Patents

Literature

74 results about "Oxygen excess" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The excess oxygen is the amount of oxygen in the incoming air not used during combustion and is related to percentage excess air. For example, 15% excess air equals 3% oxygen while firing natural gas.

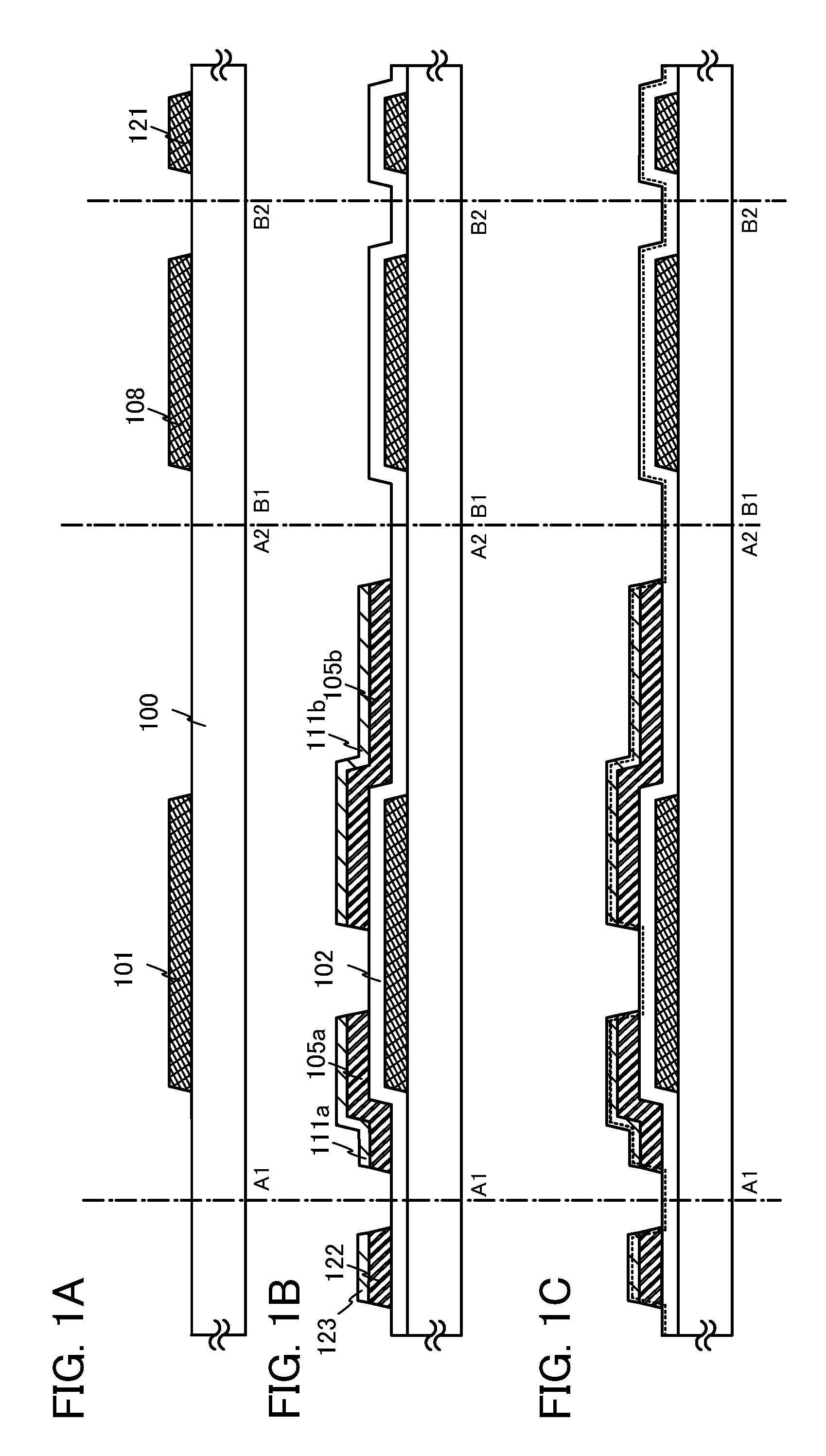

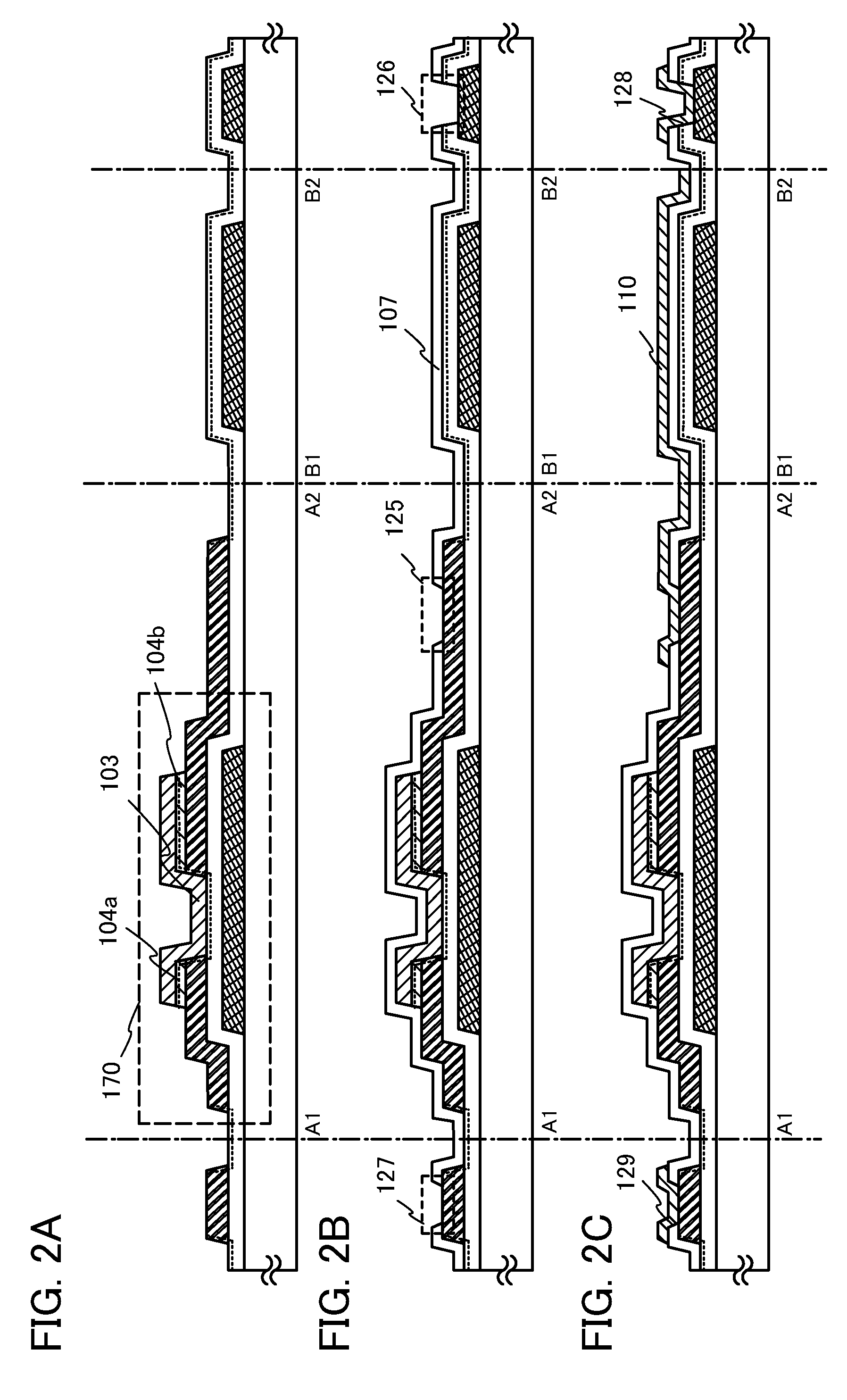

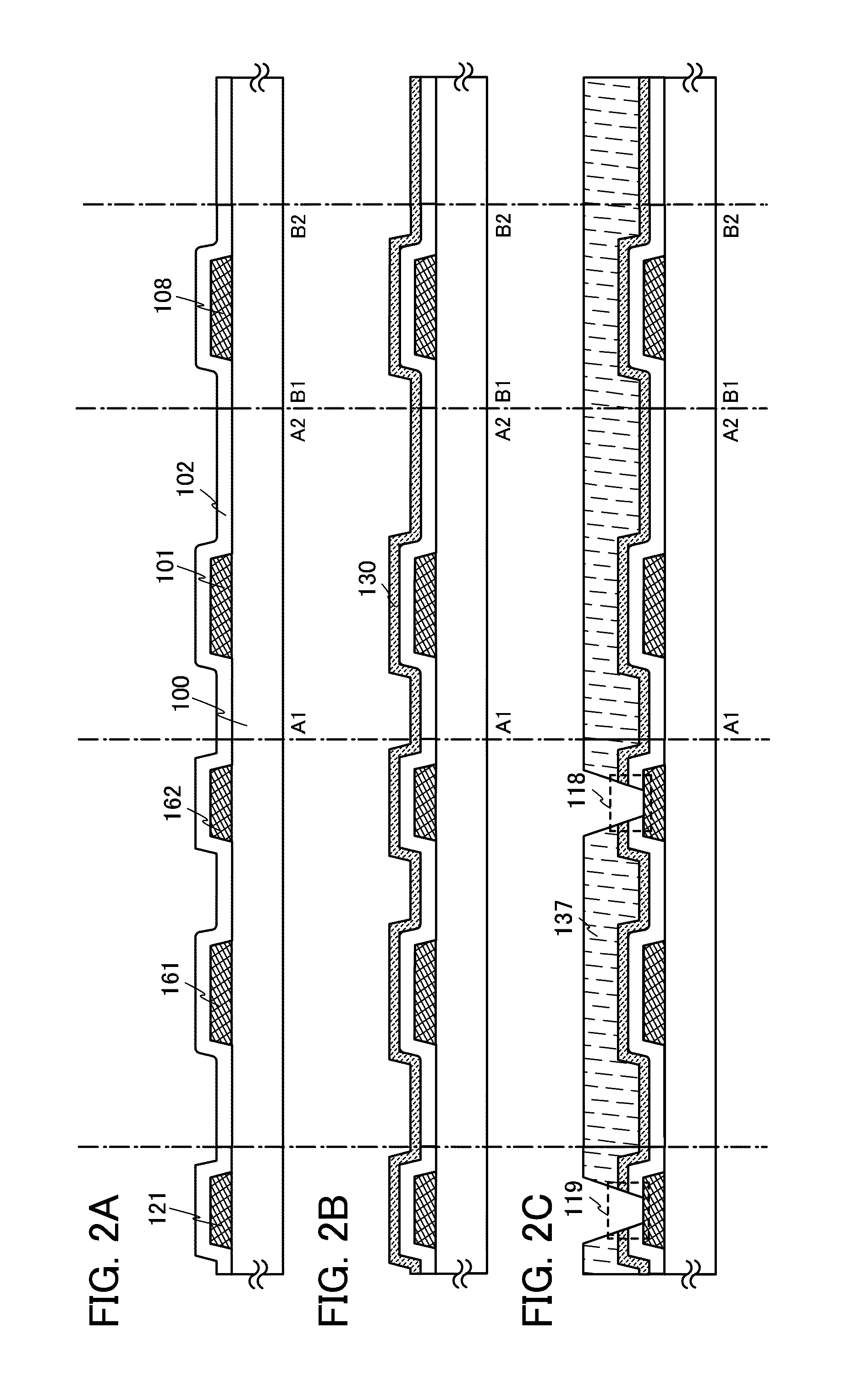

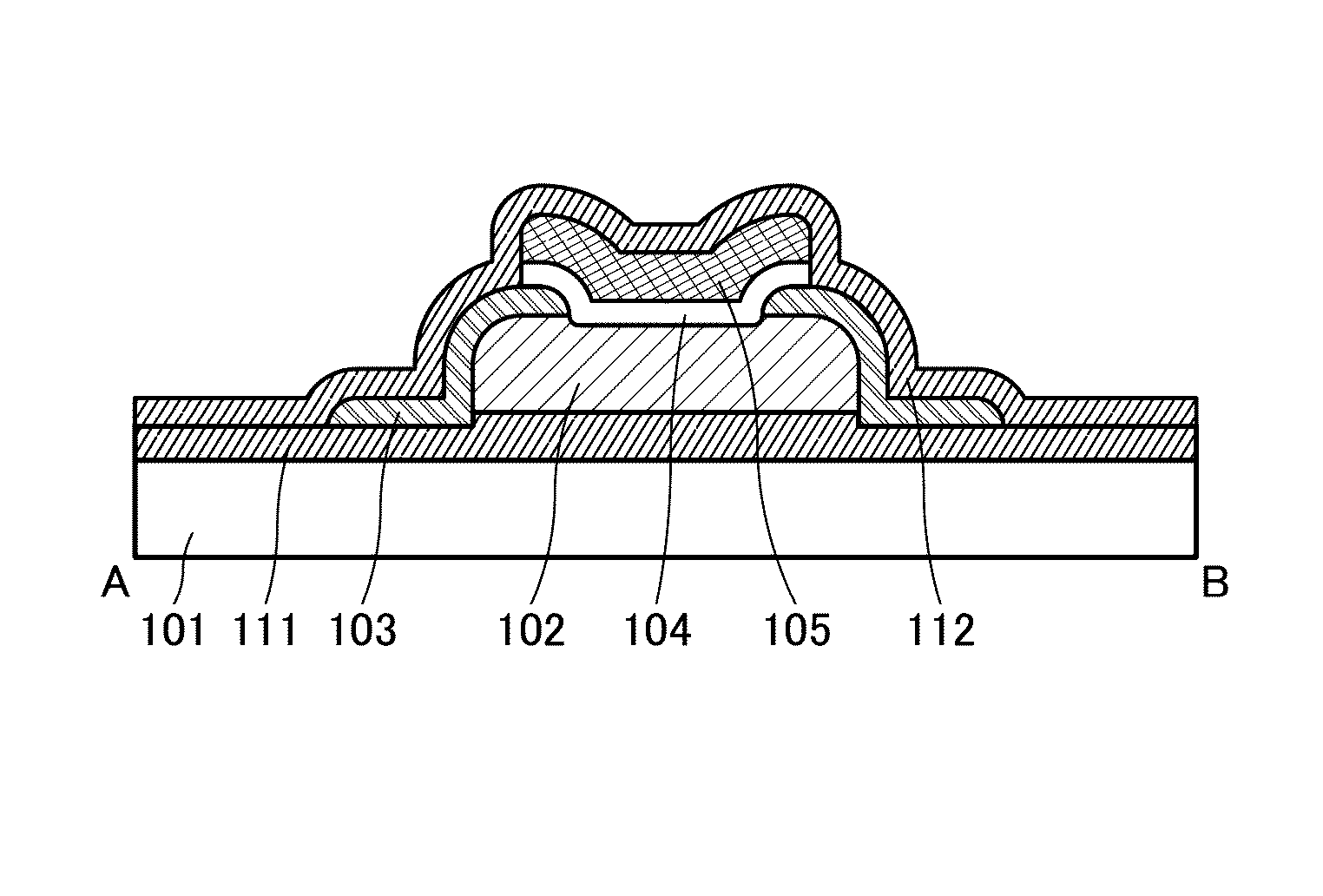

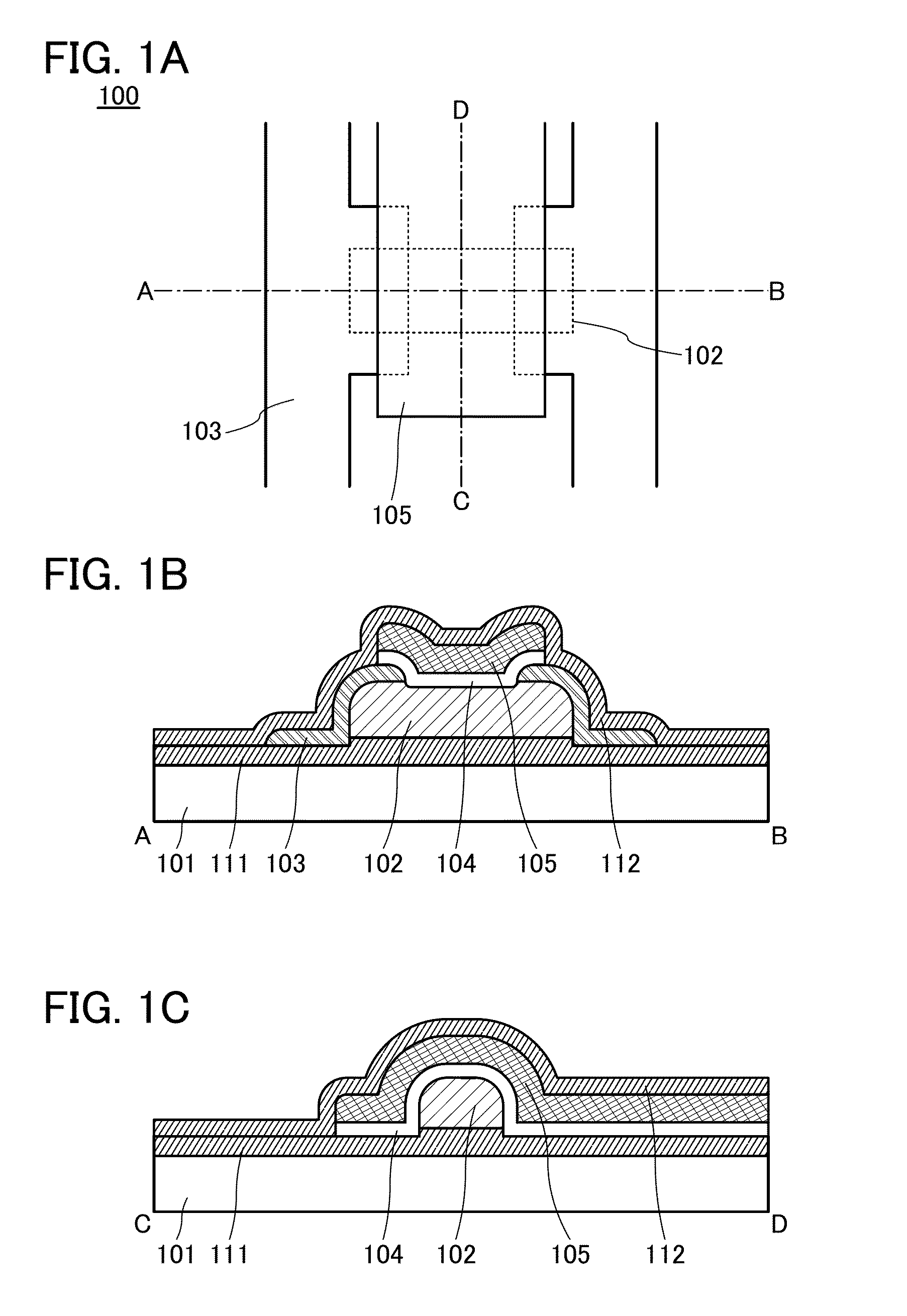

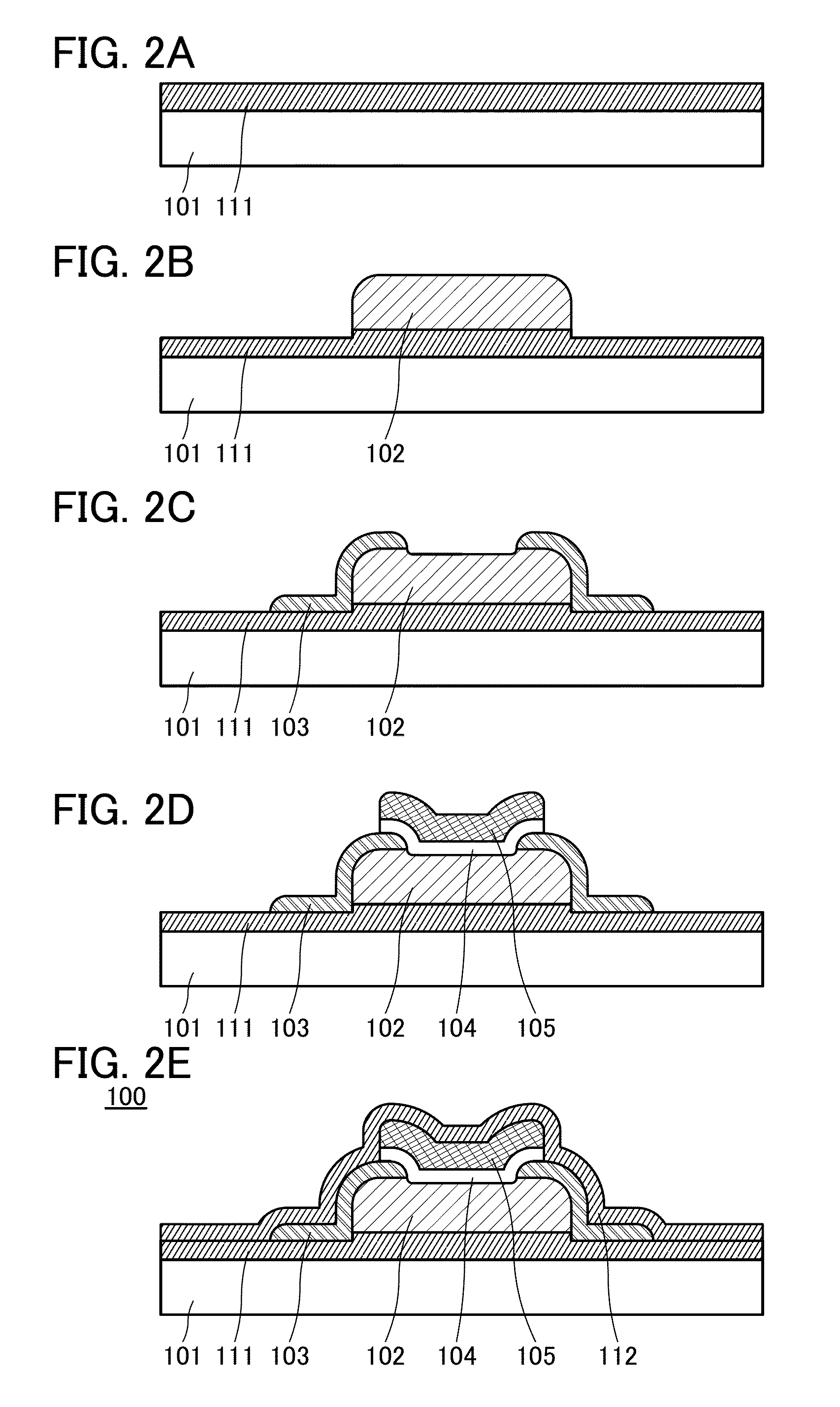

Semiconductor device and method for manufacturing the same

InactiveUS20110101335A1Stable electrical characteristicsReduce impurity concentrationSolid-state devicesSemiconductor/solid-state device manufacturingHydrogen atomDangling bond

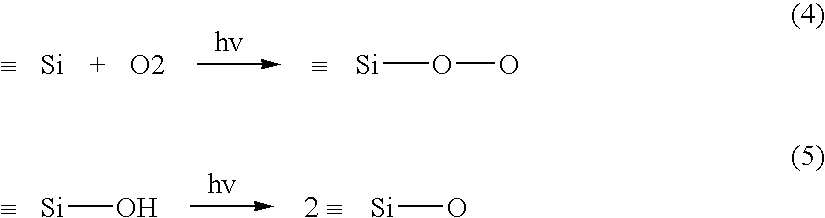

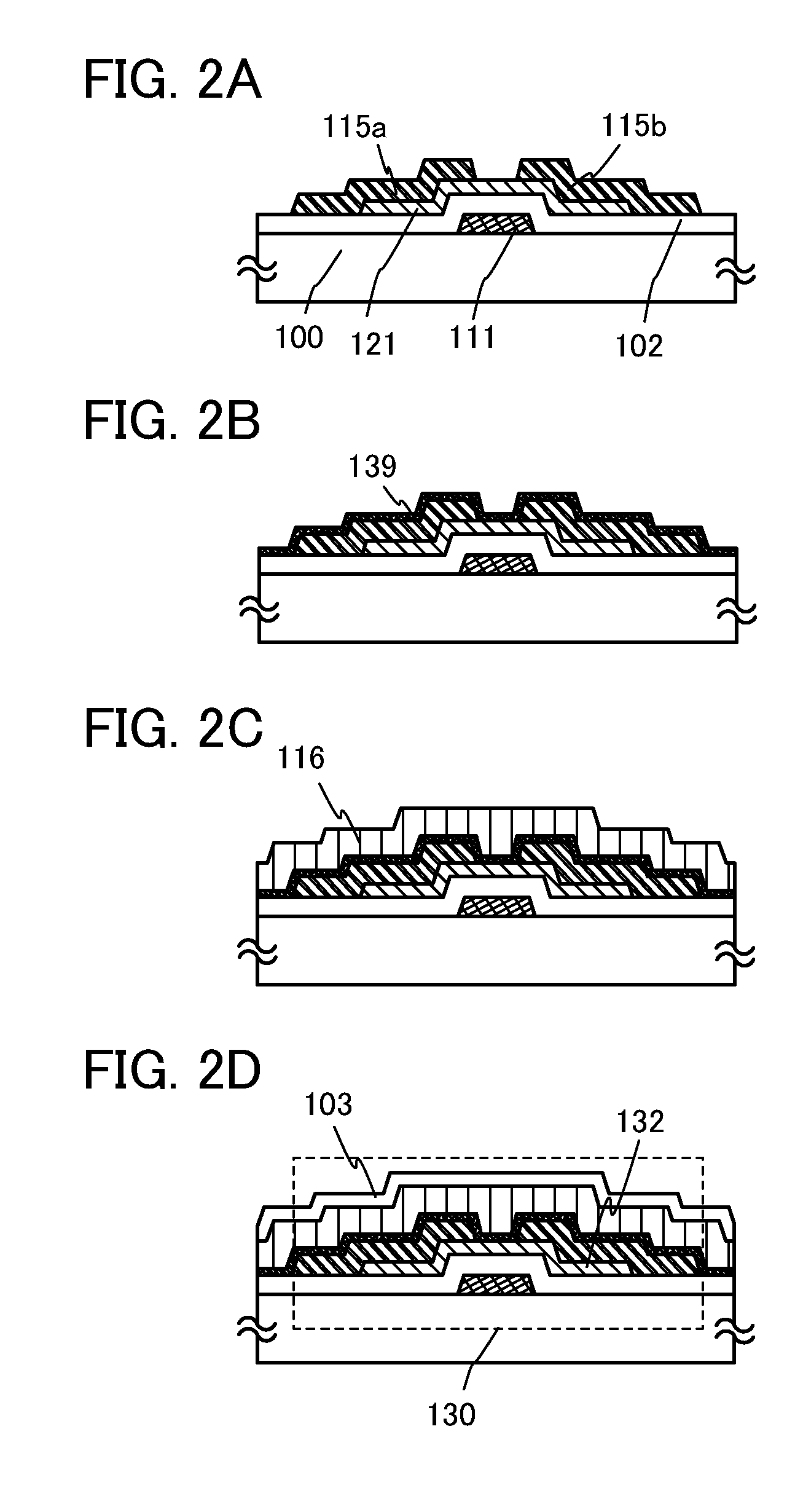

An object is to provide a semiconductor device including an oxide semiconductor with stable electric characteristics can be provided. An insulating layer having many defects typified by dangling bonds is formed over an oxide semiconductor layer with an oxygen-excess mixed region or an oxygen-excess oxide insulating layer interposed therebetween, whereby impurities in the oxide semiconductor layer, such as hydrogen or moisture (a hydrogen atom or a compound including a hydrogen atom such as H2O), are moved through the oxygen-excess mixed region or oxygen-excess oxide insulating layer and diffused into the insulating layer. Thus, the impurity concentration of the oxide semiconductor layer is reduced.

