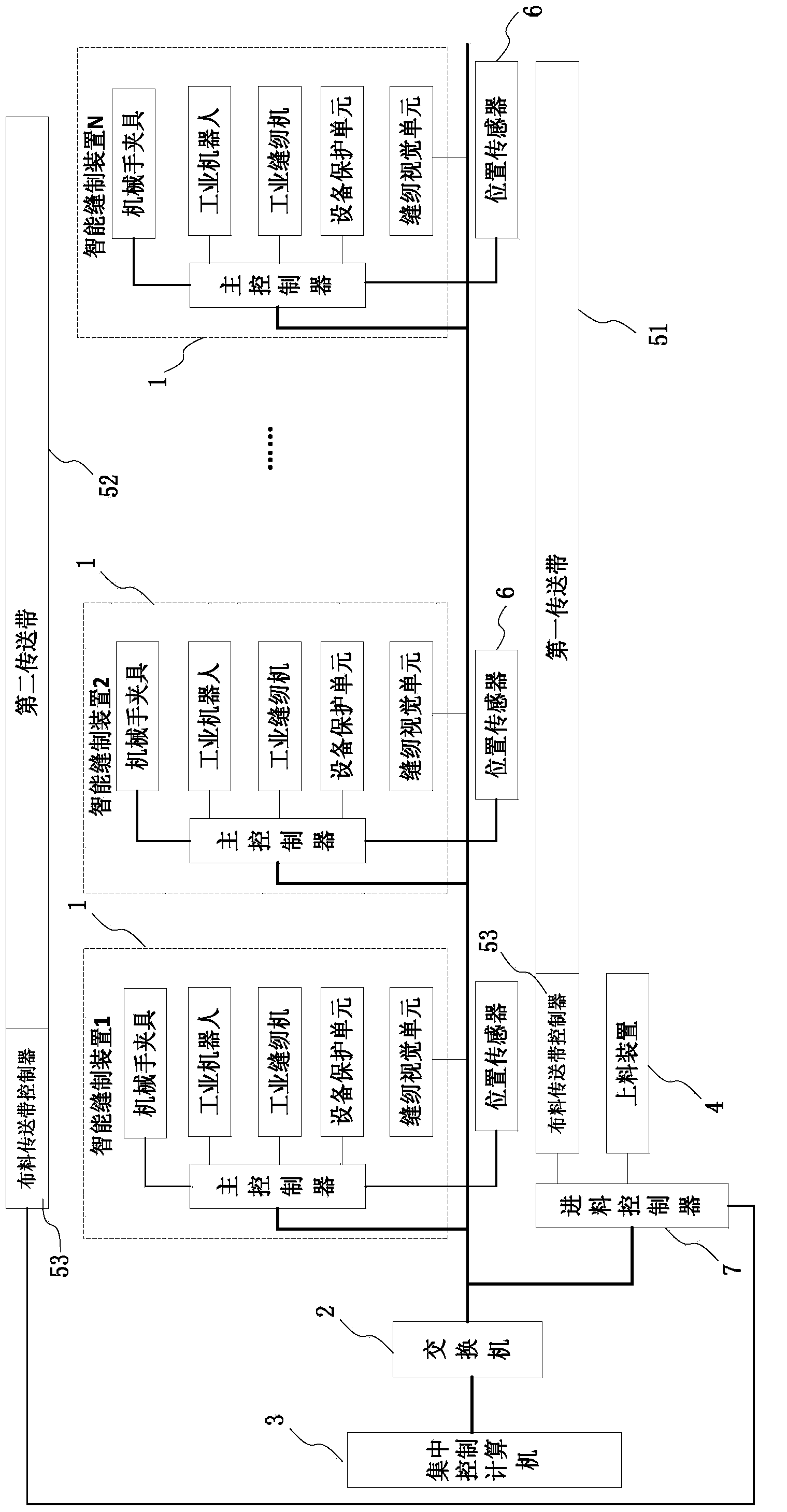

Intelligent sewing device and system

ActiveCN104018297ASewing precisionImprove work efficiencyProgramme-controlled sewing machinesSewing-machine control devicesHuman–computer interactionManipulator

The invention provides an intelligent sewing device and system. The device comprises an industrial sewing machine for sewing cloth, a mechanical arm clamp, an industrial robot, a main controller and a sewing vision unit. The industrial robot operates the mechanical arm clamp for sewing matching. The industrial sewing machine, the mechanical arm clamp, an equipment protecting device and the industrial robot are connected through the main controller which then carries out control. The sewing vision unit is used for shooting sewing workbench images and obtaining cloth images. The system comprises a plurality of intelligent sewing devices, main controllers, exchangers, feeding controllers, loading devices, feeding devices and centralized control computers. The main controllers and the exchangers are in communication connection with the intelligent sewing devices. The feeding controllers are in communication connection to the exchangers. The loading devices are connected with the feeding controllers. The feeding devices are used for placing of cloth by the loading devices and conveying the cloth to the intelligent sewing devices. The centralized control computers are in communication connection with operation man-machine interaction platforms of the exchangers. Through the system, automatic loading, feeding and sewing are achieved, during a sewing process, the cloth can be used for locating or correcting an algorithm, sewing is accurate, and working efficiency and product yield are greatly improved.

Owner:JACK SEWING MASCH CO LTD

Quilting method and apparatus

ActiveUS20050016428A1Easy to produceProgramme-controlled sewing machinesSewing-machine control devicesMotion detectorEngineering

A quilting apparatus for enabling a user to freely move a stack of fabric layers across a planar bed relative to an actuatable stitch head. The apparatus includes a motion detector which detects the movement of the stack and controls the actuation of the stitch head. Consequently, the apparatus functions to synchronize the delivery of stitch strokes by the head with the manually controlled movement of the quilt material stack. This frees the user to move the stack over a wide range of speeds, to start or stop movement at will, and to guide the stack in any direction across the planar bed.

Owner:BERNINA SEWING MACHINE

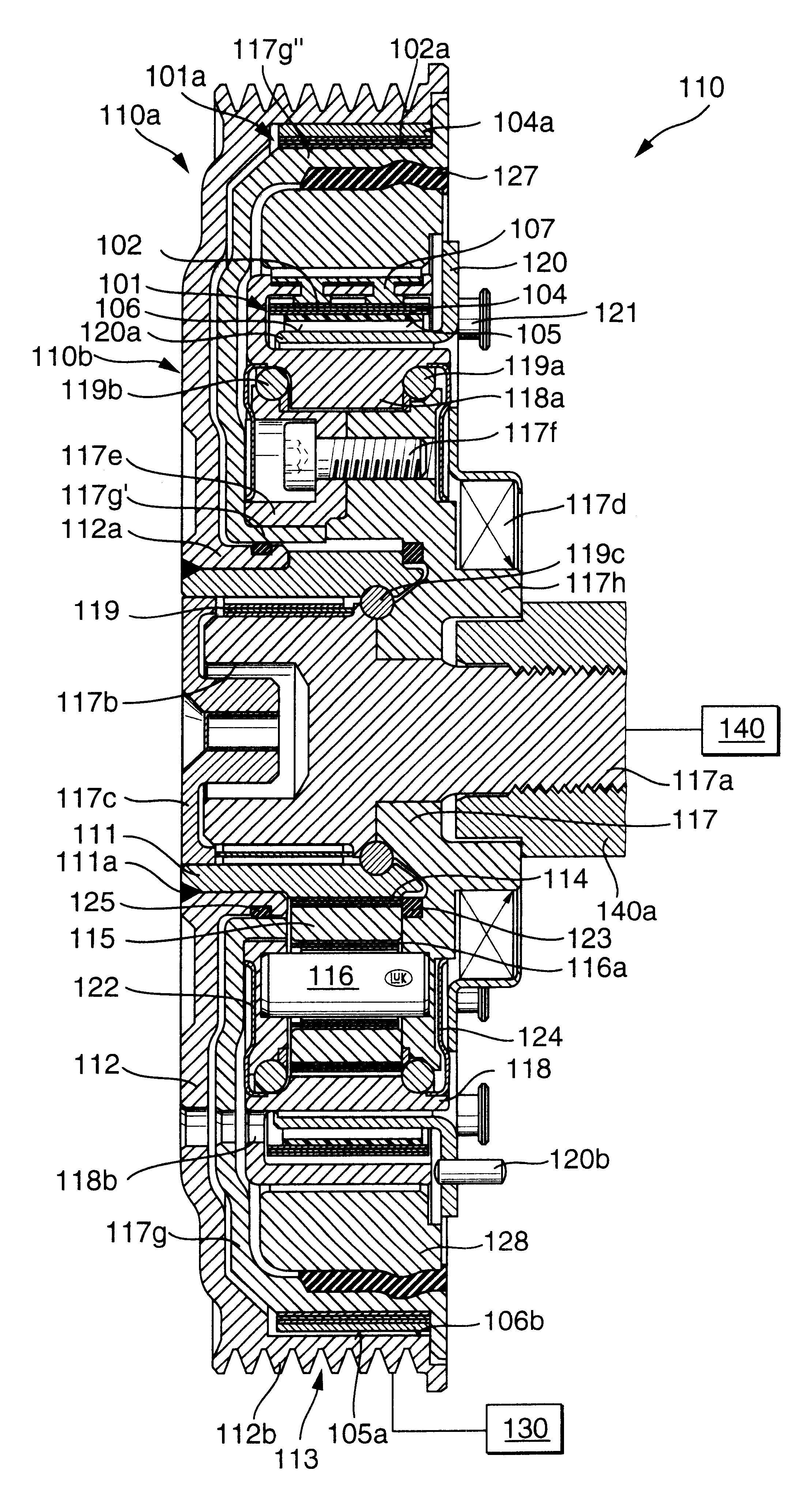

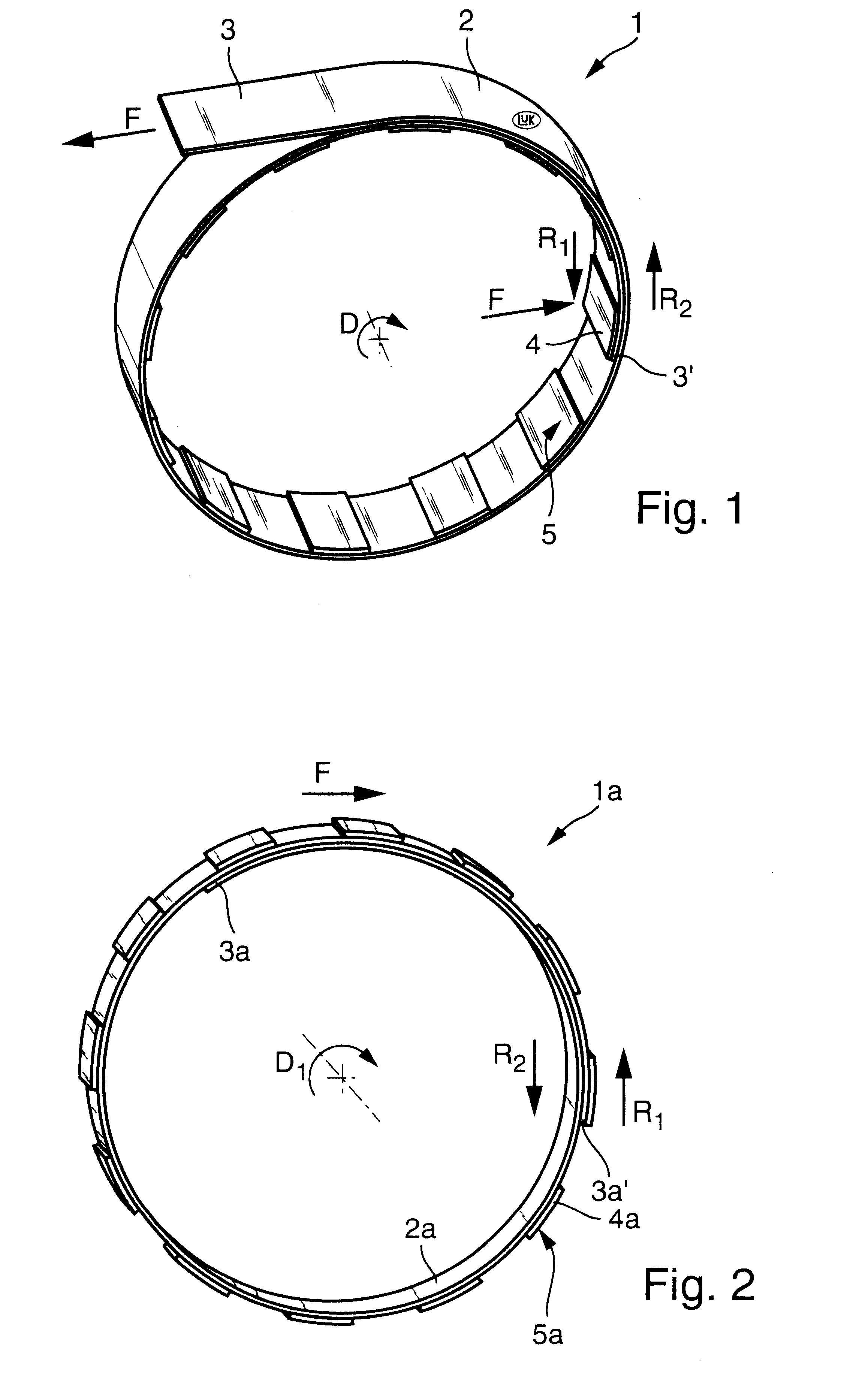

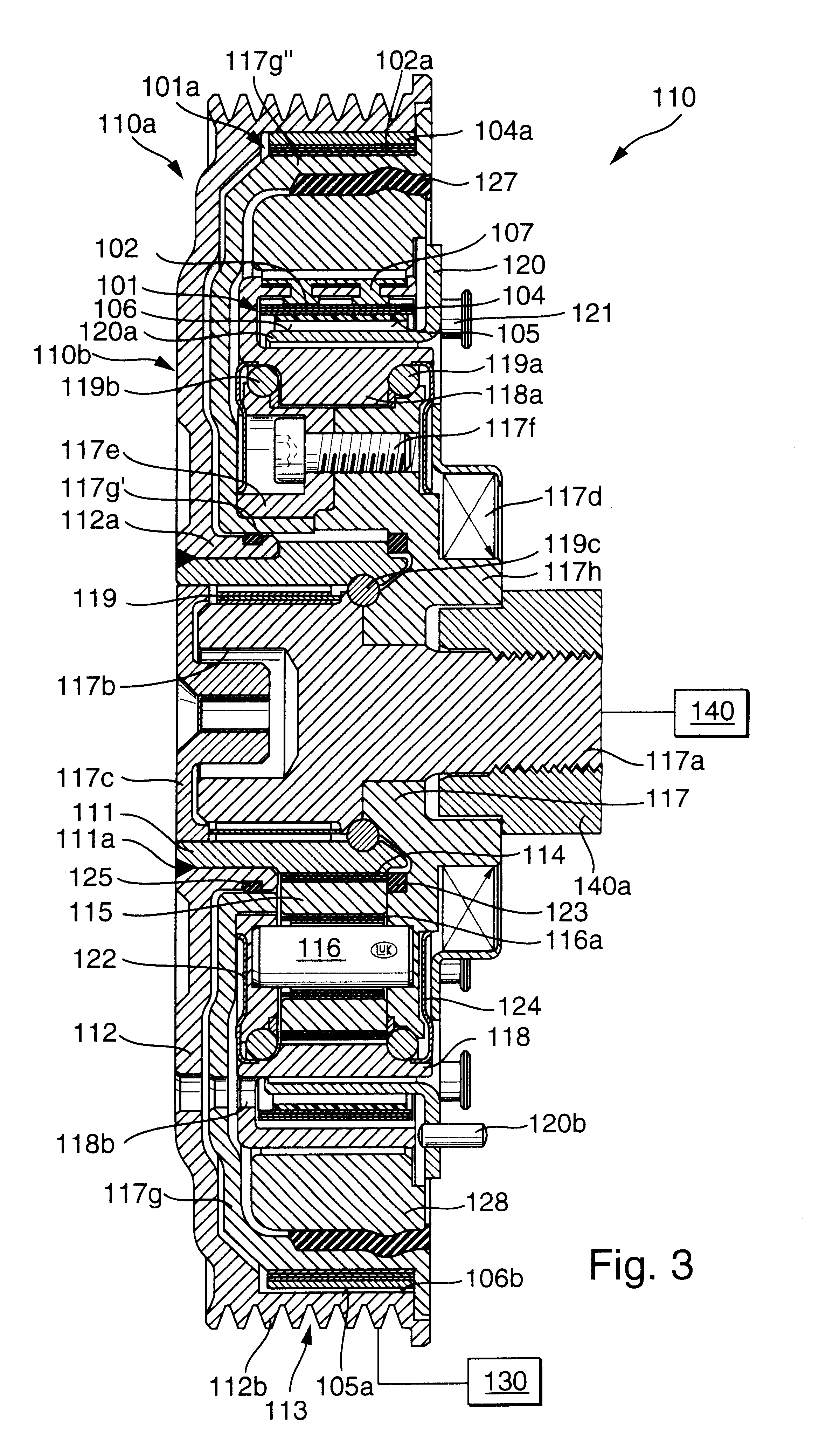

Transmission for use in the power trains of motor vehicles

InactiveUS6582333B2Less expensivePower operated startersSewing-machine control devicesFreewheelMobile vehicle

The power train of a motor vehicle has an engine which normally drives the wheels and can be started by an electric motor which acts as a generator once the engine is started. The torque transmitting connection between the crankshaft of the engine and a shaft of the motor includes a planetary and one or more freewheels of the type employing an elongated belt surrounding a rotary part and being surrounded by the internal surface of a hollow part. The belt or belts can be urged into or released from frictional engagement with one of the adjacent surfaces by centrifugal force and / or by an electromagnet.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

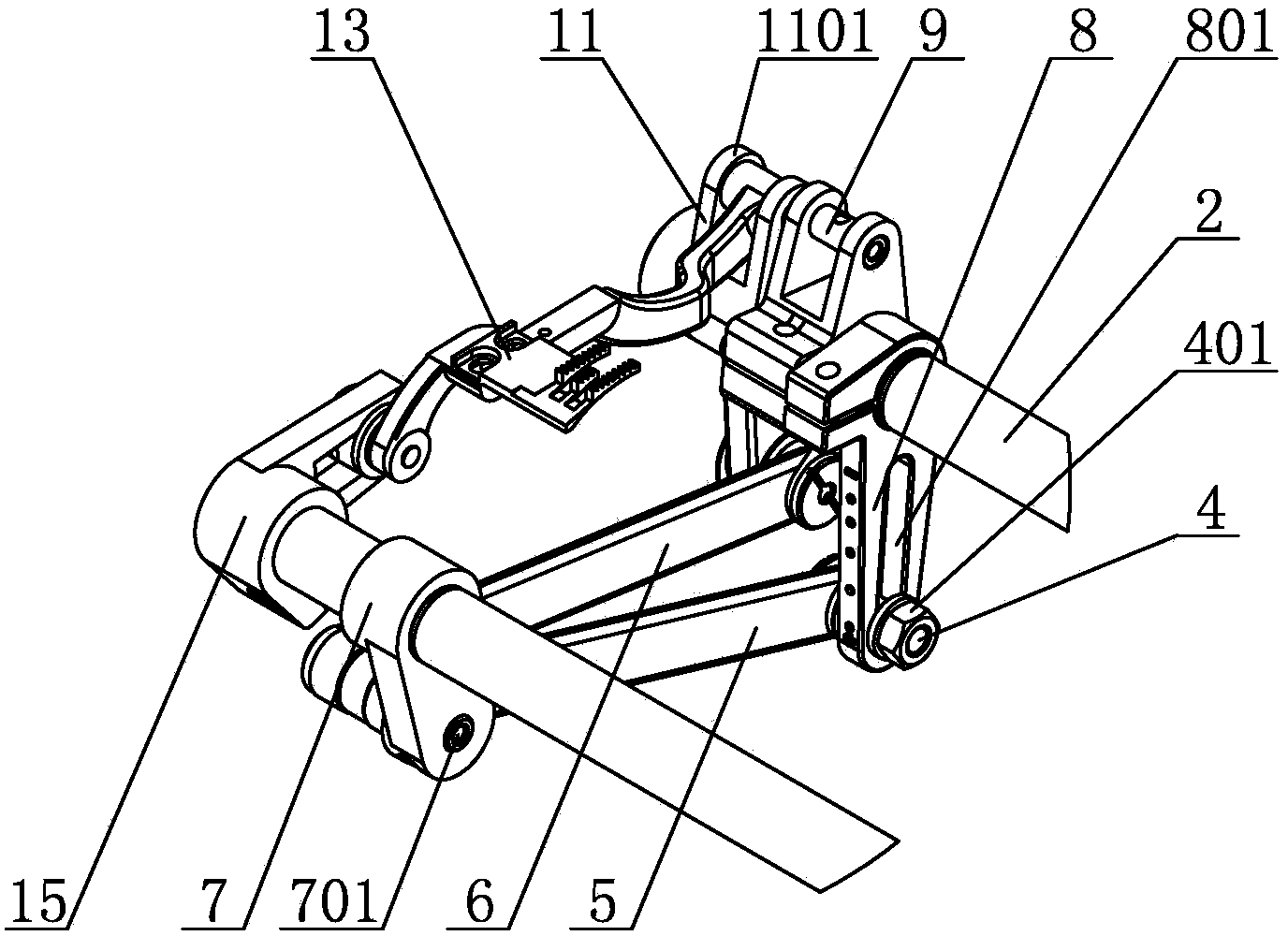

Feeding device for automatic band nailing machine

ActiveCN102493131AEasily adjust the range of motionAdjust the range of motionWorkpiece carriersWork-feeding meansEngineeringFeed tank

