Patents

Literature

963results about How to "Reduce falling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

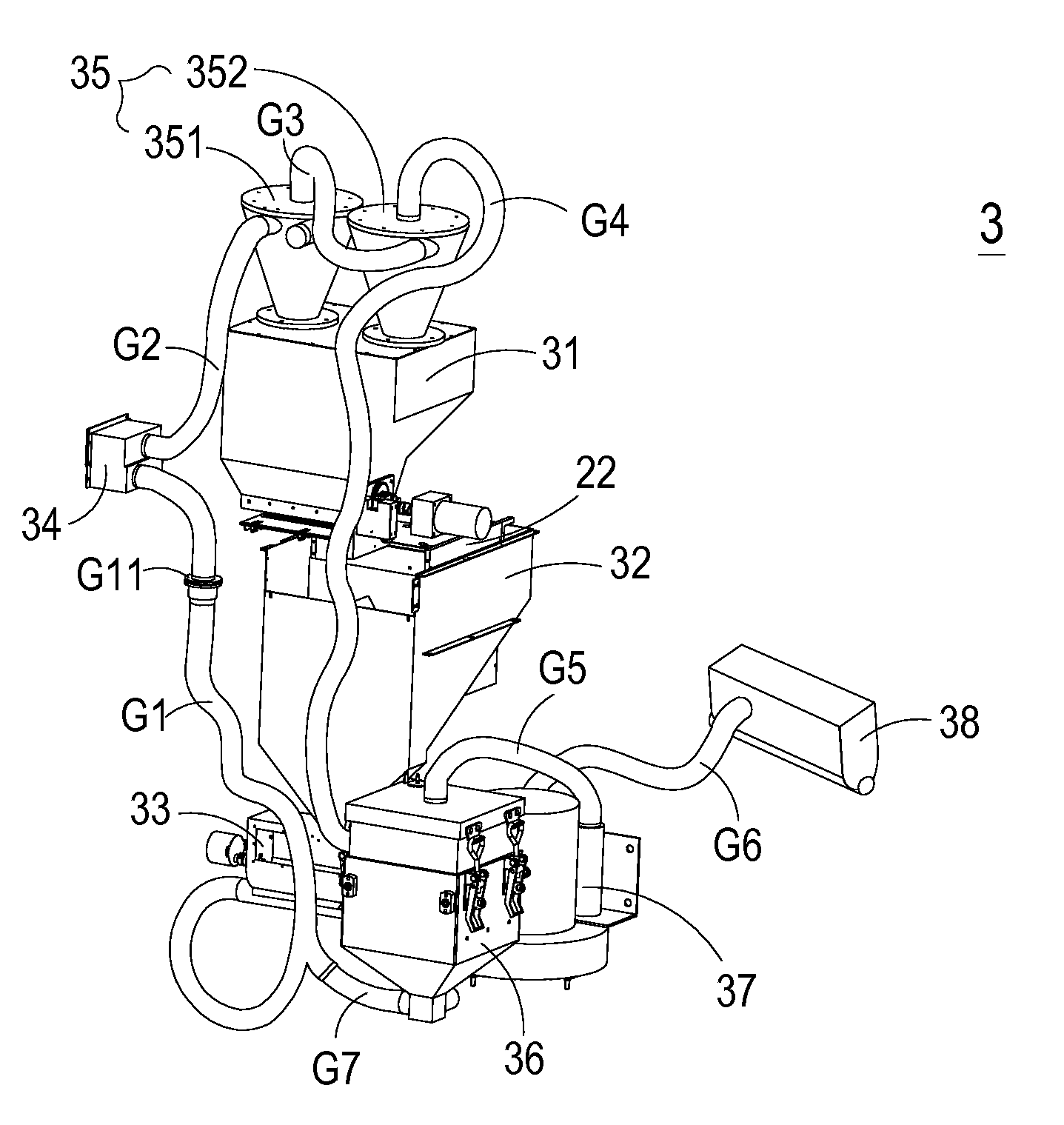

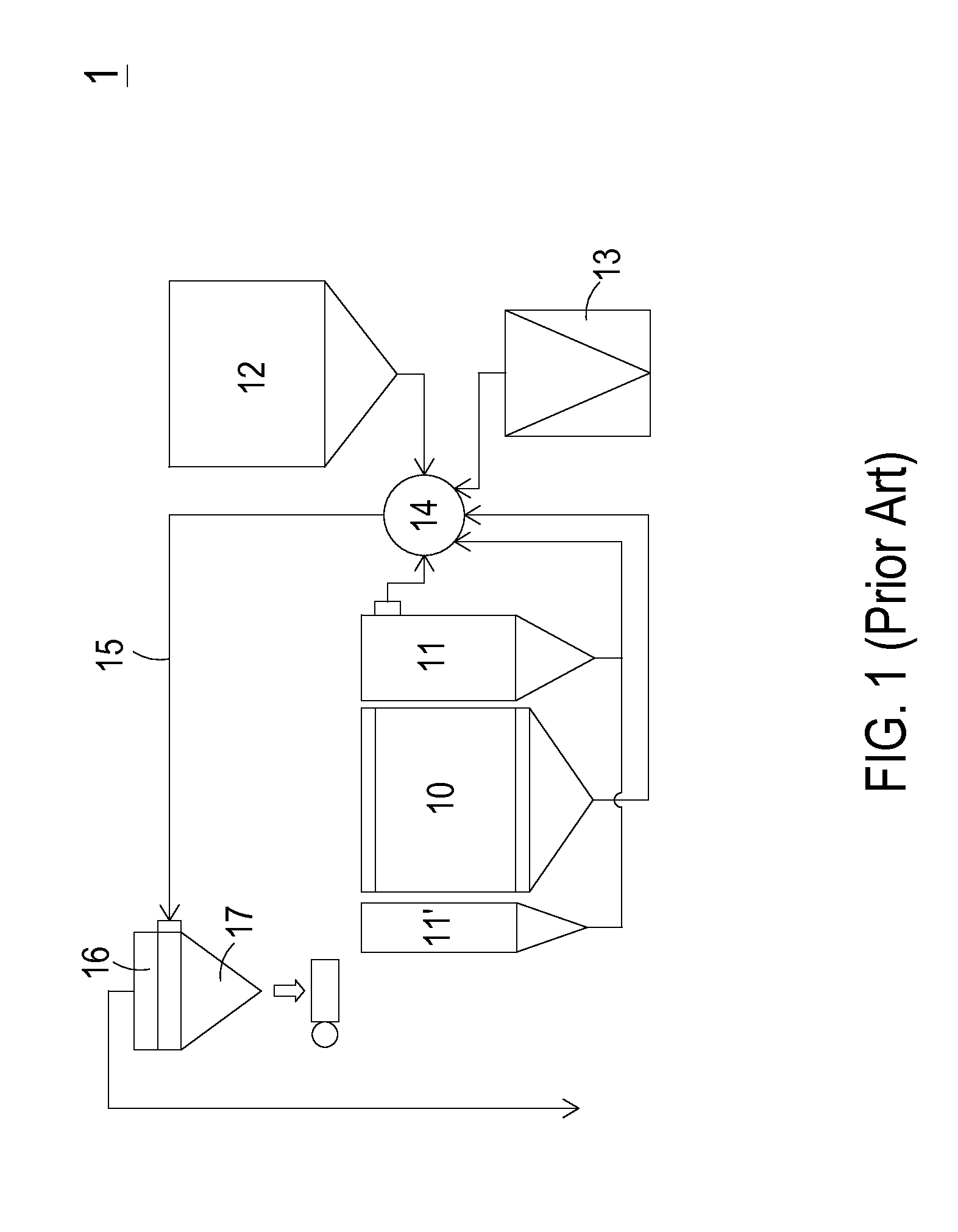

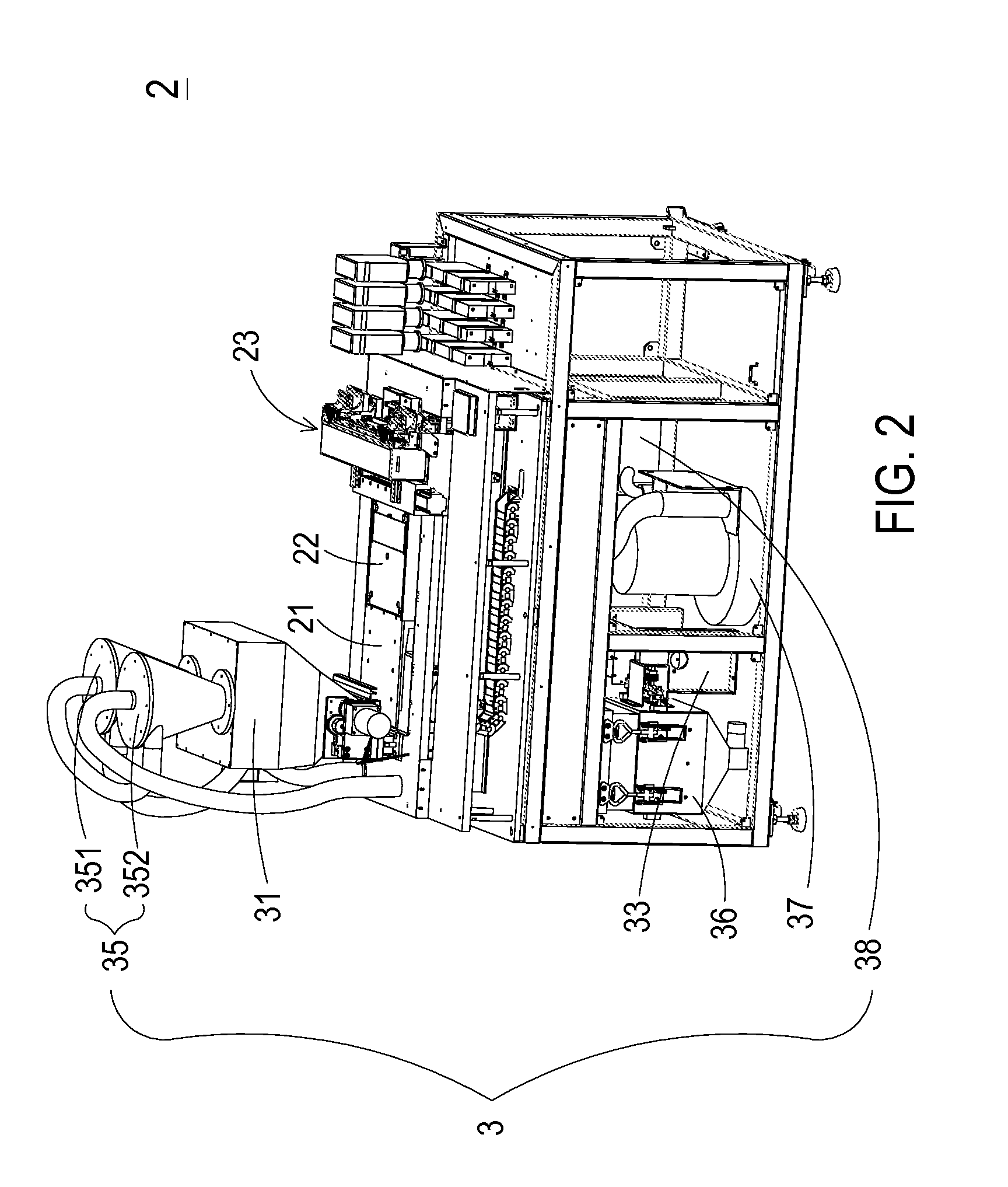

Powder recycling system

ActiveUS20150298397A1More user-friendlyCost-effectiveAdditive manufacturing apparatusGas current separationParticulatesPressure generation

A powder recycling system includes a powder feeder, a remaining powder collector, a bridge breaker, a block powder filter, a cyclone separator, a particulate filter cleaner, an air pressure generation device and an electrostatic precipitator. The powder feeder provides a construction powder to a construction platform. The remaining powder collector for collects the remaining powder. The cyclone separator is used to separate the large-size powdery particles and the small-size powdery particles of the remaining powder from each other through a rotating gaseous stream. The large-size powdery particles fall down to the powder feeder due to gravity, and the small-size powdery particles of the remaining powder is removed from the rotating gaseous stream and transmitted to the particulate filter cleaner. After the small-size powdery particles of the remaining powder are filtered by the particulate filter cleaner, the suspended small-size powdery particles are transmitted to the electrostatic precipitator.

Owner:MICROJET TECH

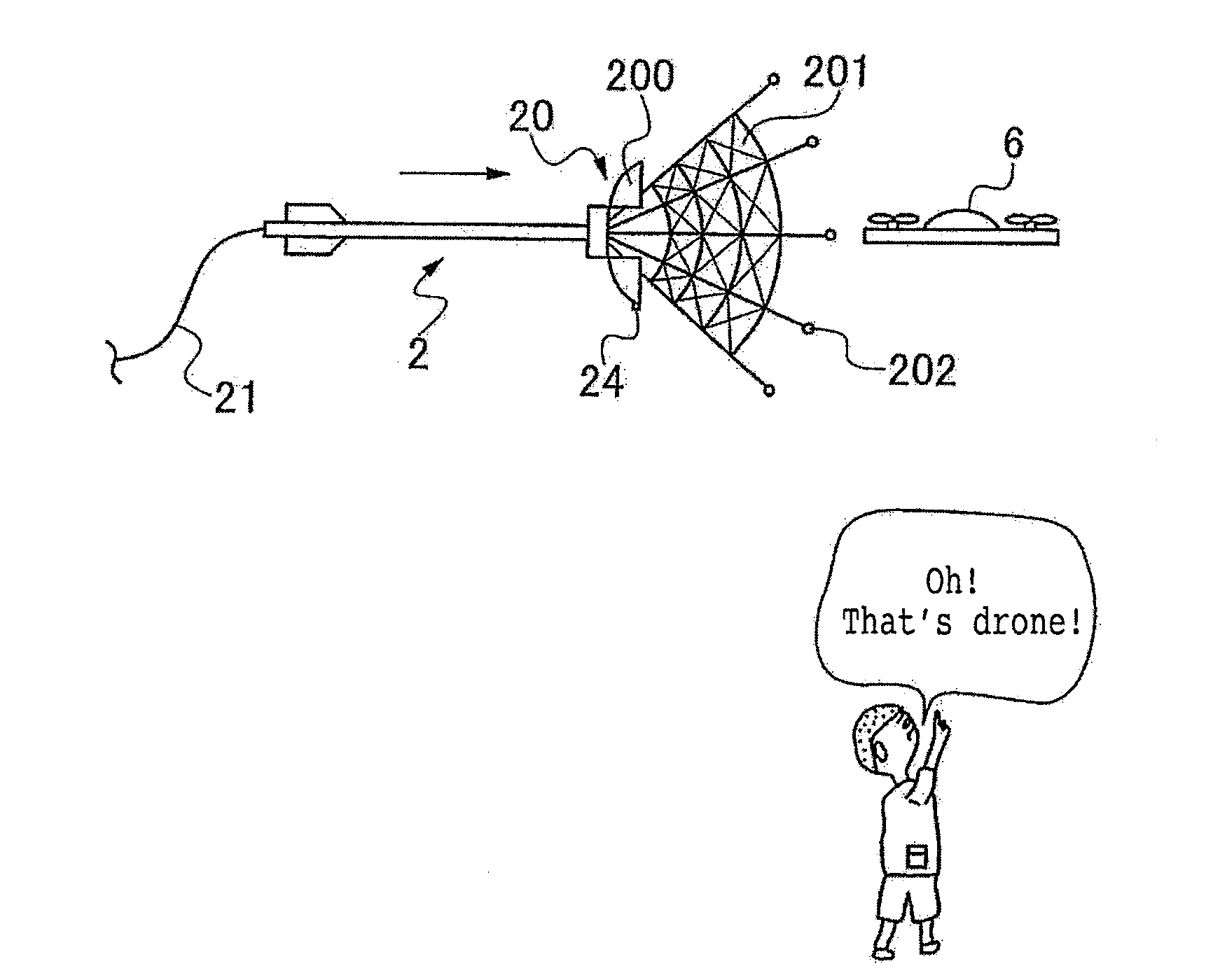

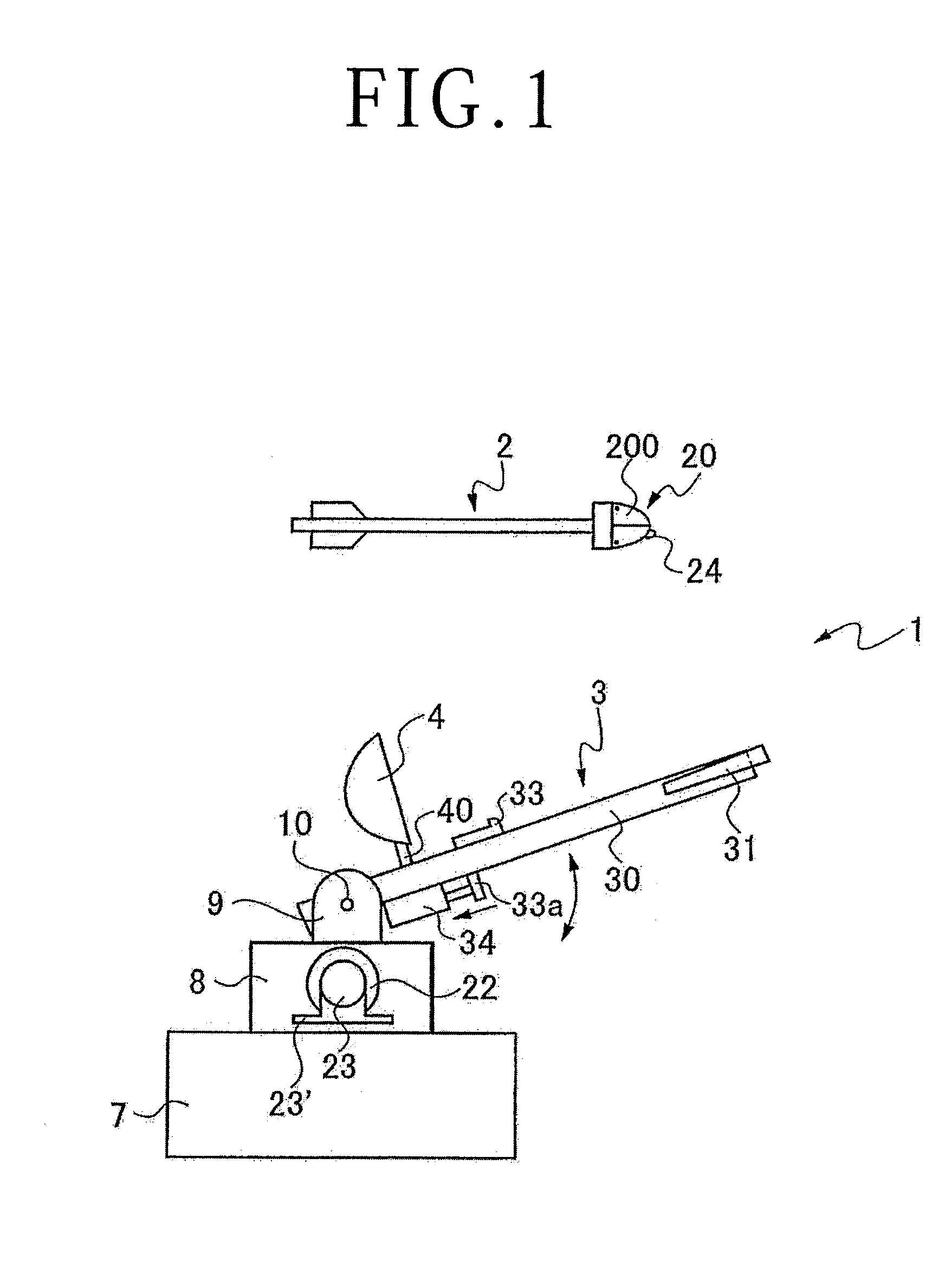

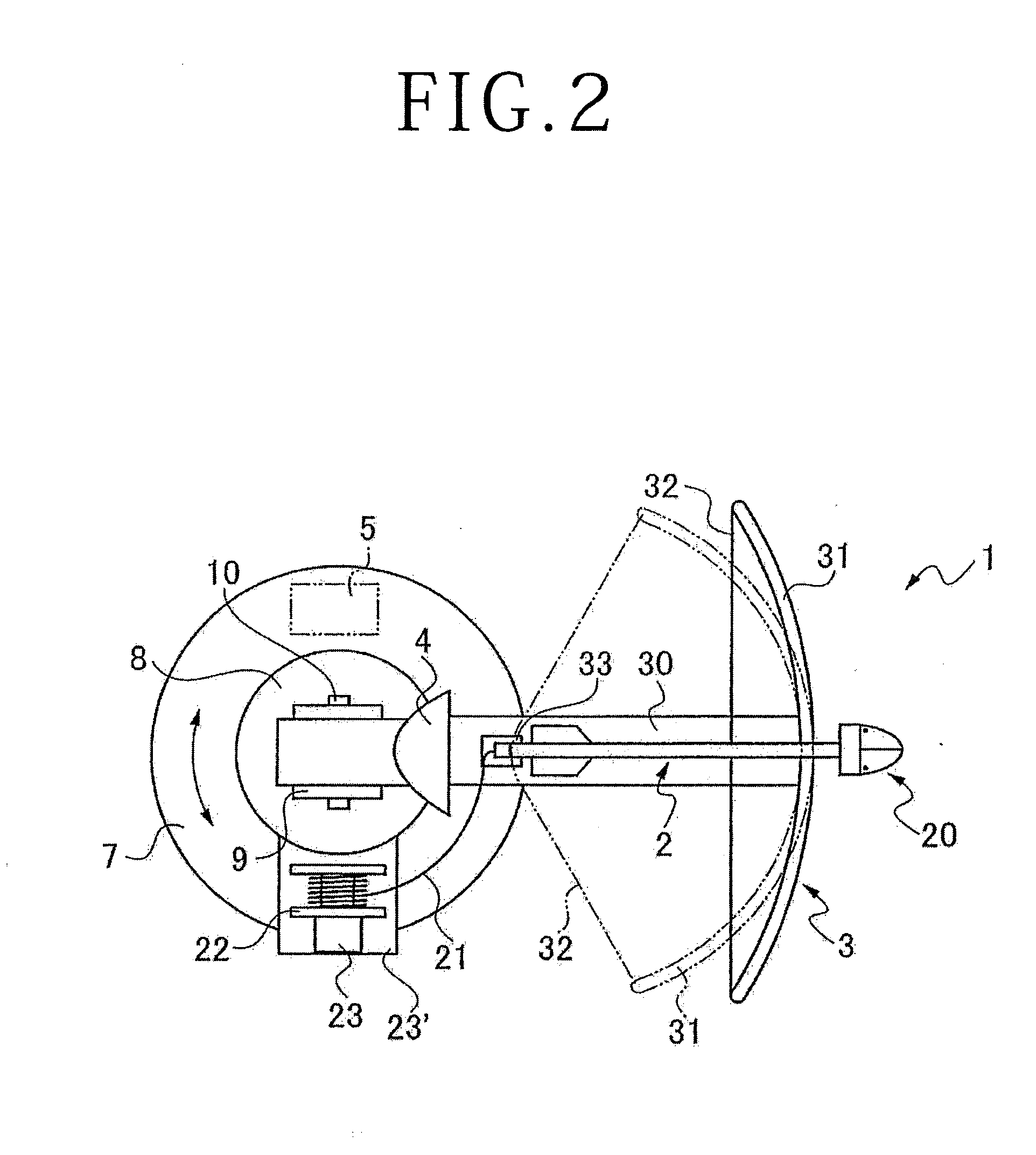

Small unmanned air vehicle repulsing apparatus

ActiveUS20160376029A1Reduce falling speedProtect safety and interestsDefence devicesAmmunition projectilesUncrewed vehicleEngineering

Owner:DISCO CORP

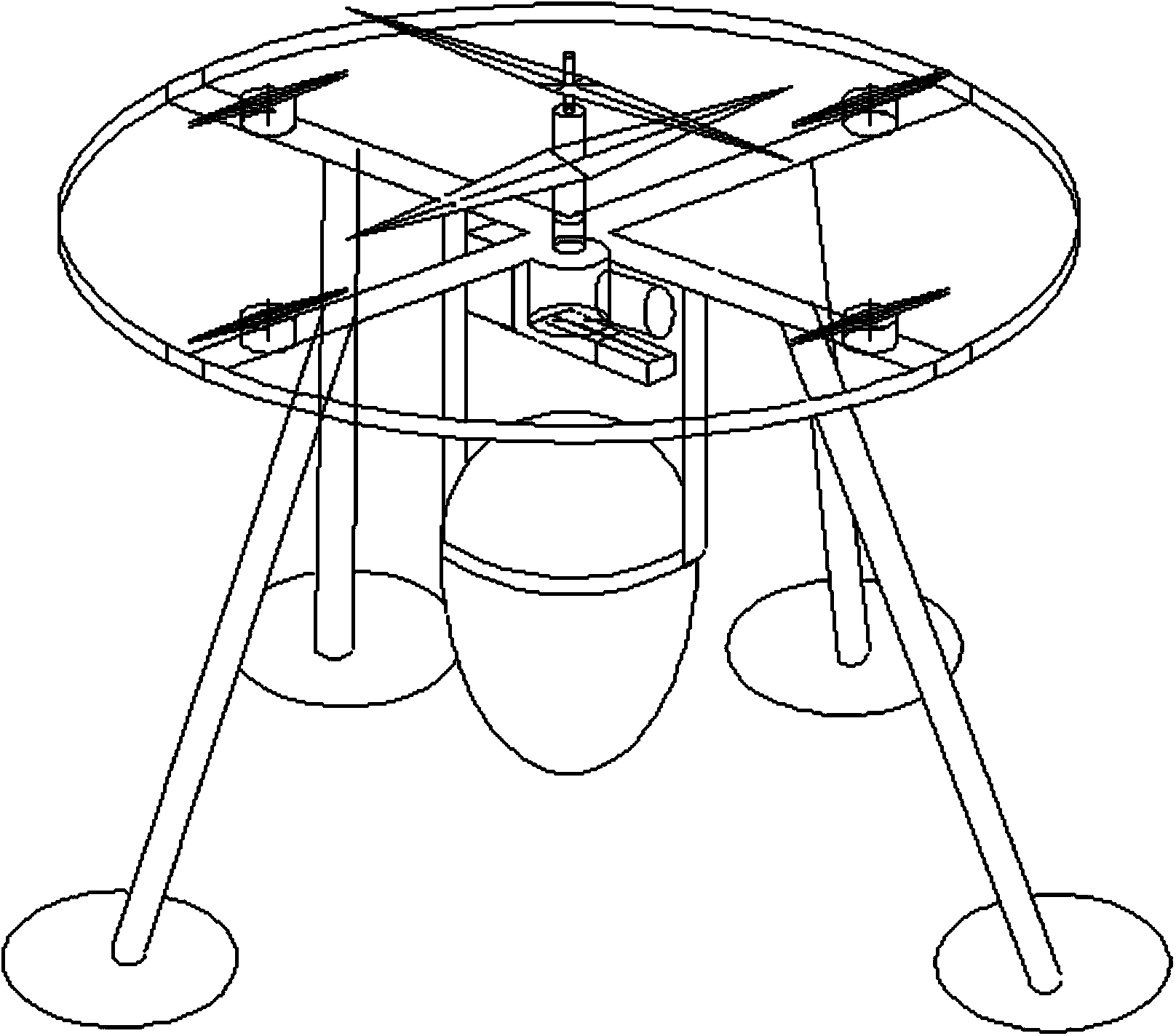

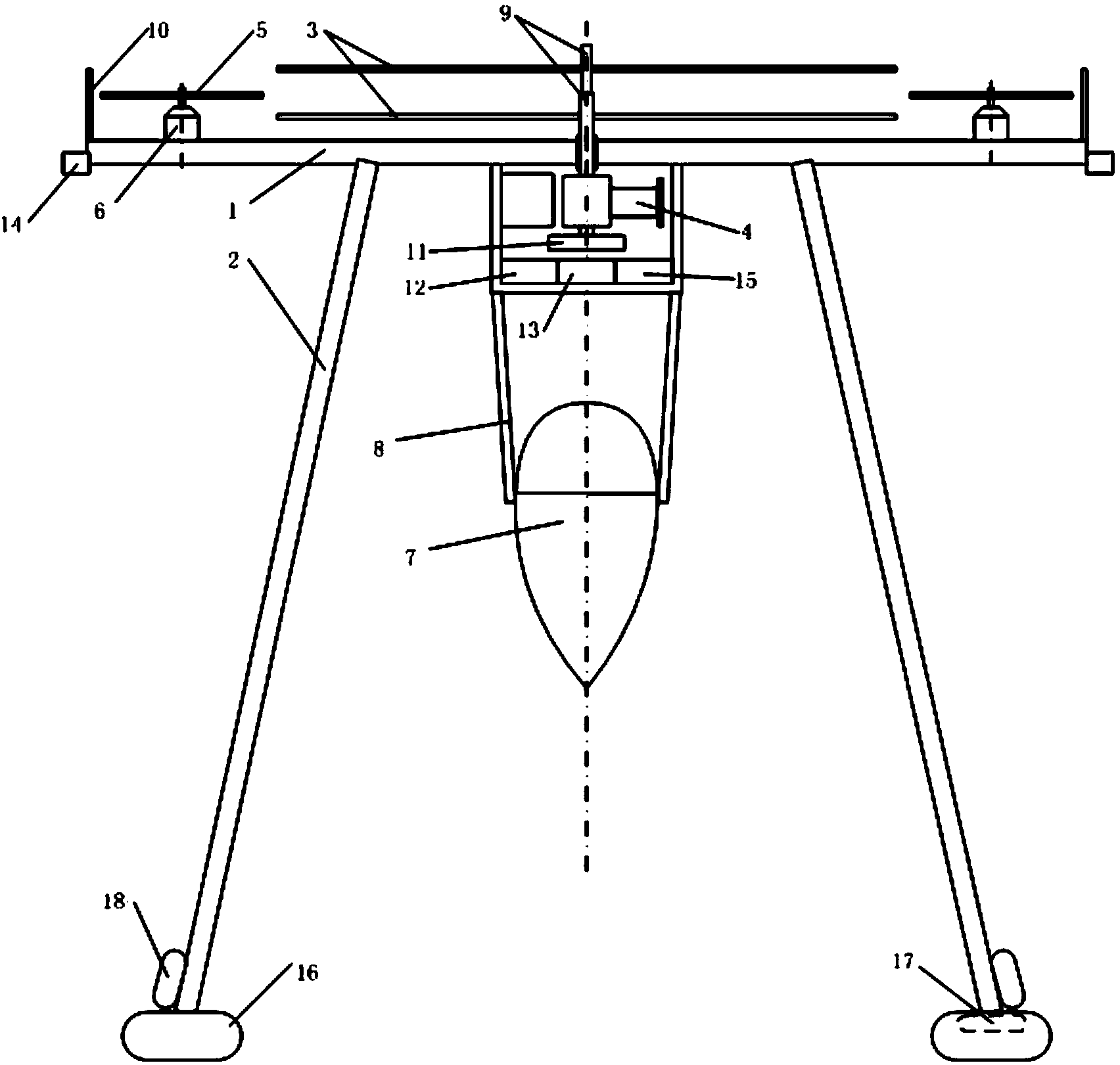

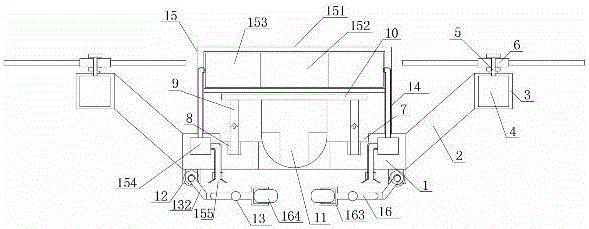

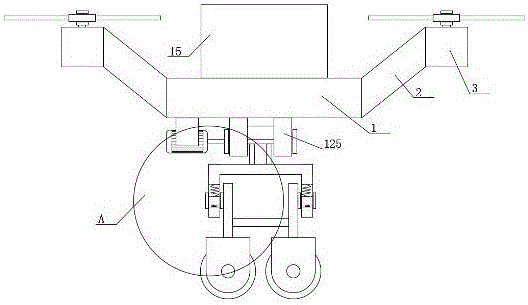

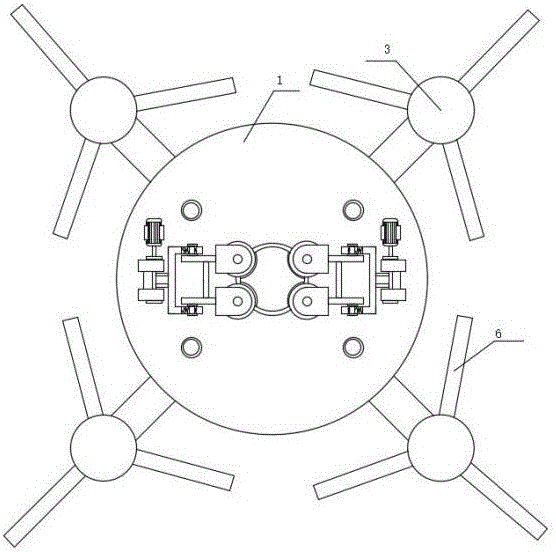

Unmanned logistics helicopter

ActiveCN104163241AEasy ground handlingReduced weight and structural complexityRotocraftRotary wingQuad rotor

The invention belongs to the technical field of aviation, relates to an unmanned aerial vehicle, and in particular relates to an unmanned logistics helicopter. The unmanned logistics helicopter comprises a body and rotor wings arranged on the body, wherein the body is of a cross-shaped structure; four body frames are fixed on the cross-shaped structure to support the body; central coaxial opposite-rotating double rotors are mounted at the central position of the body and are powered by an oil drive engine; four electric quad-rotor-wing supplying posture adjusting capacities are mounted at four tail ends of the cross-shaped structure and are powered by four brushless motors respectively; a cargo frame with a rectification shape is hung below the body through a cargo frame bracket. The unmanned logistics helicopter has the advantages of high endurance, safety, energy utilization and convenience in ground control, and can be put into use as an unmanned logistics aerial vehicle.