Owner:SEMICON ENERGY LAB CO LTD

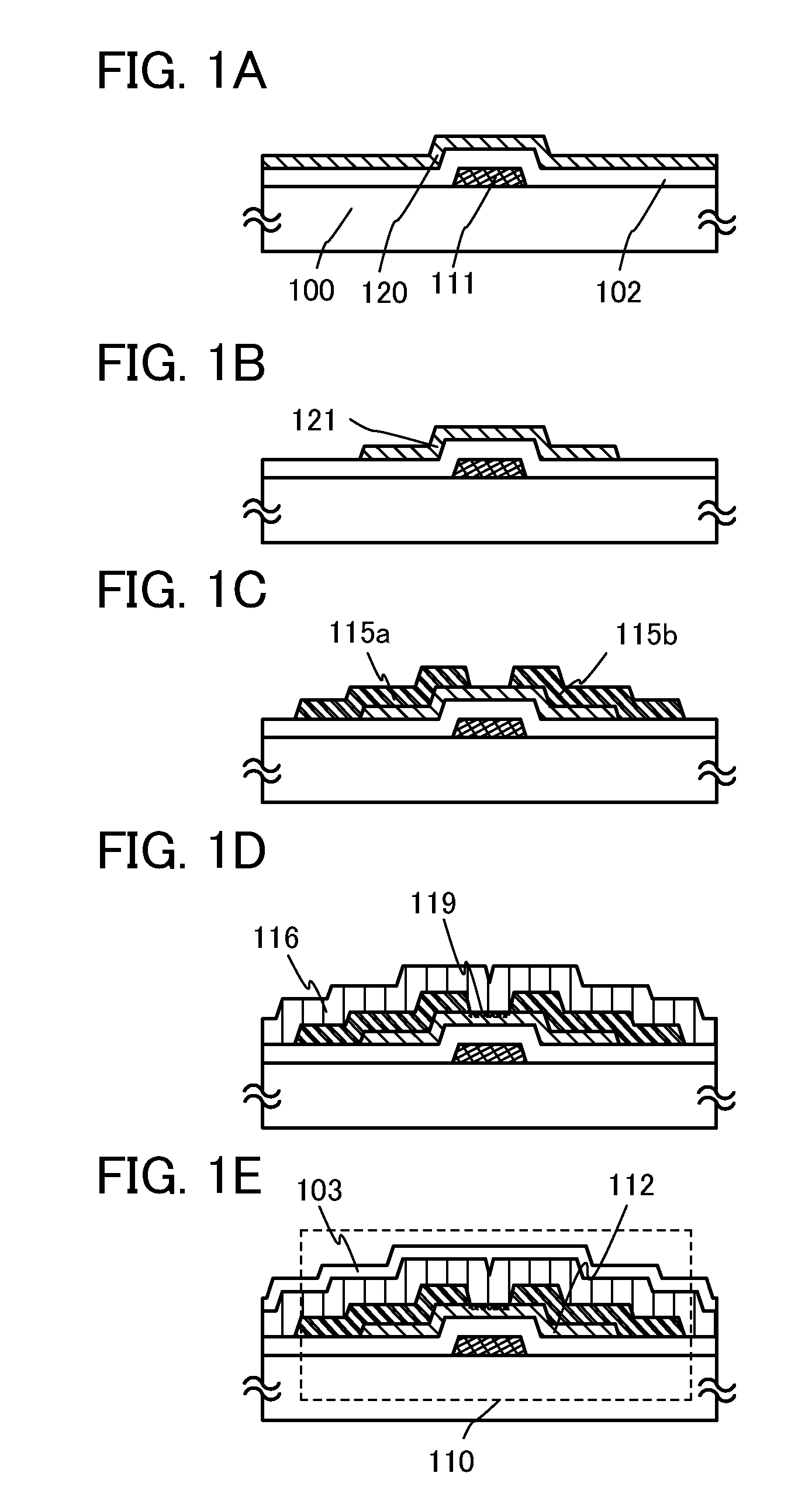

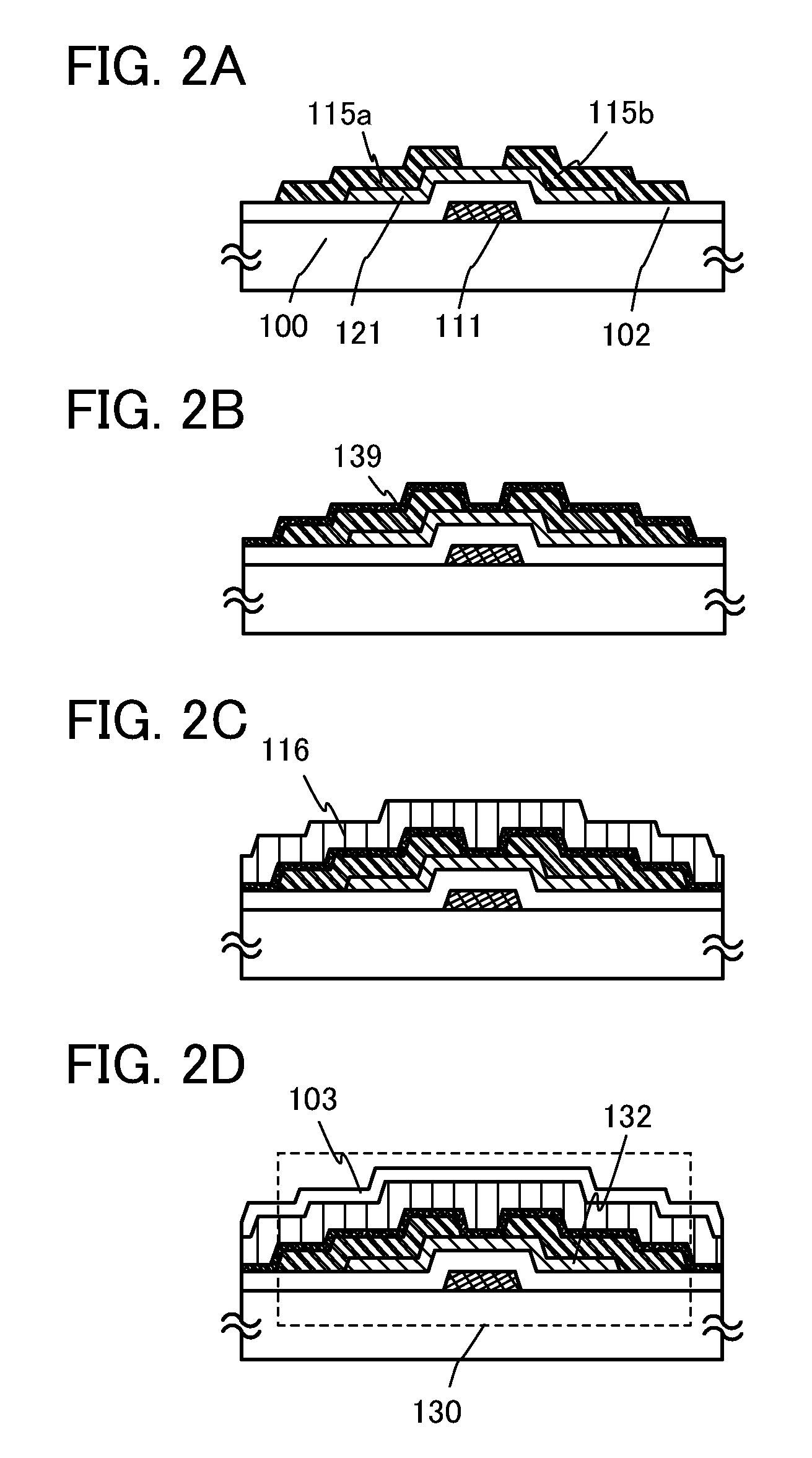

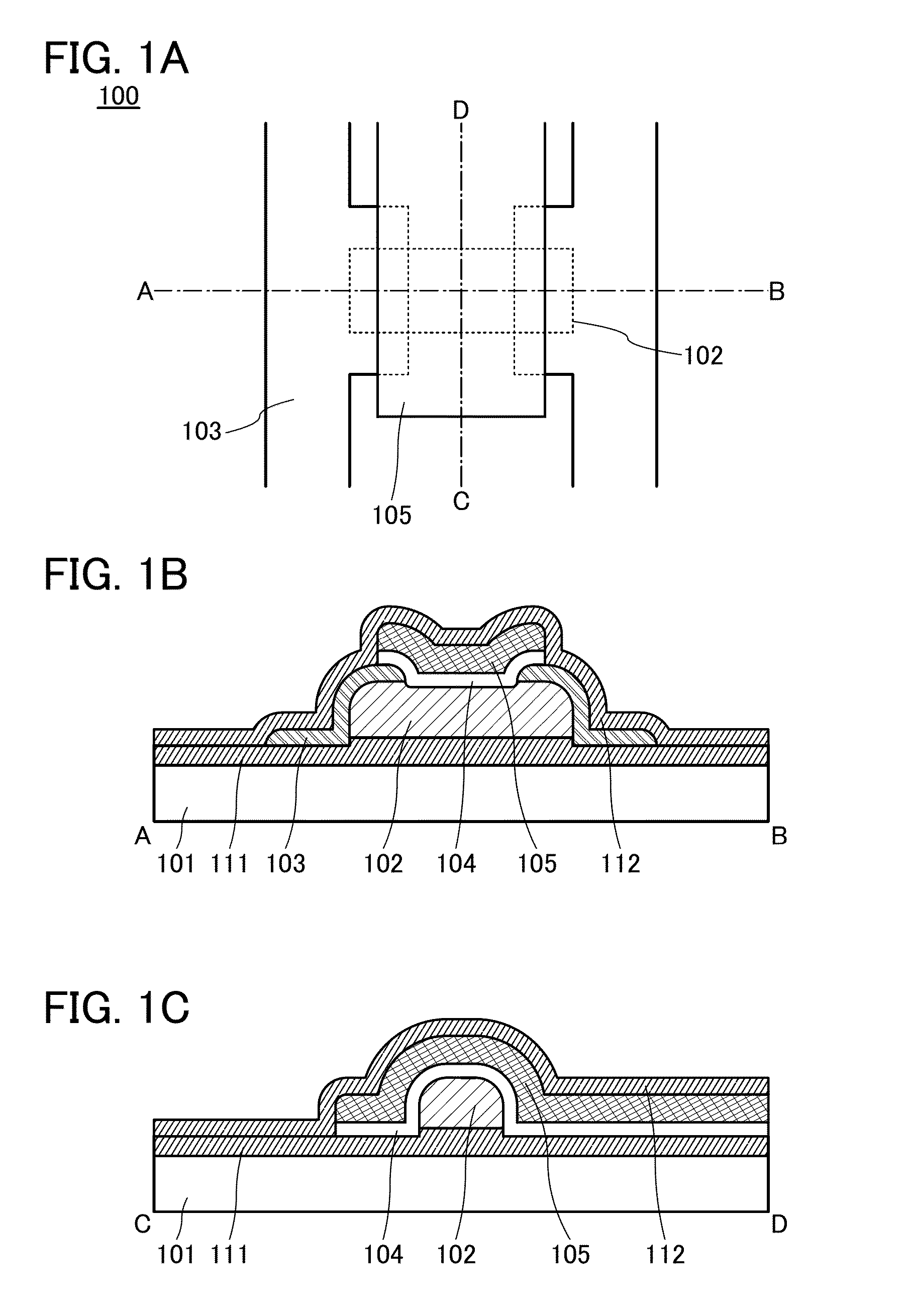

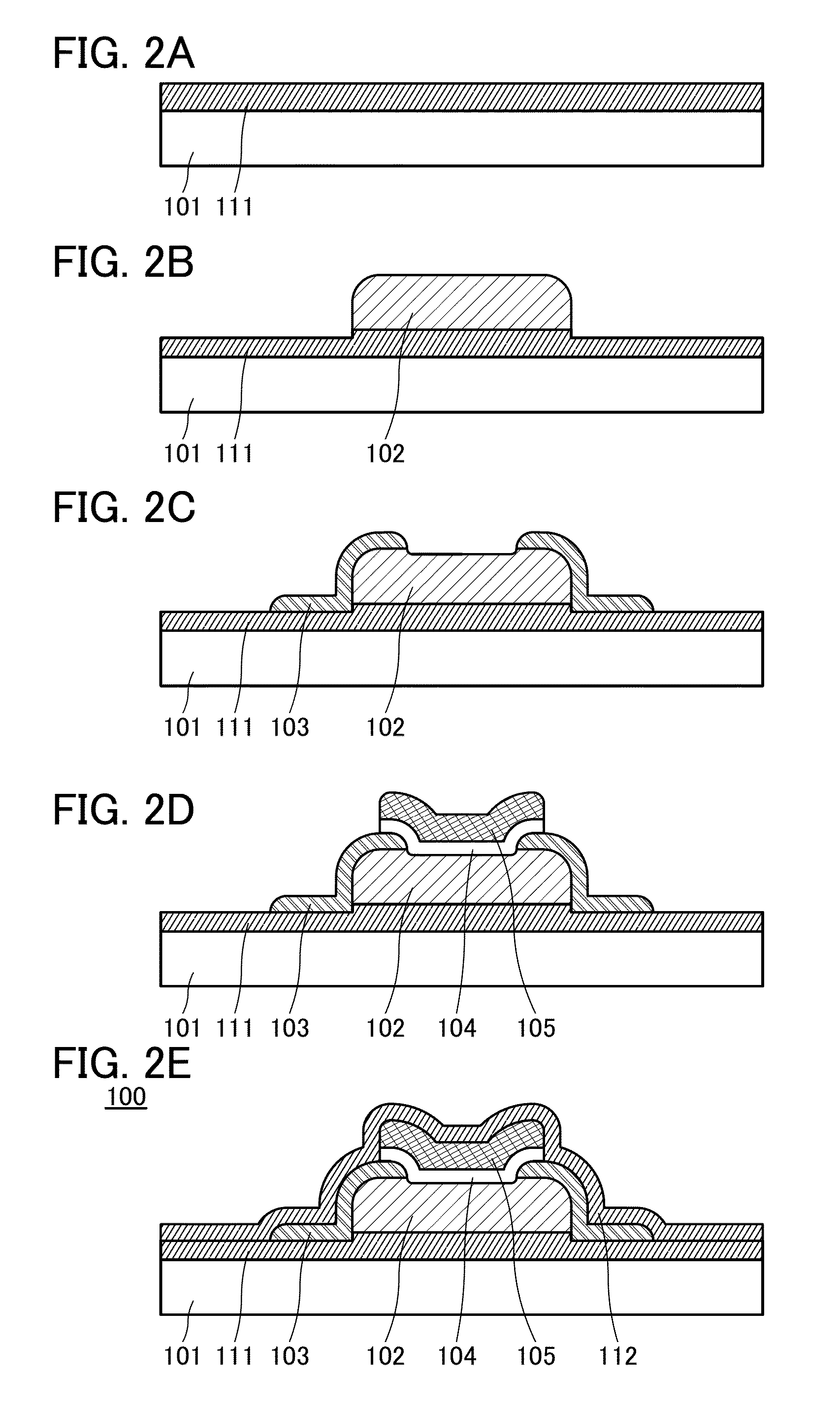

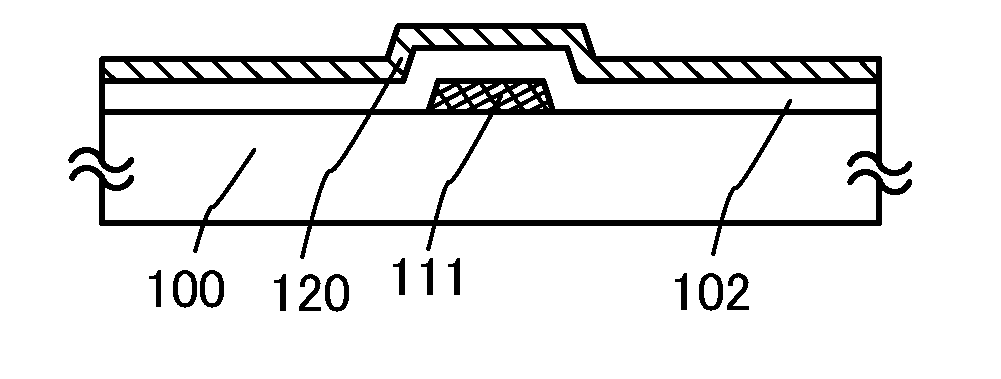

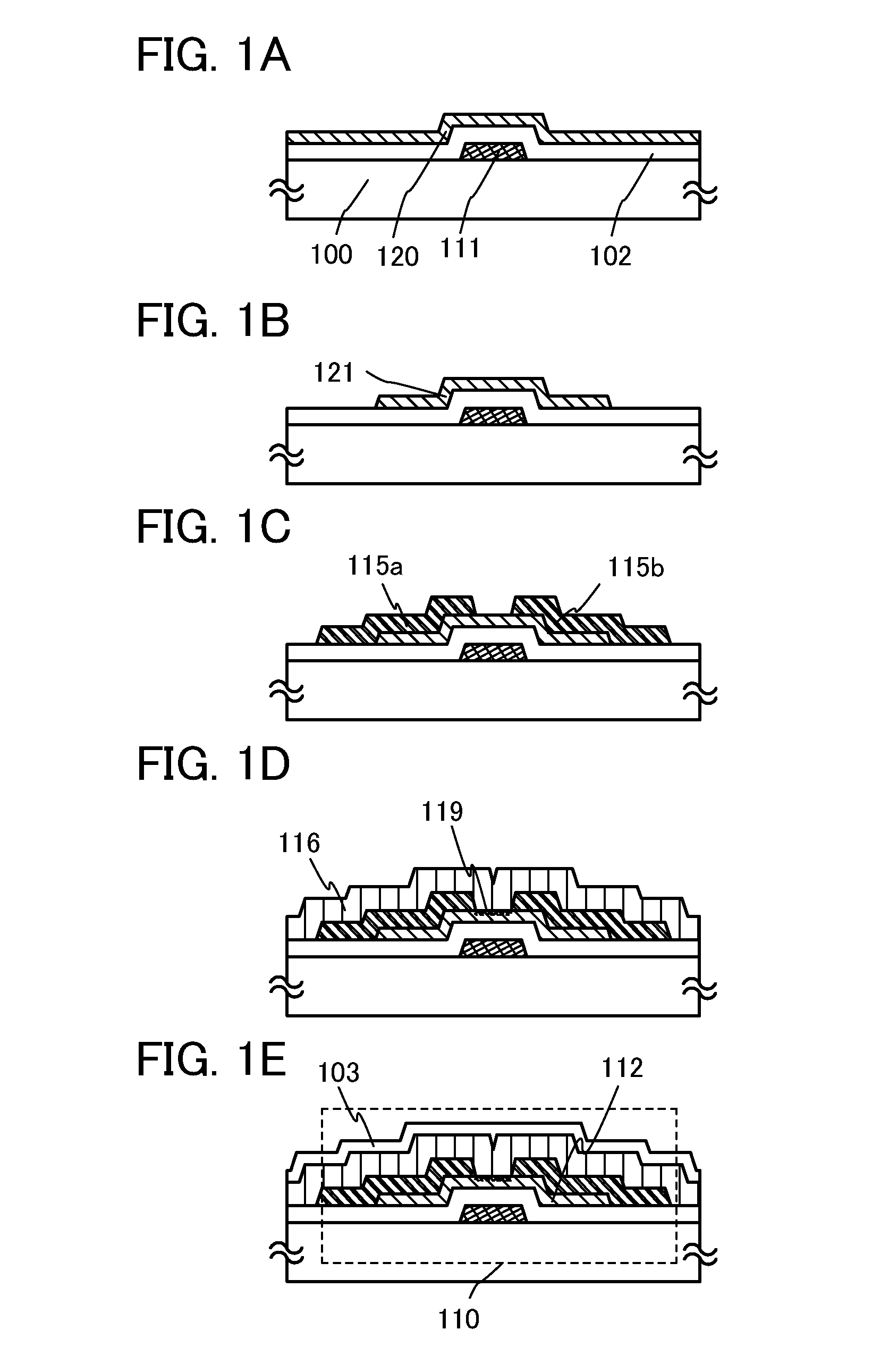

Semiconductor device and method for manufacturing the same

ActiveUS20100065838A1Small currentHigh on-off ratioTransistorSolid-state devicesProduction rateSemiconductor package

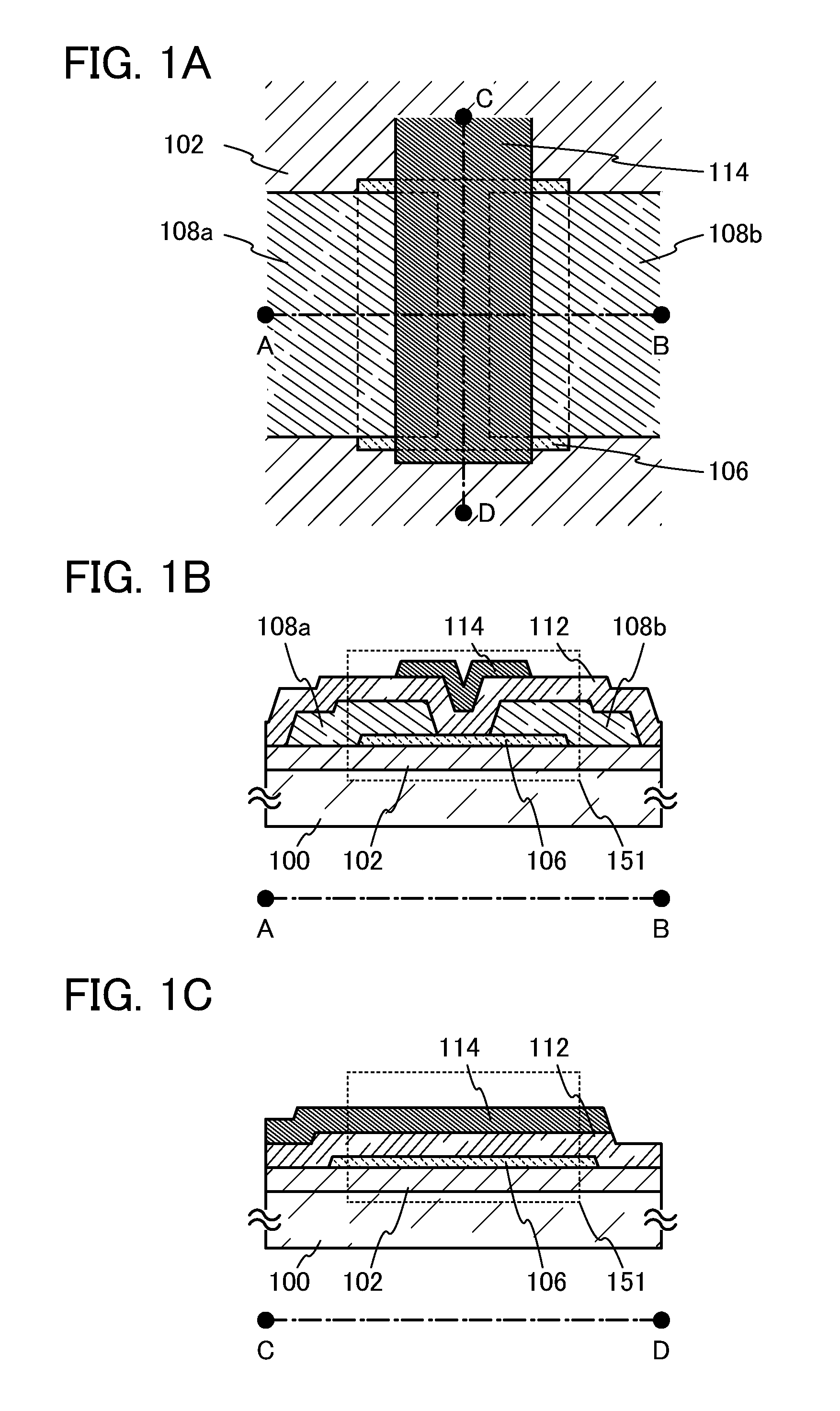

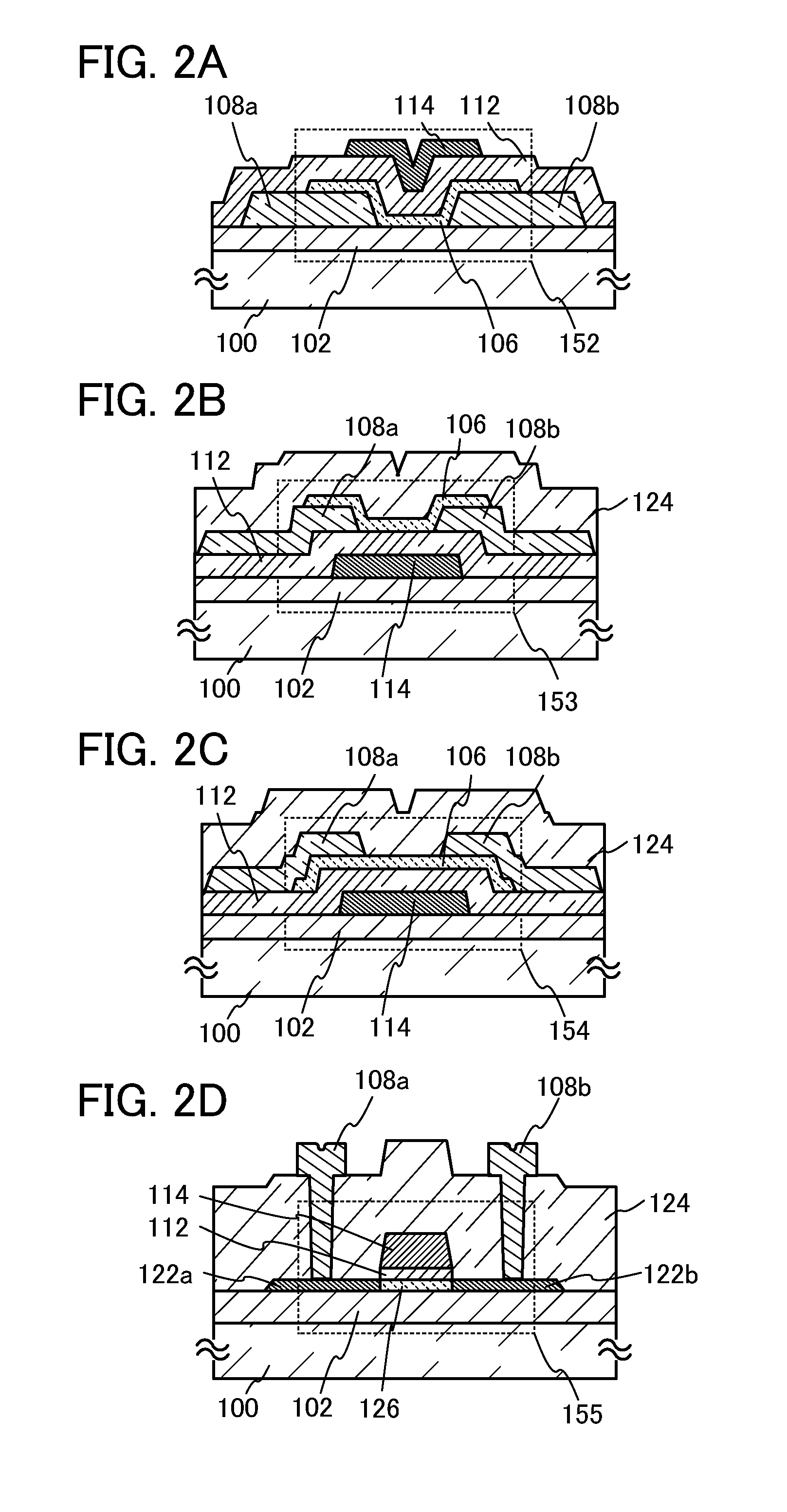

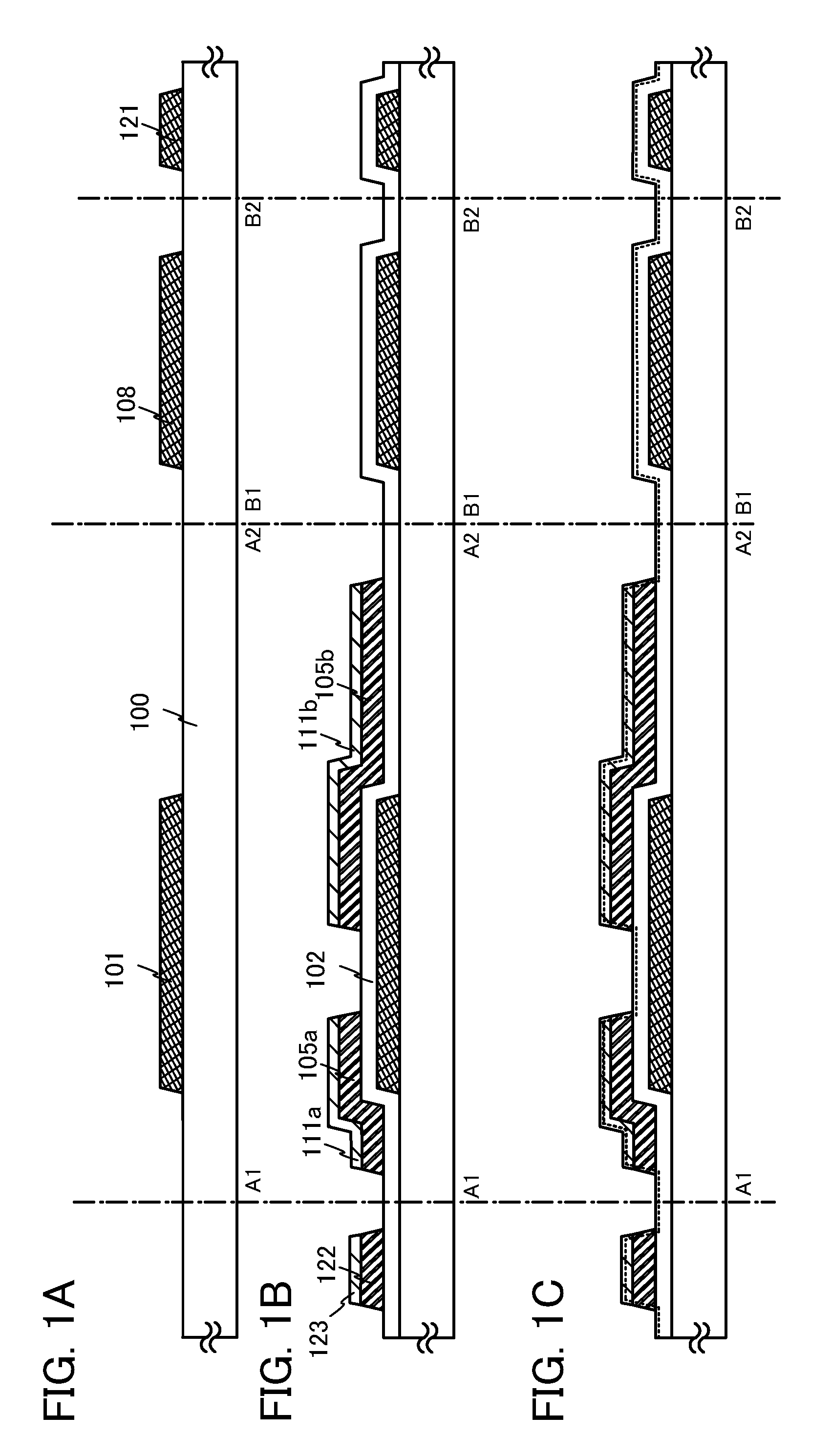

An object is to provide a semiconductor device including a thin film transistor with excellent electrical characteristics and high reliability and a method for manufacturing the semiconductor device with high mass productivity. A main point is to form a low-resistance oxide semiconductor layer as a source or drain region after forming a drain or source electrode layer over a gate insulating layer and to form an oxide semiconductor film thereover as a semiconductor layer. It is preferable that an oxygen-excess oxide semiconductor layer be used as a semiconductor layer and an oxygen-deficient oxide semiconductor layer be used as a source region and a drain region.