The invention discloses a feeding device for an automatic band nailing machine. The feeding device comprises a feeding mechanism for inputting bands, a clamping mechanism used for clamping the heads of the bands in the feeding mechanism and drawing the heads by a set length, a cutter mechanism used for cutting off the bands, and a winding mechanism used for clamping two ends of the bands and winding. The bands are input into a feeding tank through a feeding hole, are conveyed by the feeding tank to pass through a tool rest, a clamping head component can move to the tool rest to clamp the heads of the bands and draw out the bands from the feeding tank by the set length; a telescopic platform of the winding mechanism moves, two winding arms clamp and draw out the two ends of the bands; a cutter cuts off the bands at the outlet of the feeding tank; the two winding arms of the winding mechanism rotate to wind the two ends of the bands; and the telescopic platform continuously moves to feed the wound bands to a sewing area. The feeding device can automatically feed, cut and wind the bands and convey the bands to the sewing area, and has the advantages of convenience for operation, highspeed and high efficiency.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

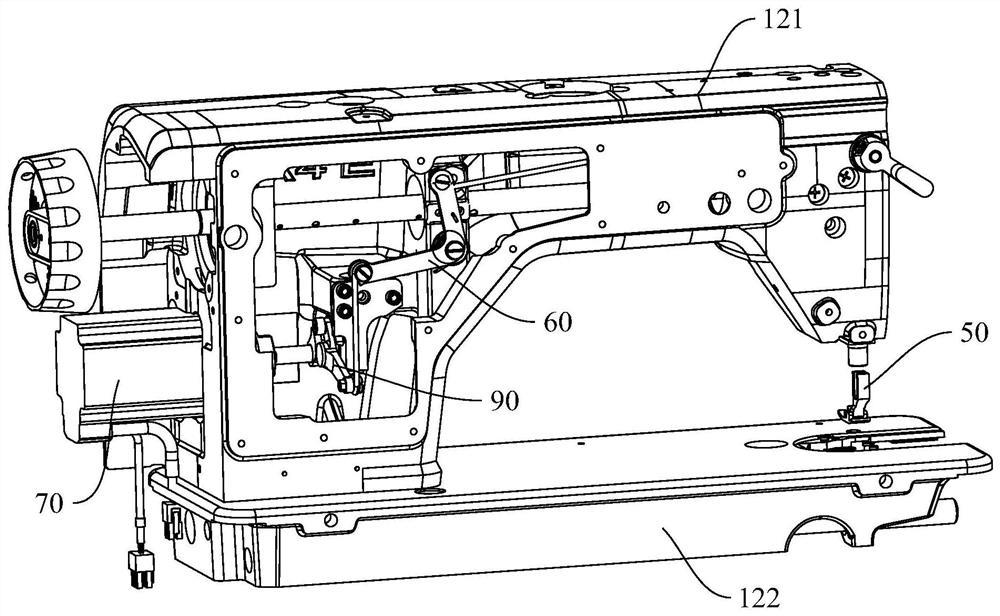

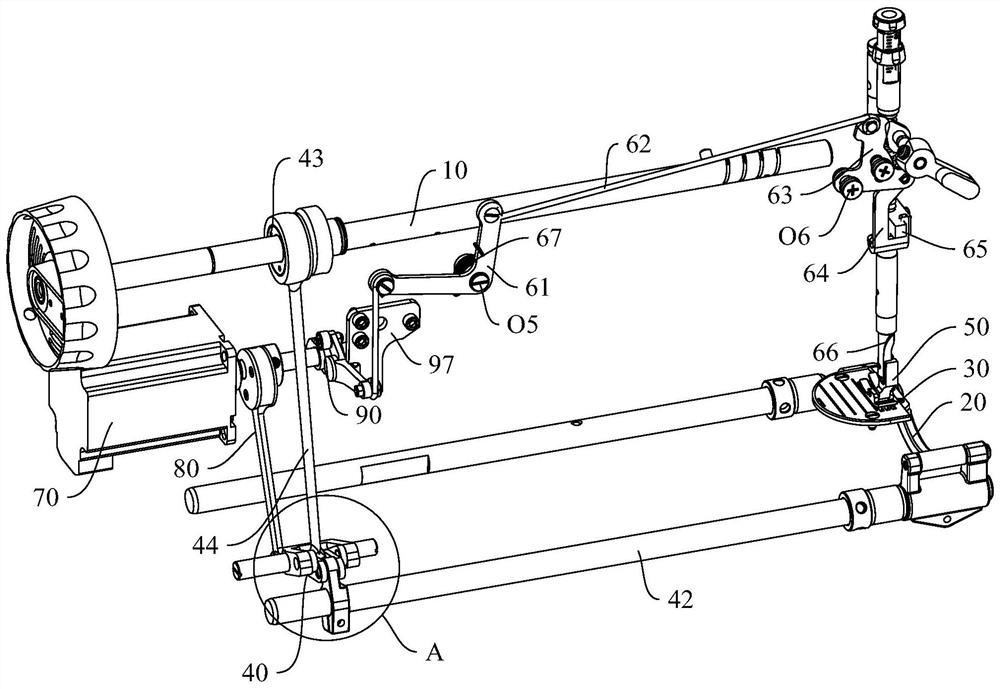

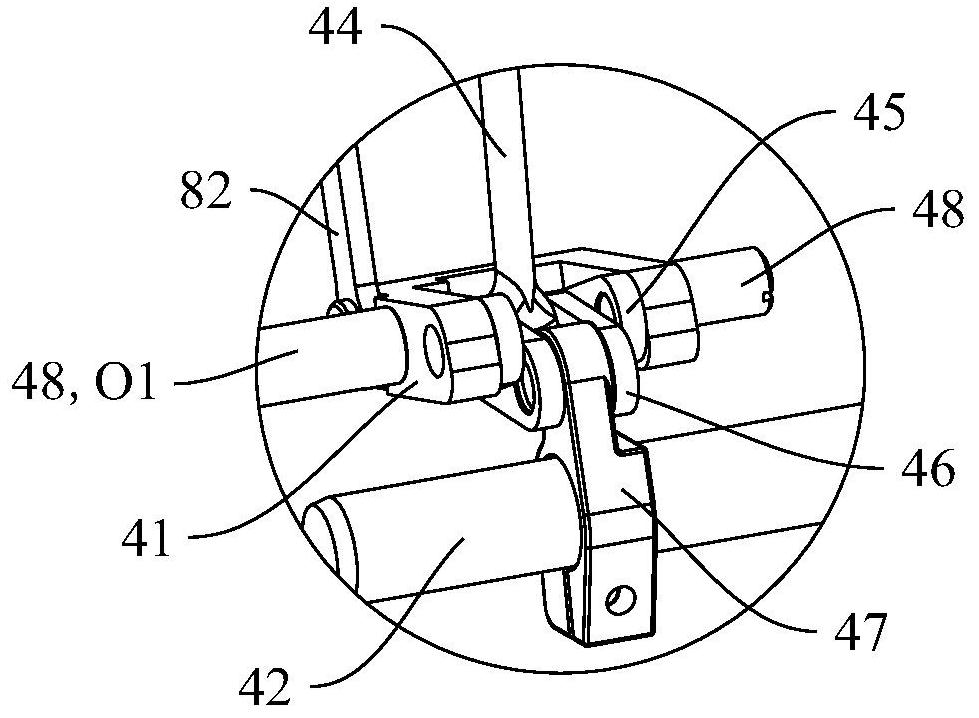

Sewing machine for up-down differential feeding

ActiveCN104233644ASimple structureCombined design is reasonableWork-feeding meansSewing-machine control devicesCrankControl engineering

The invention relates to a sewing machine for up-down differential feeding. The sewing machine comprises a secondary feeding adjusting mechanism, a feeding shaft and a feed lifting rock shaft, wherein the secondary feeding adjusting mechanism comprises a lower differential feeding adjusting crank and a first tooth frame seat which are fixed on the feeding shaft, a lower differential feeding crank which movably sleeves the feeding shaft and a lower differential transmission crank which movably sleeves the feed lifting rock shaft; the first tooth frame seat is connected with a feeding tooth; the lower differential feeding crank is connected with a lower differential feeding tooth; the lower differential feeding adjusting crank, a first lower differential feeding connecting rod, the lower differential transmission crank, a second lower differential feeding connecting rod and the lower differential feeding crank are hinged and linked in sequence; the hinging position between the lower differential feeding adjusting crank and the first lower differential feeding connecting rod is adjustable. The hinging position is adjusted so that a force arm relation between the lower differential feeding adjusting crank and the first lower differential feeding connecting rod is changed and a relation of swinging and transferring the feeding shaft to the feeding tooth and the lower differential feeding tooth is changed, namely the lower differential feeding adjustment is realized.

Owner:宁波新三合自动化有限公司

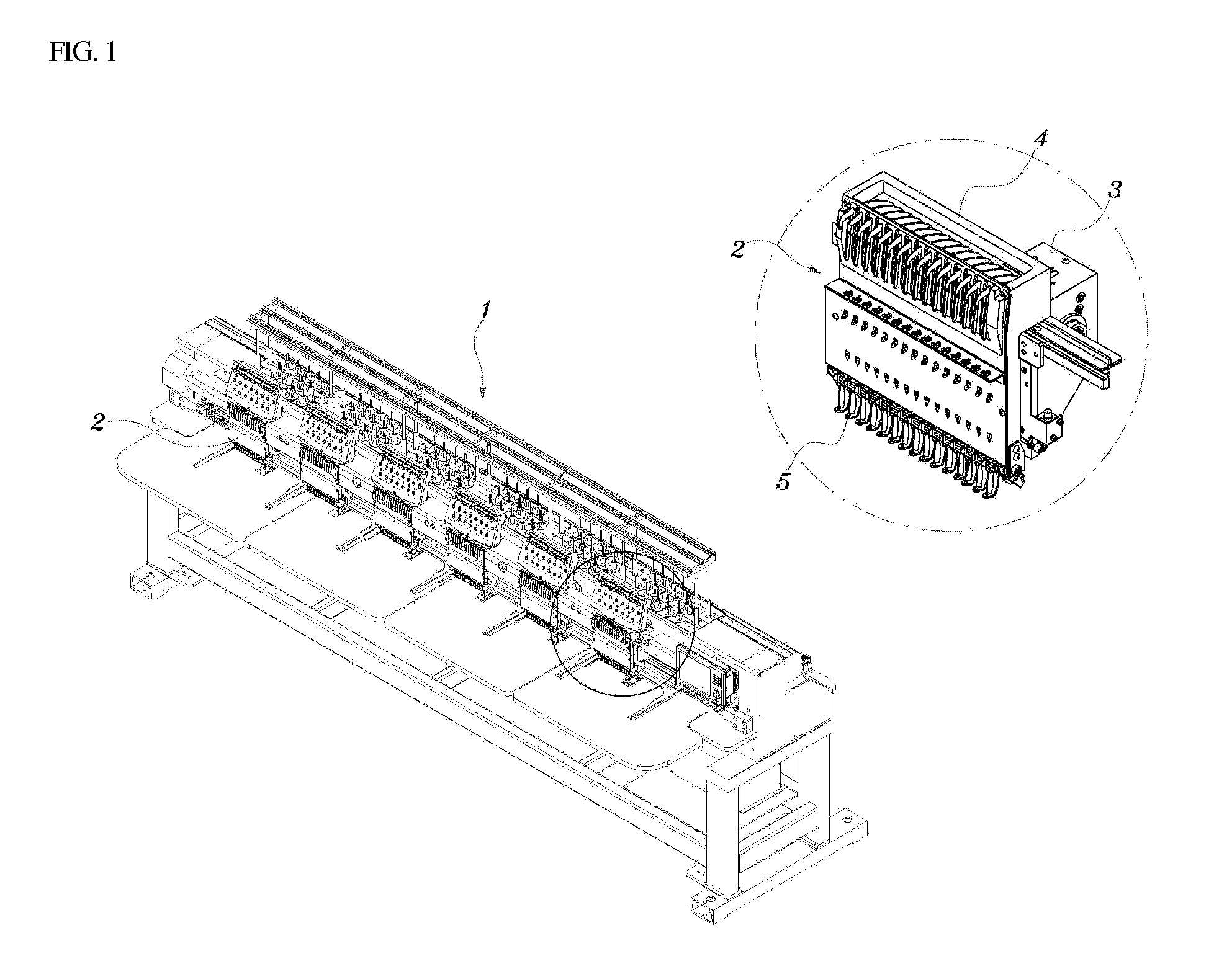

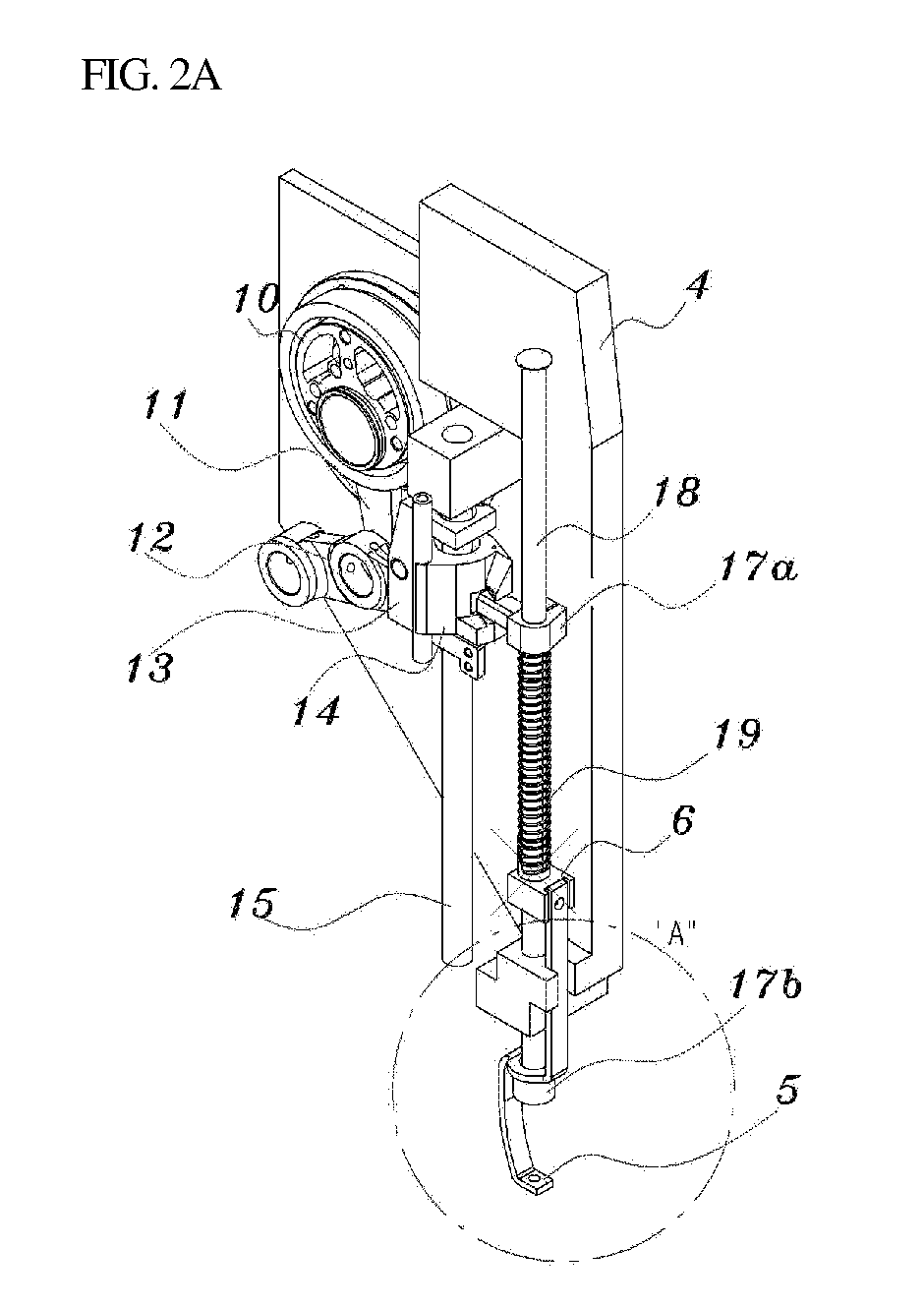

Embroidery Machine

An embroidery machine includes a sewing arm having an upper shaft for providing a driving force, a needle bar support case, which is assembled to a front portion of the sewing arm so as to be laterally movable, a needle bar provided in a needle bar support case, the needle bar having a needle at a lower end thereof and vertically carrying the needle using a rotation driving force of the upper shaft, and a presser foot, which is provided in the needle bar support case so as to be vertically movable, characterized in that each of the needle bar and the presser foot is operated by an individual drive mechanism. The presser foot is separately driven by its own drive source, independent of the drive source of the needle bar.

