Patents

Literature

778results about How to "Full heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Car engine using mixture of comprssed air and fuel oil or fuel gas

InactiveCN1382901AEasy accessPlay the role of air intake boostInternal combustion piston enginesFuel oilInternal combustion engine

A car engine using compressed air and fuel oil / gas as power source has more cylinders, Part of then uses compressed air as power source and other are IC engien unit whose exhausted gas is used to heat the input air of said non-IC unit via heat exchanger. The exhausted gas of said non-IC unit is used as the input gas of IC engine unit for boosting the input gas. Its advantages are reasonable structure, high efficiency and low environmental pollution.

Owner:ZHEJIANG UNIV

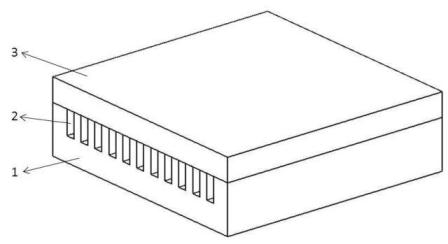

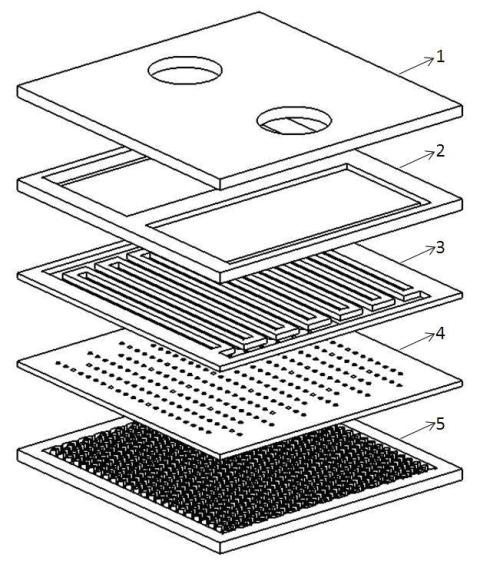

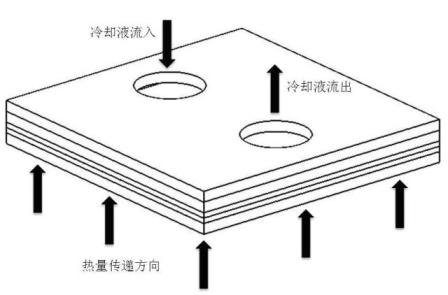

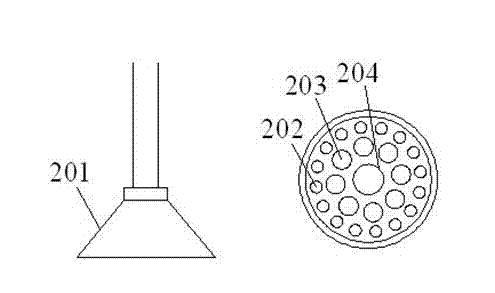

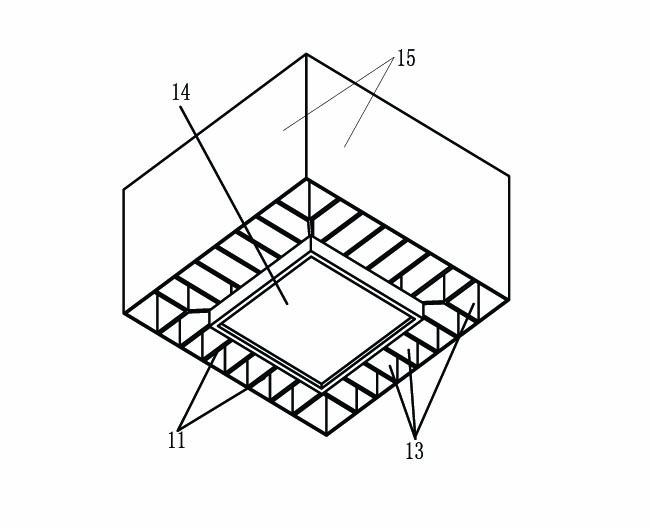

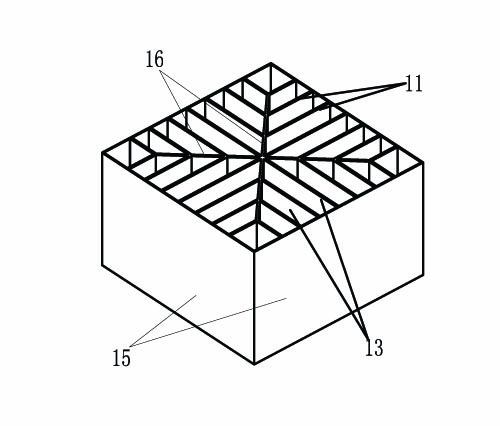

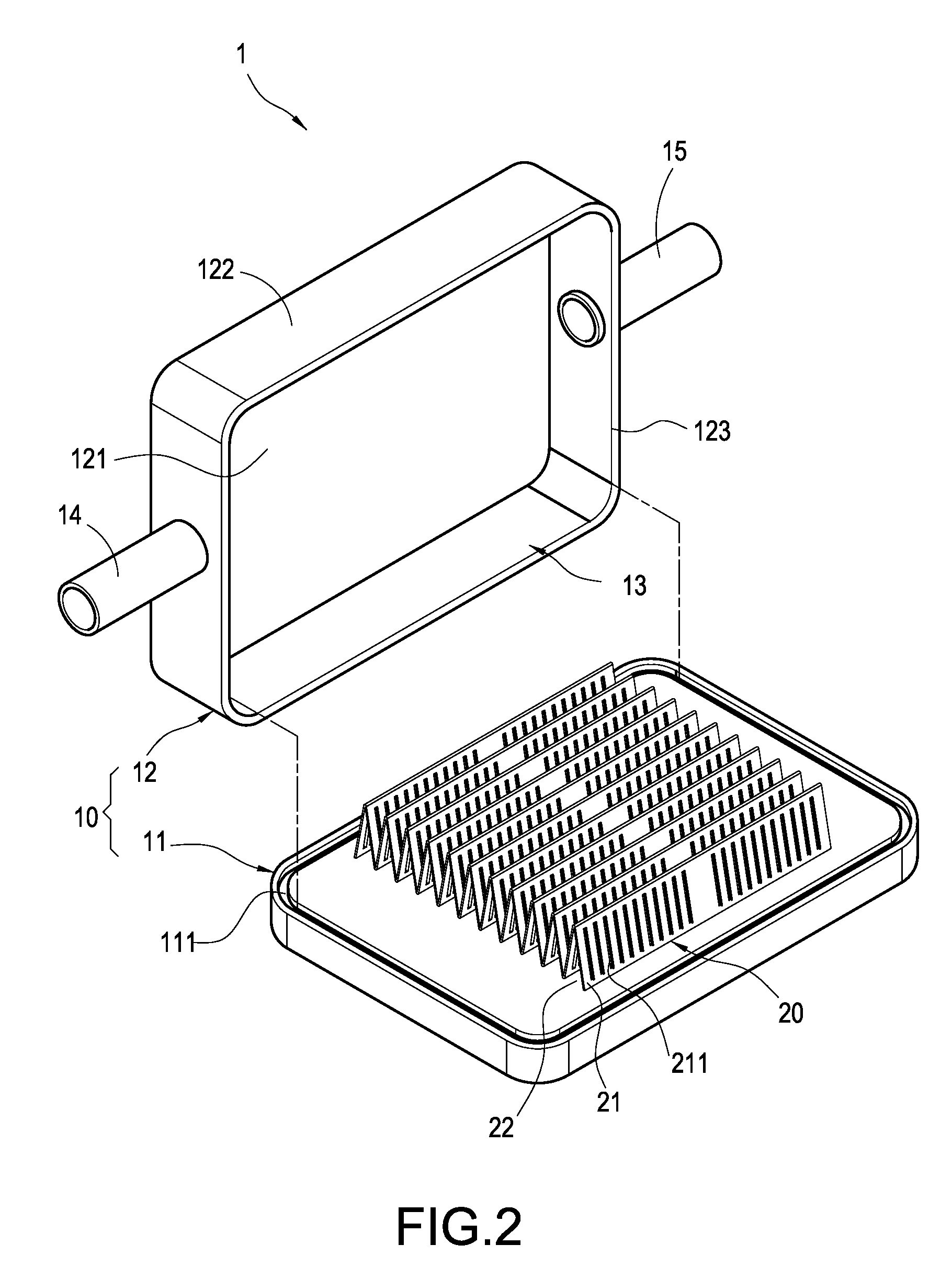

Prism-array jet micro-channel radiator

InactiveCN102014598AReduce temperature gradientFull heat exchangeCooling/ventilation/heating modificationsJet flowPrism

The invention relates to a prism-array jet micro-channel radiator. The radiator comprises a prism-array structure, a jet structure, an outlet-inlet cross structure, a liquid separating structure and an outlet-inlet arrangement structure. In the invention, cooling liquid enters the radiator via an inlet and then is led to side clearance through the liquid separating structure so as not to be mixedwith cooling liquid at an outlet; the distance between the outlet and the inlet is shortened by means of the comb-shaped outlet-inlet cross structure so as to reduce pressure drop; after reaching themultihole jet flow structure, the cooling liquid can be uniformly introduced onto a heated silicon substrate so that the temperature of the substrate is more uniform, heat is more easily taken away by the generated turbulent flow and meanwhile the pressure drop is also reduced by the jet structure; and finally the cooling liquid easily forms turbulent flow by means of the prism-array structure sothat the heat transferred to the prism structure from the substrate is more easily taken away, thus increasing the heat exchange efficiency. The prism-array radiator can be used in a cooler for microstructures such as an electronic chip, an LED and the like.

Owner:SHANGHAI UNIV

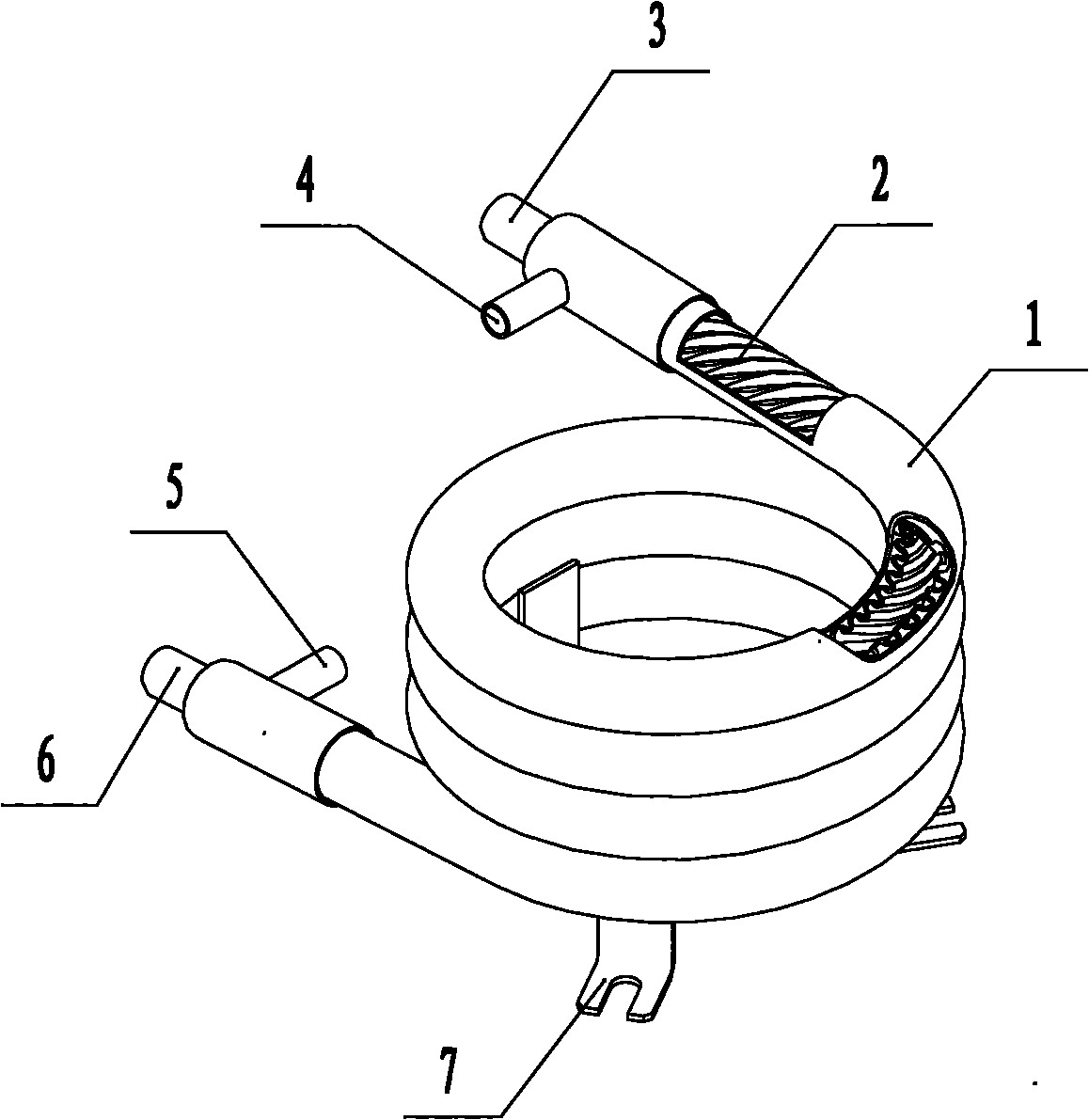

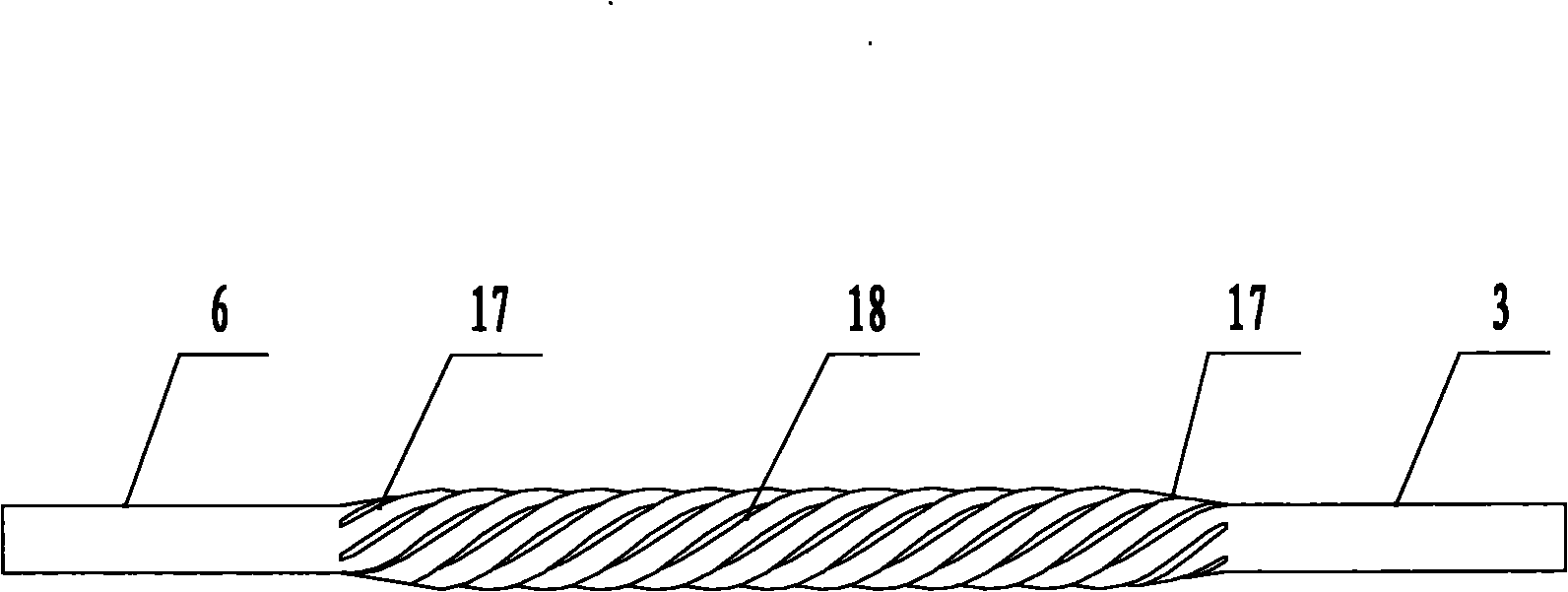

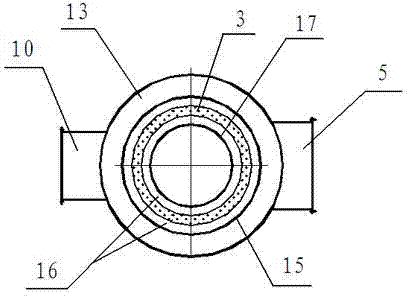

Coaxial heat exchanger

InactiveCN102116585AReduce consumptionImprove heat transfer effectHeat exhanger conduitsStationary tubular conduit assembliesEngineeringHigh heat

The invention provides a coaxial heat exchanger. The coaxial heat exchanger comprises an outer tube and an inner tube which are sleeved coaxially; the main body section of the inner tube is a multi-head spiral tube with a plurality of parallel spiral slot structures; both ends of the inner tube are used as a first fluid inlet and a first fluid outlet respectively; both ends of the outer tube are used as a second fluid inlet and a second fluid outlet respectively; a first fluid passageway is formed in the inner tube; a second fluid passageway consisting of a plurality of parallel spiral slots is formed between the outer tube and the inner tube; the second fluid passageway uniformly encircles the first fluid passageway; first fluid flows into the inner tube and flows out of the inner tube through the first fluid passageway; second fluid flows in the second fluid passageway; and the two kinds of fluid flows reversely so as to exchange heat through the tube wall of the inner tube. The coaxial heat exchanger provided by the invention has a large heat exchange area and high heat exchange efficiency; and the metal consumption of unit heat exchange area is low and the volume of the heat exchanger can be reduced, so the whole structure is compact and rational, and the coaxial heat exchanger is easy and convenient to operate and install.

