Patents

Literature

38results about How to "Optimize energy usage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

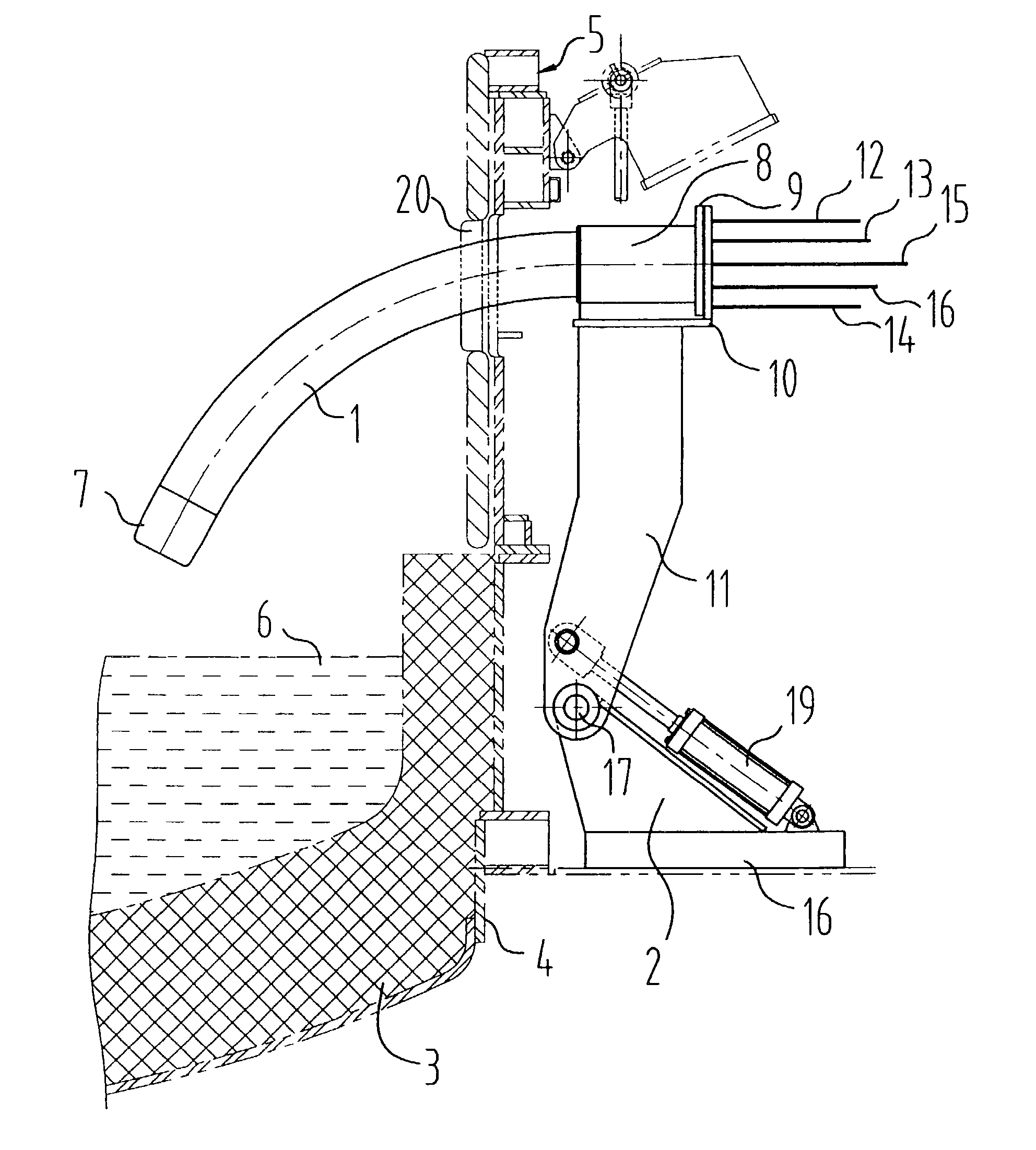

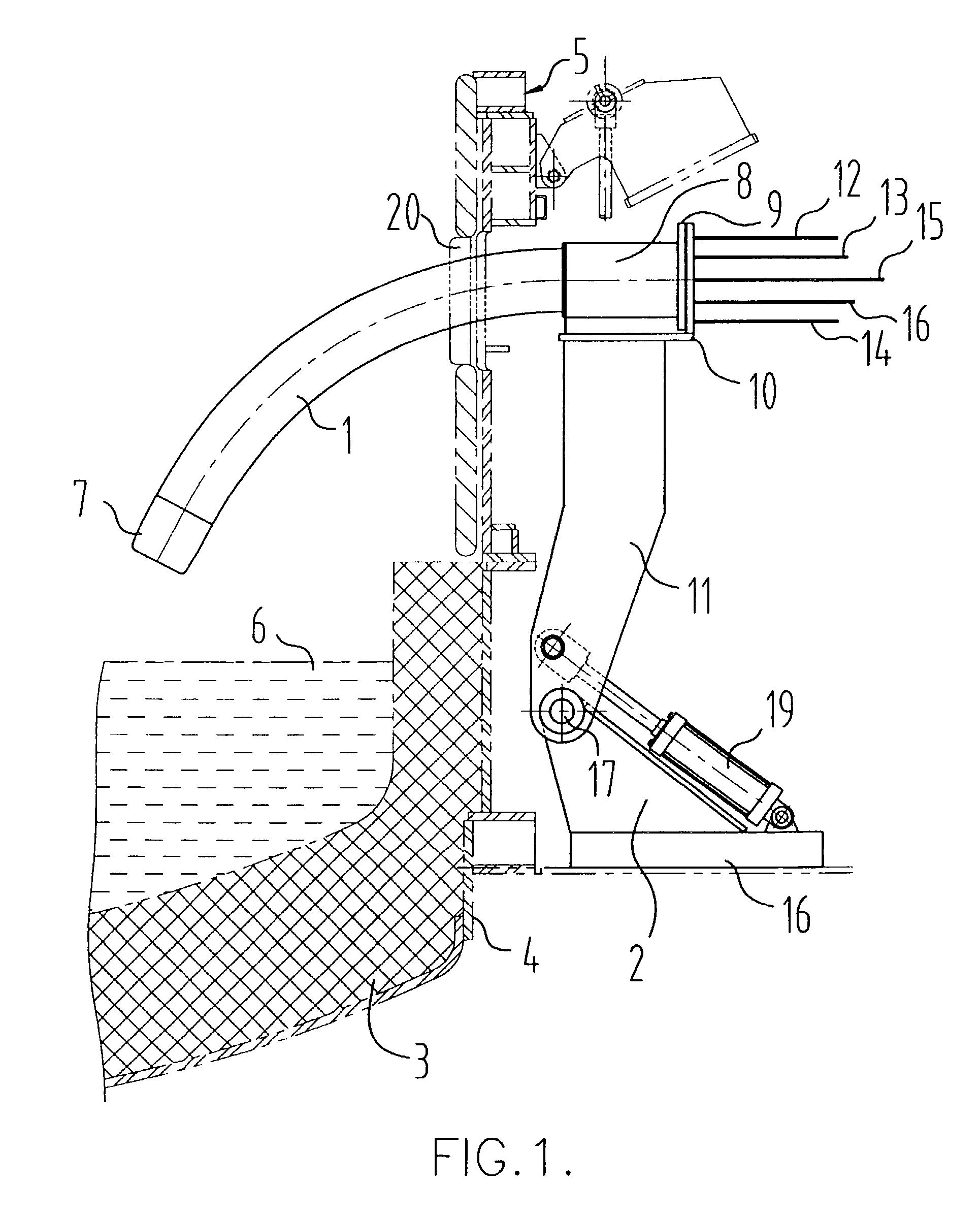

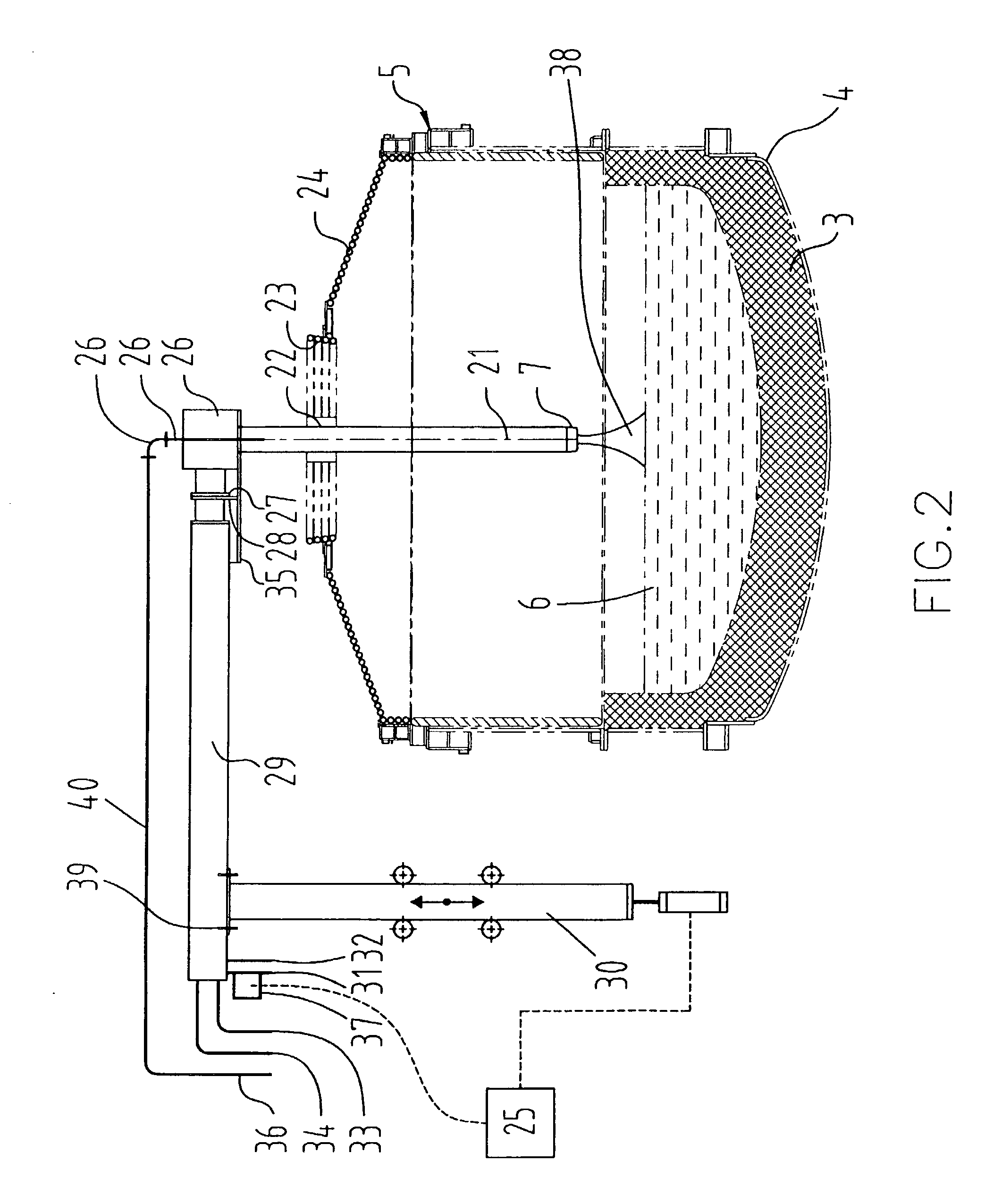

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

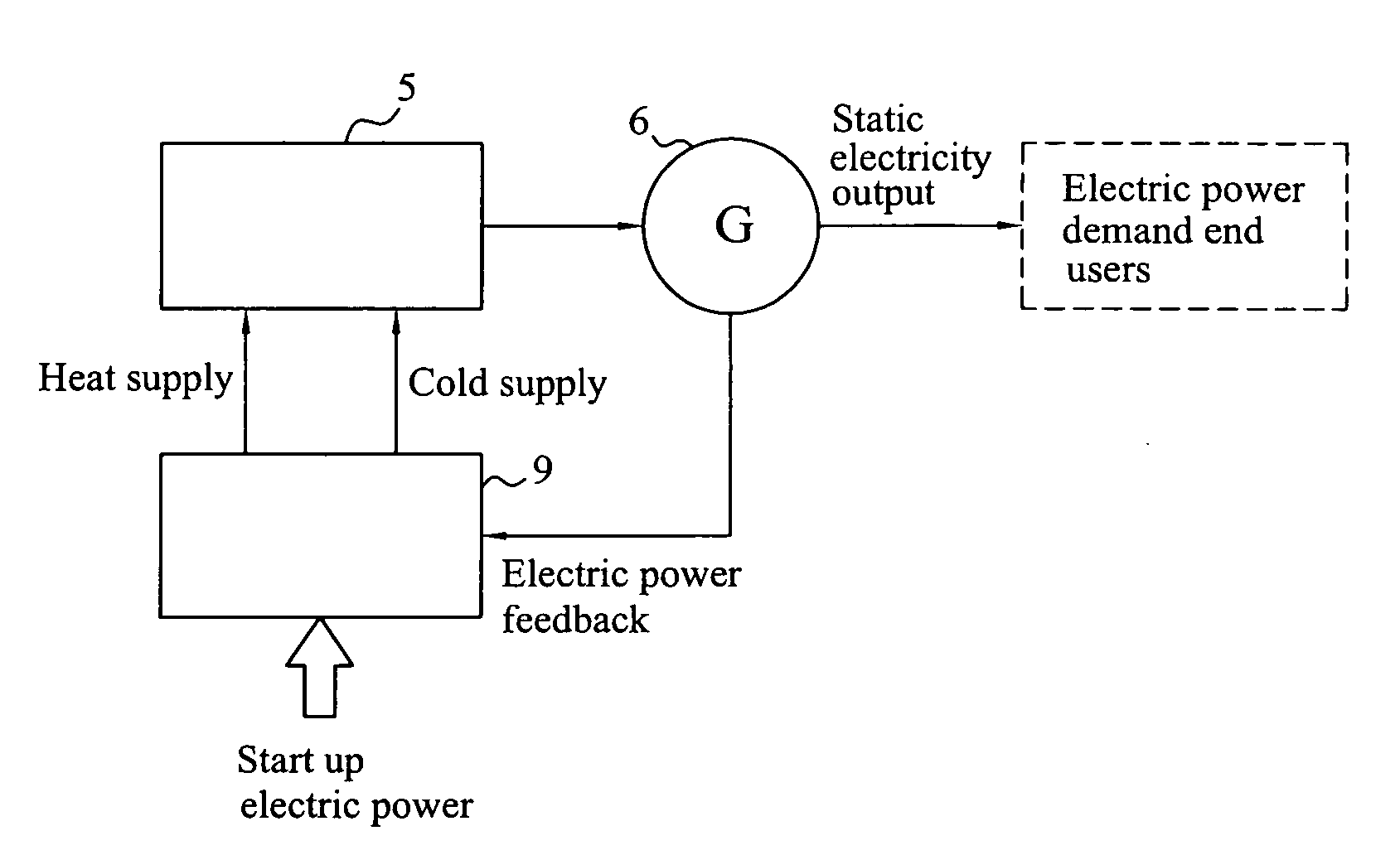

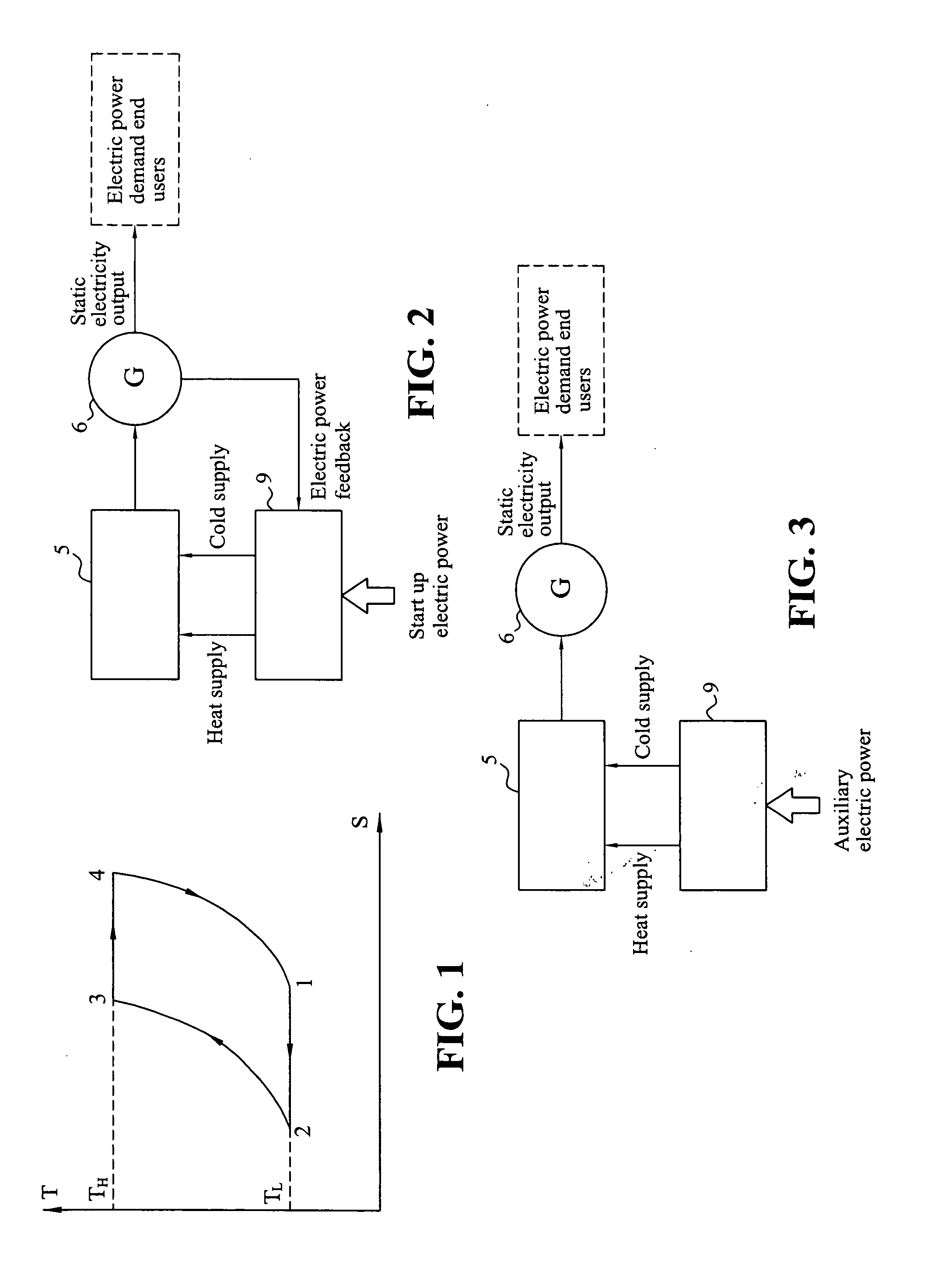

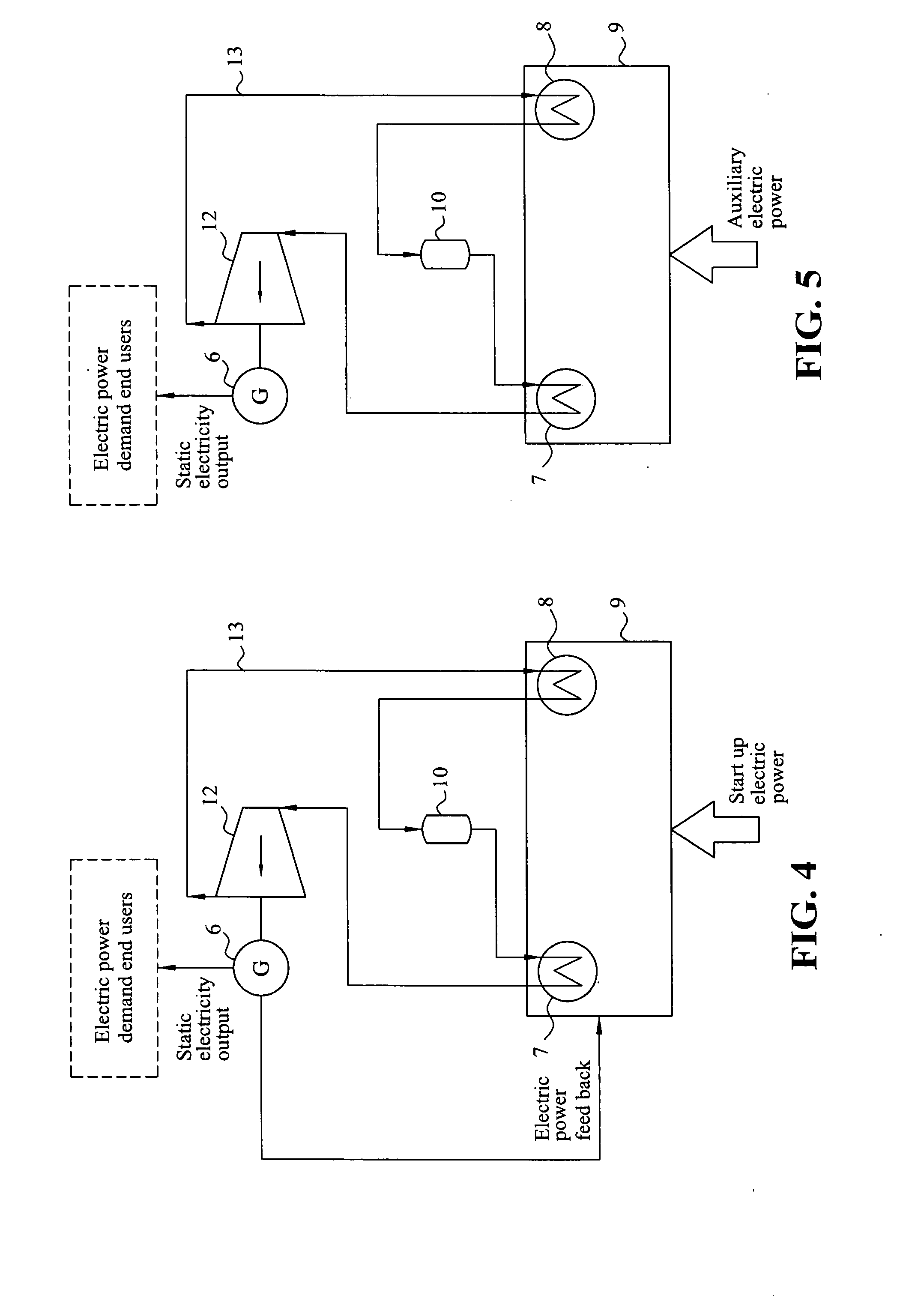

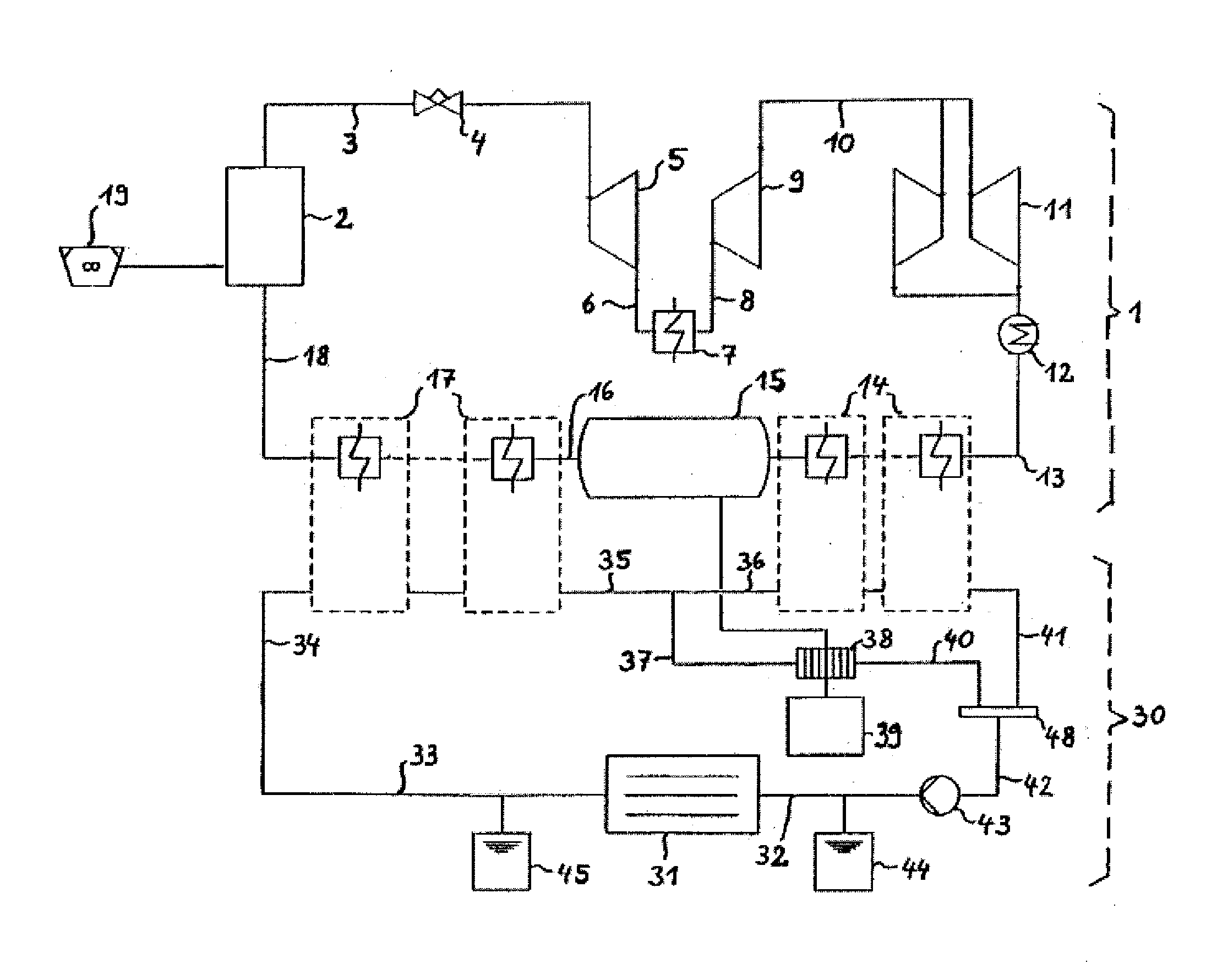

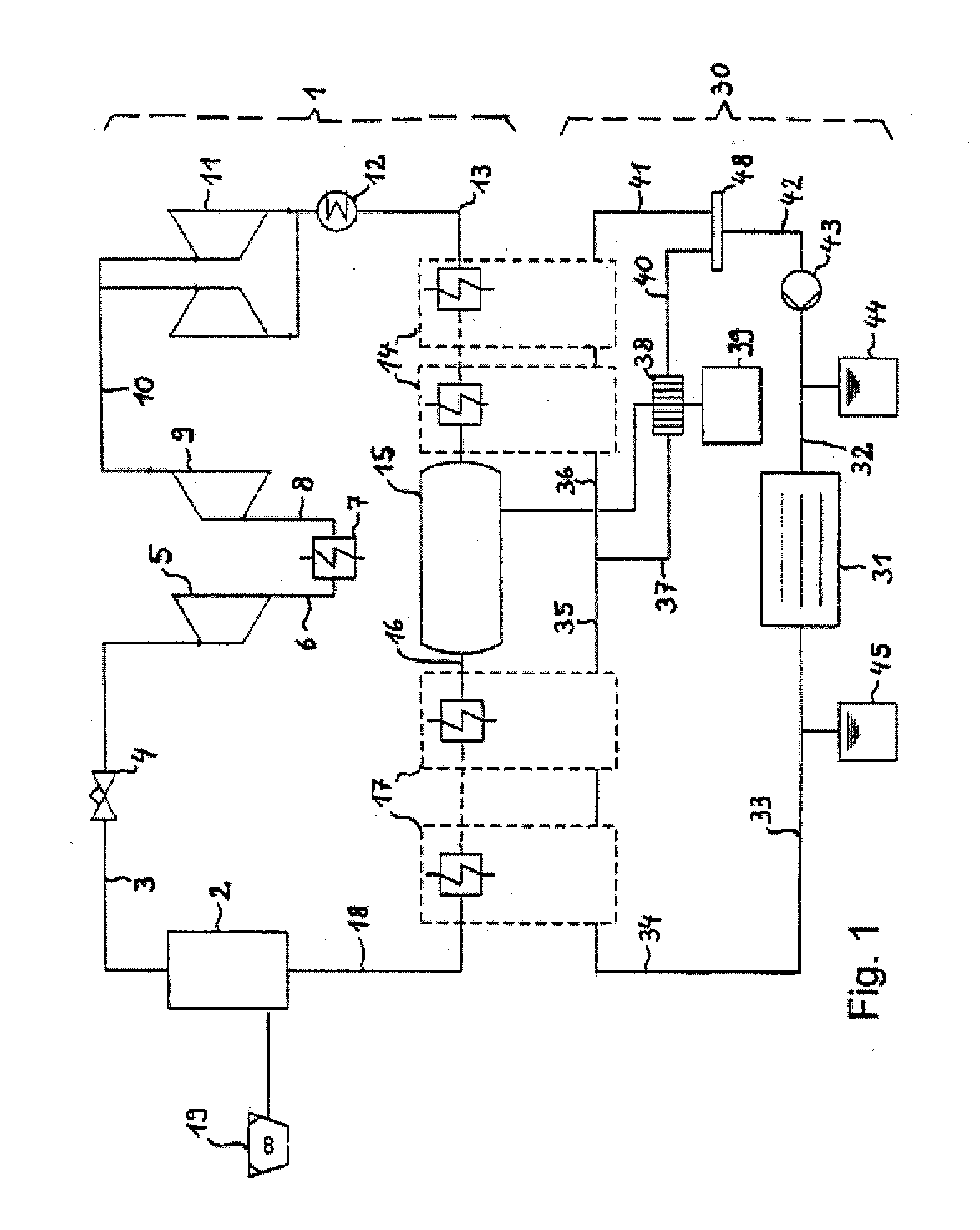

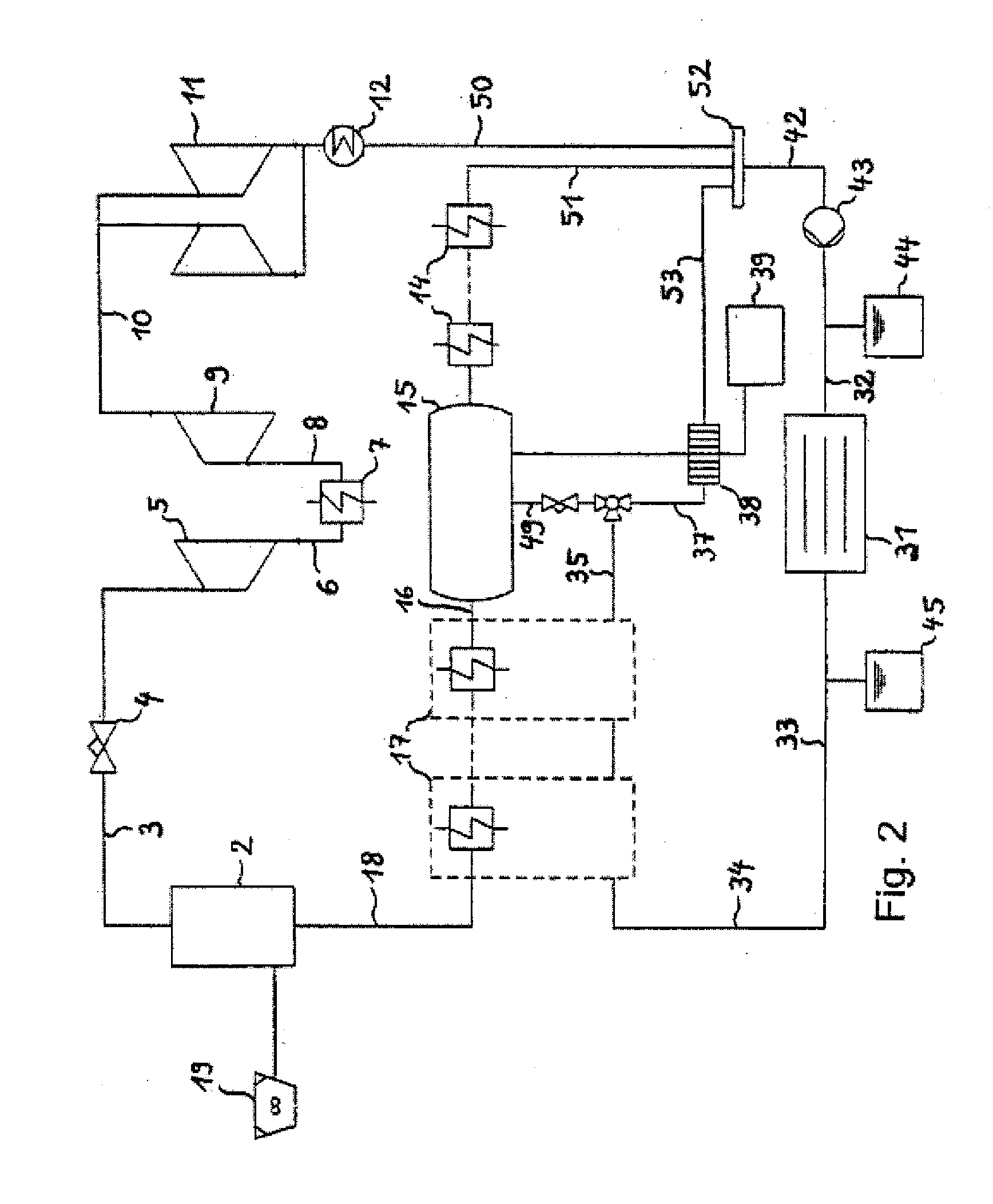

Power generation system driven by heat pump

InactiveUS20080127657A1Lower requirementAvoid it happening againSteam useCompression machines with cascade operationMechanical energyEngineering

A power generation system driven by heat pump which produces a heat source by heating and a cold source by cooling for the driving of a heat engine to produce mechanical energy to drive a generator generating electrical power. Part of the power generated by the generator is fed back to the heat pump continuously, and the remaining power is provided to end users in need of electrical power. The heat engine of the power generation system can be Stirling engine or a steam turbine, wherein the heat efficiency of the Stirling engine can reach 25%, and the heat efficiency of the steam turbine can reach above 30%. The heat pump used in the power generation system can be a vapor-compression heat pump. Under operating conditions where temperature difference between the generated heat and cold sources is over 25 degree celcius, the coefficient of performance can reach above 7.

