Patents

Literature

4423 results about "Jet flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure and Flow measurement. JET FLOW is a data acquisition system, used to display in real time and record, directly on a Windows PC, all the parameters and graphics of: – Instantaneous pressure (bar, with JET PRESS sensor) – Instantaneous flow rate (liters/min) – Pumped fluid volume (liters)

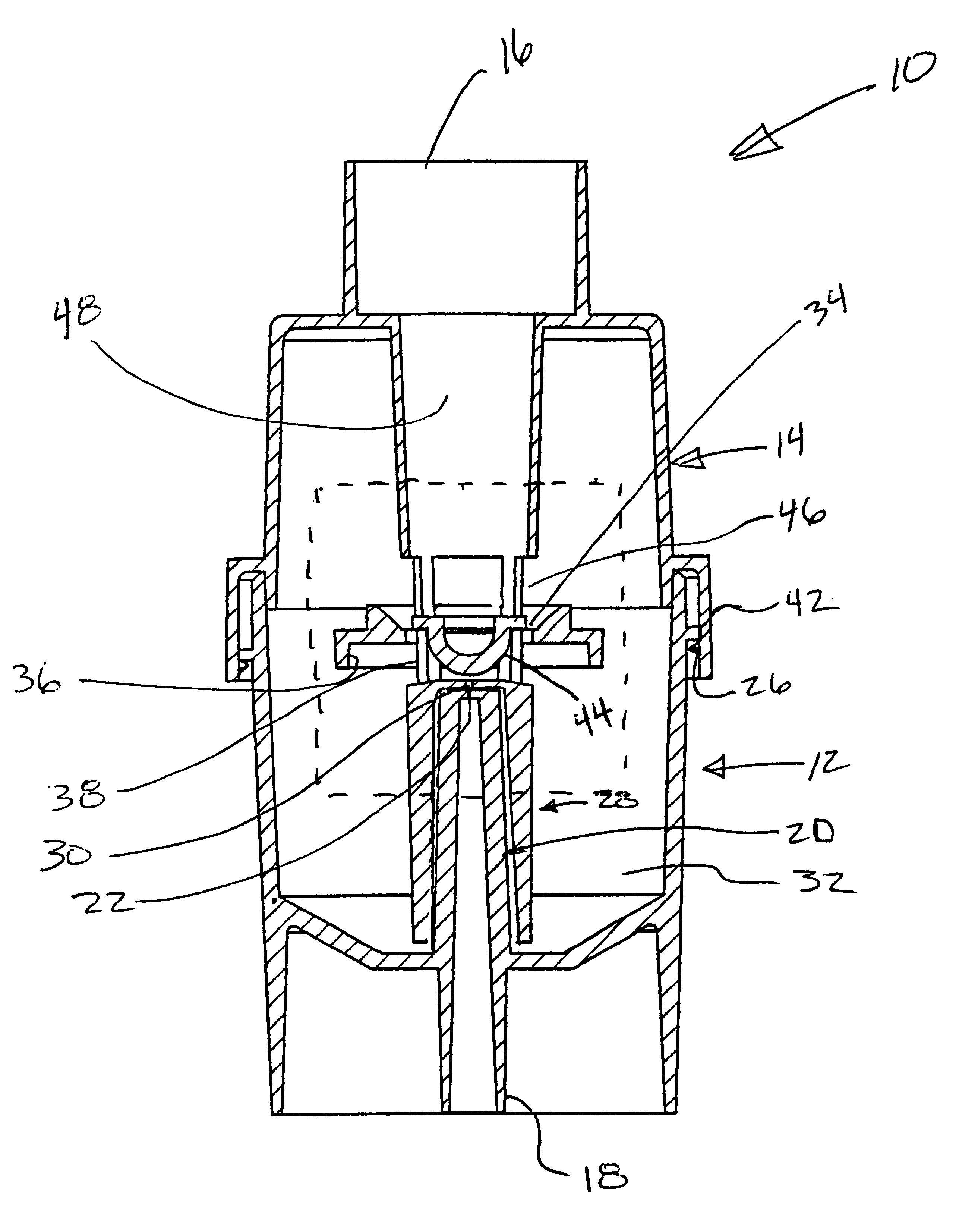

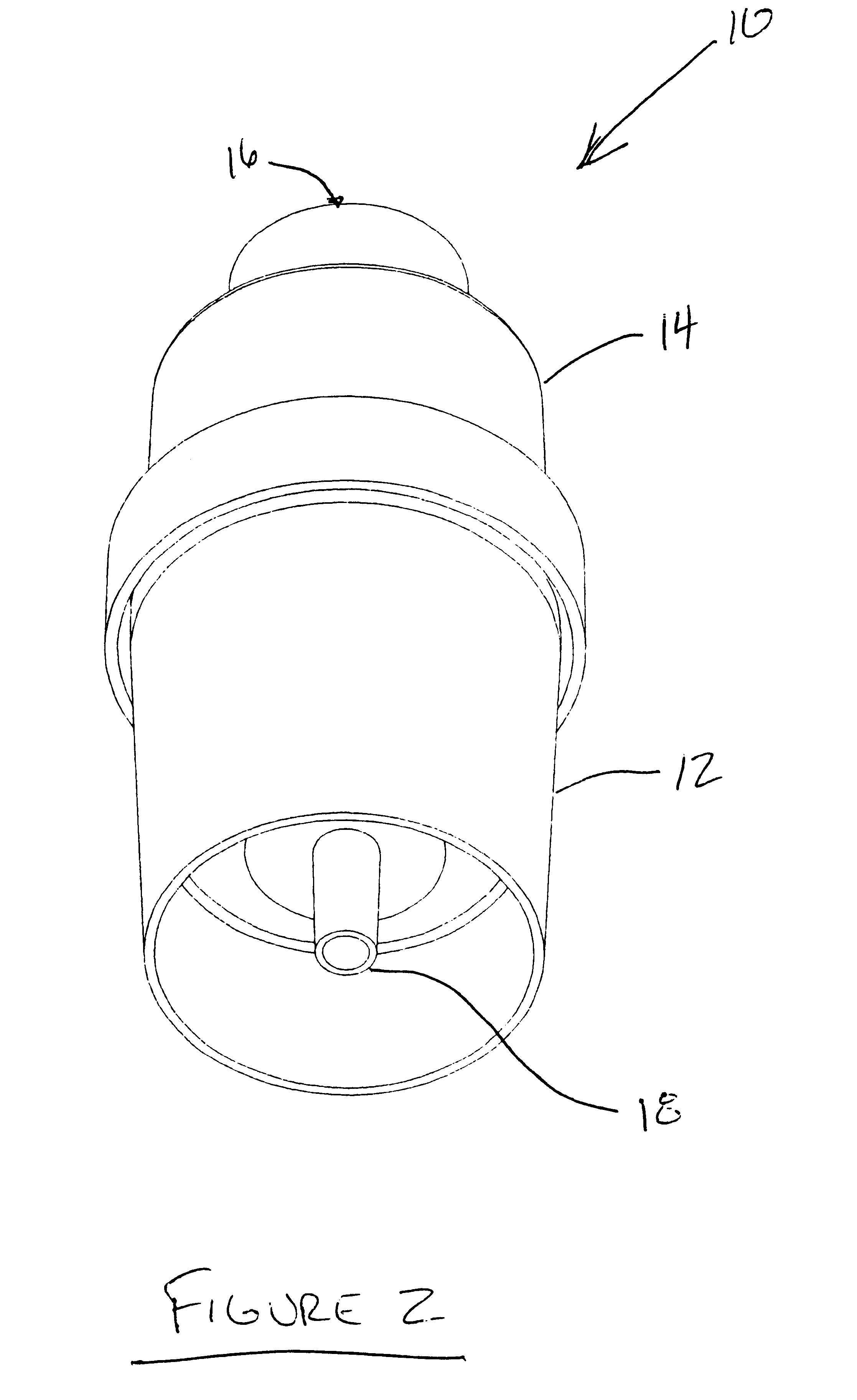

Hypodermic fluid dispenser

InactiveUS6056716AEfficient injectionEliminate the problemAmpoule syringesJet injection syringesHypodermoclysisJet flow

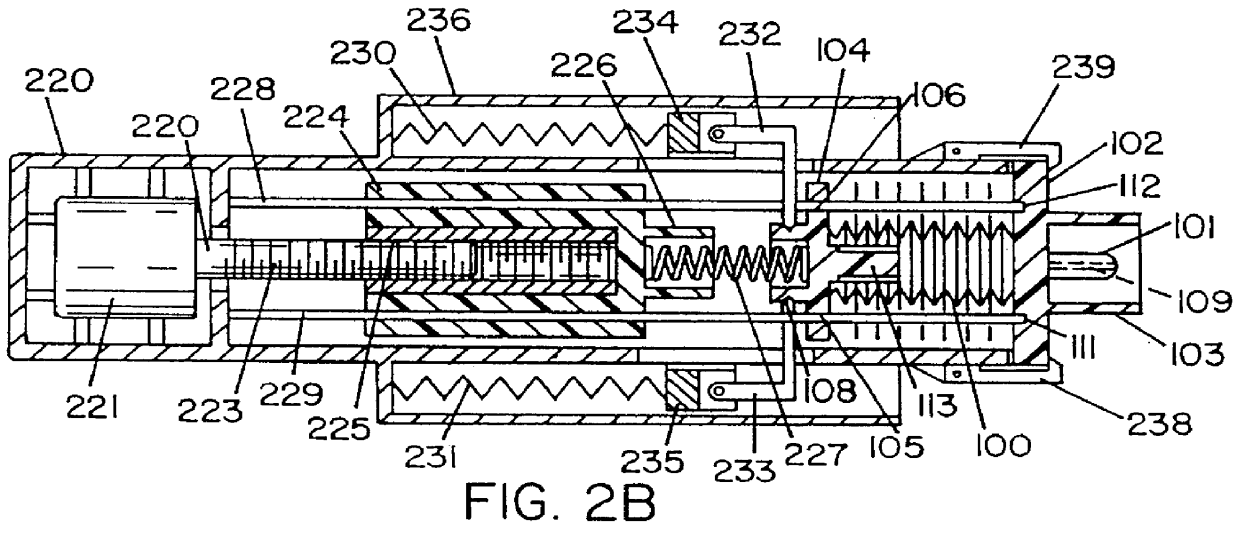

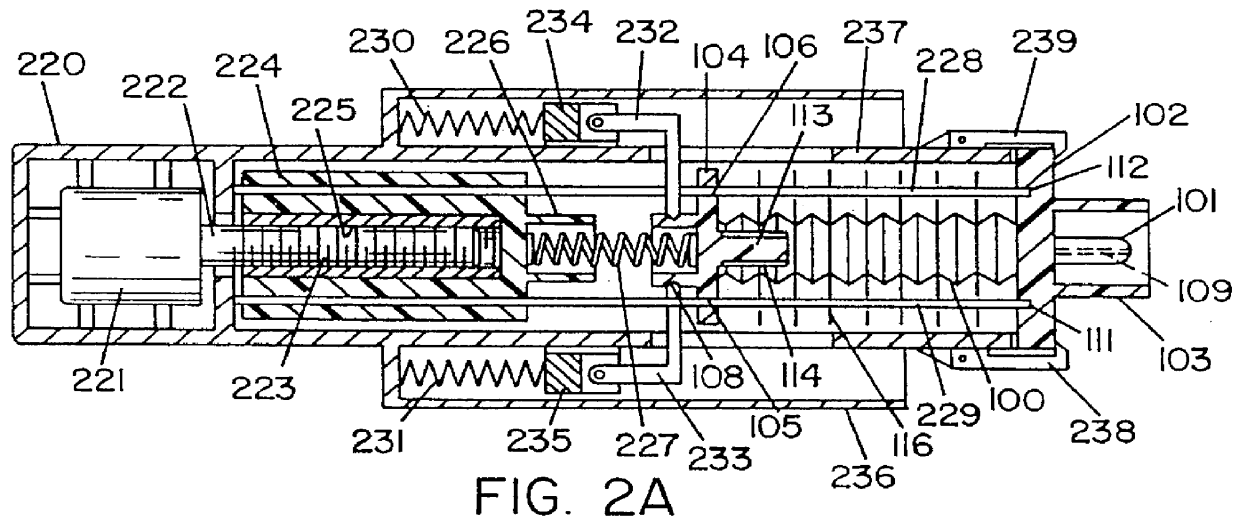

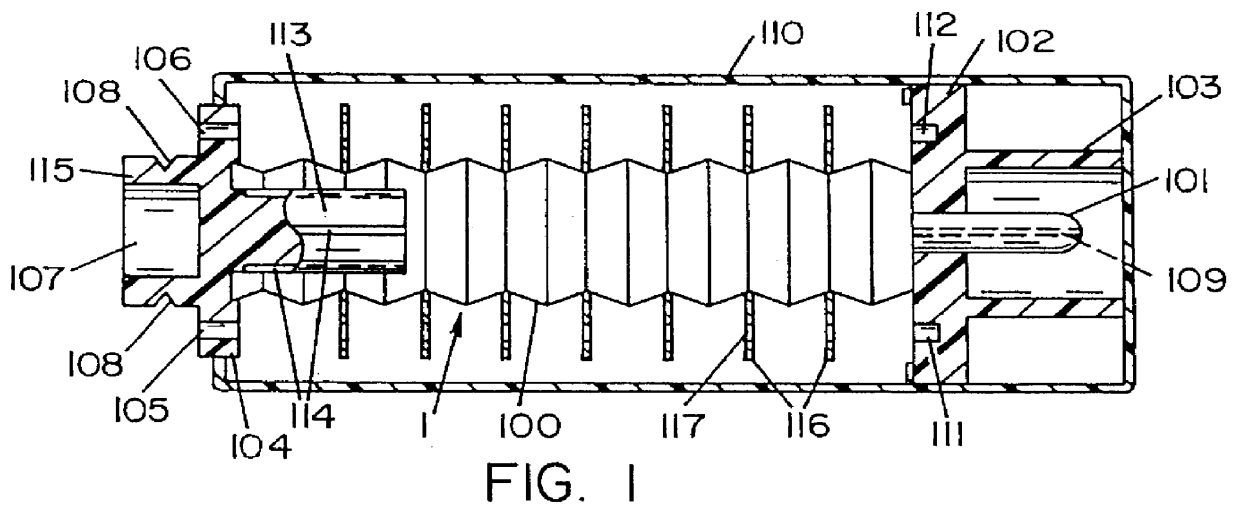

A jet injector system for injecting fluid into a body. The jet injection system includes capsules for holding the material to be injected, apparatus for applying force to the capsule(s) to eject the injection material(s) and a perforator for directing the jet stream for the respective materials into the body. A flyweight system is described for developing jet injection pressures, and latching devices control the flyweight system. An injector system for injecting more than one fluid is described.

Owner:DANTONIO CONSULTANTS INT INC

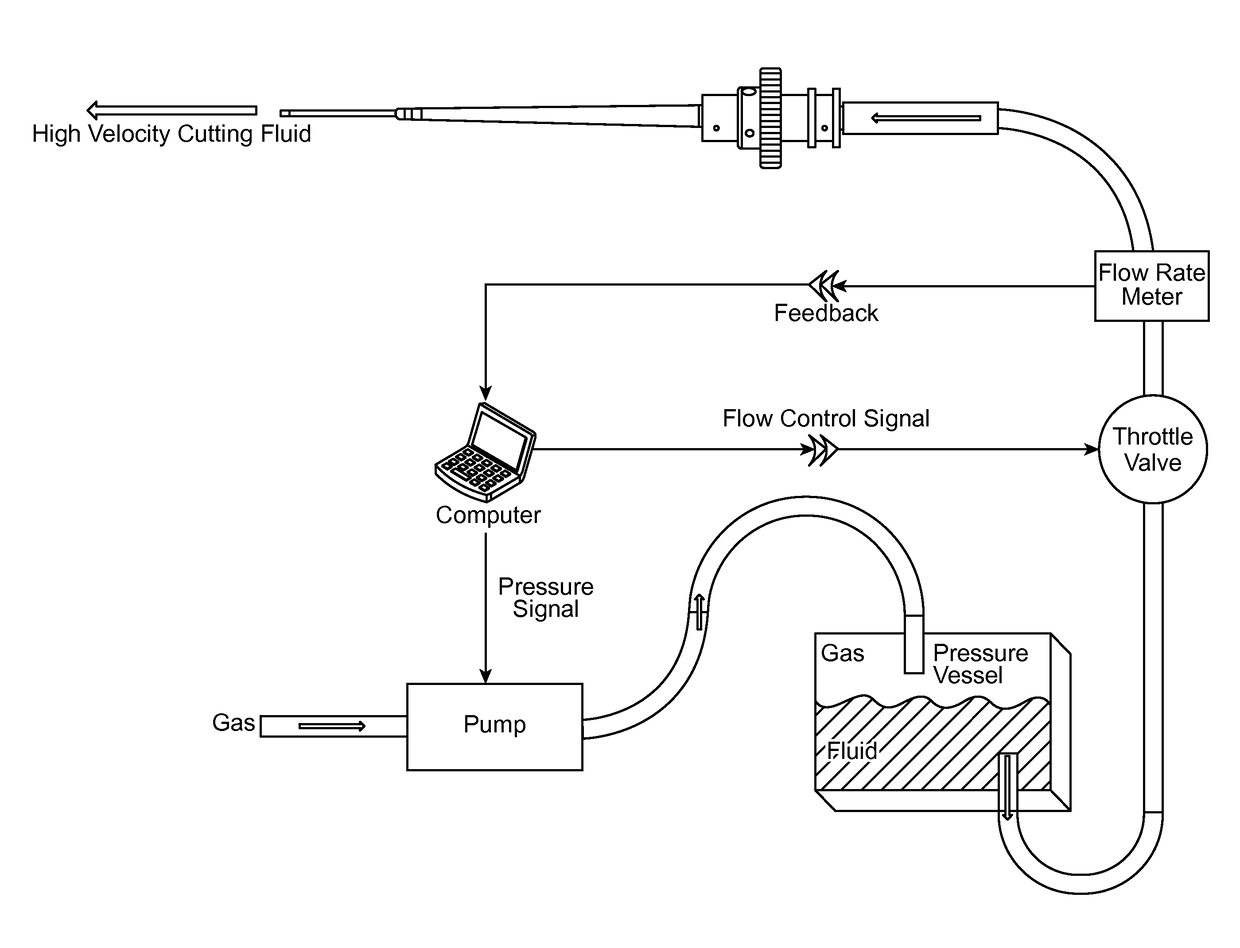

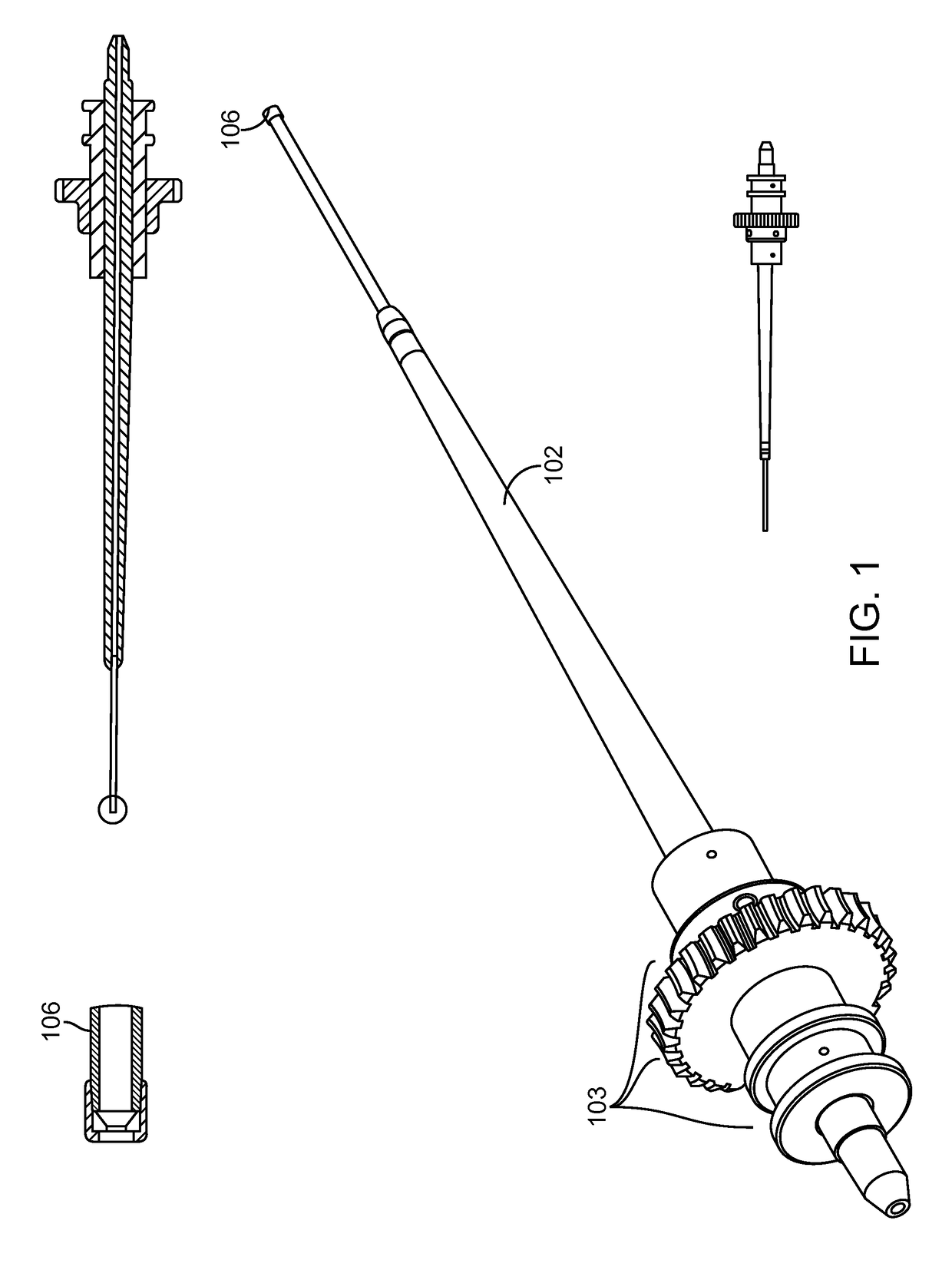

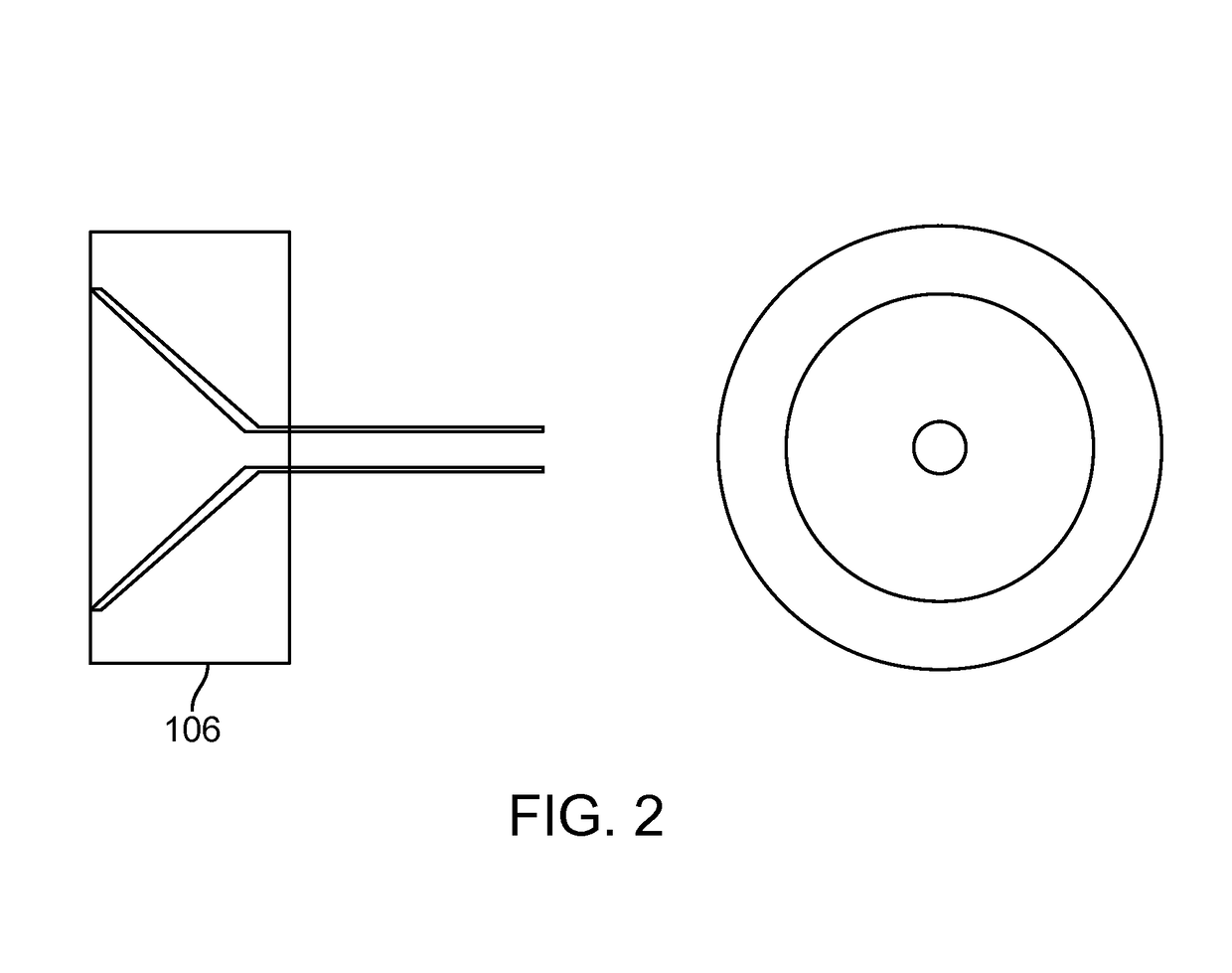

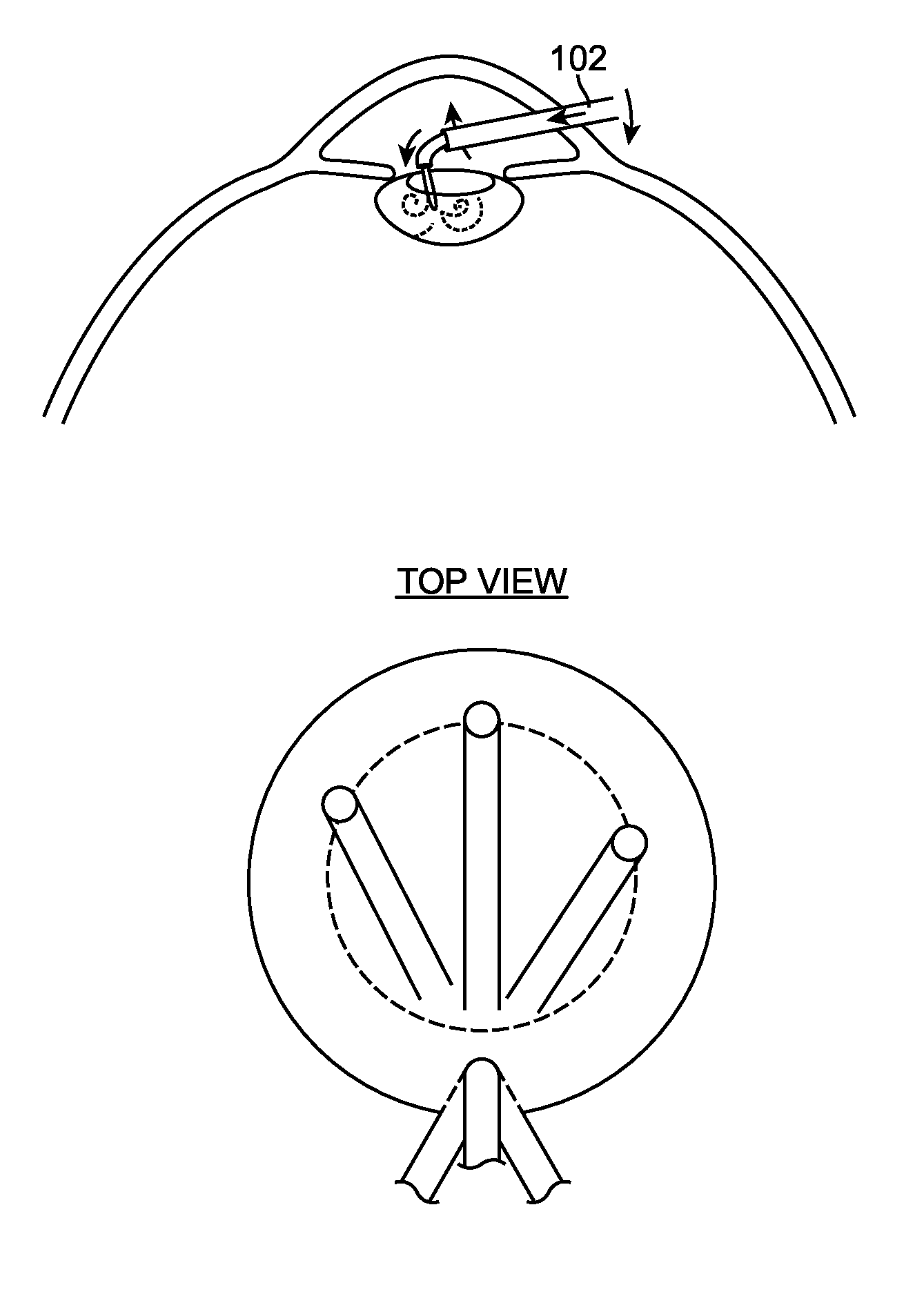

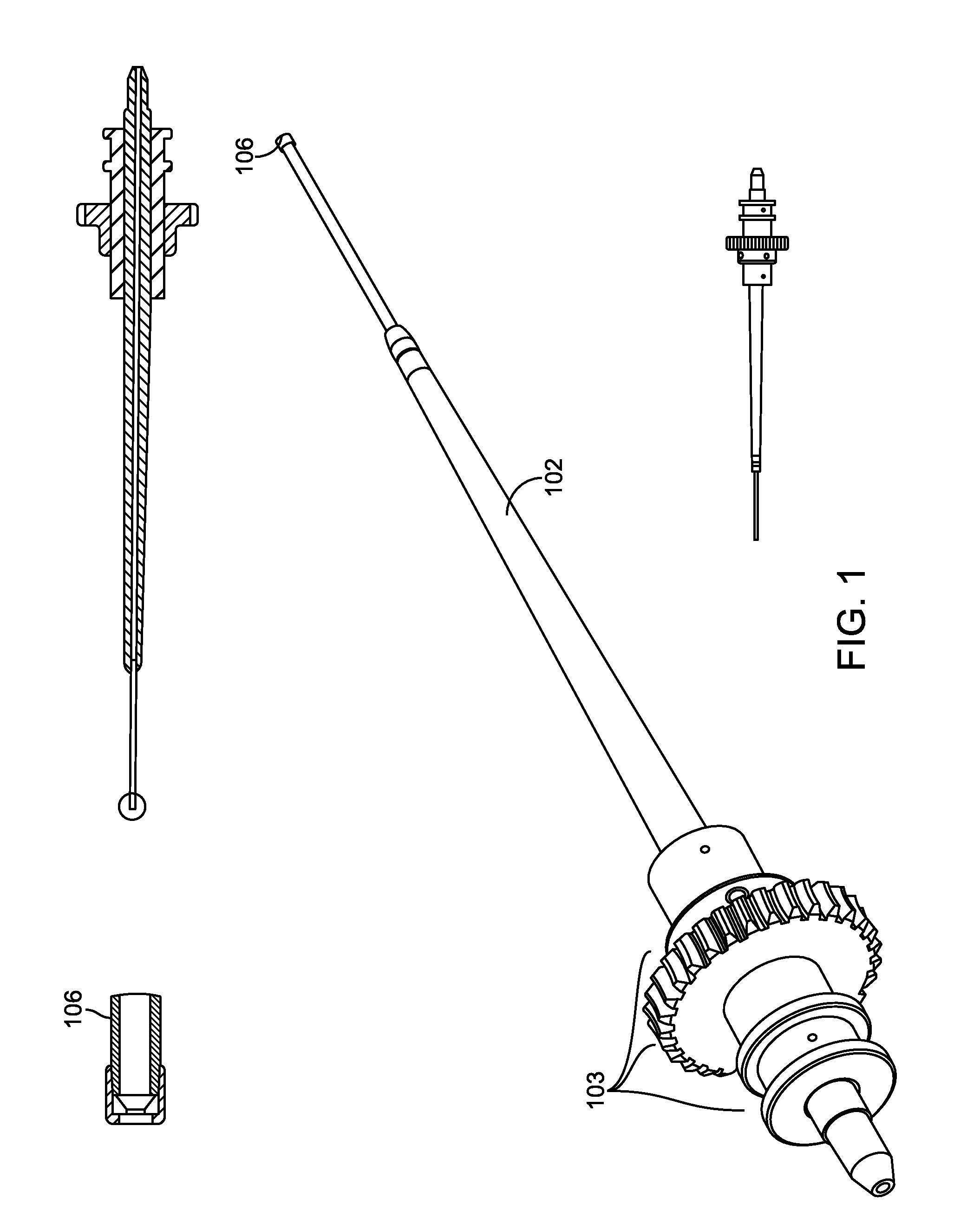

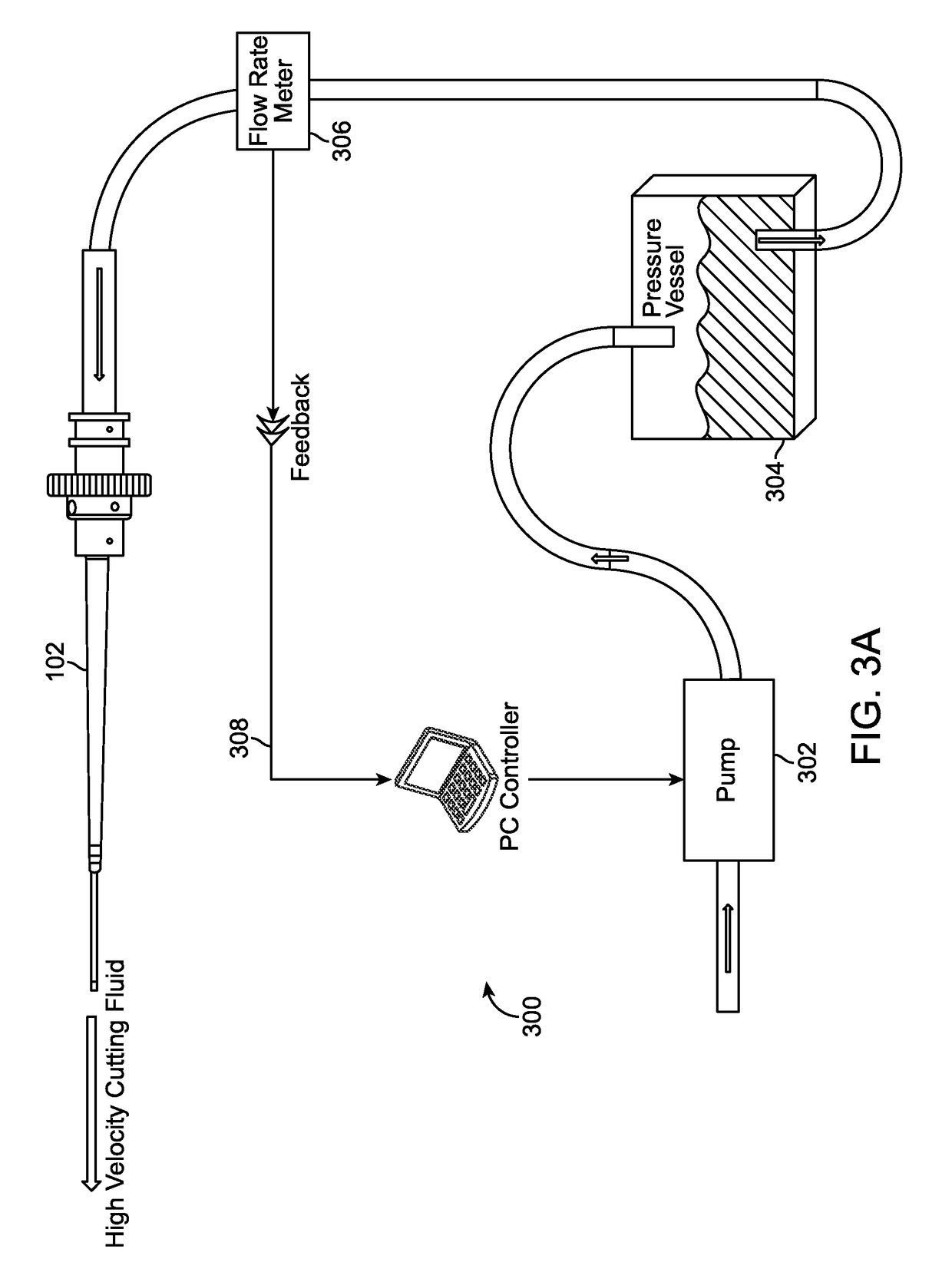

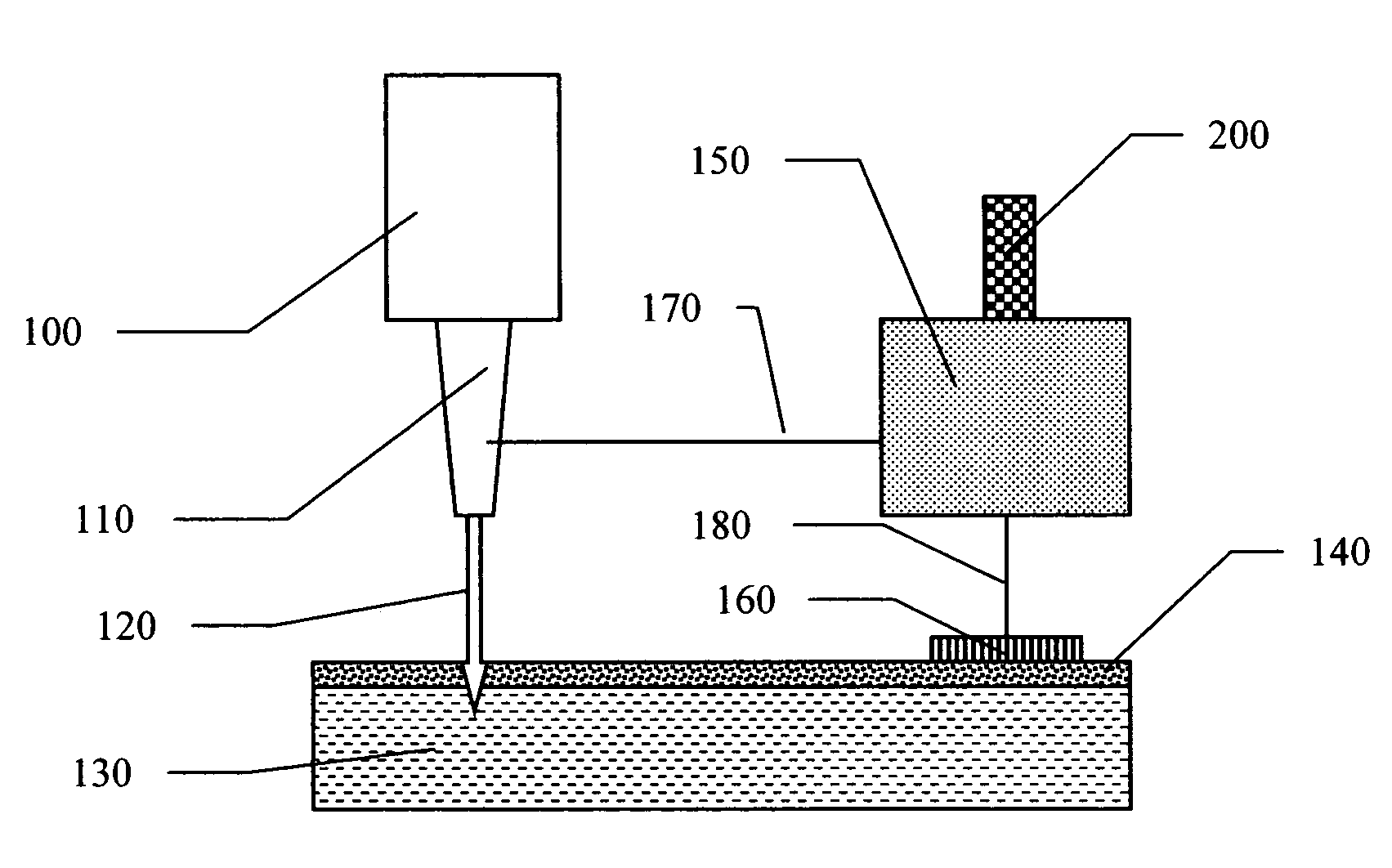

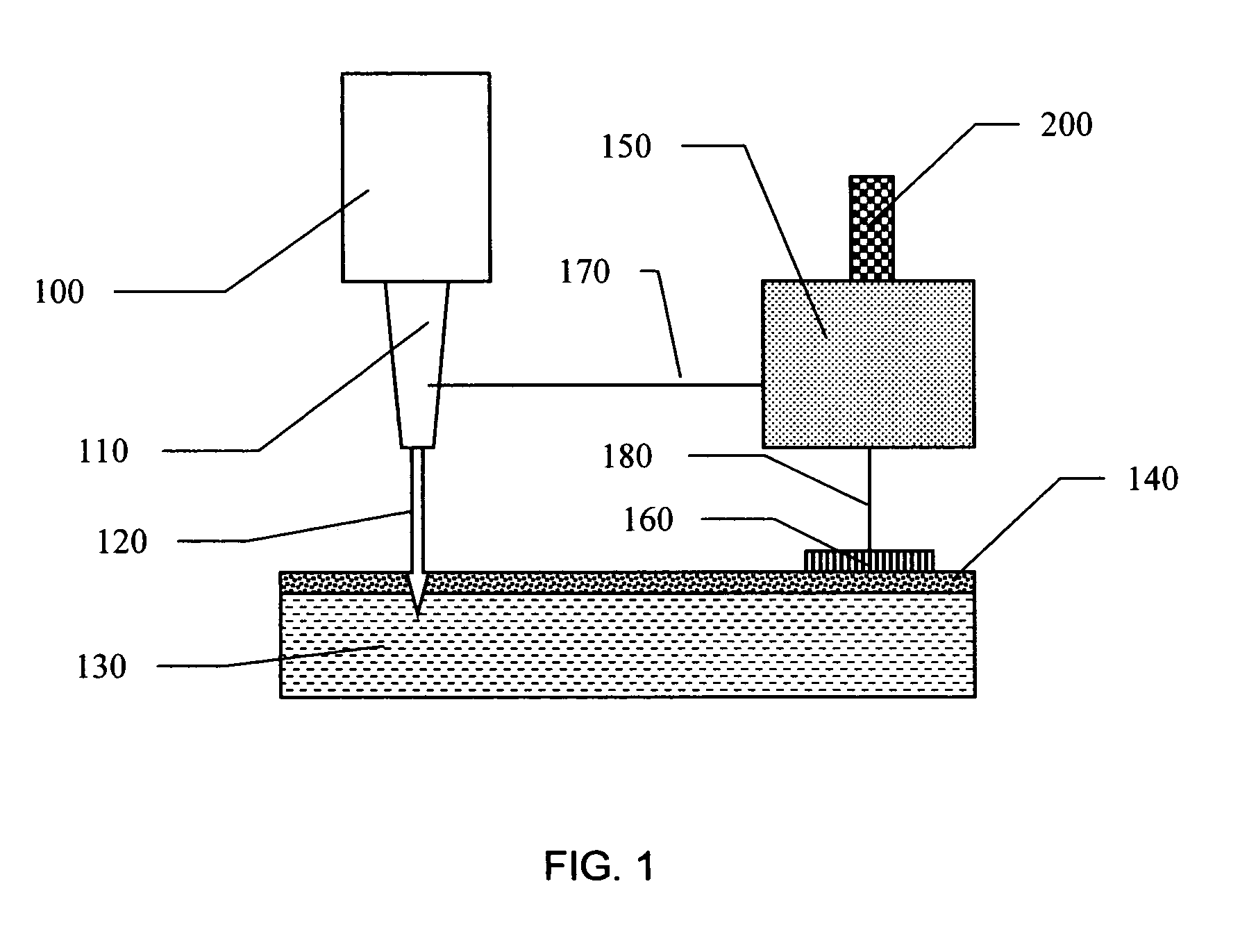

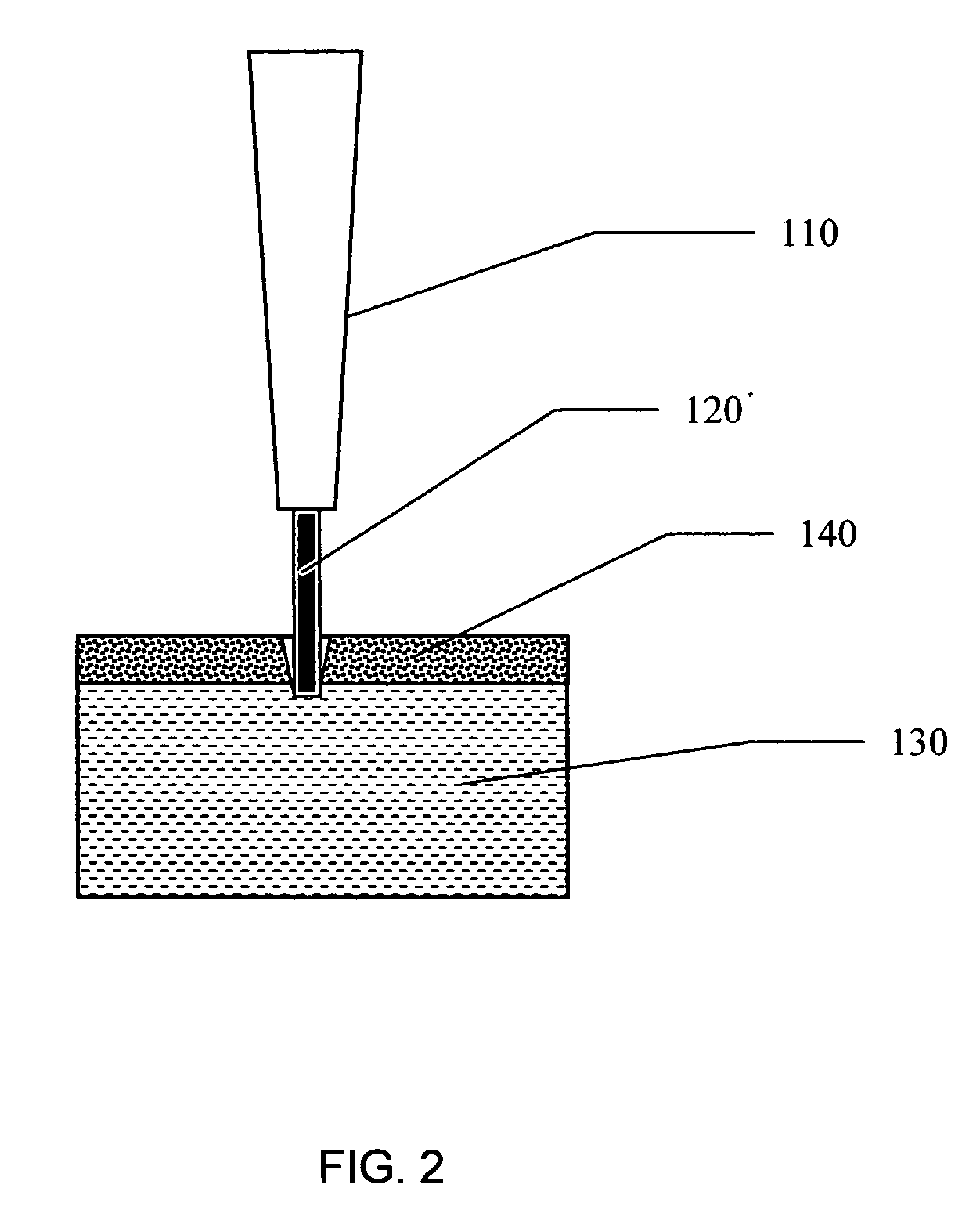

Method, apparatus and system for a water jet

A water jet instrument may be used for manually performing eye surgery such as, cataract, or perform micro-surgery (remove cartilage), or any emulsification technique. The water jet instrument may be manually controlled or controlled by a system with a robotic control. The water jet apparatus defines a jet cutting area that is based at least in part on a flow rate meter and a feedback loop.