Owner:AVIATION IND INFORMATION CENT

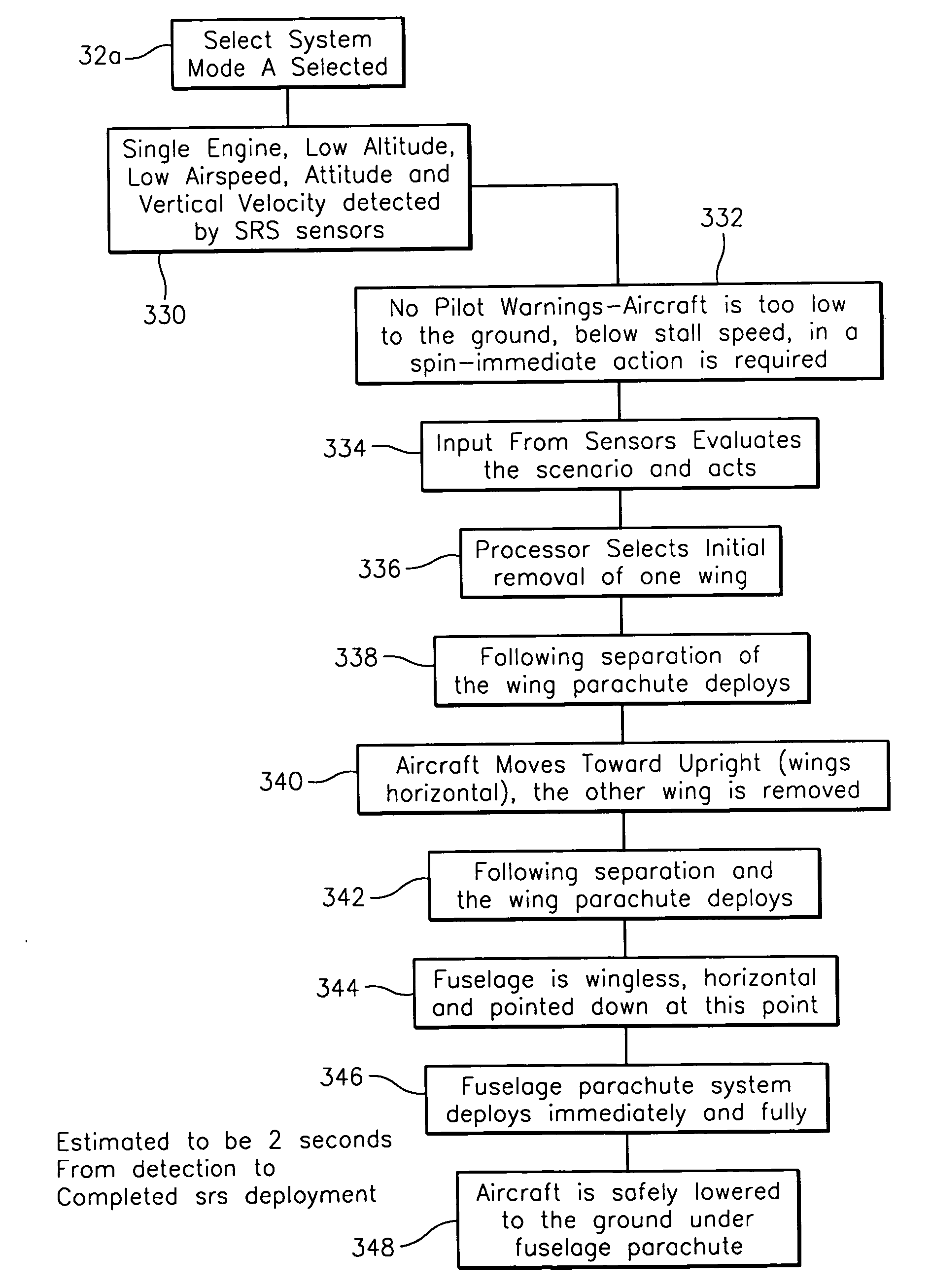

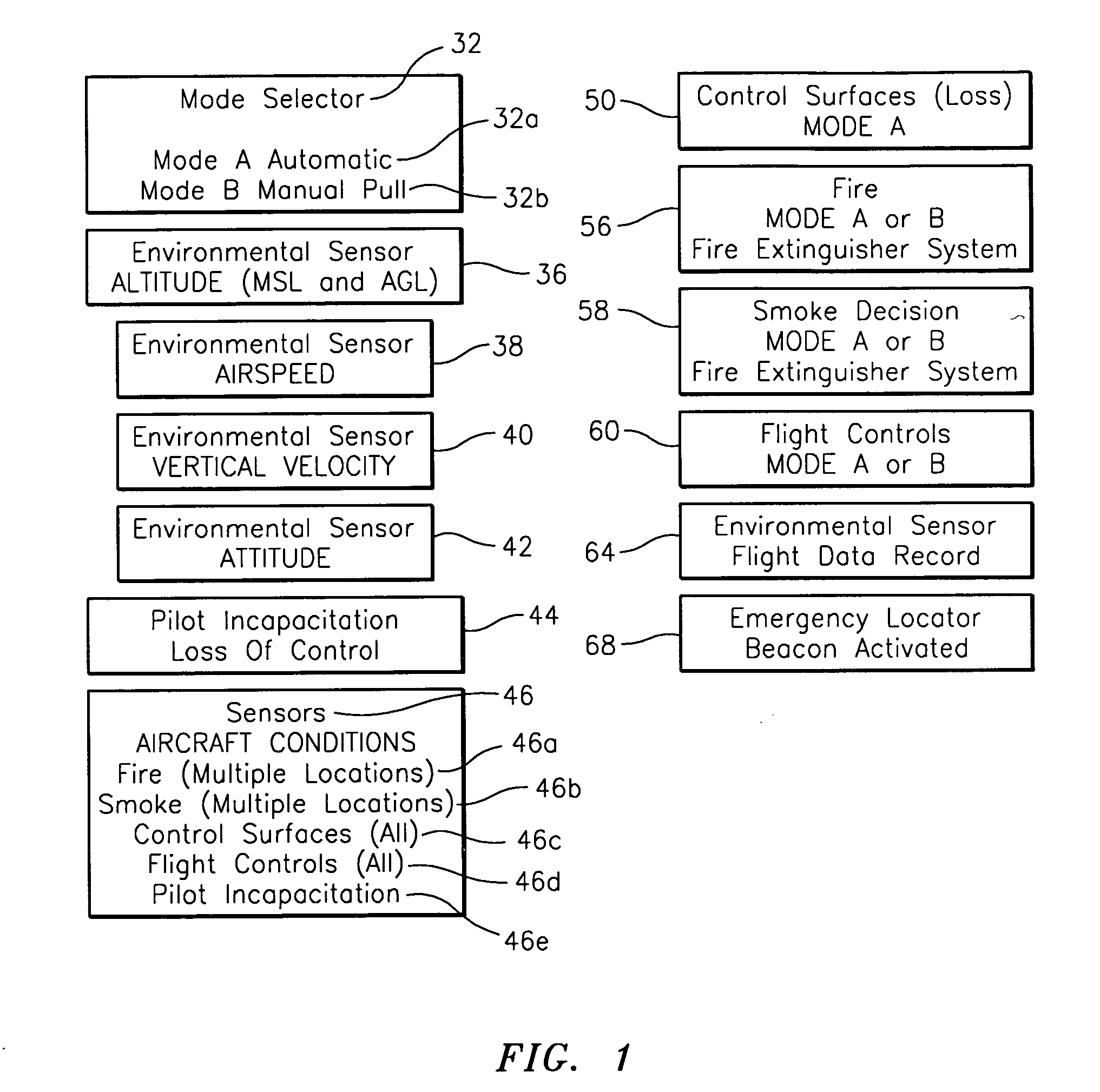

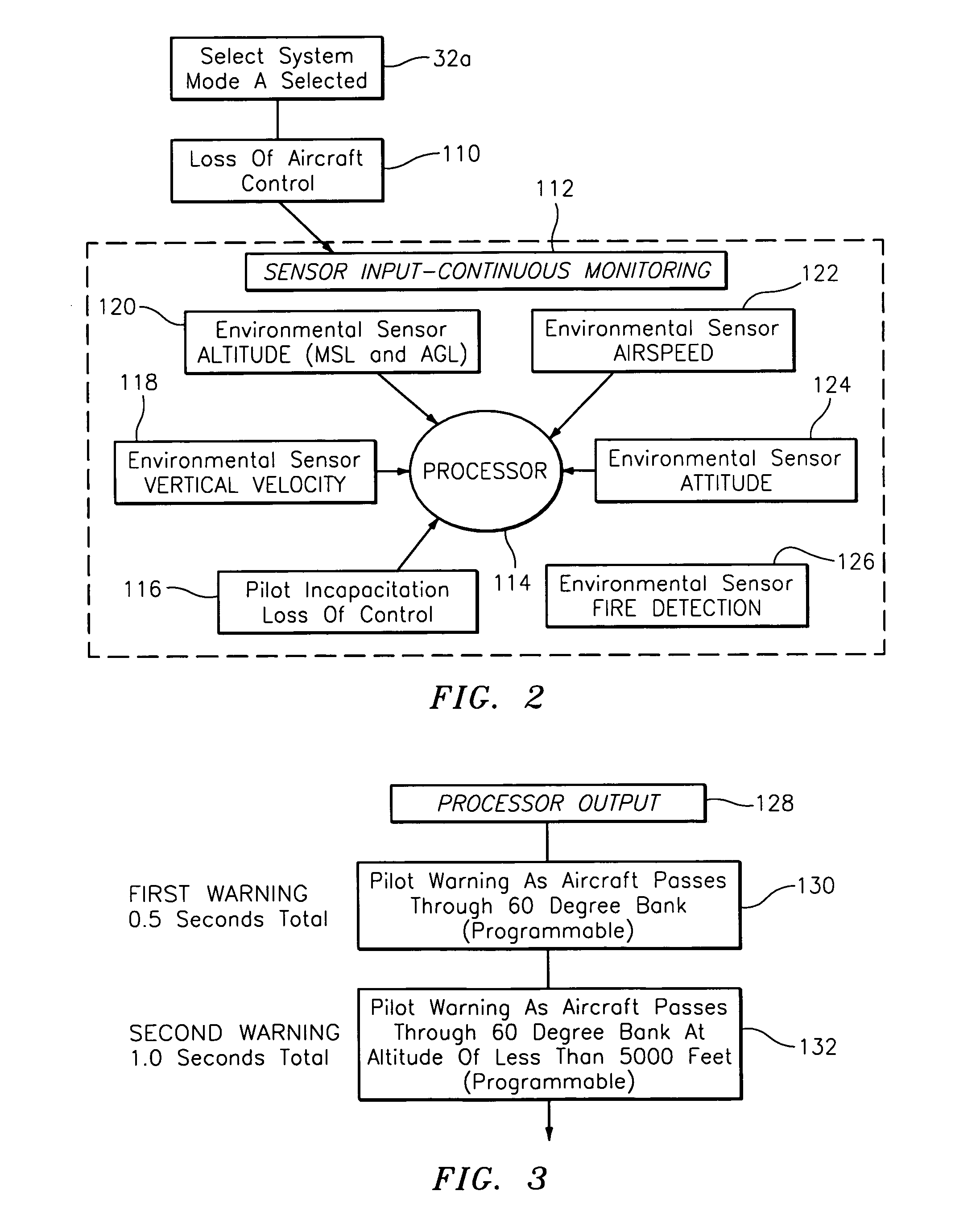

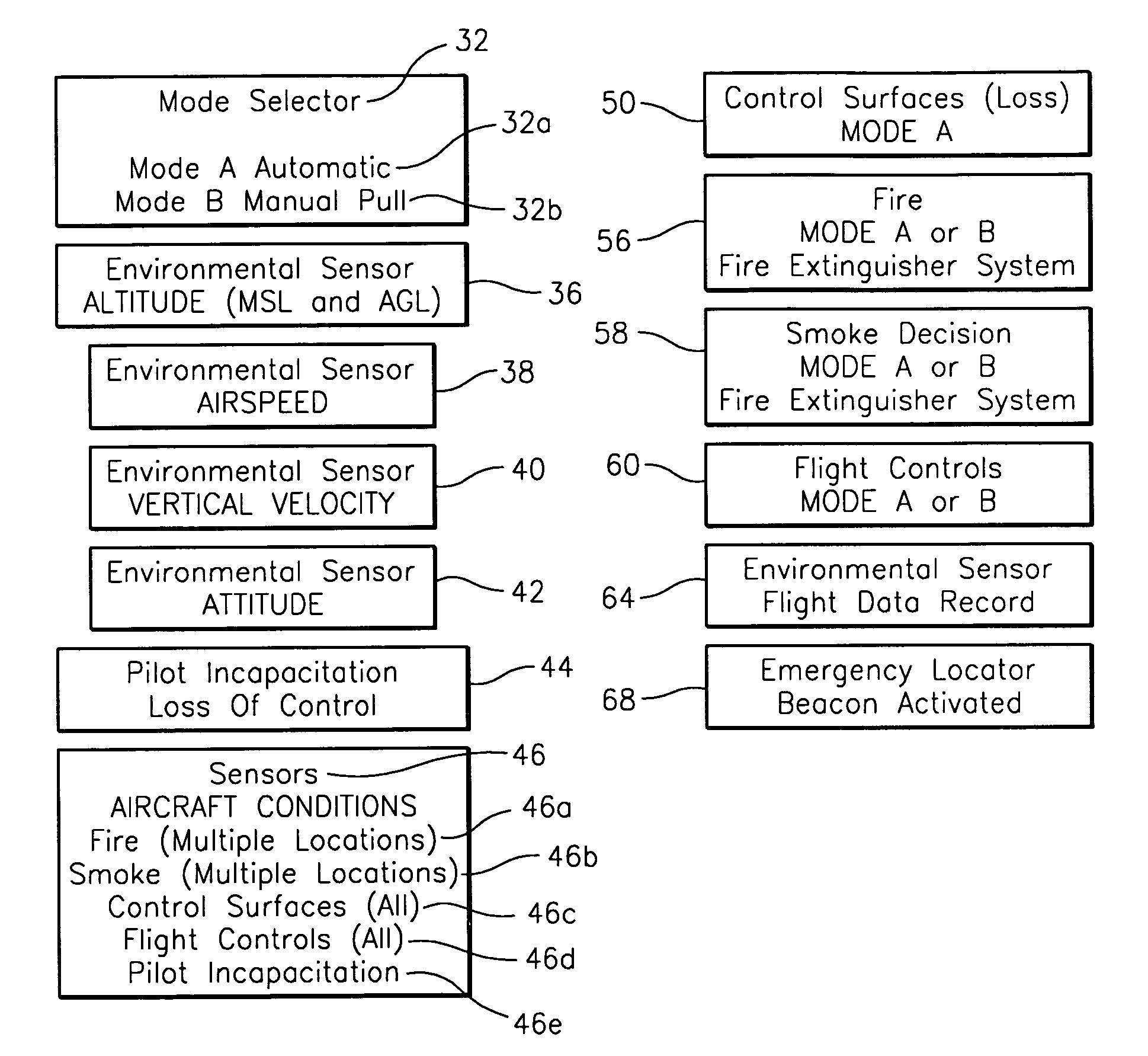

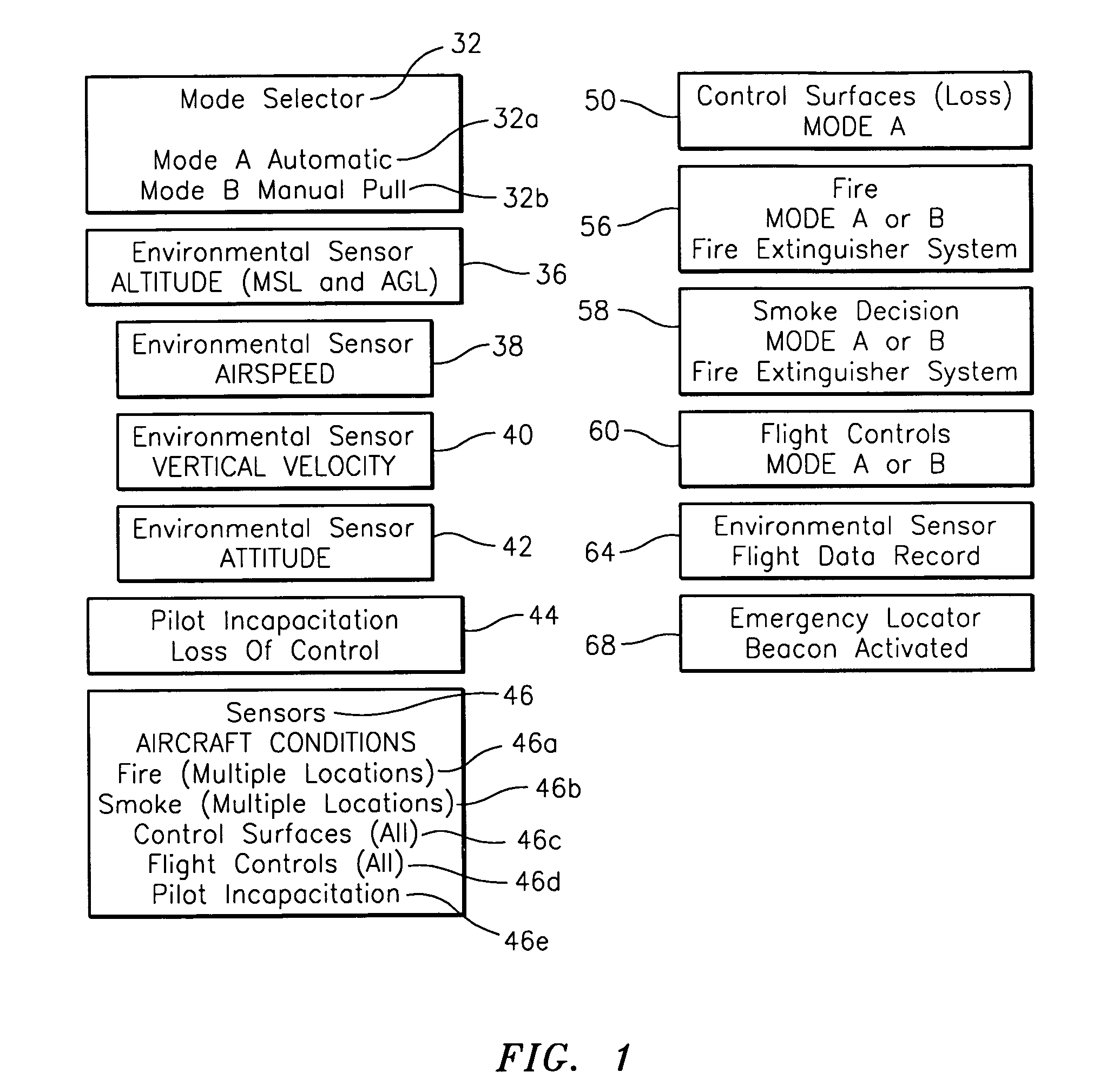

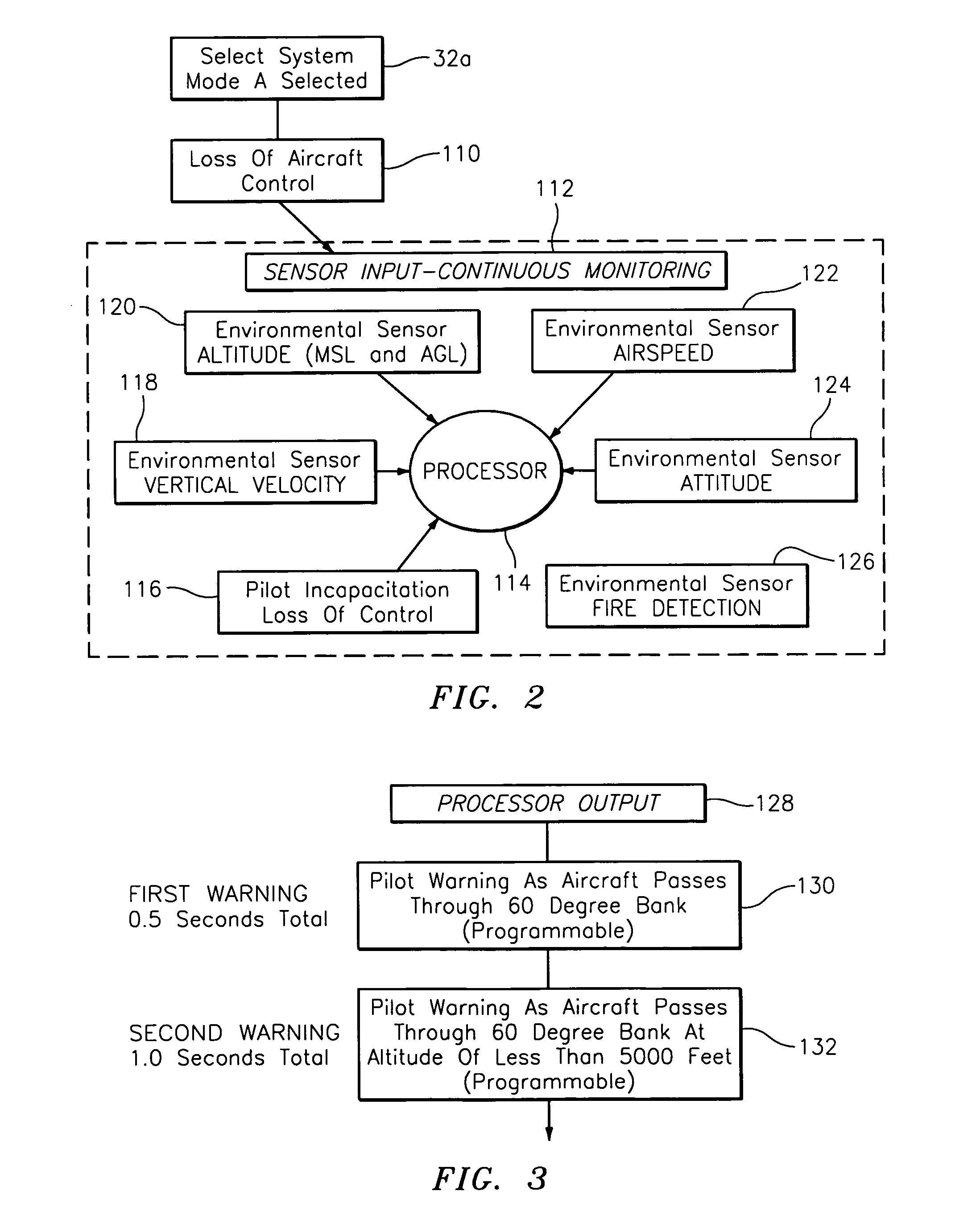

Smart recovery system

ActiveUS20100004803A1Shorten speedSlow downAnalogue computers for trafficAircraft controlOn boardSmart system

This invention relates to an intelligence system on board an aircraft that detects an emergency, assesses the situation, and then acts on the situation in a pre-determined manner.