Owner:SEMICON ENERGY LAB CO LTD

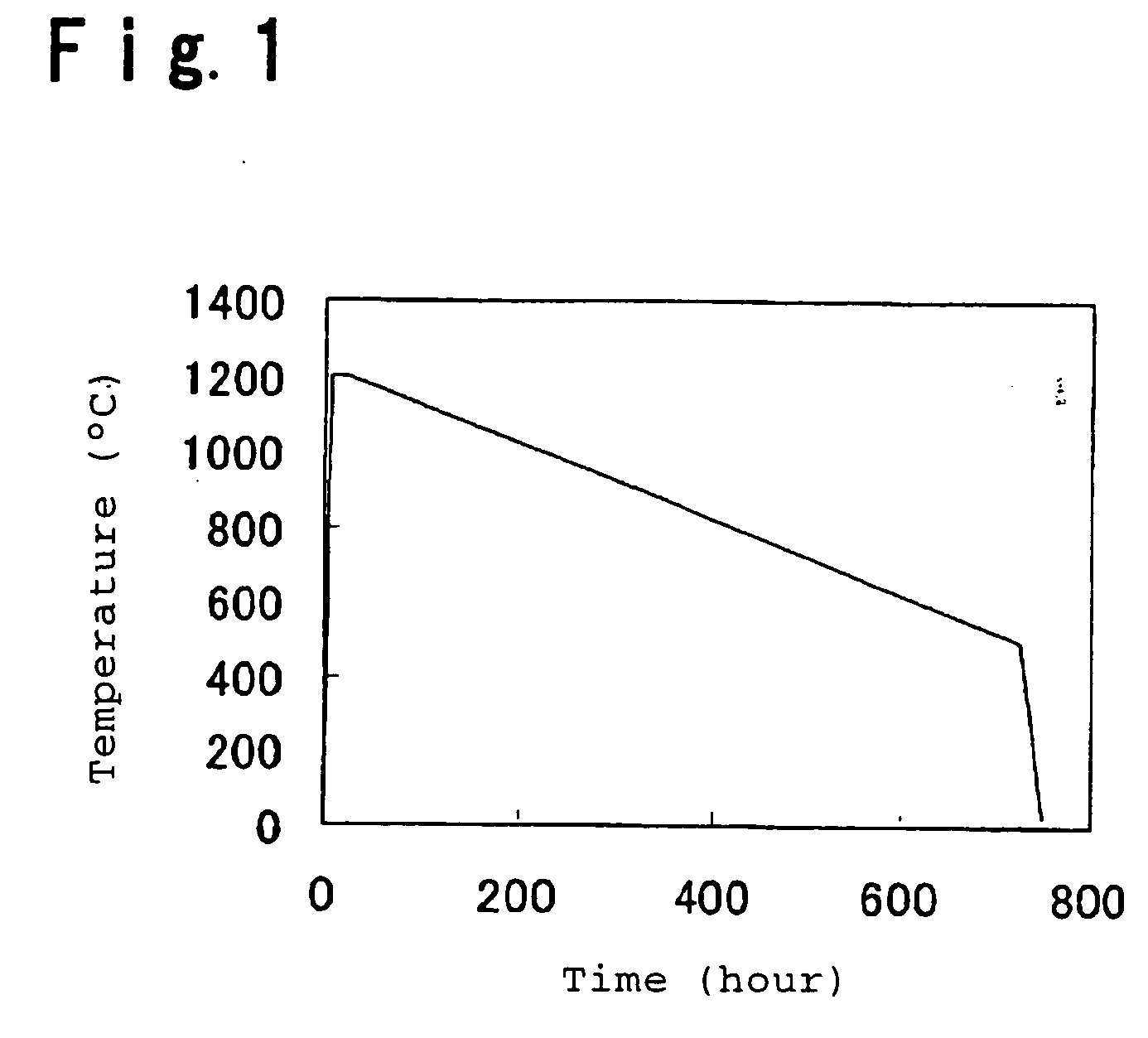

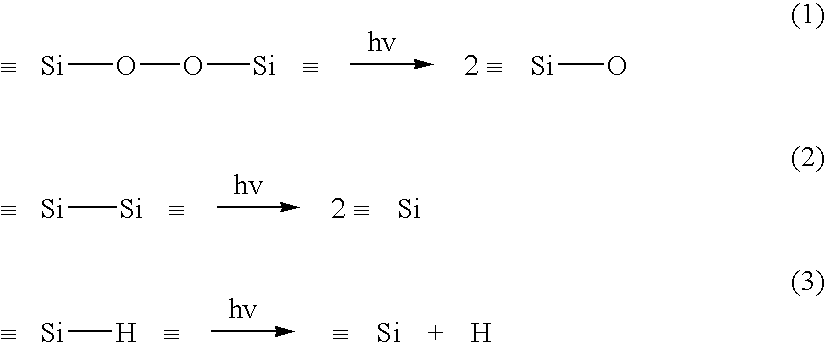

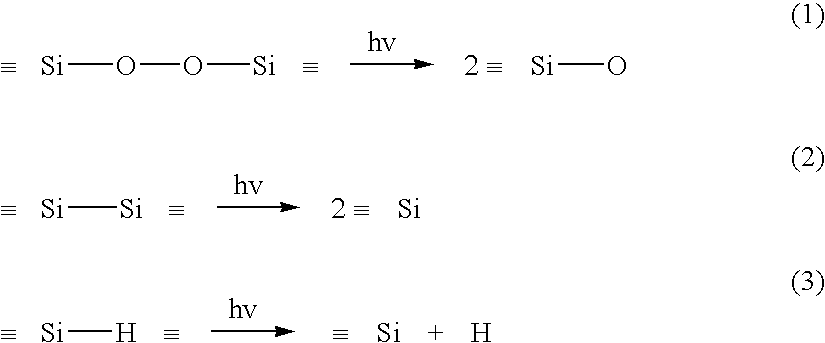

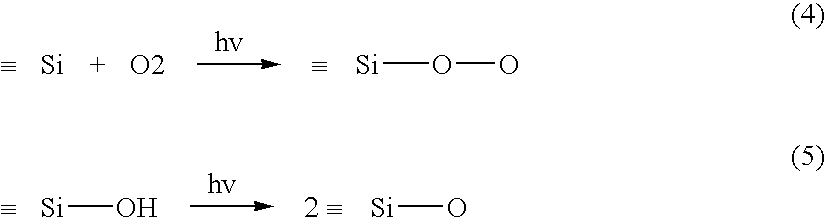

Synthetic quartz glass for optical member and its production method

ActiveUS20060183623A1Suppress compactionSlow changeGlass shaping apparatusGlass deposition burnersOxygen deficientLength wave

A synthetic quartz glass for an optical member which is free from compaction and rarefaction is obtained. A synthetic quartz glass for an optical member to be used for an optical device employing a light having a wavelength of at most 400 nm and at least 170 nm as a light source, which contains substantially no oxygen excess defects, dissolved oxygen molecules nor reduction type defects, which has a chlorine concentration of at most 50 ppm and a OH group concentration of at most 100 ppm, and which contains oxygen deficient defects within a concentration range of at most 5×1014 defects / cm3 and at least 1×1013 defects / cm3. The fluorine concentration is preferably at most 100 ppm.

Owner:ASAHI GLASS CO LTD

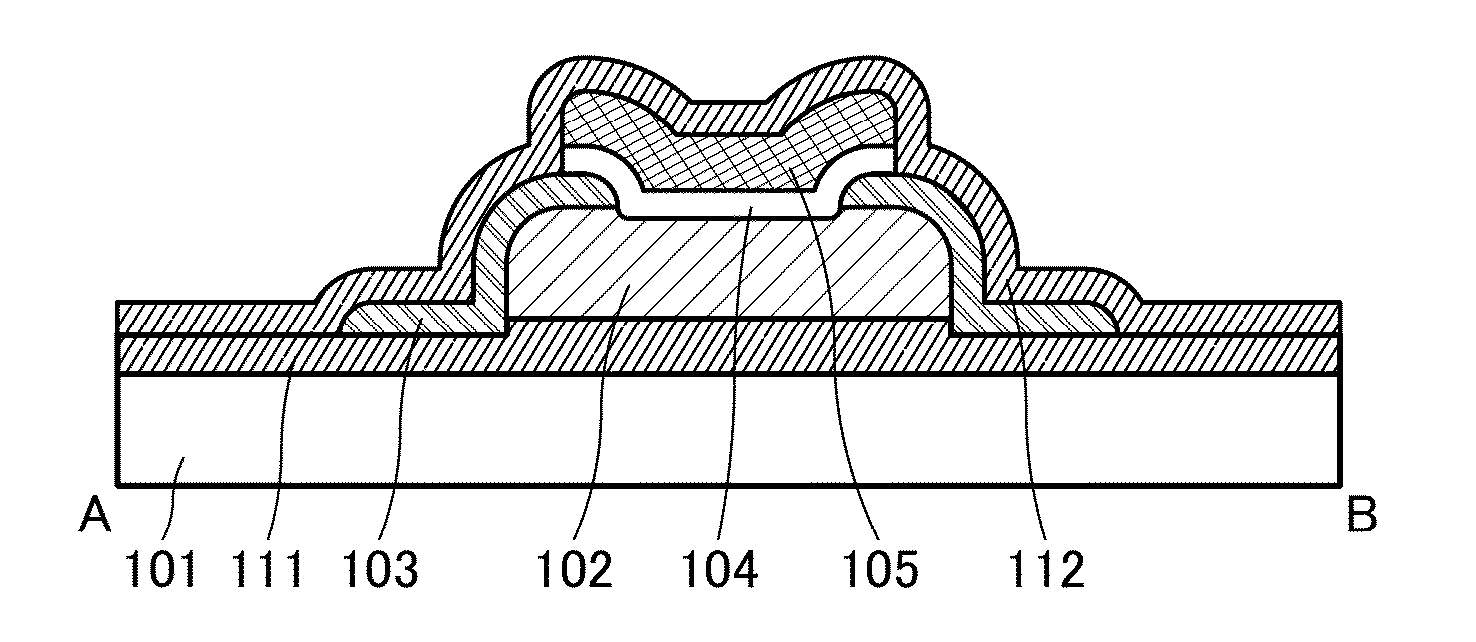

Semiconductor device and method for manufacturing the same

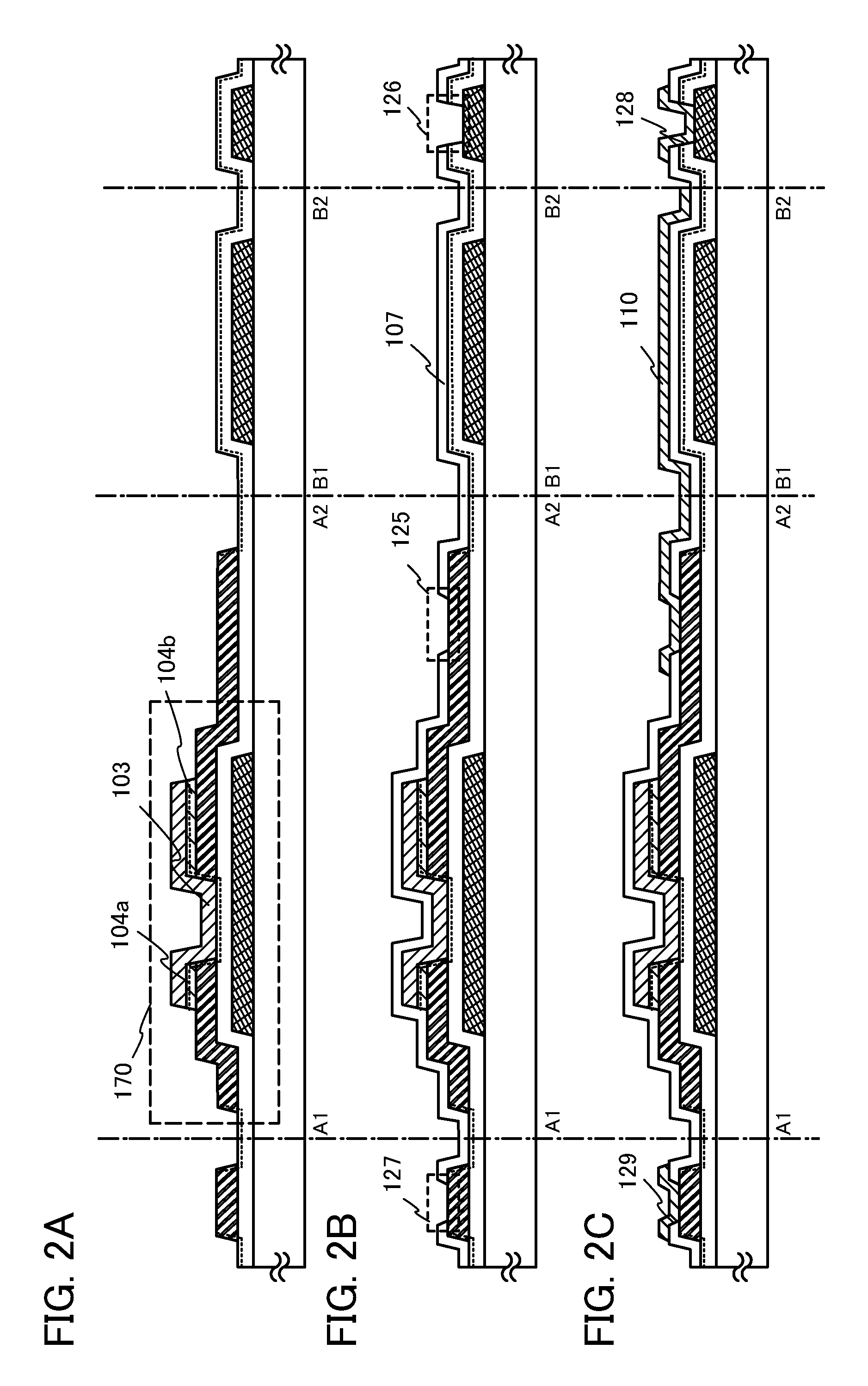

InactiveUS20110303913A1Stable electrical characteristicsElectrical instabilityTransistorSemiconductor/solid-state device testing/measurementElectricityBottom gate

An object of an embodiment of the present invention is to manufacture a highly-reliable semiconductor device comprising a transistor including an oxide semiconductor, in which change of electrical characteristics is small. In the transistor including an oxide semiconductor, oxygen-excess silicon oxide (SiOX (X>2)) is used for a base insulating layer of a top-gate structure or for a protective insulating layer of a bottom-gate structure. By using the oxygen-excess silicon oxide, oxygen is discharged from the insulating layer, and oxygen deficiency of an oxide semiconductor layer and the interface state density between the oxide semiconductor layer and the base insulating layer or the protective insulating layer can be reduced, so that the highly-reliable semiconductor device in which change of electrical characteristics is small can be manufactured.

Owner:SEMICON ENERGY LAB CO LTD

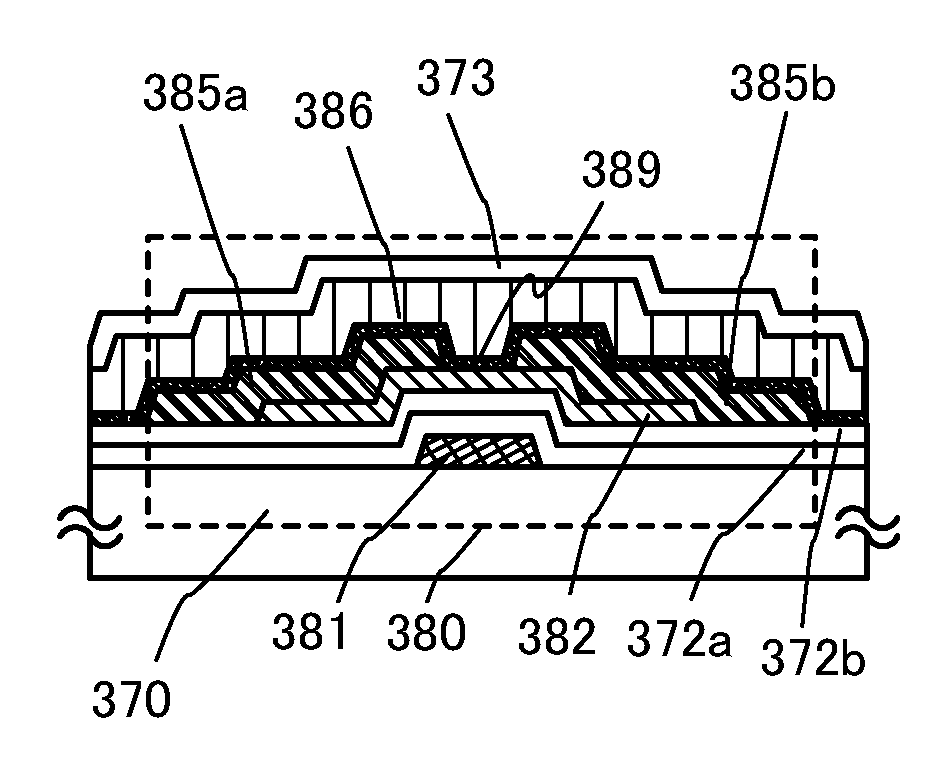

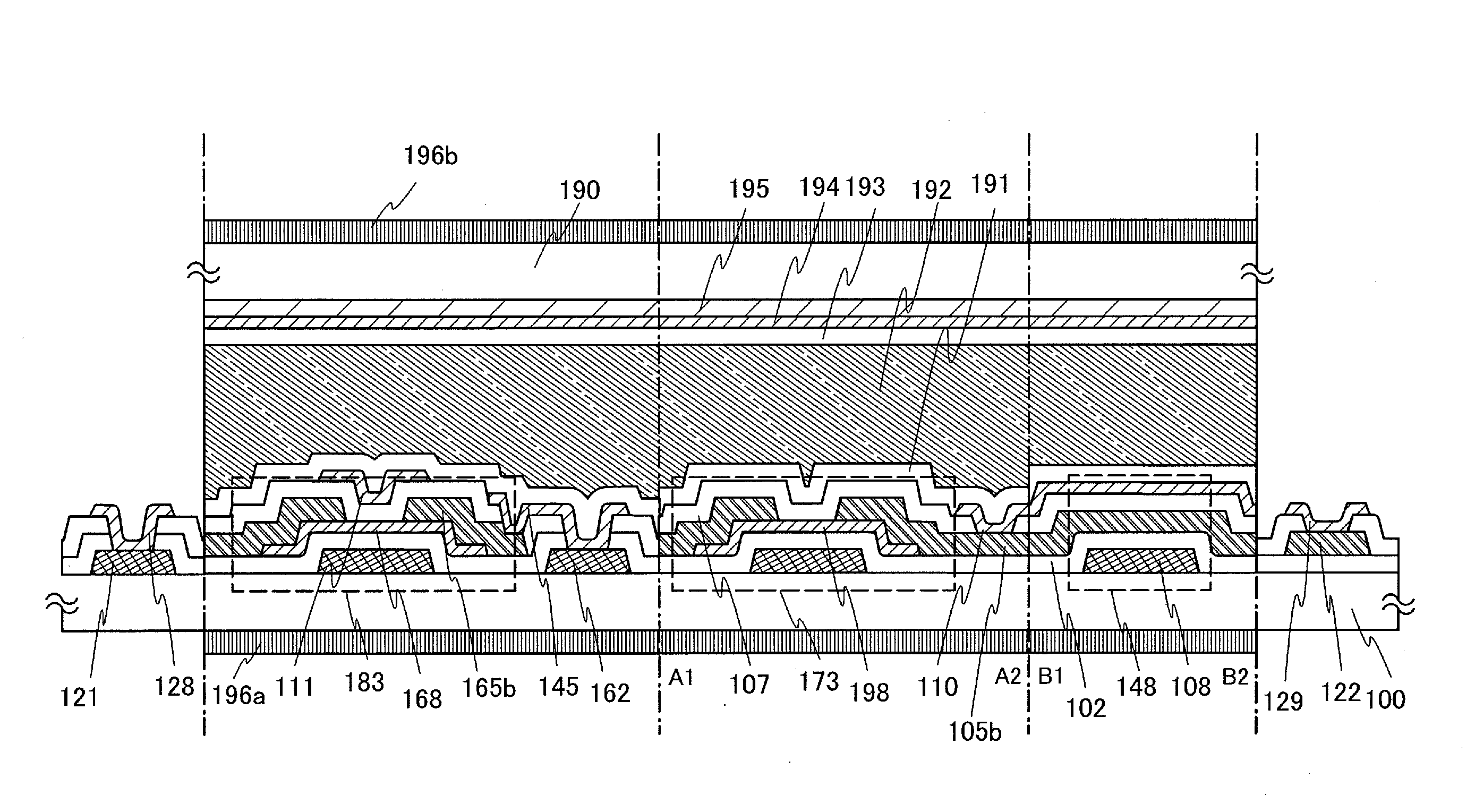

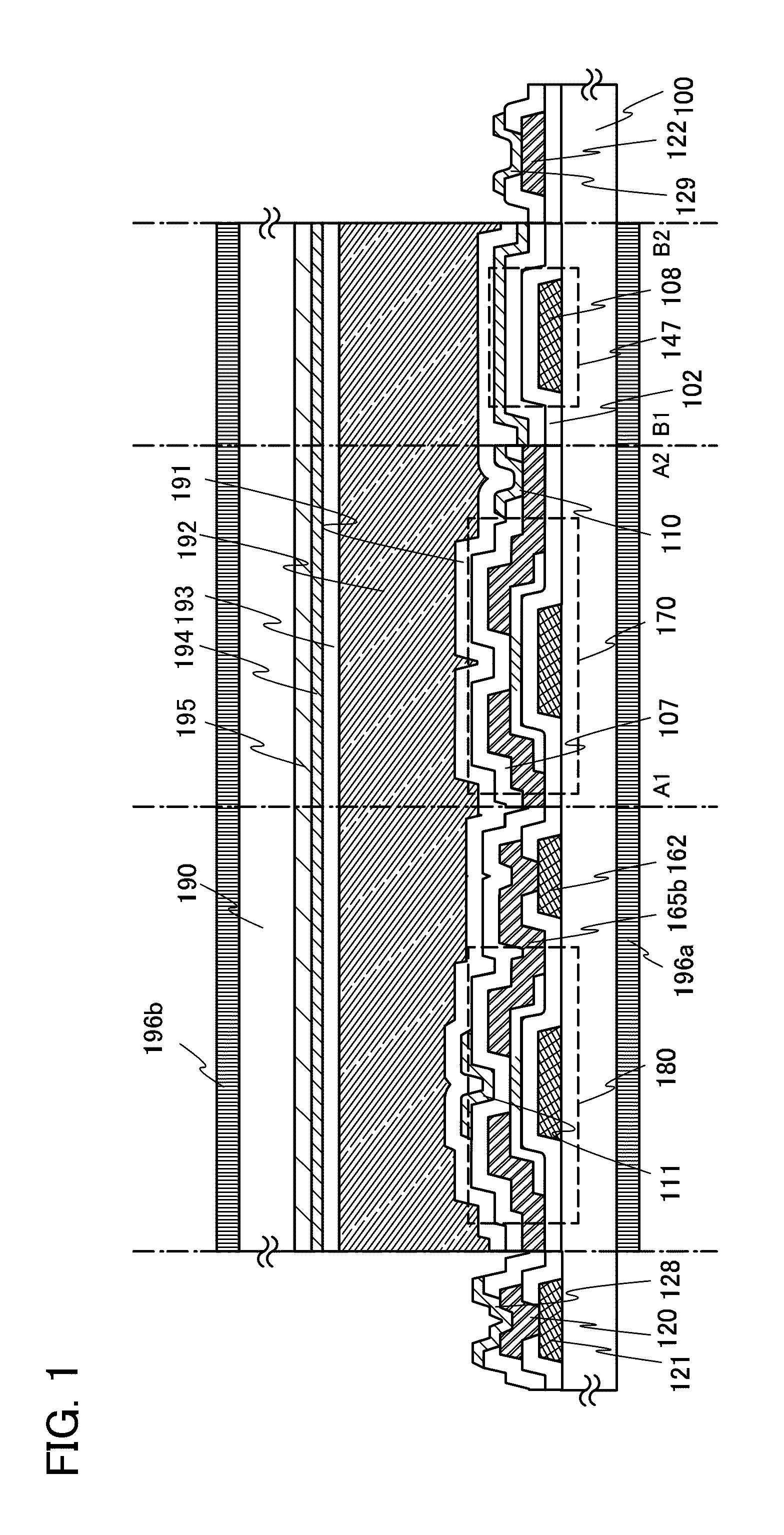

Semiconductor device

ActiveUS20140339546A1Improve reliabilityExcellent electrical propertiesTransistorSolid-state devicesSemiconductorSemiconductor device

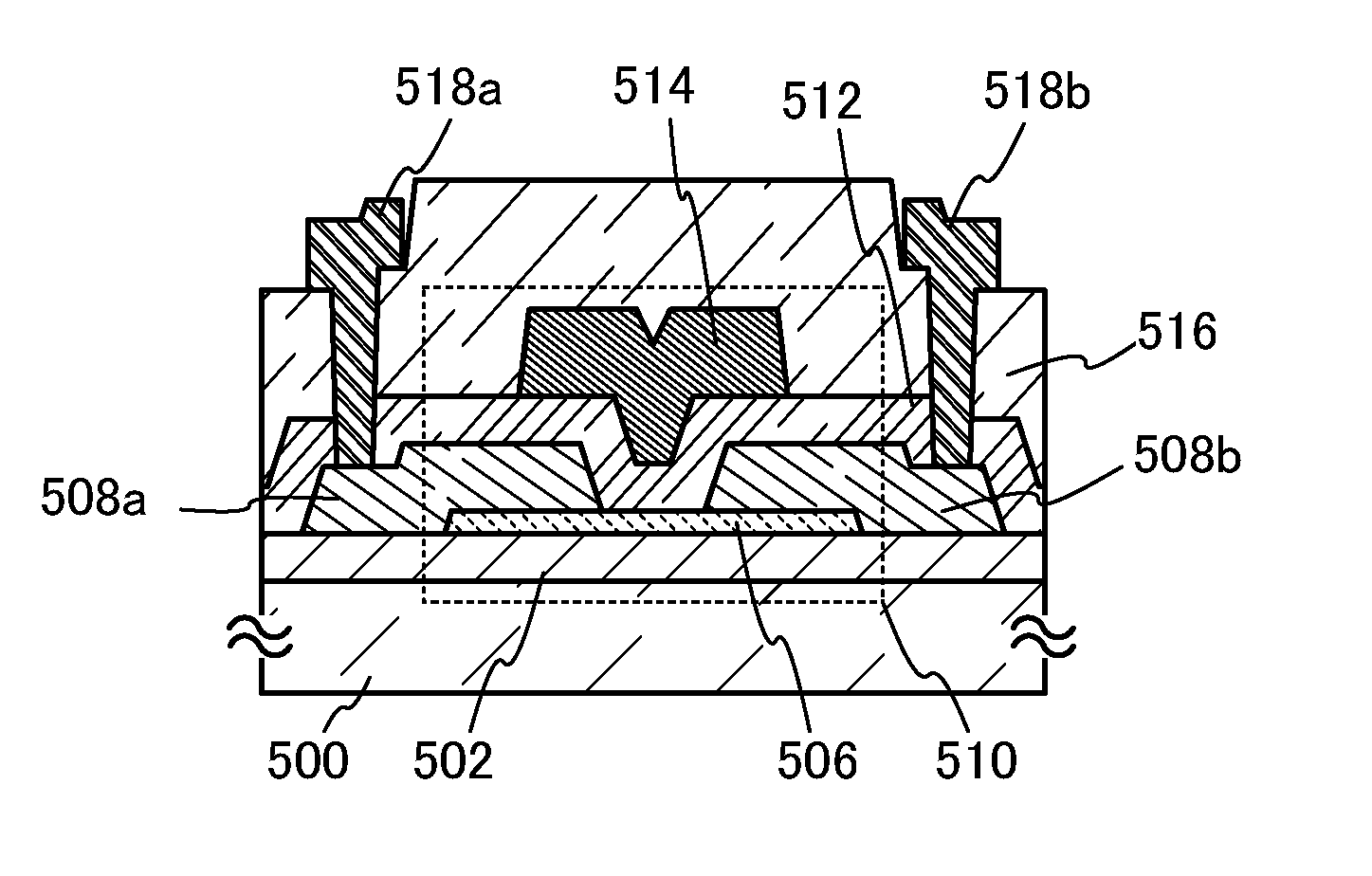

A structure is employed in which a first protective insulating layer; an oxide semiconductor layer over the first protective insulating layer; a source electrode and a drain electrode that are electrically connected to the oxide semiconductor layer; a gate insulating layer that is over the source electrode and the drain electrode and overlaps with the oxide semiconductor layer; a gate electrode that overlaps with the oxide semiconductor layer with the gate insulating layer provided therebetween; and a second protective insulating layer that covers the source electrode, the drain electrode, and the gate electrode are included. Furthermore, the first protective insulating layer and the second protective insulating layer each include an aluminum oxide film that includes an oxygen-excess region, and are in contact with each other in a region where the source electrode, the drain electrode, and the gate electrode are not provided.

