Patents

Literature

88results about How to "Fast turning speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

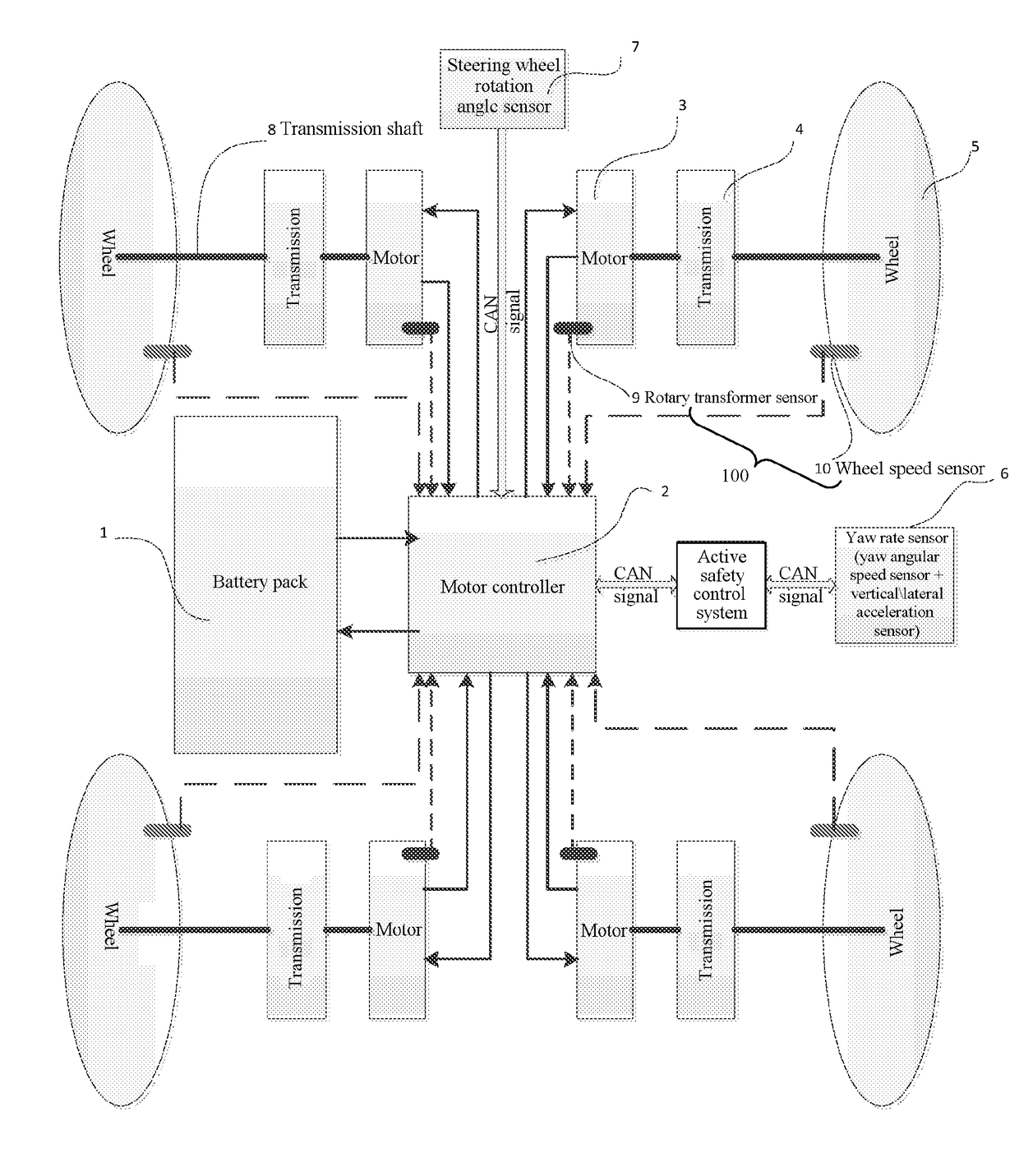

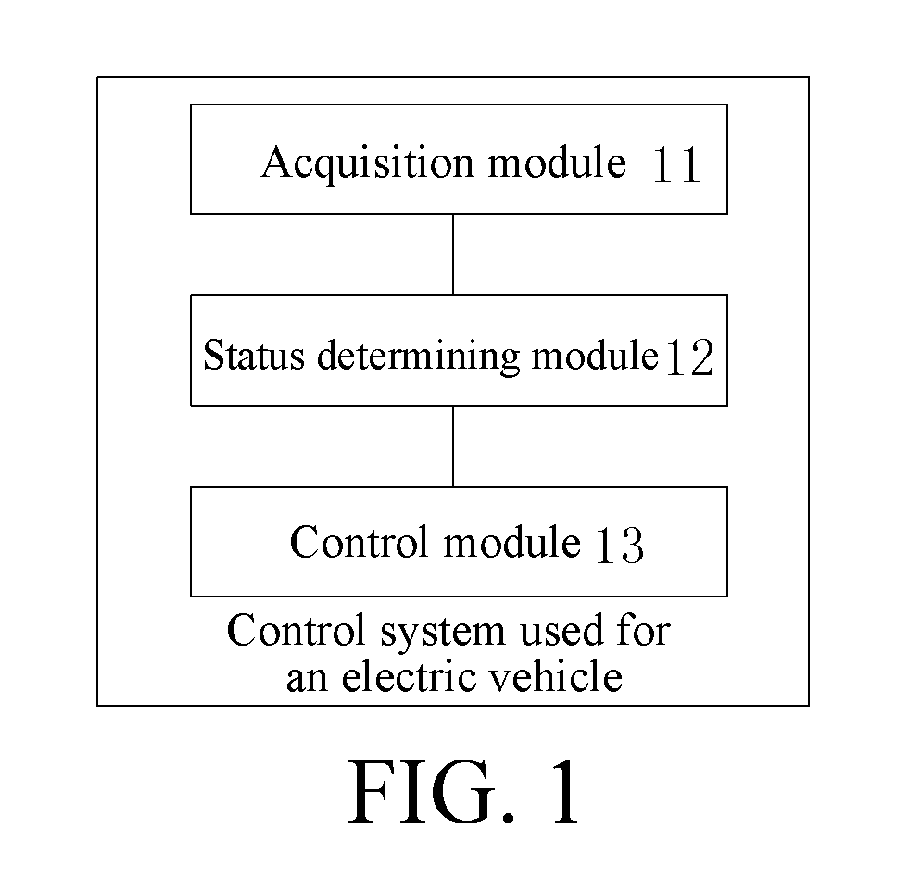

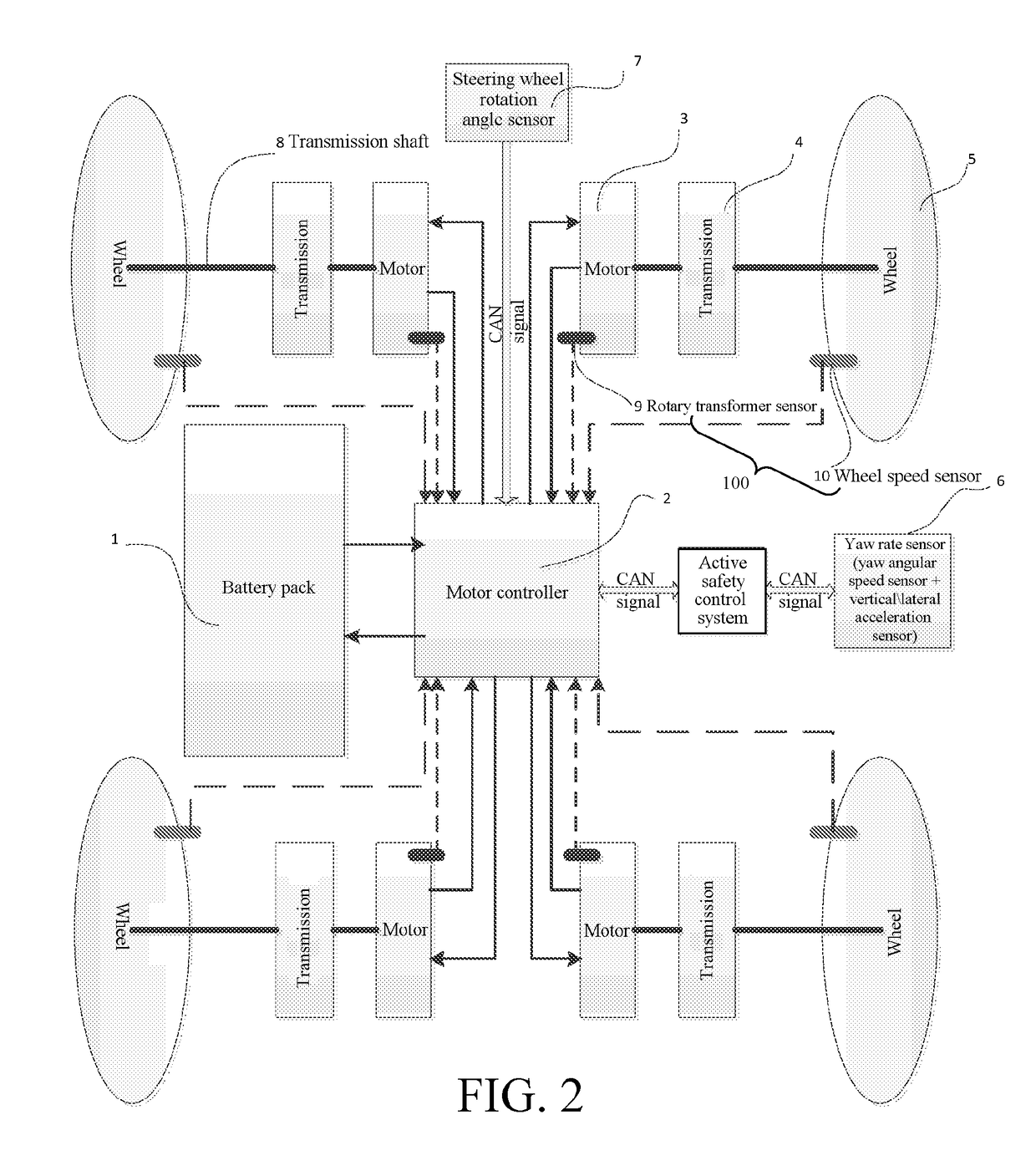

Electric vehicle, active safety control system for electric vehicle, and control method for active safety control system of electric vehicle

ActiveUS20170232848A1Improve securityIncrease mileageVehicle sub-unit featuresVehicular energy storageActive safetySteering wheel

The present disclosure discloses an electric vehicle, an active safety control system of an electric vehicle, and a control method of the active safety control system of an electric vehicle. The electric vehicle includes: multiple wheels, multiple motors, a wheel speed detection module, a steering wheel rotation angle sensor, a yaw rate sensor, and a battery pack. The active safety control system includes: an acquisition module, acquiring the wheel speed signal, the direction information, the yaw information, status information of the battery pack, and status information of the multiple motors; a status determining module, determining status of the electric vehicle; and a control module, generating a control instruction and delivering the control instruction to at least one motor.