Owner:SUSR PRECISION CO LTD

Quilting method and apparatus using frame with motion detector

Owner:KOERNER RALPH J

Computerized stitching including embroidering

InactiveUS20060064195A1Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

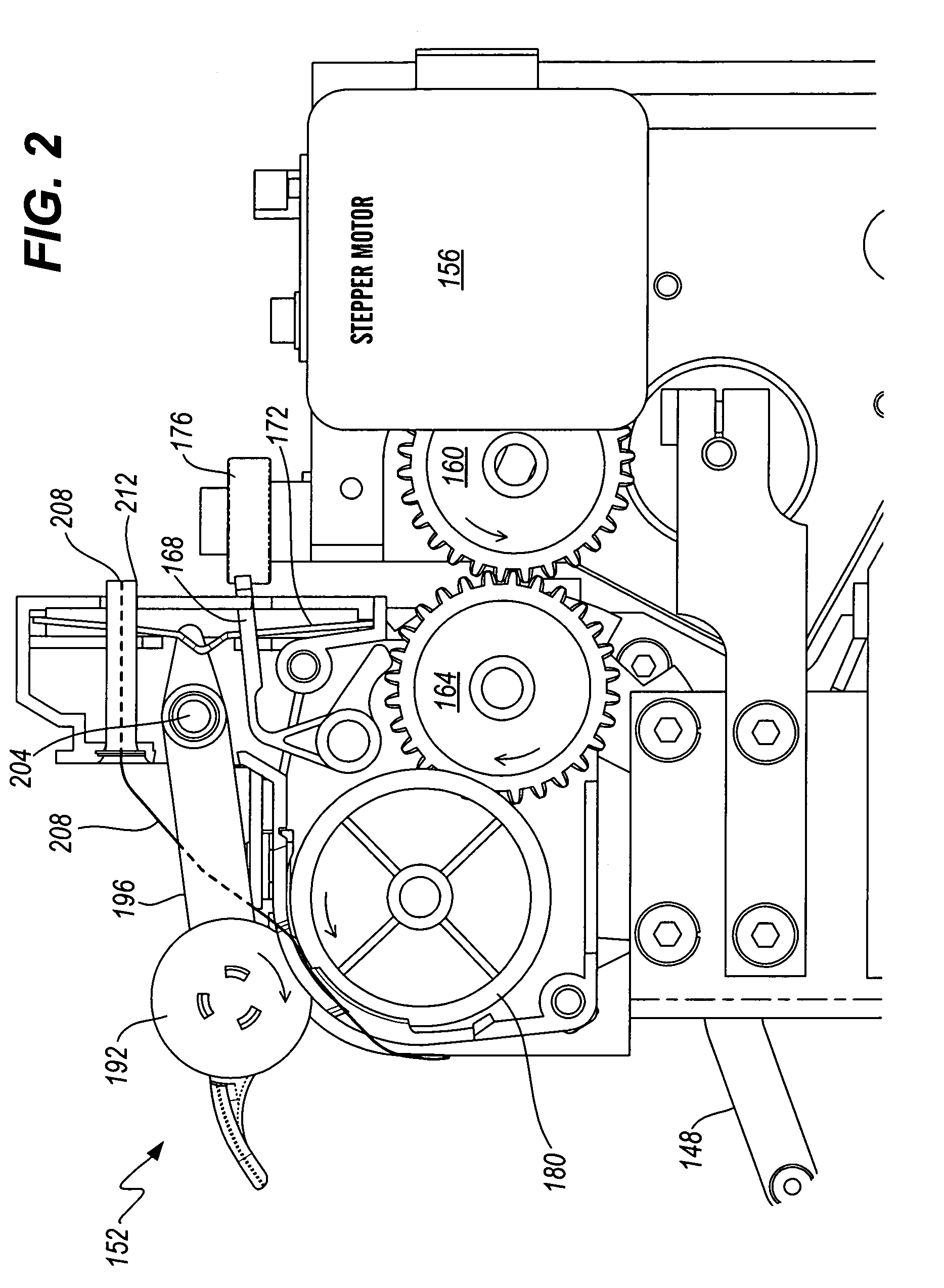

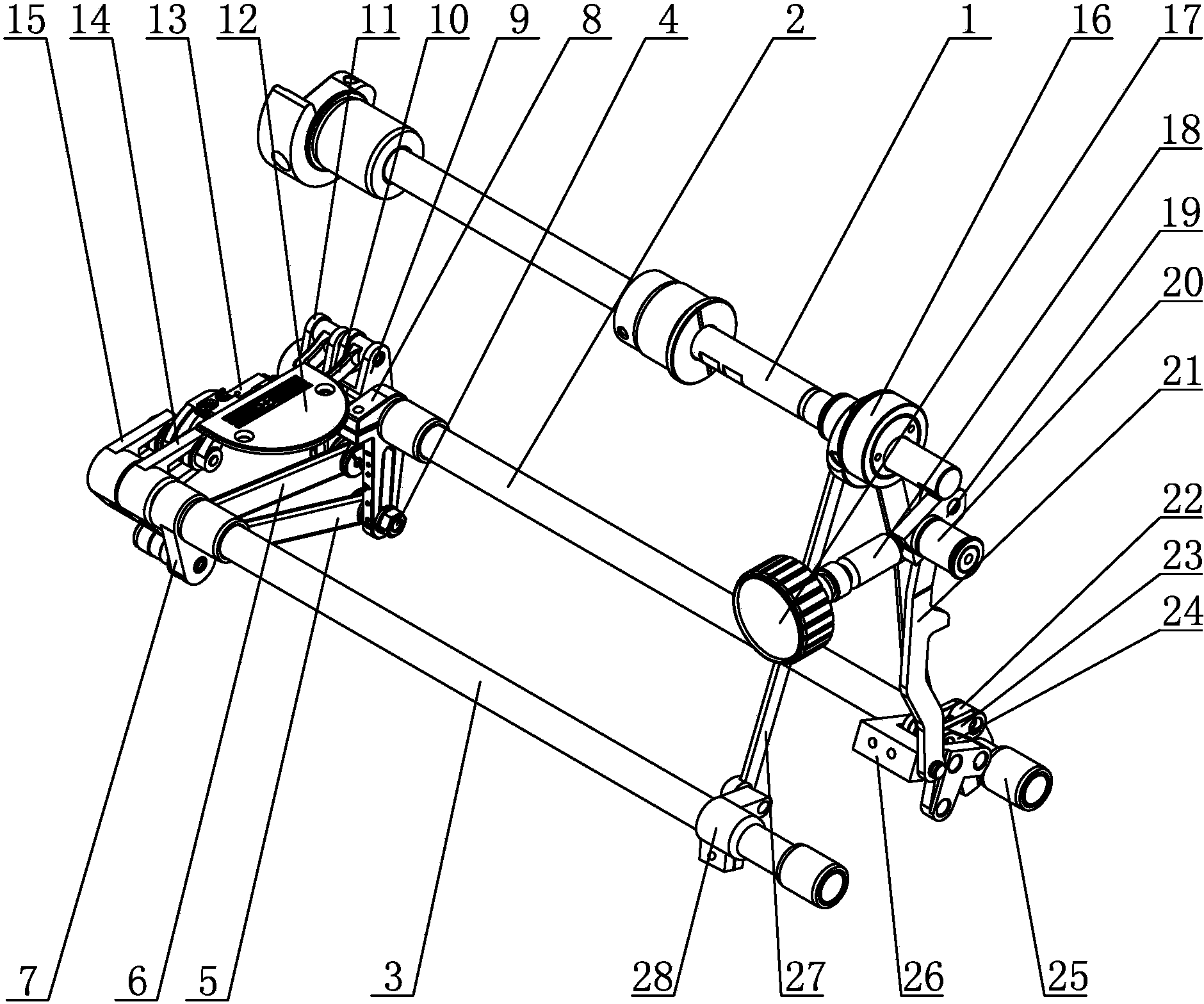

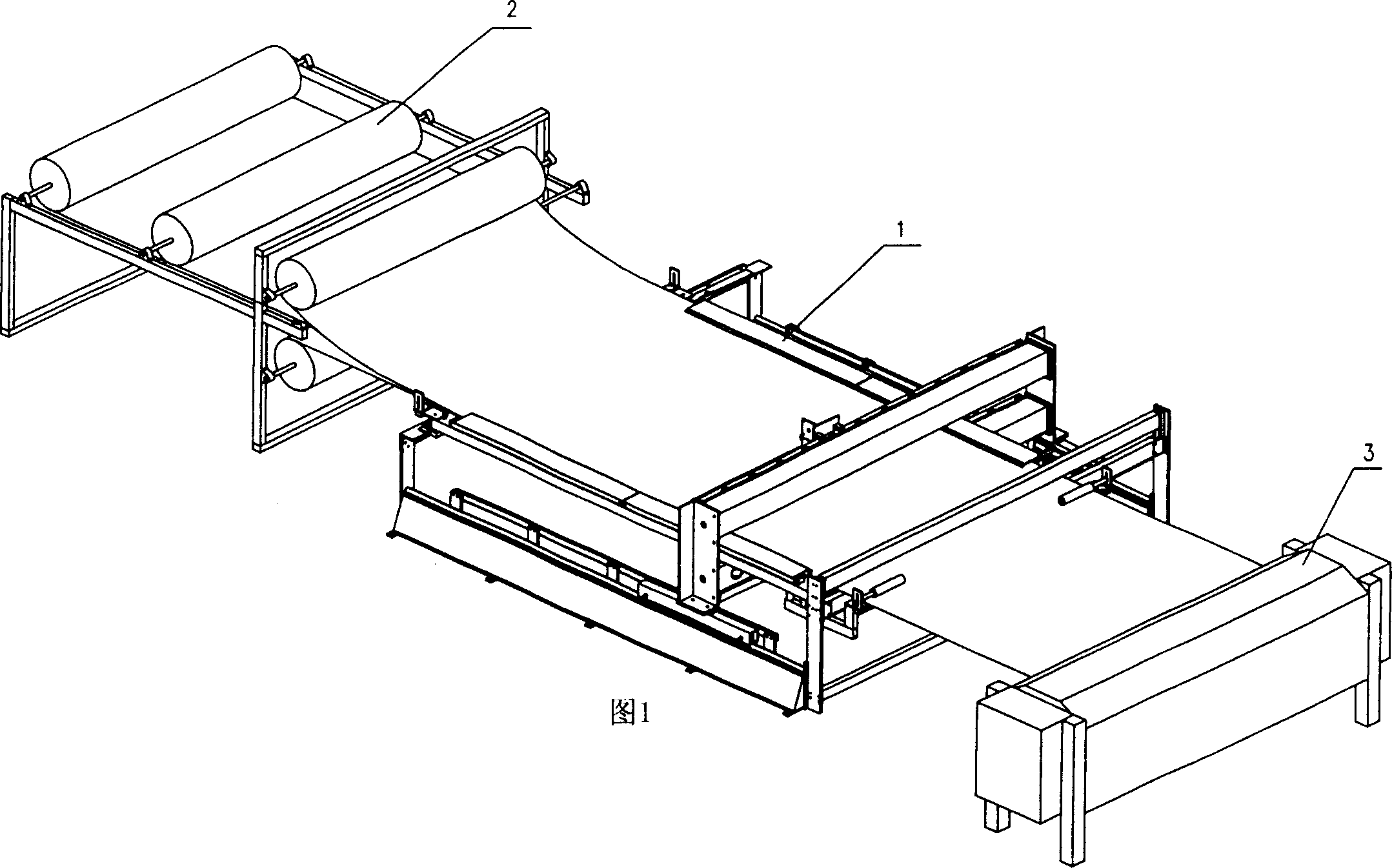

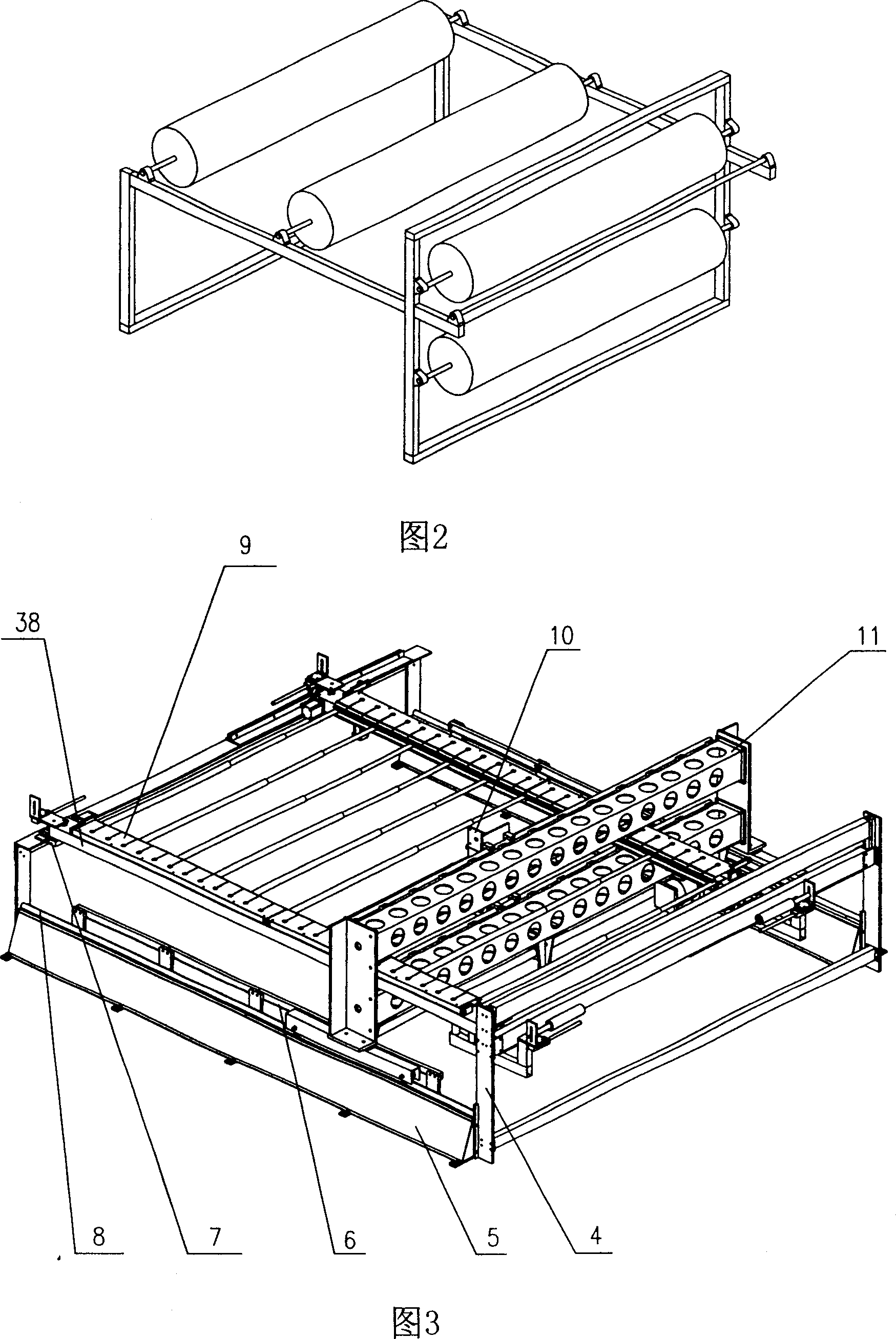

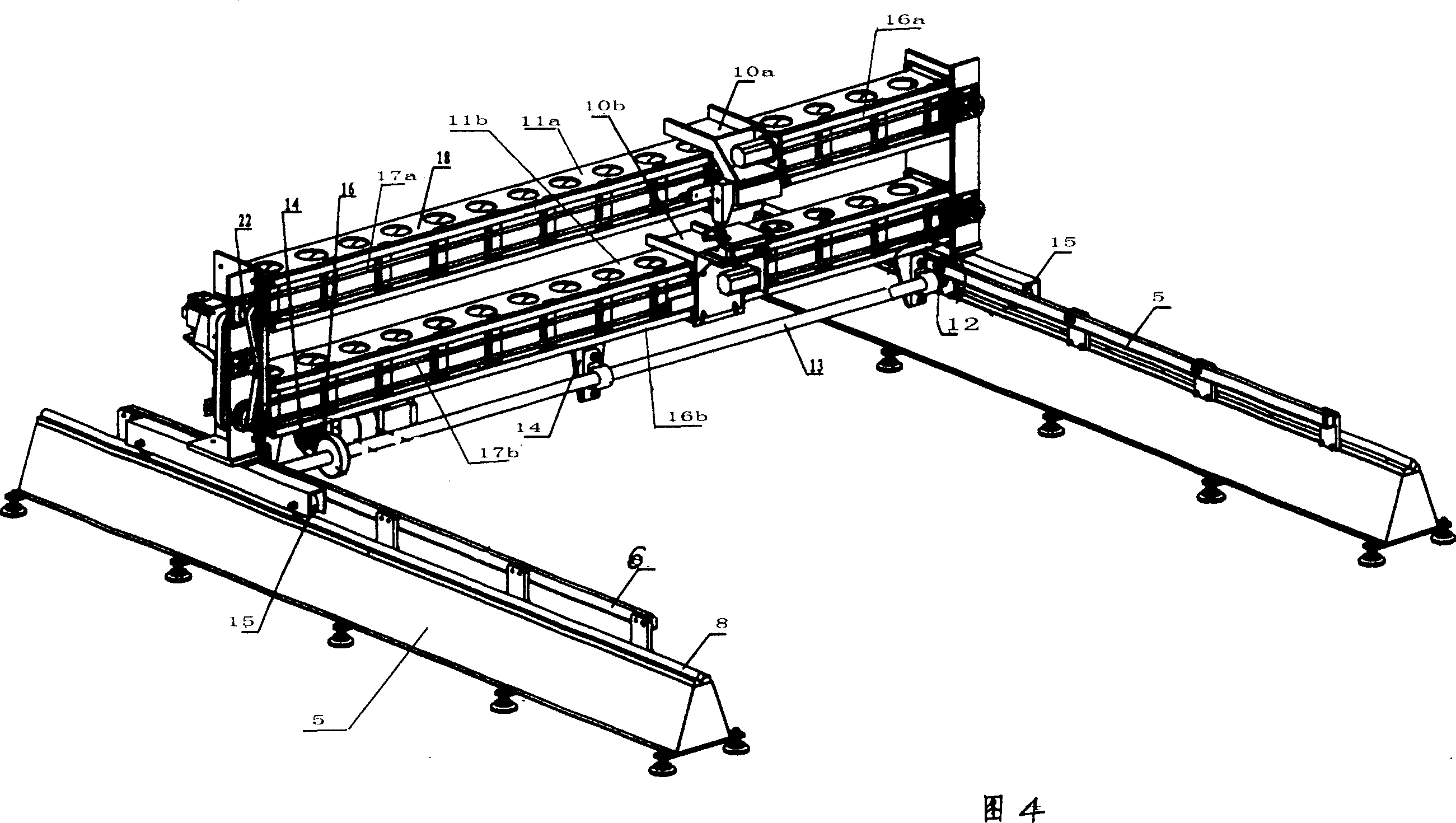

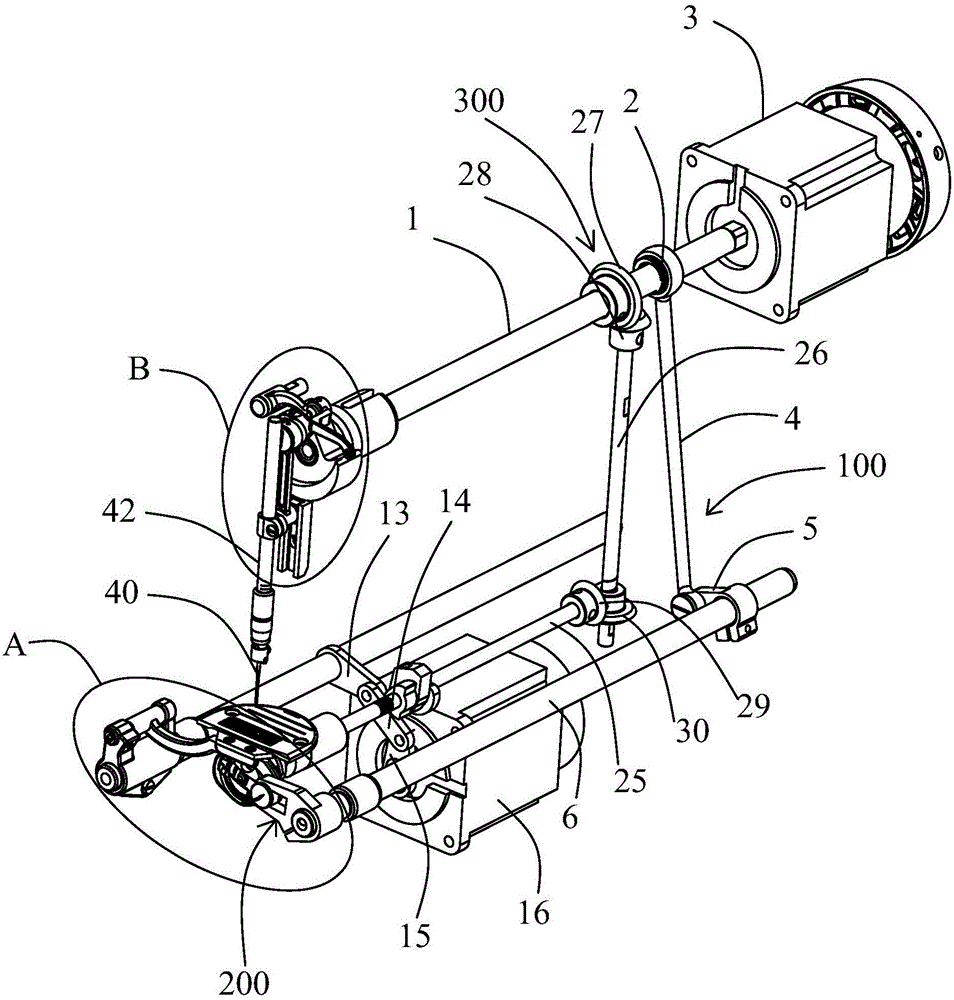

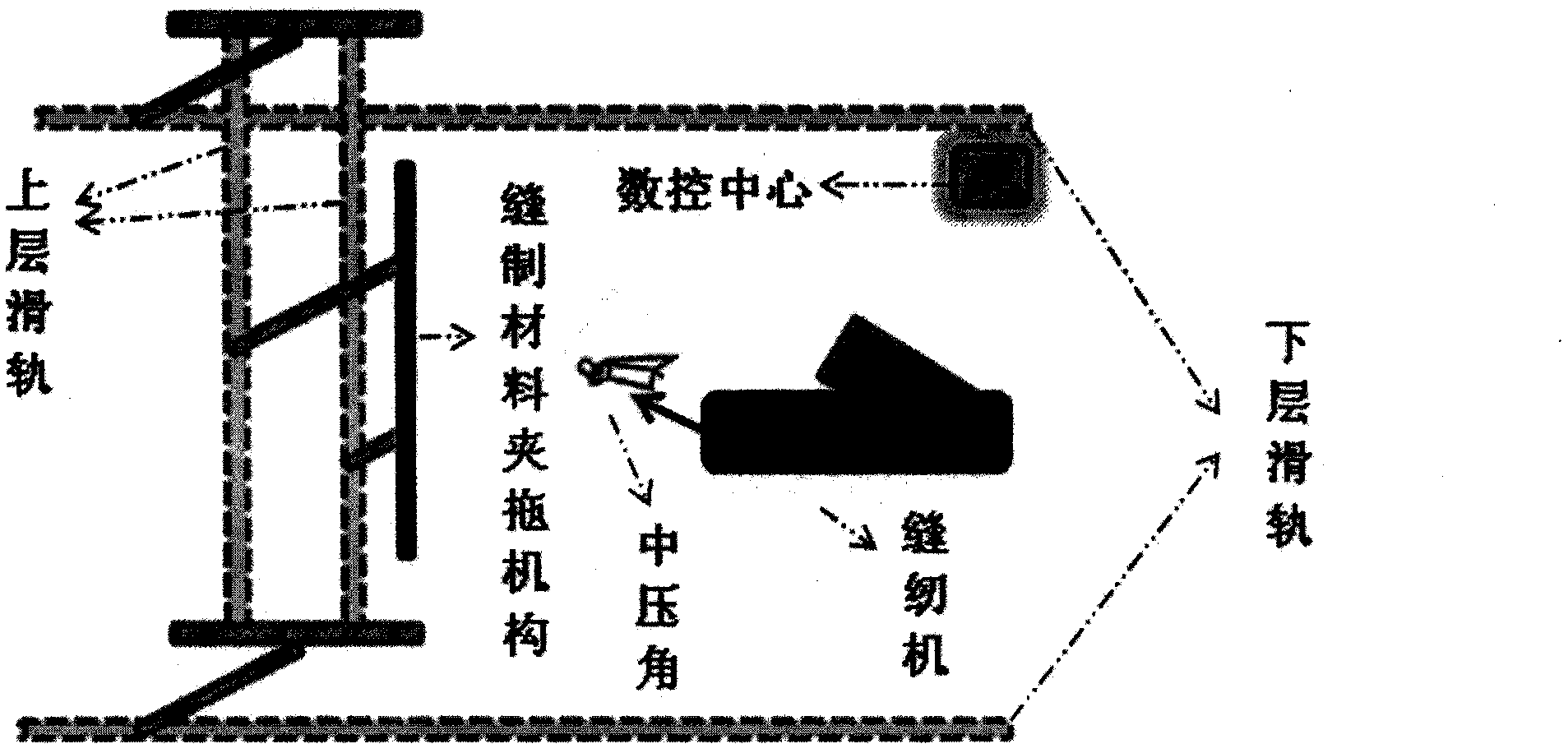

Numerically controlled single-needle quilter

InactiveCN1962987AFast quiltingGood quilting stabilityWork-feeding meansSewing-machine control devicesNumerical controlGear wheel

