Enhanced cross stream mechanical thrombectomy catheter with backloading manifold

a technology of thrombosis catheter and backloading manifold, which is applied in the field of thrombosis catheter, can solve the problems of guidewire not being reliably retracted from the catheter, inability to repair the vessel by multiple inflow/outflow, and internal turbulent eddies consumed the area, and achieves the effect of increasing the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

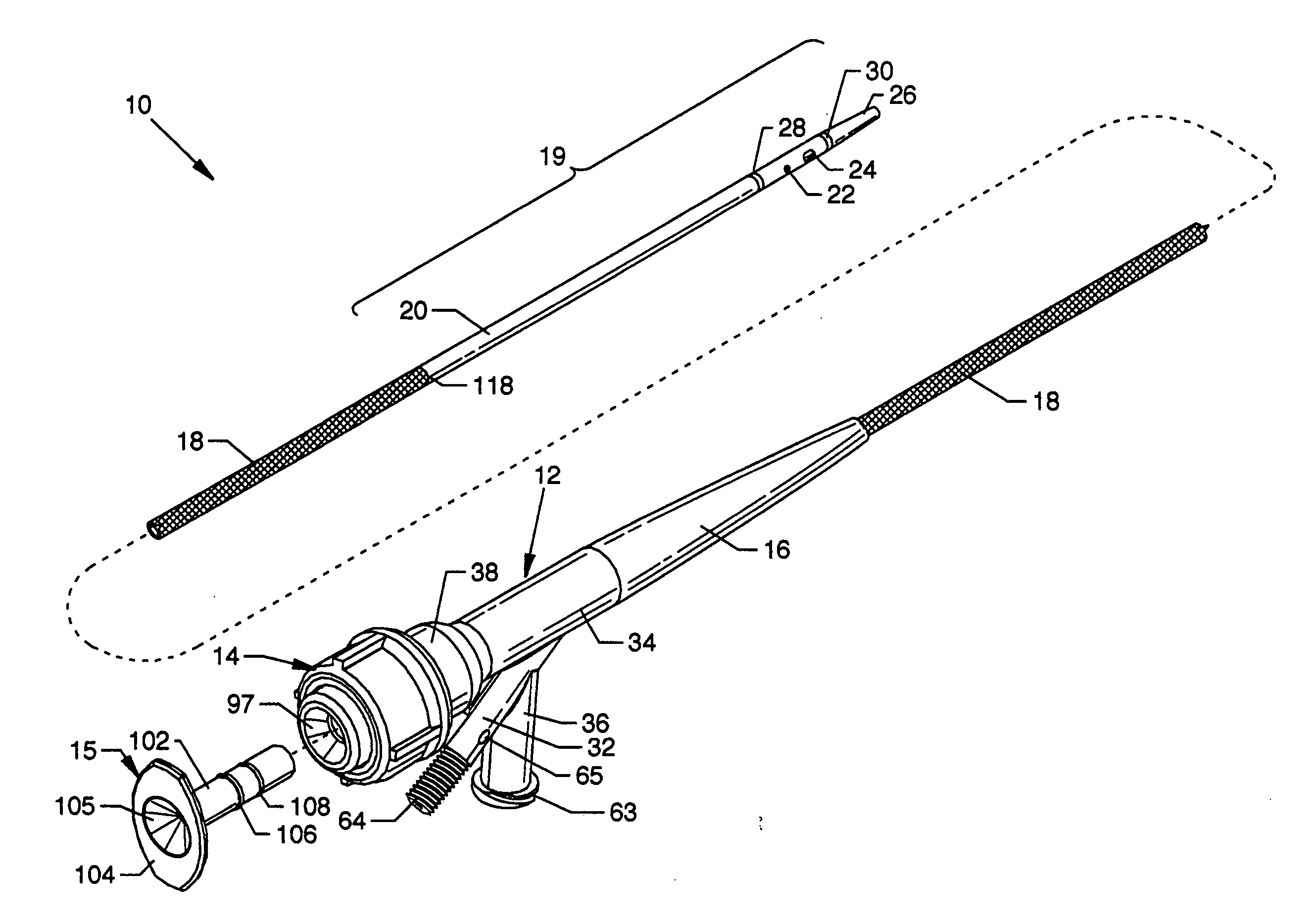

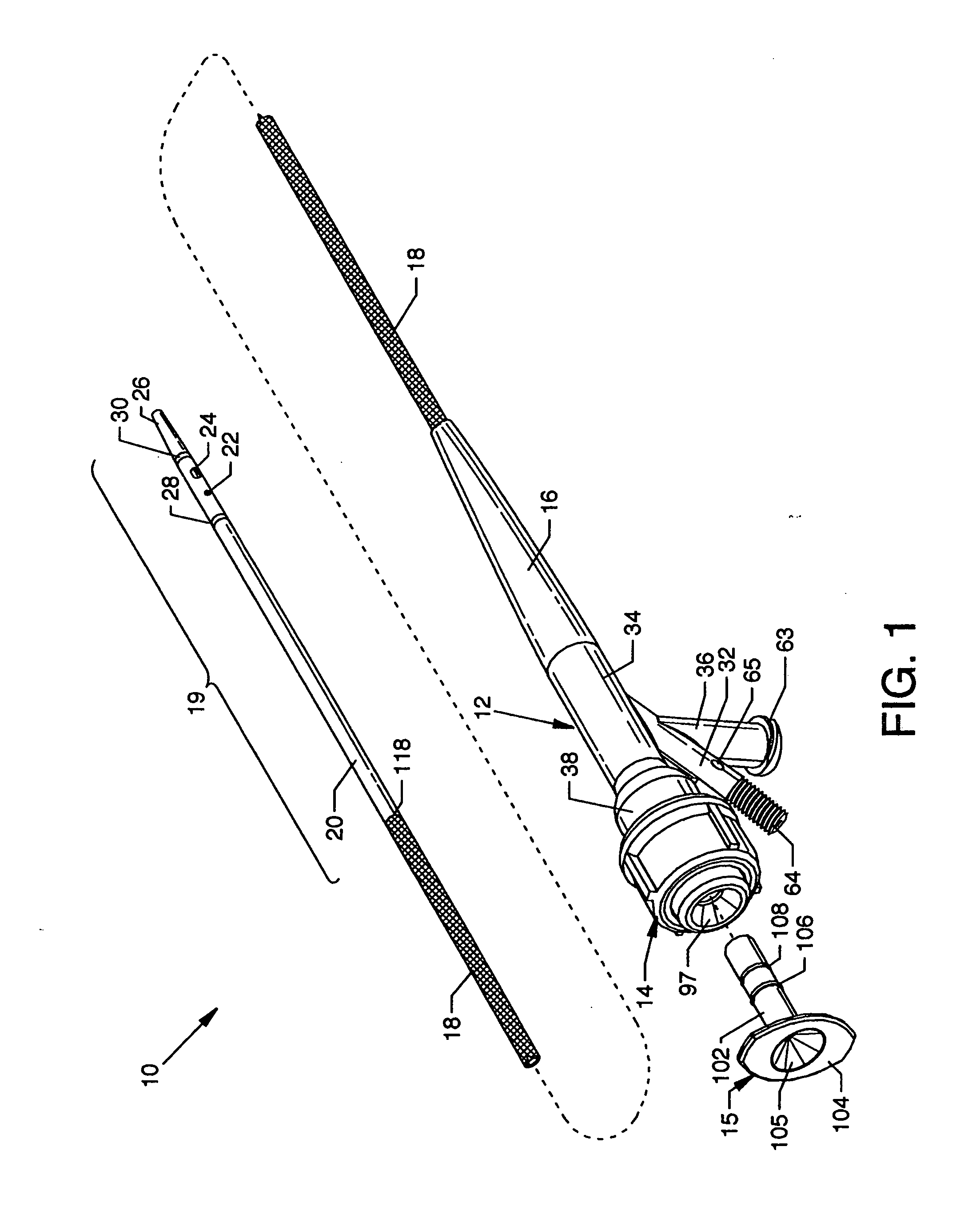

