Patents

Literature

204 results about "Lateral thrust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

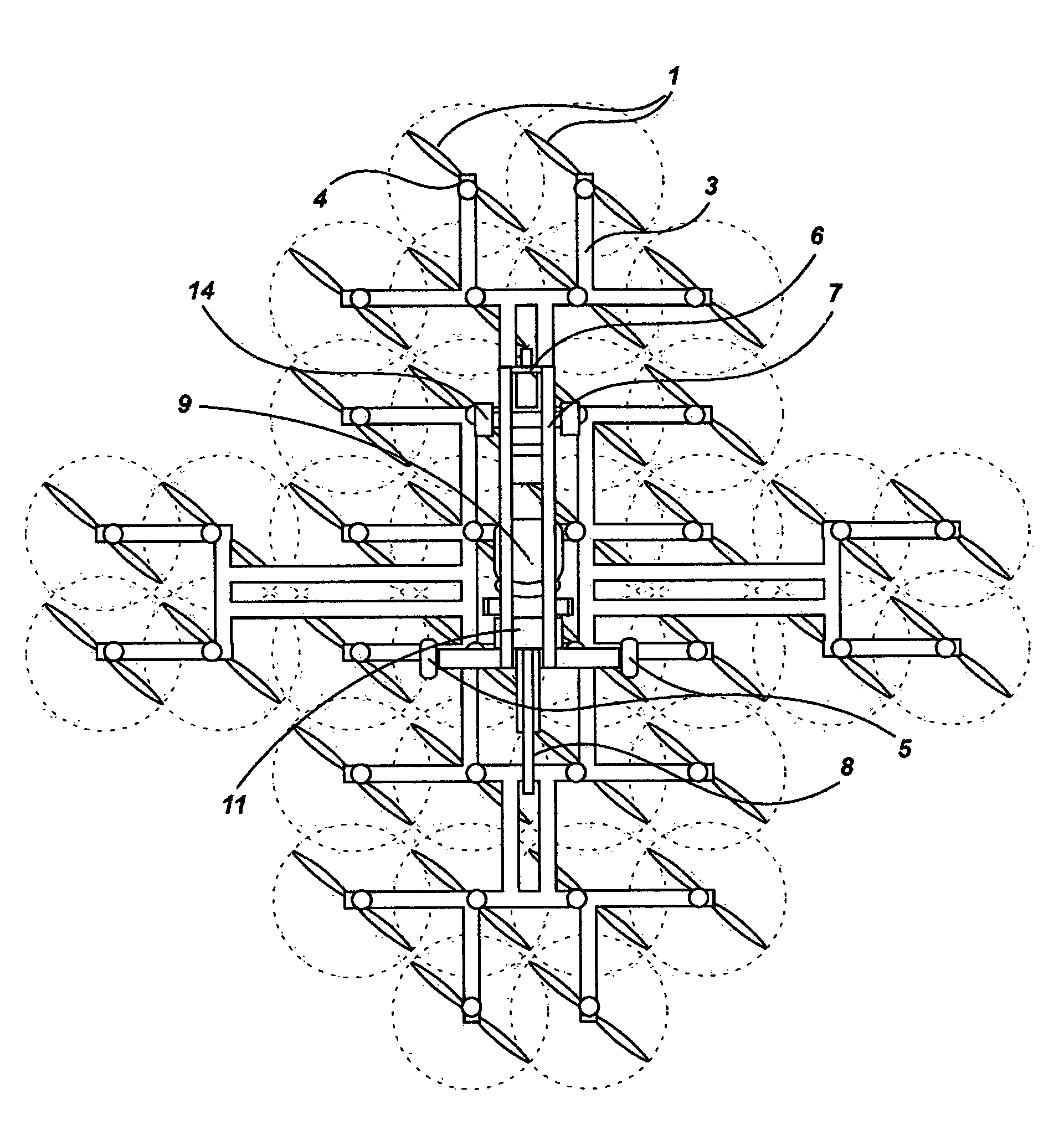

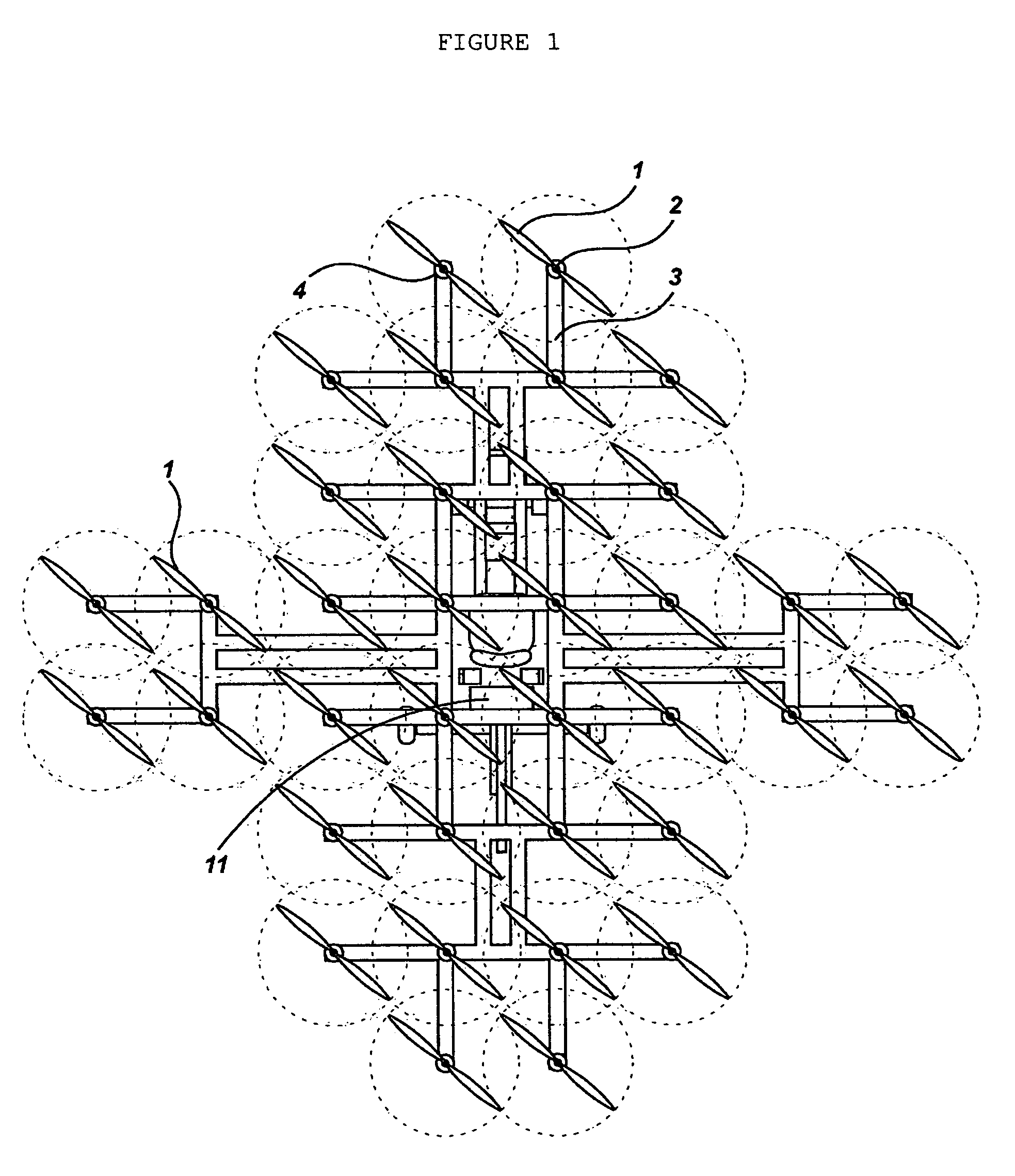

Vertical takeoff and landing aircraft using a redundant array of independent rotors

InactiveUS20060266881A1Easy to operateEasy maintenanceWingsMicrolight aircraftsFlight vehicleVertical take off and landing

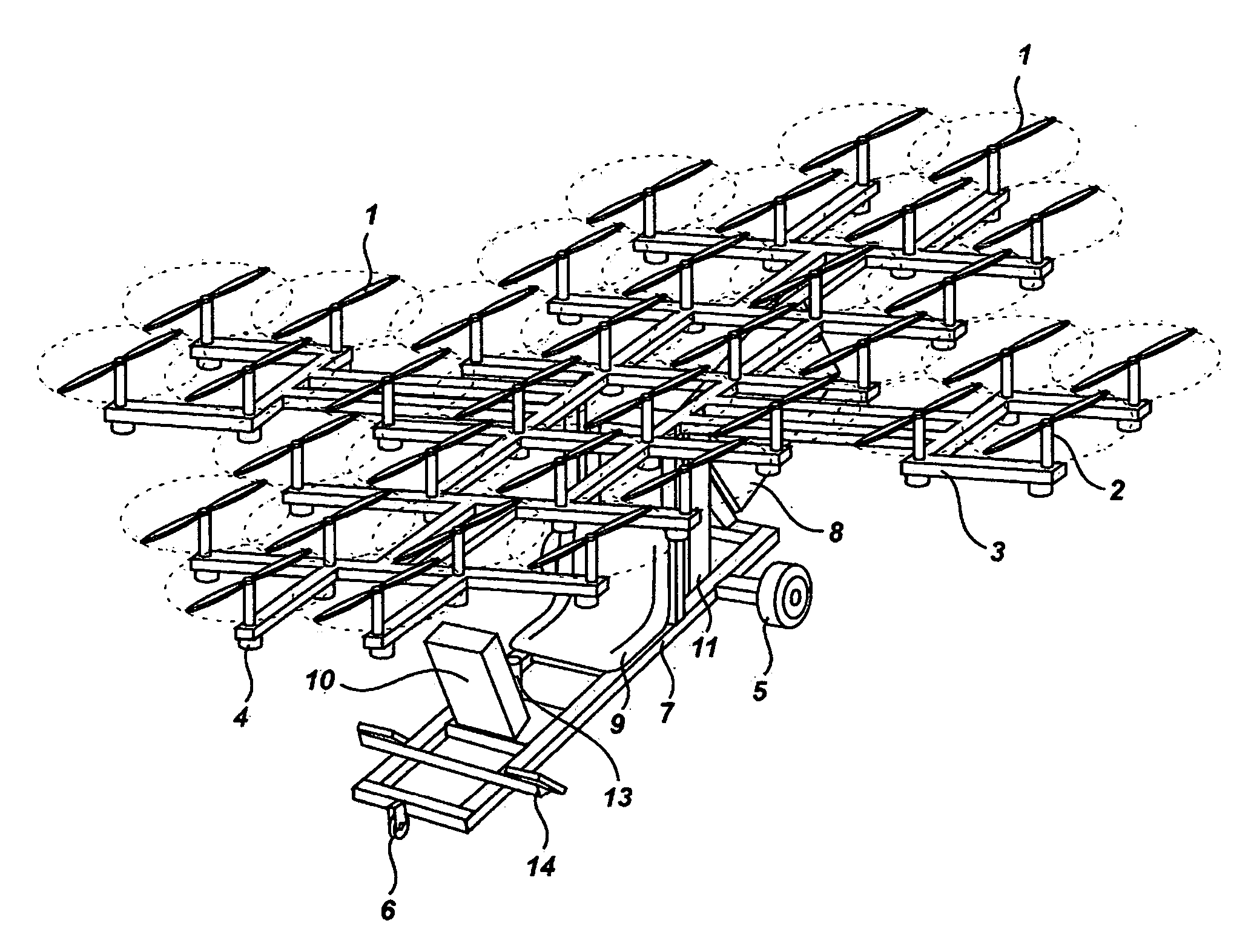

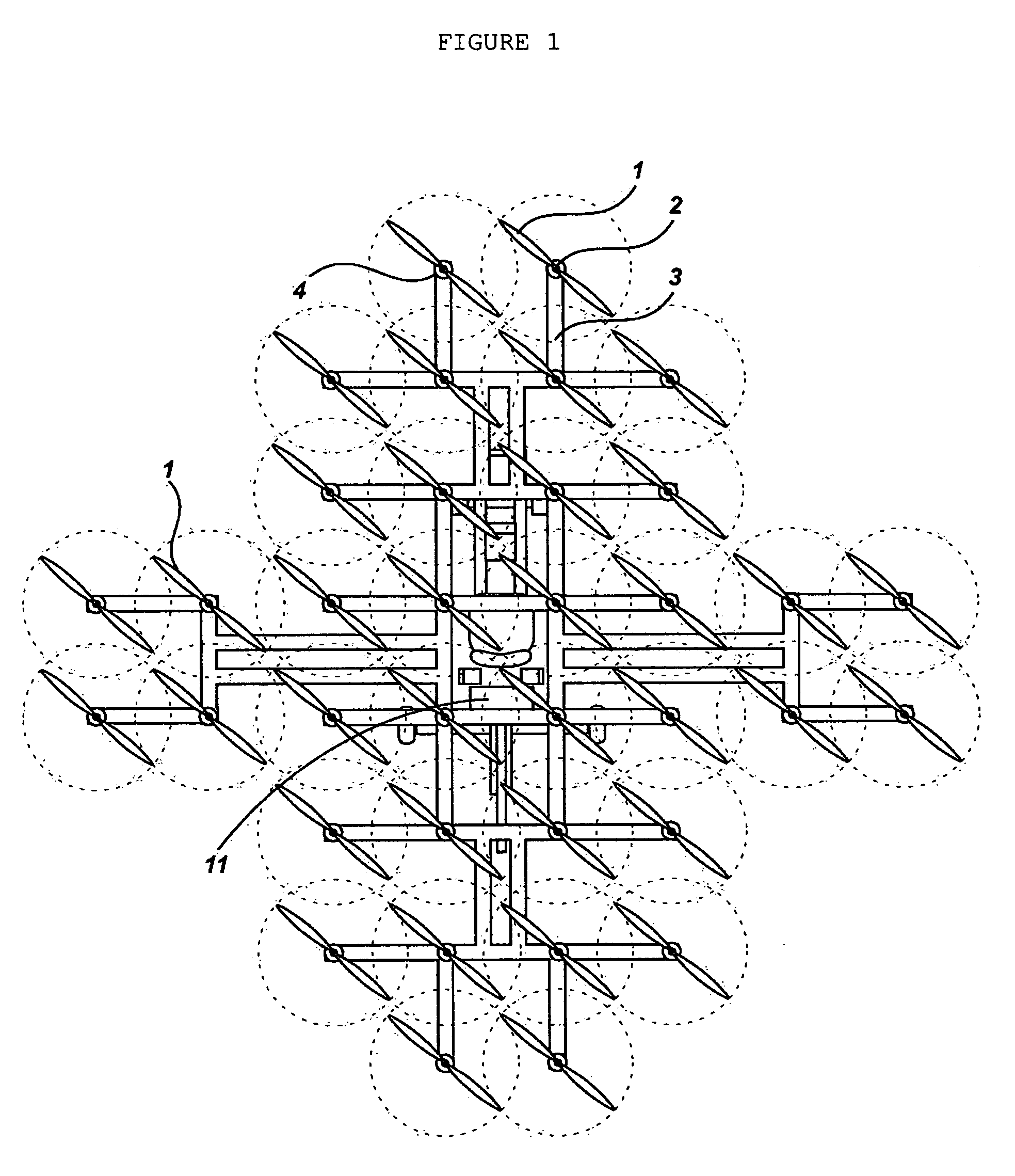

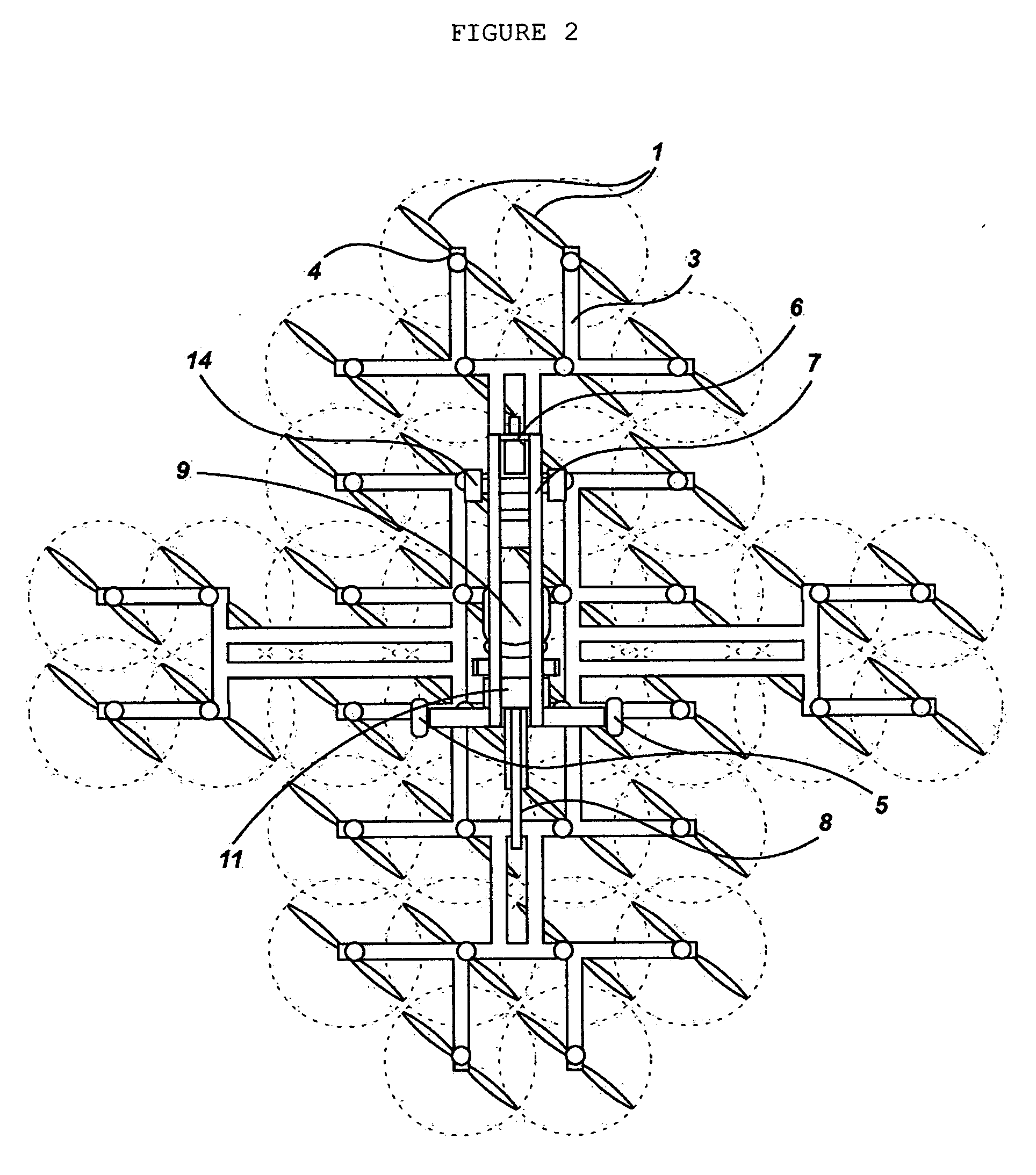

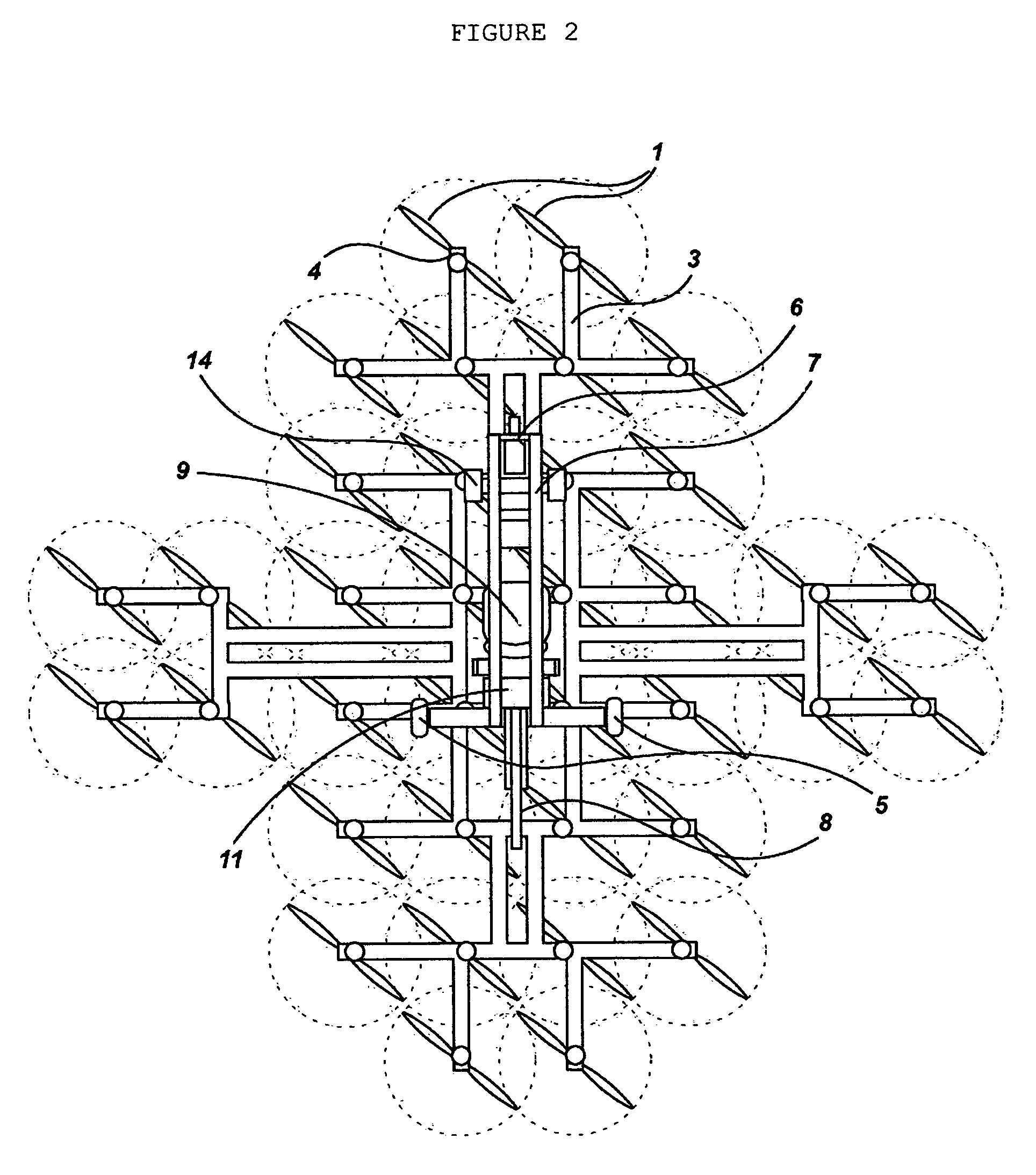

A vertical takeoff and landing aircraft, using for vertical lift and lateral thrust a redundant plurality of essentially similar electrically-powered and electronically-controlled thrust units mounted in a mechanically static or fixed fashion relative to one another in a substantially horizontal plane. The thrust units are situated in this planar array in aerodynamically approximate pairs, such that a complete failure of a single thrust unit would not substantially compromise the ability of the aircraft to maintain flight.