The numerical control single needle quilter of the invention also includes cloth discharge tensioning mechanism with a cross cutter, gantry mobile device of said quilter main is equipped with two parallel chassis and gantries symmetrically. Two chassis are provided with vertical racks respectively, gantries strung between the two chassis, two sides of gantries are supported by the vertical guiding parts equipped on the chassis with sliding and engage with racks of the chassis through the gear wheels of corresponding side, said gear wheels are fixed on the two ends of crosswise transmission shaft, the transmission shaft is fitted on the bearing block on the support of bearing of the immovable gantry floor with sliding, the gears are connected with generator to transmitting motion; the upper and lower body of gantries is equipped with guidance axis respectively, the upper and lower machine nose devices are sleeved on the two guidance axis with sliding respectively and are connected with the machine nose move synchronous belt devices, the devices are connected with the generator; gripper mechanism to adjusting fiber tension is connected with frame horizontally with sliding.

Owner:李德锵

Sewing machine

ActiveCN105113152AChange trajectoryAchieve sewingWork-feeding meansSewing-machine control devicesEngineeringFeed dogs

The invention provides a sewing machine. The sewing machine comprises an upper shaft driven by a first motor, a needle bar take-up mechanism arranged at one end of the upper shaft, a lower shaft parallel to the upper shaft, a thread take-off mechanism arranged at one end of the lower shaft, a feed dog frame and a feed dog fixed to the feed dog frame. The upper shaft is connected with the lower shaft through a drive unit. The upper shaft is connected with one end of the feed dog frame through a feed dog lifting mechanism. The sewing machine further comprises a second motor connected with the other end of the feed dog frame through a cloth feed mechanism. The feed dog lifting mechanism and the cloth feed mechanism which form a feed mechanism are driven by the two motors respectively, and therefore the output amount of the cloth feed mechanism can be regulated by regulating the output amount of the second motor, the movement tracks of the feed dog frame and the feed dog can be conveniently changed, and sewing of various patterns can be achieved.

Owner:JACK SEWING MASCH CO LTD

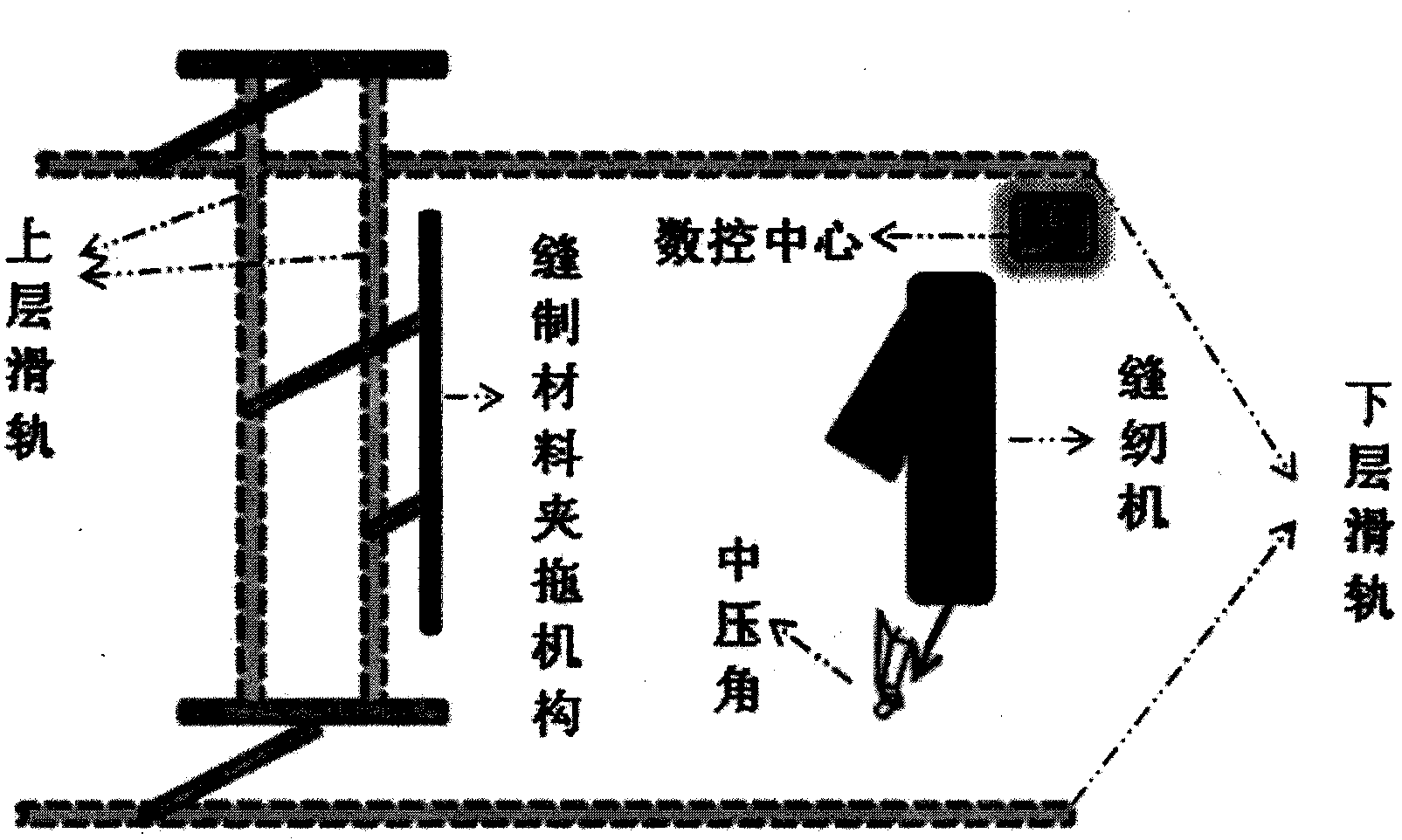

Numerical-control sewing processing equipment

InactiveCN104233647AGuaranteed operational safetyGuaranteed independenceWork-feeding meansSewing-machine control devicesNumerical controlMultiple layer

Owner:王艳玲

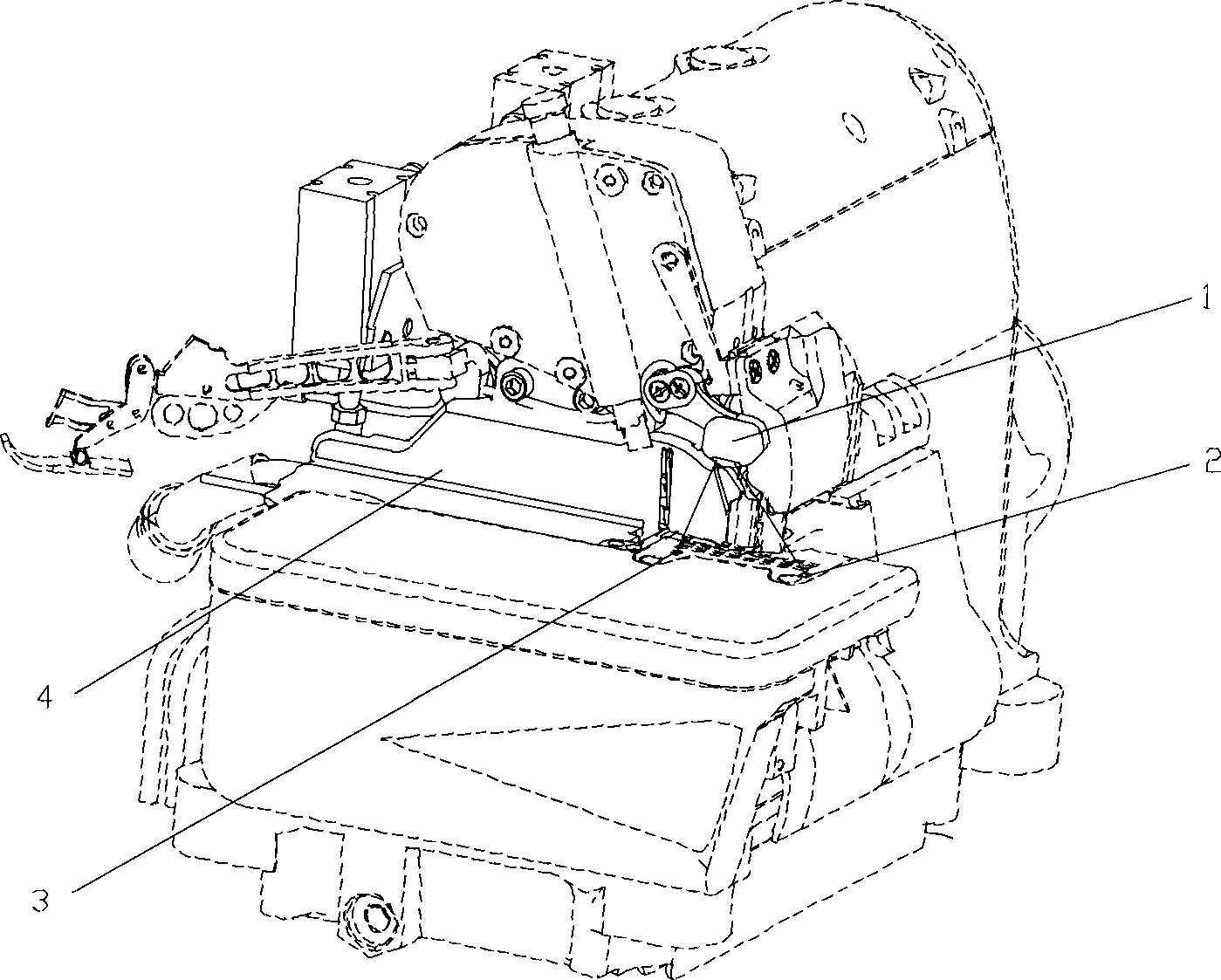

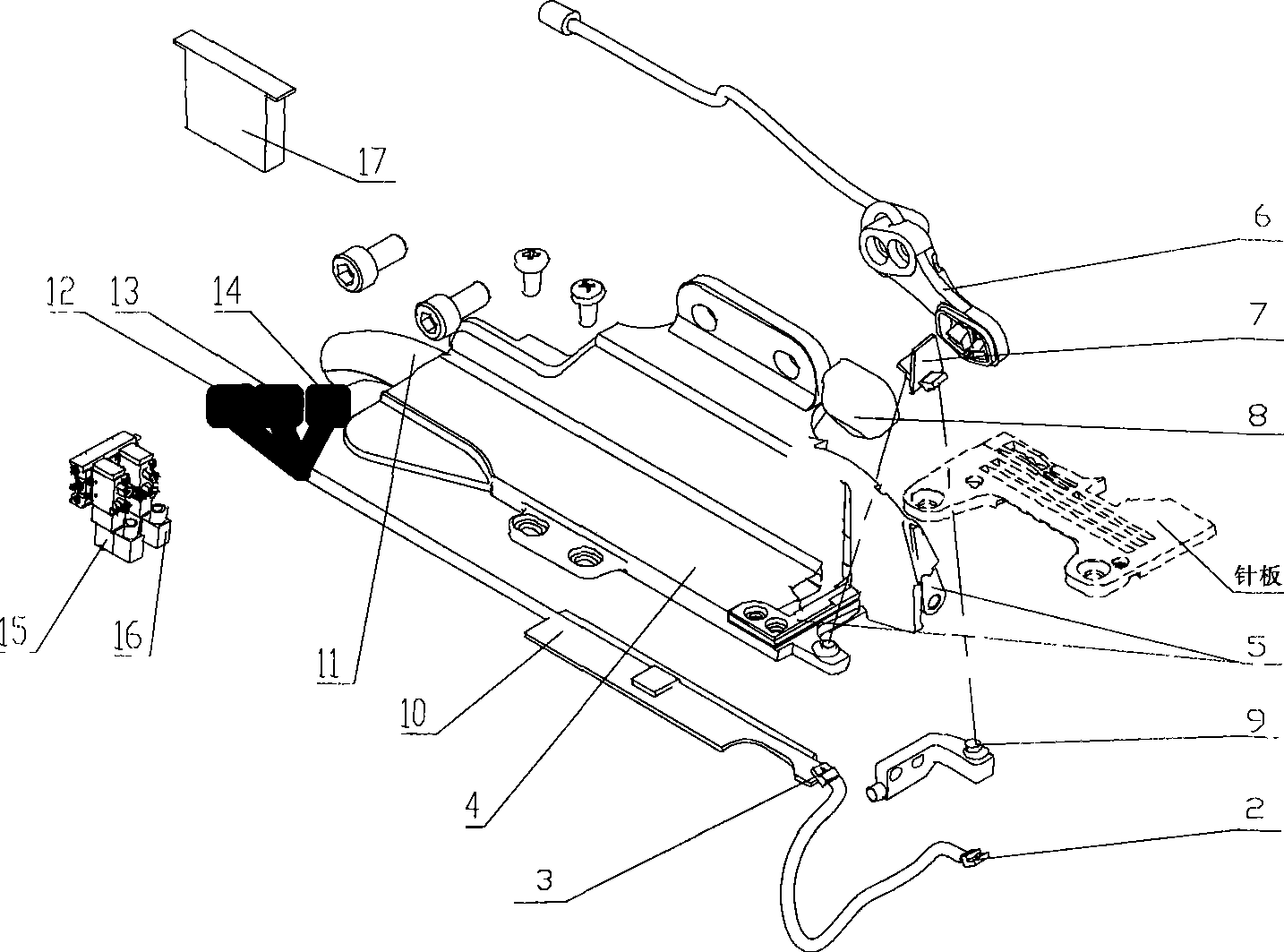

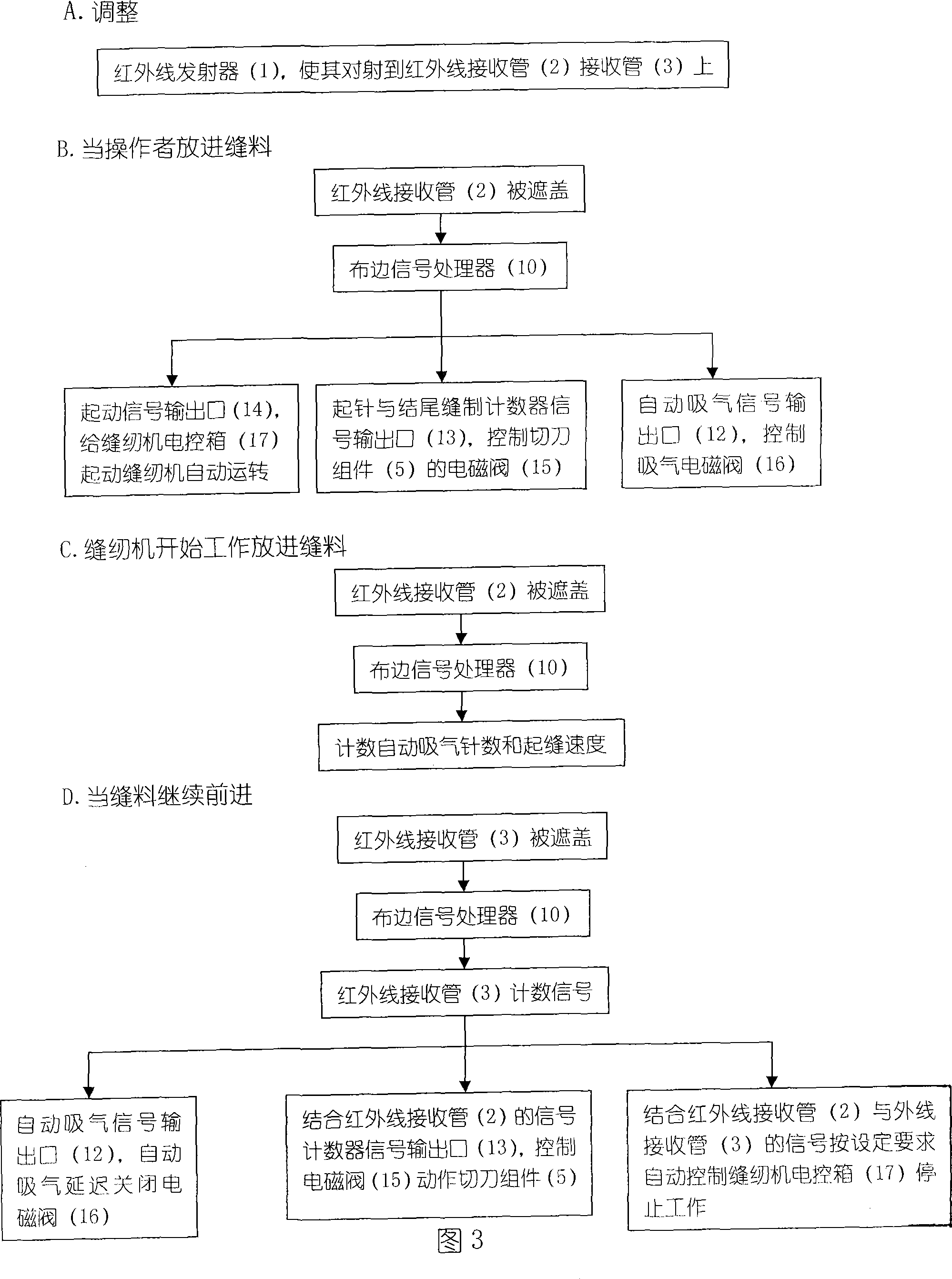

Photoelectronic control system for industrial sewing machine

ActiveCN101429712ARealize automatic start-up operationHigh control precisionSewing-machine control devicesOptical detectionControl systemWire cutting

The invention discloses a photoelectric control system for an industrial sewing machine, and relates to the technical field of photoelectric control, in particular to an infrared control system capable of detecting fabric edge length of materials sewn and whether sewing materials exist by an industrial sewing machine. The control system comprises two infrared emitters (1) independently forming a relative included angle (phi), an infrared receiver tube (2) and an infrared receiver tube (3) positioned in a front circular hole and a back circular hole of a needle plate holder, a cutter assembly (5), a fabric edge signal processor (10), an air suction pipe (11) and a sewing machine electric cabinet (17), and comprises steps of a to d. Two groups of signals about having or no fabric edges are provided to the fabric edge signal processor to be processed through judging whether the fabric edges are existed on a sewing machine needle plate; and starting, stopping, accounting, speed raising, speed reducing, wire cutting and air sucking and the like of the sewing machine are controlled automatically according to positions of the fabric edges supplied to a system controller. The control system has the characteristics of accurate output signals, good anti-interference property, easy processing and high performance cost ratio, is suitable for various industrial sewing machines, and the like.

