Patents

Literature

4769 results about "Oil filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oil filter is a filter designed to remove contaminants from engine oil, transmission oil, lubricating oil, or hydraulic oil. Oil filters are used in many different types of hydraulic machinery. A chief use of the oil filter is in internal-combustion engines in on- and off-road motor vehicles, light aircraft, and various naval vessels. Other vehicle hydraulic systems, such as those in automatic transmissions and power steering, are often equipped with an oil filter. Gas turbine engines, such as those on jet aircraft, also require the use of oil filters. Aside from these uses, oil production, transport, and recycling facilities also employ filters in the manufacturing process.

Oil filter assembly

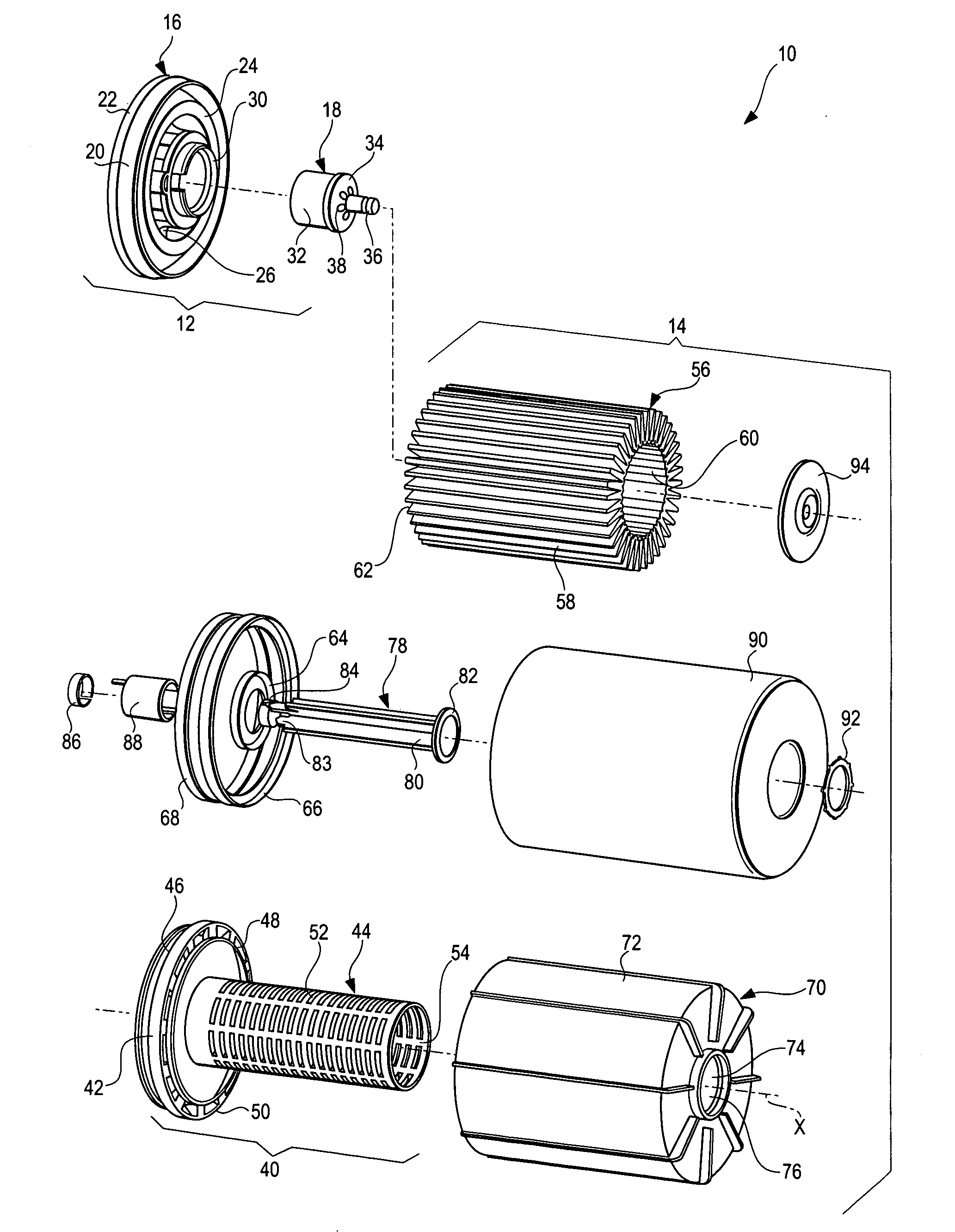

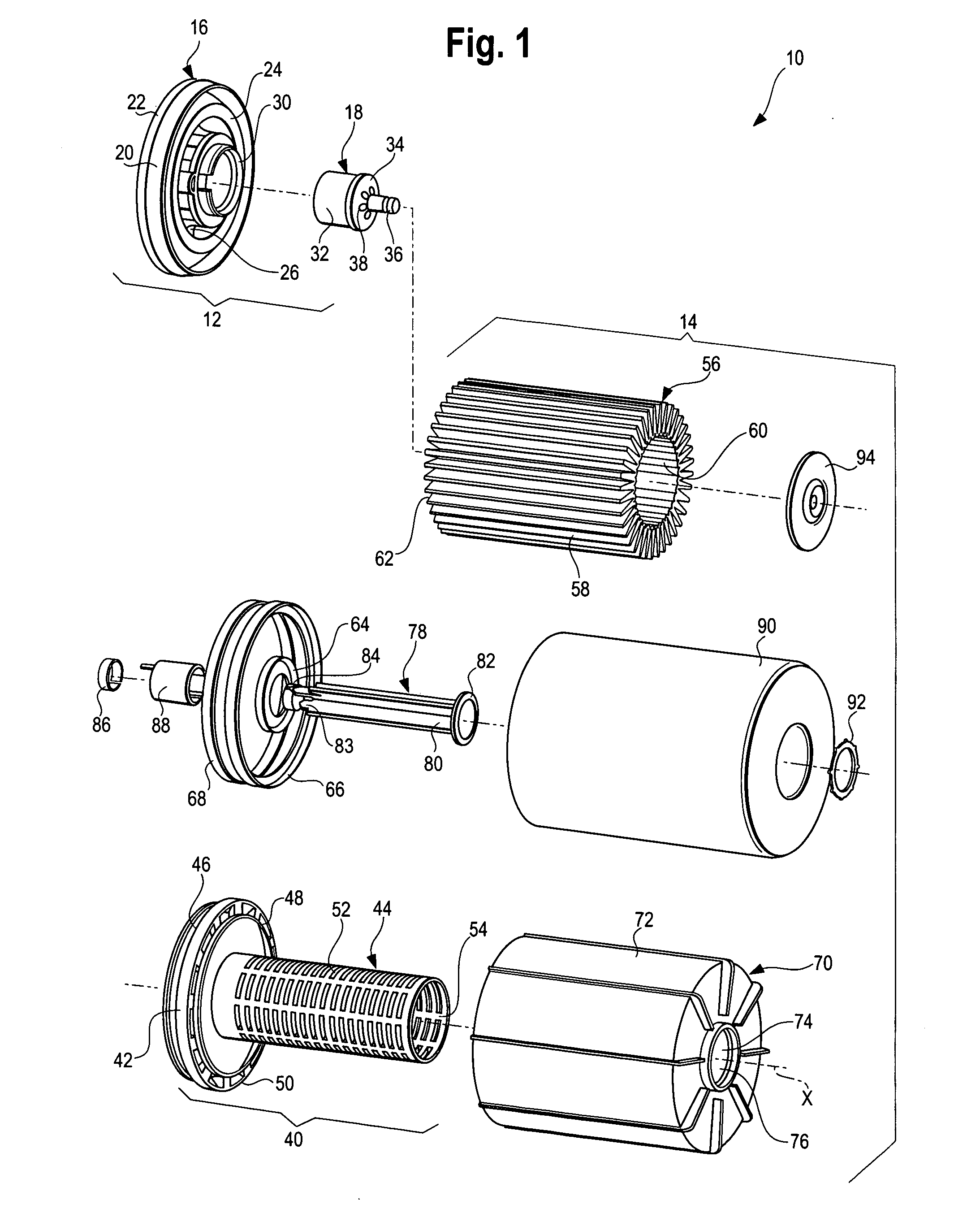

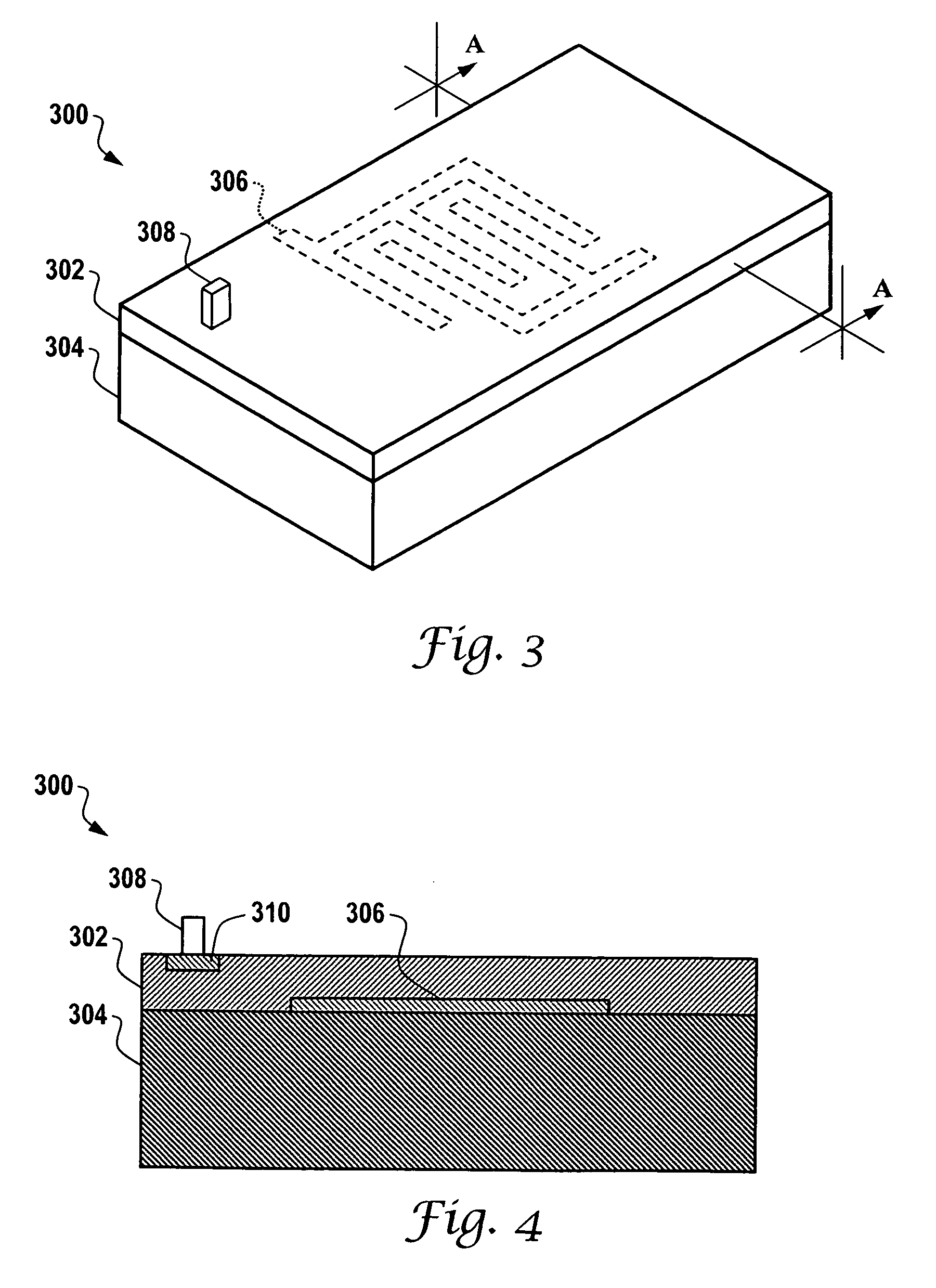

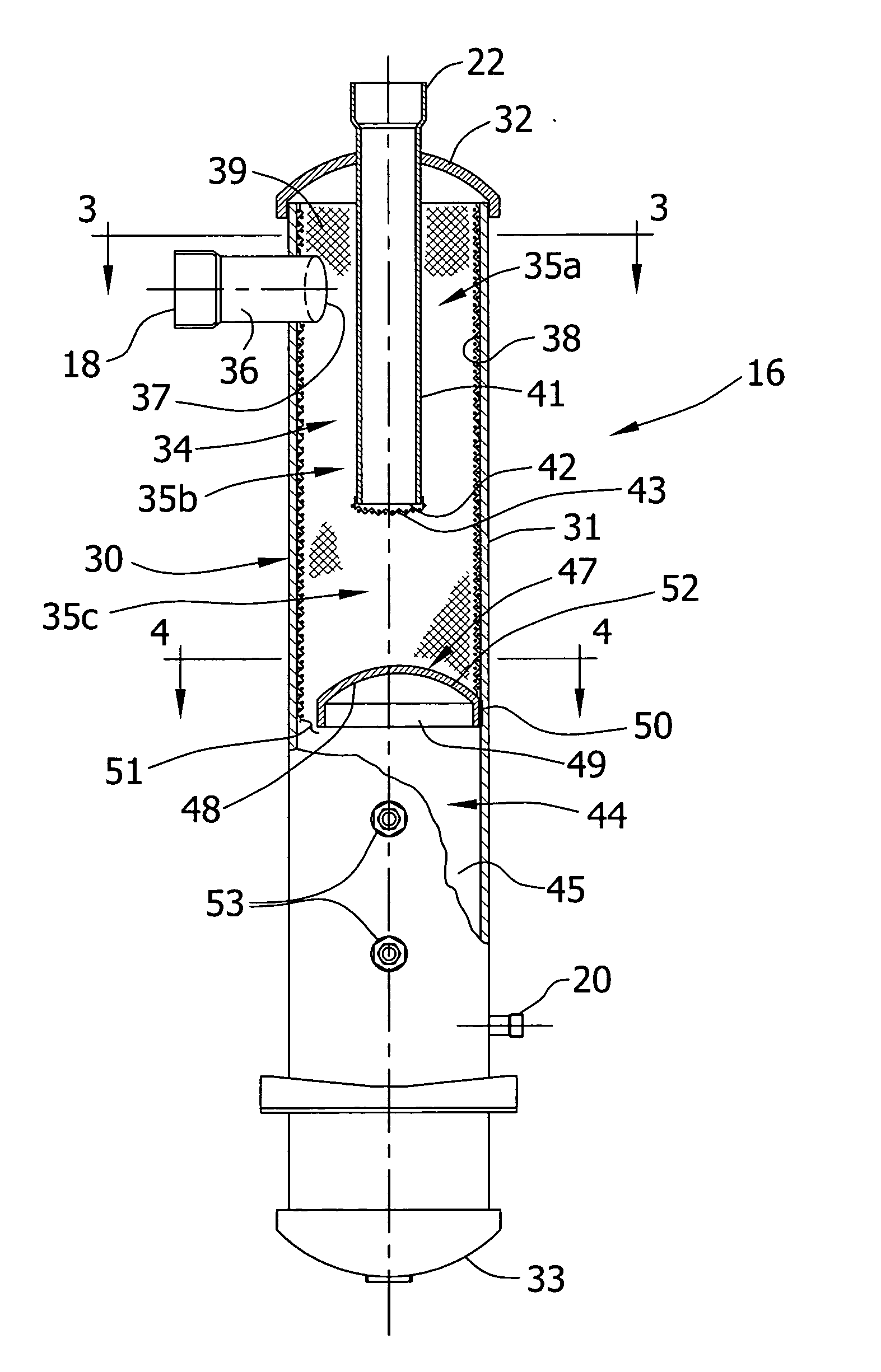

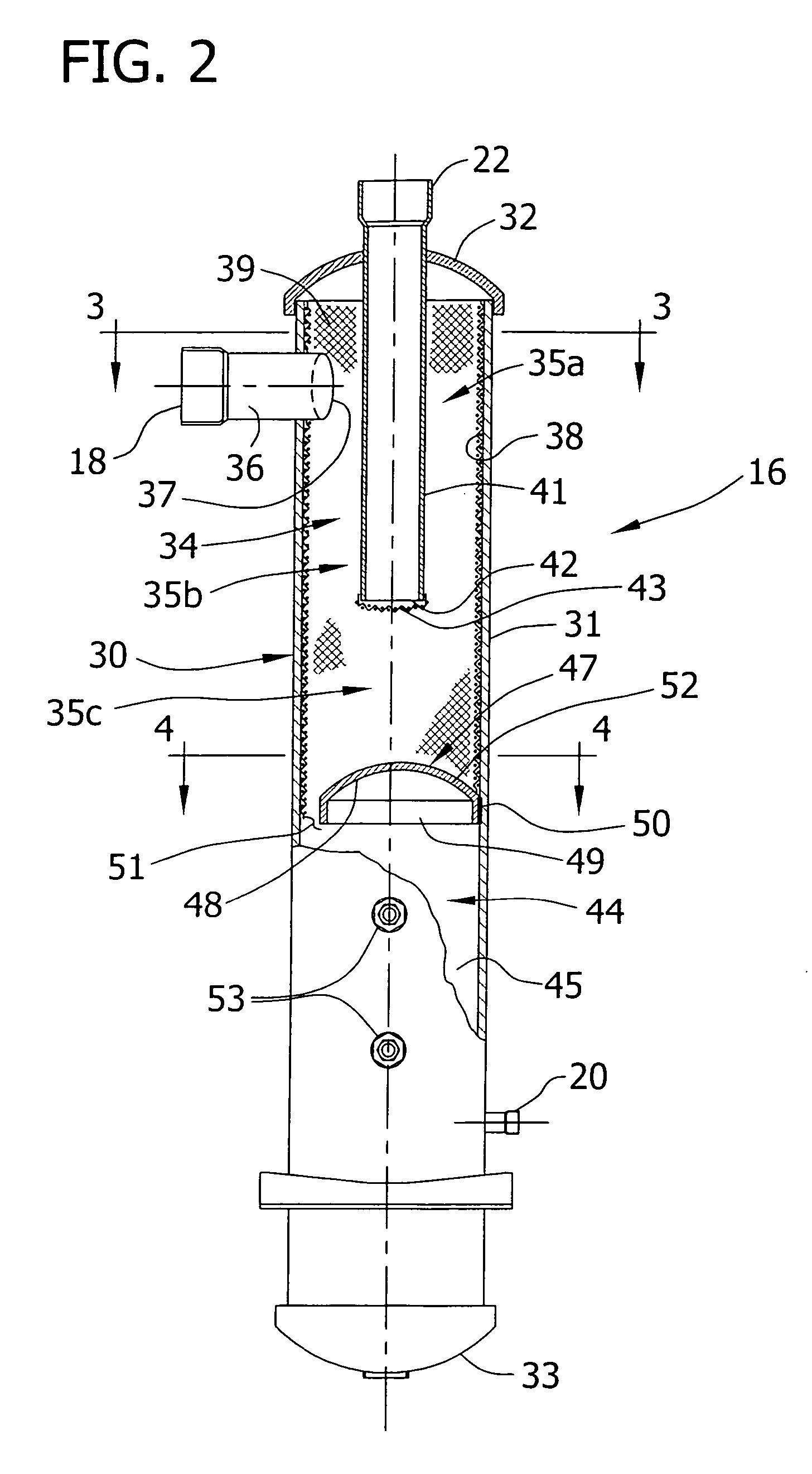

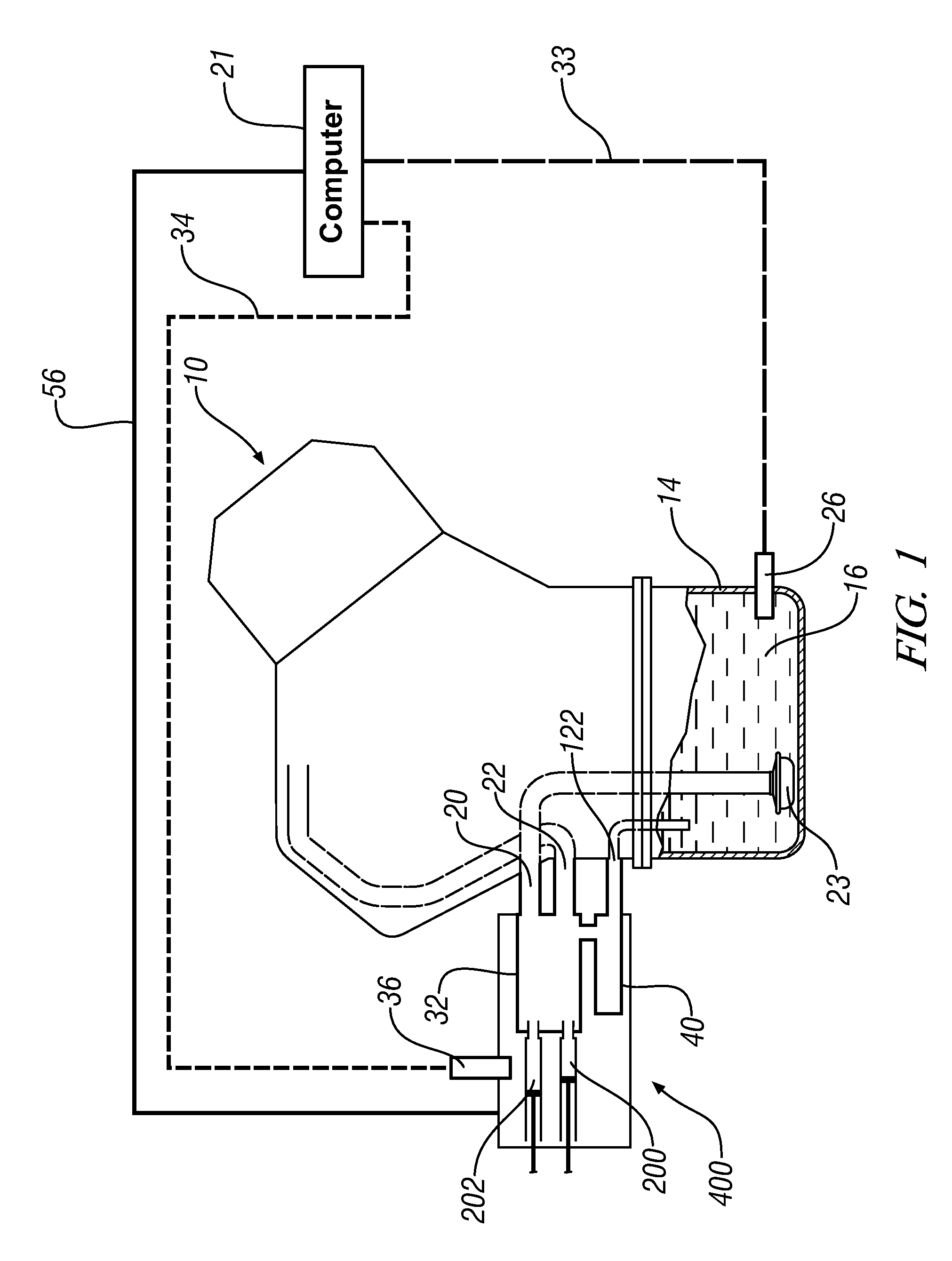

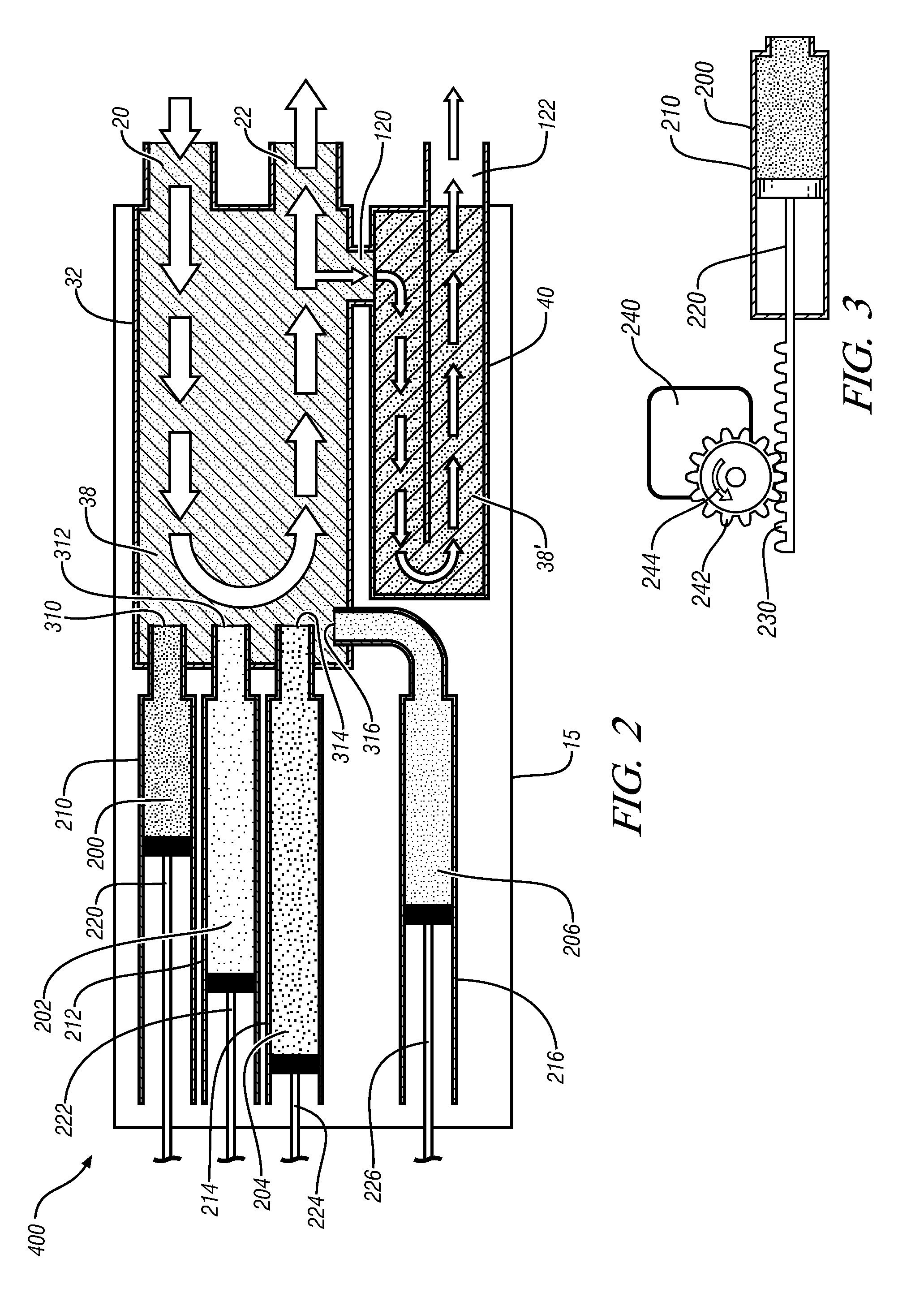

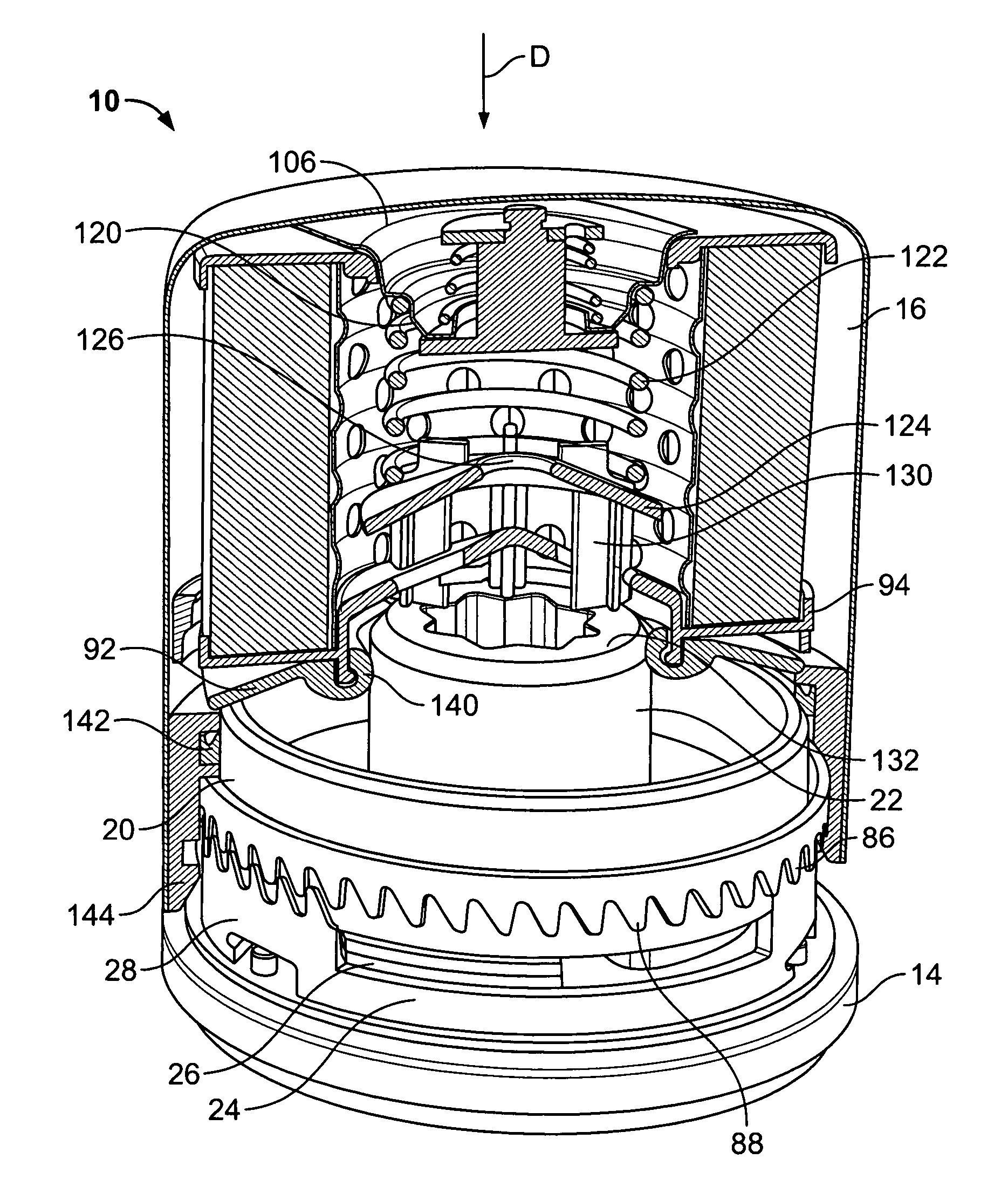

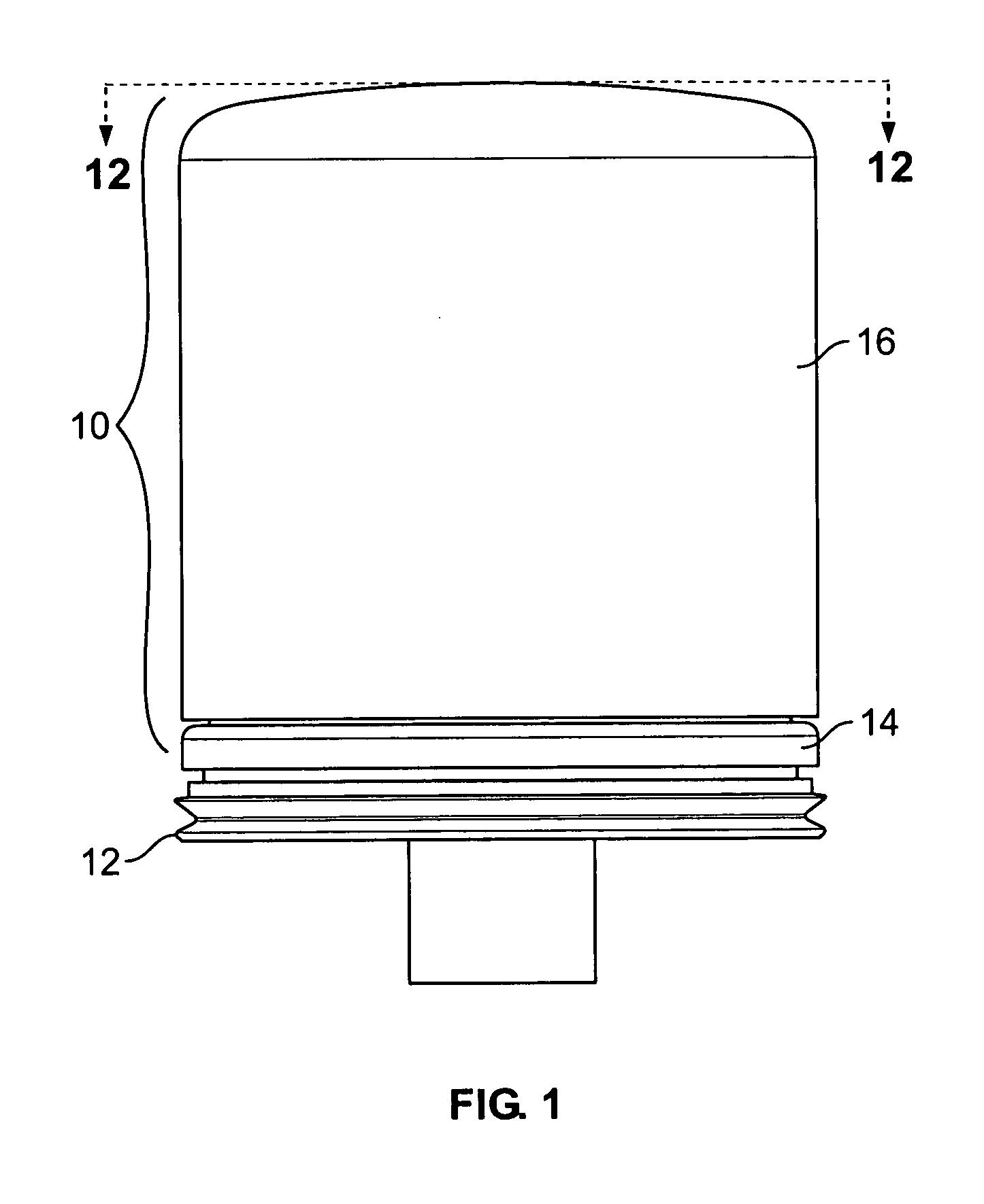

An oil filter system includes an oil filter module and an adapter. The oil filter module includes a detent and an actuator. The adapter includes a protuberance and is configured to be secured to the engine. The oil filter module connects to the adapter when the detent secures to the protuberance as the oil filter module is urged into a connection position with the adapter. The oil filter module disconnects from the adapter when the actuator is actuated, thereby disengaging the detent from the protuberance.

