Patents

Literature

680results about How to "Reduce temperature drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

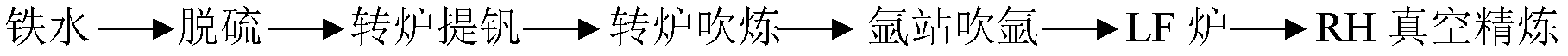

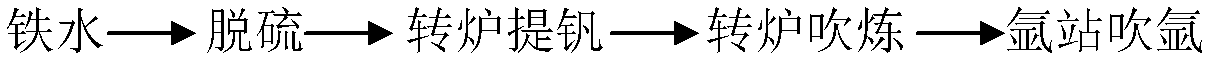

Production method of ultra low carbon steel

InactiveCN102719600AReduce the rate of oxygen blowing heating upReduce temperature dropManufacturing convertersSlagNitrogen

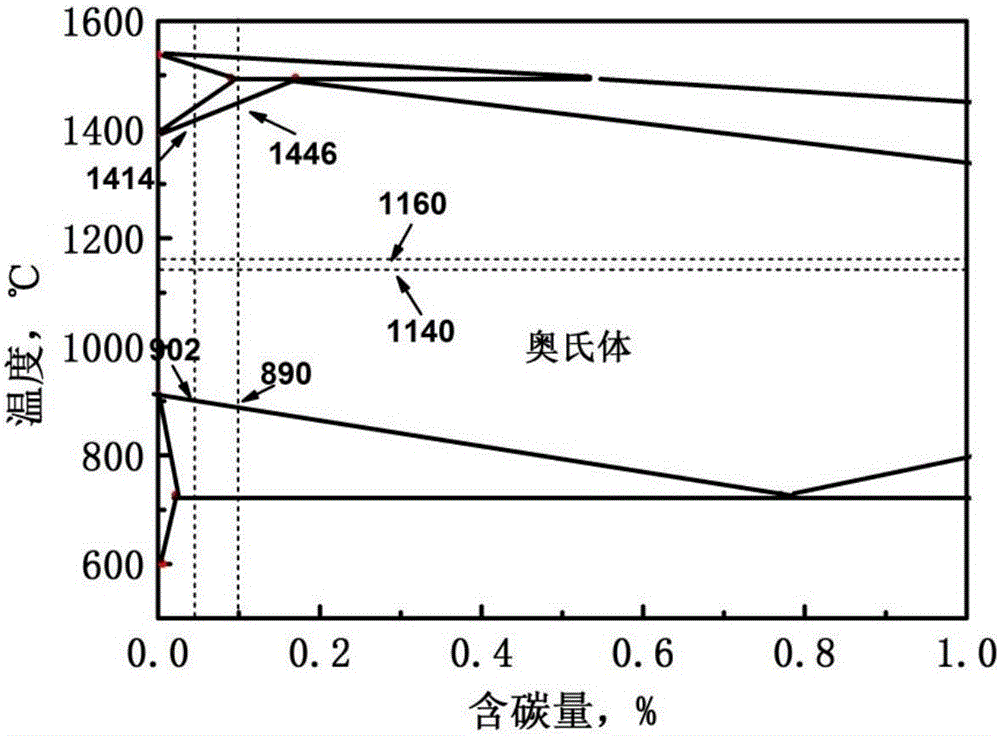

The invention provides a production method of an ultra low carbon steel. The method comprises the steps of: employing a blowing process for desulfurization and slag removal of molten iron, with control of oxygen blowing time and smelting cycle of a converter, argon bottom-blowing in the whole course, and control of S content in slag lime, [C] content at converter end point, and temperature and oxygen activity at the endpoint, adding lime in a tapping process, and modifying ladle top slag after tapping; employing natural decarburization to control carbon content in an RH, wherein Als in molten steel is less than 0.03% after deoxidation, carrying out vacuum-breaking, adding aluminum powder and top slag modifier into the top slag, blowing argon with stirring, vacuumizing again, and carrying out clean circulation for 2-10 min; and carrying out continuous casting with protective casting in the whole course, wherein a nitrogen increase amount in the molten steel is controlled at less than 2 ppm. The invention can effectively reduce temperature drop in a transmission process, reduce oxygen blowing heating rate in a subsequent RH refining treatment, save energy and shorten the time of refining. Besides, the method can effectively guarantee modification effect of the top slag, prevent nozzle clogging and realize sequence casting. Therefore, the method is particularly applicable to the production of high purity ultra low carbon steel.

