Patents

Literature

50results about "Sewing measuring devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

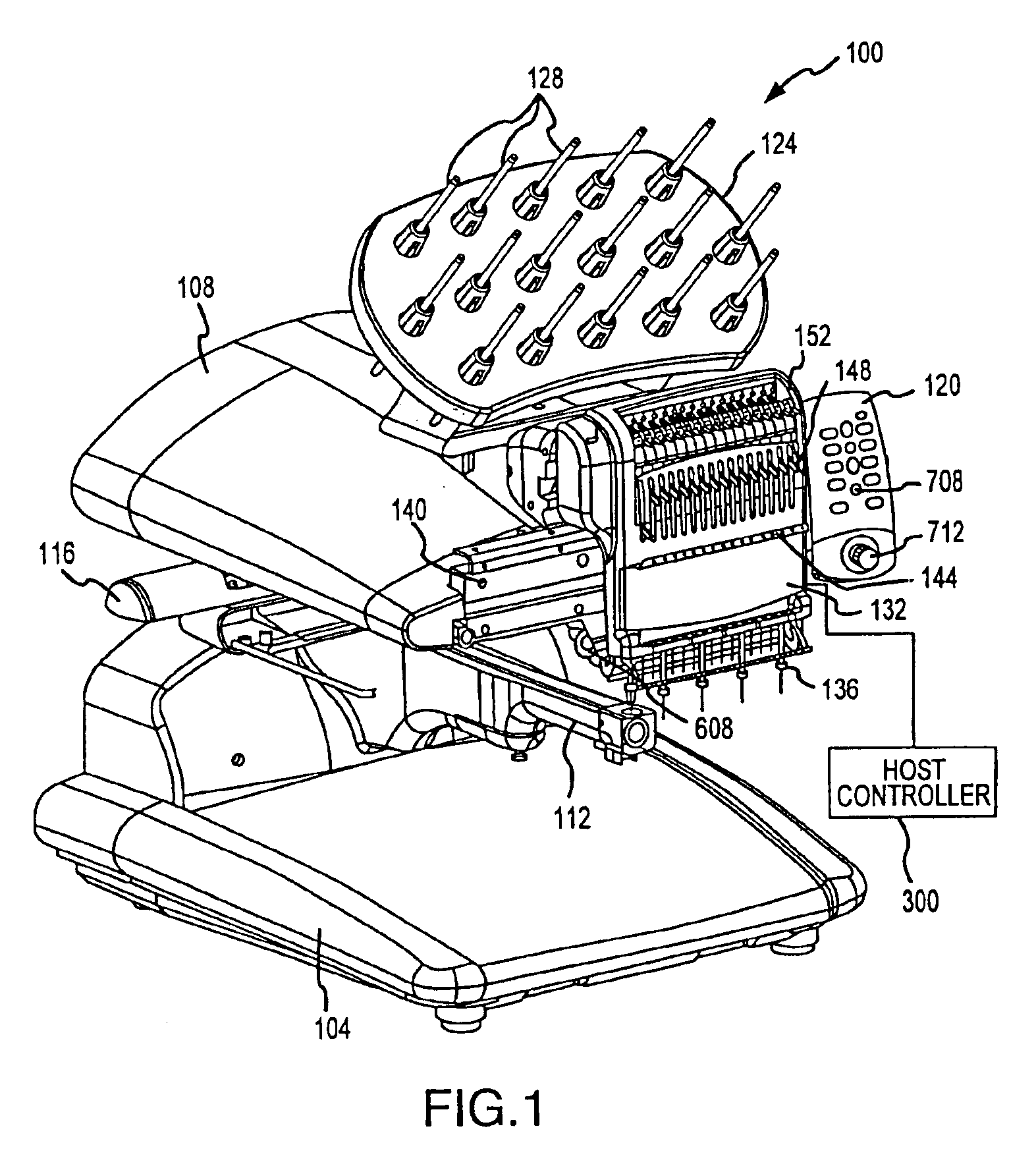

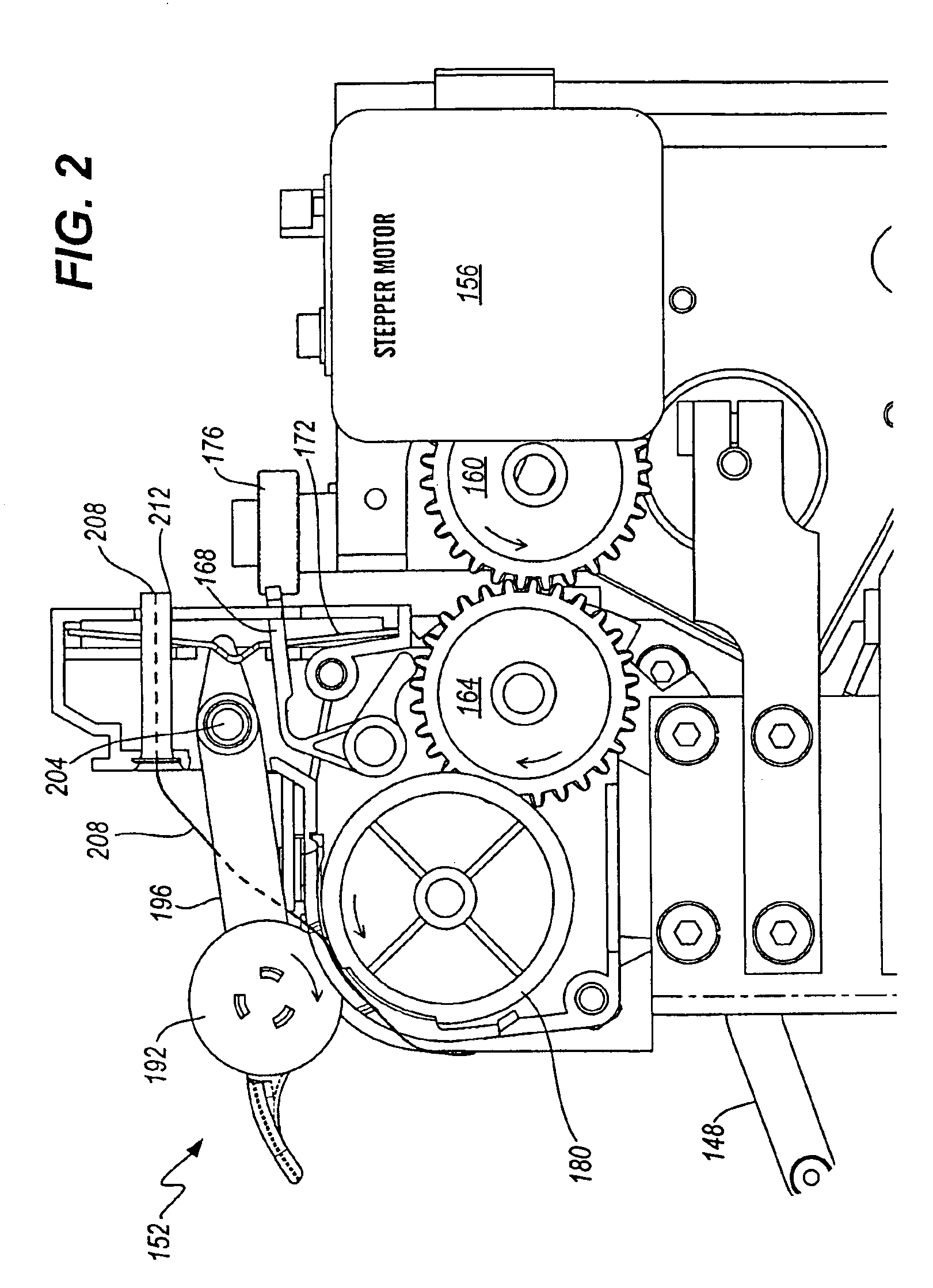

Computerized stitching including embroidering

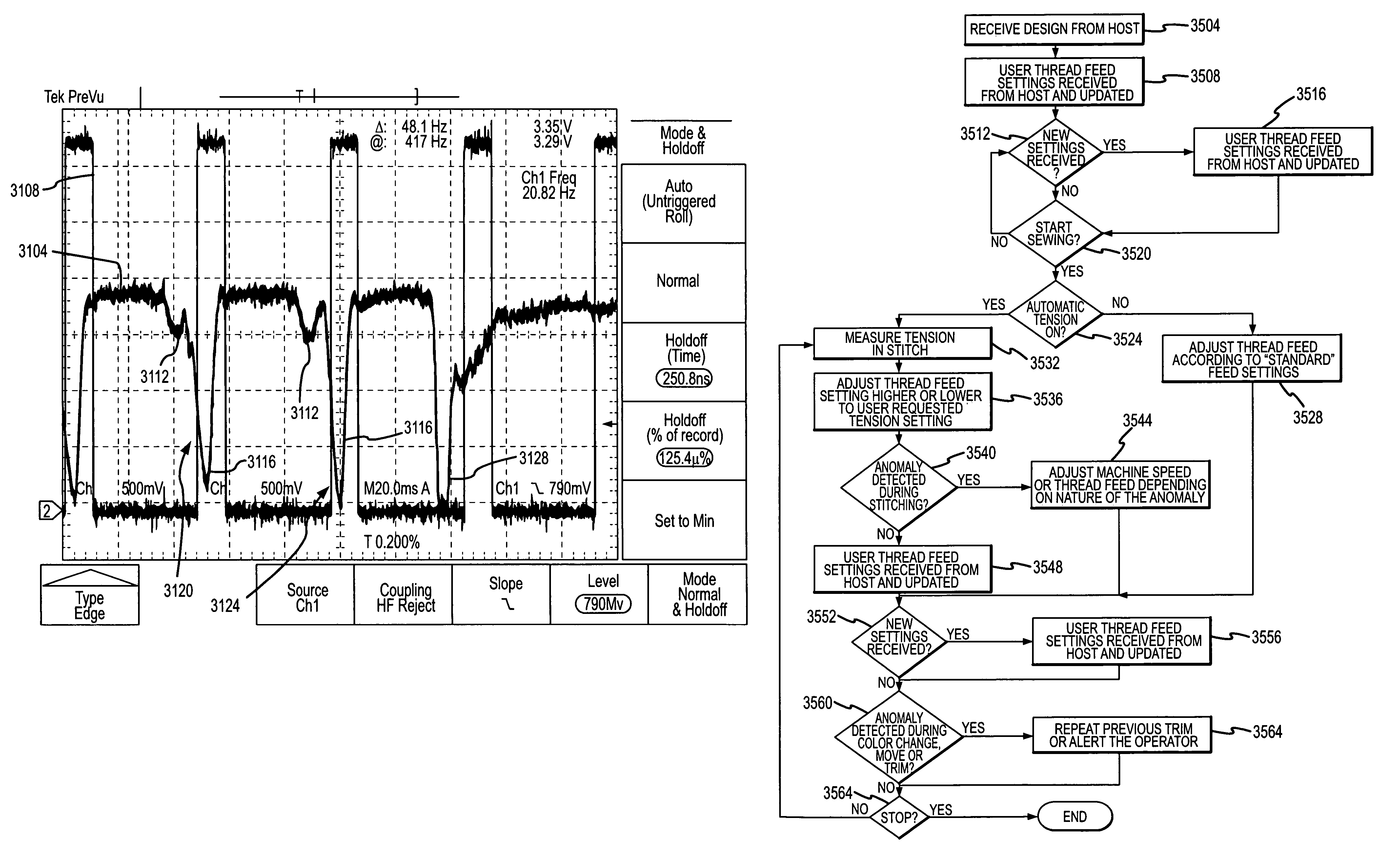

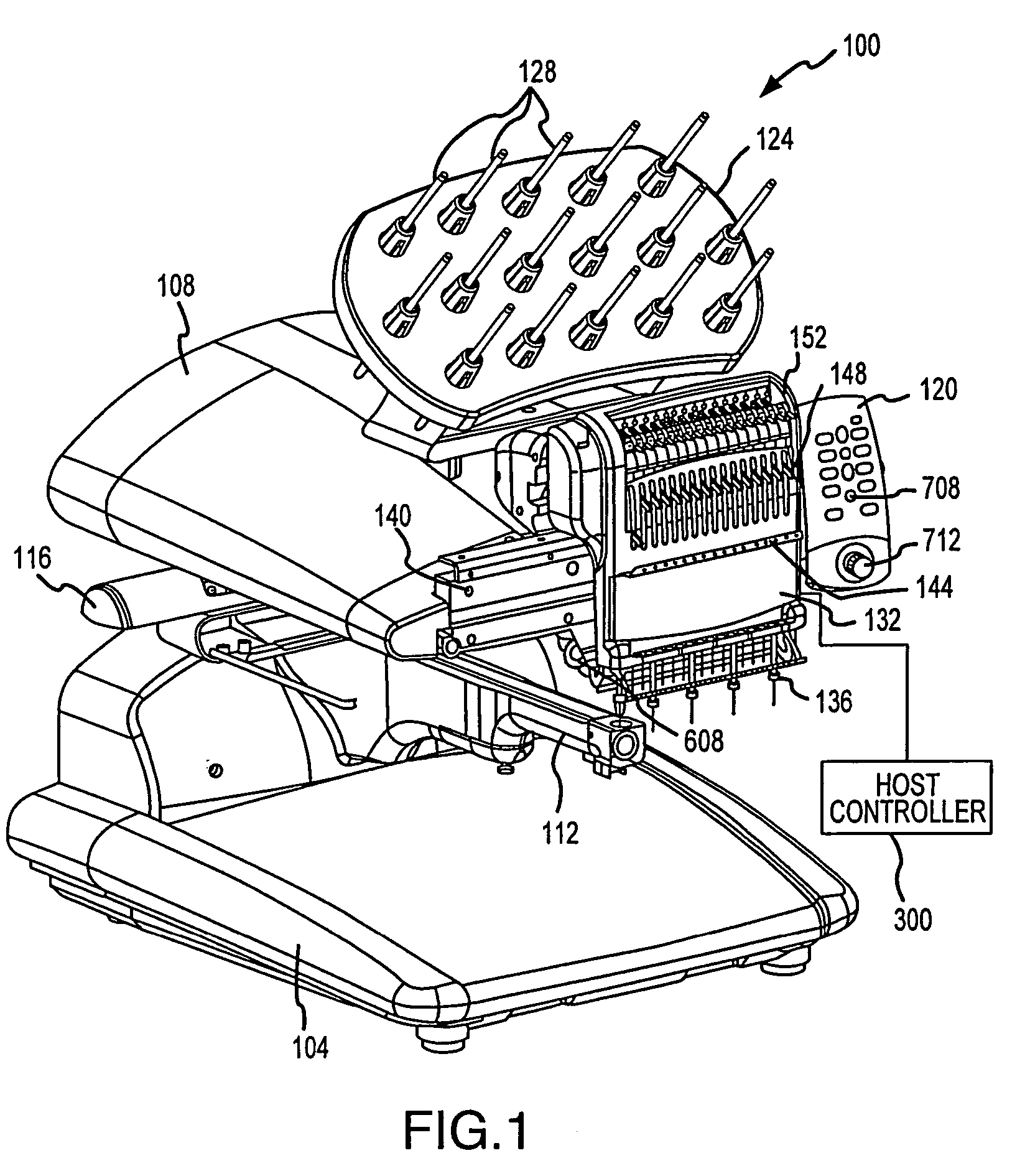

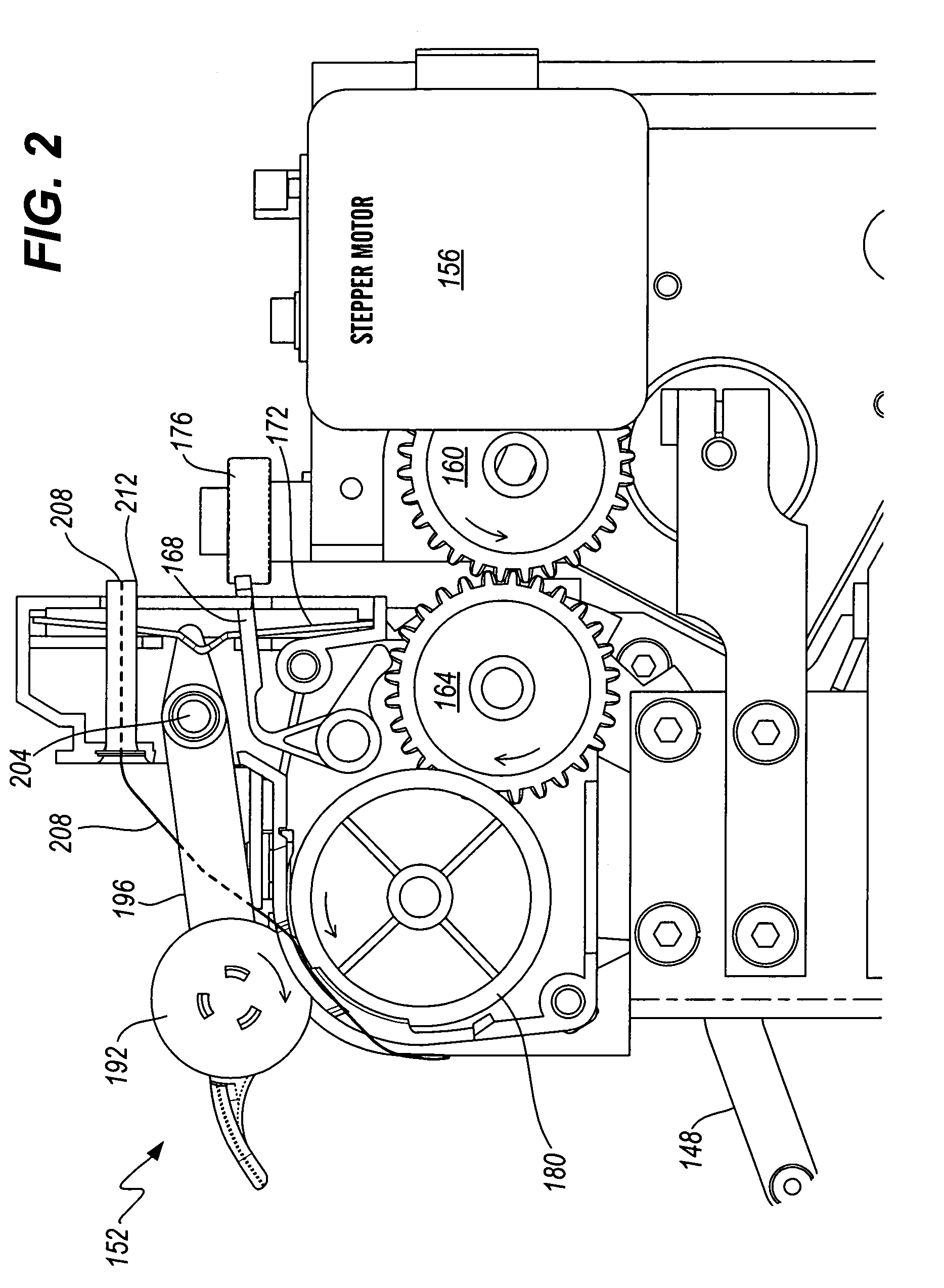

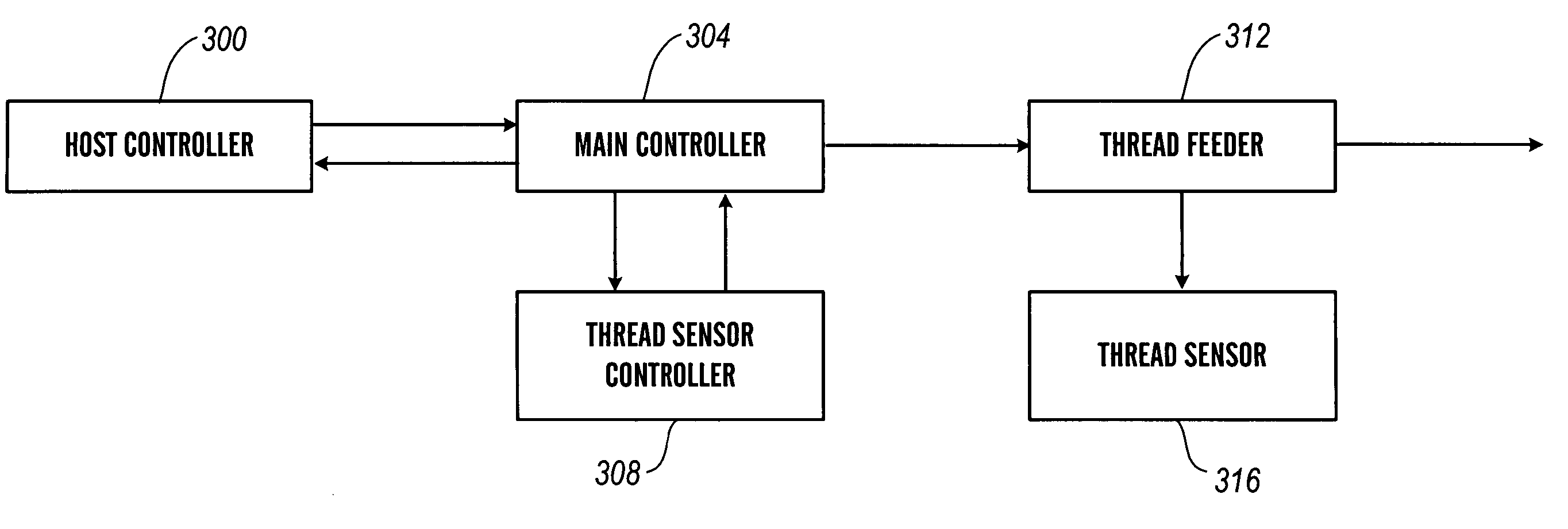

InactiveUS7308333B2Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

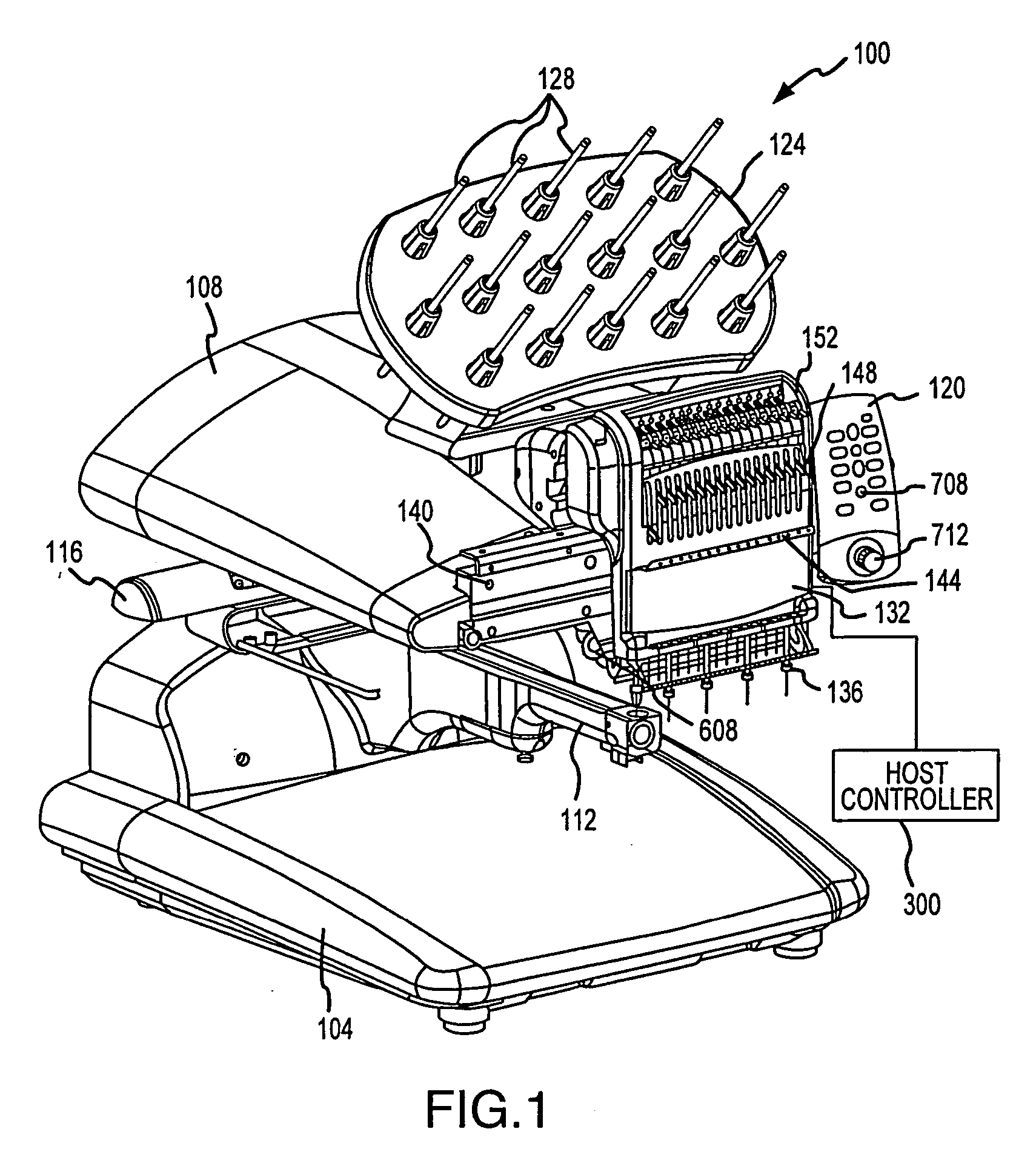

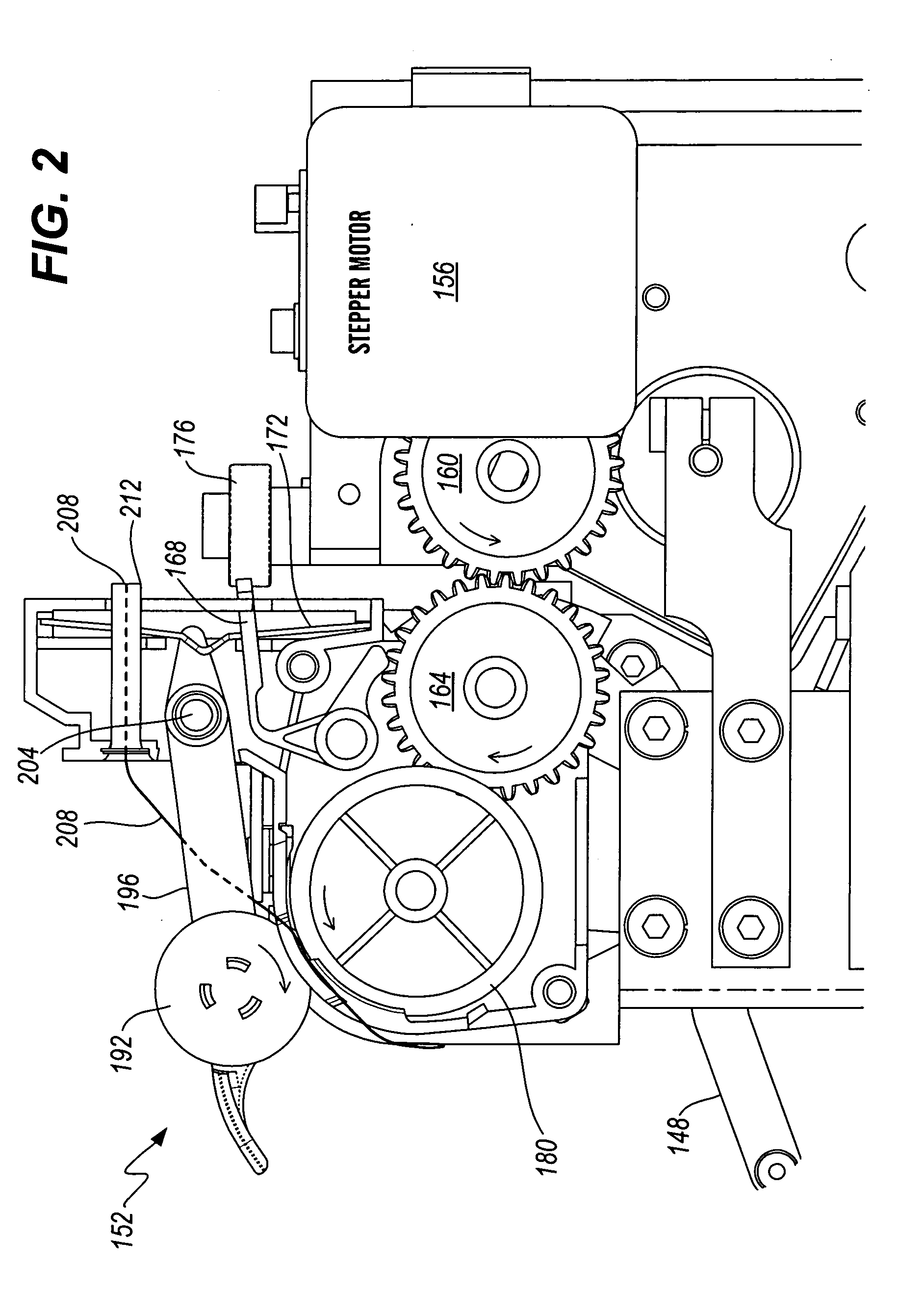

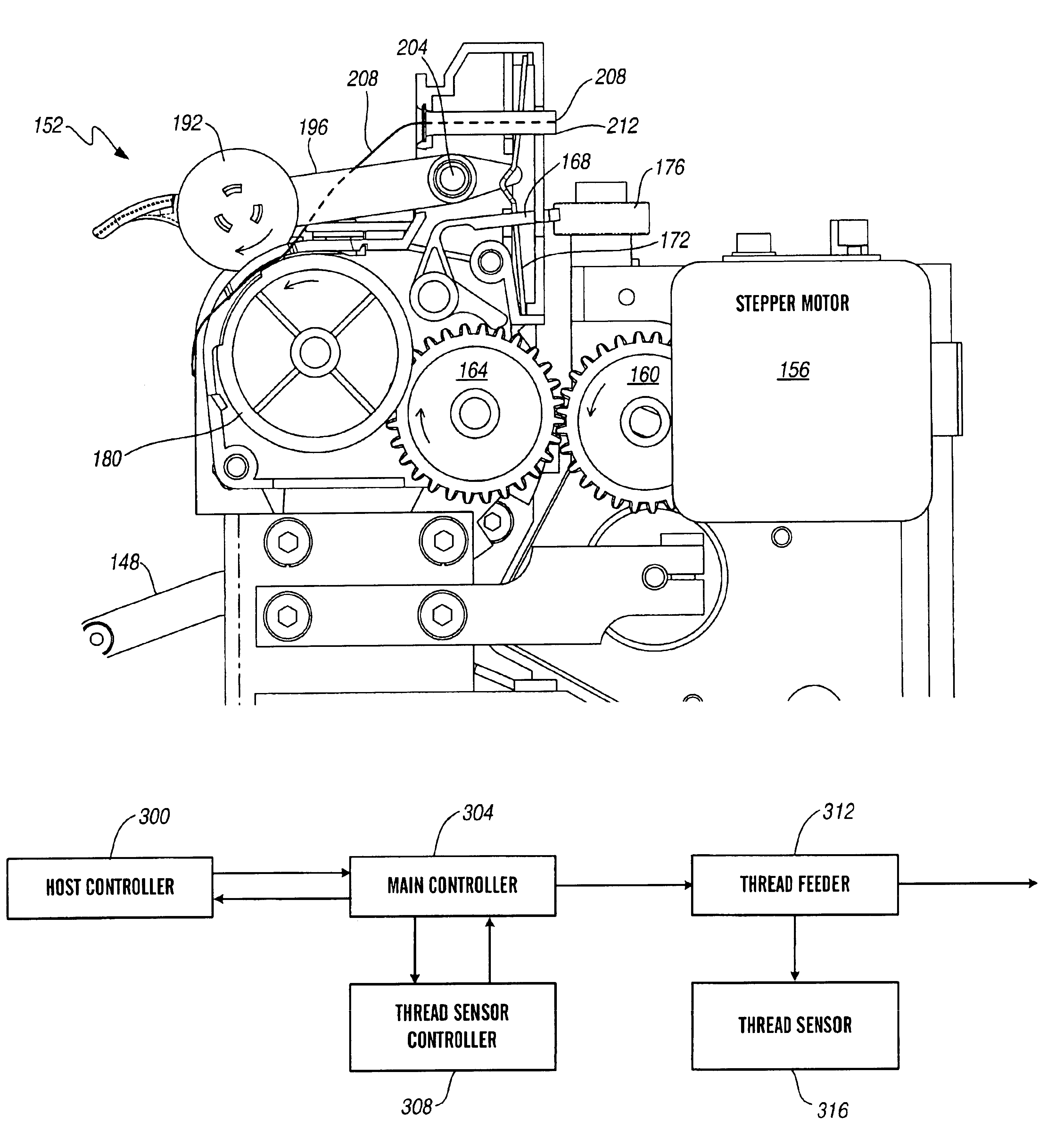

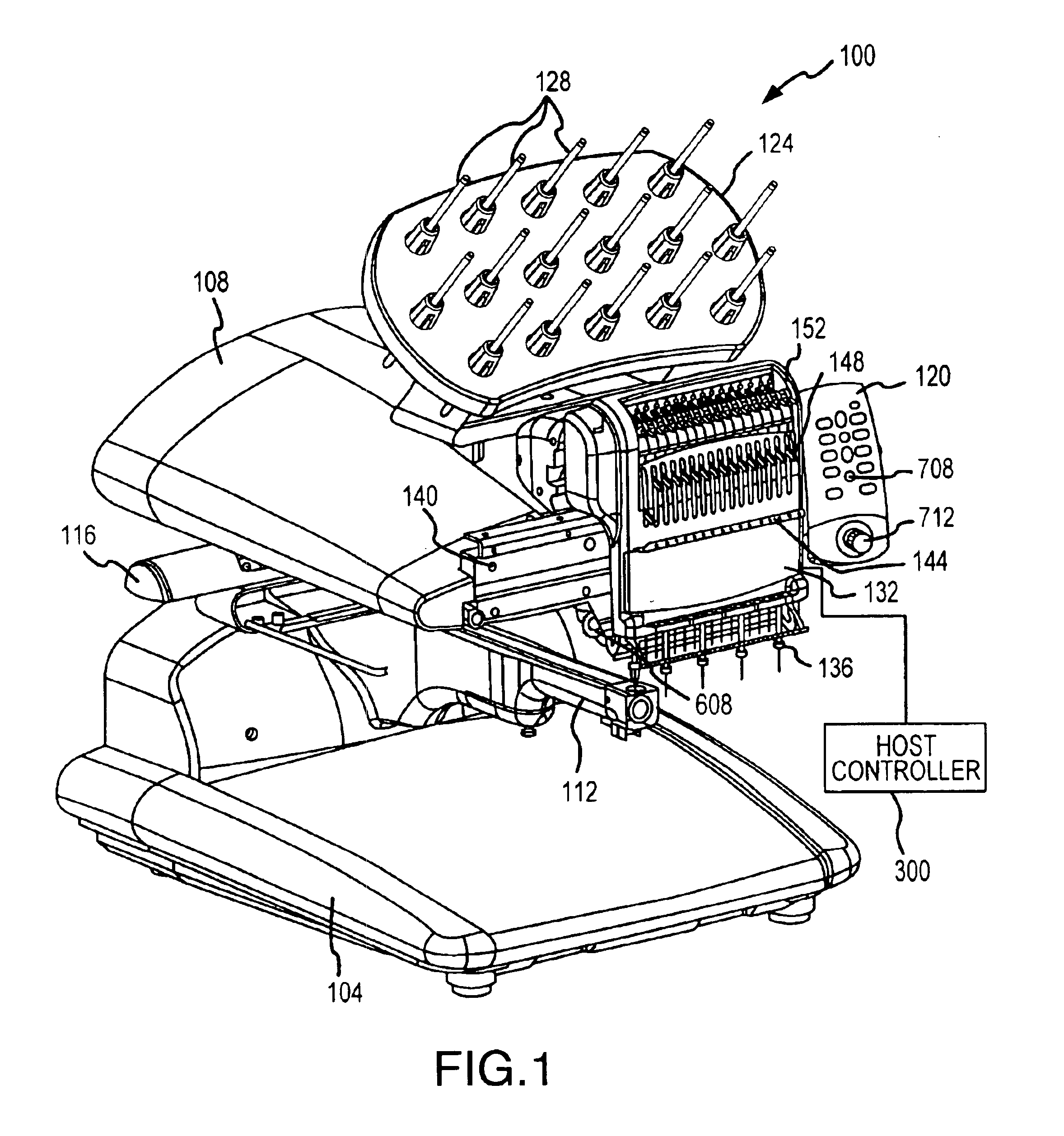

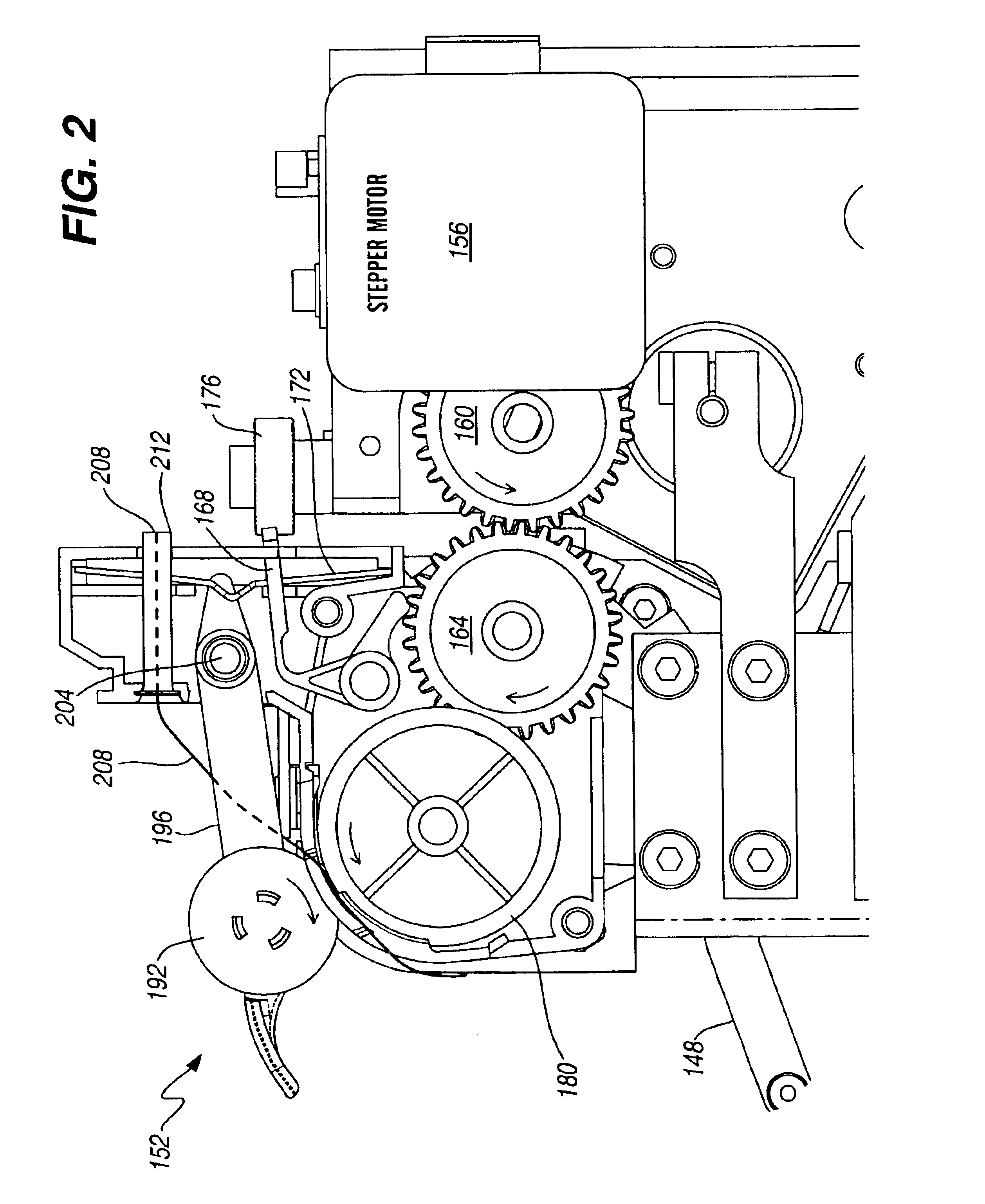

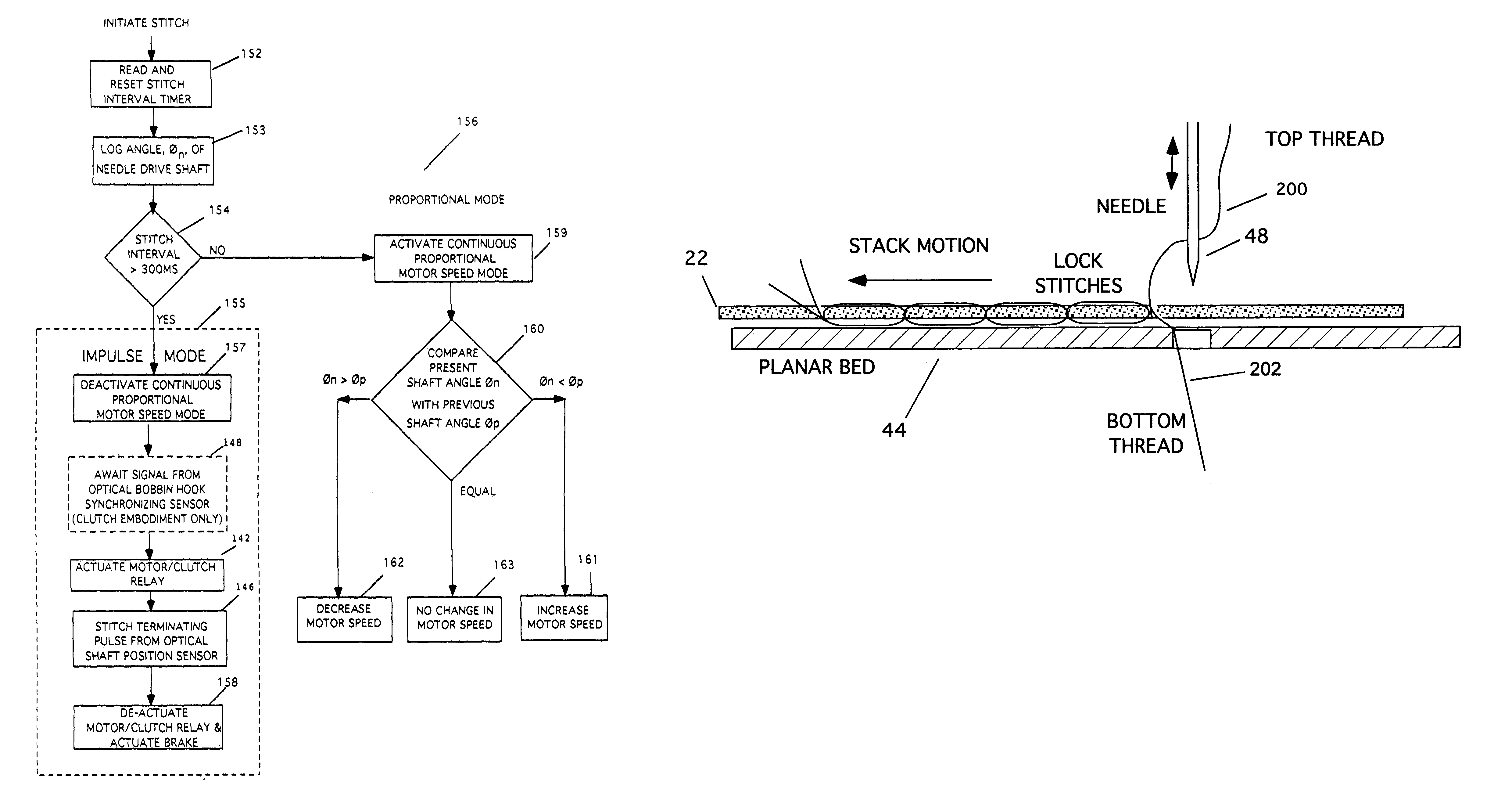

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

Computerized stitching including embroidering

InactiveUS20060064195A1Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

Apparatus and method for monitoring consumption of sewing thread supply

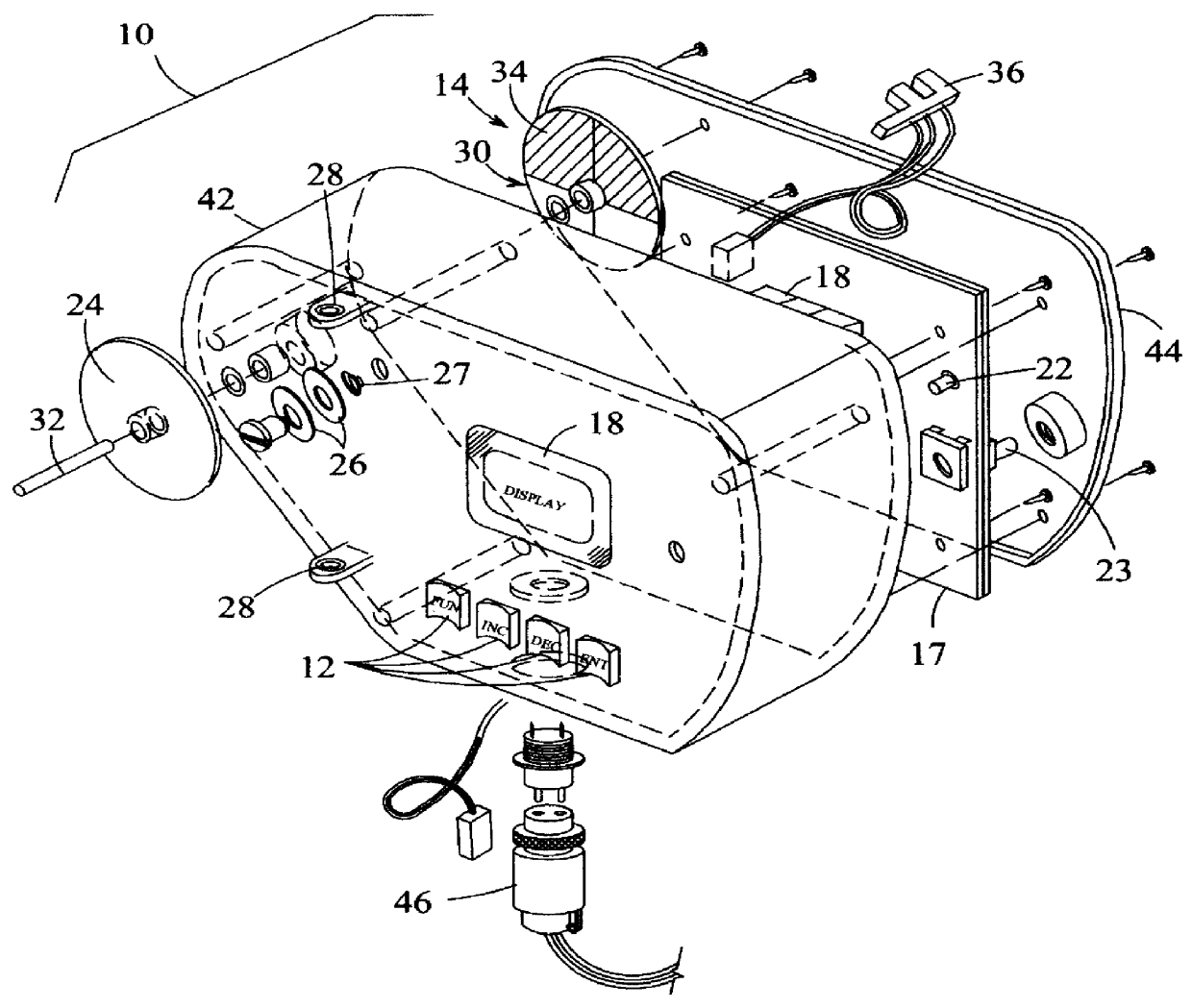

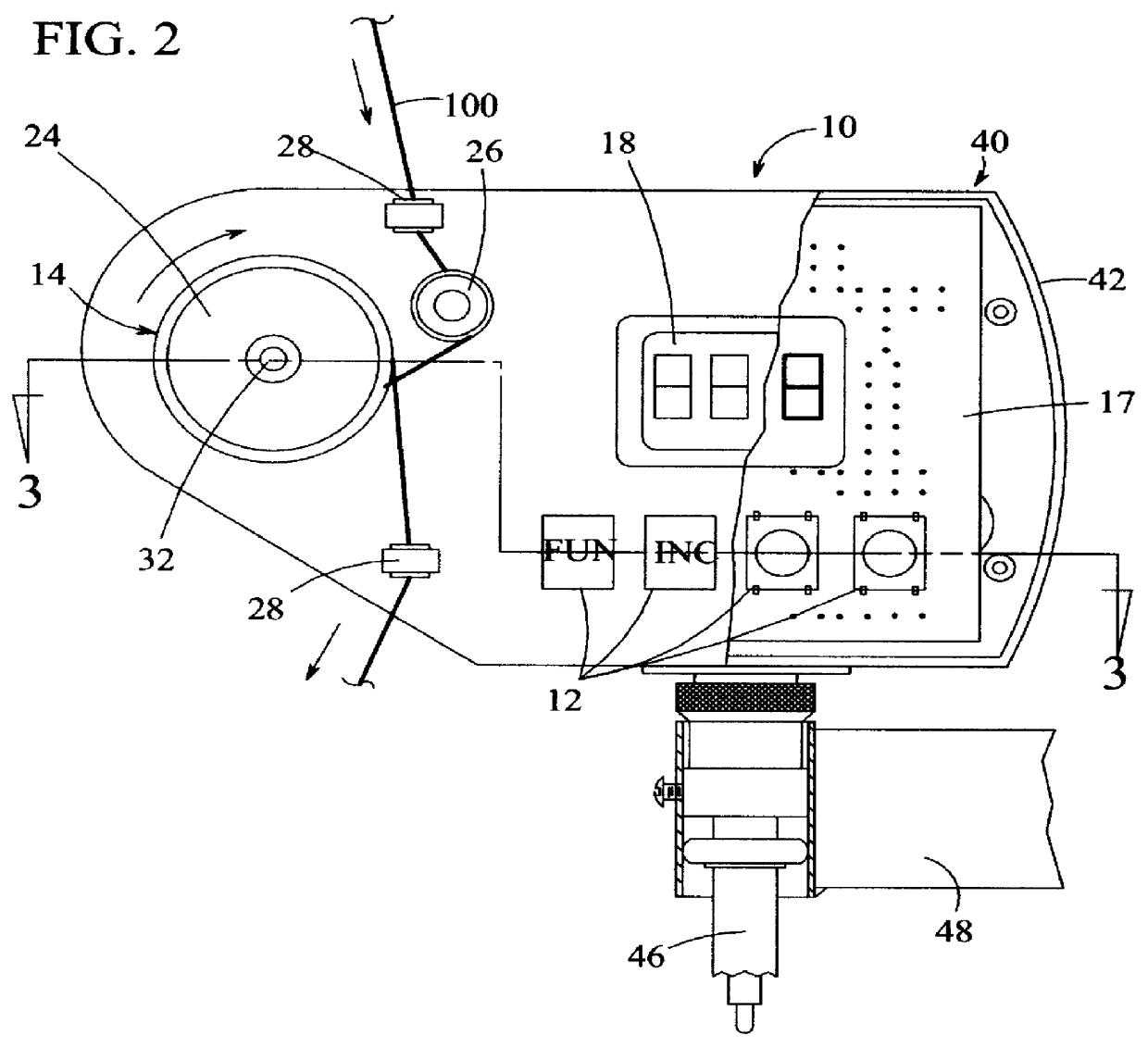

InactiveUS6092478AIncrease the number ofProgramme-controlled sewing machinesHand sewingEngineeringControl circuit

An apparatus for monitoring consumption of a supply of thread includes entry keys for allowing a user to input an initial supply of thread, and a minimum allowable supply of thread, and a detector for providing signals indicative of the rate of thread consumption. The apparatus also includes a control circuit for receiving the initial supply, the minimum allowable supply, and the signal indicative of the rate of thread consumption. The control circuit then calculates a consumed amount of thread and an actual supply of thread remaining, and produces a display signal indicative of the actual supply and / or the consumed amount, and an alarm when the actual supply of thread is equal to or less than the minimum allowable supply. The apparatus further includes a display panel for displaying the actual supply and the consumed amount upon receipt of the display signal from the control circuit.

Owner:SINGER COMPANY NV THE

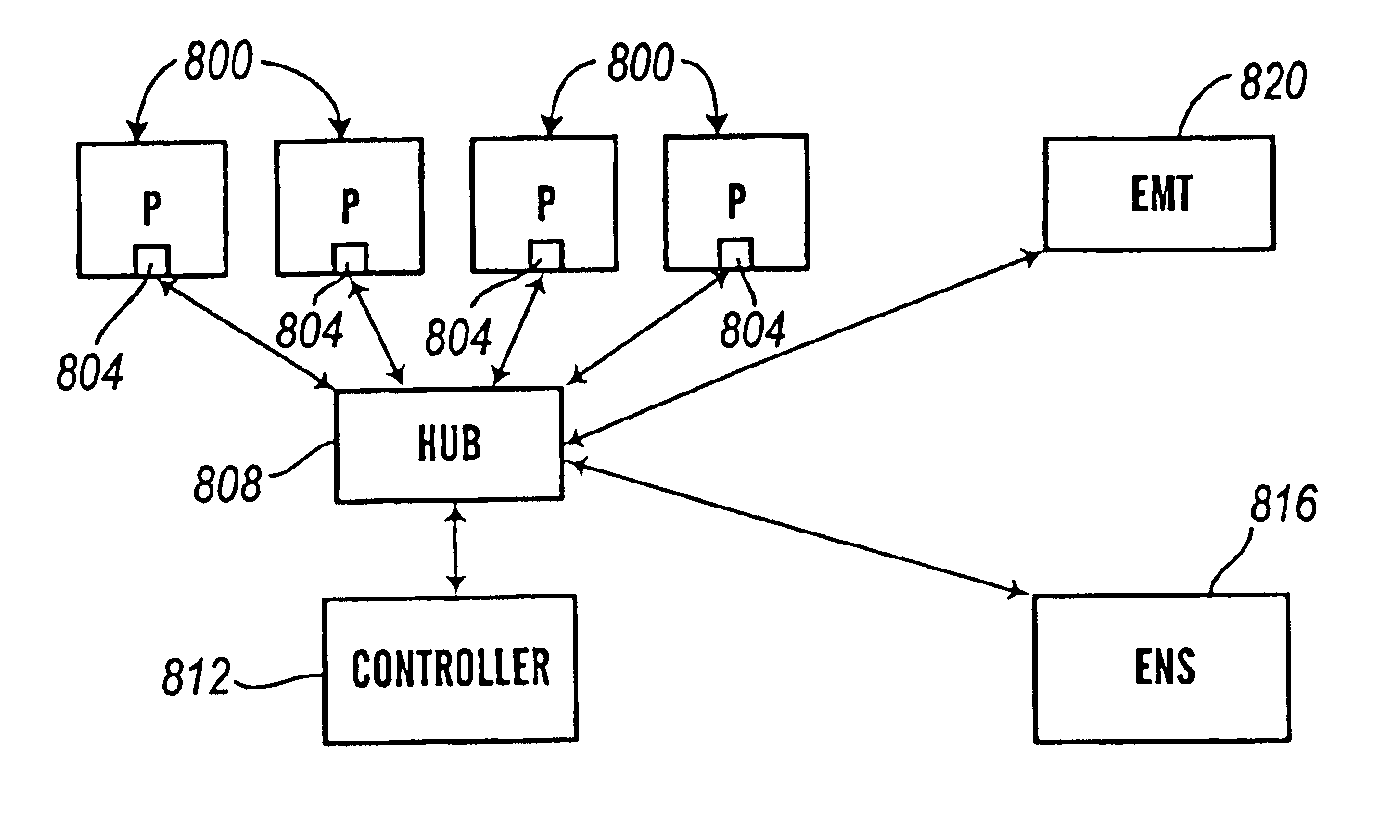

Computerized stitching including embroidering

InactiveUS6983192B2Reduce in quantityIncrease flexibilityProgramme-controlled sewing machinesCombination sewing machinesControl systemEngineering

