Patents

Literature

3468 results about "Temperature drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

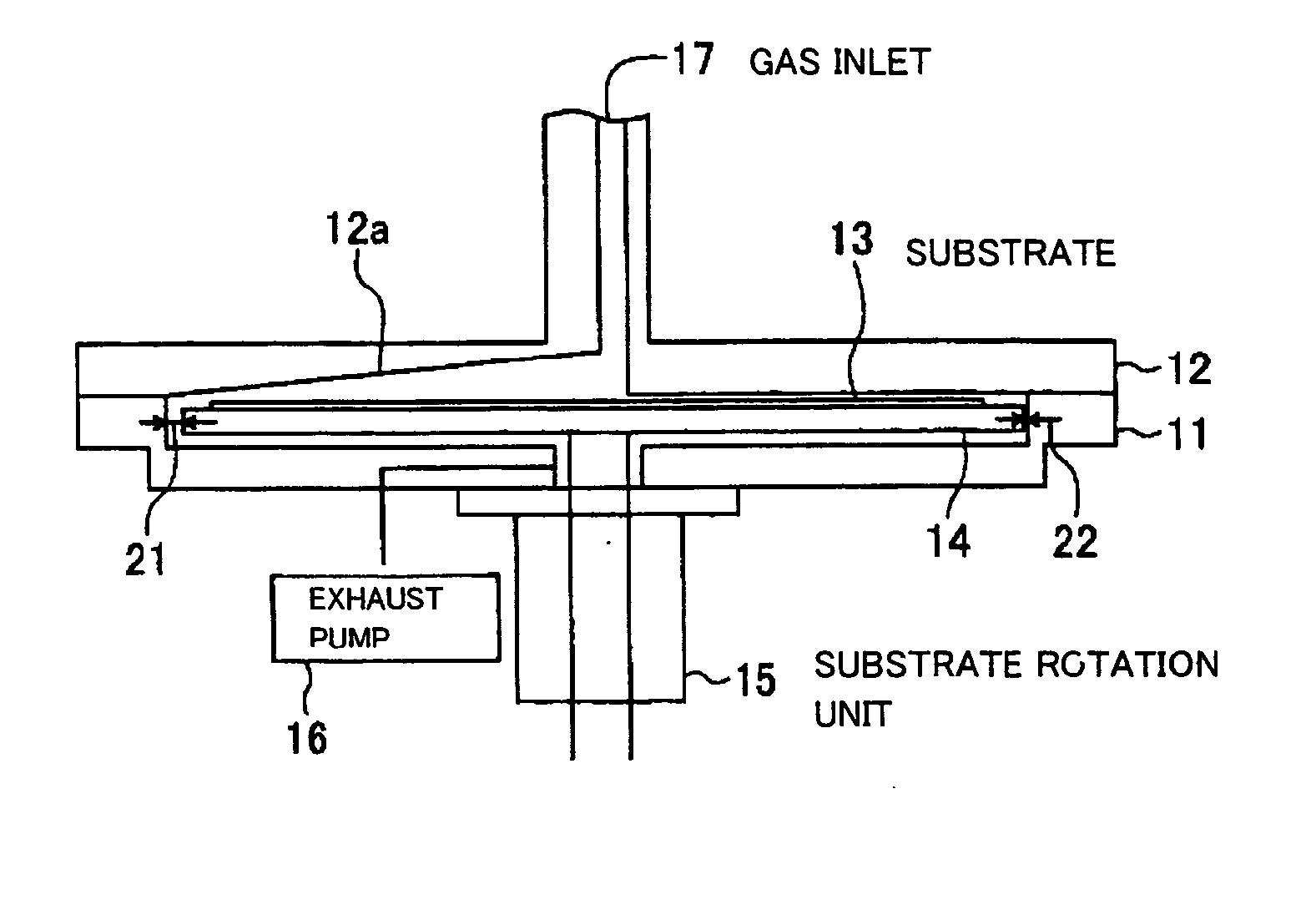

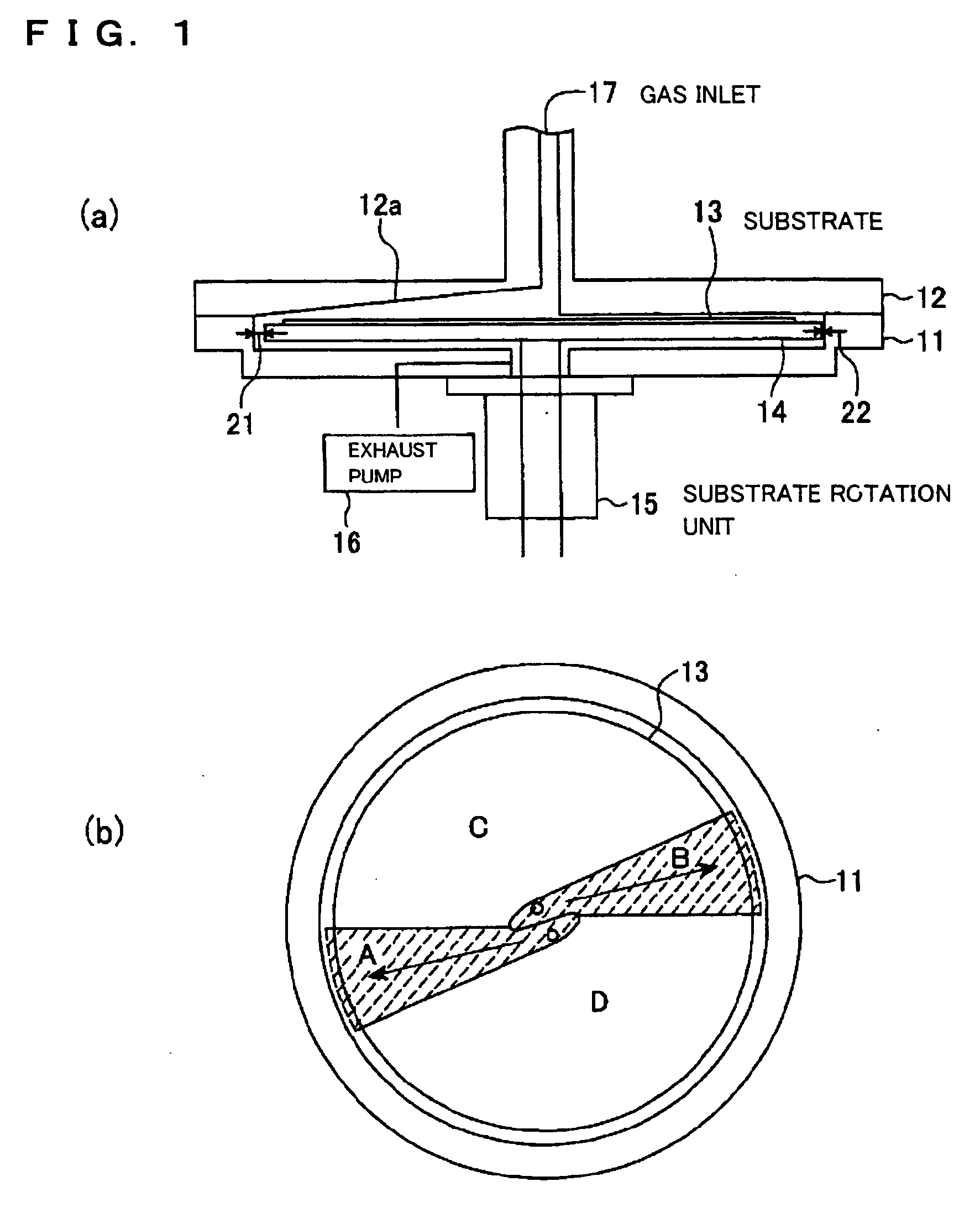

MOCVD apparatus and MOCVD method

InactiveUS20050172895A1Suppress temperature decreaseReduce gas volumeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemistryTemperature drop

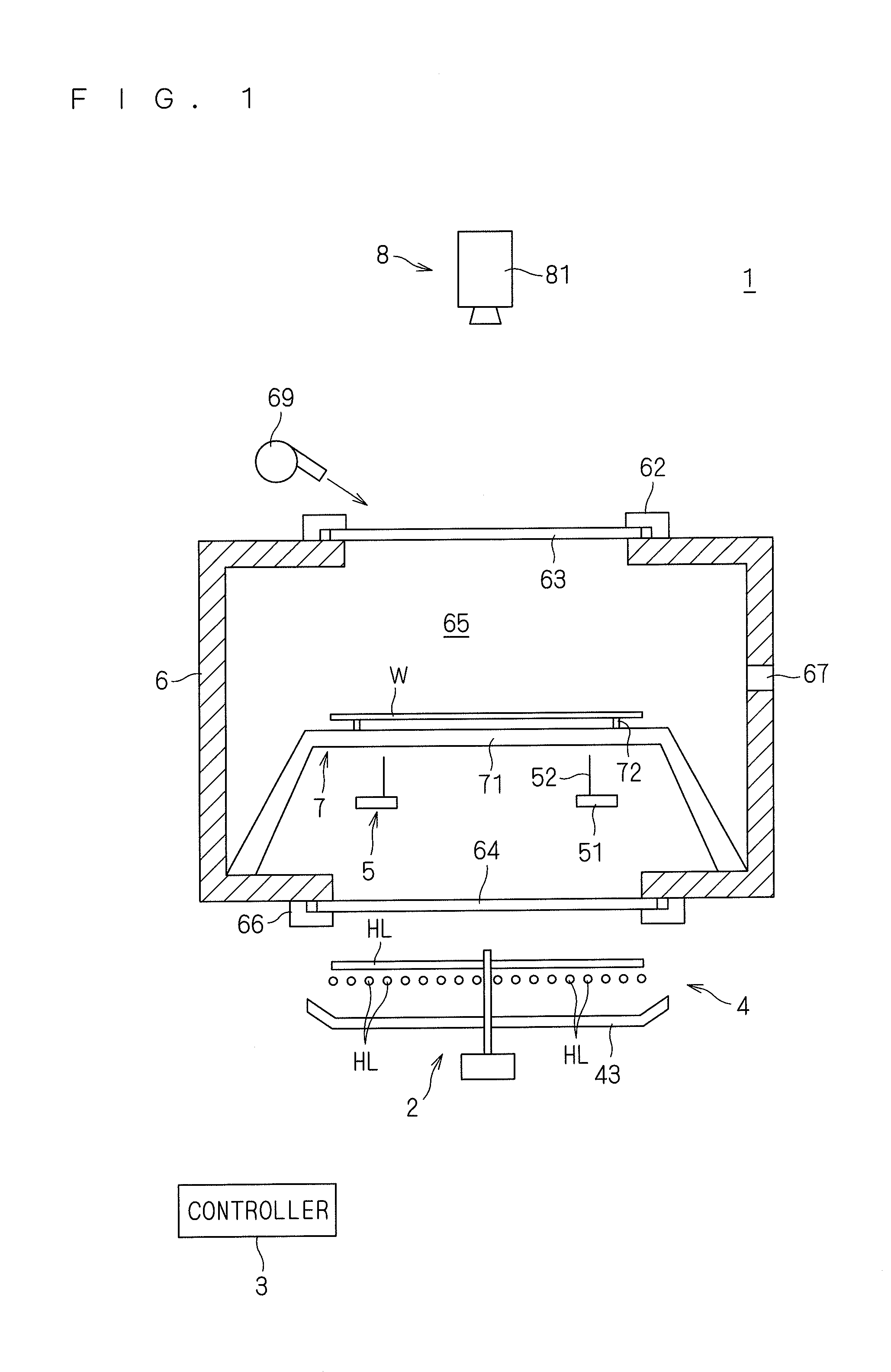

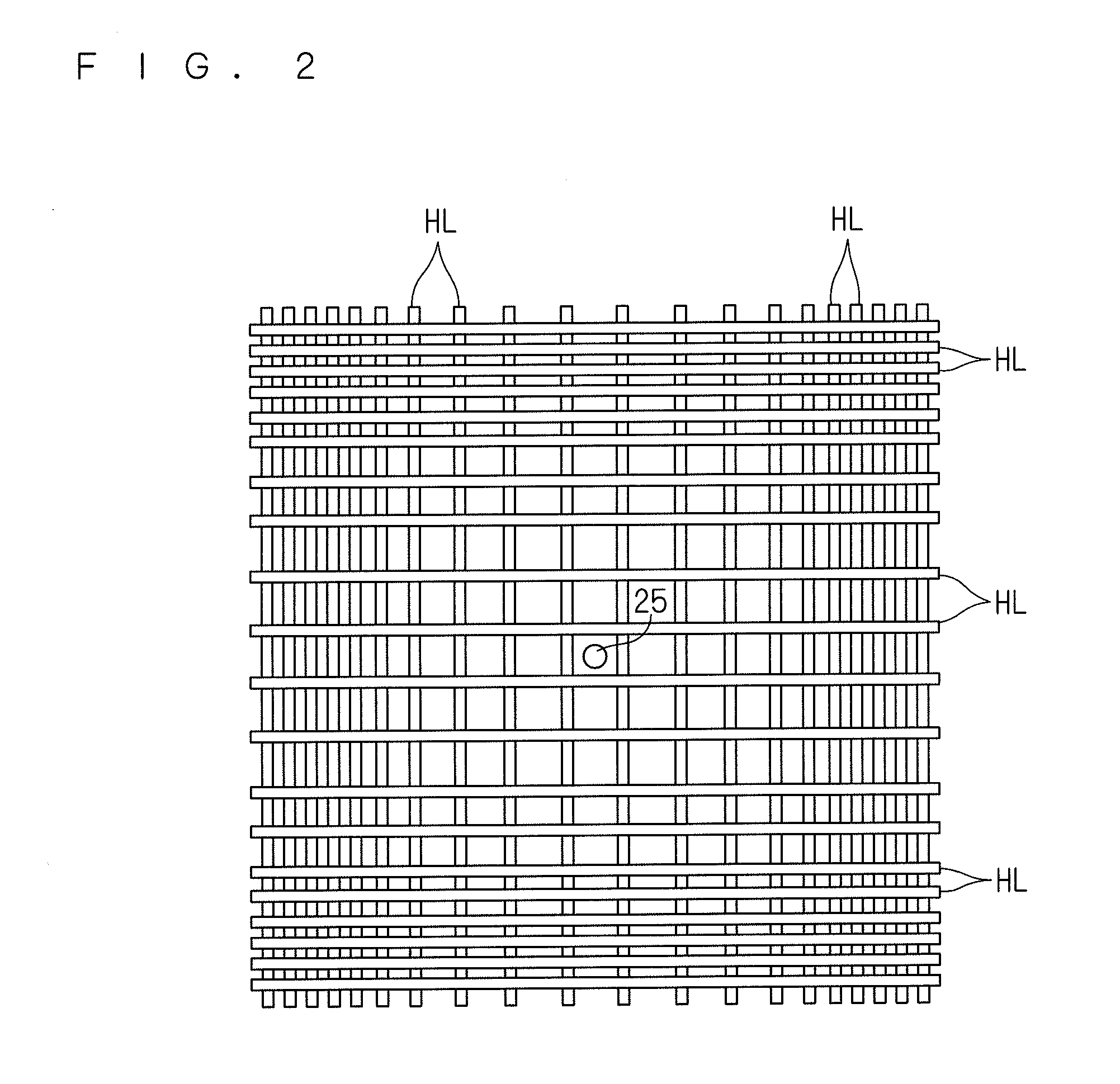

[Object] To provide an MOCVD apparatus and a MOCVD method which can deposit a thin film having satisfactory properties by preventing temperature decrease of a source gas. [Solving Means] An MOCVD apparatus according to the present invention is an apparatus for supplying a source gas as a mixture of an MO source gas with an oxidizing gas to a substrate 13 to thereby form a film. The MOCVD apparatus includes a substrate holder 14 for holding the substrate 13; a deposition chamber for housing the substrate holder; a supply mechanism for supplying the source gas to a surface of the substrate; and a heating device for heating the substrate 13 held by the substrate holder. The deposition chamber includes a substrate housing unit for housing the substrate holder holding the substrate, and a passage housing unit being connected to the substrate housing unit and constituting a passage for supplying the source gas to the substrate. The passage has a cross-sectional area smaller than the area of a deposition plane of the substrate 13 when the passage housing unit is cut in parallel with the deposition plane of the substrate 13.

Owner:SEIKO EPSON CORP +1

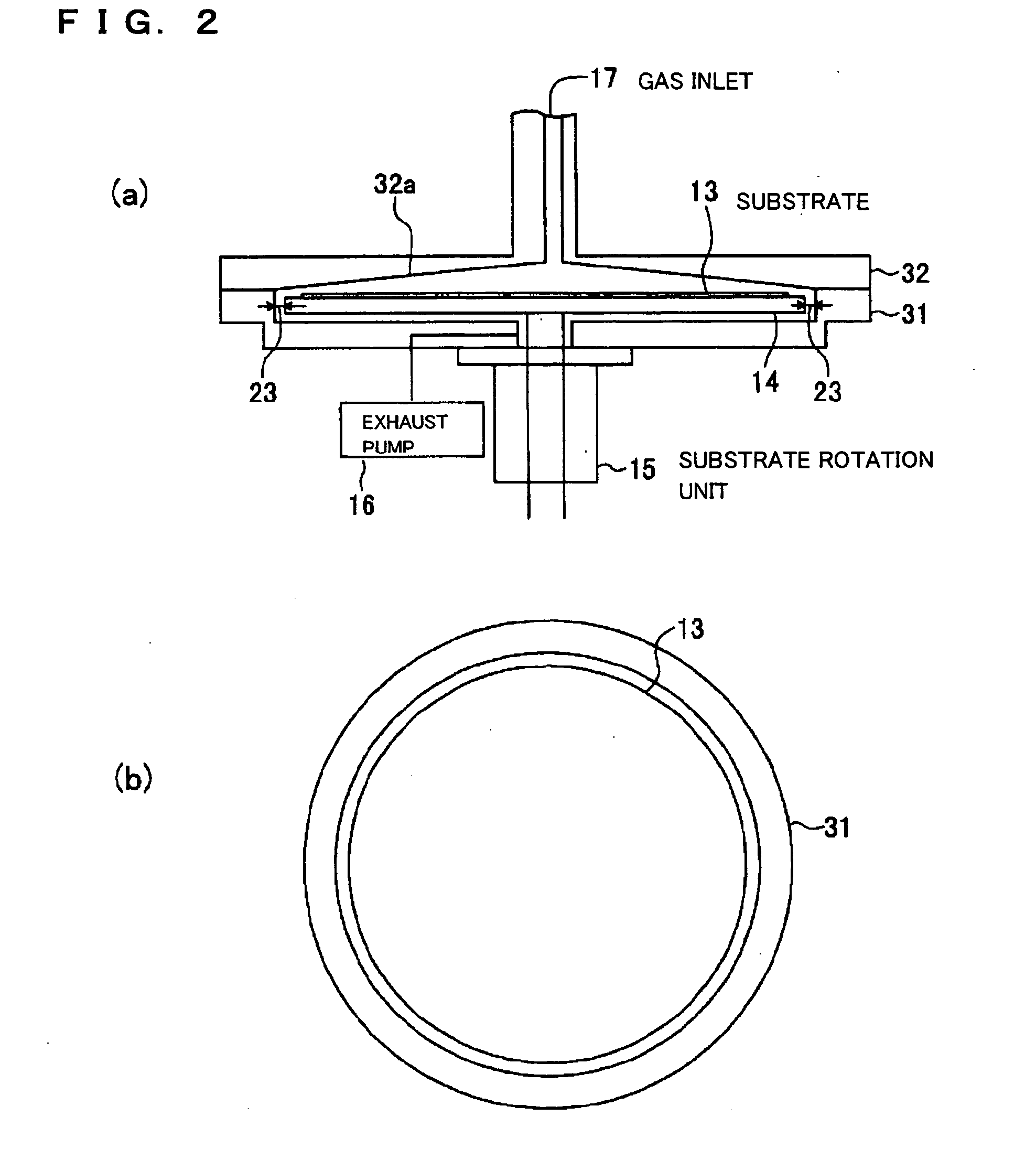

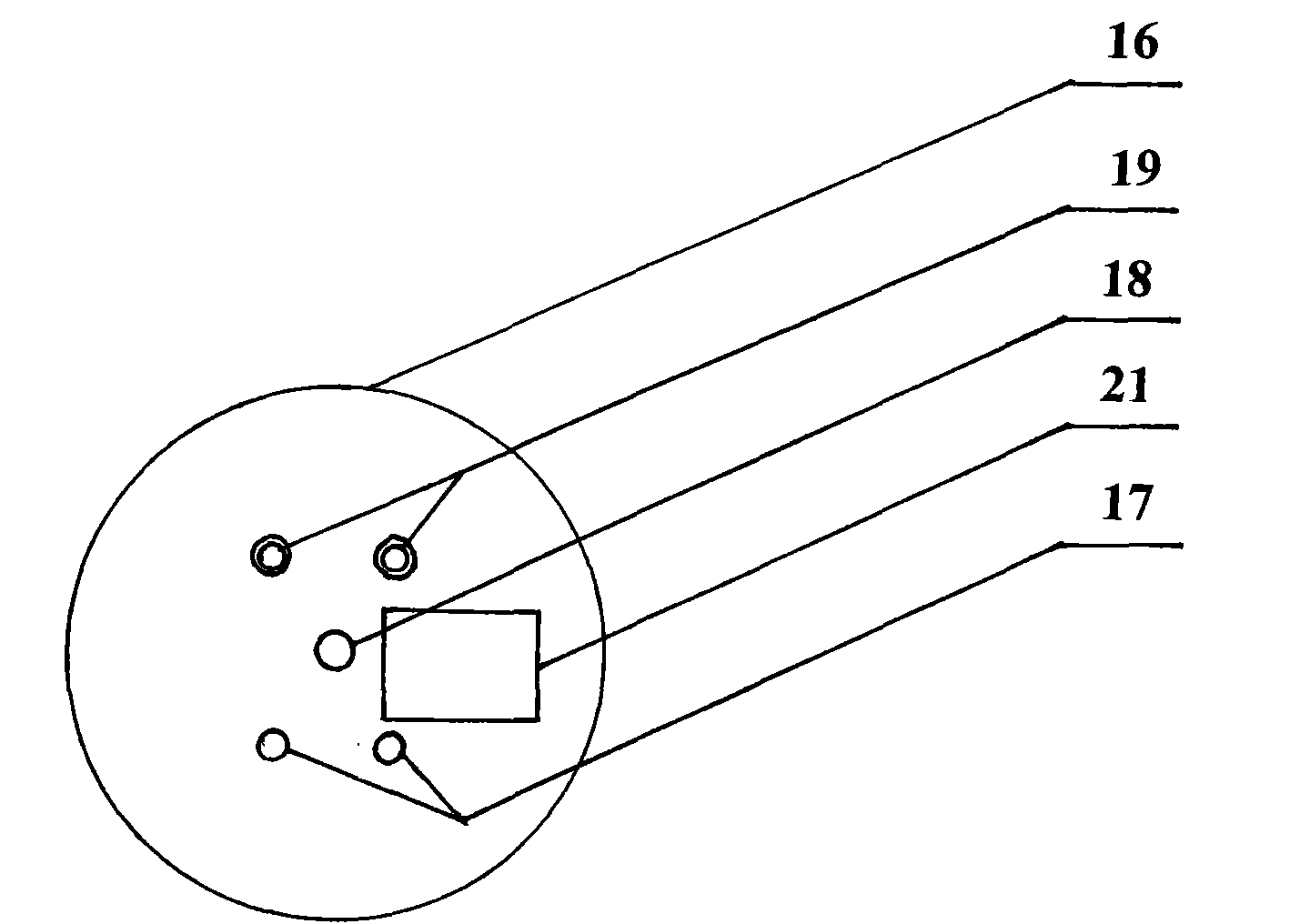

Supersonic swirling separator 2 (Sustor2)

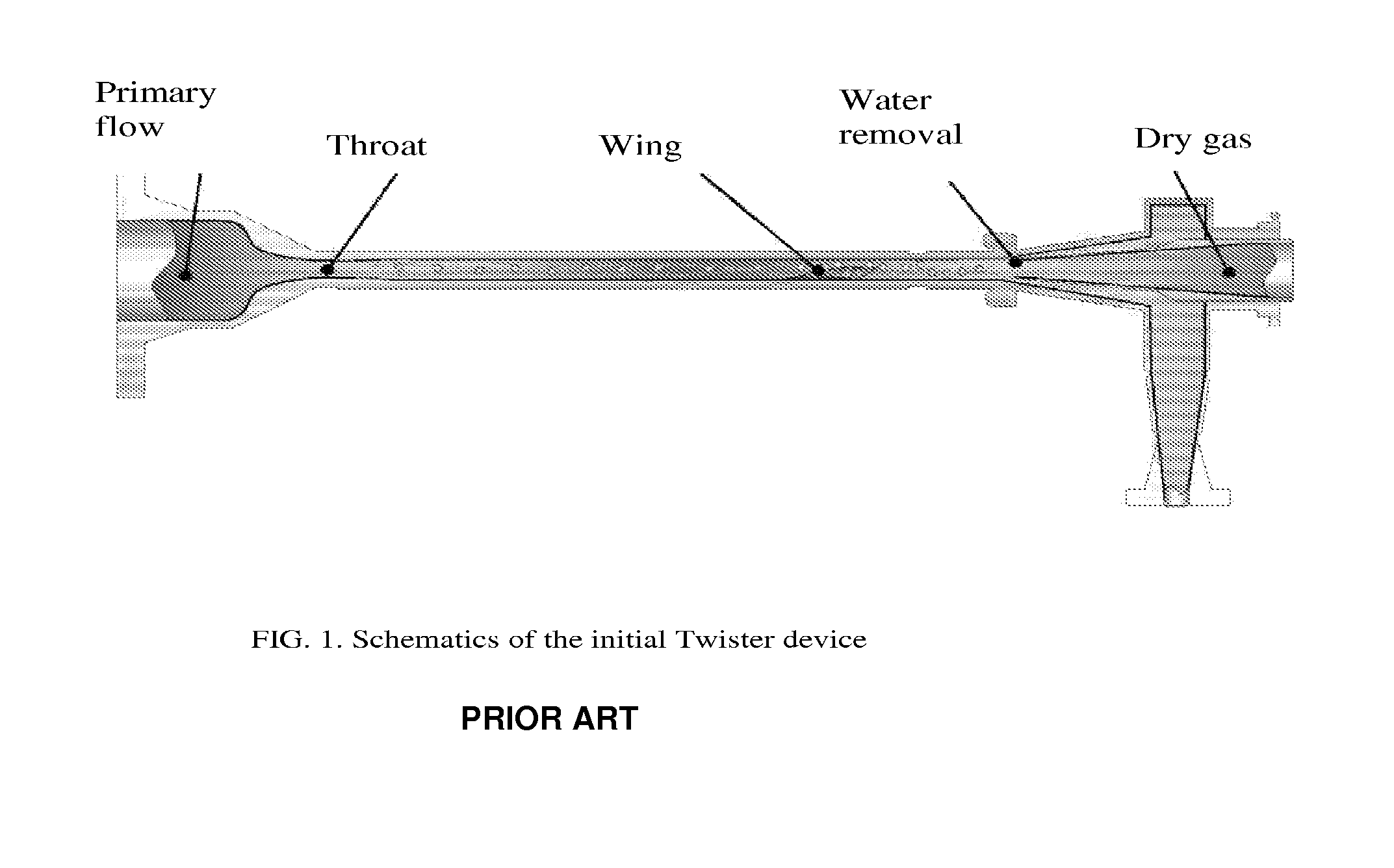

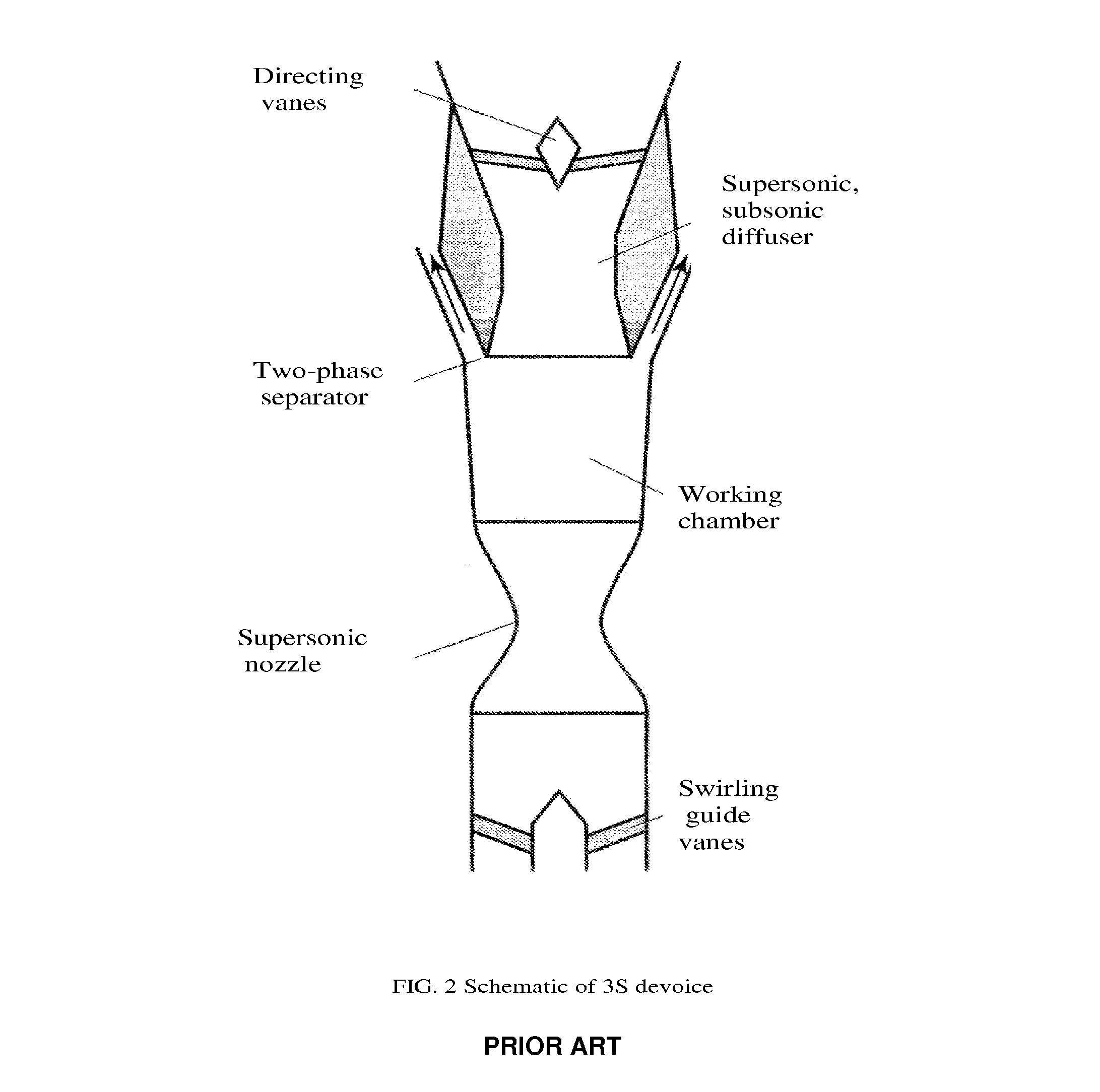

Sustor2 provides deep cooling of a gas flow, practically total condensation of a vapor, and fast and effective removal of the condensed liquid with a significantly reduced pressure losses compared with the prior art. Sustor2 performs the said operations by developing a strong swirling flow starting from its entrance, followed by spiral flow convergence in the inlet disc-like part, and then in a converging-diverging nozzle, by centrifugal removal of droplets, and removal of the liquid film through slits, then by spiral flow divergence and leaving the vortex chamber through tangential outlet.A gas enters from a pipeline (see the arrow in the A-A cross-section shown in FIG. 7) connected to Sustor2 by a flange and the inlet transition pipe ITP in FIG. 7, spirally converged in the disc-like part, marked by A-A in FIG. 6, enters the converging-diverging nozzle (FIG. 6). The flow is high-speed and swirling even at the near-entrance region of the vortex chamber. This swirl results in the centrifugal force that presses the through-flow to the sidewall. The flow accelerates near the nozzle throat up to a supersonic velocity with subsonic axial and supersonic swirl velocity components. This acceleration results in the gas temperature drop down to 200K and even less values. The reduced temperature causes rapid condensation of vapor into droplets. The centrifugal force pushes the droplets to the sidewall where they are removed through slits. Next the dried gas spirally diverges and leaves the vortex chamber through the tangential outlet. This results in the pressure recovery and transformation of the swirl kinetic energy into the longitudinal kinetic energy of the gas. Both the effects decrease pressure losses which is the Sustor2 advantage compared with the prior art.