Owner:ANGANG STEEL CO LTD

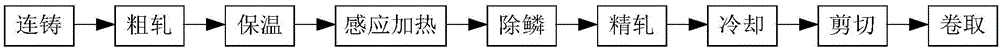

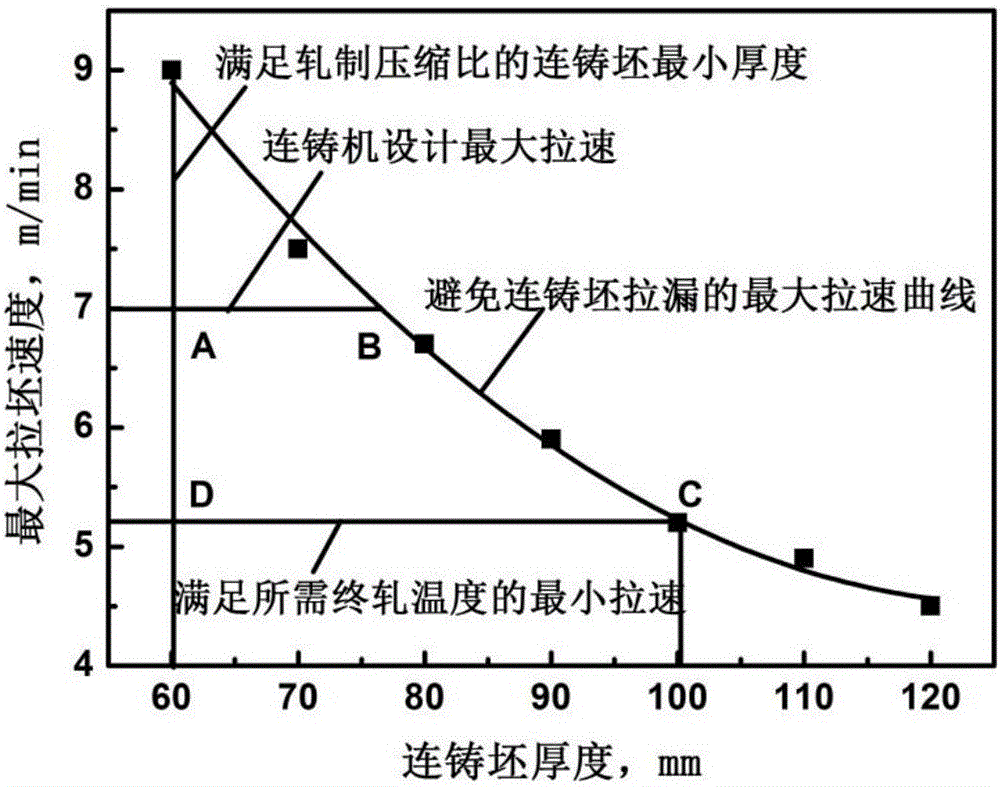

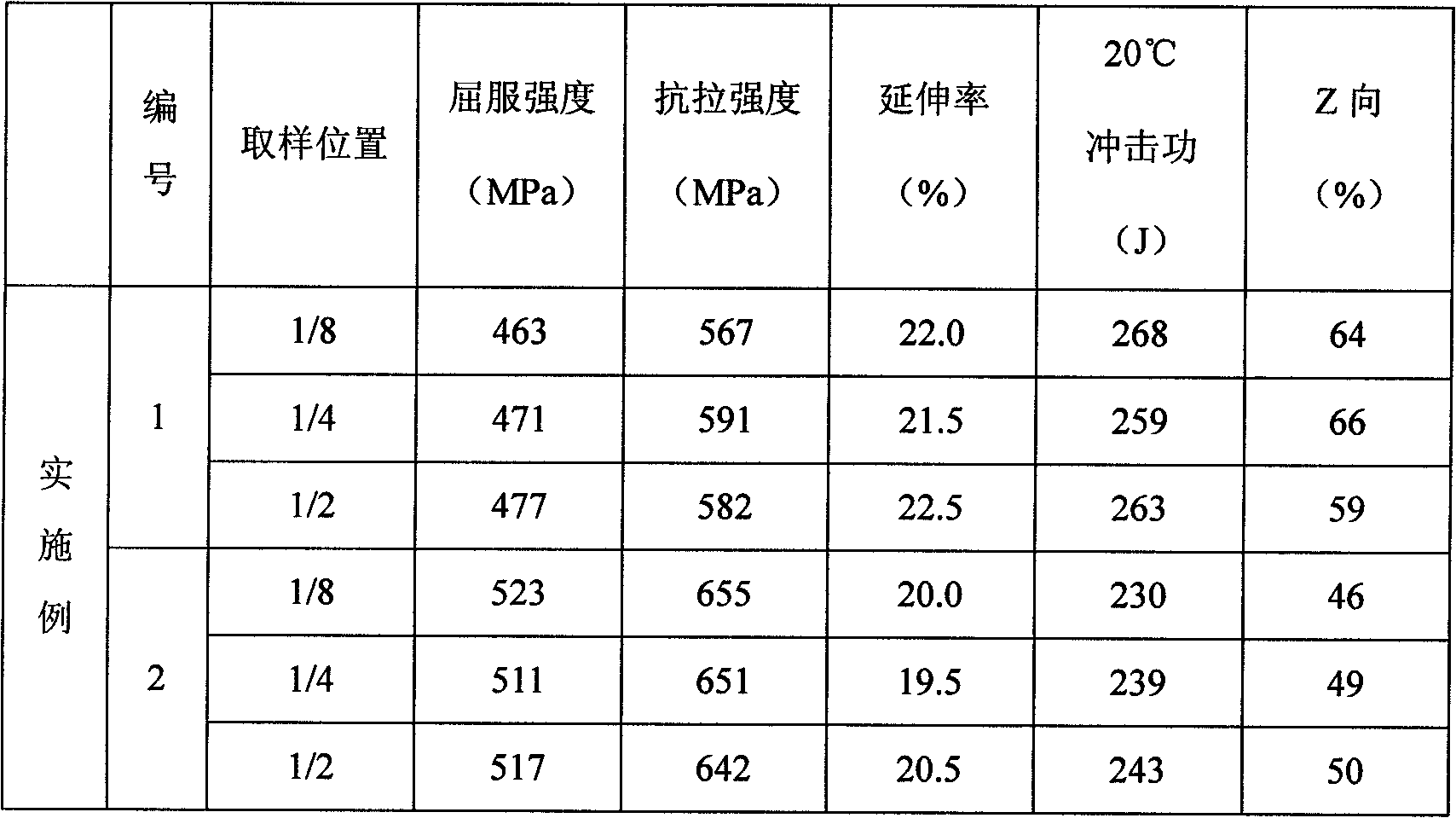

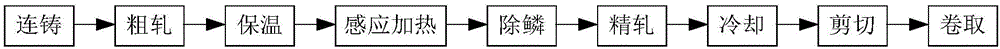

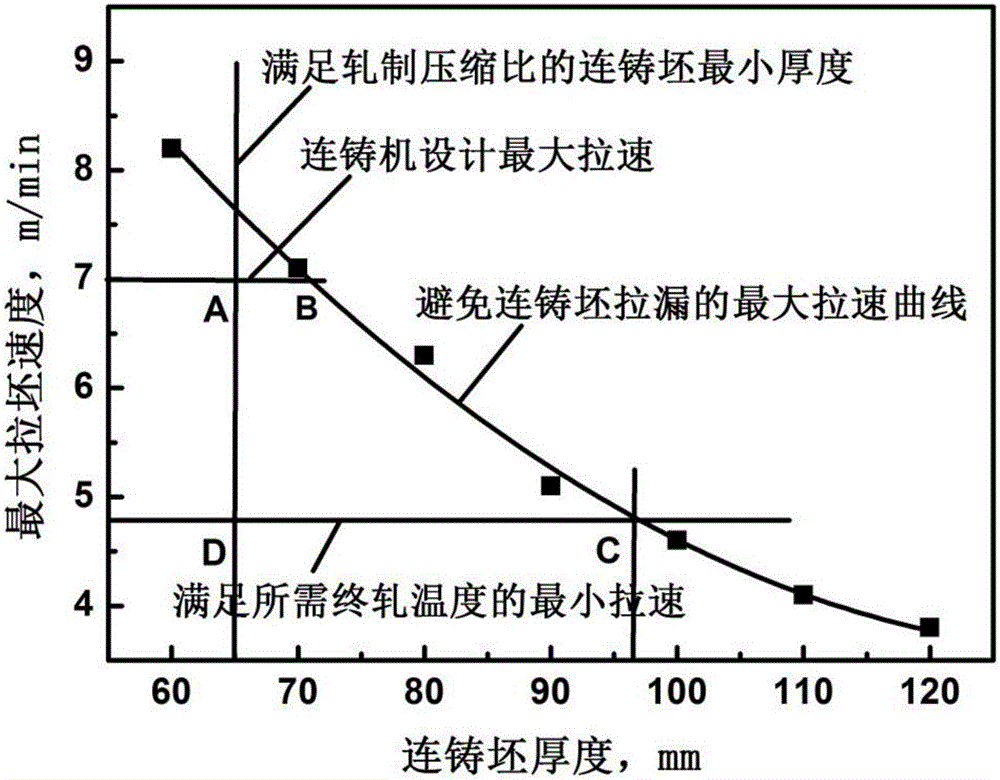

Method for producing thin-gauge dual-phase steel by applying thin slab continuous casting and rolling process