A plurality of stitching machines and a control system used in stitching patterns into a plurality of items is capable of flexible control. The plurality of stitching machines may include one or more clusters of stitching machines, with each cluster able to stitch patterns into items independently of other clusters. Stitching machines within the plurality of stitching machines, or within the clusters of stitching machines, may be set to stitch patterns into items using one of a synchronized mode and an unsynchronized mode. When in the synchronized mode, the stitching machines perform stitching substantially synchronously with other stitching machines, and when in the unsynchronized mode the stitching machines perform stitching independently of the status of other stitching machines.

Owner:MELCO INT

Thread feed for a sewing machine

Owner:SINGER SOURCING LTD LLC

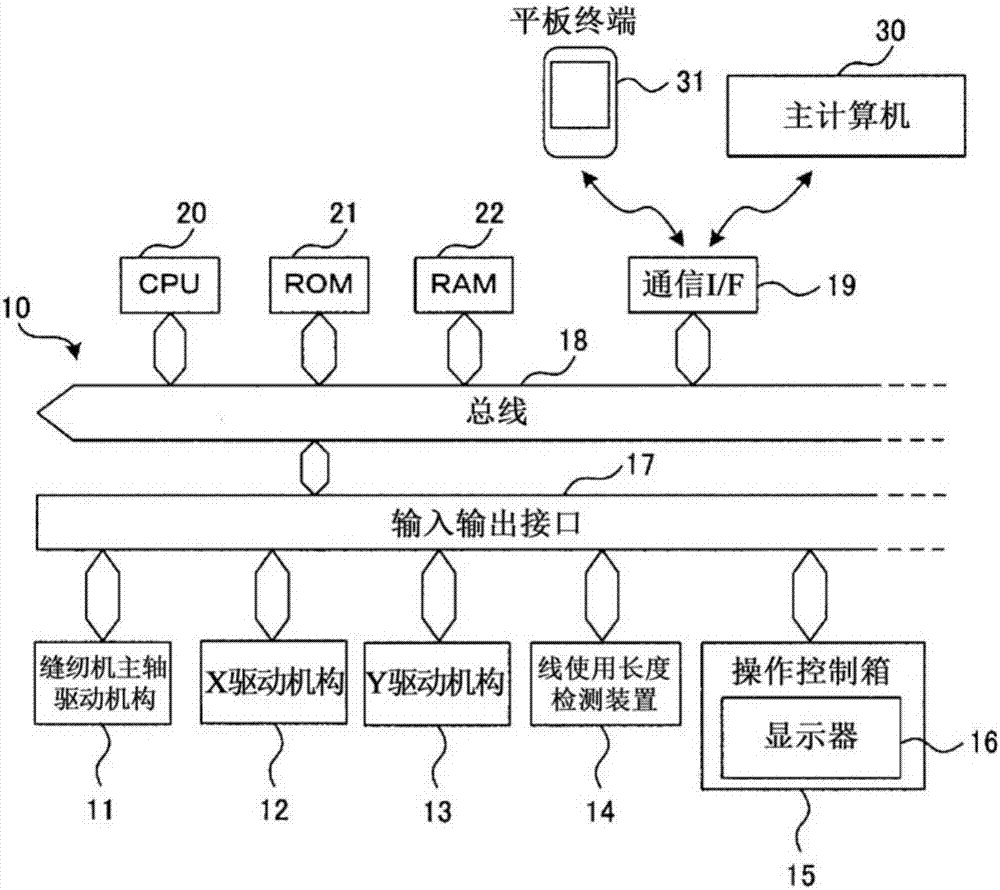

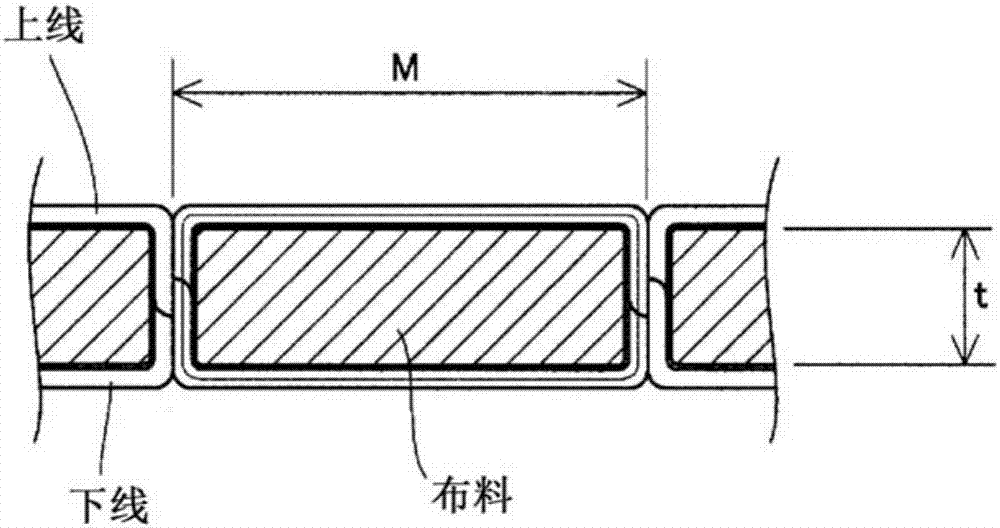

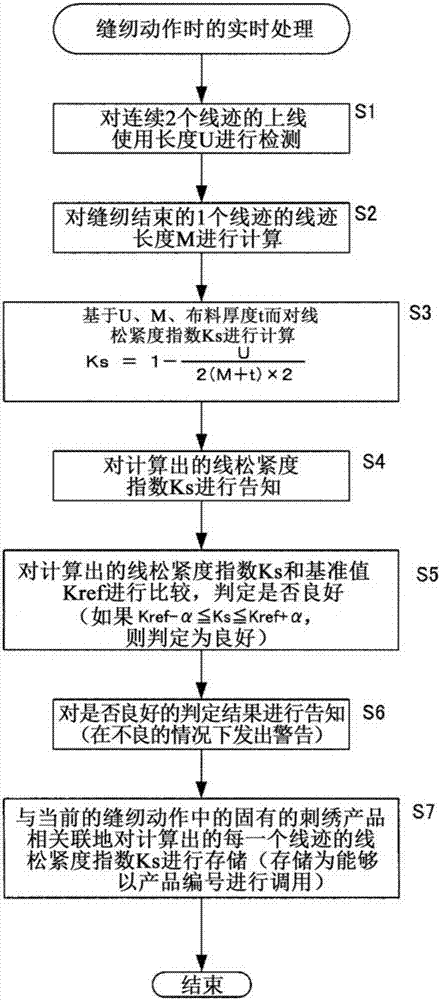

Sewing quality control in sewing machine

ActiveCN107407030AImprove sewing qualityCentralized management of production progressProgramme-controlled sewing machinesSewing measuring devicesQuality controlEngineering

The present invention relates to a sewing machine which evaluates sewing quality using a thread tightening index. During a sewing operation, an upper thread used length (U) used for each stitch is detected, and a thread tightening index (Ks) for each sewn stitch is calculated on the basis of a stitch length (M) for each stitch, defined in accordance with sewing pattern data, a fabric thickness (t) of the object being sewn, and the detected upper thread used length (U) data. A report (for example a display of the thread tightening index Ks) corresponding to the thread tightening index (Ks) calculated for each sewn stitch is issued. By comparing the thread tightening index (Ks) calculated for each sewn stitch with a reference value (Kref), the acceptability of the thread tightness for each sewn stitch can be assessed, and the assessment results can be reported.

Owner:TISM CO LTD +1

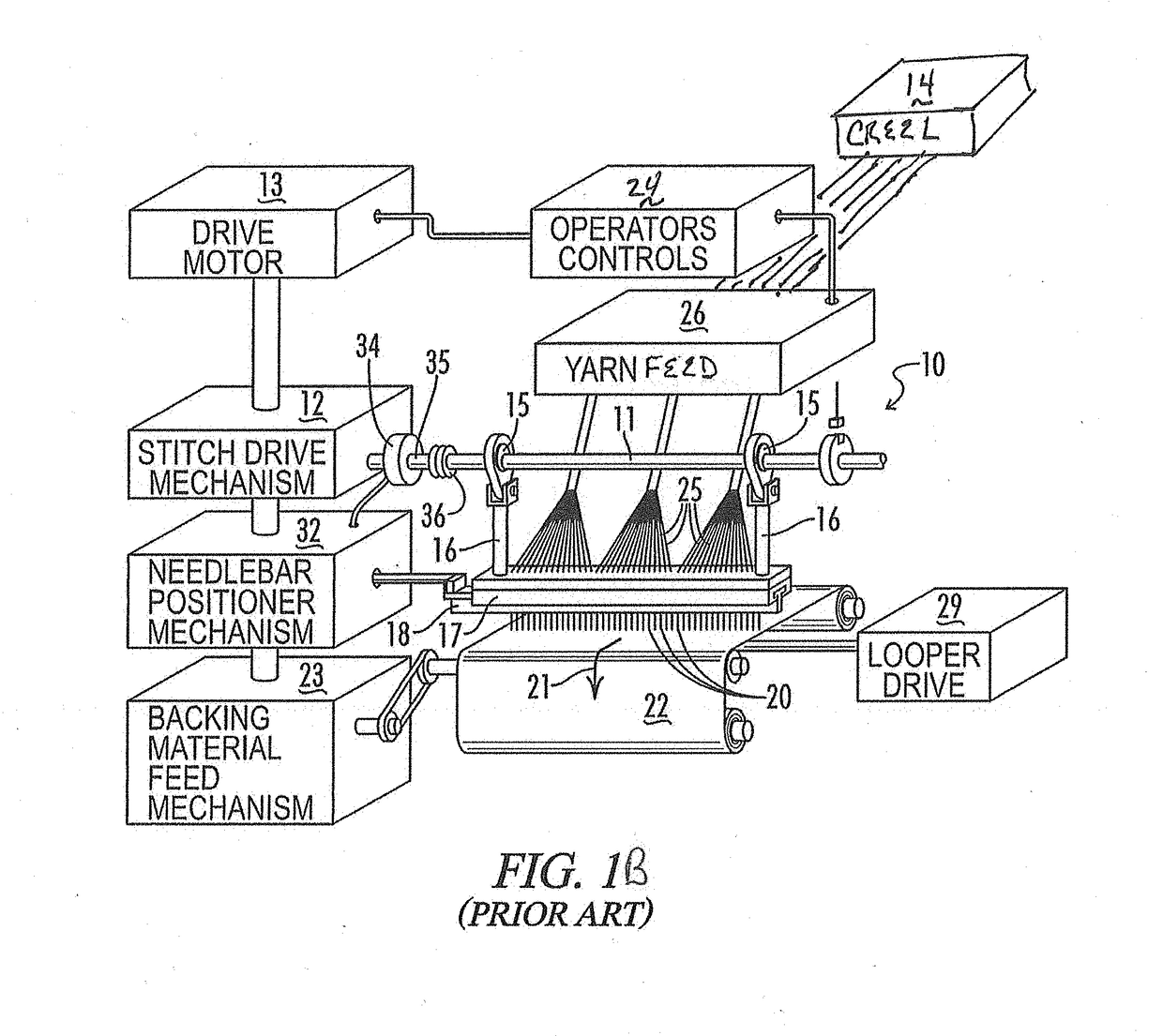

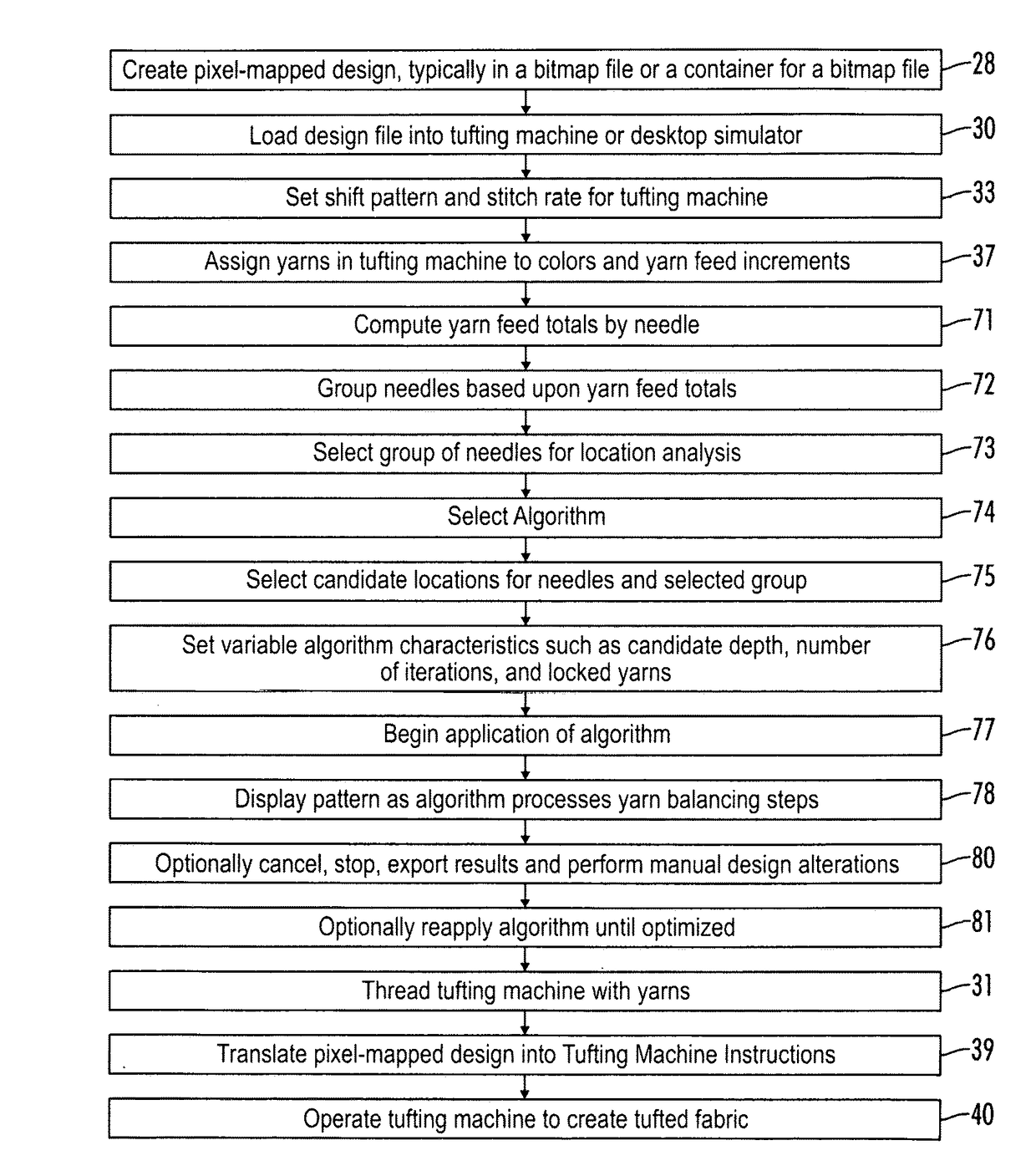

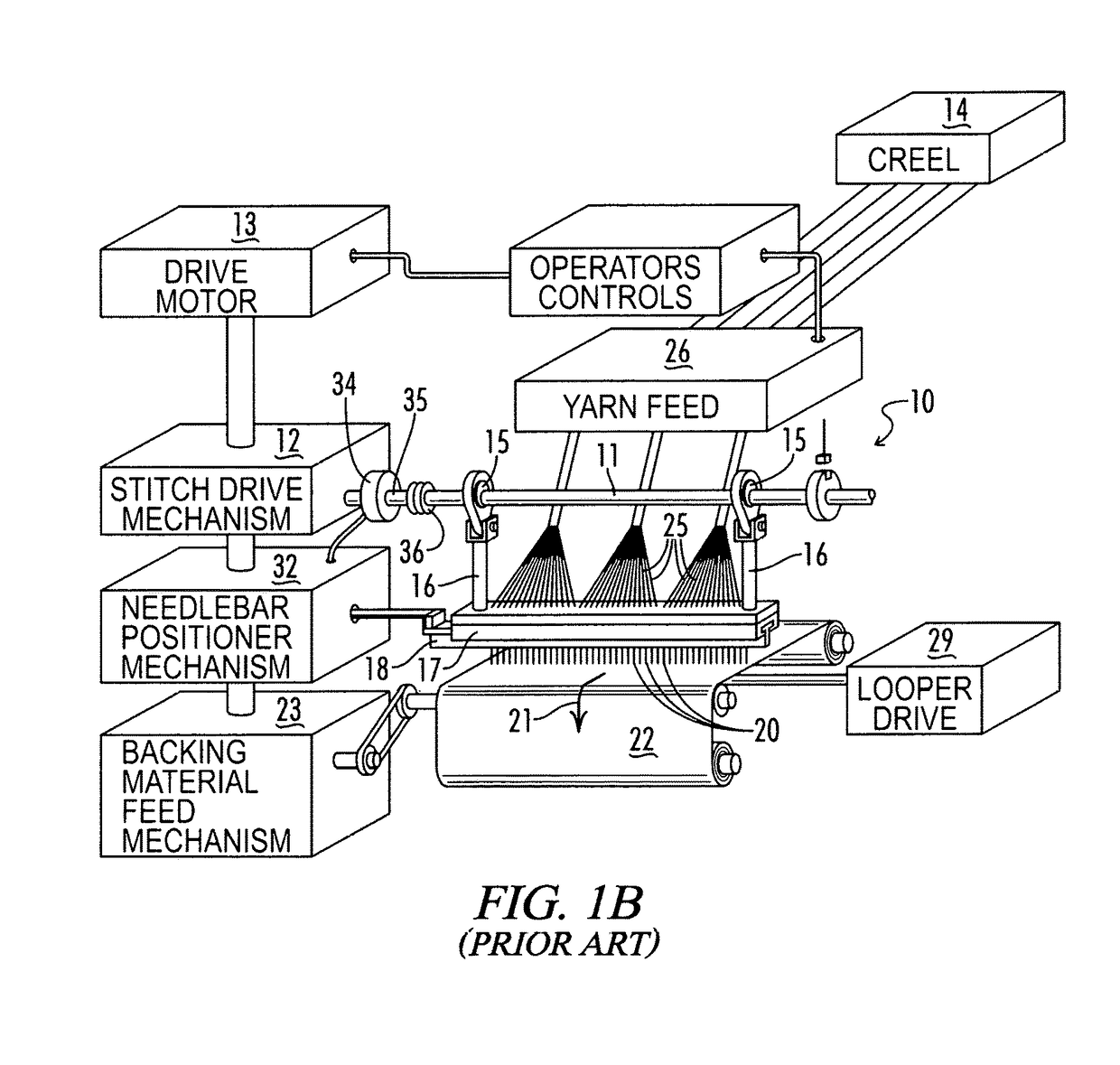

Tufted Patterned Textiles With Optimized Yarn Consumption

ActiveUS20170204546A1Promote balance between supply and demandMinimize appearanceProgramme-controlled sewing machinesTufting apparatusYarnGeneral Appearance