Owner:BORISSOV ANATOLI +2

Differential thermopile heat flux transducer

InactiveUS6278051B1Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentHeat flowThermopile

A thin sensor for heat flux and temperature, designed for adhesive attachment to a surface, is manufactured on a flexible insulated metallic substrate. The sensor exhibits a combination of high sensitivity for heat flux and low resistance to the flow of heat. These characteristics enable it to measure heat flux at surface boundaries with improved accuracy over conventional heat flux transducers because the temperature drop produced by the sensor is very small. The response by the sensor to radiation, convection and conduction are equal. As such, the sensor can be calibrated in one mode of heat transfer and used for measurement in other modes. The high sensitivity of the sensor makes it ideal for measuring heat flow through insulating materials, and well adapted to instrumenting heat flow in buildings, detecting fires at an early stage, or remotely measuring the temperature of string and web products in industrial processing.

Owner:VATELL CORP

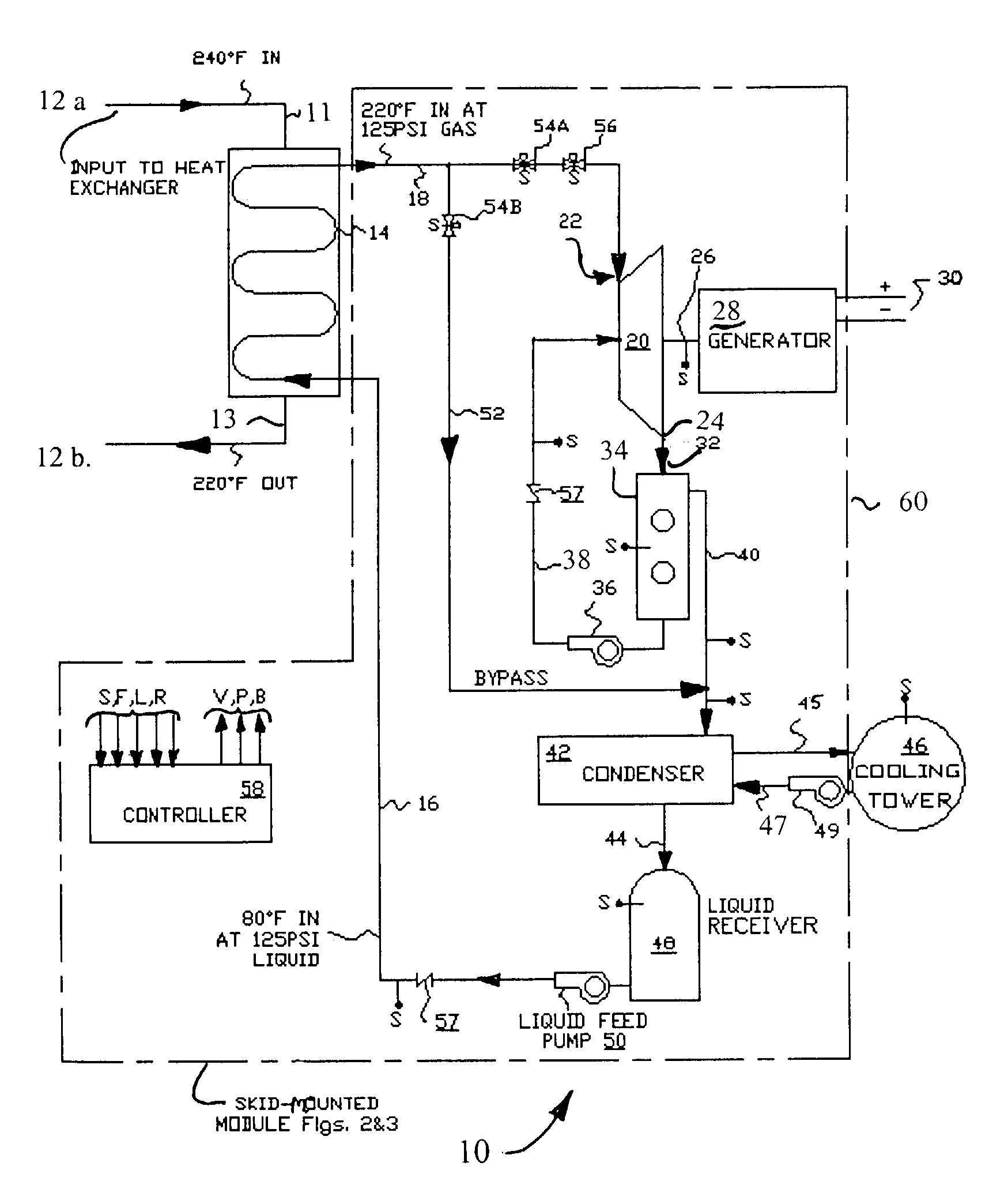

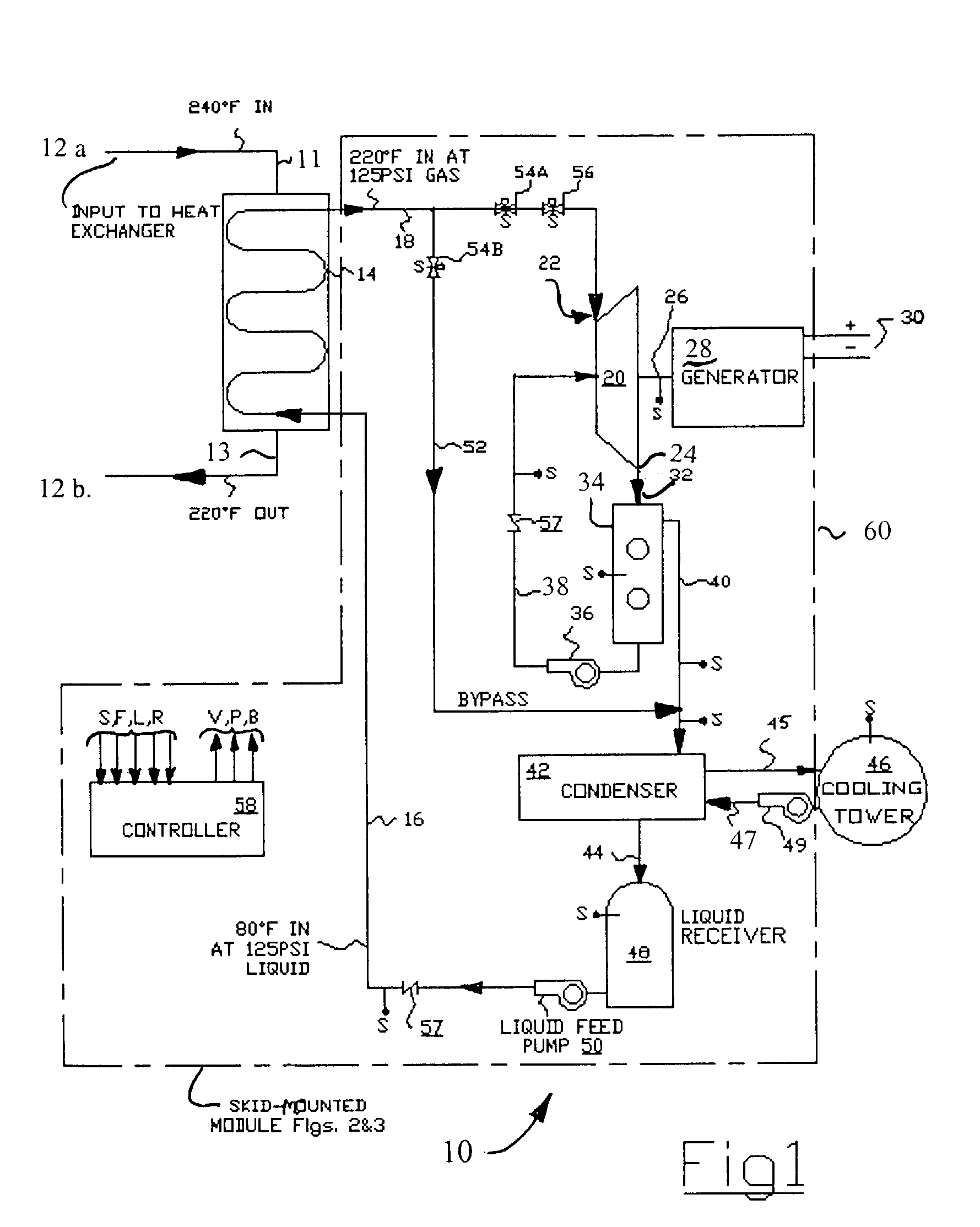

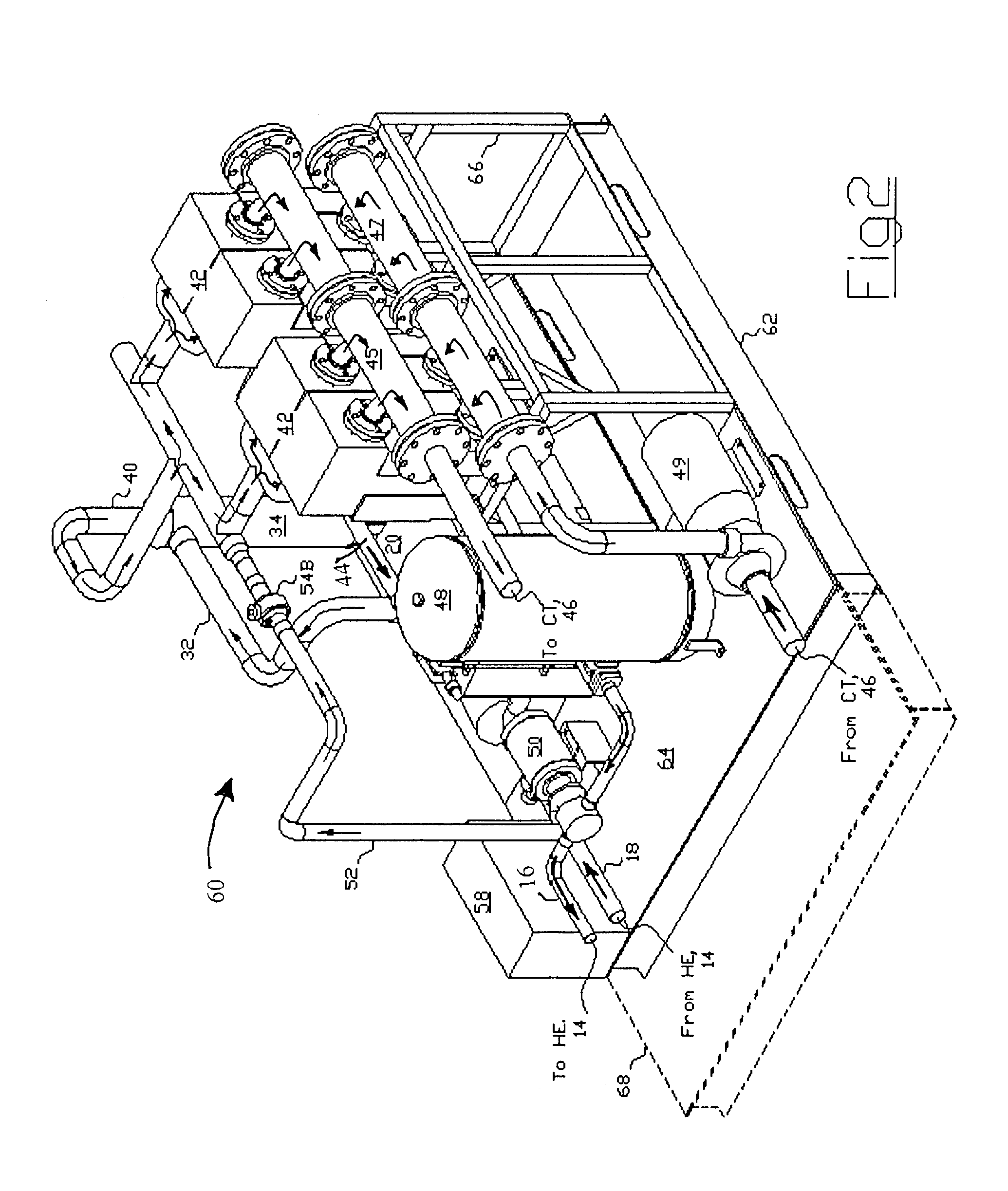

System and method for generation of electricity and power from waste heat and solar sources

InactiveUS6981377B2Conveniently skid-mountableEasy to installAuxillary drivesFrom solar energyThermal energyEngineering

Recovery of electric power from low-grade waste heat / solar energy, comprising a closed-cycle charged refrigerant loop. Pressurized refrigerant fluid is pumped at ambient temperature through a heat exchanger connected to a waste heat / solar source to extract heat energy during conversion to a high pressure gas. Heated / pressurized refrigerant gas is inlet into an expander to power an output shaft during the expansion of the fluid to a cooled gas at approximately 0 psig. Cooled gaseous refrigerant is condensed to a liquid at low pressure and ambient temperature, and recycled under pressure to the heat exchanger. The expander is a reverse-plumbed gas compressor; the pressurized, hot refrigerant gas is inlet at what is ordinarily its outlet, and the normal inlet becomes the expander end. The refrigerant gas mass flow pressure / temperature drop spins the expander shaft for direct mechanical power take-off, or coupling to a synchronous or inductive generator to produce electricity.

Owner:OUTFITTER ENERGY

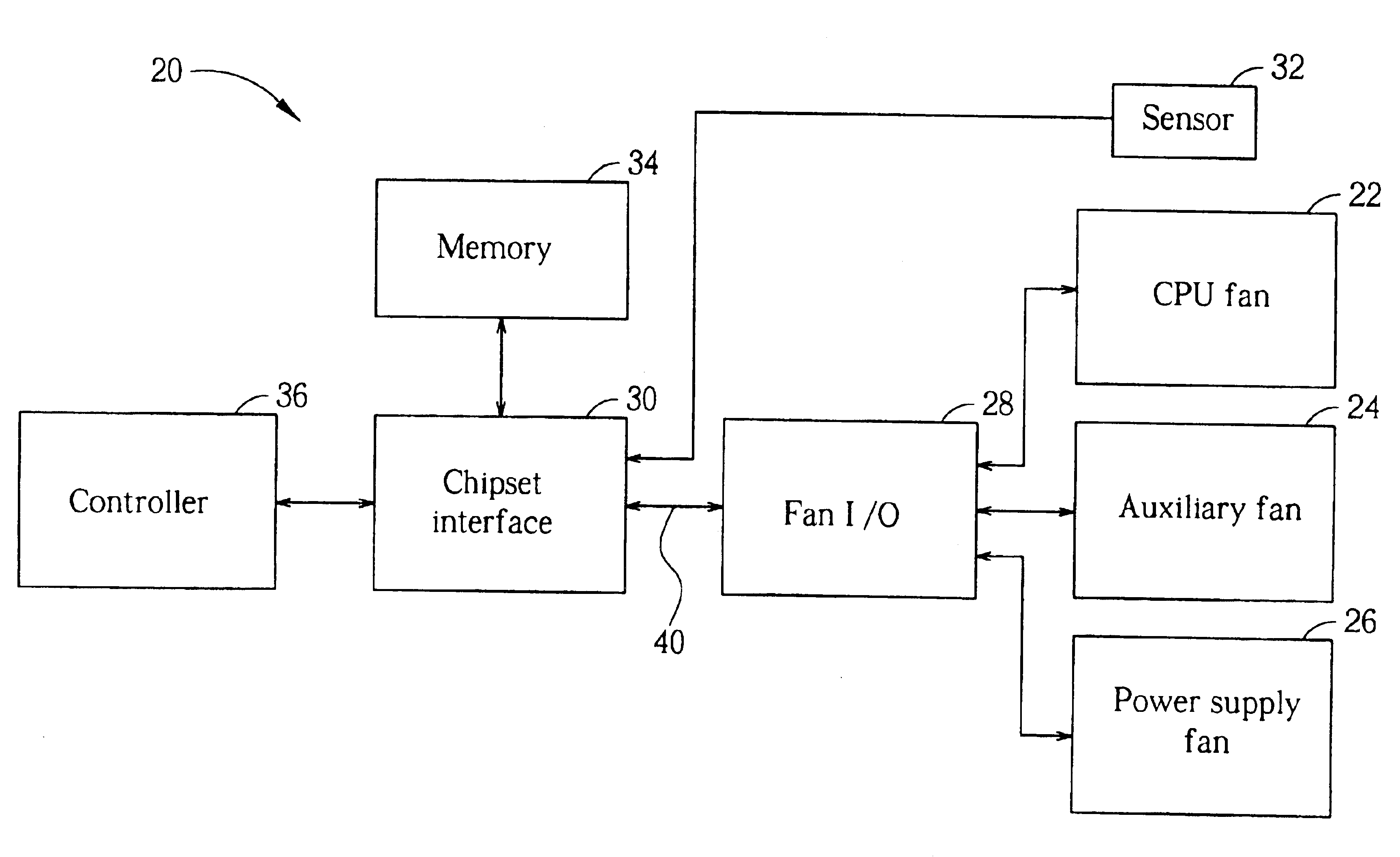

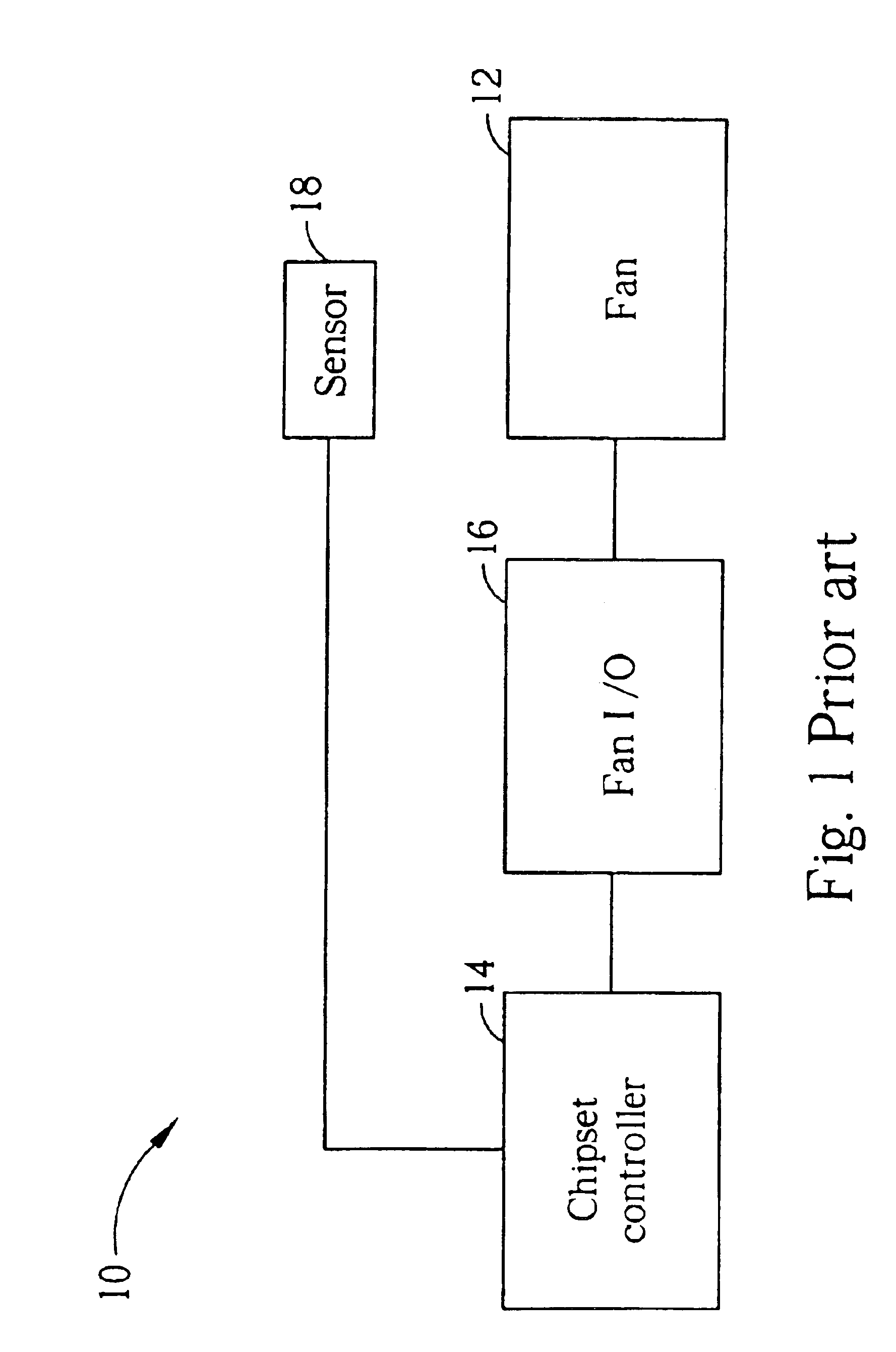

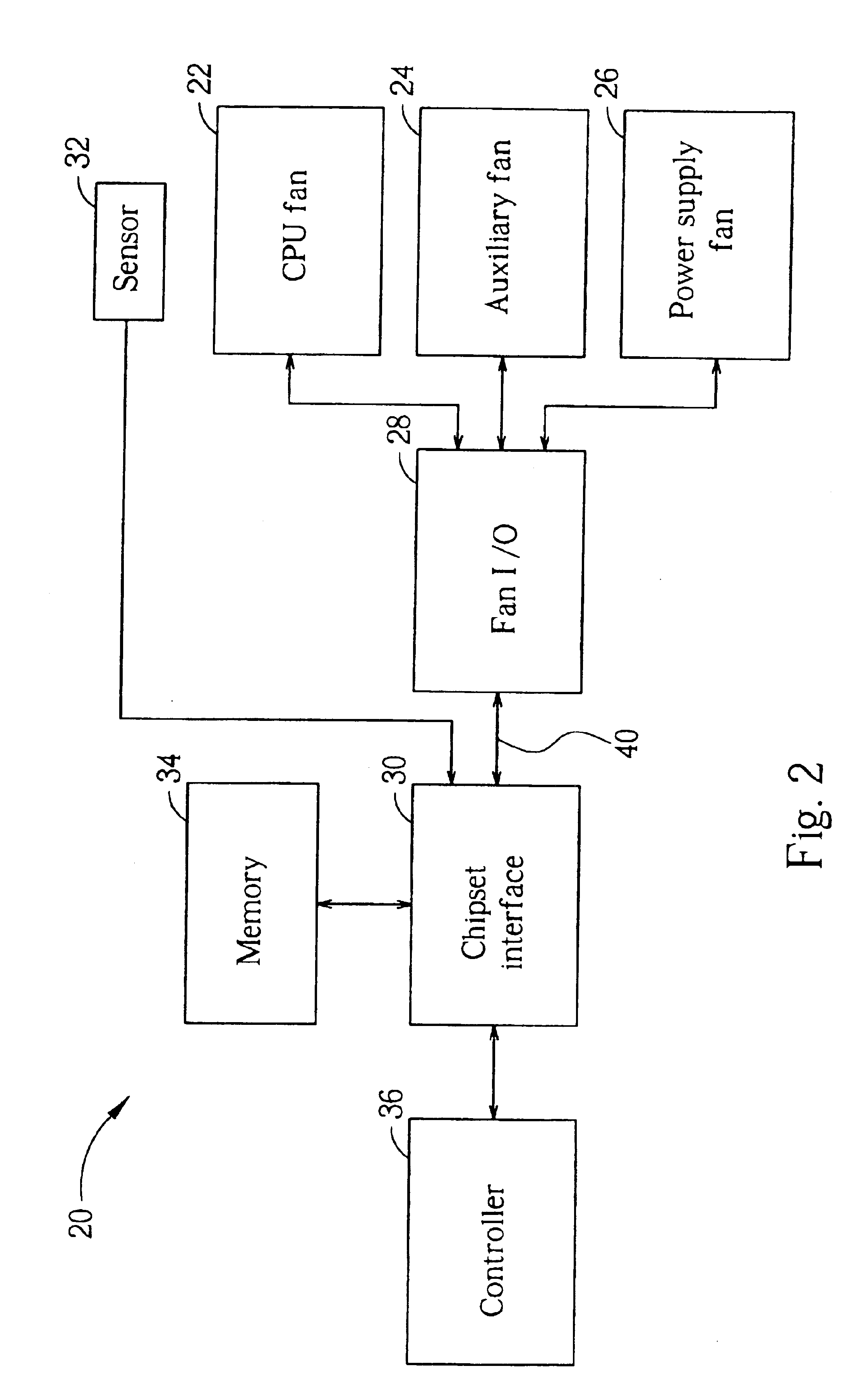

Computer cooling system

InactiveUS6935130B2Easy to controlReduce fan speedEnergy efficient ICTDigital data processing detailsControl signalTransducer

A cooling system includes a cooling fan, a fan input-output module for transmitting a control signal to the fan for controlling the rotational speed of the fan, and a chipset interface for generating the fan control signal based on a change in a vital temperature of the computer system. Further provided is a controller for receiving the vital temperature and forwarding the vital temperature to the chipset interface, and a temperature transducer for generating the vital temperature and outputting the vital temperature to the controller. The chipset interface monitors a rotational speed of the cooling fan, and monitors a vital temperature of the computer system. The chipset interface then sets the fan power based on a change in the vital temperature. When the vital temperature decreases, the fan power is reduced to slow the fan, and when the vital temperature increases, the fan power is increased to speed the fan.

