Method and device for recovering and purifying argon in monocrystalline silicon production

A single crystal silicon and argon technology, applied in chemical instruments and methods, inert gas compounds, inorganic chemistry, etc., can solve the problems of low argon recovery rate, complex coupling control of double tower structure, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

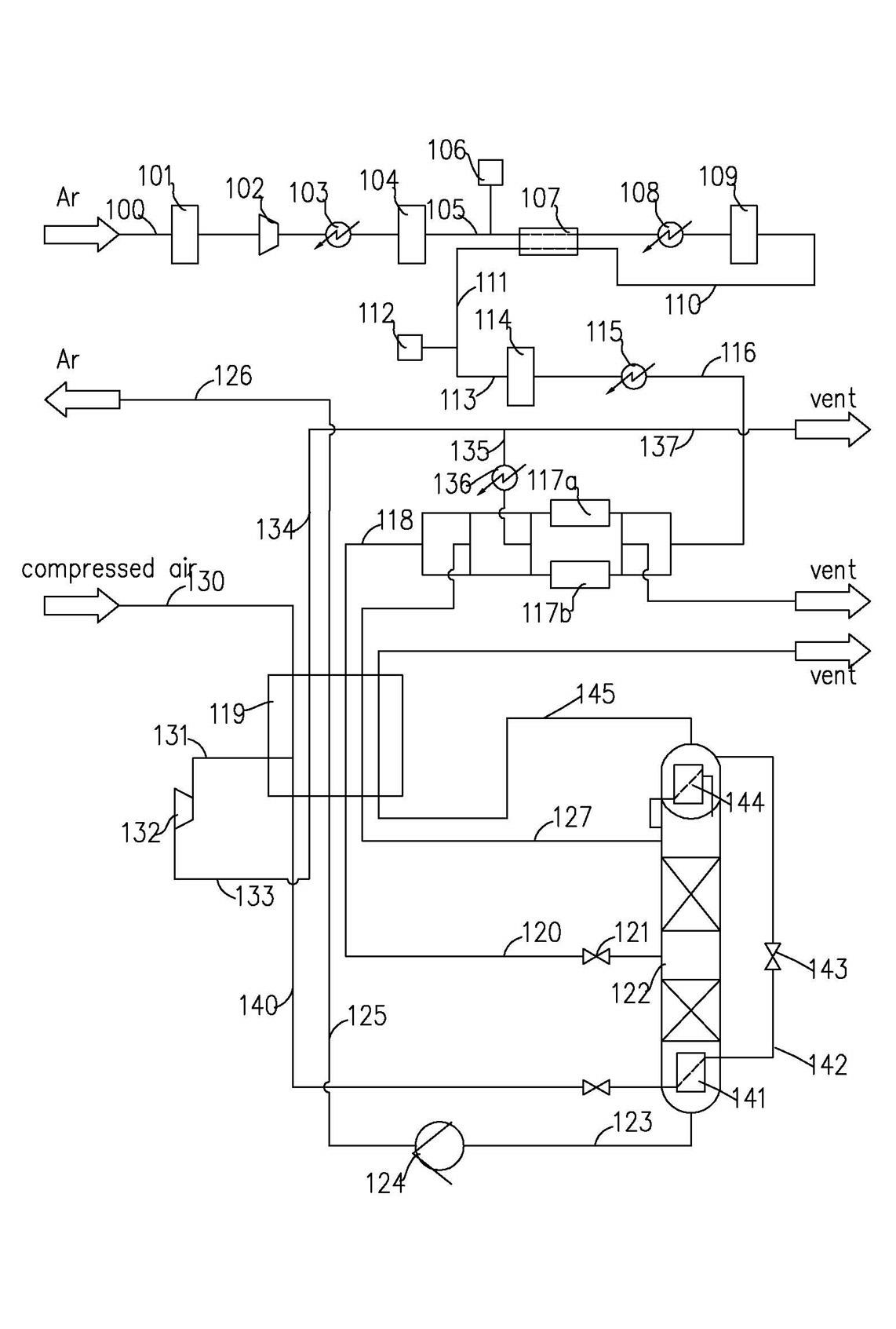

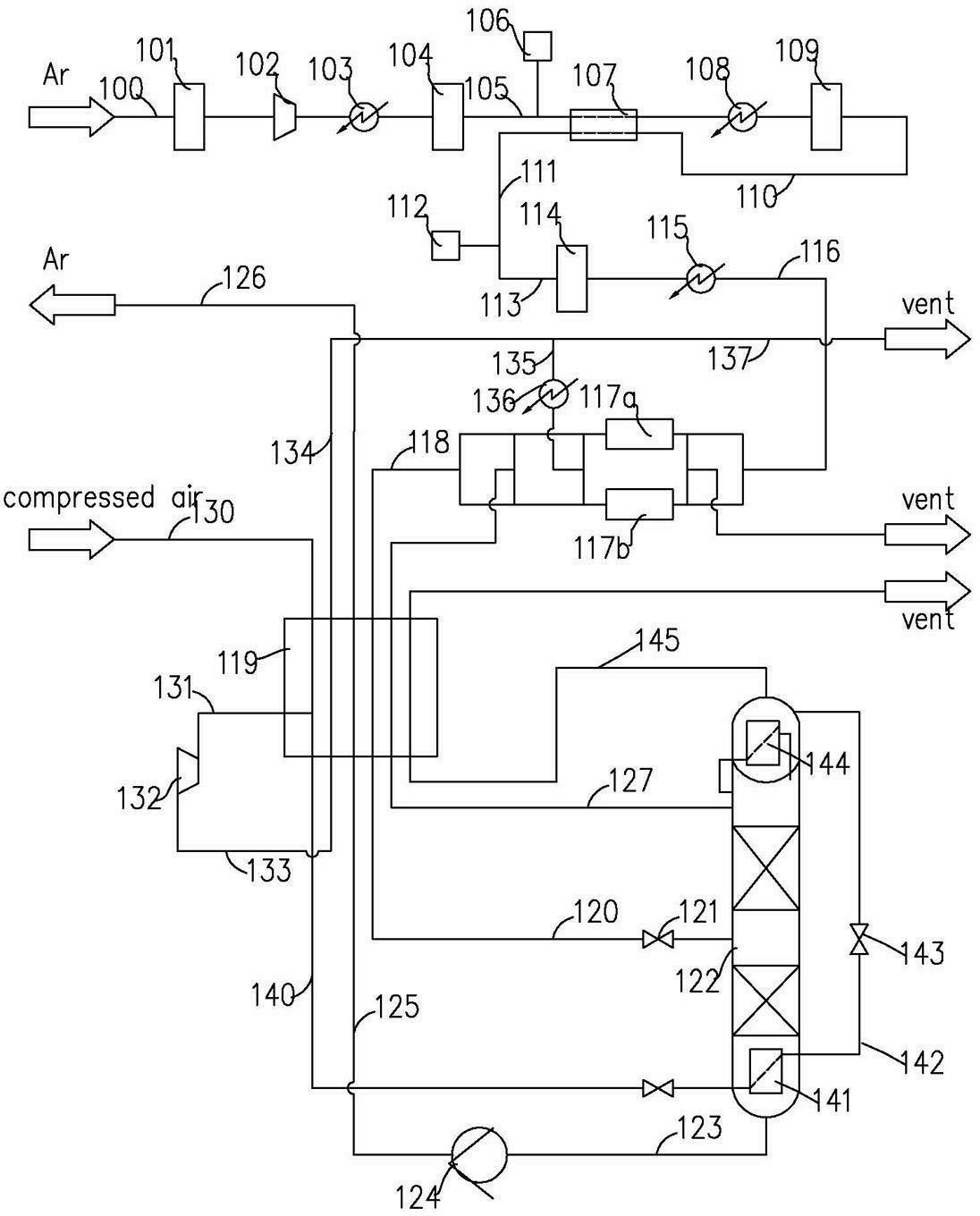

[0044] figure 1 In the shown argon gas recovery and purification device, the argon gas 100 collected from the single crystal furnace enters the crude oil filter 101, and the unit 101 performs crude oil filtration on the argon gas and can be used as a gas buffer tank. After the crude oil is filtered, the argon gas is pressurized to about 0.9 MPa (A) by the argon compressor 102, cooled to normal temperature by the water cooler 103, and then enters the high-precision degreasing system 104 to obtain argon 105, and the 104 unit includes high-efficiency degreasing filter, precision filter, activated carbon filter and high efficiency dust filter. The oil mist and solid particles in the argon gas have been removed in the argon gas 105. The analysis and control unit 106 analyzes oxidative impurities such as methane and carbon monoxide in the argon gas 105 to calculate the oxygen demand for the reaction. Argon 105, 106 unit locations can also be added to crude oil filter 101. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com