Owner:HUGHEY ELECTRICOPTER CORP

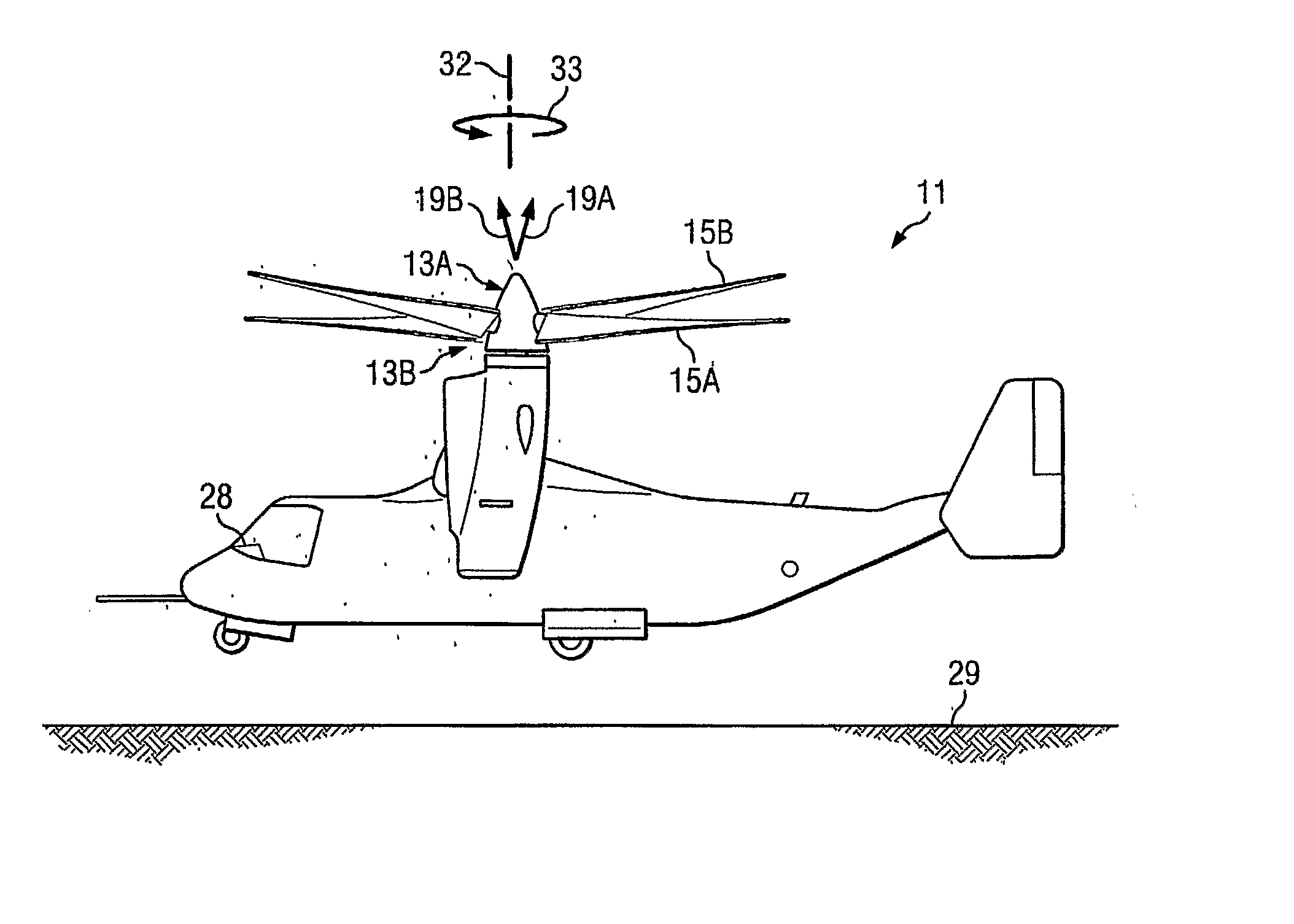

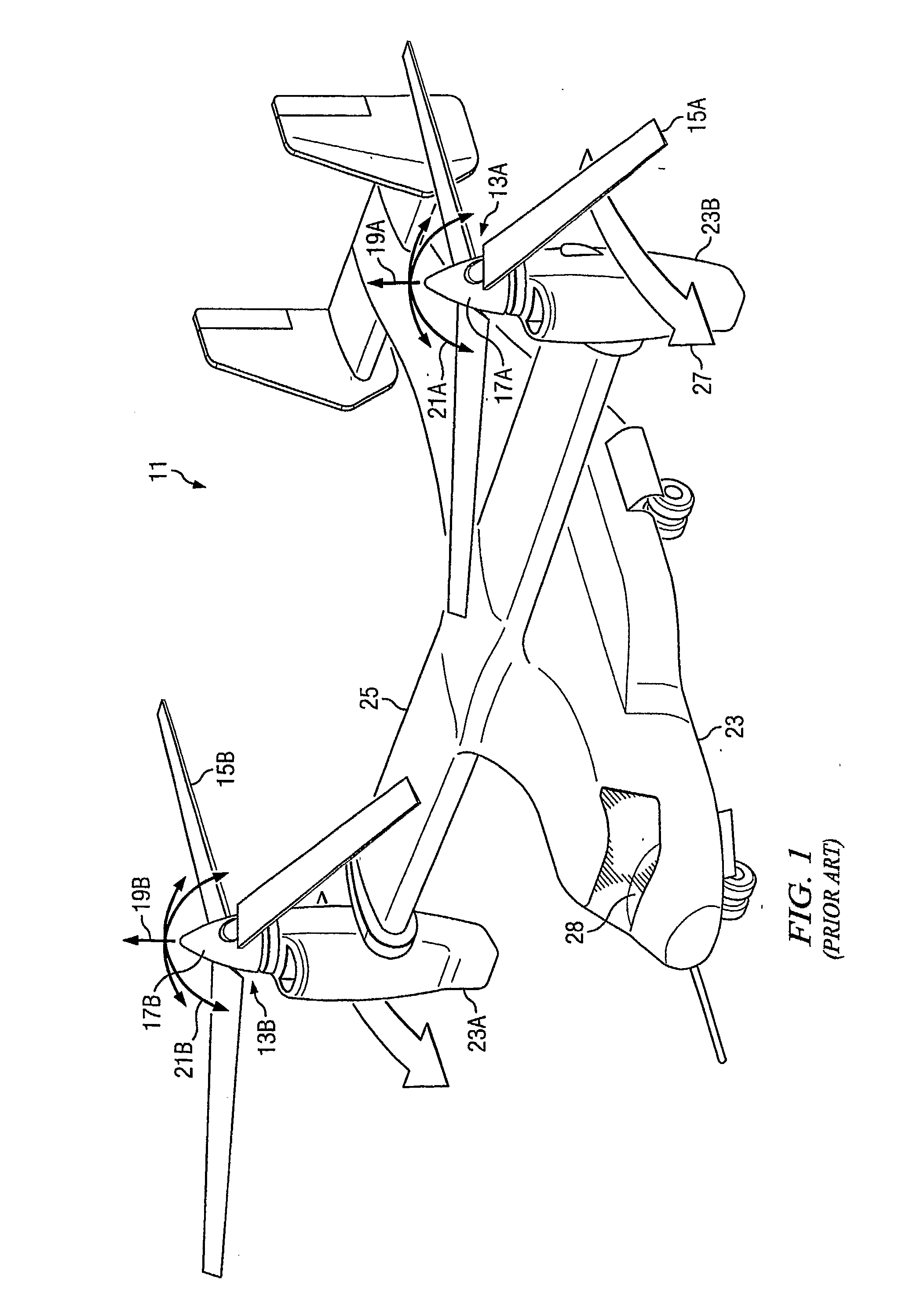

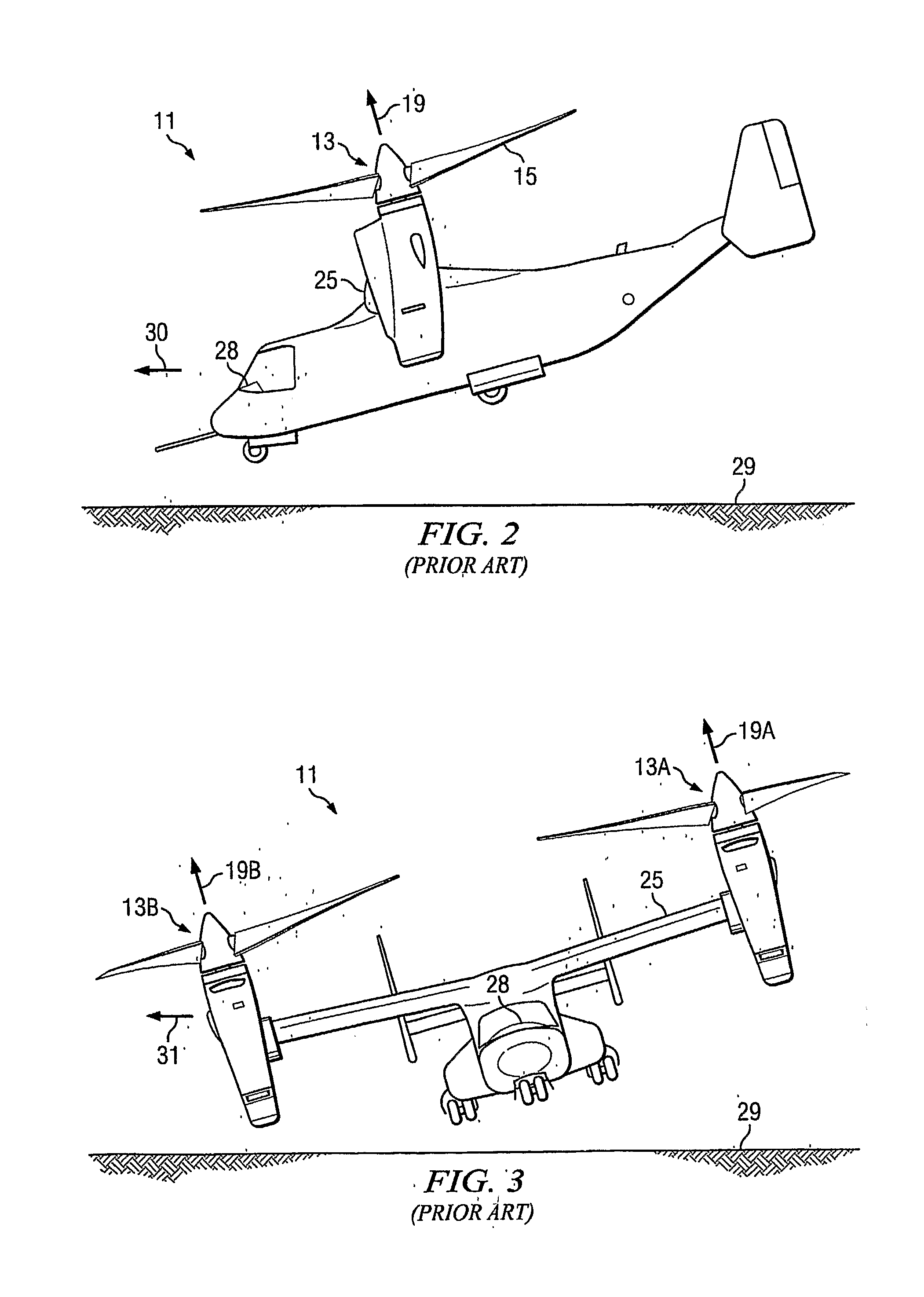

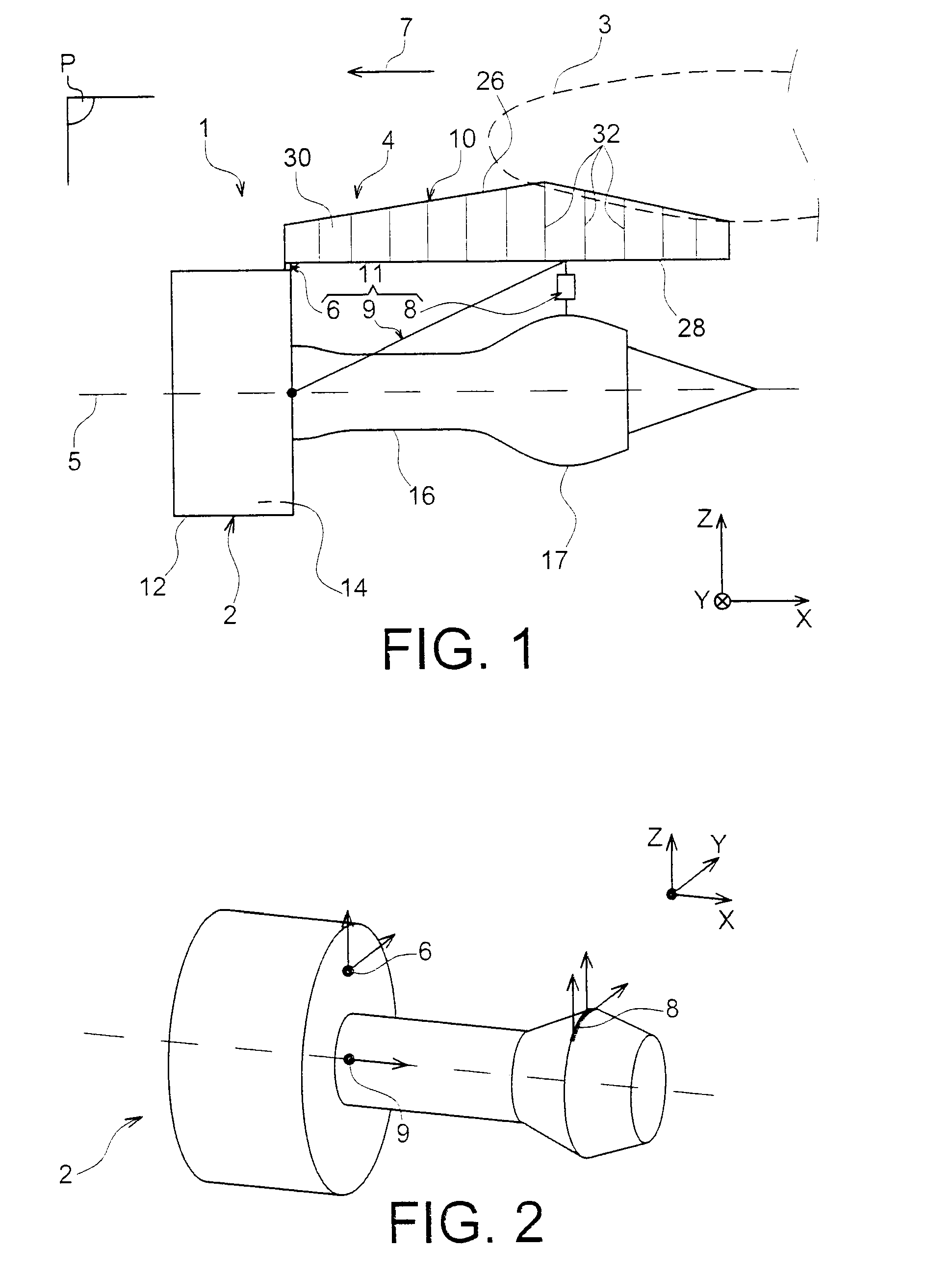

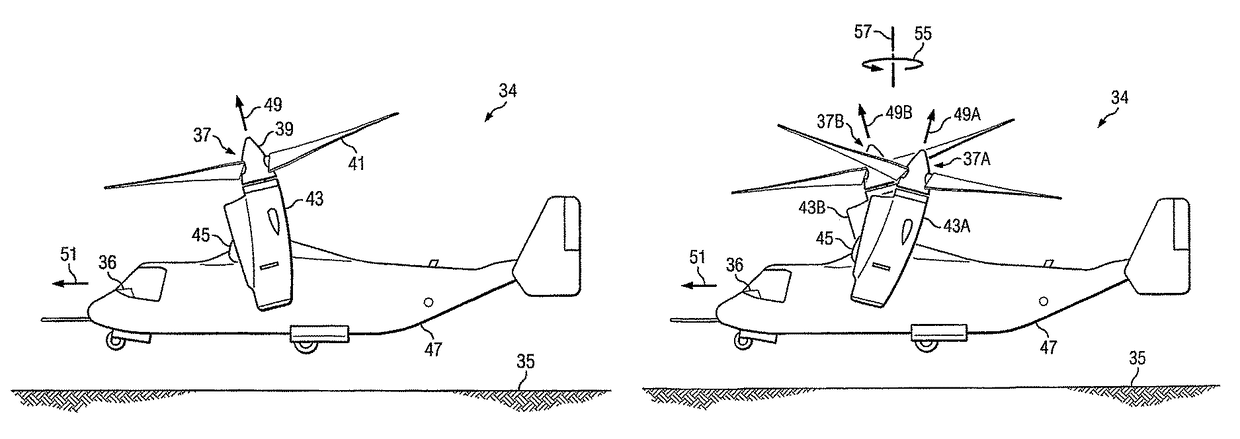

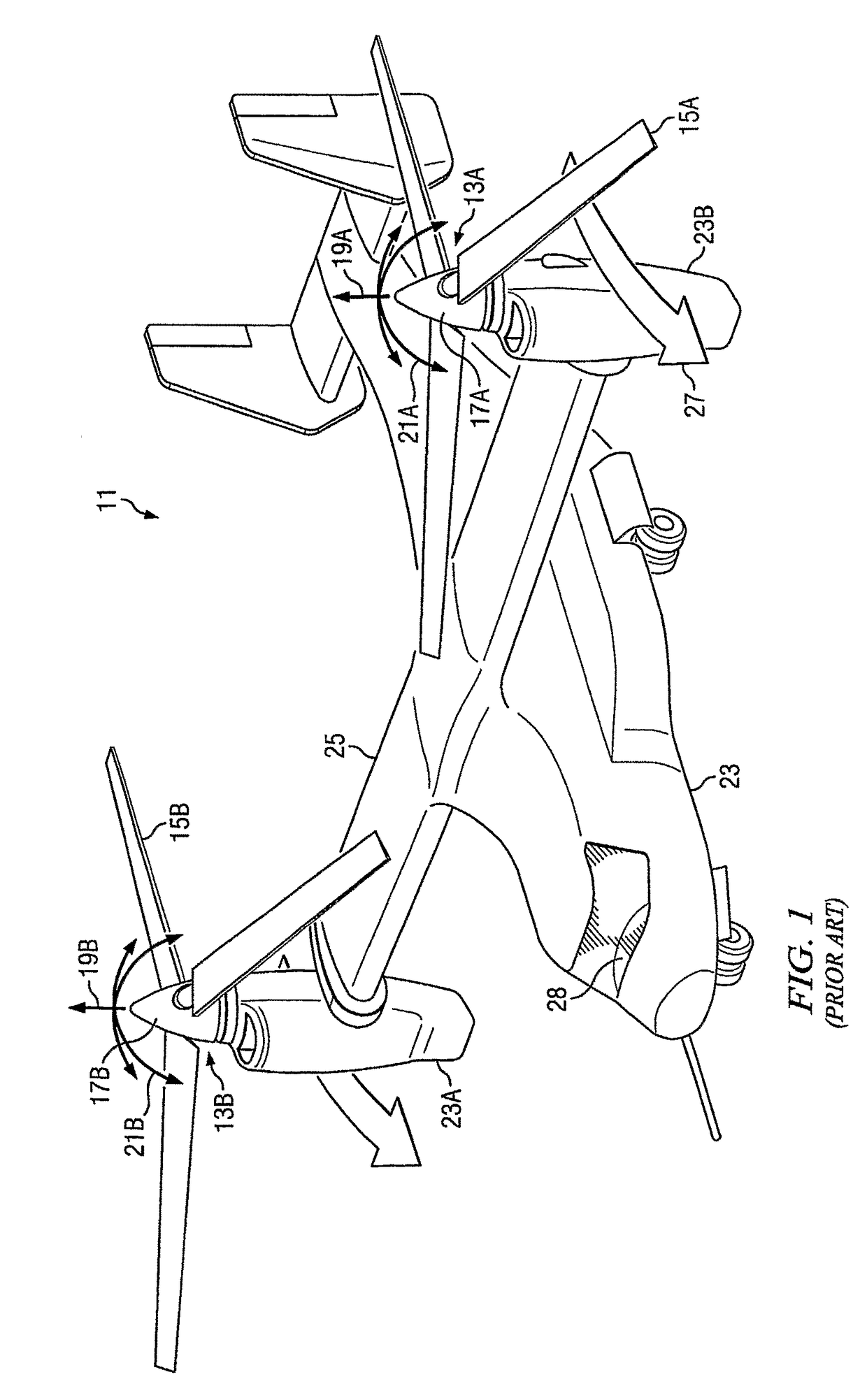

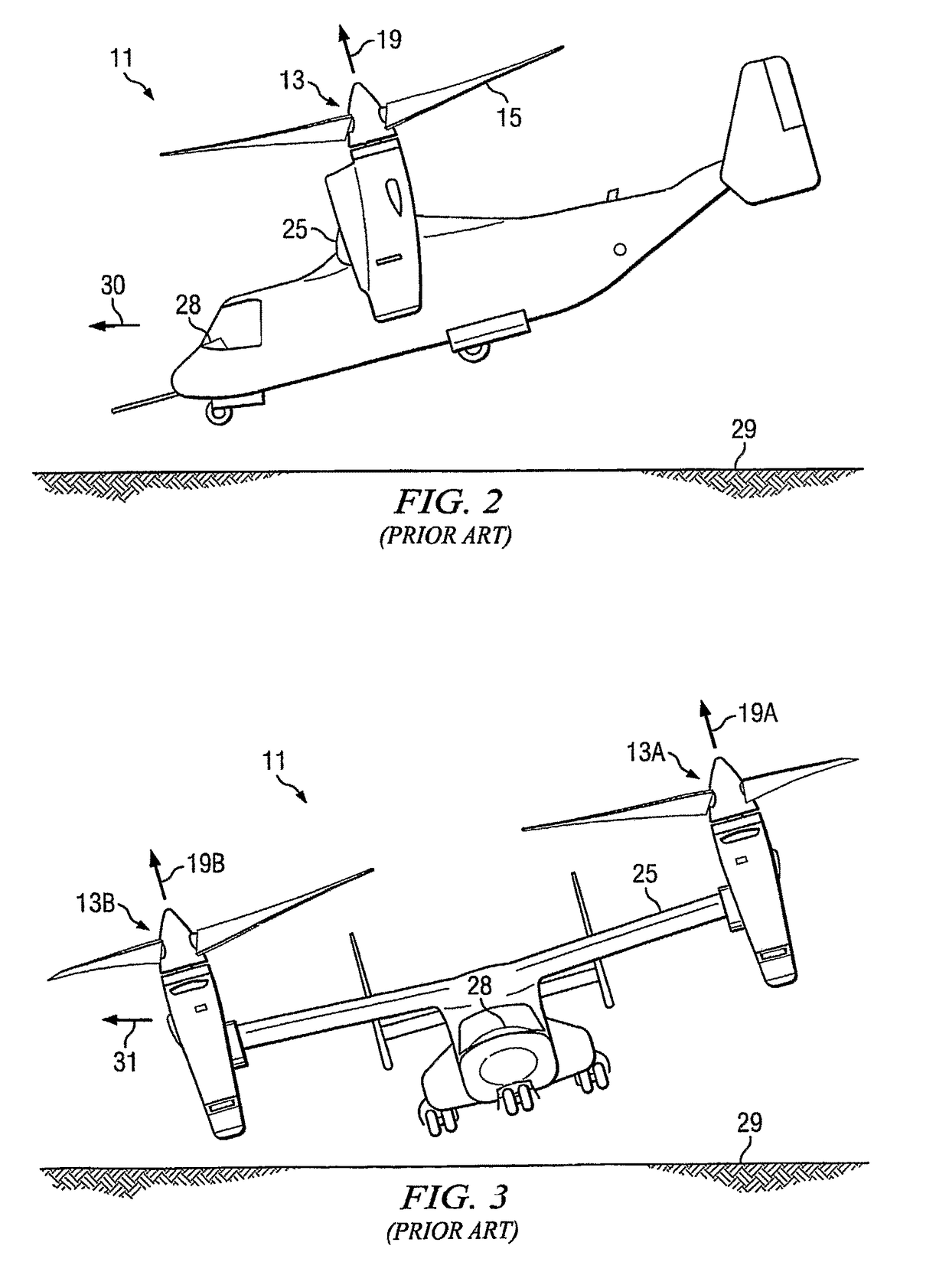

Method and Apparatus for Flight Control of Tiltrotor Aircraft

ActiveUS20070221780A1Short response timeImprove accuracyVehicle position/course/altitude controlVertical landing/take-off aircraftsAutomatic controlNacelle

A method and apparatus provide for automatically controlling the flight of a tiltrotor aircraft while the aircraft is in flight that is at least partially rotor-borne. The method and apparatus provide for automatically tilting nacelles in response to a longitudinal-velocity control signal so as to produce a longitudinal thrust-vector component for controlling longitudinal velocity of the aircraft. Simultaneously, cyclic swashplate controls are automatically actuated so as to maintain the fuselage in a desired pitch attitude. The method and apparatus also provide for automatically actuating the cyclic swashplate controls for each rotor in response to a lateral-velocity control signal so as to produce a lateral thrust-vector component for controlling lateral velocity of the aircraft. Simultaneously, collective swashplate controls for each rotor are automatically actuated so as to maintain the fuselage in a desired roll attitude. The method and apparatus provide for yaw control through differential longitudinal thrust produced by tilting the nacelles.

Owner:TEXTRON INNOVATIONS

Vertical takeoff and landing aircraft using a redundant array of independent rotors

InactiveUS7699260B2Cheap manufacturingInexpensive to maintainWingsMicrolight aircraftsFlight vehiclePlanar array

A vertical takeoff and landing aircraft, using for vertical lift and lateral thrust a redundant plurality of essentially similar electrically-powered and electronically-controlled thrust units mounted in a mechanically static or fixed fashion relative to one another in a substantially horizontal plane. The thrust units are situated in this planar array in aerodynamically approximate pairs, such that a complete failure of a single thrust unit would not substantially compromise the ability of the aircraft to maintain flight.

Owner:HUGHEY ELECTRICOPTER CORP

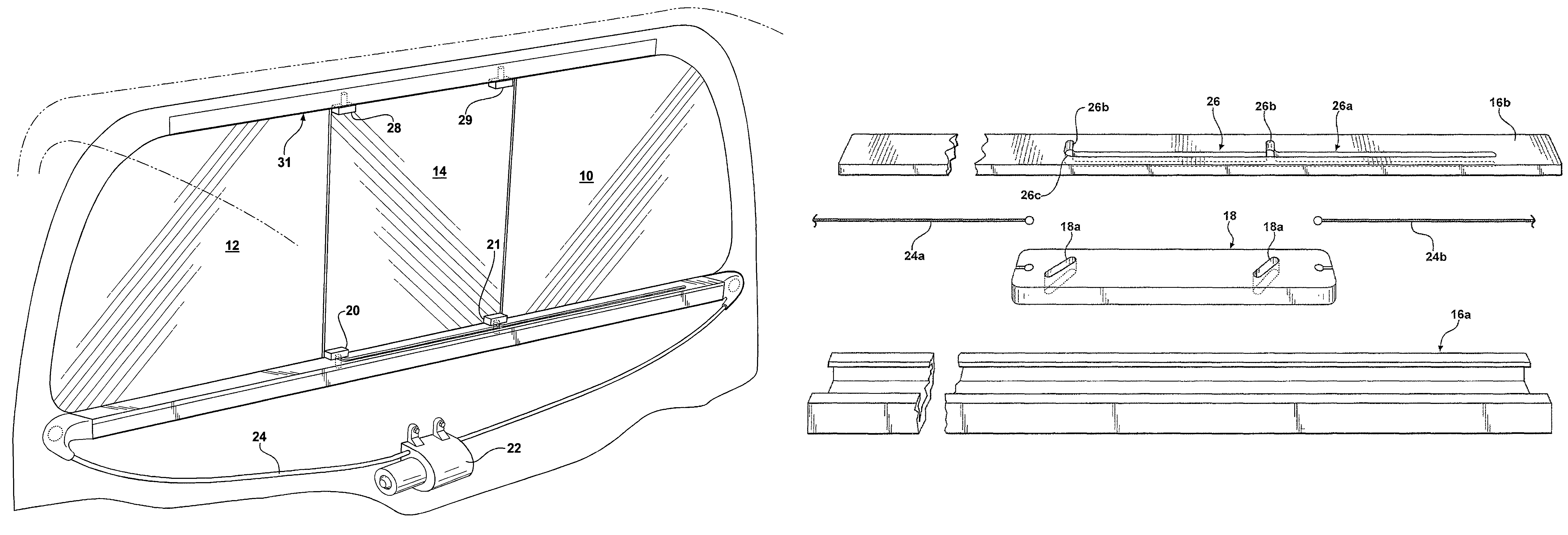

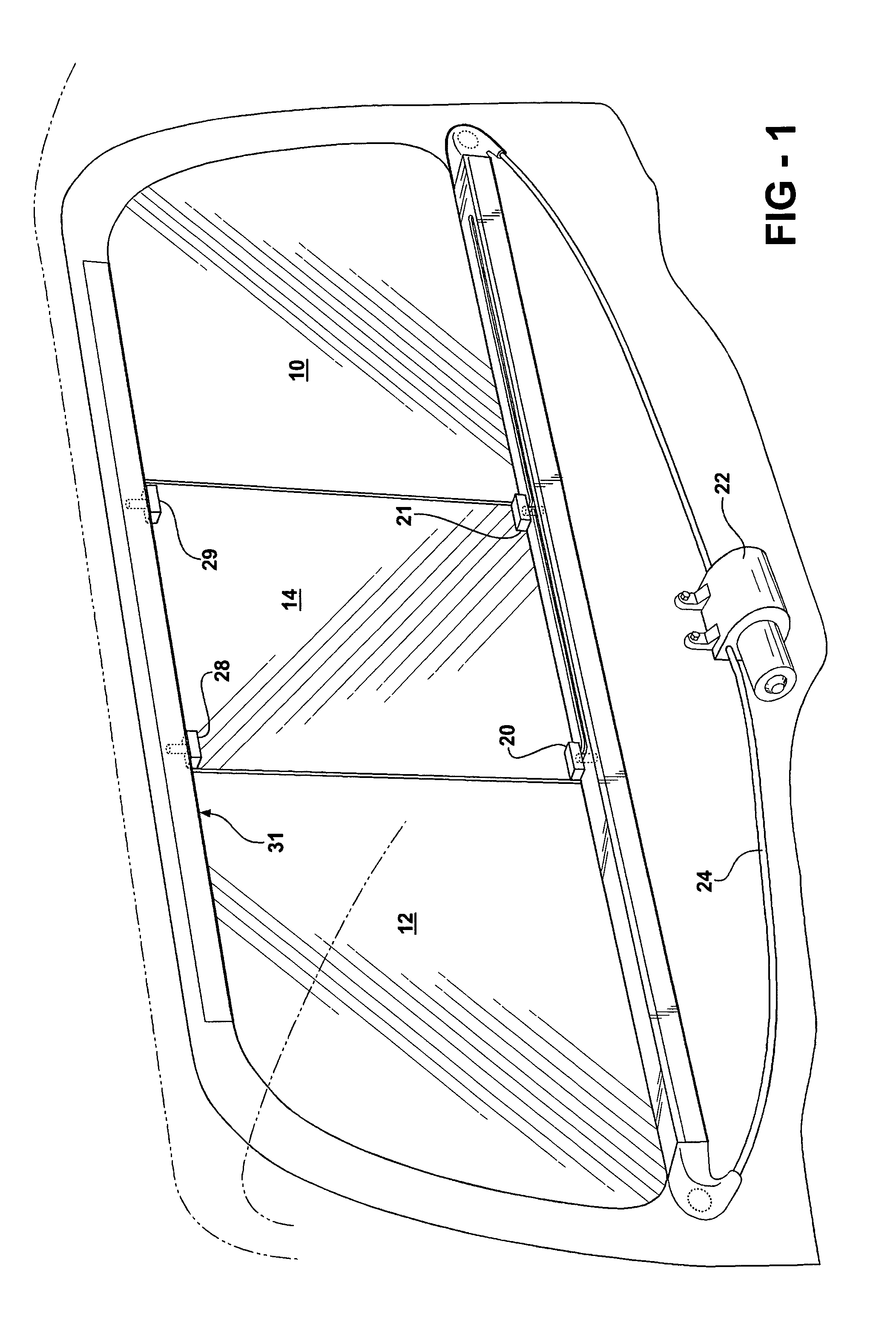

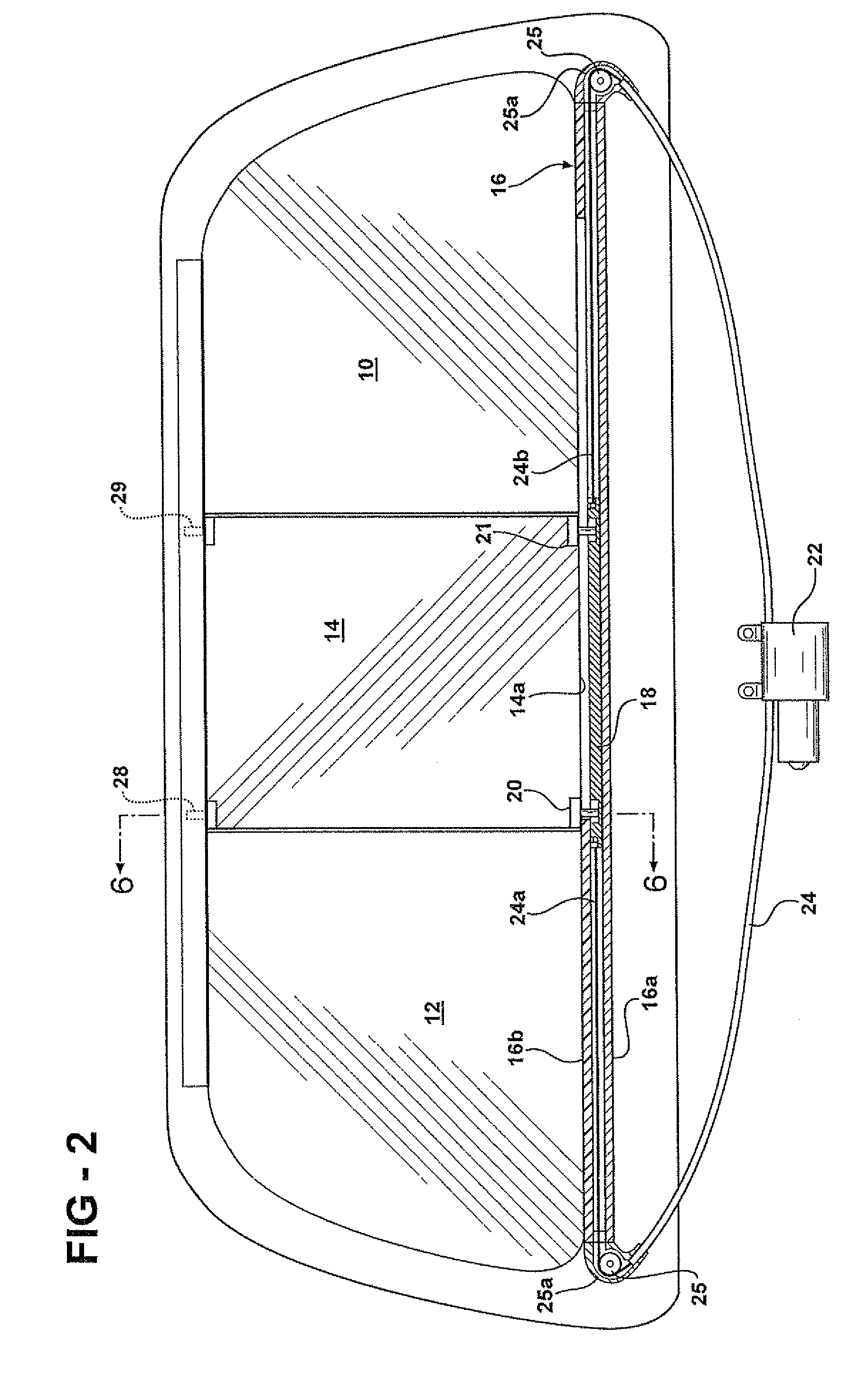

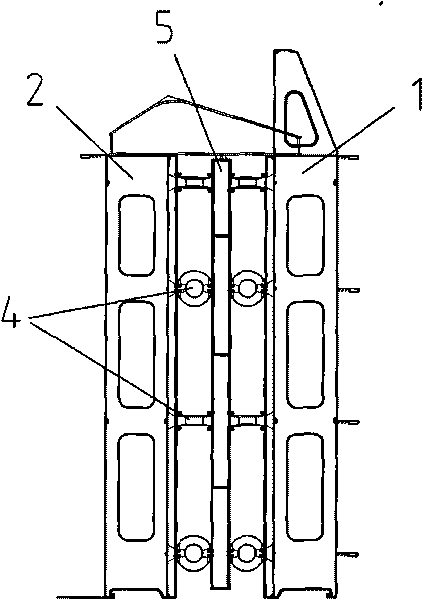

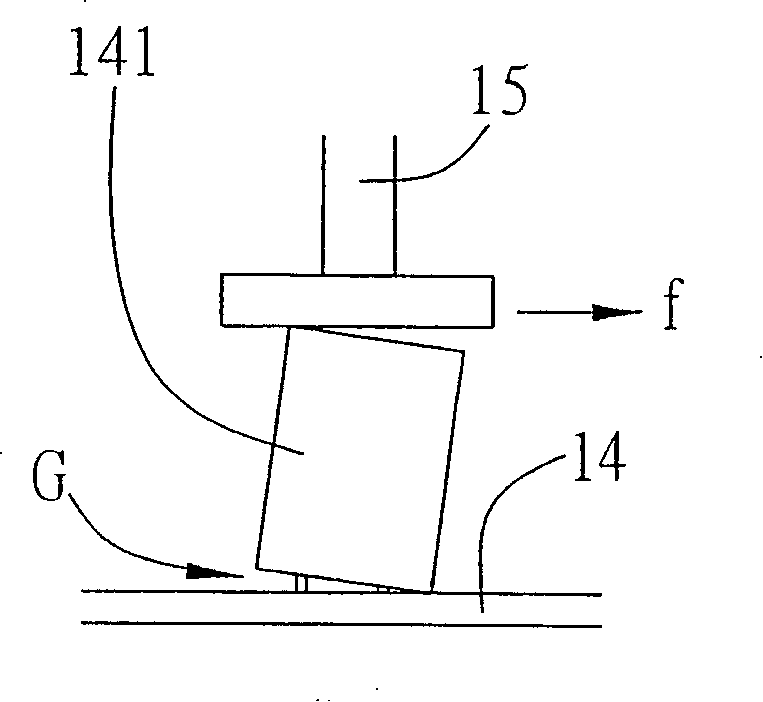

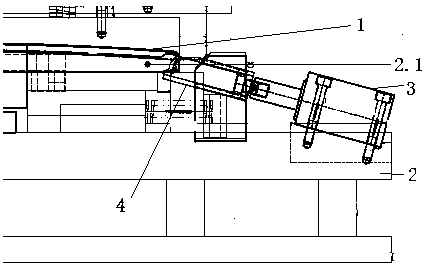

Sliding window assembly

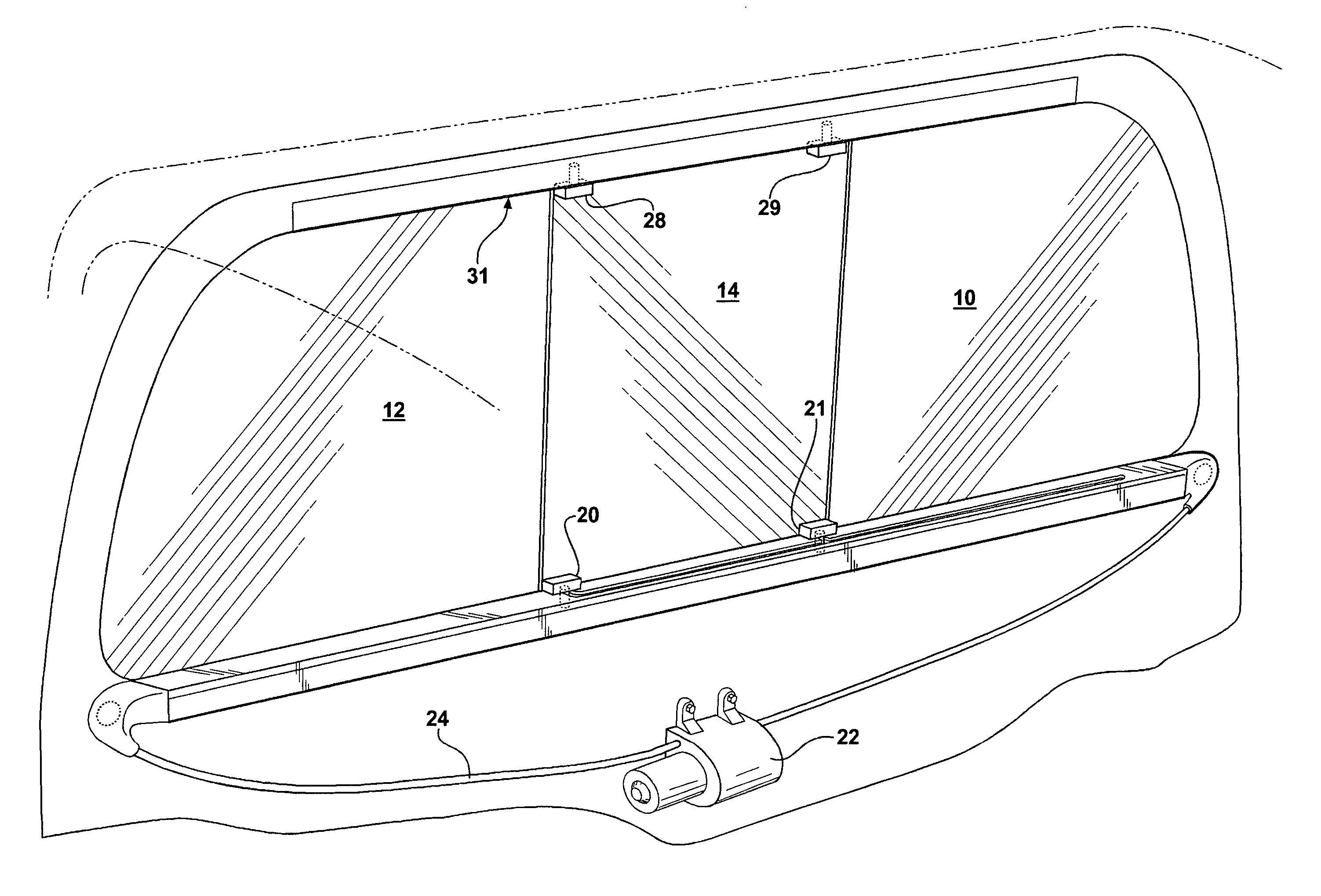

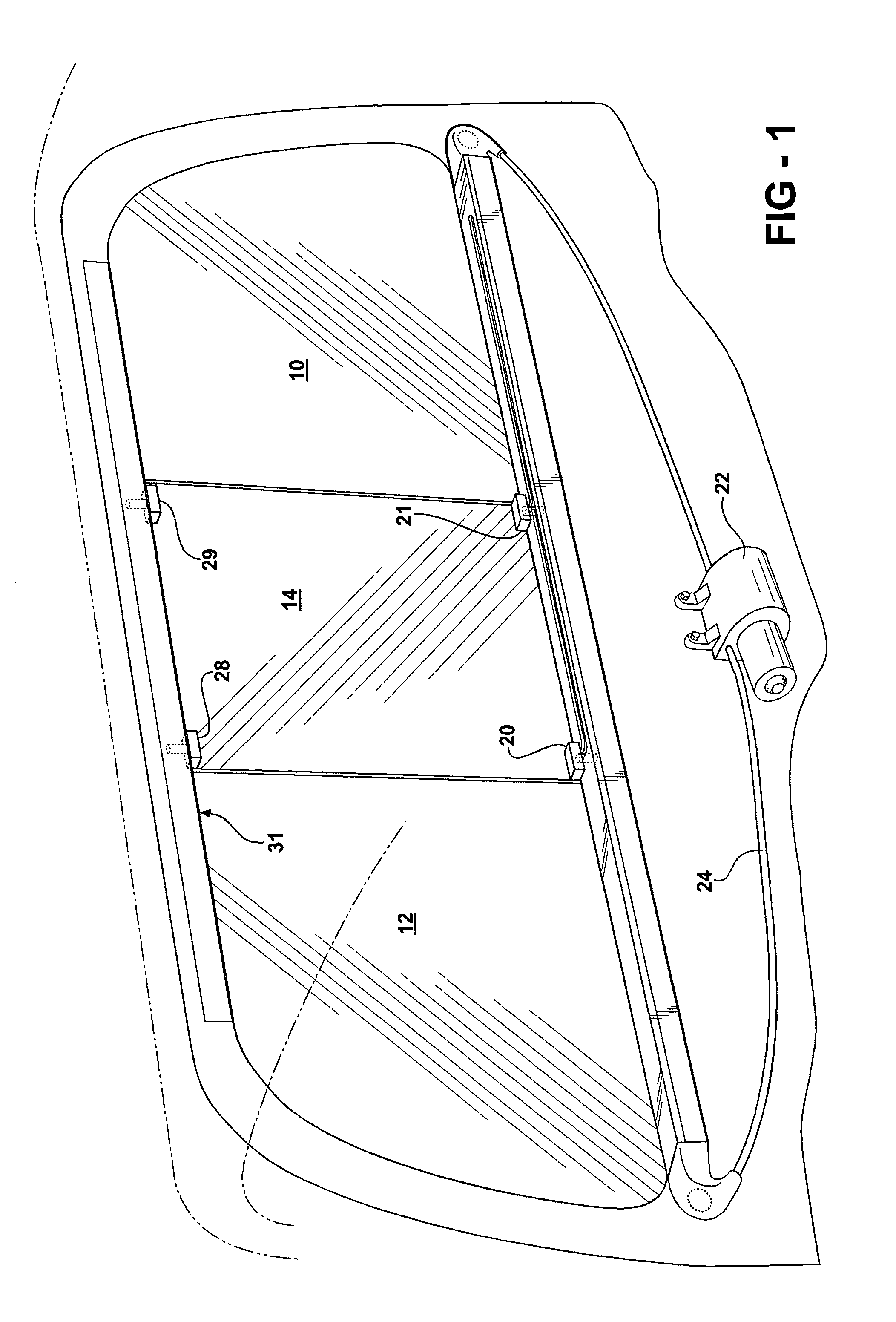

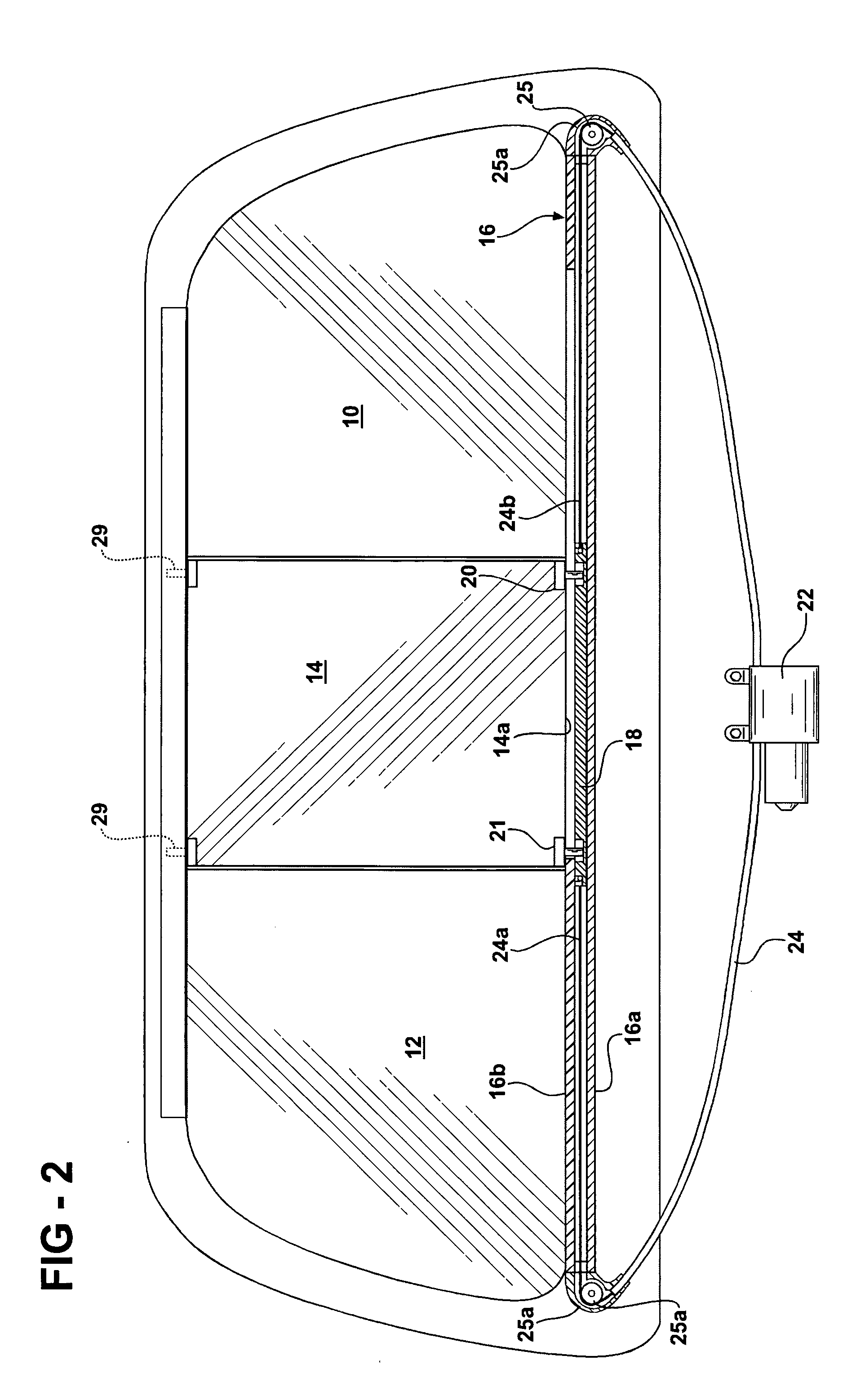

InactiveUS20060032140A1Easy to moveMan-operated mechanismPower-operated mechanismPickup truckSlide window

A sliding window assembly for use with a motor vehicle such for example as the rear window of the cab of a pickup type truck. A guide structure mounts a sliding pane for longitudinal sliding movement generally parallel to the plane of the pane between an open position and a closed position, and a lateral thrust mechanism is provided which is operative in response to arrival of the pane in its closed position to thereafter move the pane laterally relative to the plane of the pane into a position wherein the exposed face of the pane is flush with a surrounding vehicle surface such for example as the surface defined by fixed panes in the rear window of a pickup truck. The lateral movement of the pane is accomplished by a guide pin on the glass received in a compound guide slot defined by a fixed guide structure, a slider slidably mounted in a fixed guide structure for movement parallel to the plane of the pane, and a drive mechanism interconnecting the pane and the slider and operative with the pin positioned in a first portion of the compound slot to move the glass along the fixed guide structure in a direction generally parallel to the plane of a pane and operative with the pin positioned in a second angled portion of the compound slot to move the glass pane laterally relative to the plane of the pane.

