Vertical cooling and waste heat recovery furnace for sinters

A technology of waste heat recovery and sintering, which is applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of high rate of rapid cooling and crushing of sintered ore, high air leakage rate of sintered ore, high cost of heat recovery, etc., and achieve airflow direction Optimization, saving fan power consumption, and high production reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

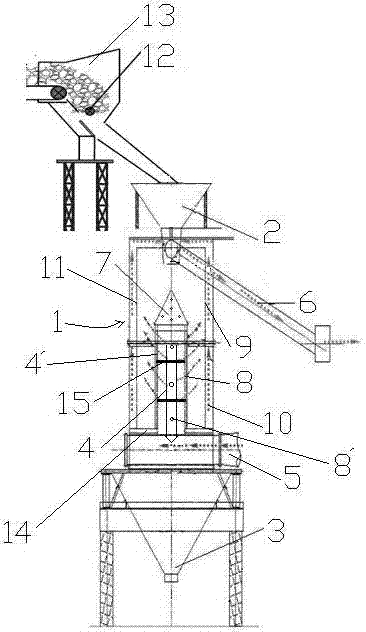

[0042] like figure 1 As shown, the present invention includes a feed hopper 2 and a discharge hopper 3 communicated with the top and bottom of the cooling chamber 1 respectively (both the discharge hopper and the feed hopper are funnel-shaped). The cooling chamber 1 is provided with first and second air pipes 4 and 4' sequentially in the same circle center, and the walls of the first and second air pipes 4 and 4' are respectively provided with a plurality of air outlet holes 8 and 8 '. still as figure 1 As shown, the top of the first air duct 4 is provided with a conical distributor 7 , and the bottom of the second air duct 4 ′ communicates with the cold air inlet duct 5 . still as figure 1 As shown, the first air duct 4 is separated by a partition 15 into three cavities, upper, middle and lower, which are not communicated with each other. The second air duct 4' passes through the lower and middle cavities and then extends into the upper cavity. The air output of the air o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com