ActiveCN106734200ARealize the demand of "replacing cold with heat"Stable productionTemperature control deviceWork treatment devicesThin slabHigh pressure water

The invention relates to a method for producing thin-gauge dual-phase steel by applying a thin slab continuous casting and rolling process. The method comprises the steps: continuously casting molten steel to form a continuous casting slab with the width of 1300-1600mm and the thickness of 62-94mm; then, sequentially carrying out rough rolling, heat insulation by a heat insulation cover, induction heating, high-pressure water scale removal and finish rolling to obtain ultrathin strip steel with the width of 1300-1600mm and the thickness of 1.5-1.8mm; and finally, carrying out controlled cooling, coil-by-coil shearing and coil winding. A finished product of the thin-gauge dual-phase steel has the yield strength of 370-390MPa, the tensile strength of 590-630MPa and the elongation rate of larger than or equal to 15%. By using the method, hot-rolled thin-gauge dual-phase steel of which the size precision, slab shape precision and comprehensive mechanical property can meet requirements can be stably produced.

Owner:WISDRI ENG & RES INC LTD

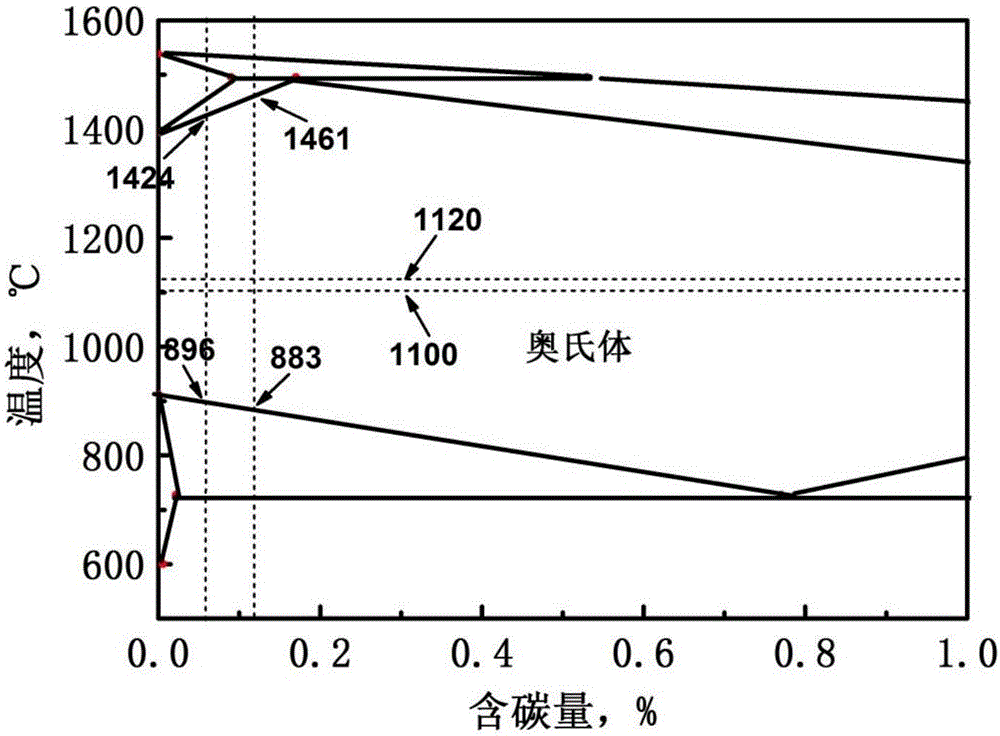

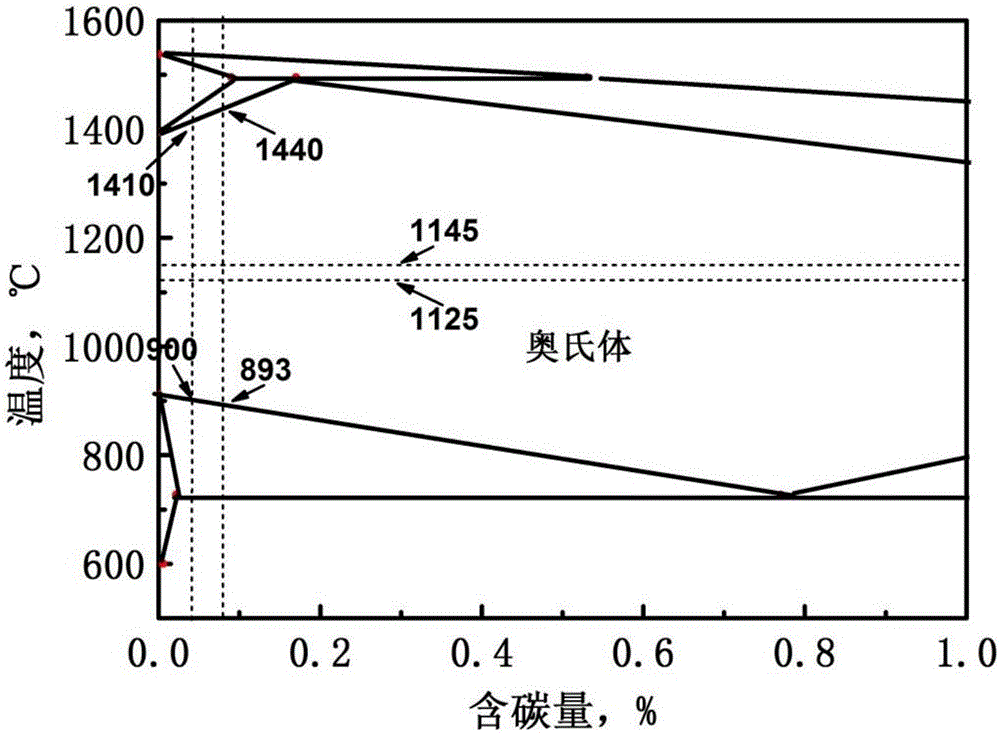

Method for producing ultrathin low-carbon steel by use of thin slab casting and rolling process