Owner:EXTEK ENERGY EQUIP ZHEJIANG

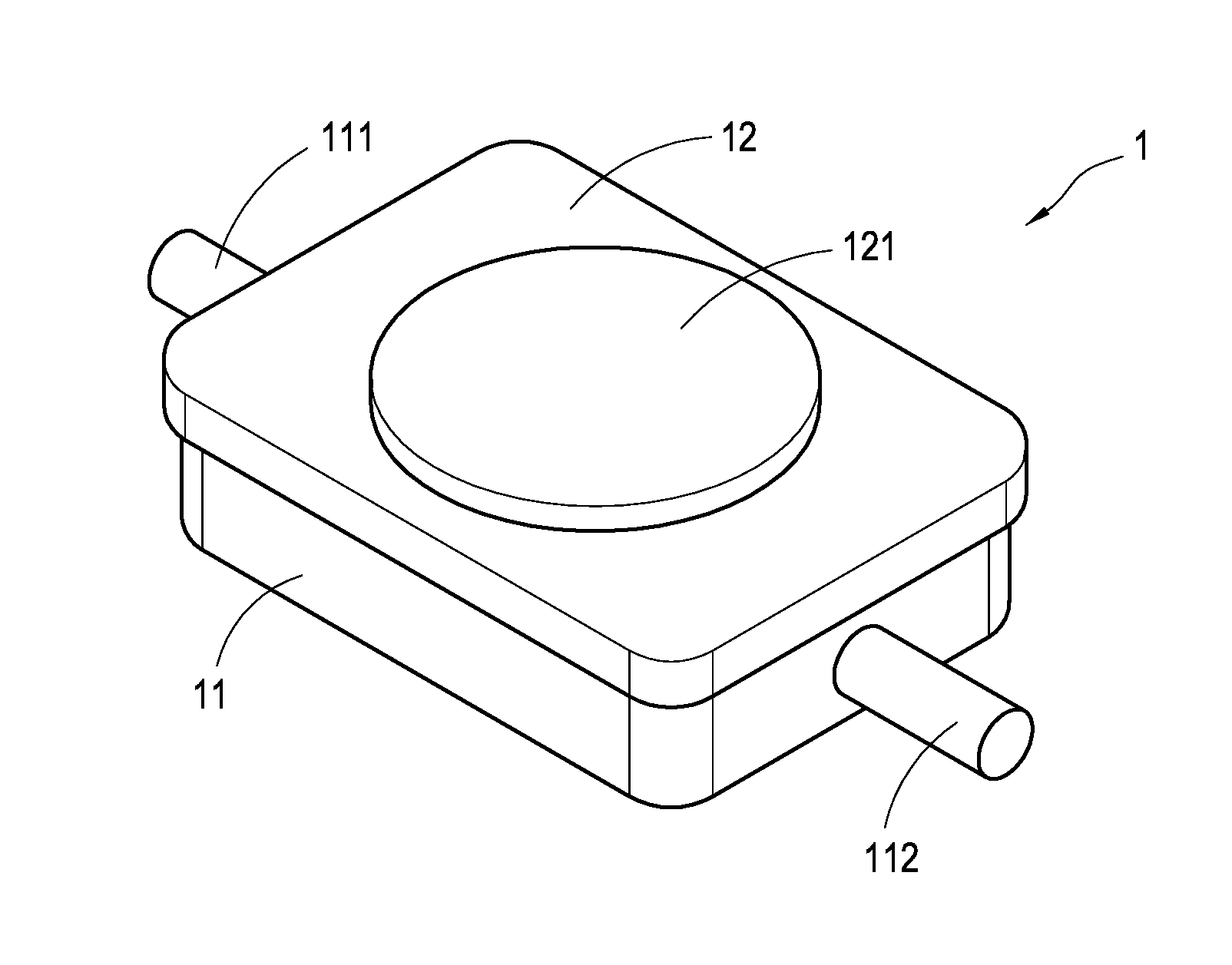

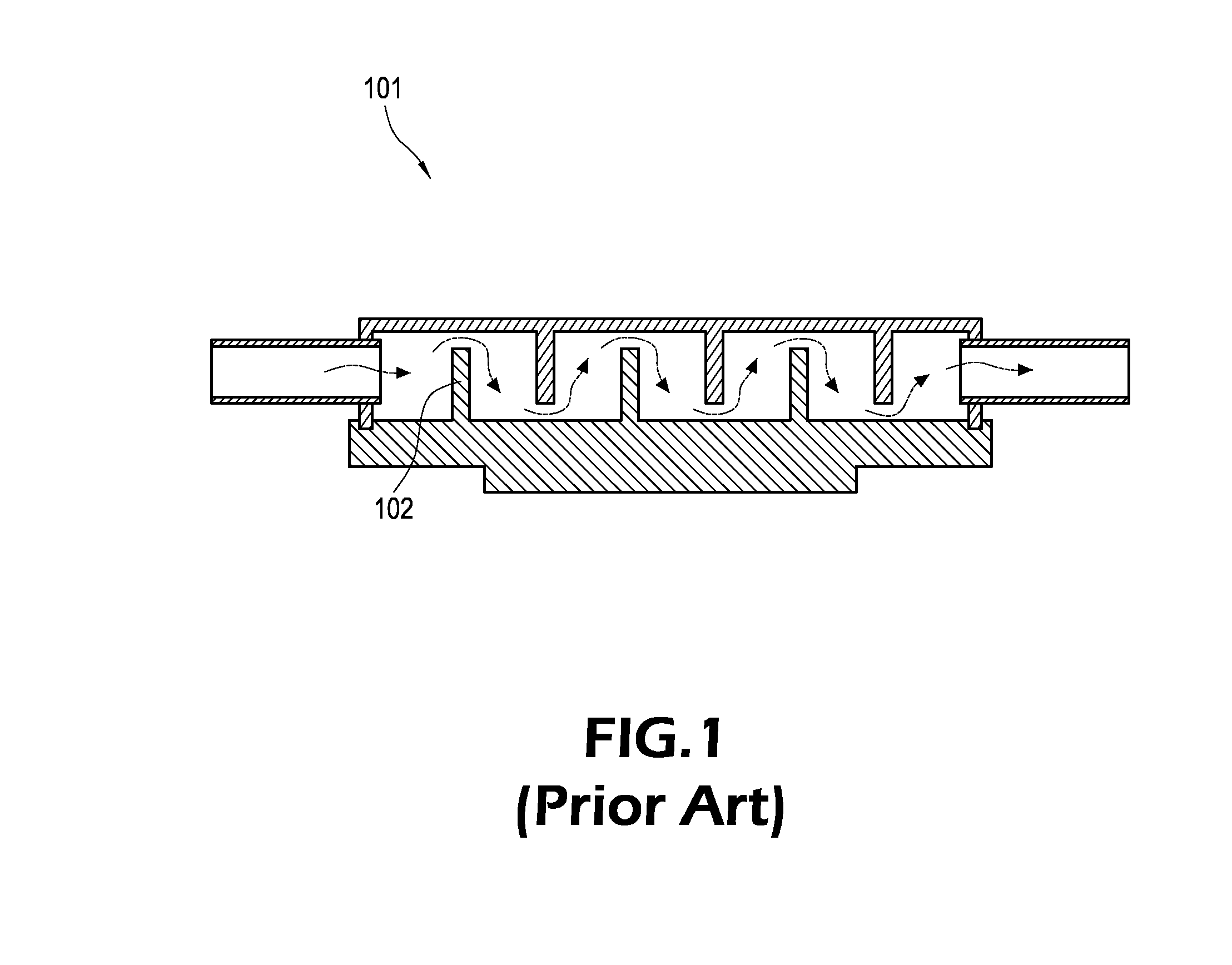

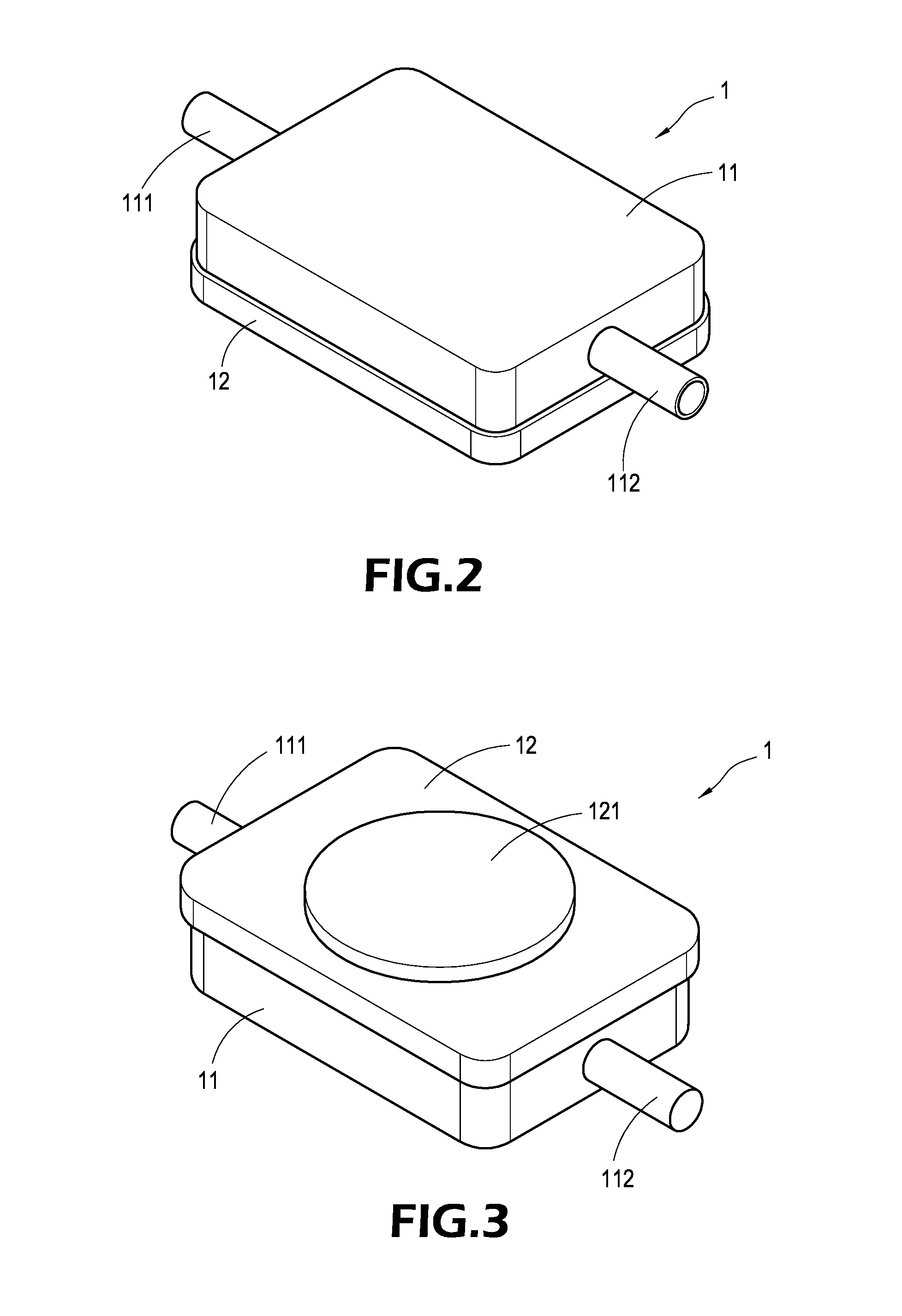

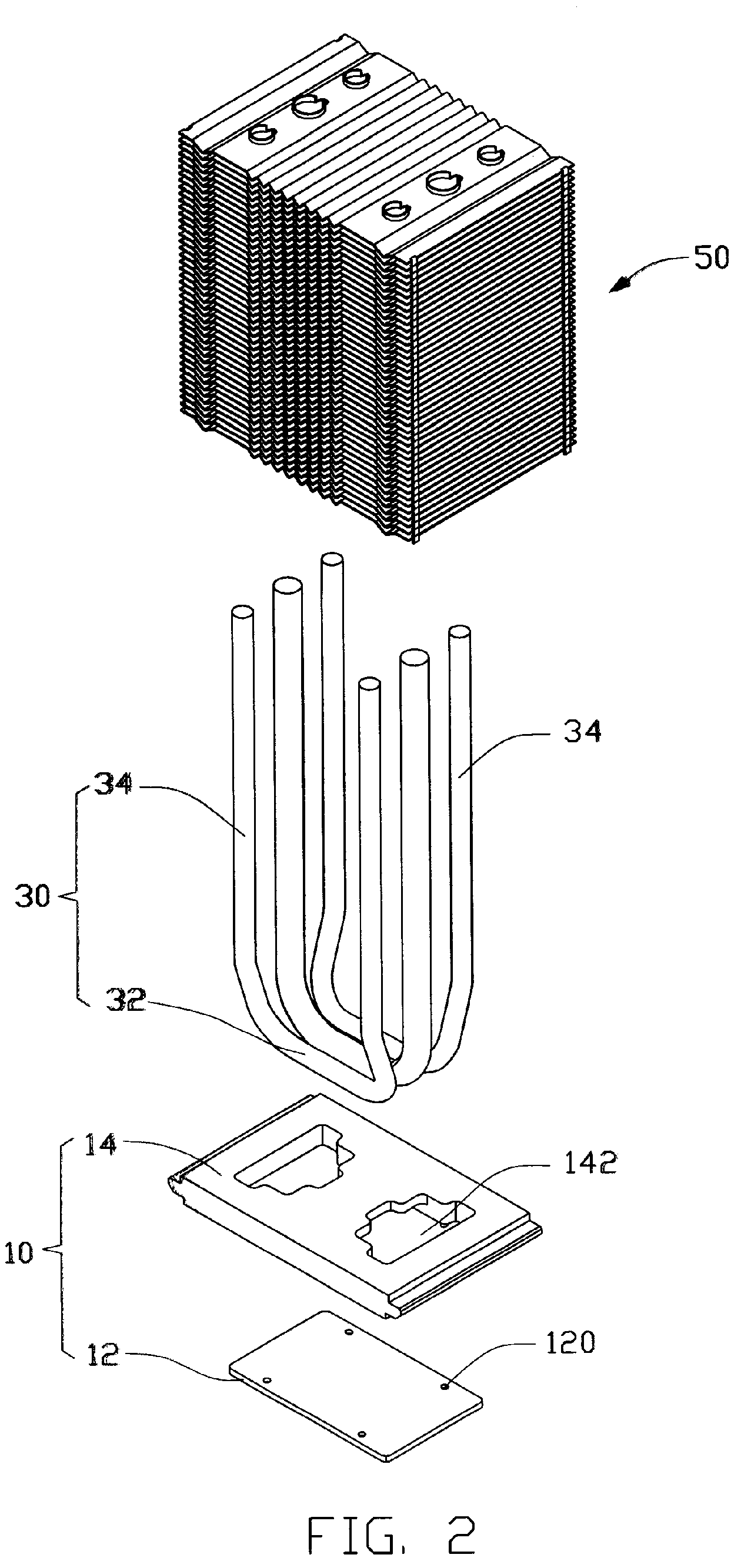

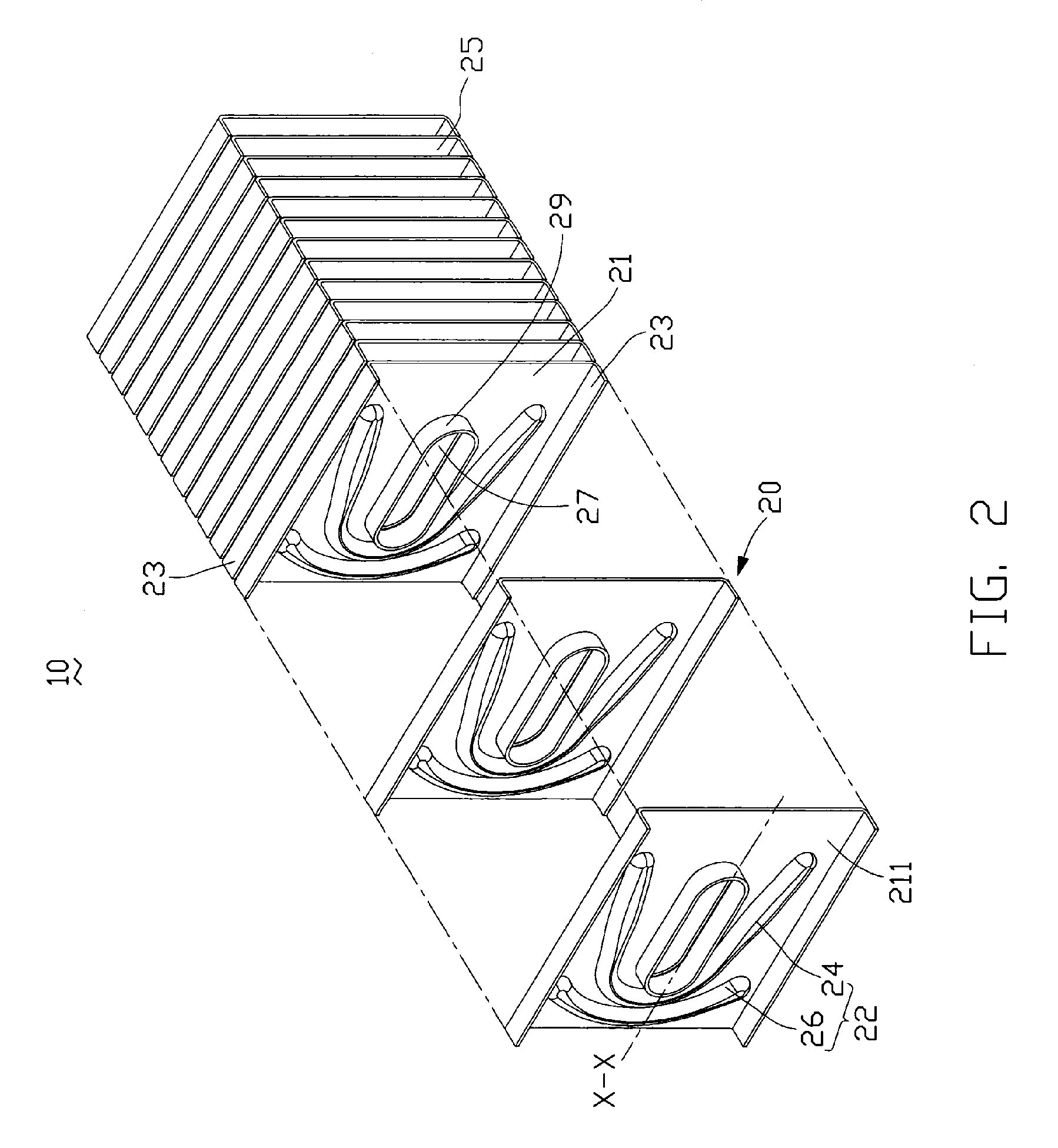

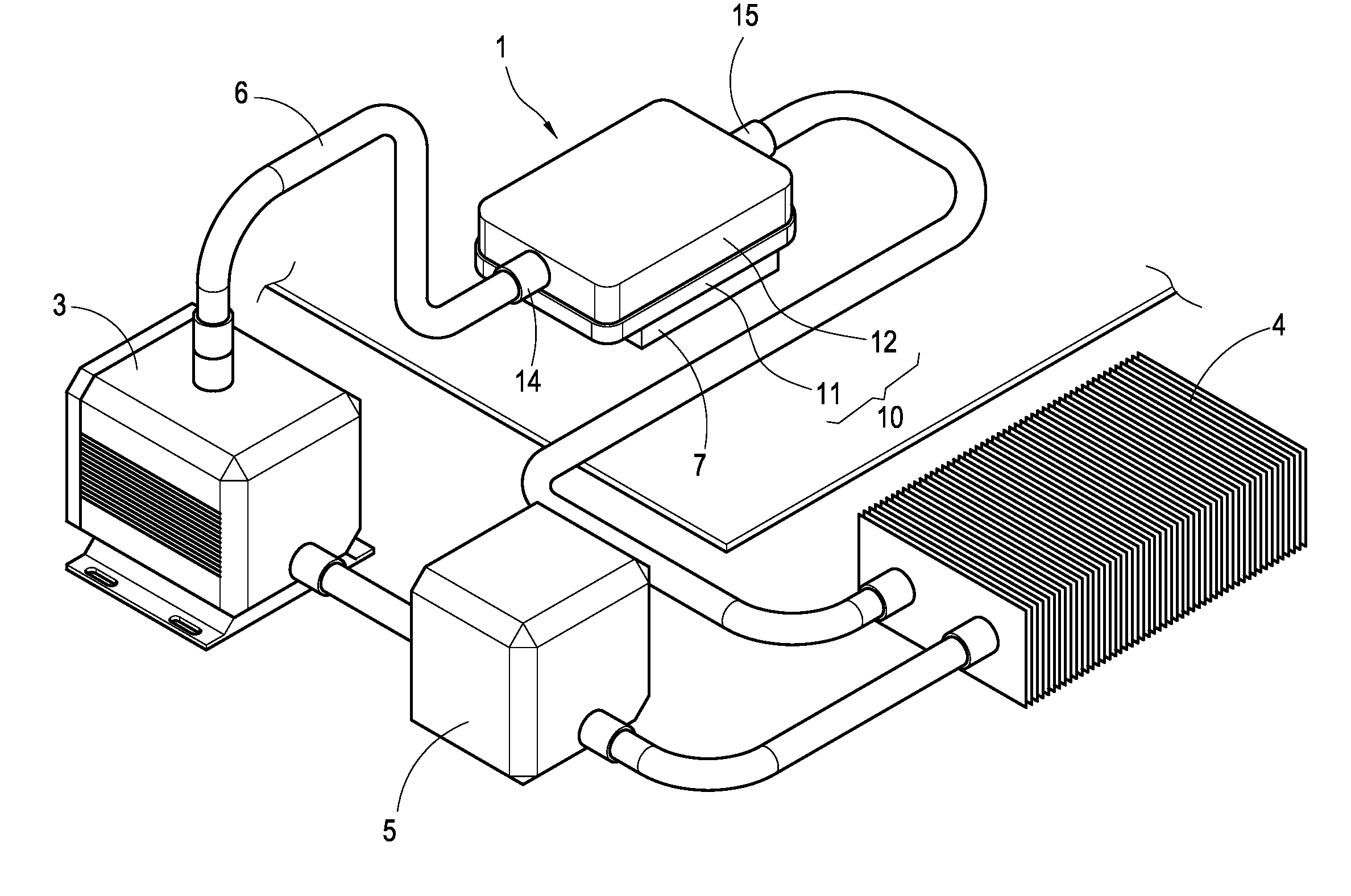

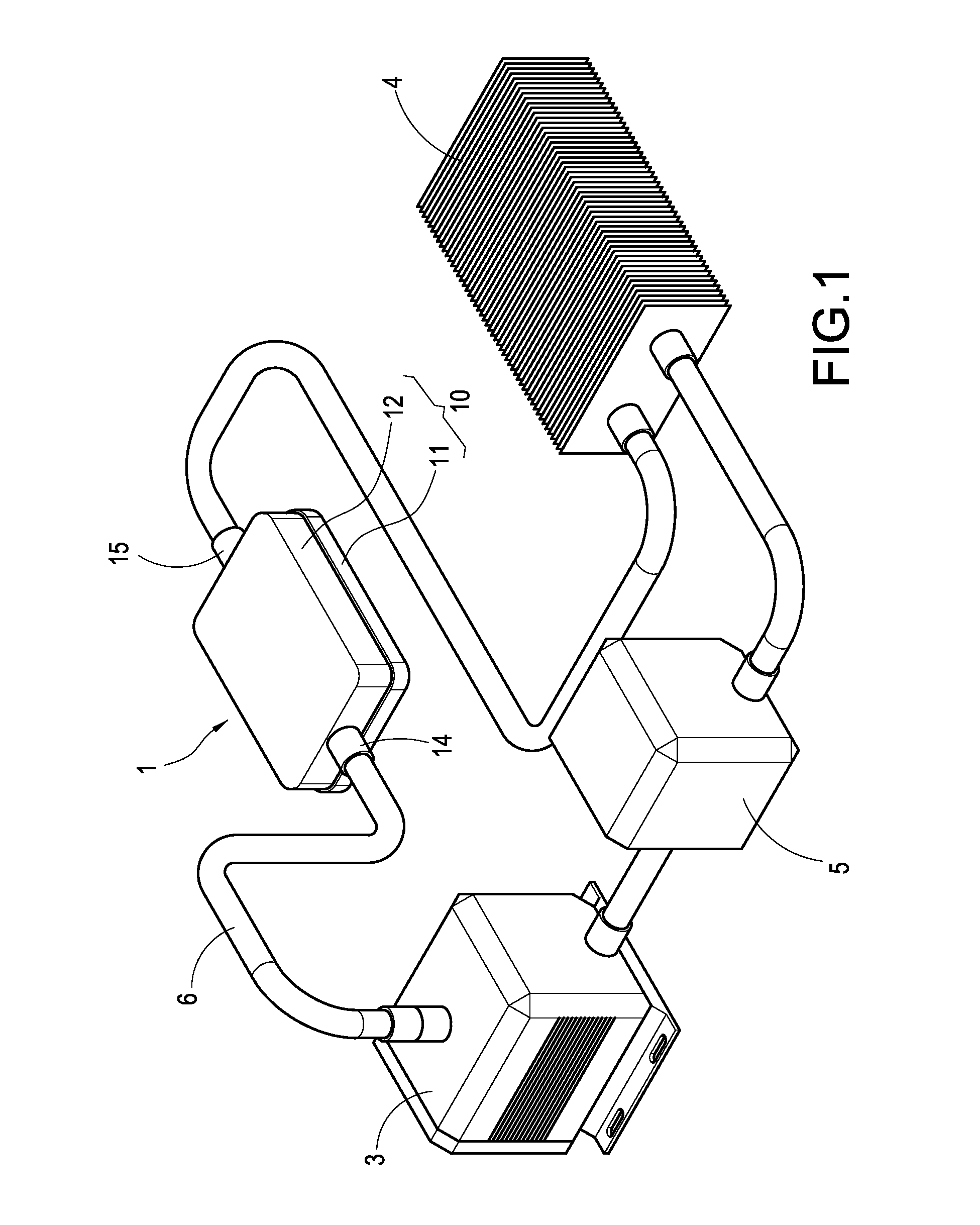

Water Cooling Type Heat Dissipation Apparatus with Parallel Runners

InactiveUS20070107874A1Full heat exchangeImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

A water cooling type heat dissipation apparatus includes a heat dissipation stage having an upper cover and a lower cover. A first passageway and a second passageway extend from two ends of the upper cover. The upper cover includes a concave on inner side thereof. The lower cover includes a contact face and a heat conduction post arranged on inner bottom side of the lower cover. A plurality of heat dissipation fins is arranged on the heat conduction post and separated to each other to define parallel runners therebetween. Heat from heat source is absorbed by the contact face and conducted to the heat conduction fins through the heat conduction post. Liquid coolant flows into the parallel runners through the first passageway and resisted by the heat conduction post. Therefore, liquid coolant has sufficient heat exchange with the heat conduction fins and then exits through the second passageway.

Owner:COOLER MASTER CO LTD

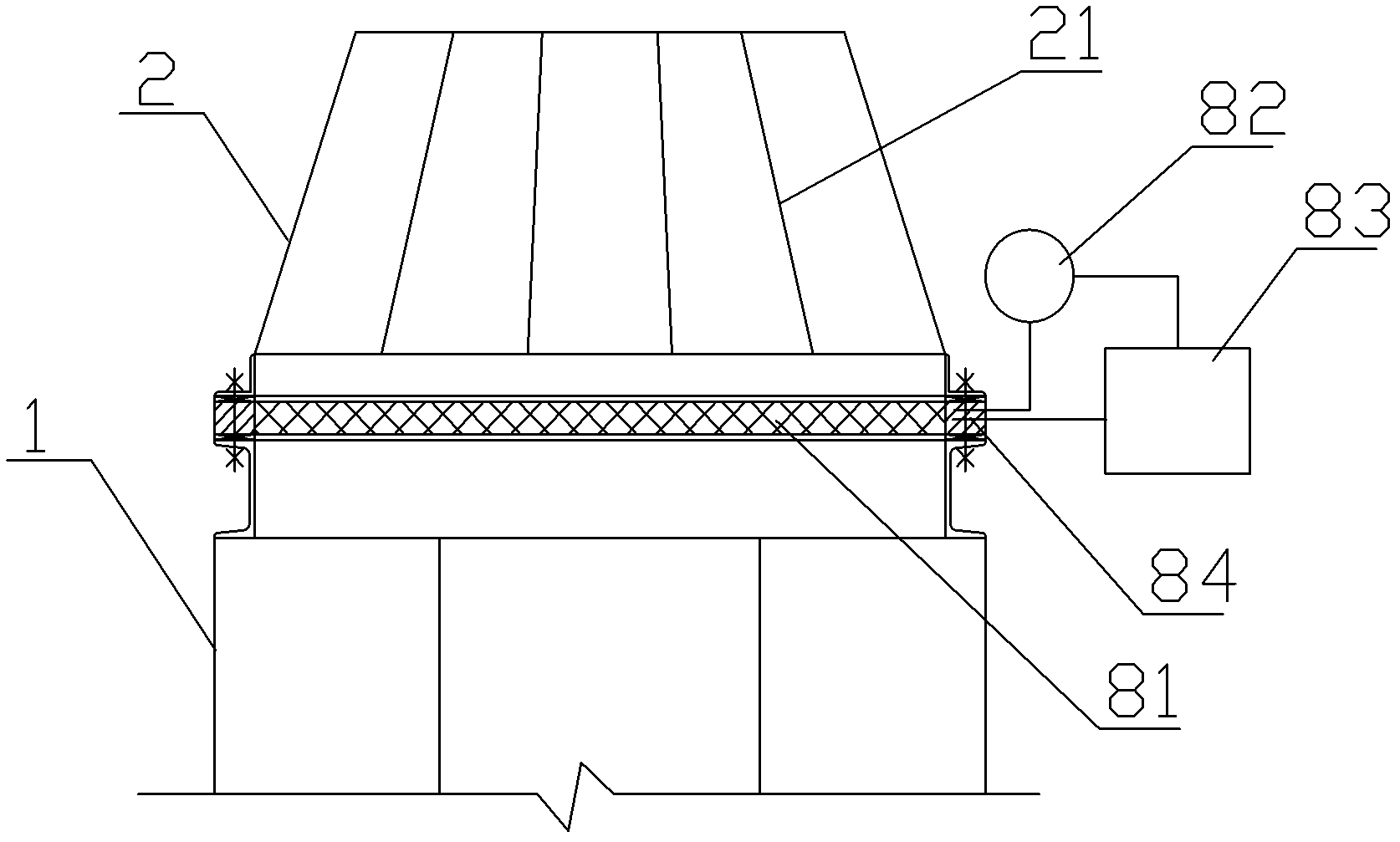

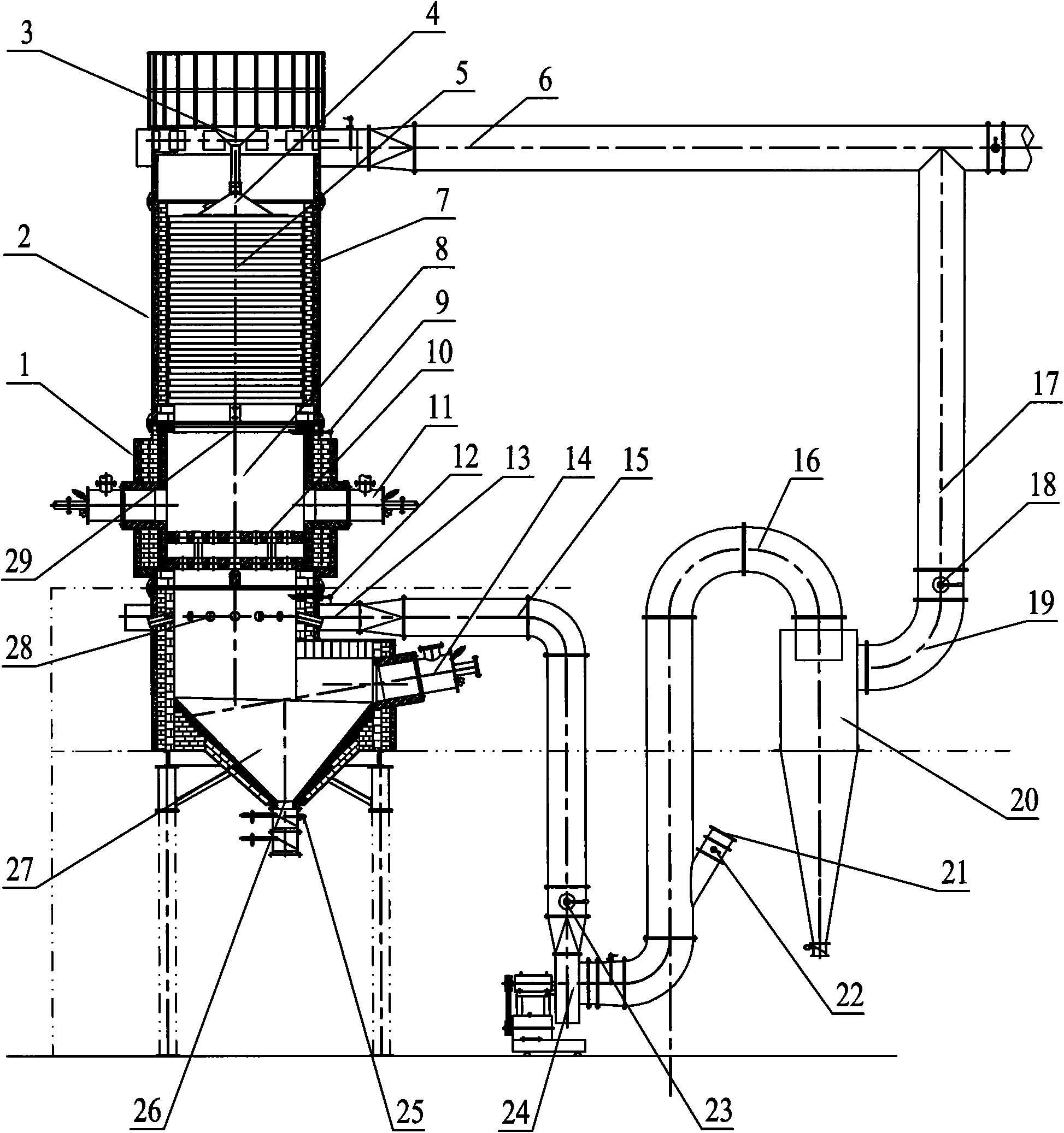

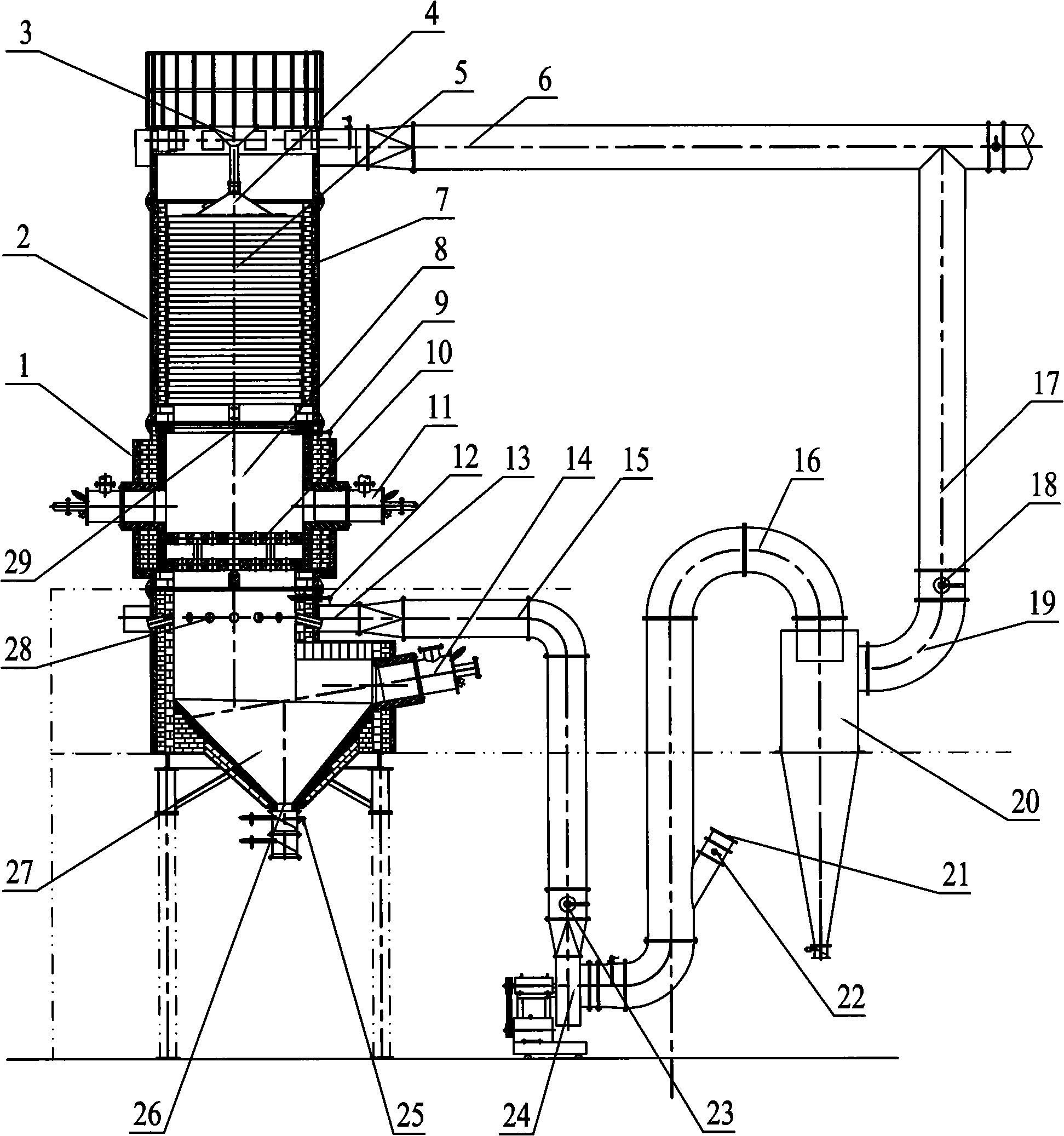

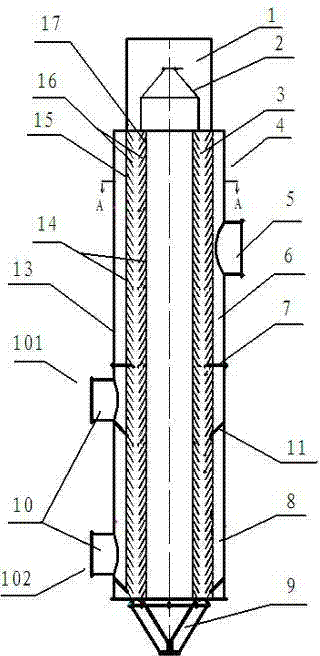

Vertical cooling and waste heat recovery furnace for sinters

ActiveCN103697707AReduce resistanceReduce power consumptionIncreasing energy efficiencyHandling discharged materialCold airFlue gas

The invention discloses a vertical cooling and waste heat recovery furnace for sinters, which comprises a feeding hopper and a discharge hopper, wherein the feeding hopper and the discharge hopper are respectively communicated with the top and the bottom of a cooling chamber; first and second air ducts are sequentially sleeved in the cooling chamber; the walls of the first and second air ducts are respectively provided with a plurality of air outlet holes; the top of the first air duct is provided with a cone distributor; the bottom of the second air duct is communicated with a cold air inlet pipe; the cooling chamber is provided with an inner sleeve; a plurality of vent holes are distributed in the wall of the inner sleeve; a hot air collecting cavity is formed between the inner sleeve and a housing of the cooling chamber; the upper part of the hot air collecting cavity is communicated with a hot waste gas exhaust pipe; and the bottom of the hot air collecting cavity is communicated with the discharge hopper. The invention provides a cooling system integrating sinter cooling with closed hot flue gas recovery and waste heat utilization; the vertical cooling and waste heat recovery furnace for the sinters operates under a negative pressure in the cooling process; emission of pollutants can be greatly reduced; the field environment is improved; and the heat recovery rate is improved.

Owner:铜陵市富鑫钢铁有限公司

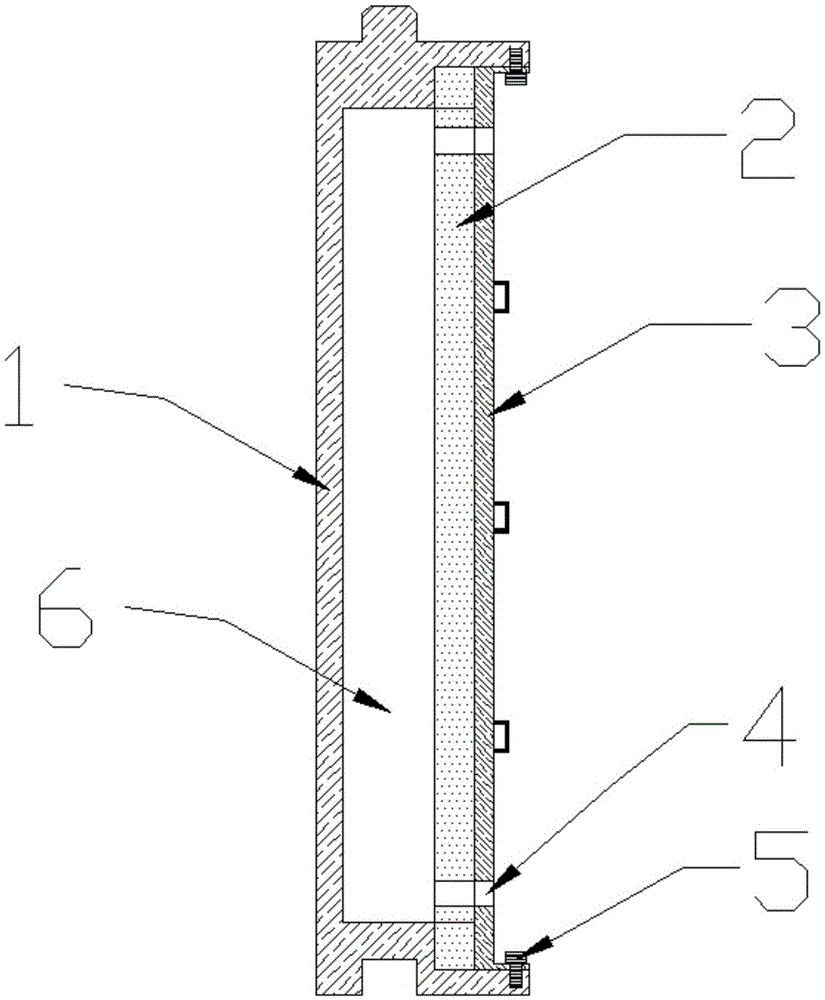

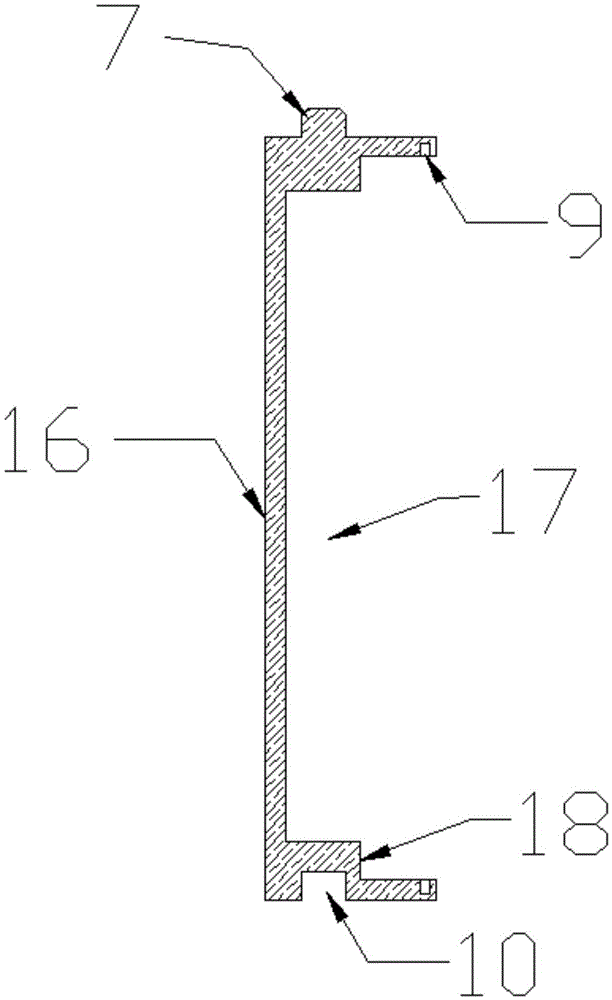

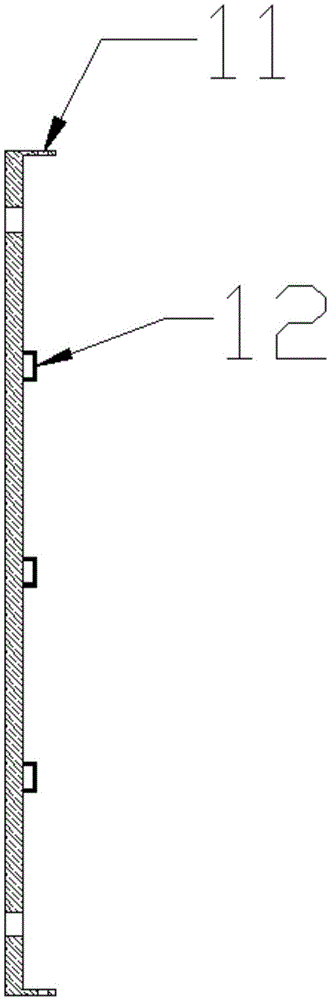

Ascending pipe heat exchange device for raw gas of coke oven

ActiveCN103436272AImprove insulation effectReduce lossesEnergy inputStationary tubular conduit assembliesSaline waterFlue gas

The invention discloses an ascending pipe heat exchange device for the raw gas of a coke oven, and belongs to the technical field of recycling utilization of raw gas afterheat. The ascending pipe heat exchange device for the raw gas of the coke oven comprises a flue gas inlet flange arranged at the lower end of the ascending pipe heat exchange device, a flue gas outlet flange arranged at the upper end of the ascending pipe heat exchange device, an inner barrel, a middle barrel and an outer barrel, wherein an inner sandwich layer is formed between the inner barrel and the middle barrel, desalted water or nitrogen or air is fed into the inner sandwich layer, and an outer sandwich layer is formed between the middle barrel and the outer barrel and is a closed thermal insulating layer. The ascending pipe heat exchange device can be used for ensuring a heat exchange effect, effectively, safely and reliably recycling the raw gas afterheat, ensuring the safe and economic operation of the coke oven and a heat exchanger under severe working conditions and meanwhile solving the problem of narrow adaptation of a conventional heat exchanger in starting and stopping processes.