Owner:AOPEN

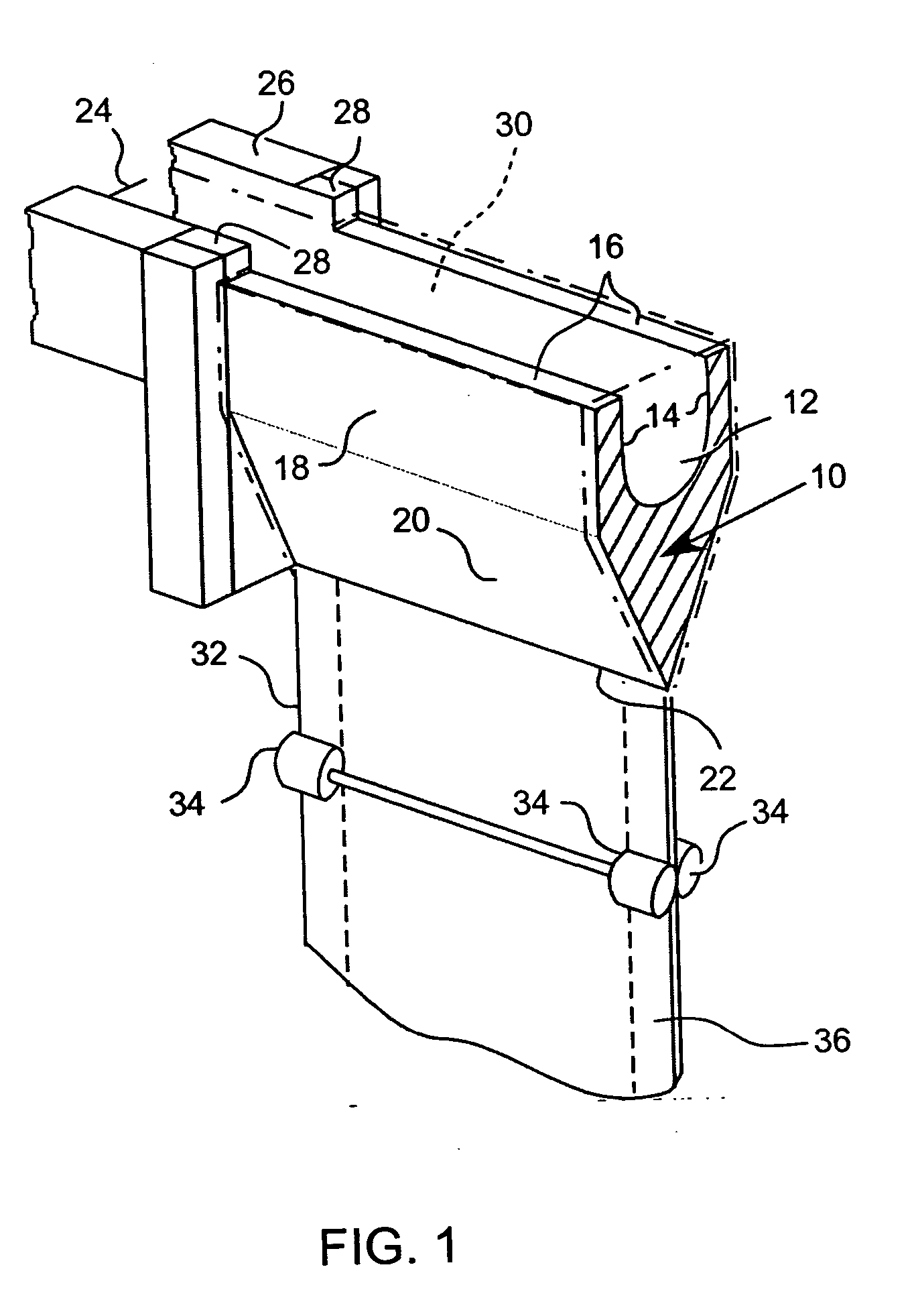

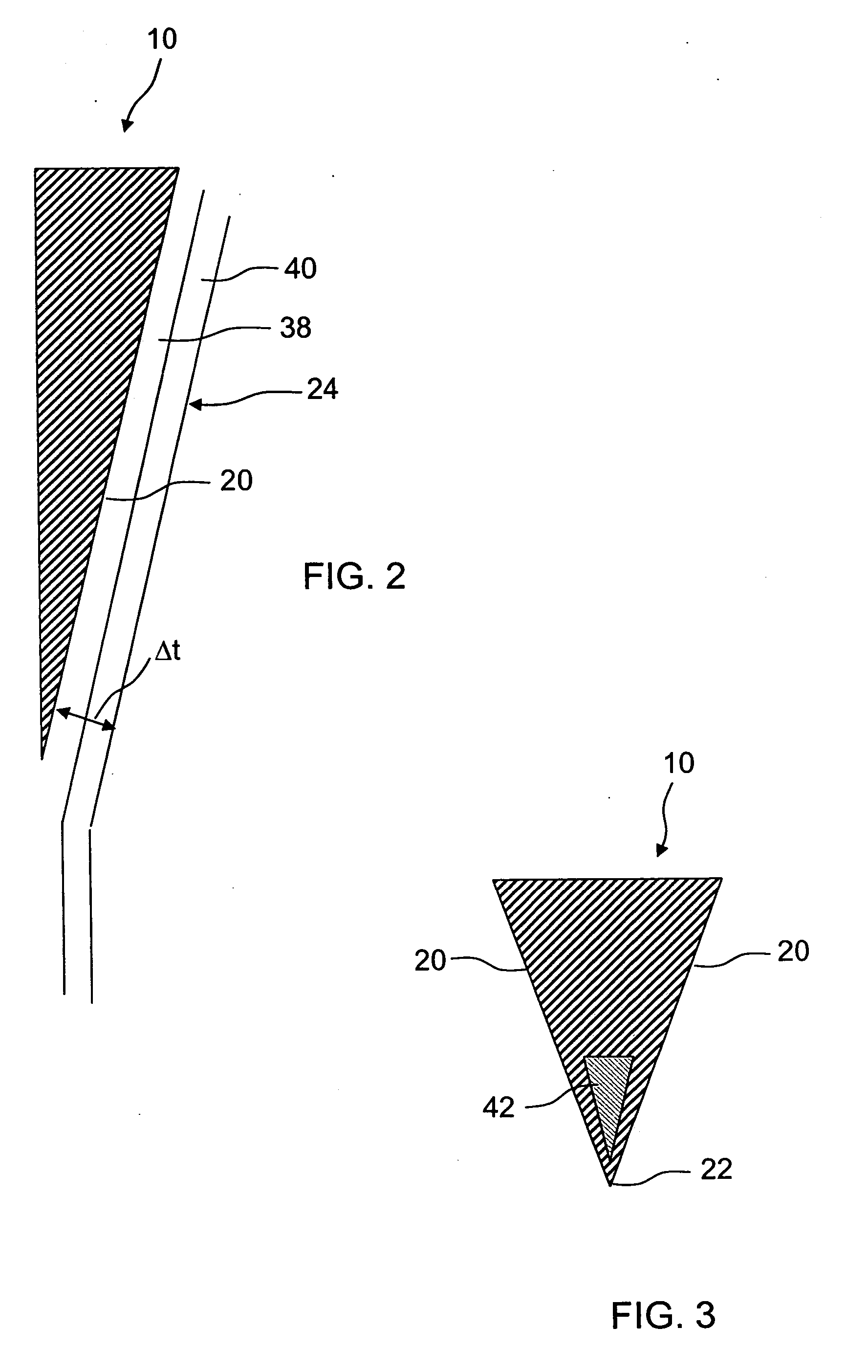

Method and apparatus for drawing a low liquidus viscosity glass

InactiveUS20070130994A1Easy to understandGlass furnace apparatusGlass drawing apparatusViscosityGlass sheet

A method of a drawing a glass ribbon from molten glass sheet via a downdraw process by creating a temperature drop across a thickness of the molten glass flowing over forming surfaces of a forming wedge. The forming wedge includes an electrically conductive material for heating the glass above the root.

Owner:CORNING INC

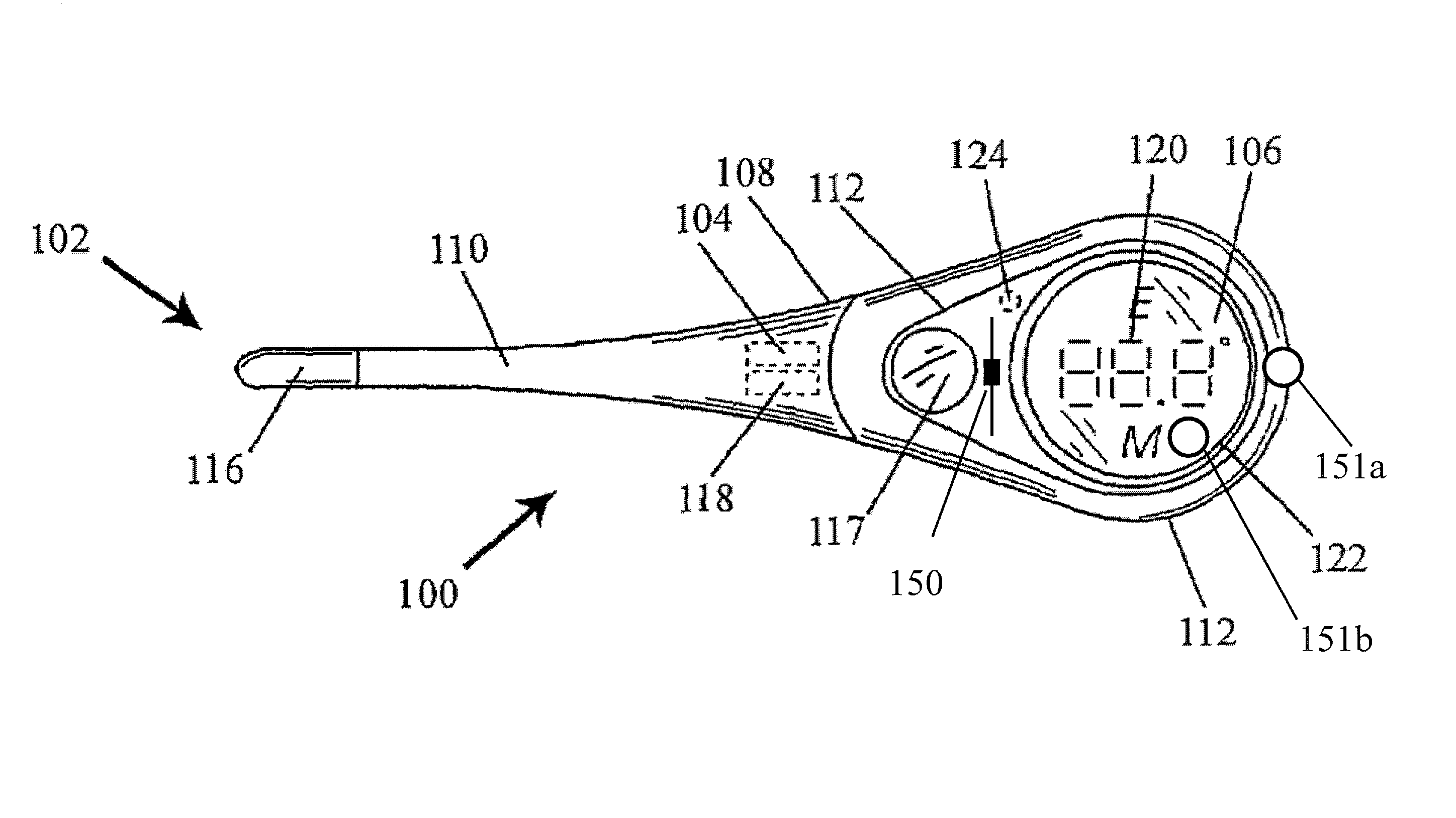

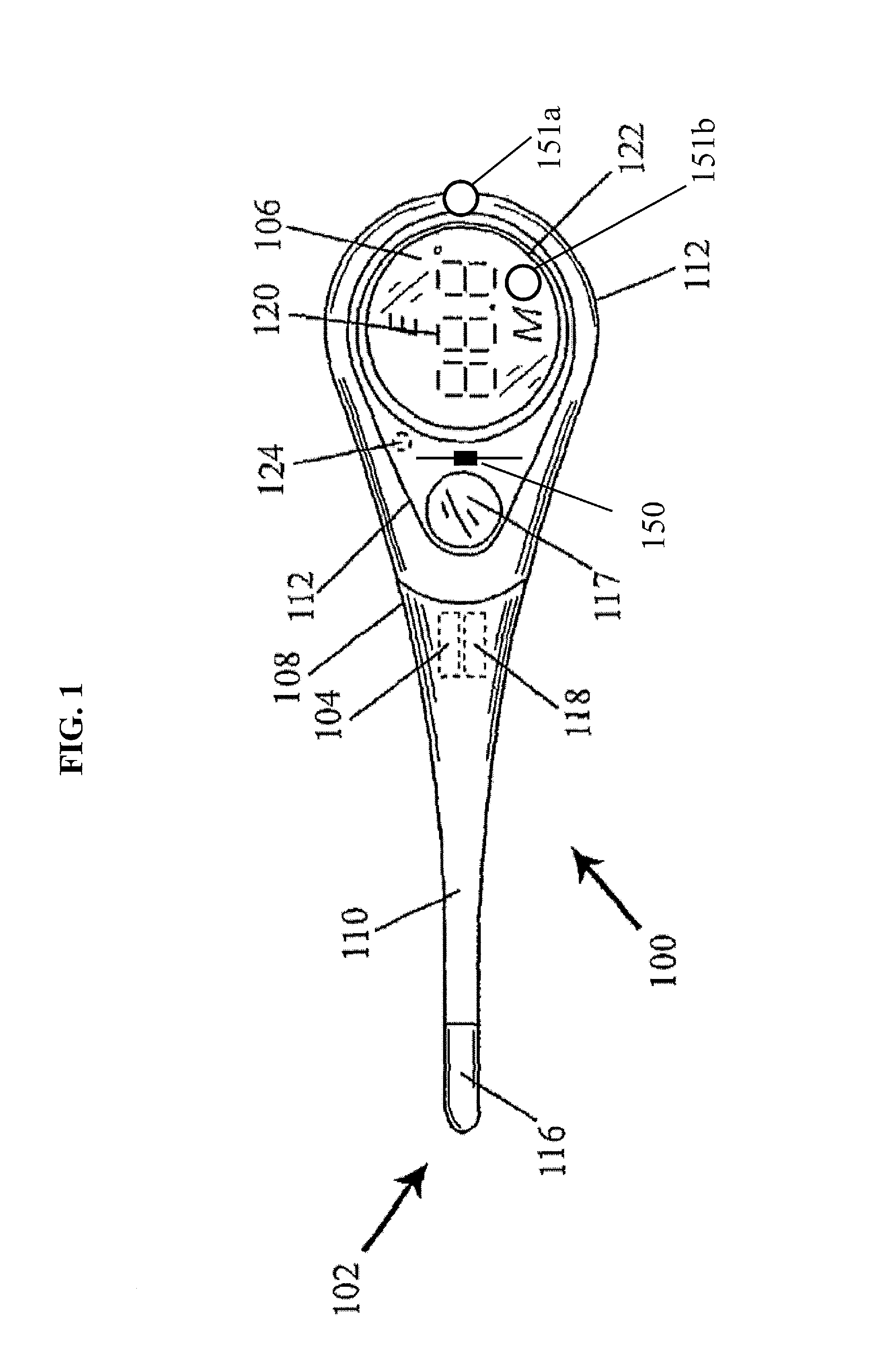

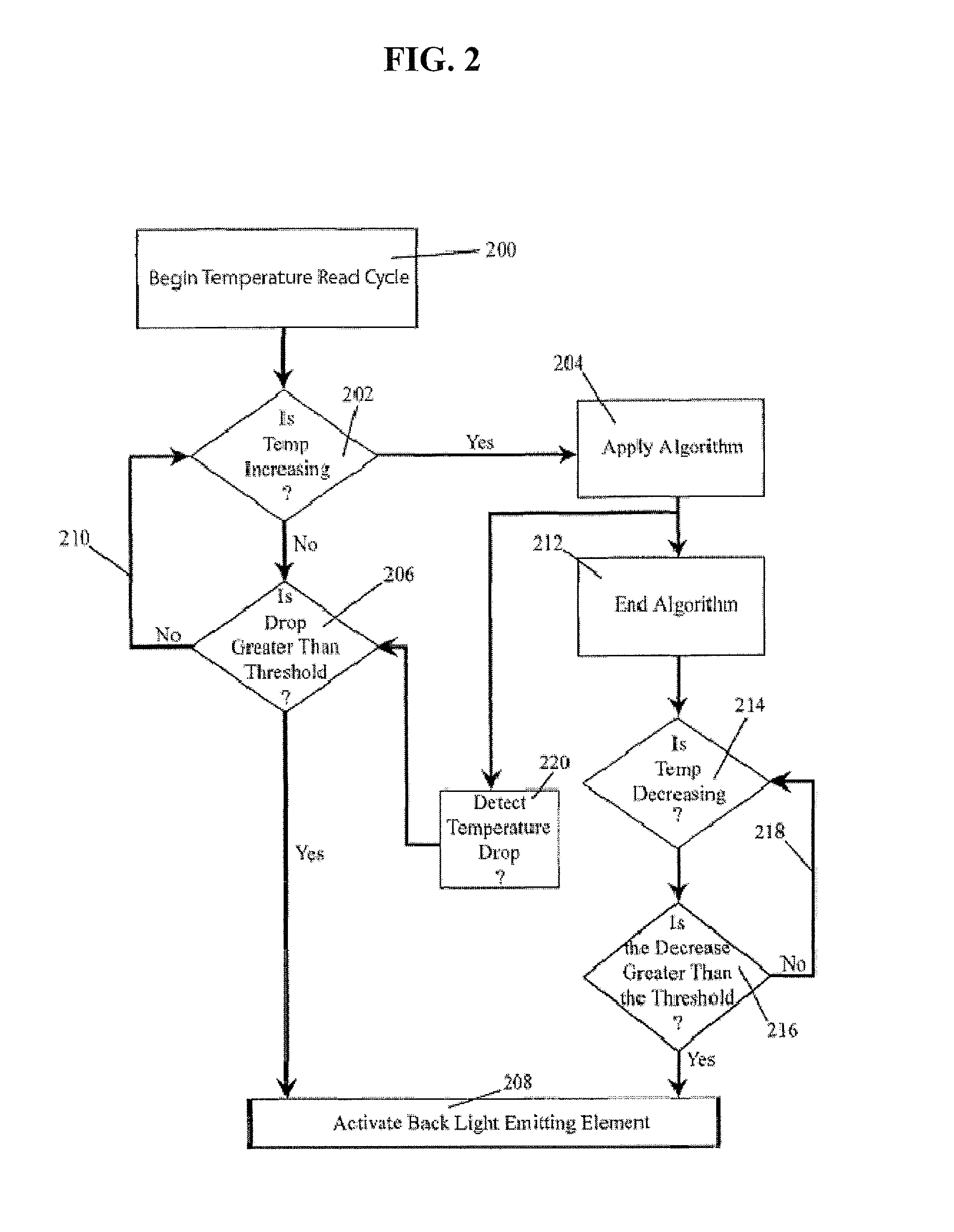

Thermometer with age specific feature selection

ActiveUS20120150482A1Improve visibilityImprove viewing angleThermometer detailsBody temperature measurementDisplay deviceOperation mode

The invention includes a thermometer with a backlight and a method for lighting the backlight. The thermometer has temperature sensing tip, a processor taking temperature readings and determining a sensed temperature reading of the living being from the temperature sensing tip. The thermometer also includes a display and a backlight for lighting the display. The backlight is activated upon a command from the processor and the processor determines whether to activate the backlight based upon the temperature readings. The method embodiment can includes the steps of using the processor to monitor a temperature change indicated by a temperature sensing element. The processor then detects a temperature decrease and activates a first color light emitting element to backlight a display if the temperature decrease exceeds or equals a predetermined threshold. The thermometer is operable in one of a plurality of selectable operating modes, and the predetermined threshold is dependent upon the selected operating mode. For example, operating modes may depend on patient age range or measurement location. Age range may include infant, toddler and adult.

Owner:HELEN OF TROY LIMITED

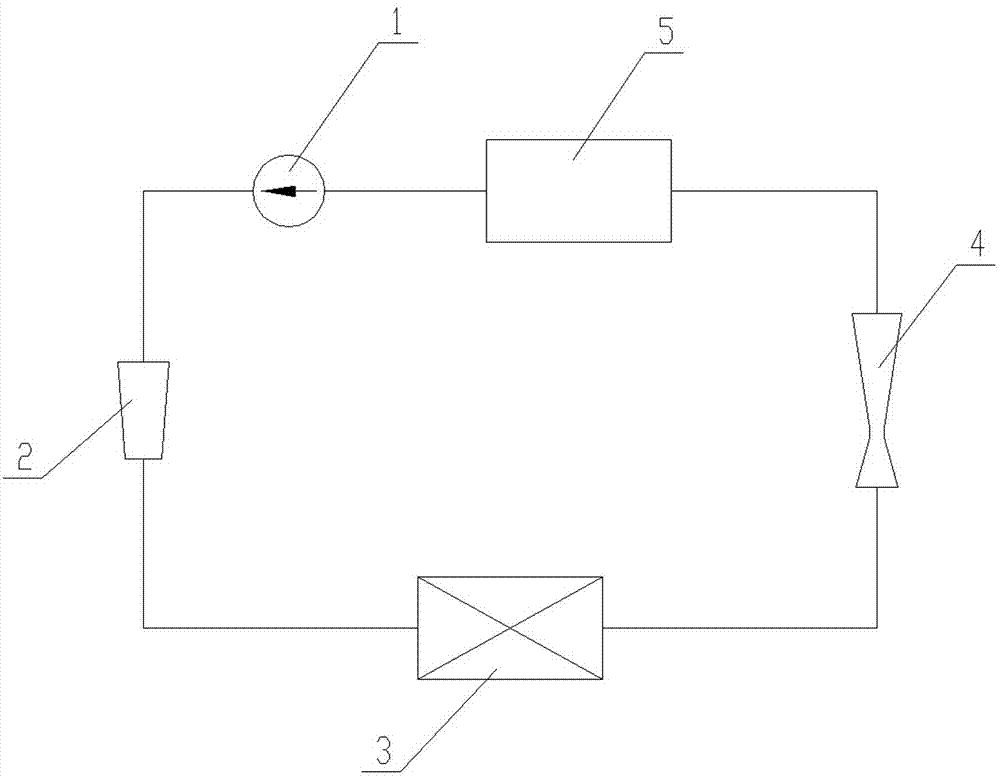

Circulating refrigerating method and refrigerating circulating system thereof

ActiveCN104729136AReduce the temperatureRealize the cooling purposeMechanical apparatusCompression machinesAtmospheric airAtmospheric ozone

The invention provides a circulating refrigerating method. As a refrigerant is expanded, the flow speed of the refrigerant is increased, kinetic energy is increased, pressure and temperature are reduced, the refrigerant absorbs heat of a cold medium in an evaporator to be evaporated, the cold medium releases the heat to reduce the temperature to achieve refrigerating, the refrigerant absorbing the heat is expanded, the flow speed is increased, the refrigerant enters a diffusion pipe to be compressed, the flow speed is reduced, the pressure and the temperature rise, refrigerant steam enters a condenser to be condensed into liquid, the refrigerant releases the heat to be condensed into the refrigerant liquid to enter a liquid pump so that refrigerating circulation can be formed, the evaporation degree of the refrigerant entering the diffusion pipe is not limited, water can be used as the refrigerant, the problems that the refrigerant like Freon destroys the atmospheric ozone layer, and equipment is corroded by a chemical absorption agent used in a liquid-steam absorption system in the refrigerating process are solved, the refrigerant absorbs the heat of the low-temperature cold medium in the evaporator, and releases the heat in the condenser through diffusion and temperature rising, the cooling medium obtains the heat, and the temperature rises to supply the heat. The invention provides a refrigerating circulating system.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

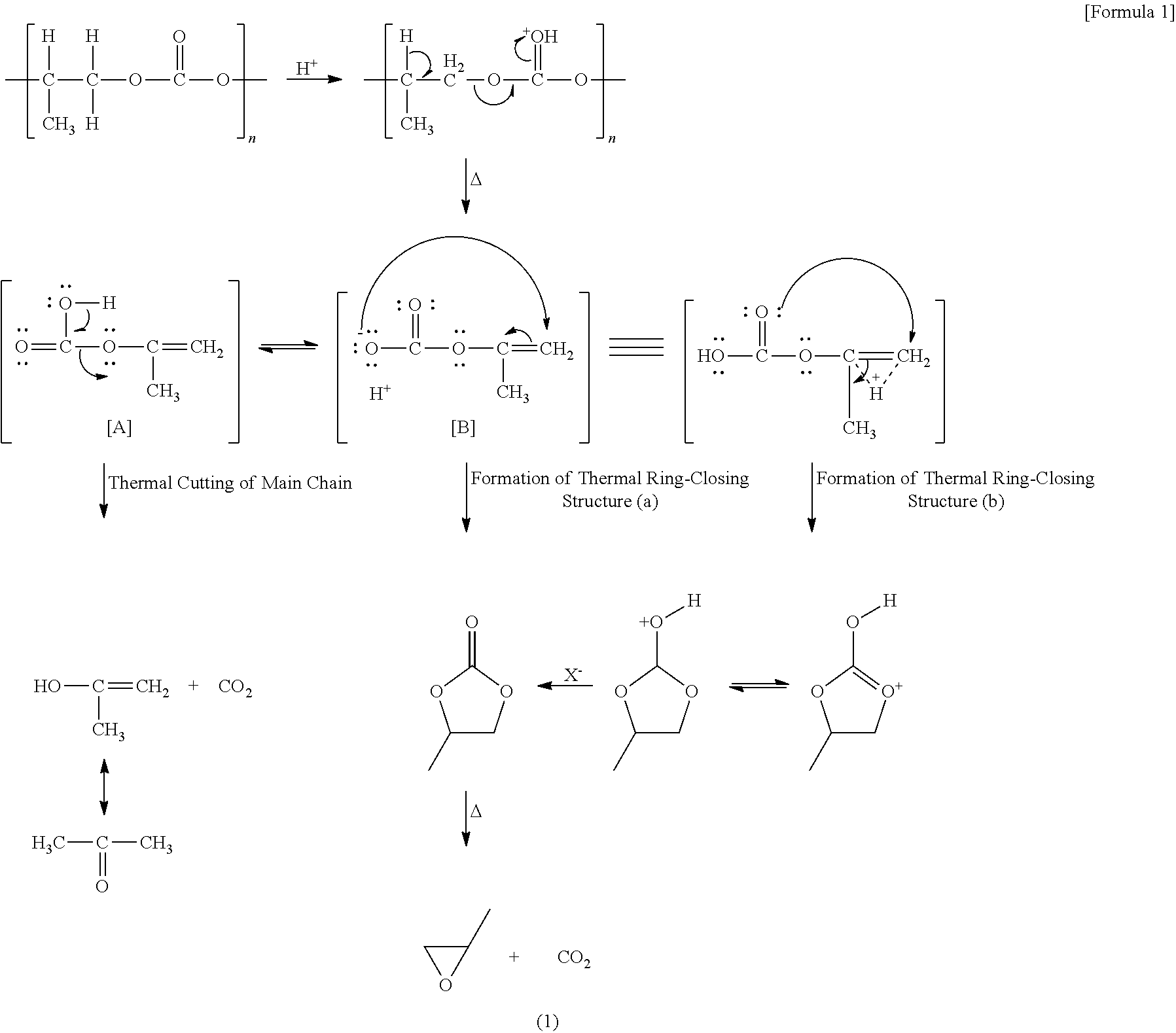

Temporary bonding adhesive for a semiconductor wafer and method for manufacturing a semiconductor device using the same

ActiveUS20110318938A1Reduce harmPrecise processingSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

To provide a temporary bonding adhesive for a semiconductor wafer that reduces damage to a semiconductor wafer, makes it readily detachable, and can shorten the time required for thermal decomposition, and a manufacturing method for a semiconductor device using this.A temporary bonding adhesive for a semiconductor wafer, being a temporary bonding adhesive used for temporarily bonding a semiconductor wafer onto a supporting substrate in order to process a semiconductor wafer, and for detaching a semiconductor wafer from a supporting substrate by heating after processing, containing a resin composition composition whereof the 50% weight loss temperature decreases after irradiation by active energy rays.

Owner:SUMITOMO BAKELITE CO LTD

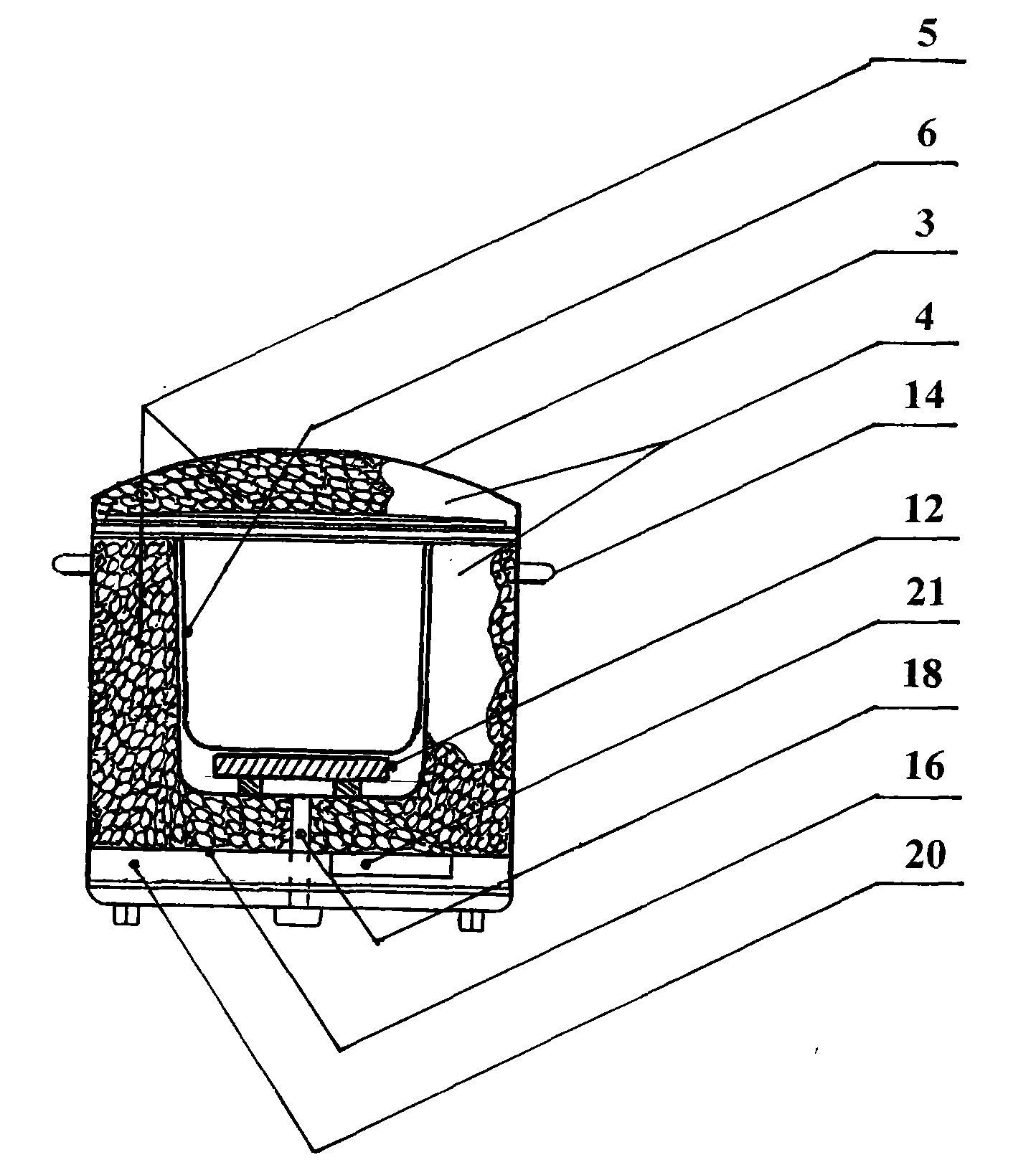

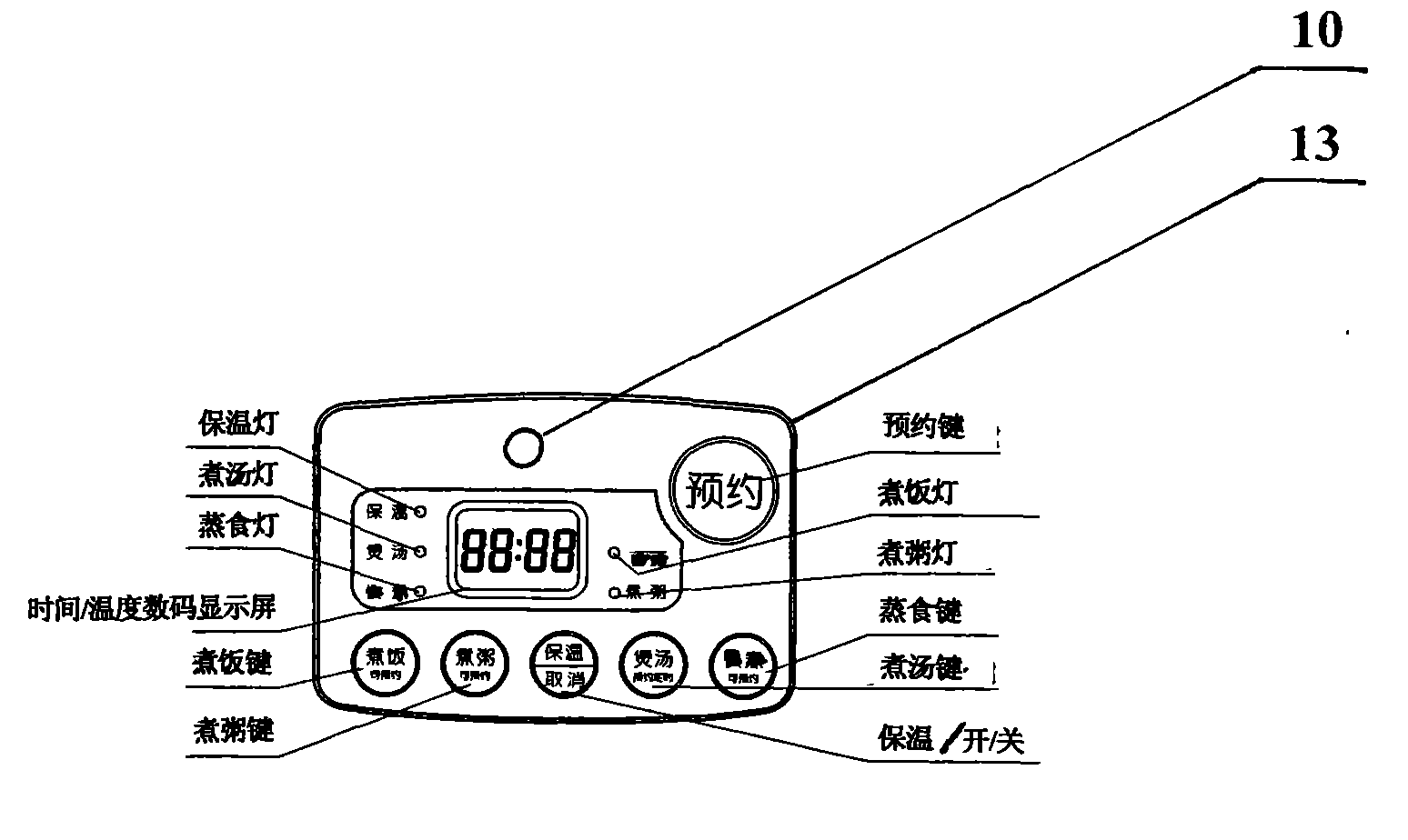

Efficient energy saving electro heating multipurpose cooker and new method of accurate temperature controlling and healthy cooking

InactiveCN101669761APlug the drainSolve technical problems that cannot withstand high temperaturesCooking-vessel lids/coversCooking utensils shields/jacketsElectricityAutomatic control

The invention discloses an efficient energy saving electro heating multipurpose cooker utilizing a new method of accurate temperature controlling and healthy cooking. The technical scheme of the invention is as follows: the outside surface of the cooker body is provided with an ambient temperature sensor; the base of the cooker is provided with an inner pot temperature sensor; the cooker body, thecooker cover and the cooker base are all set to be closed efficient heat insulation interlayers; the closed heat insulation interlayer on the cooker base is arranged between the casing of the cookerbase and the electro heating device; a hallow cavity is arranged between the casing of the cooker base and the closed heat insulation interlayer; and the purposes of energy saving, discharge reducingand healthy cooking can be realized by setting standard control values such as ambient temperature or temperature drop, cooking / steaming temperature and time and the like by an automatic control device and by comparing the ambient real-time temperature or temperature drop with the inner pot real-time temperature to control the power on and power off of the electro heating device. The efficient energy saving electro heating multipurpose cooker can be used for cooking rice, cooking congee, cooking soups and steaming food; compared with various electro rice / congee / soup cooker in the prior art, the invention can save electricity by 30%-50% and can be widely used in families, dining halls and catering enterprises in cities and towns.