ActiveCN106583453AStable productionRealize the demand of "replacing cold with heat"Roll force/gap control deviceTemperature control deviceThin slabHigh pressure water

The invention relates to a method for producing ultrathin low-carbon steel by use of a thin slab casting and rolling process. The method comprises the following steps: continuously casting molten steel into a continuous cast billet with the width of 1,300-1,600 mm and the thickness of 60-100 mm; then sequentially conducting rough rolling, heat preservation by a heat holding cover, induction heating, high-pressure water phosphorus removal and finish rolling to obtain ultrathin strip steel with the width of 1,300-1,600 mm and the thickness of 0.8-1 mm; and finally, performing controlled cooling, roll-dividing cutting and roll take-up. A produced ultrathin low-carbon steel end product has the yield strength of 250-310 MPa, the tensile strength of 350-400 MPa and the ductility of larger than or equal to 35%. By adoption of the method, stable production of hot-rolled ultrathin low-carbon steel with the thickness of 0.8-1 mm can be realized, the dimensional accuracy, the flatness accuracy and the comprehensive mechanical property can be improved, the demand for 'replacement of cold product by hot product' is met and the production cost is lowered.

Owner:WISDRI ENG & RES INC LTD

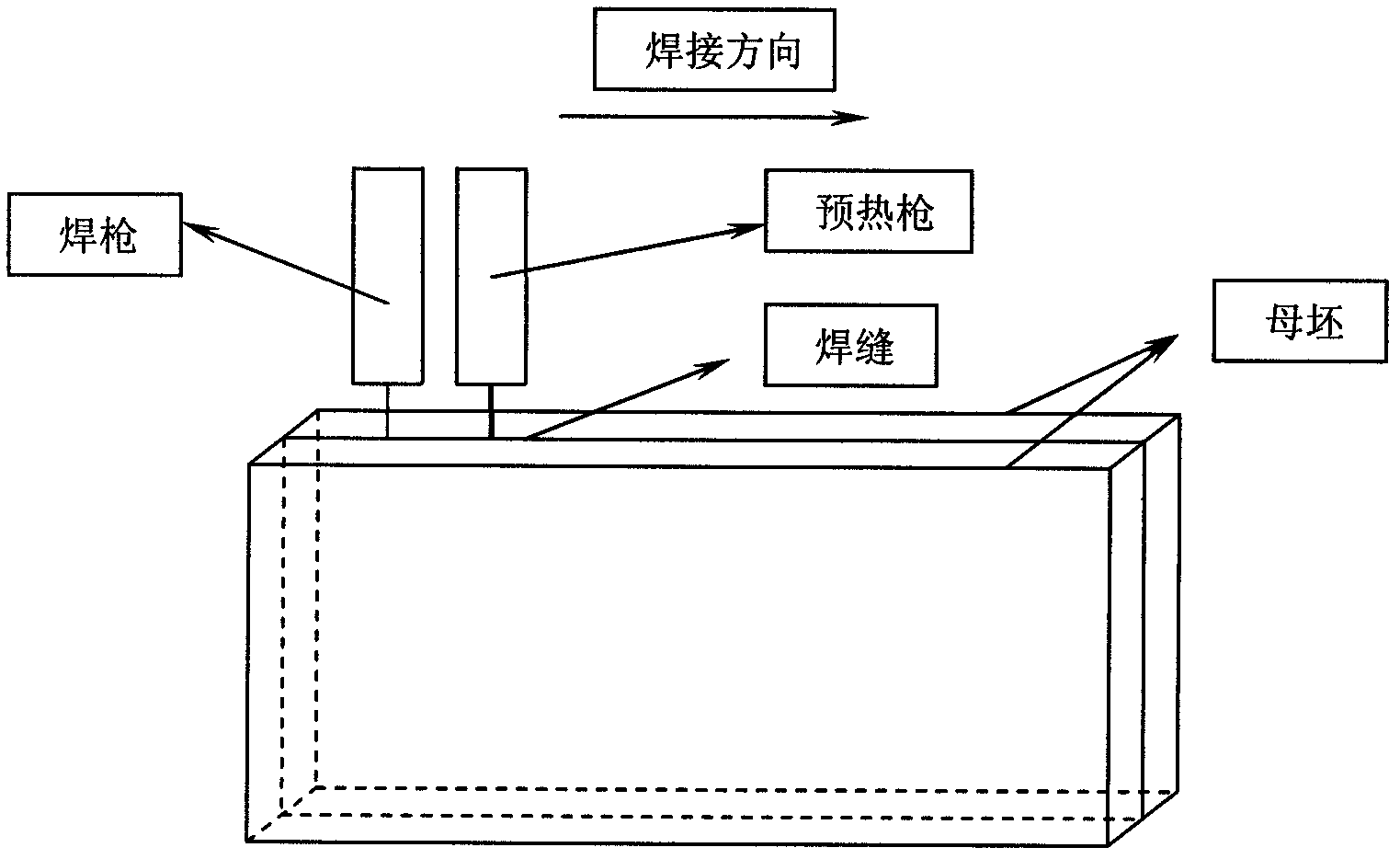

Manufacture method for cold-crack and high sensibility ultra-thick steel plate

InactiveCN103028897AWide preheating temperature rangeReduce temperature dropElectron beam welding apparatusMetal rolling arrangementsComing outSocial benefits

The invention discloses a manufacture method for a cold-crack and high sensibility ultra-thick steel plate. In a vacuum environment, a cold-crack welded sensibility steel plate with a carbon equivalent less than or equal to 0.61 percent is preheated and welded by a dual-electron-beam distribution method, and an ultra-thick steel plate is manufactured by heating and rolling. According to the manufacture method, the scope of a pre-heating temperature is wide, a temperature decrease is extremely small, no cold cracks come out on a welded ultra-thick blank, the manufacture process is simple, the working period is short, the method is suitable for industrial large-scale production, and remarkable economic and social benefits can be brought.

Owner:ANGANG STEEL CO LTD

Pure titanium two-step plastic deformation processing method

The invention relates to a pure titanium two-step plastic deformation processing method in the technical field of metallic material plastic deformation; the method comprises the following steps: level-3 industrial pure titanium block is taken as the raw material, after being coated with graphite lubricant, the material is extruded on a 300KN hydraulic pressure universal experimental machine and then is subjected to rolling treatment at liquid nitrogen temperature to carry out deformation treatment on submicron crystal industrially pure titanium block, thus obtaining the superfine crystal pure titanium. The superfine crystal pure titanium of the invention features a tensile strength of 1218MPa and a specific elongation of 12.6%.

