Patents

Literature

1141results about "Fluid-pressure converters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

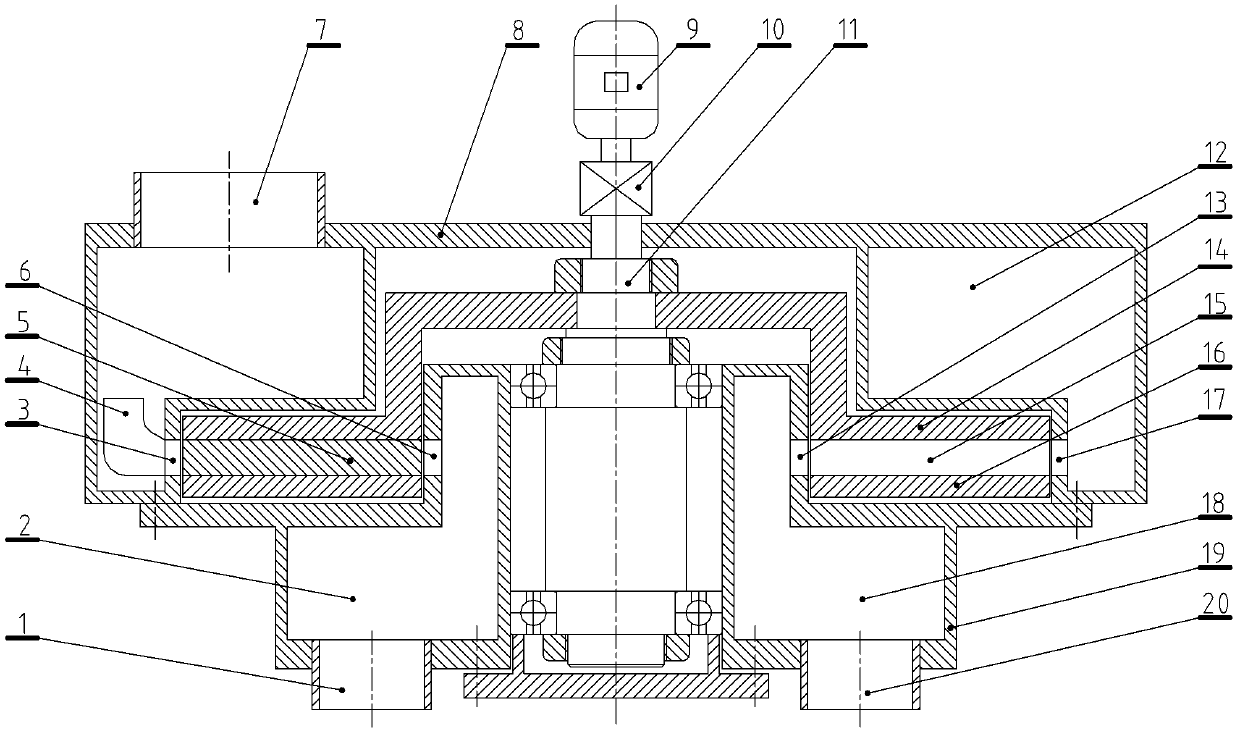

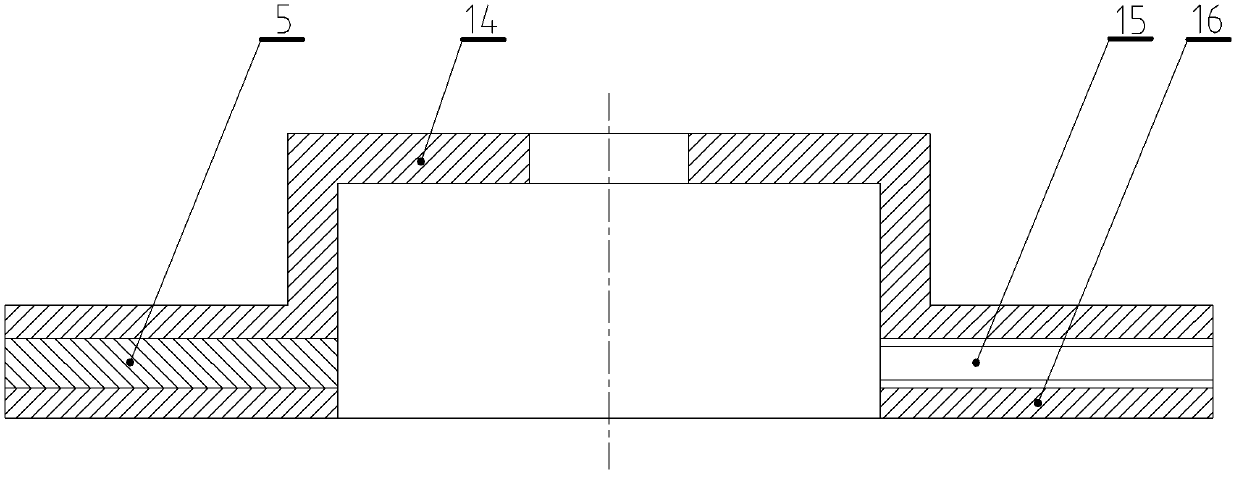

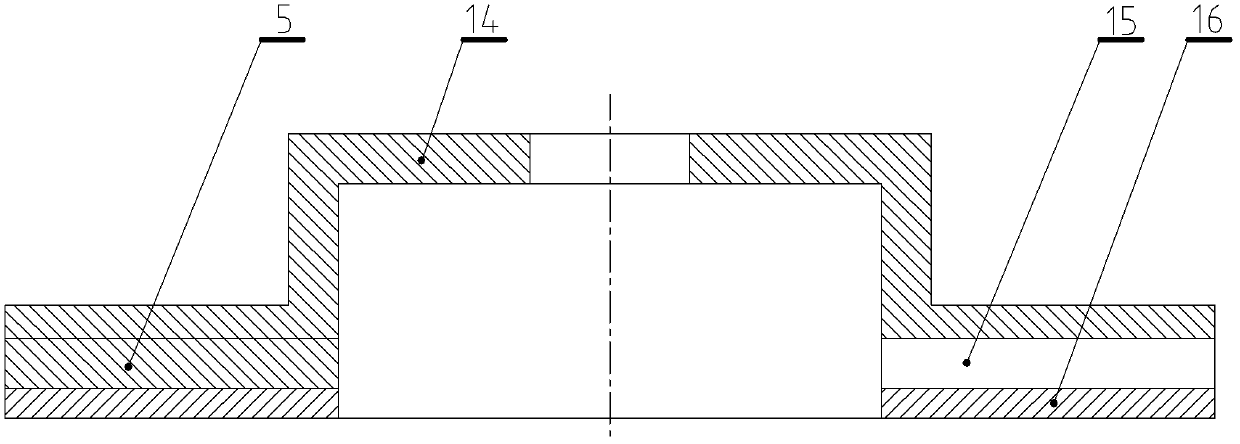

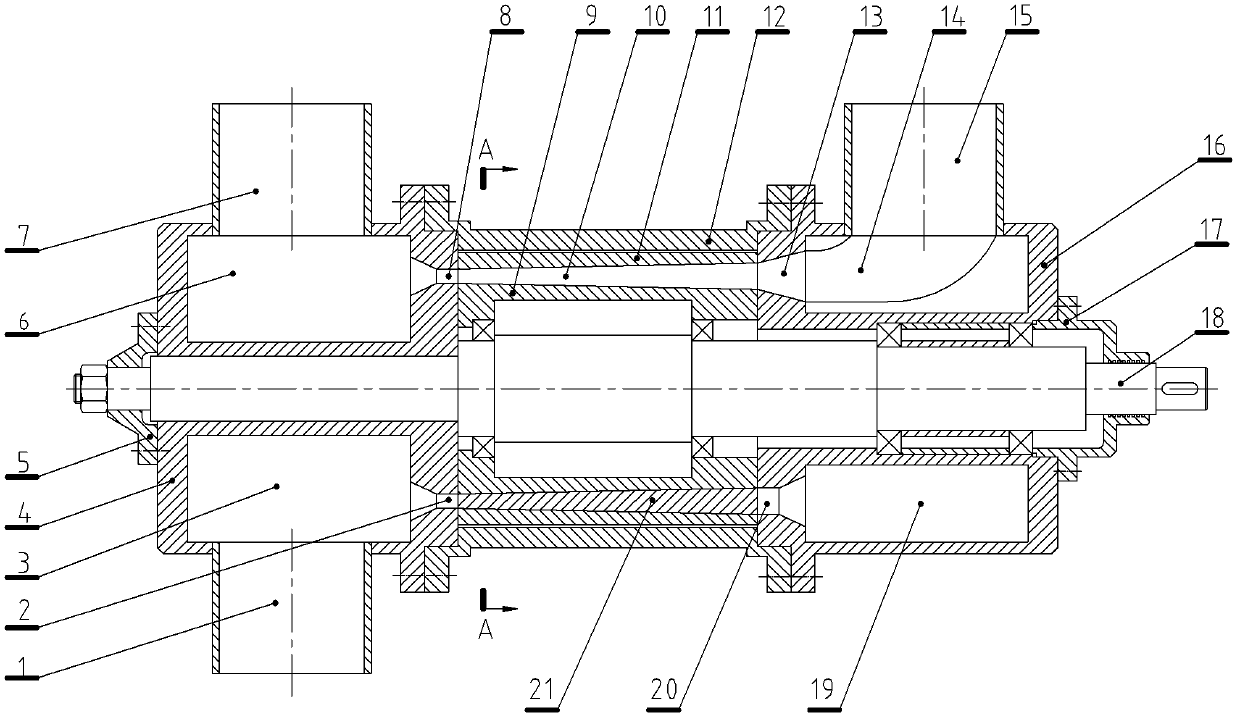

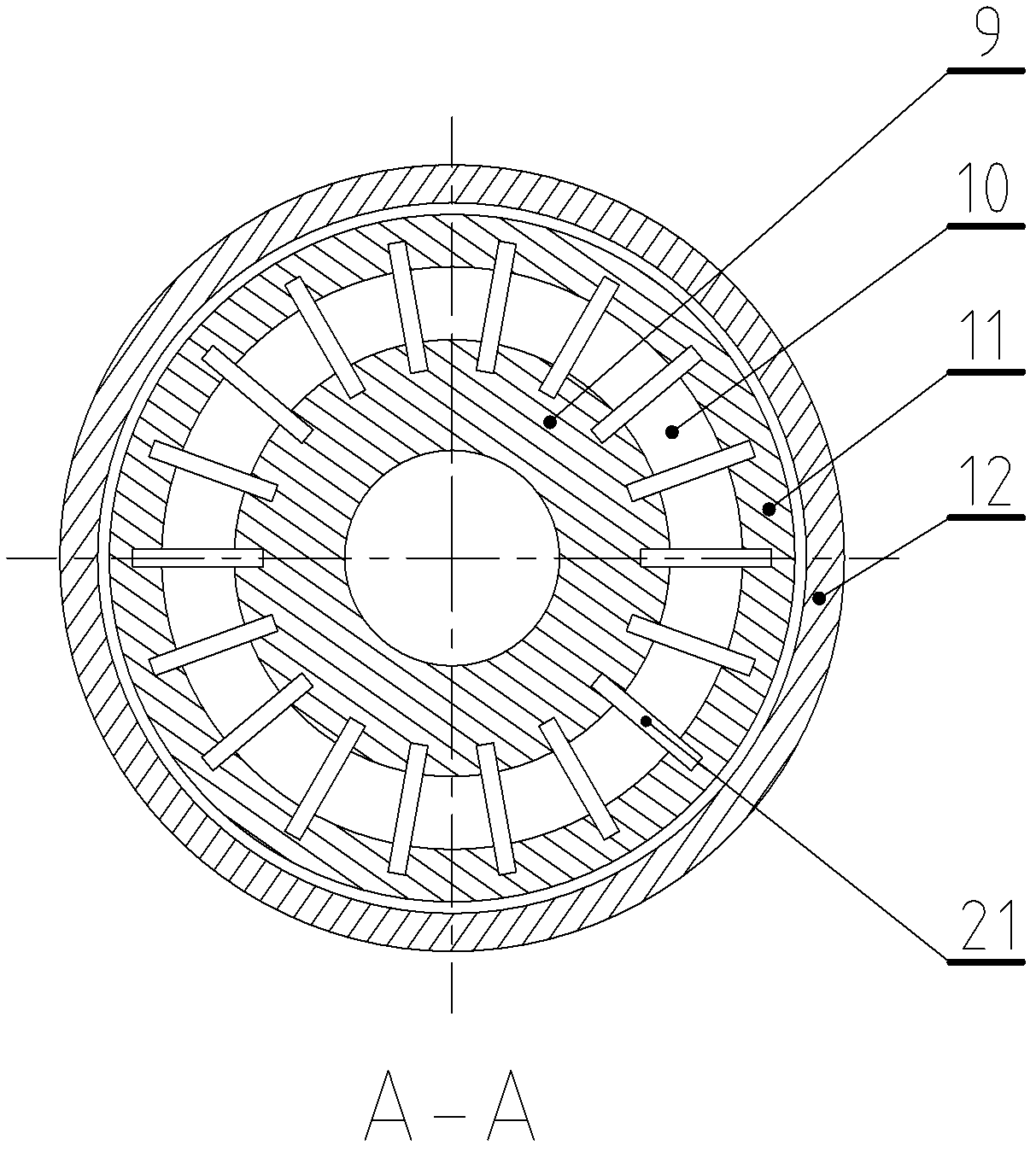

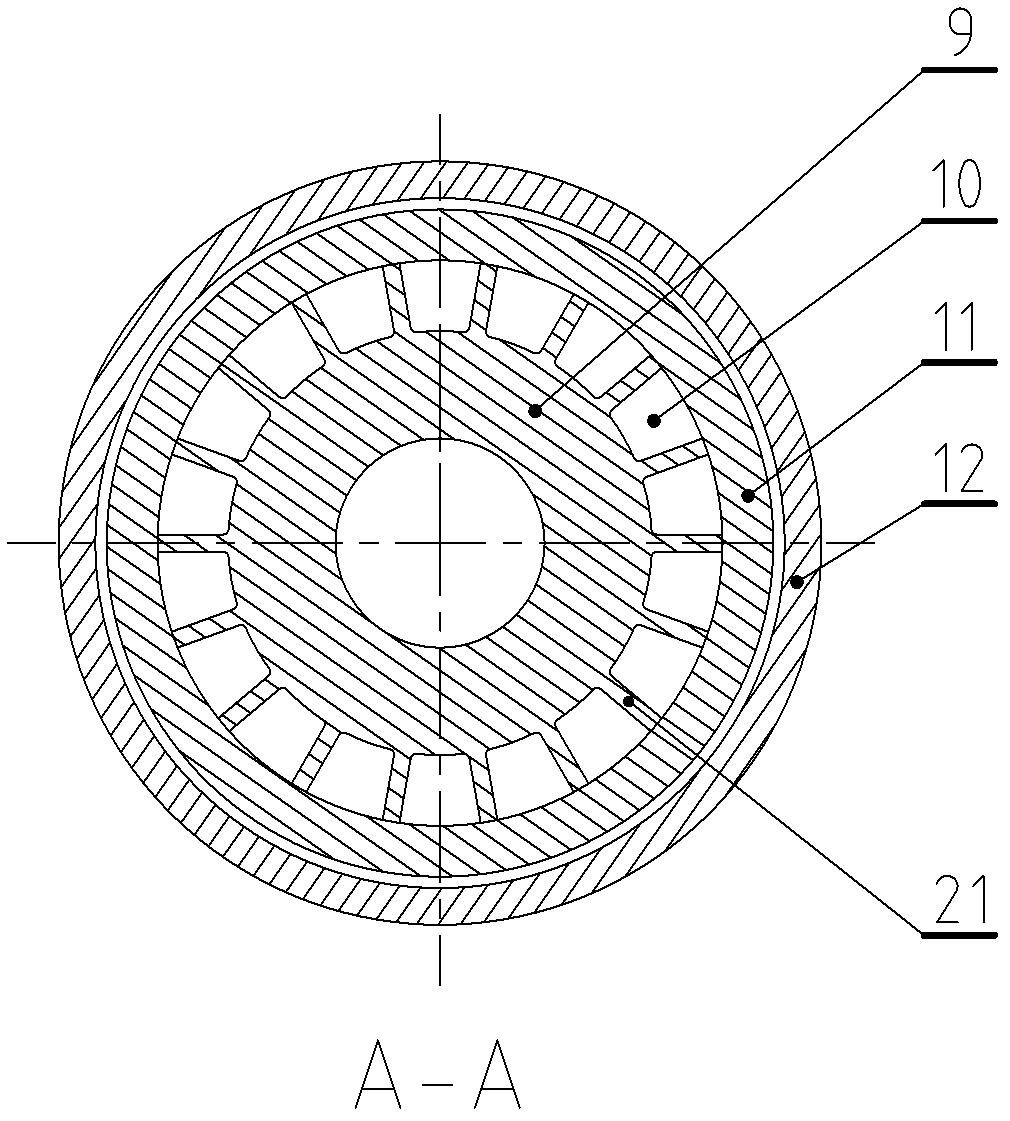

Radial-flow type fluidic pressure wave supercharger

ActiveCN102606548ARealize pressure exchangeHigh pressure levelFluid-pressure convertersJet flowDynamic energy

The invention discloses a radial-flow type fluidic pressure wave supercharger, which can realize the energy exchange between the high pressure gas and the low pressure gas by running the pressure wave, avoid loss of mixed and diffused energy and has the advantages of high isentropic efficiency, low rotating speed, operability with liquid, sufficient exhaust and on the like. For adopting a pressure oscillating tube channel with variable rectangular cross-section, the incidence loss and the flowing loss of the jet flow are reduced; the channel is a bending flow channel arranged along the radial radiation, the process of expanding and compressing is strengthened and the sufficient discharge of the compressed gas is accelerated by using the centrifugal force; pressure balancing holes are arranged in the machine, so that the performance is kept balanced at the different pressure ratios; a pressure expanding flow guider is arranged at a compressed gas outlet in order to transform the dynamic energy of the gas flow effectively. The radial-flow type fluidic pressure wave supercharger can fully utilize the pressure energy in the production process and the pressure energy in the stratums of natural gas, thereby providing an efficient device selection for utilizing the pressure energy sources effectively.

Owner:DALIAN UNIV OF TECH

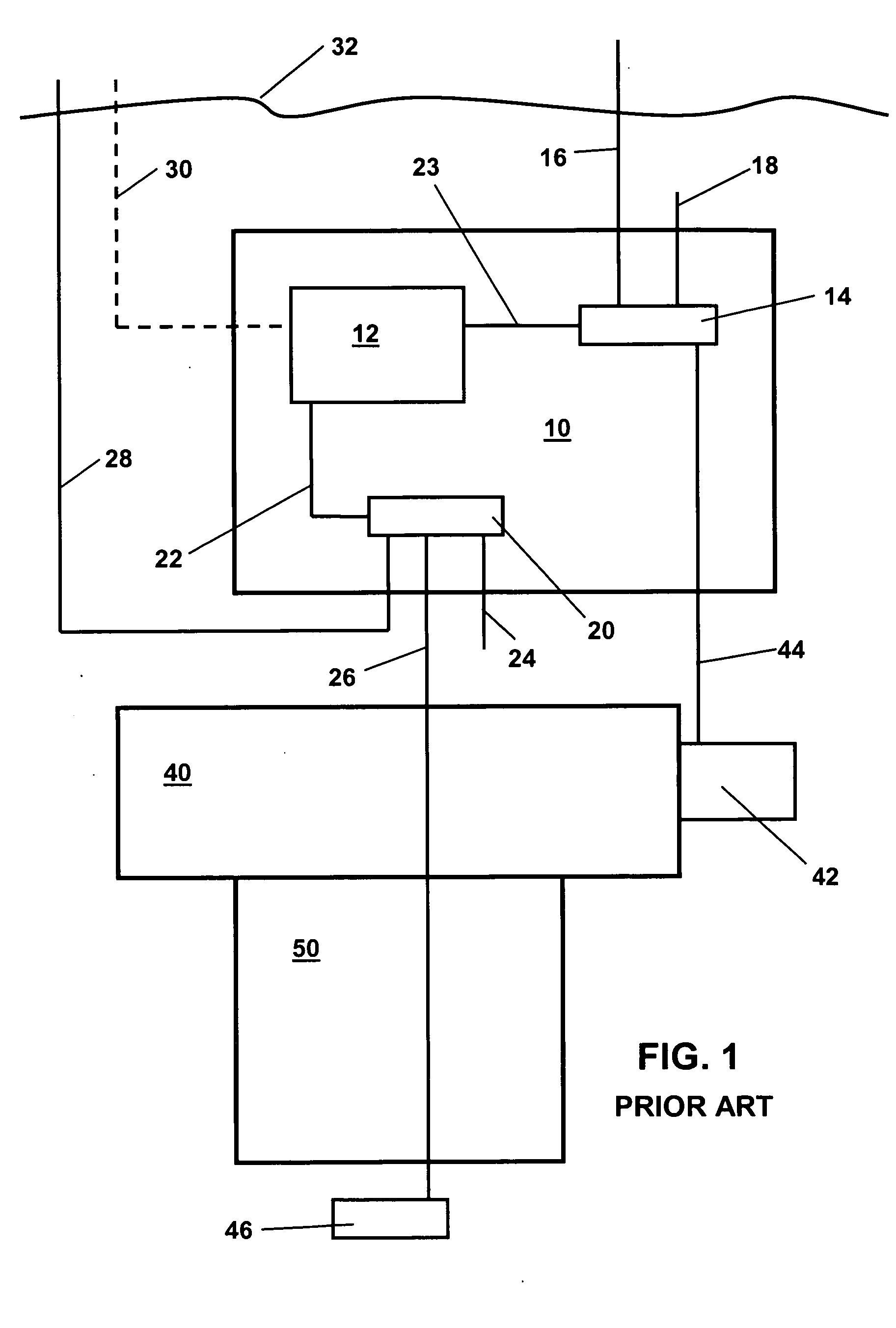

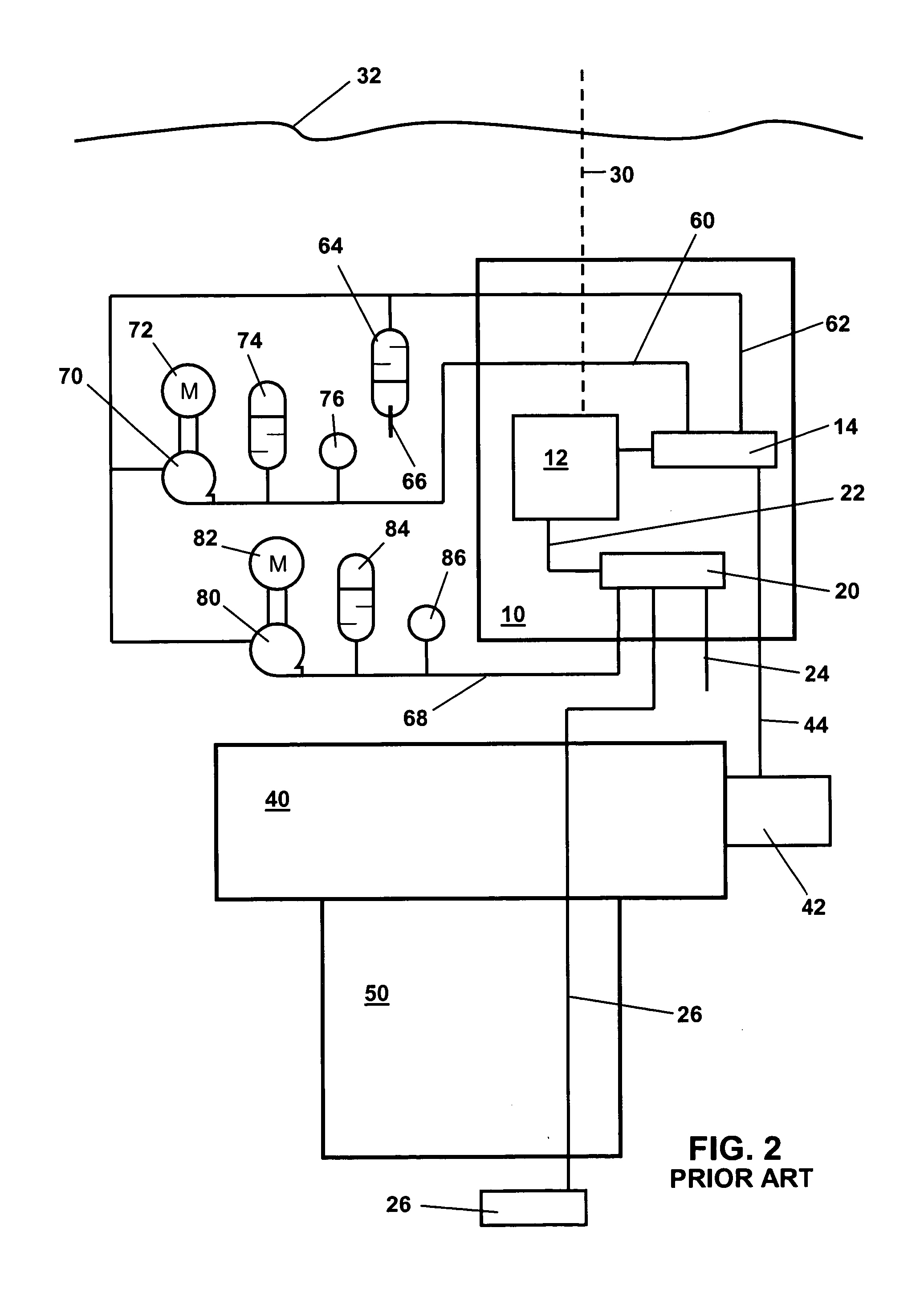

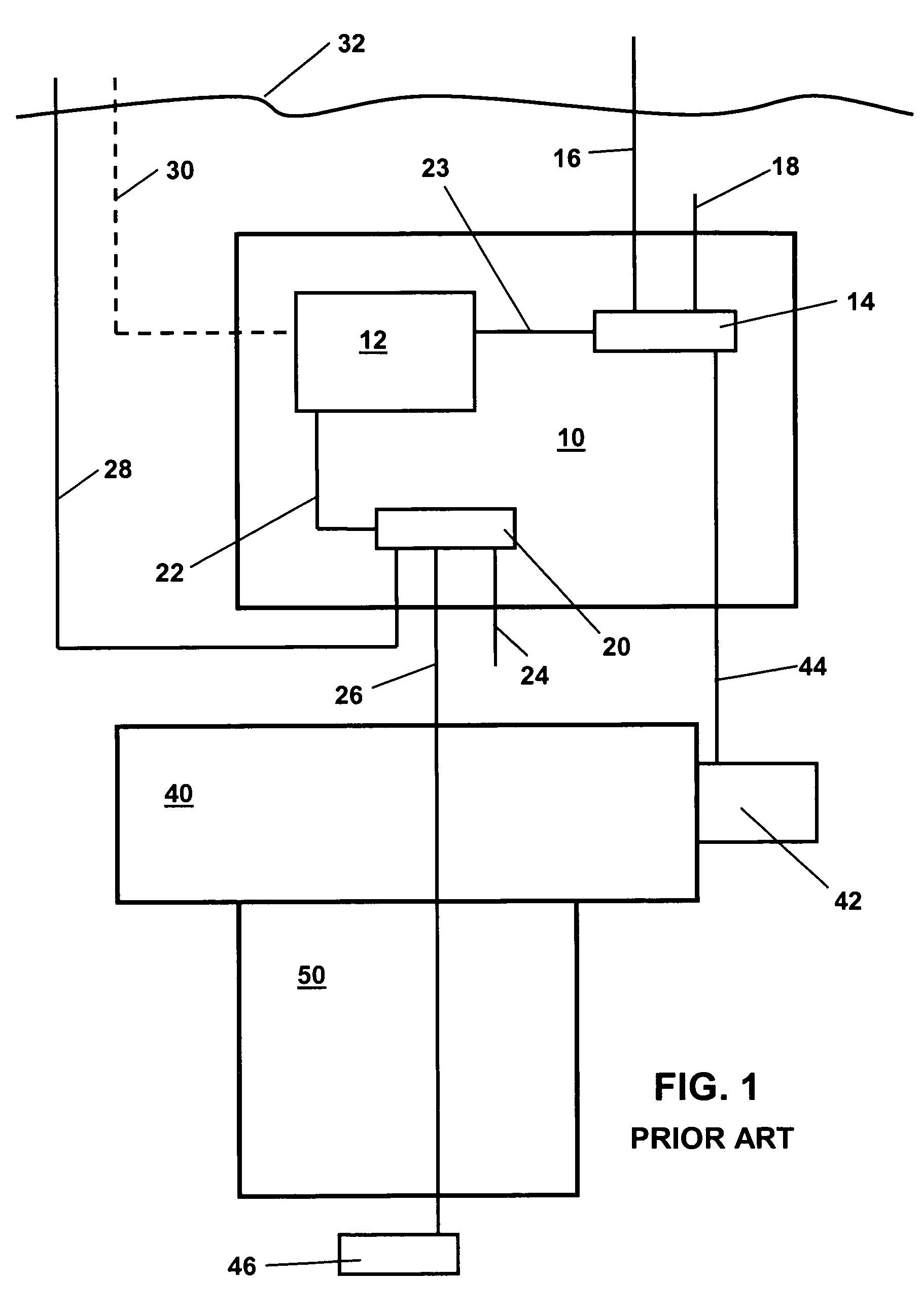

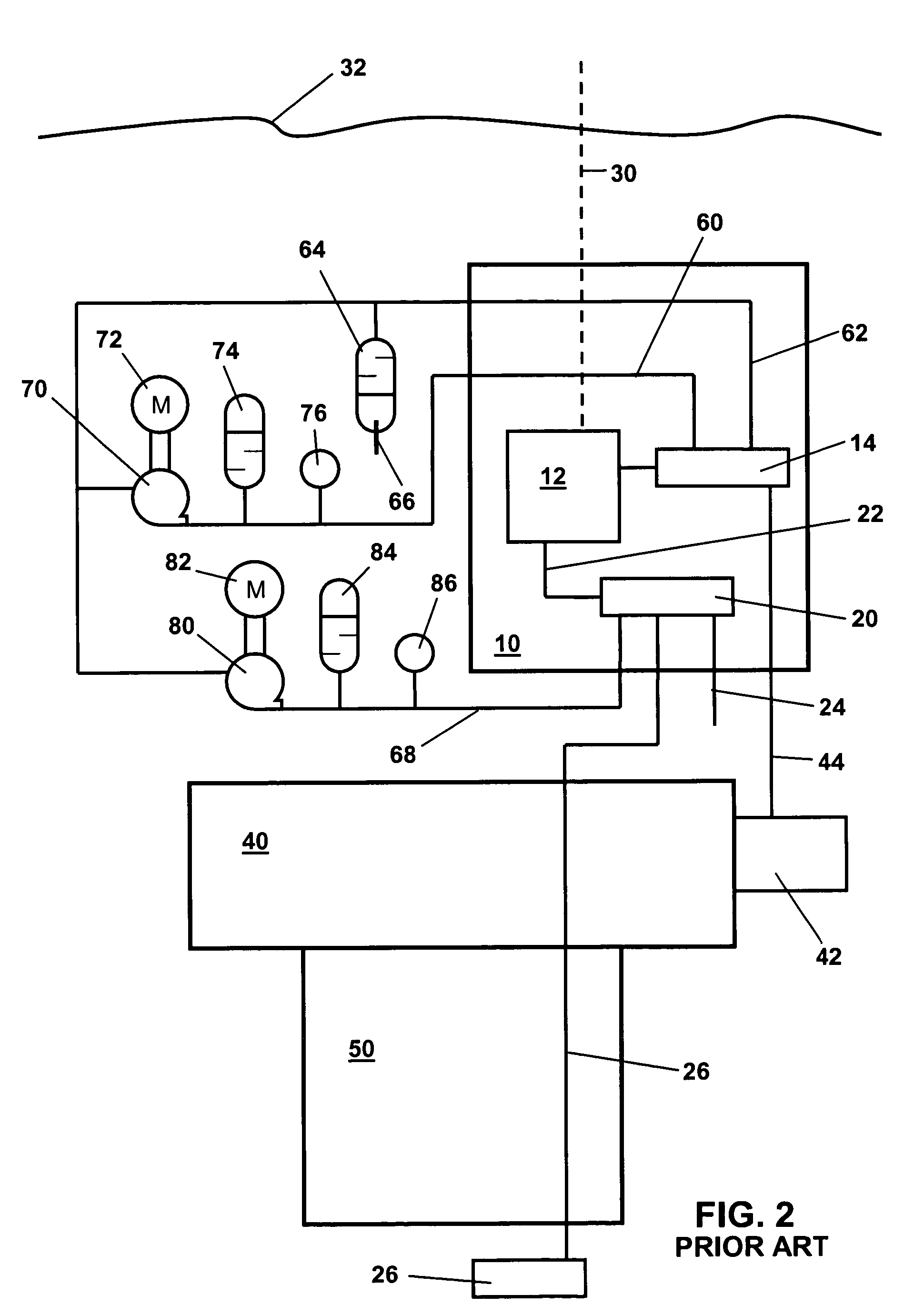

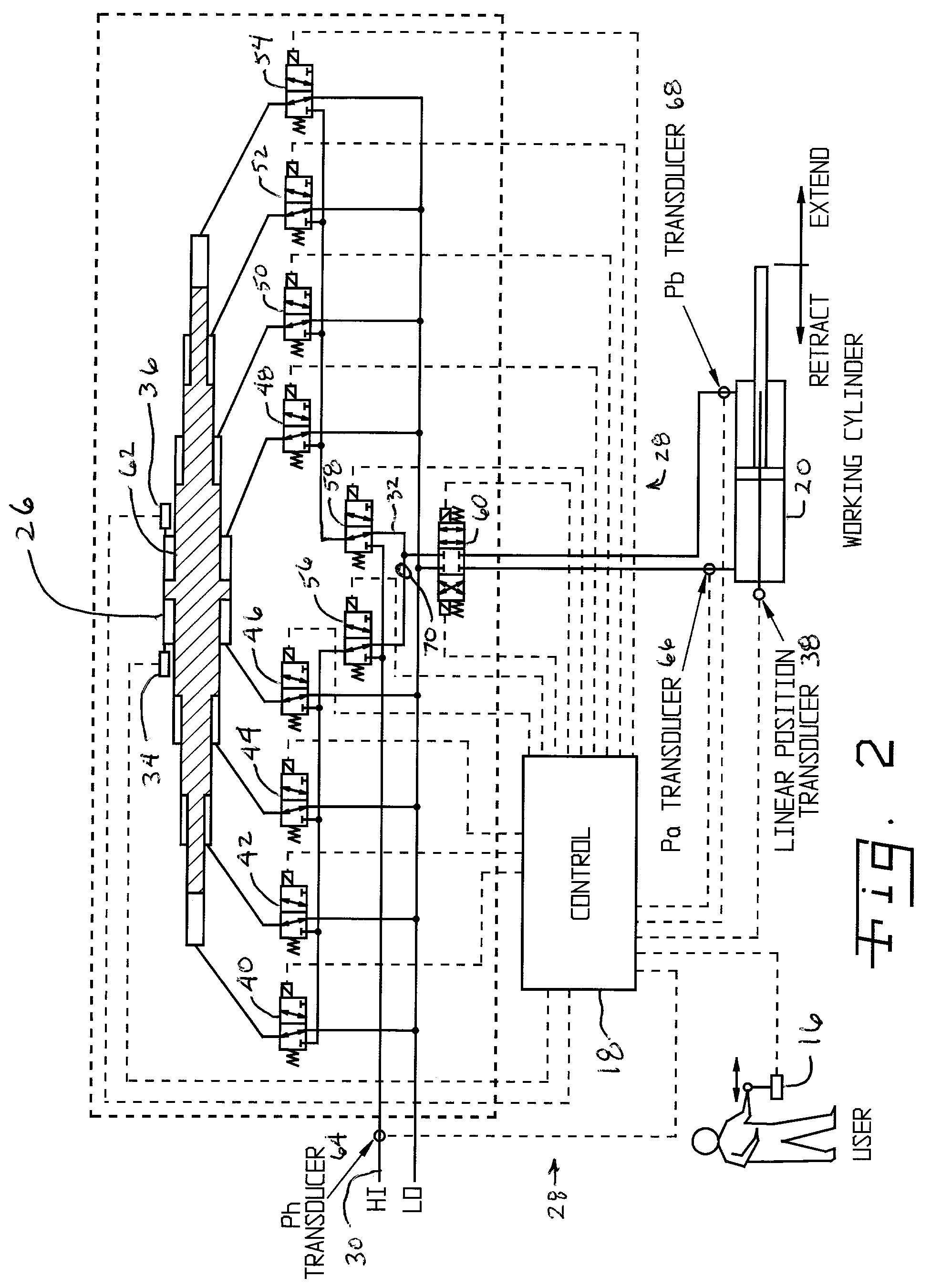

System for controlling a hydraulic actuator, and methods of using same

The present invention is directed to a system for controlling a hydraulic actuator, and various methods of using same. In one illustrative embodiment, the system comprises a first hydraulic cylinder, an isolated supply of fluid provided to the first hydraulic cylinder, the isolated supply of fluid positioned in an environment that is at a pressure other than atmospheric pressure, an actuator device coupled to the first hydraulic cylinder, the actuator device adapted to drive the first hydraulic cylinder to create the sufficient pressure in the fluid, and at least one hydraulic line operatively intermediate the first hydraulic cylinder and the hydraulic actuator, the hydraulic line supplying the sufficient pressure in the fluid to the hydraulic actuator in the remote locale.

Owner:FMC TECH INC

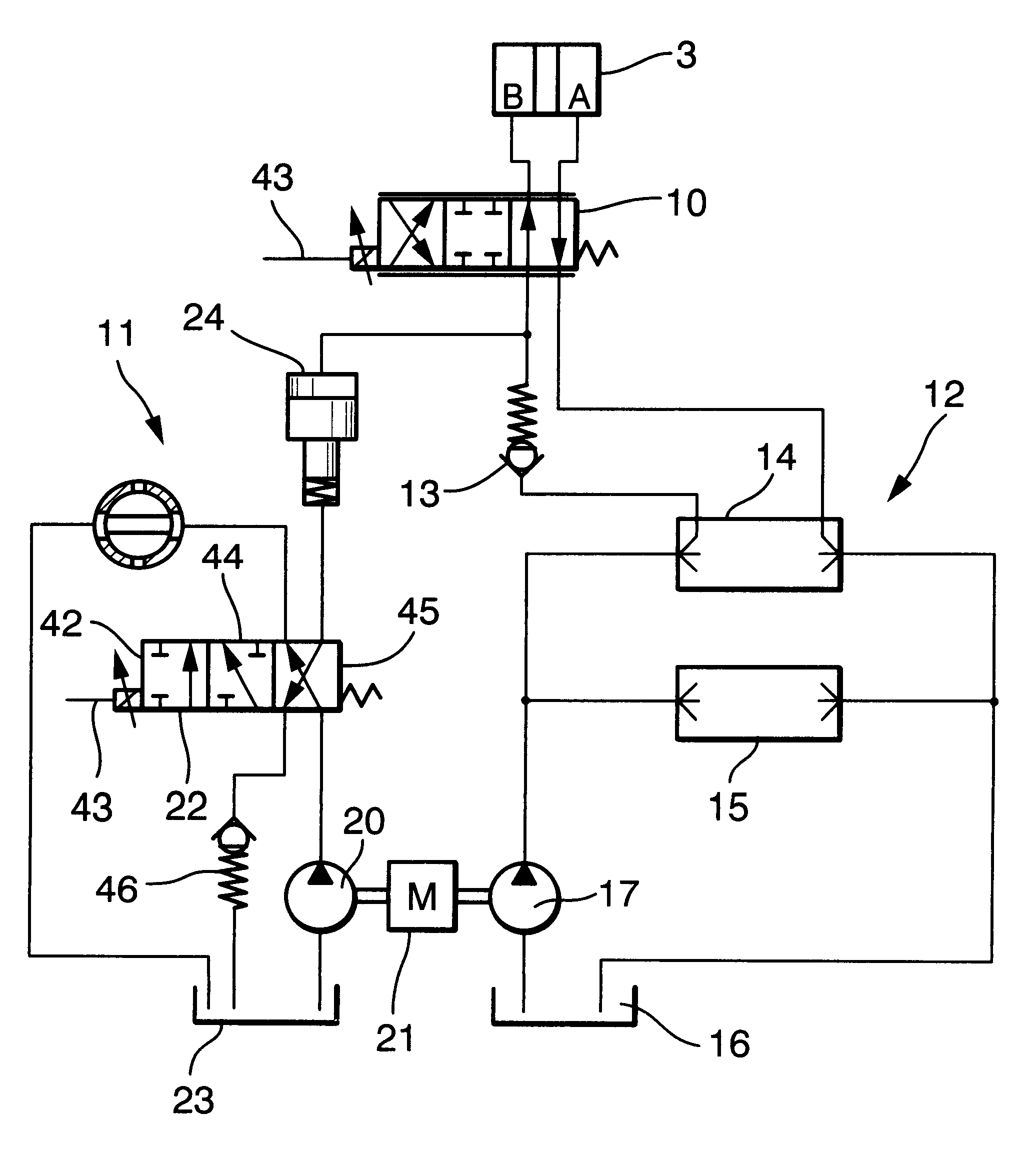

Hydraulic intensifiers

InactiveUS20090317267A1Increase the cross-sectional areaPositive displacement pump componentsFlexible member pumpsHigh pressureHydraulic fluid

A hydraulic intensifier with a piston and cylinder assembly (1) having a first piston (3) in a chamber (4) of low pressure cylinder and a second piston (7) in a chamber (8) of a high pressure cylinder. The first and second pistons are coupled together and the first piston has a larger cross-sectional area than the second piston. A high pressure output (19) is coupled to the chamber of the high pressure cylinder, there being; means (13) for supplying low pressure hydraulic fluid to the chamber of the low pressure cylinder; an electrically operated directional control valve (11) for controlling the supply of low pressure hydraulic fluid to the chamber of the low pressure cylinder; and electronic means (14) for controlling operation of the directional control valve.