Owner:江苏龙冶节能科技有限公司

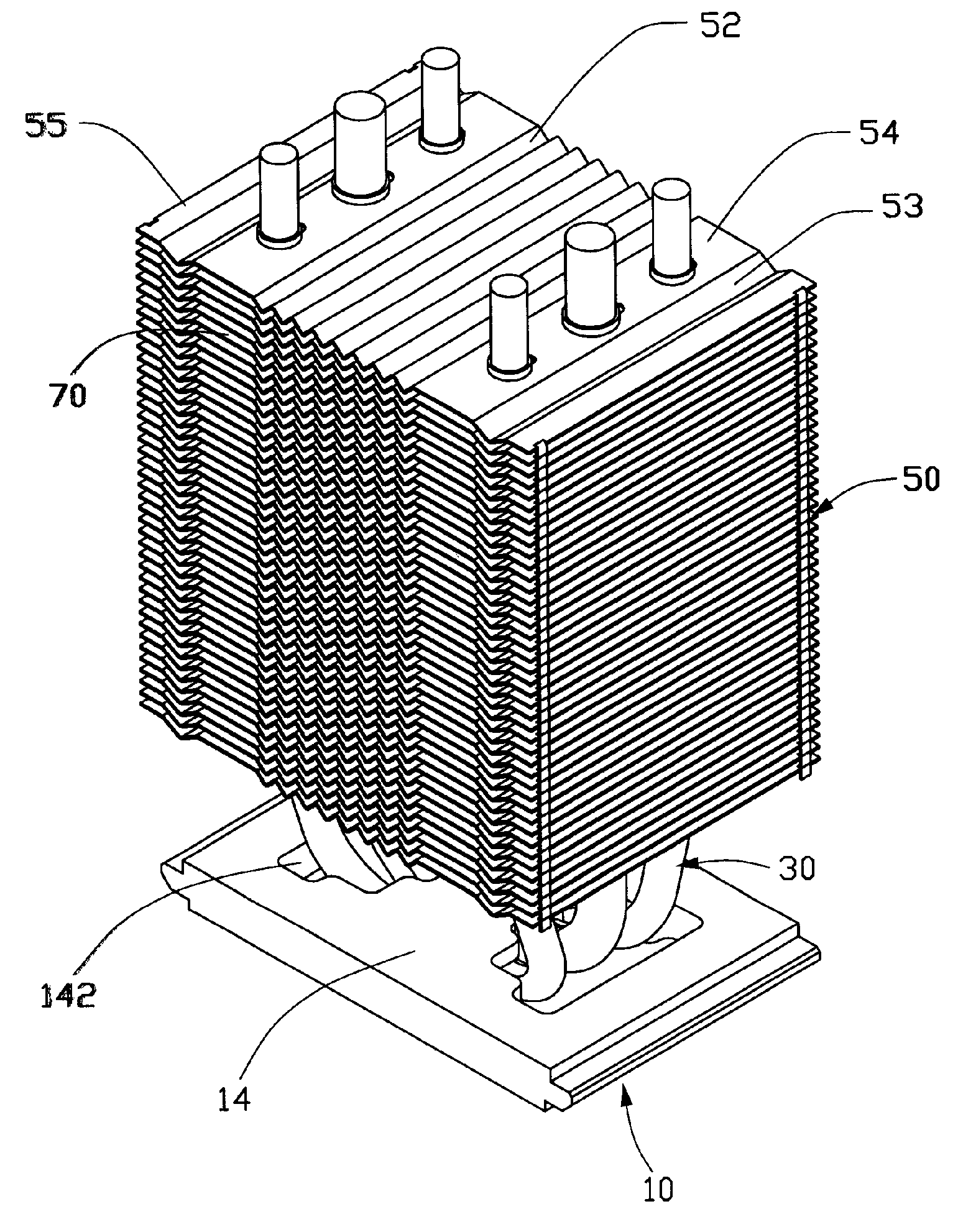

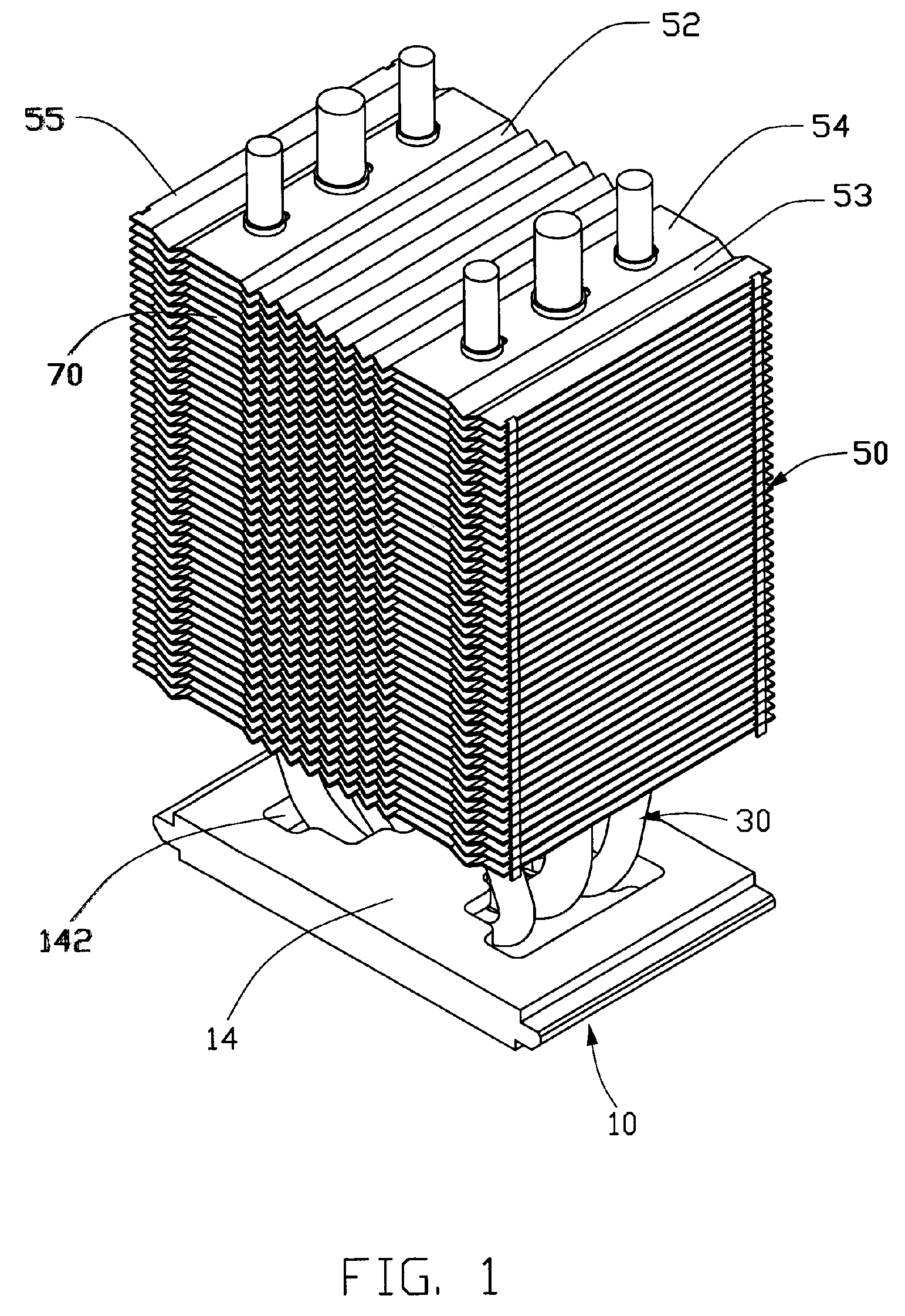

Heat dissipation device

ActiveUS7249626B2Increase cooling areaHigh strengthSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

A heat dissipation device includes a fin unit (50), and at least a heat pipe (30) including an evaporating section (32) and at least a condensing section (34) extending through the fin unit. The fin unit includes a plurality of fins stacked together. Each fin comprises a wavy and a V-shaped section (52,53) and a planar section (54) therebetween. The wavy and V-shaped sections of the fins can guide an airflow flowing into the fin unit to smoothly flow therethrough, and prevent escape of the airflow from lateral directions of the fin unit. Furthermore, the wavy and V-shaped sections increase the heat dissipation area of the fins and strengthen the fins.

Owner:CHAMP TECH OPTICAL FOSHAN

Preparation method of copper and magnesium alloy contact wire for railway electrification

ActiveCN103276237AIncrease production capacityReduce the temperatureSingle bars/rods/wires/strips conductorsMetal/alloy conductorsMisch metalNiobium

A copper and magnesium alloy contact wire for railway electrification comprises a copper base and alloy metal, wherein the alloy metal comprises components in percentage by weight as follows: 0.5-0.6% of magnesium, 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.005-0.008% of titanium and 0.02-0.04% of misch metal. A preparation technology adopts an upward continuous casting extrusion-cold rolling-stretching technology. The oxygen content of the prepared contact wire reaches an oxygen-free copper level, the grain is fine, the mechanical property is remarkably improved, the contact wire is uniform in a length direction, the flatness is good, the locomotive picking-up performance is good, the tensile strength, the elongation percentage, the grain size and the toughness are greatly improved when the copper and magnesium alloy contact wire is compared with a conventional wire, and the copper and magnesium alloy contact wire has wide popularization and application values in the high-speed railway electrification field.

Owner:山东维点技术有限公司

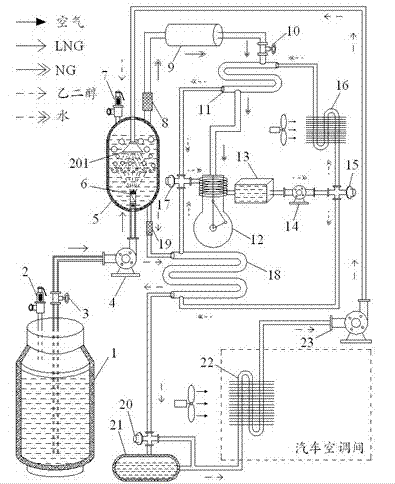

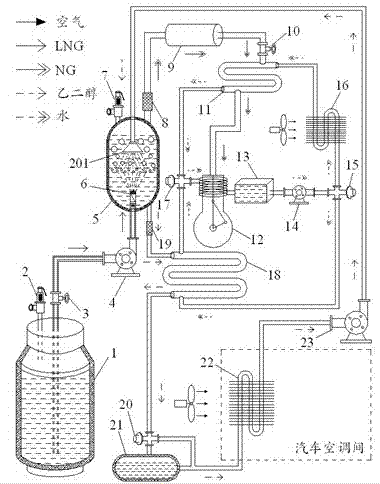

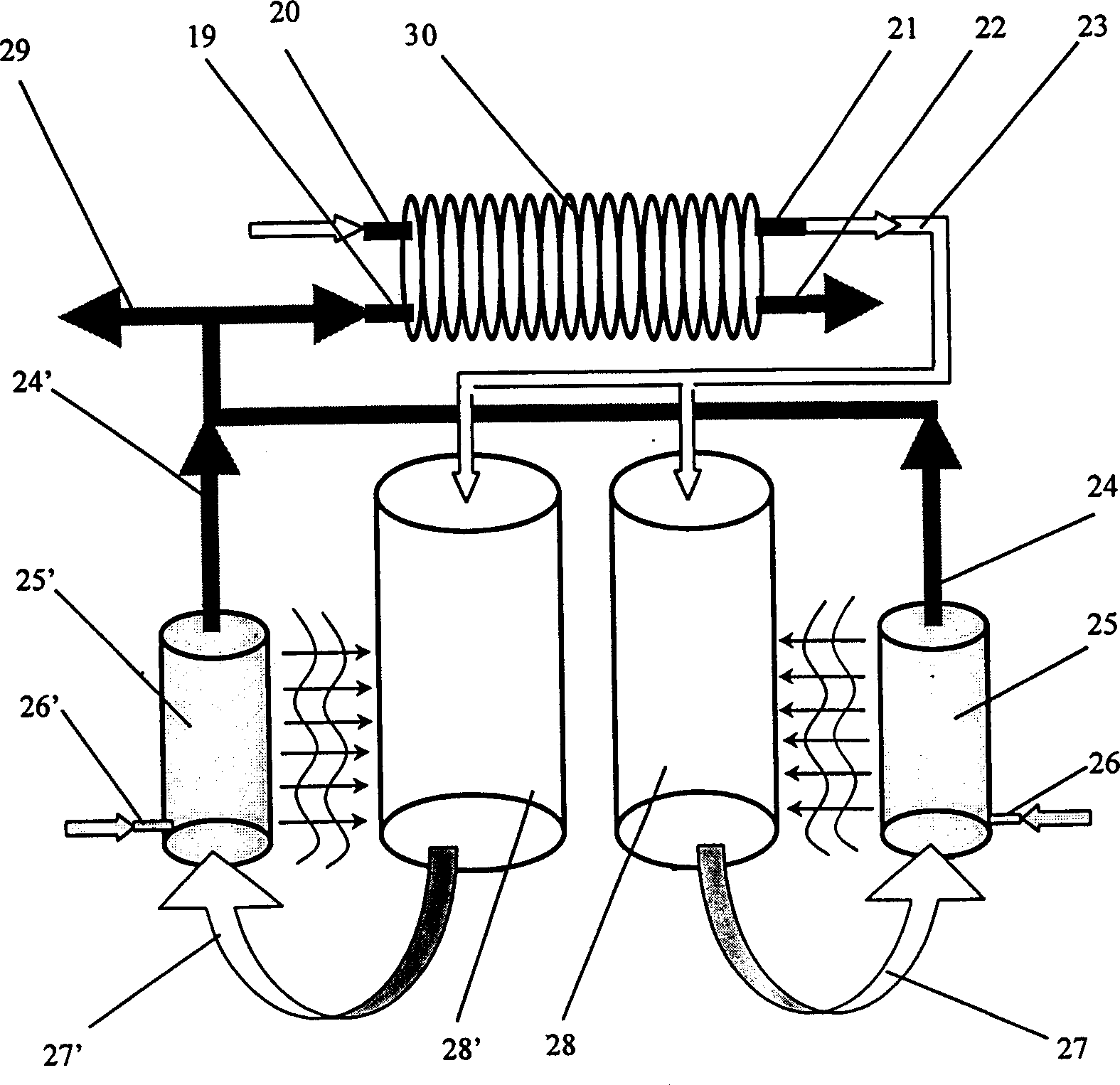

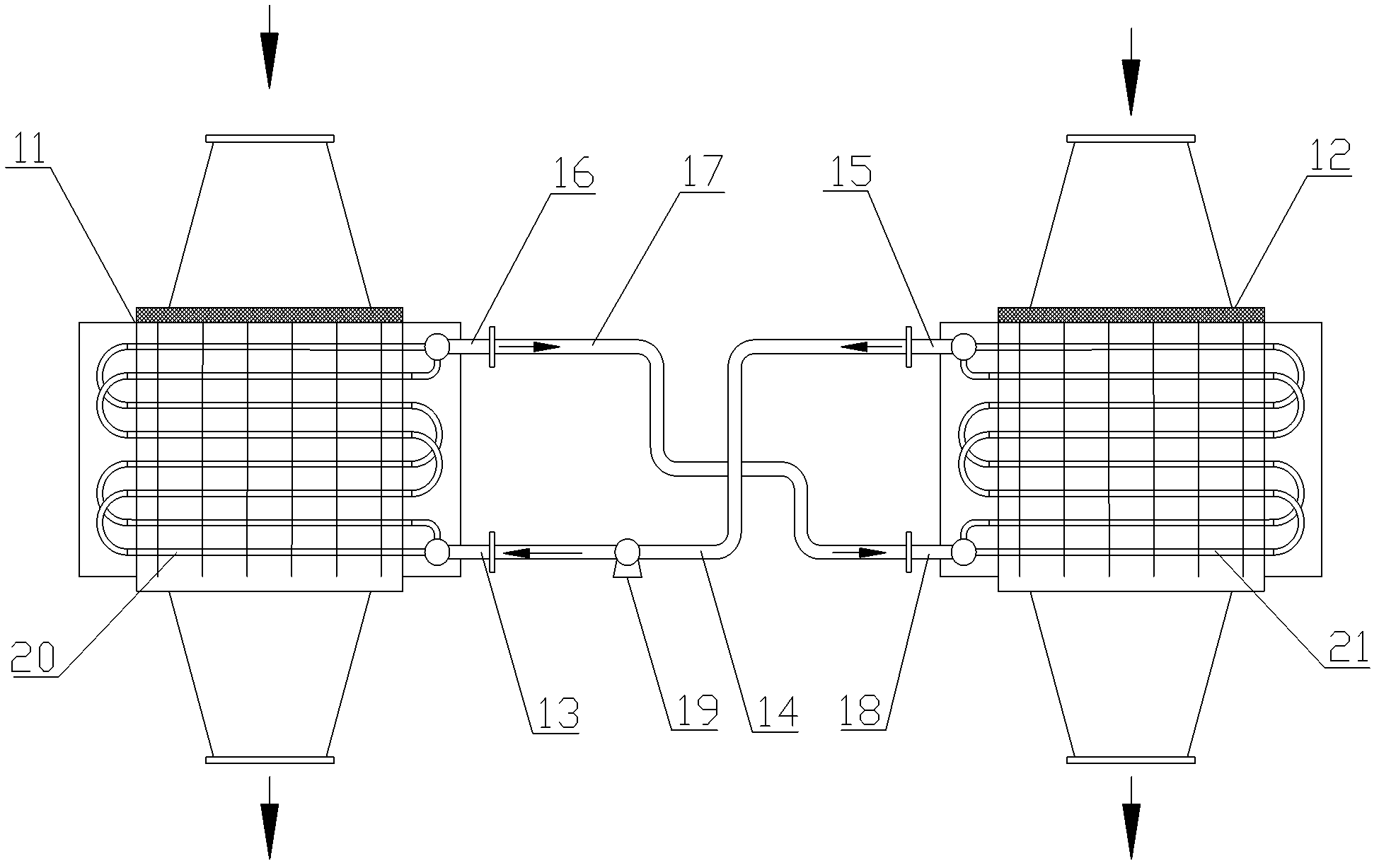

Automotive air conditioning system using cold energy of liquefied natural gas

InactiveCN102198783AFull heat exchangeRealize temperature regulationAir-treating devicesDomestic cooling apparatusSolution systemLiquefied natural gas

The invention discloses an automotive air conditioning system using the cold energy of liquefied natural gas, which comprises a liquefied natural gas system consisting of an LNG (Liquefied Natural Gas) storage tank, a low temperature valve, a low temperature pump and the like, an ethylene glycol solution system consisting of a third electric three-way regulating valve, an ethylene glycol storage unit, an air heat exchanger, an ethylene glycol solution pump and the like, a direct contact boiling heat transfer system consisting of an ethylene glycol spray tank, a first gas / liquid separator, a second gas / liquid separator, a natural gas storage tank and the like, an automobile engine cooling water system consisting of an electric valve, an automobile engine, a cooling water tank, a cooling water pump, an air cooled water cooler and the like, and connection components of the automobile engine cooling water system. In the automotive air conditioning system, ethylene glycol solution is used as cooling medium, the direct contact boiling heat transfer way in which the liquefied natural gas is sprayed upwards from the bottom and the ethylene glycol solution is jetted downwards from the top is adopted in the ethylene glycol spray tank, thus the cold energy of the ethylene glycol solution is utilized to cool the space of an automotive air conditioning room in summer and heat the space of the automotive air conditioning room in winter.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

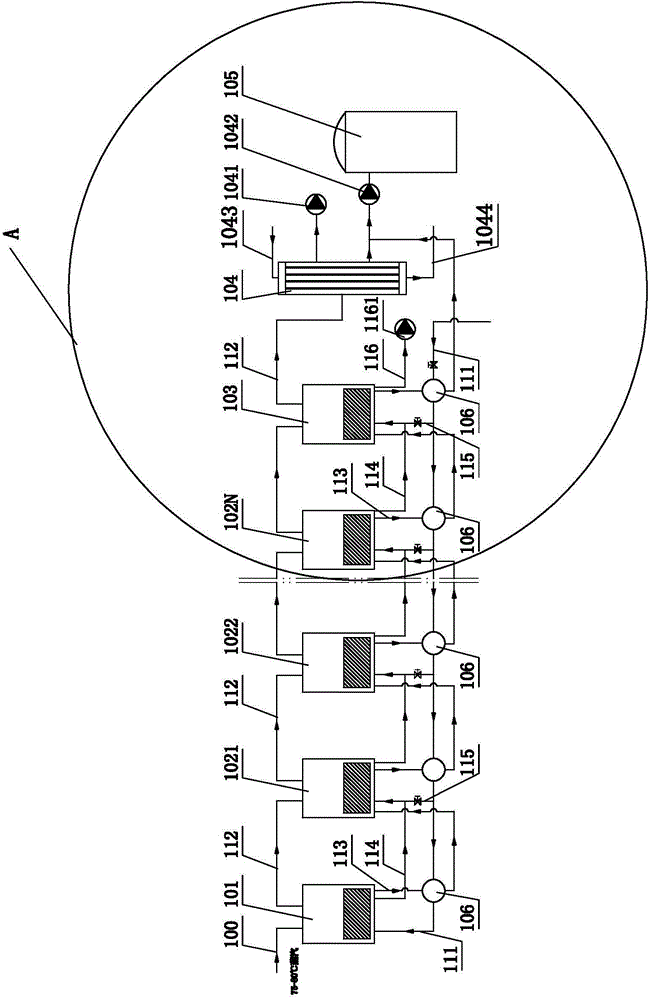

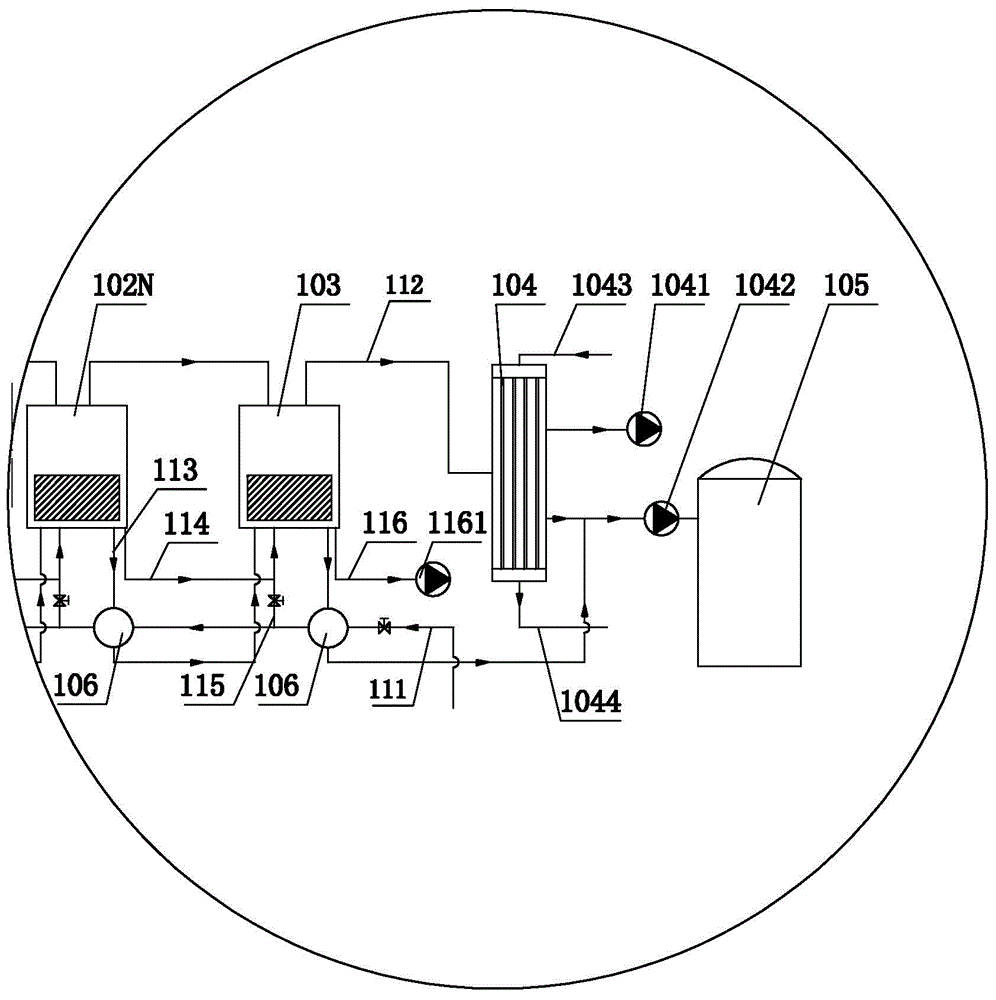

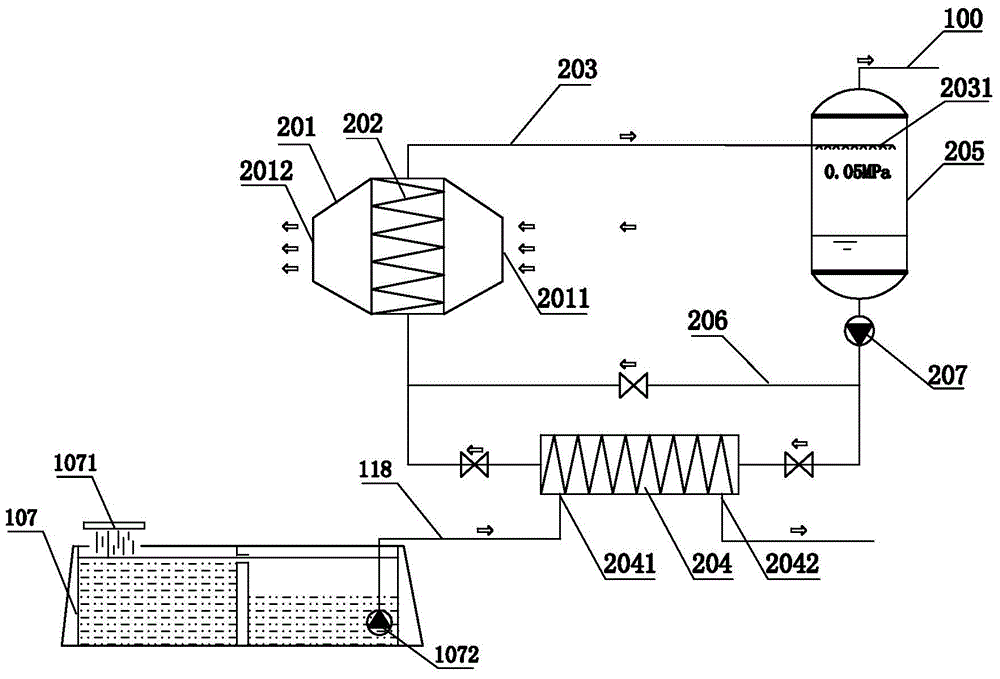

Industrial waste heat type low-temperature multi-effect sea water desaltation system and sea water desaltation method thereof

ActiveCN104402079ALower discharge temperatureEmission reductionGeneral water supply conservationSeawater treatmentResource utilizationEngineering

The invention discloses an industrial waste heat type low-temperature multi-effect sea water desaltation system and a sea water desaltation method. The system comprises a flue gas waste heat recovery device used for preparing heat source steam and preheating seawater and a low-temperature multi-effect sea water desaltation device which utilizes the heat source steam to realize sea water desaltation treatment; the low-temperature multi-effect sea water desaltation device comprises a first-effect evaporator, a plurality of intermediate-effect evaporator, a final-effect evaporator and a condenser; the condenser is connected with a vacuum-pumping device; the first-effect evaporator is connected with a feeding seawater pipe on which a plurality of preheaters are serially arranged; a fresh water pipe between every two adjacent evaporators penetrates the preheaters. According to the invention, in-order water supply is adopted, so that the scaling and corrosion problems are solved, equipment cleaning and maintenance are reduced, and therefore the sea water desaltation cost is low; the low-temperature multi-effect sea water desaltation device is combined with exhaust heat utilization, so that comprehensive resource utilization is realized, the flue gas discharge temperature is lowered, the desulphurization efficiency is favorably improved and emission of pollutants is reduced.