Owner:AURIS HEALTH INC

Method, apparatus and system for a water jet

A water jet instrument may be used for manually performing eye surgery such as, cataract, or perform micro-surgery (remove cartilage), or any emulsification technique. The water jet instrument may be manually controlled or controlled by a system with a robotic control. The water jet apparatus defines a jet cutting area that is based at least in part on a flow rate meter and a feedback loop.

Owner:AURIS HEALTH INC

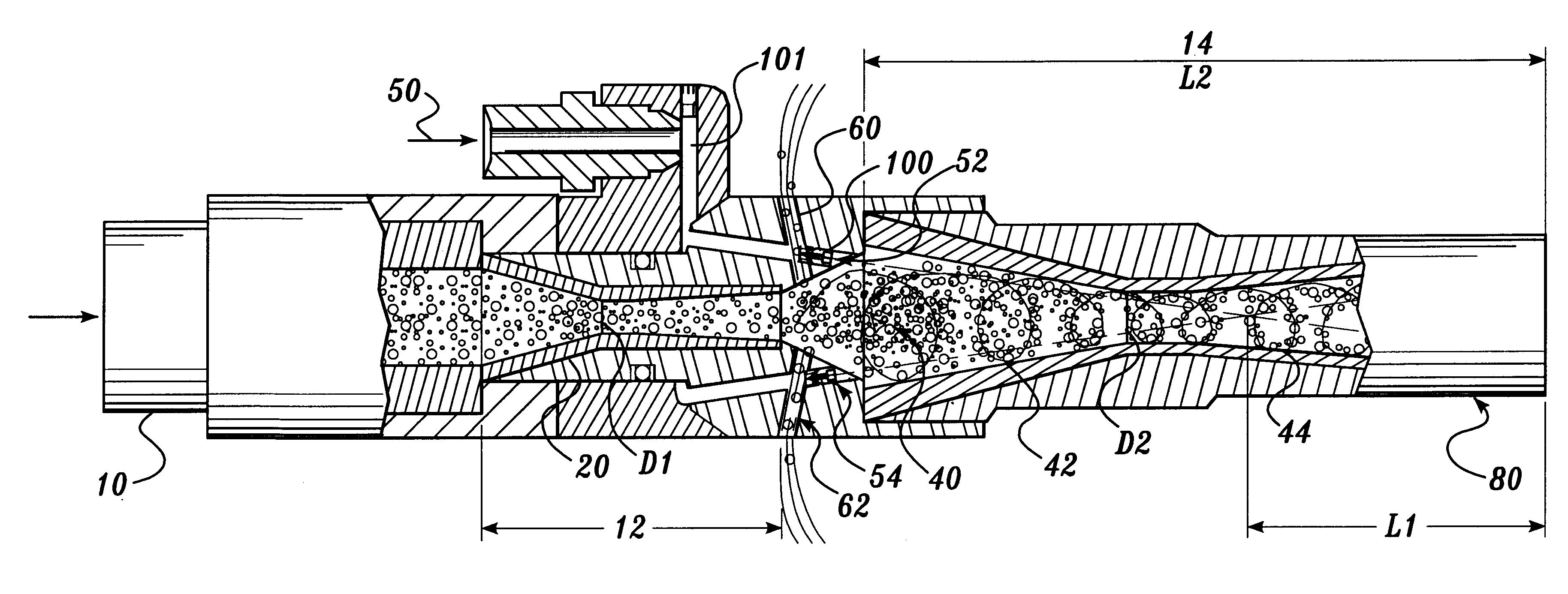

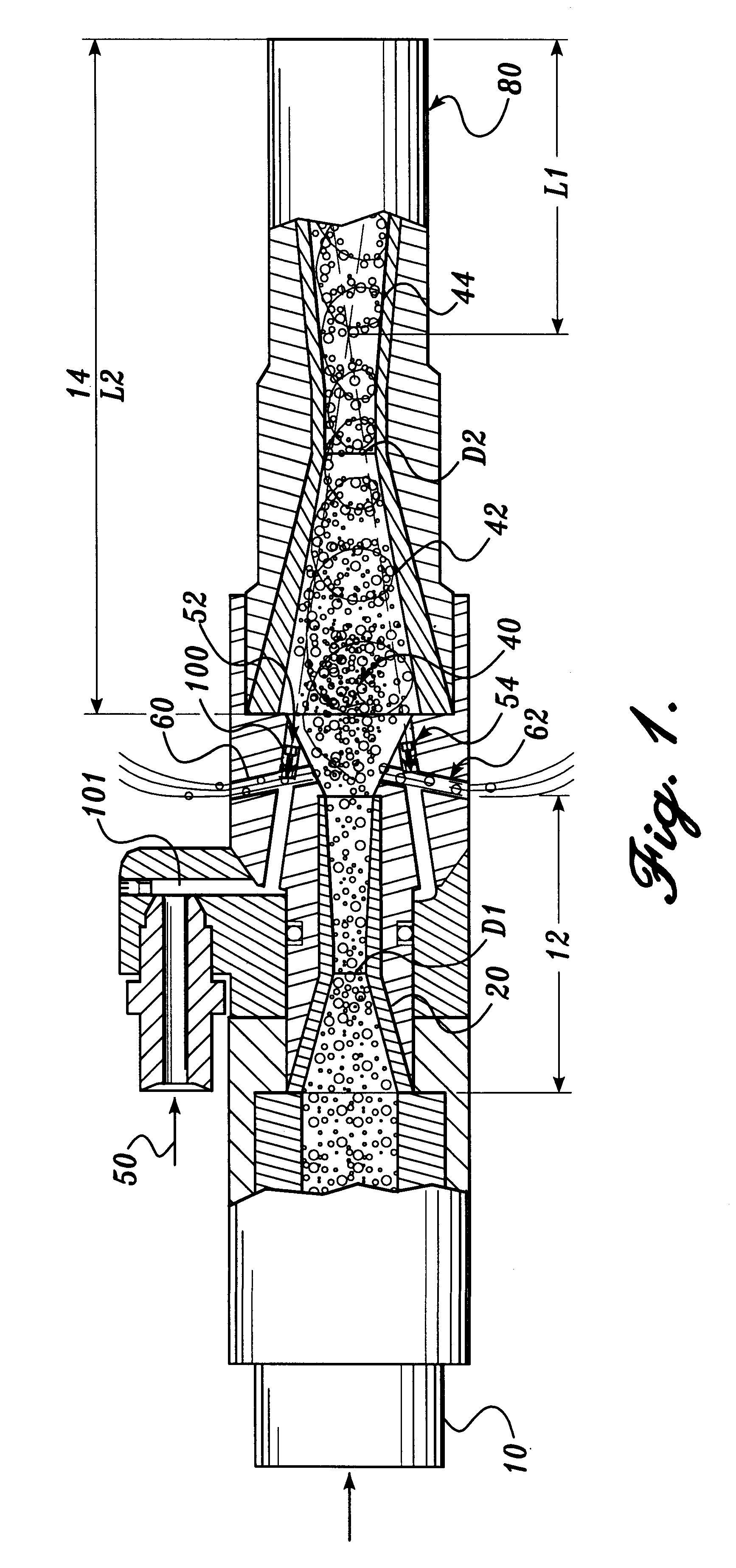

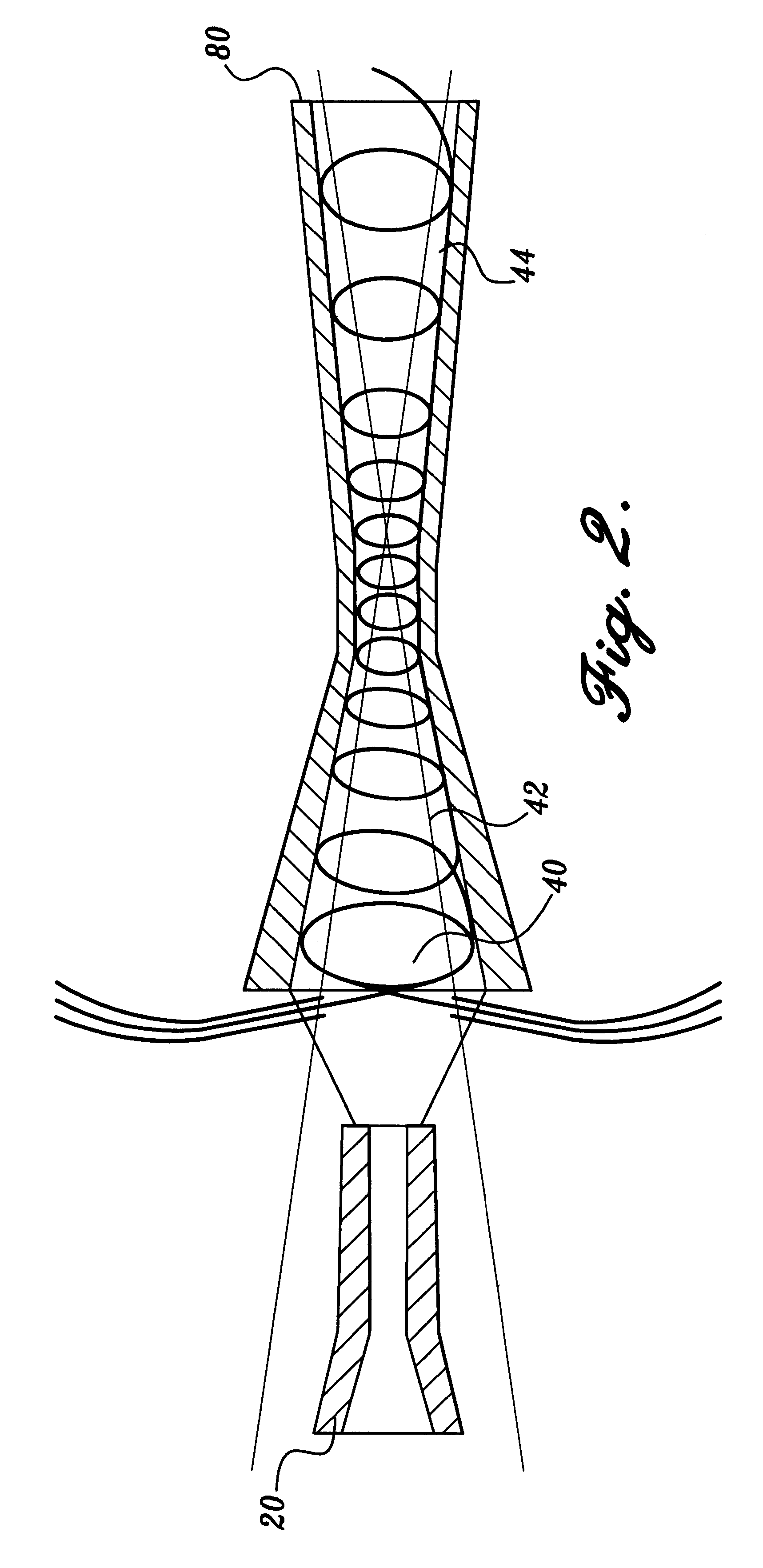

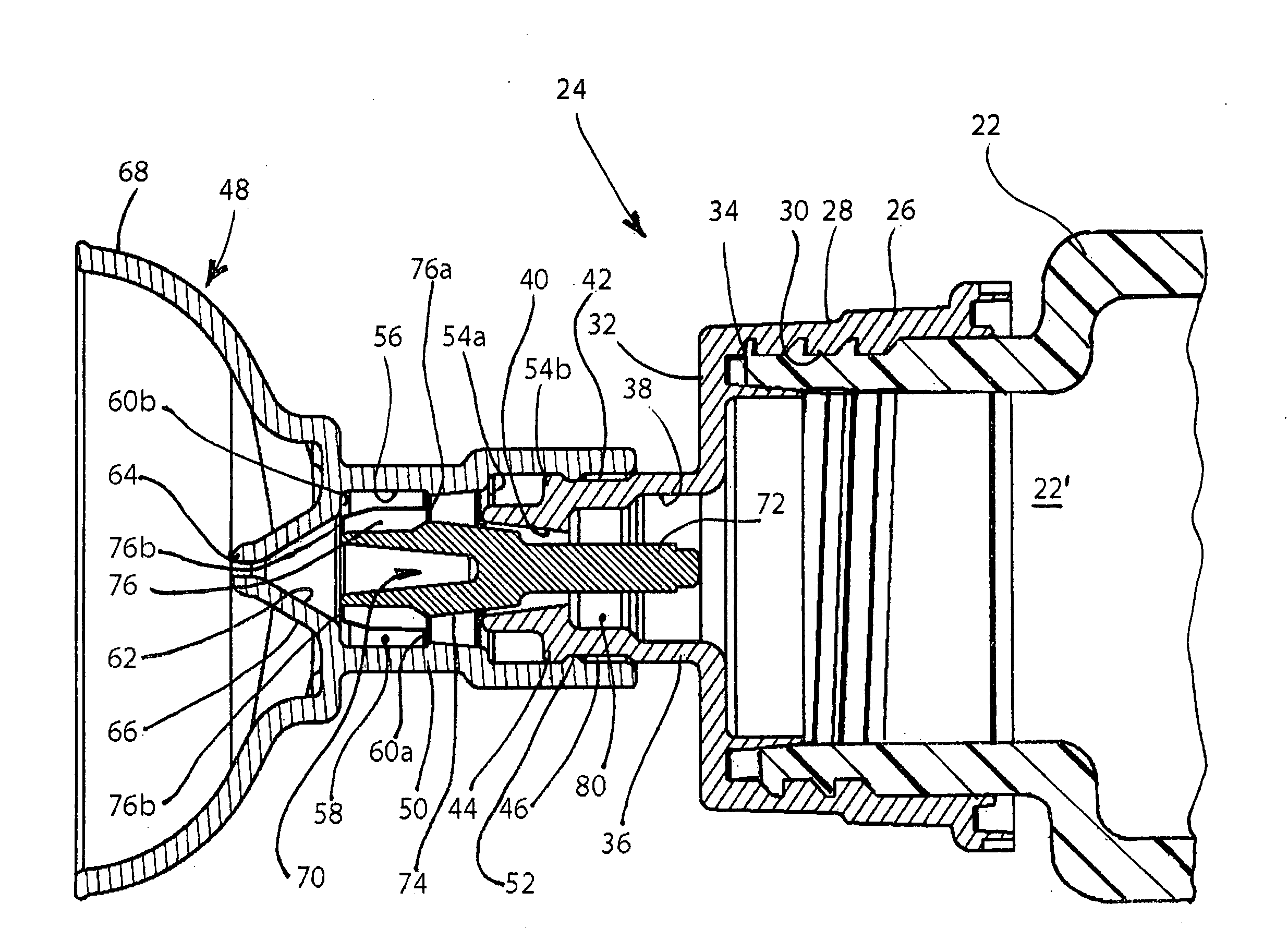

Enhanced cross stream mechanical thrombectomy catheter with backloading manifold

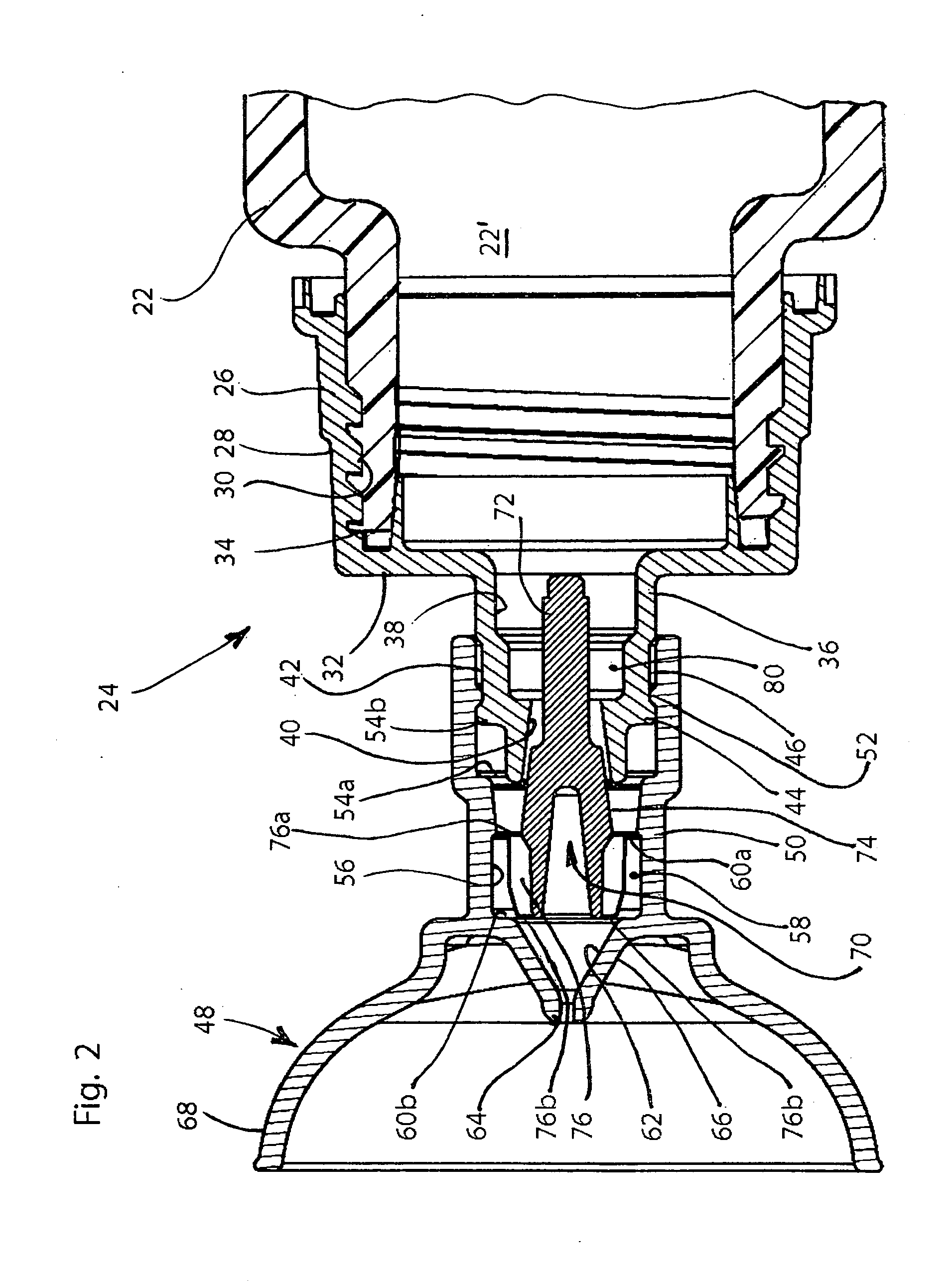

InactiveUS20060129091A1High trafficEnhanced cross stream mechanical thrombectomyMulti-lumen catheterMedical devicesSuction forceJet flow

An enhanced cross stream mechanical thrombectomy catheter with backloading manifold having a distal end with outflow and inflow orifices at one side for producing concentrated cross stream jet flow for selective and concentrated thrombus ablation during thrombectomy procedures. The invention provides for suitable distancing of high powered ablation or suction forces from the near walls of the vasculature. Cross stream flow emanating from the one side of the distal end of the catheter resultantly urges the distal end of the catheter and thus the opposing non-orificed side of the distal end of the catheter toward and against the vascular wall to inhibit contact of the inflow orifice with the vascular wall. Features of the invention include a geometrically configured insert to facilitate the backloading or exchange of guidewires.

Owner:MEDRAD INC.

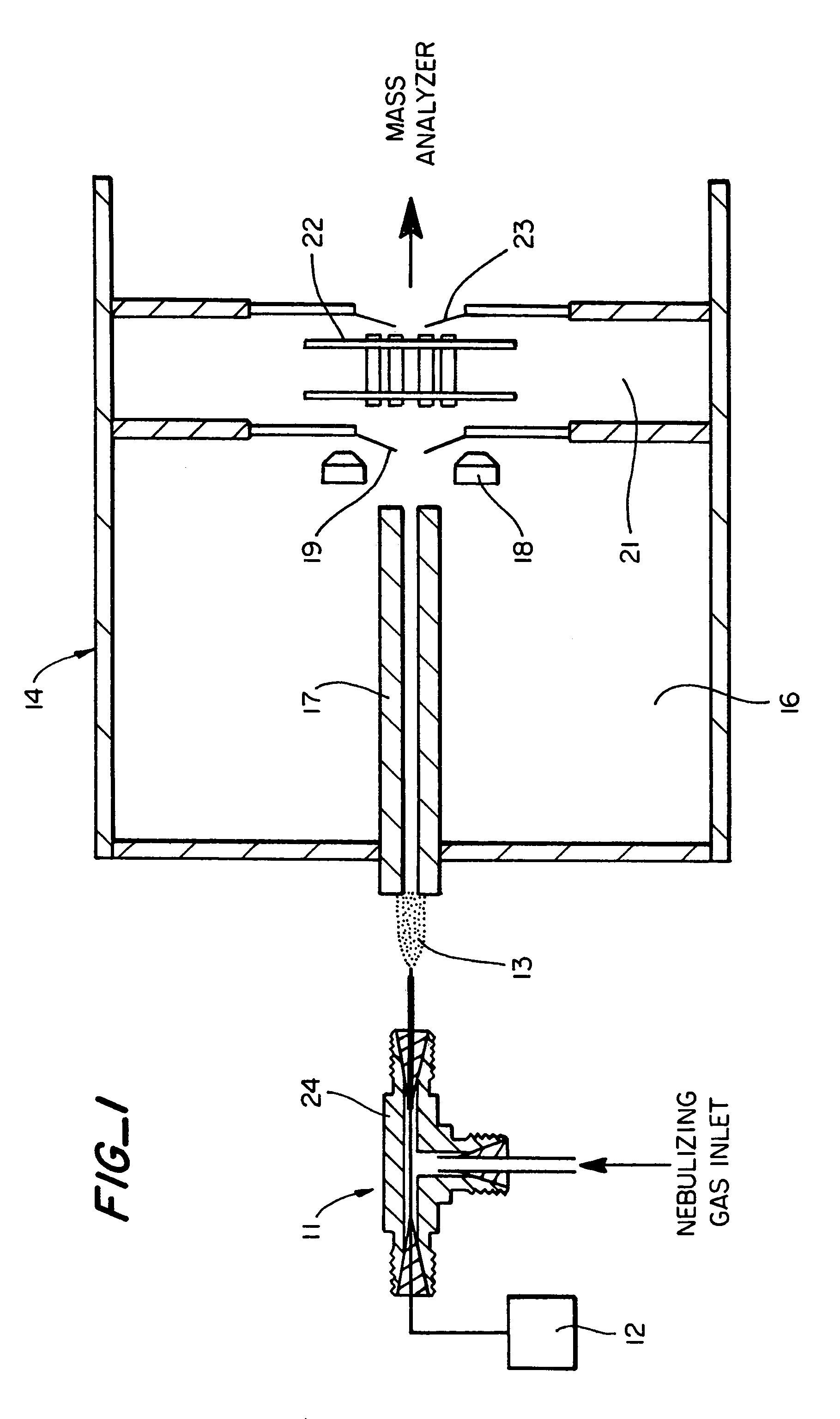

High efficiency medical nebulizer

A pneumatic nebulizer that produces a high volume of aerosols for inhalent delivery of medications and other constituencies. High pressure gas formed into a gas jet is passed through a thin choked region of fluid that is entrailed and impinged upon an aerosol amplifier which creates a spray whose aerosol components are directed up through vents to an aerosol outlet for delivery. Larger-sized liquid particles are caused to pool up in a region surrounding the aerosol amplifer and then drip down back into the liquid medication reservoir.

Owner:MERCURY ENTERPRISES

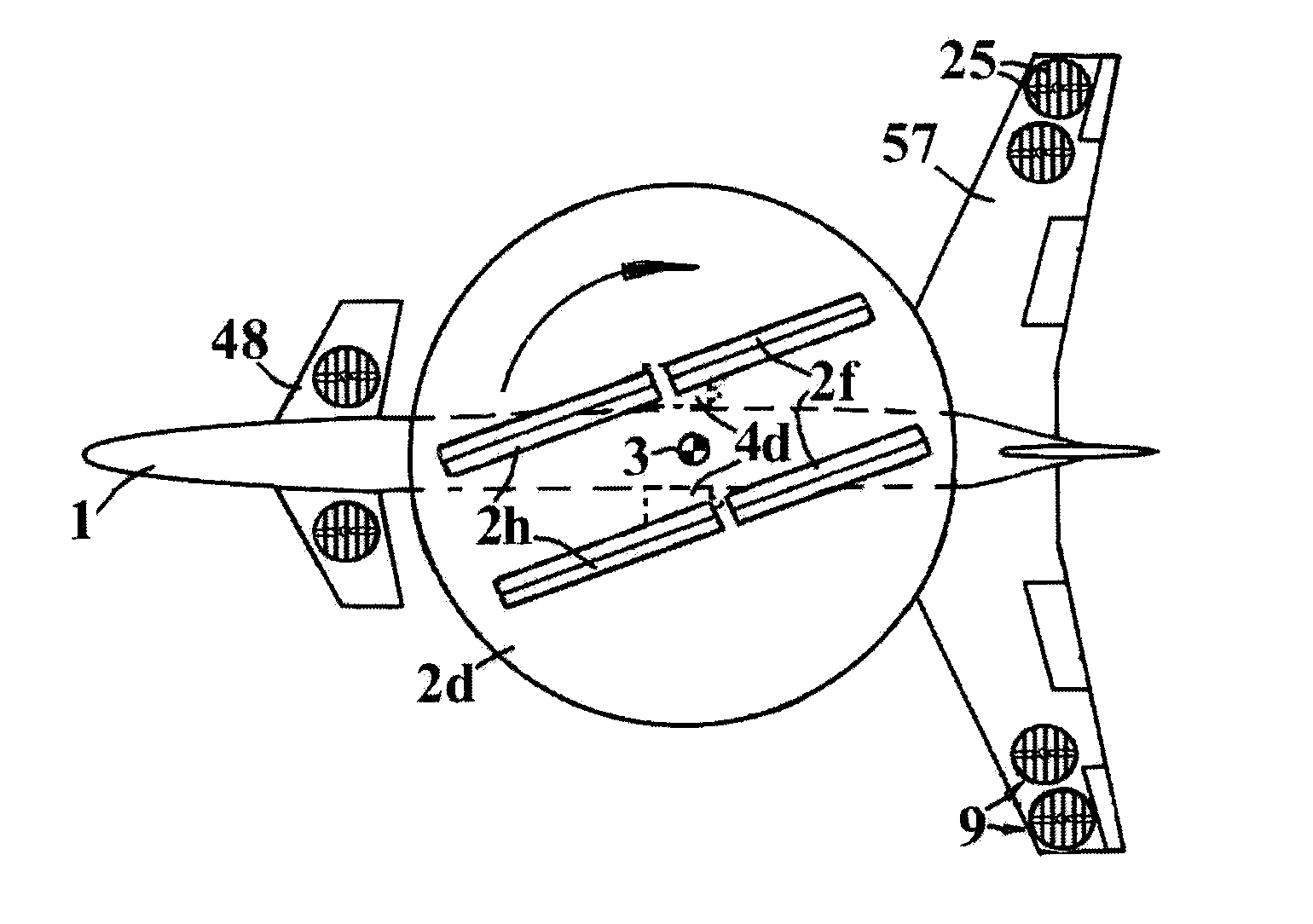

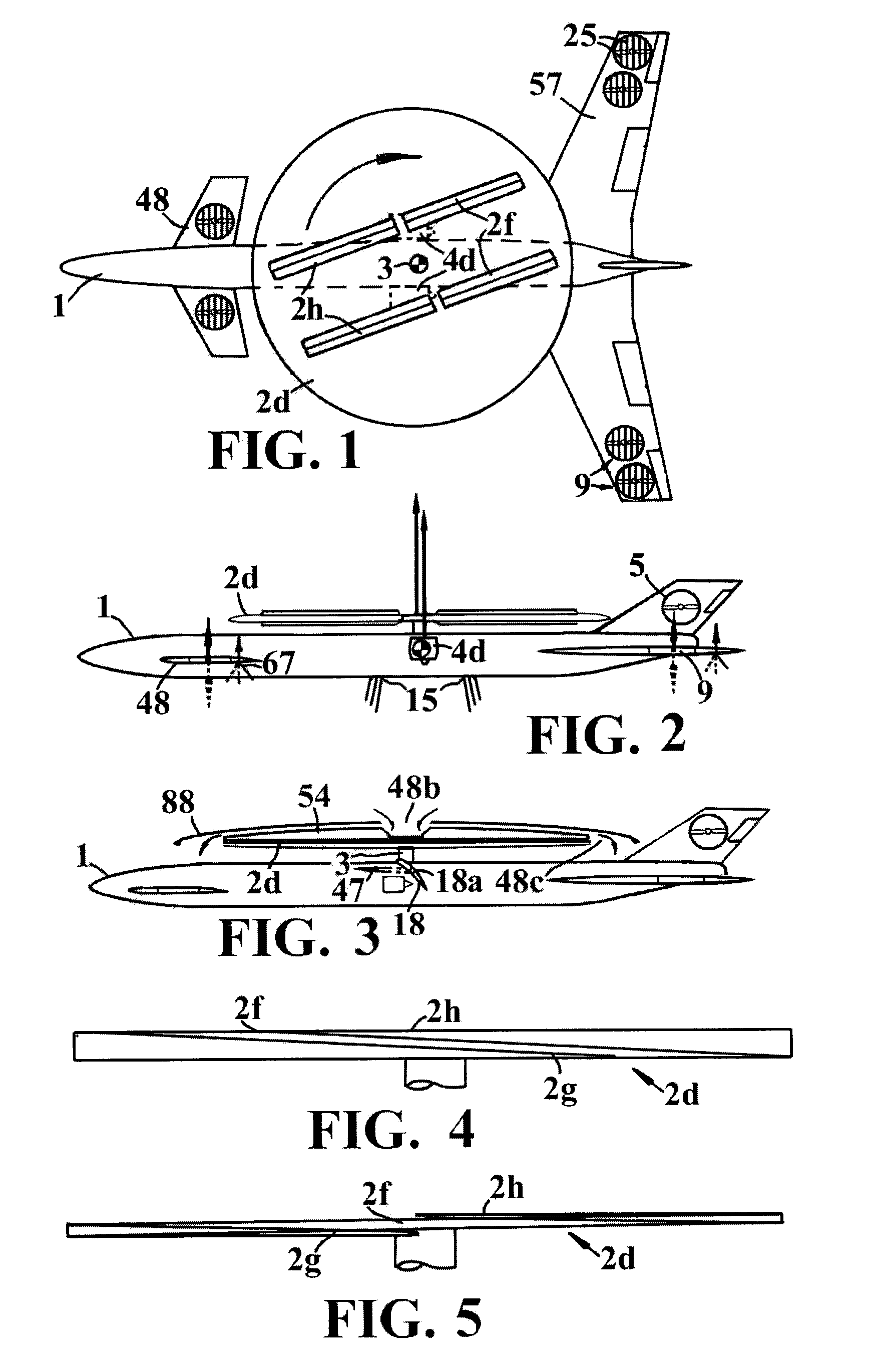

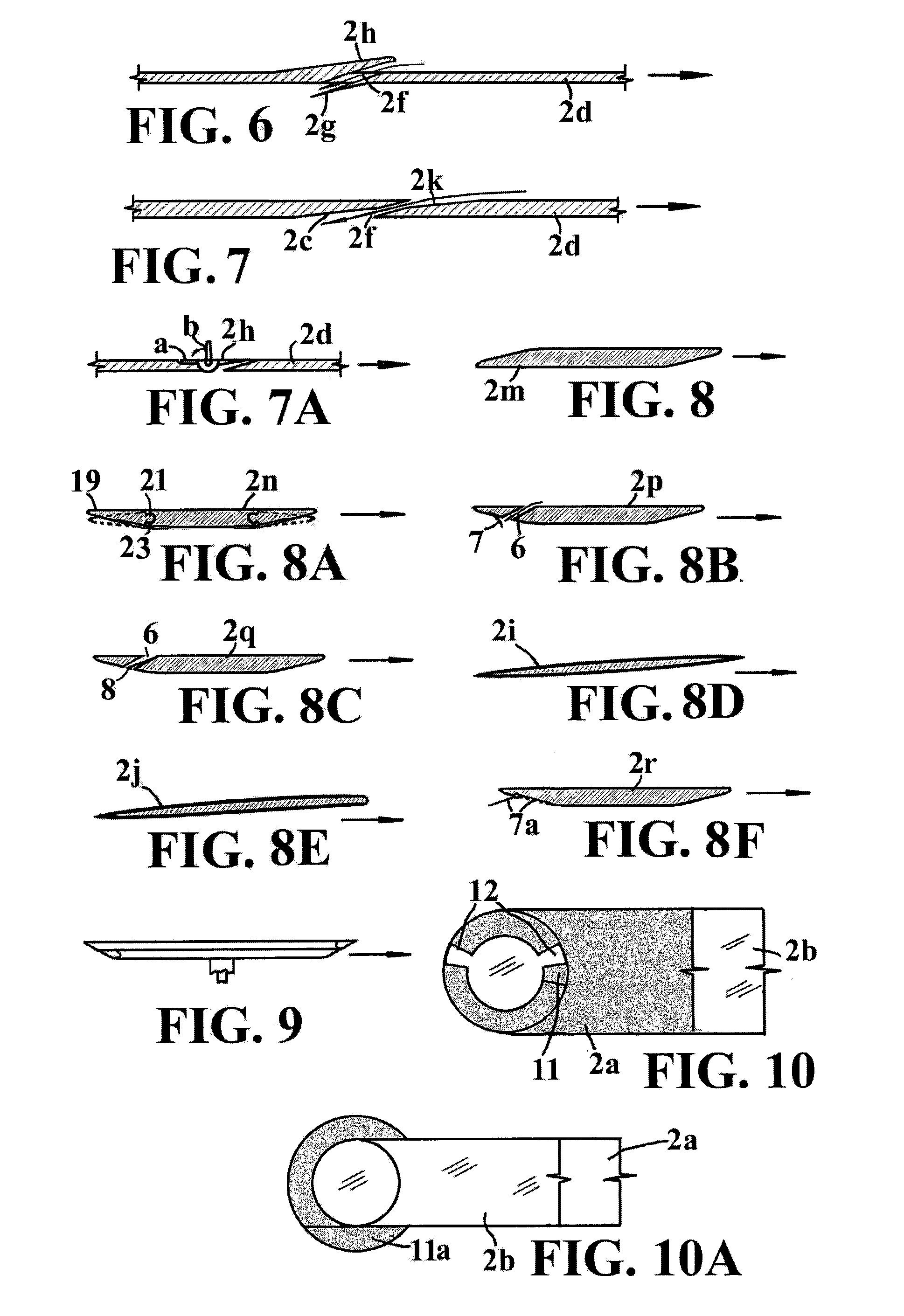

Lift Propulsion and Stabilizing System and Procedure For Vertical Take-Off and Landing Aircraft

InactiveUS20130251525A1Inhibition effectLow costElectric power distributionPropellersLeading edgeTurbine

Lift propulsion and stabilizing system and procedure for vertical takeoff and landing aircraft that consists in applying simultaneously and combined as lifters during the initial portion of the climb and at the end of the descent of: a) some fans or electric turbines, EDF, and b) at least one rotor with external blades and / or rotary and / or c) the engine flow directed downwards and / or d) pressure air jets injected on leading edges control fins, and / or e) water jets and / or f) supplemented with aerodynamic lift produced during frontal advance of the aircraft, the stabilization is achieved by the gyroscopic stiffness of the rotor and two or more lifting fans oscillating fins and / or air jets located on two or stabilizers more peripheral points in a plane perpendicular to the vertical axis of the aircraft.