Owner:HI-LEX CORPORATION

Sliding window assembly

Owner:HI-LEX CORPORATION

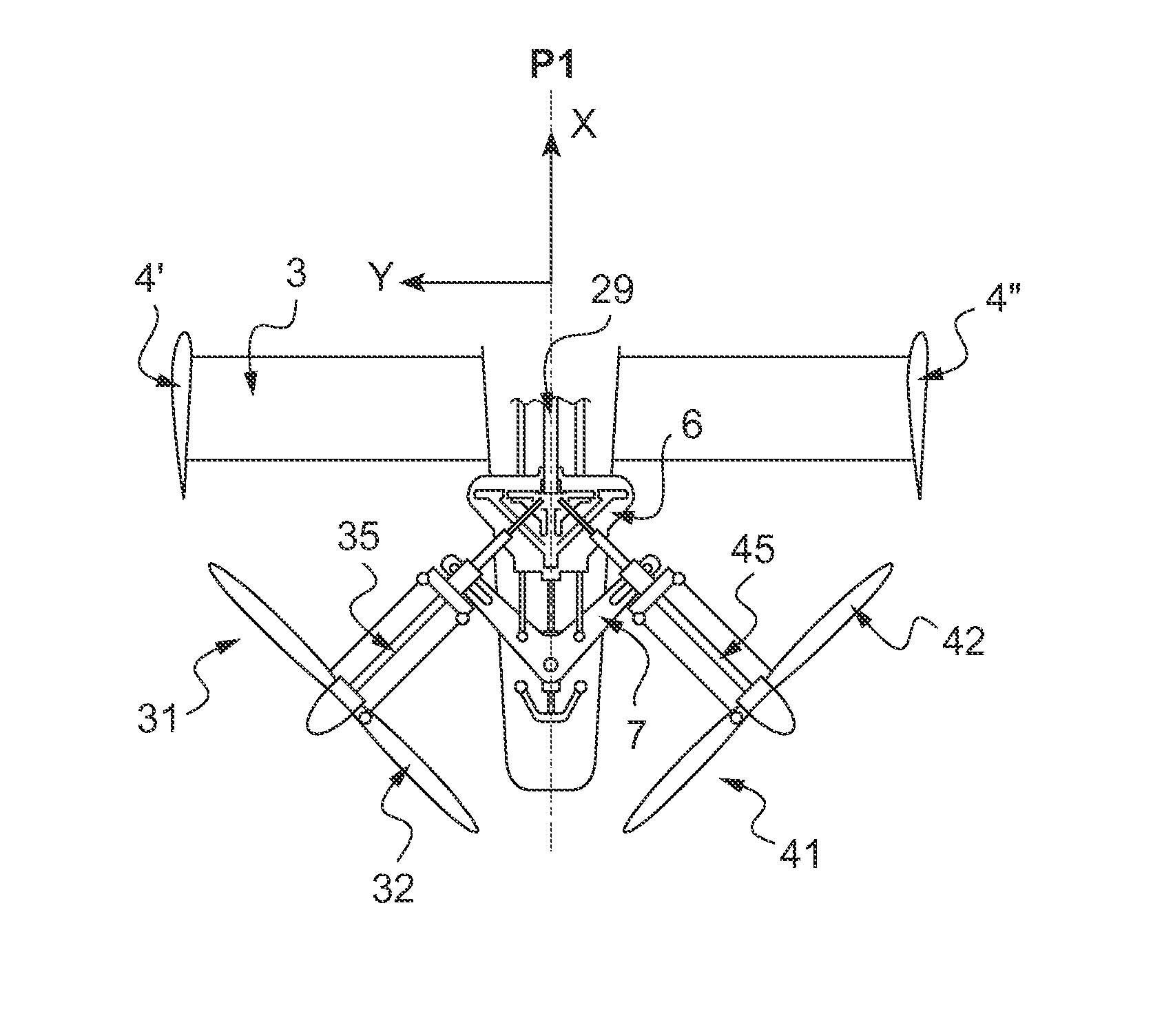

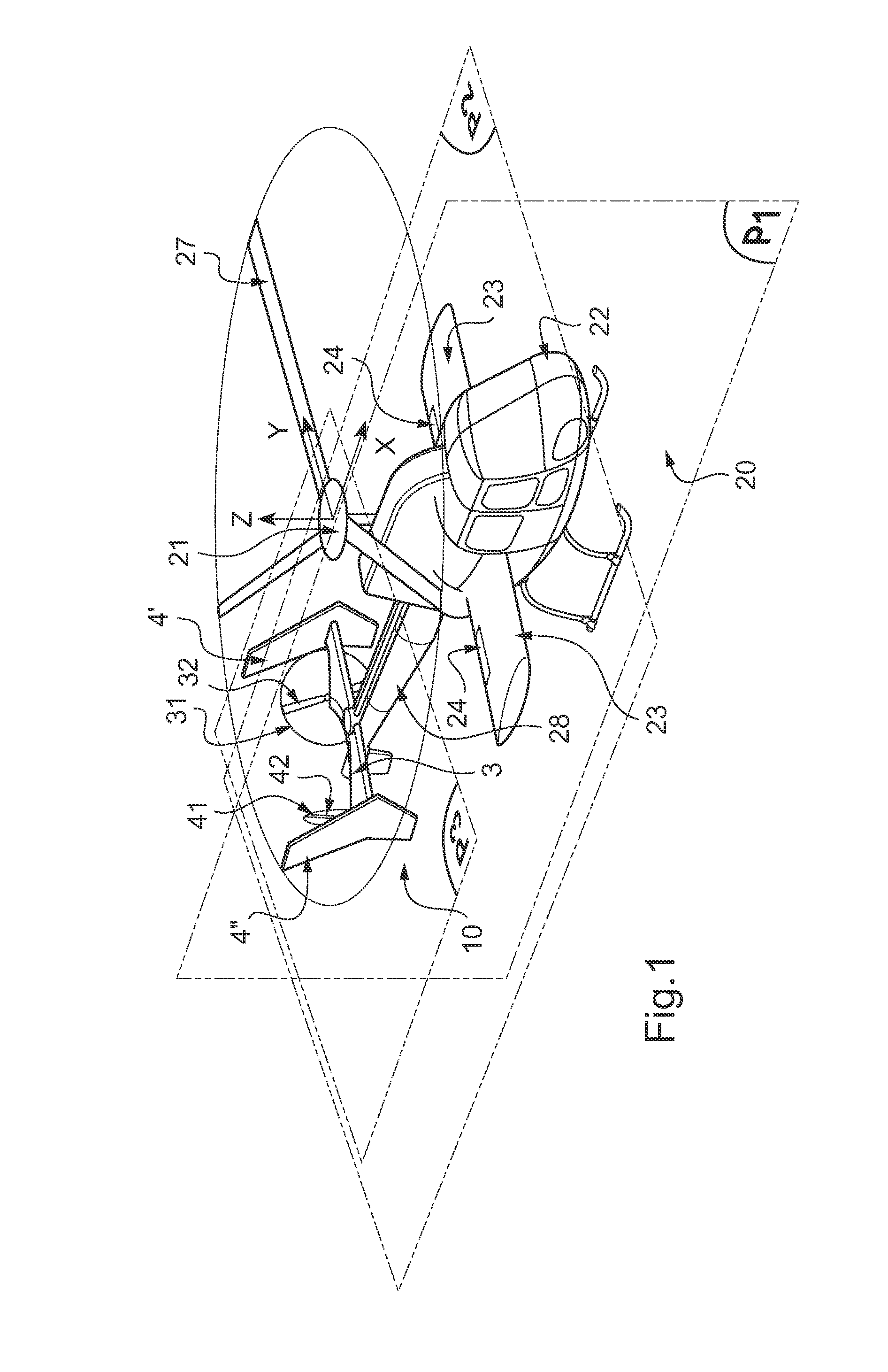

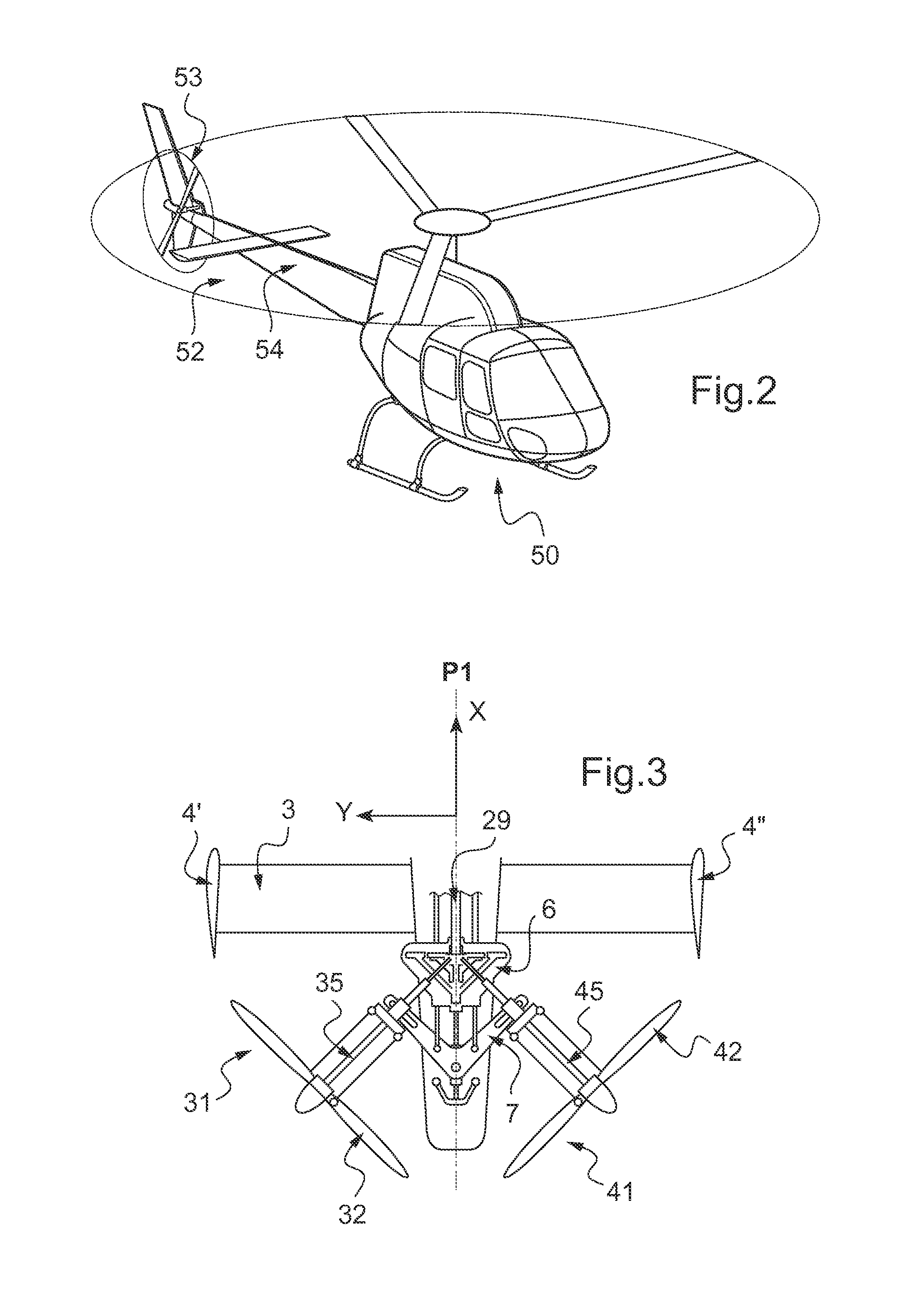

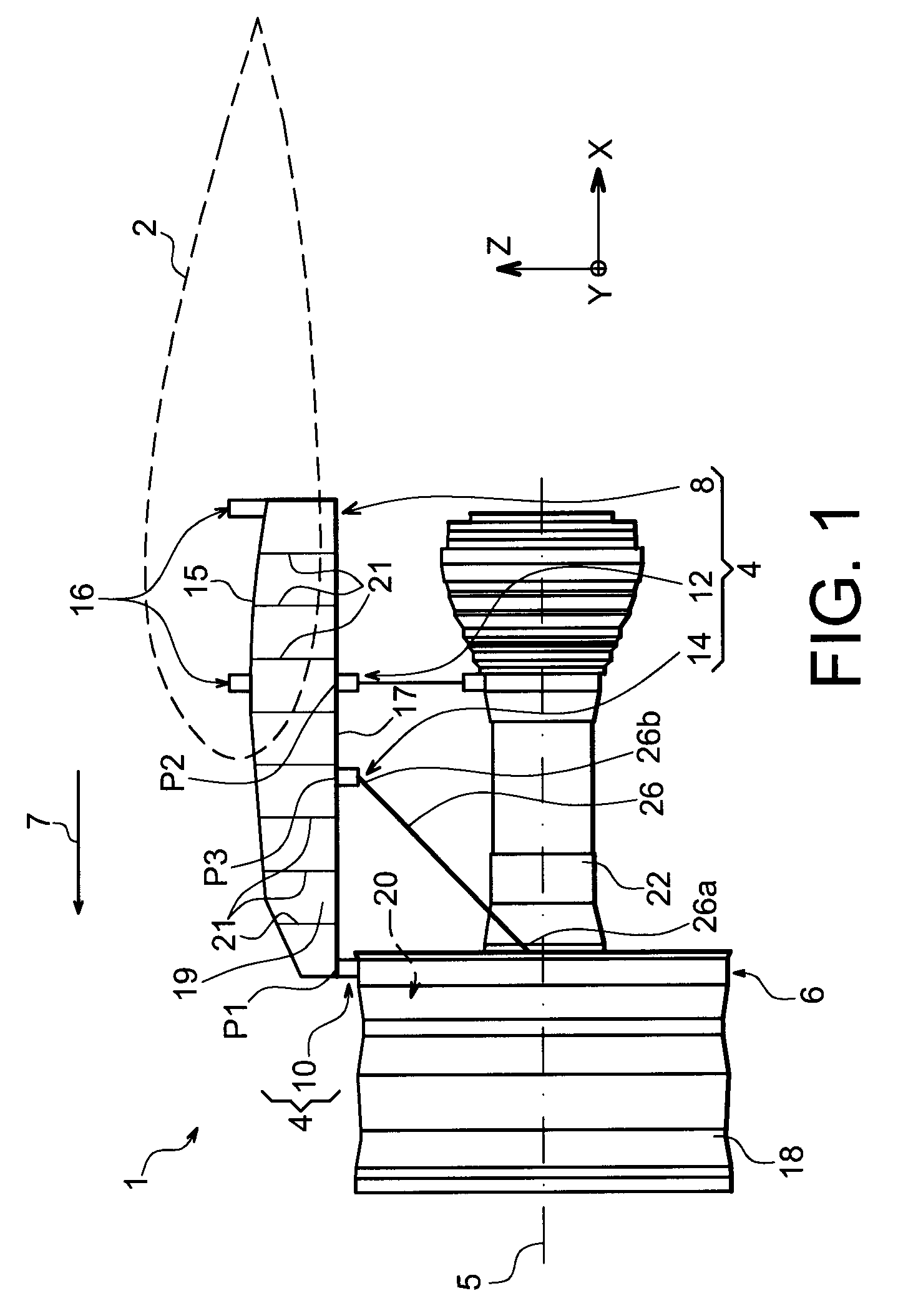

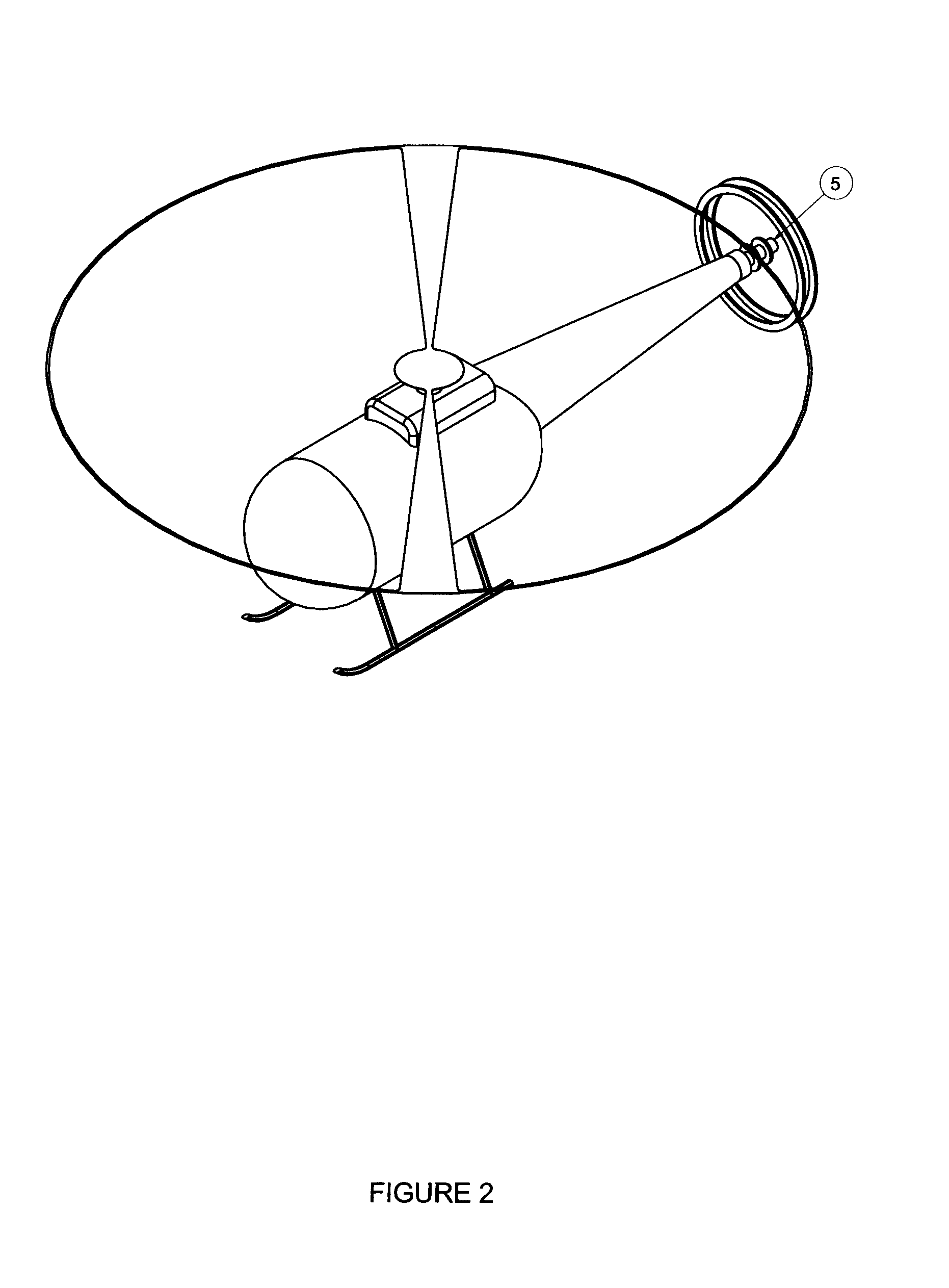

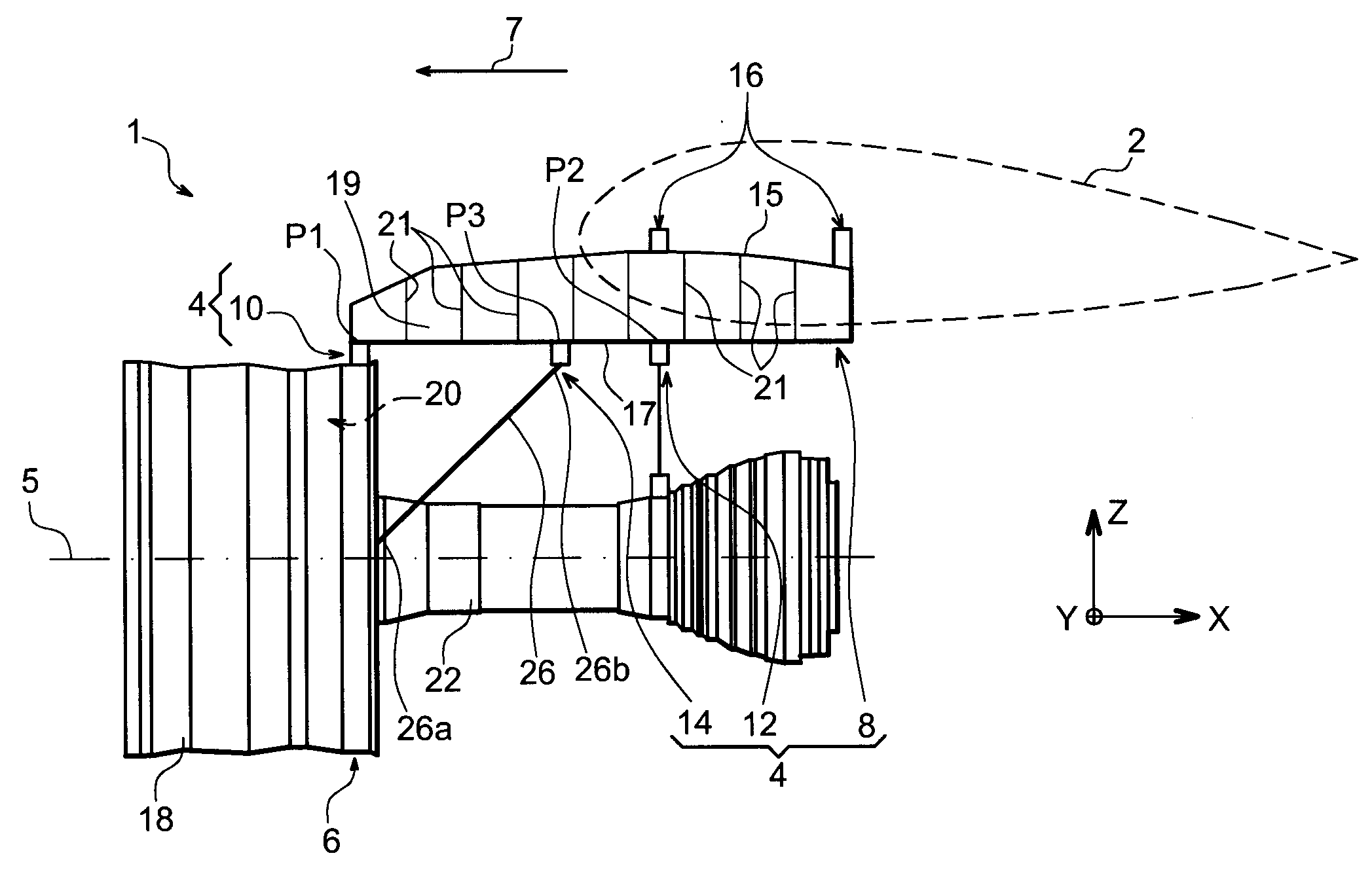

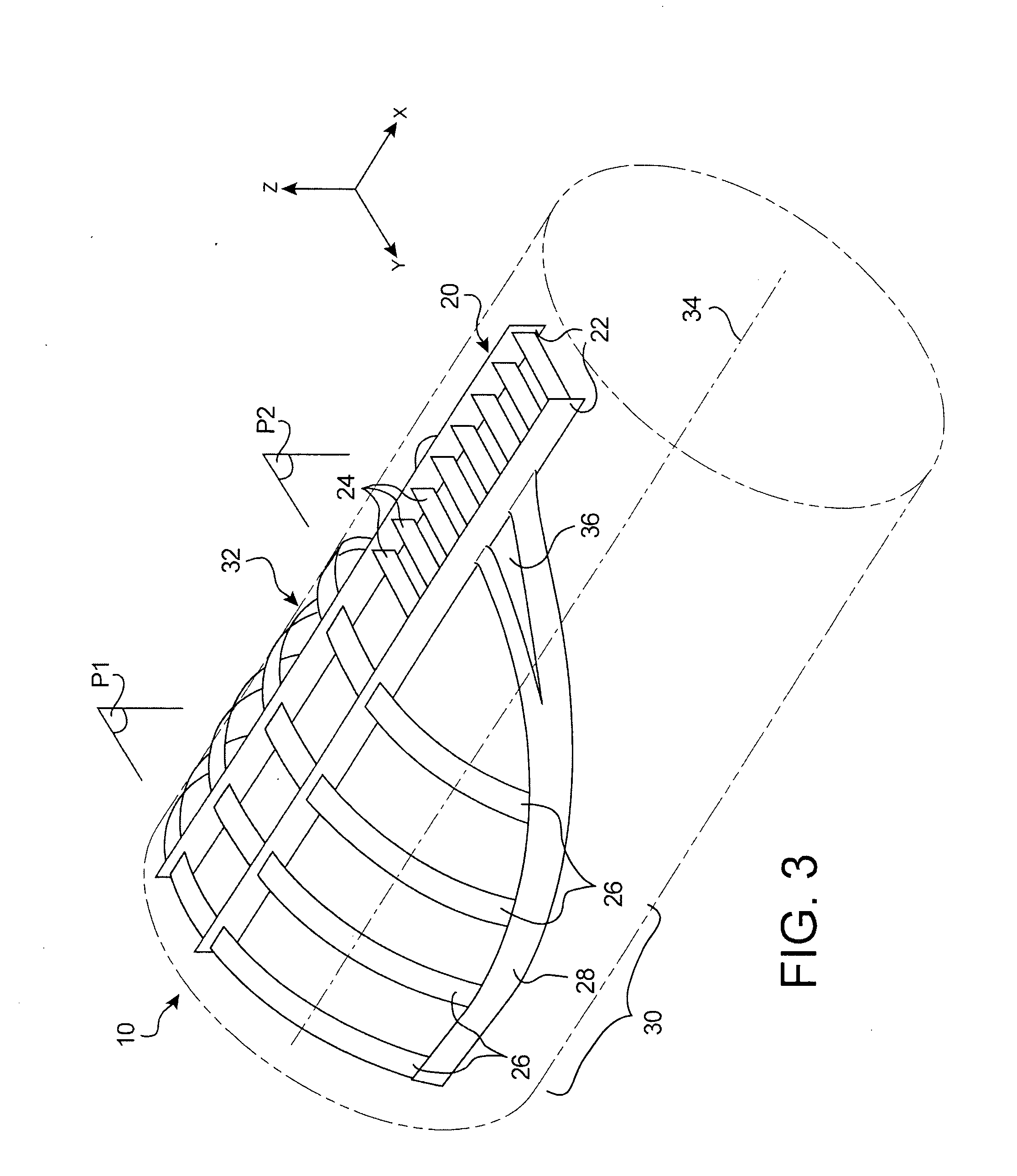

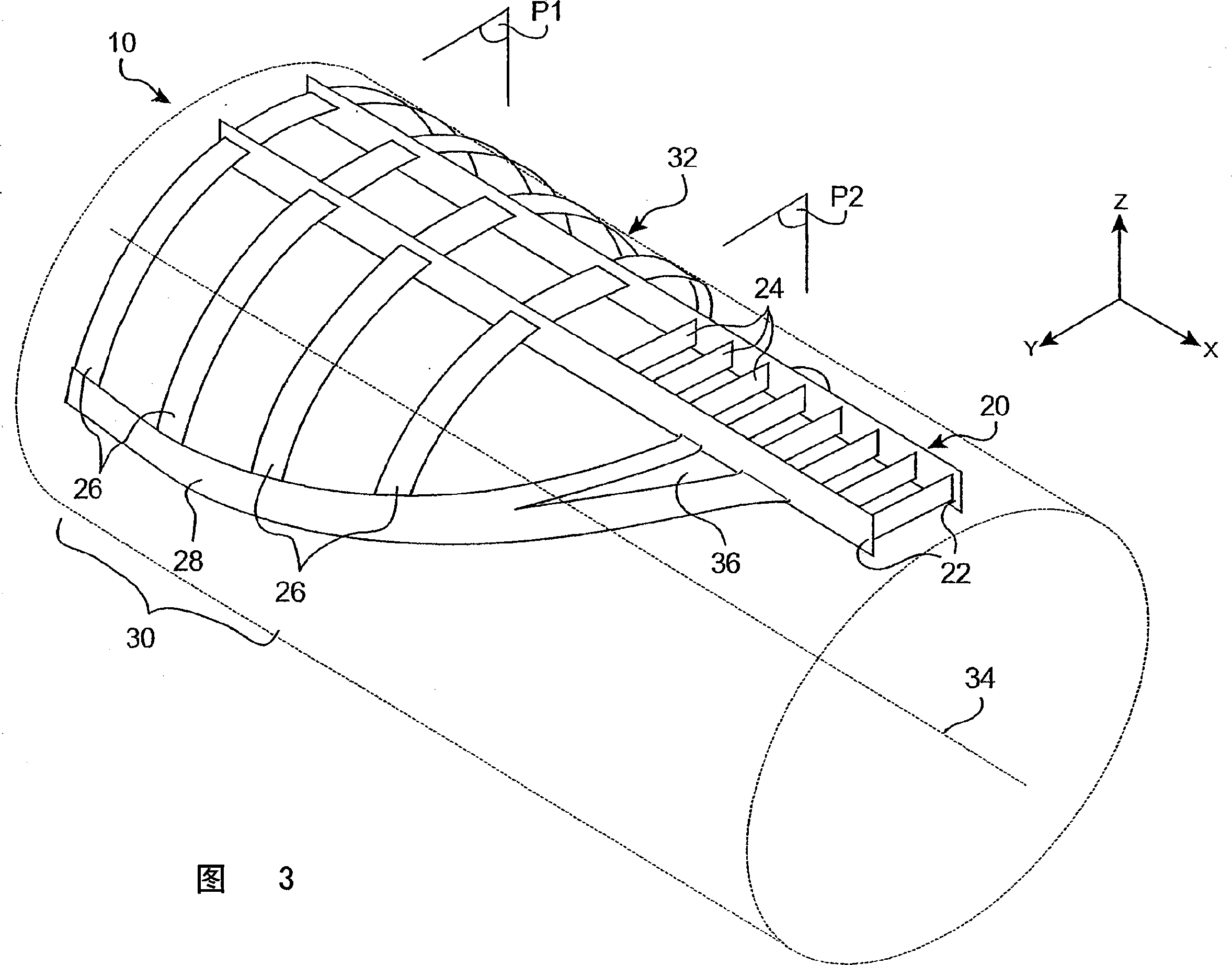

Anti-torque device with longitudinal thrust for a rotorcraft

A tail assembly (10) for a rotorcraft (20), the tail assembly (10) comprising a first stabilizer (3) extending transversely on either side of an anteroposterior plane (P1), and a second stabilizer (4, 4″) extending in elevation. Two propellers (31, 41) positioned on either side of the anteroposterior plane (P1) provide the rotorcraft (20) with at least part of its yaw control and its propulsion. The axes of the two propellers (31, 41) are situated in a plane substantially parallel to the horizontal plane (P3) and they intersect at a position in the anteroposterior plane (P1) of the rotorcraft (20) that is located between the front end of the rotorcraft (20) and the propellers (31, 41). Using both propellers (31, 41) of the tail assembly (10) simultaneously makes it possible to provide the rotorcraft (20) with longitudinal thrust while conserving its transverse thrust for the anti-torque function, it being possible to control these two thrusts independently.