Owner:WEIFANG LIANXING NEW MATERIAL TECH

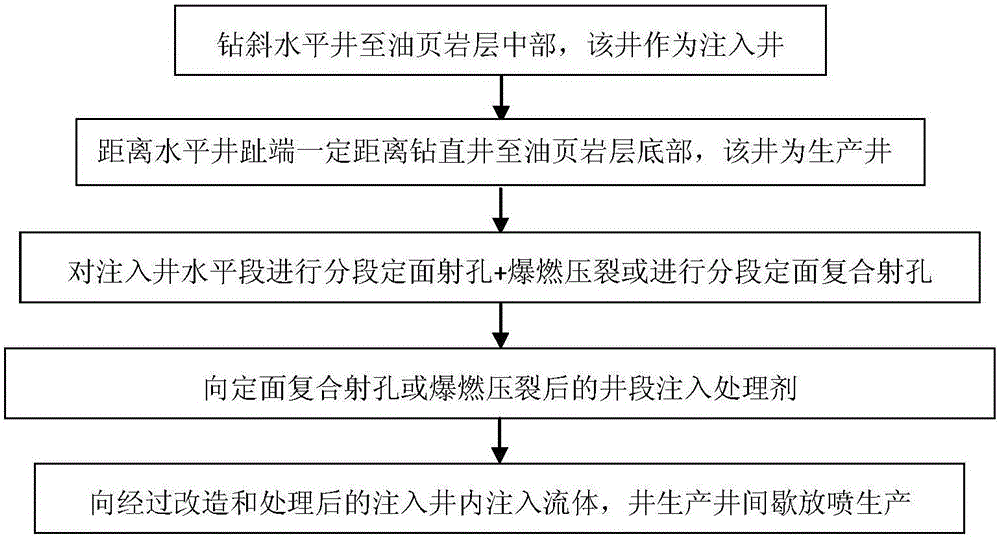

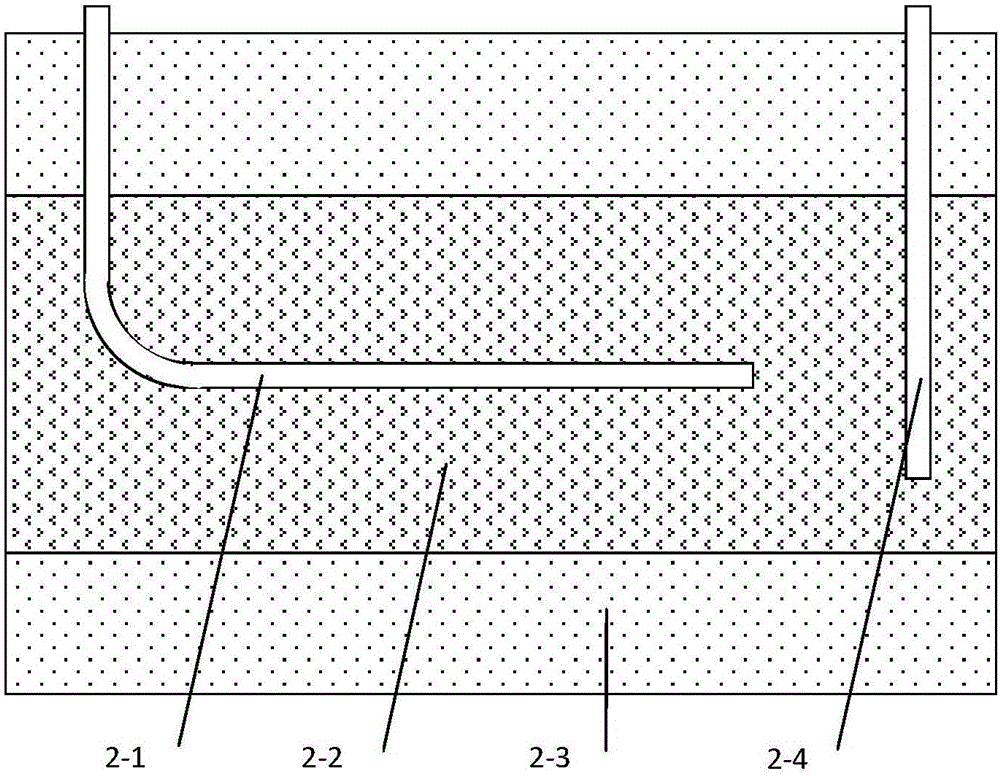

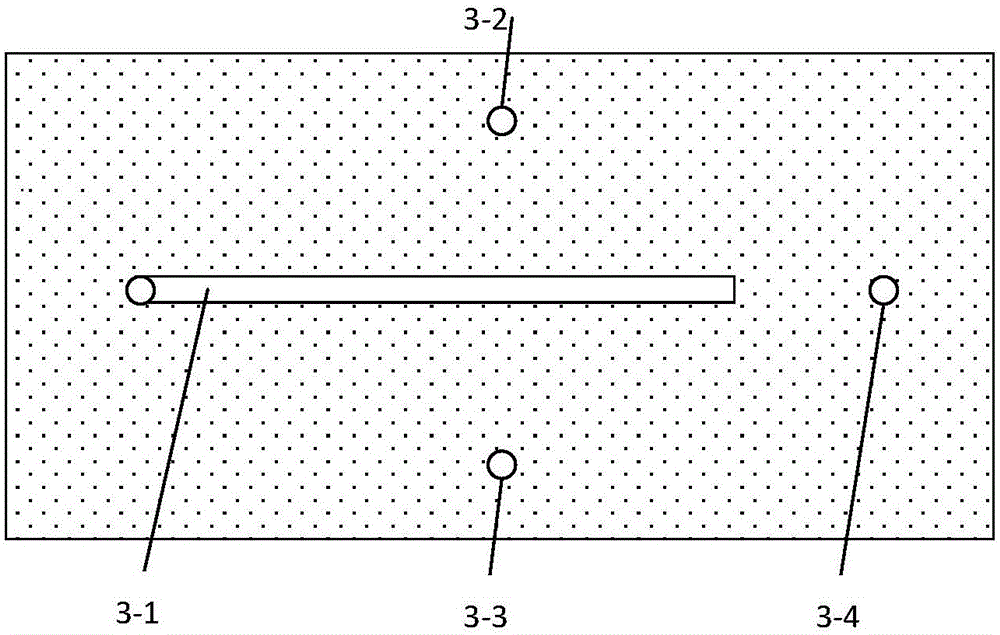

Method for modifying and exploiting oil shale in situ through fluid

InactiveCN106437657AFacilitate water evaporationIncrease contact areaFluid removalOil shale gasInjection well

The invention provides a method for modifying and exploiting oil shale in situ through fluid. The method comprises the steps that firstly, a plurality of wells are drilled to an oil shale stratum and serve as injection wells and / or producing wells; secondly, the oil shale stratum is modified, and cracks are generated accordingly; thirdly, treating agents are injected into the oil shale stratum; and fourthly, the fluid is injected into the oil shale stratum through the injection wells, the oil shale is heated to crack so as to generate oil gas, the oil gas and the injected fluid flow out of the producing wells, and oil-gas separation is conducted on the ground. According to the method for modifying and exploiting the oil shale in situ through the fluid, the fluid can be injected into the stratum and has a large contact area with the oil shale stratum, the fluid heating efficiency is improved, and the petrologen converting ratio and the oil shale oil and gas recovery rate are further increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

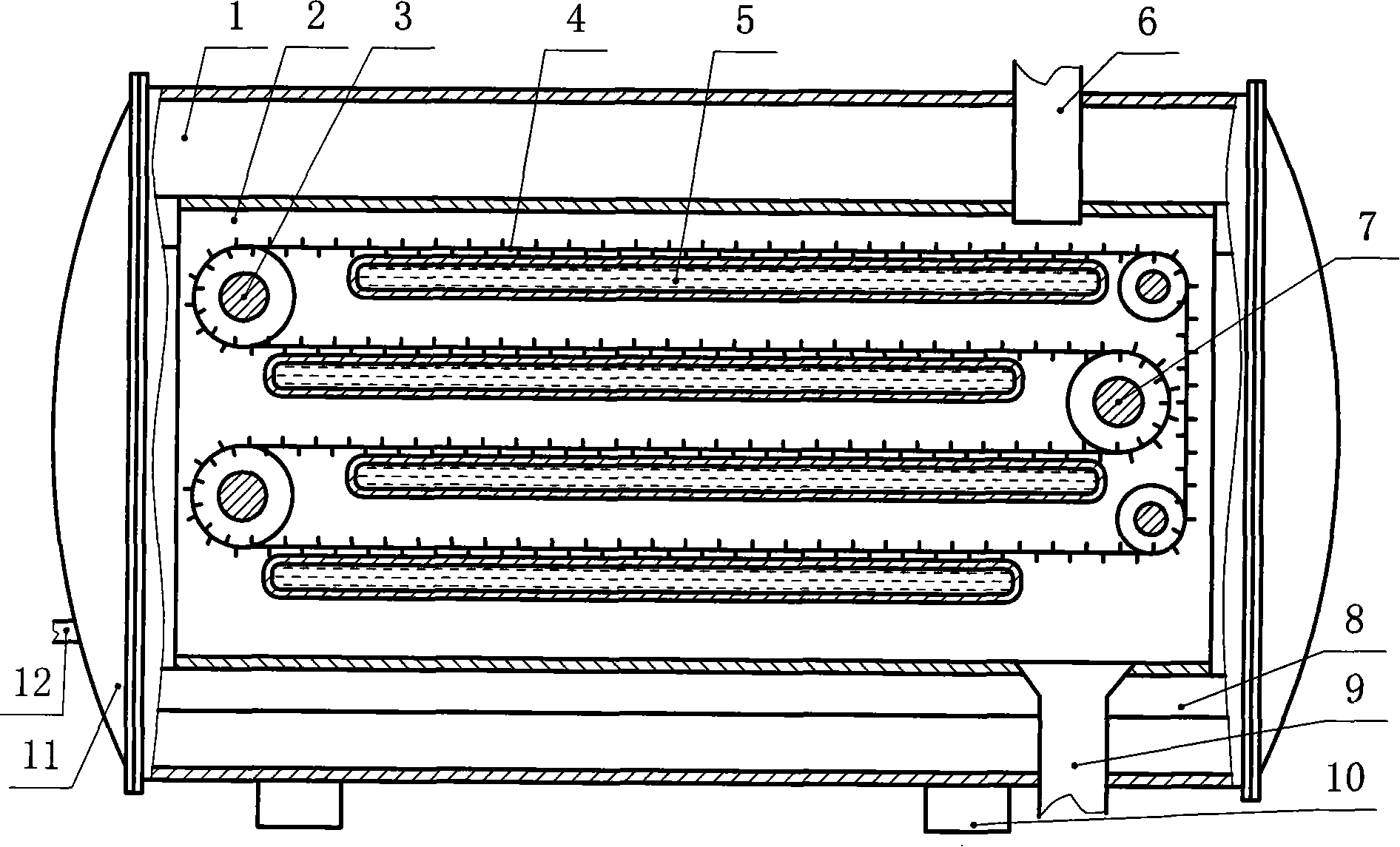

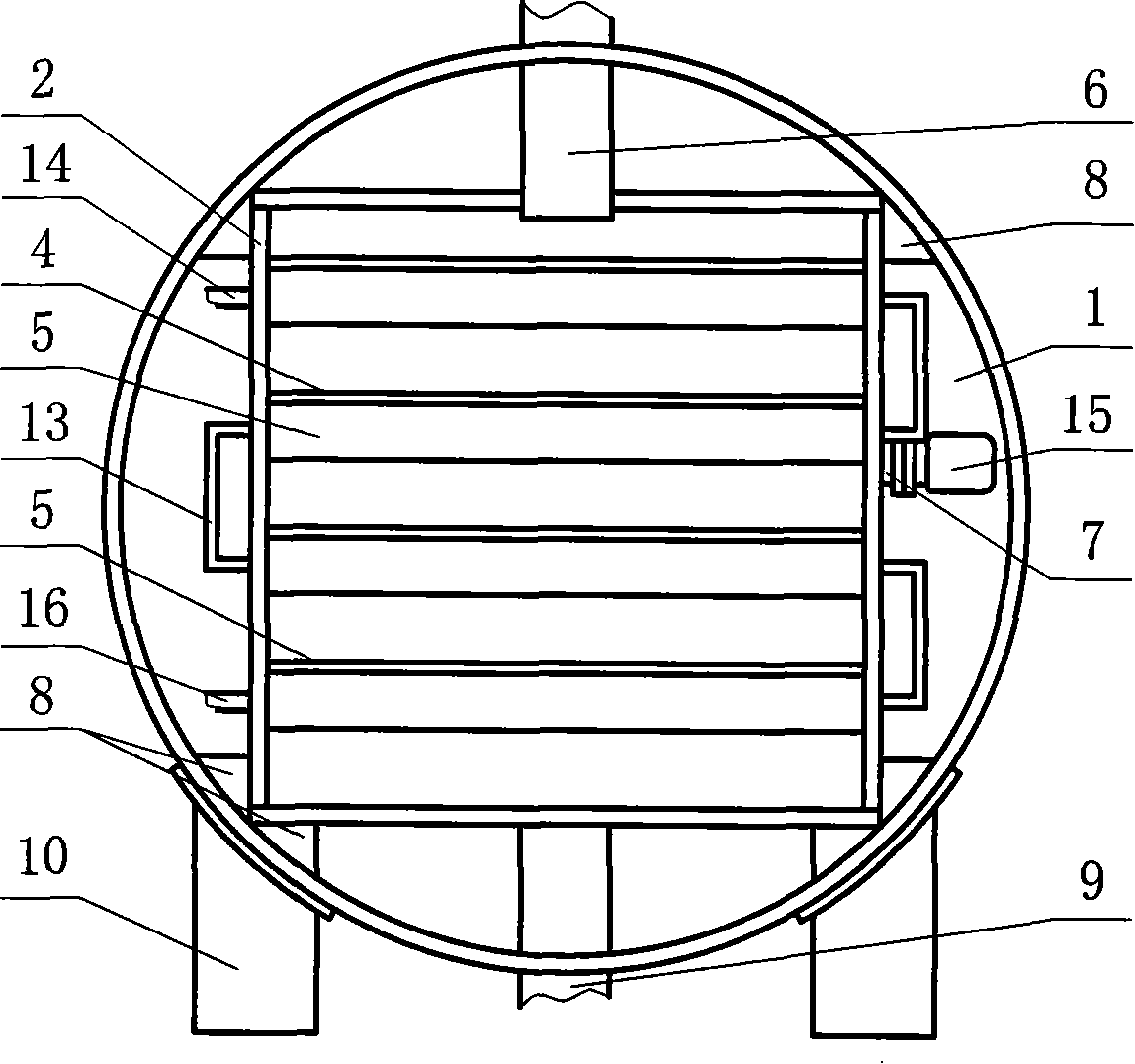

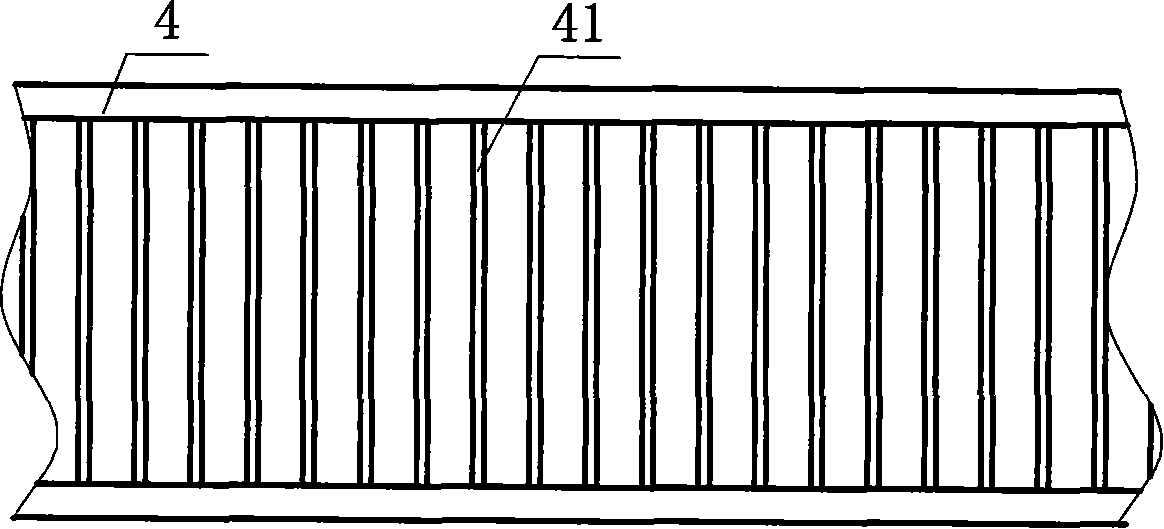

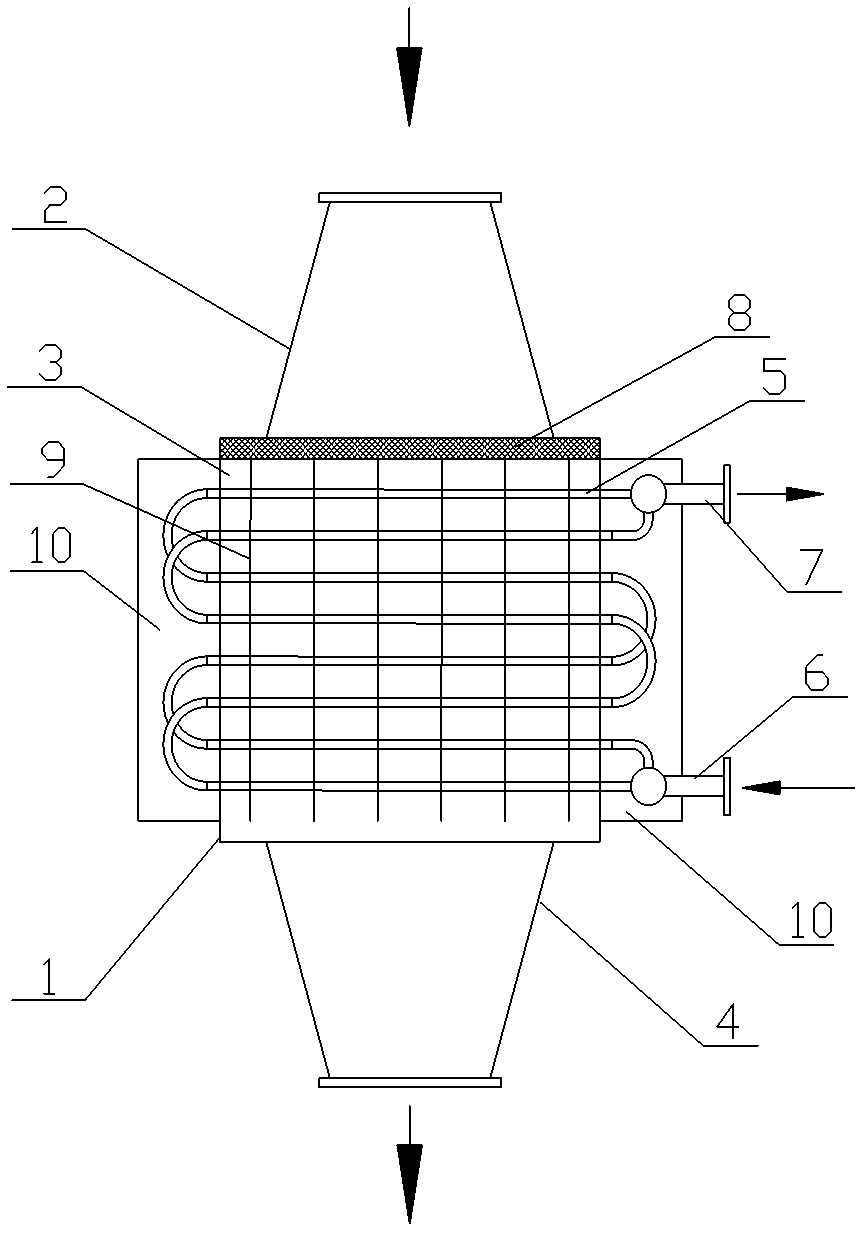

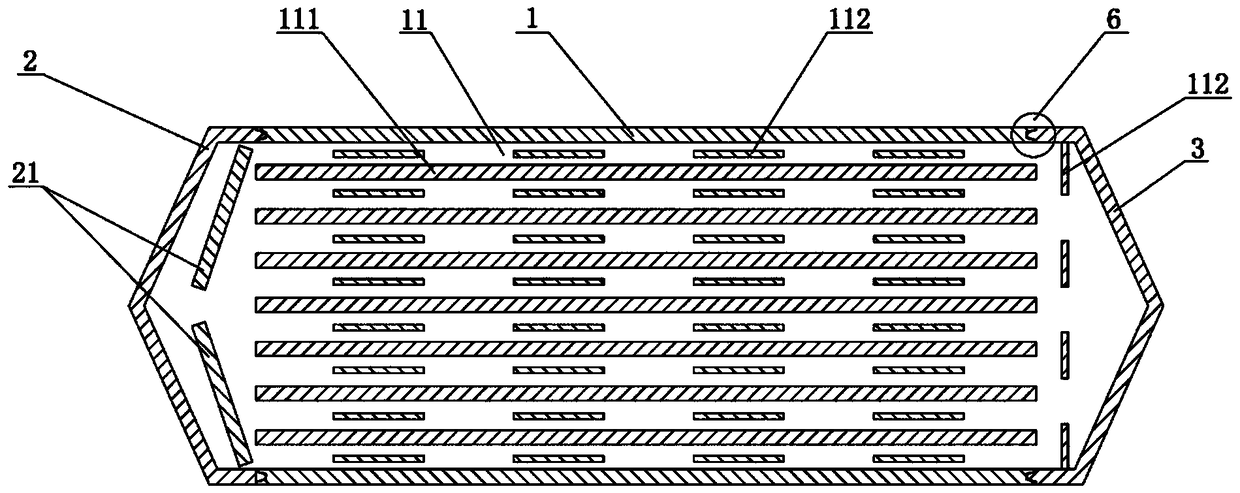

Net band transmission type vacuum continuous drying device and net band transmission type drying device

InactiveCN101187527AWon't hurtInhibit swellingDrying using combination processesDrying solid materials with heatWater flowEngineering

The invention discloses a mash belt transfer type vacuum continuous drying apparatus and a mash belt transfer type drying apparatus, which comprises a cylindrical barrel, a spherical cap-shape end cover, and an evacuating pipe, wherein the cylindrical barrel is horizontally arranged, a square silo is sleeved in the inner cavity of the cylindrical barrel, a certain number of floors of flat-type water pipes are mounted between two body walls of the square silo, and the flat-type water pipe which is on the highest layer is communicated with a water inlet pipe, and the flat-type water pipe which is on the lowest layer is communicated with a water outlet pipe, the intermediate flat-type water pipes are communicated end to end, and water glide path is led to take zigzag-shape arch type. A certain number of turn rollers which are regularly arrayed are mounted between the two body walls of the square silo, the turn rollers which are connected with a power mechanism are sleeved with ring-shaped mash belt, which leads materials on surface of the upper layer of the flat-type water pipe to convey to the surface of the lower layer of the flat-type water pipe, two lateral side of adjacent flat-type water pipes are alternatively arrayed respectively, and a feed inlet and a feed outlet are respectively arranged on the two sides of the adjacent flat-type water pipes which penetrates through the cylindrical barrel and the square silo.