Owner:SHANGHAI JIAO TONG UNIV

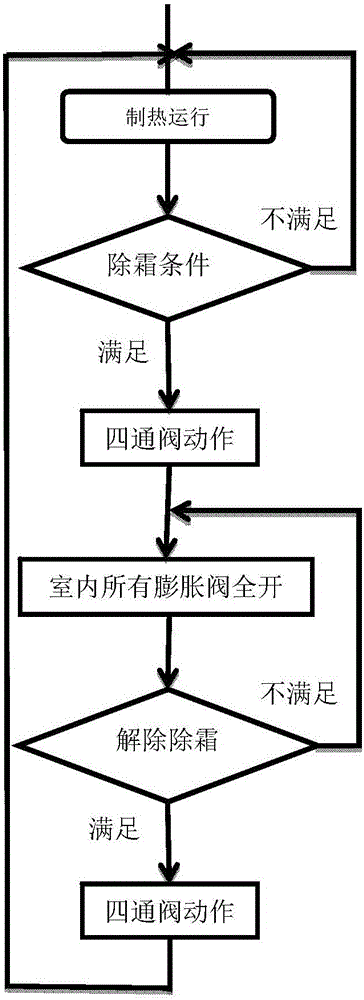

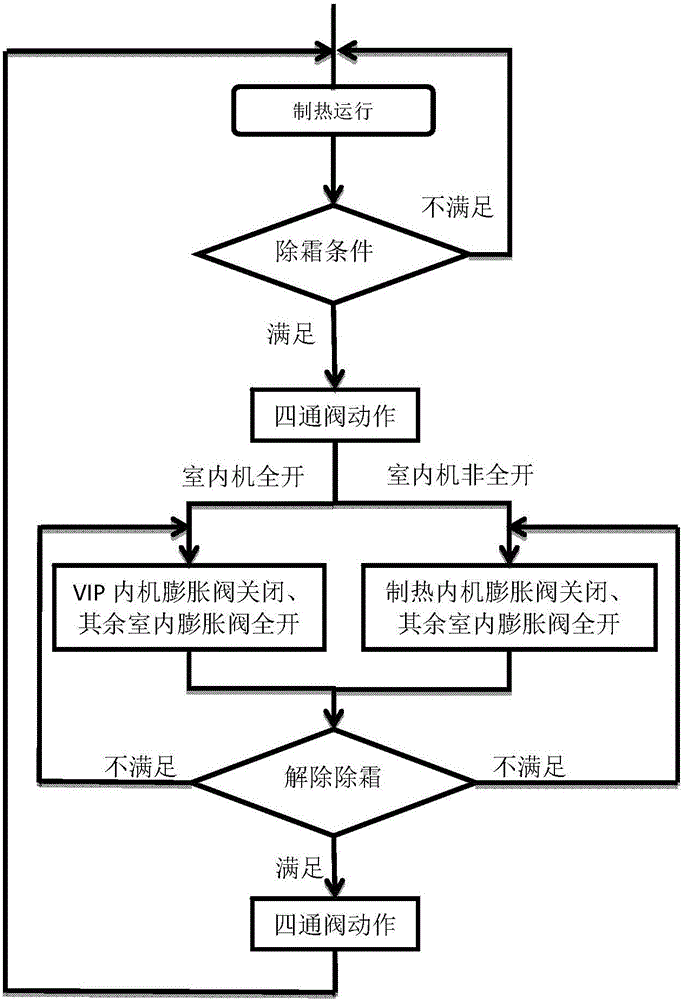

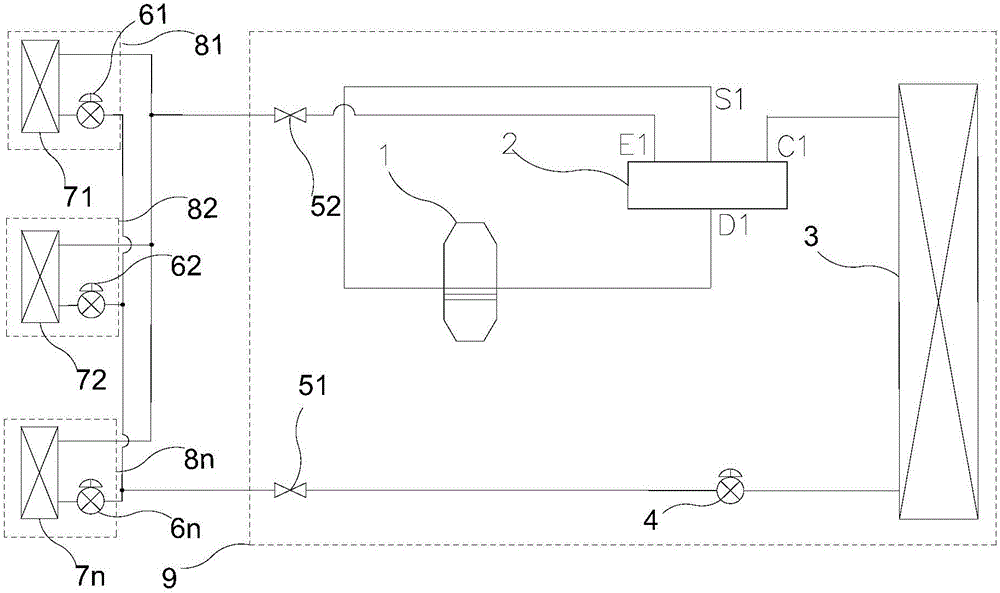

Heating-based defrost control method of multi-split air-conditioning system

ActiveCN105674648AAvoid temperature dropReduce temperature dropCorrosion preventionRefrigeration safety arrangementRefrigerantEngineering

The invention provides a heating-based defrost control method of a multi-split air-conditioning system. Each indoor machine and each outdoor machine are respectively provided with one switch valve for controlling operation of each indoor machine or each outdoor machine. The method comprises the following steps of: when the multi-split air-conditioning system is in an indoor heating operation state, judging whether a defrost condition is met or not; if the defrost condition is met, switching operation of a four-way valve so as to enable the outdoor machines to perform heating-based defrosting, and regulating to close at least one switch valve of one indoor machine needing to further heat among the multiple indoor machines; and regulating to open at least one switch valve of residual indoor machines except for the indoor machine needing to further heat. The heating-based defrost control method is capable of effectively overcoming the defects that a refrigerant of an air conditioner in the prior art inevitably absorbs away heat during a heating-based defrosting process to cause indoor temperature decrease and influence on indoor human body comfort, and reducing occurrence of a situation that temperature in a heating indoor machine room is reduced due to heat absorption of a low-temperature refrigerant for defrosting during a defrosting process to the greatest extent.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