Owner:EUROCOPTER

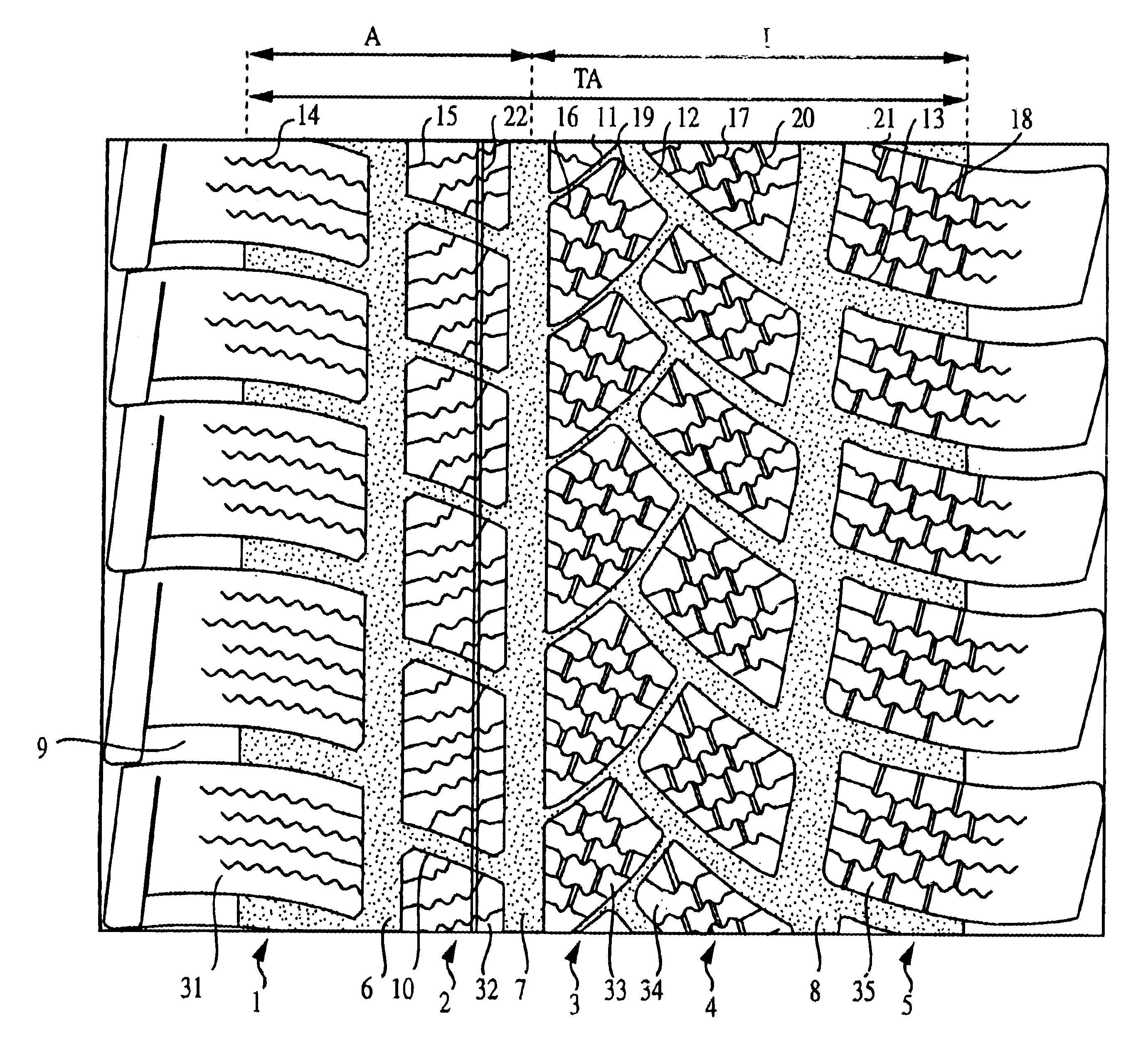

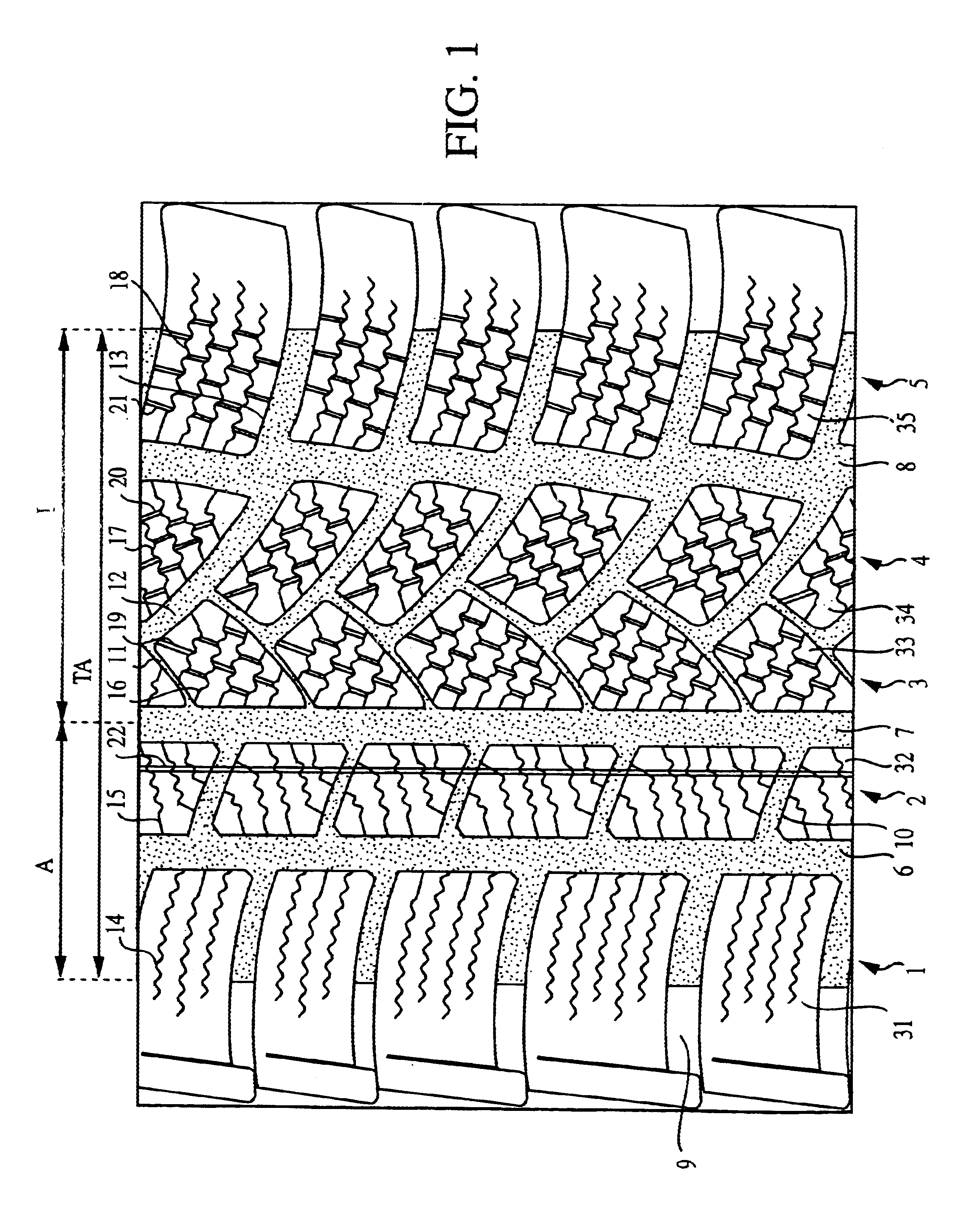

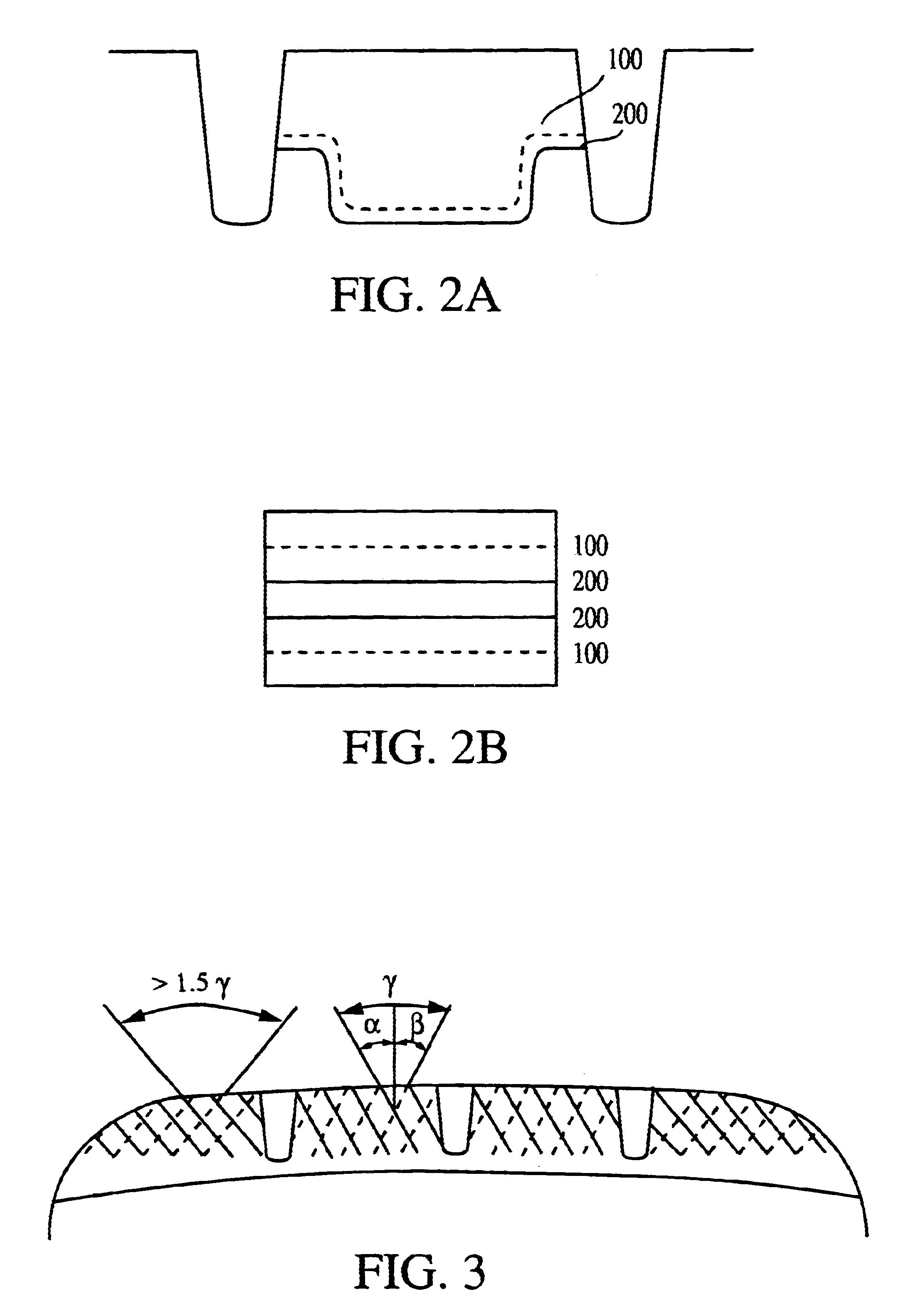

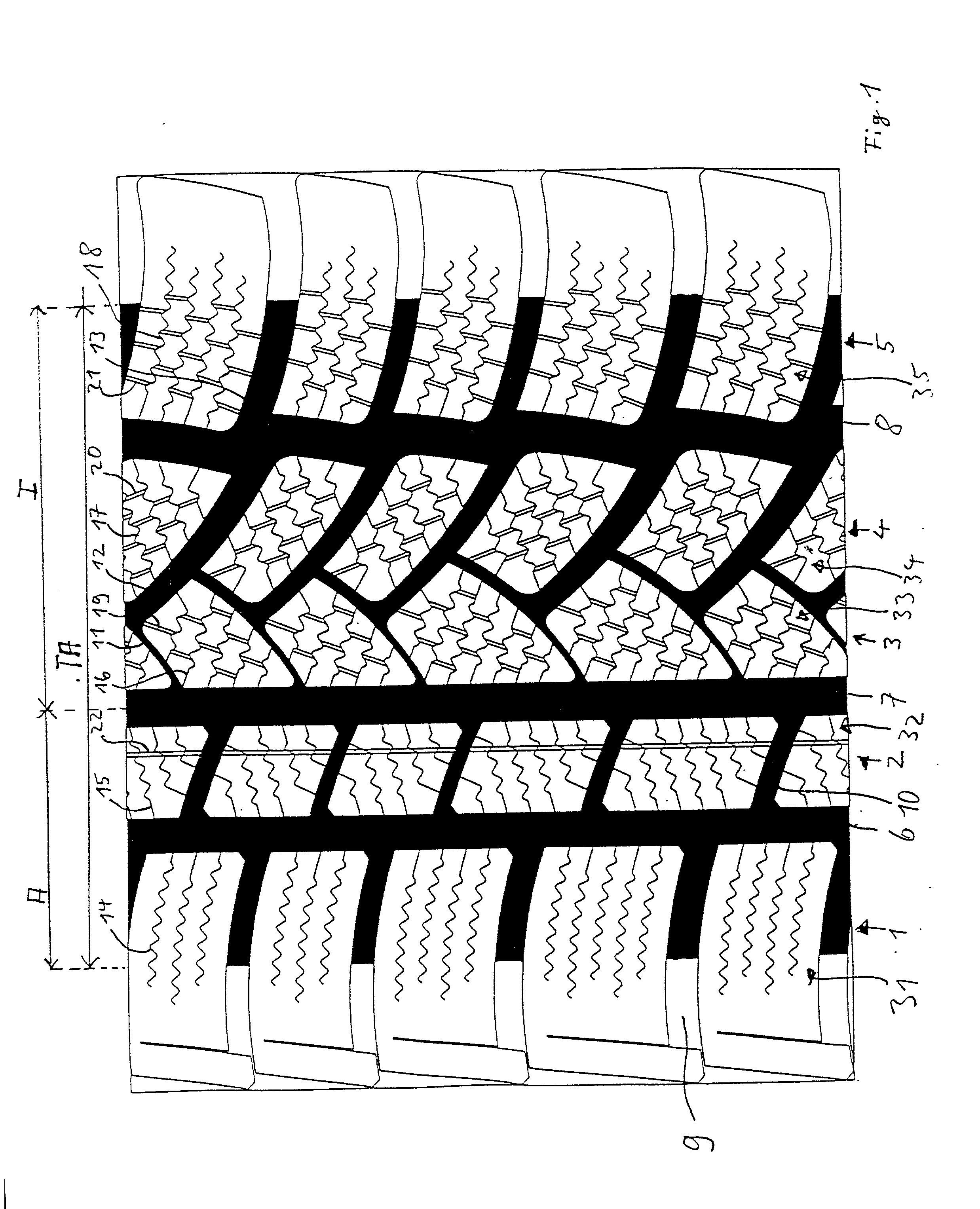

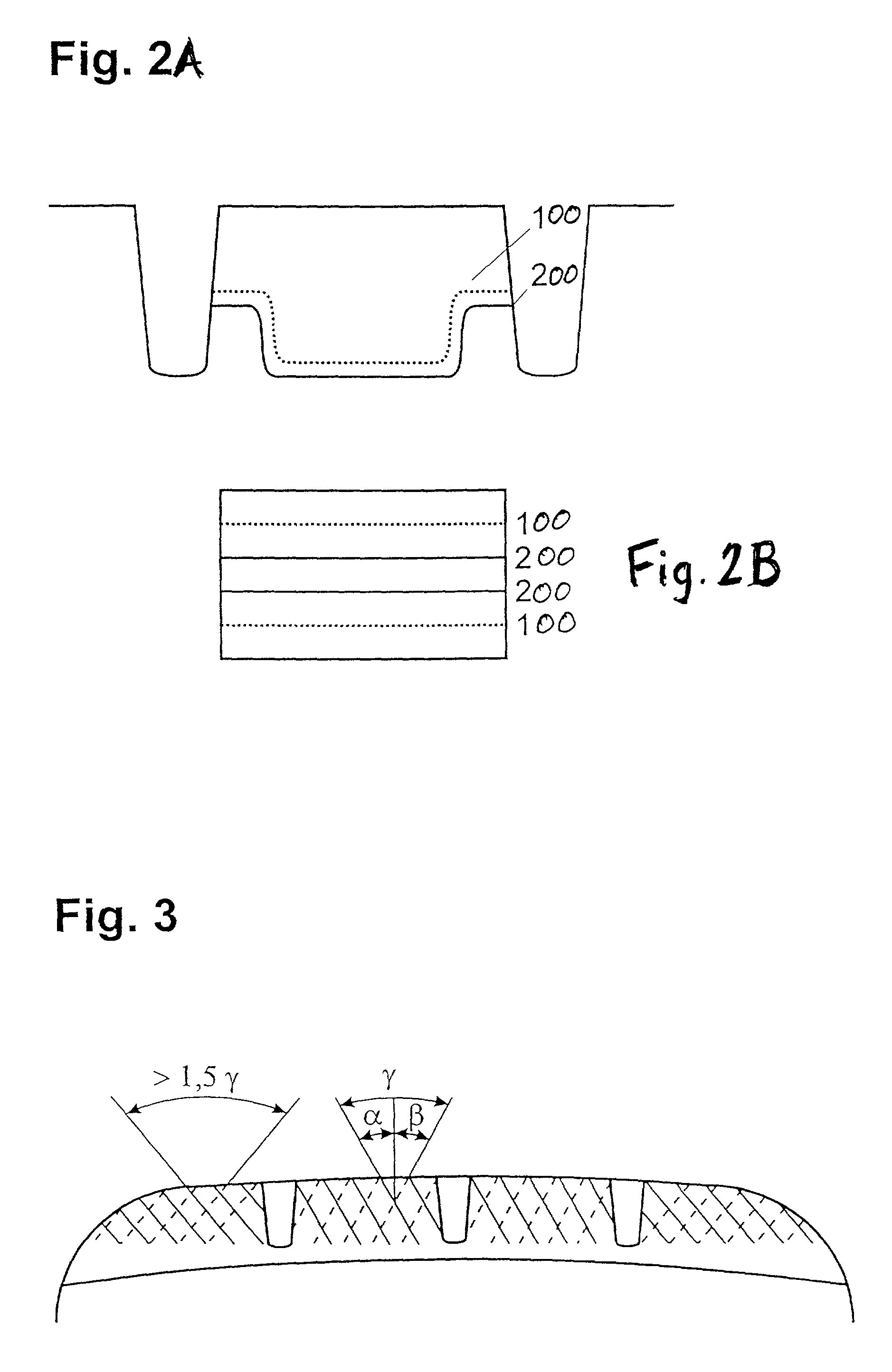

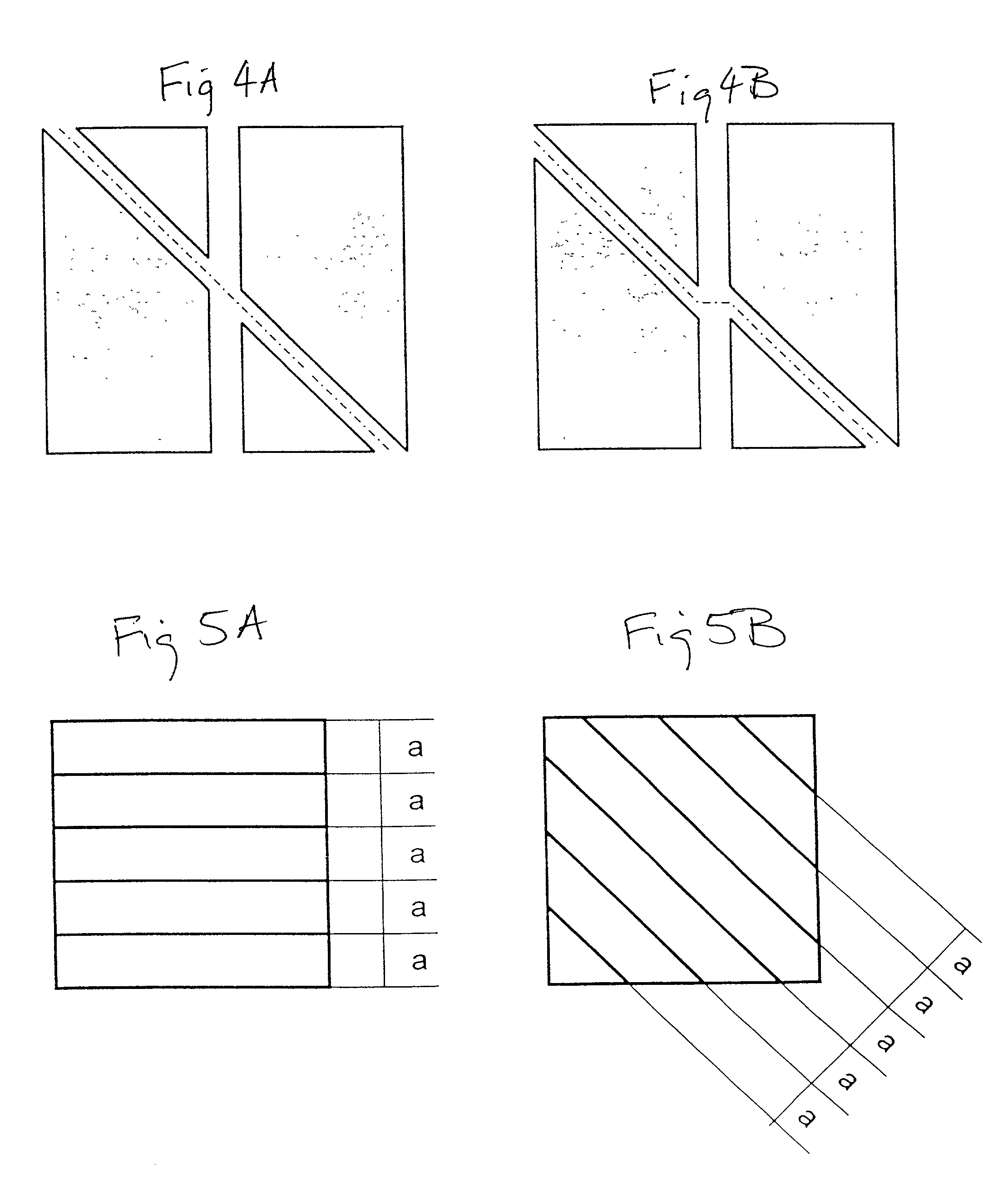

Tread profile of a snow tire

Tread profile of a snow tire for a vehicle in which at least two vehicle wheels are rotatably mountable outside of a longitudinal vehicle axis. The tread profile includes a plurality of profile block rows aligned in a circumferential direction and distributed in an axial direction from a first tire shoulder adapted to be positioned toward an outside of the vehicle in an operational state of the tire on the vehicle to a second tire shoulder adapted to be positioned toward an inside of the vehicle in an operational state of the tire on the vehicle. The tread profile also includes a plurality of channels aligned in a circumferential direction and being arranged to axially separate the plurality of profile block rows from each other, and the plurality of channels includes a first circumferential channel positioned to divide the tread profile into two axial regions of functionally different structure, and each axial region axially extending from one the first and second tire shoulders to the first circumferential channel. The plurality of profile block rows includes a plurality of profile block elements, and the plurality of profile block elements in the axial region extending from the circumferential channel to the first tire shoulder have a higher lateral thrust stiffness than the plurality of profile block elements in the axial region extending from the first circumferential channel to the second tire shoulder.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