Owner:WEINBERGER KEITH R +10

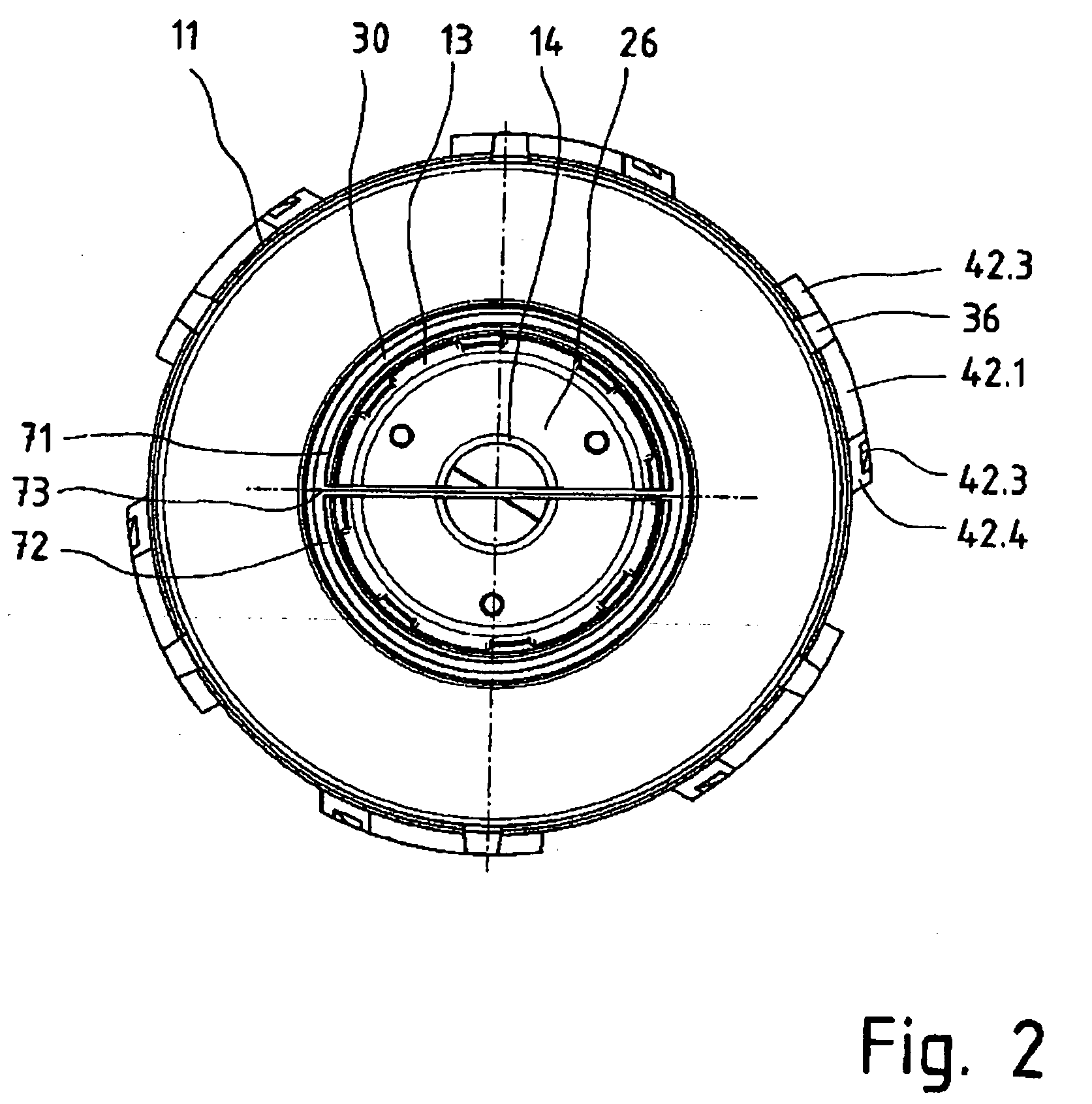

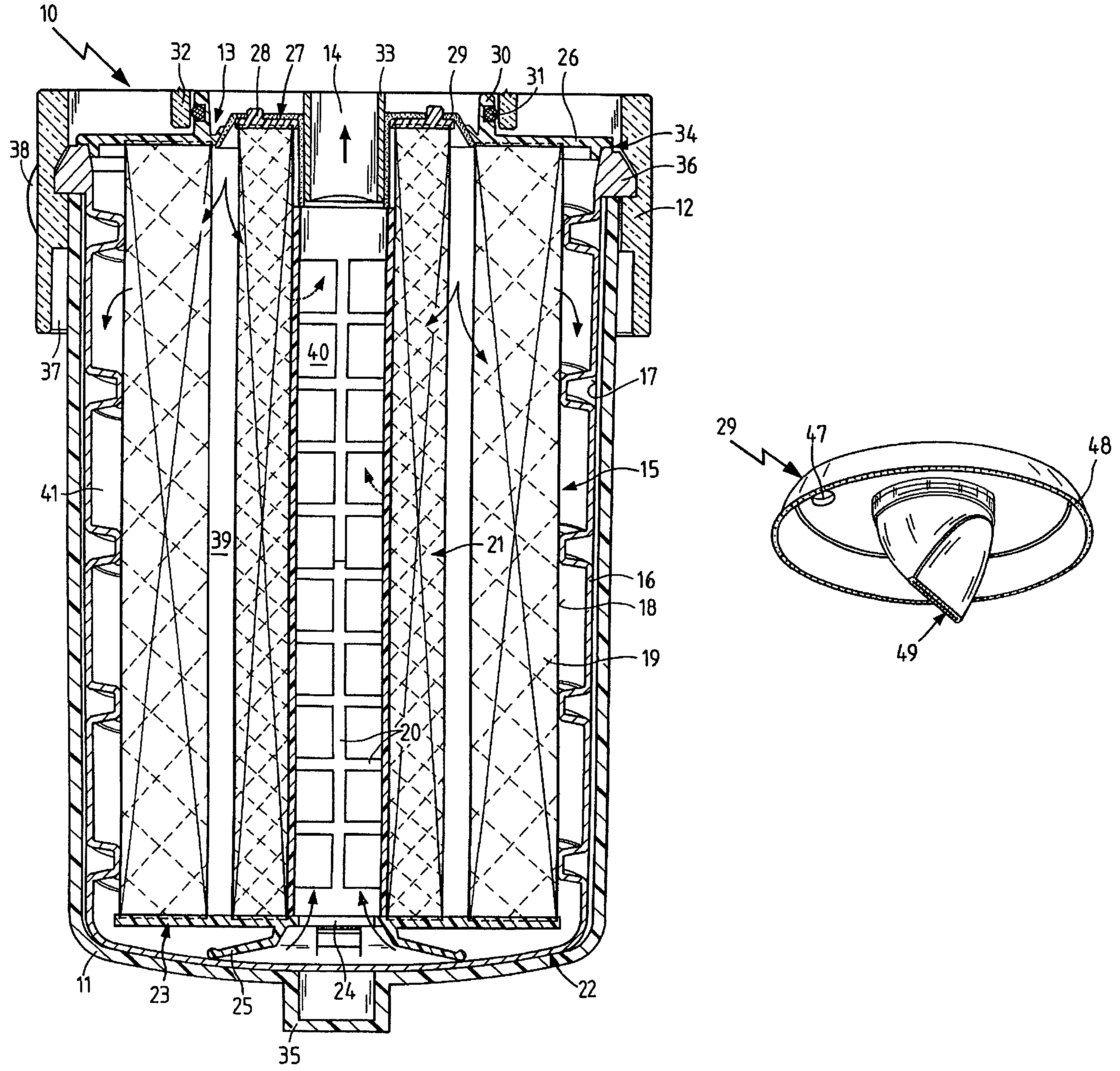

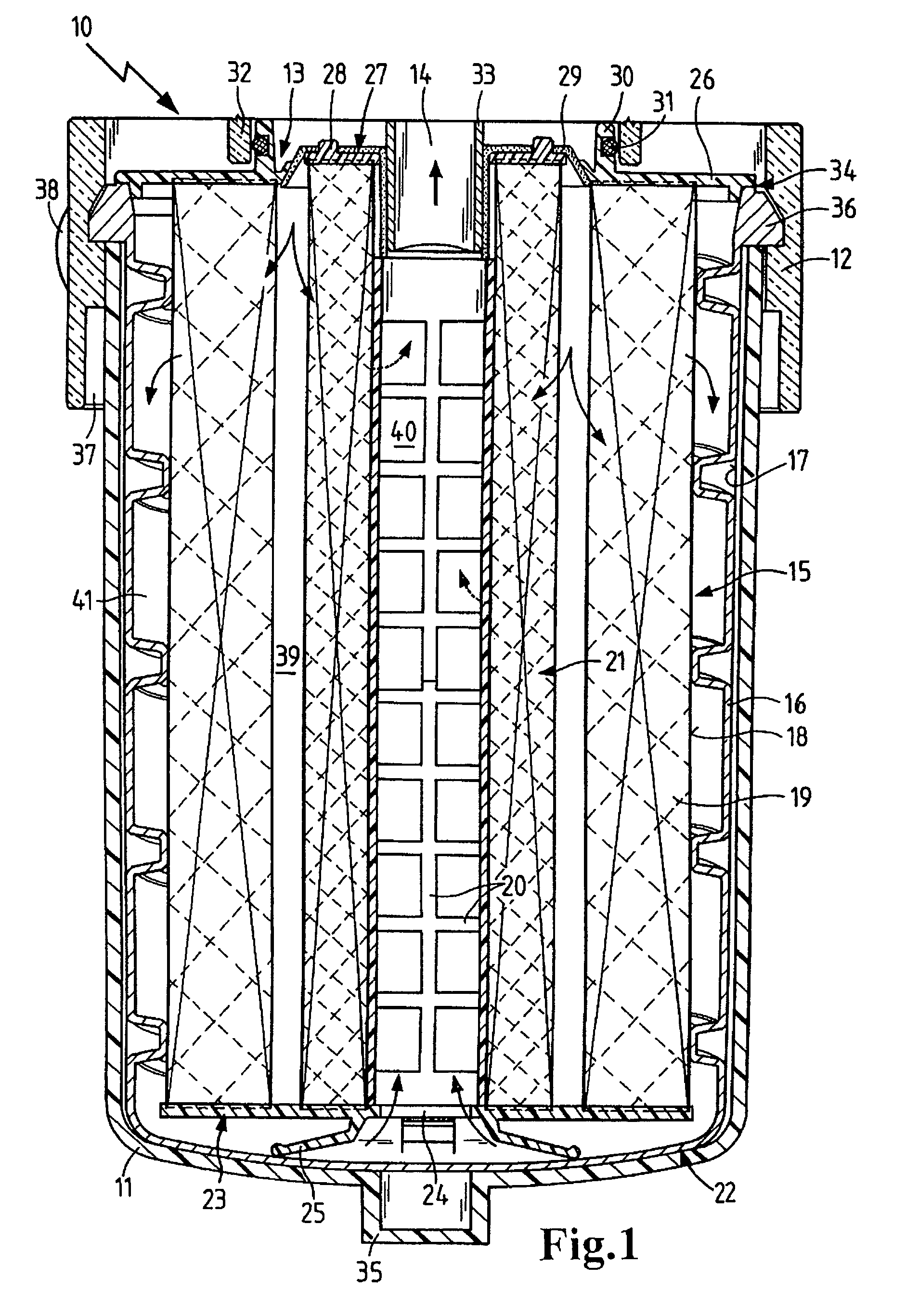

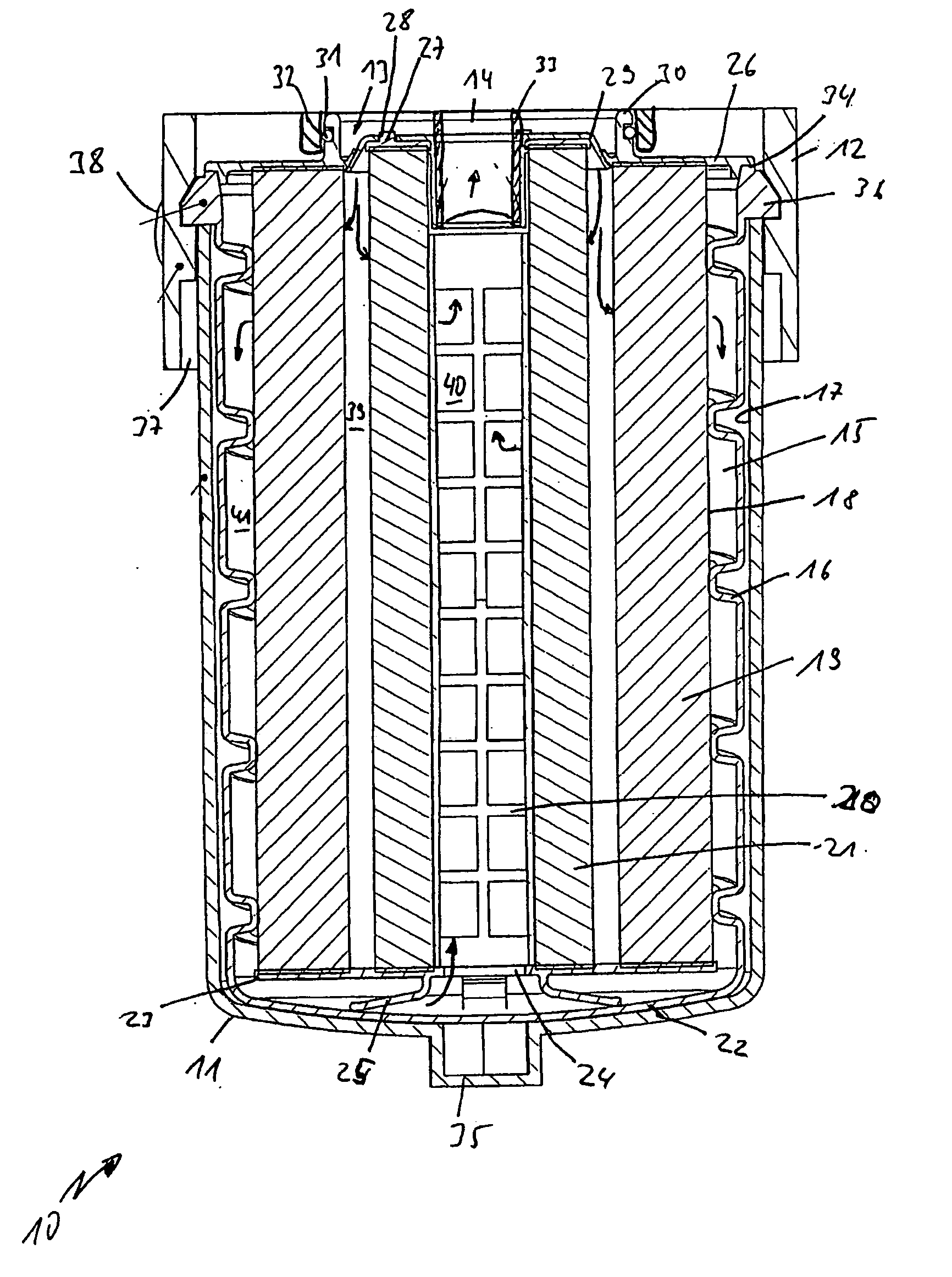

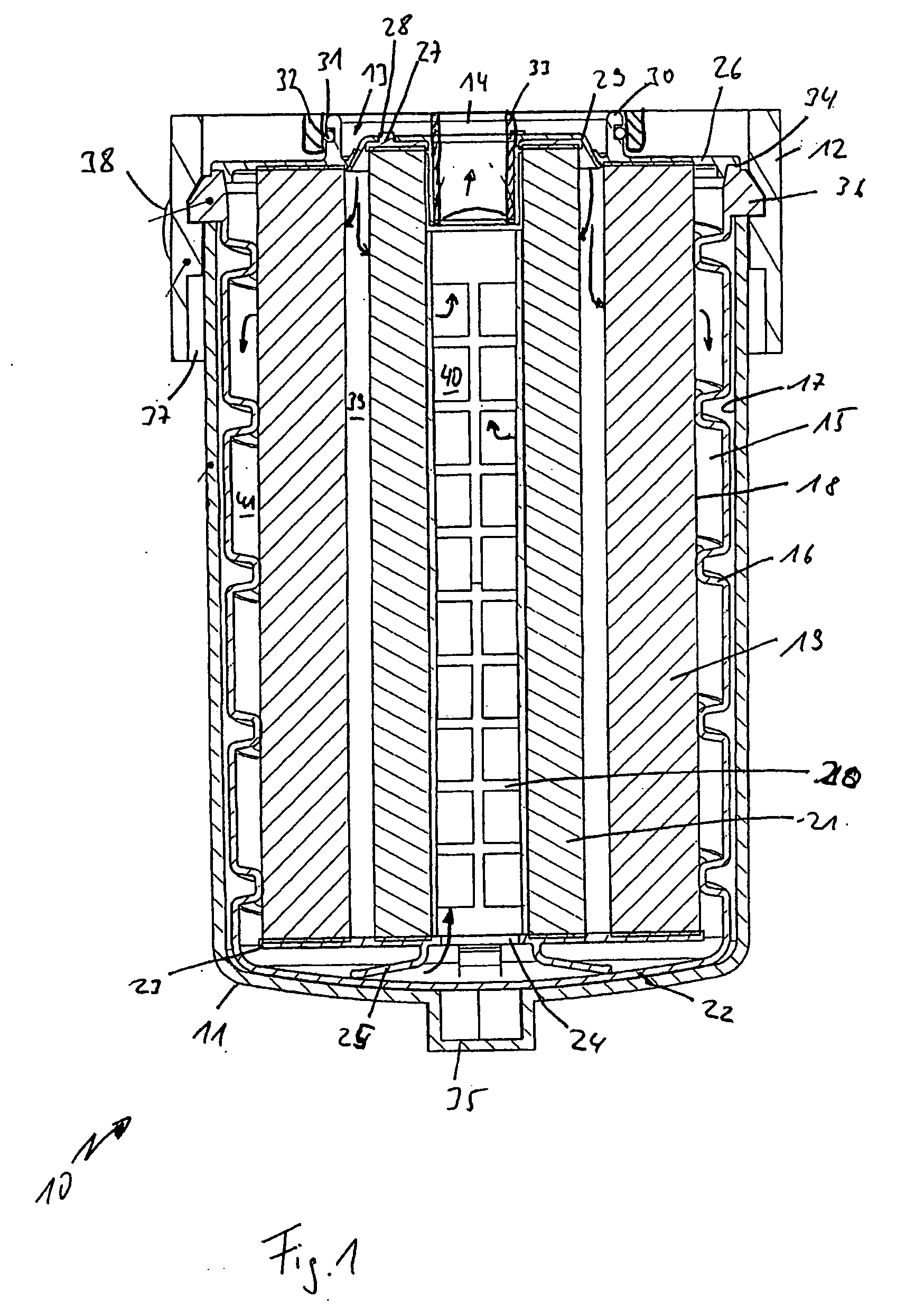

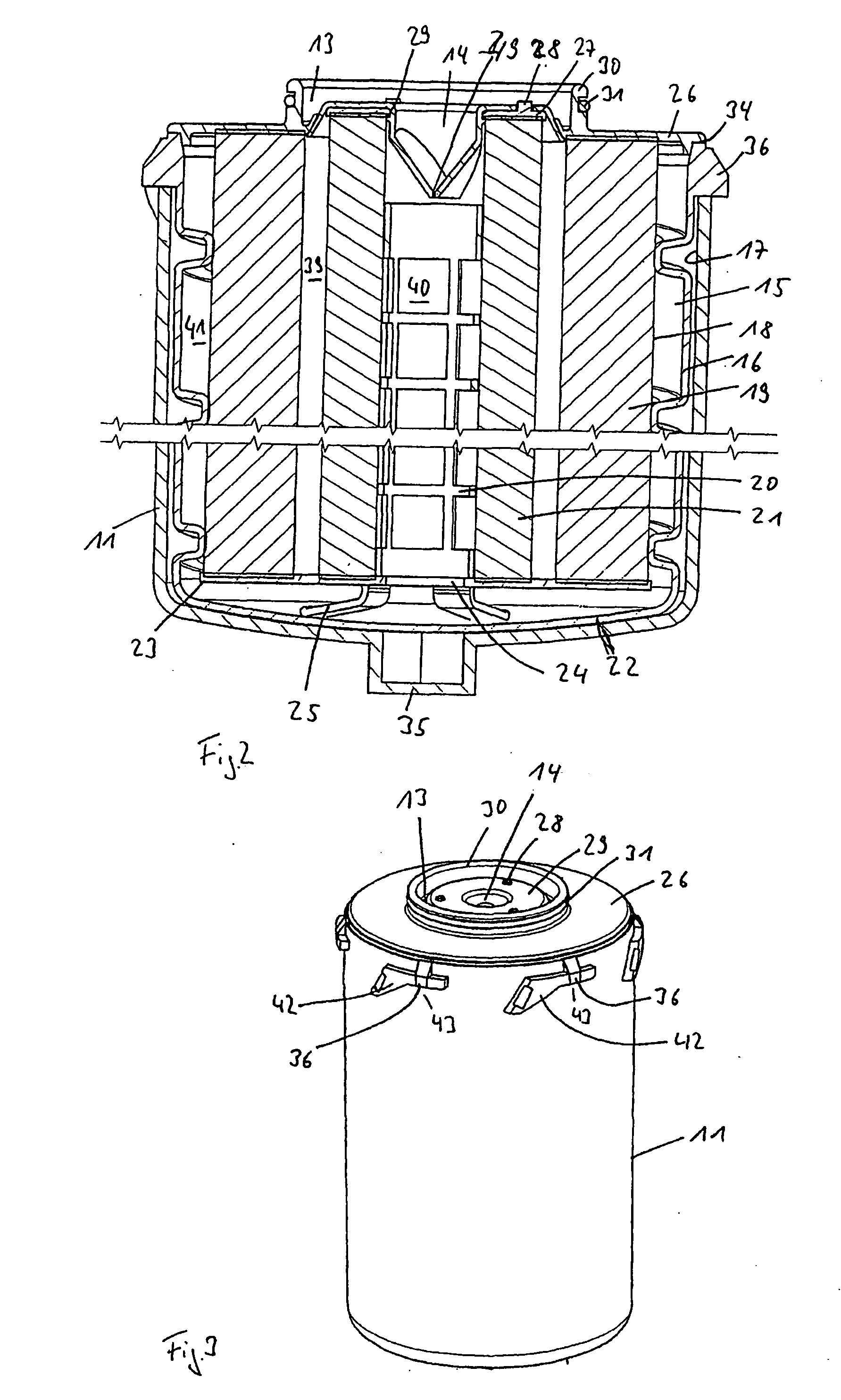

Filter system with canister filter element

InactiveUS20060219626A1Easy maintenancePrecise radialMembrane filtersLoose filtering material filtersFilter systemEngineering

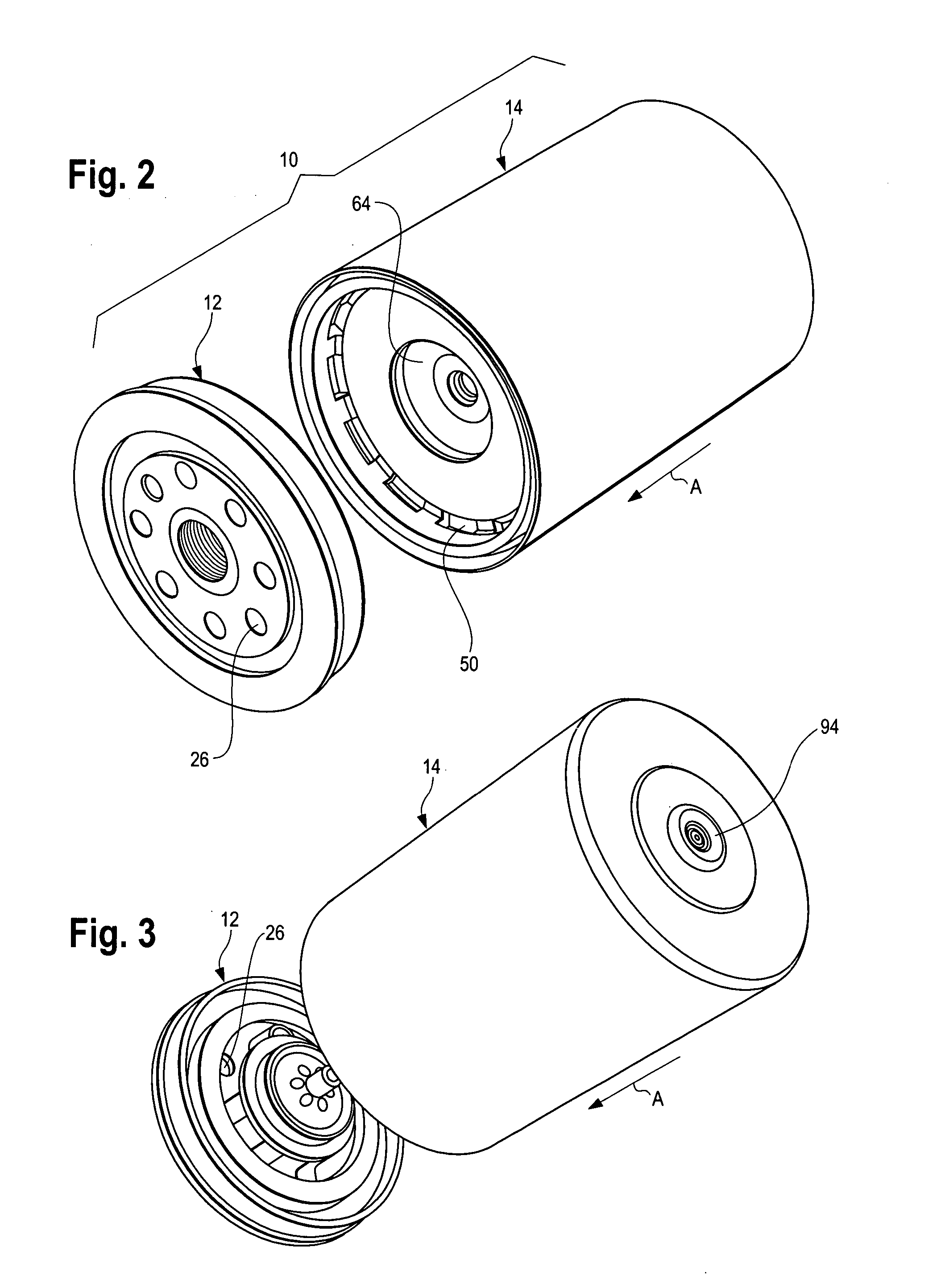

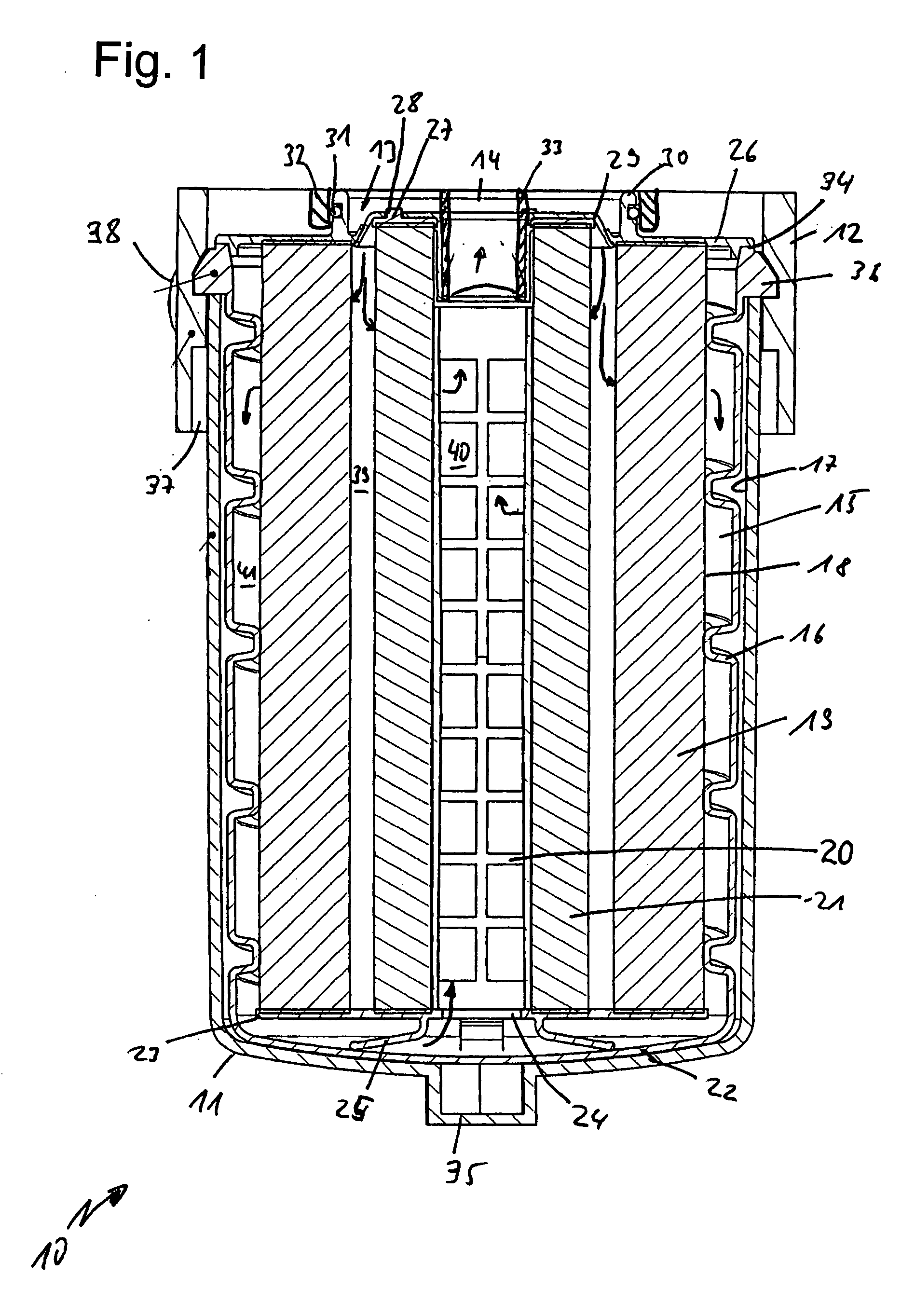

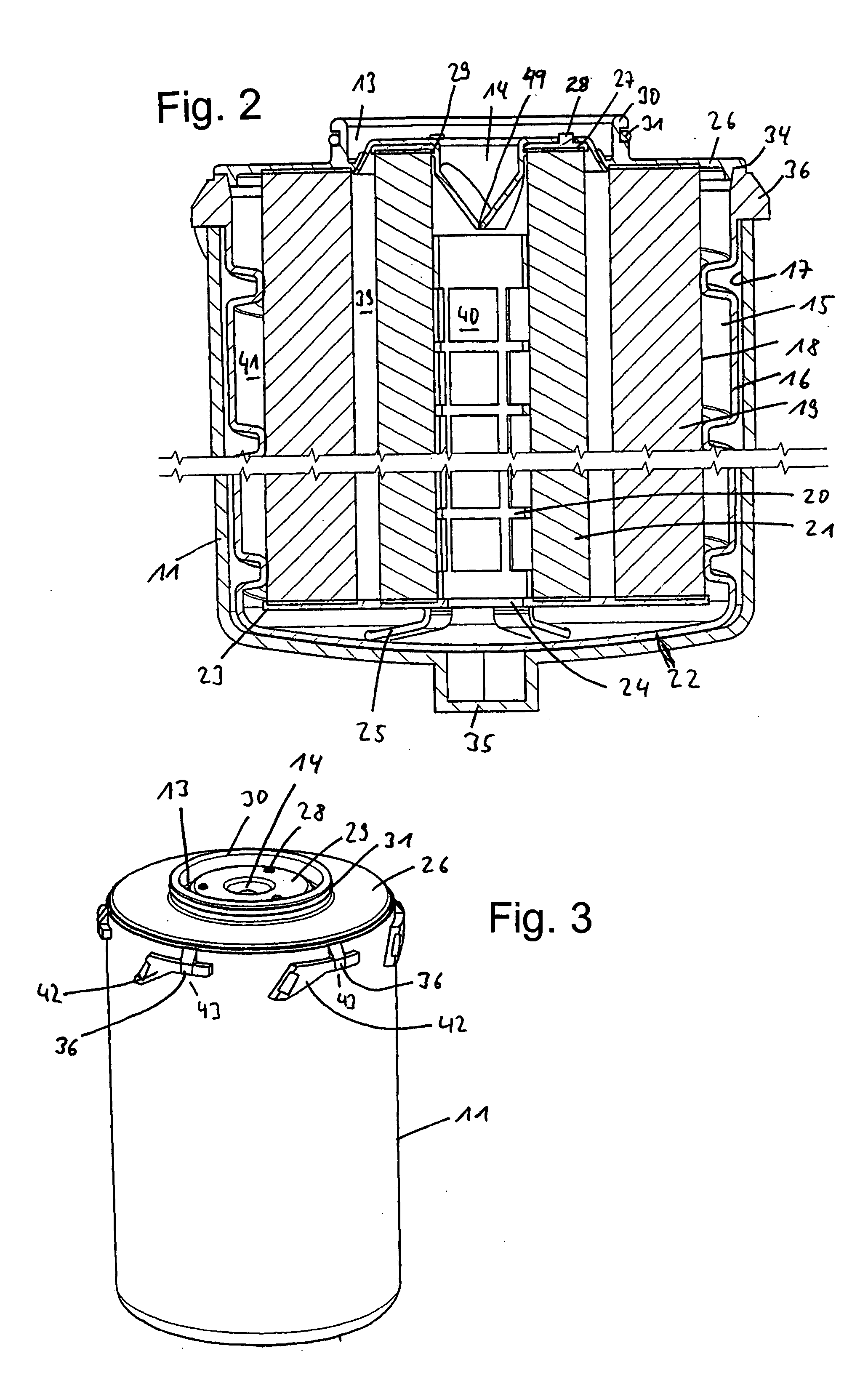

A filter system for a fluid, particularly a liquid filter, especially an oil filter for an internal combustion engine, having a receiving head, a cup-shaped housing releasably connectable to the receiving head, and a replaceable filter element disposed the cup-shaped housing, in which the filter element has a liquid-tight casing which is received in the interior of the cup-shaped housing.

Owner:MANN HUMMEL GMBH

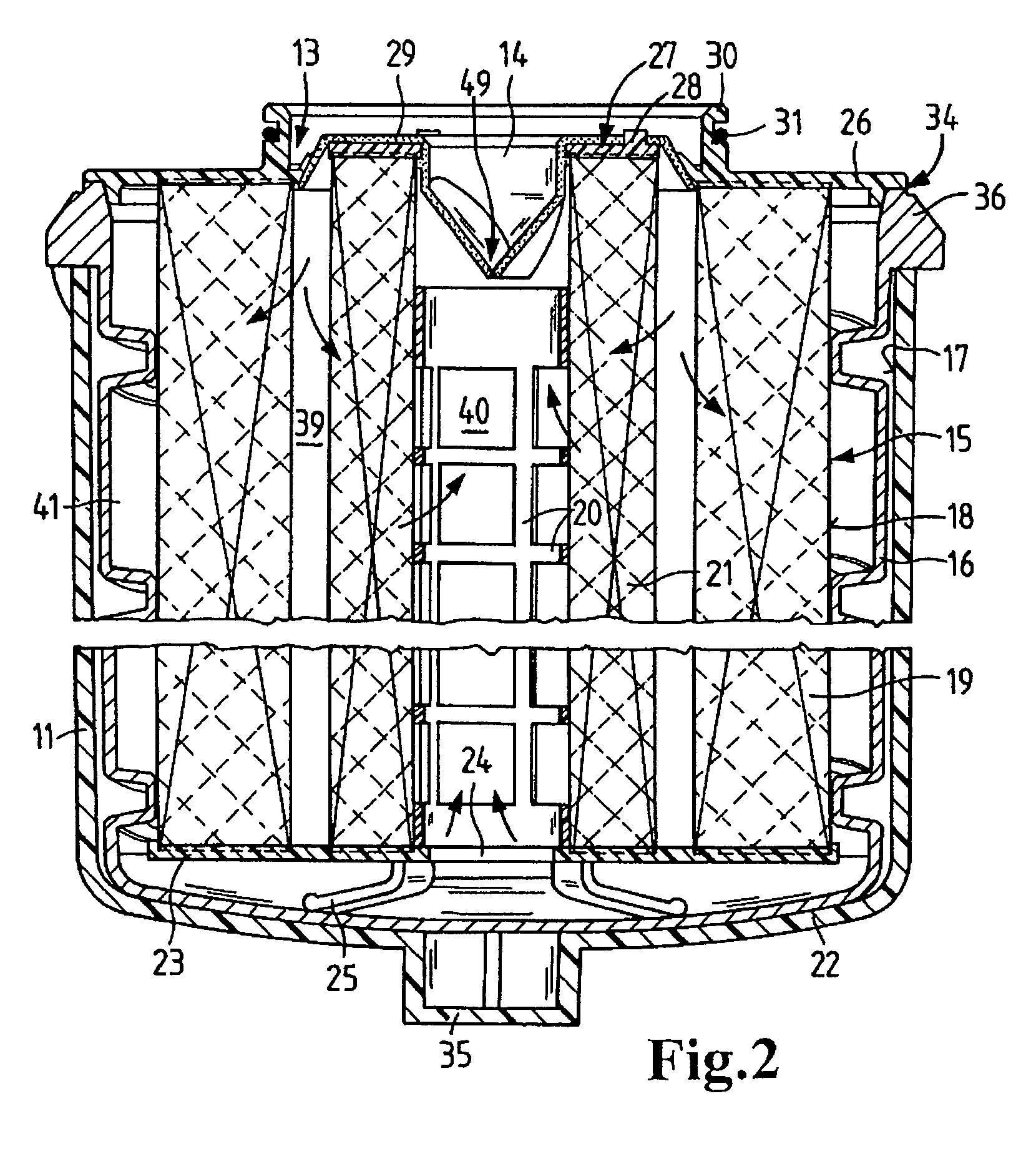

Liquid filter system

InactiveUS20060180539A1Easy to disassembleEasy to holdMembrane filtersCartridge filtersFilter systemEngineering

Owner:MANN HUMMEL GMBH

Cylinder head cooling structure for an internal combustion engine, including an oil temperature sensor and an oil temperature control system

ActiveUS20060065218A1Efficient use ofAvoid contactLiquid coolingCoolant flow controlTemperature controlCylinder head

A cylinder head cooling structure and an oil temperature control system are provided for an internal combustion engine having a plurality of cylinders, each having a plurality of intake ports and a plurality of exhaust ports. The engine includes cooling oil jackets surrounding the spark plugs in the cylinder head, a thermostat attached to the front surface of the crankcase independently of an oil filter, and an oil temperature sensor disposed on a rear face of the cylinder block above the crankcase in an oil supply path formed on the cylinder rear face for supplying oil to the oil jackets. Oil passages conducting oil into the oil jacket are provided between two separate parts of a bifucated intake port and between two separate parts of a bifurcated exhaust port, and only cooling system oil reaching high temperatures is allowed to flow through the thermostat, thereby improving temperature control response.