Owner:郭卫康

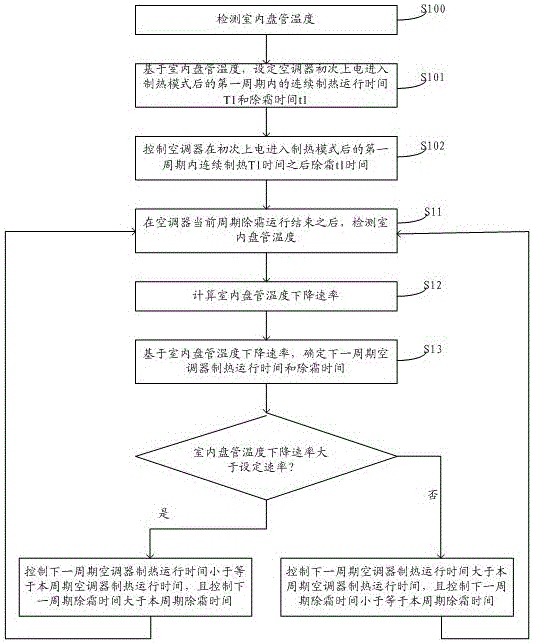

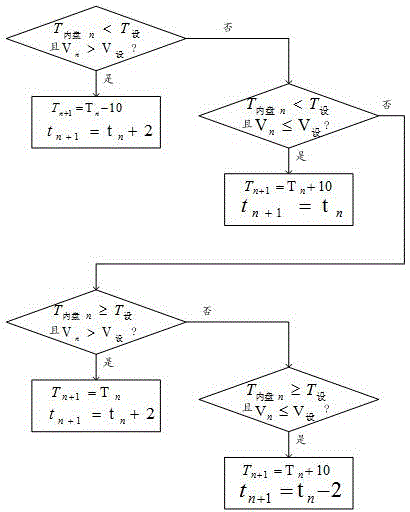

Air conditioner defrosting control method and air conditioner

ActiveCN105135629AHeating run time unchangedExtend heating timeSpace heating and ventilation safety systemsLighting and heating apparatusPower conditionerEngineering

The invention provides an air conditioner defrosting control method and an air conditioner. The method comprises the following step: after the current defrosting operation period of the air conditioner finishes, calculating and determining the heating operation time and defrosting time of the air conditioner of the next period on the basis of the indoor coil pipe temperature drop rate: when the indoor coil pipe temperature drop rate is high, controlling the heating operation time of the air conditioner of the next period to be less than or equal to the heating operation time of the air conditioner of the current period, and controlling the defrosting time of the next period to be greater than the defrosting time of the current period; and when the indoor coil pipe temperature drop rate is low, controlling the heating operation time of the air conditioner of the next period to be greater than the heating operation time of the air conditioner of the current period, and controlling the defrosting time of the next period to be less than or equal to the defrosting time of the current period. The heating operation time and defrosting time of the air conditioner of the next period are adjusted on the basis of the indoor coil pipe temperature drop rate when the operation of the current period finishes, thereby implementing dynamic adjustment on the heating and defrosting, and solving the technical problem of unclean defrosting or false defrosting when the defrosting is controlled on the basis of the indoor coil pipe temperature.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

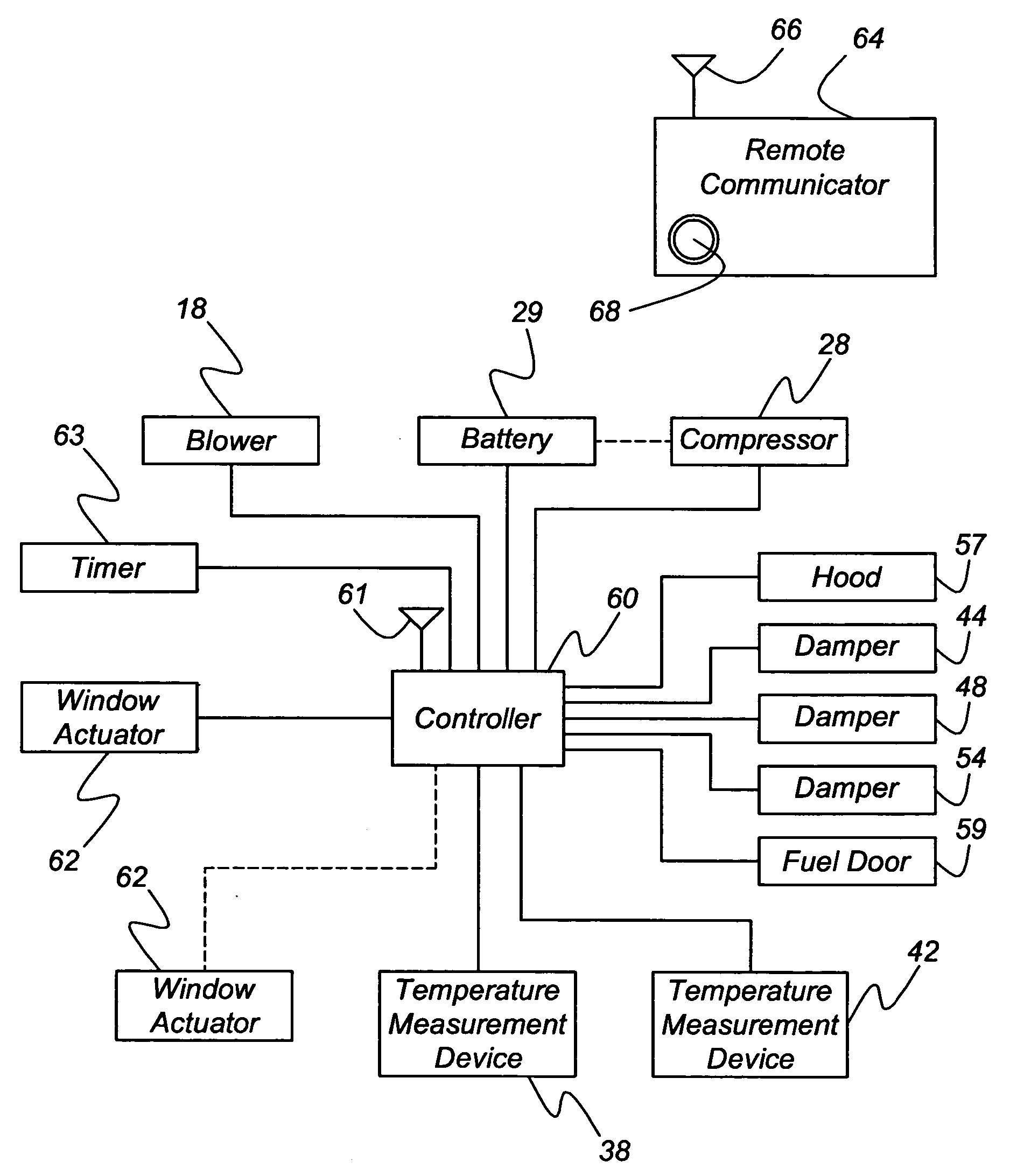

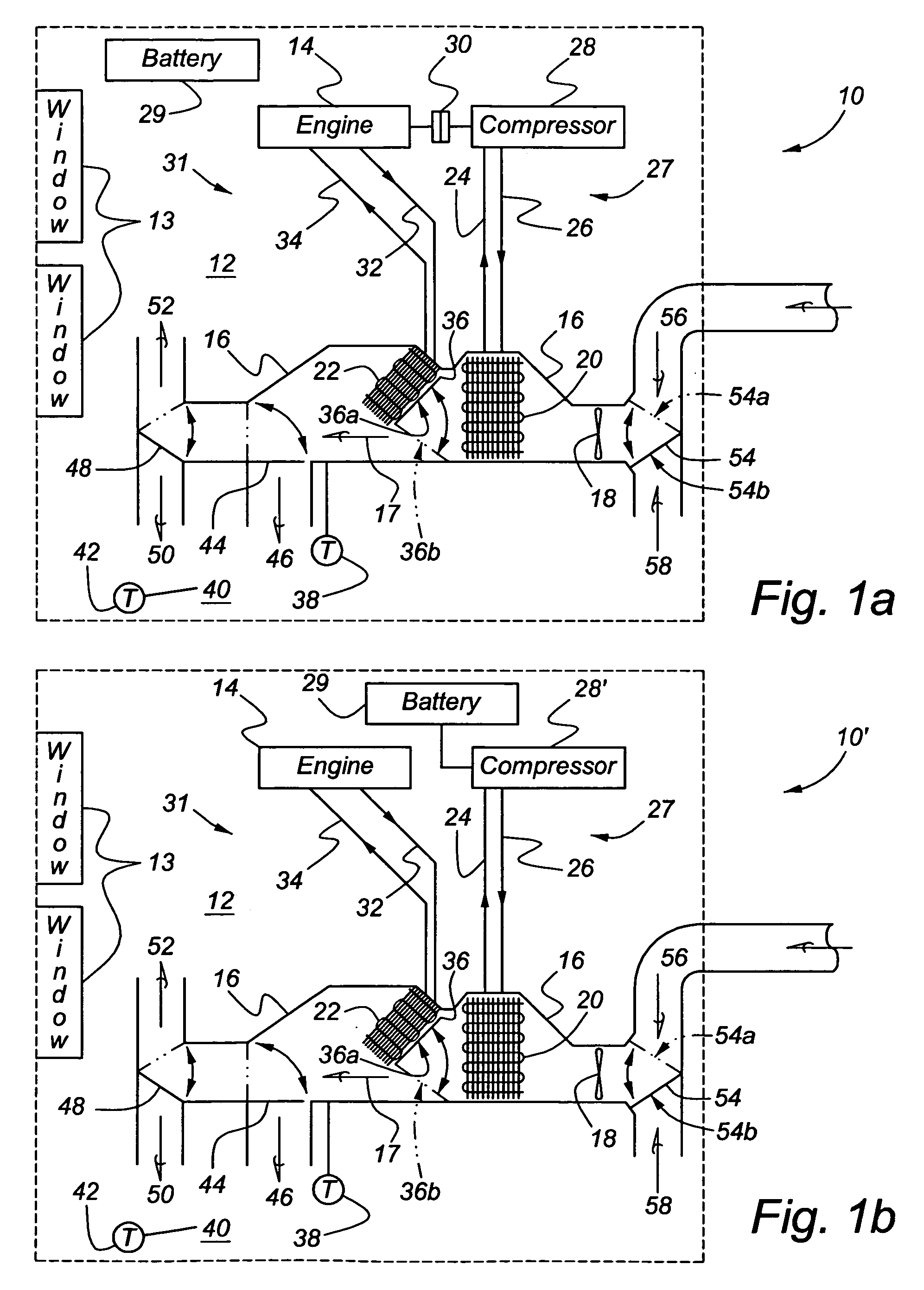

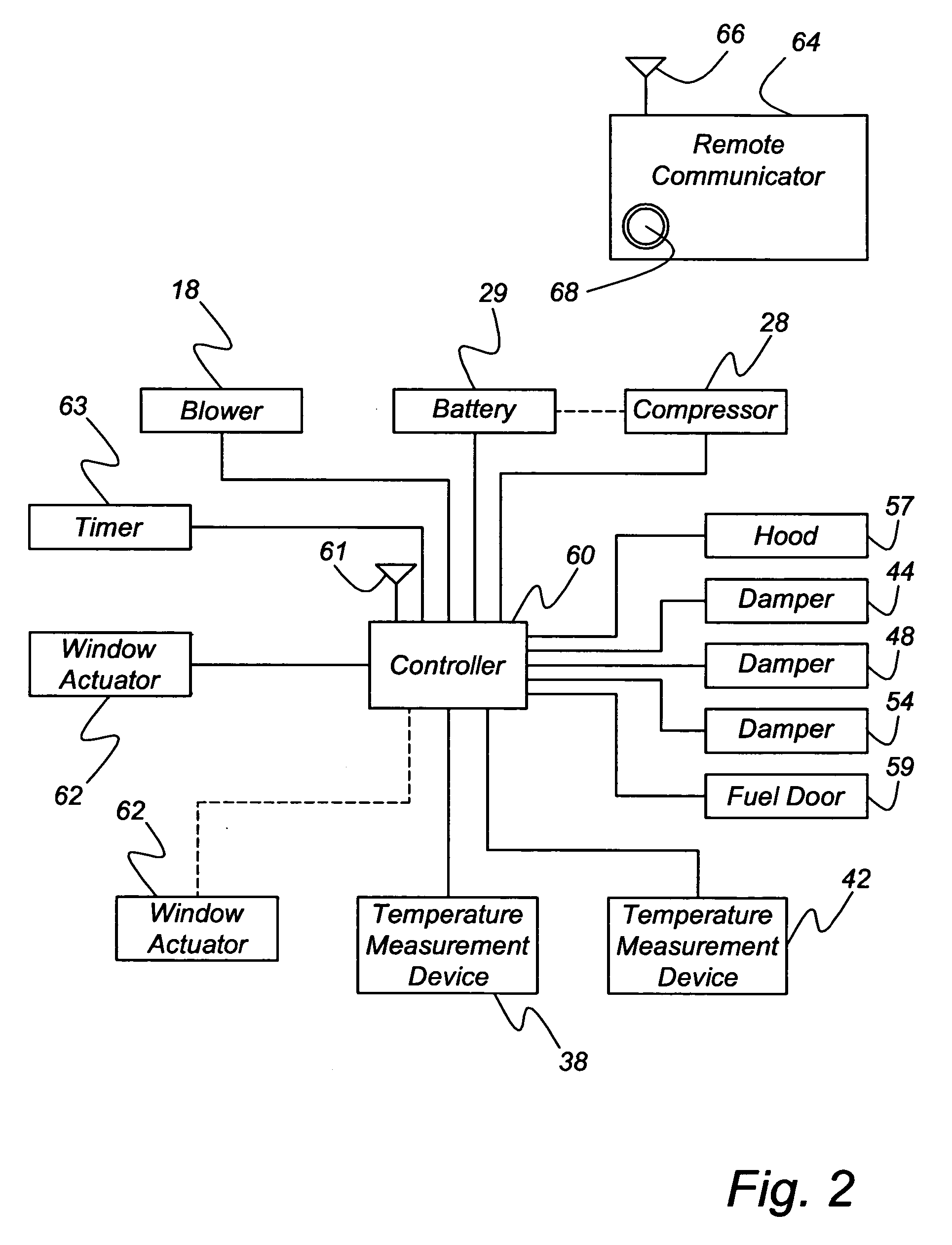

Method for pre-cooling automotive vehicle passenger compartment

InactiveUS7441414B2Air-treating devicesCompression machines with non-reversible cycleMobile vehicleMotorized vehicle

The present invention concerns a method for pre-cooling the passenger compartment of an automotive vehicle. The vehicle includes at least one electrically actuatable window and a HVAC system having at least a controller, a blower, a passenger compartment temperature sensor, and a HVAC ducting leading to the passenger compartment. The controller and the blower are connected to a vehicle battery. The method includes determining the passenger compartment temperature and comparing the temperature to a first predetermined value; cycling an blower inlet to an outside air intake position and operating the blower to provide pressurized air to the passenger compartment if the passenger compartment temperature is greater than the first predetermined value; opening the vehicle windows; comparing the passenger compartment temperature to a second predetermined value; and stopping operation of the blower when the passenger compartment temperature drops below the second predetermined value.

Owner:GM GLOBAL TECH OPERATIONS LLC

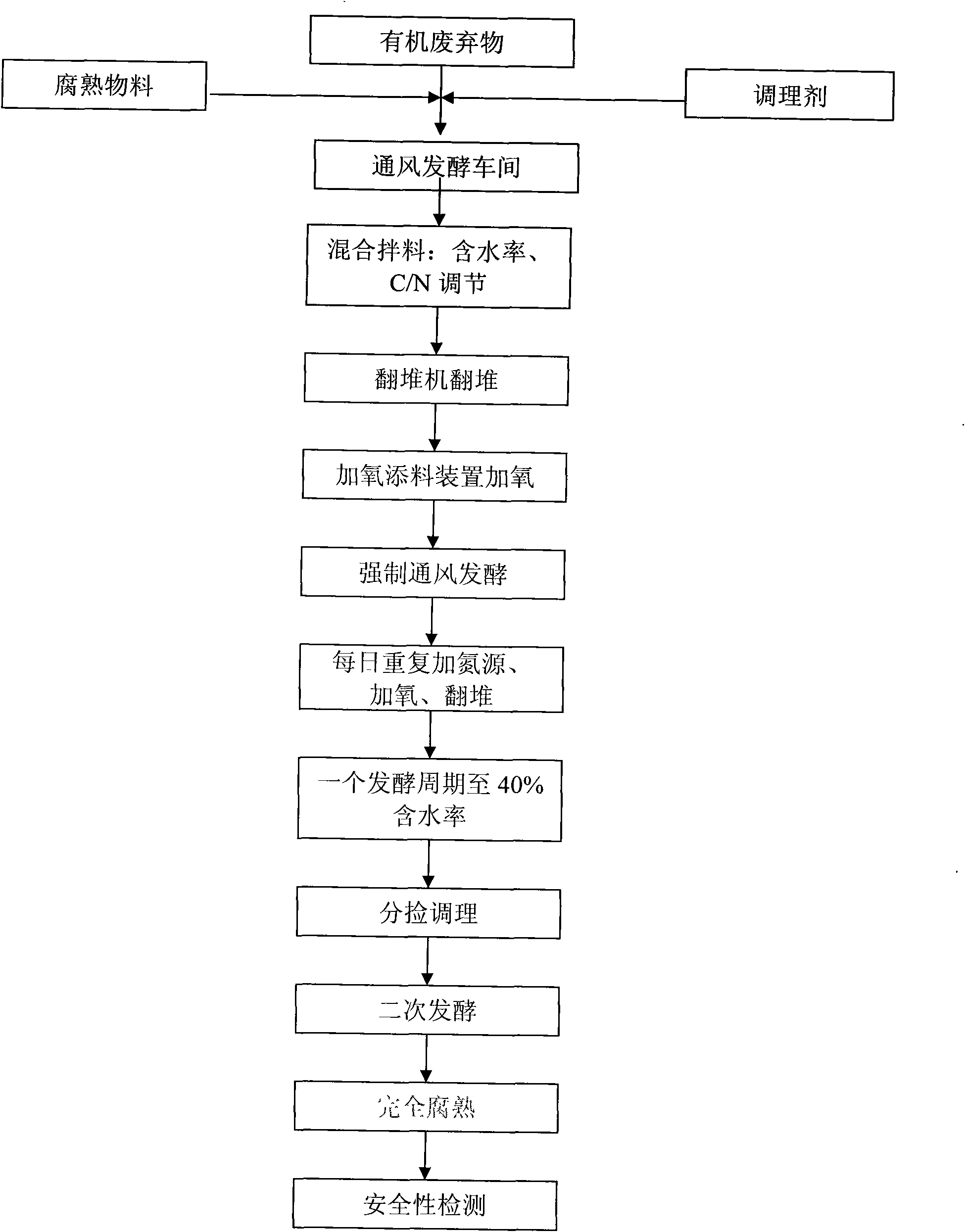

Scale high-speed composting treatment method of organic wastes

InactiveCN101555169ASave money on dehydrationIncreased automation of compostingBio-organic fraction processingClimate change adaptationMicroorganismSludge

A scale high-speed composting treatment method of organic wastes comprises the following steps: the organic wastes are taken as fermentable substrates; thoroughly decomposed materials are reused as desiccants and strains; the physicochemical property of the organic wastes is adjusted to the condition required by aerobic fermentation microorganism; forced aeration fermentation is carried out in airiness fermentation plants; the fermentation temperature of fermentation materials is increased to over 70 DEG C in a very short time and high temperature fermentation is maintained for 1-15 days; organic wastes with high water content are quickly dehydrated to below 20-60% in short time and then are transferred to a static forced aeration fermentation system for secondary fermentation; therefore, the water ratios of the fermentation materials are further reduced, the fermentation temperature drops to the ambient temperature and always remains the same, and the materials are thoroughly decomposed. The method realizes scale high-speed composting treatment of the organic wastes and boosts resource treatment of such organic wastes as municipal and industrial sludges.

Owner:肇庆奥特生态环保有限公司

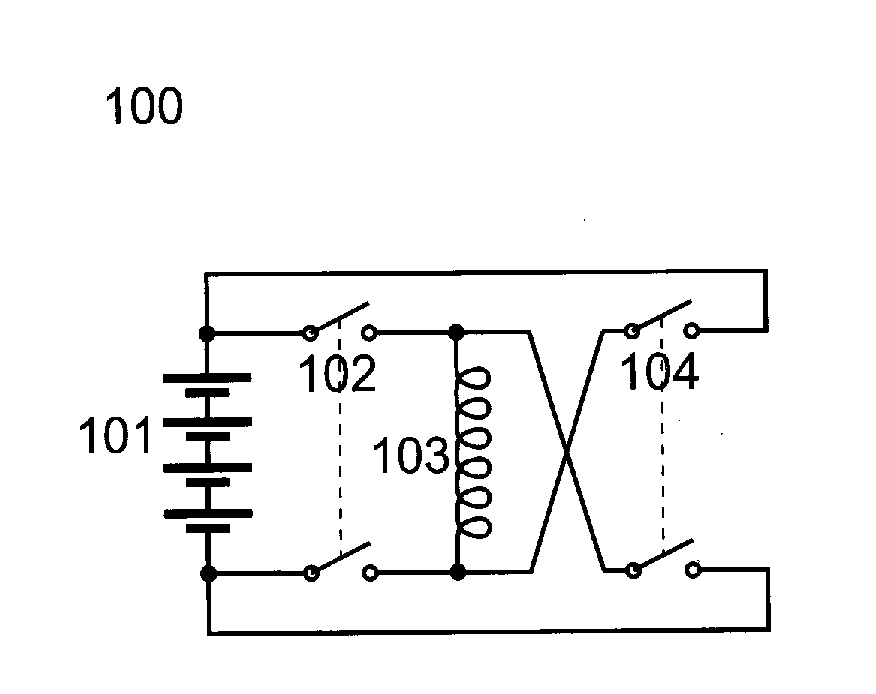

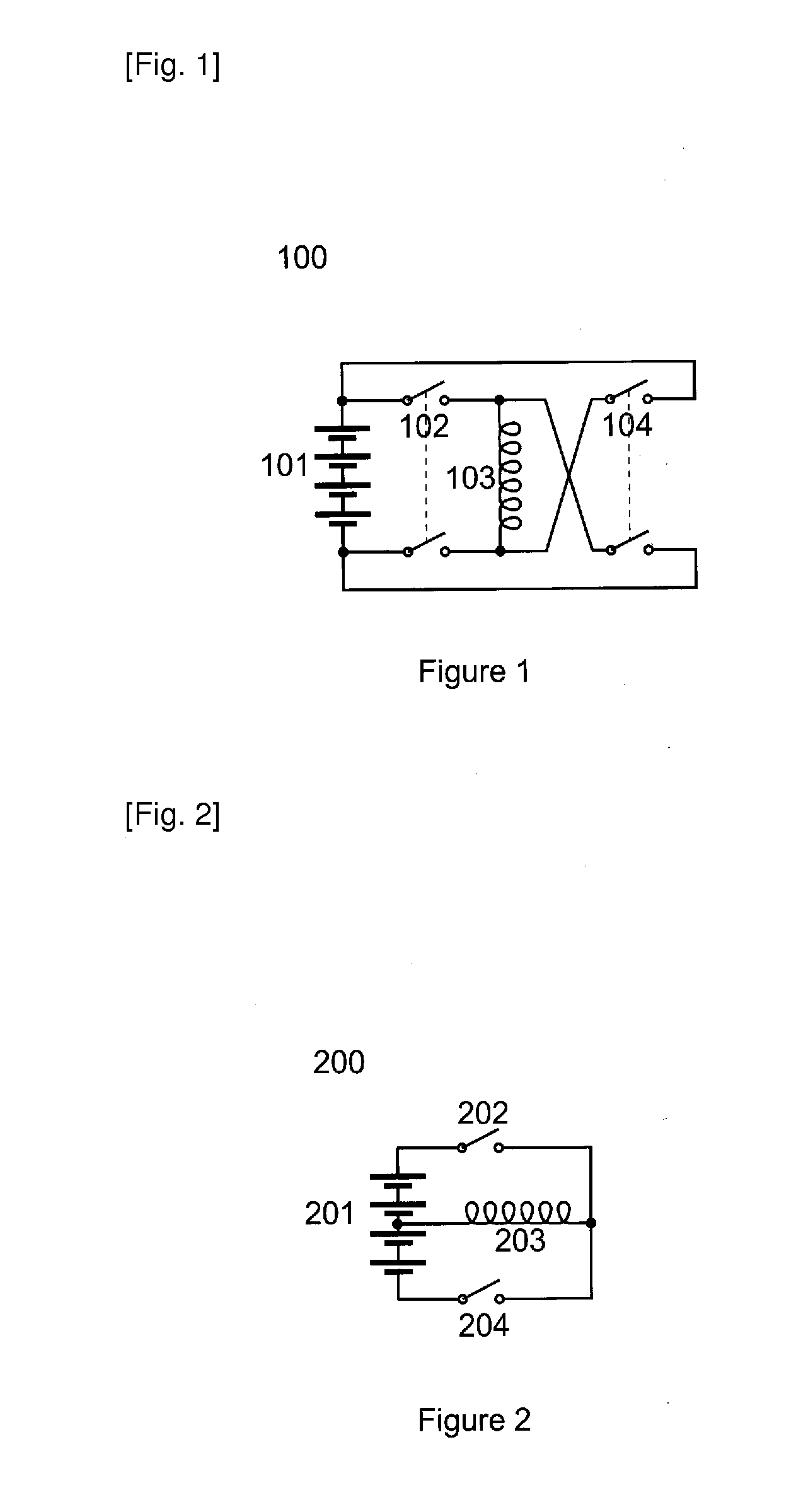

Self Heating Battery System

ActiveUS20120126753A1Supply will become excessiveHigh switching rateBatteries circuit arrangementsSecondary cellsCapacitanceCapacitive storage

A battery self heating system for batteries that experience battery impedance or internal battery resistance when temperature drops. The system comprises an energy storage element applied to the battery terminals to draw energy from the battery. The energy is stored in a magnetic or capacitive storage device. The system is self-resonant so that energy transfer from the storage device to the battery will occur at a frequency and load level that is compatible with the current state of the battery. Internal heating of the battery is accomplished by a cycle comprising the out flux and influx of energy through the impedance of the battery. Energy losses due to battery impedance are converted to heat thereby heating the battery internally.