Owner:SEMICON ENERGY LAB CO LTD

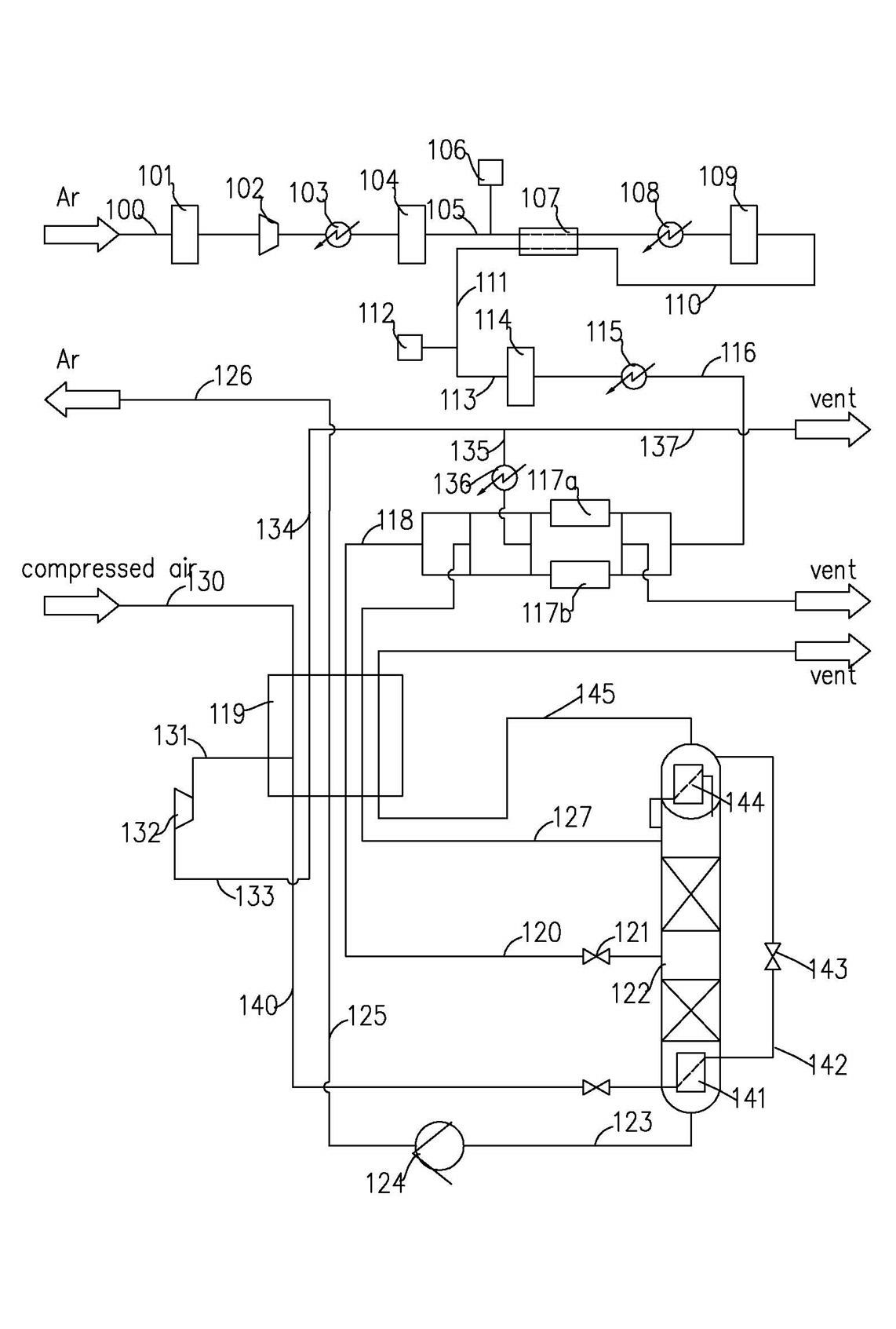

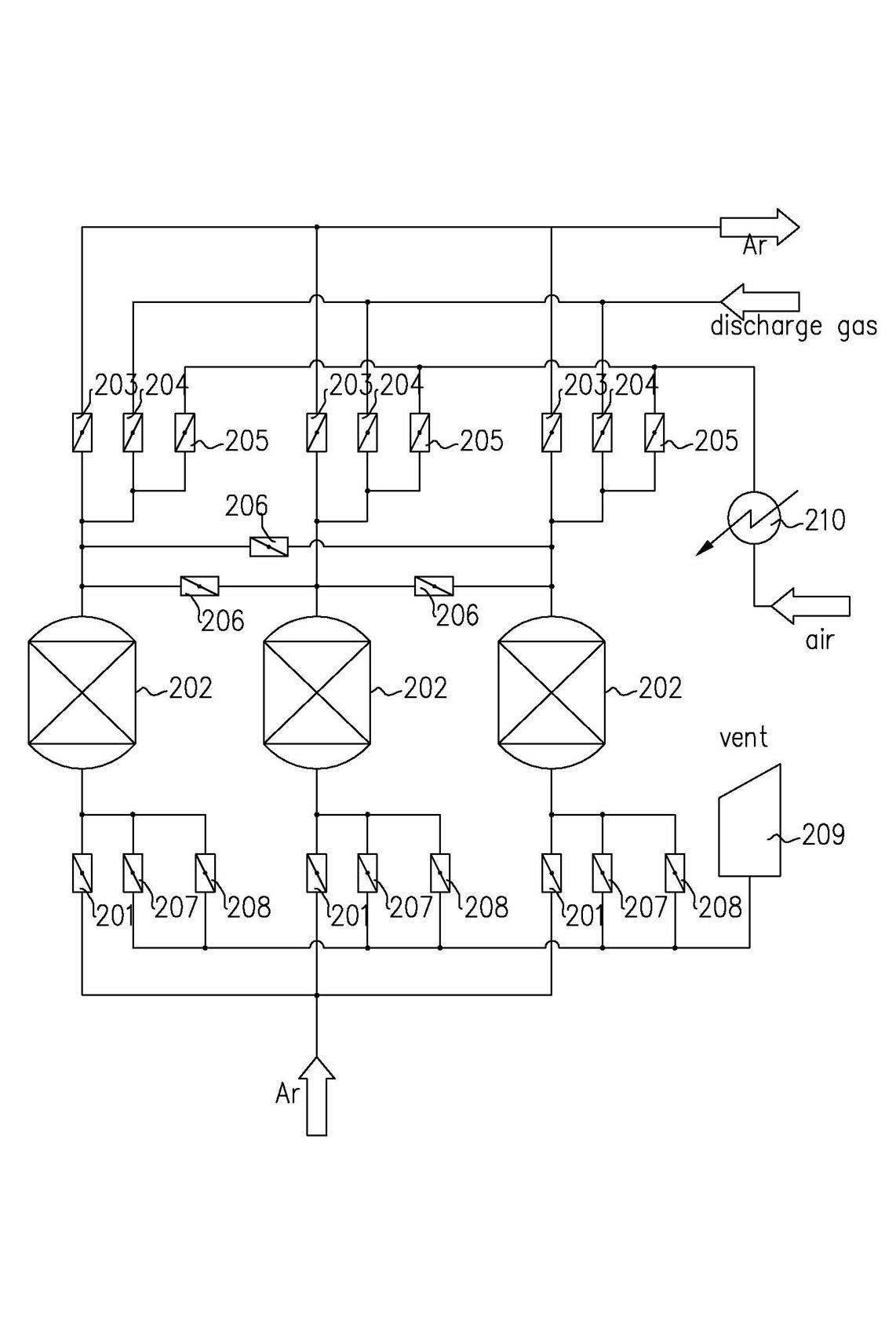

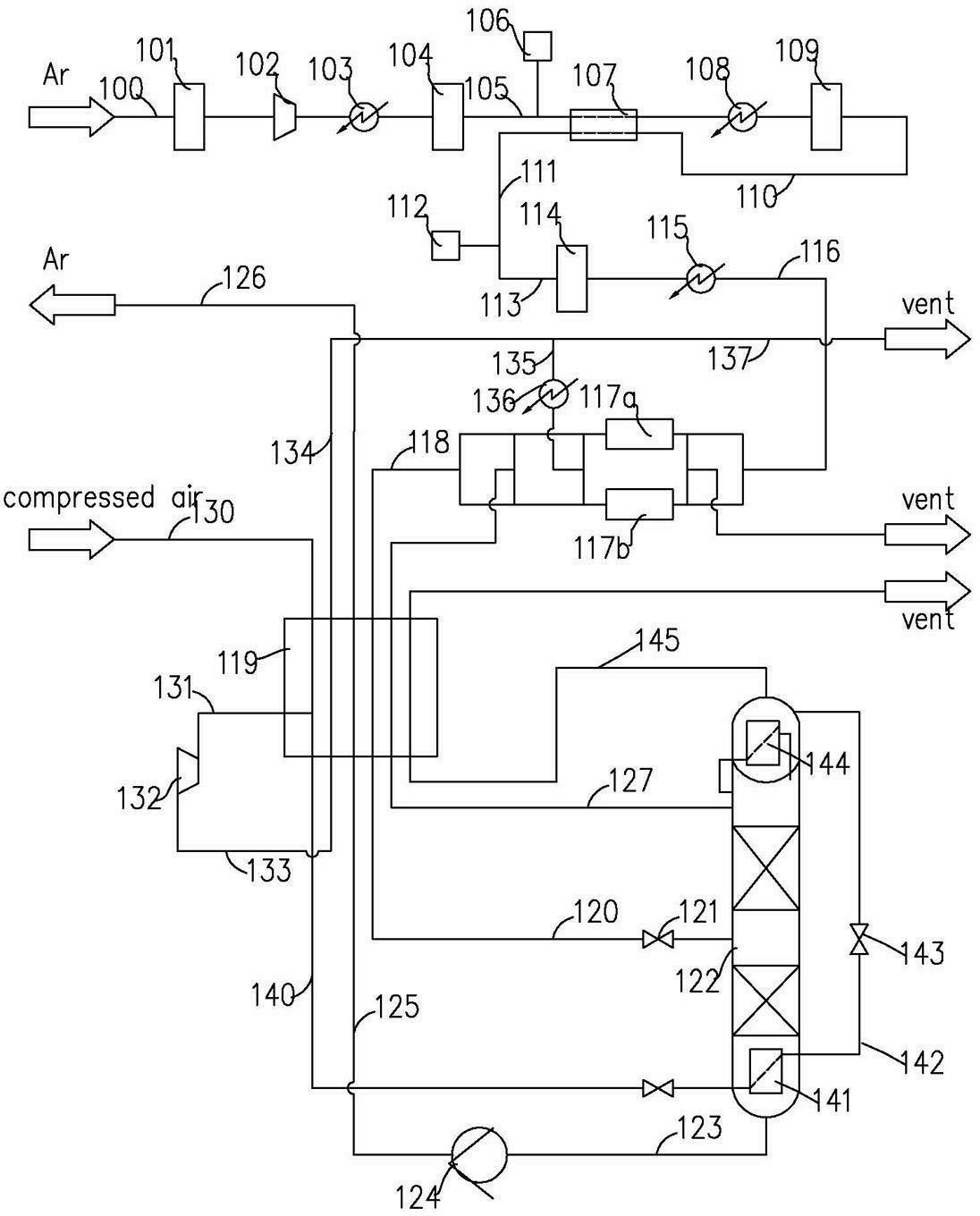

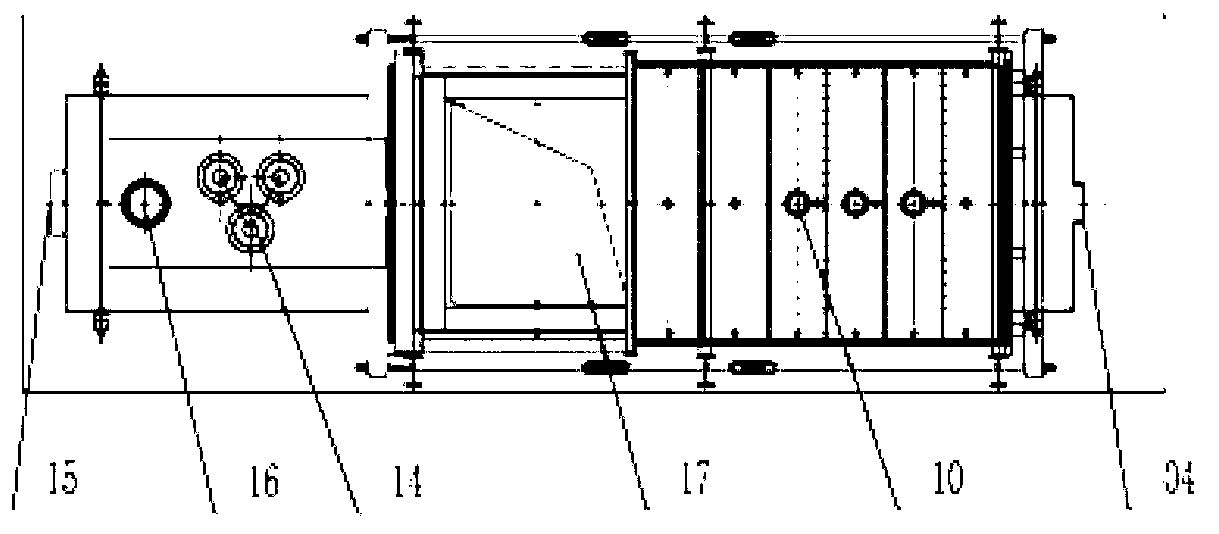

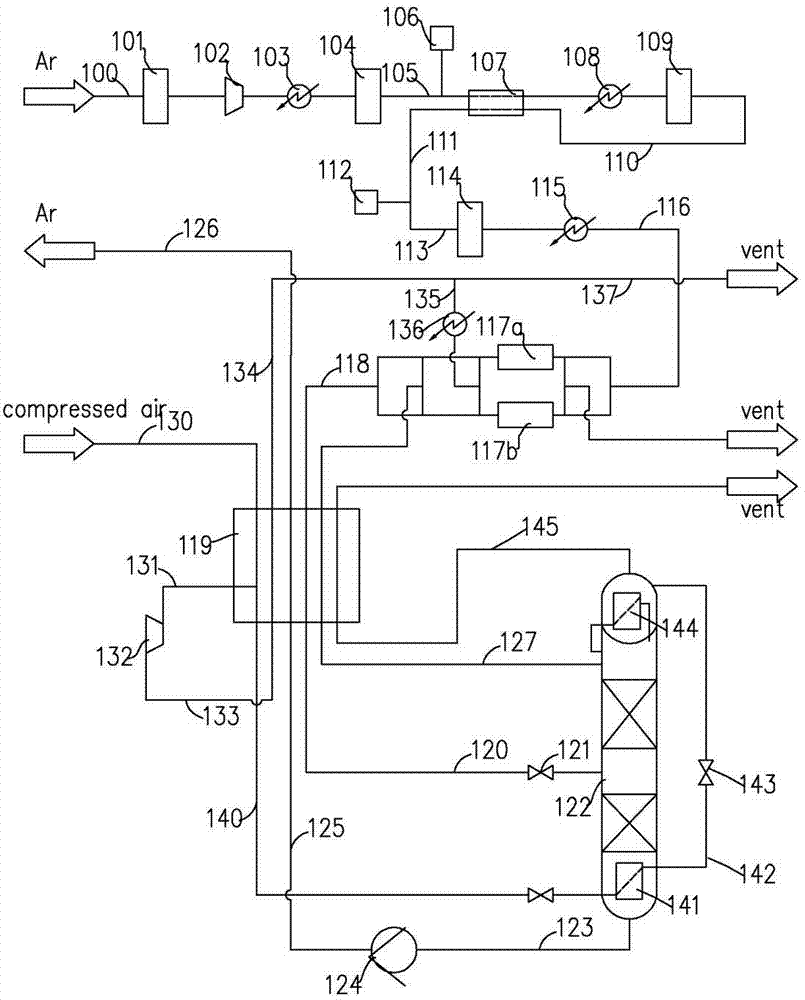

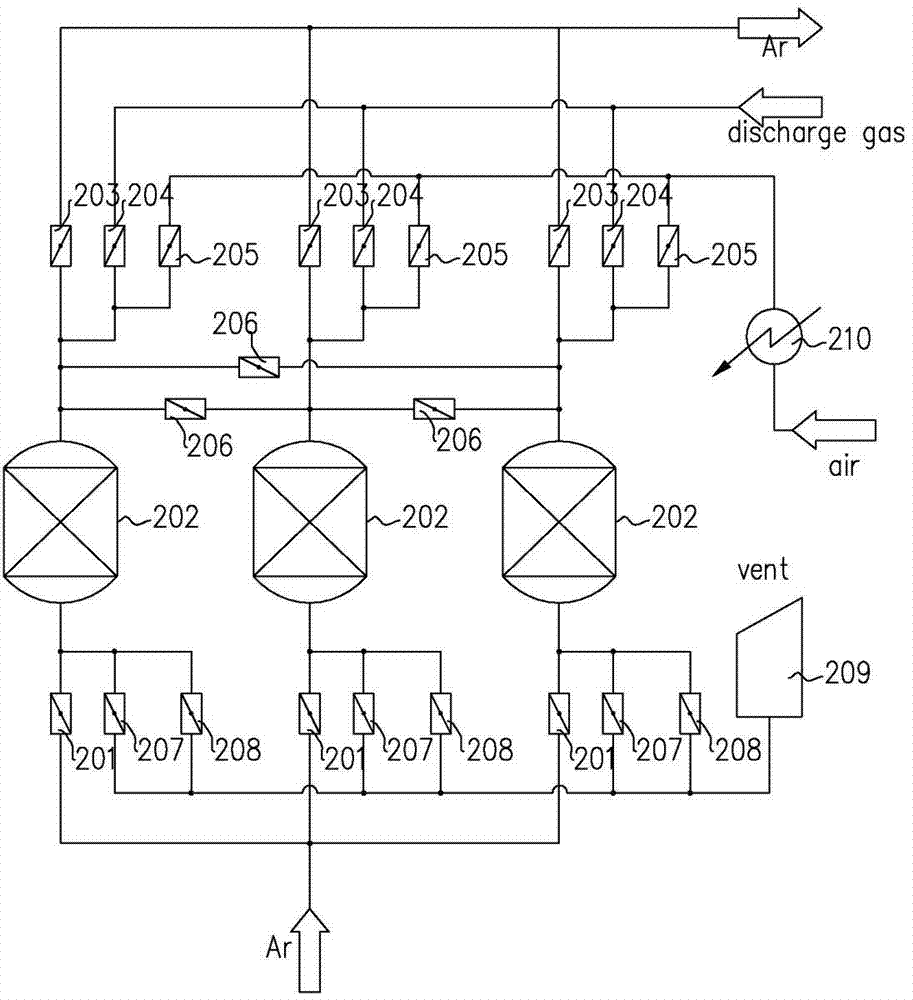

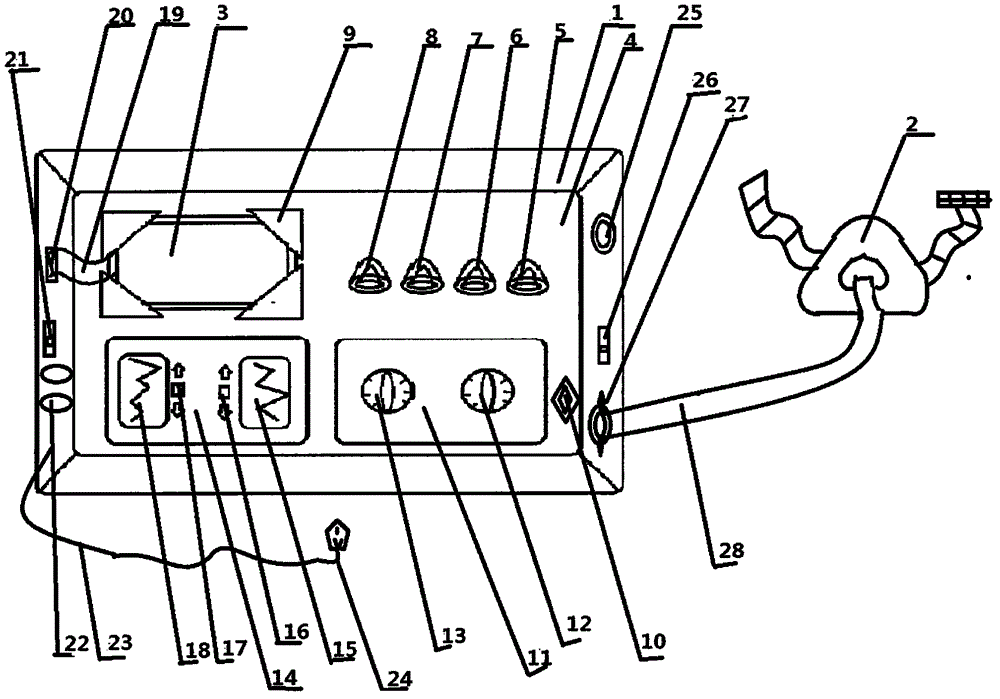

Method and device for recovering and purifying argon in monocrystalline silicon production

ActiveCN102583281AThorough responseHigh recovery rateNoble gas compoundsPtru catalystCatalytic oxidation

Provided is a method and a device for recovering and purifying argon in monocrystalline silicon production. The method comprises firstly conducting coarse oil removal on argon recovered from a single crystal furnace, compressing, cooling and conducting high-precision oil removal and dedusting; secondly enabling hydrocarbon such as methane and carbon monoxide to be reacted with oxygen to generate water and carbon dioxide through a high temperature catalytic reaction and guaranteeing the oxygen to be excessive in the catalytic reaction; thirdly enabling excessive oxygen to be reacted with added hydrogen to generate the water under effects of a catalytic agent after cooling and enabling argon after two catalytic reactions to penetrate through a normal temperature adsorption unit to absorb the water and the carbon dioxide; cooling the argon, sending a low temperature rectifying tower, enabling the argon, the nitrogen and the hydrogen to produce rectification separation, obtaining pure liquid argon, and conducting repeated heating to obtain pure argon products. The device mainly comprises an oil filter, a catalytic reactor of the hydrocarbon of high temperature catalytic oxidation carbon monoxide and methane and the like, a normal temperature hydrogenation deoxygenization catalytic reactor, a normal temperature adsorption unit for absorbing the carbon dioxide and the water at the normal temperature and the low temperature rectifying tower for rectifying and separating the hydrogen and the nitrogen at the low temperature. The device has the advantages of being high in argon recovery rate, high in purity of recovered argon, low in oxygen content, low in energy consumption for recovery and purification and the like.

Owner:HANGZHOU HANGYANG

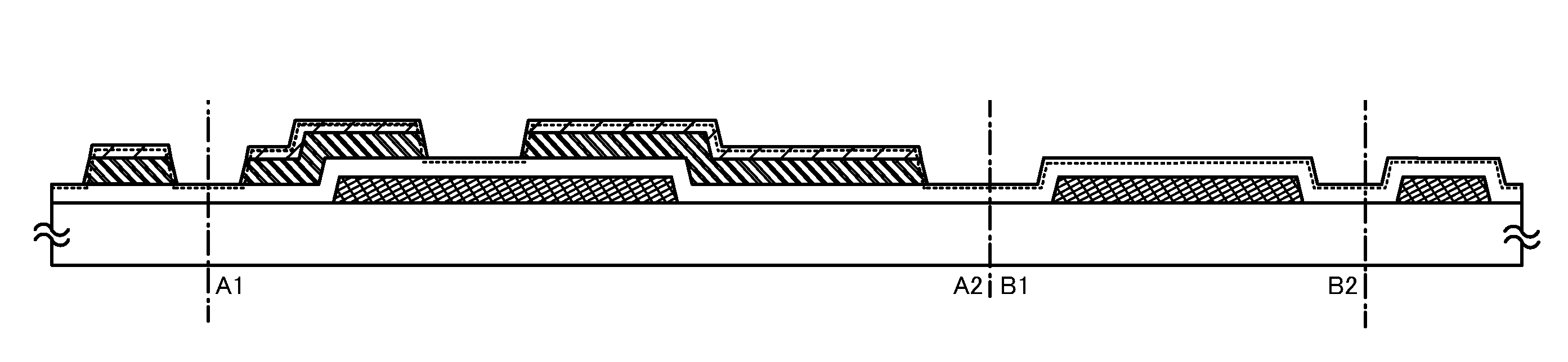

Semiconductor device wherein each of a first oxide semiconductor layer and a second oxide semiconductor layer includes a portion that is in an oxygen-excess state which is in contact with a second insulatng layer

ActiveUS8654272B2Easy to makeSufficient reliabilitySolid-state devicesDigital storagePower semiconductor deviceDriver circuit

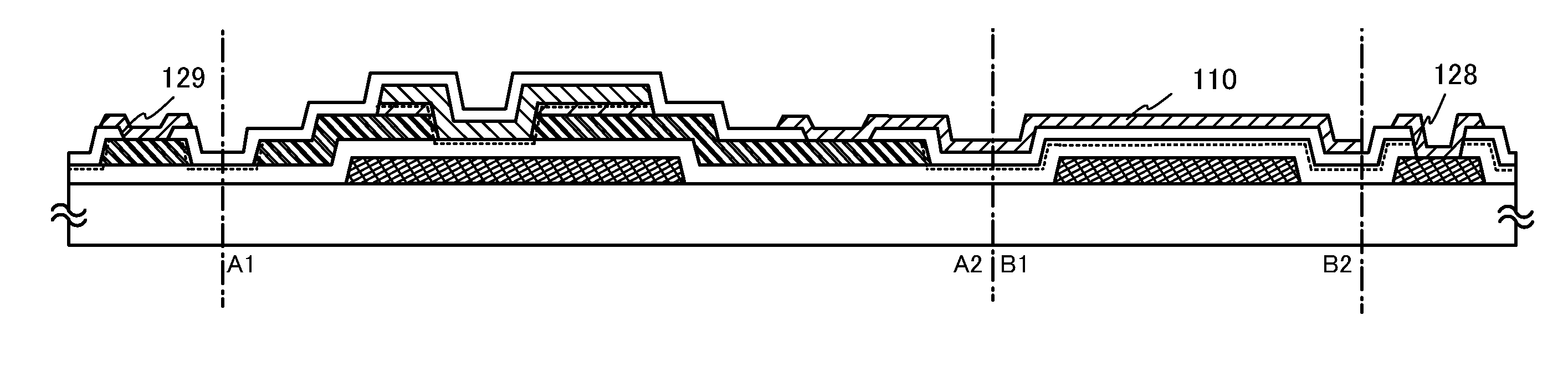

An object is to improve reliability of a semiconductor device. A semiconductor device including a driver circuit portion and a display portion (also referred to as a pixel portion) over the same substrate is provided. The driver circuit portion and the display portion include thin film transistors in which a semiconductor layer includes an oxide semiconductor; a first wiring; and a second wiring. The thin film transistors each include a source electrode layer and a drain electrode layer. In the thin film transistor in the driver circuit portion, the semiconductor layer is sandwiched between a gate electrode layer and a conductive layer. The first wiring and the second wiring are electrically connected to each other in an opening provided in a gate insulating film through an oxide conductive layer.