Owner:MANFREDI DARIO P +1

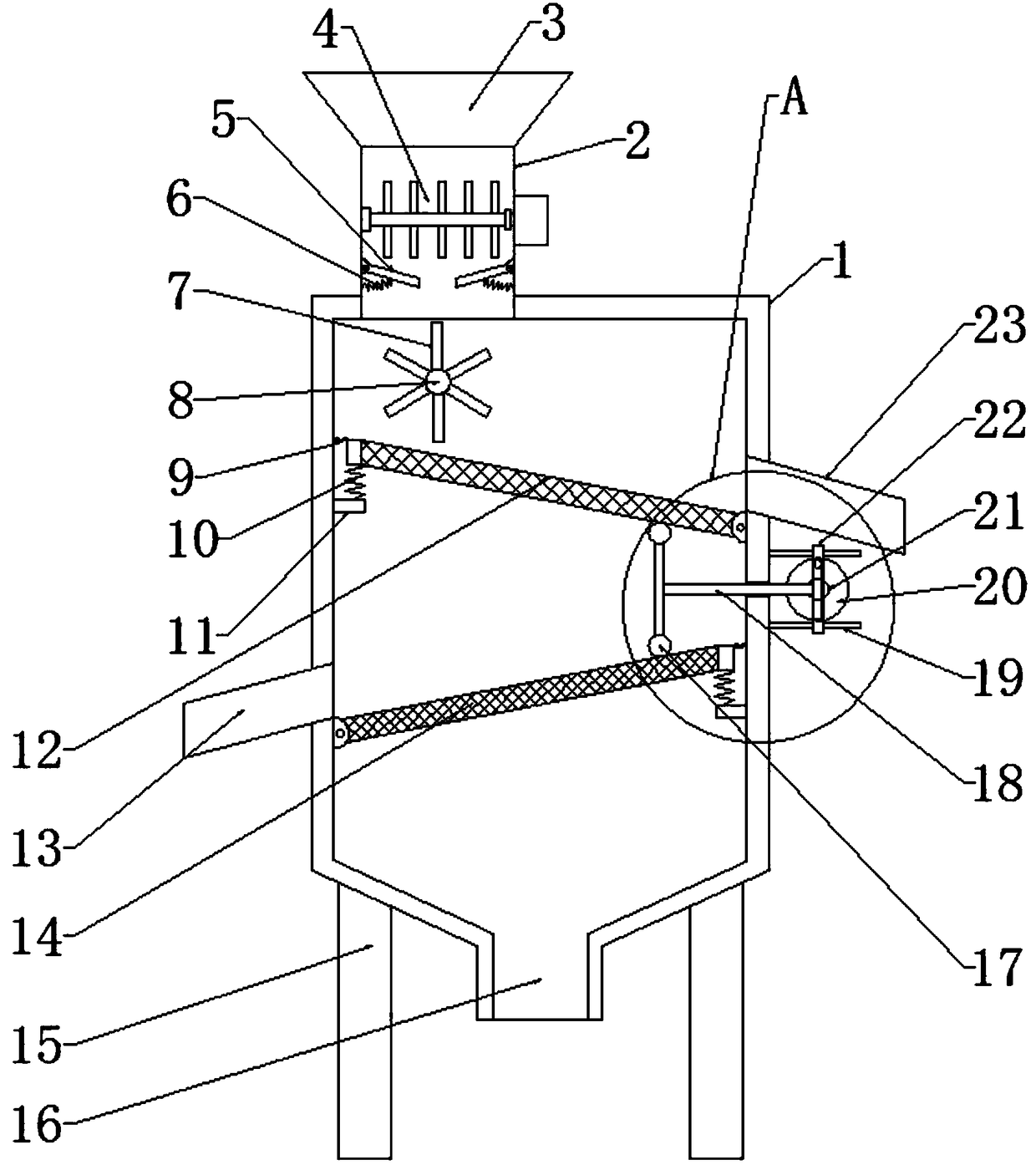

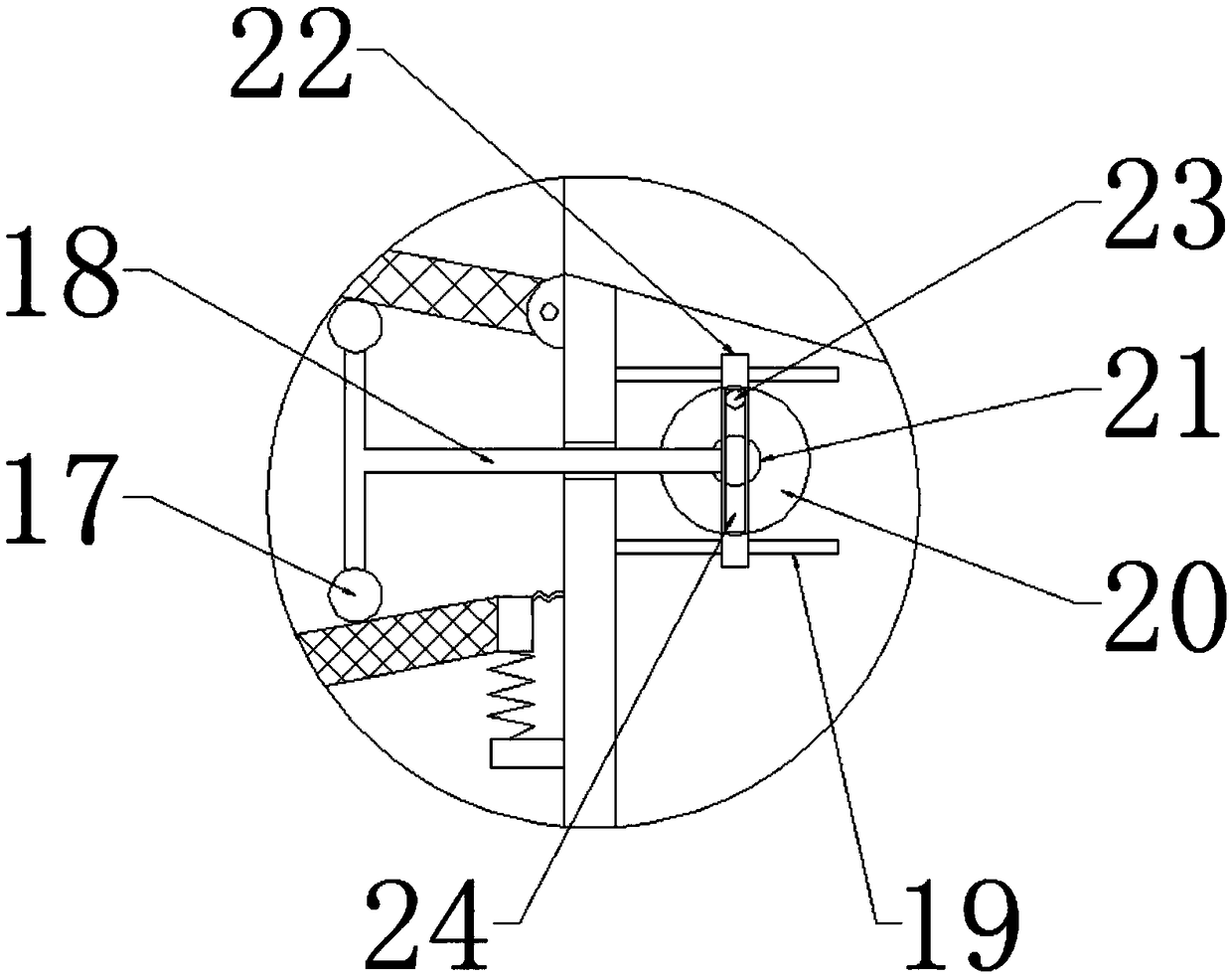

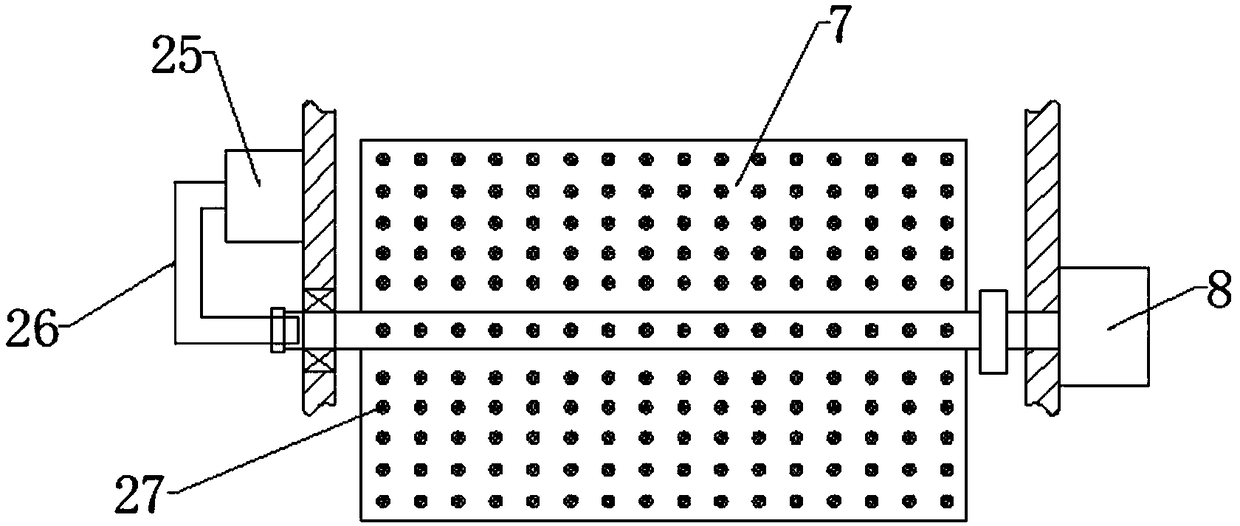

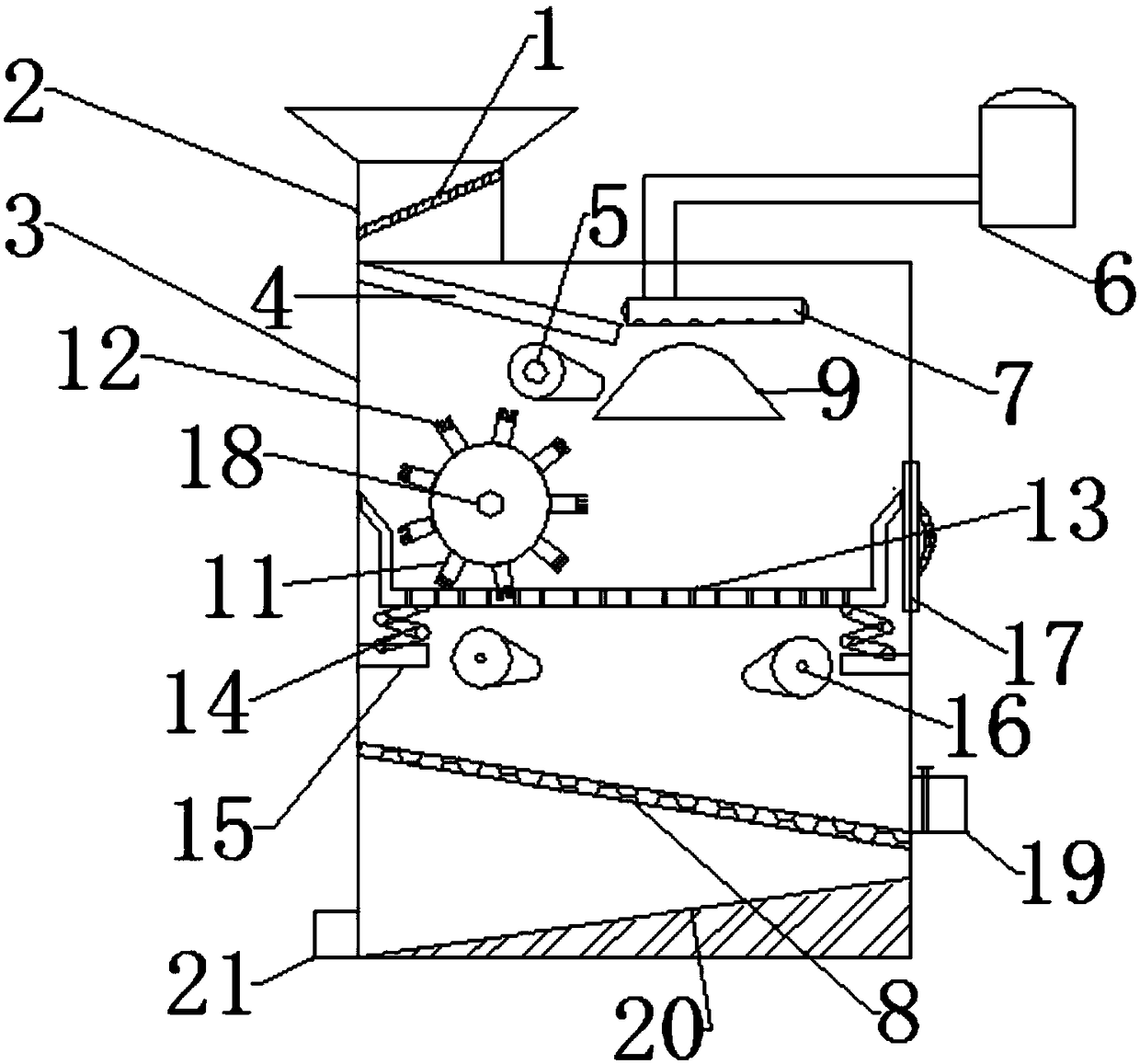

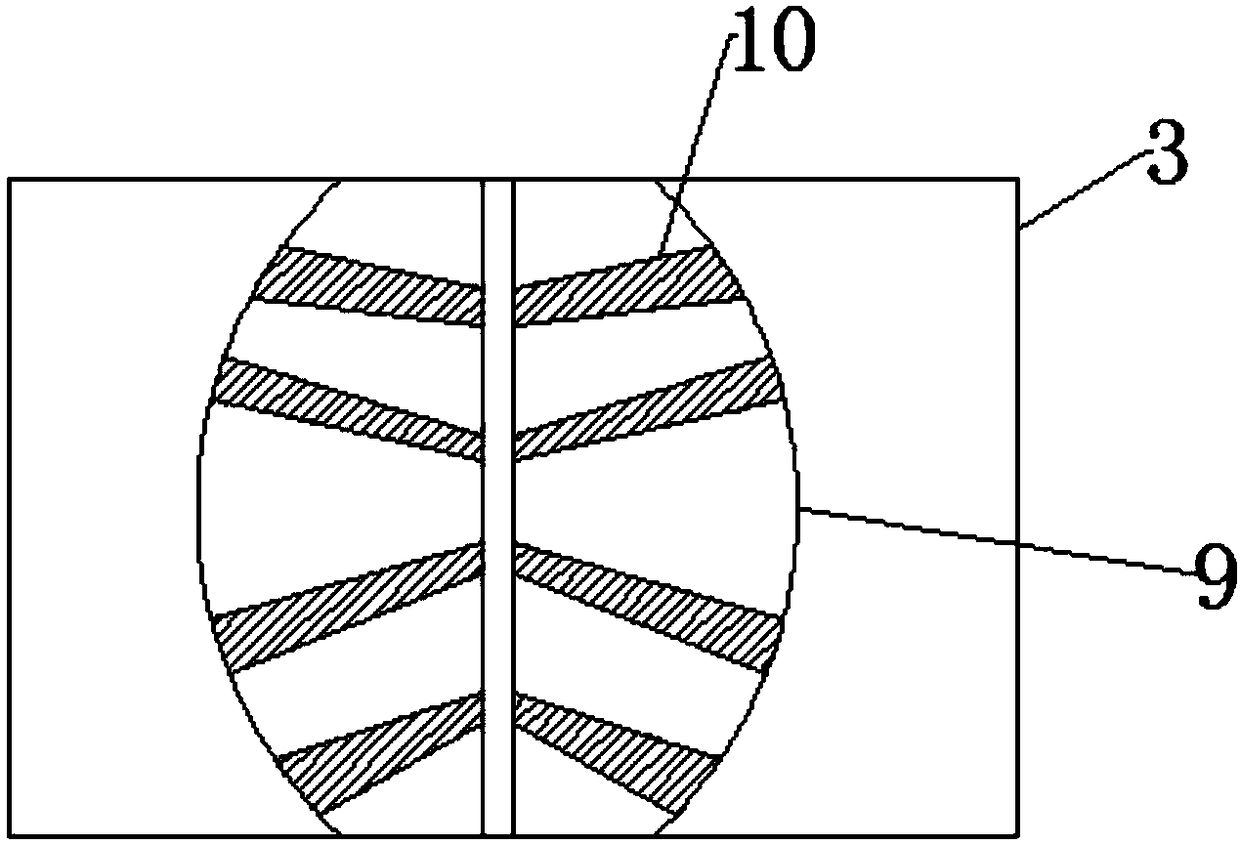

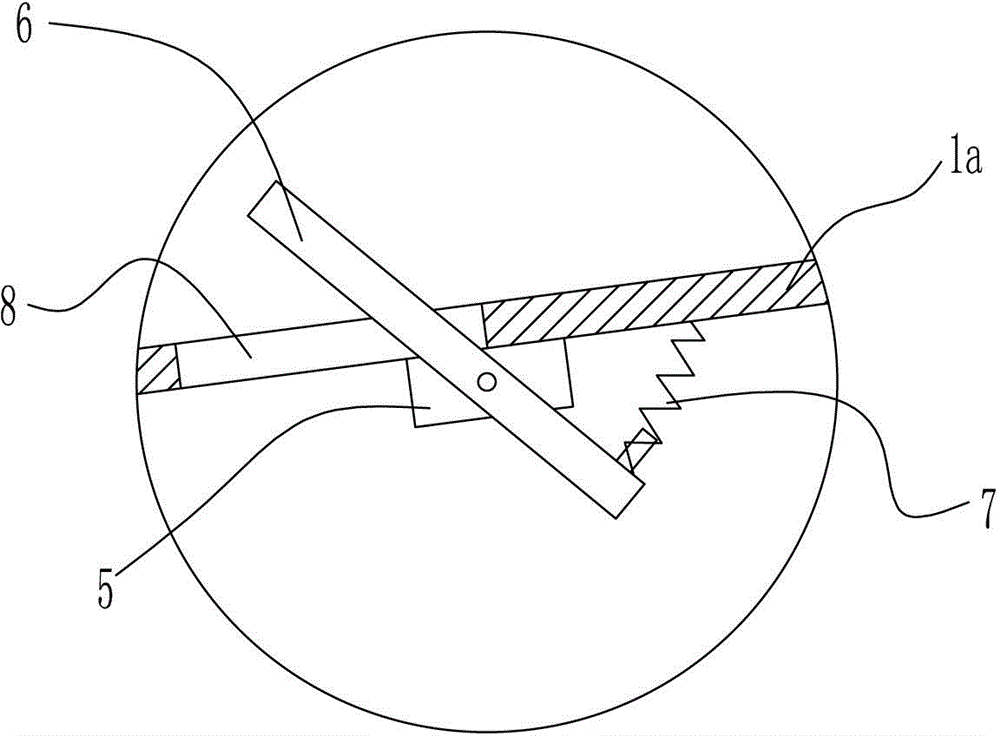

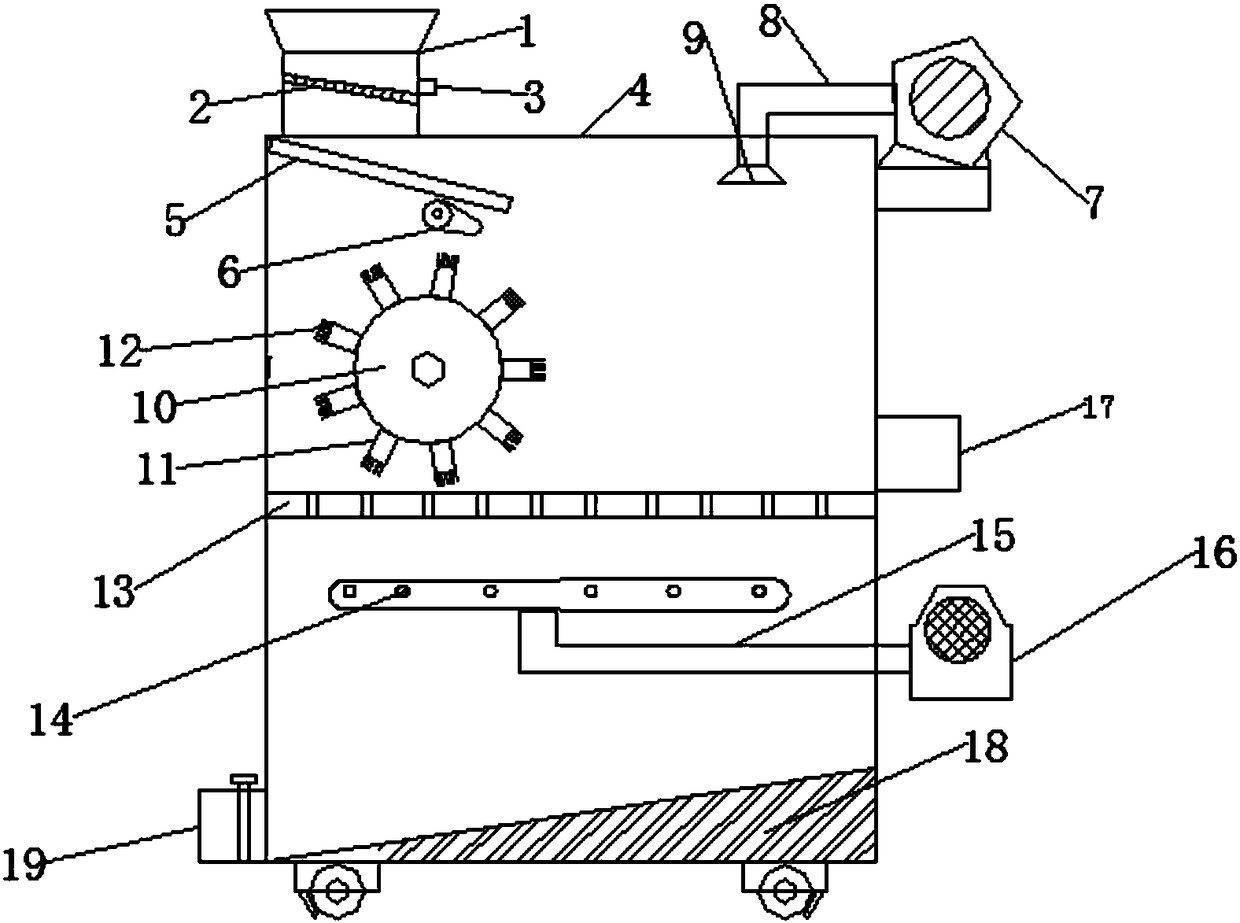

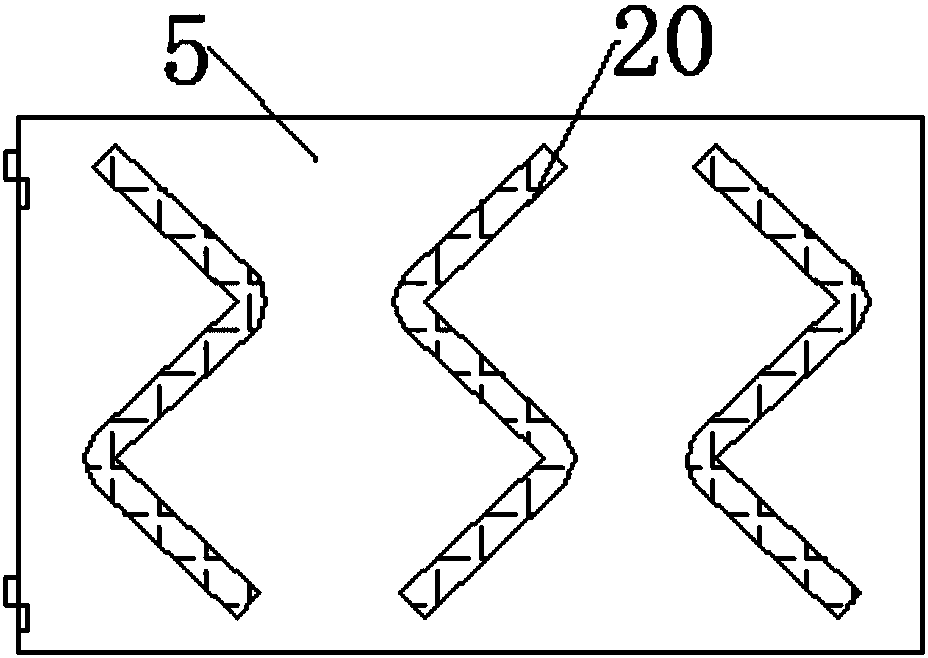

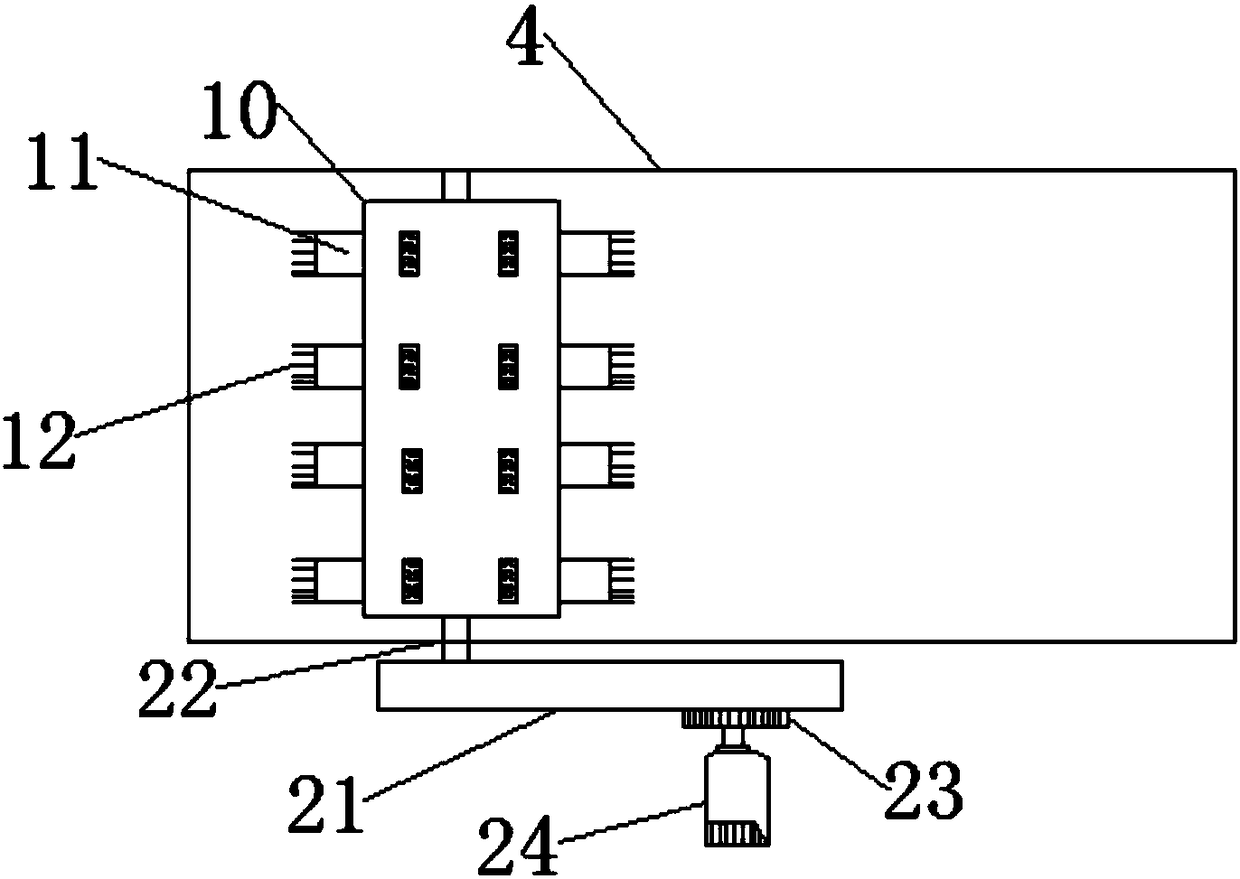

Sand sieving device for civil engineering

The invention discloses a sand sieving device for civil engineering. The sand sieving device comprises a box body, a feeding hopper, a feeding channel, a pulverizing device, a sand sliding plate, a first spring, a sand and gravel rotating fan, a first sieve net, a second sieve net, a second spring, a third motor, a disc, a moving rod, a cross rod, a vertical rod and a hitting ball, wherein the pulverizing device comprises a first motor, a stirring shaft and a pulverizing rod; and the sand and gravel rotating fan comprises a second motor, a mounting shaft, a fan plate and a hot air blower. By arranging the pulverizing device, caking sand and gravel are pulverized, and insufficient sieving is avoided; by arranging the sand and gravel rotating fan, insufficient sieving caused by too-high sandfalling speed is avoided, and at the same time, the sand and gravel are dried, so that the blocking of sieve net holes by the wet sand and gravel and the influence of engineering use are avoided; byarranging the first sieve net, the second sieve net, the third motor, the disc, the moving rod, the cross rod and the hitting ball, multi-stage sieving can be carried out; and by driving the first sieve net and the second sieve net to swing upwards and downwards through cooperation, the sieving efficiency is increased.

Owner:江西同济建设项目管理股份有限公司

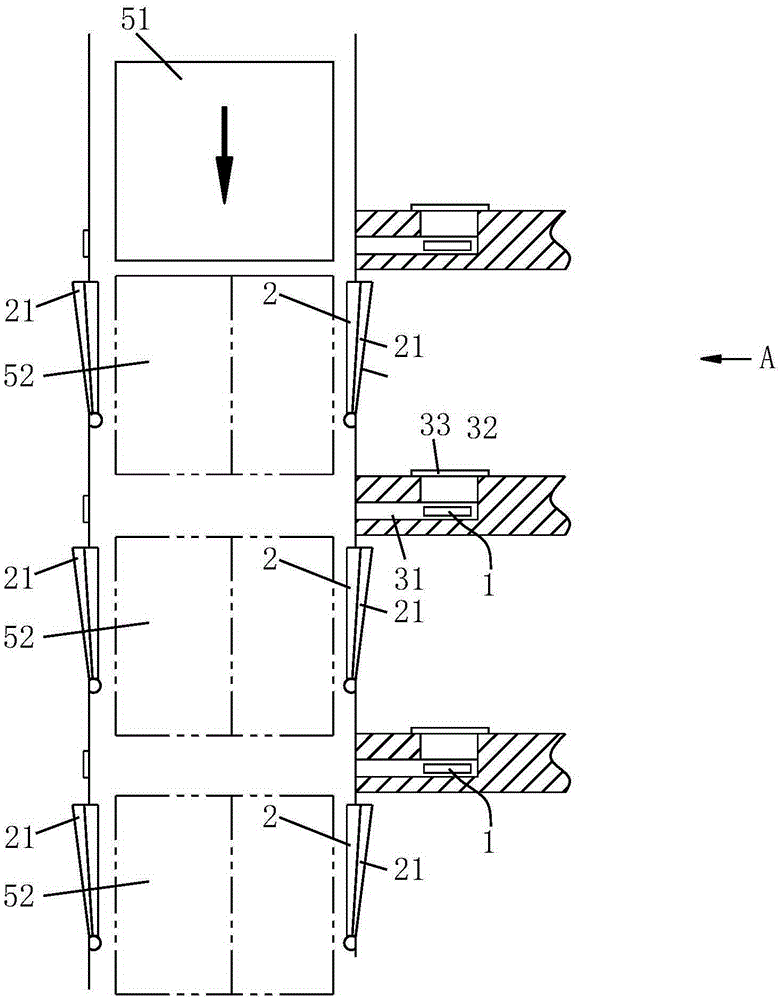

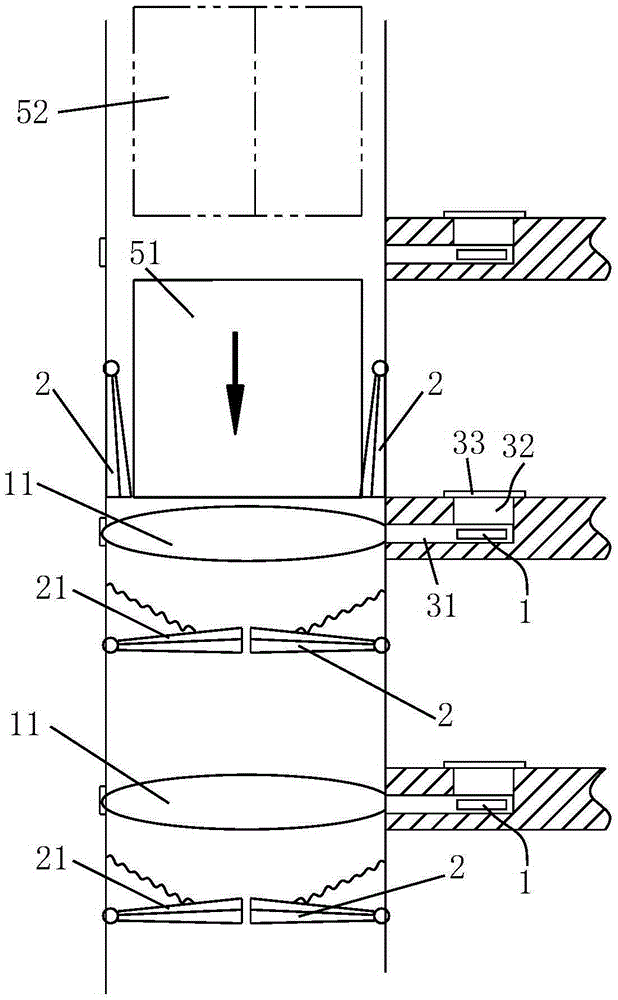

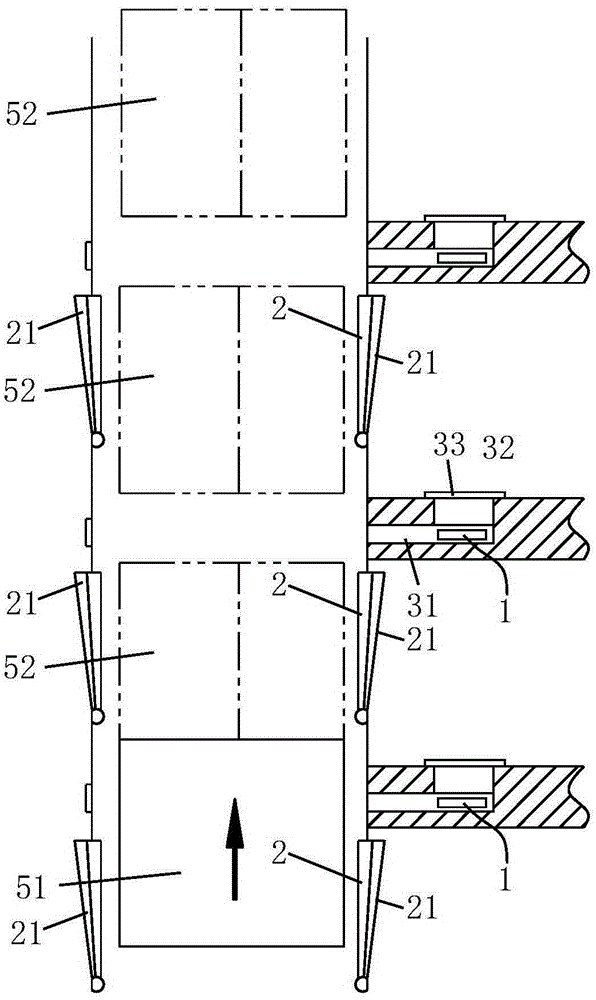

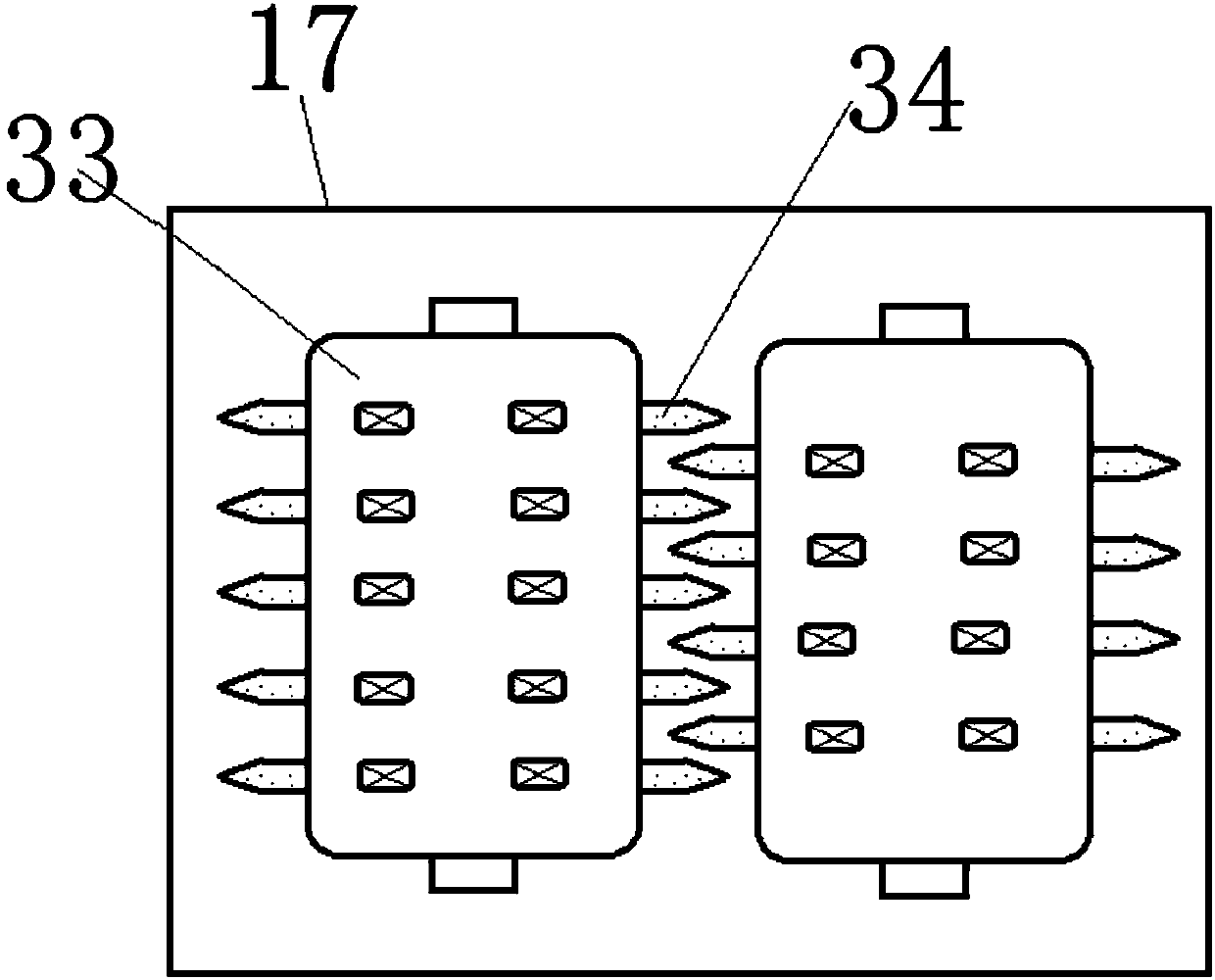

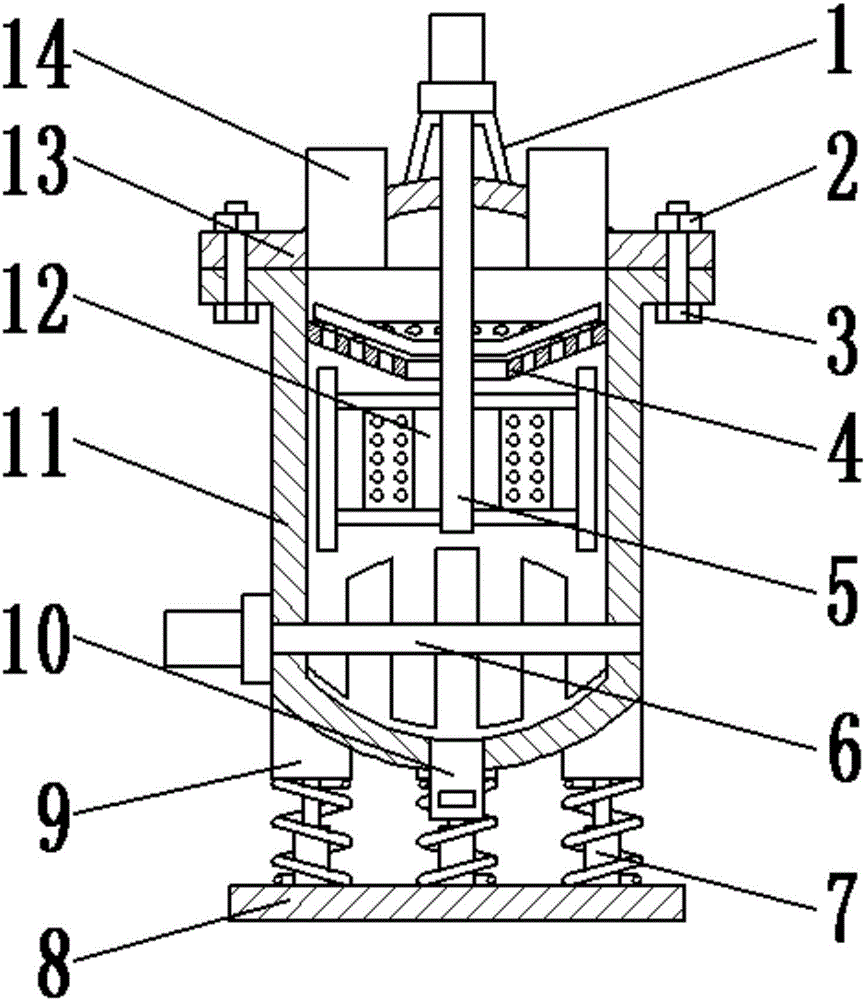

Fall-preventing emergency device for elevator

ActiveCN105253734AReduce falling speedProtect your bodyElevatorsBuilding liftsElectronic controllerEngineering

The invention particularly relates to a fall-preventing emergency device for an elevator, and aims at providing a fall-preventing safety system which is simple in structure, low in cost, safe and reliable, and effectively protects the safety of passengers. The fall-preventing safety system comprises airbag assemblies, wherein each of the airbag assemblies comprises a safe airbag, an air generator, an ignition device and an electronic controller; the airbag assemblies are arranged in accommodating holes which are formed under an elevator gateway and horizontally formed in the side wall of an elevator shaft; grooves are formed in a side wall opposite to the other side with the accommodating holes, of the elevator shaft; a speed sensor and a height sensor are arranged in a lift car; output signals of the speed sensor and the height sensor are transmitted to the electronic controller. According to the fall-preventing emergency device disclosed by the invention, when the lift cars falls, one or a plurality of airbags, which are the closest to the lift car under the lift car act so as to open the airbags, so that the falling speed of the lift car is decreased rapidly until the lift car stops falling; because the fall impact force of the lift car is small, the body safety of the passengers can be protected effectively.