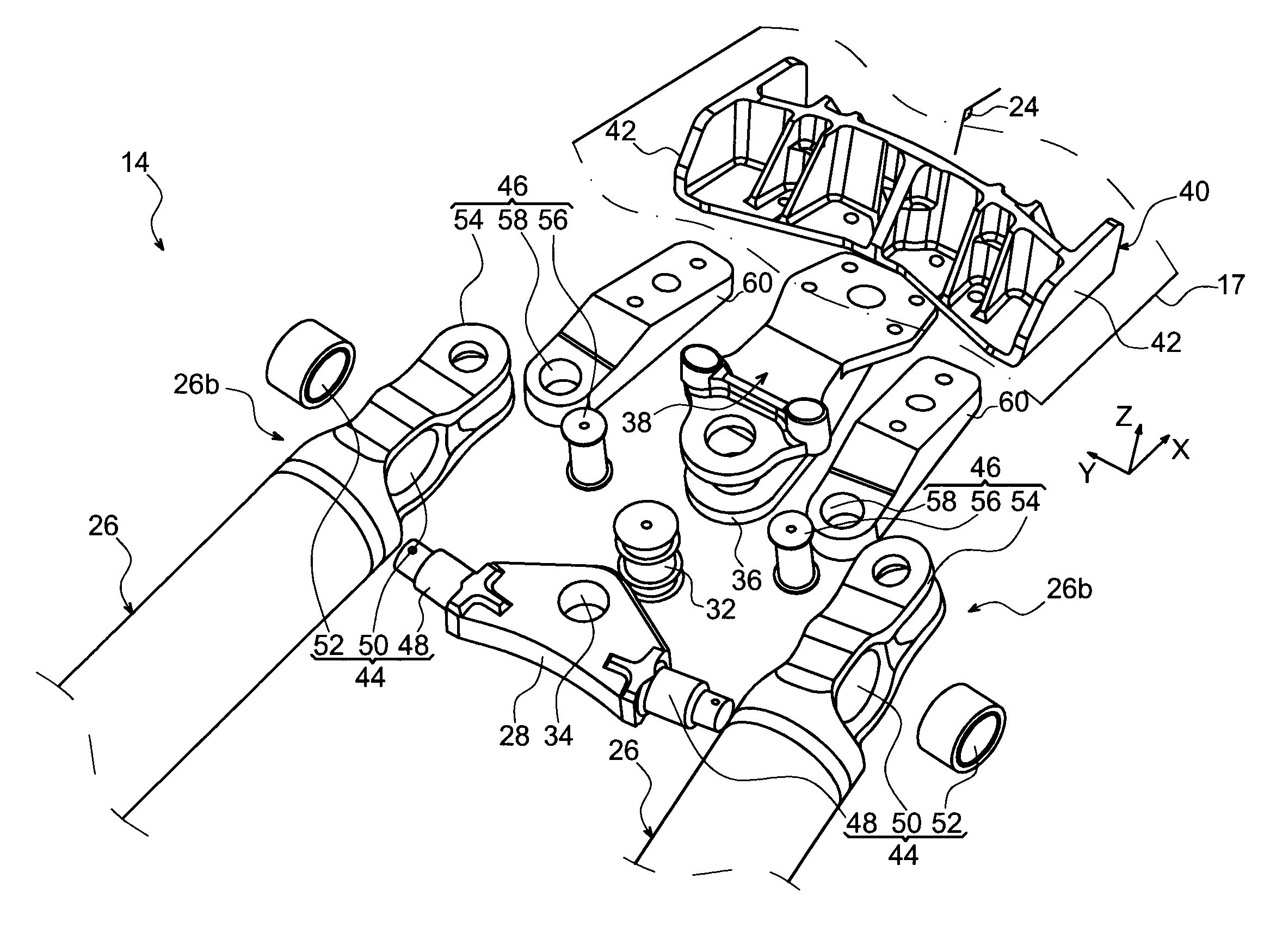

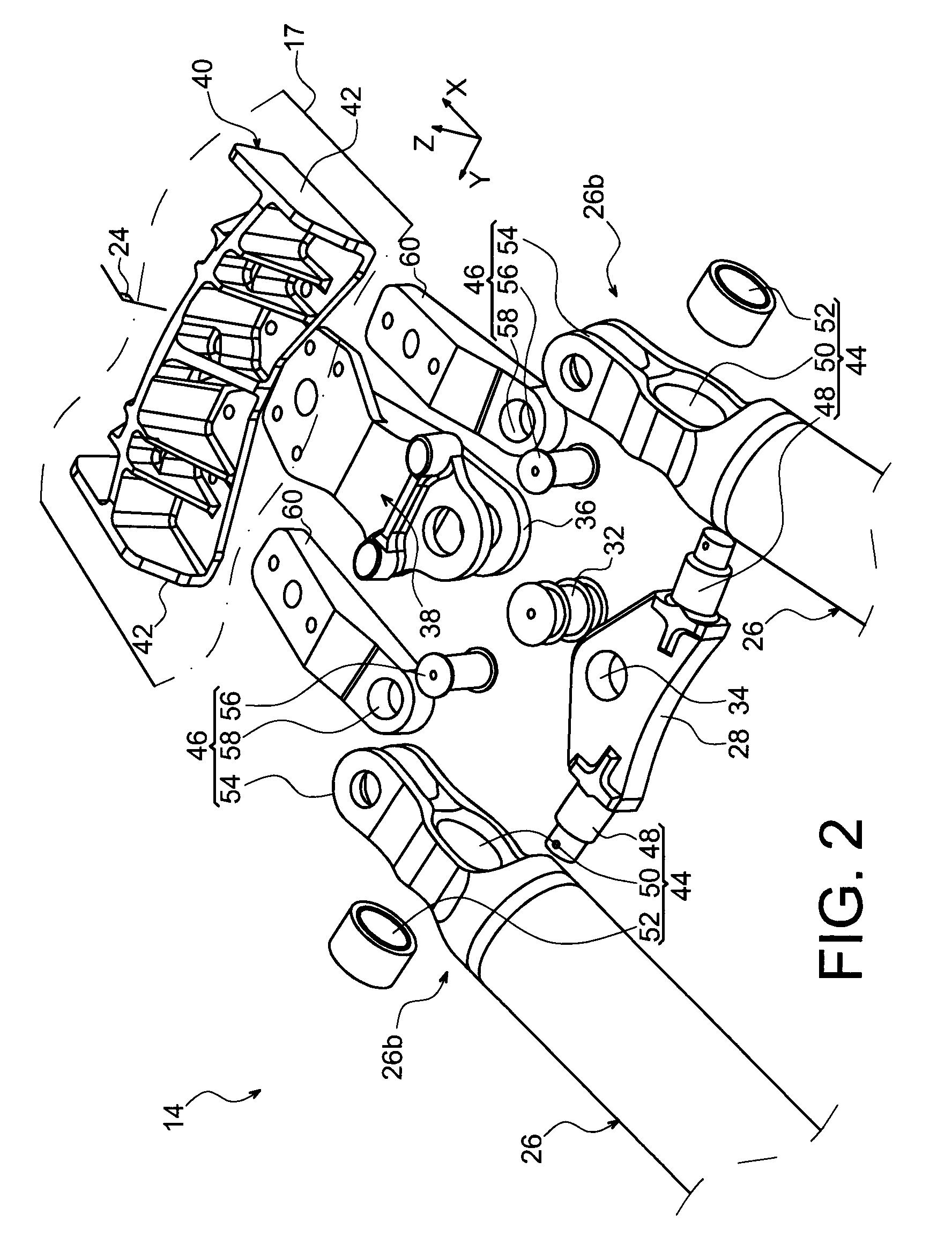

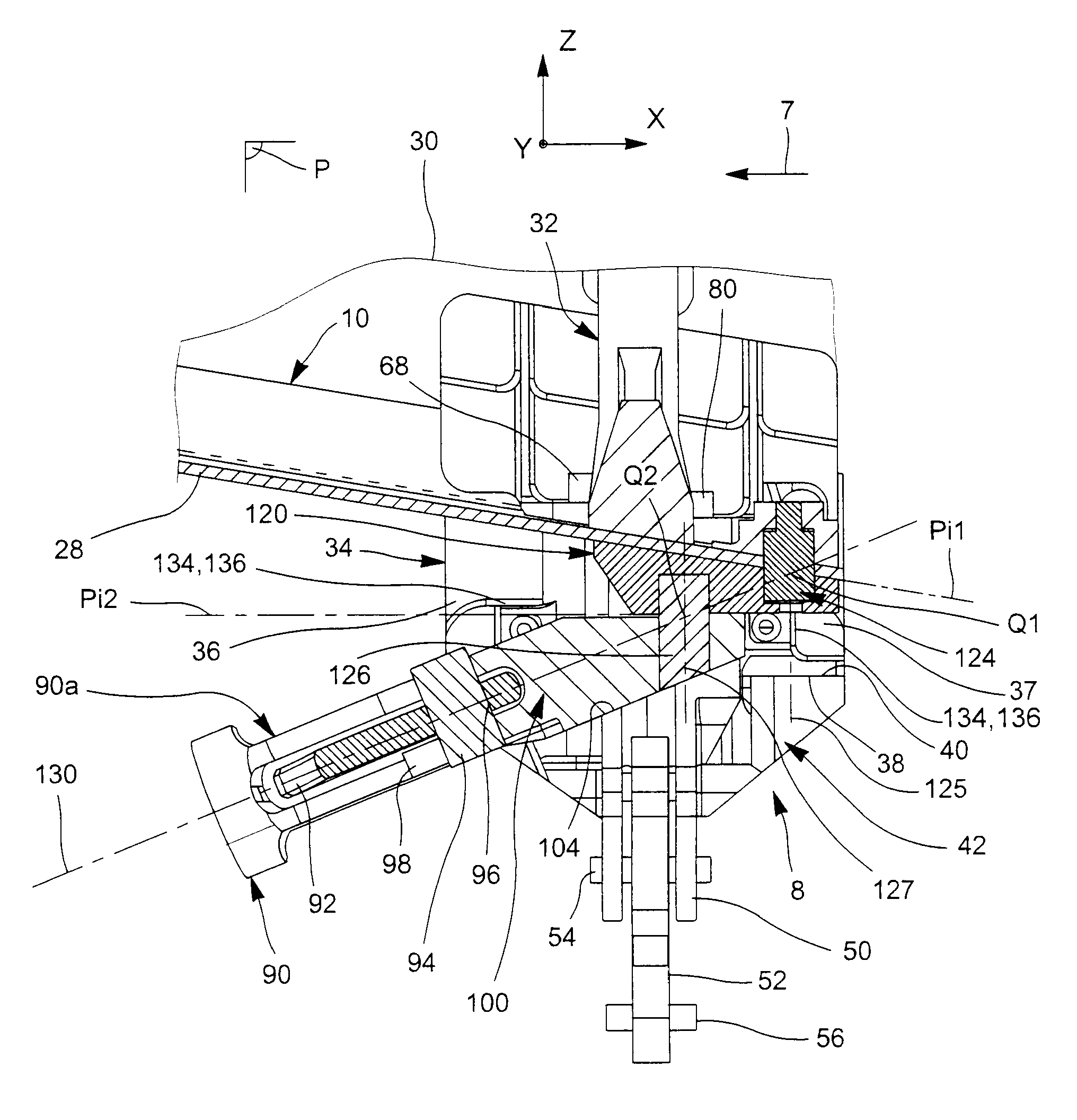

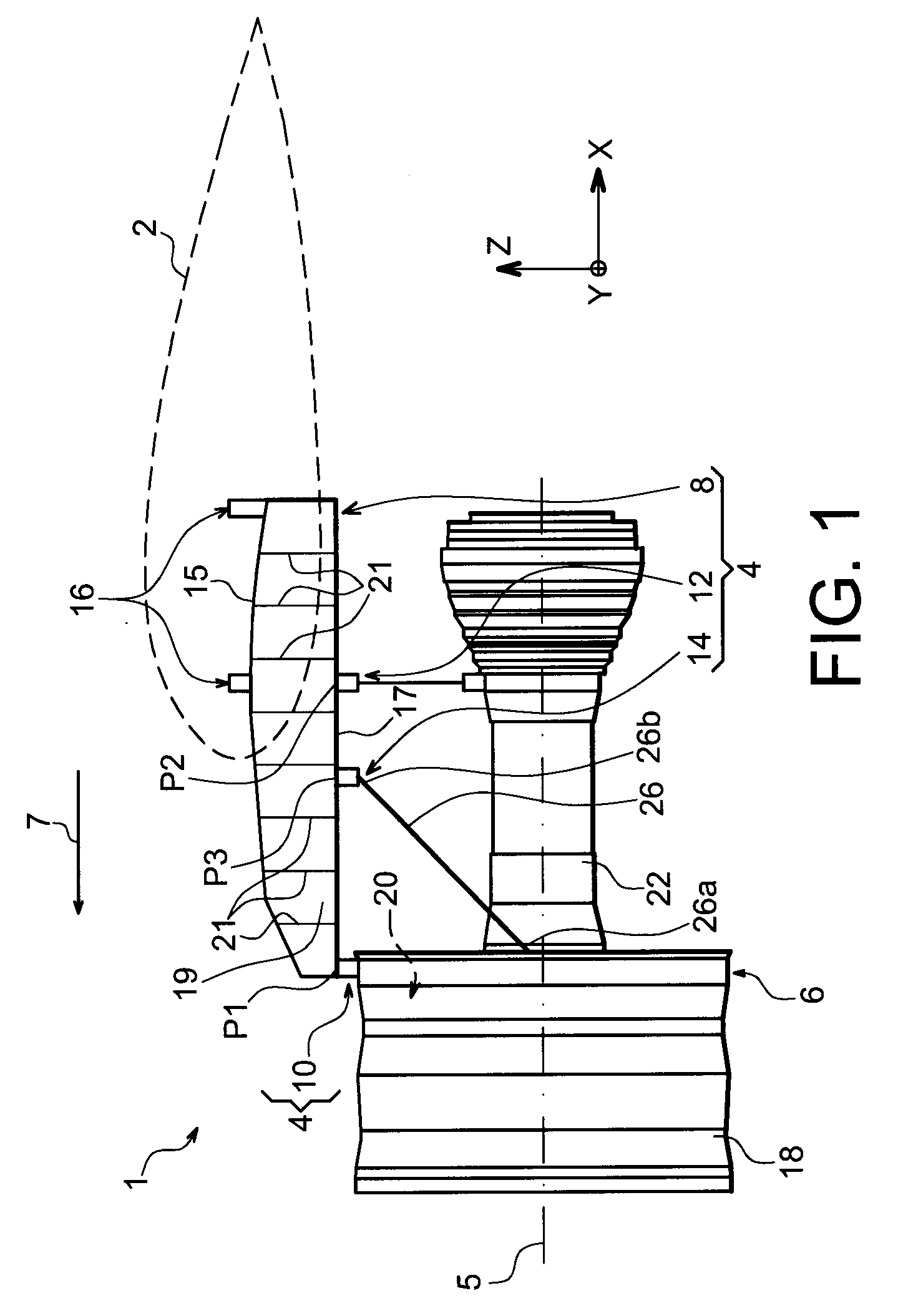

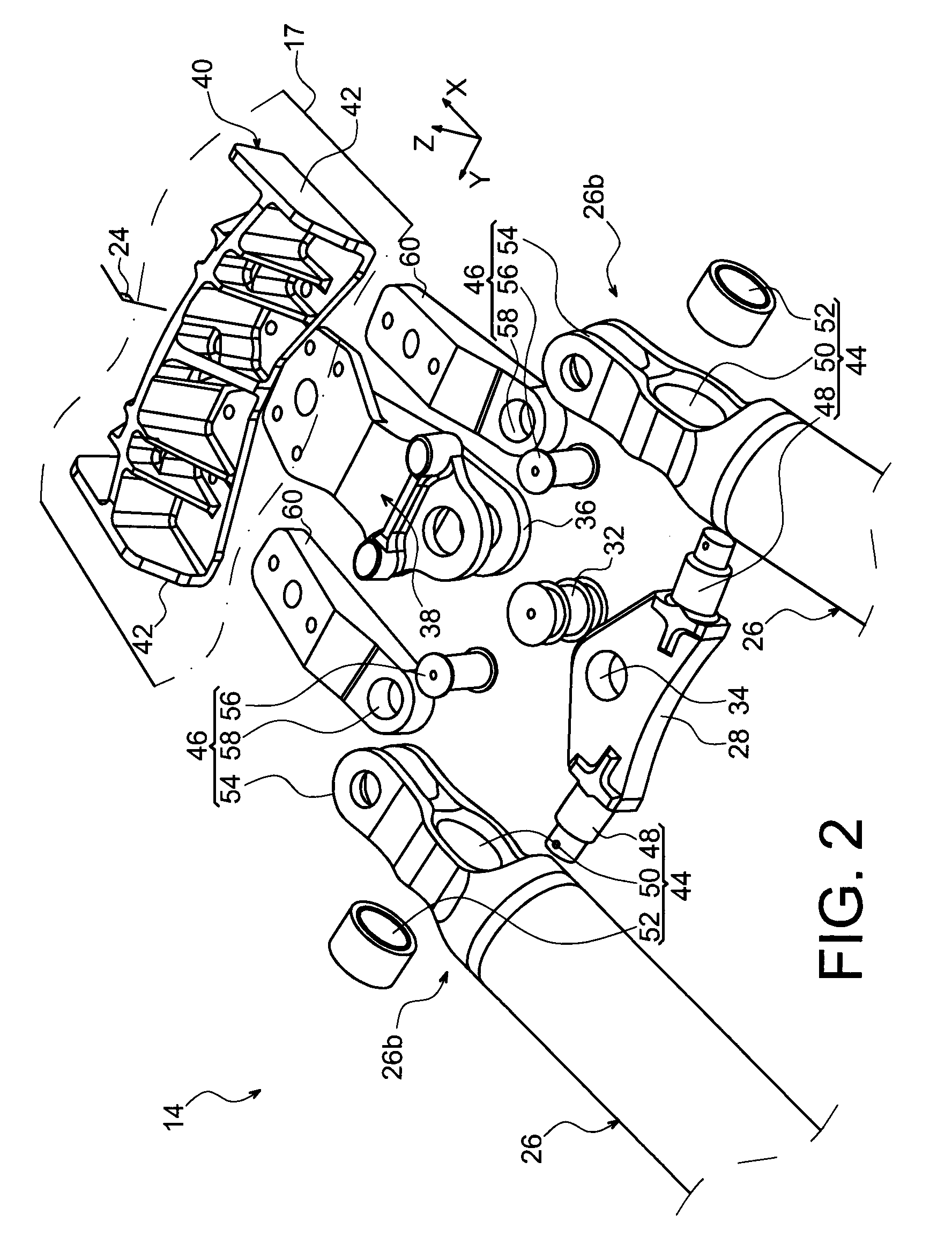

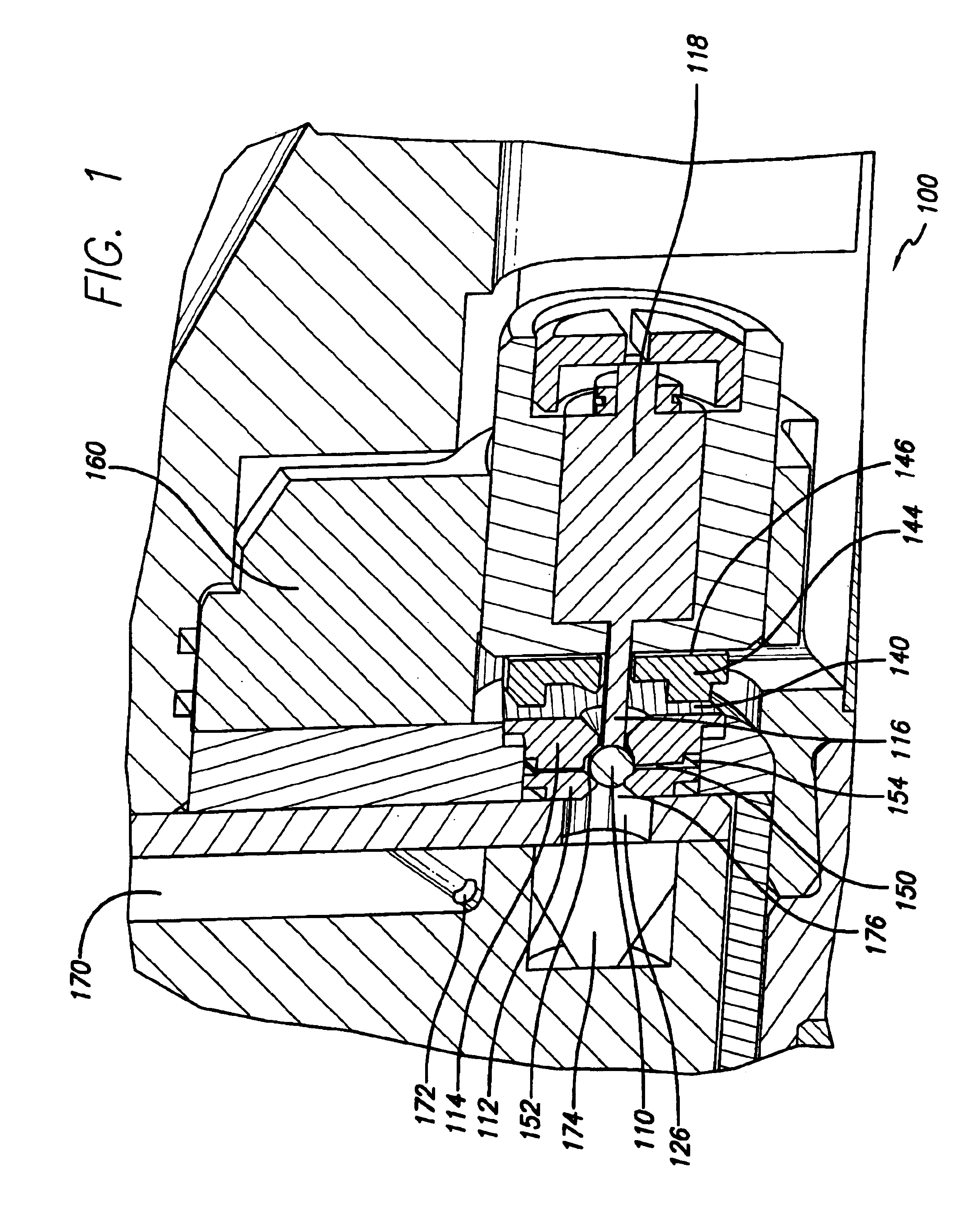

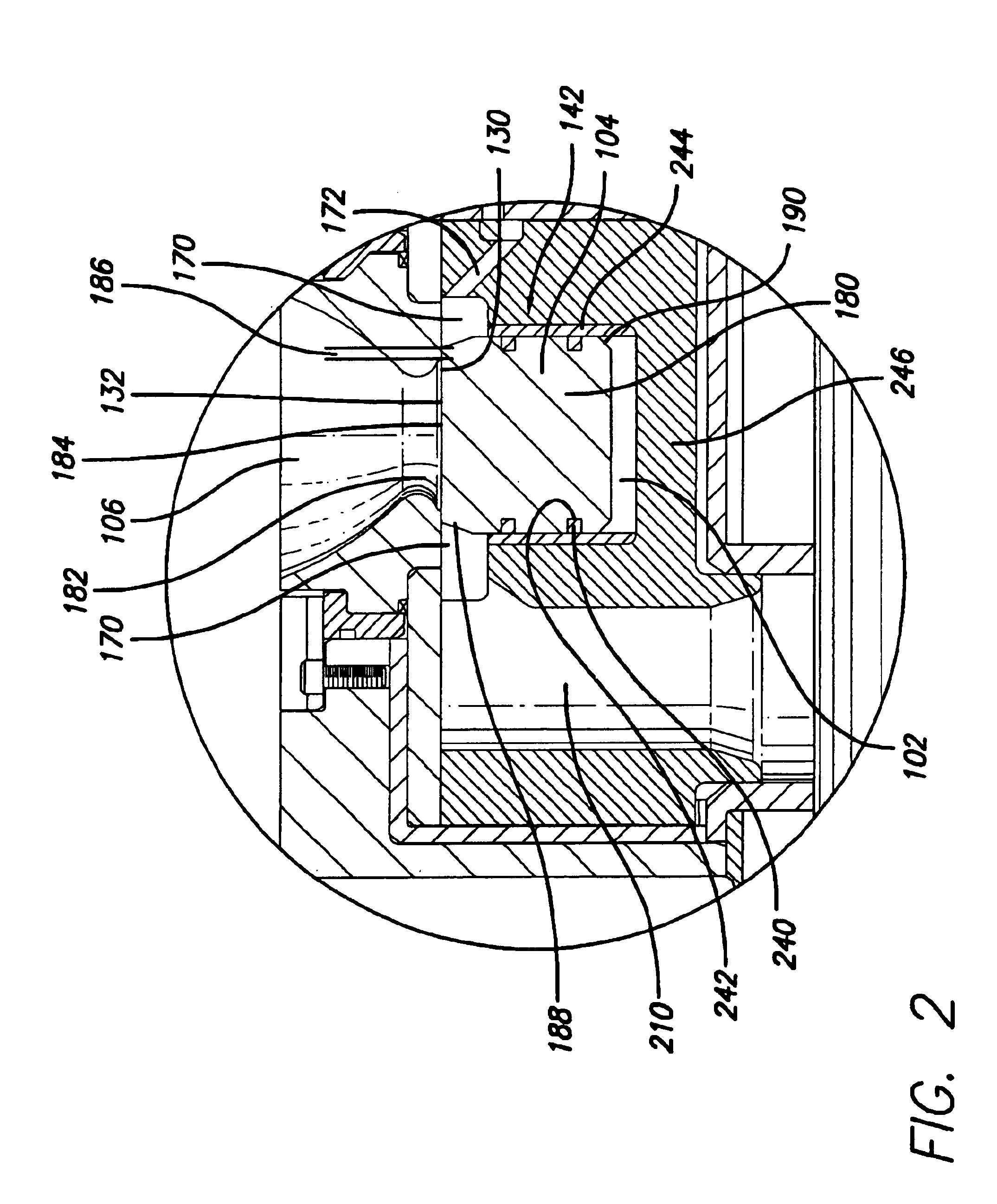

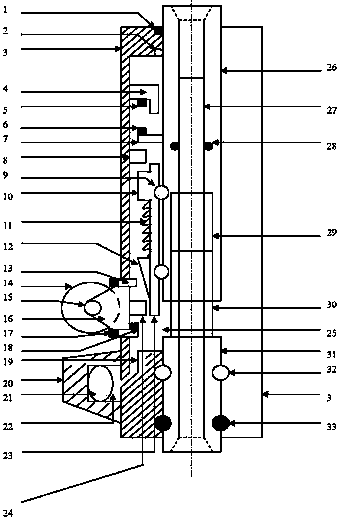

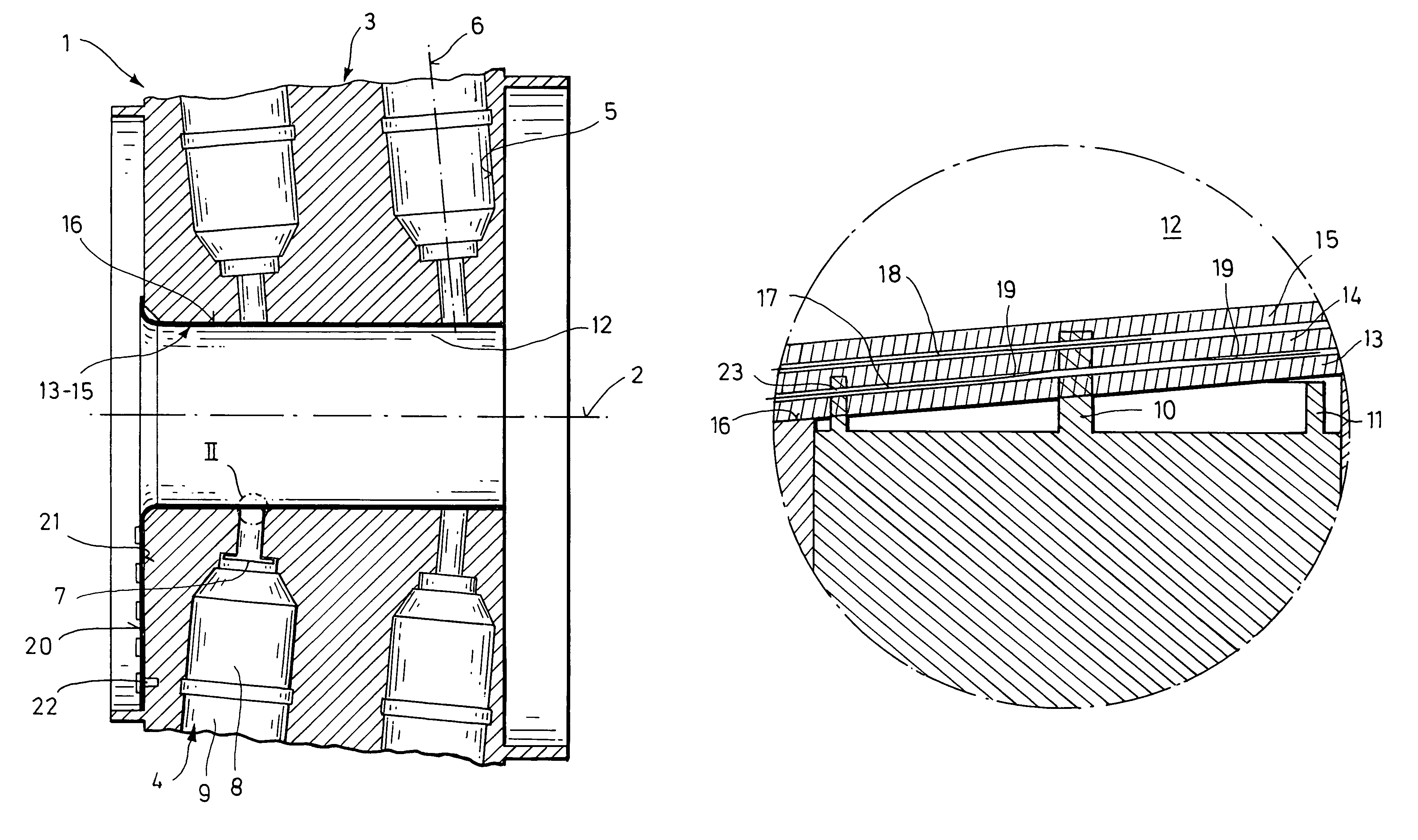

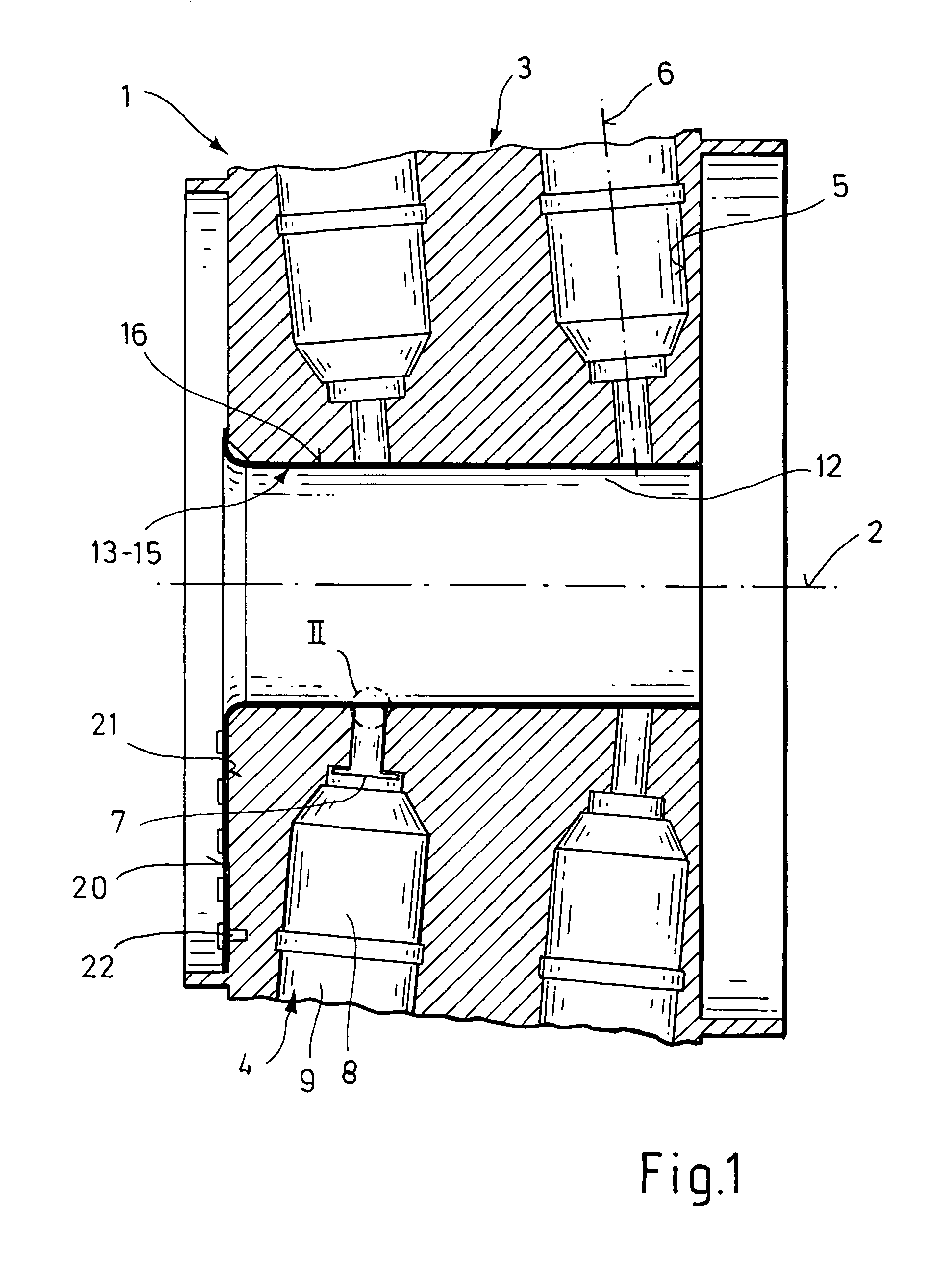

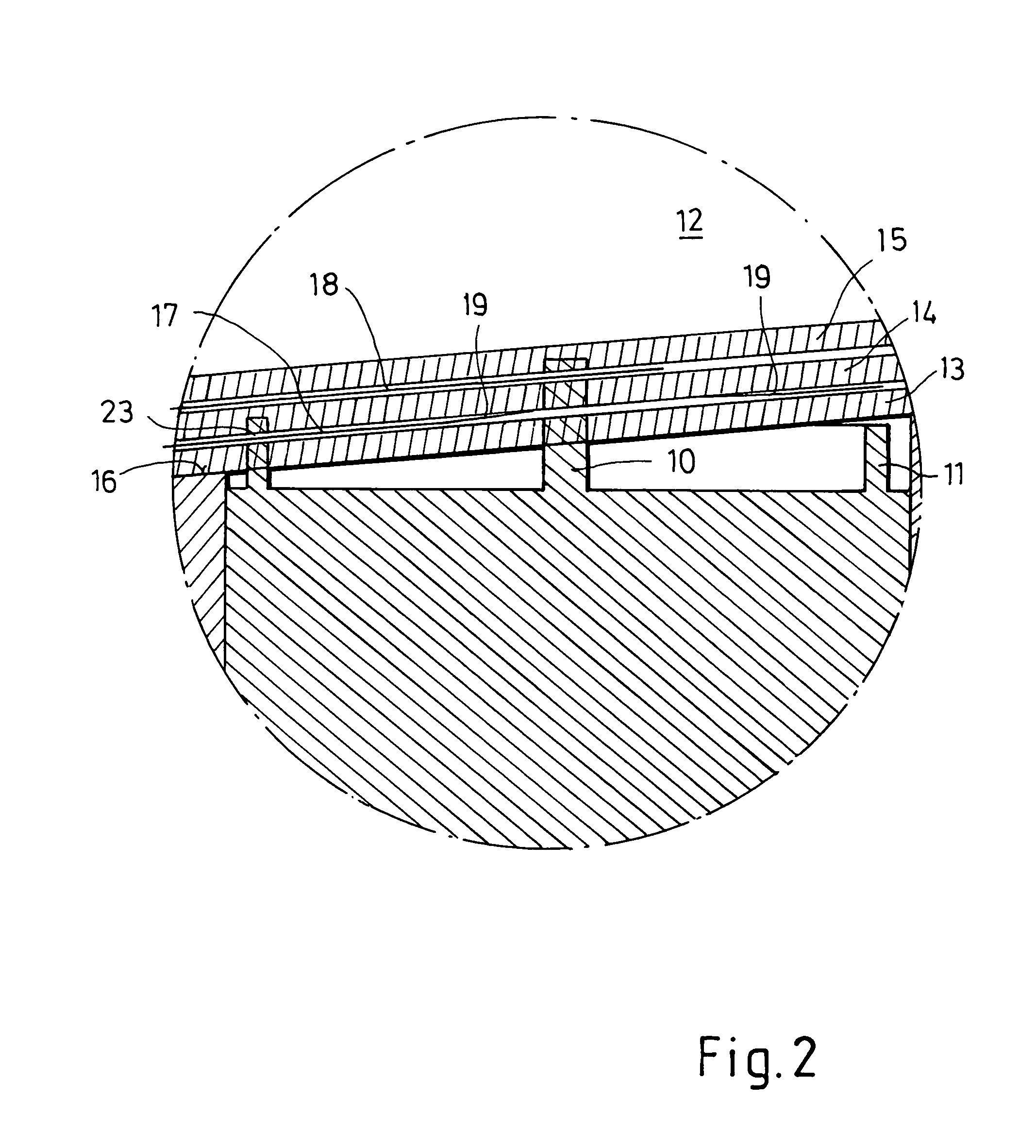

Mounting device for an aircraft engine comprising two thrust recovery rods with a double rear mechanical connection

ActiveUS7607609B2Enhanced advantageMeet growth requirementsPower plant constructionGas turbine plantsRigid structureAirplane

A mounting device for an aircraft engine includes a rigid structure and a device for mounting the engine on the rigid structure, the mounting device including a thrust load recovery device with two lateral thrust load recovery rods each having a rear end mounted on a crossbar of the recovery device with a first mechanical connection. At the rear end of each of the two rods, there is also provided a second mechanical connection with play between the rear end and a support fitting integral with the rigid structure. The first mechanical connection is implemented using a pin provided on the crossbar, passing through an orifice provided in the rear end of the rod.

Owner:AIRBUS OPERATIONS (SAS)

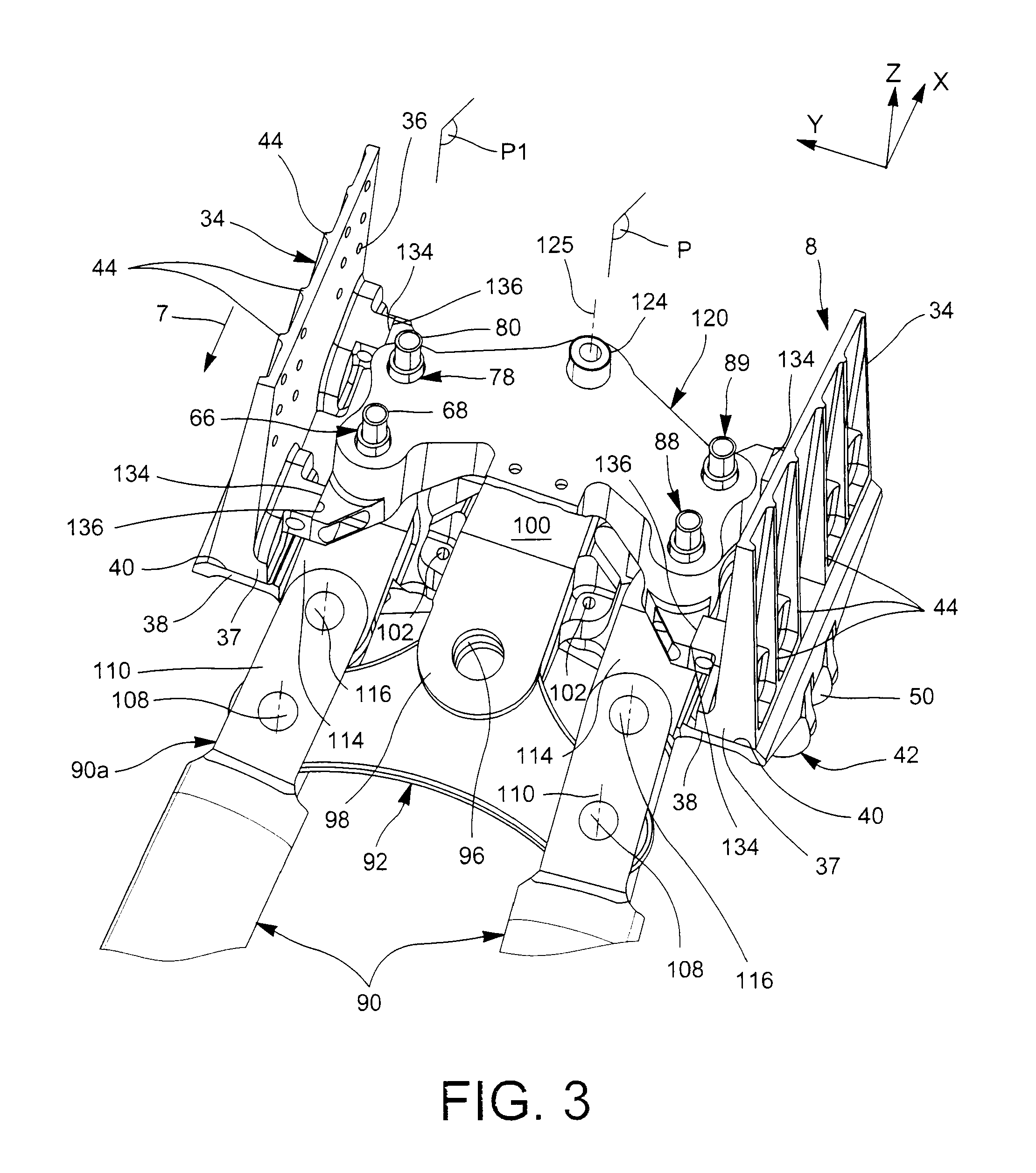

Attachment pylon for aircraft having a rear engine attachment beam offset from the caisson

ActiveUS20100127117A1Easy to assembleQuality improvementPower plant constructionPower plant typeAirplaneLateral thrust

An engine attachment pylon for an aircraft including an intermediate piece interposed between a crossbar support and a rigid caisson, a first shear slug passing through a first interface fixing plane between the piece and the caisson, and a second shear slug passing through a second interface fixing plane between the piece and the support. Also, in side elevation, the intersection point between an axis of the pin and the plane, as well as the intersection point between an axis of the pin and the plane, are located on the common axis of two lateral thrust force collection connecting rods articulated on the crossbar.

Owner:AIRBUS OPERATIONS (SAS)

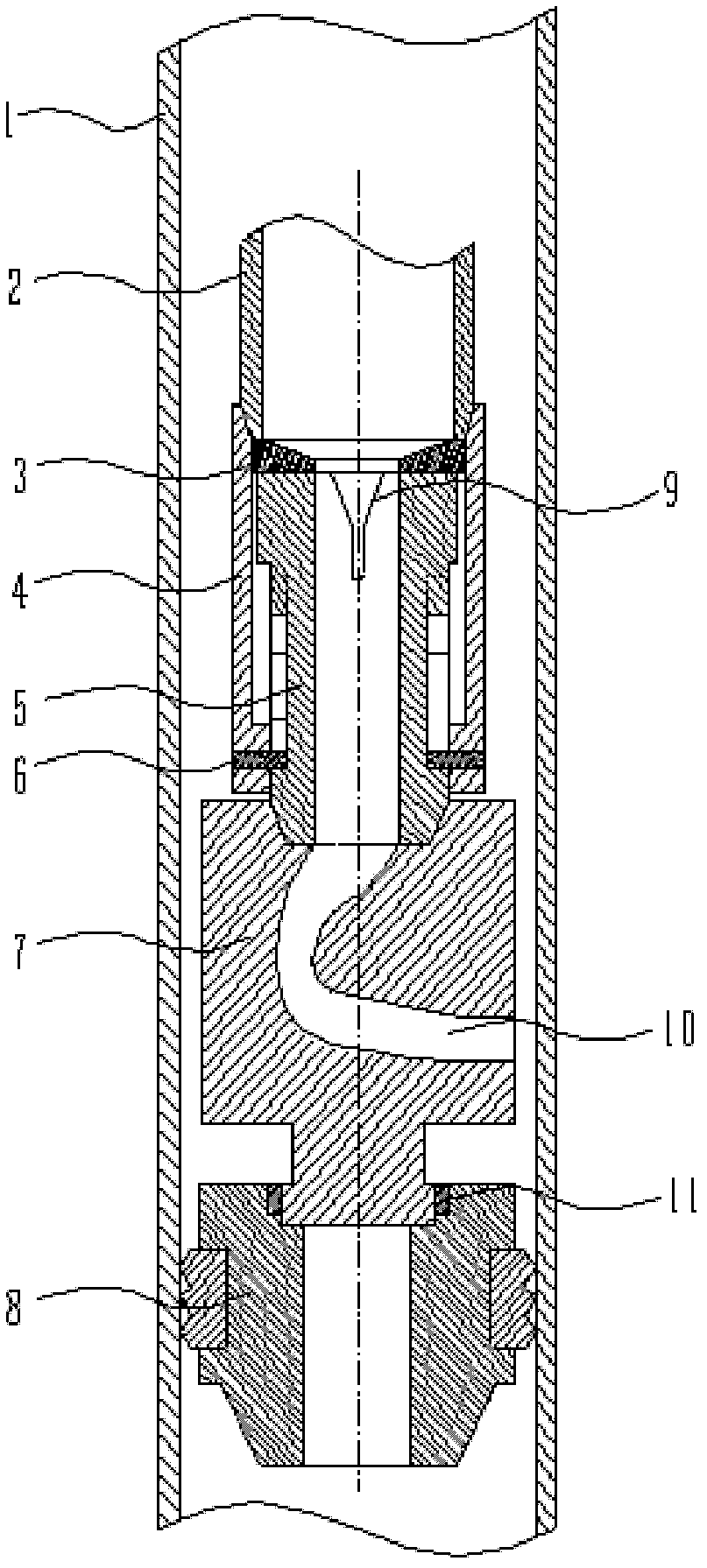

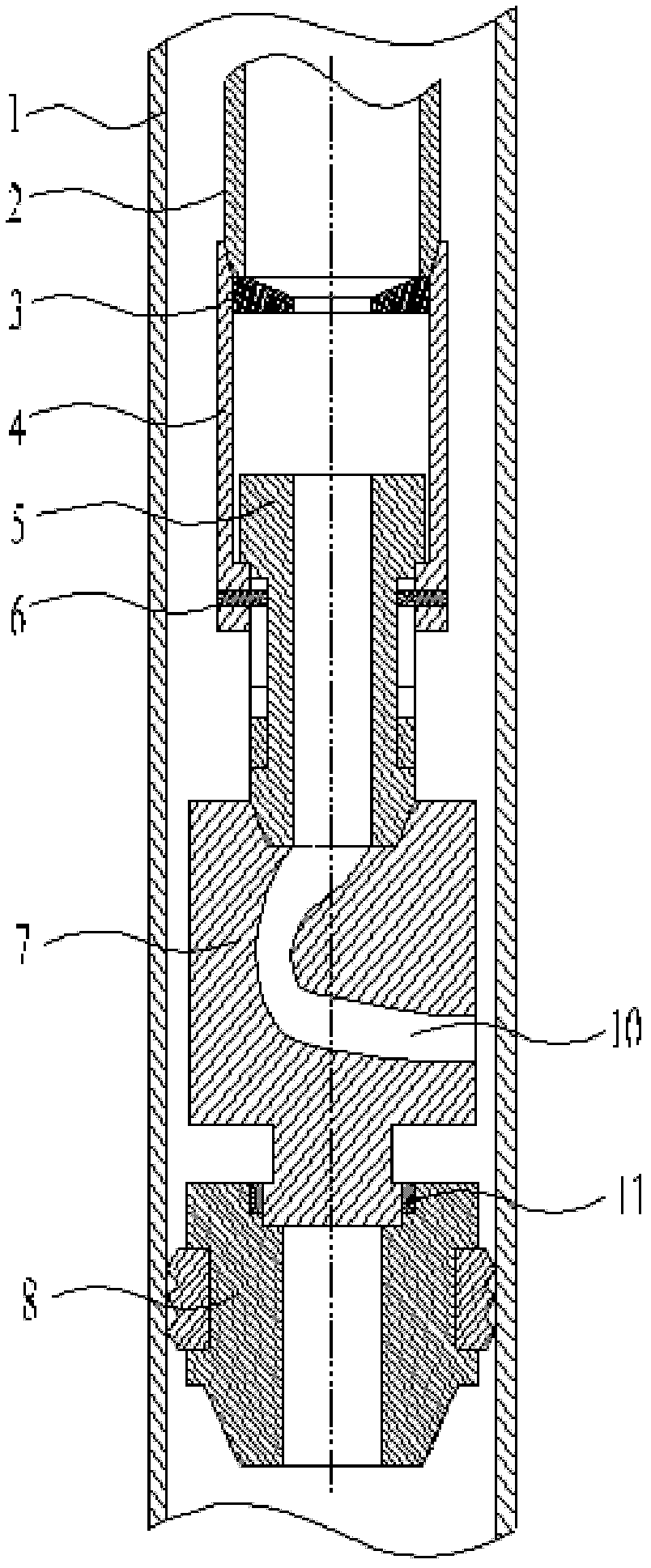

Radial horizontal well orienting device and method for operating same

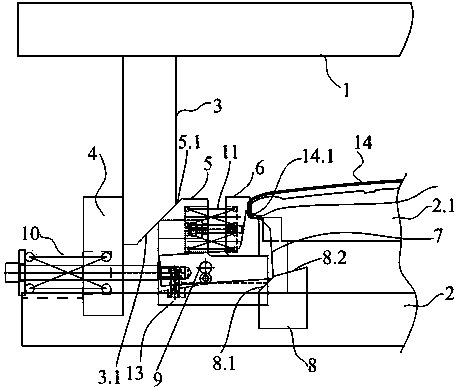

InactiveCN103375140ASolve complex directional window opening problems in radial wellsSolve the problem of directional window openingDirectional drillingBorehole/well accessoriesPetroleum engineeringLateral thrust

The invention discloses a radial horizontal well orienting device and a method for operating the same. The radial horizontal well orienting device and the method are designed for achieving the purpose of arranging a plurality of casing windows on a string at one step. The radial horizontal well orienting device is characterized in that an oil string and a steering rod are connected with a steering barrel of the device, the steering rod is connected with a steering gear, and guide pins of the steering barrel are inserted into guide slide grooves of the steering rod; when the oil string is lifted upwardly and placed downwardly and the steering barrel is driven to move up and down, the guide pins generate lateral thrust in the guide slide grooves, and the steering gear is pushed to realize a steering effect. The radial horizontal well orienting device and the method have the advantages that the radial horizontal well orienting device and the method are mainly applied to radial horizontal well operation for drilling a plurality of wells on the same oil layer, the complicated oriented windows can be arranged on a radial well without cable or down-hole electric device descending, well descending, azimuth measuring and multi-azimuth radial horizontal well orienting can be completed at one step only by the aid of the simple mechanical device, positioning and orienting are accurate, an operation procedure is simple, the operation cost is low, and the operation efficiency and accuracy are high.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