Owner:SAIZ MANUEL M

Method, apparatus and system for a water jet

Owner:AURIS HEALTH INC

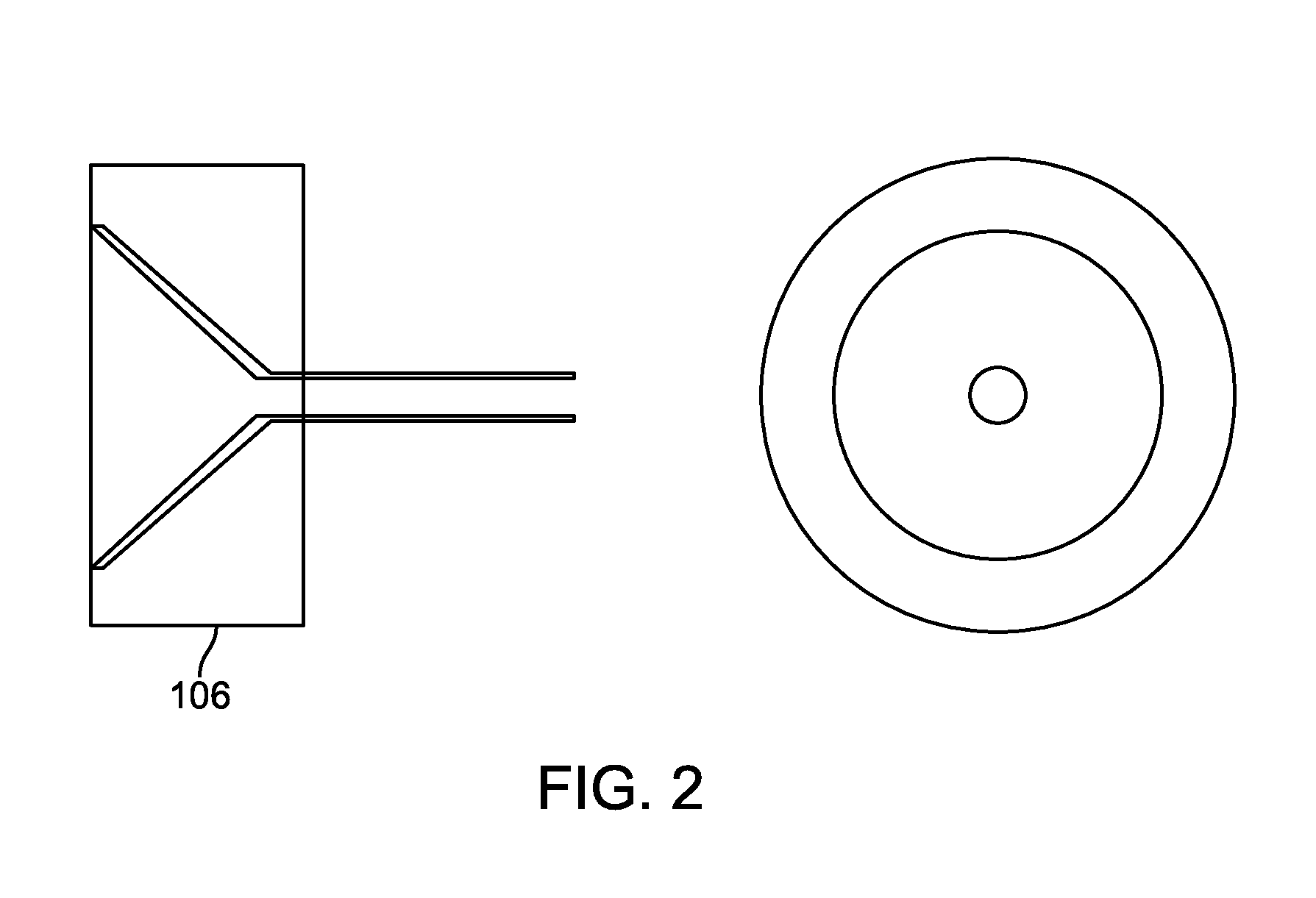

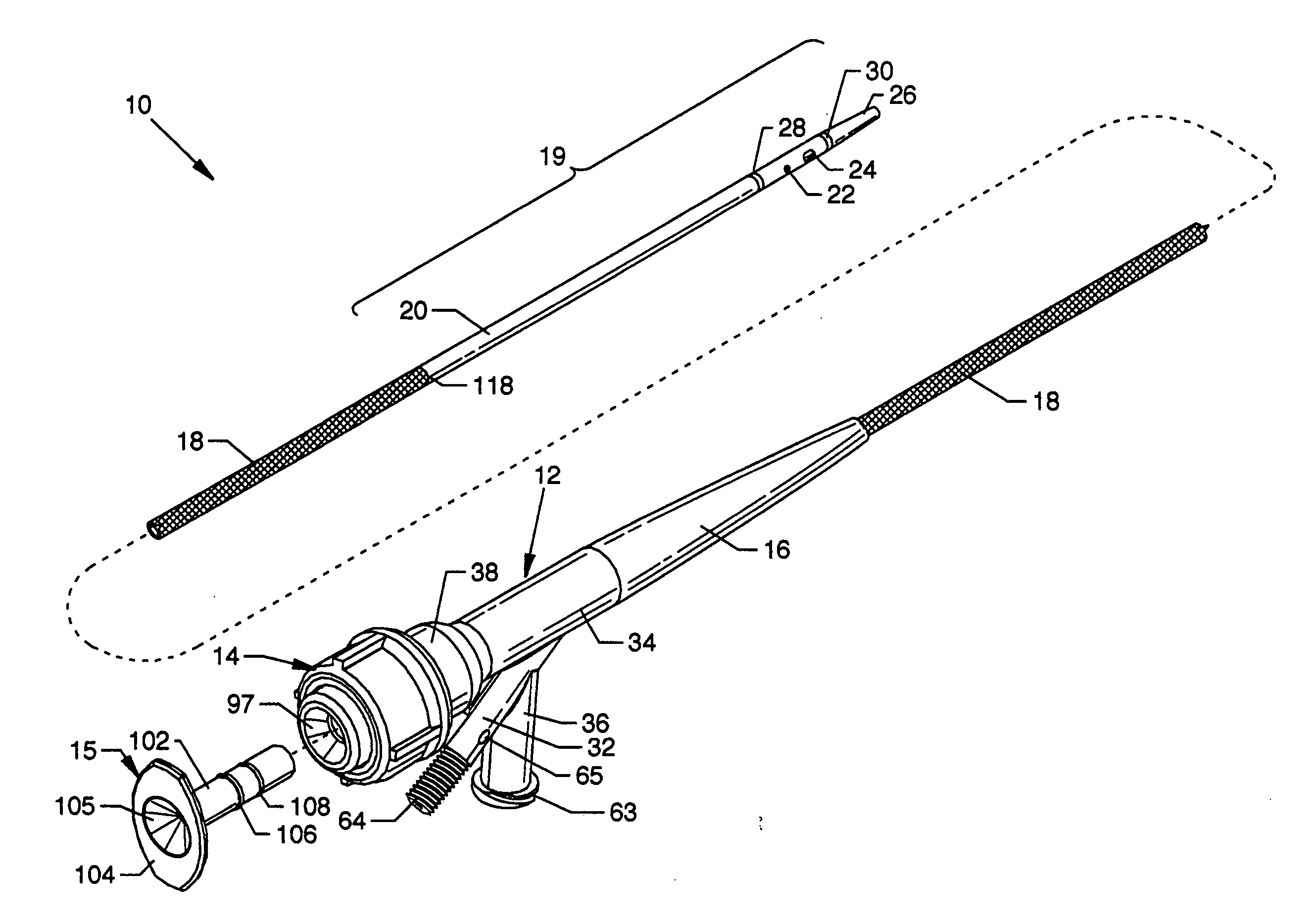

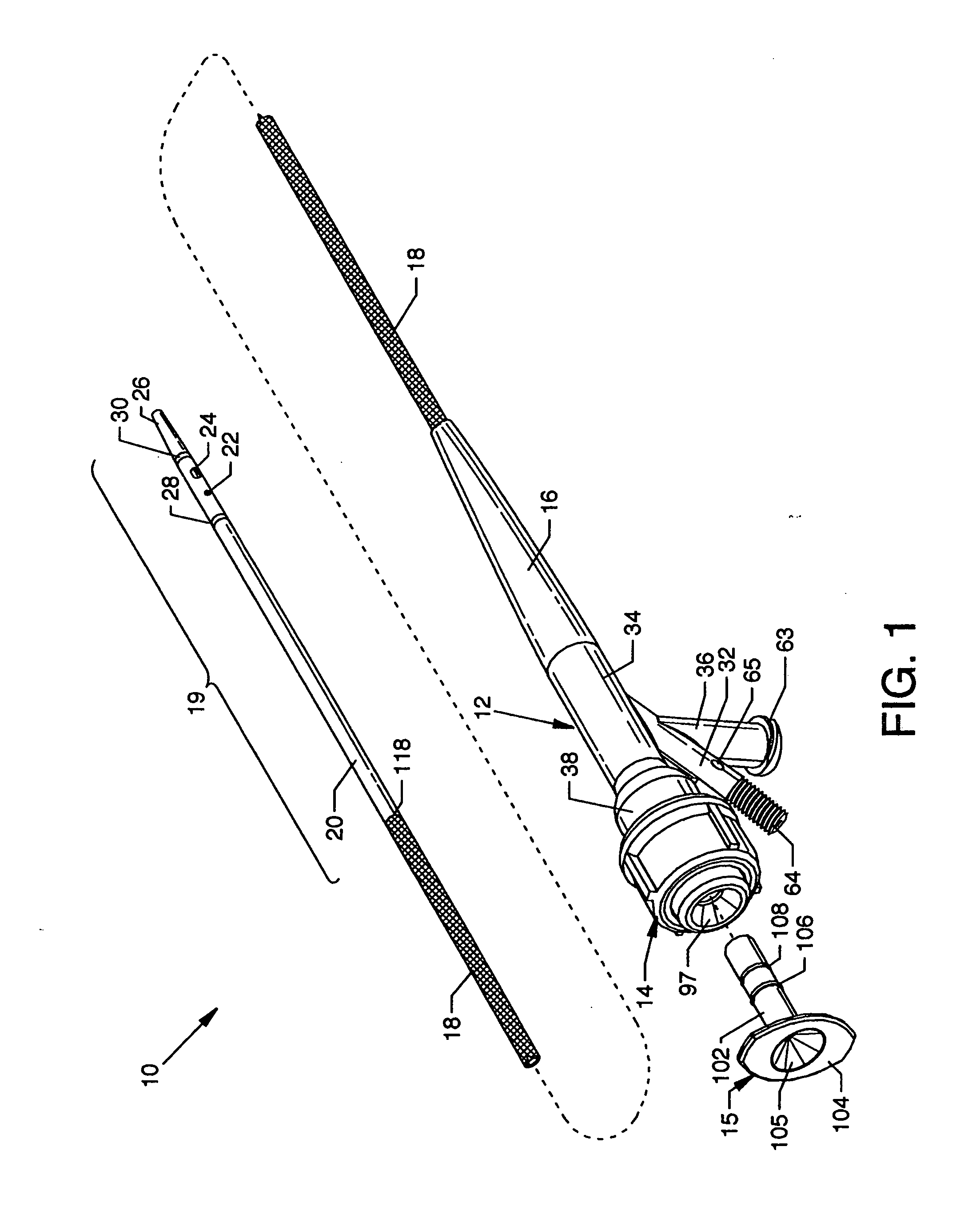

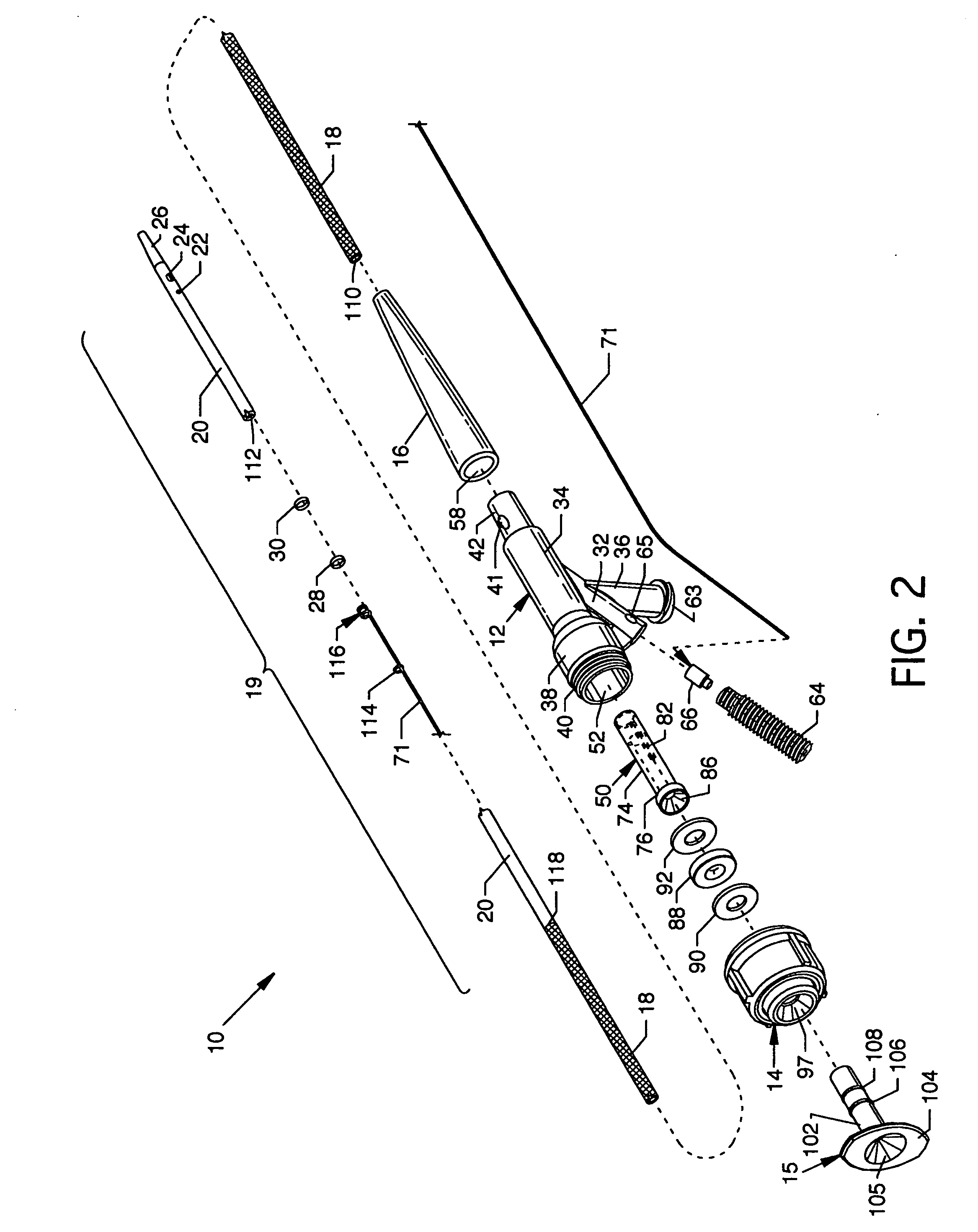

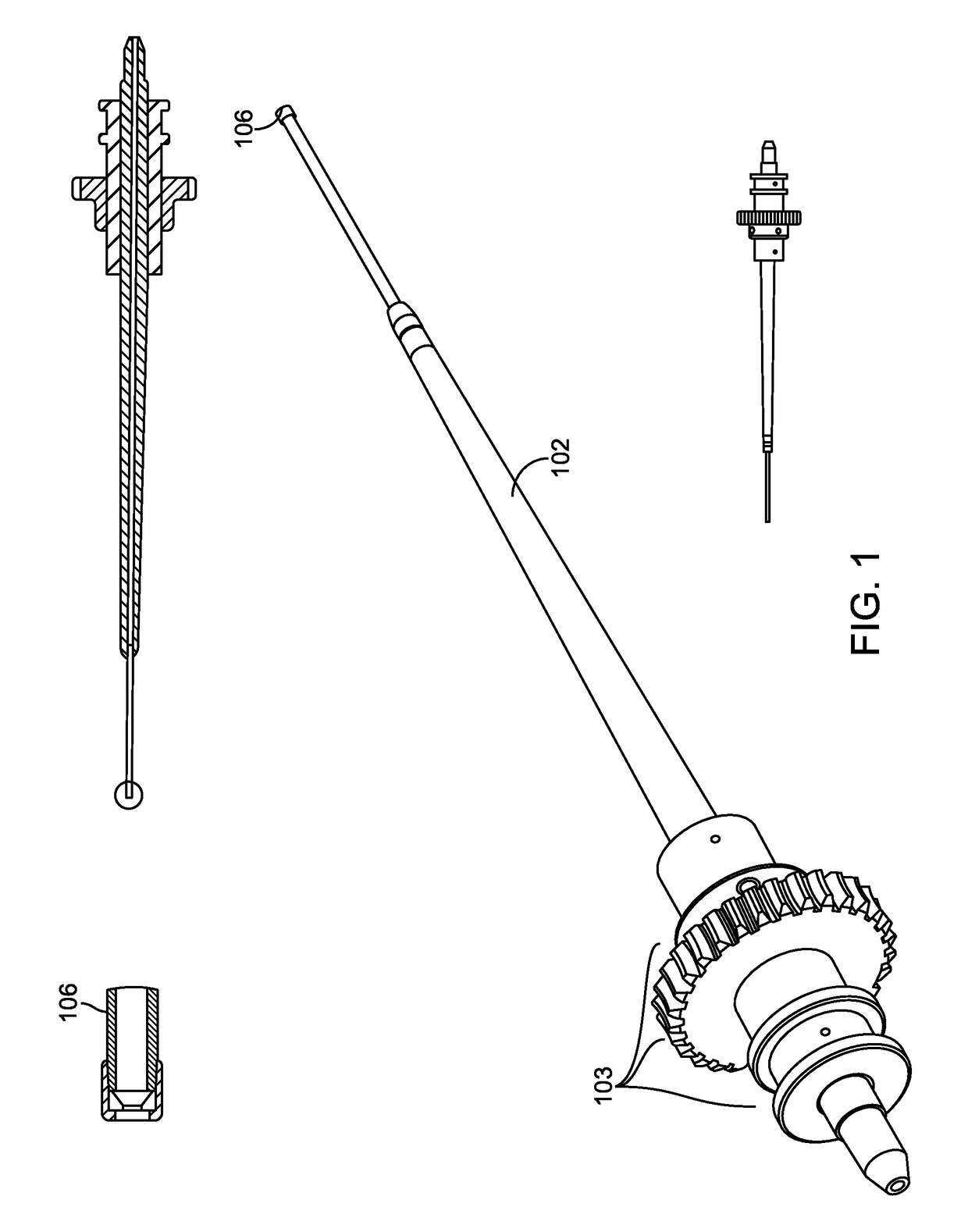

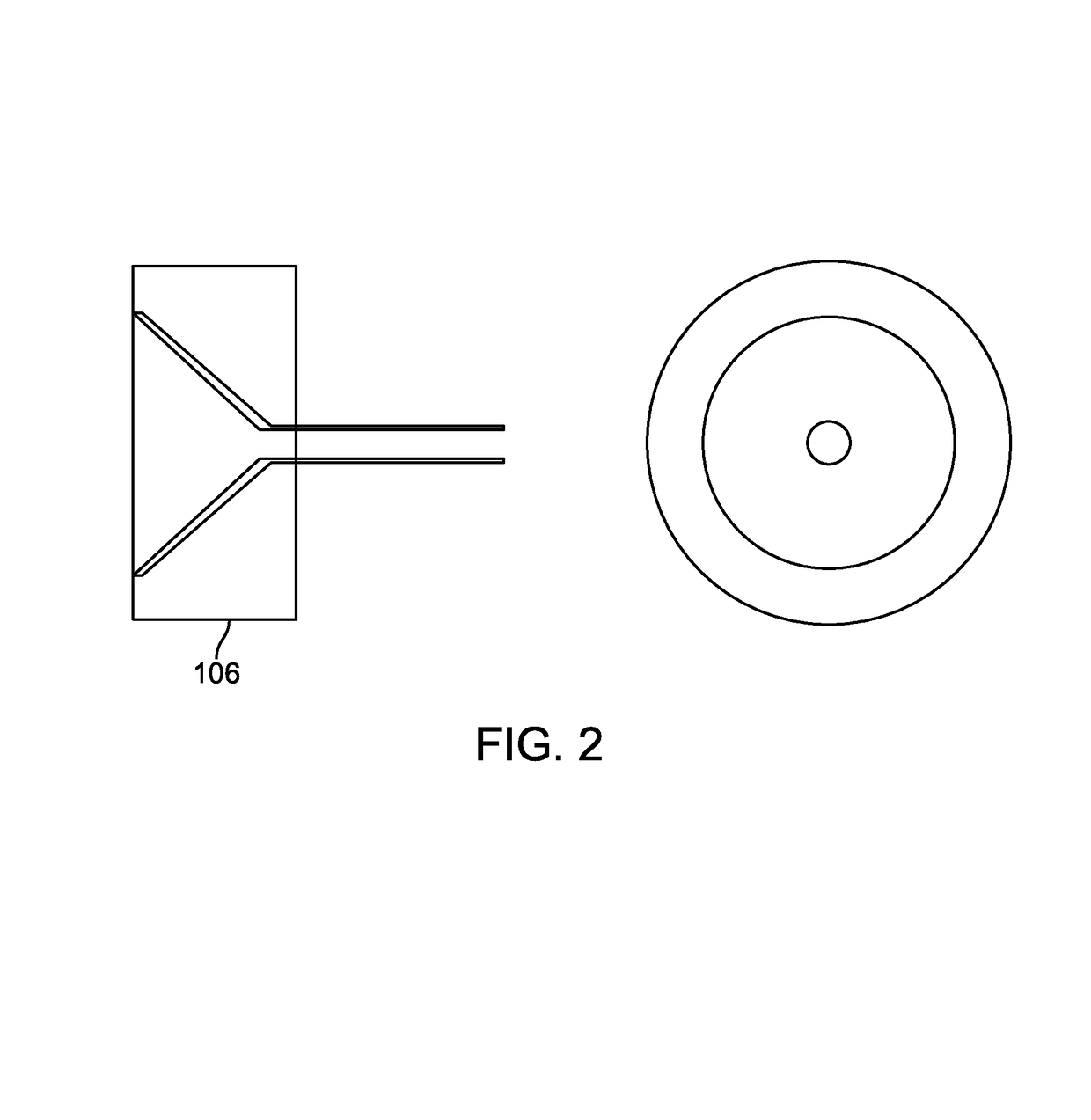

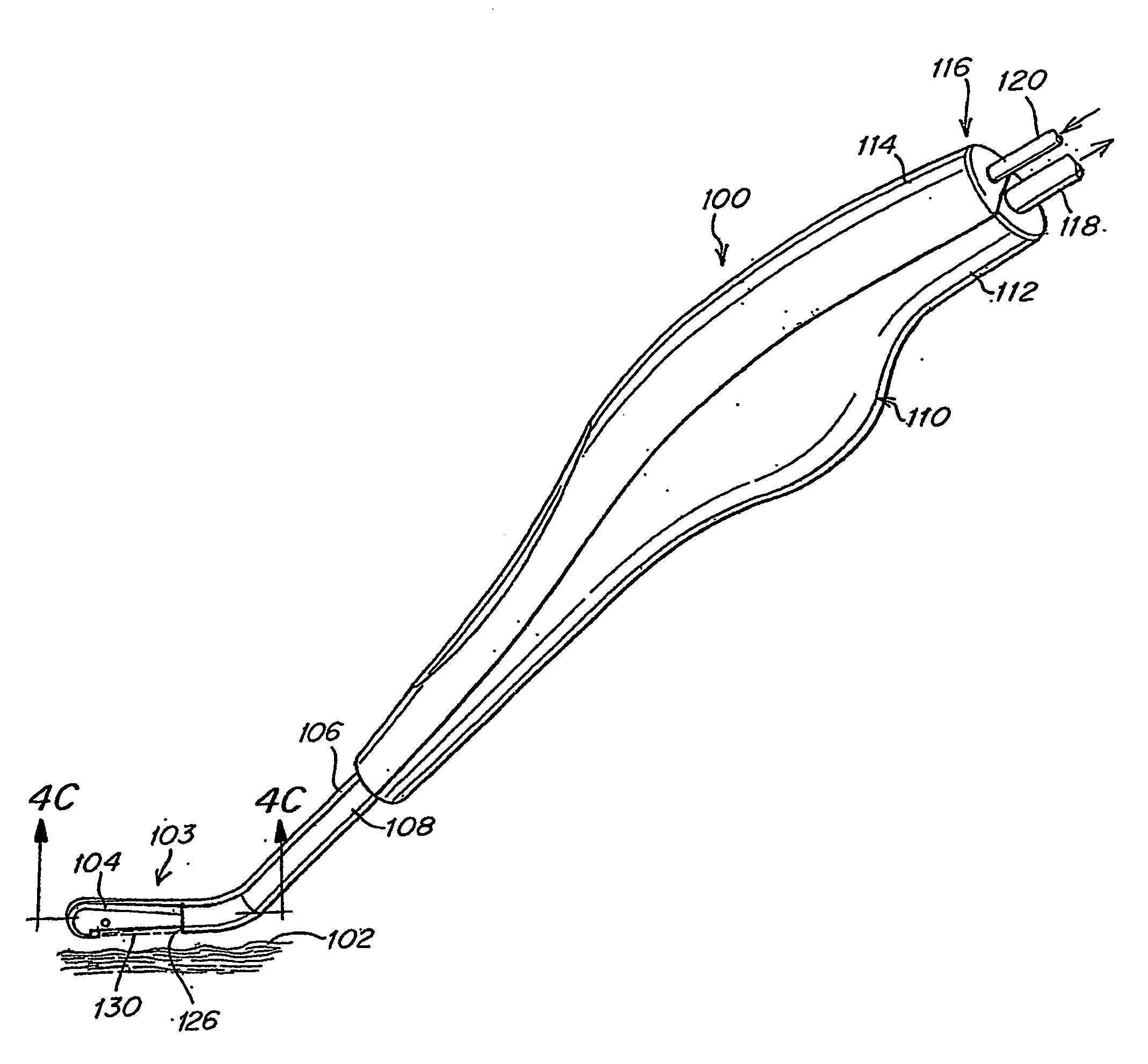

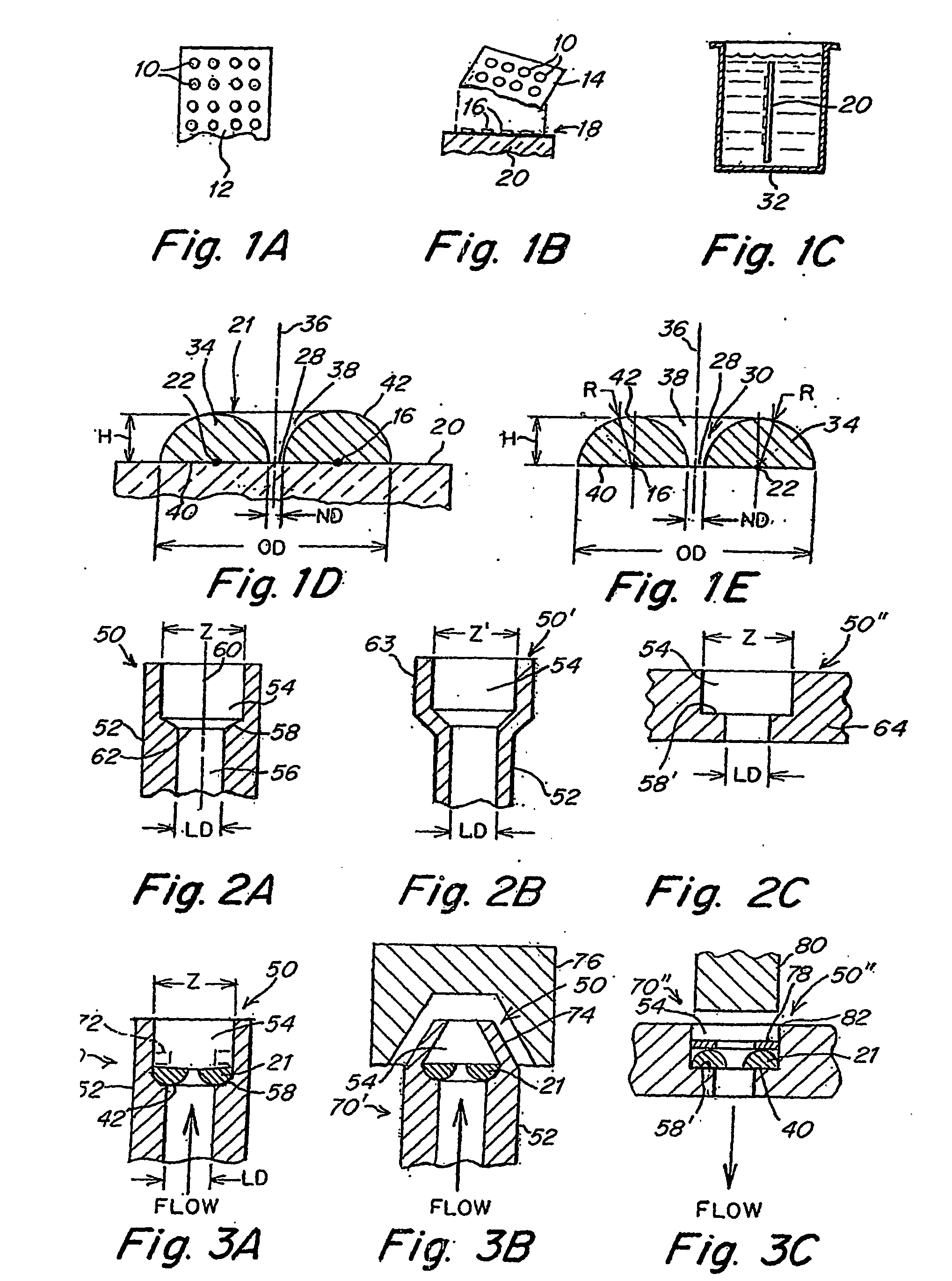

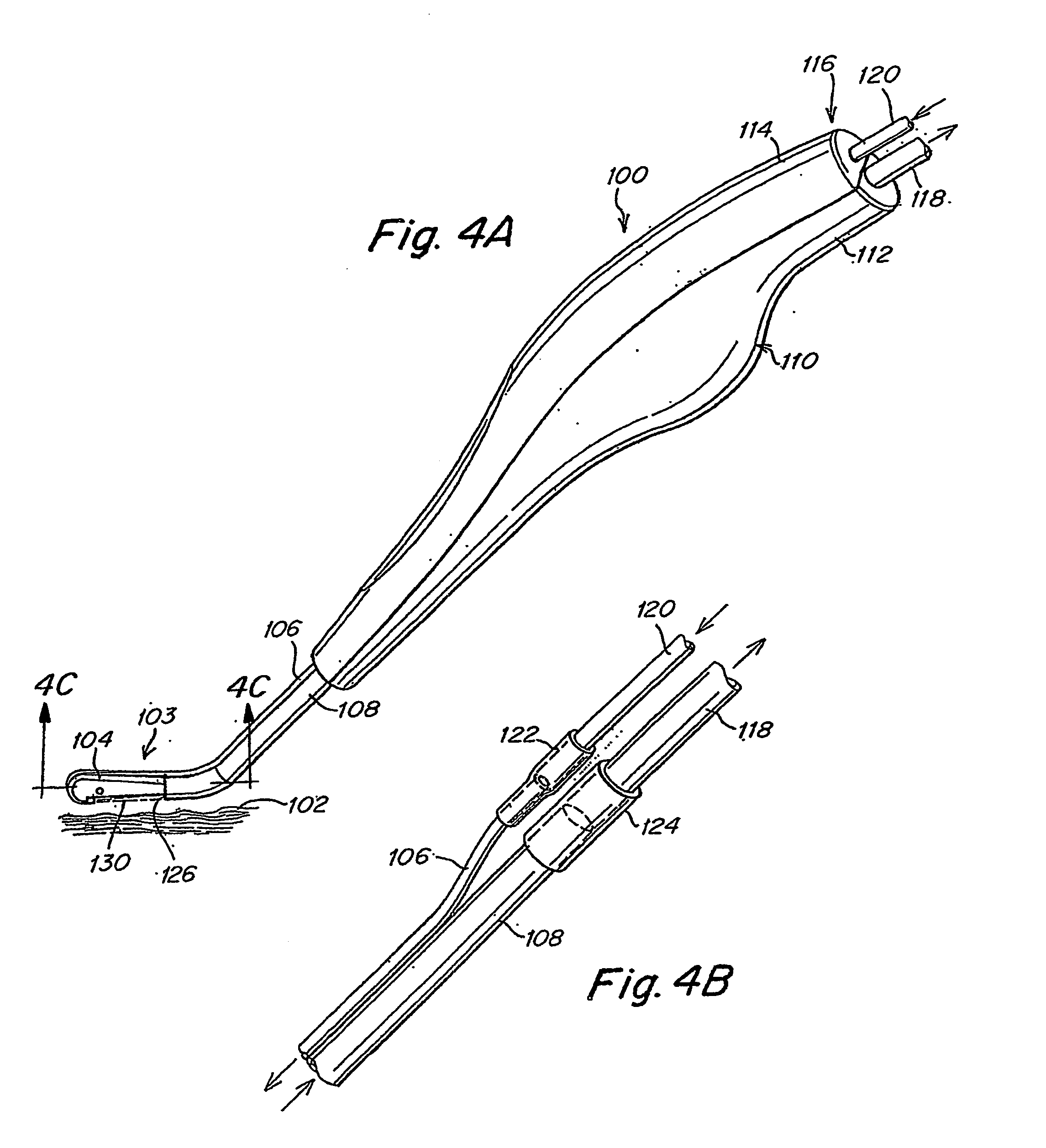

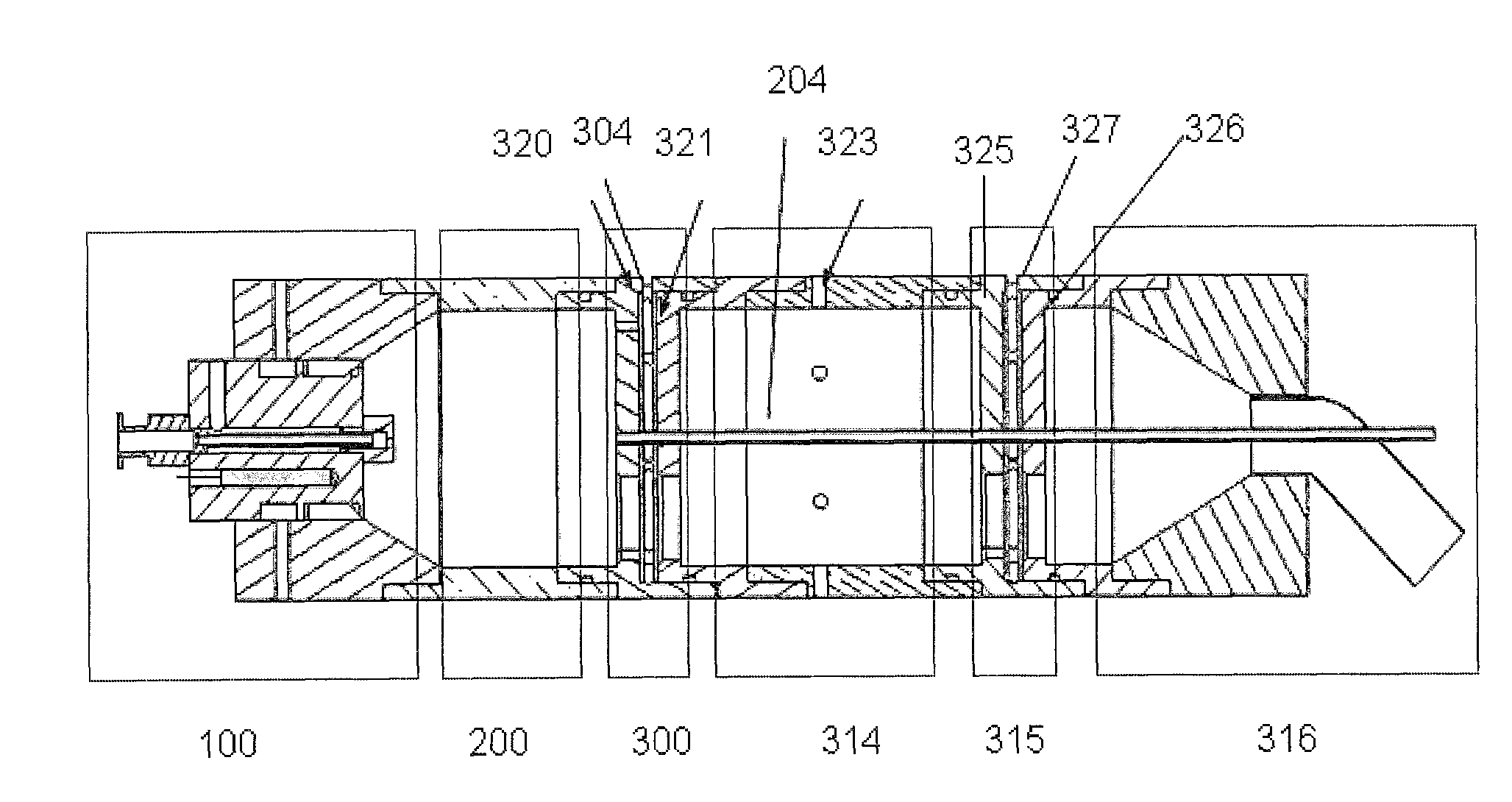

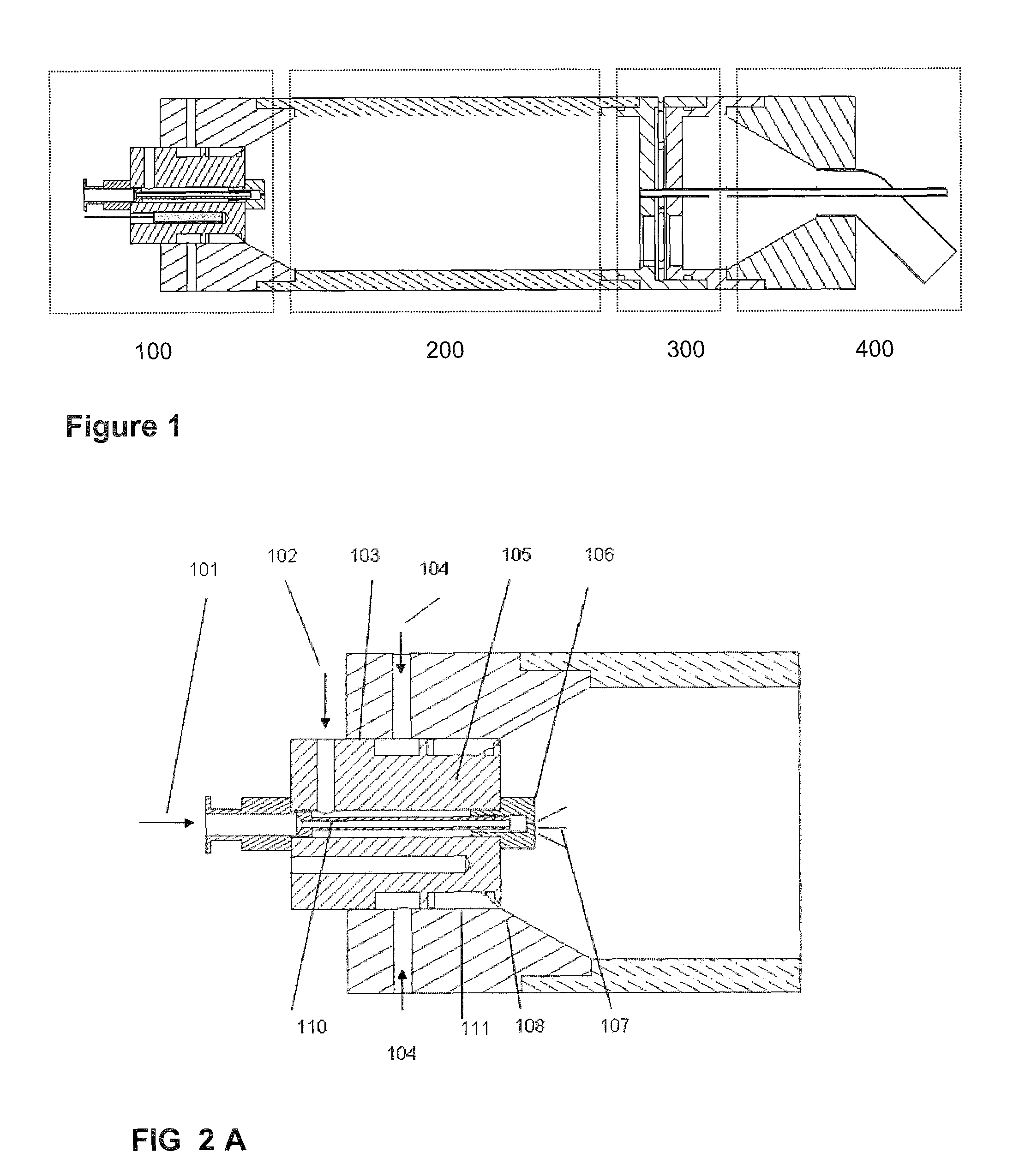

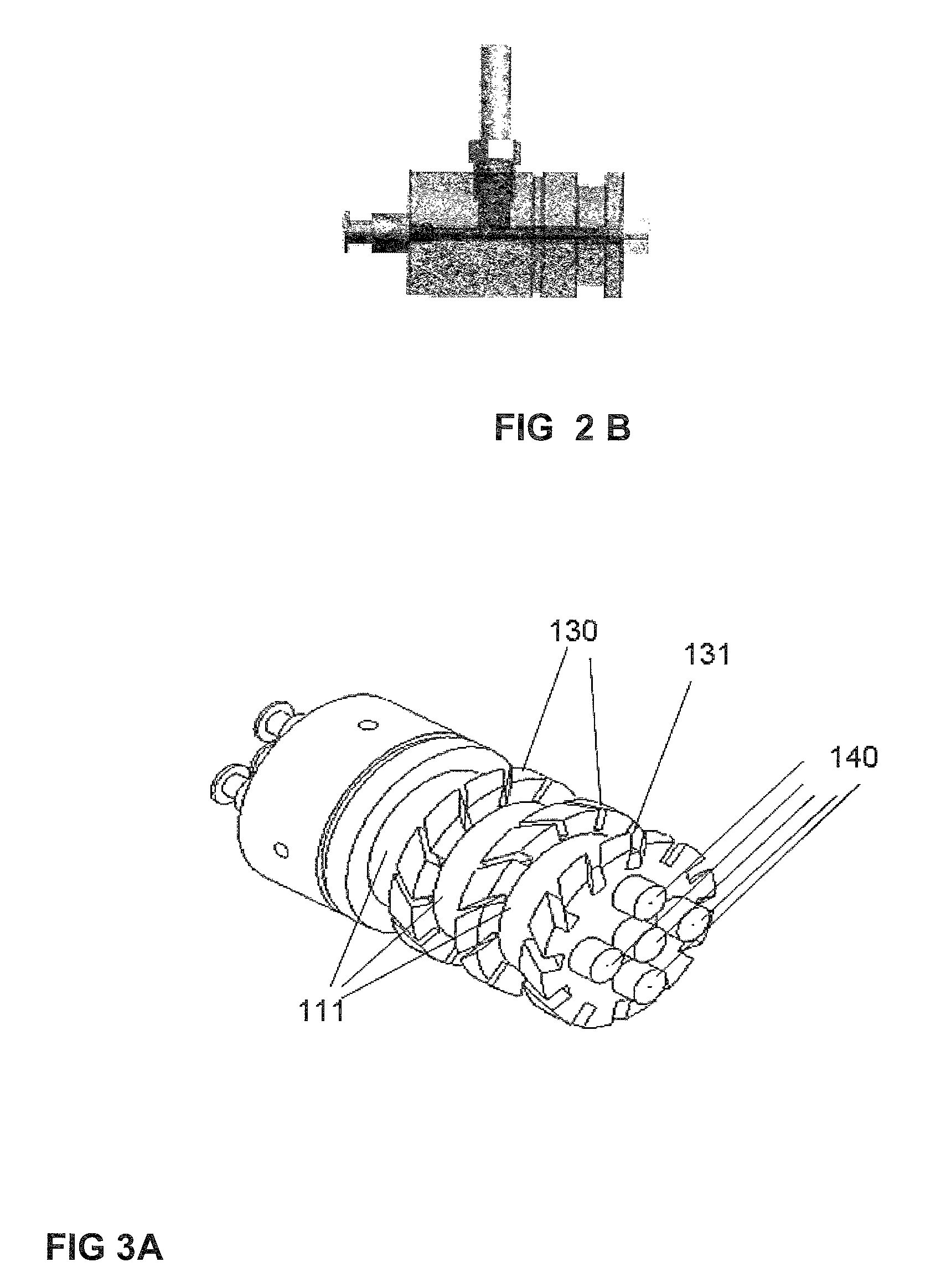

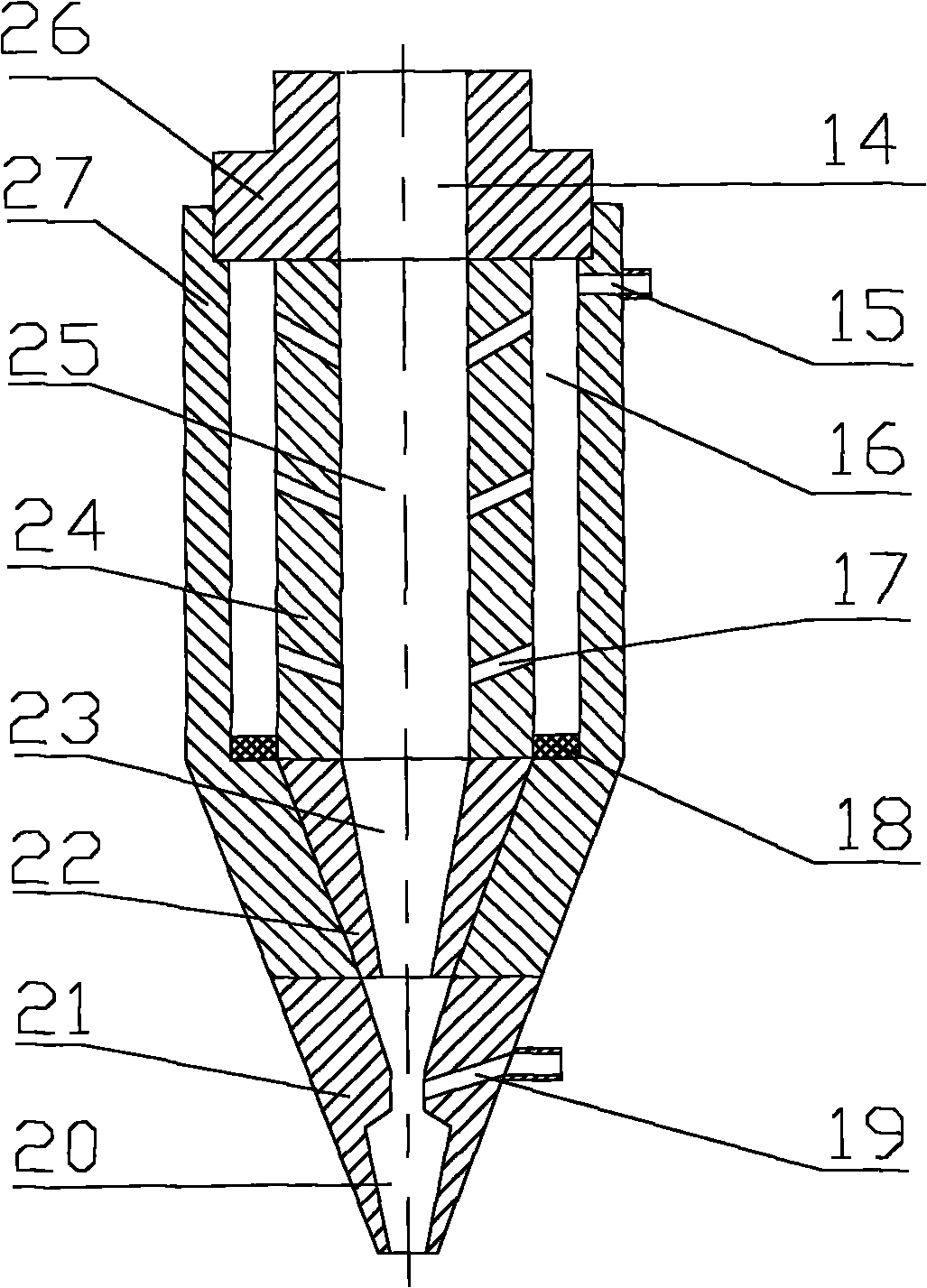

Nozzle assemblies for liquid jet surgical instruments and surgical instruments employing the nozzle assemblies

Disclosed are nozzles and nozzle assemblies of liquid jet-forming surgical instruments, surgical instruments employing such nozzles and / or nozzle assemblies, and methods of fabricating the nozzle assemblies in forming surgical instruments. Also, disclosed are liquid jet-forming surgical instruments including both liquid jet-forming nozzles and optional evacuation lumens, which when provided can be configured to receive the liquid jet and evacuate the liquid forming the liquid jet. Certain embodiments of such surgical instruments include inventive nozzle alignment component(s) to facilitate alignment of the nozzles and evacuation lumen upon assembly. In certain embodiments, surgical instruments are provided that include a nozzle that is shaped to form a liquid jet, which has surfaces that are optically smooth. In certain embodiments, the nozzle has a configuration enabling the nozzle to form a liquid jet that has the ability to remain collimated over longer distances than is typically achievable with conventional liquid jet surgical instrument nozzles having the same ratio of nozzle length to minimum inner diameter of the jet opening. In certain embodiments, nozzle assemblies comprising an operative assembly of at least two subcomponents, which together provide a nozzle are provided. In certain embodiments, the at least two sub-components may comprise a nozzle-providing component, such as a nozzle ring, and a holder that is configured to retain and position the nozzle-providing component in the nozzle assembly. In certain embodiments, the nozzle-providing component can comprise a liquid flow passage having a diameter that continuously decreases along at least a portion of its length.

Owner:HYDROCISION

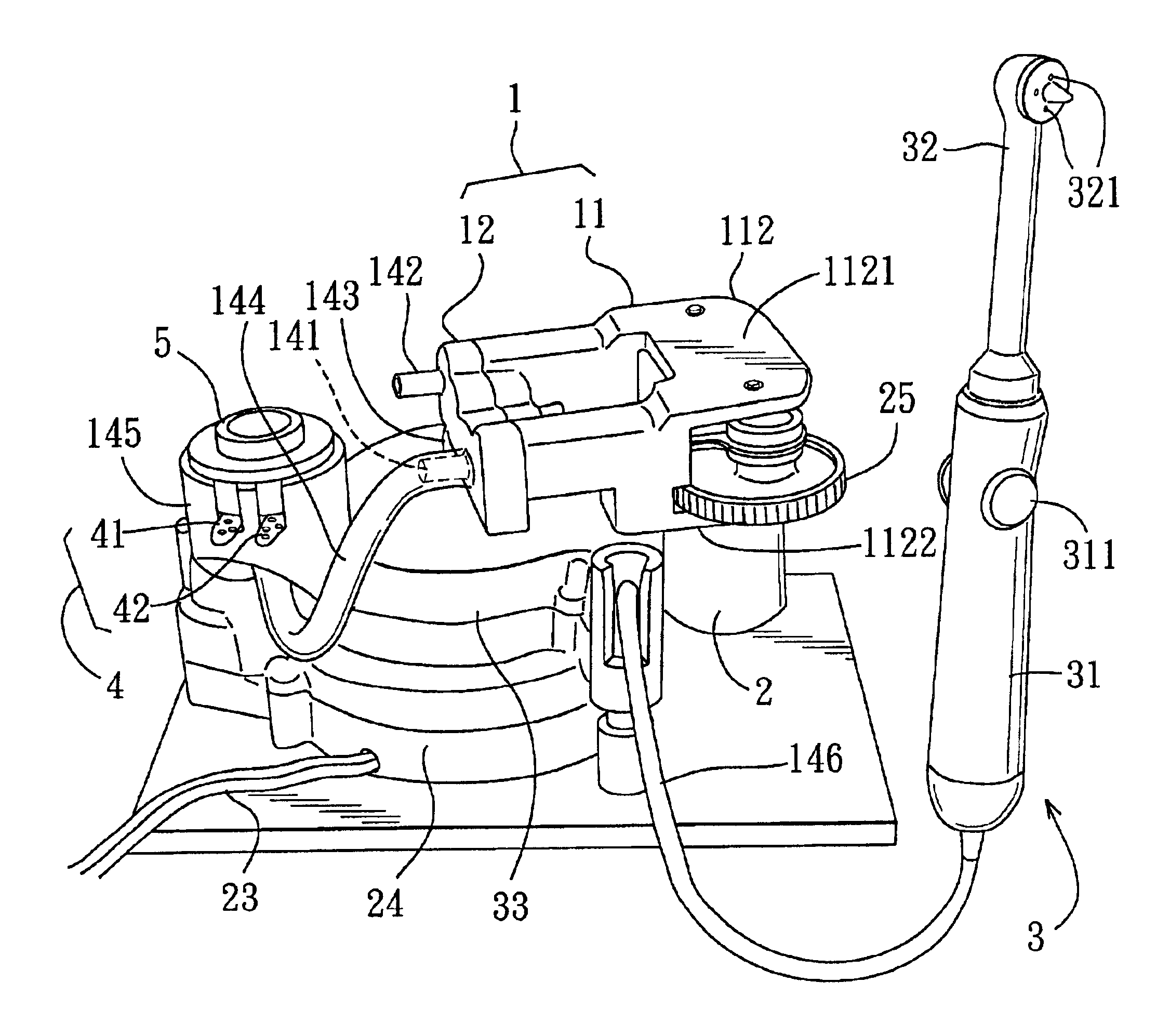

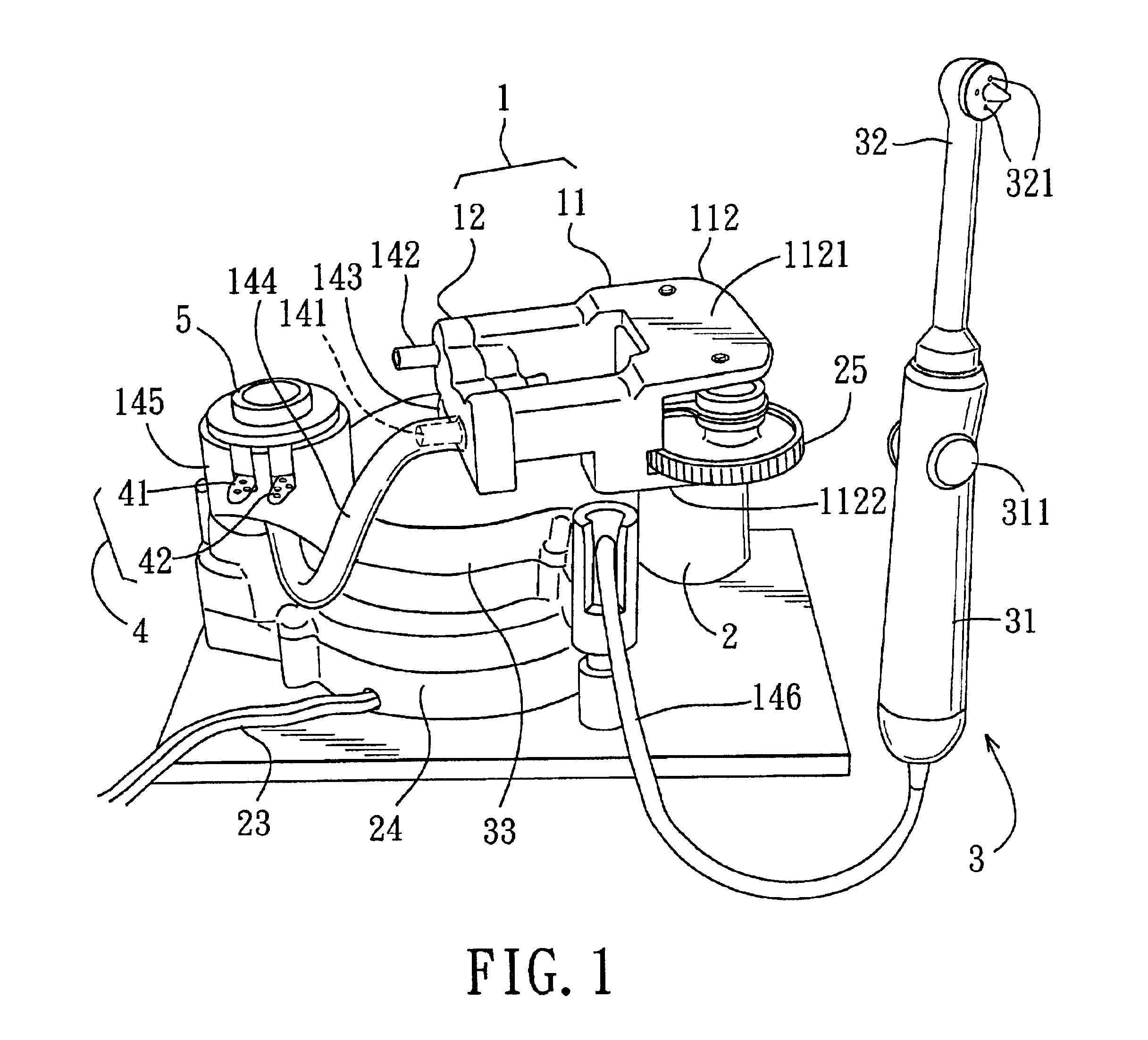

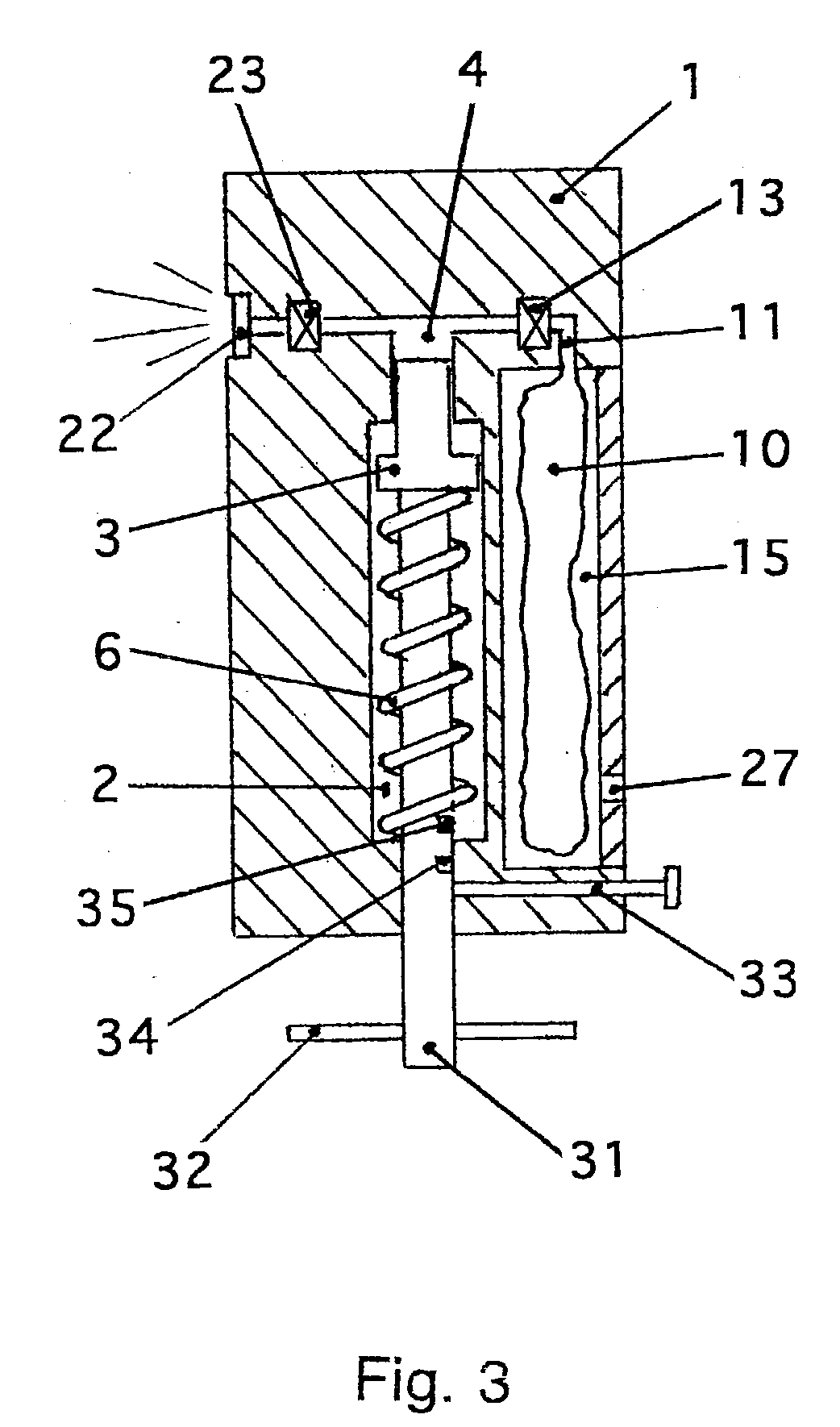

Device for generating a jet stream of air entrained water

A device for generating a jet stream of air entrained water for cleaning teeth and gums, includes two pumps disposed to respectively and sequentially pump in and out of internal ports thereof from first water and air transit chambers, water flow and air stream to generate raised water and air pressures. Two valves are disposed respectively to be moved by the water and air pressures to block or permit entry of the water flow and the air stream into second water and air transit chambers. A mixing outlet is disposed downstream of and to merge water and air outlet ports of the second water and air transit chambers to obtain an accelerated stream of the air entrained water for cleaning teeth and gums.