Owner:北京勇搏科技有限公司

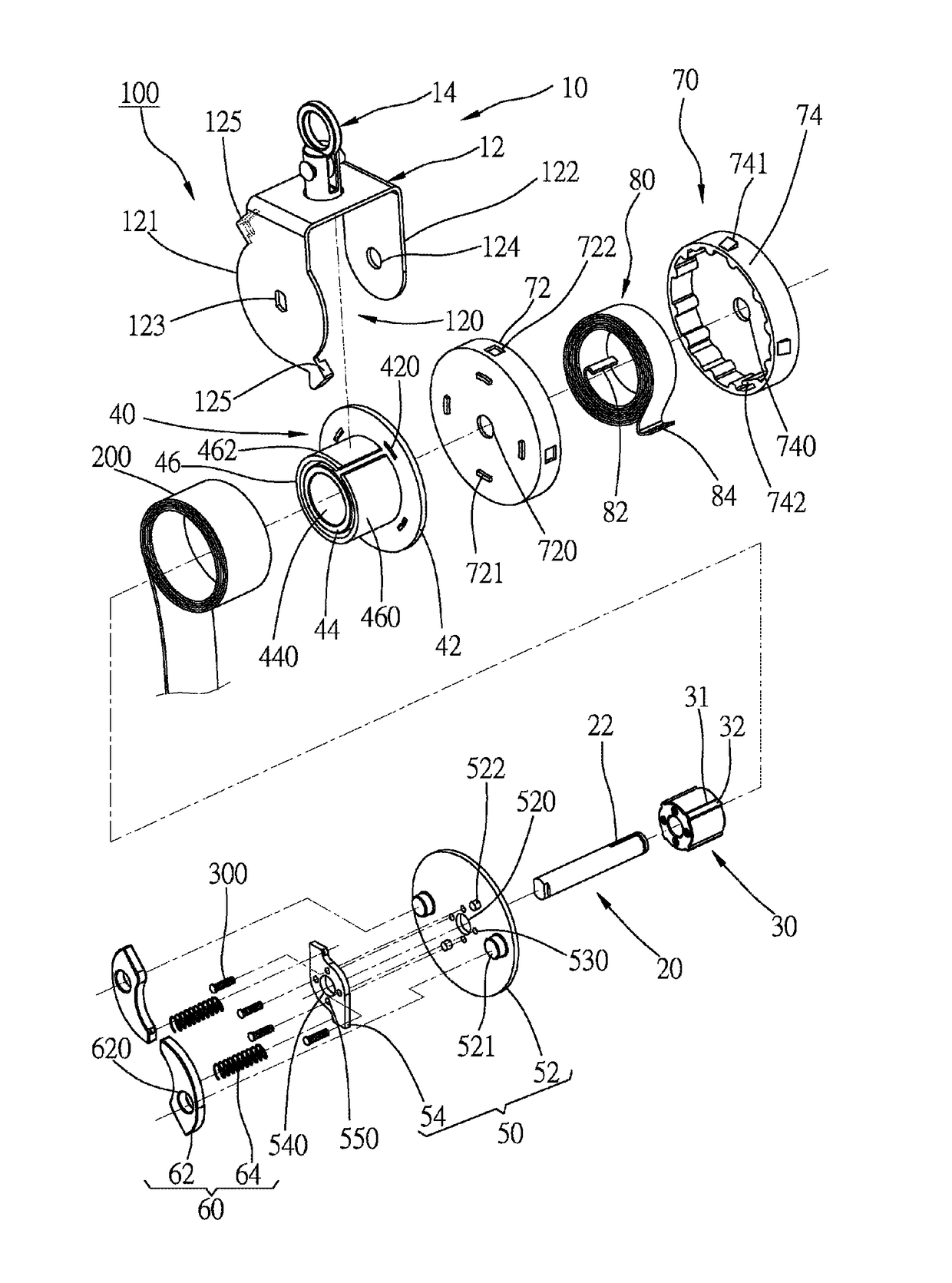

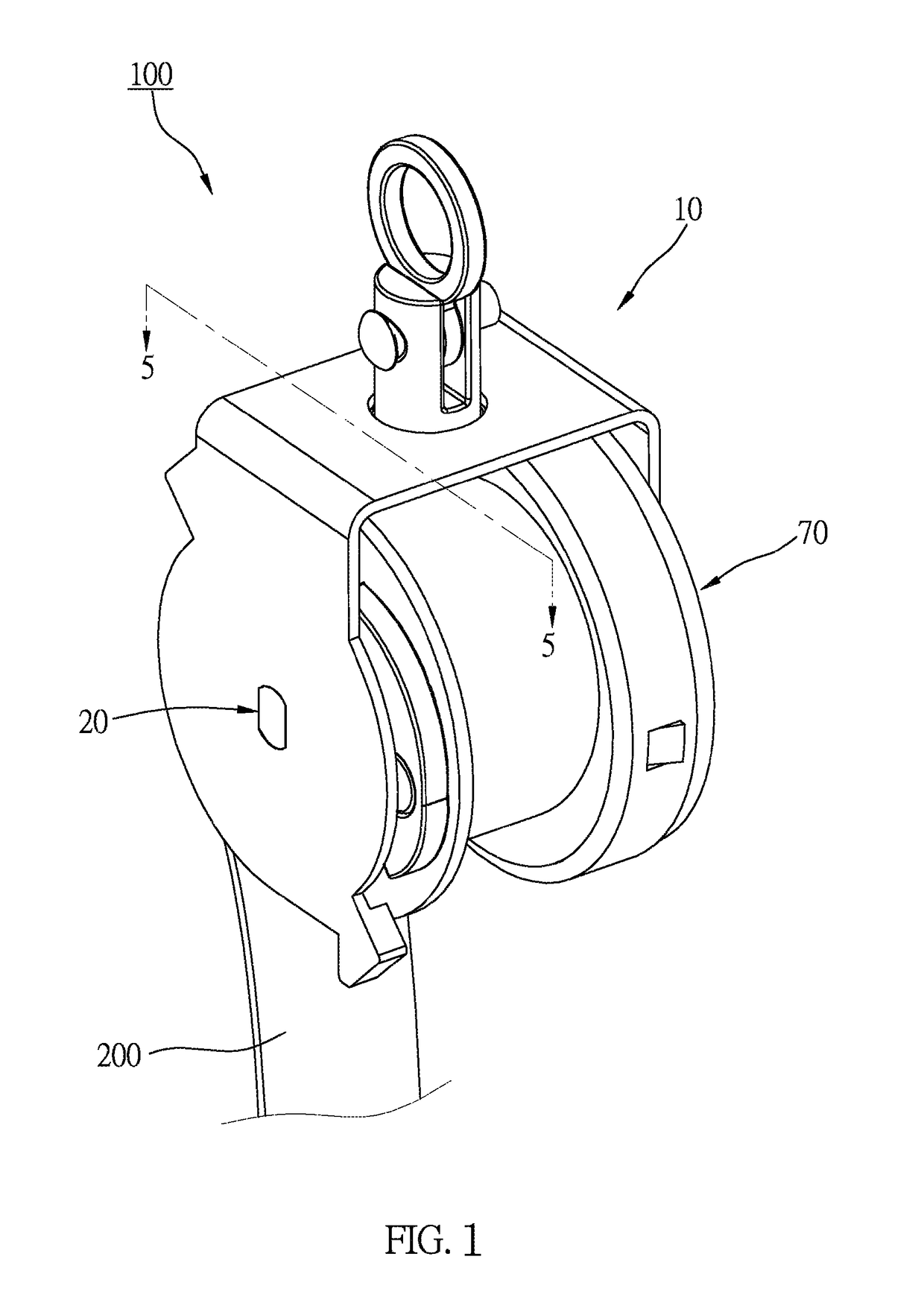

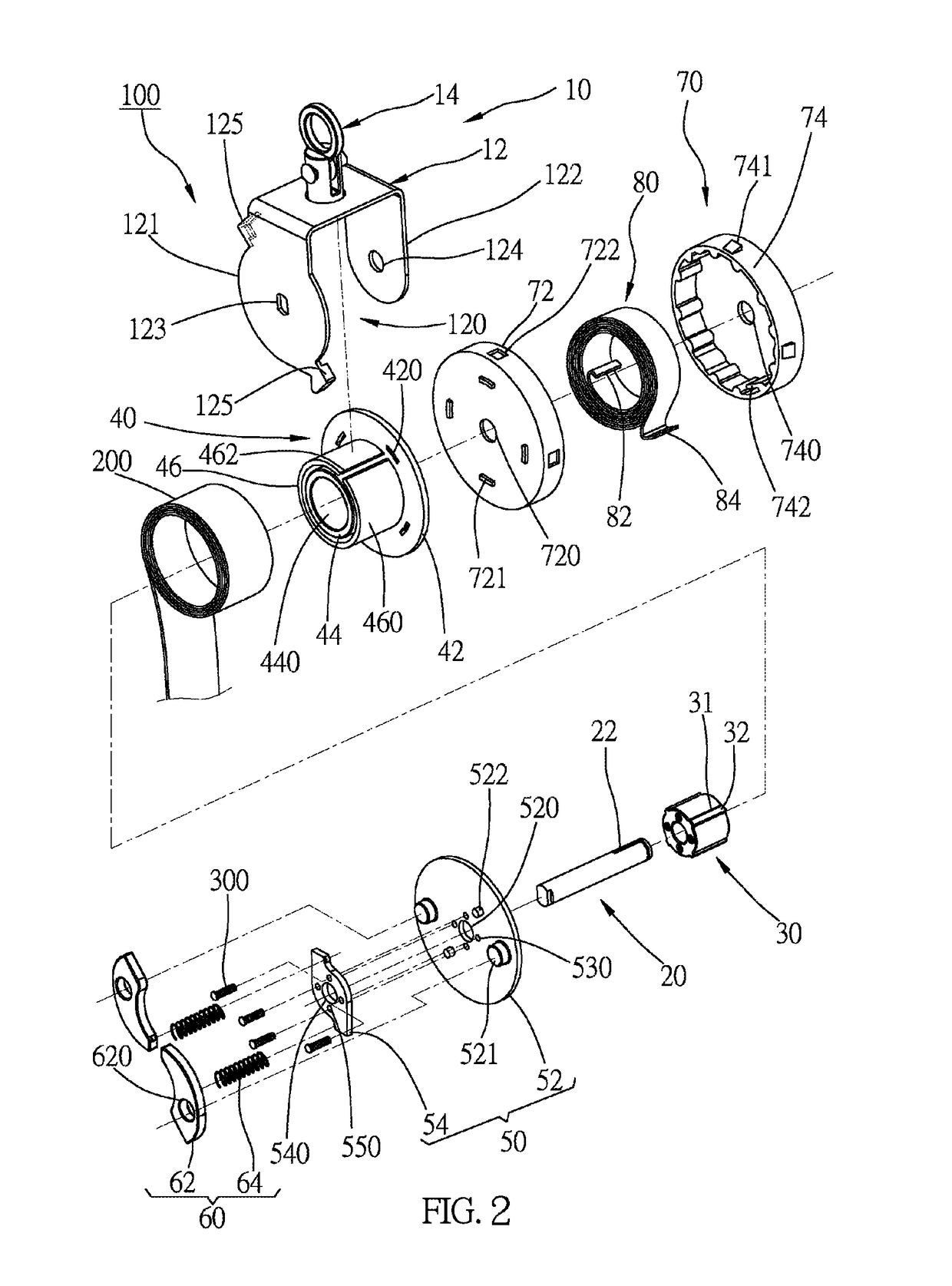

Fall protection device

A fall protection device adapted to be connected to a safety belt is provided, including a frame forming a containing space, a shaft lever provided on the frame, a retard member, and a rotary drum. The retard member is pivotally provided on the shaft lever rotatably, which is received in the containing space, and has a friction surface. The rotary drum is fitted around the retard member, and has an outer surface and an inner surface; the outer surface is adapted to be winded by the safety belt, and the inner surface faces to the friction surface. In a first operating state, the retard member and the rotary drum rotate coaxially. In a second operating state, the rotary drum rotates relative to the fixed retard member. A rotational friction is generated between the friction surface and the inner surface, which slows down the rotational speed of the rotary drum.

Owner:YOKE INDAL CORP

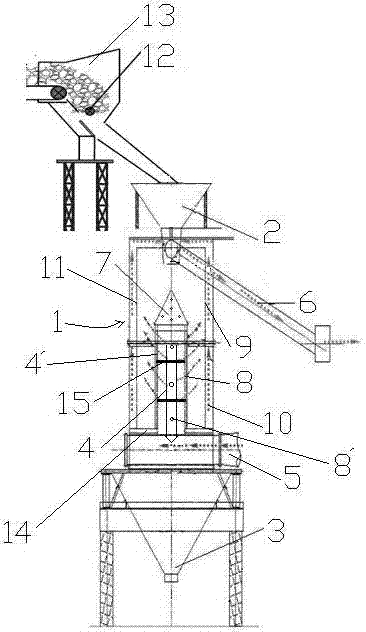

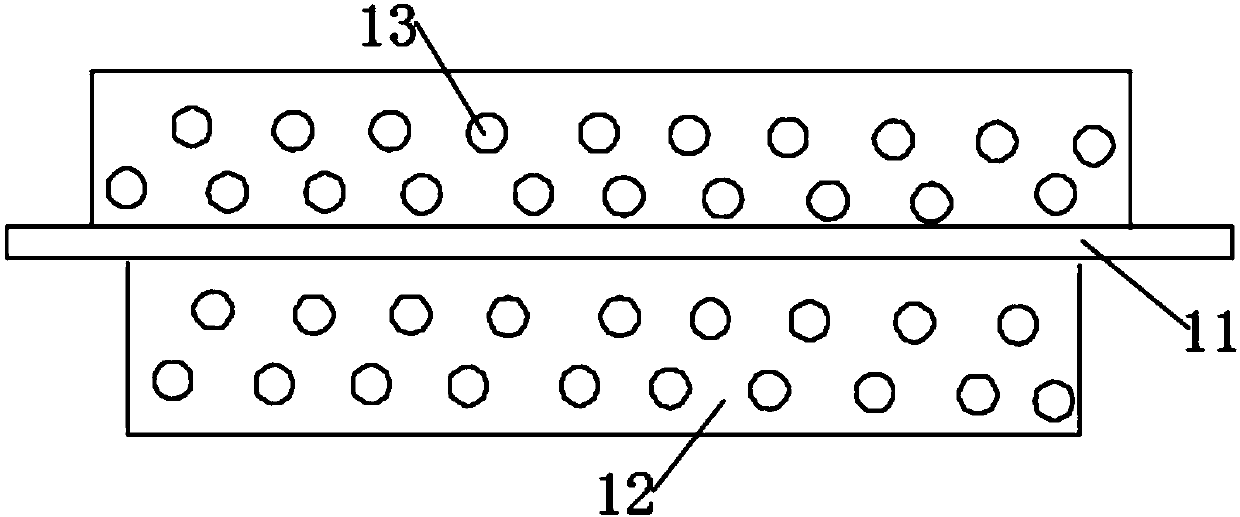

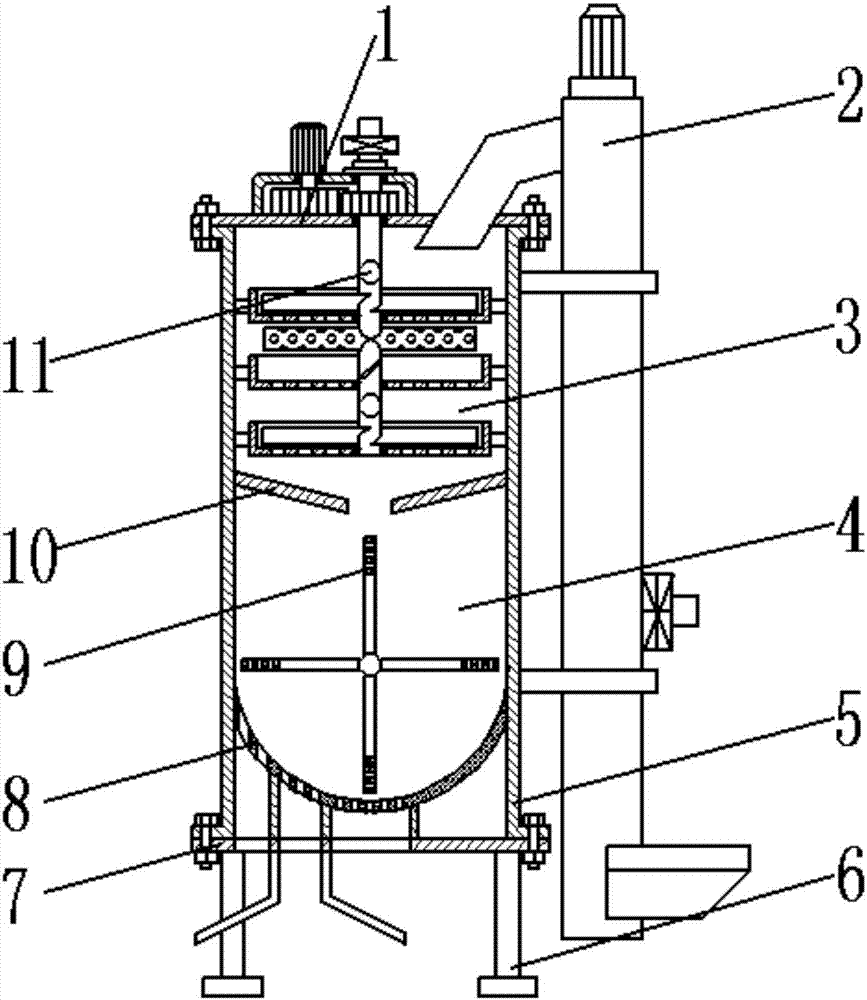

Vertical cooling and waste heat recovery furnace for sinters

ActiveCN103697707AReduce resistanceReduce power consumptionIncreasing energy efficiencyHandling discharged materialCold airFlue gas

The invention discloses a vertical cooling and waste heat recovery furnace for sinters, which comprises a feeding hopper and a discharge hopper, wherein the feeding hopper and the discharge hopper are respectively communicated with the top and the bottom of a cooling chamber; first and second air ducts are sequentially sleeved in the cooling chamber; the walls of the first and second air ducts are respectively provided with a plurality of air outlet holes; the top of the first air duct is provided with a cone distributor; the bottom of the second air duct is communicated with a cold air inlet pipe; the cooling chamber is provided with an inner sleeve; a plurality of vent holes are distributed in the wall of the inner sleeve; a hot air collecting cavity is formed between the inner sleeve and a housing of the cooling chamber; the upper part of the hot air collecting cavity is communicated with a hot waste gas exhaust pipe; and the bottom of the hot air collecting cavity is communicated with the discharge hopper. The invention provides a cooling system integrating sinter cooling with closed hot flue gas recovery and waste heat utilization; the vertical cooling and waste heat recovery furnace for the sinters operates under a negative pressure in the cooling process; emission of pollutants can be greatly reduced; the field environment is improved; and the heat recovery rate is improved.

Owner:铜陵市富鑫钢铁有限公司

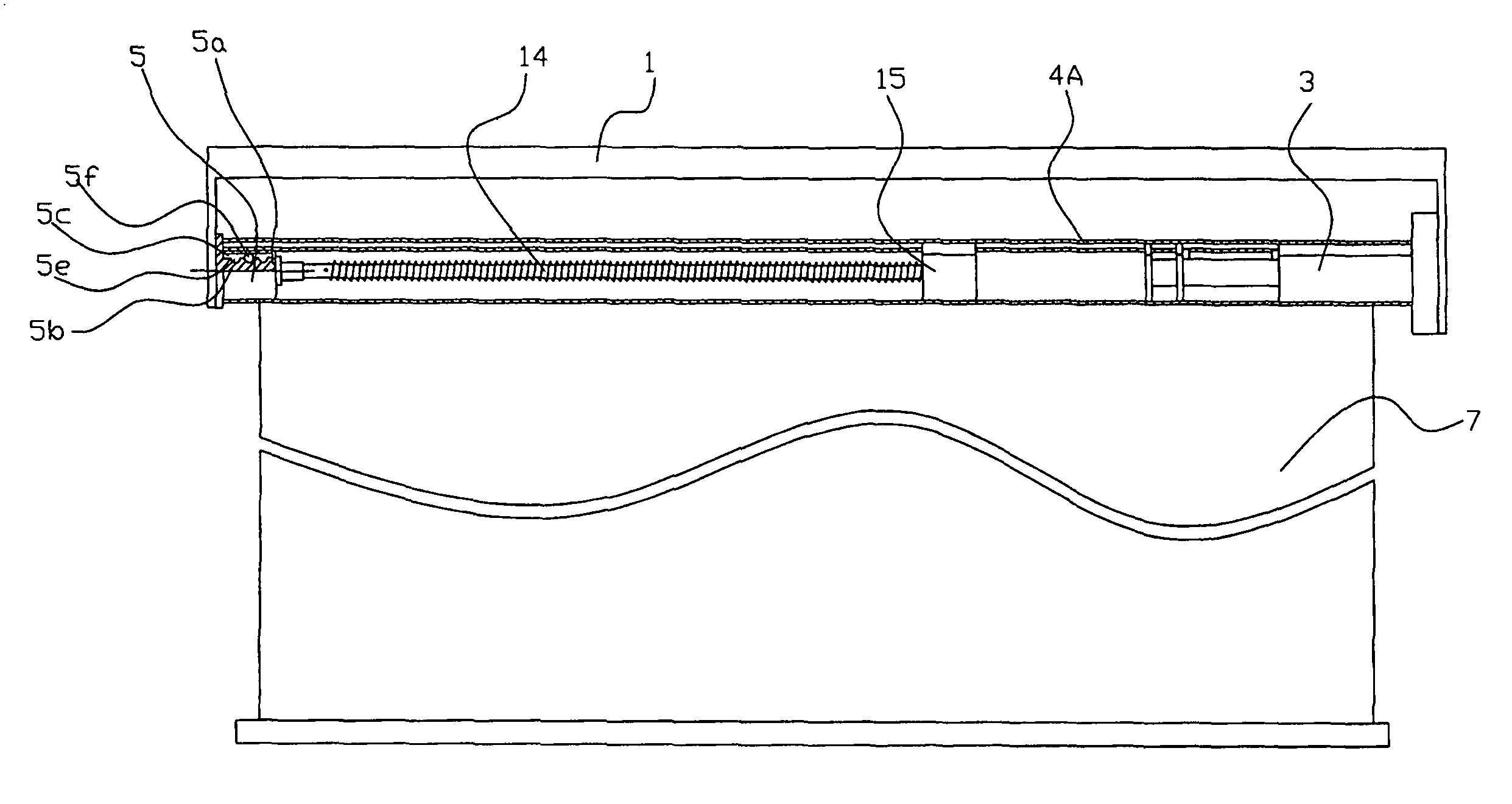

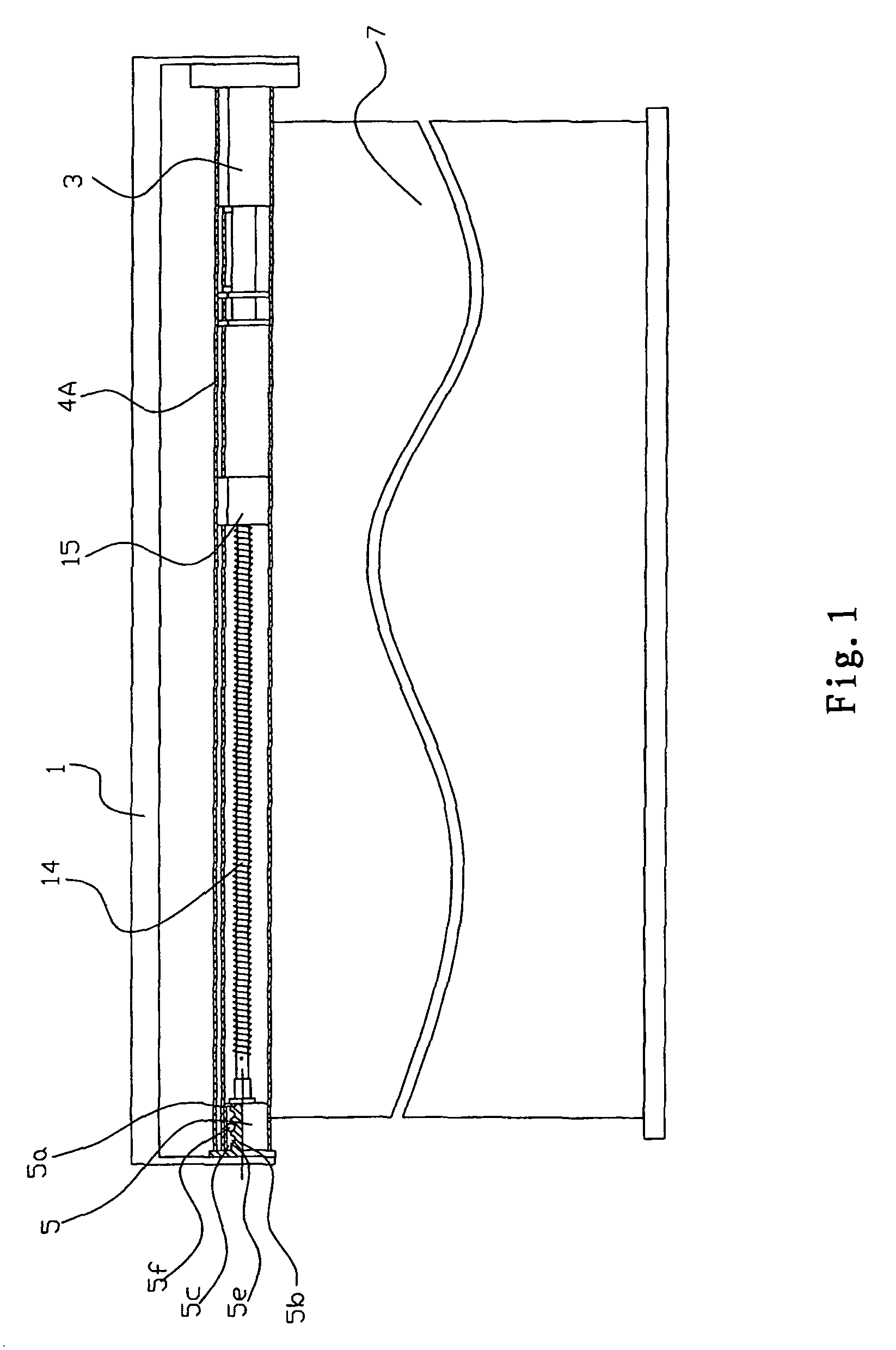

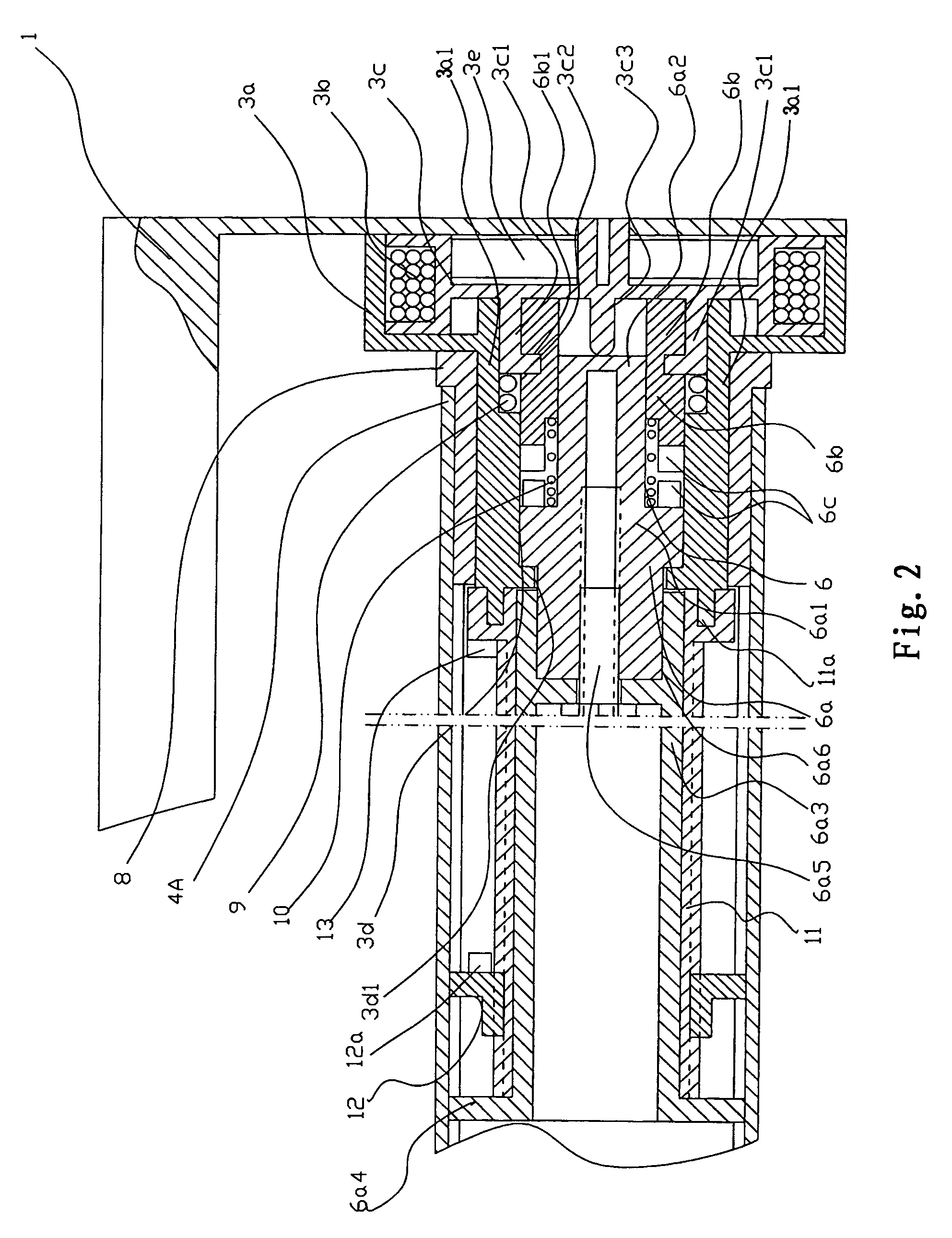

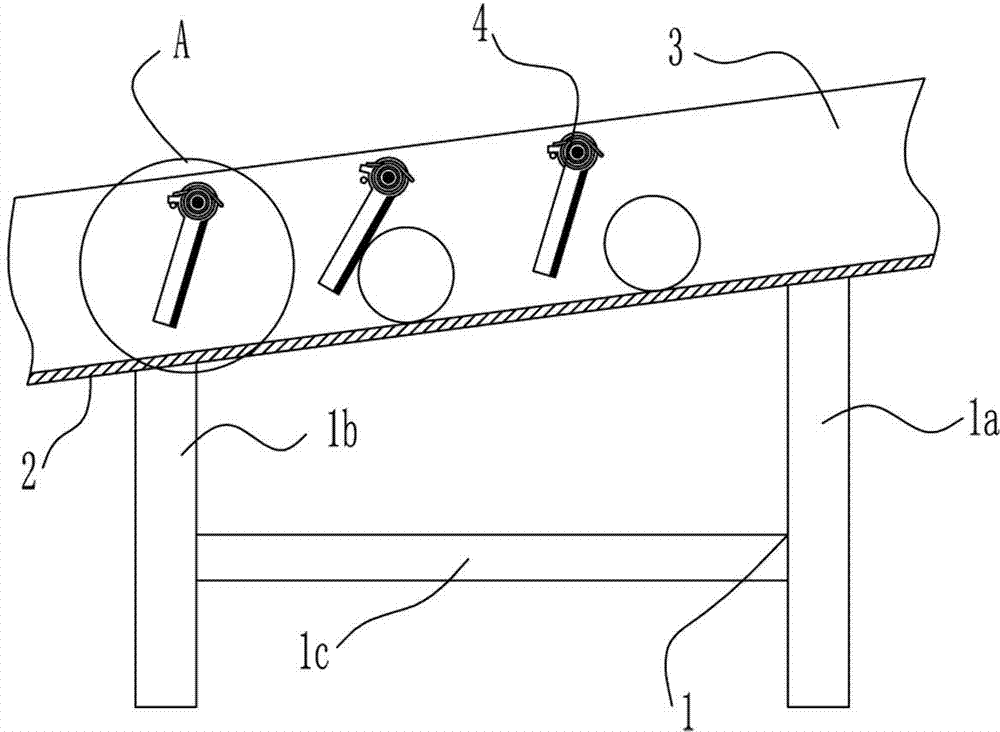

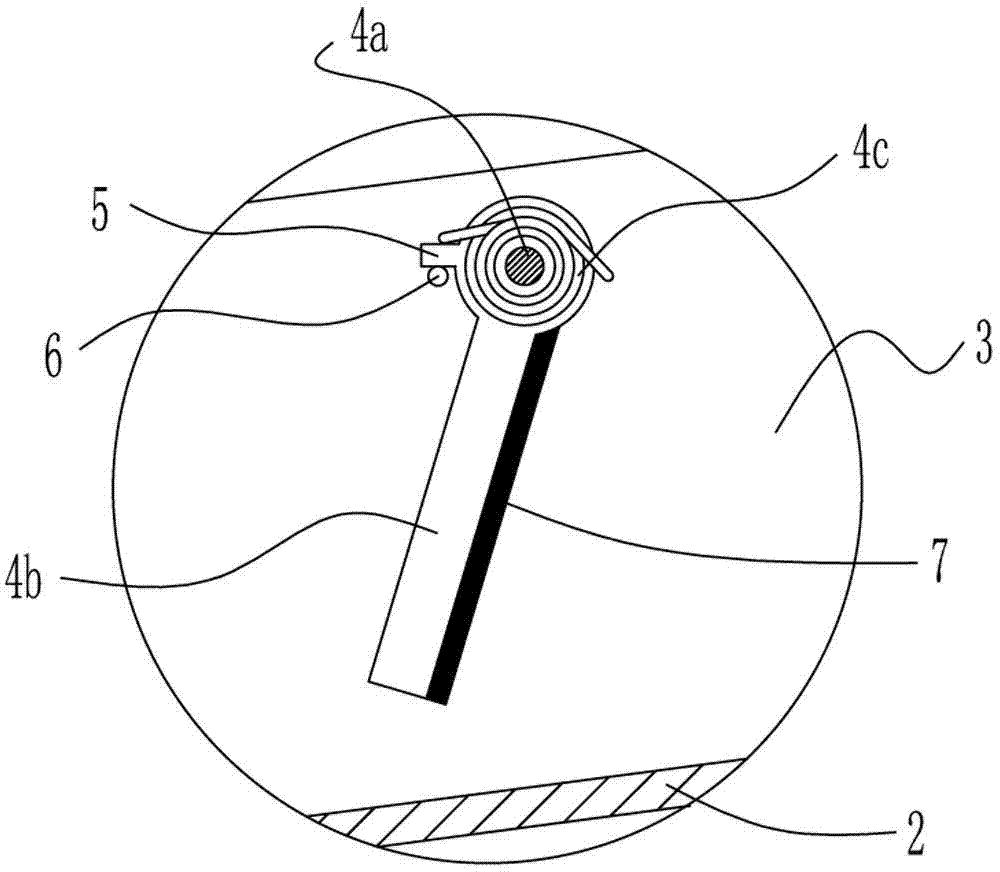

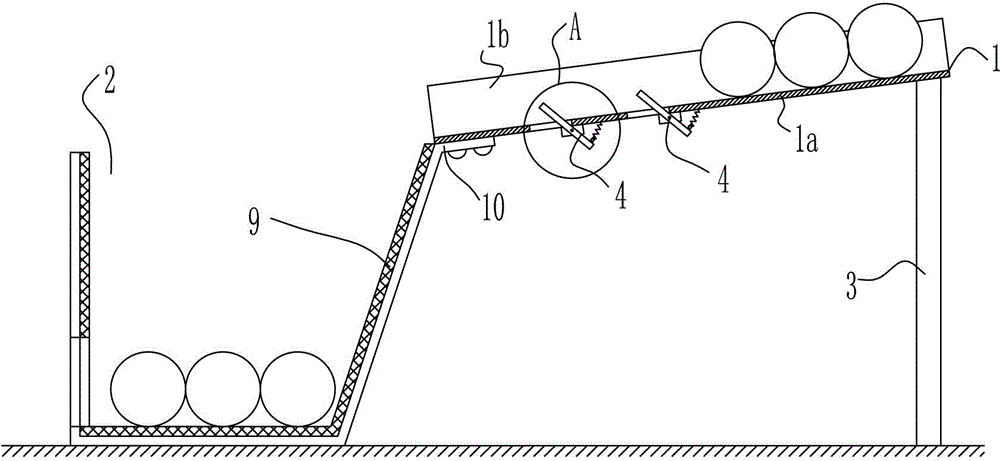

Curtain

A curtain includes a curtain bracket (1) having an end to which a rotation driving device (3) is mounted. The rotation driving device (3) can actuate a curtain reeling drum (4A) to rotate a curtain cloth (7) or actuate a reeling rope device (4) to rotate a curtain cloth or shade (7). A reverse rotation releasing device (5) and a resilience reverse rotation mechanism (14) are connected to the rotation driving device (3). The rotation driving device (3) is comprised of a pull rope rotary disc (3c), a unidirectional clutch device (6) connected to the pull rope rotary disc (3c), and a rewinding spring (3e) mounted between the pull rope rotary disc (3c) and a pull rope rotary disc box (3a). Thus, only one cord is sufficient to control opening of the curtain cloth or shade (7), and reverse rotation of the curtain reel drum (4A) is not adversely affected by the rotation driving device (3). It is convenient to use while avoiding injury to children.

