Synchronous clamping mechanism

A technology of synchronous clamping and fixing blocks, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to meet strict requirements, expensive cylinders, and difficult mechanisms, and achieve low cost, The effect of simple structure and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

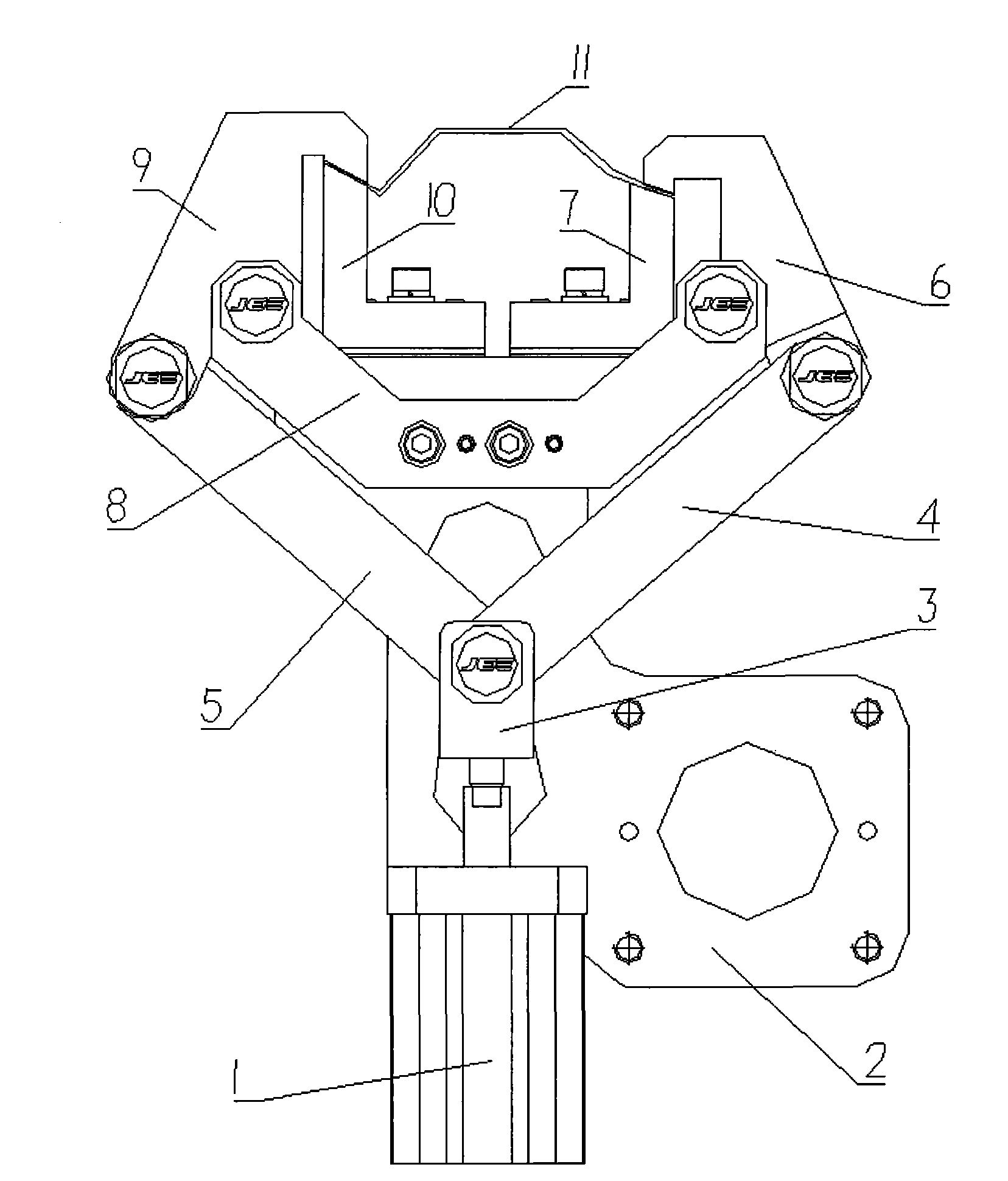

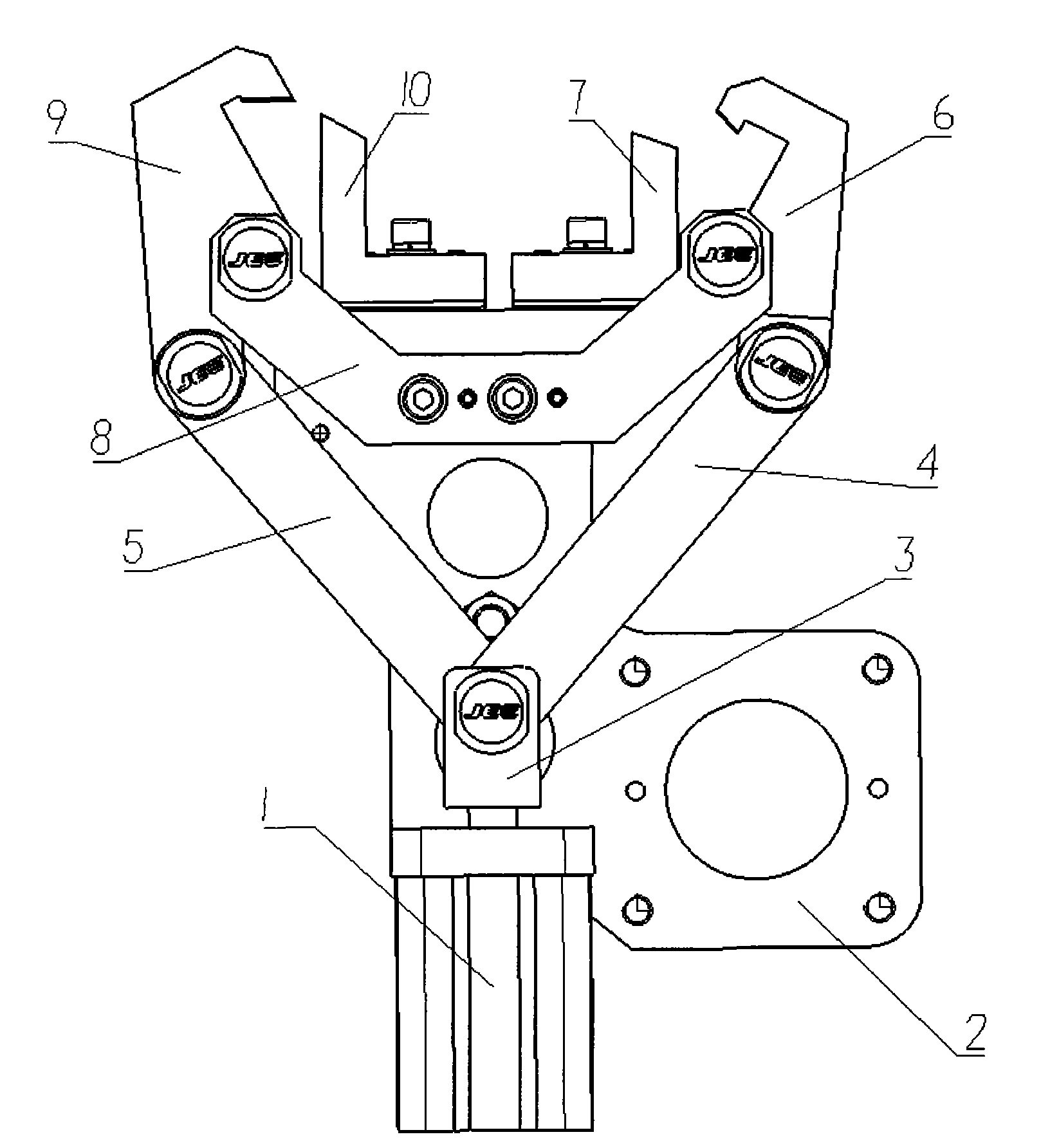

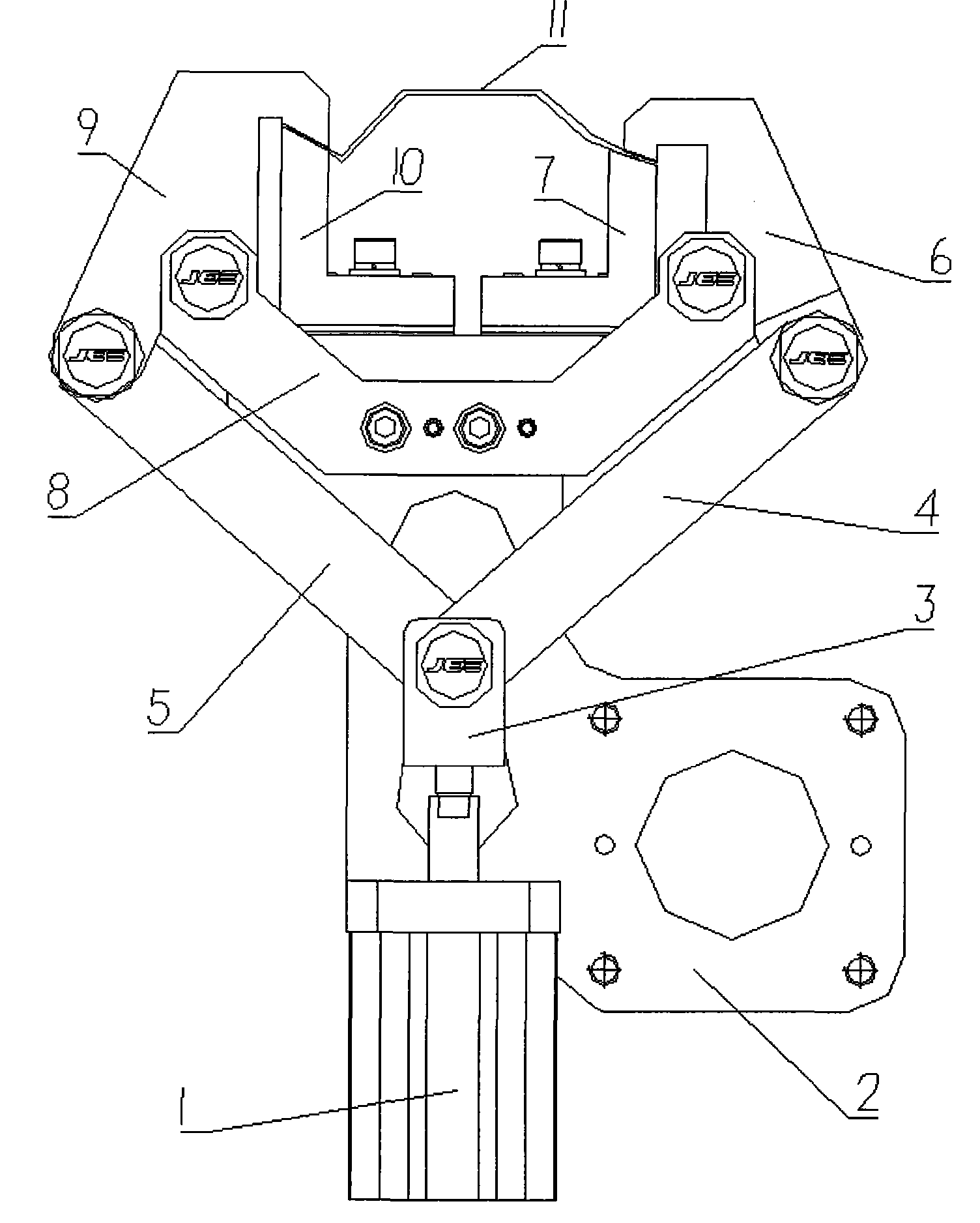

[0018] see figure 1 , with the cylinder 1 as the driving part, the rod end of the cylinder piston rod passes through the joint 3 to form a "Y" symmetrical hinged left connecting rod 5 and the right connecting rod 4, and the rod ends of the left connecting rod 5 and the right connecting rod 4 respectively pass through The rotating shaft hinges the left half claw 9 and the right half claw 6, and the left half claw 9 and the right half claw 6 are symmetrically arranged on the left and right. The waists of the claws are respectively hooked on symmetrically arranged fixed rotating shafts, and can rotate around the fixed rotating shafts.

[0019] In specific implementation, "V" shaped fixed block 8 is set, and the fixed rotating shaft is the left and right two tops of "V" shaped fixed block 8; "V" shaped fixed block 8 is fixedly arranged on the fixed pattern plate 2; The type fixed block 8 is enveloped between the left connecting rod 5 and the right connecting rod 4 arranged in a "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com