Owner:COFCO ENG & TECH ZHENGZHOU +1

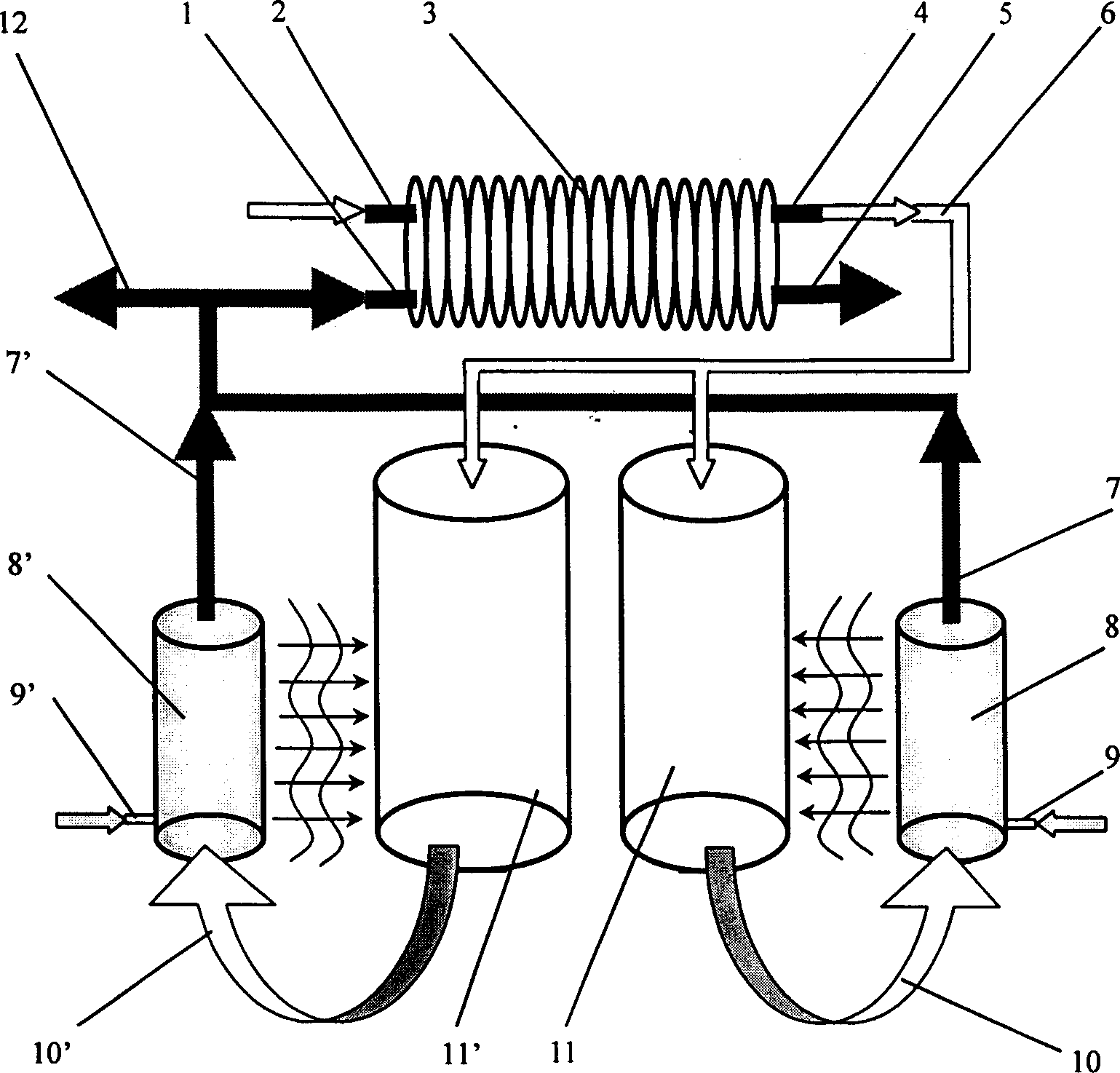

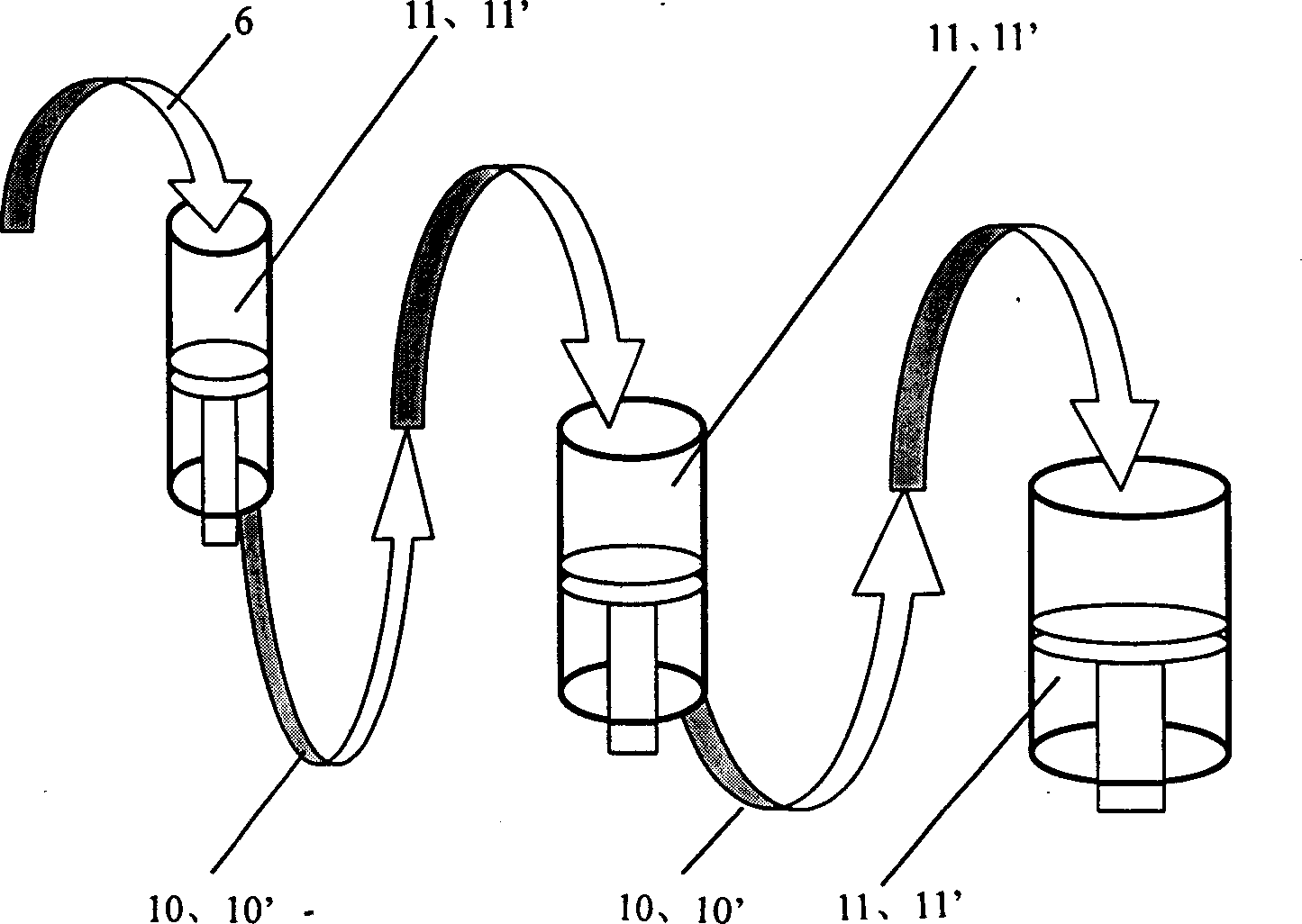

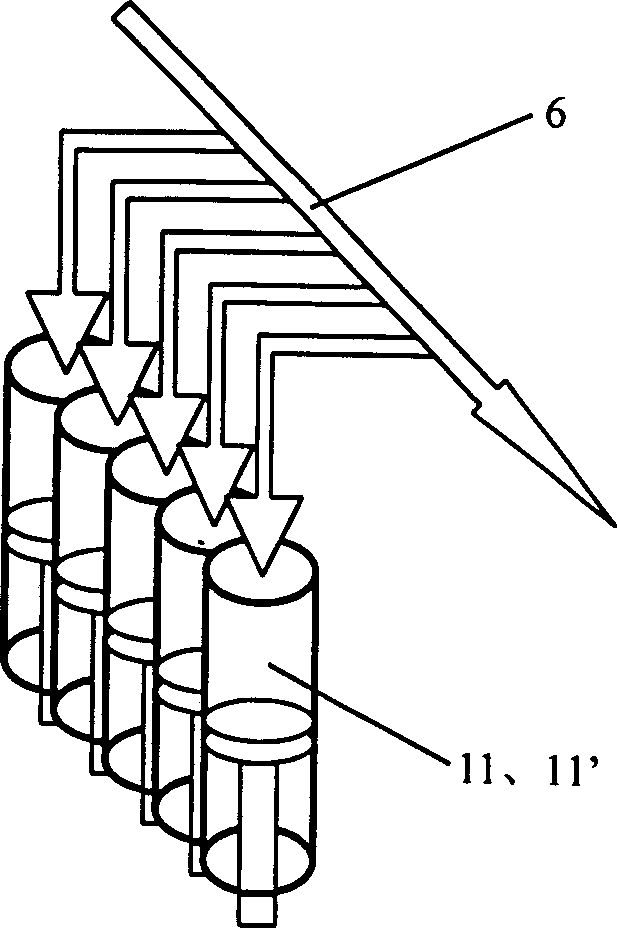

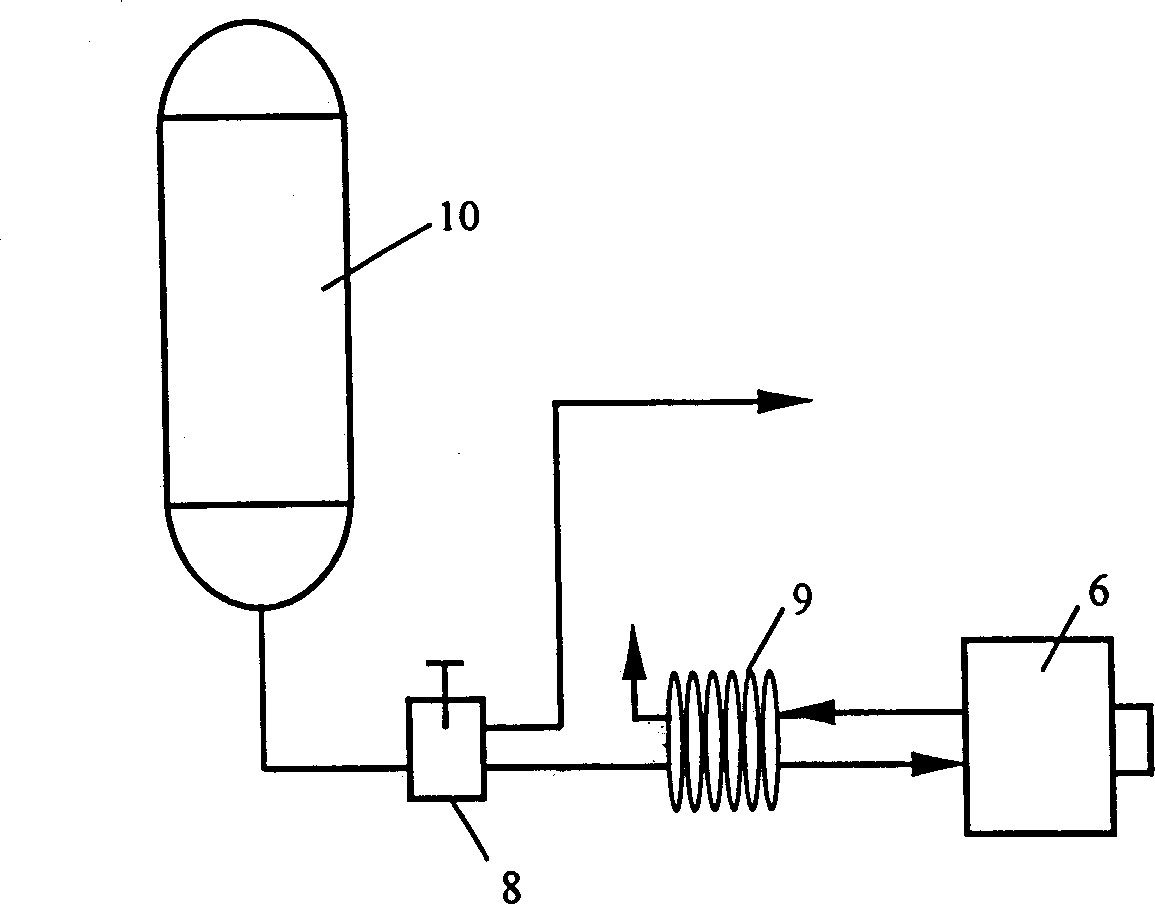

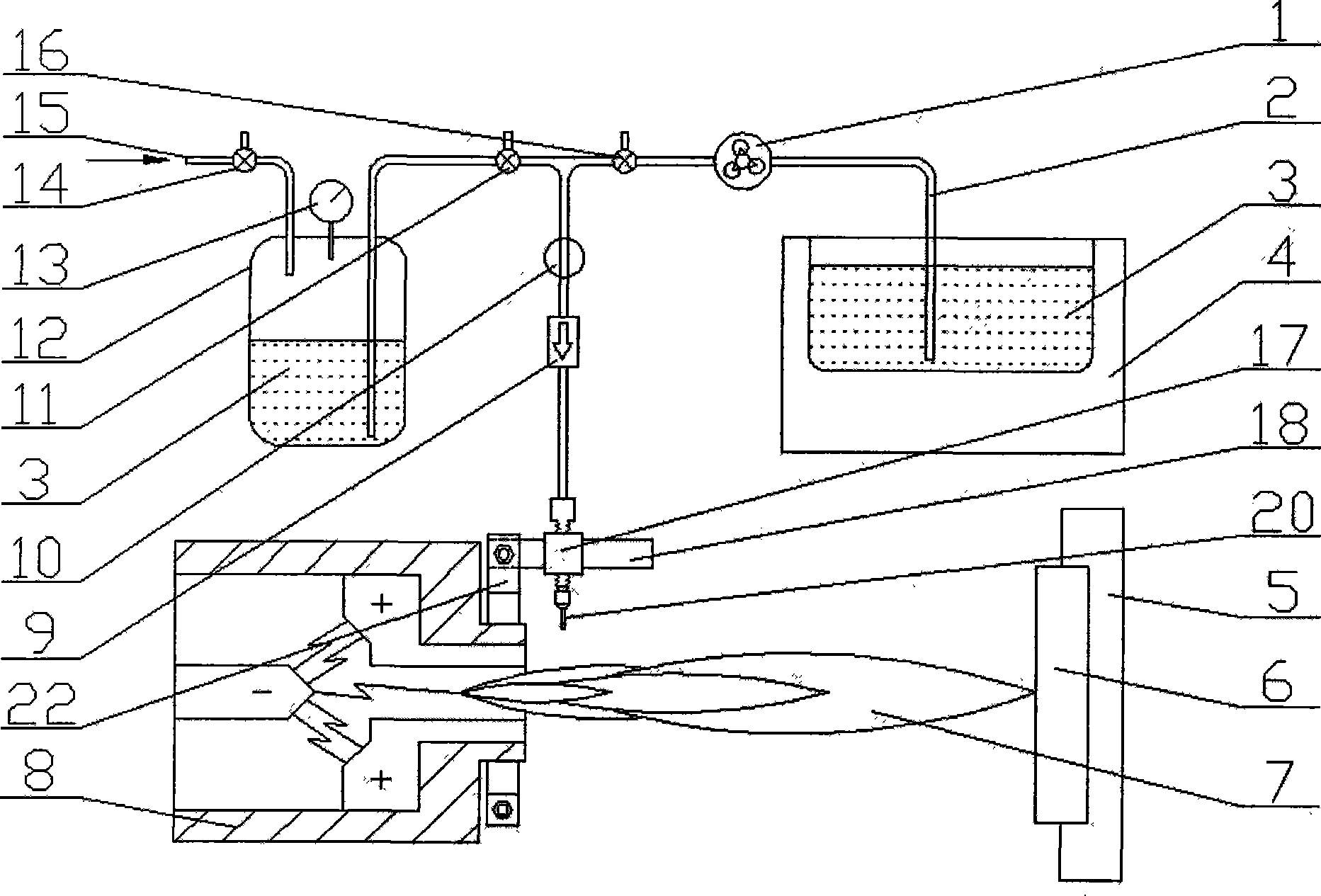

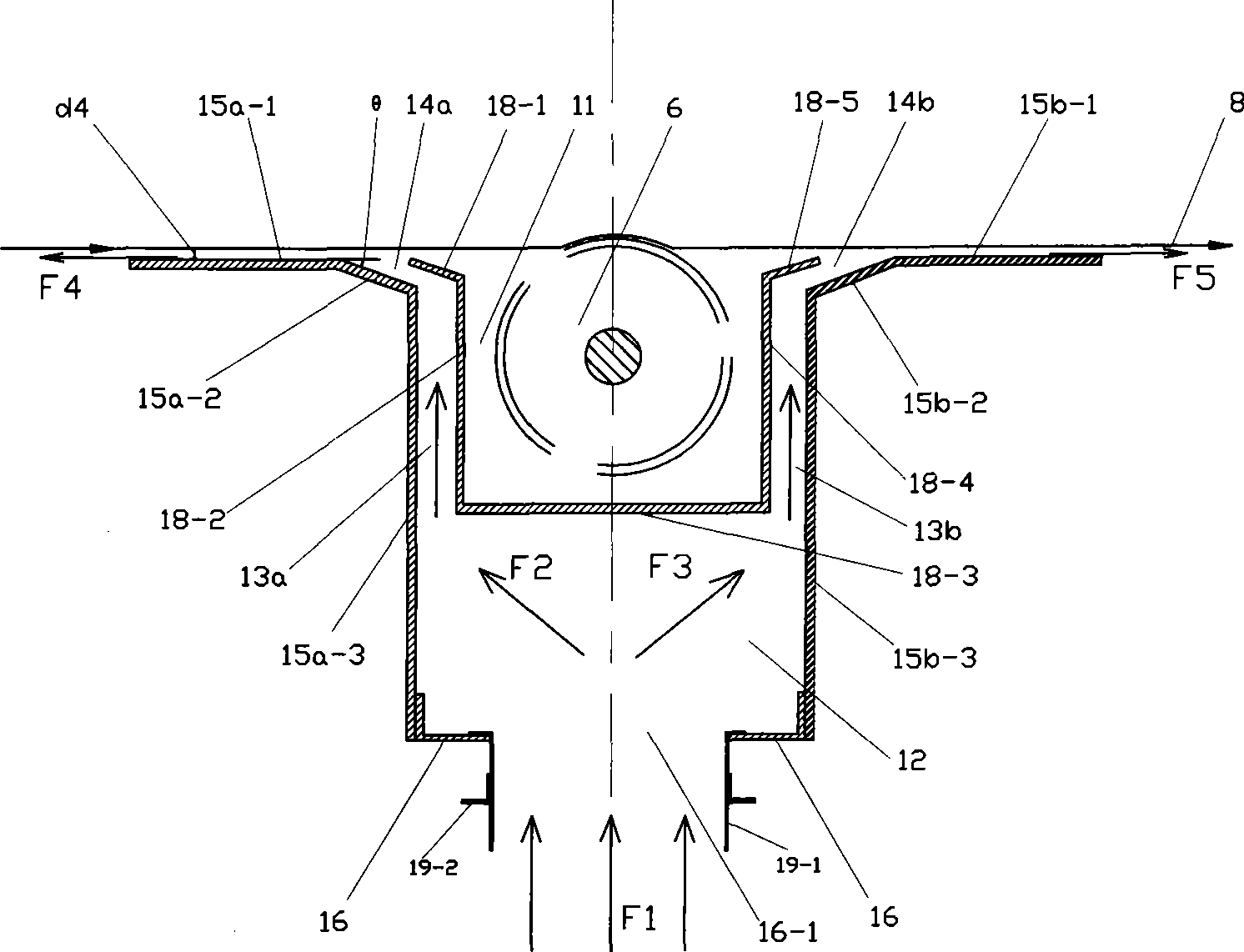

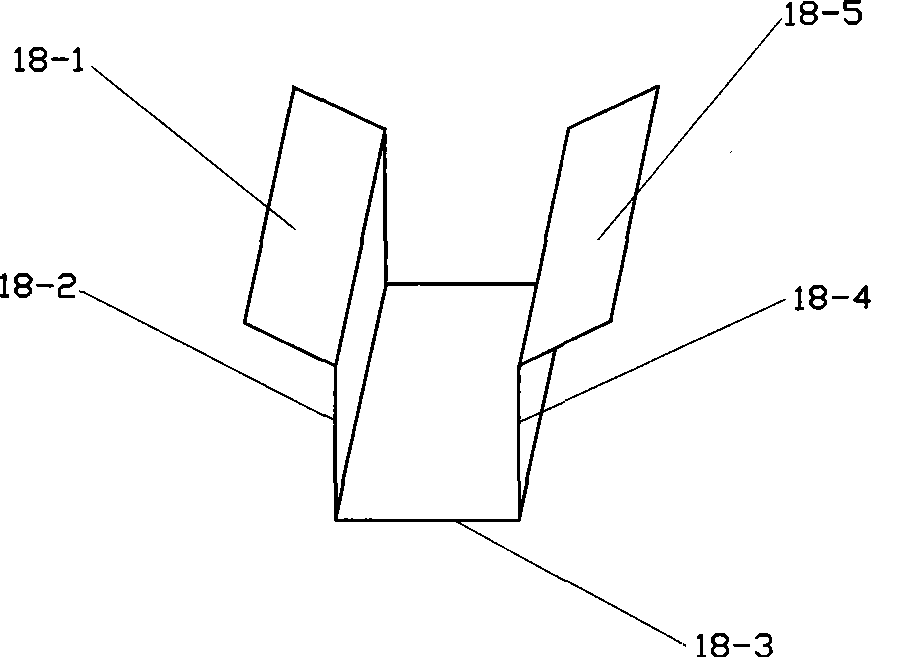

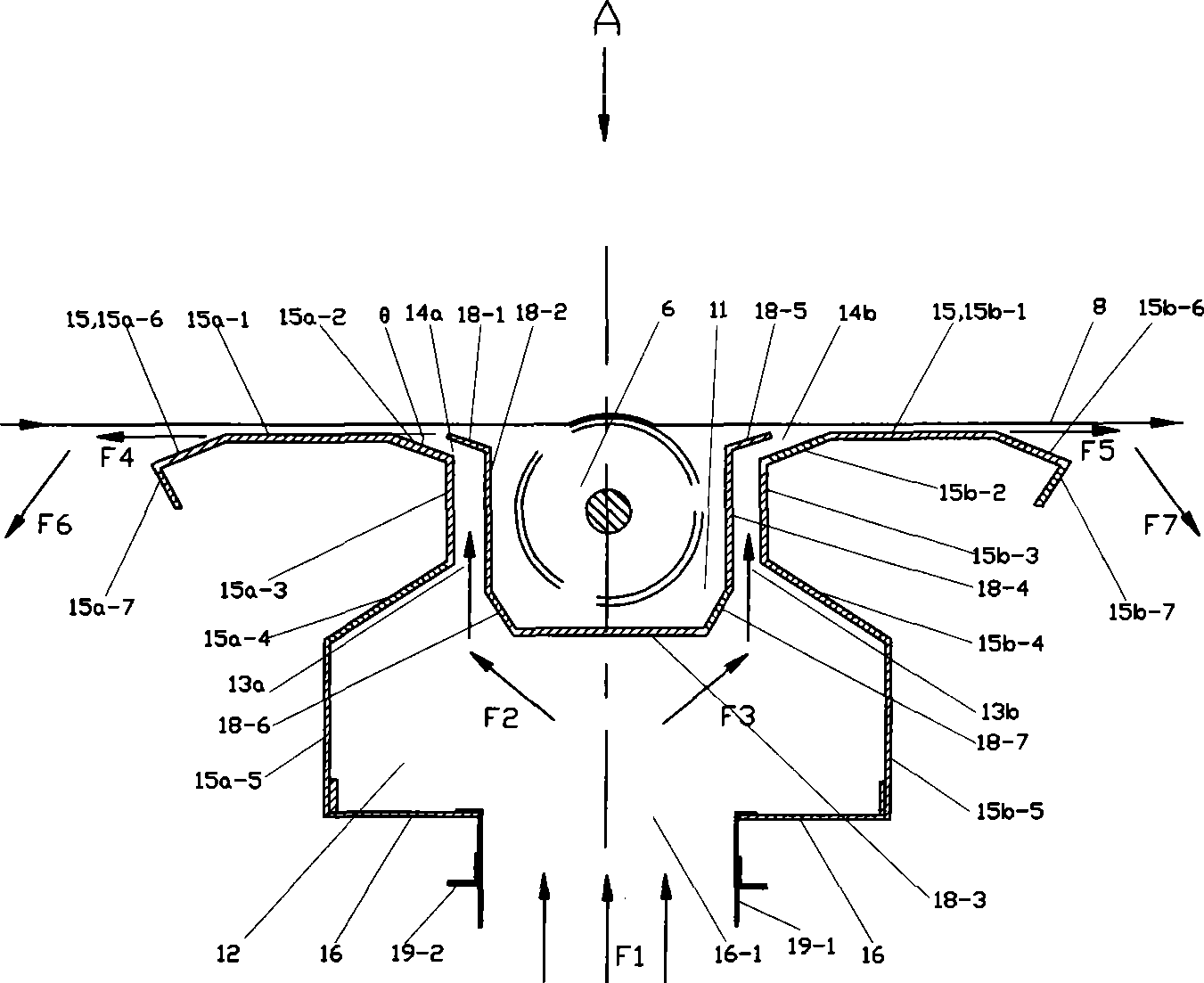

Pneumatic oil and gas mixed-power automobile

InactiveCN1398740AConvenient and easy to compress and storeConvenient Transport ControlHybrid vehiclesGas pressure propulsion mountingExternal combustion enginePneumatic tool

A mixed power automobile includes casing, wheels, wheel axles and frame, the casing is fixed to the frame and the frame is connected with and fixed to the wheel axles, and the wheel axles are connected to the wheels. A compressed air-oil / gas burning mixed power engine installed on the vehicle body is connected to the gas tank via gas pipe, adjusting valve and heat exchanger, and the engine transfers the driving force via transmission mechanism to the wheel axle to rotate the wheels. Different power combination of pneuamtic unit and internal combustion engine may be selected based on different working conditions. By using the characteristics of compressed air as clean energy source and internal combustion engine power with great heat amount and high efficiency, the present invention has greatly reduced exhaust pollution, and makes the application of compressed air power in automobile practical.

Owner:ZHEJIANG UNIV

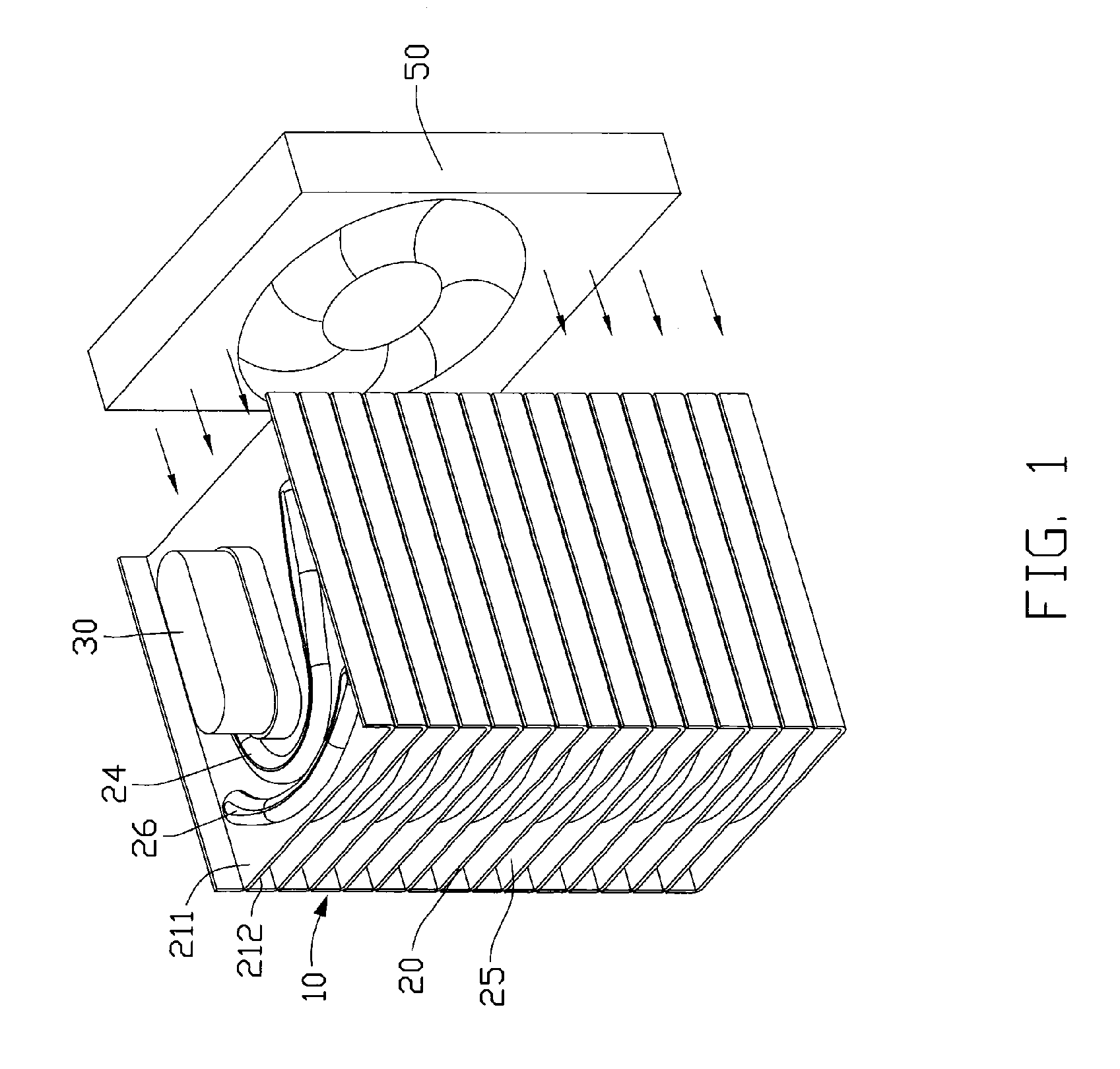

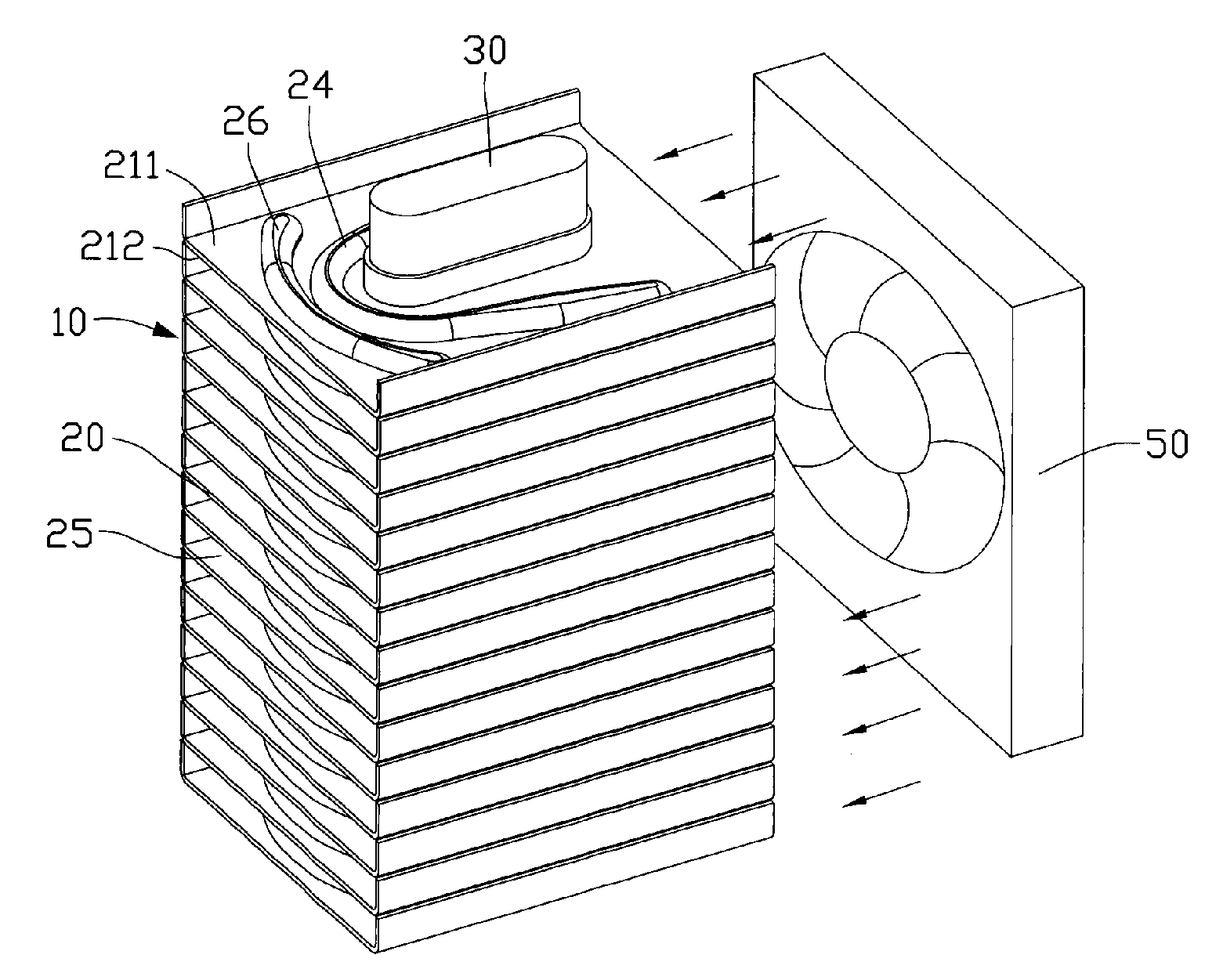

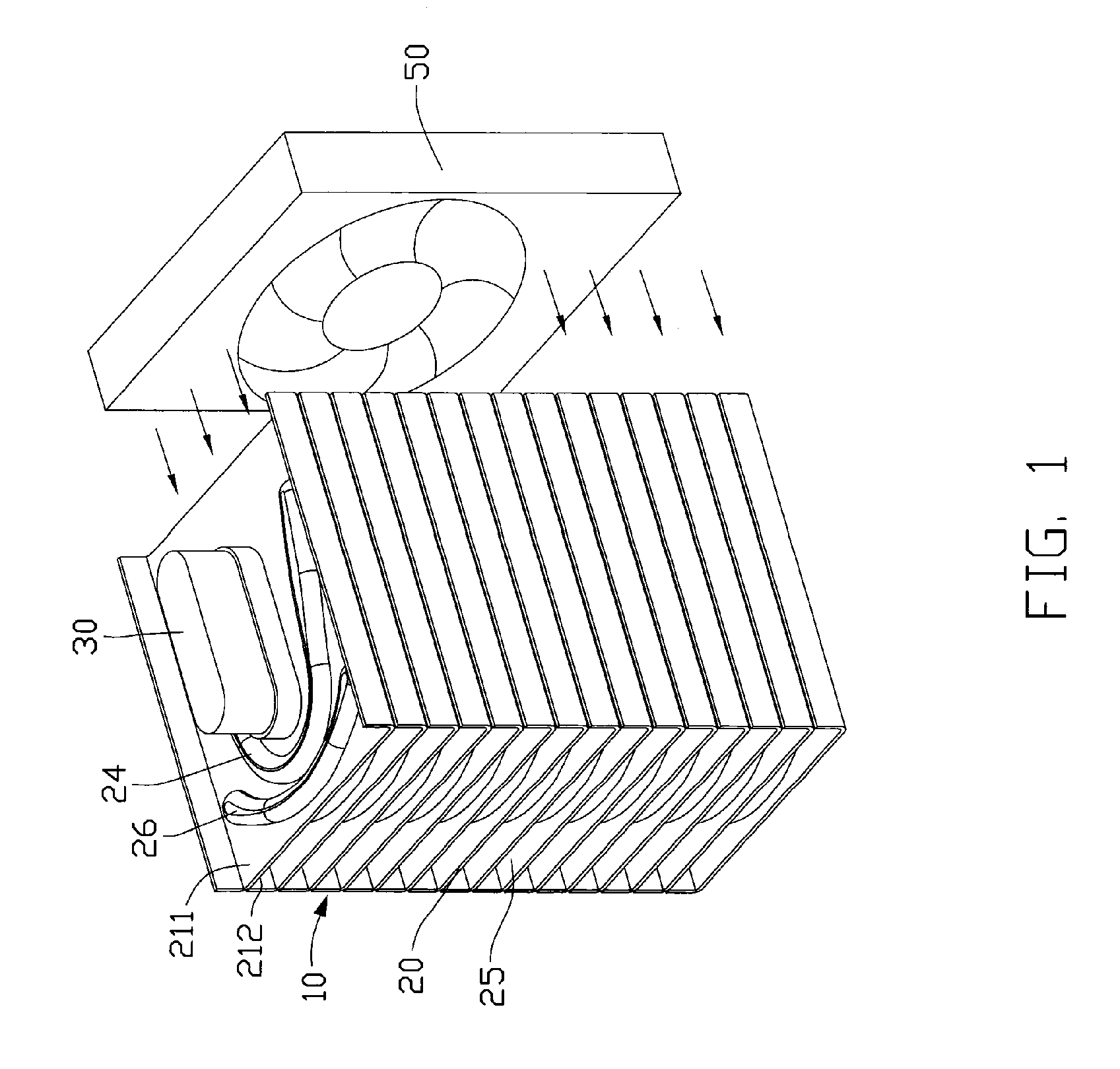

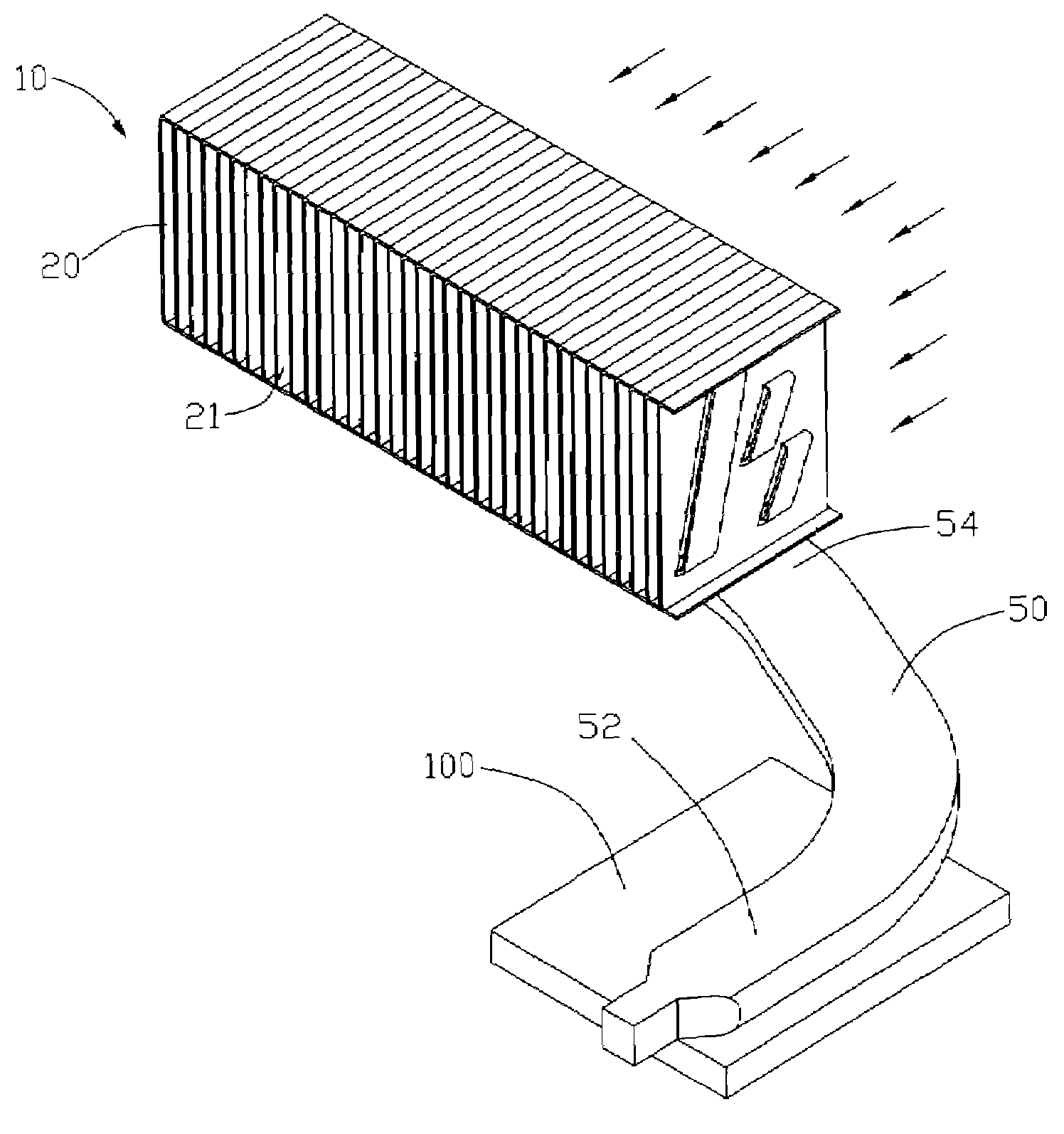

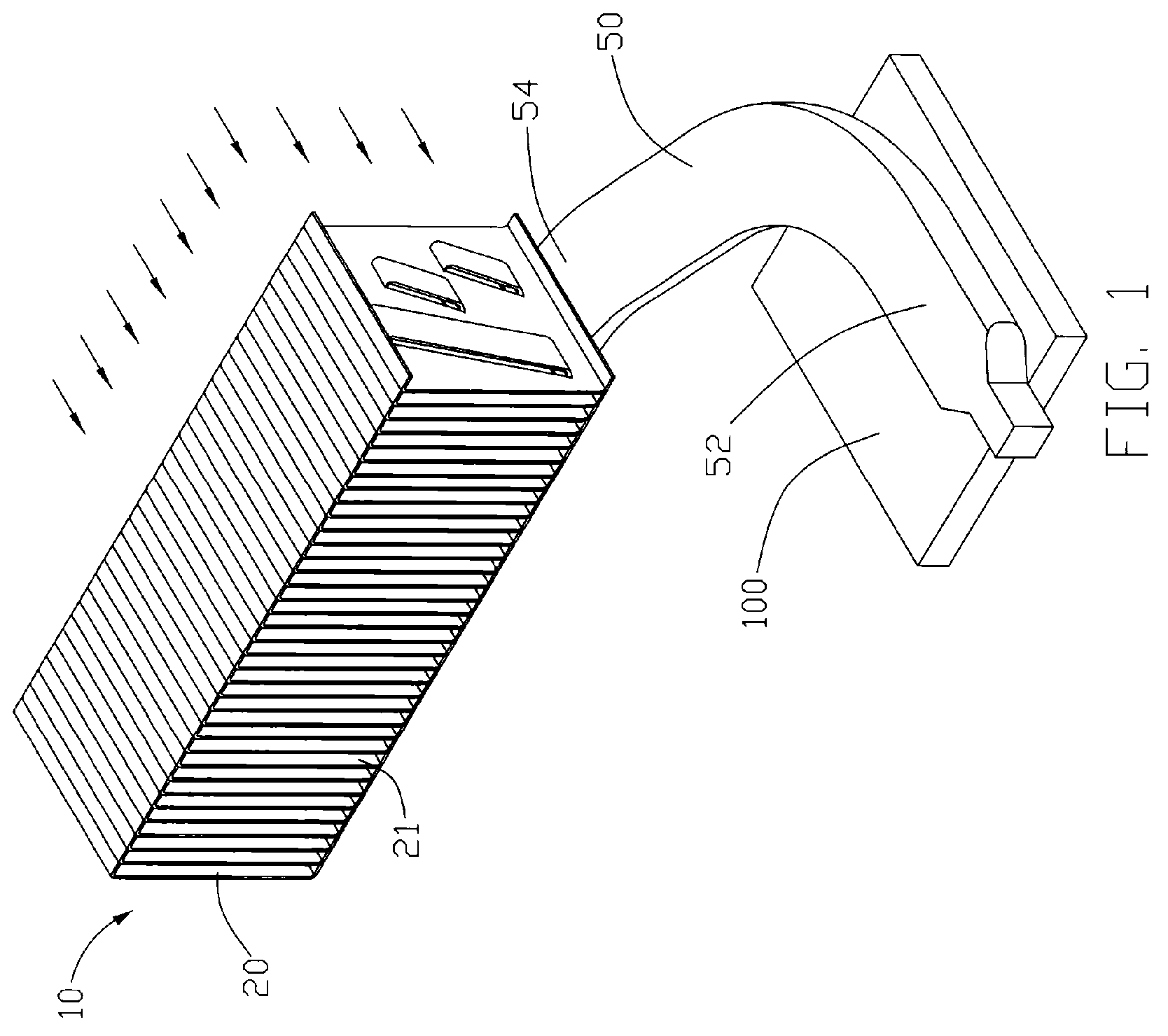

Heat sink

InactiveUS7304847B2Increased turbulenceFull heat exchangeSemiconductor/solid-state device detailsSolid-state devicesCurve shapeHeat pipe

A heat sink includes a plurality of fins parallel to each other, and one heat pipe extending through these fins. A flow channel is formed between each pair of neighboring fins for channeling an airflow generated by an electric fan. A guiding member having a curved shape is arranged around the through hole for guiding the airflow flowing to the heat pipe. A space formed and surrounded by the guiding member is a tapered space, which narrows gradually along the direction of the airflow so as to guide the airflow flowing to the heat pipe.