Owner:CHEN CHIEN LIANG +2

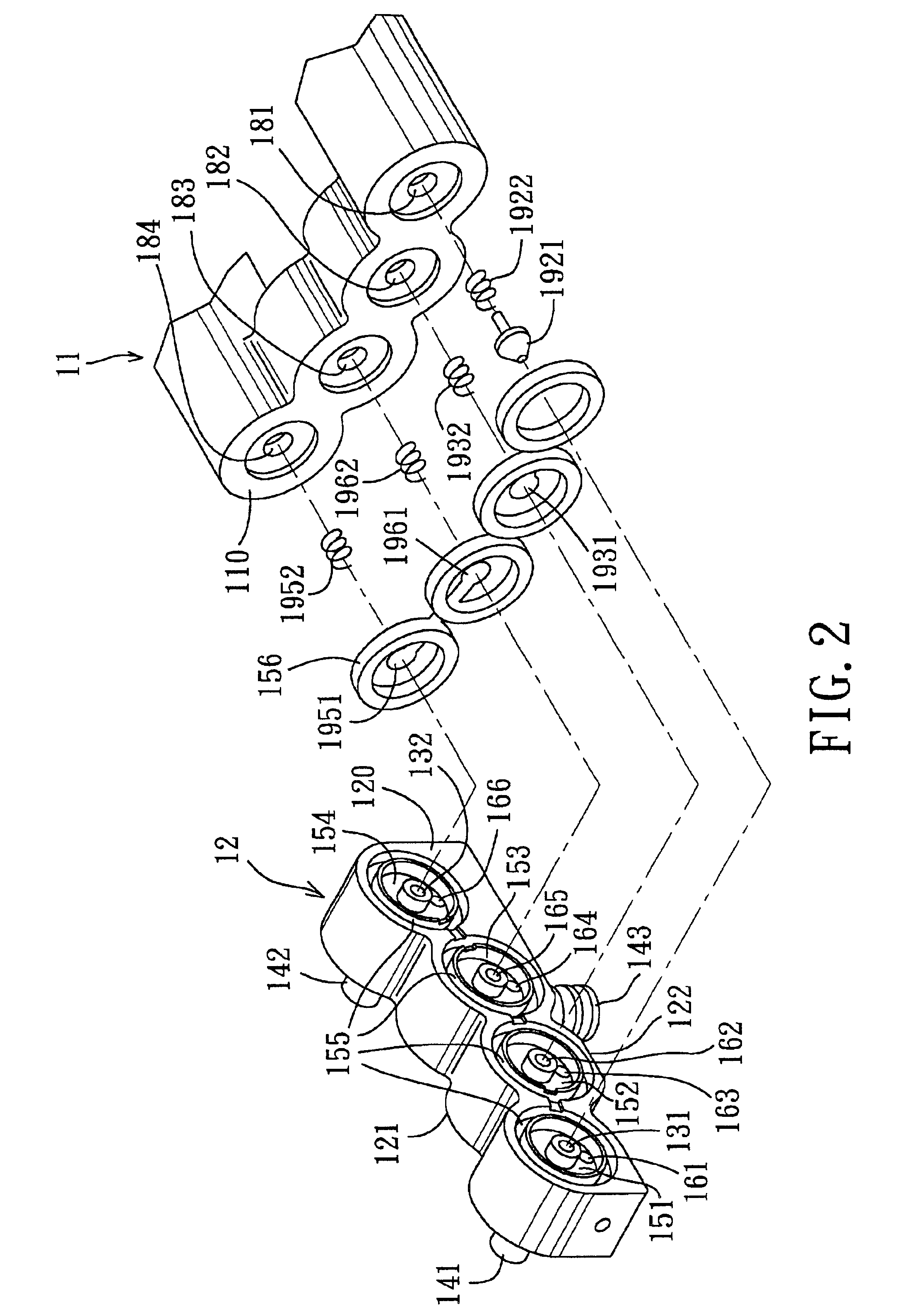

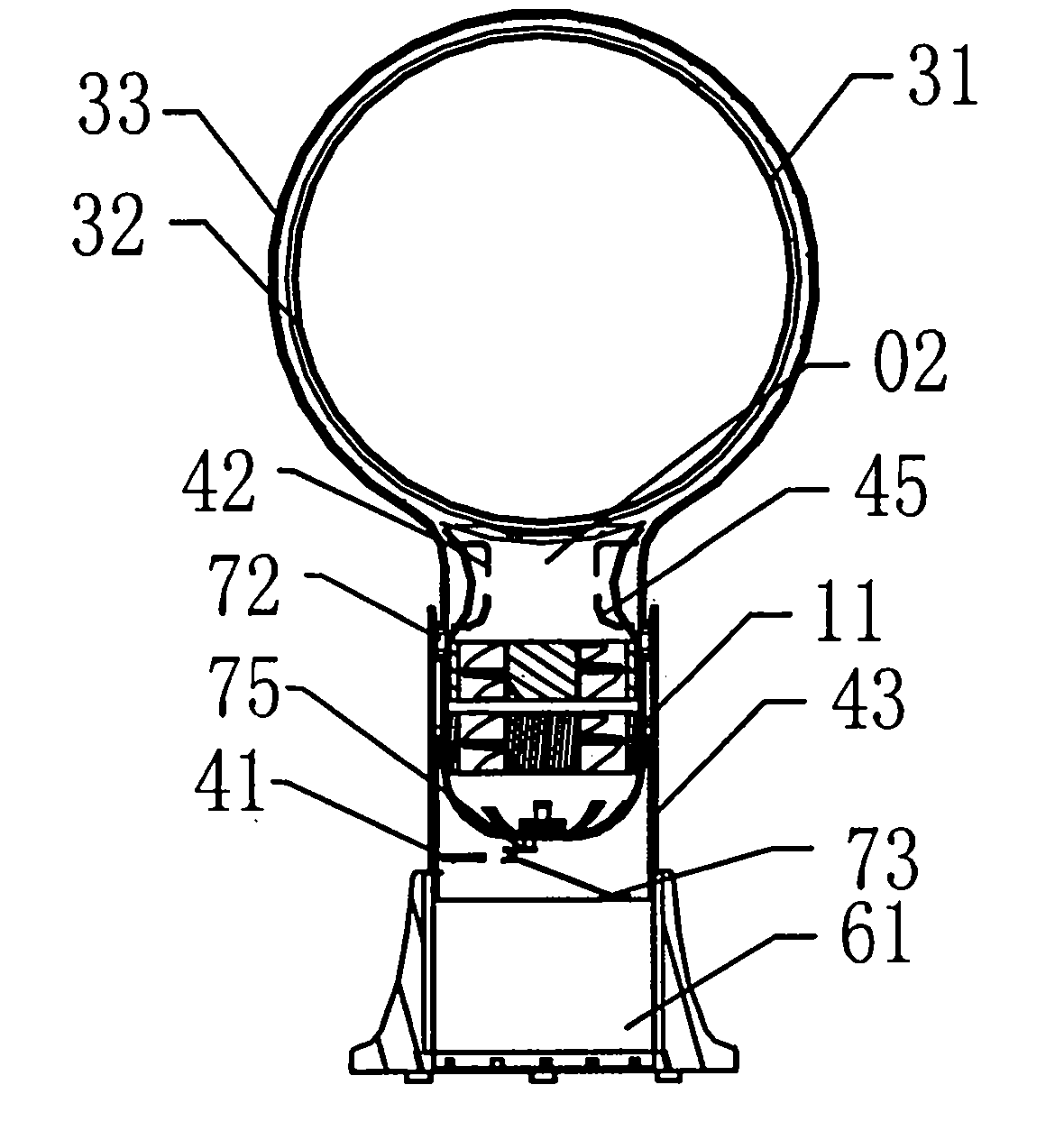

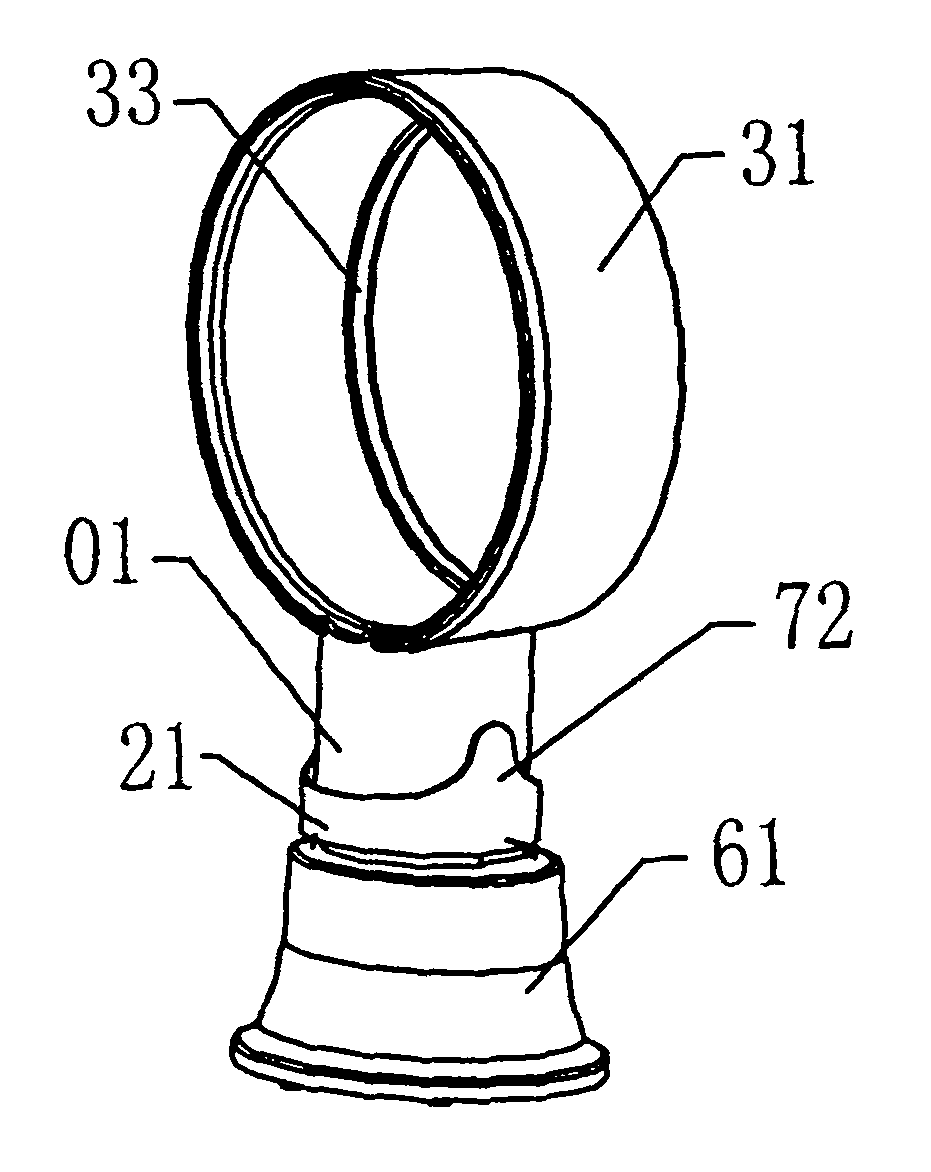

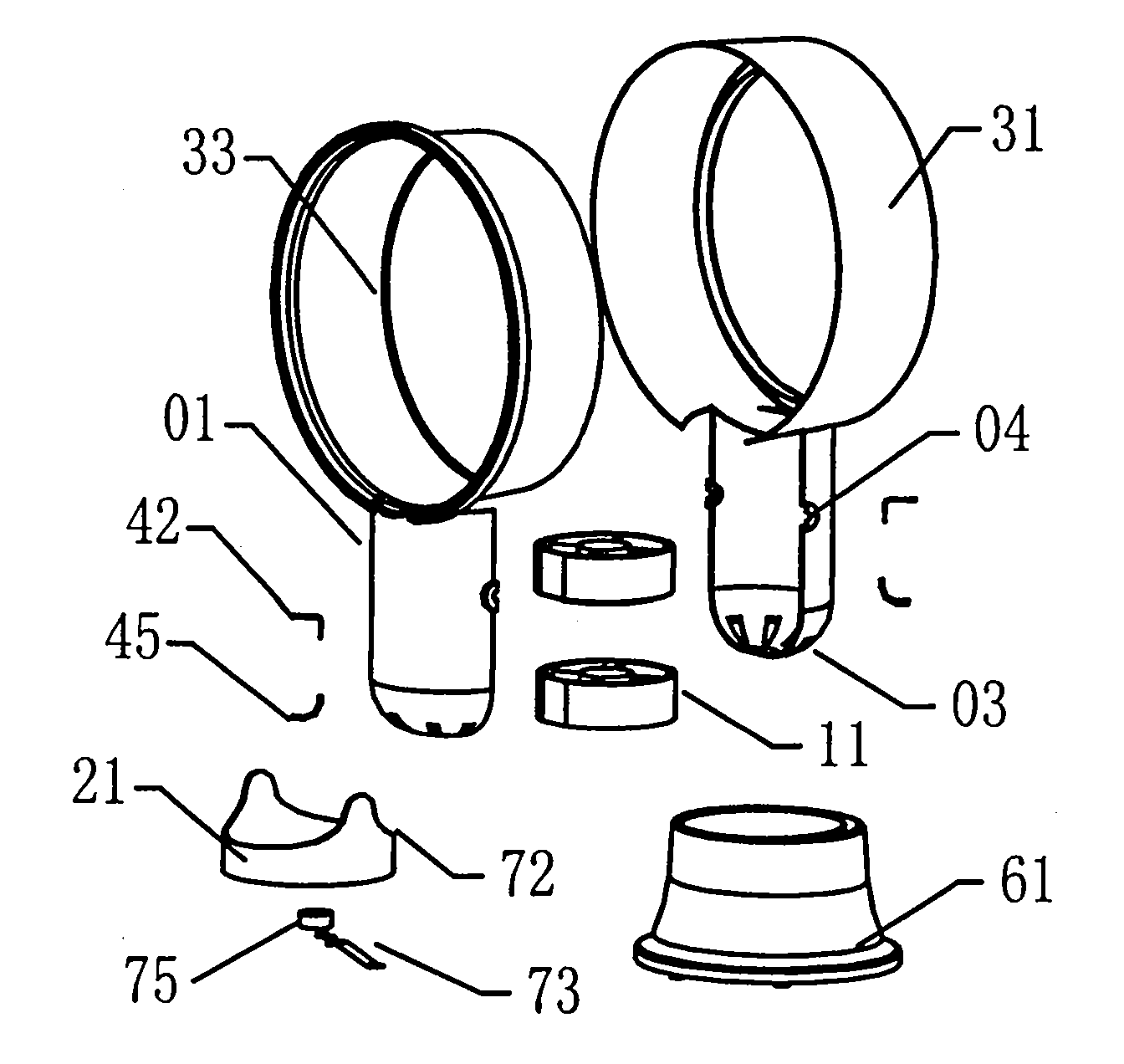

Electronic ice fan

InactiveCN101984299ASolve the problem of small amount of fog and blowing air not coolSimple structureLighting and heating apparatusJet pumpsJet flowEngineering

The invention discloses an electronic ice fan. An ice containing box is arranged below a body seat; a pressure increasing axial flow fan is arranged in the body seat; a suction port is formed below the axial flow fan; an annular flow increasing ring is arranged above the body seat; a circulation channel and a jet flow port are formed in the flow increasing ring; a mist stimulation pipe is arranged above the pressure increasing axial flow fan; a mist stimulator is arranged on the lower part of the mist stimulation pipe and connected with the ice containing box below; the mist stimulation pipe is communicated with the pressure increasing ring above; the ice water in the ice containing box flows to the mist stimulator; the pressure increasing axial flow fan sucks air from the lower suction opening to form high-pressure air flow; the high-pressure air flow flows through the mist stimulation pipe and blows the water mist of the mist stimulator through the circulation channel to form ice mist at the jet flow port of the flow increasing ring; and the ice mist is immediately gasified into ice-cold air. The invention aims at providing an air cooler device which solves the problems of small mist amount and non-cool air of the air cooler by using the axial flow fan, the flow increasing ring and the mist stimulator; and moreover, as no fan blade is arranged in the flow increasing ring, the effects of large mist amount and cool air of a bladeless ice fan are realized.

Owner:林美利

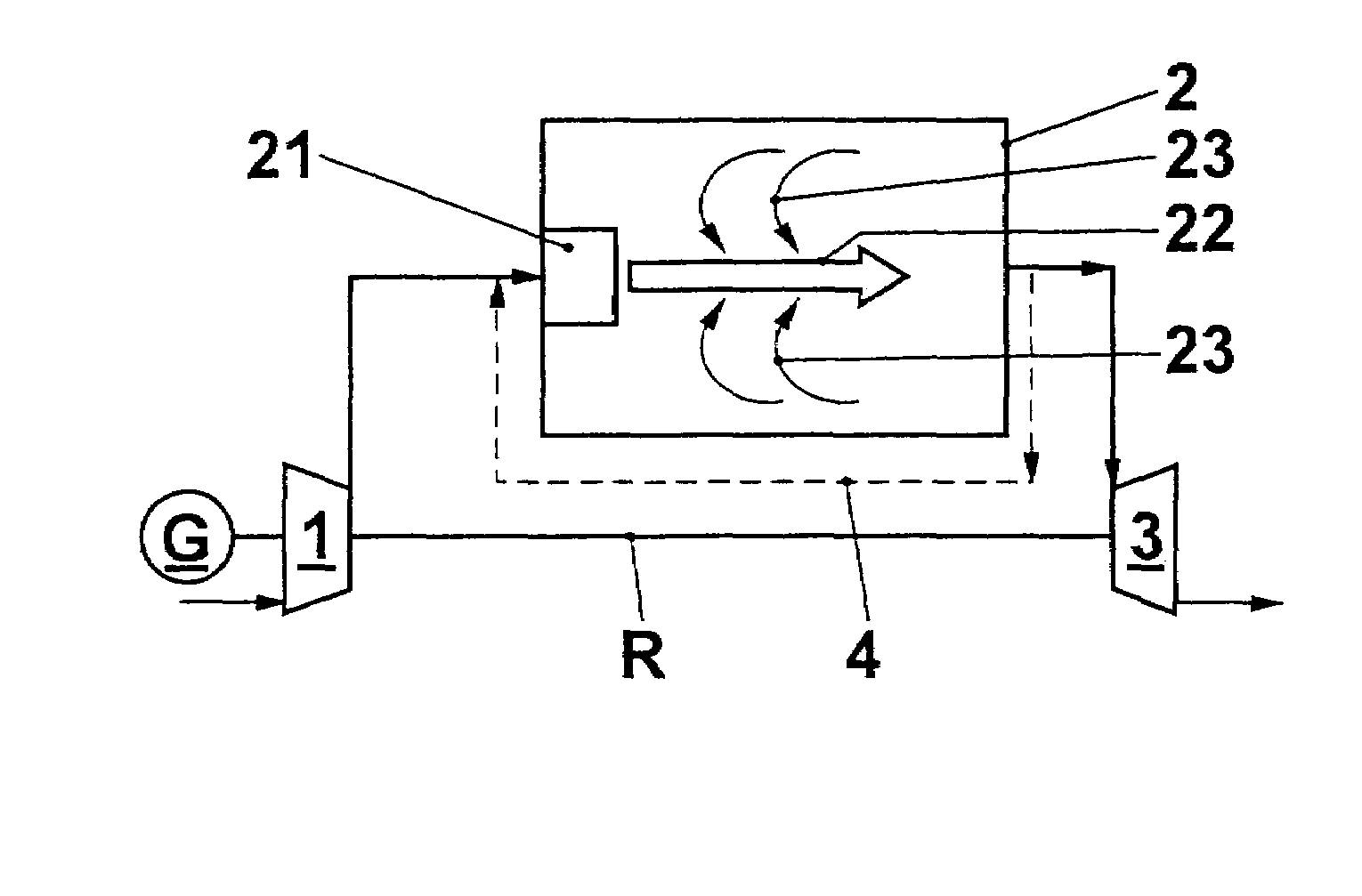

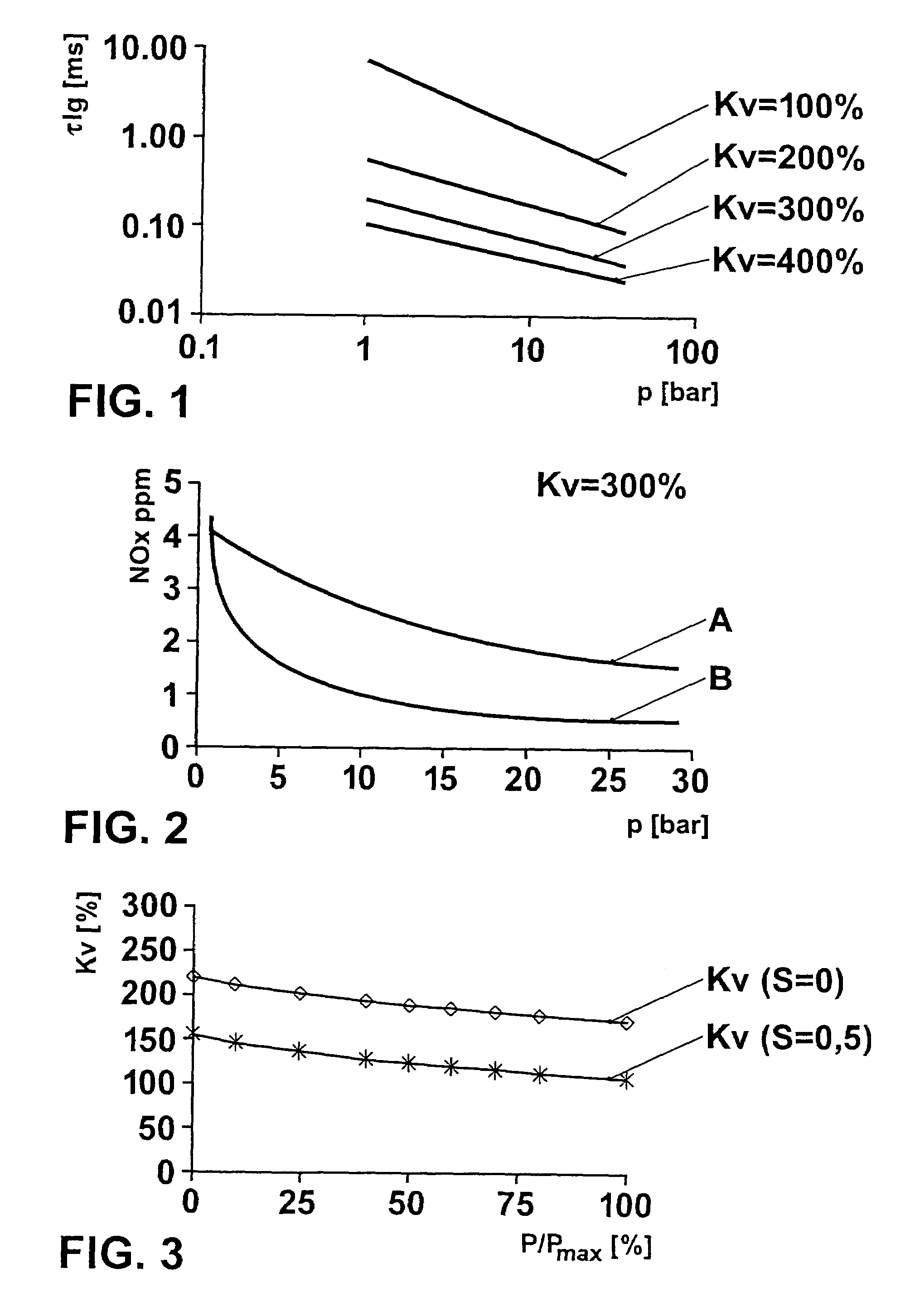

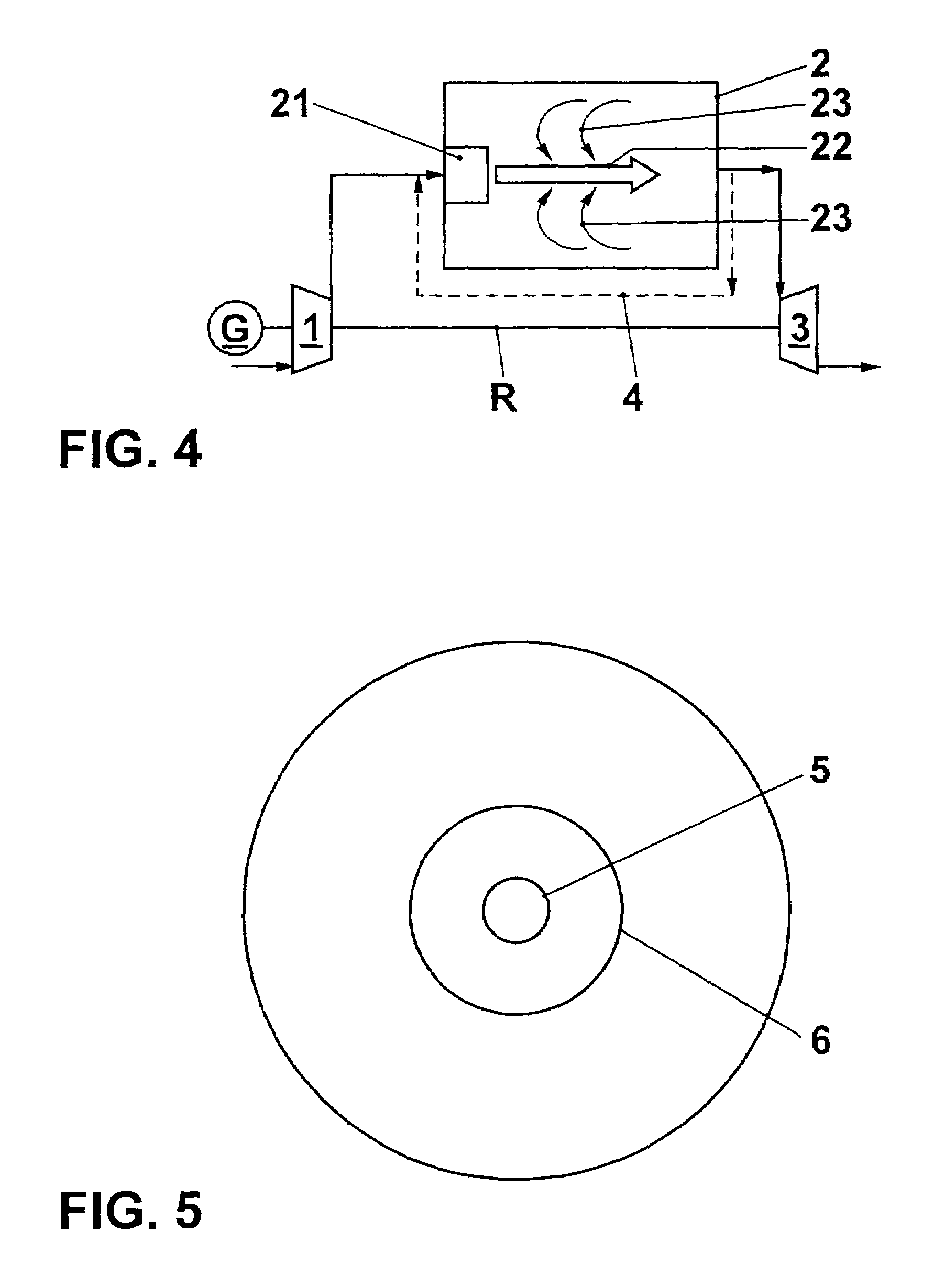

Method for combustion of a fuel

InactiveUS7363756B2Increase speedAccelerated dilutionContinuous combustion chamberGas turbine plantsCombustion chamberFront velocity

In a method for the combustion of a fuel, a fuel or a premixed combustible mixture is introduced into a combustion space as a combustible fluid open jet. The velocity of the open jet is selected in such a way that it is impossible for a stable flame front to form, i.e. is in any event greater than the flame front velocity, and that, on account of a jet pump effect, flue gas is mixed into the combustible fluid jet from the combustion chamber in a jet-induced recirculation internally within the combustion chamber. The admixed flue gas dilutes and heats the combustible fluid. The heating causes the spontaneous ignition temperature to be exceeded, and a low-pollutant volumetric flame is formed in a highly dilute atmosphere.