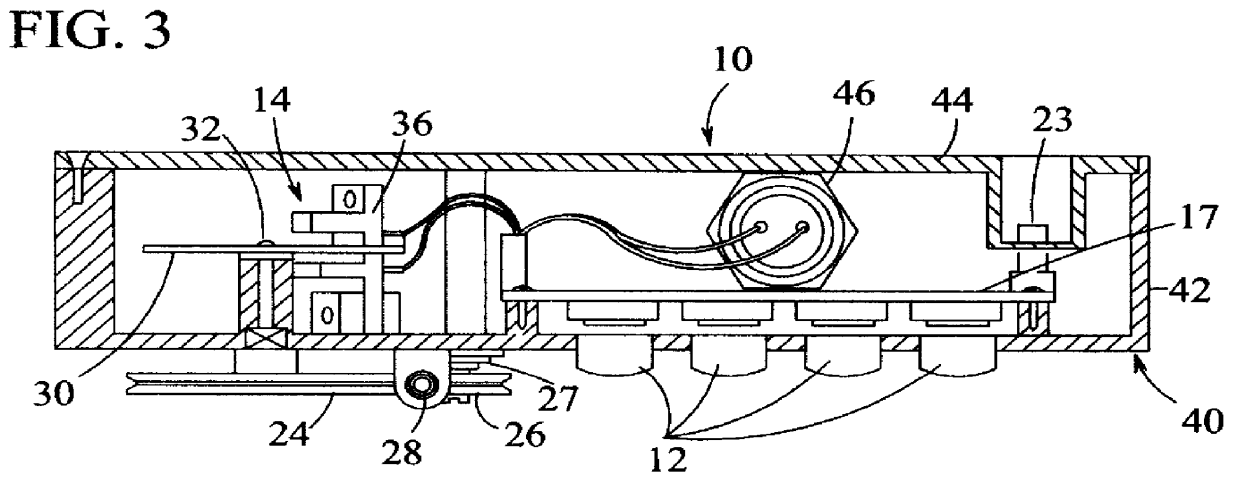

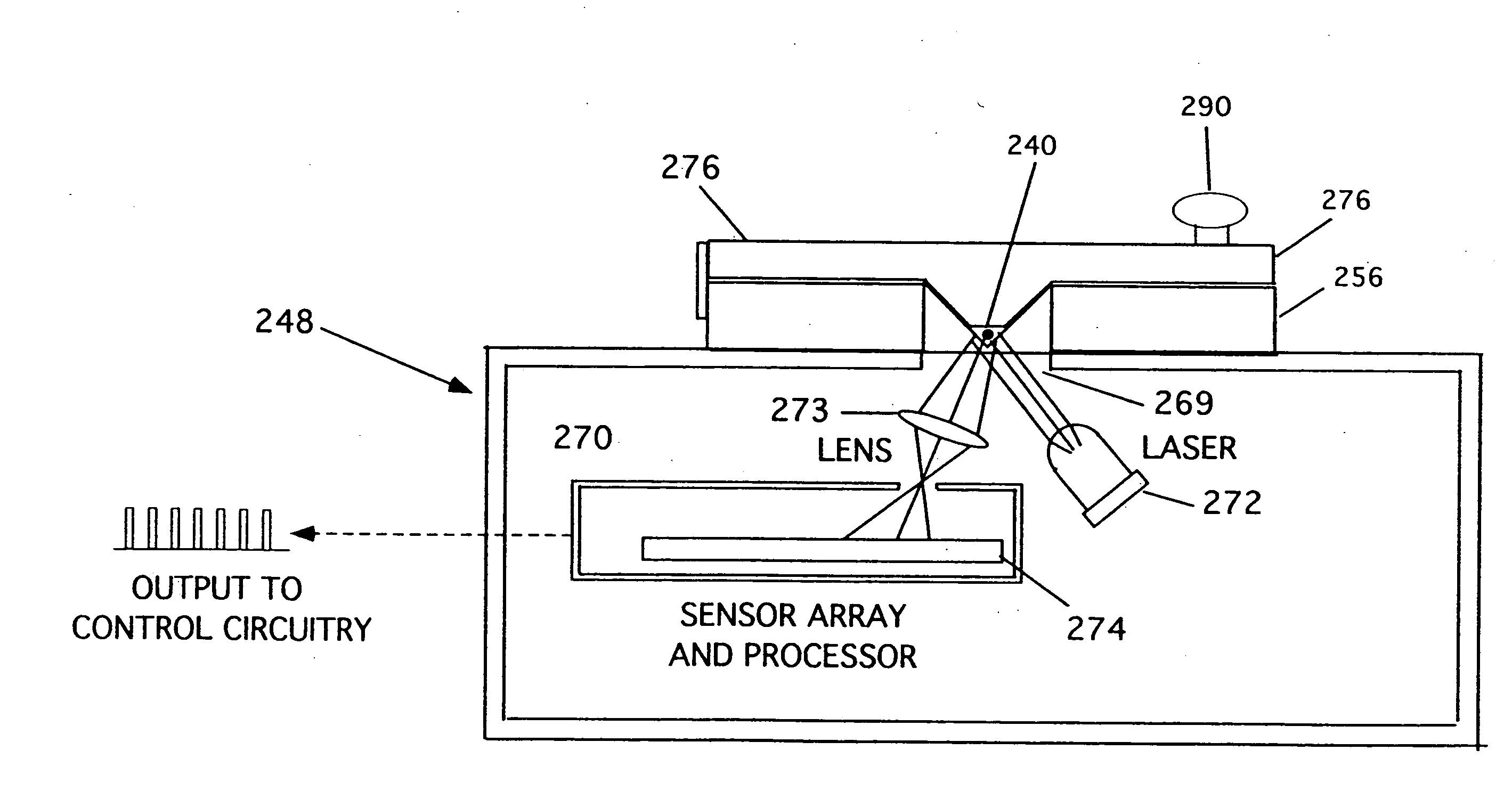

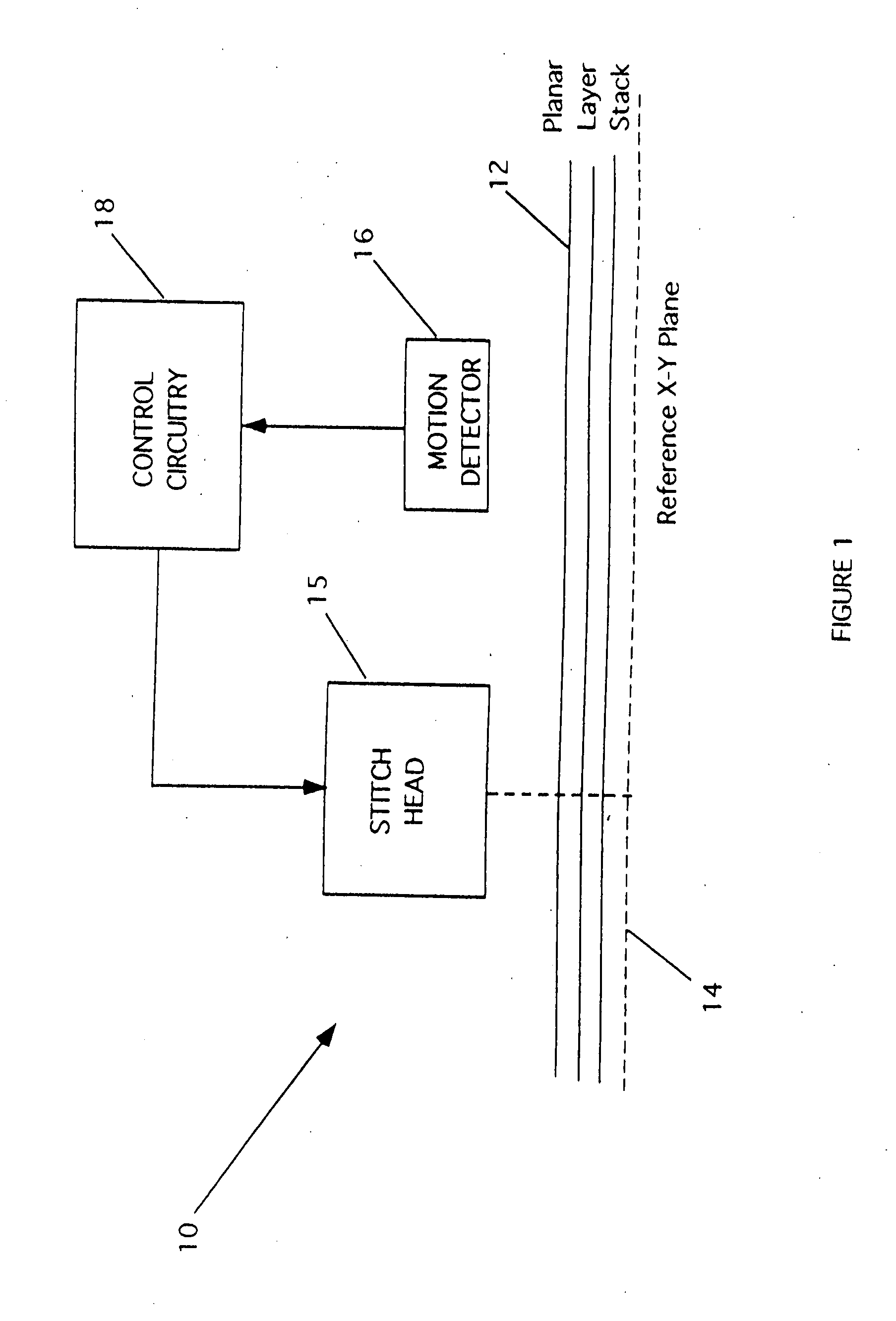

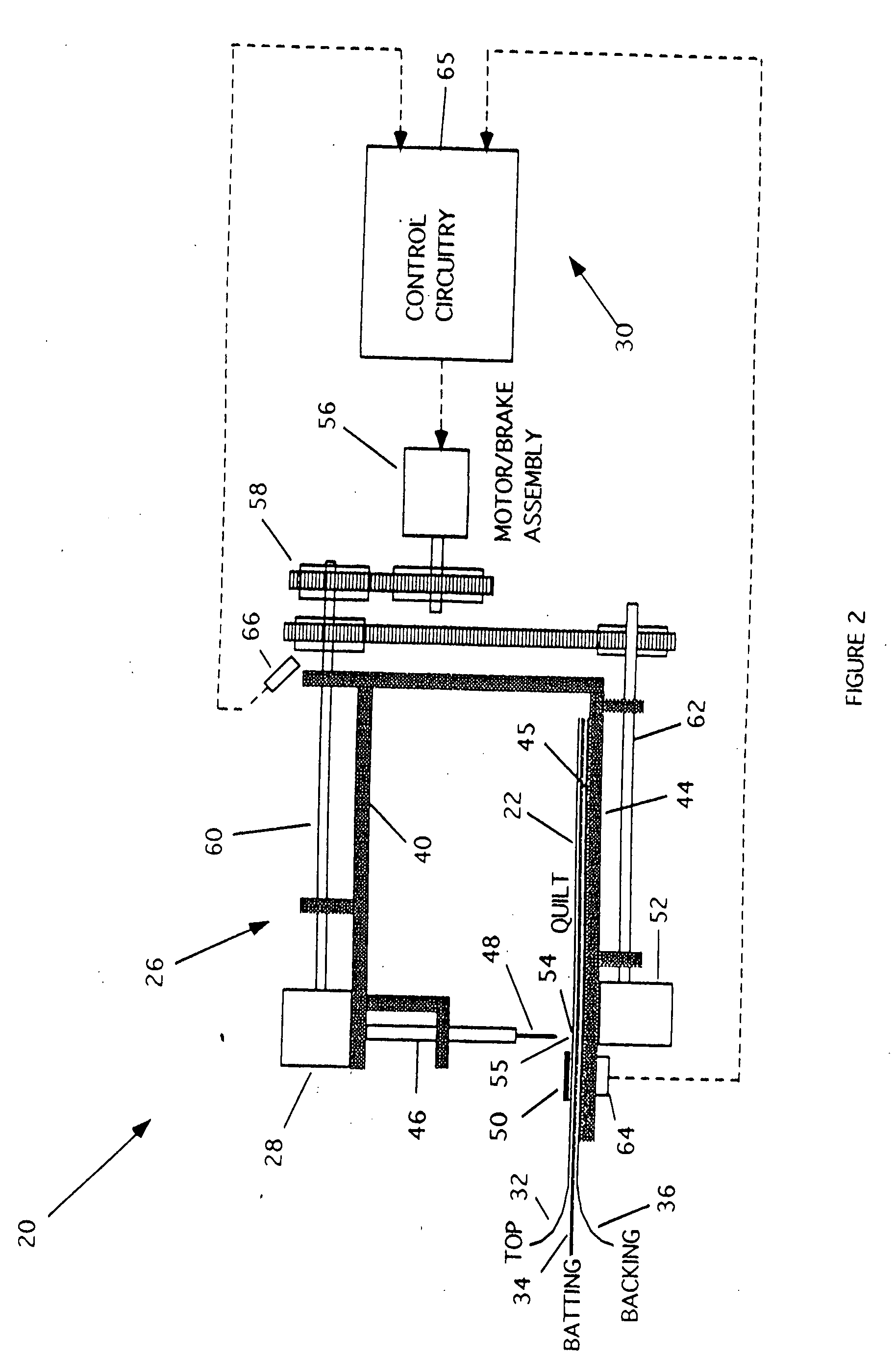

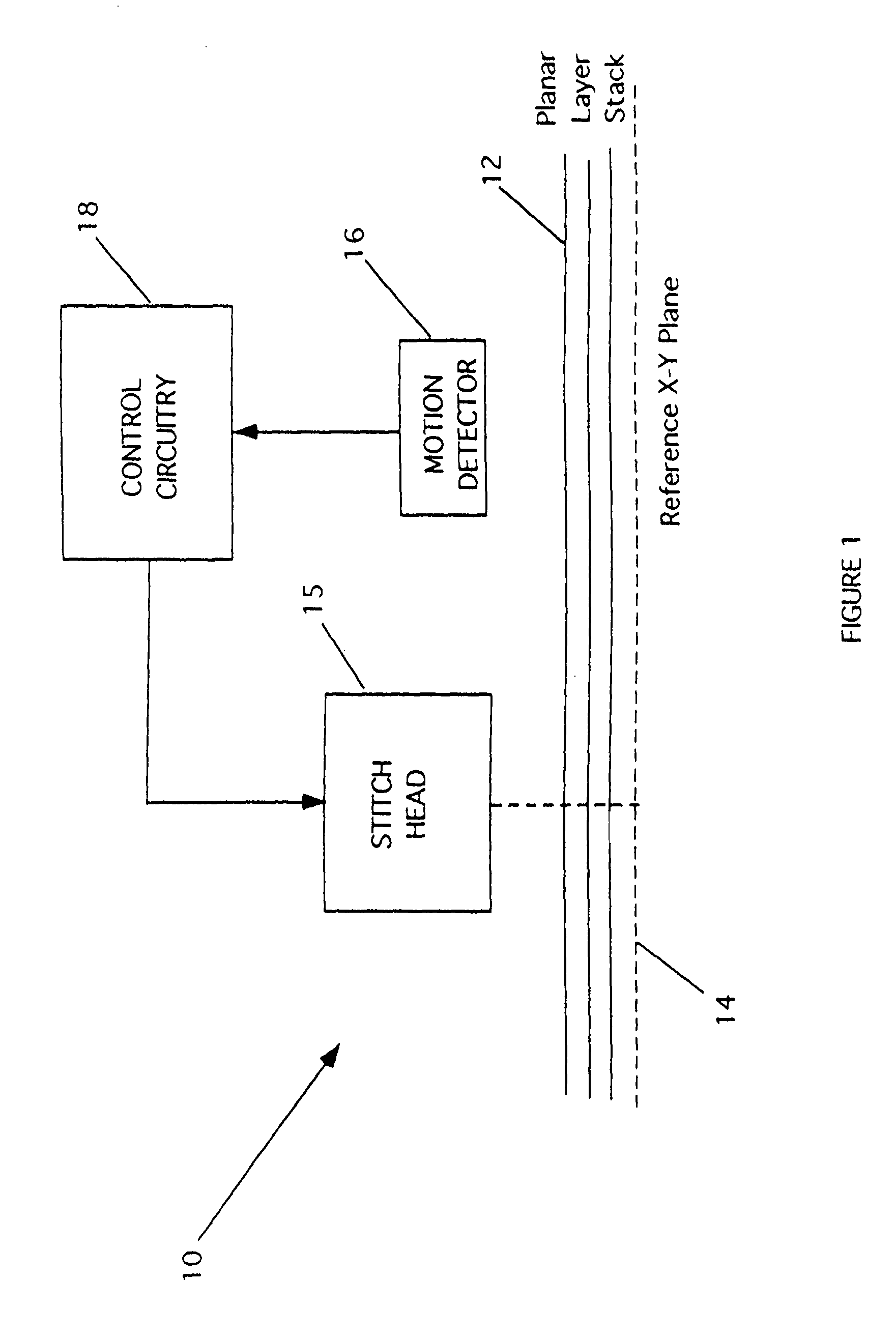

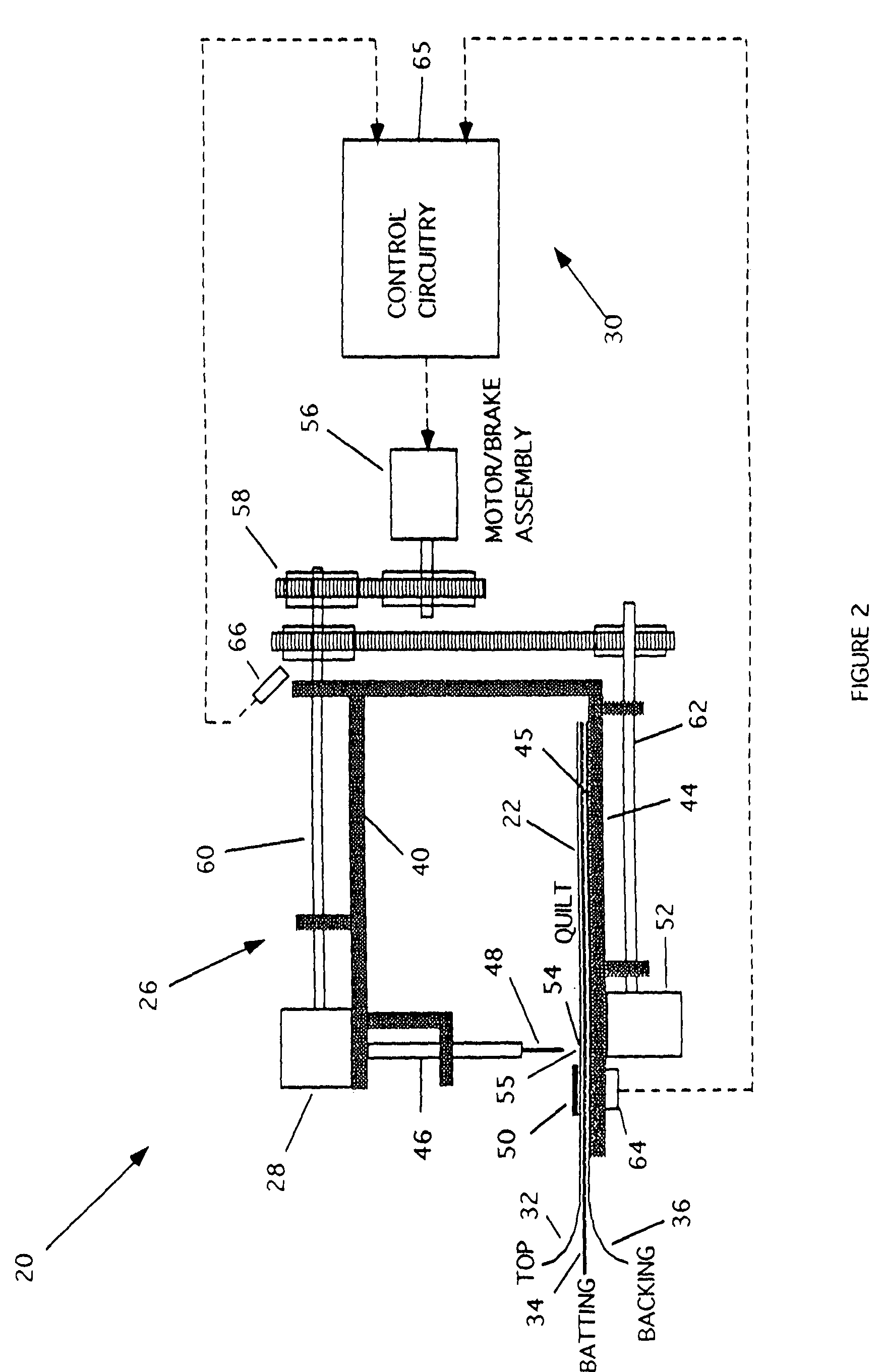

Stitching method and apparatus employing thread longitudinal movement detection

InactiveUS20070256619A1Readily move longitudinallyAvoiding lateral slackProgramme-controlled sewing machinesSewing-machine control devicesEngineeringSewing machine

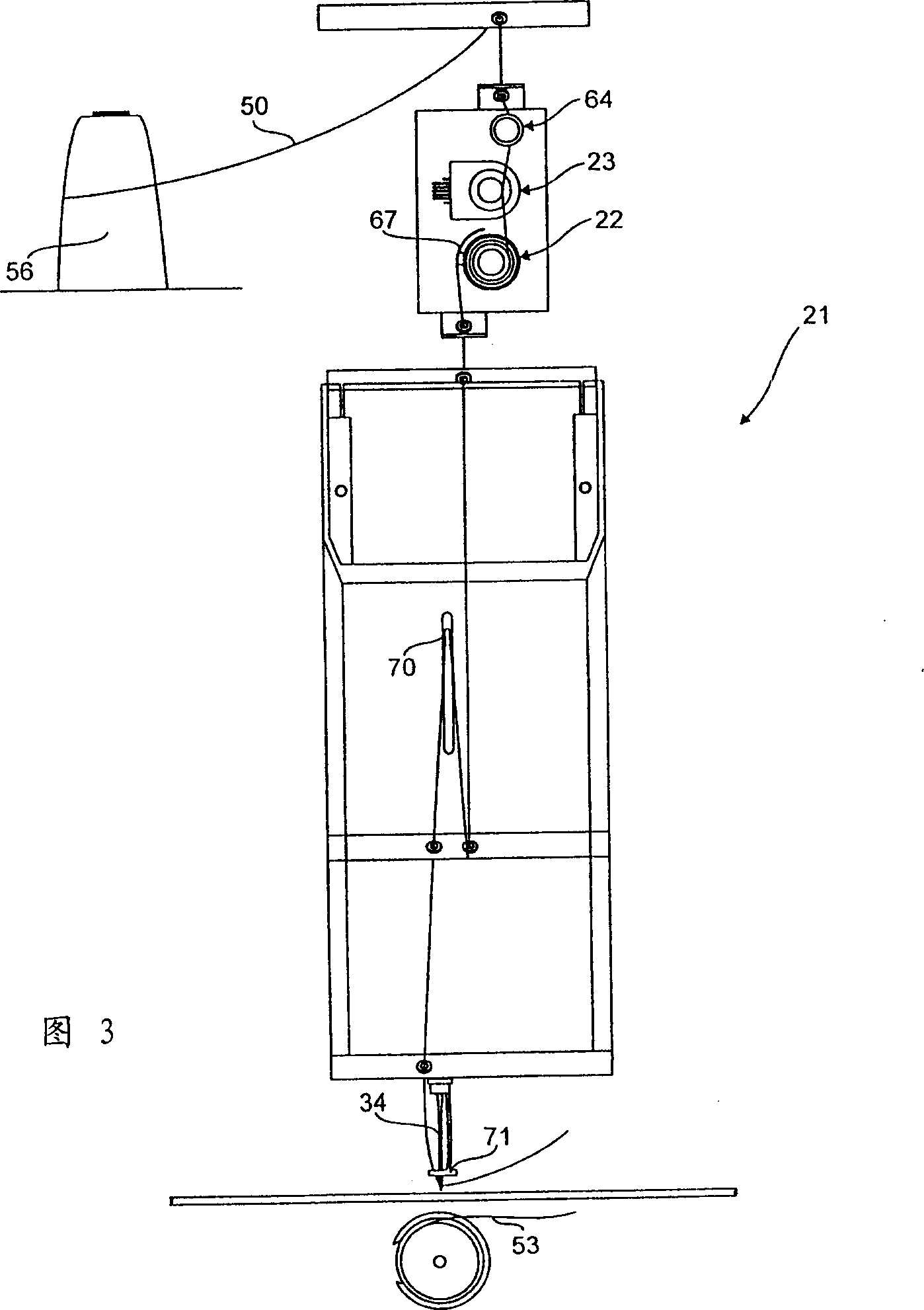

A method and apparatus for detecting longitudinal thread motion in a quilting / sewing machine for controlling the actuation of a fixedly located stitch head. A preferred detector comprises an optical sensor which directly senses the longitudinal movement of a thread as it moves along a guide path from a supply source toward a stitch head needle.

Owner:KOEMER RALPH J

Computerized stitching including embroidering

InactiveUS6871605B1Reduced thread tensionReduce needProgramme-controlled sewing machinesHand sewingEngineeringScrew thread

Owner:MELCO INT

Stitching method and apparatus employing thread longitudinal movement detection

InactiveUS7793602B2Readily move longitudinallyAvoiding lateral slackProgramme-controlled sewing machinesSewing-machine control devicesEngineeringSewing machine

A method and apparatus for detecting longitudinal thread motion in a quilting / sewing machine for controlling the actuation of a fixedly located stitch head. A preferred detector comprises an optical sensor which directly senses the longitudinal movement of a thread as it moves along a guide path from a supply source toward a stitch head needle.