Owner:SEMICON ENERGY LAB CO LTD

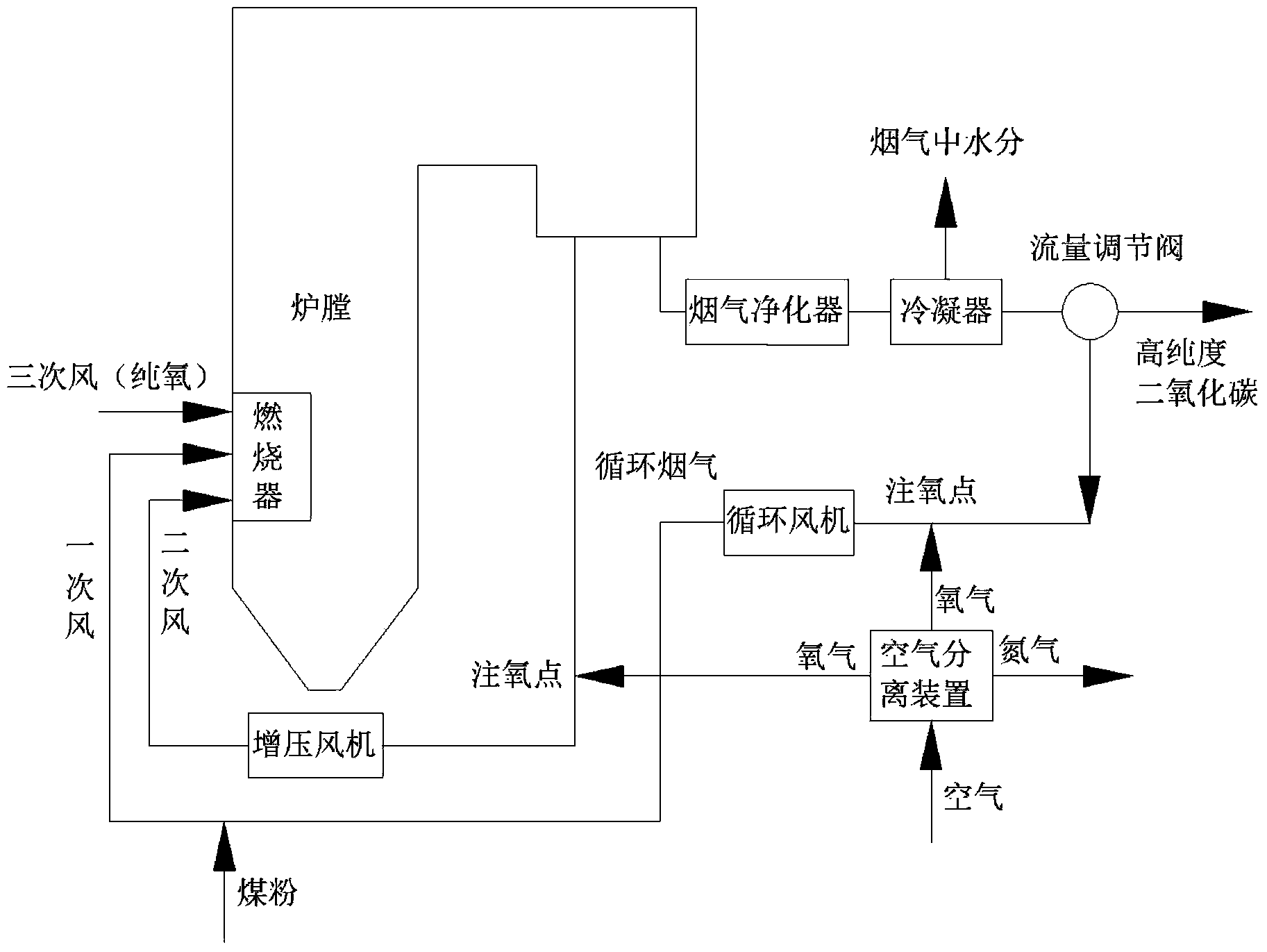

Pulverized coal oxygen-rich combustion method and system

InactiveCN103968373AEasy to captureEfficient use ofDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationCombustion systemAir volume

The invention discloses a pulverized coal oxygen-rich combustion method. According to the method, based on traditional oxygen-rich combustion CO2 enrichment, oxygen proportions in a primary air and a secondary air are adjusted to ensure that the oxygen concentration of the primary air is higher than the oxygen concentration of the secondary air, wherein the oxygen content of the primary air is about 30-50 %, the oxygen content of the secondary air is 10-25 % and a third air is pure oxygen; oxygen volume flow entering a furnace chamber takes up 25-35 % of total furnace chamber air volume flow; the pulverized coal is carried by the primary air; the proportion of the primary air to the secondary air is (5 %-25 % ) to (95 % - 75 %); the oxygen excess air coefficient is 1.0-1.2. The invention further provides a corresponding pulverized coal oxygen-rich combustion system. According to the pulverized coal oxygen-rich combustion method, the stability of combustion is improved, the temperature distribution in combustion process is changed and the NOX generation is reduced eventually; after the improvement, the thermal utilization efficiency can be increased by 5-15% and generated NOX can be reduced by 15-45 %.

Owner:HUAZHONG UNIV OF SCI & TECH

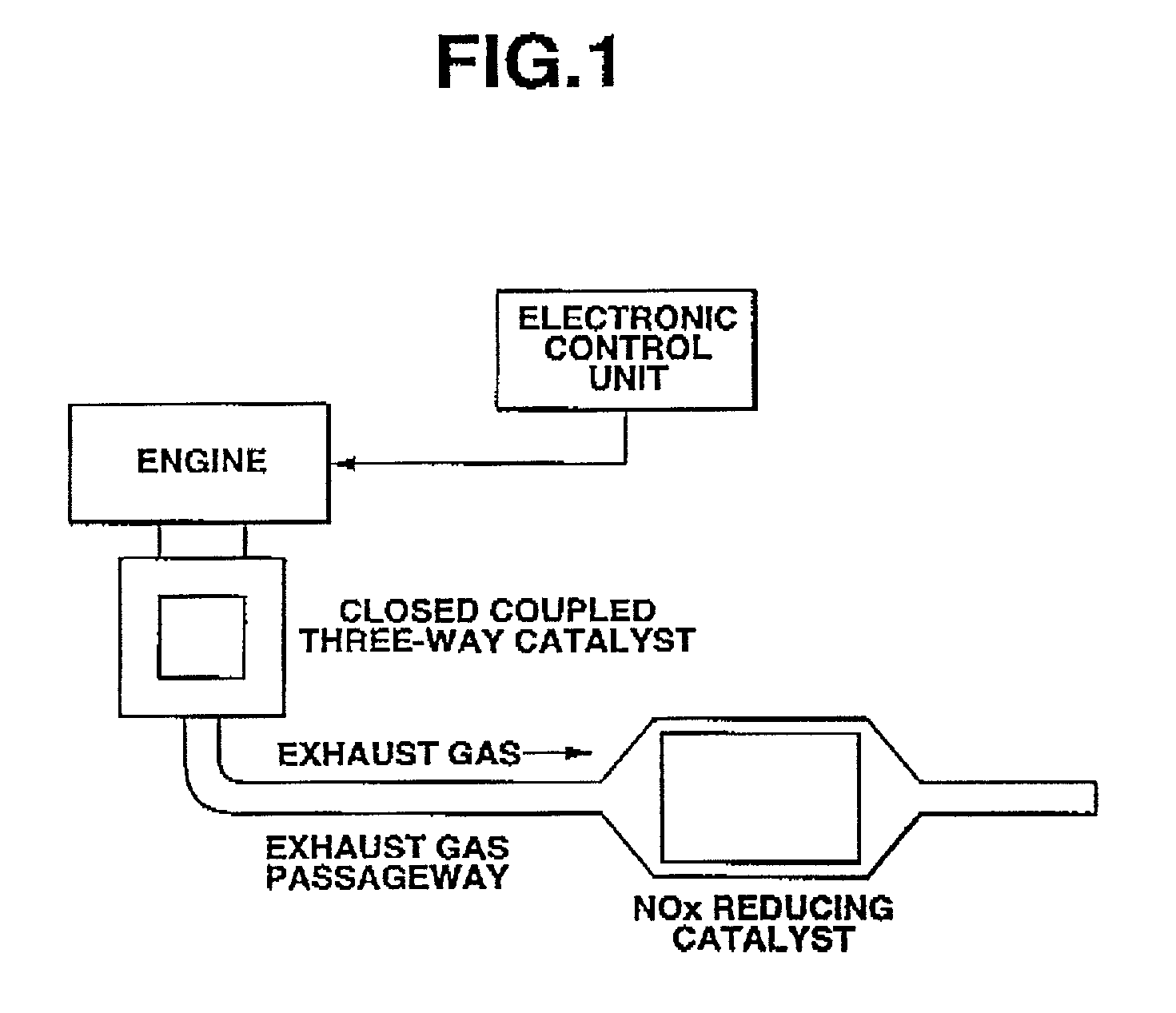

Exhaust gas purifying system and catalyst

InactiveUS20010004832A1Efficient removalHigh fuel economy improvement effectNitrous oxide captureGas treatmentPorous substratePlatinum

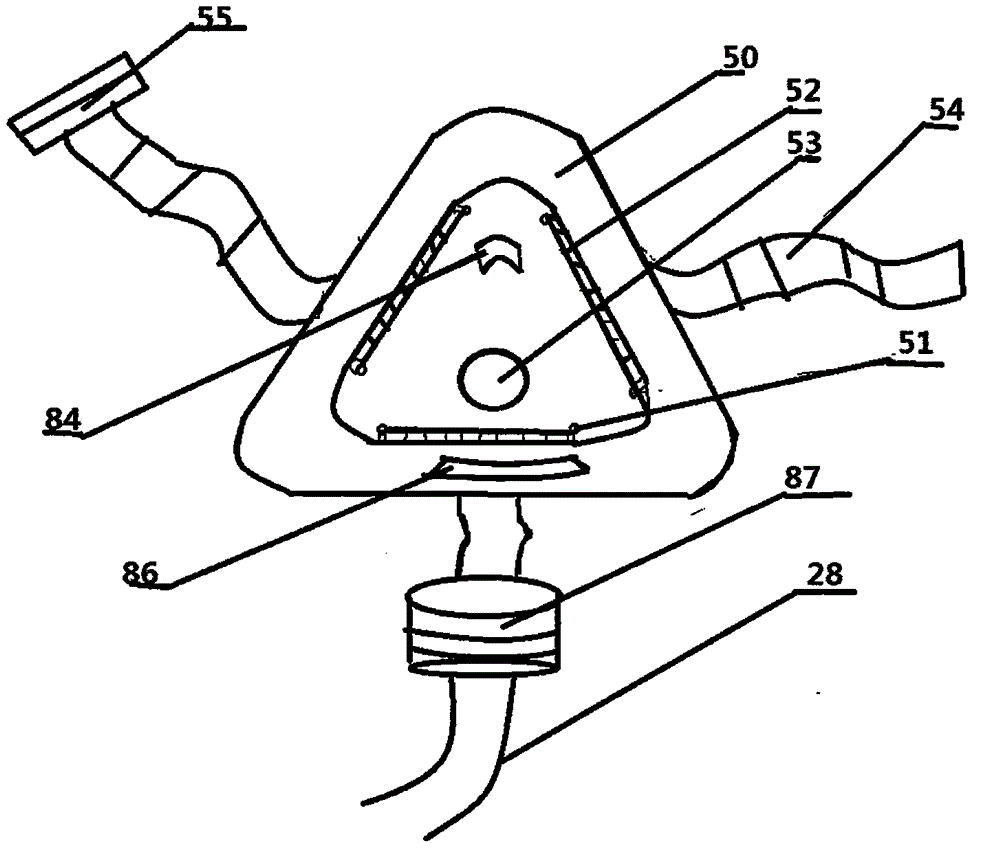

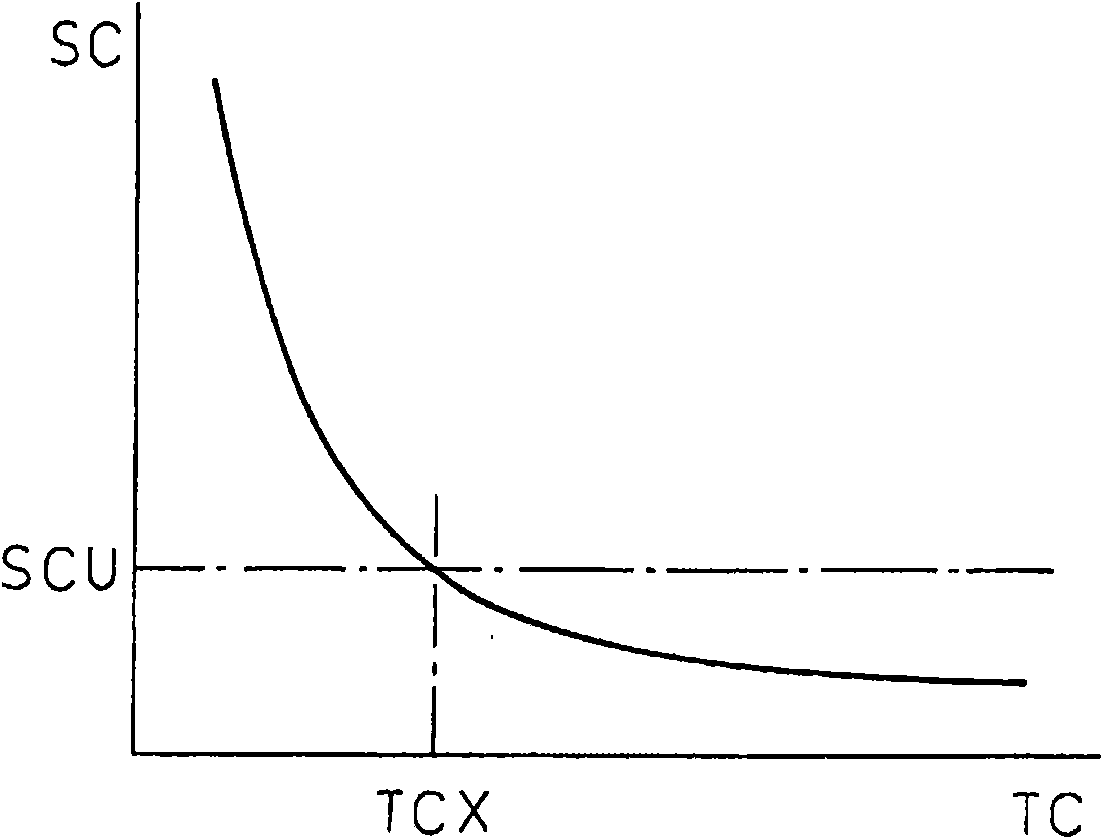

An exhaust gas purifying system for an automotive internal combustion engine which discharges oxygen-excessive exhaust gas under lean-burn operation. The exhaust gas purifying system comprises a NOx reducing catalyst for reducing NOx in the presence of at least hydrogen serving as reducing agent. The NOx reducing catalyst is disposed in an exhaust gas passageway of the engine. The NOx reducing catalyst includes a porous substrate, and platinum and cesium carried on the porous substrate. A catalyst is disposed in the exhaust gas passageway in order to produce hydrogen so as to enrich the oxygen-excessive exhaust gas with hydrogen before the oxygen-excessive exhaust gas reaches the NOx reducing catalyst. The oxygen-excessive exhaust gas enriched with hydrogen is introduced through the exhaust gas passageway to the NOx reducing catalyst. Here, the oxygen-excessive exhaust gas enriched with hydrogen is brought into contact with the NOx reducing catalyst under a condition in which temperature of at least one of the NOx reducing catalyst and the oxygen-excessive exhaust gas enriched with hydrogen is within a range of from 250 to 600° C.

Owner:NISSAN MOTOR CO LTD

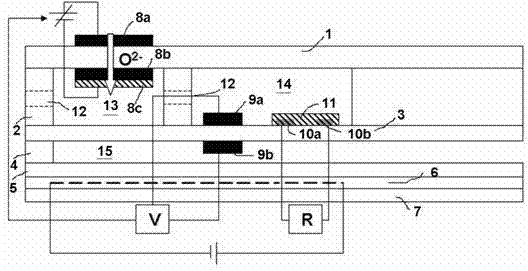

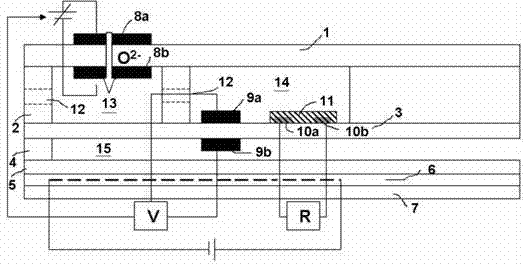

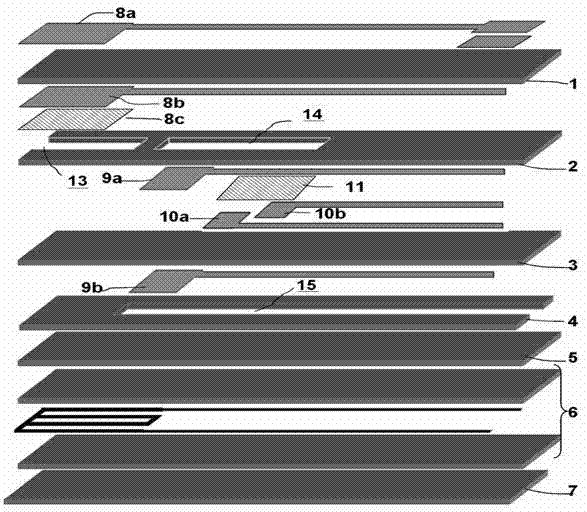

Sensor for measuring the total content of nitrogen oxides in mixed gas

ActiveCN104122303AThe principle is simpleEasy to controlMaterial resistanceNitrogen oxidesConcentration cell

The invention relates to a sensor for measuring the total content of nitrogen oxides in mixed gas. The sensor is characterized in that: the sensor comprises two inner chambers and a diffusion slit between the chambers, the first chamber is provided with an oxygen pump cell, gas to be measured can enter the first chamber, and the oxygen pump cell pumps oxygen in the gas to be measured into the chamber and oxidizes NO in the NOx mixed gas to be measured into NO2. The NO2 gas enters the second chamber through the diffusion slit between the two chambers. The second chamber is provided with a concentration cell capable of detecting the oxygen concentration in the chamber. The concentration cell and the oxygen pump cell are cooperated to allow the oxygen concentration in the second chamber to be constant and to guarantee that the oxygen in the first chamber is excessive. The second chamber is also provided with two NO2 detection electrodes. The position between the two electrodes is coated with a NO2 sensitive material. Measurement is performed by detecting the resistance value between the electrodes. The resistance value is corresponding to the NO2 concentration so as to reflect the total content of the NOx.

