Radial-flow type fluidic pressure wave supercharger

A gas wave supercharger and radial flow technology, applied in the direction of fluid pressure converters, mechanical equipment, etc., can solve the problems of difficult exhaust of compressed gas, high rotation speed, long axial dimension, etc., to reduce equipment size, The effect of fast energy transfer speed and long flow channel length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

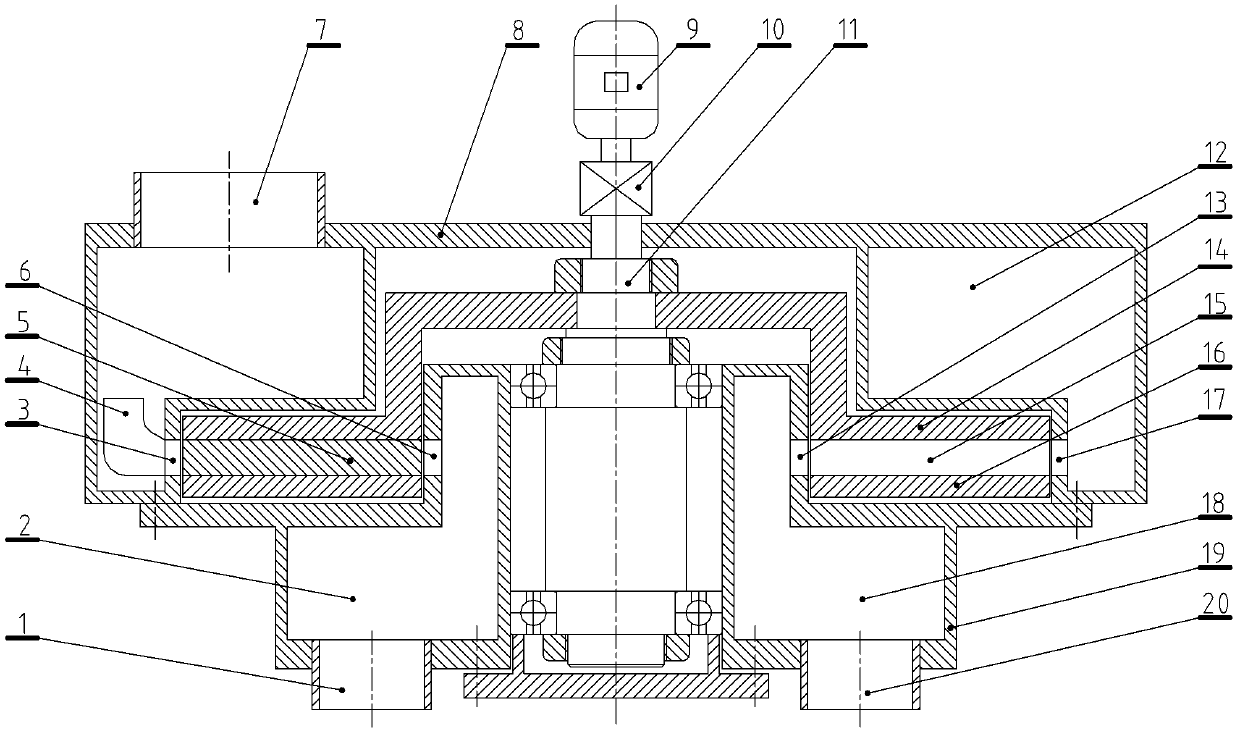

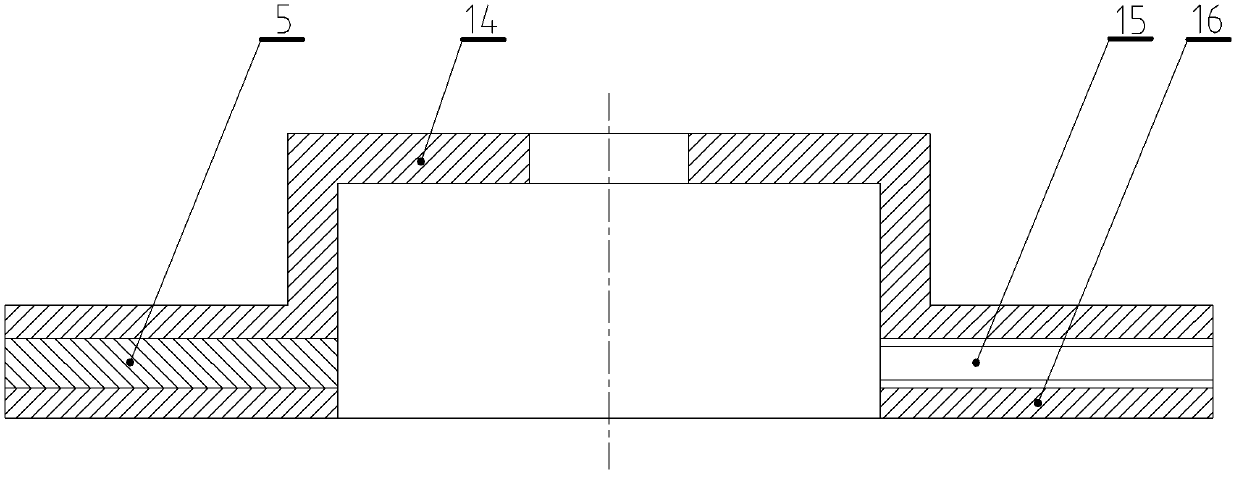

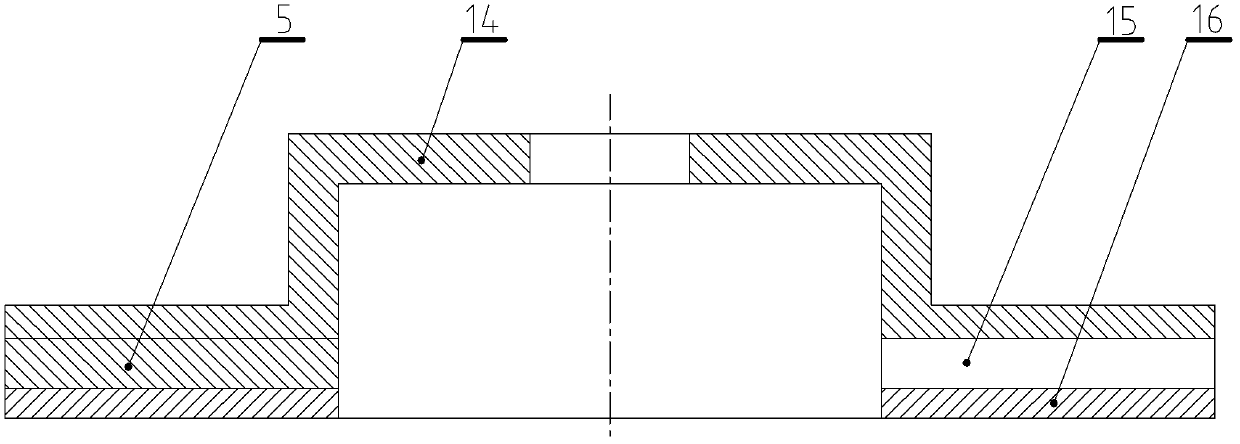

[0024] The radial jet air wave supercharger consists of a disc-shaped, frustum-shaped, or cylindrical-connected frustum-shaped turntable 14, a turntable cover plate 16, a plurality of pressure oscillation pipe channels 15, a main shaft 11, an upper body 8, and a lower body 19 , high-pressure jet nozzle 13, low-pressure air injection port 6, medium-pressure outlet 3, pressure equalization hole 17, high-pressure air inlet 20 and high-pressure buffer chamber 18, low-pressure air inlet 1 and low-pressure buffer chamber 2, medium-pressure outlet The air port 7, the medium pressure buffer chamber 12, the coupling 10 and the motor 9 are composed. In the ring cavity surrounded by the inner end surface of the turntable 14 and the inner end surface of the turntable cover plate 16, there are a plurality of partition narrow walls arranged radially. The grid plate 5 divides the ring cavity to form a plurality of radially arranged channels 15 that are open at both ends of the inner and outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com