Owner:FANG WEI +2

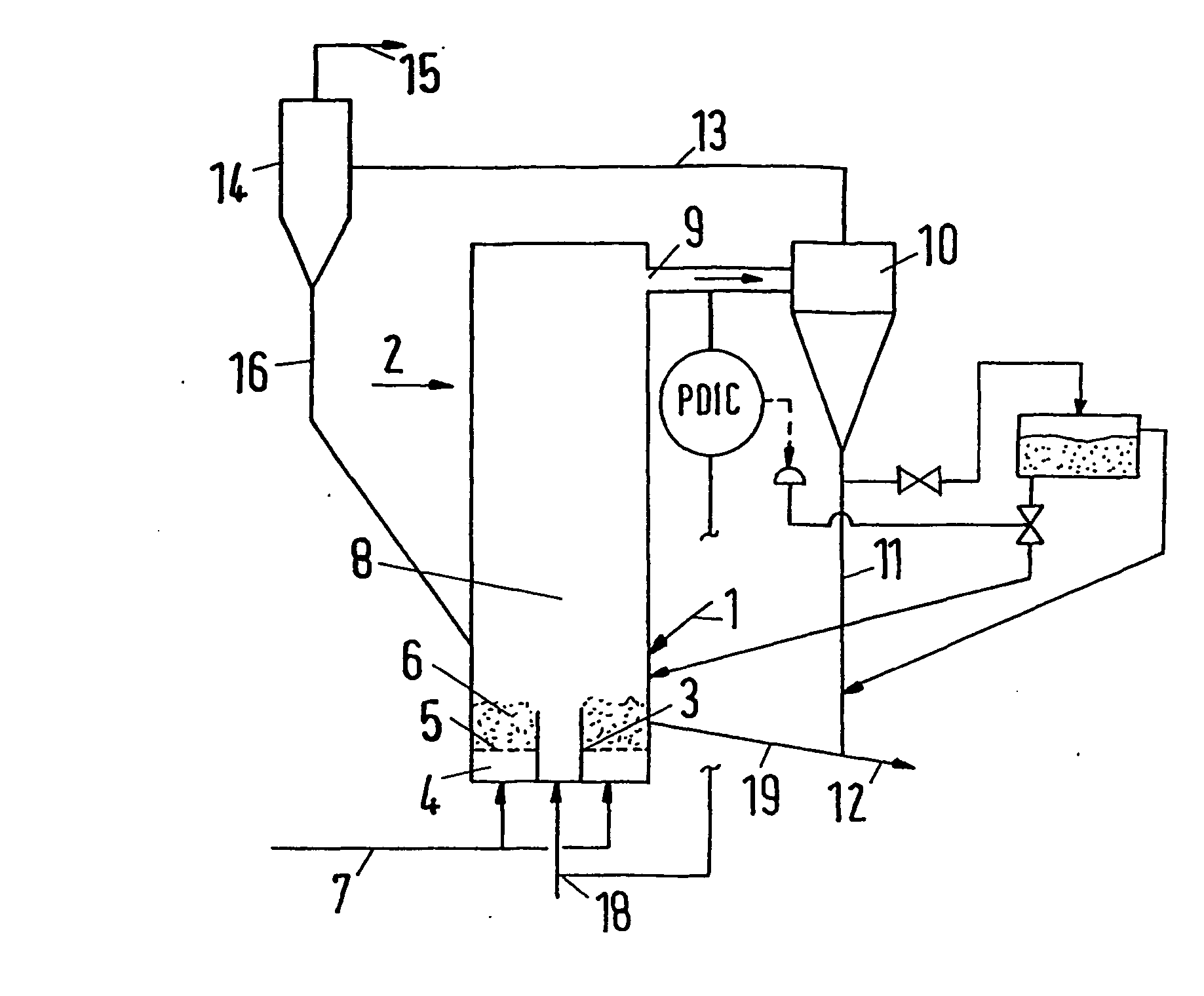

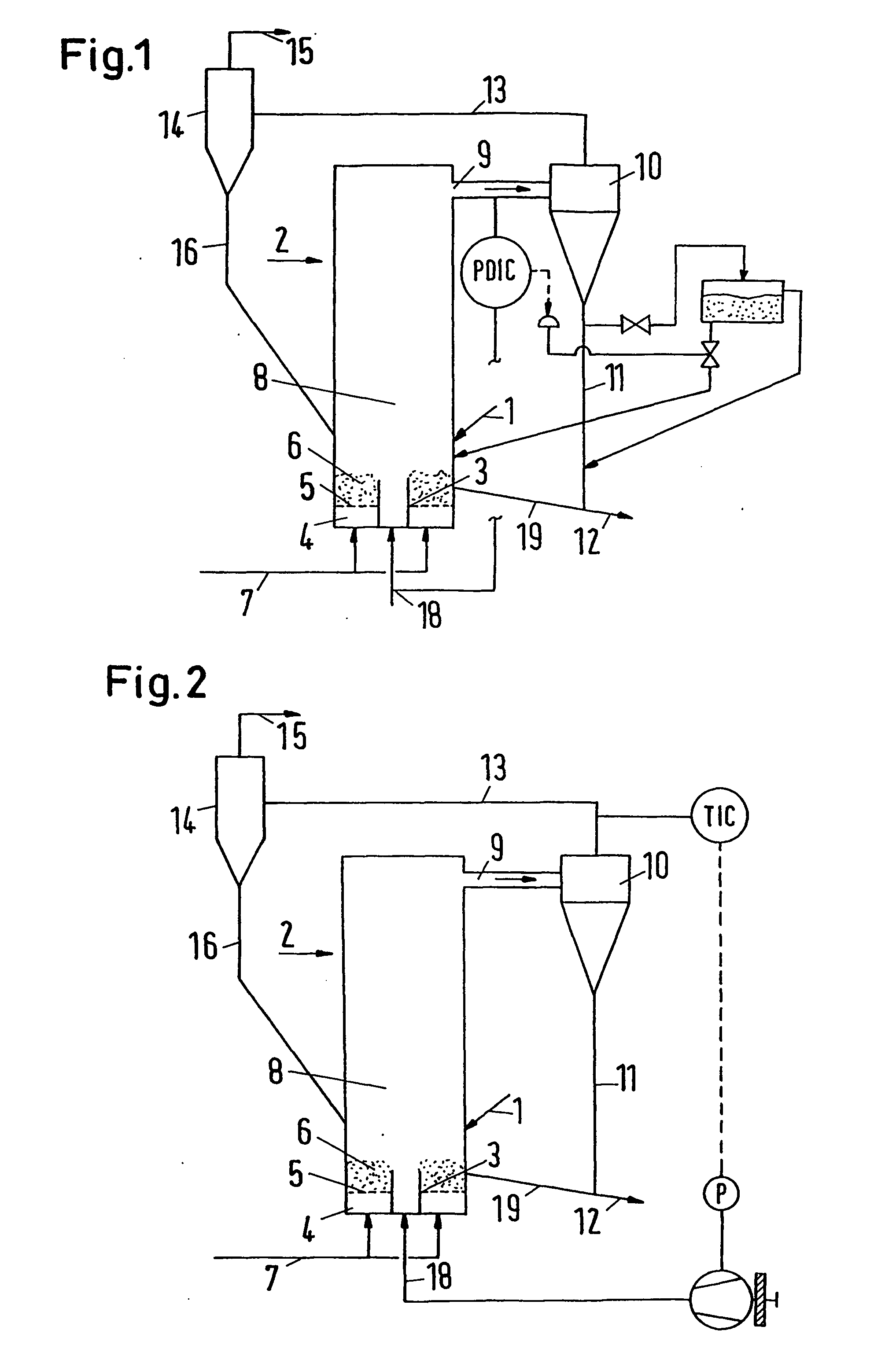

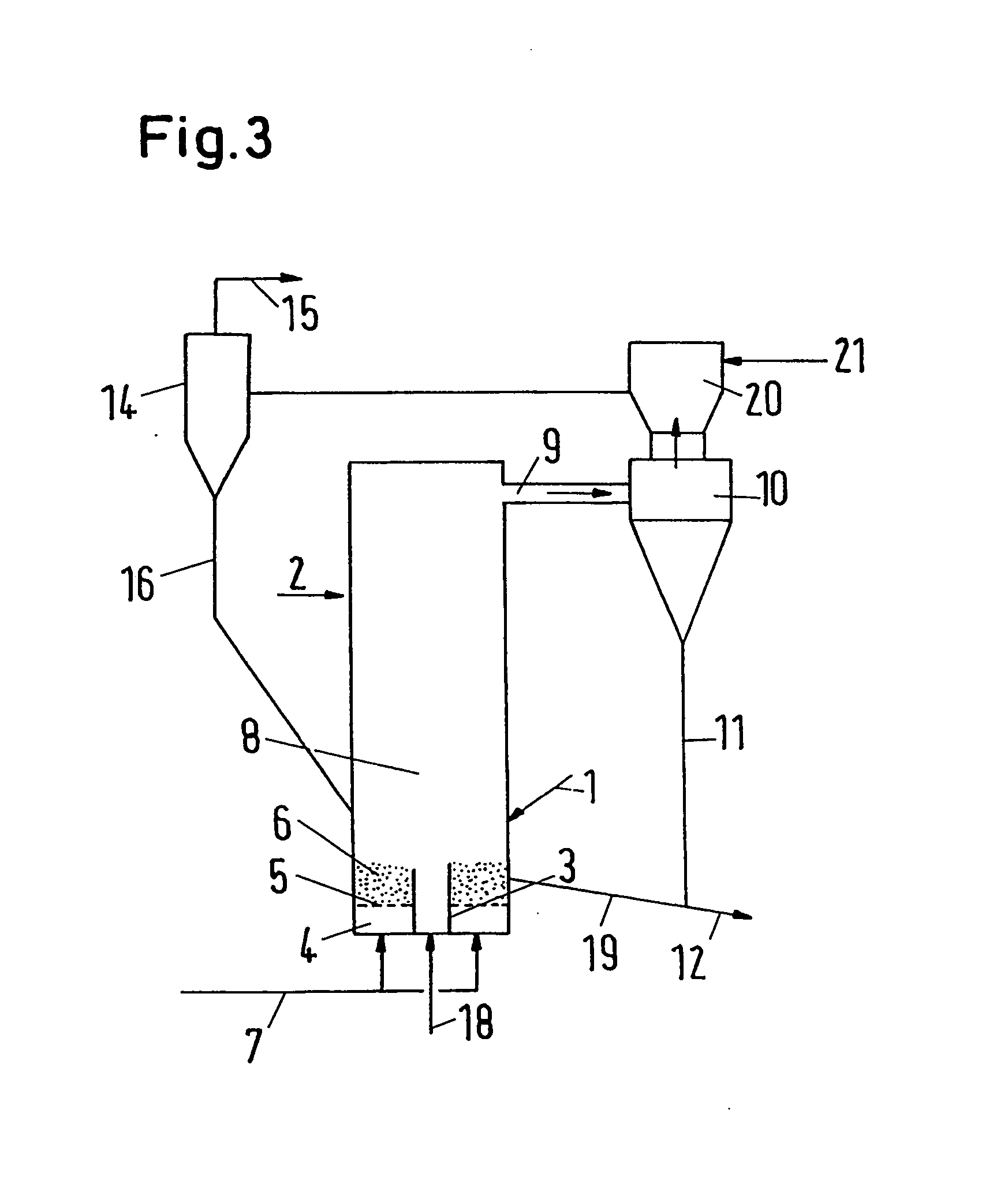

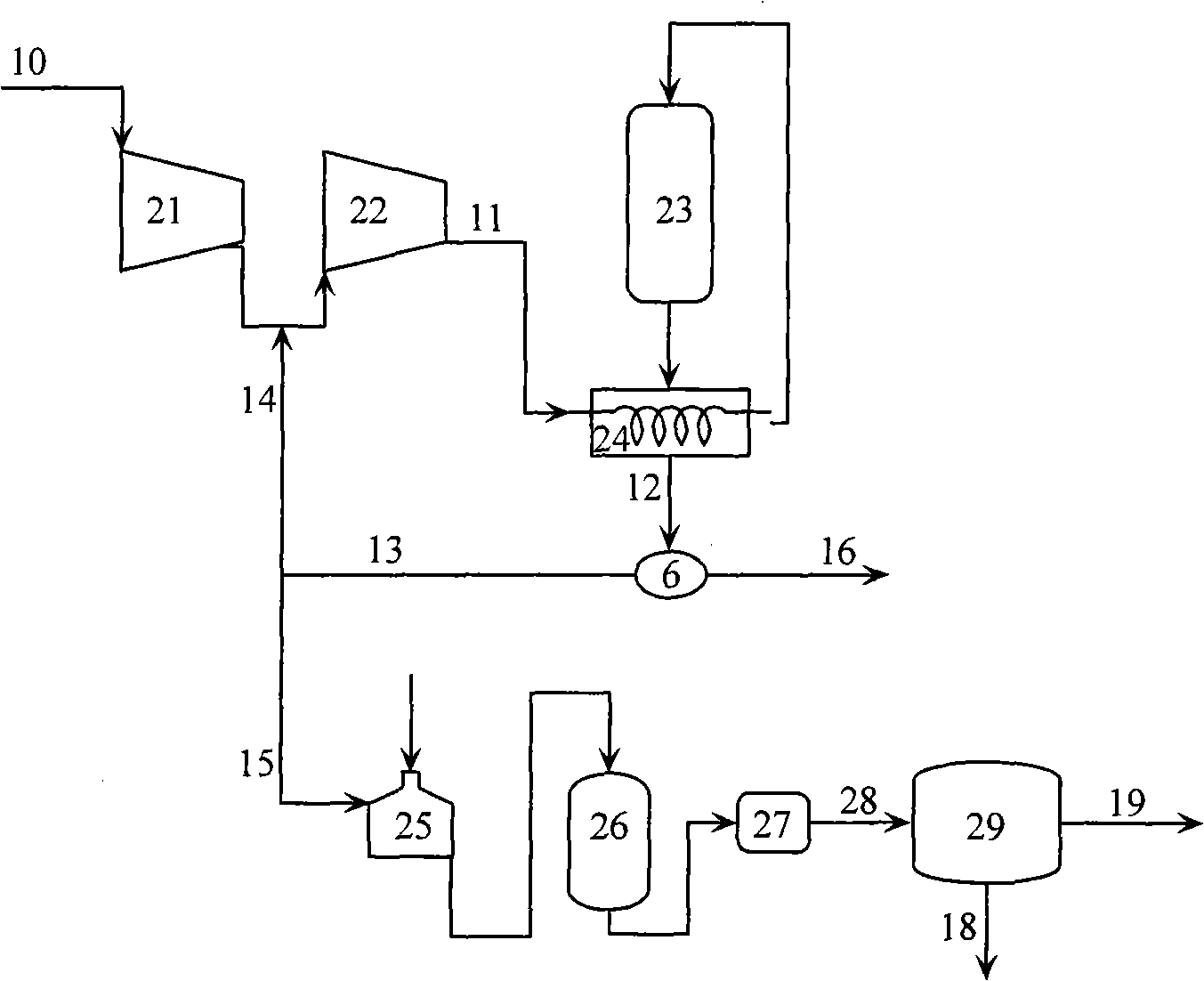

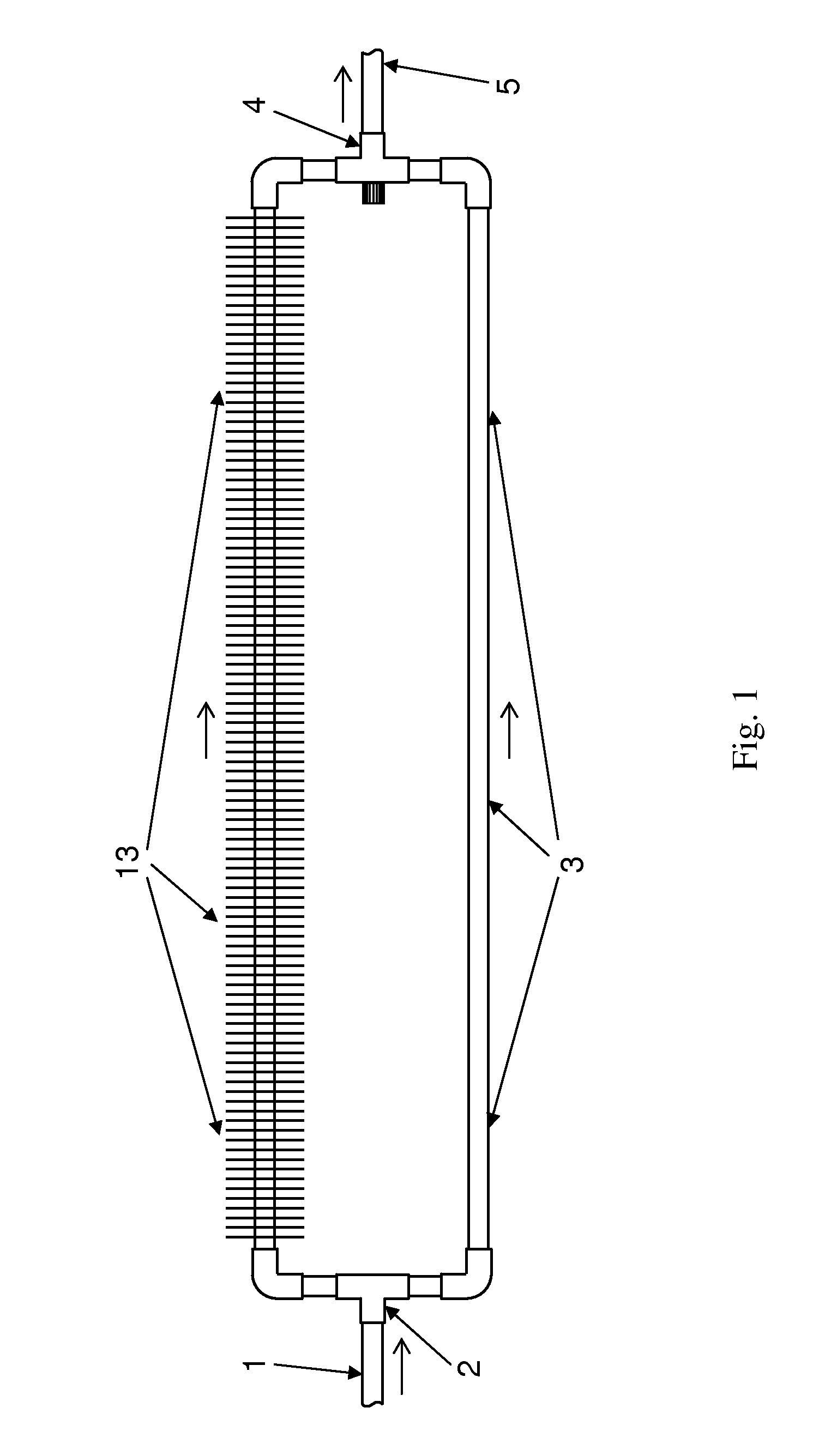

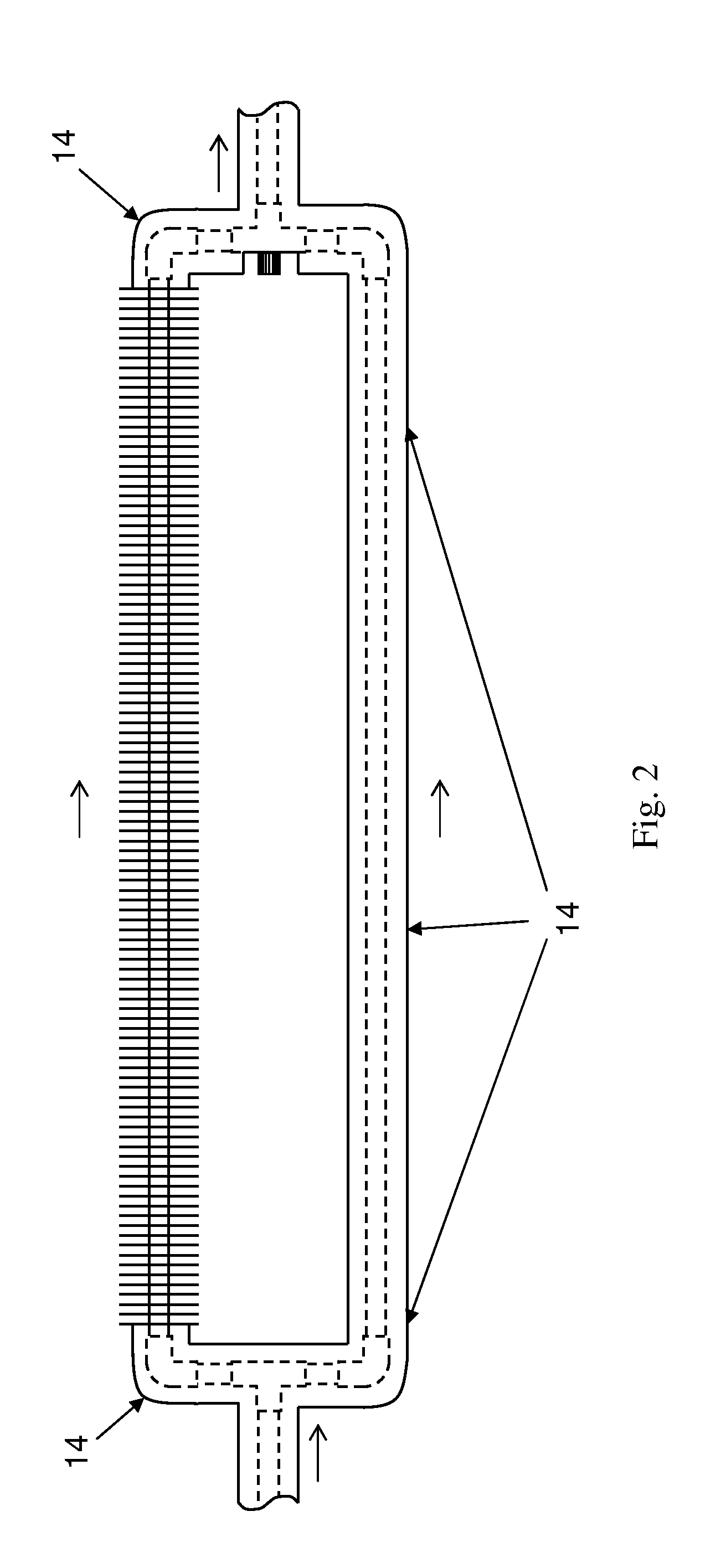

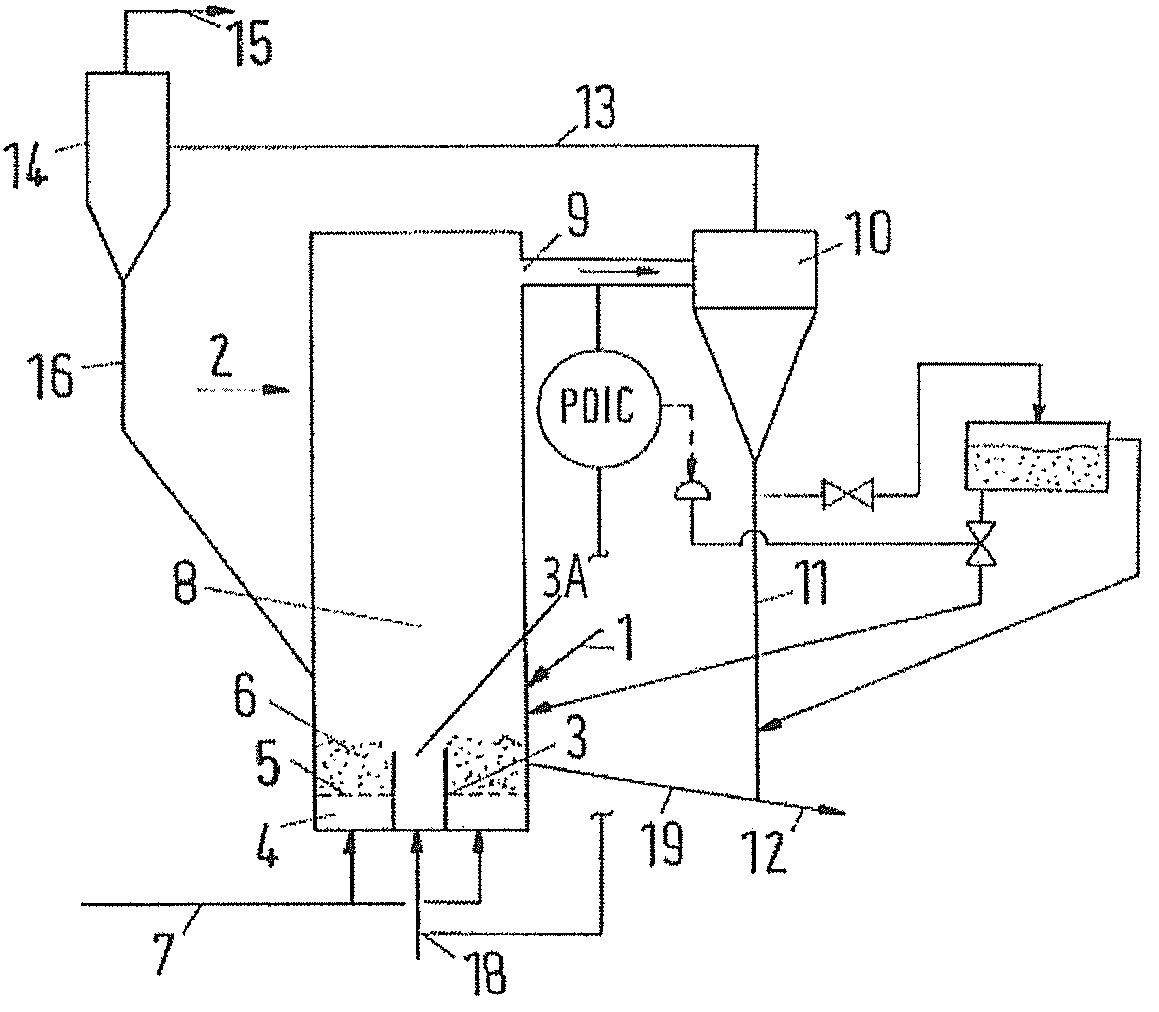

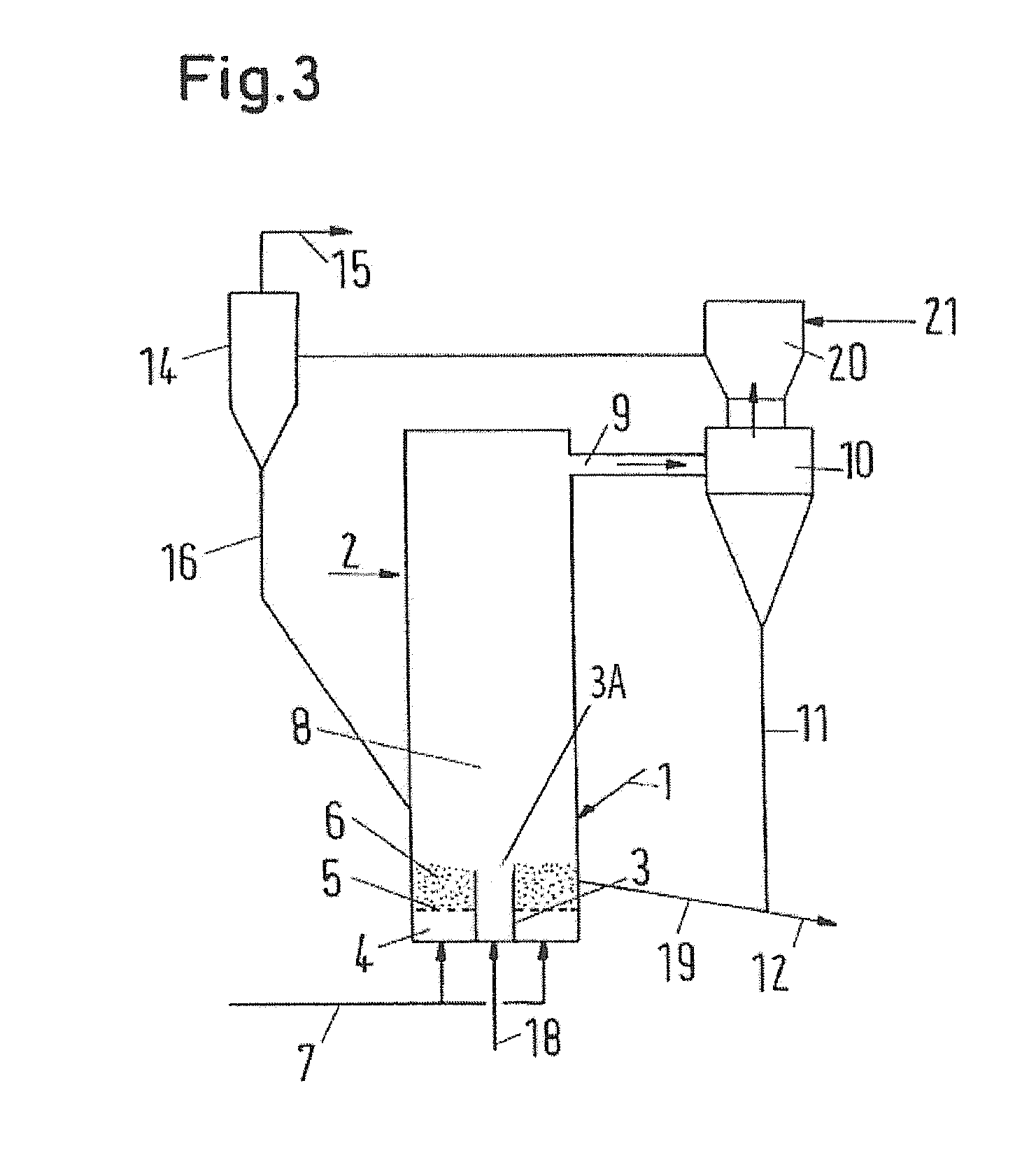

Method and plant for producing low-temperature coke

InactiveUS20060278566A1Optimize energy usageEfficient executionThermal non-catalytic crackingDirect heating destructive distillationFluidized bedProcess engineering

The present invention relates to a method and a plant for producing low 15 temperature coke, in which granular coal and possibly further solids are heated to a temperature of 700 to 1050° C. in a fluidized-bed reactor (2) by means of an oxygen-containing gas. To improve the utilization of energy it is proposed to introduce a first gas or gas mixture from below through at least one gas supply tube (3) into a mixing chamber region (8) of the reactor (2), the gas supply tube (3) being at least partly surrounded by a stationary annular fluidized bed (6) which is fluidized by supplying fluidizing gas. The gas velocities of the first gas or gas mixture and of the fluidizing gas for the annular fluidized bed (6) are adjusted such that the Particle-Froude-Numbers in the gas supply tube (3) are between 1 and 100, in the annular fluidized bed (6) between 0.02 and 2 and in the 25 mixing chamber (8) between 0.3 and 30.