Owner:VETCO GRAY CONTROLS

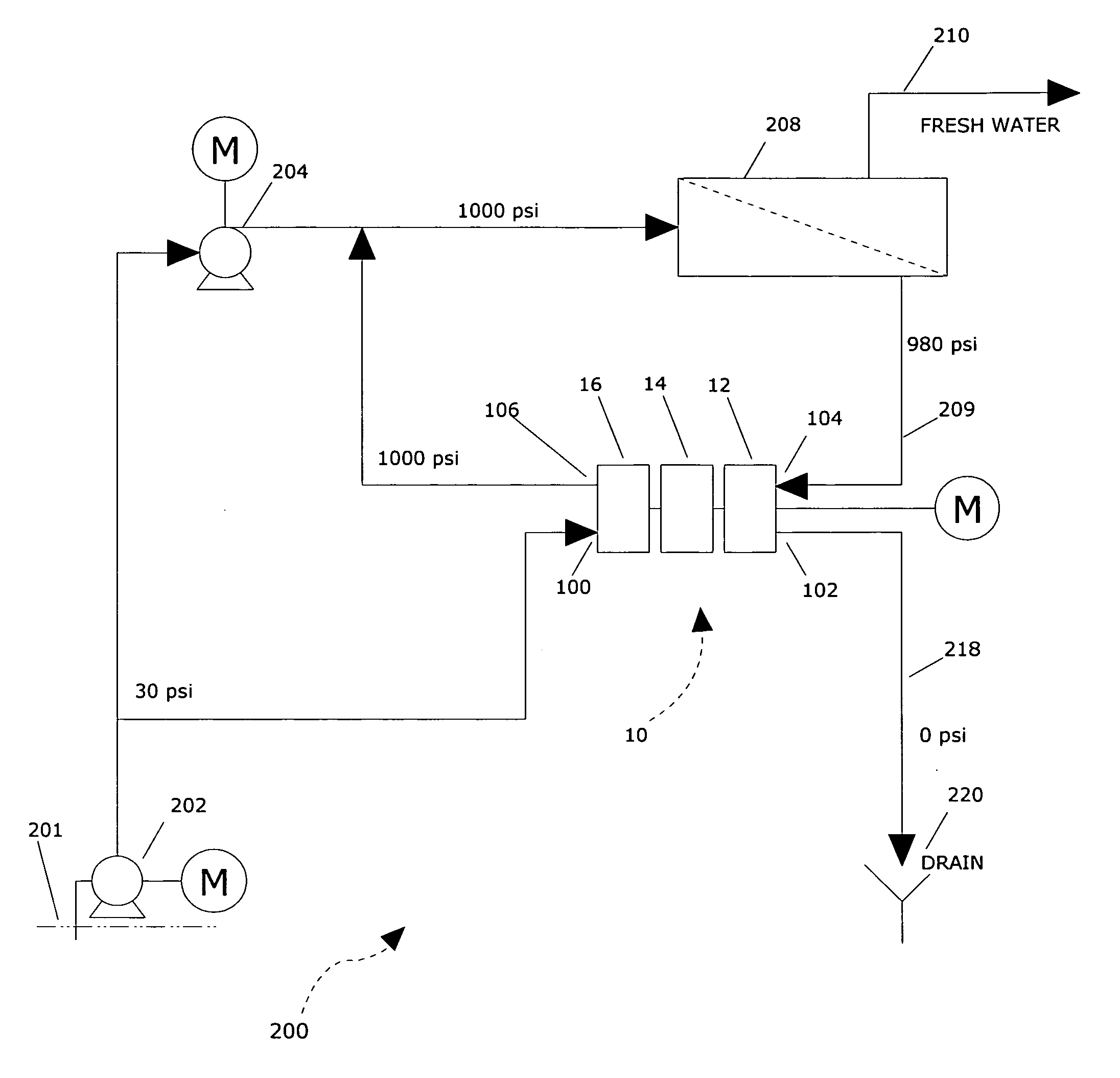

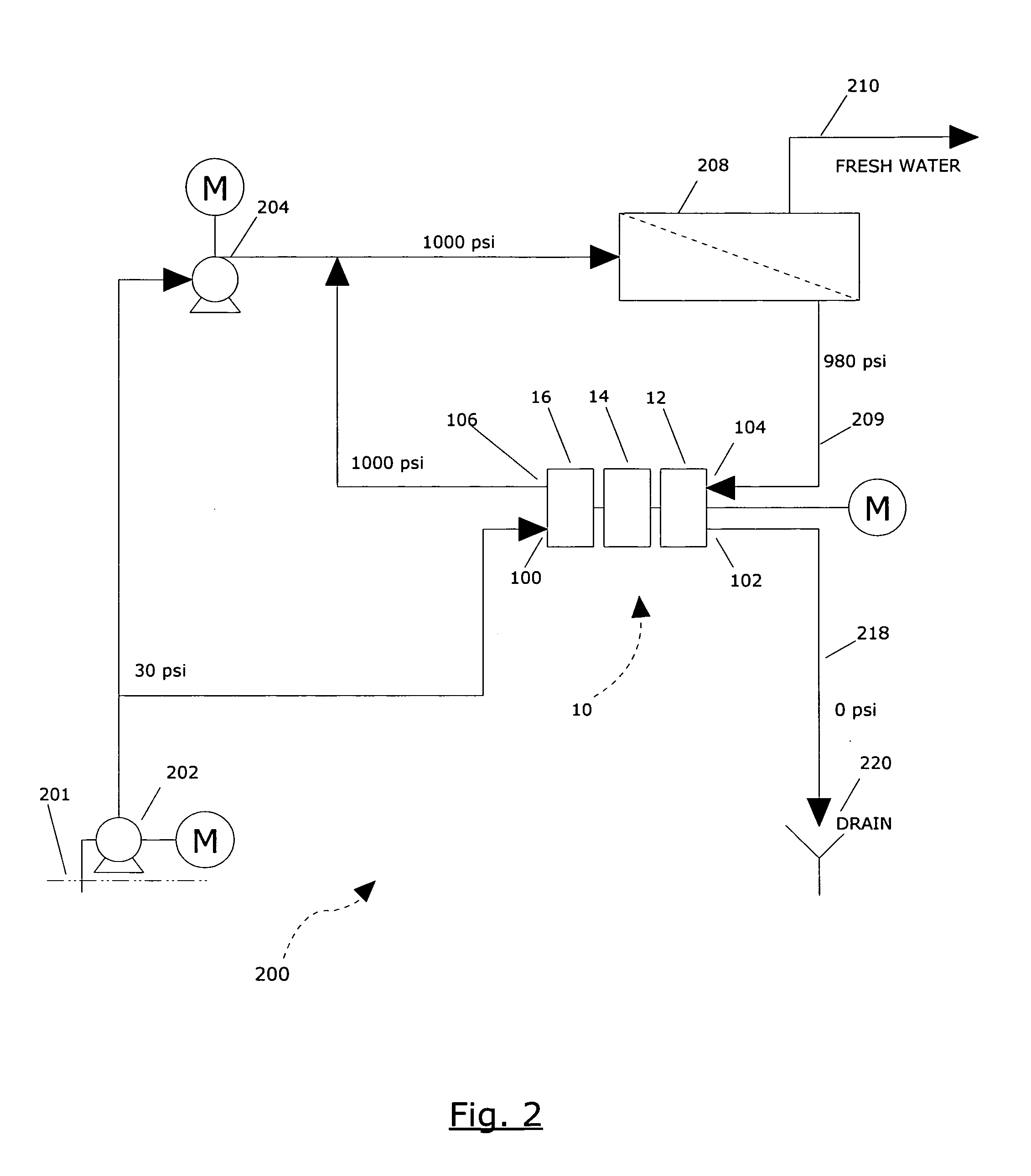

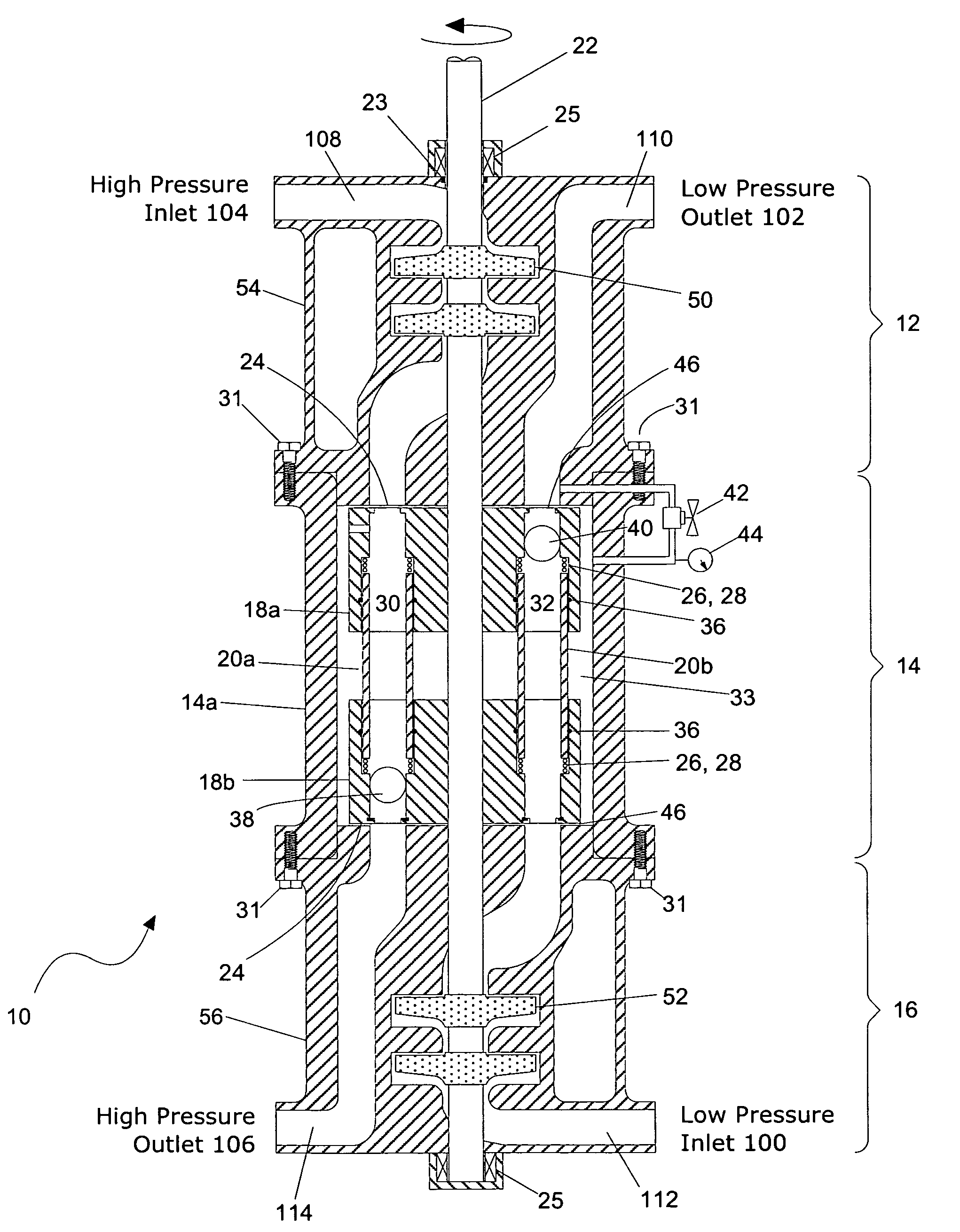

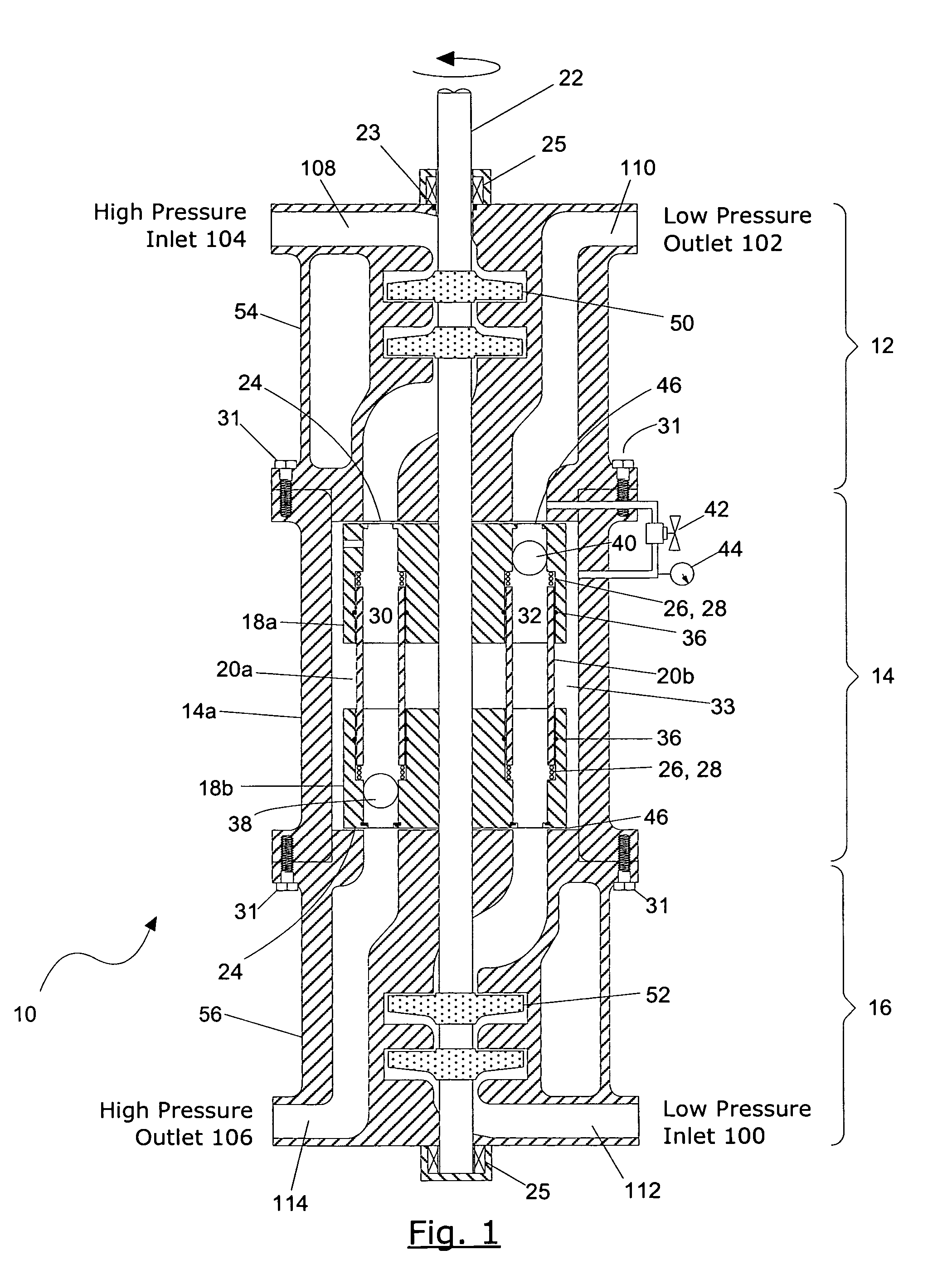

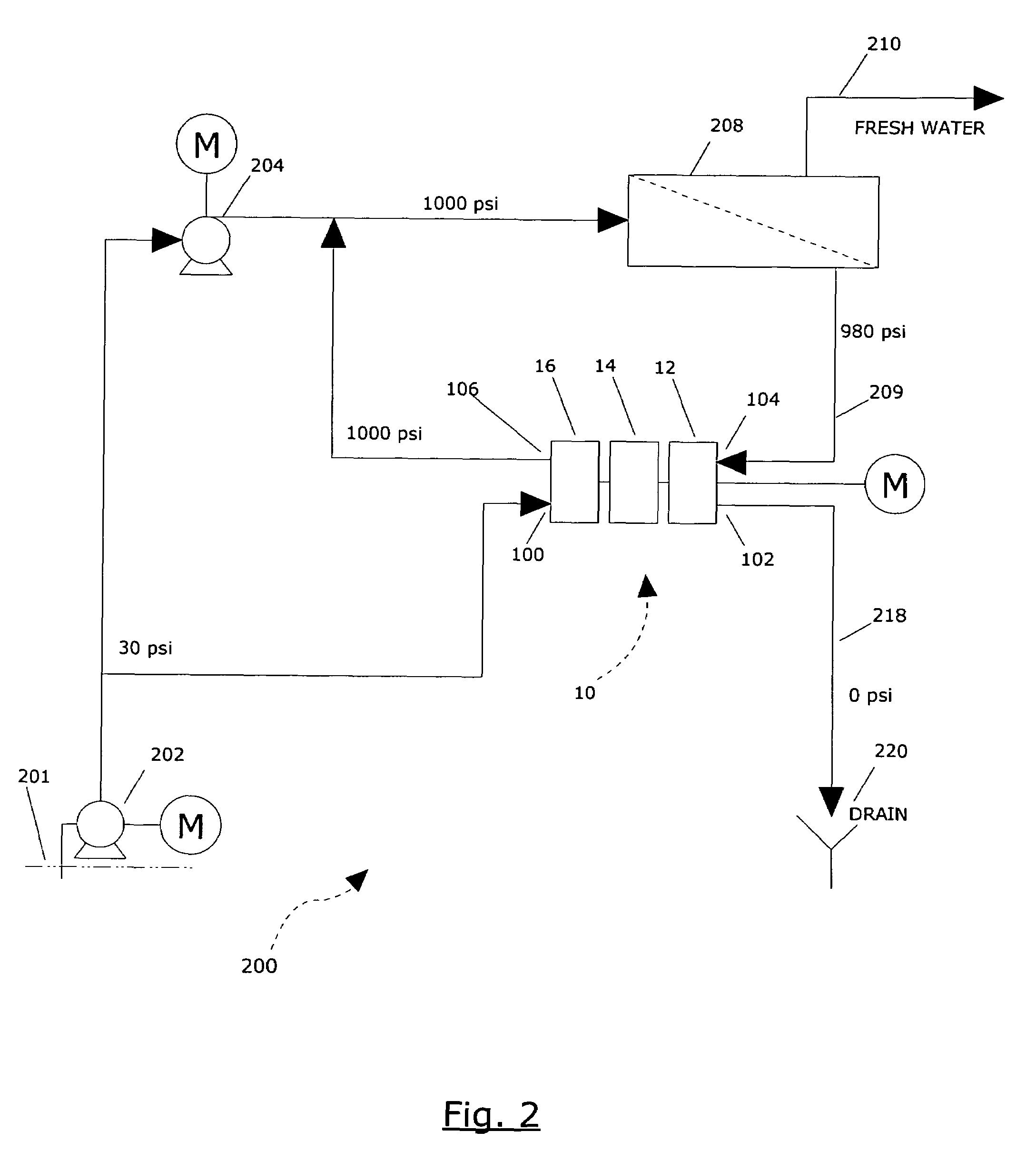

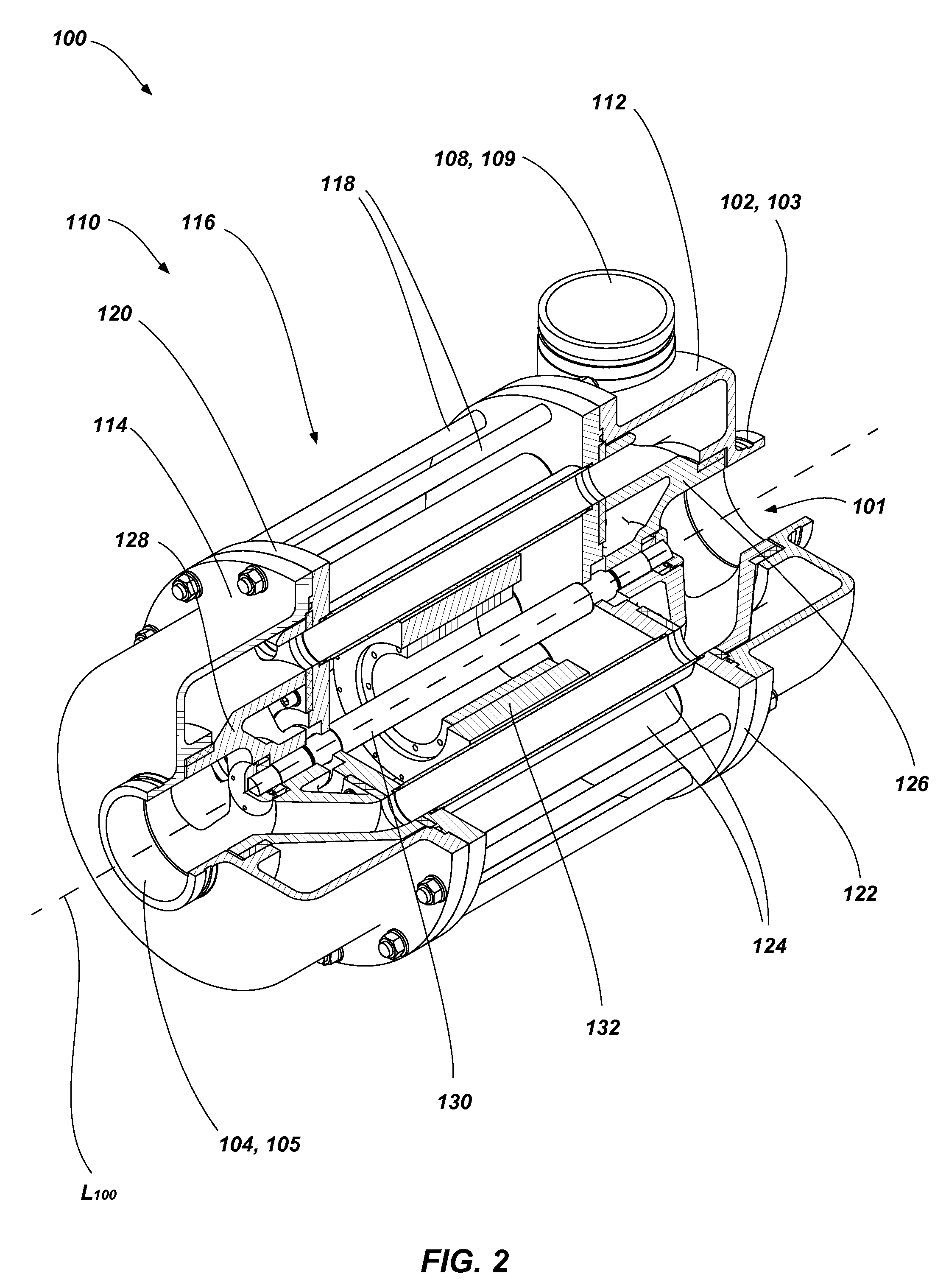

Pressure exchange apparatus with integral pump

InactiveUS20060037895A1Increase pressureRotary/oscillating piston combinations for elastic fluidsPump componentsEngineeringMechanical engineering

A pressure exchange device is provided that utilizes an integral high pressure boost pump that is in fluid communication with a pressure exchange unit. An optional low pressure boost pump unit may also be provided. The pressure exchange unit comprises a rotating rotor assembly inside a housing to transfer the pressure of a fluid from one high pressure fluid to another low pressure fluid.