Owner:BYD CO LTD

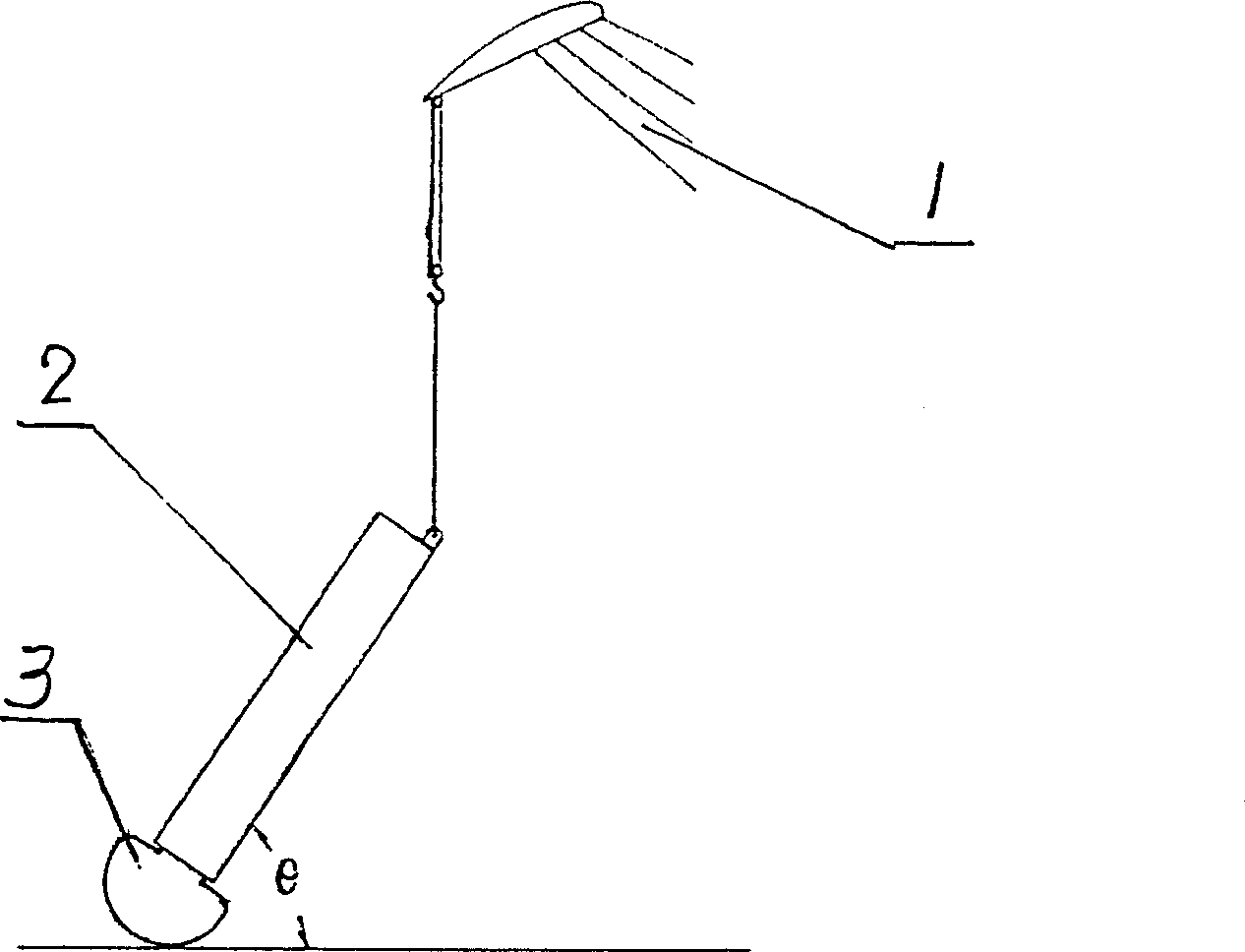

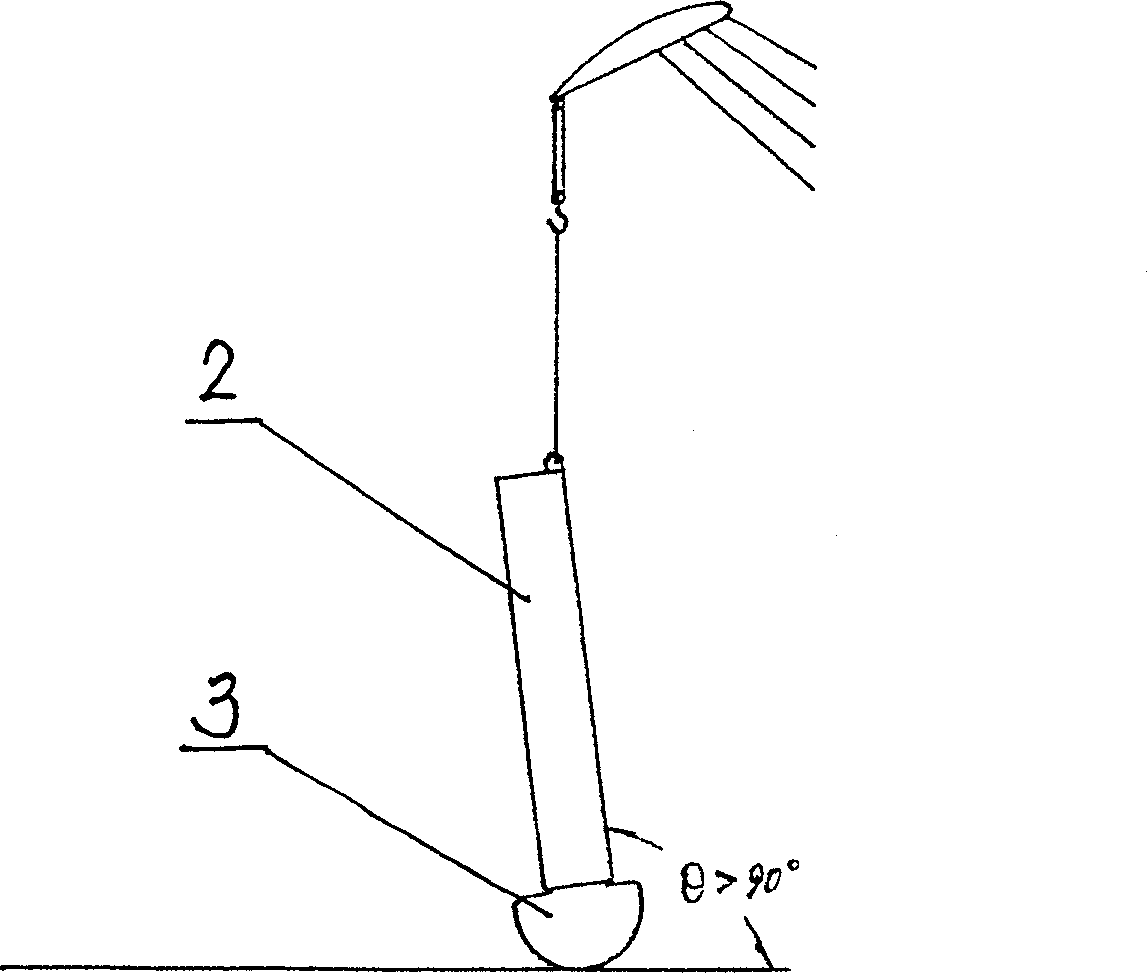

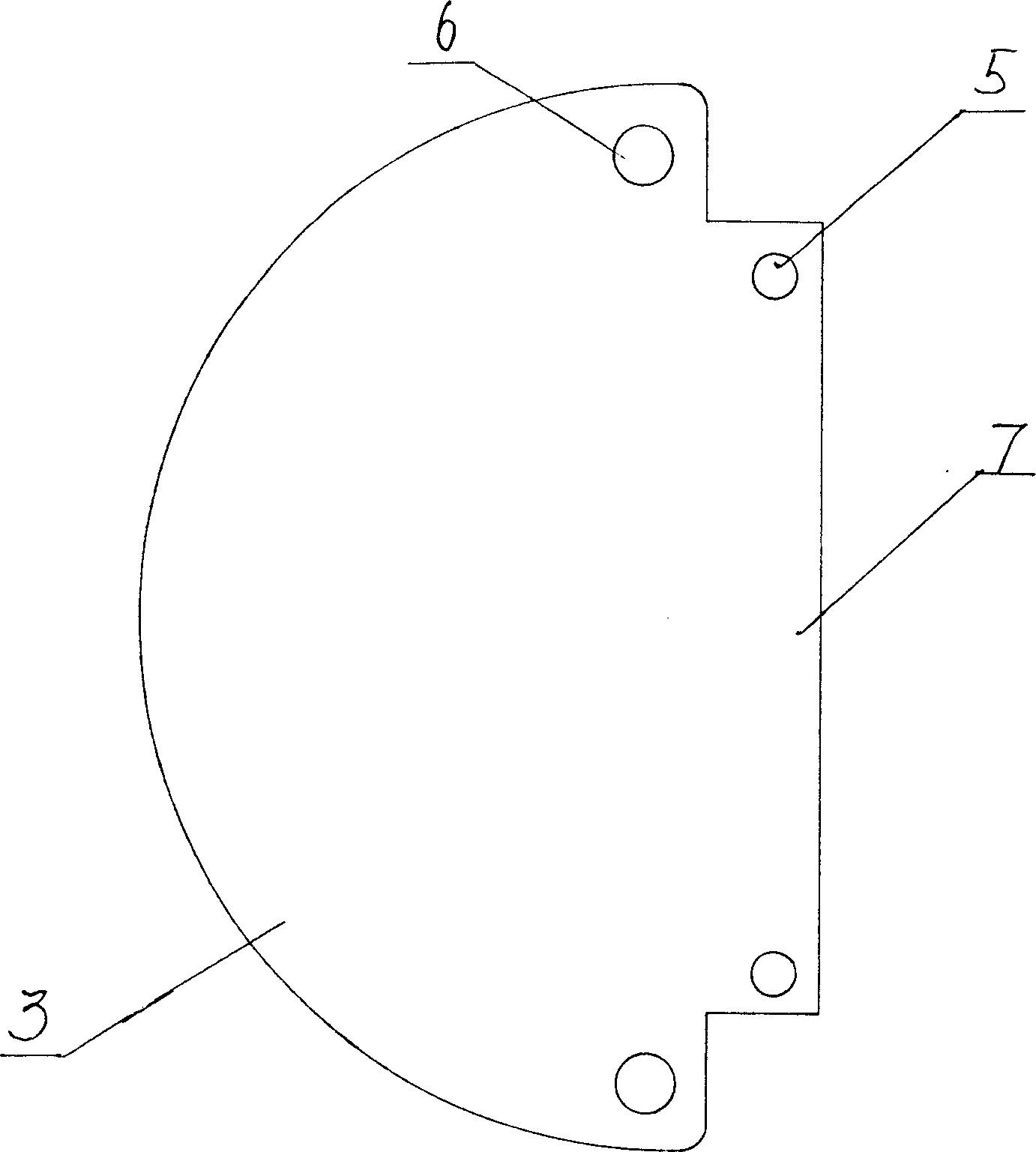

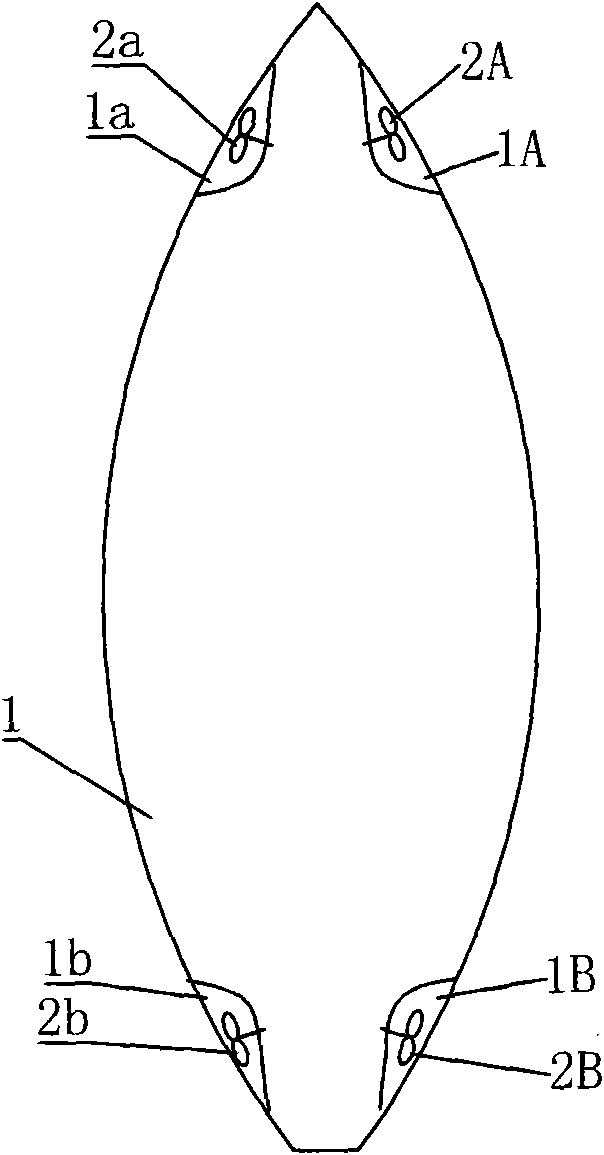

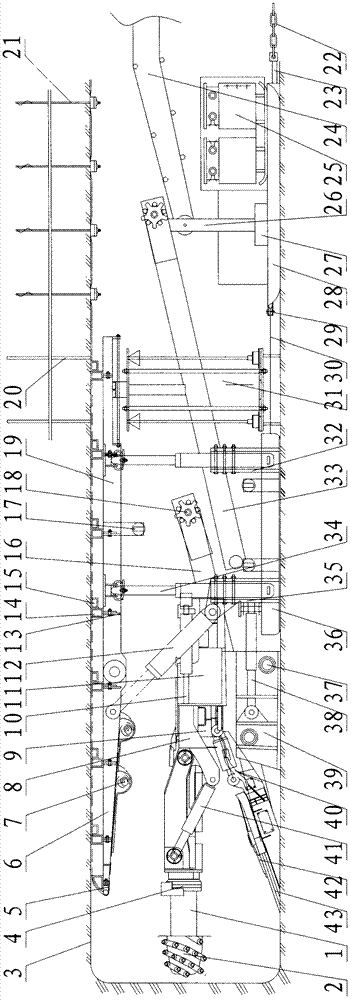

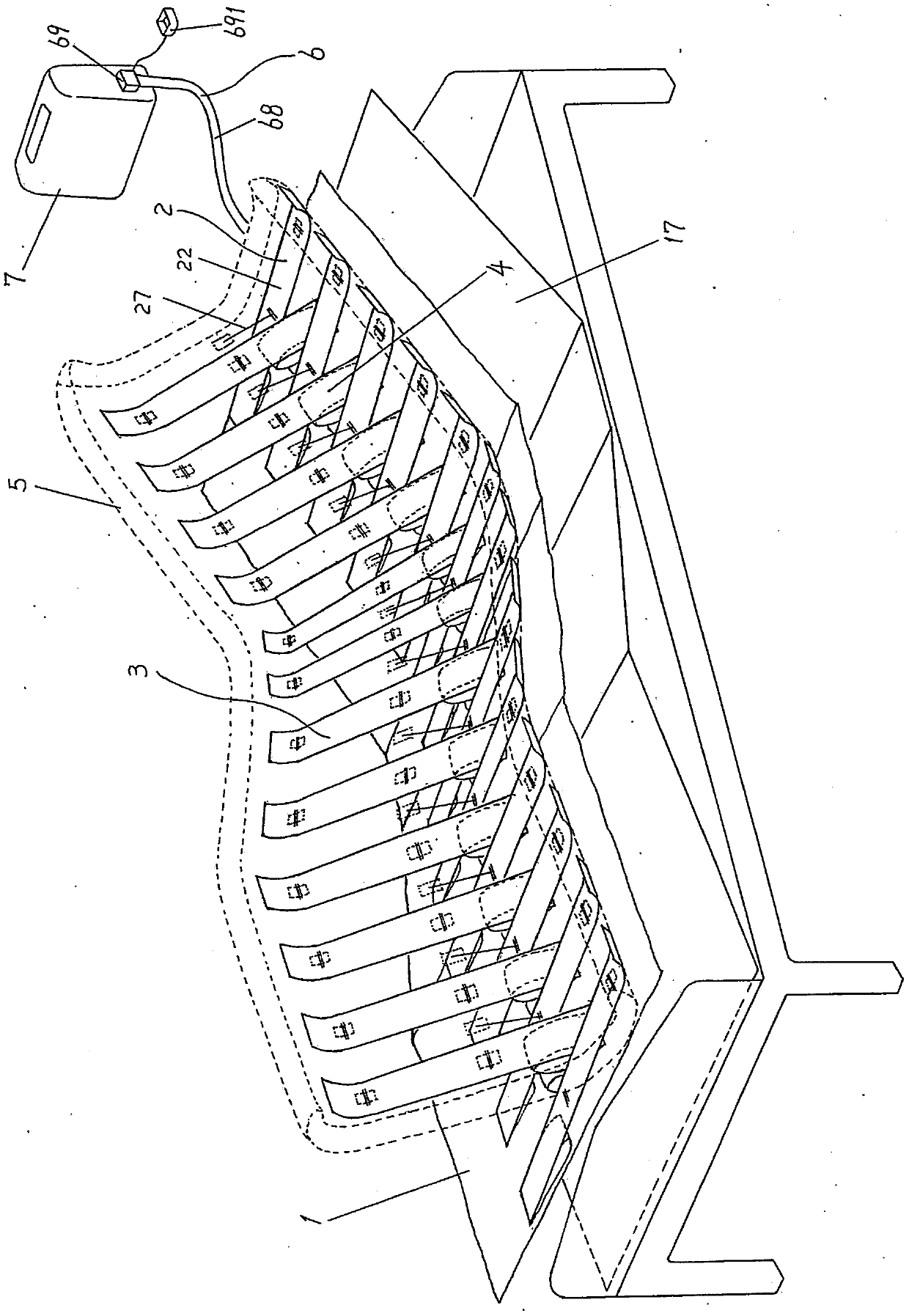

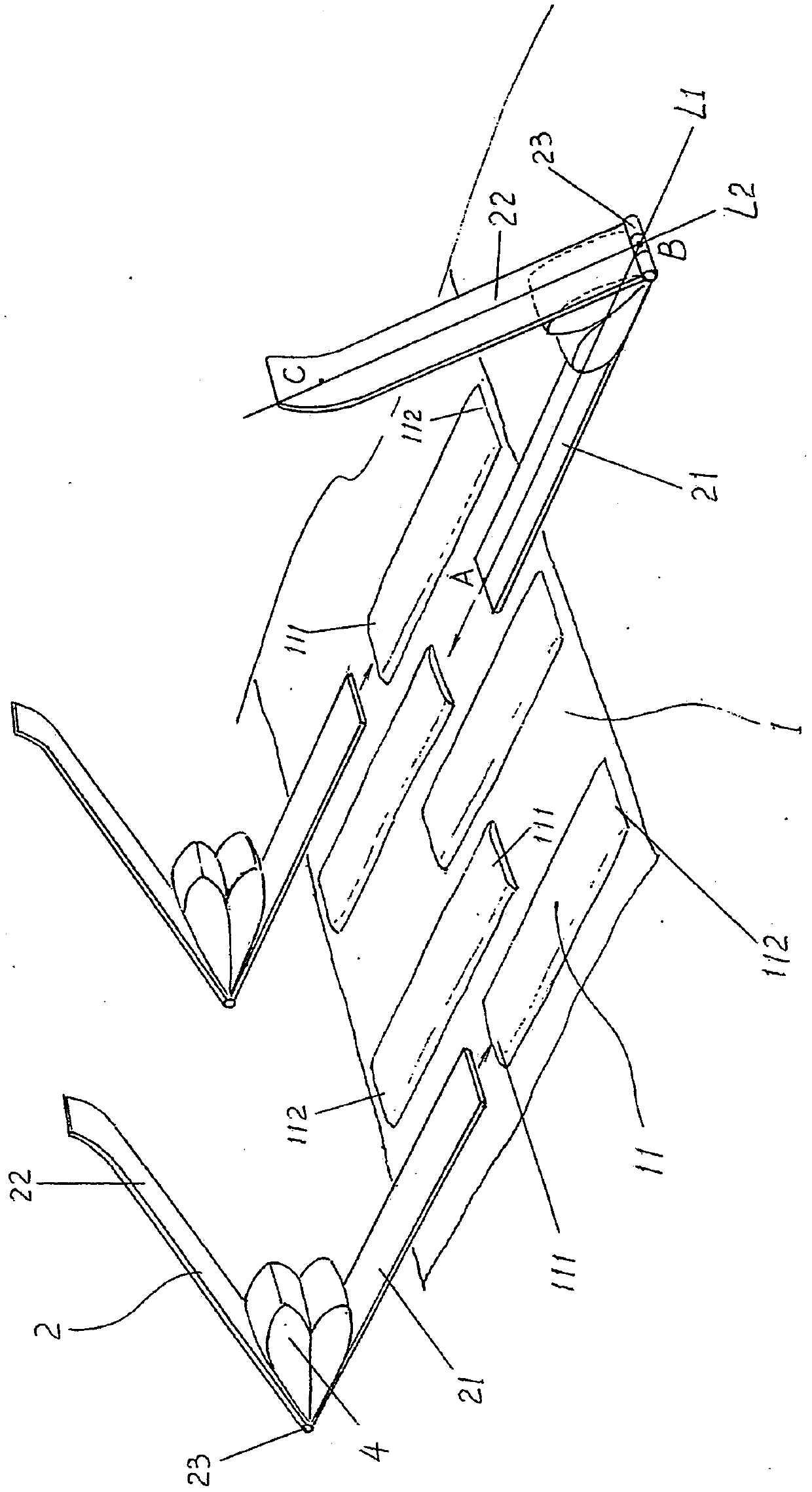

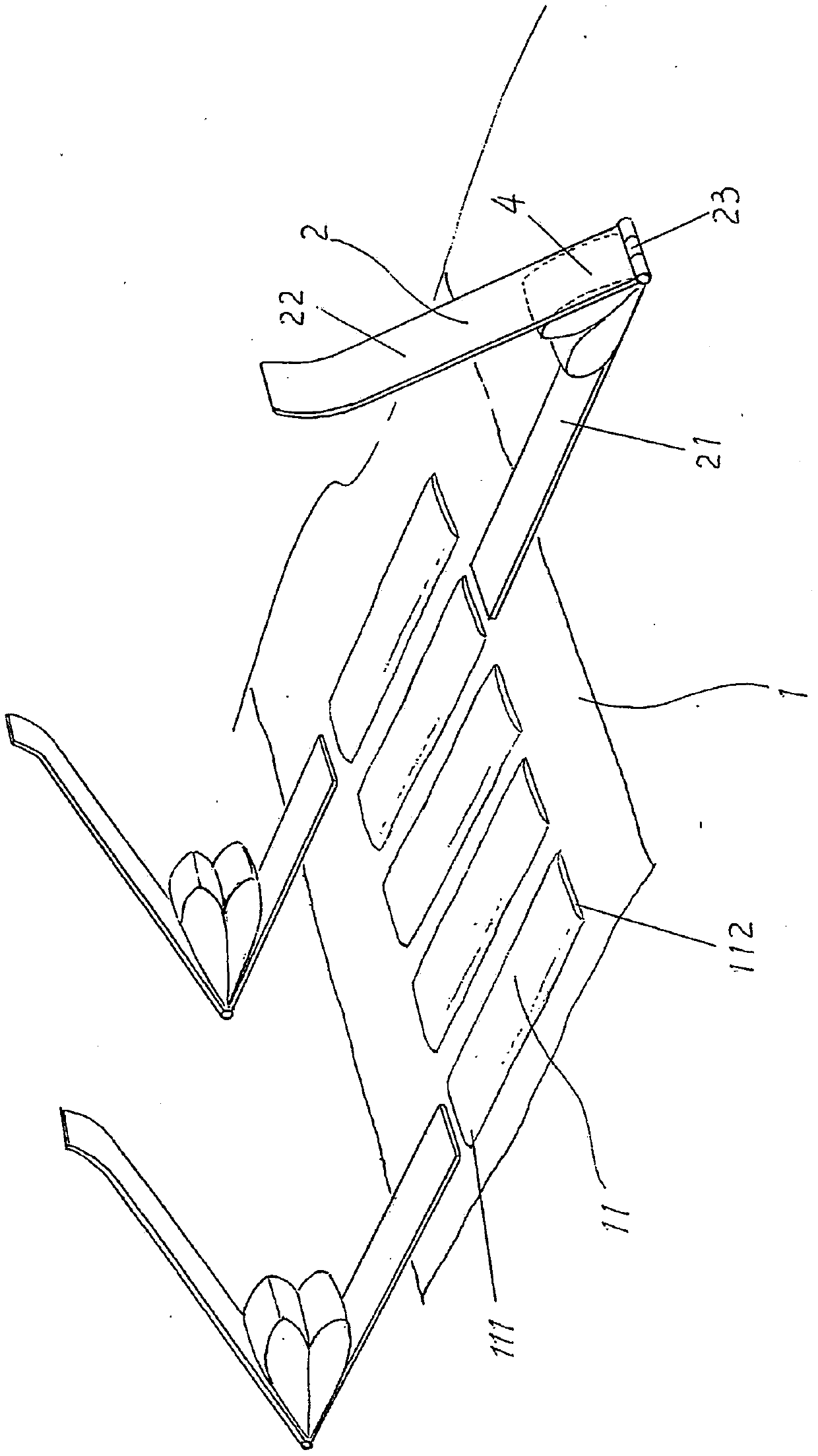

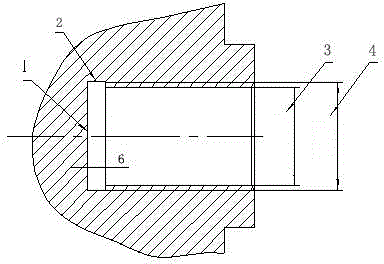

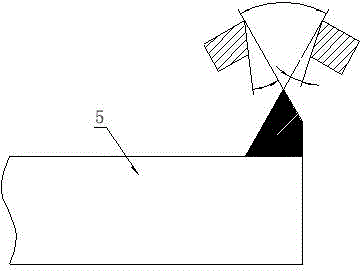

Ship hull sectional turn-over method and special-purpose rolling rack

InactiveCN1769133AGive full play to the lifting capacityReduce the number of segmentsVessel partsStructural engineeringMechanical engineering

The invention discloses a method for sectional turning the ship and special rolling bracket, comprising: (1) each side edge of one end of section has one arc rolling bracket while its axis is parallel to the sectional turning surface; (2) the invention uses the crane to hang the another end of section to turn the section for 180 degrees along the arc surface of rolling bracket to complete the sectional turning. The inventive special rolling bracket has a round arc surface and a connection plate arranged on the chord of round arc and connected to the section via connection hole. Compared to present technique, the invention can fully utilize the lifting ability of crane while the section weight can be two times of the section weight turned by two crane; since the section is large, the number of sections is fewer, the closing quality of ship is confirmed, and the period of building ship can be shorted; since the section is turned by the support of rolling bracket, it has better support condition, reliable safety, simple operation, and fast turning speed.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

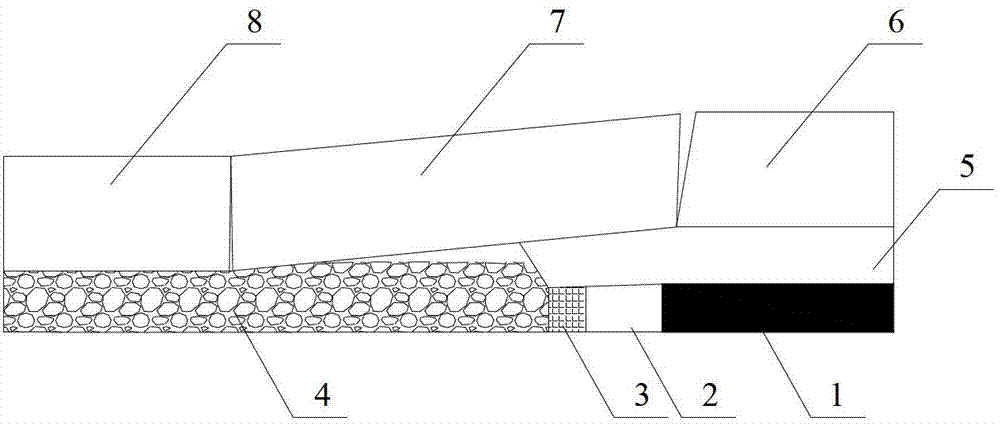

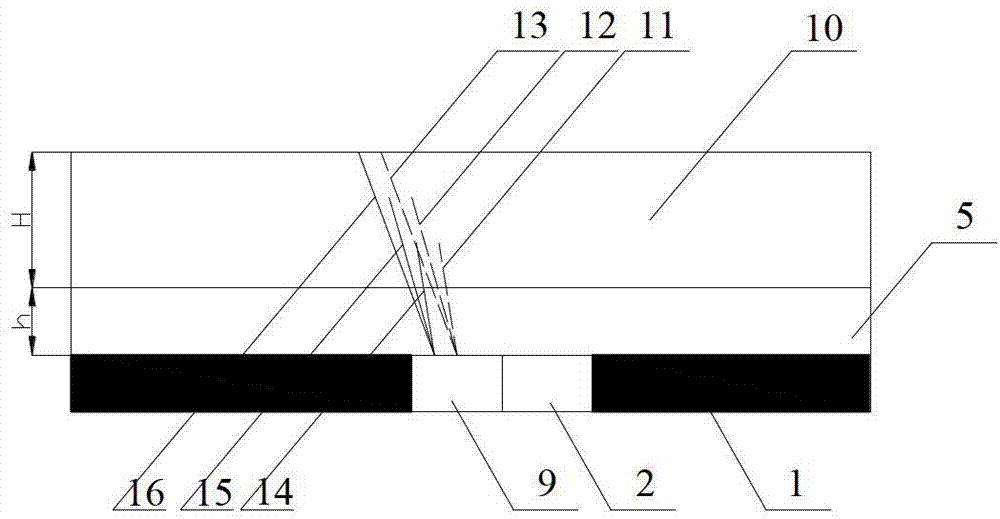

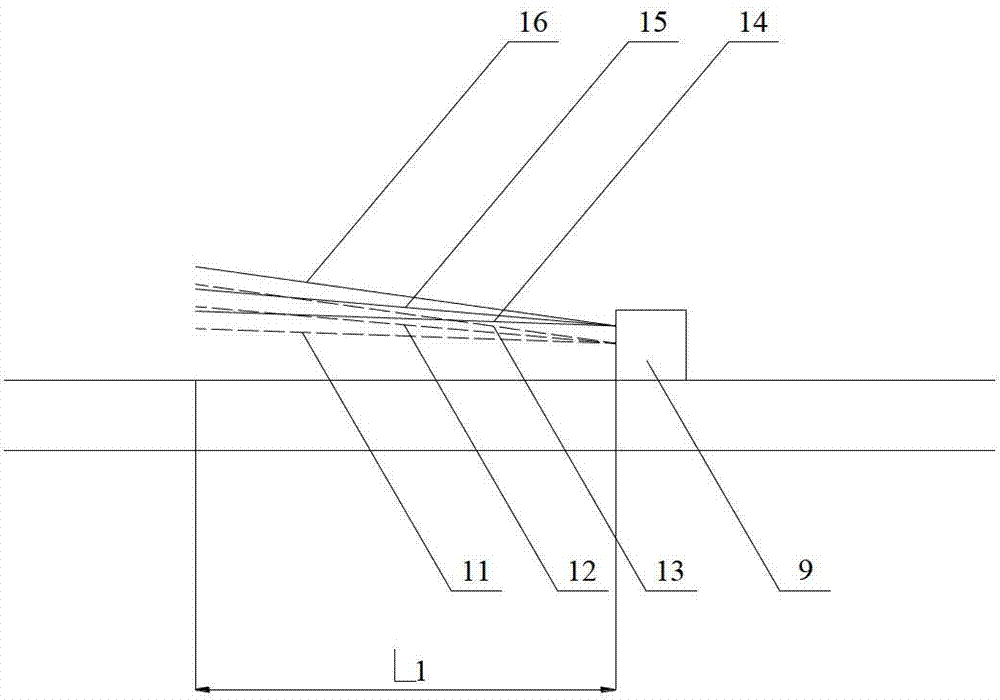

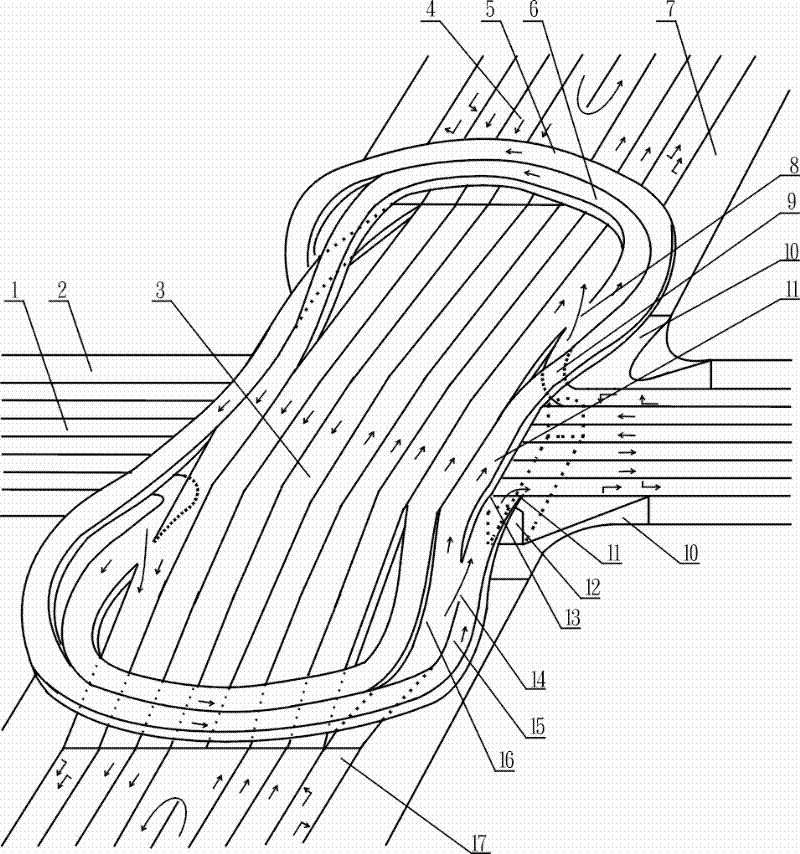

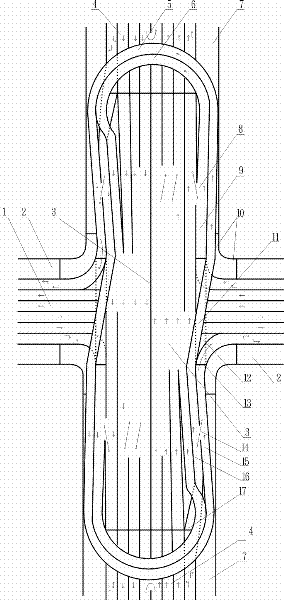

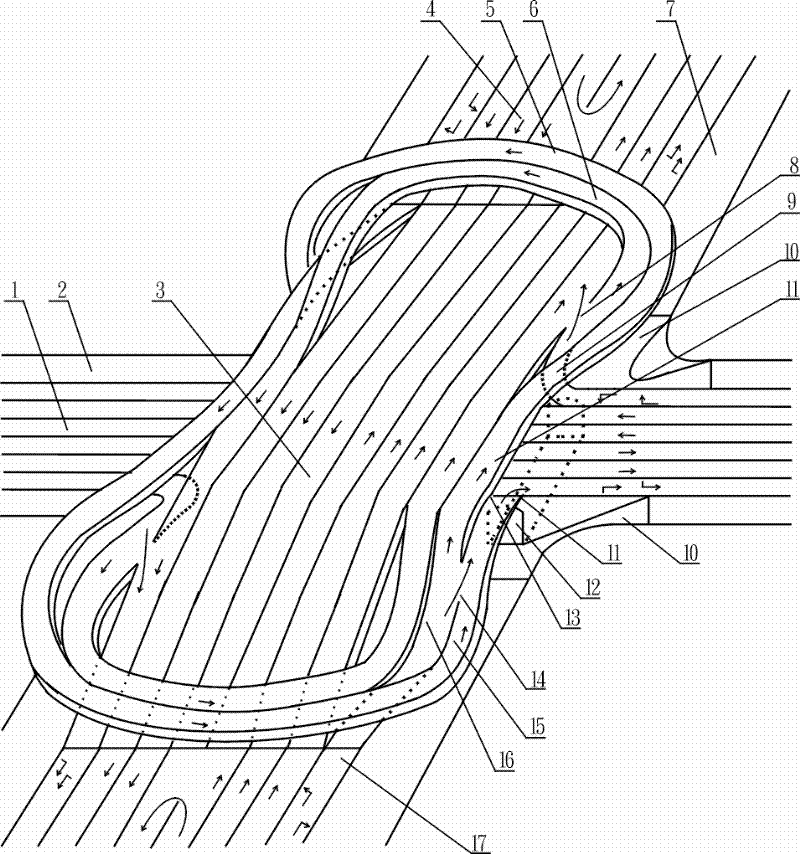

Gob-side entry retaining adjoining rock stabilizing method based on lateral rock formation pre-splitting control

ActiveCN103321642AStress Field Distribution OptimizationEliminationUnderground miningSurface miningDrill siteInduced stress

The invention provides a gob-side entry retaining adjoining rock stabilizing method based on lateral rock formation pre-splitting control. The stabilizing method is used for pre-splitting an upper roof above the gob-side entry retaining. The method comprises the steps as follows: constructing a drill site in a roadway stoping lateral coal wall; stoping a lateral top plate in the drill site; constructing two groups of six advanced pre-splitting blasting holes which take the shape of a small horizontal rotational angle in the trending direction of the roadway; loading the explosive for blasting in the position which is 10 to 40 meters to an advanced working surface. According the method provided by the invention, a top cover rock formation can be pre-split, the fracture of the top cover rock formation in an assigned position outside a wall body is guaranteed, and the contact of the turning submerged upper roof to the gob-side entry retaining adjoining rock is separated, so that the bearing pressure of the gob-side entry retaining adjoining rock is reduced, and the action time of the mining-induced stress is shortened; the method has the effects of simple operation, high efficiency of construction and fast speed.