Owner:OUTOTEC OYJ

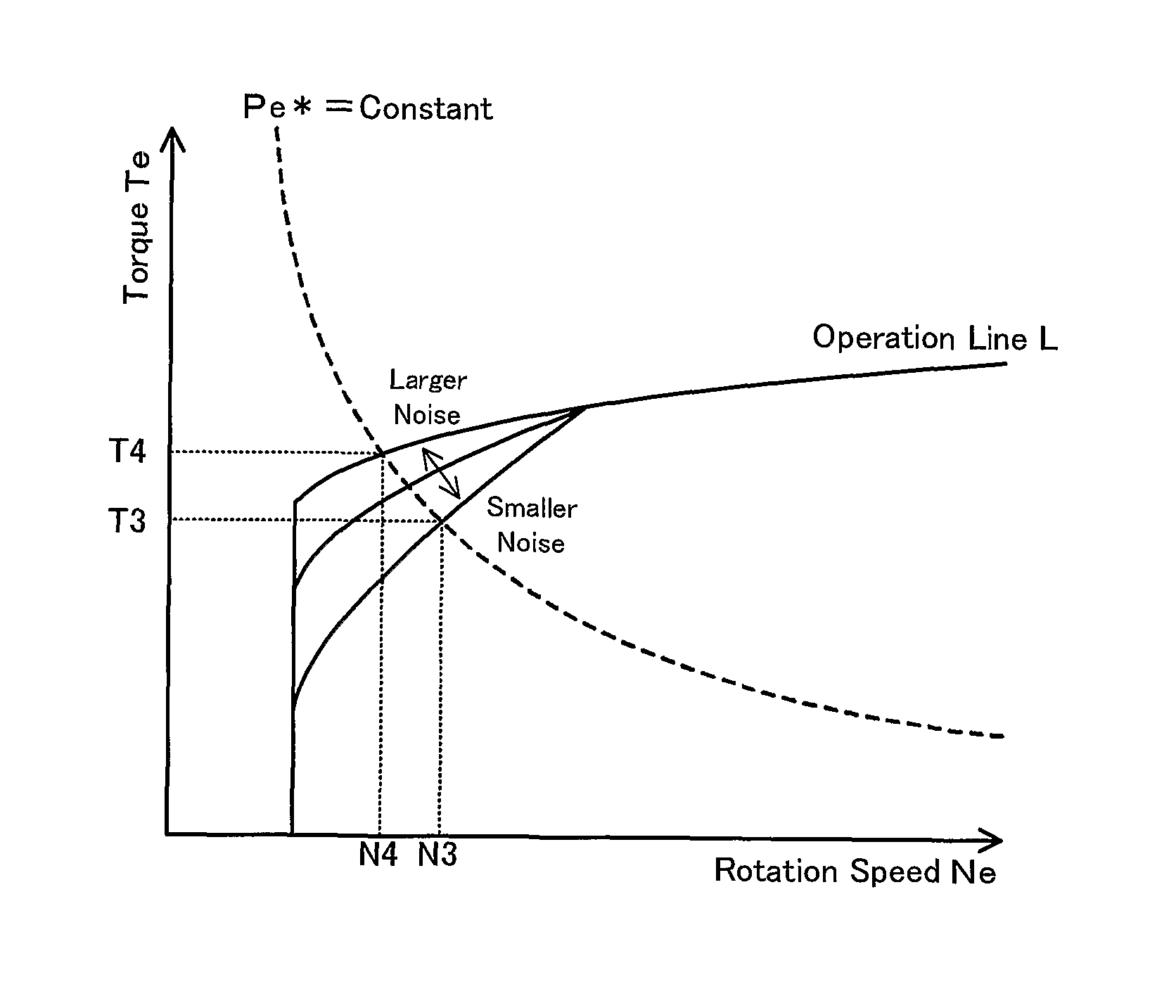

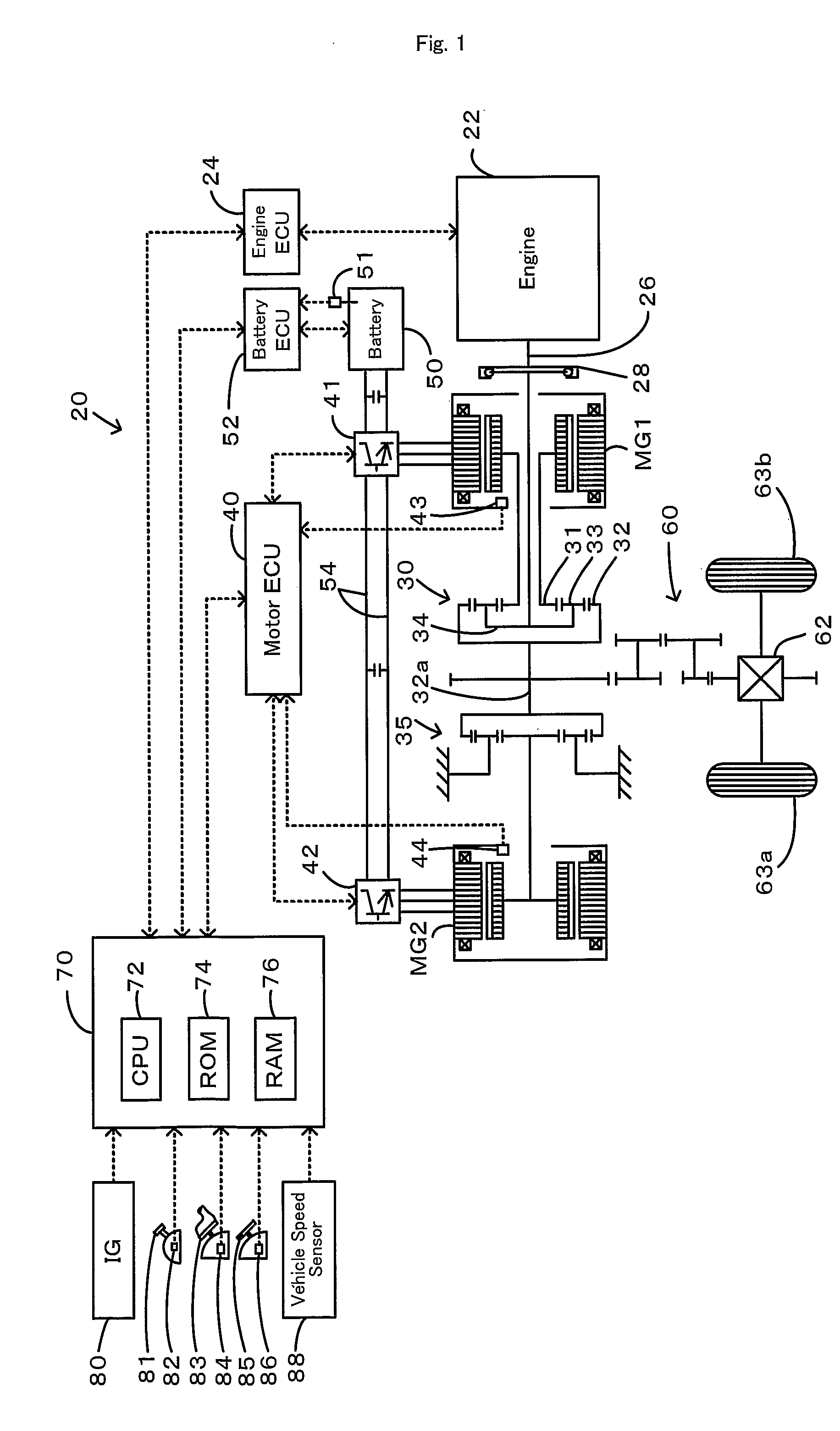

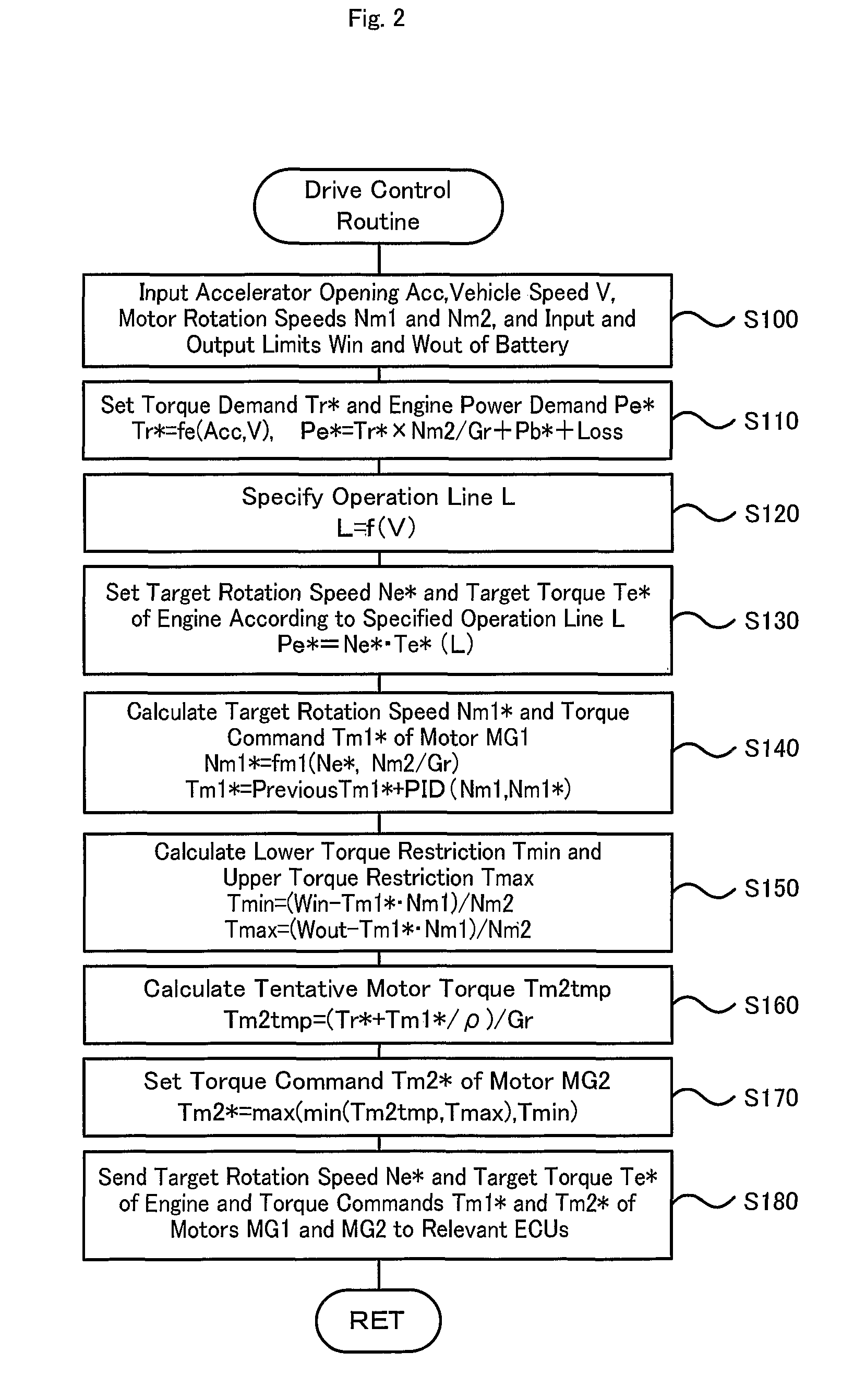

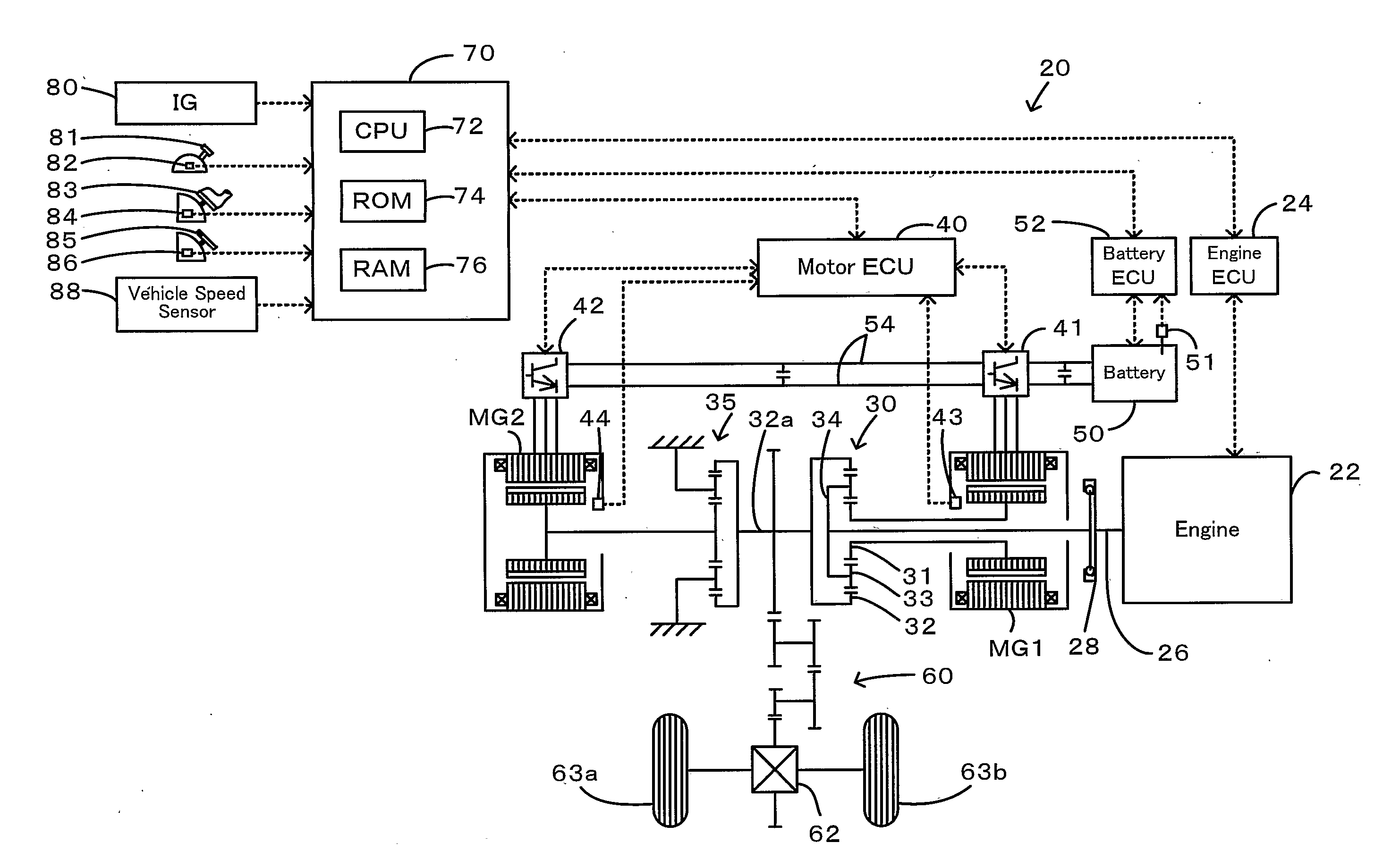

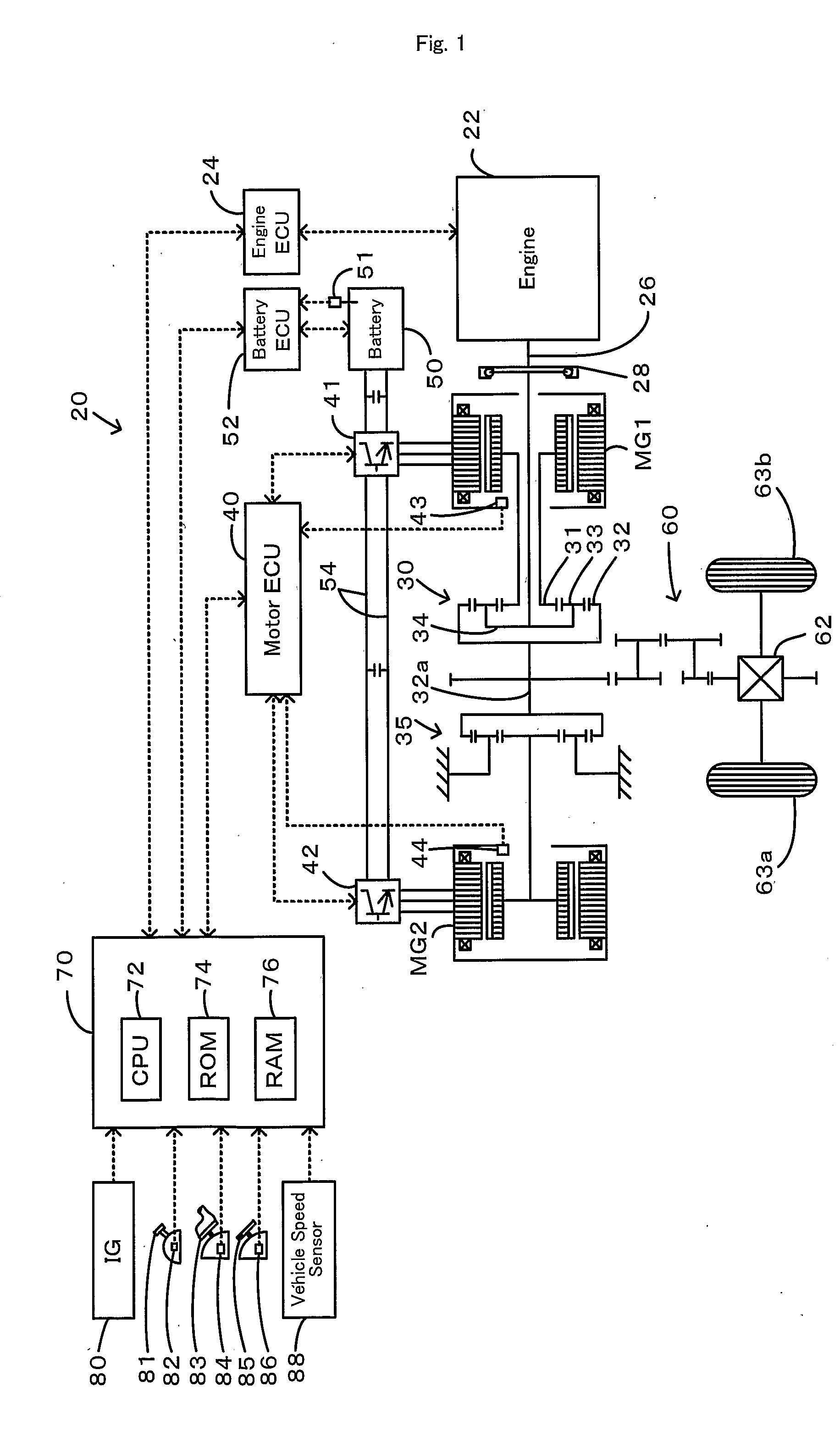

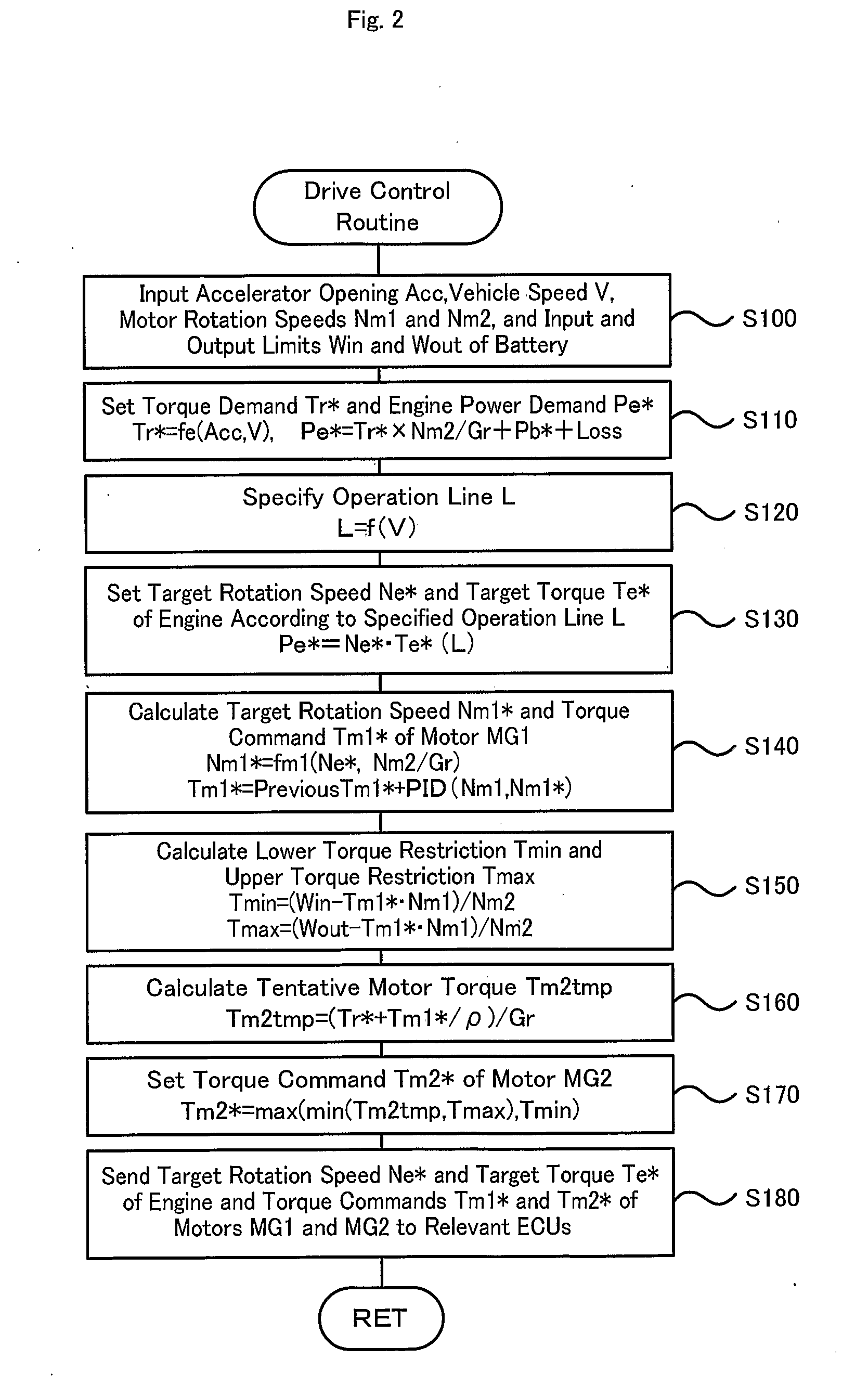

Hybrid vehicle and control method of hybrid vehicle

ActiveUS8209103B2Improve energy efficiencyOptimize energy usageHybrid vehiclesAnalogue computers for vehiclesIn vehicleHigh torque

The drive control of the invention adopted in a hybrid vehicle specifies an operation line L to give a greater torque in a low rotation speed area of an engine with an increase in vehicle speed and controls the operation of the engine according to the specified operation line L. The engine can thus be driven at a higher-efficiency drive point, while the driving-related background noise effectively masks some abnormal noise or muffled noise, which may be caused by the operation of the engine in a low rotation speed-high torque area. This arrangement desirably prevents the driver and the other passenger from feeling odd and uncomfortable due to the abnormal noise or muffled noise and enhances the energy efficiency of the hybrid vehicle.

Owner:TOYOTA JIDOSHA KK

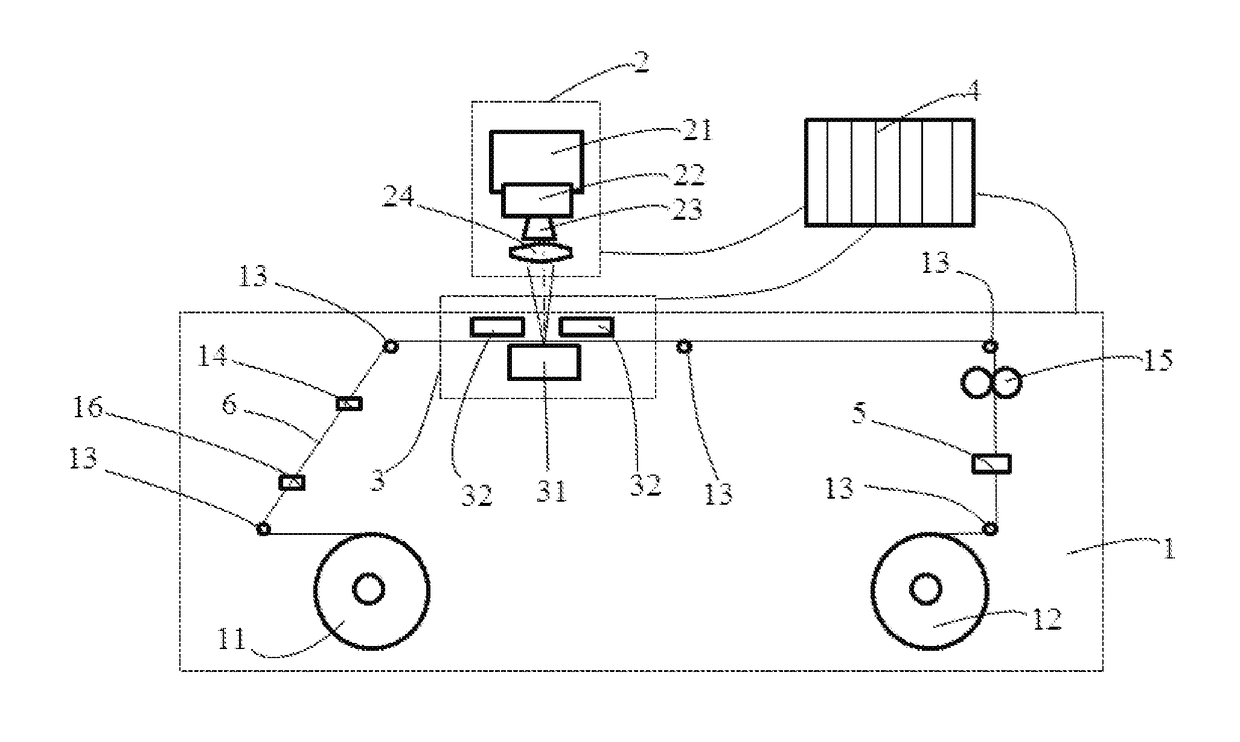

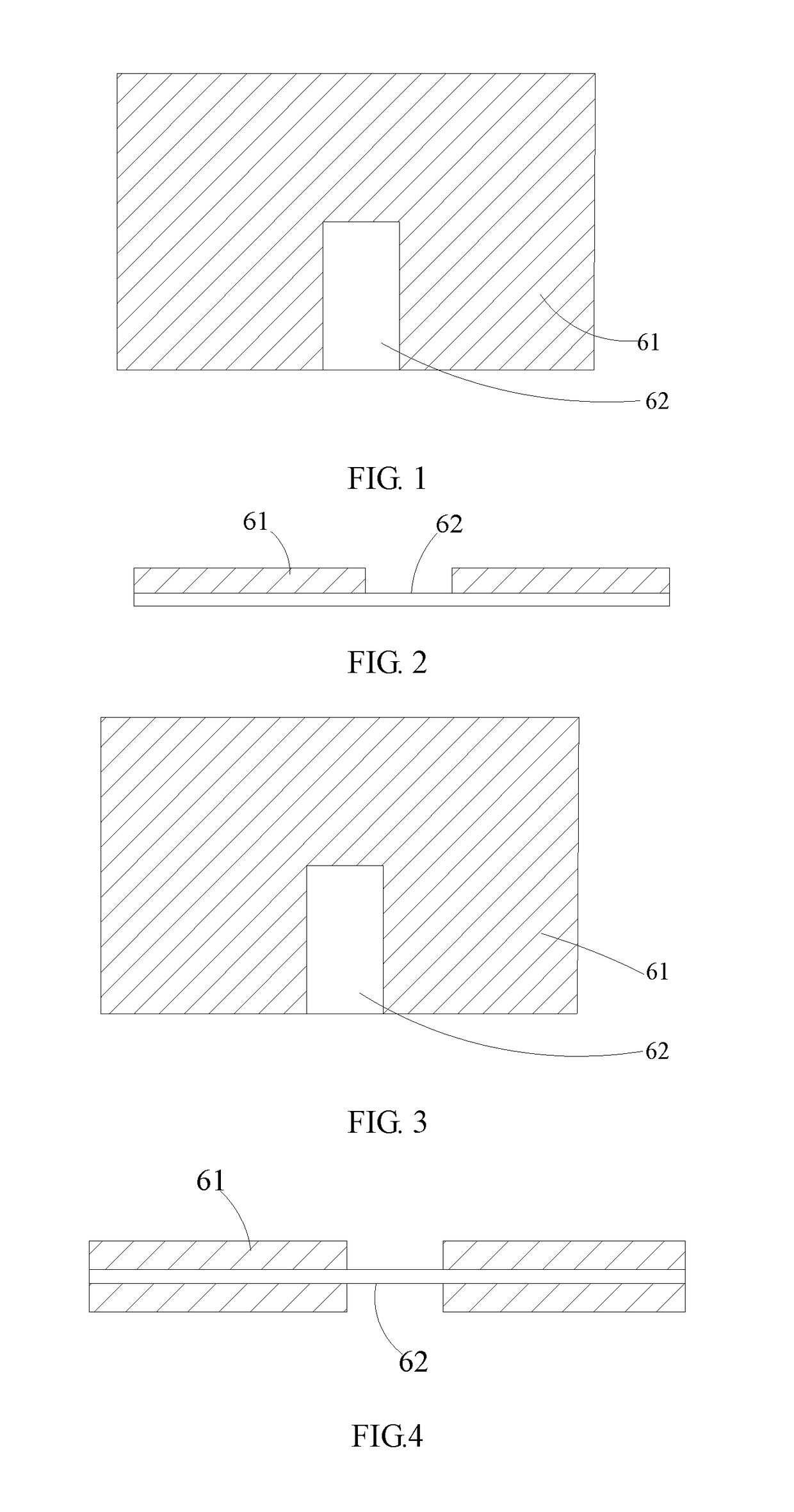

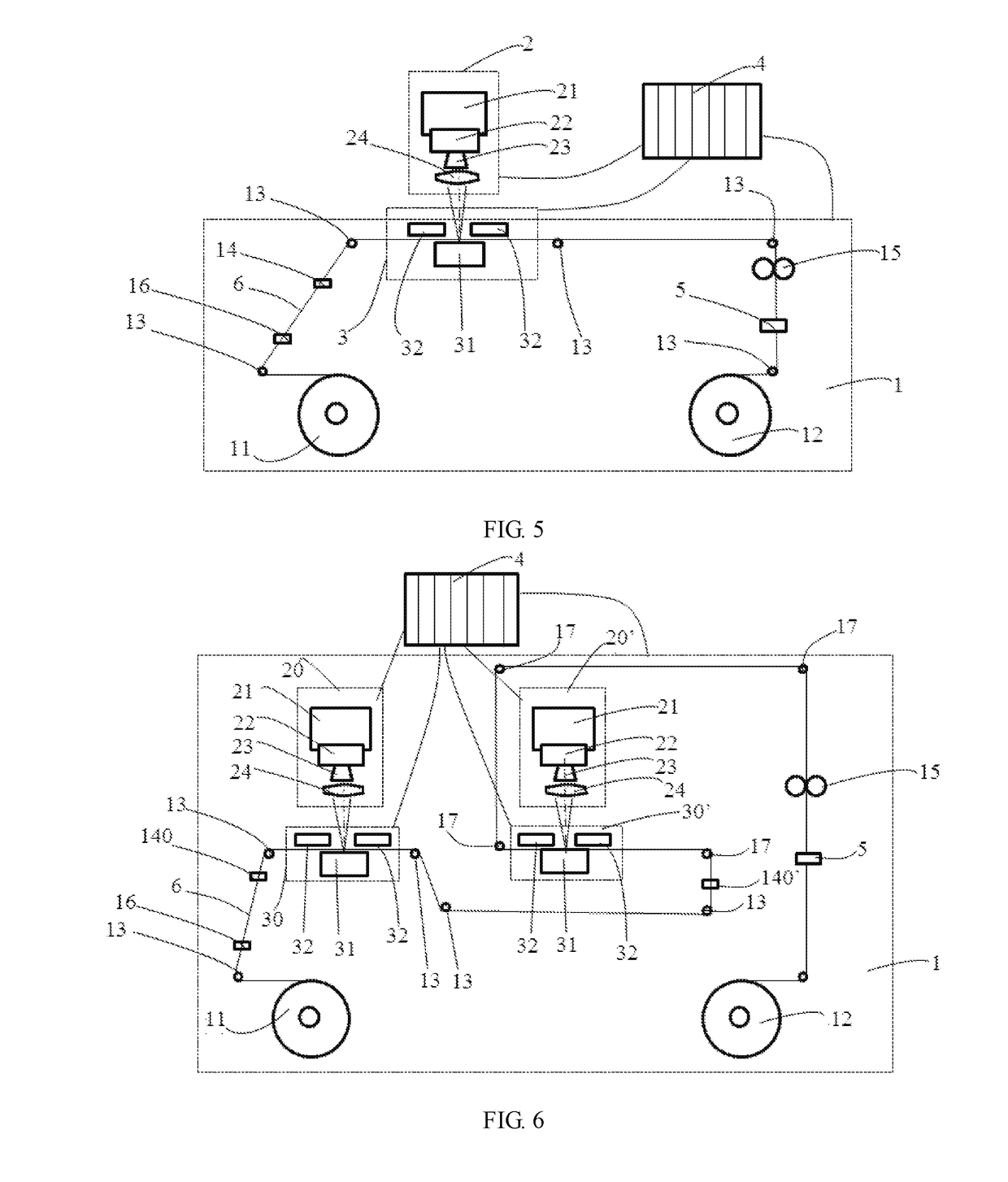

Device for cleaning coating on lithium-ion battery electrode sheet

InactiveUS20170120380A1High energyOptimize energy usageElectrode thermal treatmentSecondary cellsElectricityElectrical battery

A device for removing a coating layer of an electrode plate of a lithium-ion battery comprises a conveying system (1) for conveying an electrode plate (6) and a laser system (2), the laser system comprises at least one laser emitting head (21) for emitting a laser beam and projecting the laser beam onto the electrode plate and a beam shaping mechanism (22) for homogenizing energy of the laser beam emitted from the laser emitting head, the laser emitting head and the beam shaping mechanism are electrically connected. In the device for removing the coating layer of the electrode plate of the lithium-ion battery, the beam shaping mechanism is provided, energy of the laser beam can be homogenized, neither damages a foil of the electrode plate so that welding quality of the electrode tab is promoted, nor results in remaining of the coating layer so that the removing quality is promoted, and the energy can be effectively utilized, thereby realizing maximum utilization of the energy of the laser.

Owner:NINGDE AMPEREX TECH

Hybrid vehicle and control method of hybrid vehicle

ActiveUS20090088913A1Increase torqueImprove efficiencyHybrid vehiclesAnalogue computers for vehiclesDriver/operatorIn vehicle

The drive control of the invention adopted in a hybrid vehicle specifies an operation line L to give a greater torque in a low rotation speed area of an engine with an increase in vehicle speed and controls the operation of the engine according to the specified operation line L. The engine can thus be driven at a higher-efficiency drive point, while the driving-related background noise effectively masks some abnormal noise or muffled noise, which may be caused by the operation of the engine in a low rotation speed-high torque area. This arrangement desirably prevents the driver and the other passenger from feeling odd and uncomfortable due to the abnormal noise or muffled noise and enhances the energy efficiency of the hybrid vehicle.

Owner:TOYOTA JIDOSHA KK

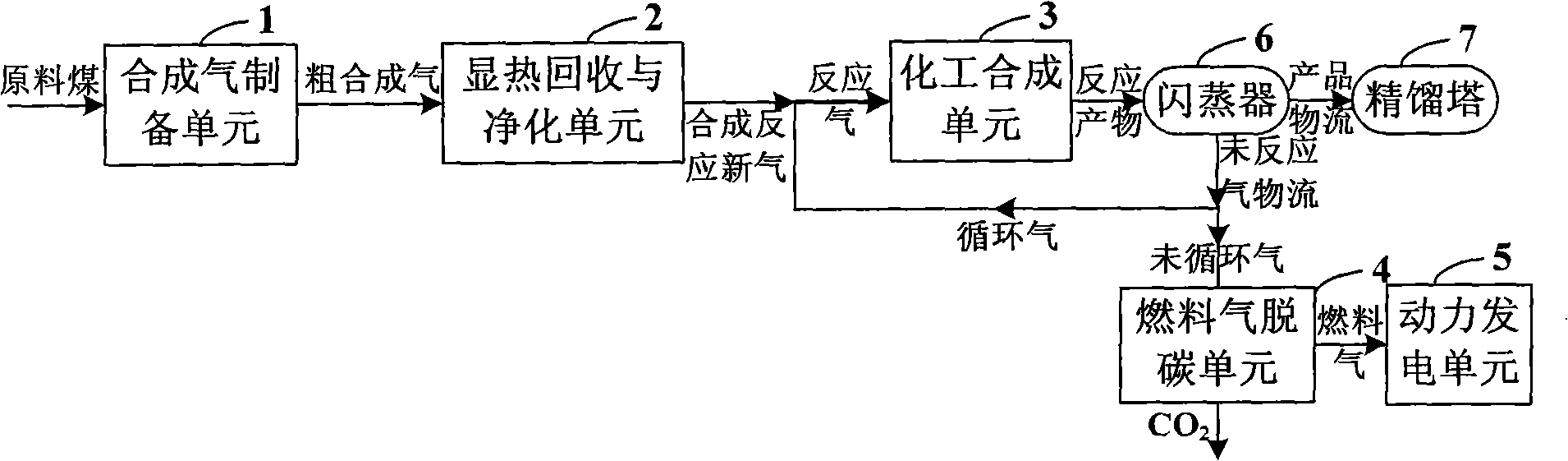

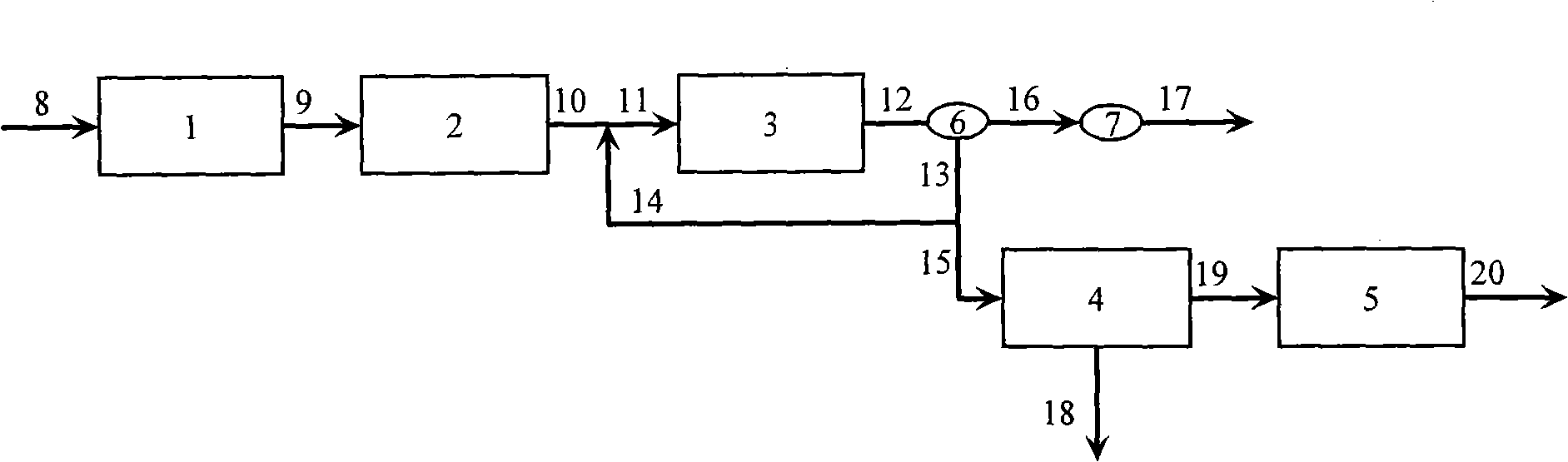

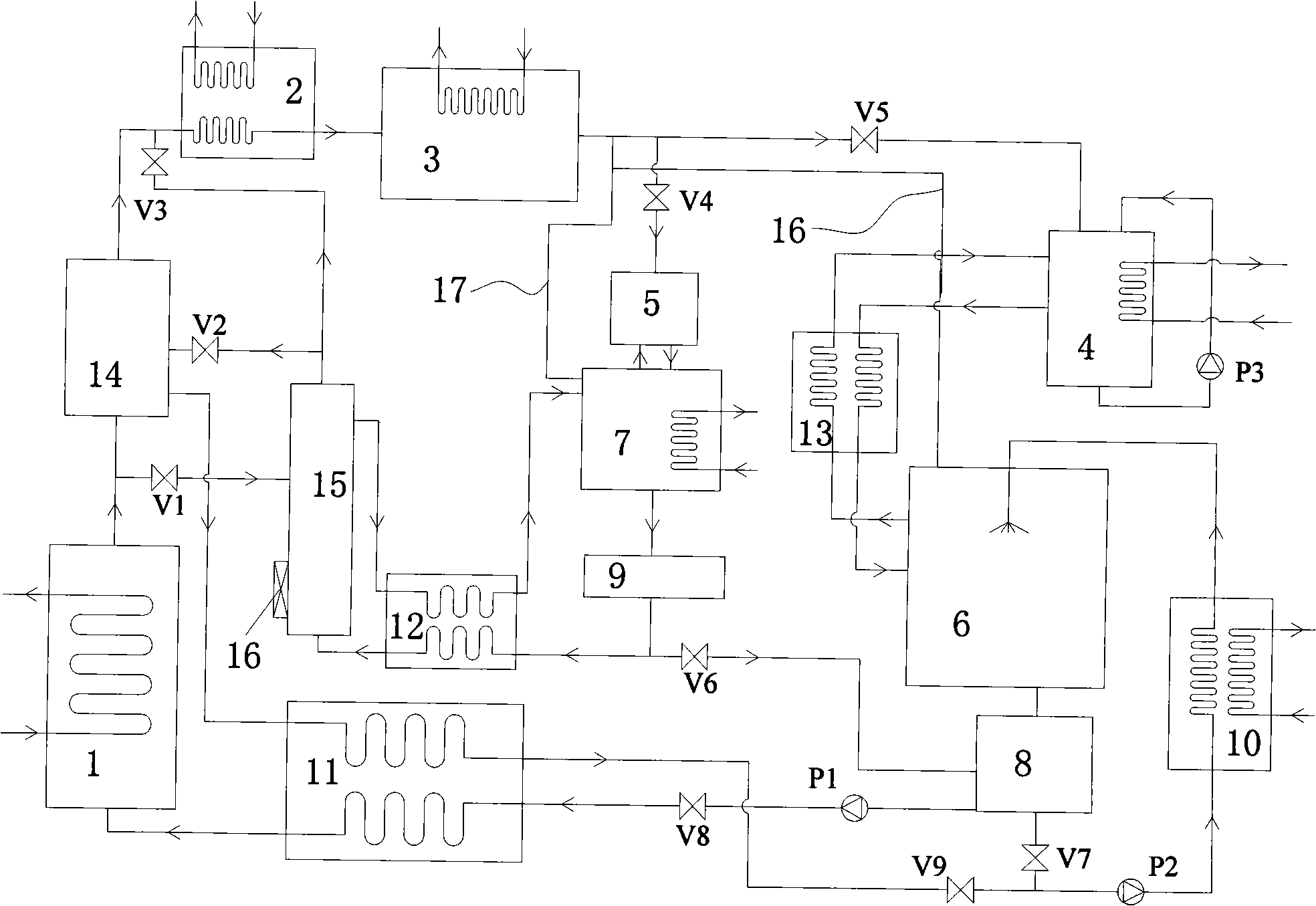

Chemical industry power multi-generation energy resource system and method for separating C02

InactiveCN101318620AImprove energy utilizationOptimize energy usageHydrogen productionChemical industryBULK ACTIVE INGREDIENT

The invention relates to the technical field of energy and environment and discloses a chemical engineering power multi-generation energy system and a method. Crude synthesis gas produced by carbon-rich raw material firstly enters a chemical engineering production flow, the synthesis gas can not carry out water-gas shift reaction to reduce the proportion of CO / H2, temperature reduction and purification are carried out for direct chemical engineering synthesis, the product of synthetic reaction is separated into unreacted gas and crude products by flash evaporation process, part of the unreacted gas circulates and carries out synthetic reaction again, while the other part of the unreacted gas carries out water-gas shift reaction and a CO2 separating unit for decarburization, the synthesis gas after decarburization is taken as fuel gas to be sent to a combined cycle power system for power generation. By adopting the invention, under the promise of ensuring that the active ingredient of new synthesis gas is fully transformed into chemical products, the energy utilization situation of the system can be improved; meanwhile, by adopting the way of separating CO2 after chemical engineering synthetic reaction, the energy consumption for separating CO2 can be lowered and the problem of the efficiency reduction of the energy system can be solved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