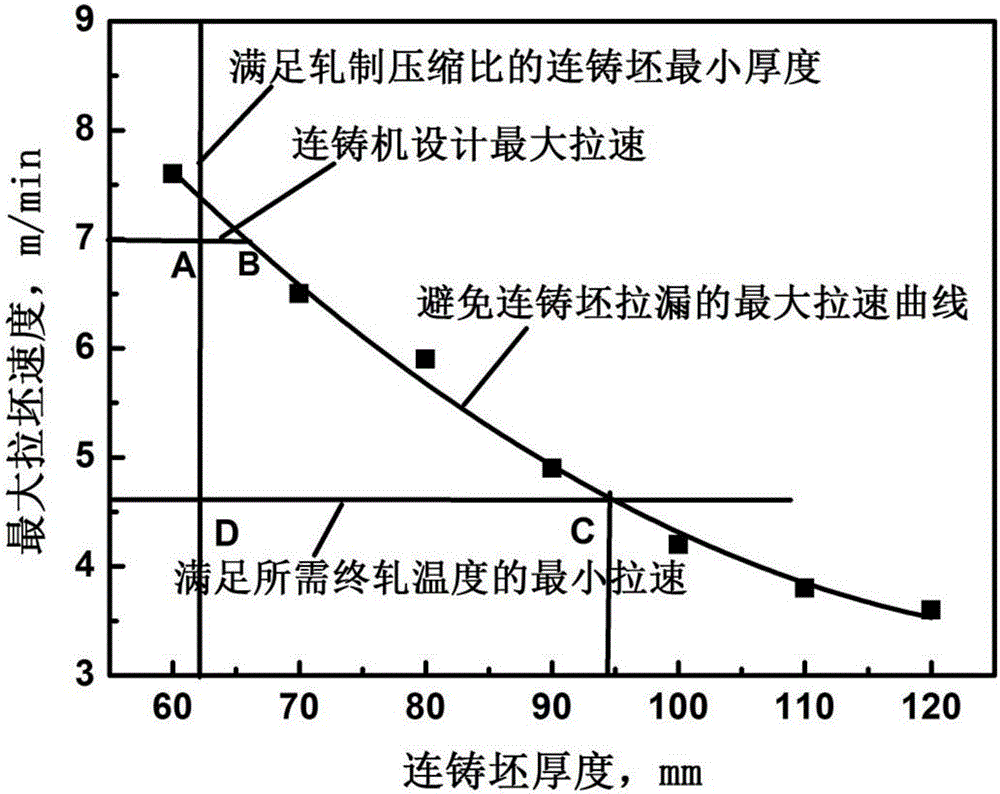

Method for using thin slab continuous casting and rolling technology for producing thin-specification, low-alloy and high-strength steel

ActiveCN106734201AIncreasing the thicknessIncrease pulling speedRoll force/gap control deviceTemperature control deviceDouble phaseThin slab

The invention relates to a method for using a thin slab continuous casting and rolling technology for producing thin-specification, low-alloy and high-strength steel. Molten steel is continuously cast into a continuous casting blank with the width being 1300 mm to 1600 mm and the thickness being 65 mm to 96 mm; then rough rolling, heat insulation cover heat insulation, induction heating, high-pressure water scale removing and finish rolling are conducted in sequence, and ultrathin strip steel with the width being 1300 mm to 1600 mm and the thickness being 1.3 mm to 1.6 mm is obtained; and finally the strip steel is controlled to be cooled, shorn in different rolled and are coiled into rolls. The yield strength of the thin-specification double-phase steel finished product ranges from 380 MPa to 430 MPa, the tensile strength ranges from 530 MPa to 610 MPa, and the elongation is larger than or equal to 25%. By means of the method, stable production of hot rolled thin-specification, low-alloy and high-strength steel with the thickness being 1.3 mm to 1.6 mm can be achieved, the size precision, the plate shape precision and the comprehensive mechanical performance are improved, the requirement for replacing cold with hot is met, and the production cost is reduced.

Owner:WISDRI ENG & RES INC LTD

Converter steelmaking process

InactiveCN1470653AImprove efficiencySave operating timeManufacturing convertersSteelmakingLate stage

The convertor steel-smelting method adopts the top and bottom combined converting process, uses molten iron and solid iron material as raw material, their weight percentage are, molten iron 85%-95% and solid iron material 5-15%. The pretreatment of desilication, dephosphorization and decarbonization of molten iron and decarbonizing refining process are implemented in same convertor, i.e. front stage is pretreatment of molten iron, and late stage is decarbonizing refining stage, in the pretreatment stage the dephosphorization agent can be added, the top-bottom combined converting process can be adopted, top converting adopts flow rate changed oxygen supply, and its medium and late stage adopts weak oxygen supply, and the decarbonizing refining stage adds lime, makes secondary slag formation and adopts large quantity of oxygen to make top and bottom combined converting process.