Owner:ANSALDO ENERGIA SWITZERLAND AG

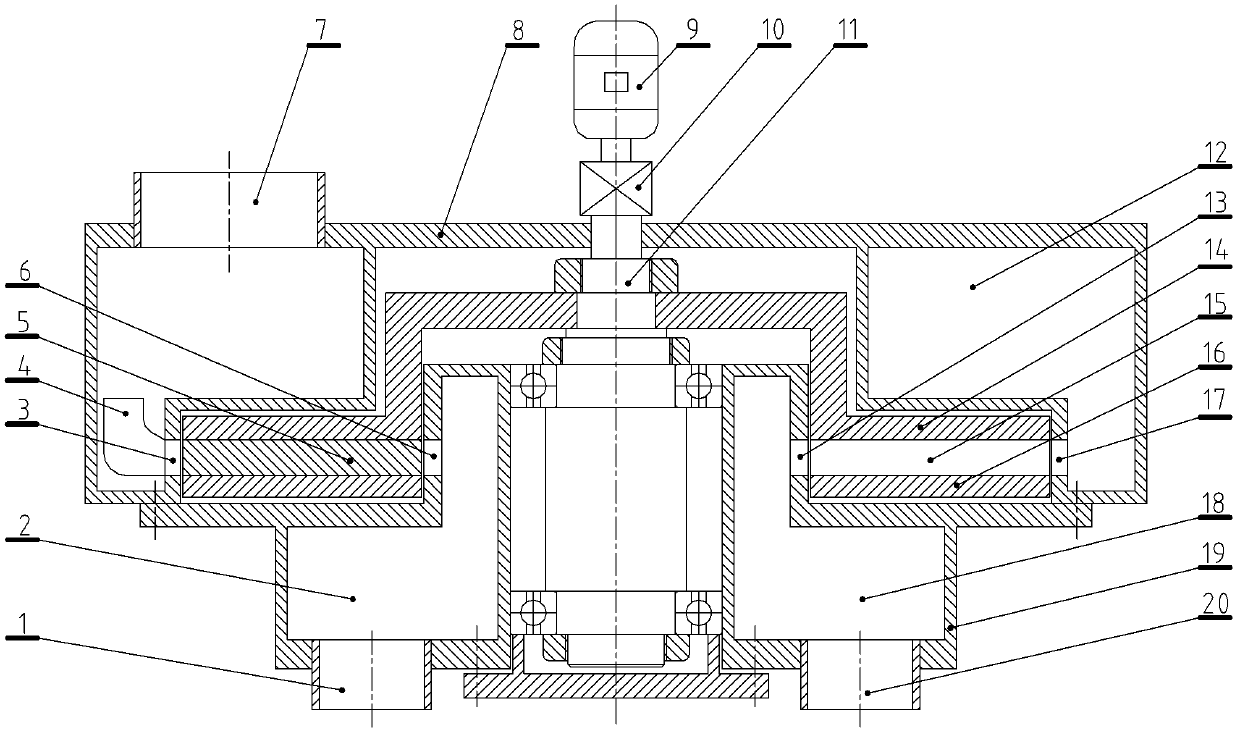

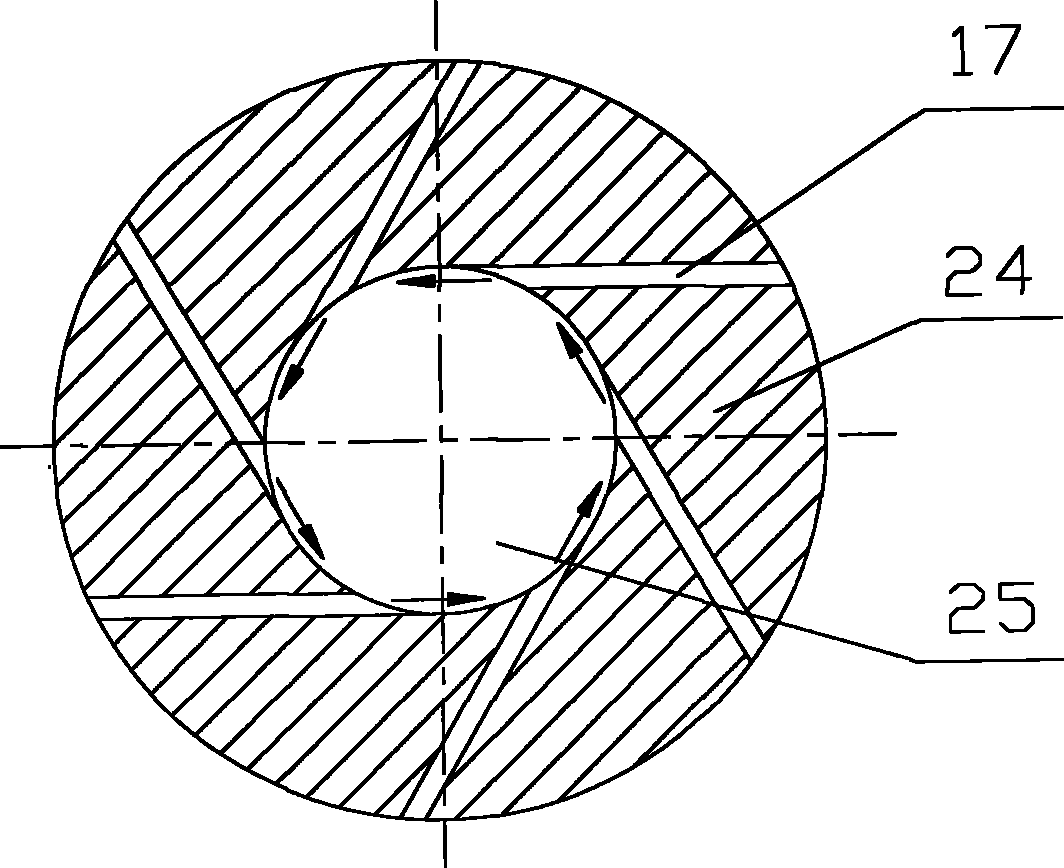

Radial-flow type fluidic pressure wave supercharger

ActiveCN102606548ARealize pressure exchangeHigh pressure levelFluid-pressure convertersJet flowDynamic energy

The invention discloses a radial-flow type fluidic pressure wave supercharger, which can realize the energy exchange between the high pressure gas and the low pressure gas by running the pressure wave, avoid loss of mixed and diffused energy and has the advantages of high isentropic efficiency, low rotating speed, operability with liquid, sufficient exhaust and on the like. For adopting a pressure oscillating tube channel with variable rectangular cross-section, the incidence loss and the flowing loss of the jet flow are reduced; the channel is a bending flow channel arranged along the radial radiation, the process of expanding and compressing is strengthened and the sufficient discharge of the compressed gas is accelerated by using the centrifugal force; pressure balancing holes are arranged in the machine, so that the performance is kept balanced at the different pressure ratios; a pressure expanding flow guider is arranged at a compressed gas outlet in order to transform the dynamic energy of the gas flow effectively. The radial-flow type fluidic pressure wave supercharger can fully utilize the pressure energy in the production process and the pressure energy in the stratums of natural gas, thereby providing an efficient device selection for utilizing the pressure energy sources effectively.

Owner:DALIAN UNIV OF TECH

Method and apparatus for producing a high-velocity particle stream

InactiveUS6283833B1Uniform particle spreadingImprove productivityBlast gunsLiquid spraying apparatusJet flowClassical mechanics

A method and apparatus for producing a high-velocity particle stream at low cost through multi-staged acceleration using different media in each stage. The particles are accelerated to a subsonic velocity (with respect to the velocity of sound in air) using one or more jets of gas at low cost, then further accelerated to a higher velocity using jets of water. Additionally, to enhance particle acceleration, a vortex motion is created, and the particles introduced into the fluid having vortex motion, thereby enhancing the delivery of particles to the target.

Owner:FLOW INT

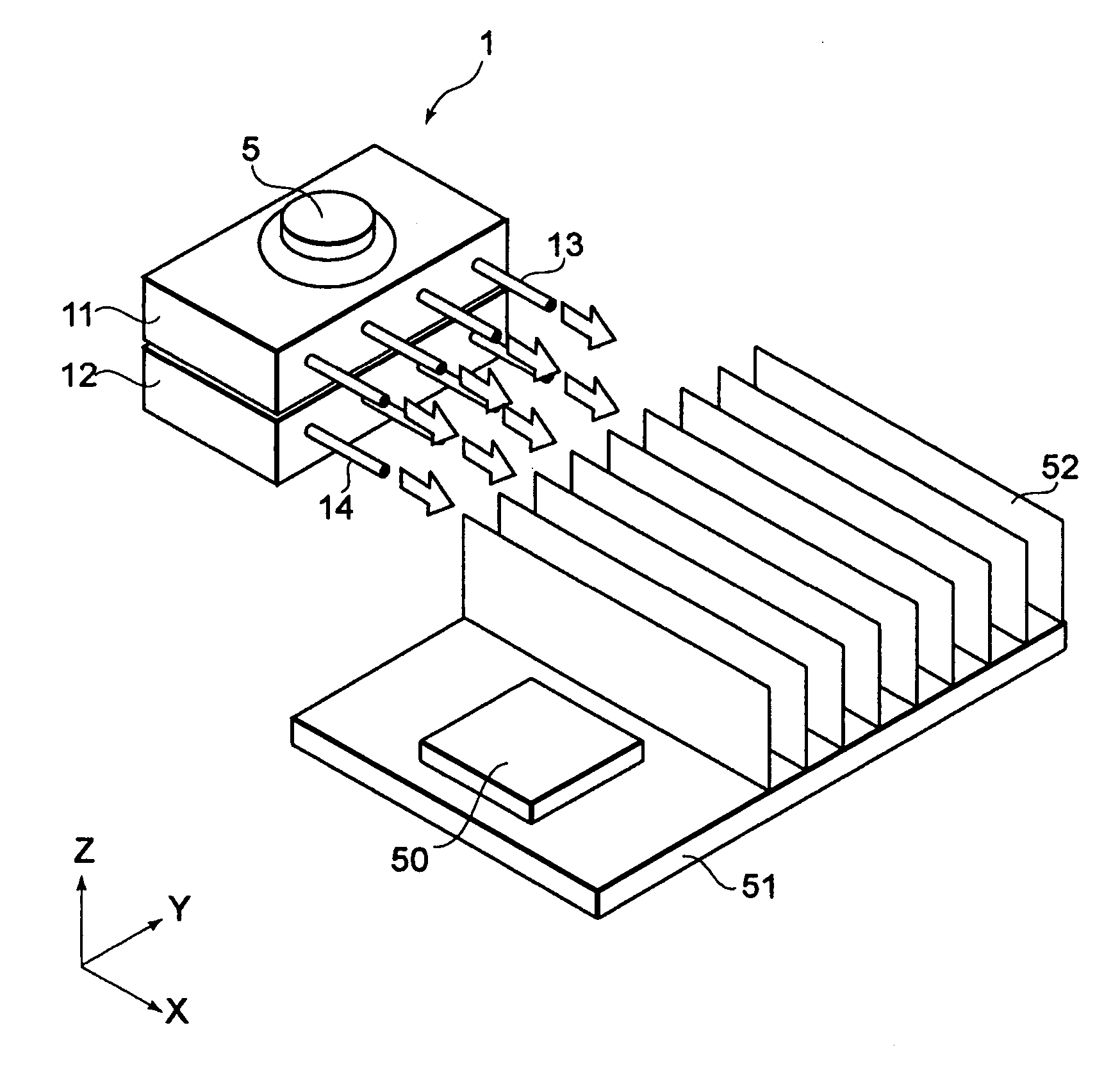

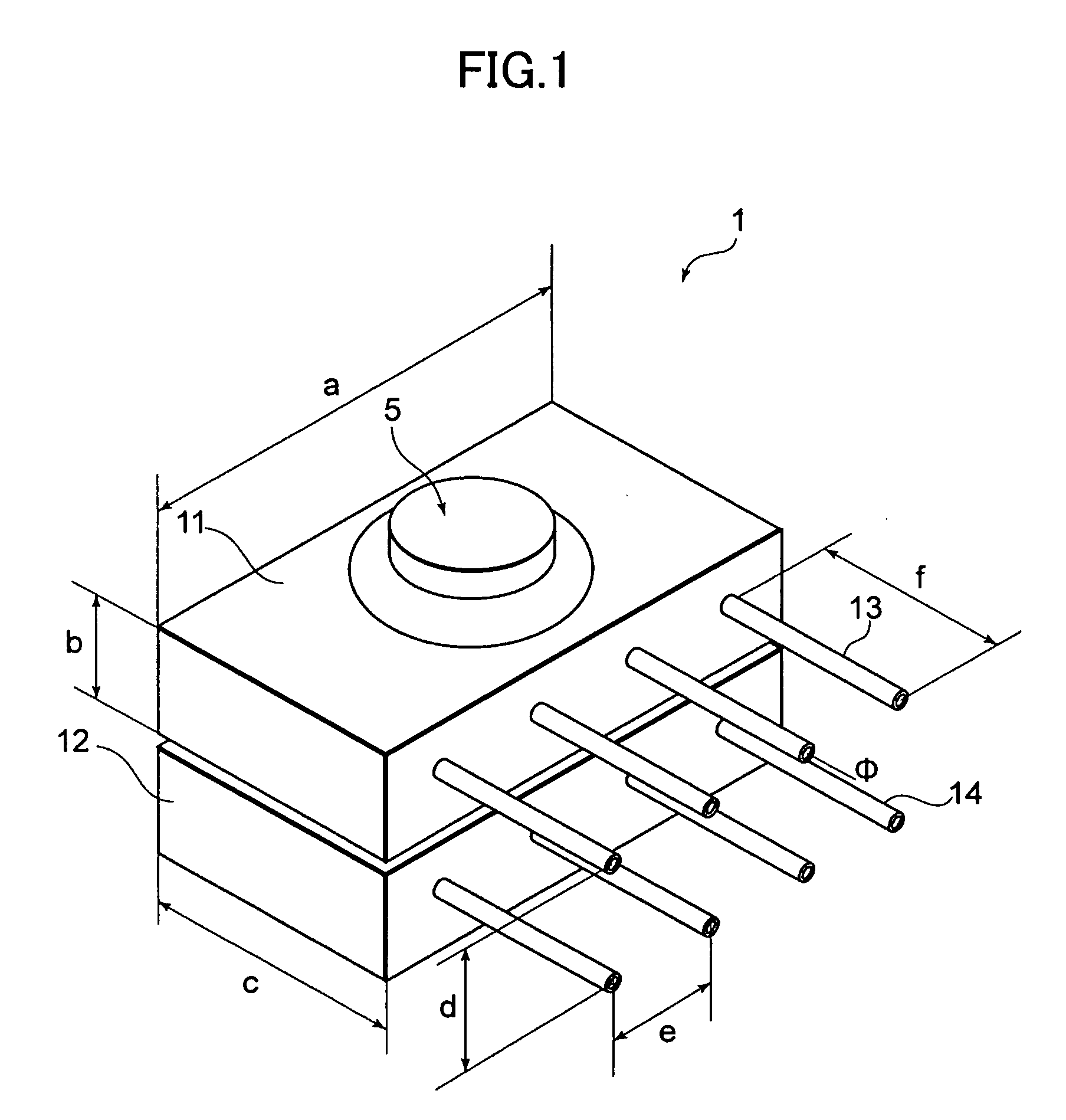

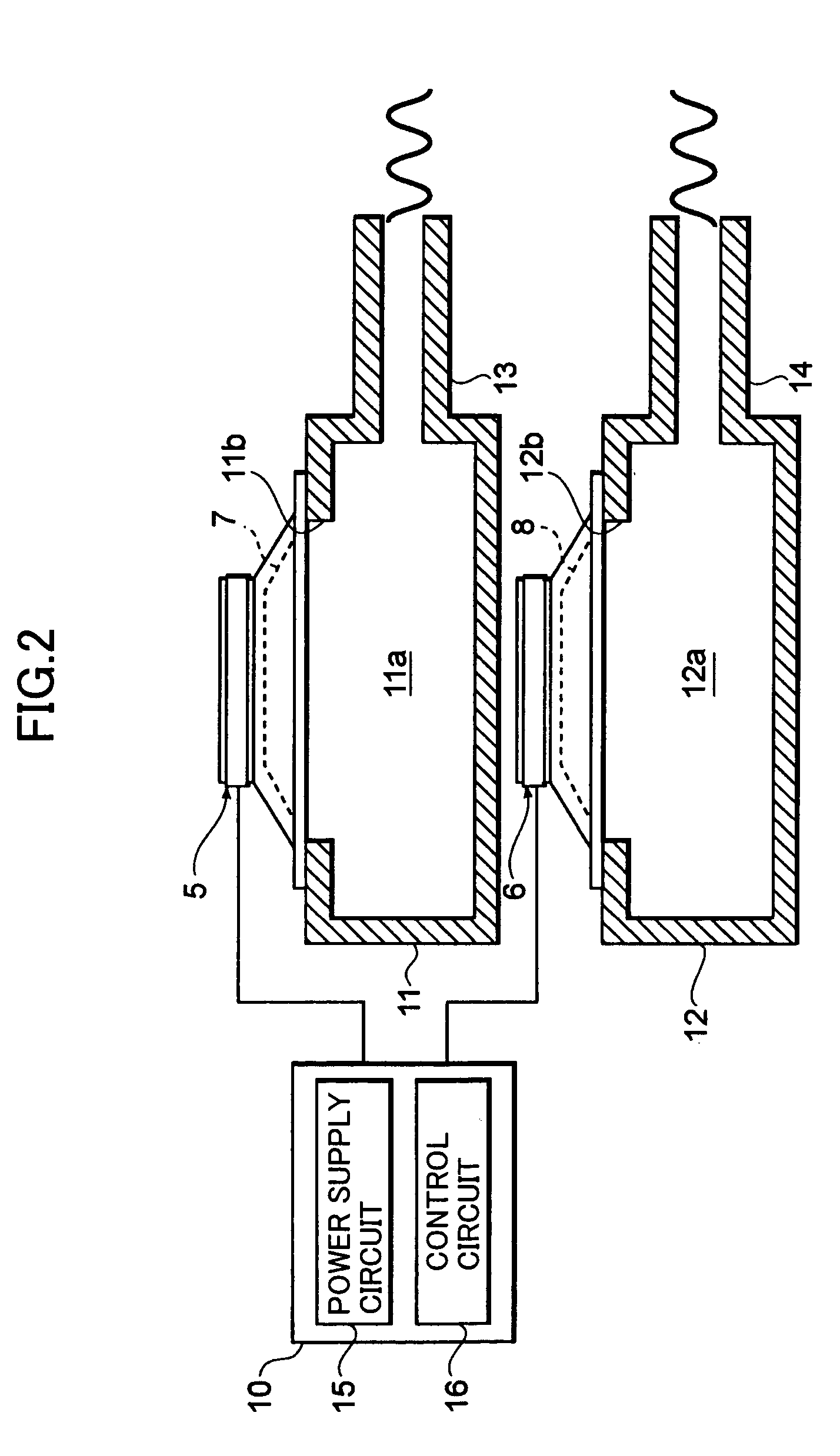

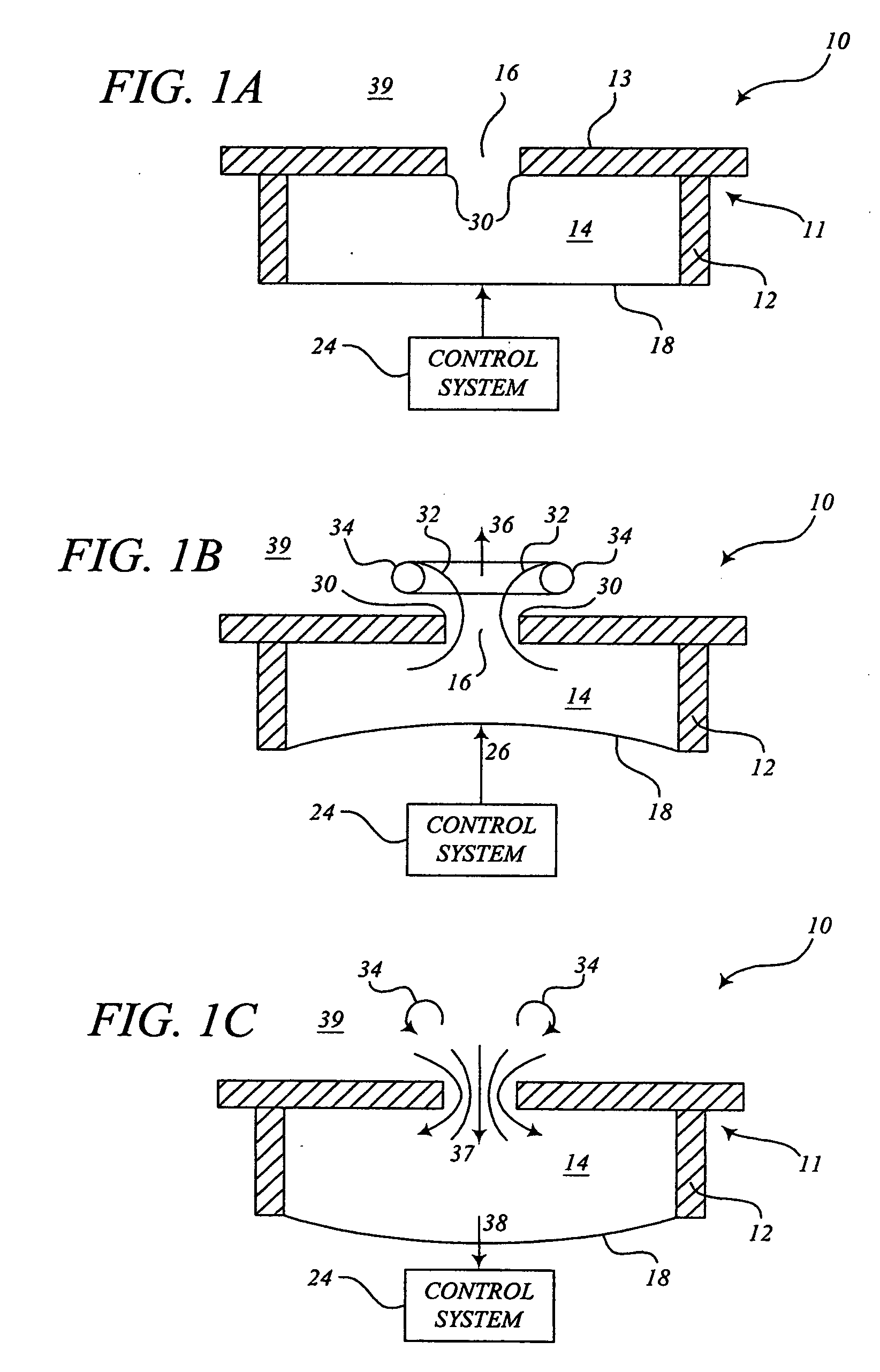

Jet flow generating apparatus, electronic apparatus, and jet flow generating method

InactiveUS20050121171A1Noise can be prevented from generatingSuppress noiseSemiconductor/solid-state device detailsFlexible member pumpsJet flowEngineering

A jet flow generating apparatus that suppresses noise as much as possible and effectively radiates the heat generated by a heat generating member, an electronic device that is equipped with the jet flow generating apparatus, and a jet flow generating method are provided. According to the present invention, a jet flow generating apparatus comprises a plurality of chambers each having an opening and each containing a coolant, a vibrating mechanism for vibrating the coolant contained in each of the plurality of chambers so as to discharge the coolant as a pulsating flow through the openings, and a control unit for controlling the vibration of the vibrating mechanism so that the sound waves generated by the coolant discharged from the plurality of chambers weaken each other.

Owner:SONY CORP

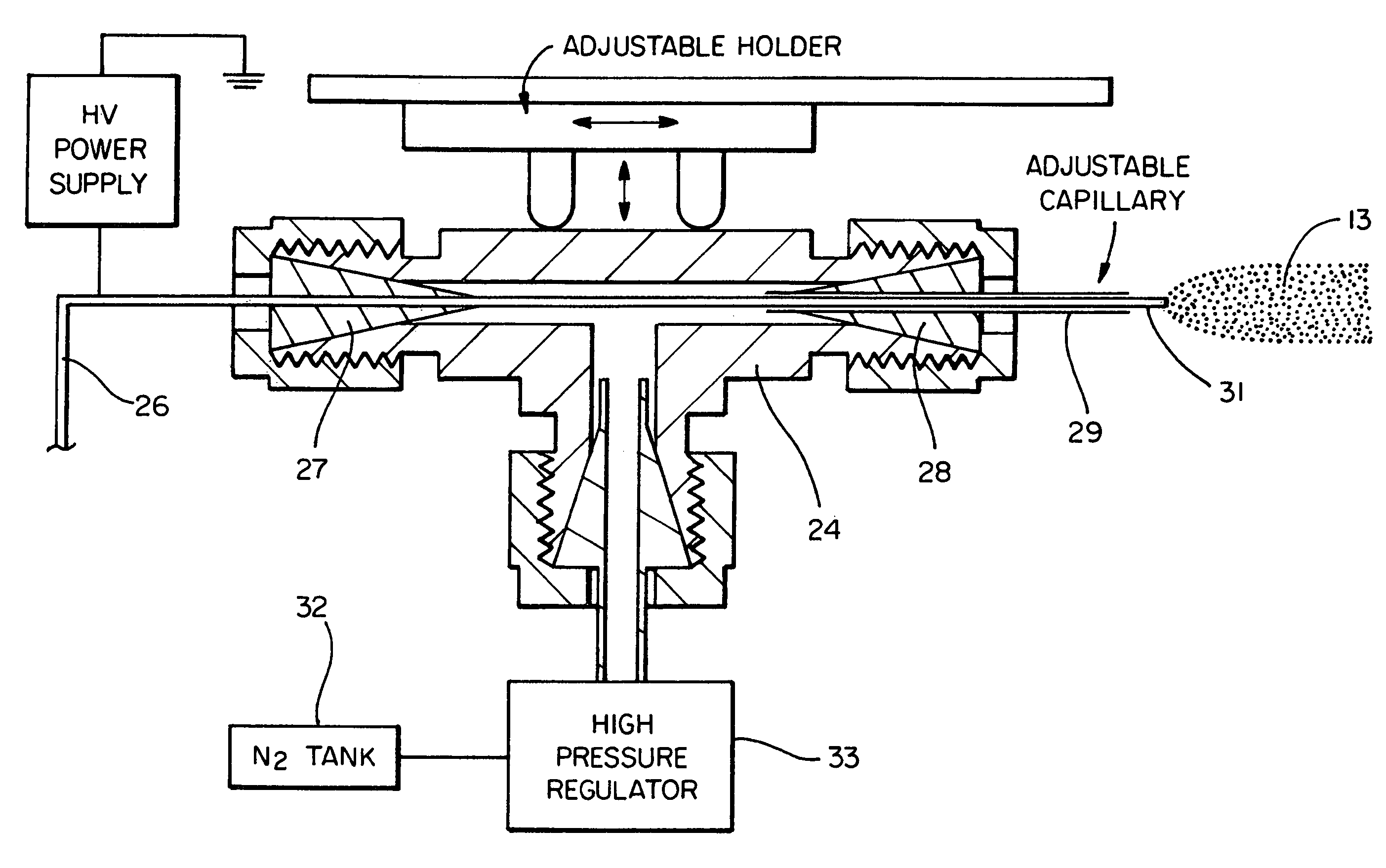

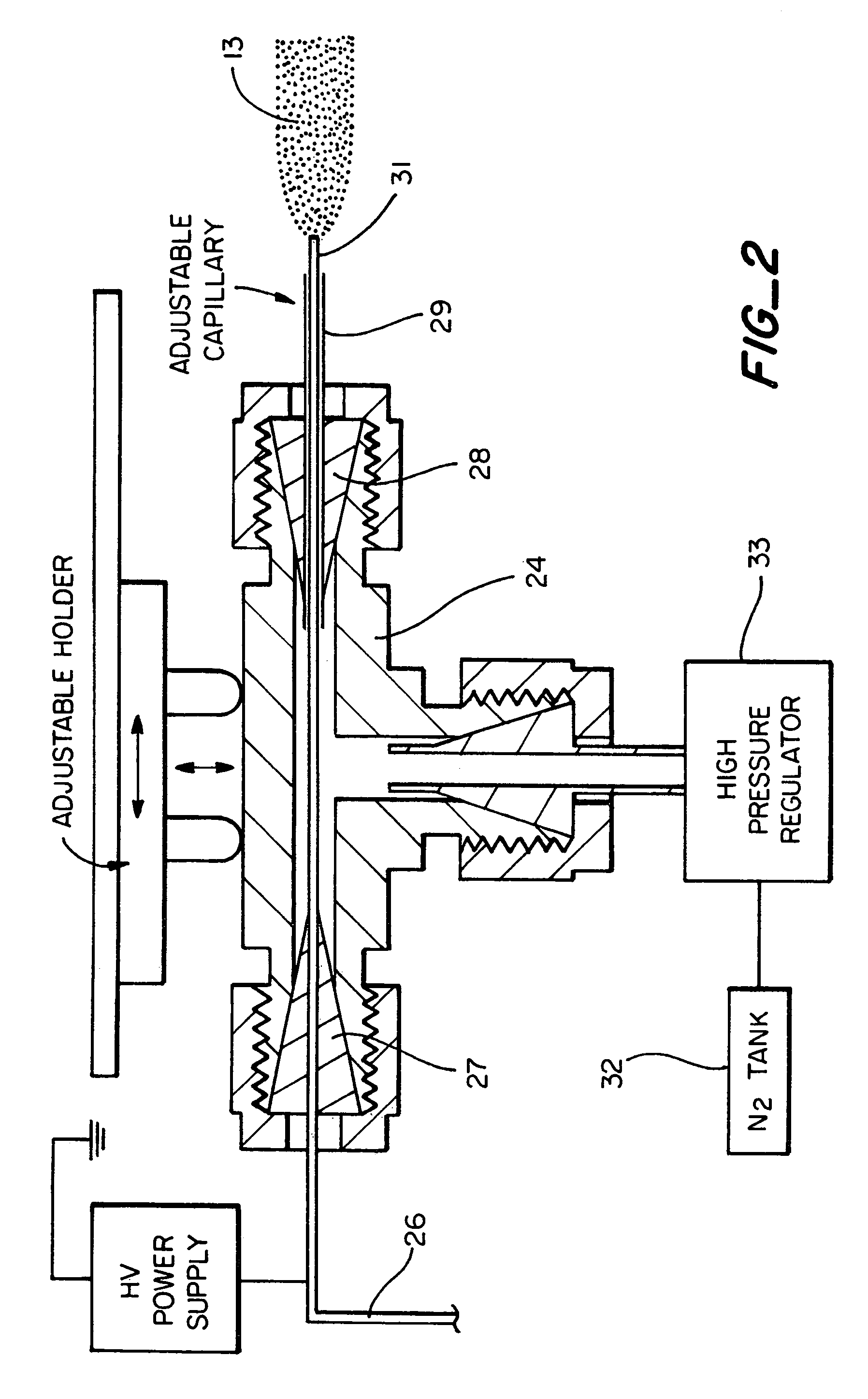

Electrosonic spray ionization method and device for the atmospheric ionization of molecules

There is described a device and method for generating gaseous ions of a sample material such as molecules in solution at atmospheric pressure. The device includes a conduit for receiving a solution containing the material to be ionized and form a stream. A jet of gas at supersonic velocity is directed at the stream and interacts therewith. Droplets are formed and by the adiabatic expansion of the gas and vigorous evaporation of the solution gaseous ions are generated. In the method a stream of the sample solution is delivered from a conduit with an electric potential. A gas jet at supersonic velocity interacts with the delivered solution and through the action of adiabatic expansion of the gas and evaporation of the solution gaseous ions are formed.