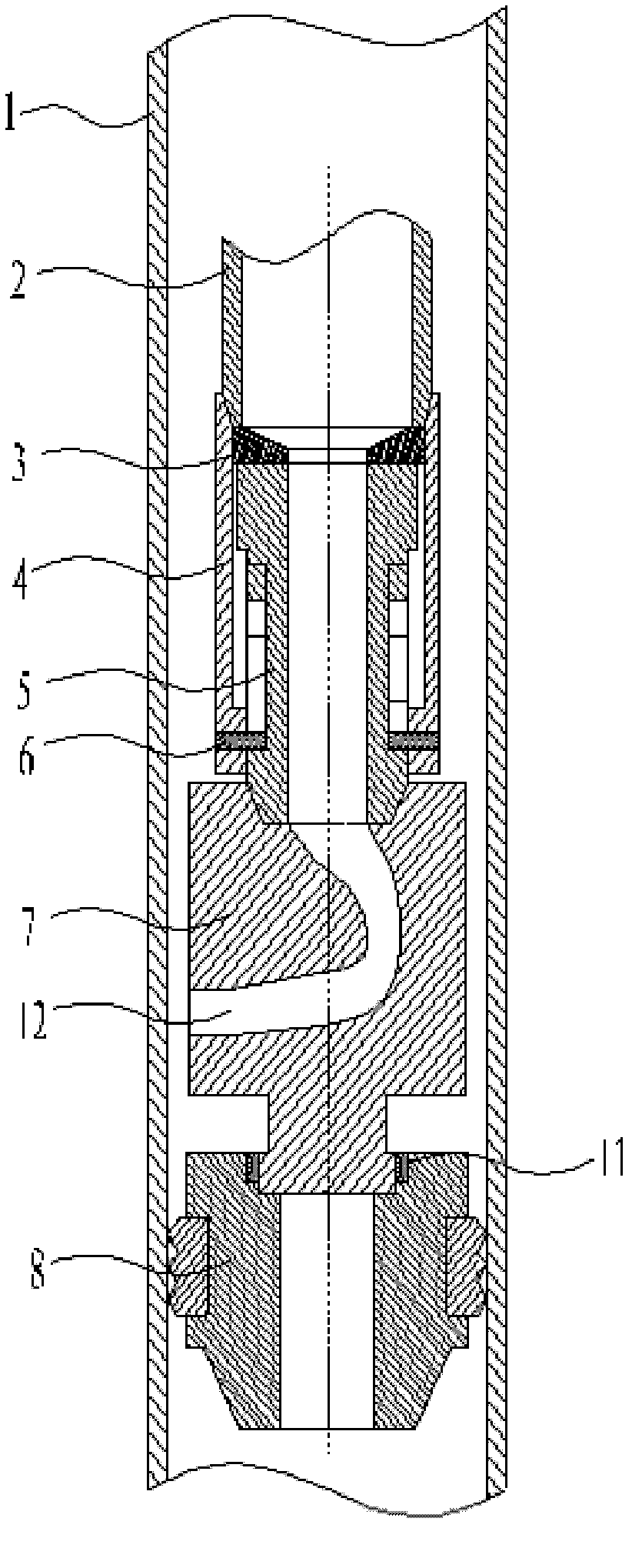

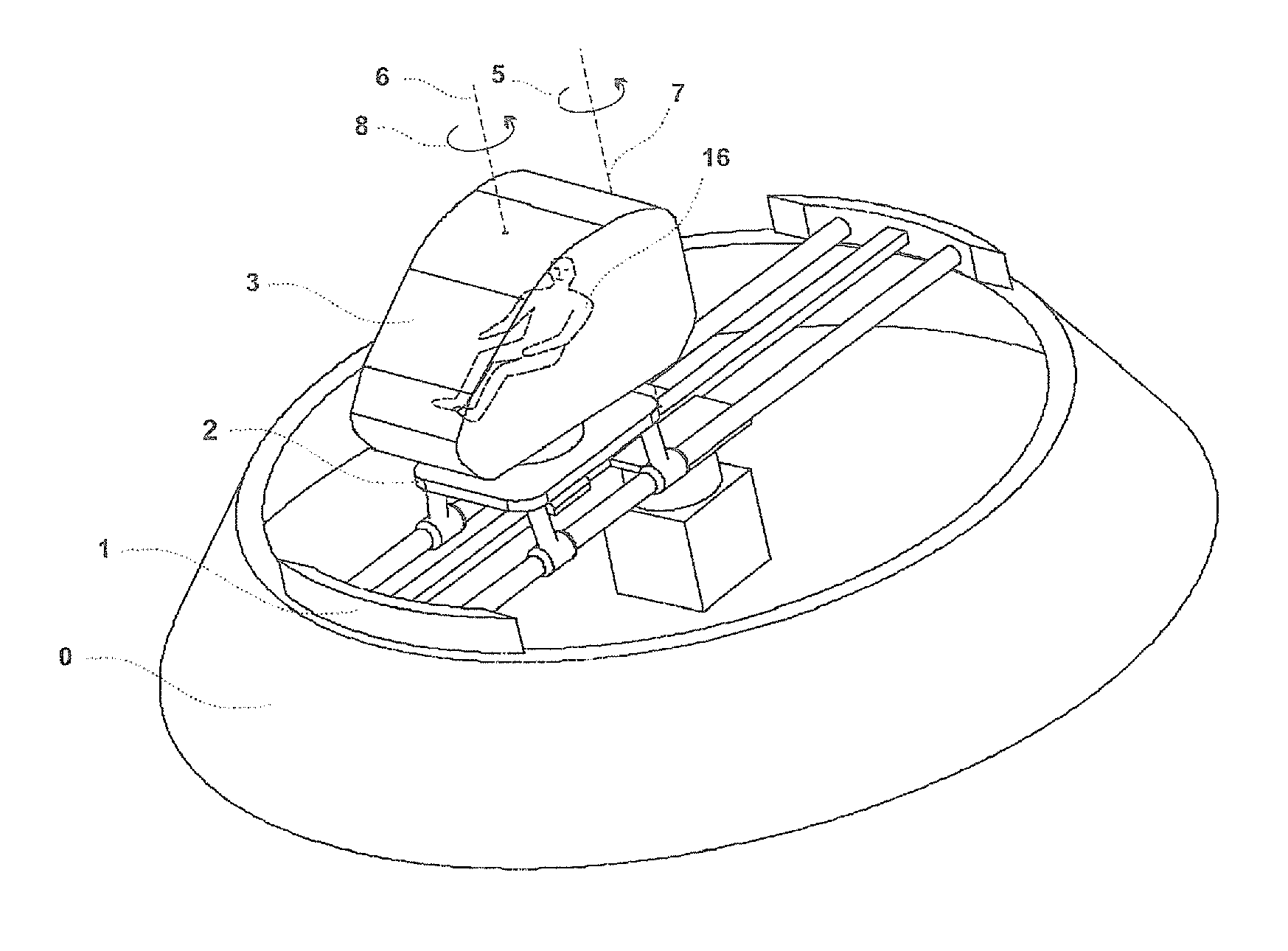

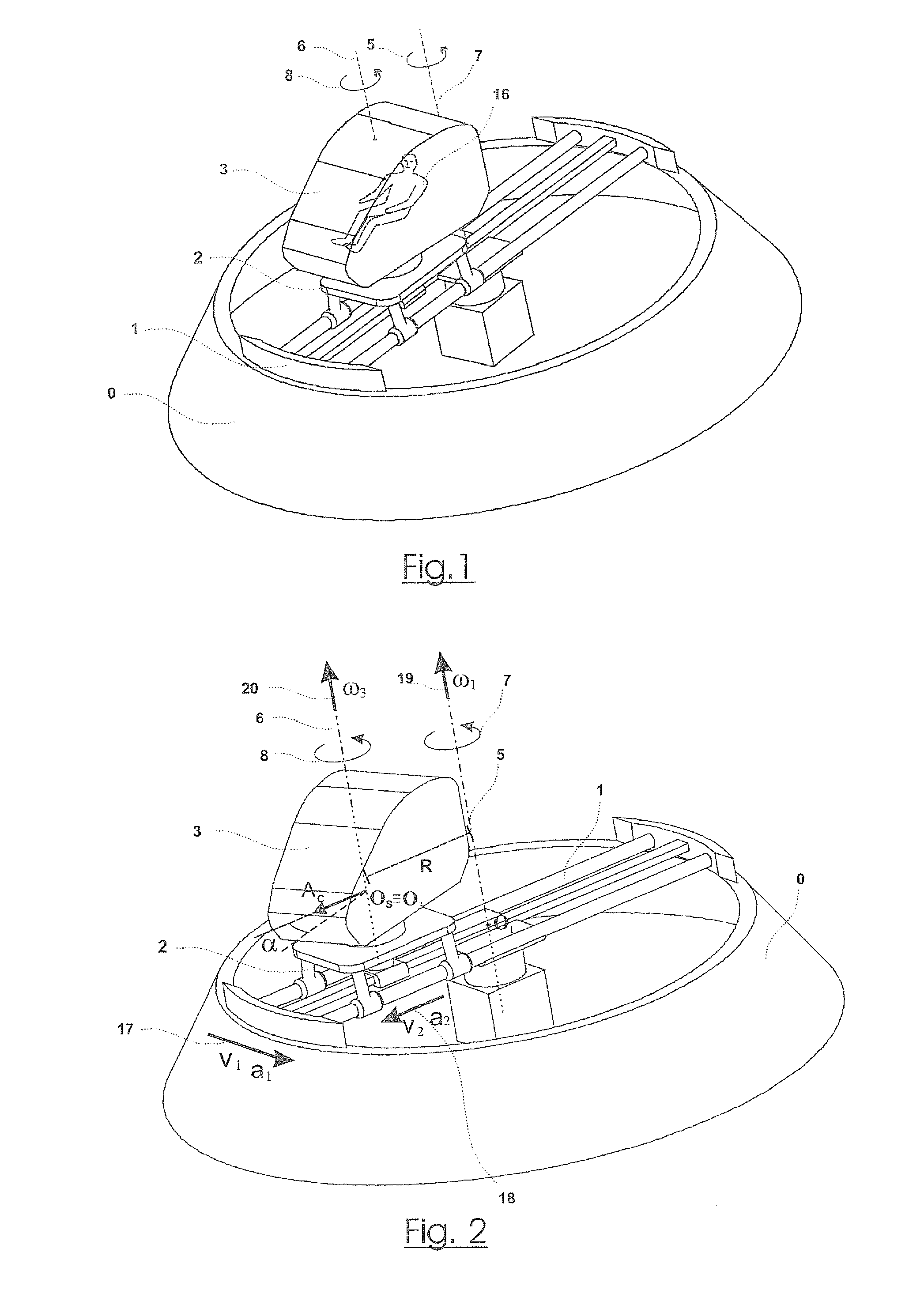

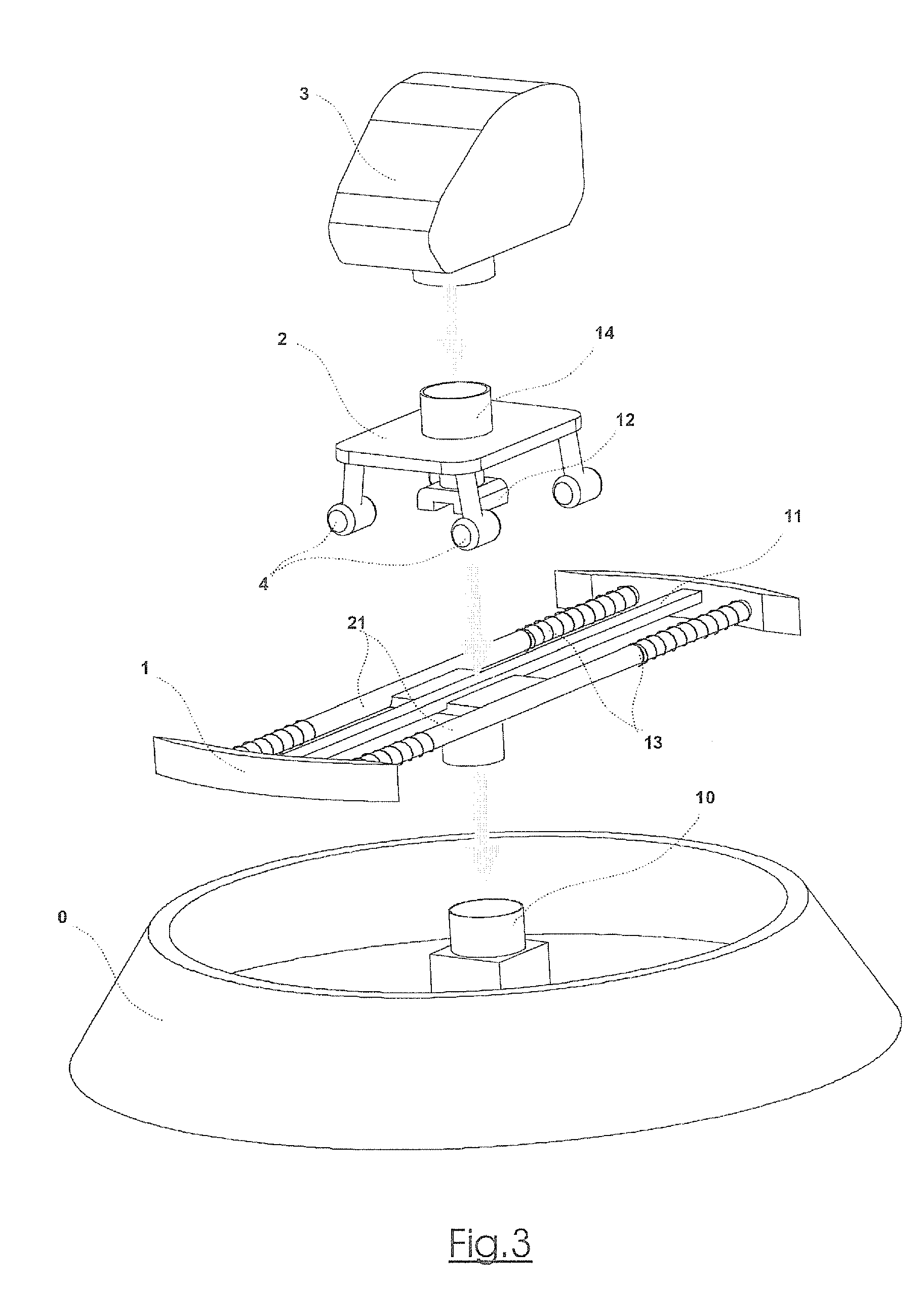

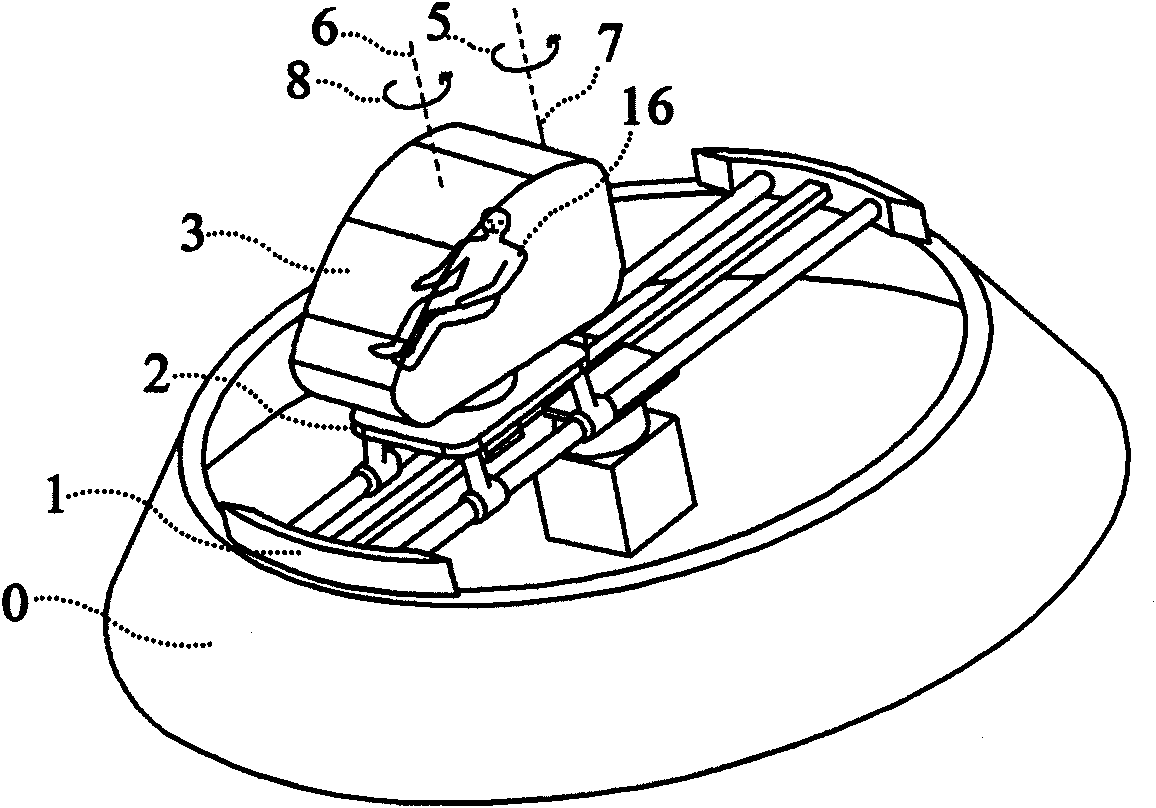

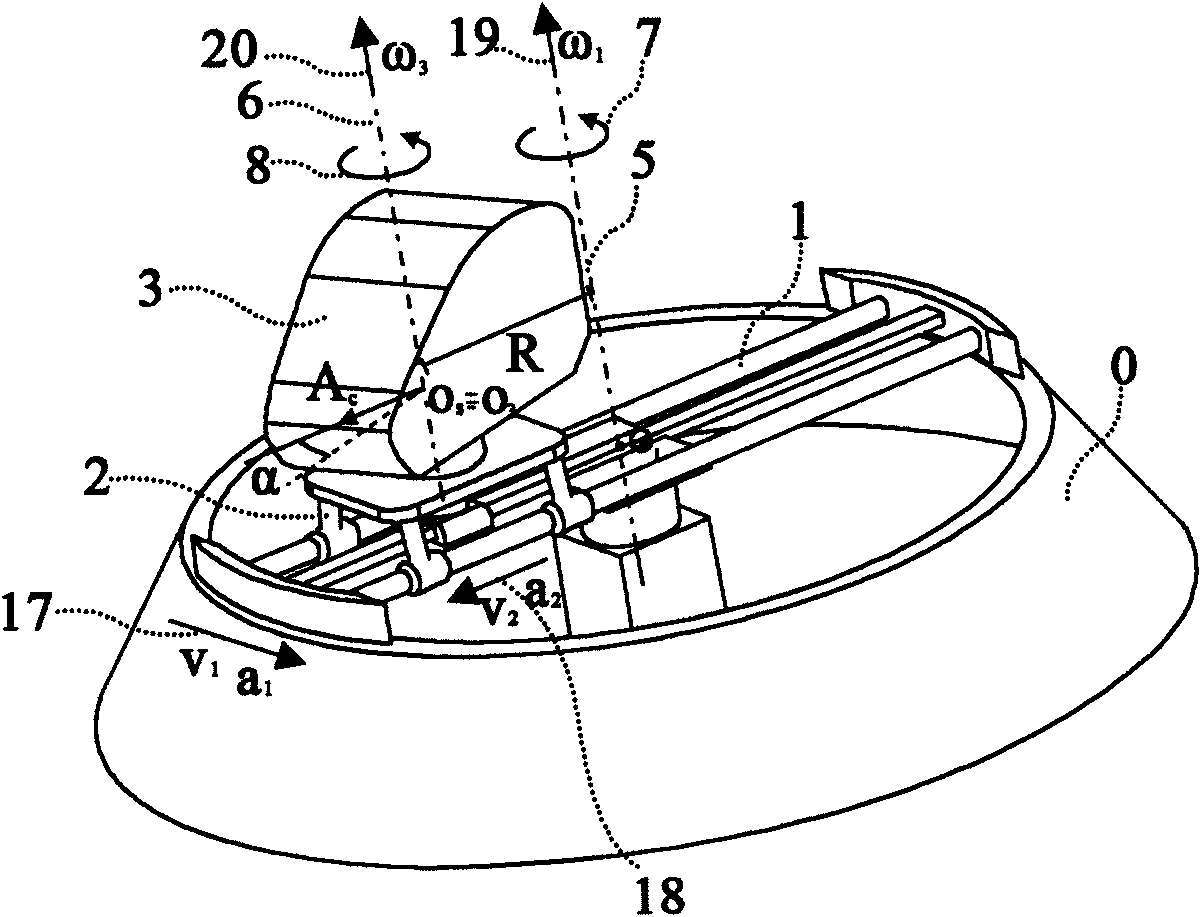

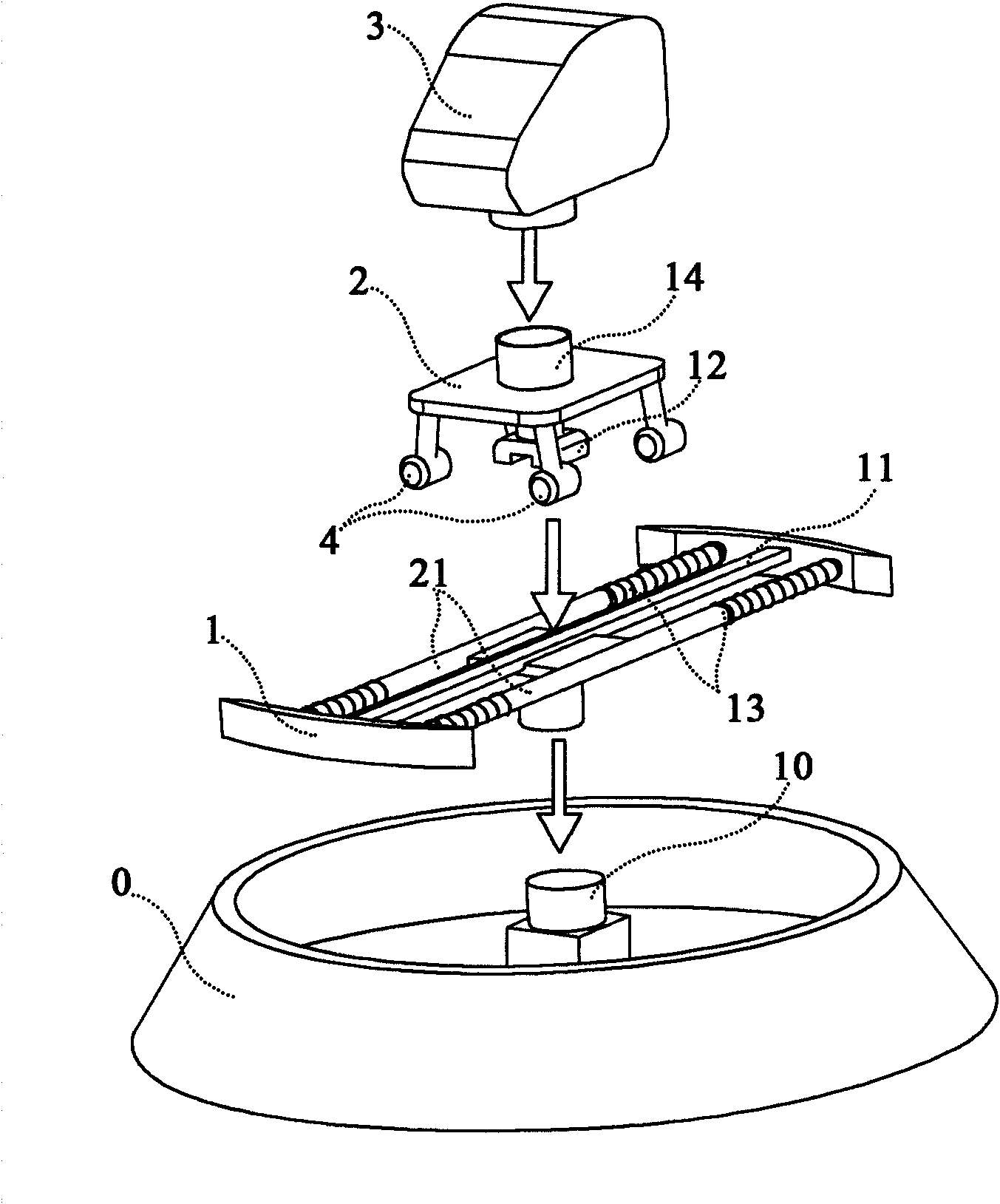

Realistic mechanic simulator for sensations of vehicles in movement

InactiveUS20100216097A1Increase ‘ degreeIncrease heightCosmonautic condition simulationsSimulatorsMobile vehicleDriver/operator

The invention consists of a prototype comprising three moving parts that can realistically simulate all the forces which subject a driver positioned in any moving vehicle. The first part has a circular motion with respect to its vertical axis of rotation and is supported by a fixed base, the second part, integral to the first part has a longitudinal movement (horizontal) perpendicular to the rotation axis of the first part. The third part, integral to the second part, acts as positioning for the user who is subject to the simulator's effects which has a circular motion with respect to its vertical axis of rotation that is parallel to the axis of rotation of the first part. The longitudinal movement of the second part in synergy with the first rotation of the first part and the instantaneous angular positioning of the third part, can continuously represent a development of any force such as acceleration, deceleration (braking) and lateral thrust present in any moving phase of a vehicle.The invention simulates high acceleration in any dynamic condition, reproducing, thanks to the installation of small size motors, the sensations felt inside high powered vehicles (eg. F1 car).The principle underlying the present invention is that at any moment, a person, who is inside a moving vehicle, being subjected to a resulting force, which, if it was artificially reproduced constantly, makes it imperceptible from a real driving situation.Present mechanic emulators, despite the existing varieties and their differentiation in size and type of movement, have physical limits in creating realistic sensations of driving. They are not capable of reproducing a faithful simulation, such as direction and intensity of strength of the force which the driver is subjected to, but above all they do not reproduce the simulation of these forces continuously over time.This invention is strongly innovative compared to those previous because it makes it possible to manufacture simulators which generate realistic physical sensations of intensity, direction, speed of transitional reply and persistence in time, so that a user cannot distinguish between reality and fiction. This total realism is achieved without the necessity of using high powered and expensive motors, thanks to the synergy of movement of the simulator components, so that the invention can be manufactured immediately.

Owner:ROMAGNOLI CLAUDIO +2

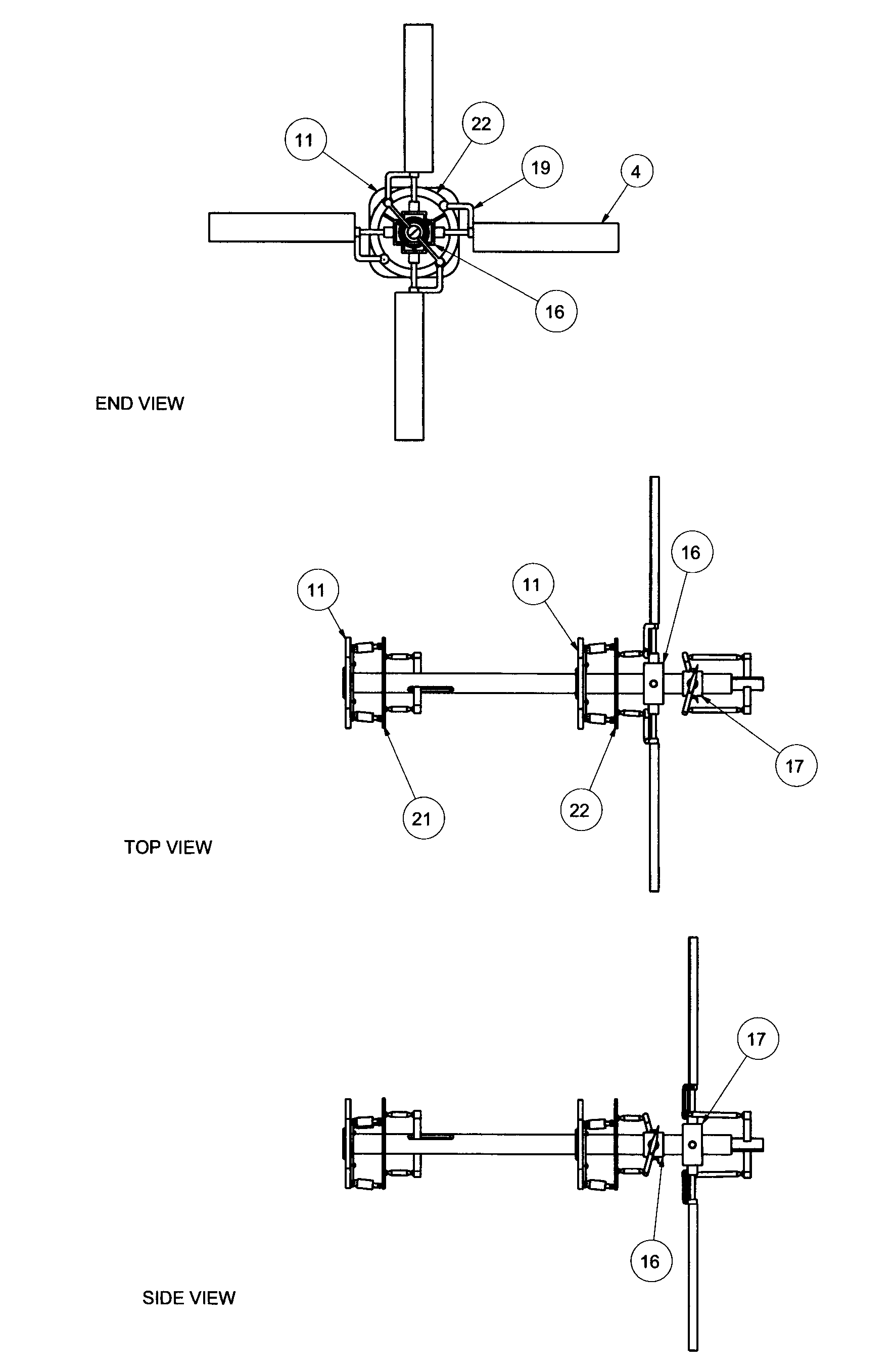

Omni-Directional Thrust Vectoring Propulsor

A propulsion system comprising independent rotor sub-systems producing a thrust force of a desired magnitude in any desired radial direction from the centre of the propulsion system, driven from a single driveshaft that may be fixed in its position in the vehicle. When the propulsion system is fitted, for example, to a single-main-rotor helicopter in place of the convention anti-torque tail rotor, the helicopter is thereby equipped with a propulsion system that can produce yaw, pitch, the anti-torque lateral thrust for stability in hover, aft thrust or drag as well as the direct forward thrust that will enable the helicopter to fly at higher speeds. The propulsion system may also be applied in other aeronautical systems as well as to marine and industrial systems to impart energy into a fluid and thereby induce movement in that fluid.

Owner:ADAM MARTIN LEON

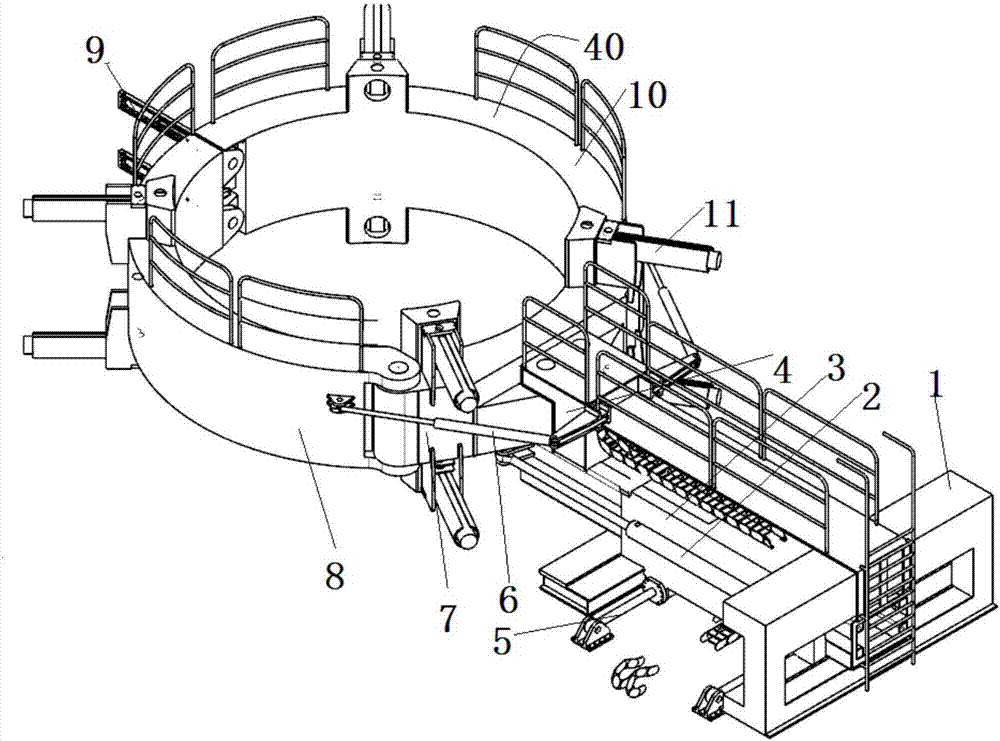

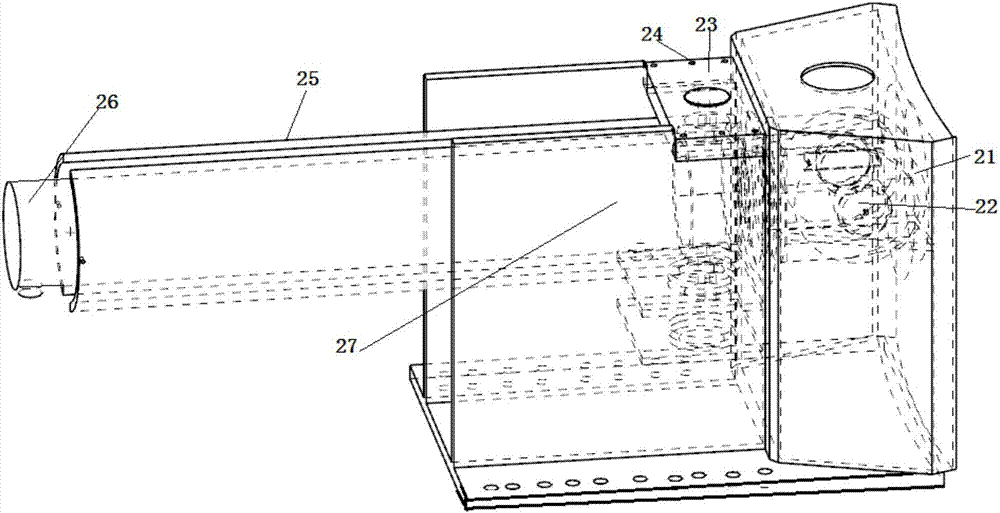

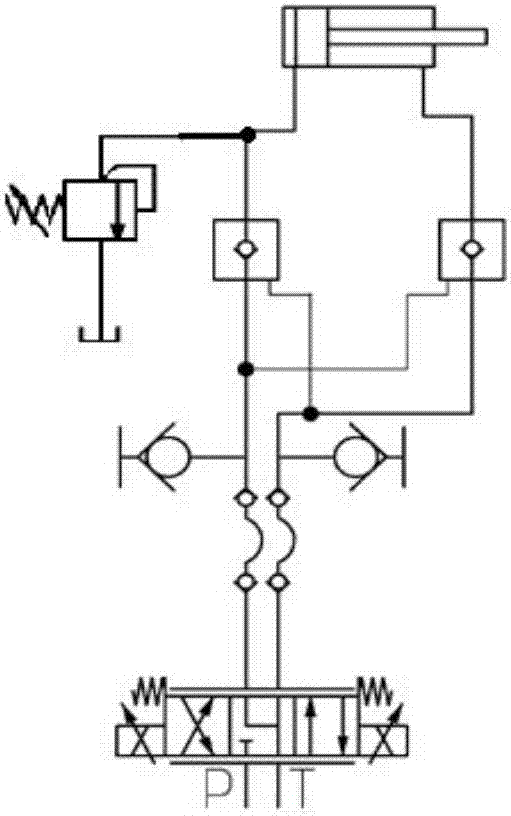

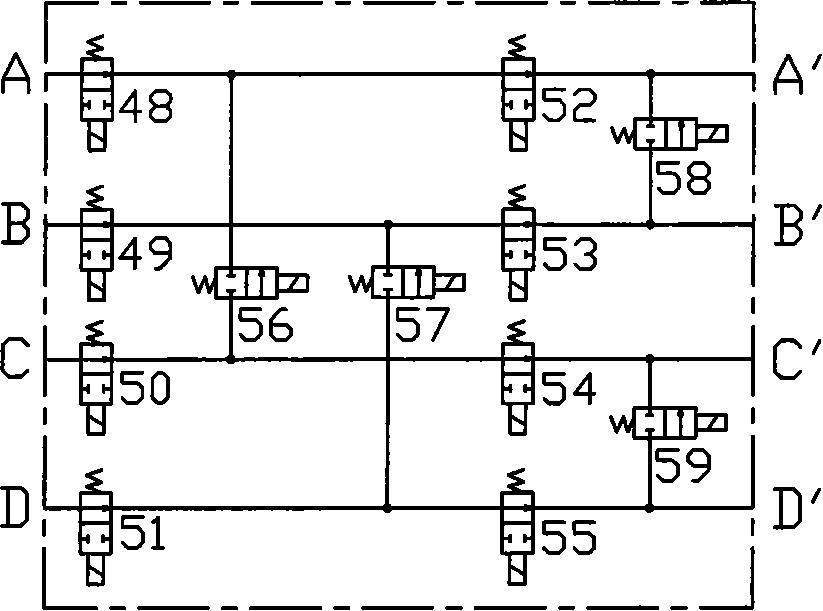

Pile gripper for offshore piling

The invention relates to a pile gripper for offshore piling. The pile gripper for offshore piling is composed of a pile gripper mechanism system, a hydraulic system and an electrical control system. A large base is connected with a sliding base through a sliding rail. A cross beam is installed in a sliding groove of the sliding base. A lateral thrust cylinder is installed on the portion, between a deck and the sliding base, of a mounting base. A main thrust cylinder is installed on the portion, between the sliding base and the cross beam, of the mounting base. A hoop is installed at the front end of the cross beam. The left side and the right side of the front end of a hoop base are connected with a left hoop body and a right hoop body separately. The left hoop body and the right hoop body are connected with the two sides of the cross beam through hoop opening and closing cylinders correspondingly. The hoop is provided with a pile gripping and clamping mechanism. Two sets of locking mechanisms are installed at the front end of the left hoop body. The right hoop body is provided with pin holes corresponding to taper pins of the locking mechanisms. Each pile gripping cylinder is connected with a proportional valve and controlled to act by the proportional valve. A programmable logic controller (PLC) performs closed-loop control over the opening degree and direction of the proportional valves according to a feedback signal of a magnetostrictive displacement sensor, so that the pile gripping cylinders are controlled to perform pile jacking guidance on steel piles and keep guidance on the steel piles within a required range.

Owner:SHANGHAI HUNTER MARINE EQUIP CO LTD +1

Mounting device for an aircraft engine comprising two thrust recovery rods with a double rear mechanical connection

ActiveUS20080169377A1Designing can be facilitatedEasy to installPower plant constructionGas turbine plantsRigid structureAirplane

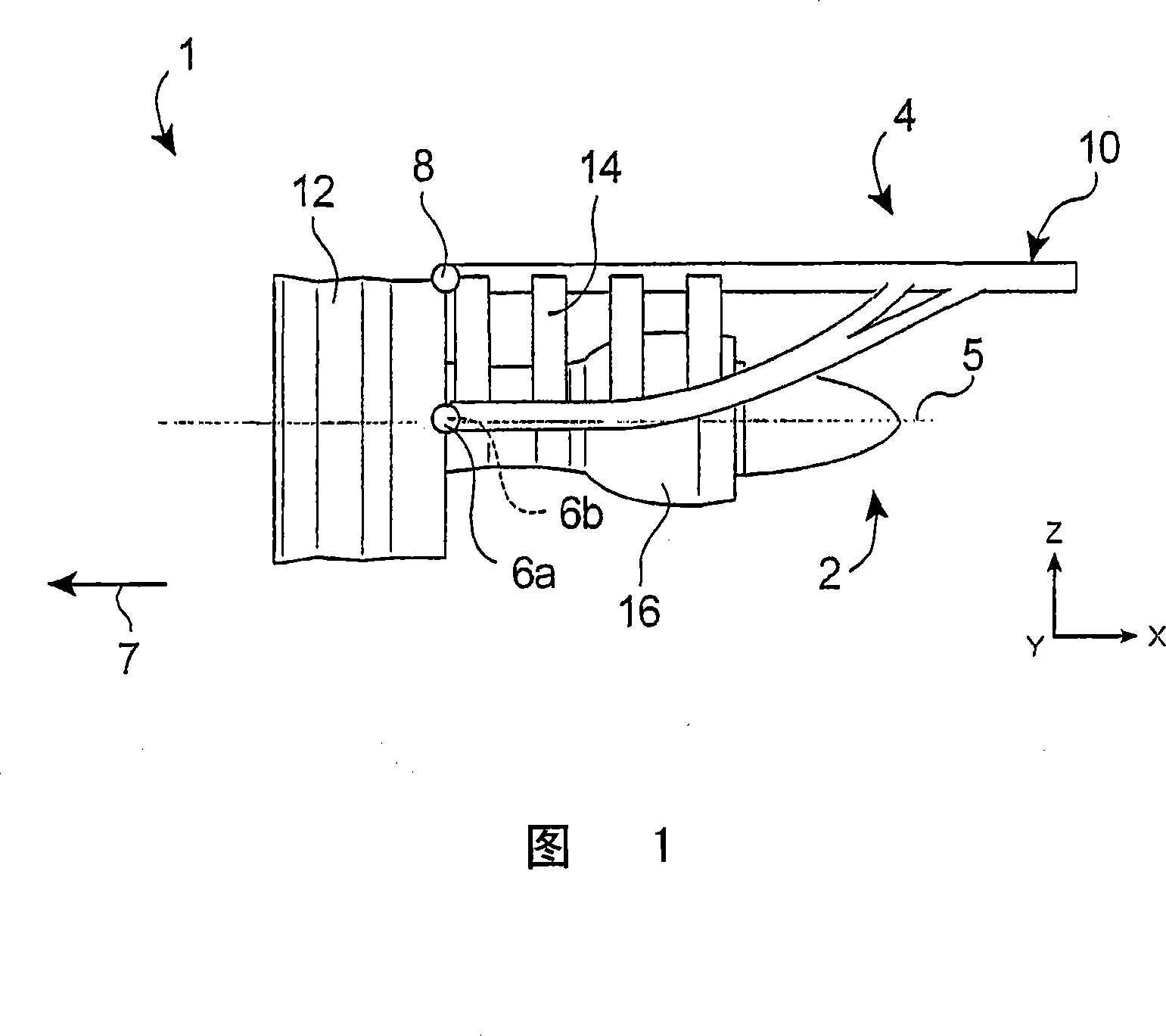

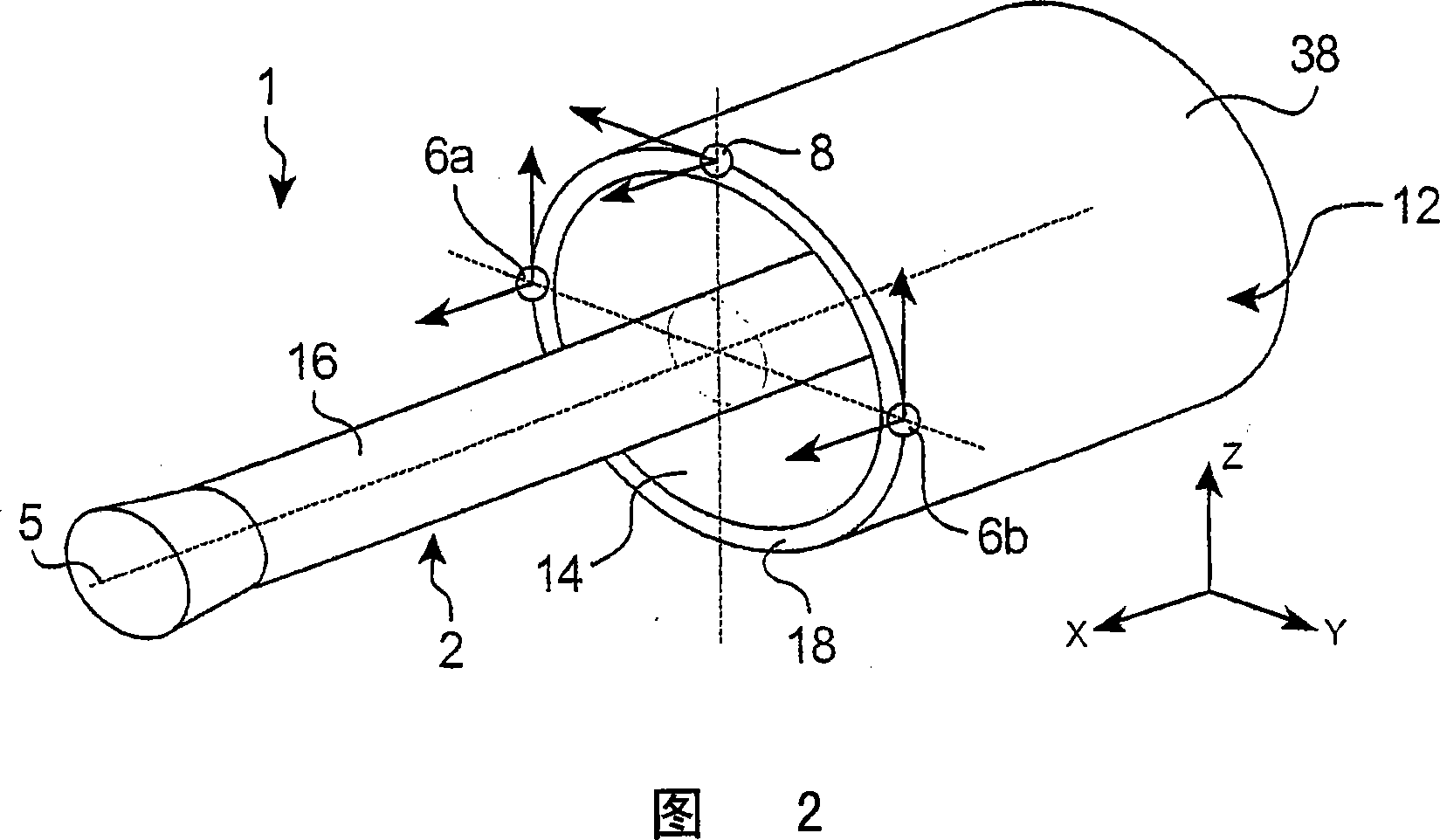

The present invention relates to a mounting device for an aircraft engine comprising a rigid structure and means for mounting the engine on the rigid structure, the mounting means comprising a thrust load recovery device (14) comprising two lateral thrust load recovery rods (26) each having a rear end (26b) mounted on a crossbar (28) of the device (14), by means of a first mechanical connection (44). At the rear end of each of the two rods, there is also provided a second mechanical connection (46) with play between the rear end (26b) and a support fitting (60) integral with the rigid structure. According to the invention, the first mechanical connection (44) is implemented using a pin (48) provided on the crossbar, passing through an orifice (50) provided in the rear end of the rod (26).