Owner:HONDA MOTOR CO LTD

Liquid filter

InactiveUS7744758B2Reduce Design ComplexitySimple structureSemi-permeable membranesSedimentation separationEngineeringInternal combustion engine

Owner:MANN HUMMEL GMBH

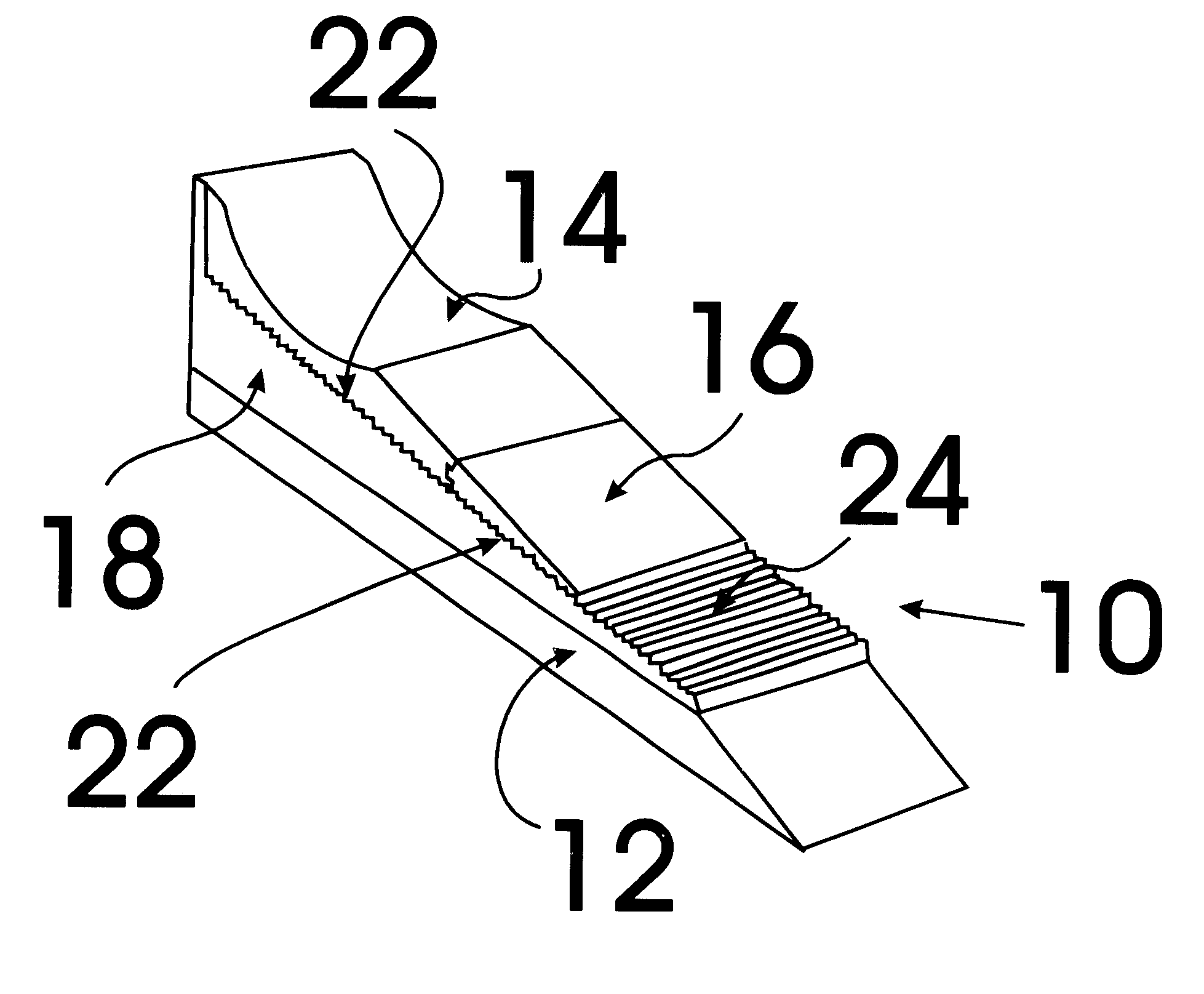

Vehicle tire saver system

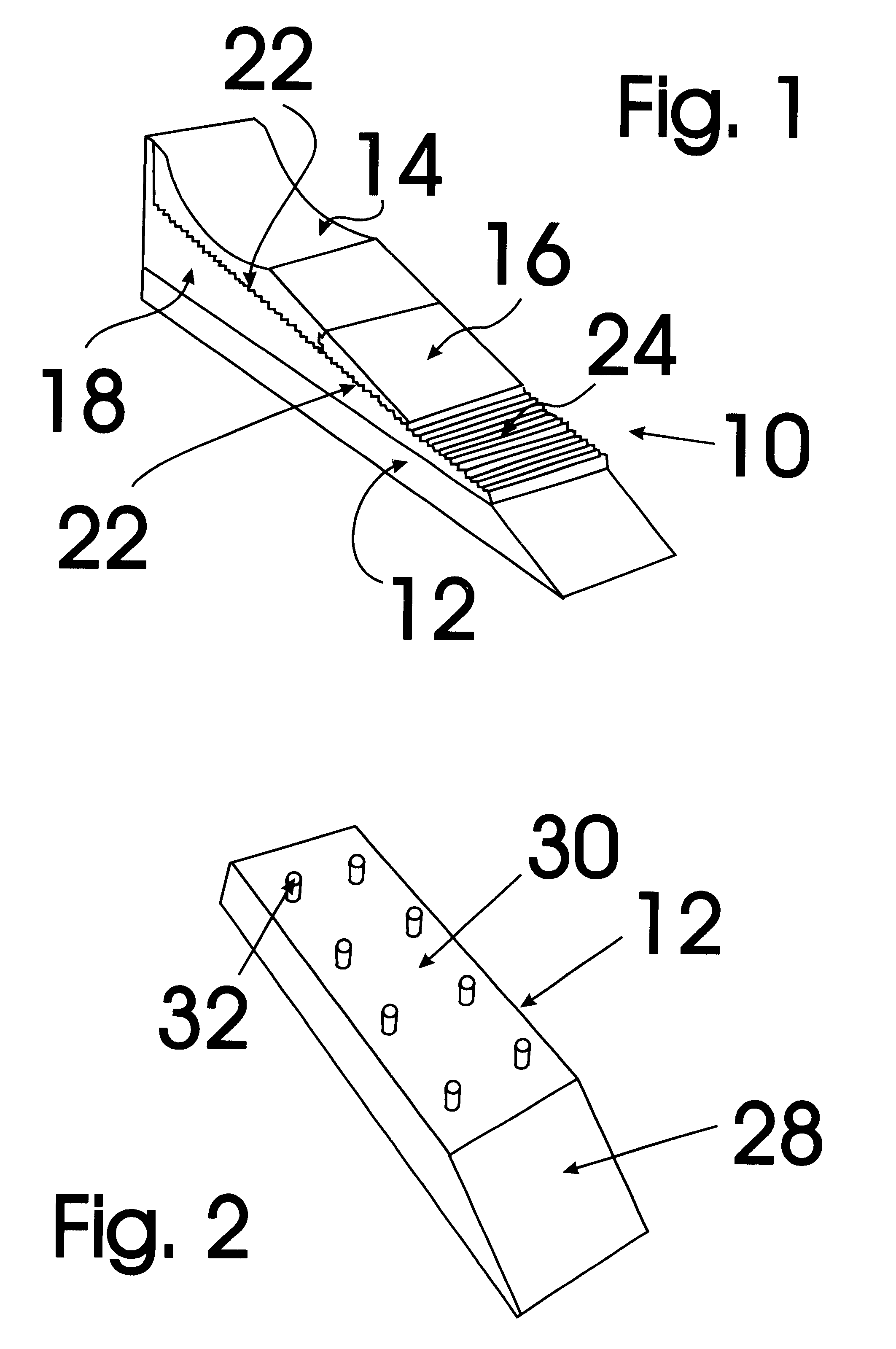

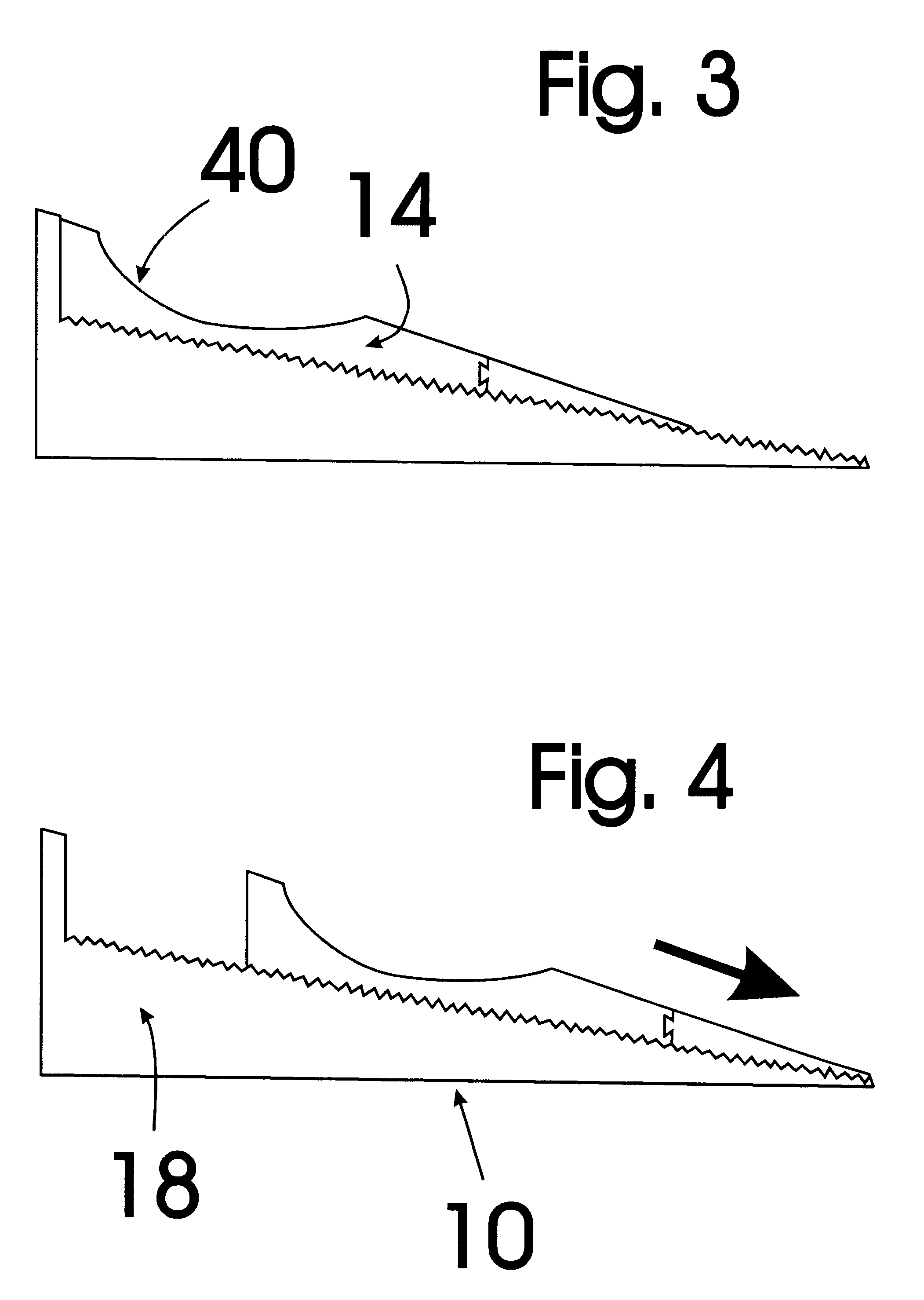

InactiveUS6517051B1Prevent dry rotEliminate and minimize detrimental effectInclined ship-liftingLifting framesEngineeringOil filter

A vehicle tire saving system or device which includes blocks having a contoured surfaced sized and shaped to receive a particular size tire and evenly support an arched section of the tire to prevent crushing of the side wall of the tires during extended period of storage thereby eliminating or minimizing the occurrence of dry rot to the tires. The device or system could also be used as a jacking mechanism for tandem tire assemblies and as a stand system for elevating a portion of a vehicle while performing work such as changing the oil filter or the like.

Owner:CAVANAUGH MICHAEL A

High-temperature resistant fiber filter paper for engine oil filter and preparation method of high-temperature resistant fiber filter paper

ActiveCN102912680AImprove high temperature resistanceImprove toughnessNon-macromolecular organic additionPaper/cardboardBursting strengthFiber

The invention discloses high-temperature resistant fiber filter paper for an engine oil filter and a preparation method of the high-temperature resistant fiber filter paper. The high-temperature resistant fiber filter paper comprises, by weight, 60-70 parts of coniferous wood pulp, 20-30 parts of cotton pulp, 20-30 parts of modified polyimide fiber, 2-5 parts of kaoline, 1-3 parts of lithopone, 2-4 parts of silica gel, 1-2 parts of nanometer titania, 0.5-0.8 part of ammonium polyphosphate, 1-2 parts of modified acrylic emulsion, 2-4 parts of acetic styrene-acrylic emulsion, 0.5-1 part of stearic acid monoglyceride, 0.5-1 part of silane coupling agent KH590, 0.4-0.8 part of sodium lauryl sulfate, and 2-5 parts of urea resin. The high-temperature resistant fiber filter paper prepared is good in water permeability, large in filtering area, small in maximum hole diameter, high in filtering precision, strong in bursting strength, high in temperature resistance and the like, has stable performance index under normal-temperature and high-temperature working conditions and is provided with good temperature resistance and filtering effects, and filtering efficiency of the high-temperature resistant fiber filter paper can reach 99.97%.

Owner:ANHUI PHOENIX INT CO LTD

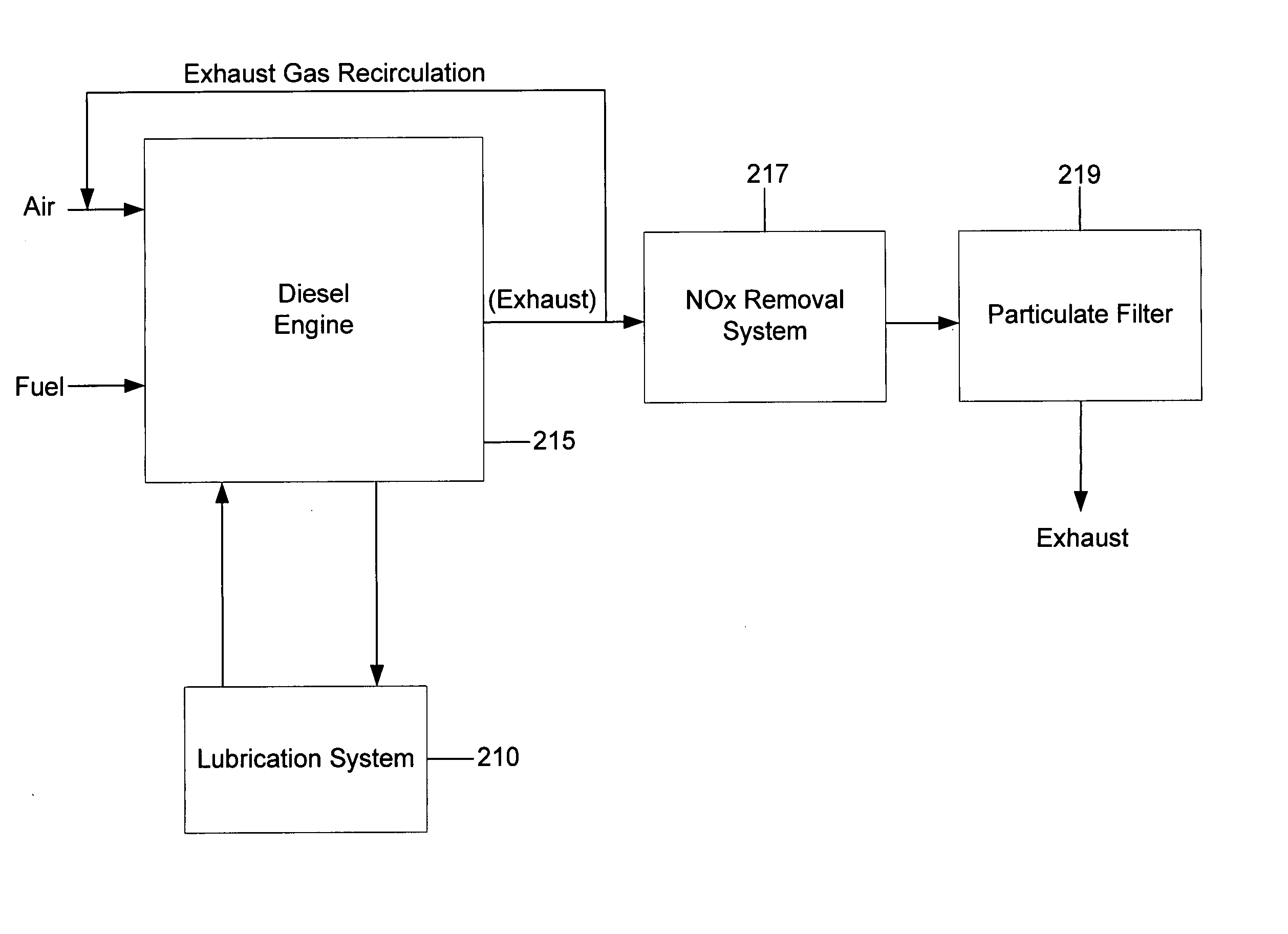

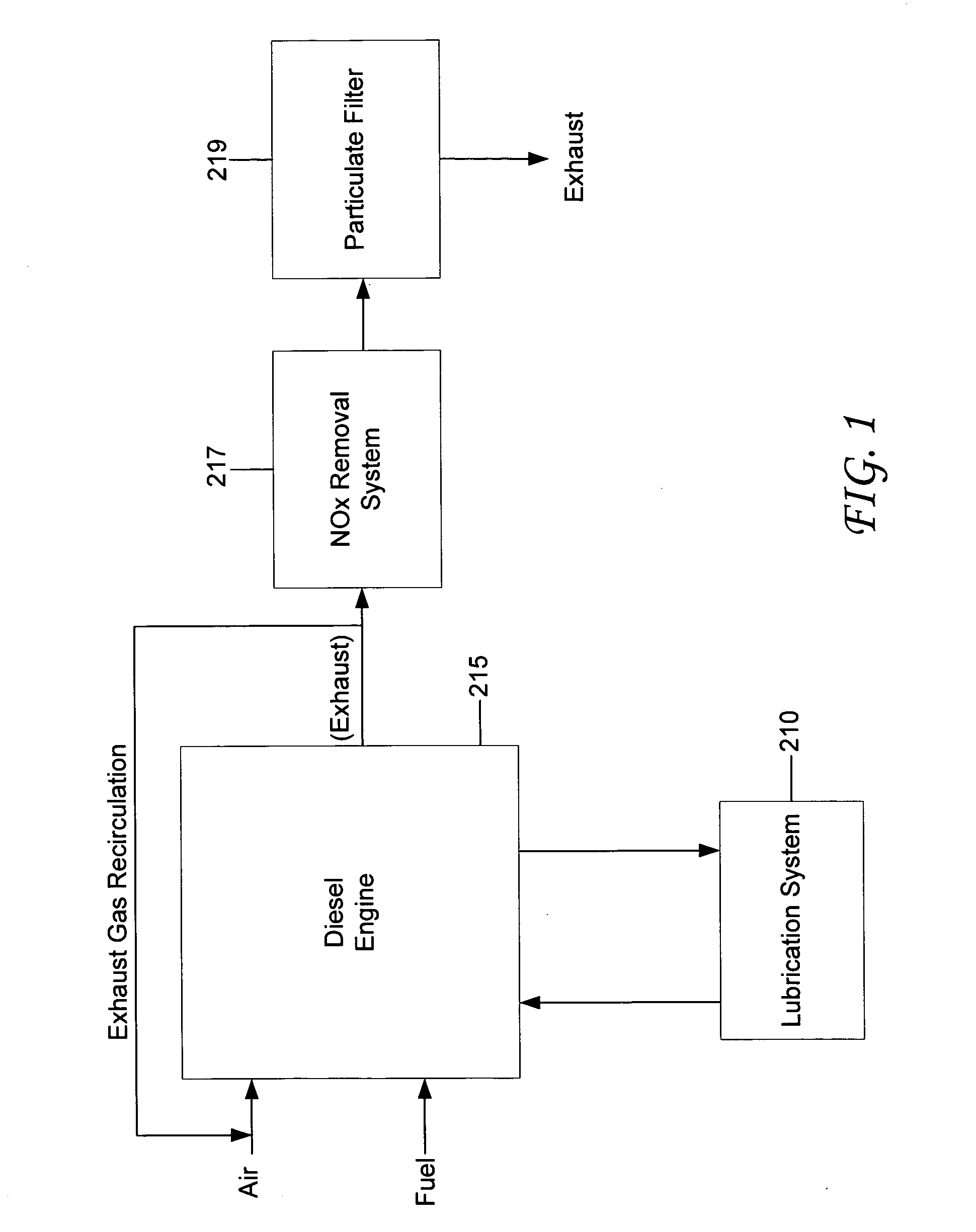

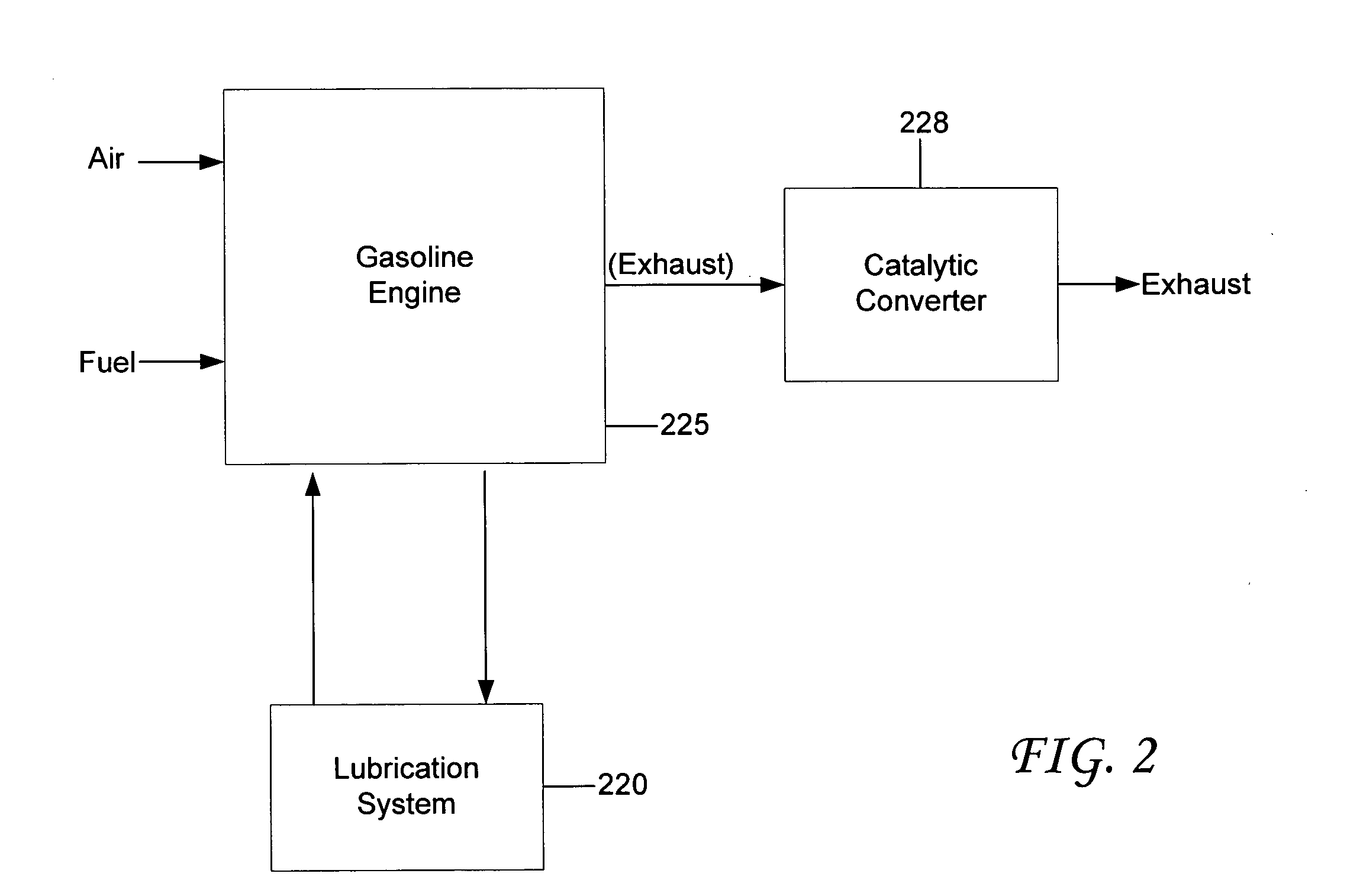

Materials and processes for reducing combustion by-products in a lubrication system for an internal combustion engine

InactiveUS20060260874A1Minimizes engine depositEfficient emissionsMachines/enginesLubricant mounting/connectionSolubilityExternal combustion engine

A lubrication system having an oil filter modified to replace or supplement the performance of lubricant additives that may be used within an internal combustion engine to increase the performance of a lubricant. The formulation of the lubricant is changed in accordance with the chemicals placed in the oil filter. For example, when the oil filter contains a strong base, the lubricant concentration of detergent will decrease, in some cases to zero, while the dispersant concentration in the lubricant will increase. The dispersant is the ideal weak base to neutralize combustion acid at the piston ring zone, carry the resultant weak base-combustion acid complex to the strong base in the oil filter, undergo ion exchange with the strong base, immobilize the acid in the oil filter and recycle back to the piston ring zone for reuse as an acid neutralization agent. The reduction or elimination of detergent from the lubricant will reduce the fouling of the emission filter and of deposit formation on engine parts such as the piston. The oil filter may also contain an additive which is slowly released into the lubricant. For example, a ZnDDP anti-wear additive may be slowly released from the oil filter to the lubricant. Because the ZnDDP has low molecular weight alkyl groups it has limited solubility in the lubricant. The rate of release is limited by the equilibrium concentration of the additive in the lubricant. As a result, a relatively constant concentration of the additive may be maintained in the lubricant. The resultant closed system allows the oil drain intervals to be significantly extended.

