Dragging motor coupling cooling system and method

A technology for driving motors and cooling systems, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of easy formation of heat island effect, reduction of cooling system efficiency, poor energy saving effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

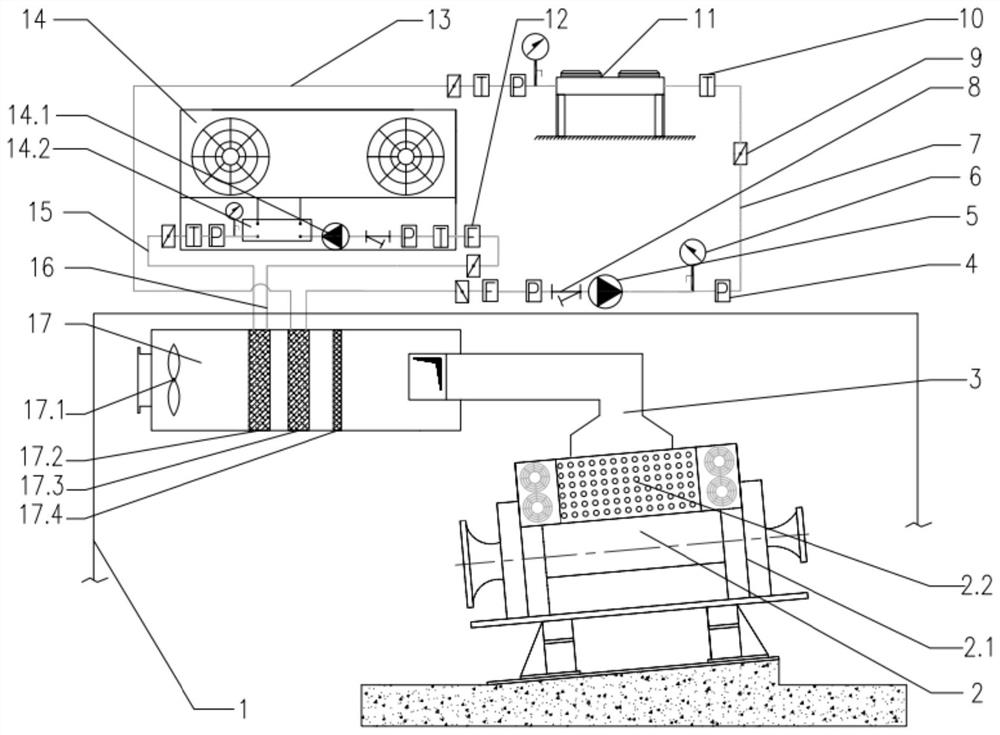

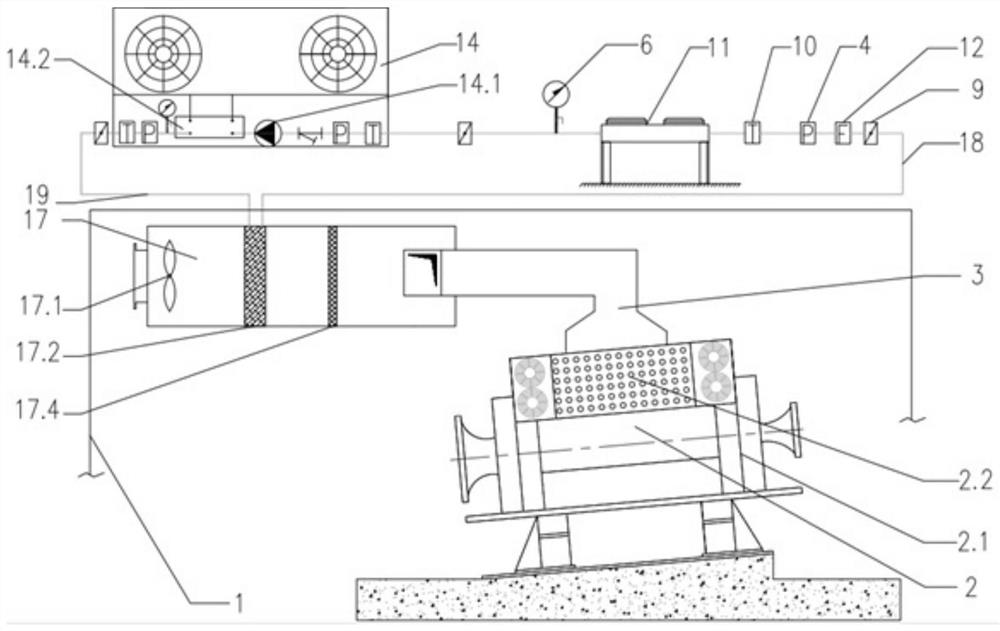

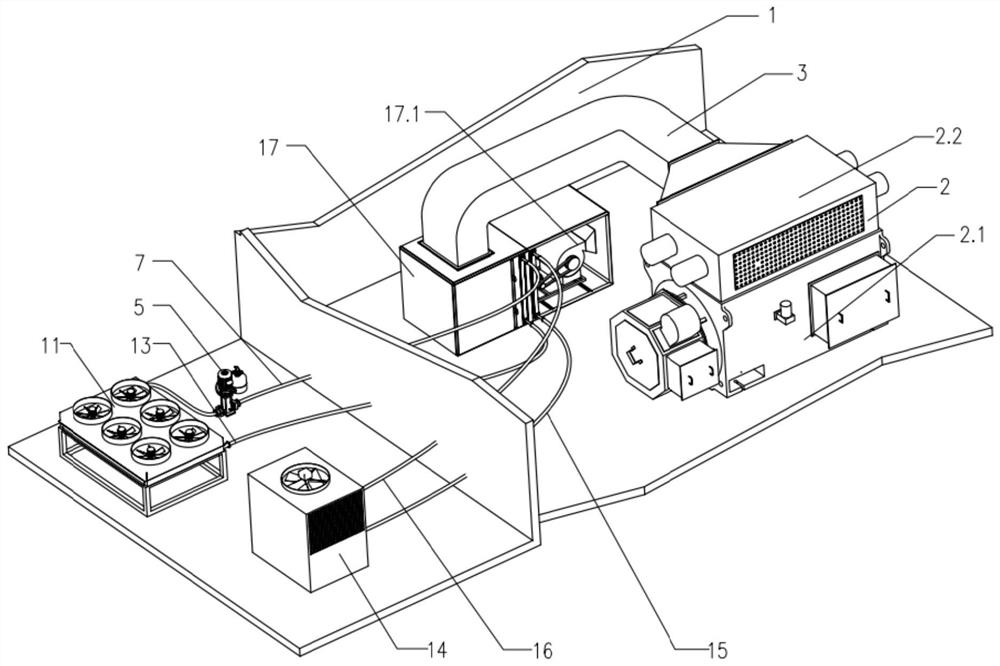

[0044] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0045] A driving motor coupling cooling system of the present invention includes a test bench building 1, a driving motor 2, a return air duct 3, a pressure transmitter 4, a dry cooler pump station 5, a pressure gauge 6, a first cooling return pipe 7, Filter 8, valve 9, temperature sensor 10, dry cooler 11, flow sensor 12, first cooling water supply pipe 13, air-cooled chiller 14, second cooling water supply pipe 15, second cooling return water pipe 16, air conditioning wind Chamber 17, return water pipeline 18, water supply pipeline 19.

[0046] The driving motor 2 includes a motor 2.1 and an air-to-air cooler 2.2. The air-cooled chiller 14 includes a water chiller water pump 14.1 and a heat exchanger 14.2 in the chiller. The dragging motor 2 is inclined relative to the bottom surface.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com