Special oil filtering device for steam turbine capable of removing impurities and oil filtering method

An oil filter device and steam turbine technology, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problem that the oil filter absorbs a lot of impurities, and achieve the effects of fast turning speed, stable performance, and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

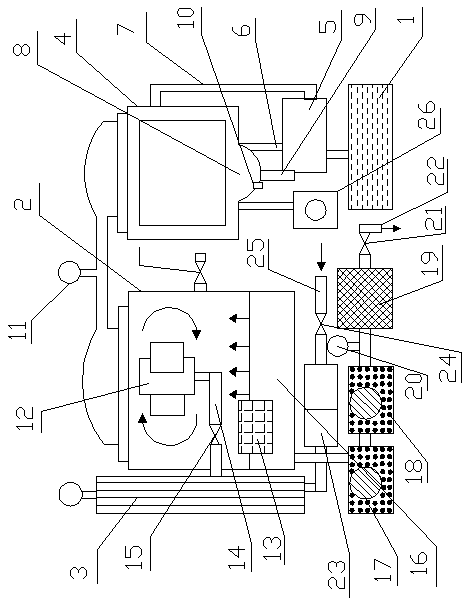

[0025] A special oil filter device for steam turbines capable of removing impurities, comprising: a water tank 1, a vacuum tank 2, a heater 3, a condenser 4 and a vacuum pump 5, the water tank is connected to the vacuum pump through a water pipe, and the The top of the vacuum pump is connected to the condenser through the inlet pipe 6, the side of the vacuum pump is connected to the condenser through the condenser outlet pipe 7, and the bottom of the condenser has a water storage tank 8. The bottom of the water storage tank is respectively connected with an exhaust pipe 9 and a drain pipe 10, and the top of the condenser is connected with the vacuum tank through a pipeline, and a vacuum gauge 11 is installed on the pipeline, and the water storage tank passes through the vacuum tank. The above air inlet pipe and the water outlet pipe of the condenser are combined with the condenser.

Embodiment 2

[0027] According to the special oil filter device for steam turbines that can remove impurities described in Embodiment 1, the vacuum tank has an atomizer 12 and a buoy 13, the bottom of the atomizer is connected to the nozzle 14, and the nozzle The pipe is connected with the heater, the nozzle is equipped with an automatic valve 15, the vacuum tank has an oil layer 16, and the buoy is arranged in the oil layer.

Embodiment 3

[0029] According to the special oil filtering device for steam turbines capable of removing impurities described in Embodiment 1 or 2, the bottom of the vacuum tank is connected to the propeller 17 through a pipeline, and the propeller is connected to the oil drain pump 18, and the drain The oil pump is connected to the fine filter 19 through a pipeline, and a pressure gauge 20 is installed on the pipeline, and the fine filter is connected to the oil outlet pipe 22 through a check valve 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com