Owner:CENT IRON & STEEL RES INST

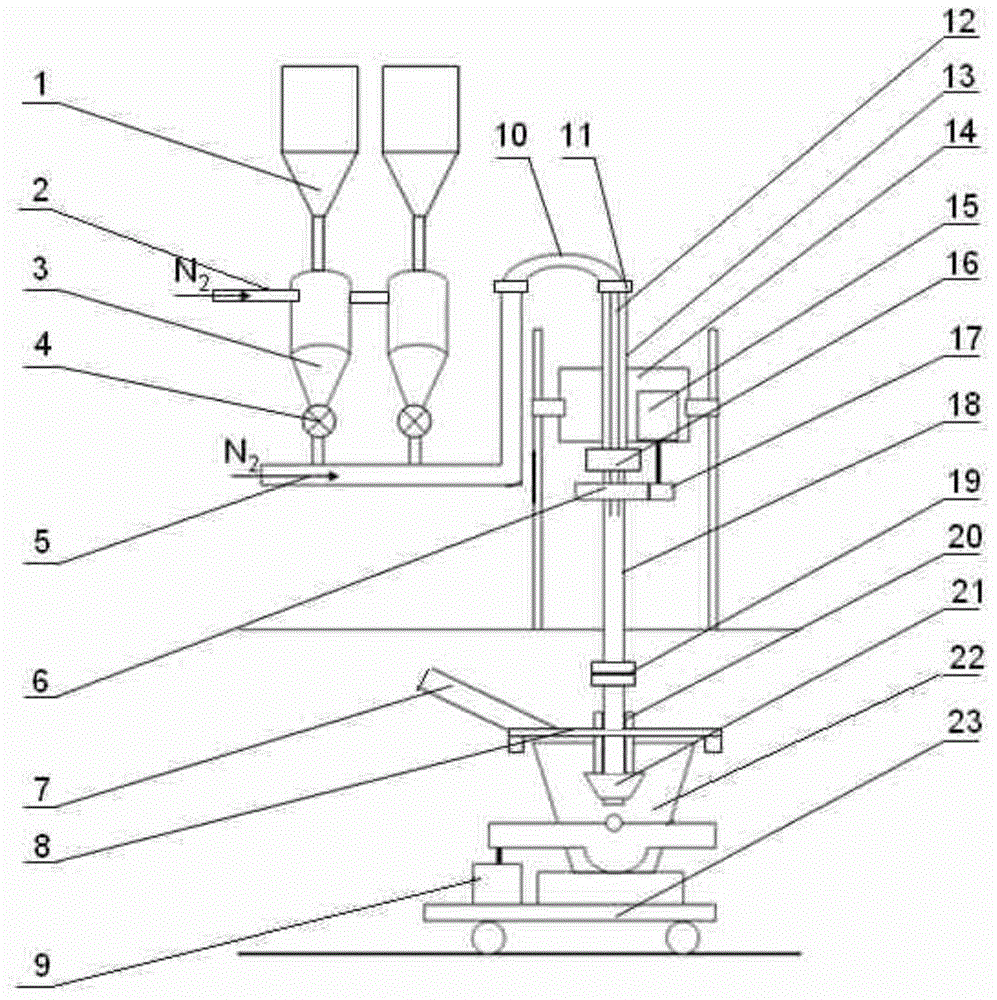

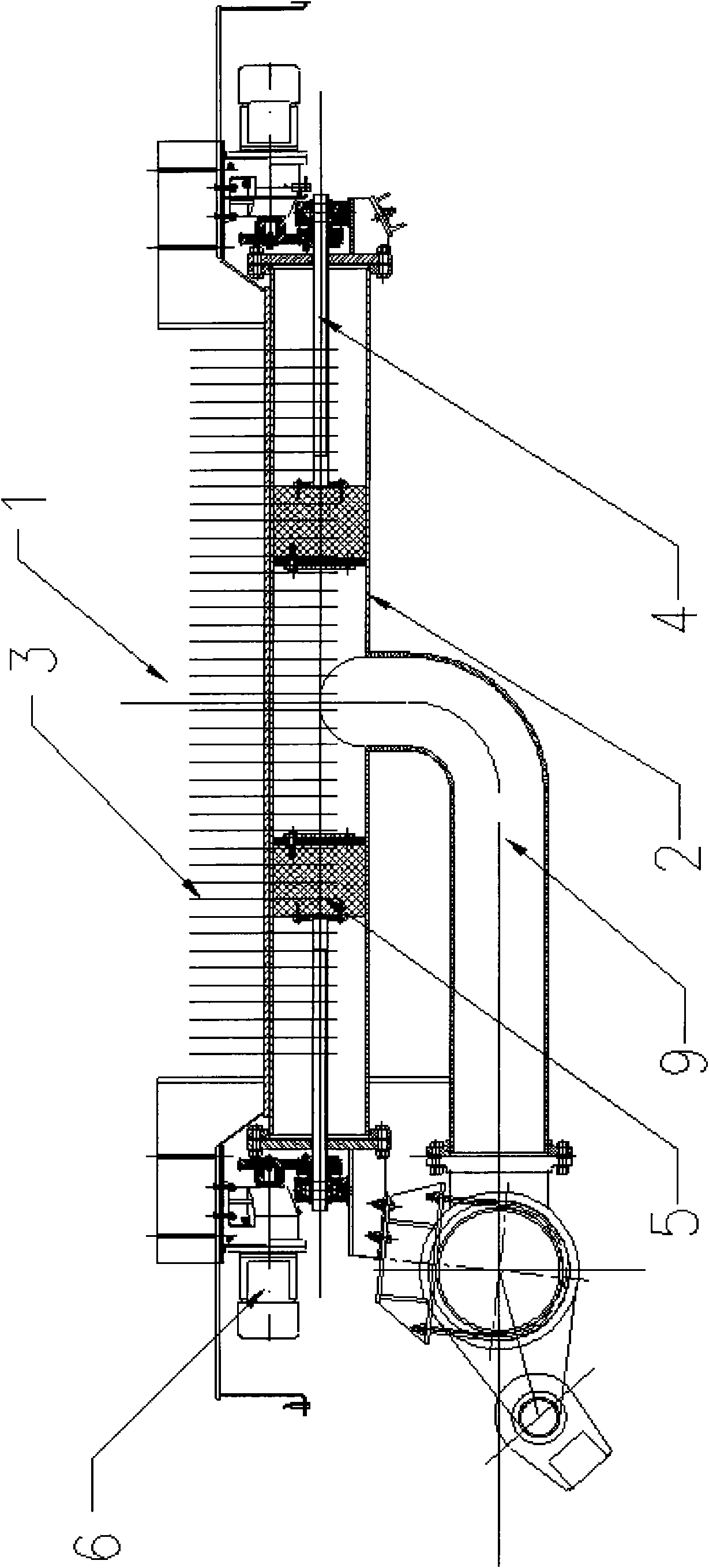

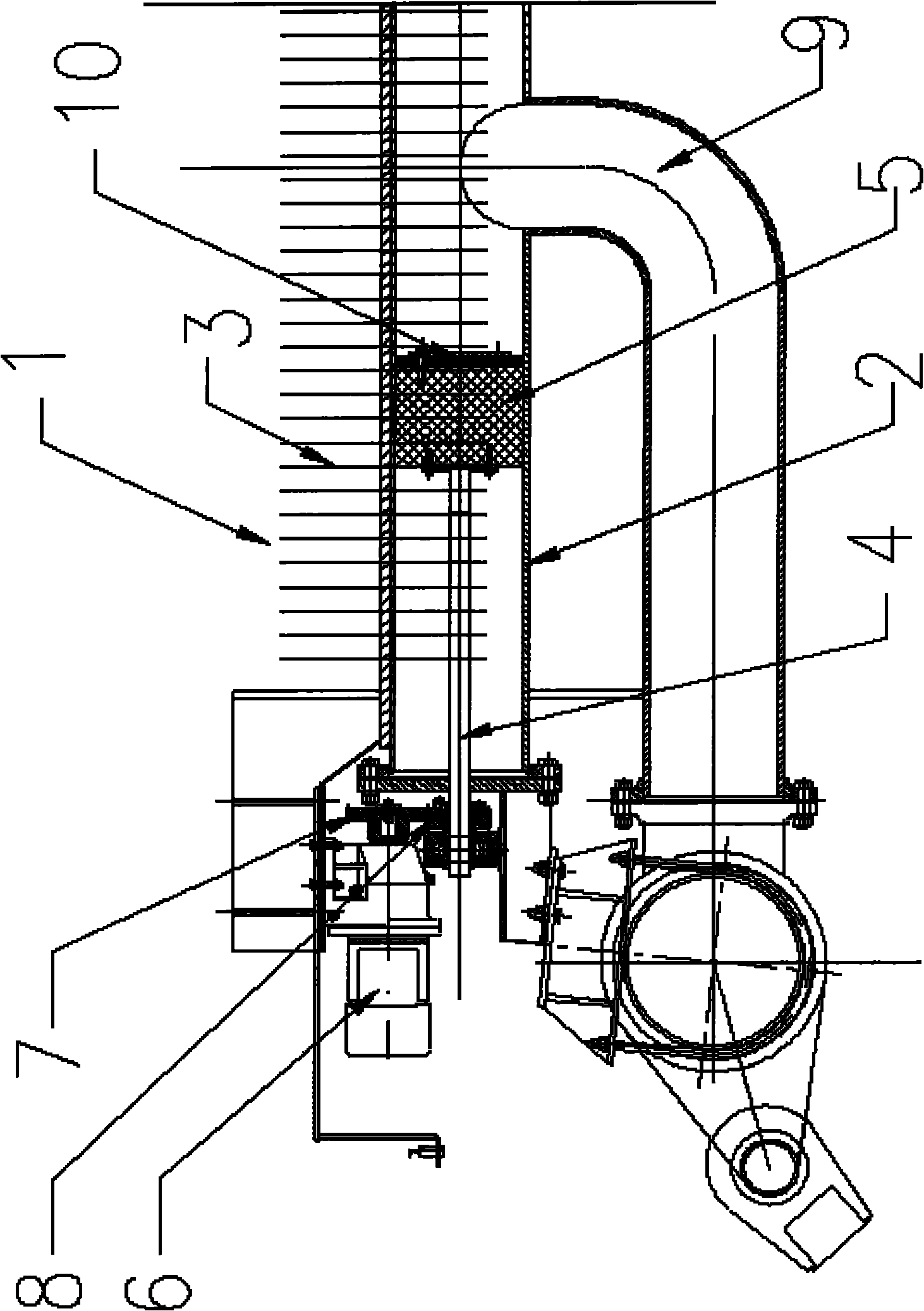