Owner:KOEMER RALPH J

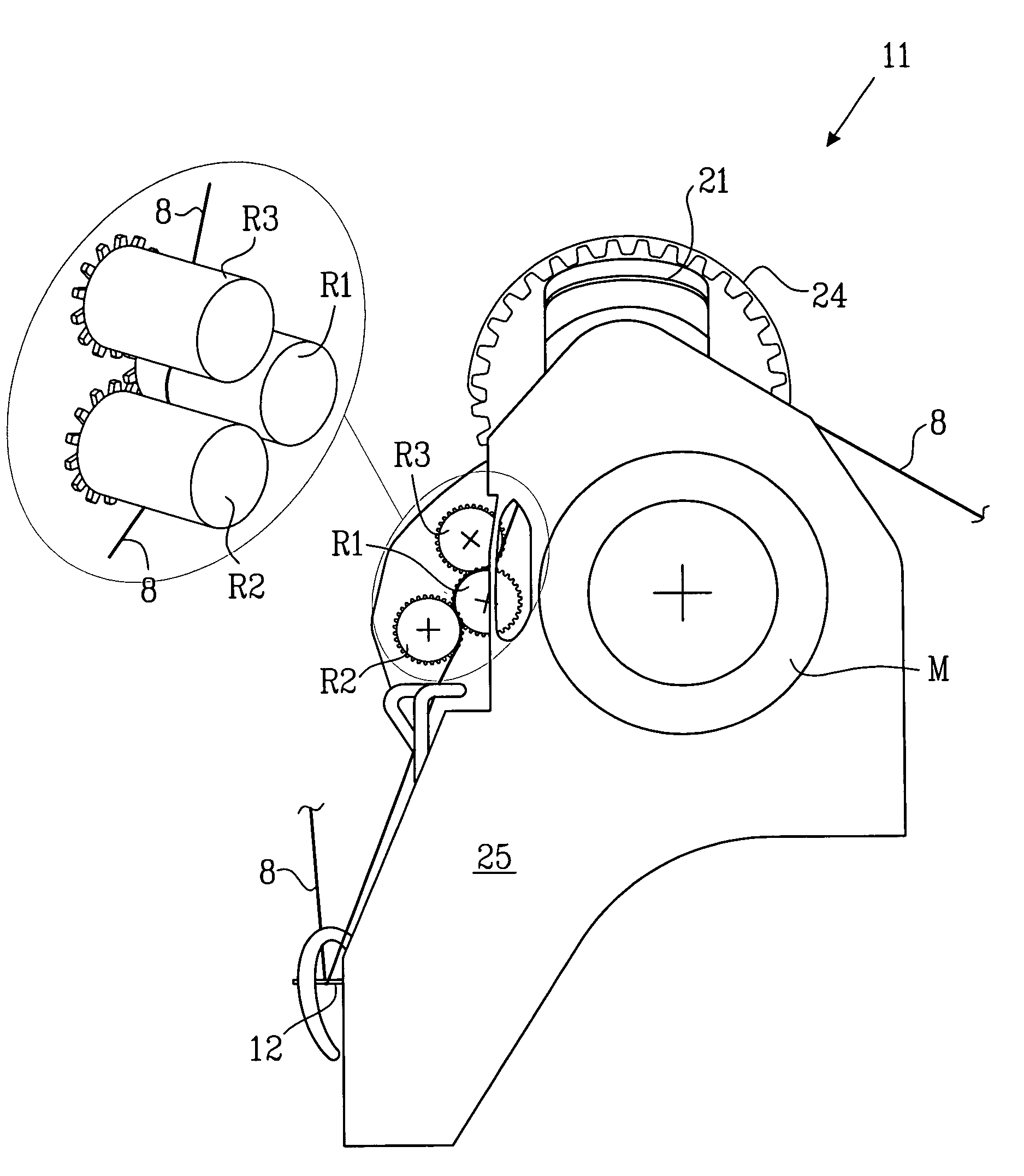

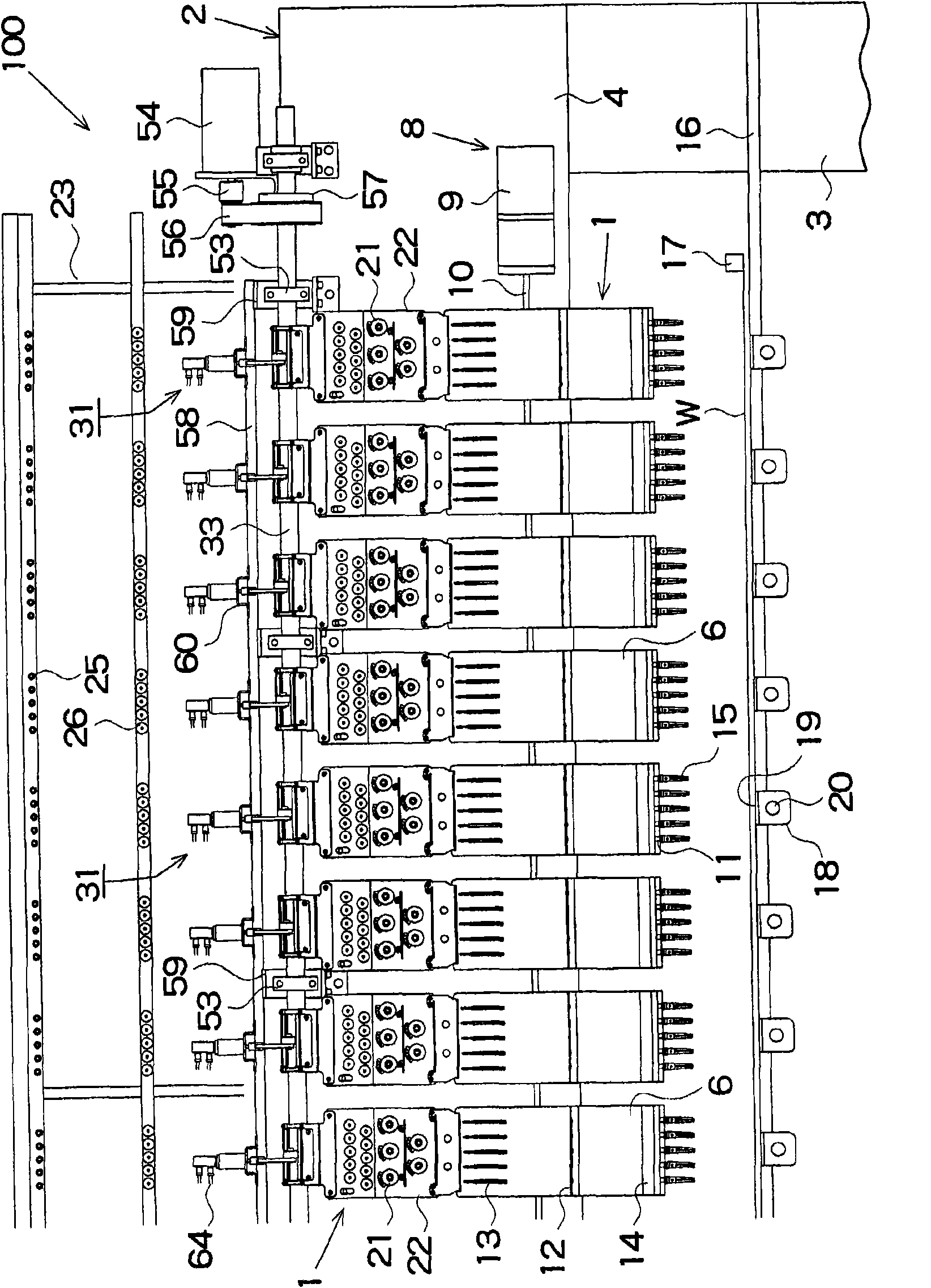

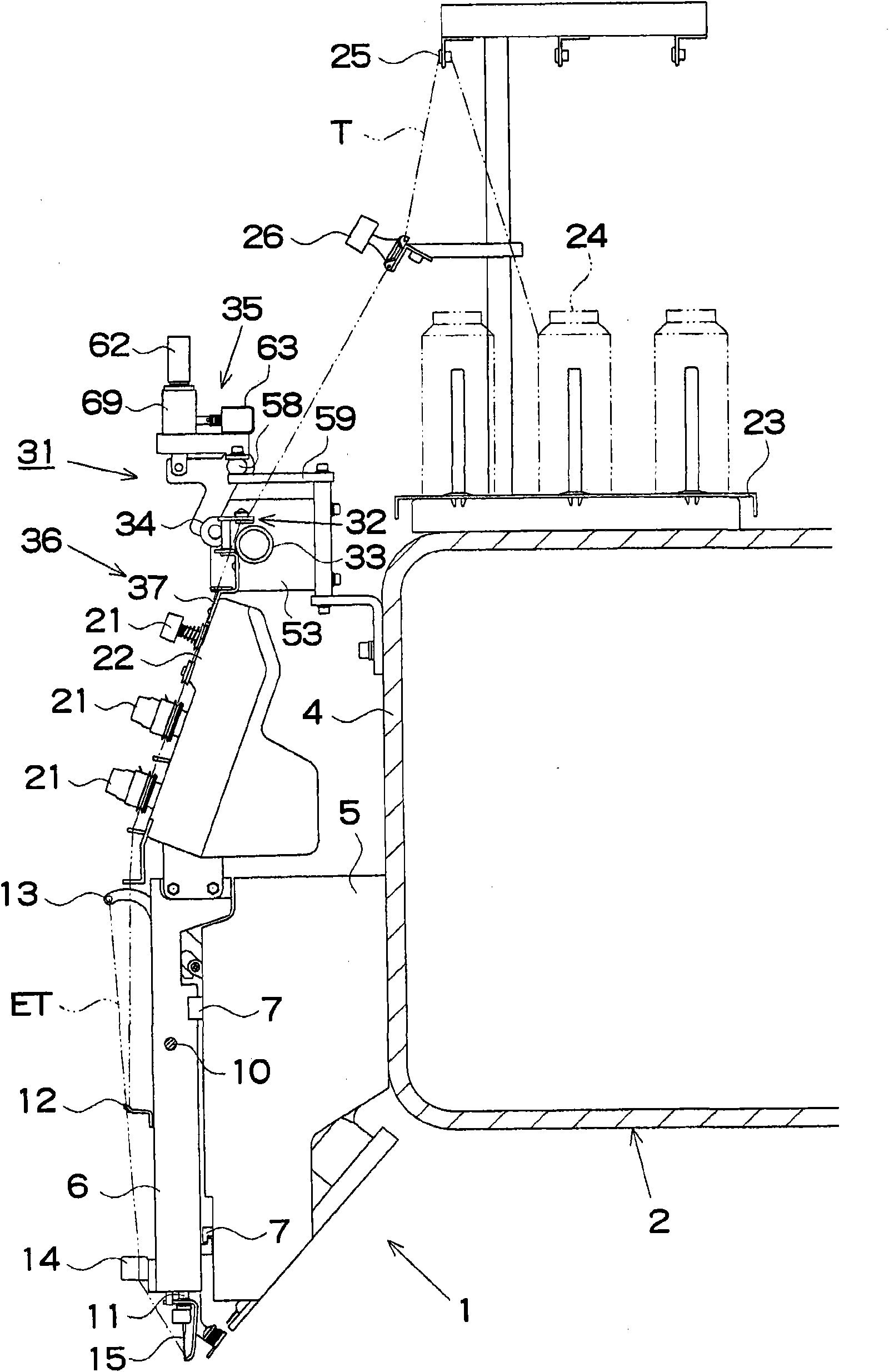

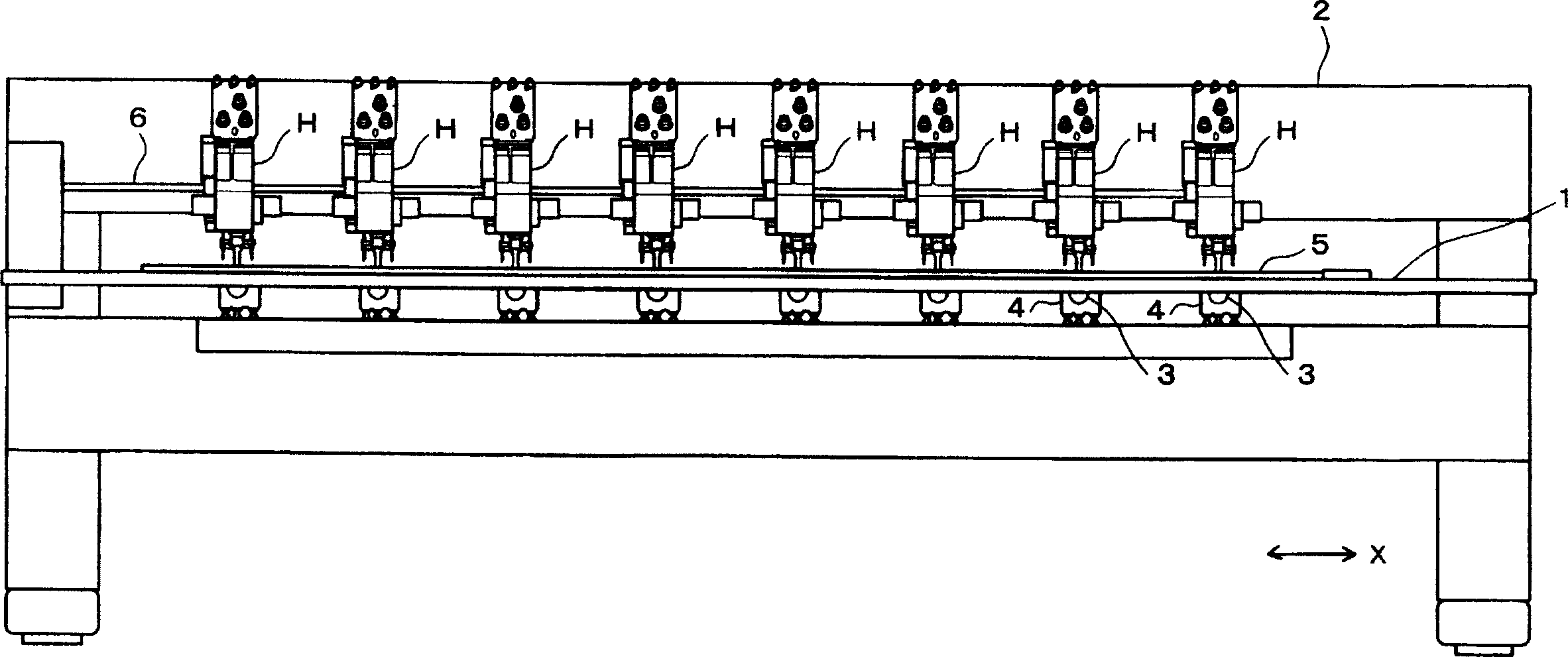

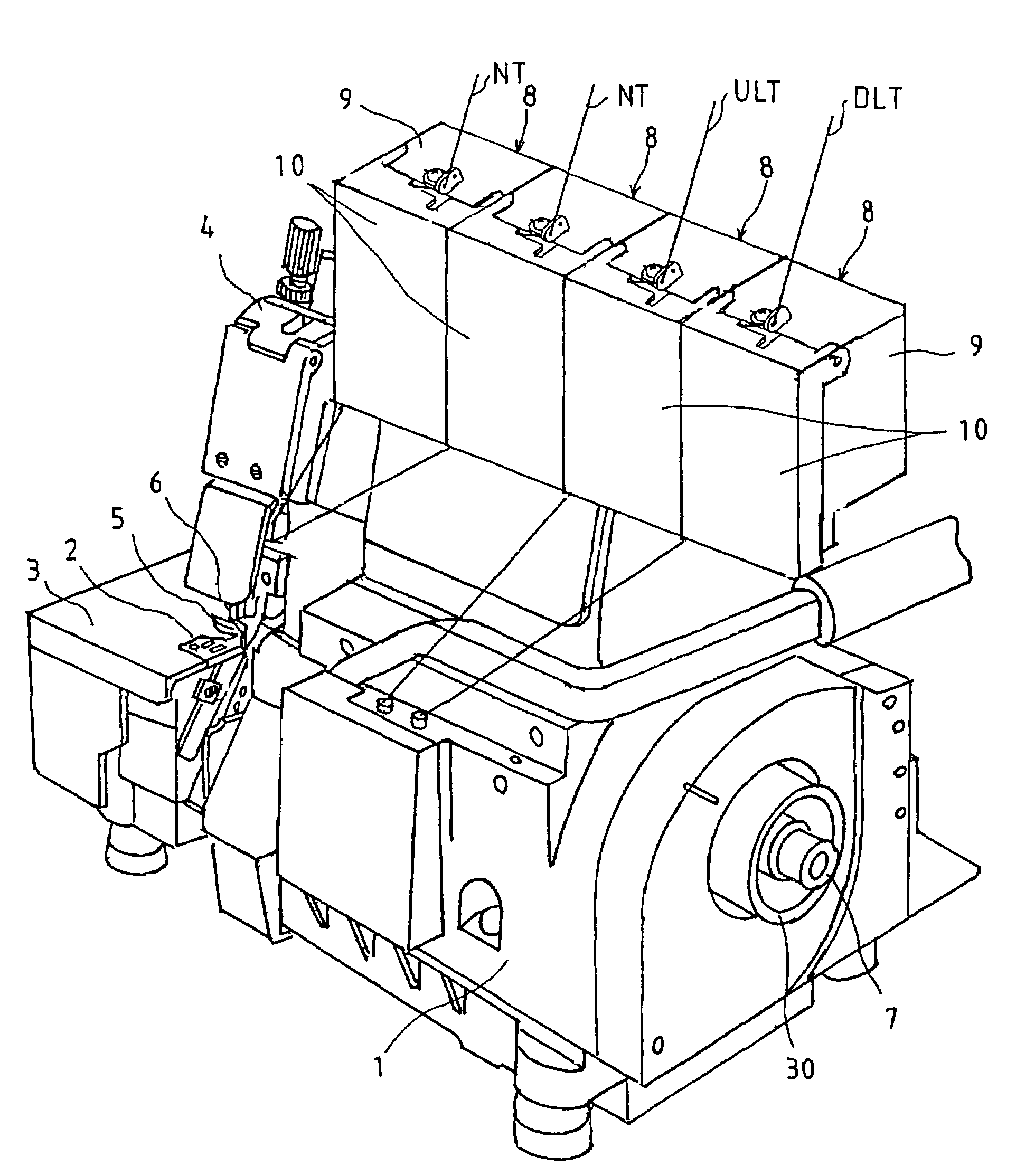

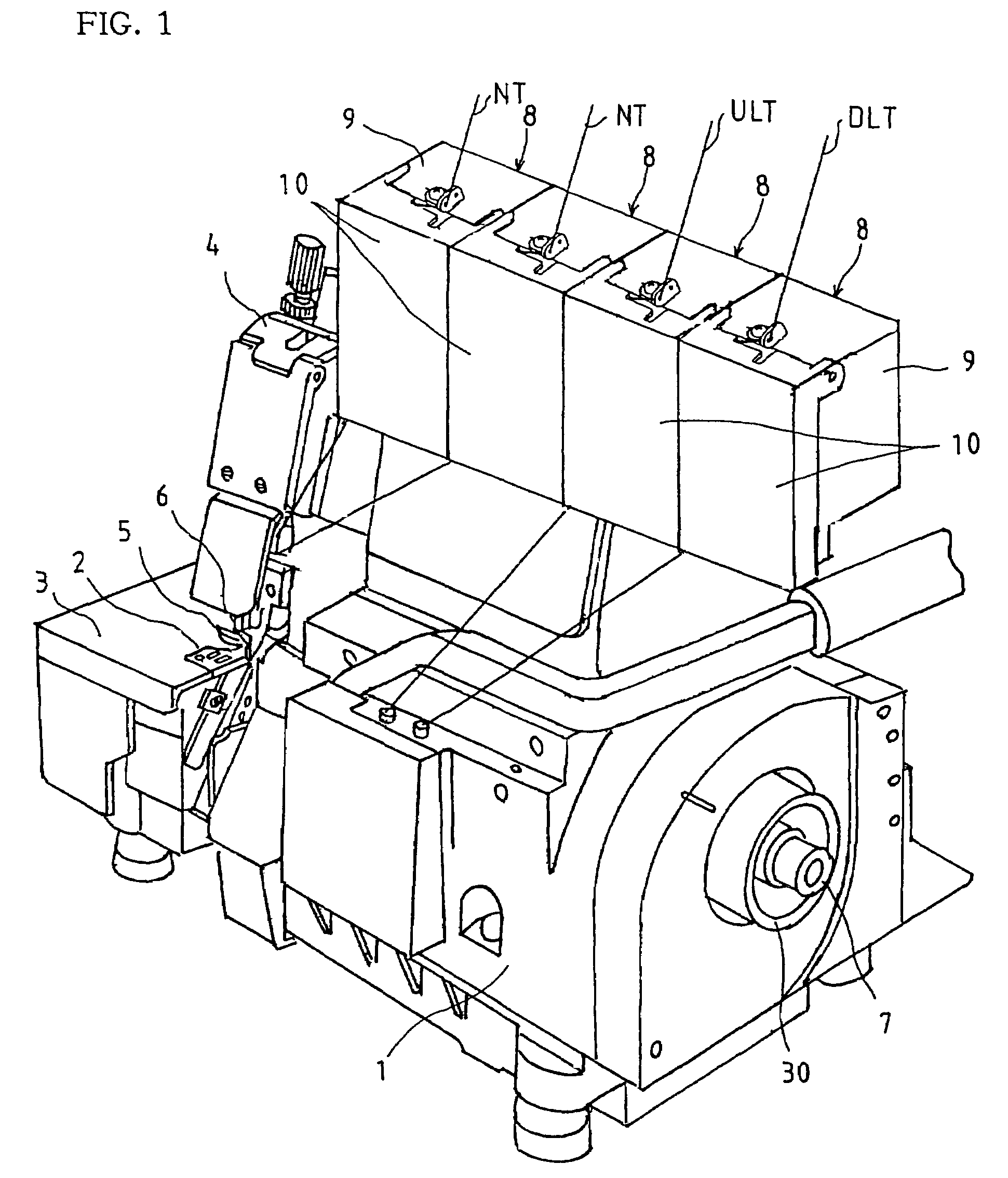

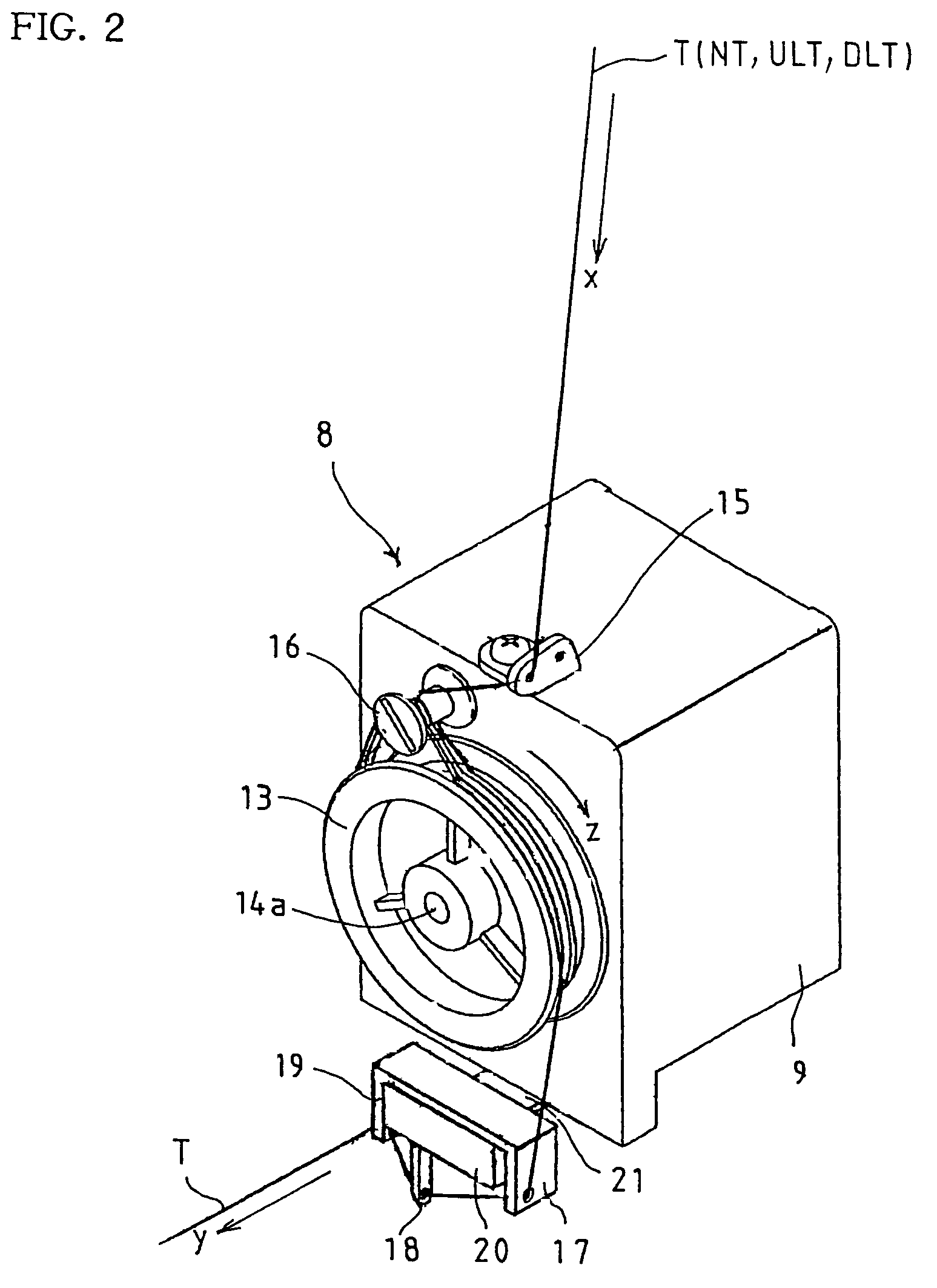

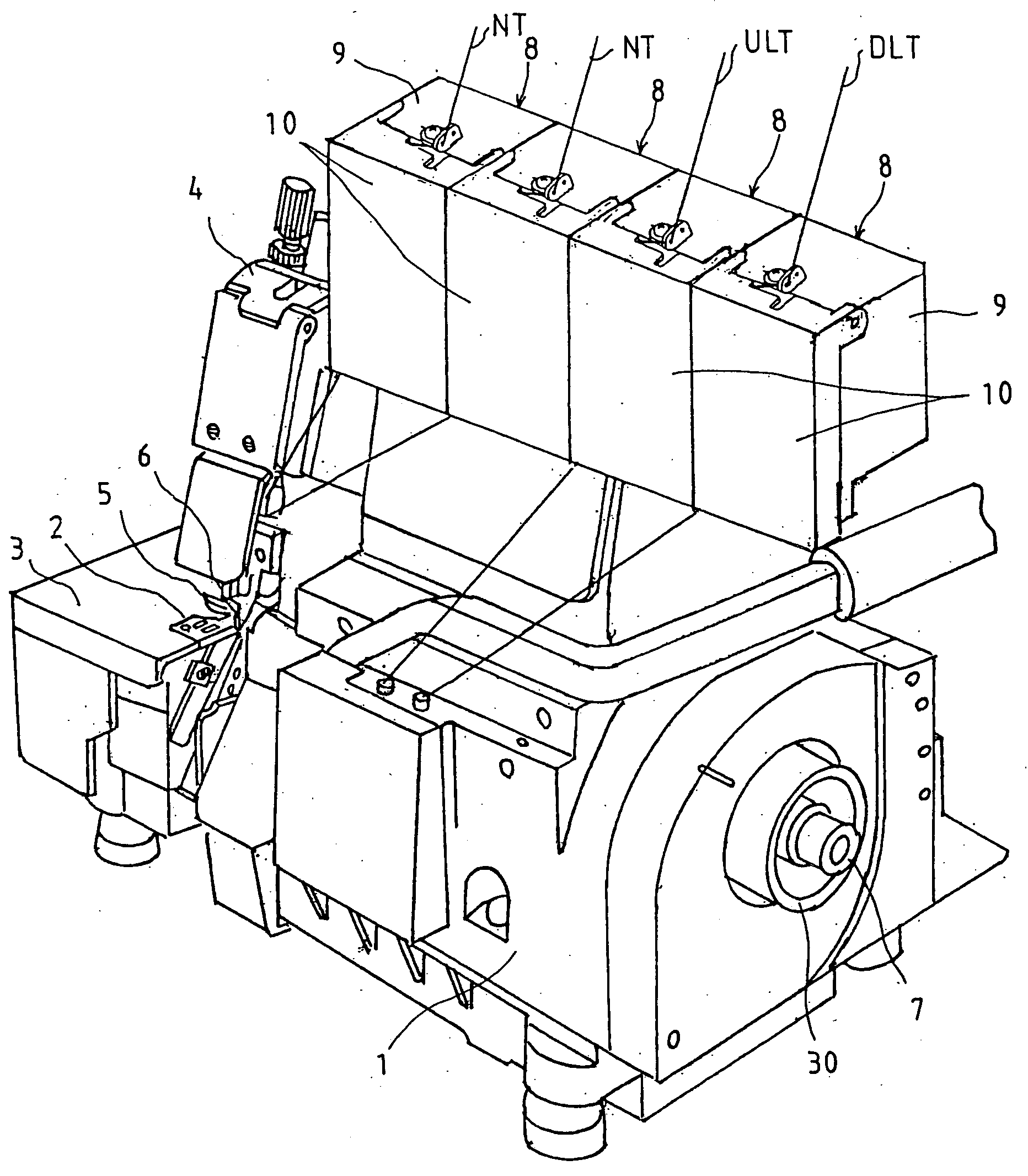

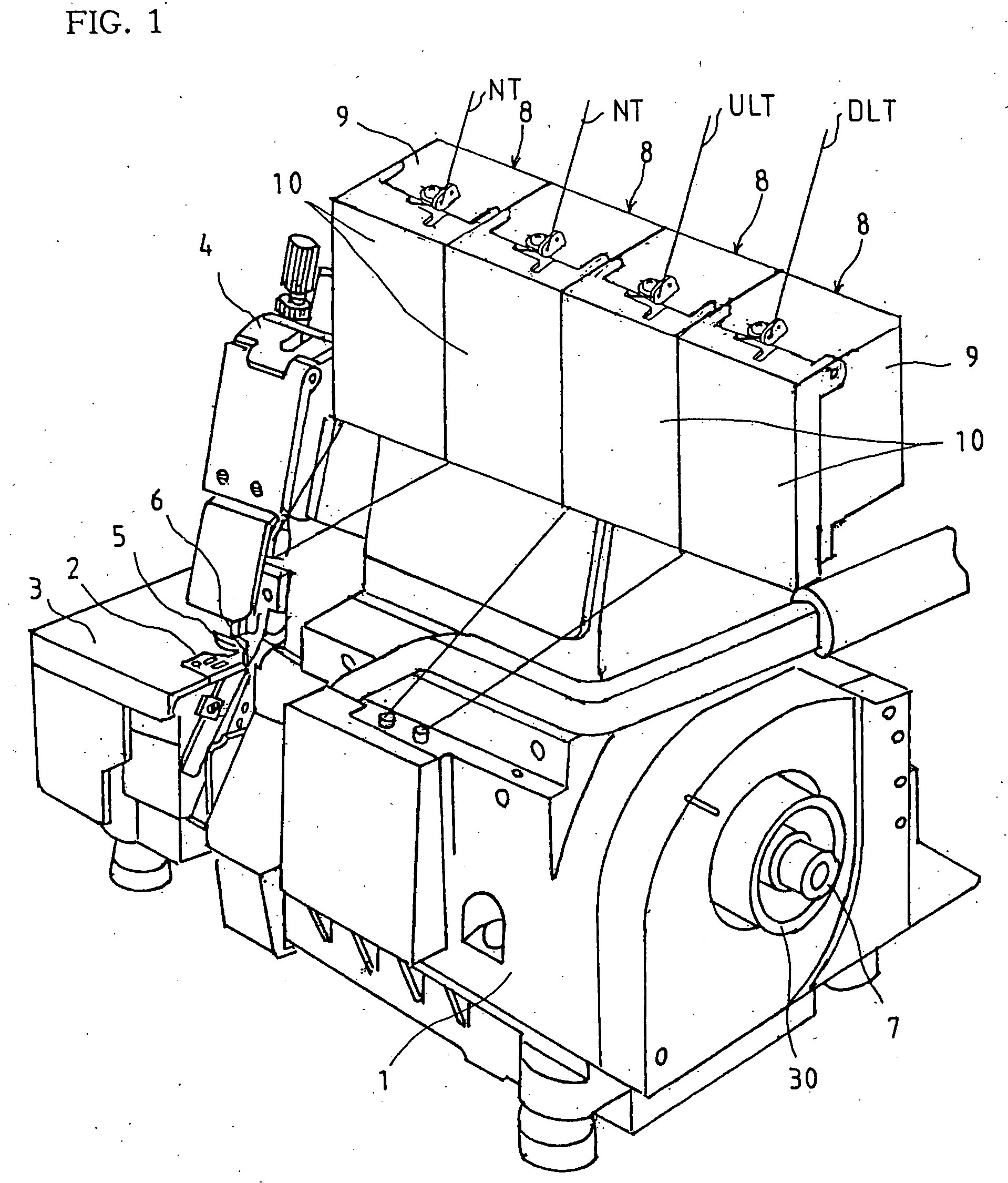

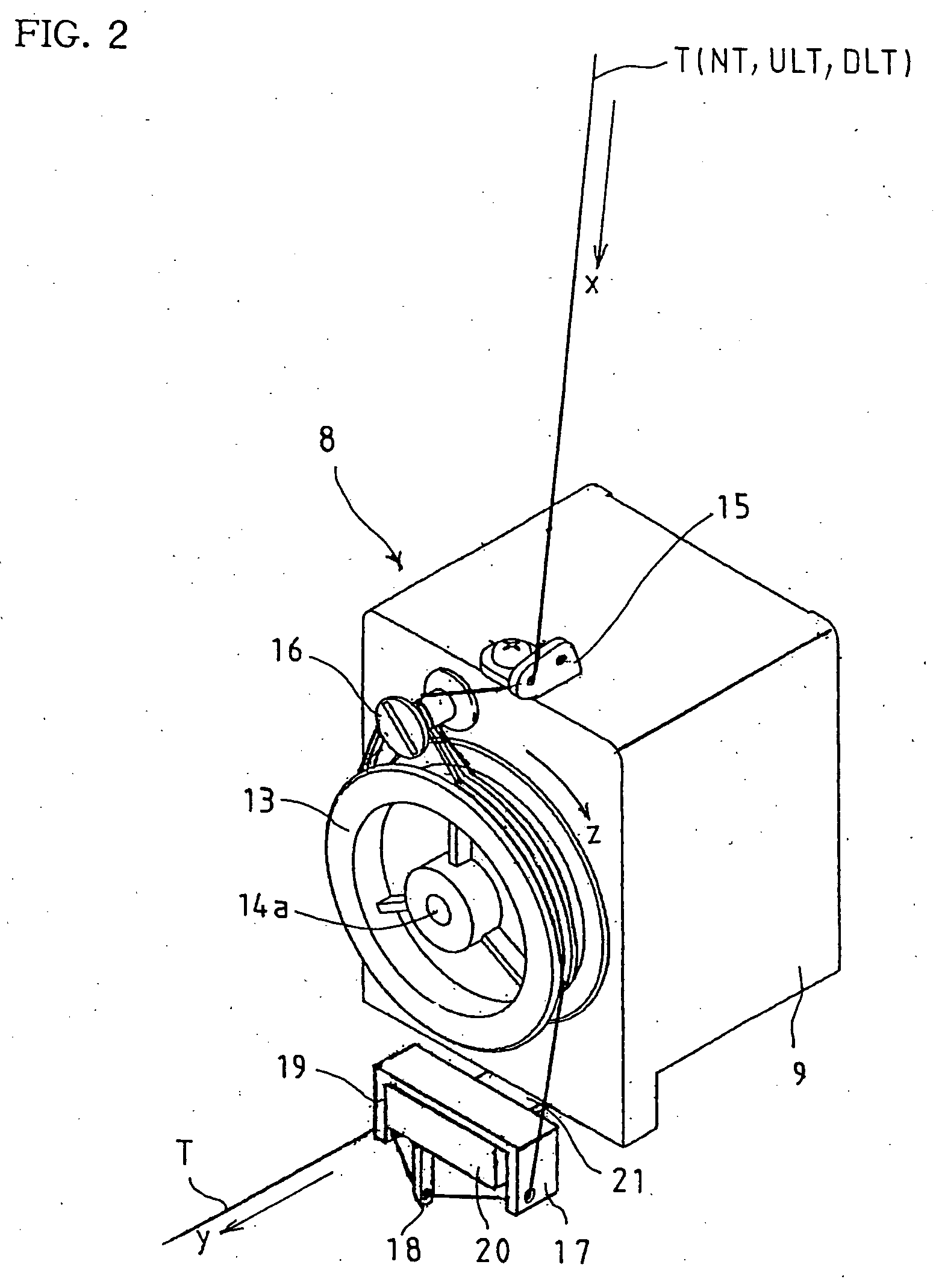

Needle thread feeding device for multi-needle embroidery sewing machine

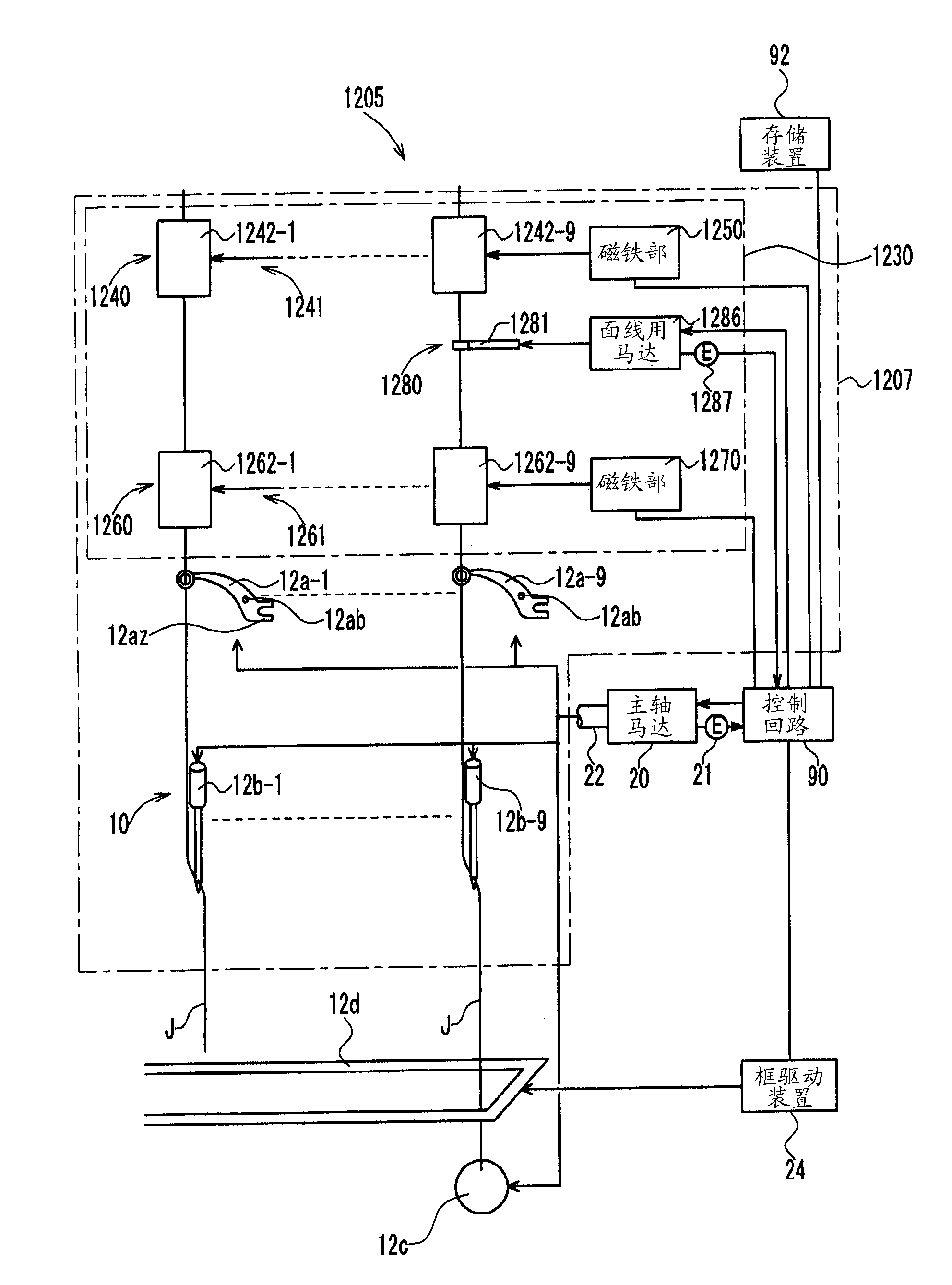

ActiveCN101597841AReduce in quantityImprove styling qualitySewing measuring devicesThread-break detectorsEngineeringSewing machine

The present invention provides a needle thread feeding device for a multi-needle embroidery sewing machine that moves a sewing machine head to selectively locate one of a plurality of needles in a sewing position, and feeds out, out of a plurality of needle threads, a selected needle thread passing through the needle in the sewing position from a needle thread supply source to the needle, the needle thread feeding device includes a drive roller having a length that extends across the plurality of needle threads, a needle thread guide mechanism that arranges the needle threads side by side in an axial direction of the drive roller and guides the needle threads, a pressure roller that presses the selected needle thread onto the drive roller, and a thread distributing mechanism that relatively moves the needle thread guide mechanism and the pressure roller in the axial direction of the drive roller in synchronization with movement of the sewing machine head. The thread distributing mechanism interposes the selected needle thread between the drive roller and the pressure roller.

Owner:BARUDAN KK

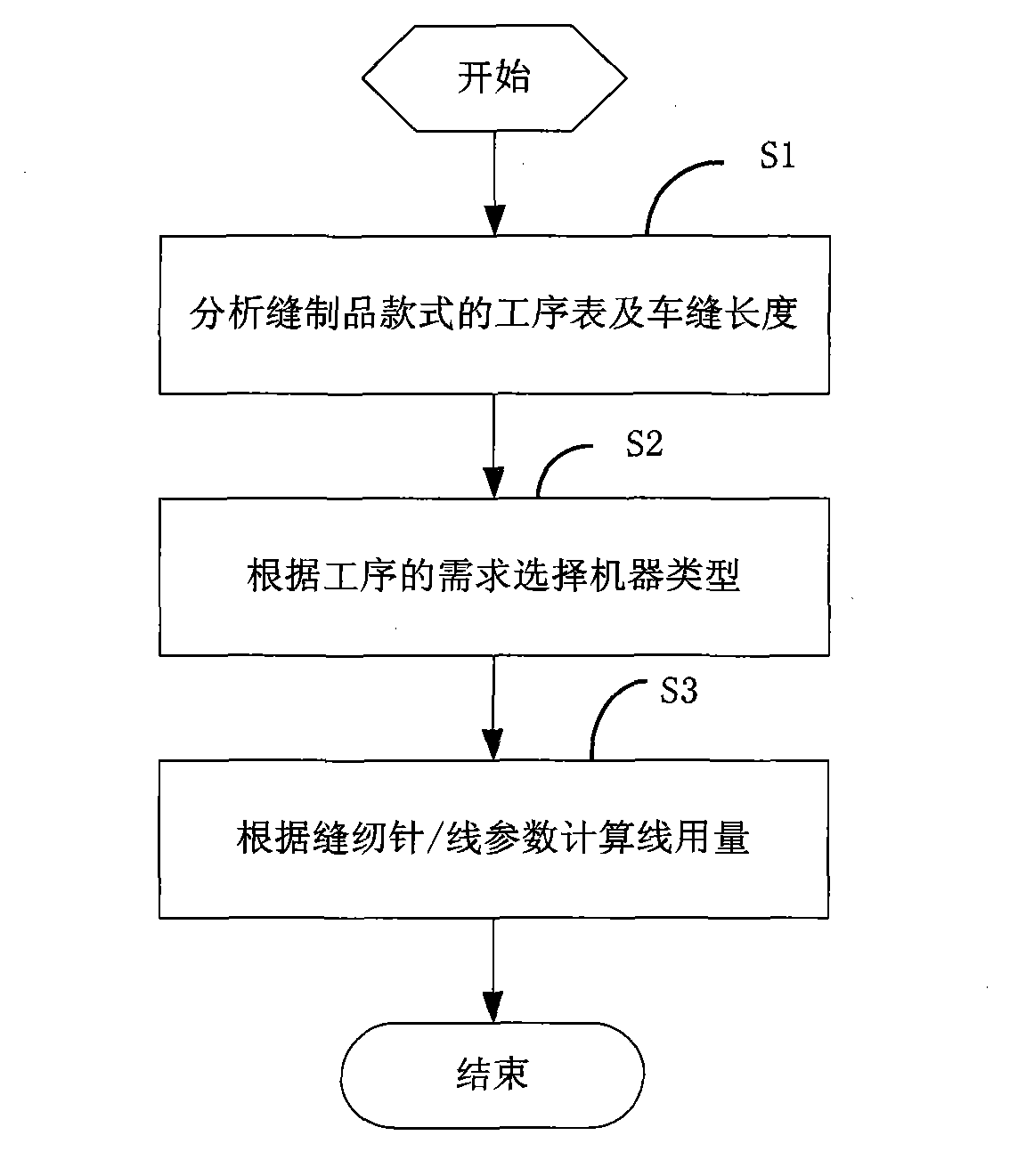

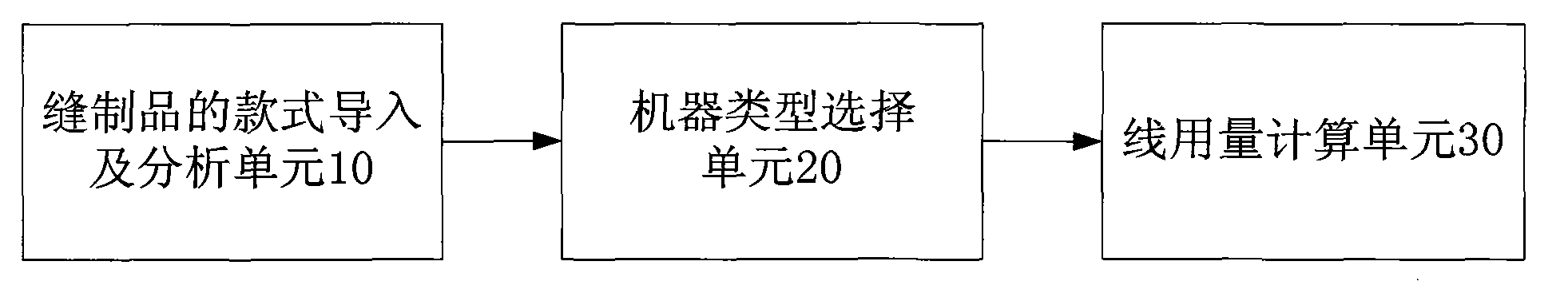

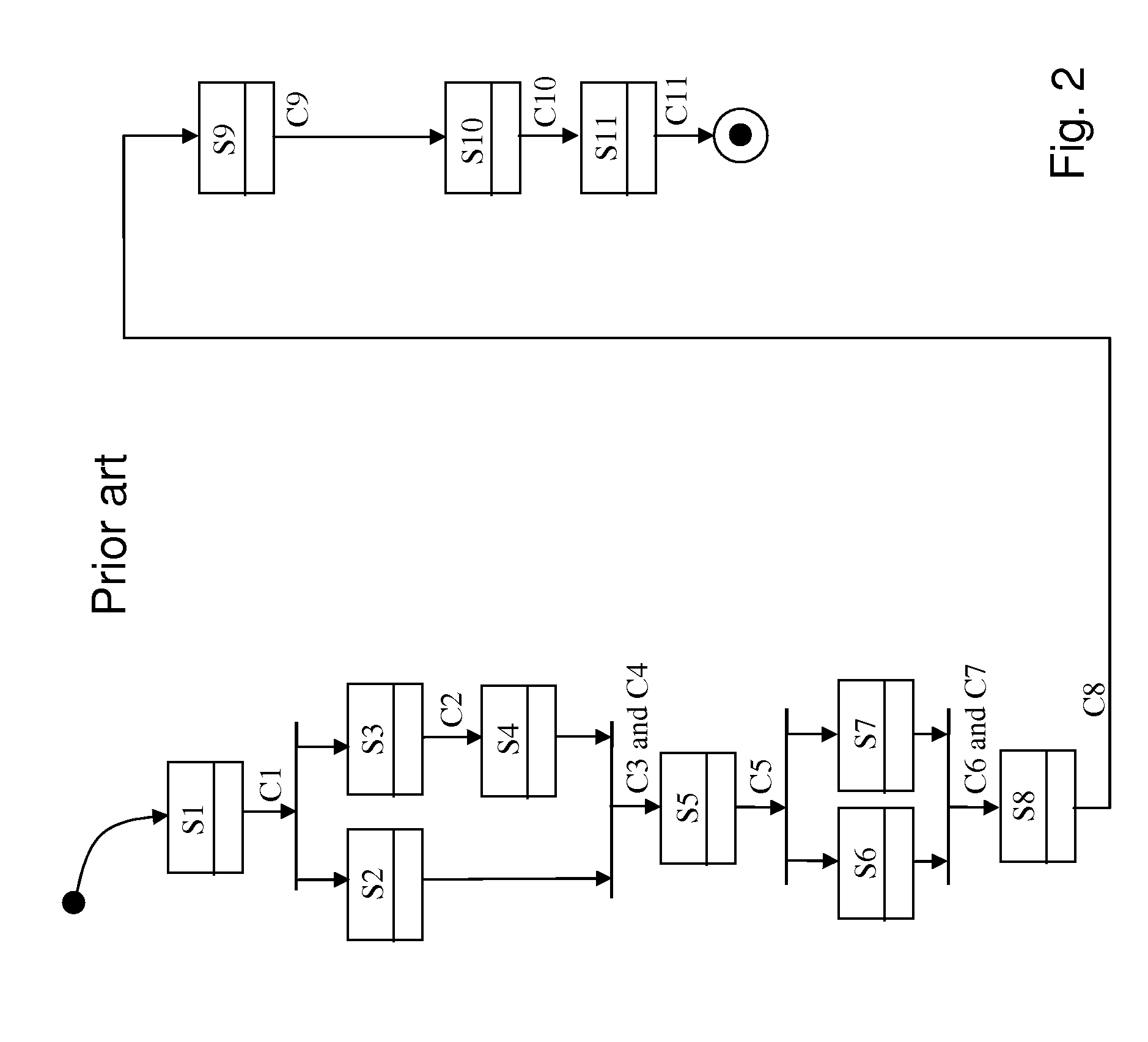

Method and device for calculating number of adopted sewing threads

ActiveCN103668808ASolve the purchaseSolution planSewing measuring devicesEngineeringCost calculation

The invention provides a method for calculating the number of adopted sewing threads. The method is applied to a sewn product production and operation system, and the production and operation system is provided with sewing equipment, a sewing needle and a sewing thread parameter database. The method comprises the steps that S1, style information of sewn products is guided in, styles are analyzed based on a preset movement analysis method, and a style process table and style process sewing length are set; S2, the machine type of the process corresponding sewing equipment is selected according to actual production needs; S3, the sewing needle and sewing thread parameters of the corresponding sewing equipment are guided in, and the number of the adopted sewing threads is calculated according to the sewing needle and sewing thread parameters and the sewing length. The invention further discloses a device for calculating the number of the adopted sewing threads. According to the method and device for calculating the number of the adopted sewing threads, the number of the adopted sewing threads of the product of each style can be accurately calculated, and therefore cost calculation and control over the sewing threads in sewn product industries are facilitated.

Owner:GUANGZHOU CHUNXIAO INFORMATION TECH

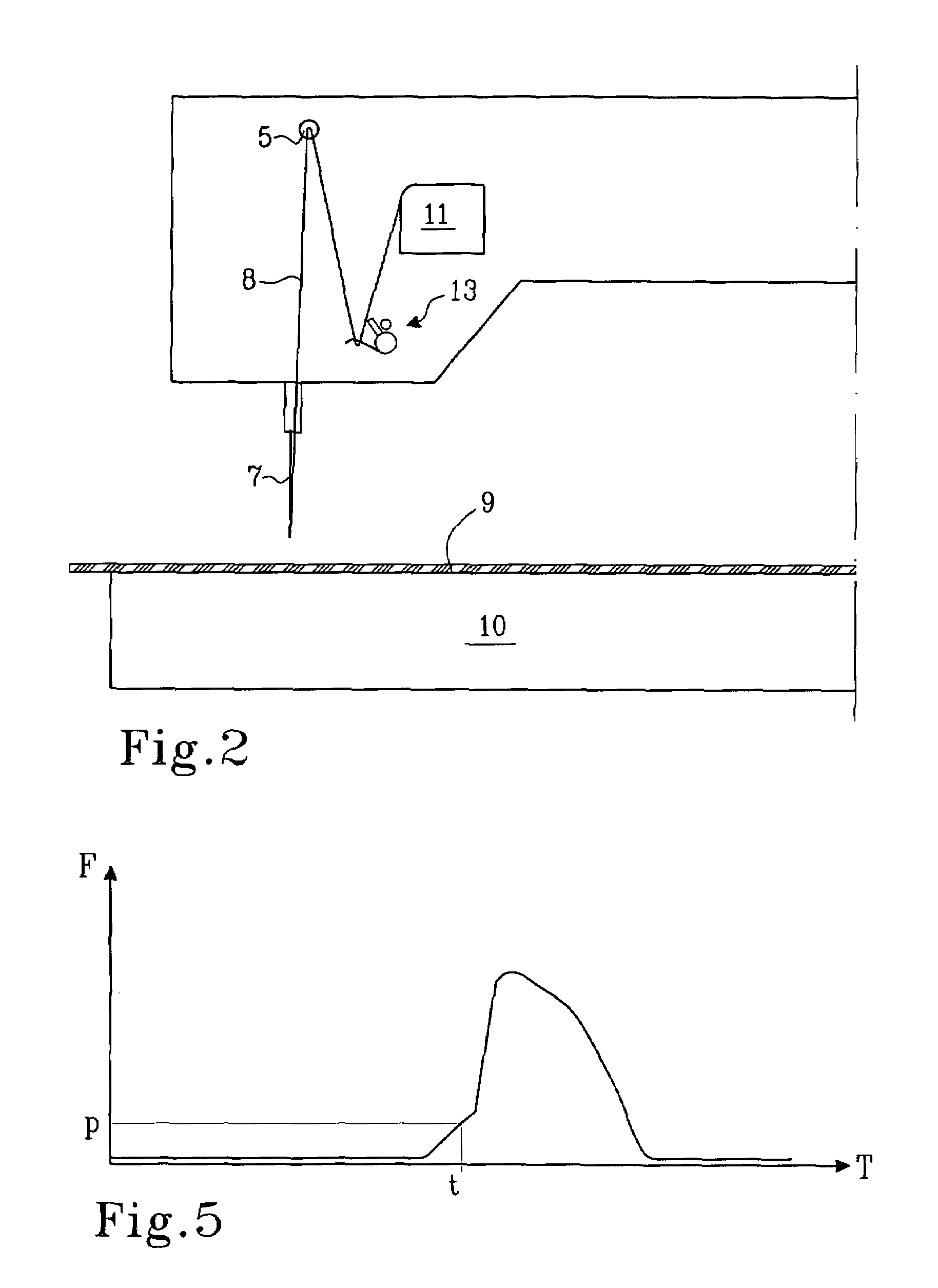

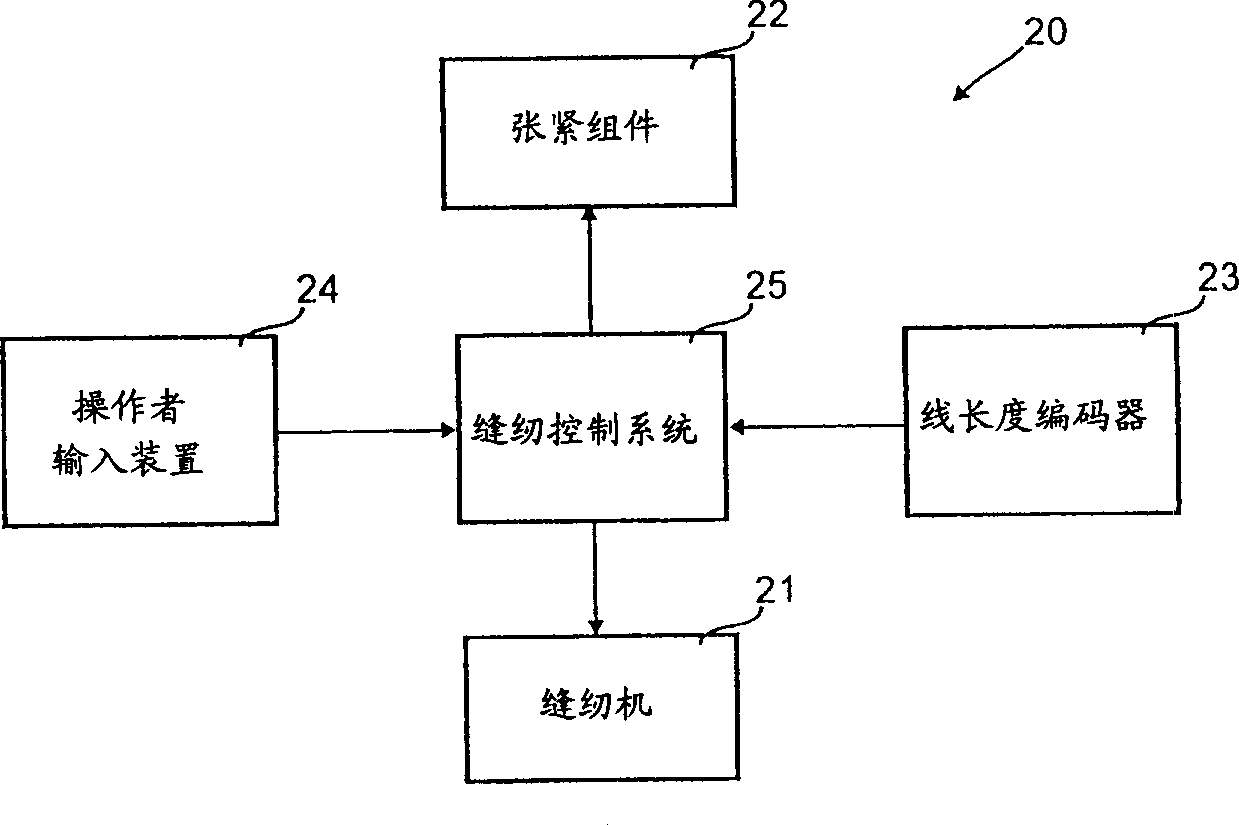

Method and apparatus for automatic adjustment of thread tension

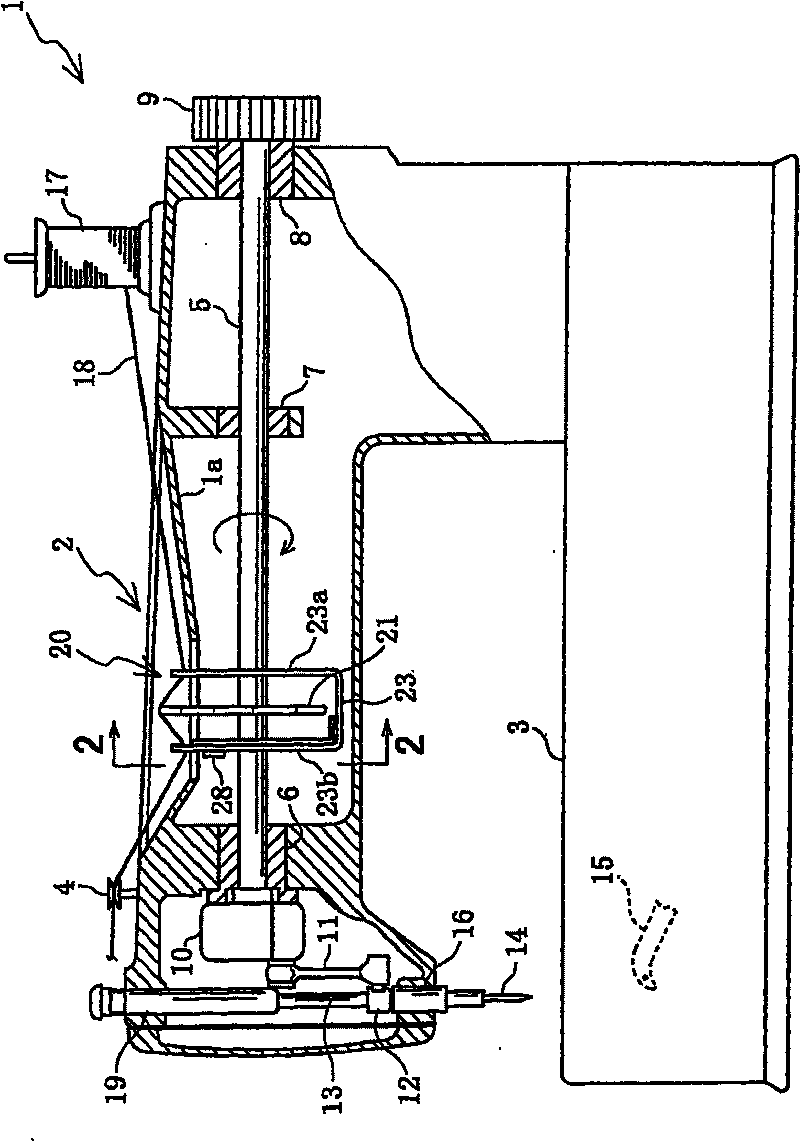

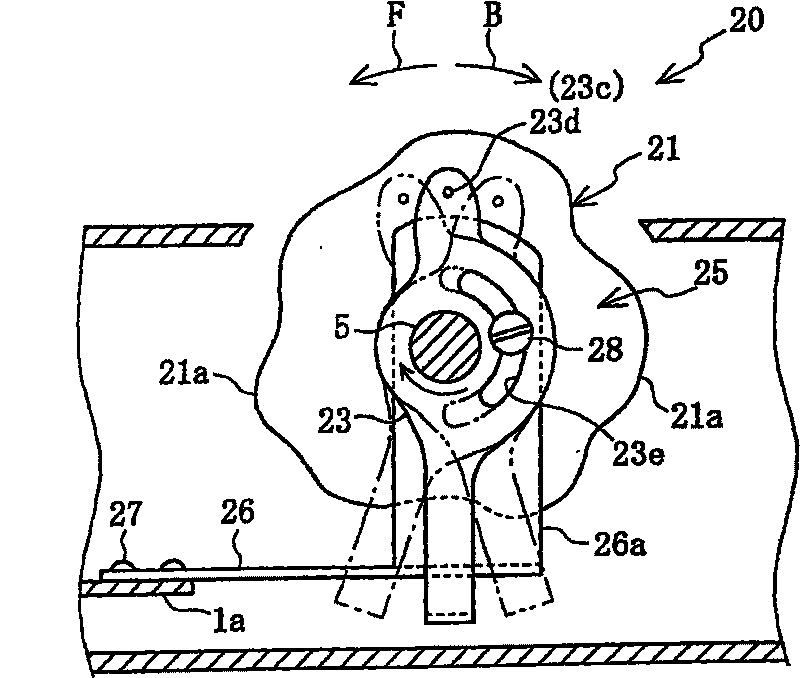

InactiveCN1305547AAccurate adjustmentImprove uniformityProgramme-controlled sewing machinesSewing measuring devicesAutomatic controlControl system

