Heat compensation method in coal gas blowing smelting process

A smelting process and heat compensation technology, applied in the field of gas injection smelting, can solve problems such as temperature drop in the swing zone, influence of blast furnace smelting conditions, unfavorable coke oven gas effective injection, etc. Effects of reduced reduction reaction and reduced melting loss reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

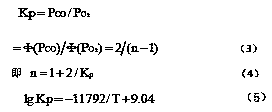

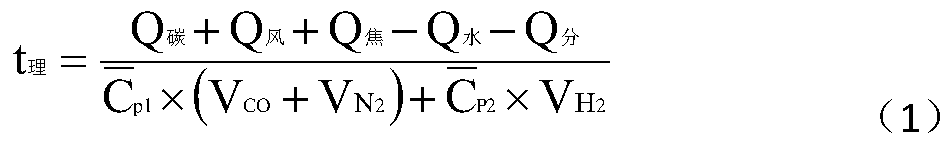

[0012] A thermal compensation method in the smelting process of injecting gas, comprising the following steps:

[0013] (1) After the coke oven gas is processed by the fine desulfurization process, the coke oven gas is pressurized by a pressurizer to 100kPa higher than the hot air pressure, and then transported to the blast furnace through a pipeline;

[0014] (2) Spray the coke oven gas in the pipeline in step (1) into the blast furnace through the spray gun in the tuyere area of the blast furnace, and participate in the reaction in the furnace together with the pulverized coal;

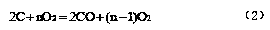

[0015] (3) Through the oxygen-enriched pipeline in the tuyere swirl area of the blast furnace, increase the oxygen supply to increase the oxygen excess coefficient n to enhance the combustion of the combustion zone, thereby increasing the temperature in this area. Among them, the oxygen excess coefficient n satisfies the Formula n=1+2 / Kp, where 1gKp=-11792 / T+9.04, T is the absolute temperature. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com