Owner:SHUMWAY SCOTT

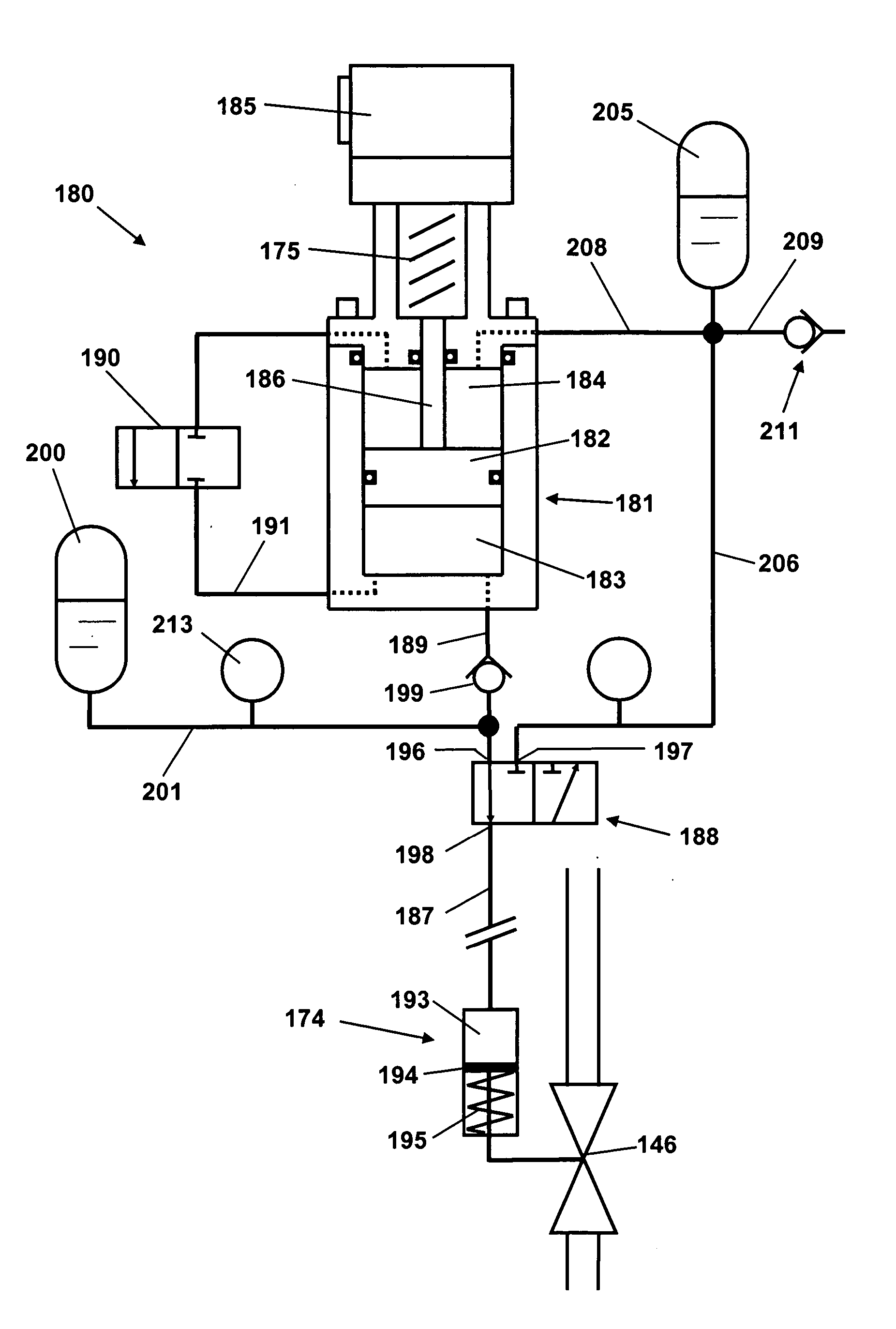

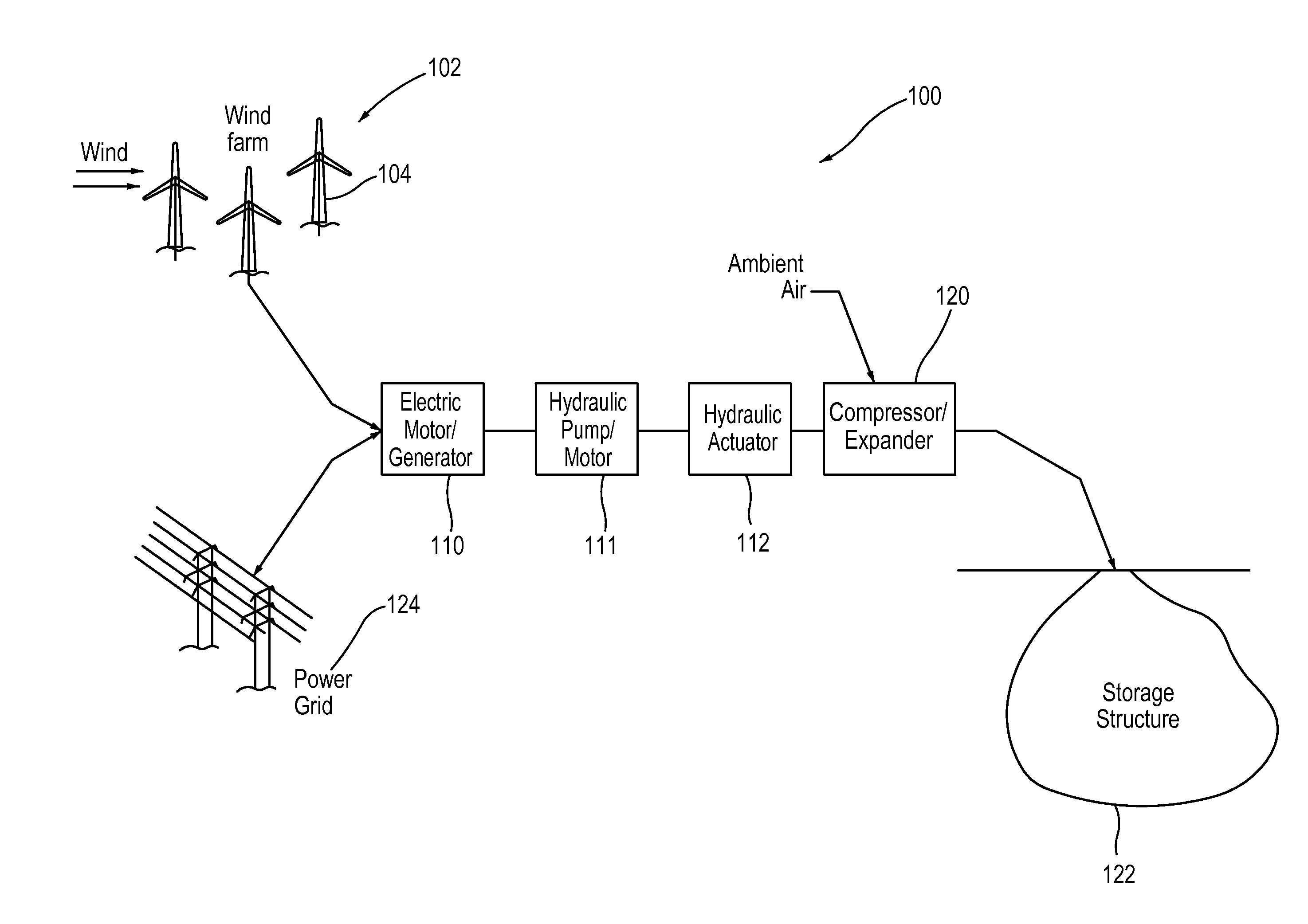

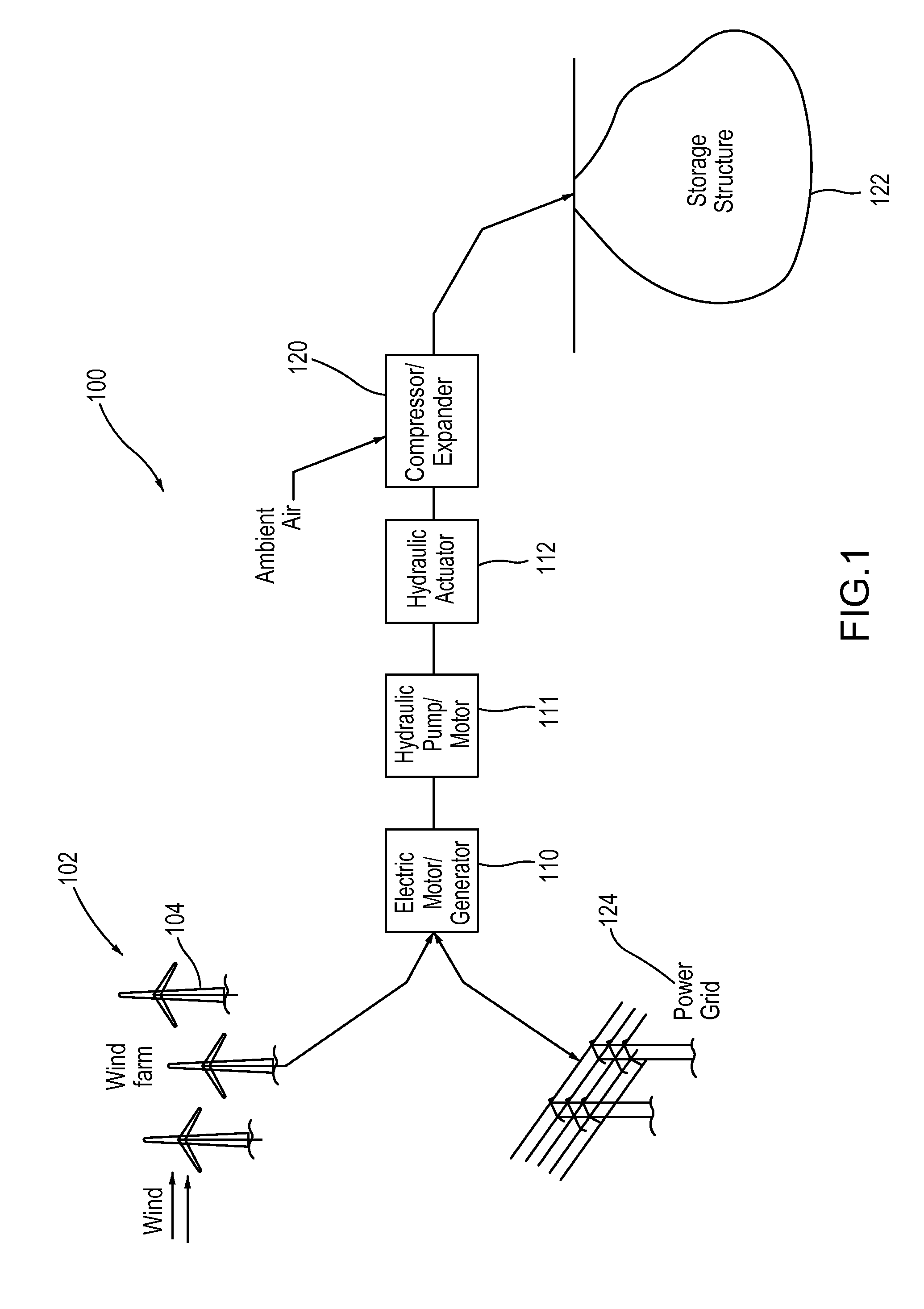

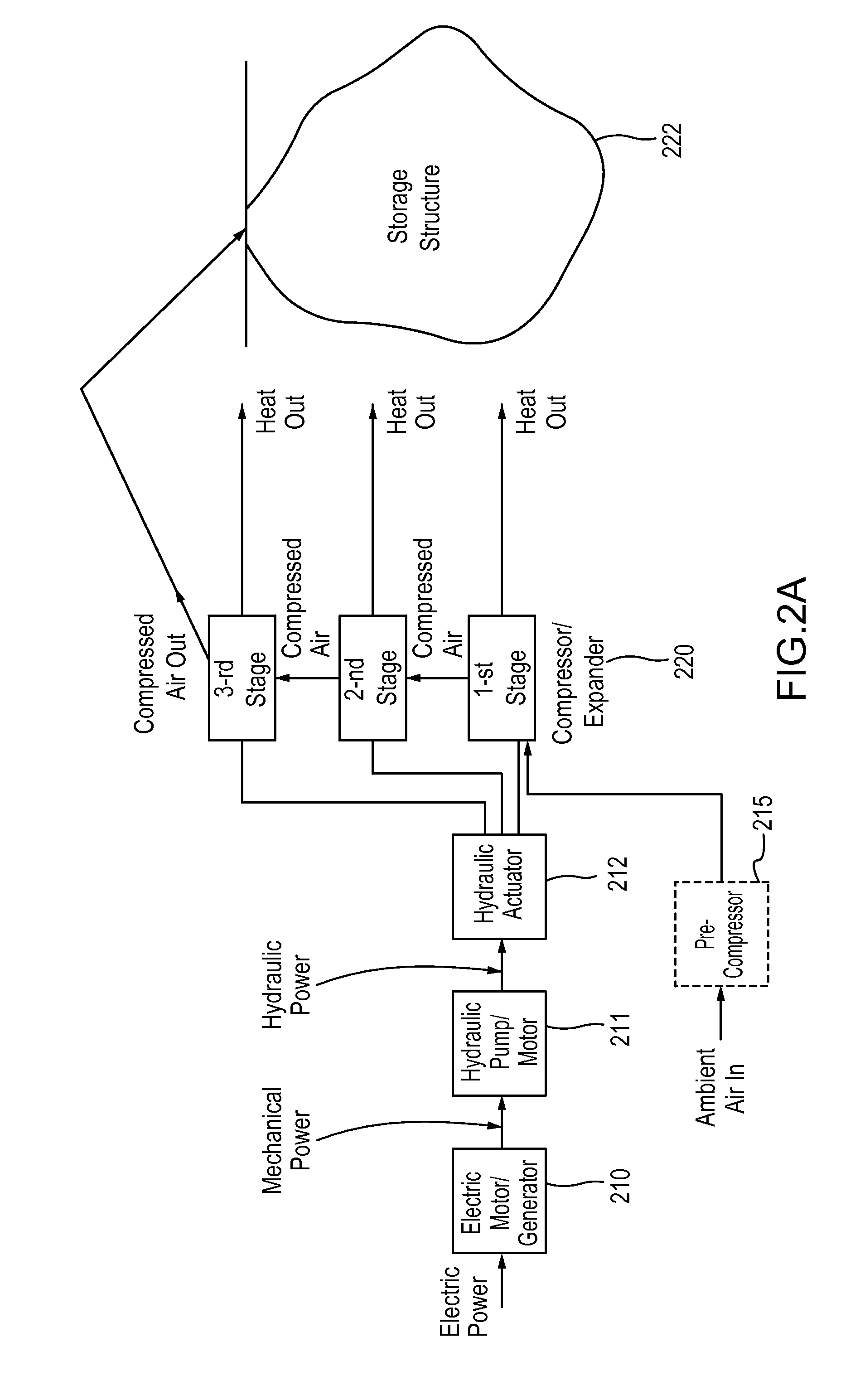

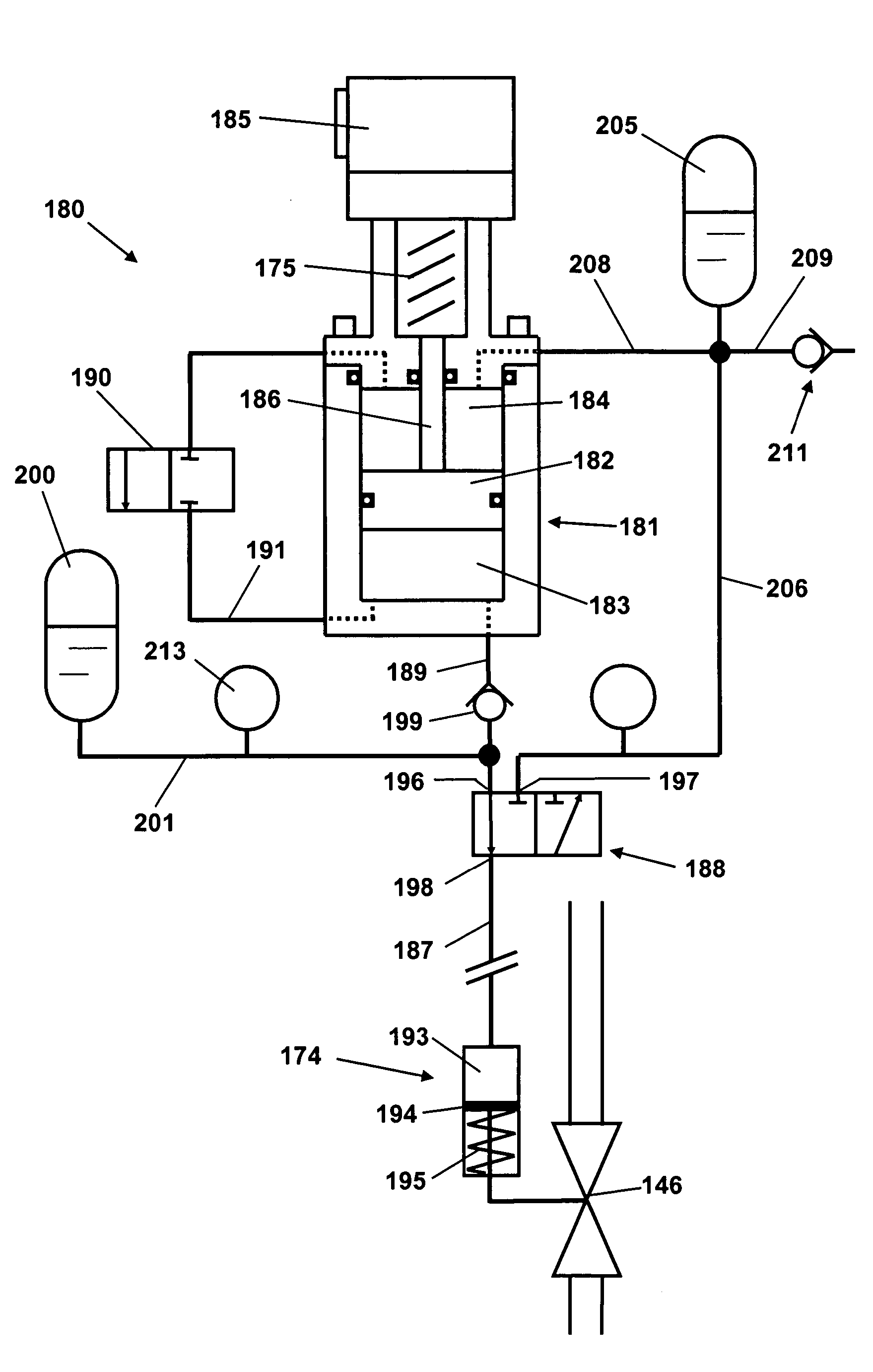

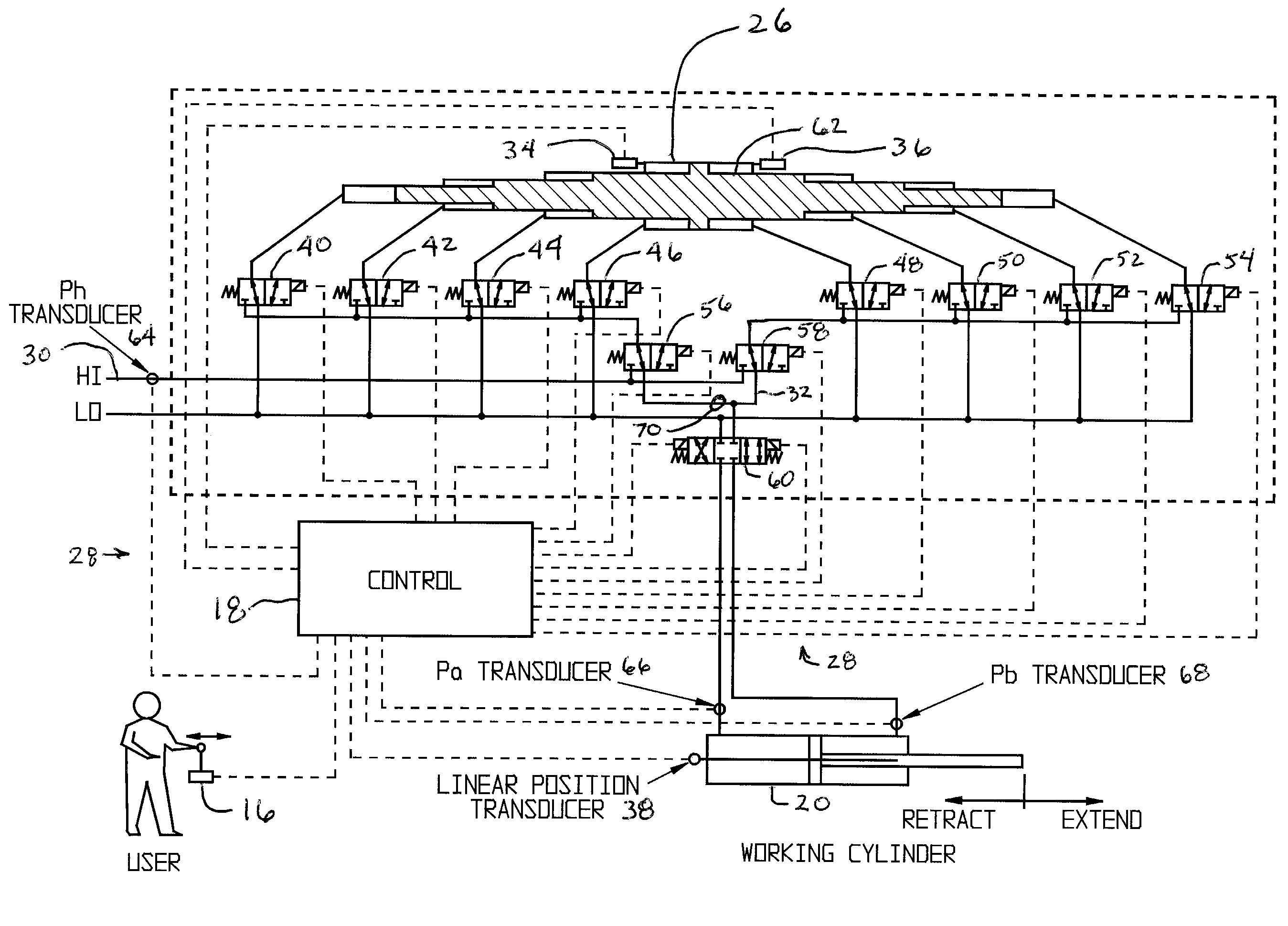

System and methods for optimizing efficiency of a hydraulically actuated system

InactiveUS20110258996A1Increase gas pressureEasy to operateFluid couplingsServomotor componentsHydraulic cylinderHydraulic pump

Systems and methods for efficiently operating a hydraulically actuated device / system are described herein. For example, systems and methods for efficiently operating a gas compression and expansion energy storage system are disclosed herein. Systems and methods are provided for controlling and operating the hydraulic actuators used within a hydraulically actuated device / system, such as, for example, a gas compression and / or expansion energy system, within a desired efficiency range of the hydraulic pump(s) / motor(s) used to supply or receive pressurized hydraulic fluid to or from the hydraulic actuators. In such a system, a variety of different operating regimes can be used depending on the desired output gas pressure and the desired stored pressure of the compressed gas. Hydraulic cylinders used to drive working pistons within the system can be selectively actuated to achieve varying force outputs to incrementally increase the gas pressure within the system for a given cycle.

Owner:GENERAL COMPRESSION

System for controlling a hydraulic actuator, and methods of using same

The present invention is directed to a system for controlling a hydraulic actuator, and various methods of using same. In one illustrative embodiment, the system comprises a first hydraulic cylinder, an isolated supply of fluid provided to the first hydraulic cylinder, the isolated supply of fluid positioned in an environment that is at a pressure other than atmospheric pressure, an actuator device coupled to the first hydraulic cylinder, the actuator device adapted to drive the first hydraulic cylinder to create the sufficient pressure in the fluid, and at least one hydraulic line operatively intermediate the first hydraulic cylinder and the hydraulic actuator, the hydraulic line supplying the sufficient pressure in the fluid to the hydraulic actuator in the remote locale.

Owner:FMC TECH INC

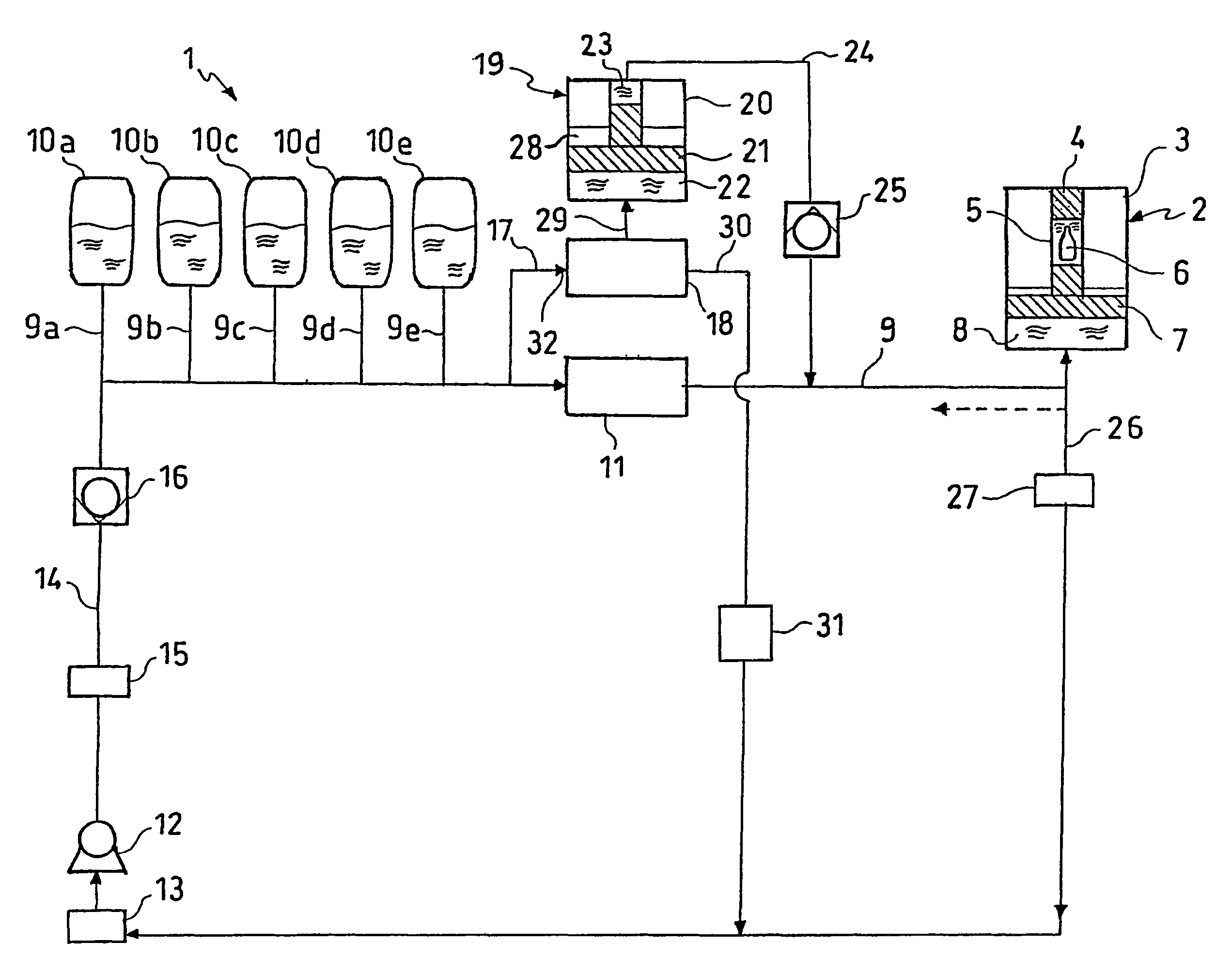

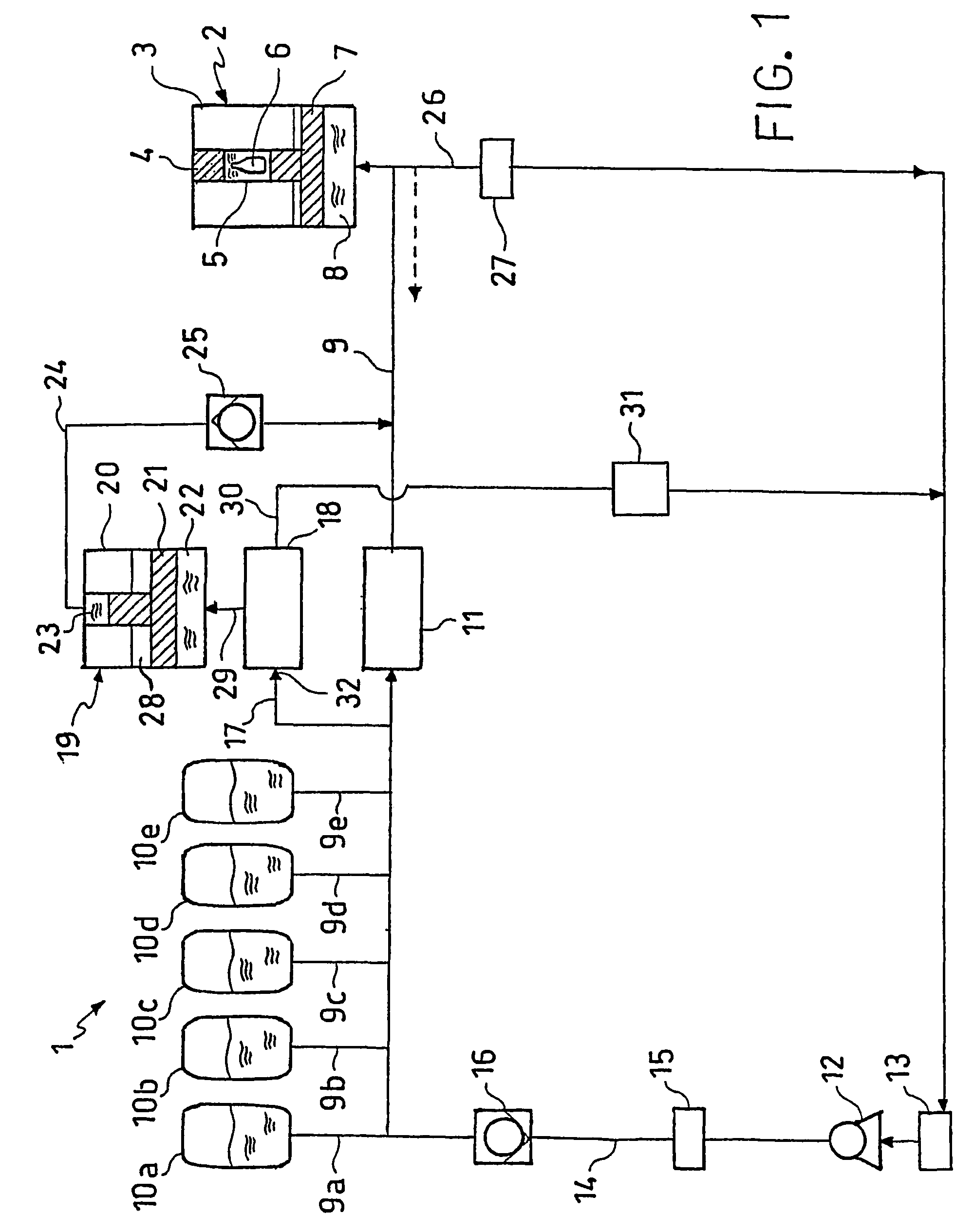

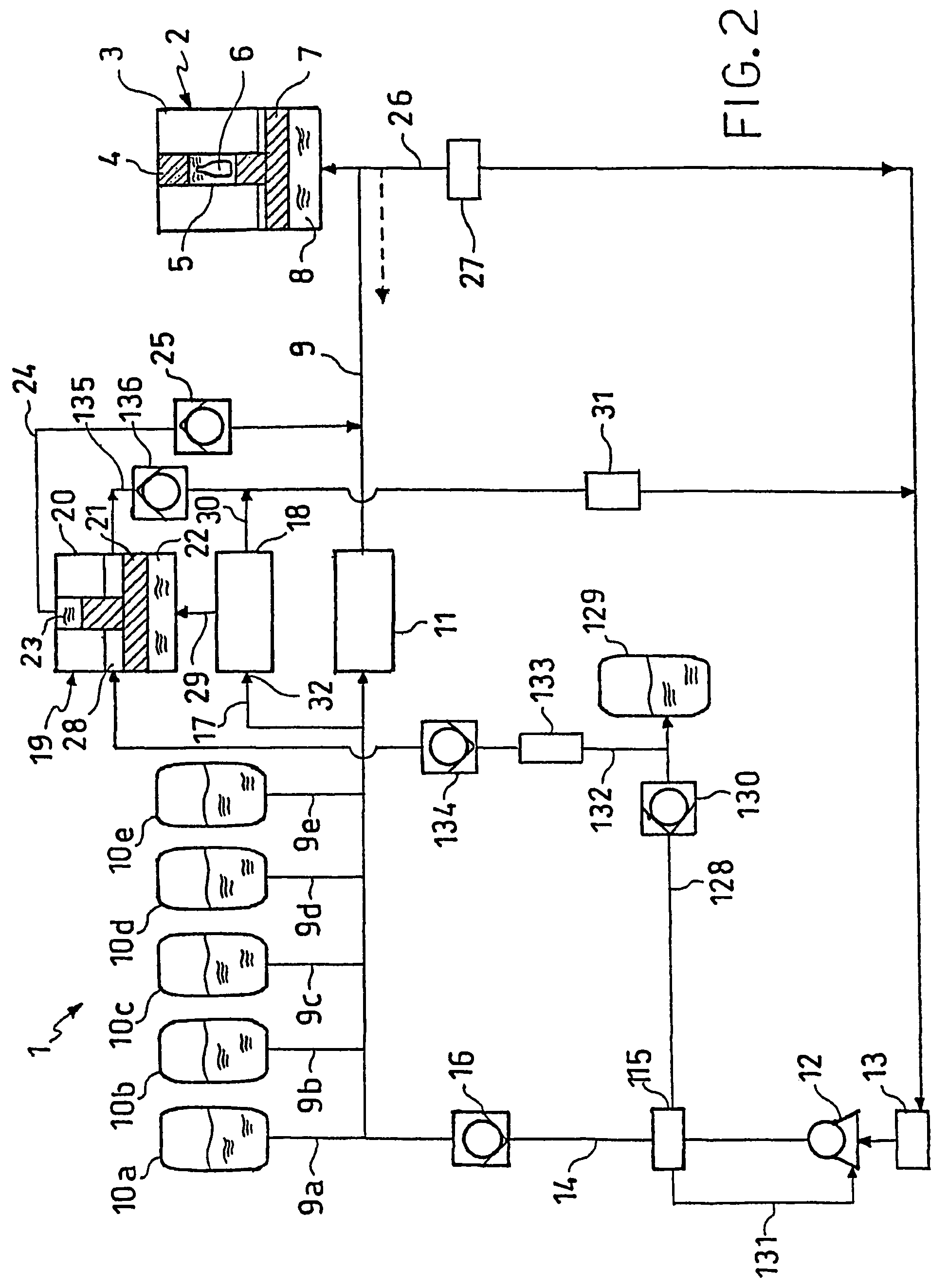

Hydraulic pressurization system

InactiveUS7107766B2Quick and effective pressurizationPressurized chemical processServomotor componentsControl mannerHydrostatic pressure

The present invention relates to a hydraulic pressurization system, in particular for application to pressurization devices operating in accordance with the high hydrostatic pressure principle. In particular, the present invention provides a pressurization system for modifying the pressure in a pressurization device. The system comprising a first hydraulic circuit in which one or more primary pressure accumulators are connected to the pressurization device in controlled manner in order to permit a substantially incompressible fluid to be admitted to and removed from the pressurization device at a first pressure, the primary pressure accumulators being precompressed-gas pressure accumulators.

Owner:SIDEL SPA

Pressure intensifier

ActiveUS7354252B2Cavitation phenomenon can be preventedReliable startFluid-pressure convertersPiston pumpsControl lineEngineering

A pressure intensifier for fluids has an intensifier piston with a high-pressure piston and a low-pressure piston having a greater diameter than the high-pressure piston. The pistons are moveable in a high-pressure cylinder and a low-pressure cylinder, respectively, and move together. The high-pressure cylinder is connected to a high-pressure connection. A first control line is connected to a supply connector. A second control line is connected to a control valve having first and second switching positions. A first connection connects the control lines. The low-pressure cylinder is connected via the control valve in the first switching position to a supply connector and in the second switching position to a return connector. The switching positions are controlled by the intensifier piston. The intensifier piston opens or closes the first connection between the control lines. The first connection is arranged completely within a movement stroke of the high-pressure piston.

Owner:MINIBOOSTER HYDRAULICS

Fracturing pump assembly and method thereof

A fracturing pump assembly includes an intensifier including a hydraulic cylinder, a compression member arranged within the hydraulic cylinder and a rotatable member, wherein the compression member is linearly actuated within the hydraulic cylinder by rotation of the rotatable member.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