Owner:CHINA FIRST AUTOMOBILE +1

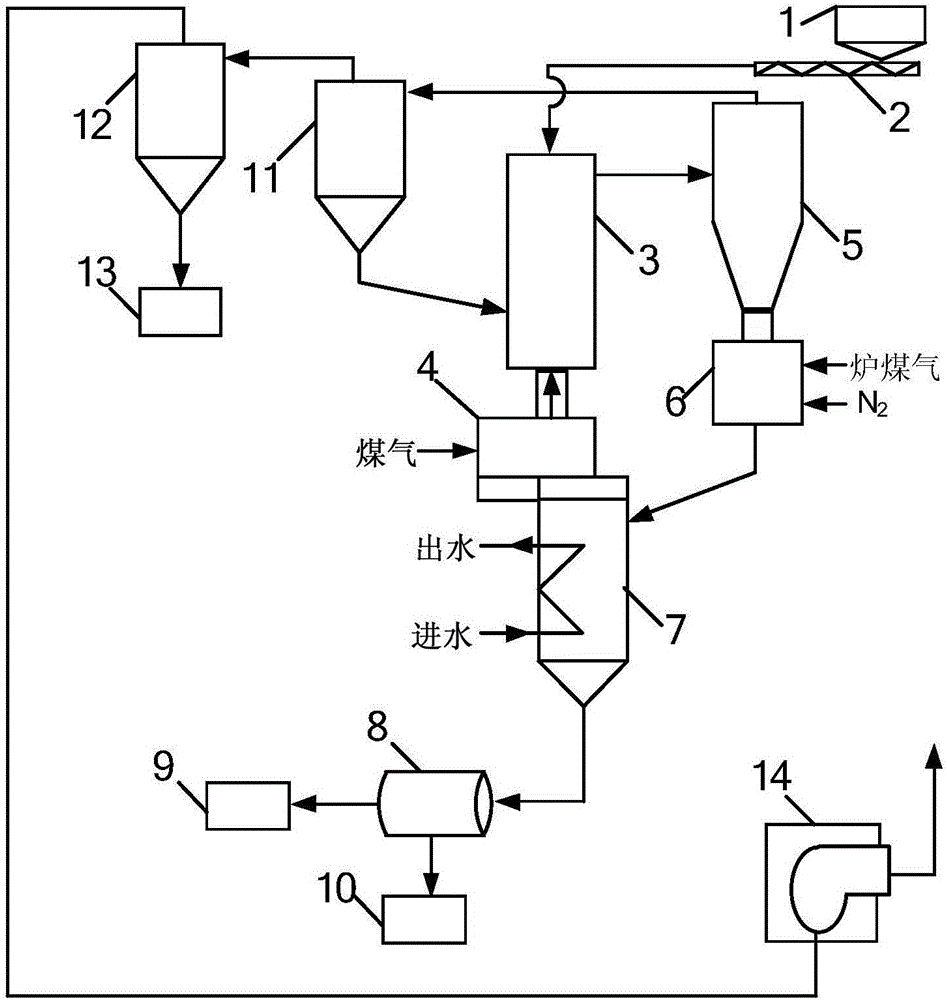

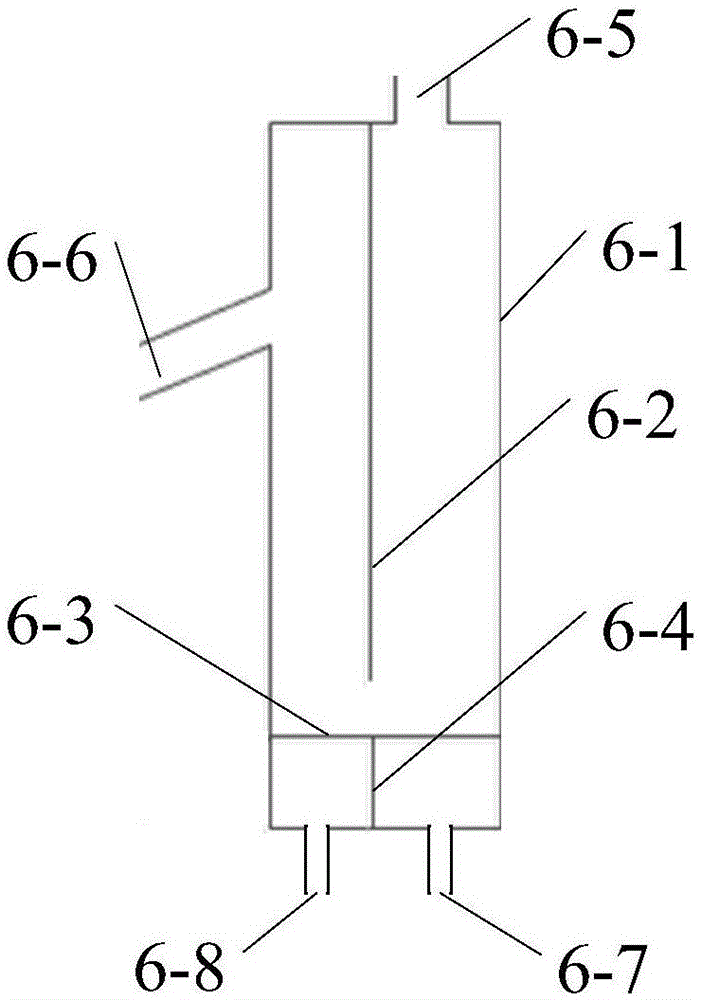

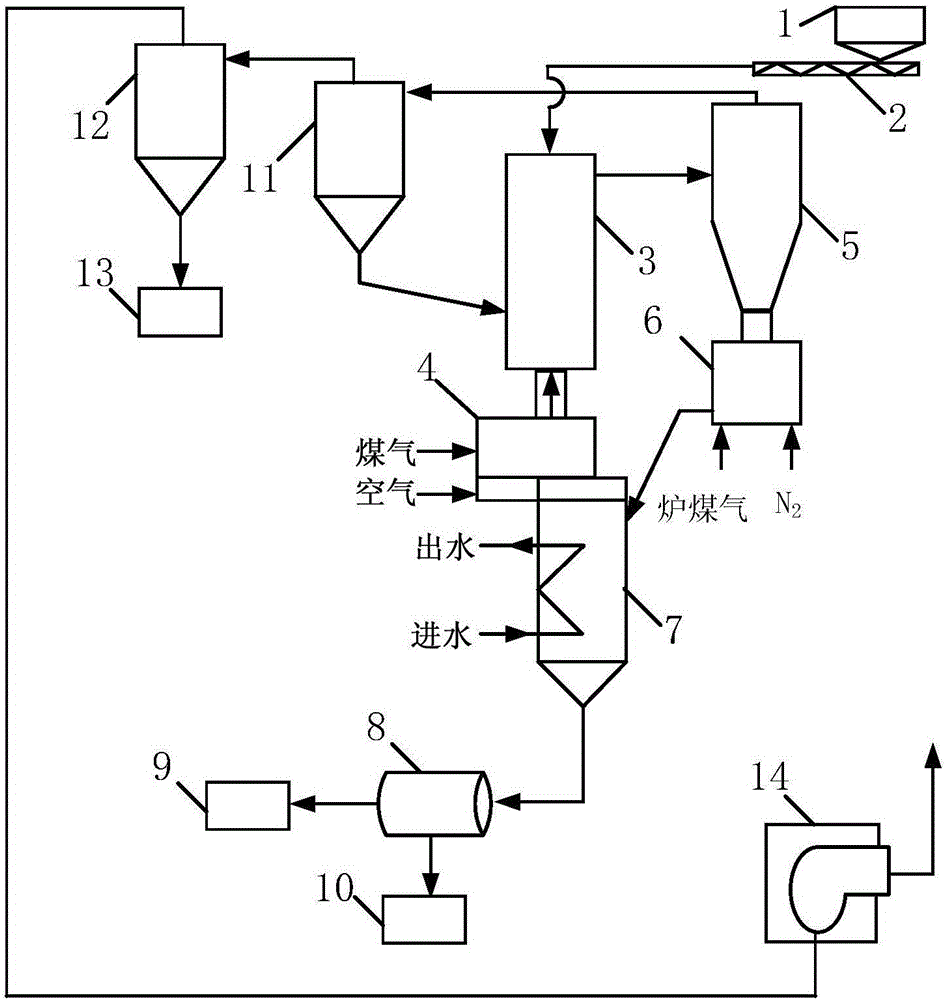

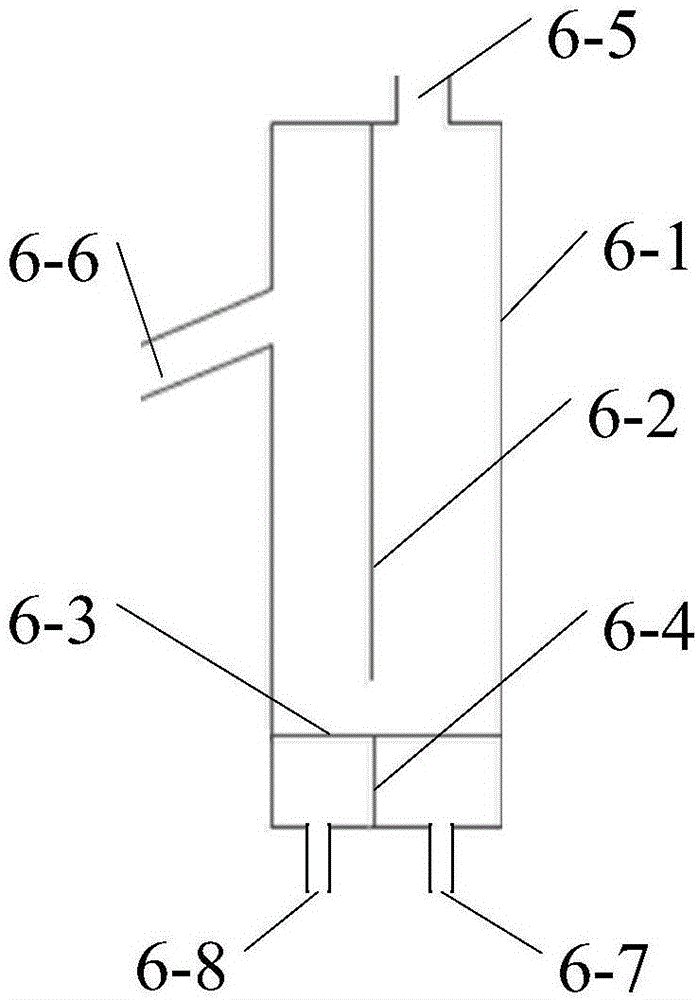

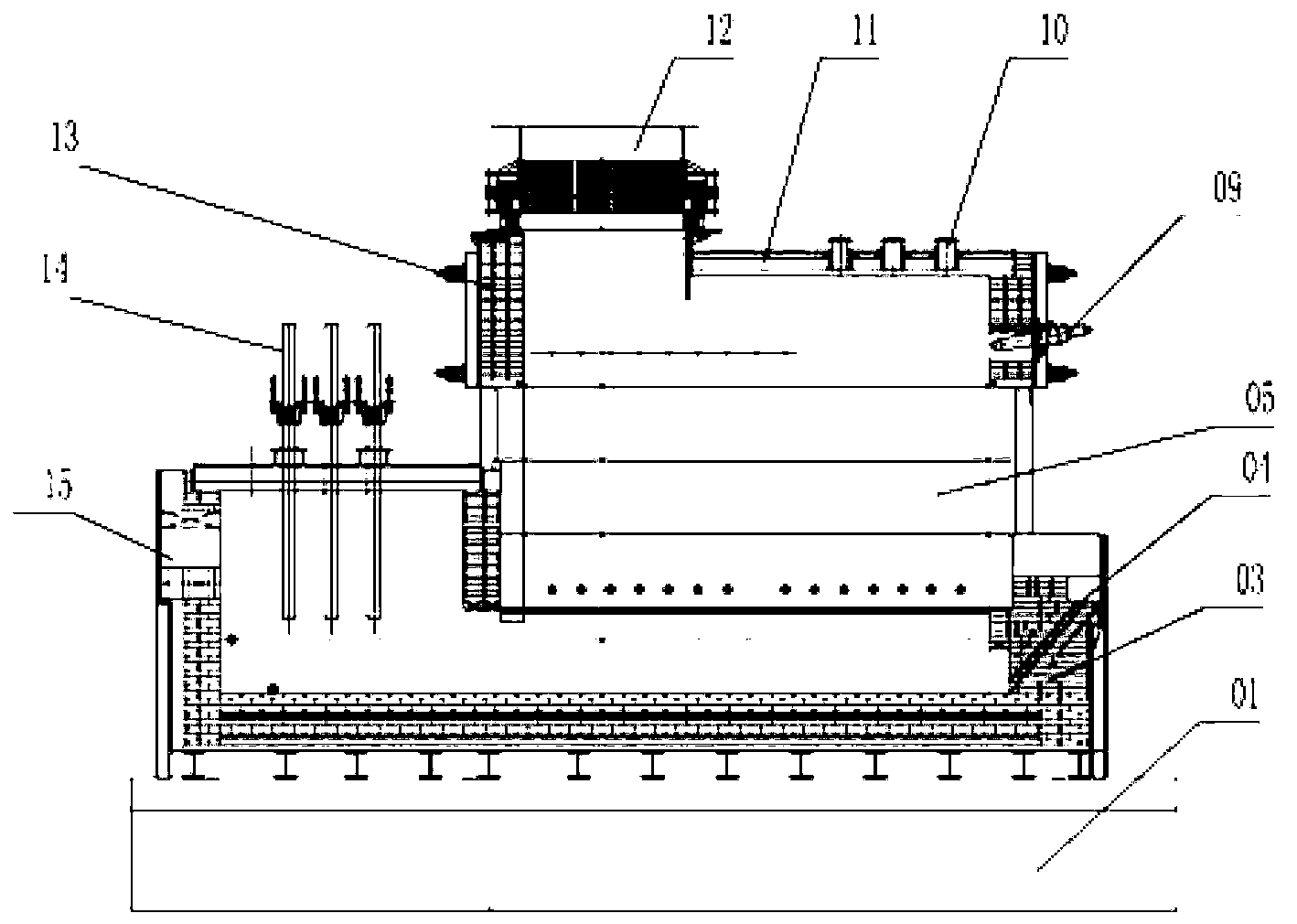

Suspension roasting comprehensive utilization system and method for iron containing manganese ore

ActiveCN107523685AHigh heat and mass transfer efficiencyWaste heat can be recoveredCombustorMagnetic separator

The invention discloses a suspension roasting comprehensive utilization system and method for iron containing manganese ore. The system comprises a feeding bin (1), a cyclone separator (11), a suspension roasting heat accumulator (3), a combustor (4), a suspension roasting oxygenizer (5), a reducer (6), a cooler (7) and a magnetic separator (8). The method comprises the steps that firstly, the iron containing manganese ore is crushed and arranged in the feeding bin; secondly, the iron containing manganese ore is conveyed into the cyclone separator through a spiral feeder, and bottom materials enter the suspension roasting heat accumulator; thirdly, the combustor is inflated with air and coal gas, and oxygen-excess combustion of the materials in the suspension roasting heat accumulator is kept; fourthly, a roots blower is started, and the preheated materials enter the suspension roasting oxygenizer; fifthly, the materials enter the reducer to be subjected to the reducing reaction after being oxidized; and sixthly, the materials enter the cooler to be subjected to heat exchange after being reduced and then enter the magnetic separator. The suspension roasting comprehensive utilization system and method have the beneficial effects that the heat and mass transfer efficiency is high, waste heat can be recycled, the treating capability is high, and the suspension roasting comprehensive utilization system and method are suitable for large-scale industrial production.

Owner:NORTHEASTERN UNIV

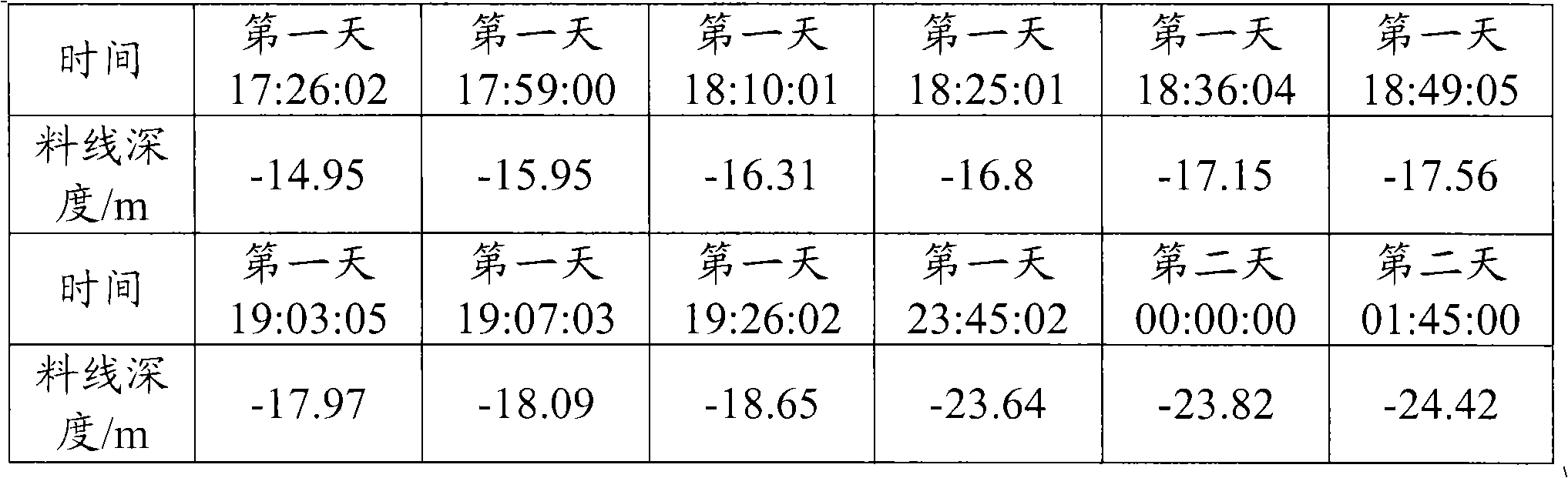

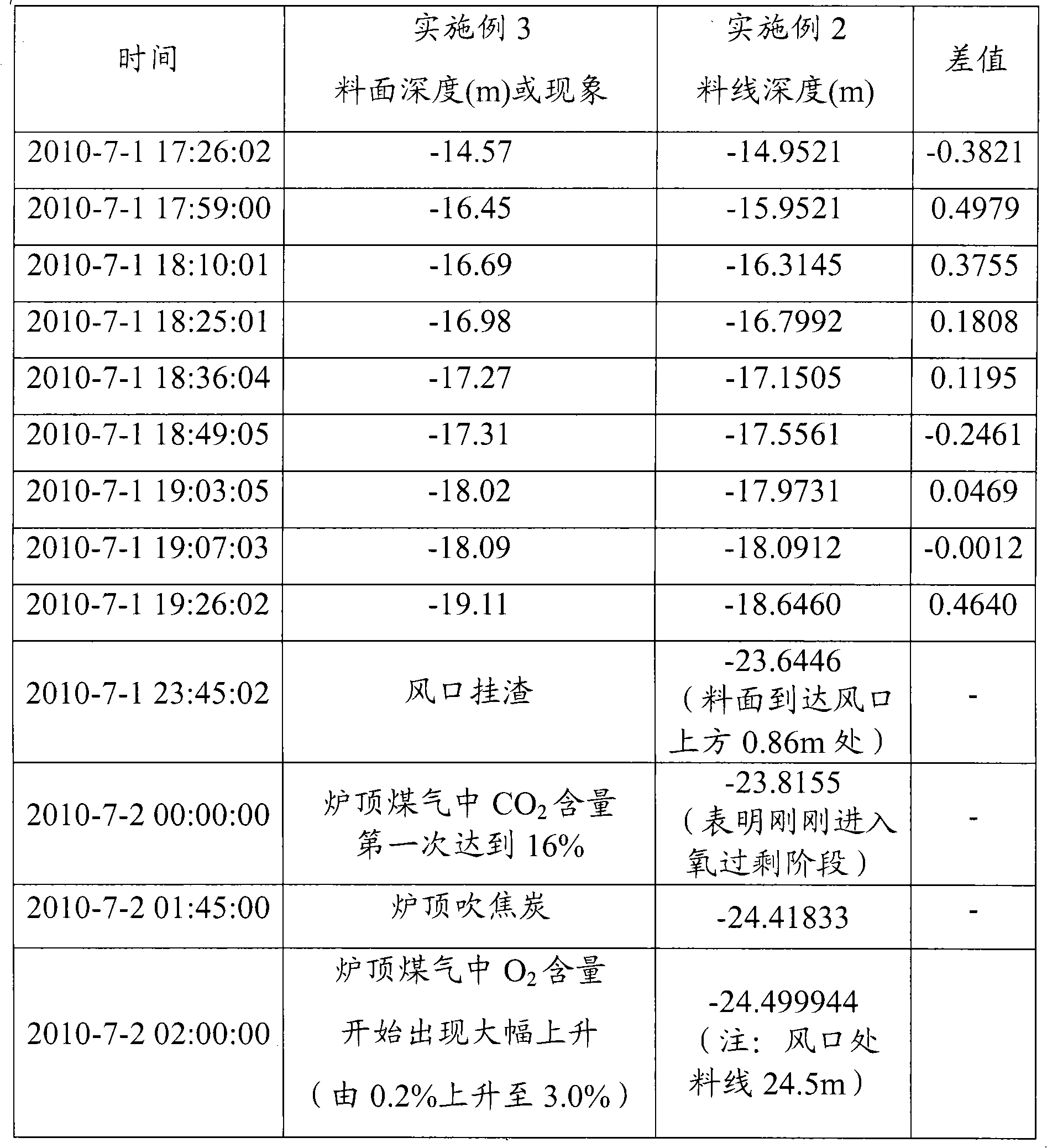

Blowing-out descending stockline control method for blast furnace

The invention provides a blowing-out descending stockline control method for a blast furnace, which comprises the following steps: according to the time order, dividing the blowing-out process of a blast furnace into an ore reduction process, a coke excess process and an aerated oxygen excess process; measuring or calculating the real-time position of a stockline; and for the different positions of the stockline in different processes, adopting different blast volumes and different amounts of roof sprayed water in the blast furnace, and scheduling corresponding operations at appropriate tapping times to realize the blowing-out descending stockline operation of the blast furnace. The blowing-out descending stockline control method for a blast furnace can realize safe and fast blowing-out operation.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Semiconductor device and method for manufacturing the same

InactiveUS20140367682A1Reduce impurity concentrationIncrease binding energyTransistorSolid-state devicesHydrogen atomDangling bond

An object is to provide a semiconductor device including an oxide semiconductor with stable electric characteristics can be provided. An insulating layer having many defects typified by dangling bonds is formed over an oxide semiconductor layer with an oxygen-excess mixed region or an oxygen-excess oxide insulating layer interposed therebetween, whereby impurities in the oxide semiconductor layer, such as hydrogen or moisture (a hydrogen atom or a compound including a hydrogen atom such as H2O), are moved through the oxygen-excess mixed region or oxygen-excess oxide insulating layer and diffused into the insulating layer. Thus, the impurity concentration of the oxide semiconductor layer is reduced.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and method for manufacturing the same

ActiveUS20130092932A1Simple interfaceIncrease oxygen concentrationSolid-state devicesSemiconductor devicesProduction rateDevice material

An object is to provide a semiconductor device including a thin film transistor with excellent electrical characteristics and high reliability and a method for manufacturing the semiconductor device with high mass productivity. A main point is to form a low-resistance oxide semiconductor layer as a source or drain region after forming a drain or source electrode layer over a gate insulating layer and to form an oxide semiconductor film thereover as a semiconductor layer. It is preferable that an oxygen-excess oxide semiconductor layer be used as a semiconductor layer and an oxygen-deficient oxide semiconductor layer be used as a source region and a drain region.

Owner:SEMICON ENERGY LAB CO LTD

Device and method for preparing fine iron powder through suspension roasting of red mud

The invention relates to a device and a method for preparing fine iron powder through suspension roasting of red mud, and belongs to the technical field of mineral processing. The device comprises a feeding bin (1), a cyclone separator (11), a suspension roasting heat accumulator (3), a combustor (4), a suspension roasting oxidizer (5), a reducer (6), a cooler (7) and a magnetic separator (8). The method comprises the steps of (1) preparing the red mud into red mud mineral powder, and placing the red mud mineral powder into the feeding bin; (2) conveying the powder to the cyclone separator through a screw feeder, and enabling the powder to enter the suspension roasting heat accumulator; (3) enabling materials in the suspension roasting heat accumulator to be kept in oxygen excess combustion through the combustor; (4) starting a roots blower, wherein preheated solid materials in the suspension roasting heat accumulator enter the suspension roasting oxidizer; (5) oxidizing the materials, enabling the materials to enter the reducer, and carrying out the reduction reaction; (6) enabling the materials to enter the cooler, and then enabling the materials to enter the magnetic separator to be subject to magnetic separation. The device and method provided by the invention have the advantages of high heat and mass transfer efficiency, recoverability of waste heat, large processing capacity, suitability for large-scale industrial production, and the like.

Owner:SHANGHAI MILESTONE TECH CO LTD

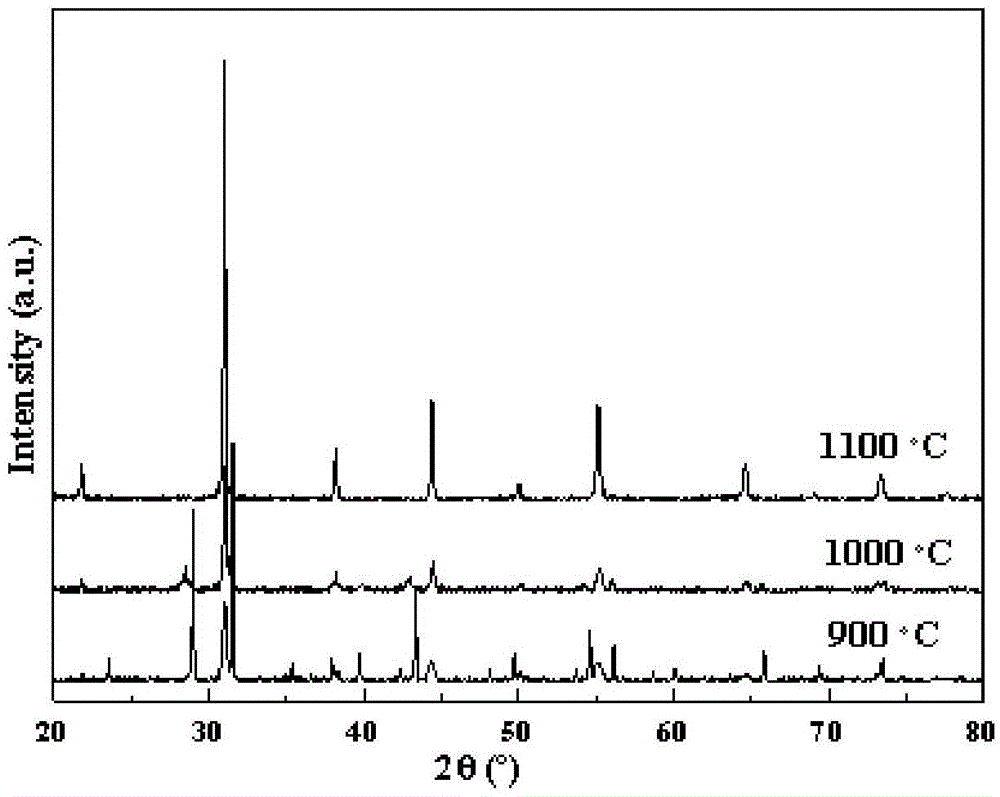

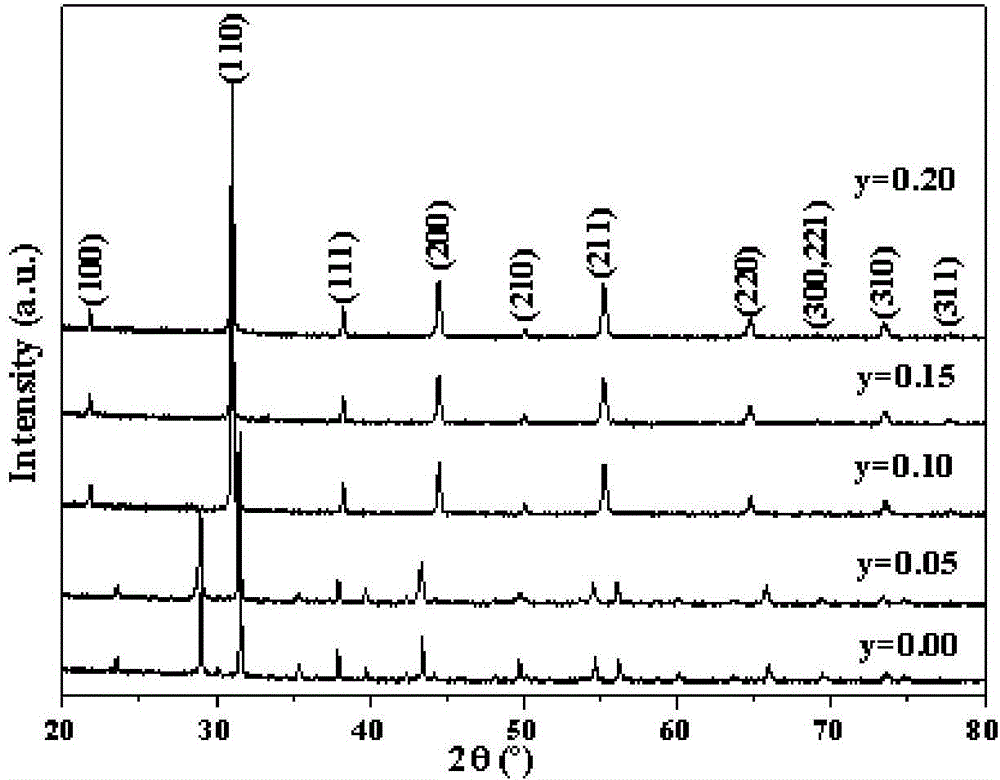

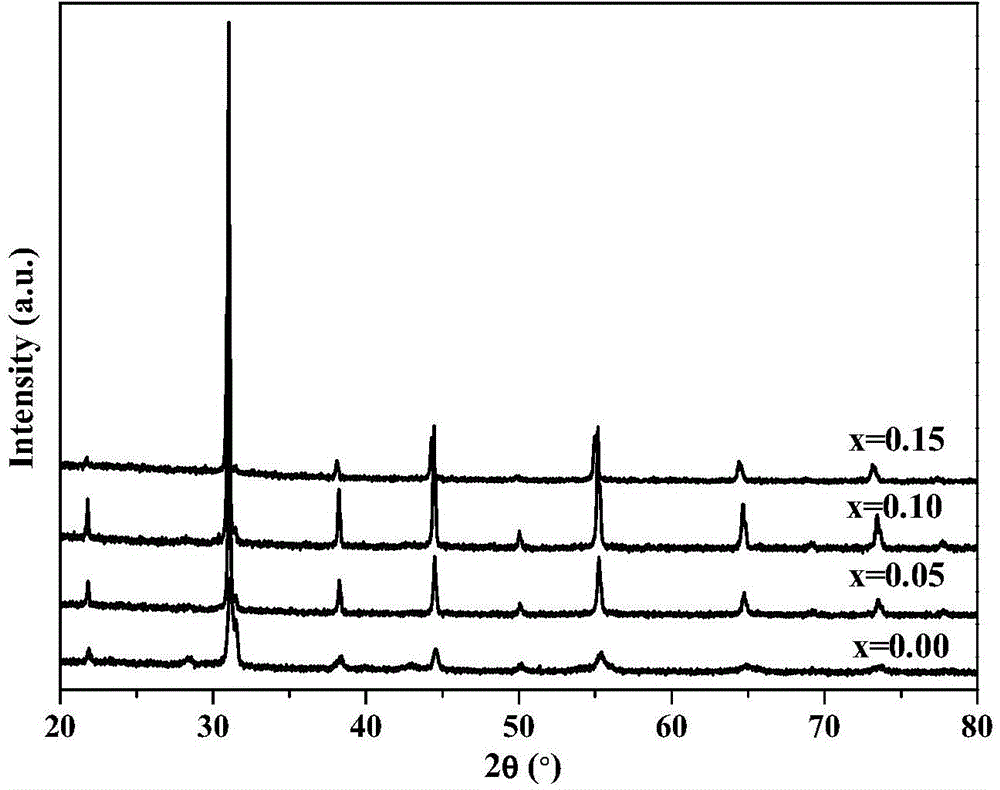

BaCoO3-delta base B-position Bi2O3-Nb2O5 co-doped cathode material of solid oxide fuel cell, preparation method and applications thereof

InactiveCN104409742AImprove structural stabilityCo-doping improvesCell electrodesOxygen ionsChemical compatibility

The invention discloses a BaCoO3-delta base B-position Bi2O3-Nb2O5 co-doped cathode material of solid oxide fuel cell, a preparation method and applications thereof. The provided cathode material has a perovskite type structure and is represented by a chemical formula: BaBi<x>Nb<y>Co<1-x-y>O<3-delta>, wherein the delta represents oxygen excess or oxygen deficiency (-1=<delta=<1), the x represents the doping amount of Bi2O3 (0=<x=<0.15), and the y represents the doping amount of Nb2O5 (0=<y=<0.2). The chemical compatibility between the provided BaBi<x>Nb<y>Co<1-x-y>O<3-delta> cathode material and the conventional electrolyte material such as GDC, and the like is good. In the air the current can be well conducted by the oxygen ions and electrons. In the temperature range of 450 to 850 DEG C, the provided cathode material has a very good oxidation-reduction catalytic activity. The cathode material is suitable for a solid oxide fuel cell used at a mid-low temperature.

Owner:HARBIN INST OF TECH

Catalyst for clarification of nitrogen oxides

InactiveUS20030144144A1Improve stabilityResistance to durabilityDispersed particle separationCatalyst activation/preparationIridiumInorganic compound

A catalyst for purifying NOx is provided which efficiently decomposes and purify the NOx in an exhaust gas in an oxygen-excess atmosphere, excels in resistance to heat and in durability in a high temperature range under a high-temperature oxidizing atmosphere and in the presence of moisture and SOx, and manifests the catalytic activity over a wide range of temperature. It is a catalyst for purifying nitrogen oxides formed by coating (A) a catalytically active component comprising (A-a) iridium and (A-b) at least one element selected from the group consisting of the elements of Group IIIB and Group IVB in the Periodic Table of the Elements with (B) a refractory inorganic compound. It is further a nitrogen oxide expelling catalyst containing as catalytically active substances (A) iridium (A-a) and at least one element selected from the group consisting of the elements of Group IIIB and Group IVB in the Periodic Table of the Elements (A-b) and (C) at least one element selected from the group consisting of the Elements IIIA in the Periodic Table of the Elements.