Owner:AIRBUS OPERATIONS (SAS)

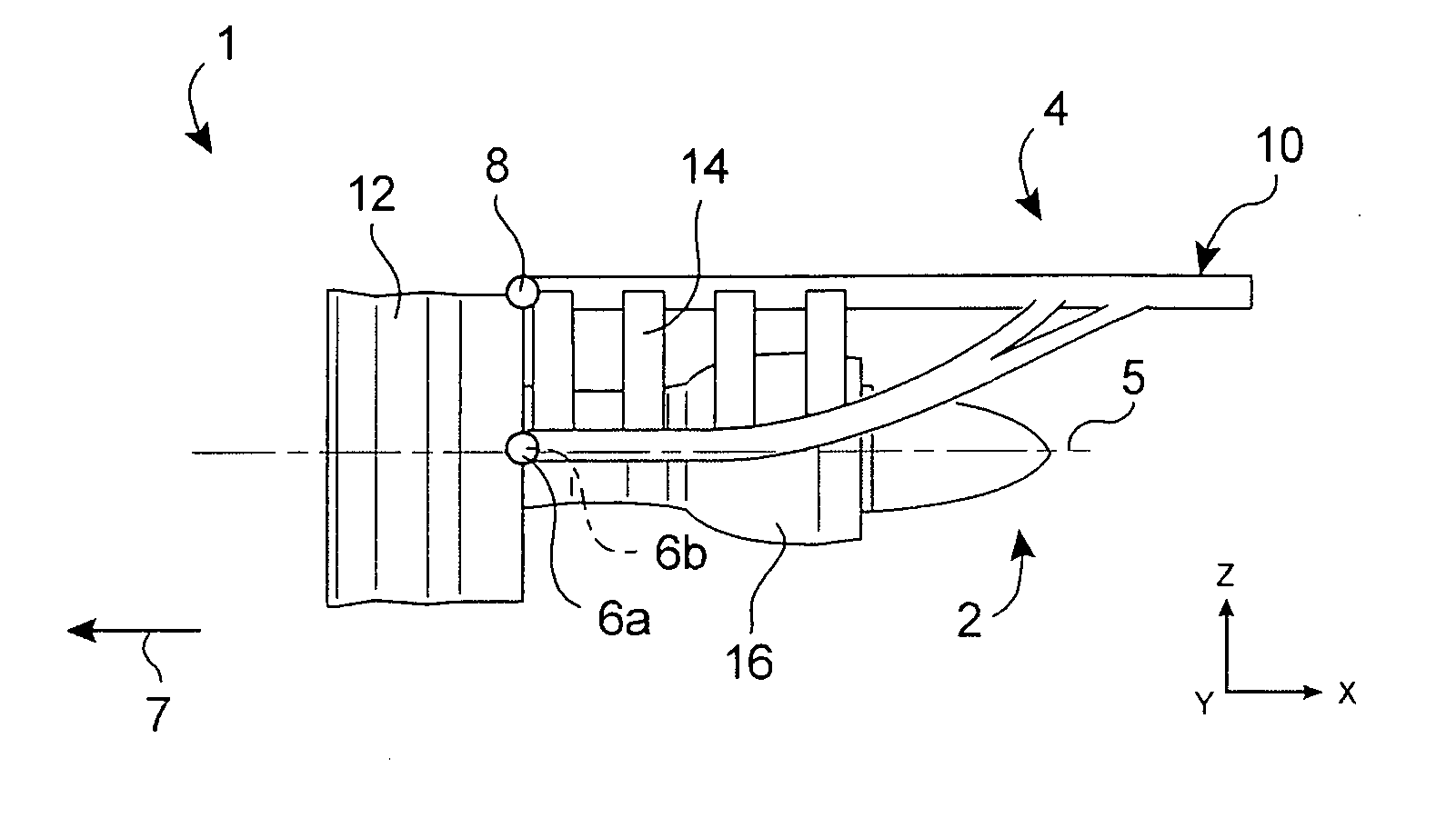

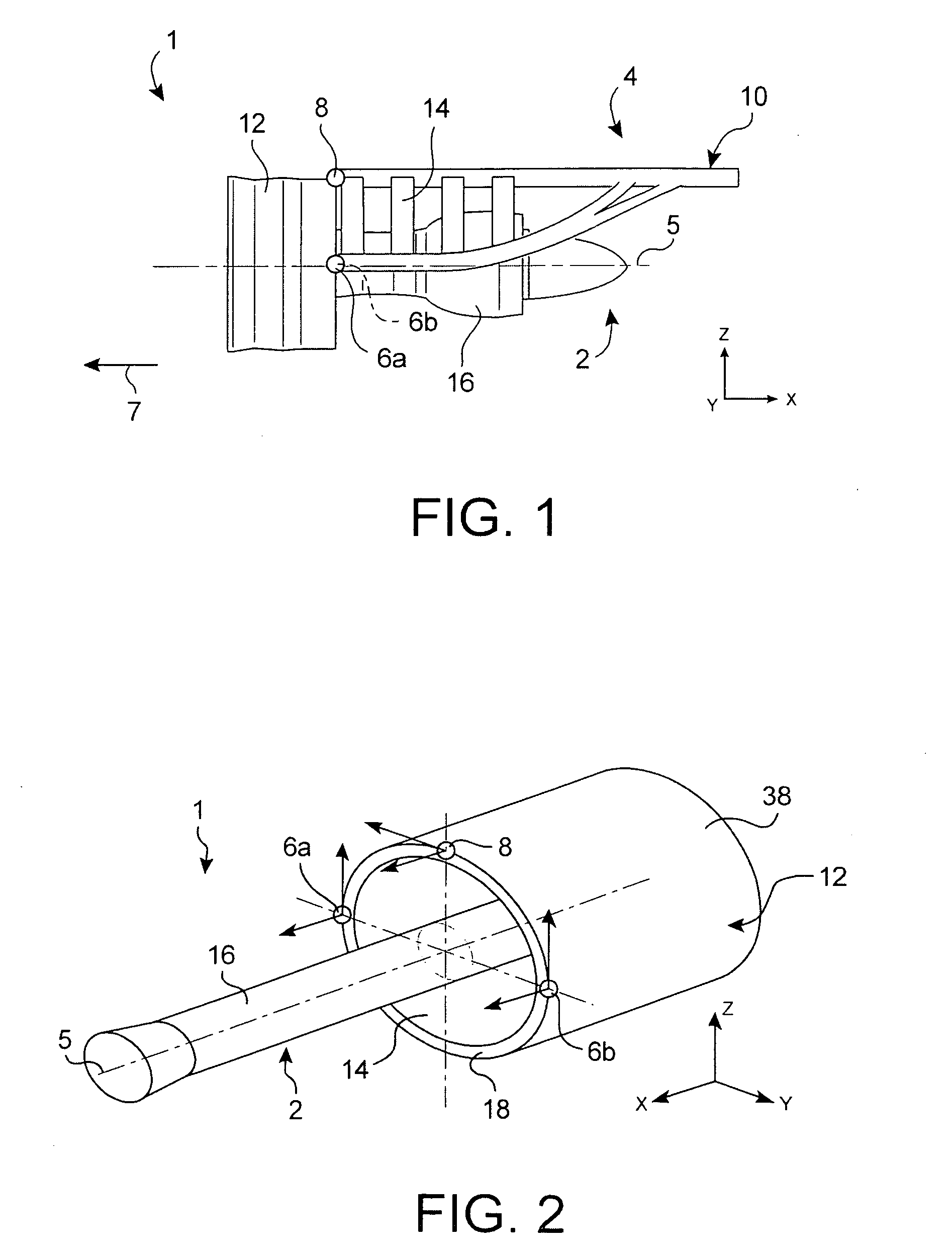

Turbojet Pylon for Aircraft

A turbojet-mounting pylon for an aircraft. The pylon includes a rigid structure including a plurality of arcs arranged so as to jointly delimit a part of a fictitious approximately cylindrical surface with a circular section. The plurality of arcs also includes two lateral thrust resisting arcs located on each side of the central box, each of the two lateral arcs being fixed to each arc in the form of an annular portion, and on each side of the central box.

Owner:AIRBUS OPERATIONS (SAS)

Realistic mechanic simulator for sensations of vehicles in movement

InactiveCN101632110AInnovativeIncrease "degrees of freedomCosmonautic condition simulationsSimulatorsMobile vehicleHigh acceleration

The invention consists of a prototype comprising three moving parts that can realistically simulate all the forces which subject a driver positioned in any moving vehicle. The first part has a circular motion with respect to its vertical axis of rotation and is supported by a fixed base, the second part, integral to the first part has a longitudinal movement (horizontal) perpendicular to the rotation axis of the first part. The third part, integral to the second part, acts as positioning for the user who is subject to the simulator's effects which has a circular motion with respect to its vertical axis of rotation that is parallel to the axis of rotation of the first part. The longitudinal movement of the second part in synergy with the first rotation of the first part and the instantaneous angular positioning of the third part, can continuously represent a development of any force such as acceleration, deceleration (braking) and lateral thrust present in any moving phase of a vehicle. The invention simulates high acceleration in any dynamic condition, reproducing, thanks to the installation of small size motors, the sensations felt inside high powered vehicles (eg. F1 car). The principle underlying the present invention is that at any moment, a person, who is inside a moving vehicle, being subjected to a resulting force, which, if it was artificially reproduced constantly, makes it imperceptible from a real driving situation. Present mechanic emulators, despite the existing varieties and their differentiation in size and type of movement, have physical limits in creating realistic sensations of driving. They are not capable of reproducing a faithful simulation, such as direction and intensity of strength of the force which the driver is subjected to, but above all they do not reproduce the simulation of these forces continuously over time.

Owner:克劳迪奥·若玛格诺丽 +1

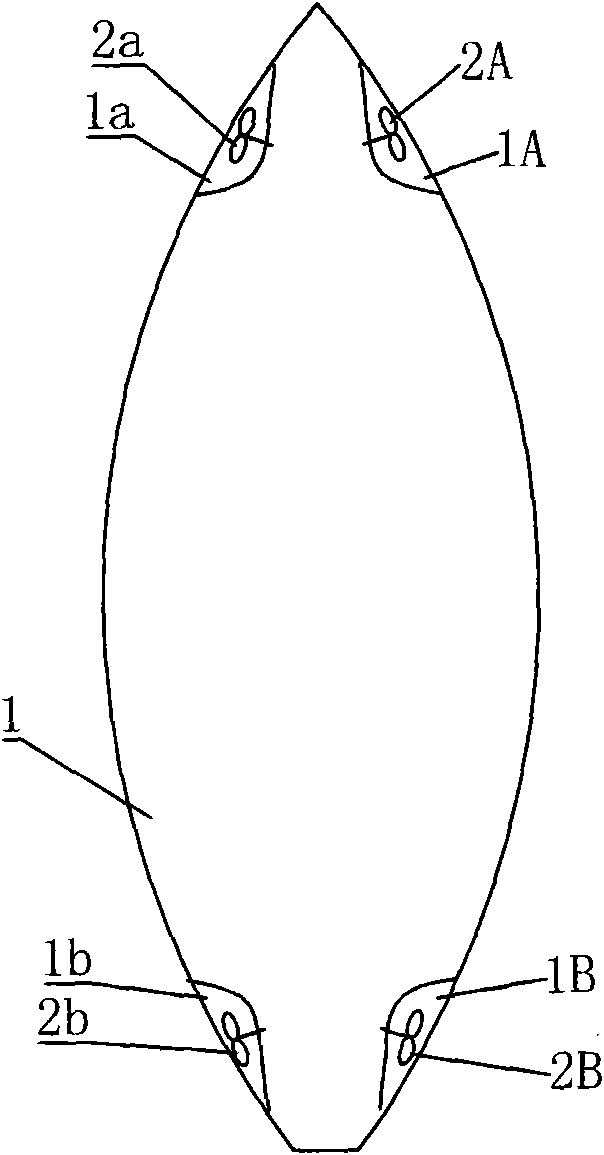

Tread profile of a snow tire

InactiveUS20010035244A1Low stiffnessEasy to handleTyre tread bands/patternsNon-skid devicesTreadSnow

Tread profile of a snow tire for a vehicle in which at least two vehicle wheels are rotatably mountable outside of a longitudinal vehicle axis. The tread profile includes a plurality of profile block rows aligned in a circumferential direction and distributed in an axial direction from a first tire shoulder adapted to be positioned toward an outside of the vehicle in an operational state of the tire on the vehicle to a second tire shoulder adapted to be positioned toward an inside of the vehicle in an operational state of the tire on the vehicle. The tread profile also includes a plurality of channels aligned in a circumferential direction and being arranged to axially separate the plurality of profile block rows from each other, and the plurality of channels includes a first circumferential channel positioned to divide the tread profile into two axial regions of functionally different structure, and each axial region axially extending from one the first and second tire shoulders to the first circumferential channel. The plurality of profile block rows includes a plurality of profile block elements, and the plurality of profile block elements in the axial region extending from the circumferential channel to the first tire shoulder have a higher lateral thrust stiffness than the plurality of profile block elements in the axial region extending from the first circumferential channel to the second tire shoulder.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

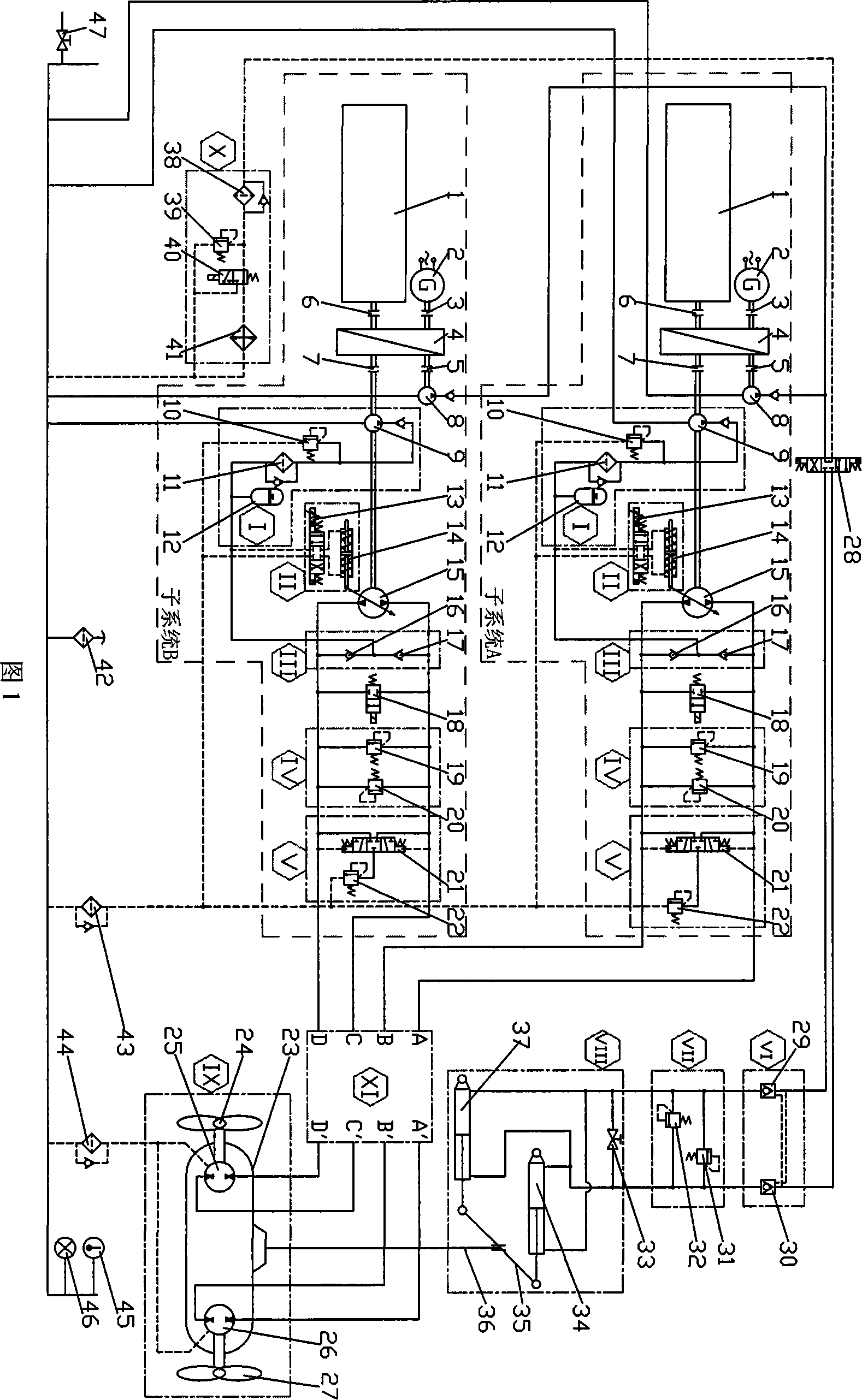

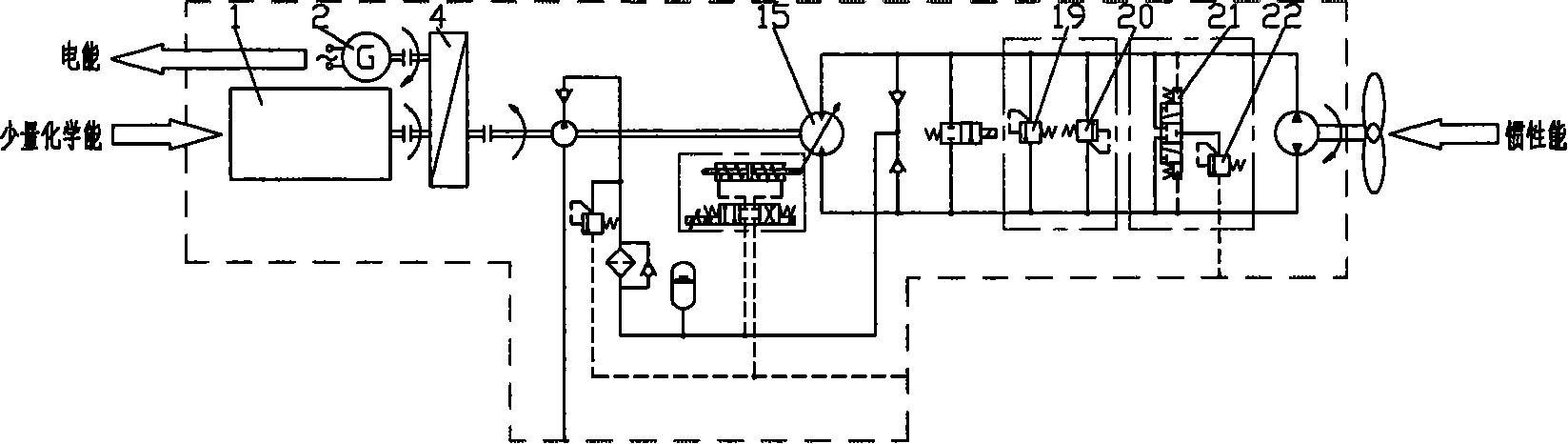

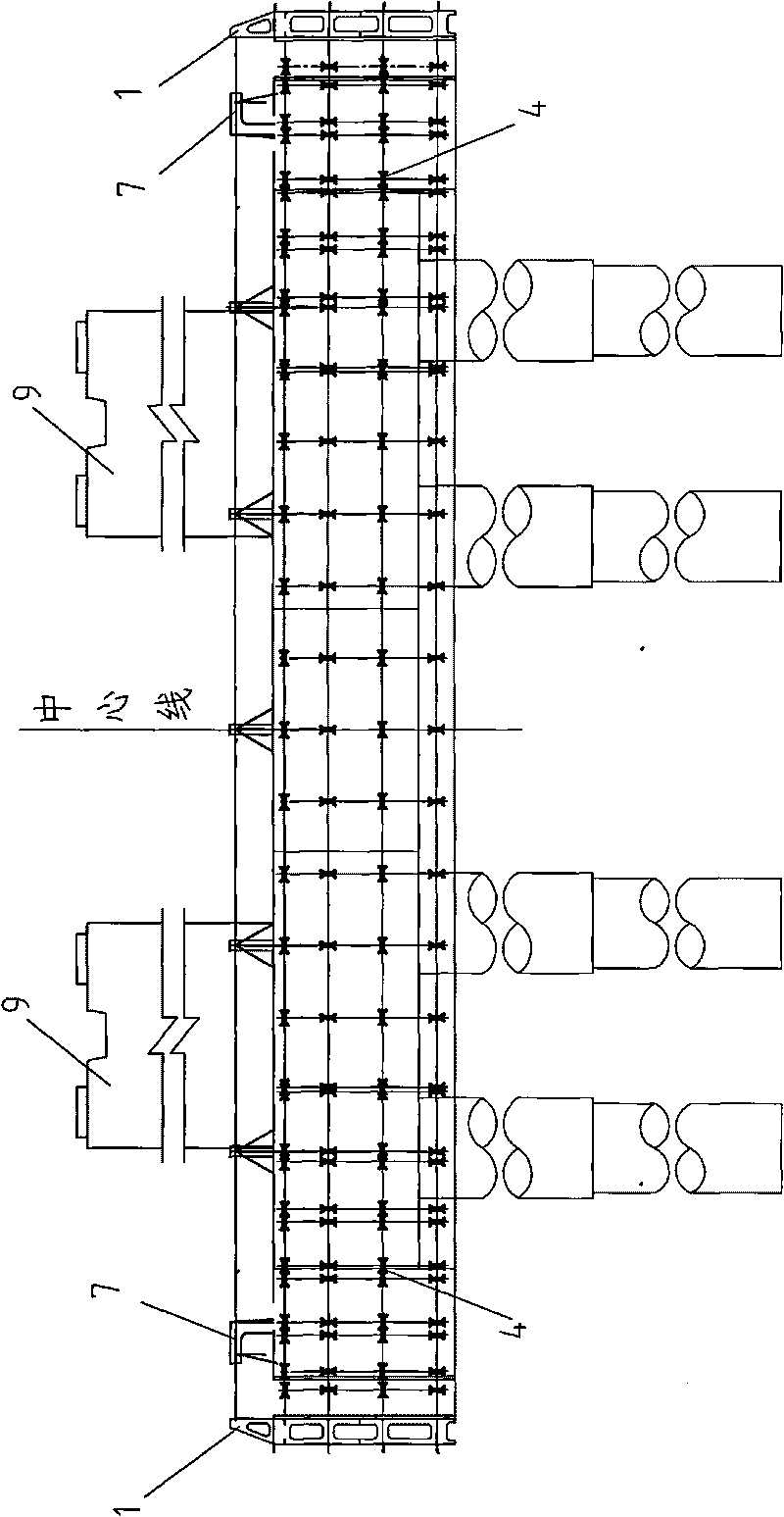

Ship craft integrated hydraulic propulsion method and device

InactiveCN101249884ARealize speed regulationRealize commutationTransmission with non-mechanical gearingPropellerMechanical energy

Disclosed are a propelling method and a device for vessels and other navigating machinery in water. The method based on the hydraulic transmission principle includes transforming mechanical energy output by a plurality of main engines (more than two) into pressure energy of hydraulic oil, after power integration and distribution, respectively driving a propeller screw, a steering engine (which can be canceled after employing a pod revolving device), a lateral-thrust unit and other auxiliary devices, using a shaft generator to replace a ship auxiliary engine, adjusting revolution rate and steering of the propeller screw by controlling a pump and the main engines, realizing coordinated working of other auxiliary devices of the propeller screw, the steering engine, the lateral-thrust unit and the like and various working modes of the main propelling system, simultaneously recycling inertia energy produced by the propeller screw and vessel in the brake process and the like. The propelling method has the advantages of flexible engine room arrangement, large power-to-weight ratio of devices, high safety and reliability, high maneuverability, good work condition engaging characteristic, strong overload protection capacity, inertia energy recycle and the like.

Owner:纪玉龙

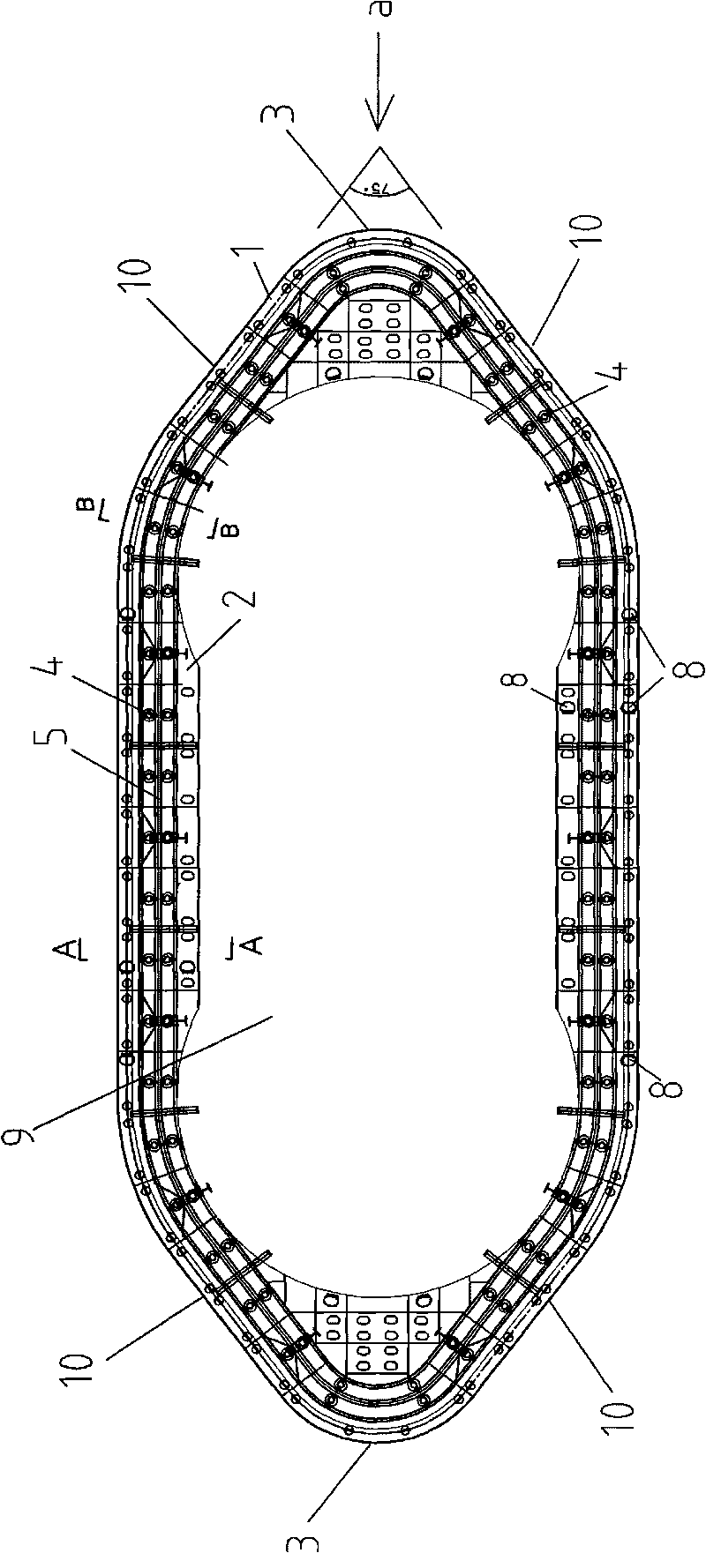

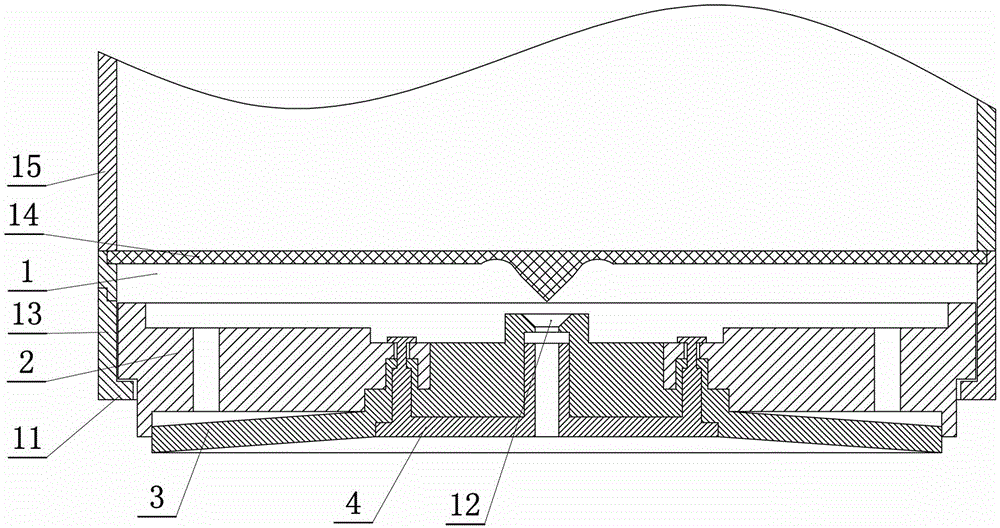

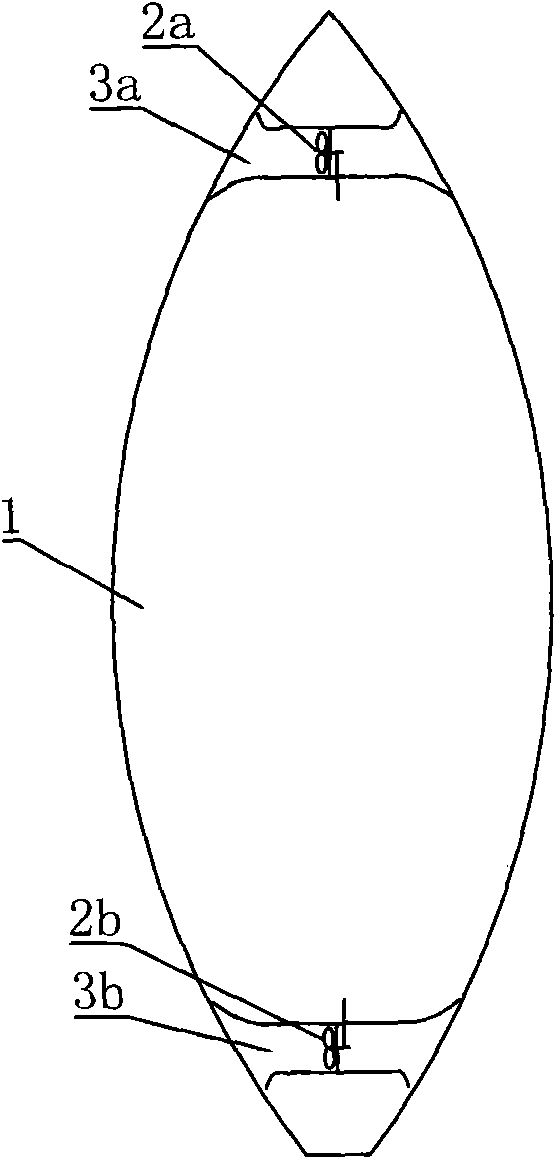

Flexible energy-absorbing anti-impact structure

InactiveCN101748706AImprove energy consumptionSo as not to damageClimate change adaptationShipping equipmentVertical displacementImpact structure

The invention discloses a flexible energy-absorbing anti-impact structure which has high protective capability and a reasonable structure and can protect both the impacted object and the impacting object. The anti-impact structure comprises an outer steel enclosure (1) and an inner steel enclosure (2), a plurality of flexible combined energy-absorbing anti-impact rings (4) are arranged between the inner steel enclosure (2) and the outer steel enclosure (1), the outer steel enclosure (1) is provided with an impact-receiving angle (3), the angle of which ranges from 25 degrees to 170 degrees, and the outer steel enclosure (1) is provided with positioners for reducing the vertical displacement of the outer steel enclosure (1). The whole anti-impact structure can first shift when impact occurs, the viscoelastic anti-impact rings then absorb a great deal of impact energy, and generate a lateral thrust on the impacting object at the same time, so that partial impact energy can be converted into the turning movement energy of the impacting object, and thereby the pier, the anti-impact structure and the moving ship can be prevented from being damaged or the damage of the pier, the anti-impact structure and the moving ship can be reduced to the max.