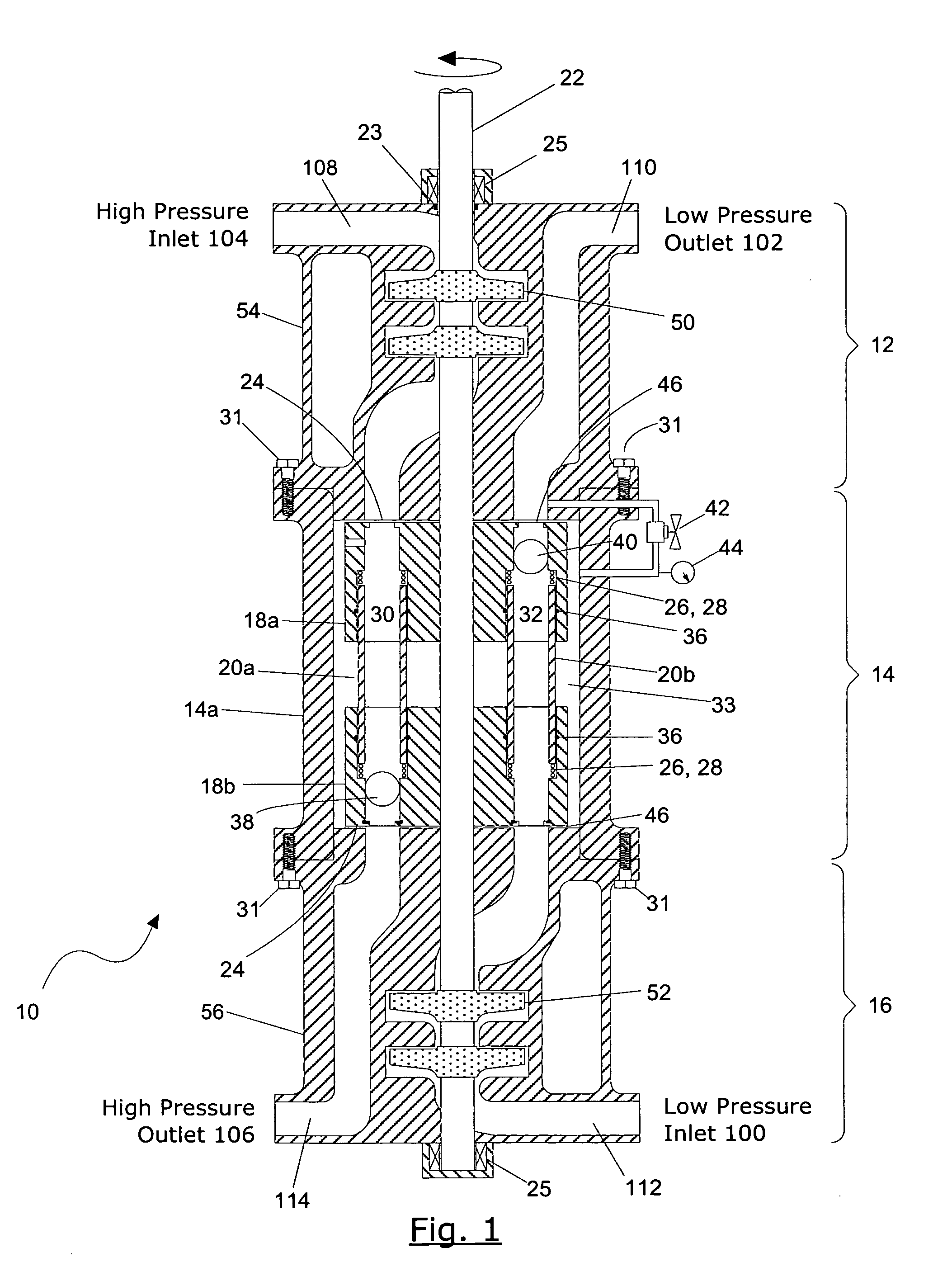

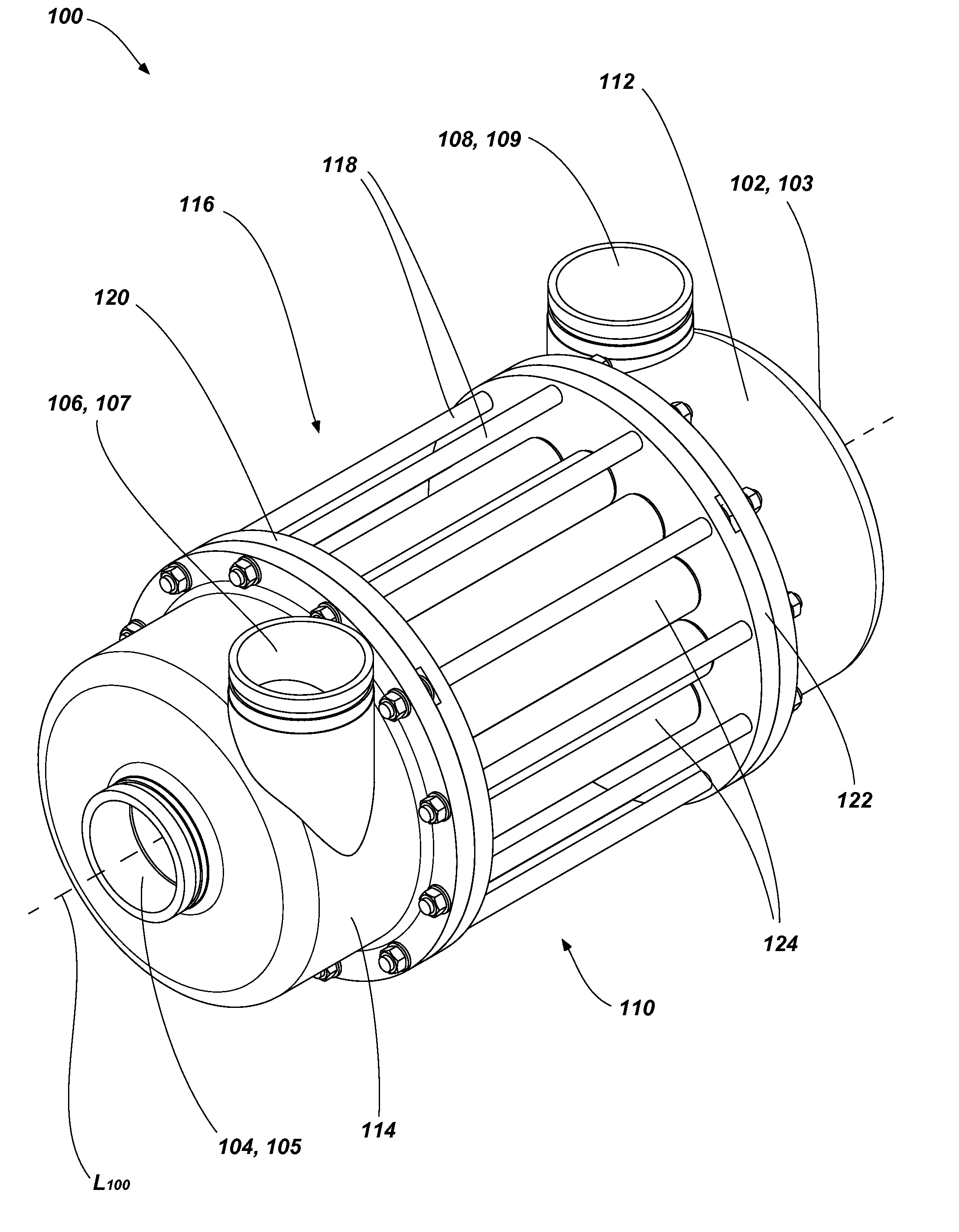

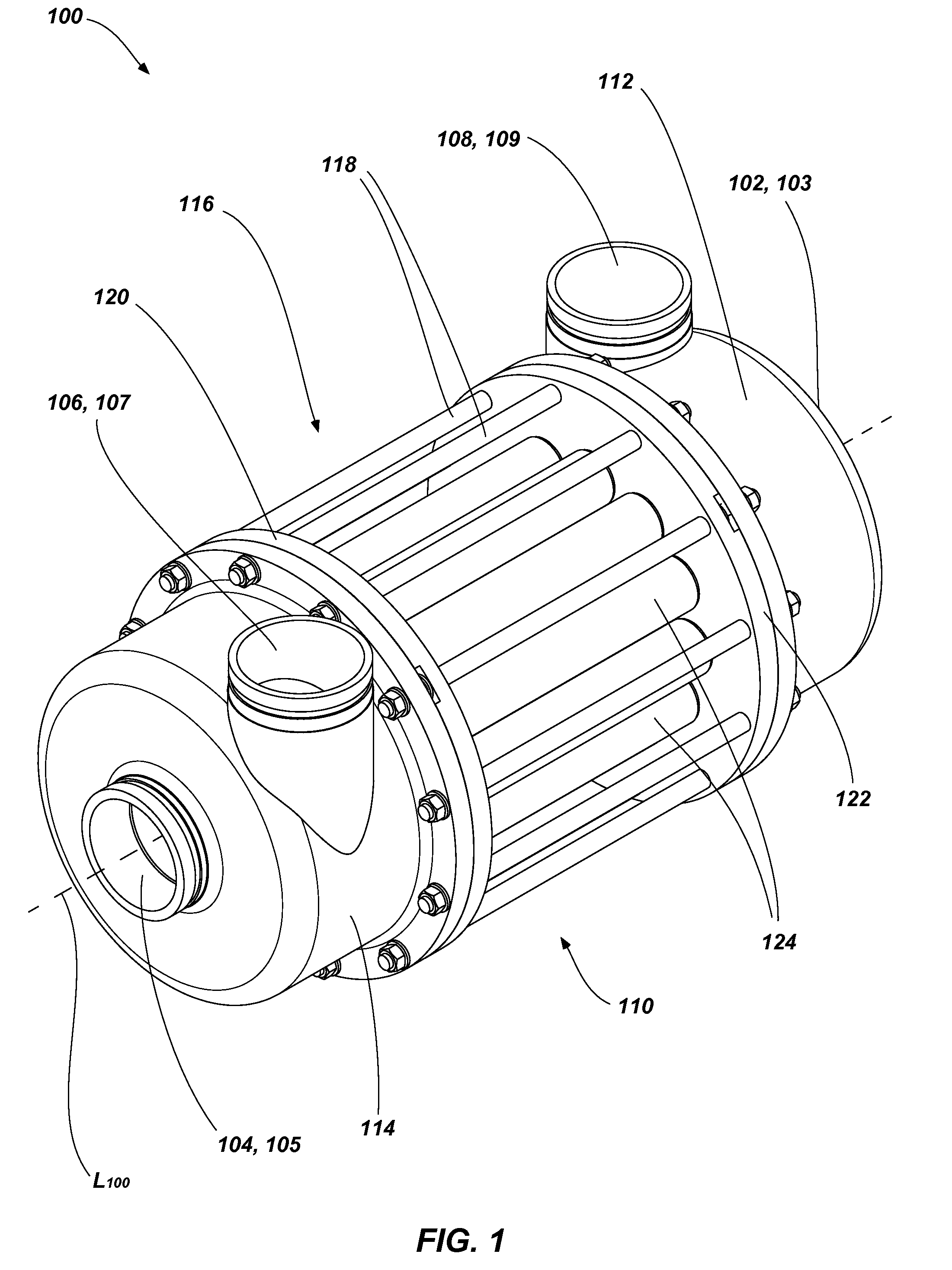

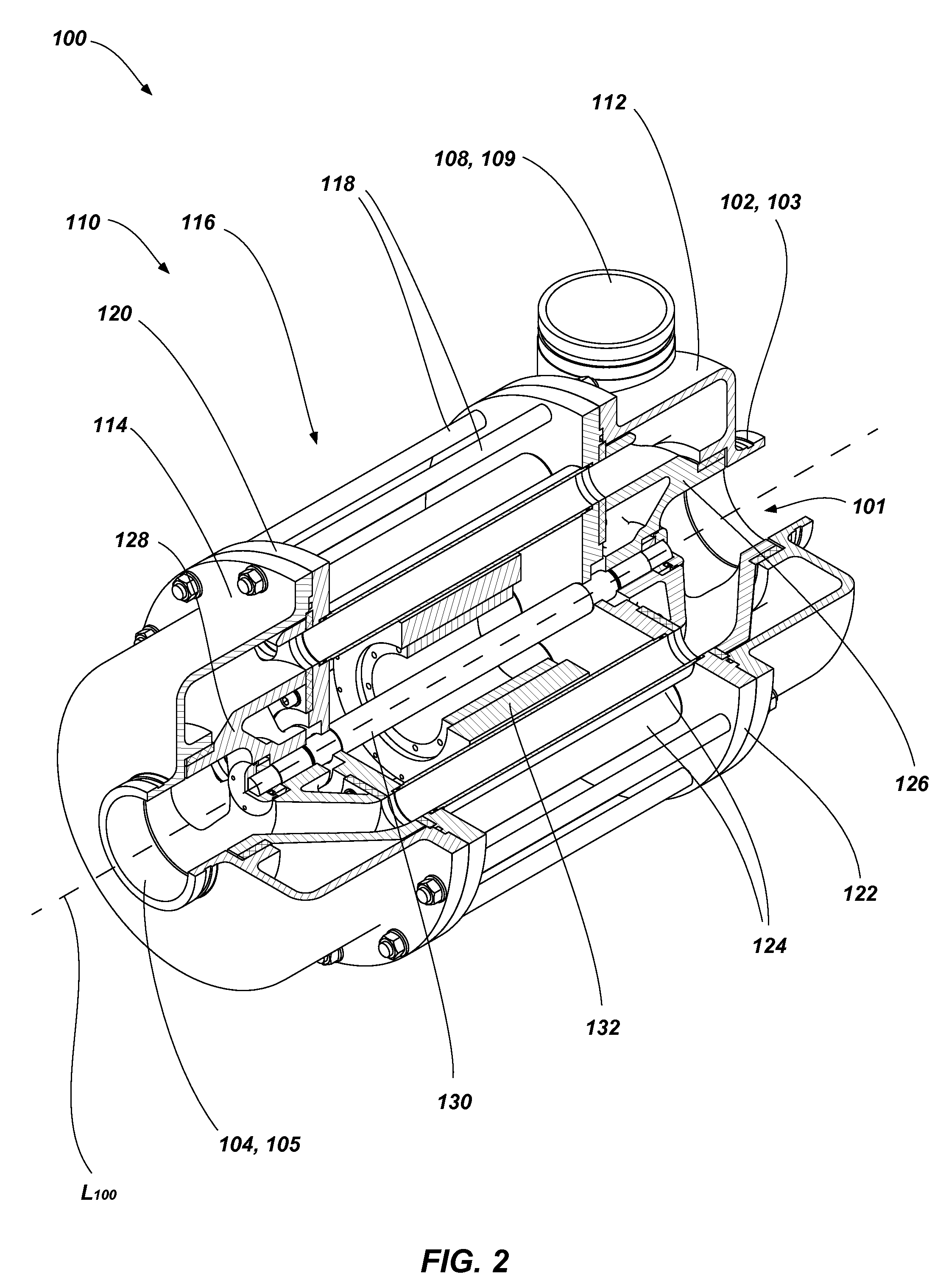

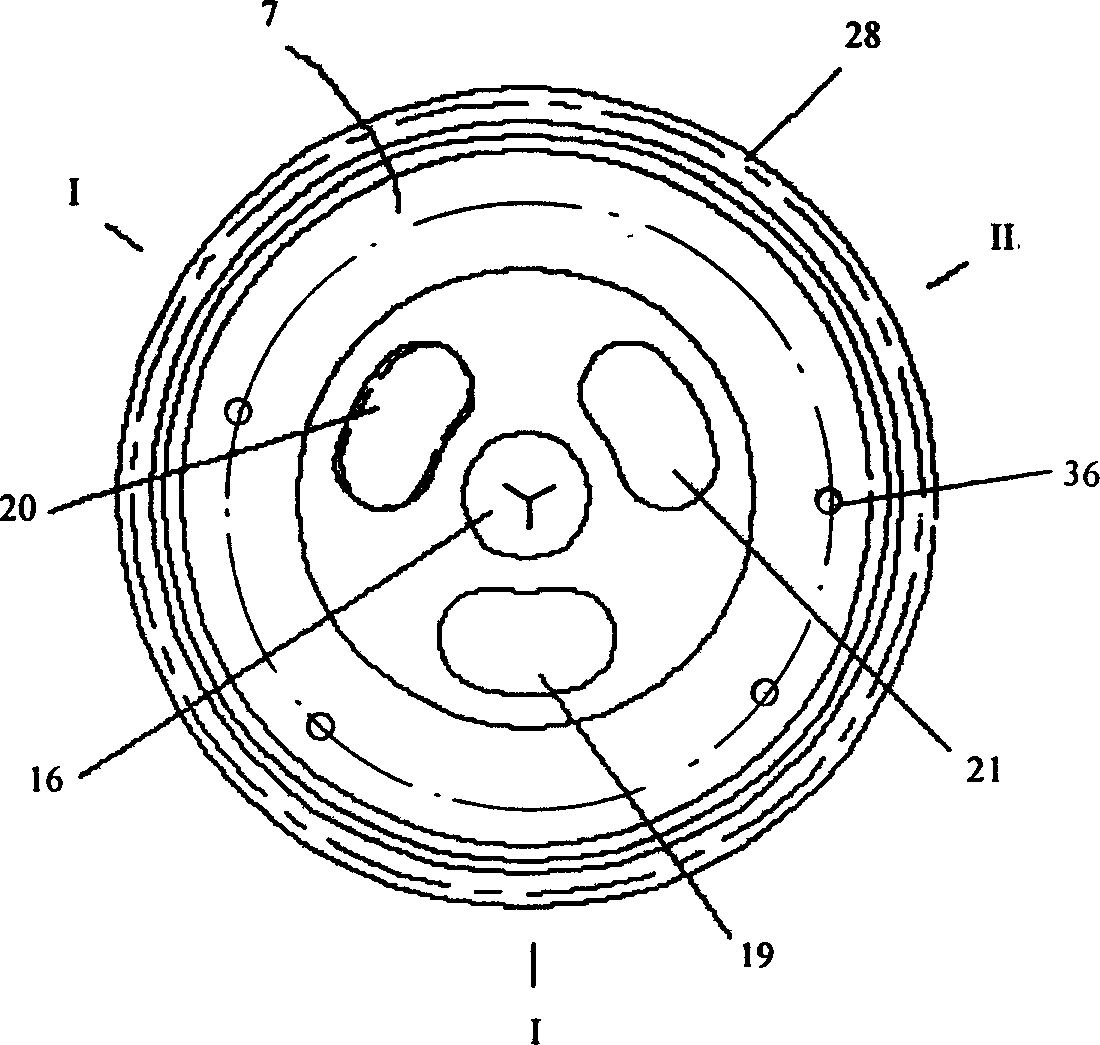

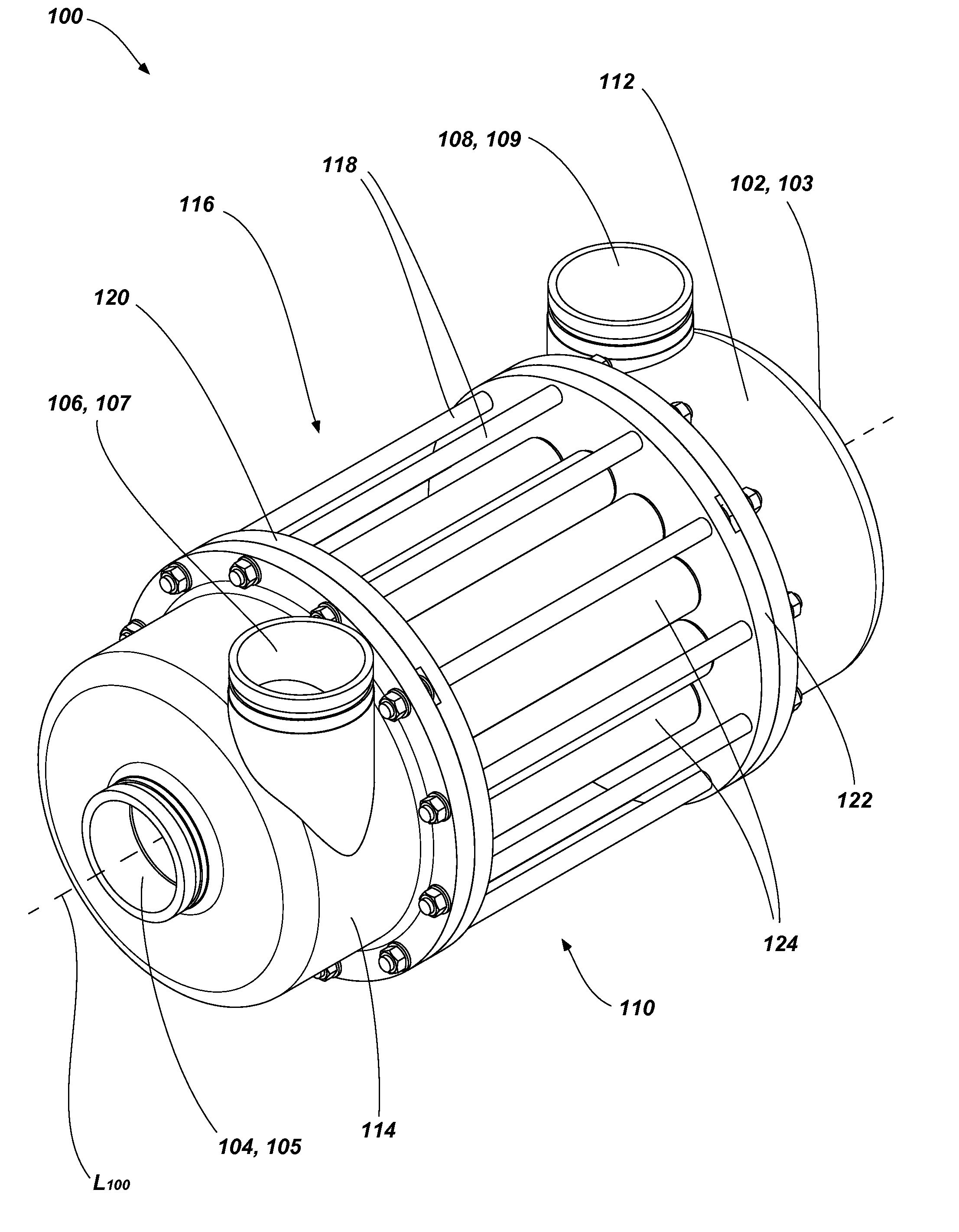

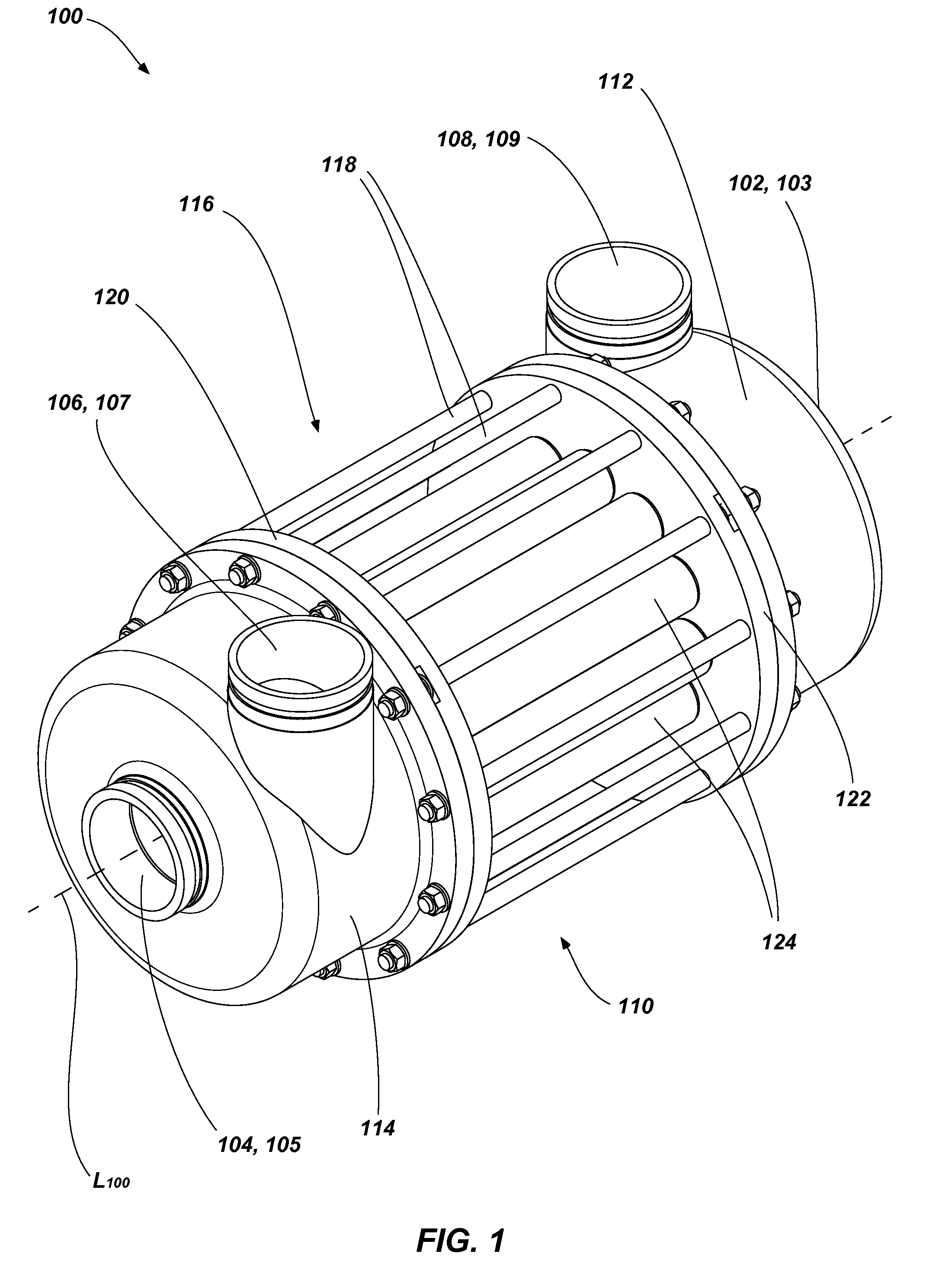

Fluid exchanger devices, pressure exchangers, and related methods

ActiveUS20140048143A1Scale upSpecific water treatment objectivesWater/sewage treatmentRotary valveEngineering

Exchanger devices include a plurality of fixed exchange ducts and a rotating valve assembly for directing flow to and from the plurality of exchange ducts. Methods of exchanging pressure between fluid streams may include directing fluids through an exchange device and pressurizing a fluid in the plurality of exchange ducts of the exchanger device.

Owner:FLOWSERVE PTE LTD

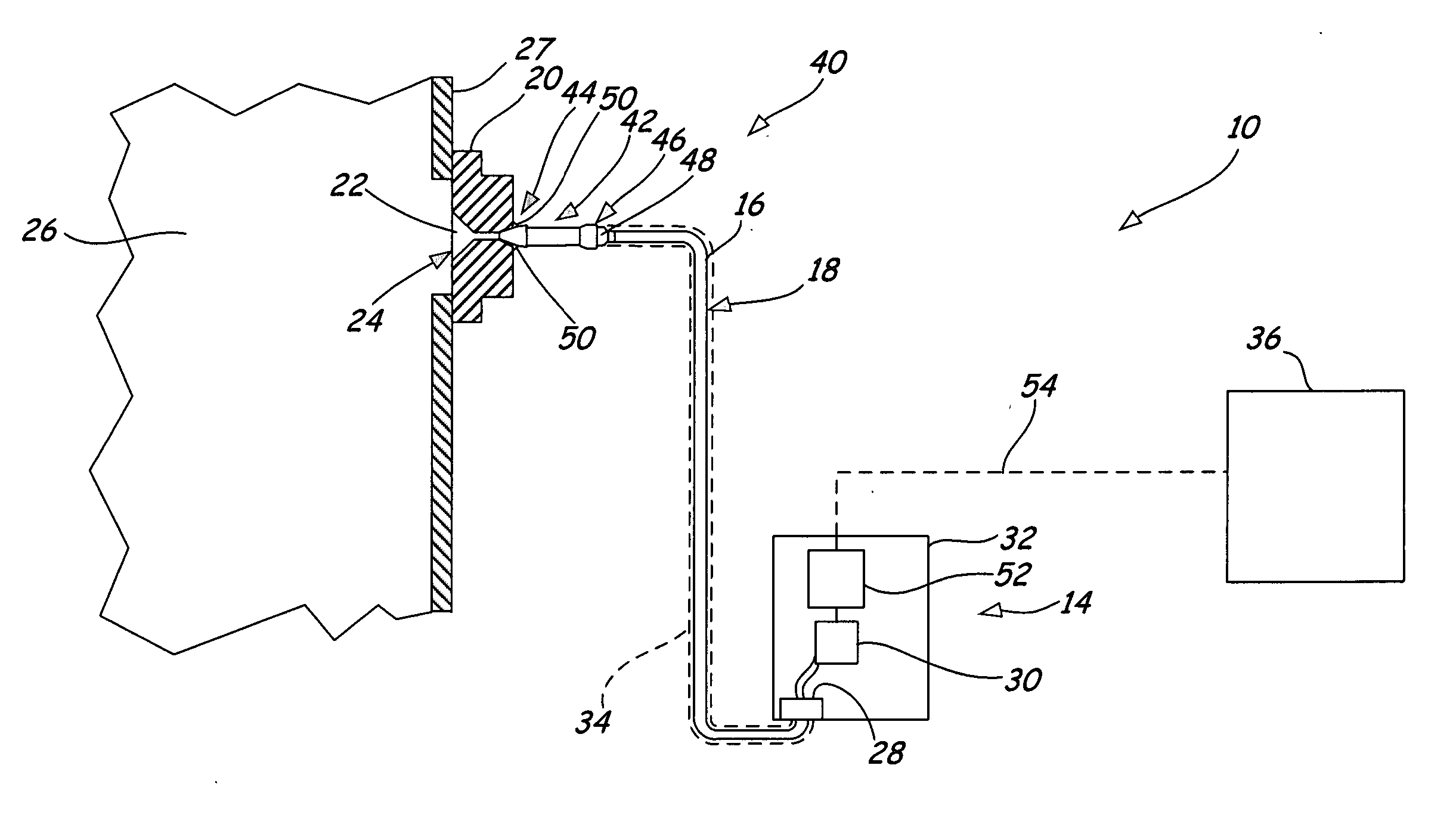

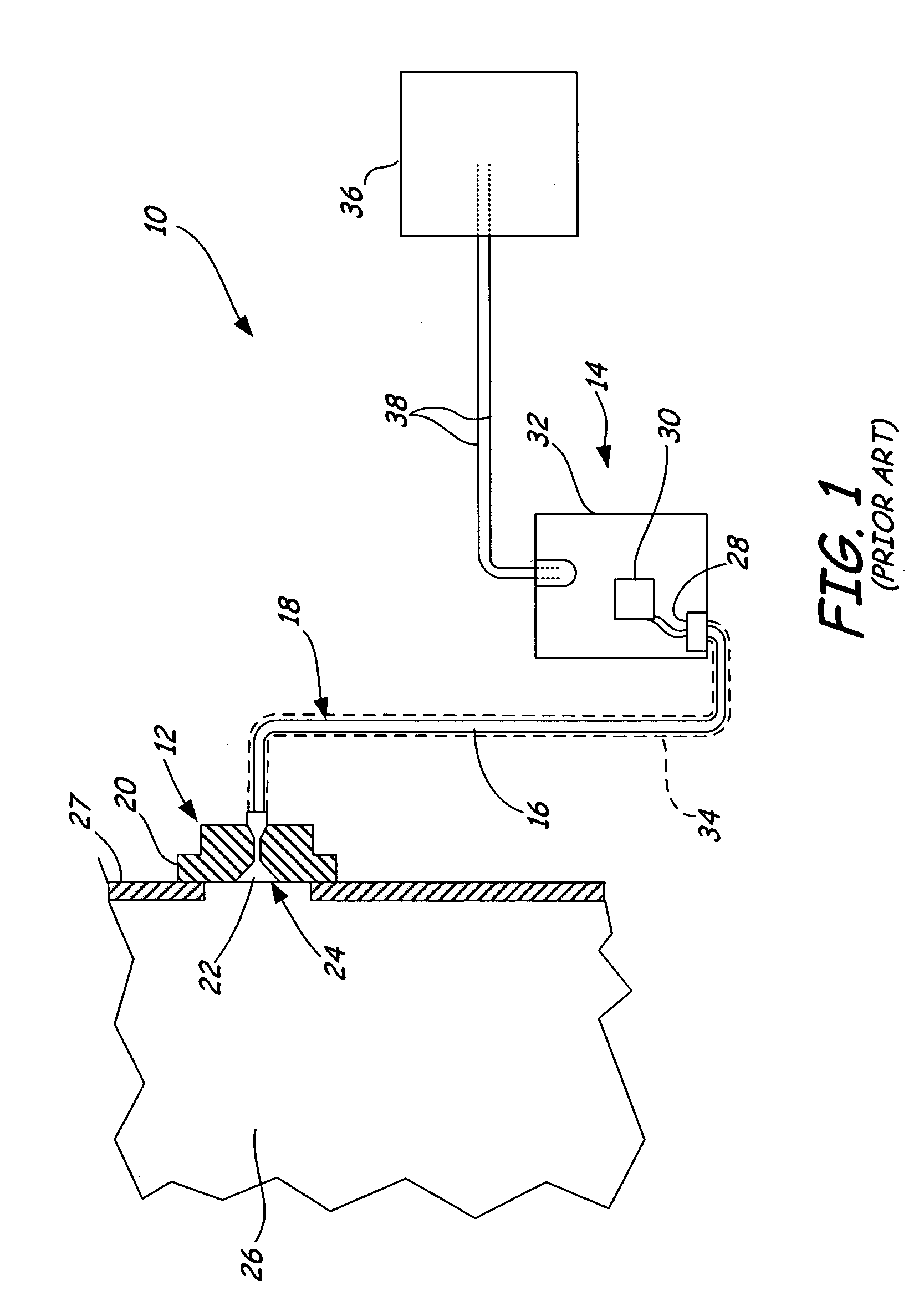

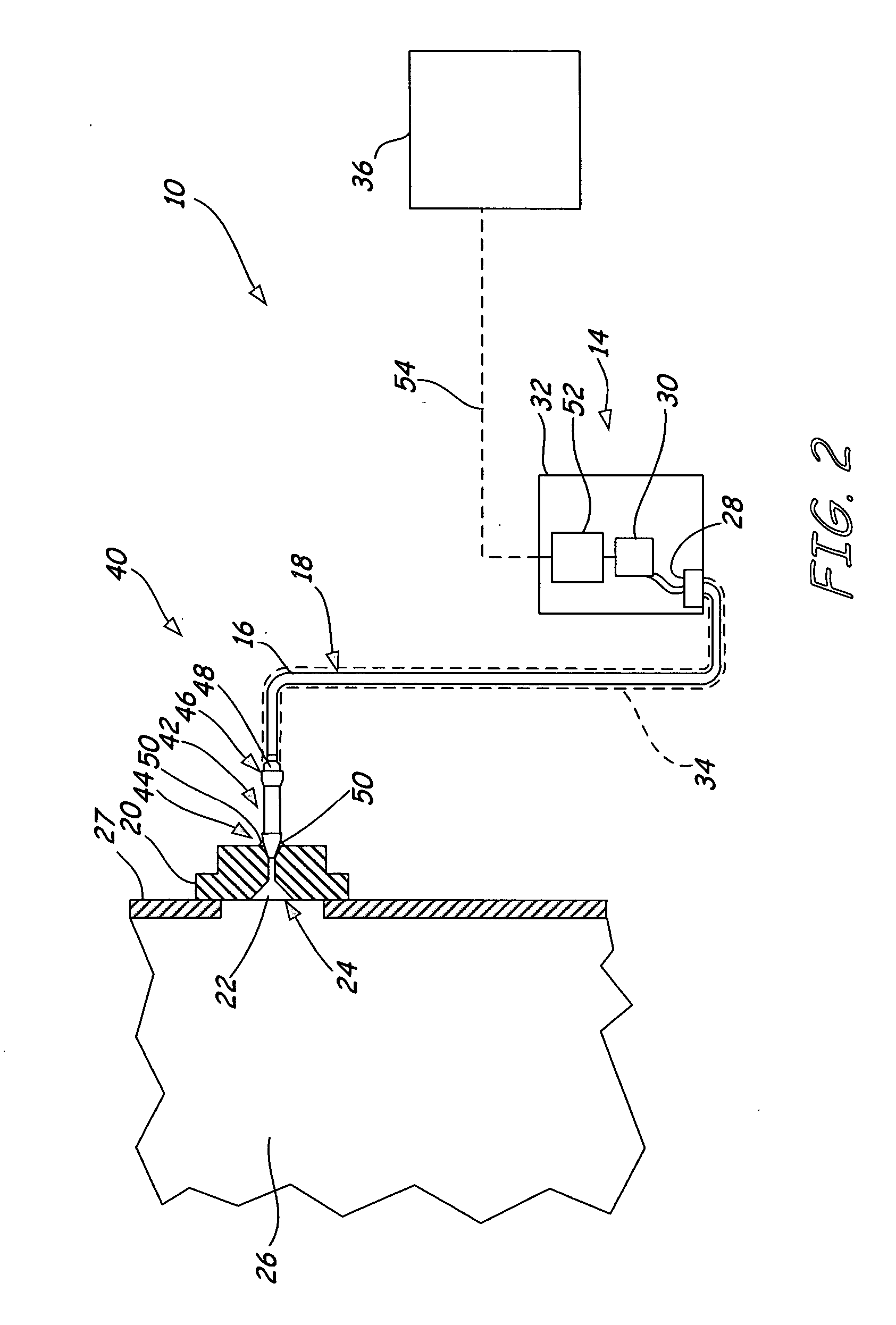

Capillary weld extension with thermal isolation

ActiveUS20050225035A1Avoid pollutionEngine sealsFluid-pressure convertersThermal isolationCapillary Tubing

A remote seal assembly includes a seal body and an extension. The seal body defines a cavity with a diaphragm that seals the cavity from a process fluid. The extension is connected with the seal body on a first end and is configured for connection to a capillary tube on a second end. The extension defines a bore extending from the first end to the second end that is fluidically coupled to the cavity. A length of the extension is related to a temperature of the second end of the extension such that the second end of the extension is at or below an outgassing temperature of the material used to connect the extension and the capillary tube.