Owner:ZHU XIANGRONG

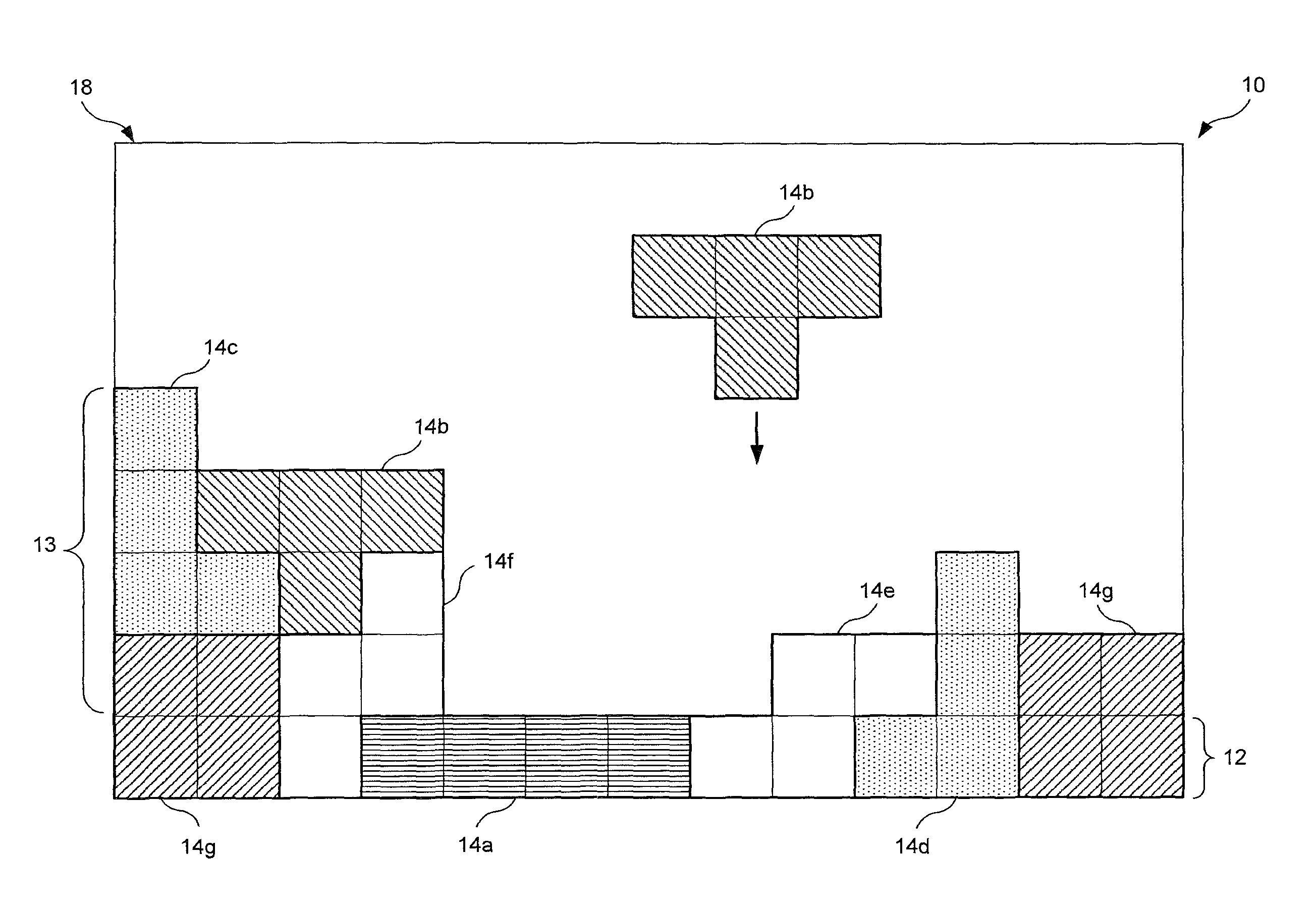

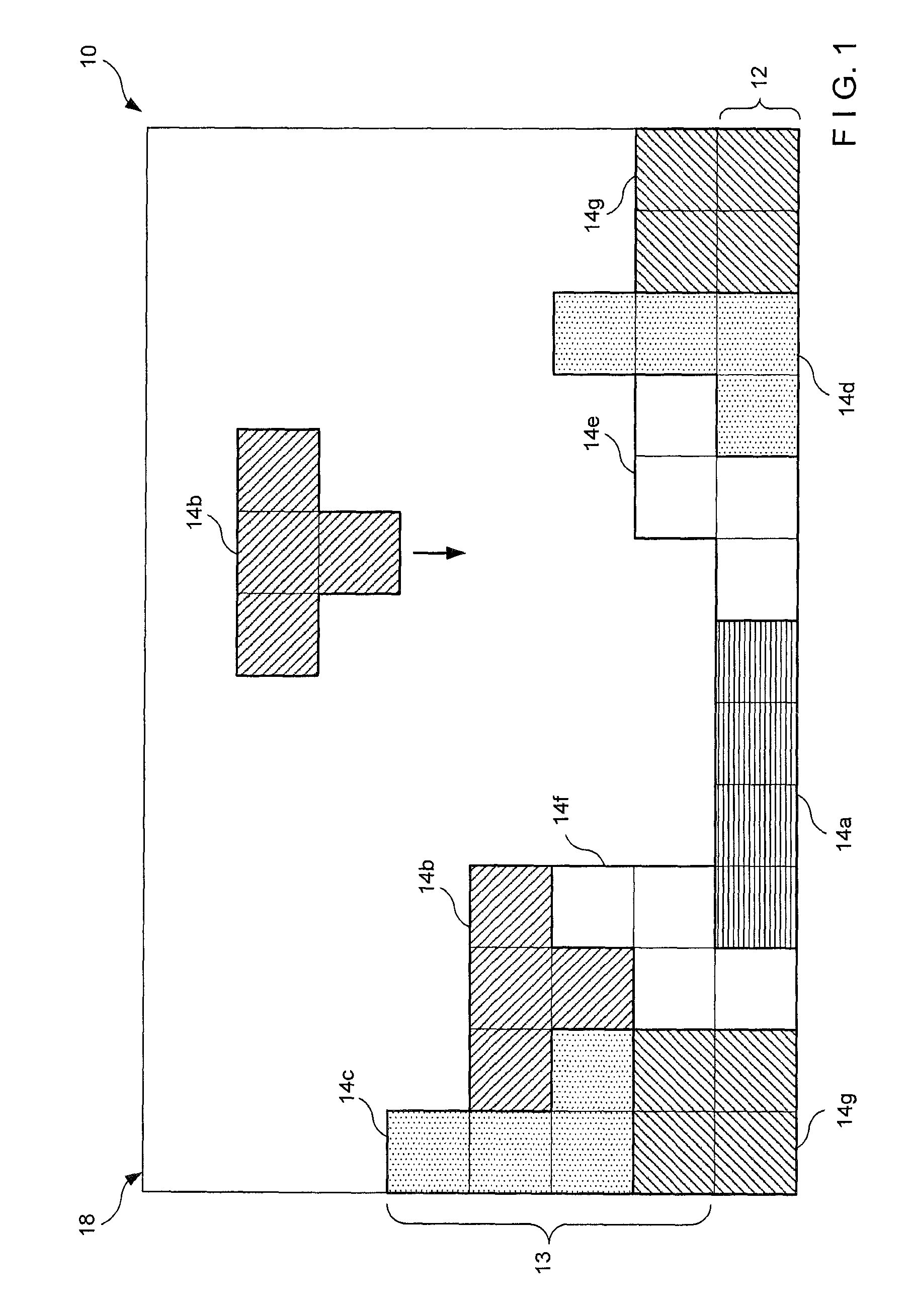

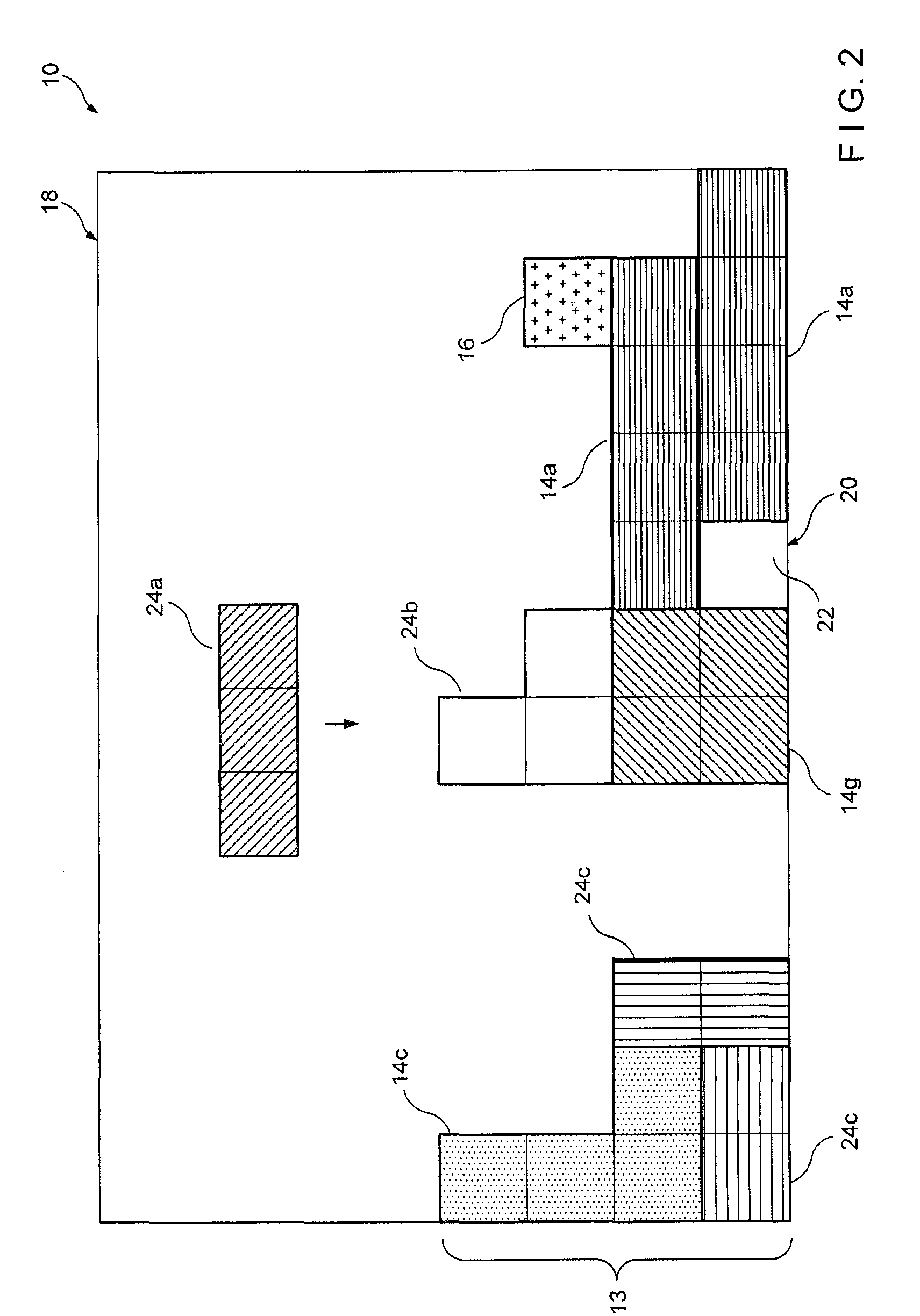

Video game systems and methods for providing software-based skill adjustment mechanisms for video game systems

ActiveUS8313370B2The implementation process is simpleReduce the overall heightVideo gamesSpecial data processing applicationsSkill setsGame play

Video game systems and methods provide one or more software-based skill adjustment mechanisms for video game systems to adjust a difficulty level of the video games based on an existing skill level or game play of a player. The difficulty level of the video games is adjustable to correspond to an existing skill level of the player for removing digital blocks from a digital matrix, clearing digital complete horizontal lines from the digital matrix and / or avoiding game ending conditions. The difficulty level of the video game may be adjusted to facilitate skill-building game play for the player. The difficulty level of the video games is adjustable during game play that is approaching or leading to a game ending condition via software for one or more primary and / or secondary skill adjustment mechanisms. The one or more primary and / or secondary skill adjustment mechanisms include matrix dimension adjustments, line clear adjustments, level and fall speed adjustments, piece adjustments and / or a top-out, lock-out and / or block-out meter.

Owner:TETRIS HLDG

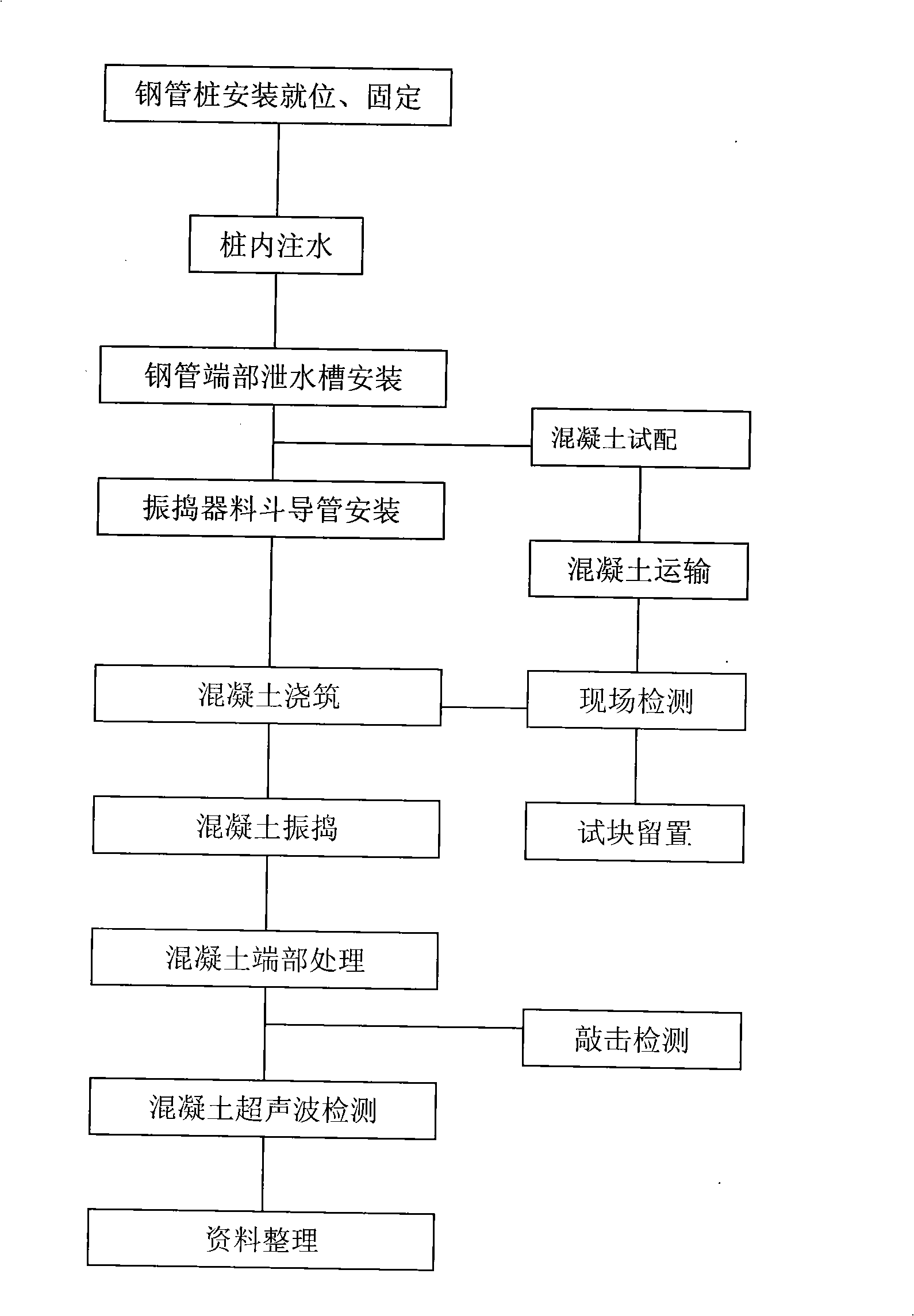

Construction method of steel pipe concrete column

InactiveCN101319550AImprove compactnessReduce air bubblesStrutsCeramic shaping apparatusSteel tubeAir bubble

The invention relates to the building field. The invention relates to a construction method for a concrete filled steel tubular column, comprising the following steps that: a tube is filled with water at first, and then a tremie is put down to the bottom of a pile; concrete is poured into the steel tube by a hopper through the tremie, and a vibrating tamper which is attached to the outerwall of the tube performs concrete vibrating when placing is performed simultaneously; primary concrete placing is performed until the height is 3 to 5 meters on the upper side of a nozzle of the tremie, and the tremie is lifted and guaranteed that the embedding depth of the tremie in concrete is not less than 2 meters; secondary concrete placing is performed, and the vibrating tamper which is attached to the outside of the tube on the bottom layer is started; lifting and placing are repeated, and the concrete is placed to the top of the column; and laitance is removed. The construction method solves the problem of the separation phenomenon caused by overhigh concrete placing height, increases the compactness of the concrete, reduces the number of air bubbles, has small shrinkage clearance between the concrete and the steel tube, can well give play to the function of stress, is convenient in construction, is mechanized, and is simple and convenient in operation. Moreover, the quality can be guaranteed; the equipment is saved by 30 percent; the stability is strong; and 50 percent of raw steel materials and 35 percent of the concrete are saved when the steel tube and the concrete are under same stress, thereby the production cost is effectively reduced.

Owner:DALIAN SANCHUAN CONSTR GROUP

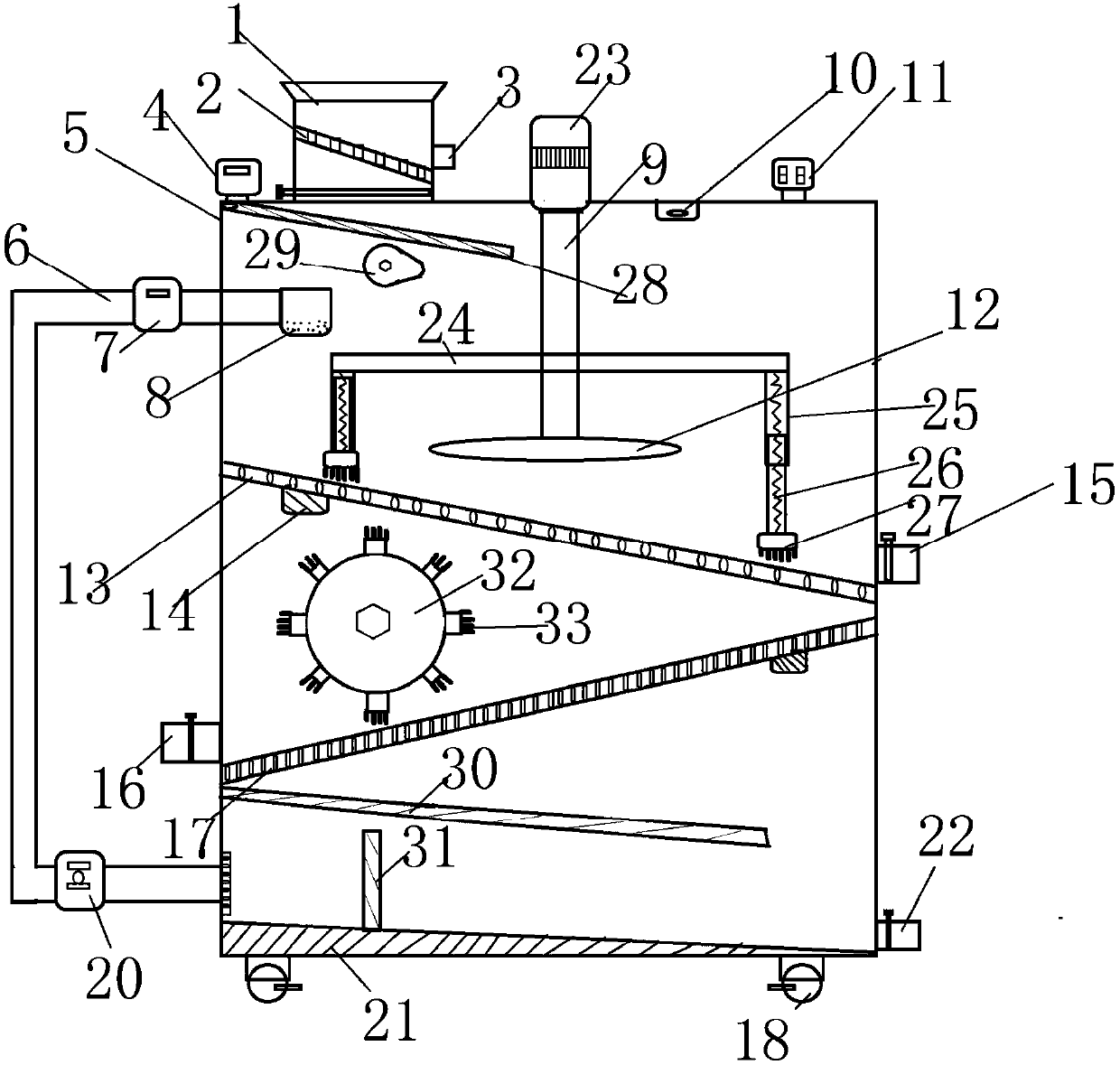

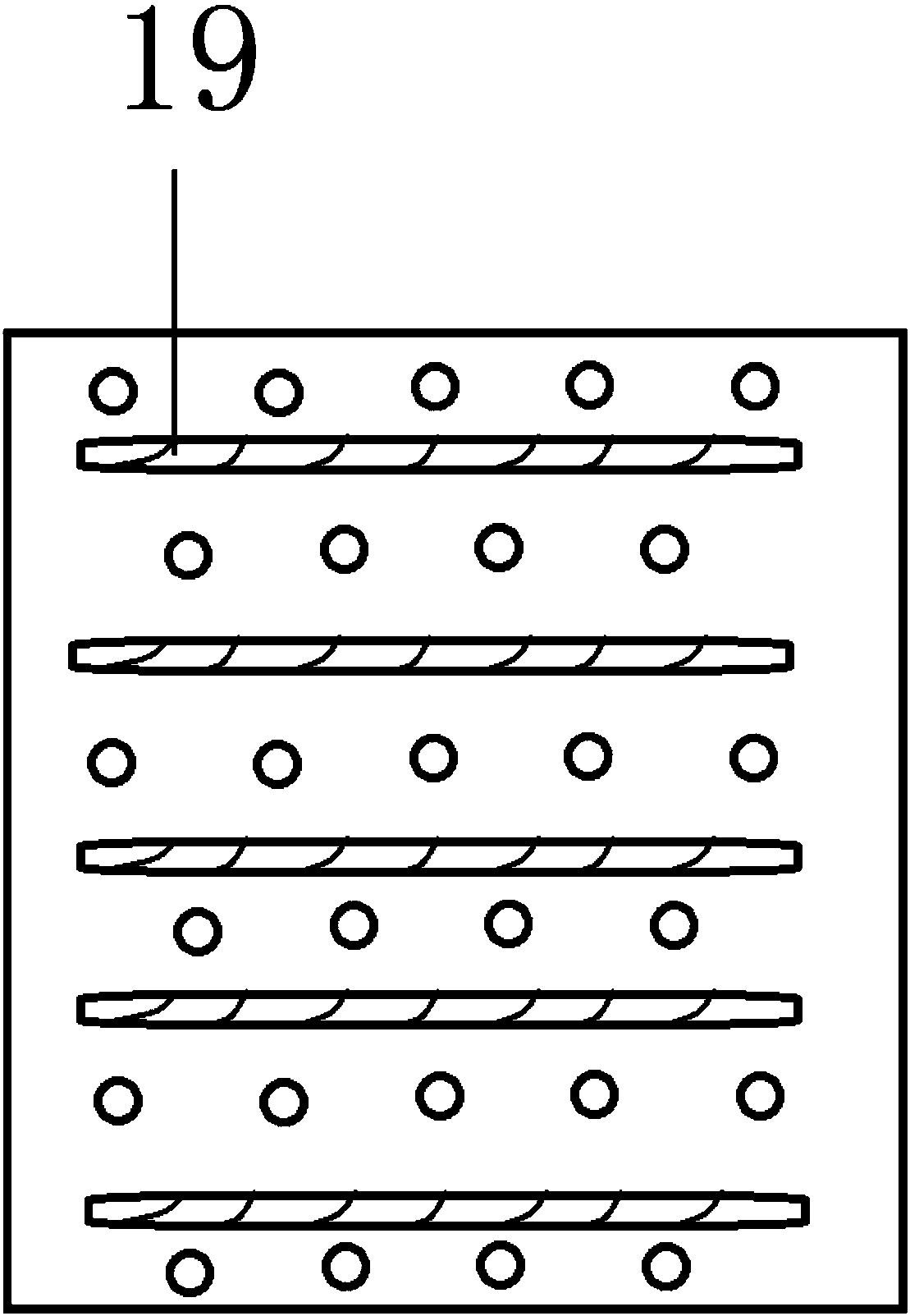

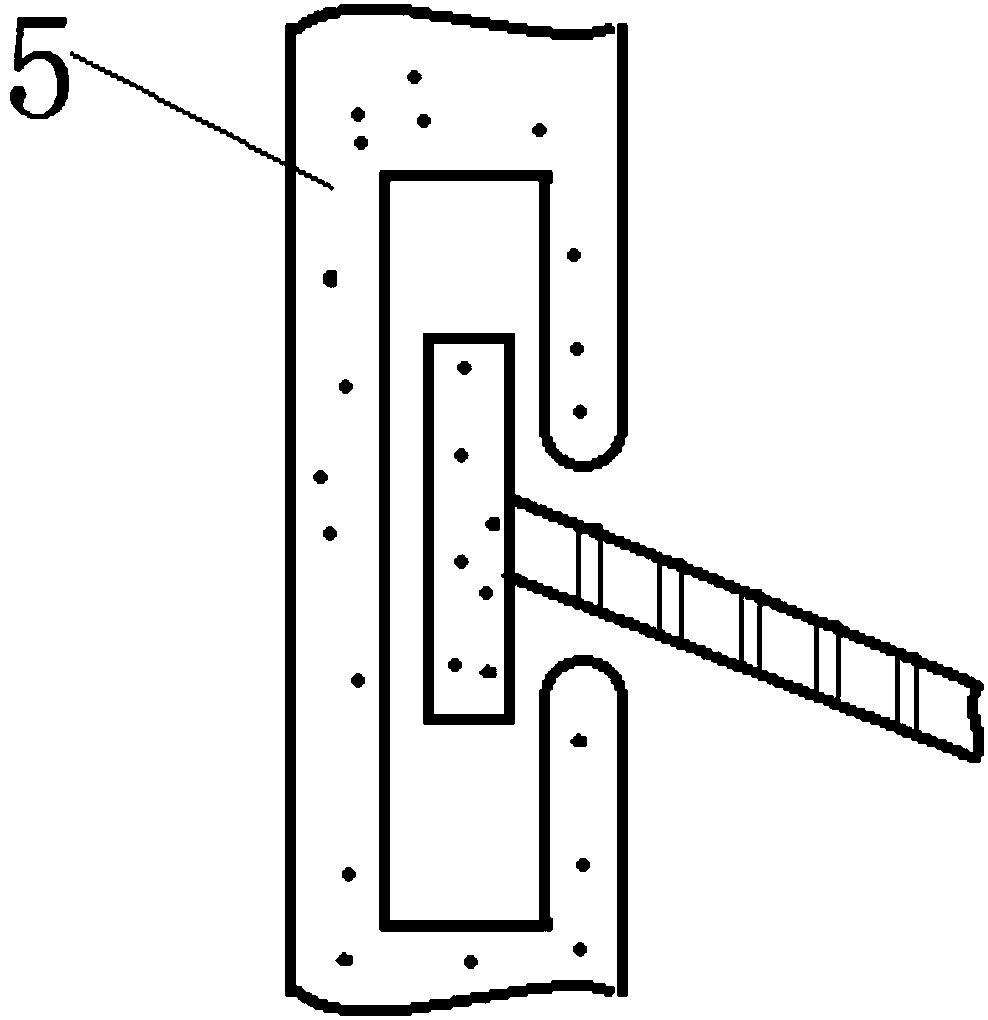

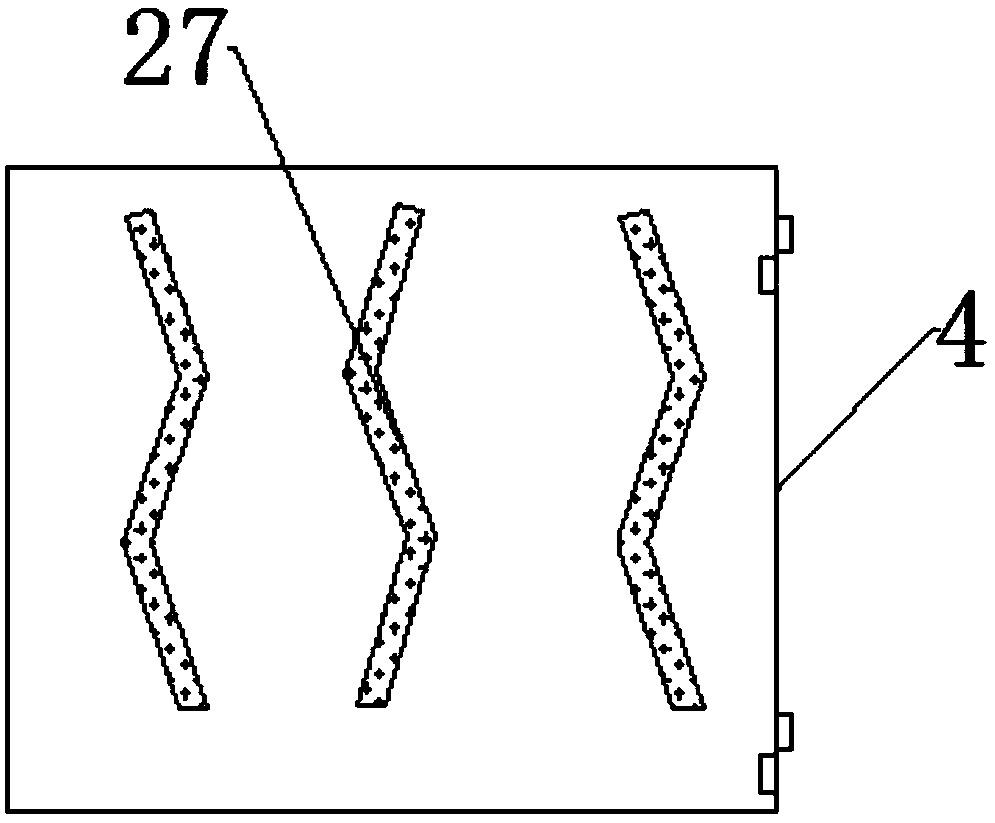

High-efficiency graded screening and cleaning device for construction sand and gravel

InactiveCN107931124AReduce falling speedAffect cleanlinessSievingGas current separationImpellerArchitectural engineering

The invention discloses a high-efficiency graded screening and cleaning device for construction sand and gravel. The high-efficiency graded screening and cleaning device for construction sand and gravel comprises a feed pipe, a grid, a liquid level meter, a tank, a water inlet pipe, a flow meter, a sprayer, a rotary shaft, a camera, a timer, an impeller, a screen plate, a vibrator, a coarse sand discharge pipe and a fine sand discharge pipe, wherein the feed pipe is arranged at the top end of the tank; the grid is arranged in the feed pipe obliquely; the lowest end of the grid is provided withan impurity discharge pipe; the tank is provided with the liquid level meter and communicates with the water inlet pipe; the outlet end of the water inlet pipe is provided with the sprayer; the flowmeter is installed on the water inlet pipe; the camera is arranged on the inner wall of the top end of the tank; the rotary shaft is arranged in the tank and provided with the impeller; the screen plate is obliquely arranged in the tank; the vibrator is arranged on the lower surface of the screen plate; and the screen plate comprises a first screen plate body and a second screen plate body. The high-efficiency graded screening and cleaning device for construction sand and gravel is used for screening sand and gravel, improves the working efficiency, saves time and labor, and is simple in structure, convenient to use and beneficial to popularization.