Owner:LUTEK

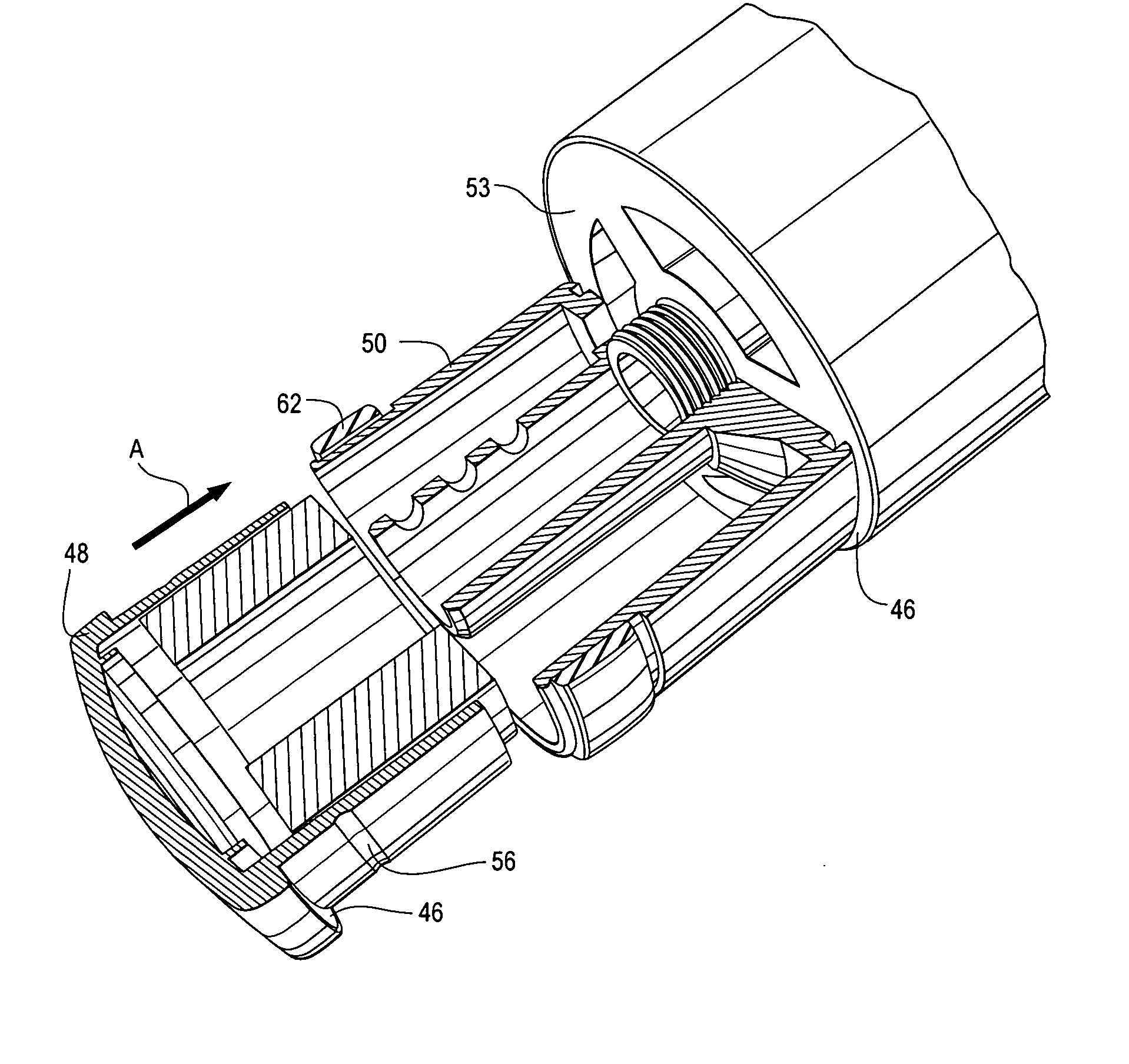

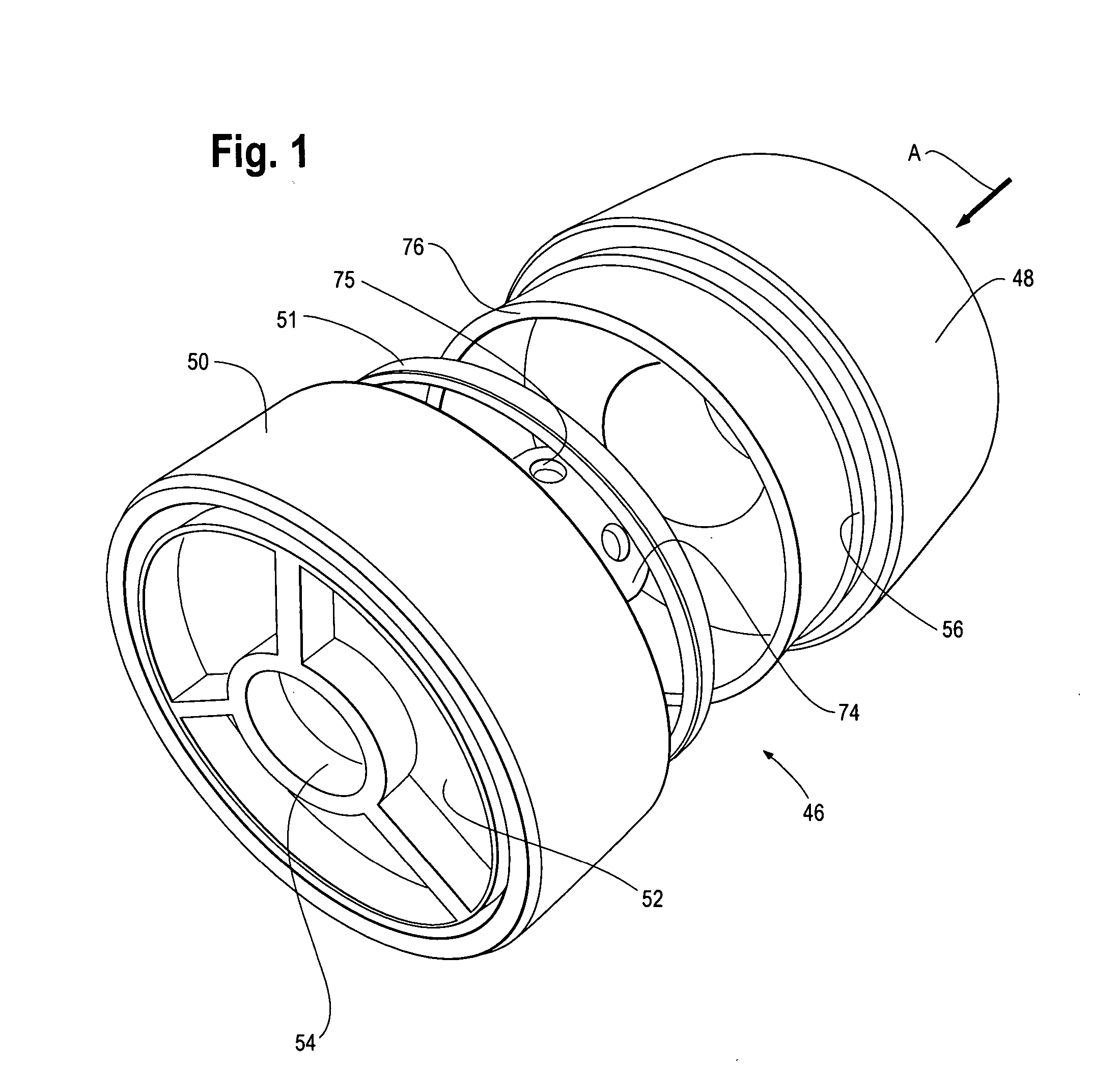

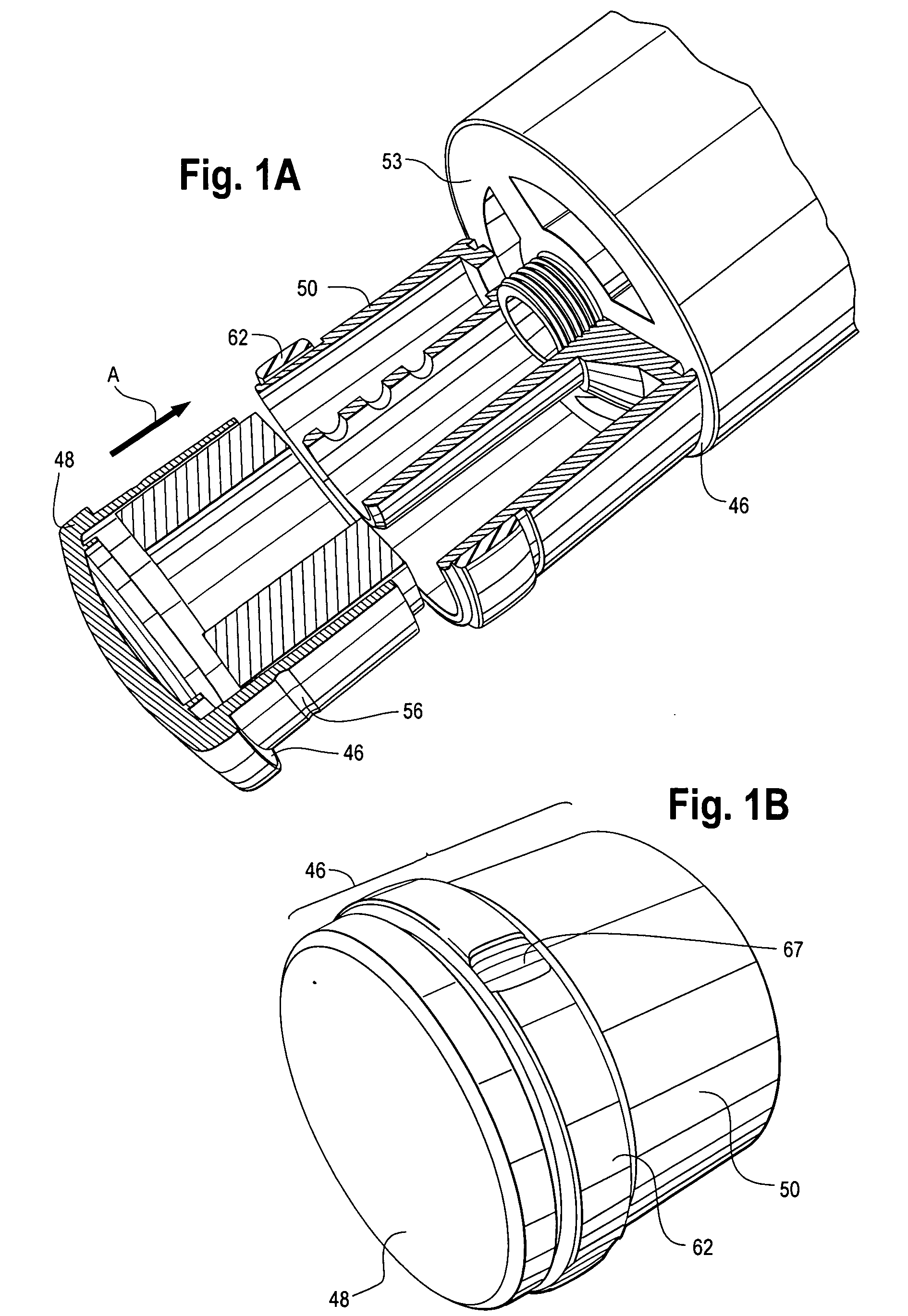

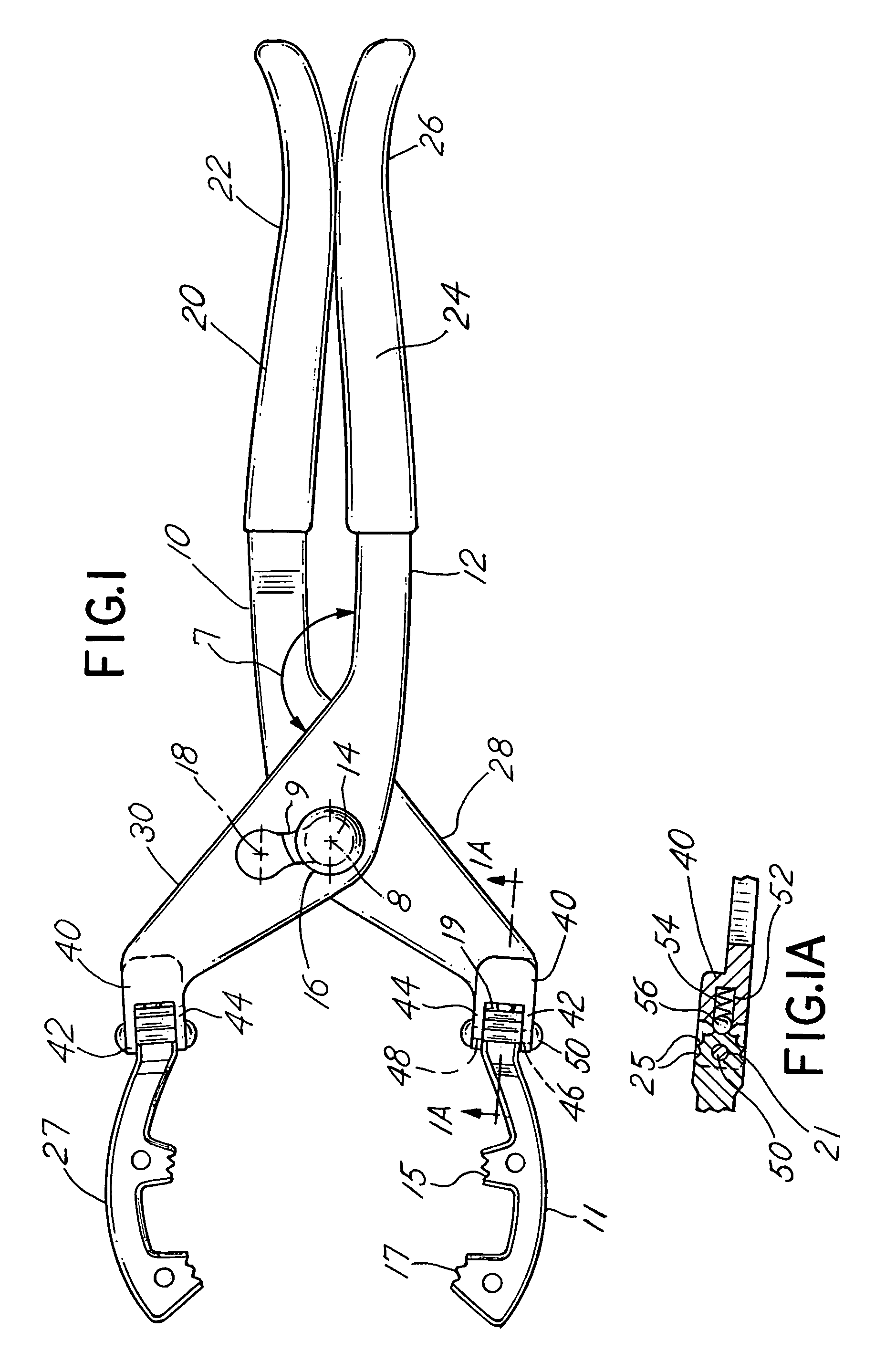

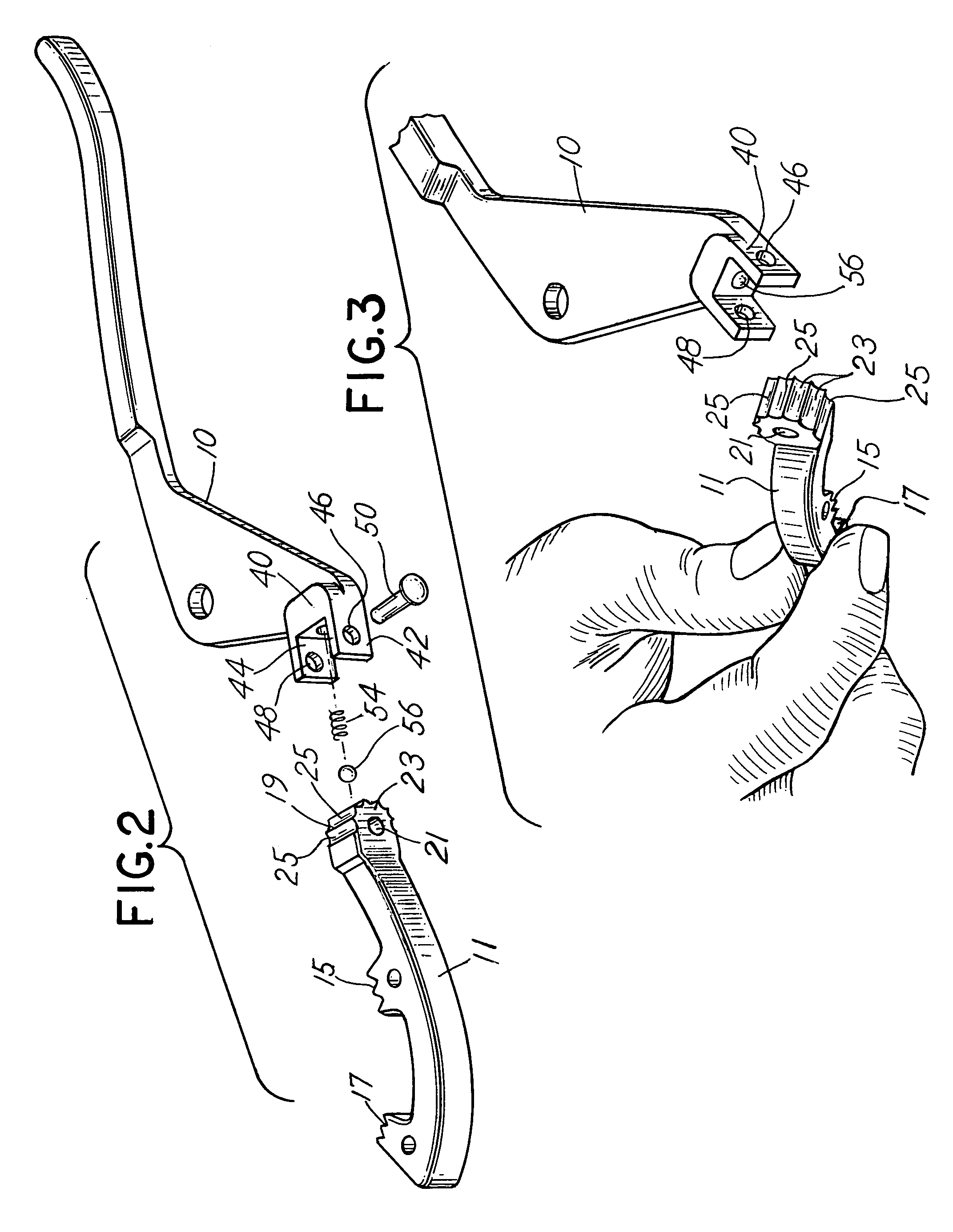

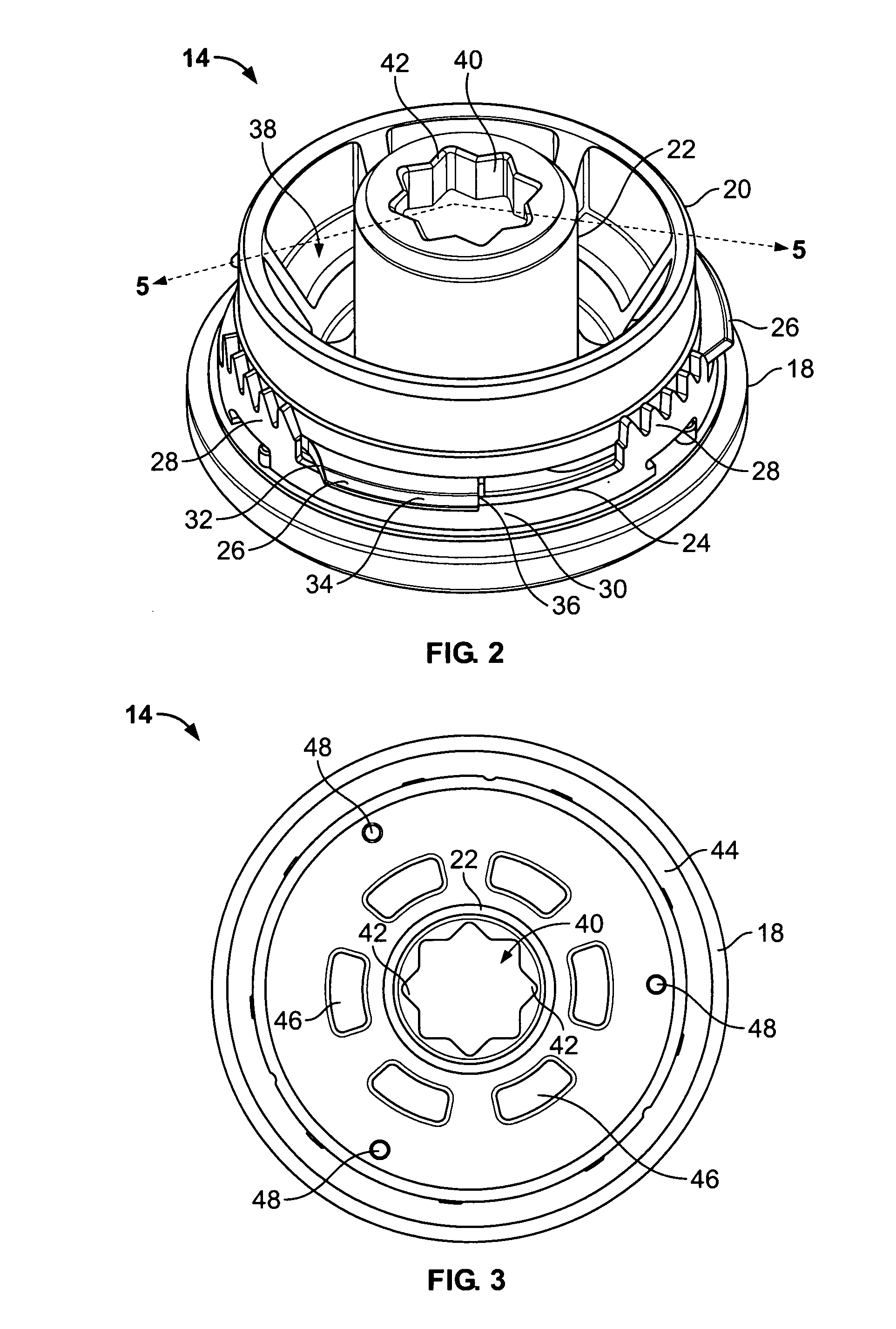

Oli filter assembly

InactiveUS20060151371A1Prevent leakageConnection securityMembrane filtersFiltration separationEngineeringMechanical engineering

Embodiments of the present invention provide an oil filter system that is quick and easy to connect and disconnect from an engine. In general, embodiments of the present invention provide a system and method of quickly and efficiently changing an oil filter without using a tool.

Owner:WEINBERGER KEITH R +5

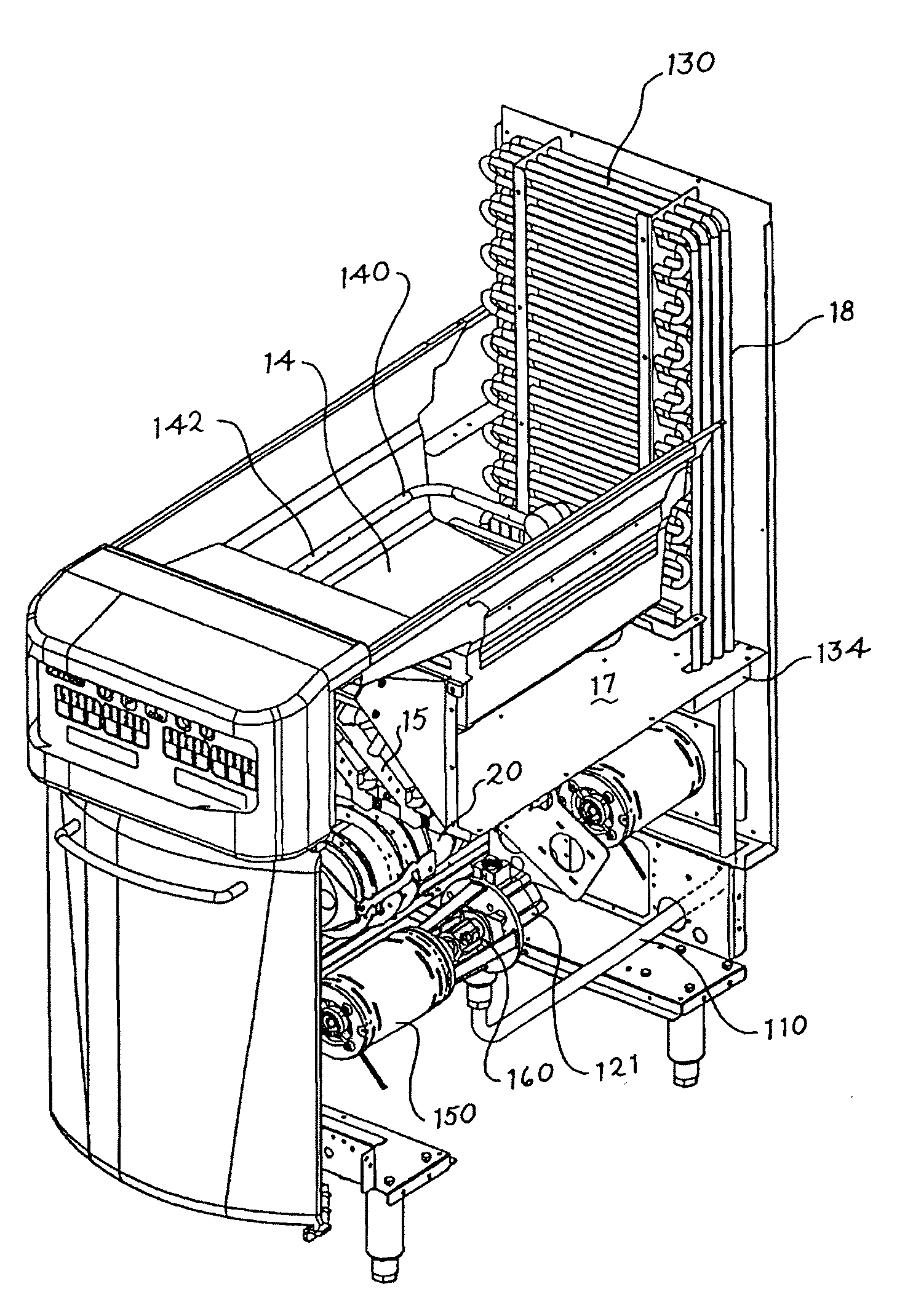

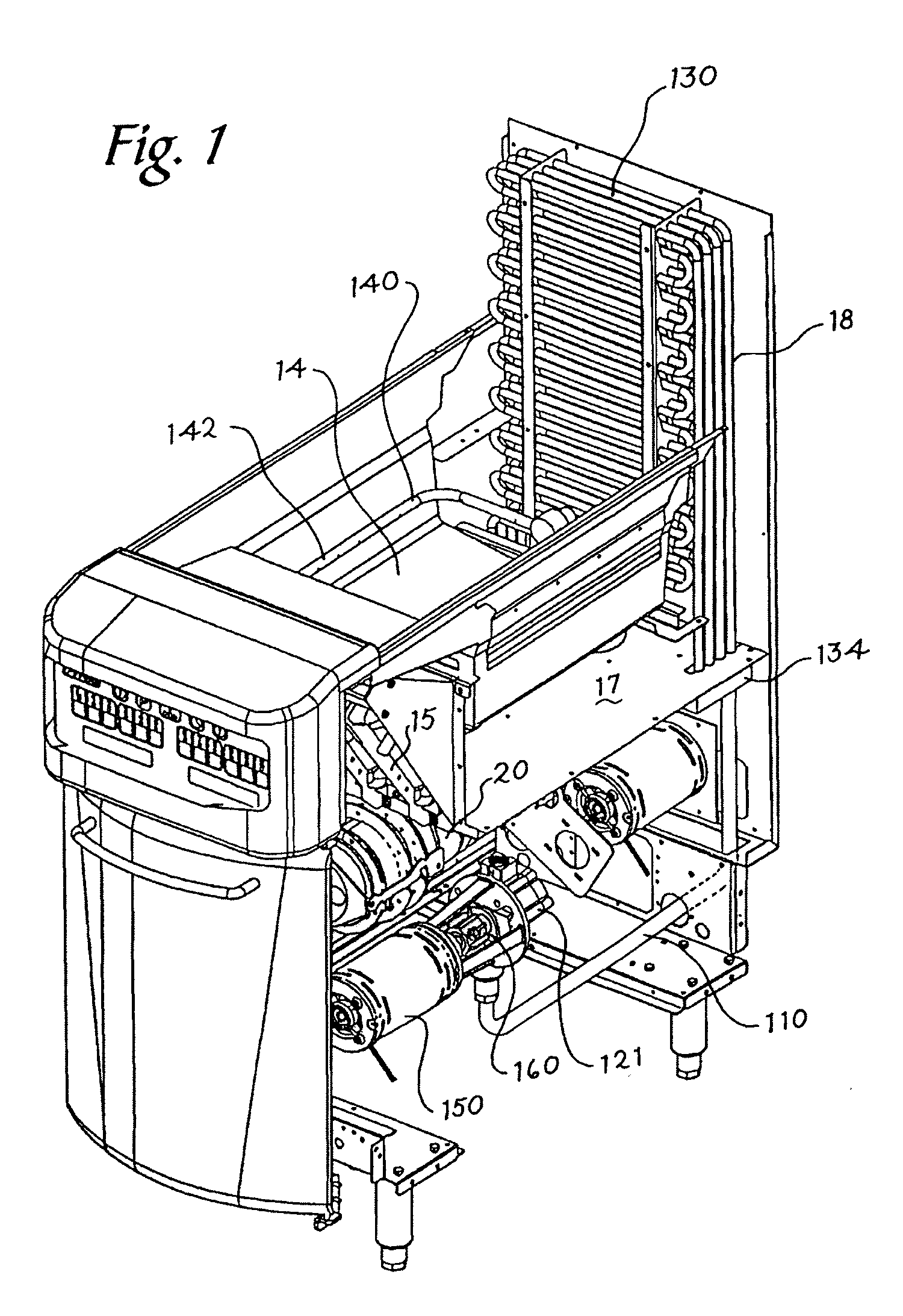

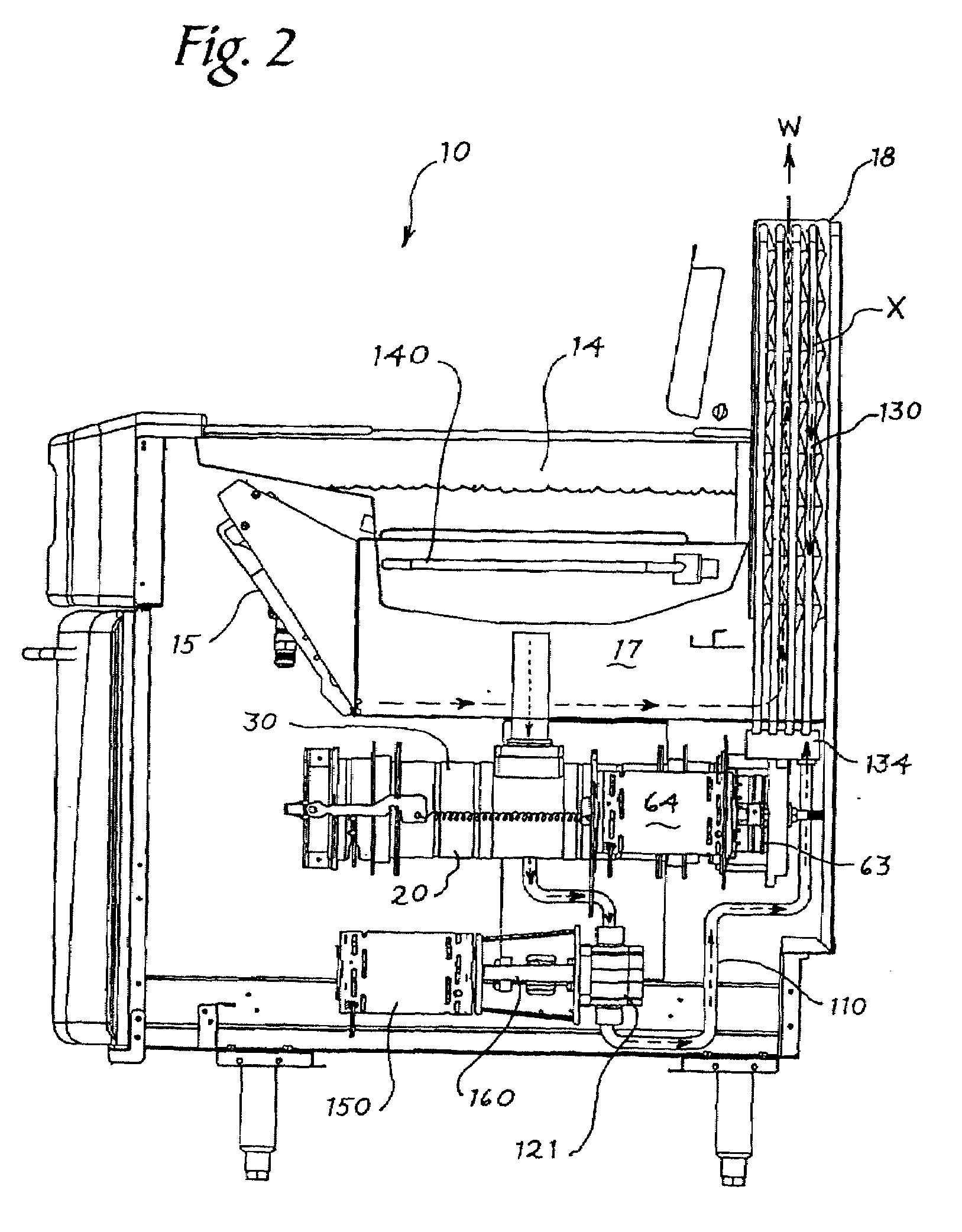

Continuously operating filtering apparatus

A deep fat fryer with continuous oil filtering and purging of sediments therefrom during uninterrupted fryer operation is provided. The filter includes a cylindrical hollow housing with a first end and a second end and a hollow cylindrical screen with a longitudinal axis and first and second ends. The screen is disposed coaxially within the hollow housing to define an annulus therebetween. A piston mounted within the screen and reciprocatingly movable along the longitudinal axis between the first and second ends of the screen. A pump, seal, and associate motor are provided to provide continuous oil flow through the filter and the remainder of the fryer. A heat exchanger is provided downstream of the pump to transfer heat from the fryer to the oil flowing through the heat exchanger.

Owner:PITCO FRIALATOR LLC

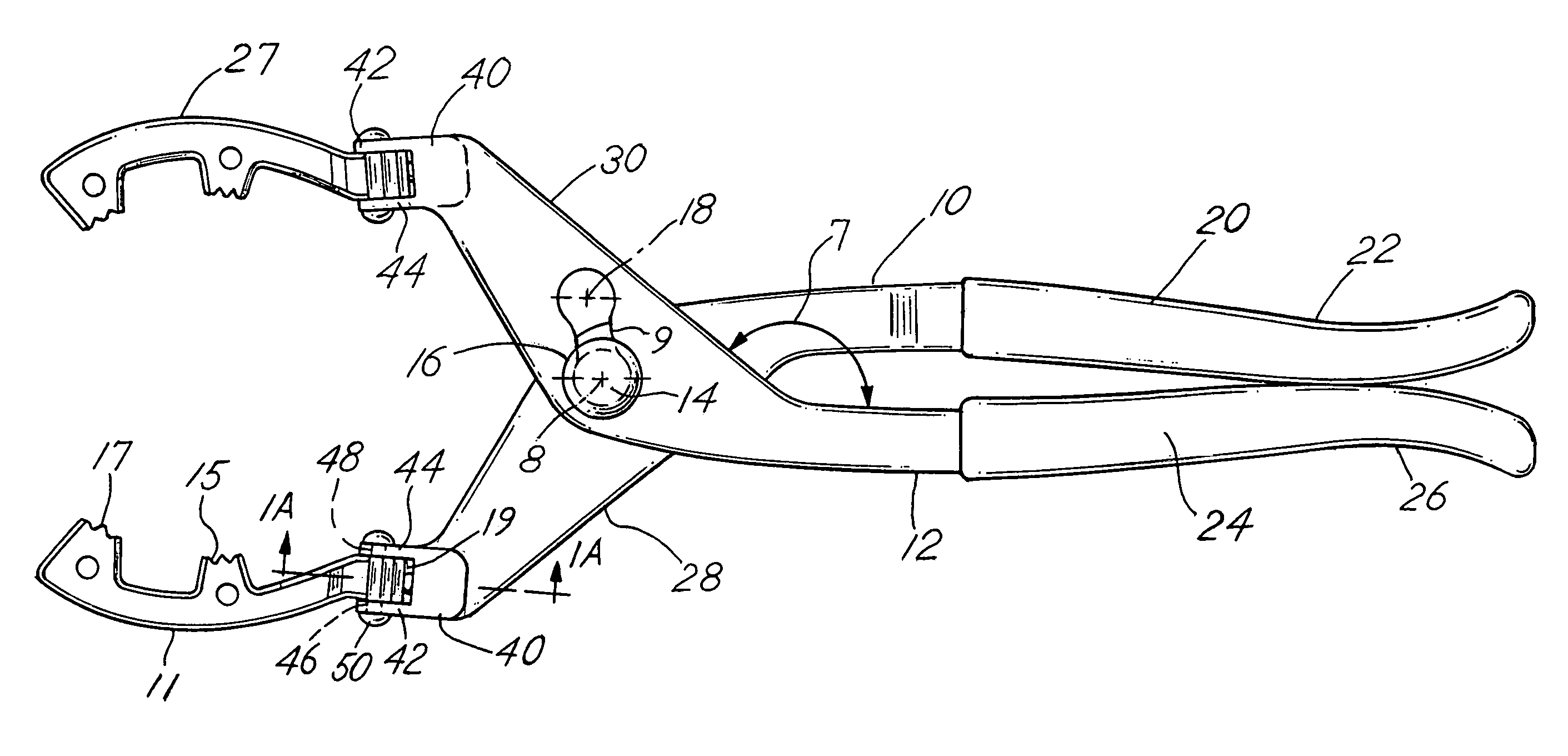

Adjustable wrench for removal of vehicle oil filters

An adjustable wrench for gripping and rotation of a generally cylindrical canister, such as an oil filter canister, includes handles which are pivotally connected to each other for rotation about a first axis. Each handle is also connected by an articulatable joint to a gripping jaw that may be positioned about the canister or body, to thereby alter the angle of the handles with respect to the jaws in order to enable use of the tool in confined spaces.

Owner:LISLE CORPORATION

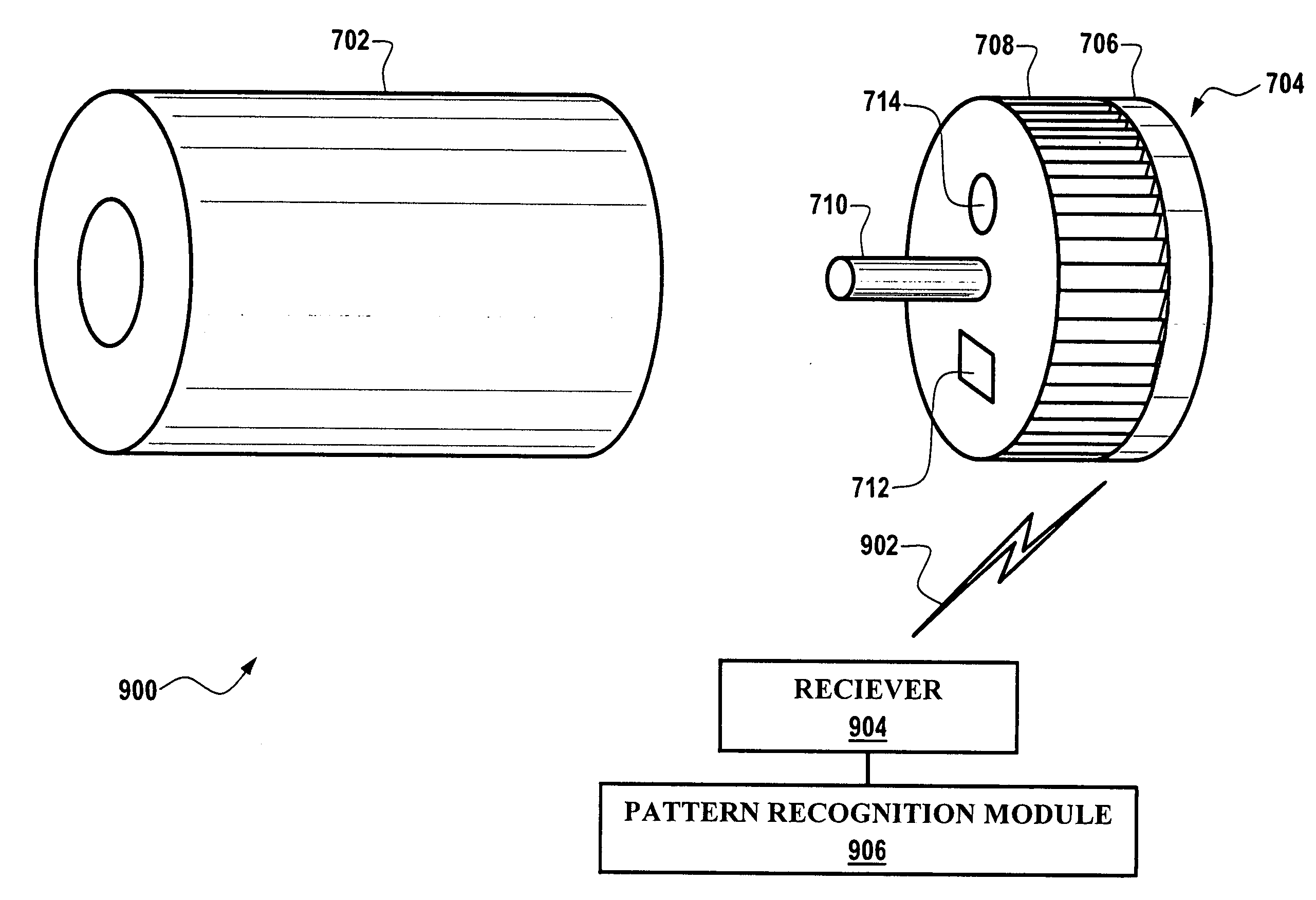

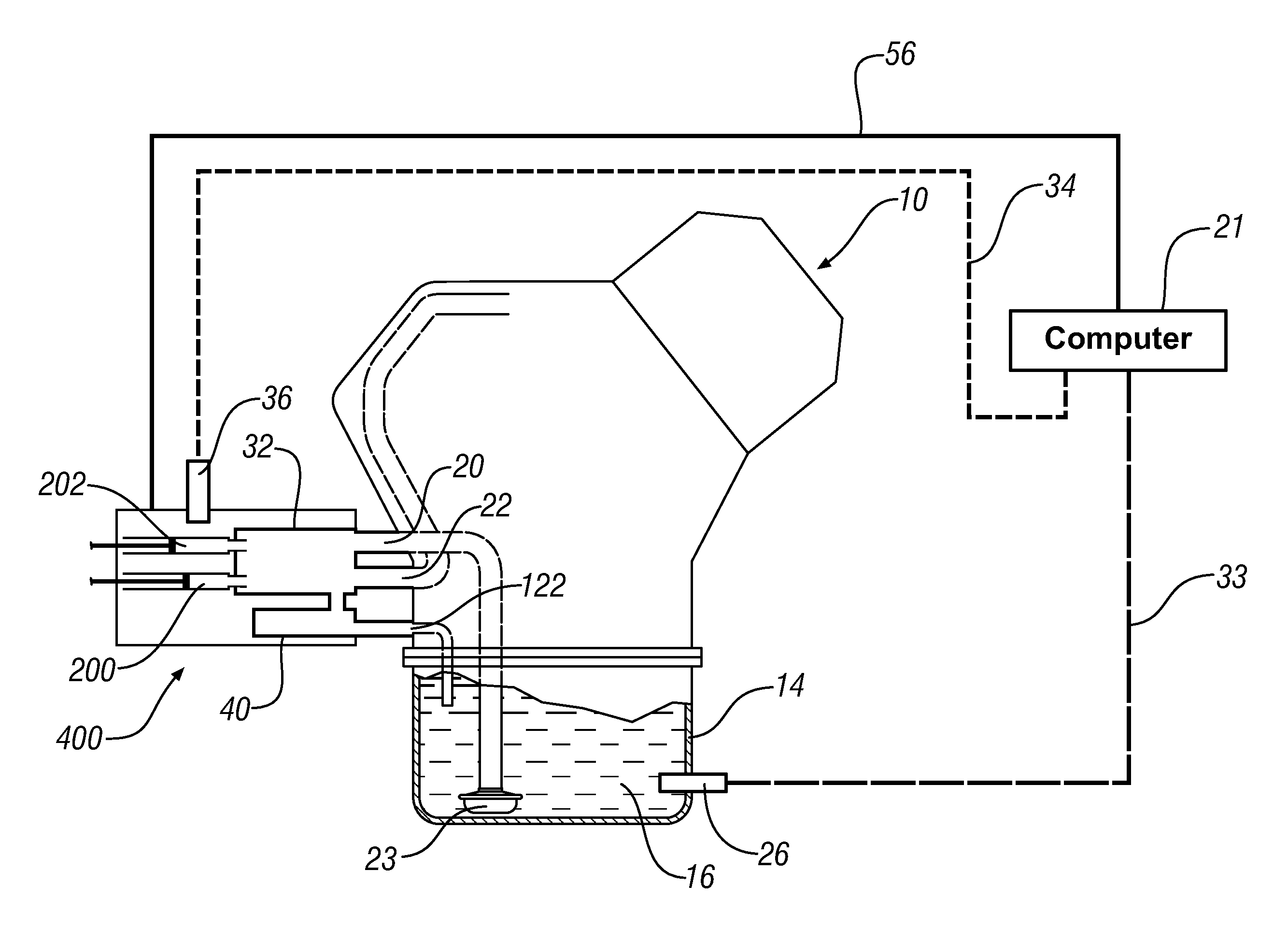

Wireless oil filter sensor

InactiveUS20060230833A1Subsonic/sonic/ultrasonic wave measurementFlow propertiesWireless transmissionEngineering

A wireless oil filter sensing system includes an oil filter and a sensing mechanism that is connectable to the oil filter. The sensing mechanism includes one or more acoustic wave sensing elements and at least one antenna that communicate with the acoustic wave sensing element(s). An external interrogation system could excite the acoustic wave sensing element(s) wireless and passively. When the acoustic wave sensing elements are in contact with oil contained in the oil filter, the acoustic wave sensing elements detect acoustic waves associated with the oil in response to an excitation of the acoustic wave sensing elements, thereby generating data indicative of the quality of the oil for wireless transmission through the antenna(s).

Owner:HONEYWELL INT INC

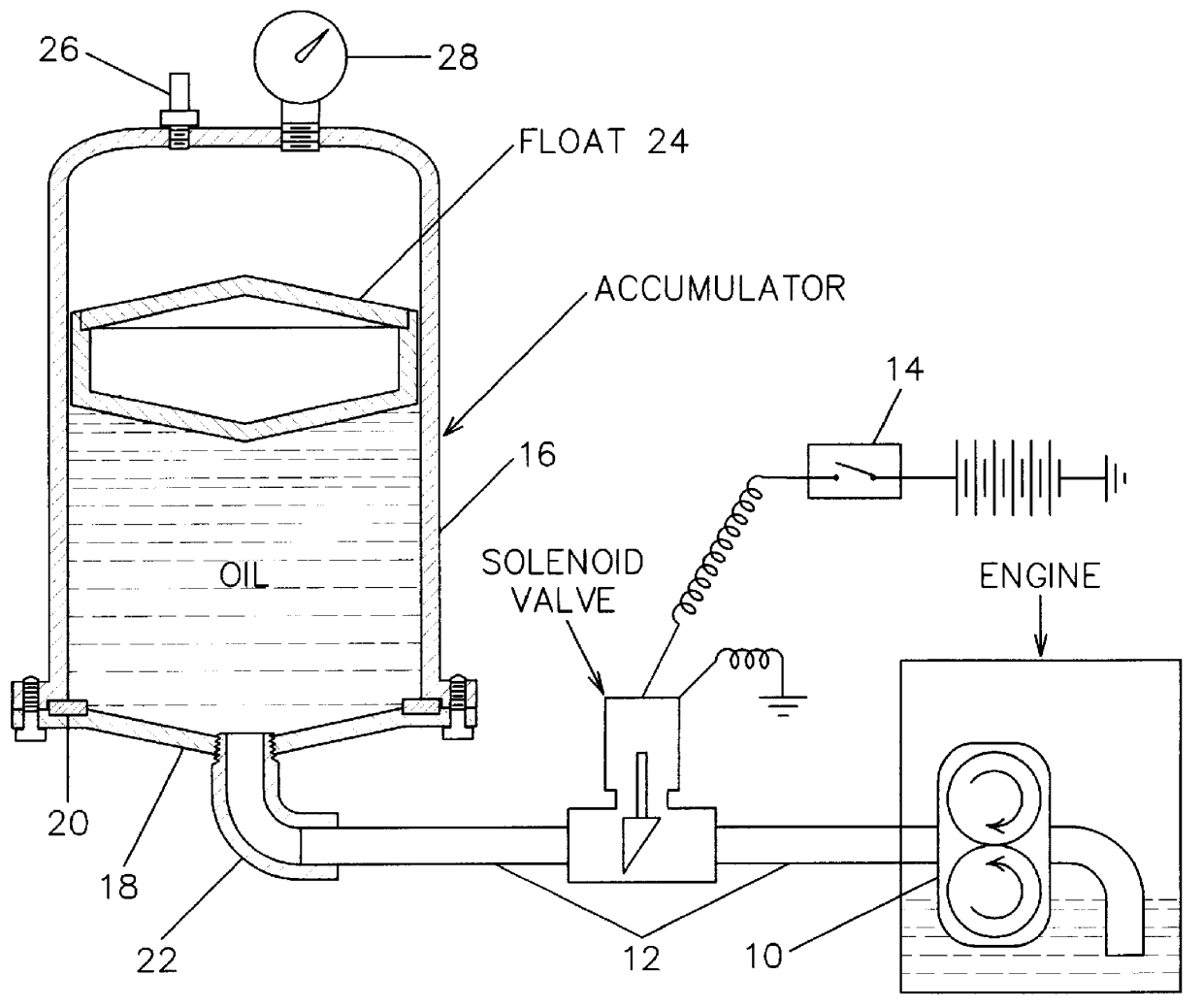

Engine-pressurized prestart oiler

InactiveUS6148789AEasy to modifyMinimal modificationLubrication of auxillariesLubricant conduit arrangementsAutomatic controlSolenoid valve

An engine-pressurized prestart oiler for an engine having pressure lubrication is provided, which rapidly lubricates critical engine bearing surfaces prior to the starting sequence. An accumulator for storing oil and pressurized air contains an air-oil separation float, which essentially fills the internal cross-sectional area and prevents absorption of the air. Discharge and recharge of the accumulator is preferably implemented by a normally closed solenoid valve. Discharge is controlled either manually by a switch or automatically by circuitry containing ignition-off time and accumulator pressure comparators, a starter interrupter, and a prestart oiling timer. Recharge is automatic, as the solenoid valve allows oil flow whenever the engine oil pressure sufficiently exceeds the accumulator pressure. A conduit connects the accumulator, solenoid valve, and engine, connecting to the engine either at the oil pressure sensor port or through an adaptor installed between the oil filter and the oil filter mount.