Owner:ROSEMOUNT INC

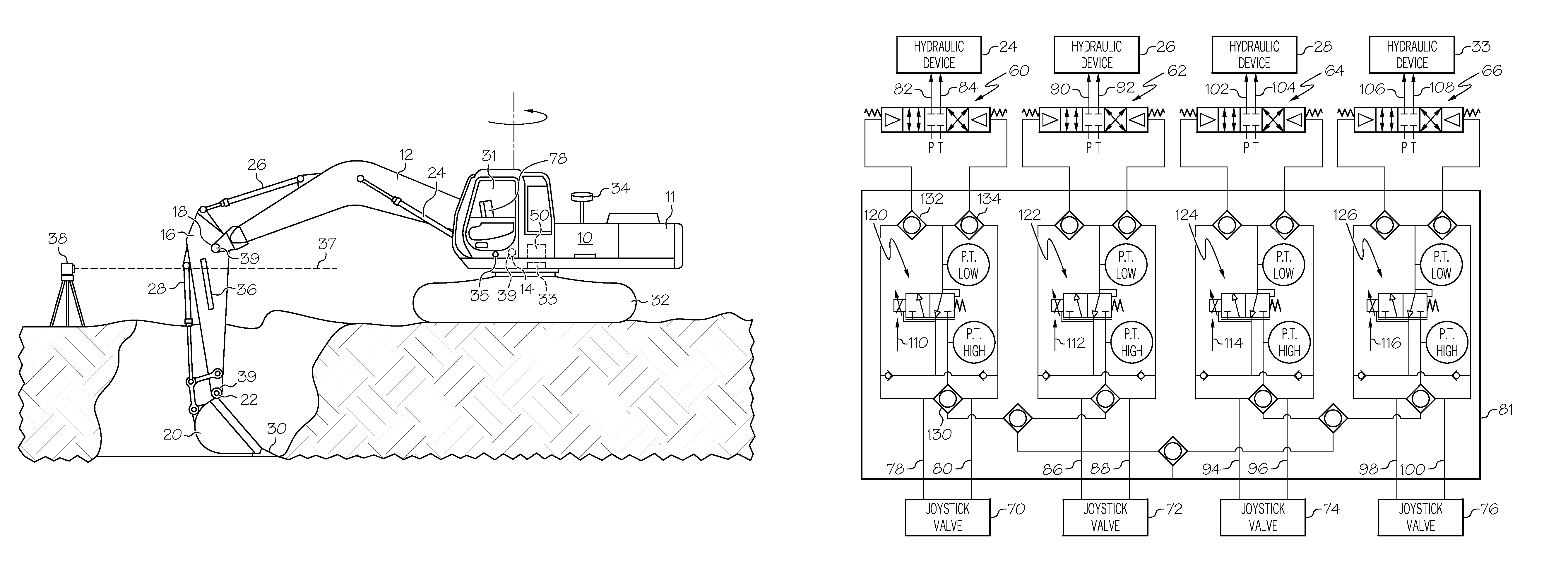

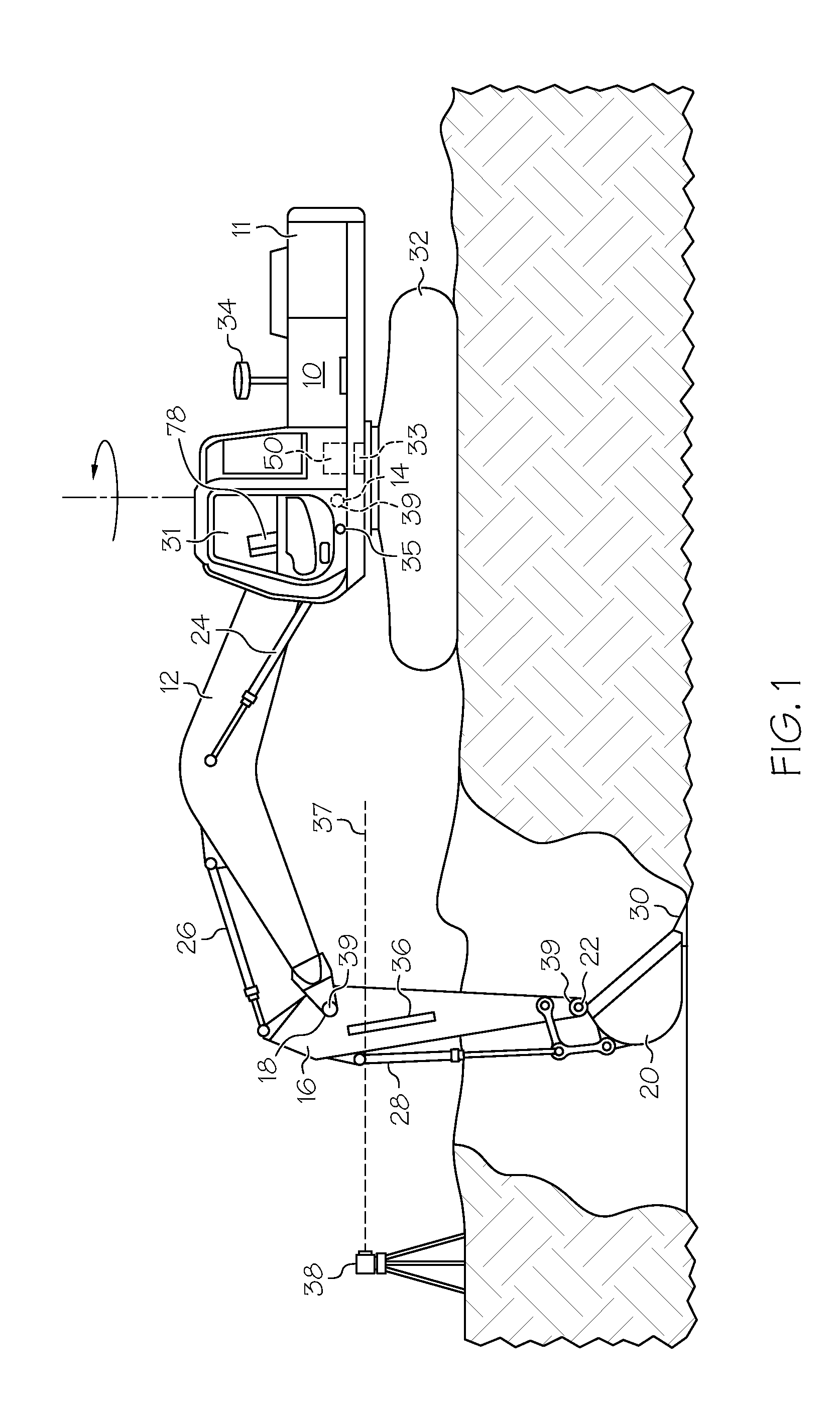

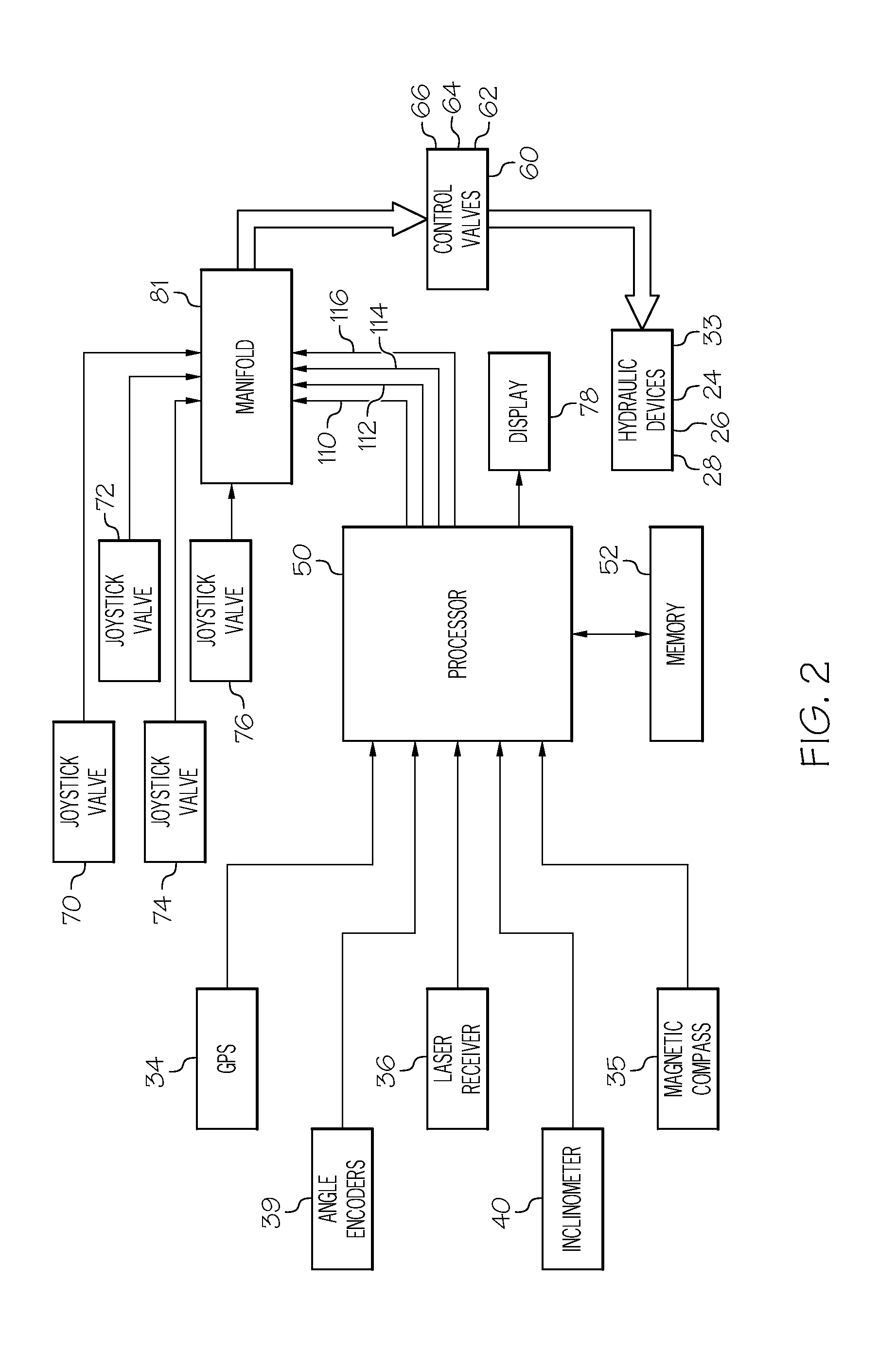

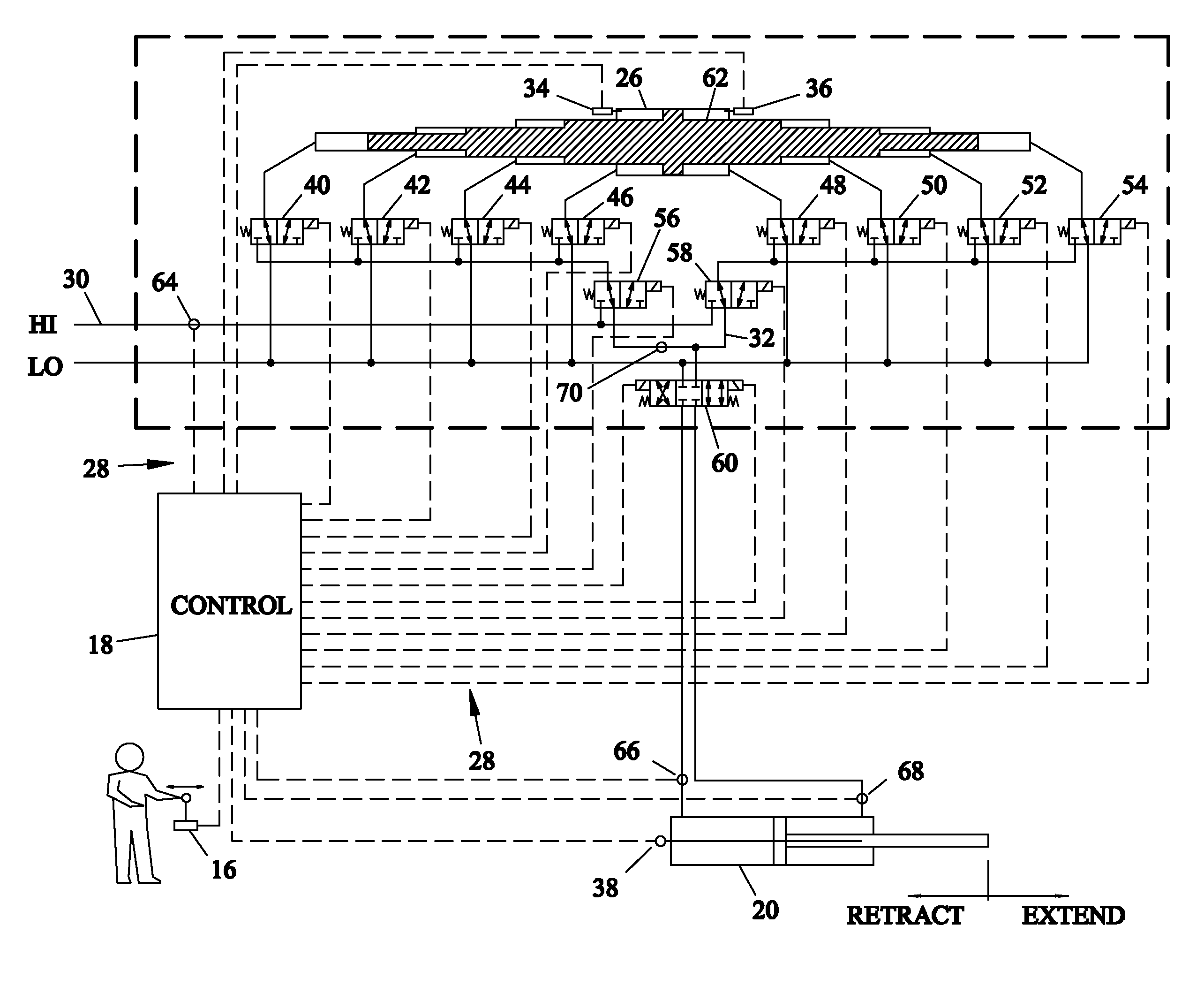

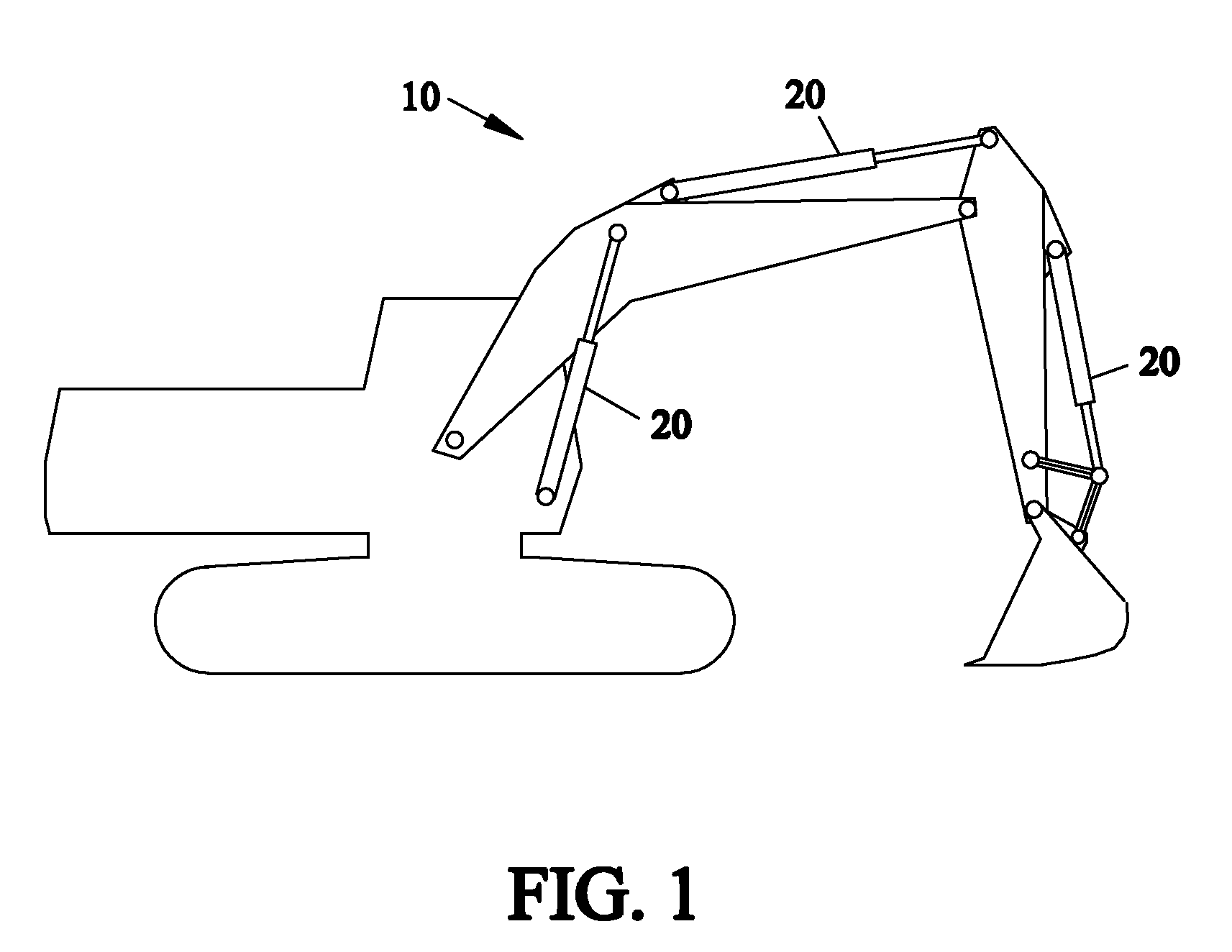

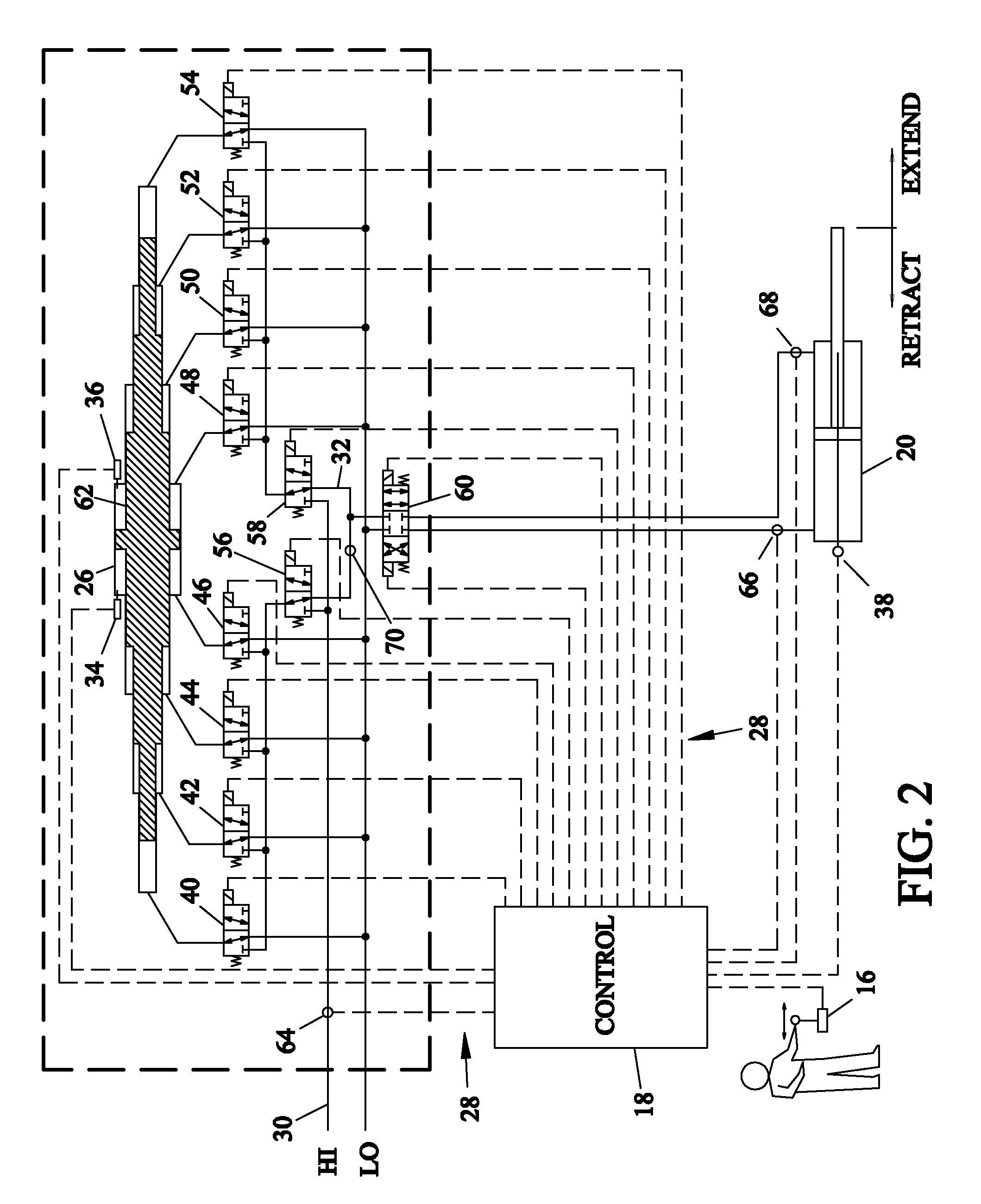

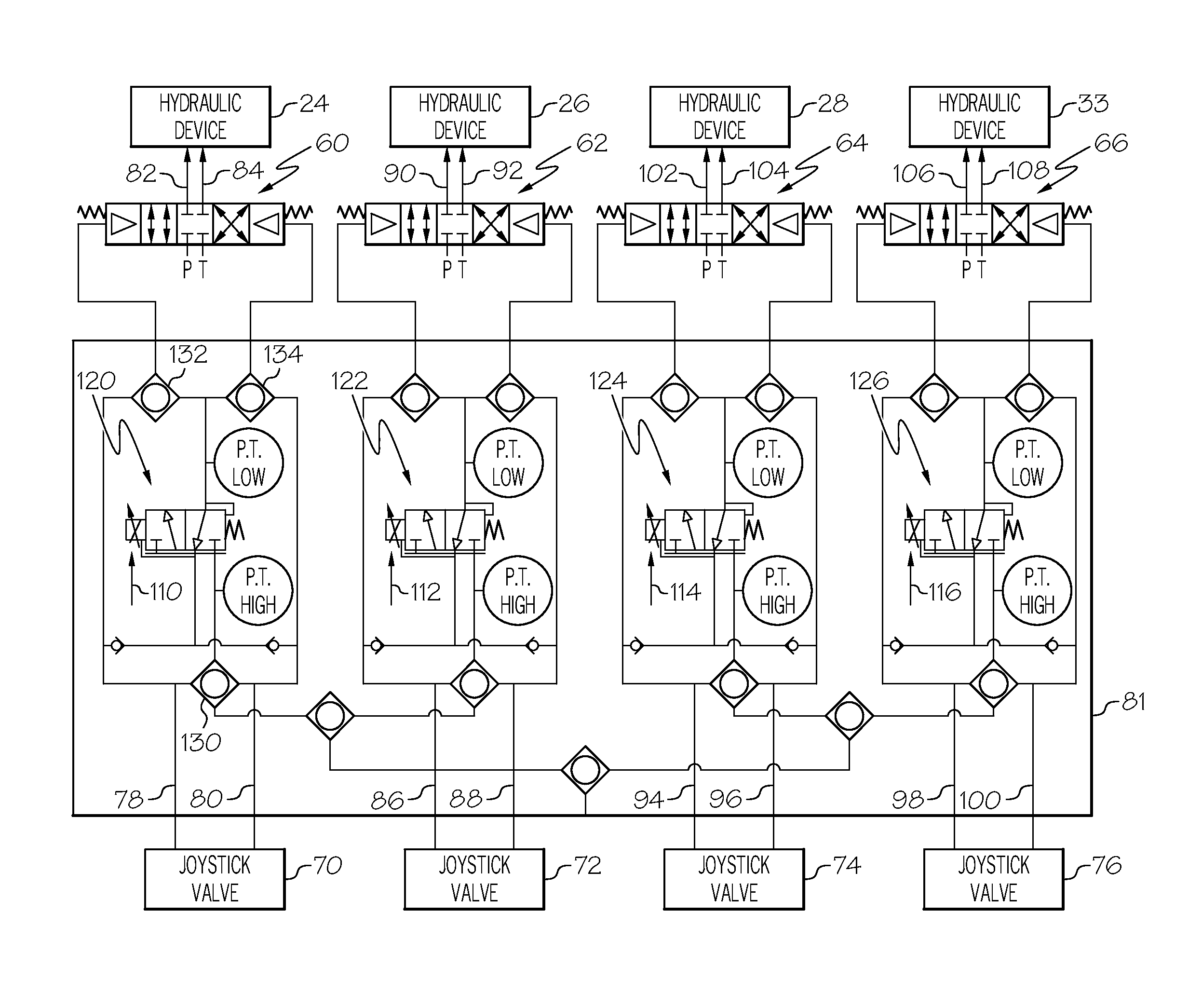

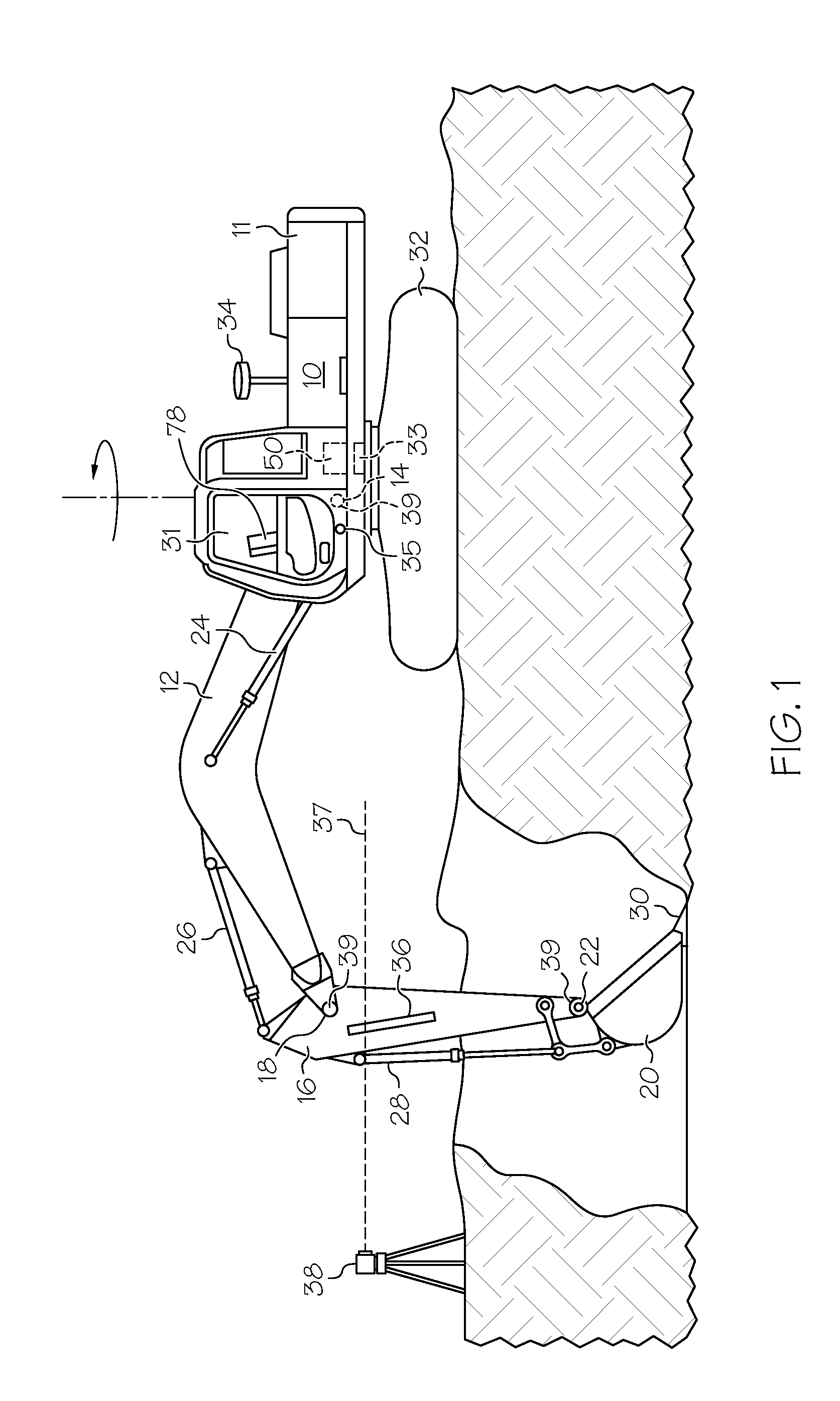

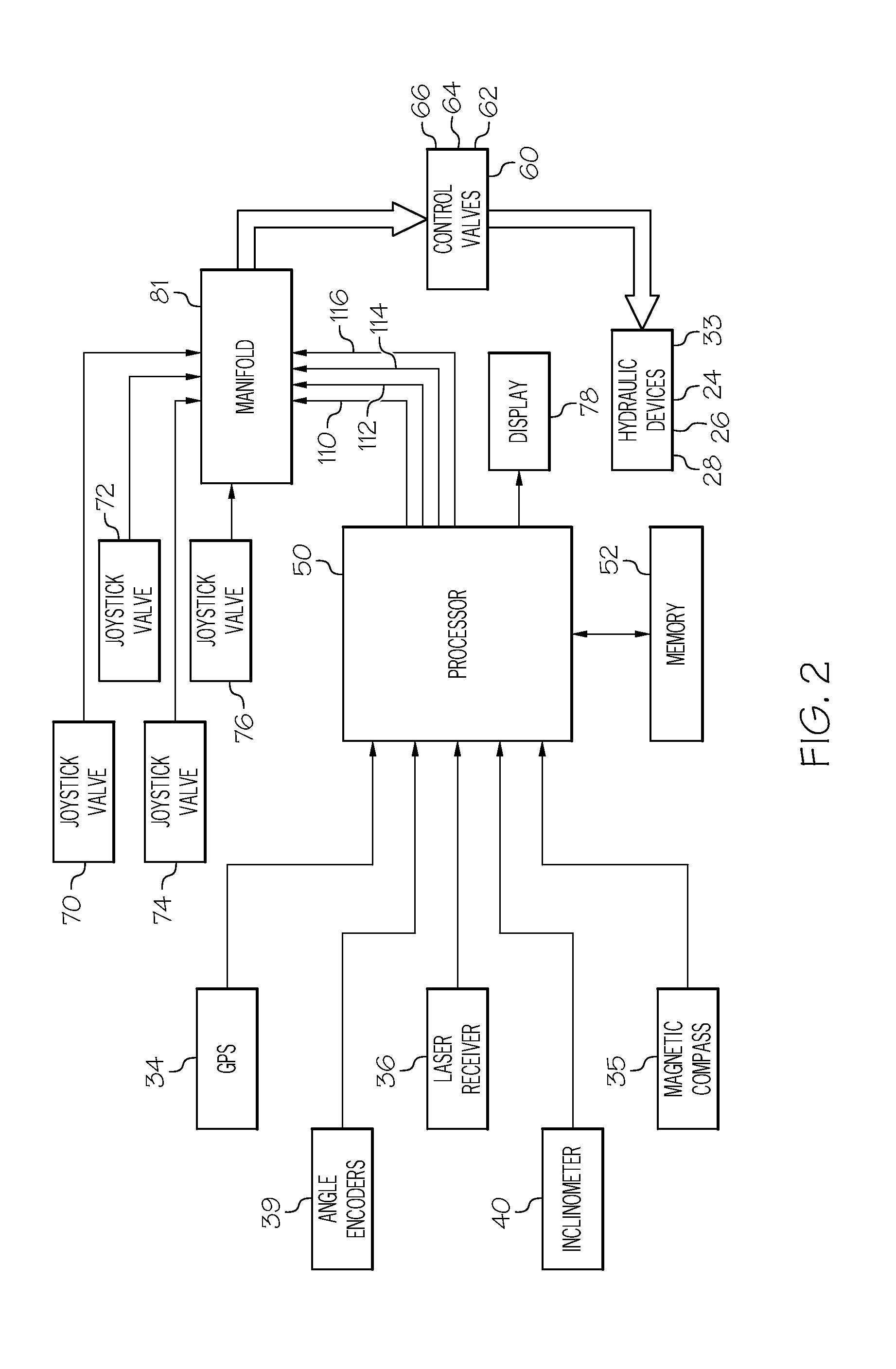

Method and system for controlling an excavator

A control for an excavator of the type having a plurality of hydraulic cylinders for moving excavator components such that digging is accomplished at a worksite with an excavator bucket or other excavator implement, includes a plurality of hydraulic control valves, each of which is associated with a respective one of the hydraulic cylinders for controlling the application of hydraulic fluid pressure to the respective one of the hydraulic cylinders, and a plurality of manually actuated joystick valves for supplying hydraulic fluid pressure to the respective hydraulic control valves to control the movement of the hydraulic cylinders. The control includes a sensor arrangement for sensing the position of one or more excavator components.

Owner:CATERPILLAR TRIMBLE CONTROL TECH

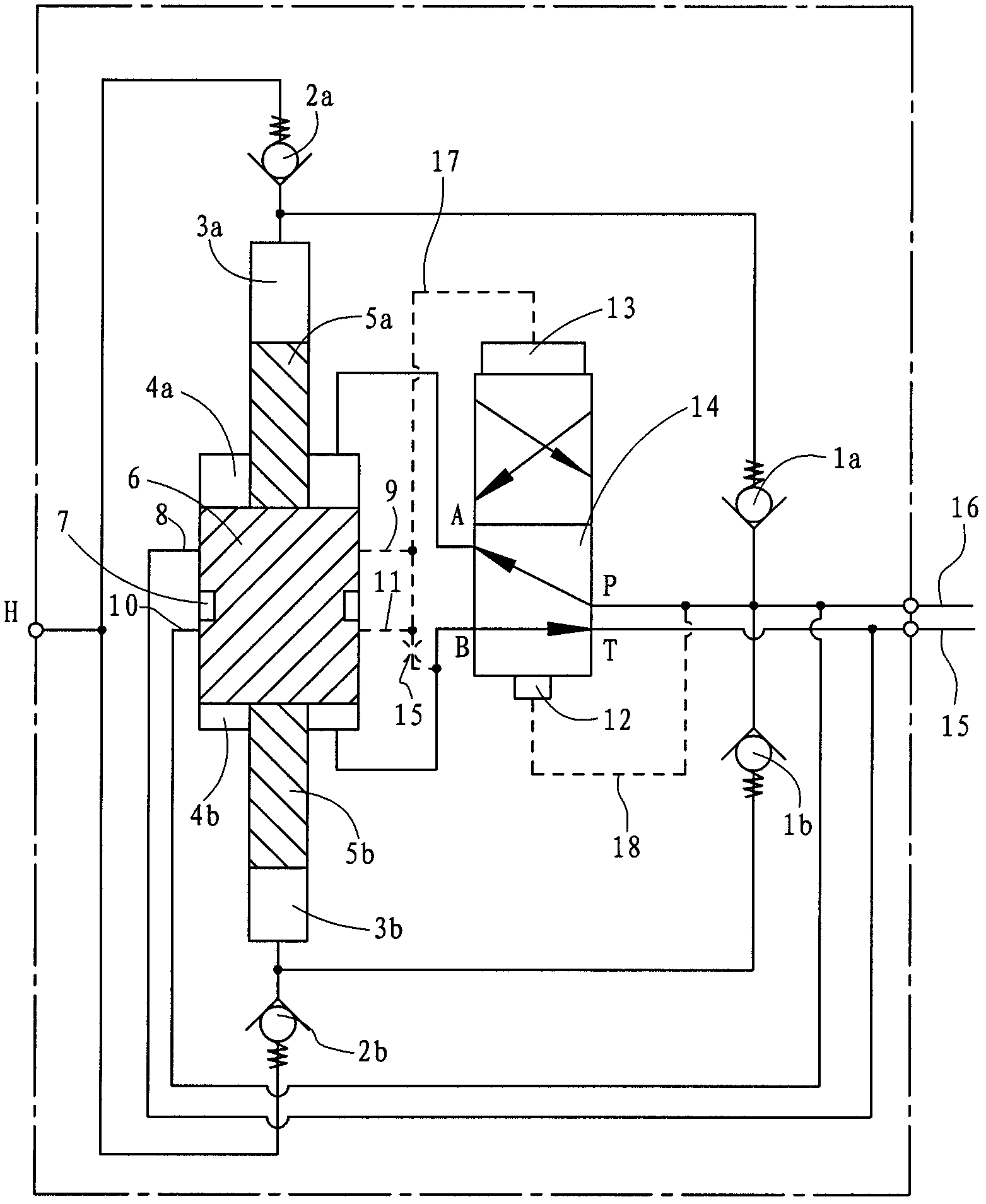

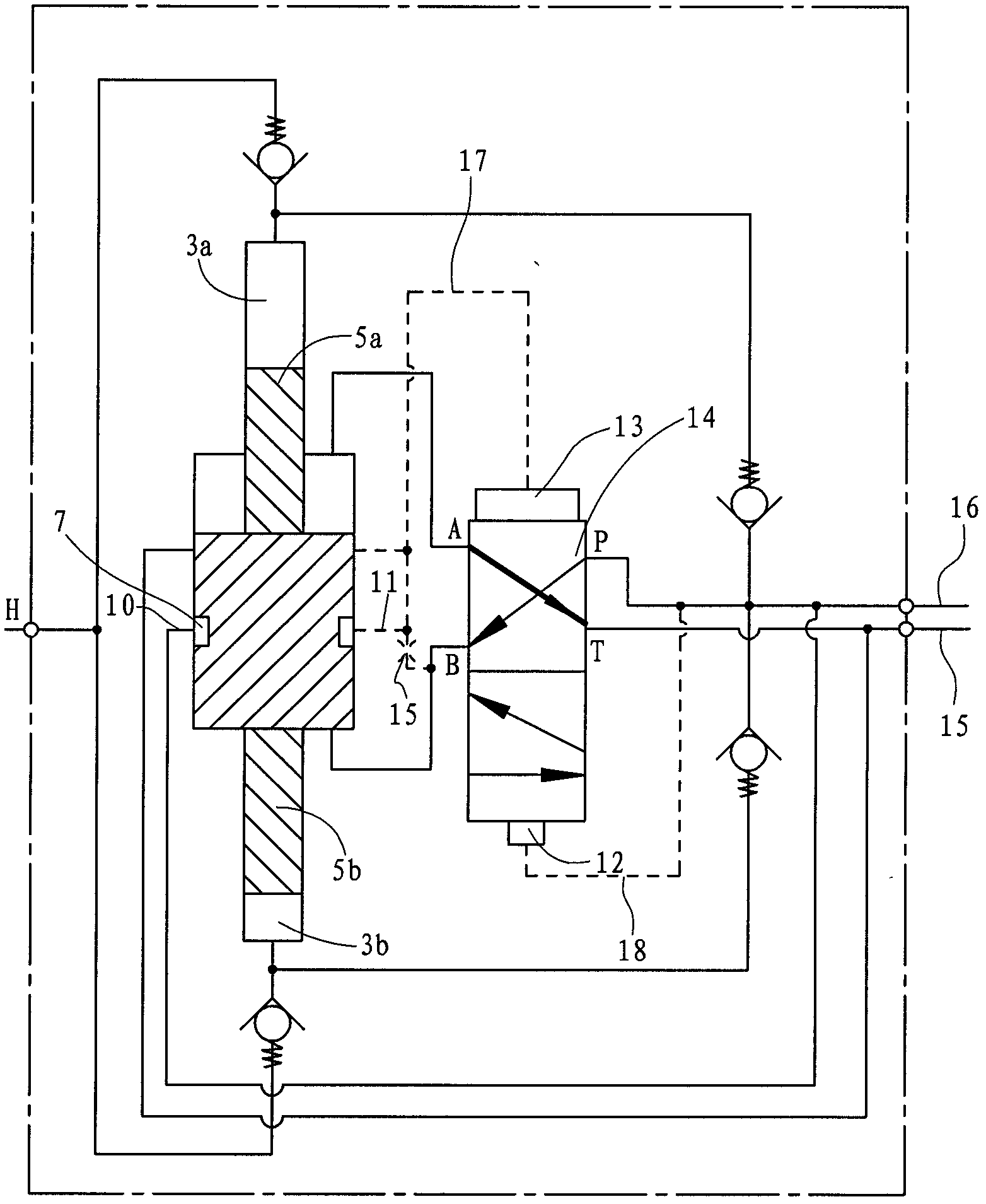

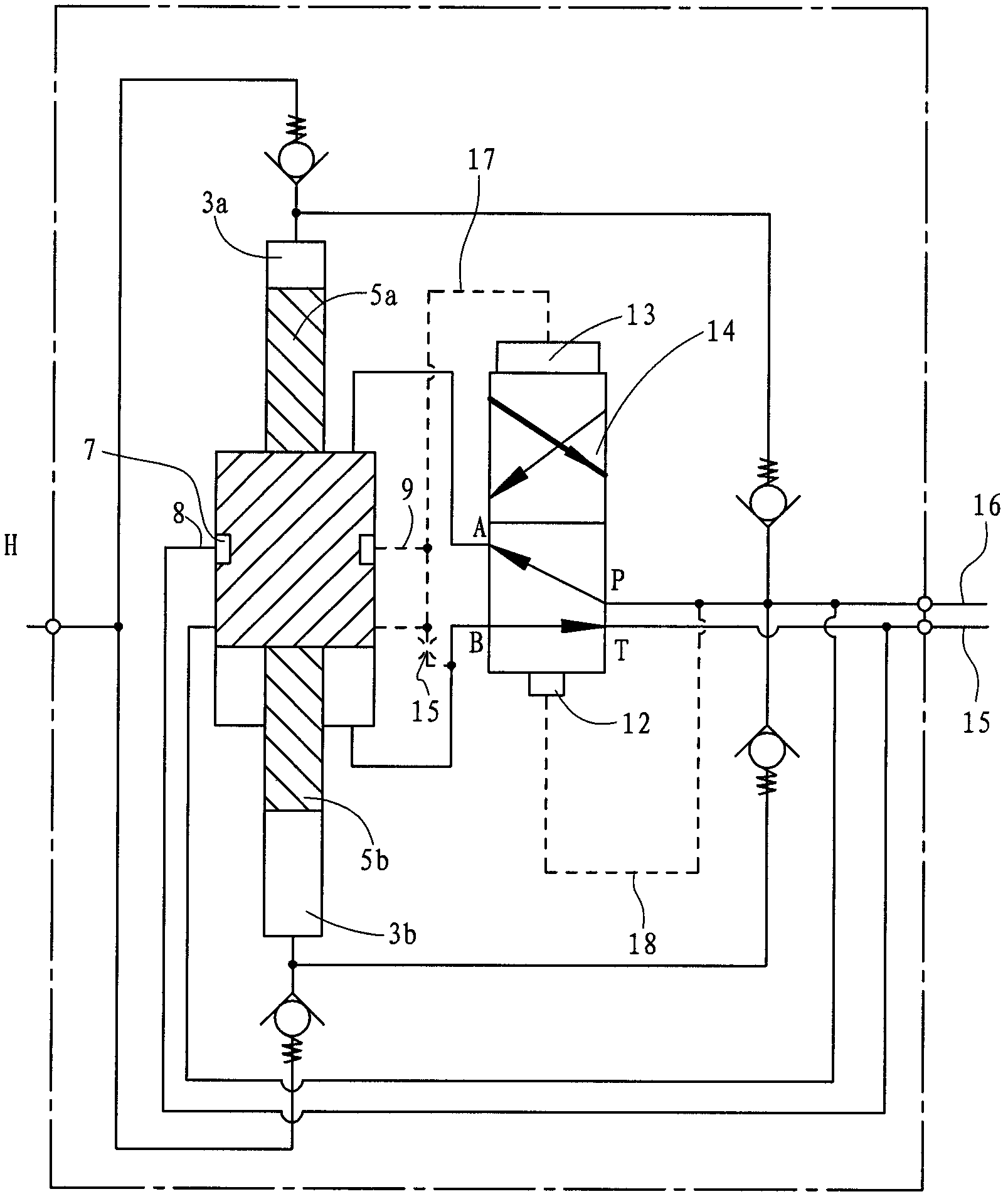

A double-acting reciprocating hydraulic pressure booster

InactiveCN102287407ANo boost frequency reductionSimple structureFluid-pressure convertersControl valvesHigh pressure

The invention relates to a double-action reciprocating hydraulic booster which comprises a boosting device and an automatic reversing control valve, and is characterized in that: the upper end and the lower end of the control valve core of the automatic reversing control valve are respectively connected with an upper piston and a lower piston; the cross sectional area of the upper piston is more than that of the lower piston; a first oil port of the automatic reversing control valve is communicated with a lower low-pressure cavity, a second oil port of the automatic reversing control valve is communicated with an upper low-pressure cavity, an oil return port of the automatic reversing control valve is communicated with an oil return channel, and a high-pressure oil port of the automatic reversing control valve is communicated with a high-pressure oil channel; the boosting part is also provided with an oil inlet runner, an oil return runner, a first control runner and a second control runner; a circular communicating groove is arranged on the peripheral surface of a low-pressure plunger; and the first control runner and the second control runner are communicated with an upper chamber of the upper piston through first bypass channels. Compared with an electromagnetic reversing valve, the automatic reversing control valve has a simpler structure, is controlled with a single pole, so that the boosting frequency is not reduced, the operation is reliable, and the purpose of high-frequency boosting can be achieved.

