Vertical oil separator

a vertical oil separator and oil separator technology, applied in refrigeration, lighting and heating apparatus, refrigeration and liquid storage, etc., can solve the problems of reducing the efficiency of the condenser and evaporator functions, lubricating oil serves no useful purpose outside the compressor, and oil does not have as good heat transfer capability, so as to achieve a high degree of centrifugal action and convenient service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

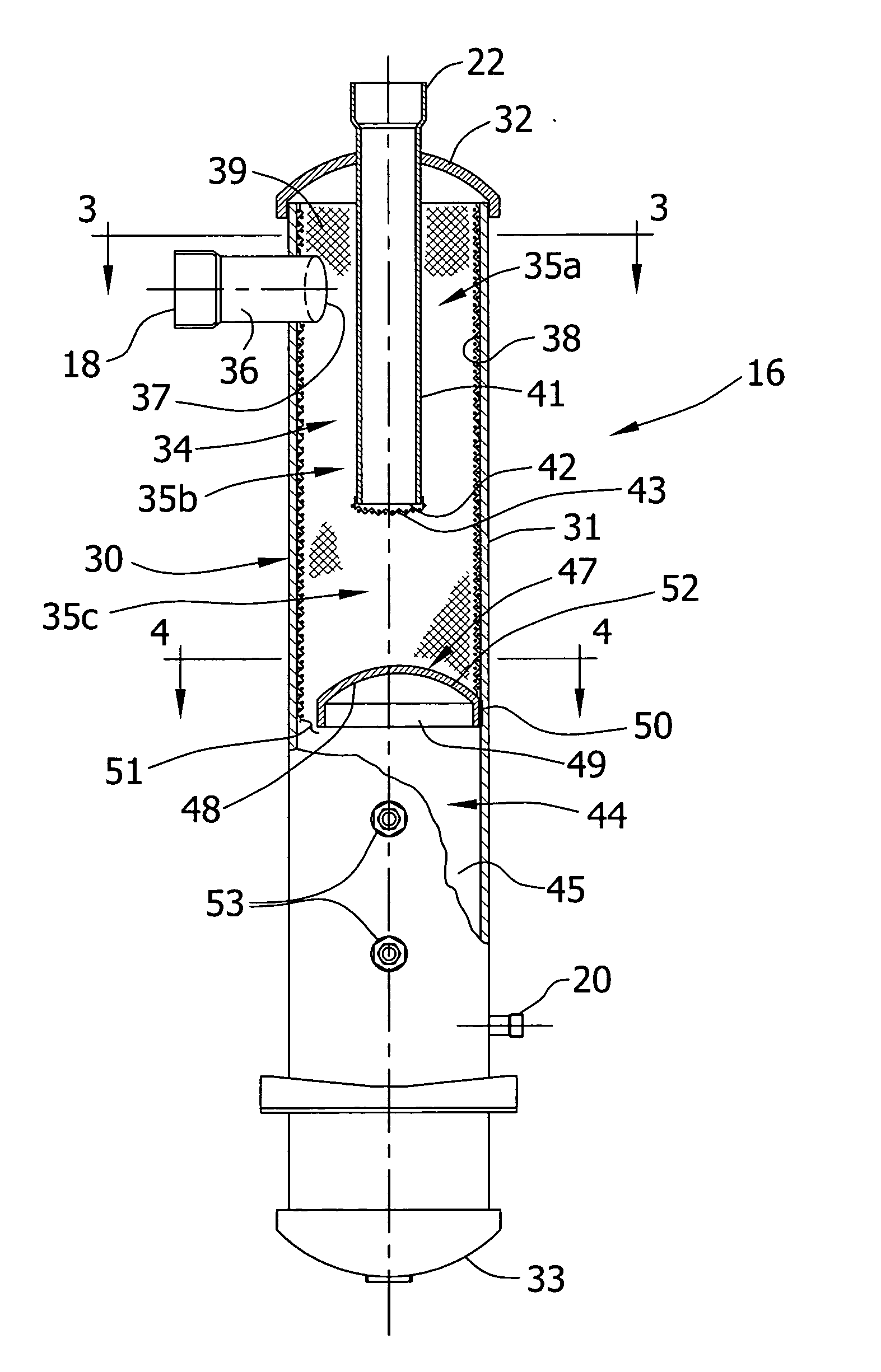