Owner:上海富山精密机械科技有限公司

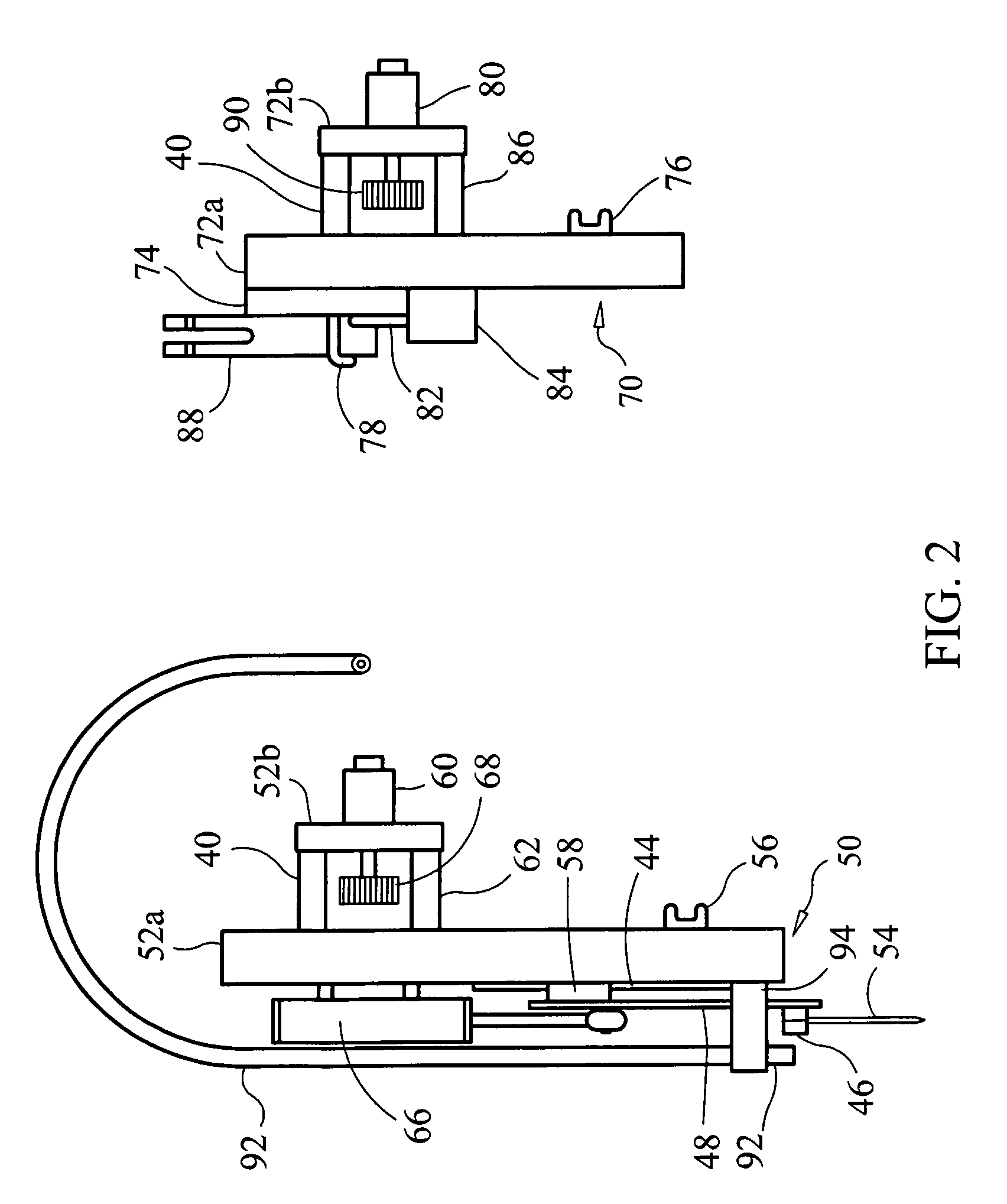

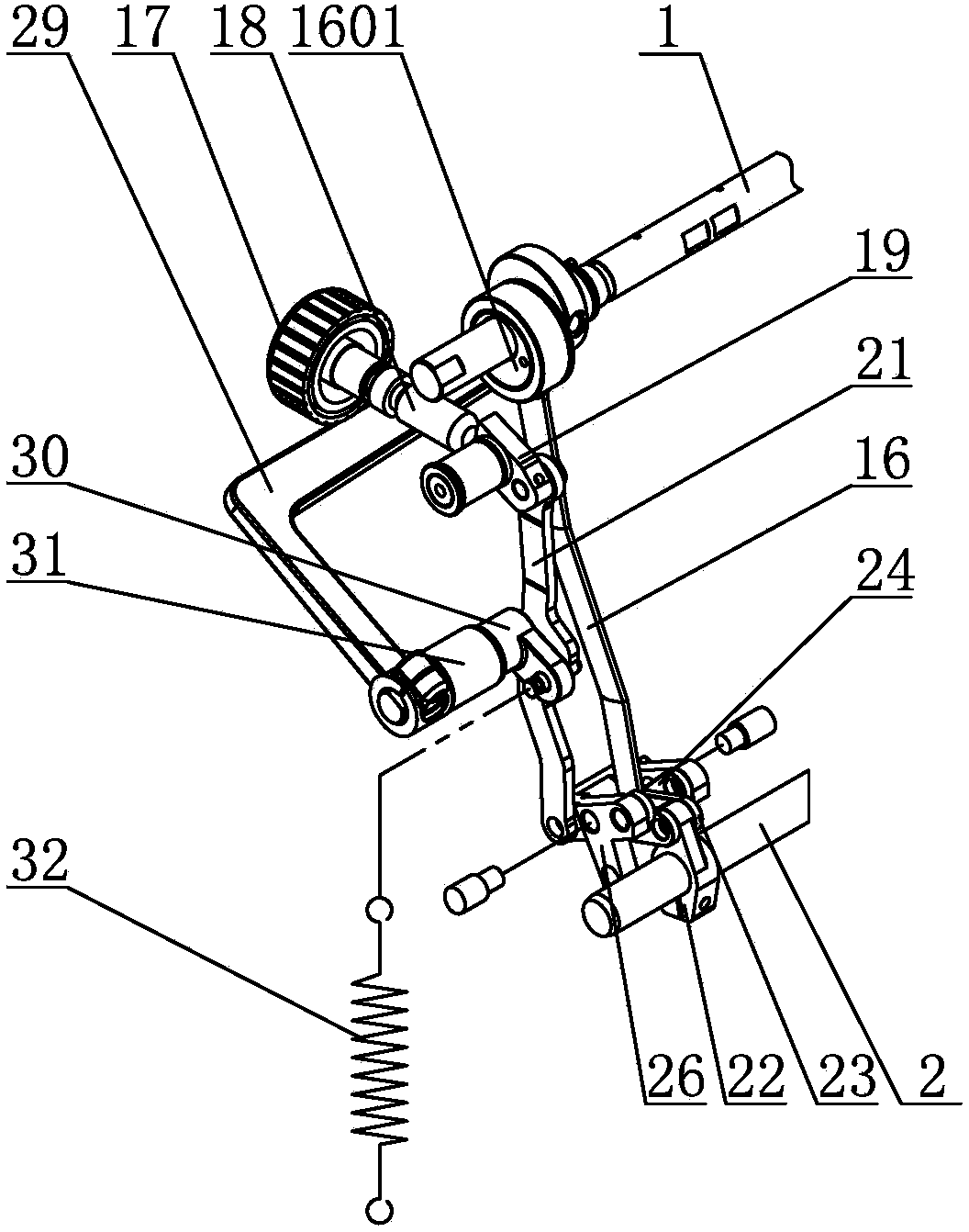

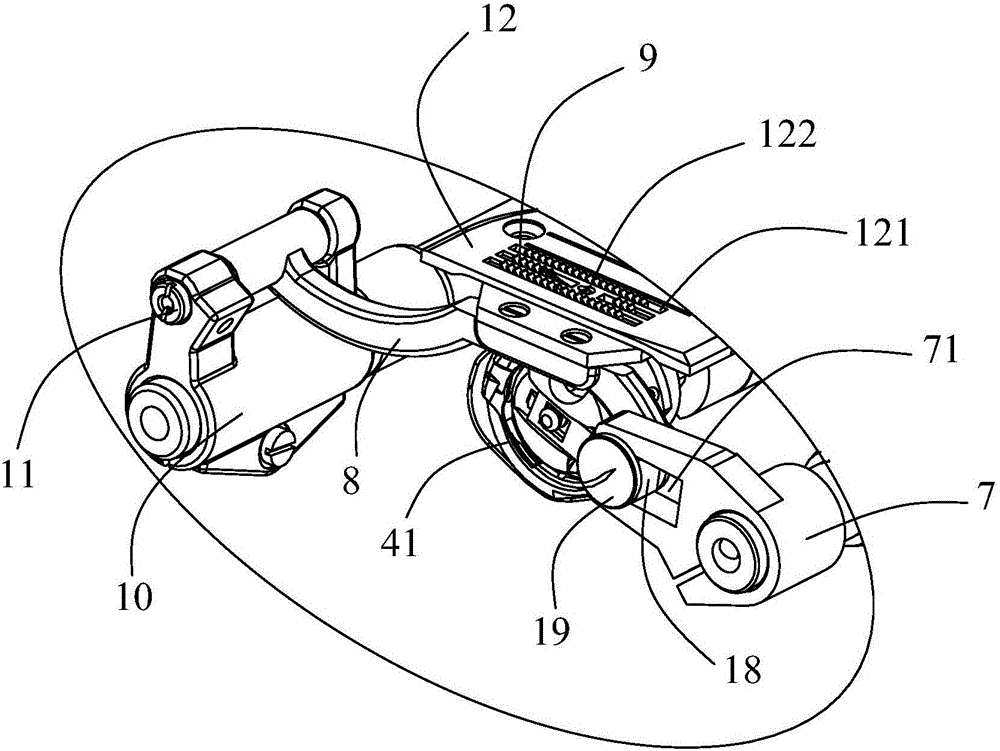

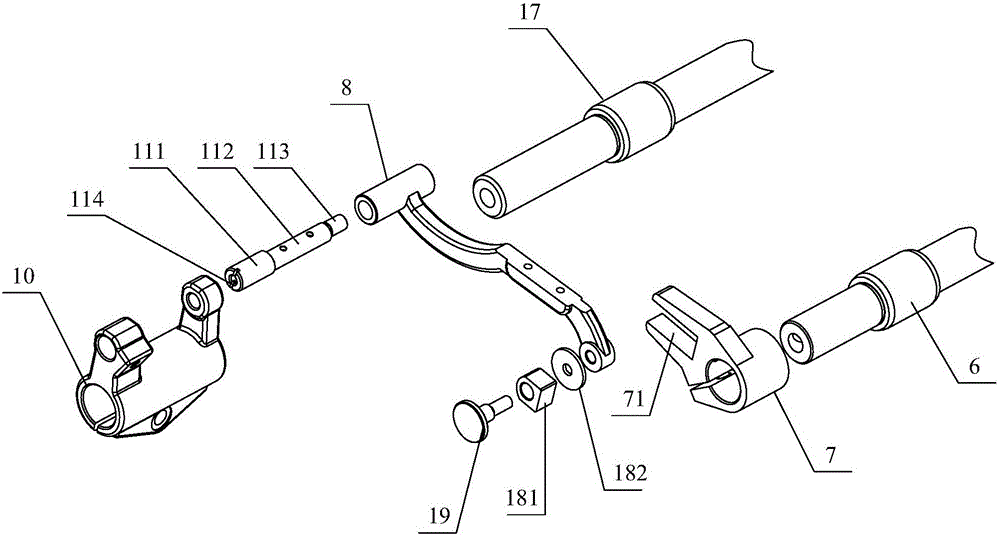

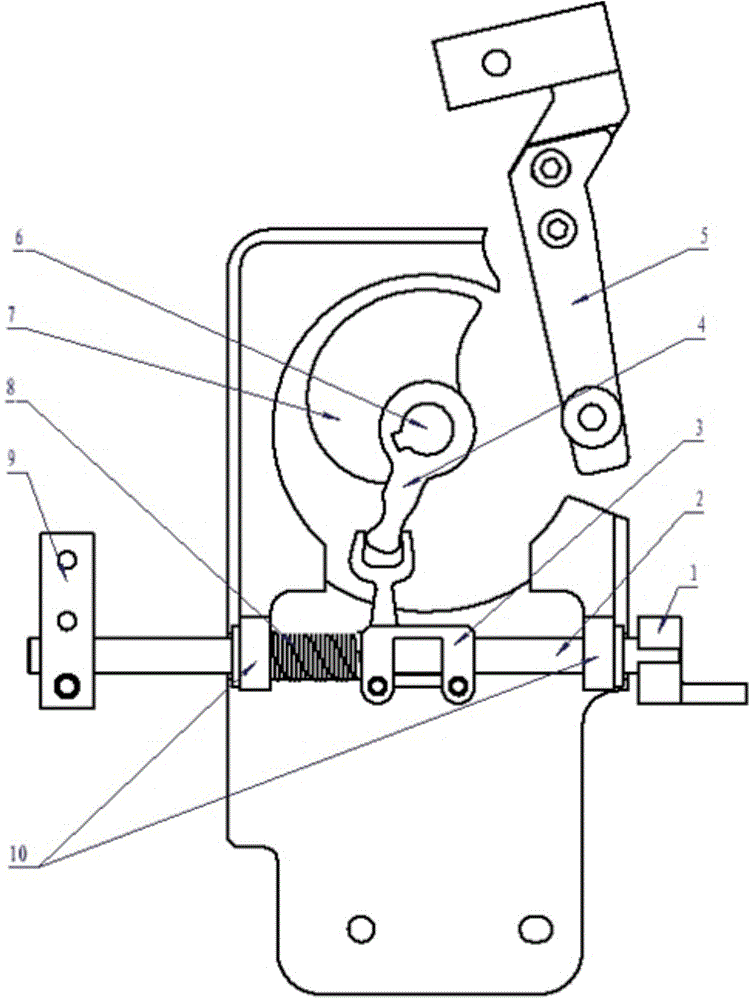

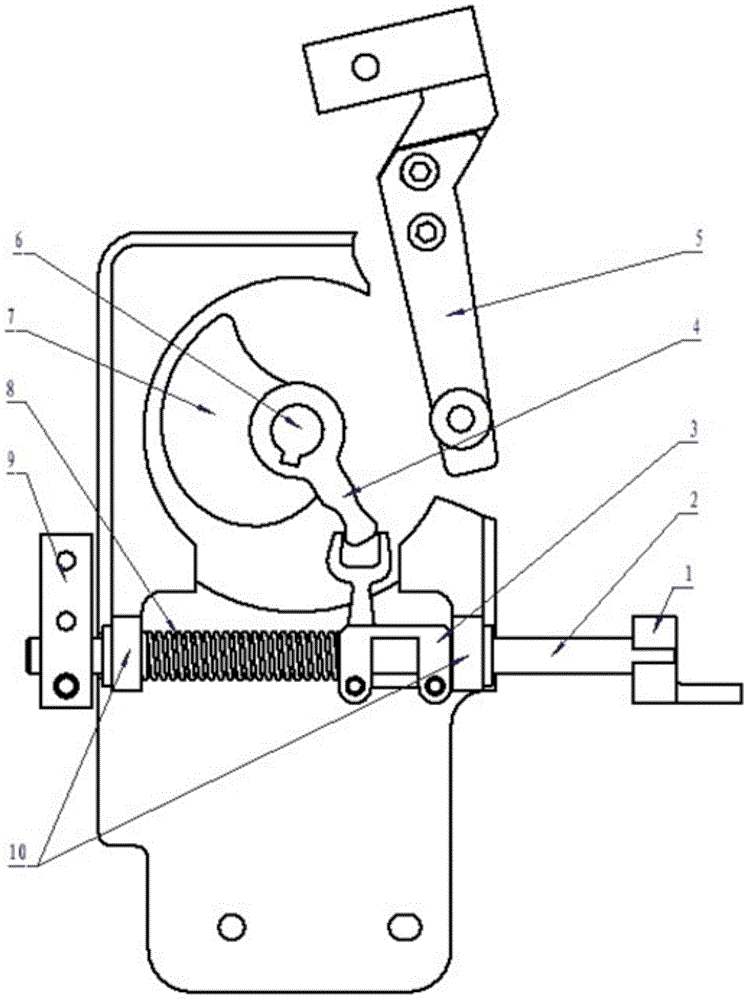

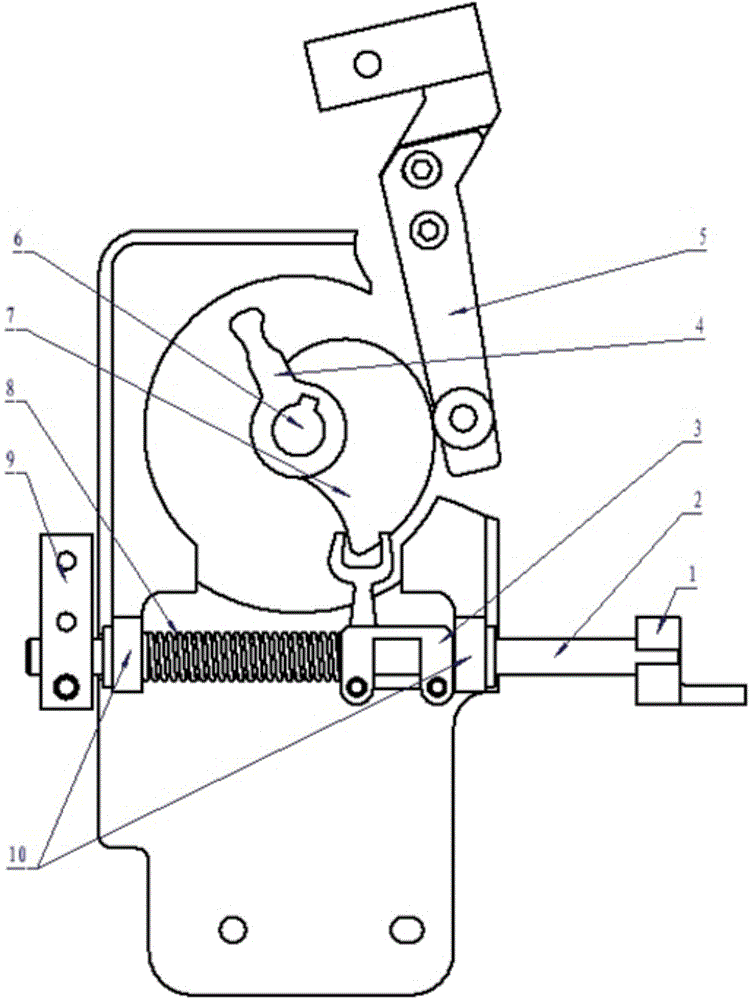

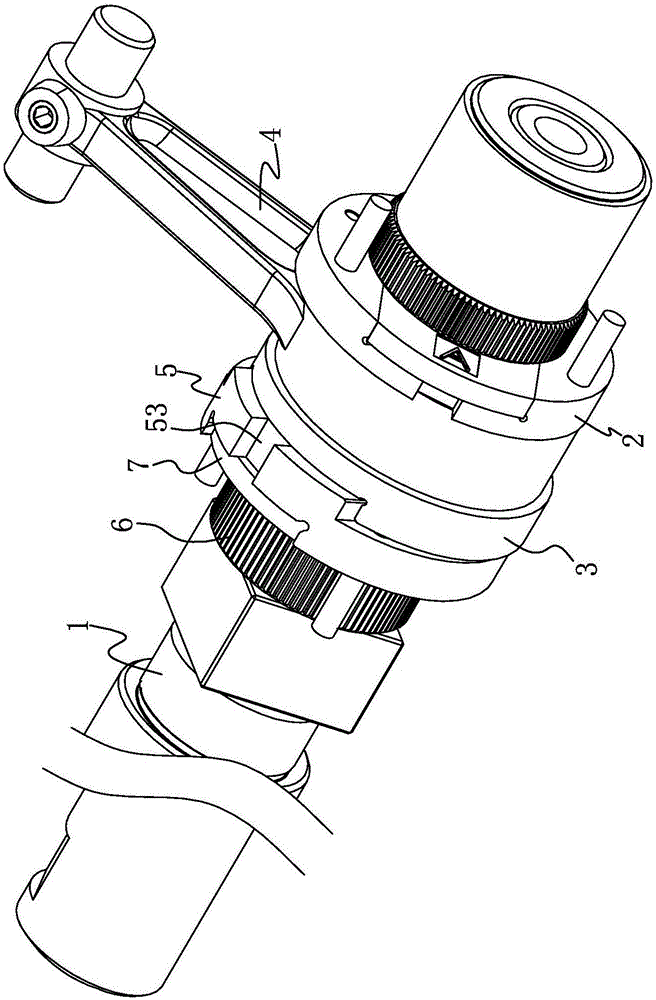

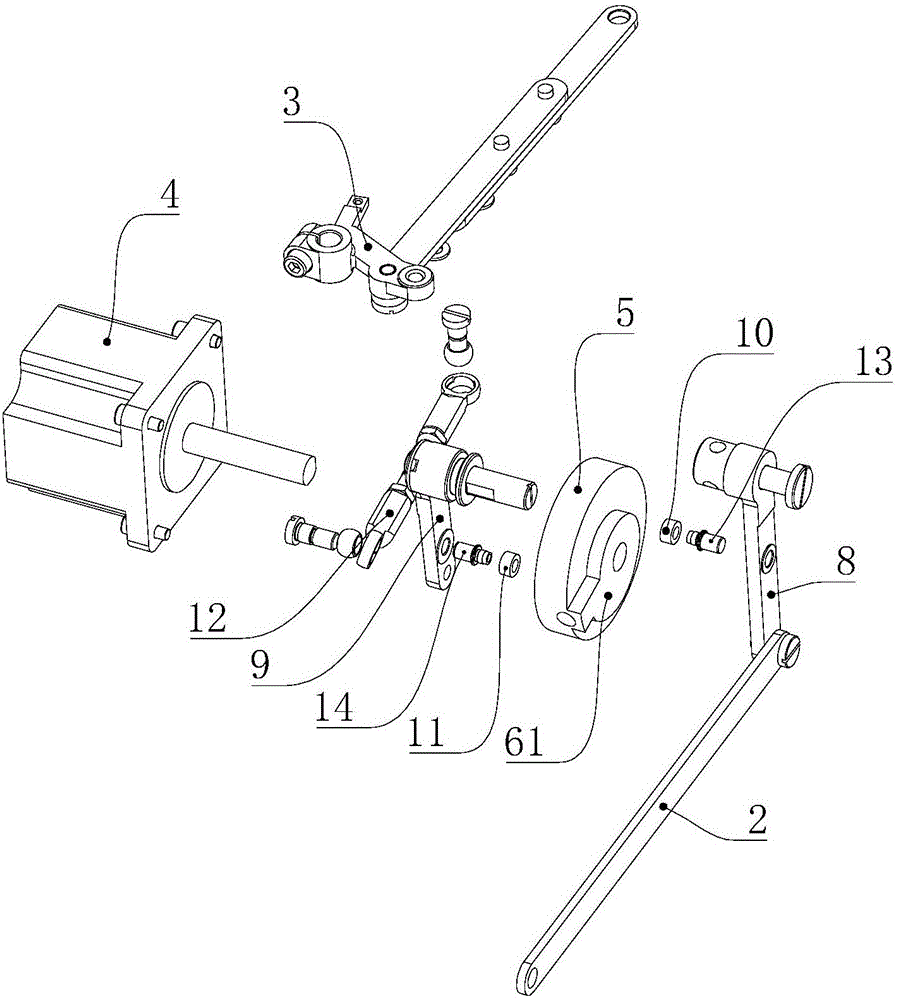

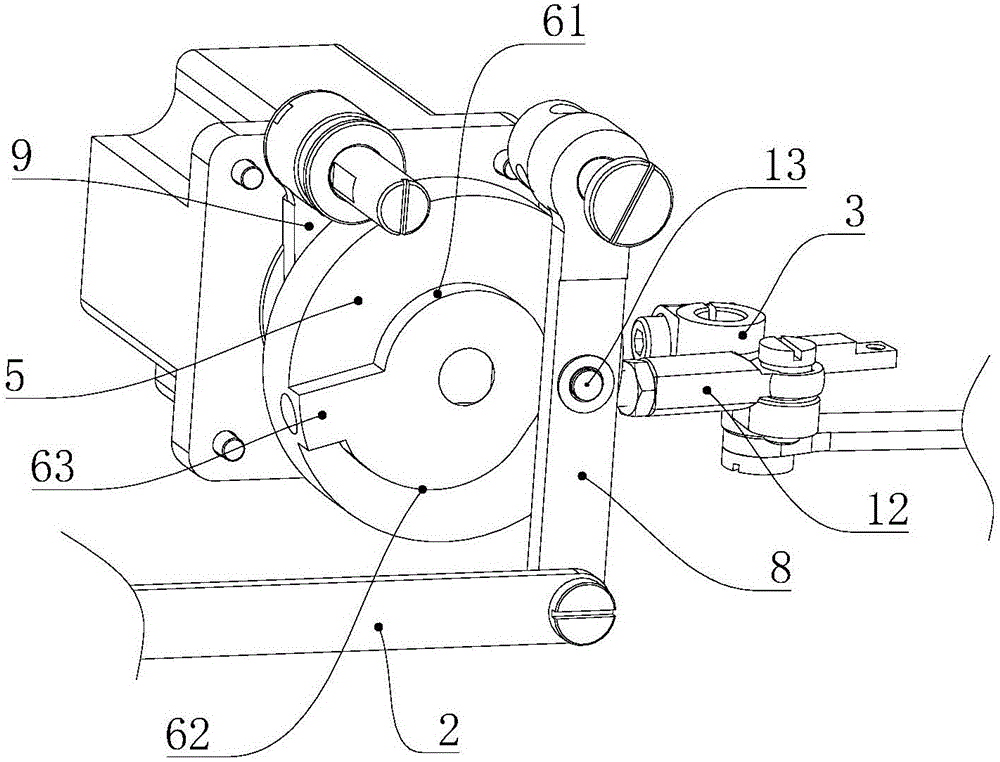

Thread trimming and presser foot raising driving device of sewing machine

ActiveCN104878529AFew partsLow costNeedle severing devicesSewing-machine control devicesEngineeringCam

The invention provides a thread trimming and presser foot raising driving device of a sewing machine. The technical problems that thread trimming, thread loosening and presser foot raising are implemented by two existing thread trimming and presser foot raising driving devices, the cost is high, occupied space is large, noises are large, mounting time is long, and mounting is not facilitated are solved. The thread trimming and presser foot raising driving device of the sewing machine comprises a stepping motor, a shifting fork mechanism and a cam, wherein the shifting fork mechanism comprises a shifting rod, a fork rod, a sliding rod and at least two fixing rings; one end of the shifting rod and the cam are fixed on a spindle of the stepping motor; the other end of the shifting fork can extend in the fork rod and drives the fork rod to move; the fork rod is fixed on the sliding rod; the sliding rod is positioned in the two fixing rings and can slide in the fixing rings; and a movement trace of the cam and a free end of a presser foot raising connecting rod of the sewing machine are intersected. A lower thread trimming device and a thread slacking device are driven to perform thread trimming, thread clamping and thread slacking through the shifting fork mechanism, and presser foot raising is implemented through the cam.

Owner:STRONG H MACHINERY TECH

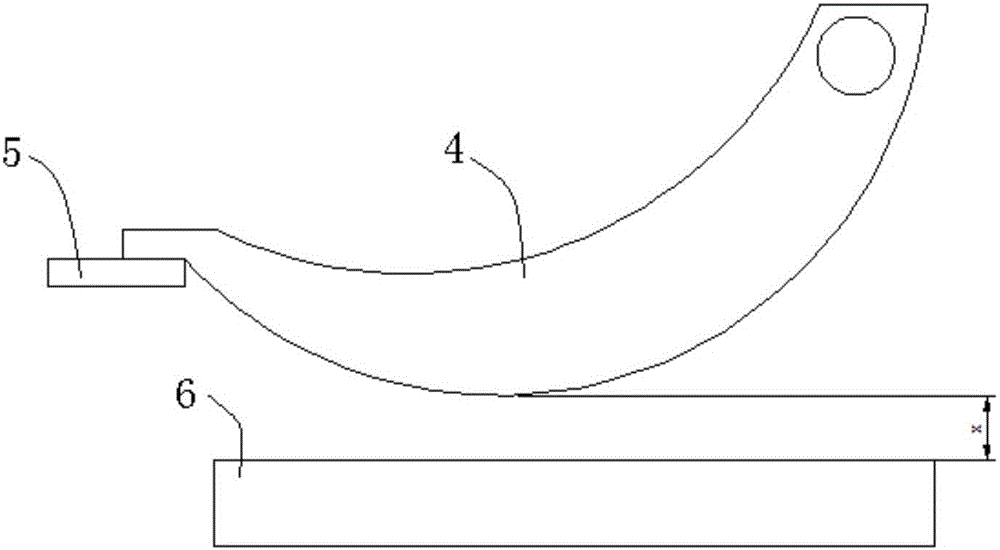

Thin-thick material detection device and sewing machine control system and method

InactiveCN105973137AAvoid jammingSolve bad sewing stitchesSewing-machine control devicesElectrical/magnetic thickness measurementsControl systemInductor

The invention provides a thin and thick material detection device, a sewing machine control system and a method. The thin and thick material detection device includes: a detection part arranged by rotation, the detection end of the detection part is placed above the sewing table, and the gap between the detection part and the sewing table is as follows: The thickness of the cloth to be sewn, when the thickness of the cloth to be sewn changes, the detection part is driven to rotate; the signal generating mechanism includes an inductor for sensing whether the detection part rotates and / or the magnitude of the rotation, and is connected to the sensor And it is a signal generator that sends out the variable generated by the sensor as different signals. The present invention avoids the phenomenon of jamming when sewing over-thickness and over-stemming and sewing at different rotational speeds with different thicknesses of fabrics, which can well solve the problem of poor sewing stitches in the state of continuous sewing of thin and thick fabrics and sewing of thick fabrics question.

Owner:JACK SEWING MASCH CO LTD

Cloth feeding mechanism of sewing machine

ActiveCN106637707AEasy to adjust the tilt angleWork-feeding meansSewing-machine control devicesEngineeringCanis lupus familiaris

The invention discloses a cloth feeding mechanism of a sewing machine and belongs to the technical field of sewing machines. By means of the cloth feeding mechanism, the problem that an original cloth feeding mechanism of the sewing machine is narrow in application range is solved. The cloth feeding mechanism of the sewing machine comprises a main shaft which is sleeved with a stitch length eccentric wheel, a first eccentric wheel is arranged on the outer side of the stitch length eccentric wheel, the first eccentric wheel is internally provided with a first sliding groove, the stitch length eccentric wheel can slide in the first eccentric wheel, the sliding direction in which the stitch length eccentric wheel slides in the first eccentric wheel is eccentrically arranged relative to the first eccentric wheel, and a cloth feeding connecting rod is arranged outside the stitch length eccentric wheel in a sleeving mode; a base is arranged on the main shaft in a sleeving mode, and the first eccentric wheel is arranged on the base in a sliding mode in the radial direction of the main shaft; a clutch mechanism is arranged between the base and the main shaft. Due to the arrangement of the clutch mechanism between the base and the main shaft, the inclination angle of the elliptical motion track of a cloth feeding dog can be conveniently adjusted by means of the cloth feeding mechanism.