Owner:PURDUE RES FOUND INC

Aerosol processing and inhalation method and system for high dose rate aerosol drug delivery

ActiveUS7802569B2Risk minimizationIncrease dose rateRespiratorsDispersed particle separationCounter flowSolvent vapor

Owner:KAER BIOTHERAPEUTICS CORP

Apparatus and method for applying coatings onto the interior surfaces of components and related structures produced therefrom

ActiveUS20090017217A1Limited effectivenessWide rangeMolten spray coatingElectric discharge heatingEngineeringVacuum chamber

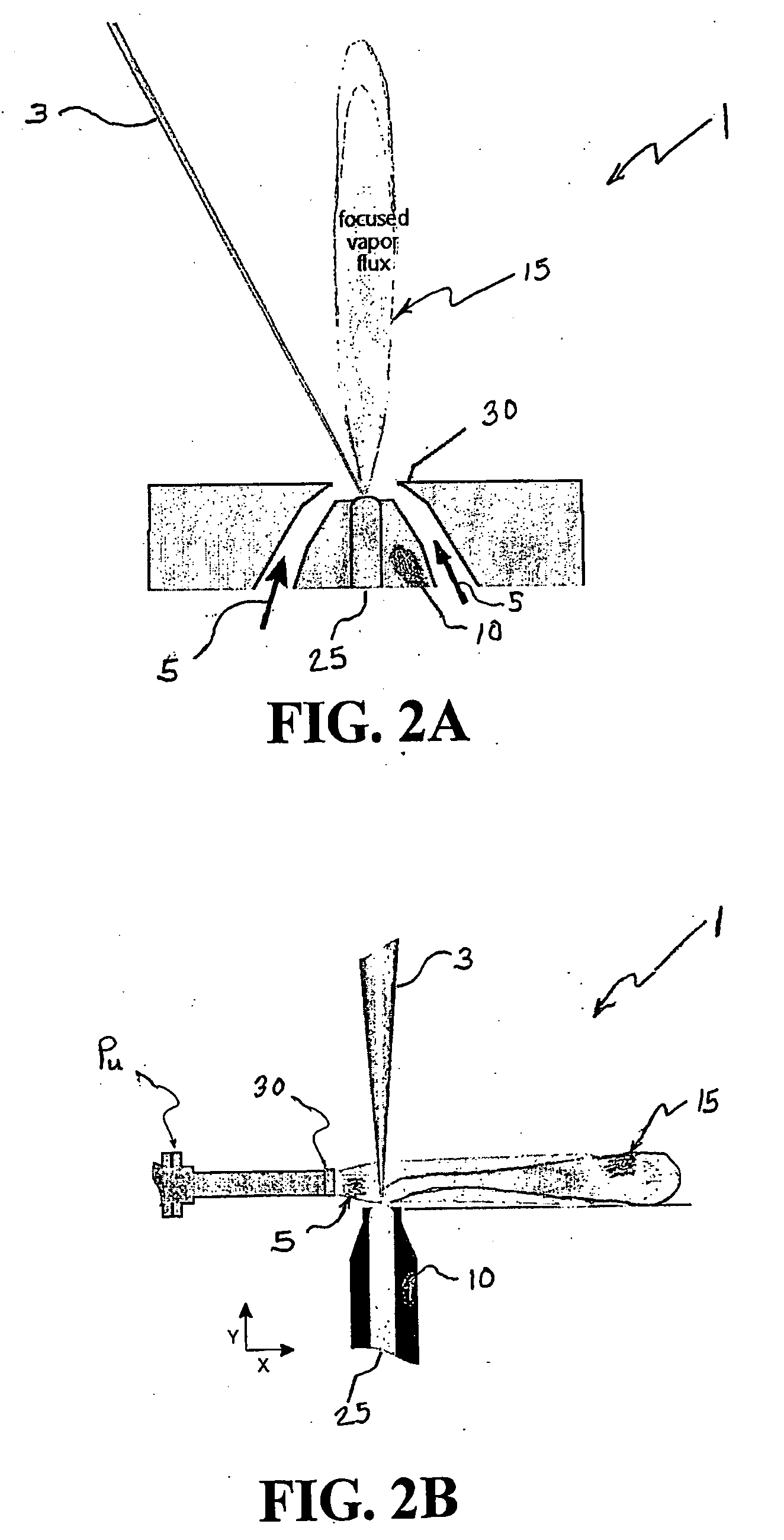

Provided is a methodology and system for applying coatings onto the interior surfaces of components. The approach comprises a vapor creation device (for example an electron beam or laser that evaporates a single or multiplicity of solid or liquid sources), a vacuum chamber having a moderate gas pressure (between about 10−4 to about 103 Torr) and a inert gas jet having controlled velocity and flow fields of gas jet. The gas jet is created by a rarefied, inert gas supersonic expansion through a nozzle. By controlling the carrier gas flow into a region upstream of the nozzle an upstream pressure is achieved (i.e. the gas pressure prior to its entrance into the processing chamber through the nozzle). The carrier gas flow and chamber pumping rate control the downstream (or chamber) pressure (i.e., downstream of the nozzle). The ratio of the upstream to downstream pressure along with the size and shape of the nozzle opening controls the speed of the gas entering the chamber. The carrier gas molecular weight (compared to that of the vapor) and the carrier gas speed controls its effectiveness in redirecting the vapor atoms via binary collisions towards the substrate. The speed and flux of the atoms entering the chamber, the nozzle parameters, and the operating chamber pressure can all vary leading to a wide range of accessible processing conditions. Vapor created from a source is transported into the interior regions of a component using binary collisions between the vapor and gas jet atoms. Under certain process conditions these collisions enable the vapor atoms to scatter onto the interior surfaces of the component and deposit.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

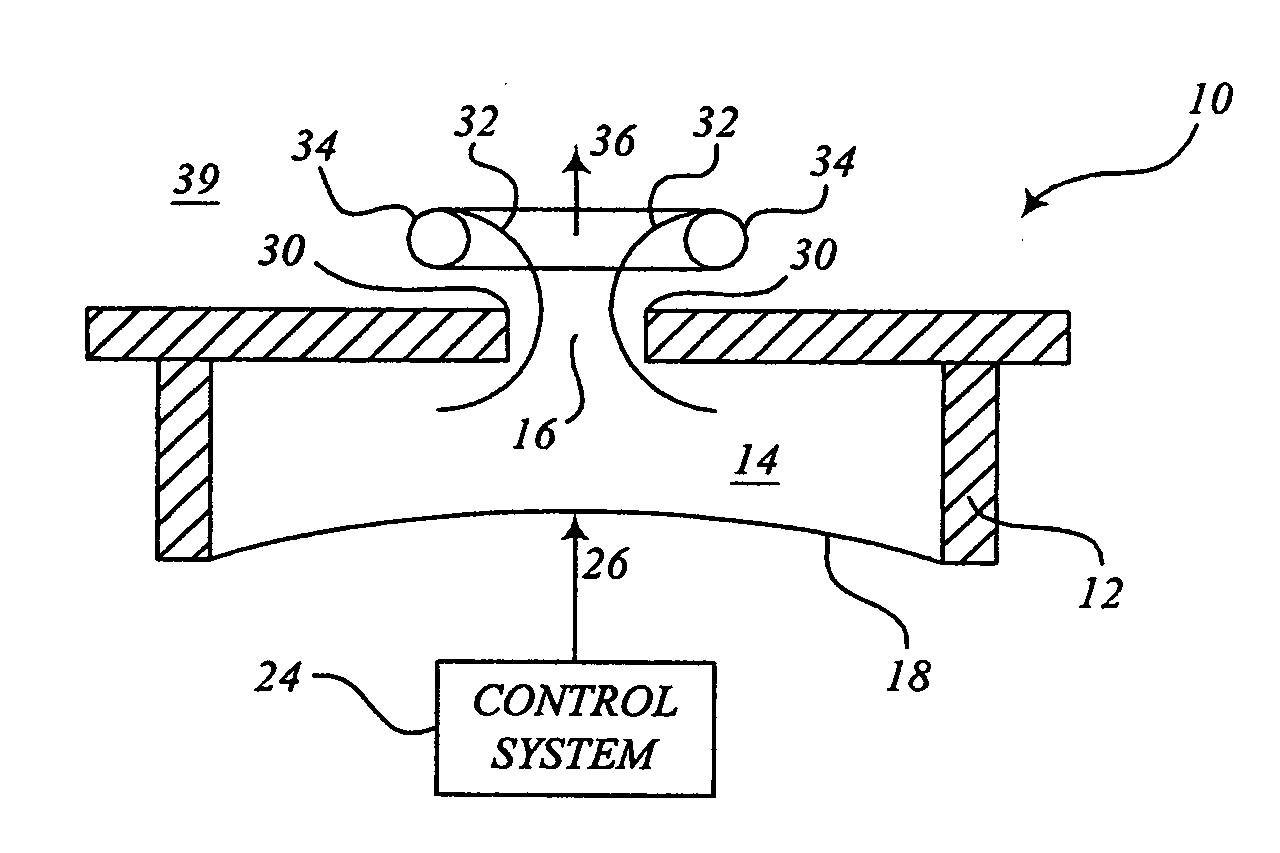

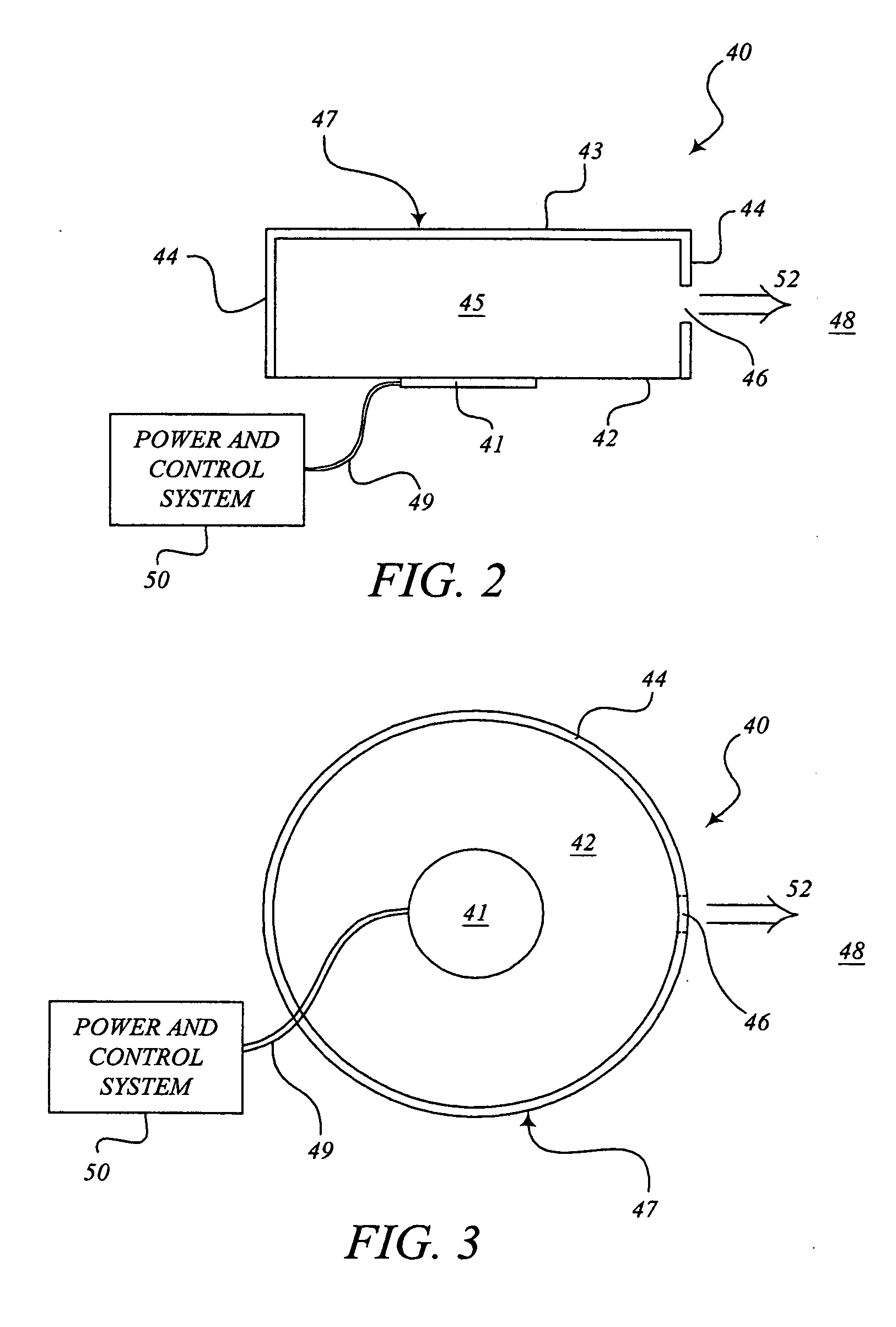

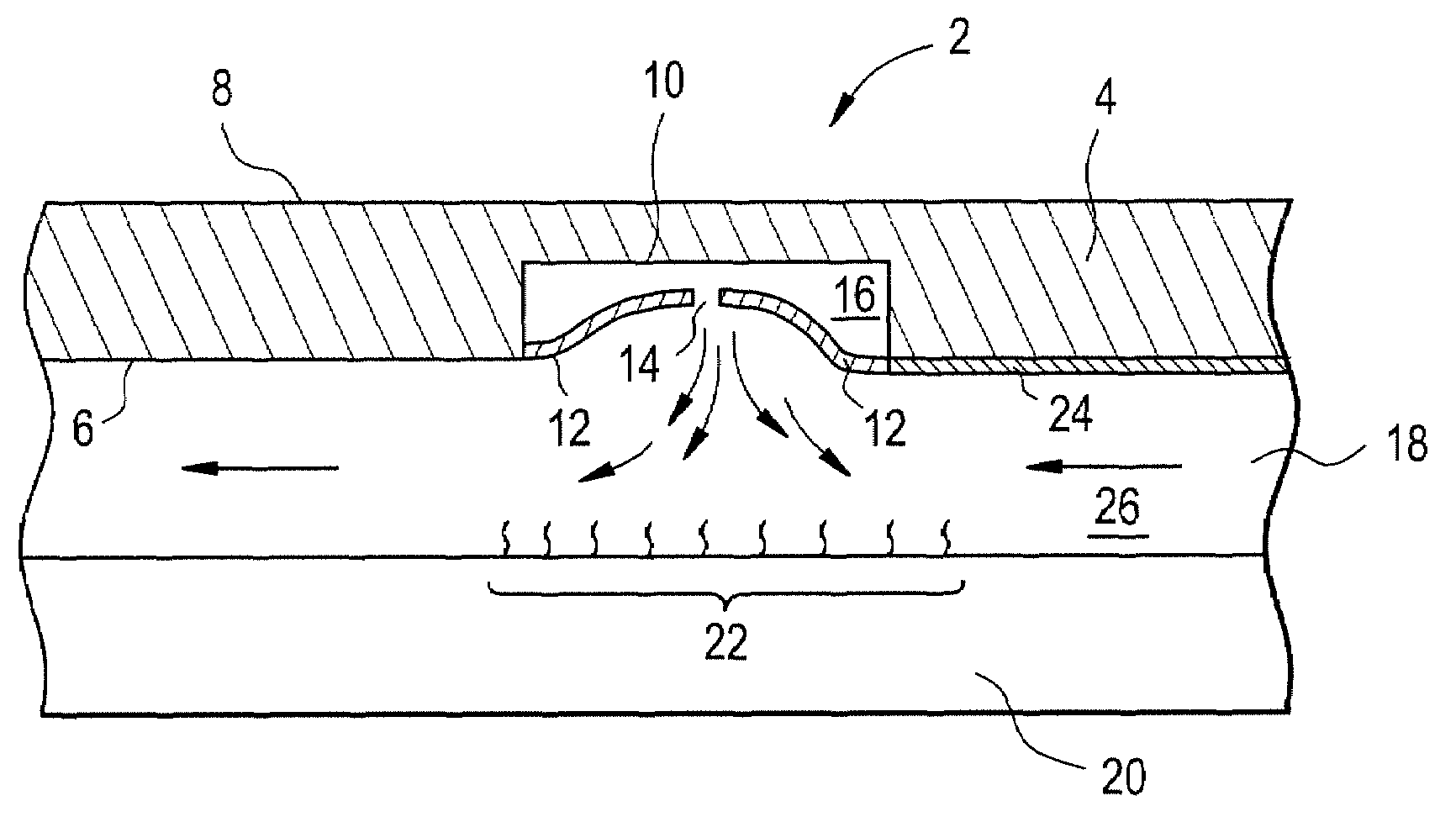

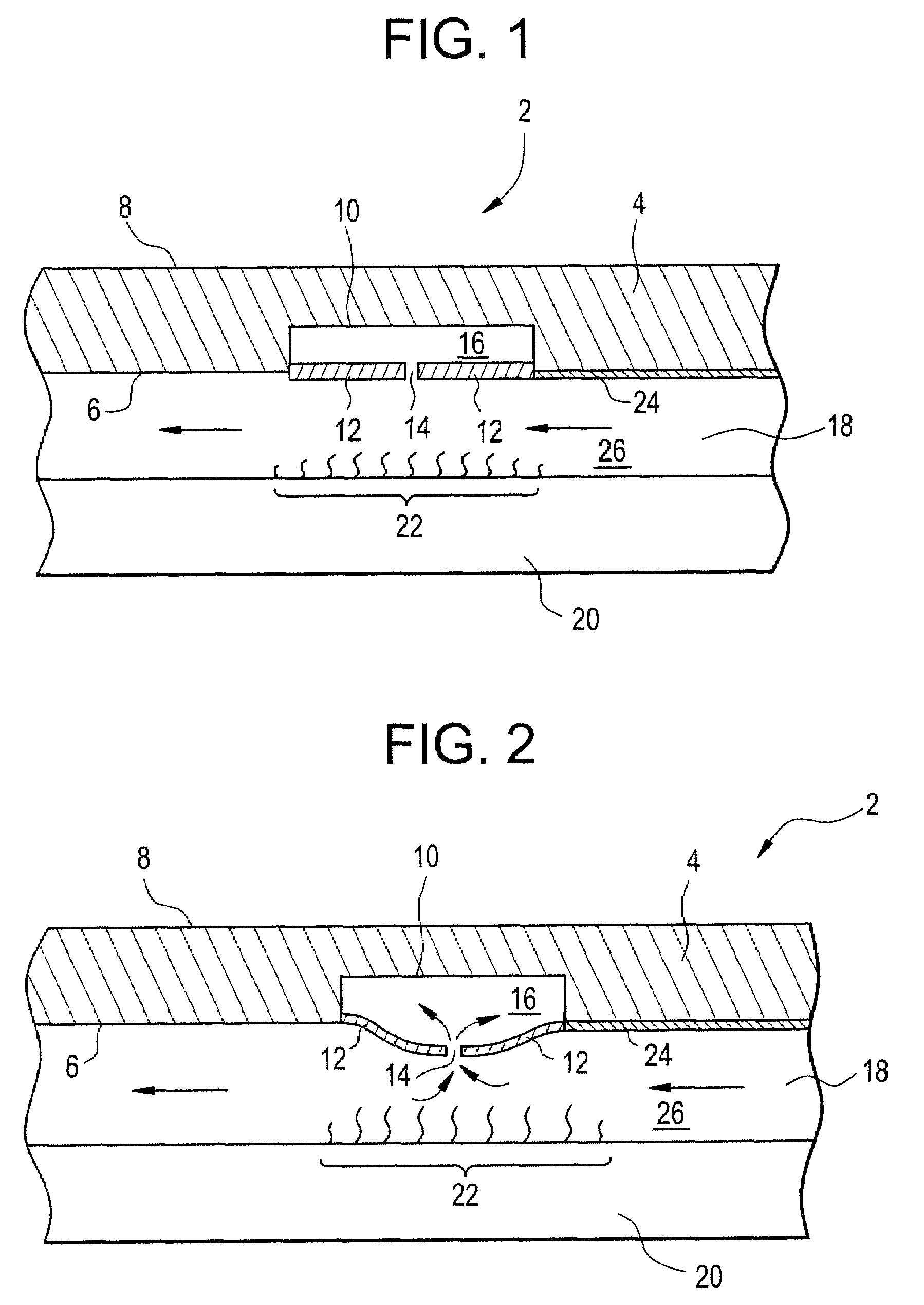

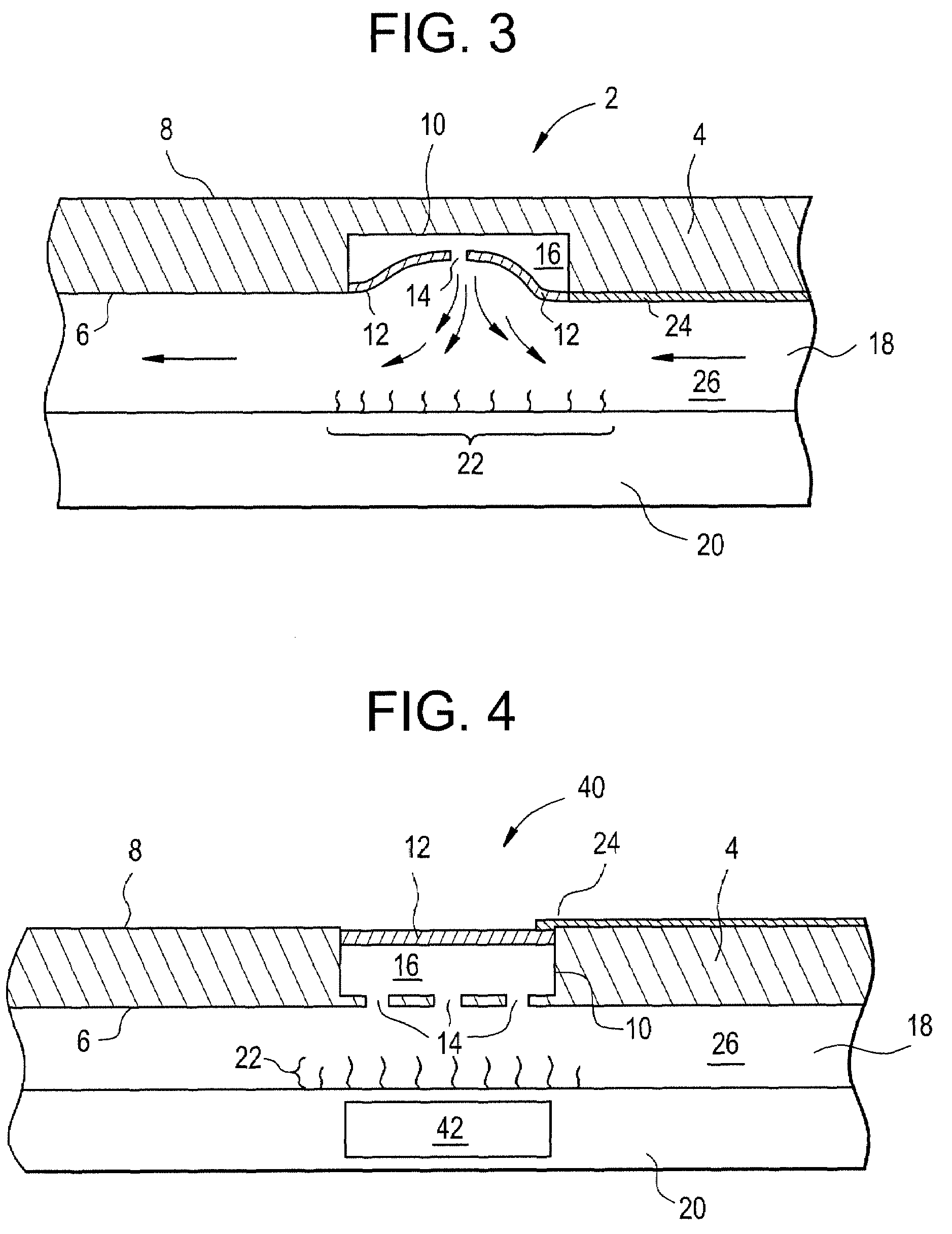

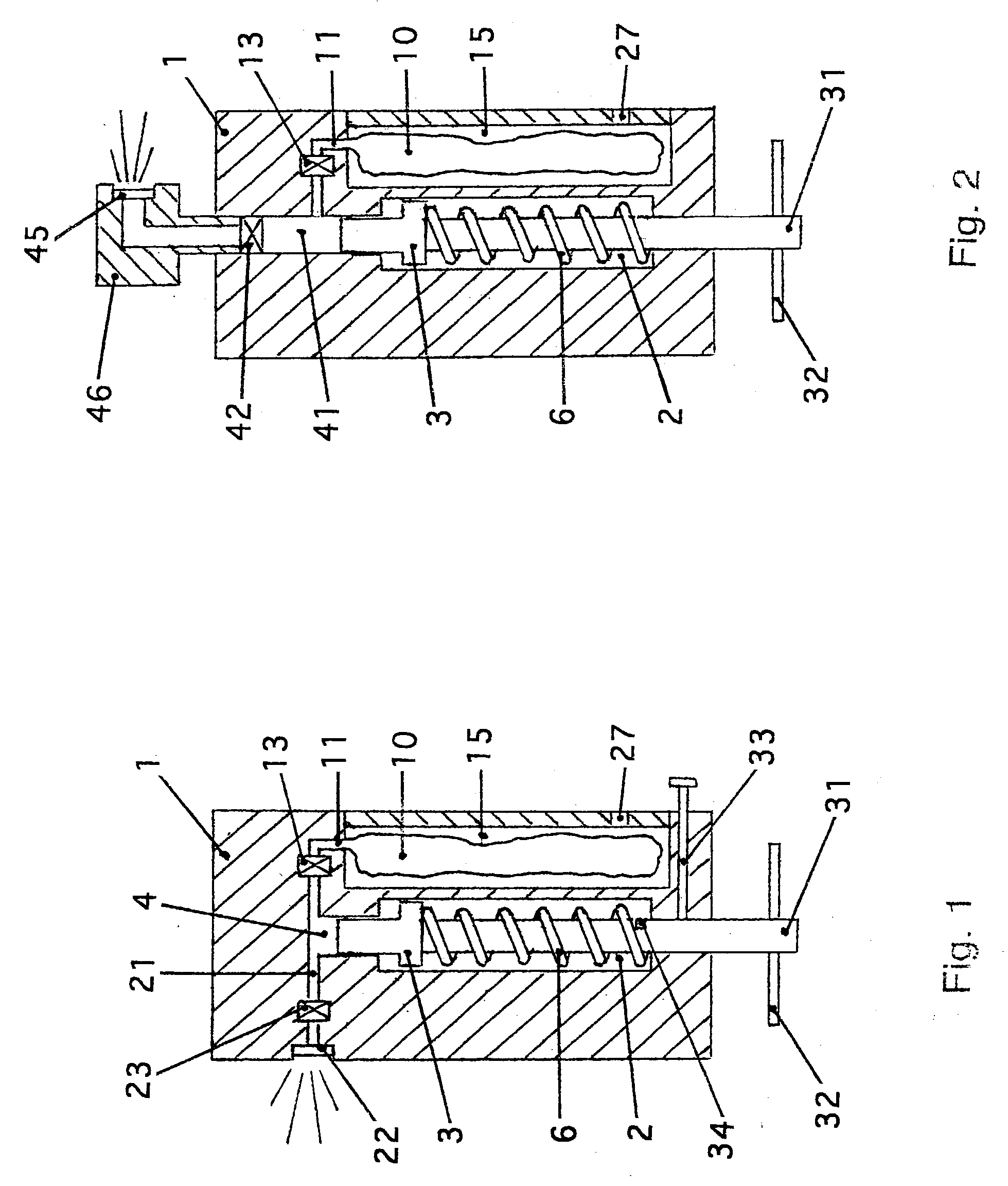

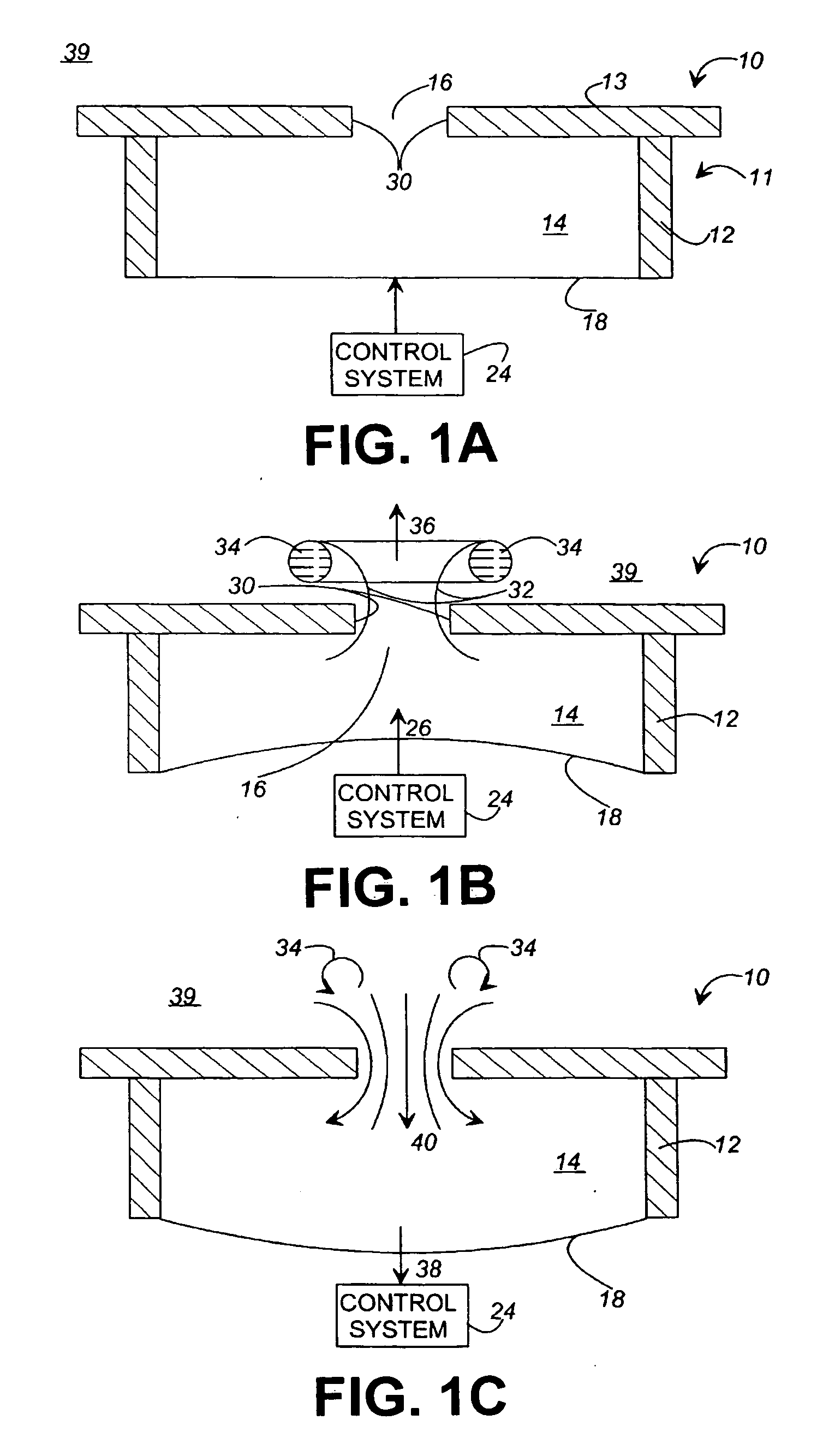

System and method for thermal management using distributed synthetic jet actuators

InactiveUS20060185822A1Digital data processing detailsSemiconductor/solid-state device detailsActuatorJet stream

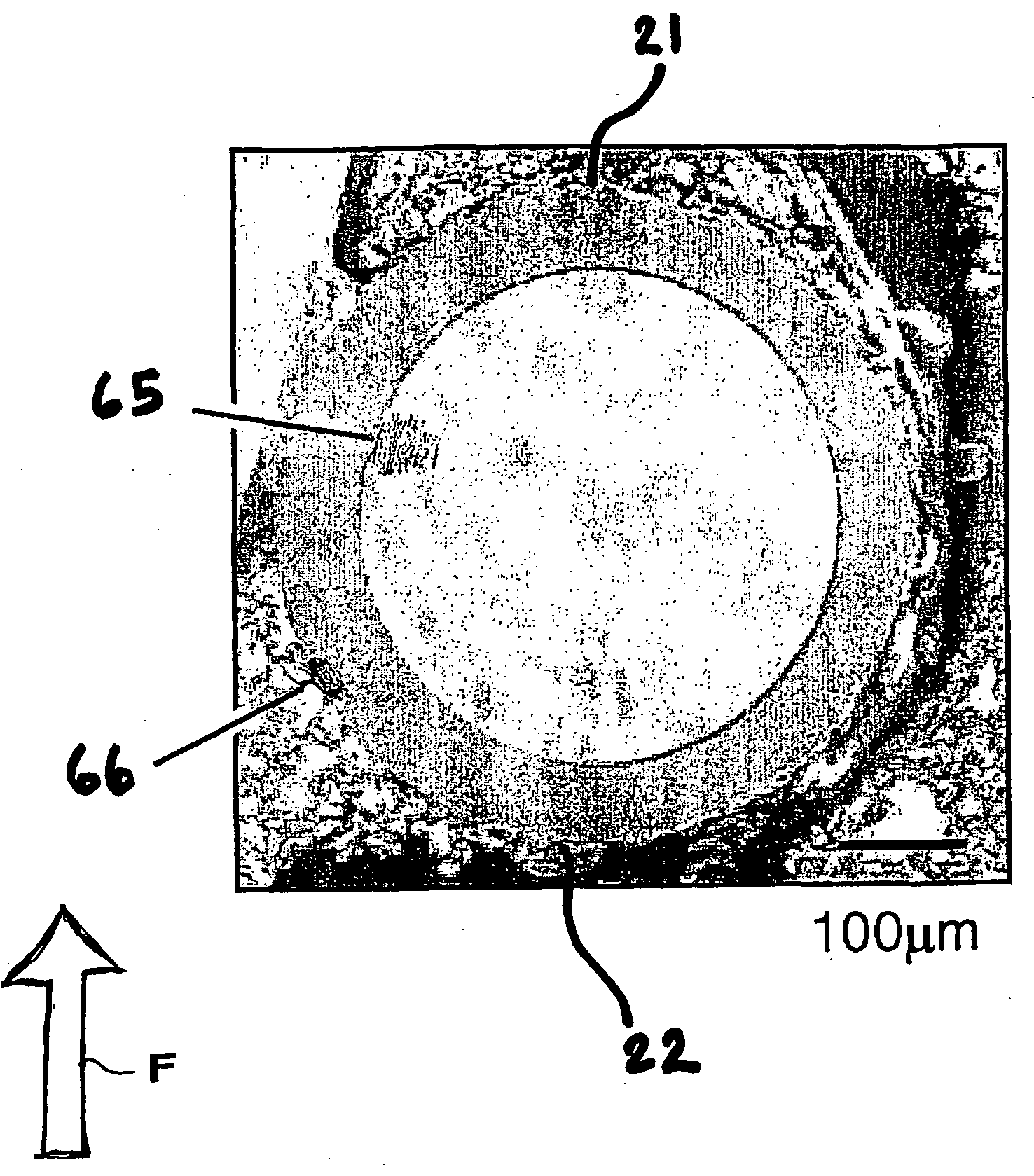

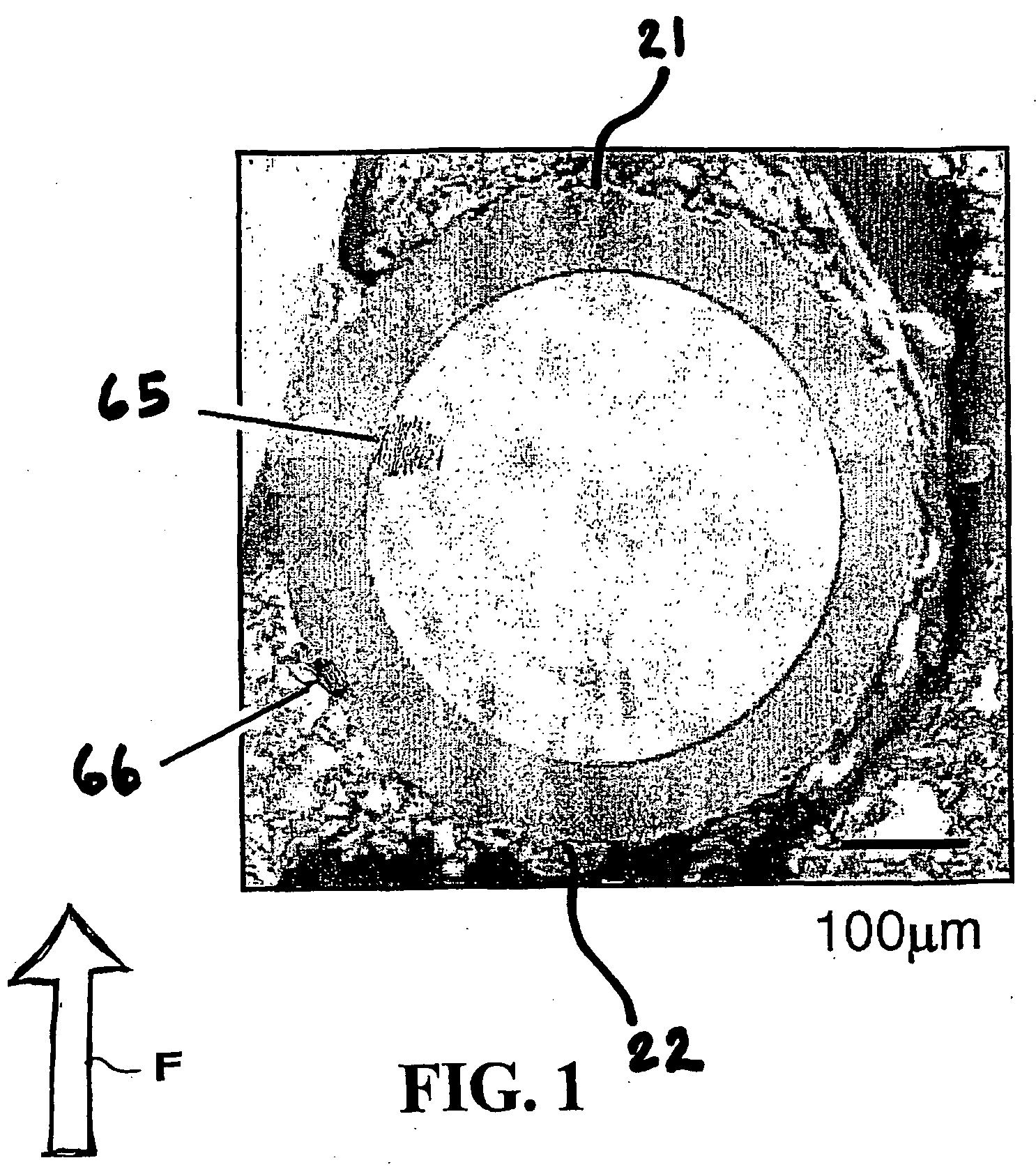

One embodiment of the device comprises a device for thermal management. More particularly, one embodiment comprises a synthetic jet actuator (60) and a tube (61). The synthetic jet actuator (60), though not required, typically comprises a housing (47) defining an internal chamber (45) and having an orifice (46) in a wall (44) of the housing (47). The synthetic jet actuator (60) typically also comprises a flexible diaphragm (42) forming a portion of the housing (47). The tube (61) of this exemplary embodiment typically comprises a proximal end (64) and a distal end (65), the proximal end (64) being positioned adjacent to the synthetic jet actuator (60). In this embodiment, operation of the synthetic jet actuator (60) causes a synthetic jet stream (52) to form at the distal end (65) of the tube (61).