Owner:STRYTEN ENERGY LLC

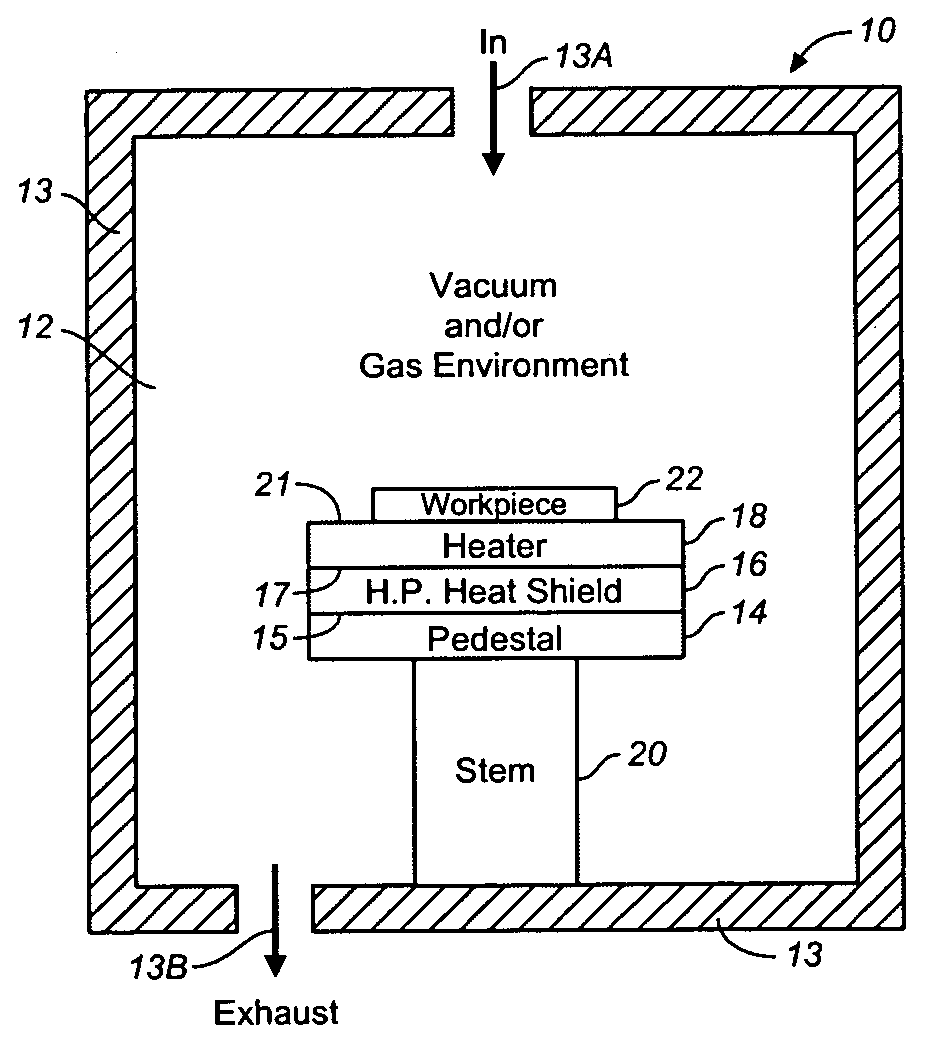

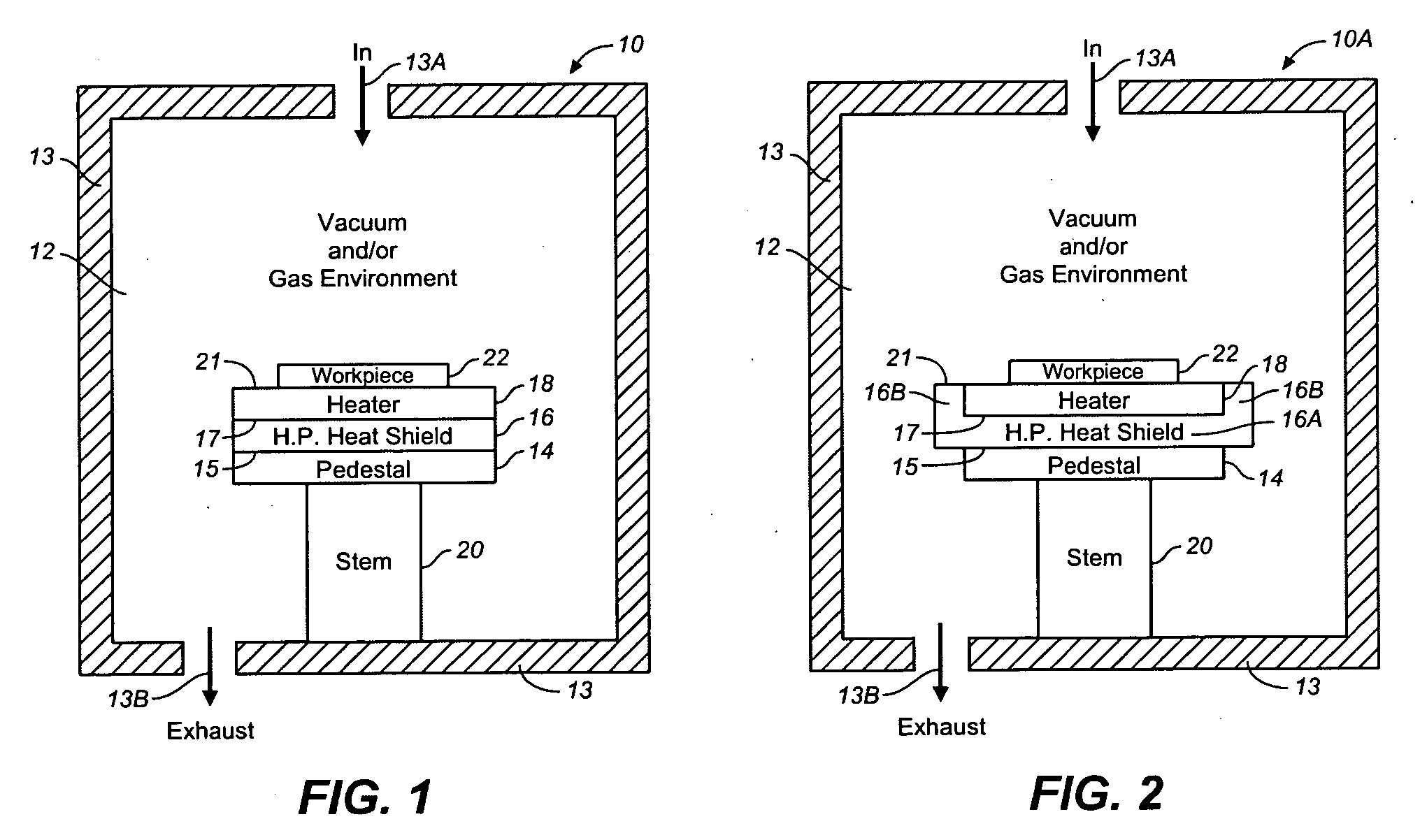

Heat Shield for Heater in Semiconductor Processing Apparatus

ActiveUS20100317197A1Reduce conductivityImprove performanceCellsWave amplification devicesEngineeringOrder of magnitude

A heat shield employed in semiconductor processing apparatus comprises a high performance insulation that has low thermal conductivity, such as, below the thermal conductivity of still air over a wide range of temperatures utilized in operation of the apparatus. As an example, the thermal conductivity of the insulation may be in the range of about 0.004 W / m·h to about 0.4 W / m·h over a temperature range of about 0° C. to about 600° C. or more. The deployment of the high performance heat shield reduces the power consumption necessary for the heater by as much as 20% to reach a desired processing temperature as compared to a case of heater power consumption required to reach the same desired temperature without the shield. Further, the heat shield significantly reduces the amount of undesired depositions from gas-entrained constituents on components in the chamber of the apparatus, particularly below or beyond the heat shield, by as much as 90% since the temperature drop is as much as ten orders of magnitude difference.

Owner:NOVELLUS SYSTEMS

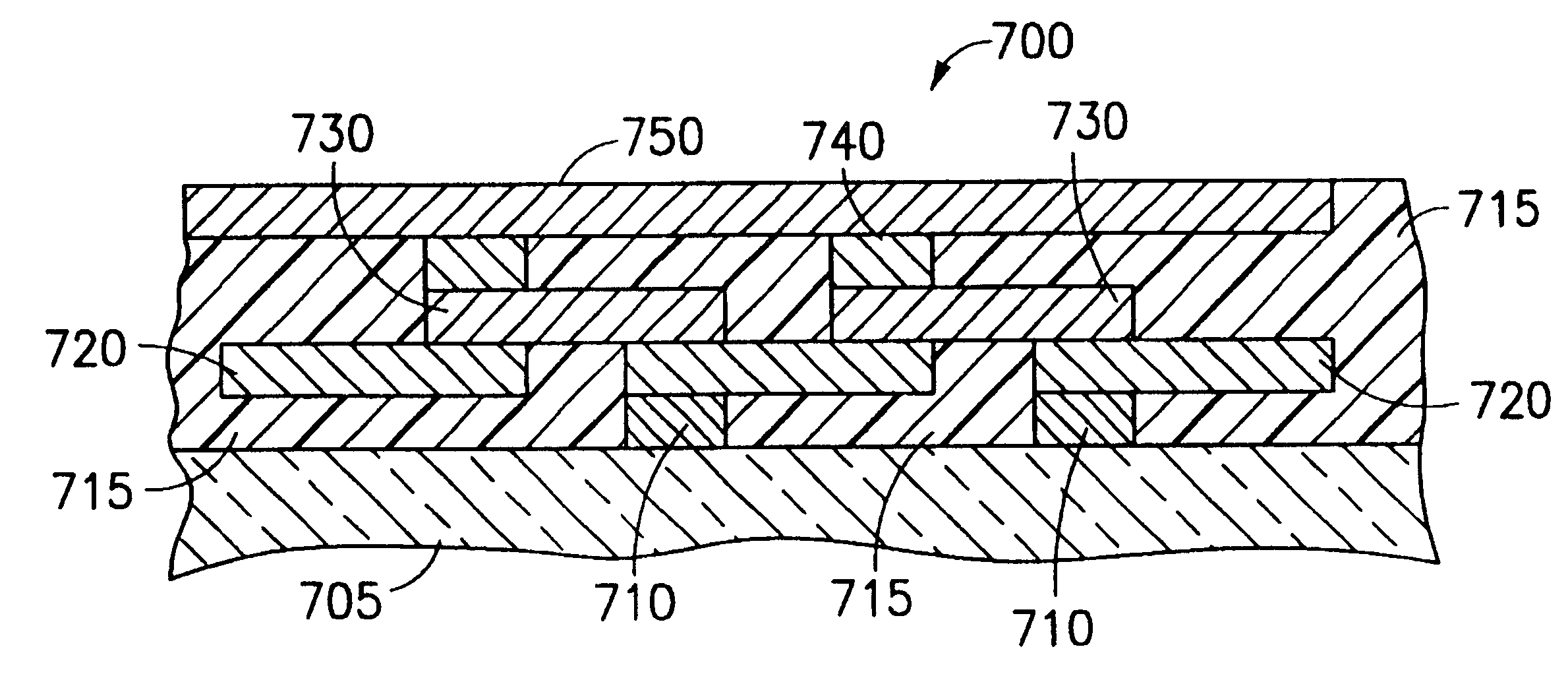

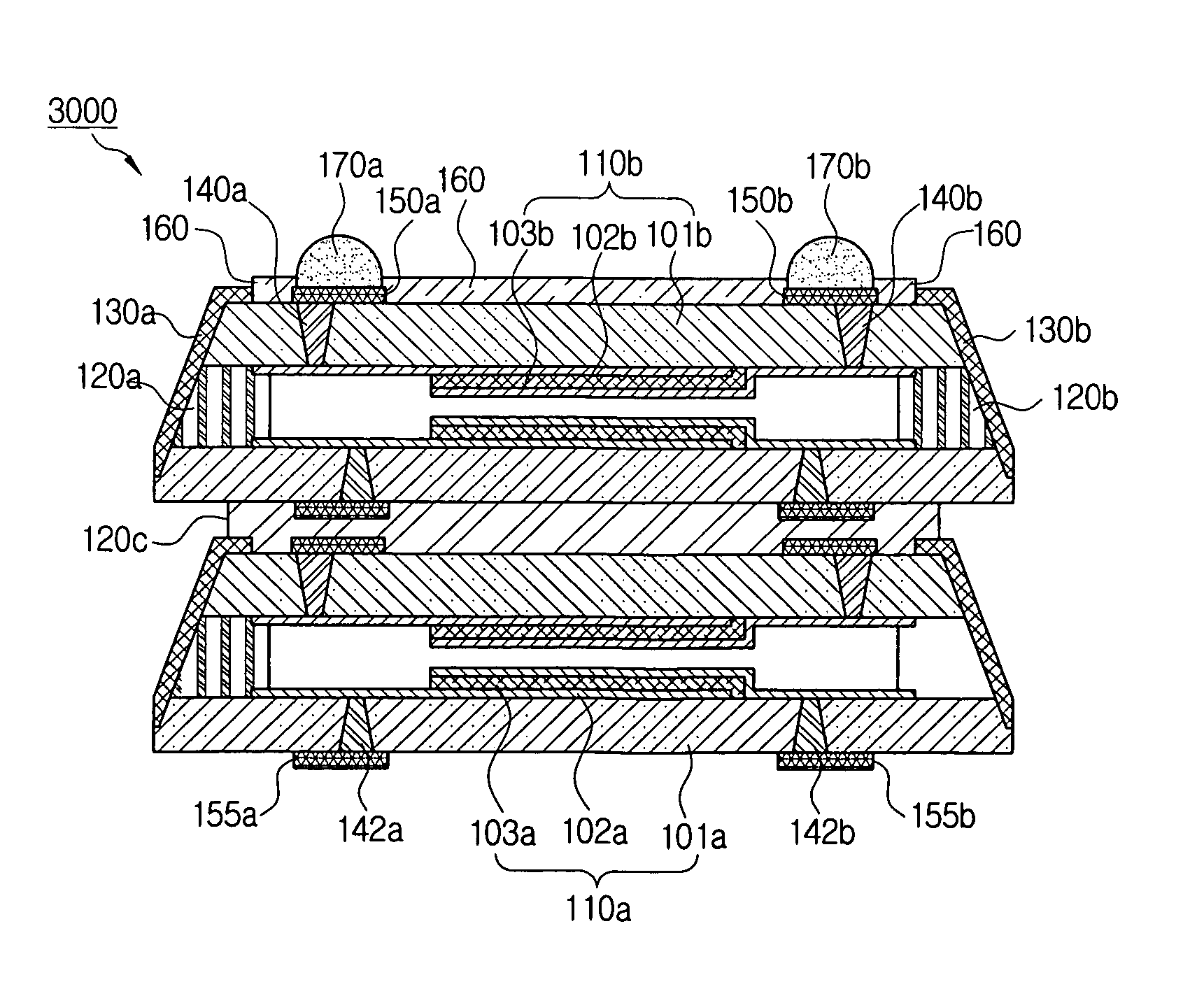

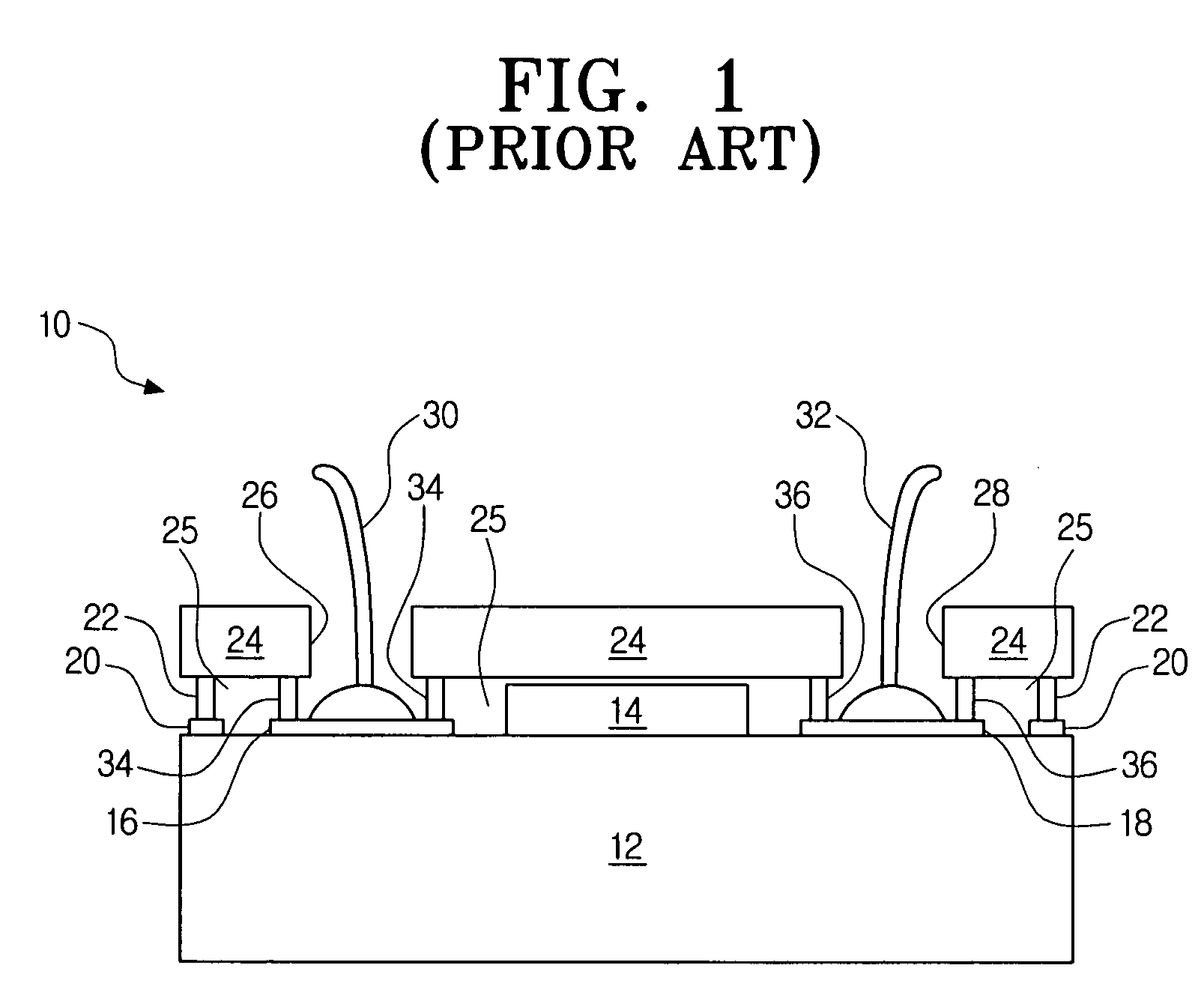

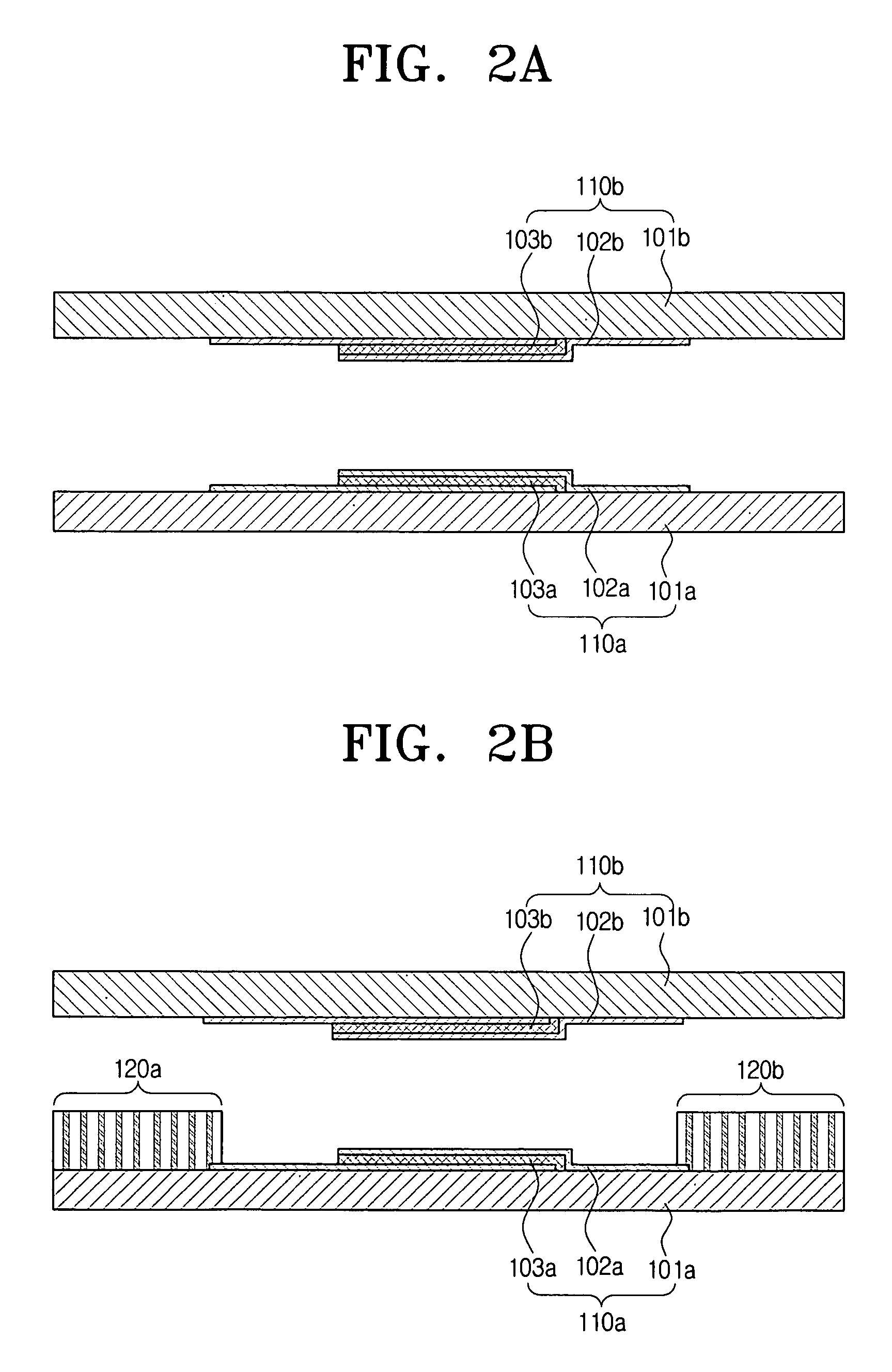

Micro-package, multi-stack micro-package, and manufacturing method therefor

ActiveUS7285865B2Improve air tightnessAvoid damageSemiconductor/solid-state device detailsSolid-state devicesPOLYMER SUBSTANCEMoisture absorption

A micro package, a multi-stack micro package, and a manufacture method therefor are provided. A micro package according to the present invention includes a device substrate for mounting a devices, being a circuit module; a protection cap for protecting the device; bonding substances which, formed by patterning on predetermined areas on the device substrate, bond the device substrate and the protection cap; layers formed on a portion of the device substrate and a portion of the protection cap and exterior sides of the bonding substances; vias which are formed by etching away another portion of the protection cap, and electrically connected to an upper surface of the device substrate through the bonding substances; under barrier metals (UBMs) formed on the vias; and solder bumpers, being connection terminals for an external signal, formed on the UBMs. As stated above, the present invention has advantages of guaranteeing the hermetical sealing since the above layers prevent moisture absorption from outside at the same time of lowering possibility of damages to the device inside the package since the processing temperature drops below 150° upon wafer bonding due to the use of the polymer substance as a bonding substance.