Owner:NINGBO HANSHANG HYDRAULIC

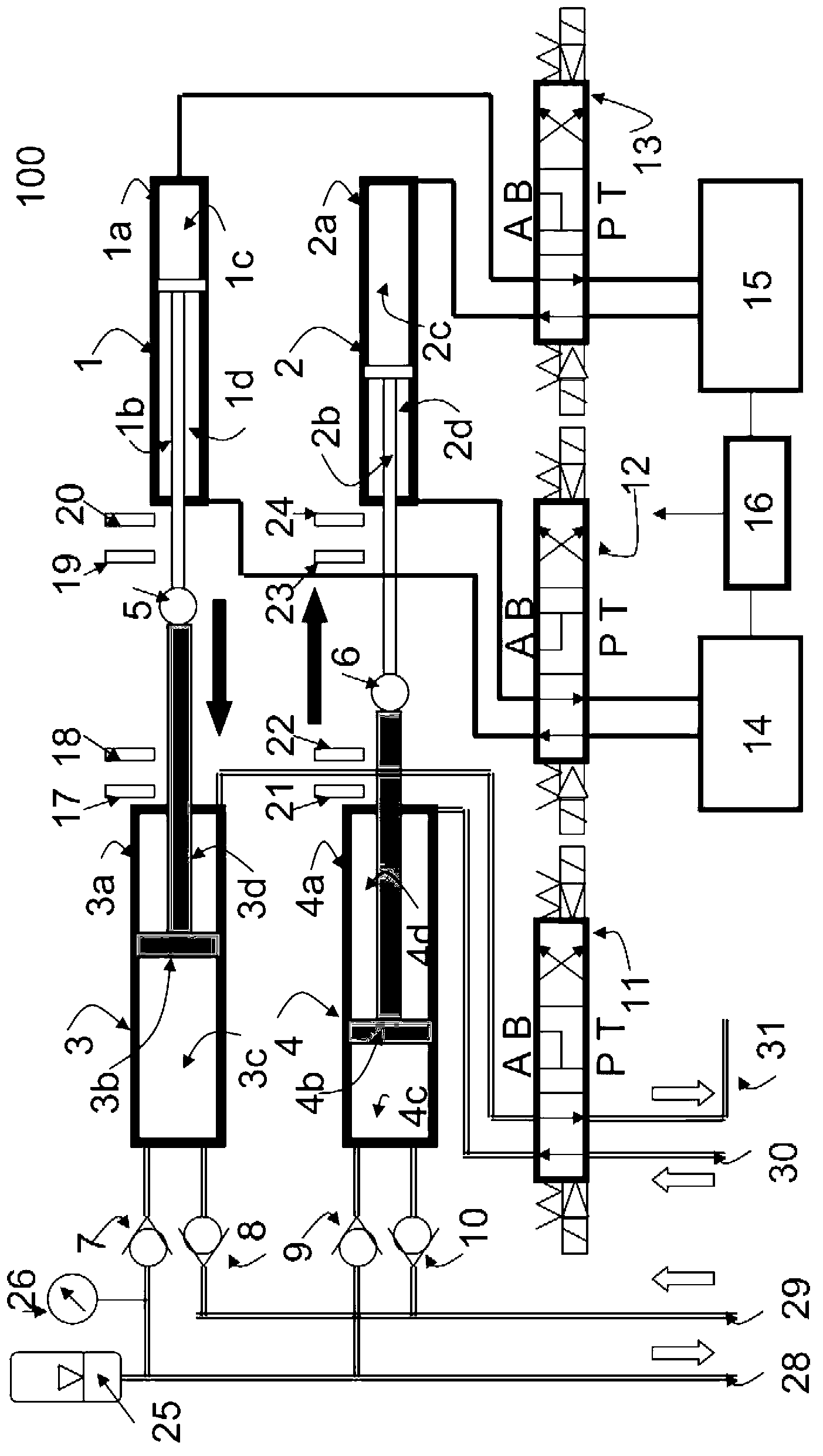

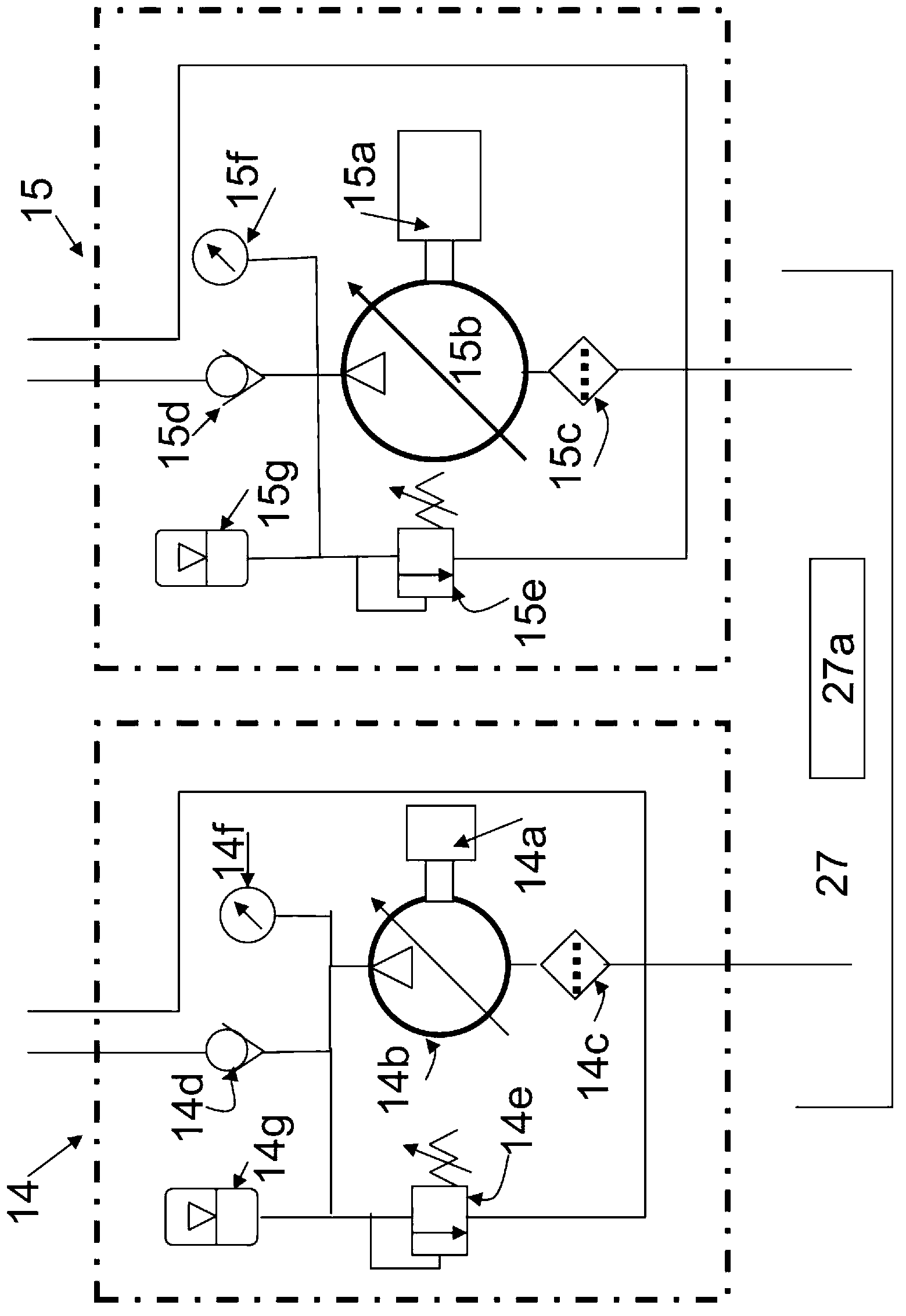

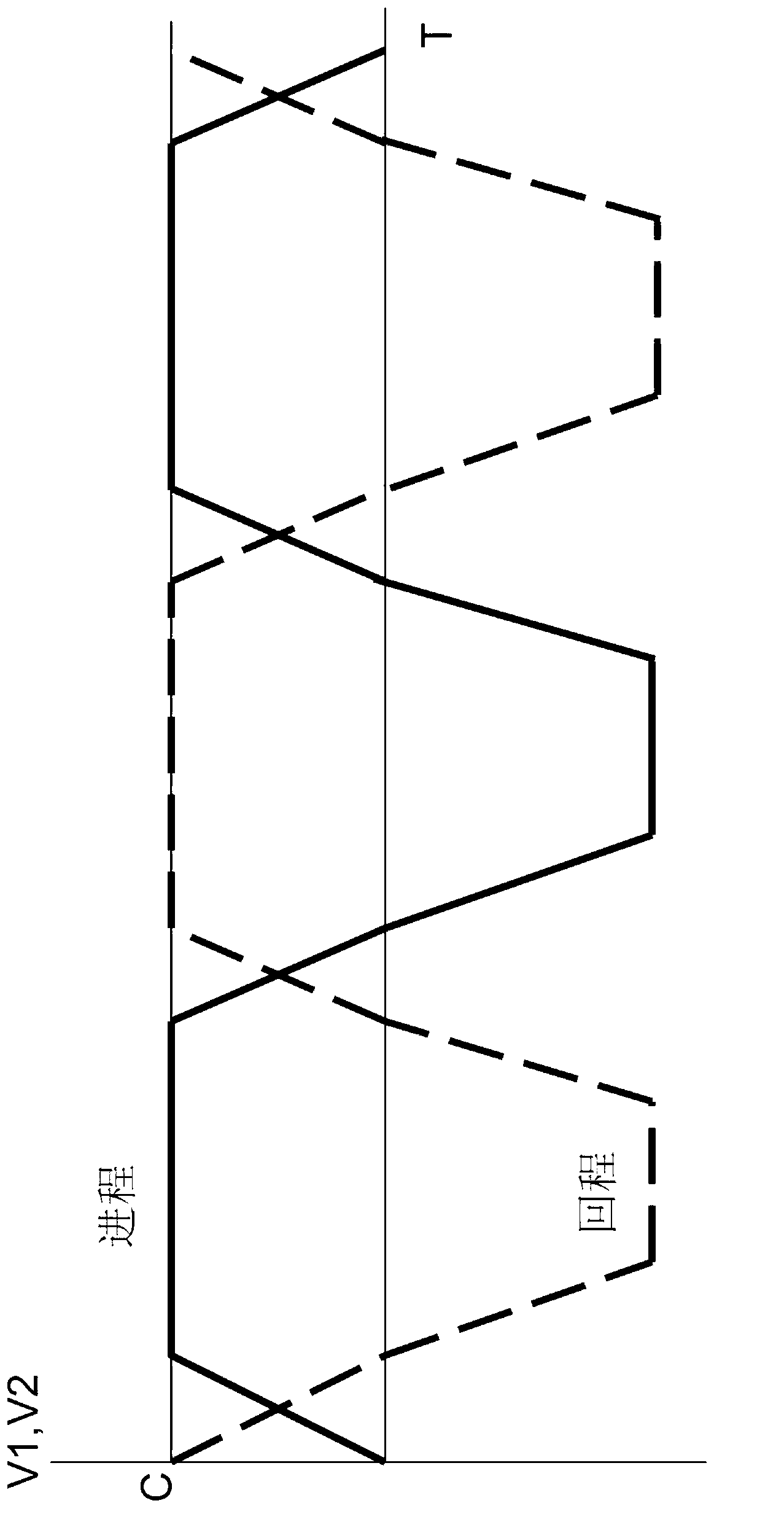

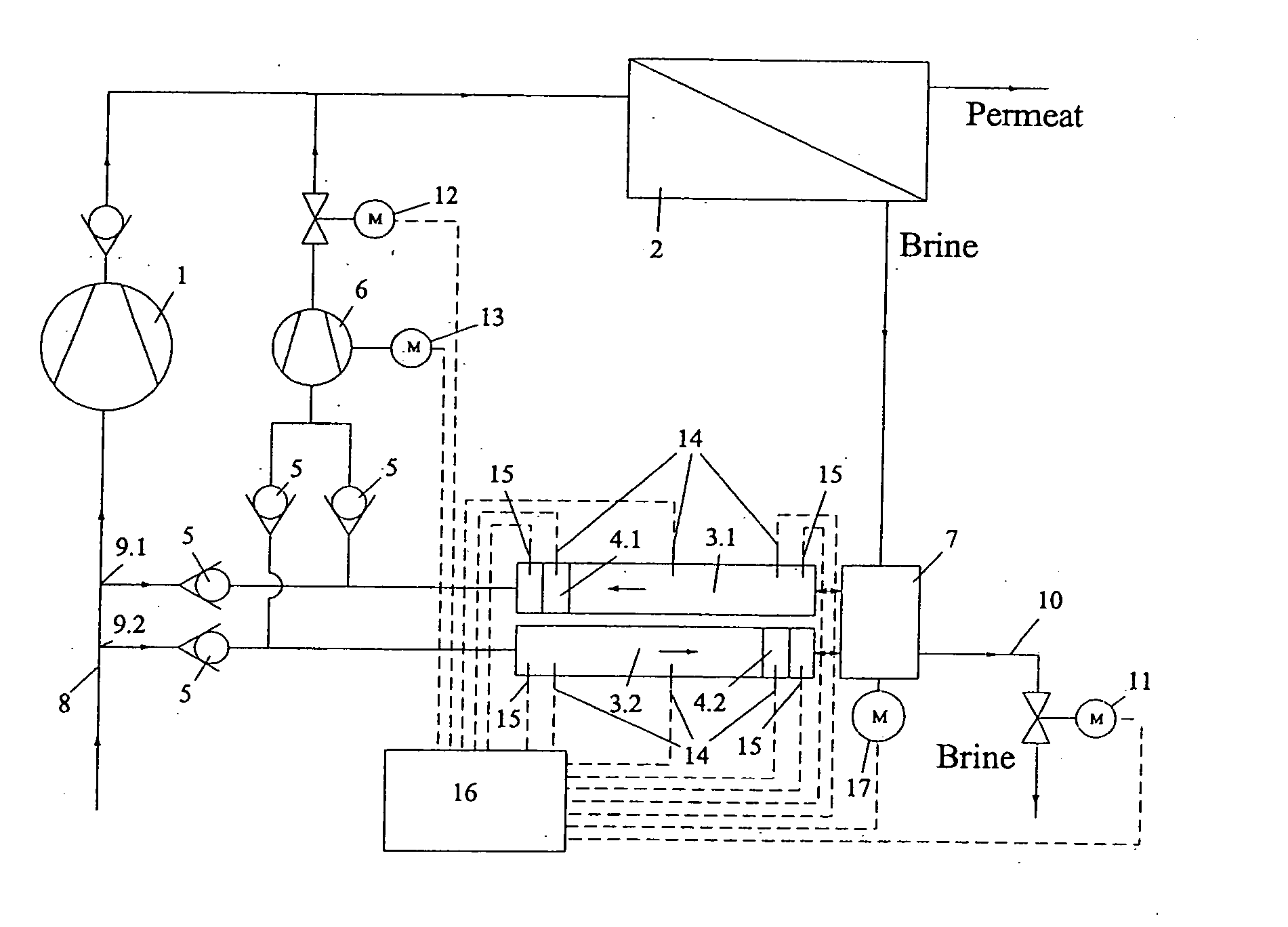

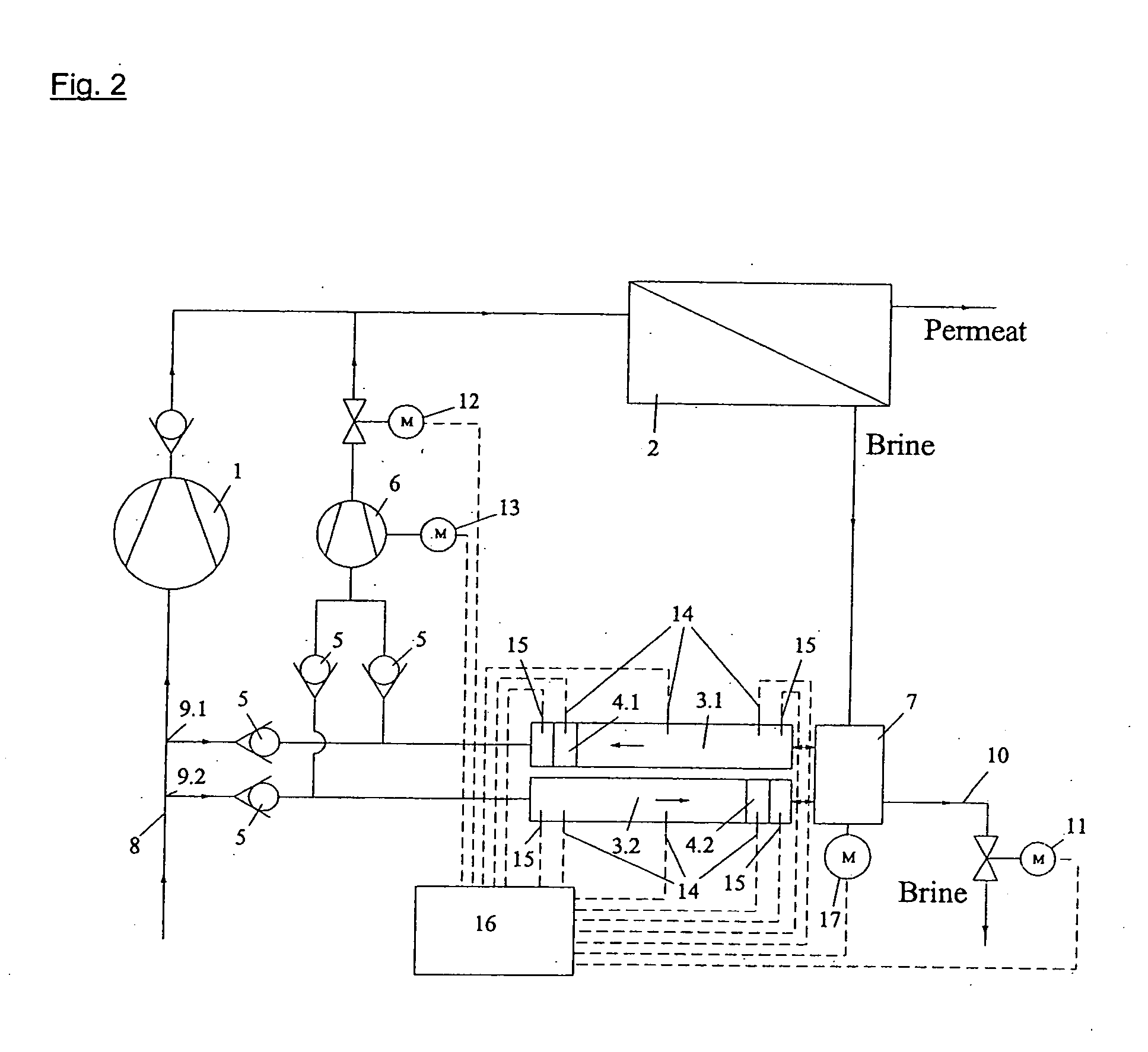

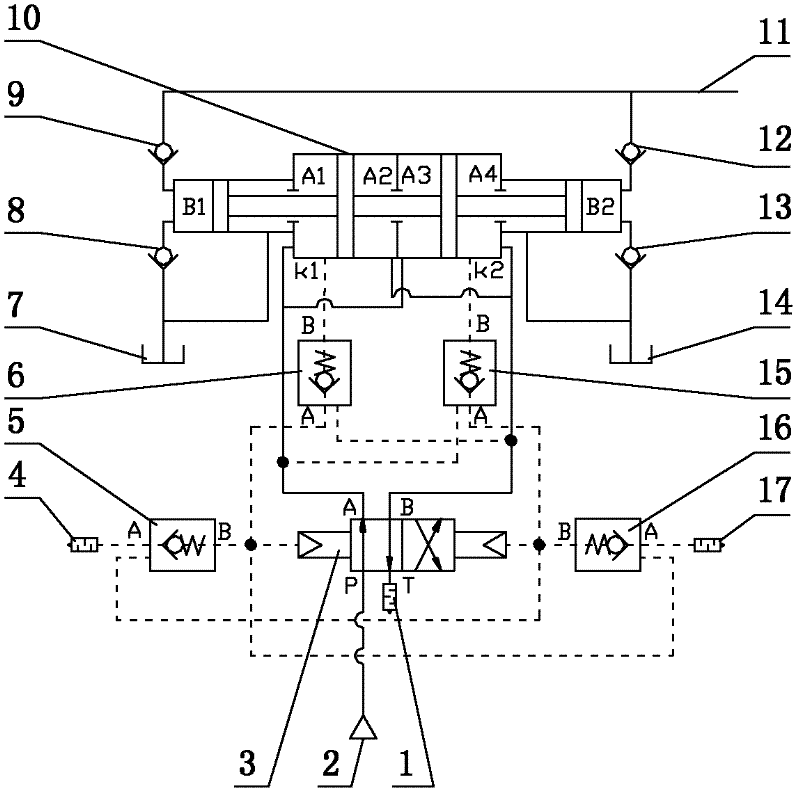

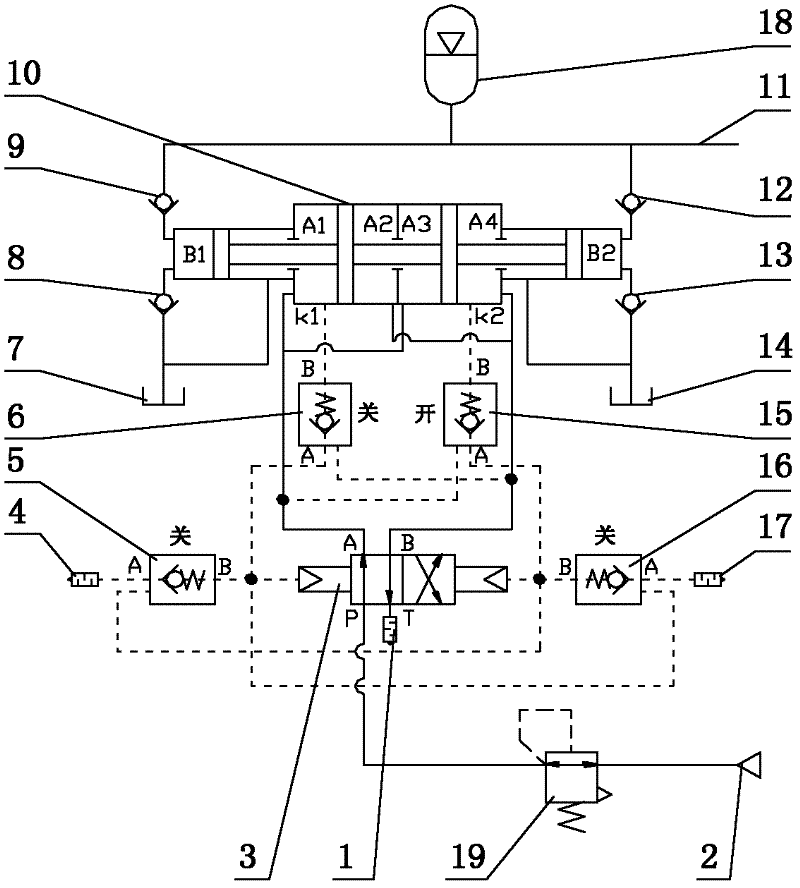

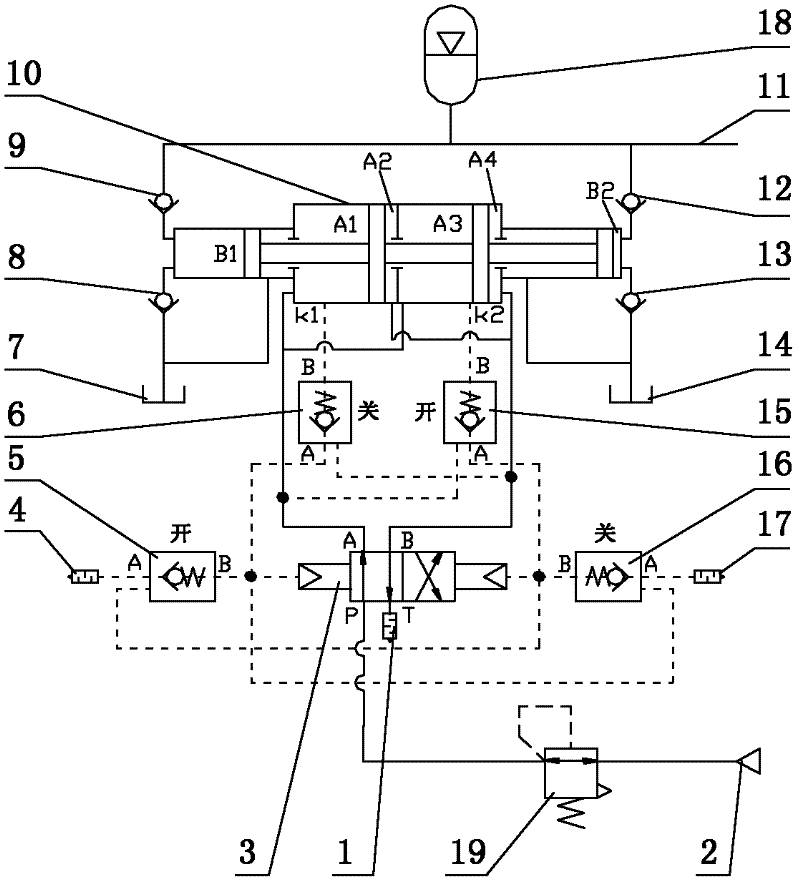

Membrane seawater desalination pressurization and energy recovery integrated method and device

ActiveCN102838186AReduce initial investment costHigh priceMembranesWater treatment parameter controlEngineeringEnergy recovery

The invention relates to a membrane seawater desalination pressurization and energy recovery integrated method and a membrane seawater desalination pressurization and energy recovery integrated device. Piston rods of single-rod seawater cylinders are connected with single-rod oil cylinders to form two or more working combined bodies which operate alternately; the oil cylinders drive the seawater cylinders to move back and forth; one piston cavities of the seawater cylinders suck high pressure strong brine in the process of moving forward and drain the high pressure strong brine in the returning process; and the other piston cavities of the seawater cylinders suck raw seawater in the returning process, pressurize the raw seawater in the process of moving forward and continuously and stably output the pressurized high pressure raw seawater to a reverse osmosis membrane modulus.

Owner:北京赛美环能科技有限公司

Digital hydraulic system

InactiveUS20090178399A1Optimize energy usageMost efficientFluid couplingsAccumulator installationsControl systemHydraulic fluid

A control system for a work machine having a hydraulic energy source, a hydraulic accumulator, a digital hydraulic system having a digital hydraulic transformer, a hydraulic actuator and a movable element. The hydraulic accumulator being fluidically couplable with the hydraulic energy source. The digital hydraulic system including a digital hydraulic transformer fluidically couplable with the hydraulic accumulator. The hydraulic actuator being fluidically couplable with the digital hydraulic transformer. The movable element being movable by the hydraulic actuator. The control system including means to estimate at least one of potential energy and kinetic energy in the movable element; means to measure a fill level of hydraulic fluid in the hydraulic accumulator; and means to vary the amount of hydraulic energy added to the hydraulic accumulator by the hydraulic energy source responsive to the potential energy, the kinetic energy and / or the fill level of the hydraulic accumulator.

Owner:DIGITAL HYDRAULICS

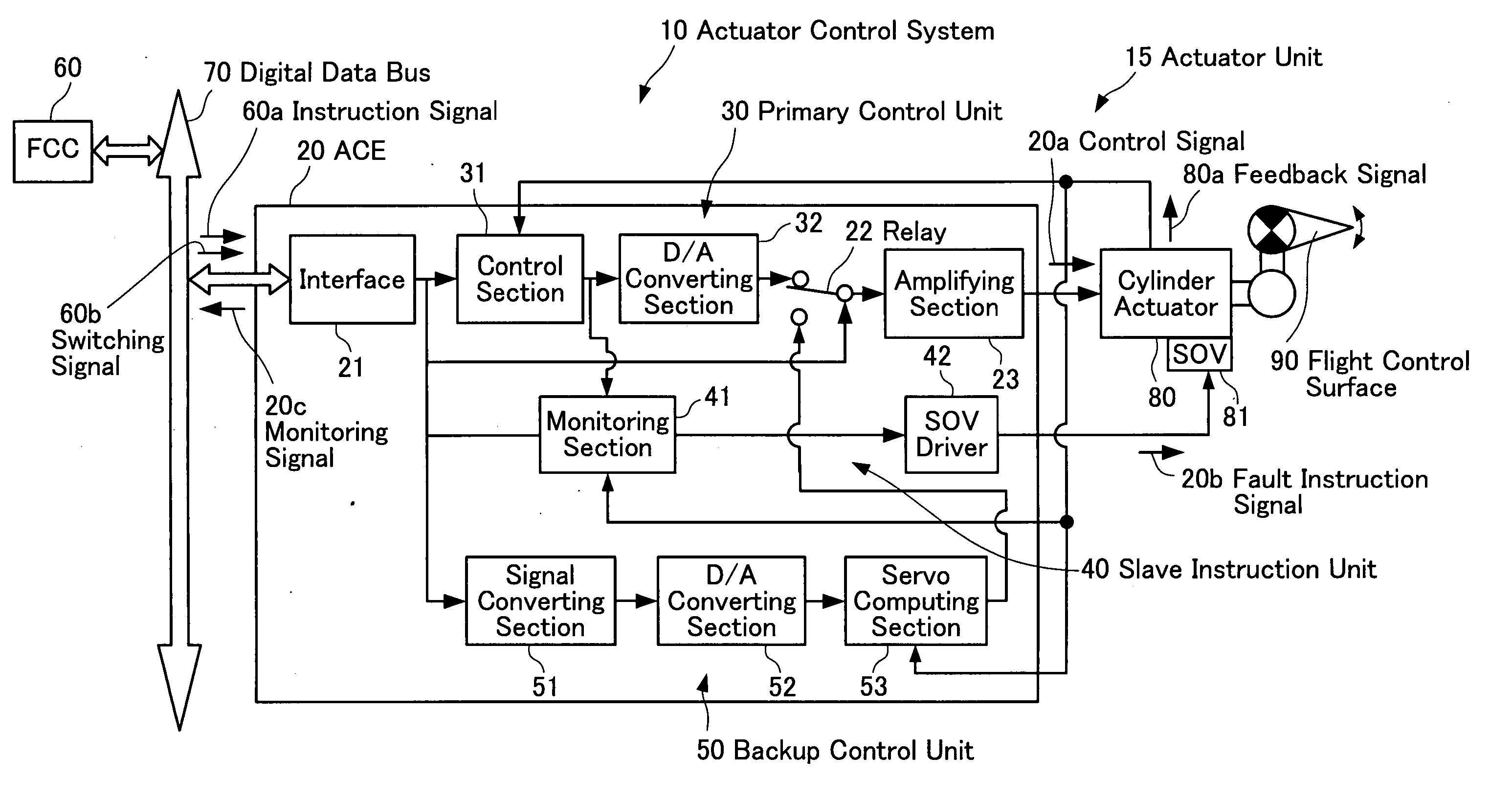

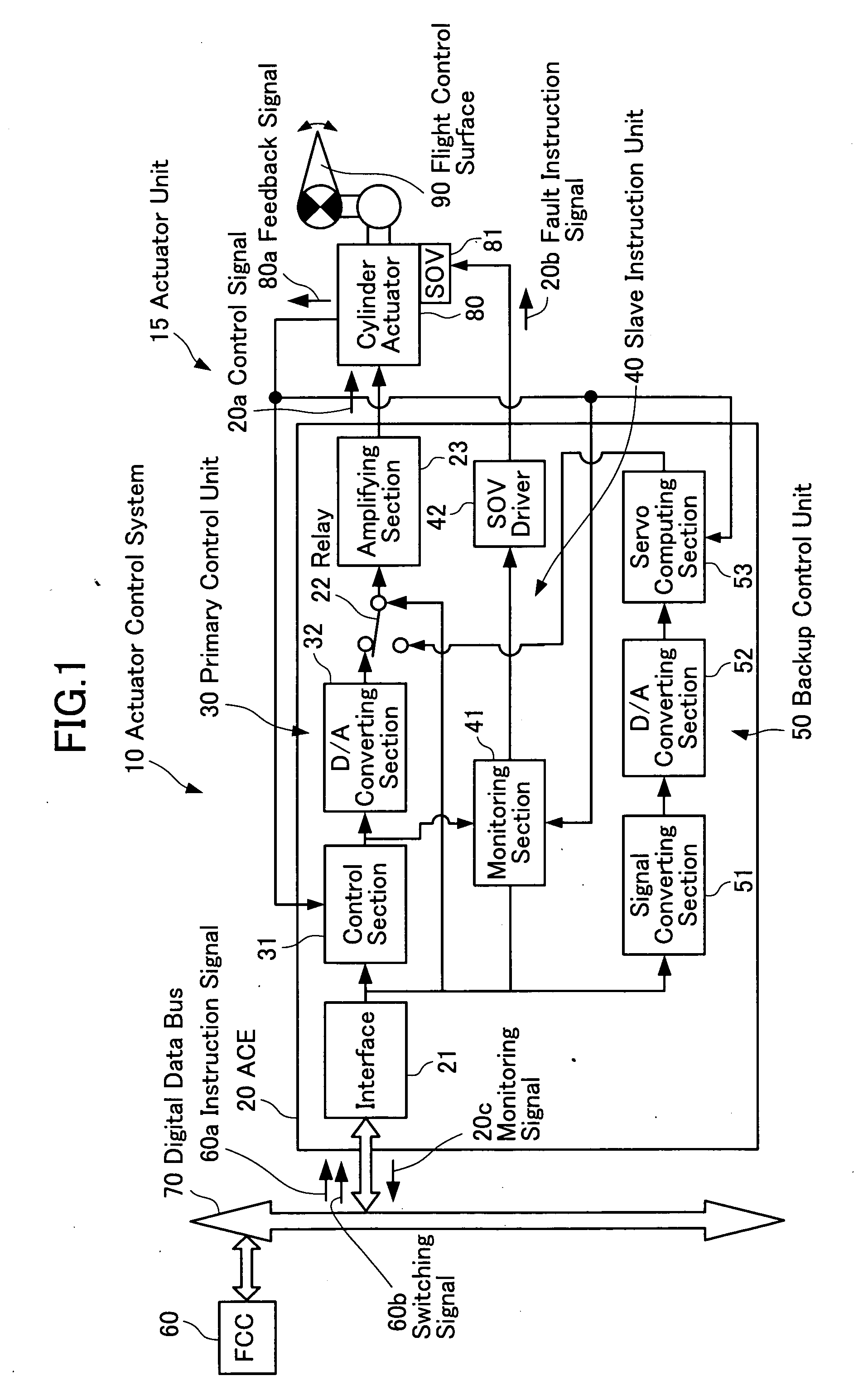

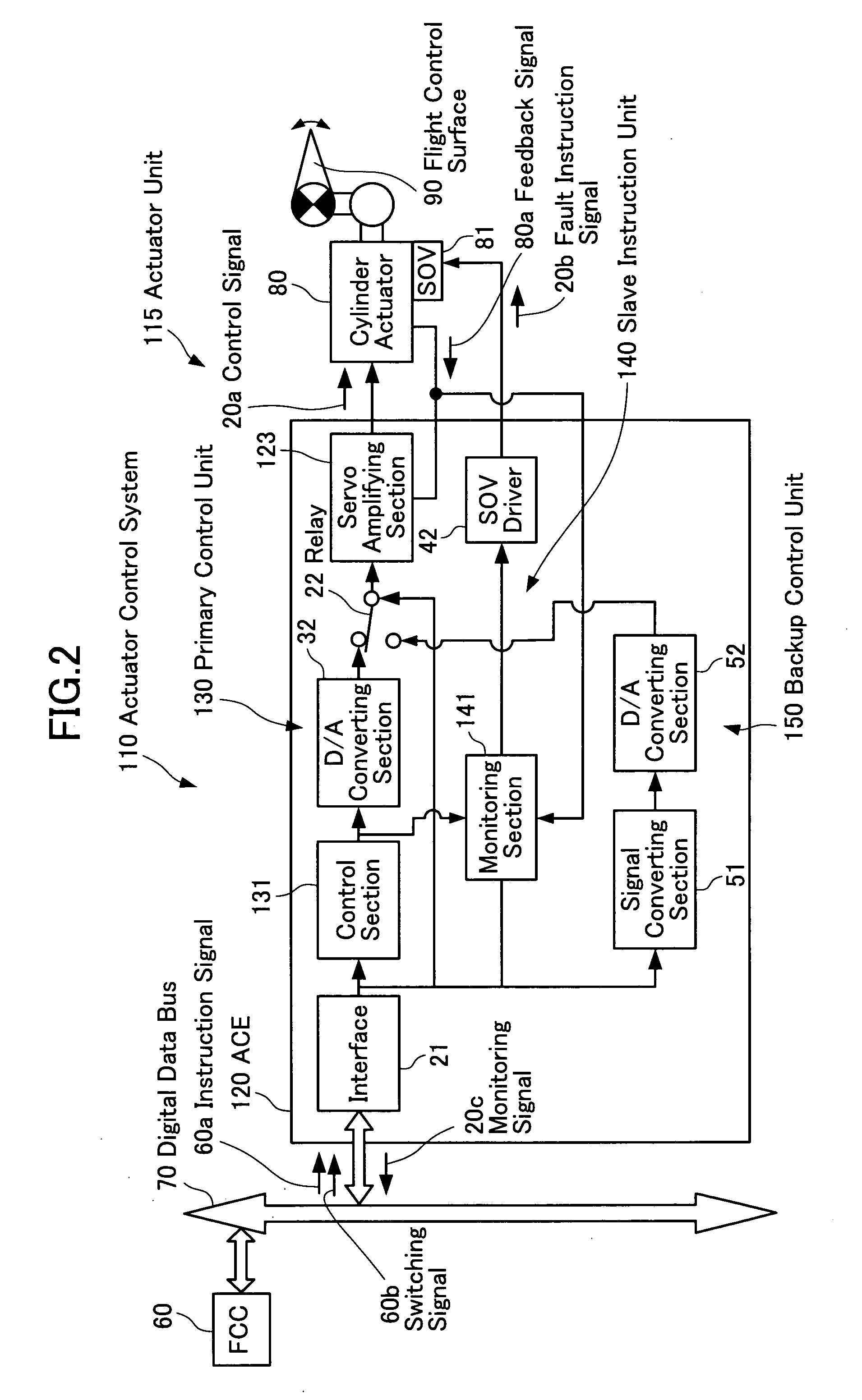

Actuator control apparatus

ActiveUS20060198737A1Easy in fault verificationConvenient verificationTelemotorsSpecial data processing applicationsControl signalEngineering

Herein disclosed is an actuator control apparatus, comprising primary control means for producing a control signal used to control an operation of an actuator in accordance with an instruction signal indicative of an operation of the actuator, secondary control means for producing a control signal in accordance with the instruction signal; and switching means for selectively switching one of the primary control means and the secondary control means to the other, and in which the secondary control means is less in the number of functions than the primary control means, and each of components constituting the secondary control means is easier in fault verification than a component constituting the primary control means the most difficult in fault verification among all of components constituting the primary control means.

Owner:NABTESCO AEROSPACE +1

Digital Hydraulic system

A digital hydraulic system including a hydraulic source, a housing and a transtatic bridge. The transtatic bridge being substantially contained within the housing. The transtatic bridge being in fluid communication with the hydraulic source. The transtatic bridge communicating a force to or from a shaft or a fluid.

Owner:DIGITAL HYDRAULICS

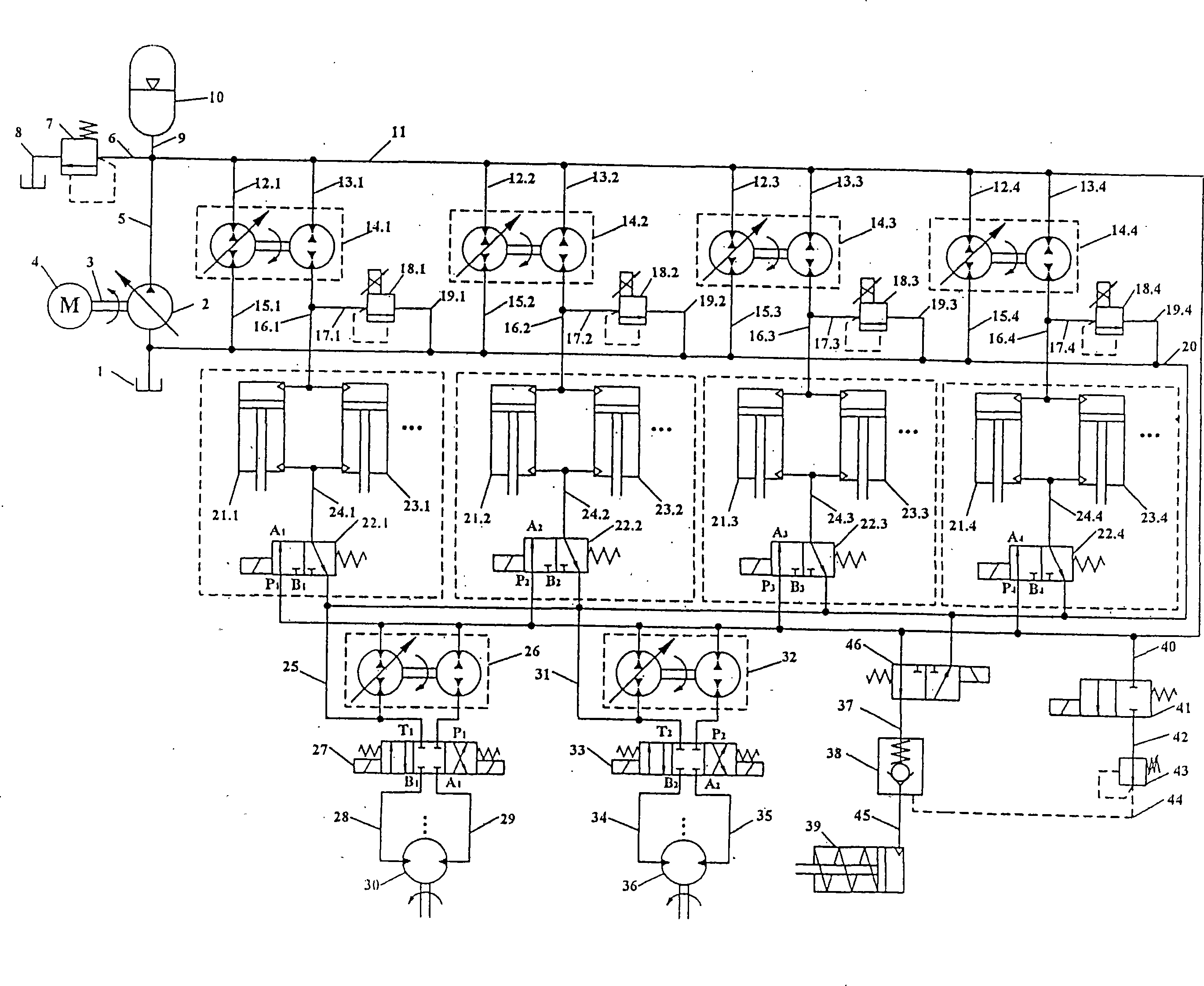

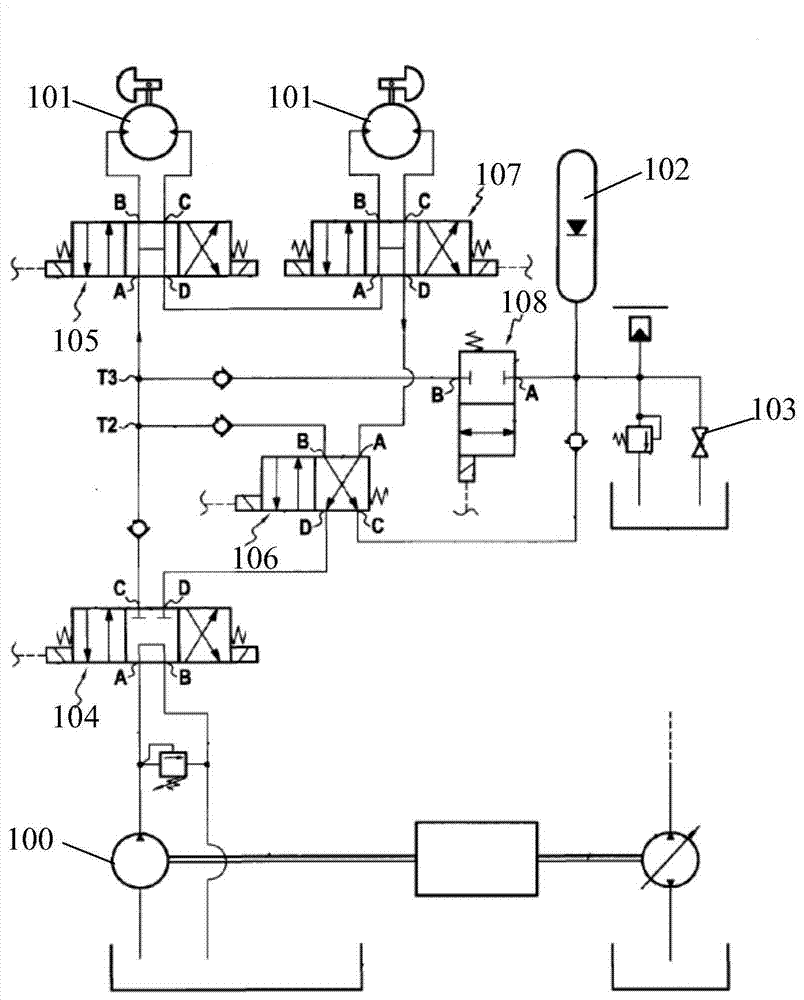

Energy-saving type shield hydraulic pressure control system using hydraulic pressure transformer

InactiveCN101225839AAvoid lostSimple structureServomotor componentsServometer circuitsMotor speedControl manner

The invention discloses an energy-saving shield machine hydraulic pressure control system, adopting hydraulic transformer, which comprises a hydraulic transformer, a motor, a constant pressure variable displacement pump, a two-position three-way reversing valve, a proportional overflow valve, a safety valve, an accumulator, a hydraulic cylinder, a three-position four-way reversing valve, a hydraulic motor, a reducing valve and a two-position two-way reversing valve; wherein, the shield machine driving, the cutter head drive and the spiral transportation system are integrated in a loop; the constant pressure network comprising the constant pressure variable displacement pump and the accumulator provides the system with power energy; the propulsion system adopts group control and comprises a plurality of groups; the discharge capacity of variable displacement pump / motor inside the hydraulic transformer is adjusted in real-time to control the speed and the propulsive force of the propulsion hydraulic cylinder and the rotational speed and the output torque of the hydraulic motor. The energy-saving shield machine hydraulic pressure control system has the advantages of adopting hydraulic transformer and other energy-saving elements and control methods, lossless transfer of energy, guarding against energy loss in the throttling speed regulation system, and good performance of energy-saving.

Owner:ZHEJIANG UNIV

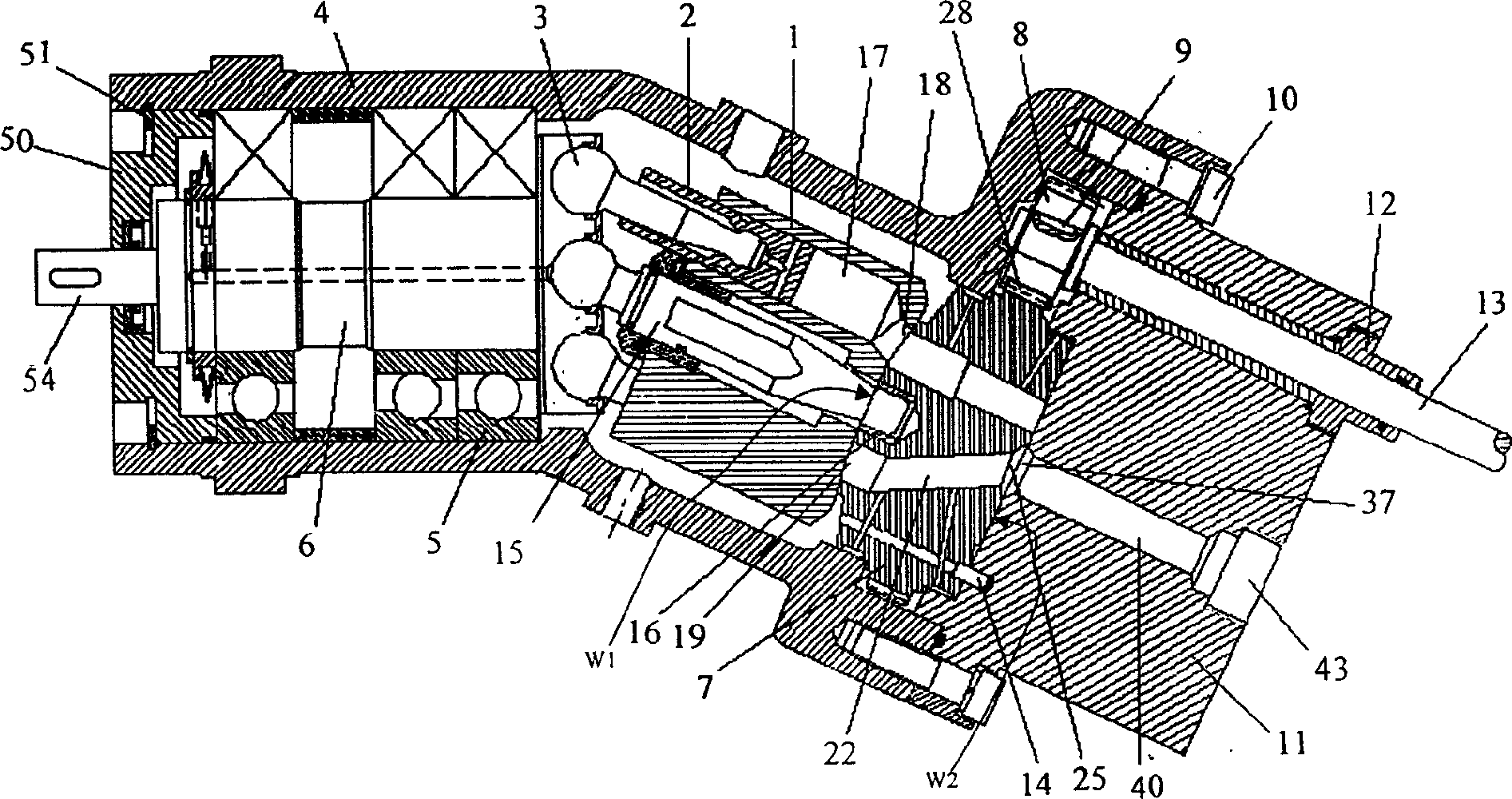

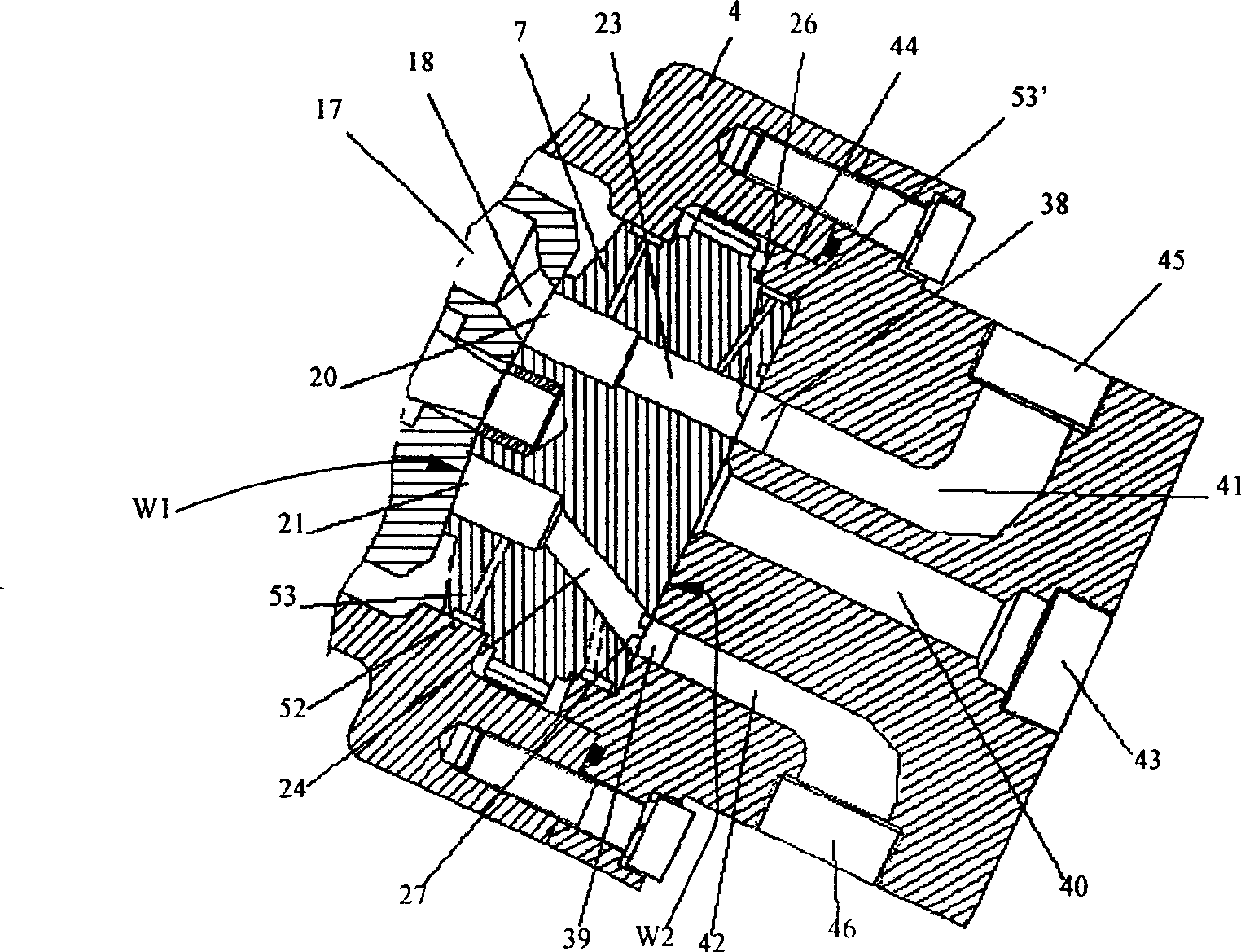

Hydraulic transformer

InactiveCN1455119AReasonable forceEasy to adjustFluid-pressure convertersPositive-displacement liquid enginesEngineeringRate change

The present invention discloses a hydraulic pressure changer, formed from shell, front end cover, rotating shaft, plunger, cylinder, port plate and rear end cover. According to the working principle of hydraulic pressure changer it utilizes the control of rotating angle of port plate of said hydraulic pressure change, regulation of flow rate change of three oil holes of the pressure changer and further control of output pressure of the pressure changer to drive lienar load or rotary load to make it move. By adopting special port plate and rear end cover structure said invention can resolve the oil liquor throttling loss between the port plate and rear end cover, exaggerate the pressure-regulating ratio range of hydraulic pressure changer and can make it implement the functions of regulating pressure.

Owner:ZHEJIANG UNIV

Pressure exchange apparatus with integral pump

InactiveUS7214315B2Rotary/oscillating piston combinations for elastic fluidsPump componentsEngineeringHigh pressure

A pressure exchange device is provided that utilizes an integral high pressure boost pump that is in fluid communication with a pressure exchange unit. An optional low pressure boost pump unit may also be provided. The pressure exchange unit comprises a rotating rotor assembly inside a housing to transfer the pressure of a fluid from one high pressure fluid to another low pressure fluid.