Owner:GEORGIA TECH RES CORP

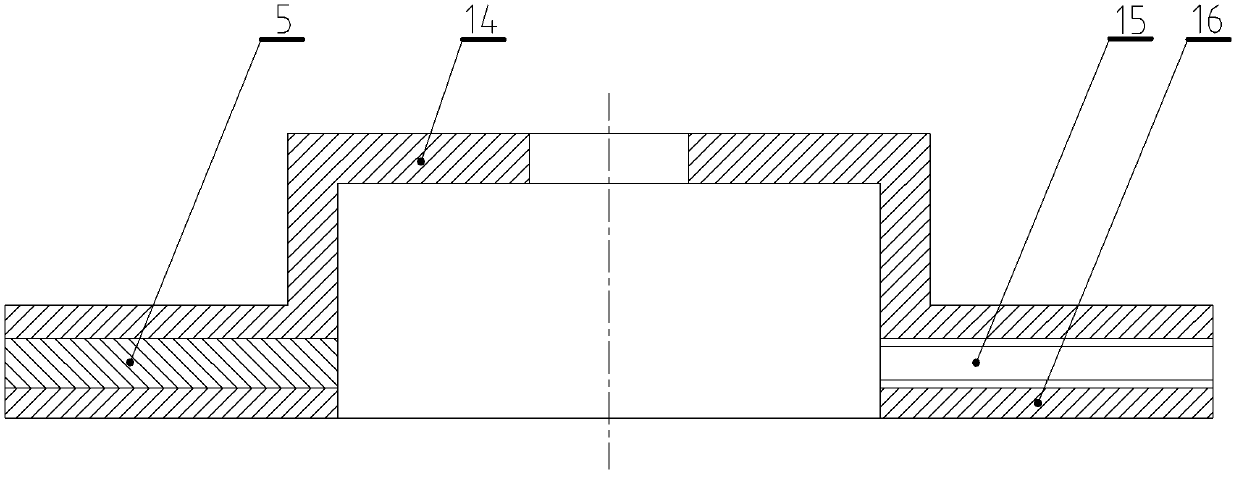

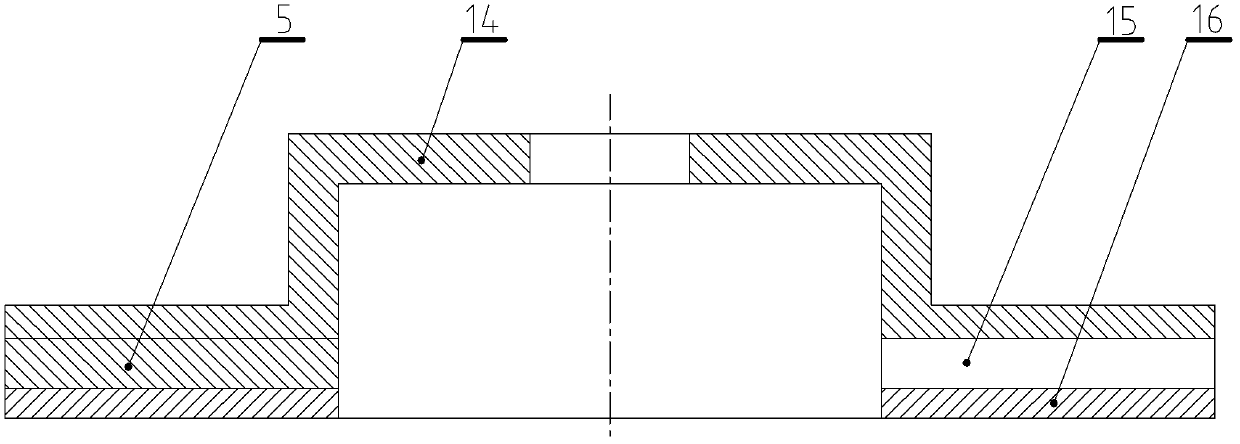

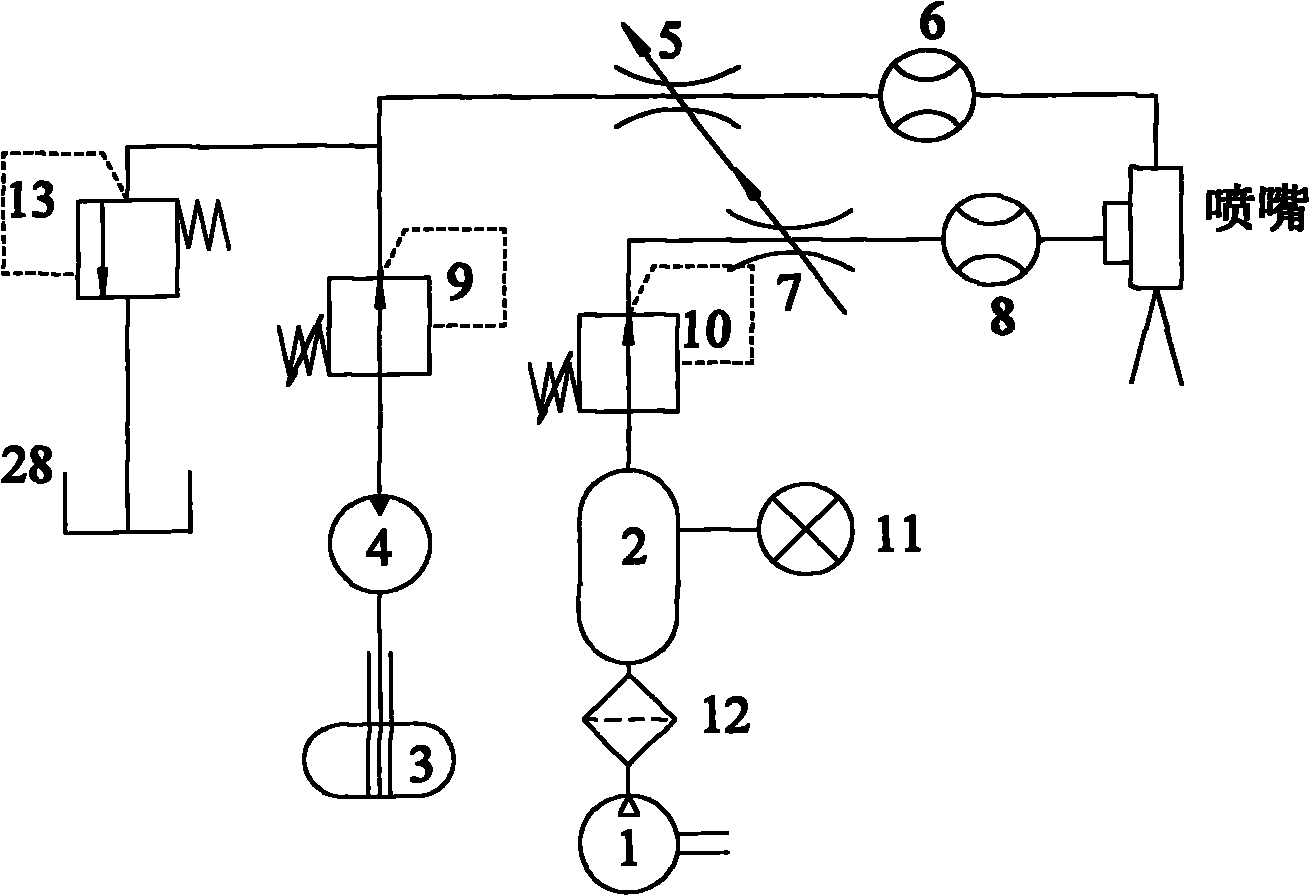

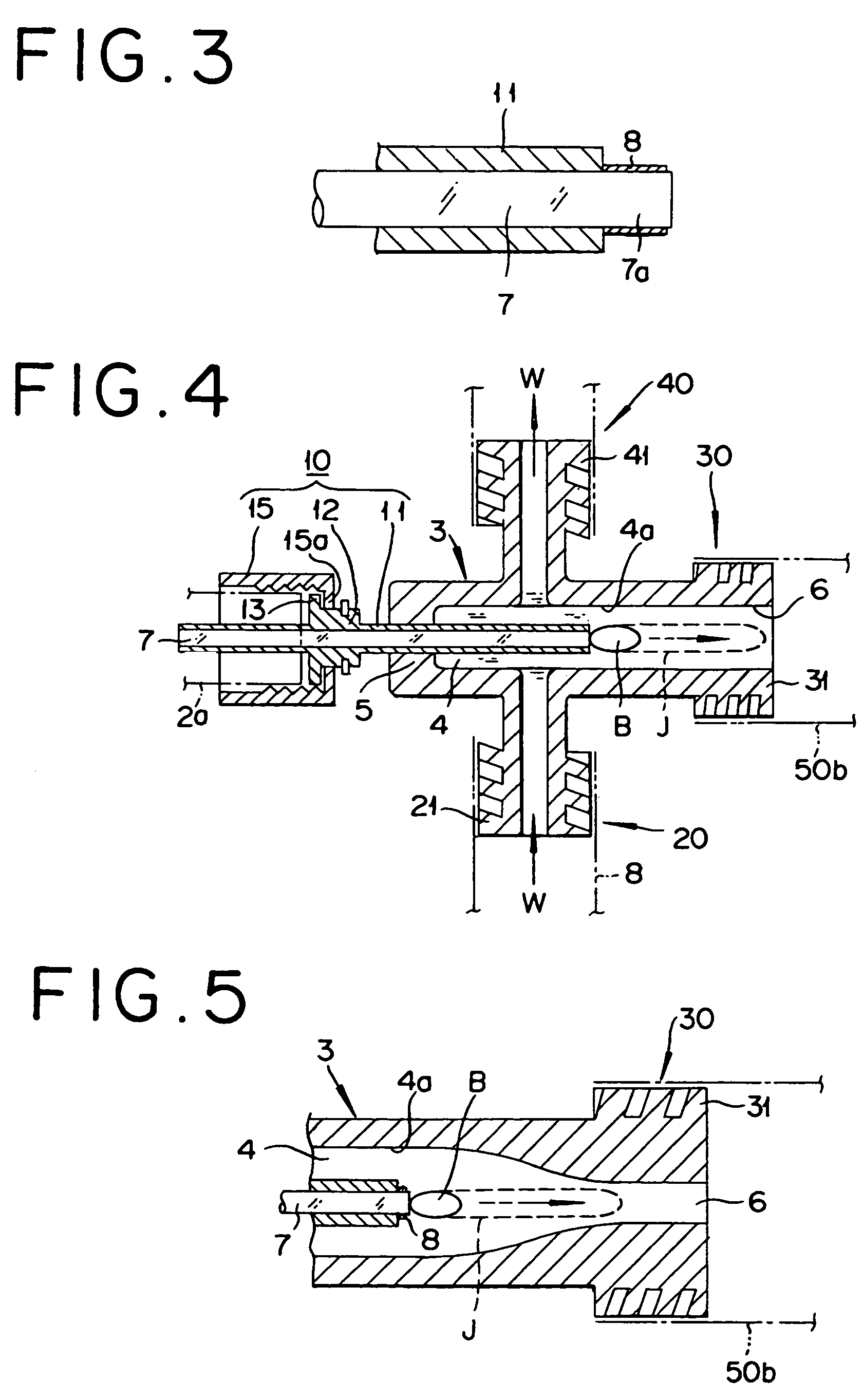

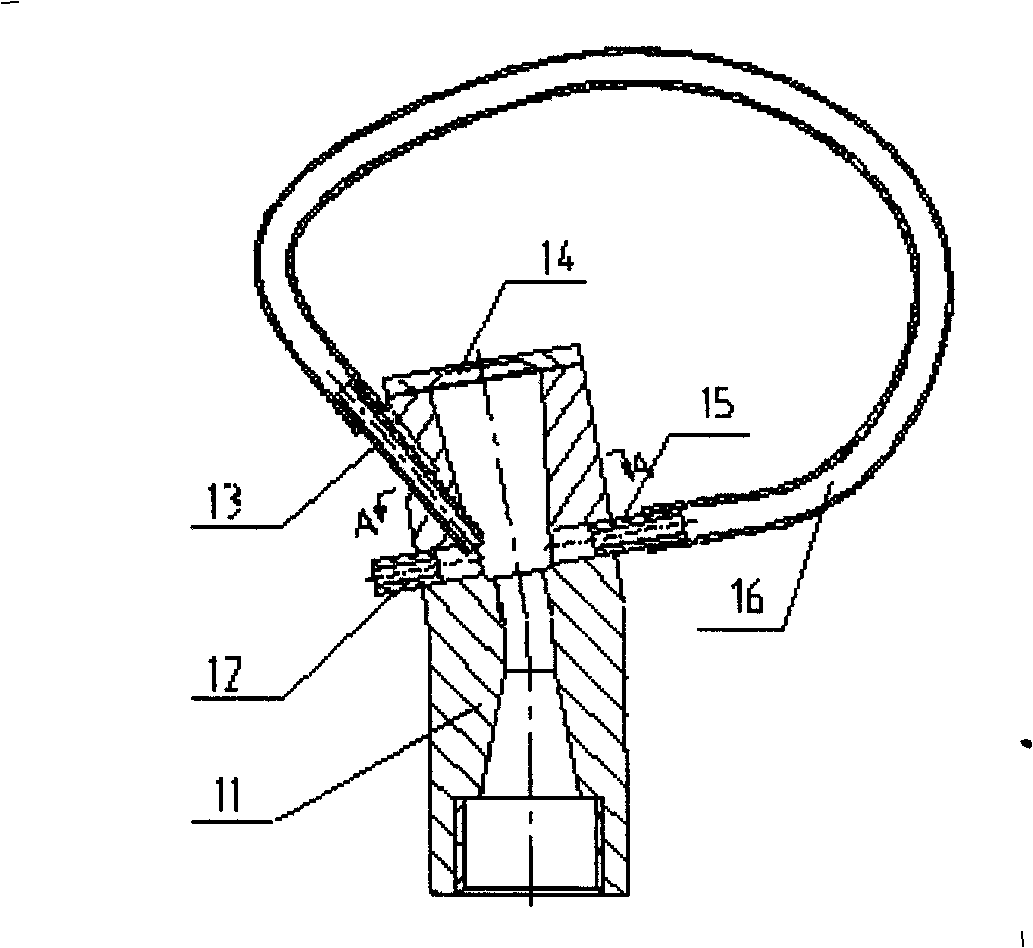

Three-phase flow supply system for nanoparticle jet micro-lubrication grinding

ActiveCN102287606AWell mixedIncrease the diameterConduits/junctionsLubrication check valvesEngineeringHigh pressure

The invention relates to the field of machining, in particular to a nano particle jet flow micro-scale lubricating and grinding three-phase flow supply system. The system is characterized in that: nano fluid is conveyed to a nozzle by a liquid path, high temperature gas enters the nozzle through a gas path at the same time, the high pressure gas and the nano fluid are fully mixed and atomized in the mixing room of the nozzle, the mixed high pressure gas and nano fluid are accelerated in an acceleration room and enter a vortex room, compressed gas enters from the vent hole of the vortex room, and a three-phase flow is further mixed and accelerated by rotating, and is jetted in the form of atomized liquid drops to a grinding area through the outlet of the nozzle. The system has the advantages that: the helical vent hole of the mixing room of the nozzle is tangent to the wall surface of the mixing room, and the nano fluid and the gas are uniformly mixed; pressure adjusting valves, throttles and flow meters are arranged in the gas path and the liquid path, and the pressure and the flow of the nano fluid and the high pressure gas can be adjusted as required so as to achieve an optimal micro-scale lubricating effect; and the problems of insufficient cooling capability in micro-scale lubricating, the large using quantity of a lubricant in pouring type grinding, high waste liquid processing cost and heavy environment pollution are solved.

Owner:青岛前瞻产业园区运营管理有限公司

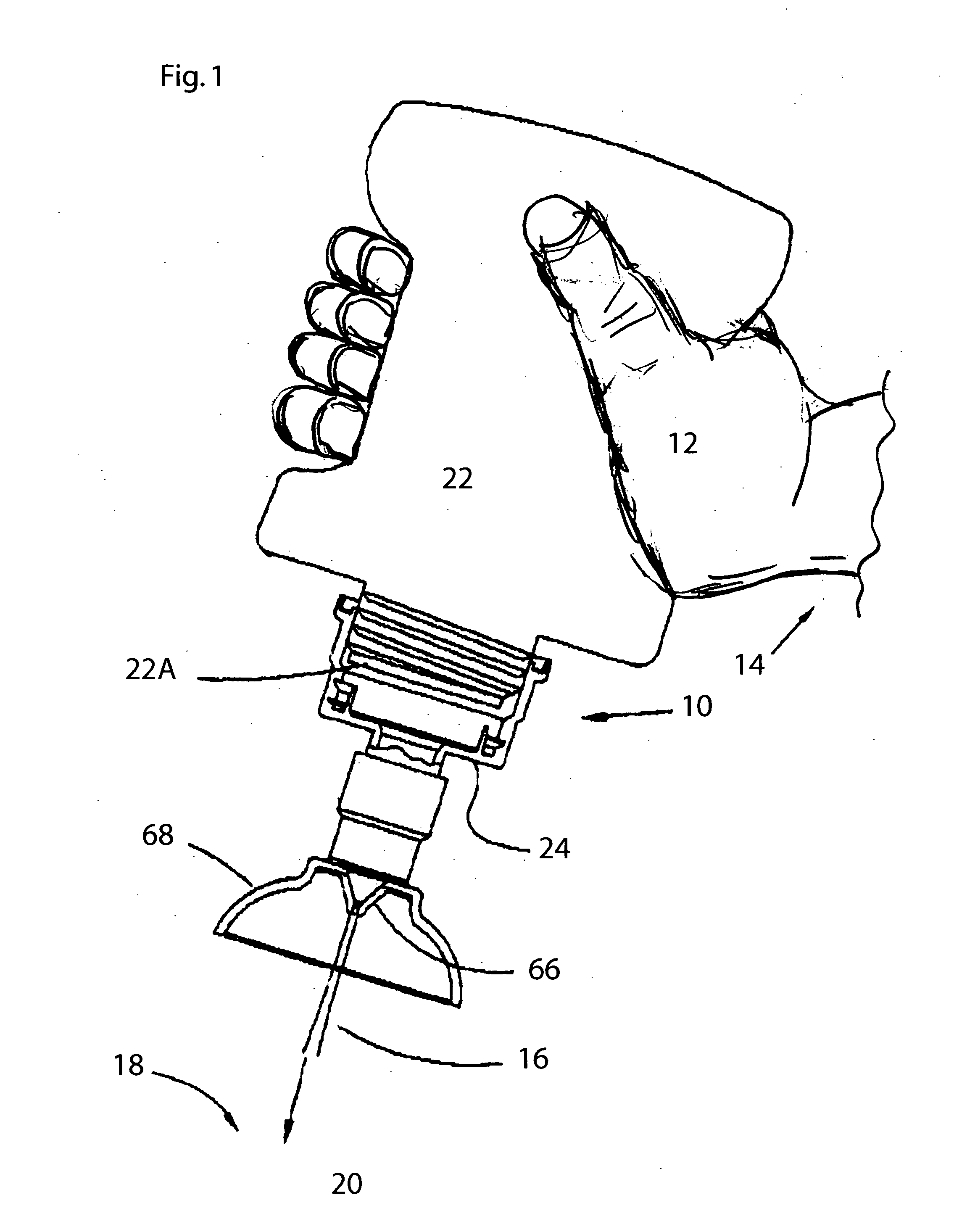

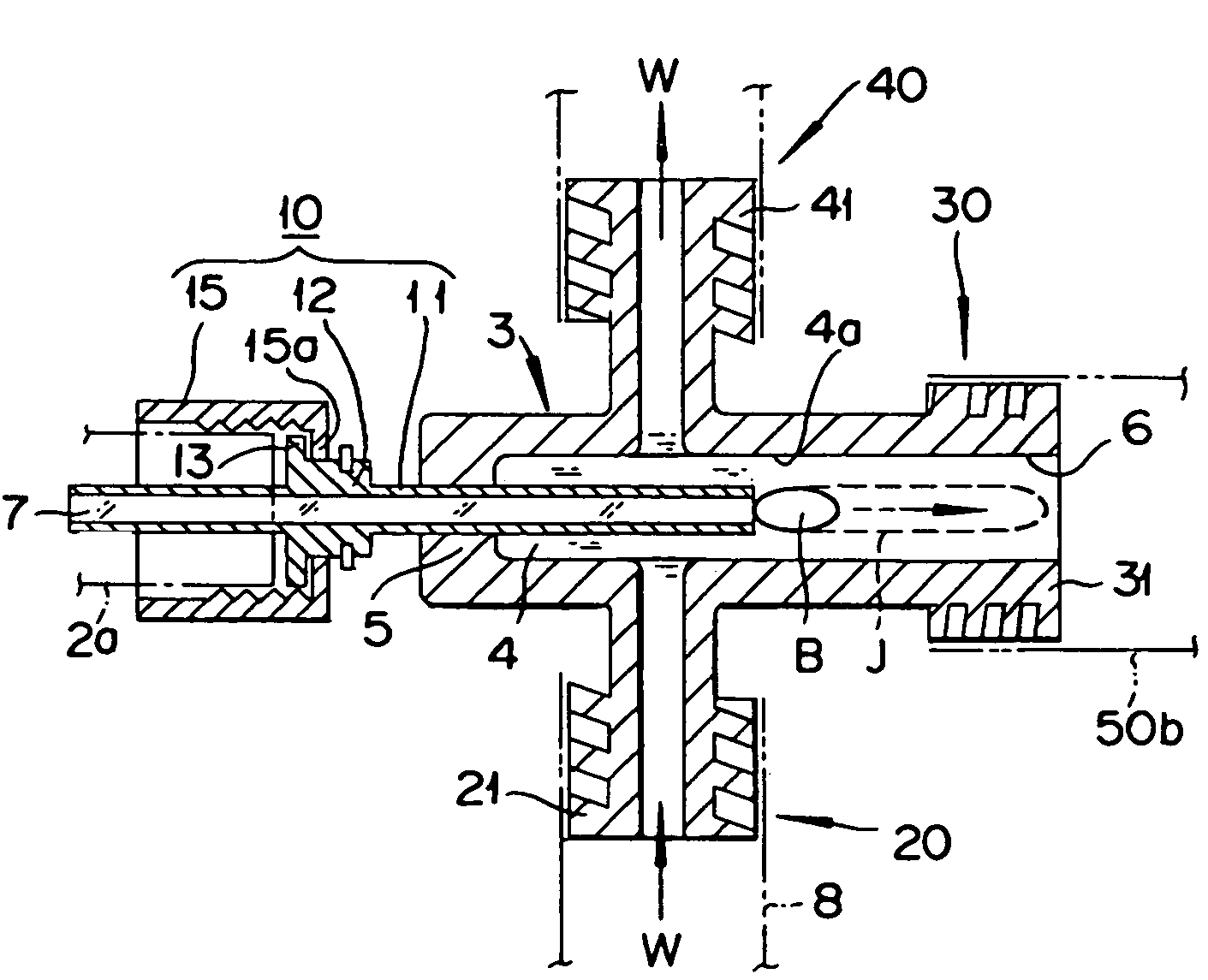

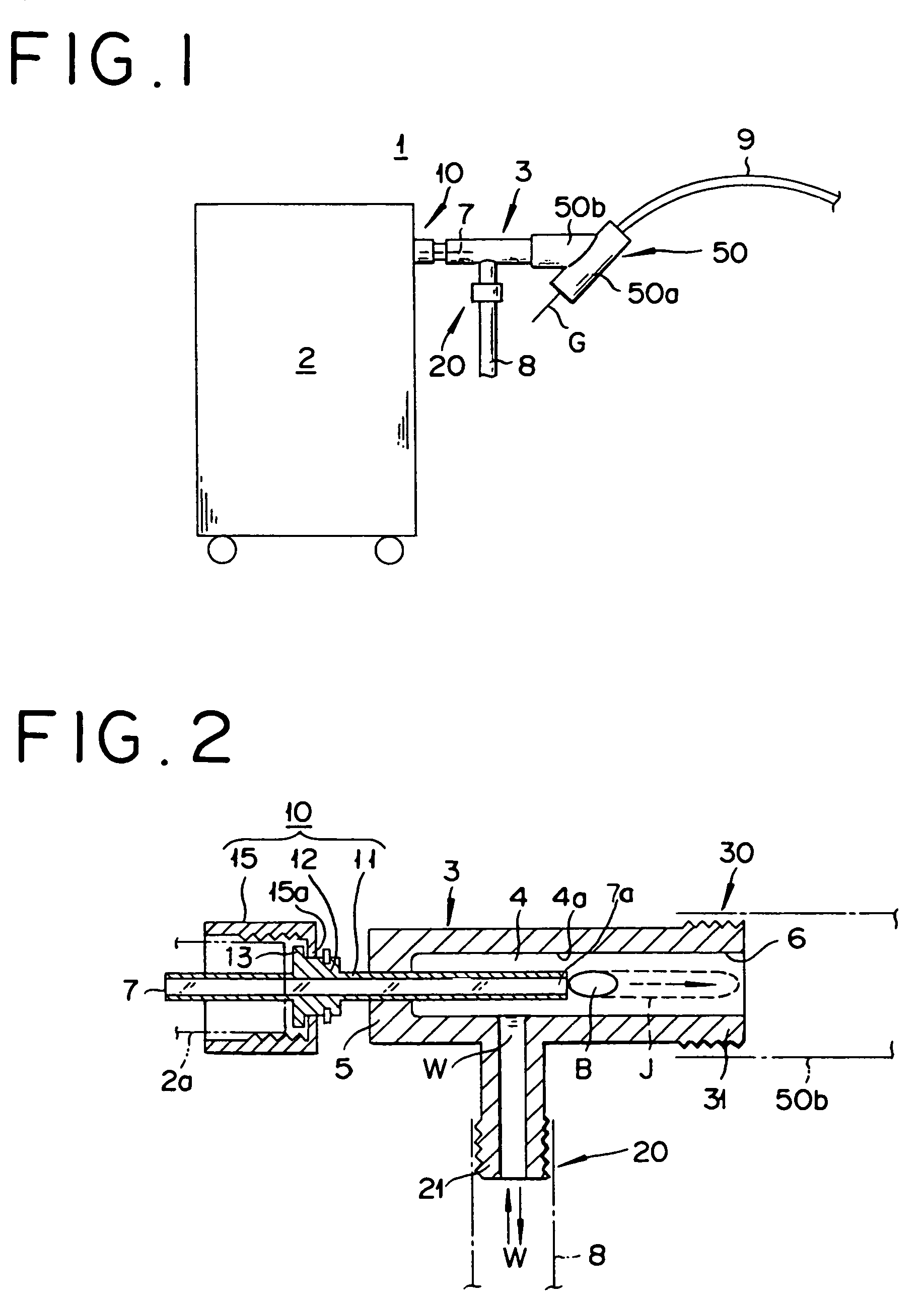

Needleless hypodermic jet injector apparatus and method

InactiveUS7347851B1Less painful experienceLess discomfortJet injection syringesAutomatic syringesLiquid jetJet flow

In the present invention, the impedance between patient's body and the jet injection drug delivery device is measured through the liquid jet during the drug delivery process. The liquid jet completes the electrical circuit formed by impedance monitor, drug delivery device, and the patient's body. When the jet pierces stratum corneum, the impedance in the circuit immediately decreases, thus an indicating the successful drug delivery. The impedance monitor then provides a signal, visible, audible, or electronic, indicating that the process of the drug delivery through skin was successful.

Owner:KRIKSUNOV LEO B

Cooling Systems Employing Fluidic Jets, Methods for Their Use and Methods for Cooling

ActiveUS20080041574A1Component can be removedEasy to understandTemperatue controlSemiconductor/solid-state device detailsThermal energyJet flow

In one embodiment, a cooling system is disclosed. The cooling system comprises: a cooling channel for receiving a cooling media, a substrate disposed near the cooling channel, and a fluidic jet disposed within the substrate and in fluid communication with the cooling channel. The cooling channel is for thermal communication with a component to be cooled. The cooling channel has a height of less than or equal to about 3 mm and a width of less than or equal to 2 mm. The fluidic jet comprises a cavity defined by a well and a membrane. In one embodiment, a method of cooling an electrical component comprises: passing a cooling media through a cooling channel, drawing the cooling media into one or more of the fluidic jets, expelling the cooling media from the one or more fluidic jets into the cooling channel, and removing thermal energy from the electrical component.

Owner:GENERAL ELECTRIC CO

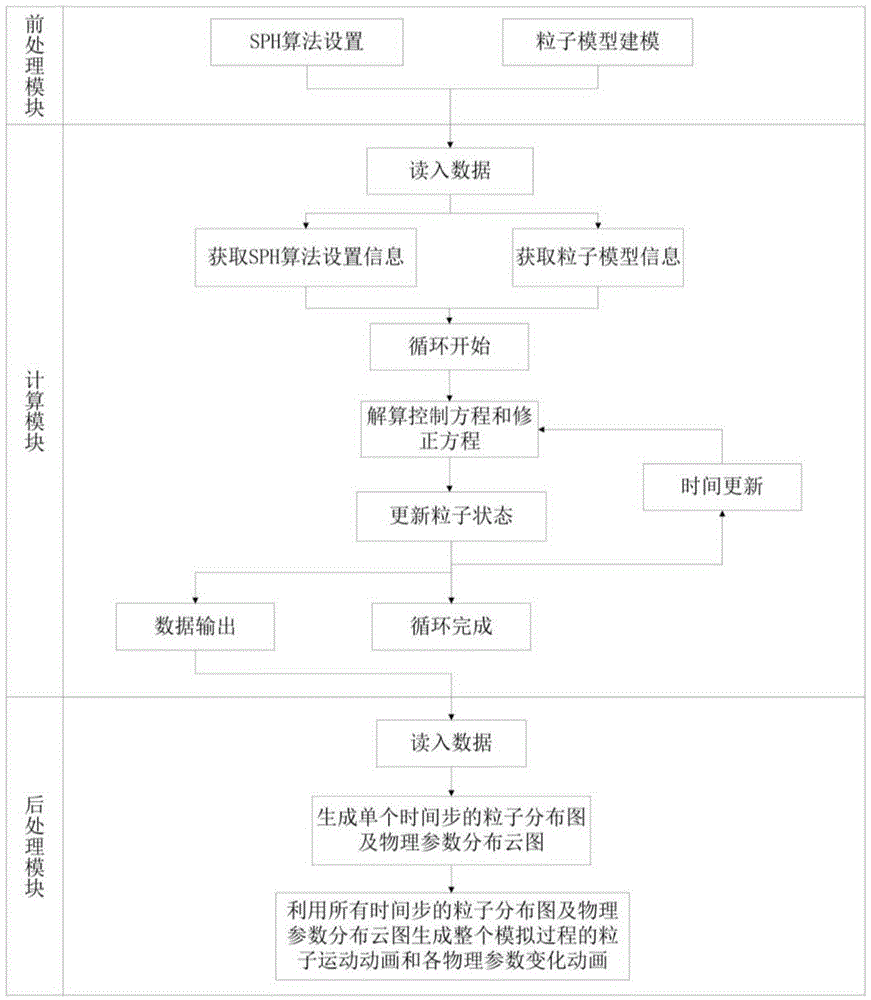

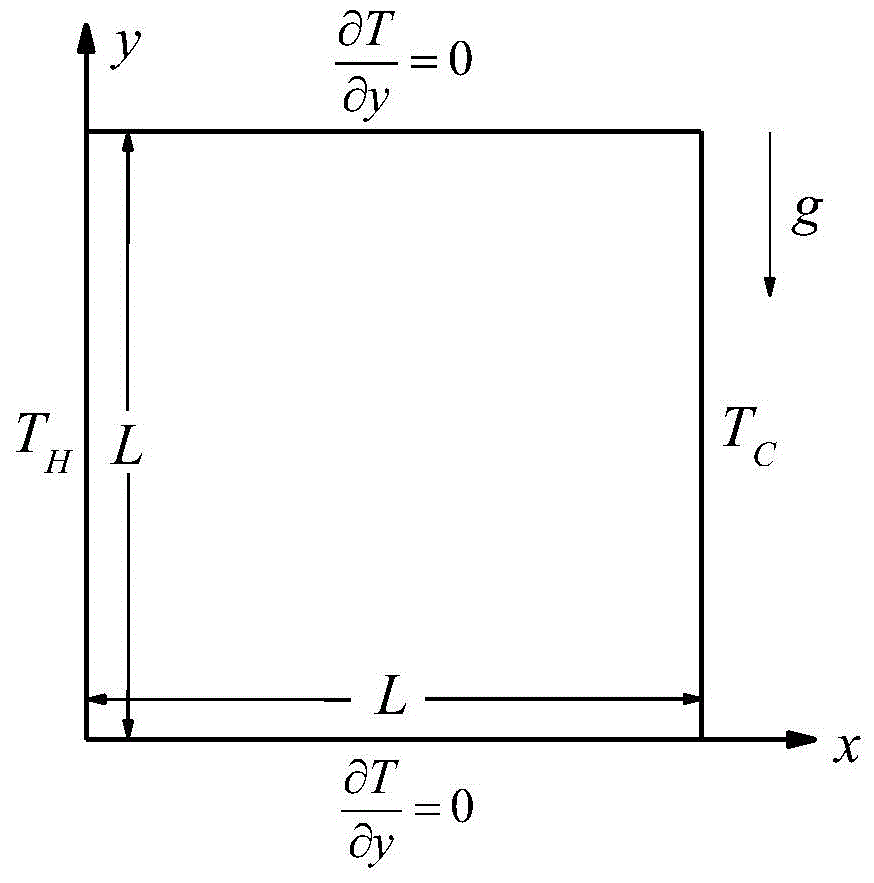

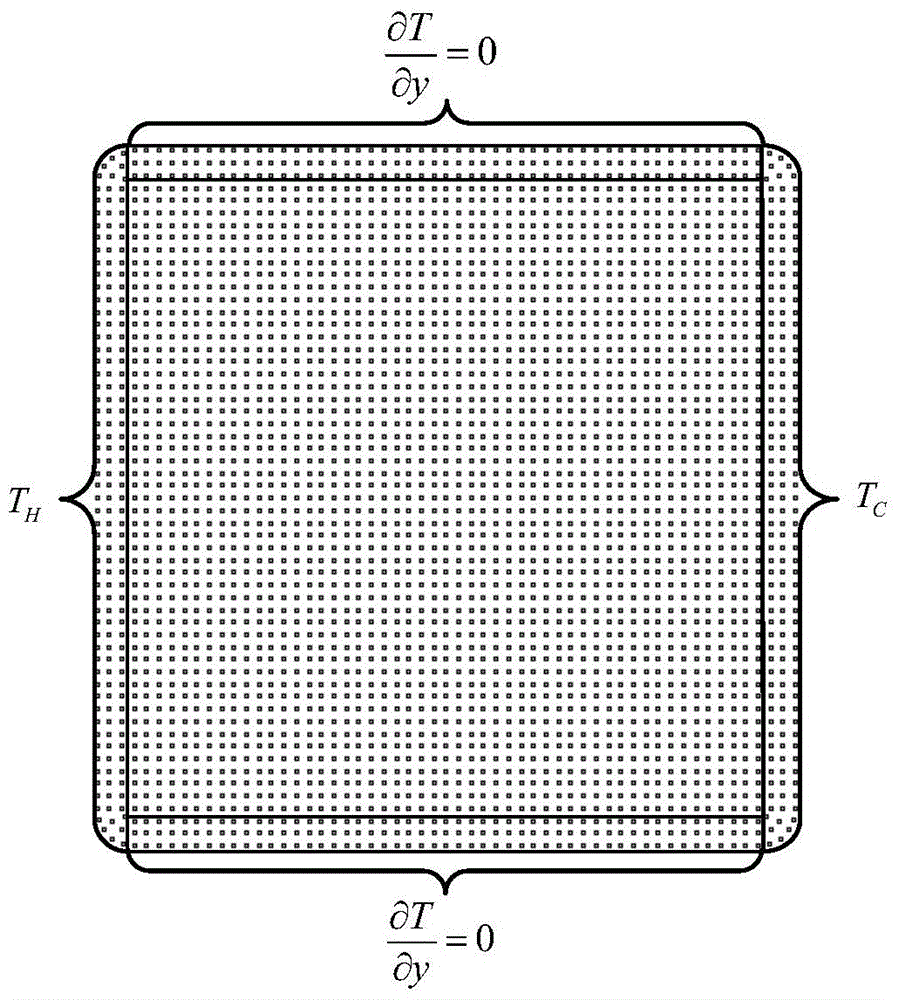

Fluid thermal motion simulation system based on SPH algorithm

InactiveCN104143027AImprove stabilityImprove calculation accuracySpecial data processing applicationsThermodynamic simulationGraphics

The invention relates to a fluid thermal motion simulation system based on the SPH algorithm and belongs to the field of thermodynamics simulation and visual flowing. The method comprises the steps of conducting modeling on fluid according to calculation examples and calculation requirements, solving a fluid control equation and a modified equation based on the SPH algorithm to achieve analogue simulation of fluid Lagrange thermal motion, and finally showing the thermal motion process of fluid visually in the form of graphs and animations by means of the visual processing technology. Compared with an existing meshing CFD simulation system, the fluid thermal motion simulation system has the advantage that a more reasonable simulation result can be obtained when the system is used for simulating certain advanced non-linear problems such as the jet flow problem, the ocean motion problem, the dam break problem and the dynamic boundary problem. Compared with an existing mesh-free CFD simulation system, the fluid thermal motion simulation system has the advantages that calculation stability and calculation accuracy are improved, and the gap of fluid thermal motion simulation and turbulent flow simulation is filled.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Wound irrigation apparatus and method

InactiveUS20050124946A1Efficient removalProtect the woundEnemata/irrigatorsSuction devicesJet flowEngineering

A dispenser cap for combination with a standard flexible irrigation solution bottle to make a portable wound irrigation dispenser includes a collar threadably engageable with the irrigation bottle, and closed at one end by a wall defining a tubular neck. The tubular neck forms a flow path from the bottle to a splash shield including a nozzle for directing irrigation solution. A valve is disposed in the flow path for opening and closing this flow path. A combination apparatus includes the flexible irrigation solution bottle, which may be inverted and squeezed in order to direct a jet of cleansing liquid into a wound. A single use version of the apparatus includes a valve which is closed in a storage and shipping configuration of the apparatus, and an indicator which is freed within the transparent or translucent flexible bottle when the valve is opened, thus irreversibly indicating that the apparatus has been used. An alternative embodiment of the apparatus includes a safety valve which also prevents misuse of the apparatus without the splash shield installed.

Owner:LANDAU SERGIO +1

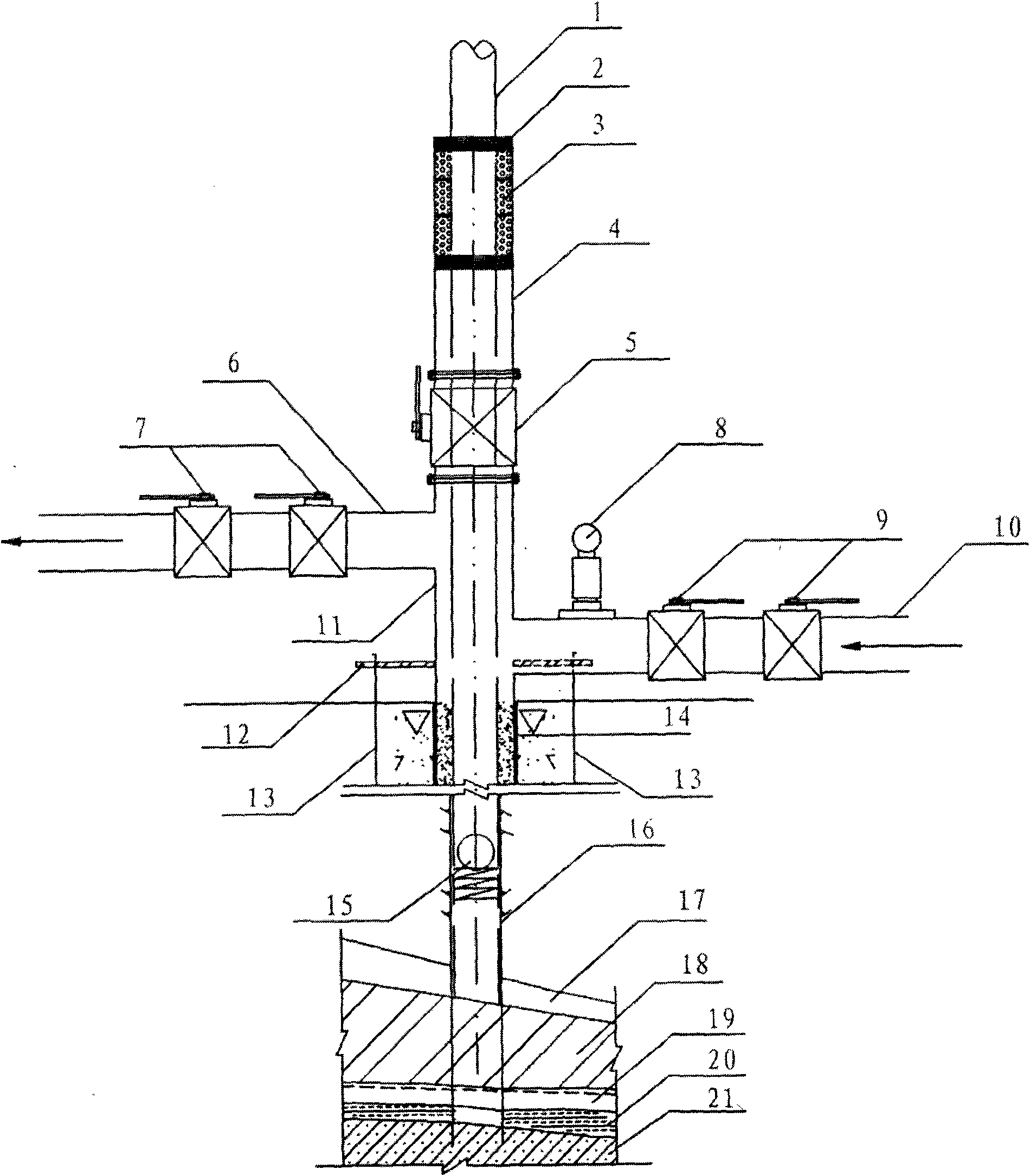

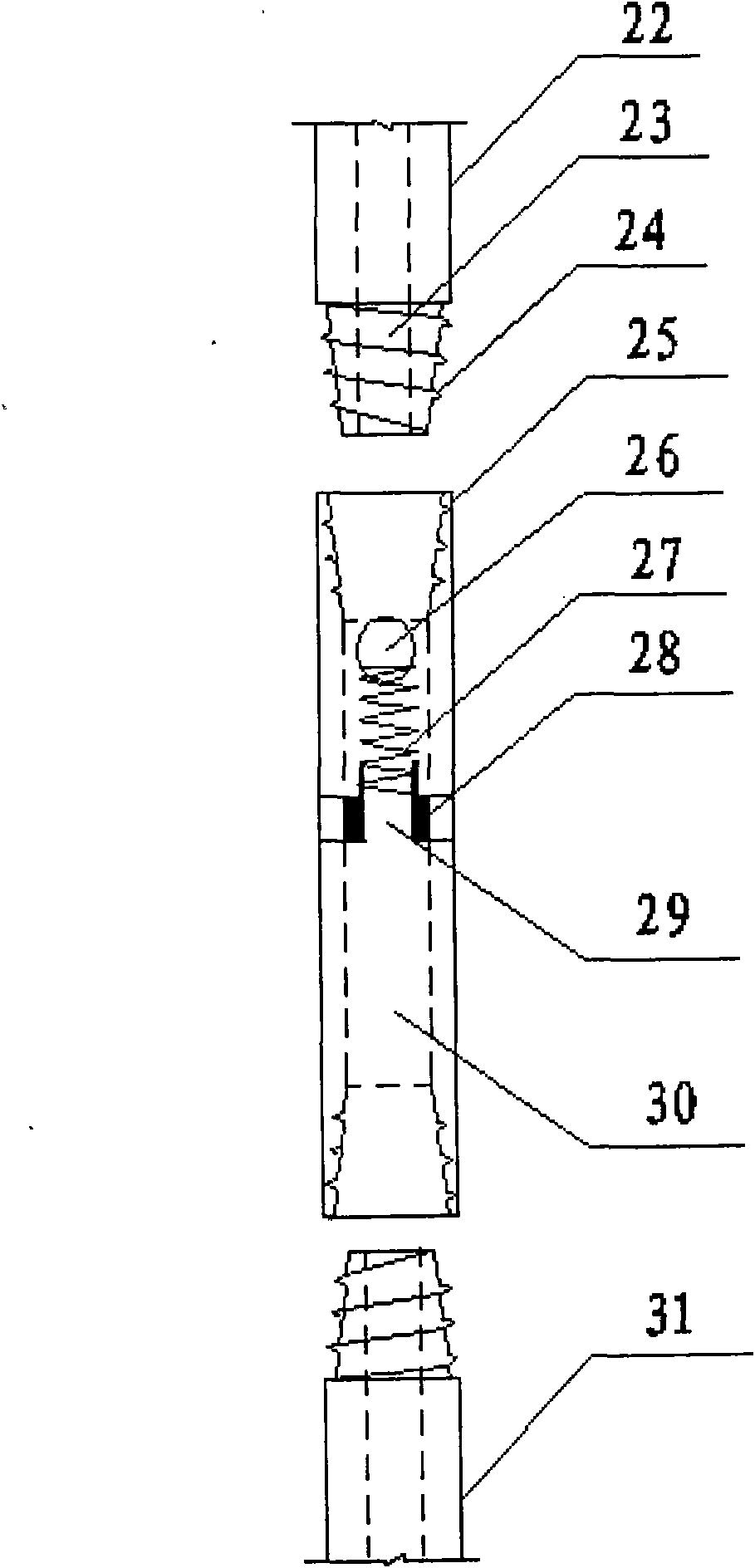

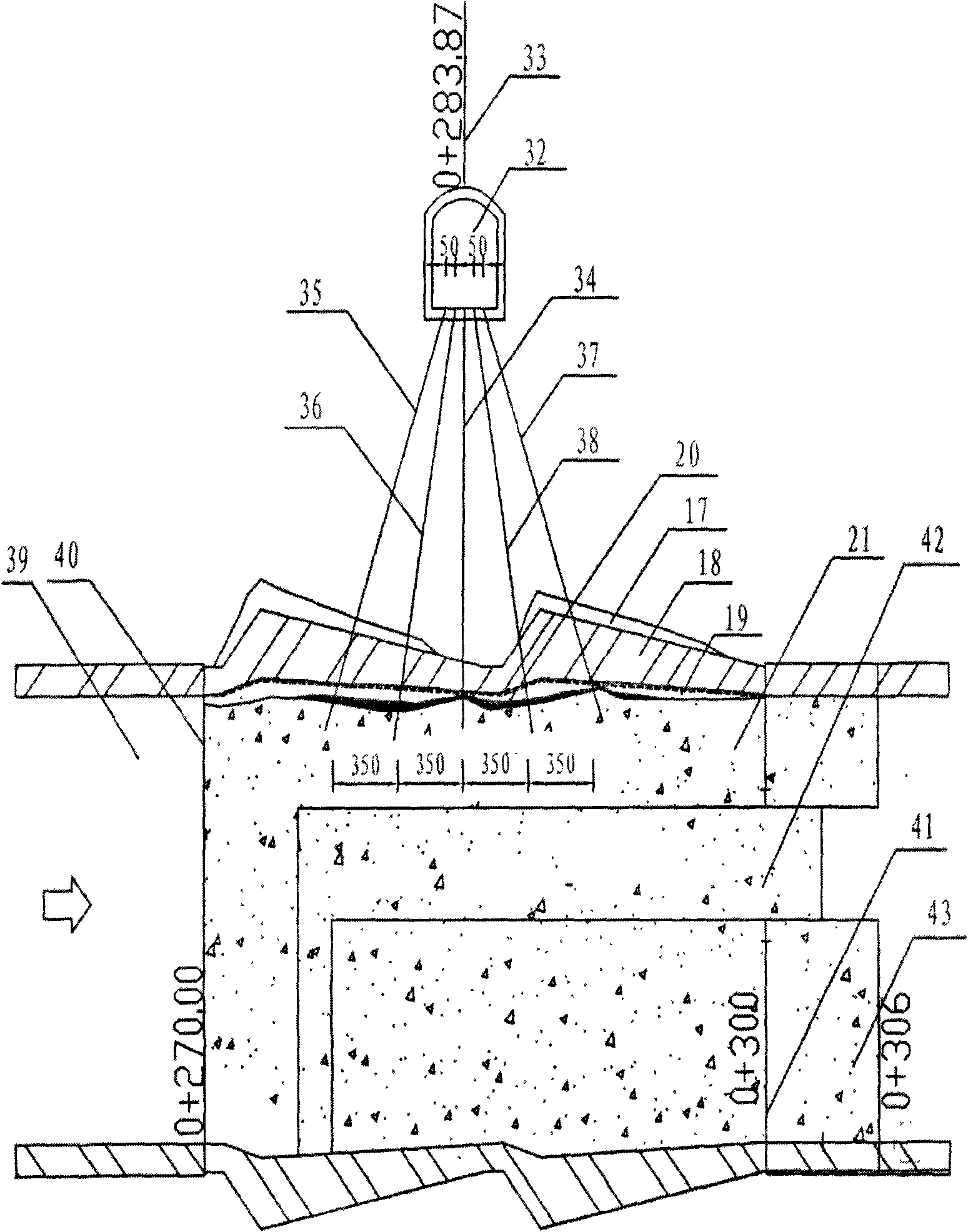

High-flow high-speed jet plugging grouting technique under high-pressure water head of hydropower station

InactiveCN101654907ASafe Drilling and Irrigation ConstructionSolve unreported problemsLiquid/gas jet drillingFoundation engineeringHydropower engineeringEngineering

The invention relates to a high-flow high-speed jet plugging grouting technique under a high-pressure water head of a hydropower station. For water permeability and water seepage of flow guide holes under pressure of the high water head of 50m to 130m, the technique adopts a 'high-flow high-speed jet plugging drilling orifice safety control device under the high-pressure water head' and a 'high-pressure-resisting water-returning safety control device in a drilling rod under the high-pressure water head' which integrate multiple functions of water stopping in the drilling rod, water drainage, pressure relieving, orifice closing, safe drilling construction and the like, solves the construction of safe drilling and grouting under the working condition of water burst of the high water head inthe orifice and completes plugging under the condition of the high water head, which is a difficulty without being recorded in world hydropower engineering construction. The high-flow high-speed jet plugging grouting technique reduces direct and indirect economic losses of over ** and has good economic benefit, simultaneously creates a new way for the plugging difficulties of water permeability and water seepage of flow guide holes under pressure of the high water head of 130m of the hydropower station in China.