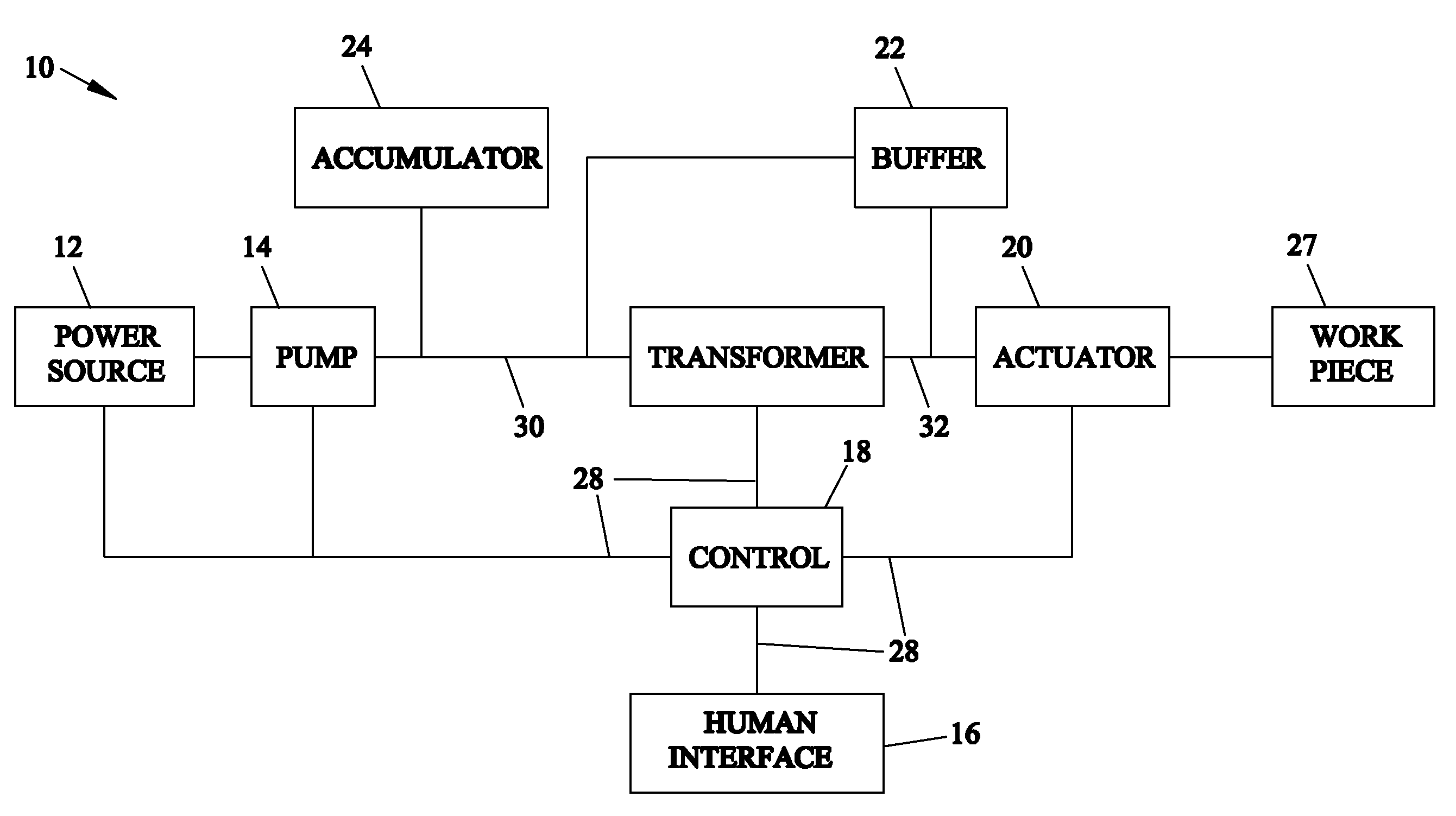

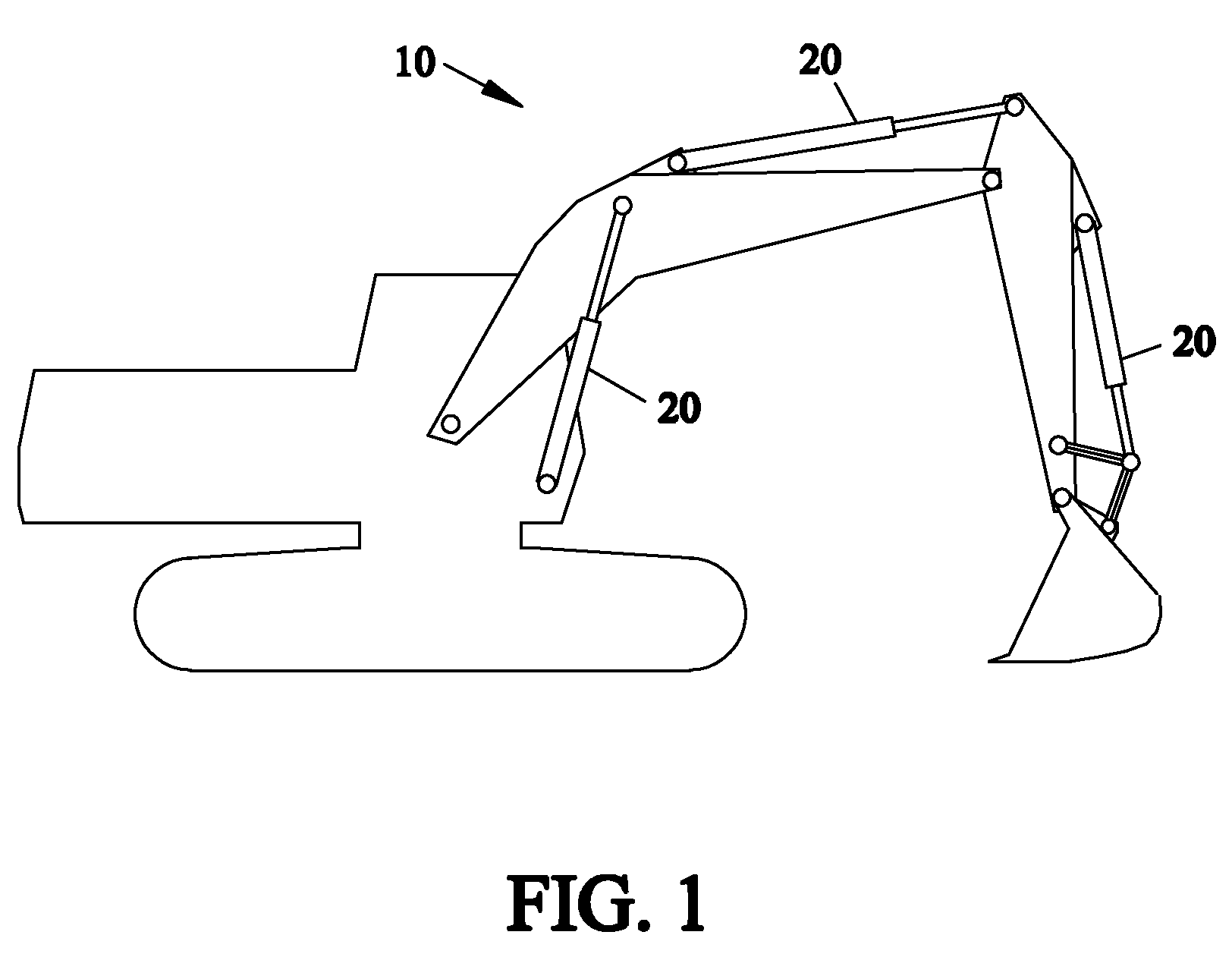

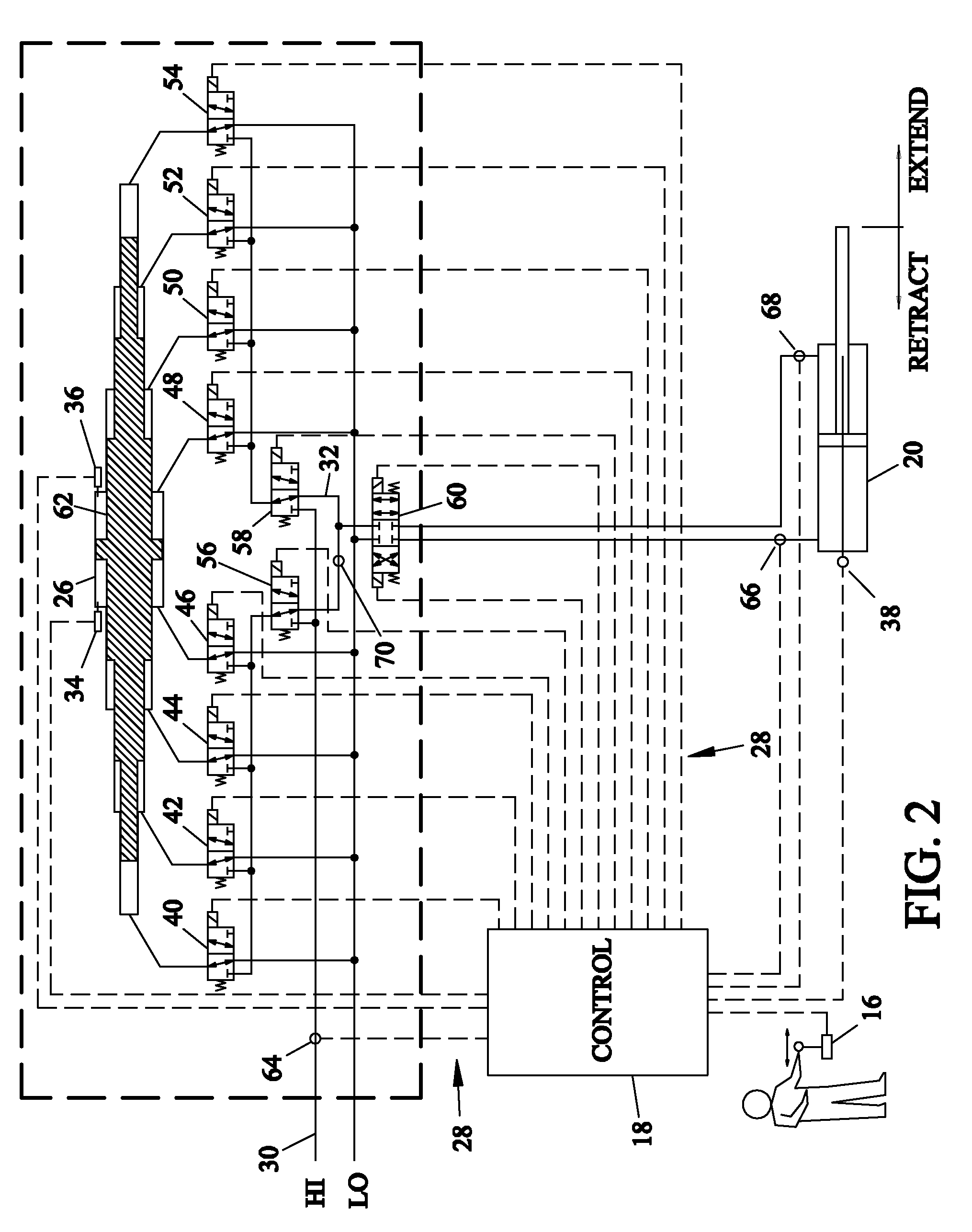

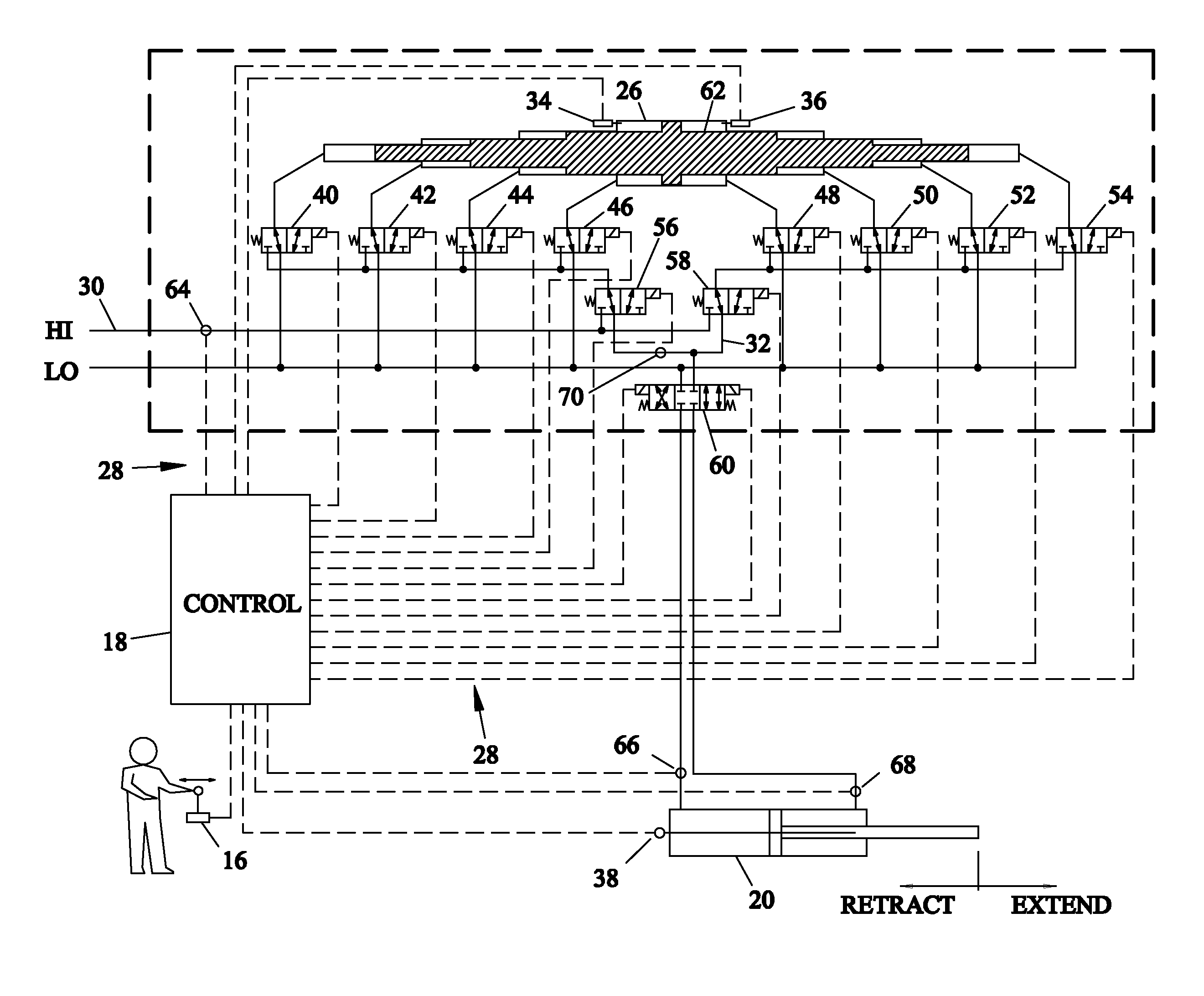

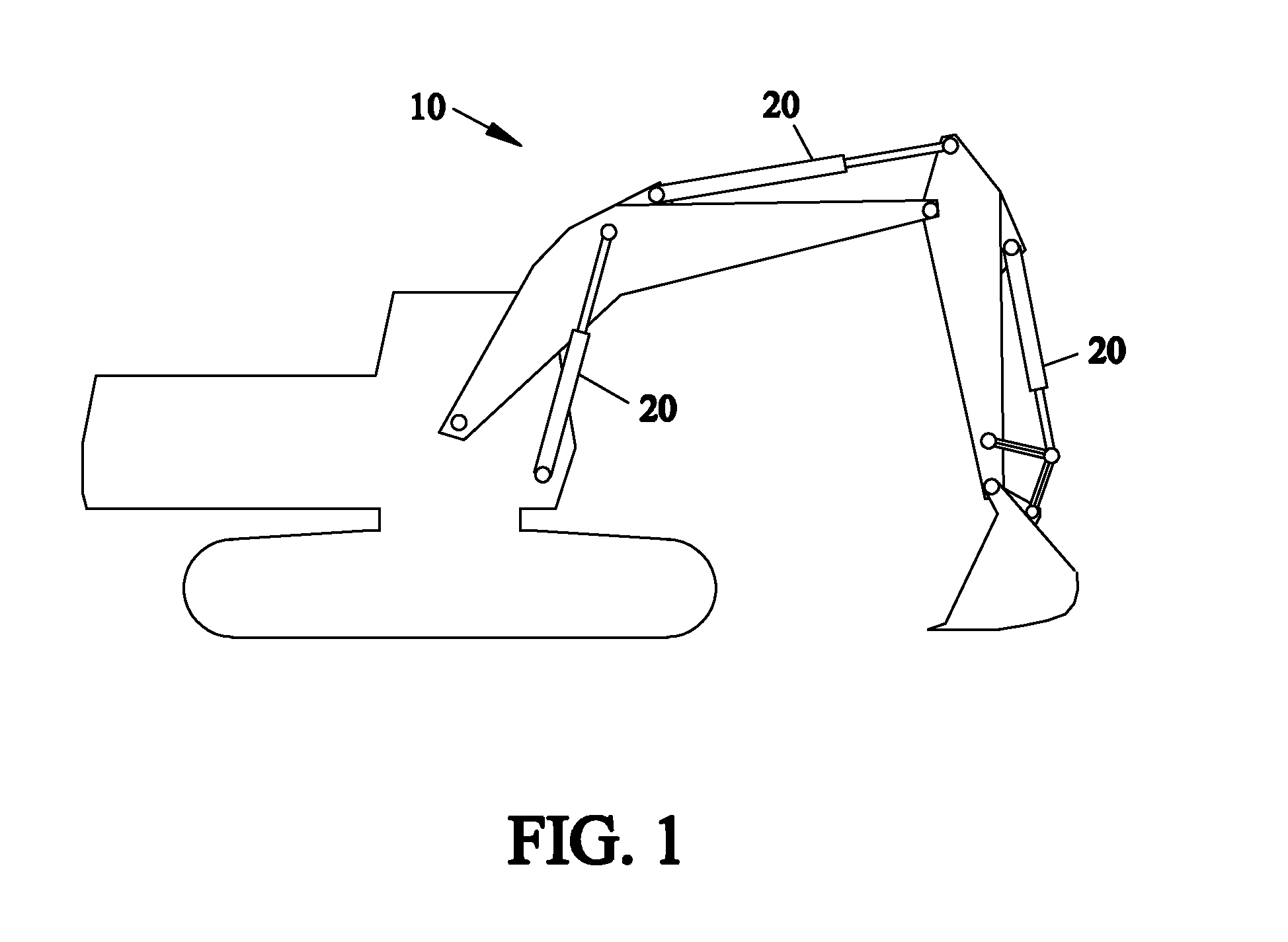

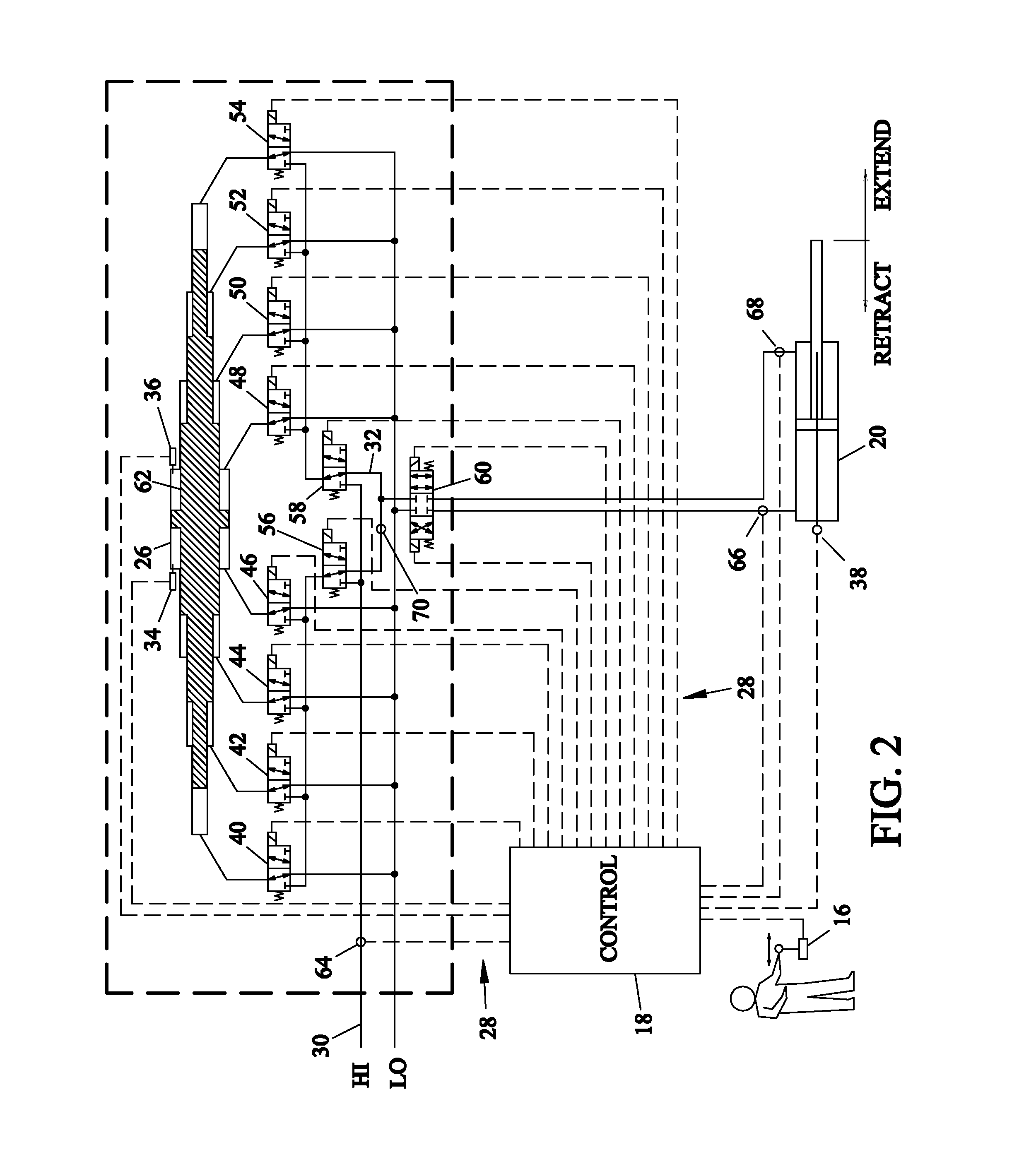

Digital hydraulic system

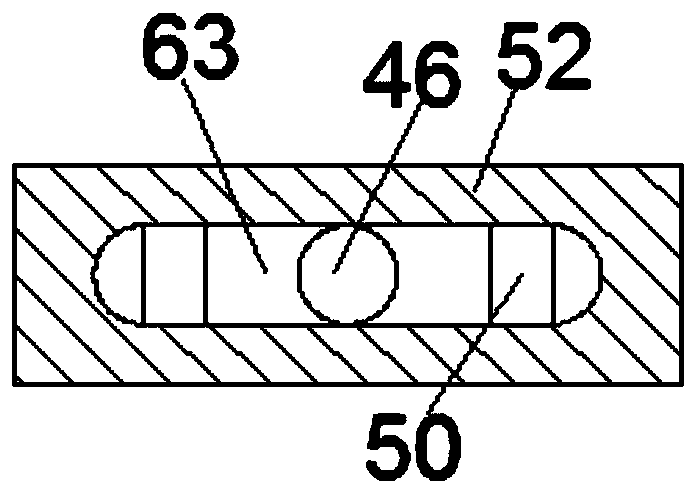

InactiveUS8286426B2Optimize energy usageMost efficientFluid couplingsAccumulator installationsControl systemHydraulic fluid

A control system for a work machine having a hydraulic energy source, a hydraulic accumulator, a digital hydraulic system having a digital hydraulic transformer, a hydraulic actuator and a movable element. The hydraulic accumulator being fluidically couplable with the hydraulic energy source. The digital hydraulic system including a digital hydraulic transformer fluidically couplable with the hydraulic accumulator. The hydraulic actuator being fluidically couplable with the digital hydraulic transformer. The movable element being movable by the hydraulic actuator. The control system including means to estimate at least one of potential energy and kinetic energy in the movable element; means to measure a fill level of hydraulic fluid in the hydraulic accumulator; and means to vary the amount of hydraulic energy added to the hydraulic accumulator by the hydraulic energy source responsive to the potential energy, the kinetic energy and / or the fill level of the hydraulic accumulator.

Owner:DIGITAL HYDRAULICS

Temperature limiter for fluidic systems

InactiveUS20150168020A1Simple and inexpensiveControl circuitry was requiredTemperature control without auxillary powerSolar heating energyThermal energyEngineering

The present invention limits fluid temperature at a point in a fluidic system to below a predetermined temperature by cooling the fluid when needed and without requiring a separate cold fluid source. The present invention “clips” the temperature of the fluid at a point in the system to within a temperature range and prevents overcooling the fluid. When the fluid temperature is below the temperature range, the temperature of the fluid is unchanged as it passes through the apparatus of the present invention. The present invention may operate without external power, can function in any orientation, and works for unpressurized and pressurized systems. The present invention has application in the areas of solar thermal energy systems, fluid tanks, engine oil and coolant systems, transmission fluid systems, hydraulic systems, machining fluid systems, and cutting fluid systems, among others.

Owner:PO BOX 32598

Diffusion absorption type refrigeration system

InactiveCN101280981AEfficient replacementEfficient use ofEnergy efficient heating/coolingClimate change adaptationVapor–liquid separatorProcess engineering

The invention relates to a dispersing absorption type cooling system, comprising a high evaporation temperature cooling loop, a low evaporation temperature cooling loop and a heat retriever that can respectively independently run; the high evaporation temperature cooling loop comprises a first generator, a gas-liquid separator, a condenser and a first evaporator and a first absorber; the first generator is driven by external heat source and connected with the condenser through the gas-liquid separator; the heat retriever is in series connection between the gas-liquid separator and the condenser. The dispersing absorption type cooling system of the invention, because including two respectively independently cooling loops with different evaporation temperatures, can efficiently use the remaining heat, the waste heat, the solar energy, the gas and the power energy as energy to cool and generate sanitary hot water, thus effectively performing energy replacement and improving comprehensive utilization of the energy, which is beneficial to solve the problem about shortage of power and environment protection radically in our country and to improve the energy consumption efficiency at the same time of protecting the natural environment of earth.

Owner:SHENZHEN POLYTECHNIC

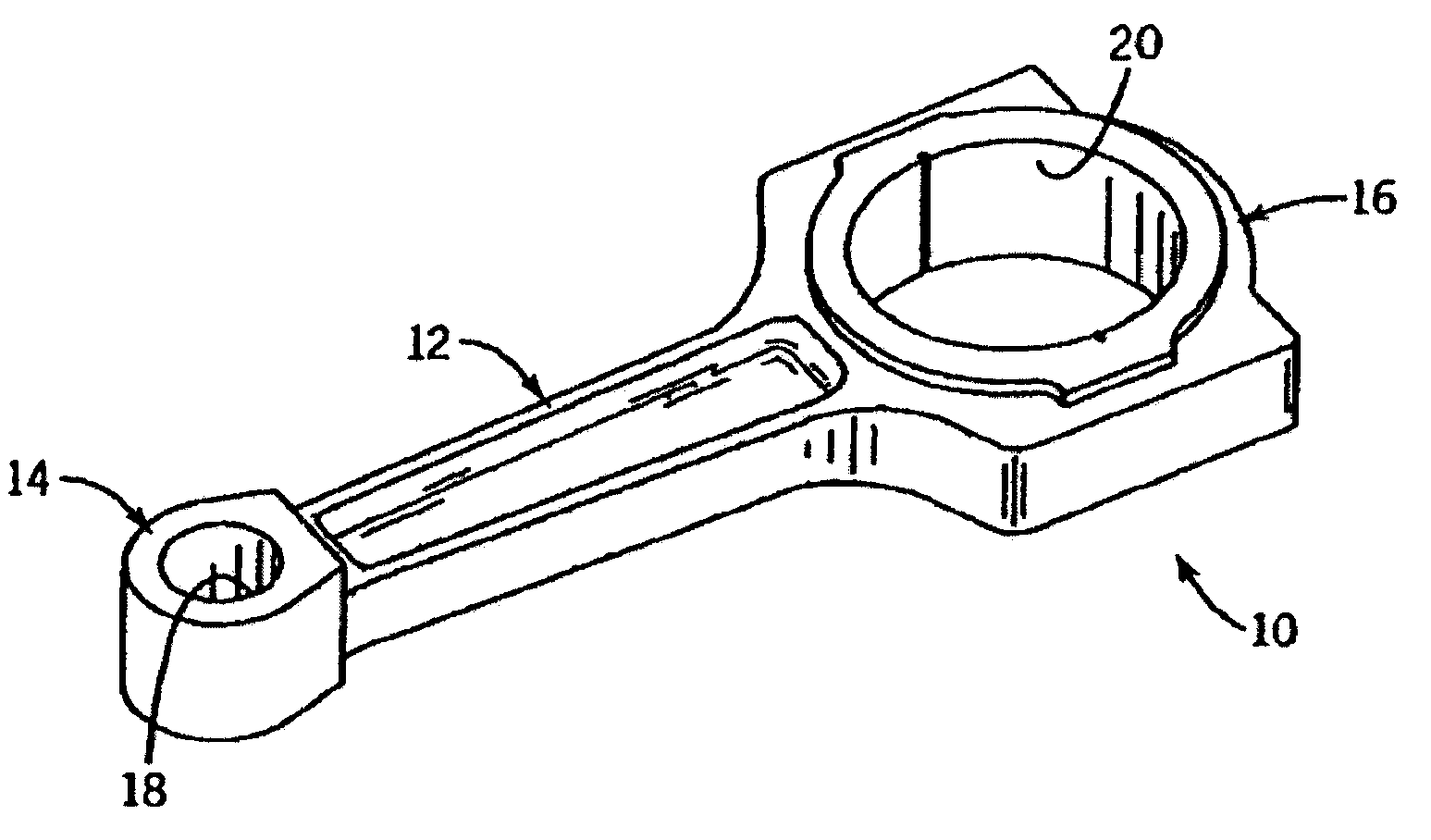

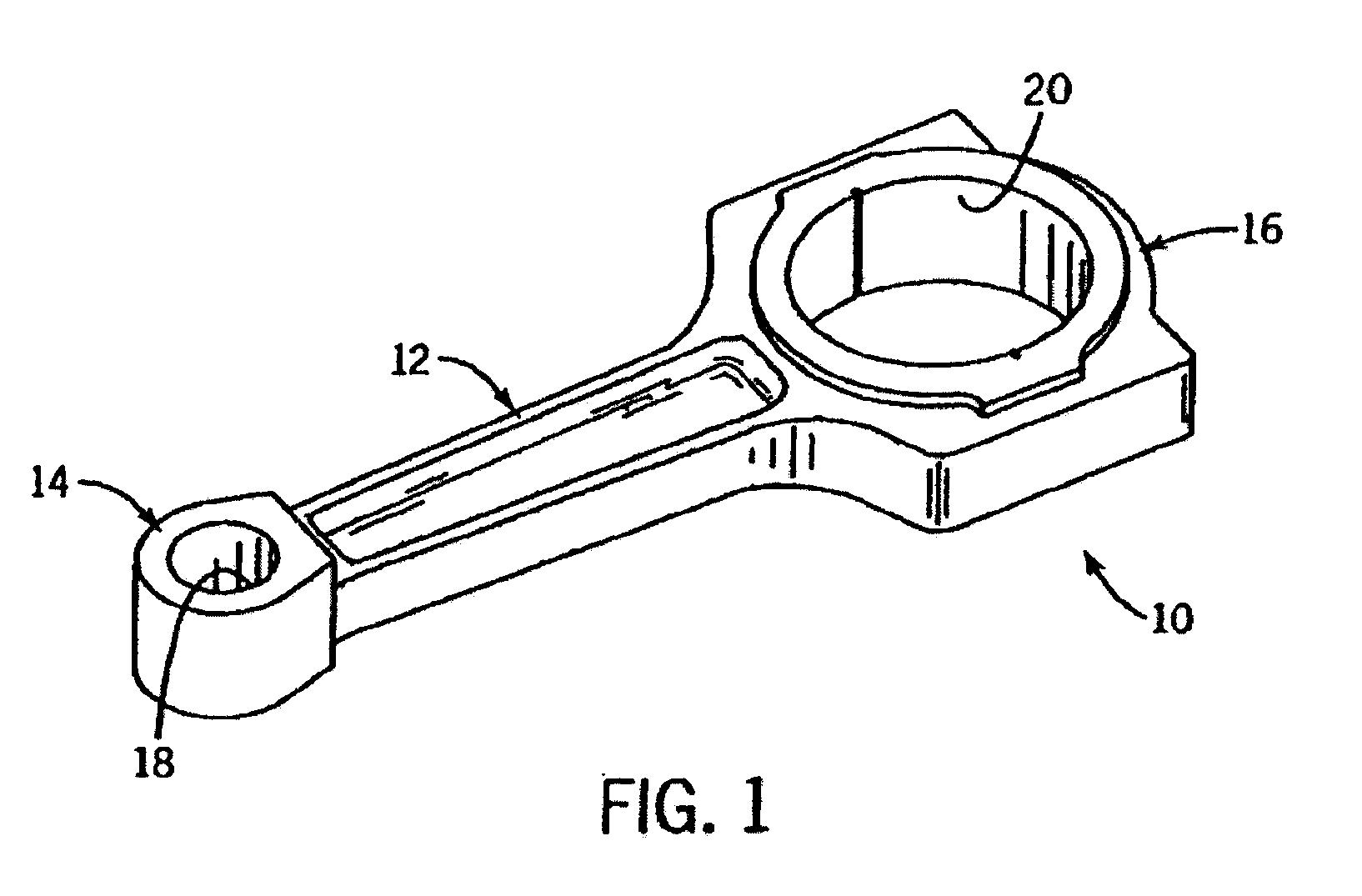

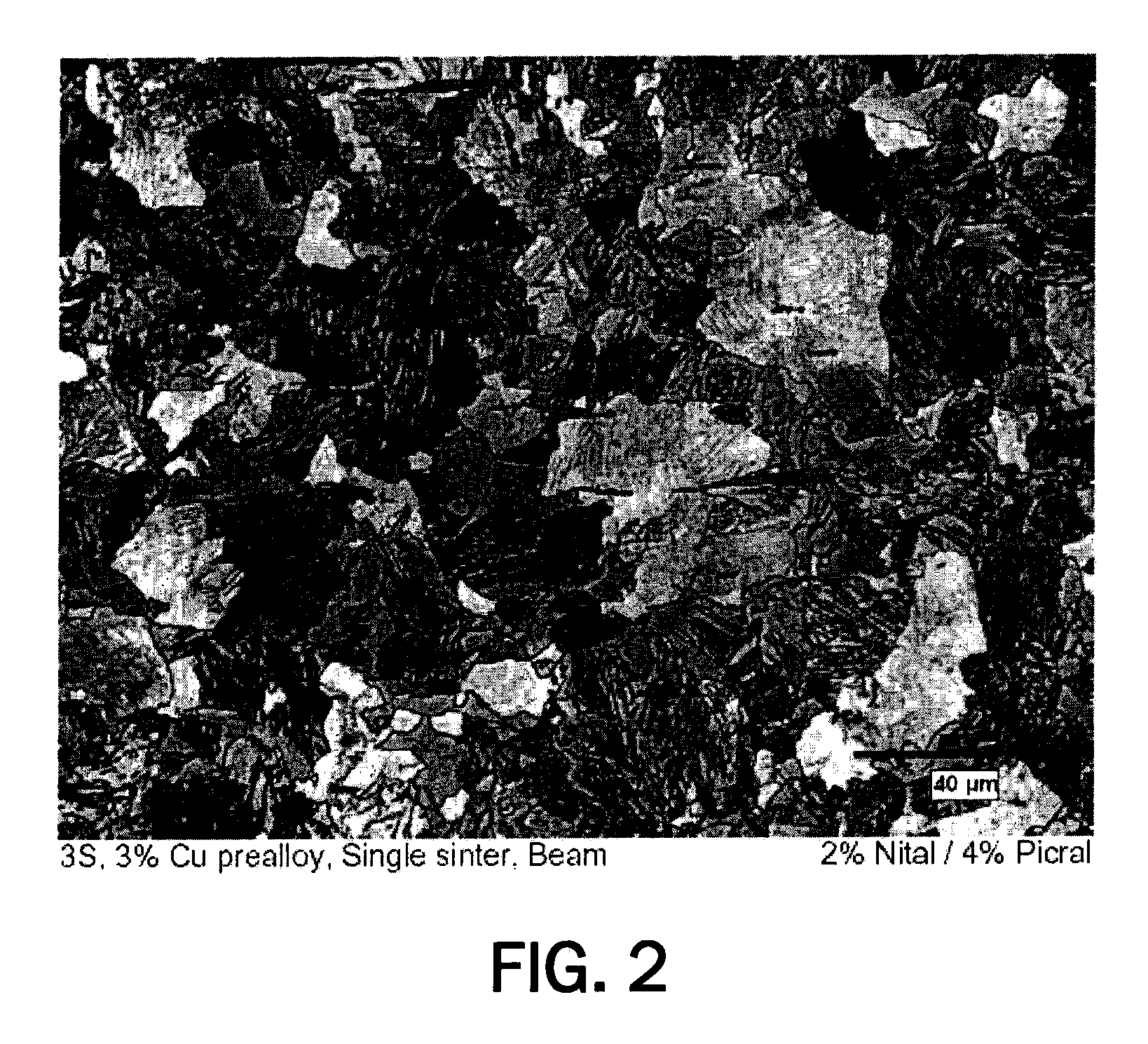

Prealloyed copper powder forged connecting rod

A process for manufacturing connecting rods is provided which comprises the steps of compacting, sintering, and powder forging a powder metal comprising a carbon source and a prealloyed powder consisting essentially of iron and copper. The connecting rods made from this process have sufficient hardness and strength to be used in an engine and do not require any additional quenching or tempering.

Owner:SKN SINTER METALS LLC (US)