Owner:SAMSUNG ELECTRONICS CO LTD

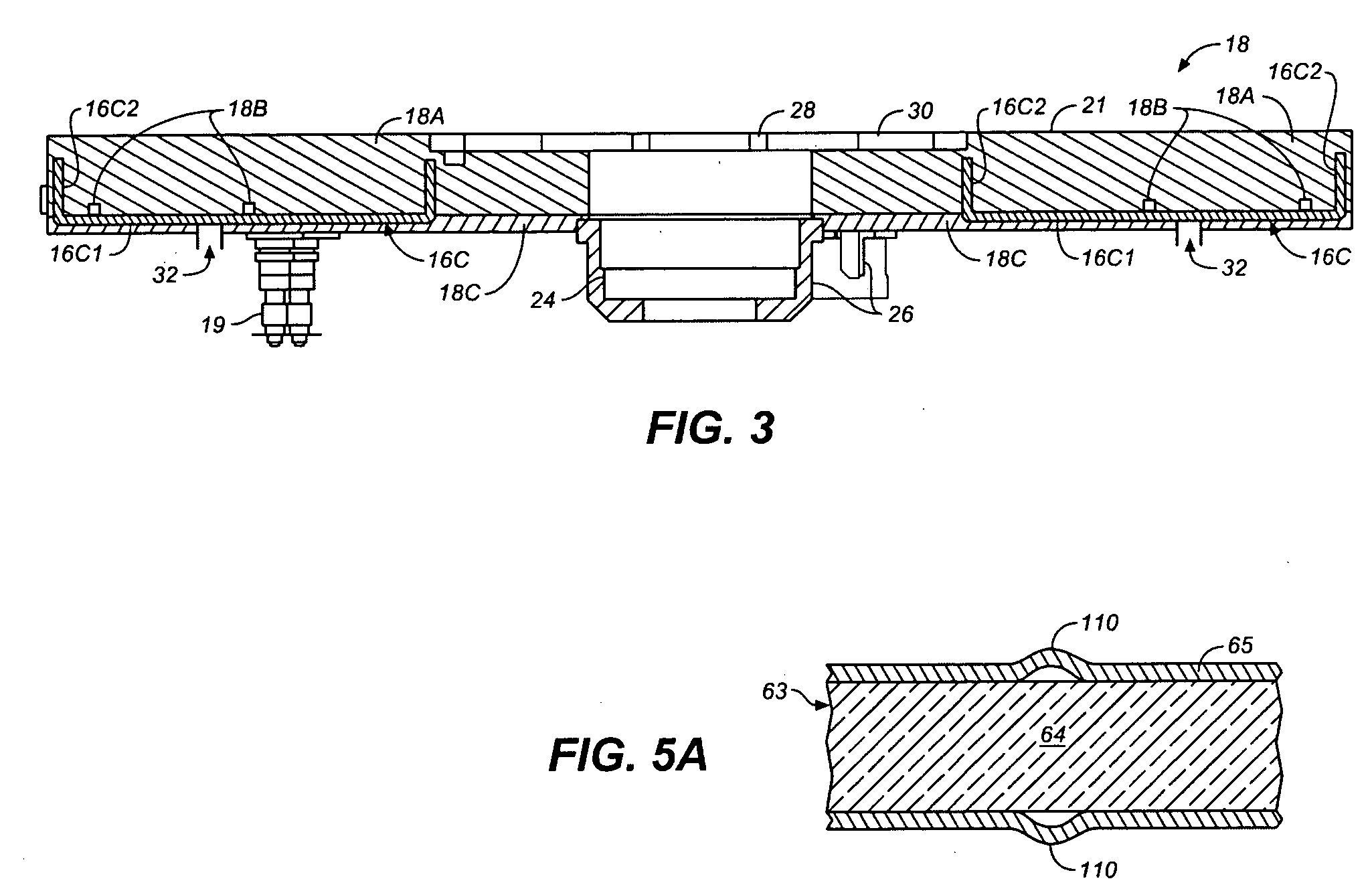

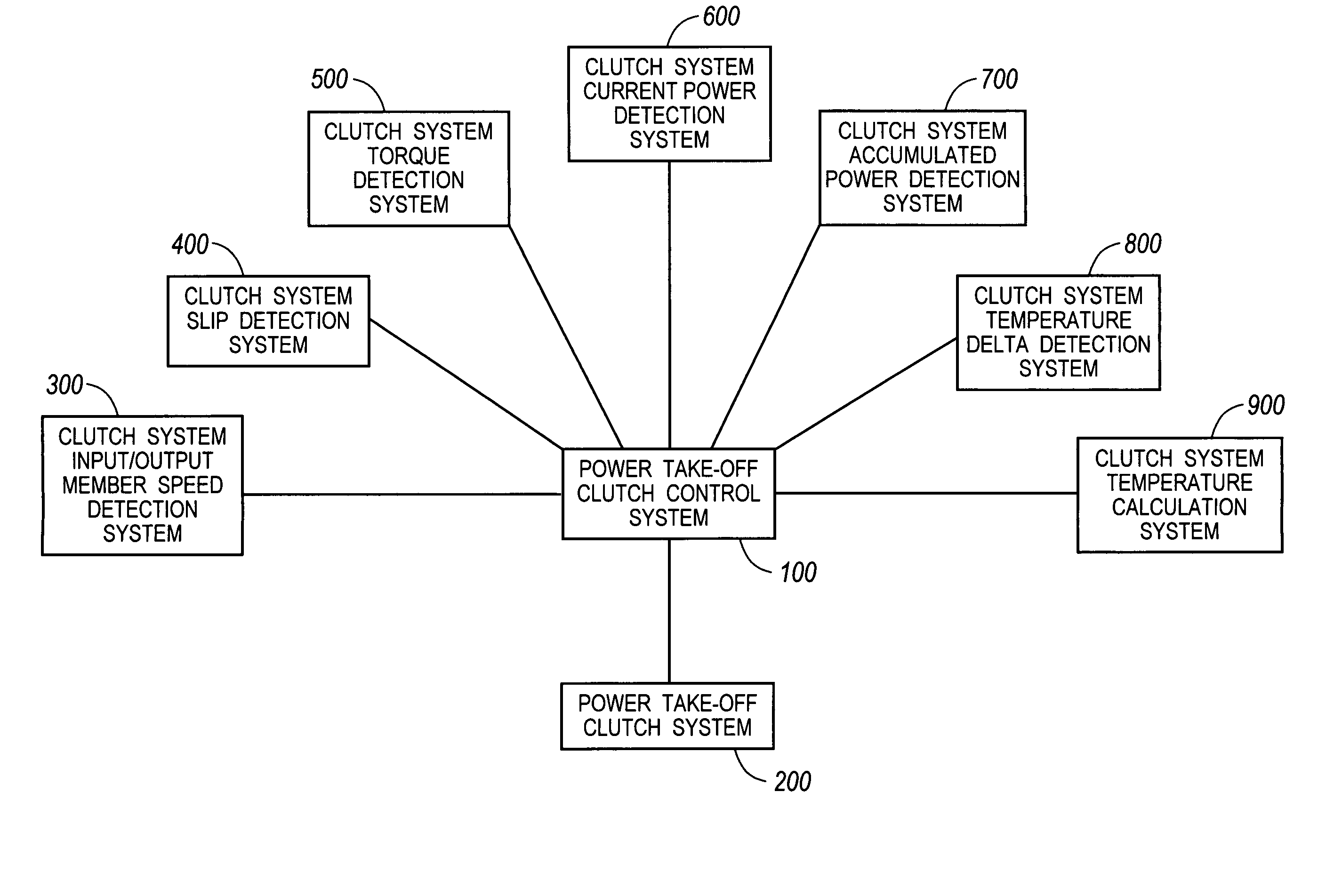

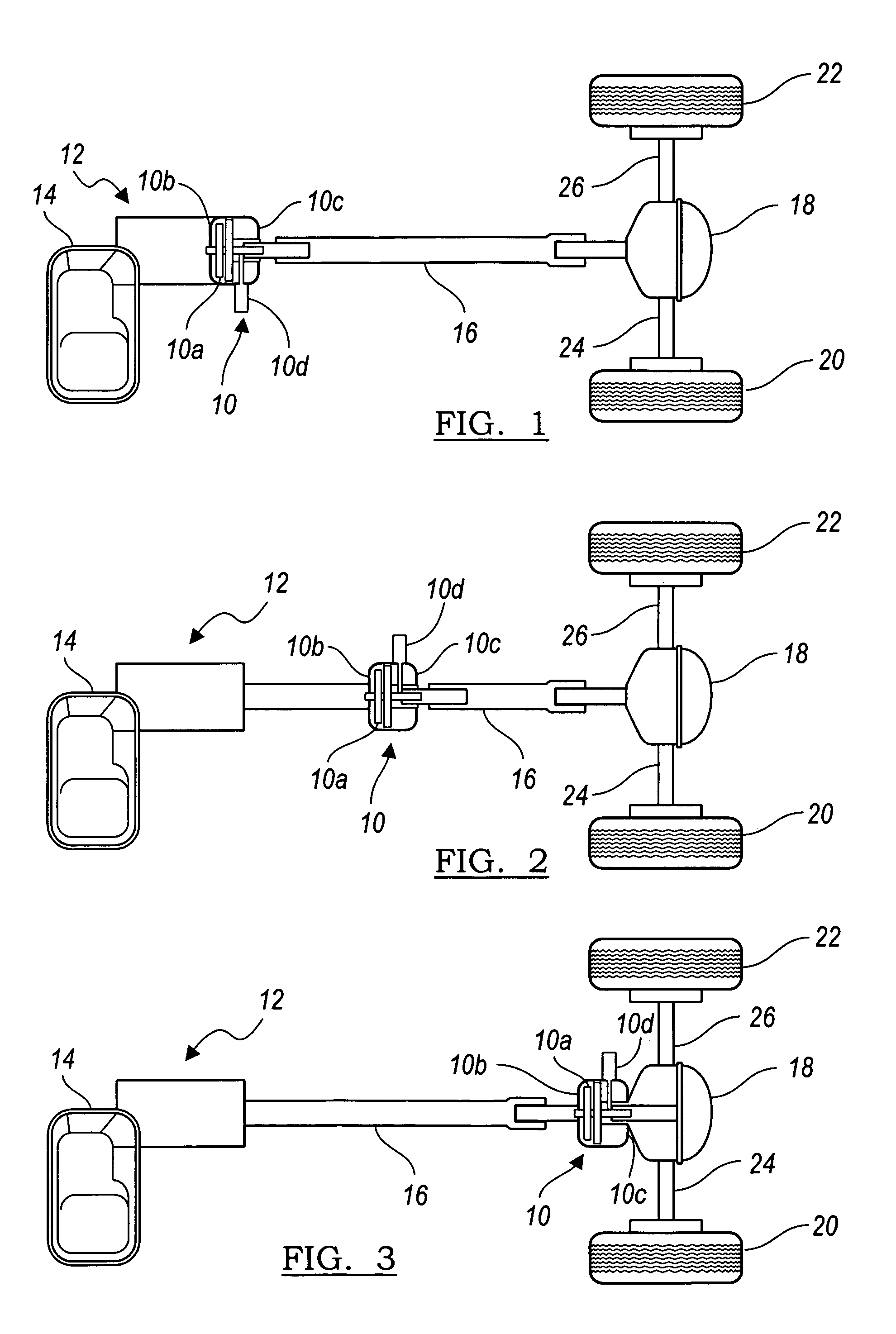

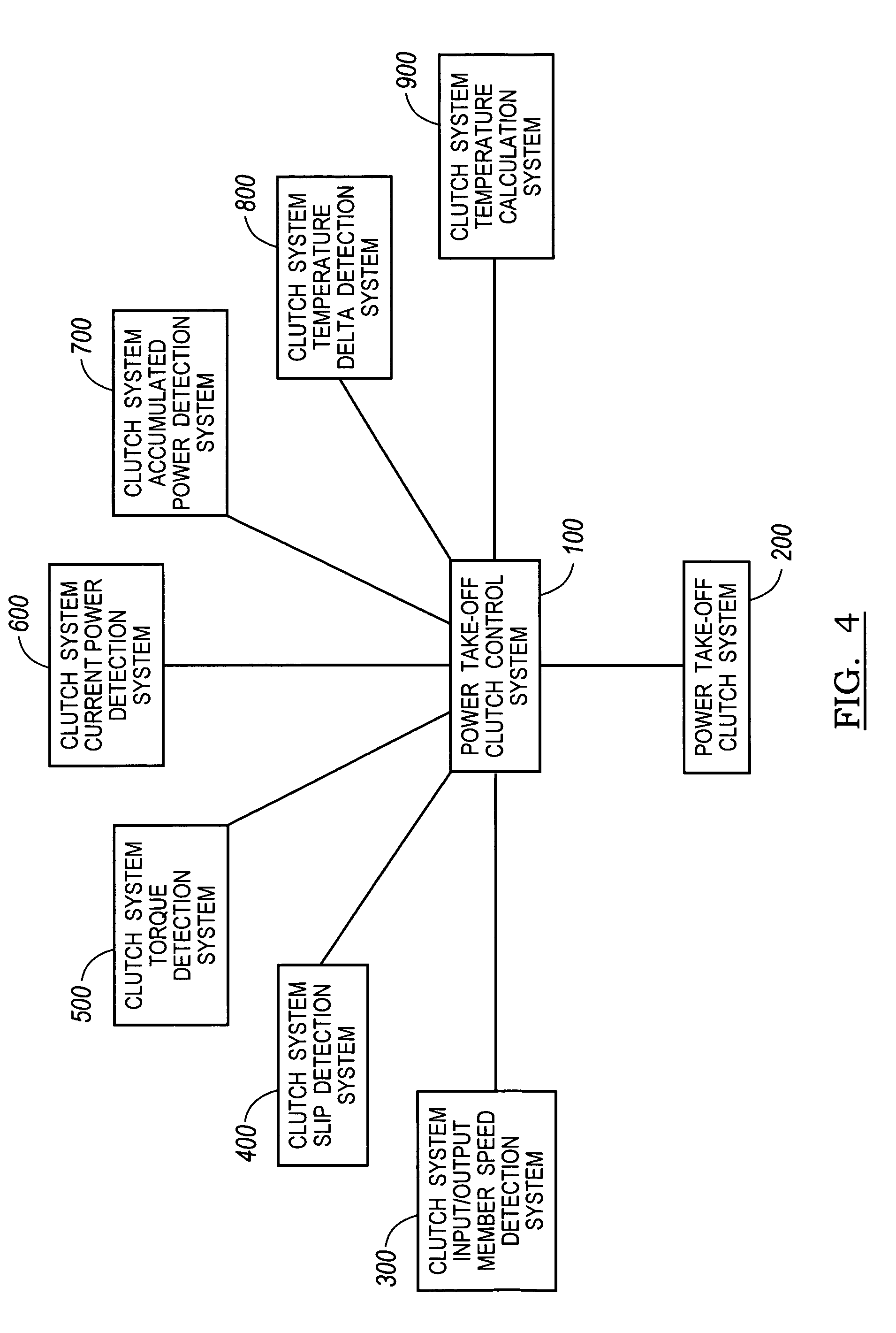

Power take-off clutch control system

Owner:BORGWARNER INC

Production method of ultra low carbon steel

InactiveCN102719600AReduce the rate of oxygen blowing heating upReduce temperature dropManufacturing convertersSlagNitrogen

The invention provides a production method of an ultra low carbon steel. The method comprises the steps of: employing a blowing process for desulfurization and slag removal of molten iron, with control of oxygen blowing time and smelting cycle of a converter, argon bottom-blowing in the whole course, and control of S content in slag lime, [C] content at converter end point, and temperature and oxygen activity at the endpoint, adding lime in a tapping process, and modifying ladle top slag after tapping; employing natural decarburization to control carbon content in an RH, wherein Als in molten steel is less than 0.03% after deoxidation, carrying out vacuum-breaking, adding aluminum powder and top slag modifier into the top slag, blowing argon with stirring, vacuumizing again, and carrying out clean circulation for 2-10 min; and carrying out continuous casting with protective casting in the whole course, wherein a nitrogen increase amount in the molten steel is controlled at less than 2 ppm. The invention can effectively reduce temperature drop in a transmission process, reduce oxygen blowing heating rate in a subsequent RH refining treatment, save energy and shorten the time of refining. Besides, the method can effectively guarantee modification effect of the top slag, prevent nozzle clogging and realize sequence casting. Therefore, the method is particularly applicable to the production of high purity ultra low carbon steel.

Owner:ANGANG STEEL CO LTD

Short-flow casting and rolling composite forming method for ferrule piece

The invention relates to a short-flow casting and rolling composite forming method for a ferrule piece, which belongs to a machining and forming method for a large-sized ferrule piece and mainly overcomes the technical difficulty that the conventional rolling method has high material waste and serious energy waste. The invention adopts the technical scheme that the short-flow casting and rolling composite forming method for the ferrule piece comprises the steps of alloy melting, molten steel refining, centrifugal casting of a ring blank, hot rolling and expanding, rough machining, heat treatment and finish machining, wherein the molten steel refining refers to external refining with an LF furnace and argon stirring to obtain high-purity molten steel; the centrifugal casting of the ring blank comprises that the refined molten steel is centrifugally cast at the temperature of 1,600 DEG C to form the ring blank, and meanwhile the cast blank grains are thinned by adopting electromagnetic stirring; and the hot rolling and expanding comprise that when the ring blank casting is solidified and the temperature drops to initial forging temperature of 1,200 DEG C, the rolling and expanding are directly performed on a rolling and expanding machine, the feeding amount is controlled during rolling and expanding, and the rolling-expanding ratio is 2 to 3.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

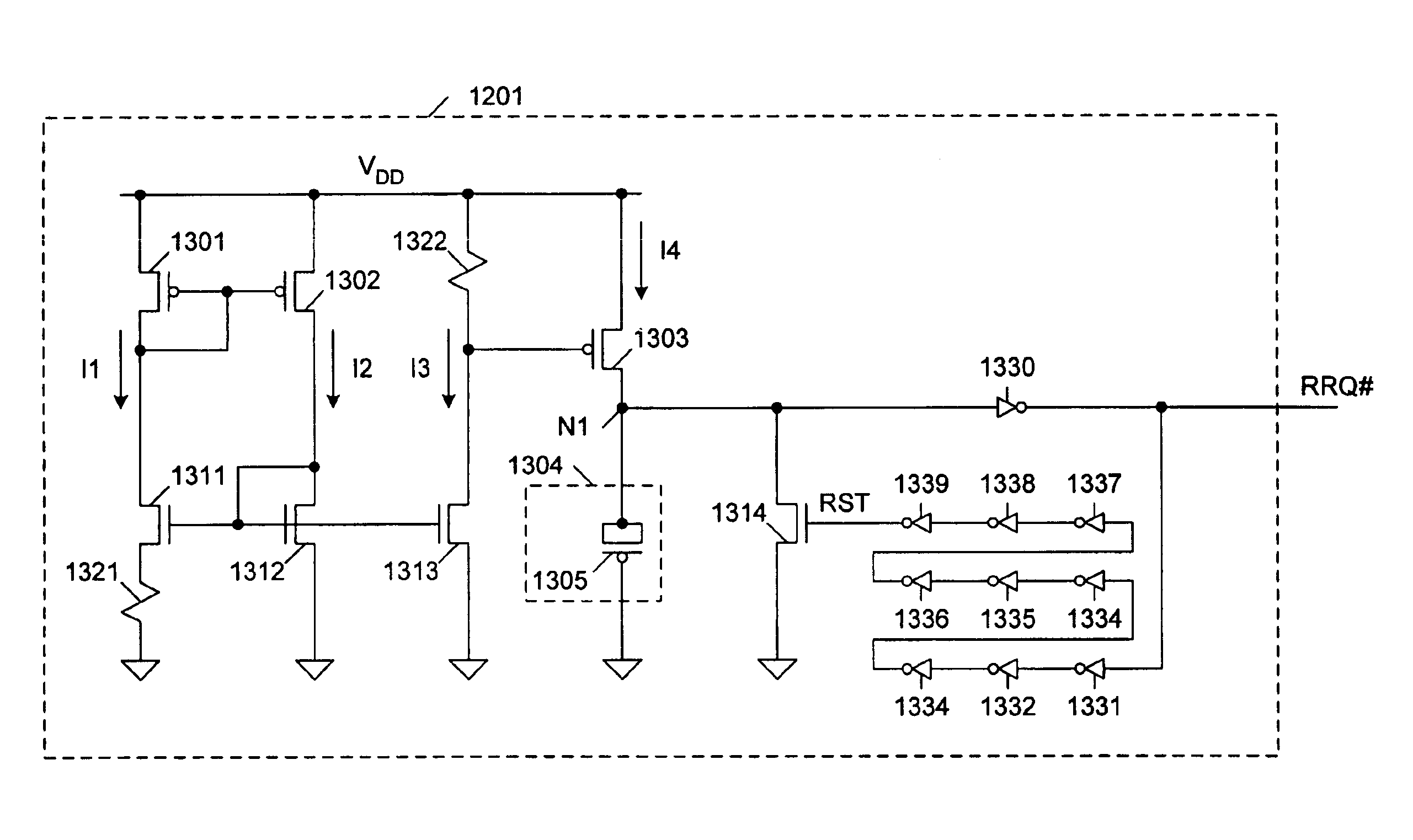

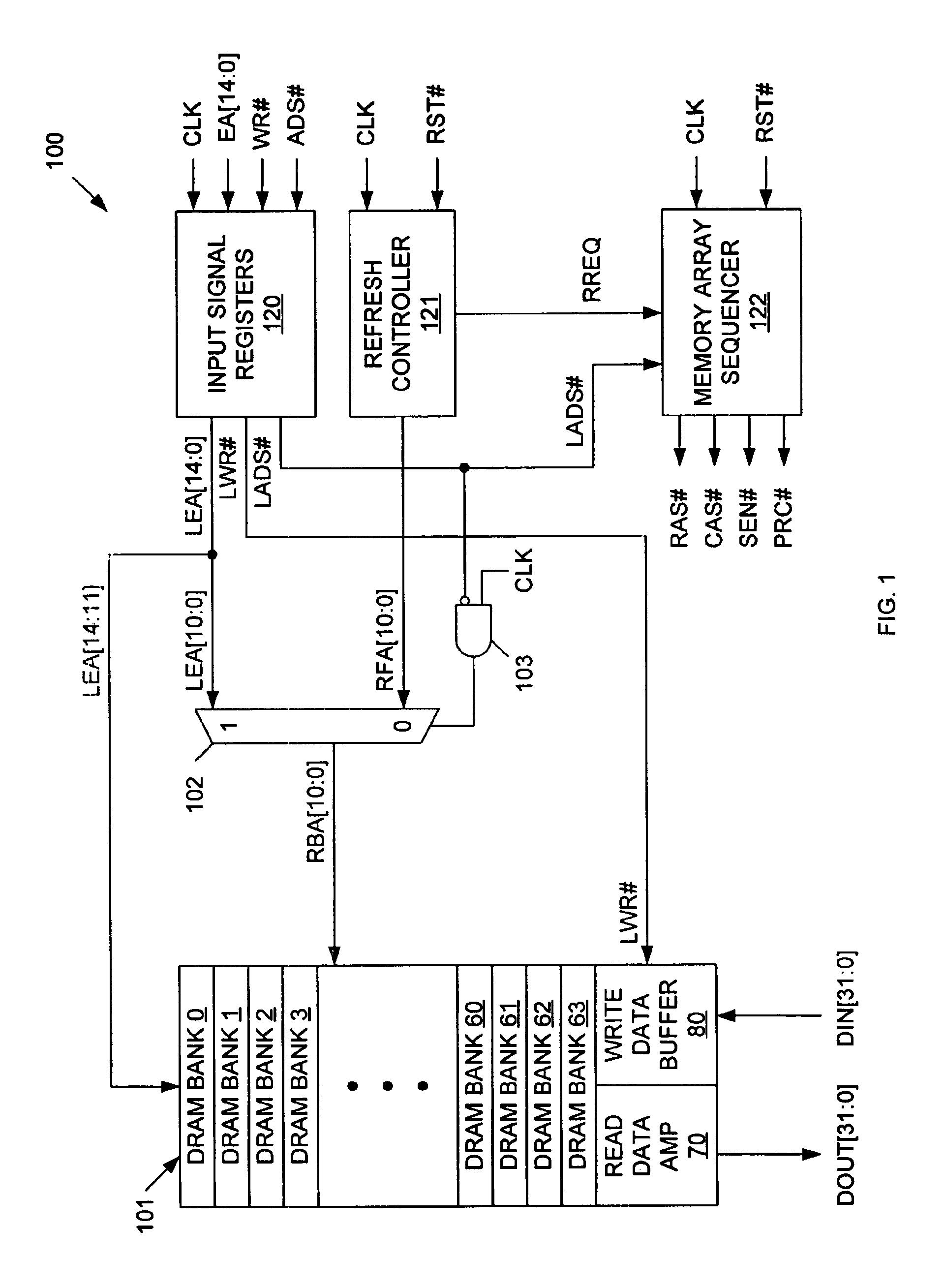

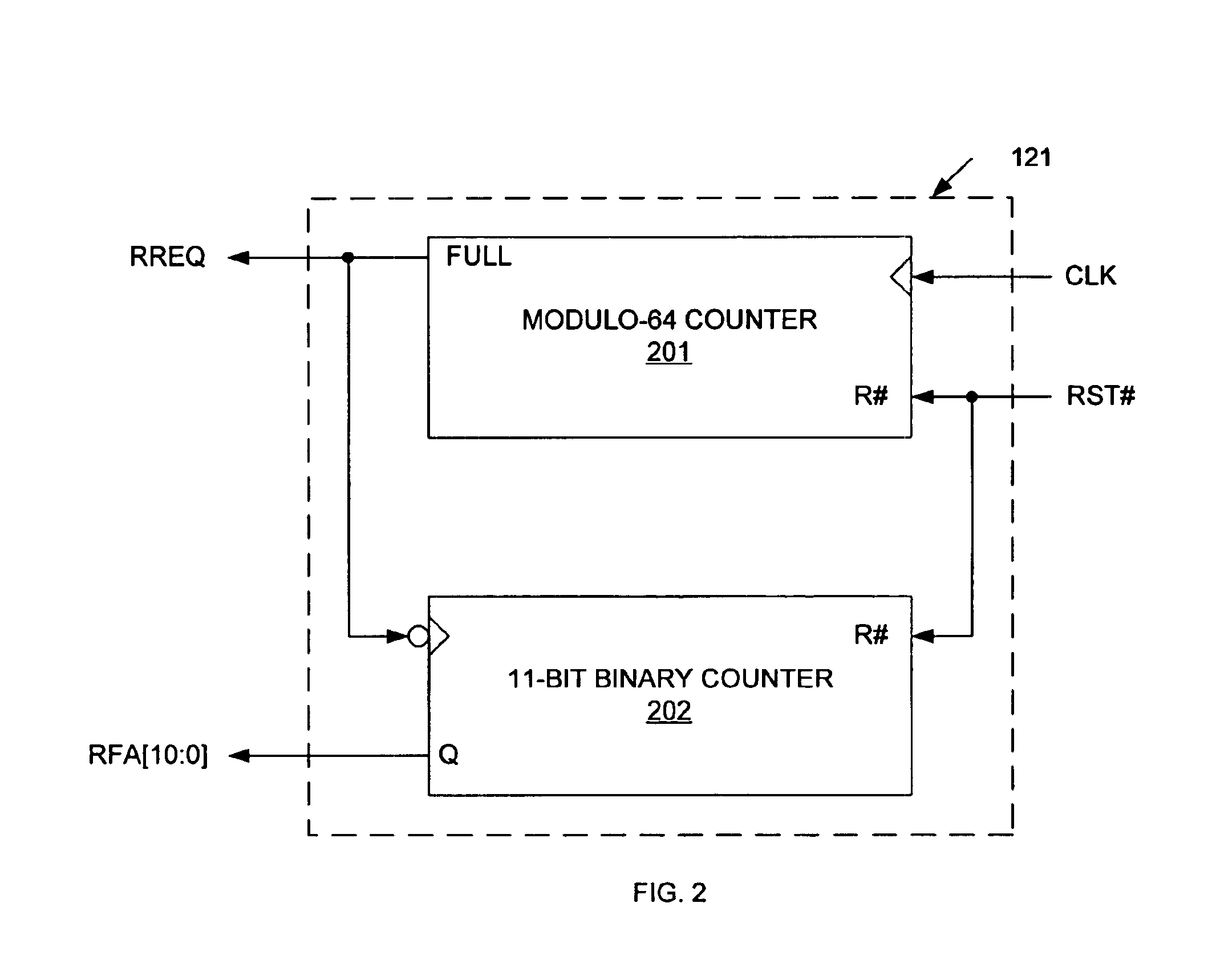

Method and apparatus for temperature adaptive refresh in 1T-SRAM compatible memory using the subthreshold characteristics of MOSFET transistors

A memory system is provided that includes an array of memory cells that require periodic refresh, and a temperature-adaptive refresh controller. Data retention time of the memory cells decreases exponentially as temperature increases. The temperature-adaptive refresh controller selects the refresh period of the memory cells in response to the subthreshold current of a reference transistor. The subthreshold current of the reference transistor increases exponentially as temperature increases As a result, the refresh period is empirically tied to the data retention time. Consequently, the power required for refresh operations decreases as temperature decreases. Power is therefore conserved in applications that operate predominantly at room temperature.

Owner:INVENSAS CORP

Continuous casting slab high-temperature oxidation resistant coatings and preparation process thereof

InactiveCN101693791AGood anti-oxidation effect at high temperatureRaw materials are easy to getCoatingsOxidation resistantSuspending Agents

The invention relates to a preparation process of continuous casting slab high-temperature oxidation resistant coatings, which is characterized in that less than 120 meshes of powder, reductant containing carbon, inorganic binders, surfactants, suspending agents and the like with the compositions such as 25-55 wt% SiO2, 10-20 wt% Al203, 11-23 wt% MgO and the like are respectively grinded and mixed evenly, then water is used to be mixed and stirred sufficiently evenly, and finally the density of the coatings are adjusted within 1200-1500 kg / m3. The coatings can not only be sprayed onto continuous casting slabs at normal temperature, but also be sprayed onto high-temperature casting slabs, form continuous whole protective coating layers under the action of high temperature, effectively reduce temperature drop of the casting slabs and oxidation burning loss in even heating process of a heating furnace without changing original performance of matrixes, and effectively decrease dilution of alloying elements on the surfaces of the casting slabs. After the casting slabs are out of the heating furnace, natural spalling capability of the coating layers is strong, and oxidation matrixes of the casting slabs are smooth. Raw materials of the oxidation resistant coatings are easy to be obtained, and the coatings have low cost and simple preparation process and are adaptable to oxidation resistance for various steels when being heated at 700-1300 DEG C / 2-8 hours.

Owner:UNIV OF SCI & TECH BEIJING

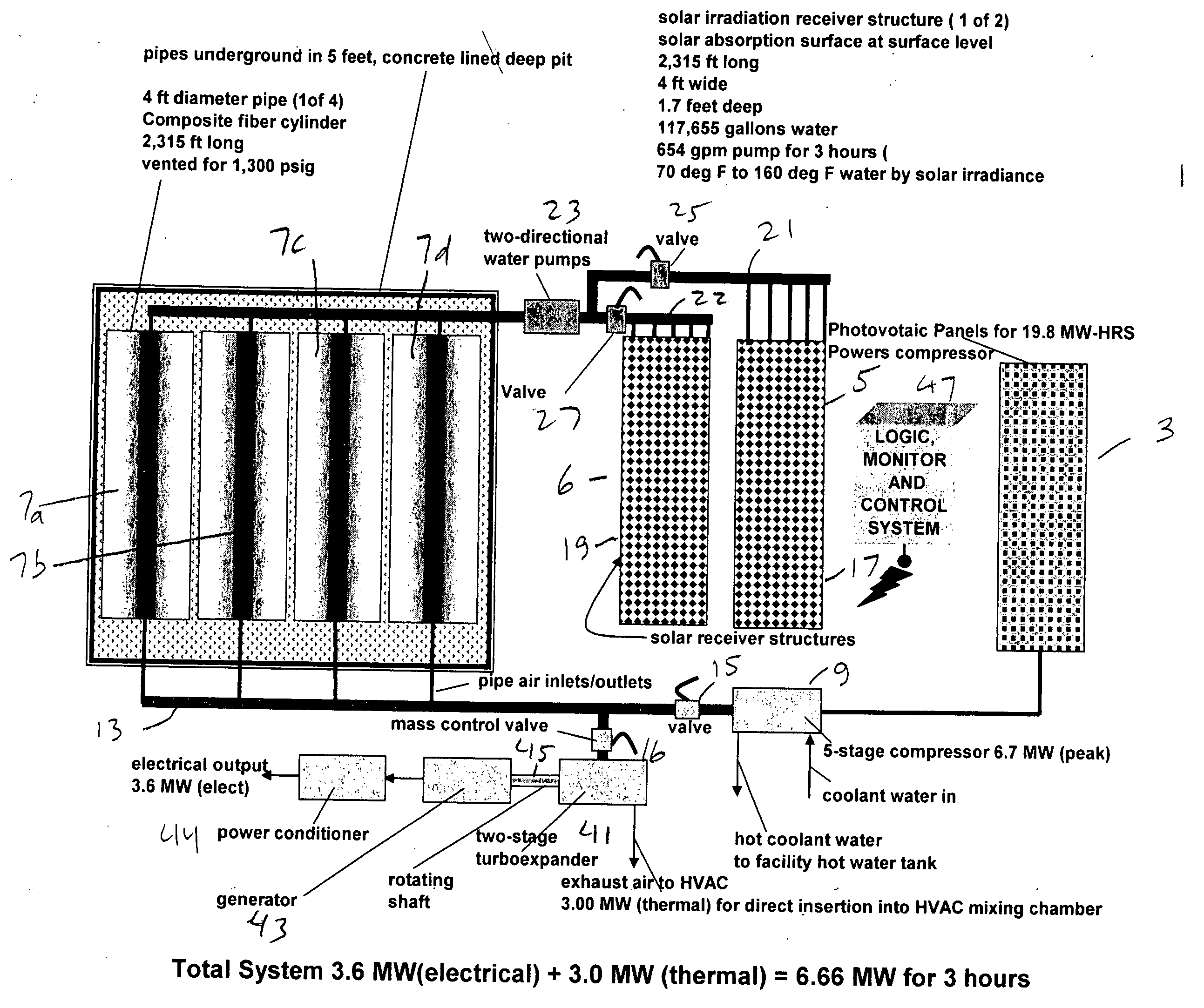

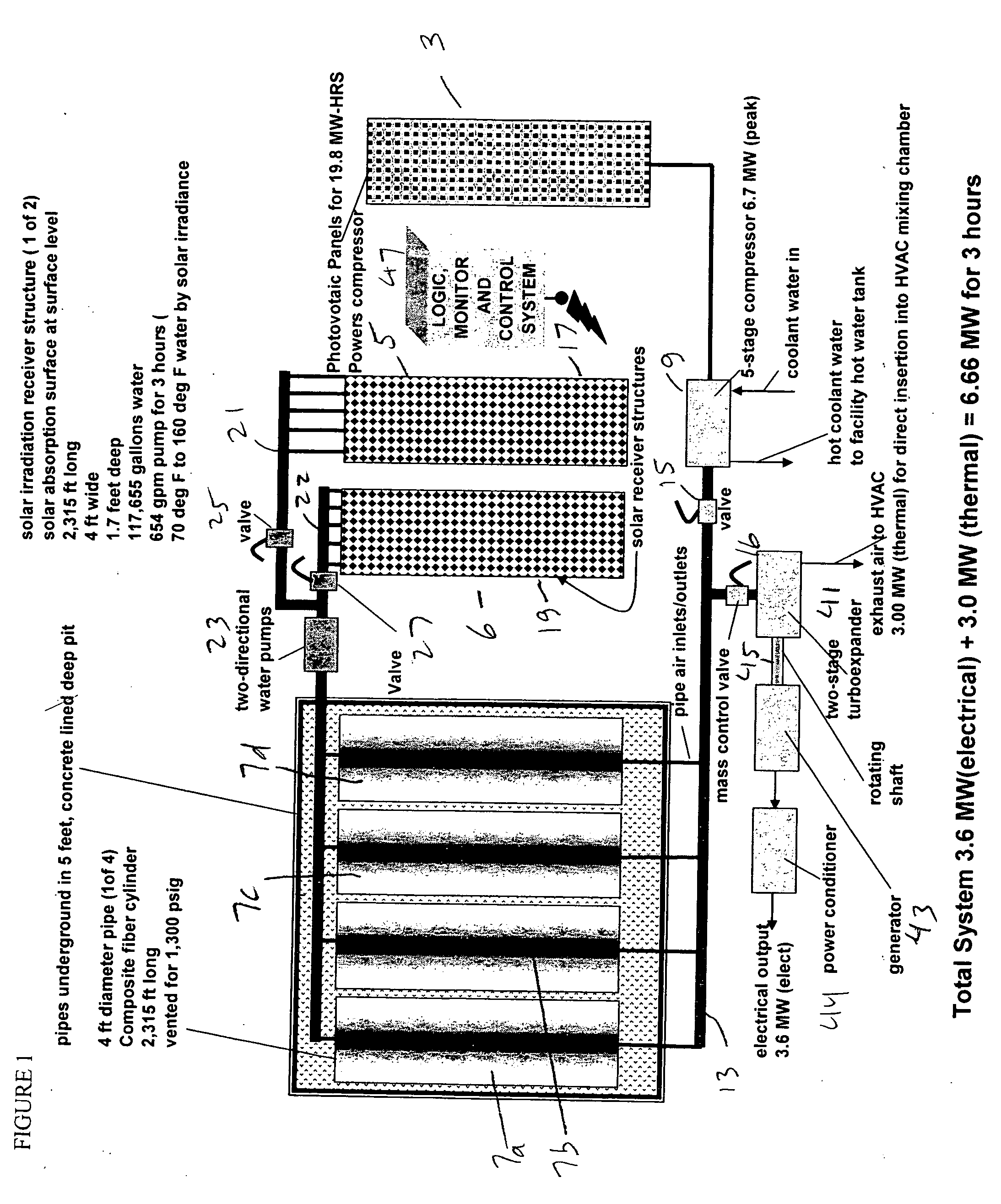

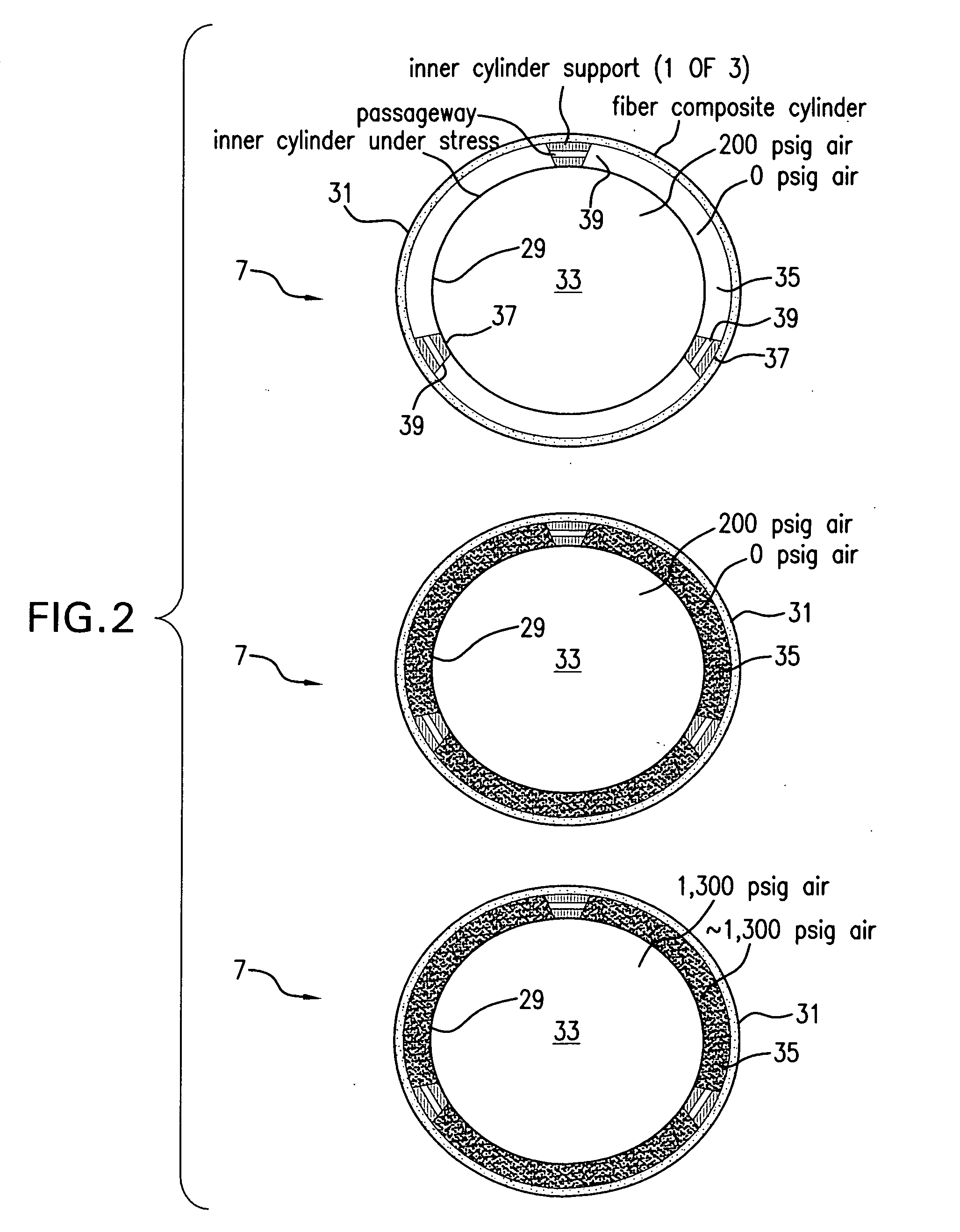

Method and apparatus for using solar energy to enhance the operation of a compressed air energy storage system

ActiveUS20090230696A1Reduce inconsistencyReduce inefficienciesSolar heating energyAuxillary drivesThermal energy storageCogeneration

The invention relates to a method and apparatus for using solar energy to enhance the efficiency of a compressed air energy storage system (and visa-versa). The apparatus comprises a photovoltaic panel to drive a compressor, which provides compressed air energy into an inner vessel housed within a storage tank. Two solar receiving panels are used to heat water which can be circulated and stored within an annulus surrounding the inner vessel, wherein the heated water can help regulate the temperature of the compressed air within the tank. This way, when air is released using a turbo expander, any excess temperature drops that can otherwise result from air expansion can be avoided. The overall system efficiency is enhanced by the chilled air by-product of the turbo expander which is used to generate more electrical power from an associated fuel-driven generator set, and / or by the waste heat from the compressor and from the generator set exhaust which is used in a Combined Heat and Power system (CHP) to power either a steam-driven generator set or an absorption chiller.