Owner:SINOHYDRO BUREAU 9

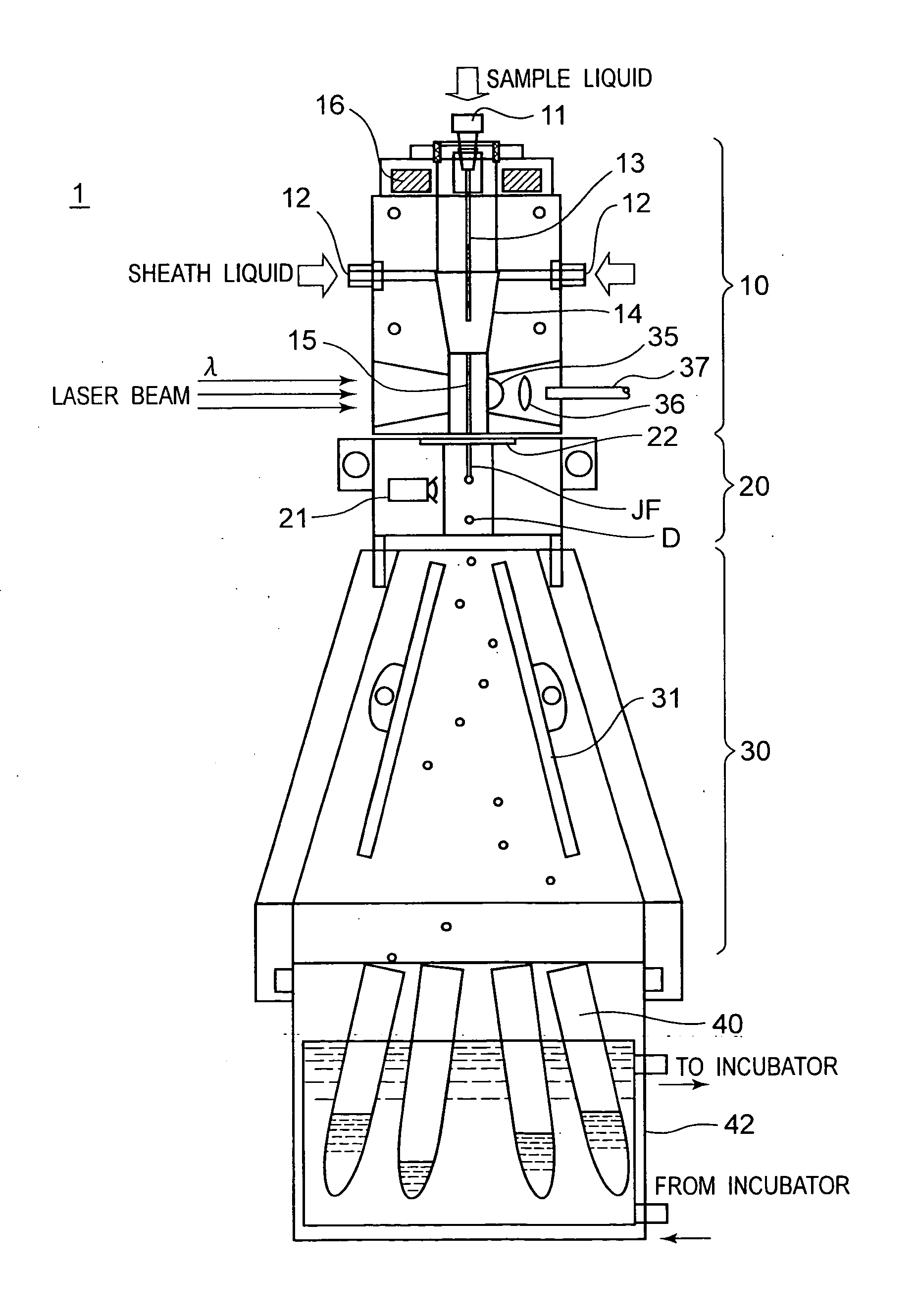

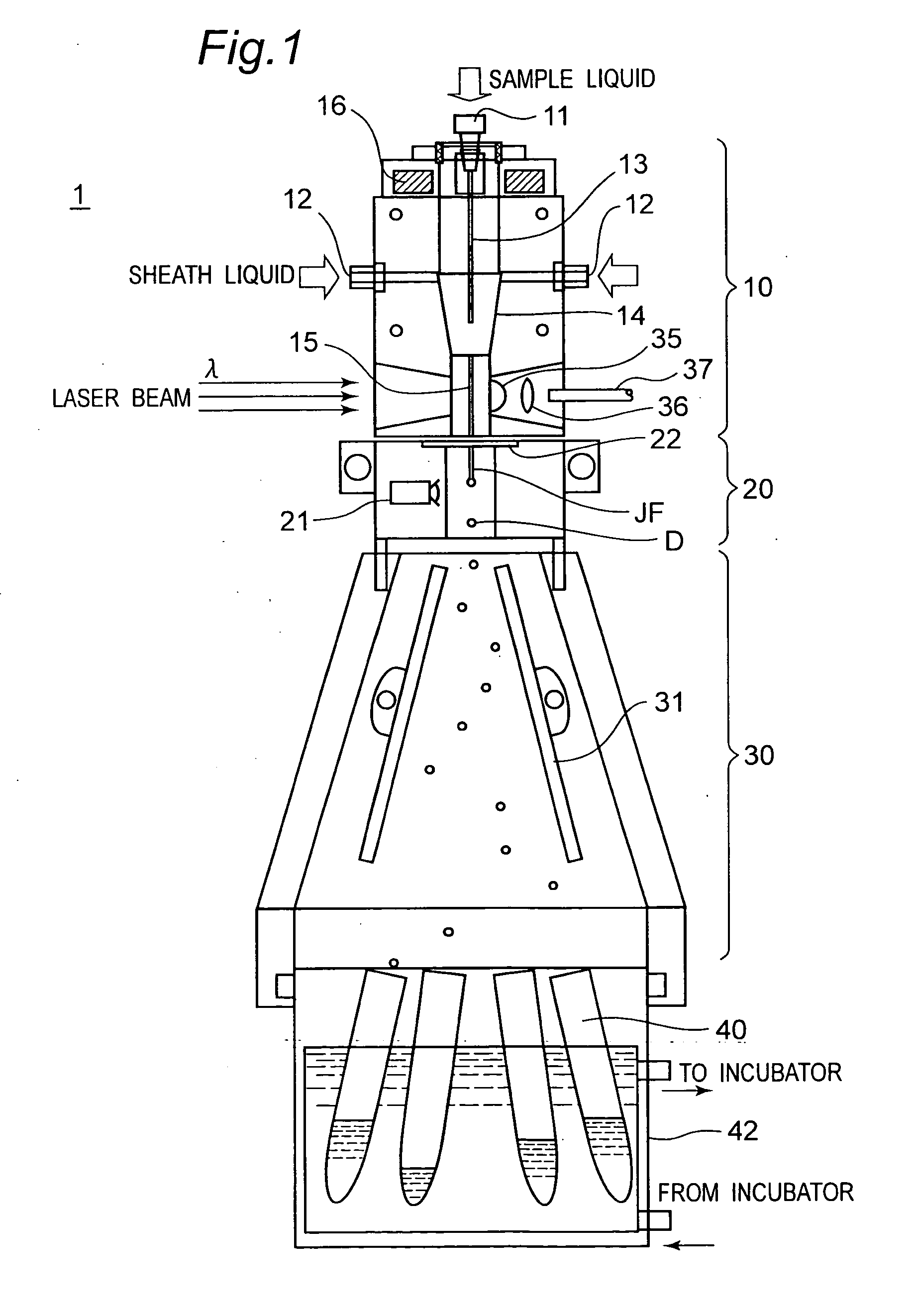

Flow cytometer and flow cytometry

InactiveUS20110259749A1Sludge treatmentMaterial analysis by electric/magnetic meansJet flowFlow cell

One embodiment of the present invention is to provide a system for sorting cell particles in a liquid flow, which comprises a flow-defining block including a flow chamber receiving a sample conduit and a flow cell having a flow channel. The system also comprises a strobe block including a imaging device for taking an image of a jet flow ejected from the flow-defining block and a plurality of droplets in a given image area. The flow-defining block and the strobe block are detachably connected each other. Further the strobe block includes a nozzle plate having a nozzle channel between a receiving end and a nozzle. The flow-defining block includes a discharge end opposite to the receiving end and a channel enlarged portion of which cross section taken along a predetermined plane perpendicular to a flow direction has an area increasing towards the discharge end. The discharge end and the receiving end have substantially the same open distance in the predetermined plane perpendicular to the flow direction.

Owner:BAY BIOSCI

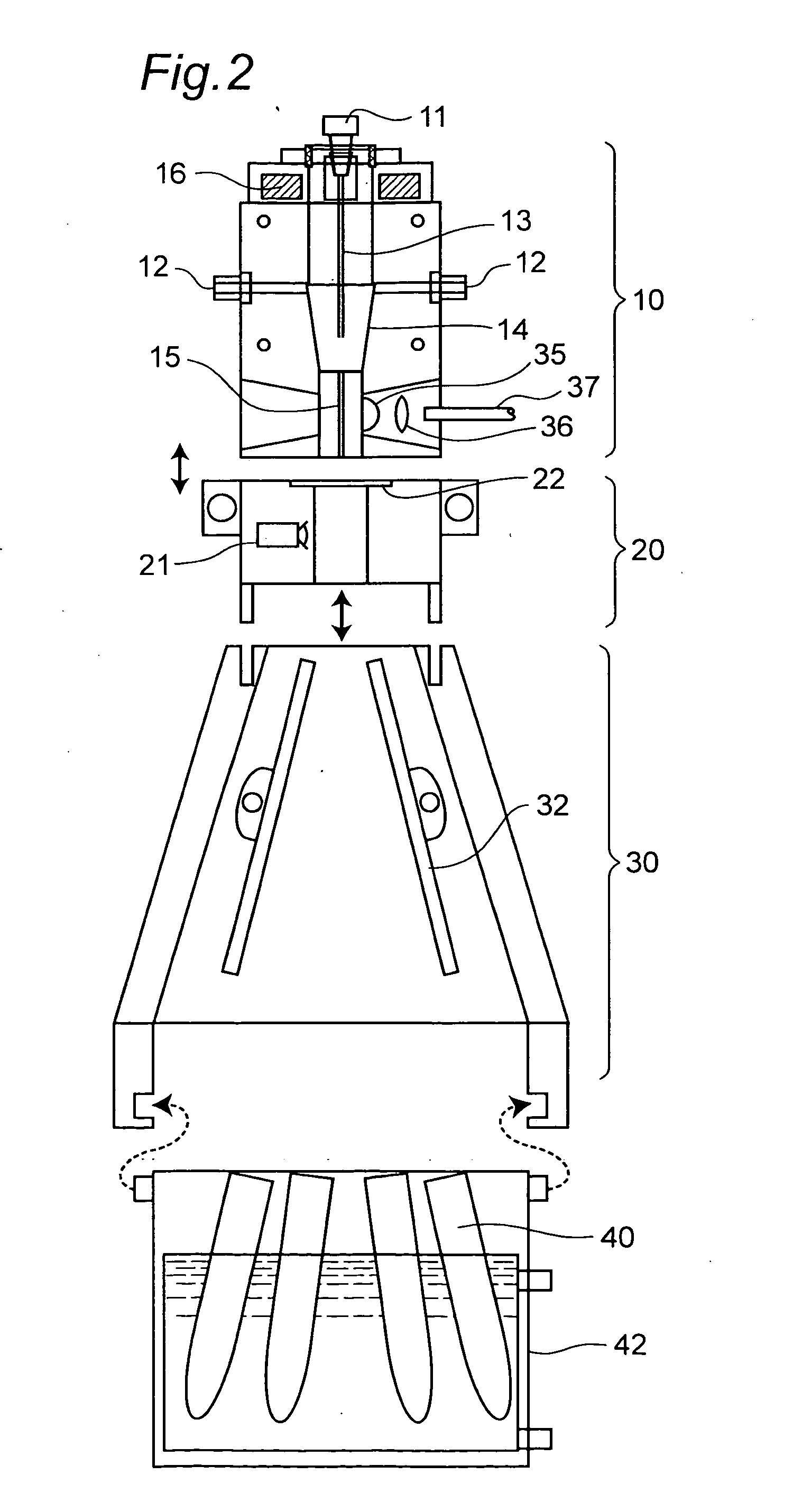

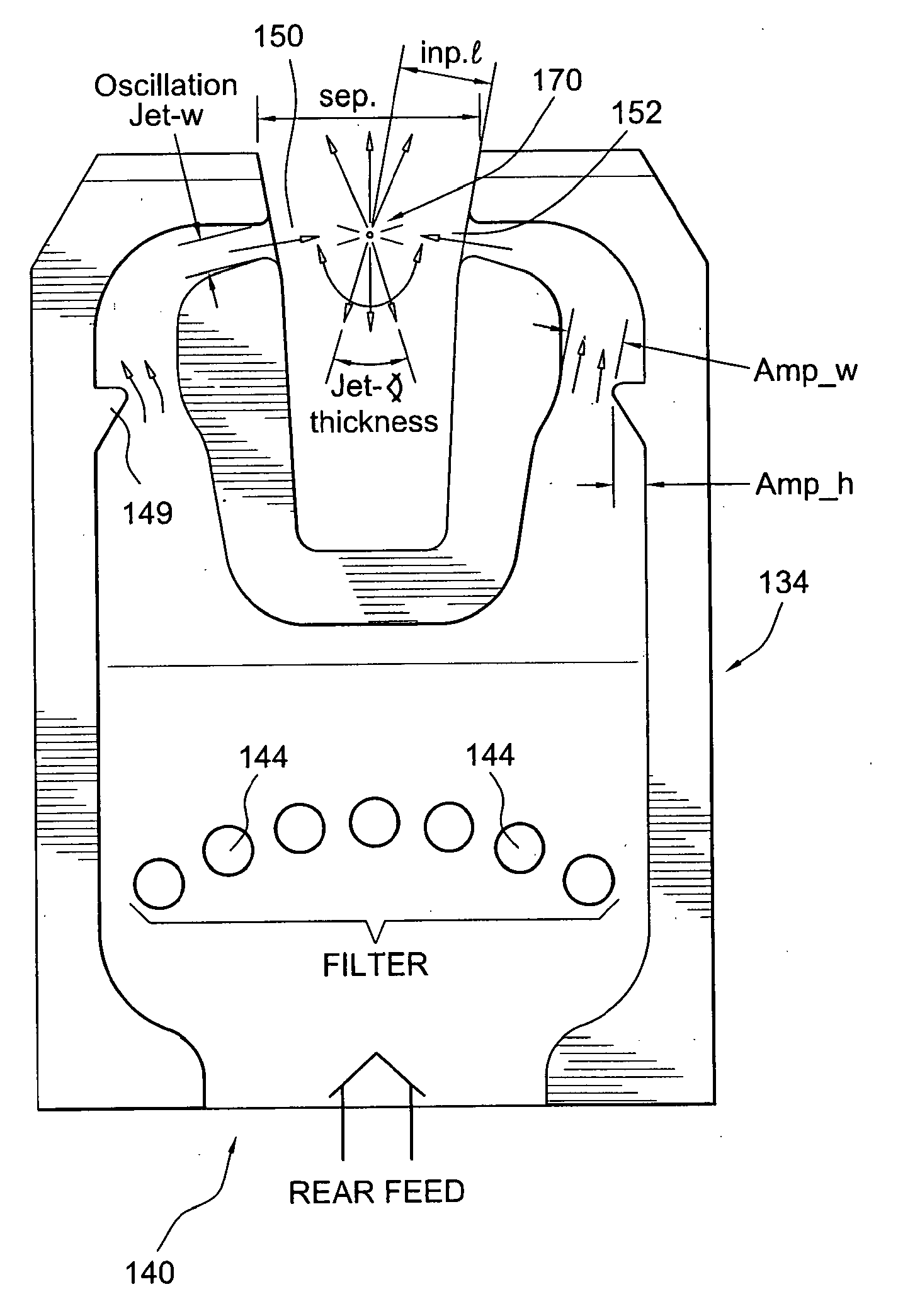

Full coverage fluidic oscillator with automated cleaning system and method

InactiveUS20110061692A1Increase heightImprove spraying effectUrinalsWater closetsAudio power amplifierFluidic oscillator

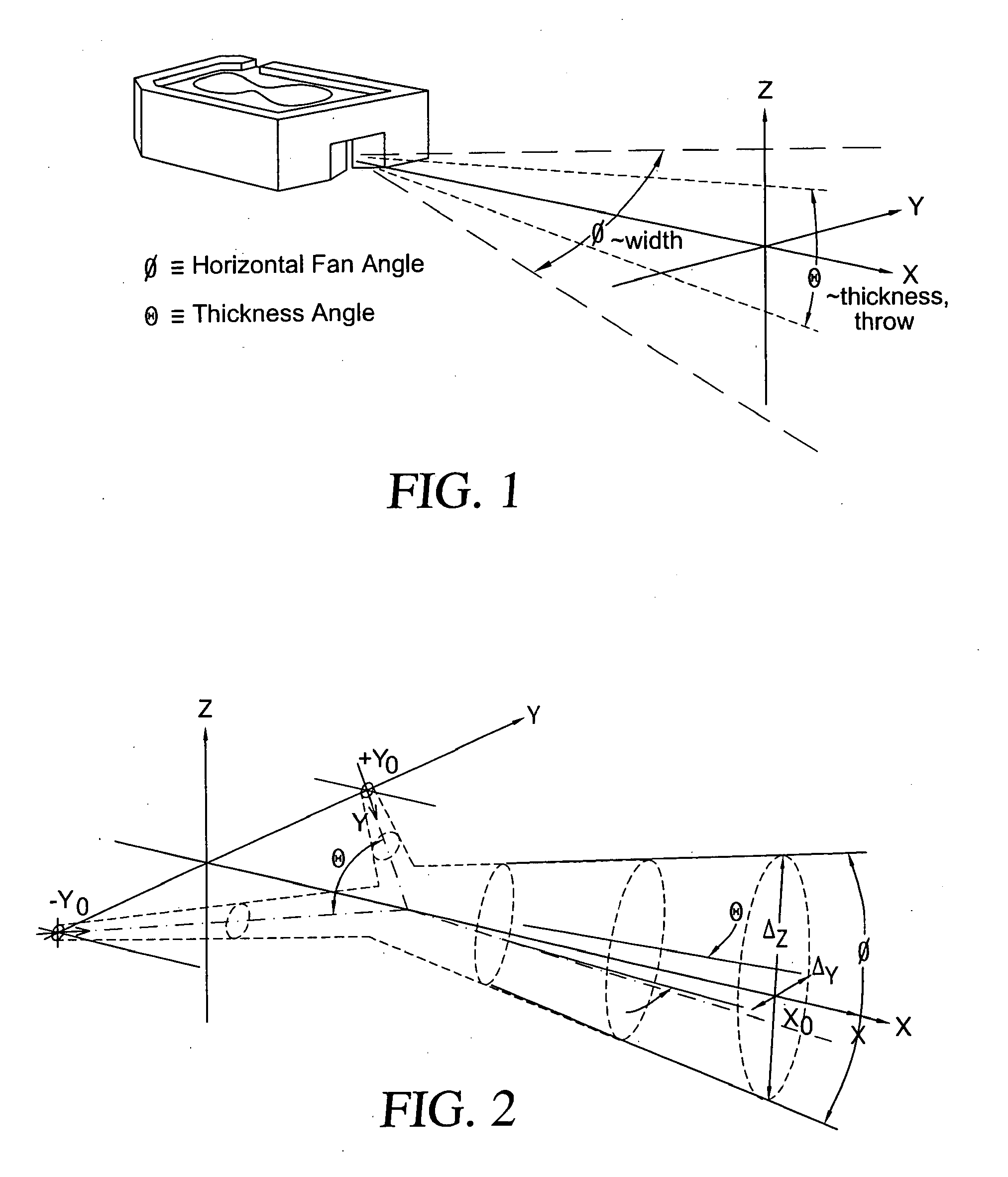

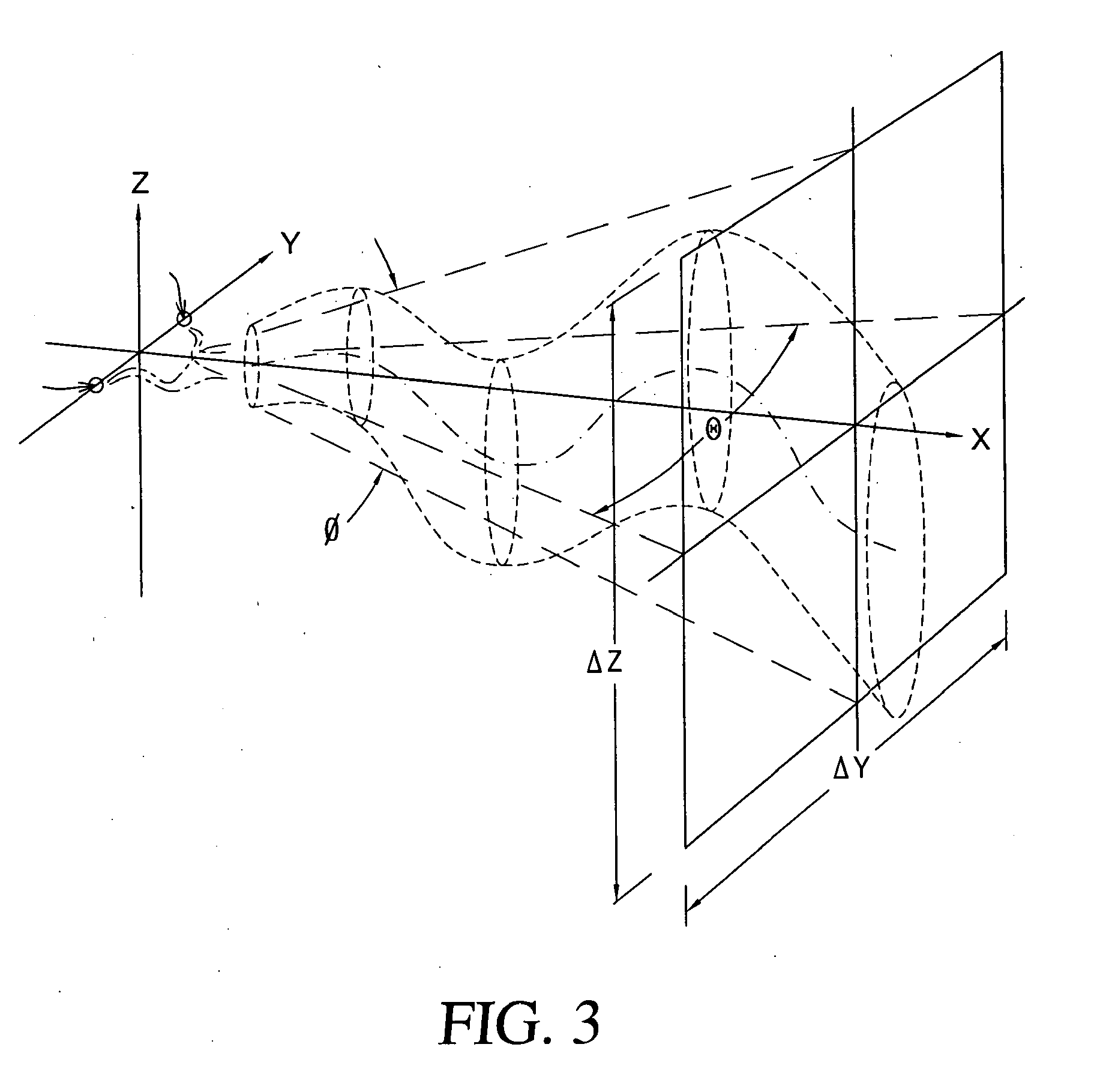

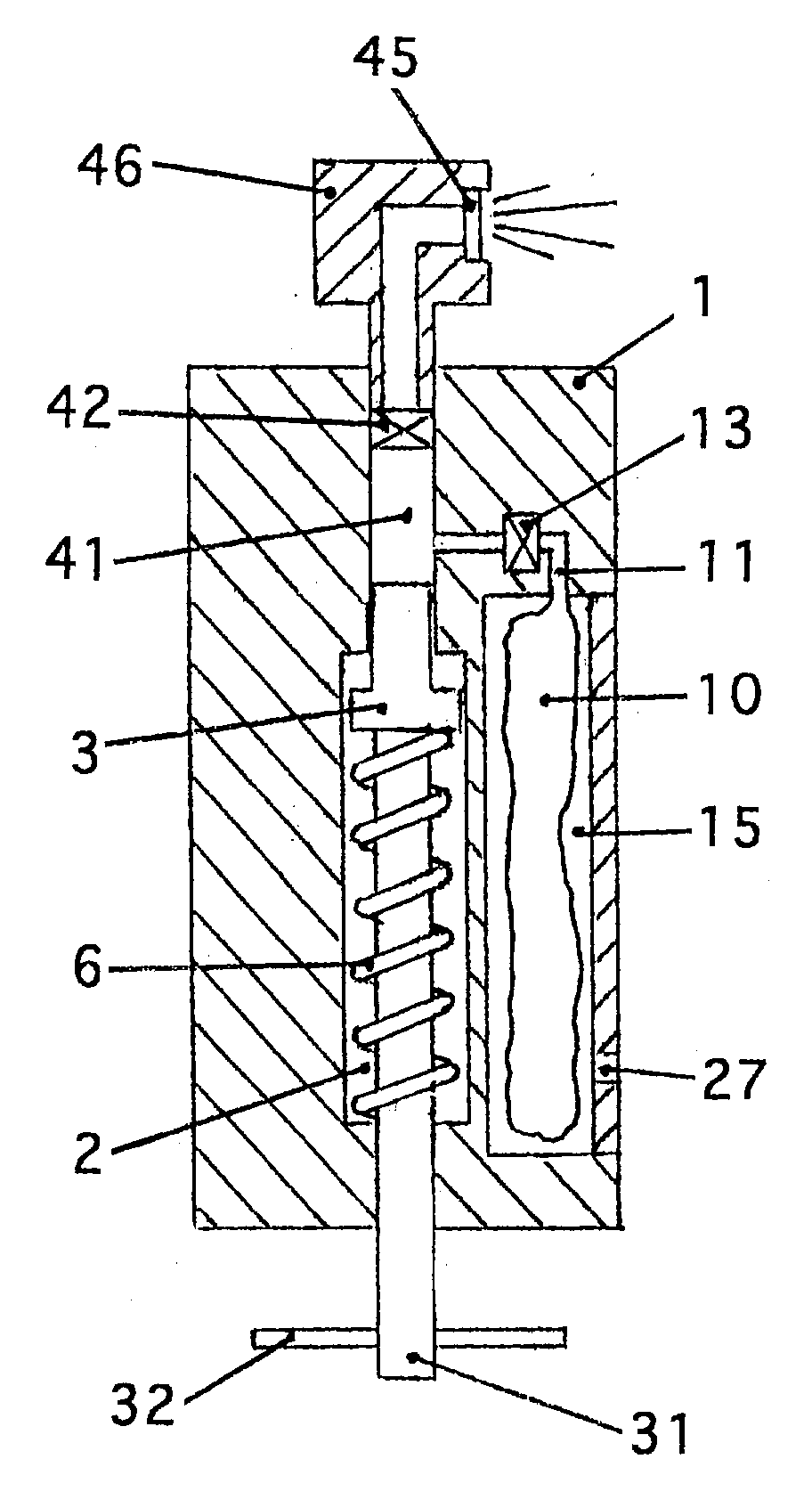

A full coverage fluidic oscillator (2) includes a fluidic circuit member preferably having an oscillation inducing internal chamber, at least one inlet (8) or source of fluid under pressure, at least a pair of output nozzles (14, 16) connected to the source of fluid for projecting at least first and second impinging fluid jets into free space, where the first and second impinging jets collide or impinge upon one another at a selected jet angle to generate a substantially omni-directional sheet jet having selected thickness. The first and second jets are aimed at a pre-selected intersection point in free space where impingement is to occur. The sheet jet's thickness Δy is determined by the time-varying path or oscillation of each of the first and second impinging jets. The first and second impinging jets can be made to oscillate or pulsate by use of vortex generating amplifier structures (68, 70, 72, 149) within the internal chamber's fluid flow paths.

Owner:DLHBOWLES INC

Atomizer for manual actuation

A fluid can be discontinuously atomized with an atomizer of the present invention. The atomizer can include a helical spring, disk spring or gas spring, acting as a pressure spring, as an energy storage device, a cylinder, piston, two ducts and two valves. Atomization can be initiated manually by triggering a locking mechanism. The energy storage device can be disposed outside a storage container for the fluid. The energy storage device can be provided mechanical energy manually. Via the piston, the stored energy can exert pressure onto the fluid in the cylinder, which ranges from 1 MPa to 5 MPa (10 bar to 50 bar). Distribution of the droplet size in the atomized jet can be independent from the level of experience and behavior of the person actuating the atomizer, and can be adjusted in a reproducible manner. The mean droplet diameter can be smaller than about 50 micrometers. The mass flow of the fluid through the nozzle can be less than about 0.4 g / s. The design and function of the atomizer can be adjusted to properties of the fluid, to a planned application, and to a desired manner for handling the atomizer.

Owner:BOEHRINGER INGELHEIM MICROPARTS

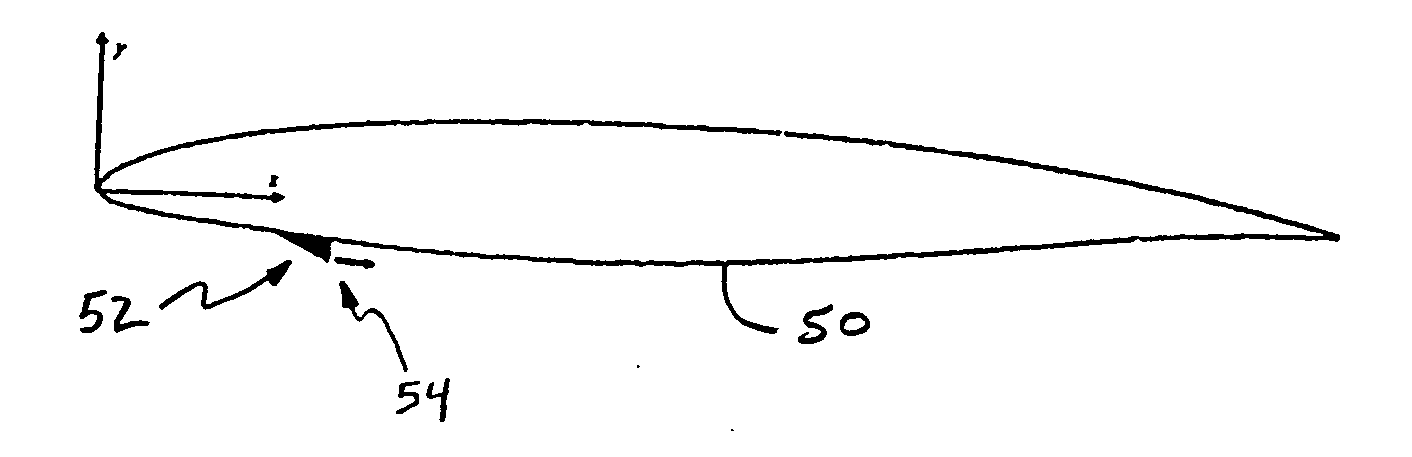

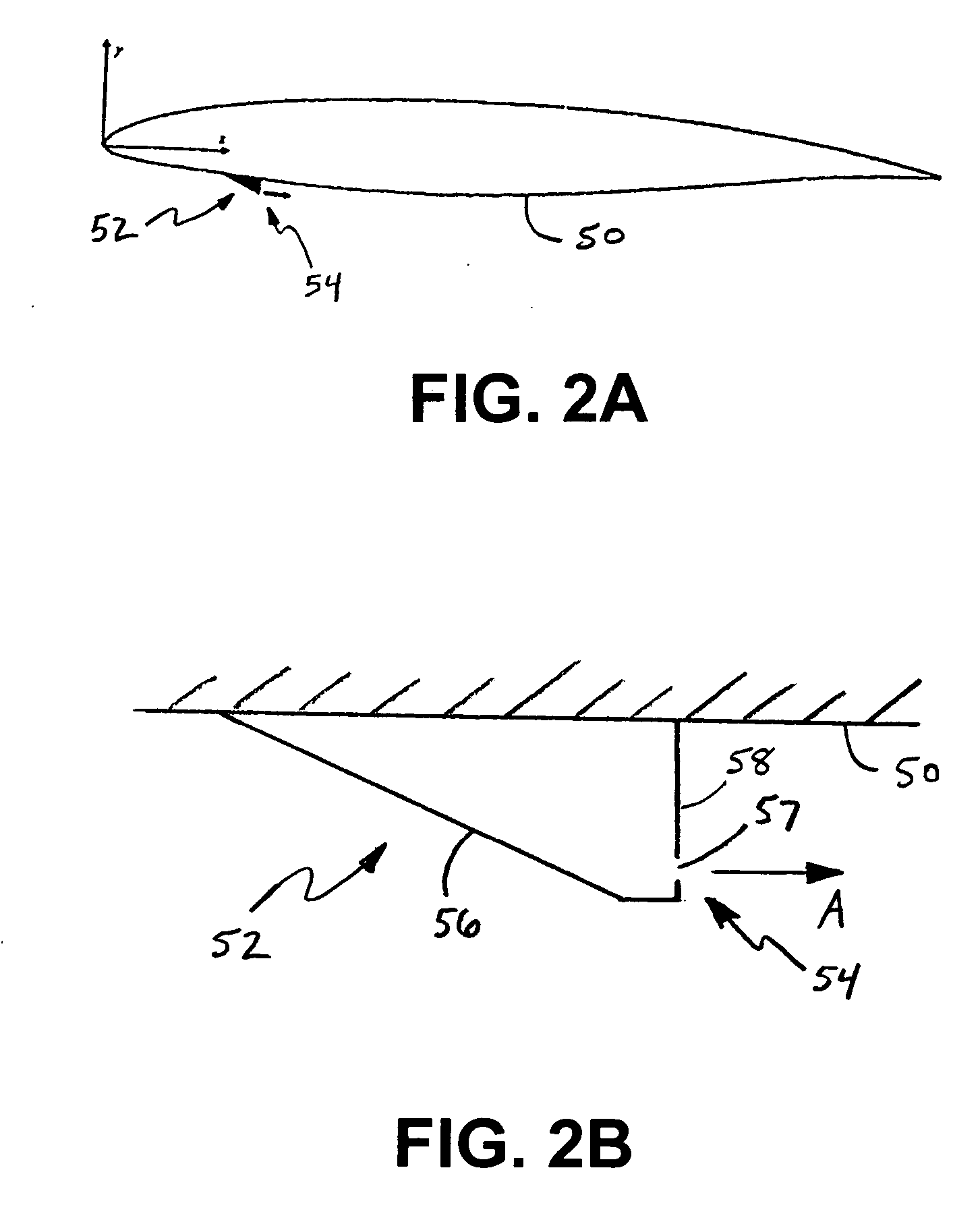

Airfoil performance modification using synthetic jet actuators

ActiveUS20070095987A1Reduce pressure resistanceInfluencers by generating vorticesBoundary layer controlsSolid bodyEngineering

Systems and methods for modifying fluid flowing over solid bodies are provided. A representative system incorporates a vorticity concentration-producing component and a synthetic jet actuator. The vorticity concentration-producing component is disposed on a pressure side of the solid body. The fluid flowing over the solid body remains attached to a surface of the solid body in a vicinity of the vorticity concentration-producing component. The synthetic jet actuator includes a jet housing that incorporates an internal chamber with a volume of fluid and an opening in the jet housing connecting the internal chamber to an external environment having the fluid. The synthetic jet actuator is operative to periodically change the volume within the internal chamber such that a synthetic jet stream comprising a series of fluid vortices is generated and projected in the external environment out from the opening of the jet housing resulting in a reduction in pressure drag of the solid body compared to the pressure drag exhibited by the solid body without operation of the synthetic jet actuator.

Owner:GEORGIA TECH RES CORP

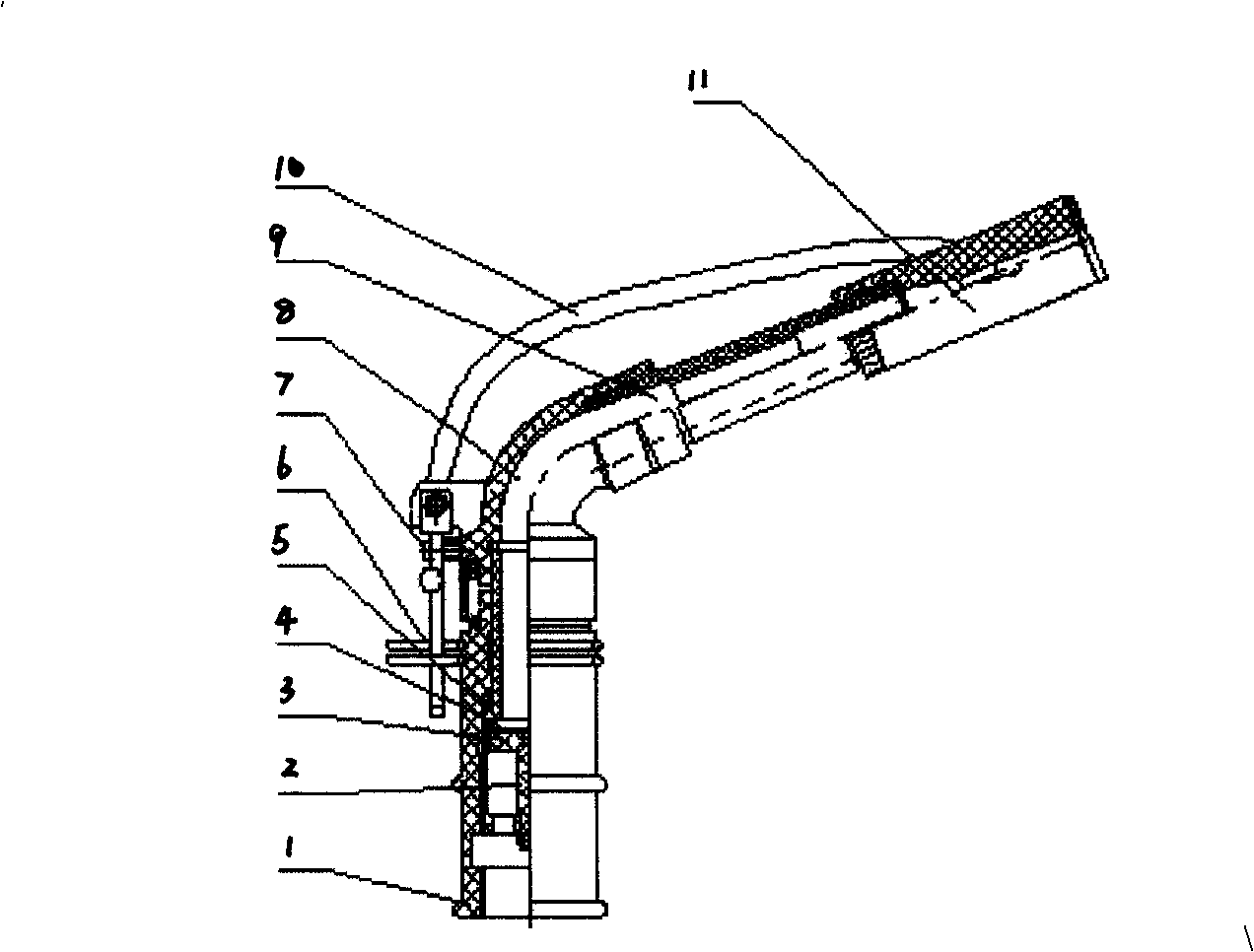

Laser induced liquid jet generating apparatus

InactiveUS7740626B2Guaranteed uptimeAllow useSurgical instrument detailsFluid jet surgical cuttersLiquid jetThermal impact

Owner:TERUMO KK

Variable-spray whole-torrential flow showerhead

InactiveCN101352702ASimple structureGuaranteed uptimeWatering devicesMovable spraying apparatusJet flowDifferential pressure

The invention pertains to a key device for water-saving irrigation, which is a wall-attached fluidic nozzle that realizes variable spraying; the nozzle comprises a static plate, a moving plate, a spraying body, a spraying tube, a rotating seal mechanism, a knighthead, a spacing ring, a reversing mechanism and a fluidic element body and is characterized in that the static plate and the moving plate are added to a nozzle spin; the moving plate is pressed to match a hollow shaft, and rotates along with the nozzle. The fluidic element body comprises a reverse air supply nozzle, a signal water receiving nozzle, an outlet cover plate, a signal water intake nozzle and a honeycomb duct; signal water in a signal water receiving nozzle leads one side of main jet-flow to form a low-pressure spiral area at intervals; by opening and closing an air supply receiving nozzle, the other side of the main jet-flow is led to switch between high pressure and low pressure so as to form a differential pressure between the right and the left ends of the main jet-flow, thus realizing the wall attachment of water flow and finishing direct spraying, stepping and reverse running of the nozzle. The static plate and the moving plate at the position of the nozzle spin move relatively to change the area of stopflow at an inlet and regulate the flow and the pressure of the inlet so as to change the spraying range of nozzle and realize variable spraying.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com