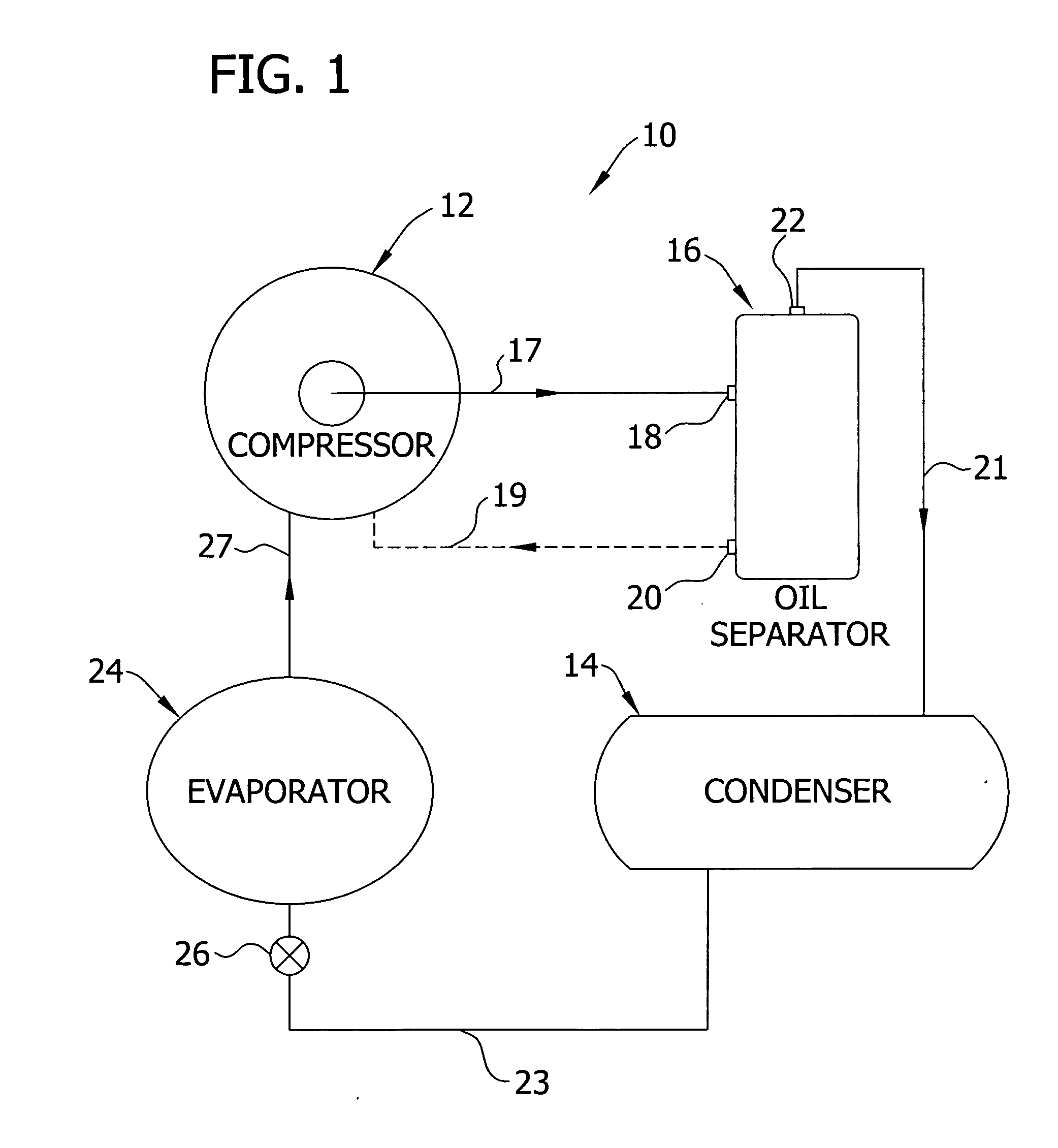

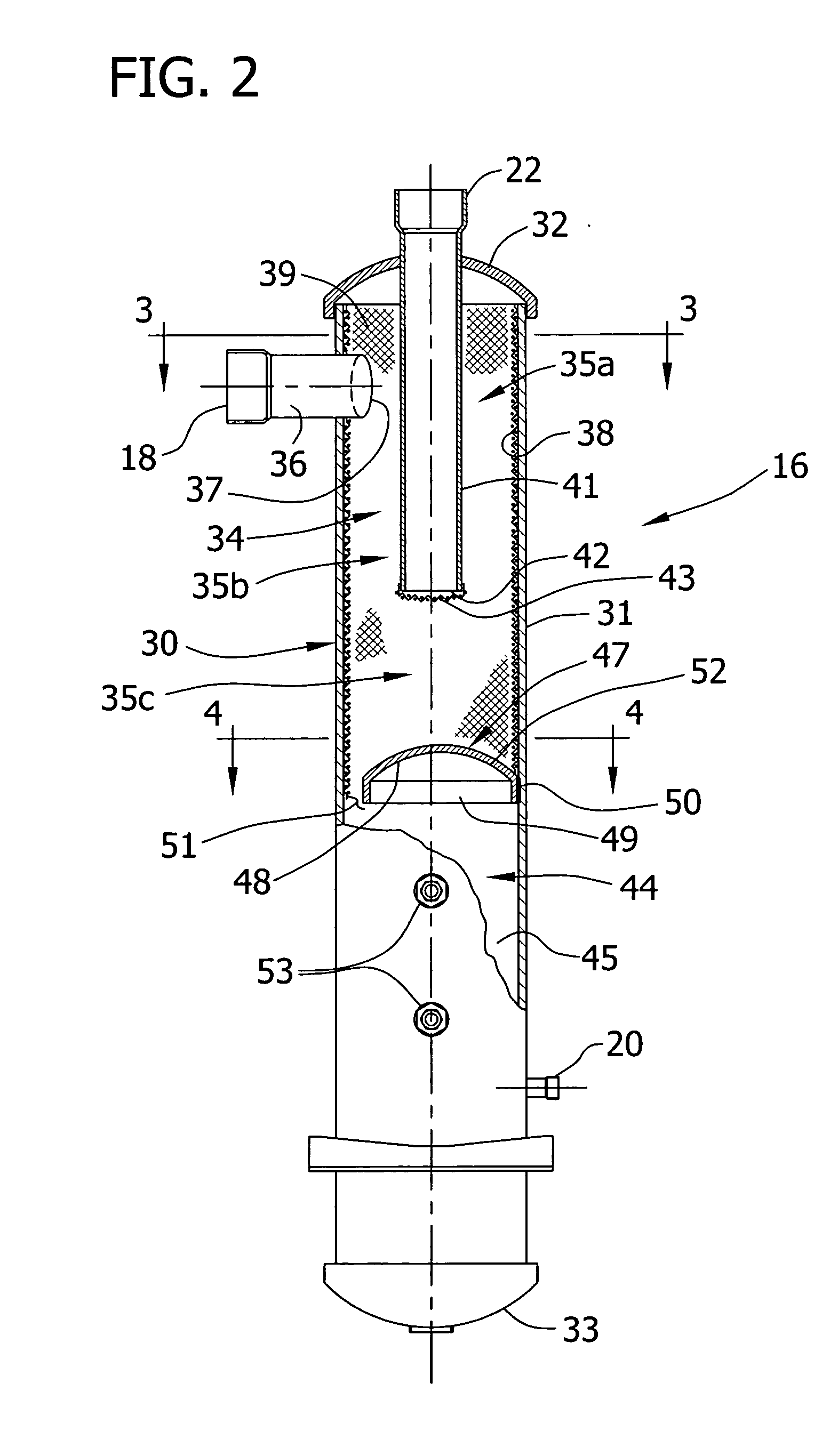

[0023] For the purposes of disclosure, a closed refrigeration or chiller system 10 includes a compressor 12 connected on its high pressure outlet side to a condenser 14 through an oil separator 16 embodying the invention to be described. Typically the compressor 10 requires a large amount of lubricating and cooling oil in operation, and such oil is entrained in the hot compressed refrigerant to form an oil-gas mixture that is discharged on the compressor high side through conduit 17 to the oil separator inlet 18. It has been reported that the oil content in the oil and refrigerant gas mixture from a chiller system compressor is over 50,000 ppm (parts per million). The compressor 12 is also in fluid communication with the oil separator 16 through an oil return conduit 19 from oil outlet 20 through which oil is returned to and maintained in the compressor at a preselected level by a conventional oil level regulator (not shown) or the like. The condenser 14 is connected in fluid commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com