Owner:CHINA UNIV OF MINING & TECH

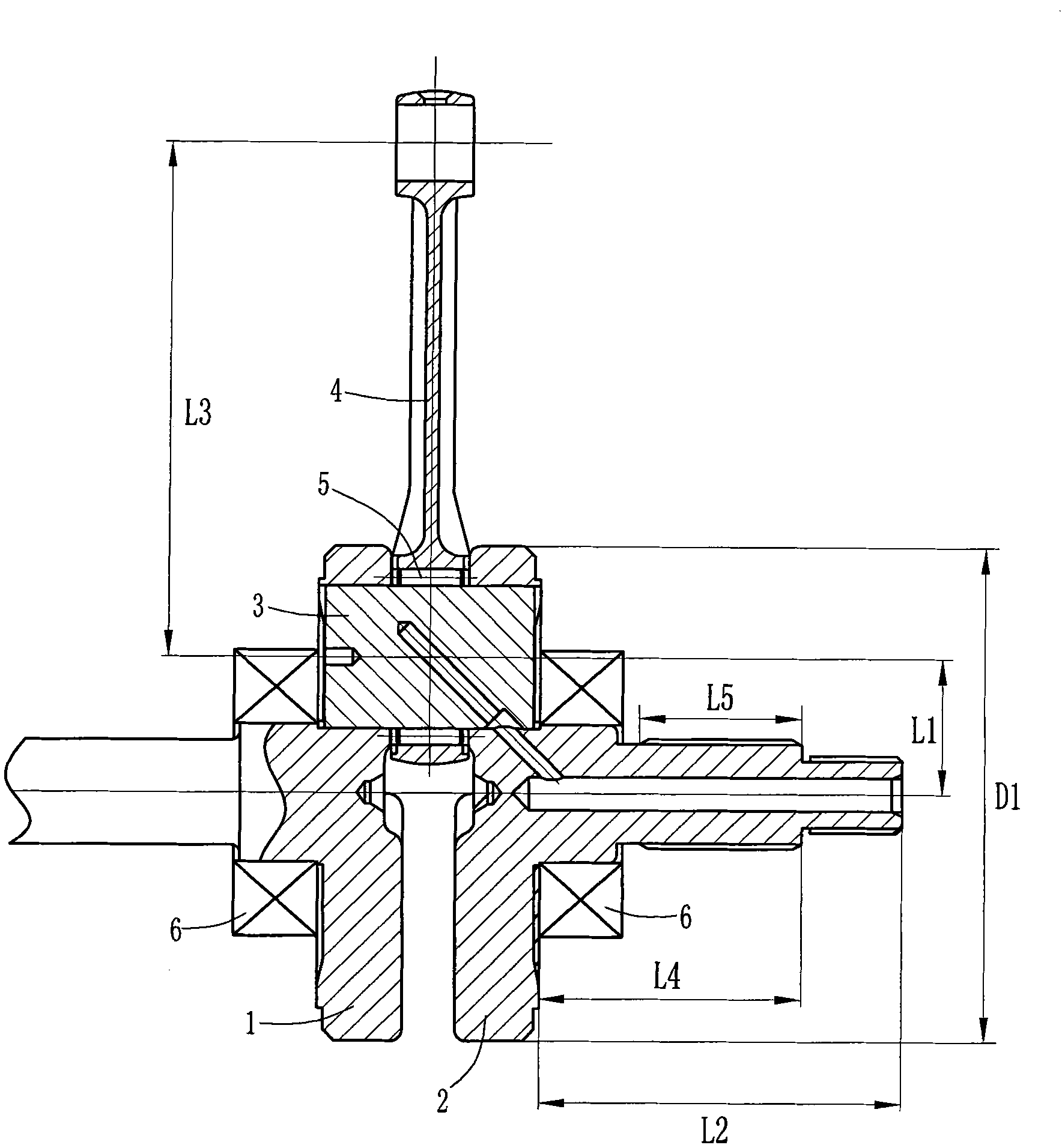

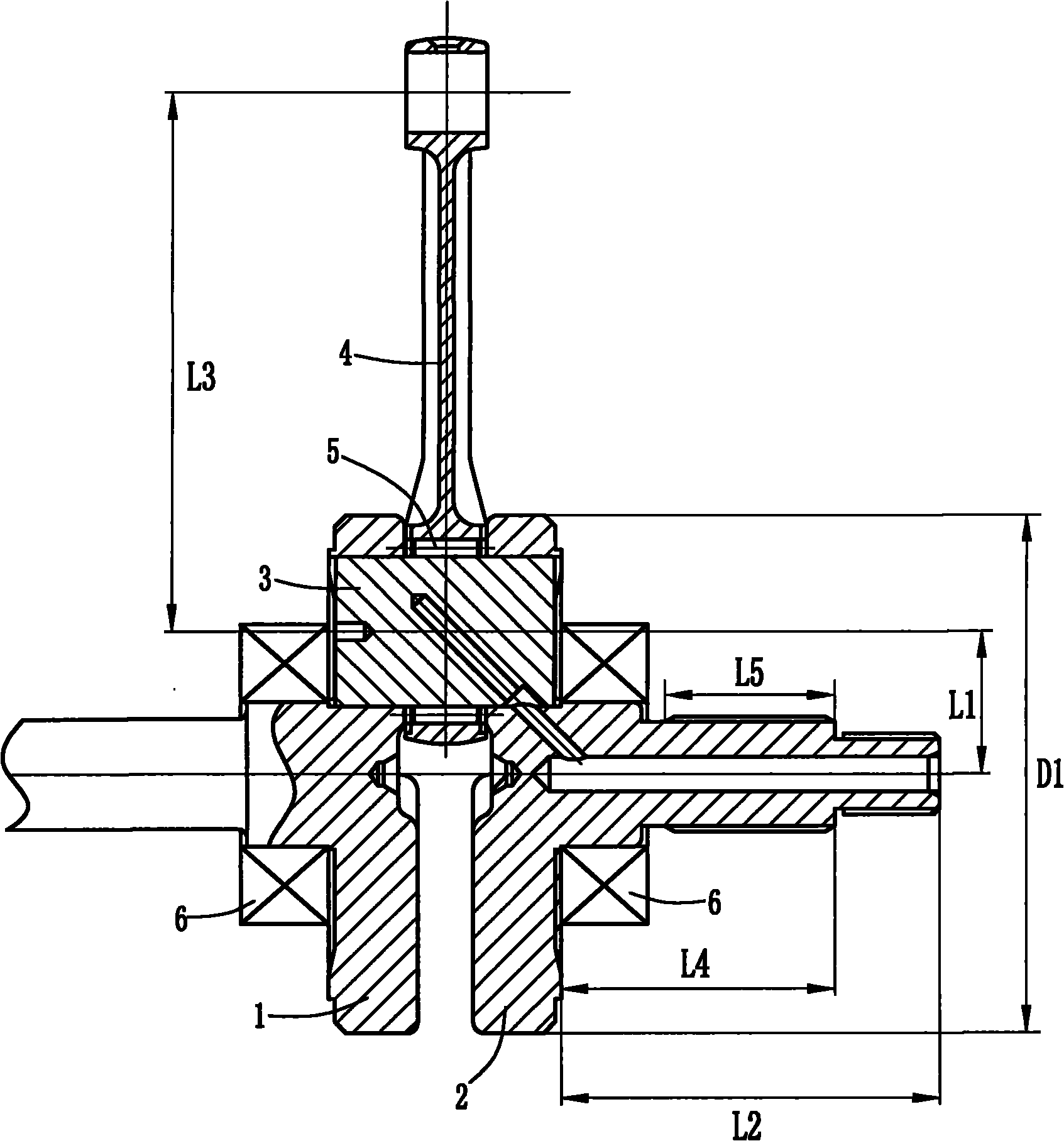

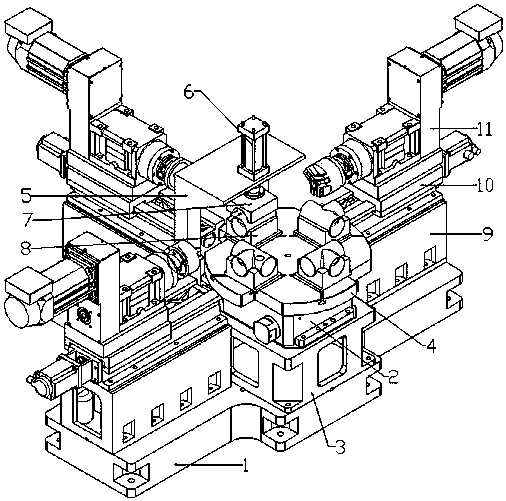

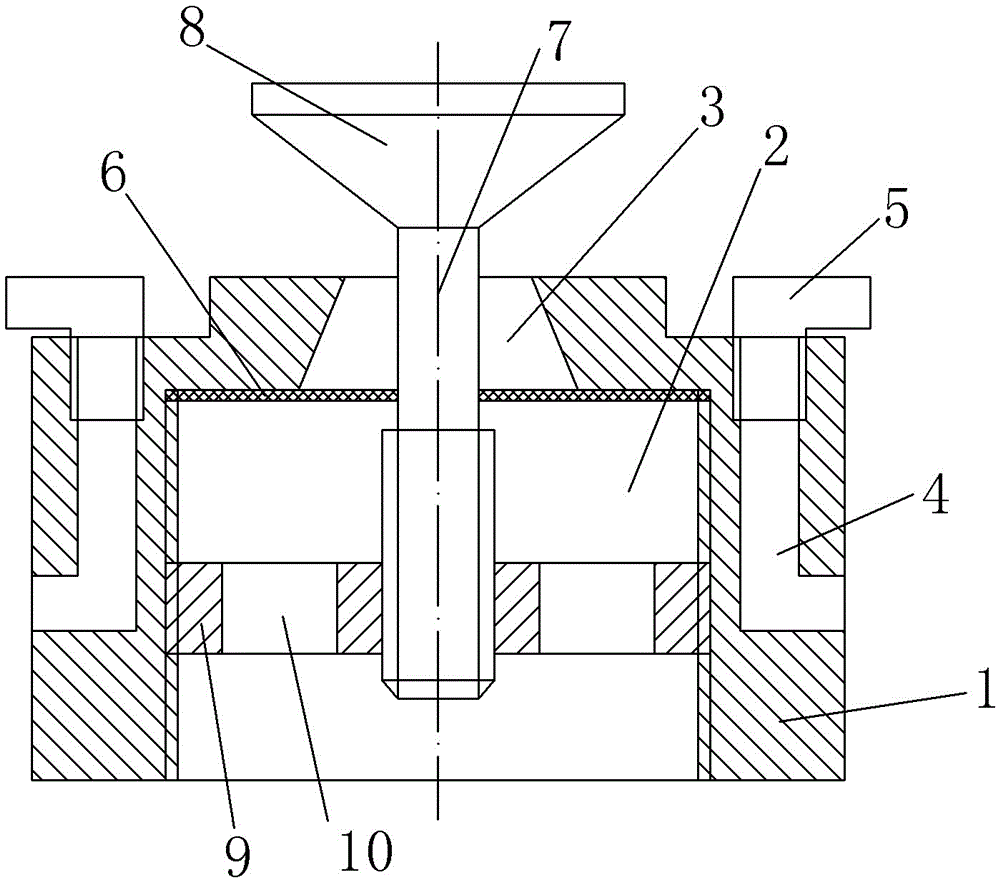

Static-pressure direct drive rotating table

InactiveCN103128561AImprove axial stiffnessReduce processing difficultyLarge fixed membersEngineeringMechanical engineering

The invention relates to a static-pressure direct drive rotating table which comprises a base seat and a rotating plate, wherein the rotating plate is assembled on the base seat in a rolling mode through a static-pressure bearing, and the axial line of the rotating plate extends along an up-and-down direction. The static-pressure bearing is arranged in the middle part of the rotating plate. At least one circle of static-pressure bearing guide rail pair is arranged in the periphery of the static-pressure bearing between the base seat and the rotating plate. The static-pressure direct drive rotating table is small in processing amount of the rotating plate and large in axial bearing capacity.

Owner:HENAN UNIV OF SCI & TECH

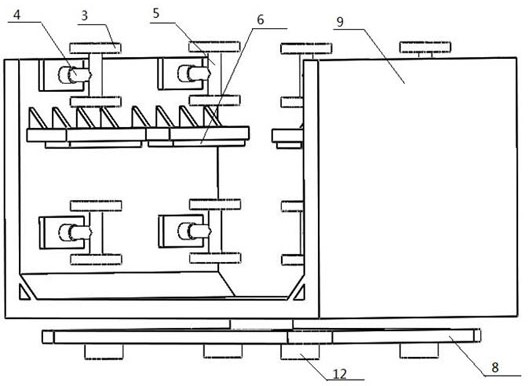

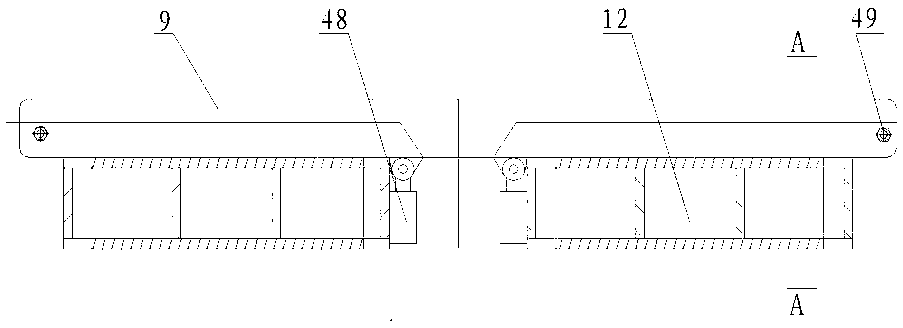

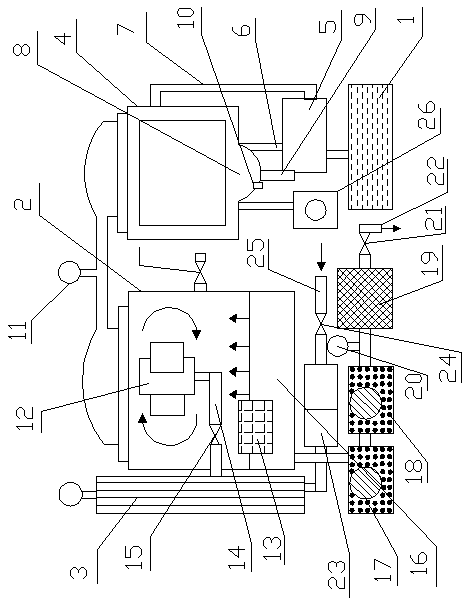

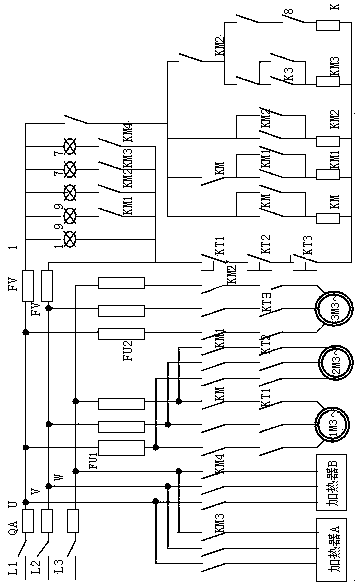

Novel rotating miller

InactiveCN101648287AEasy to locate and installLow costLarge fixed membersMilling equipment detailsEngineeringOrbit plane

The invention discloses a novel rotating miller which comprises a main beam that is connected with an electric appliance cabinet; a drag link mechanism is arranged above the main beam, a workbench isarranged below the main beam, a rotating mechanism is arranged at the lower end of the workbench, and a left beam and a right beam are arranged at the left end and the right end of the main beam, wherein the right beam is connected with a longitudinal beam, the left beam and the right beam are connected to a power cutting head, a support structure is arranged at the side of the connection part ofthe main beam and the right beam, and alarm lamps are arranged at two ends of the main beam. The invention has good security, small volume, convenient installation and gas milling speed and can achieve the advantages that two annular orbit planes are processed simultaneously after once positioning, and the parallelism degree is high after being processed.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

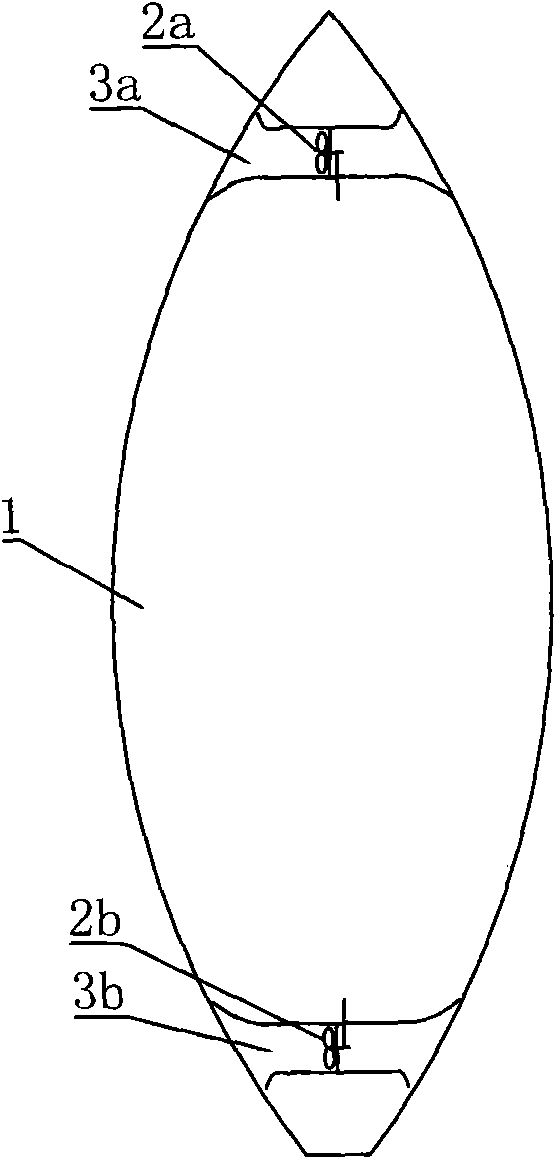

Flexible steering gear for steamships

The invention discloses a flexible steering gear for steamships. The flexible steering gear is a propelling device which is arranged on bow and / or stern at a position below steamship waterline for generating lateral thrust on a hull. The flexible steering gear for steamships can realize quick steering of steamships, add a braking device, automatically match the use to improve flexibility of the steering gear, and is especially suitable for large steamships and battleships.

Owner:徐国彬

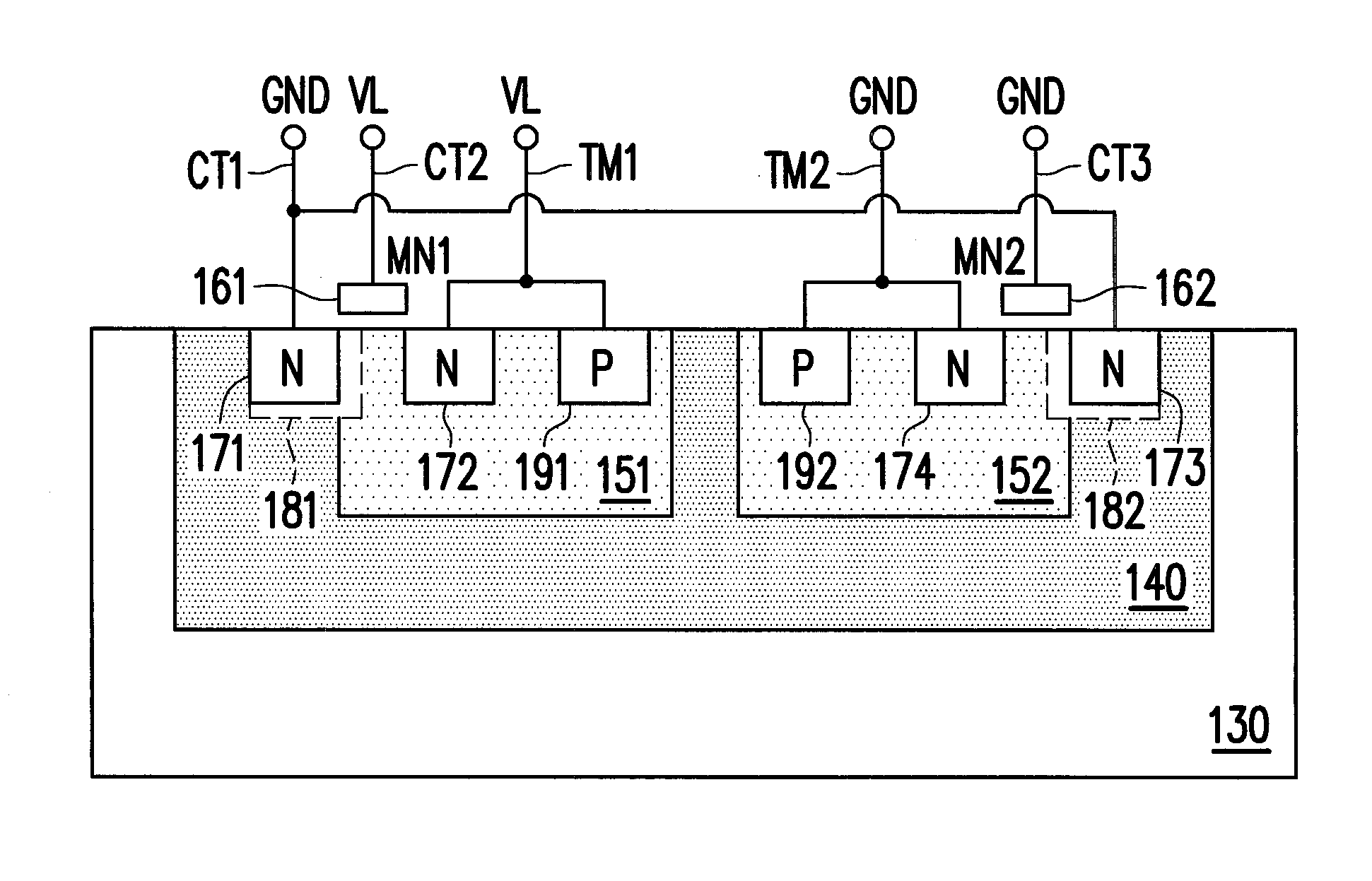

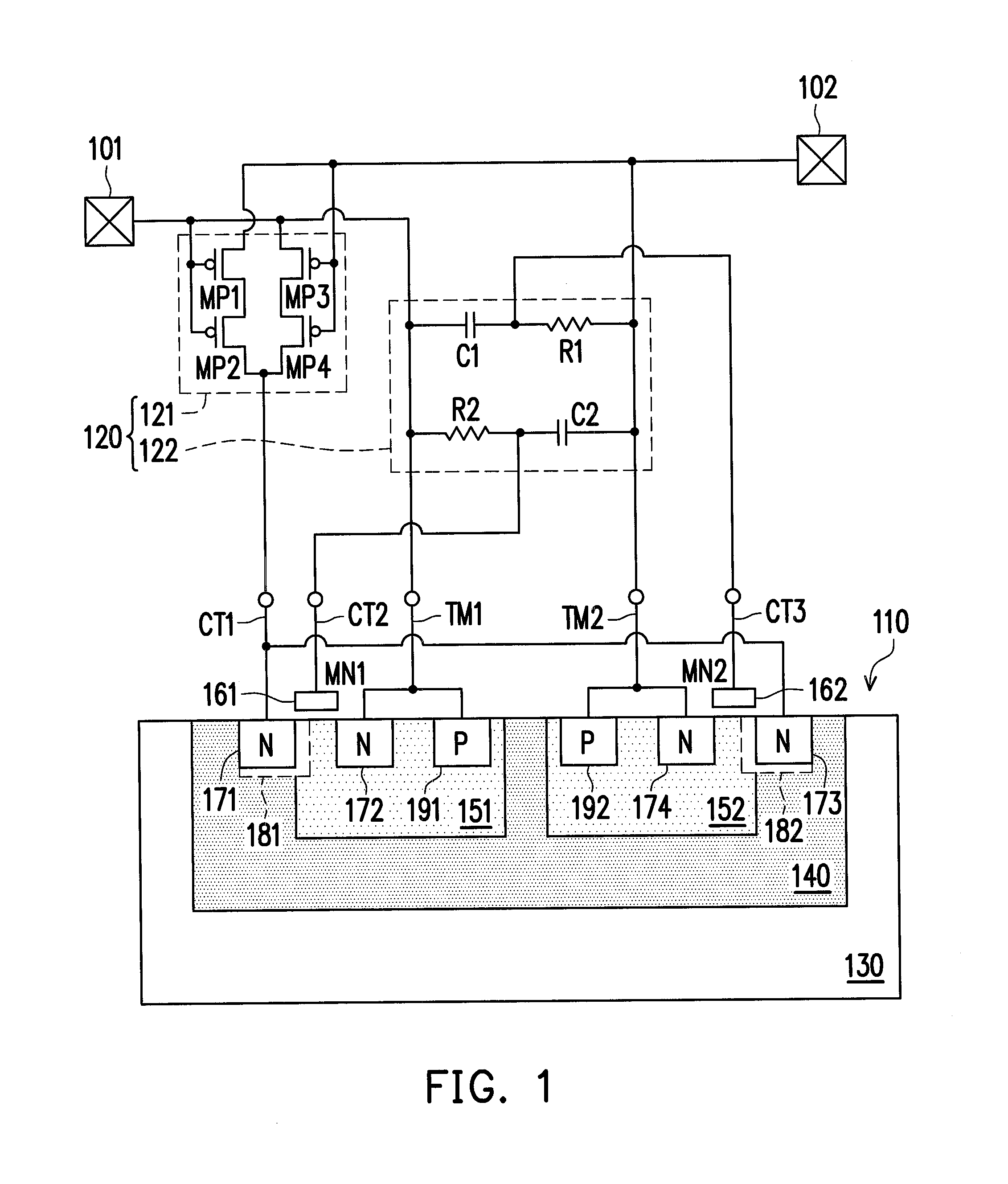

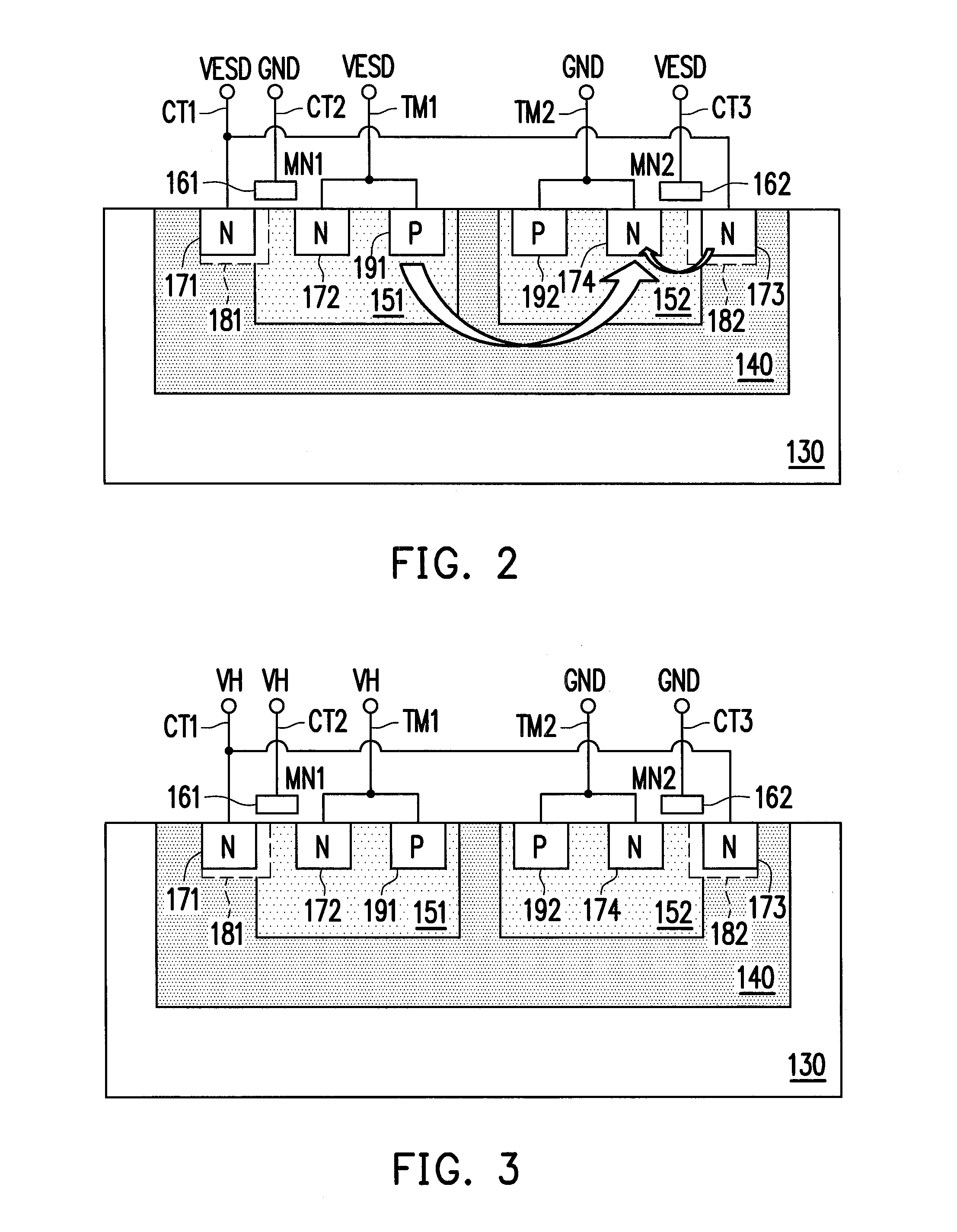

Protection component and electrostatic discharge protection device with the same

ActiveUS20130328125A1Fast turning speedFunction increaseTransistorSemiconductor/solid-state device detailsElectrostatic discharge protectionElectrical and Electronics engineering

An electrostatic discharge protection device includes a protection component and a component controller. The protection component includes a first and a second P-type wells which are disposed in an N-type deep well, a first N-type transistor which is formed in the N-type deep well and the first P-type well, and a second N-type transistor which is formed in the N-type deep well and the second P-type well. When an electrostatic pulse occurs at a first pad or a second pad, the component controller turns on one of the first and the second N-type transistors to discharge the electrostatic pulse. When a first and a second operating signals are supplied to the first and the second pads, the component controller turns off the first and the second N-type transistors according to the first and the second operating signals so that the protection component is incapable of generating the current path.