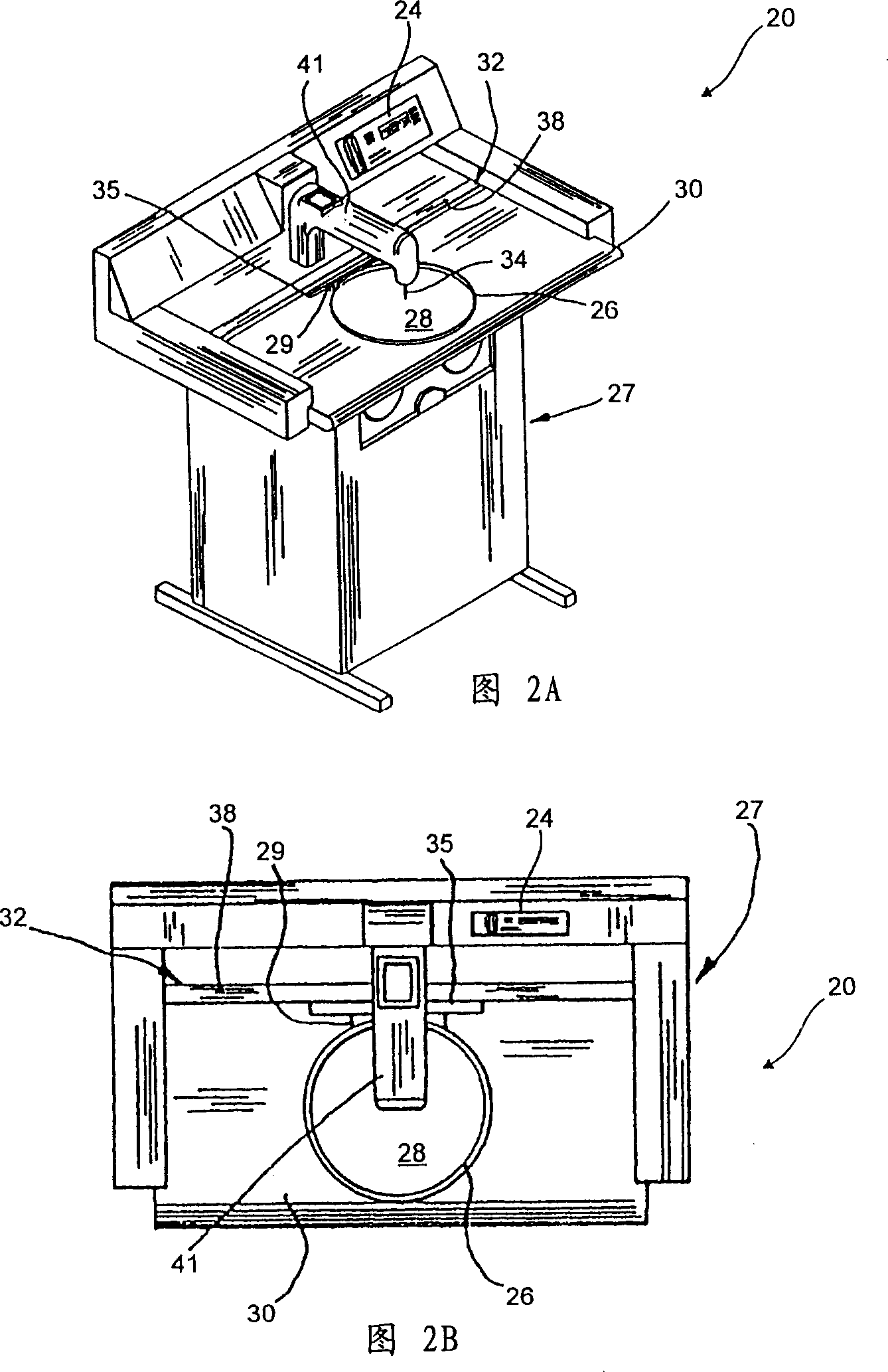

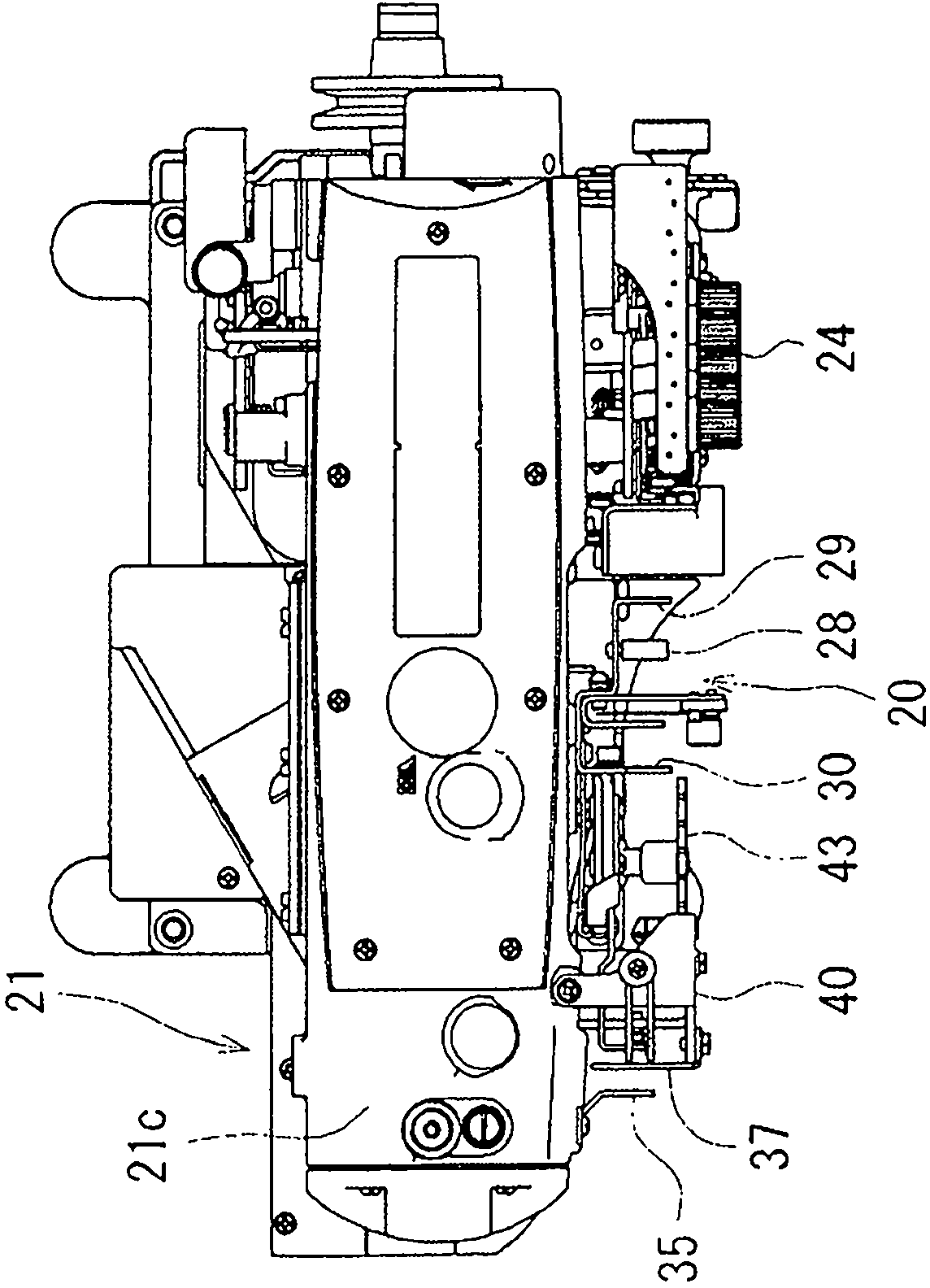

A computerized stitching apparatus that automatically controls thread tension is disclosed. In one embodiment, at least two factors are used to determine the desired thread consumption for the next stitch. A thread length encoder (23) is used to determine the amount of thread actually consumed for a particular stitch. The operator must enter a desired thread length ratio or an equivalent factor related to desired thread length used for a particular stitch into the operator input device (24). Another factor such as speed, stitch length, fabric thickness, or stitch angle change is used with at least the operator's input to determine the desired thread consumption. The tension of the thread is adjusted by a stitch control system (25) which will affect the actual thread consumed for the particular stitch.

Owner:MCET

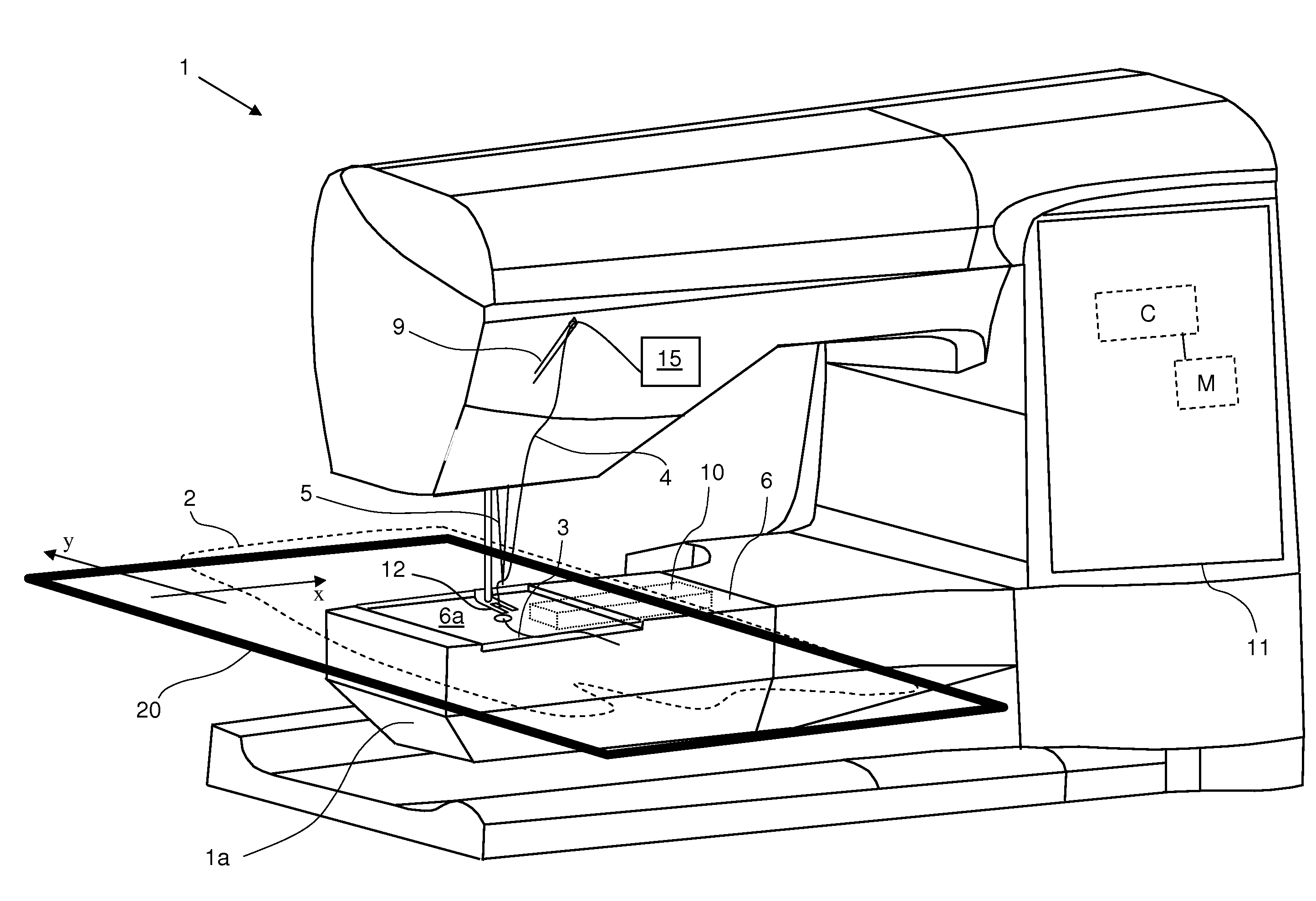

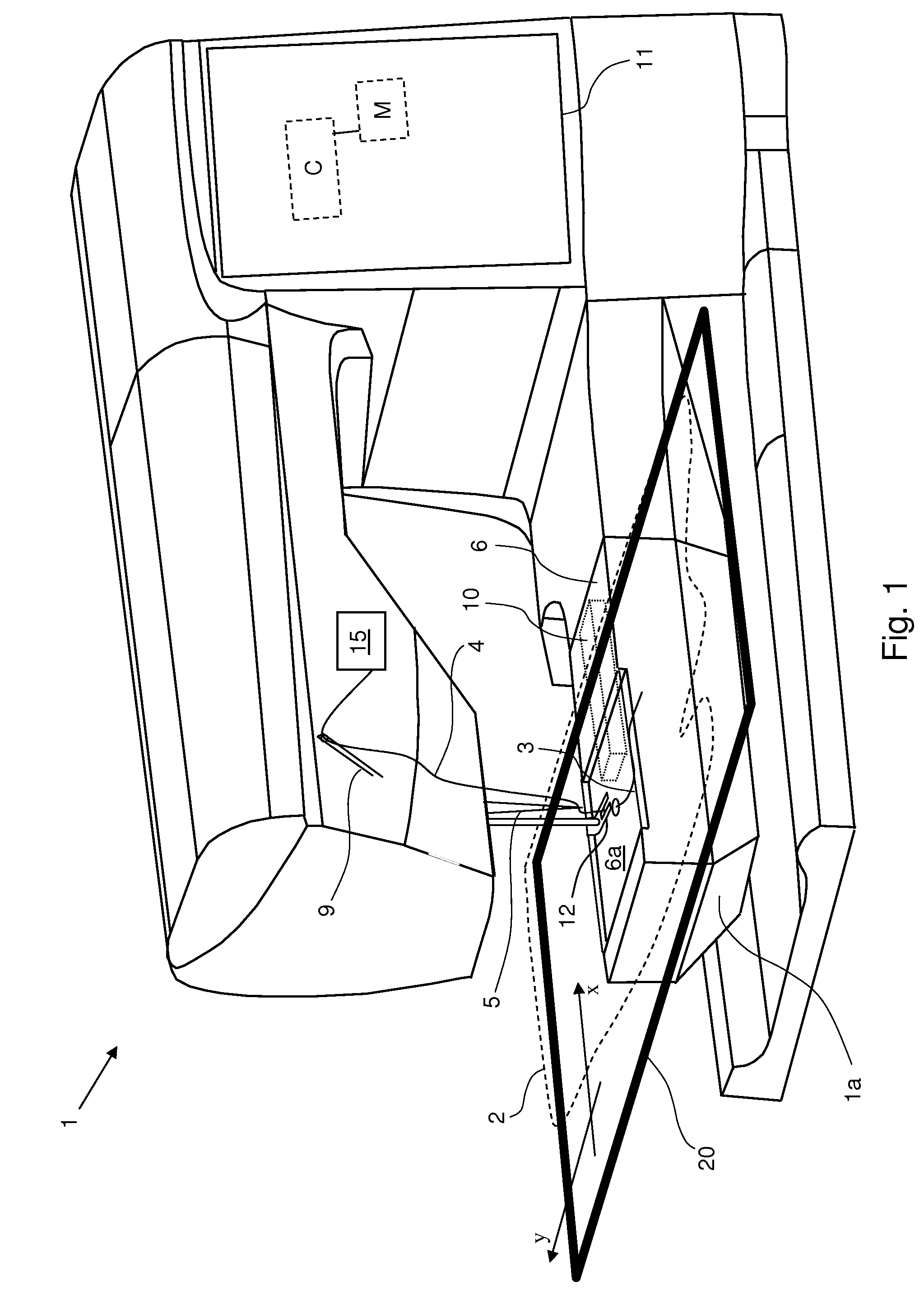

Thread feed for a sewing machine

ActiveUS20050199165A1Minimize biasProgramme-controlled sewing machinesSewing-machine control devicesBobbinReciprocating motion

A sewing machine including a needle being supplied with an upper thread, a loop taker which accommodates a bobbin for a bottom thread. and a drive unit, which forces the needle to perform a reciprocating movement. The needle, during its movement and in cooperation with the loop taker, executes a stitch on a sewing material being advanced between the upper thread and the bottom thread. A take-up lever, for each stitch, pulls tight a knot being formed in the sewing material by the upper thread and the bottom thread in cooperation. The sewing machine further includes a thread transfer member supplying the needle with an upper thread with either a thread portioner or a friction braking assembly for friction braking of the upper thread. A switch switches between thread supply with the thread portioner or with the friction braking assembly. A control unit controls the thread supply from the thread portioner or, alternatively, controls the friction braking assembly.