Owner:JOHNS RALPH HOWARD

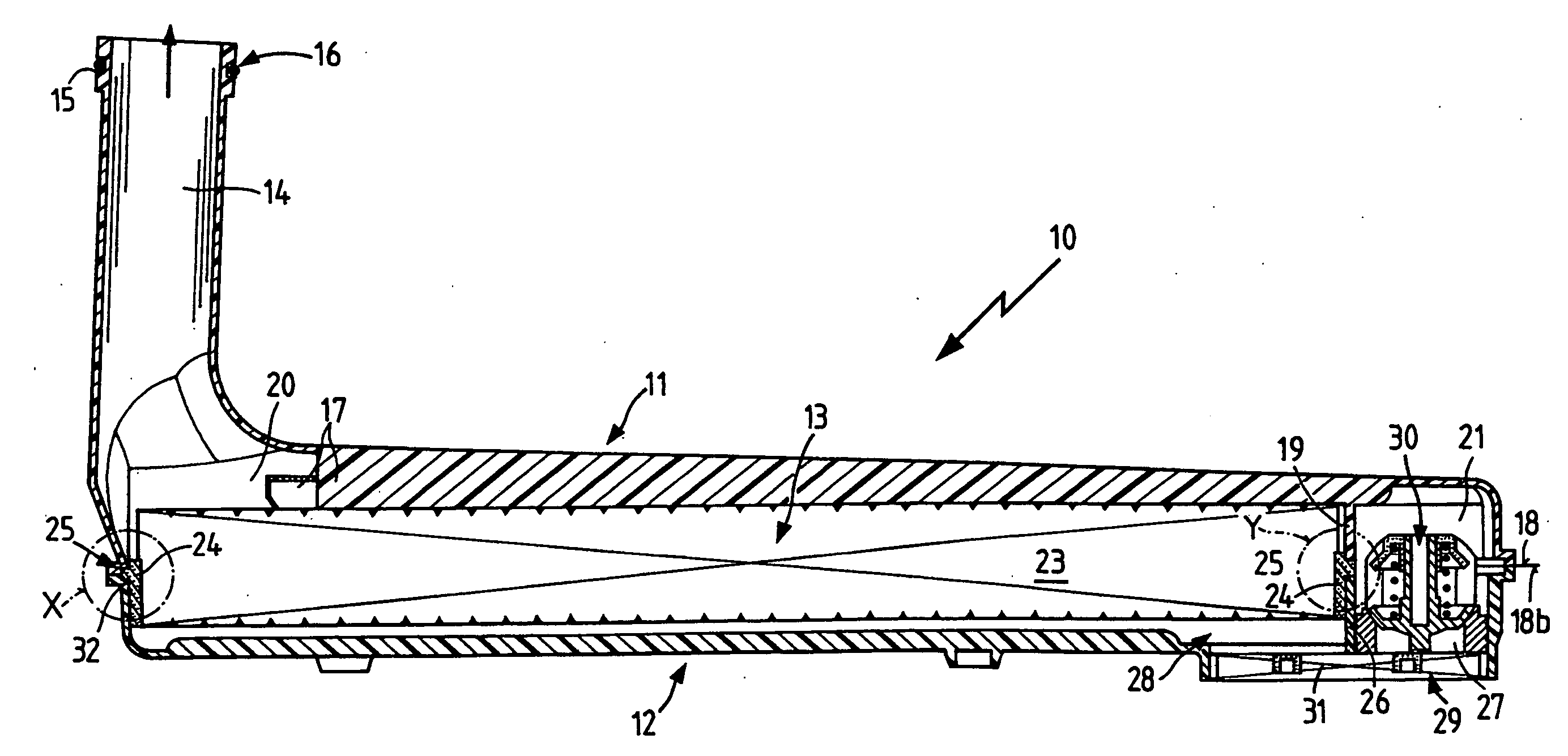

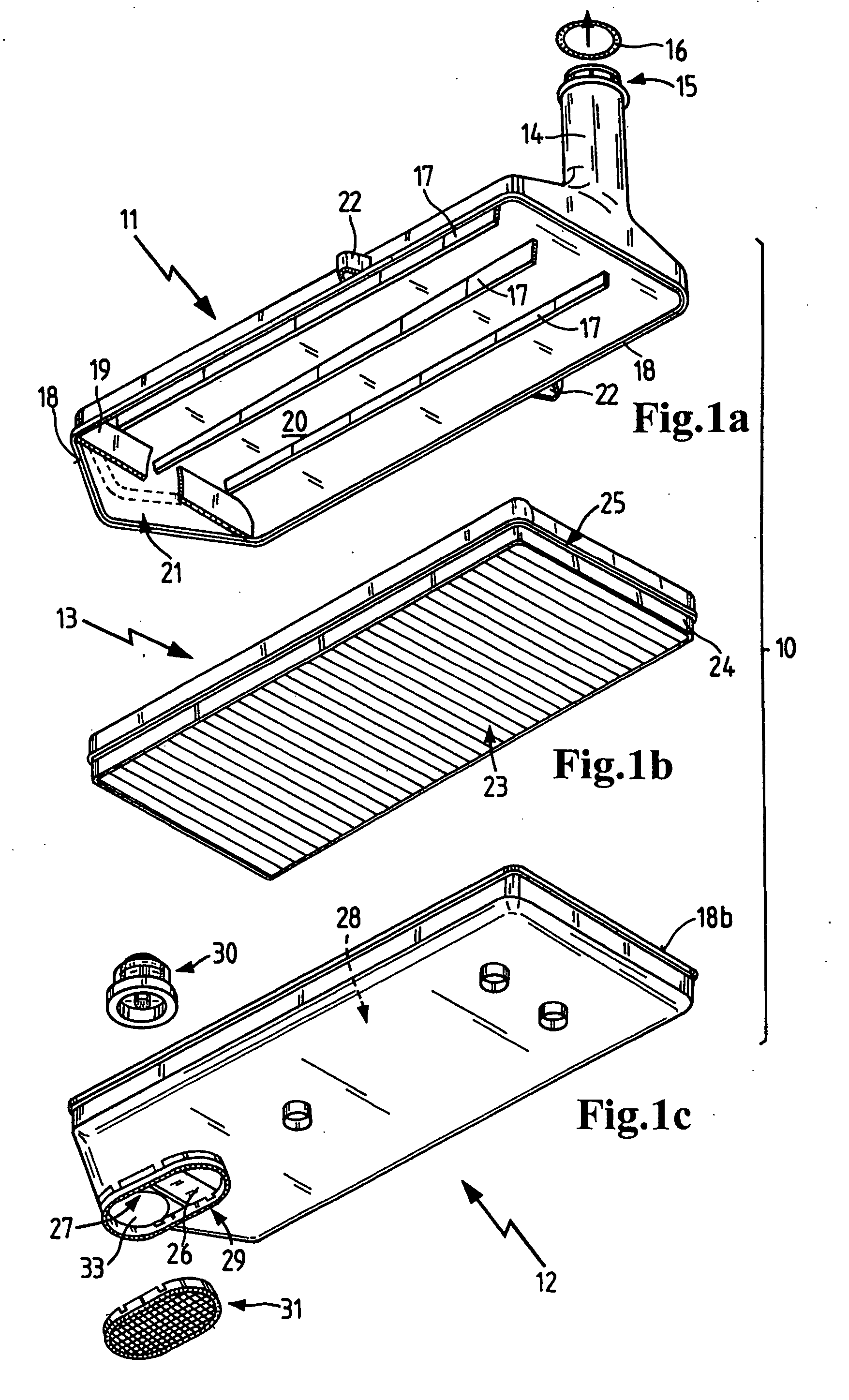

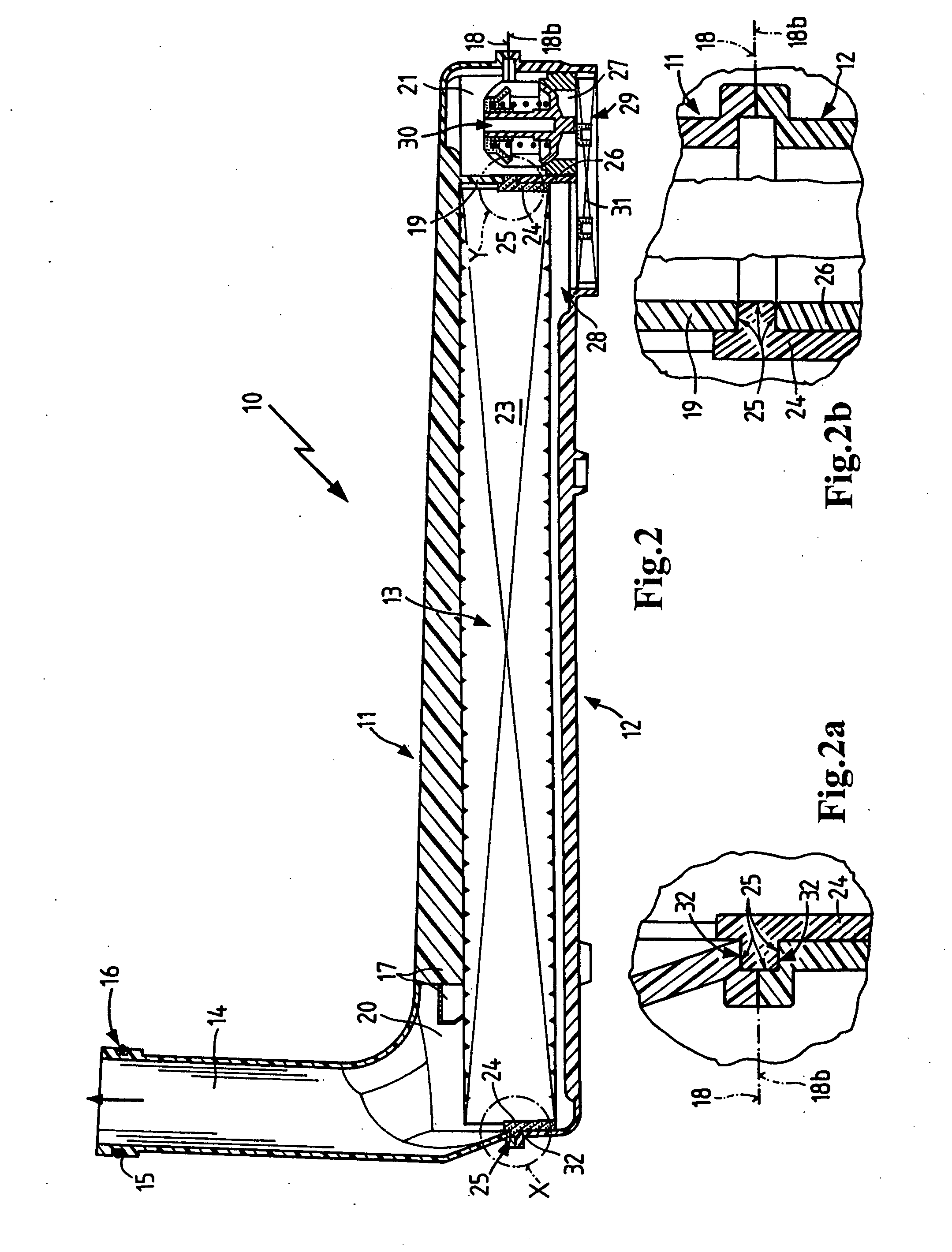

Oil filter unit

ActiveUS20060180541A1Reduce differential pressureImprove dirt holding capacityLoose filtering material filtersCartridge filtersAutomatic transmissionFilter media

An oil filter unit for arrangement in the oil sump of an oil circuit, particularly in an automatic transmission. The oil filter unit has a multi-part filter housing with a filter chamber disposed therein such that an oil inlet and an oil outlet communicate with the filter chamber. A filter element is sealingly mounted in the housing between the oil inlet and the oil outlet. The filter element has a pleated filter medium, which is sealingly enclosed by a frame, and the frame has seal contours designed to cooperate with the contours of the filter housing.

Owner:MANN HUMMEL GMBH

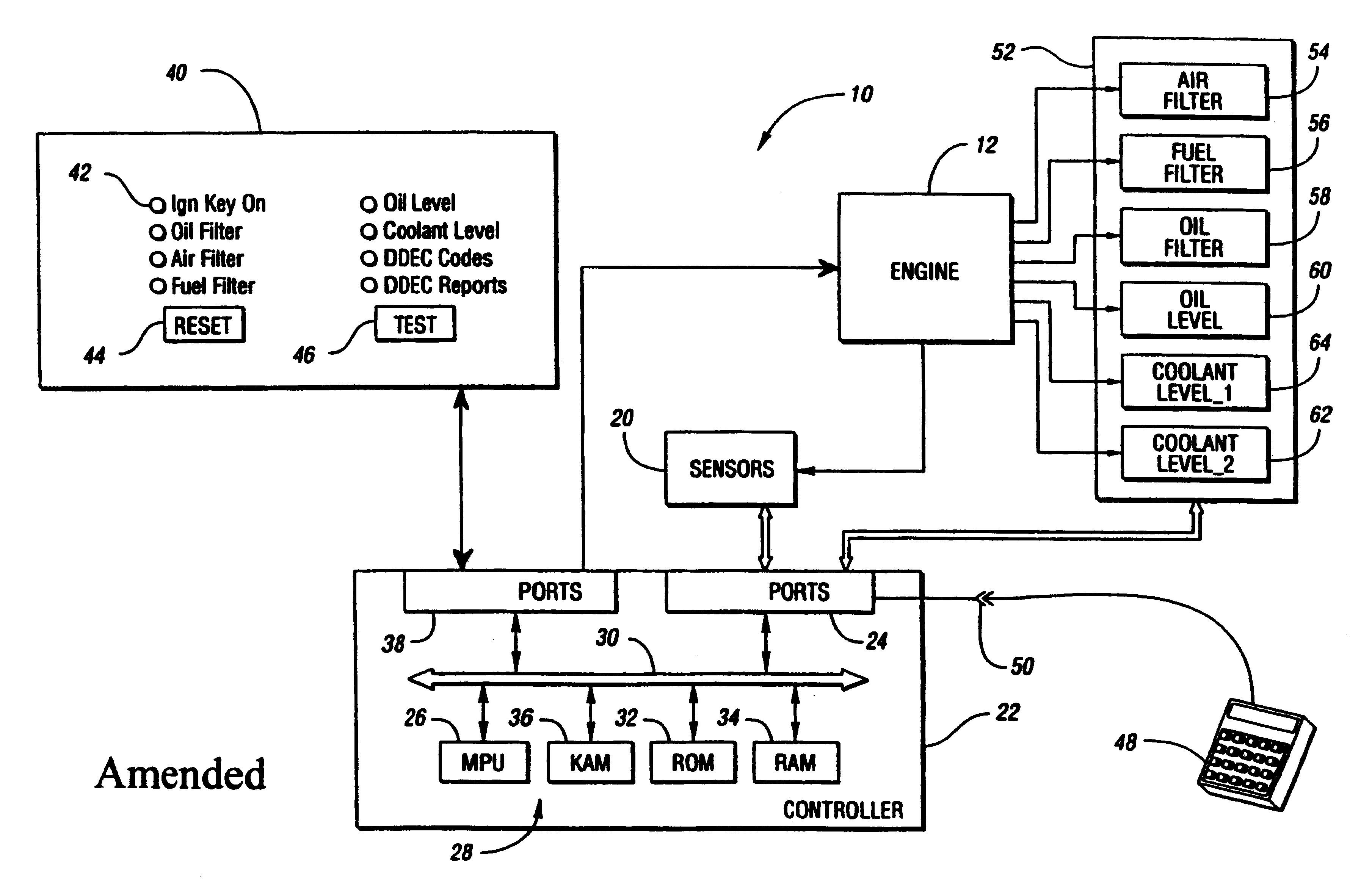

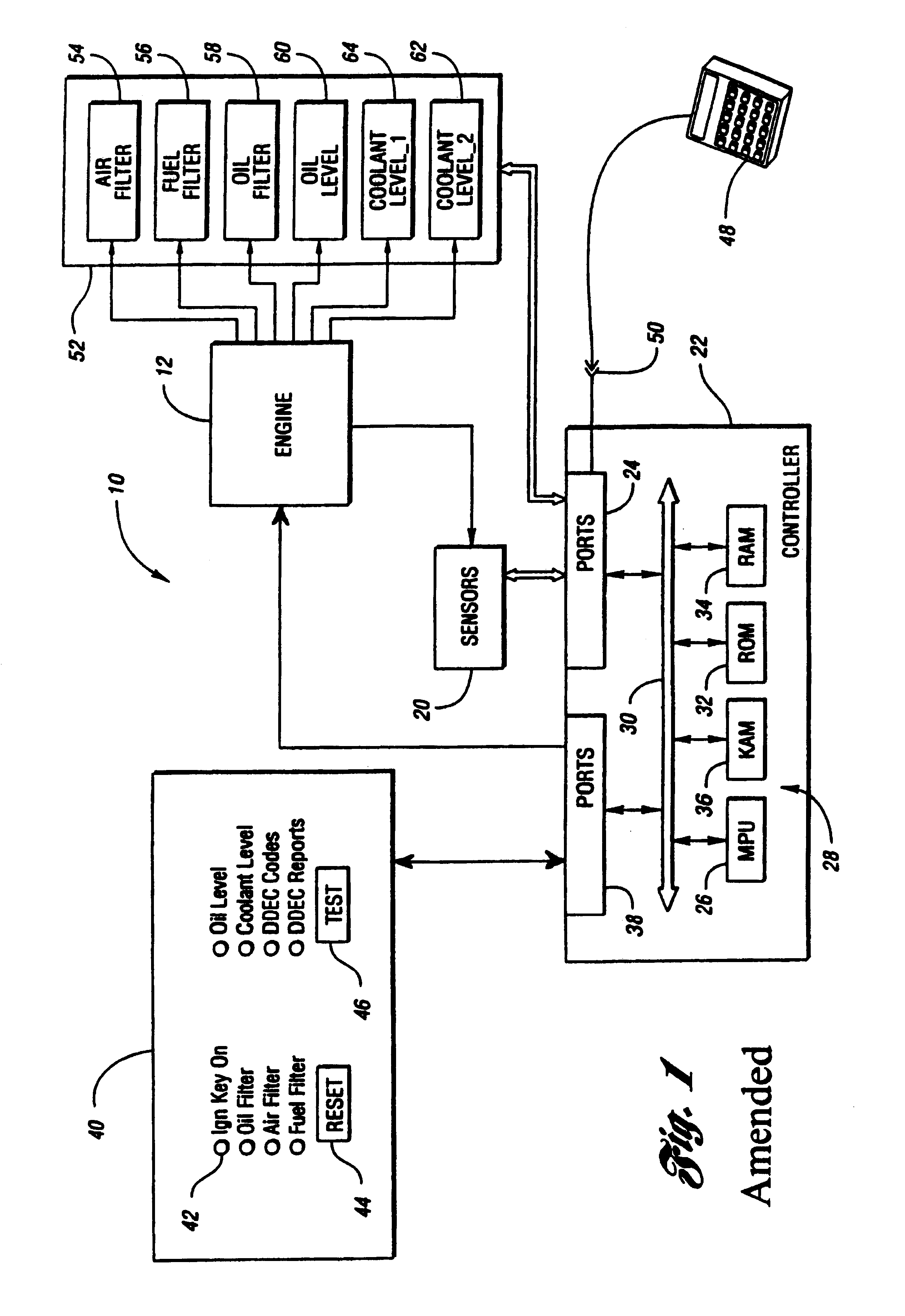

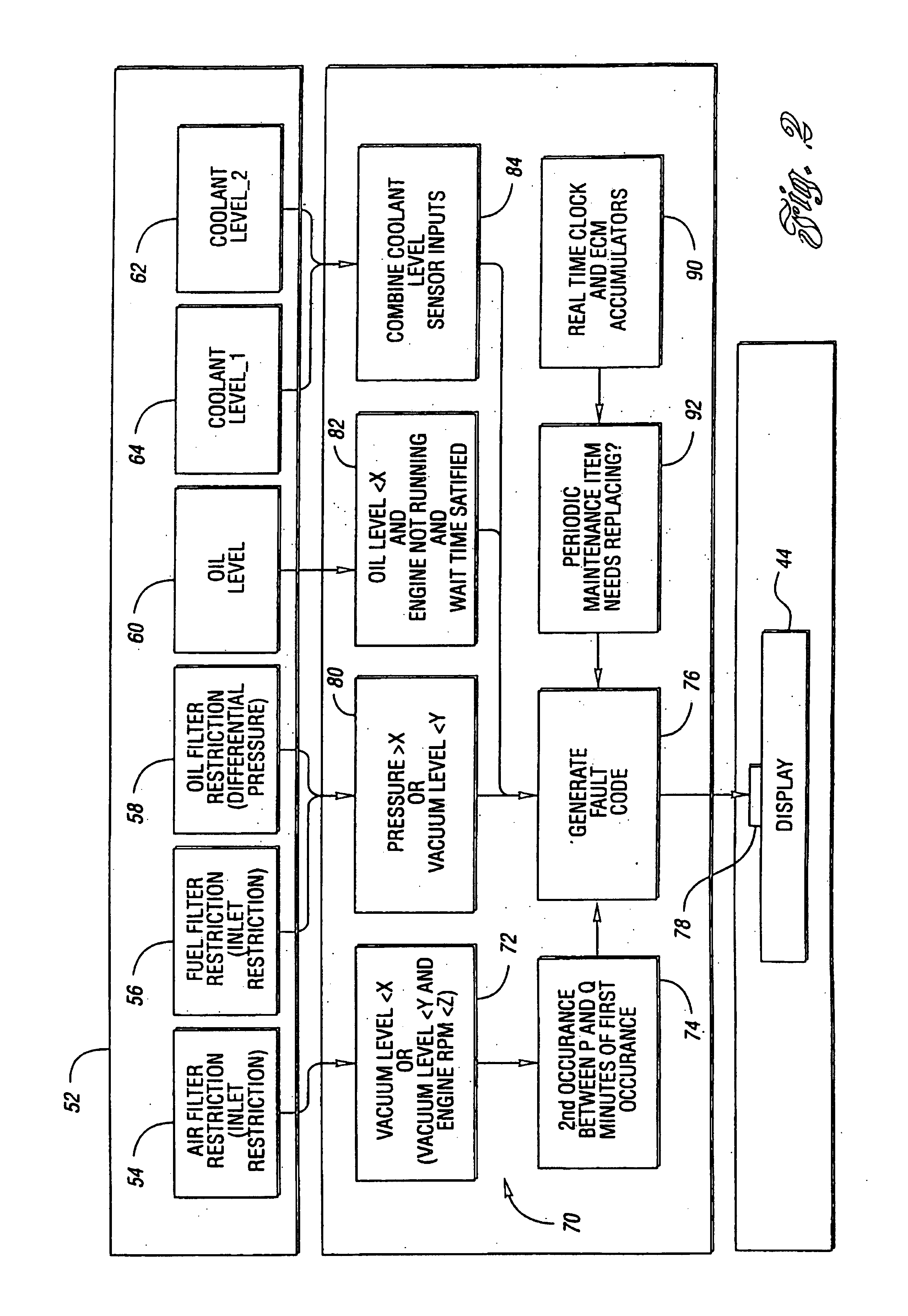

Maintenance alert system for heavy-duty trucks

A real-time maintenance alert system and method for use in a heavy-duty truck having an engine controller with memory are provided. The system includes a sensor operative to indicate an engine condition from the group consisting of: oil filter restriction, air filter restriction, fuel filter restriction, oil level, and coolant reserve tank fluid level. Control logic at the engine controller processes the sensor signal to determine a real-time fault condition, when appropriate.

Owner:DETROIT DIESEL CORP

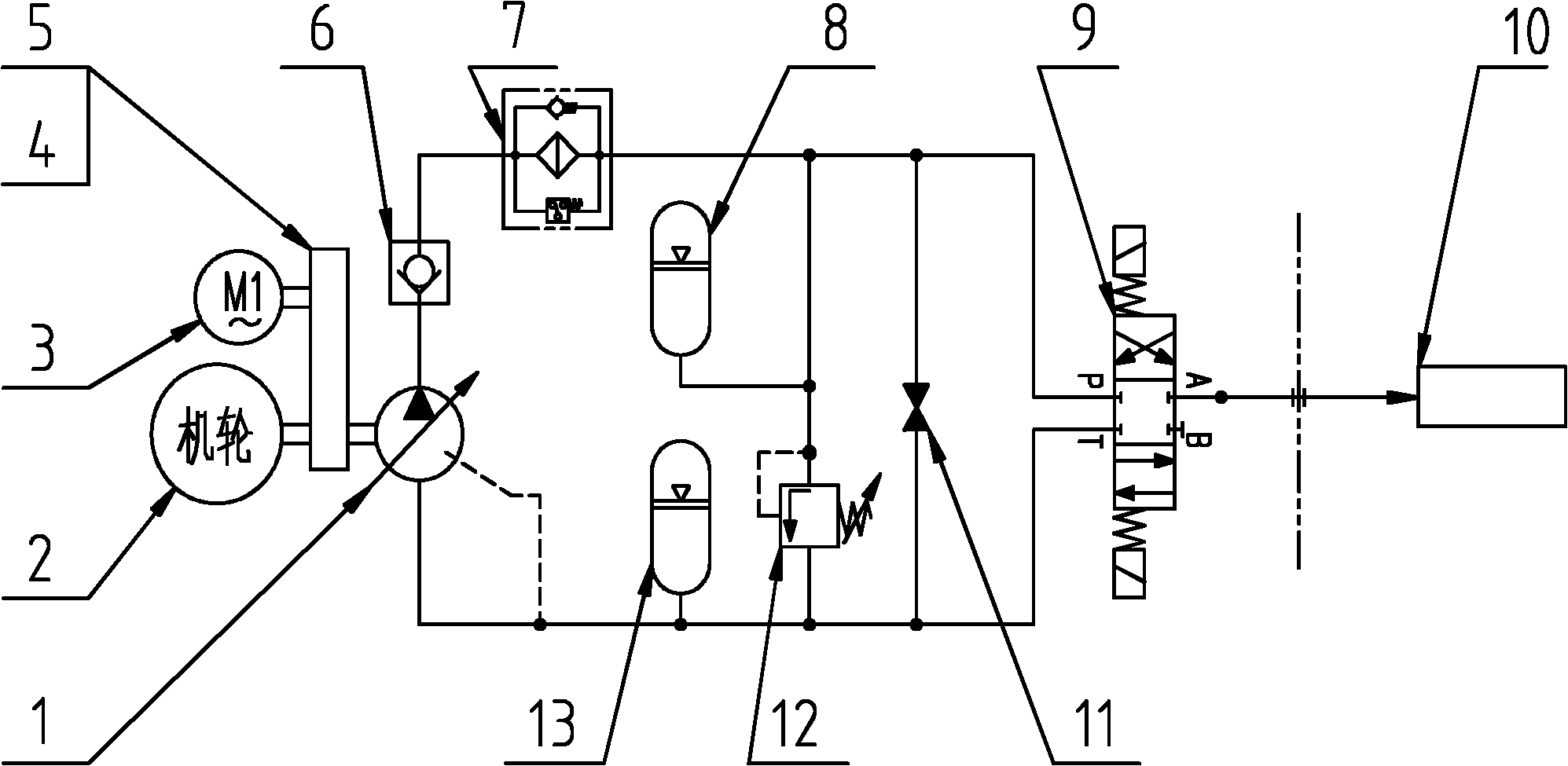

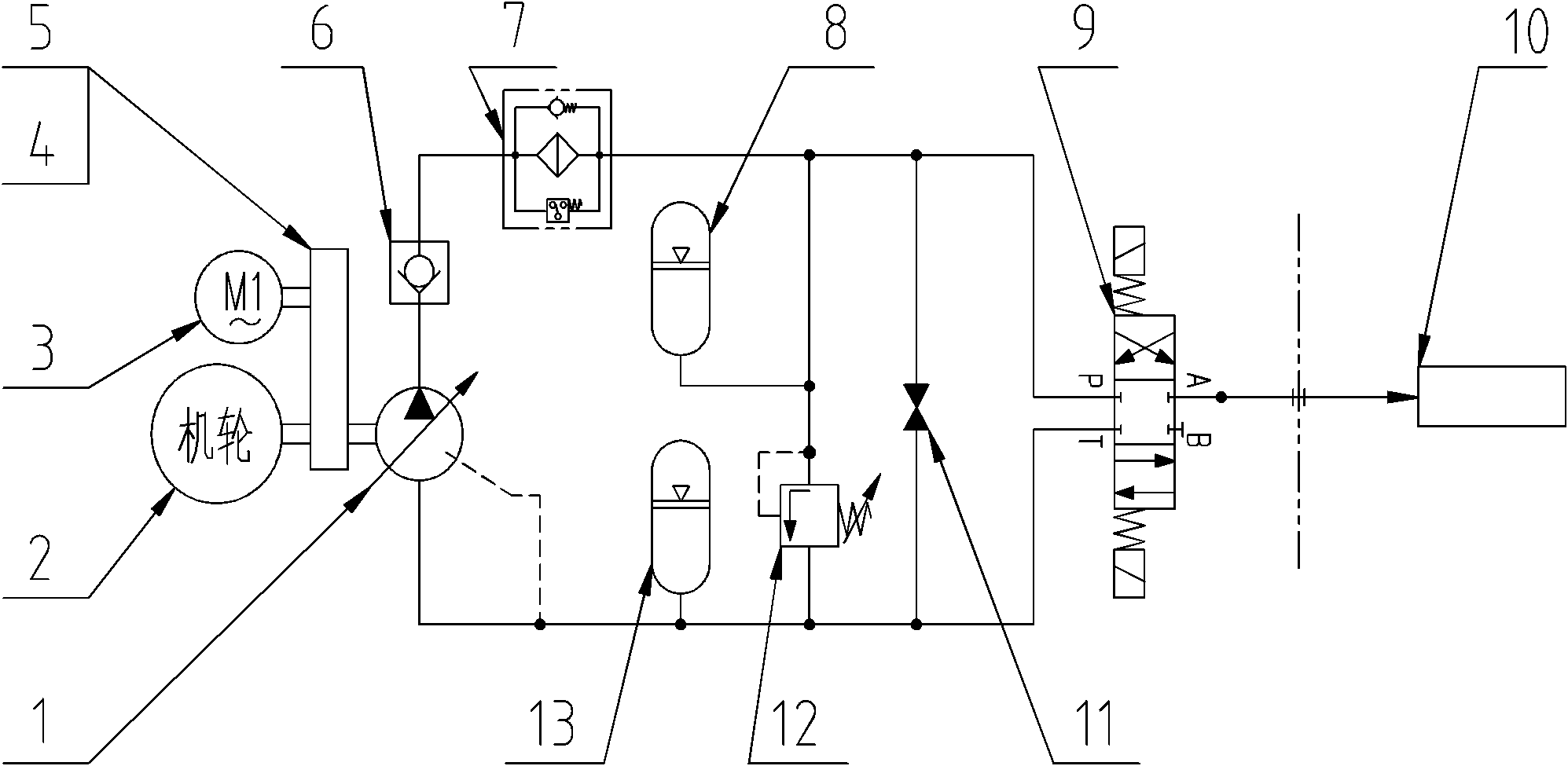

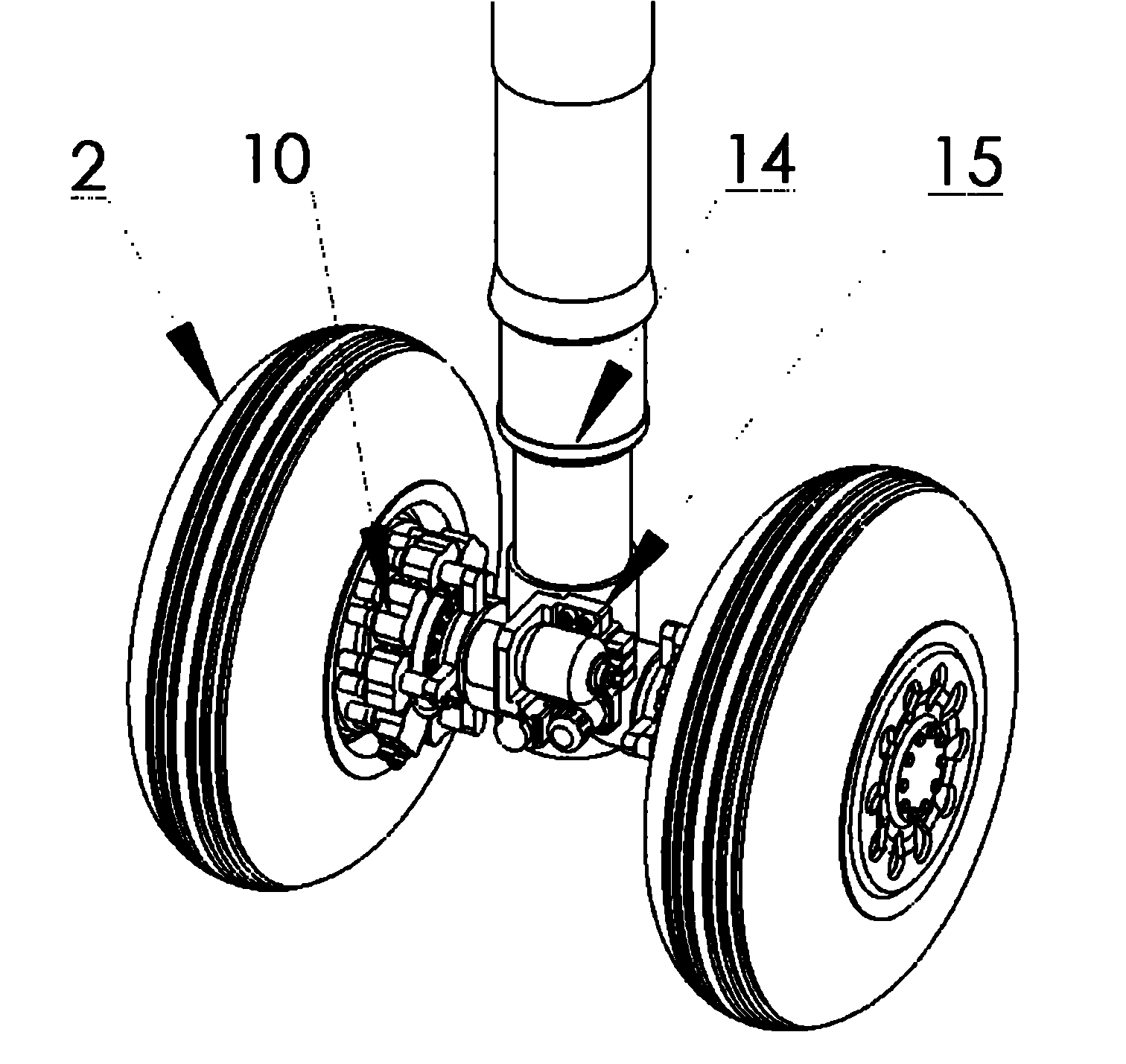

Self-energy feeding type brake device for airplanes

ActiveCN102092472ALayout benefitsSimple structureAircraft braking arrangementsReduction driveFuel tank

The invention discloses a self-energy feeding type brake device for airplanes, belonging to the technical field of an airplane brake system, comprising a hydraulic pump, an auxiliary motor, a reducer, an electromagnetic clutch, a one-way valve, a high pressure oil filter, an energy accumulator, a brake valve, a by-pass valve, an overflow valve and an oil tank, wherein an input shaft of the hydraulic pump is connected with wheel shafts of airplane wheels via the electromagnetic clutch and the reducer; the electromagnetic clutch and the reducer are connected with the auxiliary motor; an oil suction port of the hydraulic pump is connected with the oil tank; an oil outlet of the hydraulic pump is sequentially connected with the one-way valve and the high pressure oil filter; then the oil passage is divided into three parallel branch oil passages; the first branch oil passage is sequentially connected with the energy accumulator and the overflow valve; the second branch oil passage is connected with the by-pass valve; the third branch oil passage is connected with a brake pressure servo valve; the three branch oil passages are gathered to enter into the oil tank; and the brake valve isconnected with a brake actuator via the oil passage. The brake device adopts an integral structure design and electrical interfaces, and directly converts the energy after the airplane lands into theenergy needed by the brake device for anti-skidding braking.

Owner:BEIHANG UNIV

Liquid filter

InactiveUS20060191836A1Compact designSave spaceSemi-permeable membranesSedimentation separationEngineeringInternal combustion engine

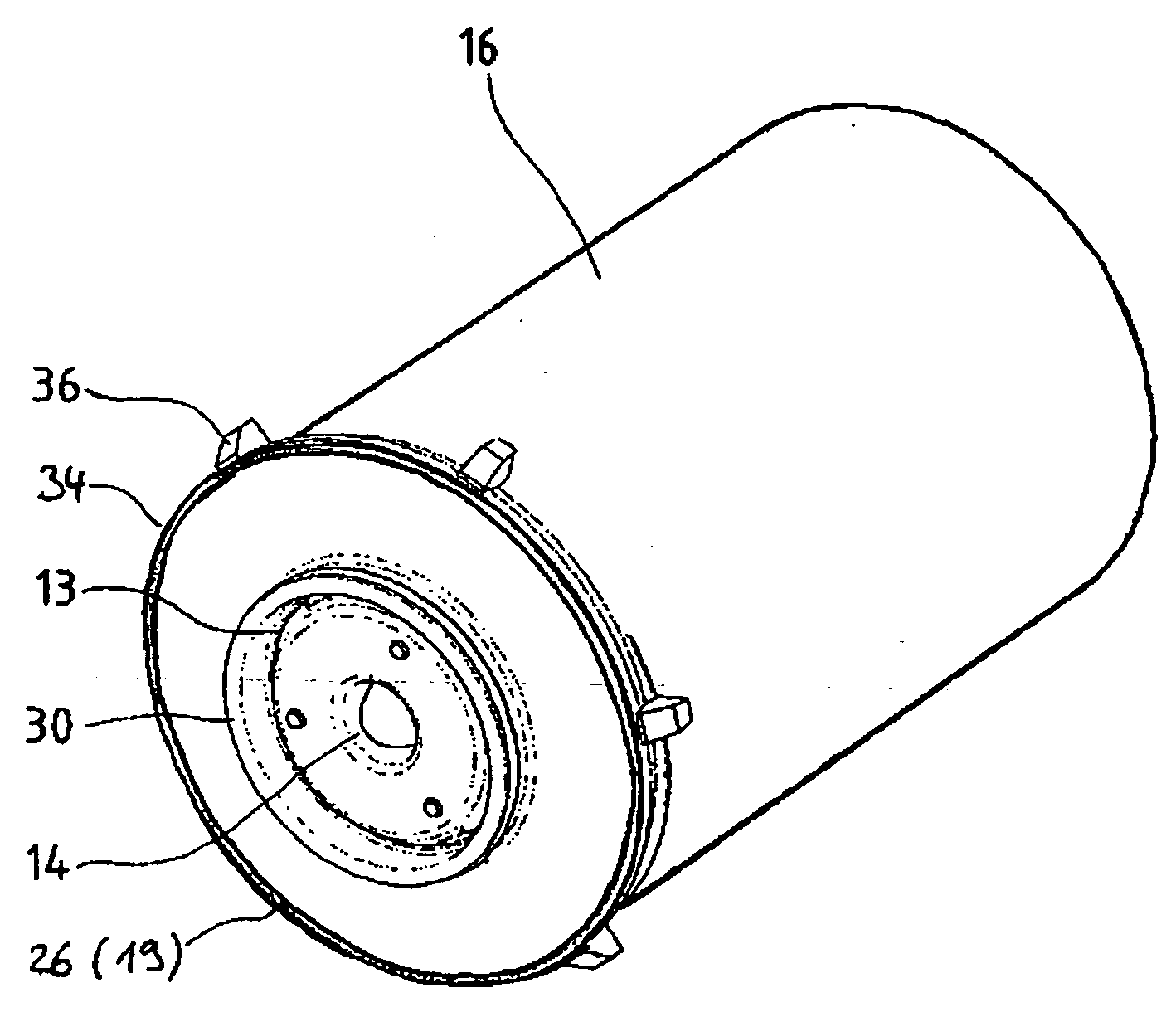

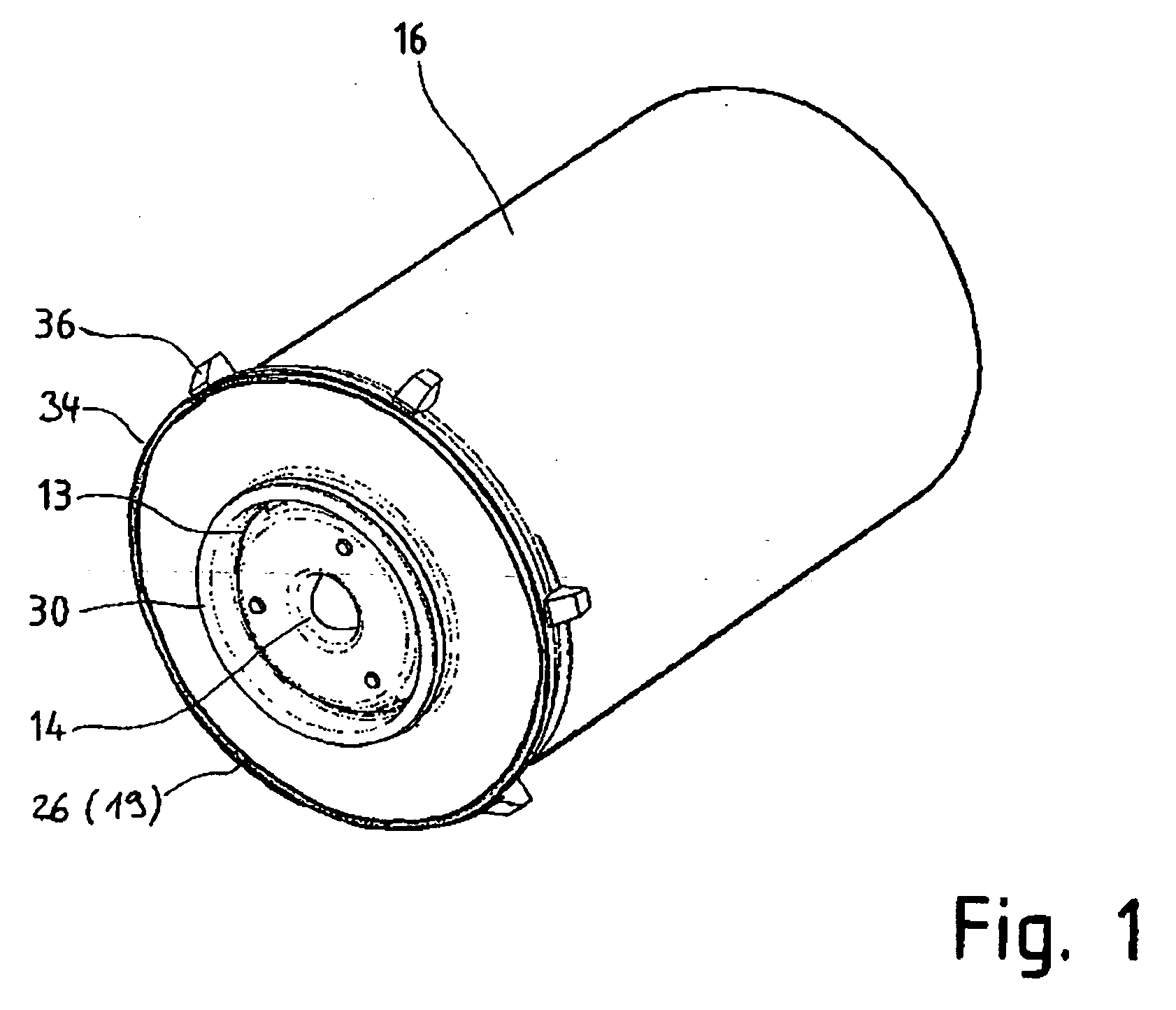

A liquid filter, especially oil filter for an internal combustion engine, having a cup-shaped housing with a liquid inlet and a liquid outlet, a filter element arranged with a seal between the inlet and outlet, and a one-piece barrier membrane arranged in the area of the opening of the cup-shaped housing such that the liquid inlet and / or the liquid outlet can be closed by the barrier membrane.