Owner:ENIS BEN M +1

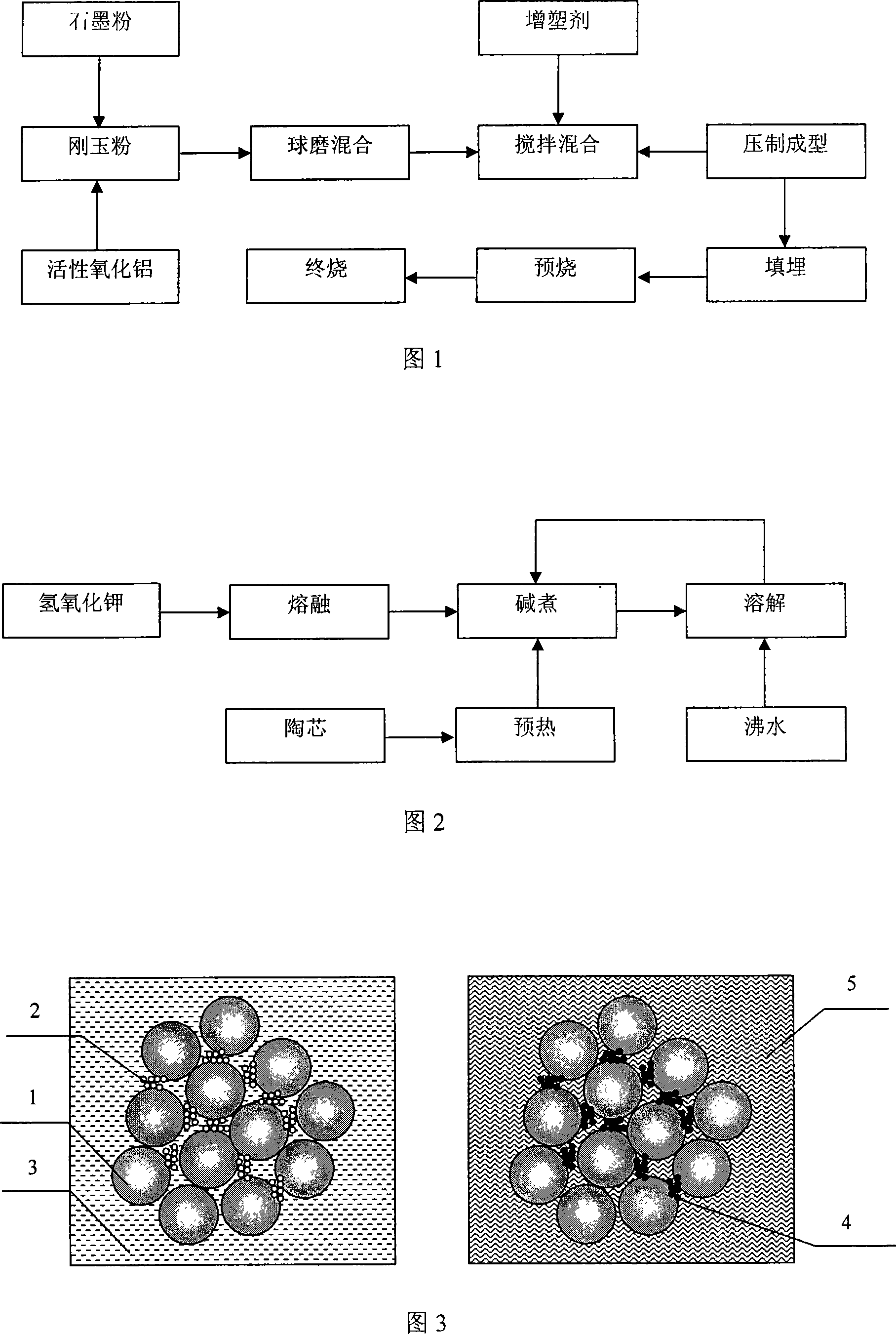

Method for making alumina ceramic core and core leach method

The invention discloses a method for manufacturing alumina ceramic cores, which adopts sintering of solid phase reaction, comprising two sintering methods of pre-sintering and final sintering; sintering temperature decreases to 1,350 to 1,500 DEG C from more than 1,500 DEG C in the prior art and creep resistance of high temperature is favorable. The invention also discloses a method for leaching the alumina ceramic cores. As in the process of the manufacture of the alumina ceramic cores, a volatile pore forming agent is adopted so that the forming alumina ceramic cores have relatively high porosity; in core leaching, melting alkali can reach the internal part of the alumina ceramic cores so as to integrally disperse the alumina ceramic cores. In the invention, a boiling water process and a repeated alkali cooking-dissolving- alkali cooking method are adopted, thus accelerating permeation, reaction and dissolving of the melting alkali to the internal part of the ceramic cores; the core leaching speed decreases to 10 to 16 hours from 25 to 30 hours in the prior art and the core leaching speed is accelerated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

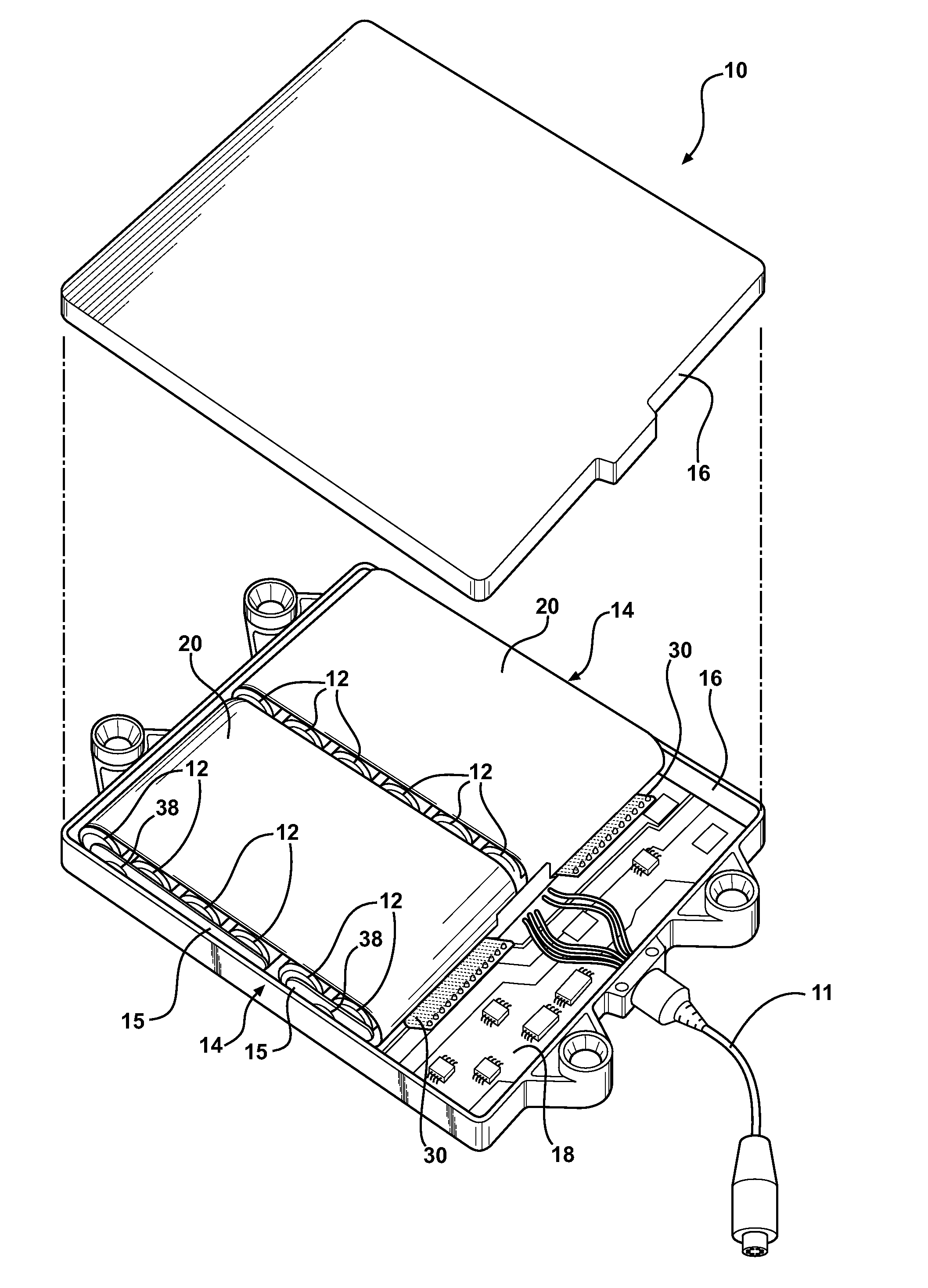

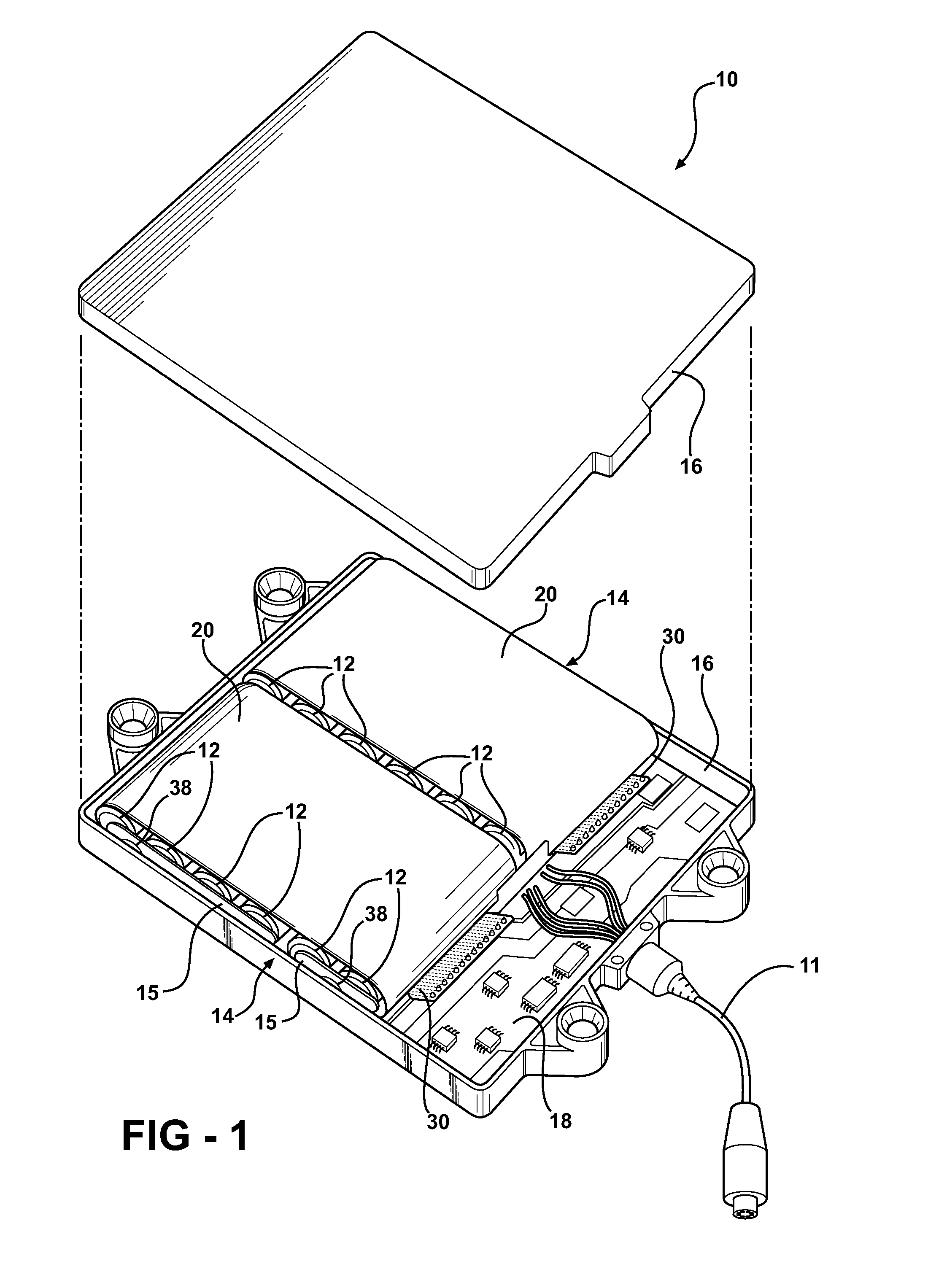

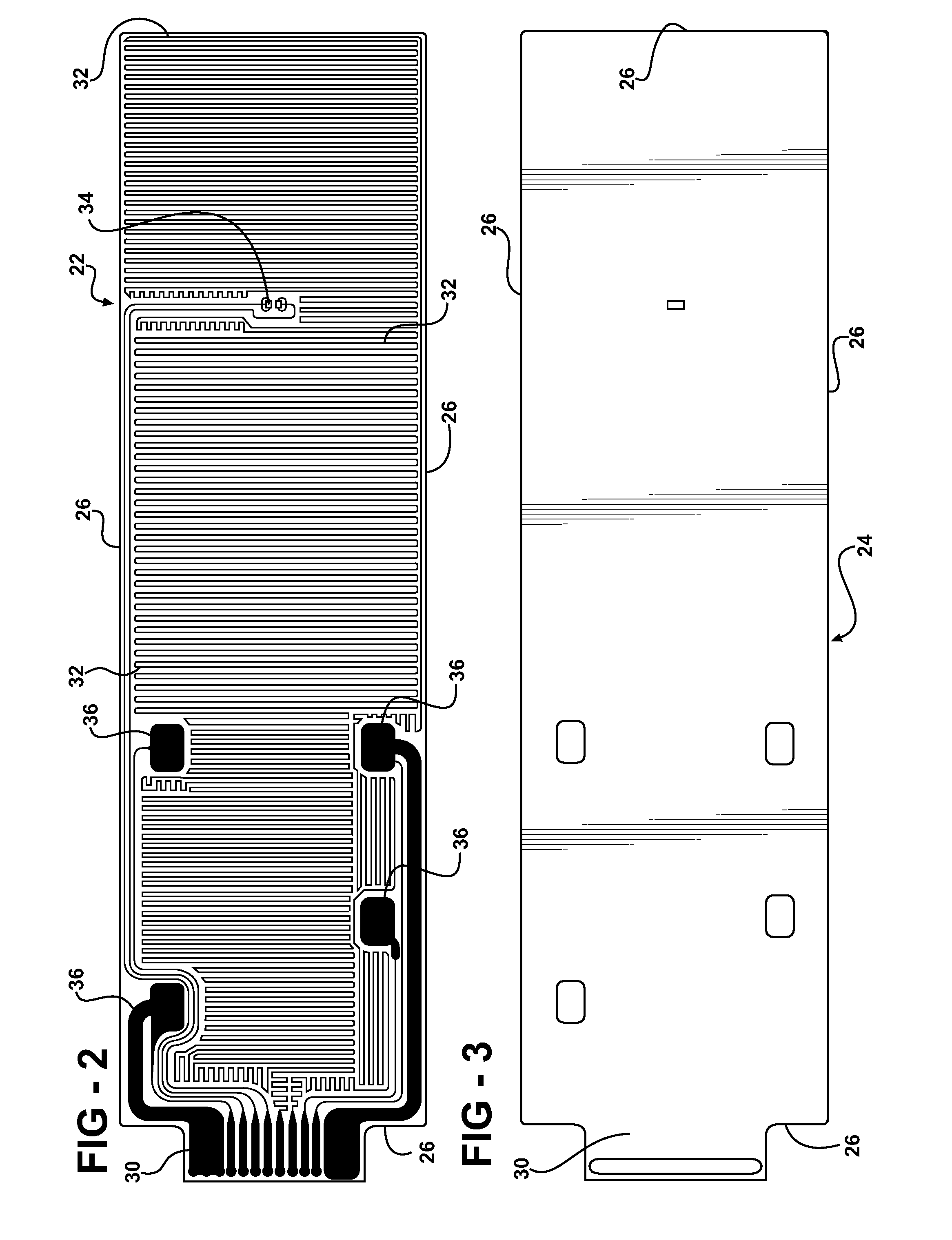

Battery pack assembly with integrated heater

InactiveUS20080226969A1Excellent battery pack performanceSaving reliability of assemblyCell temperature controlHeater elementsLithiumElectric power system

A battery pack assembly for providing electric power to a load includes a battery pack, preferably made up of a plurality of lithium ion cells. A heating device formed of a flexible material flexes and covers at least part of the battery pack. The heating device includes a meandering heating strip. A thermal sensor is surrounded by the heating strip to sense the temperature of the battery pack. Electric current is applied to the heating strip to heat the battery pack when its temperature falls too low, thus improving performance of the battery pack. The heating device also includes a plurality of tabs extending beyond the peripheral sides of the heating device for direct connection to the cells. Thus, electric current for the heating strip is provided directly from the cells of the battery pack.

Owner:ENERDEL

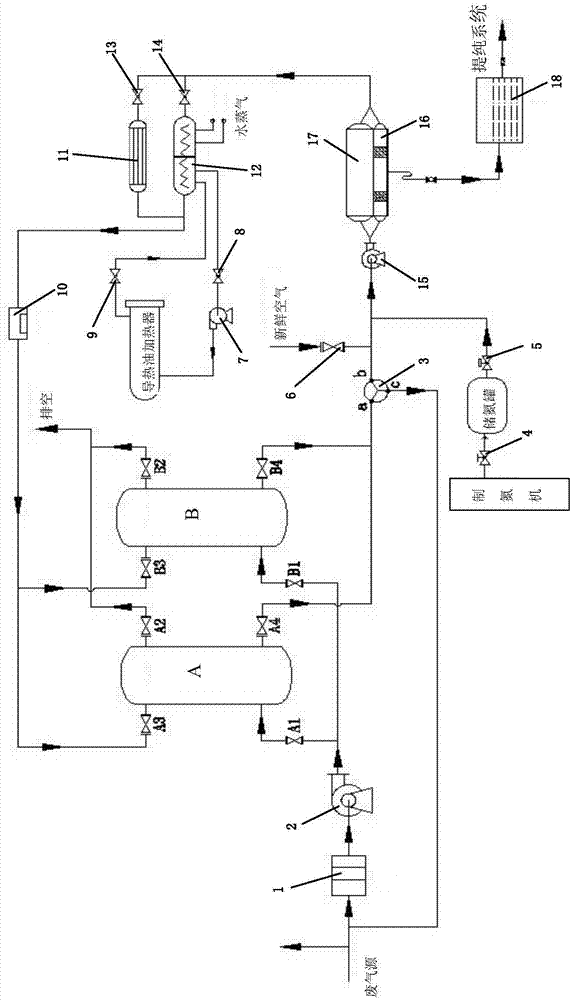

Technology for recovering and processing organic exhaust gas by activated carbon adsorption and N2 desorption

ActiveCN103585854AOvercome the limitations of large investmentPure qualityDispersed particle filtrationActivated carbonOrganic solvent

The invention provides a technology for recovering and processing organic exhaust gas by activated carbon adsorption and N2 desorption. The technology comprises the following steps: organic exhaust gas is pretreated by a coil-cooling filter; the organic exhaust gas which has been pretreated is then sent into a first activated carbon adsorption tank for adsorption; after adsorption of the first activated carbon adsorption tank, the system enters a desorption stage, and a second activated carbon adsorption tank enters an adsorption stage; the desorbed organic exhaust gas is condensed and then recovered, and after desorption of the system, the first activated carbon adsorption tank is cooled to a certain temperature, and back-purging is conducted on the first activated carbon adsorption tank, and the temperature drops to normal temperature after back-purging so as to use the exhaust gas in the next circulation; and the first activated carbon adsorption tank and the second activated carbon adsorption tank recycle and alternate the above steps. By the adoption of the technology, secondary pollution will not be caused; energy consumption is low; and the quality of recovered organic solvents is pure.

Owner:GARDEN ENVIRONMENTAL PROTECTION

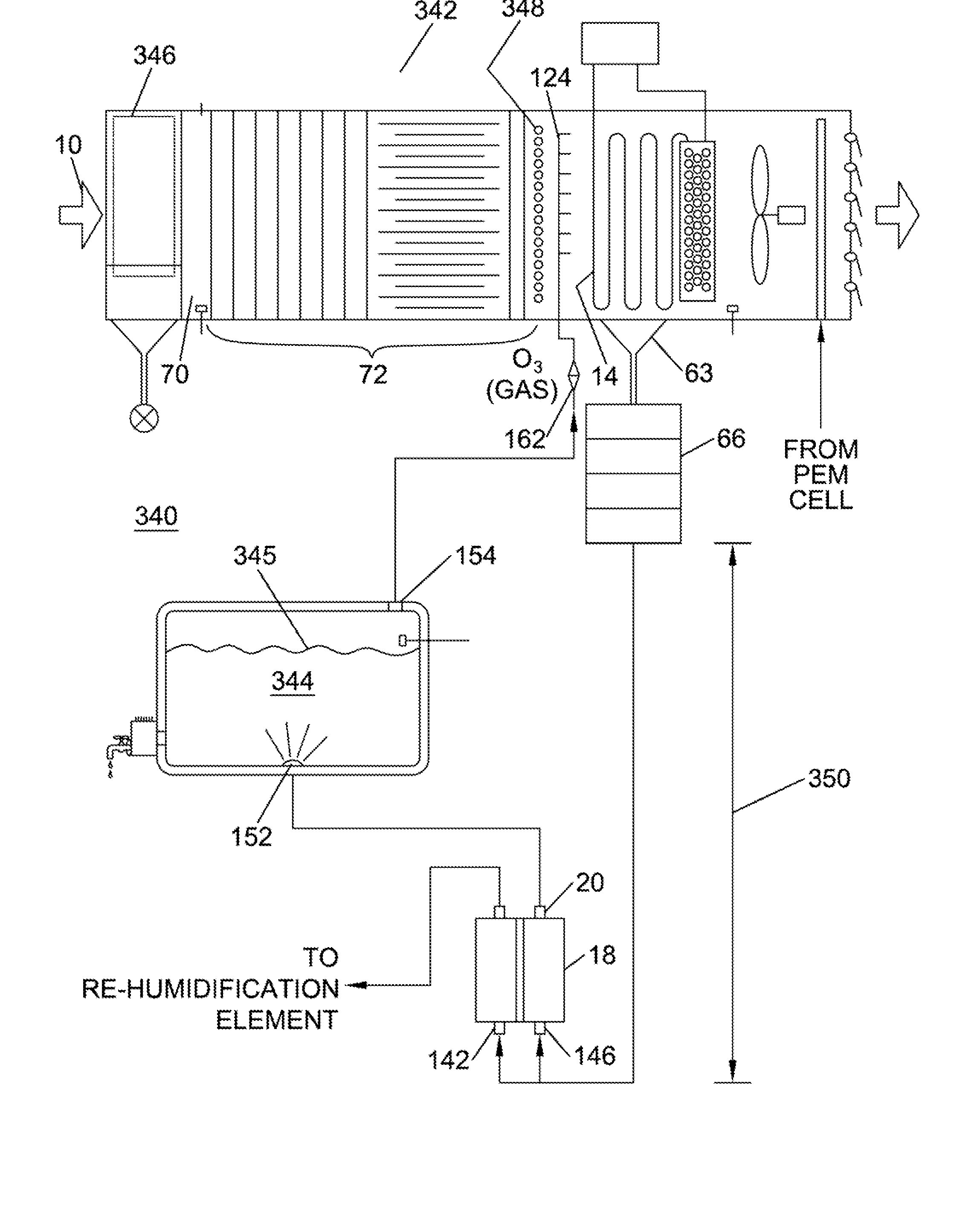

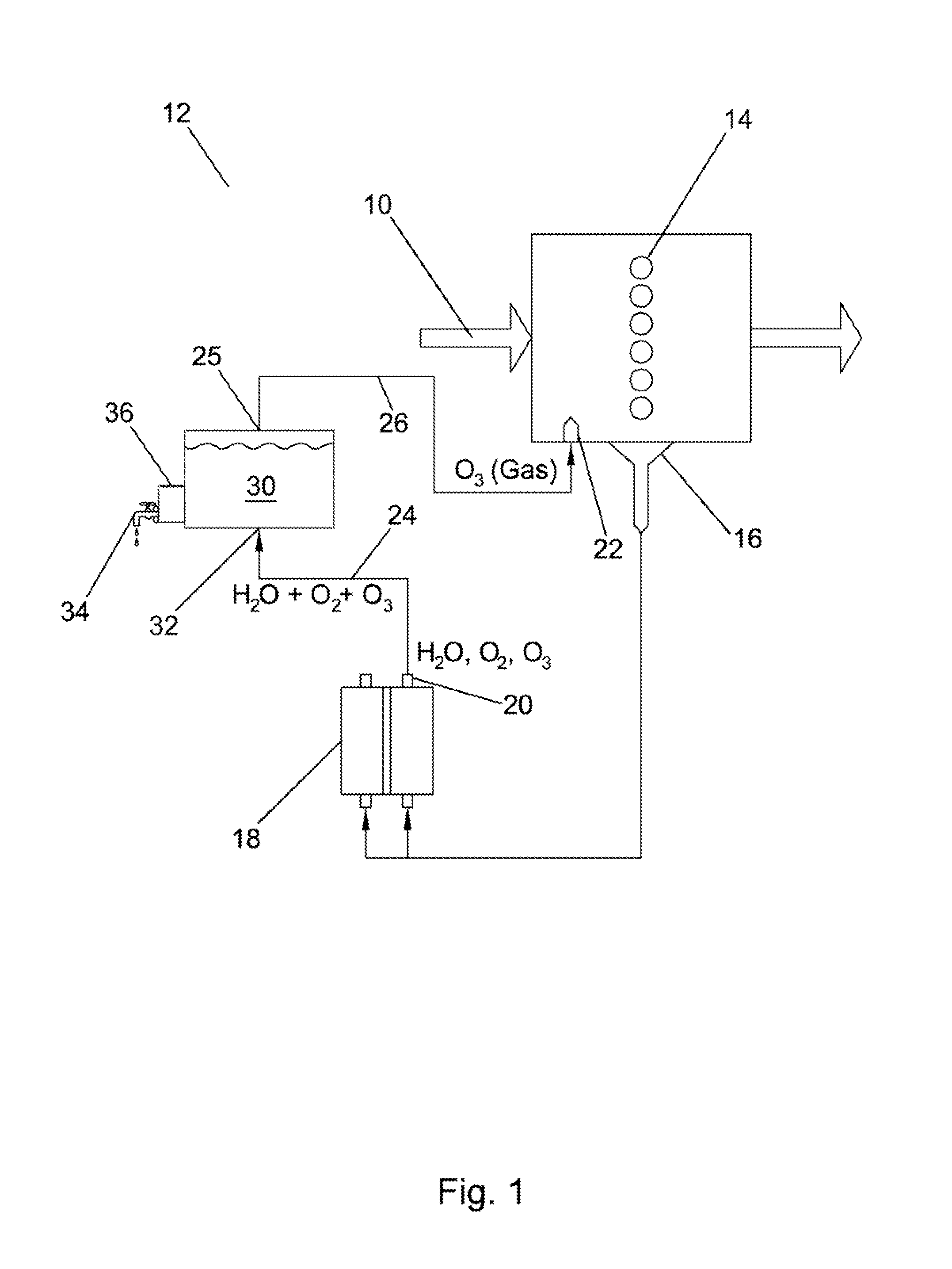

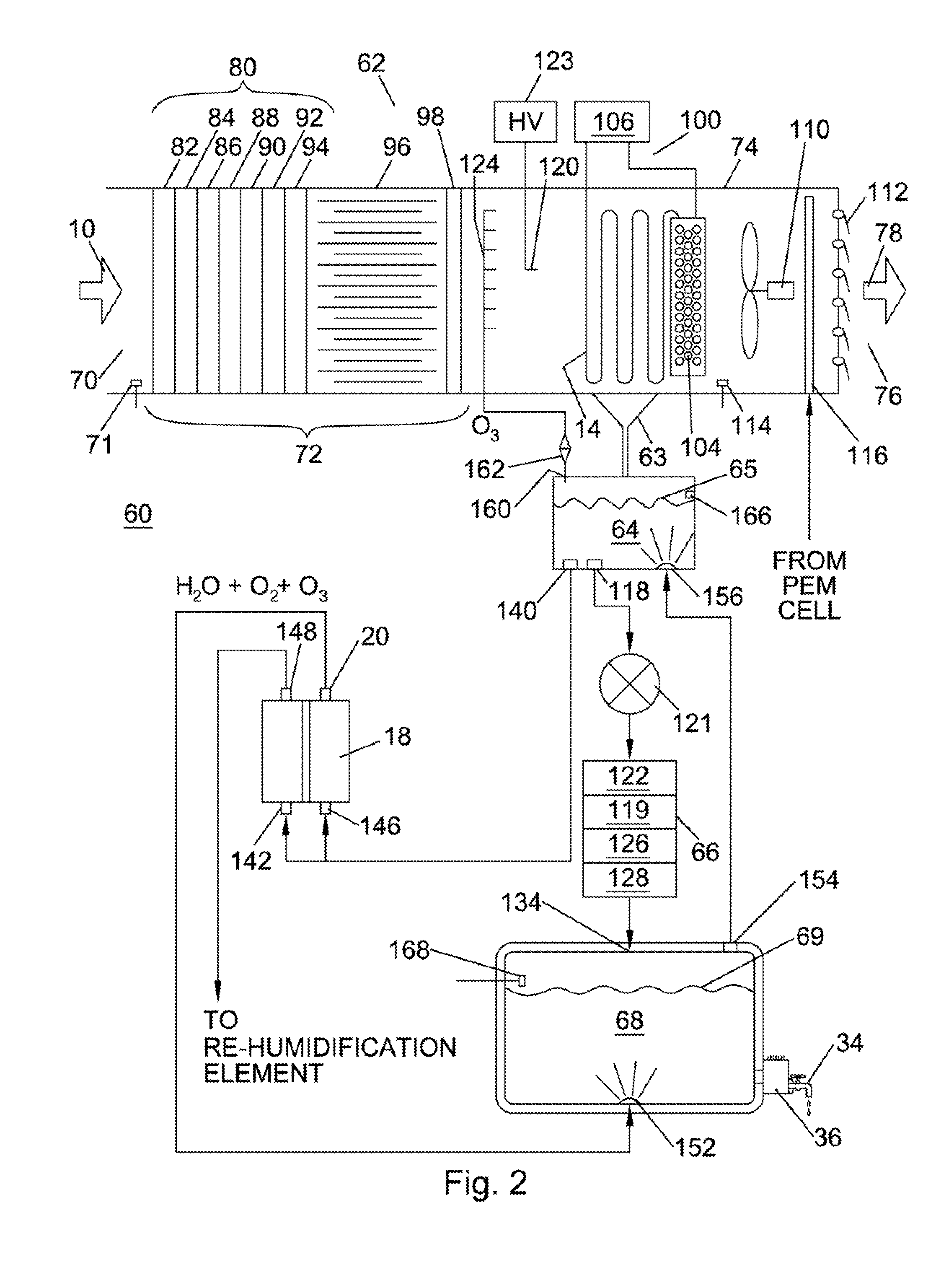

Apparatus and Method For Generating Water From an Air Stream

InactiveUS20070295021A1Fuel cell combinationsLighting and heating apparatusOzone generatorEnvironmental engineering

An apparatus and method for generating water from an air stream is disclosed. The apparatus has an inlet for receiving an air stream, a condensing element located in the air stream, a collector for gathering water vapor condensate that is formed on the condensing element when the condensing element temperature drops below the dew point temperature of the ambient air stream, and an ozone generator that precisely generates ozone required to disinfect the water vapor condensate. In some embodiments of the invention, the ozone is also added to the air stream for disinfecting the air stream and associated elements of the apparatus.