Owner:SHUMWAY SCOTT

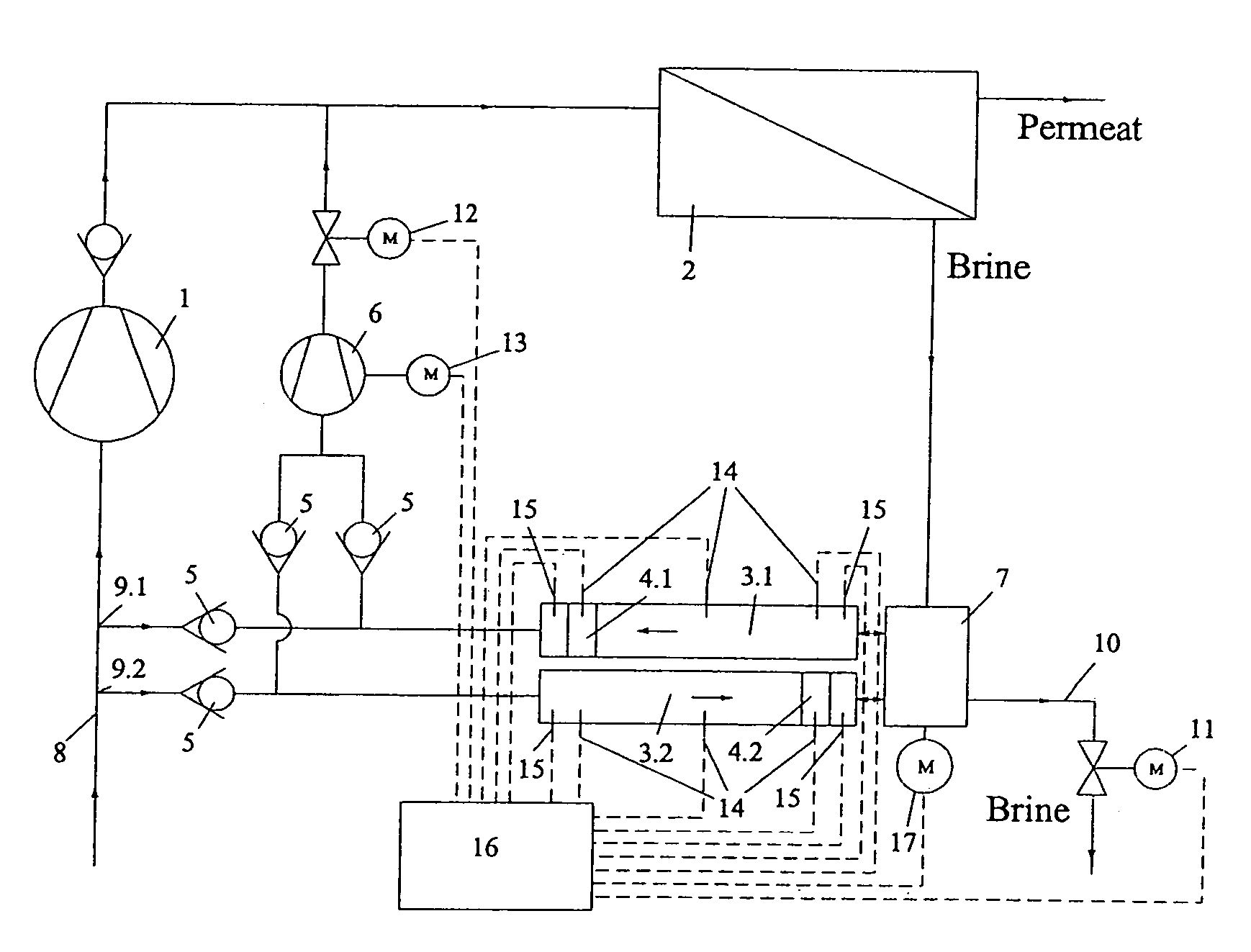

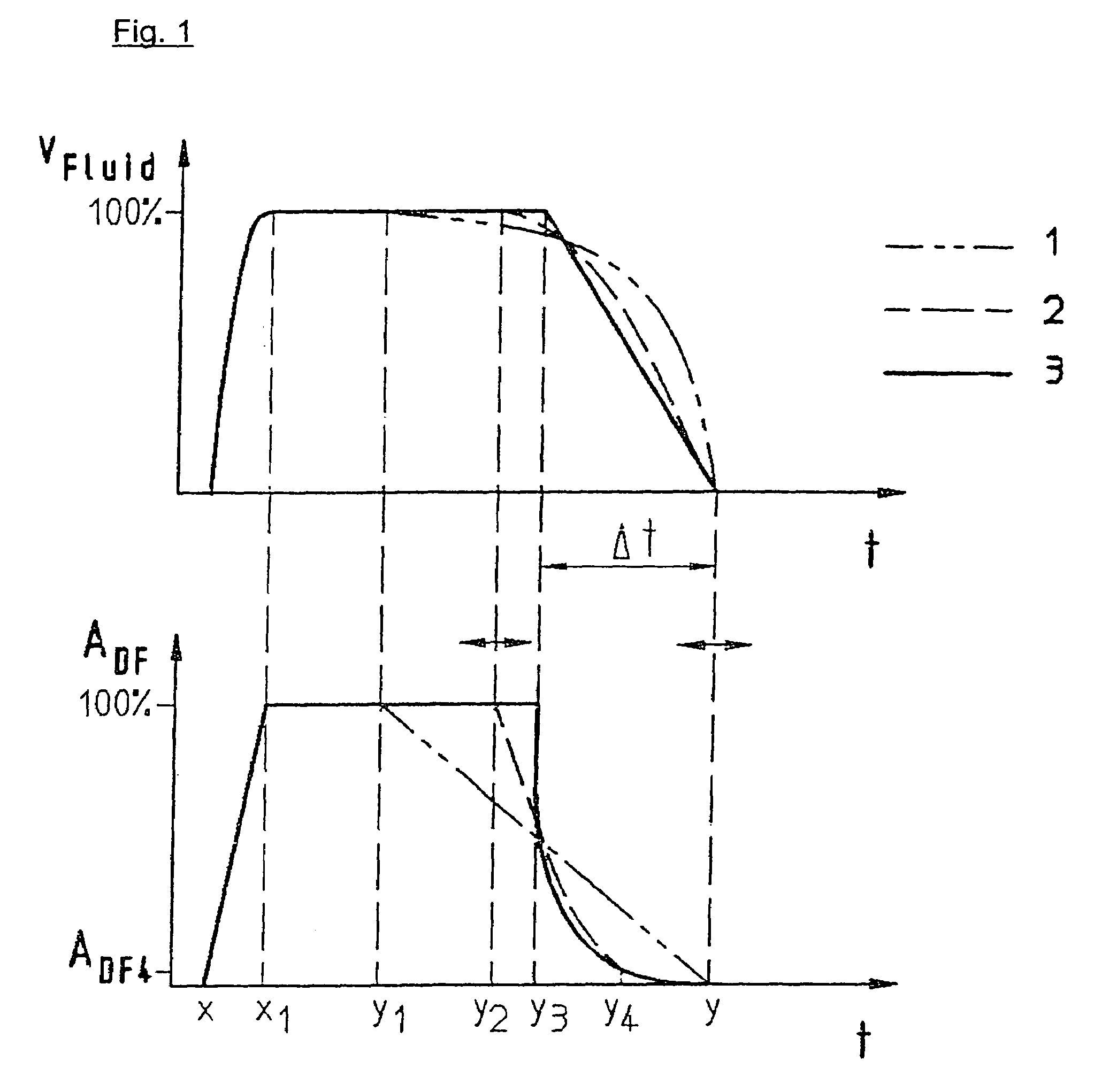

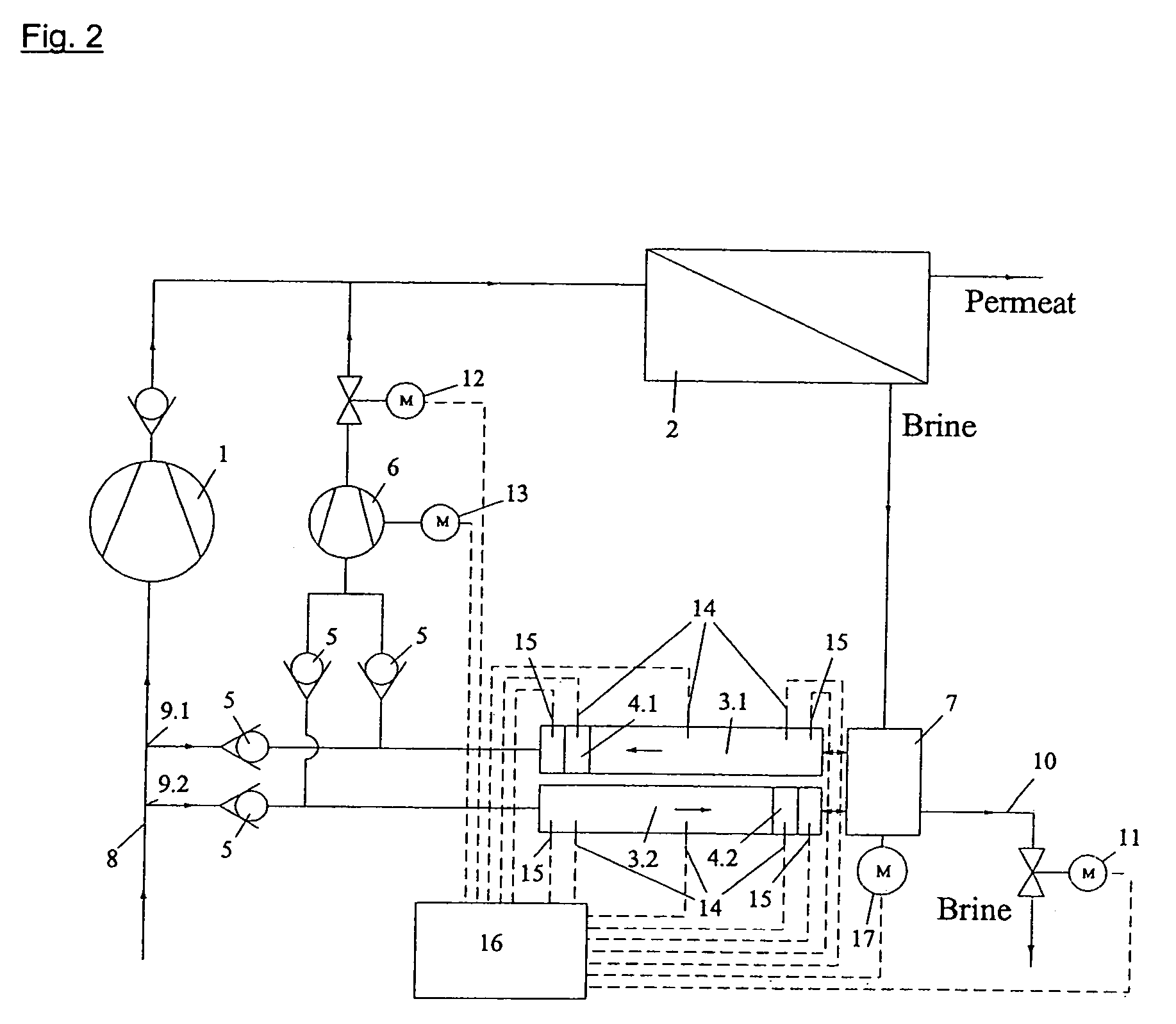

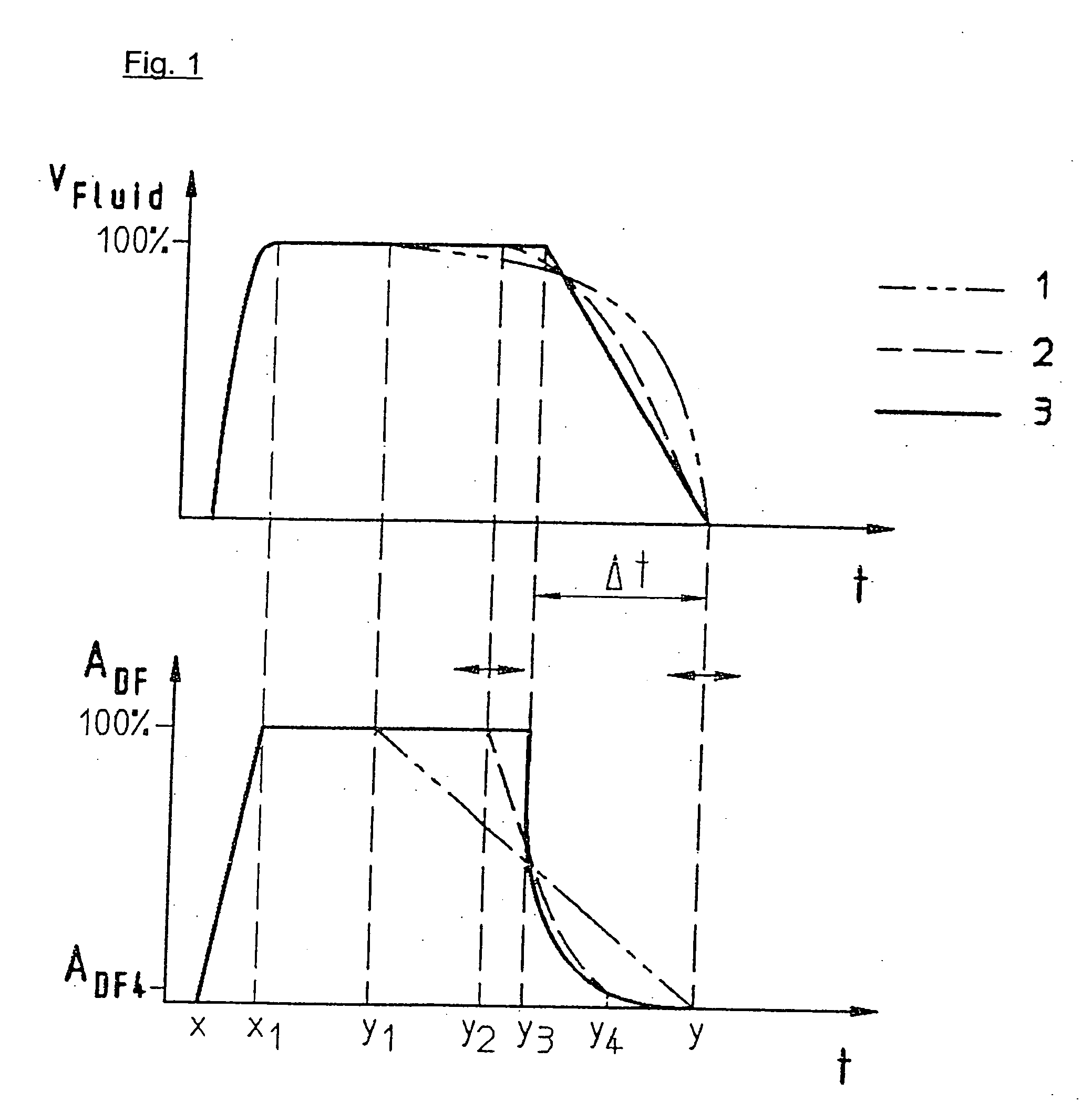

Pressure exchanger system

InactiveUS7168927B2Guaranteed uptimeIncrease loadPump componentsFluid-pressure convertersHigh energyEngineering

A pressure exchanger system having at least two tubular chambers, in which a plurality of reversing valves reverse the flow paths of fluid flows through the at least two tubular chambers. At least one driven reversing valve alternately reverses the flow paths between a supply source, which supplies a high-energy high-pressure fluid, and the tubular chambers. In reversing the liquid flows and shutting off previously open flow paths, the driven reversing element in the reversing valve executes a discontinuous or variable movement sequence.

Owner:KSB AG

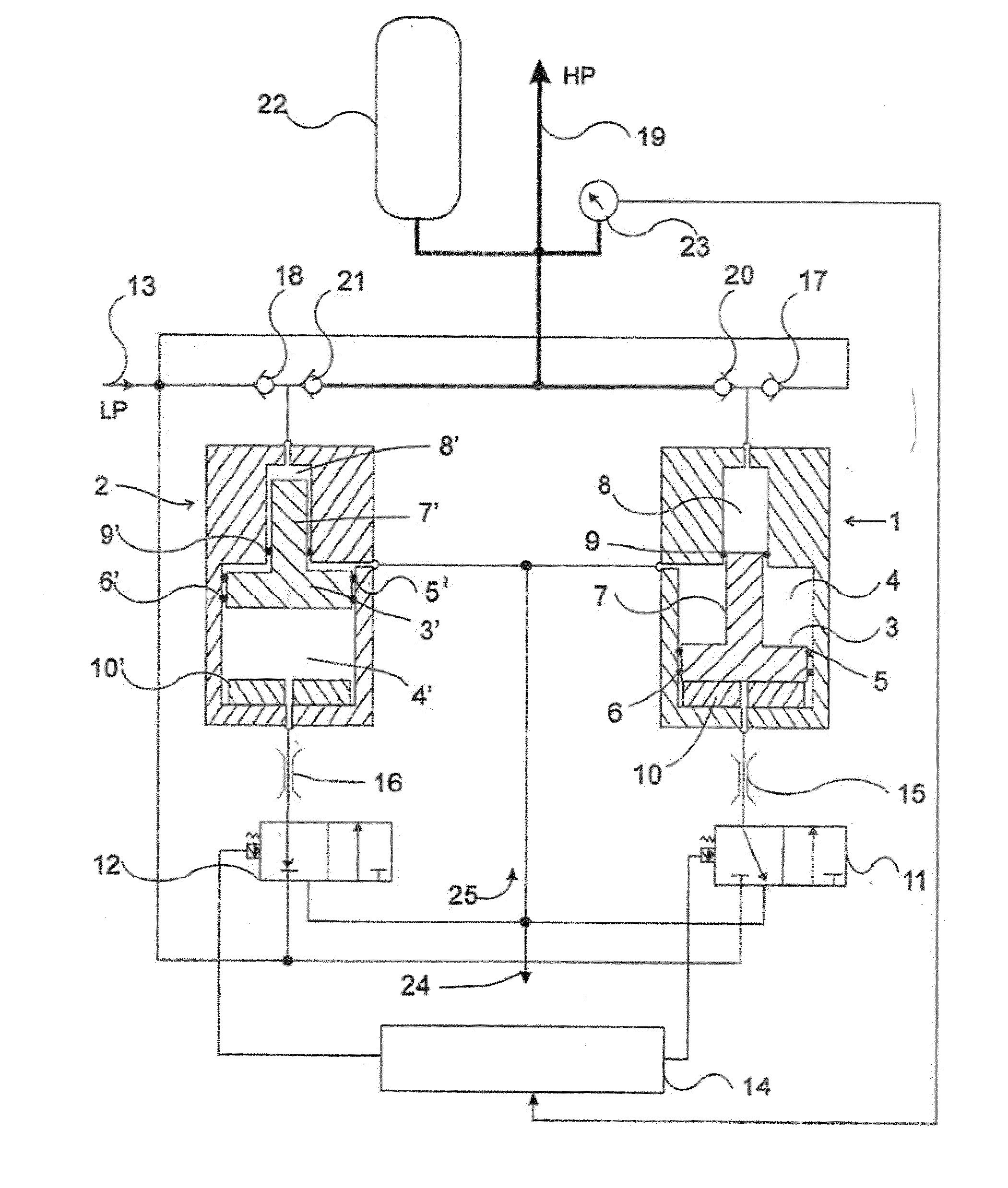

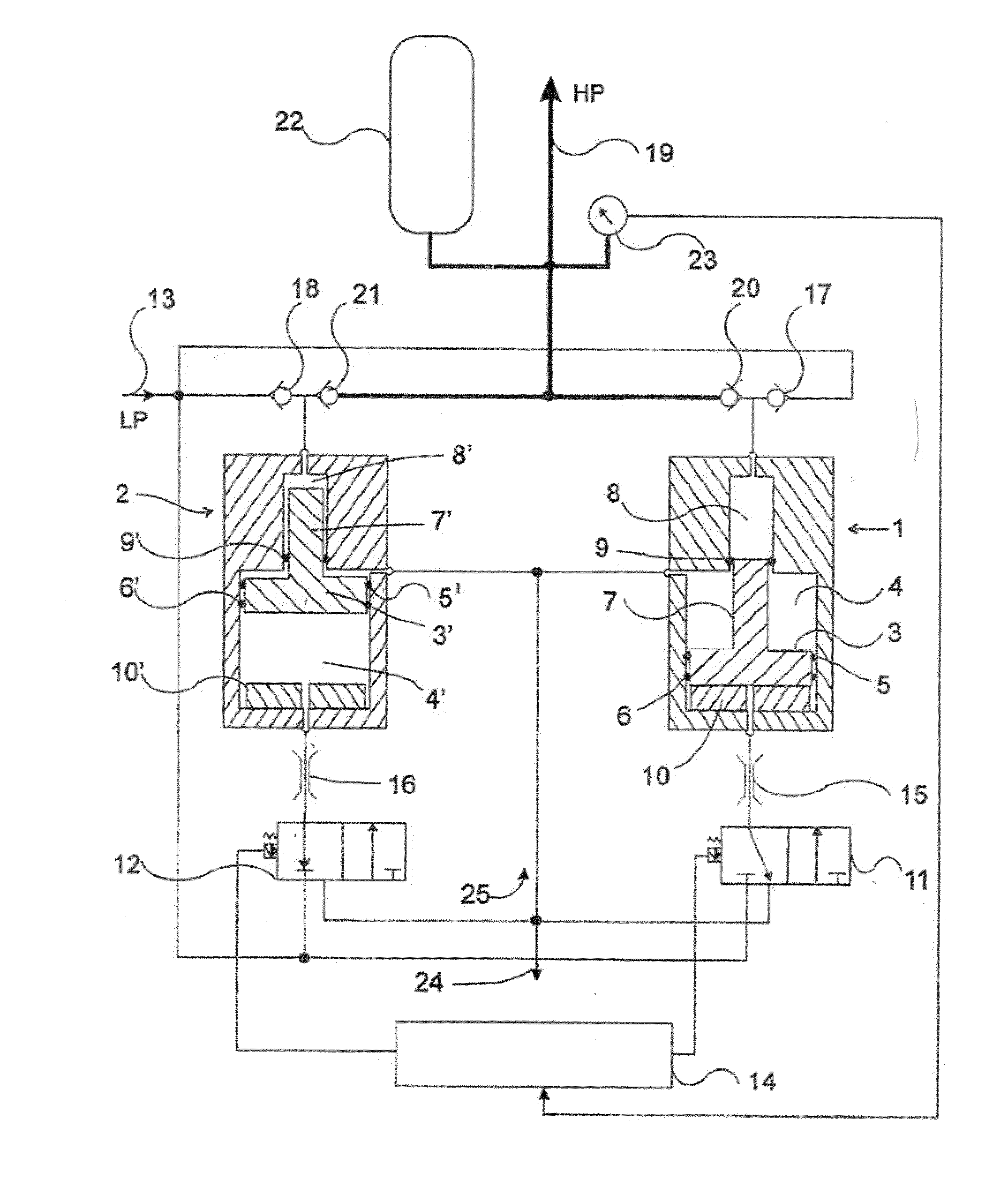

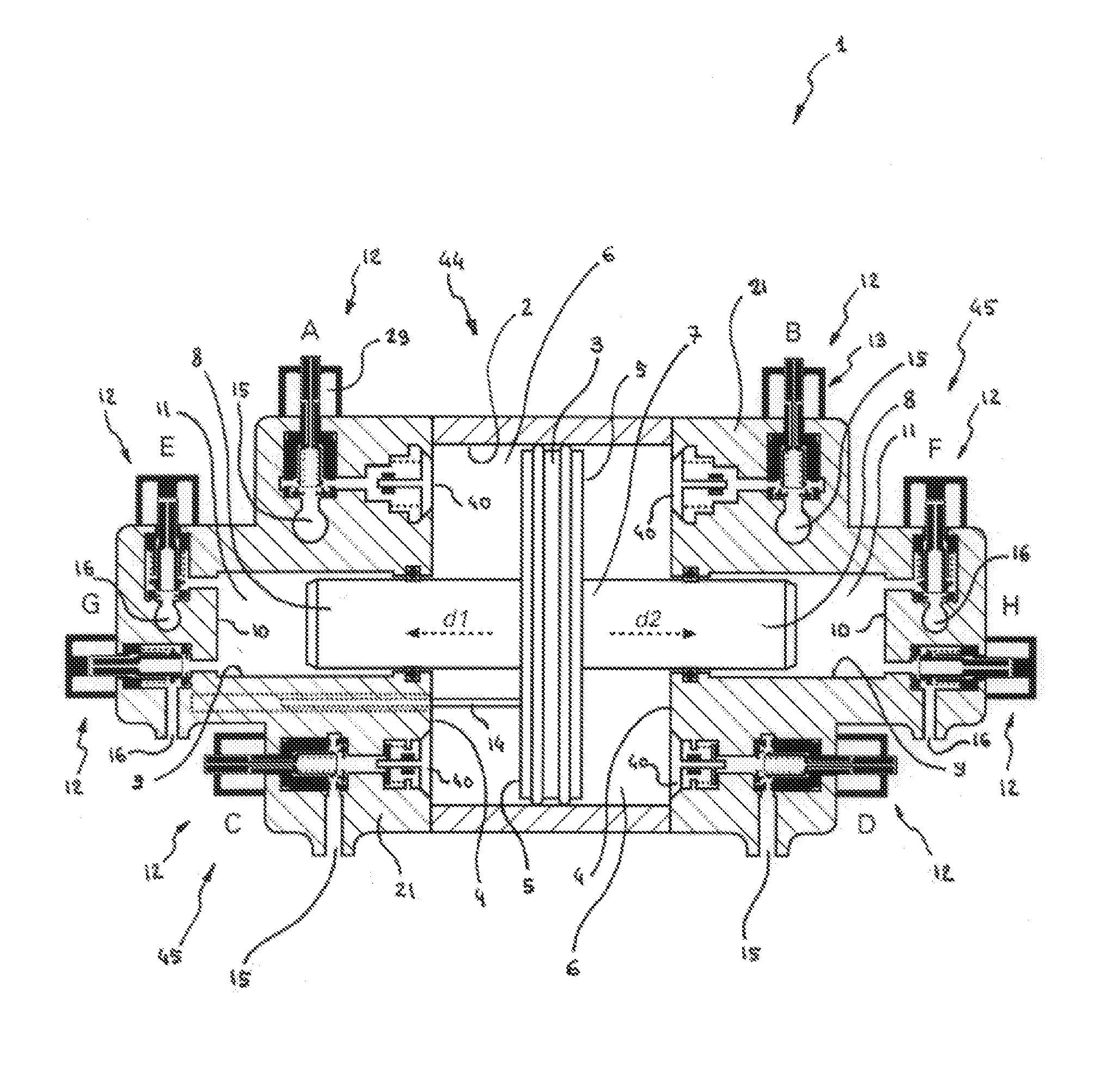

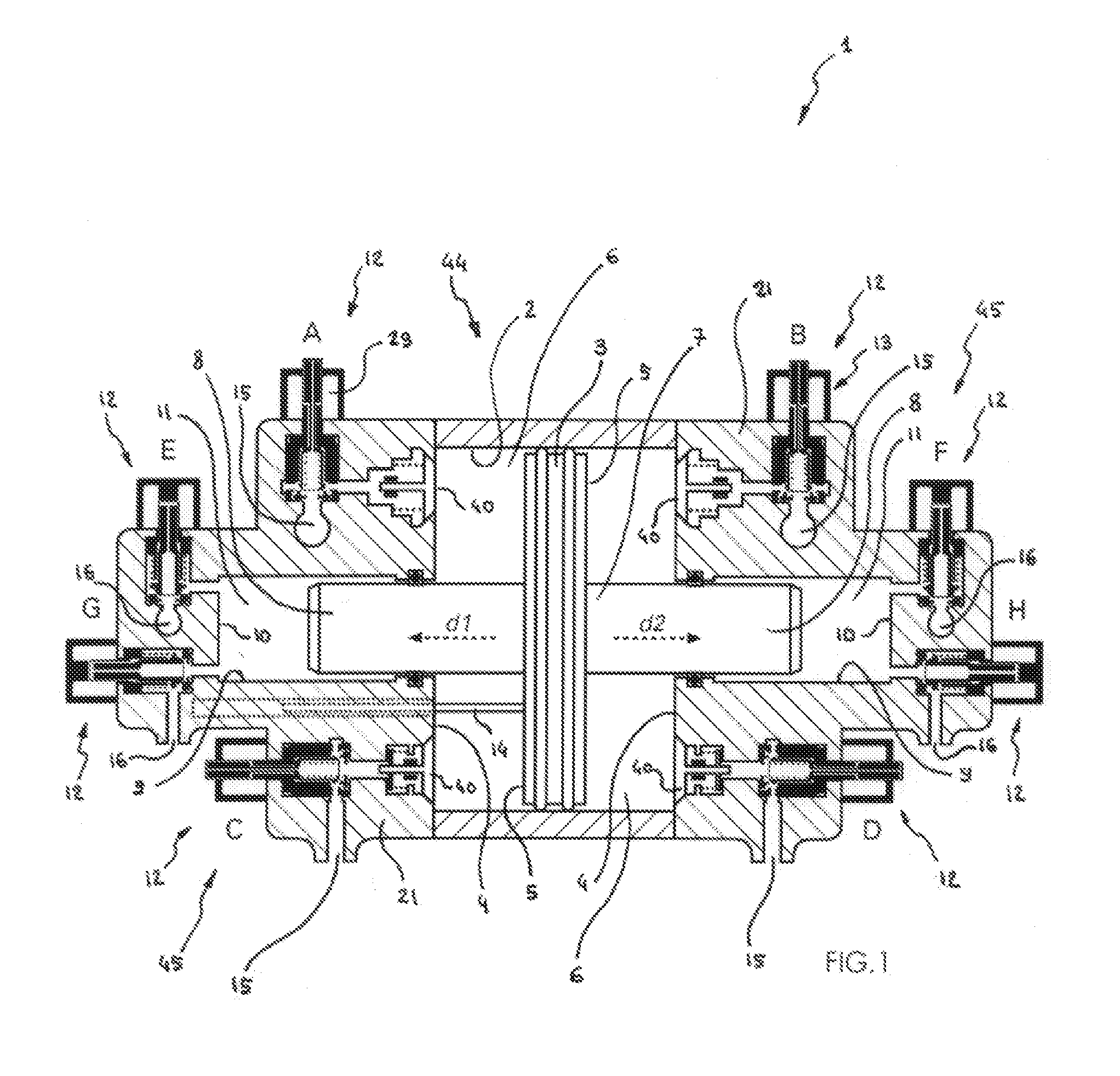

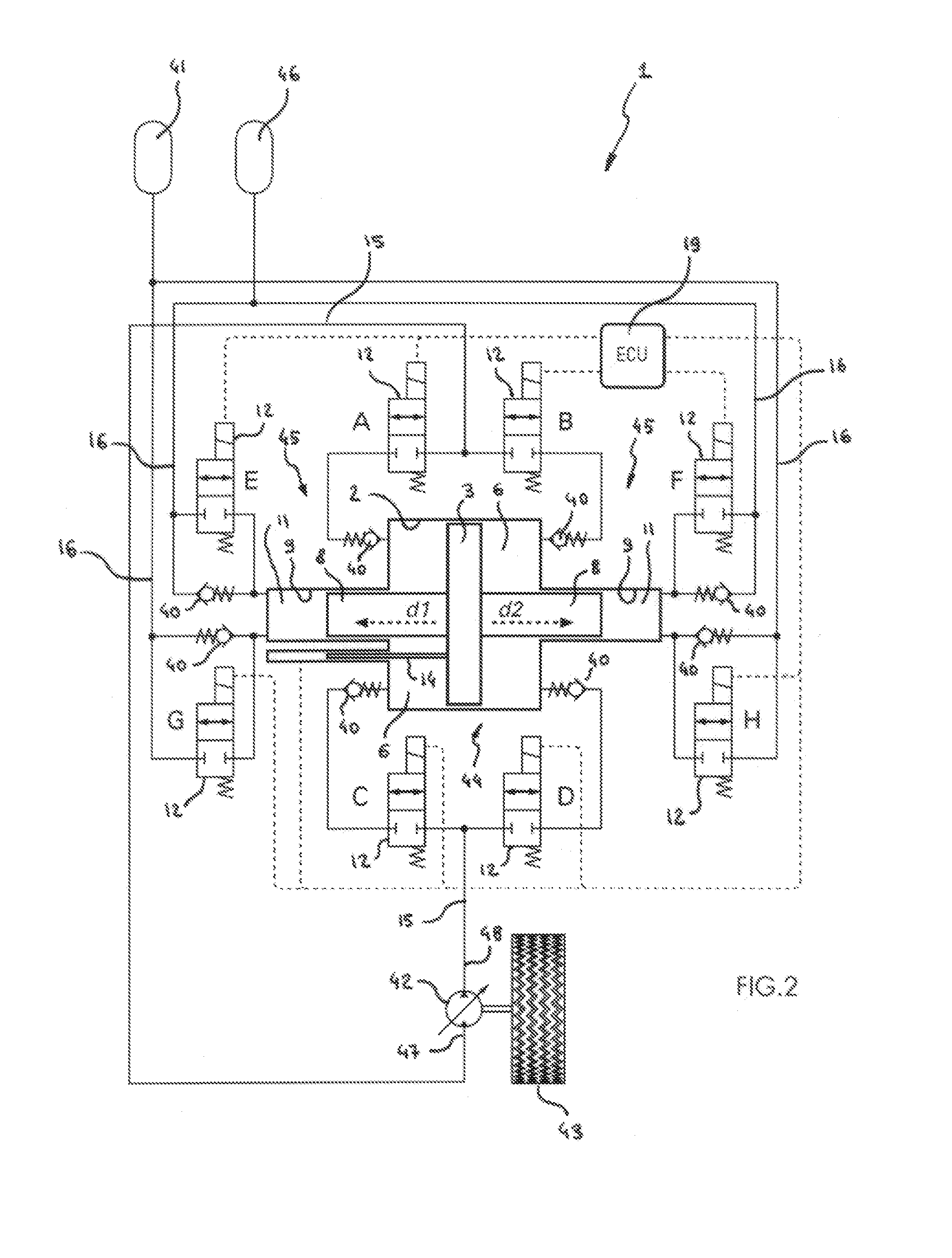

Reversible hydraulic pressure converter employing tubular valves

ActiveUS20150053075A1Improve efficiencyImprove hydraulic efficiencyPropulsion power plantsAccumulator installationsValve actuatorEngineering

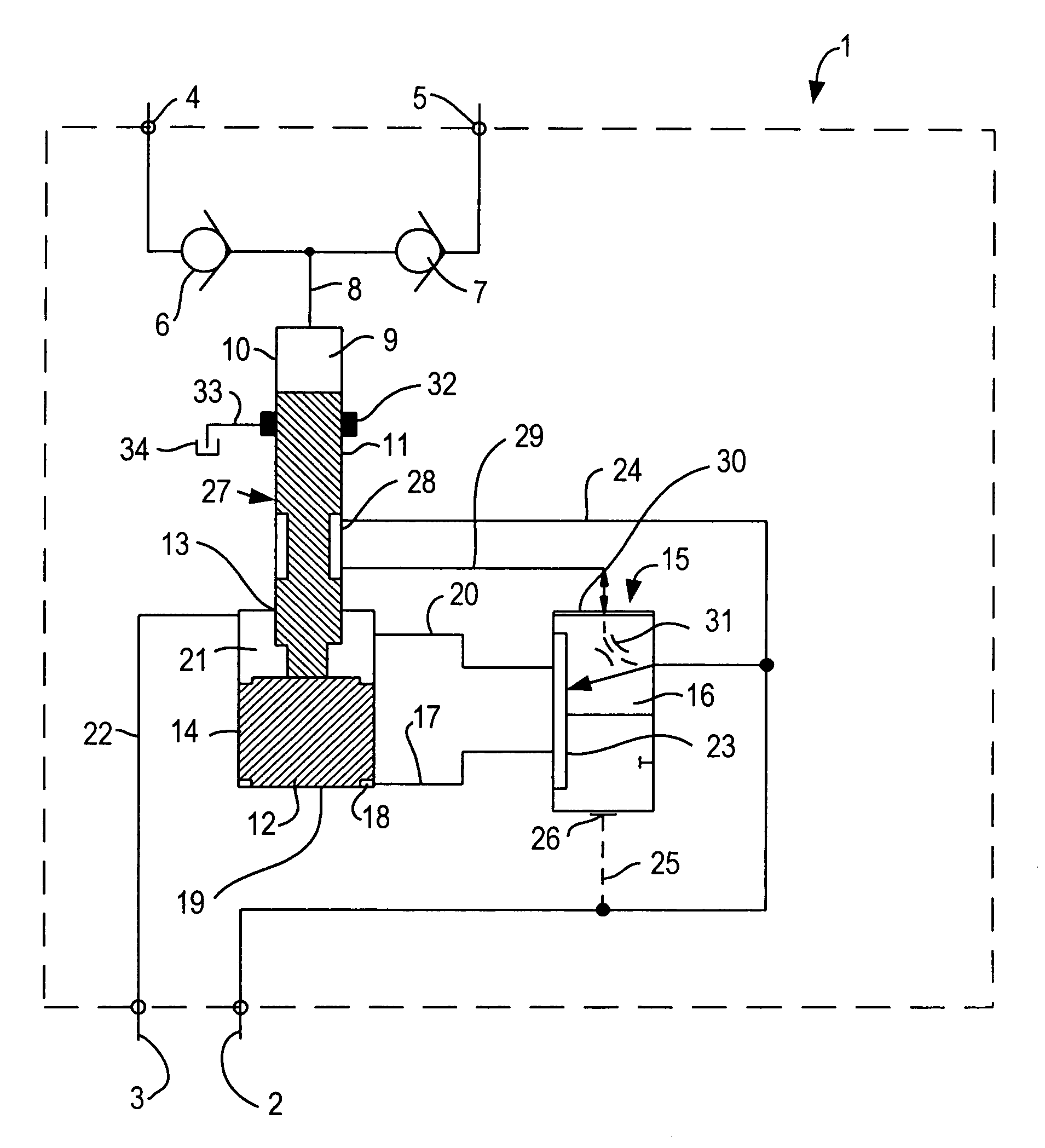

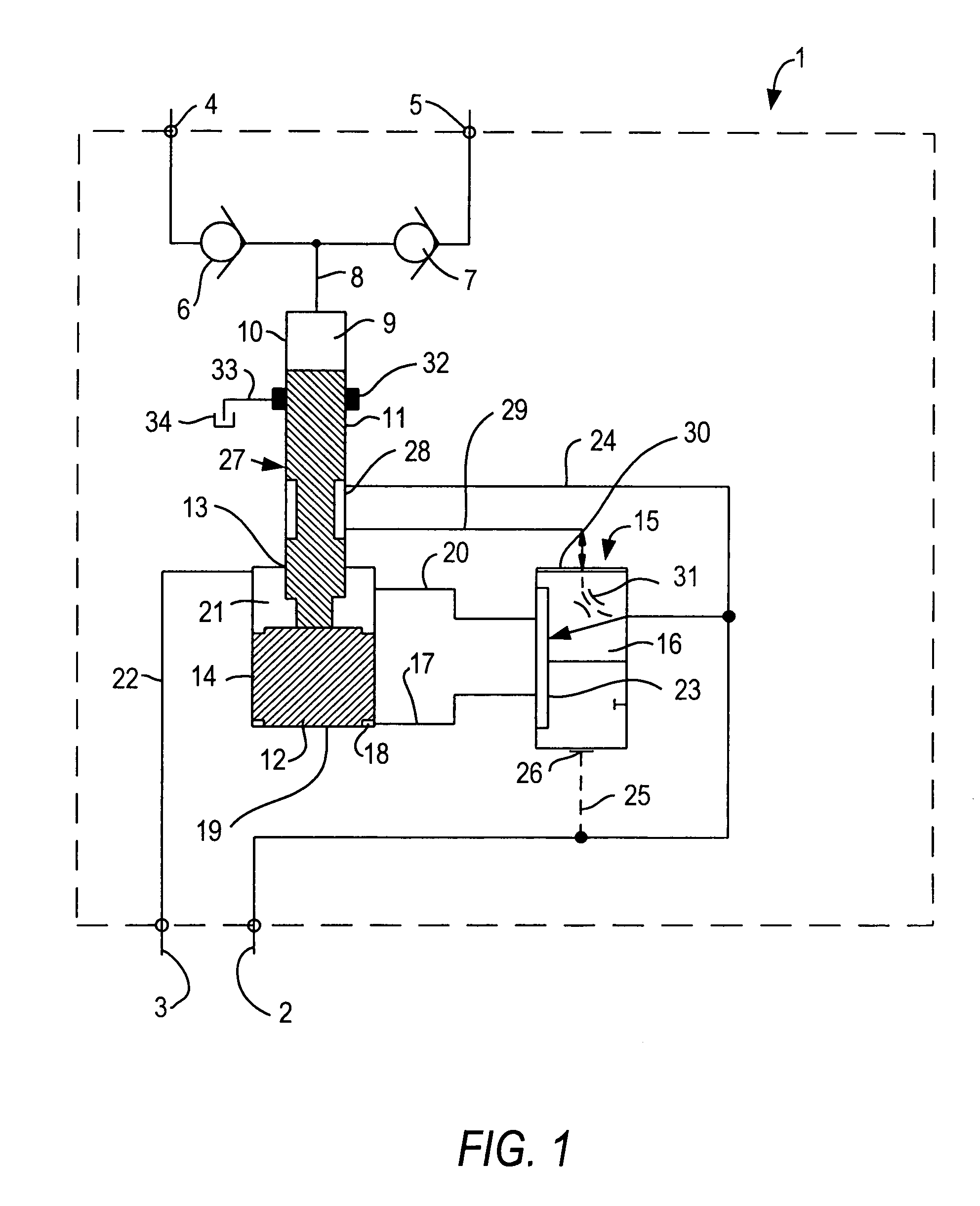

The reversible hydraulic pressure converter (1) employing tubular valves includes a medium-pressure stage (44) consisting of a medium-pressure cylinder (2) and a double-acting medium-pressure piston (3) the position of which is sent to a control computer of the converter (19) by a piston position sensor (14), the cylinder (2) and the piston (3) forming two medium-pressure chambers (5) that can be placed in communication with a medium-pressure inlet-outlet circuit (15) by at least one tubular valve (12), the converter (1) also including two high-pressure cylinders (9) each cooperating with a high-pressure piston (8) of smaller diameter and defining two high-pressure chambers (11) that can be placed in communication with a high-pressure inlet-outlet circuit (16) by at least one tubular valve (12), each of the various tubular valves (12) cooperating with an independent valve actuator (13).