Owner:郑诗永

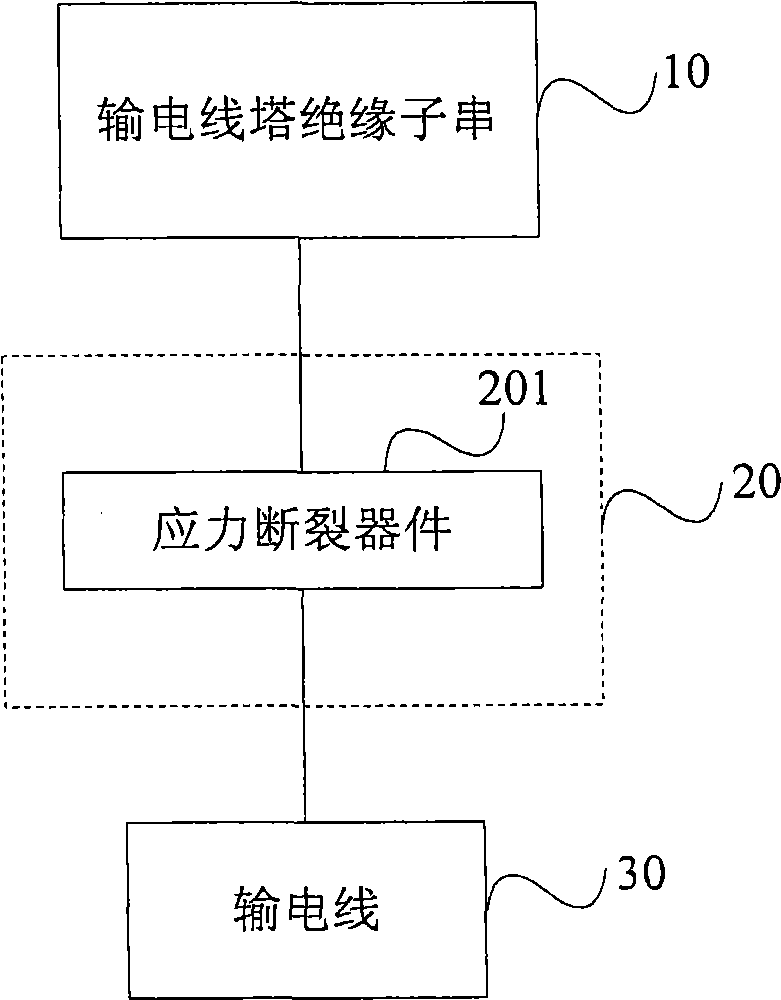

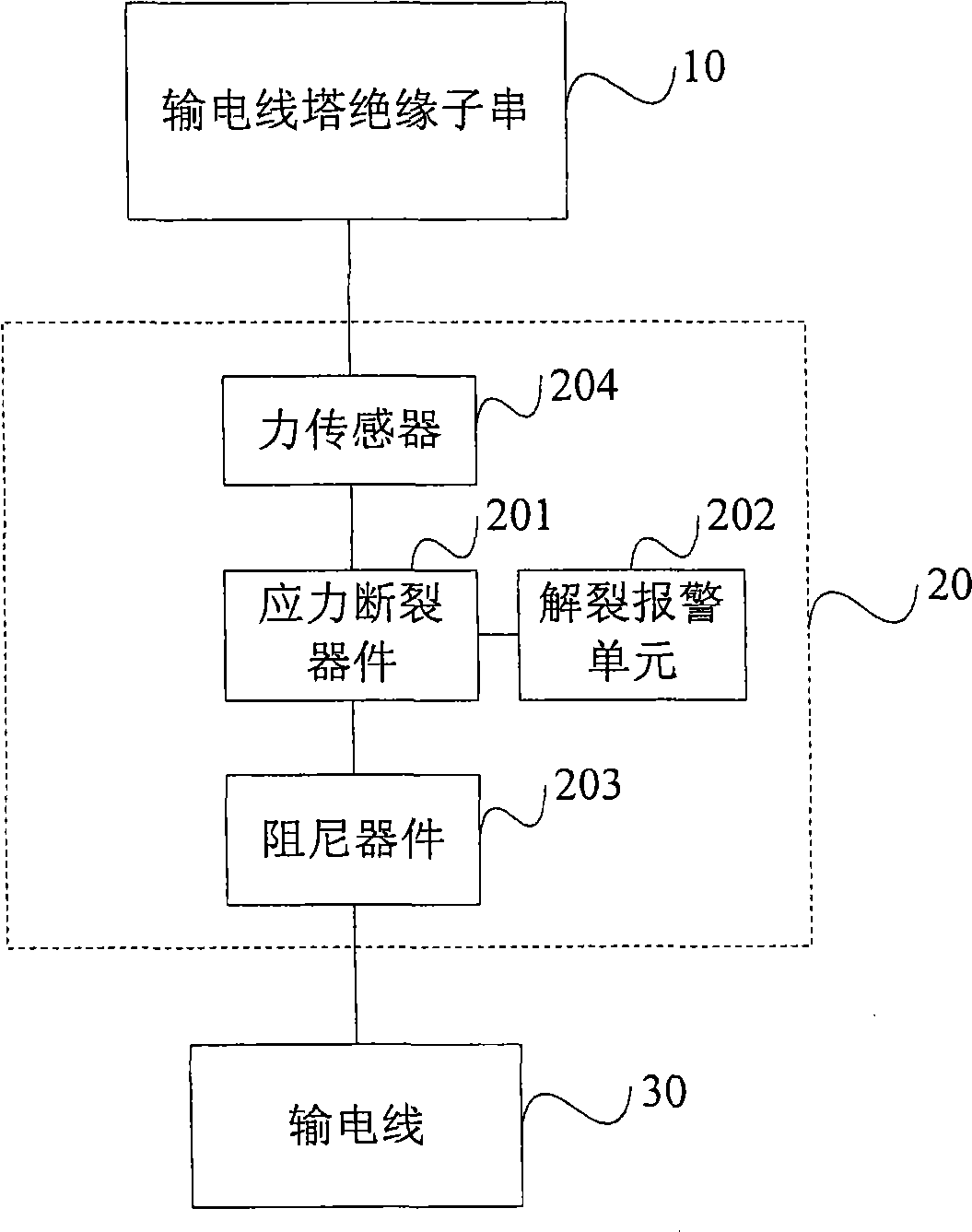

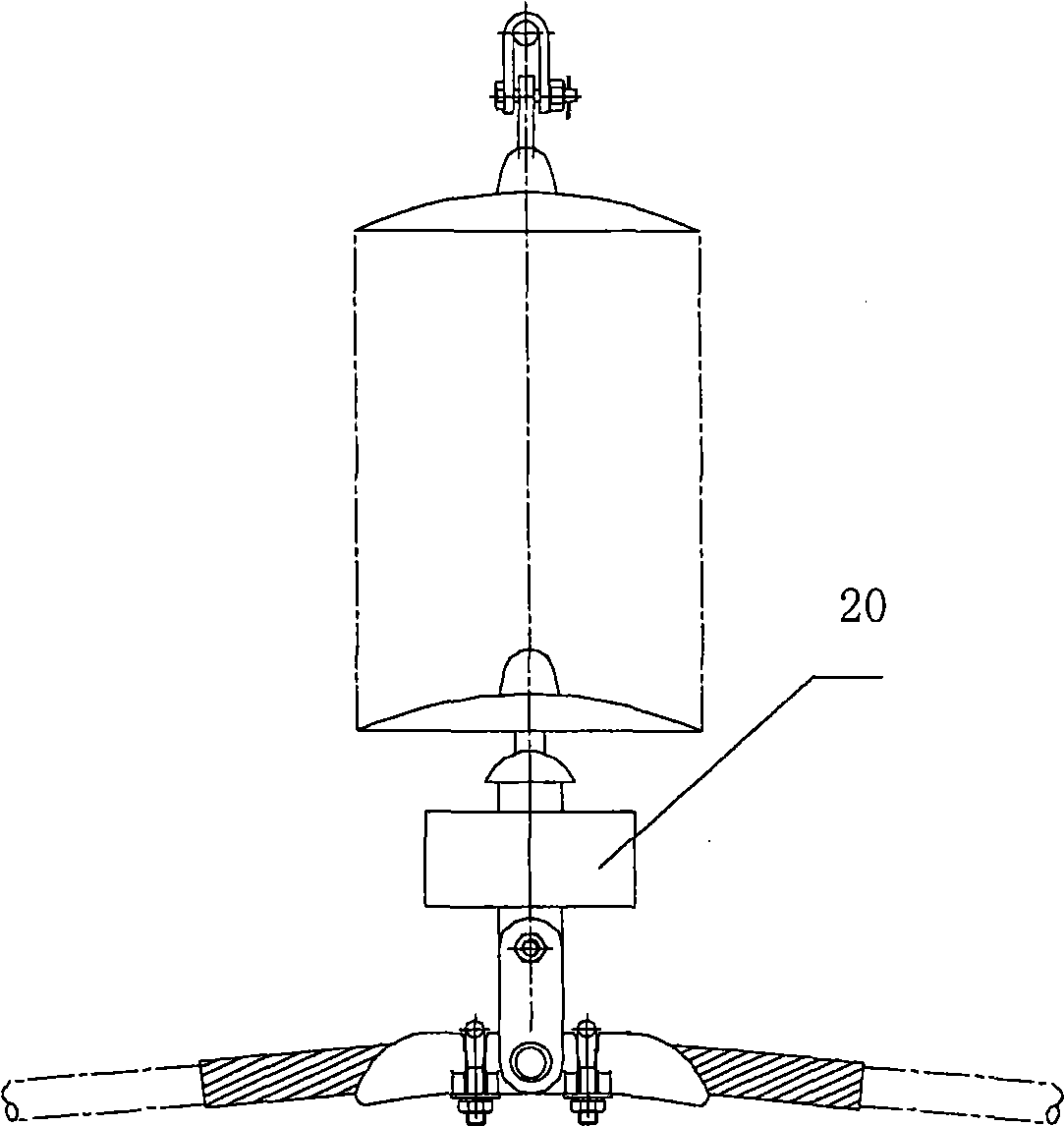

Protecting method, device and system for electric power pylon

ActiveCN101521363AProtection securityReduce tensionTransmission systemsSuspension arrangements for electric cablesElectric powerElectric wire

The invention provides a protecting method, a device and a system for an electric power pylon. A power line is hung and connected with the electric power pylon, and the method comprises the following steps: the stretching force of the power line to the electric power pylon is sensed in real time; if the stretching force of the power line to the electric power pylon reaches a set threshold value, the power line drops off the electric power pylon. In the technical scheme, when the power line is overloaded seriously and the safety of the electric power pylon is in danger, the overloaded power line is ensured to automatically drop off the electric power pylon so as to reduce the stretching force to the electric power pylon, the safety of the electric power pylon is protected, the loss scope is shortened, and the maintenance cycle and the maintenance cost of the power line are greatly reduced.

Owner:BEIJING GUOWANG FUDA SCI & TECH DEV

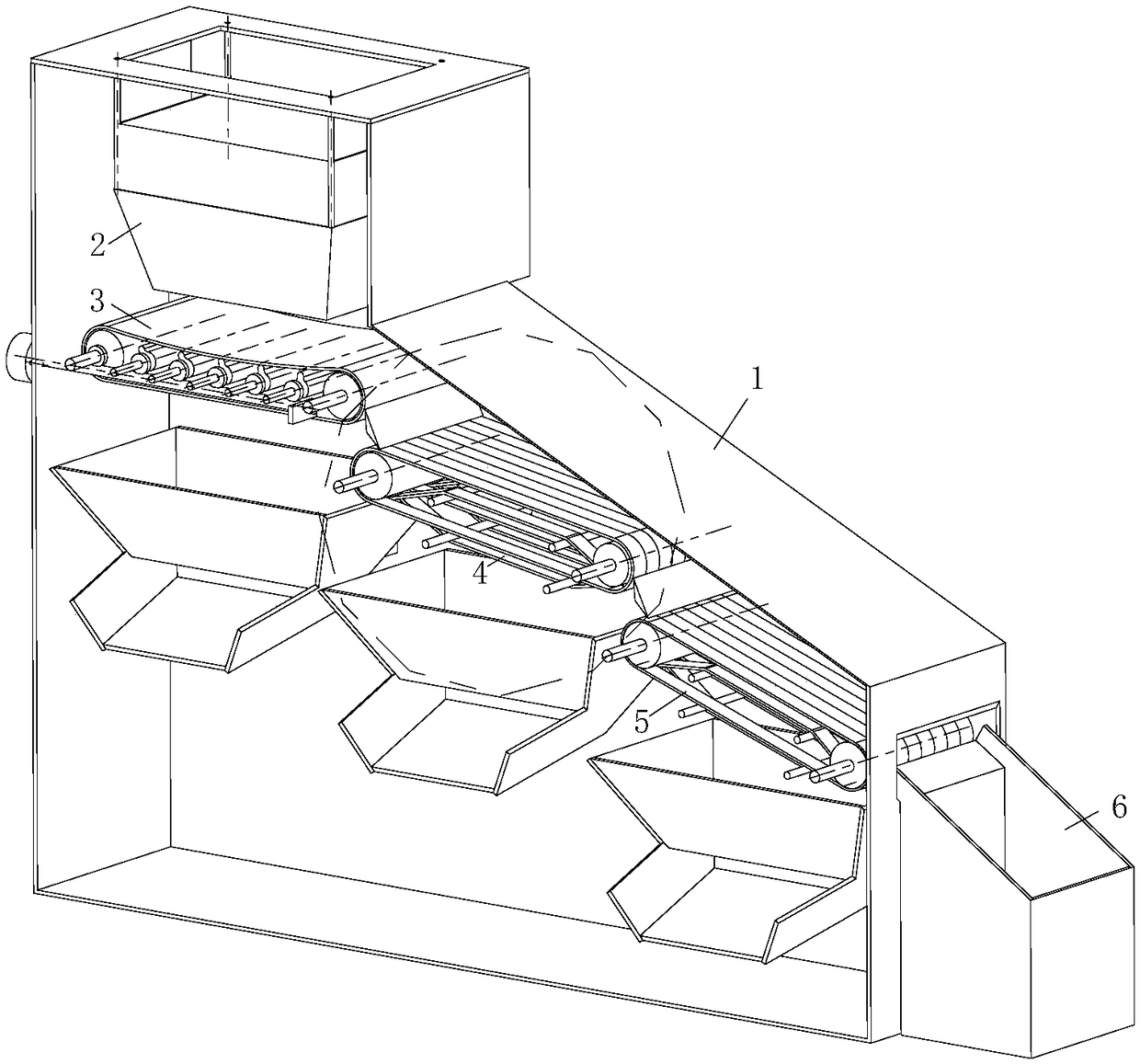

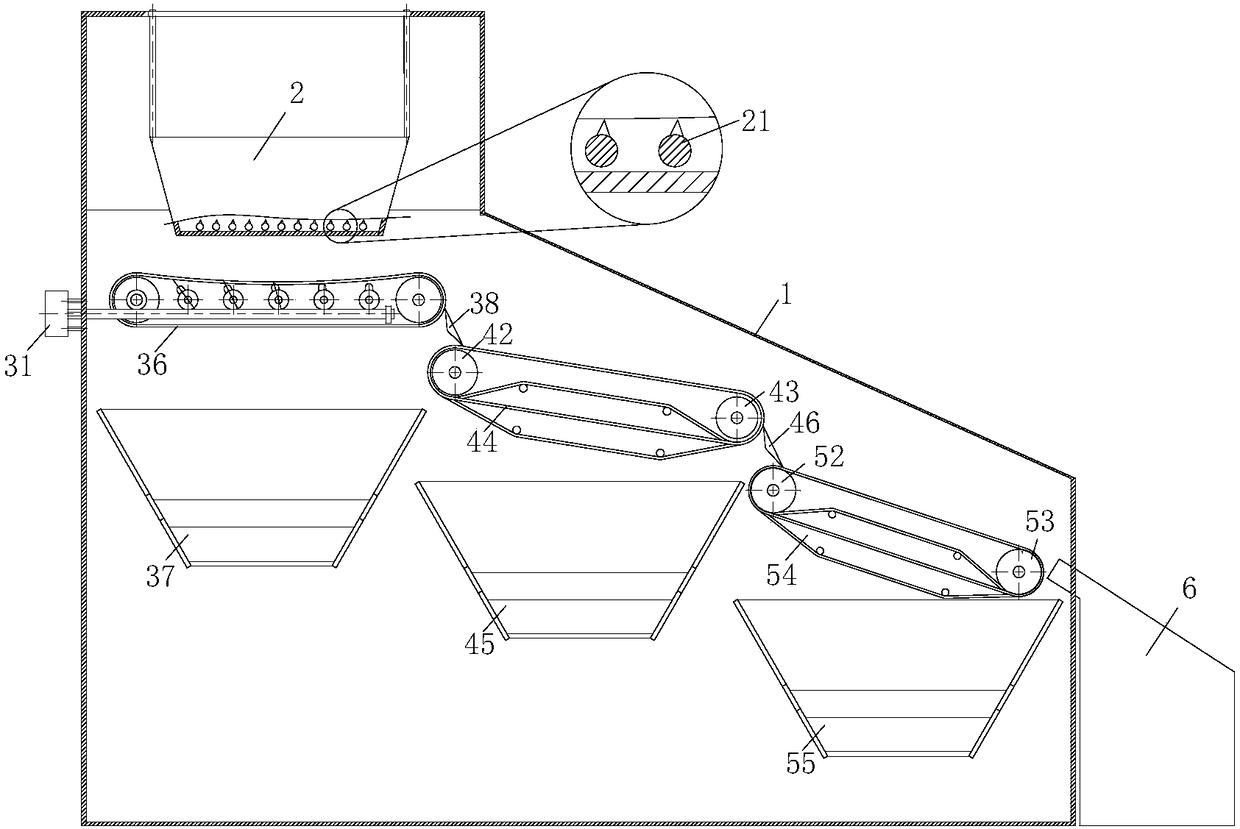

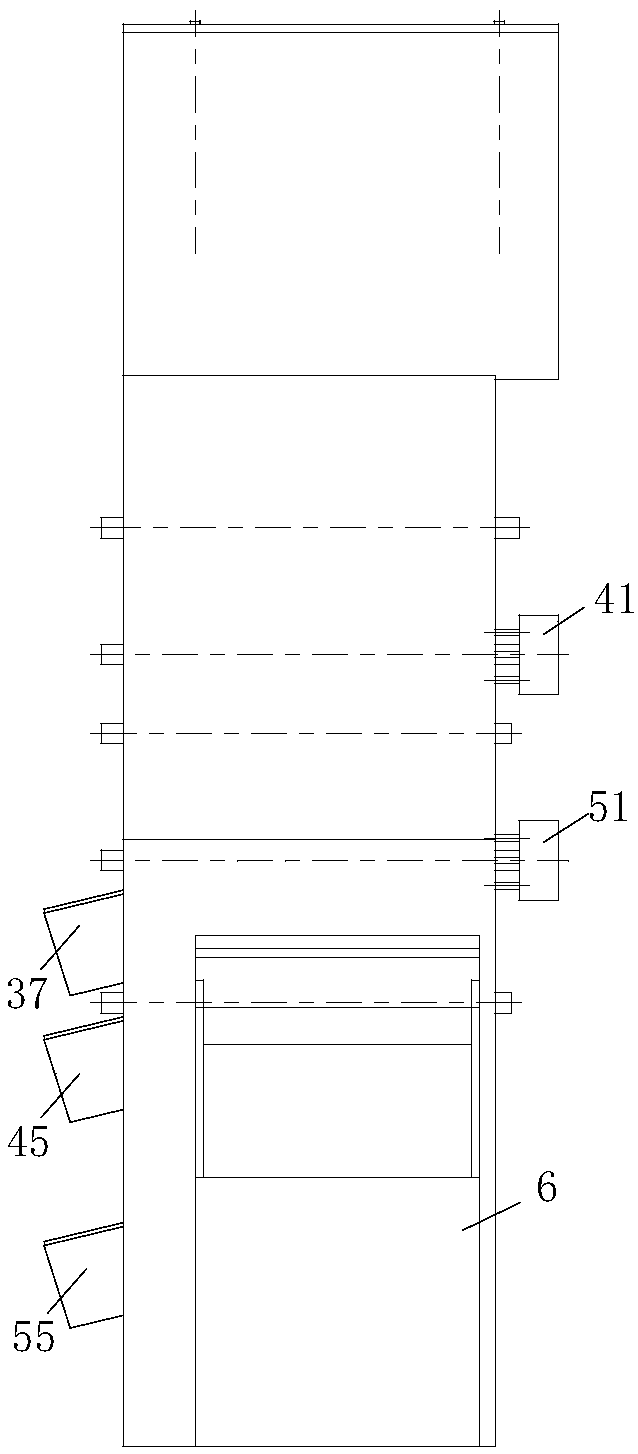

Organic fertilizer screening equipment with low damage percentage

ActiveCN108097430AImprove screening efficiencySolve the problem of a small amount of cakingSievingScreeningAgricultural engineeringBreakage rate

The invention belongs to the technical field of organic fertilizer processing, and particularly relates to organic fertilizer screening equipment with the low damage percentage. The organic fertilizerscreening equipment comprises a shell, a hopper, a first screening unit, a second screening unit, a third screening unit and an object storing box; the first screening unit is arranged below the hopper and comprises a first motor, a worm, a first driving roller, a pushing device, a first driven roller, elastic conveying belts and a first discharging hopper; the conveying belts are arranged to bea set of narrow cloth belts which are staggered up and down through a set of limiting wheels and are arranged in a layered staggering manner; organic fertilizer particles to be screened gradually falllayer by layer, the material falling speed is decreased, and falling damage due to too high speed is avoided. According to the organic fertilizer screening equipment, the first screening unit is usedfor screening chippings, particles with one particle size range are screened out through the second screening unit, and particles with another particle size range are screened out through the third screening unit; and multi-stage screening is carried out on organic fertilizer, and the damage percentage can be effectively reduced.

Owner:南通惠农生物有机肥有限公司

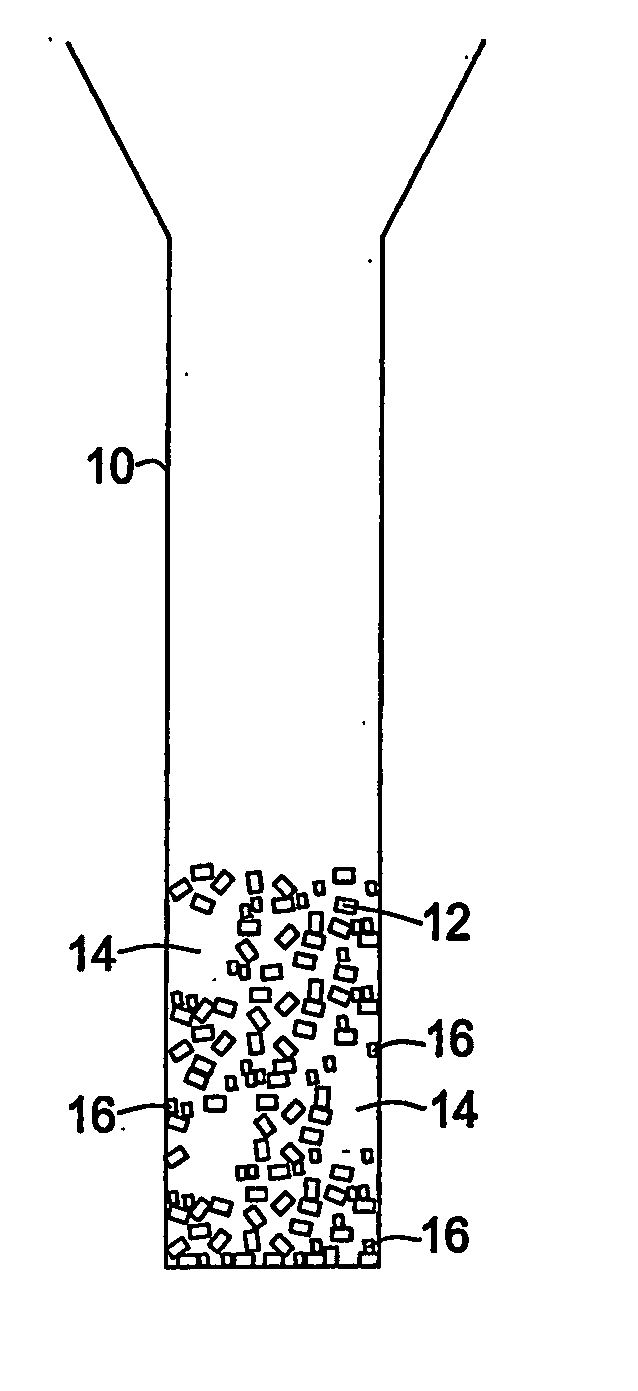

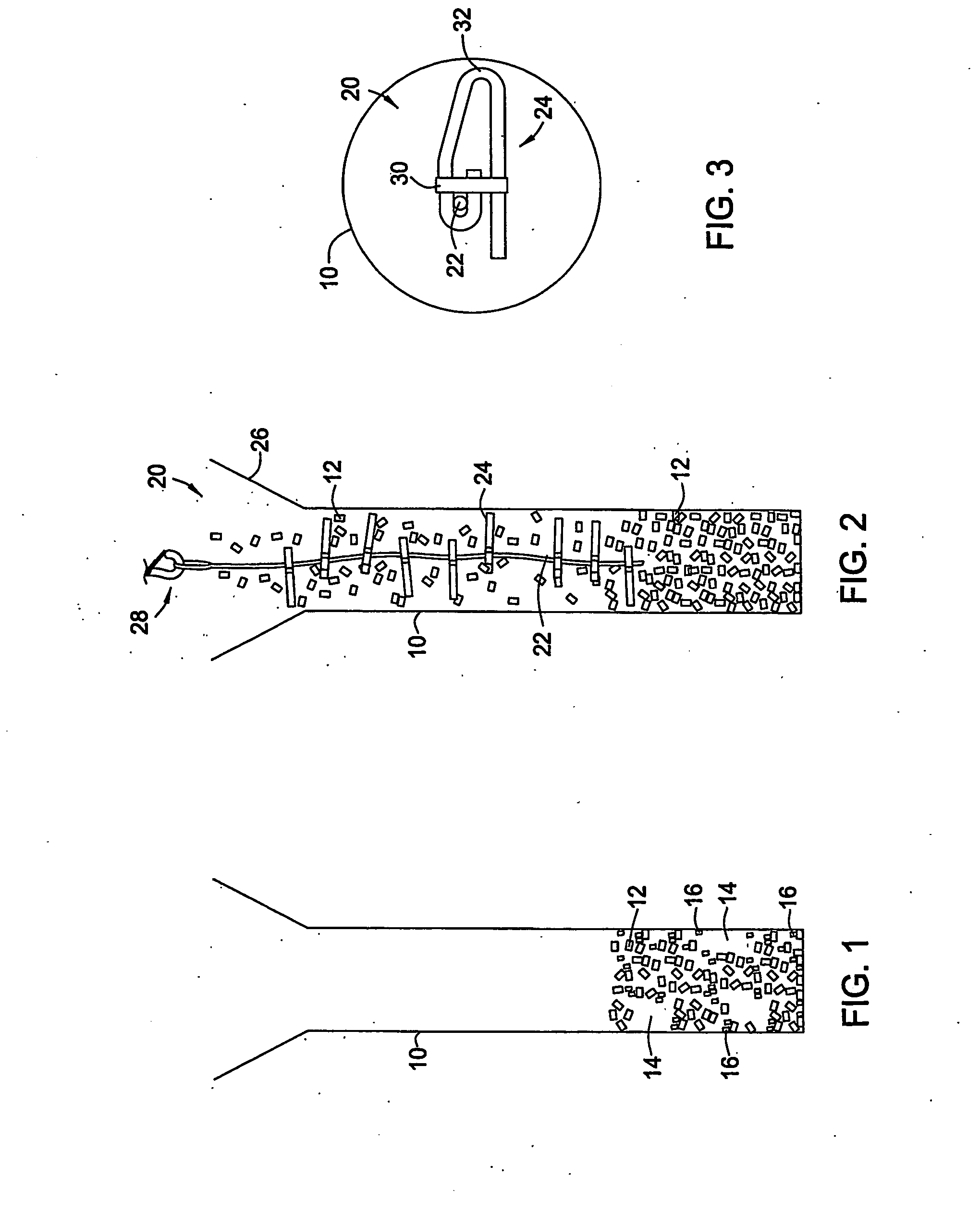

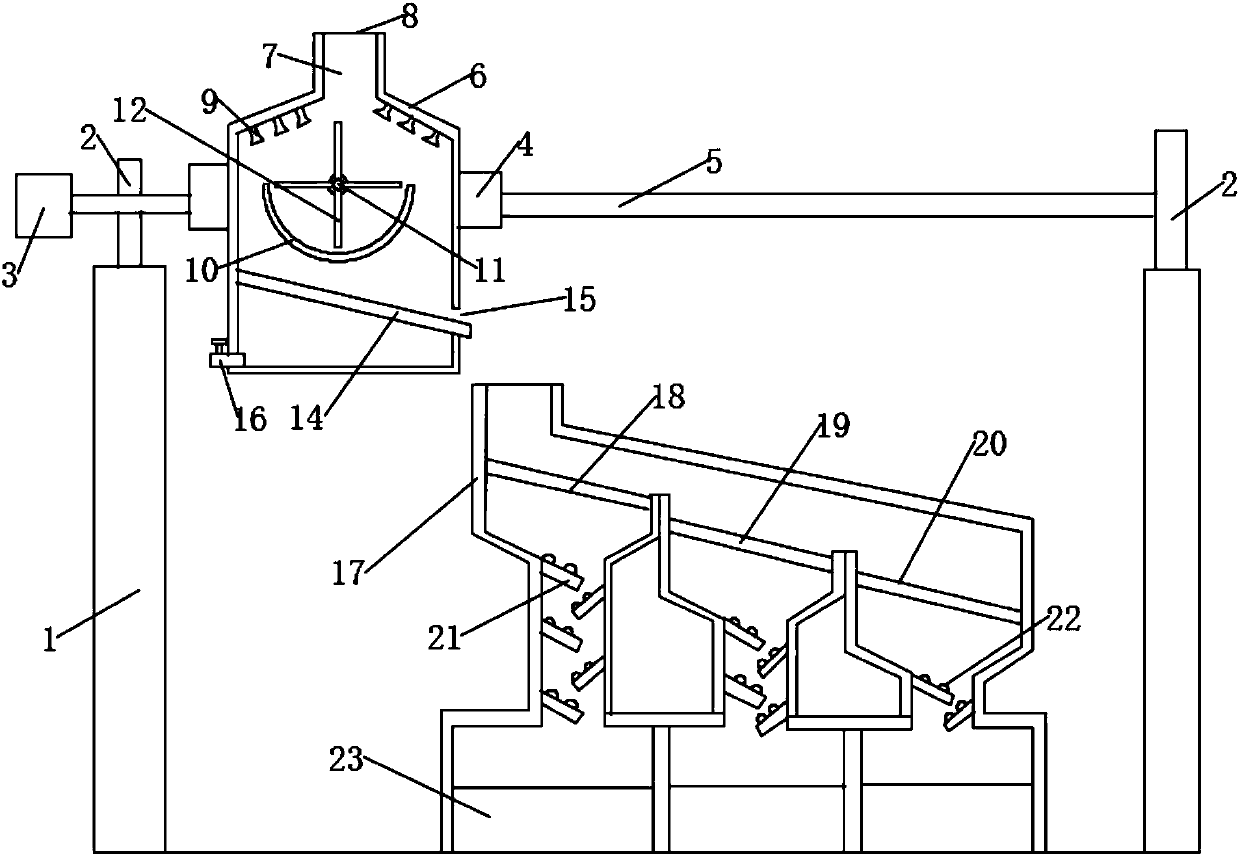

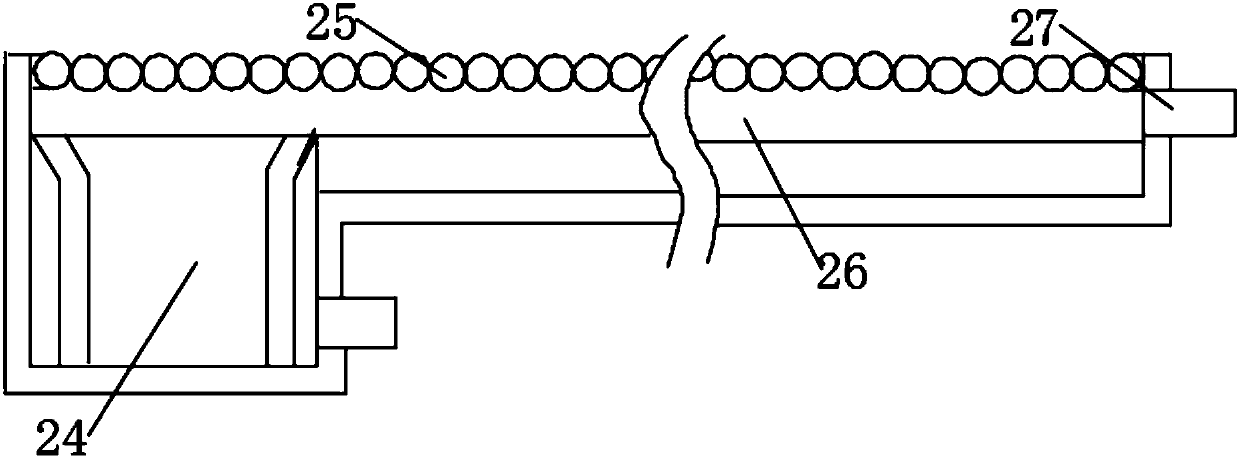

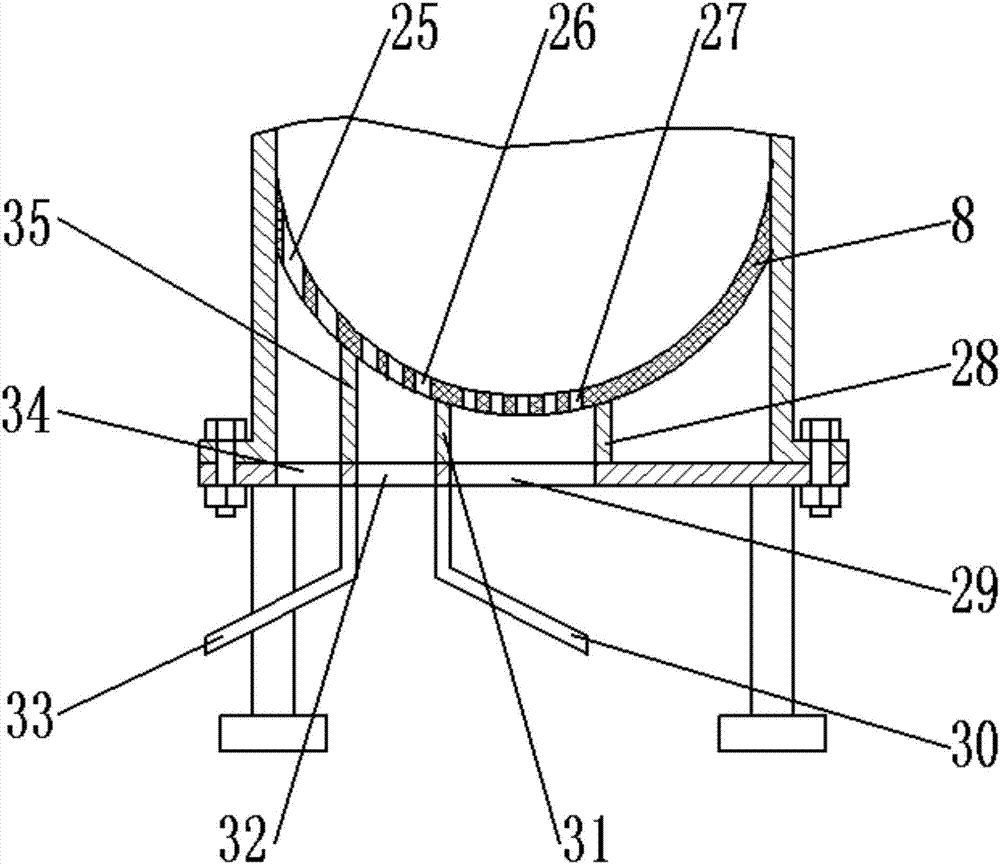

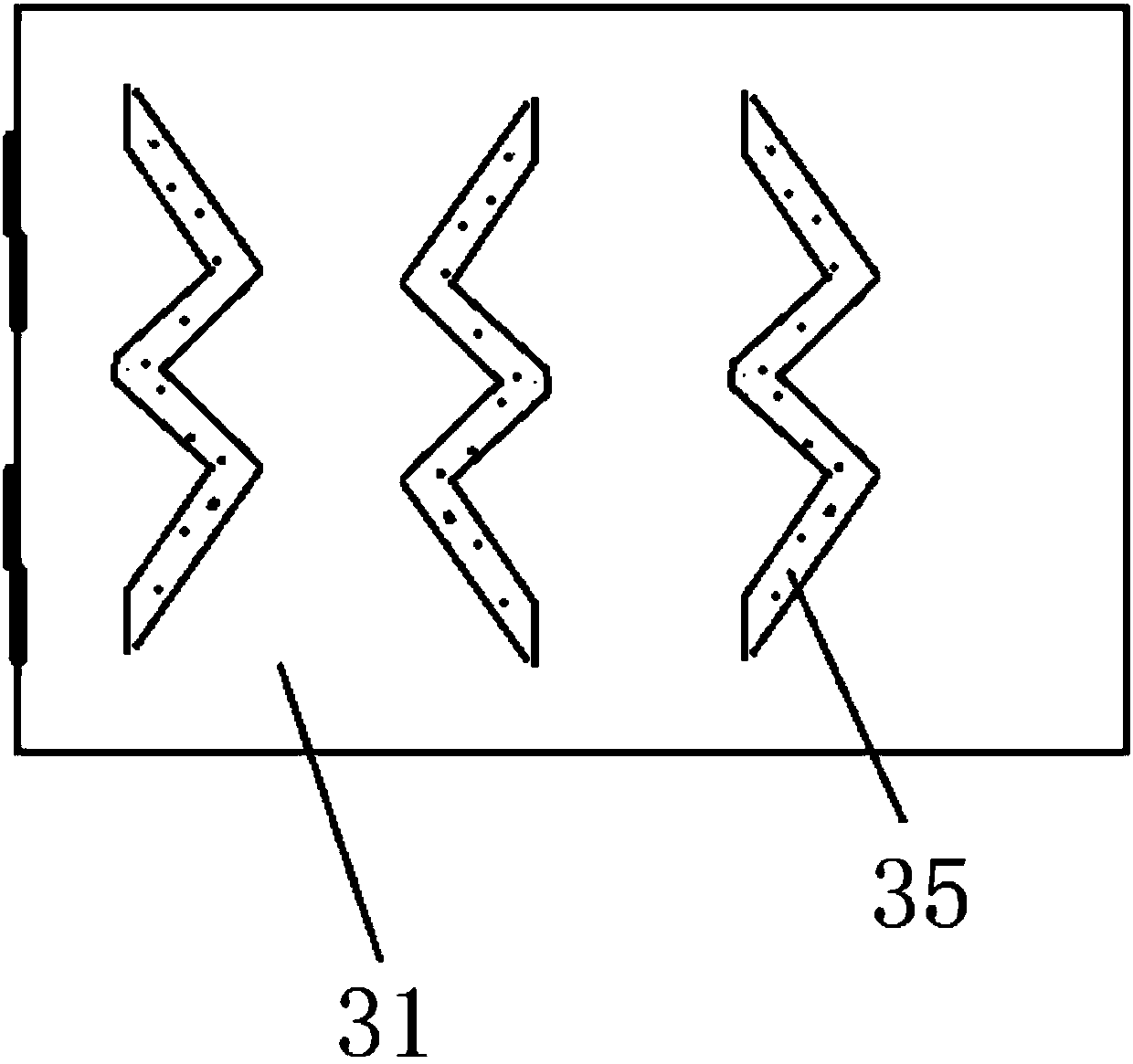

Method and apparatus for loading catalyst

ActiveUS20070084519A1FallReduce falling speedSolid materialLiquid materialVertical tubeSolid particle

Methods and apparatus are disclosed for filling solid particles into a vertical tube by conveying the particles downwardly into the tube along a loading tool that softens the fall of the particles and provides even filling of the tube. The loading tool includes a center member and a plurality of damper members that can be adapted in particular cases to the actual type of particles and the tube diameter. The damper members can be stiff or flexible since they do not occupy a substantial portion of the cross section of the tube at any particular axial location. In operation, the center member can be jerked during the filling operation while simultaneously being lifted up gradually as the tube fills or it can be sequentially lifted. The damper members reduce the falling velocity of the particles and divert the particles from falling in straight downward paths. This avoids bridge formation and breakage of the particles during filling.