Owner:HON HAI PRECISION IND CO LTD +1

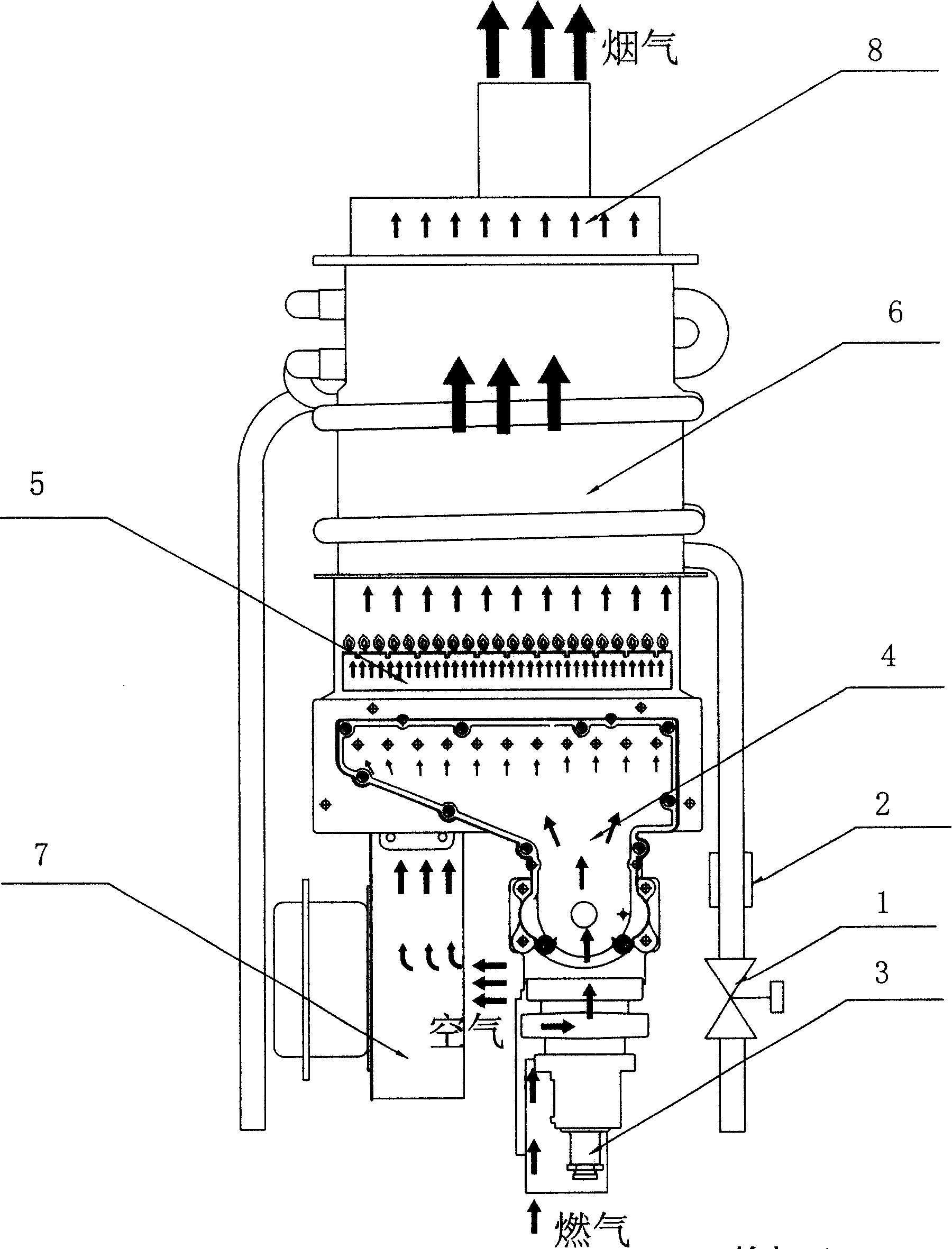

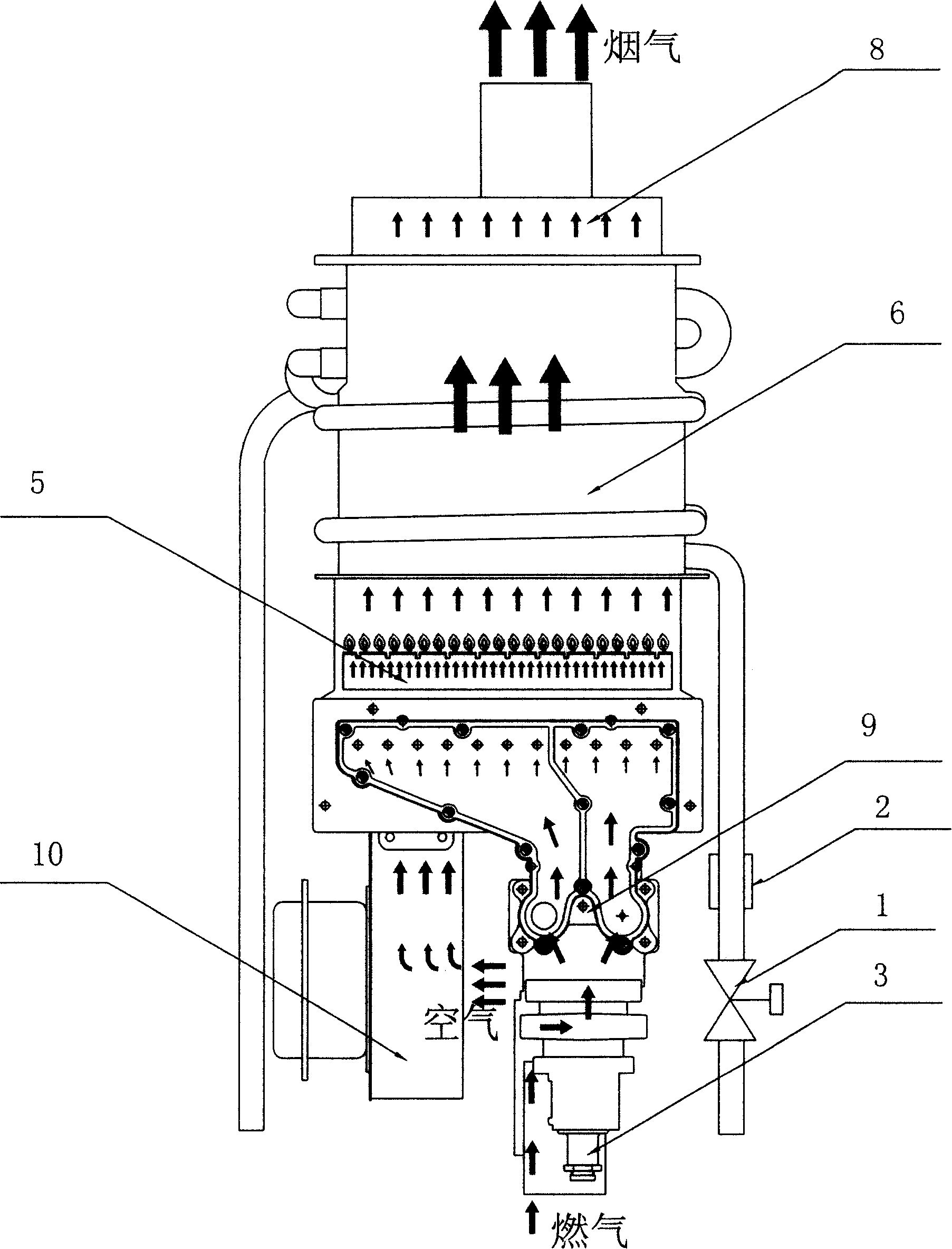

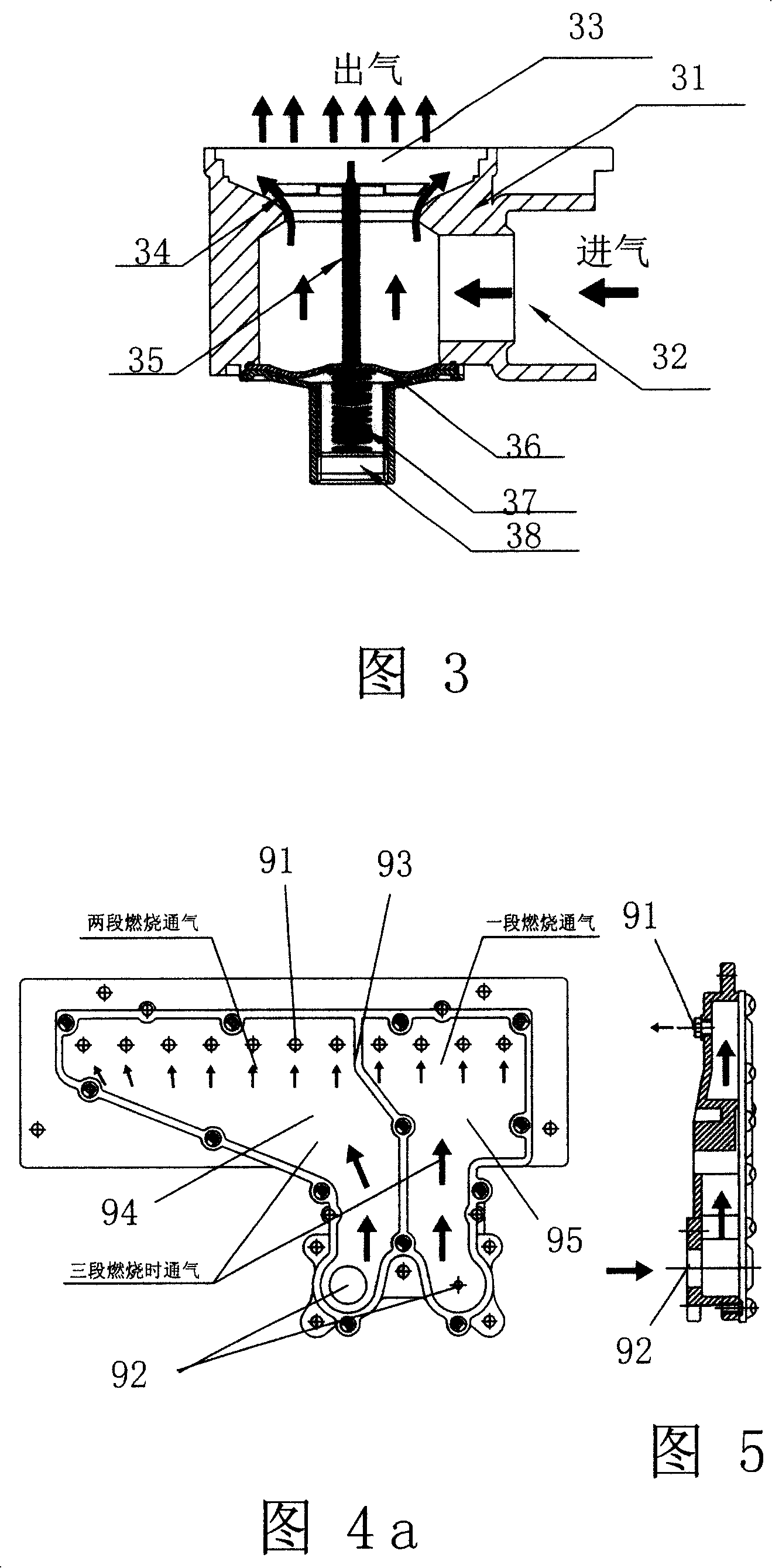

Blue flare subsection air feed gas water heater

The present invention relates to a water heater, in particular to a blue flame segmental air supply gas water heater, comprising: a water inlet valve, a water inlet flow sensor, a gas valve, a pulse igniter, a multi-column fire row burner, a heat exchanger and The fan is characterized in that it is provided with an n-way distributor, the gas valve is connected to the n-1 distributor through n-1 solenoid valves, and one of the n-way distributors is directly connected to the gas valve, Each distributor is provided with a plurality of gas nozzles, and each gas nozzle is directly facing the injection hole of a fire row burner; the fan is an n-speed fan. Divide the air intake channel into multi-stage control, combined with multi-speed variable speed fans to correspond to the low fire, medium fire, and high fire of the burner, so that the excess air coefficient α during combustion is always maintained within the range of 1.5, so that the burner burns in the best state , the content of CO in the flue gas is below 300PPm, and the thermal efficiency is higher than 88%.

Owner:HAIER GRP CORP +1

Heat sink

InactiveUS20070188992A1Increased turbulenceFull heat exchangeSemiconductor/solid-state device detailsSolid-state devicesCurve shapeEngineering

A heat sink includes a plurality of fins parallel to each other, and one heat pipe extending through these fins. A flow channel is formed between each pair of neighboring fins for channeling an airflow generated by an electric fan. A guiding member having a curved shape is arranged around the through hole for guiding the airflow flowing to the heat pipe. A space formed and surrounded by the guiding member is a tapered space, which narrows gradually along the direction of the airflow so as to guide the airflow flowing to the heat pipe.

Owner:HON HAI PRECISION IND CO LTD +1

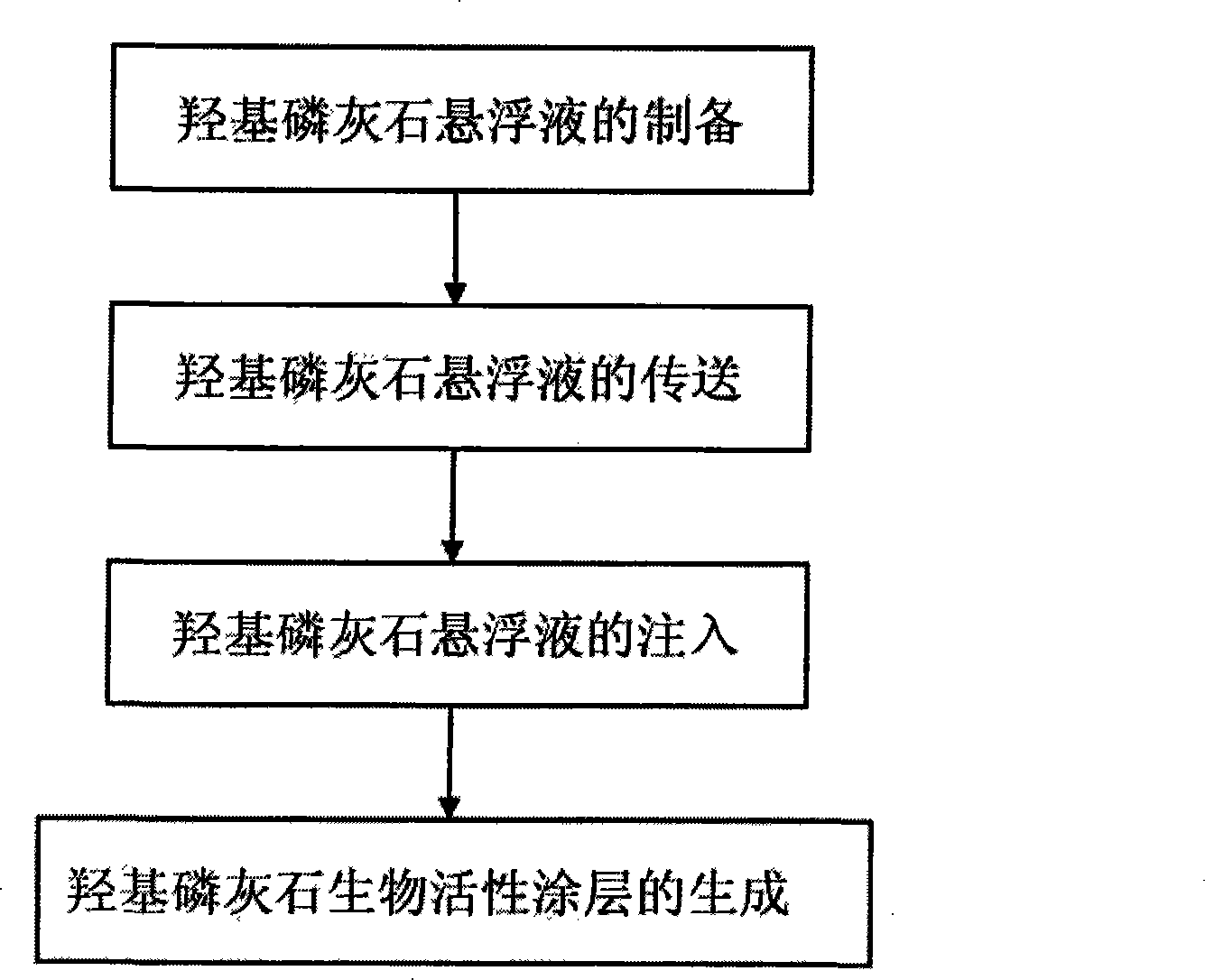

Method for suspending liquid plasma spraying preparation of hydroxyapatite bioactivity coatings

InactiveCN101250681AIncrease productivityReduce manufacturing costMolten spray coatingProsthesisPeristaltic pumpApatite

The invention relates to a method for spraying suspending liquid plasma to prepare hydroxyapatite bioactive coating, which comprises following steps: adopting hydroxyapatite suspending liquid as plasma spraying raw materials, adopting a pressure tank or an electronic peristaltic pump as a power transmitting device to transmit the hydroxyapatite suspending liquid, adopting an atomizing nozzle with a small angle to inject the hydroxyapatite suspending liquid into a central region of plasma flame directly and radially or adopting a duct with small diameter to inject the hydroxyapatite suspending liquid into the central region of the plasma flame directly and radially in a linear type jet-flow mode, exchanging heat between the suspending liquid and high temperature plasma flame through transmitting and injecting the suspending liquid, and directly generating the hydroxyapatite bioactive coating on the surface of a biological medical metal base through vaporizing liquid in the suspending liquid, crushing particles, smelting and depositing. The method simplifies a tedious technological link for preparing the spraying raw materials in a method for spraying powder plasma, the spraying raw materials and energy are saved, and the structural homogeneity of the hydroxyapatite bioactive coating which is prepared is good.

Owner:SICHUAN UNIV

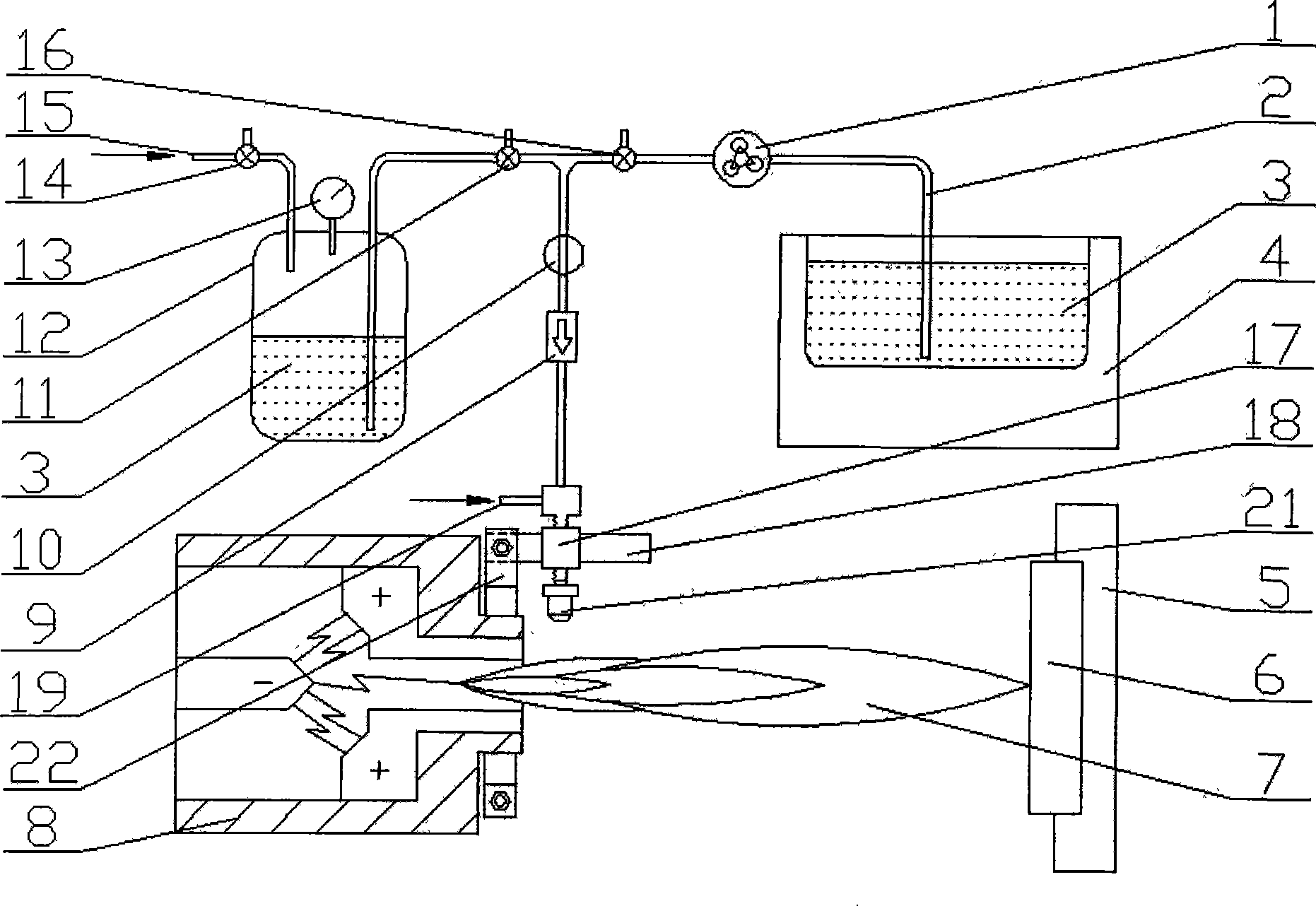

Pelletizing and calcination method for vanadium-containing stone coal ash

The invention relates to a pelletizing and calcination method for vanadium-containing stone coal ash. The equipment adopted by the method includes a moving-bed calcinator, which comprises a vertical furnace body, a chimney, a clinker discharger and a fan. The method includes the following steps that: NaCl, CaF2 and CaCO3 are prepared into complex additive, vanadium-containing stone coal, the complex additive and anthracite or stone coal as fuel needed by calcination are mixed into mixture material, the mixture material is uniformly mixed, fine-ground and pelletized into raw pellets, the raw pellets are fed into the furnace body via a feeder on the top of the furnace body, meanwhile, the fan blows the air into the furnace body via the clinker discharger on the bottom of the furnace body, the raw pellets and the air are calcined and reversely flow under the internal temperature condition of 800 DEG C to 900 DEG C, the calcined material enters the clinker discharger and is discharged out of the furnace body via the clinker discharger, and after cooling, clinker for the leaching of V2O5 is produced; and after calcination, the air is exhausted out via the chimney on the top of the furnace body. The technique and the equipment adopted by the method are relatively simple, the heat utilization rate is high, the product quality is stable, and the production cost is low.