Owner:MACRONIX INT CO LTD

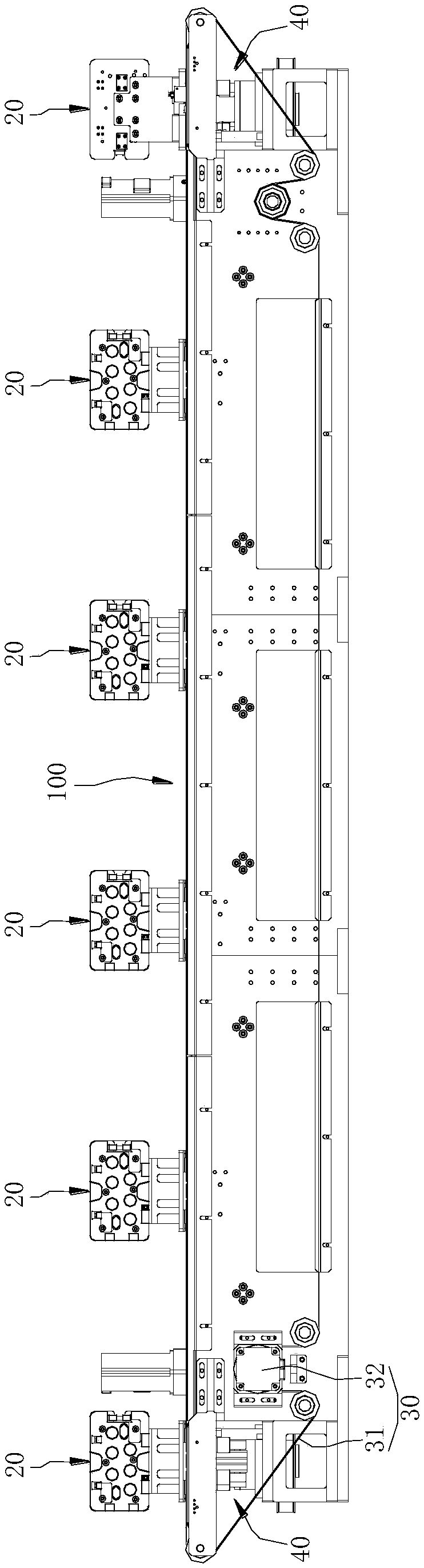

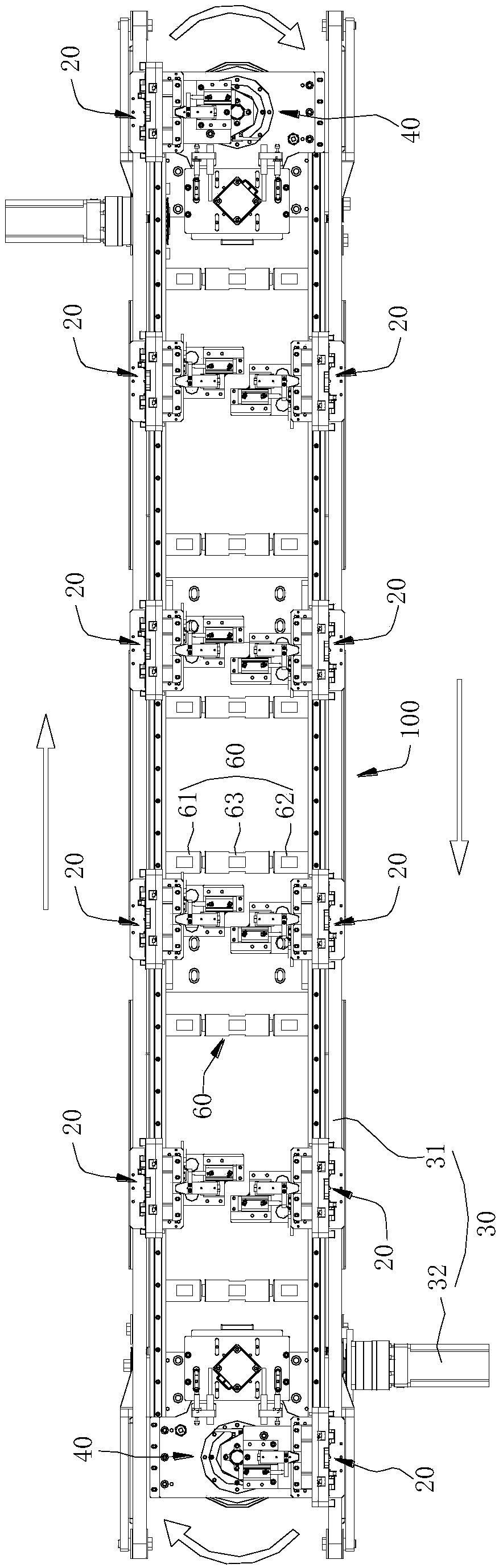

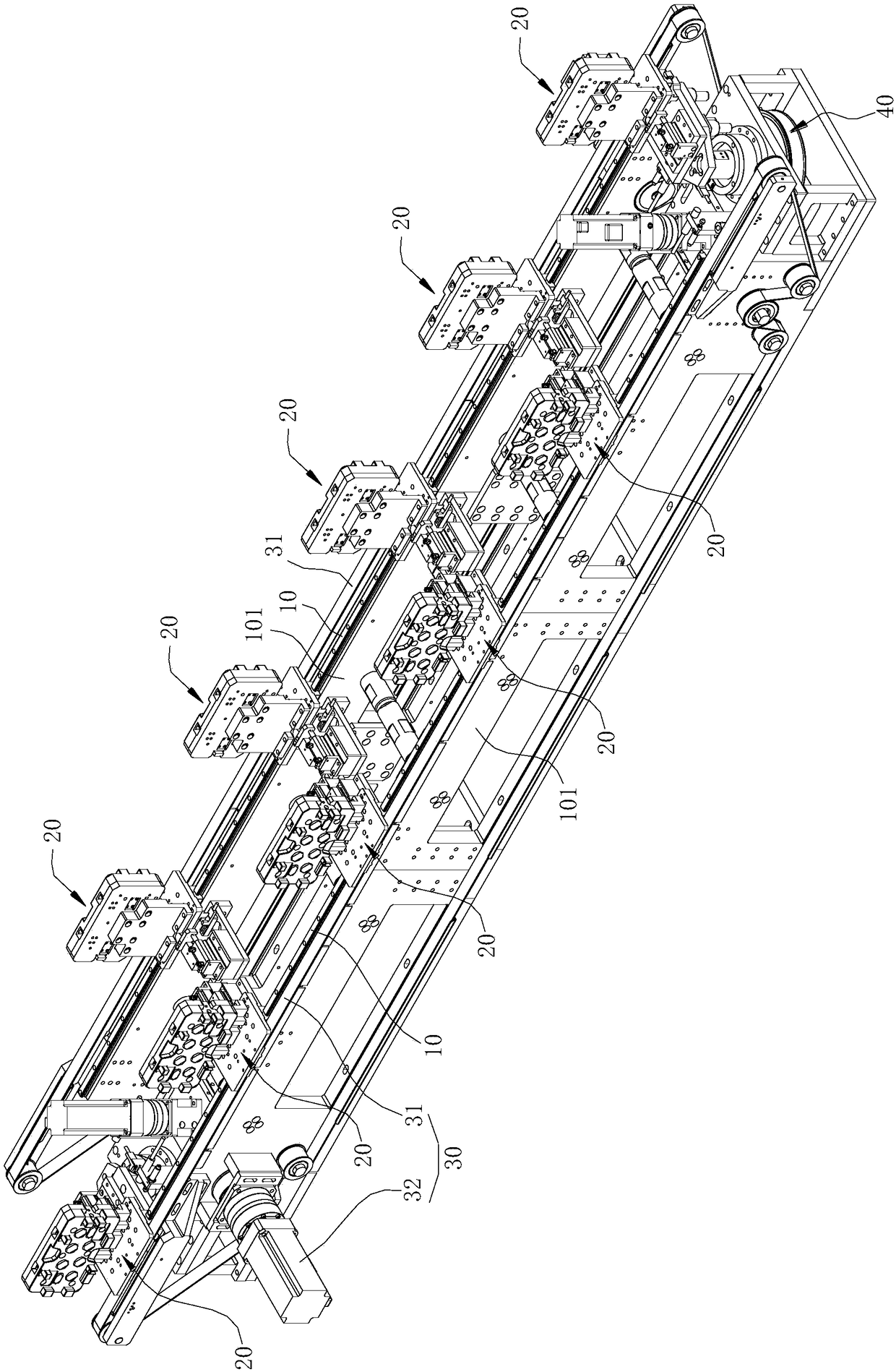

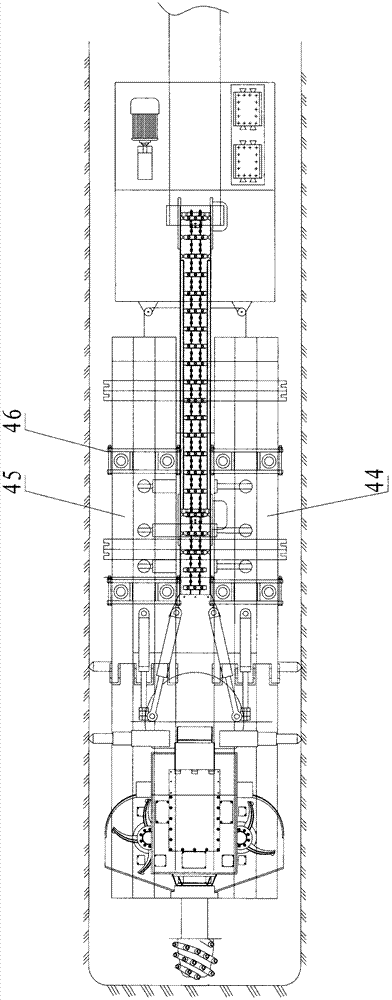

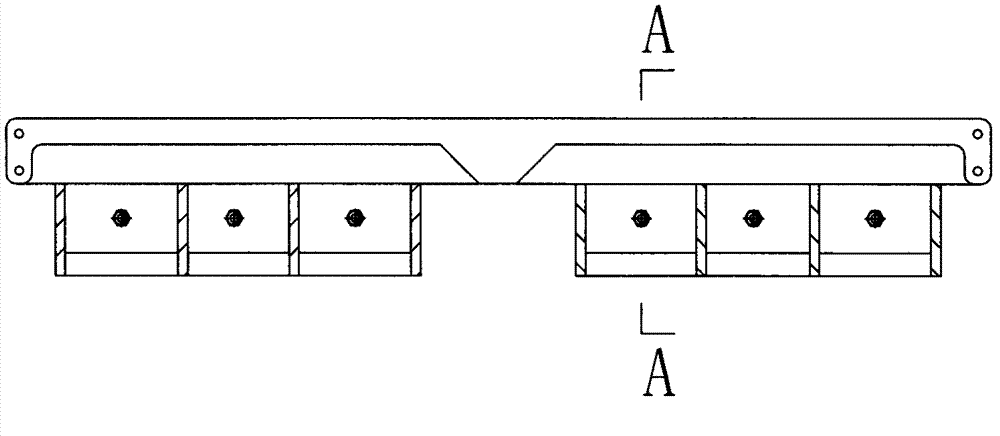

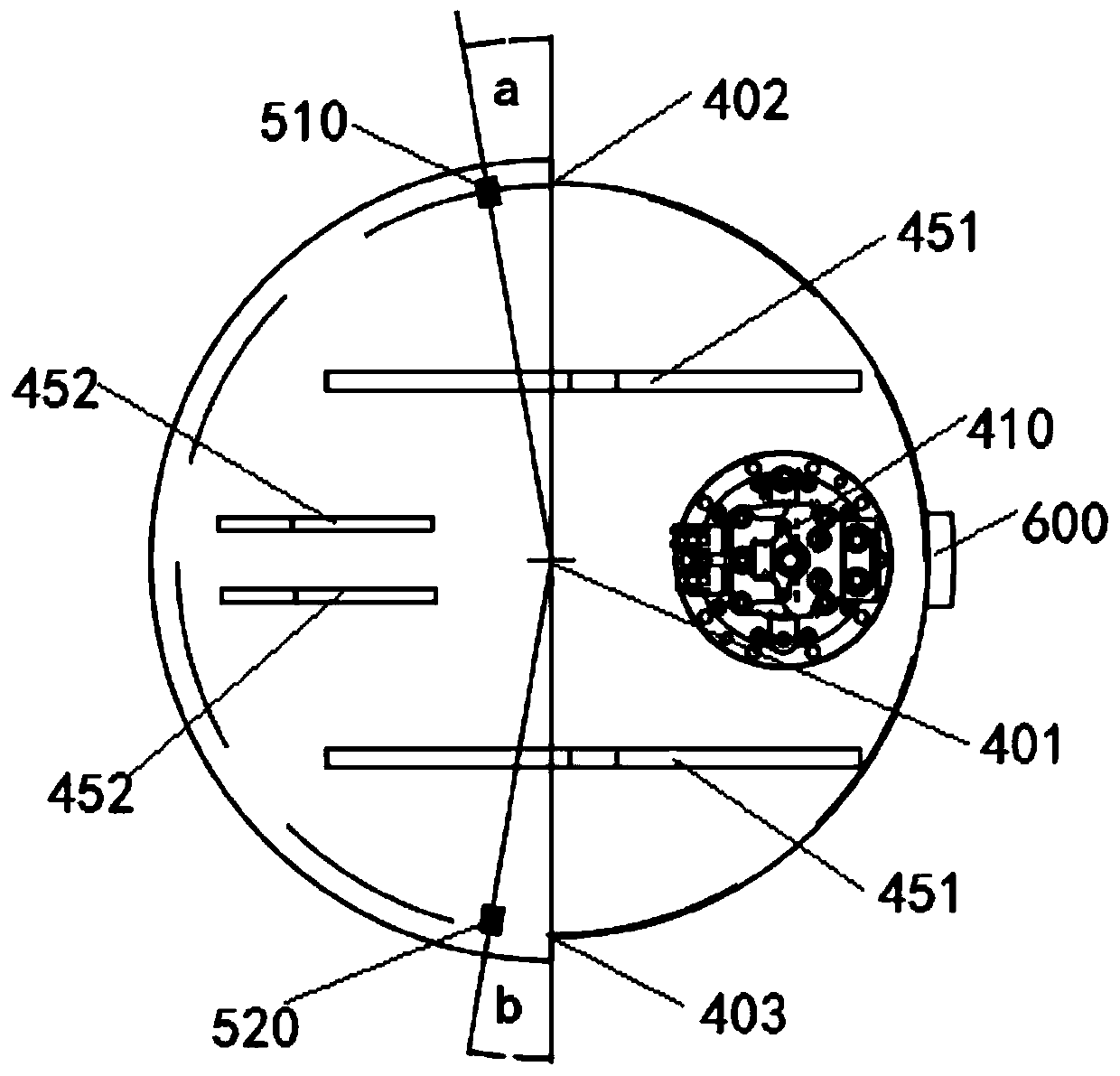

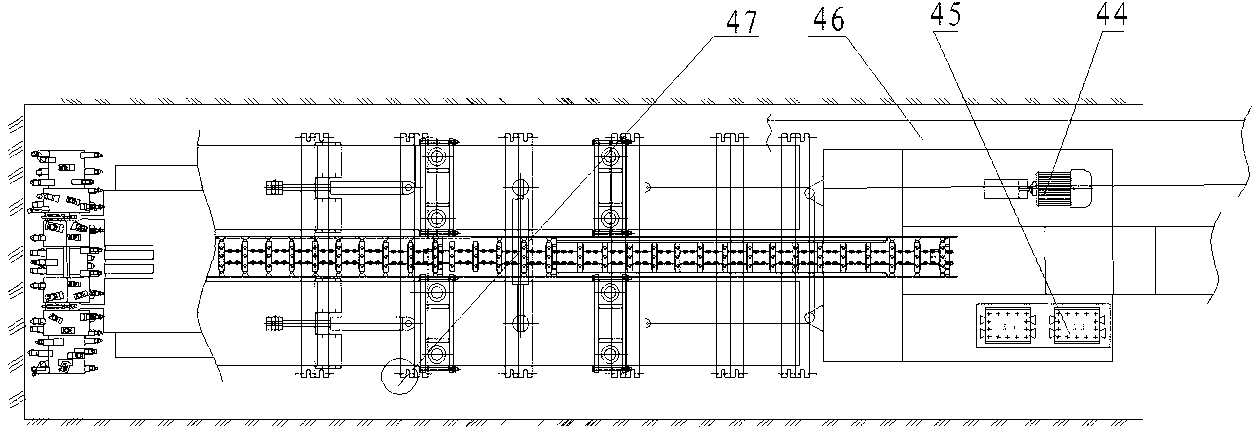

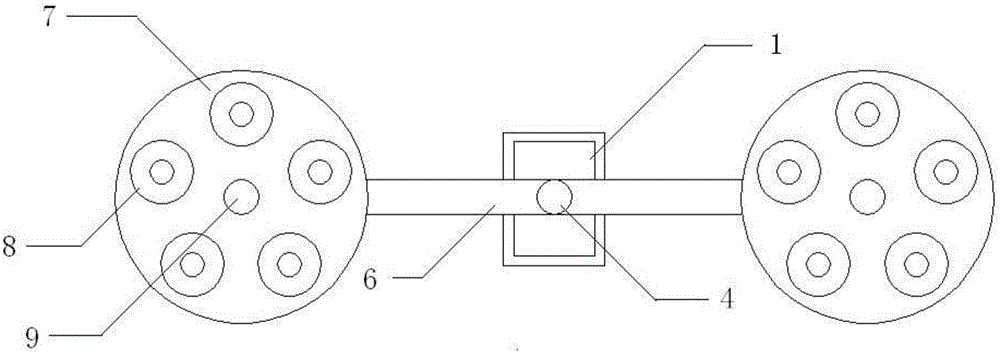

Plane type jig assembly rotating flow channel device

The invention discloses a plane type jig assembly rotating flow channel device. The plane type jig assembly rotating flow channel device comprises a base frame and rotating devices at the two ends ofthe base frame; the base frame is provided with two parallel fixing slide rails in a left-right extending manner; each rotating device comprises a rotating mechanism and a rotating platform; a transferring slide rail is arranged on each rotating platform; the rotating platforms are driven by the rotating mechanisms to be capable of rotating between a first position and a second position; when therotating platforms are located at the first position, the transferring slide rails are in butt joint with one of the fixing slide rails; and when the rotating platforms rotate to the second position,the transferring slide rails are in butt joint with another fixing slide rail. According to the technical scheme, due to the fact that the two ends of the base frame are each provided with the corresponding rotating device, a jig assembly on one fixing slide rail can move to the other fixing slide rail after rotating by 180 degrees through the rotating devices, it is achieved that the jig assemblyrotates on the two fixing slide rails cyclically, the rotating speed is high, the rotating effect is high, positioning is accurate, and the front side of the jig assembly faces the outer side of thebase frame all the time.

Owner:SHENZHEN SHIZONG AUTOMATION EQUIP CO LTD

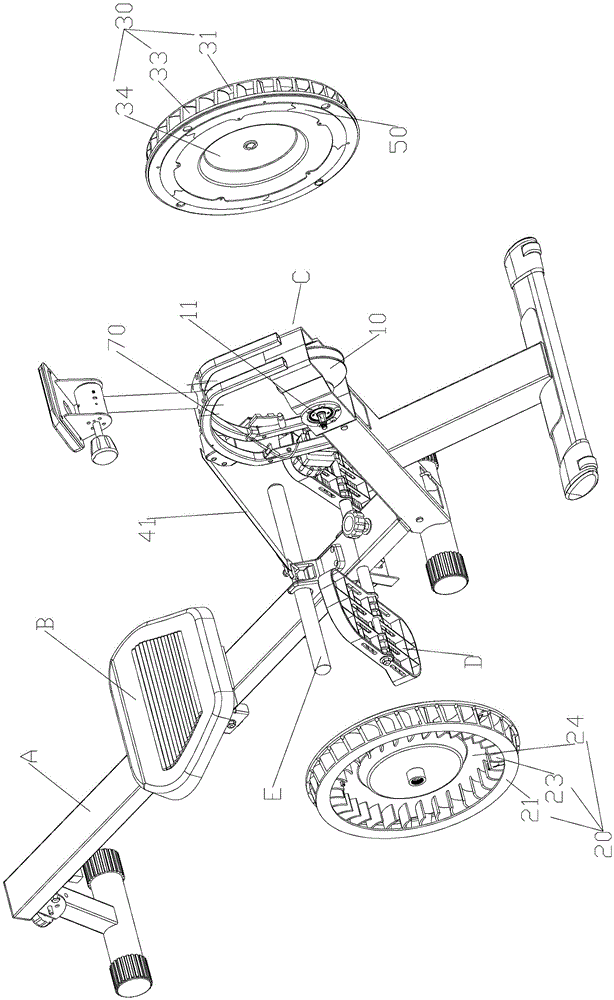

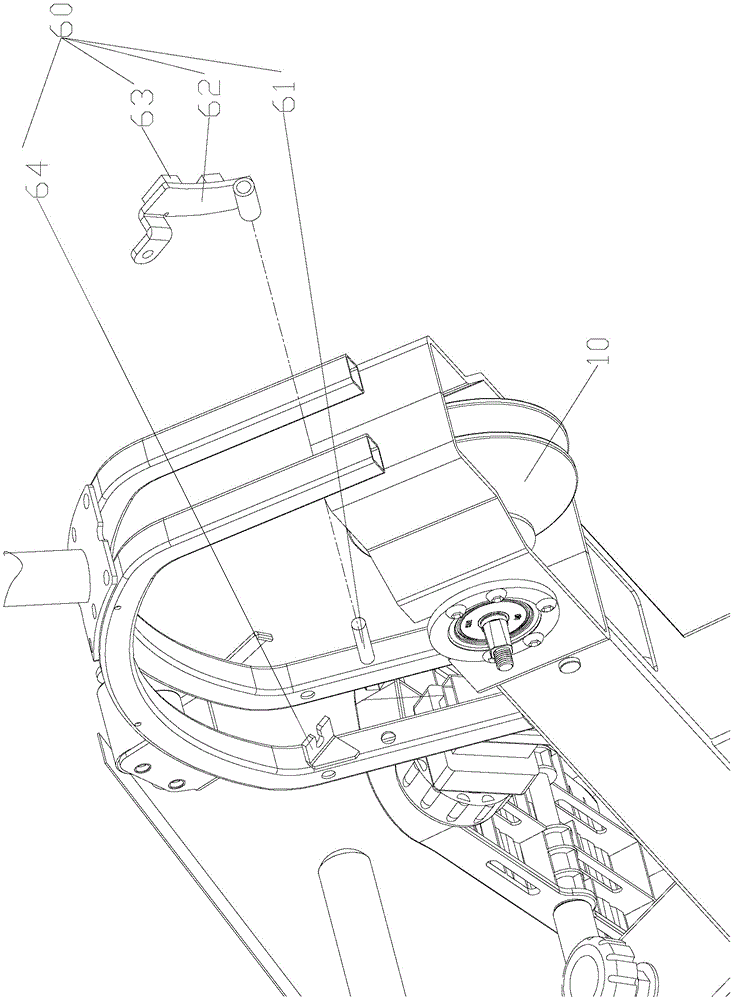

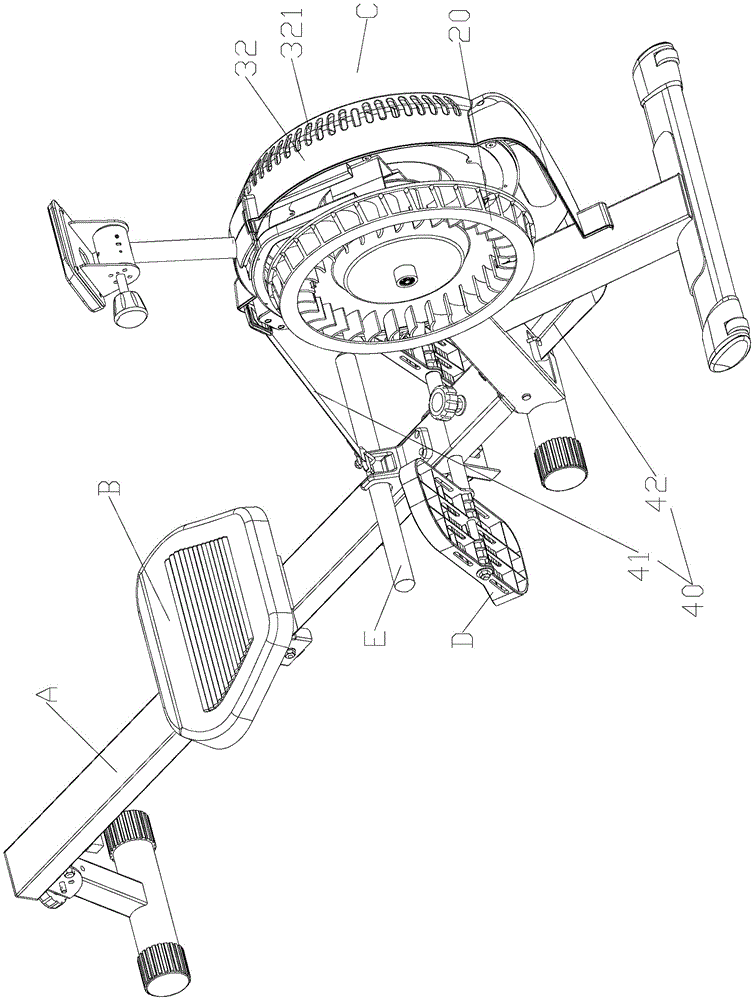

Fan magnetic control resistance rowing machine

InactiveCN105457215ASmall inertia forceLower body temperatureMuscle exercising devicesMovement coordination devicesEngineeringMotion resistance

The invention discloses a fan magnetic control resistance rowing machine. A fan resistance mechanism comprises a one-way rotating wheel rotationally connected to a main frame. The two sides of the one-way rotating wheel are each coaxially and rotationally connected with a fan wheel. One end of a pull rope connected to the one-way rotating wheel in a winding mode is fixed to the main frame, and the other end of the pull rope is fixedly connected to a handle stem. A magnetic control wheel resistance mechanism comprises an aluminum coil and a magnet assembly. The aluminum coil is at least fixed to the inner side face of one fan wheel. The magnet assembly is rotationally connected to the main frame. A multi-gear micro-adjuster is linked with the magnetic assembly for rotation so as to adjust the relative positions of the magnet assembly and the aluminum coil, and the magnetic control resistance is adjusted. The rotating center axis of the magnet assembly is perpendicular to the rotating center axis of the one-way rotating wheel in the space. The rowing machine decreases inertia force of the magnetic control wheel, improves the safety of the magnetic control wheel, further improves motion resistance and enhances motion comfort.