Owner:QUANTA ASSOC

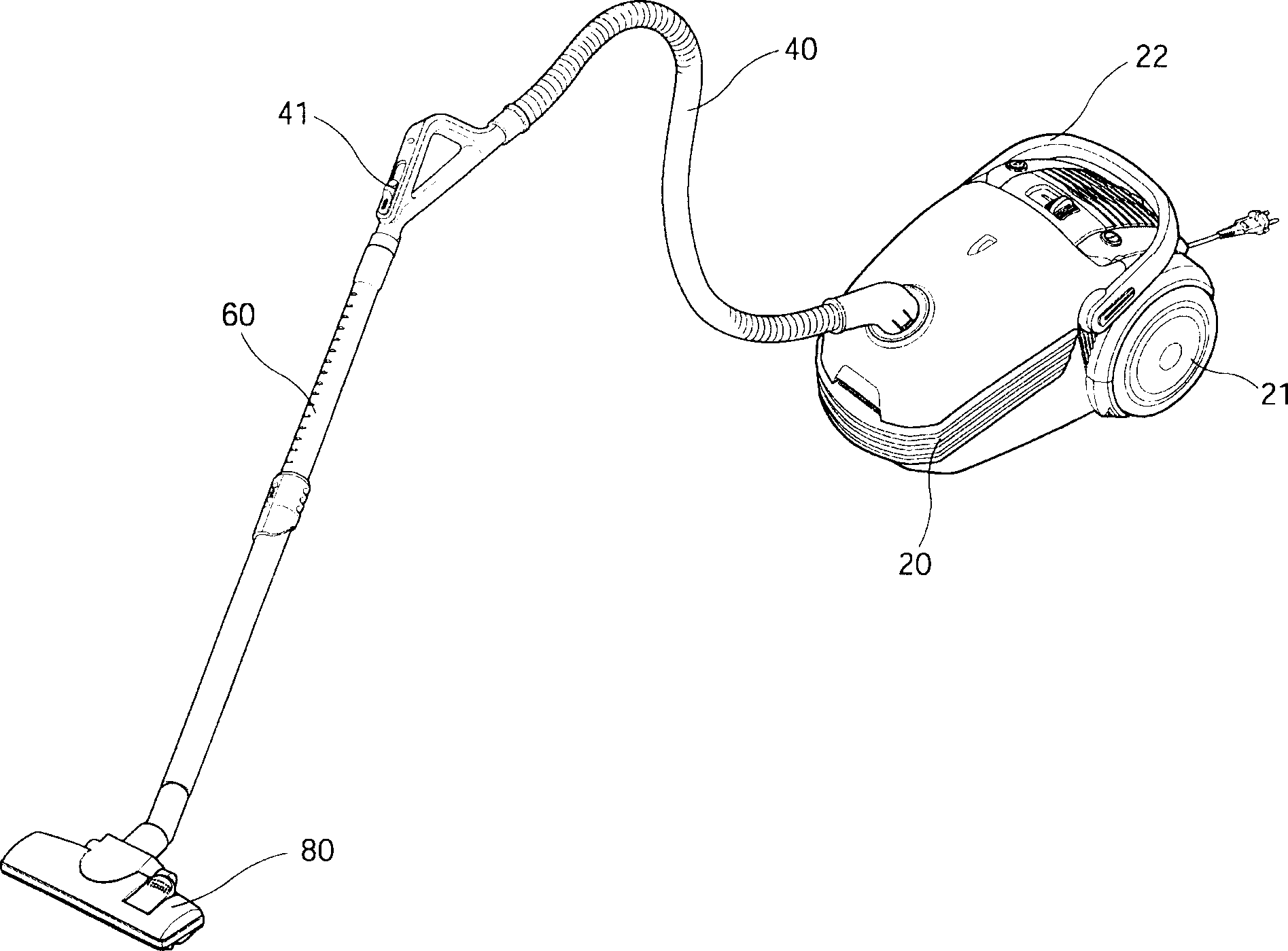

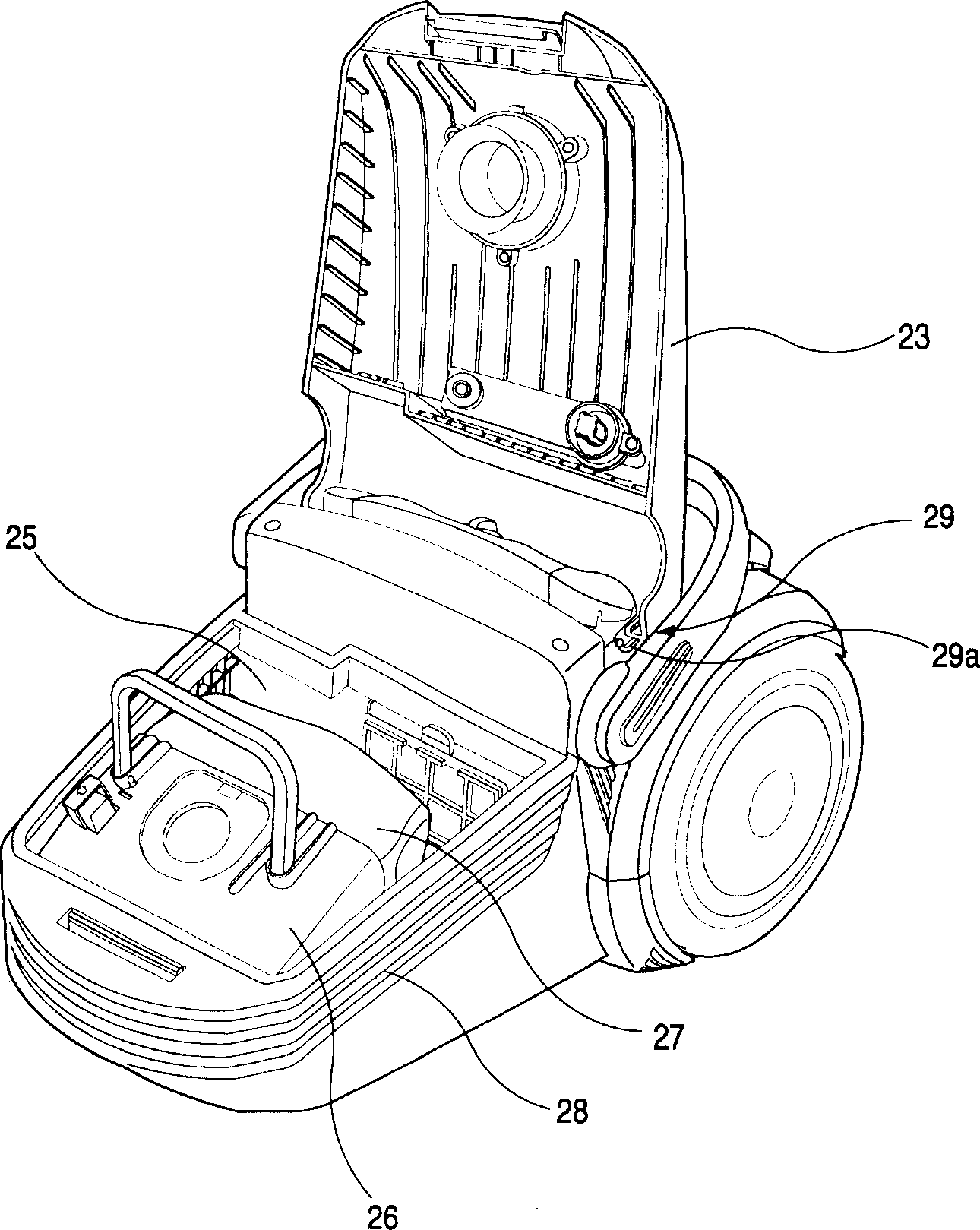

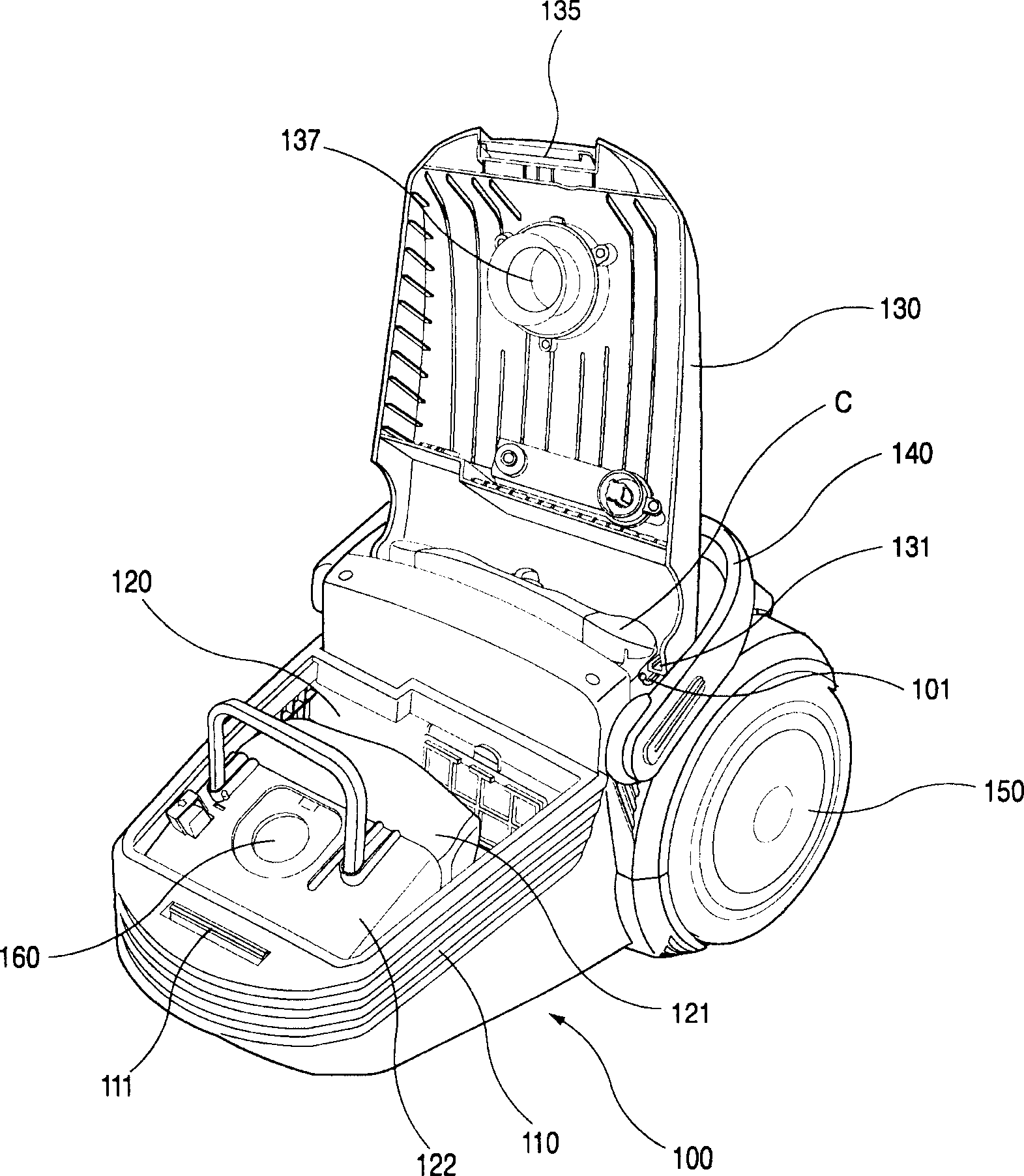

Rotation speed reducing structure of dust collection chamber cap of vacuum cleaner

InactiveCN1698527AReduce falling speedReduce impact noiseSuction filtersForeign matterVacuum cleaner

The invention provides a rotation speed reducing structure of dust collection chamber cap of vacuum cleaner, characterized by that the arrangement comprises a dust collection chamber cover and a speed reduction projection, wherein the dust collection chamber cover is arranged on one side of the bottom casing of the body member for opening and closing the dust collection chamber, the speed reduction projection can slow down the rotational speed of the dust collection chamber cover.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Integrated cleaning, drying and screening device for red date

InactiveCN107660805AFast cleaningReduce falling speedSievingGas current separationMotor drivePulp and paper industry

The invention discloses an integrated device for cleaning, drying and screening jujube, which comprises a support column, a cleaning box, a screening box and a drying device. The upper ends of the support columns are all provided with bearing seats, and a bearing seat rotates on the A rotating shaft is connected, the other bearing seat is rotationally connected with the rotating shaft and the rotating shaft is connected with the rotating motor, both the rotating shaft and the rotating shaft are connected with the cleaning box, a nozzle is installed in the cleaning box, and a cleaning tank and a material guide plate are installed inside the cleaning box , the cleaning tank is provided with a stirring shaft and a brush is provided on the stirring shaft, the end of the material guide plate is connected with the discharge port, and the screening inlet of the screening box is located below the bottom end of the material guide plate. In this device, the rotating motor drives the cleaning box to rotate, while the stirring motor drives the stirring shaft and the brush to rotate, which can stir the jujubes in the cleaning tank and improve the cleaning speed of the jujubes. The screening box can screen jujubes of different specifications and is equipped with a drying device. , no need to transport red dates, reducing the work intensity.

Owner:姜伟龙

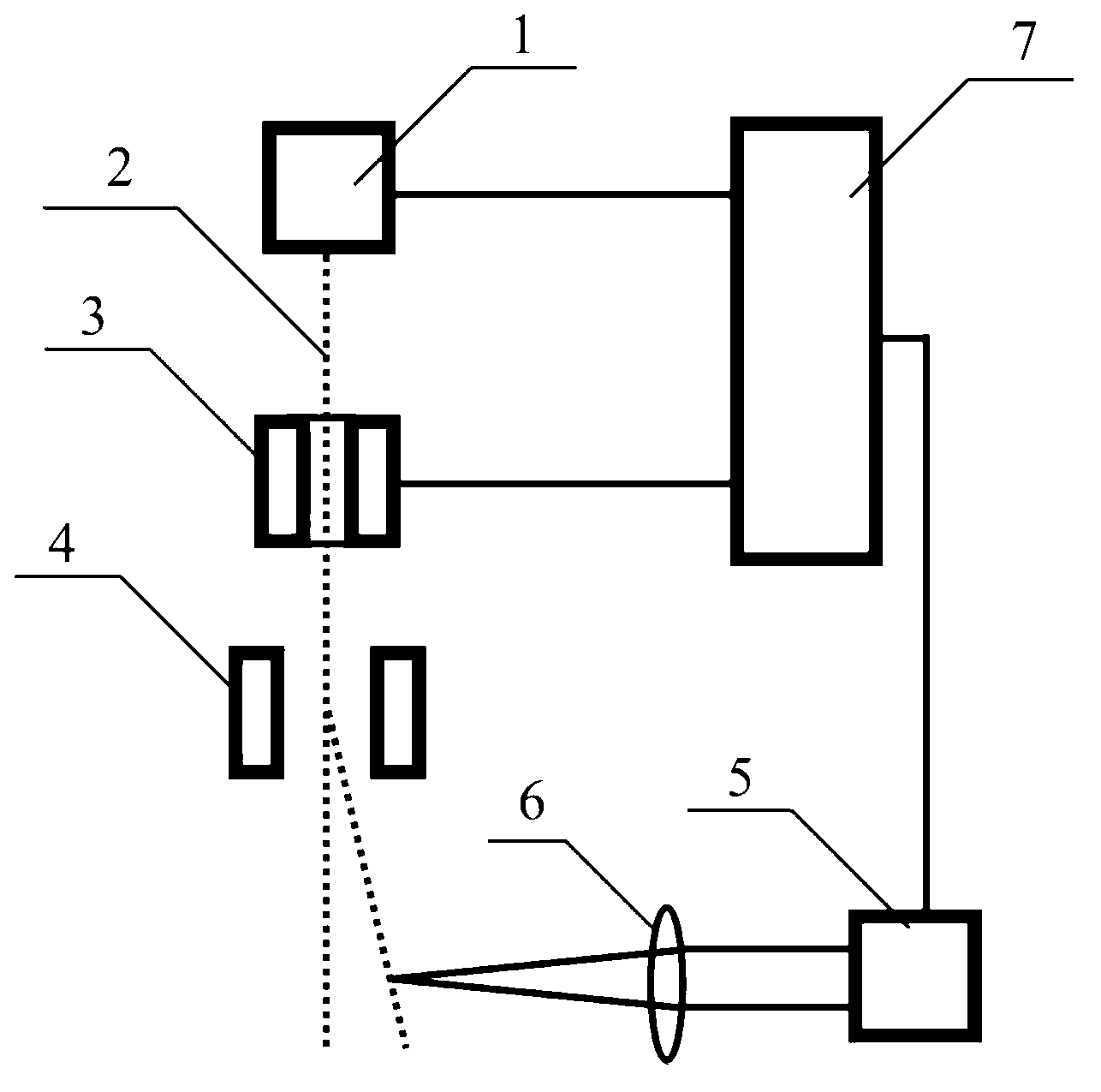

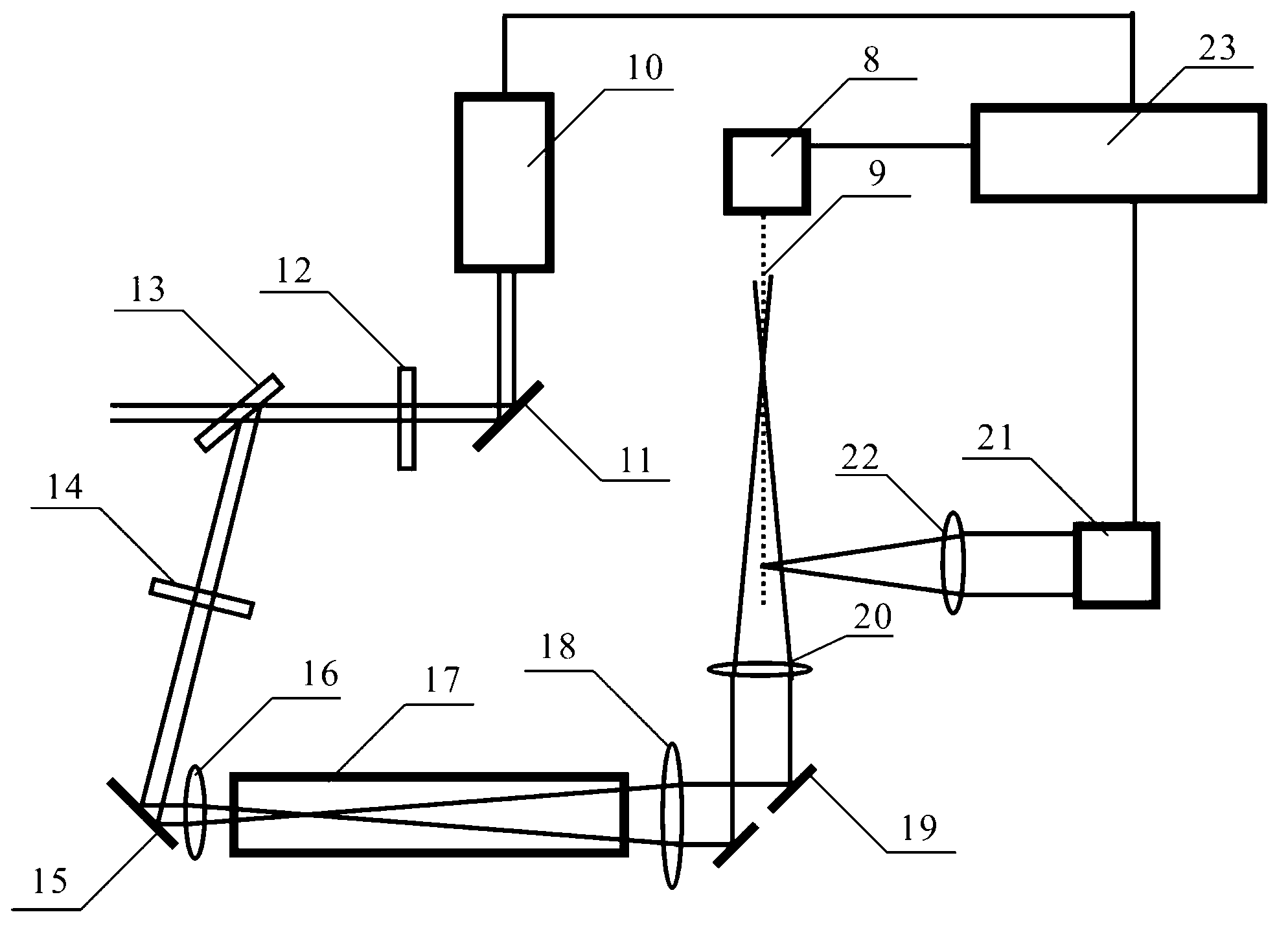

Droplet target control system guided by laser beam

ActiveCN103217870AStrong tractionNo electrification requirementPhotomechanical exposure apparatusMicrolithography exposure apparatusTime delaysMetal droplets

The invention discloses a droplet target control system guided by a laser beam. The droplet target control system comprises a droplet nozzle, a high-power pump laser, a third focusing lens and a time delay pulse generator, and further comprises a laser source, a first reflector, a half valve plate, a Brewster angle polarizing film, a quarter wave plate, a second reflector, a first focusing lens, a vacuum tube, a second focusing lens, an annular plane reflector and an annular focusing lens. A dropping track of metal droplets in 20 micron dimension can be precisely controlled by the droplet target control system, and the dropping speed of the droplets can be regulated. The system is capable of stably working for a long time, the time synchronization and the space coincidence of the droplets and the high-power pump laser are guaranteed.

Owner:上海中科神光光电产业有限公司

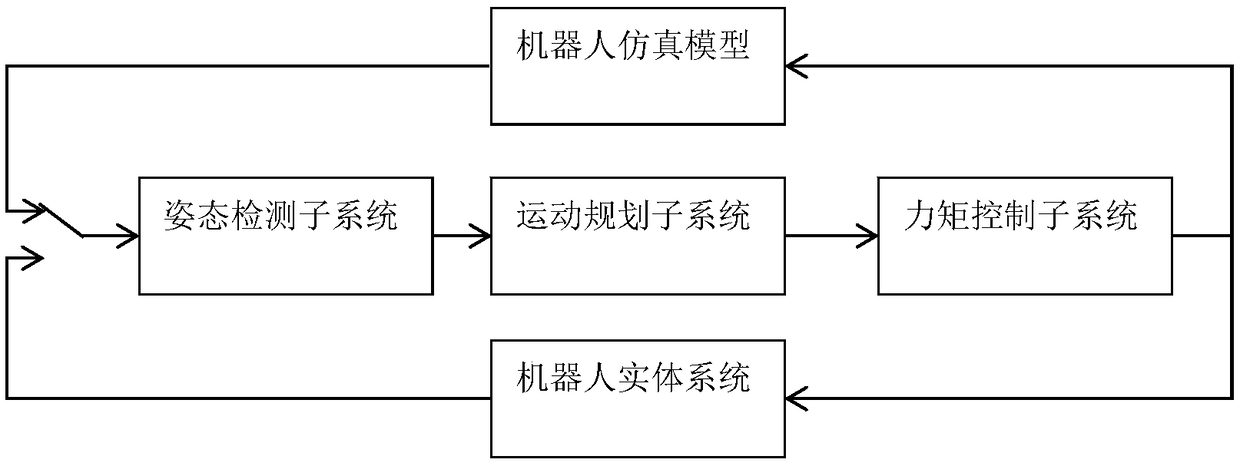

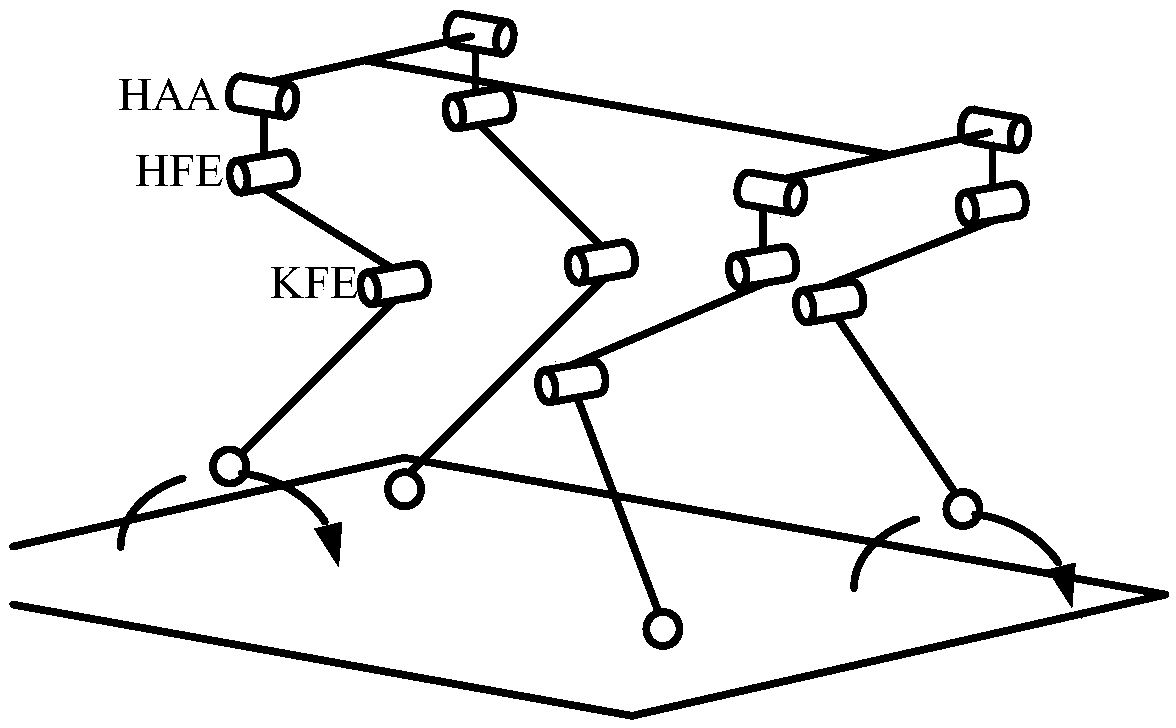

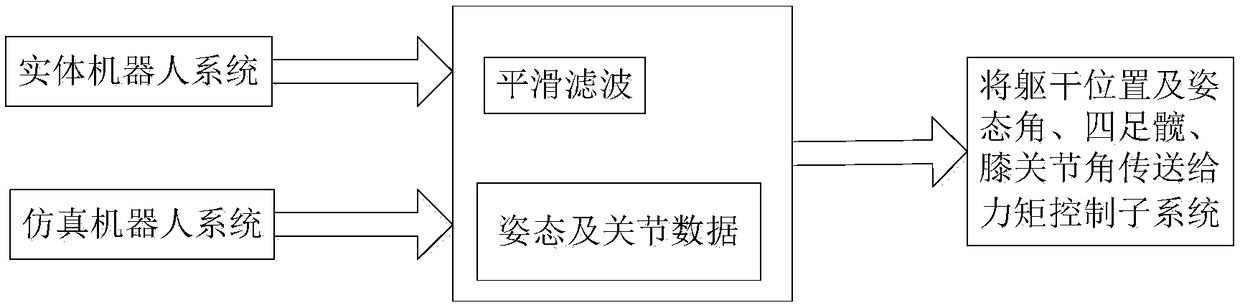

Obstacle-jumping system for quadruped robot

The invention provides an obstacle-jumping system for a quadruped robot. The system comprises a posture detecting subsystem, a motion planning subsystem and a torque control subsystem which are sequentially connected and is characterized in that the posture detecting subsystem processes posture and joint signals returned by the robot and transmits the data to the motion planning subsystem; the motion planning subsystem analyzes topographical change and the size of an obstacle to plan the jump motion trajectory of the robot and calculates the expected displacement, speed and acceleration of therobot; the torque control subsystem calculates the required input torque of each joint according to the planned motion trajectory. By the obstacle-jumping system, when the robot faces a large obstacle or a high step, the robot can jump over the obstacle or jump onto the step.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Grading sand screening device for building construction

InactiveCN107252765AKeep dryEasy to move with each otherSievingSand dryingSquare cross sectionEngineering

The invention provides a kind of grading and sand screening equipment for building construction, which comprises a tank body; the tank body is set as a hollow cuboid with a square cross section, an upper cover is set at the top opening of the tank body, and a bottom opening is set at the bottom opening of the tank body. cover; the middle part of the tank body is divided into a drying chamber and a screening chamber by a partition; a drying device is provided in the drying chamber; a screening plate and a screening device are provided in the screening chamber; feeding device; the present invention adds the sand added by the feeding hopper into the tank body at a uniform speed through the feeding device, which is also beneficial to reduce the labor intensity of the workers; through the setting of the drying device, the three-layer rotating material guide plate is used to control the sand falling on the guide The sand in the material tray is turned over, and the hot air blown by the hot air blower is used to evenly distribute the hot air blown in by the three-layer rotating air distribution pipe, so as to facilitate the full drying of the sand; The sand is graded and screened to improve the screening quality.

Owner:合肥多智科技开发有限公司

Gravel flushing device for constructional engineering

InactiveCN108687020AImprove cleanlinessUniform feedingSievingScreeningWater filterArchitectural engineering

The invention discloses a gravel flushing device for constructional engineering. The gravel flushing device comprises a sand inlet pipe, a screening box, a water spray tank, a water filter film plate,a table plate, a vibration screening basket, a rotating barrel and a water outlet pipe. The sand inlet pipe is arranged at the top end of the screening box. A grid is obliquely arranged in the sand inlet pipe. One side of a feeding plate is hinged to the inner wall of the top end of the screening box. The table plate is arranged in the screening box. Sand sliding grooves are formed in the side wall of the table plate. The water spray tank is mounted at the top end of the screening box. The bottom end of the water spray tank is connected with a spray head through a water passing pipe. The spray head is arranged in the top end of the screening box. Fixed blocks are arranged on the inner wall of the screening box. The upper surface of each fixed block is fixedly connected with one end of a spring, and the other ends of the springs are in contact connection with the bottom face of the vibration screening basket. The rotating barrel is arranged above the vibration screening basket. A semicircular gear is connected with an output shaft of a rotary motor. The water filter film plate is obliquely arranged in the screening box. According to the gravel flushing device, gravel flushing is facilitated, resources are saved, waste is avoided, the structure is simple, use is convenient, and popularization is facilitated.