Owner:UMICORE SHOKUBAI JAPAN CO LTD +1

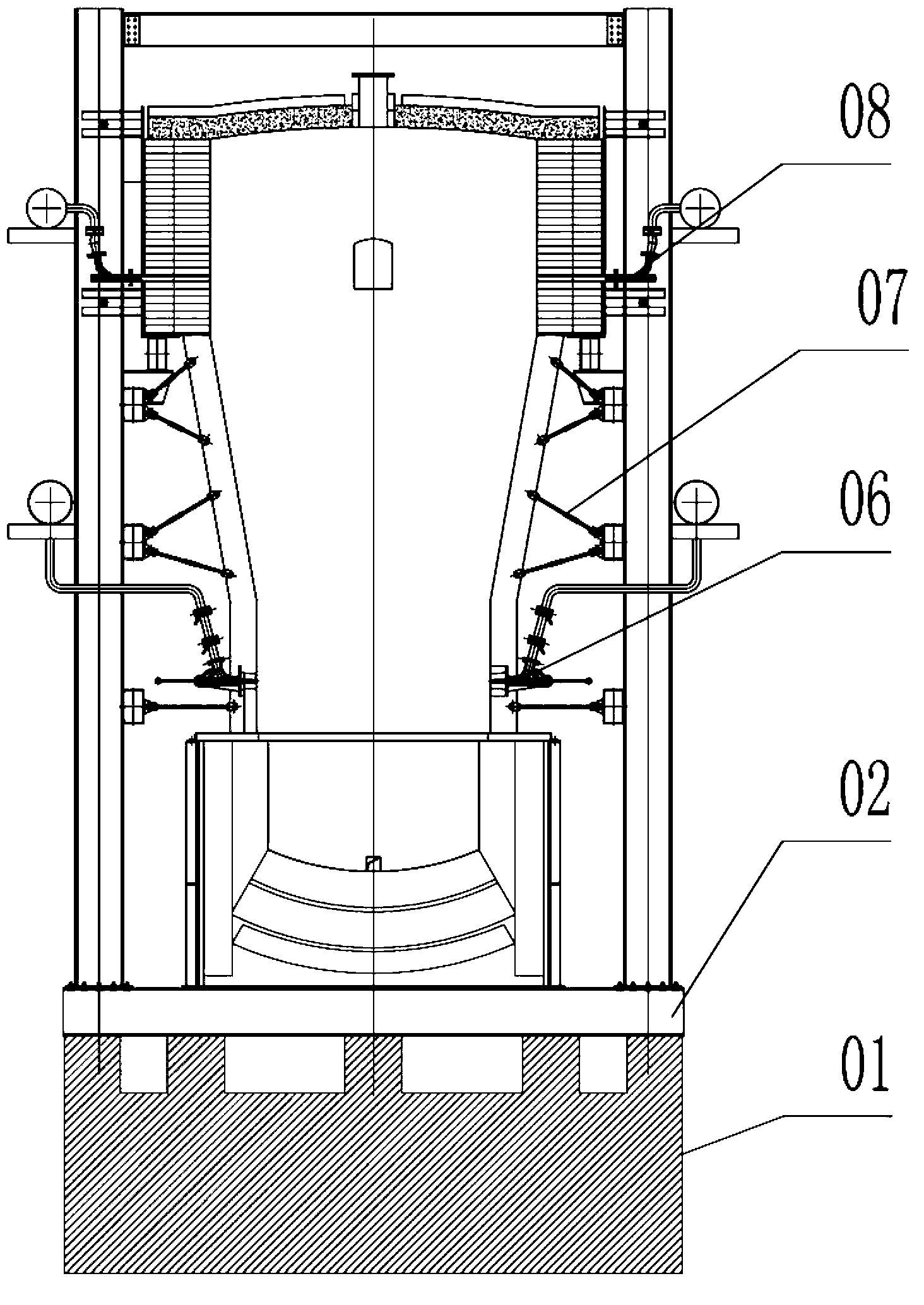

Oxygen-enriched side-blown smelting furnace for complicated and unworkable gold concentrate

The invention discloses an oxygen-enriched side-blown smelting furnace for complicated and unworkable gold concentrate. The smelting furnace is divided into a heating zone and a reaction zone; a cooling water jacket is arranged all around the side wall of the reaction zone, and the cooling water jacket is divided into three or more layers and can be detached independently; the three-layer water jacket on the side wall of the reaction zone is provided with two rows of air ports, high concentration oxygen-enriched air is fed into the lower air ports to react with materials during working, and the upper air ports adjust the produced smoke gas to be at oxygen excess state; compact high-temperature resistant heat insulation coating is embedded in the cooling water jacket and the contact zone of the smelting furnace, and a layer of 5-10mm high-temperature resistant heat insulation material is coated for heat insulation on the outer layers of the flame retardant coatings inside and at the top of the smelting furnace respectively; and a furnace slag and gold concentrate separation zone is arranged at one end of a smelting furnace body, gold concentrate and furnace slag are respectively discharged out from a gold concentrate discharge port and a furnace slag discharge port at both ends, three heating electrodes are arranged at the top of the separation zone for adjusting and controlling the temperature of the furnace slag so as to ensure the thorough separation of gold concentrate and furnace slag. The smelting furnace has low energy consumption, high synthetic recovery rate of gold, silver, bronze, sulfur and the like, high material adaptability and good operating environment simultaneously.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

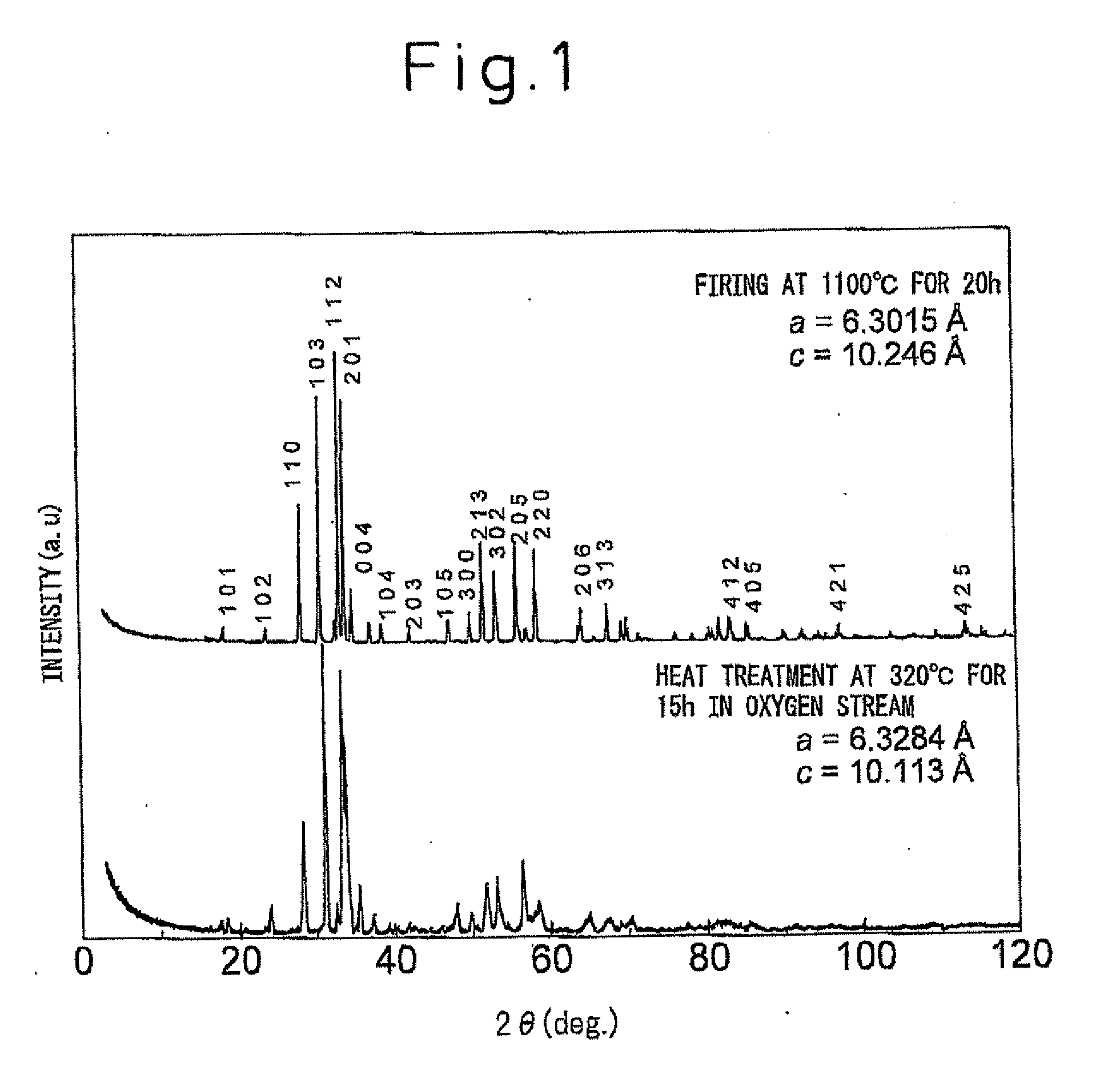

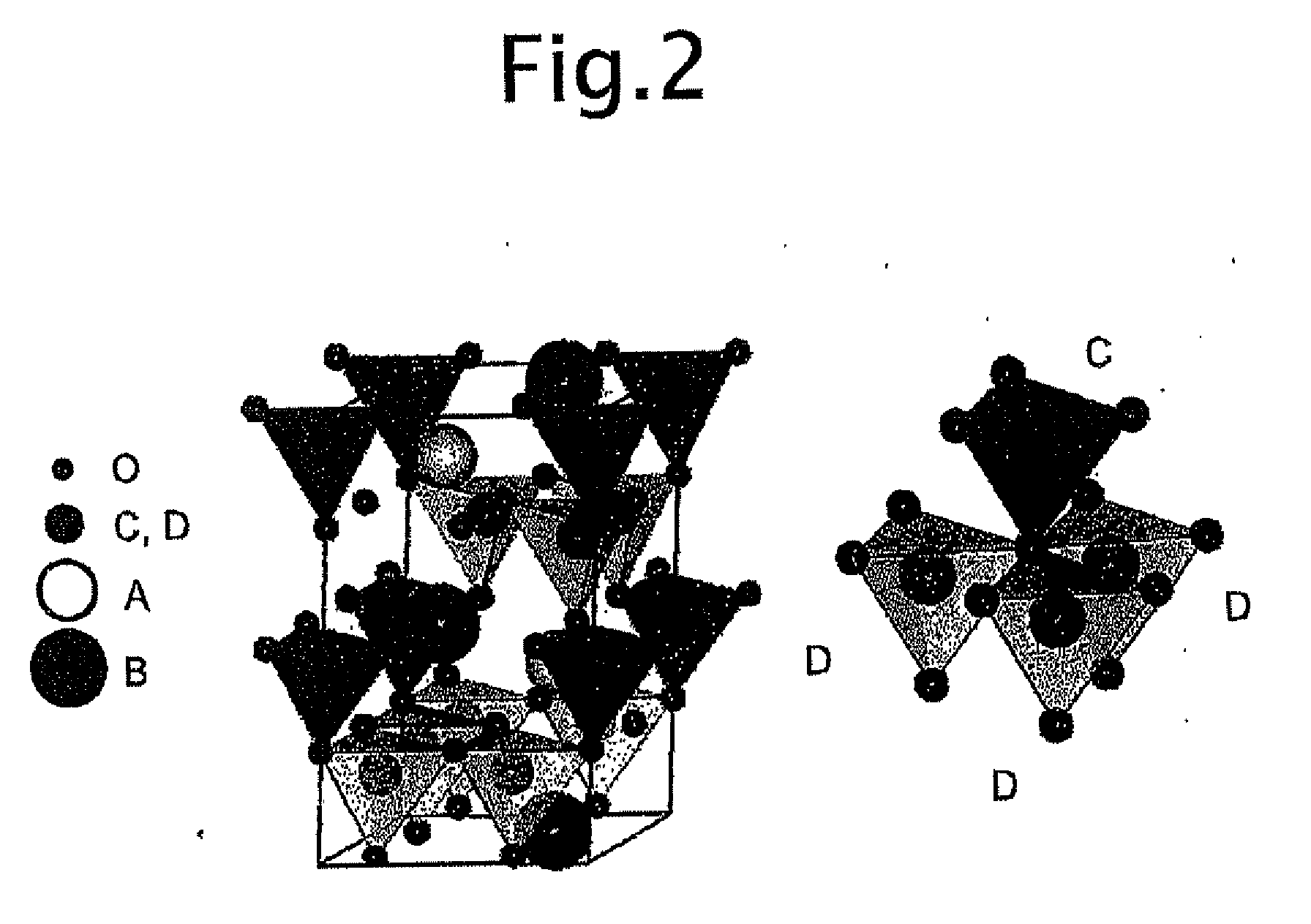

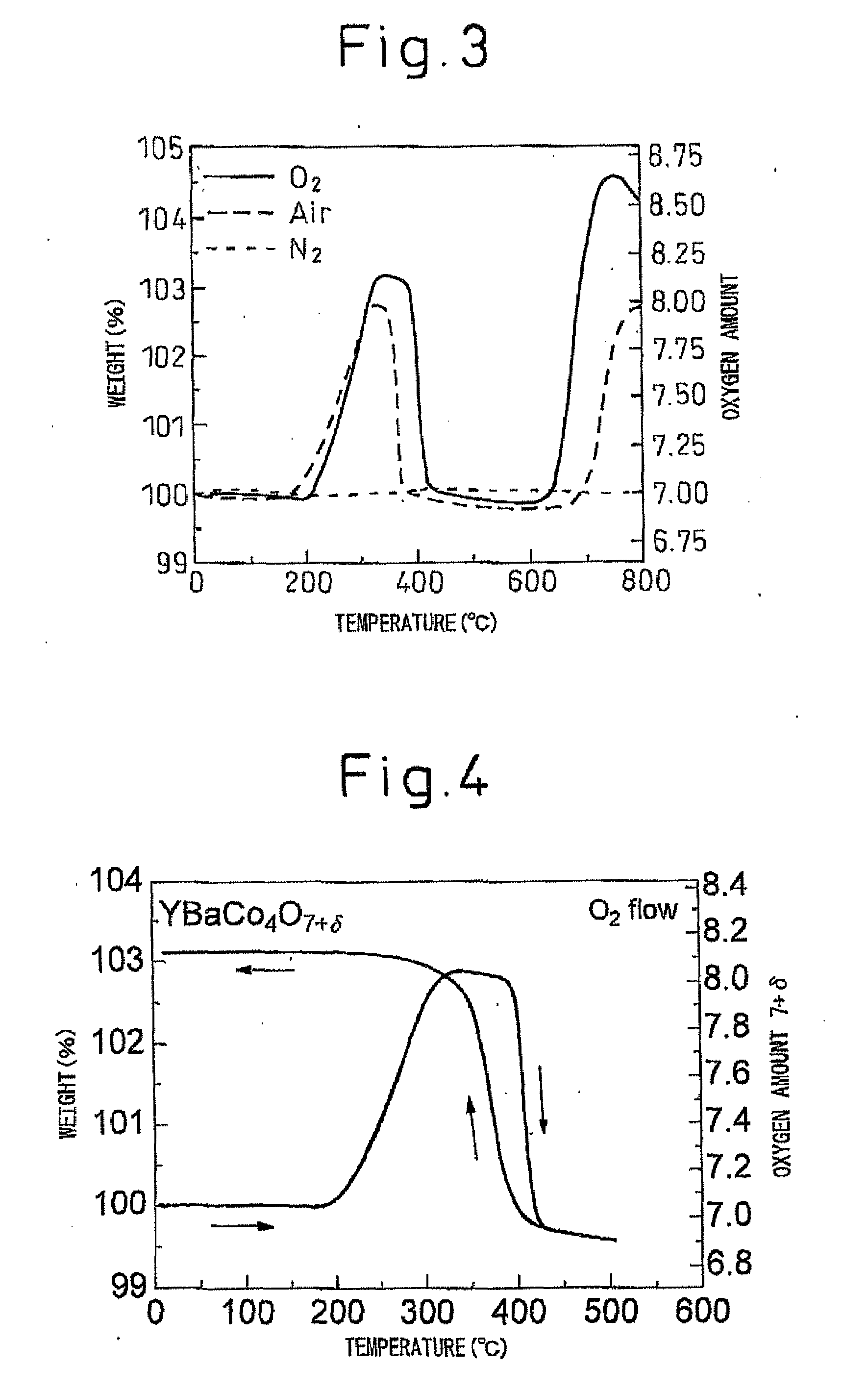

Oxygen excess type metal oxide, ceramic for oxygen storage and/or an oxygen selective membrane, and methods and apparatuses using said metal oxide

An oxygen excess type metal oxide expressed with the following formula (1) and exhibiting high speed reversible oxygen diffusibility whereby a large amount of excess oxygen is diffused at a high speed and reversibly in a low temperature region:AjBkCmDnO7+δ (1)whereA: one or more trivalent rare earth ions and CaB: one or more alkaline earth metalsC, D: one or more oxygen tetra-coordinated cations among which at least one is a transition metal,where j>0, k>0, and, independently, m≧0, n≧0, and j+k+m+n=6, and 0<δ≦1.5.

Owner:TOKYO INST OF TECH

Semiconductor device

ActiveUS9202925B2Improve reliabilityRun at high speedTransistorSolid-state devicesSemiconductorSemiconductor device

A structure is employed in which a first protective insulating layer; an oxide semiconductor layer over the first protective insulating layer; a source electrode and a drain electrode that are electrically connected to the oxide semiconductor layer; a gate insulating layer that is over the source electrode and the drain electrode and overlaps with the oxide semiconductor layer; a gate electrode that overlaps with the oxide semiconductor layer with the gate insulating layer provided therebetween; and a second protective insulating layer that covers the source electrode, the drain electrode, and the gate electrode are included. Furthermore, the first protective insulating layer and the second protective insulating layer each include an aluminum oxide film that includes an oxygen-excess region, and are in contact with each other in a region where the source electrode, the drain electrode, and the gate electrode are not provided.

Owner:SEMICON ENERGY LAB CO LTD

Catalyst

InactiveUS7795170B2High catalytic activityEffective supportHeterogenous catalyst chemical elementsCatalyst activation/preparationRare-earth elementAlkaline earth metal

Owner:CATALER CORP

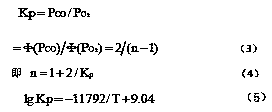

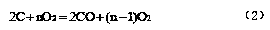

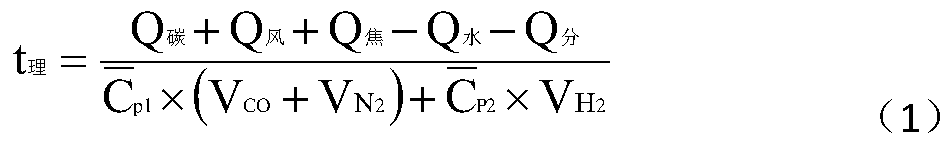

Heat compensation method in coal gas blowing smelting process

InactiveCN110484665AIncrease temperatureIncrease the oxygen excess coefficientBlast furnace detailsSmelting processEngineering

The invention discloses a heat compensation method in a coal gas blowing smelting process. The method comprises the following steps that (1), after being pressurized to be at least 100 kPa higher thanhot air pressure by a pressurizing machine, coke oven gas is conveyed to a blast furnace through a pipeline; (2), in a blast furnace tuyere zone, the coke oven gas in the pipeline in the step (1) issprayed into the blast furnace through a spray gun, and the coke oven gas and pulverized coal together participate in a reaction in the furnace; and (3) the oxygen supply amount is increased through an oxygen enrichment pipeline in a blast furnace tuyere rotary zone, so that the oxygen excess coefficient n is increased, the combustion of a combustion zone is enhanced, and then the temperature of the zone is increased. According to the method, the problems that the temperature of the rotary zone is decreased, so that the temperature of molten iron, the heat supply of a furnace cylinder and thelike are changed, effective blowing of the coke oven gas is not facilitated, and working of the blast furnace during smelting is affected are effectively solved.

Owner:JIUQUAN IRON & STEEL GRP

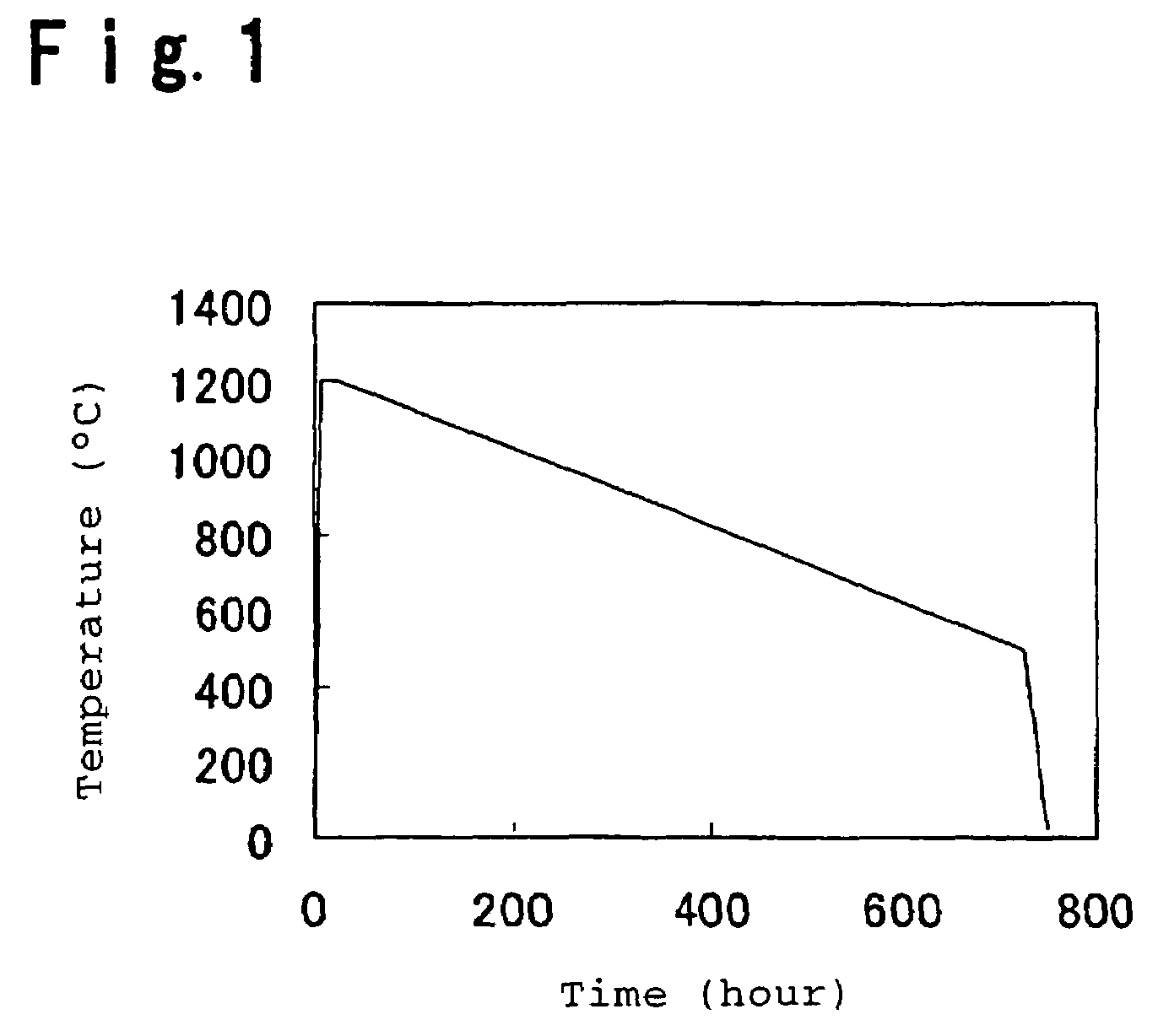

Synthetic quartz glass for optical member and its production method

ActiveUS7514382B2Improve uniformityStably smallGlass shaping apparatusGlass deposition burnersOxygen deficientLength wave

A synthetic quartz glass for an optical member which is free from compaction and rarefaction is obtained. A synthetic quartz glass for an optical member to be used for an optical device employing a light having a wavelength of at most 400 nm and at least 170 nm as a light source, which contains substantially no oxygen excess defects, dissolved oxygen molecules nor reduction type defects, which has a chlorine concentration of at most 50 ppm and a OH group concentration of at most 100 ppm, and which contains oxygen deficient defects within a concentration range of at most 5×1014 defects / cm3 and at least 1×1013 defects / cm3. The fluorine concentration is preferably at most 100 ppm.

Owner:ASAHI GLASS CO LTD

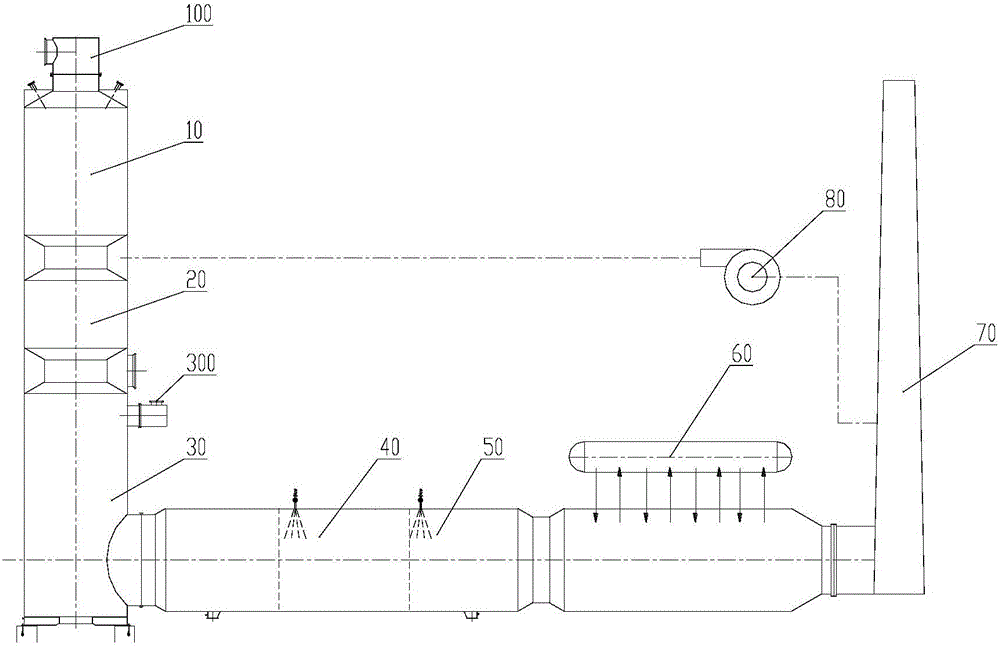

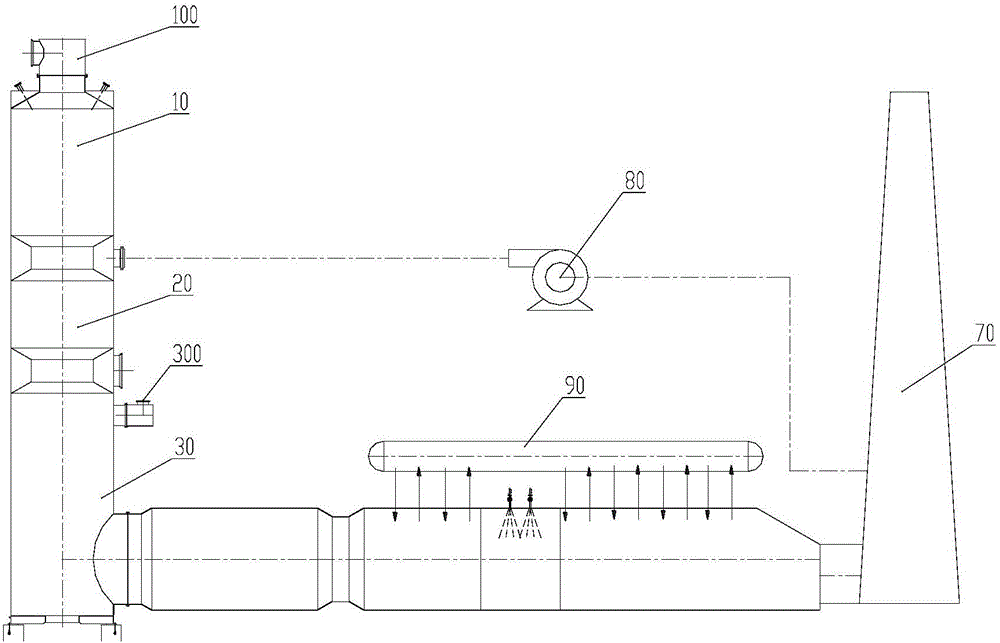

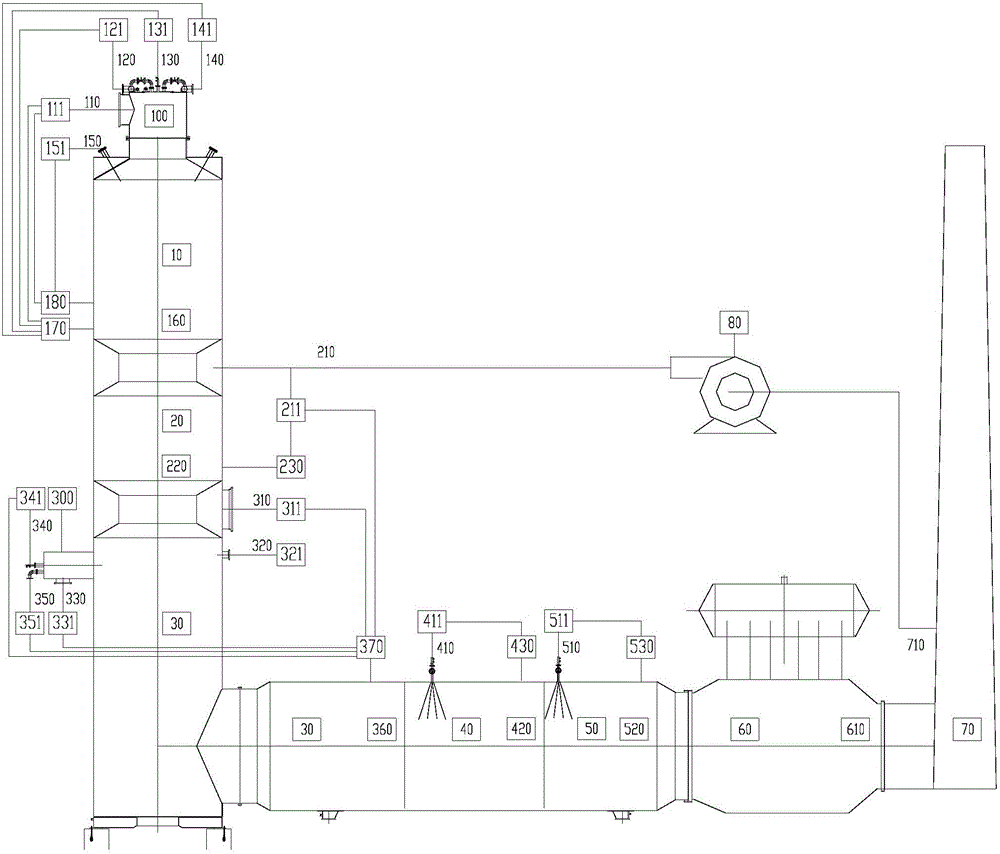

Low nitrogen oxide incinerating device used for treatment of nitrogen containing waste gas and nitrogen containing waste liquid and low nitrogen oxide incinerating method used for treatment of nitrogen containing waste gas and nitrogen containing waste liquid