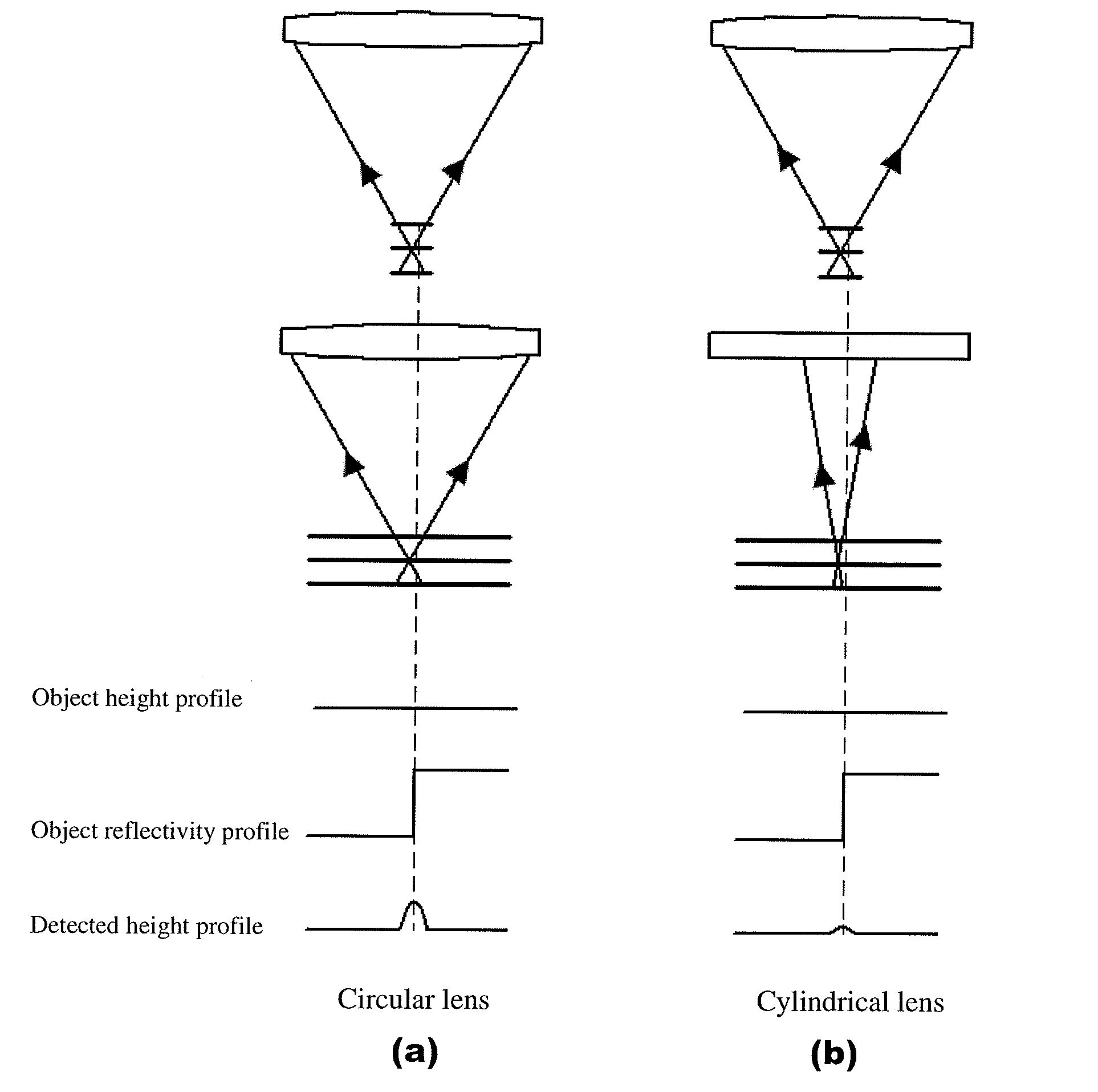

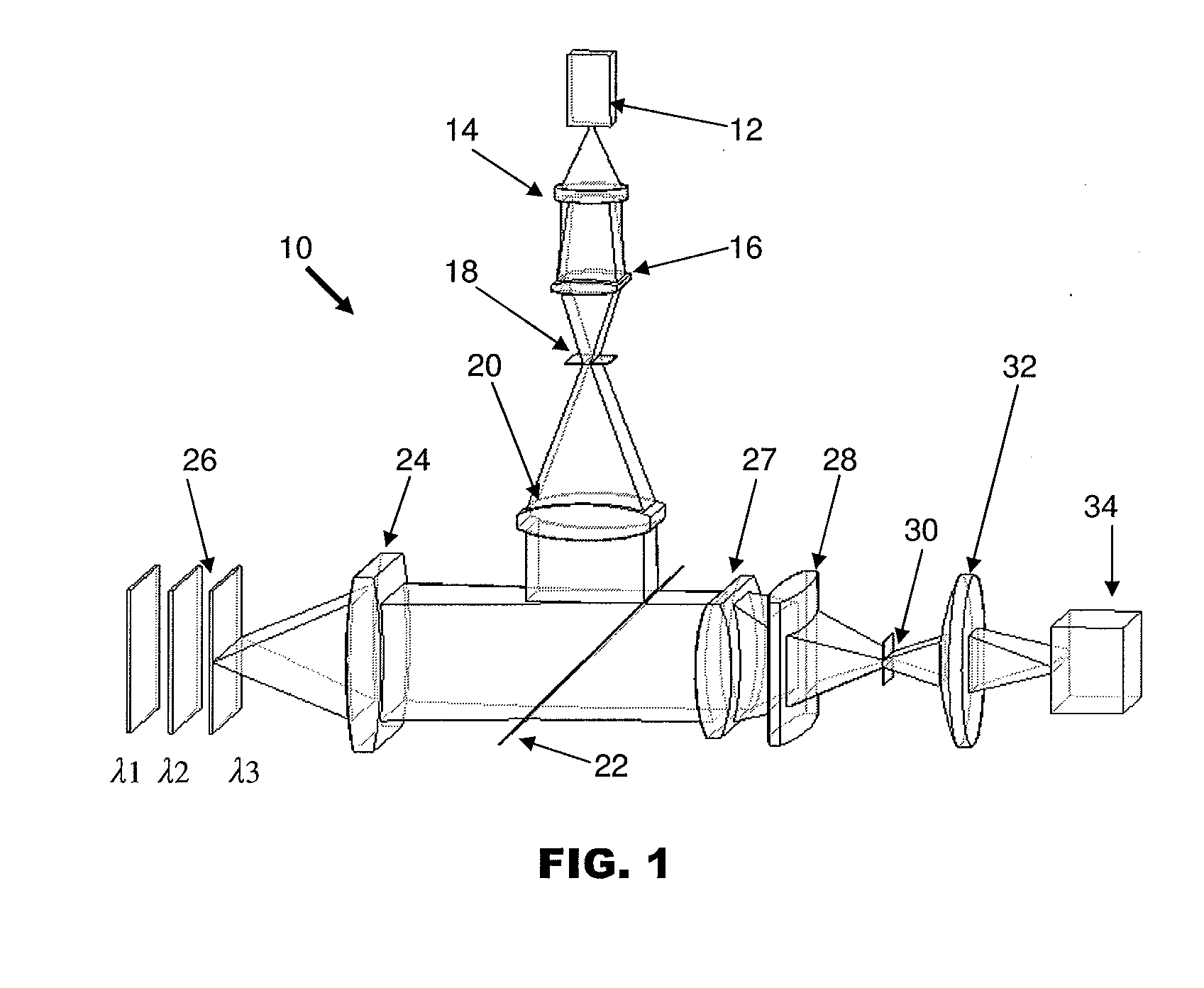

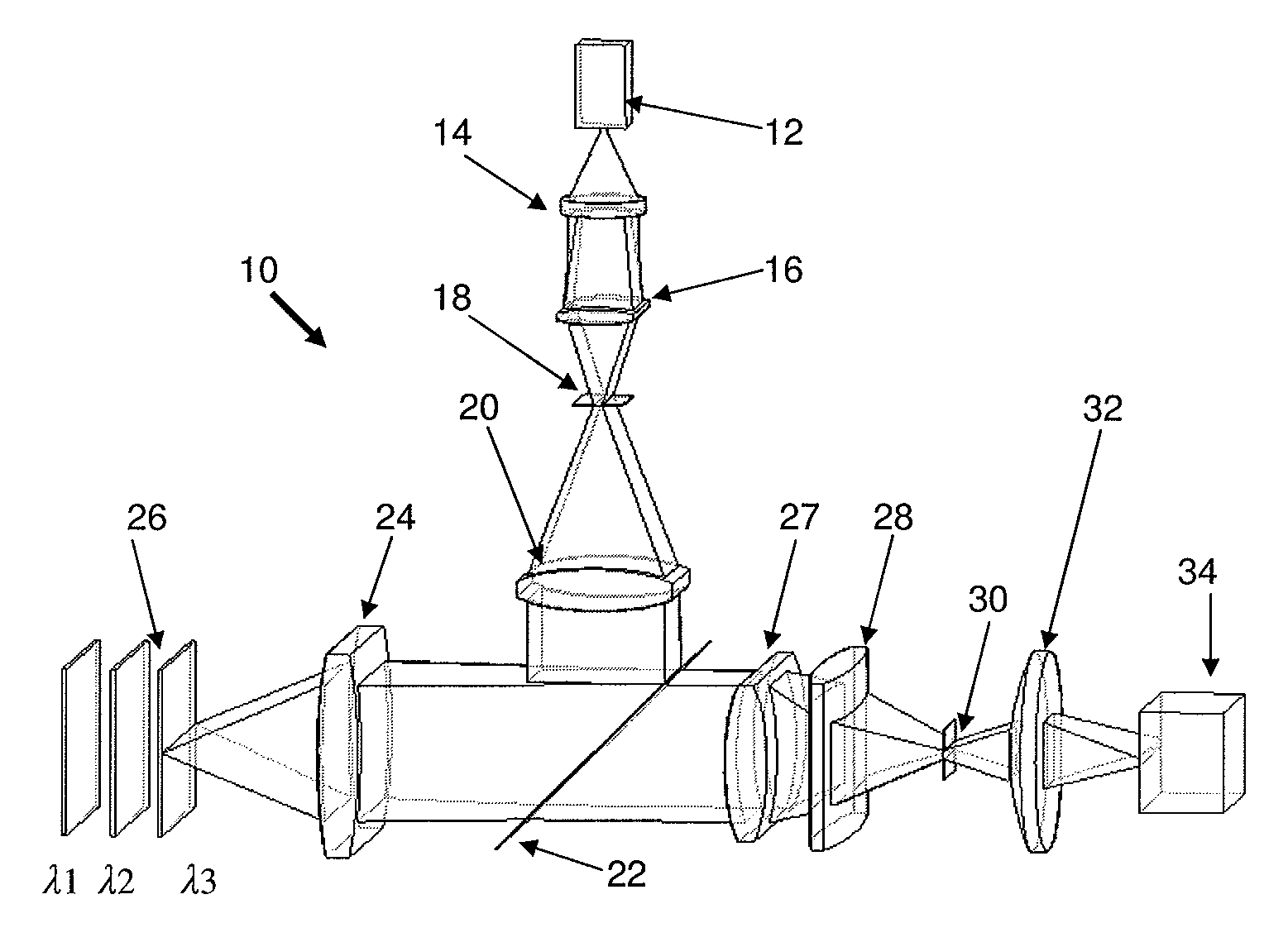

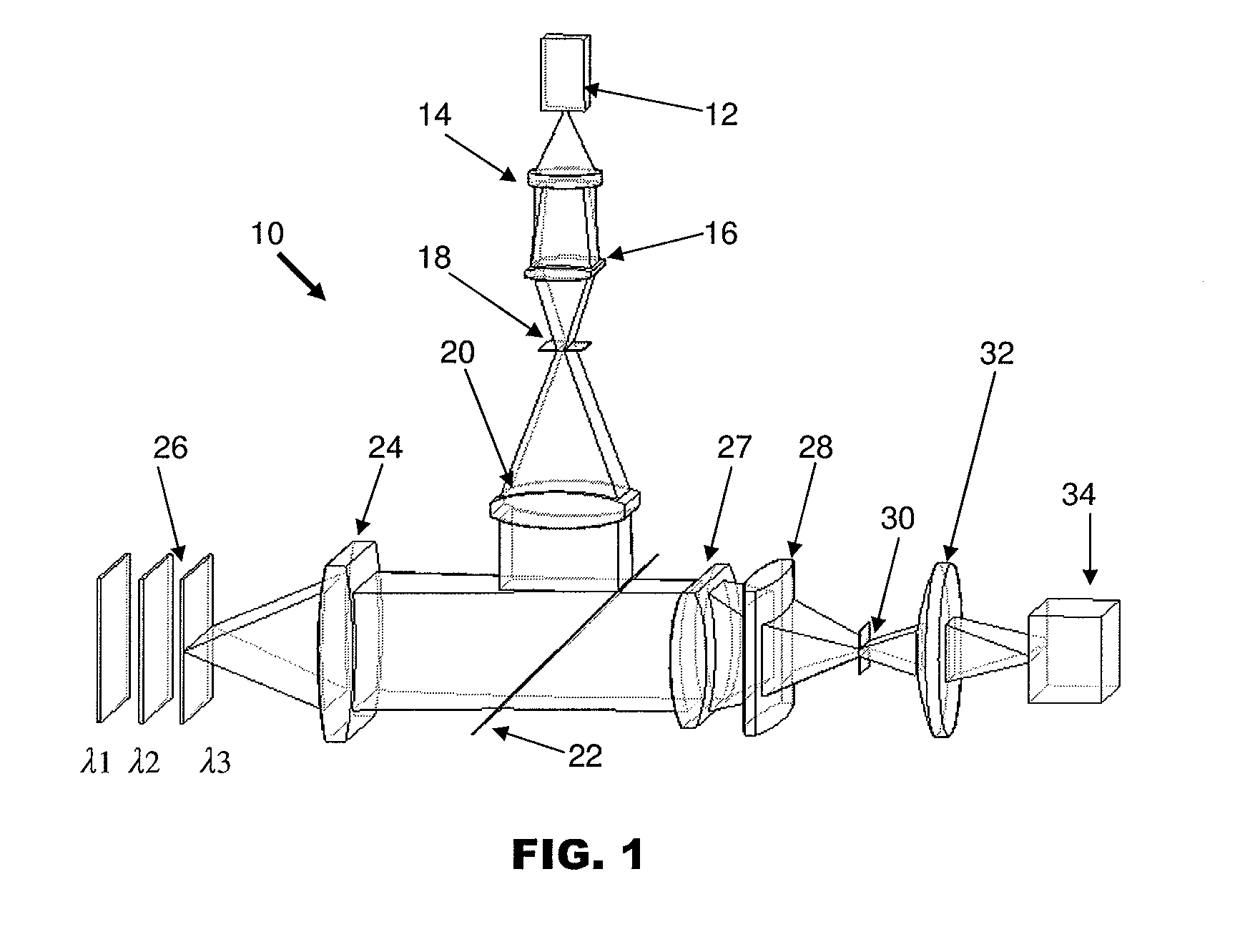

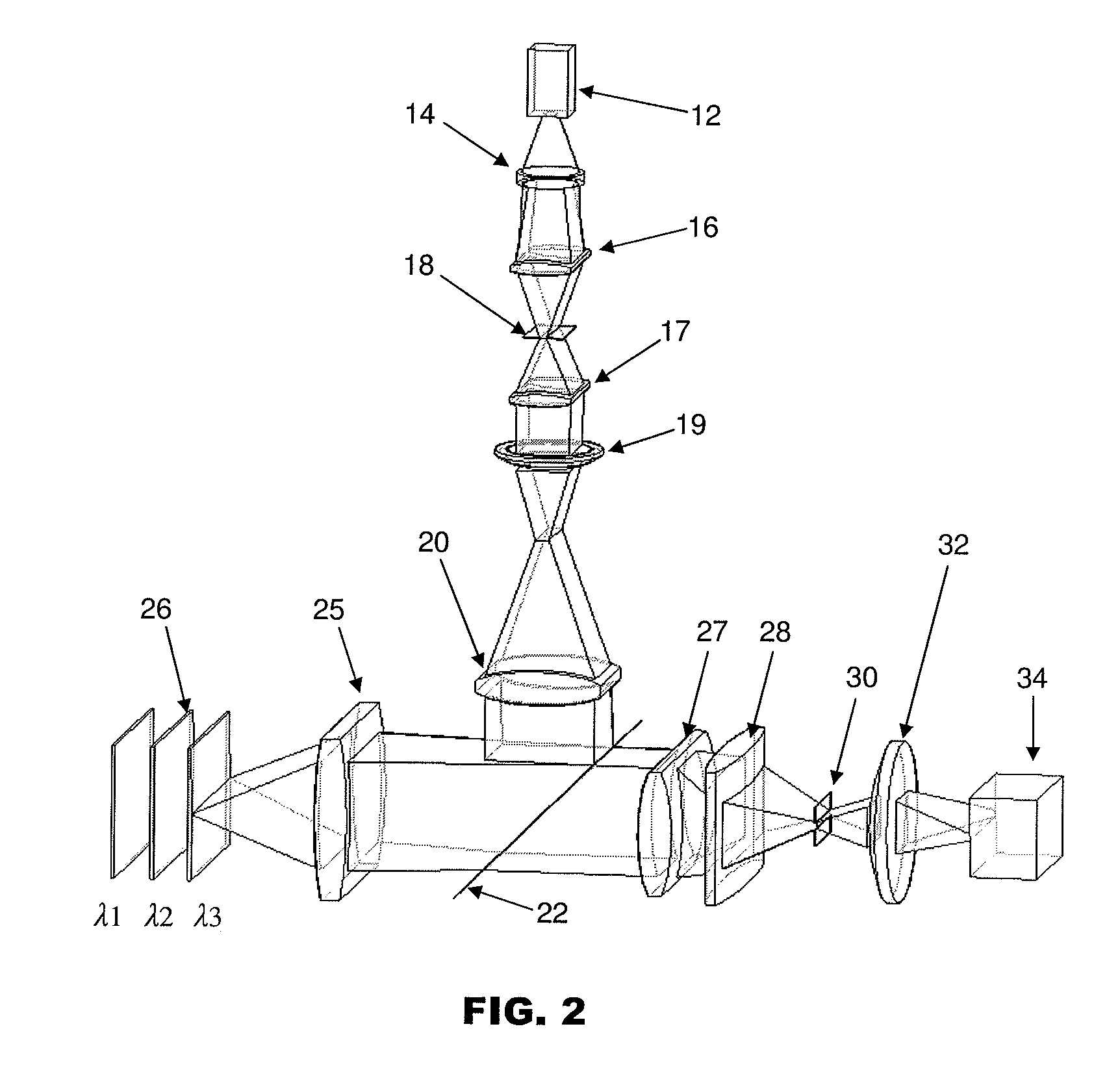

Chromatic confocal scanning apparatus

ActiveUS20140043619A1Well energetic utilizationAccurately measureUsing optical meansLight sourceColor sensor

A chromatic confocal scanning apparatus comprises a light source for producing light rays comprising a plurality of wavelengths, a first screen having an open elongated slit which allows a strip of light rays produced from the light source to pass through the slit and a cylindrical objective lens both to converge the light rays onto an object surface that is to be measured, and to image light rays reflected from the object surface. An intermediate cylindrical lens set converges a strip of light rays imaged from the cylindrical objective lens to pass through an open elongated slit comprised in a second screen, and a color sensor receives light rays which have passed through the slit of the second screen for determining a plurality of wavelengths of the said strip of light rays, to thereby construct a height profile of at least a portion of the object surface.

Owner:ASMPT SINGAPORE PTE LTD

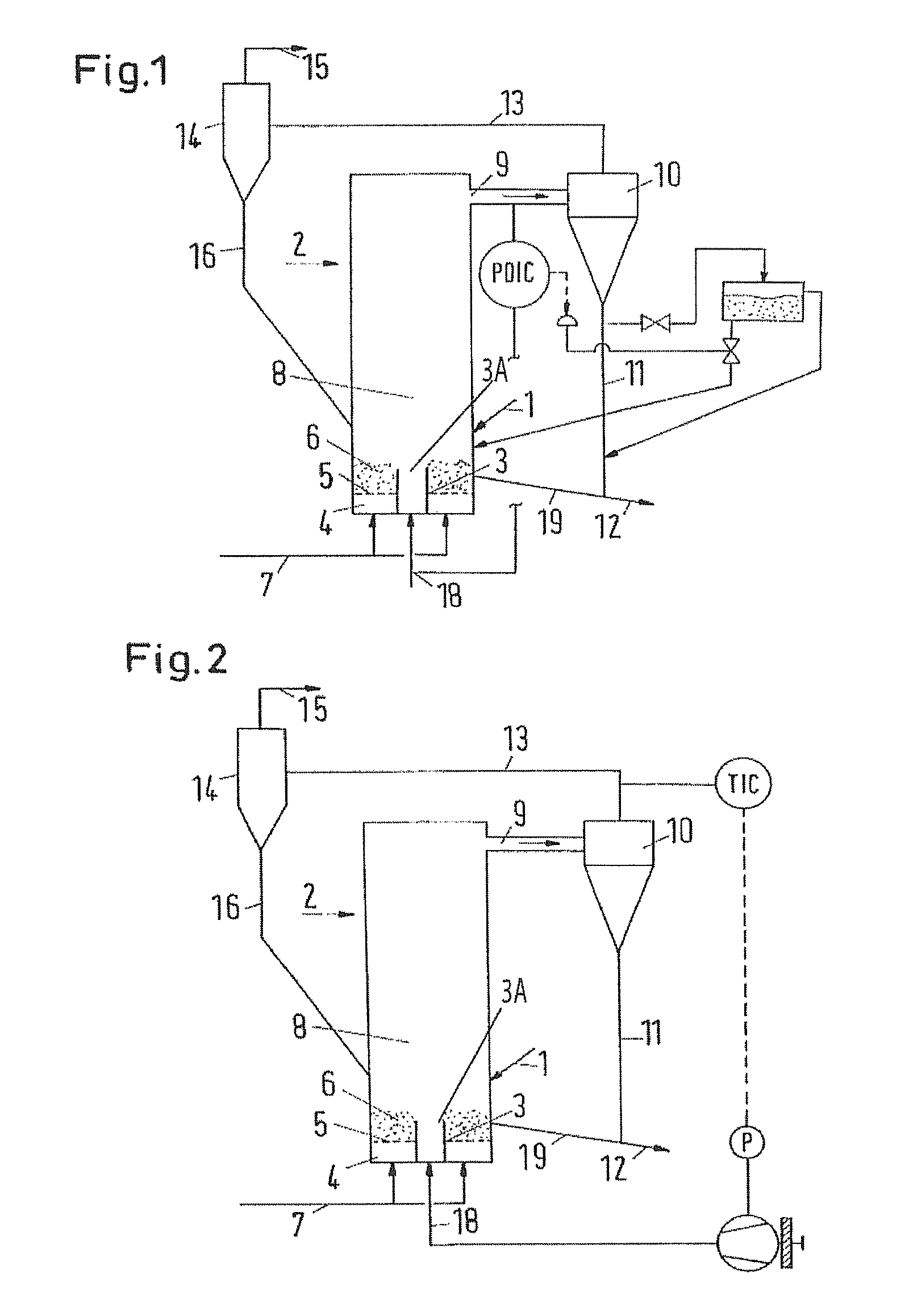

Method and plant for producing low-temperature coke

InactiveUS7803268B2Optimize energy usageEfficient executionThermal non-catalytic crackingFluidized bed combustionFluidized bedCoke

The present invention relates to a method and a plant for producing low 15 temperature coke, in which granular coal and possibly further solids are heated to a temperature of 700 to 1050° C. in a fluidized-bed reactor (2) by means of an oxygen-containing gas. To improve the utilization of energy it is proposed to introduce a first gas or gas mixture from below through at least one gas supply tube (3) into a mixing chamber region (8) of the reactor (2), the gas supply tube (3) being at least partly surrounded by a stationary annular fluidized bed (6) which is fluidized by supplying fluidizing gas. The gas velocities of the first gas or gas mixture and of the fluidizing gas for the annular fluidized bed (6) are adjusted such that the Particle-Froude-Numbers in the gas supply tube (3) are between 1 and 100, in the annular fluidized bed (6) between 0.02 and 2 and in the 25 mixing chamber (8) between 0.3 and 30.

Owner:OUTOTEC OYJ

Method for operating a power plant

InactiveUS20120117969A1Rapid change in outputLow costFrom solar energySteam engine plantsPower stationEngineering

A method for operating a hybrid power plant comprising fuel-operated heating and solar energy heating of carrier fluids, wherein a first portion of total power provided by the power plant is based on fuel-operated heating of carrier fluids and a second portion of the total power is based on solar energy heating of carrier fluids, the heat absorbed by a solar energy heated carrier fluid is transferred to a carrier fluid circuit of a fuel-operated part of the power plant. When a sudden increase or reduction of the total power provided by the power plant is required as compared to a basic state, the second portion is first increased or reduced over a short time period in order to provide a positive or negative reserve power. Subsequently, the first portion is slowly increased or reduced and the second portion based on solar energy heating is correspondingly reduced or increased again.

Owner:STEAG ENERGY SERVICES

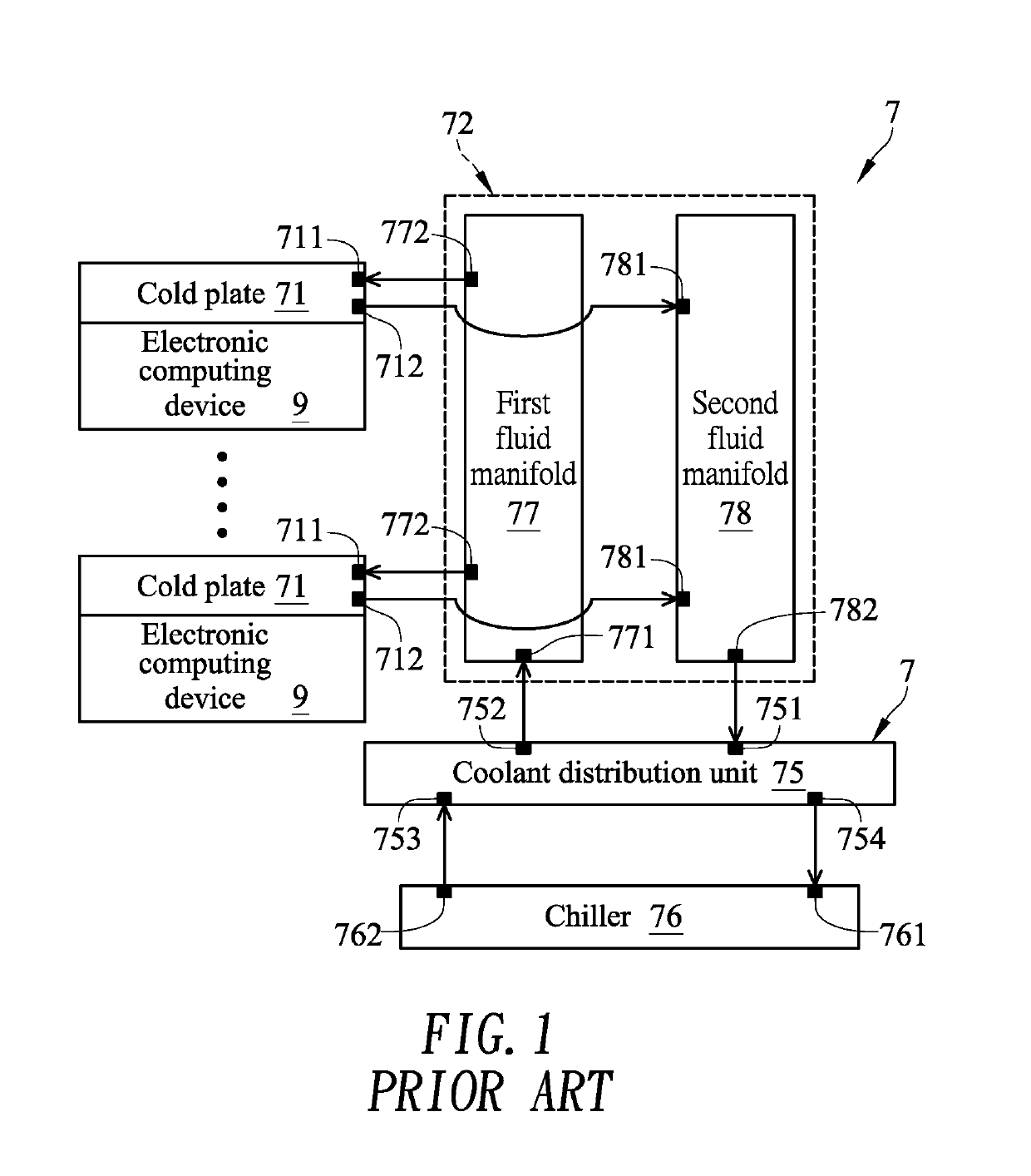

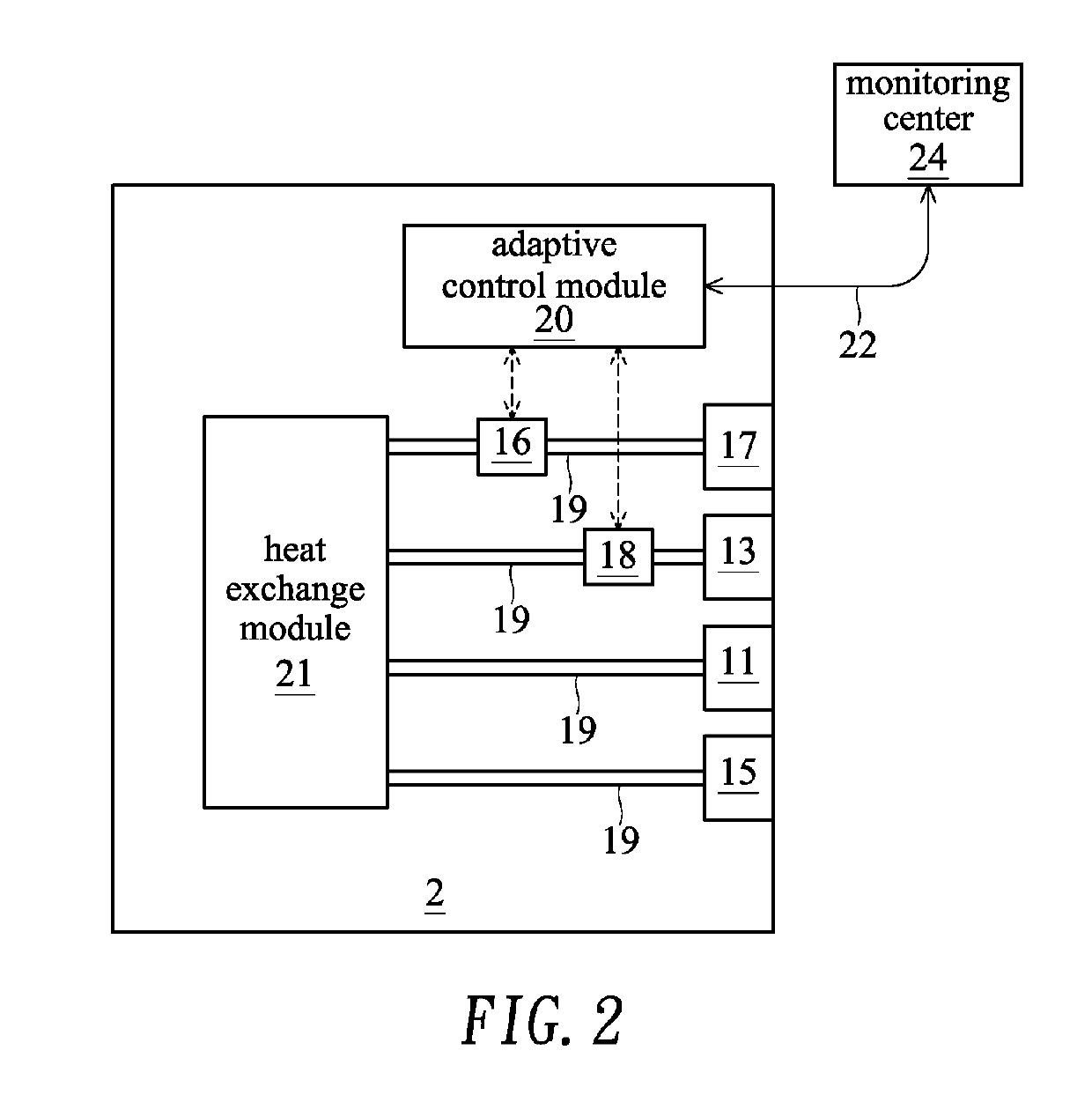

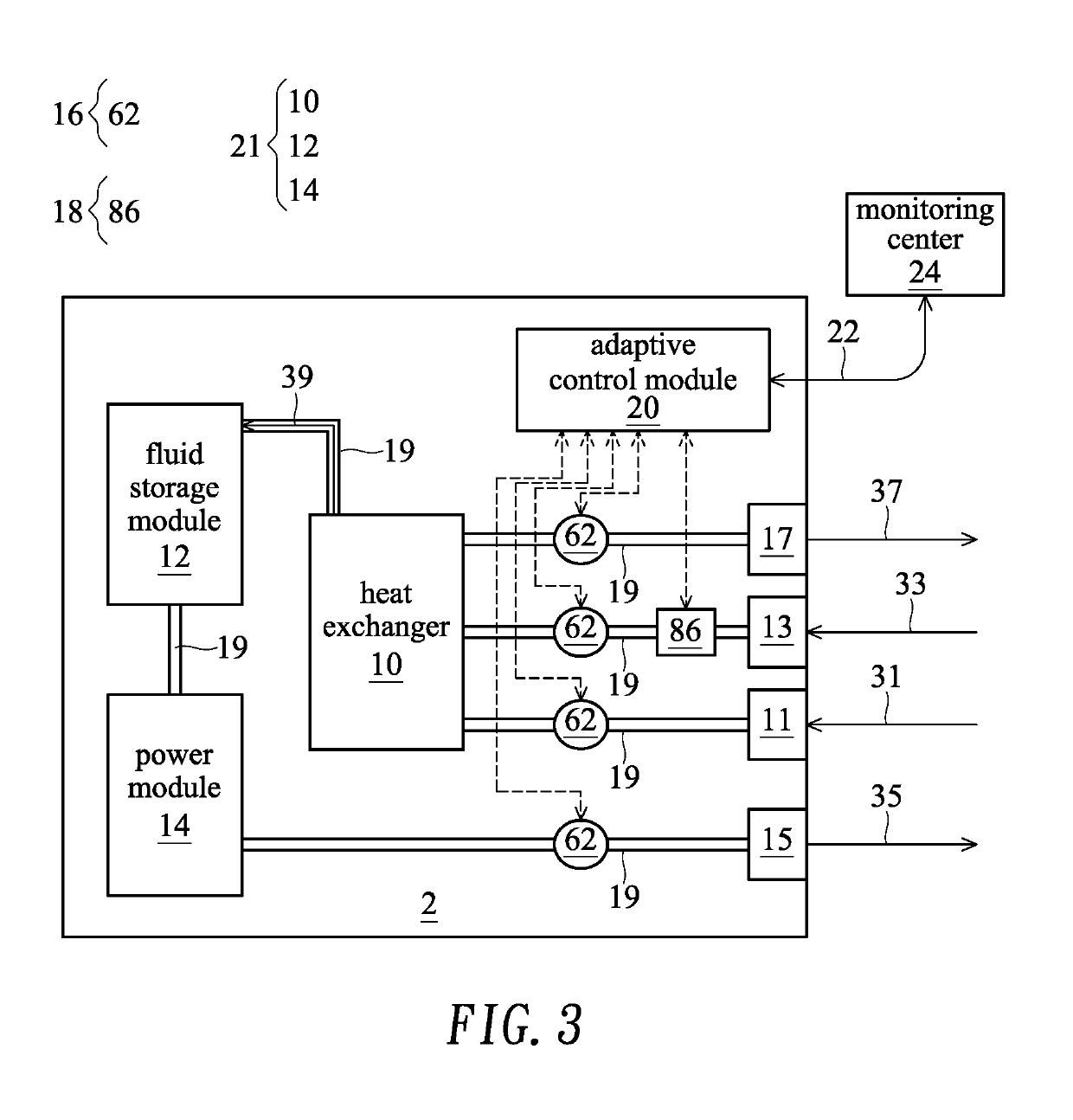

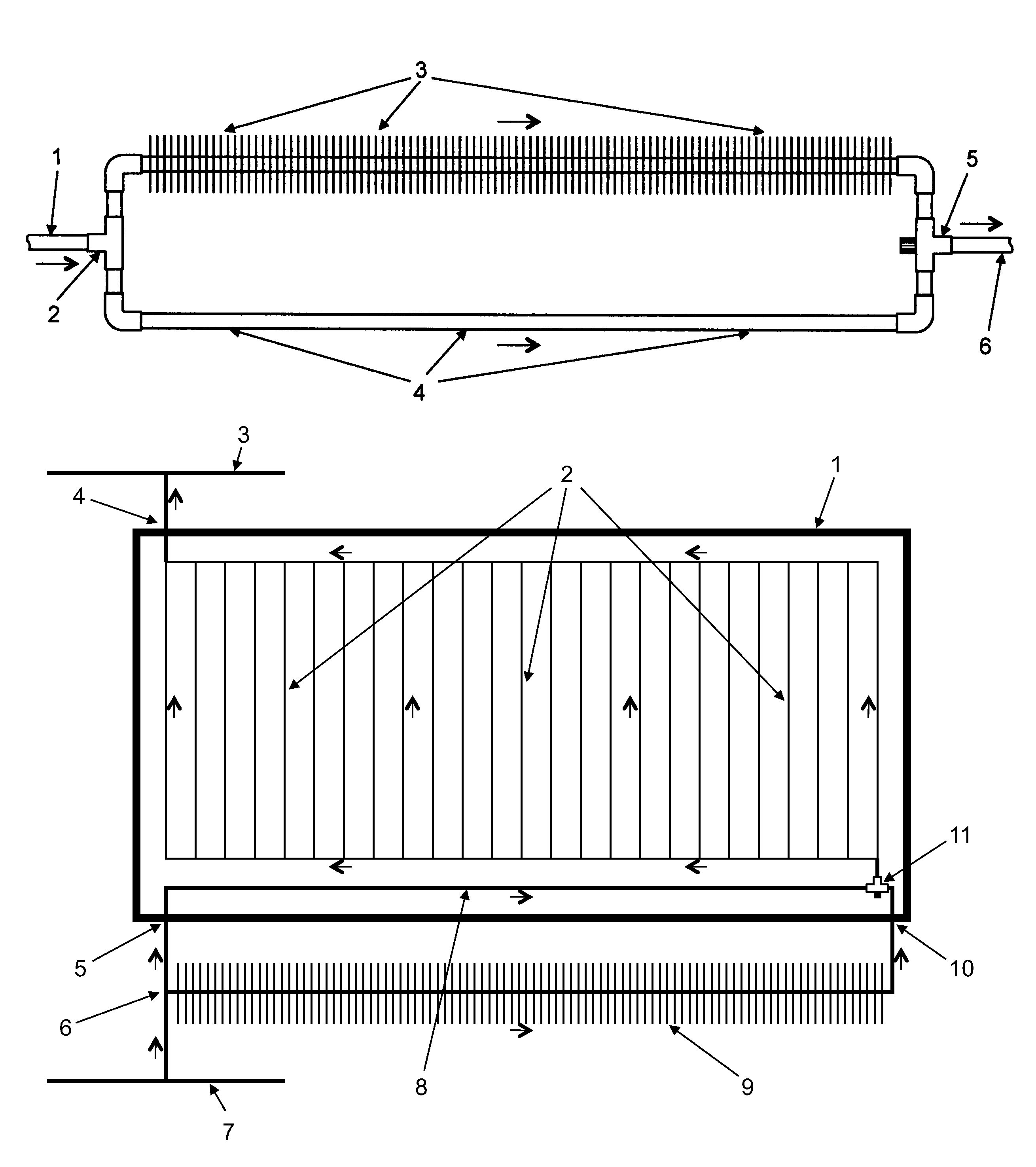

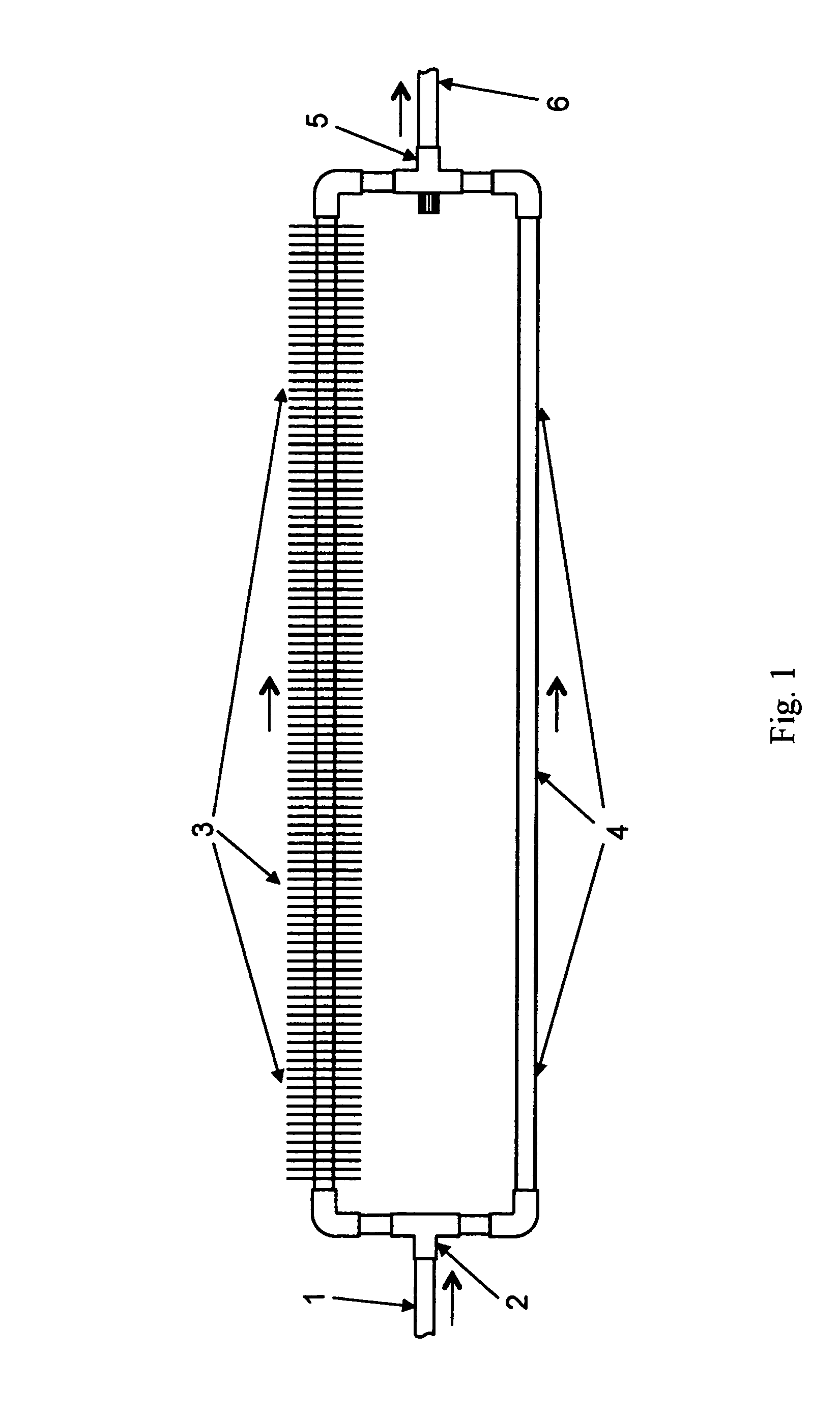

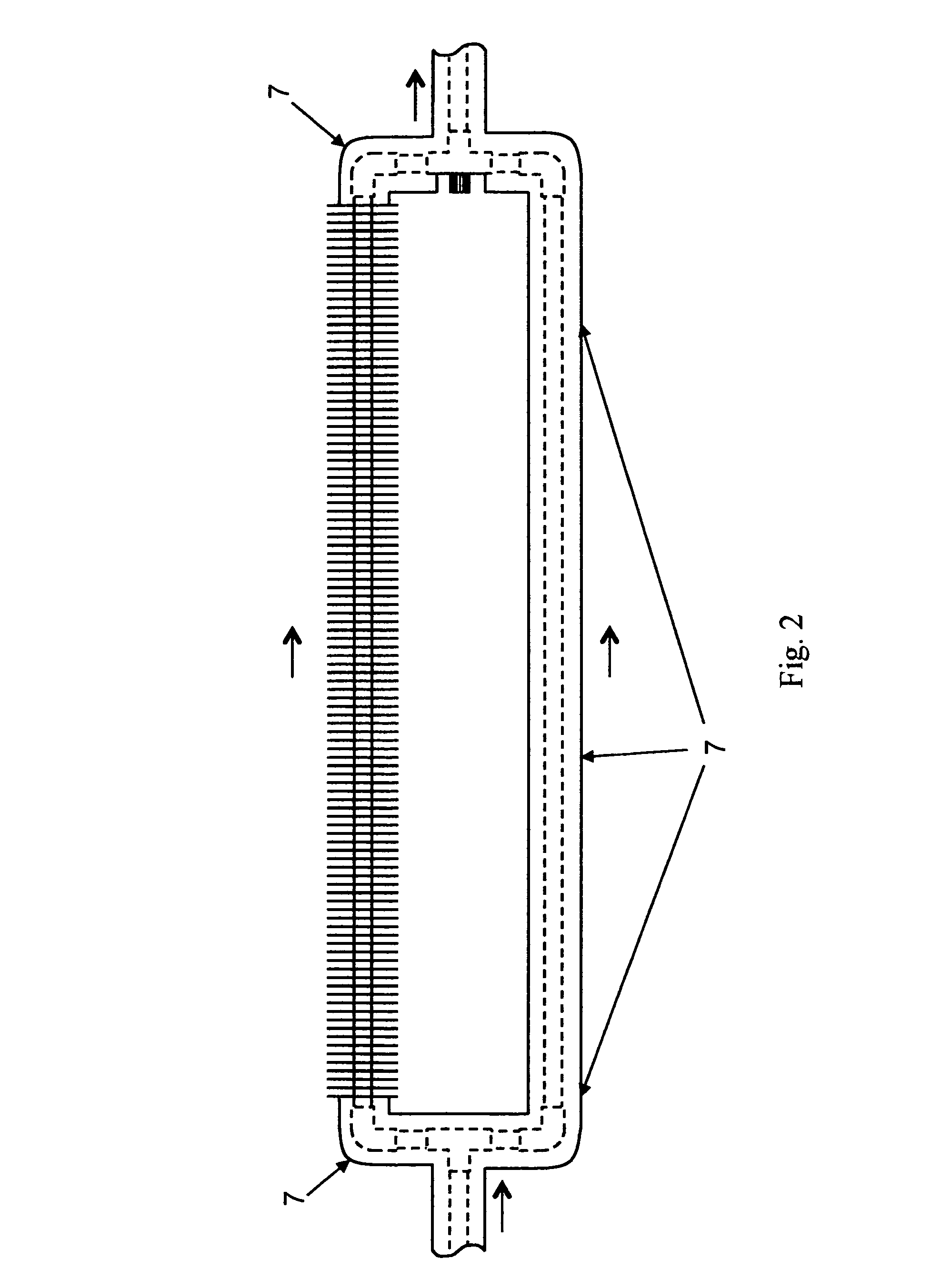

Coolant distribution unit

InactiveUS20190178592A1Optimize energy usageRealize the operationElectrical apparatus contructional detailsHeat exchange apparatusWorking fluidEngineering

A coolant distribution unit includes plural fluid inlets, plural fluid outlets and a piping channel. The piping channel is connected with the fluid inlets and the fluid outlets. The sensed temperature or the measured pressure or flowrate of a working fluid in the piping channel is transmitted to an adaptive control module. The sensed temperature or the measured pressure or flowrate is further transmitted to an external monitoring center. Consequently, the supervisor of the monitoring center can manage and control the operating situation of the coolant distribution unit.