Owner:ZHEJIANG UNIV

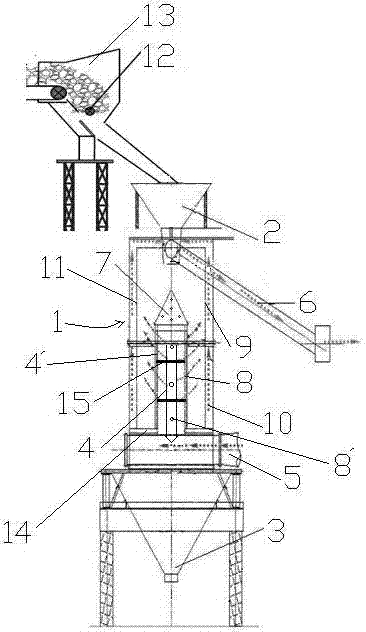

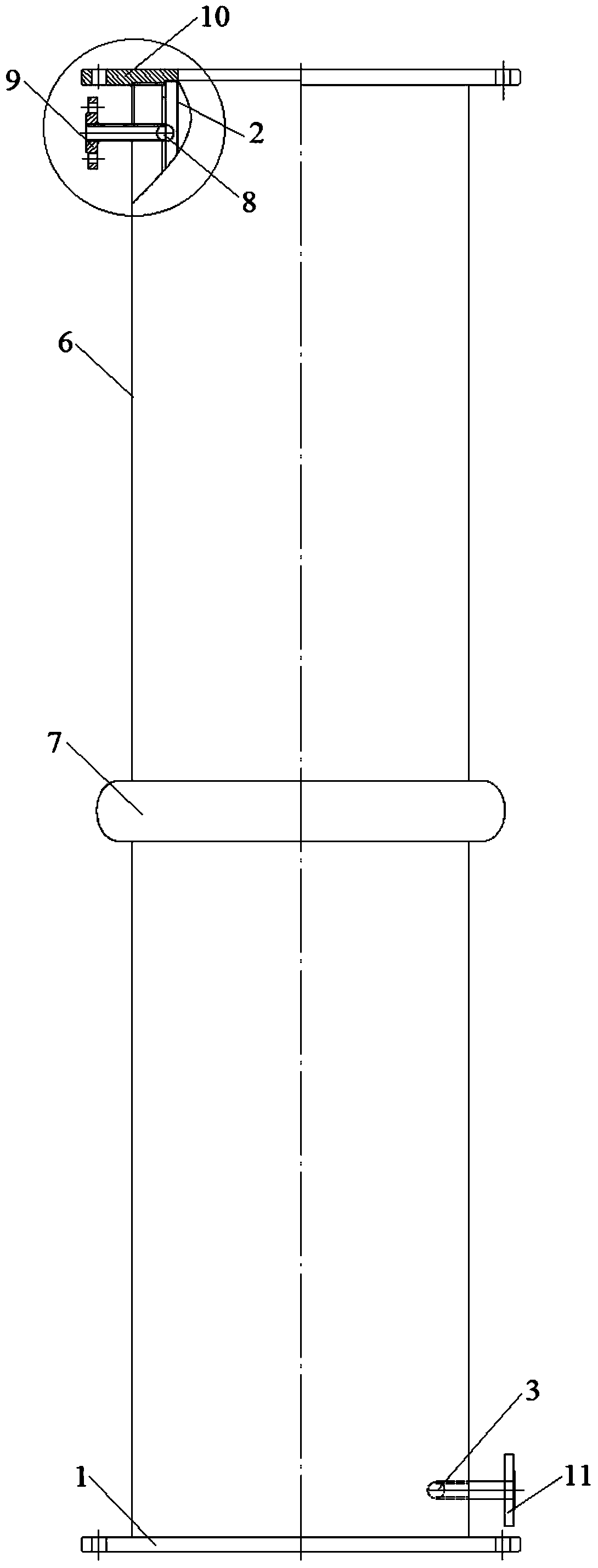

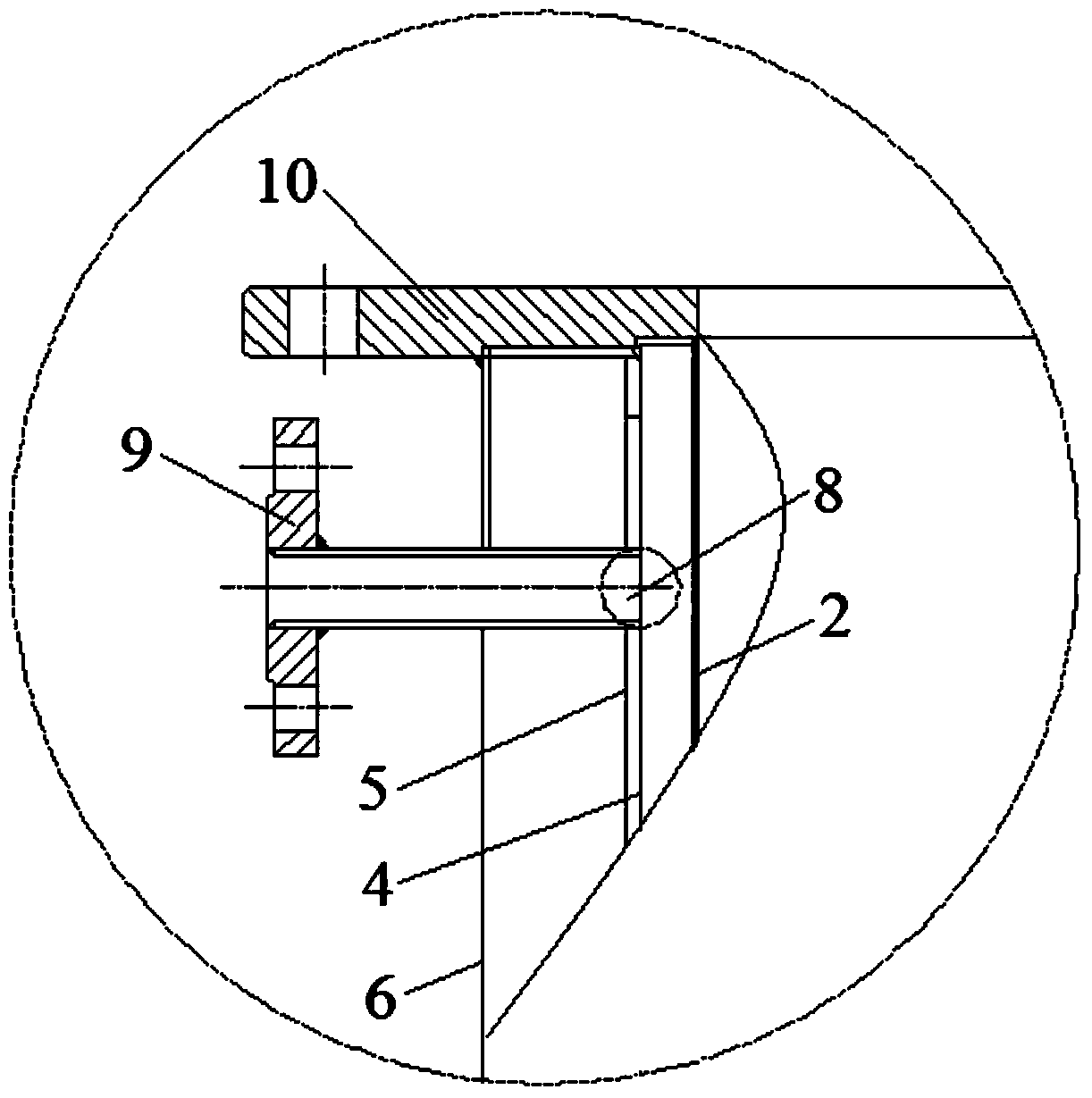

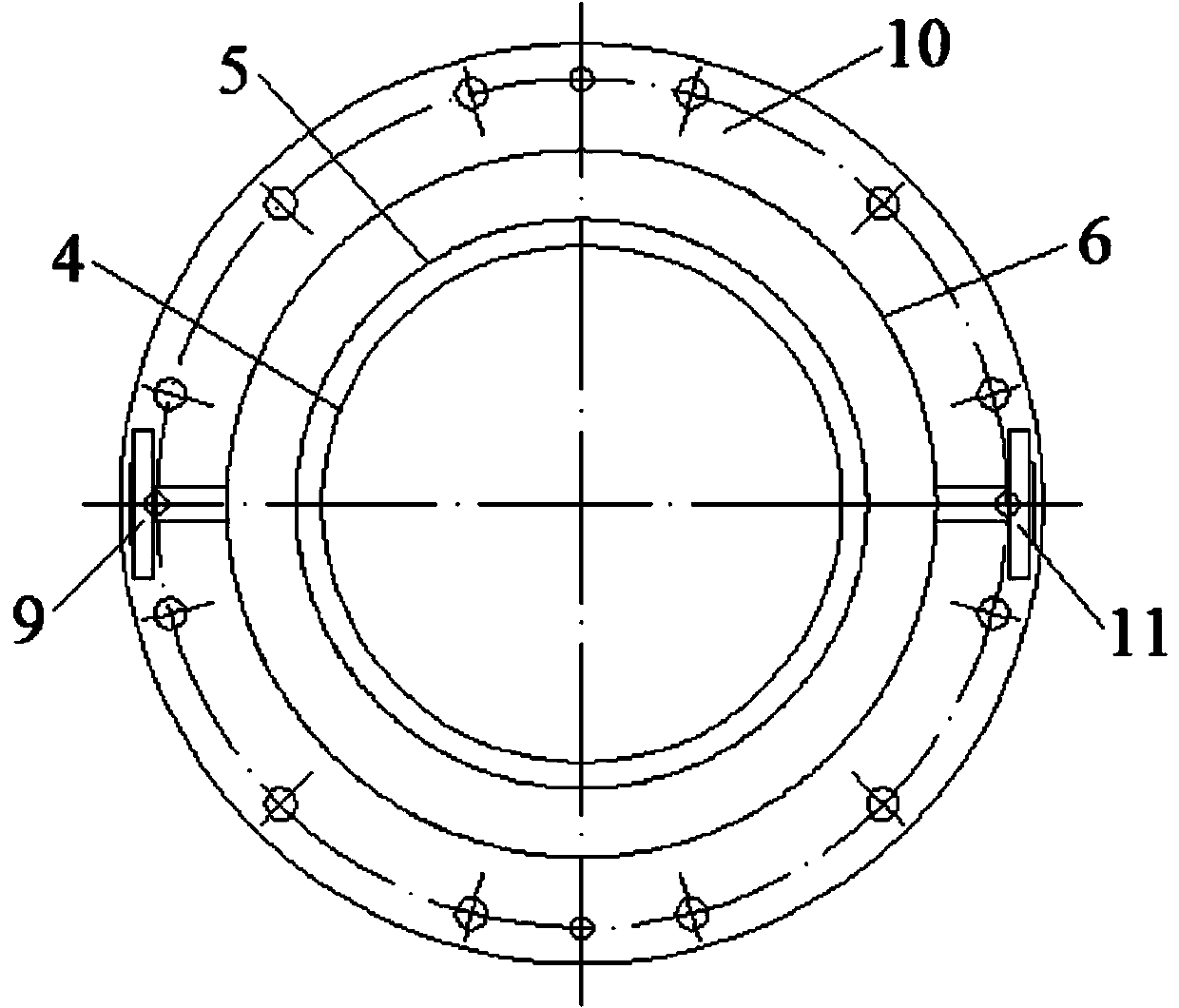

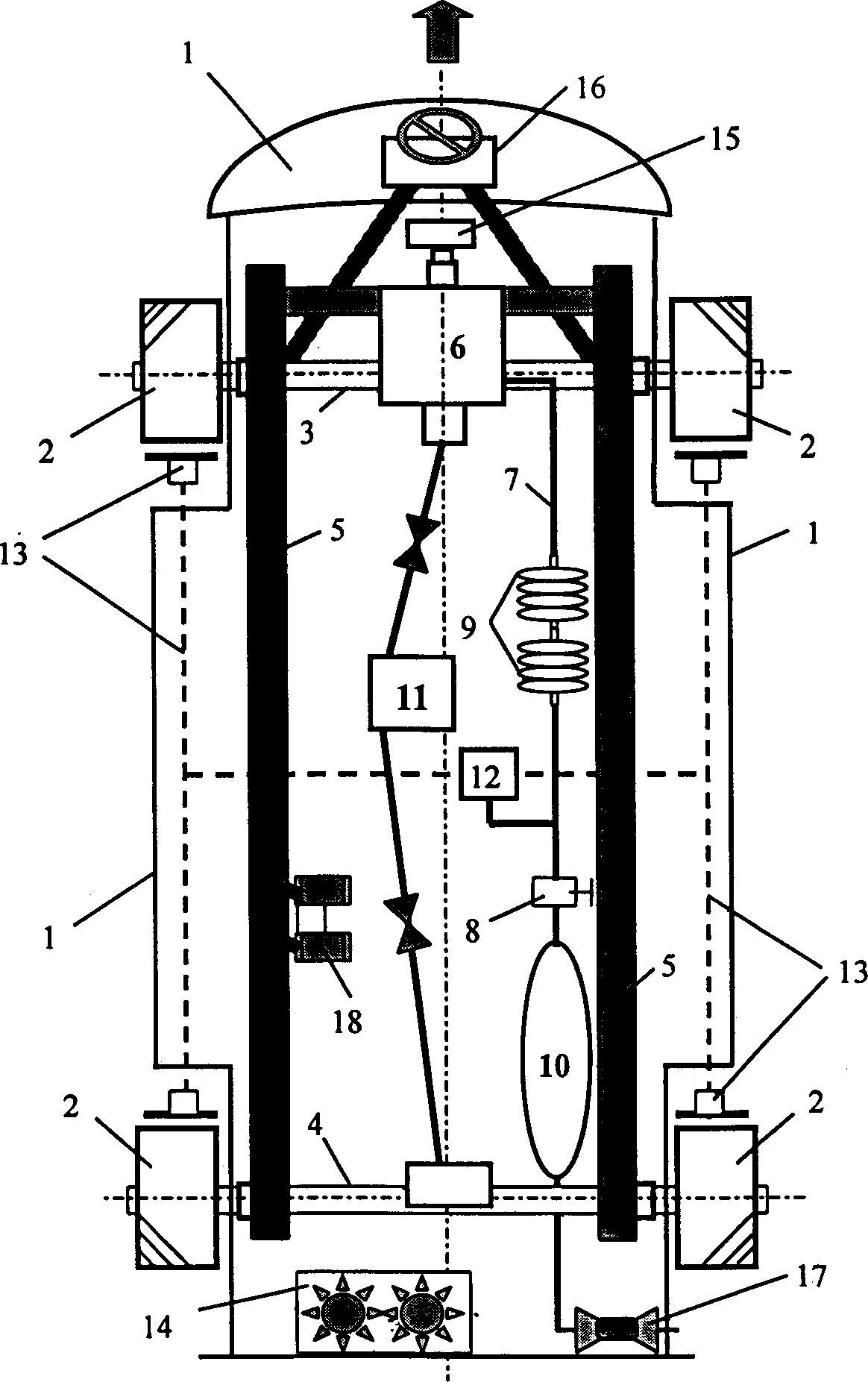

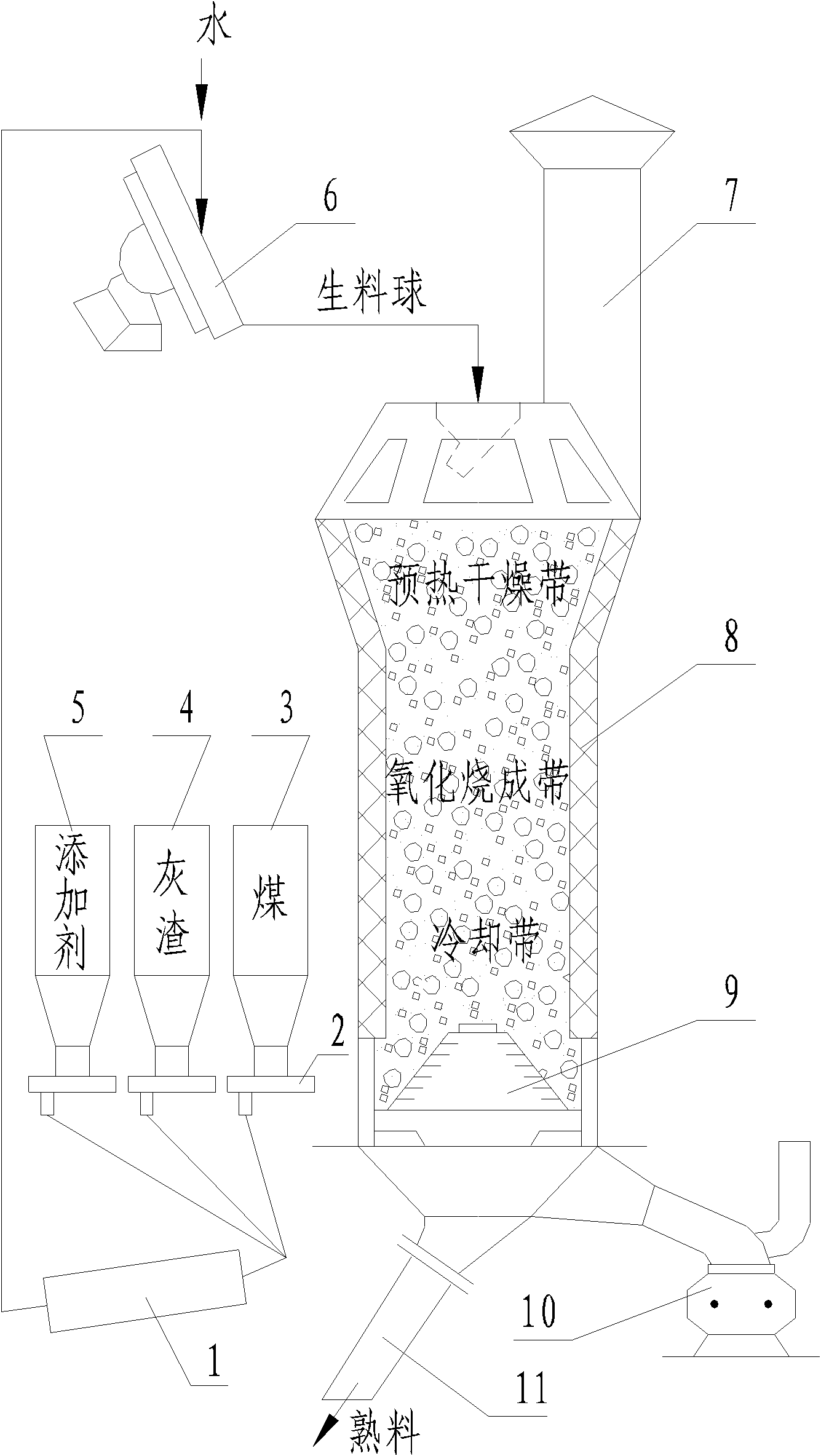

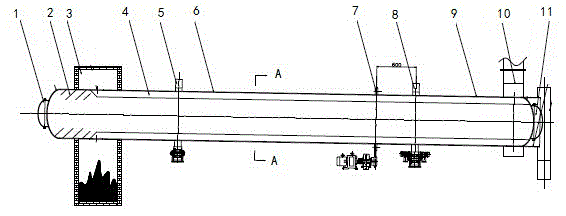

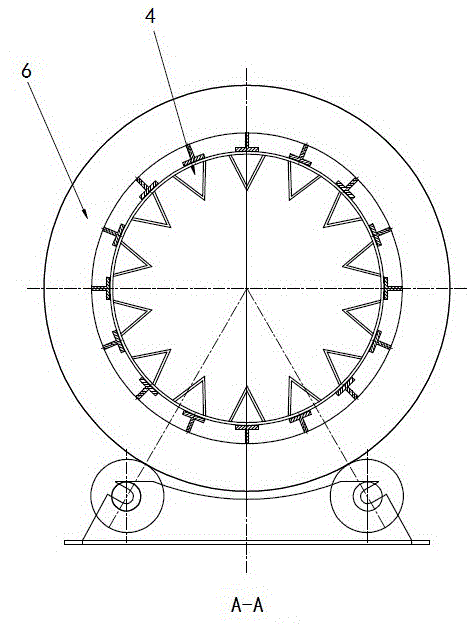

Solid particle heat exchanger

ActiveCN102322753ATemperature controlAdequate heat transferStationary tubular conduit assembliesHeat exchange apparatusSolid particleInductor

The invention relates to a solid particle heater exchanger, which comprises a cylindrical shell, wherein the top of the shell is provided with an upper connecting box for receiving particles, the middle part of the shell is provided with a heat exchange chamber, the bottom of the shell is provided with a lower connecting box for discharging the particles, a heat exchange pipe bundle is arranged in the heat exchange chamber, the heat exchange pipe bundle is provided with a fluid inlet and a fluid outlet on the shell, and a heat transfer fluid source is connected to the fluid inlet; a distributor is arranged between the upper boxing box and the heat exchange chamber; the distributor comprises a silk screen layer which is connected with a control device; the control device comprises a weight inductor and a vibrator, wherein the signal output end of the weight inductor is electrically connected with the controlled end of the vibrator, and the inducting end of the weight inductor and the output end of the vibrator are respectively connected with the silk screen layer. The invention also relates to a solid particle heat exchange system adopting the solid particle heat exchanger. According to the invention, sufficient heat transfer can be ensured, the particle discharge temperature can be controlled to meet the requirements, the discharging temperature of the heat transfer fluid can be ensured to be basically constant, and favorable energy-saving effect is achieved.

Owner:NANJING HUADIAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

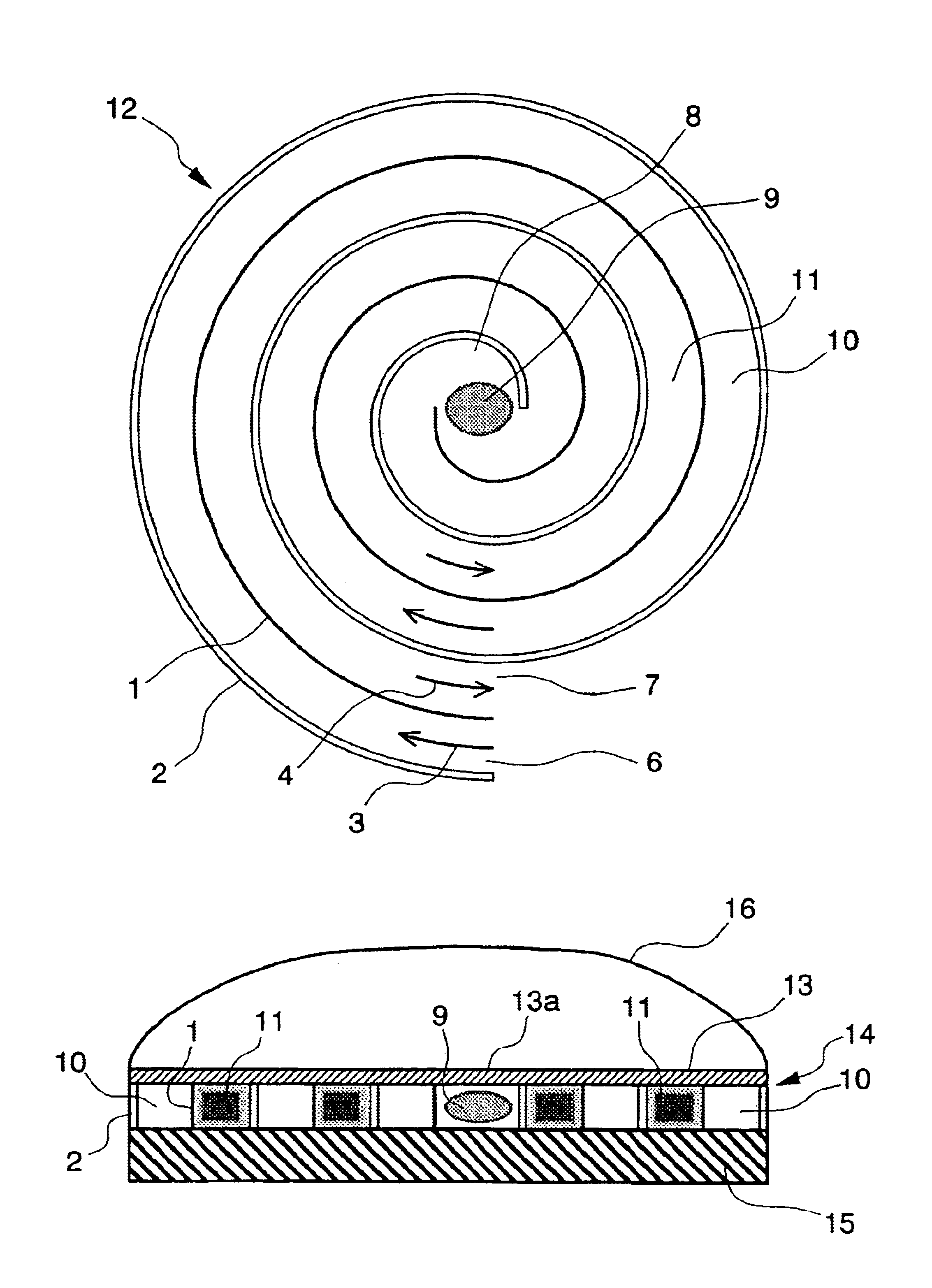

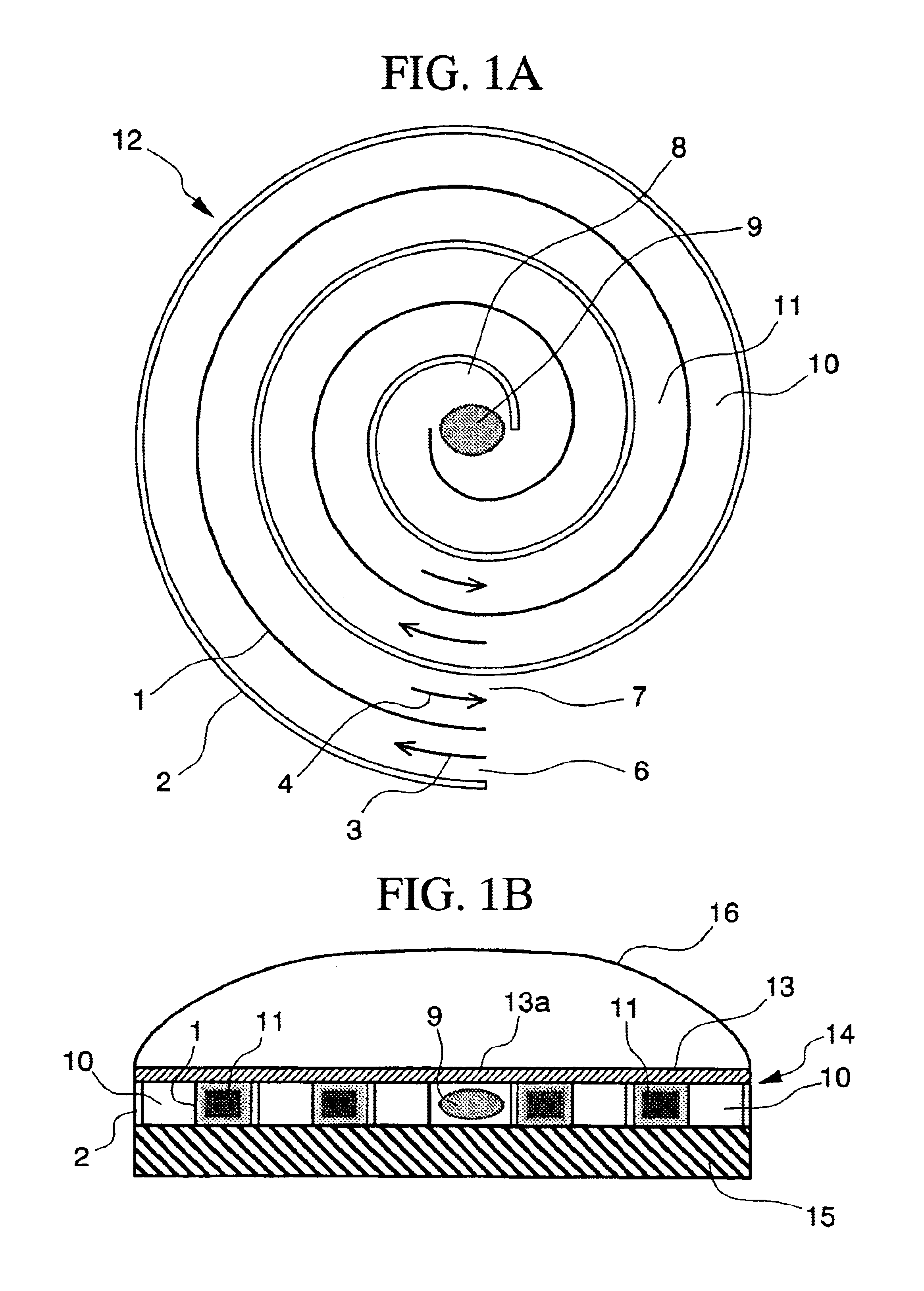

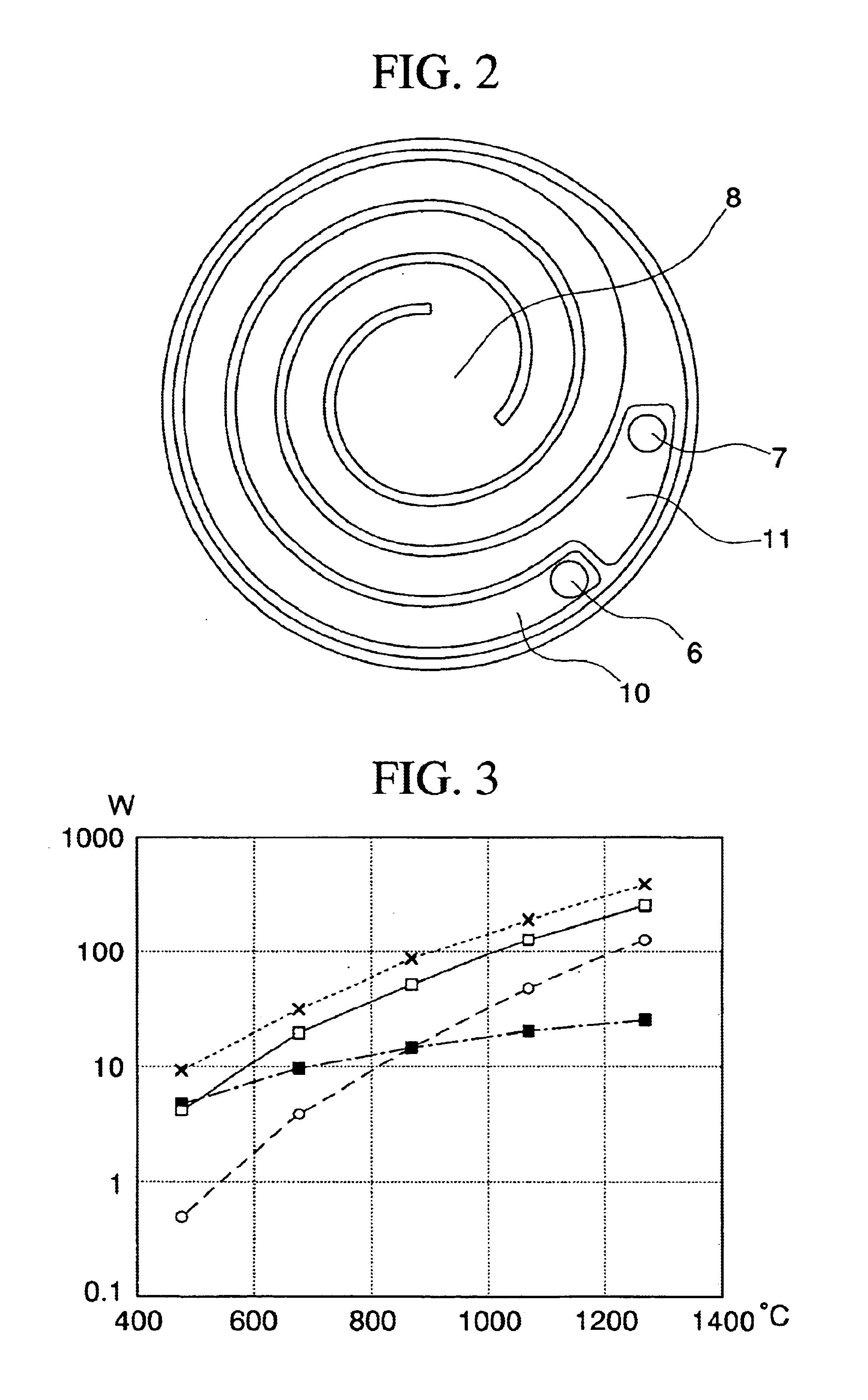

Microcombustion heater having heating surface which emits radiant heat

InactiveUS6840762B2Reliable combustionHigh thermal efficiencyFurnace componentsIndirect carbon-dioxide mitigationRadiant heaterCombustion chamber

A small microcombustion heater which can realize reliable combustion. The heater has a premixed gas passage which reaches a combustion chamber, and a passage for a combustion gas drawn from the combustion chamber. The passages are arranged in a spiral form in a manner such that a heating wall is provided between the passages. The width of the premixed gas passage is a quenching distance or less, where the quenching distance is determined depending on the premixed gas. The heater has two outer faces for holding the spiral passages from both sides of the upper and lower edges of the heating wall, and at least one of the outer faces is a heating surface for emitting radiant heat. Typically, the spiral passages are placed between a heat-resisting heating plate and a heat insulating plate, and an outer face of the heat-resisting heating plate functions as the heating surface.