Owner:KSIN LUXEMBOURG II

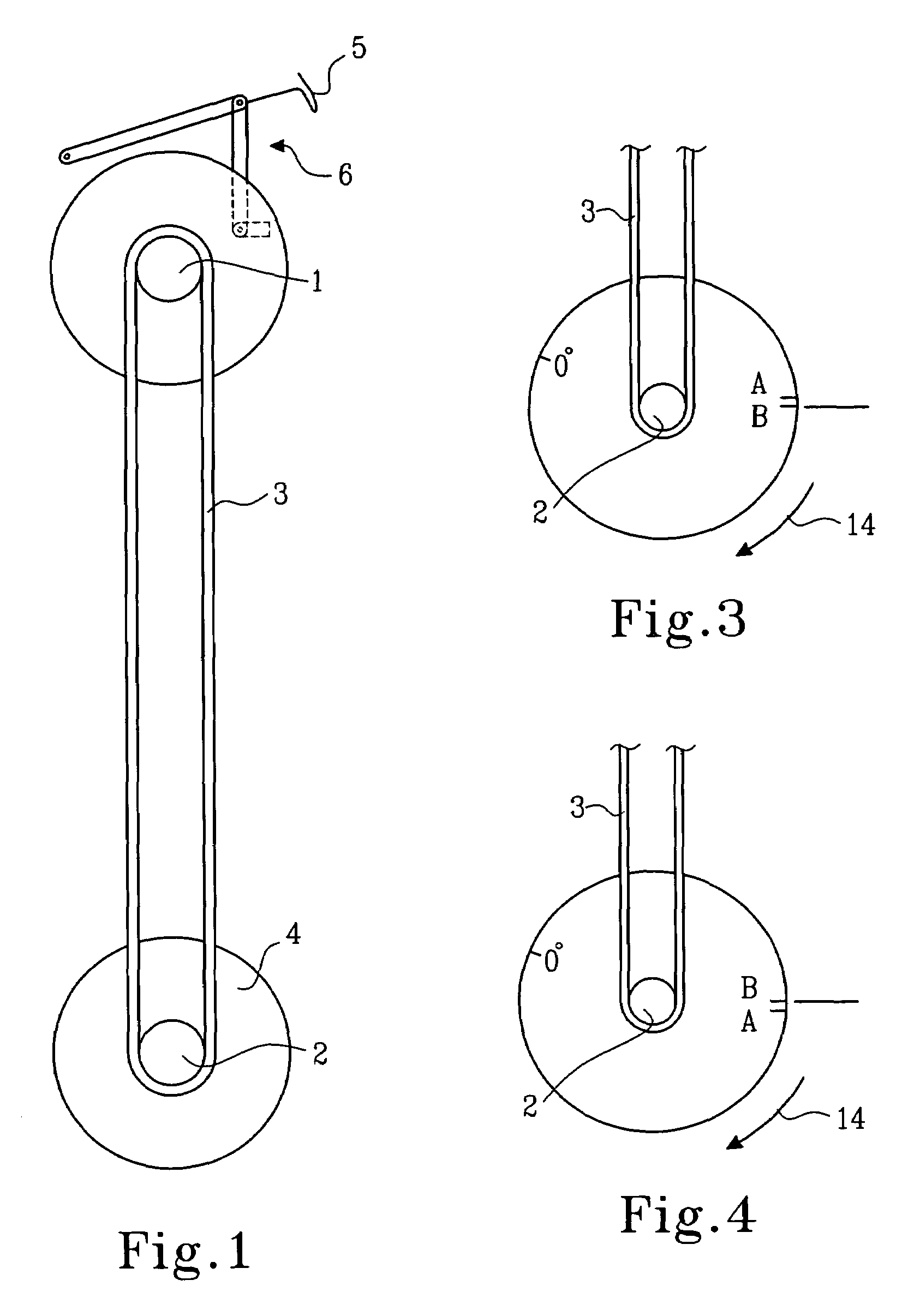

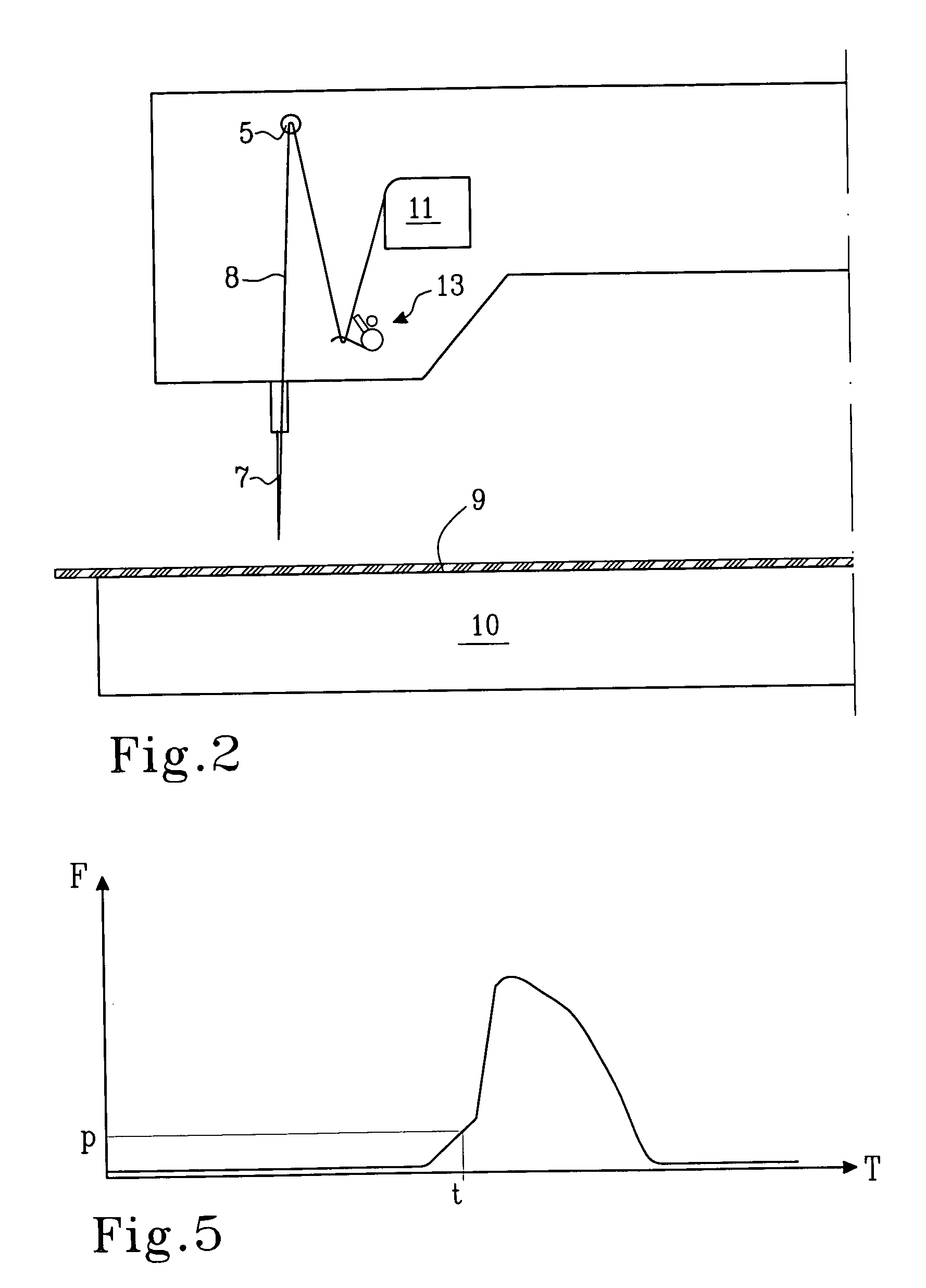

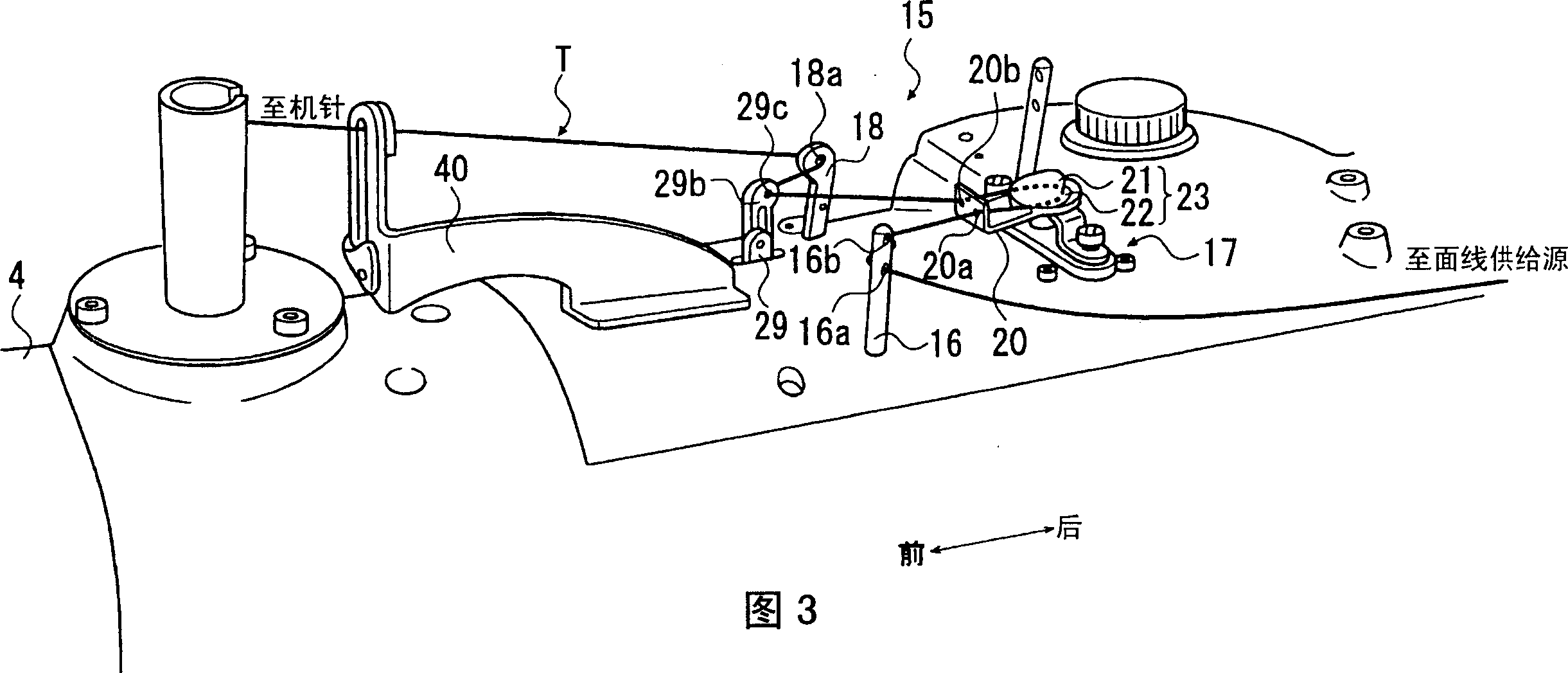

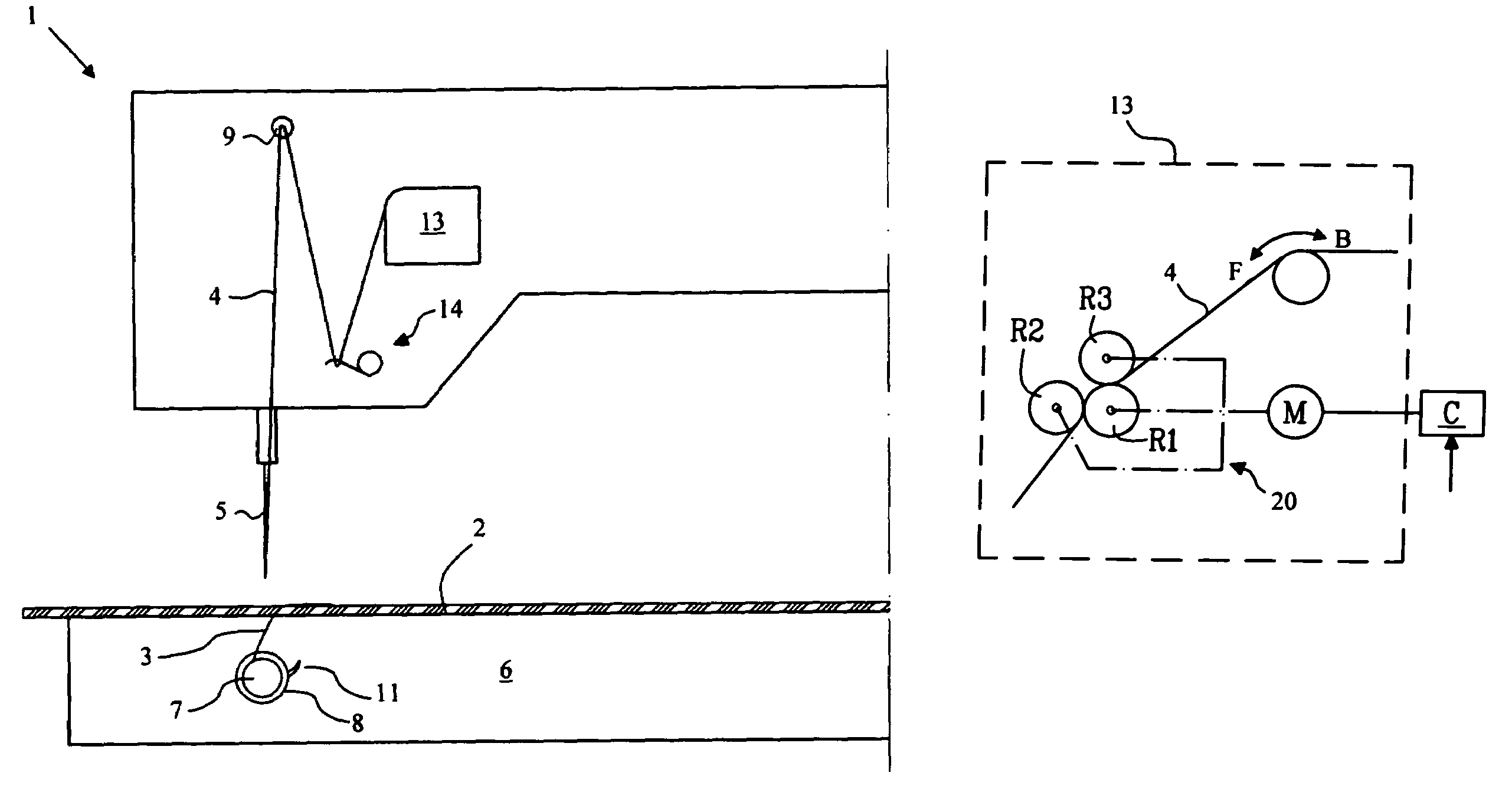

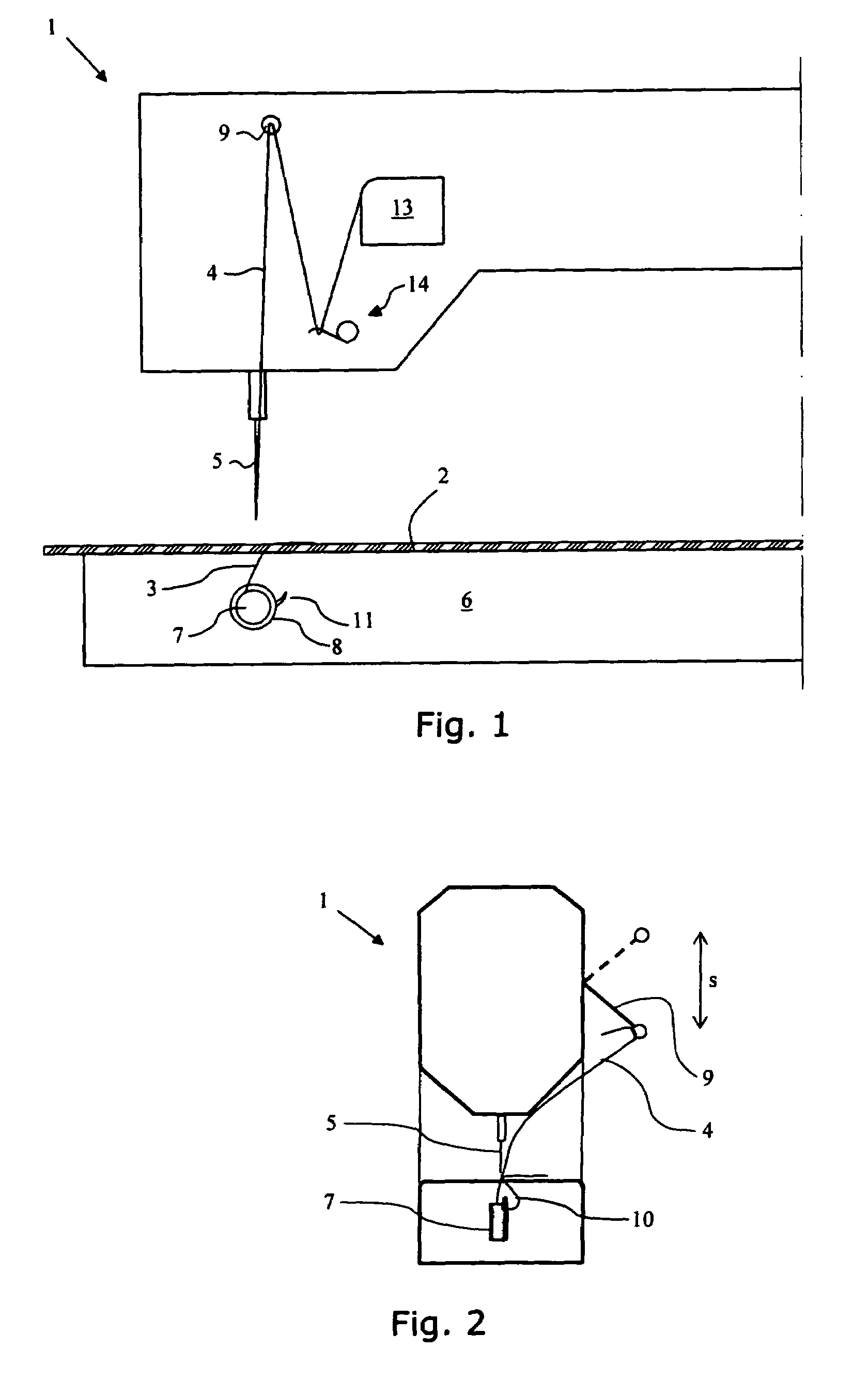

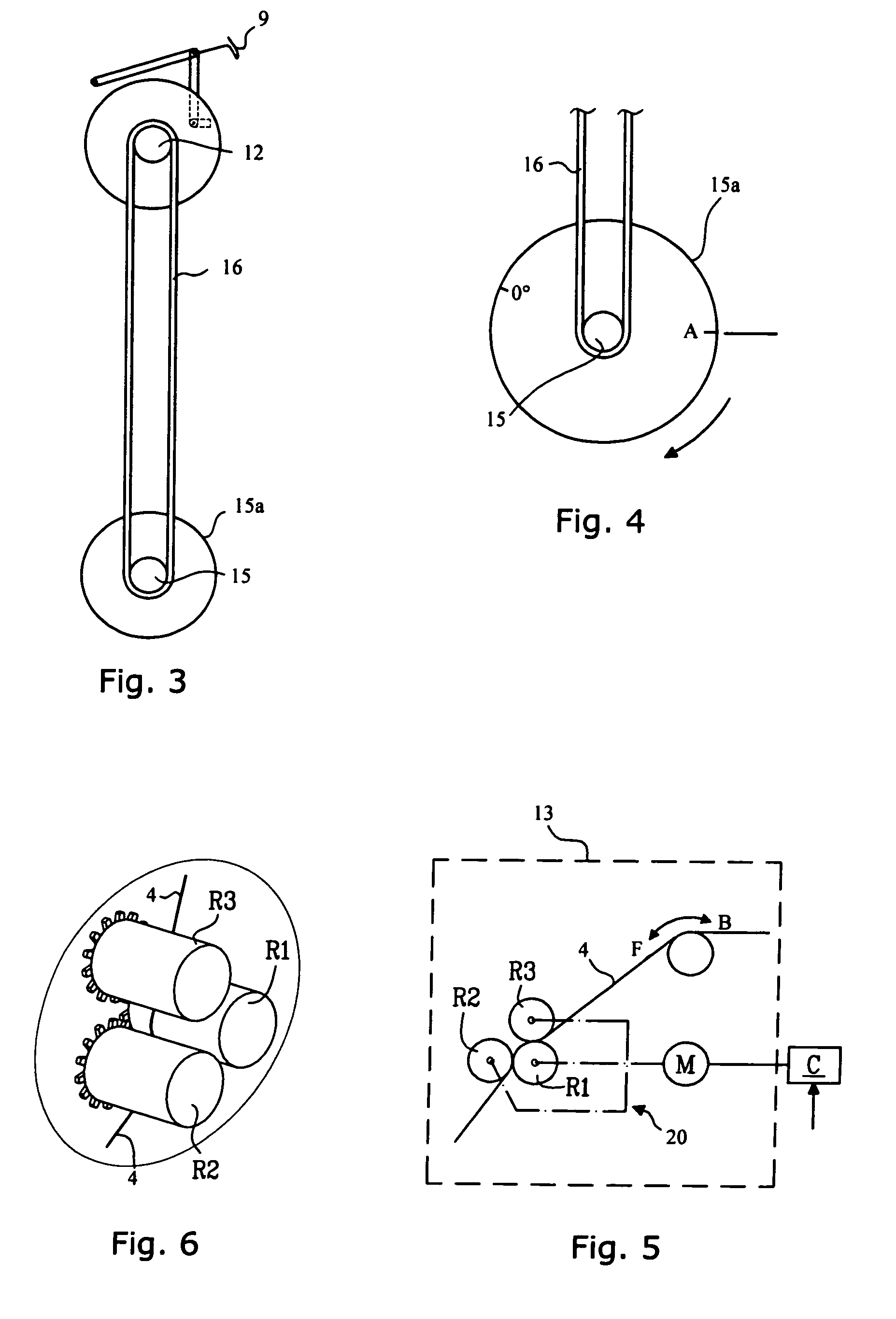

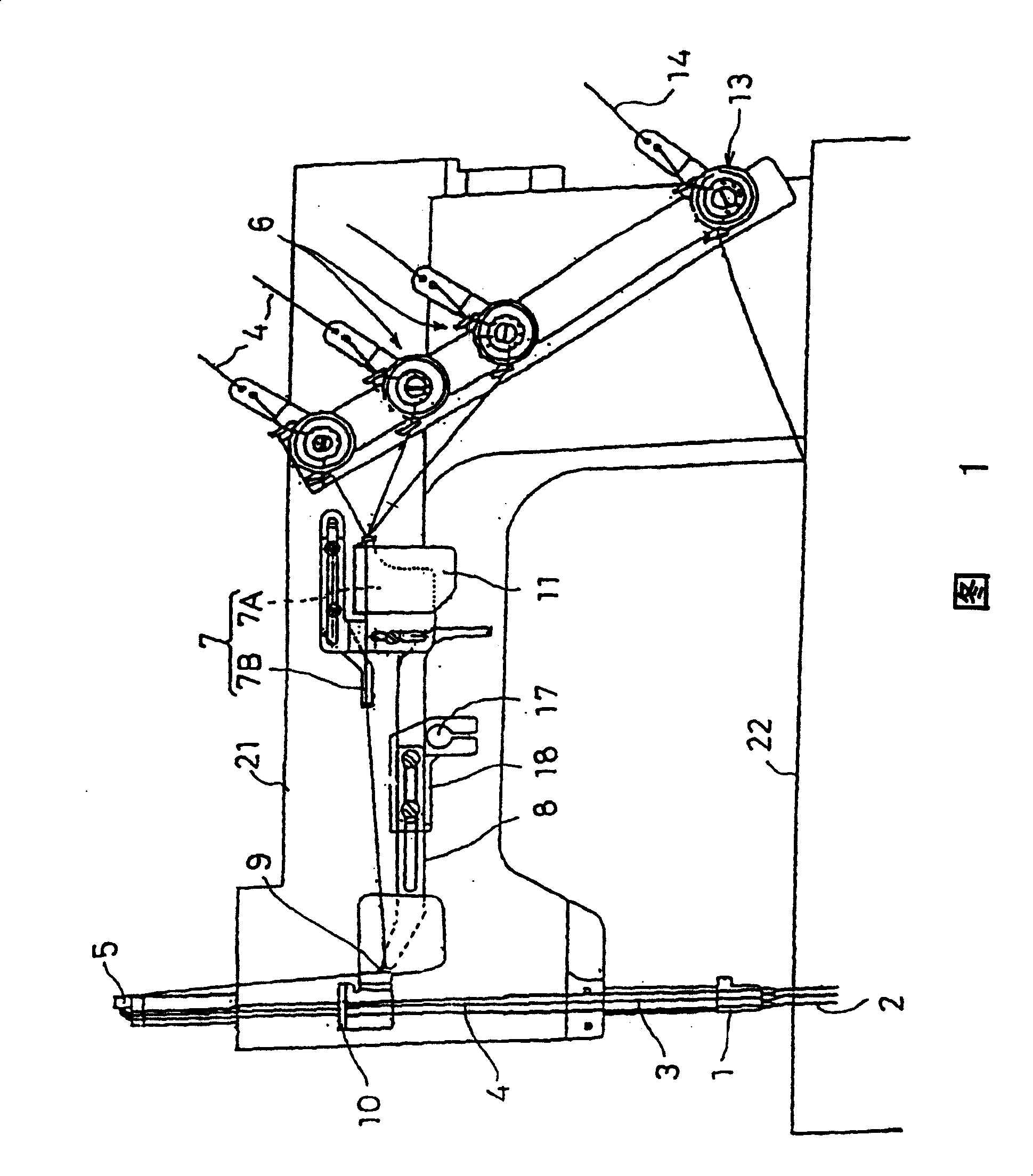

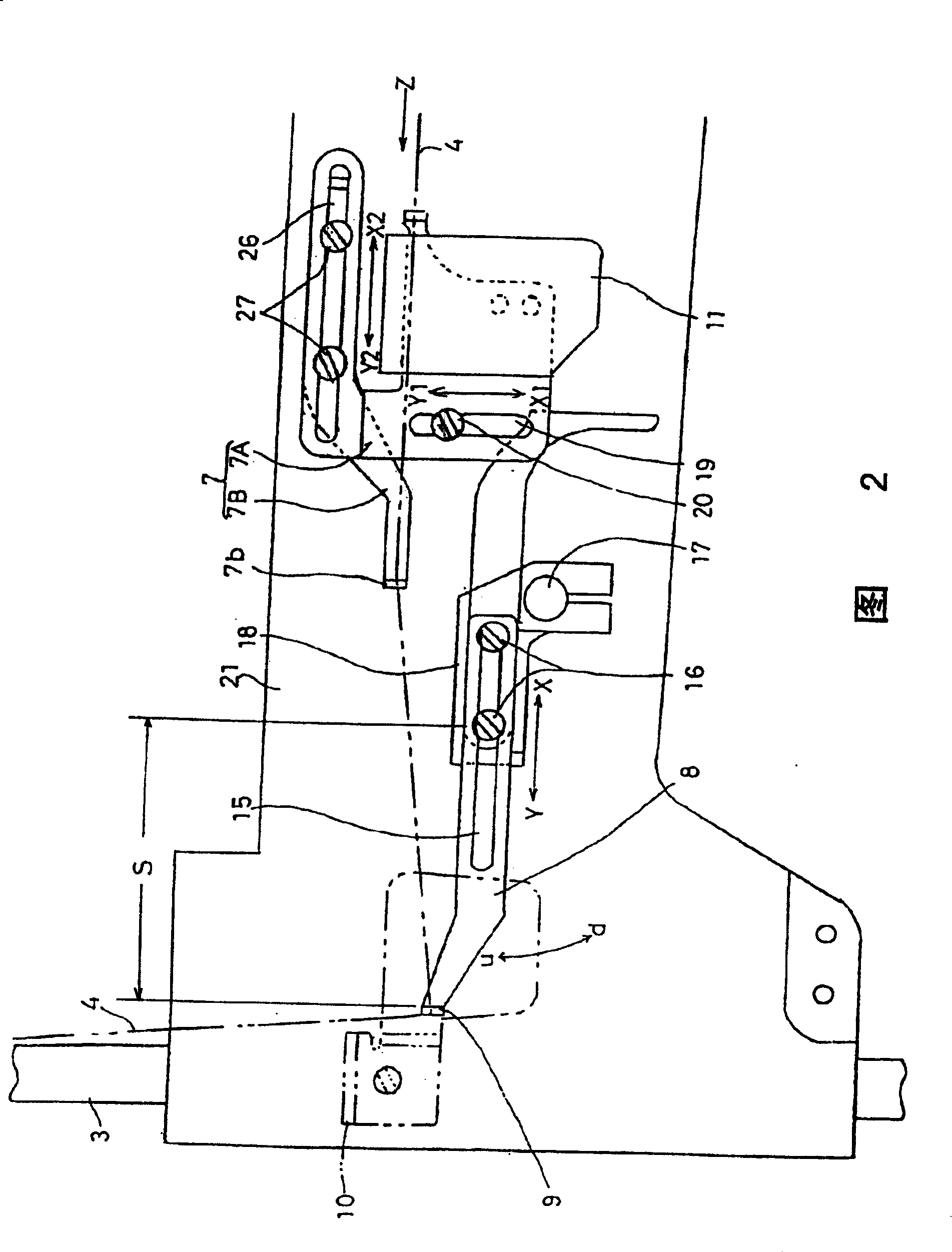

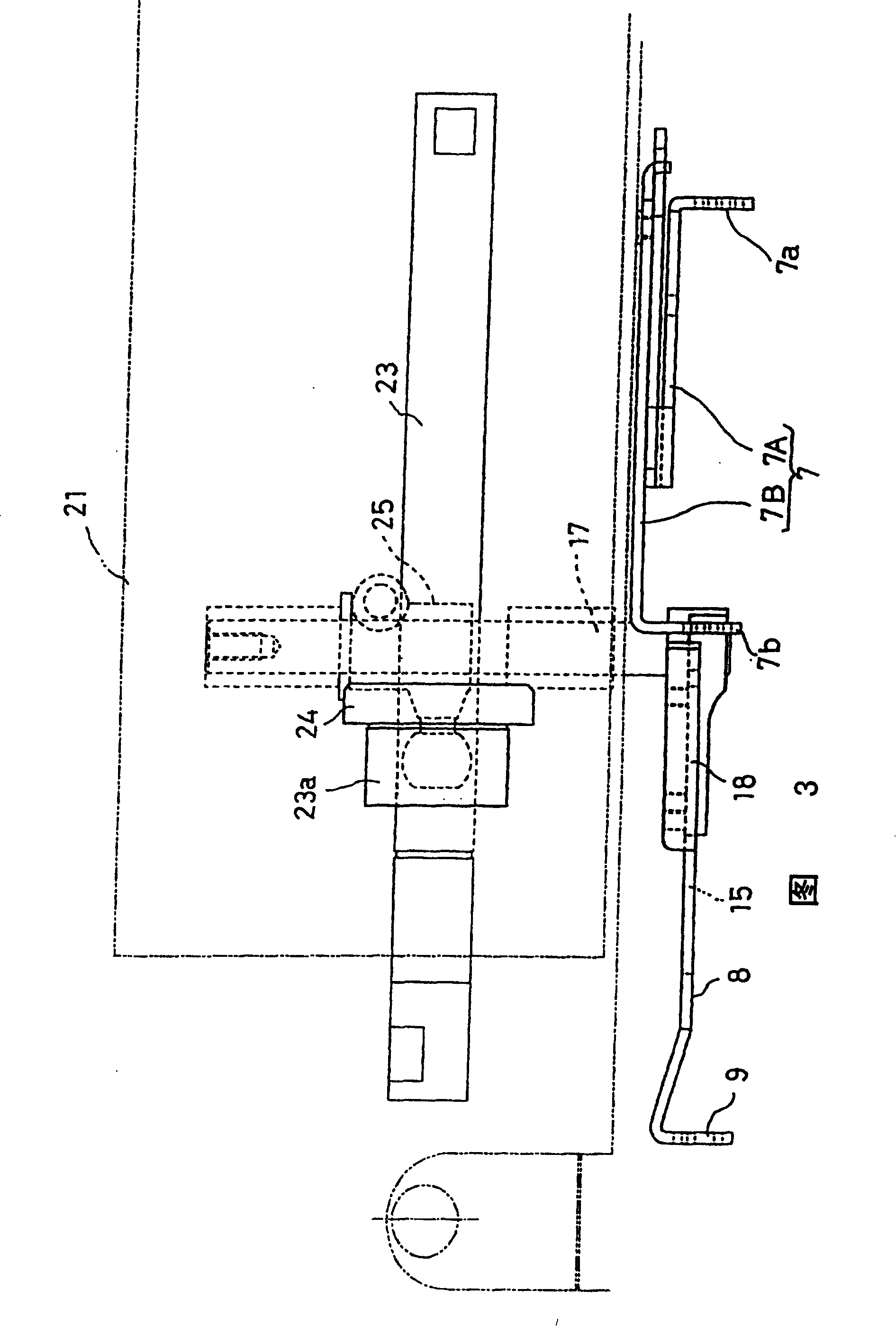

Thread cut with variable thread consumption in a sewing machine

ActiveUS20110094426A1Increase consumptionIncrease the lengthProgramme-controlled sewing machinesHand sewingEngineeringScrew thread

A method and a device for cutting at least an upper thread of a sewing machine provided with a fabric clamping member (20), wherein a length of the thread consumed for a cut can be set within a predetermined interval. The method for cutting at least the upper thread (4) of a sewing machine (1) includes the steps: feeding a predetermined length x of said upper thread (4) utilizing a thread feeder (15), pulling out the upper thread (4) said predetermined length utilizing a displacement of said fabric clamping member (20) from a current position to a second position executing by means of a sewing machine processor (C) program sequences stored in a memory (M) for controlling a thread cutter (10) to perform a cut of at least said upper thread (4).

Owner:SINGER SOURCING LTD LLC

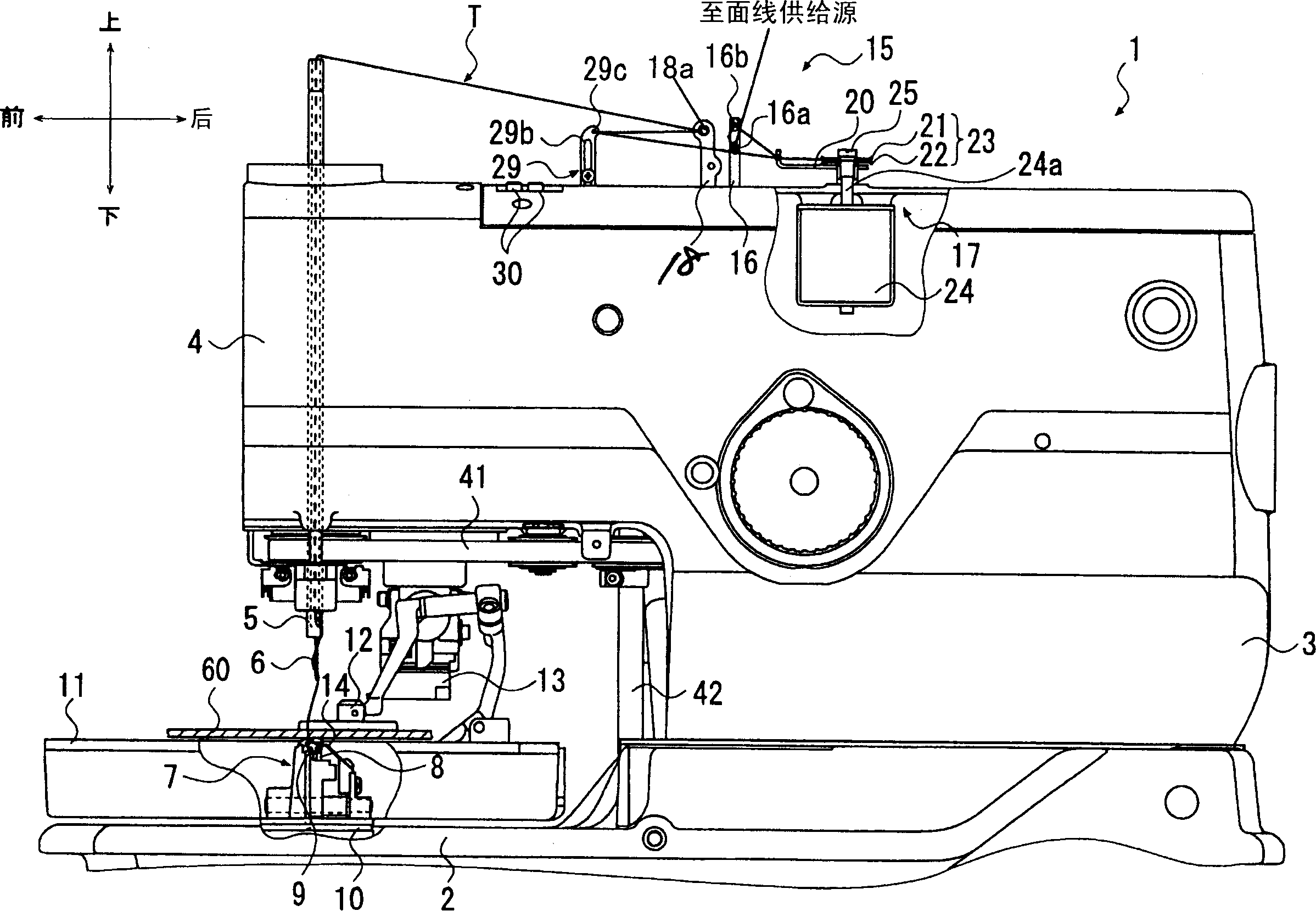

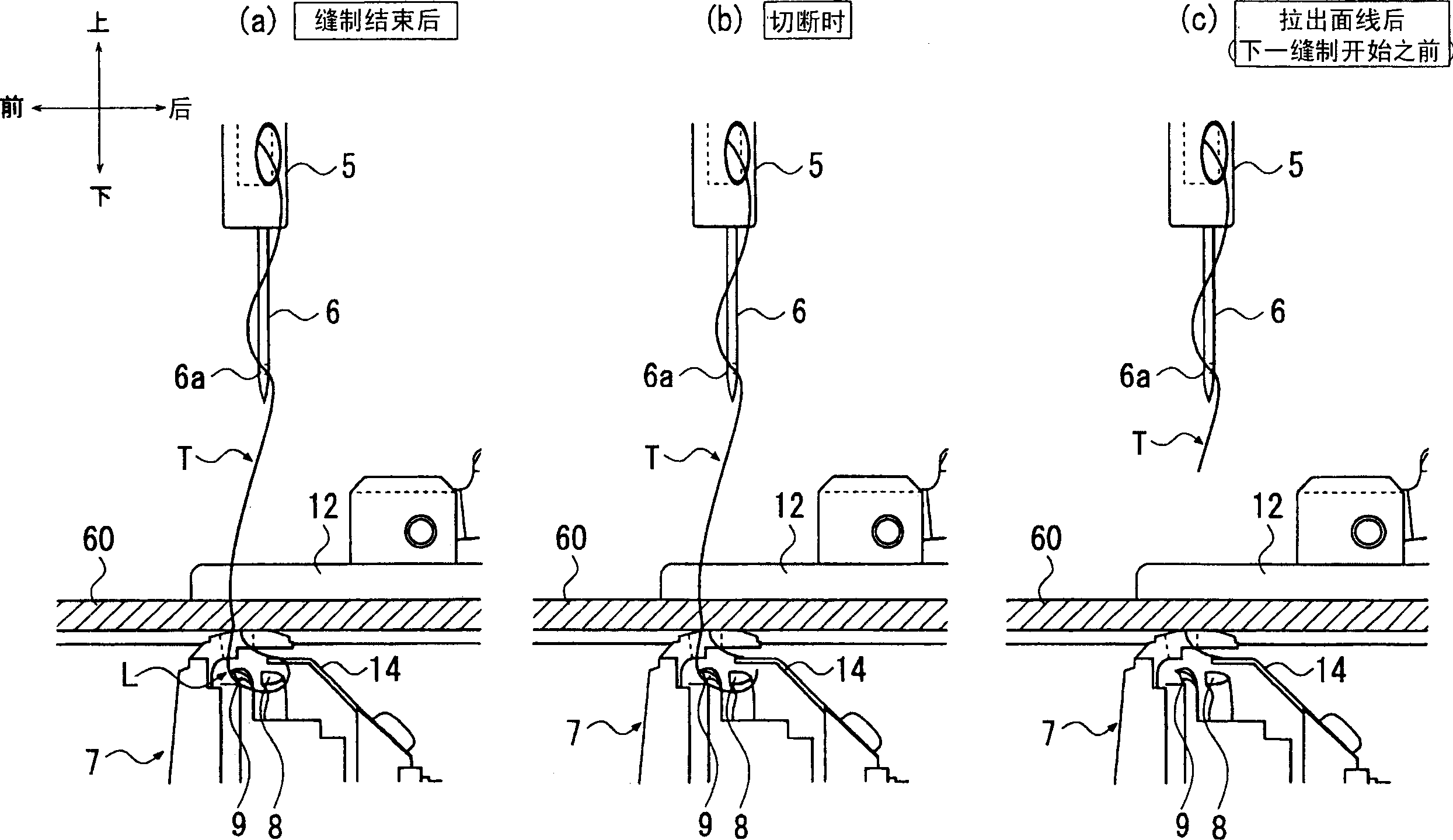

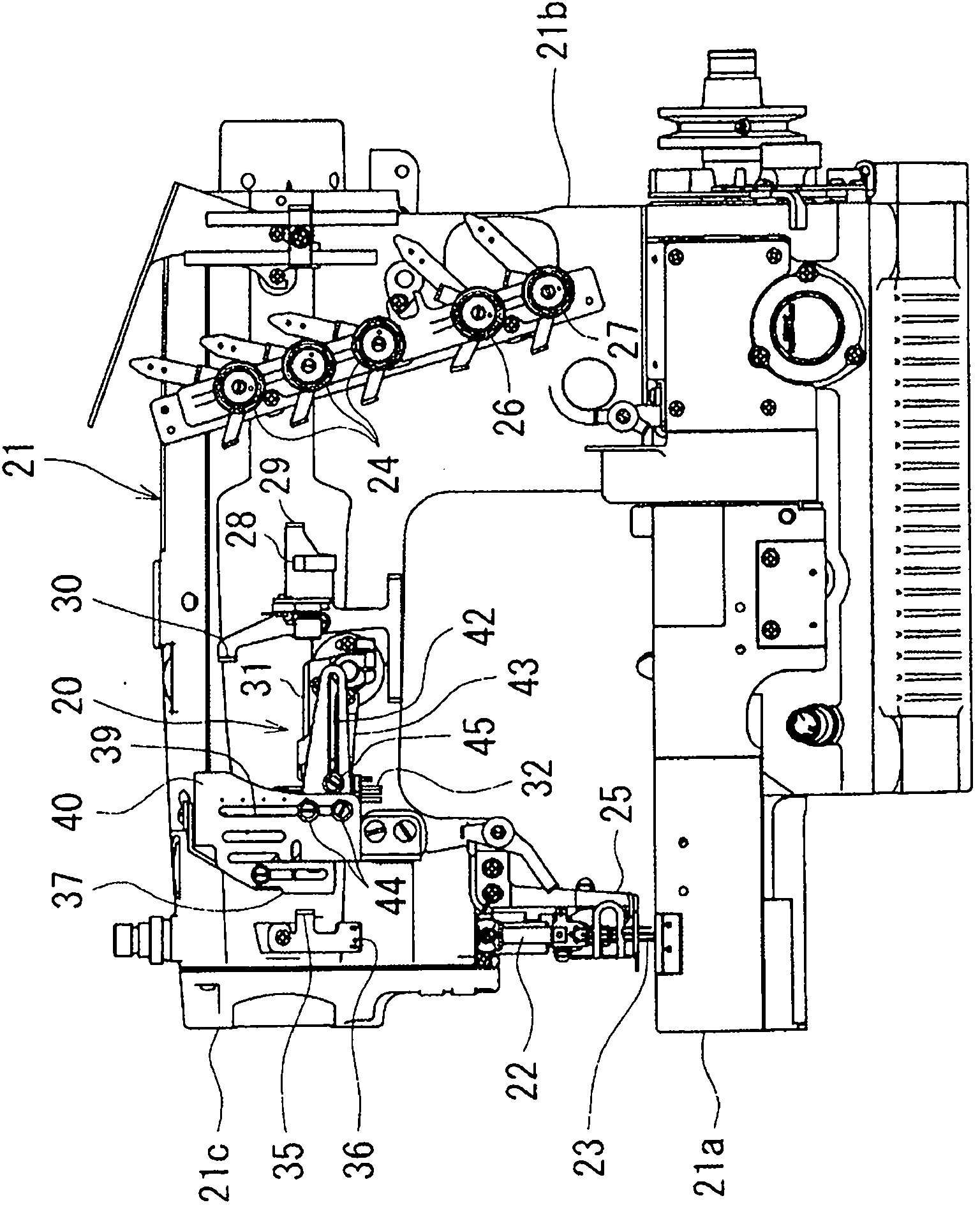

Sewing machines

InactiveCN1439759APrevent offlinePrevent getting involvedProgramme-controlled sewing machinesNeedle severing devicesEngineeringSewing machine

This sewing machine 1 includes a thread tension device 17 for applying pressing force to the needle thread, a needle thread handling member 29 for handling the needle thread guided from the thread tension device 17, air cylinders 26, 27 for moving the needle thread handling member 29 from the foremost position P10 through the middle position P30 to the last position P20, a needle thread cutting knife 14 for cutting the needle thread, and a control device 50 for controlling the air cylinders 26, 27. The needle thread is guided from the needle thread handling member 29 to a needle thread take-up lever 18 to finally reach a thread passing hole 6a of a needle 6. Immediately before the start of sewing, the needle thread handling member 29 is moved from the foremost position P10 to the last position P20. After the end of sewing, the needle thread handling member 29 is moved from the last position P20 to the middle position P30. After that, the pressing force to the needle thread is increased by the thread tension device. Subsequently, the needle thread handling member 29 is moved from the middle position P30 to the foremost position P10.

Owner:JUKI CORP

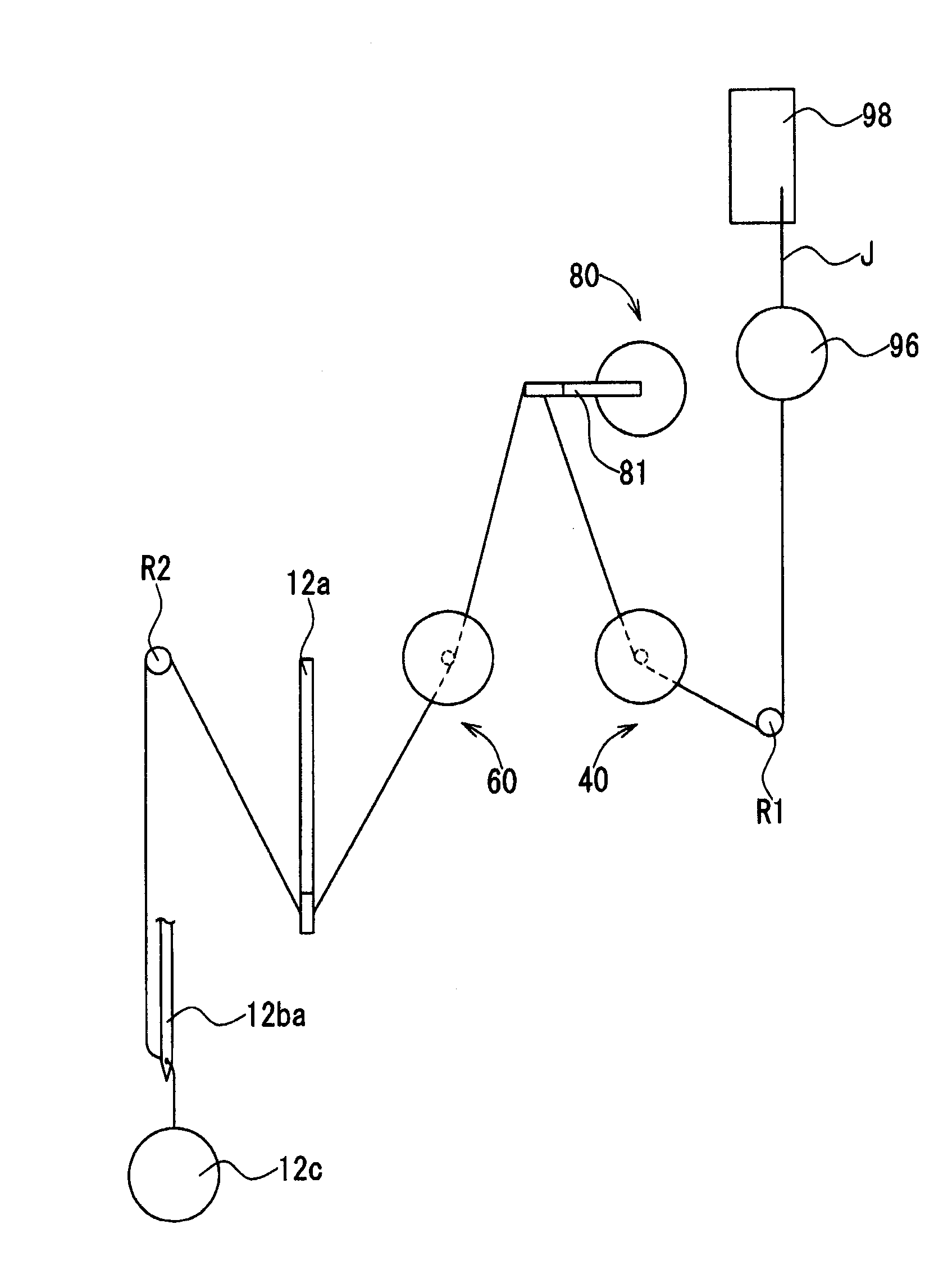

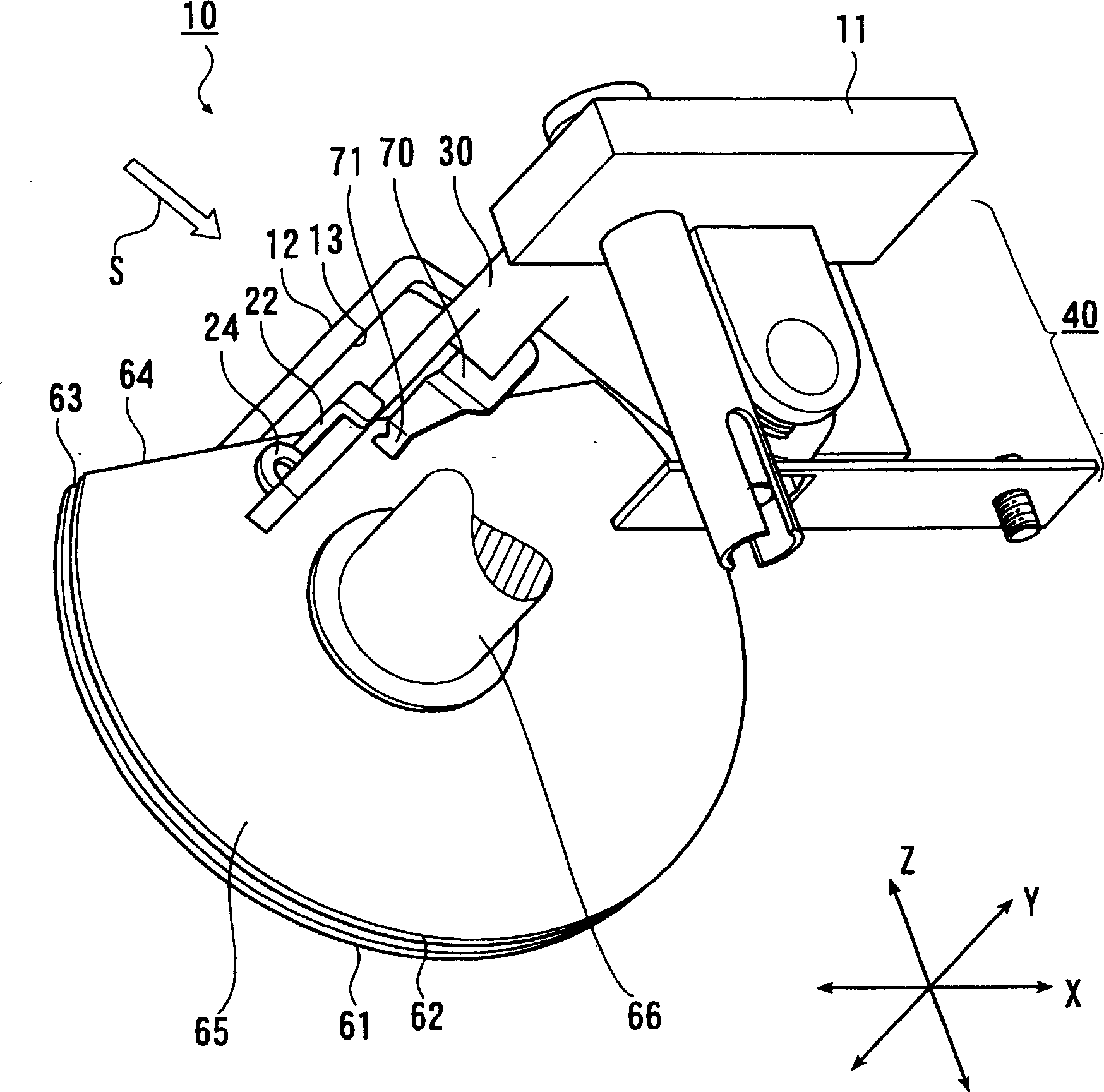

Sewing machine

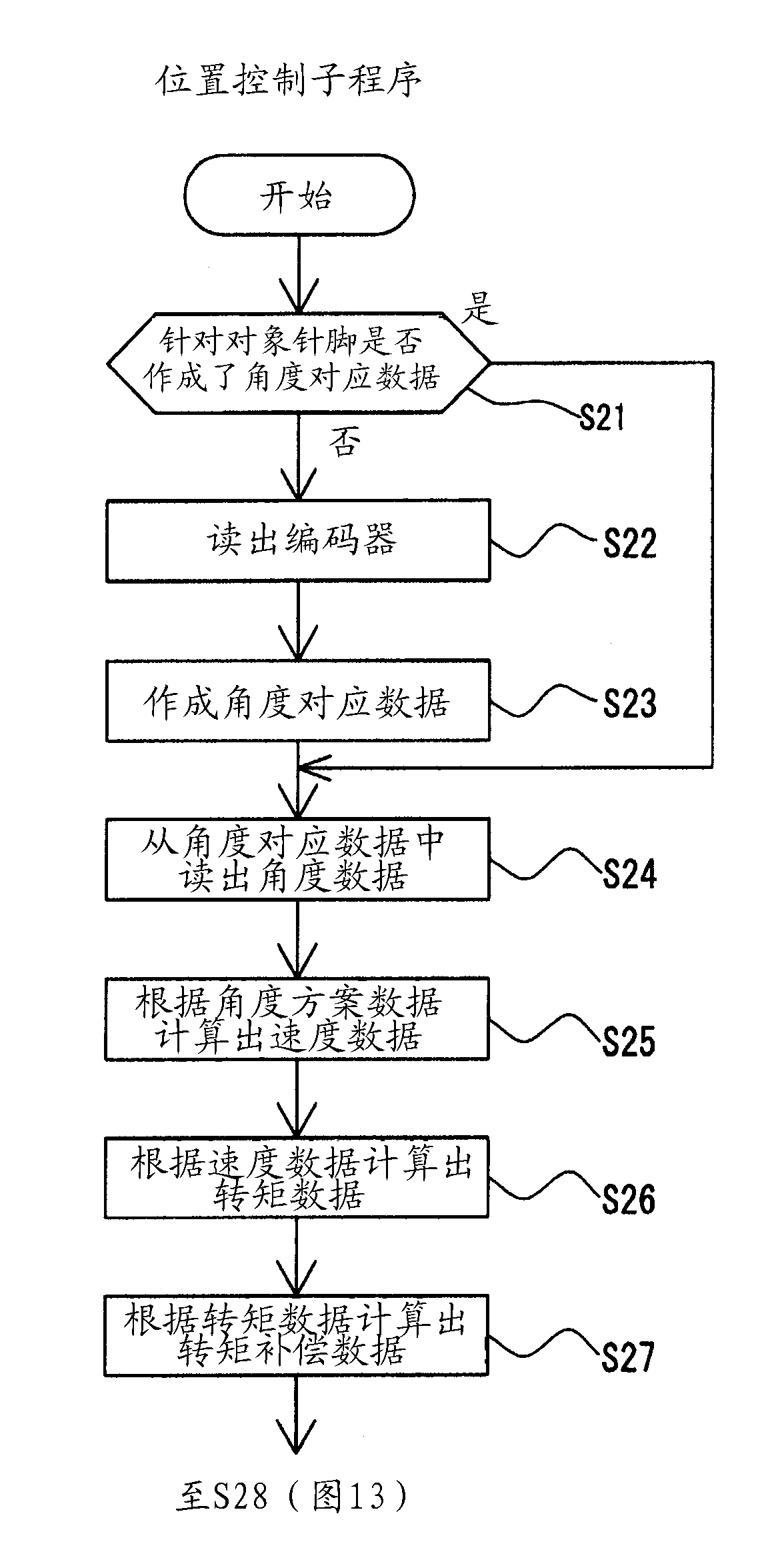

ActiveCN103140617APull out smoothlyReduce the possibility of disconnectionSewing measuring devicesThread-break detectorsYarn tensionEngineering

Disclosed is needle yarn tension control device that can control the amount of tension in a needle yarn for each stitch, can draw out the needle yarn, provides little risk of yarn breakages, readily and accurately detects any yarn breakages, and has no excess or insufficient amount of accumulated yarn from pulling out the needle yarn. Said needle yarn tension control device comprises an upstream grip (40) that grips the needle yarn, a downstream grip (60), and a rotating section (80) that rotates the needle yarn. In a torque control section, a balance (12a) applies rotational force to a rotating arm in accordance with a torque value such that tension is applied to the needle yarn against the direction that the needle yarn is pulled, while an upstream grip main body (41) is closed and a downstream grip main body (61) is open. In the position control section, the balance applies rotational force to the rotating arm (81) in accordance with position data for the angle of a needle yarn motor (86) such that the needle yarn motor angle returns to an initial position for the needle yarn motor (86) angle, while the upstream side grip main body (41) is open and the downstream side grip main body (61) is closed.