Owner:AURAS TECH

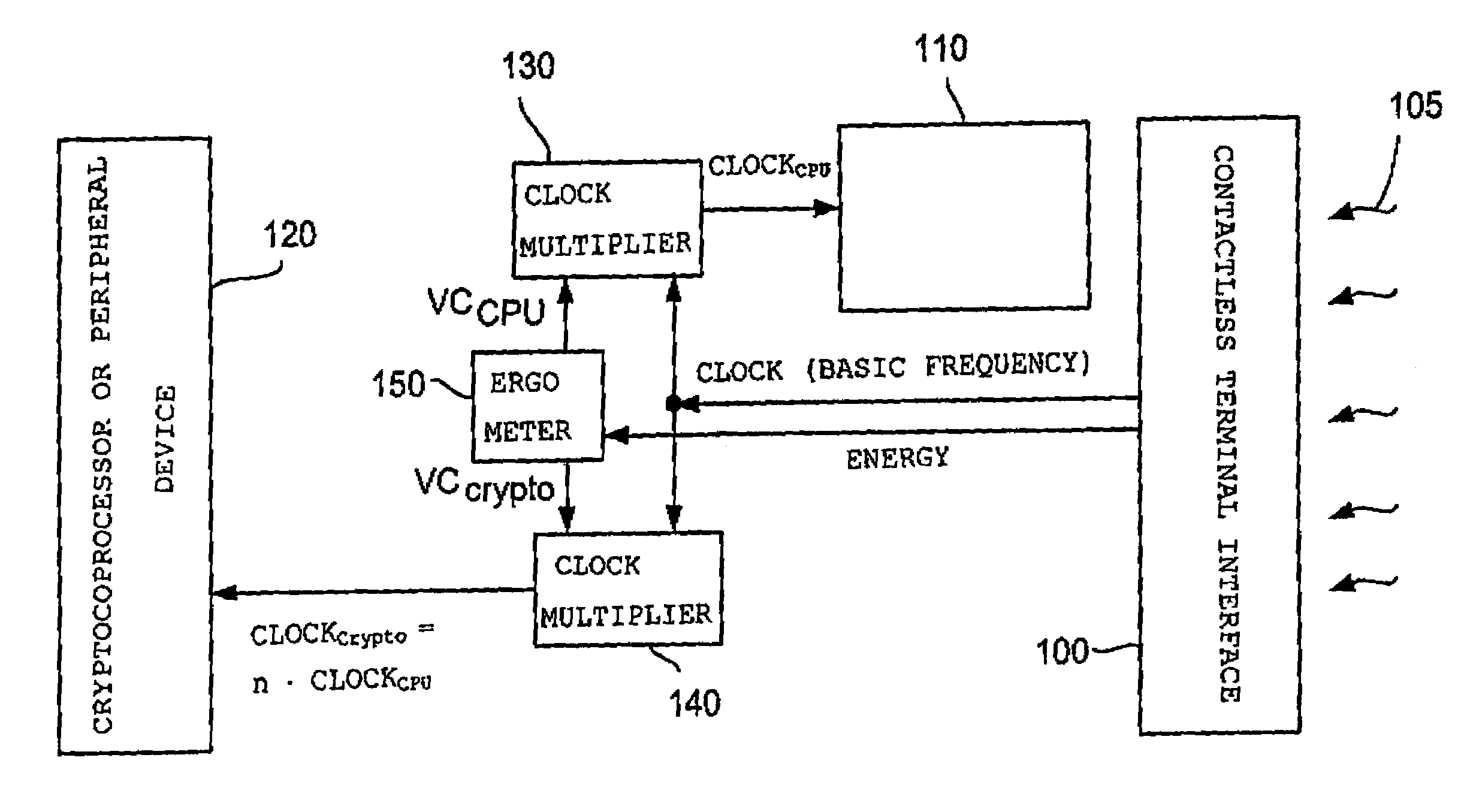

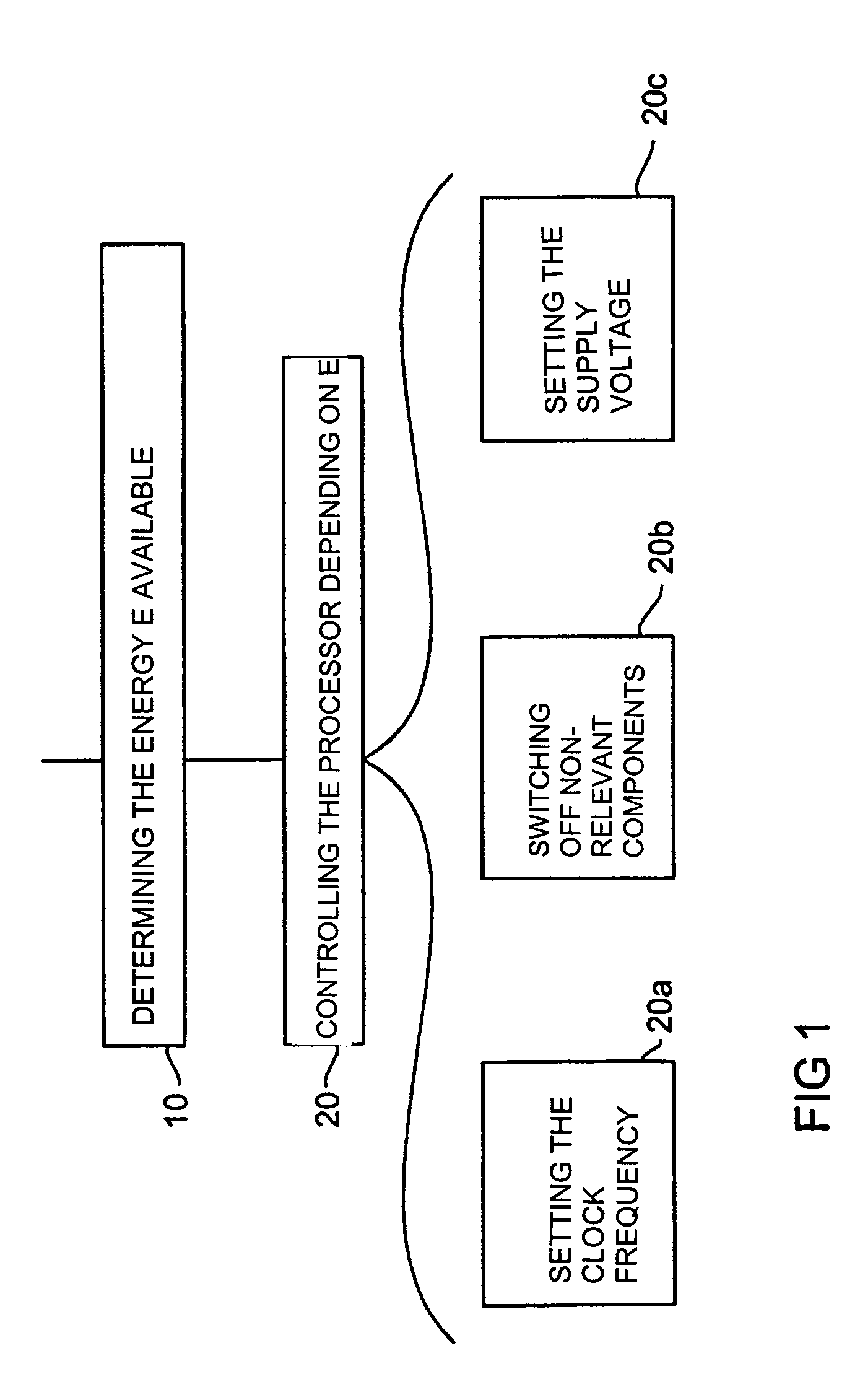

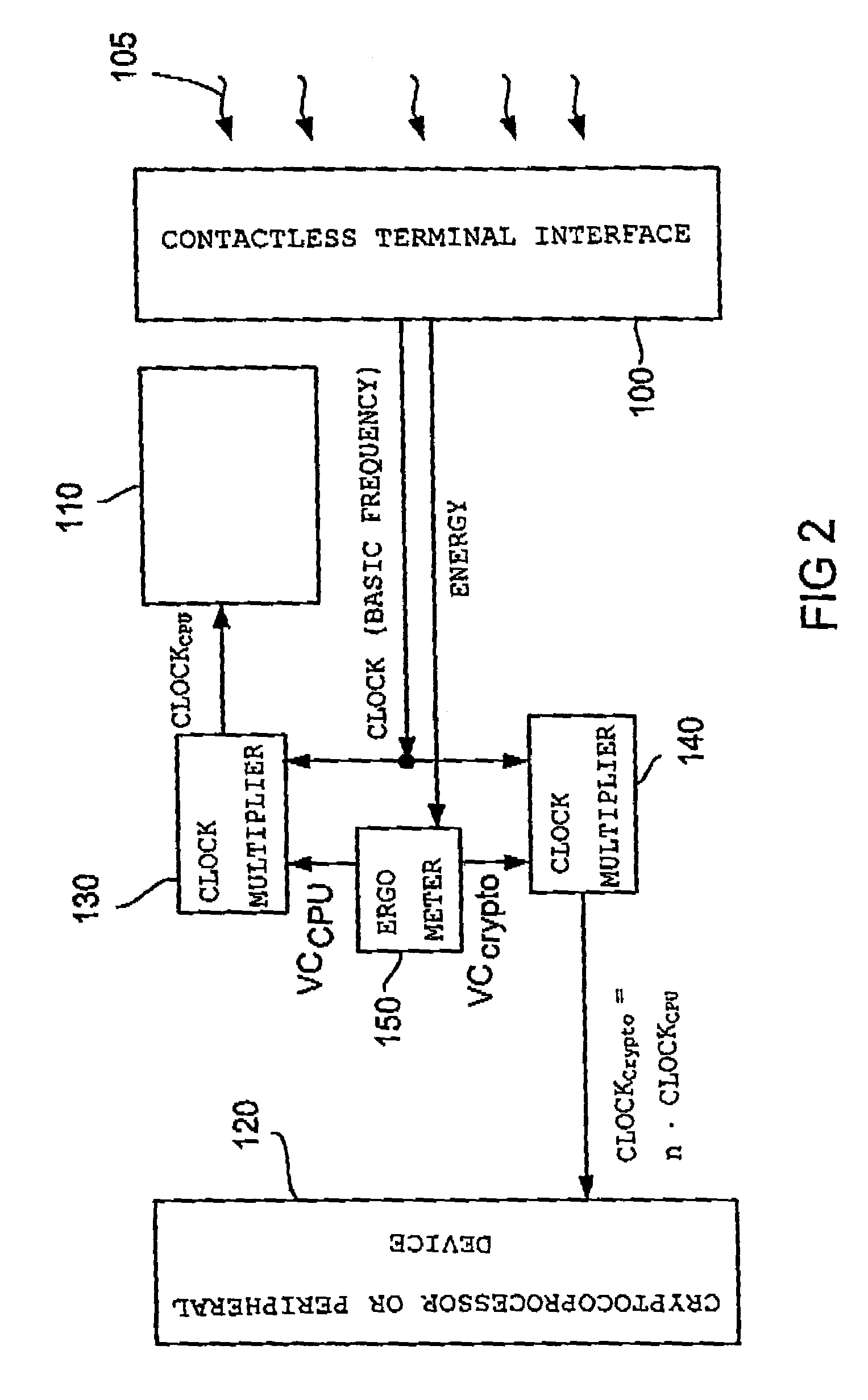

Electronic circuit with energy control

ActiveUS7395439B2Optimize operating timeIncreased complexityVolume/mass flow measurementPower supply for data processingEnergy controlEngineering

An inventive electronic circuit includes a controller for processing a processor task as well as an energy determination means for determining the energy available to the controller. A control means of the electronic circuit controls the controller depending on the energy available to the controller. An optimum utilization of the energy available and, thus, an optimization of the computing speed with maximum energy utilization is achieved by means of the energy control.

Owner:INFINEON TECH AG

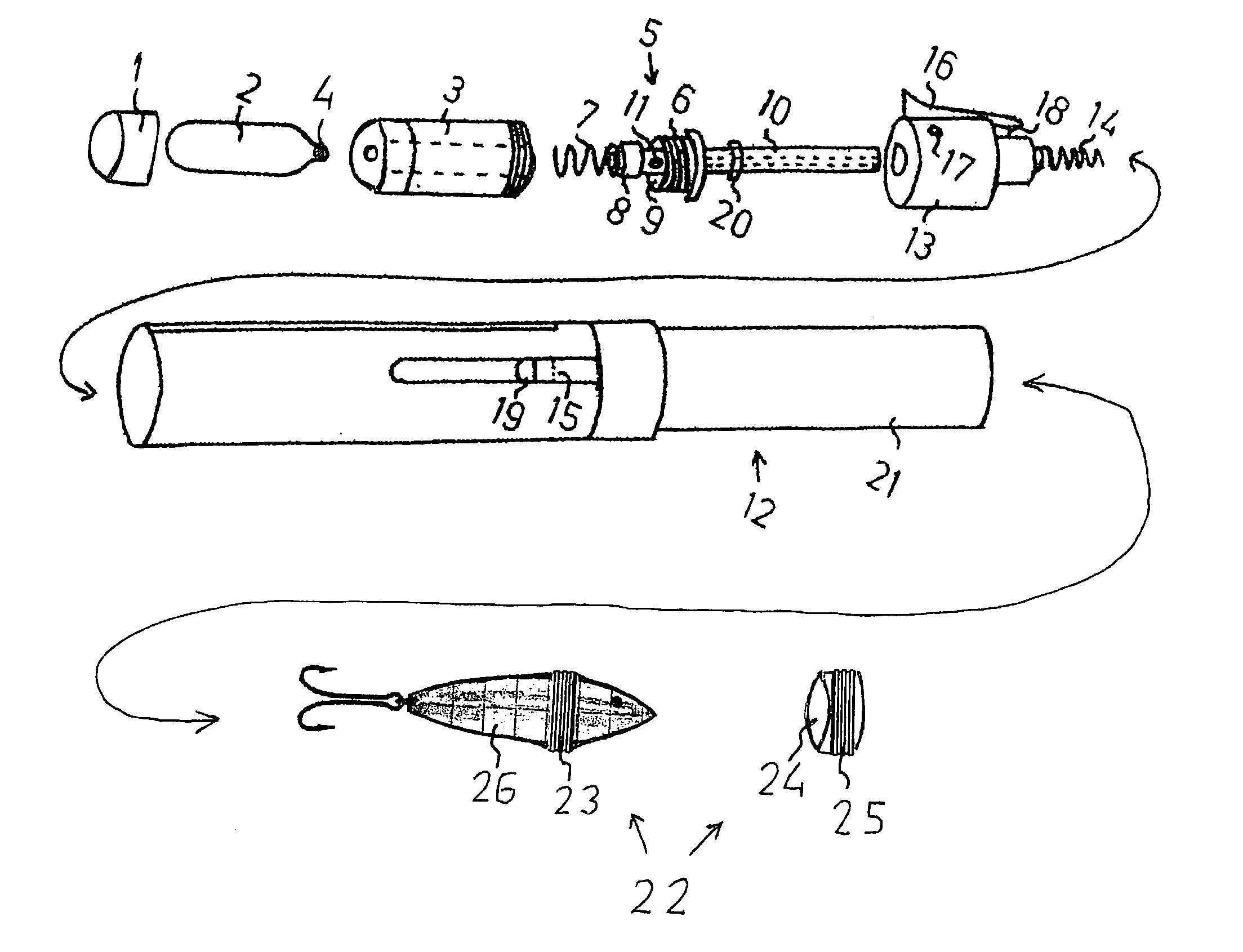

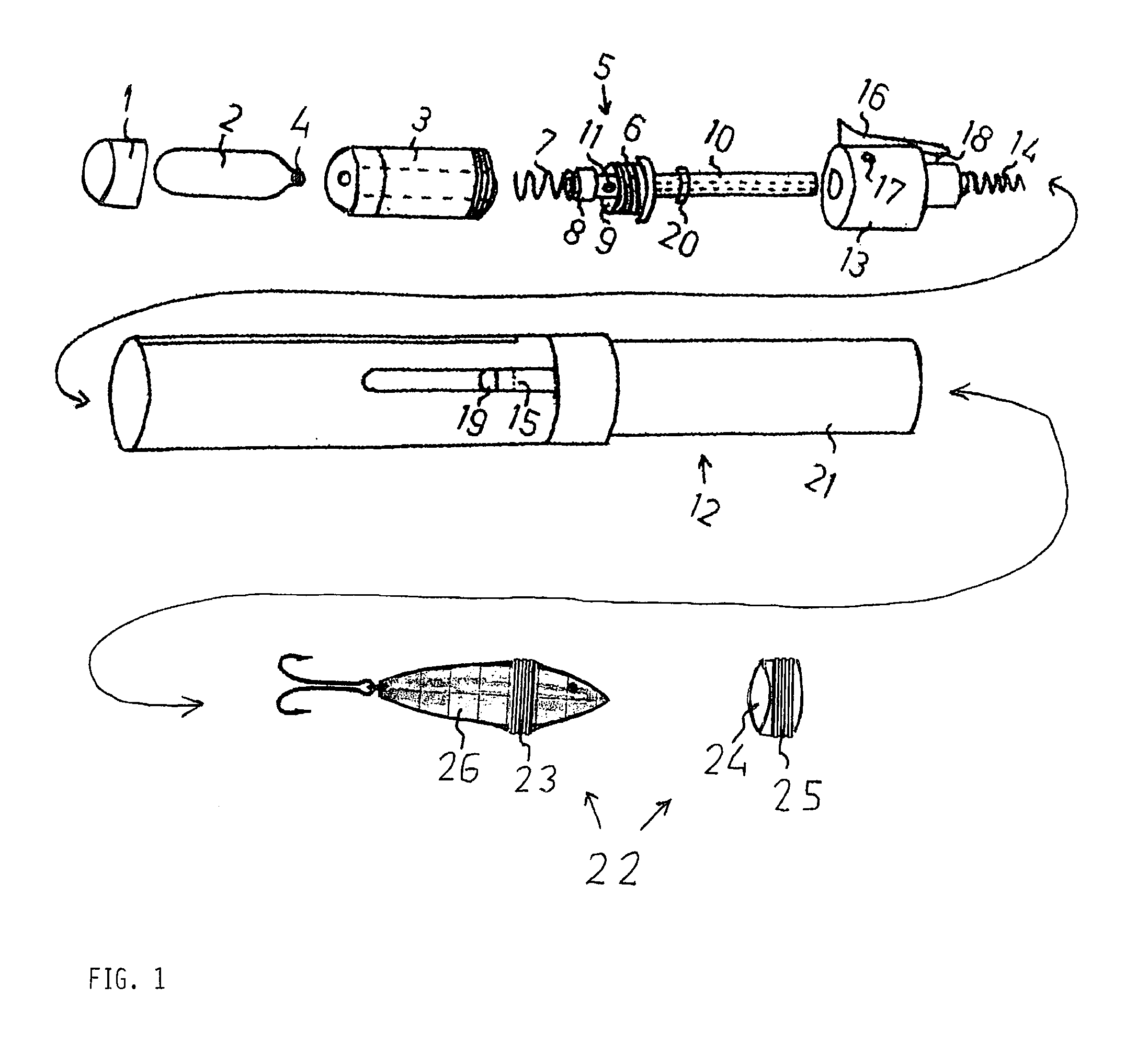

Device for fishing object ejection

InactiveUS20150230445A1Optimize energy usageImprove accuracyLinesCompressed gas gunsFishingEnergy source

Device for ejection of a fishing object is presented, comprising a launch tube (21), a fishing object (22) adapted to be placed in the launch tube (21) and an energy source (2) for creating a fluid pressure in the launch tube (21) and thereby ejecting the fishing object through the launch tube (21), where the fishing object is equipped with a sealing cross-section (23.25) for sealing against launch tube.

Owner:FOTLAND ARWE

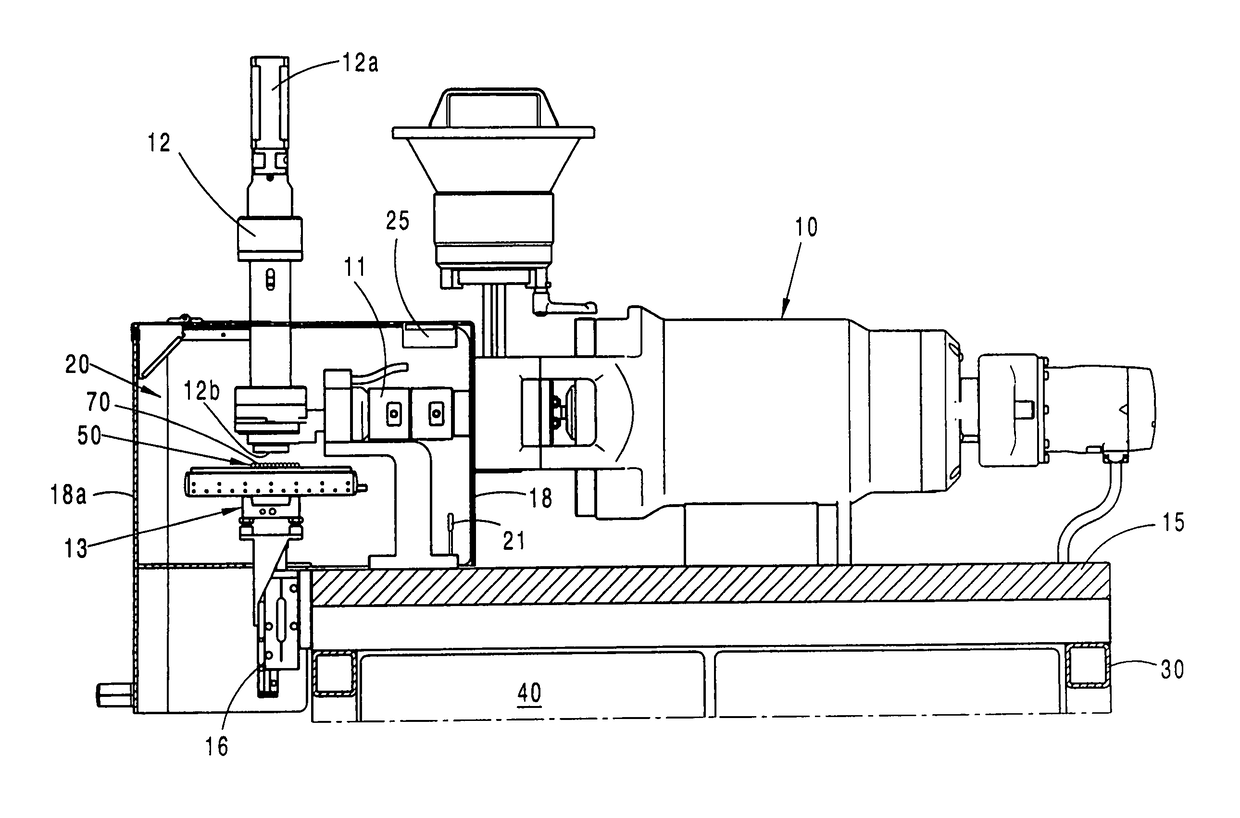

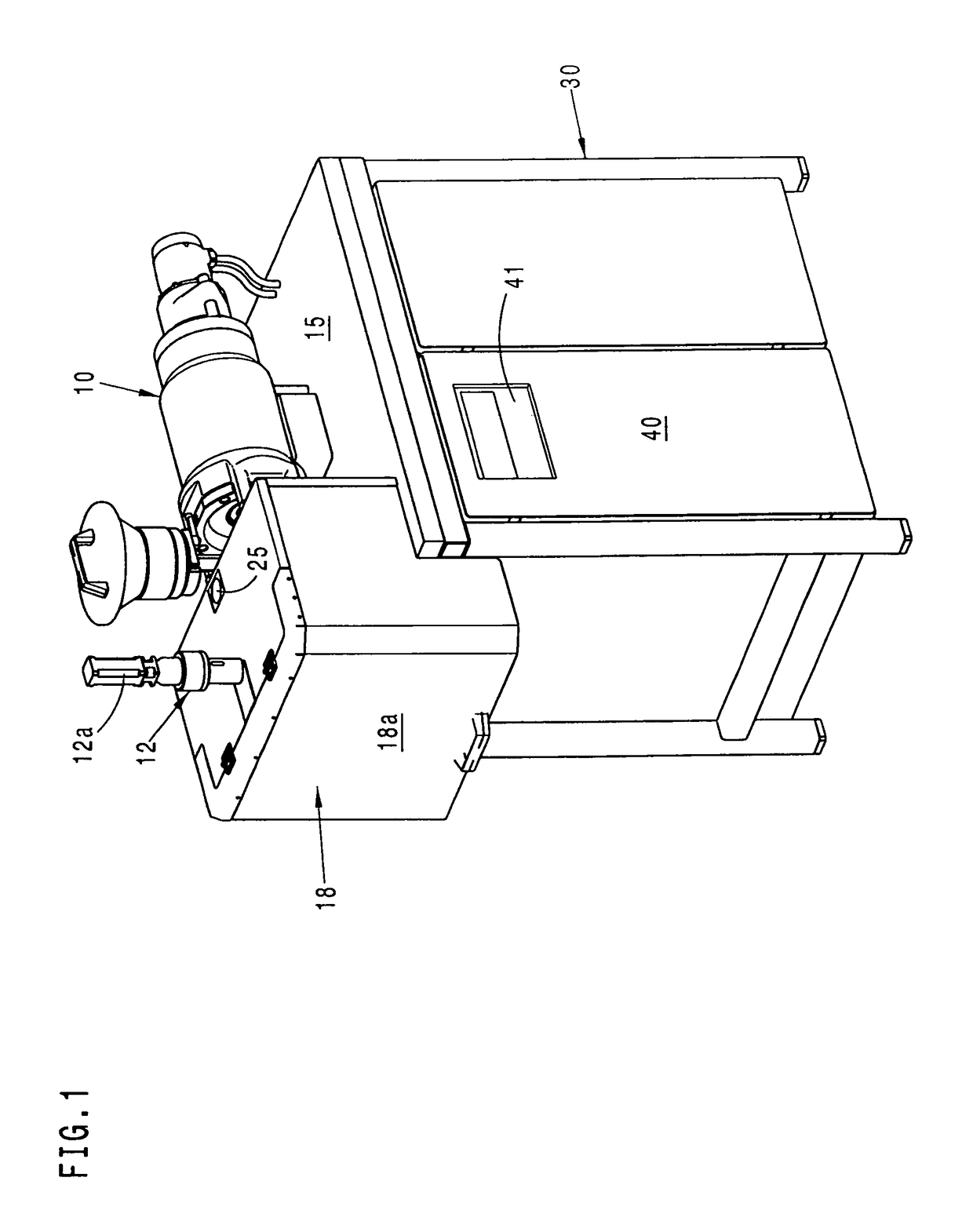

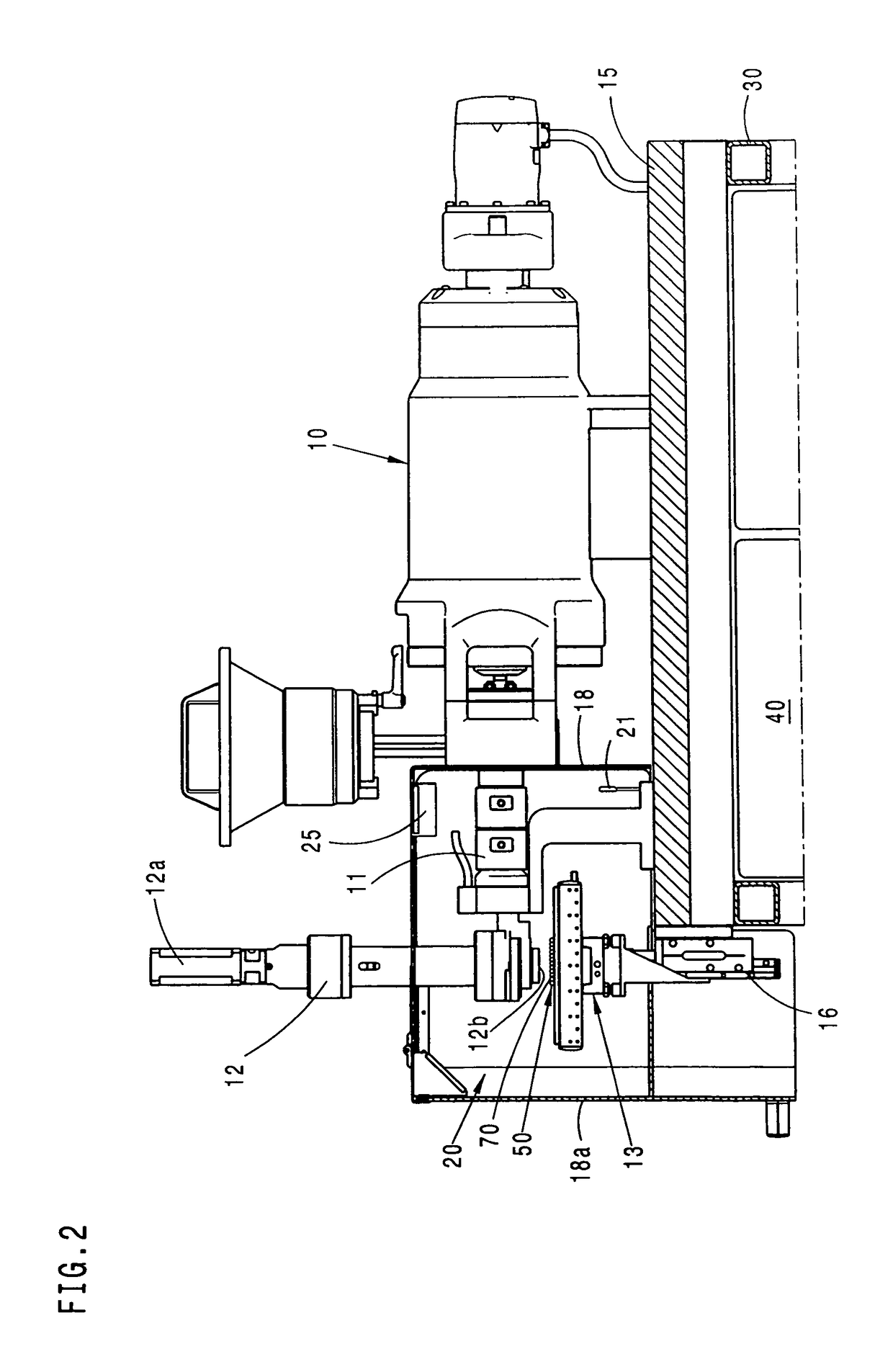

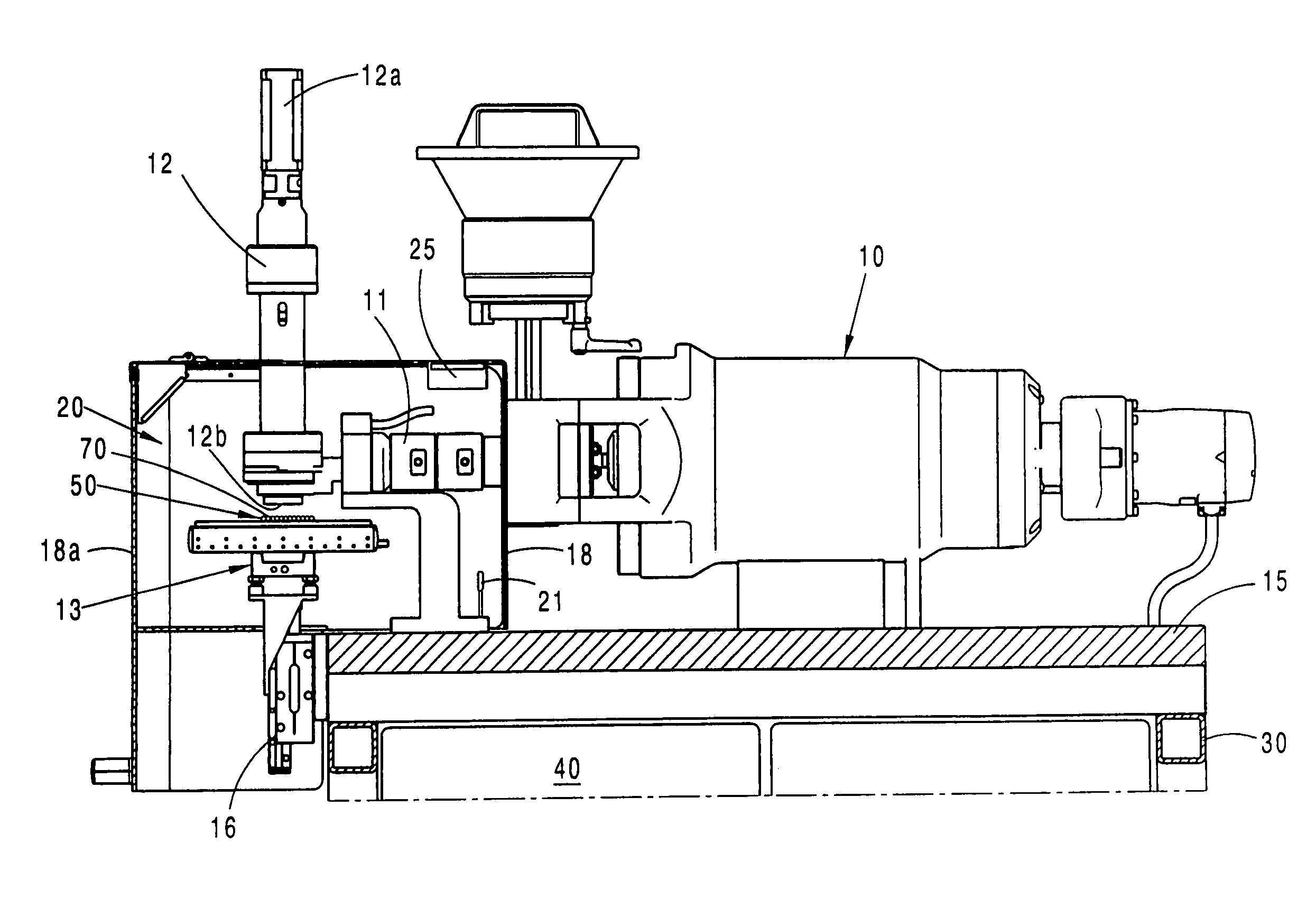

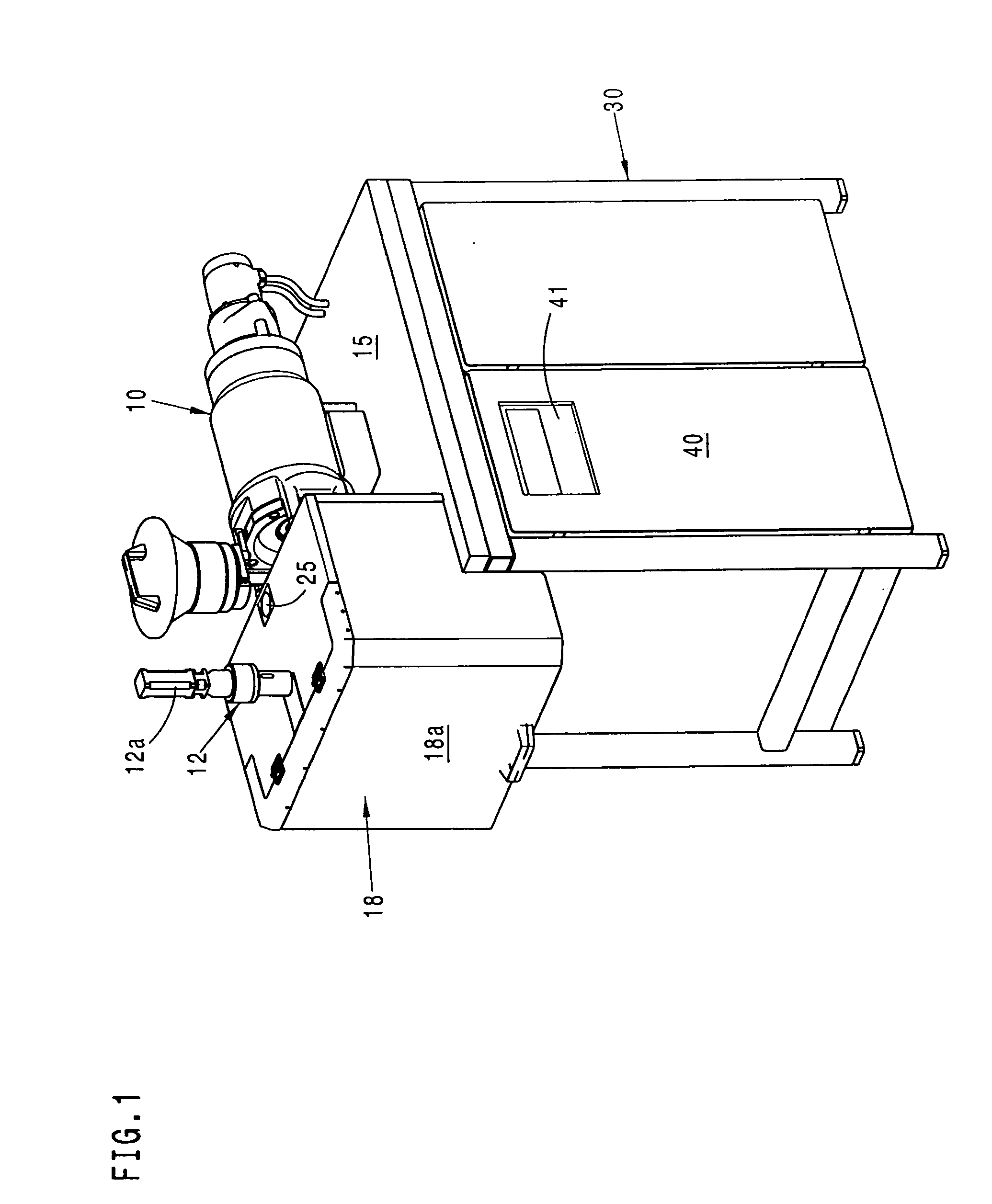

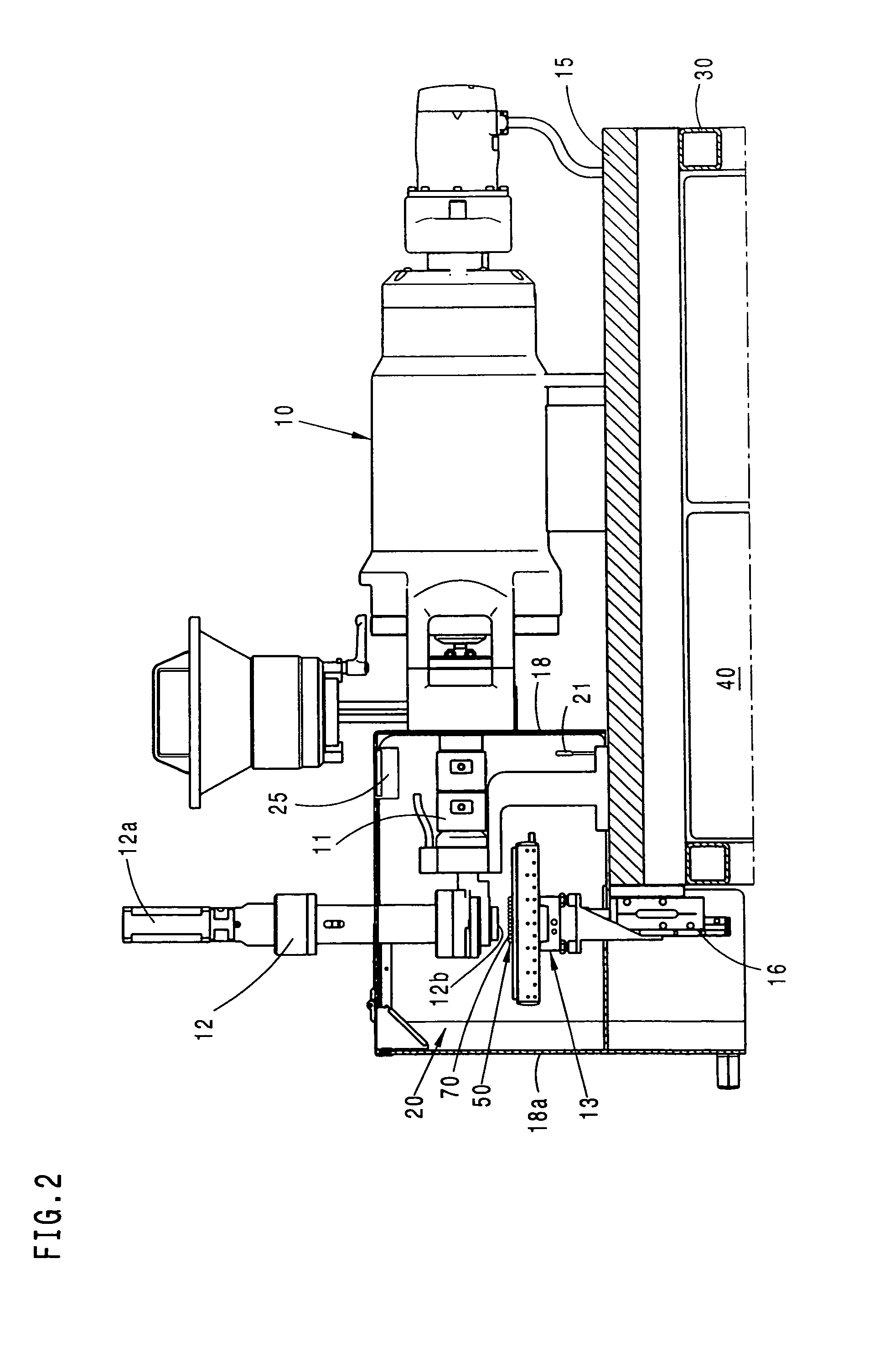

Device for the production of a three-dimensional object

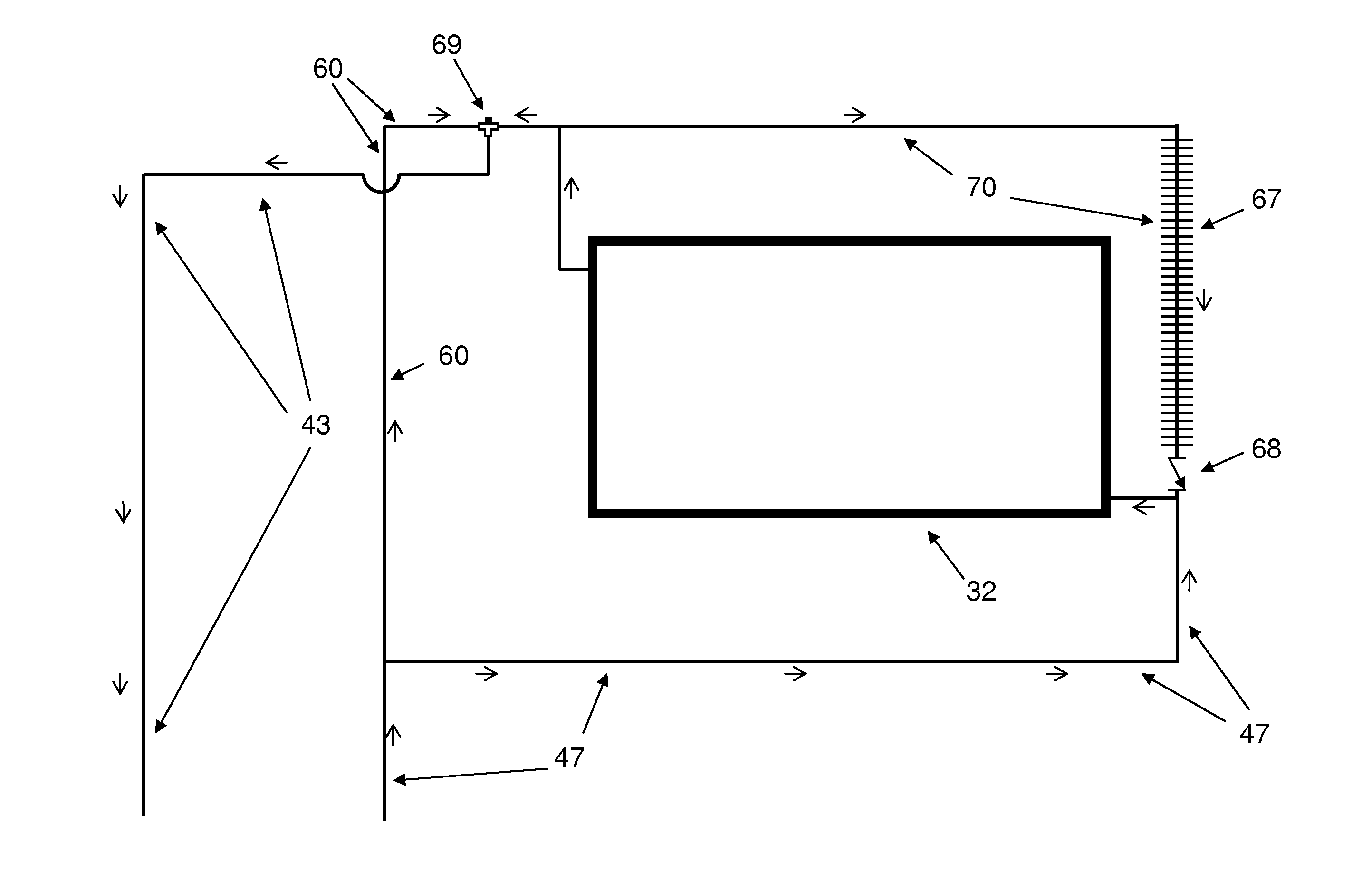

ActiveUS9889604B2Avoid flowOptimize energy usageManufacturing heating elements3D object support structuresTemperature controlFluid phase

A device for producing a three-dimensional object from hardenable material has a construction space (20) for constructing the object (50), a temperature control unit for controlling the temperature of the construction space (20), and a preparation unit (11) for preparing the hardenable material in such a way that the material is in the fluid phase. A pressure generation unit (10) applies pressure to the fluid phase in the preparation unit. A discharge unit (12) is provided for discharging the hardenable material through an outlet (12b) in the form of drops in the direction of the construction space (20). In order to optimize the energy required to control the temperature that promotes bonding of the material on the object (50), the temperature-controlled construction space (20) is surrounded by a construction space frame (18) in which at least the outlet of the discharge unit (12), the preparation unit (11), and the object support (13) for producing the object are accommodated.

