Multifunctional polyester vortex spinning fabric and production method thereof

A production method, vortex spinning technology, applied in the field of textile industry, can solve the problems that the finished product has not been widely applied and promoted, and the development of the fiber downstream is not mature, so as to ensure the anti-permeability and anti-ultraviolet performance, good uniformity, and guarantee The effect of function and style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail in conjunction with specific embodiments below, so as to make the advantages of the present invention more obvious. It should be understood that the content therein is only used for illustration, rather than limiting the protection scope of the present invention.

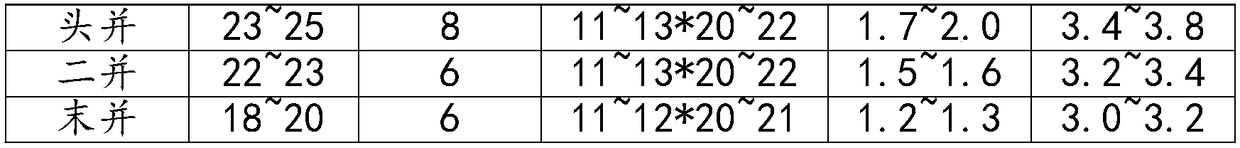

[0046] Raw materials used: The fiber raw materials are 0.9D*38mm Micronova601 fiber and 1.4D*38mm cationic polyester, which are first spun into Mvs Micronova601 90 / cationic polyester 10 60S / 2K strands.

[0047] Equipment used: a complete set of German Trützschler blowing carding unit, Swiss Rieter foreign fiber separator, pre-draw frame, comber and draw frame, roving frame with German Suessen drafting system, German Suessen Imported compact spinning frame, Japanese Murata automatic winding machine, large circular knitting machine.

[0048] The specific production process includes the following steps:

[0049] Spinning→weaving→finishing, in which:

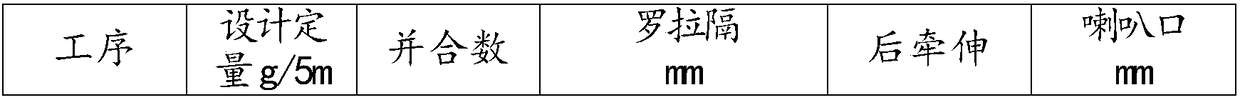

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com