Owner:NSD

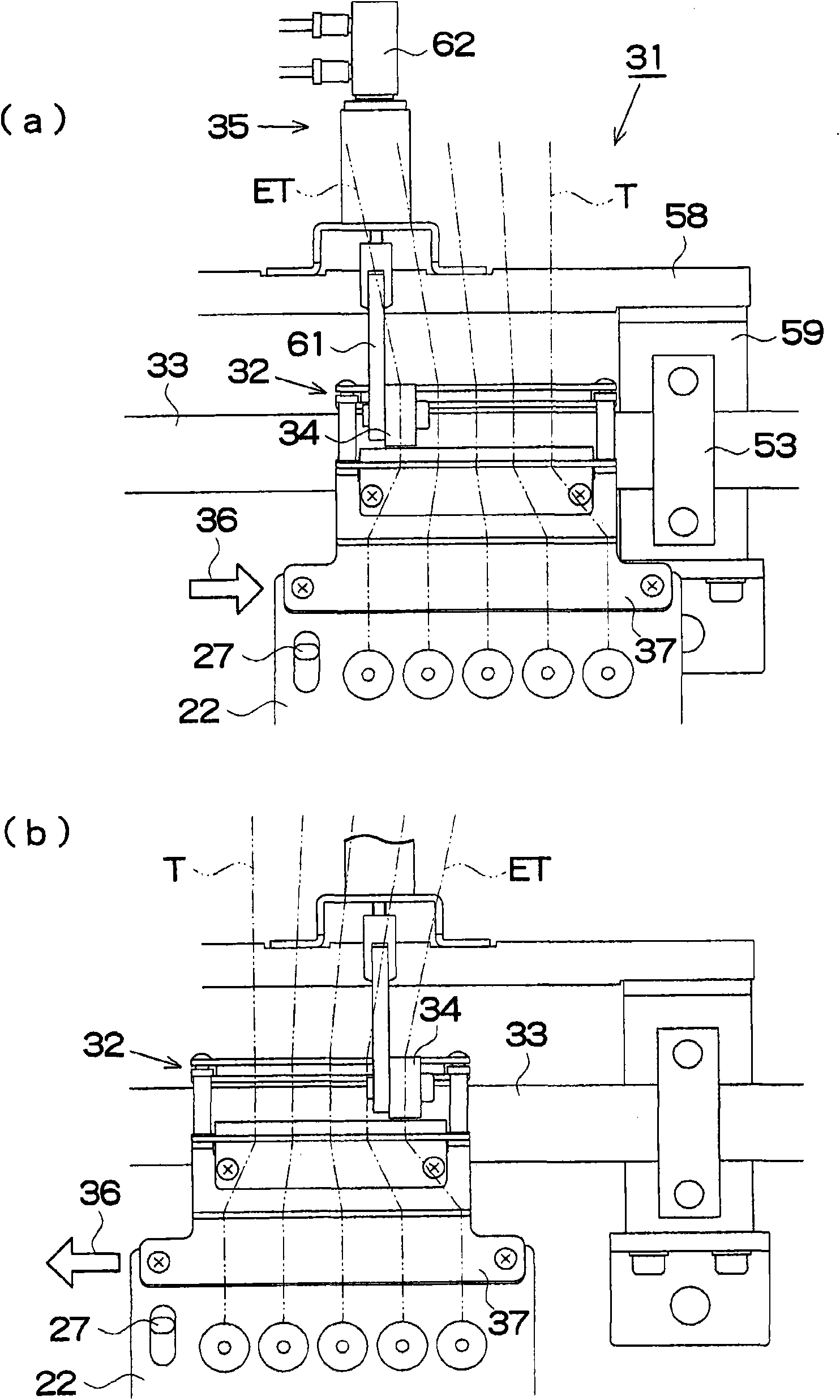

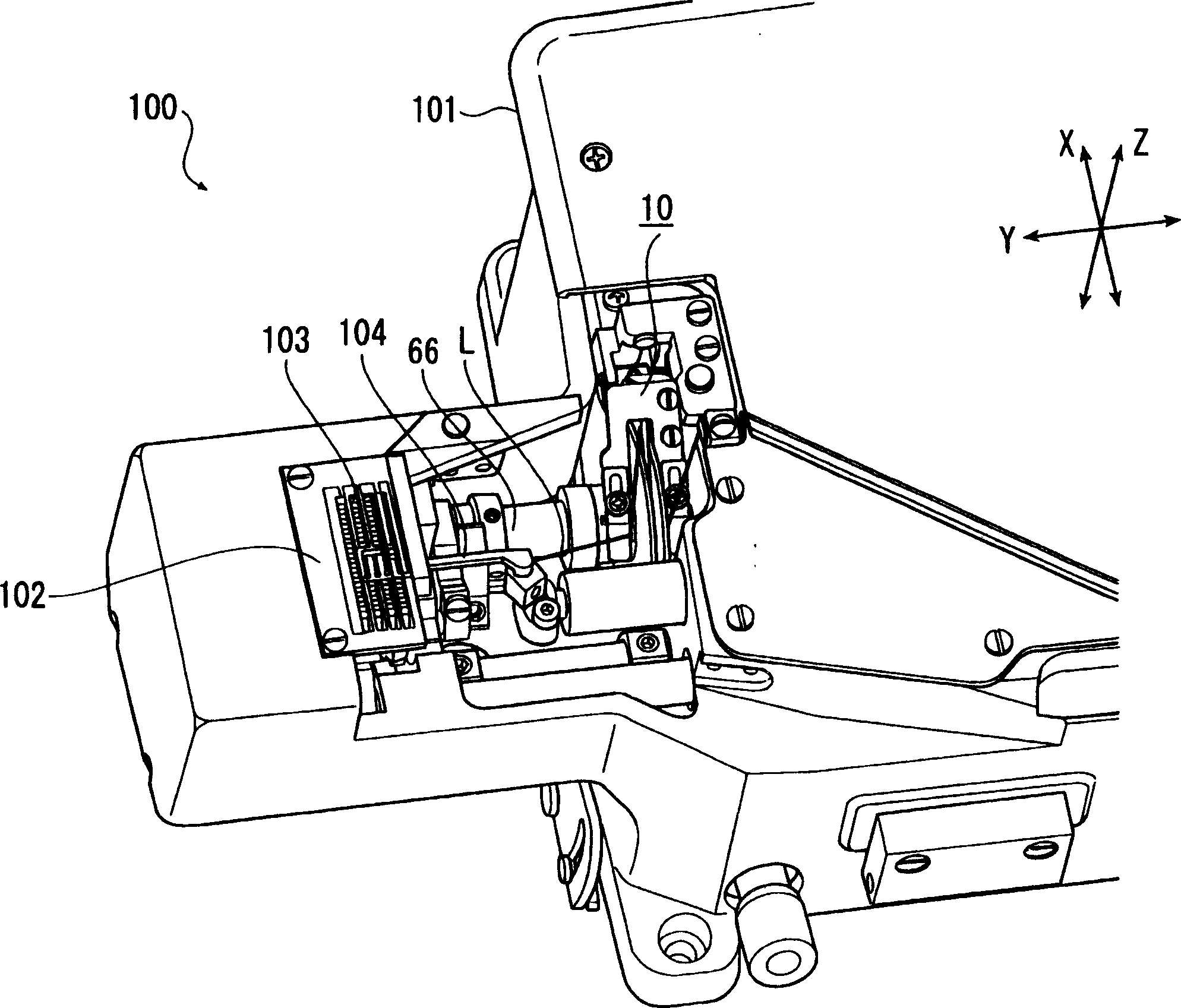

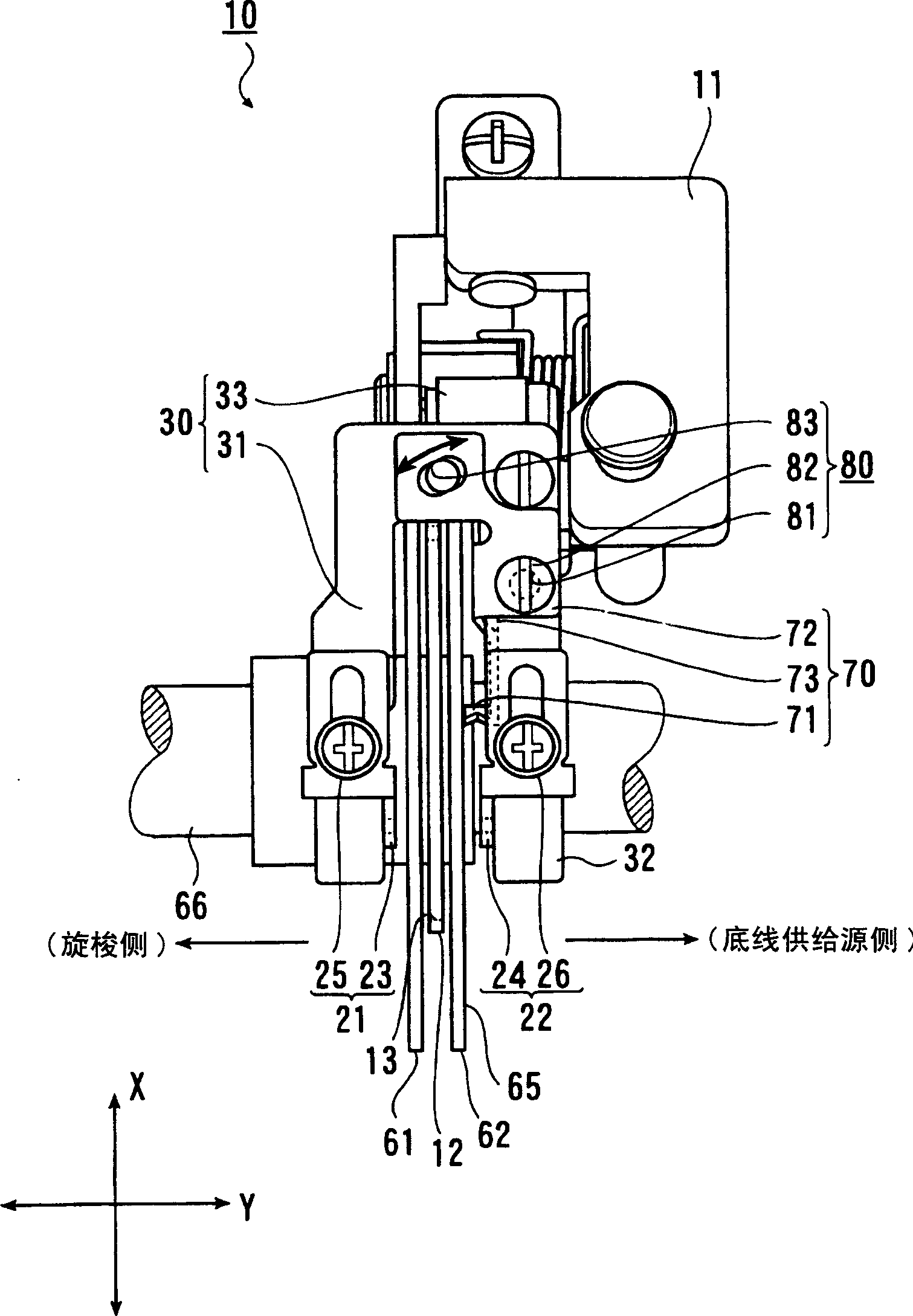

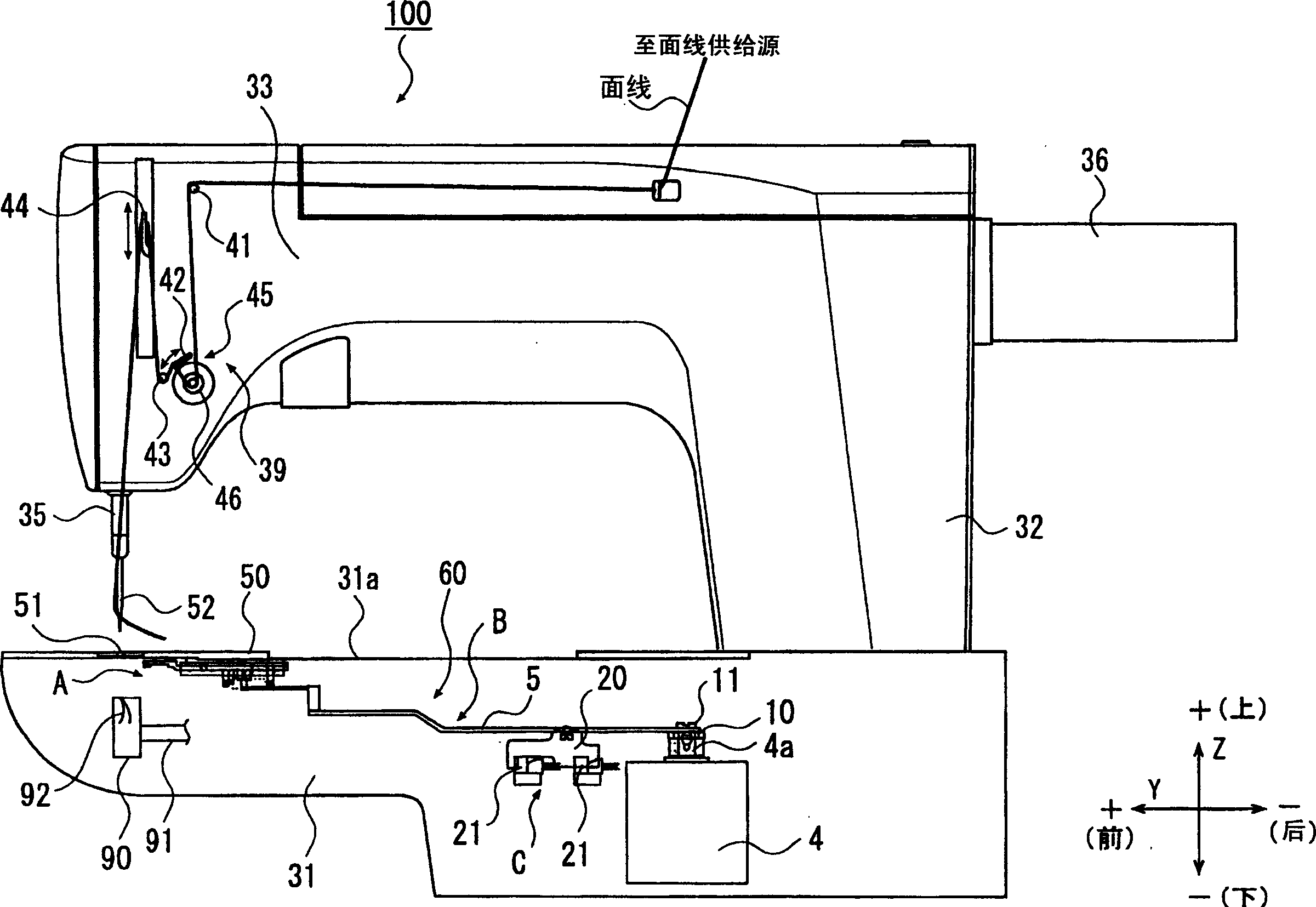

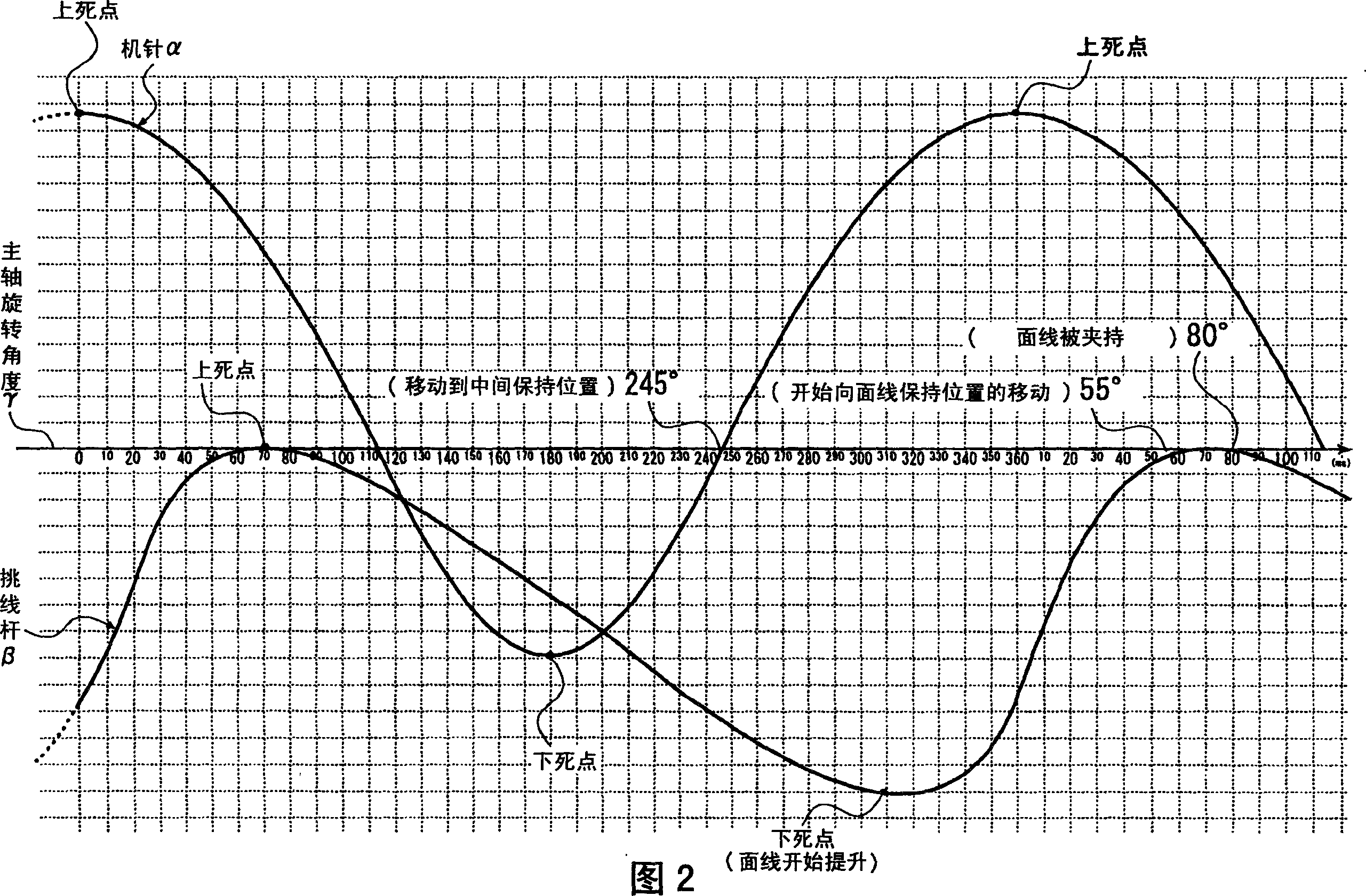

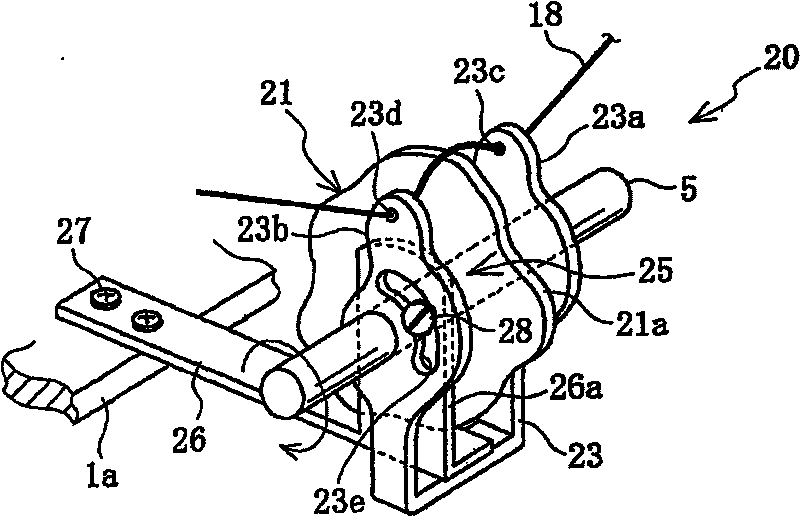

Thread return device of sewing machine

To easily and quickly perform restoration work from cutting of a thread. The tread feeding device (10) of a sewing machine (100) is provided between a thread supply source and a sewing position and is provided with first and second thread insertion means (21, 22) having insertion parts (23, 24) for inserting the thread (L), a supporting body (30) for supporting the respective thread insertion means, a rotary shaft (66) rotated associated with a sewing machine motor, rotary cam plates (61, 62) fixed to the rotary shaft, arranged between the respective insertion parts and brought into slidable contact with the thread inserted between the respective insertion parts at the outer edge part, and a hook member (70) arranged such that the tip part is positioned near the plane part (65) on the thread supply source side of the rotary cam plates.

Owner:JUKI CORP

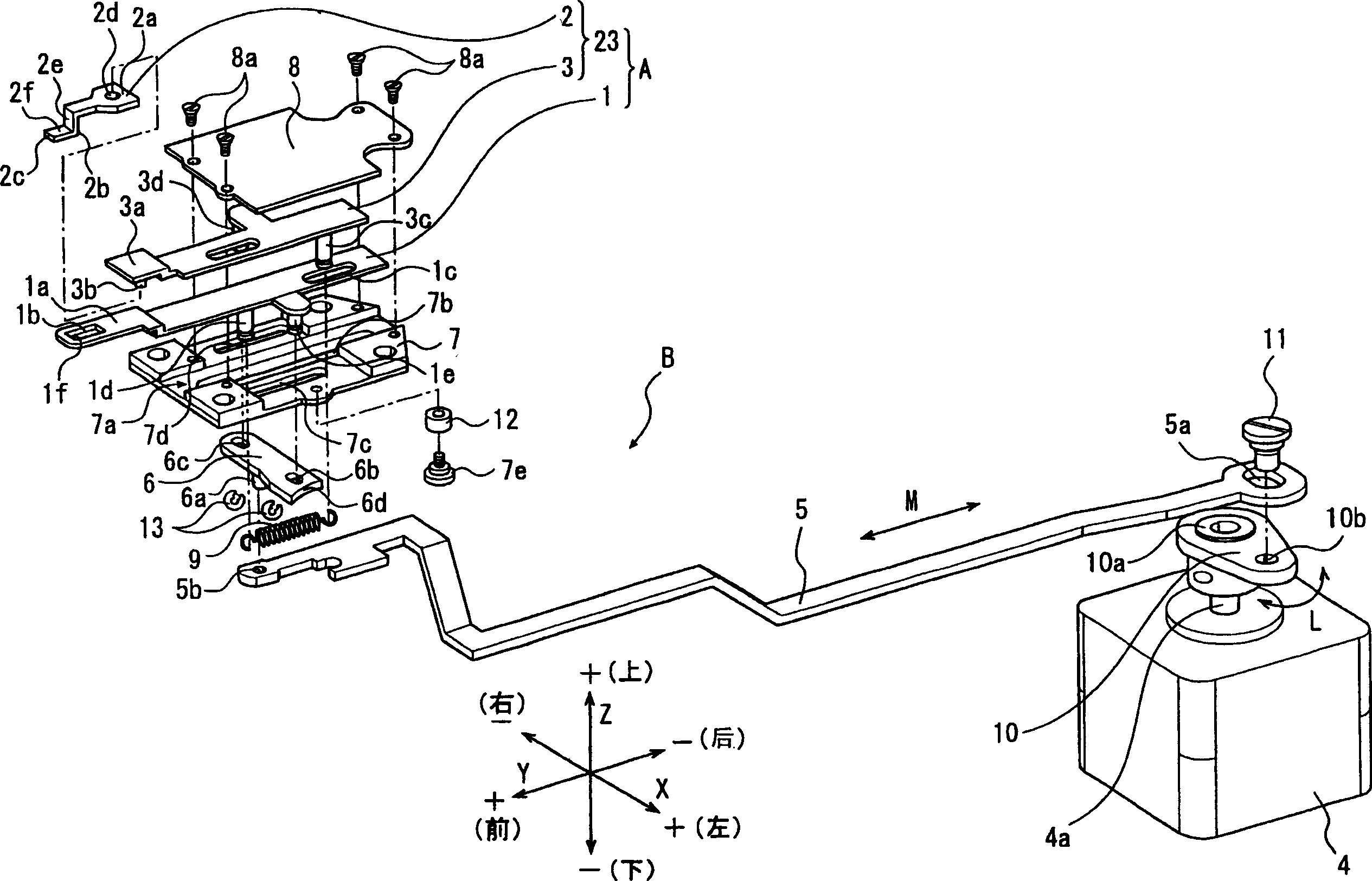

Face thread holder for sewing machine

ActiveCN1502737APrevent pulling outAvoid slackProgramme-controlled sewing machinesNeedle severing devicesEngineeringResistance force

The upper thread holding device (60) for the sewing machine (100) bends the upper thread with a projection part (2c) which is arranged in a pinching member, when the upper thread is held between the holding surface (1f) of a holding member and the pinching surface (2e) of the pinching member. A holding force for holding the upper thread by the upper thread holding device is adjusted in two steps, i.e., a resistance force in bending which is given to the projection part, and a pinching force for pinching the upper thread between the holding surface and the pinching surface. The upper thread is held after adjusting the length of the upper thread on the rear side surface of the fabric.

Owner:JUKI CORP

Method and arrangement for a sewing machine

ActiveUS7513203B2Increase in sizeOptimize quantityFilament handlingSewing measuring devicesBobbinReciprocating motion

A sewing machine including a needle that is supplied with an upper thread. A a reciprocating movement carries the upper thread through a sewing material and forms a loop beneath the sewing material. A shuttle houses a bobbin for lower thread and a shuttle arm catches the loop of the upper thread and carries the upper thread around the lower bobbin, so that a stitch is executed on the sewing material. A thread feeder feeds the upper thread to the needle and a control element on each stitch causes the thread feeder at the beginning of a stitch to advance a predetermined length of upper thread, including an excess thread, and at the end of the stitch to correct the length of the upper thread by recovering the excess upper thread, or advancing the further upper thread required.

Owner:SINGER SOURCING LTD LLC

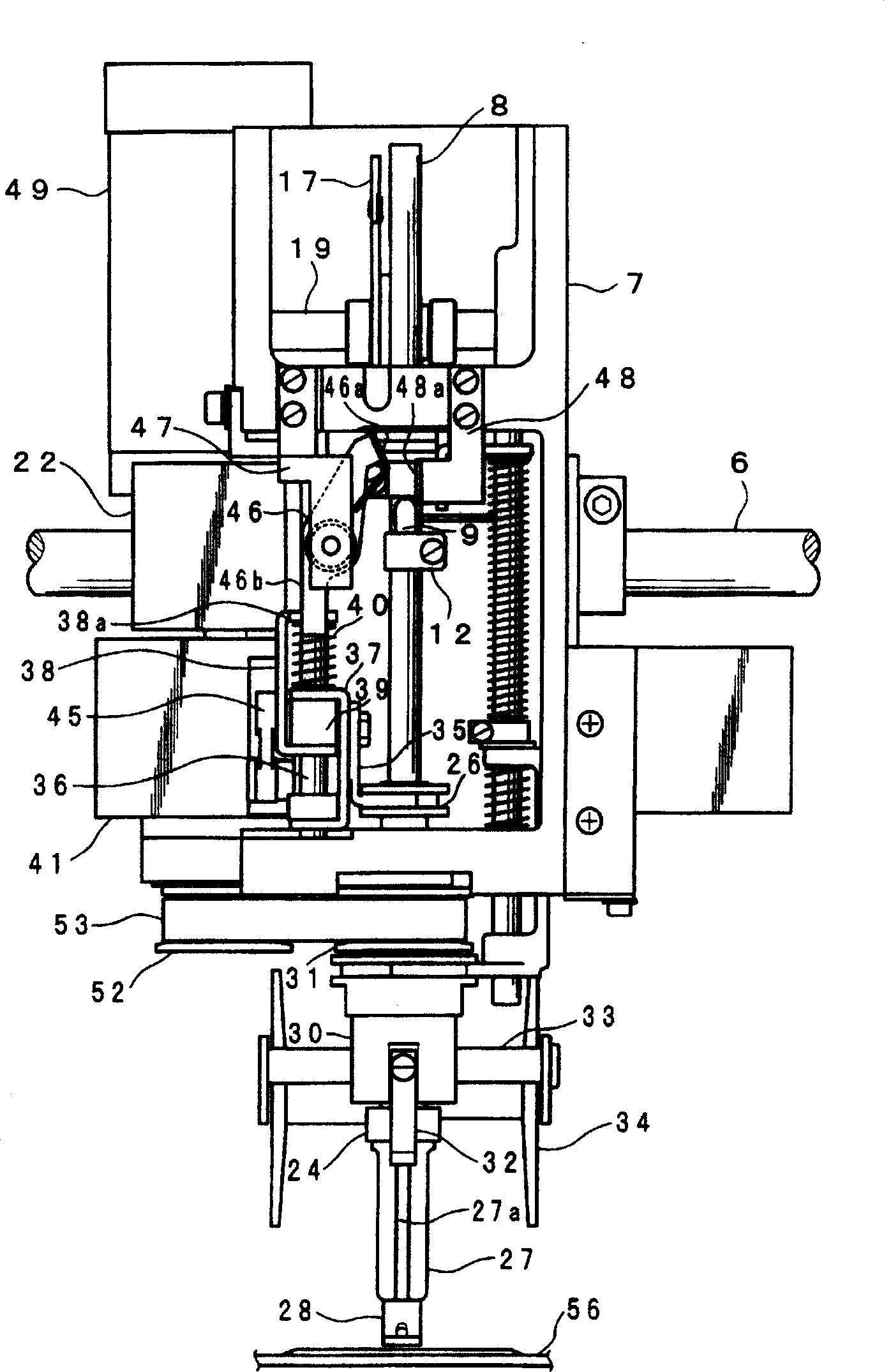

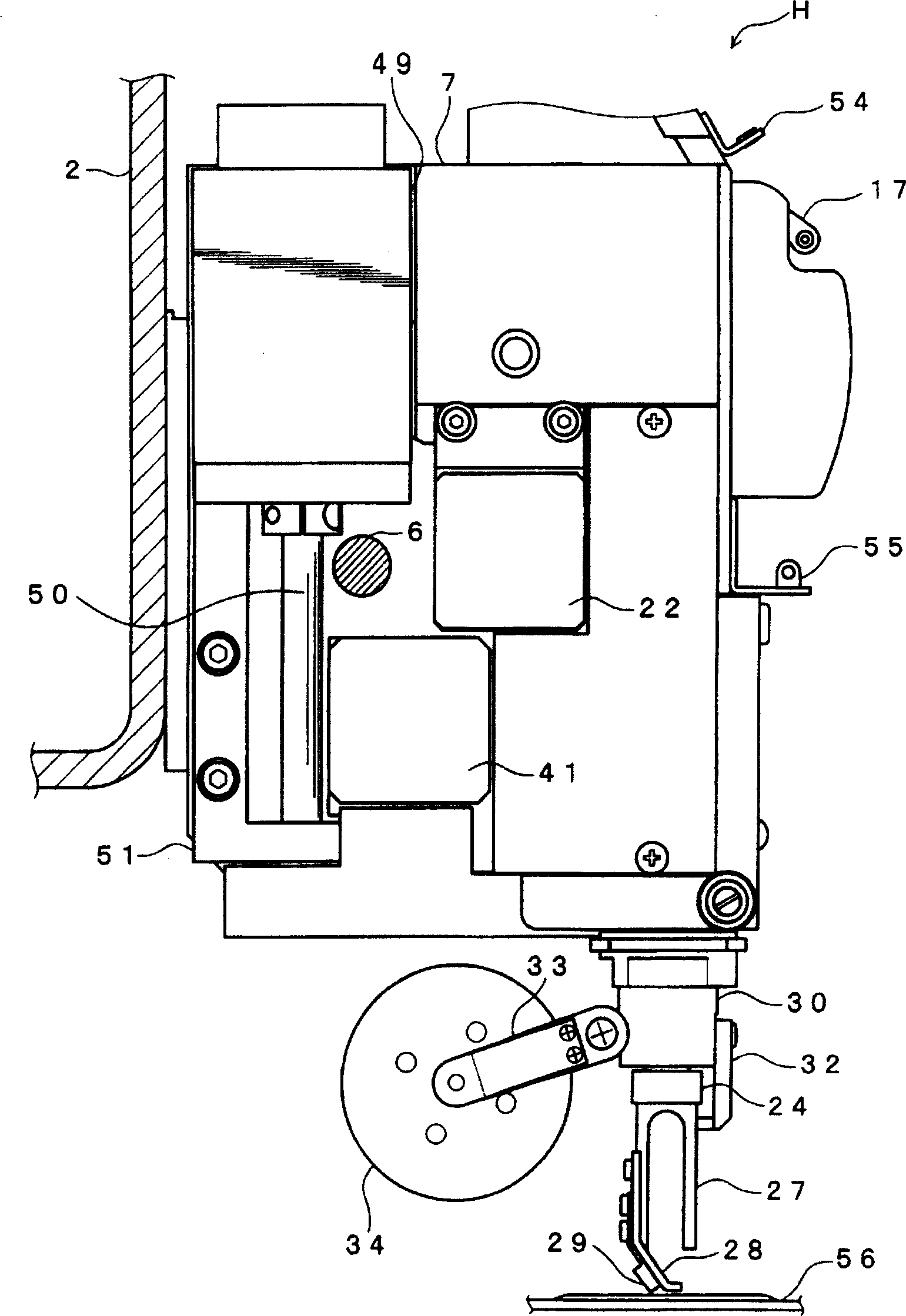

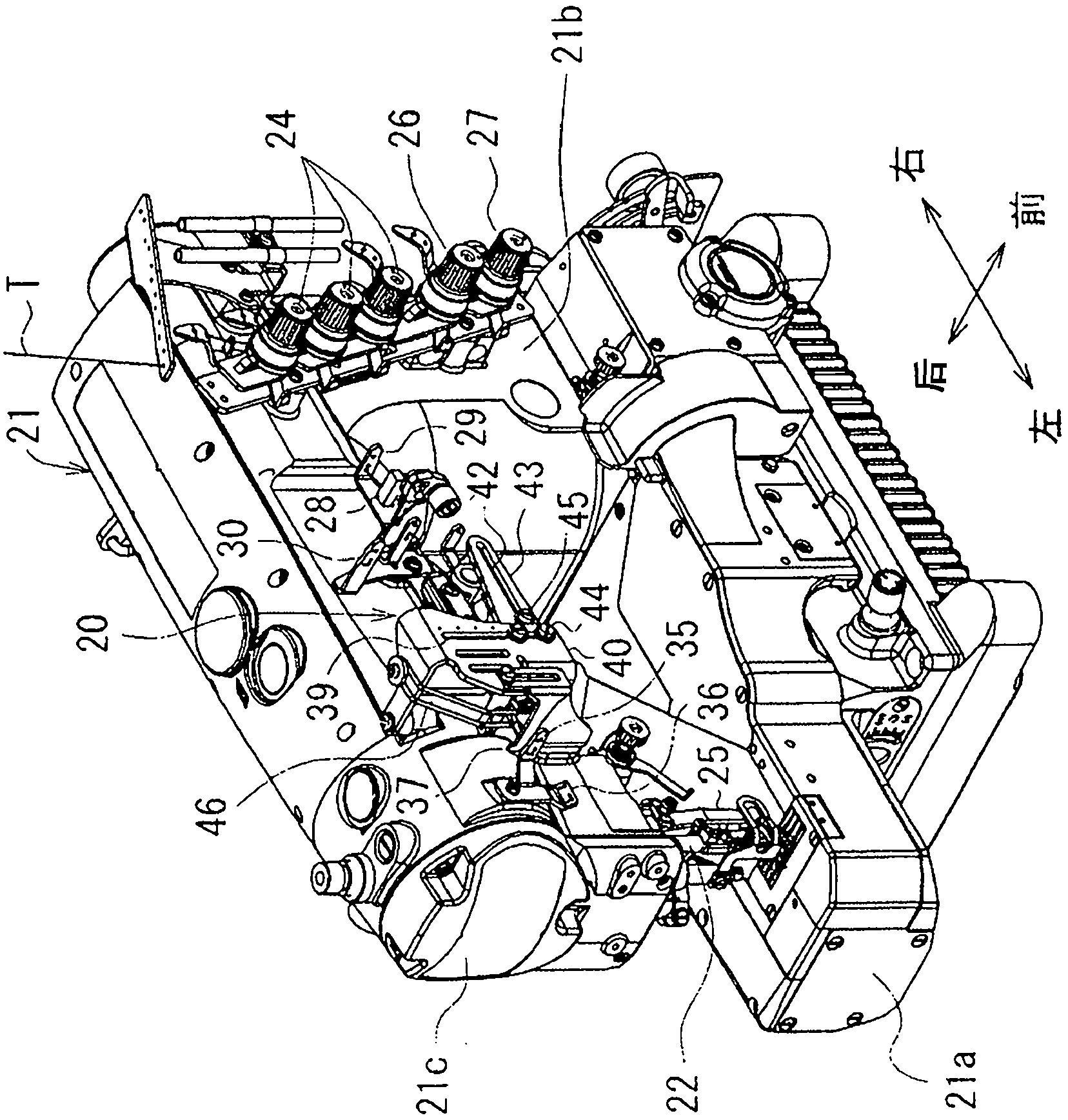

Sewing machine

InactiveCN1906343ASimple structureCost increase can be suppressedWork-feeding meansPressersSewing needleBiomedical engineering

A sewing machine, wherein holding members (46) and (48) for holding a thread hung on a needle thread take-up (17) to be swung at a position on the downstream side of the needle thread take-up and on the upstream side of the sewing needle fitted to a needle bar are provided in a sewing machine head. During the rest of operation of the sewing machine head, the movement of the thread on the downstream side of the needle thread take-up is stopped irrespective of whether the needle thread take-up is swung or not since the thread (T) is held by the holding members. The tip of the thread hung on the needle thread take-up is passed through the pin hole of the sewing needle fitted to the needle bar. When the needle thread take-up is swung, the hung thread is tensed or loosened according to the swing movement. However, since the thread is held by the holding members on the downstream side of the needle thread take-up in the sewing machine head in the rest of operation, the thread passed through the pin hole is not extracted from the pin hole even if the needle thread take-up is swung. By such a simple structure, the thread can be prevented from being extracted from the pin hole.

Owner:TOKAI IND SEWING MACH CO LTD

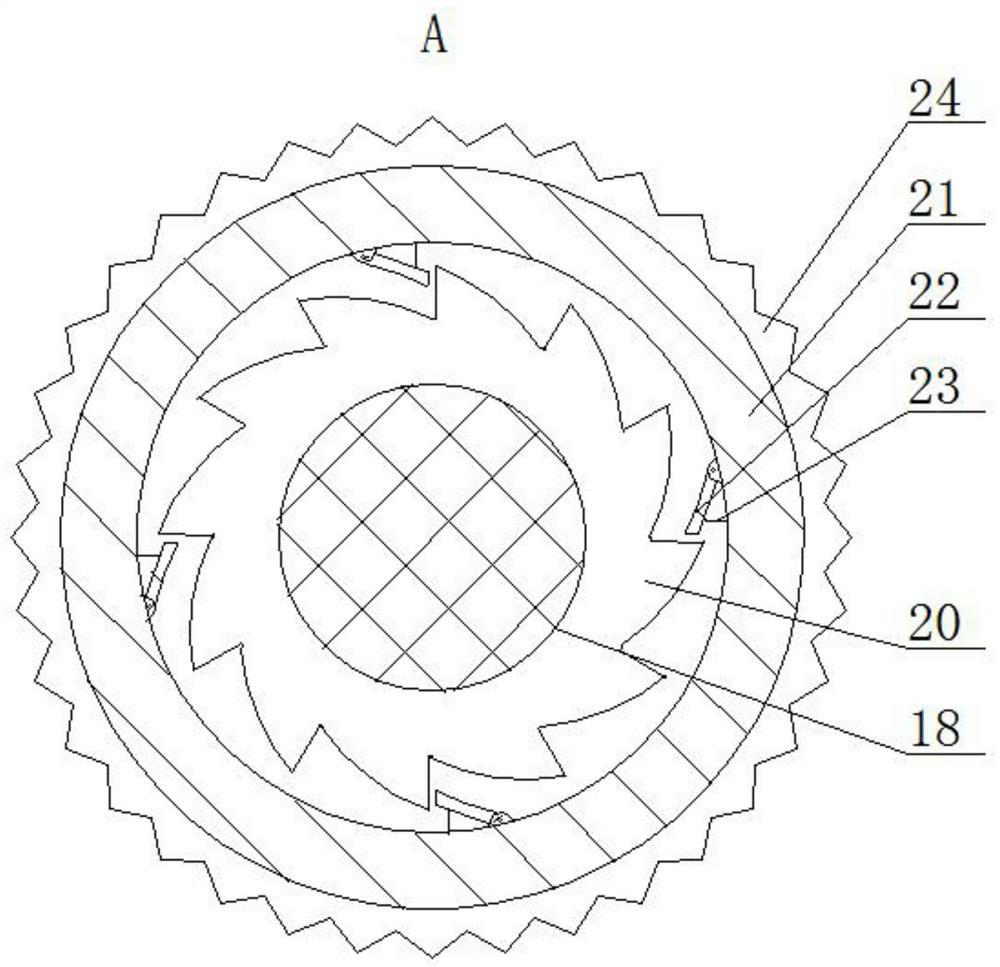

Thread ram means of sewing machine

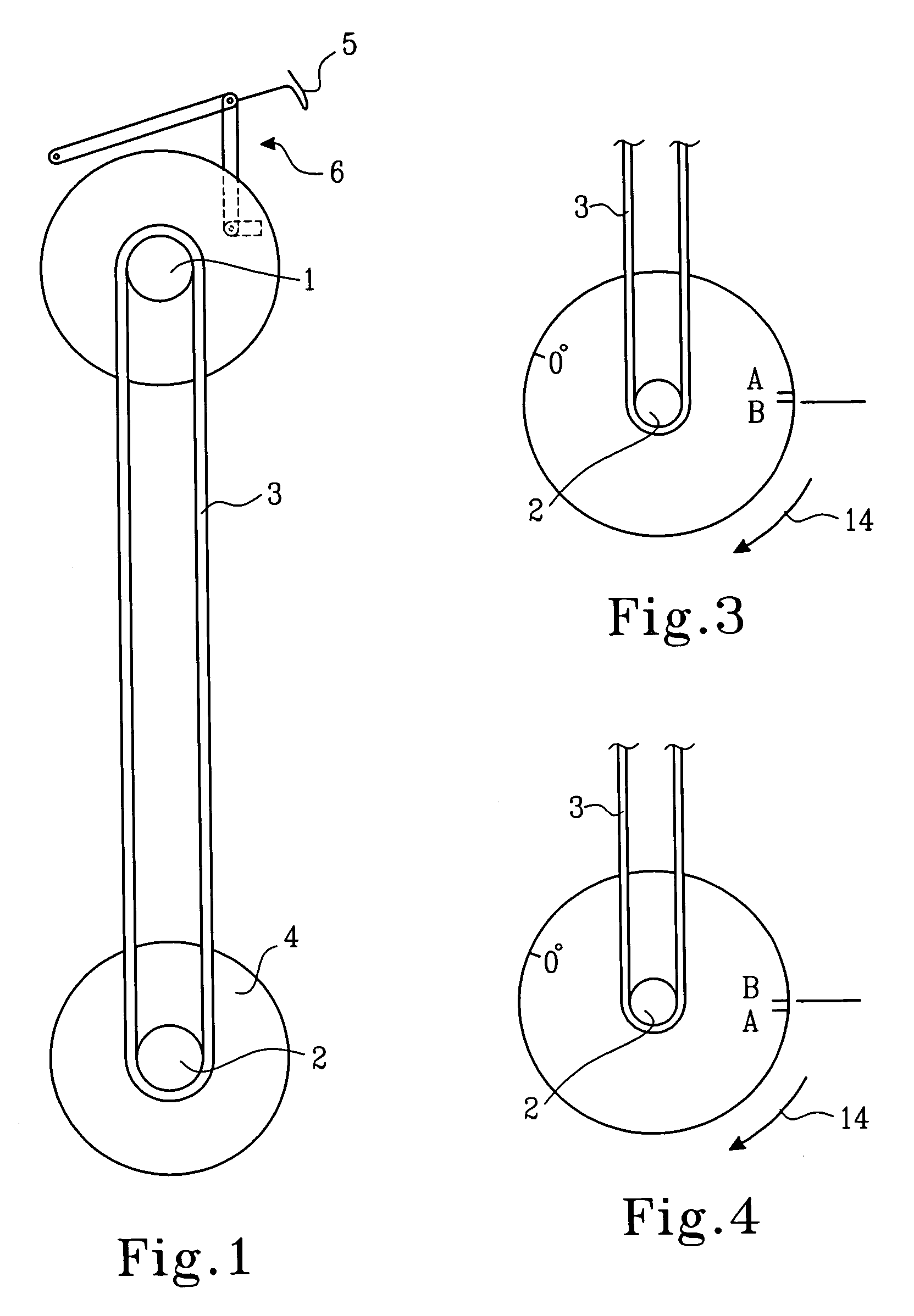

A thread take-up lever device of sewing machine is provided with a sewing machine main shaft arranged in the arm and a needle lever mechanism driven synchronize with the rotation of the sewing machinemain shaft. The device is characterized in that the device comprises a drive shaft which is integrated or separated with the sewing machine main shaft and can be driven rotatably synchronize with thesewing machine main shaft; a rotary thread take-up lever which is in round disc shape and has a thread take-up amount adjusting cam in outer circumferential part and is fixed not rotatable with the drive shaft; a thread guide member which is rotatably pivoted to the drive shaft and is formed with thread guide device which is used for guide needle thread supplied form a bobbin to engage the threadwith the thread take-up amount adjusting cam of the rotating thread take-up lever; and a phase adjusting mechanism circumferentially adjusting the phase of the thread guide device by turning the thread guide member around the drive shaft.

Owner:BROTHER KOGYO KK

Thread supplying device of sewing machine

InactiveUS7347153B2Improve performanceAmount of feed of a fabric is greatly increased or decreasedSewing measuring devicesFilament handlingAutomatic controlRotation velocity

A thread supplying device includes a rotator feeding a thread downstream of a thread supply path, the rotator winding a periphery thereof the thread several times and locating in the path extending from a thread supply part to a needle and loopers, a stepping motor continuously drivingly rotating in one way the rotator in synchronism with the main shaft of a sewing machine, thread feed setting means setting a unit thread feeding amount necessary for formation of seams per stitch, and control means automatically controlling the rotation of the motor to feed the unit thread feeding amount set by the setting means for each formation of seams per stitch. This device can stably supply a predetermined amount of the unit thread, and achieve stabilization of stitch performance, irrespective of the type of the thread, and whether the feed of a fabric increases or decreases by a rapid change in the rotational speed of the sewing machine.

Owner:YAMATO SEWING MASCH MFG CO LTD

Thread supplying device of sewing machine

InactiveUS20070119353A1Improve performanceAmount of feed of a fabric is greatly increased or decreasedSewing measuring devicesFilament handlingElectric machineryComputer science

A thread supplying device includes a rotator feeding a thread downstream of a thread supply path, the rotator winding a periphery thereof the thread several times and locating in the path extending from a thread supply part to a needle and loopers, a stepping motor continuously drivingly rotating in one way the rotator in synchronism with the main shaft of a sewing machine, thread feed setting means setting a unit thread feeding amount necessary for formation of seams per stitch, and control means automatically controlling the rotation of the motor to feed the unit thread feeding amount set by the setting means for each formation of seams per stitch. This device can stably supply a predetermined amount of the unit thread, and achieve stabilization of stitch performance, irrespective of the type of the thread, and whether the feed of a fabric increases or decreases by a rapid change in the rotational speed of the sewing machine.