Owner:ARBURG GMBH & CO KG

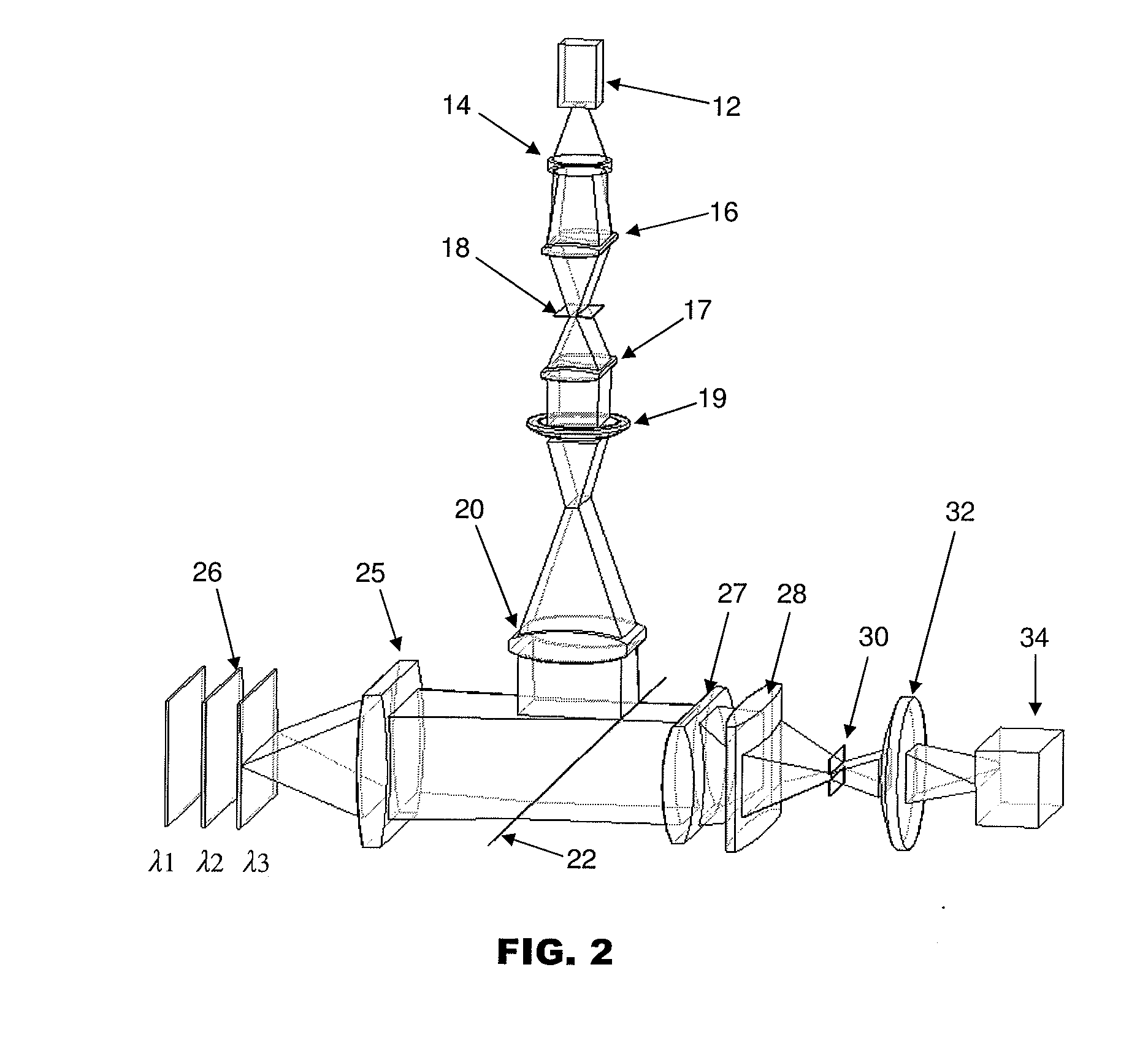

Chromatic confocal scanning apparatus

ActiveUS8654352B1Expand field of viewOptimize energy usageUsing optical meansMicroscopesLength waveColor sensor

A chromatic confocal scanning apparatus comprises a light source for producing light rays comprising a plurality of wavelengths, a first screen having an open elongated slit which allows a strip of light rays produced from the light source to pass through the slit and a cylindrical objective lens both to converge the light rays onto an object surface that is to be measured, and to image light rays reflected from the object surface. An intermediate cylindrical lens set converges a strip of light rays imaged from the cylindrical objective lens to pass through an open elongated slit comprised in a second screen, and a color sensor receives light rays which have passed through the slit of the second screen for determining a plurality of wavelengths of the said strip of light rays, to thereby construct a height profile of at least a portion of the object surface.

Owner:ASMPT SINGAPORE PTE LTD

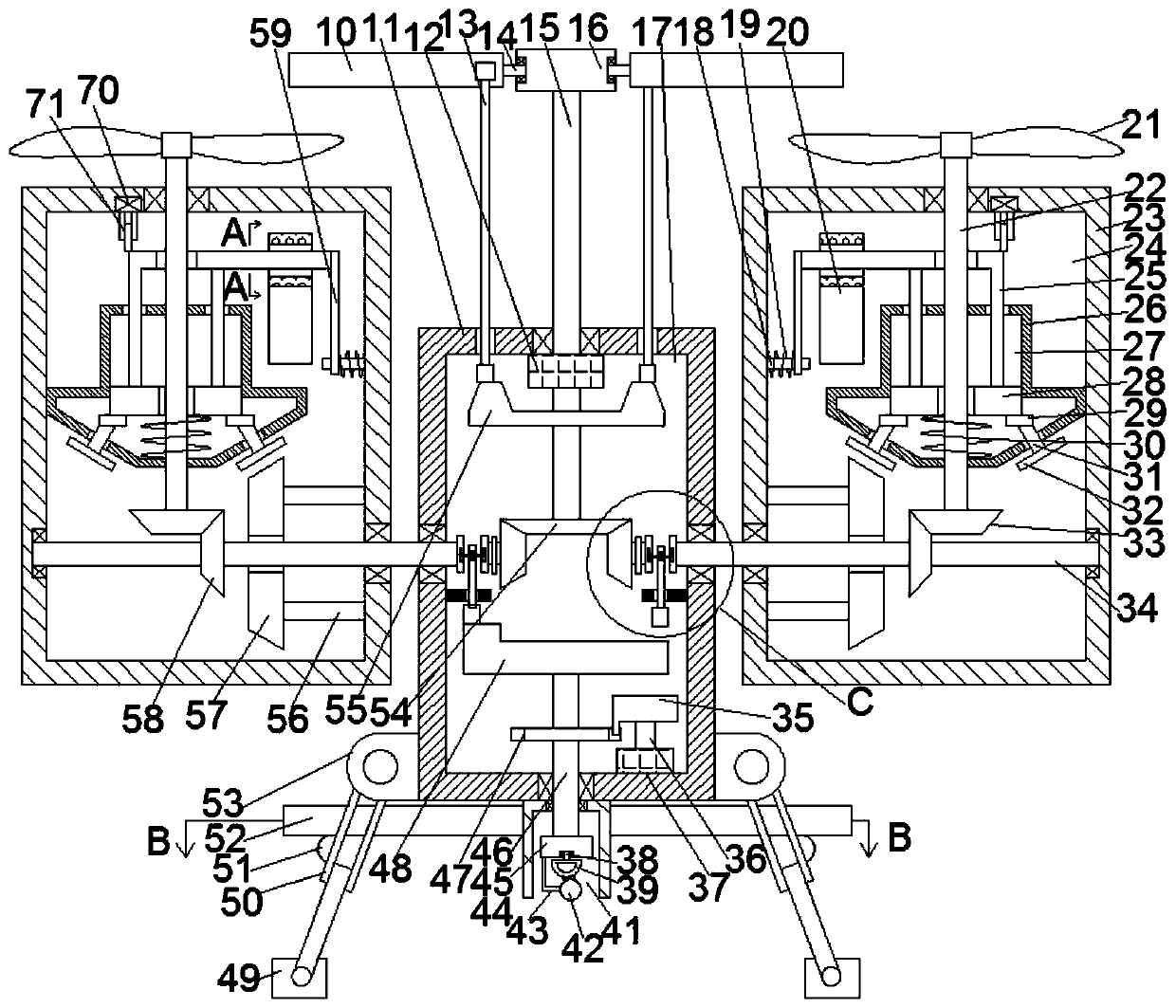

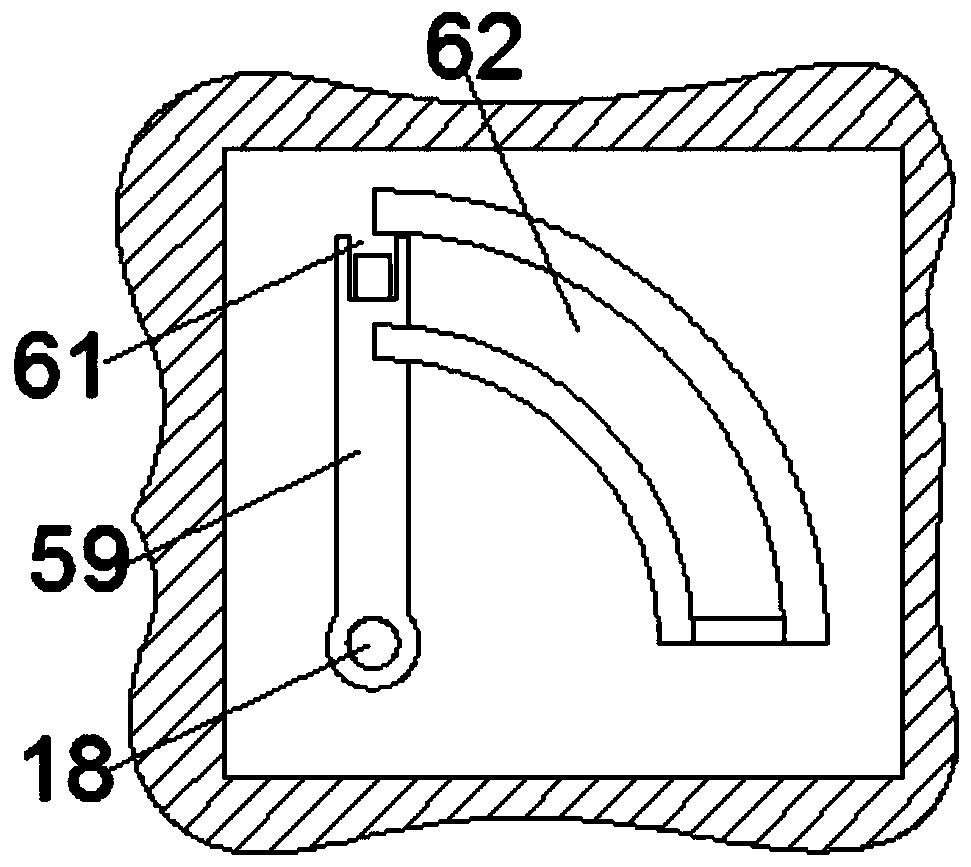

Shooting aircraft

InactiveCN110254718ANot destroyedImprove efficiencyAlighting gearAircraftsFlight vehicleShort radius

The invention discloses a shooting aircraft. The shooting aircraft comprises a power box, the outer sides of the left part and the right part of the power box are provided with symmetrical direction boxes, direction cavities are formed in the direction boxes correspondingly, driven rail components are arranged in the direction cavities, wherein the driven rail components are provided with extending shafts extending leftwards and rightwards and are connected with the power box in a rotating fit manner, reversing devices are arranged in the direction cavities, the direction cavities are controlled by the driven rail components, signal switch components are arranged in the reversing devices, the signal switch components are used for controlling the reversing devices, and when the aircraft needs to be turned, the signal switch components are turned on to enable the reversing devices to be connected with the driven rail components to generate lateral thrust, so that the aircraft can be steered to turn in a shortest radius range. The shooting aircarft is simple in structure and convenient to operate, the turning in the shortest radius range is realized through the circumferential lateral thrust, and a camera rotates at the same time, so that the picture shooting is stable.

Owner:ANHUI YINUOQINGCHUN IND DESIGN CO LTD

Digital hydraulic system

InactiveUS20130061946A1Optimize energy usageMost efficientValve arrangementsFluid-pressure convertersControl systemMechanical engineering

A digital hydraulic system including a fluid having three portions each at a pressure and a digital hydraulic transformer having a first and second element. The first element has a first end and a second end. The first and second elements operating along a common axis, and together defining at least four variable volume working chambers. The at least two of the at least four variable volume working chambers containing fluid directing force on the second element in a direction toward the first end. Another two of the at least four variable volume working chambers containing fluid directing force on the second element toward the second end. A control system individually selectively fluidically connects and disconnects each of the four variable volume working chambers to and from the three portions of the fluid at the three pressures.

Owner:DIGITAL HYDRAULICS

Device for the production of a three-dimensional object

ActiveUS20140113017A1Avoid flowOptimize energy usageManufacturing heating elementsAuxillary shaping apparatusTemperature controlPressure generation

A device for producing a three-dimensional object from hardenable material has a construction space (20) for constructing the object (50), a temperature control unit for controlling the temperature of the construction space (20), and a preparation unit (11) for preparing the hardenable material in such a way that the material is in the fluid phase. A pressure generation unit (10) applies pressure to the fluid phase in the preparation unit. A discharge unit (12) is provided for discharging the hardenable material through an outlet (12b) in the form of drops in the direction of the construction space (20). In order to optimize the energy required to control the temperature that promotes bonding of the material on the object (50), the temperature-controlled construction space (20) is surrounded by a construction space frame (18) in which at least the outlet of the discharge unit (12), the preparation unit (11), and the object support (13) for producing the object are accommodated.

Owner:ARBURG GMBH & CO KG

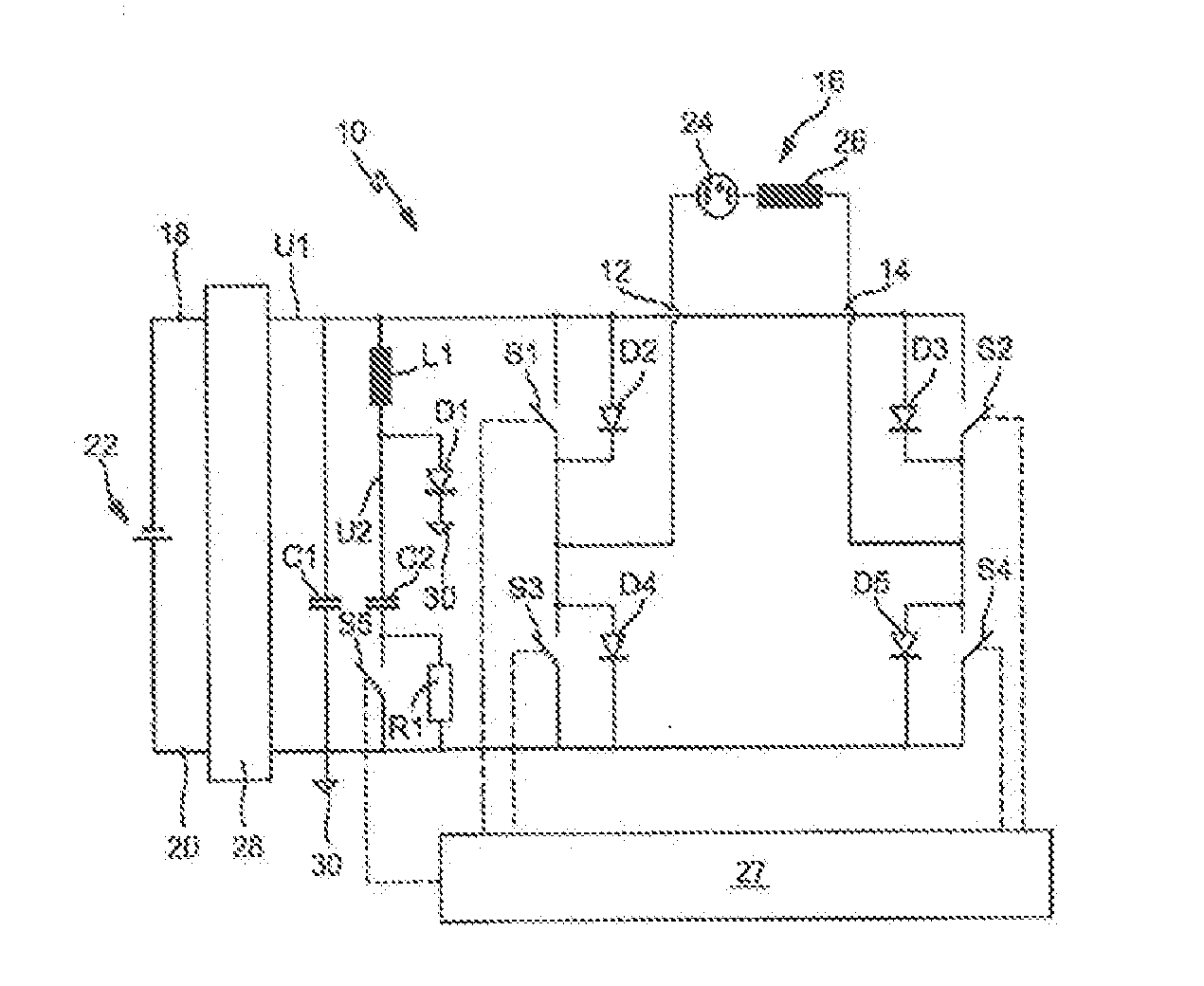

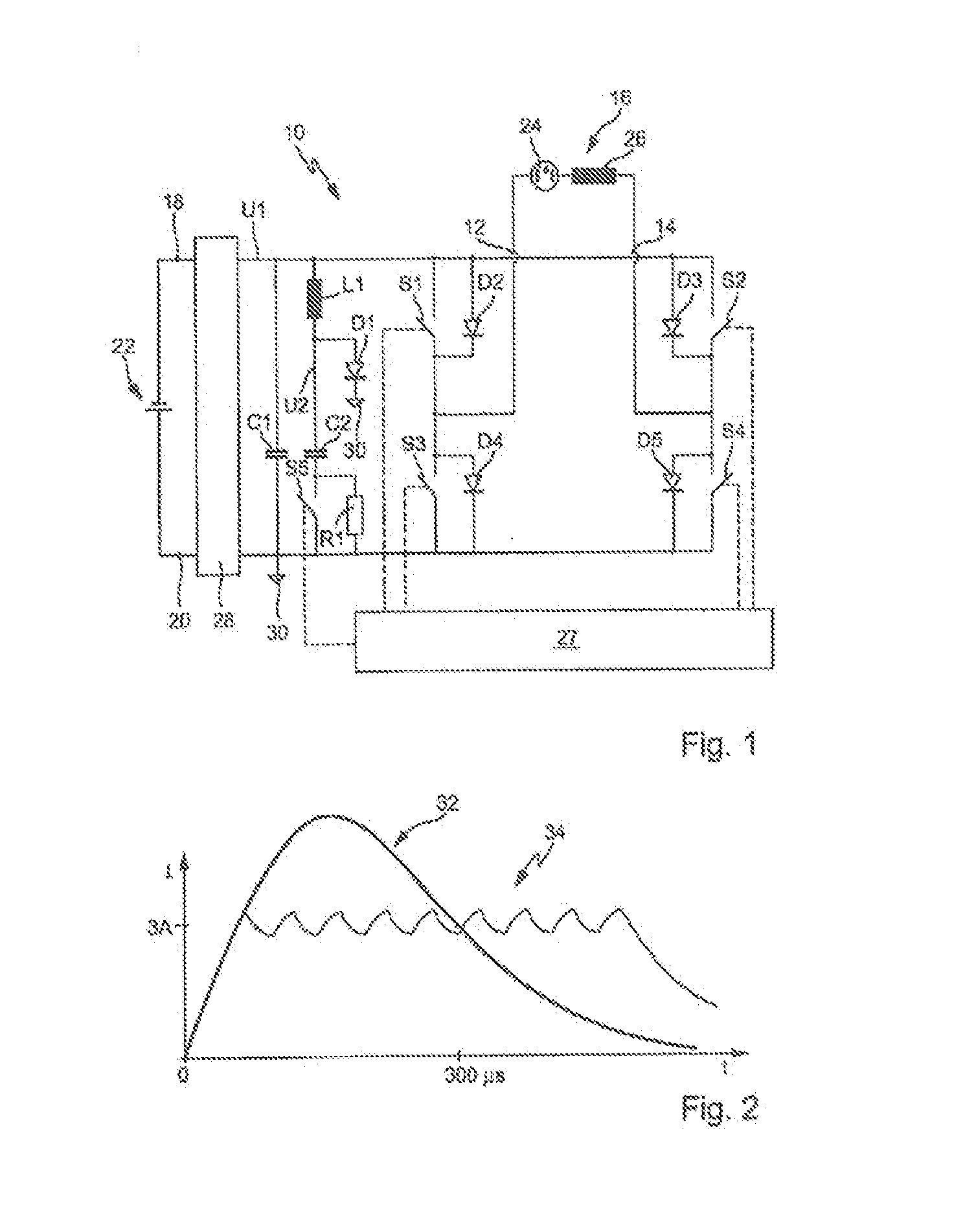

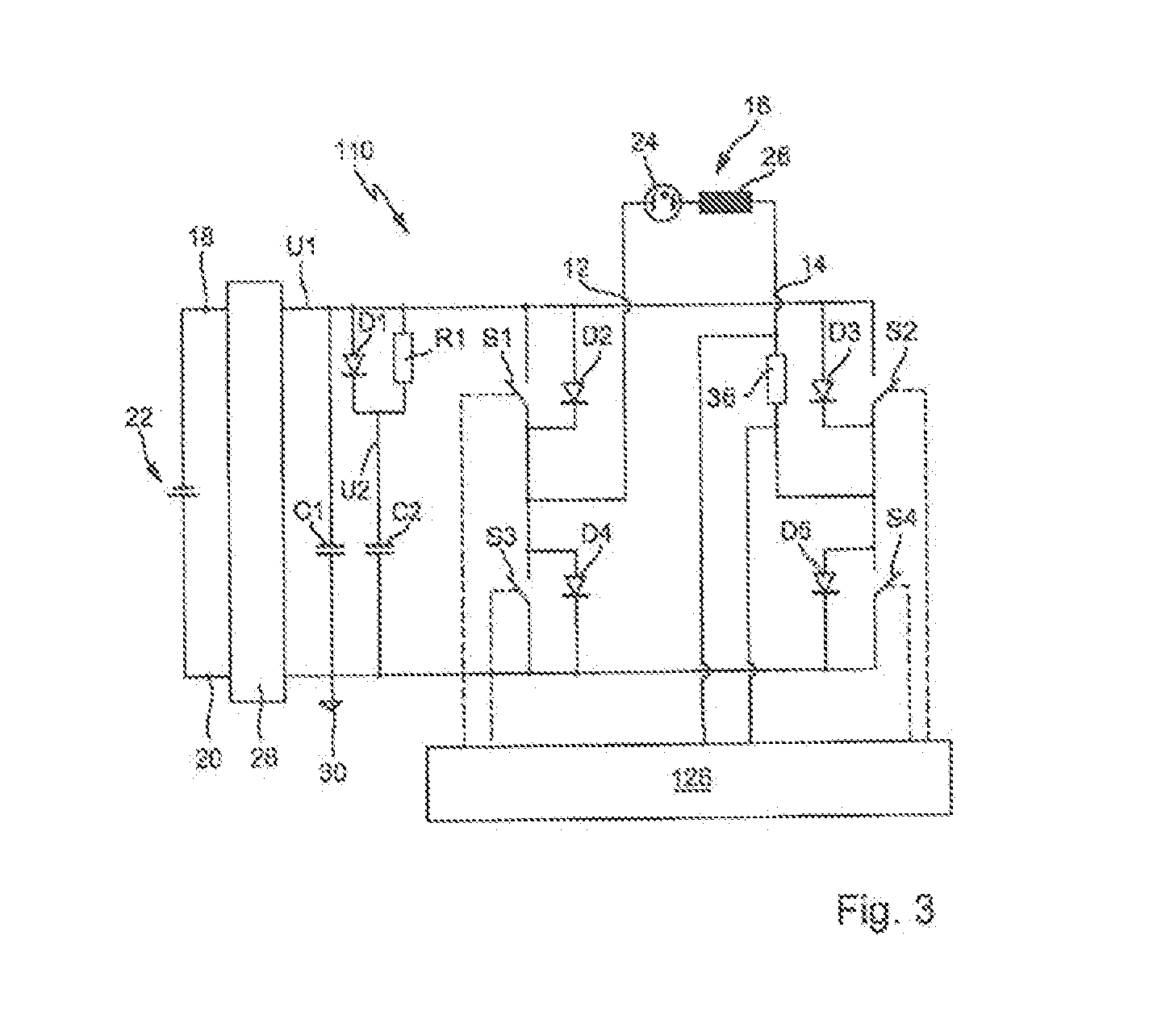

Method and control circuit for starting a gas-discharge lamp

ActiveUS20130214694A1Significant portionLow thermalElectrical apparatusElectric light circuit arrangementInductorElectric arc

A method operates a gas-discharge lamp (16) in a transition from a “deactivated” state without an electric arc to a stable “light-generating” state. The method comprises steps of discharging a booster capacitor (C2) in an “acquisition” phase following an ignition-voltage impulse via a current path that conducts a current flowing through the gas-discharge lamp (16) and in which an inductor (L1) having at least one switch (S5) lies in series and cyclically discharging the booster capacitor (C2) by a repeated alternating closing and opening of the switch (S5).

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

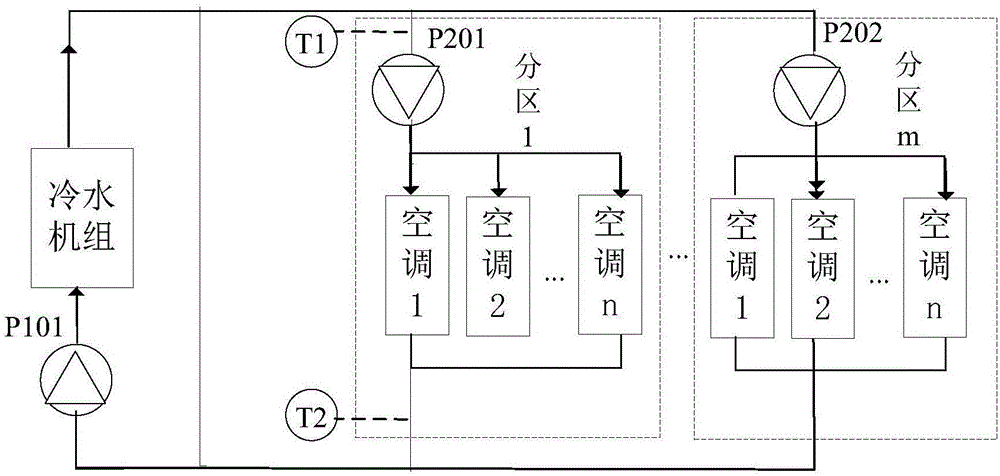

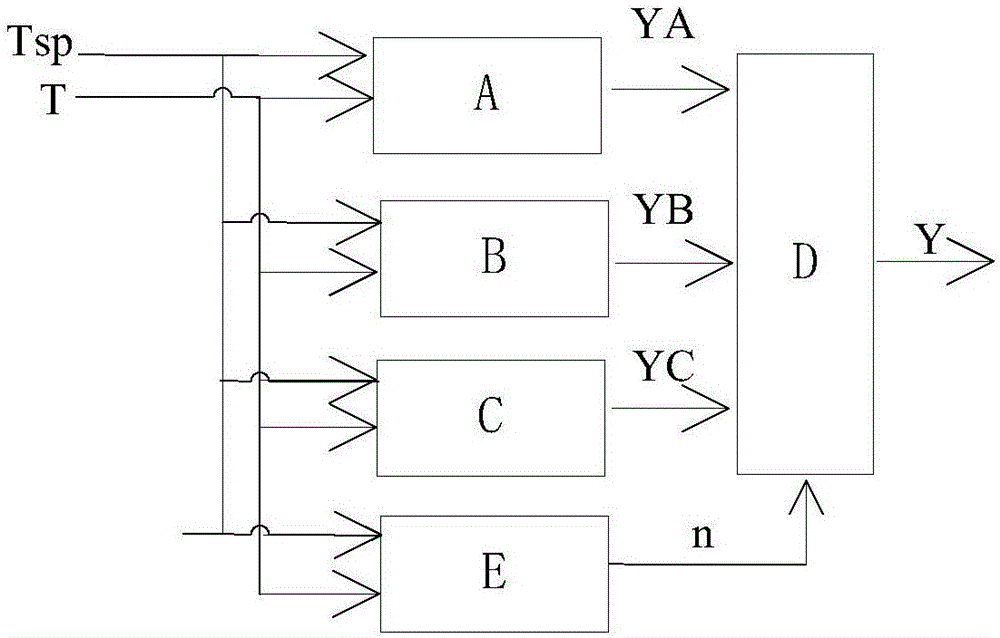

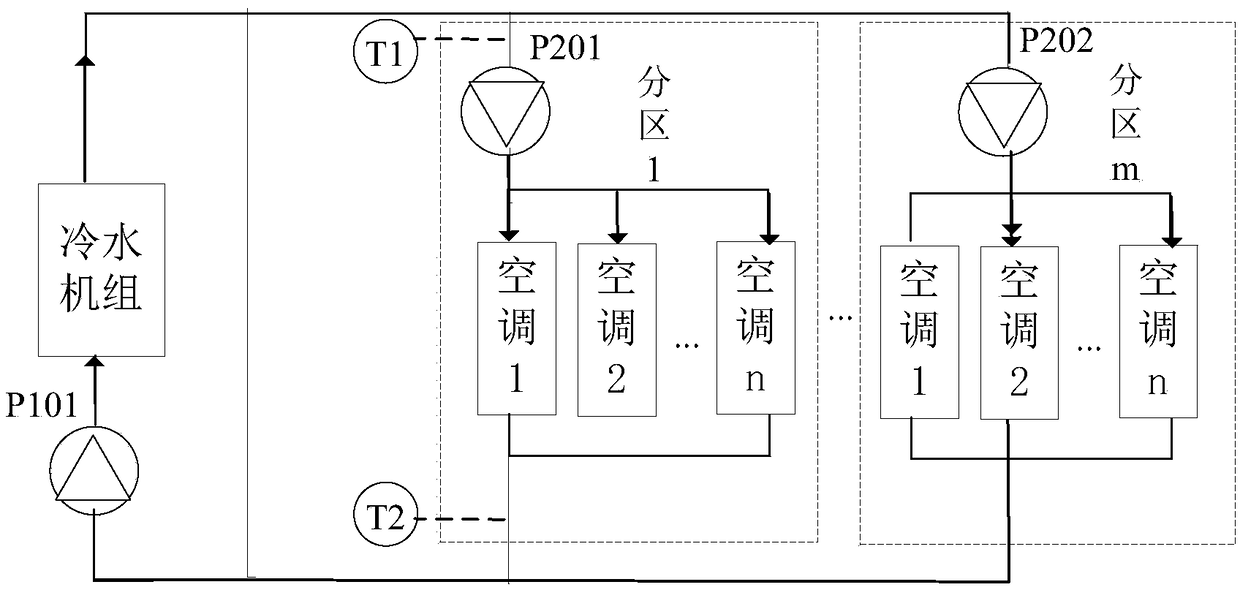

Water supply temperature-variable control system based on tail end comfort level

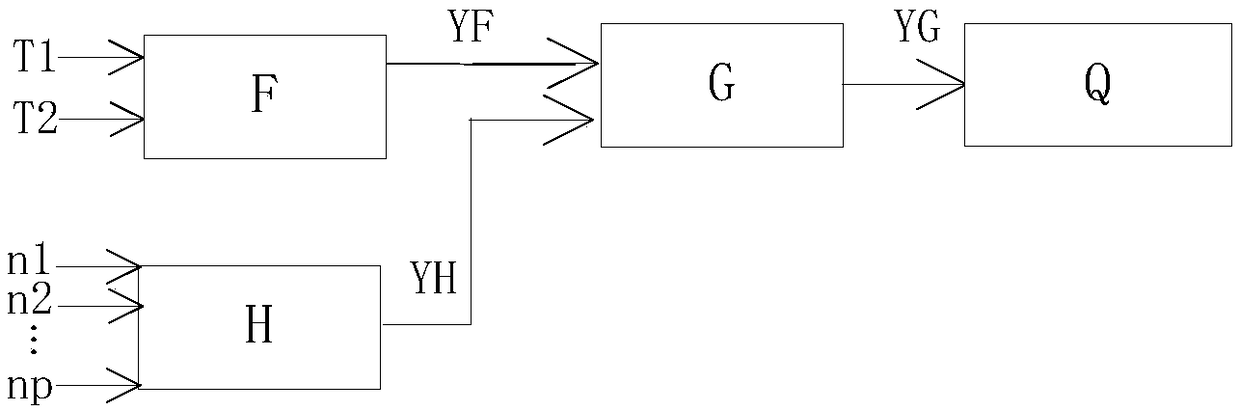

ActiveCN106765955AMake up for the defect that the air conditioner terminal information is not consideredGuaranteed comfortMechanical apparatusSpace heating and ventilation safety systemsTemperature controlControl system

The invention discloses a water supply temperature-variable control system based on tail end comfort level and relates to the technical field of air conditioners. The water supply temperature-variable control system is used for solving the problem that a large-scale multi-zone air-conditioning system is difficult to meet the requirements of all the zones for the comfort level in all the time periods by adopting a traditional zone temperature control system or the energy waste exists. The water supply temperature-variable control system comprises a load rate calculator, a draining water temperature setter, an over-temperature room rate calculator, an over-temperature room rate controller, a plurality of temperature control systems, a gain feature averaging calculator, a gain controller, a draining water temperature calculator and a unit controller. The water supply temperature-variable control system provided by the invention is applied to a central air conditioner.