Owner:XIAMEN EVERE SPORTS GOODS

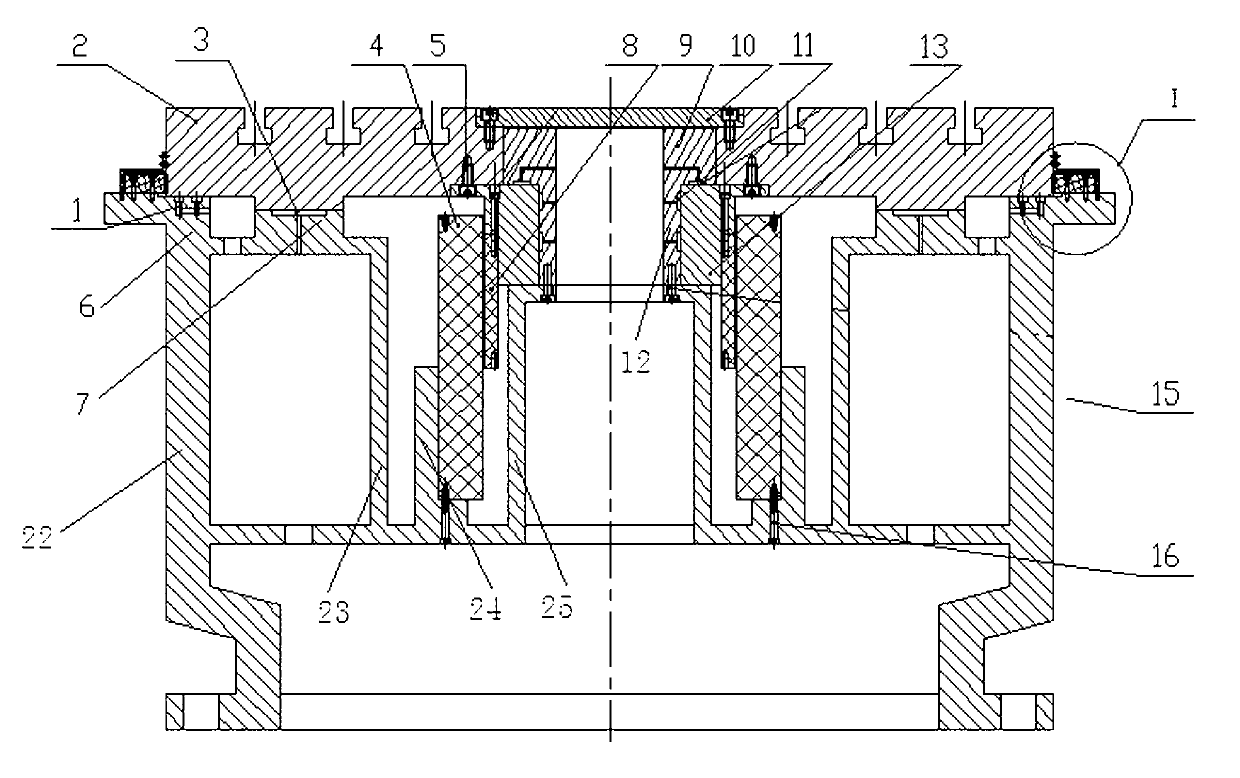

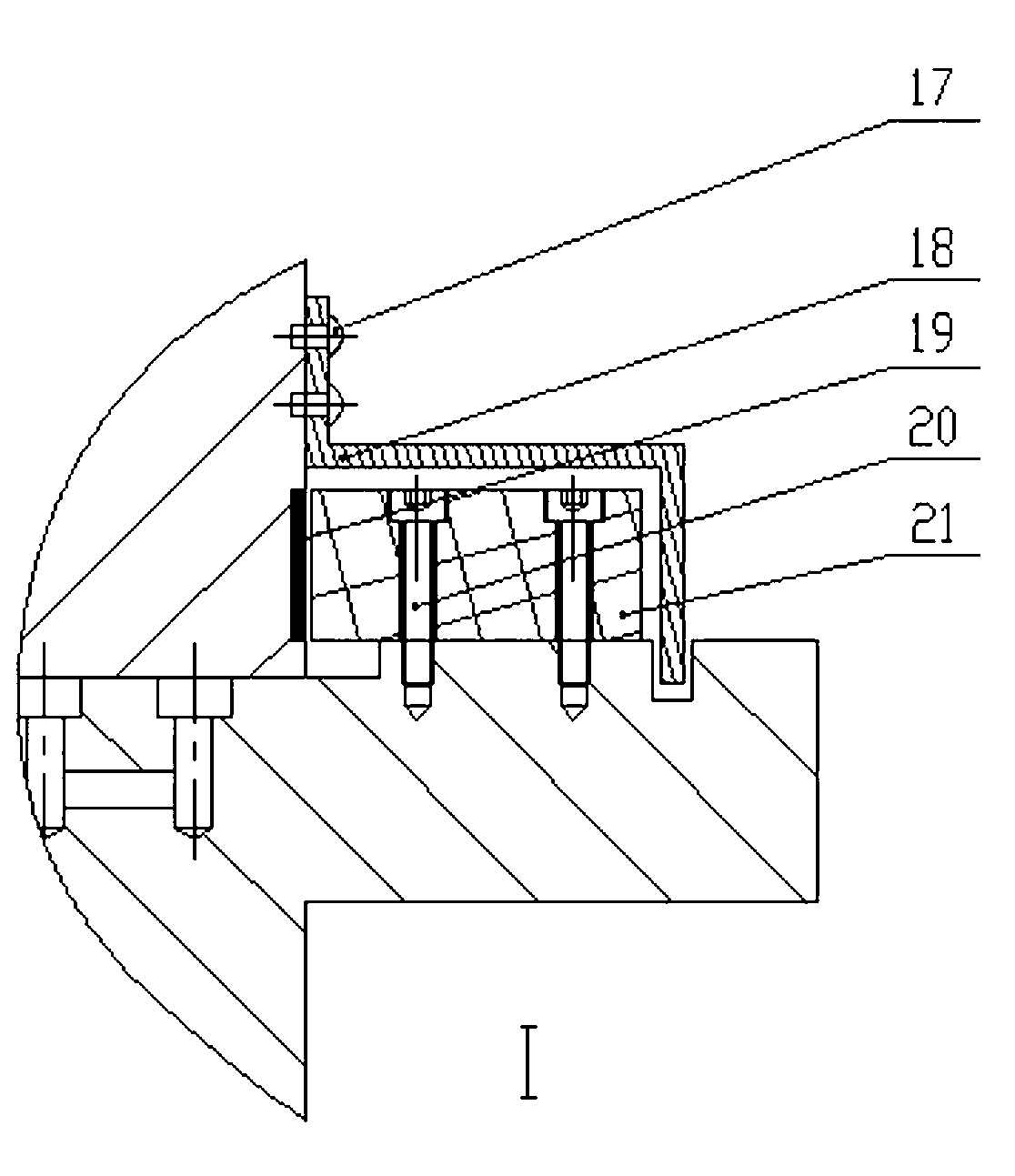

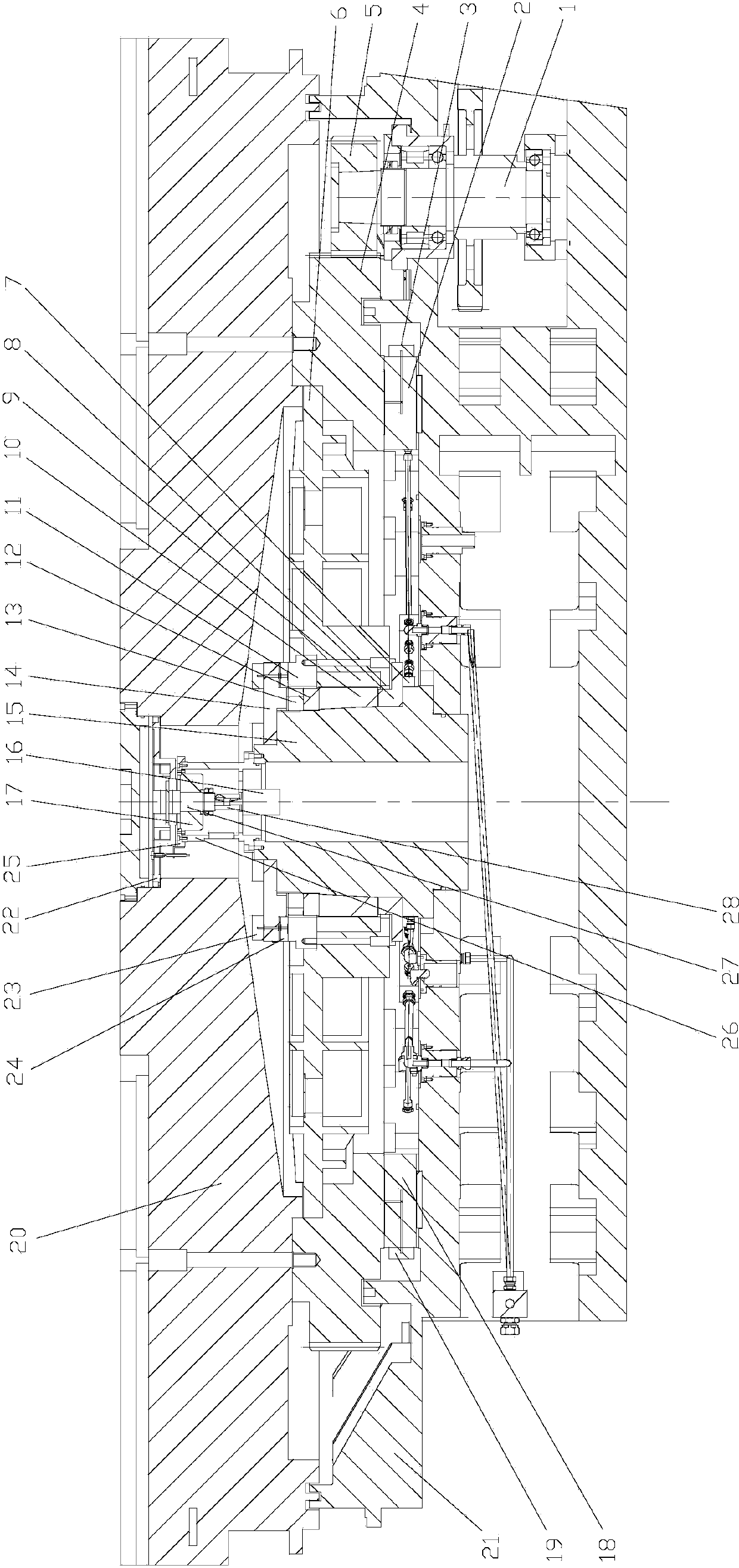

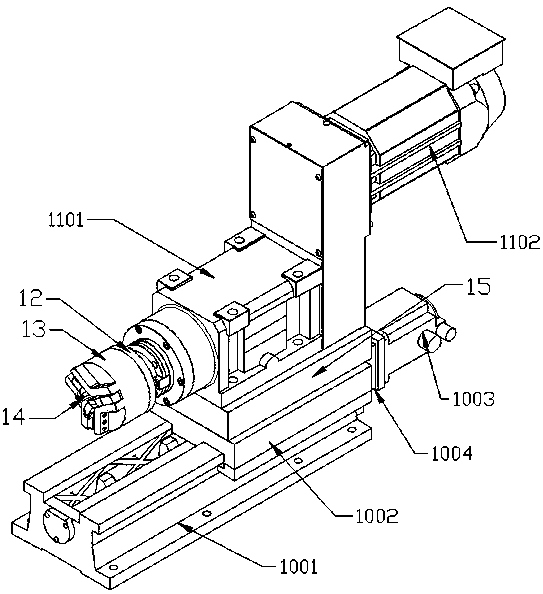

Large vertical lathe workbench with C axis function

InactiveCN103419028AFast turning speedHigh positioning accuracyPrecision positioning equipmentLarge fixed membersGratingPunching

The invention provides a large vertical lathe workbench with a C axis function. The large vertical lathe workbench comprises a base, a workbench, a driving shaft, a driving gear, a gear ring, a radial inner ring seat, a spindle support, a spindle, an encoder, a circular grating, a rotary disk, an axial pressing disk, an axial pressing static pressure plate and a pressing flow controller, wherein the driving gear is connected to the driving shaft, the gear ring is connected to the workbench, and the driving gear is engaged with the gear ring; the radial inner ring seat is fixedly arranged on the gear ring, and a radial static pressure bearing outer ring is fixedly arranged on the radial inner ring seat; the spindle support is fixedly arranged on the base, a flow distributor is fixedly arranged on the spindle support, a radial flow controller is fixedly arranged on the flow distributor, and a radial static pressure bearing inner ring is fixedly arranged on the spindle support; the encoder is connected with the spindle, and the circular grating is installed on the spindle; the rotary disk is fixedly connected with the workbench and the spindle; the axial pressing disk is fixedly arranged on the spindle support, and the axial pressing static pressure plate and the pressing flow controller are installed on the axial pressing disk. The large vertical lathe workbench has the advantages of capability of rotation and indexing positioning, high rotating speed and high positioning accuracy and is suitable for processes of punching of the end surfaces of parts, groove milling and the like.

Owner:SUZHOU JIANG YUAN PRECISION MACHINERY

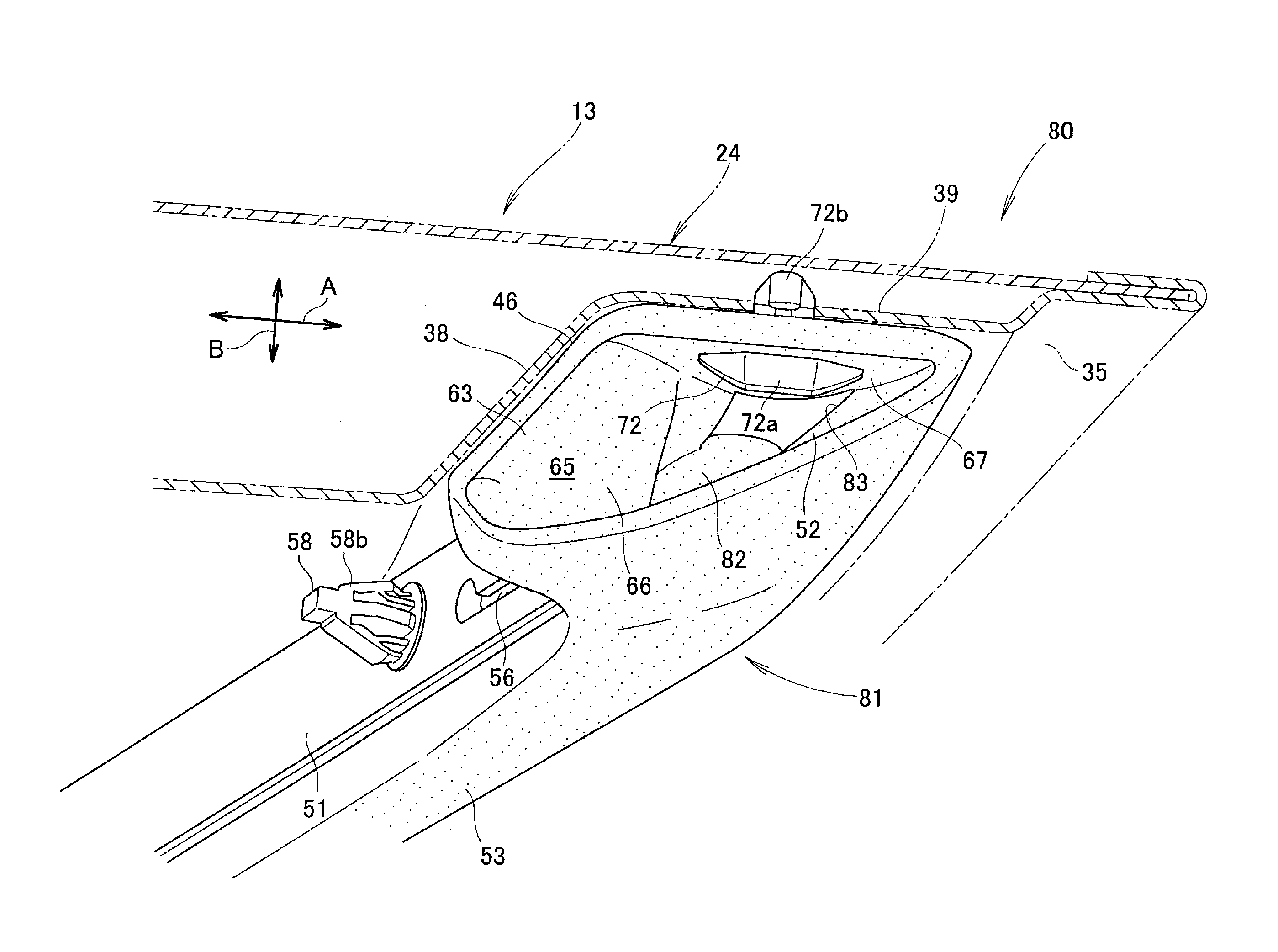

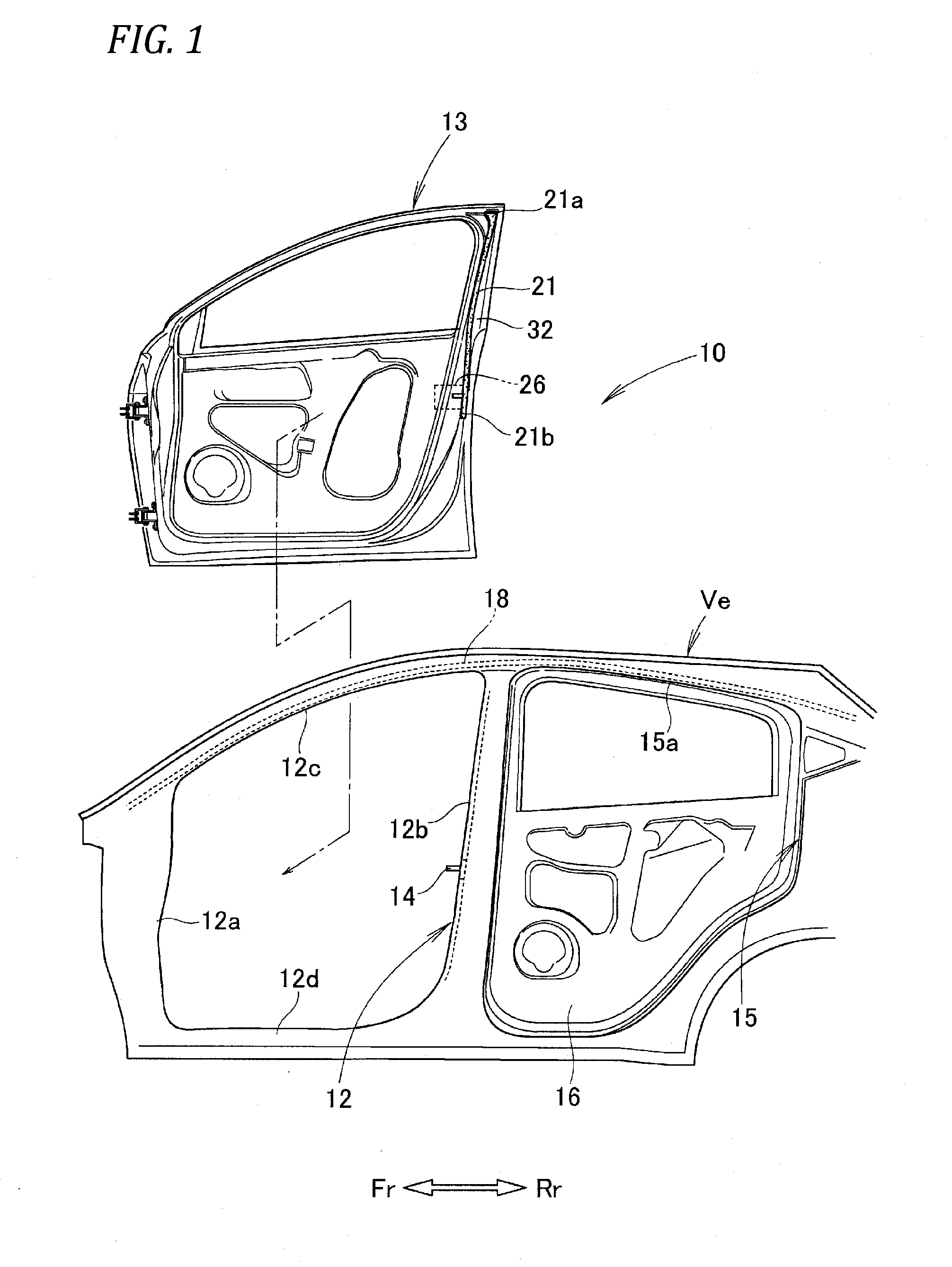

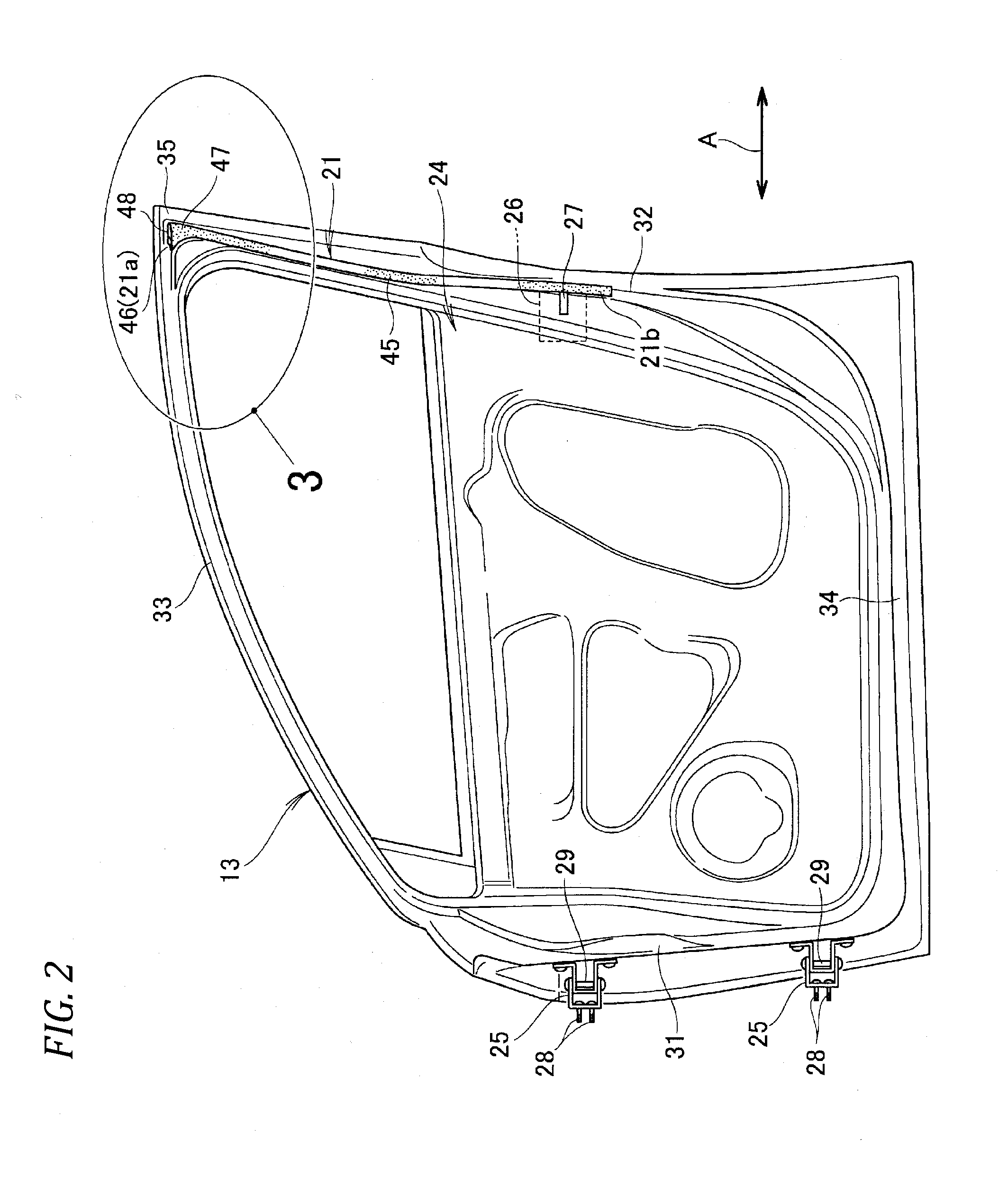

Door seal-equipped vehicle body structure

ActiveUS20160368356A1Reliable captureFast turning speedEngine sealsVehicle sealing arrangementsHollow shapeCar door

A vehicle structure with a door seal includes an upper-edge seal member which is attached to a vehicle body along an upper edge of a front door opening and a vertical seal member which is attached to a rear end portion of a front side door (door body) in a state of being separated from the upper-edge seal member in a vertical direction. The vertical seal member includes a hollow portion which is formed downward in a hollow shape, an upper-end opening which is open upward in communication with an upper end of the hollow portion, and an enlarged portion which is interposed between the upper-end opening and the hollow portion and is enlarged larger than the hollow portion.

Owner:HONDA MOTOR CO LTD

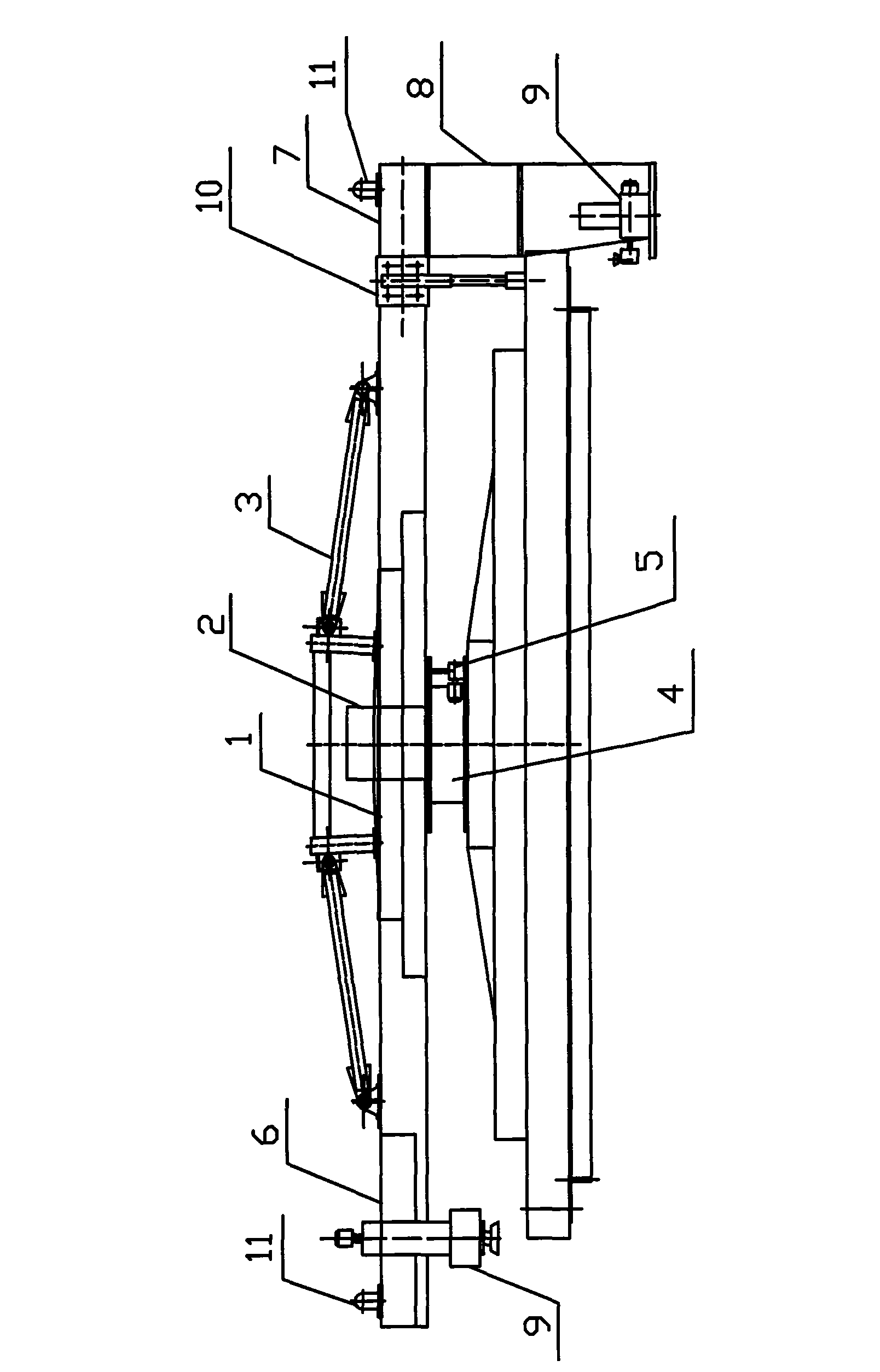

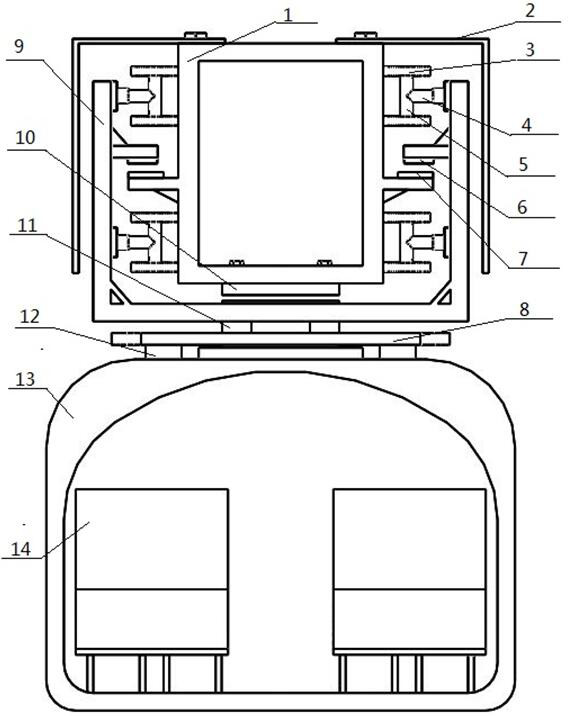

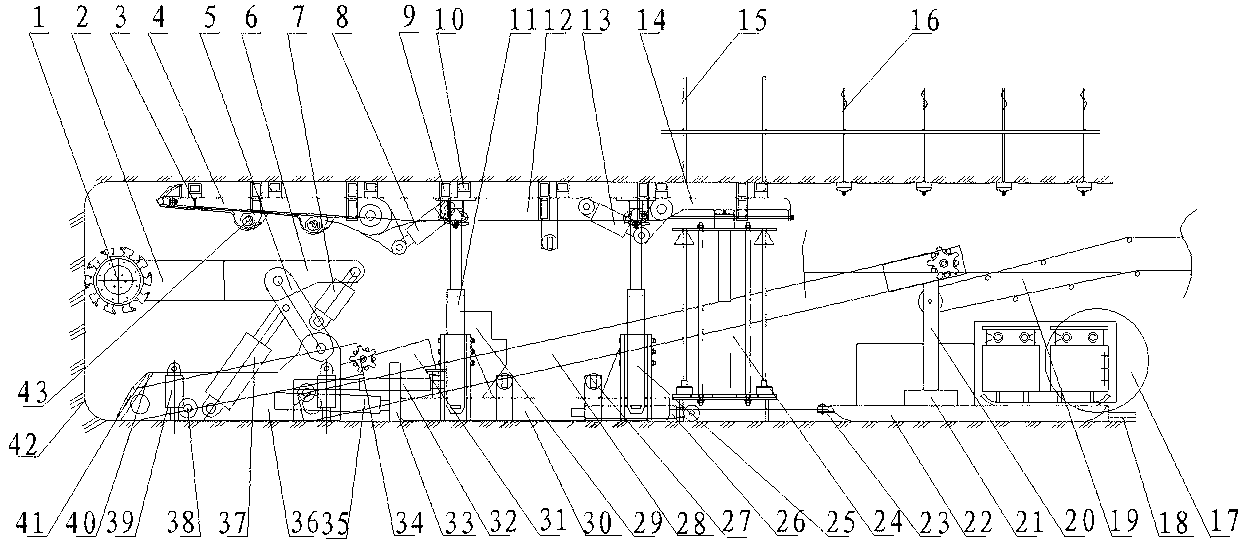

Support-type comprehensive tunneler

ActiveCN102022122BOvercome the disadvantages of not being able to drill holes and support at the same timeIncrease the speed of excavationMine roof supportsTunnelsEngineeringMetal mesh

The invention relates to a support-type comprehensive tunneler which comprises a non-tracked tunneler, a tunneler chassis, a left hydraulic support, a right hydraulic support, a drilling rig and scraper conveyors, wherein the tunneler is arranged on the tunneler chassis, and two advancing jacks are arranged on the tunneler chassis; the other ends of the two advancing jacks are respectively connected with the left hydraulic support and the right hydraulic support, and the two sides of the tunneler chassis are respectively provided with a lateral pushing oil cylinder; forestopes of the left and right hydraulic supports are respectively provided with a group of metal mesh storages, and the tail of a main top beam of the support is hung with the drilling rig; the tail of a first scraper conveyor is arranged on a spade plate of the tunneler, and the head of the first scraper conveyor and the tail of a second scraper conveyor are overlapped; and the head of the second scraper conveyor and the tail of a belt loader are overlapped, and sleds are arranged at the back of the two hydraulic supports. The tunneler has the advantage that the drilling support and the coal cutting of the tunneler are simultaneously carried out, and also has the automatic lapping function, thus reducing labor intensity and increasing the coal mining efficiency by over 4 times.