Owner:YAMATO SEWING MASCH MFG CO LTD

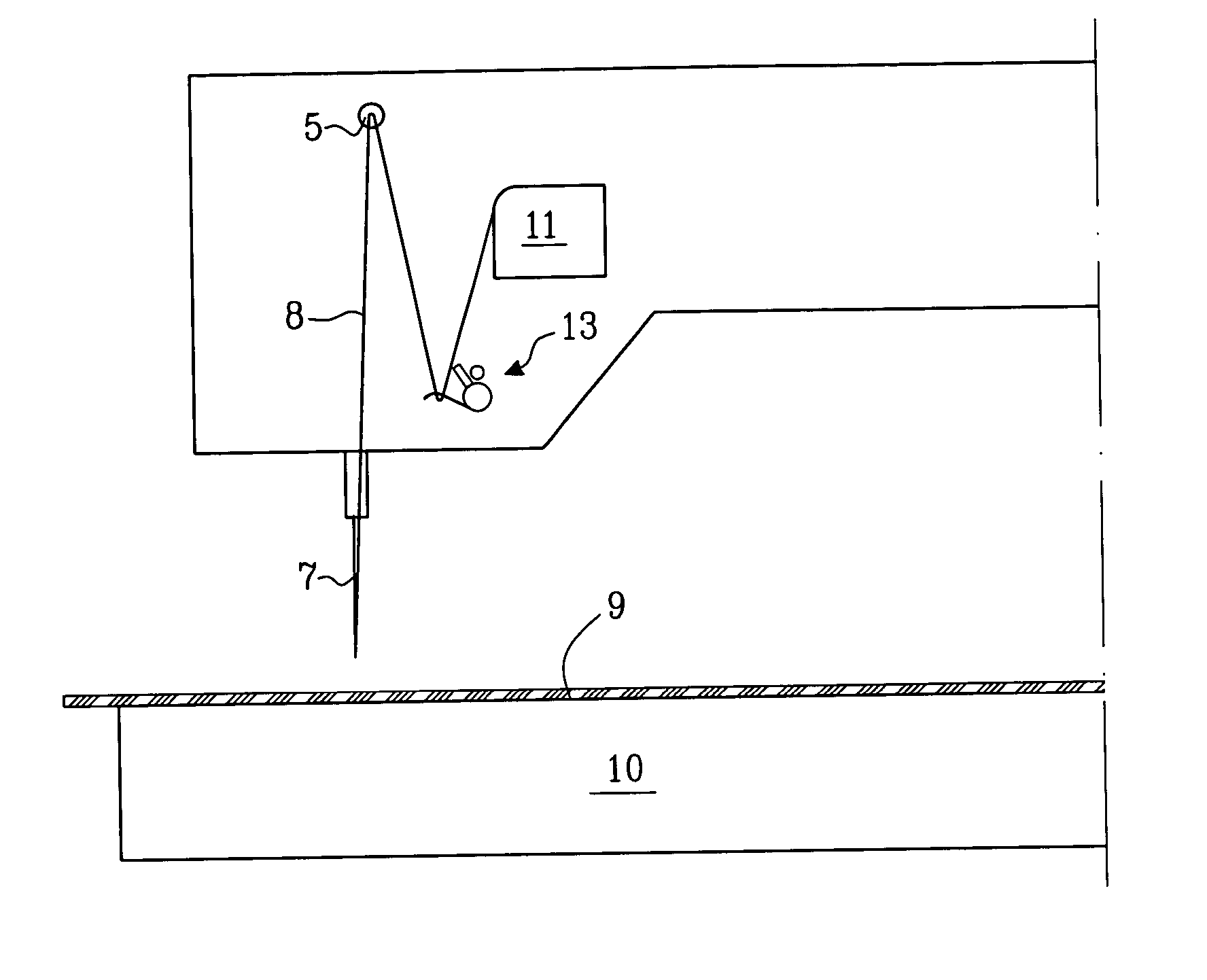

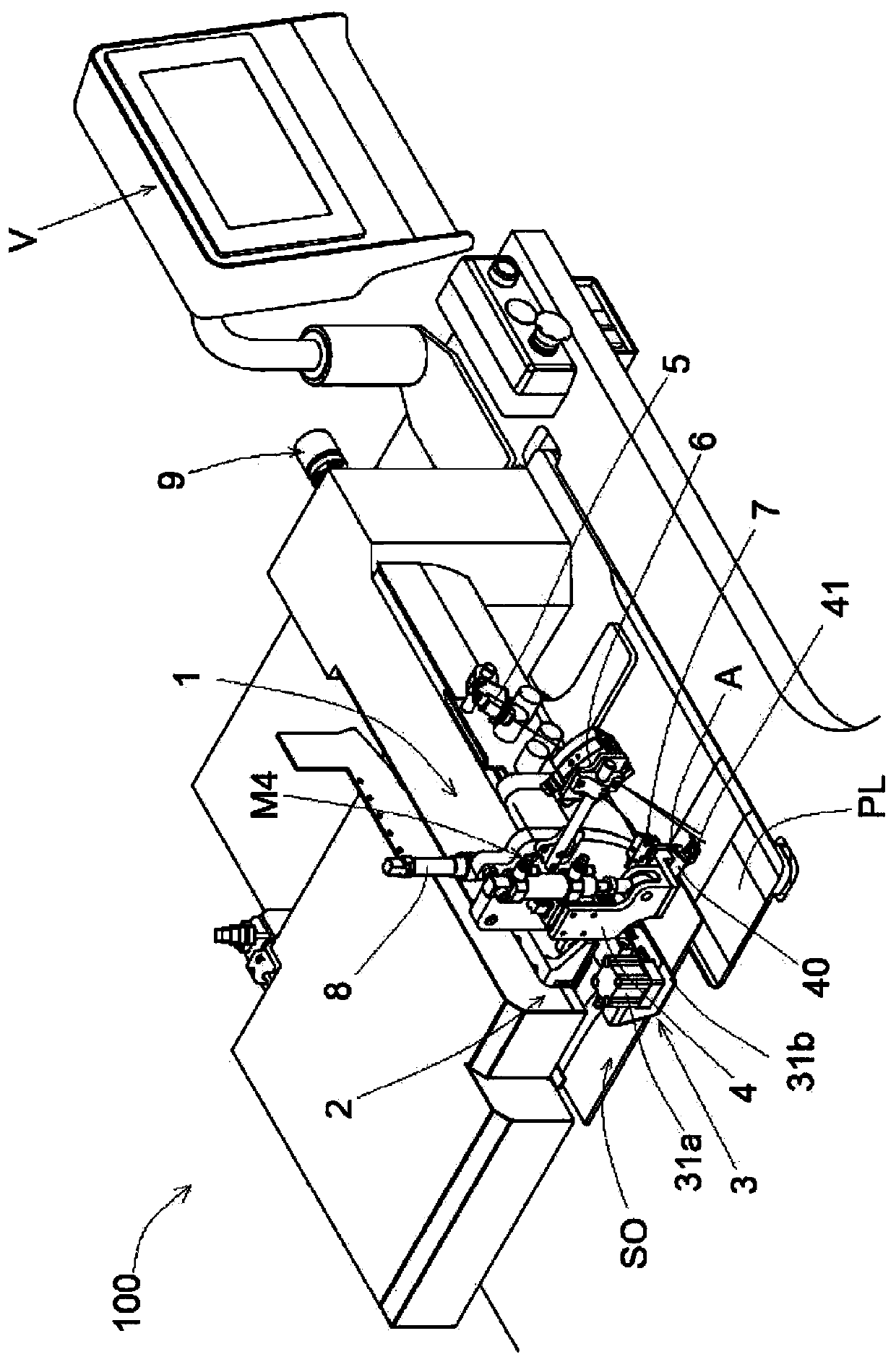

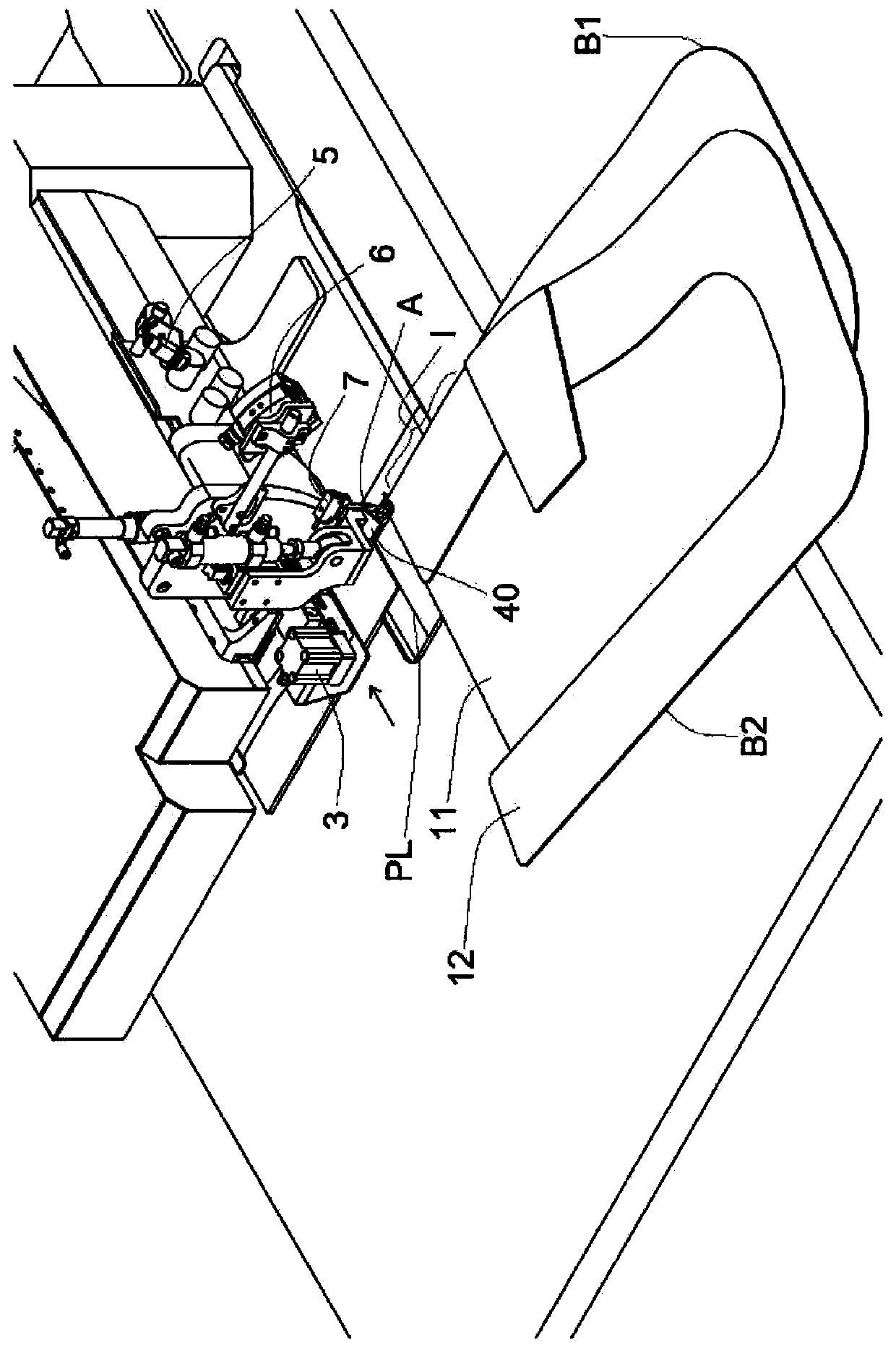

Sewing machine for making seams in a programmed, measured and controlled way

InactiveCN111188131APrecision SeamsNo need to change locationWork-feeding meansPressersEngineeringPhysics

The invention relates to a sewing machine (100) for making seams on fabrics (11, 12, 13, 14) in a programmed, measured and controlled way; the sewing machine (100) of the invention provides for easilyand accurately sewing fabrics (11, 12, 13, 14) with edges with a different radius of curvature, making very accurate seams, wherein the stitch pitch coincides with a preset pitch; the sewing machine(100) comprises: a needle (A), a claw, a blocking unit (4, 41) that firmly blocks the fabrics (11, 12, 13, 14) in the vicinity of the place where the needle (A) makes the seam, a dragging assembly (2)suitable for dragging the fabrics (11, 12, 13, 14) along a work surface (PL), a clamp (3) that is integral with the dragging assembly (2), and a detector (R) to detect the length between two adjacentstitches, in such a way to measure and check the accuracy of the seam made by the needle (A).

Owner:DERIM

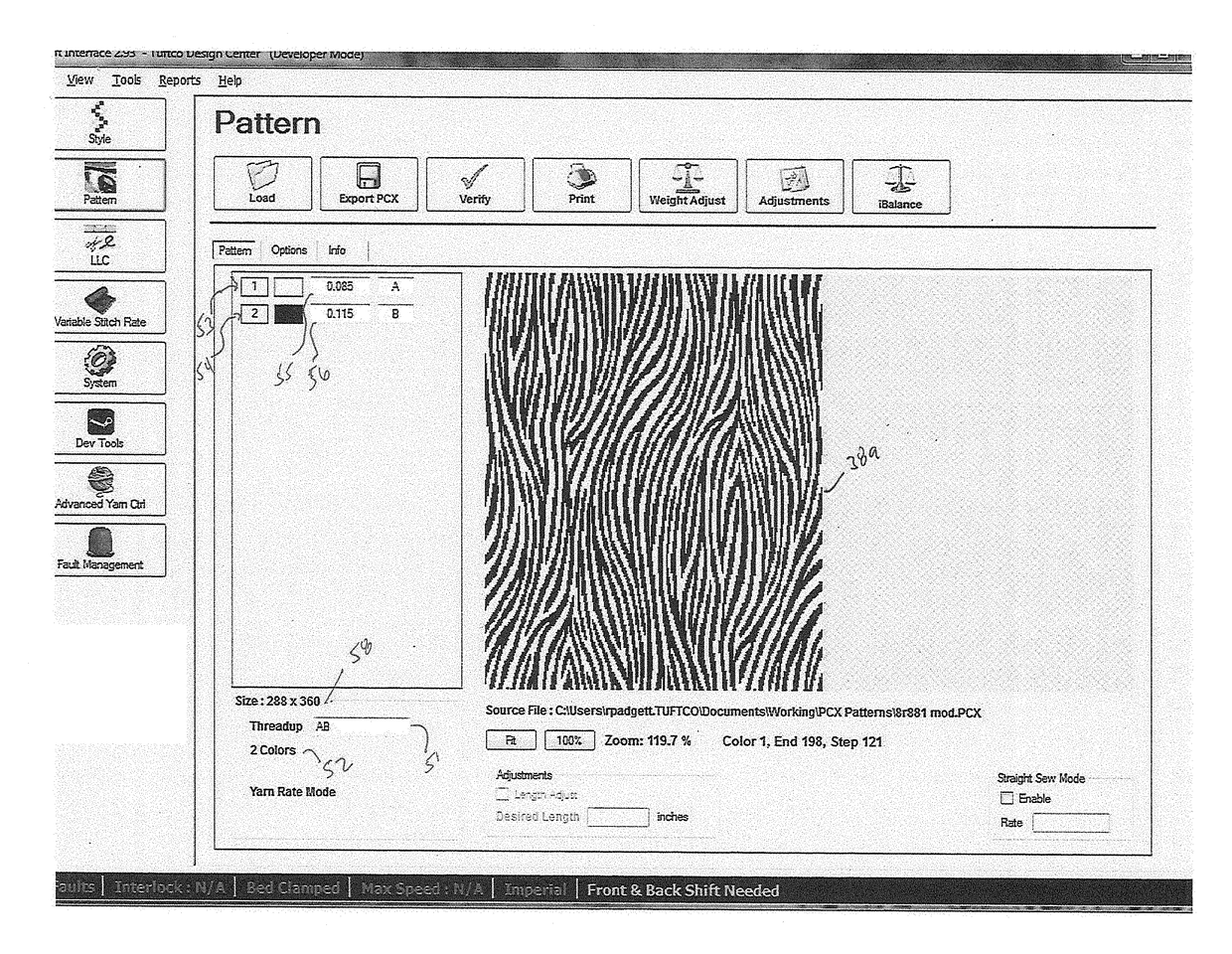

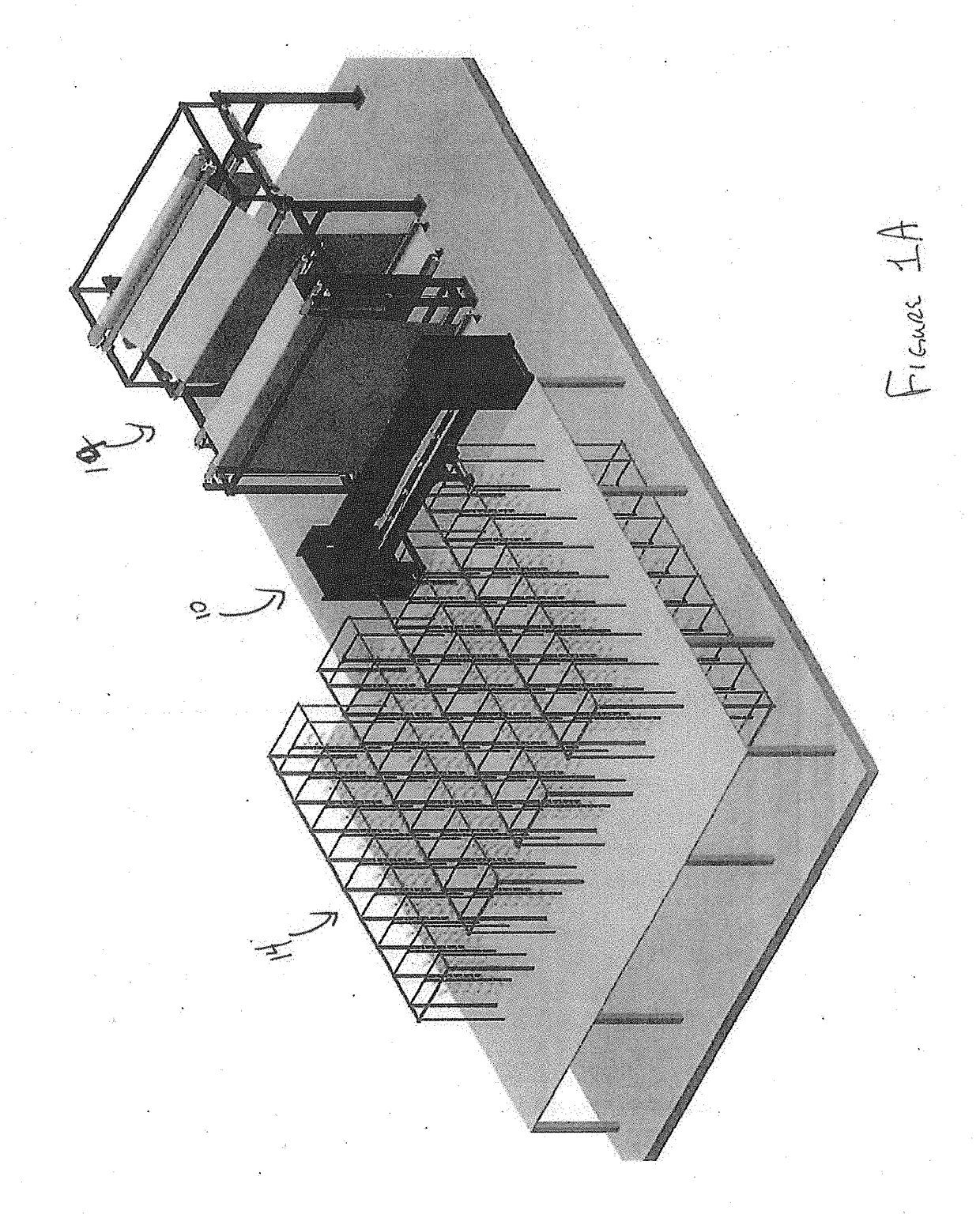

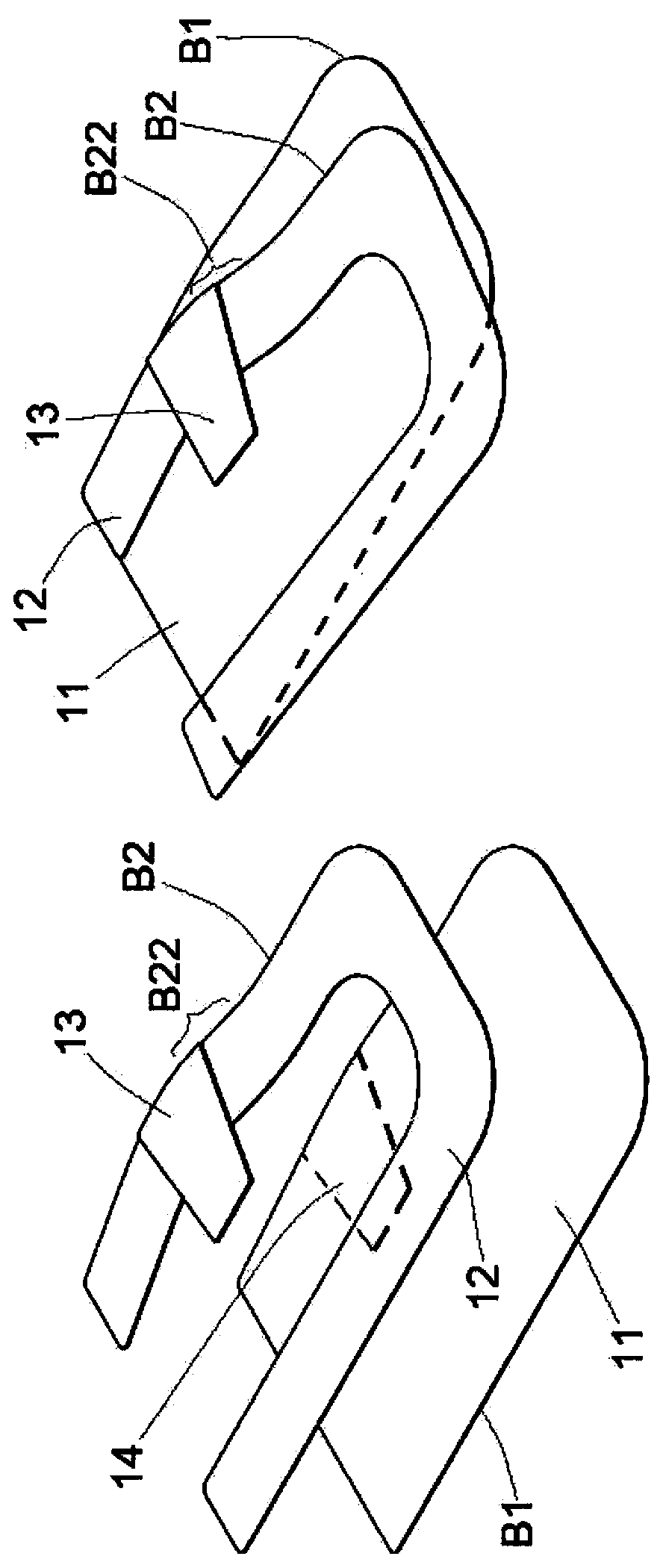

Tufted patterned textiles with optimized yarn consumption

ActiveUS9915017B2Promote balance between supply and demandMinimize appearanceProgramme-controlled sewing machinesTufting apparatusYarnGeneral Appearance

A method is provided for optimizing the yarn consumption in patterned textiles by applying cell automata algorithms to bitmapped-type pattern designs including operator selected rules to influence the general appearance of the pattern design.

Owner:TUFTCO

Thread tension device of sewing machine

InactiveCN100389236CAvoid too much tensionAvoid bulgingSewing measuring devicesTensometerPath lengthEngineering

A thread passing unit for sewing machine has a path length regulator for feeding thread, which features that the path length formed by fixed thread path, movable thread path and the thread path on needle rod is set up to 1 for the upper dead point of needle rod and more than 1 for the lower dead point. As a result, when the needle rod is raised up or lowered down, the thread is in relaxation state to ensure sewing quality.

Owner:YAMATO SEWING MASCH MFG CO LTD

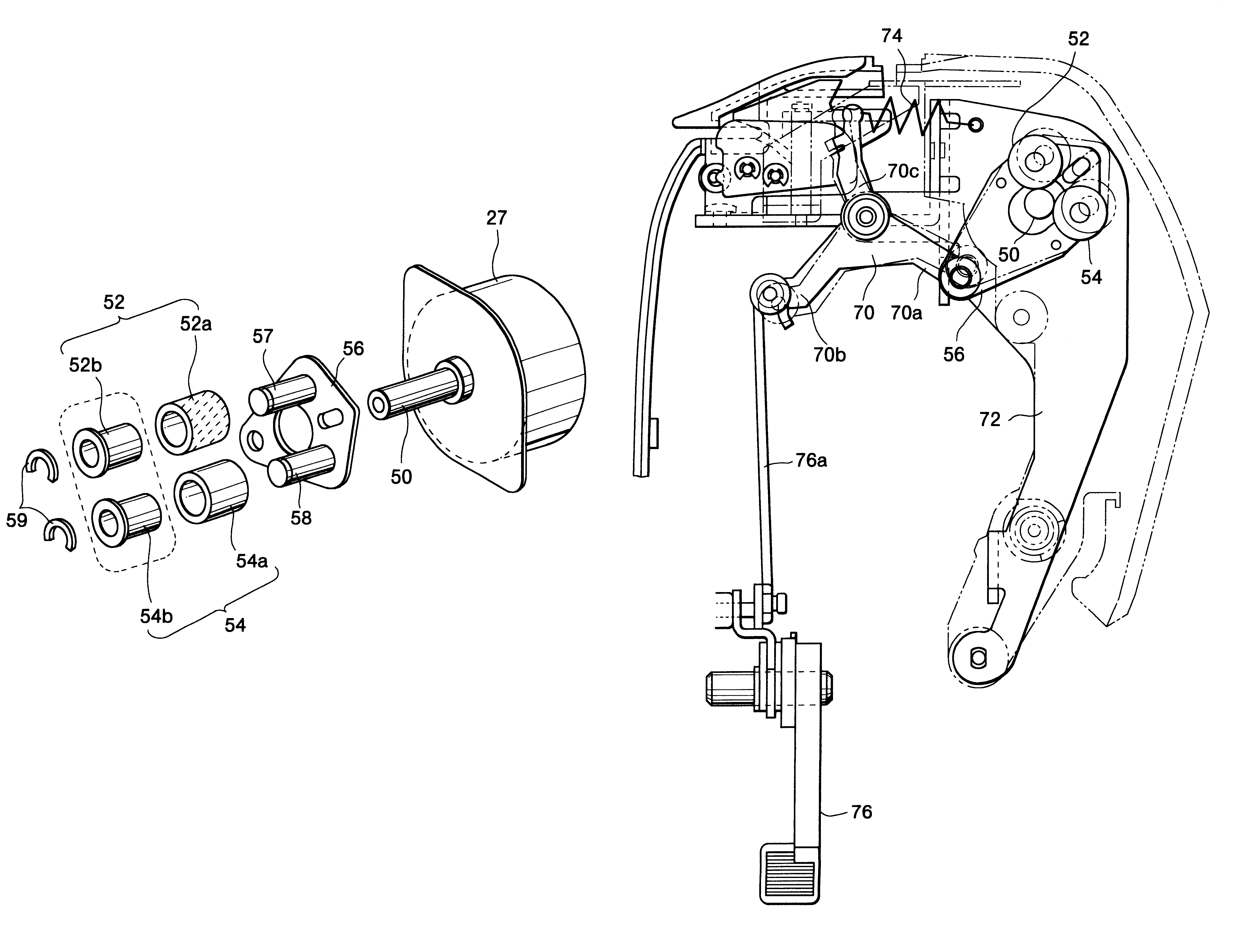

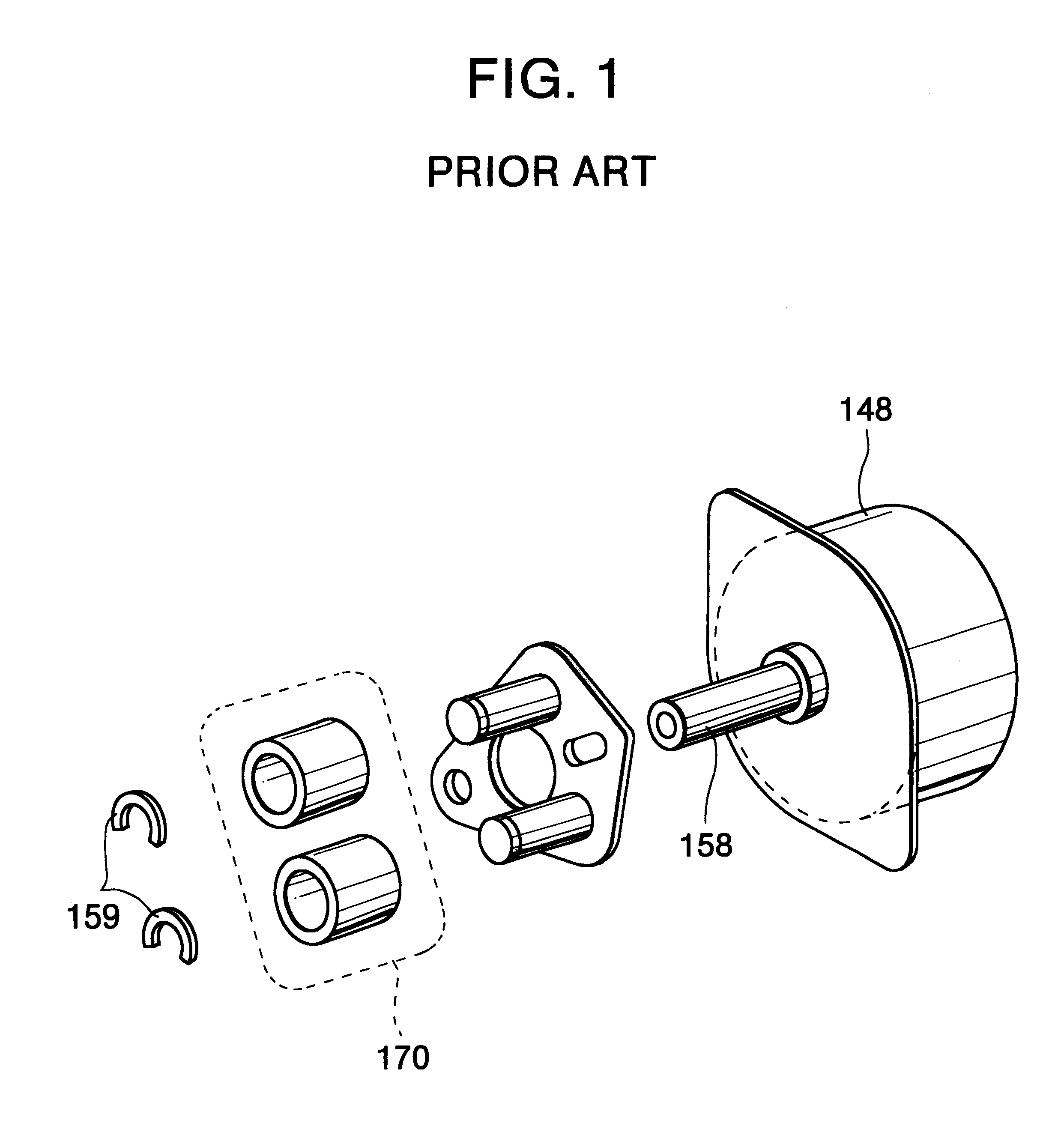

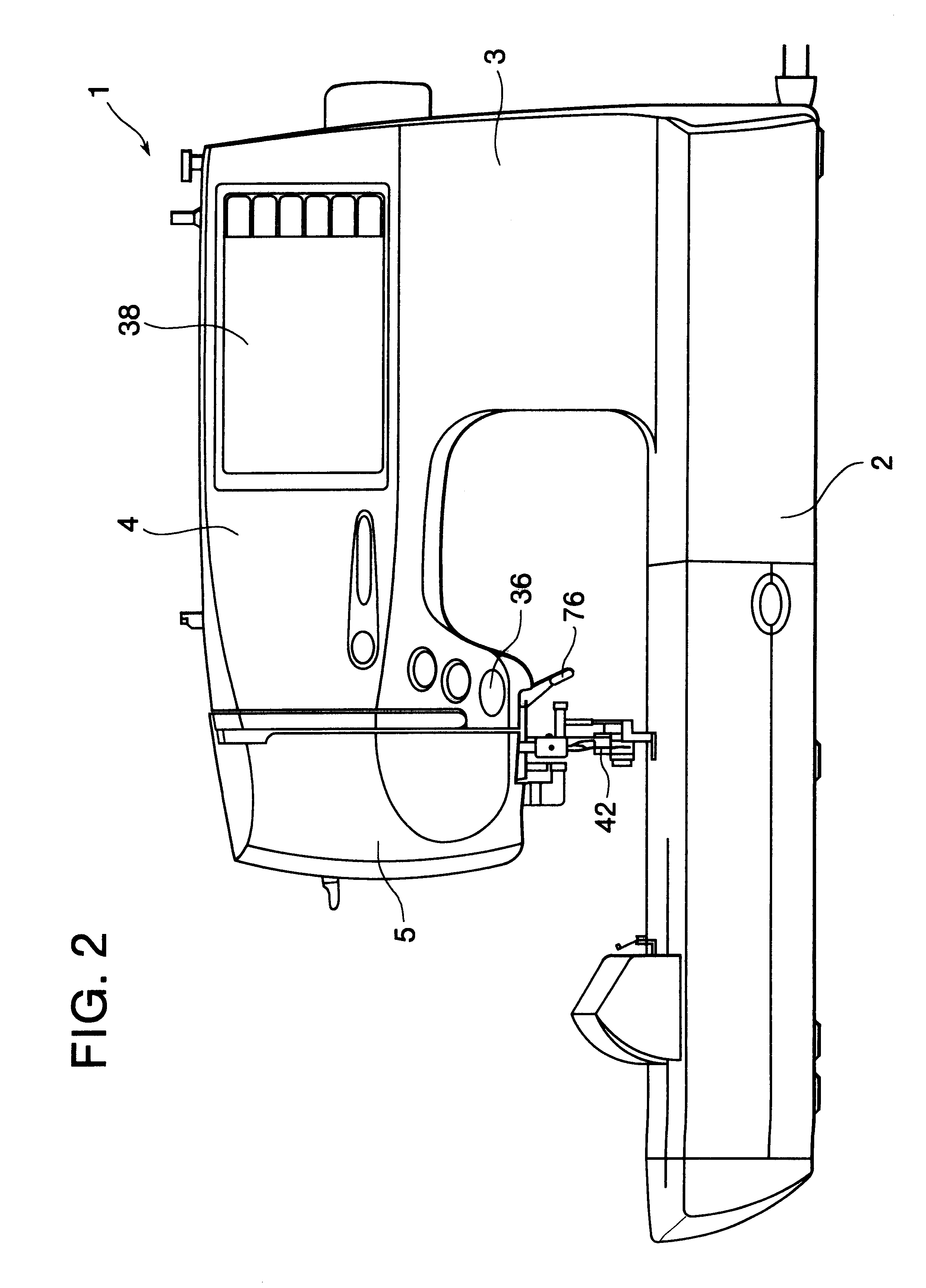

Device for supplying upper thread of sewing machine

An upper thread supply device includes a drive roller 50 and two slave rollers 52, 54. The slave roller 52 has a thread contacting portion 52a formed from a soft metal. The slave roller 54 has a thread contacting portion 54a formed from a resilient material. The drive roller 50 is formed from a hard metal. A thread is supplied by the upper thread supply device following a thread feed pathway. The drive roller 50 and the soft metal thread contacting portion 52a sandwich the thread at one position along the thread feed pathway and the drive roller 50 and the resilient thread portion 54a sandwich the thread at a separated position along the thread feed pathway. The resilient thread contacting portion 54a is positioned downstream from the position where the thread is sandwiched by the hard metal thread contacting portion 54a and the soft metal thread contacting portion 52a. The hard metal thread contacting portion of the drive roller 50 and the soft metal thread contacting portion 52a sandwich the thread and prevent it from being excessively drawn out from the thread spool by vertical movement of a thread take-up lever. The hard metal drive roller 50 and the resilient thread contacting portion 54a mainly reliably feed out the upper thread by sandwiching the upper thread there-between.

Owner:BROTHER KOGYO KK

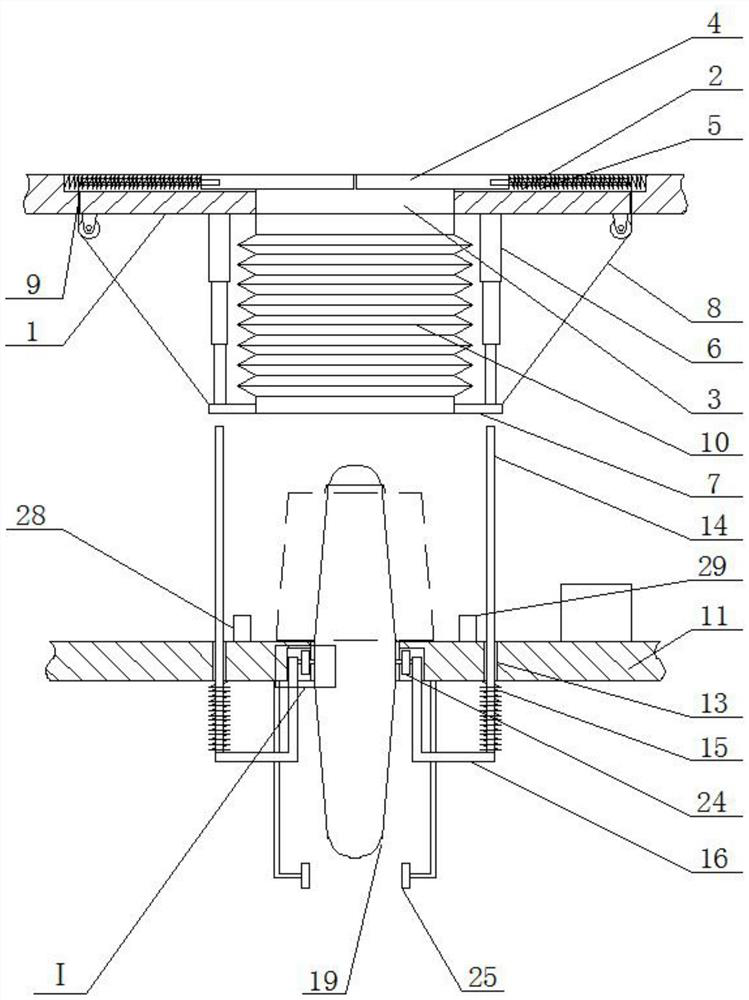

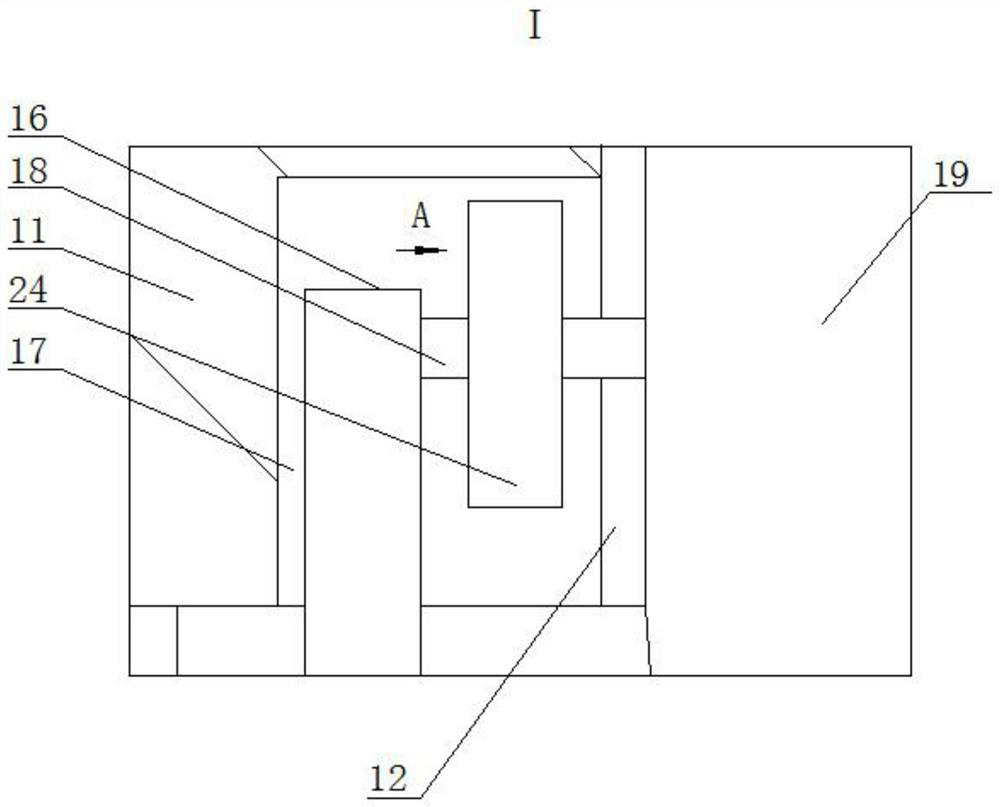

An automatic feeding device for shoemaking equipment

ActiveCN112267221BRealize automatic replacementReduce falling speedSewing measuring devicesSpool-pin assembliesBobbinStructural engineering

An automatic feeding device for shoe-making equipment, comprising a first fixed platform, a first groove is provided on the first fixed platform, two moving plates are arranged in the first groove, and the front and rear sides of the moving plate are in contact with the inner wall of the first groove. There is a limited guide device between them, the first fixed platform is connected to two electric push rods, the electric push rod is connected to the fixed plate, and the two fixed plates are connected to the same telescopic tube, there is a second fixed platform under the first fixed platform, and the second fixed platform There are two guide holes on the top, there is a guide rod in the guide hole, the guide rod is equipped with a tension spring, there is a rack under the second fixed platform, there is a transmission platform on the first fixed platform, there is a baffle on the first fixed platform, and the second fixed platform There is a wire amount detection device on the stage. The user only needs to place several shoe thread spools sequentially on the conveying table to use this device. The winding of the old shoe thread spools is separated from the guide shaft and placed simultaneously with the placement of the new shoe thread spools, which greatly shortens the The time required for shoe line barrel replacement is shortened, which in turn helps to improve the production efficiency of shoes.

Owner:广东粤盛新材料科技有限公司

Wire feeding device of sewing machine

The invention provides a wire feeding device of a sewing machine, which can simplify tedious operations of wearing sewing wires again during switching a hard stitch with a soft stitch. The wire feeding device (20) of the sewing machine (21) has a wire stirring and picking part (31), a first wire guide part (29), a second wire guide part (30) and a movable wire guide member (32). The wire stirring and picking part (31) having a wire feeding hole (34) at a swing front end side is arranged in a way that the wire stirring and picking part (31) can vertically swing surrounding a swing shaft (31a) which supports a swing base end side. The movable wire guide member (32) is formed independent of the wire stirring and picking part (31) and is arranged between the wire feeding hole (34) and the second wire guide part (30) to adjust positions vertically and horizontally.

Owner:株式会社飞马

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com