Owner:XINZHI ENERGY SYST CONTROL

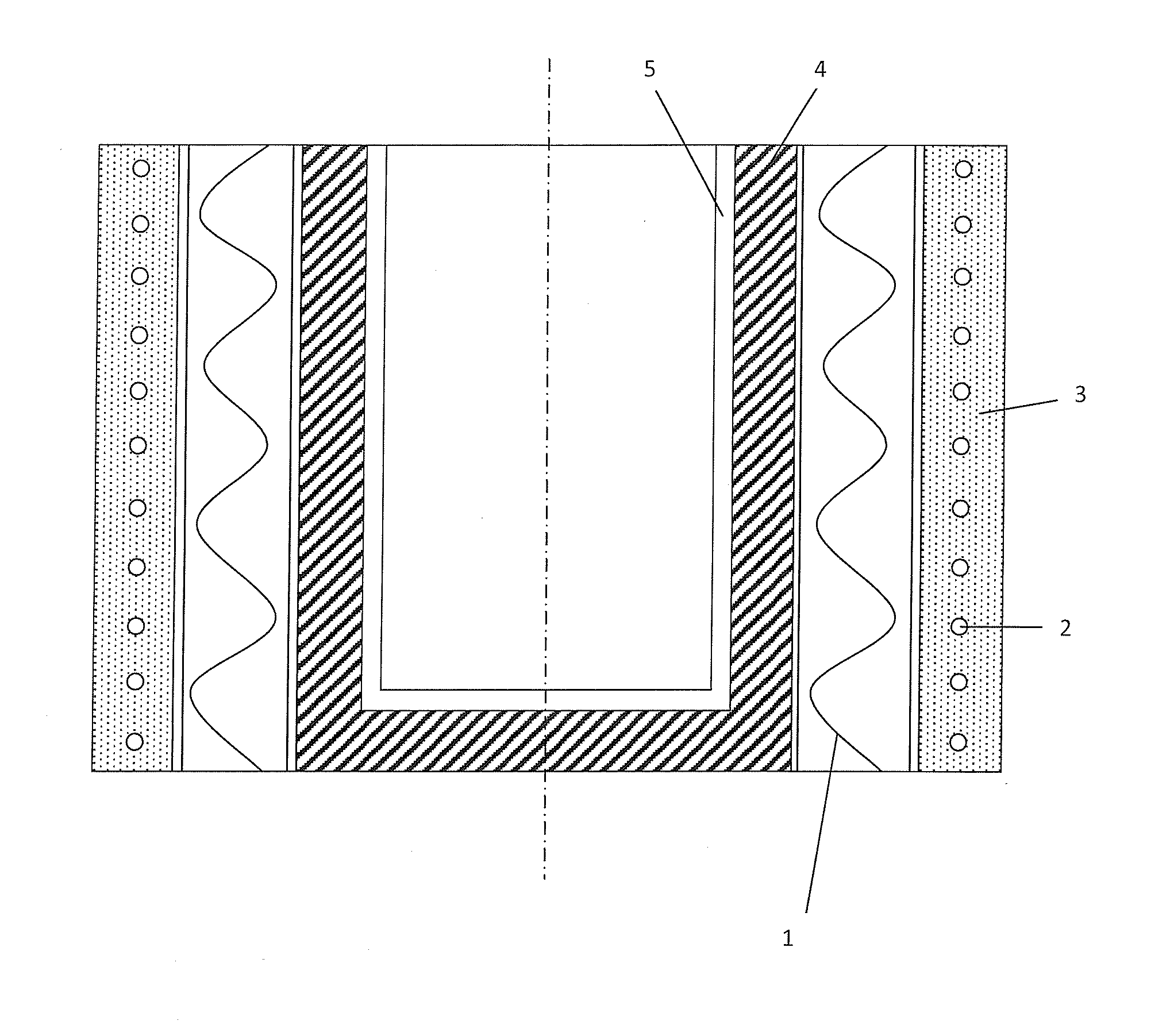

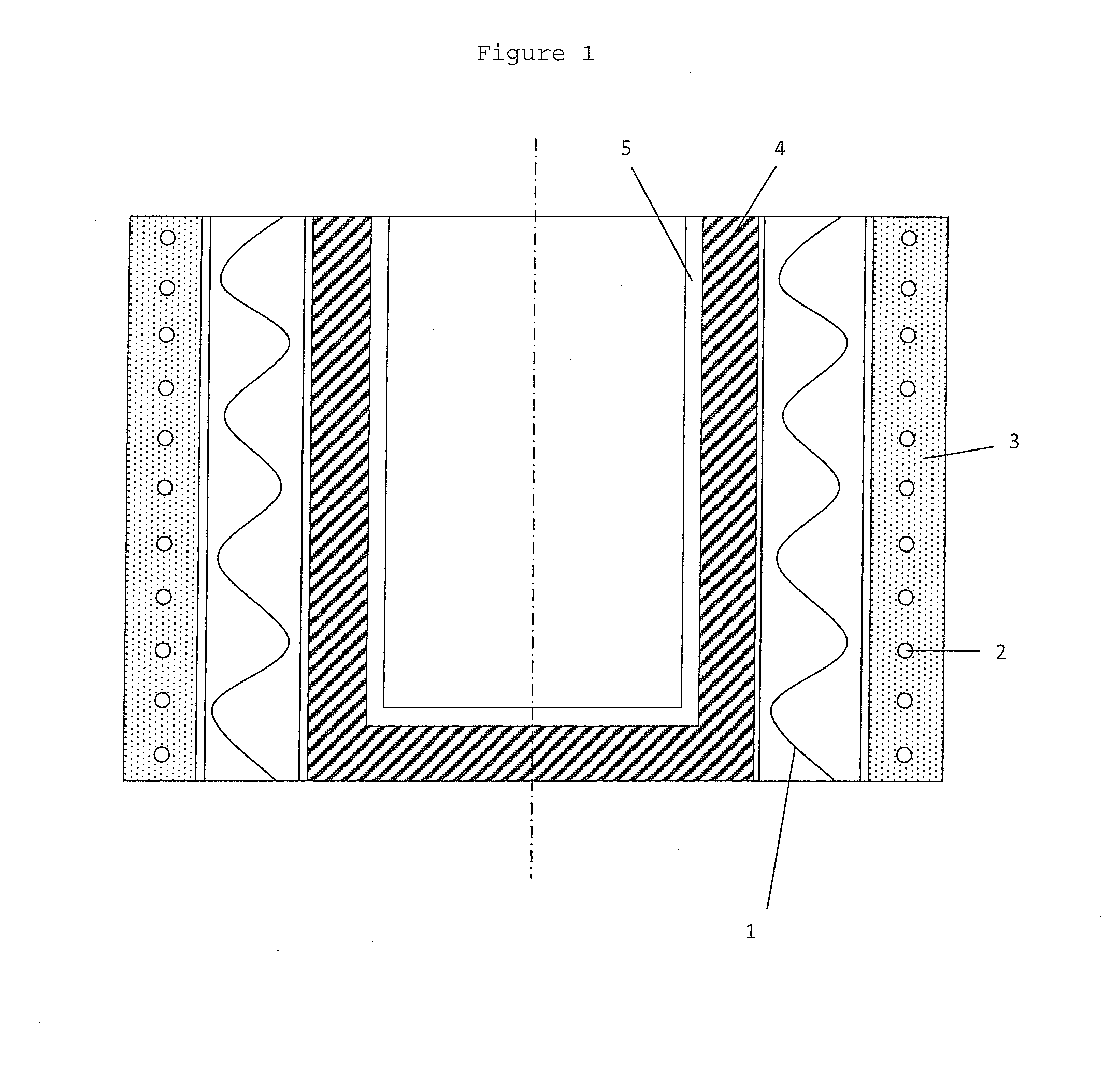

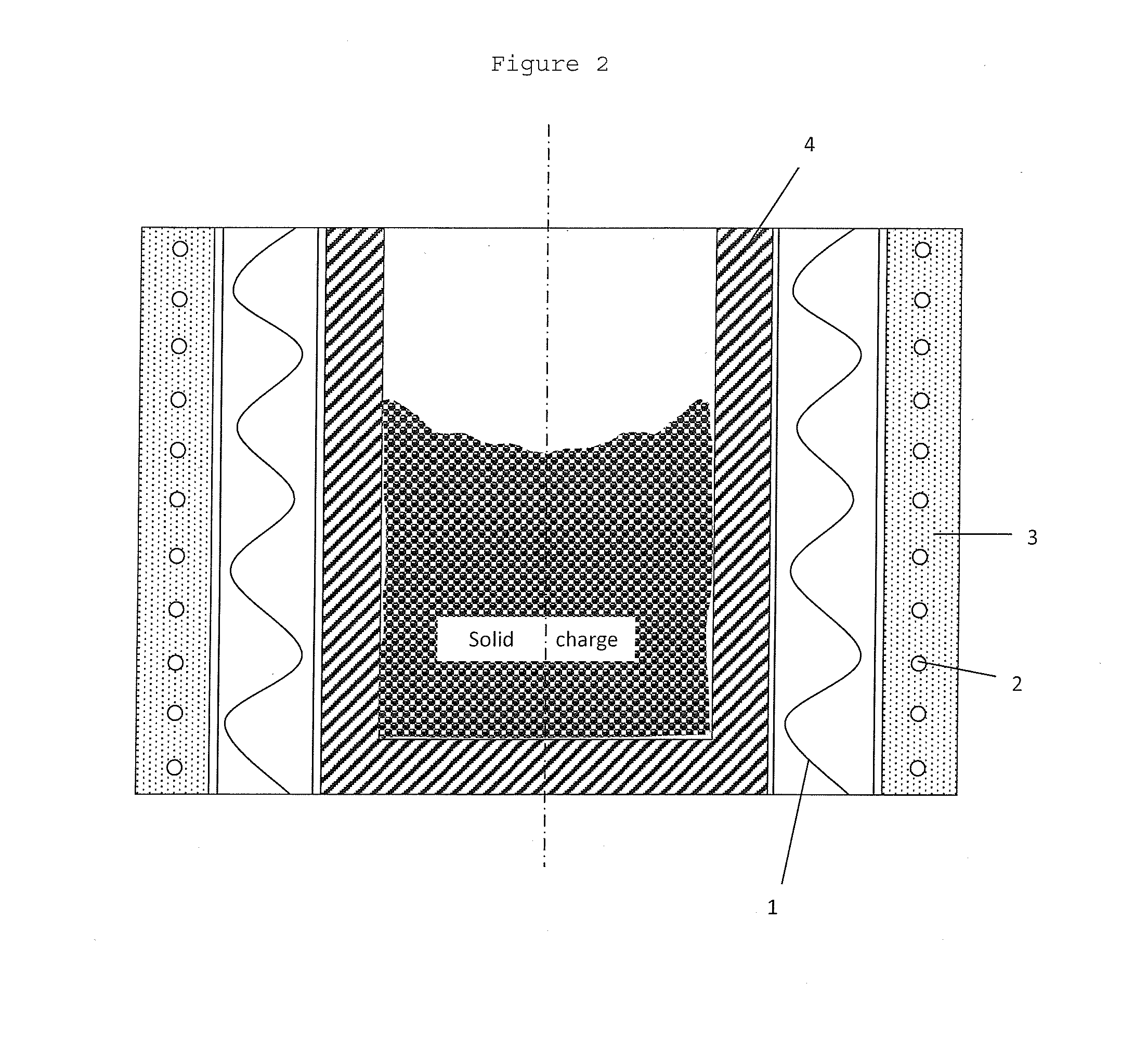

Induction furnace for melting of metals, lining for an induction furnace and method for production of such lining.

InactiveUS20120205829A1Promote exchangeImprove conductivityFurnaces without endless coreLinings repairMolten stateGraphite

Owner:ELKEM CARBON

Over-temperature protection for flowing fluid systems

InactiveUS9110477B2Prevent overcoolingTemperature controlSolar heating energyTemperature control without auxillary powerThermal energyEngineering

Owner:WEHNER THOMAS RICHARD

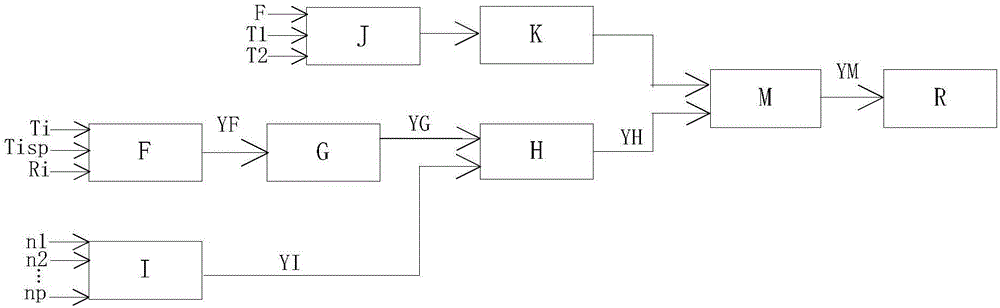

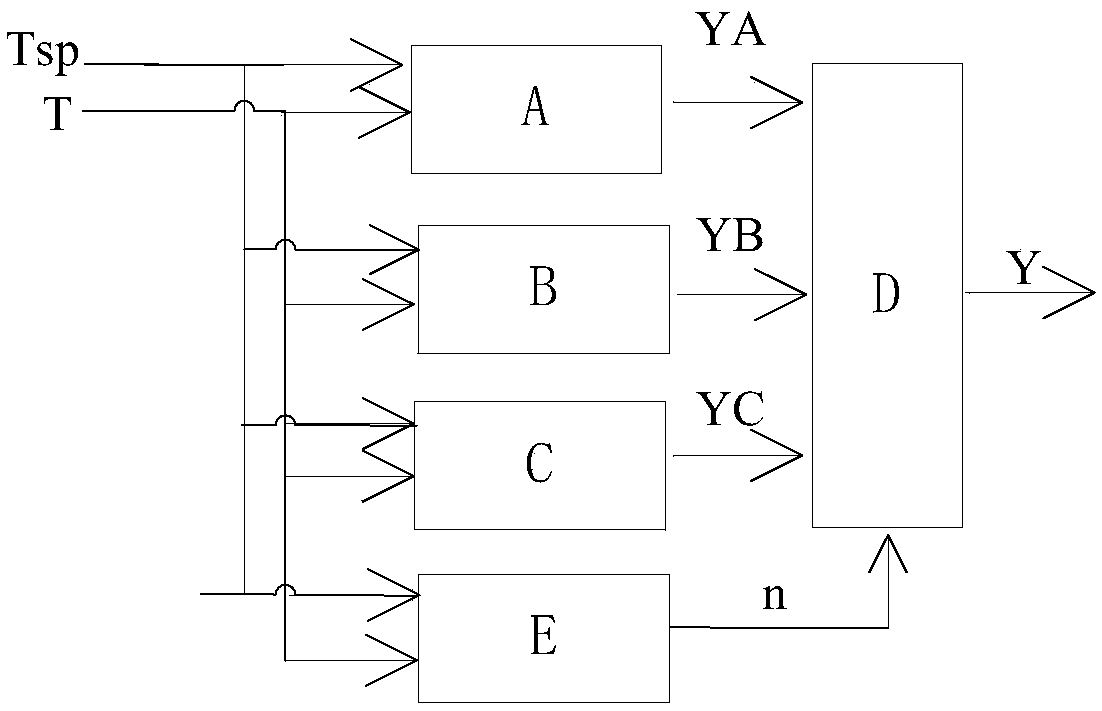

Supply and return water temperature difference control system

ActiveCN106594997BGuaranteed comfortReasonable increase in comfortMechanical apparatusSpace heating and ventilation safety systemsTemperature controlControl system

The invention discloses a control system for temperature difference of supply and return water, relates to the technical field of air conditioners, and is used for solving the problem that energy oversupply is liable to occur, comfort requirements are hard to meet, or temperature difference of supply and return water is hard to effectively control due to the fact that supply water flow adjustment according to temperature difference is delayed. The control system for temperature difference of supply and return water comprises a temperature difference controller, a plurality of temperature control systems, a gain characteristic average computer and a gain controller, wherein the difference of supply water temperature and return water temperature is adopted as a measurement value of the temperature difference controller; the temperature control systems are used for controlling the room temperature; gain characteristic values of the temperature control systems are adopted as input of the gain characteristic average computer; gain characteristic average values are adopted as output of the gain characteristic average computer; output of the temperature difference controller is adopted as a set value of the gain controller; and output of the gain characteristic average computer is adopted as a measurement value of the gain controller. The control system for temperature difference of supply and return water is used for central air conditioning systems.

Owner:XINZHI ENERGY SYST CONTROL

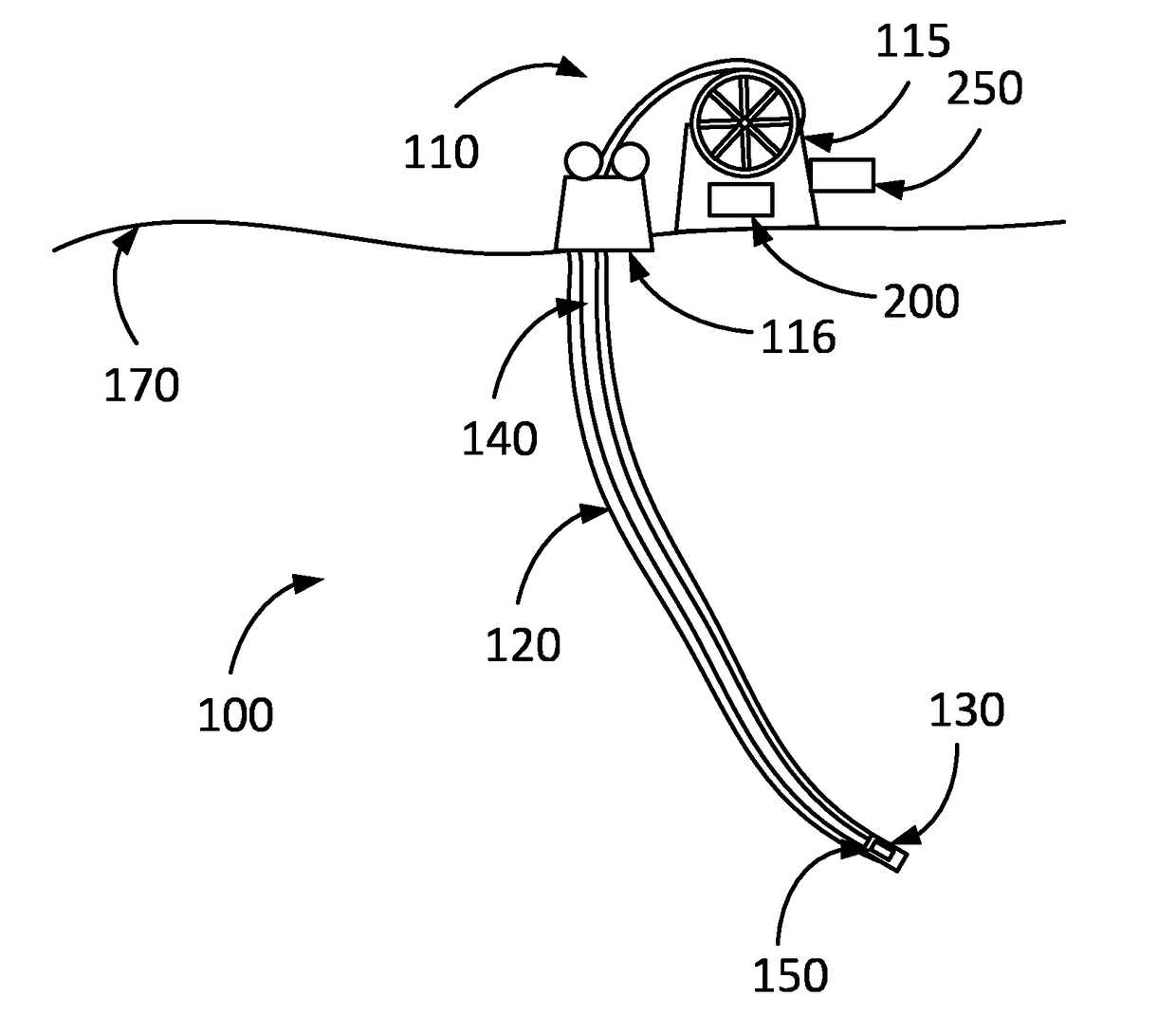

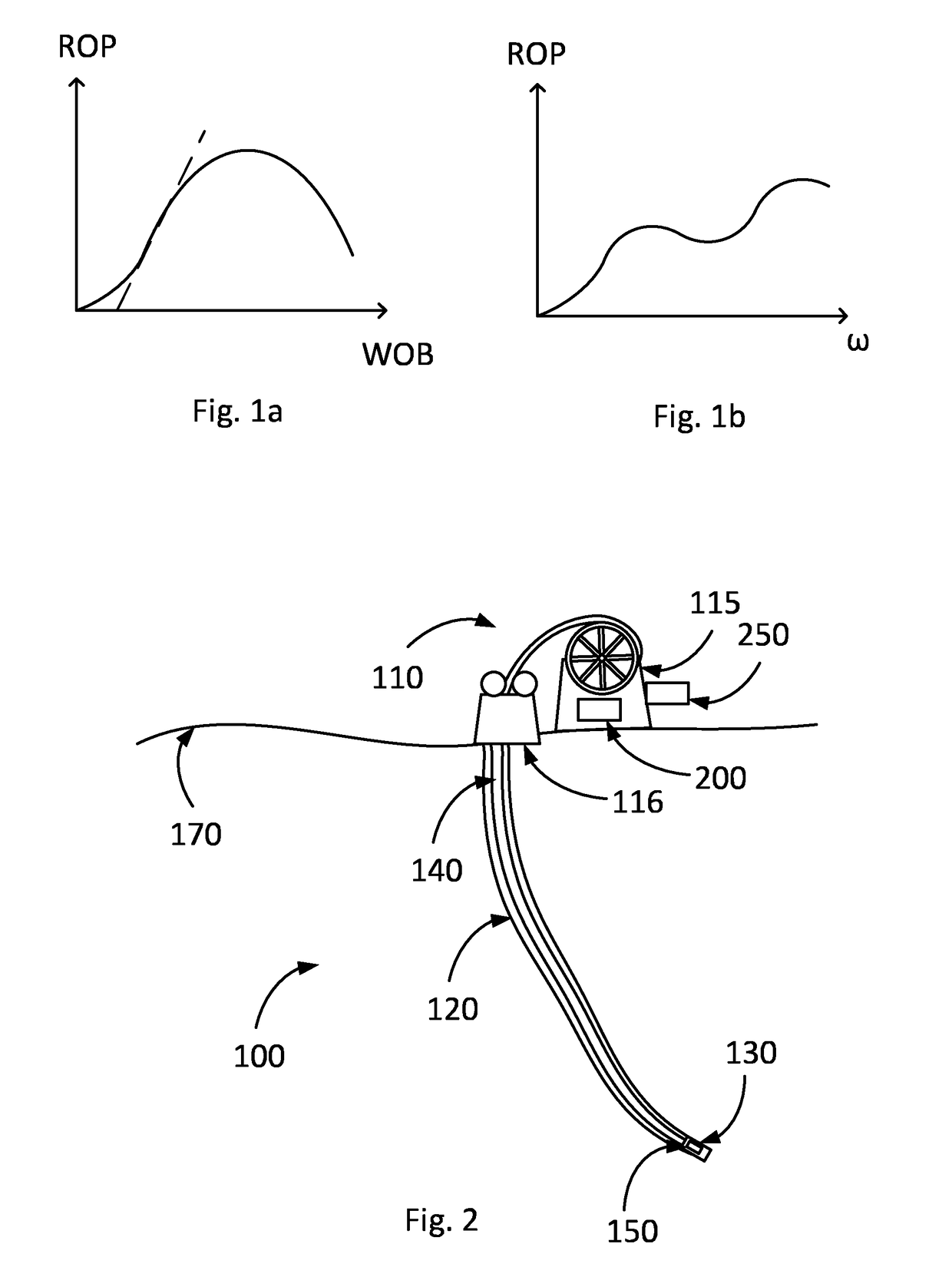

A method and a system for optimising energy usage at a drilling arrangement

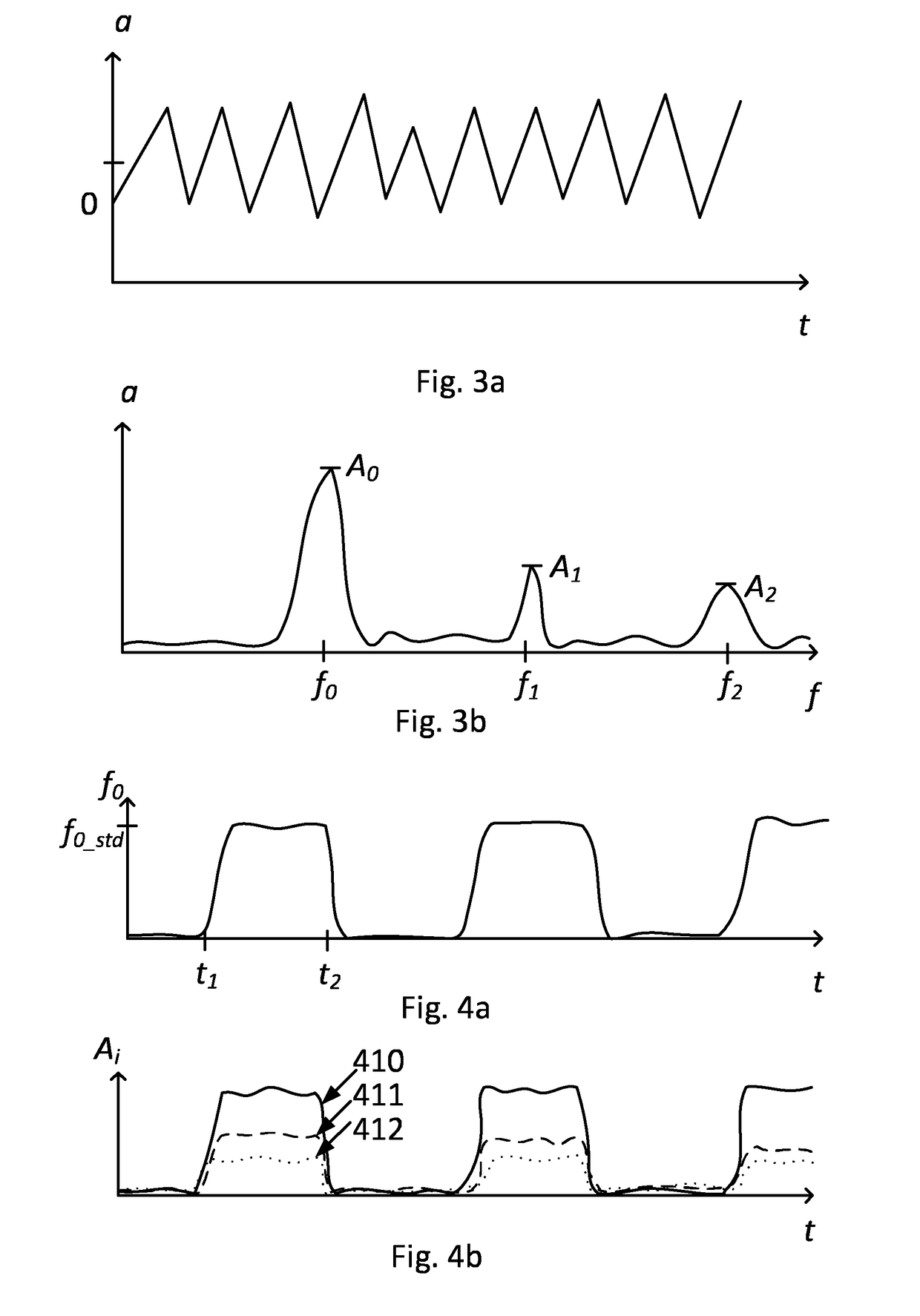

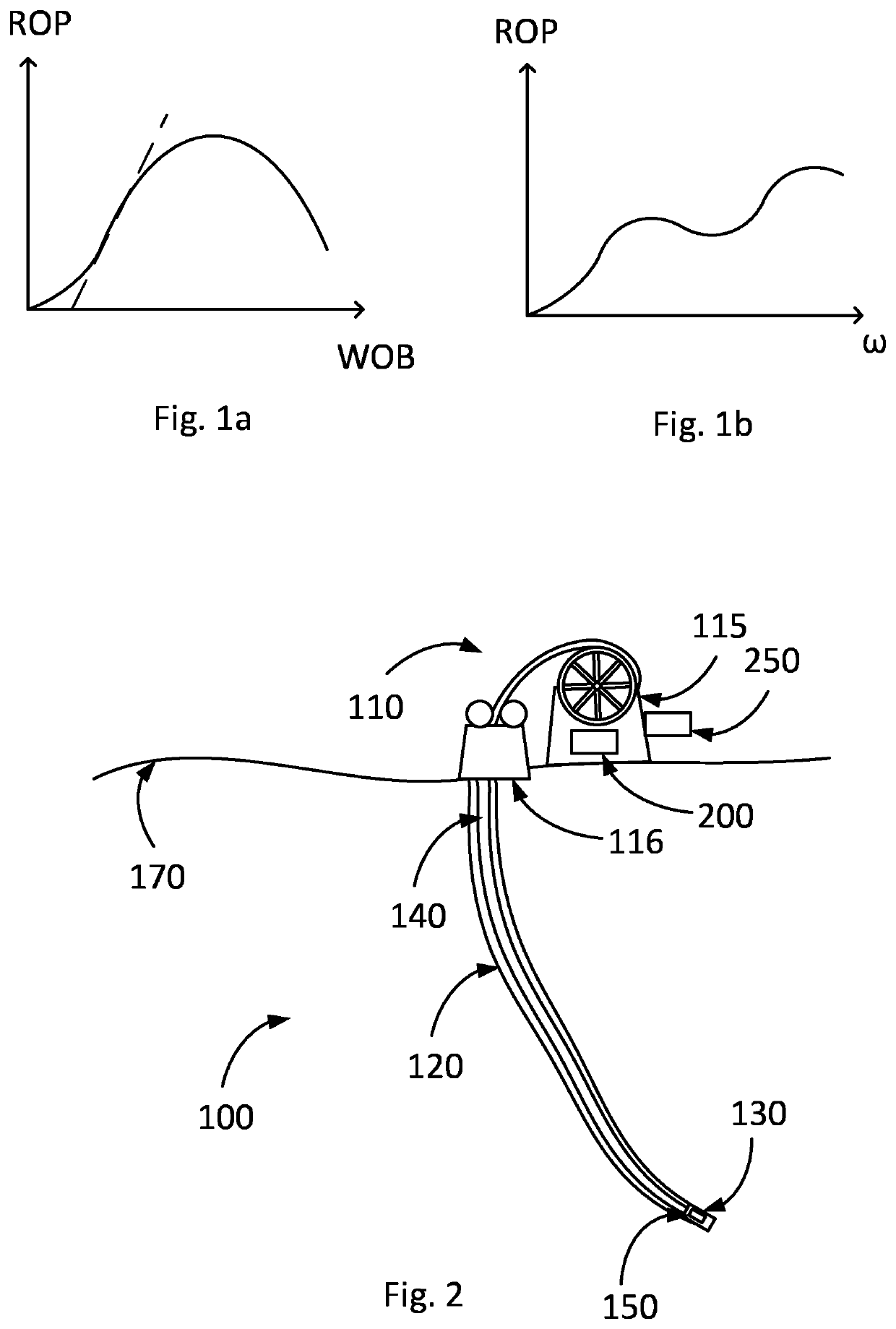

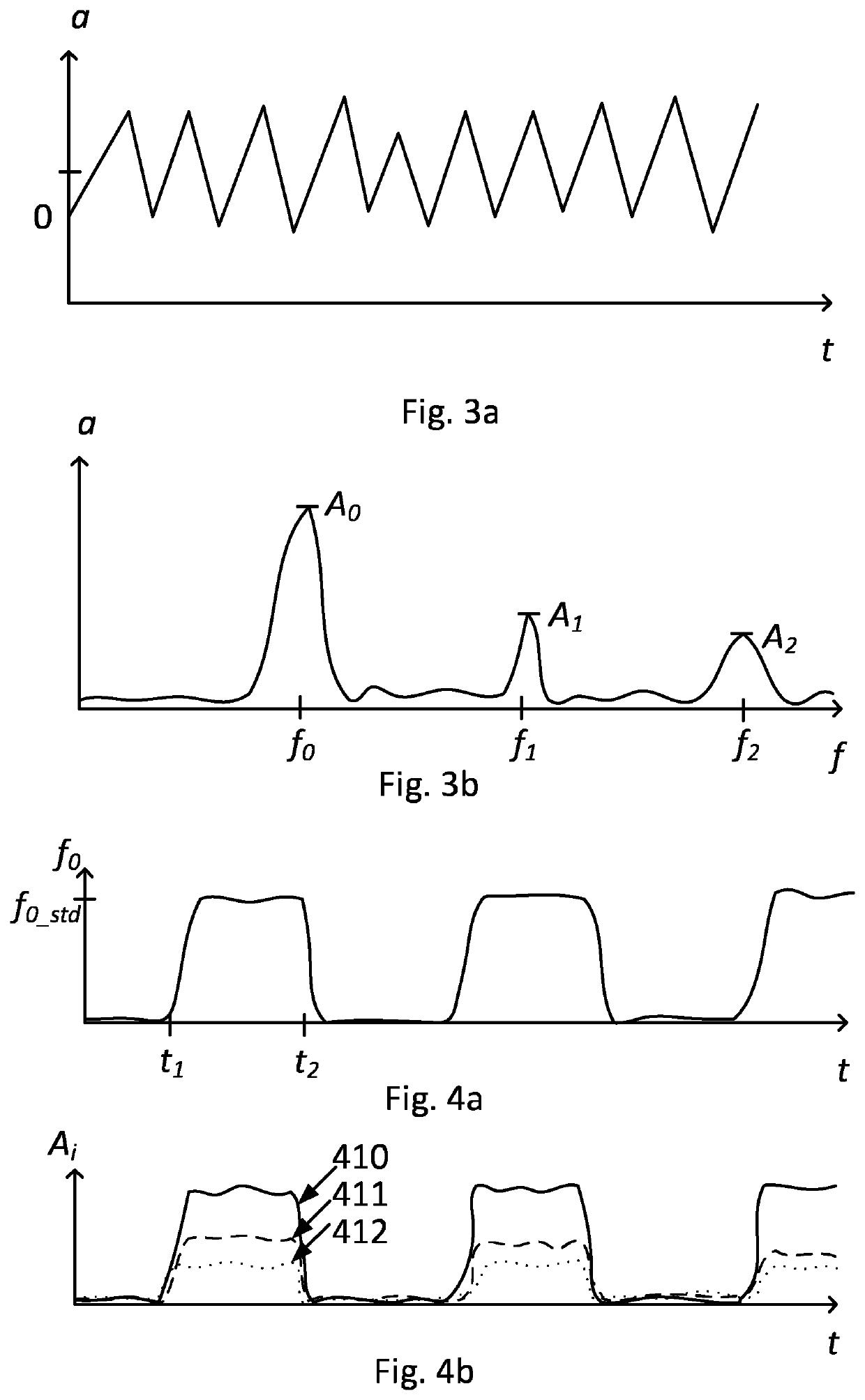

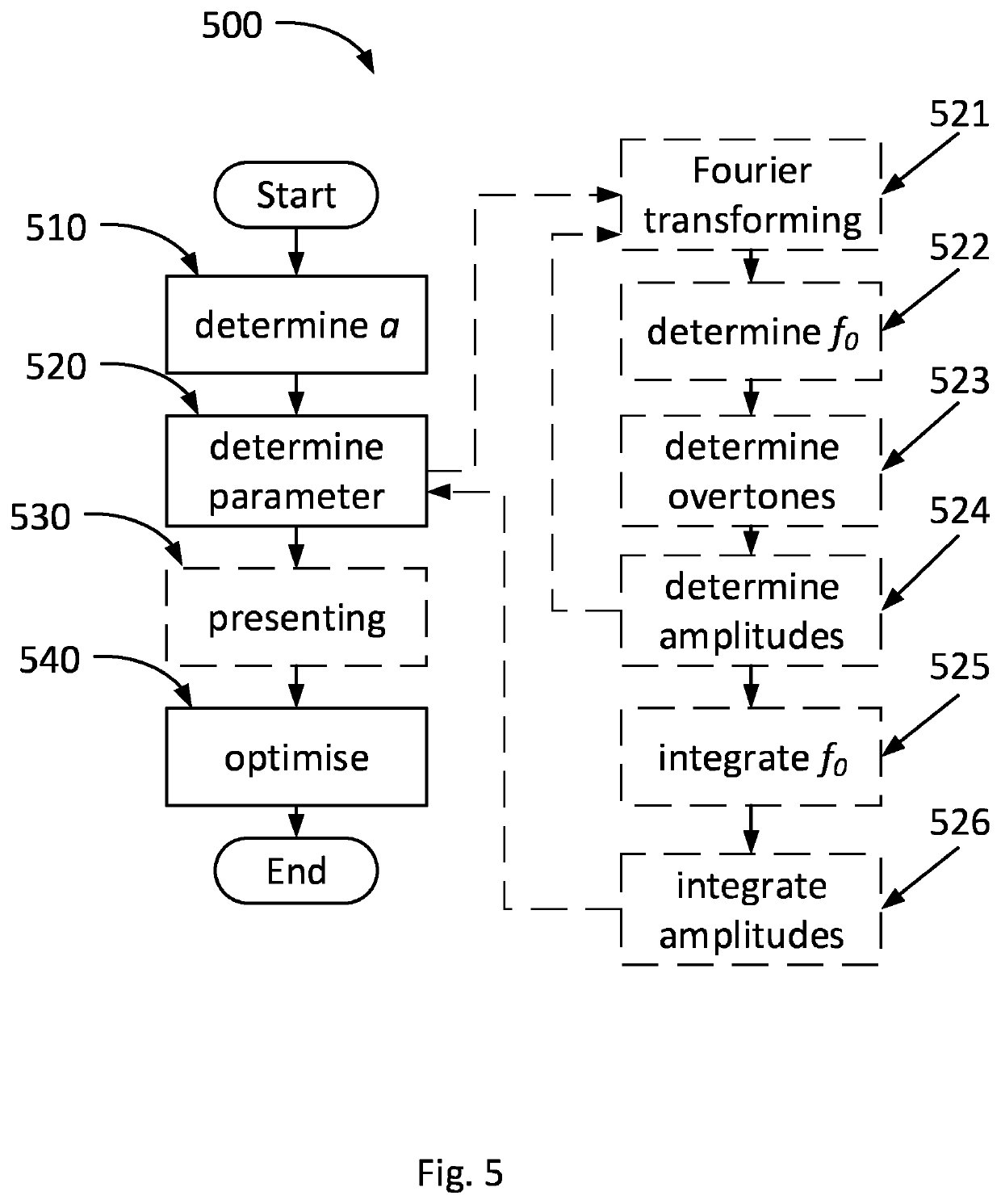

ActiveUS20180283144A1Reduce complexityOptimize energy useProgramme controlConstructionsAcceleration UnitComputer program

The present invention relates to a method for optimising energy usage at a drilling arrangement. The method includes the step of determining an acceleration of a drilling head in the drilling arrangement. The method further includes determining a parameter related to the energy usage at the drilling arrangement based on the determined acceleration. The method even further includes optimising the energy usage based on the determined parameter. The present invention also relates to a system for optimising energy usage at a drilling arrangement, to a computer program, and to a computer program product.

Owner:LKAB WASSARA AB

Method and a system for optimising energy usage at a drilling arrangement

ActiveUS10801306B2Reduce complexityOptimize energy usageProgramme controlConstructionsWell drillingControl engineering

The present invention relates to a method for optimising energy usage at a drilling arrangement. The method includes the step of determining an acceleration of a drilling head in the drilling arrangement. The method further includes determining a parameter related to the energy usage at the drilling arrangement based on the determined acceleration. The method even further includes optimising the energy usage based on the determined parameter. The present invention also relates to a system for optimising energy usage at a drilling arrangement, to a computer program, and to a computer program product.

Owner:LKAB WASSARA AB

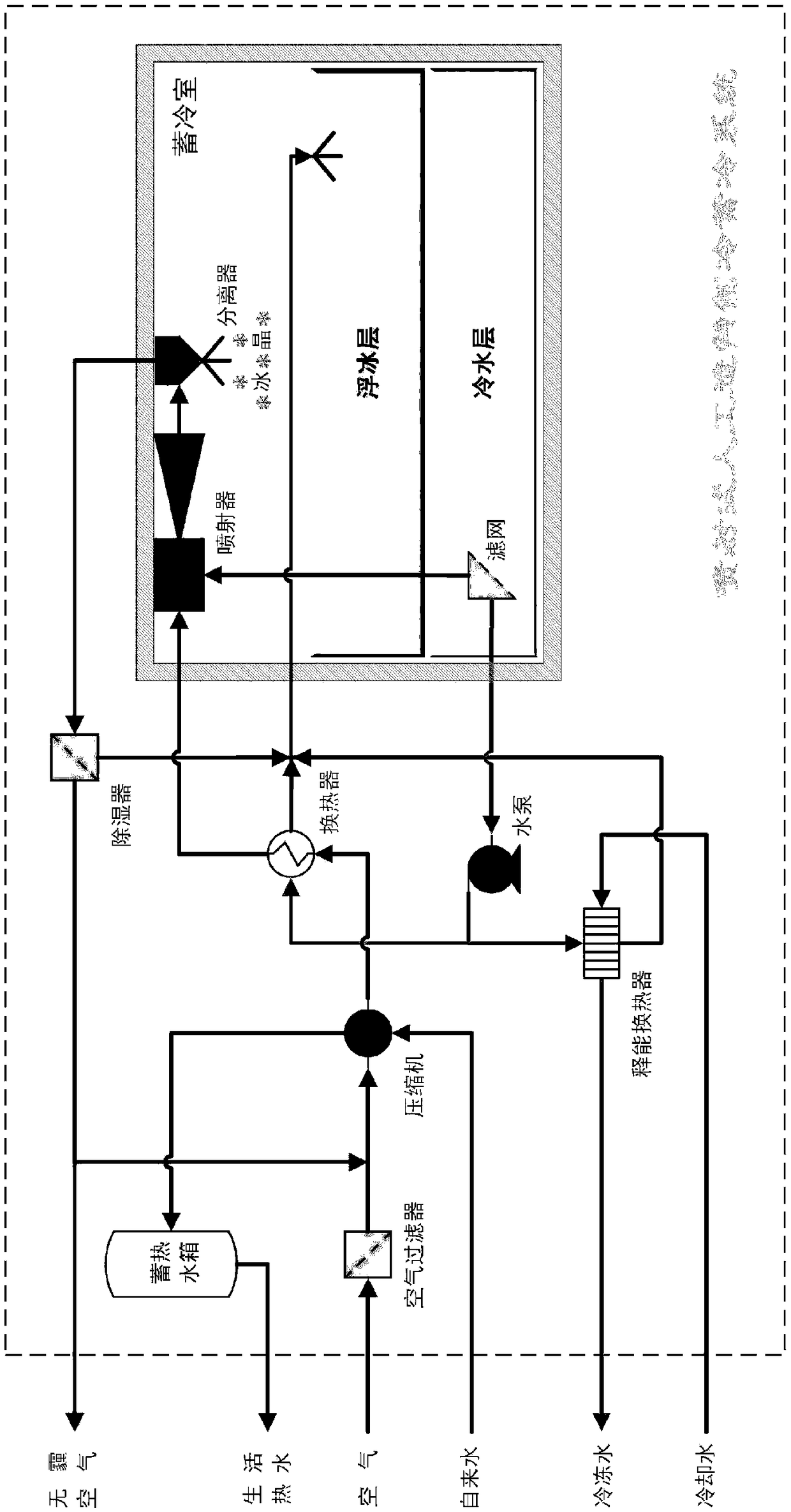

Injection type artificial snow-making refrigeration and cooling storage system

PendingCN109084495ACompact processImprove stabilityMechanical apparatusCompression machinesElectricityAir filter

The invention discloses an injection type artificial snow-making refrigeration and cooling storage system which comprises an air filter, a compressor, a heat exchanger, an ejector, a separator, a cooling storage chamber, a moisture ejector, a cold release heat exchanger and a heat storage water tank. The injection type artificial snow-making refrigeration and cooling storage system consumes a small amount of electricity to drive the compressor, through an injection and ejection system, heat in water (ice) is transferred to domestic hot water, cooling capacity is provided for the outside, and at the same time domestic hot water can be produced incidentally.

Owner:CECEP CHANGZHOU INST FOR ENERGY SAVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com