Owner:DATONG COAL MINE GRP CO LTD HENGAN EQUIP CO LTD

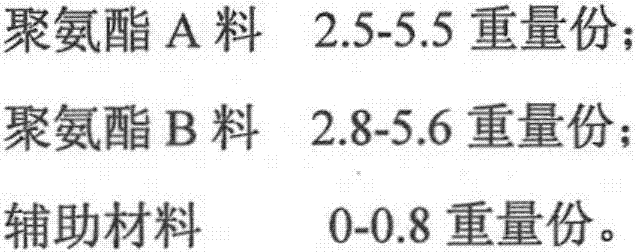

Polyurethane grinding wheel

InactiveCN106938446ALower sintering temperatureHigh energyAbrasion apparatusGrinding devicesMixed materialsGrinding wheel

The invention discloses a polyurethane grinding wheel and a production process thereof. According to the polyurethane grinding wheel, abrasive materials in raw materials are carborundum, and polyurethane is adopted as a binding agent; and the polyurethane comprises a polyurethane material A and a polyurethane material B. The production process includes the steps that material mixing is firstly carried out, wherein the carborundum and the polyurethane material A are put into a material mixing machine to be mixed, and the polyurethane material B and auxiliary materials are sequentially added to be evenly mixed; then a mixed material is screened to be placed into a die to be subject to pressing molding; and finally, a green body is sintered for 8 h to 24 h at the temperature ranging from 125 DEG C to 165 DEG C, and is cooled to be discharged out of a furnace. According to the production process, the polyurethane serves as the binding agent to produce the grinding wheel, the auxiliary materials in an existing grinding wheel recipe can be applied to the method according to the production requirement, and the manufactured grinding wheel has the beneficial effects that the sintering temperature is low, saved energy resources are many, pollution is avoided, the molding density is large, the grinding wheel balance is good, the rotating speed is high, the grinding performance is high, and the production period is short, and the quality of products in the machine tool industry, the bearing industry, the bent axle industry, the engine industry and the steel rolling industry is improved.

Owner:龙口东润砂轮有限公司

Crank-connecting rod mechanism for engine of miniature cross-country motorcycle

InactiveCN101798954AFast turning speedReduce weightReciprocating piston enginesEngineeringHigh torque

The invention discloses a crank-connecting rod mechanism for an engine of a miniature cross-country motorcycle. The crank-connecting rod mechanism comprises a left crank, a right crank, a crank pin and a connecting rod, wherein the big head end of the connecting rod is positioned between the left crank and the right crank; the big head end of the connecting rod, the left crank and the right crank are connected with each other through the crank pin; the axial lines of the left crank and the right crank are in the same line and are parallel to the axial line of the crank pin; the distance between the axial lines of the left crank and the right crank and the axial line of the crank pin is 28.5 to 30.5 mm; the diameter of the shaft part of the right crank is 95 to 97 mm; the axial length of the right crank is 64 to 66 mm; and the distance between the centre of an installing hole at the big head end of the connecting rod and the centre of the installing hole at the small head end of the connecting rod is 94.3 to 96.3 mm. By changing a plurality of key parameters of the crank-connecting rod mechanism, the crank-connecting rod mechanism for the engine of the miniature cross-country motorcycle meets the functional requirements on high raising speed, strong explosive power, high torque, high crank rotating speed of the engine of the miniature cross-country motorcycle, and has the characteristics of ingenious conception, simple structure, easy implementation and the like.

Owner:重庆动源摩托车配件销售有限公司

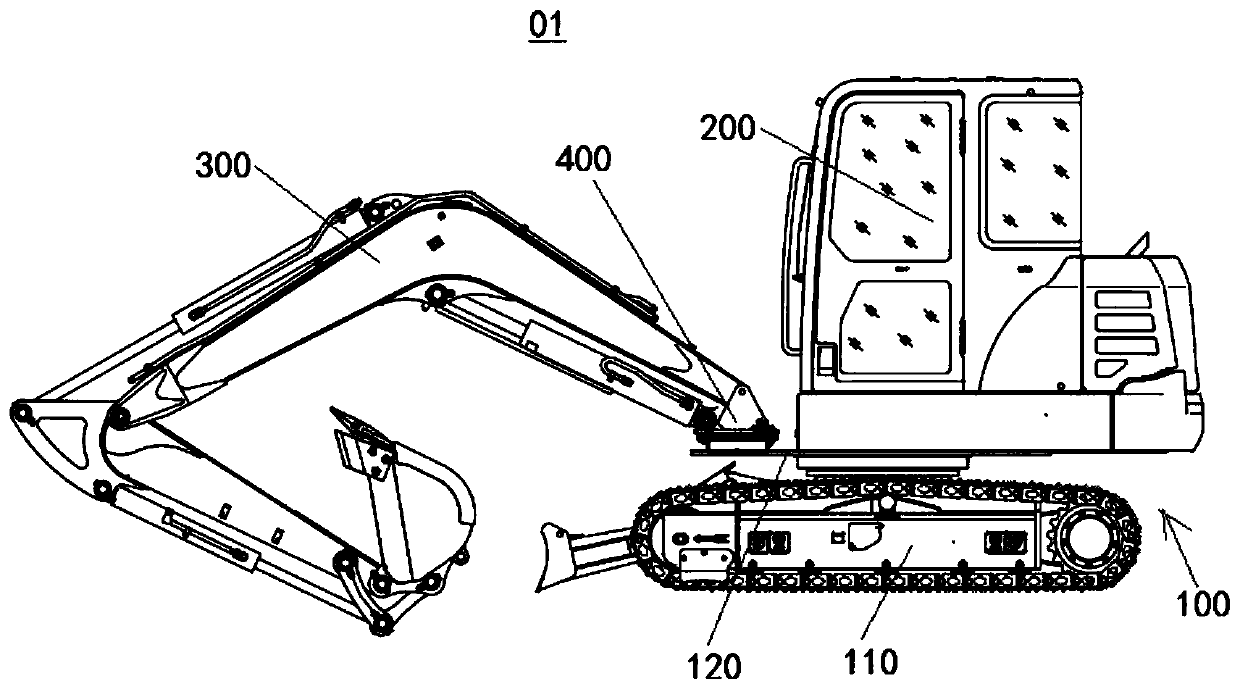

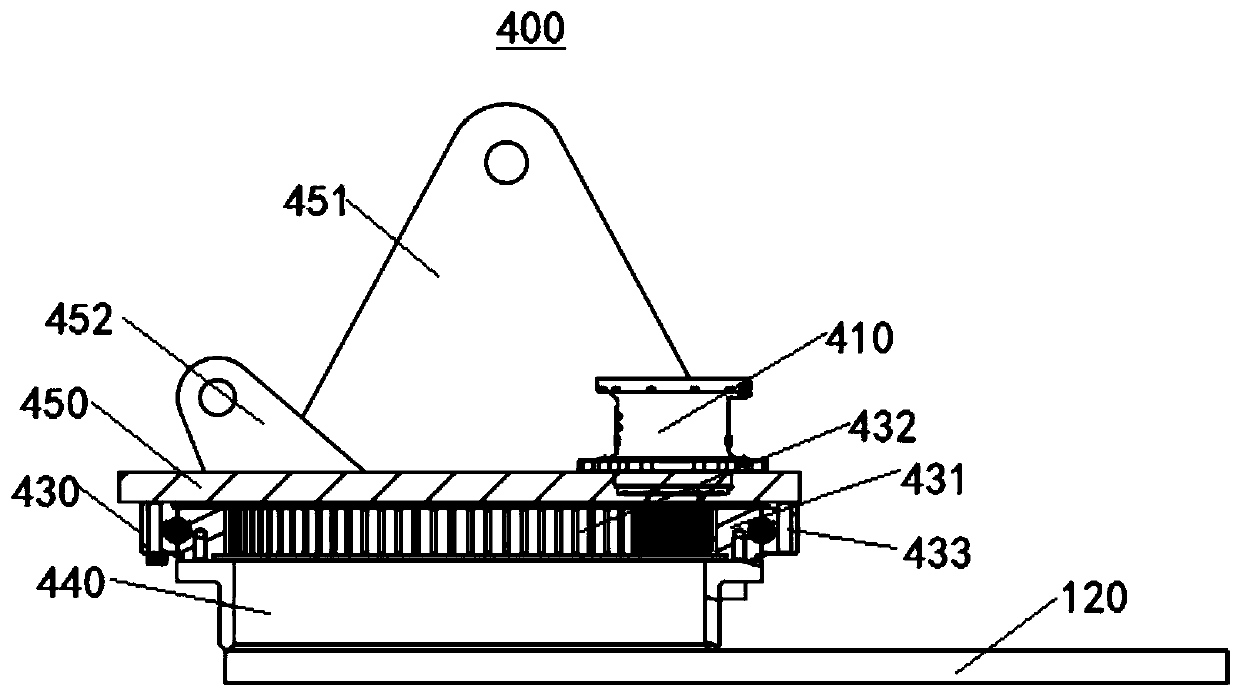

Excavator

The invention provides an excavator, and relates to the field of excavating. The problem that an existing excavator is poor in work efficiency can be solved. The excavator comprises a vehicle body, acab, a movable arm and a rotation device, the cab is fixedly connected with the vehicle body, the rotation device comprises a motor, a transmission gear and a rotation support, the rotation support comprises an inner ring and an outer ring which are coaxially arranged and mutually rotatably matched, the inner ring is provided with an inner gear ring and is fixed to the vehicle body, the transmission gear is engaged with the inner gear ring, the motor is fixed to the outer ring, an output shaft of the motor is in transmission connection with the transmission gear, the movable arm is fixed to the outer ring, the movable arm is arranged on the vehicle body through the rotation device, only through rotation of the movable arm, the square throwing work can be carried out, and the rotation loadis reduced; and meanwhile, through the motor, the rotation support is driven to achieve movable arm rotation, the driving speed of the motor is high, the rotation speed is improved, and the deflectionefficiency and the work efficiency of the excavator can be wholly improved.

Owner:SANY HEAVY MACHINERY

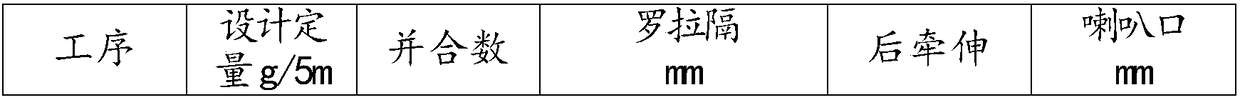

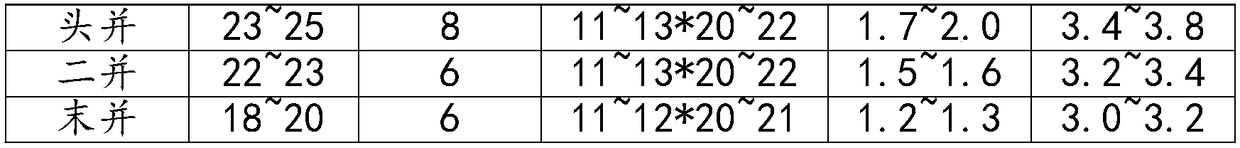

Multifunctional polyester vortex spinning fabric and production method thereof

InactiveCN108468146AFast turning speedShorten speedWeft knittingContinuous wound-up machinesYarnPolyester

The invention provides a multifunctional polyester vortex spinning fabric and a production method thereof. The fabric is woven by Micronova fiber and blended cation polyester; the production method comprises the steps that the multifunctional polyester vortex spinning fabric is finally obtained after spinning, weaving and finishing are conducted on the Micronova fiber taking up the dry weight ratio of 88.5%-91.5% and the blended cation polyester taking up the dry weight ratio of 8.5%-11.5%, wherein the spinning step comprises opening picking, cotton carding, drawing, Murata vortex spinning anddouble twisting, the weaving step comprises yarn steaming, waxing and machine weaving, and the finishing step comprises knitted fabric singeing, boiling and bleaching, dyeing, soft winding processing, dehydrating, drying and finishing. By means of the method, the antibacterial, wear resistant and ultraviolet resistant fabric with light and soft fabric surface and better permeable preventing performance can be obtained.

Owner:江苏悦达棉纺有限公司

Portable full-automatic overturning nursing mattress

PendingCN110327172AEasy to installFast turning speedNursing bedsAmbulance serviceLow speedControl system

The invention relates to a portable full-automatic overturning nursing mattress. The portable full-automatic overturning nursing mattress consists of a bottom cushion, independent overturning frame, overturning air chambers, a supporting cushion, air ducts, an air pump and a control system, wherein the flexible back surface of the bottom cushion is skidproof; a plurality of independent overturningframes which are arrayed on the surface of the bottom cushion are arranged on the front surface of the bottom cushion; each independent overturning frame consists of a bottom plate, a supporting plate and an overturning air chamber, and one end of each bottom plate is hinged to one end of the corresponding supporting plate; each overturning air chamber is arranged between the corresponding bottomplate and the corresponding supporting plate; the length direction of the bottom plate of each independent overturning frame is parallel to the width direction of the bottom cushion; the hinging endsof the adjacent independent overturning frames are mutually inverted; the overturning air chambers of the independent overturning frames at odd number positions and the overturning air chambers of the independent overturning frames at even number positions are separately connected in parallel by the different air ducts, and communicate with the air pump through corresponding valves; a flexible supporting cushion is arranged on an overturning frame group consisting of all the independent overturning frames; and the bottom of the supporting cushion is elastically connected with the center location of the supporting plate of each independent overturning frame and ends which are not hinged of each independent overturning frame. According to the overturning nursing mattress, small-angle overturning can be performed in a low speed, and integral large-angle overturning can be quickly performed as needed; and simple components are mounted, so that the operations of back lifting and leg bending can be autonomously completed.