Owner:MANN HUMMEL GMBH

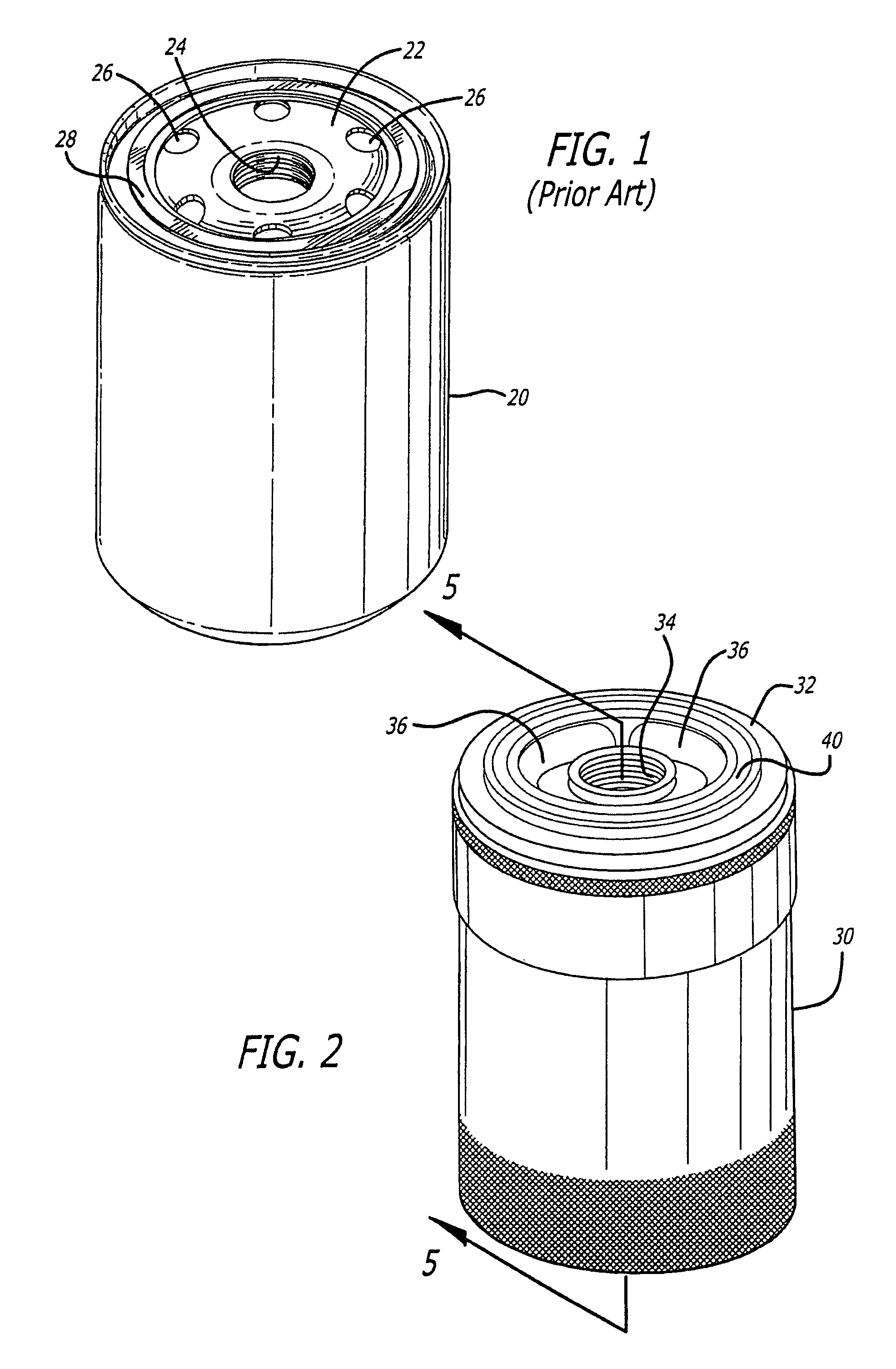

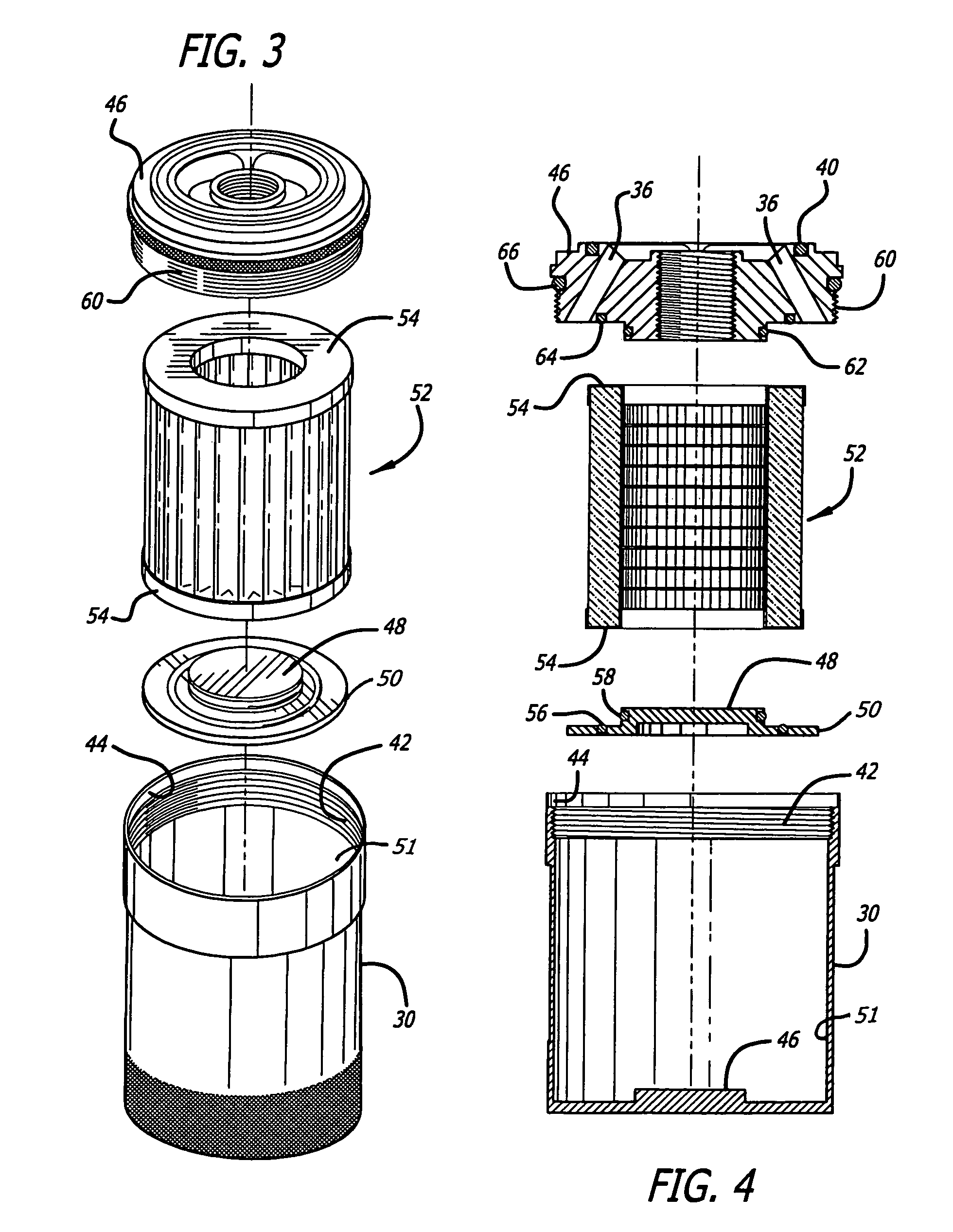

Reusable cartridge oil filter

A replacement filter for conventional throw-away spin-on oil filter cartridge on an internal combustion engine. The replacement filter uses a porous metallic filter element, preferably a woven stainless steel, pleated filter element, within a housing physically simulating the conventional throw-away spin-on oil filter cartridge. The housing is disassembleable, typically by unscrewing the top cap of the housing, for removal, cleaning and reuse of the filter element. This avoids the problems of cost and availability of replacement filters and of disposal of used filters. Various embodiments are disclosed.

Owner:HAMMOND ENTERPRISES INC

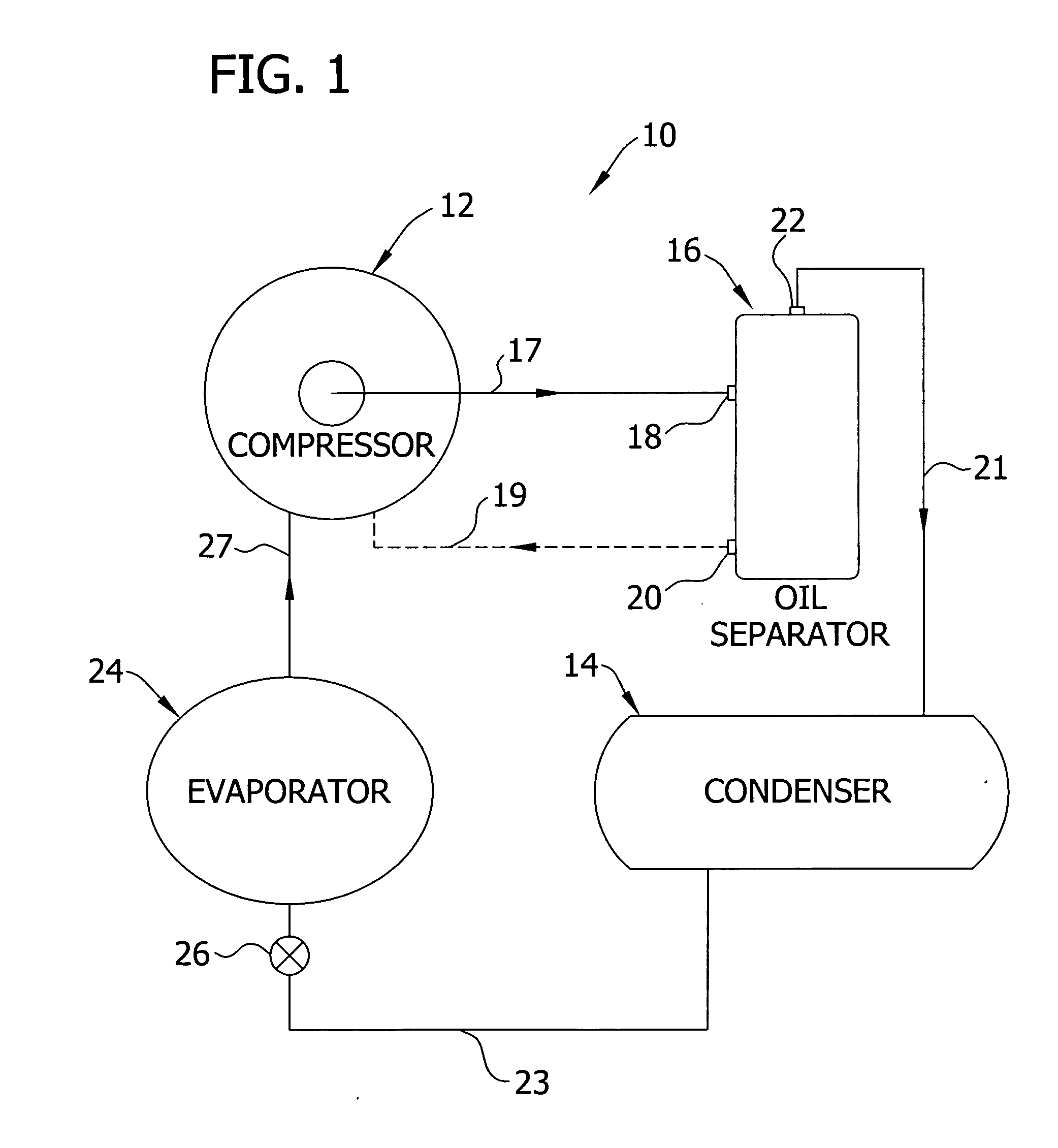

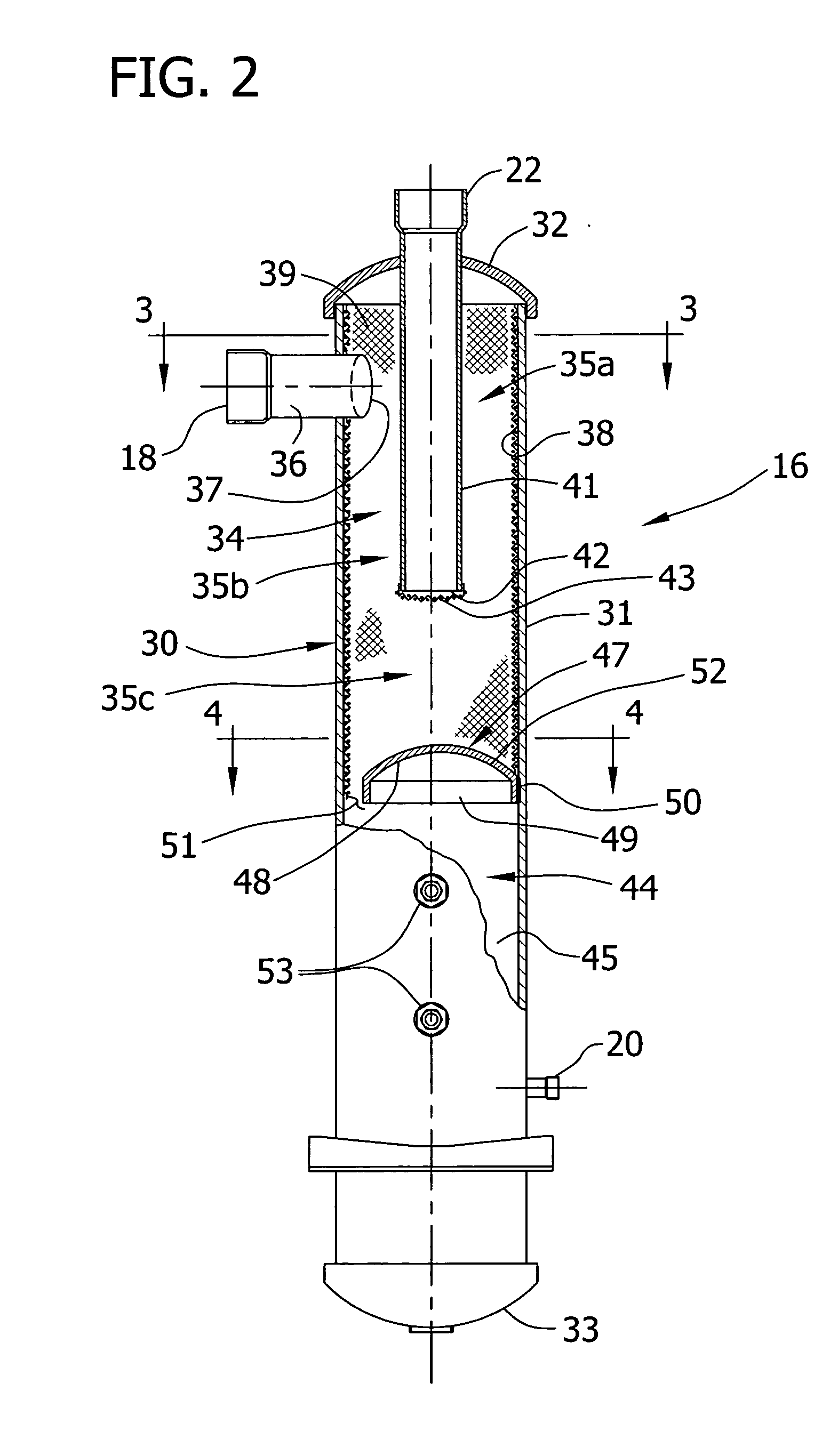

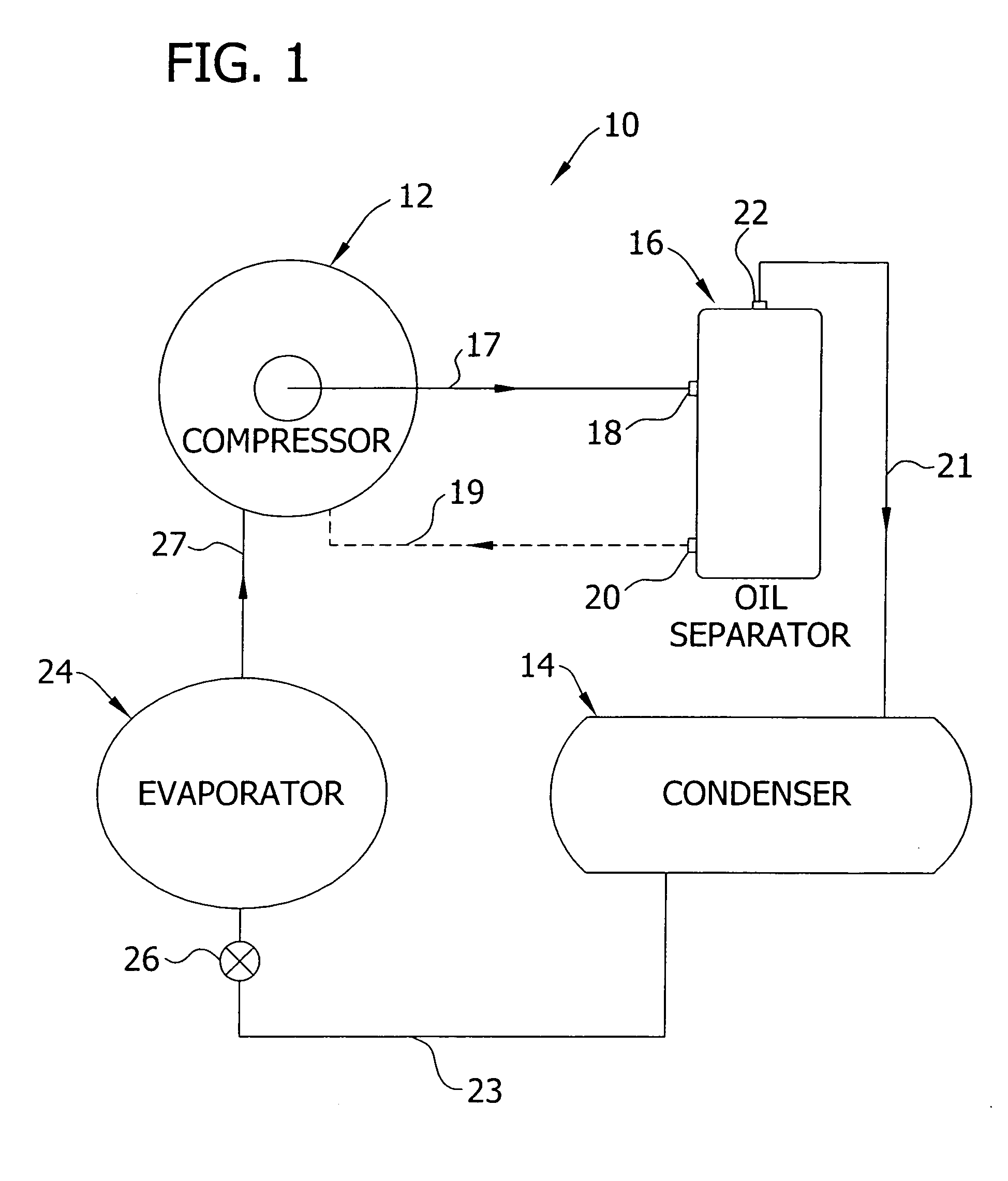

Vertical oil separator

A vertical oil separator for separating oil from a refrigerant gas and oil mixture on the high side of a refrigeration / chiller system comprising, a vertical housing having an upper chamber with a cylindrical sidewall and tangentially oriented inlet for the refrigerant gas and oil mixture, said upper chamber having a refrigerant gas outlet therefrom, said housing also having a lower chamber below the upper chamber with an oil outlet therefrom, a baffle constructed and arranged in said housing to define said upper and lower chamber, at least one oil filter in said upper chamber for removing oil out of the mixture and transferring such oil downwardly from the upper chamber.

Owner:WESTERMEYER GARY W

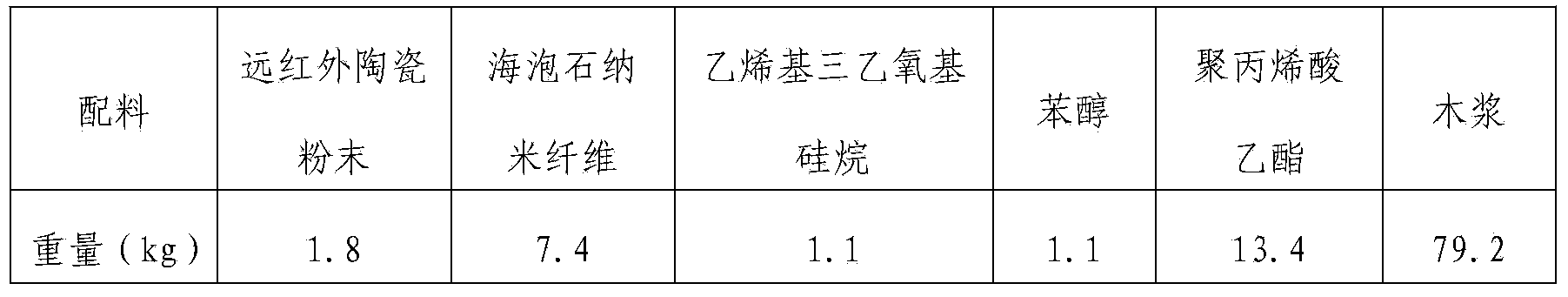

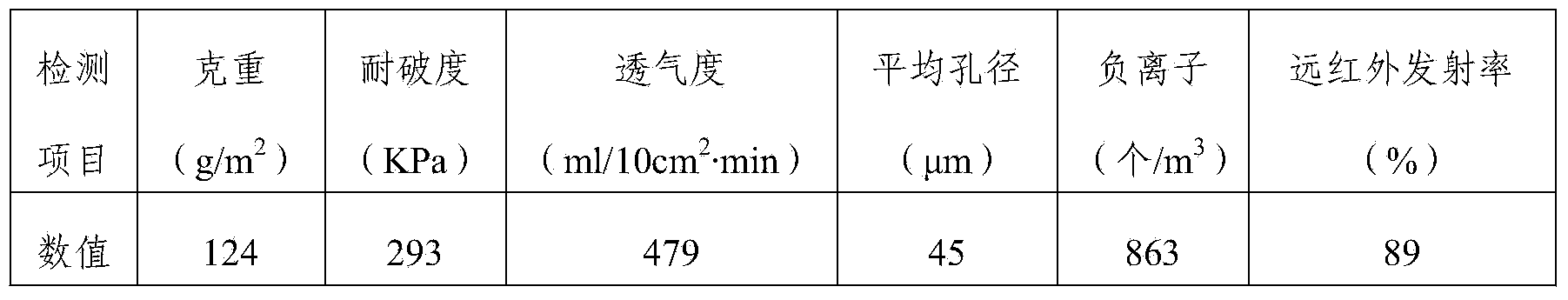

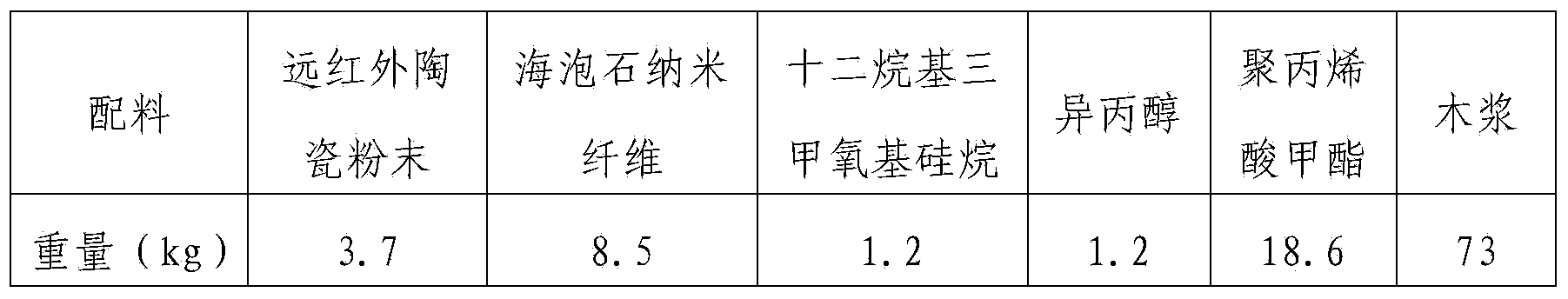

Filter paper for environmental-friendly automobile filter and preparation method of filter paper

InactiveCN103774503ASimple processHigh filtration precisionInorganic fibres/flakesWater-repelling agents additionExhaust gas emissionsEmission standard

The invention relates to filter paper for an environmental-friendly automobile filter. The filter paper for the environmental-friendly automobile filter is prepared from the following components in parts by weight: 1-5 parts of far infrared ceramic powder, 2-20 parts of sepiolite nanofibers, 0.8-1.6 parts of a silane coupling agent, 0.8-1.6 parts of a diluent, 9-20 parts of a sizing agent and 60-96 parts of wood pulp. Air, fuel oil and engine oil filters made of the filter paper are obvious in comprehensive effect; pollutants generated by exhaust gas emission of an automobile are reduced by 16-47%; the dynamic performance is improved by 6-12%; fuel oil can be saved by 2-5%; the emission standard reaches the European IV standard.

Owner:北京联飞翔科技股份有限公司

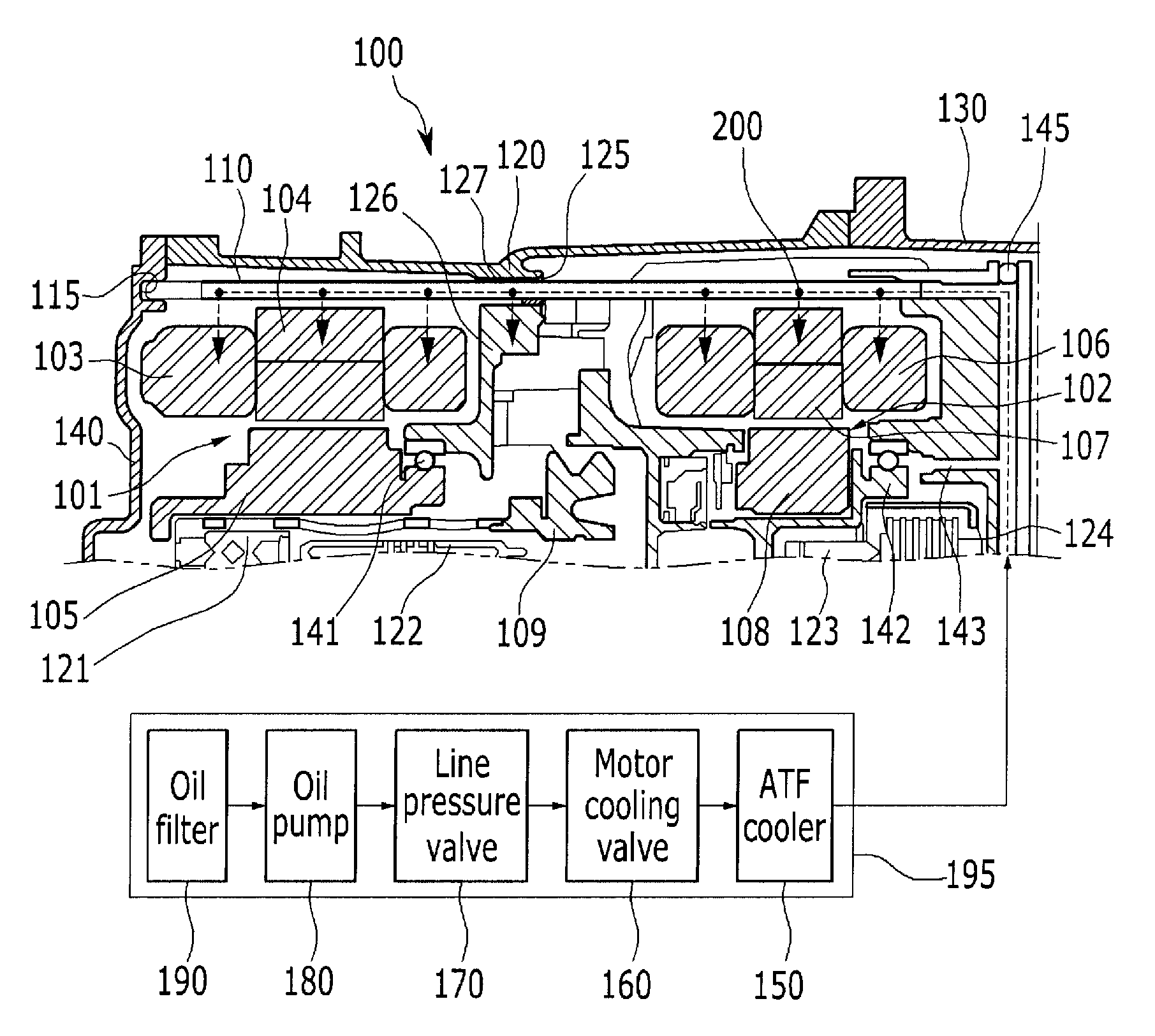

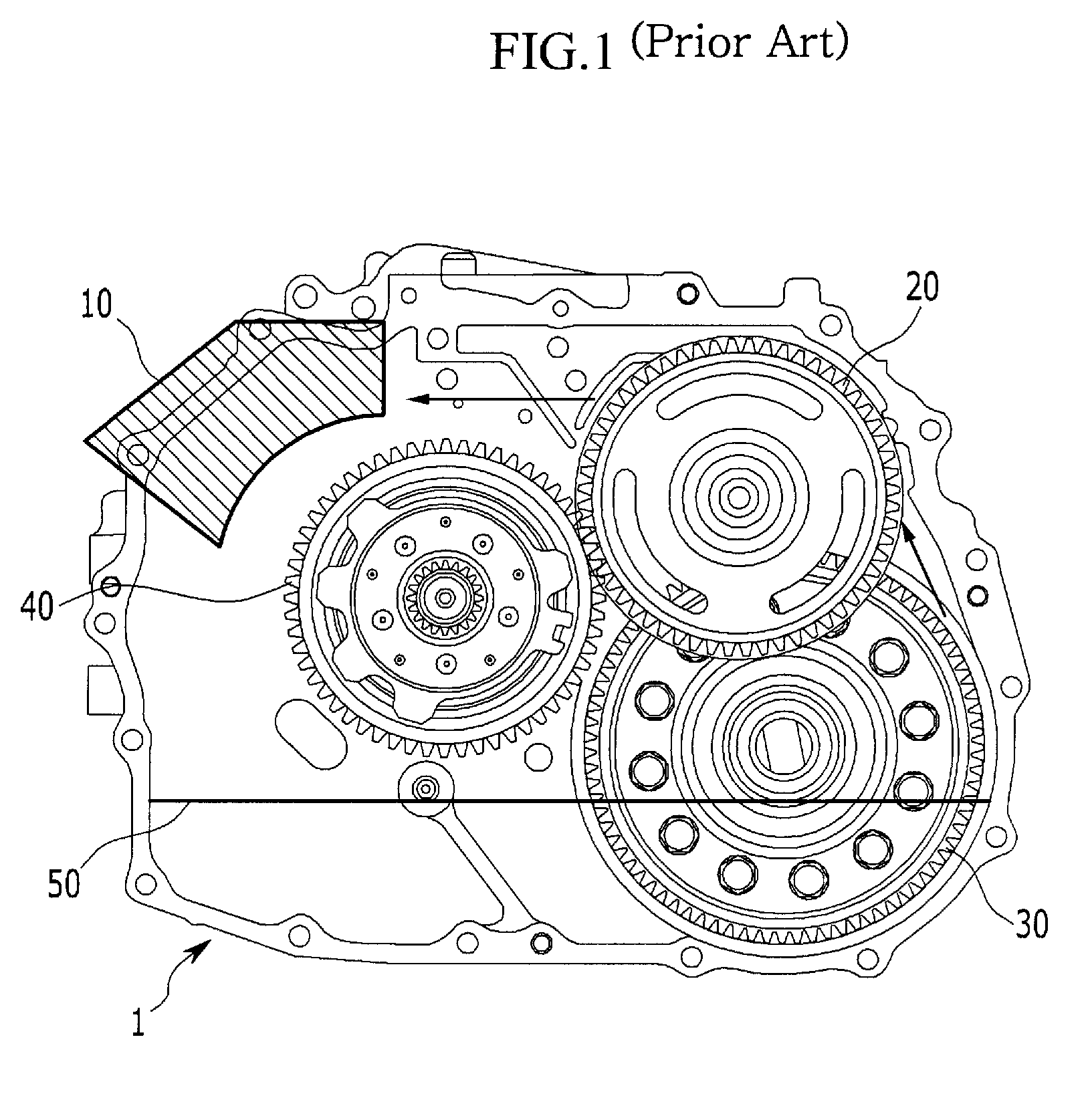

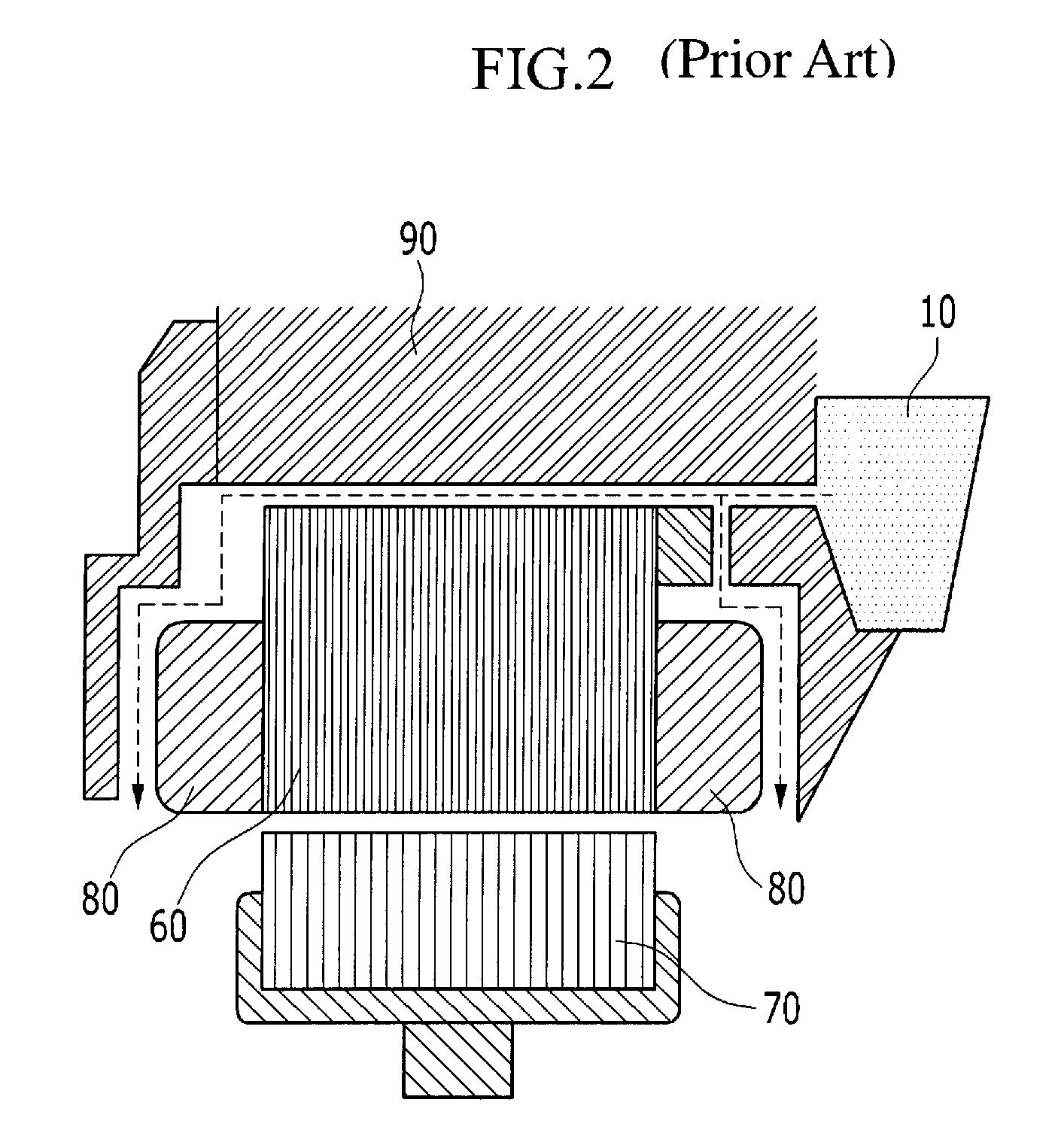

Motor-Generator Cooling System of Hybrid-Automobile

InactiveUS20120091835A1Simplify pipeline structureImprove transmission efficiencyElectric propulsion mountingPropulsion using engine-driven generatorsHydraulic pumpEngineering

A motor / generator cooling system of a hybrid vehicle that has a first and second motor / generator disposed in an axial direction in a transmission, may include a cooling pipe that may be disposed in an axial direction along an upper and outside of the first and second motor / generator in the transmission, a rear cover that may be connected to a downstream side of the cooling pipe such that the cooling pipe may be fixed thereto, an input supporter that may be connected to an upstream side of the cooling pipe, forms a cooling oil passage, and rotatably supports a rotor of the first motor / generator, and a case that the rear cover and the input supporter may be mounted thereon, an oil filter connected to a hydraulic pump may be mounted therein, a penetration hole may be formed therein, and the cooling pipe penetrates the penetration hole to be fixed thereto.