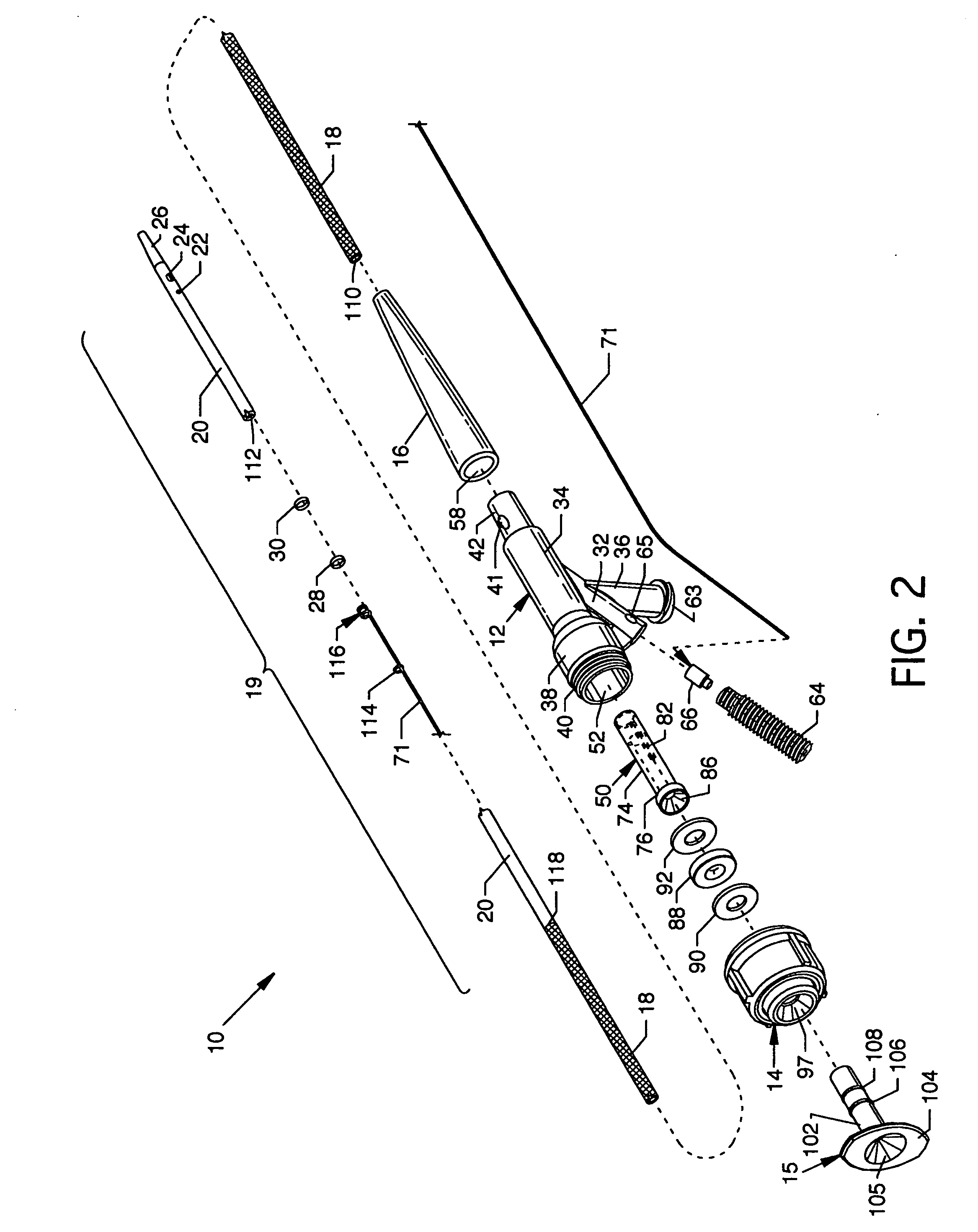

[0062]FIG. 1 is an isometric view of an enhanced cross stream mechanical thrombectomy catheter with backloading manifold 10, the present invention. Externally visible major components of the invention include a centrally located backloading manifold 12, a hemostatic nut 14 threadingly secured to the backloading manifold 12, an introducer 15, a flexible and tapered strain relief 16 connected to and extending from the backloading manifold 12, a catheter tube composed of a braided catheter tube 18 of flexible or semi-flexible material, preferably polyimide or other such suitable composition, connected to the backloading manifold 12 and extending through the tapered and flexible strain relief 16 and a smooth catheter tube assembly 19 having a smooth catheter tube 20 of plastic composition connected to and extending distally from the braided catheter tube 18, and an outflow orifice 22 and an inflow orifice 24 located in longitudinal alignment along an imaginary line at the distal portion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com