Owner:JACK SEWING MASCH CO LTD

Sewing machine

ActiveCN111648053AAvoid collisionCompact structureWork-feeding meansPressersElectric machineryEngineering

The invention provides a sewing machine. The sewing machine comprises a main shaft, a material feeding mechanism, a presser foot lifting mechanism, a driving motor, a needle pitch adjusting power transmission mechanism and a presser foot lifting transmission mechanism, wherein the material feeding mechanism is provided with a material feeding swinging seat; the needle pitch adjusting power transmission mechanism enables power transmission to continuously exist between the driving motor and the material feeding swinging seat; a collision avoidance structure is arranged in the presser foot lifting transmission mechanism; a corner of an output shaft of the driving motor is provided with a needle pitch active adjusting area and a presser foot lifting area; when the output shaft of the drivingmotor operates within the needle pitch active adjusting area, the sewing machine is provided with effective needle pitch; the collision avoidance structure enables no power transmission to exist between the driving motor and a presser foot lifting mechanism; when the output shaft of the driving motor operates within the presser foot lifting area, the presser foot lifting transmission mechanism enables power transmission to exist between the driving motor and the presser foot lifting mechanism; and the absolute value of a needle pitch corresponding to an angle of the material feeding swinging seat is not larger than a maximum absolute value of the effective needle pitch. According to the sewing machine, timely response, suspended seam and very good needle pitch adjusting stability of the needle pitch adjusting mechanism are realized.

Owner:JACK SEWING MASCH CO LTD

Tufting machine for producing athletic turf having a graphic design

ActiveUS20080134949A1Reduce positioning accuracyEfficient constructionProgramme-controlled sewing machinesTufting apparatusYarnGraphics

A tufting machine capable of producing individual articles of athletic turf bearing precise graphic patterns is disclosed. The machine includes a support frame to which a backing material is statically held, a tufting frame that spans above and below the backing and is computer-controlled to travel along the support frame, a yarn-inserting needle carriage disposed above the backing along the tufting frame and a yarn-catching looper carriage disposed below the backing along the tufting frame. The carriages are computer-controlled to asynchronously shift relative to each other as may be necessary for their individual yarn-inserting components and yarn-catching components to cooperate

Owner:SIGNATURE BANK OF GEORGIA +1

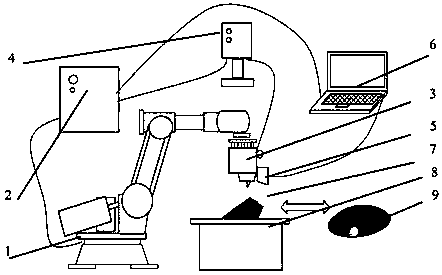

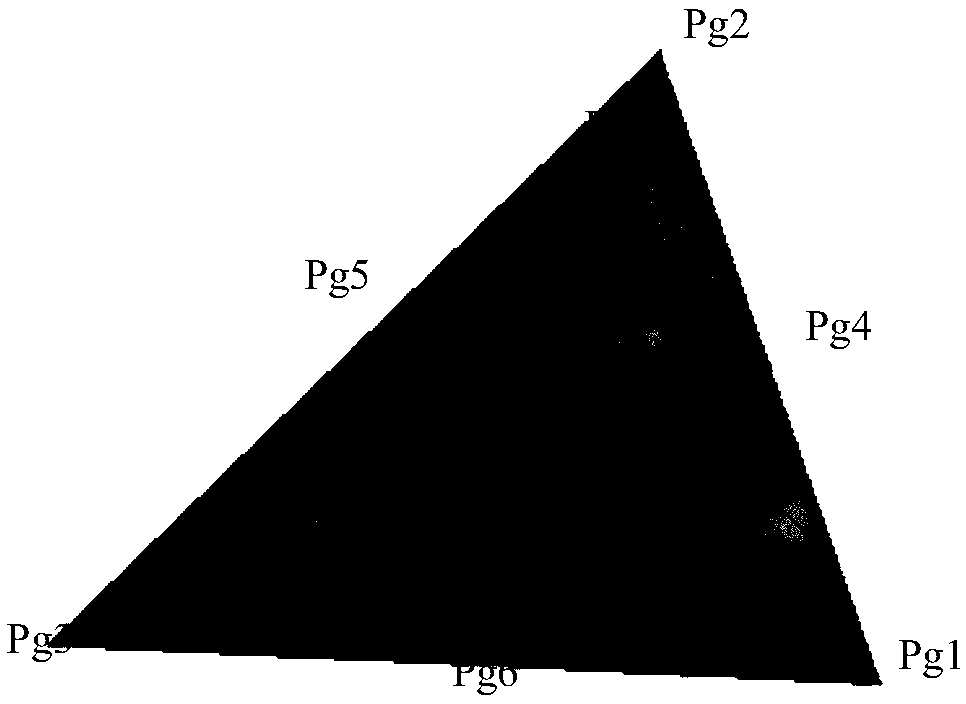

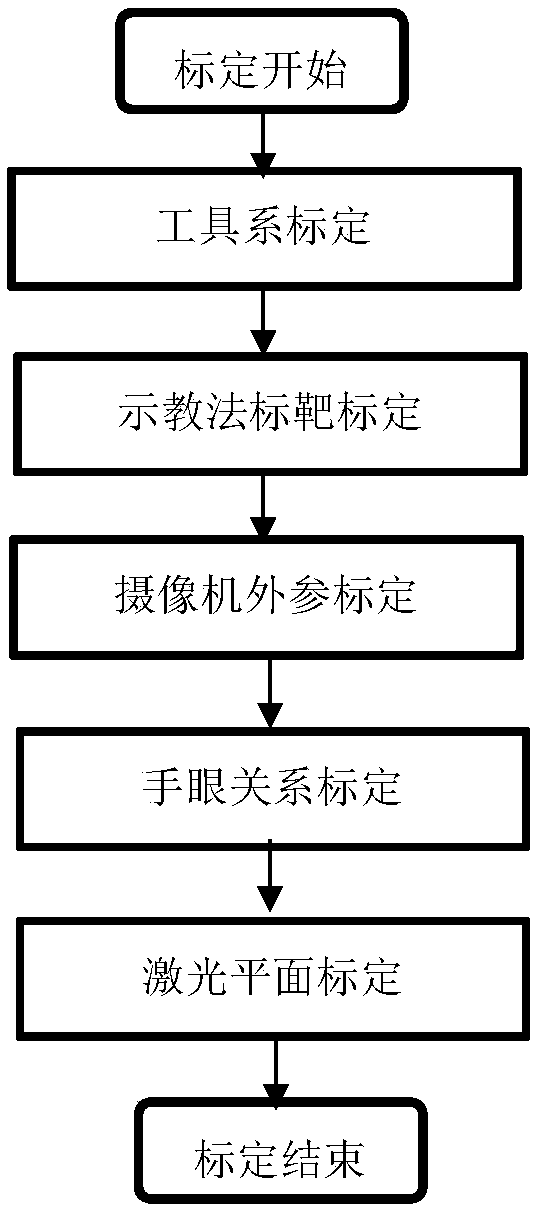

Method for automatically tracking unilateral sewing laser visual sense paths of composite material three-dimensional structural member

ActiveCN109591011ARapid positioningImprove calibration efficiencyProgramme-controlled manipulatorProgramme-controlled sewing machinesLaser lightVisual perception

The invention discloses a method for automatically unilateral sewing laser visual sense paths of a tracking composite material three-dimensional structural member. The method comprises the following steps of performing demarcating with a three-stripe laser light source visual tracking system and performing real-time extraction on robot operation paths. According to the method disclosed by the invention, an eye-in-hand manner is adopted; laser stripes of a laser seam tracker are projected to the surface of a three-dimensional target, and corresponding three-dimensional position information is obtained, so that the relative pose relationship between the wrist of a robot and the laser visual sense system is determined; and the shape of a space curved surface character workpiece is matched bya laser visual system in a real-time manner, and the working path of the robot is extracted for tracking calculation. Compared with a conventional plane target, the method can effectively improve thedemarcating efficiency and the demarcating accuracy; the working plane of a three-stripe laser light source can be demarcated at the same time, and on the other side, the quick positioning of the space curved surface character workpiece and tracking requirement of unilateral sewing paths can be realized.

