Vertical convector radiator and vertical convector radiating down lamp

A technology of vertical convection and heat sink, which is applied in the direction of lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., and can solve problems such as poor heat dissipation effect and heat island effect of passive radiators, and achieve Save interior decoration costs, avoid the heat island effect, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

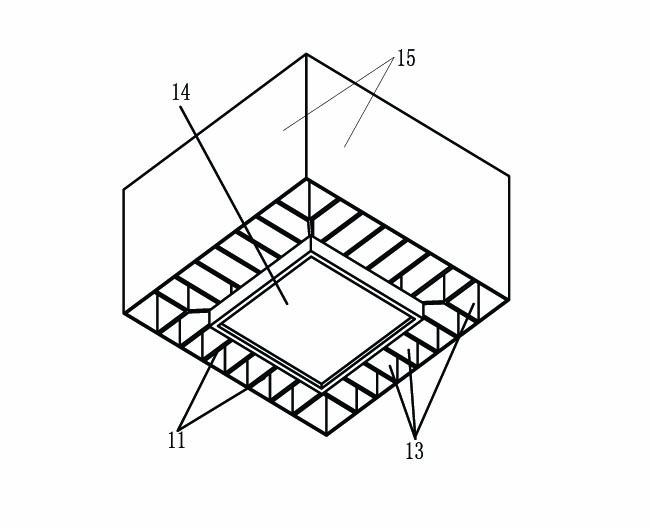

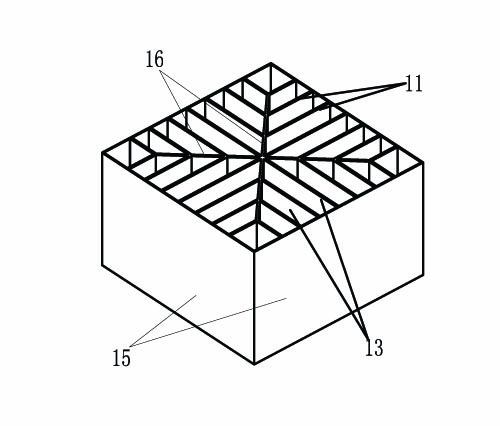

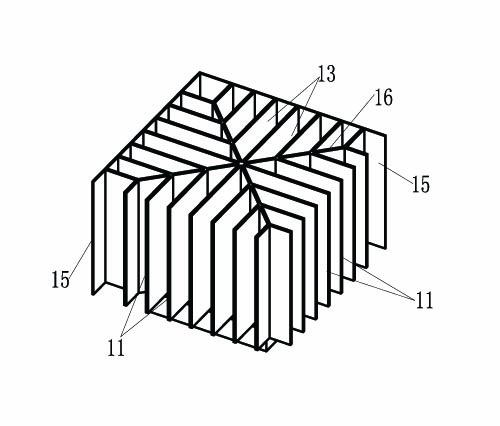

[0035] The vertical convection radiator of this embodiment improves the structure of the existing aluminum extruded radiator based on the "chimney effect". The structure of the improved vertical convection radiator is as follows figure 1 with figure 2 As shown, a plurality of heat dissipation fins 11 are included, a frame 15 and a connecting rib 16 are also included, and a light source mounting part is provided with a mounting position 14 on the light source mounting part. Such as image 3 As shown, the obvious difference between the vertical convection heat sink of this embodiment and the existing aluminum extruded heat sink is that most of the gaps formed between the heat dissipation fins 11 and the frame 15 and the connecting ribs 16 run through the entire Radiator, thereby forming a number of convection channels 13. When the vertical convection radiator is working, the cold air at the bottom of the vertical convection radiator (near the heat source) is continuously heated a...

Embodiment 2

[0044] The vertical convection radiator of the present invention can have several deformations in specific shapes, such as Image 6 with Figure 7 What is shown is another vertical convection heat sink provided by this embodiment.

[0045] The biggest difference between the vertical convection radiator in this embodiment and the first embodiment is that the overall shape is cylindrical. The heat dissipation fins radiate uniformly from the center to the outside. The outermost is a cylindrical frame 15 with two cylindrical connecting ribs 16 in the middle, and the connecting ribs 16 and the frame 15 are arranged concentrically. Of course, the core essence is that the gaps between the radiating fins and the frame 15 and the connecting ribs 16 form a convection channel 13 passing through the upper and lower sides of the radiator, which can also form a "chimney effect", thereby improving the heat dissipation effect. Correspondingly, the light source mounting component and the mounting...

Embodiment 3

[0047] This embodiment provides a vertical convection radiator such as Figure 8 As shown, the difference from the second embodiment is that the aluminum substrate (not shown in the figure) on which the LED is mounted is not sleeved on the periphery of the frame 15 but is arranged inside the frame 15. Moreover, the cylindrical connecting rib 16 as in the second embodiment is not provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com