Owner:NINGBO UNIV +1

Vehicle, lightweight pneumatic pilot valve and related systems therefor

InactiveUS6951317B2Reliable wayTargeting and operationCosmonautic vehiclesDirection controllersSolenoid valveReciprocating motion

Owner:HONEYWELL INT INC

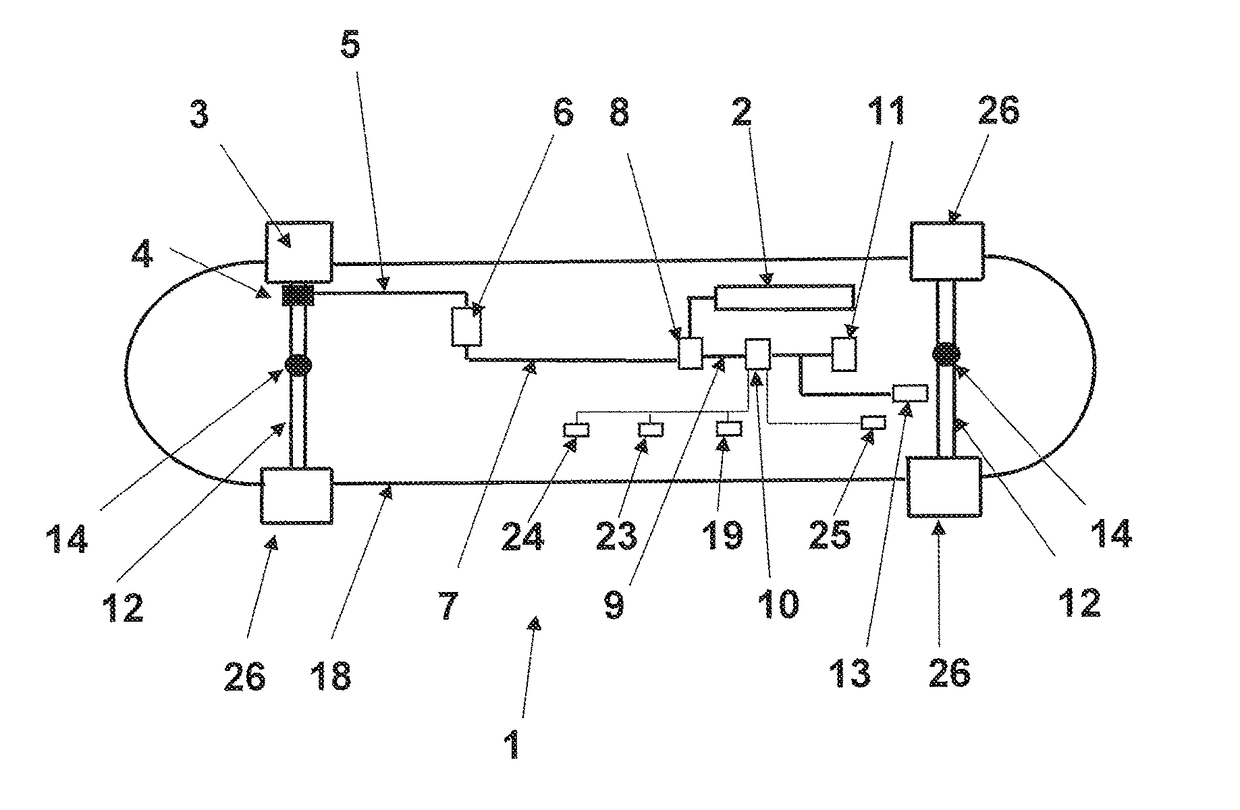

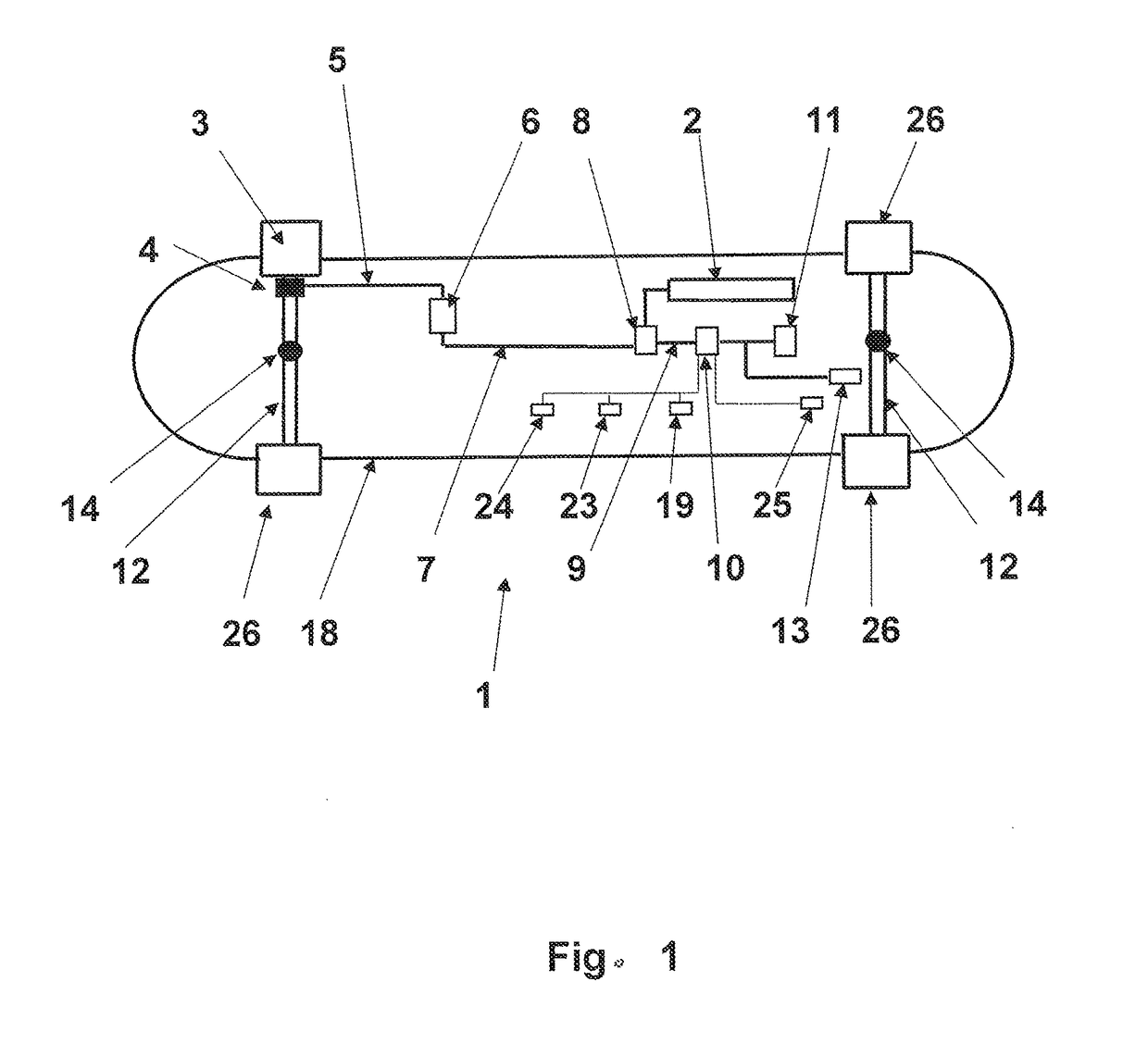

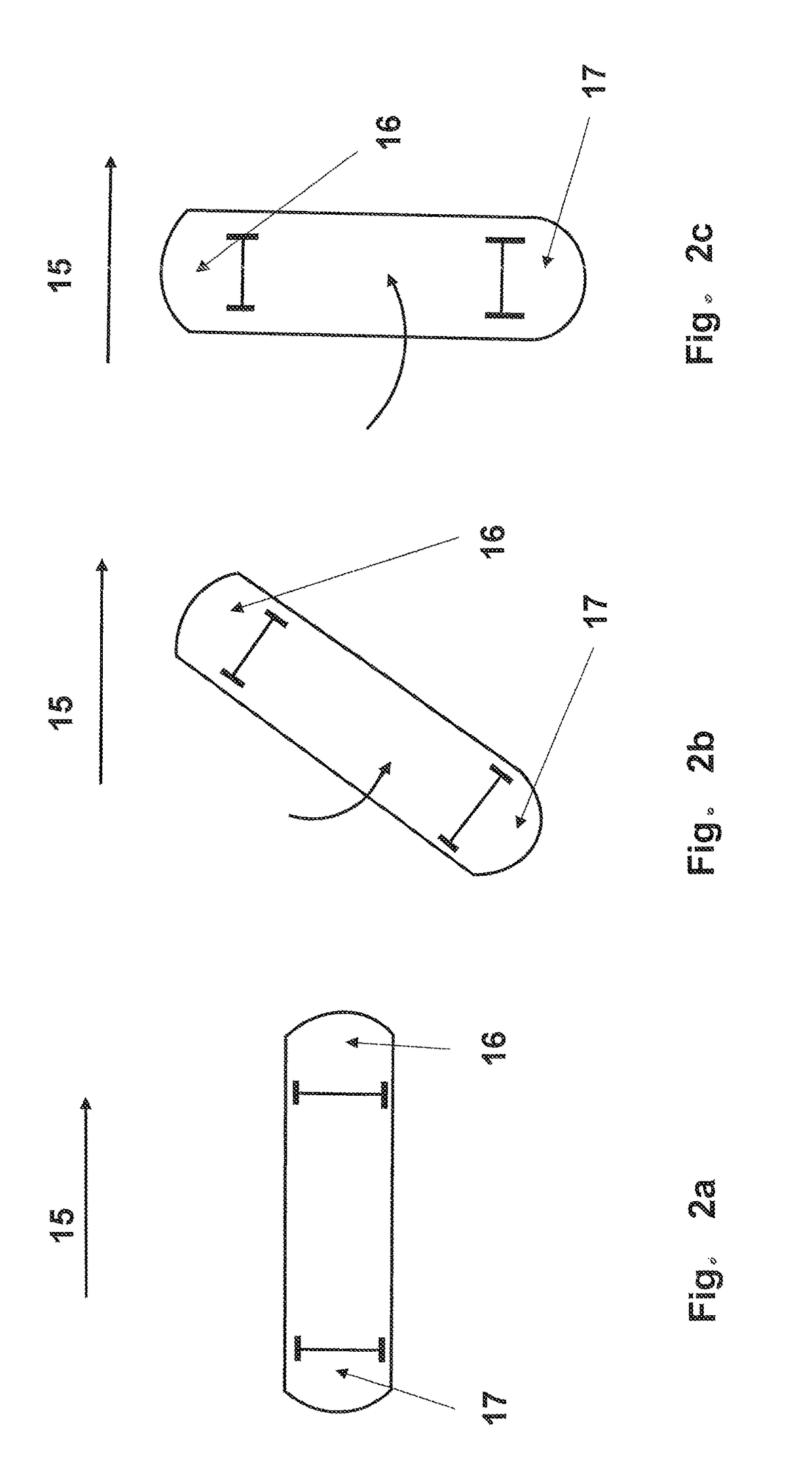

Motor control and regulating device, especially for an electrically driven skateboard or longboard

InactiveUS9987547B2High degree of freedom of movement and safetyLight weightSkate-boardsRoller skatesTurn angleAngular degrees

A motor control and regulating device has a sensor system for detection of forces acting sideways on a skateboard or longboard relative to the travel direction, sensor systems for control of the rpm of an electric motor, measurement of rpm and direction of rotation of rollers of the skateboard or longboard, and detection of the turning angle of the skateboard or longboard relative to the travel direction. There is an electronic data processor with sin integrated controller, which controls the rpm and direction of rotation by processing the signals received by the sensor systems. Forces acting sideways on the skateboard or longboard are deflected into a lateral thrust force. Without an external controller, the direction of rotation of the electric motor is reversed approximately in real time when the skateboard exceeds an defined angle so it is no longer in a rolling mode but instead in a sliding mode.

Owner:RUSCHKOWSKI JUERGEN

Knock-down prevention base of cup

The invention relates to a knock-down prevention base of a cup. By the aid of the knock-down prevention base, the cup is difficult to knock down when placed on smooth object surfaces. The technical scheme includes that the knock-down prevention base of the cup comprises a cup base and a sucker. A movable block is concavely arranged on the bottom surface of the cup base, the side surfaces of the concave cup base are protruded towards the center of the concave cup base to form limiting protrusions, an exhaust cone vertex is arranged in the center of the bottom surface of the cup base, a sucker accommodating hole is formed in the middle of the movable block, the sucker is fixed into the sucker accommodating hole of the movable block, an air hole support is arranged on a suction zone of the sucker and is communicated with the inside of the cup base, and a conical radial opening is formed in the upper portion of the air hole support. The knock-down prevention base has the advantages that a conical air-tight door of the sucker is controlled by the aid of a sucker principle and mechanical force of the nature; the movable block can fall, so that air in the suction zone of a lower sucker can be exhausted to form a vacuum zone, the atmospheric pressure can tightly press the sucker on the object surfaces, and accordingly a cup body which is connected with the sucker can resist lateral thrust under the effect of the atmospheric pressure and can be prevented from being knocked down.

Owner:曹东方

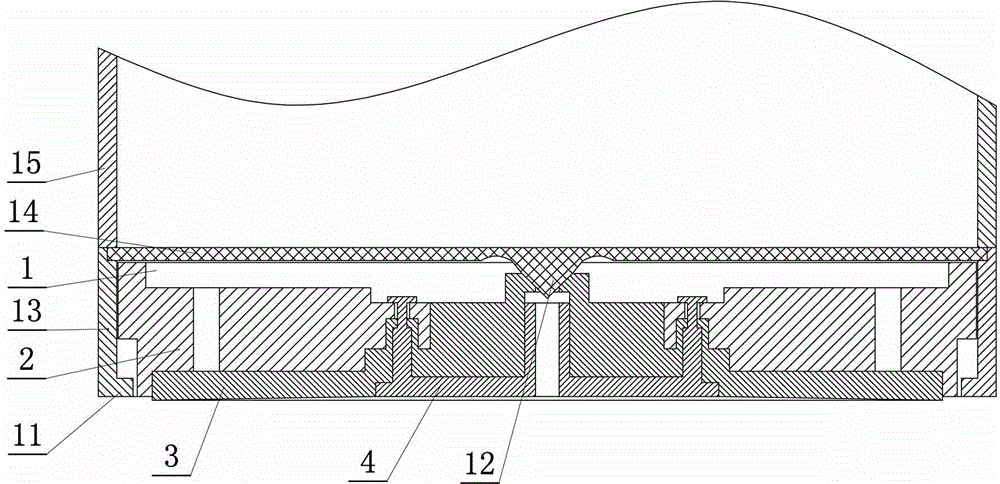

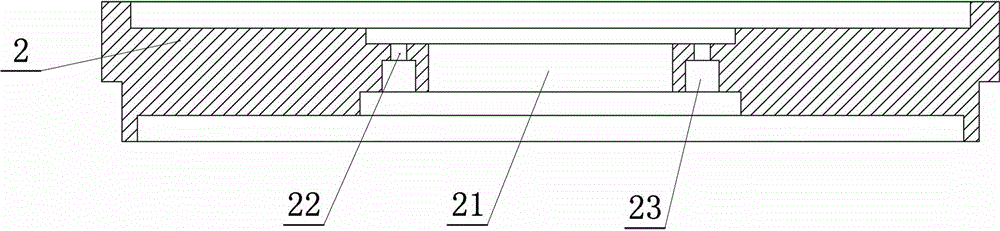

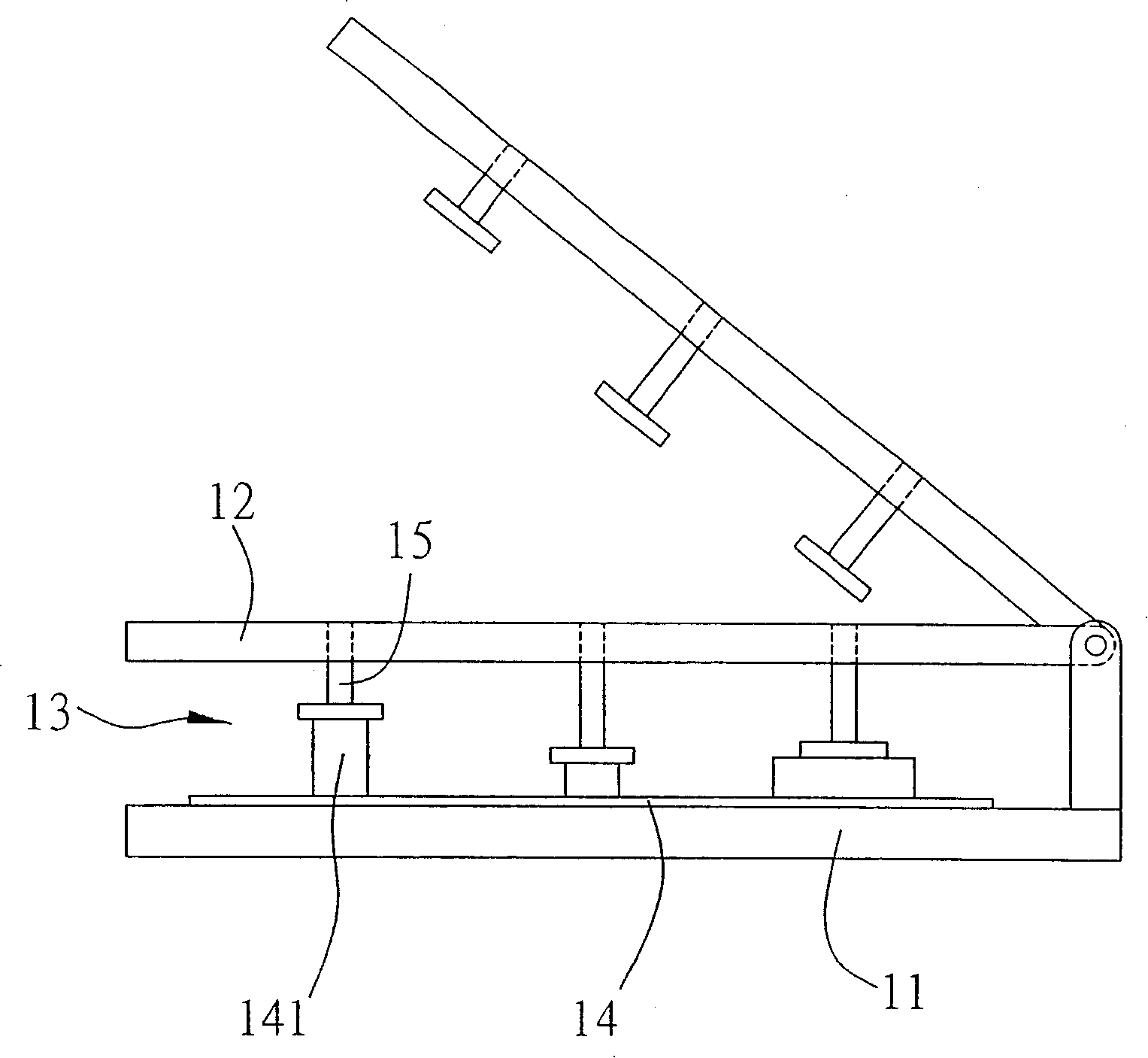

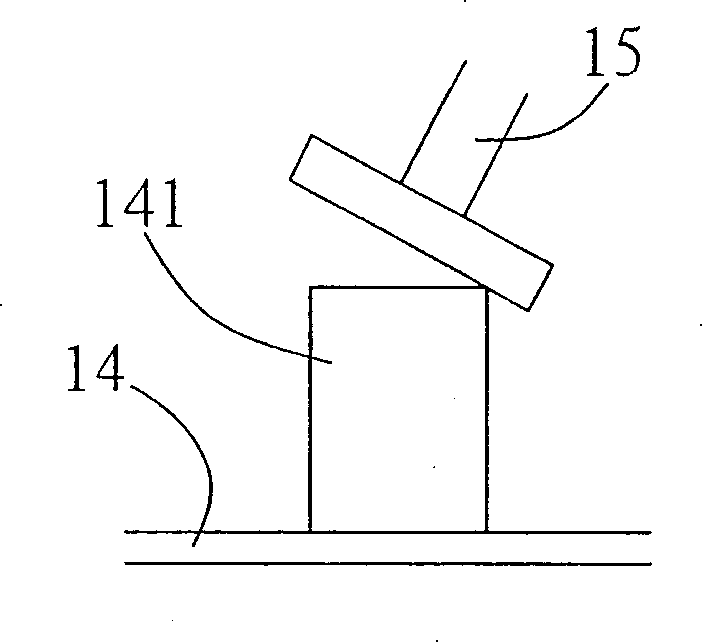

Welding fixture of circuit board

The invention relates to a welding fixture of a circuit board, which is used for clamping electronic modules on the circuit board. The welding fixture comprises a pedestal; a mobile board which is articulated above the pedestal, thereby which forms a clamping space between the pedestal and the mobile board; a pressure plate which is arranged above the mobile board in sliding way and is provided with a plurality of ;moulding dies , wherein, the moulding dies pass through the mobile board, and extend into the clamping space, and vertically press and cling to the top parts of the electronic modules on the circuit board; and an orientation module which is arranged on the side of the mobile board and is used for positioning the pressure plate; therefore, the moulding dies are enabled to be vertically and downwards contacted with the top parts of the electronic modules, thereby avoiding the faults that the electronic modules cannot tightly cling to the circuit board which is caused by lateral thrust.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Method and apparatus for flight control of tiltrotor aircraft

ActiveUS9851723B2Minimize tiltHigh control precisionWing adjustmentsAttitude controlAutomatic controlNacelle

A method and apparatus provide for automatically controlling the flight of a tiltrotor aircraft while the aircraft is in flight that is at least partially rotor-borne. The method and apparatus provide for automatically tilting nacelles in response to a longitudinal-velocity control signal so as to produce a longitudinal thrust-vector component for controlling longitudinal velocity of the aircraft. Simultaneously, cyclic swashplate controls are automatically actuated so as to maintain the fuselage in a desired pitch attitude. The method and apparatus also provide for automatically actuating the cyclic swashplate controls for each rotor in response to a lateral-velocity control signal so as to produce a lateral thrust-vector component for controlling lateral velocity of the aircraft. Simultaneously, collective swashplate controls for each rotor are automatically actuated so as to maintain the fuselage in a desired roll attitude. The method and apparatus provide for yaw control through differential longitudinal thrust produced by tilting the nacelles.

Owner:TEXTRON INNOVATIONS

Turbojet pylon for aircraft

InactiveUS7784733B2Increase consumptionImprove efficiencyPower plant constructionEngineeringRigid structure

A turbojet-mounting pylon for an aircraft. The pylon includes a rigid structure including a plurality of arcs arranged so as to jointly delimit a part of a fictitious approximately cylindrical surface with a circular section. The plurality of arcs also includes two lateral thrust resisting arcs located on each side of the central box, each of the two lateral arcs being fixed to each arc in the form of an annular portion, and on each side of the central box.

Owner:AIRBUS OPERATIONS (SAS)

Flexible steering gear for steamships

The invention discloses a flexible steering gear for steamships. The flexible steering gear is a propelling device which is arranged on bow and / or stern at a position below steamship waterline for generating lateral thrust on a hull. The flexible steering gear for steamships can realize quick steering of steamships, add a braking device, automatically match the use to improve flexibility of the steering gear, and is especially suitable for large steamships and battleships.

Owner:徐国彬

Rotary guiding drilling tool

InactiveCN103527083AReduce the risk of stuck cardsSolve the speed problemDirectional drillingThermodynamicsWell drilling

The invention relates to a downhole guiding drilling tool, and belongs to the technical field of petroleum engineering stratigraphical drilling downhole tools. The downhole guiding drilling tool consists of an irrotational coat, a rotary mandrel and a directed control mechanism, wherein a fixed centralizer and a guiding roller are arranged on the outer surface of the irrotational coat; the directed control mechanism is arranged in an inner cavity; and the guiding roller can be controlled to extend and retract by rotation and vertical movement of the drilling tool. When the guiding roller extends, a lateral thrust is applied to a drill bit, and a well track can forwards move along a certain direction. When extending, the roller is supported on a well wall, and the irrotational coat is prevented from rotating, but can downwards move when the drilling tool is fed, so that the purpose of directed drilling of the drilling tool under the state of rotation is realized. When retracting, the guiding roller does not have a guiding function, and the drilling tool drills like the conventional drilling tool.

Owner:CHINA PETROCHEMICAL CORP +1

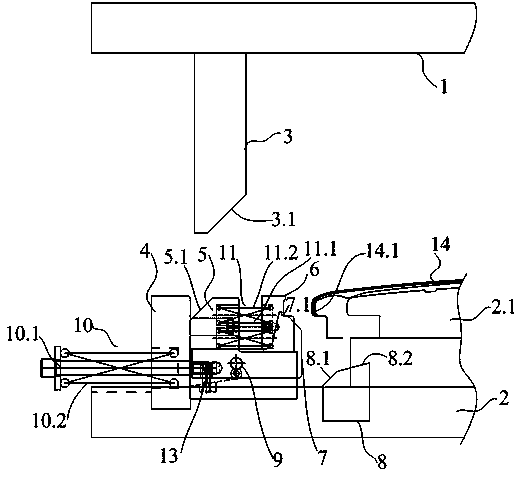

Rotary angle-wrapping forming stamping die

ActiveCN103990667AReduce maintenance costsRemove heightShaping toolsEngineeringMechanical engineering

The invention provides a rotary angle-wrapping forming stamping die. The rotary angle-wrapping forming stamping die can solve the problems that according to the prior art, an oil cylinder lateral thrusting forming mechanism is used for forming, the control difficulty is large, production efficiency is low, and the structure is complex. The rotary angle-wrapping stamping die comprises an upper die base, a lower die base and an angle-wrapping forming mechanism. The angle-wrapping forming mechanism comprises a lateral thrusting assembly and a rotary angle-wrapping forming assembly; the lateral thrusting assembly comprises a push rod, a push rod limiting block, a sliding block base, a pressure plate and a sliding block base elastic reset component. The rotary angle-wrapping forming assembly comprises a rotatable swinging block and an ejector block and the swinging block is of a forming structure. The ejector block is fixedly arranged on the lower die base and the side face, facing the side face of the swinging block, of the ejector block is a guiding slope. According to the rotary angle-wrapping forming stamping die, rotary angle-wrapping forming operation is in linkage with die closing operation, the forming cycle is shortened, and the production efficiency is greatly improved; the problem that due to the fact that the rotary angle-wrapping forming operation and the die closing operation are independent, if signal transmission and execution of the rotary angle-wrapping forming operation and the die closing operation are false, an angle-wrapping forming punch is prone to breakage is solved, and the maintenance cost of the die is reduced.

Owner:QINGDAO HISENSE MOLD

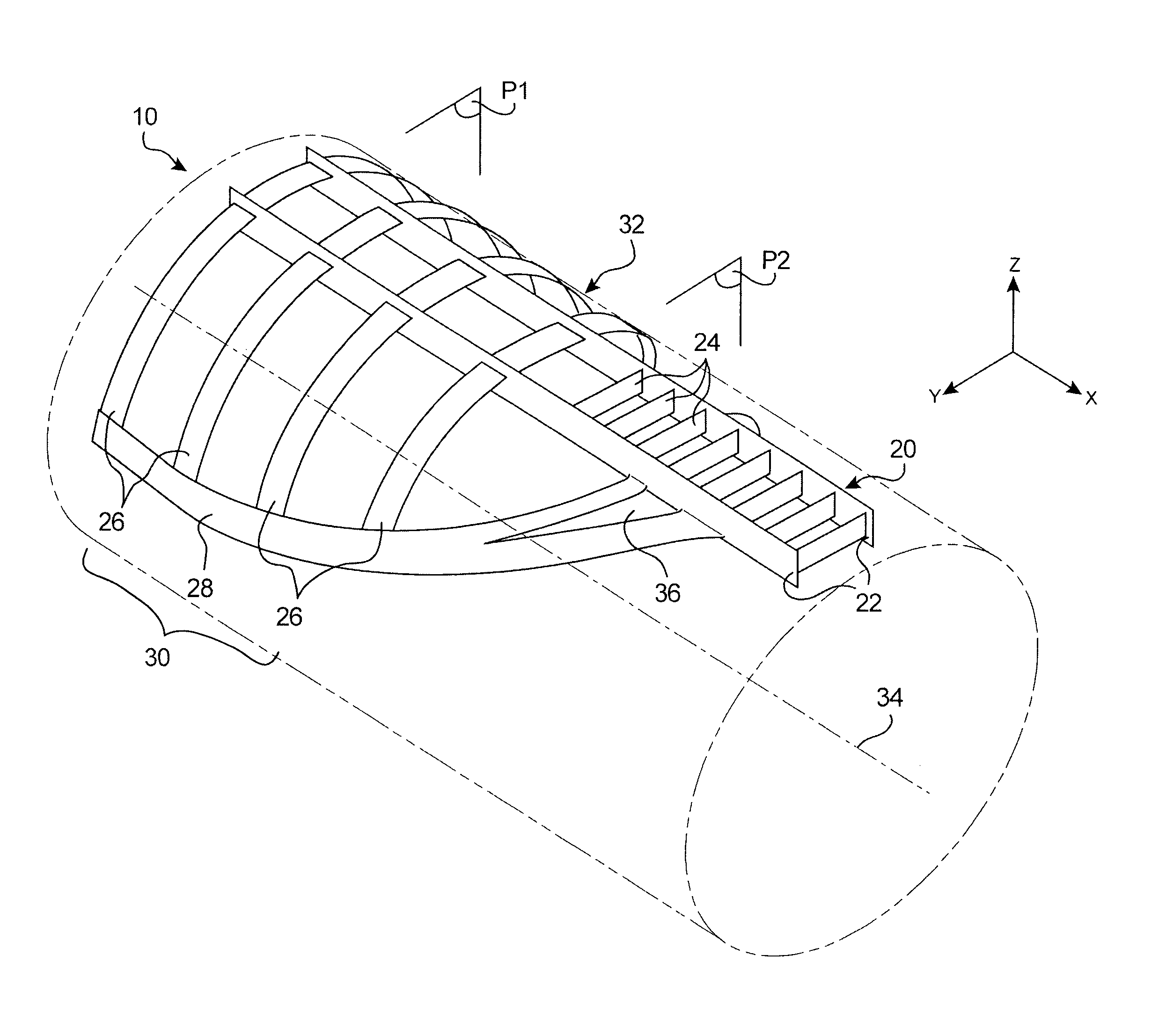

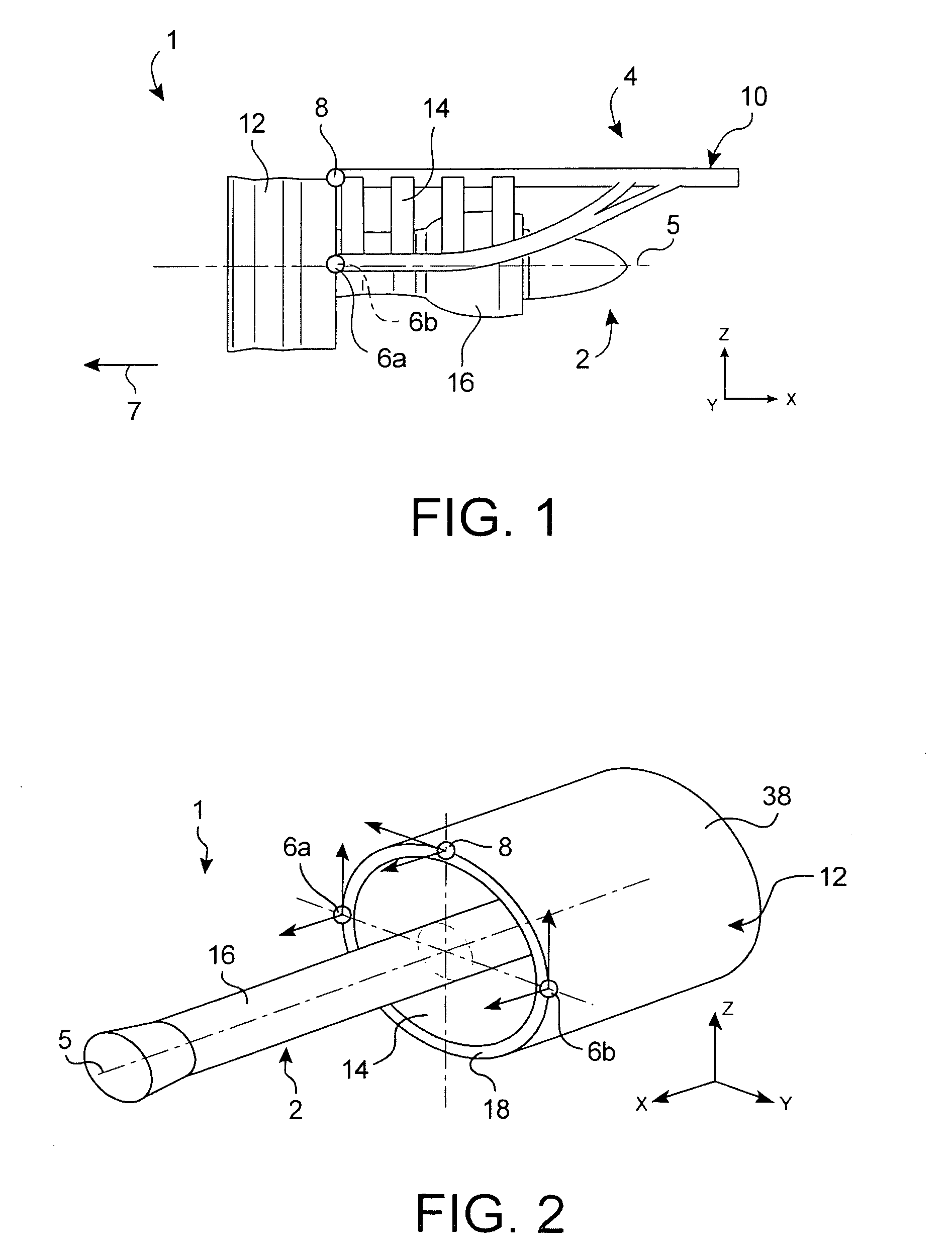

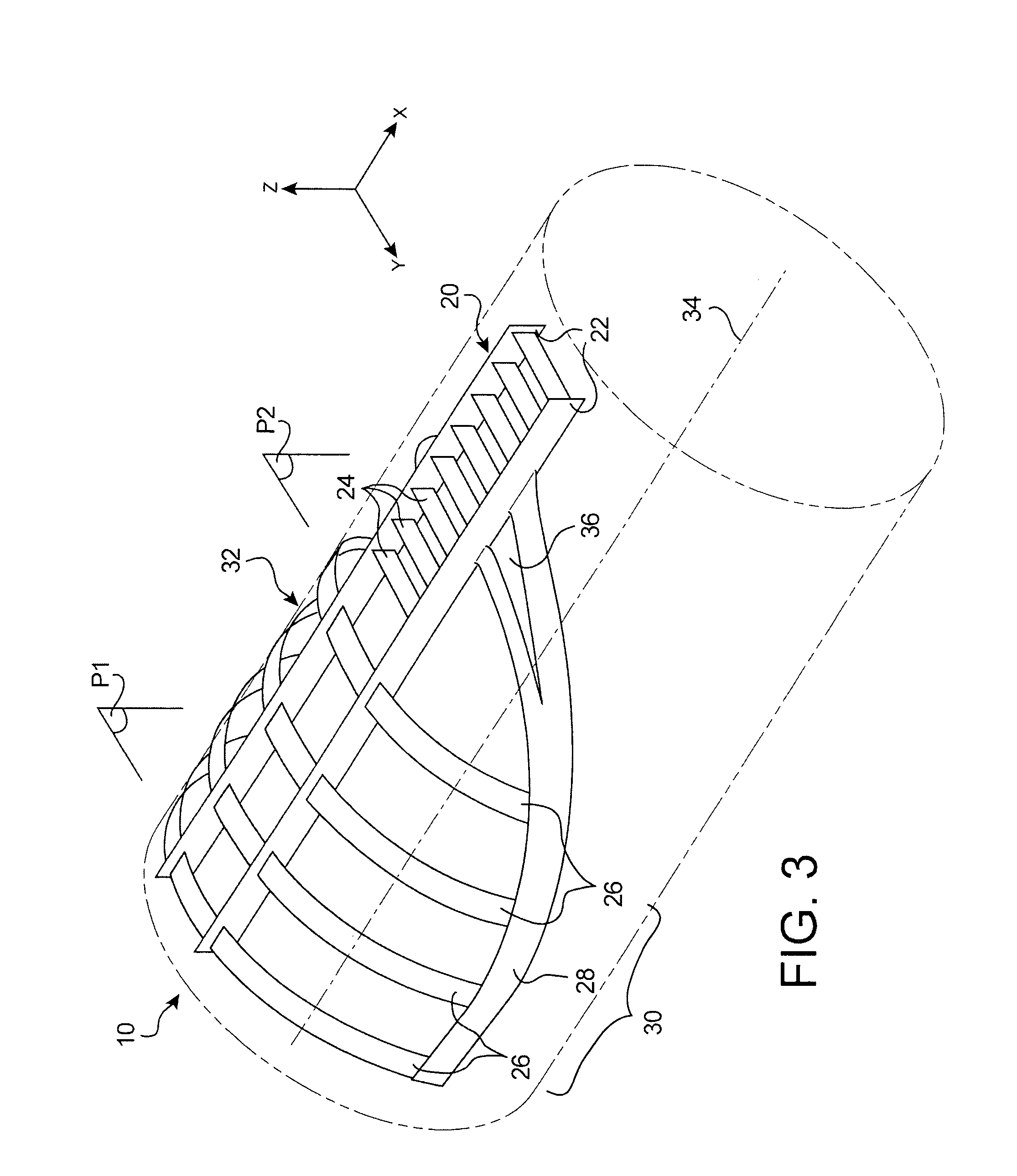

Turbojet pylon for aircraft

The invention relates to a turbojet pylon for an aircraft, comprising a rigid structure (10) which is equipped with a plurality of half-rings (30) that are arranged such as to define part of an essentially-cylindrical imaginary surface (32) with a circular cross-section. The aforementioned half-rings include two lateral thrust-bearing half-rings (28) which are disposed on either side of a central casing (20). Each of said two lateral half-rings (28) is solidly connected to (i) each half-ring taking the form of an annular segment (26) that is centred on the longitudinal axis of the imaginary surface and (ii) the central casing.

Owner:AIRBUS OPERATIONS (SAS)

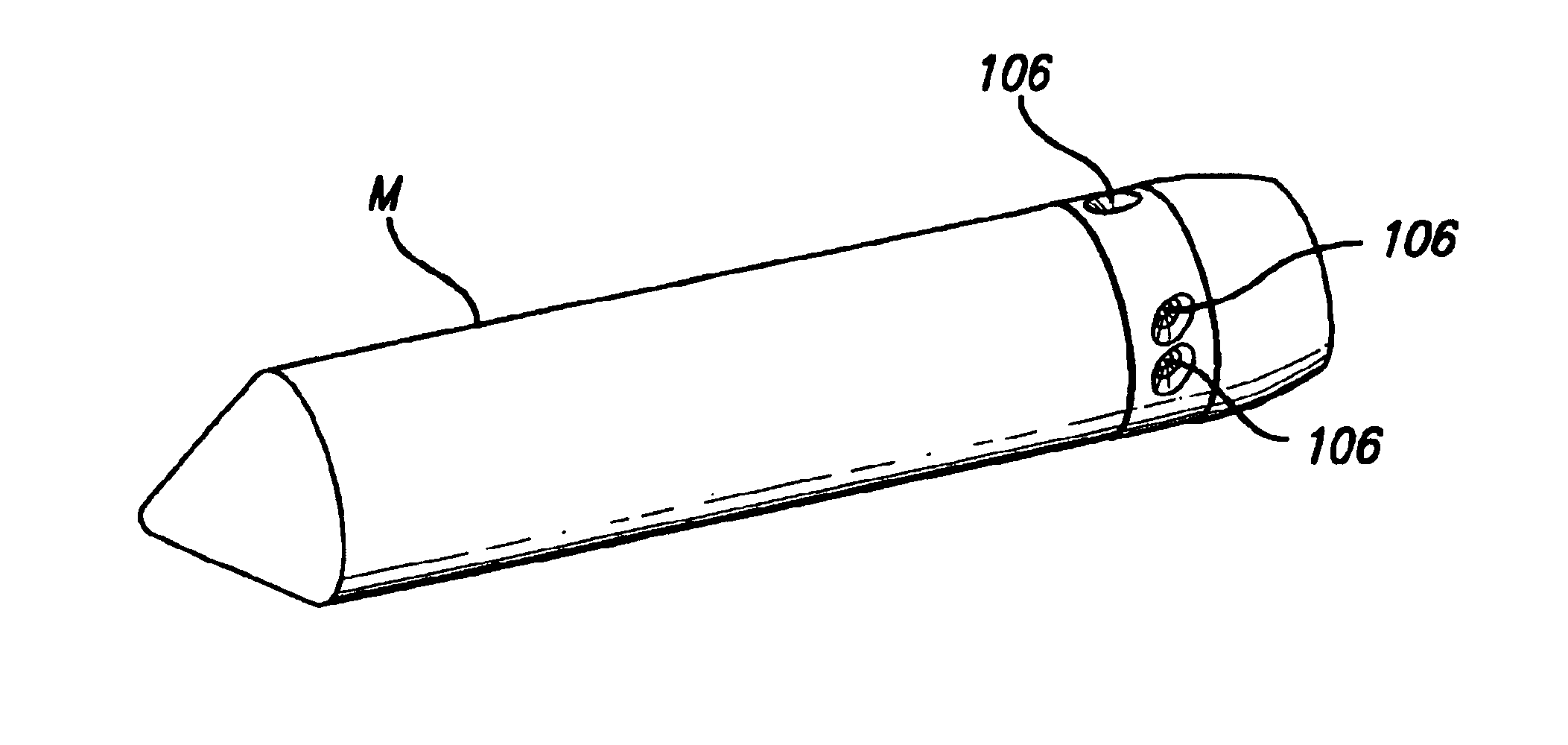

Lateral thrust control

InactiveUS7118065B1Easily brokenAssembly is requiredAircraft navigation controlDirection controllersElectricityElectrical conductor

A lateral thrust control is provided for influencing the flight trajectory of a projectile. The control has a main control unit; a central, axially extending main recess in the main control unit; a plurality of thruster recesses in the main control unit for accepting correction thrusters; an ignition element for one of the correction thrusters disposed in each of the thruster recesses; and at least one tubular conductor support of an electrically insulating material arranged inside the main recess of main control unit. At least some of the electrical conductors are in the form of conductive tracks fixedly arranged on the at least one tubular conductor support such that a particular contact element for a particular ignition element contacts the conductive track assigned to the particular contact element.

Owner:RHEINMETALL WAFFE MUNITION GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com