Owner:TIANJIN POLYTECHNIC UNIV

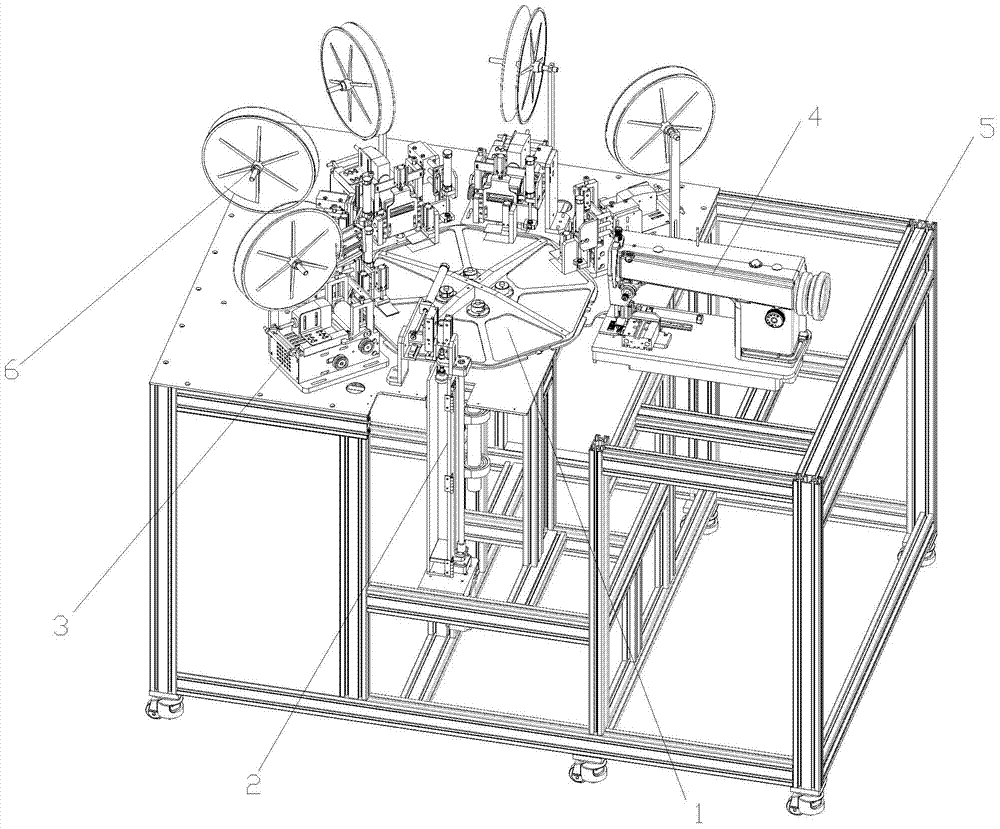

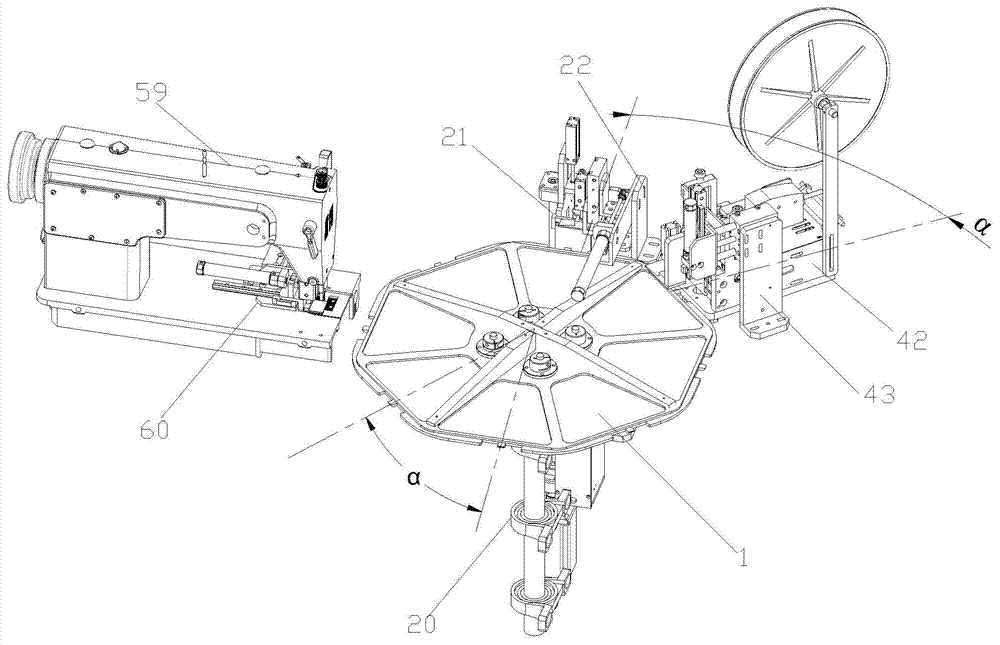

Trademark sewing machine

ActiveCN104328604AImprove work efficiencyWork-feeding meansSewing-machine control devicesManufacturing engineeringSewing machine

The invention relates to a trademark sewing machine, which comprises a rotary worktable, a trademark supply device, a trademark folding and sending device and a trademark sewing device, wherein the rotary worktable is used as a center, the trademark supply device, the trademark folding and sending device and the trademark sewing device are sequentially arranged around the rotary worktable, the trademark supply device is used for supplying bottom layer trademarks to the rotary worktable, the rotary worktable is used for obtaining the bottom layer trademarks and rotating the bottom layer trademarks to the trademark folding and sending device, the trademark folding and sending device is used for overlapping upper layer trademarks on the bottom layer trademarks, the rotary worktable rotates and sends the layered trademarks to the trademark sewing device, and the trademark sewing device is used for clamping and sewing the layered trademarks. By adopting the method, the trademark sewing machine has the advantages that the equipment is divided in a unitization way according to working steps; the center rotary worktable is used as the basis, and the trademarks are overlapped in the layering way and are finally sewed; the trademark sewing machine can quickly and efficiently complete the sewing of different types of trademarks, and is suitable for multiple types of production operation flow lines, and the working efficiency of the production of the whole flow line is improved.

Owner:苏州琼派瑞特科技股份有限公司

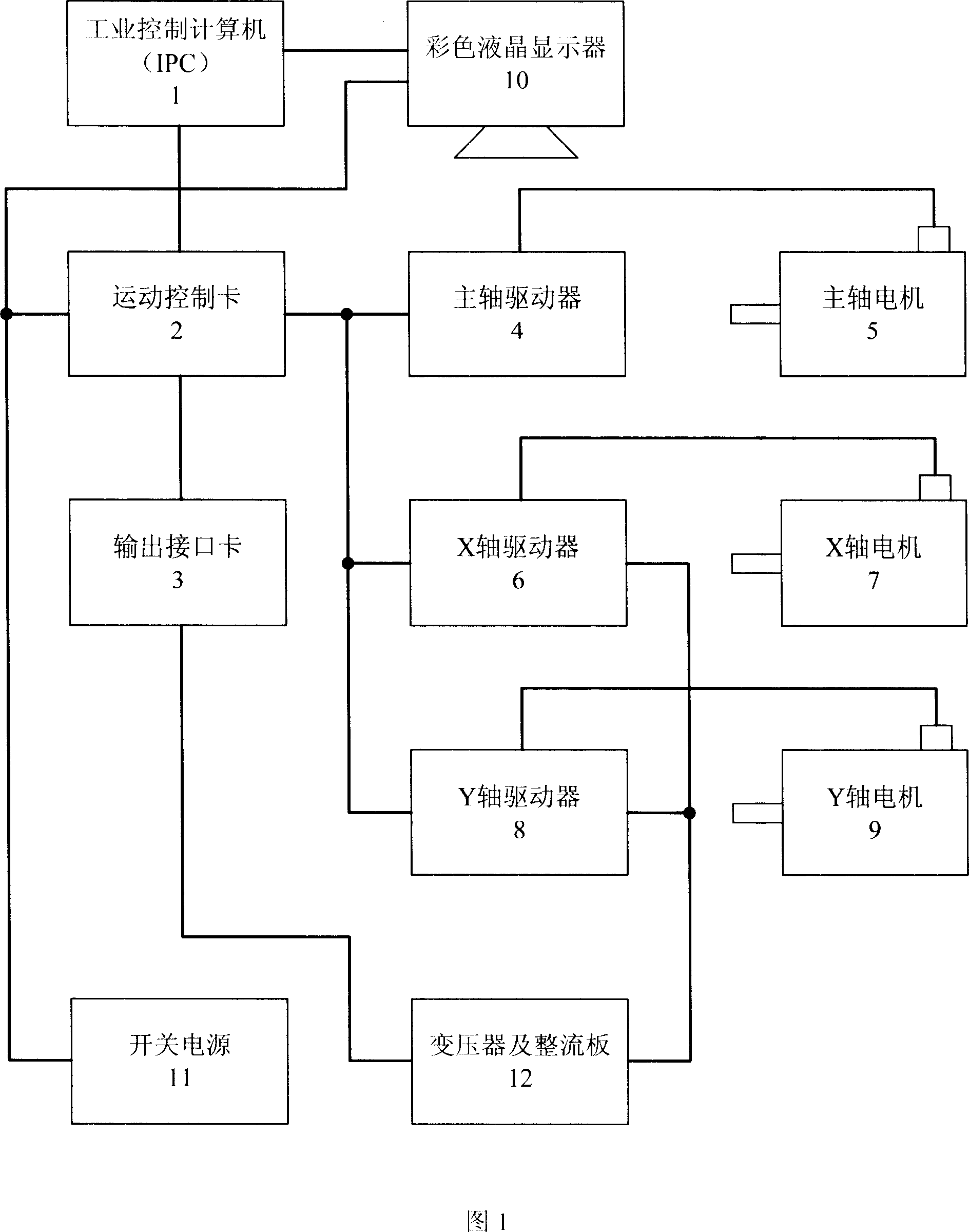

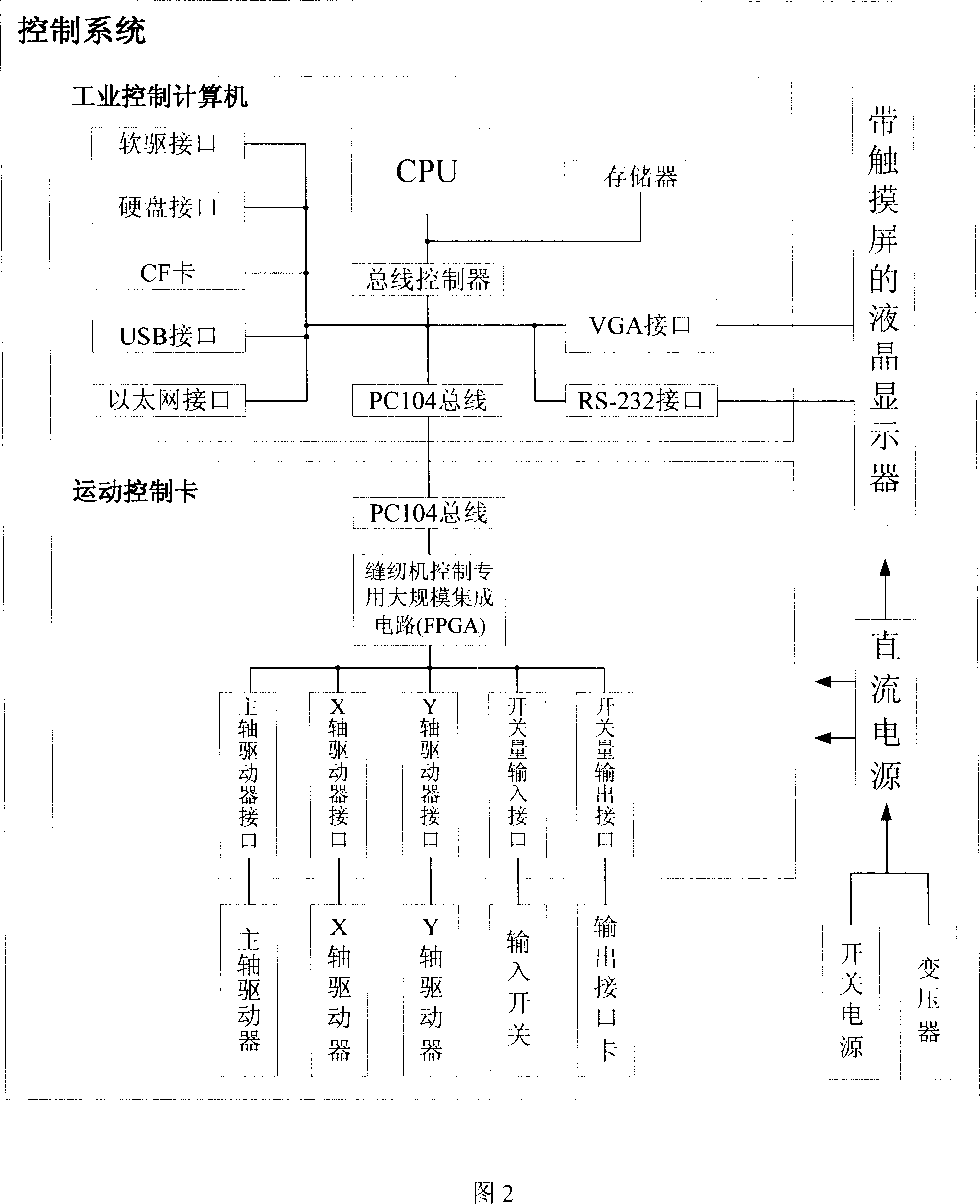

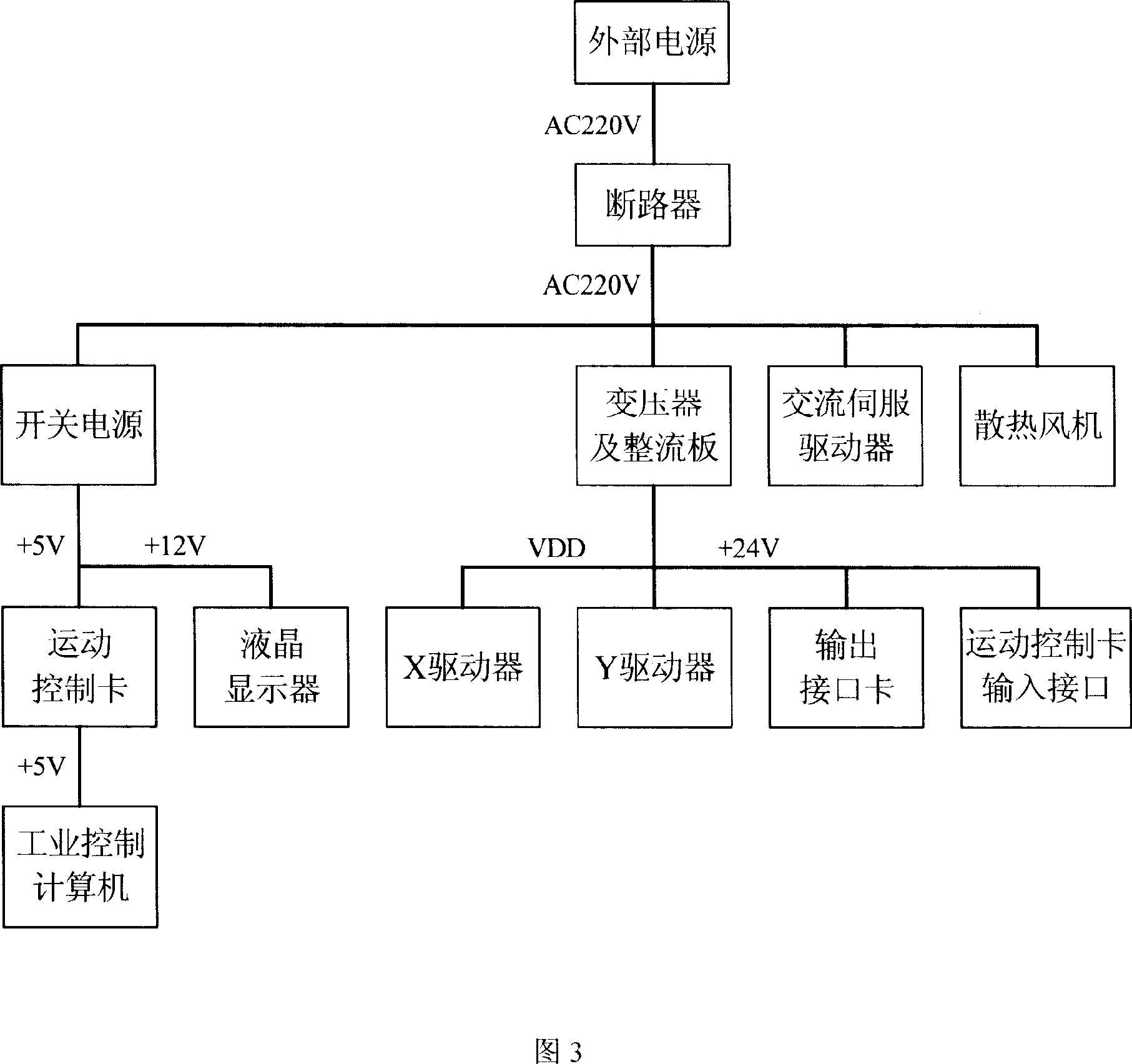

Computer control system of industrial sewing machine

InactiveCN101012604AFunction increaseIncrease the spindle speedProgramme-controlled sewing machinesSewing-machine control devicesHuman–machine interfaceTransformer

The invention provides a computer control system for industrial sewing machines, comprising a computer control cell containing an industrial control computer, a motion control card and an output interface card, a servo driving cell containing AC servo motor or step motor, a man-machine interface cell containing color liquid crystal display with touch screen performance, and a power supply cell for system containing switching power supply, transformer and rectifying plate. The invention adopts the module cell structure. The inside of each cell is relatively independent, self-contained and high integrated degree. It can configure relative parts flexibly to constitute the system according to the difference of host of industrial sewing machine. By the system software program, sewing every designs, lines or schemes automatically in high speed is accomplished. It is provided with convenient operation, simple plate-marking program, improved speed and low labor intensity.