Owner:北京艺轩吉装饰工程有限公司

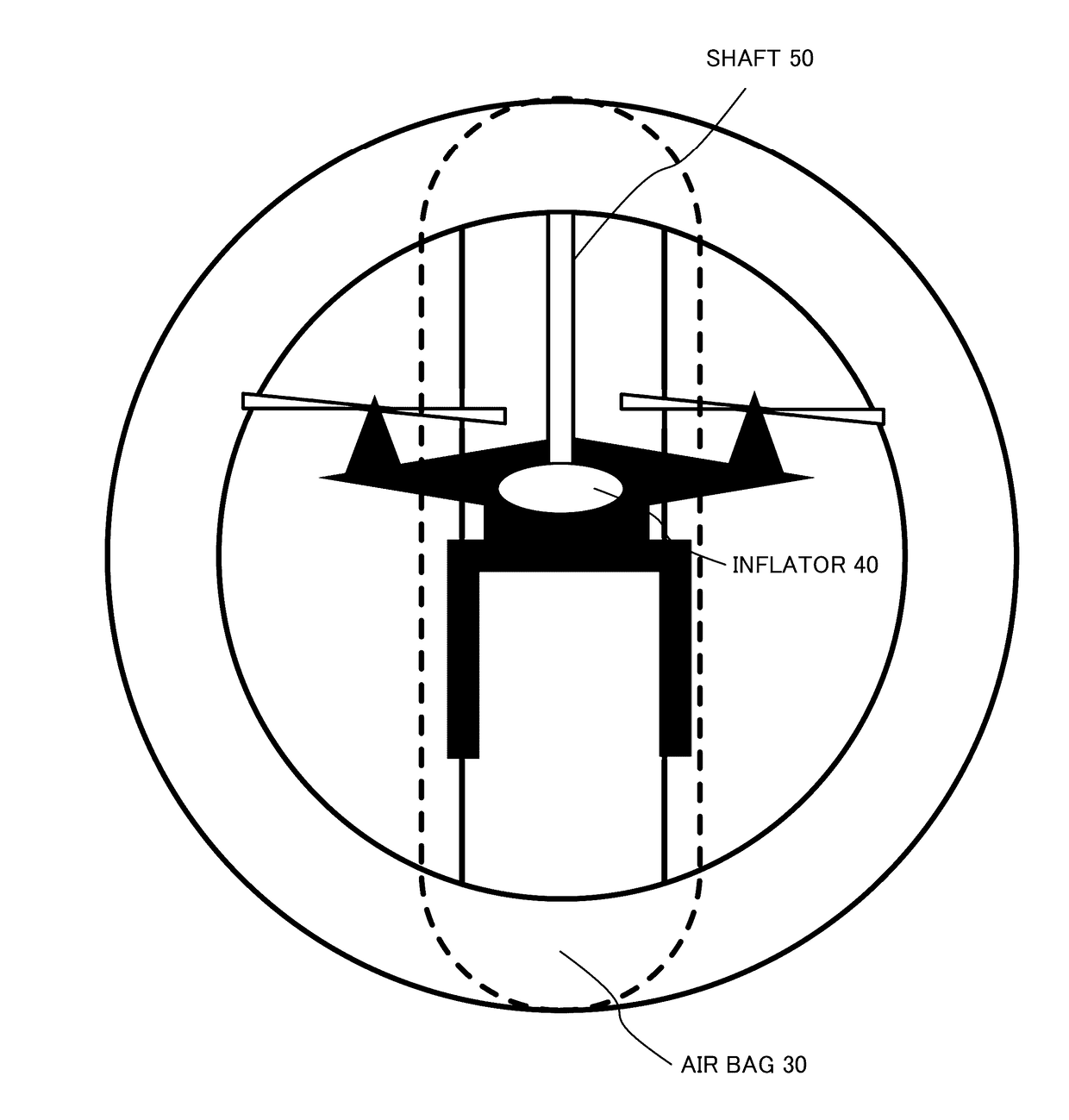

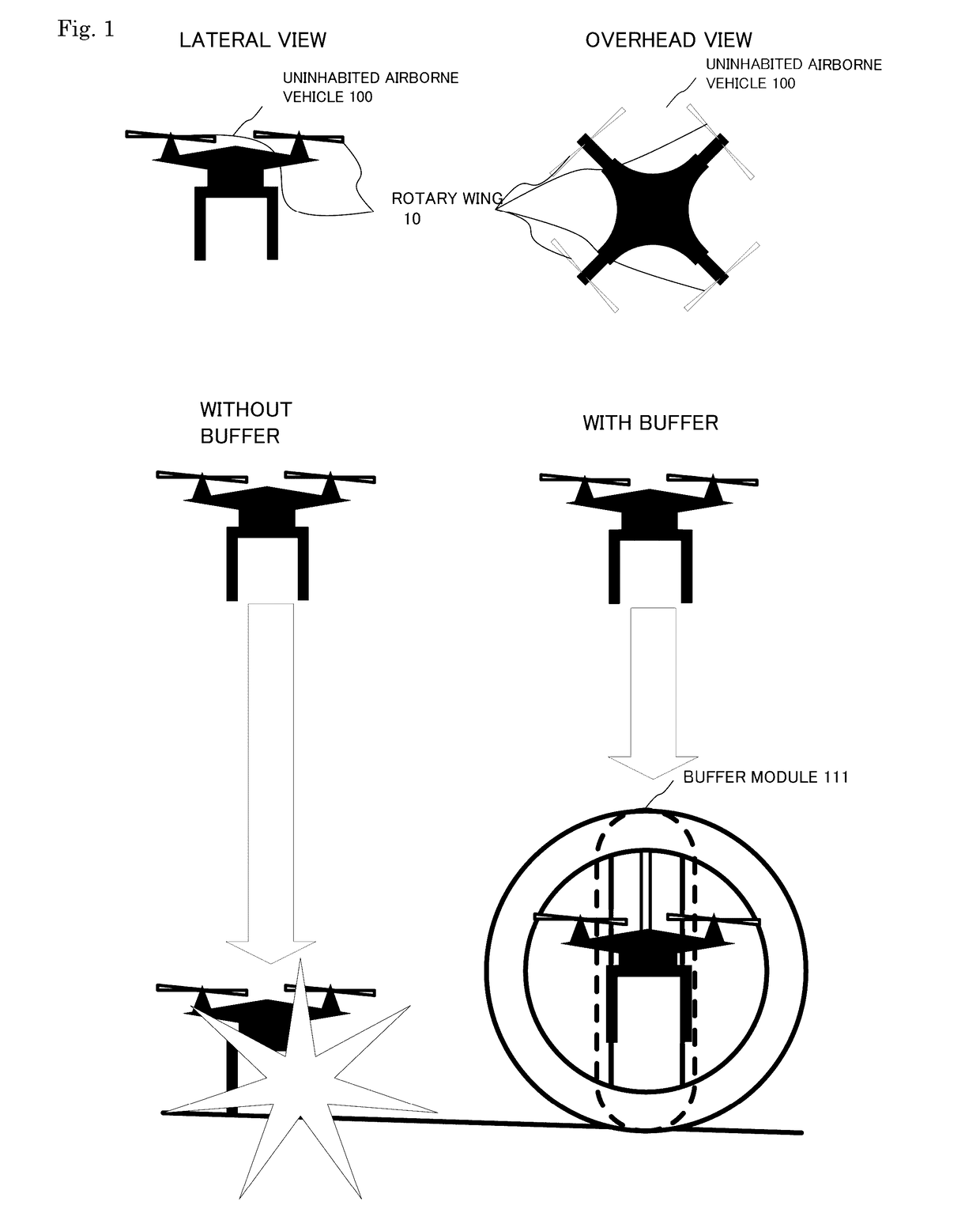

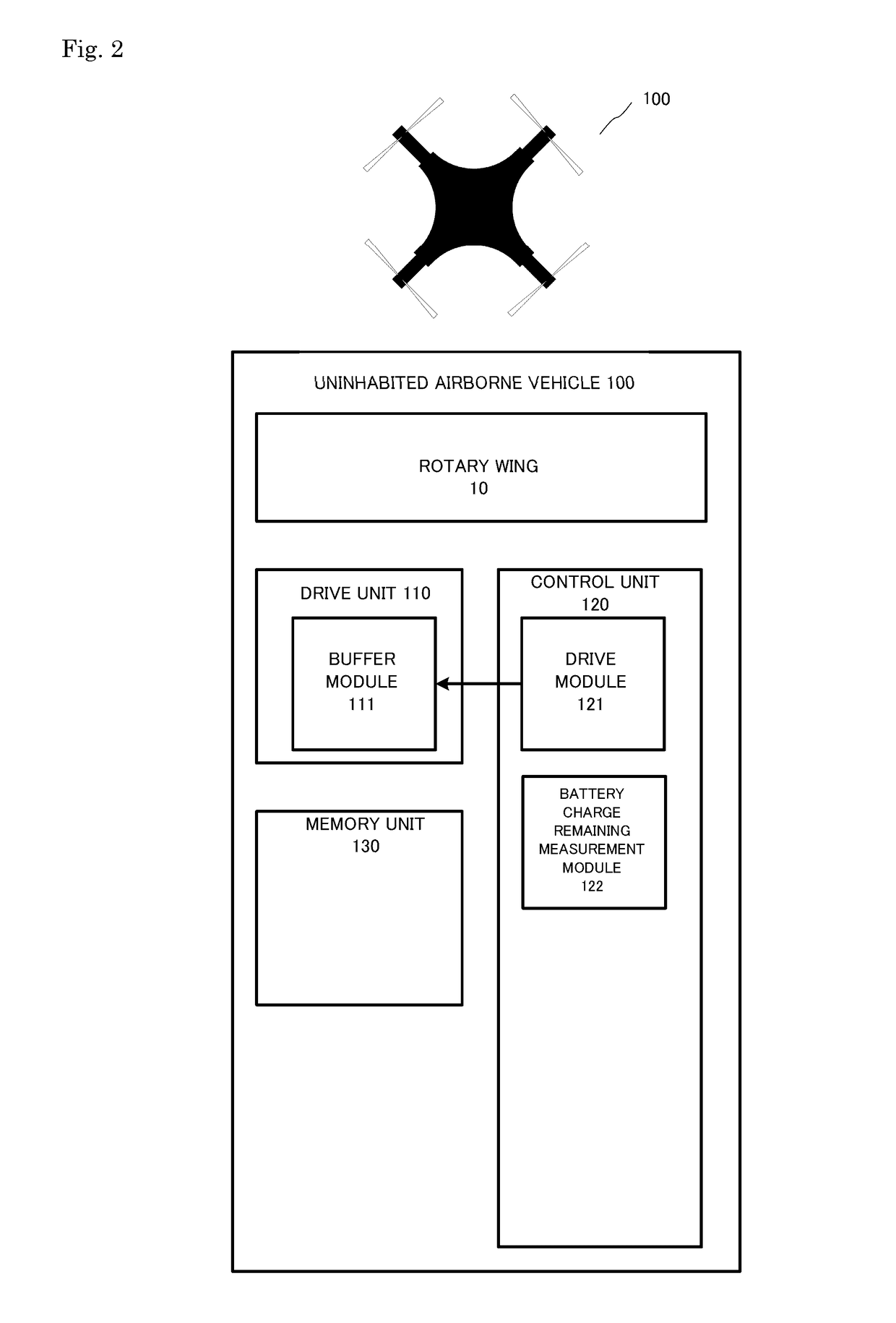

Uninhabited airborne vehicle and method of controlling the same

ActiveUS20170152051A1Reduce the impactReduce falling speedRemote controlled aircraftEmergency apparatusBattery chargeFlight vehicle

The present invention is to prevent an uninhabited airborne vehicle from crashing due to fall impact and from being damaged and to protect an object and a living being at the fall point. The uninhabited airborne vehicle 100 includes a rotary wing 10 and a buffer 111 that reduces impact on the airframe when crashed. The battery charge remaining measurement module 122 and the distance measurement module 123 measure the battery charge remaining and the distance to an object, respectively, and compare the measurement with the respective thresholds. If the measurement is less than the respective thresholds, the buffer module 111 is driven by the drive module 121.

Owner:OPTIM

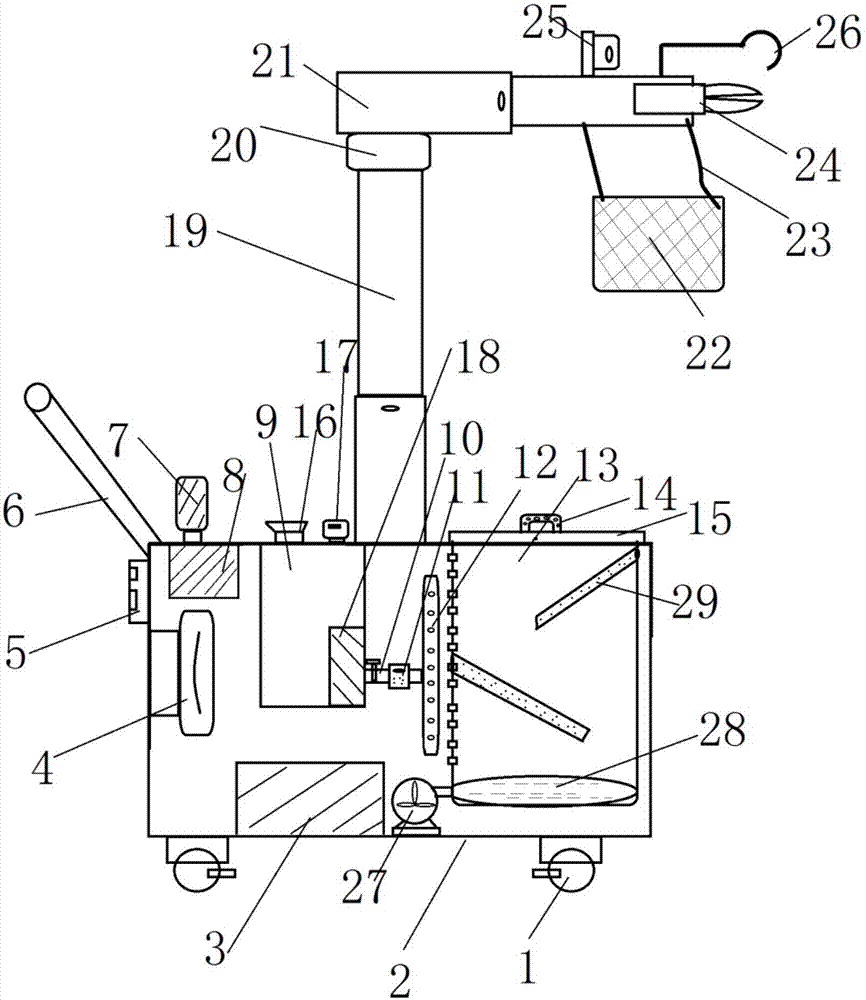

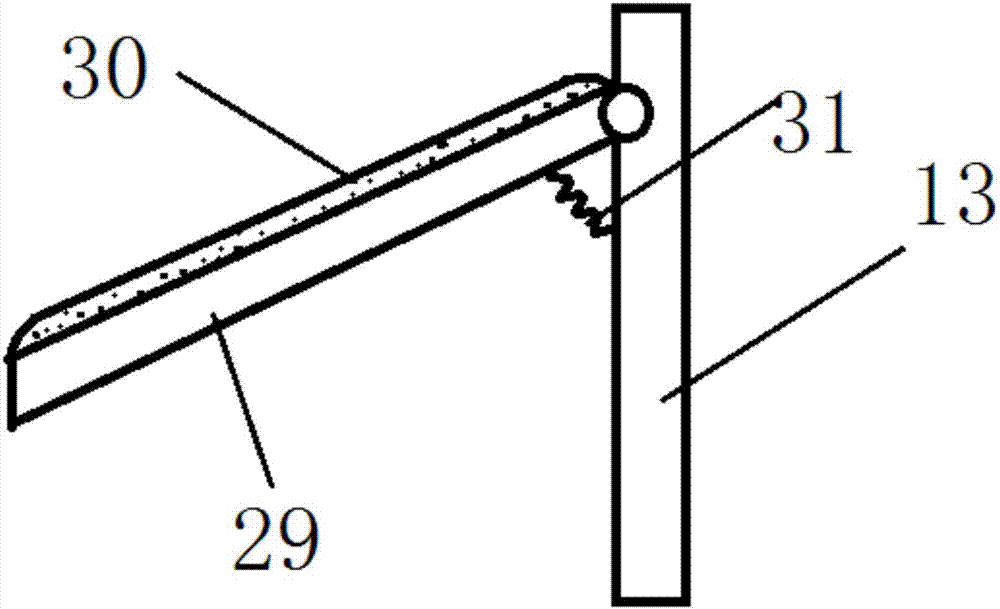

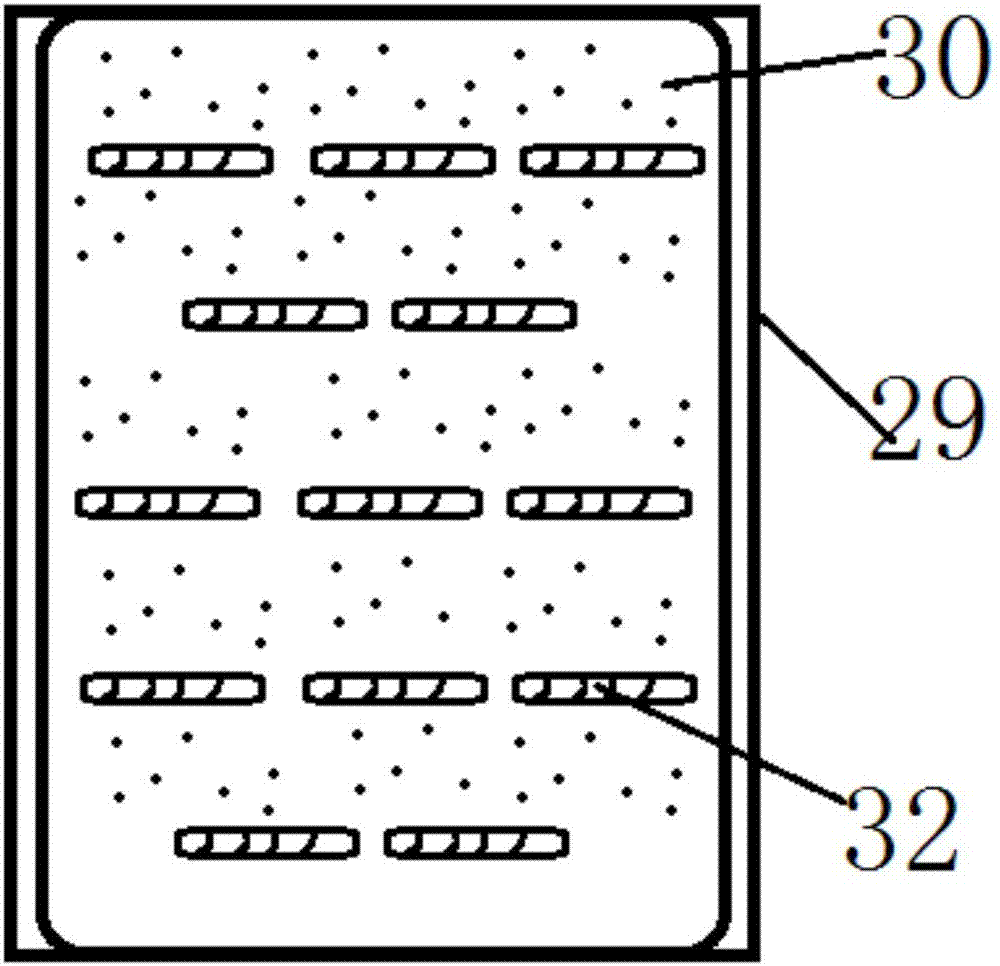

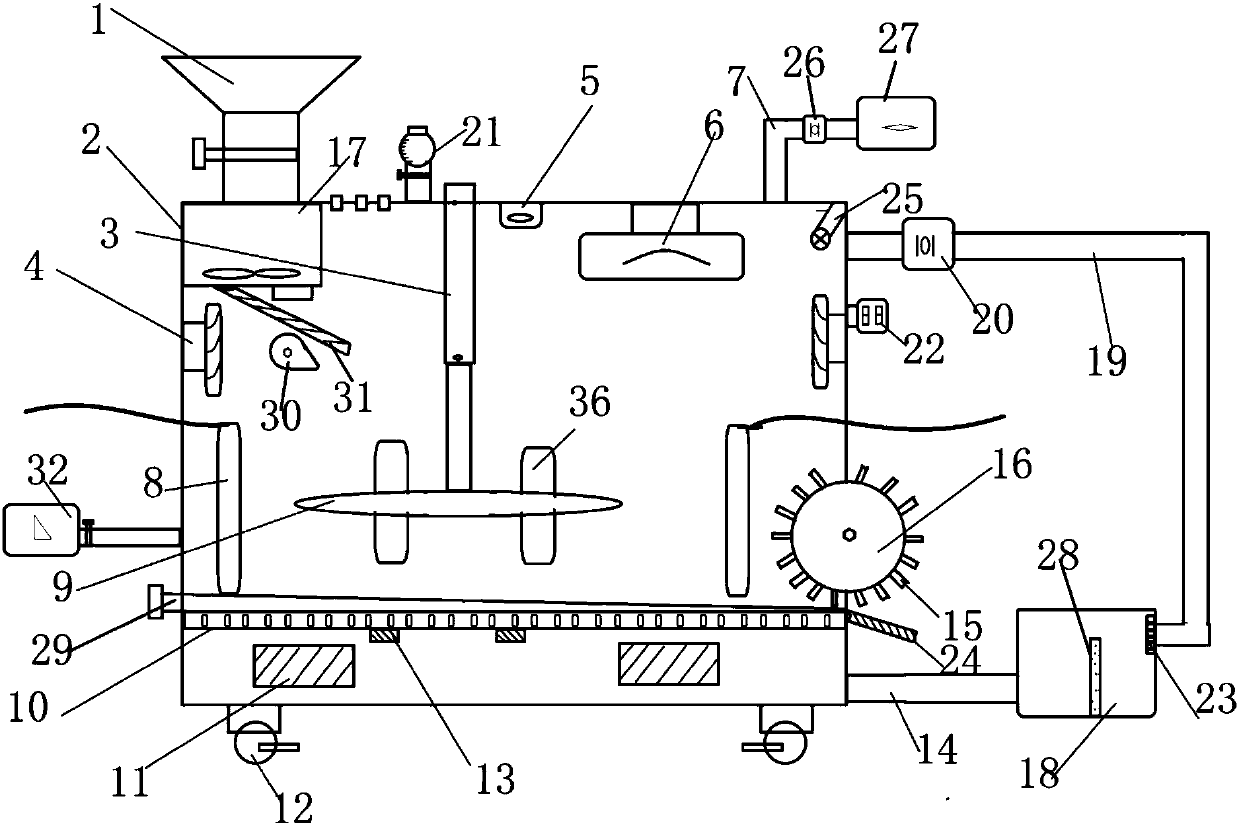

Safe efficient orchard high-branch fruit shearing device

The invention discloses high-efficiency fruit pruning equipment for safe orchards, including a box body, a temperature regulator, a fan, a controller, a display device, a water tank, a spray row, a fruit basket, a telescopic column, a horizontal telescopic rod, a net pocket, and electric scissors , a camera and a hook, the bottom surface of the box is provided with a guide wheel, a fruit basket is provided in the box, through holes are evenly provided on the side wall of the fruit basket, a temperature regulator is provided in the box, and a fan is provided on the side wall of the box , there is a water tank in the box, a water pipe at the bottom of the water tank, a spray discharge at the outlet of the water pipe, a display device on the box, a telescopic column on the upper surface of the box, and the top of the telescopic column passes through the rotary joint It is connected with one end of the horizontal telescopic rod, the other end of the horizontal telescopic rod is provided with electric scissors, the horizontal telescopic rod is provided with a camera, and the horizontal telescopic rod is provided with a hook close to the movement of the electric scissors. The invention ensures good ventilation conditions, avoids drying of fruits, ensures the completion and quality of fruits, has simple structure, is convenient to use, and is beneficial to popularization.

Owner:黄海

Efficient safety environment-friendly sludge treatment apparatus

InactiveCN107804956AReduce falling speedEasy dischargeSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesImpellerSludge

The invention discloses a high-efficiency, safe and environmentally friendly treatment equipment for sludge, which includes a feeding port, a treatment box, a rotating shaft, a UV violet lamp, a camera, a fan, an electrode, an impeller, a filter plate, a heater, a guide wheel, a drain pipe, a runner and sedimentation The top of the treatment box is provided with a feeding port, the outlet of the feeding port is provided with a pulverizer, the processing box is provided with a rotating shaft, an impeller is installed on the rotating shaft, a fan is provided on the inner wall of the top of the processing box, and a UV purple light is also provided on the inner wall of the processing box. There are electrodes in the treatment box, a filter plate at the bottom of the treatment box, a heater under the filter plate, a drainage pipe at the bottom of the treatment box, and the drainage pipe is set under the filter plate, and the drainage pipe is connected with the sedimentation tank. The side wall of the box is provided with runners. The invention sterilizes the bacteria and viruses in the sludge, reduces its diffusion, reduces the damage to people and the environment, separates the heavy metal ions in it, and prevents them from polluting other soil sources during landfill or other treatments. It has a simple structure and is easy to use. Good for promotion.

Owner:广西综改咨询服务有限公司

Anti-crash type aerial photographing unmanned aerial vehicle capable of automatically controlling drop speed

InactiveCN106542084AThe recovery step is smooth and safeAvoid direct contactAircraft landing aidsRotocraftAir compressionMultiple buffering

The invention relates to the field of unmanned aerial vehicles, in particular to an anti-crash type aerial photographing unmanned aerial vehicle capable of automatically controlling drop speed. The anti-crash type aerial photographing unmanned aerial vehicle comprises a mainframe, wherein a plurality of wing brackets are symmetrically arranged at the two sides of the mainframe, the mainframe and the wing brackets are of an integral forming structure, and a power device mounting cavity is fixedly mounted at the side, far from the mainframe, of each wing bracket. According to the anti-crash type aerial photographing unmanned aerial vehicle capable of automatically controlling drop speed, by additionally arranging an air pressure compression device, air compression and jetting are carried out; by additionally arranging a jet head at the bottom of the mainframe, force which is opposite to a drop direction is applied, so that drop speed is reduced, and a buffering effect is realized; by additionally arranging a buffering limiting frame and a shock absorbing limiting frame, the direct contact of the mainframe with the bottom surface is avoided, and damage risk is reduced; and by additionally arranging shock absorbing springs, buffering springs, sliding limiting components and shock absorbing rollers, multiple buffering treatment is carried out, and the retracting step of the unmanned aerial vehicle is more stable and safe.

Owner:合肥齐飞信息技术有限公司

Buffer type conveyor line

Owner:WUXI MINGZHU STEEL BALL

Steel ball receiving tank

InactiveCN104444338AReduce falling speedAvoid collision damageConveyor partsArchitectural engineeringSteel ball

The invention discloses a steel ball receiving tank. The steel ball receiving tank mainly comprises a guide rail, a receiving tank body and a supporting frame. The two ends of the guide rail are connected to the top end of the supporting frame and the sidewall of the receiving tank body in a lap joint mode respectively. The guide rail comprises an inclined plate and two supporting plates. Two identical blocking devices are arranged on the inclined plate in the inclining direction. The two blocking devices are located in the same straight line. Each blocking device comprises a fixed block, a check block and a compression spring, wherein the fixed block is fixed to the bottom of the inclined plate, the check block is hinged to the fixed block, and the two ends of the compression spring are fixed to the inclined plate and the rear end of the check block respectively. Strip-type through holes are formed in the inclined plate and correspond to the front ends of the check blocks. The front ends of the check blocks are connected into the strip-type through holes in an inserted mode. By the adoption of the steel ball receiving tank, the rolling and falling speed of steel balls can be effectively decreased, the situation that the steel balls collide with one another and are damaged due to the fact that the speed of the steel balls falling into the receiving tank body is too high is avoided, the outgoing quality of the steel balls is guaranteed, loss is reduced for an enterprise, resources are saved, and the application range is wide.

Owner:WUXI MINGZHU STEEL BALL

Smart recovery system

ActiveUS8200379B2Shorten speedSlow downAnalogue computers for trafficParachutes testing apparatusOn boardSmart system

This invention relates to an intelligence system on board an aircraft that detects an emergency, assesses the situation, and then acts on the situation in a pre-determined manner.

Owner:MANFREDI DARIO P +1

Safe and high-efficiency grain air injection screening device

InactiveCN108097591AImprove efficiencyGood effectSievingGas current separationBristleWorking environment

The invention discloses a safe and high-efficiency grain air injection screening device. The safe and high-efficiency grain air injection screening device comprises a feeding pipe, a screening box, amaterial shaking plate, a dust collector, a rotary drum, scraper plates, bristle brushes, a filter plate, an aerating device, an inclined guide plate and a rotary motor. The feeding pipe is arranged at the top end of the screening box. The material shaking plate is arranged in the screening box. The top end of the screening box communicates with the dust collector. A dust collection pipe is arranged on the dust collector. A dust collection port is formed in the outlet end of the dust collection pipe. The inner walls of the screening box are movably connected with the two ends of the filter plate. A discharging pipe is arranged on one side of the screening box. The screening box communicates with the aerating device. The rotary drum is arranged above the filter plate. The scraper plates arearranged on the outer edge wall of the rotary drum. The bristle brushes are arranged at the ends of the scraper plates. Full grain is screened out, meanwhile, the situation that dust and other thingsfly to the air and affect the air quality is avoided, the health safety of the working environment is improved, the safety and health of respiratory tracts are ensured, the working efficiency and effect are improved, and the safe and high-efficiency grain air injection screening device is simple in structure, convenient to use and beneficial for popularization.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

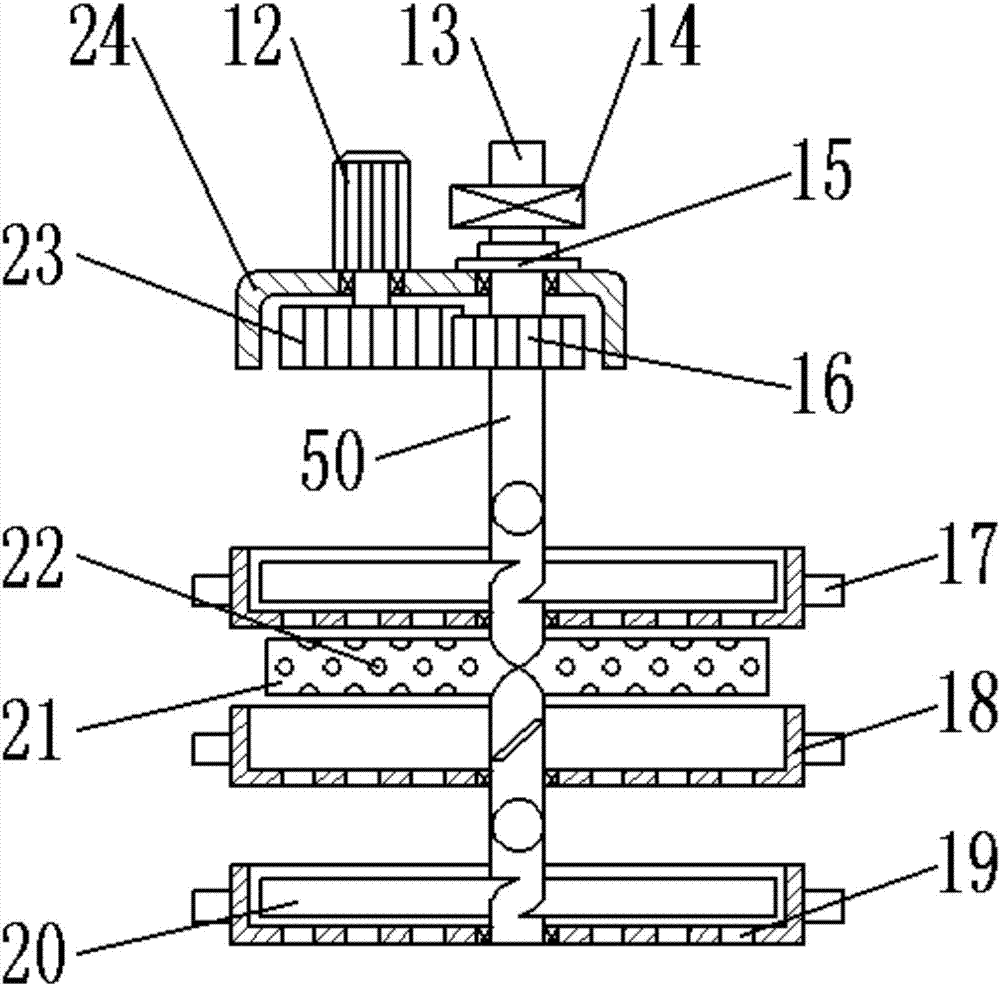

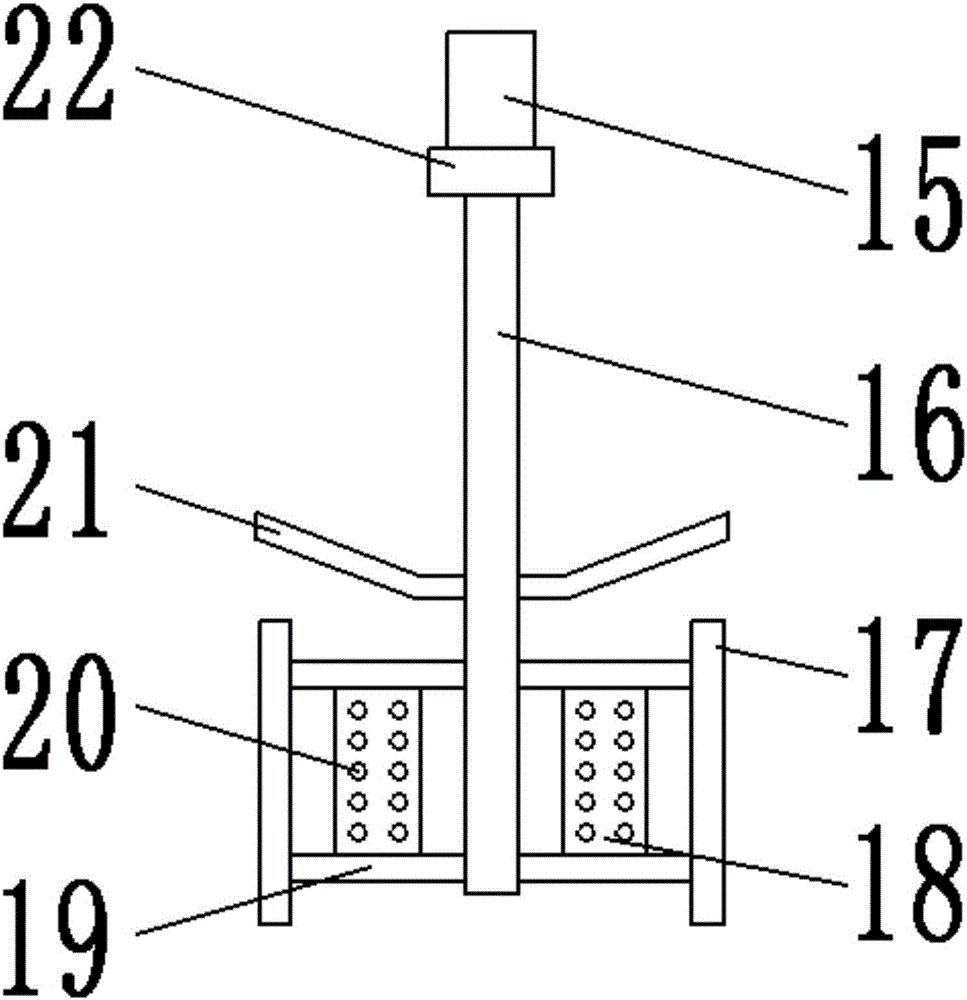

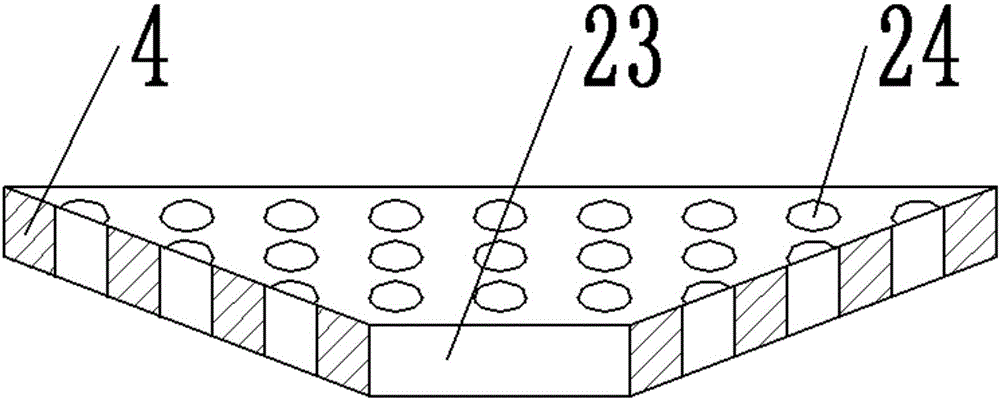

Vibration reducing, completely dischargeable, double stirring reaction device for material supply

InactiveCN106334512AReduce falling speedWell mixedRotary stirring mixersTransportation and packagingBiochemical engineeringMaterial supply

The invention provides a vibration reducing, completely dischargeable, double stirring reaction device for material supply. The device includes a tank body and an upper lid; inside the aforementioned tank body is placed with a reactor chamber; on the aforementioned upper lid is arranged a feeding pipe; inside the aforementioned reactor chamber is arranged with a first stirring device and a second stirring device; the aforementioned first stirring device consists of a first stirring motor, a first stirring shaft, a first stirring piece and a stock guide plate; the aforementioned second stirring device is placed on the bottom part of the tank body, and the second stirring device consists of a second stirring motor, a second stirring shaft and a second stirring piece; the bottom of the tank is connected with a vibration reducing device through a supporting piece; the present invention stirs the material supplies from different directions through the placements of the first stirring device and the second stirring device, thus preventing the loop current from being produced by the material supplies in the tank body, facilitating a full blending of the material supplies and the high efficiency reactions of material supplies; through the vibration reducing device, the vibrations are absorbed during the reaction process of stirring material supplies, which prevents the equipment from shortening service life by long-term use.

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com