Owner:HYUNDAI MOTOR CO LTD

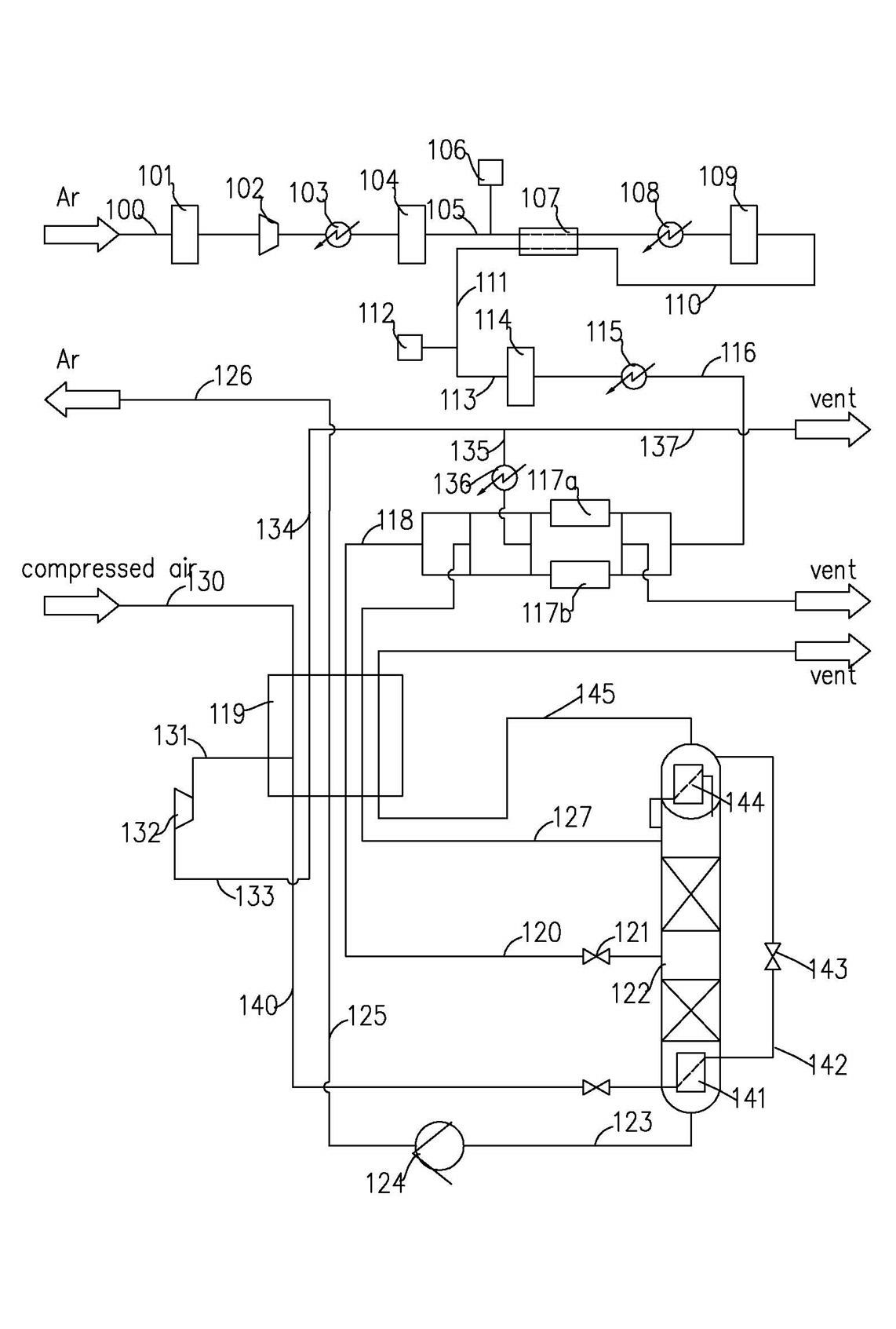

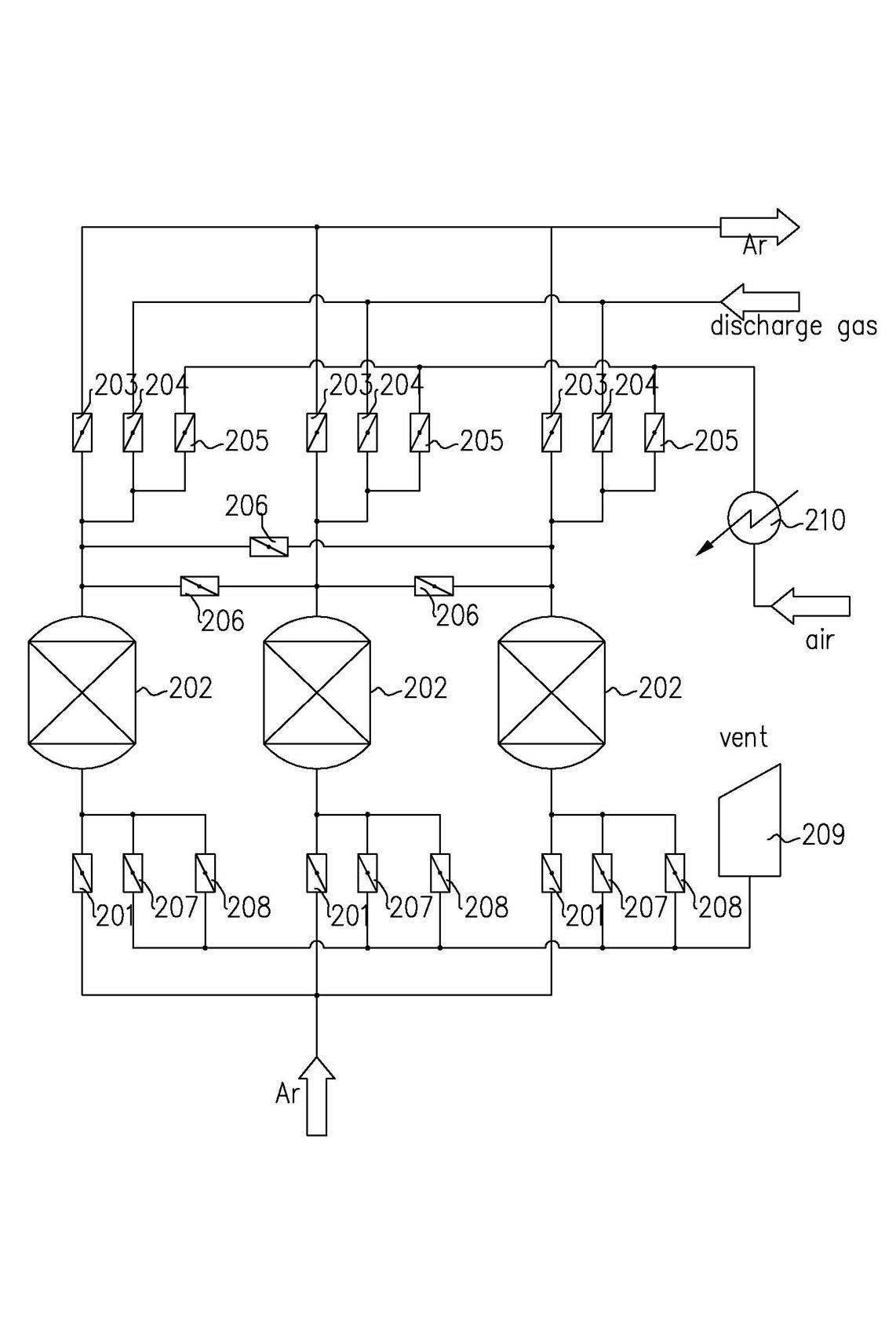

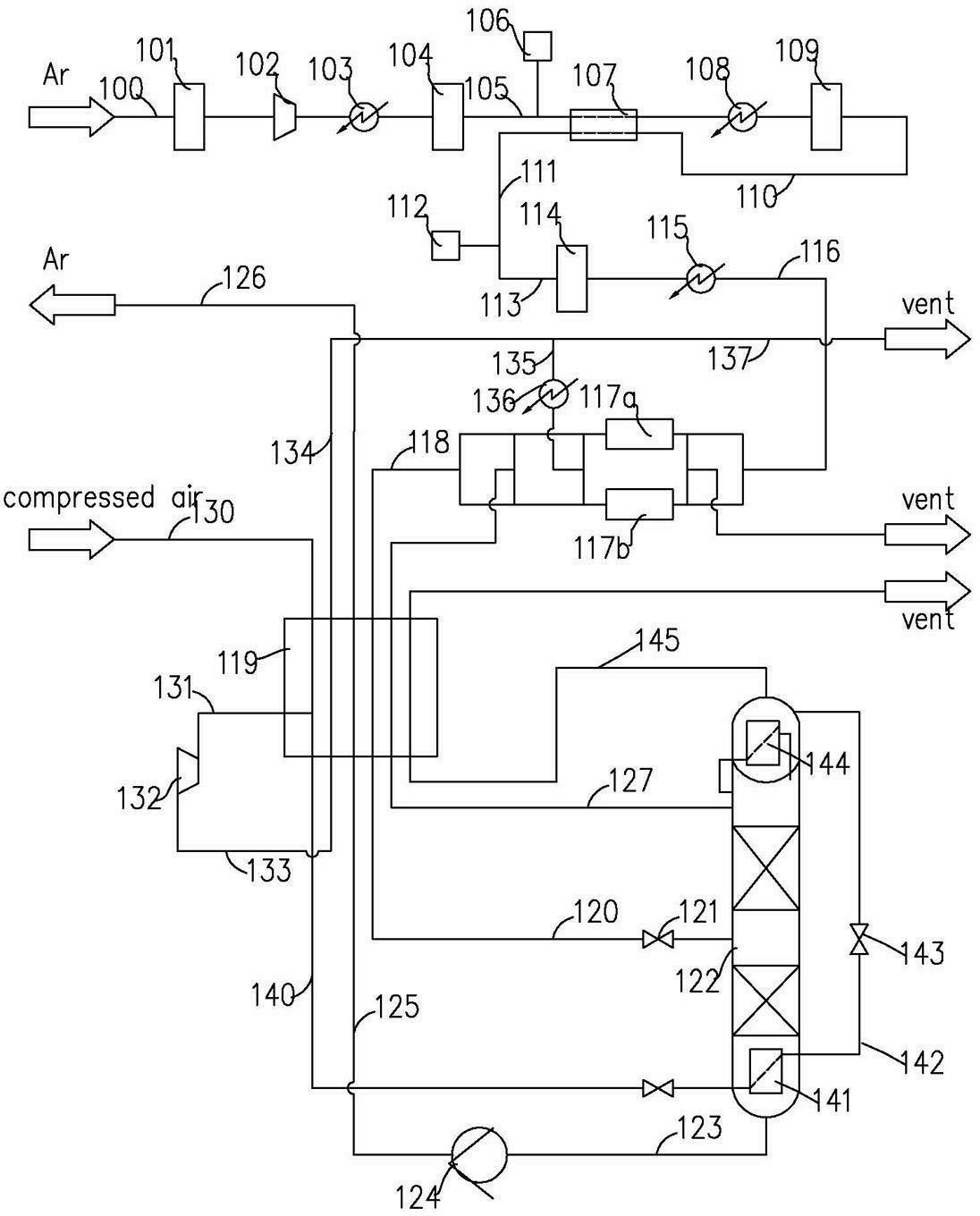

Method and device for recovering and purifying argon in monocrystalline silicon production

ActiveCN102583281AThorough responseHigh recovery rateNoble gas compoundsPtru catalystCatalytic oxidation

Provided is a method and a device for recovering and purifying argon in monocrystalline silicon production. The method comprises firstly conducting coarse oil removal on argon recovered from a single crystal furnace, compressing, cooling and conducting high-precision oil removal and dedusting; secondly enabling hydrocarbon such as methane and carbon monoxide to be reacted with oxygen to generate water and carbon dioxide through a high temperature catalytic reaction and guaranteeing the oxygen to be excessive in the catalytic reaction; thirdly enabling excessive oxygen to be reacted with added hydrogen to generate the water under effects of a catalytic agent after cooling and enabling argon after two catalytic reactions to penetrate through a normal temperature adsorption unit to absorb the water and the carbon dioxide; cooling the argon, sending a low temperature rectifying tower, enabling the argon, the nitrogen and the hydrogen to produce rectification separation, obtaining pure liquid argon, and conducting repeated heating to obtain pure argon products. The device mainly comprises an oil filter, a catalytic reactor of the hydrocarbon of high temperature catalytic oxidation carbon monoxide and methane and the like, a normal temperature hydrogenation deoxygenization catalytic reactor, a normal temperature adsorption unit for absorbing the carbon dioxide and the water at the normal temperature and the low temperature rectifying tower for rectifying and separating the hydrogen and the nitrogen at the low temperature. The device has the advantages of being high in argon recovery rate, high in purity of recovered argon, low in oxygen content, low in energy consumption for recovery and purification and the like.

Owner:HANGZHOU HANGYANG

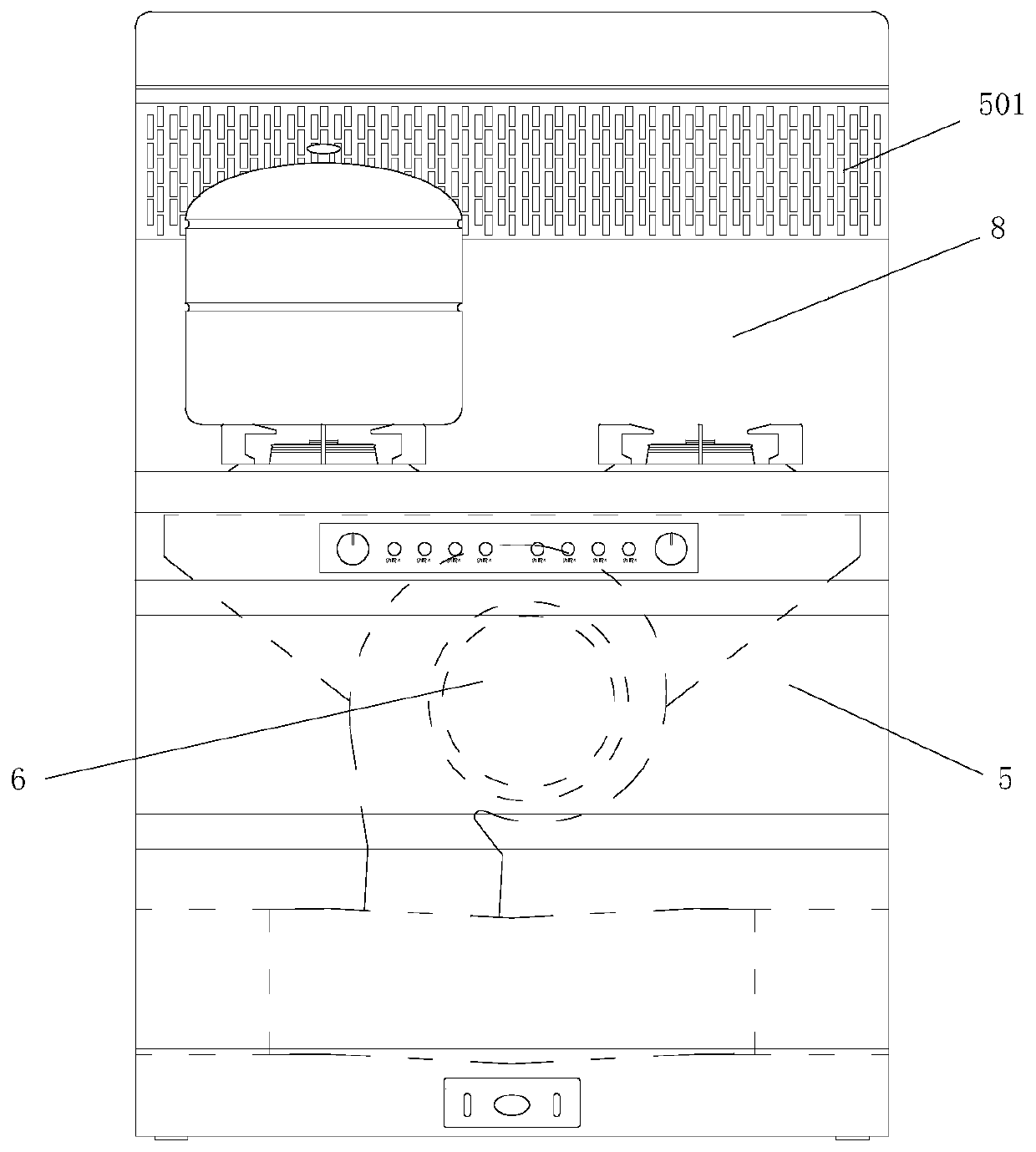

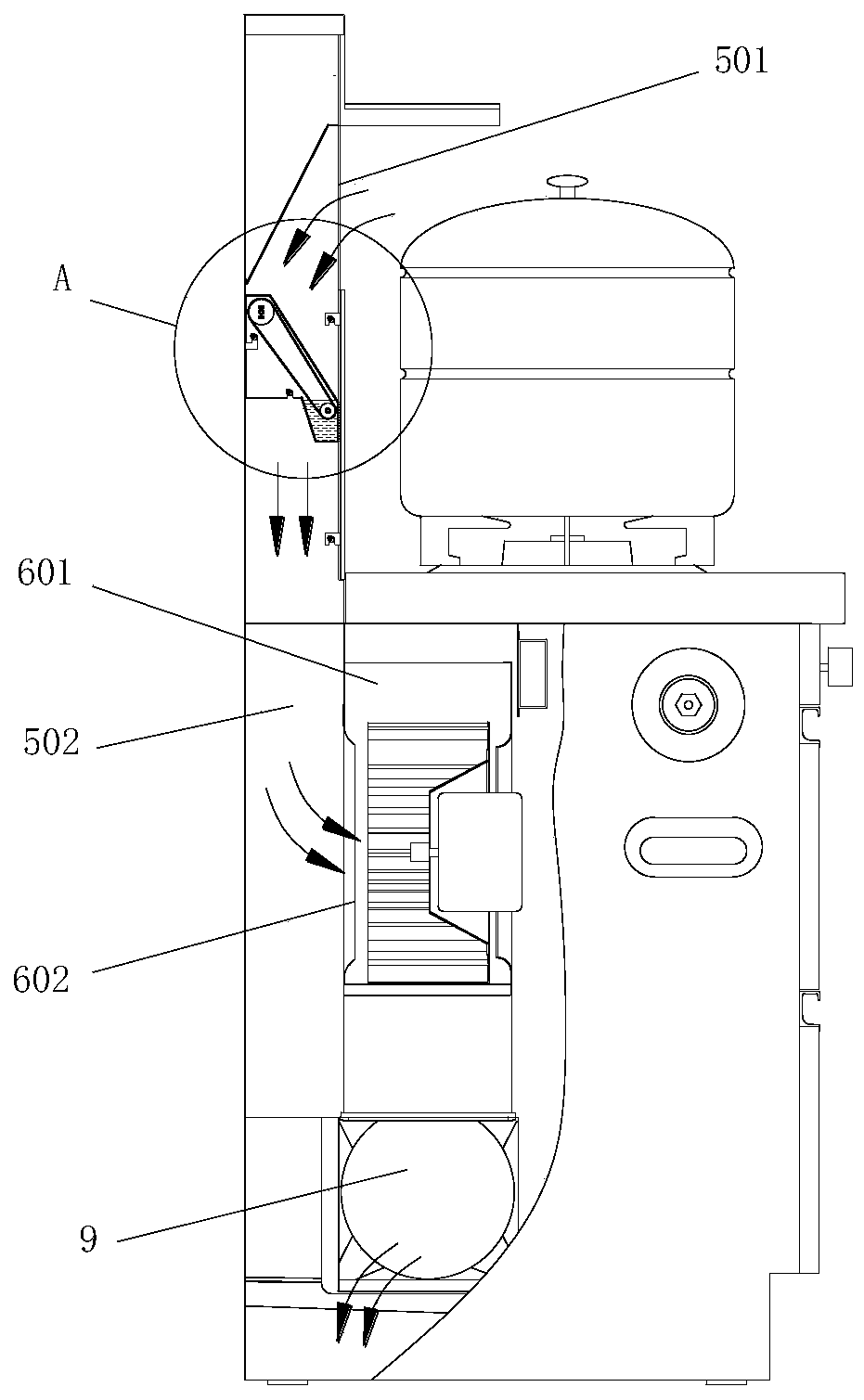

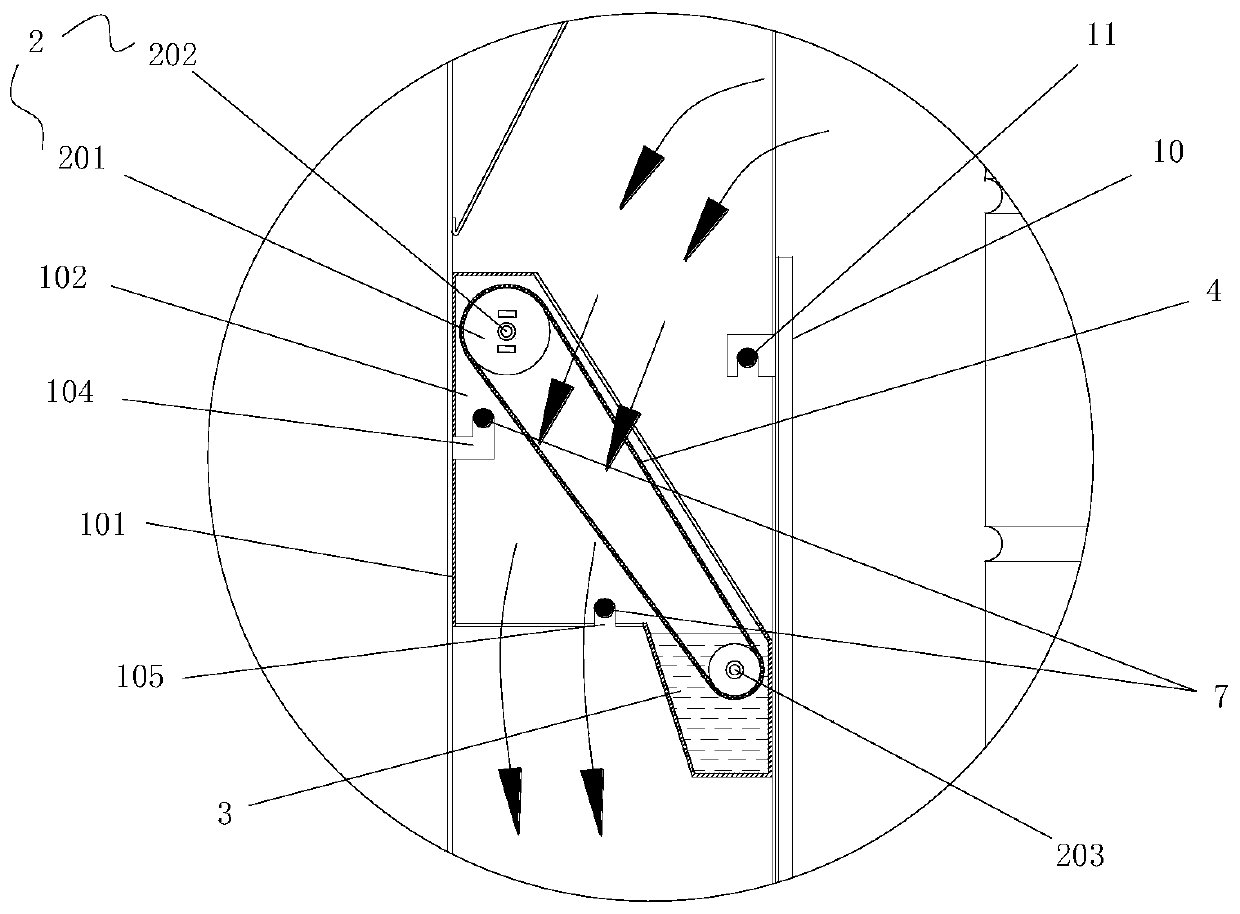

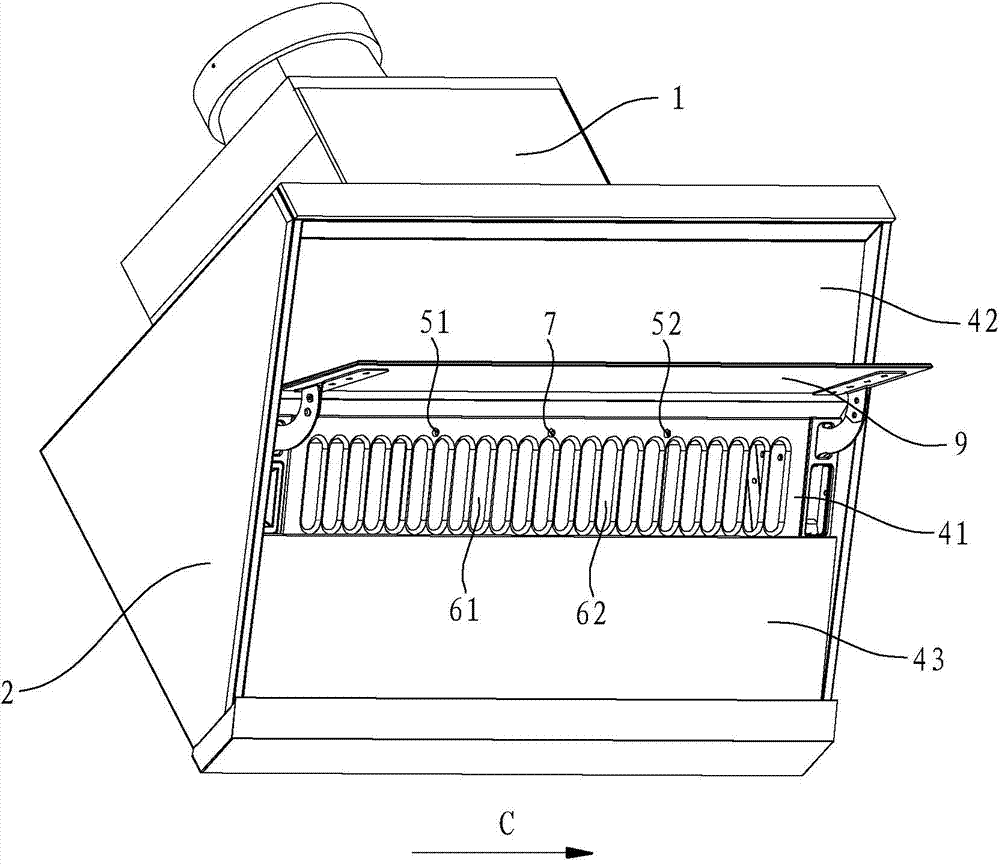

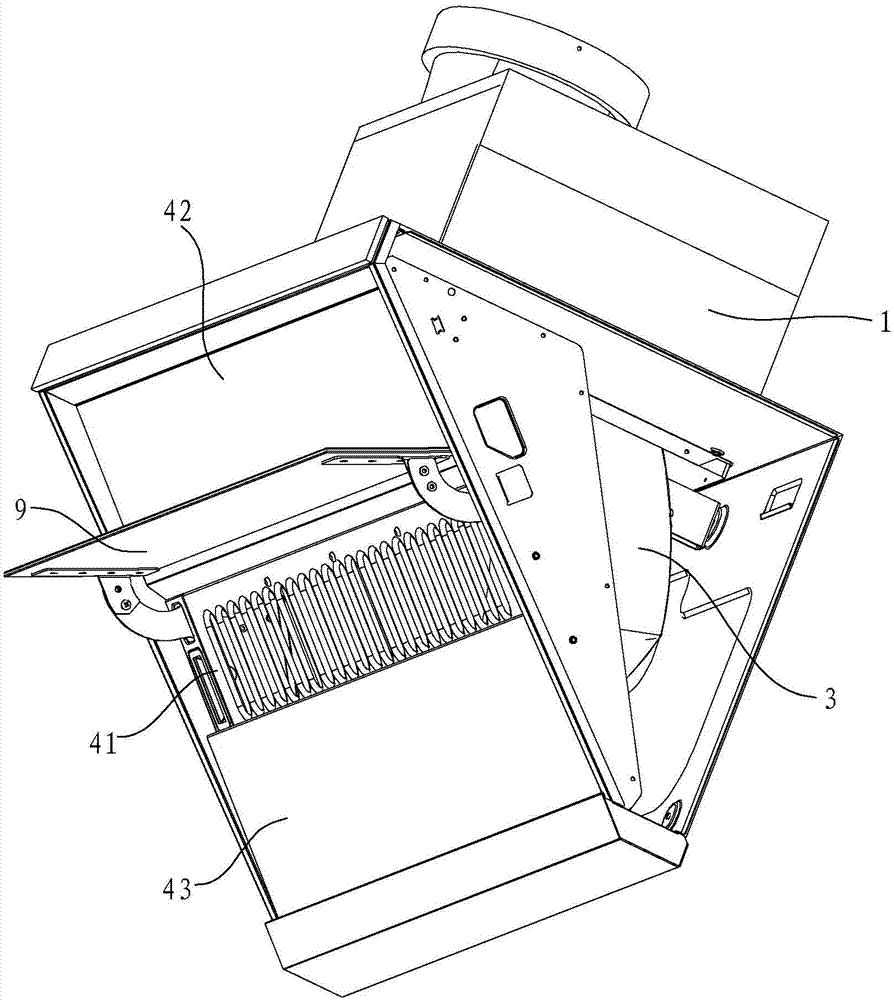

Oil filtering device and integrated cooker with oil filtering device

PendingCN111389135AEasy to assemble and disassemblePrevent adhesionDomestic stoves or rangesLighting and heating apparatusOil and greaseHazardous substance

The invention discloses an oil filtering device and an integrated cooker with the oil filtering device. The oil filtering device comprises a driving assembly, a containing groove and a filtering part.The driving assembly is connected with the filtering part and drives the filtering part to circularly pass through the containing groove. A medium which can be attached to the surface of the filtering part and is used for treating lampblack is contained in the containing groove. The driving assembly comprises a driving part, a first rotating shaft and a second rotating shaft, the first rotating shaft is connected with the driving part, and the second rotating shaft is located in the containing groove. The dynamic oil filtering device is arranged in a negative pressure cavity of the integratedcooker, so that harmful substances such as grease in lampblack of the integrated cooker are efficiently intercepted, and the situation in which the lampblack suction effect of a range hood is reduceddue to the fact that the grease enters a volute and then is attached to an impeller of the range hood is prevented; the trouble that a user needs to periodically clean the impeller of the range hoodto keep the oil suction effect of the range hood is eliminated; the emission of harmful substances in the lampblack to the atmosphere is reduced; and the oil filtering device is arranged in an independent modular mode and is convenient to disassemble and assemble.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

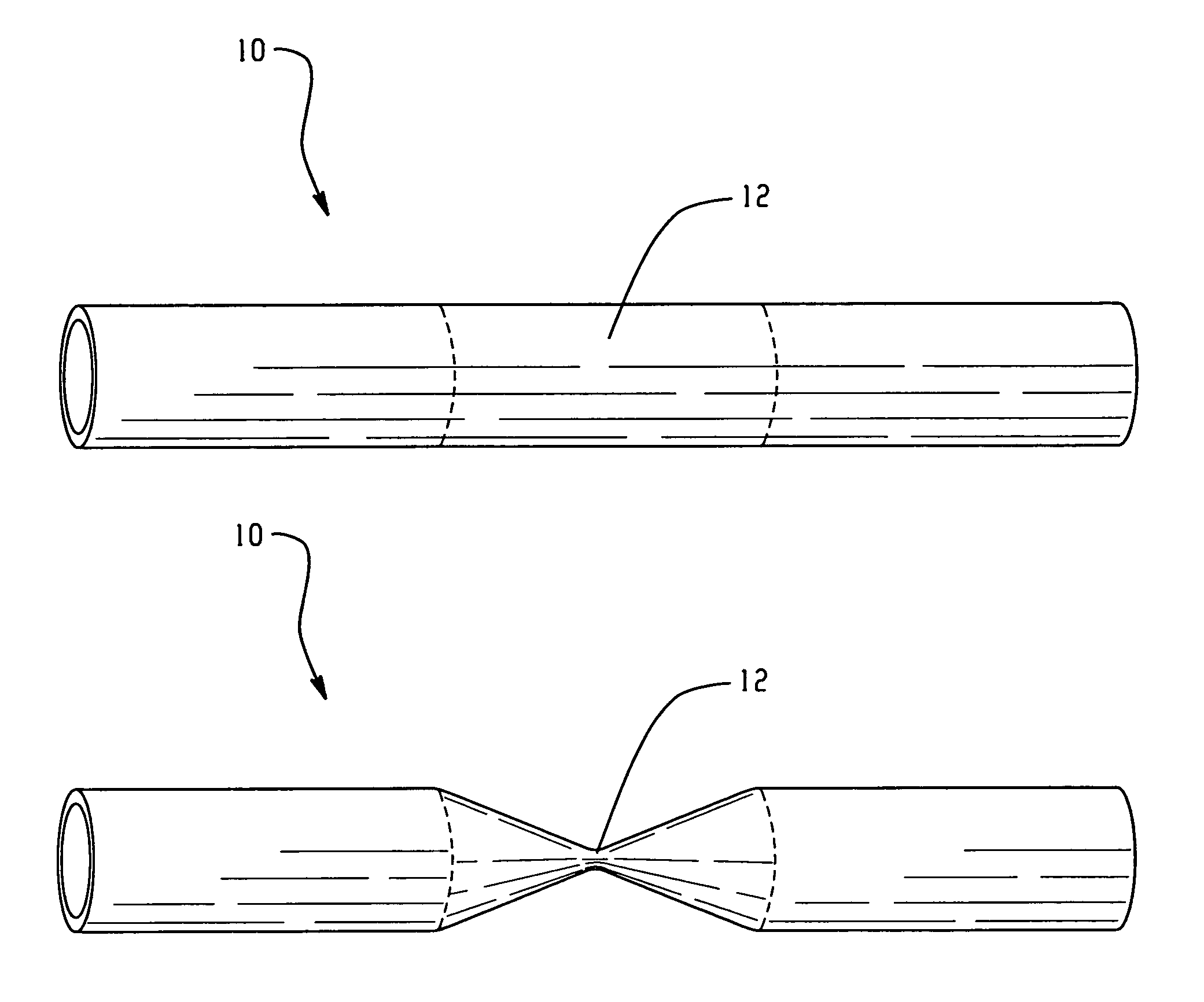

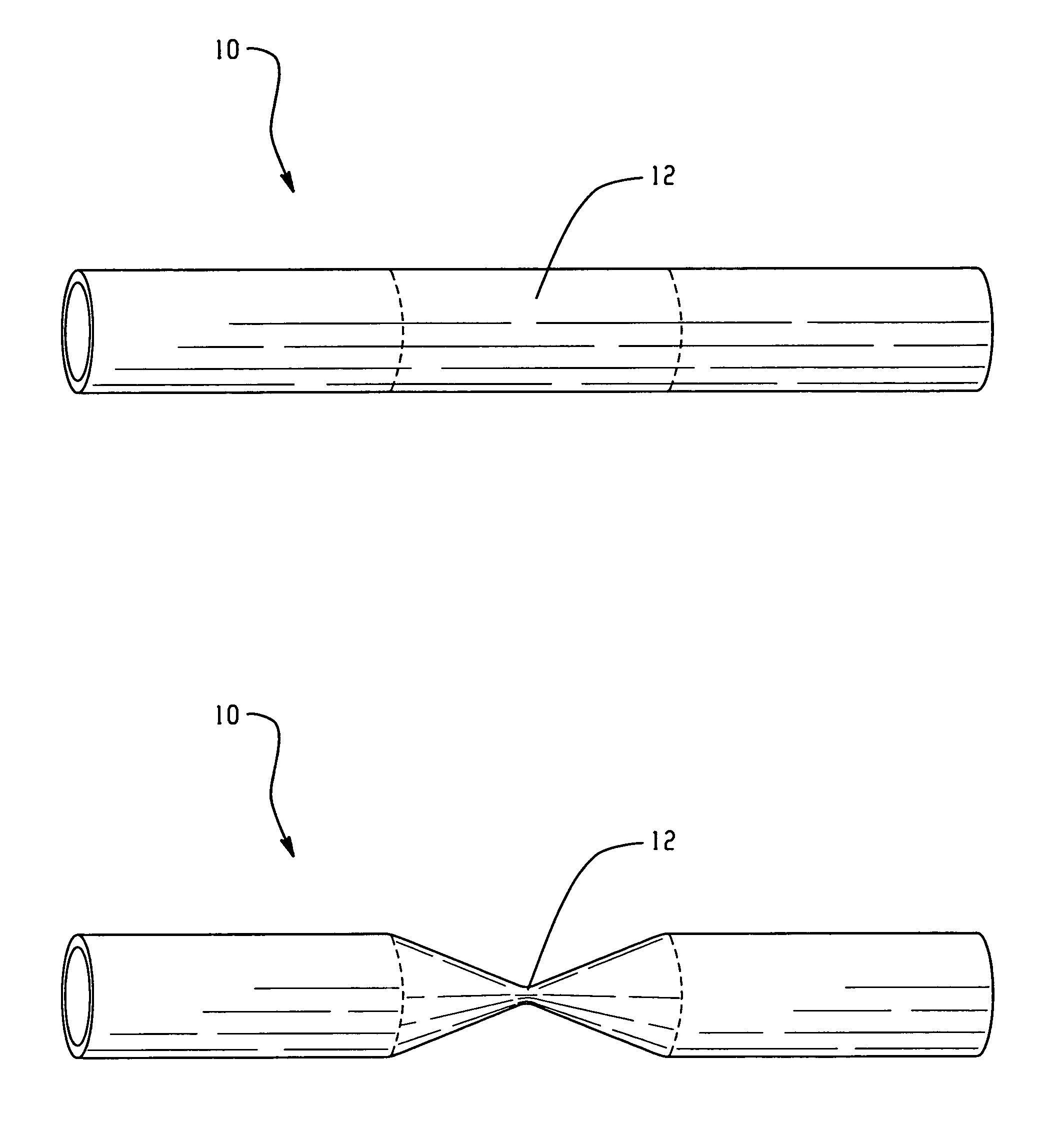

Shape memory polymer conduits and methods of use

ActiveUS7607634B2Diaphragm valvesOperating means/releasing devices for valvesMobile vehicleRespirator

A method comprises applying a thermal activation signal to a conduit comprising a shape memory polymer, causing a change in at least one property of the shape memory polymer, and regulating fluid flow through the conduit by the change in the at least one property of the shape memory polymer. A conduit comprises a shape memory polymer in an amount effective to regulate fluid flow through the conduit by a change in at least one property of the shape memory polymer caused by application of a thermal activation signal. The conduits and methods disclosed herein may find use as drinking utensils, respirator tubes, pump intake tubes, motor vehicle cooling system bypass hoses, motor vehicle engine oil filter bypass hoses, or motor vehicle powertrain fluid circulation hoses.