Owner:刘尊群

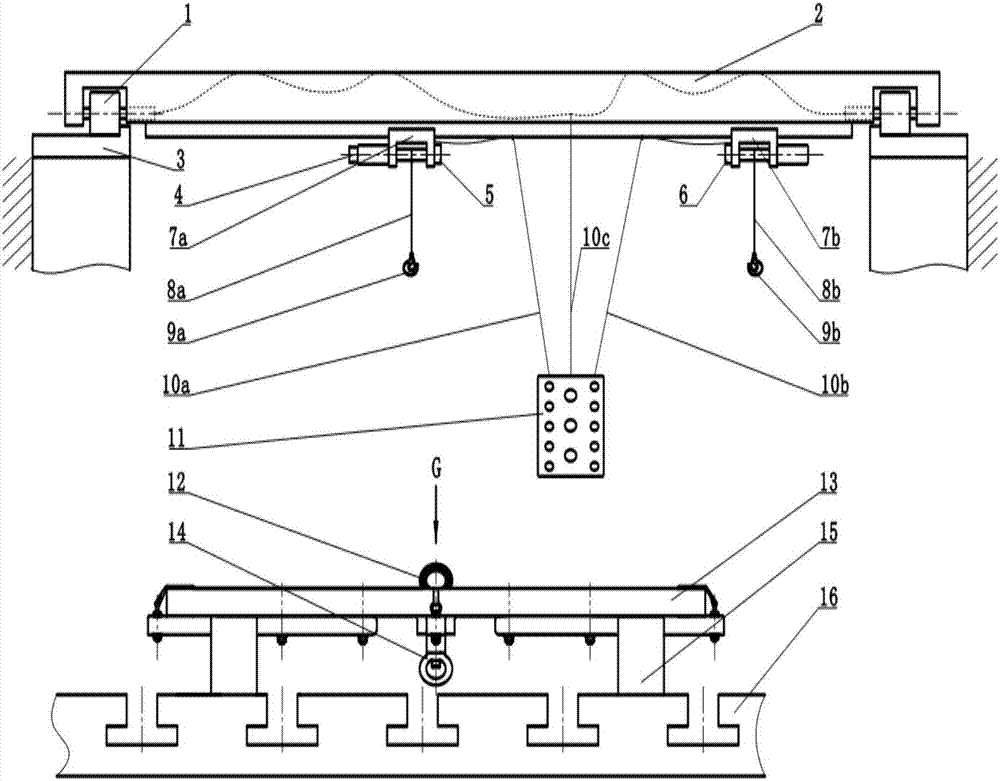

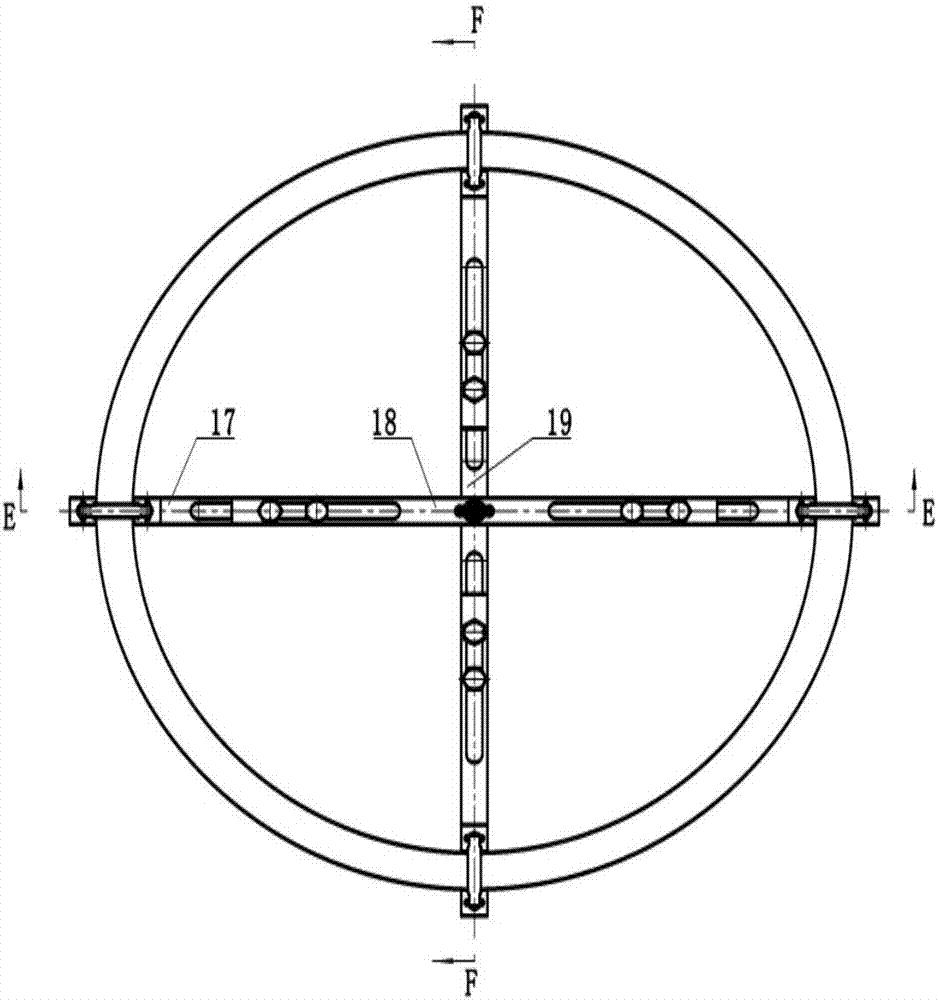

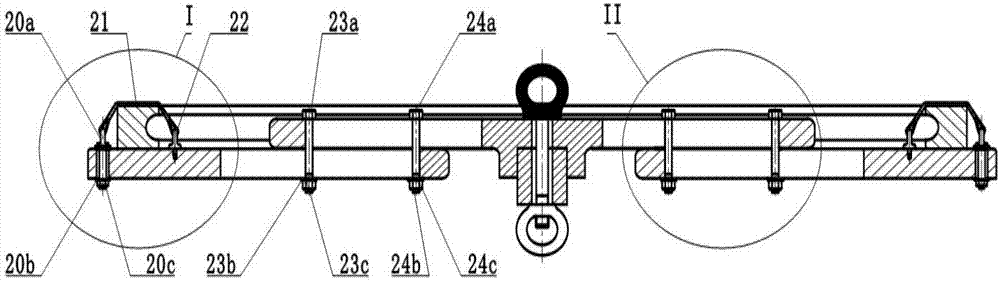

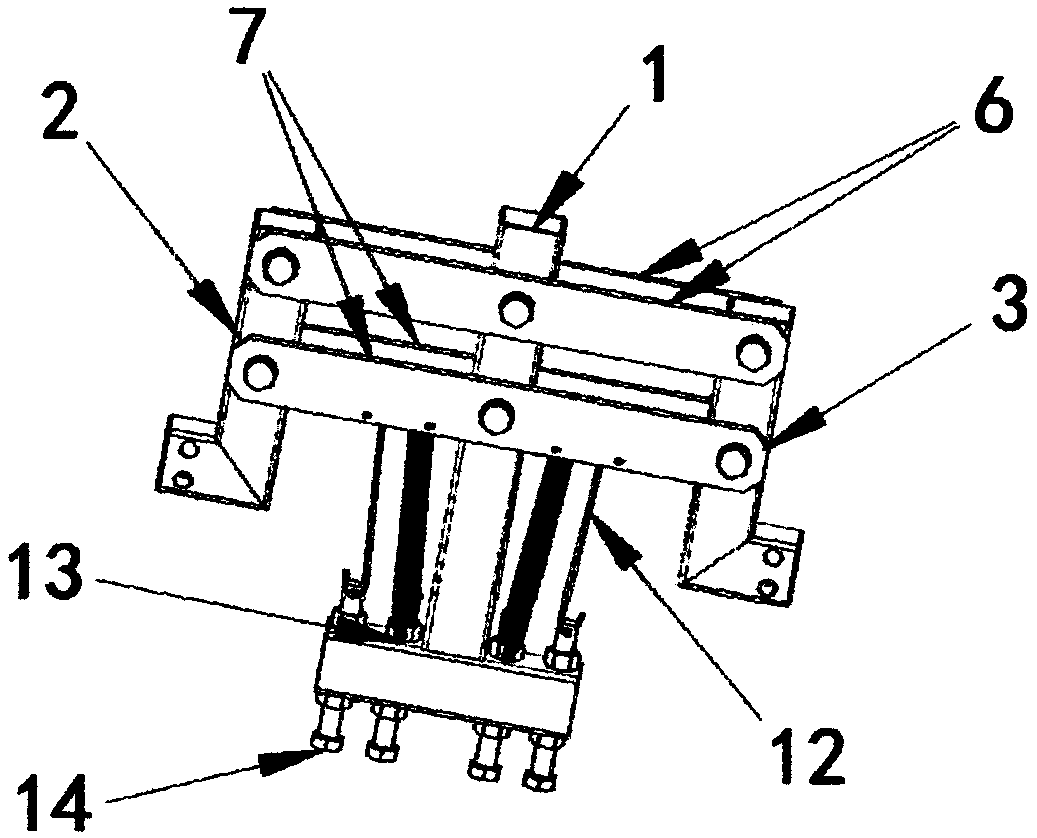

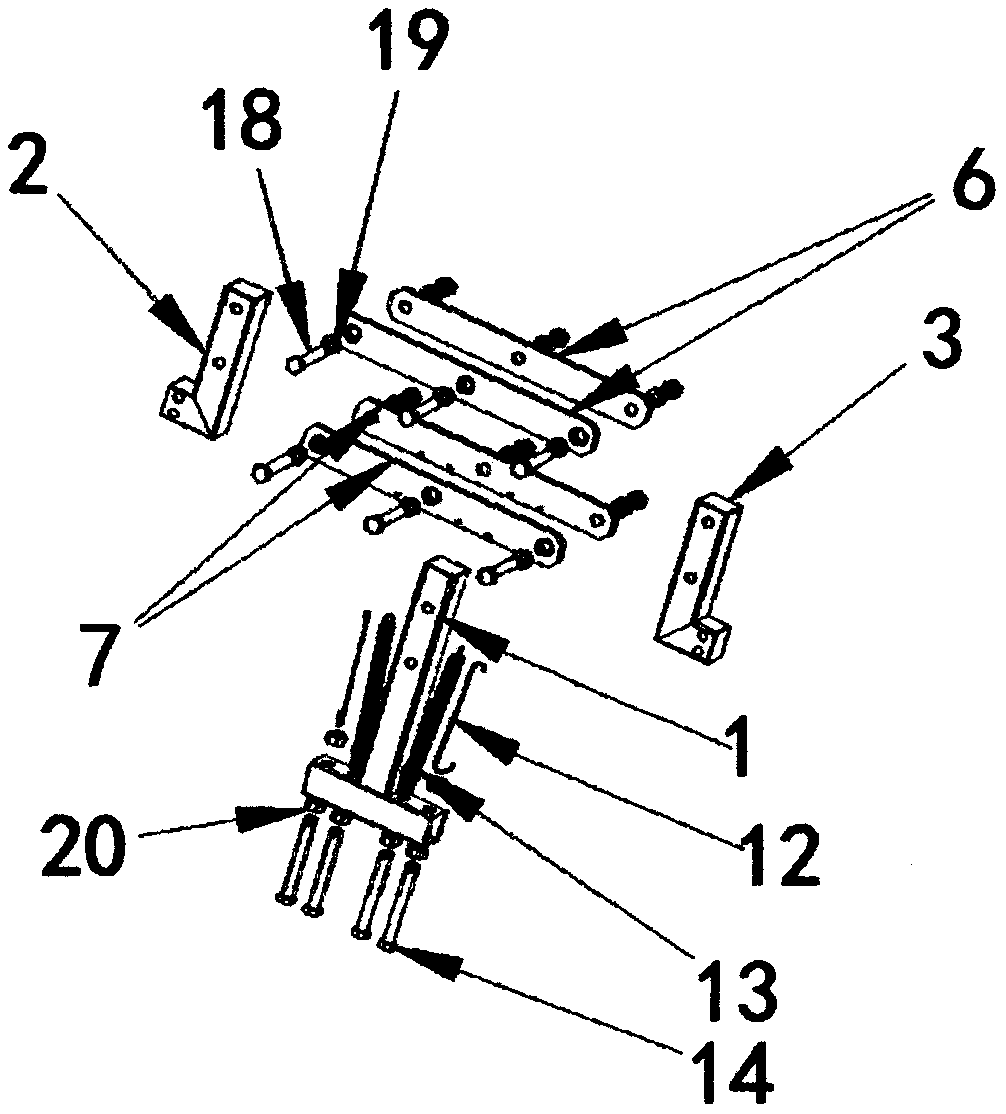

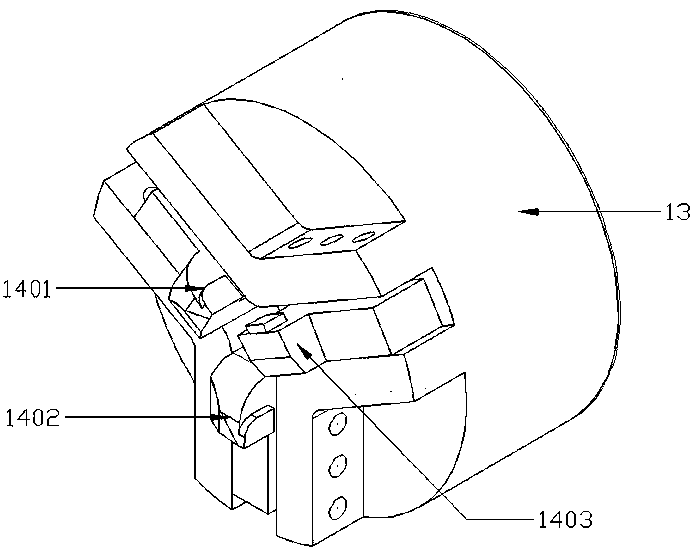

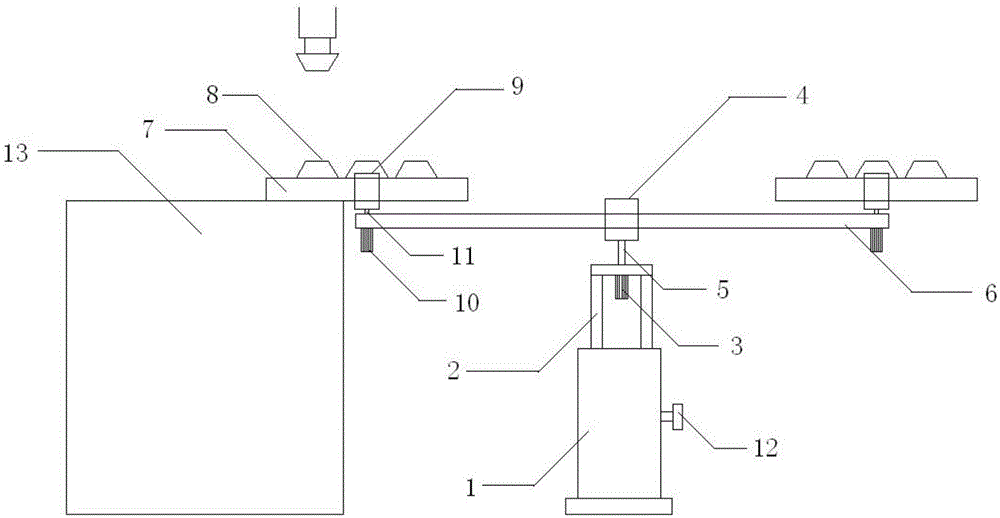

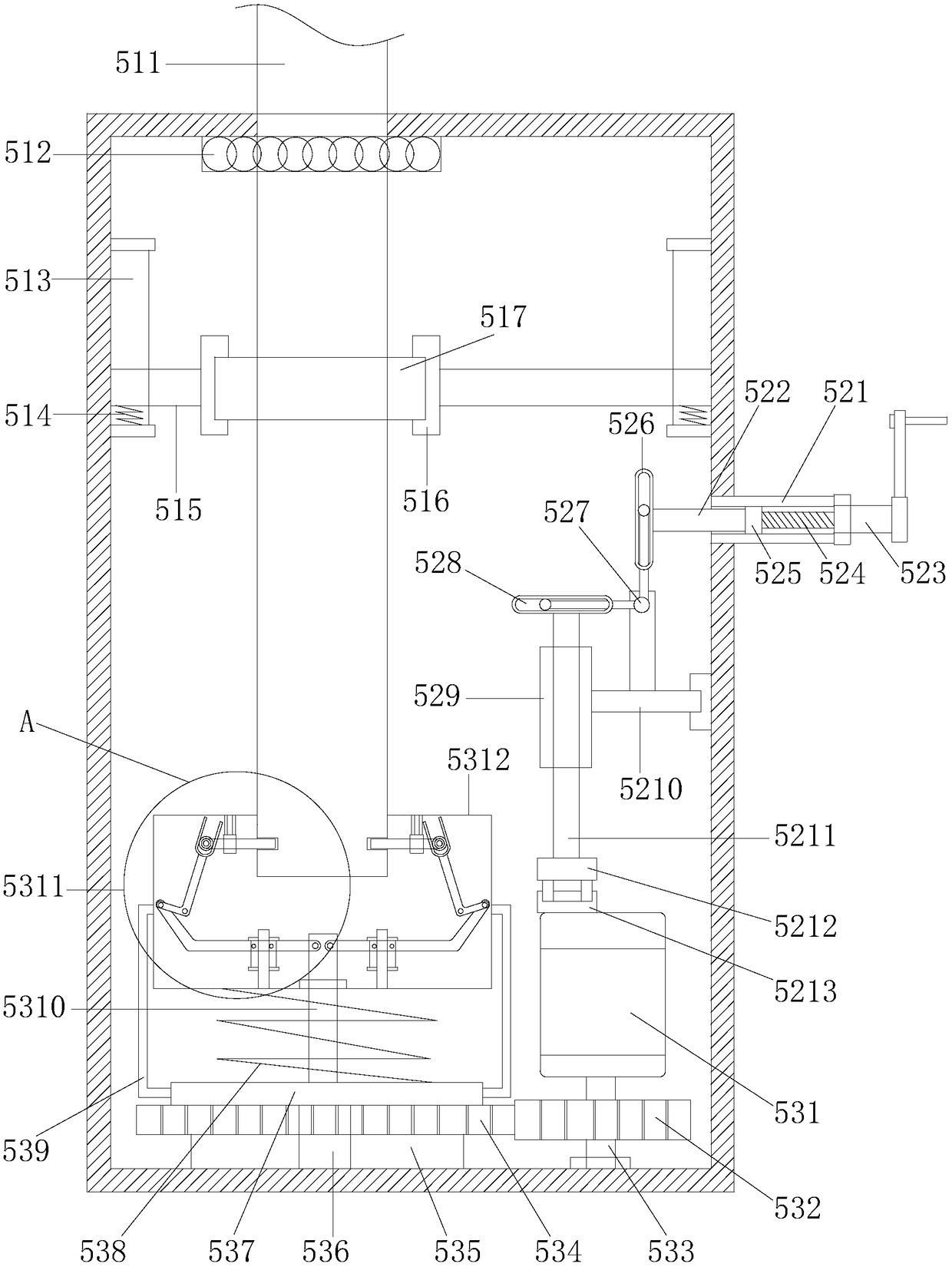

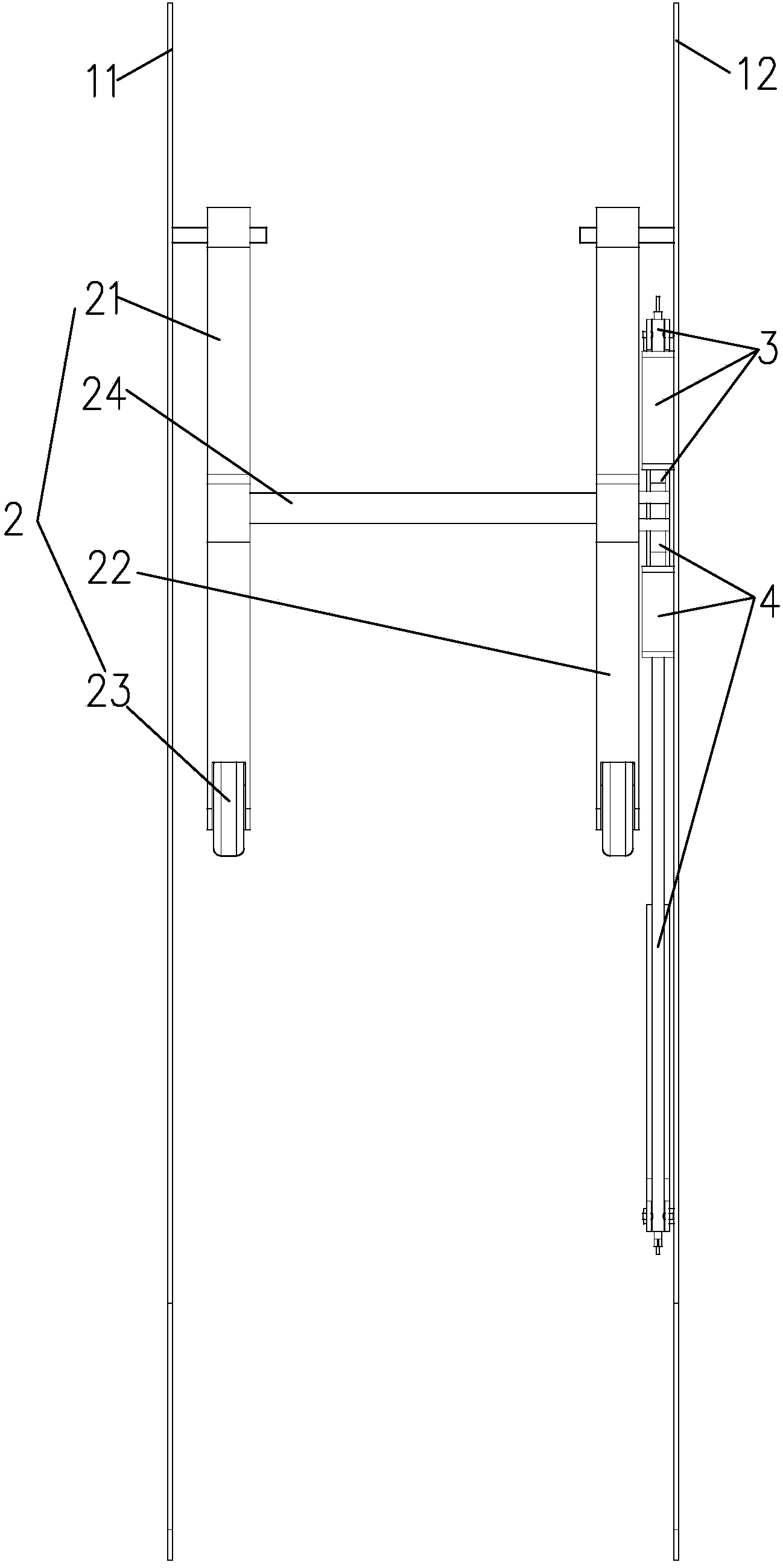

Turning-over device and method for tooth ring of rotation bearing

ActiveCN107283184AReduce in quantityIncrease profitPositioning apparatusMetal-working holdersControl systemPotential market

The invention discloses a turning-over device and method for a tooth ring of a rotation bearing and belongs to the technical field of machining. The turning-over device for the tooth ring of the rotation bearing is used for achieving turning-over of the tooth ring and the like of the large-sized rotation bearing in multiple machining procedures. The turning-over device for the tooth ring of the rotation bearing comprises a lifting system, a control system, a workpiece clamp system and a protective system. According to the turning-over device, two lifters are installed on a cross beam, and the workpiece is turned over through paying off and taking up of lifting ropes between the two lifters. The turning-over device and method for the tooth ring of the rotation bearing have the technological advantages of achieving simple assembly, small deformation, high turning-over efficiency and the like and has huge potential market application prospect.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for processing internal threads of blind hole

InactiveCN104096922ARoughness is easy to controlFast turning speedThread cutting machinesSurface roughnessEngineering

A method for processing internal threads of a blind hole comprises the following steps: firstly turning an inner hole, then turning an inner groove and finally processing the internal threads of the blind hole, wherein the processing of the internal threads of the blind hole is realized in a manner that a threading tool is fed from the inner groove in a reverse-turning way. According to the method, the internal threads of the blind hole are processed in a manner that the threading tool is fed from the inner groove in a reverse-turning way, so that the threading tool is not collided with and damage the bottom surface of the blind hole, the threading tool is positioned in a fixed-tool manner, and can reach the inner groove to turn the internal threads of the blind hole, thus roughness of the bottom surface of the blind hole can be controlled, the turning speed is high, the efficiency is improved, and the rejection rate is reduced.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

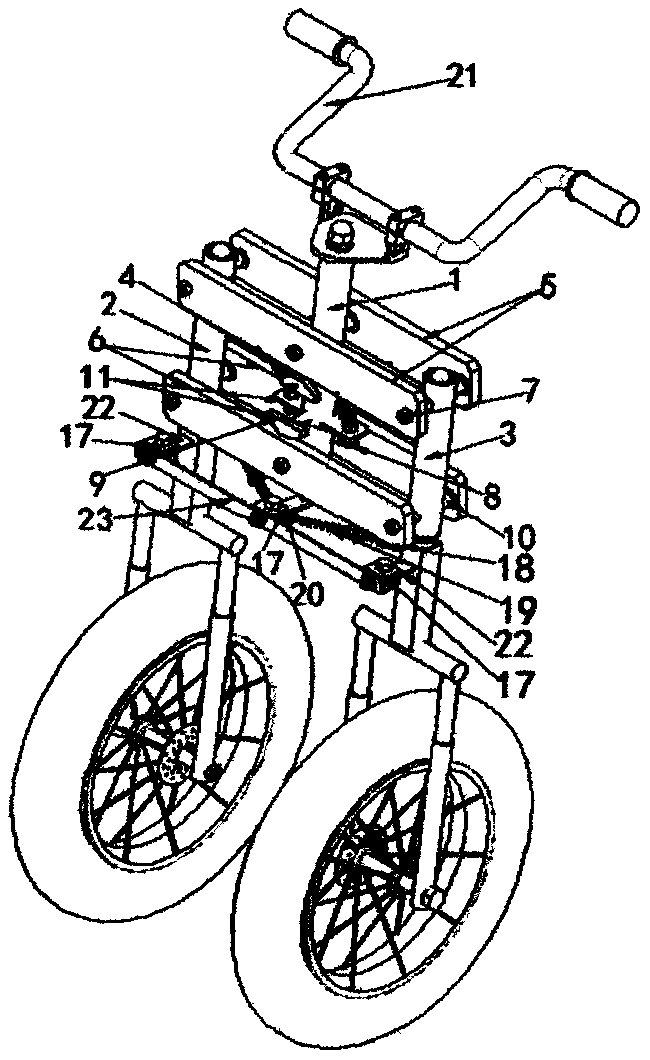

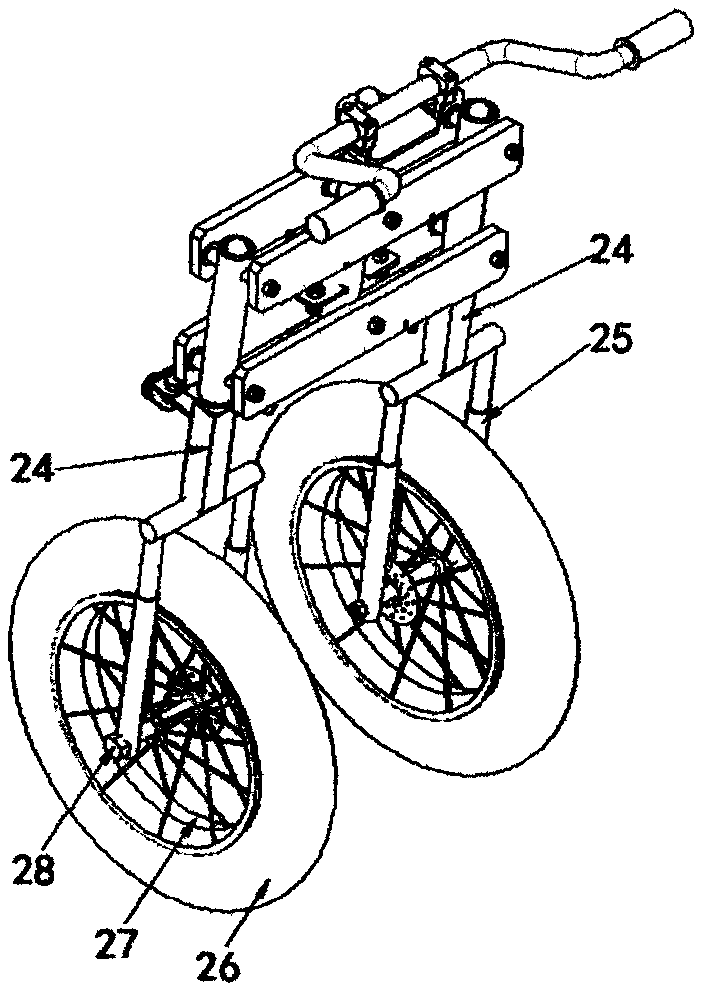

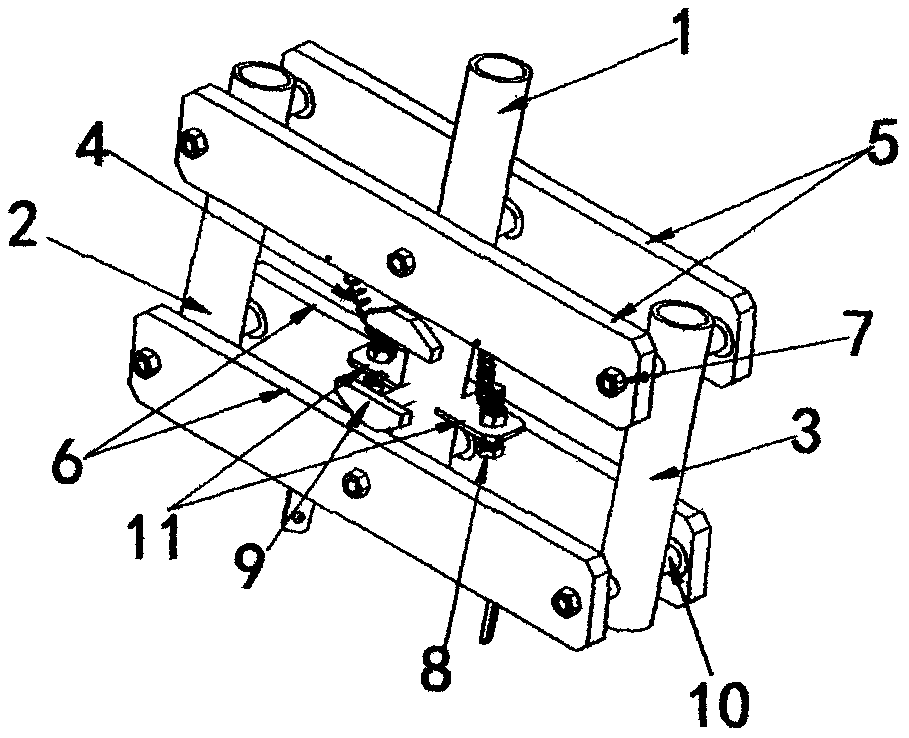

Variable shape optimization device for front double-wheel self-aligning balance assembly of inverted three-wheel vehicle

The invention discloses a variable shape optimization device for a front double-wheel self-aligning balance assembly of an inverted three-wheel vehicle. The device comprises a connecting assembly, a swing arm upper assembly, a swing arm lower assembly, a movable frame, a bearing pin, a spring, a spring seat and an angle limiting positioning piece, and a middle shaft fixing column is parallel to ahandlebar steering shaft in a handlebar steering assembly. All the assemblies are connected through bearing pins and nuts to form a self-aligning balance assembly capable of enabling the swing arm andthe movable frame to move up and down within an angle limiting range. And the self-aligning balance assembly cannot perform steering motion along with the steering shaft of the handlebar. And after the shock absorbers in each group (2) are connected through a shock absorber steering assembly or a rocker arm type shock absorption steering rack or an integrated shock absorption steering rack, the other ends of the shock absorbers clamp the wheels in the middle for connection, or the wheels are placed on the inner side or the outer side of the lower end of the shock absorber group for connection. Three appearances for placing the front double wheels (inner, middle and outer) are formed.

Owner:吕榕志

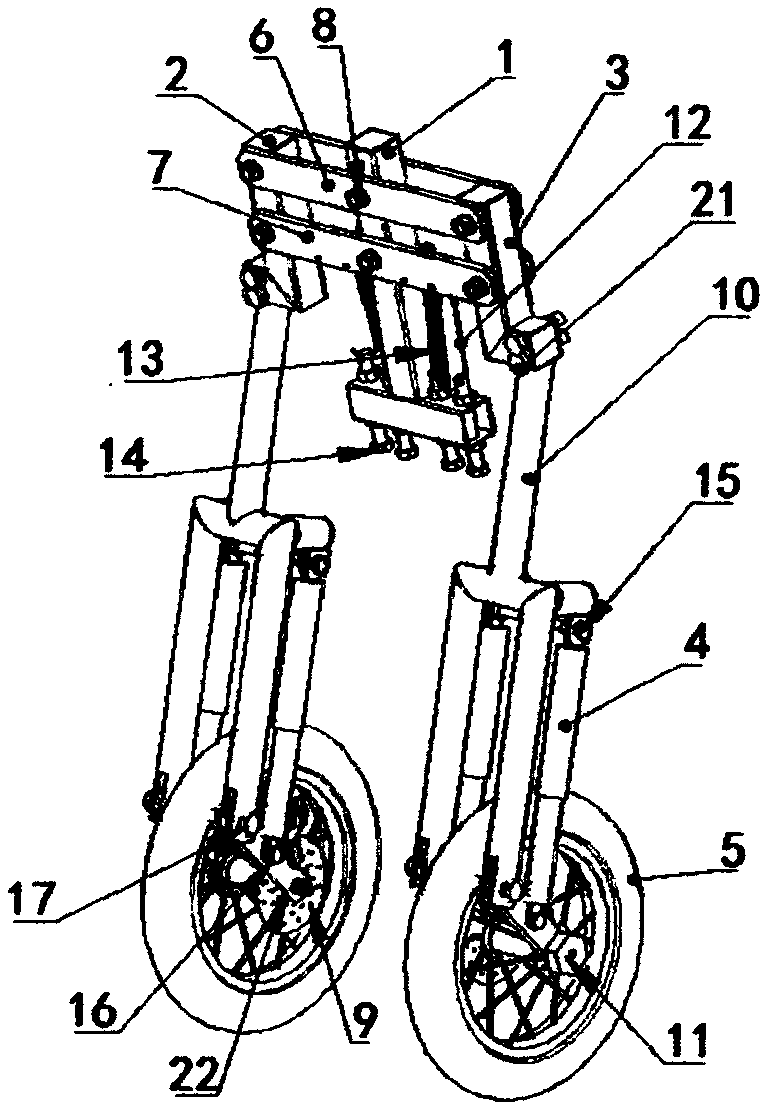

Front dual-wheel self-aligning balancing assembly rocker arm plate deformable device of reversed motor tricycle

The invention discloses a front dual-wheel self-aligning balancing assembly rocker arm plate deformable device of a reversed motor tricycle. The front dual-wheel self-aligning balancing assembly rocker arm plate deformable device comprises connecting assemblies, a rhomboid axisymmetric (vertical) motion deformation self-aligning balancing mechanism, dampers, damping frames, rocker arm blocks, wheel bell assemblies and tires. A rhomboid center shaft column is connected with a vehicle body handlebar assembly, and the two ends of each damper are connected with the corresponding damping frame andthe corresponding rocker arm block correspondingly. The left rocker arm block and the right rocker arm block are connected with the damping frame and then connected with the tires on the left side andthe right side. The rocker arm blocks and the tires are connected through three methods to form three appearances; according to the first method, the two rocker arm blocks and the front wheels are arranged longitudinally in parallel, and the two wheels are clamped to be mounted; and according to the other two methods, each front wheel is connected to the inner side or the outer side of one rockerarm block. According to the technical scheme, by means of a large number of road surface tests, when the reversed motor tricycle runs linearly or makes a turn, the vehicle is safer and more stable, easy and convenient to control and suitable for long-distance and short-distance driving.