Owner:CONVERGITECH

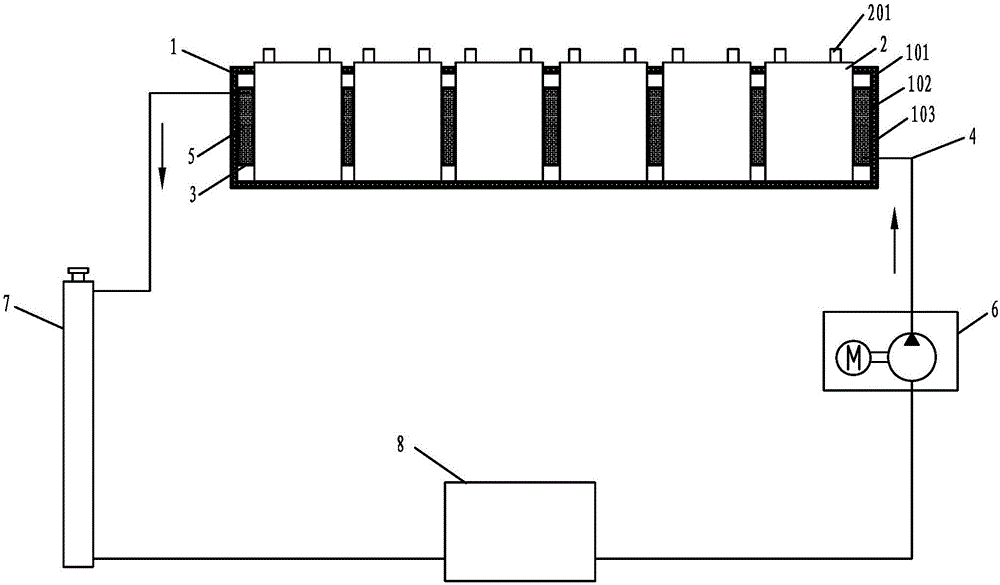

Temperature drop and extinguishment liquid cooling device, monitoring system and monitoring method for thermal runaway of power battery

PendingCN106816668AEnsure safetyGuaranteed reliabilitySecondary cellsVehicular energy storageElectrical batteryEngineering

The invention relates to a temperature drop and extinguishment liquid cooling device, a monitoring system and a monitoring method for thermal runaway of a power battery. The liquid cooling device comprises a plurality of liquid cooling units, wherein each liquid cooling unit comprises a liquid cooling unit body and a coolant in the liquid cooling unit body; the liquid cooling unit bodies are prepared from high-temperature fusible materials, and tightly bound with the surfaces of corresponding single batteries by respective matched structures; when thermal runaway temperatures of the single batteries exceed fusion points of the high-temperature fusible materials, the liquid cooling unit bodies are fused and then the coolants in the liquid cooling unit bodies enter a battery pack to perform temperature drop cooling or extinguishment on the single batteries. The temperature drop and extinguishment liquid cooling device for the thermal runaway of the power battery is simple in structure, and lower in cost, can effectively monitor and treat the thermal runaway of the power battery of an electromobile, eliminates a potential safety hazard in first time, and ensures the safety and the reliability of an electromobile system.

Owner:BEIJING HANGSHENG NEW ENERGY TECH CO LTD

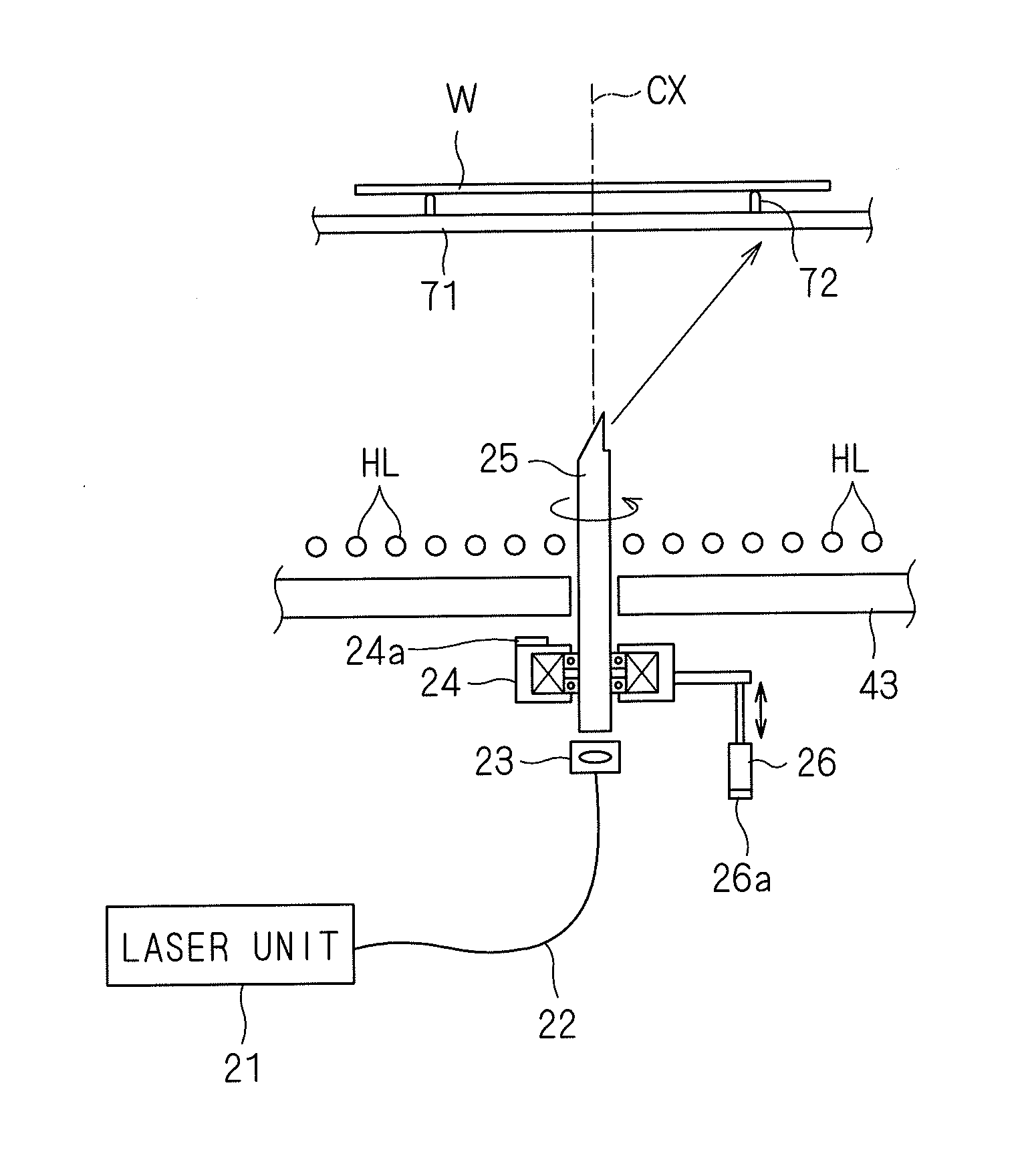

Heat treatment apparatus for heating substrate by light irradiation

ActiveUS20130248504A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesInfraredLight irradiation

The temperature of a semiconductor wafer is raised by light irradiation heating performed by halogen lamps. An infrared ray emitted from the semiconductor wafer whose temperature has been raised transmits through an infrared-transparent window made of silicon, and then is detected by an infrared camera. The infrared camera two-dimensionally detects the temperature of an entire surface of the semiconductor wafer. Based on a result of the detection obtained by the infrared camera, a temperature drop region having a relatively low temperature among the region of the semiconductor wafer is irradiated with laser light emitted from a laser light emission part. Accordingly, without rotating the semiconductor wafer, a temperature distribution can be made uniform with a high accuracy throughout the entire surface of the semiconductor wafer.

Owner:DAINIPPON SCREEN MTG CO LTD

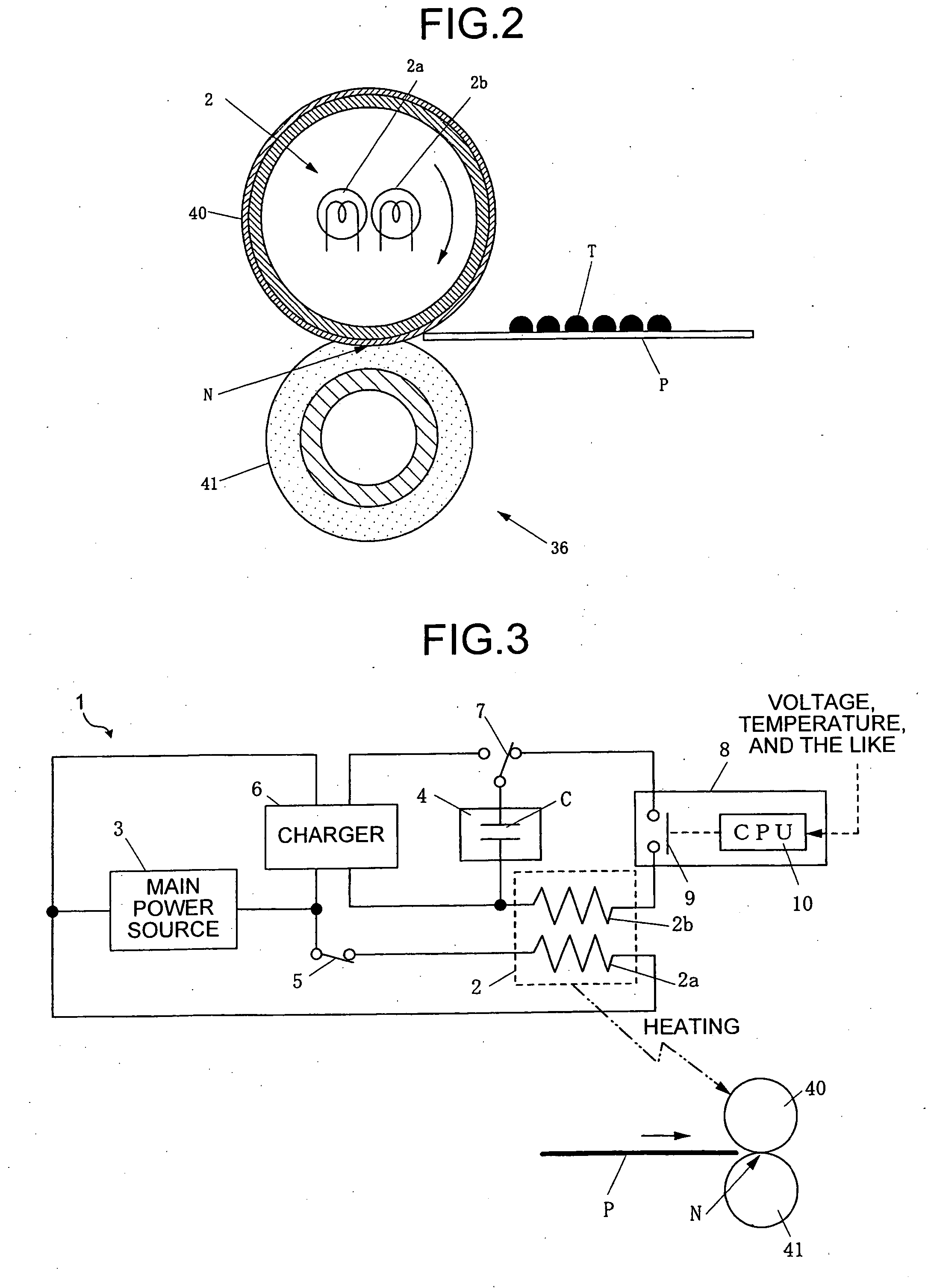

Image forming apparatus

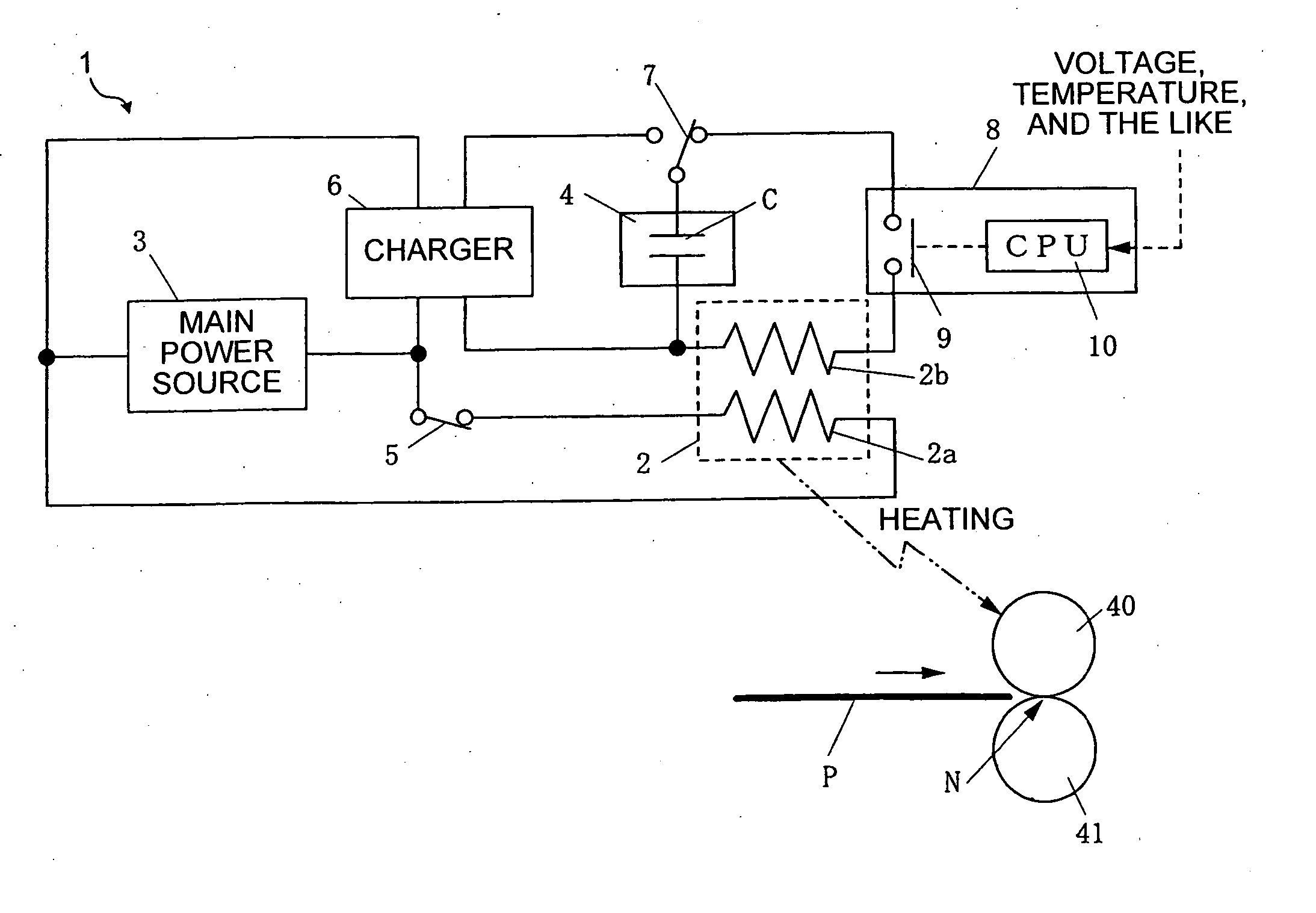

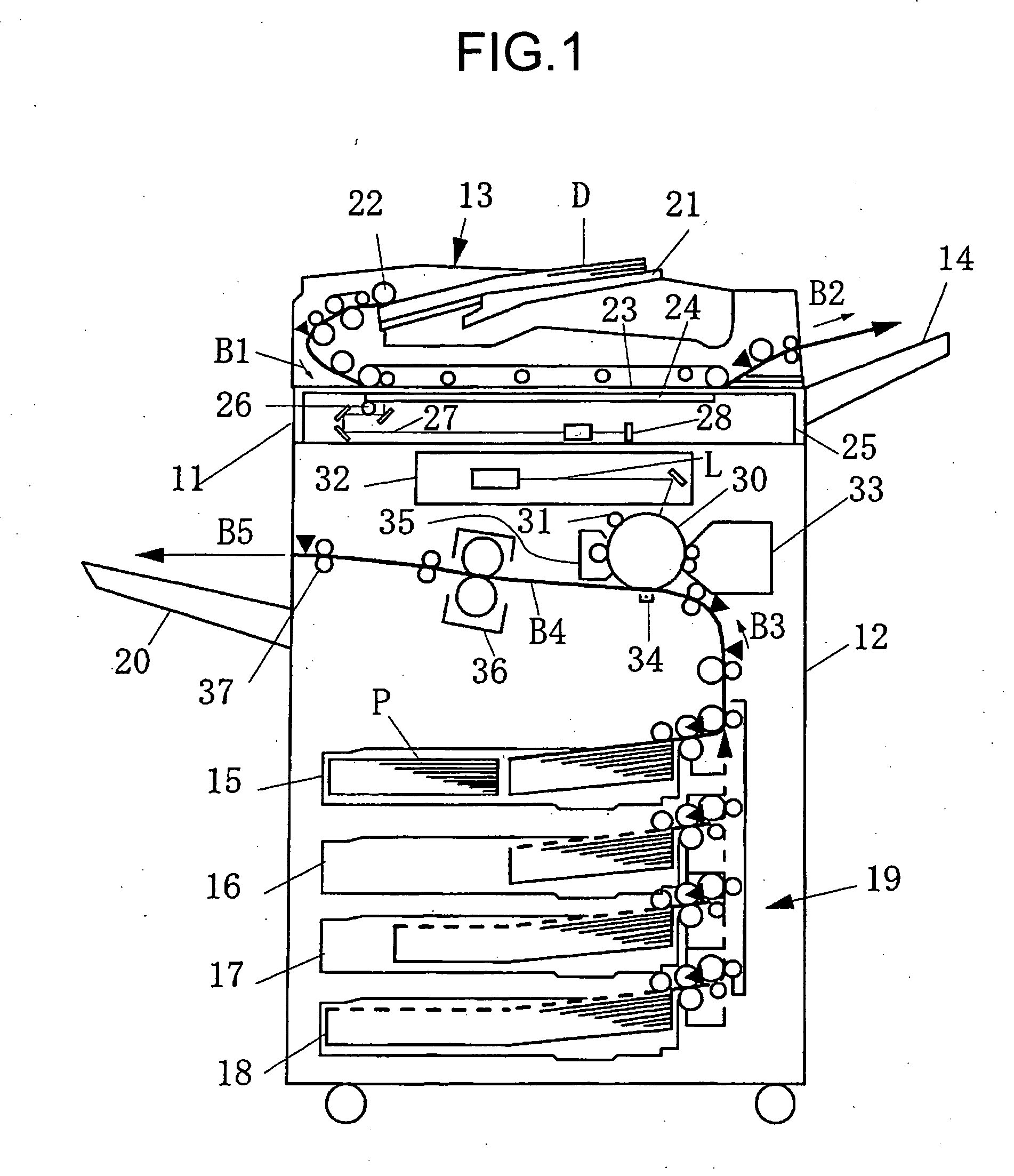

Power is supplied from a capacitor of an auxiliary power source to a secondary heating element of a heating unit, thereby preventing temperature drop of a fixing roller at the time of continuous paper delivery. An allowable range for starting discharge from the capacitor is set to, for example, 30 to 40 volts. A discharge time in which the voltage of the capacitor reduces to a termination value, such as 20 volts, is longer than a time necessary for a reading unit to read a maximum number (for example, 100 sheets) of documents that can be read at one time.

Owner:RICOH KK

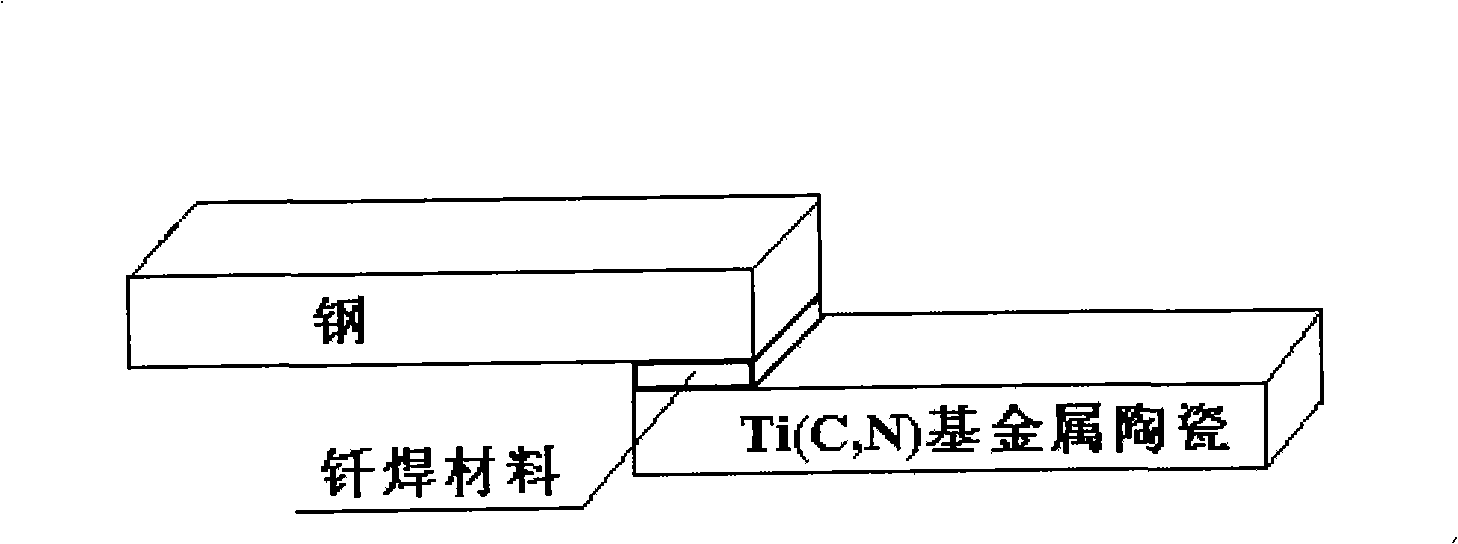

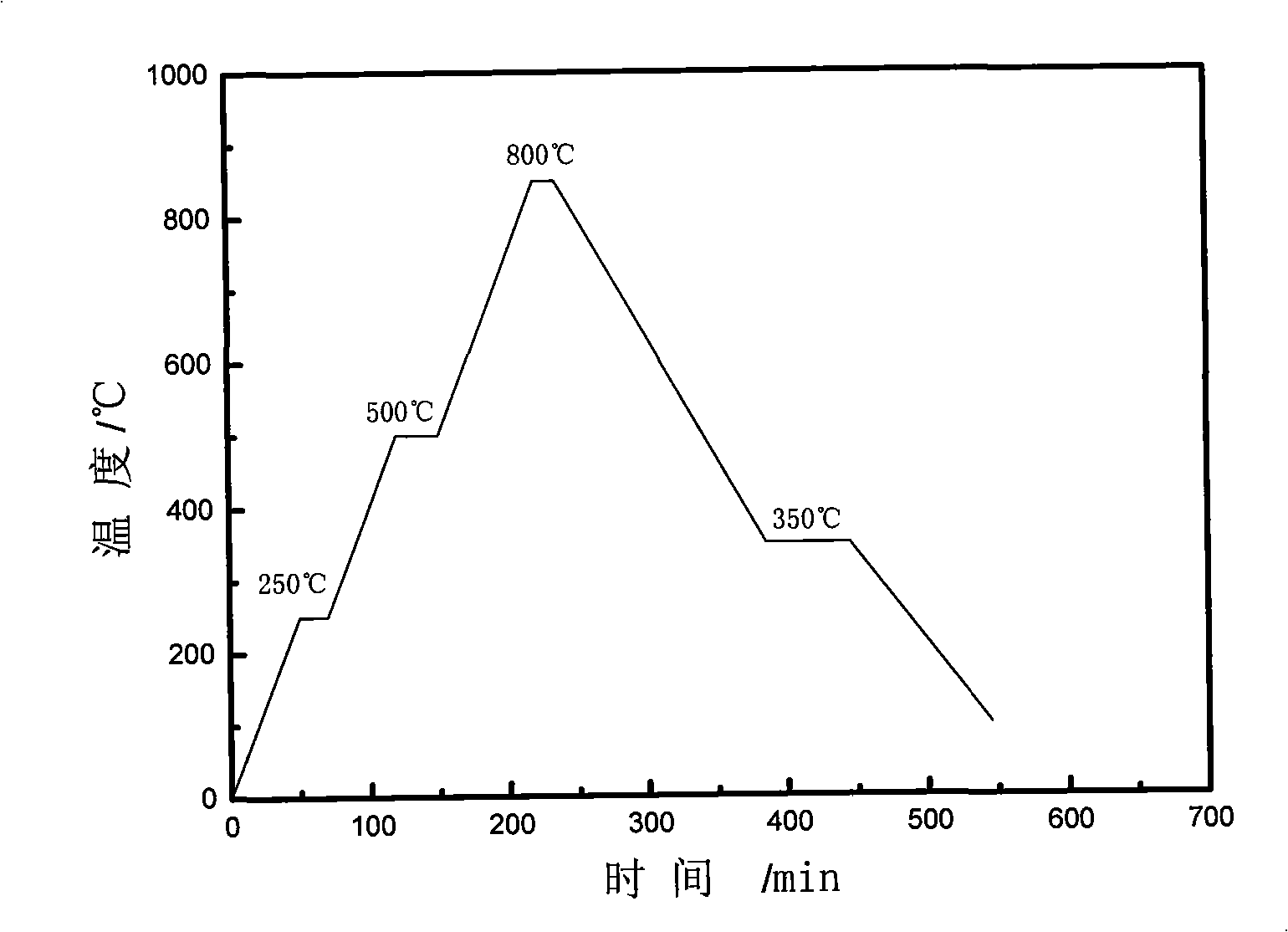

Brazing material and preparation method thereof as well as brazing method using the material

InactiveCN101327551AFirmly connectedIncreased shear strengthWelding/cutting media/materialsSoldering mediaRoom temperatureWorking temperature

The present invention relates to a soldering material, a preparation method thereof and a soldering method with the soldering material, which belong to the preparation methods and applications of soldering materials. The present invention resolves the problem that the connection strength and the working temperature are low after the prior Ti(C, N)-based cermet is connected with a metal, thus realizing the firm connection between the Ti(C, N)-based cermet and steel, and ensures that the joint has good connection strength and a high working temperature. The mass percentage of the ingredients of the soldering material of the present invention is as follows: 40 percent to 45 percent of Cu, 20 percent to 25 percent of Ag, 21 percent to 23 percent of Zn, 5 percent to 10 percent of Ni, 1 percent to 3 percent of Ti and 1 percent to 5 percent of Si. The preparation method includes the following steps: mixing, pressing, sintering and rolling, rolling the soldering material into a soldering material sheet. The soldering method with the soldering material includes the following steps: presoldering preparation, assembly, temperature increasing and temperature decreasing. The soldering material and the soldering method which are adopted by the present invention successfully realize the firm connection between the Ti(C, N)-based cermet and 45 steel, the maximum room-temperature shearing strength of the joint reaches 268.5MPa, and the average shearing strength reaches 240.9MPa.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com