Owner:GM GLOBAL TECH OPERATIONS LLC

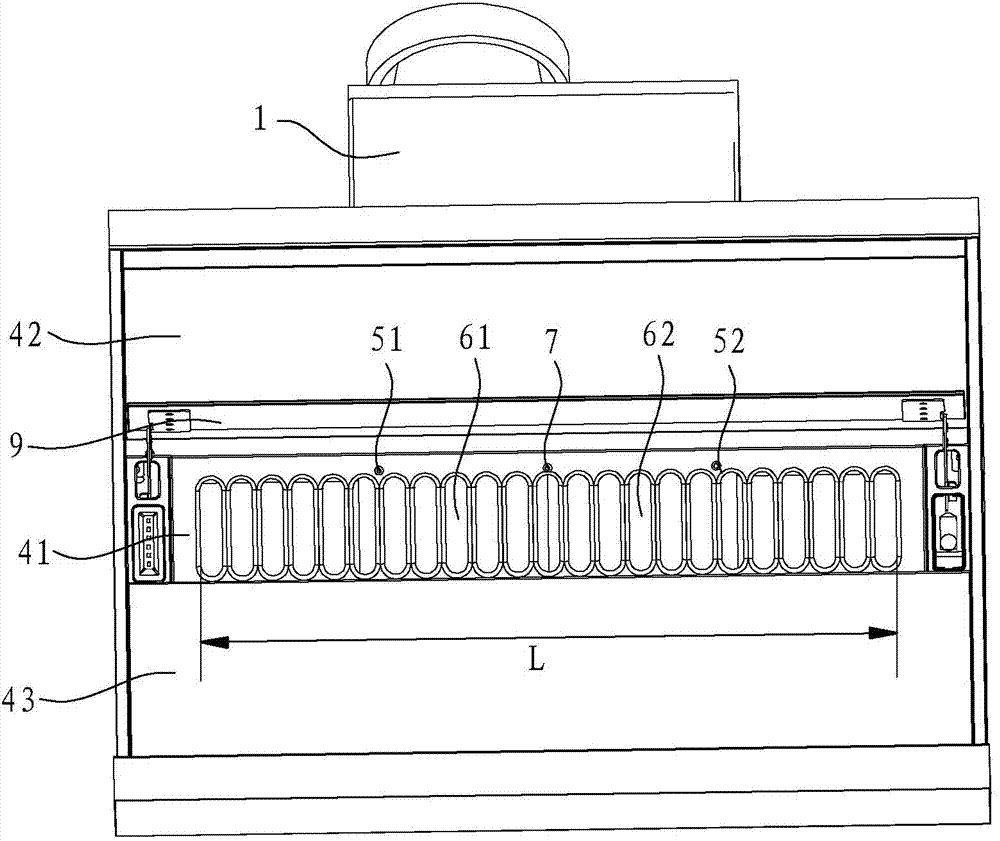

Near suction type range hood

ActiveCN104329708AImprove the smoke effectDomestic stoves or rangesLighting and heating apparatusEngineeringOil filter

A near suction type range hood comprises a body, a smoke collecting hood and a blower fan; a panel and an oil filtering screen are installed on the smoke collecting hood, and the near suction type range hood is characterized in that a first temperature sensor senses the temperature an air inlet zone at the left side of the oil filtering screen; a second temperature sensor senses the temperature of an air inlet zone at the right side of the oil filtering screen; a first flow bypassing plate and a second flow bypassing plate are both installed at the back side of the oil filtering screen; a driving mechanism is installed at the back side of the oil filtering plate, drives the first flow bypassing plate and / or the second flow bypassing plate to make transverse left-right movement according to the sensed temperatures, and enables the air inlet area of two sides of the oil filtering screen to be matched with the temperature of the same-side air inlet zone. The near suction type range hood has the advantages that the near suction type range hood determines the heating status of two sides by utilizing the temperature sensors to sense the temperature filed distribution at the left and right sides of the oil filtering screen, and then determines the possibly-appeared large smoke and small smoke directions in advance, the near suction type range hood employs the driving mechanism to drive the first flow bypassing plate and the second flow bypassing plate to make transverse left-right movement for adjusting the left and right air inlet area and further for adjusting the left and right negative-pressure zone distribution, thereby improving the oil and smoke suction effect.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

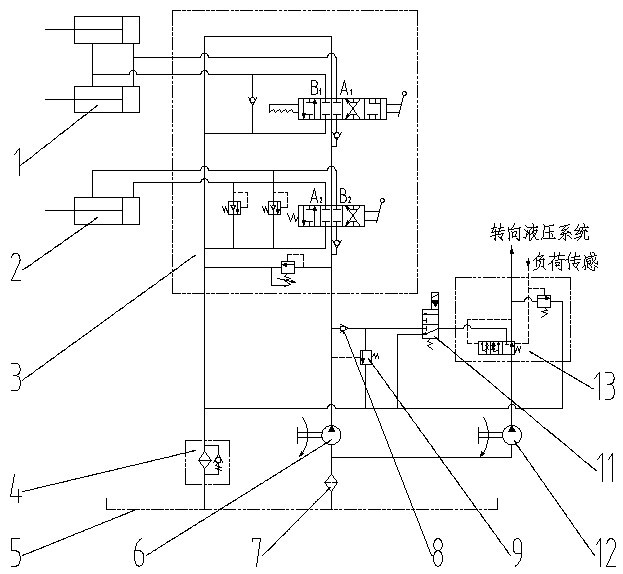

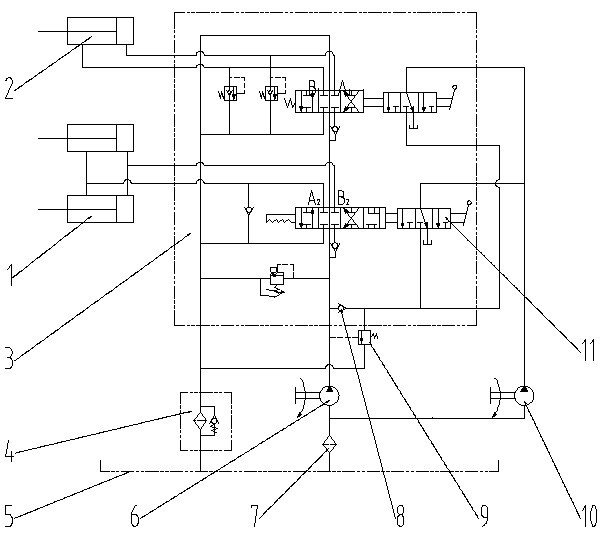

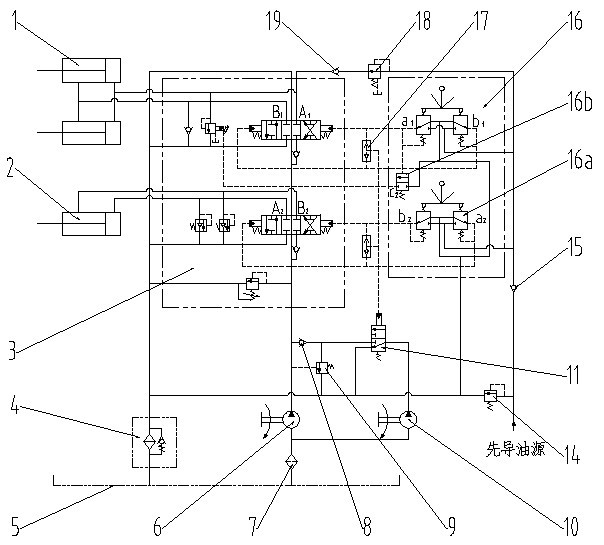

Hydraulic system of loading machine working device

InactiveCN102518170AOptimal Power MatchingSolve the problem that cannot be unloadedSoil-shifting machines/dredgersHydraulic cylinderControl engineering

The invention discloses a hydraulic system of a loading machine working device, which belongs to the technical field of engineering machinery. Under different conditions, a handle is adopted to control whether an auxiliary pump and a working pump jointly supply oil for the working device in a flow converging mode, the problems that the hydraulic system of an existing working device is high in power loss and poor in matching of the pump and load, and simultaneously high cost of using two variable pumps is avoided. The hydraulic system of the loading machine working device comprises a movable arm hydraulic cylinder, a rotating bucket hydraulic cylinder, a multi-way reserving valve, an oil filter, an oil tank, the working pump, the auxiliary pump, an equivalent unloading valve and a flow converging control valve. The hydraulic system mainly used for a loading machine and can also be used for other engineering machinery.

Owner:SICHUAN UNIV

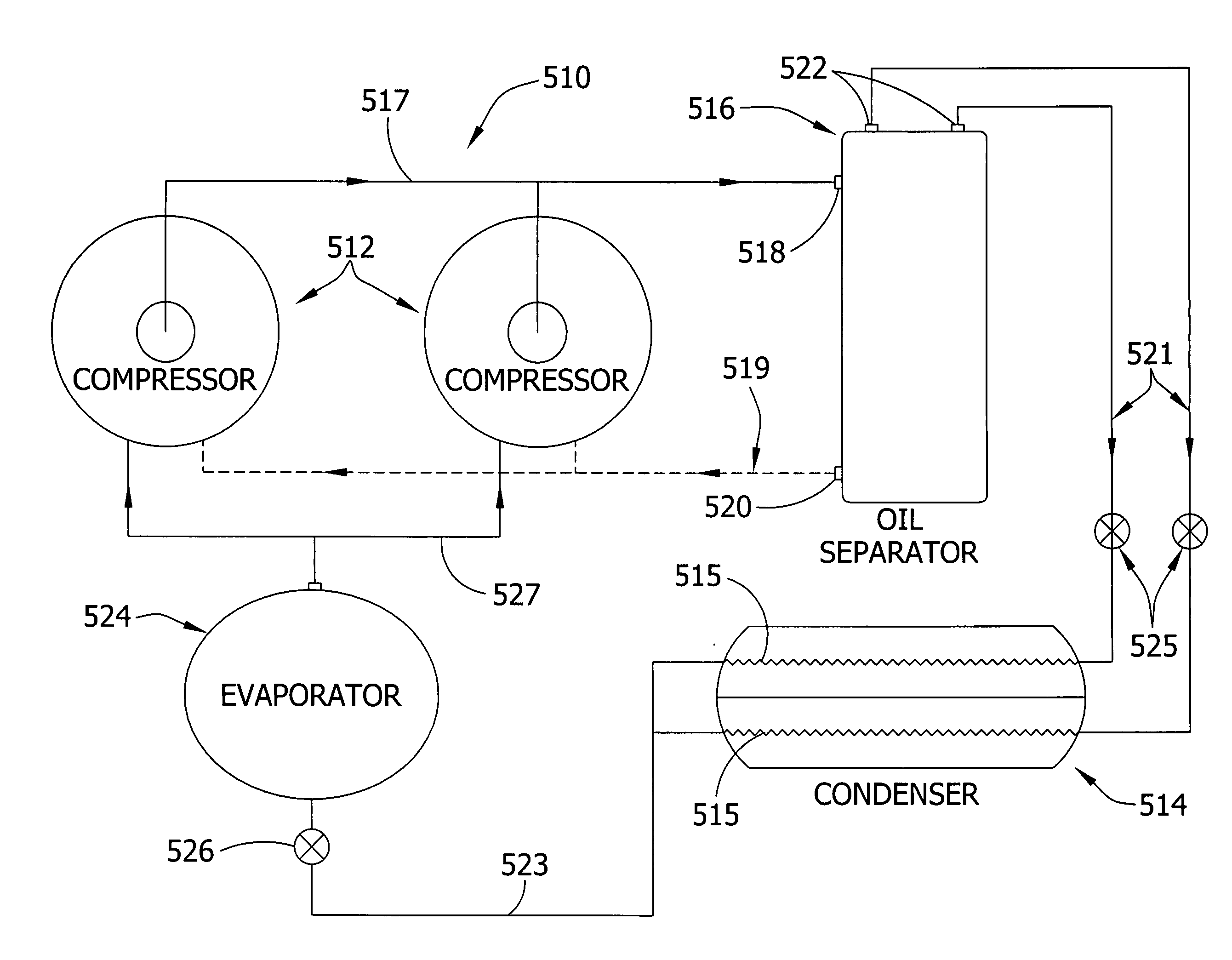

Multiple outlet vertical oil separator

ActiveUS20060196221A1Suppress actionEasy maintenanceRefrigeration componentsRefrigerantRefrigeration

An oil separator for separating oil from a refrigerant gas and oil mixture on the high side of a refrigeration / chiller system comprising, a housing having an upper chamber with an inlet for the refrigerant gas and oil mixture, and having a refrigerant gas outlet therefrom, the outlet conduit being connected to multiple outlets for delivery of refrigerant gas to multiple condenser circuits in the system, and said housing also having a lower chamber with an oil outlet therefrom, and at least one oil filter in said upper chamber for removing oil out of the mixture for transfer to the lower chamber.

Owner:WESTERMEYER AS CO TRUSTEES OF THE GARY W WESTERMEYER TRUST NO 2013 DATED NOV 1 2013 GARY & TERESA

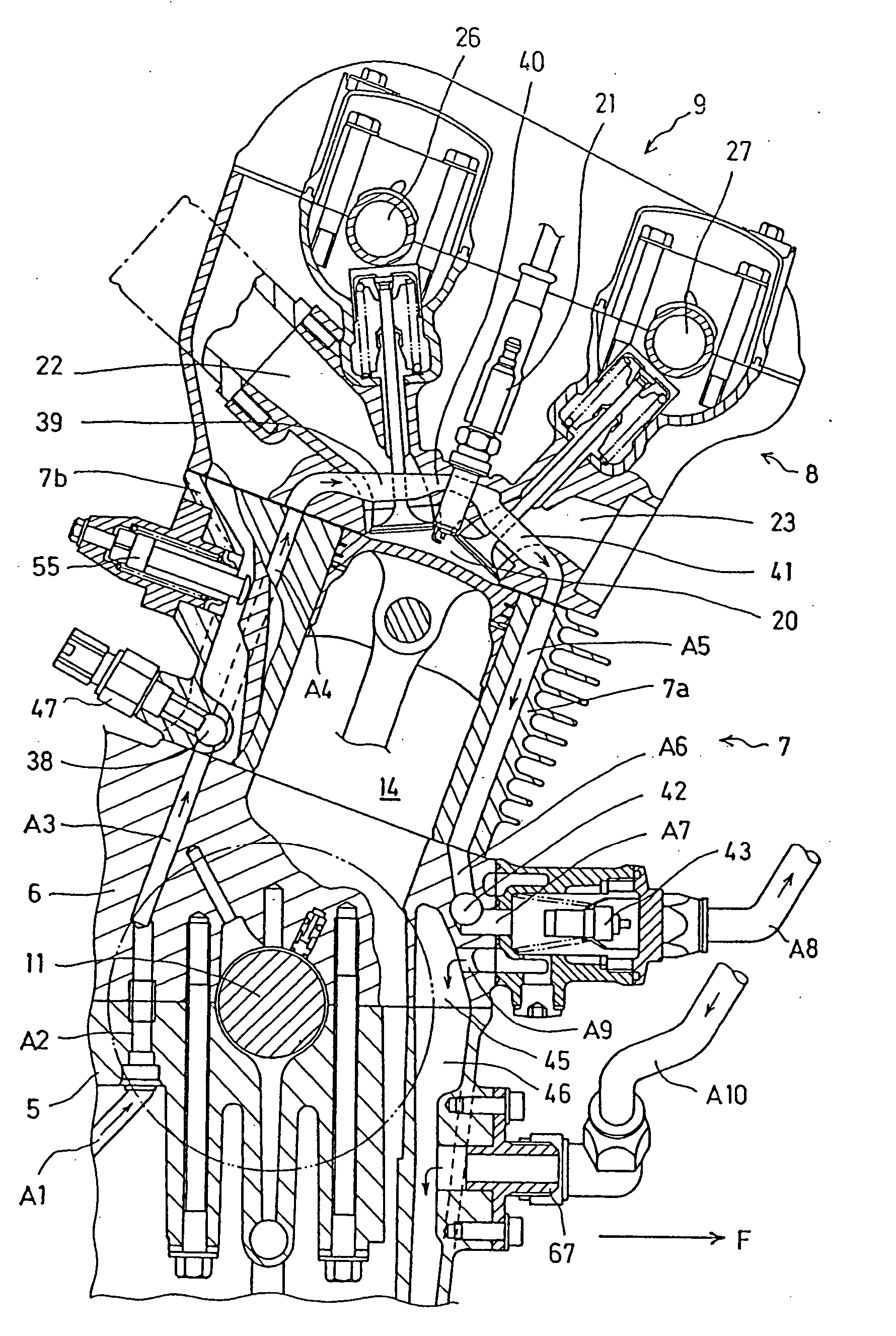

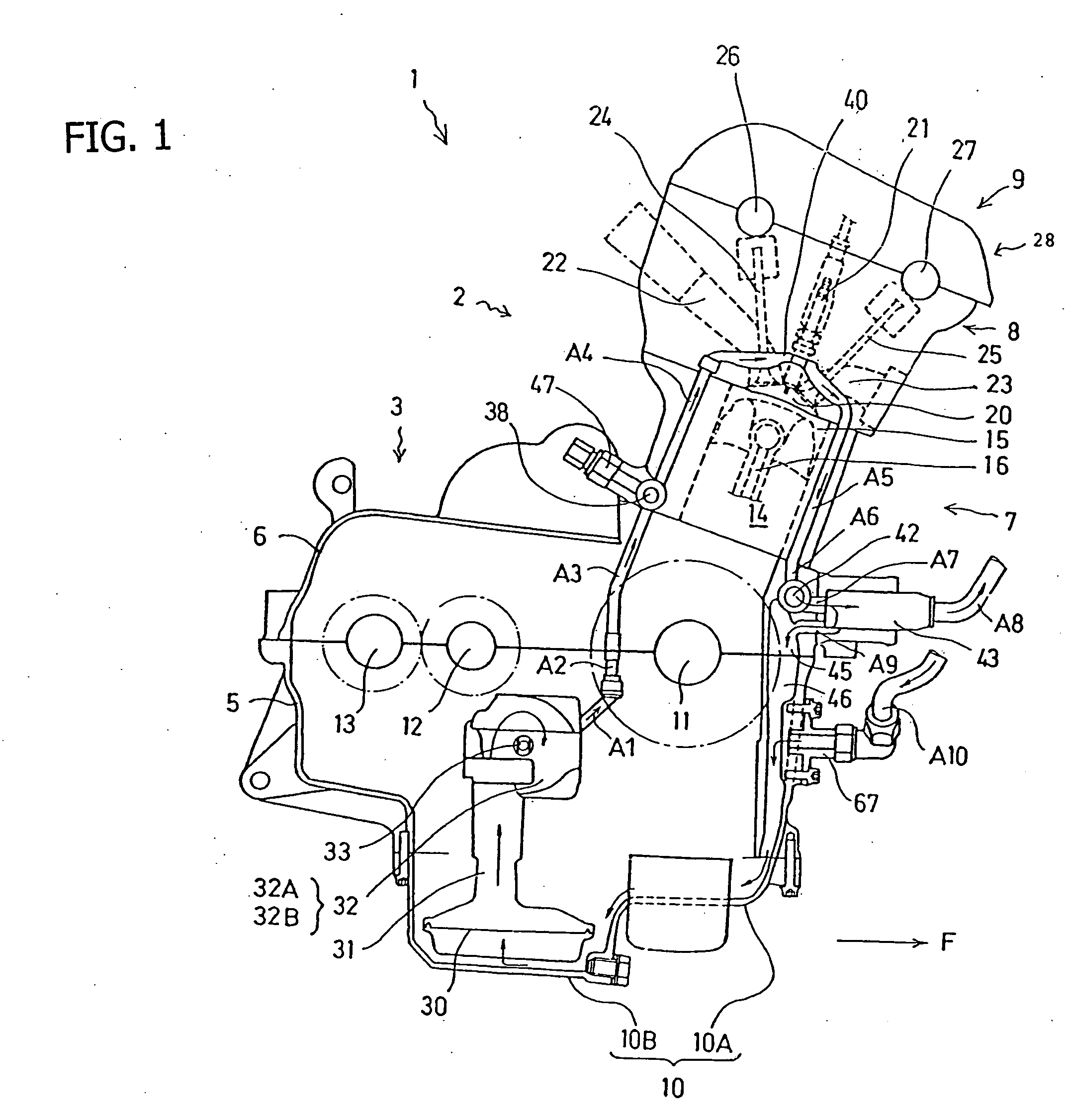

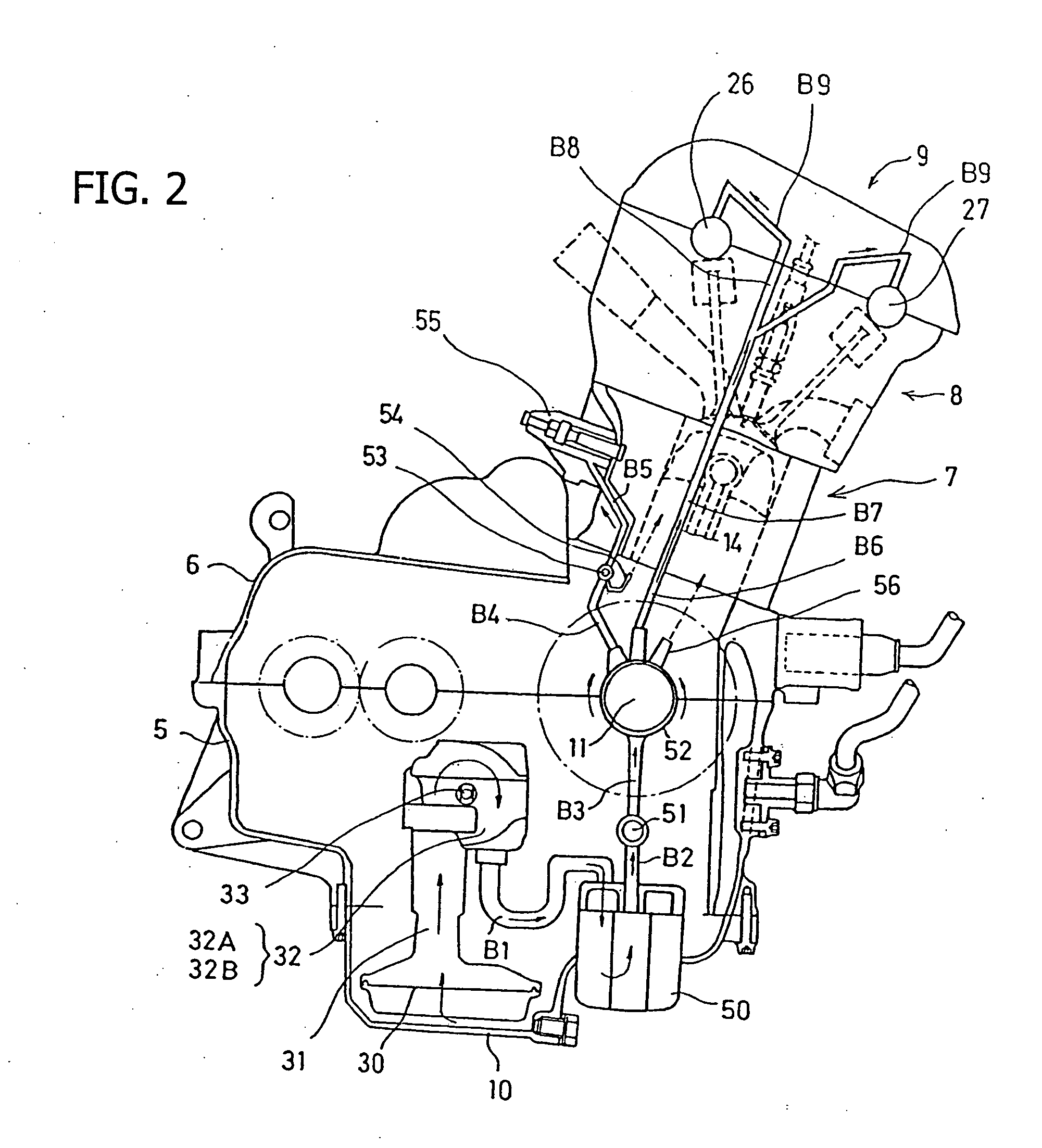

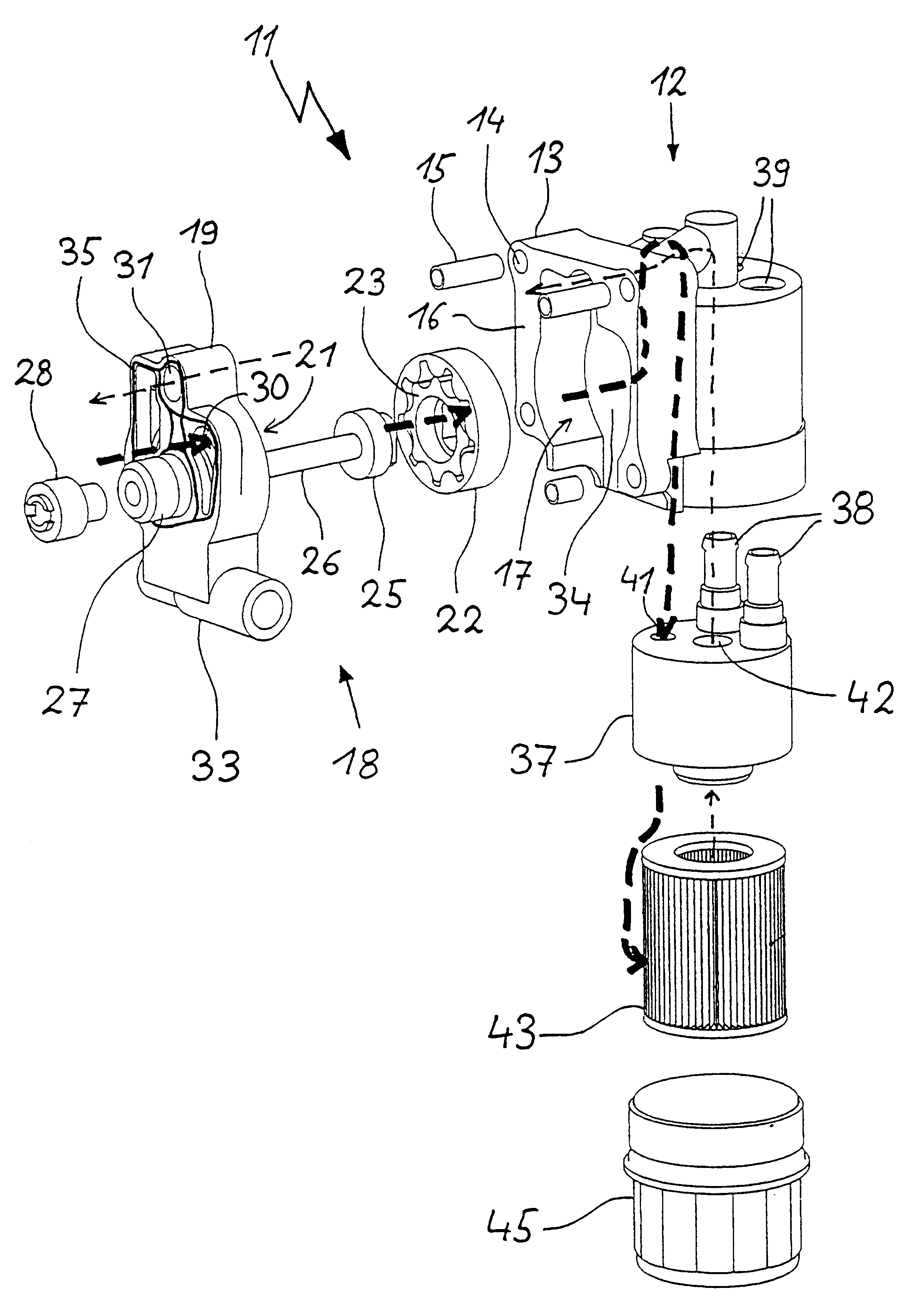

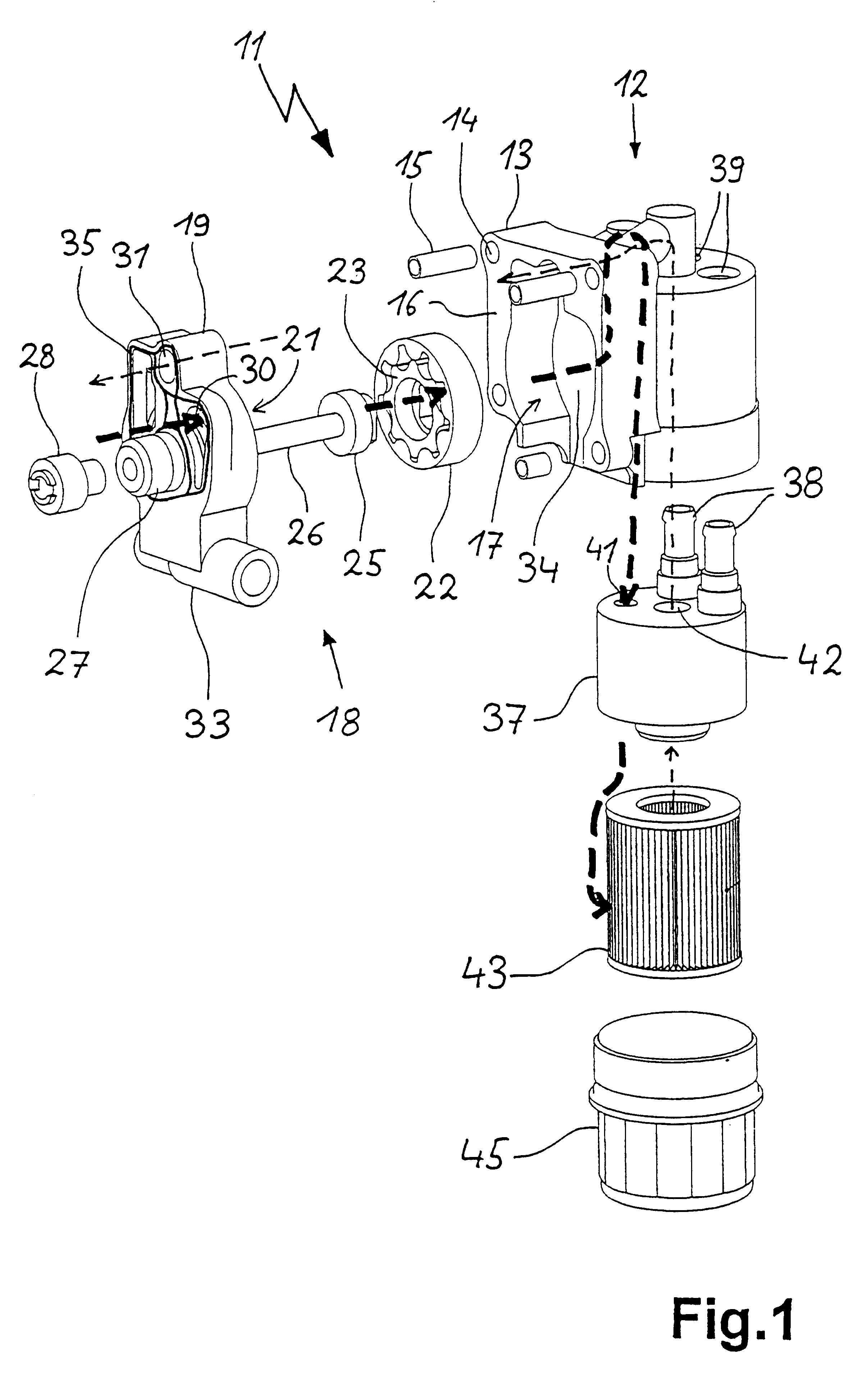

Oil pump module with filter in particular for internal combustion engine lubricating oil

InactiveUS6267094B1Sufficient integrationEasy to installCombustion enginesPressure lubrication with lubrication pumpExternal combustion engineInternal combustion engine

The invention concerns an oil pump module (11) for assembling in one structural unit, an oil pump (18), an oil cooler (37) and an oil filter (43). Said module has a base element (12) capable of being produced in the form of a plastic housing. An oil pump (18) is inserted from one side and, from the other side, an oil cooler (37) and an oil filter (43). Moreover, the oil pump (18) is sealingly pressed, by the base element (12), against an internal combustion engine frame, so as to be driven by said engine. The invention enables to obtain not only a particularly compact and light oil pump module (11), but also an entire pre-assembled unit, with complete module control at the supplier's.

Owner:MANN HUMMEL GMBH

Oil make-up and replenishment oil filter and method of use

An oil filter and oil-additive dispensing device comprising an oil filter and oil additive replenishment system further comprising: a full-flow oil filter; a by-pass oil filter; an oil additive dispensing system; and an on-vehicle controller to dispense additive as required, track additive consumption and signal the need for a replacement system is described. Also a method of using such oil filter and oil-additive dispensing device to extend the useful life of lubricating oil in a vehicle engine is described.

Owner:GM GLOBAL TECH OPERATIONS LLC

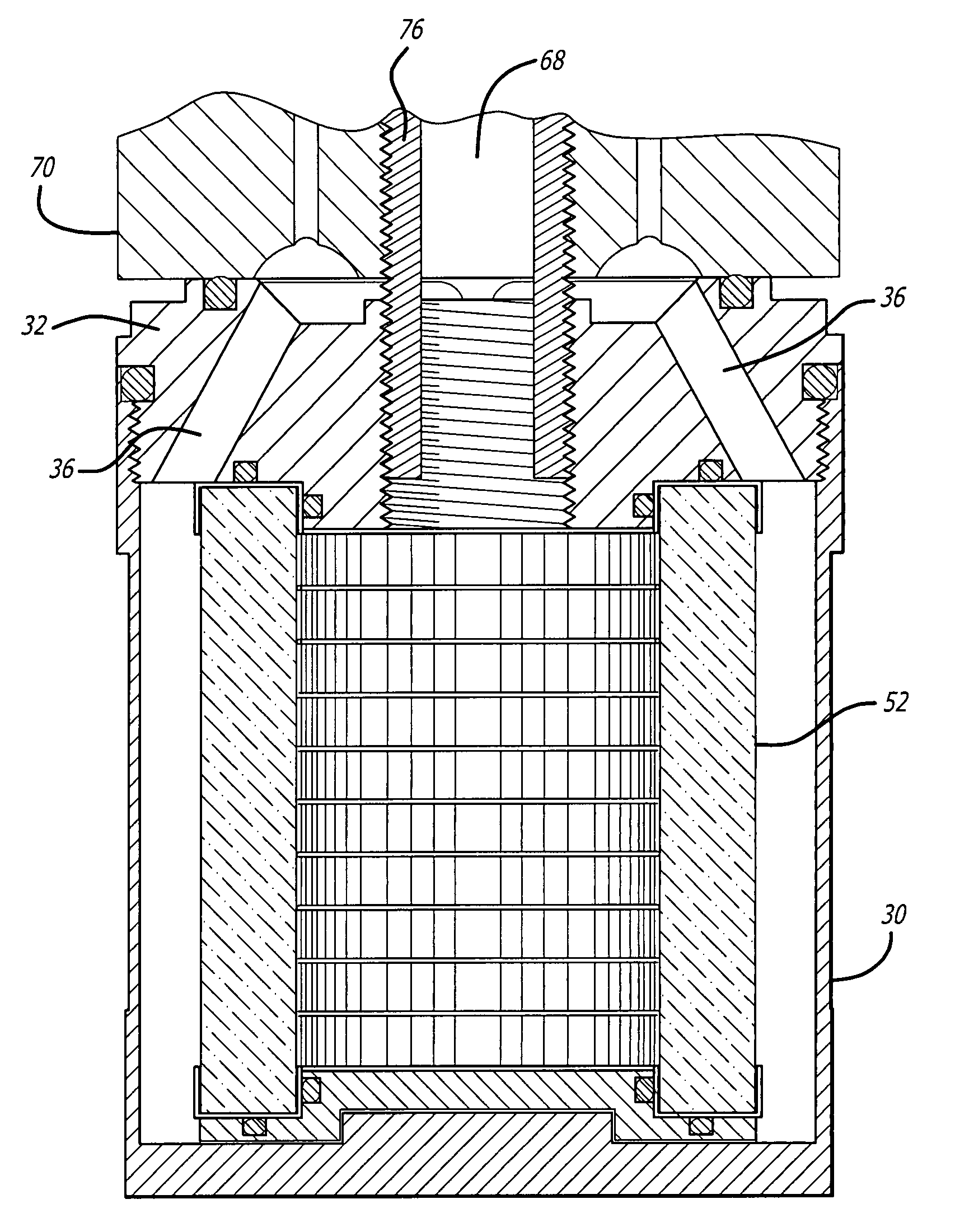

Oil filter assembly

A fluid filter system includes a first segment and a second segment. The first segment includes a filter medium, a notch adapted to engage a detent, and a first actuation member. The second segment includes a detent engageable with the notch to secure the first segment to the second segment, and a second actuation member. The detent is moveable between a locked position and an unlocked position, and is normally biased into the locked position. The second actuation member is configured to cooperate with the first actuation member in order to move the detent between the locked and unlocked positions.

Owner:WEINBERGER KEITH R +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com