InactiveCN105937766AControl generationSuppress generationIncinerator apparatusNitrogen oxidesLow nitrogen

The invention provides a low nitrogen oxide incinerating device used for a treatment of nitrogen containing waste gas and nitrogen containing waste liquid and a low nitrogen oxide incinerating method used for the treatment of the nitrogen containing waste gas and the nitrogen containing waste liquid. The device comprises an oxygen debt reducing section, a primary quenching section, an oxidizing section, a secondary quenching section, SNCR denitrating section and a waste heat boiler. The method comprises the following steps: (1) oxygen debt incinerating; (2) primary quenching; (3) oxygen excess incinerating; (4) secondary quenching; (5) SNCR denitrating; (6) waste heat recovery. According to the device and the method, the technology of combining the staged combustion of the air over a furnace, the flue gas recycling and the SNCR denitrating is utilized, and a whole set of incinerating device, incinerating method and controlling philosophy are provided, so that the generating of the nitrogen oxide during the combustion of the waste such as nitrogen containing waste gas, nitrogen containing waste liquid and like can be effectively controlled, particularly the generating of the fuel type nitrogen oxide can be inhibited significantly and the transformation rate that the nitrogen generates the nitrogen oxide in the fuel composition can be lowered.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

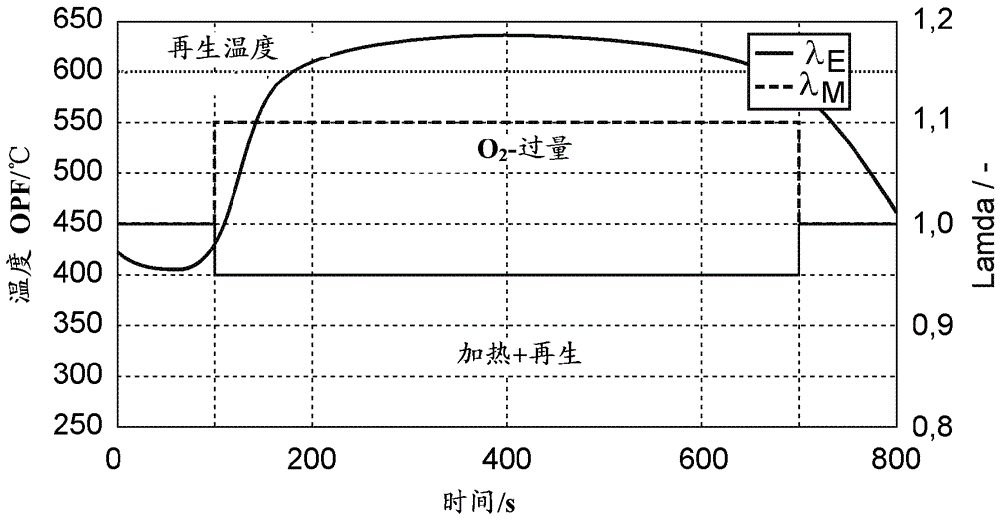

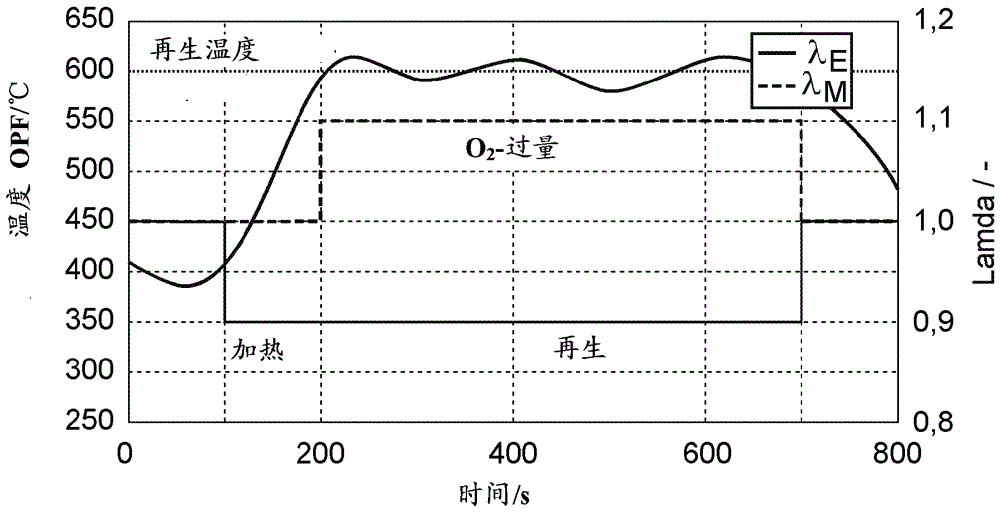

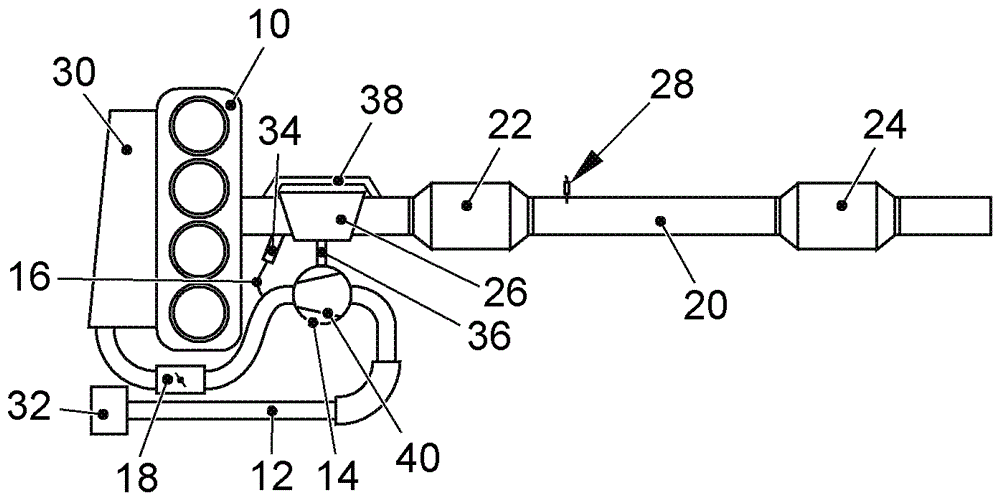

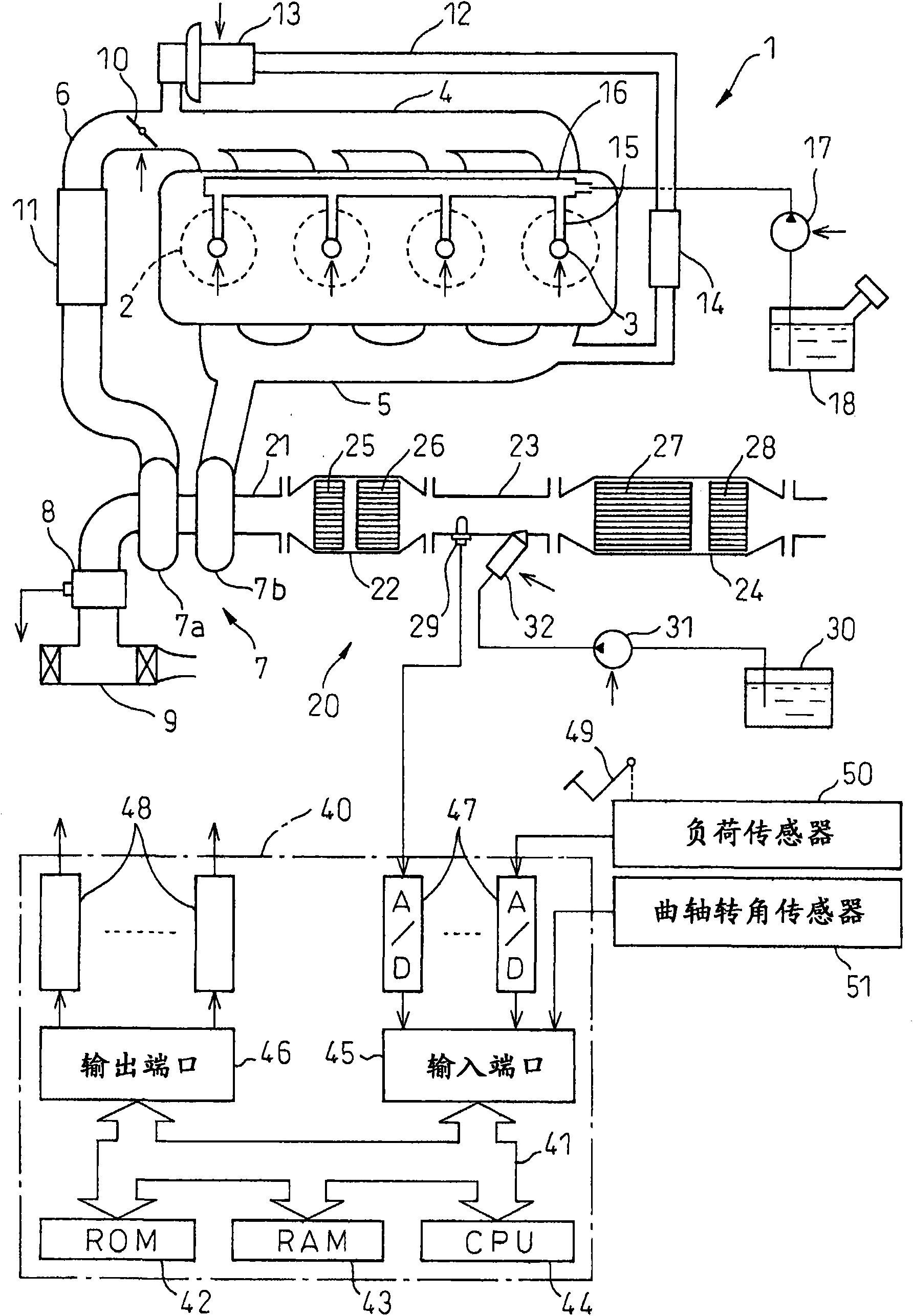

Internal combustion engine exhuast gas post treatment method and apparatus for executing same

ActiveCN106437973APromote regenerationImprove purification effectInternal combustion piston enginesExhaust apparatusParticulatesSoot

The invention relates to a method and an apparatus for the exhaust gas post treatment of a combustion engine. The apparatus comprises an internal combustion engine comprising a fresh air duct and an exhaust gas duct. A compressor for compressing the fresh air is arranged in the fresh air duct and the downstream of the compressor is provided with a secondary air pipeline. A three-way catalytic converter is arranged in the exhaust gas duct. The downstream of the three-way catalytic converter is provided with a particle filter. The method comprises the following processes: determining a loading condition of the particulate filter, when the loading condition requires a regeneration of the particulate filter, raising the exhaust temperature to a regeneration temperature of the particulate filter by at least temporarily adjusting a mixture formation for the internal combustion engine to a combustion air ratio ([lambda]E <1) and at least simultaneously introducing secondary air into the exhaust gas channel upstream of the three-way catalytic converter, wherein the unburned hydrocarbons in the exhaust gas channel, the super stoichiometric mixing air ratio ([lambda]M> 1) is set in the exhaust gas channel before entry into the particle filter, so that soot is formed on the exhaust air mixture particle filter is oxidized by the oxygen excess.

Owner:VOLKSWAGEN AG

Method and device for recovering and purifying argon in monocrystalline silicon production

ActiveCN102583281BLow recovery and purification energy consumptionNoble gas compoundsPtru catalystCatalytic oxidation

Provided is a method and a device for recovering and purifying argon in monocrystalline silicon production. The method comprises firstly conducting coarse oil removal on argon recovered from a single crystal furnace, compressing, cooling and conducting high-precision oil removal and dedusting; secondly enabling hydrocarbon such as methane and carbon monoxide to be reacted with oxygen to generate water and carbon dioxide through a high temperature catalytic reaction and guaranteeing the oxygen to be excessive in the catalytic reaction; thirdly enabling excessive oxygen to be reacted with added hydrogen to generate the water under effects of a catalytic agent after cooling and enabling argon after two catalytic reactions to penetrate through a normal temperature adsorption unit to absorb the water and the carbon dioxide; cooling the argon, sending a low temperature rectifying tower, enabling the argon, the nitrogen and the hydrogen to produce rectification separation, obtaining pure liquid argon, and conducting repeated heating to obtain pure argon products. The device mainly comprises an oil filter, a catalytic reactor of the hydrocarbon of high temperature catalytic oxidation carbon monoxide and methane and the like, a normal temperature hydrogenation deoxygenization catalytic reactor, a normal temperature adsorption unit for absorbing the carbon dioxide and the water at the normal temperature and the low temperature rectifying tower for rectifying and separating the hydrogen and the nitrogen at the low temperature. The device has the advantages of being high in argon recovery rate, high in purity of recovered argon, low in oxygen content, low in energy consumption for recovery and purification and the like.

Owner:HANGZHOU HANGYANG

Heat accumulation type waste liquid combustor

The invention provides a heat accumulation type waste liquid combustor, and belongs to the technical field of environment protection. The heat accumulation type waste liquid combustor comprises a shell, a waste liquid atomization nozzle, a combustion supporting nozzle, a heat accumulation gasification cover and an igniter used for igniting waste liquid. The heat accumulation gasification cover is arranged in the shell and prevents heat generated during combustion from diffusing, the waste liquid sprayed out of the atomization nozzle can be rapidly gasified at the high temperature, sufficient combustion of the waste liquid is promoted, and the waste liquid can be treated more thoroughly; and more superoxide cannot be generated even when high-temperature oxygen-excess combustion happens, more environment protection treatment cost is saved, and the environment is protected.

Owner:CHINA PETROLEUM & CHEM CORP +1

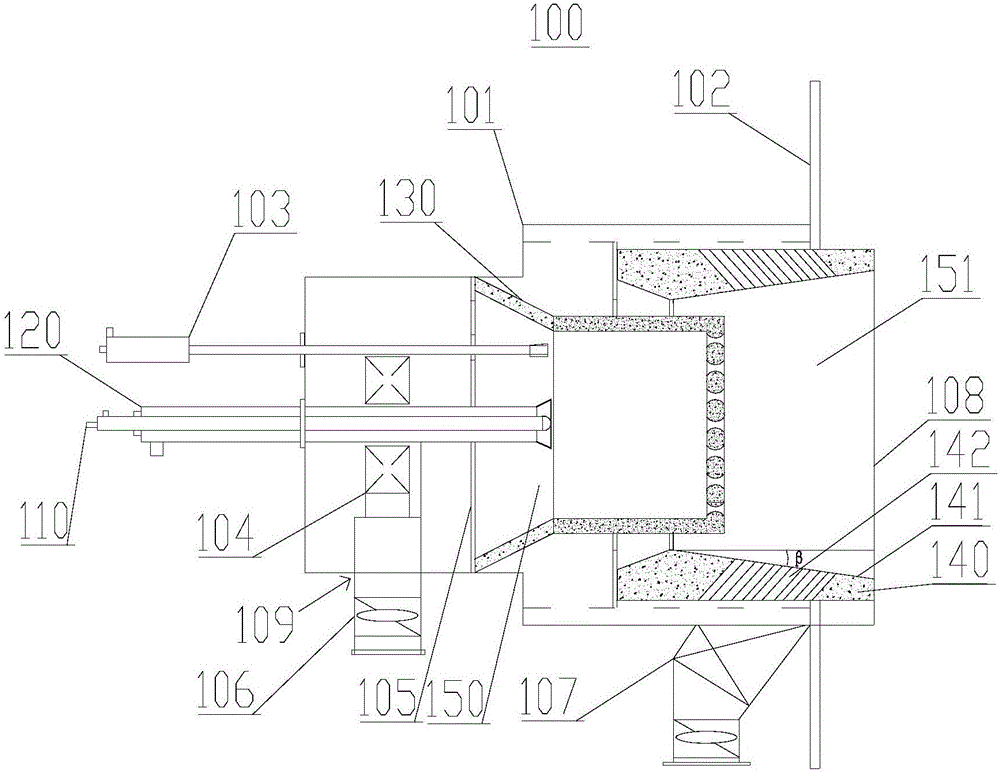

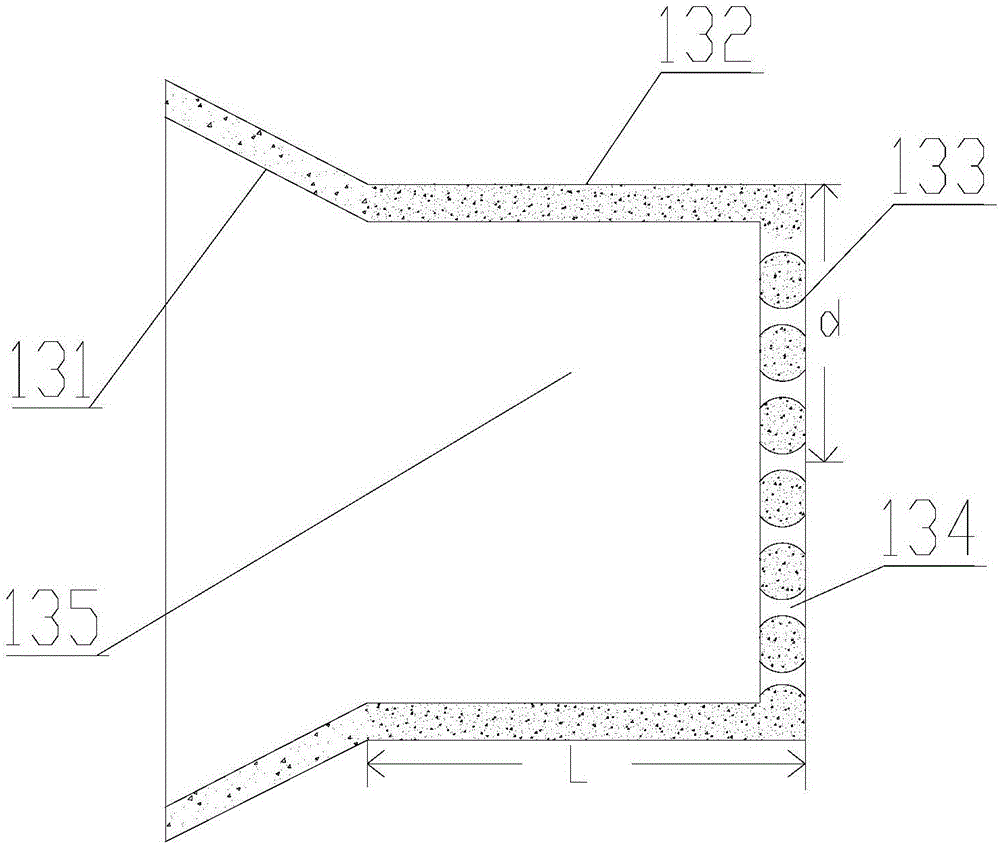

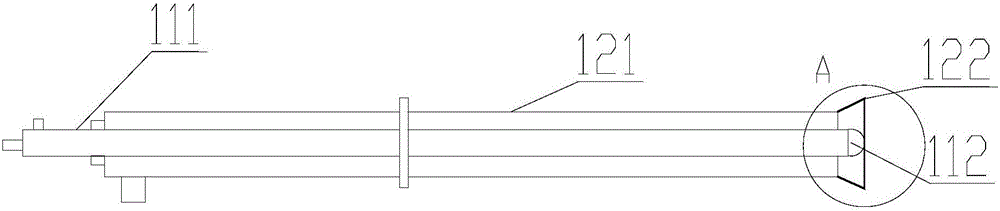

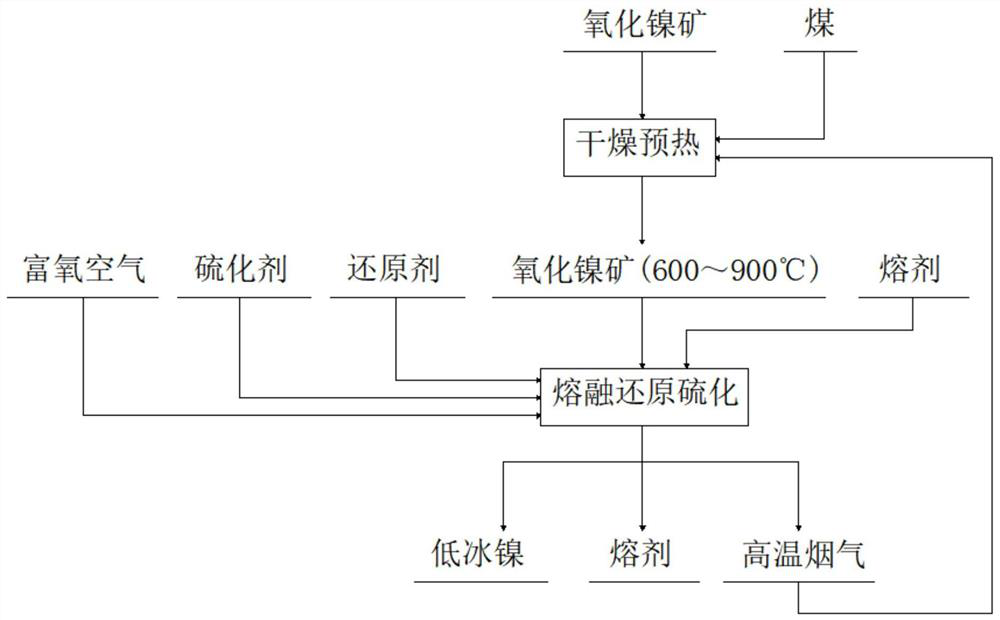

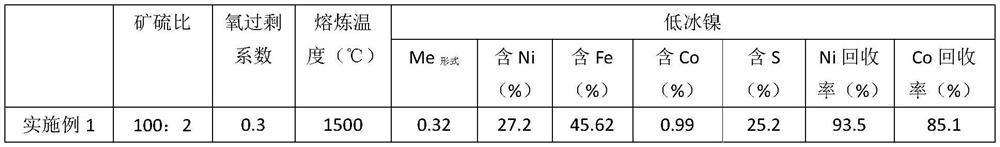

Method for producing low nickel matte by smelting, reducing and vulcanizing nickel oxide ore

PendingCN113293296AEasy to controlReduce processing costsProcess efficiency improvementMolten stateSlag

The invention discloses a method for producing low nickel matte by smelting, reducing and vulcanizing nickel oxide ore. The method mainly comprises the following steps: drying and preheating the nickel oxide ore to produce thermal nickel oxide ore at the temperature of 600-900 DEG C; continuously adding the dried and preheated nickel oxide ore and flux into a melting pool of the melting furnace; spraying a reducing agent, a vulcanizing agent and oxygen-enriched air into a reaction zone of a molten pool in the smelting furnace, and controlling the oxygen excess coefficient alpha of the oxygen-enriched air to the reducing agent to be 0.3-0.4; and controlling the temperature in the furnace to be 1400-1550 DEG C, wherein the materials added into the furnace are subjected to a reduction vulcanization reaction in a molten state to produce low nickel matte and slag. The method is used for nickel oxide ore smelting, and has the characteristics of good environmental protection, short process, strong raw material adaptability, low production cost and the like.

Owner:CNGR ADVANCED MATERIAL CO LTD +1

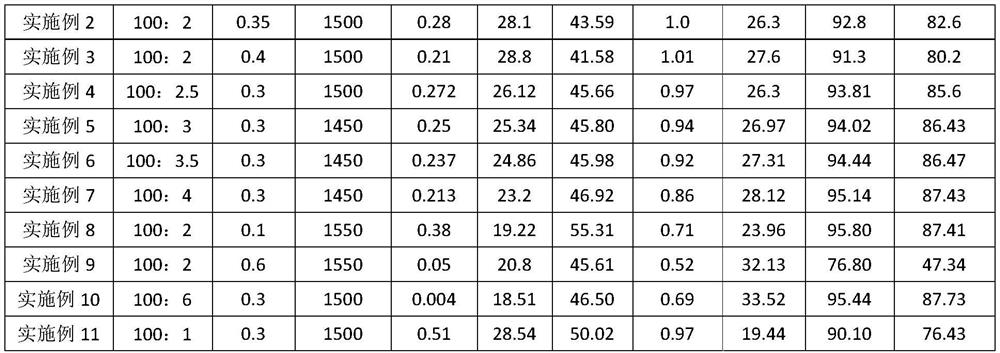

Respirator for respiratory department

The invention relates to a respirator for a respiratory department, belonging to the technical field of medical appliances. The respirator for the respiratory department provided by the invention comprises a body, a mask and a humidifier, wherein the body is provided with a plastic shell; the upper side of the plastic shell is provided with a respiratory disorder alarming lamp; an oxygen excess alarming lamp is arranged at the left side of the respiratory disorder alarming lamp; a carbon dioxide excess alarming lamp is arranged at the left side of the oxygen excess alarming lamp; a toxic impurity load alarming lamp is arranged at the left side of the carbon dioxide excess alarming lamp; a humidifier fixing bracket is arranged at the left side of the toxic impurity load alarming lamp. The respirator for the respiratory department has the advantages of complete functions and convenience in use; when the respirator for the respiratory department is used for performing emergent treatment on a patient in the respiratory department, time and labor are saved, the effects of scientificity, convenience, safety and high efficiency are achieved, and the working difficulty of medical personnel is relieved.

Owner:海门市知舟工业设计有限公司

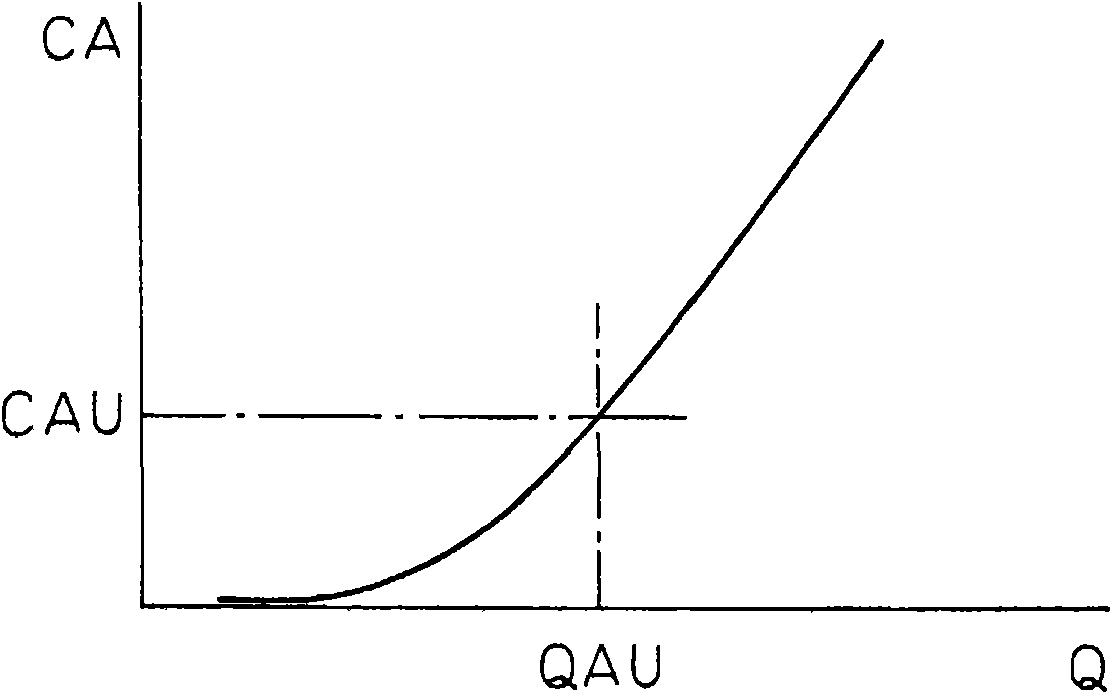

Exhaust gas purification apparatus for internal combustion engine

InactiveCN101646845AAvoid dischargeGas treatmentInternal combustion piston enginesInternal combustion engineControl valves

A catalyst (27) suitable for the reduction of an NOx in an exhaust gas with ammonia in an oxygen-excess atmosphere is placed in an engine exhaust passage. An aqueous urea solution is supplied to the catalyst (27) through a supply control valve (32) to store a part of urea supplied to the catalyst (27) in the inside of the catalyst (27) and reduce the NOx contained in the exhaust gas with ammonia produced from urea stored in the catalyst (27). It is determined whether or not the storage volume of the catalyst (27) is larger than a predetermined allowable upper limit volume. The supply of the aqueous urea solution is stopped when the storage volume of the catalyst (27) is determined to be larger than the allowable upper limit volume.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com