Owner:吕榕志

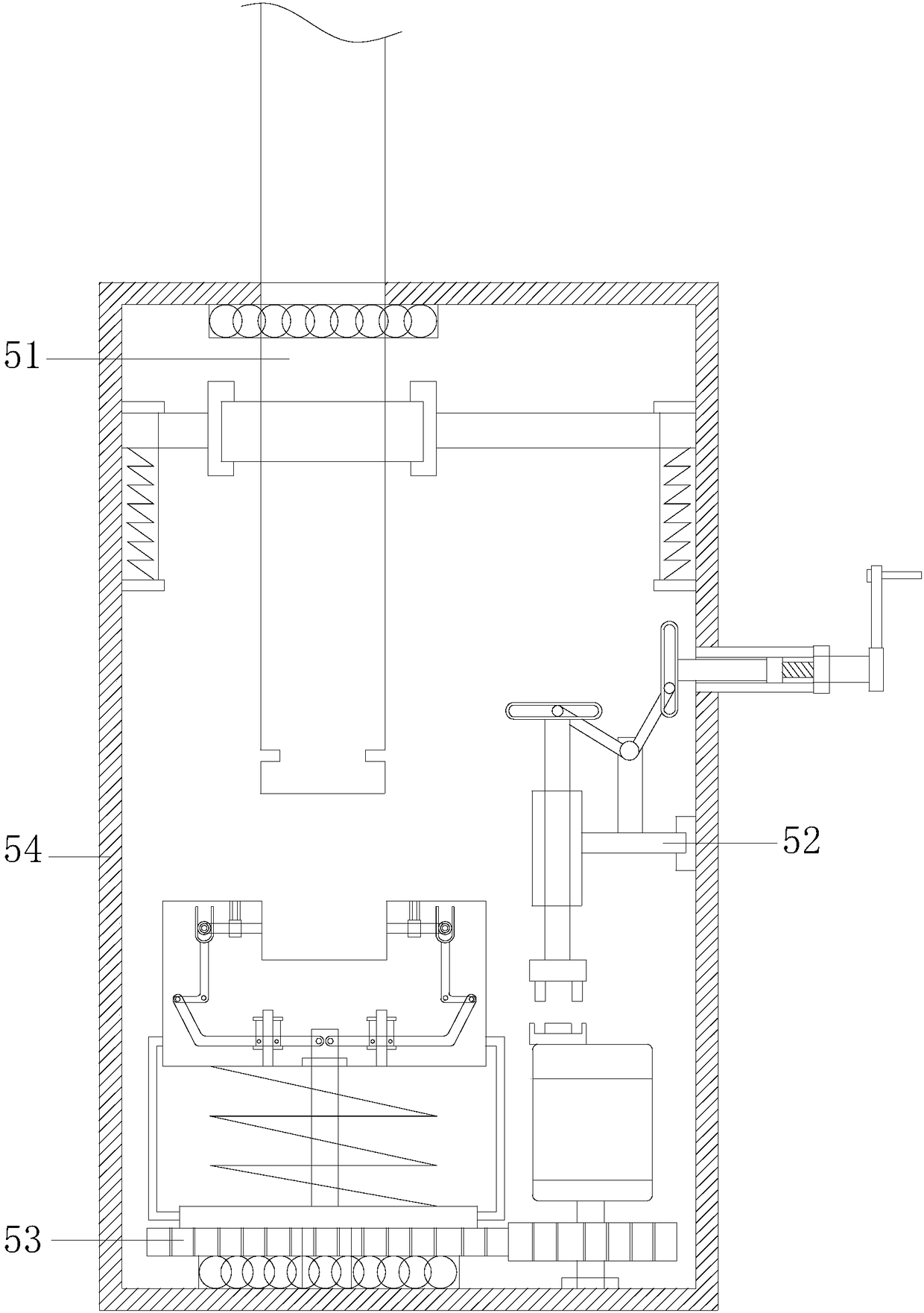

Full-automatic pipe fitting opening lathing machine

PendingCN108161034AHigh degree of automationSave human effortLarge fixed membersMetal working apparatusPipe fittingAgricultural engineering

The invention relates to a full-automatic pipe fitting opening lathing machine. The full-automatic pipe fitting opening lathing machine comprises a base, and the top of the base is provided with a rotating feeding mechanism, a pipe fitting fixing mechanism and an automatic turning mechanism; the rotating feeding mechanism includes an index plate base disposed above the base, a hydraulic index plate disposed above the index plate base and a rotating table disposed above the hydraulic index plate, and the base is a cross-shaped structure; the bottom of the index plate base is fixedly connected with the top of the base, and the bottom of the hydraulic index plate is fixedly connected with the top of the index plate base; and the rotating table is a circular plate with right angle notches around. According to the full-automatic pipe fitting opening lathing machine, the labor is replaced with machines, and the manpower is saved; the turning speed is high, and the production efficiency is significantly improved; and the tool distance is accurately controlled by a servo motor, the consistency of pipe fitting ports is high, and the product quality is stable.

Owner:NANYANG DINGGANG IND CO LTD

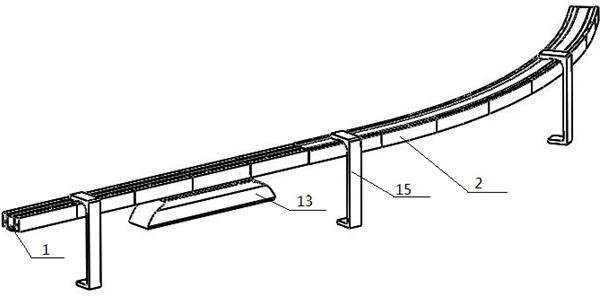

Suspension structure of suspension type permanent magnet magnetic levitation rail transit equipment

ActiveCN111891143AGuaranteed distanceGuaranteed parallelismRope railwaysElevated railway with suspended vehicleBogieHydraulic cylinder

The invention discloses a suspension structure of suspension type permanent magnet magnetic levitation rail transit equipment. Through a sky beam, permanent magnet rails, a bogie, permanent magnet blocks, hydraulic cylinders, rubber wheels, side plates and connecting plates, a lift car and the sky beam are subjected to suspension separation, a driving system between the connecting plates and the sky beam is used for providing power, the bogie is used for providing guidance, and the lift car is driven to move in the sky beam track direction. According to the invention, the sky beam is set as asquare closed structure and can be conveniently formed through welding or direct casting, and the permanent magnet rails are arranged outside the formed sky beam, so that machining is convenient; thedistance, parallelism and planeness of the two side walls of the bogie are accurately guaranteed, the stable guide distance is guaranteed, guide force cannot be suddenly changed, stable guide is guaranteed, and noise generated when the rail transit equipment runs is reduced.

Owner:江西永磁磁浮科技有限责任公司

Comprehensive dredging machine

ActiveCN102155219BOvercome the disadvantages of not being able to drill holes and support at the same timeIncrease the speed of excavationMine roof supportsTunnelsPush and pullEngineering

The invention discloses a comprehensive dredging machine. The comprehensive dredging machine comprises a crawler-free type dredging machine, a hydraulic support, a drilling machine, a scraper conveyor, a runner and the like. The upper end of the hydraulic support is provided with a main top beam, a front canopy, a back canopy and a cross beam; the dredging machine is arranged on a foundation; thefront and rear ends of the foundation are provided with a slope regulation jack respectively; one end of a front pushing and pulling jack is connected with the foundation of the dredging machine, andthe other end of the front pushing and pulling jack is connected with the hydraulic support; the rear of the dredging machine is provided with a self-advancing jack, and two sides of the foundation are provided with a side push cylinder respectively; and the drilling machine is arranged below the main top beam or the back canopy; and the runner is arranged behind the hydraulic support and is connected with a rear push and pull jack arranged on the hydraulic support by an anchor chain and a pulley. The comprehensive dredging machine has the advantages of parallel operation of hole drilling andsupporting, and coal cutting of a development machine, a roadway turns flexibly, the turning radius is small, the turning speed is high, the tunneling speed is high, and the safety is guaranteed.

Owner:DATONG COAL MINE GRP CO LTD HENGAN EQUIP CO LTD

Auxiliary turning device

InactiveCN106475578AReasonable structureLow costAutomatic workpiece supply/removalLarge fixed membersMechanical engineering

According to the scheme, the invention provides an auxiliary turning device. The auxiliary turning device comprises a supporting base, an adjusting rod, a first transmission device, a driven rod, second transmission devices, a lock device and a workbench. The first transmission device comprises a first motor, a first rotating shaft and a first transmission rod. Each second transmission device comprises a driven tray, a clamping device, a second rotating shaft, a second motor and a second transmission rod. The auxiliary turning device is reasonable in structure and low in cost, deflection of the turning position due to the movement of a turning tool can be reduced, the reject rate is reduced, the turning speed is increased, and the turning efficiency is improved.

Owner:TIANJIN MEINENG PIPE FITTING

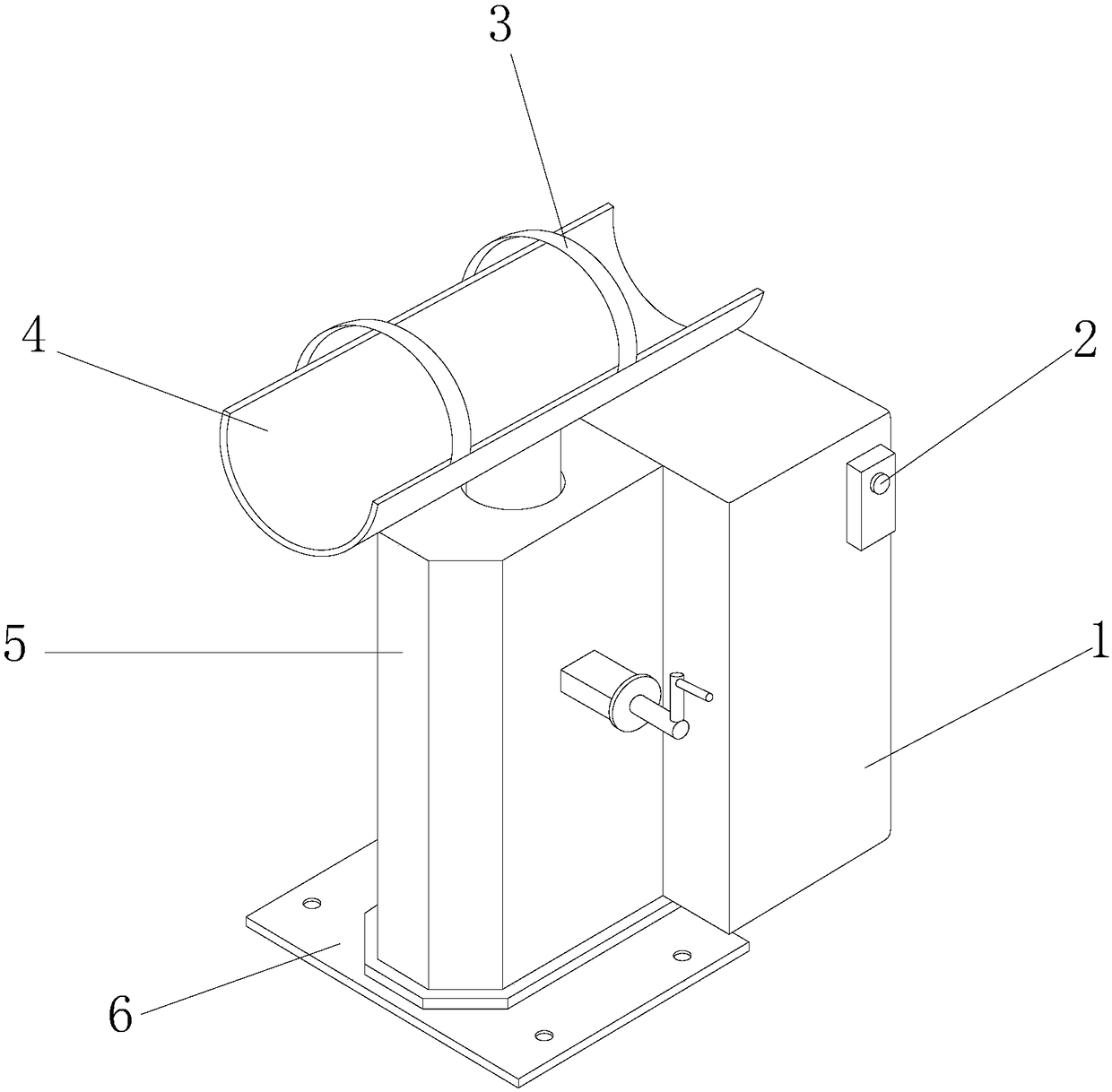

Rotary turning device for oil pipeline processing

InactiveCN108557730AFast stability controlEasy to controlLifting devicesHoisting equipmentsInterference fitPower switching

The invention discloses a rotary turning device for oil pipeline processing. The device structurally comprises a power supply cabinet, a power switch, pipeline adjustable fixing sleeves, a pipeline supporting base, a rotary turning device and a fixed baseplate. The pipeline supporting base is arranged above the rotary turning device and is in interference fit with the rotary turning device, and the two pipeline adjustable fixing sleeves are uniformly arranged on the pipeline supporting base at an interval and are in clearance fit with the pipeline supporting base; an oil pipeline is placed inthe pipeline supporting base and tightly locked on the pipeline supporting base by means of the pipeline adjustable fixing sleeves, the direction of the pipeline can be adjusted on site through the rotary turning device, and the consumed time is short. The turning speed is high, the pipeline can quickly enter a next step for processing, improvement of the efficiency of continuous production of thepipeline is facilitated, only one worker is needed in the turning process, the operation is simple, and the risk during turning of the pipeline is reduced.

Owner:郑逸凡

Long-shot type sprayer for fruit and vegetable irrigation

InactiveCN105457780ALong Jet RangeStrong penetrating powerLiquid spraying apparatusCircular discInlet channel

The invention discloses a long-shot type sprayer for fruit and vegetable irrigation. The long-shot type sprayer comprises a sprayer body and a refraction cone. The sprayer body is provided with a liquid runner and a spraying hole. An installing frame is arranged in the liquid runner. A liquid passing hole is formed in the installing frame. The refraction cone penetrates the spraying hole and is connected with the installing frame. The refraction cone is provided with a taper disc located above the spraying hole. Two air inlet channels are symmetrically arranged on the sprayer body and connected with bent pipes. The scheme has the beneficial effects that the sprayer body is additionally provided with the air inlet channels, high-speed compressed air is introduced in the air inlet channels, when irrigation water is sprayed out of the spraying hole and is injected all around through the taper disc, high-speed air flow crushes thick water drops into small water drops to be blown remotely, and therefore the spraying range of the sprayer is long, the requirement for irrigation of fruits and vegetables can be sufficiently met, and the application range of the sprayer is enlarged.

Owner:CHONGQING DONGRUN FRUIT & VEGETABLE IND DEV CO LTD

Urban single-layer totally-enclosed and totally-communicated flyover

InactiveCN102400427ASmall footprintFully functionalRoadwaysClimate change adaptationEngineeringRidge

The invention relates to the technical field of flyovers and is characterized in that: a longitudinal left-turn ramp is arranged between the outer side of an arched overpass bridge of a longitudinal road and the inner side of a longitudinal left-turn downgrade ramp for an opposite coming vehicle; the longitudinal left-turn ramp and the overpass bridge are abreast upward; after bridging over a transverse road surface, the longitudinal left-turn ramp is parallel to the ground between the airspace of the transverse road surface and the airspace of the bridge head at the downgrade end of the overpass bridge; then the longitudinal left-turn ramp turns left to bridge over a longitudinal road surface and a longitudinal left-turn upgrade ramp on the outer side of the other end of the overpass ridge, and turns around and moves downwards to get into a first lane of the transverse road surface; after the first lane of the transverse road surface underneath passes through a longitudinal left-turn air ramp, namely the first lane turns right and moves upwards along the inner side of the first lane until the first lane is connected to the corner of the longitudinal left-turn ramp, the first lane turns left on the inner side and bridges over the longitudinal road surface, then turns left again at a position close to the inner side of the longitudinal left-turn upgrade ramp and moves forwards in a state of being parallel to the ground, and gets into the overpass bridge at the highest part of the arched overpass bridge; furthermore, intersection platforms are arranged at intersections between the longitudinal and transverse left-turn upgrade ramps and the middle part of the left-turn downgrade ramp for the opposite coming vehicle, so that longitudinal and transverse right turns can be realized.

Owner:张航

Special oil filtering device for steam turbine capable of removing impurities and oil filtering method

PendingCN109794096AEffective cycle dryingEasy to separateFiltration circuitsWater dischargeWater storage tank

The invention relates to a special oil filtering device for a steam turbine and an oil filtering method. The oil filtering device is mainly used for treating the turbine oil of a generator set and canquickly and effectively remove moisture, gas and impurities in the oil. The oil filtering device comprises a water tank (1), a vacuum tank (2), a heater (3), a condenser (4) and a vacuum pump (5), wherein the water tank is connected with the vacuum pump through a water pipe; the top of the vacuum pump is connected with the condenser through an air inlet pipe (6); the side surface of the vacuum pump is connected with the condenser through a condenser discharging pipe (7), the bottom of the condenser is provided with a water storage tank (8), the lower part of the water storage tank is connected with an air discharging pipe (9) and a water discharging pipe, the upper part of the condenser is connected with the vacuum tank through a pipeline, a vacuum meter (11) is arranged on the pipeline,the invention relates to the oil filtering device of the steam turbine.

Owner:大唐绥化热电有限公司

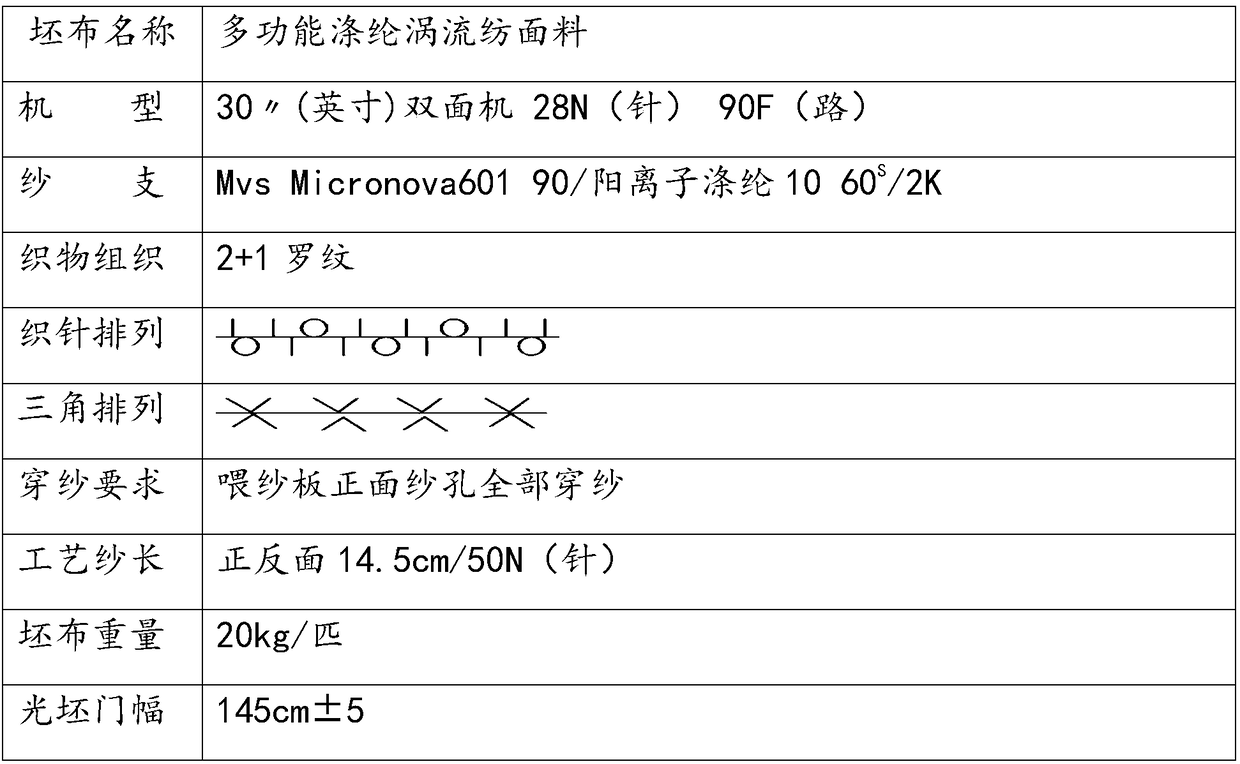

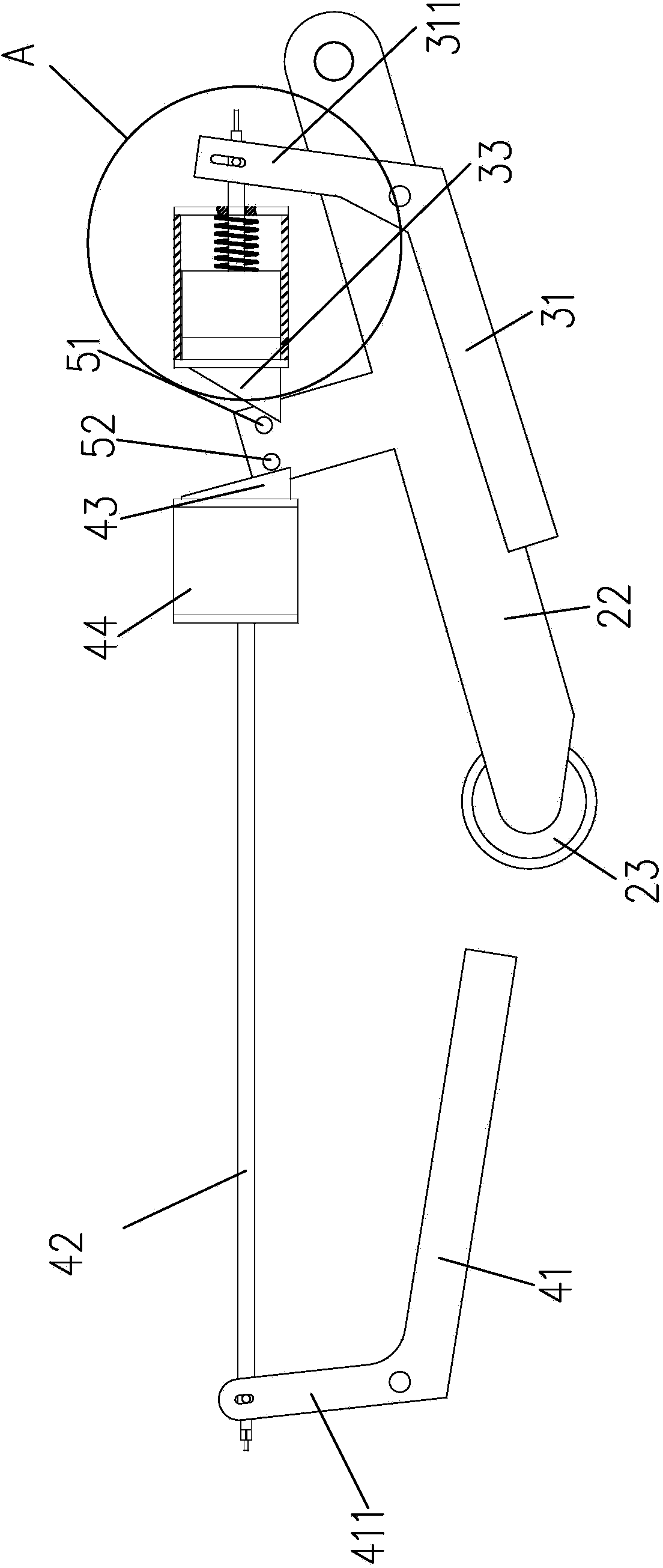

Double-wheel touch locking type turning advancing mechanism and firefighting moped with same

InactiveCN103895706AFast turnTurn easilyEndless track vehiclesNon-deflectable wheel steeringFirefightingEngineering

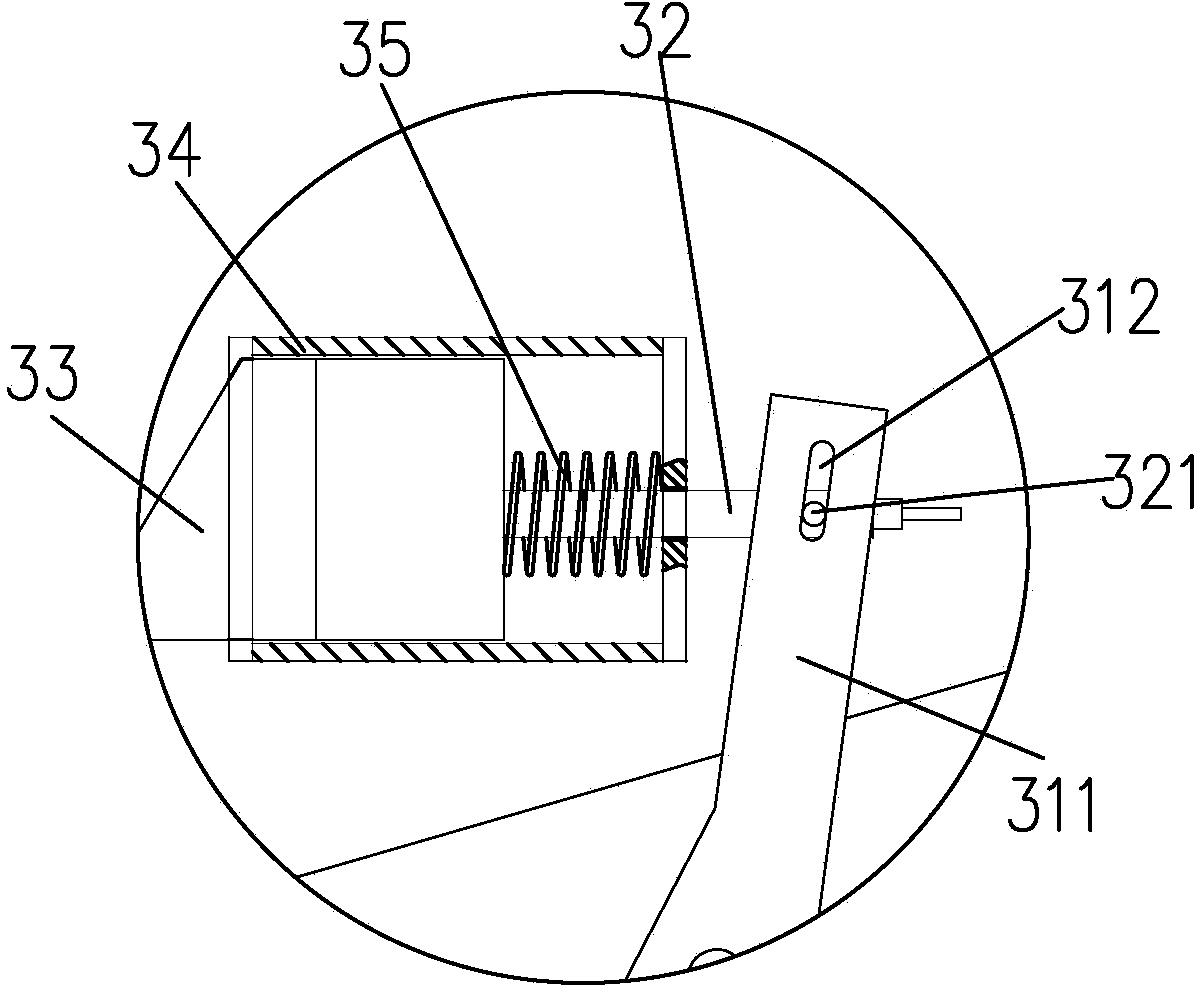

The invention relates to a vehicle capable of climbing on stairs, in particular to an accessory of a stair-climbing vehicle for firefighting, and provides a double-wheel touch locking type turning advancing mechanism and a stair-climbing vehicle. The double-wheel touch locking type turning advancing mechanism can rapidly advance on the stairs and make a turn on a stair landing rapidly and conveniently. The double-wheel touch locking type turning advancing mechanism mainly comprises a supporting leg assembly, a front touch locking assembly and a rear touch locking assembly. The supporting leg assembly comprises a left supporting leg and a right supporting leg, wherein wheels are arranged at the rear end of the left supporting leg and the rear end of the right supporting leg respectively, and a supporting leg front lock rod (51) and a supporting leg rear lock rod (52) are fixed to the supporting leg assembly. The front touch locking assembly comprises a front touch rod (31), a front touch rod crank arm (311), a front touch rod crank arm oval hole (312), a front connecting pin (321), a front locking dog pull rod (32), a front locking dog (33), a front lock box (34) and a front compression spring (35), wherein the front touch rod drives the front locking dog to move so as to stop or release the supporting leg assembly, and the rear touch locking assembly is similar to the front touch locking assembly.

Owner:北京北消防冻技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com