Owner:MIANYANG WEIBO ELECTRONICS

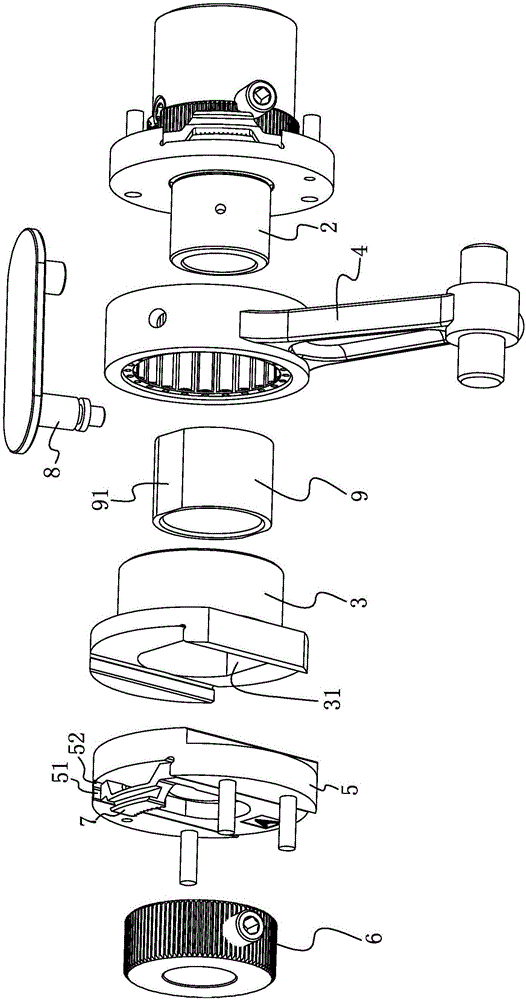

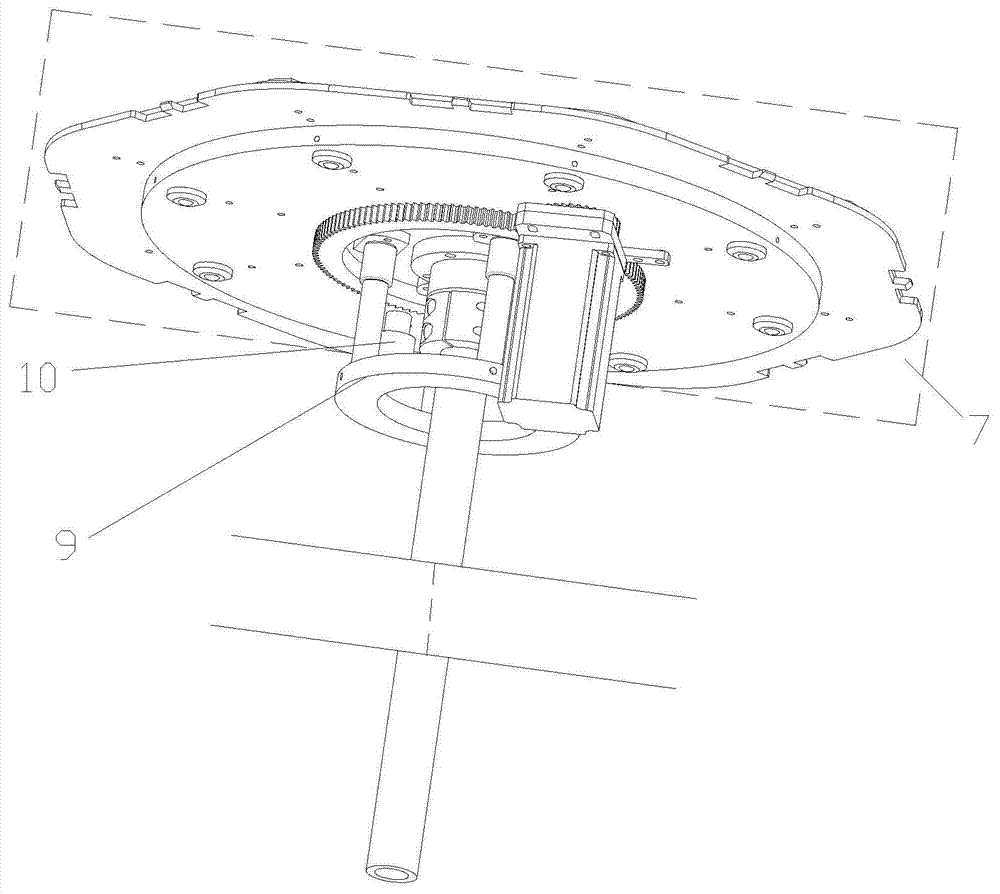

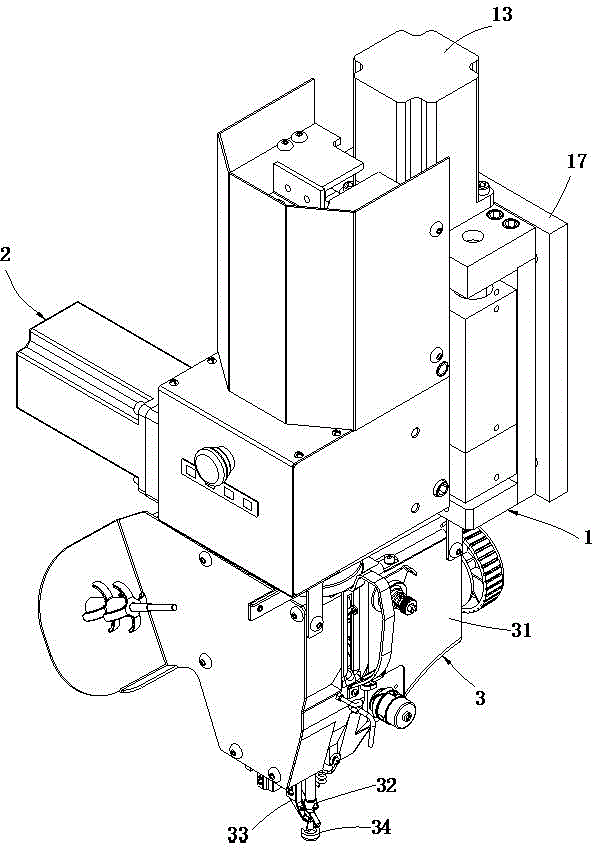

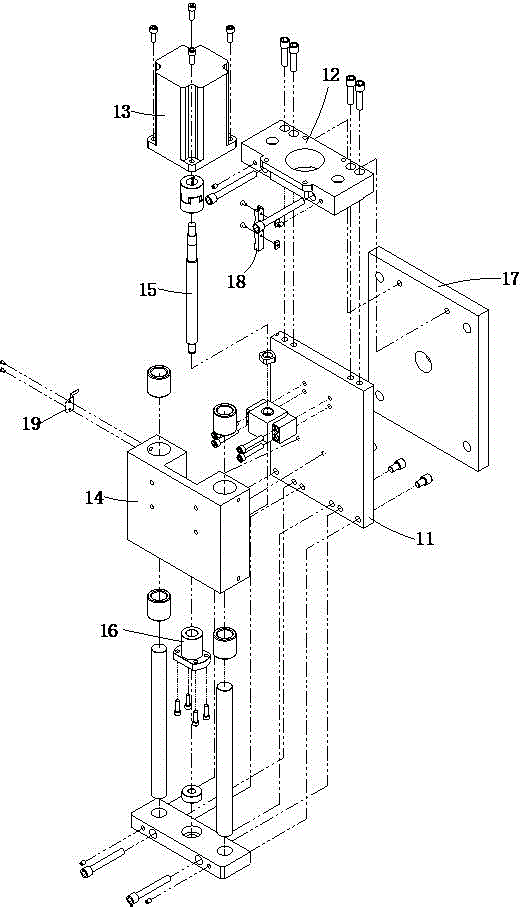

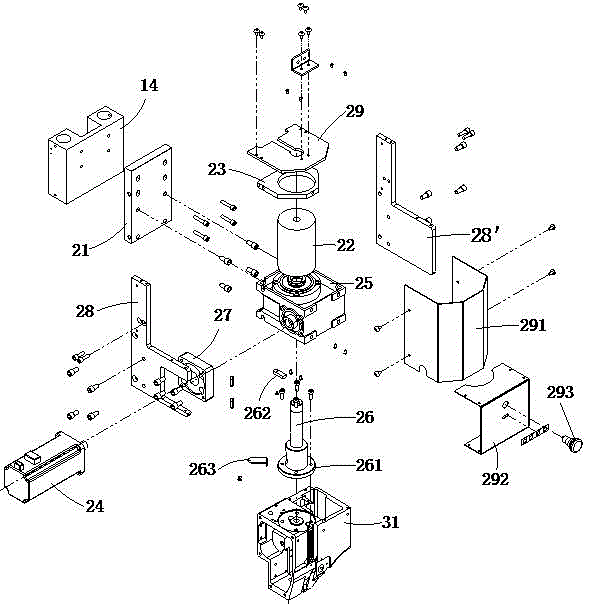

Upper machine head of independently-driven rotary type automatic sewing device

ActiveCN103981649AReduce volumeHigh degree of integrationPressersSewing-machine control devicesFailure rateMachining

The invention relates to an upper machine head of an independently-driven rotary type automatic sewing device. The upper machine head comprises a machine head lifting assembly, a machine head rotating assembly and a machine head assembly, wherein the machine head rotating assembly is fixedly arranged on the machine head lifting assembly; the machine head assembly is fixedly arranged at the lower part of the machine head rotating assembly; the machine head rotating assembly comprises a conductive slip ring, a slip ring fixing seat, a machine head installation plate, a machine head rotating motor, a gearbox and a rotating shaft, the upper end of the rotating shaft is connected with the conductive slip ring for driving the conductive slip ring to rotate, and the rotating shaft can drive the machine head assembly to rotate clockwise or anticlockwise by 360 degrees; the machine head lifting assembly can drive the machine head assembly to move up and down through the machine head rotating assembly. The upper machine head disclosed by the invention can be lifted and can be rotated as well, various machining needs can be met, and the application range is greatly enlarged; the size is small, the integration degree is high, the upper machine head can be matched with a lower machine head for realizing synchronous high-speed rotating, the stability is high, the failure rate is low, and the maintenance is simple and convenient.

Owner:浙江锦上智控科技有限公司

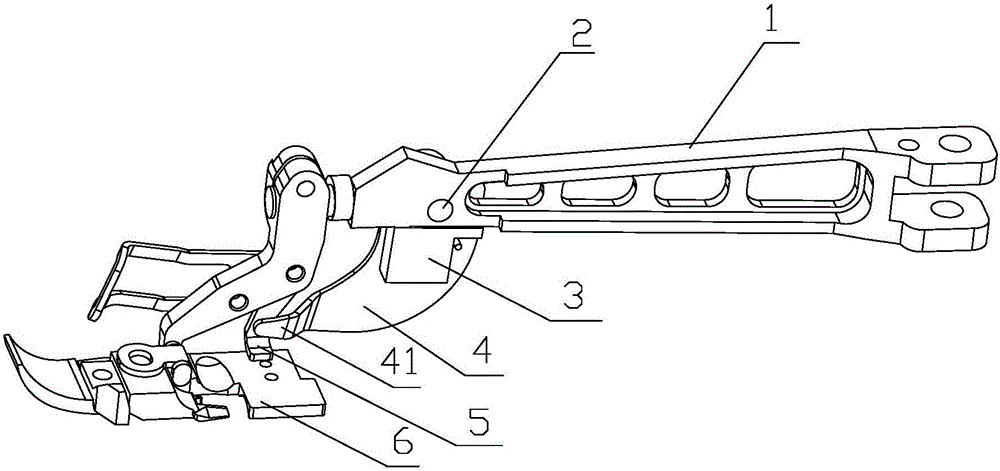

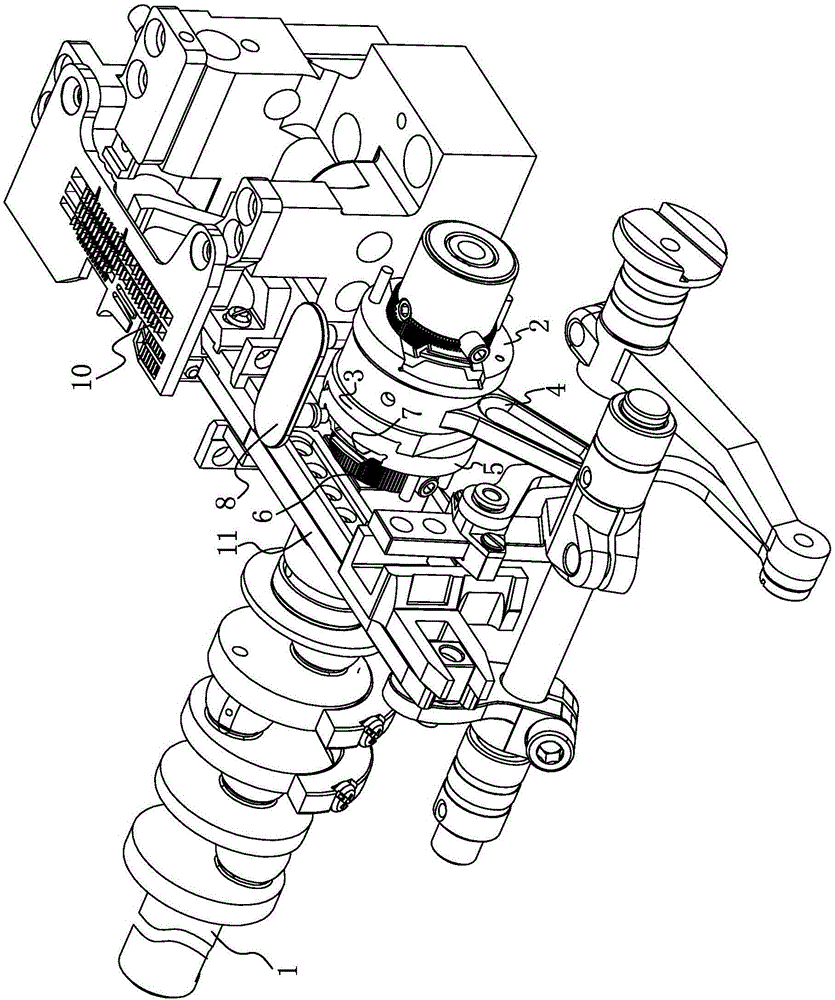

Driving device for automatic thread trimming and automatic presser foot lifting

ActiveCN106012323ACompact structureSame rotation speedNeedle severing devicesPressersMotor driveEngineering

The invention belongs to the technical field of sewing machines, and particularly discloses a driving device for automatic thread trimming and automatic presser foot lifting. The driving device is simple in structure and capable of guaranteeing stable operation of a sewing machine. The driving device comprises a presser foot lifting transmission rod, a thread trimming transmission rod, a stepping motor, a cam body arranged on the stepping motor, a pressure foot lifting connecting rod and a thread trimming connecting rod. The cam body is provided with a pressure foot lifting driving cam surface and a thread trimming driving cam surface, both of which comprise a base circle surface and a lift curved surface. The other end of the pressure foot lifting connecting rod is hinged to one end of the pressure foot lifting transmission rod, and the pressure foot lifting connecting rod is provided with a first driven pin. The thread trimming transmission rod is hinged to the other end of the thread trimming connecting rod, and the thread trimming connecting rod is provided with a second driven pin. When the stepping motor drives the cam body to rotate clockwise by a certain angle, one driven pin enters the lift curved surfaces from the base circle surfaces, and the other driven pin slides on the base circle surfaces; when the stepping motor drives the cam body to rotate anticlockwise, one driven pin slides on the base circle surfaces, and the other driven pin enters the lift curved surfaces from the base circle surfaces.

Owner:ZHEJIANG DUMA SEWING MACHINE

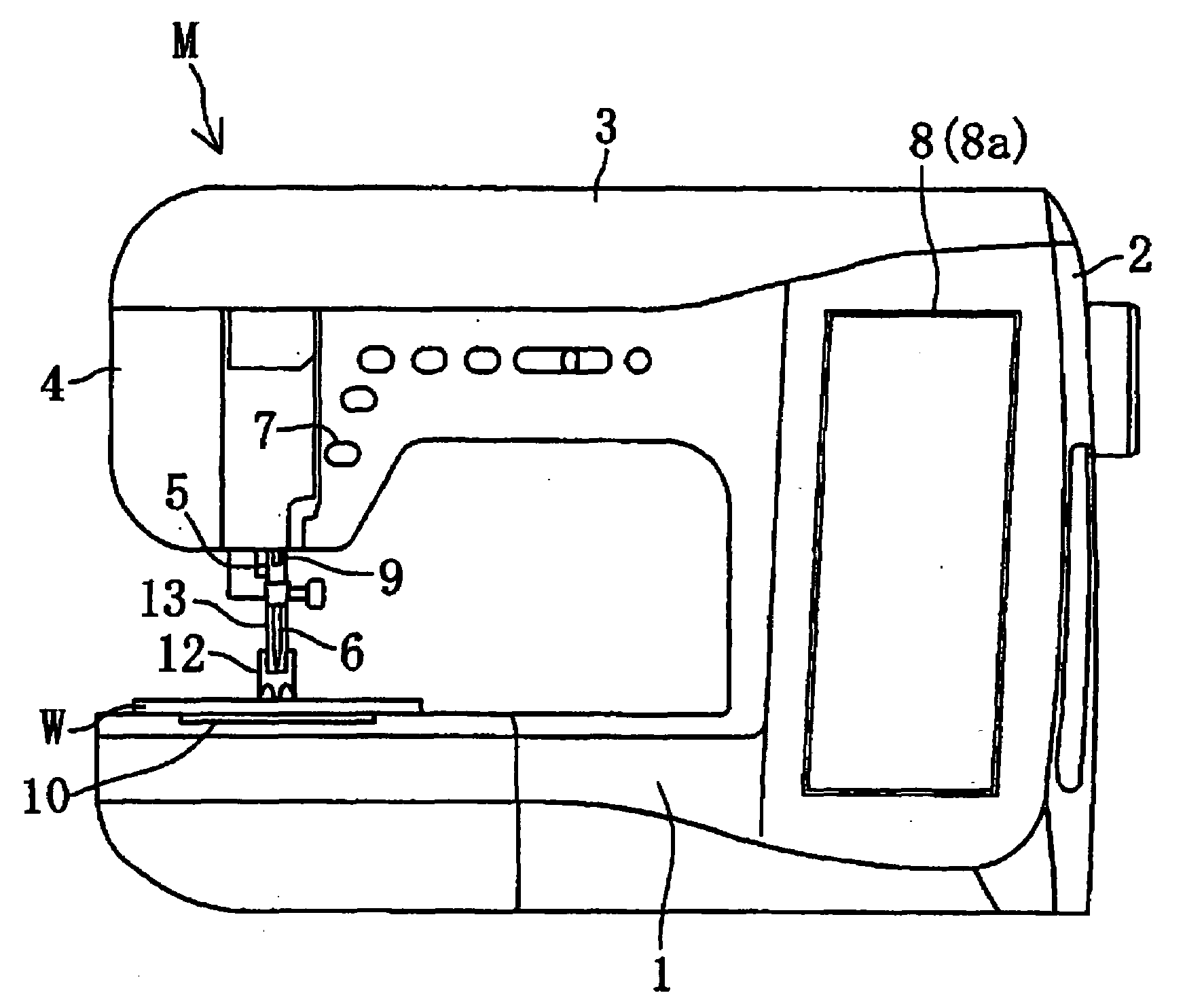

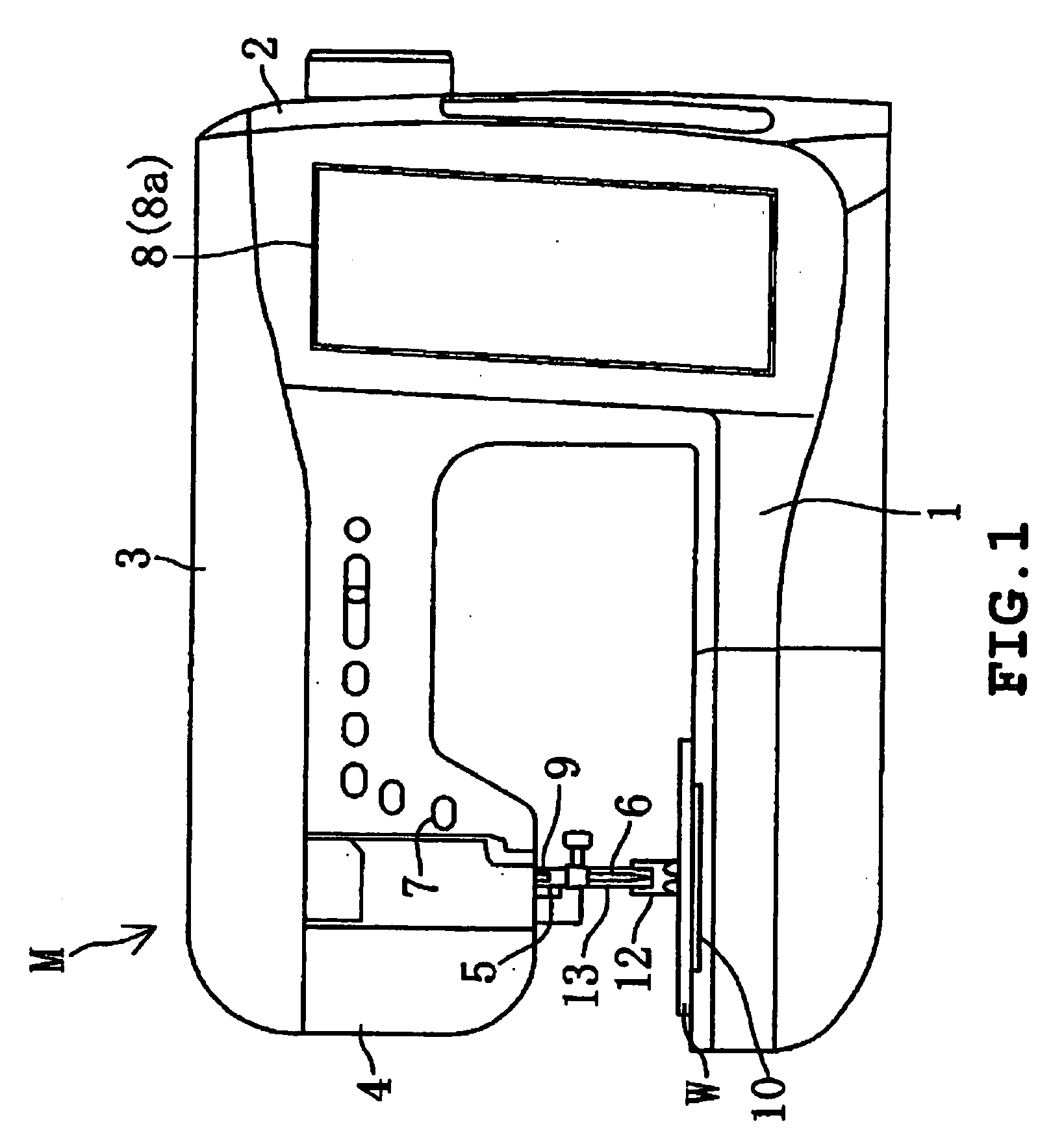

Sewing machine

ActiveUS20080078313A1Amount of movement is limitedProgramme-controlled sewing machinesPressersEngineeringSewing needle

A sewing machine capable of sewing while a workpiece cloth is moved by a manual operation includes a needlebar having a lower end to which a sewing needle is attached, a needlebar driving mechanism vertically driving the needlebar via a main shaft, a presser foot pressing the workpiece cloth, an imaging device imaging at least an area of the workpiece cloth near to the sewing needle, a movement amount operating device obtaining by operation a movement amount of the workpiece cloth based on image data supplied from the imaging device, a setting device setting a stitch pitch on the workpiece cloth, a comparing device comparing the obtained movement amount of the workpiece cloth and the set stitch pitch, a cloth movement limiter limiting movement of the workpiece cloth by the manual operation, and a control device controlling the cloth movement limiter according to a result of comparison.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com