Owner:MARUTA KAORU +1

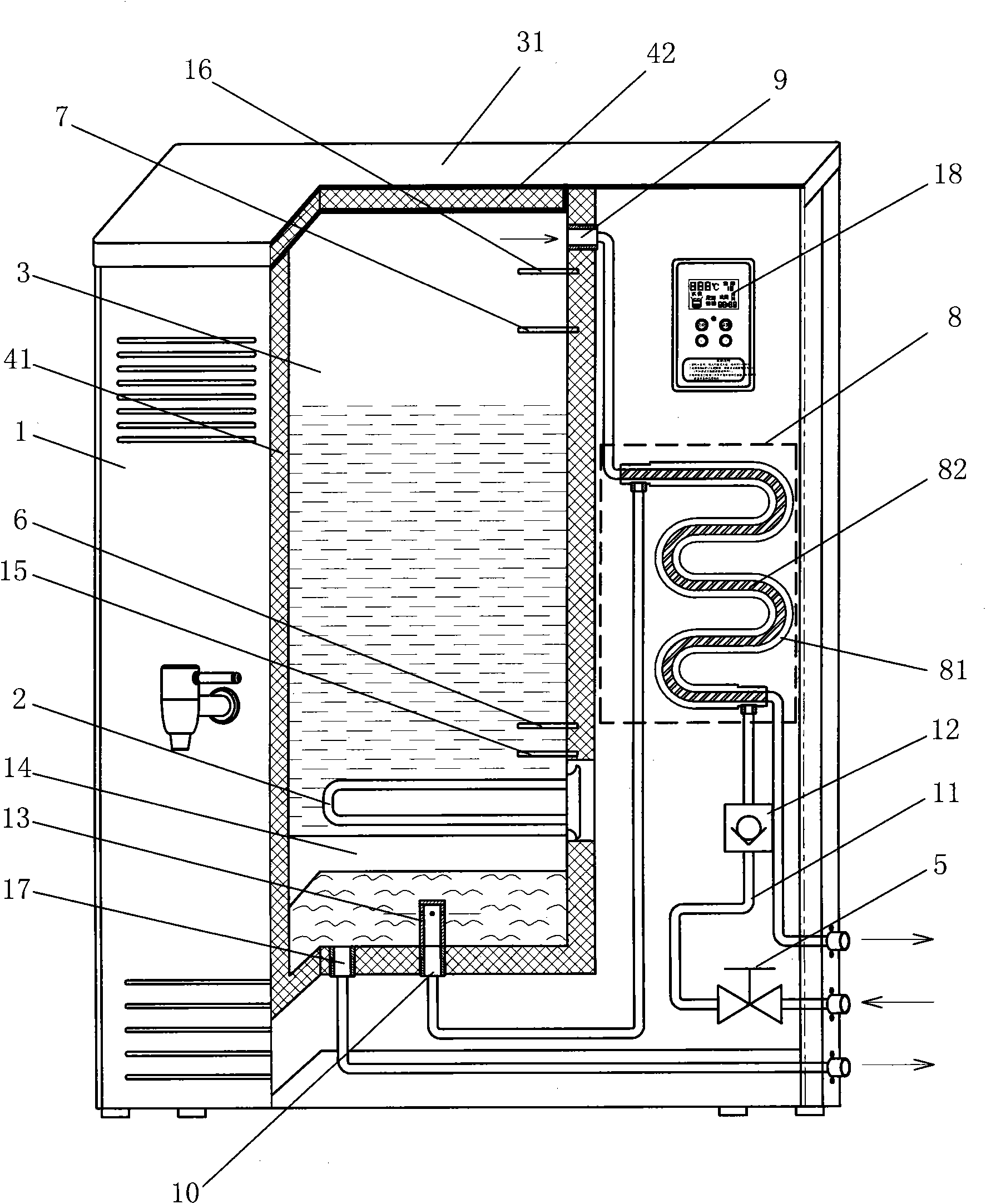

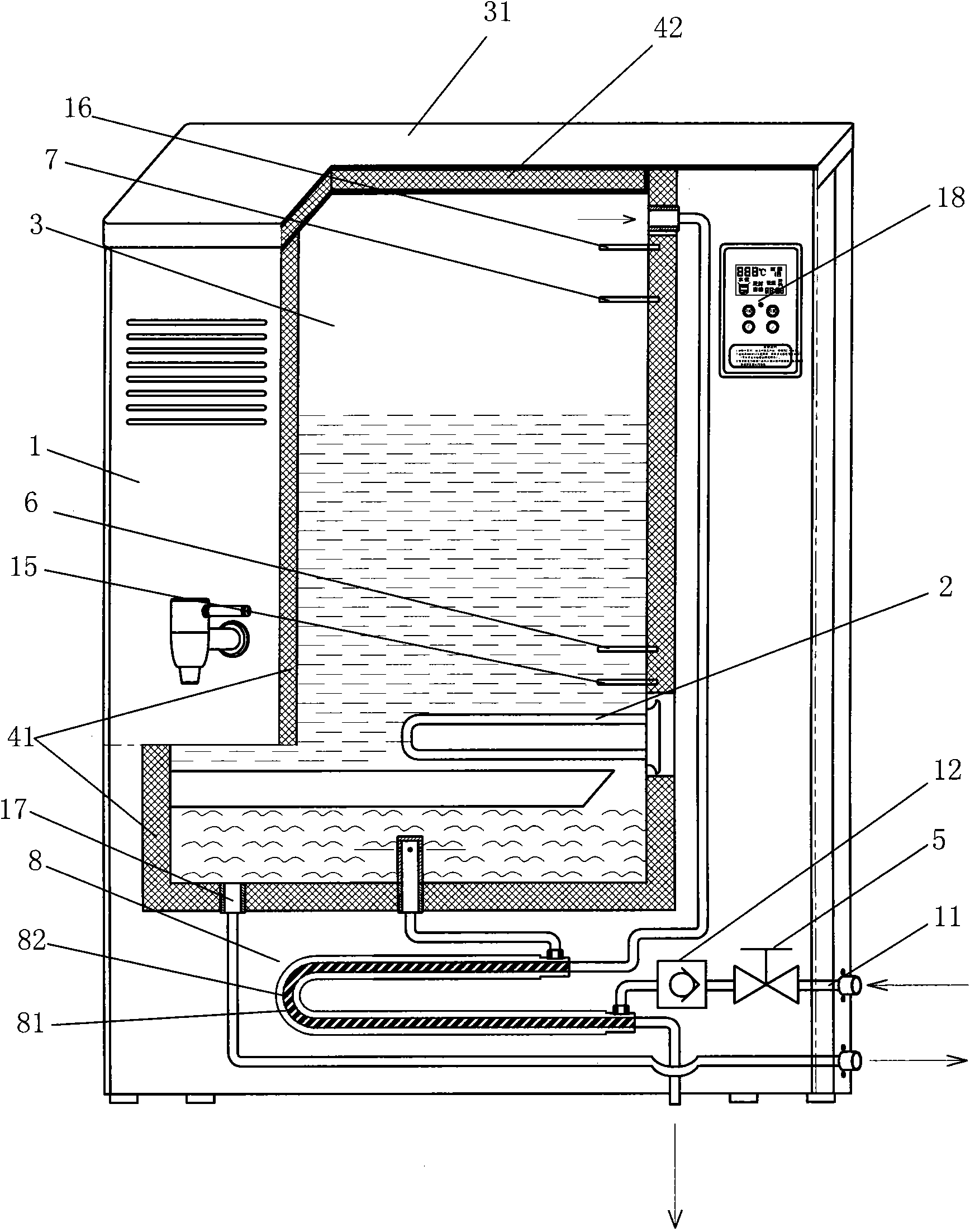

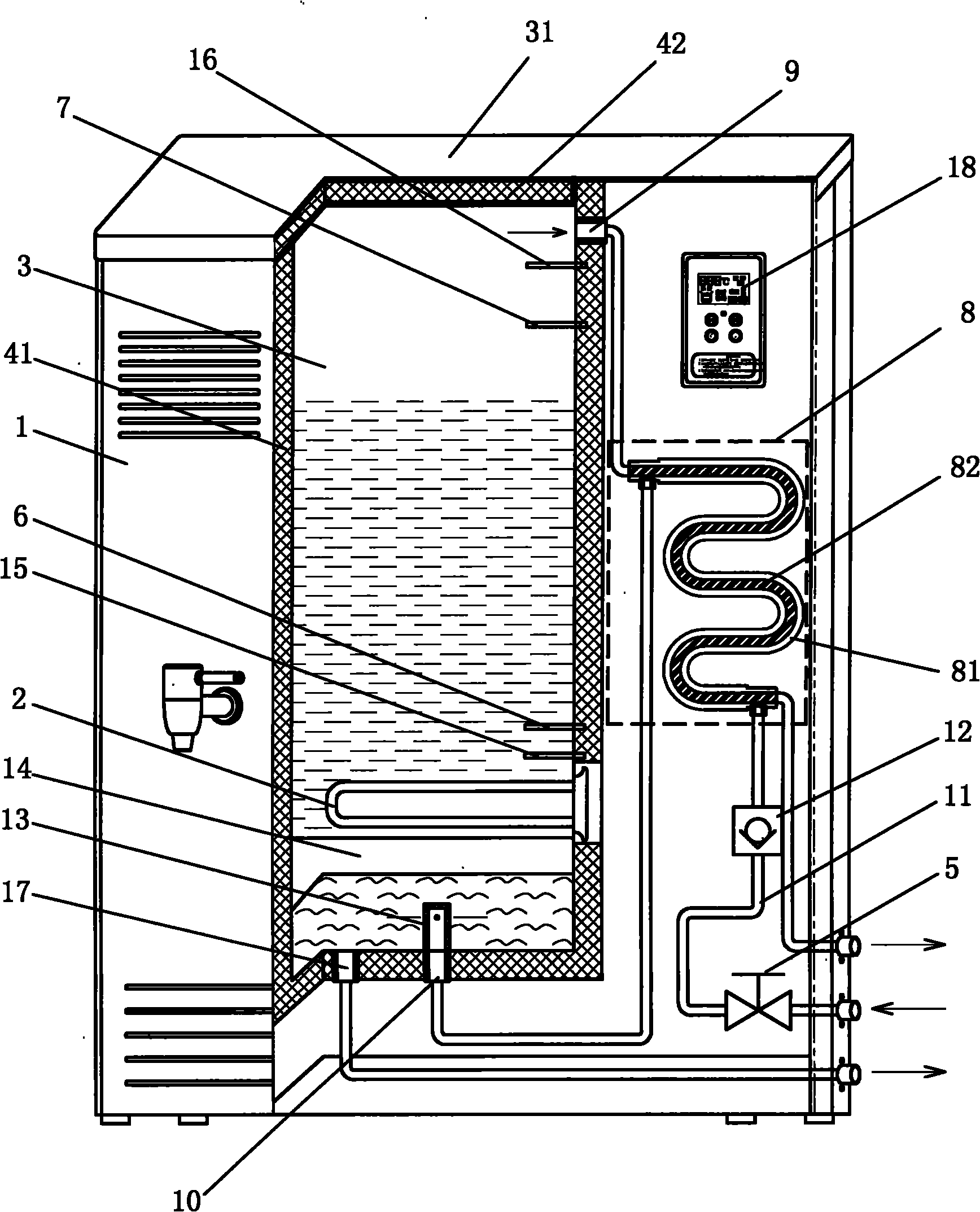

Double energy collection stepping water boiler

The invention discloses a double energy collection stepping water boiler which comprises a shell, an electric control device, a water inlet solenoid valve, high and low water level electrodes and a heat energy recoverer, wherein a water tank is arranged in the shell, and the bottom and side walls of the water tank are respectively provided with a thermal insulation layer. The invention is characterized in that the top of the water tank is additionally provided with a thermal insulation layer; the high and low water level electrodes are installed in the water tank; the upper part of the water tank is provided with a steam outlet; the heat energy recoverer is composed of a heat exchange body formed by sheathing an outer tube on an inner tube; one end of the inner tube is communicated with the steam outlet of the water tank, and the other end extends out of the shell through a guide tube; one end of the outer tube is communicated with a water inlet on the bottom of the water tank, and the other end is connected with a water supply pipeline on the shell; and the water inlet solenoid valve is arranged on the water supply pipeline and electrically connected with the high and low water level electrodes and the electric control device. The periphery of the entire water tank (including bottom, top and side walls) is provided with a thermal insulation layer for sealing and thermal insulation, and the water boiler recovers steam heat by cooperating with the heat energy recoverer, thereby realizing the effect of double energy collection. In addition, the water level electrodes are used instead of floating ball water level with poor stability and reliability, thereby obviously enhancing the stability and reliability of the overall system of the water boiler.

Owner:GUANGDONG BILI DRINKING WATER EQUIPMENT CO LTD

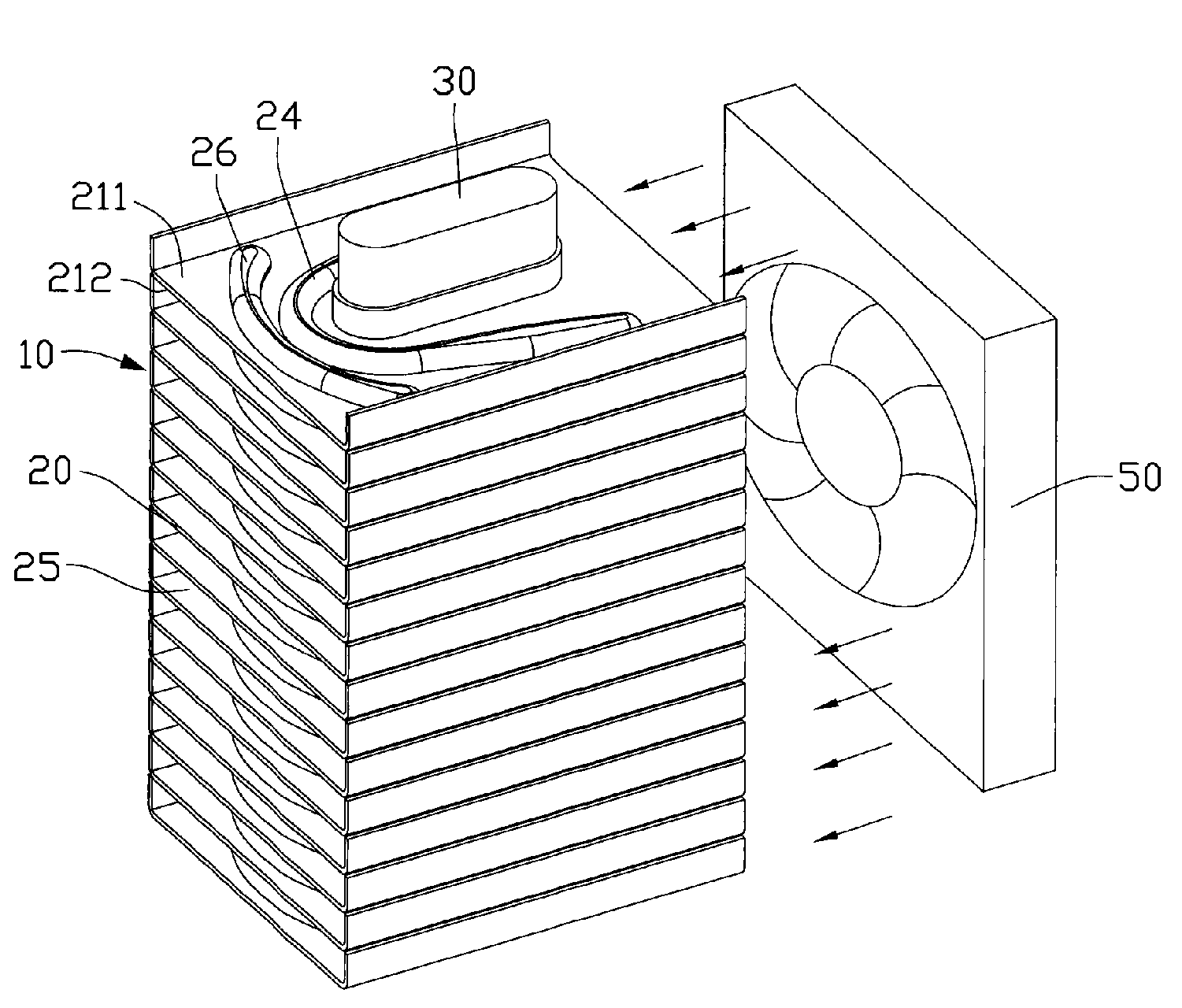

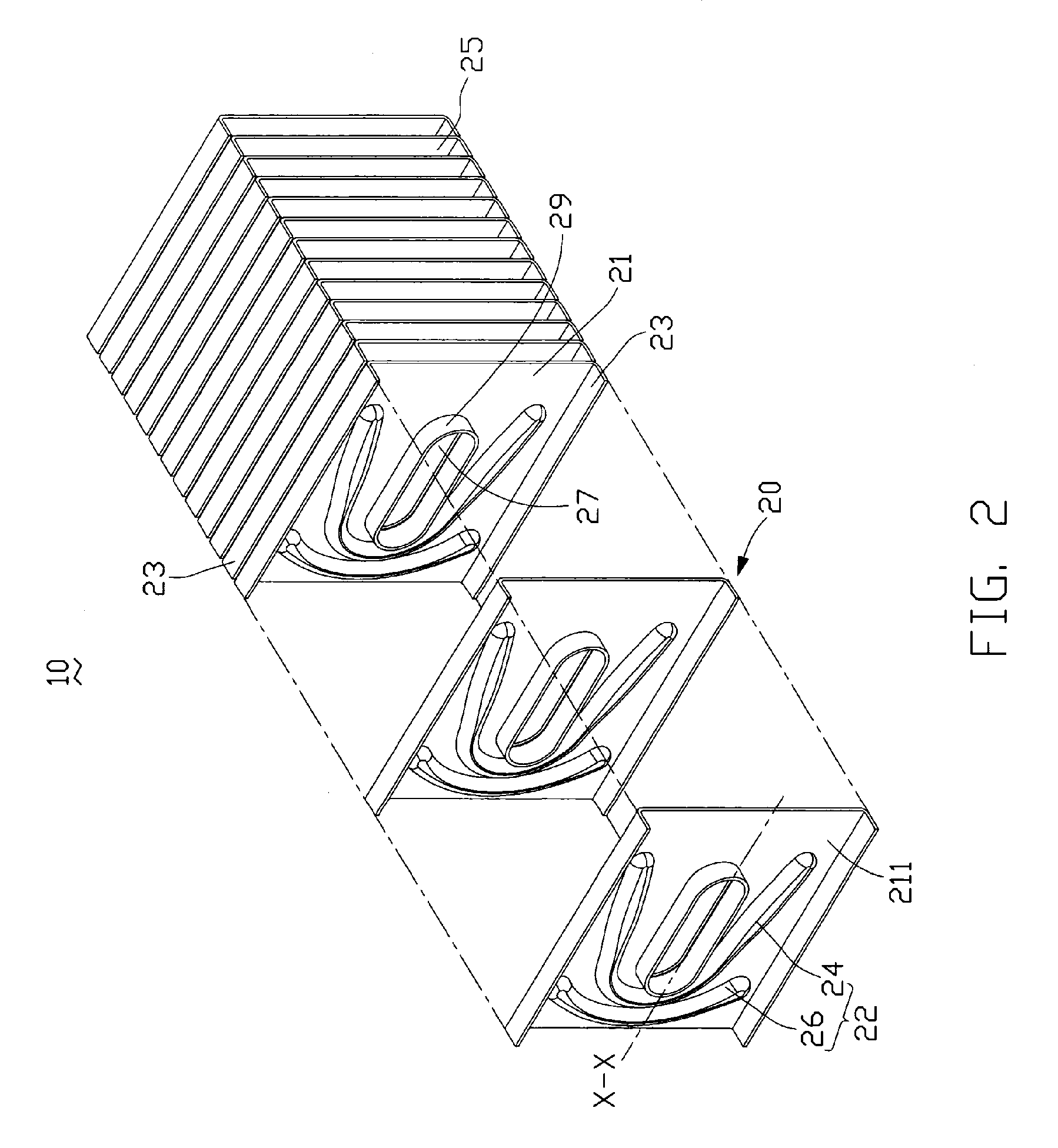

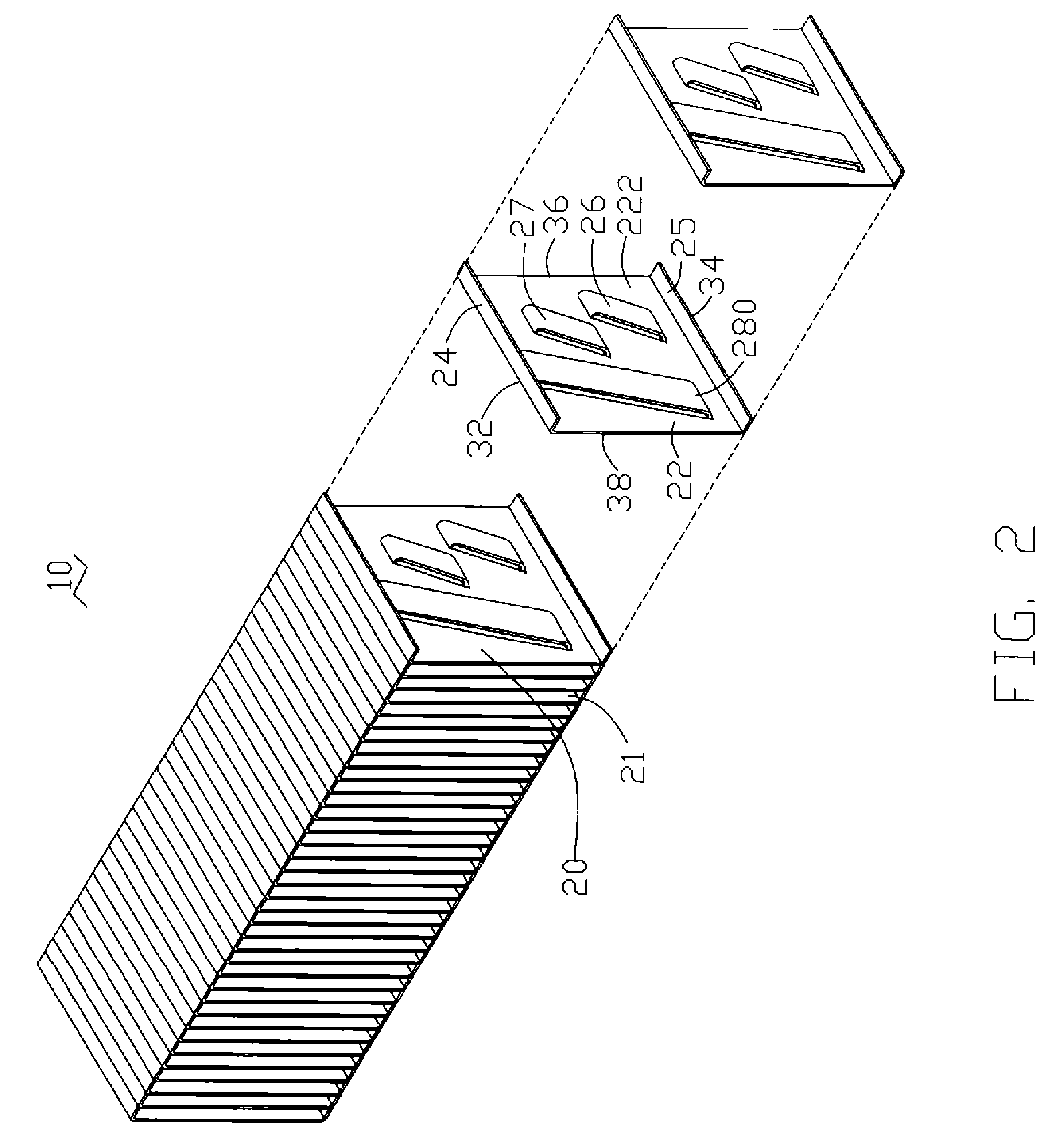

Heat sink

InactiveUS20080017349A1Increase heat exchangeIncreased turbulenceSemiconductor/solid-state device detailsSolid-state devicesAirflowEngineering

A heat sink includes a fin unit (10) having a plurality of fins (20) parallel to each other. A flow channel (21) is formed between any of two neighboring fins for an airflow flowing therethough. Three protrusions (26, 27, 28) are arranged on each of the fins and each define a through hole (42) therein. The through hole communicates with two neighboring flow channels of the fin for the airflow flowing therethrough from one of the two neighboring flow channels to the other one of two neighboring flow channels of the fin.

Owner:HON HAI PRECISION IND CO LTD +1

Vertical convector radiator and vertical convector radiating down lamp

ActiveCN102221189AAvoid heat island effectImprove heat dissipationLighting heating/cooling arrangementsElectric lightingUrban heat islandEngineering

The invention discloses a vertical convector radiator and comprises a vertical convector radiating down lamp of the vertical convector radiator. The vertical convector radiator comprises light source installation parts and a plurality of heat radiating fins of which the lower ends are connected with the light source installation parts in a heat conducting mode, wherein the vertical convector radiator comprises a plurality of convection passageways which penetrates through and is vertical to the upper surface and the lower surface of the convector radiator. When the vertical convector radiator in the technical scheme adopted operates, the lower end of the heat dissipation rectangular fin continuously heats the neighbouring air and the air rises, simultaneously, the neighbouring cold air can continuously complement to generate convection, thus the vertical convector radiator of the specific implement method can form a higher air velocity field even under the passive voice radiating condition, full heat exchange is generated between the cold air and the heat dissipation rectangular fin surface of the vertical convector radiator, the heat is rapidly take away, thereby avoiding the generation of the heat island effect in the bottom of the radiator, and the heat dissipation capacity is greatly improved.

Owner:KINGSUN OPTOELECTRONIC CO LTD

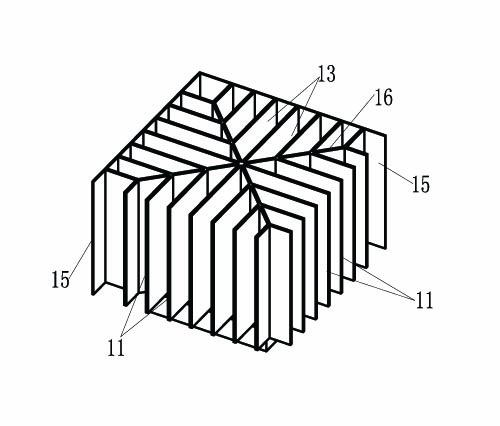

Waste molding sand or core sand regenerating equipment

InactiveCN101862808ATake advantage ofFull heat exchangeMould handling/dressing devicesConvection heatHeat energy

The invention relates to waste molding (core) sand regenerating equipment. The regenerating equipment comprises a fluidizing roasting furnace, wherein the fluidizing roasting furnace is provided with a roasting feeding hole, a roasting discharging hole, an air inlet passage and an air outlet passage. The regenerating equipment is characterized in that the waste molding sand or core sand regenerating equipment also comprises a sand separating heating device; the sand separating heating device is arranged above the fluidizing roasting furnace and comprises a sand separating heating chamber, a sand separating heating beam and a sand separating cone, wherein the sand separating heating beam and the sand separating cone are arranged in the sand separating heating chamber; the top and the bottom of the sand separating heating chamber are provided with openings; the sand separating cone is arranged on the opening at the top of the sand separating heating chamber and fixed at the top of the sand separating heating beam; a sand discharging hopper is arranged above the sand separating heating chamber, and communicated with the sand separating cone; and the opening at the bottom of the sand separating heating chamber is communicated with the roasting material inlet of the fluidizing roasting furnace. The invention has skillful and reasonable structure, skillfully combines a convection heat exchange technology and a boiling and fluidizing heating technology, sufficiently utilizes the heat energy, and enhances the heat efficiency and the treating capability of the equipment.

Owner:WUXI XINAN FOUNDARY MACHINERY

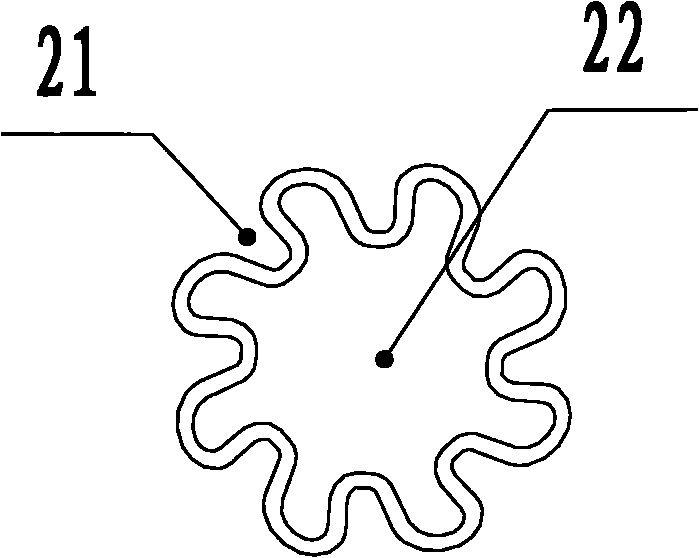

Water-cooling heat dissipation device and water block for the same

InactiveUS20070209784A1Improve performanceFull heat exchangeSemiconductor/solid-state device detailsSolid-state devicesWater blockCooling fluid

A water-cooling heat dissipation device includes a water block and a pump communicated with the water block and having cooling liquid therein. The water-cooling includes a casing and a metal panel, where the casing includes a hollow and closed cavity, a water inlet and a water outlet outside the casing and communicated with the cavity. The metal panel includes a plurality of continuously-bent heat-dissipating plates, a heat-dissipating channel defined between two adjacent heat-dissipating plates, one end of the heat-dissipating plate is attached to bottom of the cavity of the casing. Therefore, the heat-dissipating plate has more contact area with the cooling liquid in a limited space to increase heat exchange effect.

Owner:COOLER MASTER CO LTD

Vertical drying machine uniform in air distribution

InactiveCN103759516AHeating evenlyAvoid uniformityDrying gas arrangementsPulp and paper industryHeating energy

The invention provides a vertical drying machine comprising a feed bin, a distribution cone, a drying barrel and a discharge hopper. The vertical drying machine is characterized in that the drying barrel comprises an inner barrel, an outer barrel and an air duct, a retainer ring is arranged between the inner barrel and the outer barrel, a drying passage is formed by gap of the retainer ring, and a circular vent is formed between the inner barrel and the outer barrel. The air duct is a circular barrel surrounding the outer barrel and divided into an upper exhaust barrel and a lower air-inlet barrel, the upper exhaust barrel is provided with an exhaust outlet, the lower air-inlet barrel is provided with an air inlet, and a partition is arranged between the exhaust barrel and the air-inlet barrel to prevent direct circulation between the exhaust barrel and the air-inlet barrel. By the aid of the circular air duct and the circular vent, hot air circulates uniformly along the circumference, and defects that materials are uneven in drying and even caught fire due to local overheating are avoided. In addition, materials are heated twice by hot air, heat exchange is carried out sufficiently, and heat utilization efficiency is improved.

Owner:XINXIANG ZHONGDE ENERGY TECH

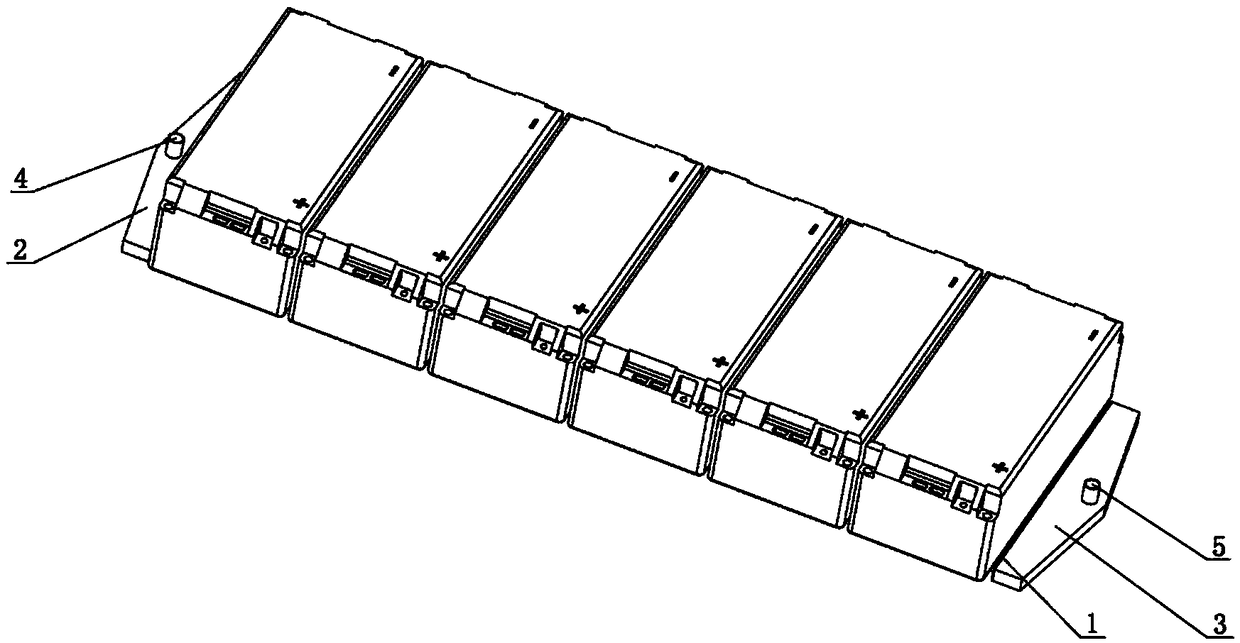

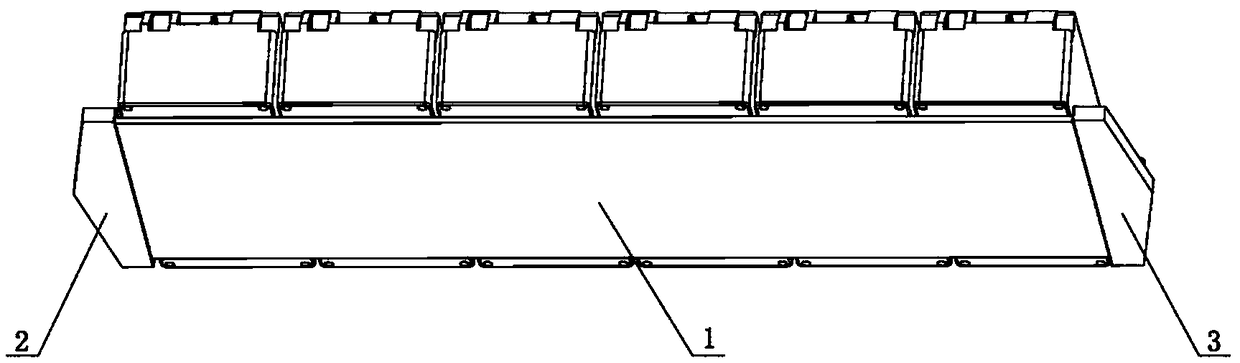

A liquid-cooled plate for power battery of electric vehicle

A liquid-cooled plate for a power battery of an electric vehicle belongs to the technical field of electric vehicles, the liquid-cooled plate for a power battery of an electric vehicle comprises an integrally formed liquid-cooled plate body, both ends of the liquid-cooled plate body are provided with openings and a flow channel structure is arranged inside the liquid-cooled plate body, the two ends of the liquid-cooled plate body are connected with a first hollow end plate and a second hollow end plate communicating with the liquid-cooled plate body in a sealing manner, a water inlet joint isarranged on the first hollow end plate, a water outlet joint is arranged on the second hollow end plate, the invention has the beneficial effect that, the electric vehicle power battery liquid-cooledplate has the advantages of simple and stable overall structure, low manufacturing cost, increases heat exchange contact area and contact time with the power battery module, improved heat exchange efficiency, improved cooling effect of the power battery module, and light overall weight, which meets the lightweight requirements of the whole vehicle.

Owner:奇瑞新能源汽车股份有限公司

Air-flow type drying oven for drying coating layer of radiate material and blast nozzle parts thereof

ActiveCN101417276AUniform heating on the surfaceIncrease the direct contact areaPretreated surfacesSpray nozzlesEngineeringAirflow

The invention discloses an air flow drying oven for drying the coating of a radiate material and a blast nozzle part thereof. The blast nozzle part is a case, the lower part of which is provided with an air inlet. The middle of the upper part of the case is provided with a guide roller groove, and the case is provided with an inner cavity at the lower part and a left air duct and a right air duct which are positioned at the left side and the right side of the upper part and directly communicated with the inner cavity. An air outlet of the left air duct is a left parallel air flow blast nozzle which inclines towards the left, and the air outlet of the right air duct is a right parallel air flow blast nozzle which inclines towards the right. When the blast nozzle part is used in the drying oven, the left and right blast nozzles accelerate the flow flowing to the left and right sides of the blast nozzle part, and a left horizontal supporting plate and a right horizontal supporting plate lead the air flow to form parallel wind which is parallel to the radiate material, thus increasing the direct contact area between the wind and the radiate material, leading the radiate material surface to be heated evenly and the heat exchange between the parallel hot wind and the radiate material to be more sufficient, improving the heat exchange efficiency and having better drying quality due to even heating.

Owner:CHANGZHOU YONGSHENG NEW MATERIALS EQUIP CO LTD

Concrete temperature-control mold plate and use method thereof

ActiveCN105715040AAchieve warmingReduce the temperatureForming/stuttering elementsTemperature controlTemperature difference

The invention discloses a concrete temperature-control mold plate and a use method thereof. The concrete temperature-control mold plate comprises a steel plate structure body, a heat-preservation material plate and a reinforced plate, wherein the steel plate structure body and the heat-preservation material plate are matched together to form a hollow structure; the heat-preservation material plate is covered by the reinforced plate; a vent interface is formed in a double-layer structure of the reinforcing plate and the heat-preservation material plate; vent interfaces can be connected through an air connecting tube so as to communicate hollow structures of adjacent temperature-control mold plates and air flow of set temperature can be conveyed into the hollow structures through air conveying tubes; air flow is subjected to heat exchange with concrete through a steel plate surface, and thus temperature regulation and control of the temperature-control mold plate to concrete can be achieved. The concrete temperature-control mold plate mainly aims to solve the problem of temperature cracks of concrete of a wall structure, particularly a long (lateral) wall structure, and the problems that temperature cracks can be easily generated as the molding temperature and the hydration temperature of concrete are increased in a high temperature environment in summer, and a structure can be damaged as concrete at an early cast stage can be frozen and cracks can be generated as the surface and inner temperature difference is too large in a severe cold environment in winter.

Owner:JIANGSU SOBUTE NEW MATERIALS

Rotary crystallization kiln for alpha gypsum powder

The invention discloses a rotary crystallization kiln for alpha gypsum powder. The rotary crystallization kiln for alpha gypsum powder comprises a rack, a kiln body, a feeding end, a discharging end, a tail gas collector, a heat supply chamber, a heat exchanging pipe, an inlet end socket, an outlet end socket and a power transmission device, wherein the kiln body and the power transmission device are mounted on the rack; the power transmission device is used for driving the kiln body to rotate on the rack, and when the inlet end socket and the outlet end socket are closed, the kiln becomes an airtight space; and a circle of heat exchanging pipe communicated with the heat supply chamber and having the function of a lifting board is fixed on the inner wall of the kiln body. The rotary crystallization kiln is in a dynamic mode rather than a static mode; the heat exchanging area is increased due to the arrangement of the heat exchanging pipe; heat energy is fully used through multiple technical methods, and therefore, energy consumption is lowered; the functions of pre-drying, autoclaving crystallization and product drying are integrated, the process steps are reduced, the quantity of equipment is lowered, the production time is shortened, and the production cost is lowered; and no external high-temperature steam or aqueous solution participates in heat exchange and reaction, and hemihydrate gypsum is prevented from being hydrated again into dihydrate gypsum, so that the product quality is more stable.

Owner:湖南昌迅科技环保股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com