Owner:RABHI VIANNEY

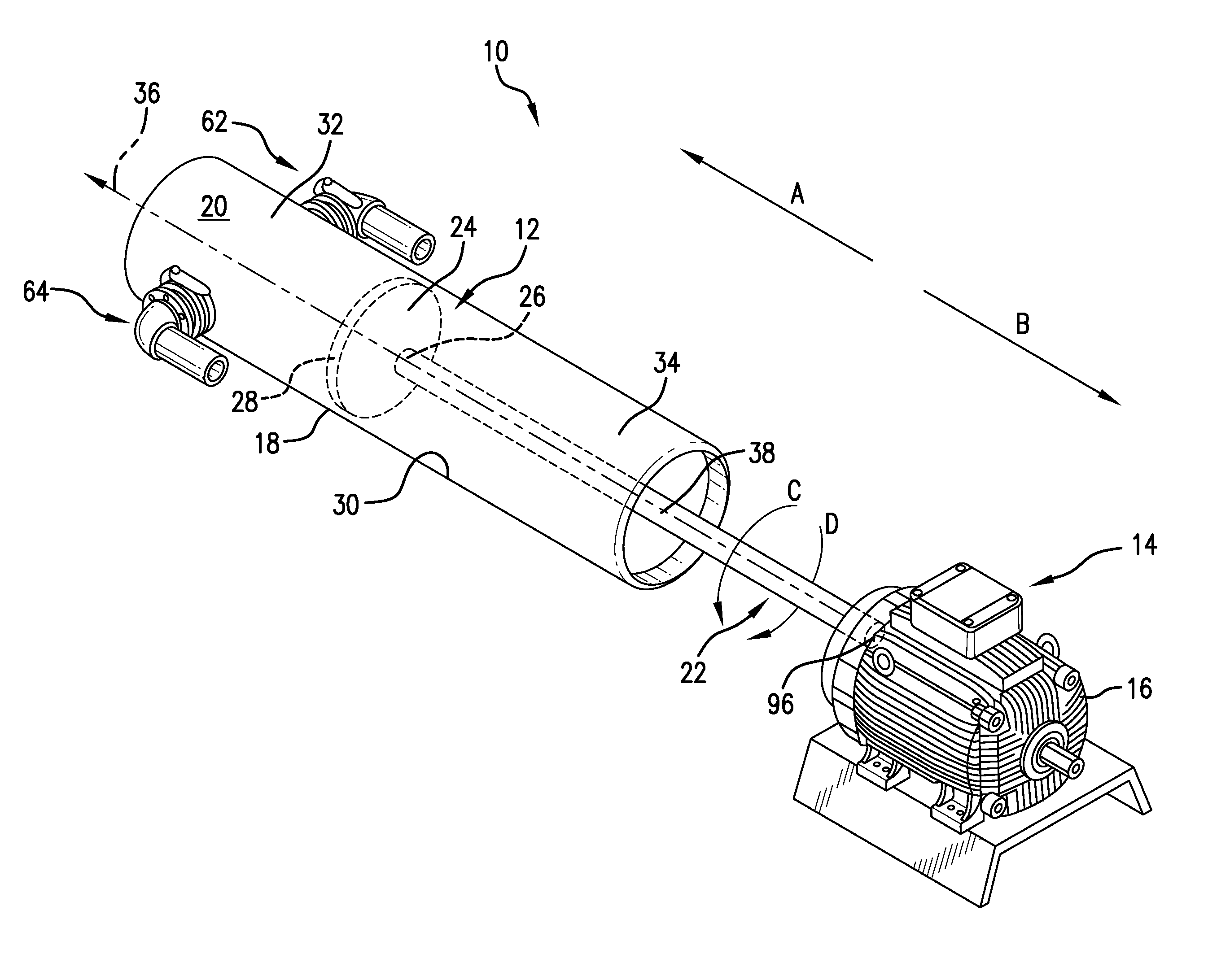

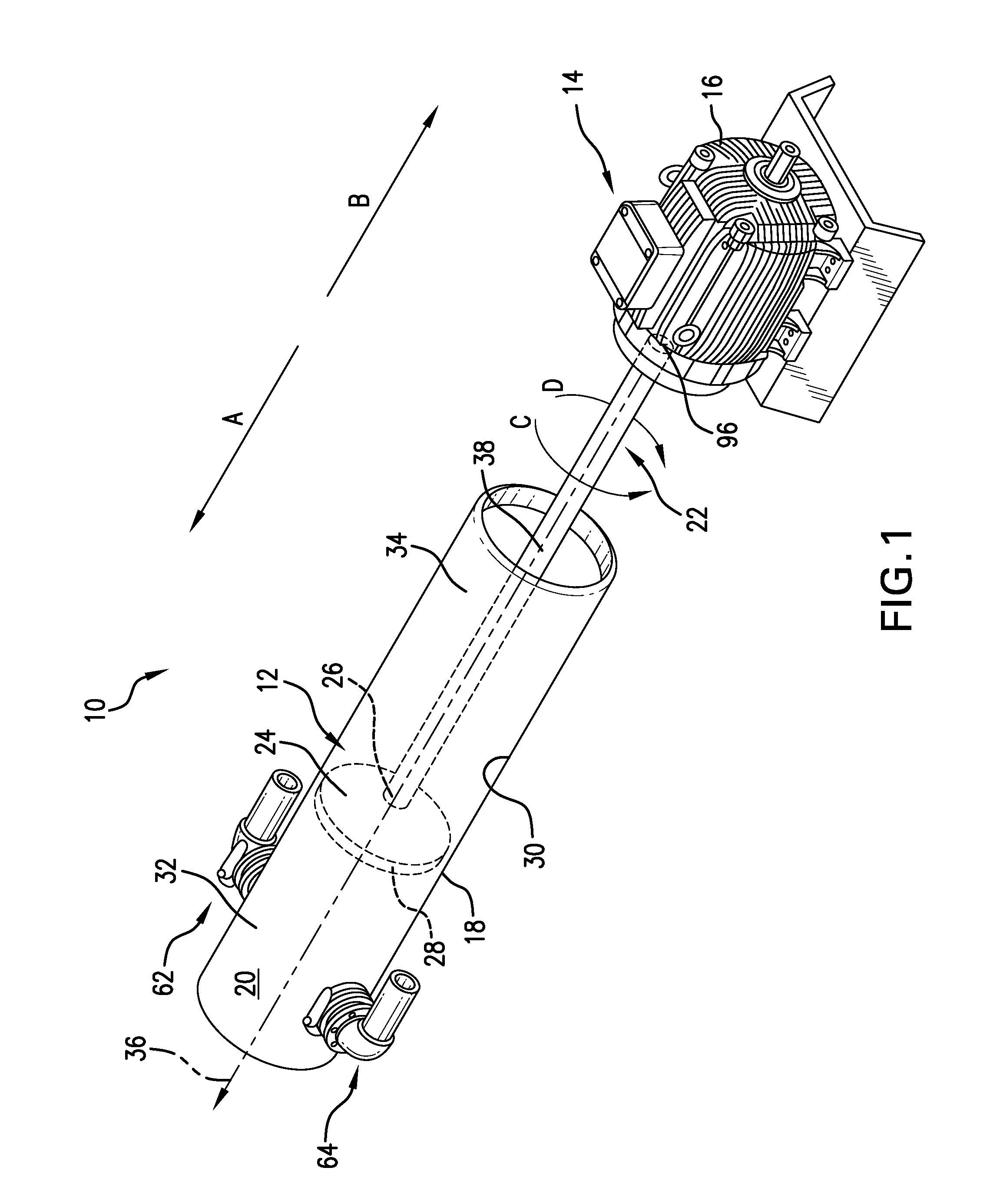

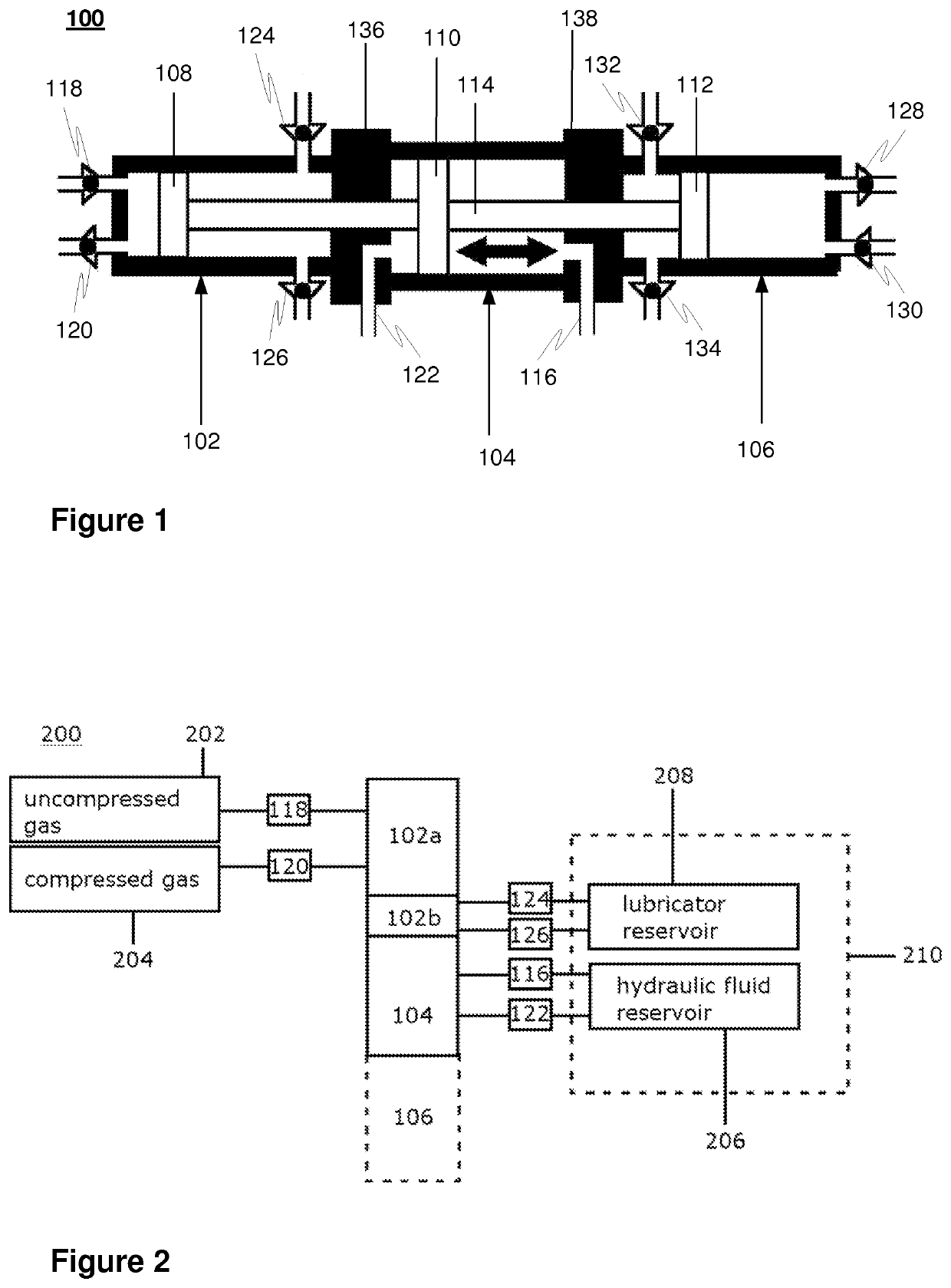

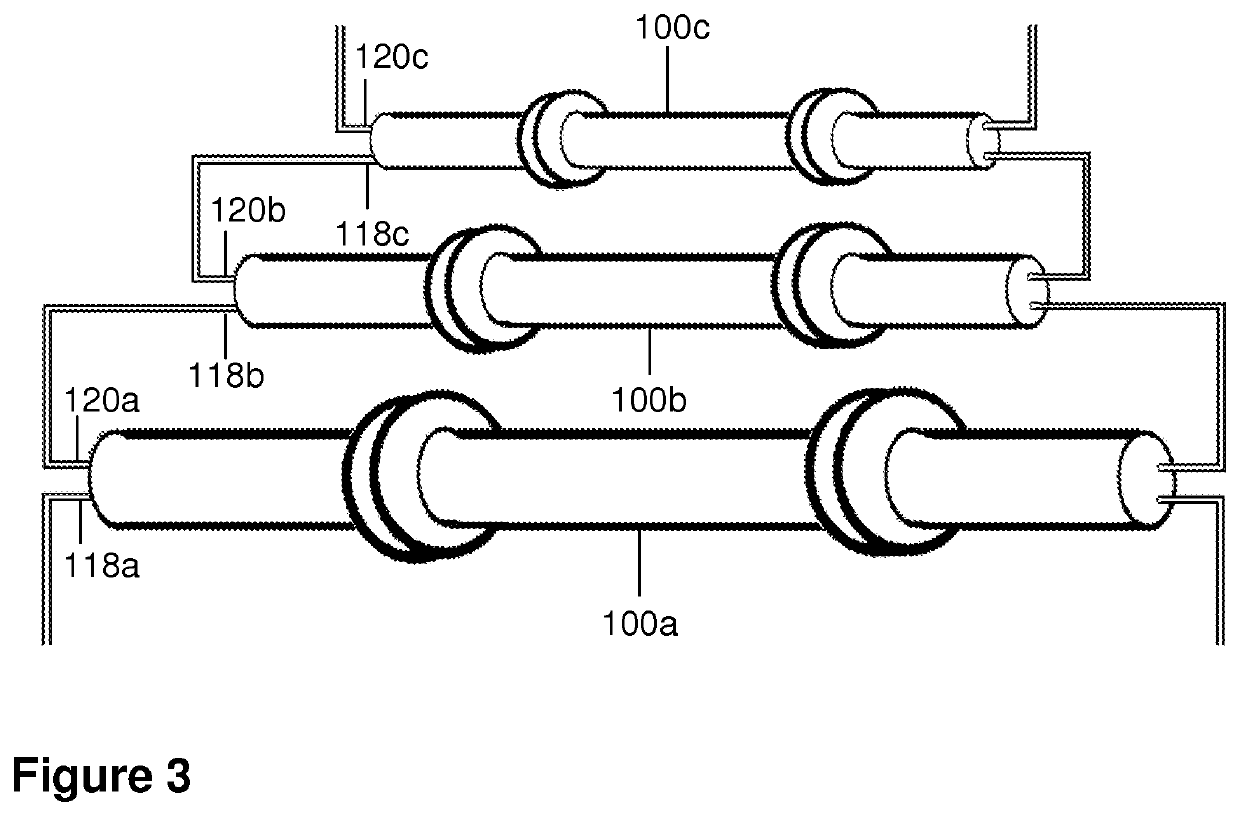

Gas intensifier with lubrication

InactiveUS20200040882A1Extended service lifeReduce decreasePositive displacement pump componentsFluid-pressure convertersLubricationPiston

A hydraulically driven intensifier for increasing pressure of gas comprising a piston-driven compression chamber for gas, operatively connected to an adjacent hydraulic chamber, with lubricant coupling in the compression chamber of the intensifier to circulate the lubricating fluid for cooling and lubricating the piston. A multistage compression system for gas, comprising the aforementioned intensifier, preferably several thereof operatively connected in series.

Owner:METENER OY

Pressure exchanger system

InactiveUS20050166978A1Guaranteed uptimeIncrease loadPump componentsFluid-pressure convertersHigh energyEngineering

A pressure exchanger system having at least two tubular chambers, in which a plurality of reversing valves reverse the flow paths of fluid flows through the at least two tubular chambers. At least one driven reversing valve alternately reverses the flow paths between a supply source, which supplies a high-energy high-pressure fluid, and the tubular chambers. In reversing the liquid flows and shutting off previously open flow paths, the driven reversing element in the reversing valve executes a discontinuous or variable movement sequence.

Owner:KSB AG

Apparatus for angular adjustment of camshafts relative to crankshafts in combustion engines

An apparatus for varying the phase of the camshaft in the combustion engine of a motor vehicle has an adjuster which is connected to the camshaft and is operable to adjust the phase of the camshaft prior and subsequent to starting of the engine. To this end, the adjuster is connected with a hydraulic drive system which can operate the adjuster while the engine is idle. Once the engine is started, the drive system receives pressurized fluid from the lubricating circuit of the engine. Prior to starting of the engine, the drive system receives pressurized fluid from a source other than the lubricating circuit or from a source which is provided in addition to the lubricating circuit. The other source is preferably the hydraulic circuit of the power steering system (such as a speed-sensitive power steering system) of the motor vehicle.

Owner:ATLAS FAHRZEUGTECHN GMBH

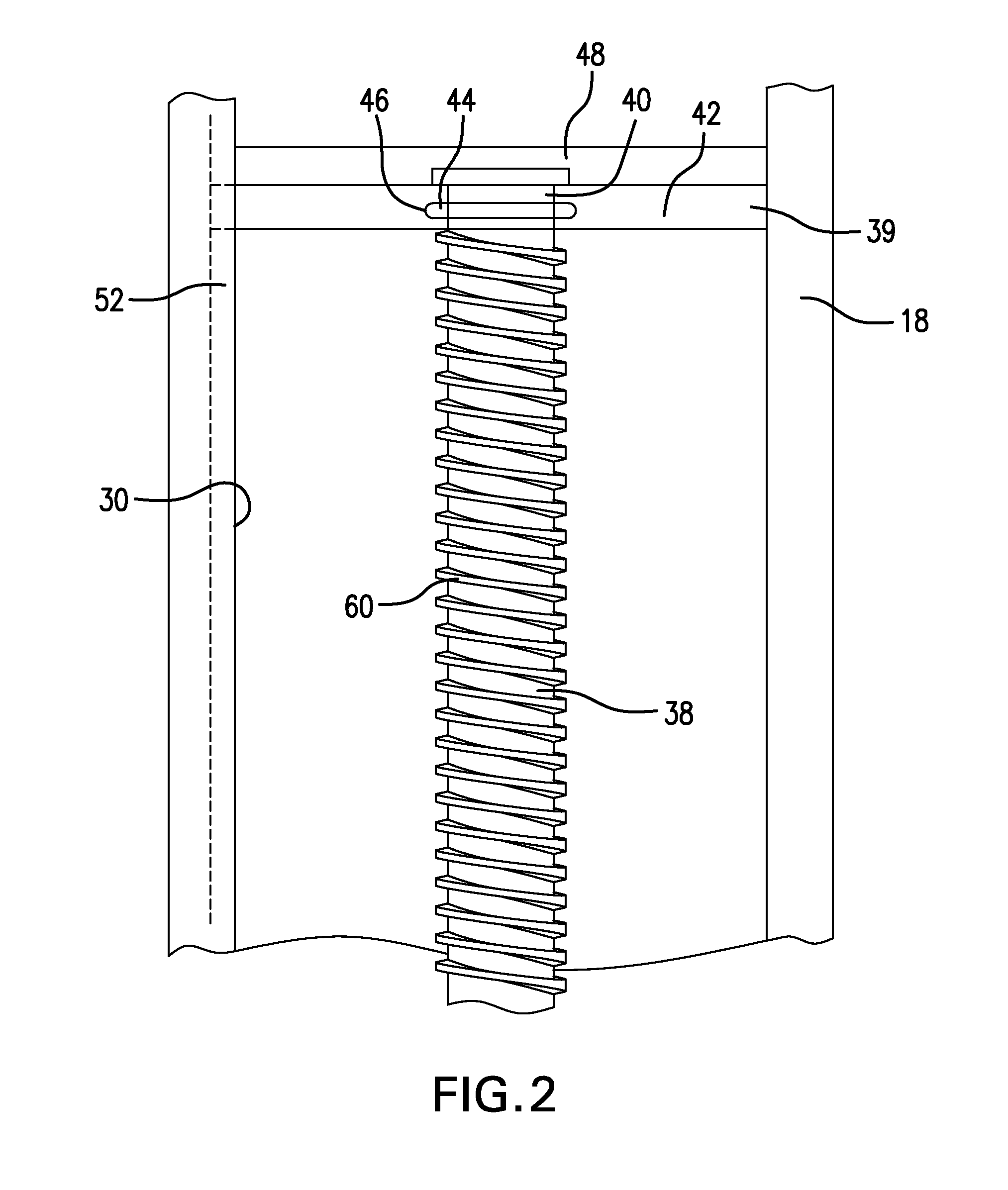

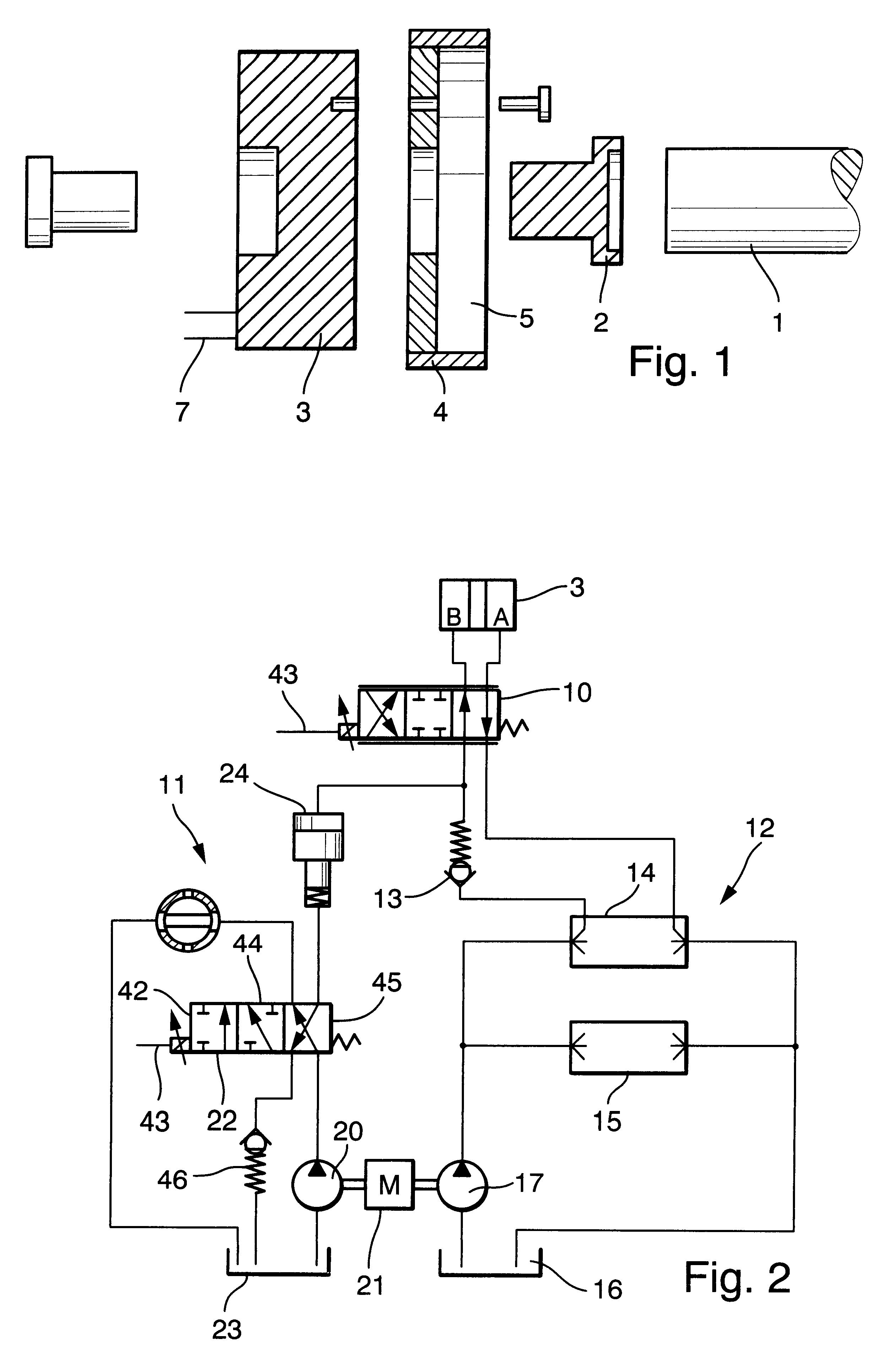

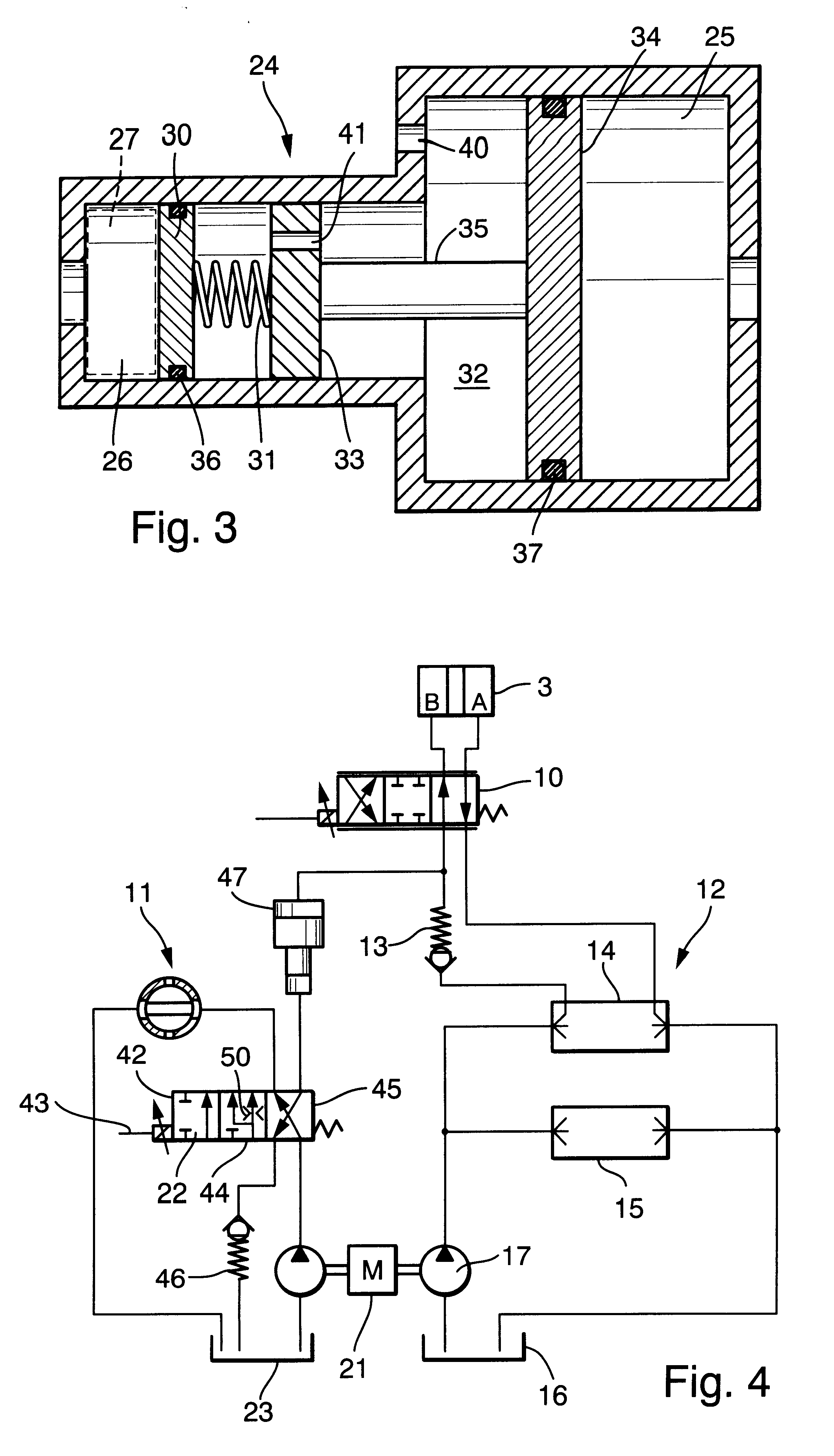

Axial-flow type jet flow gas wave pressure supercharger

InactiveCN102606547ARealize pressure exchangeHigh pressure levelFluid-pressure convertersJet flowEnergy exchange

An axial-flow type jet flow gas wave pressure supercharger relies on operation of pressure wave to achieve energy exchange between high-pressure gas and low-pressure gas, avoids mixed diffusion energy loss and has the advantages of being high in isentropic efficiency, low in rotation speed, capable of working with fluid and the like. A pressure oscillation tube channel with variable rectangular cross section is adopted to reduce incident loss and flow loss of jet flows. A pressure equalizing port is arranged in the pressure supercharger so that performance of different pressure ratios is balanced. A pressure expansion fluid director is arranged at the position of a compression fluid outlet to effectively convert air flow kinetic energy. The axial-flow type jet flow gas wave pressure supercharger can fully utilize pressure energy in the production process and stratal pressure energy such as natural gas and can serve as an efficient device for effectively utilizing the pressure energy.

Owner:DALIAN UNIV OF TECH

Method and system for controlling an excavator

A control for an excavator of the type having a plurality of hydraulic cylinders for moving excavator components such that digging is accomplished at a worksite with an excavator bucket or other excavator implement, includes a plurality of hydraulic control valves, each of which is associated with a respective one of the hydraulic cylinders for controlling the application of hydraulic fluid pressure to the respective one of the hydraulic cylinders, and a plurality of manually actuated joystick valves for supplying hydraulic fluid pressure to the respective hydraulic control valves to control the movement of the hydraulic cylinders. The control includes a sensor arrangement for sensing the position of one or more excavator components.

Owner:CATERPILLAR TRIMBLE CONTROL TECH

Integrated continuous gas-driving hydraulic force booster

ActiveCN102230484ARealize automatic reversingRealize uninterrupted oil supplyFluid-pressure convertersEngineeringCylinder block

The invention discloses an integrated continuous gas-driving hydraulic force booster, comprising a gas-liquid boosting cylinder, a hydraulic check valve, a two-position four-way pneumatic control reversing valve, a pneumatic check valve and a silencer, wherein the gas-liquid boosting cylinder is a double-action boosting cylinder; two big pistons and two small pistons are arranged on a piston rod of the gas-liquid boosting cylinder; the two small pistons and the cylinder body form two oil cavities; the two big pistons and the cylinder body form four air cavities; and the middles of the two air cavities on two sides are provided with two travel signal ports. If the pistons and the piston rods of the boosting cylinder move rightwards, the travel information of the pistons and the piston rod is fed back to the reversing valve to cause the reversing valve to reverse by the control of the pneumatic check valve in the mode of pressure air mode when the right big piston crosses the right travel signal port; the pistons and the piston rod of the boosting cylinder can be reversed because of the reversal of the pneumatic control reversing valve; and thus, the pistons and the piston rod of the boosting cylinder can be automatically reversed on the tail end of the travel of the pistons and the piston rod. The device disclosed by the invention has the advantages of compact structure and big supercharge ratio, automatic reversal can be realized, and uninterrupted oil supply can be realized.

Owner:TONGJI UNIV

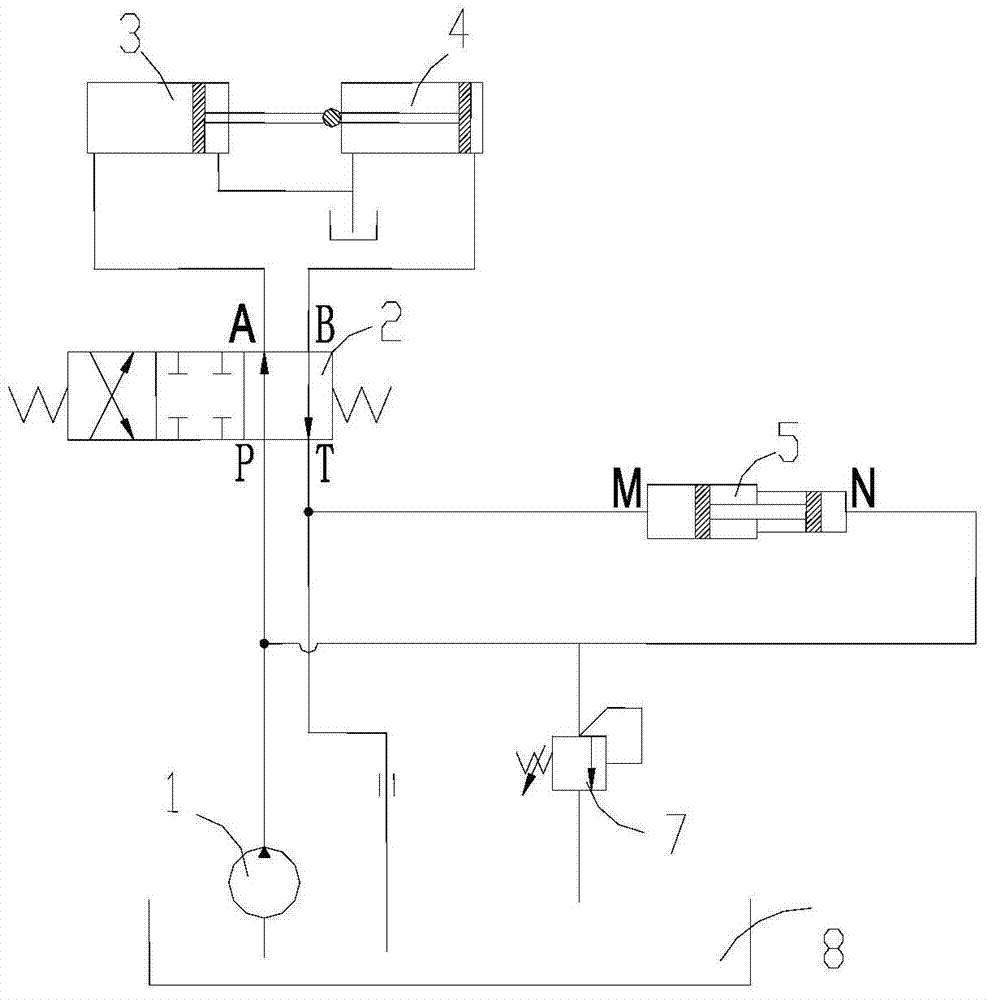

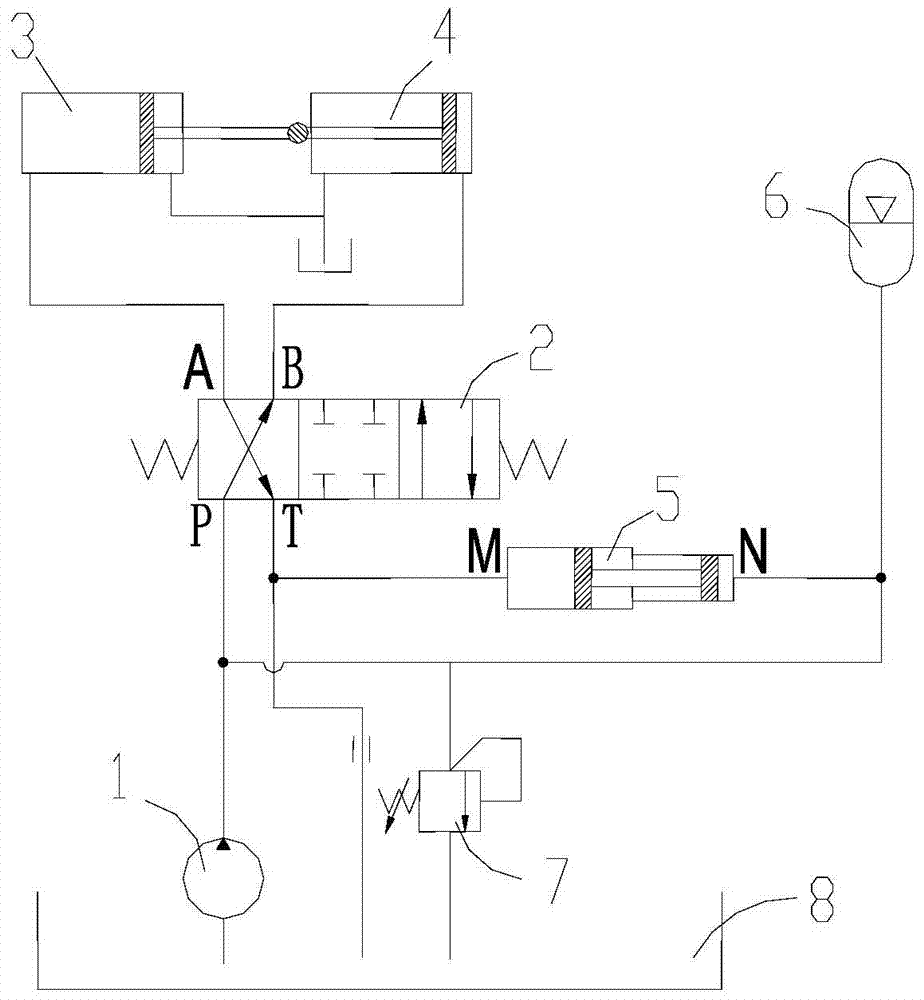

Energy recovery hydraulic system and engineering machine

InactiveCN103615443ALow costImprove real-time performanceFluid-pressure convertersFluid-pressure actuator componentsFuel tankEnergy recovery

The invention discloses an energy recovery hydraulic system which comprises a pressure oil source, an oil tank, a reversing valve, an actuator and a supercharging device. The supercharging device is arranged in a hydraulic oil line, the two ends of the supercharging device are directly connected between an oil inlet line and an oil outlet line, the two ends of the supercharging device are not connected with control valves, that is the low-pressure end of the supercharging device is communicated with an oil line between a third oil port of the reversing valve and the oil tank, and the high-pressure end of the supercharging device is communicated with an oil line between the pressure oil source and a first oil port of the reversing valve, and therefore operation of the supercharging device does not need to be controlled by a control valve. The energy recovery hydraulic system can be used for recycling energy at any time and is good in energy recycling instantaneity, simple in structure, easy and convenient to control, and low in cost. Besides, the invention further discloses an engineering machine provided with the energy recovery hydraulic system and pumping equipment provided with the energy recovery hydraulic system.

Owner:SANY AUTOMOBILE MFG CO LTD

Fluid exchanger devices, pressure exchangers, and related methods

ActiveUS9435354B2Specific water treatment objectivesFluid-pressure convertersEngineeringFluid exchange

Exchanger devices include a plurality of fixed exchange ducts and a rotating valve assembly for directing flow to and from the plurality of exchange ducts. Methods of exchanging pressure between fluid streams may include directing fluids through an exchange device and pressurizing a fluid in the plurality of exchange ducts of the exchanger device.

Owner:FLOWSERVE PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com