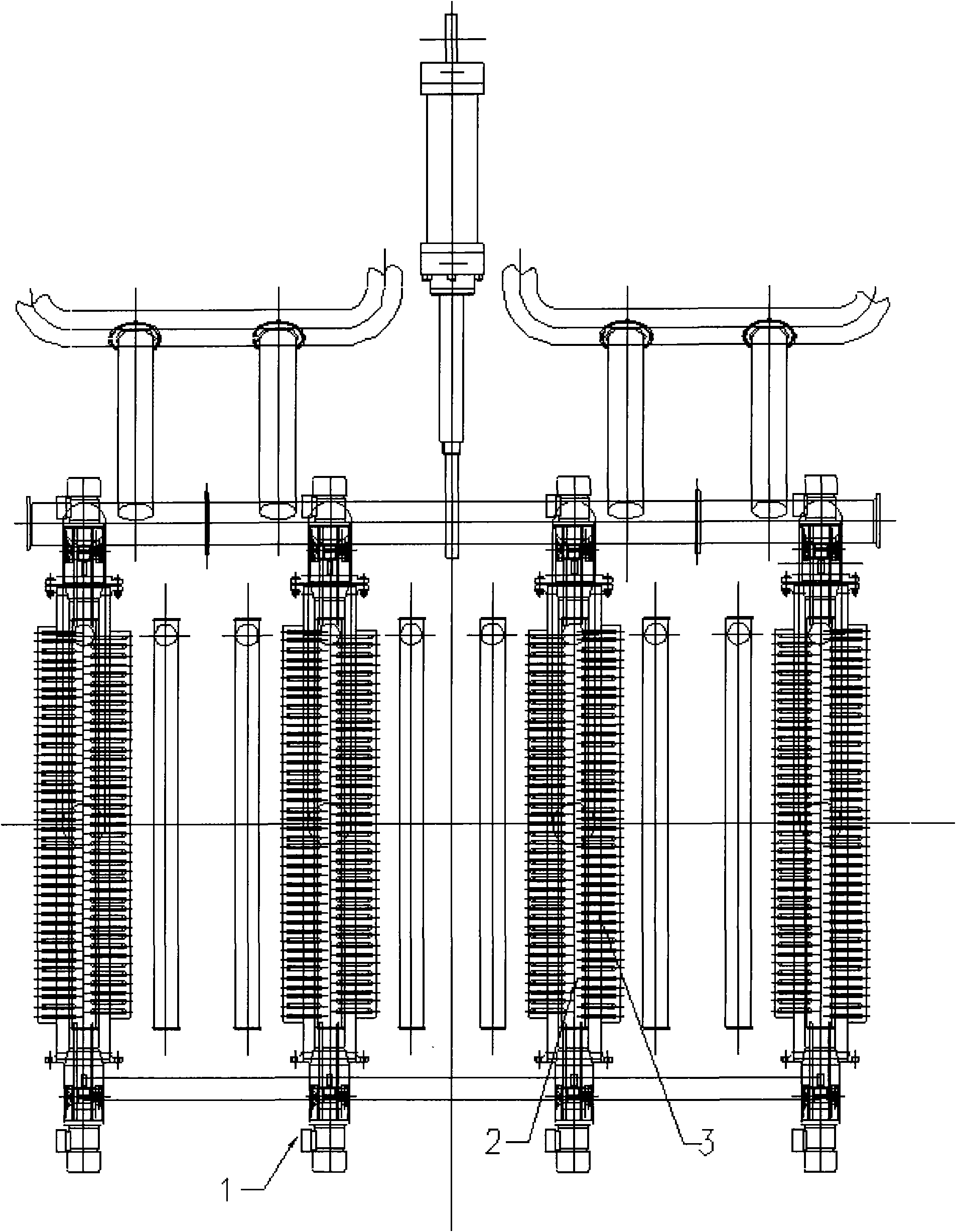

Blowing and stirring integrated type molten iron pretreatment desulphurization device and method

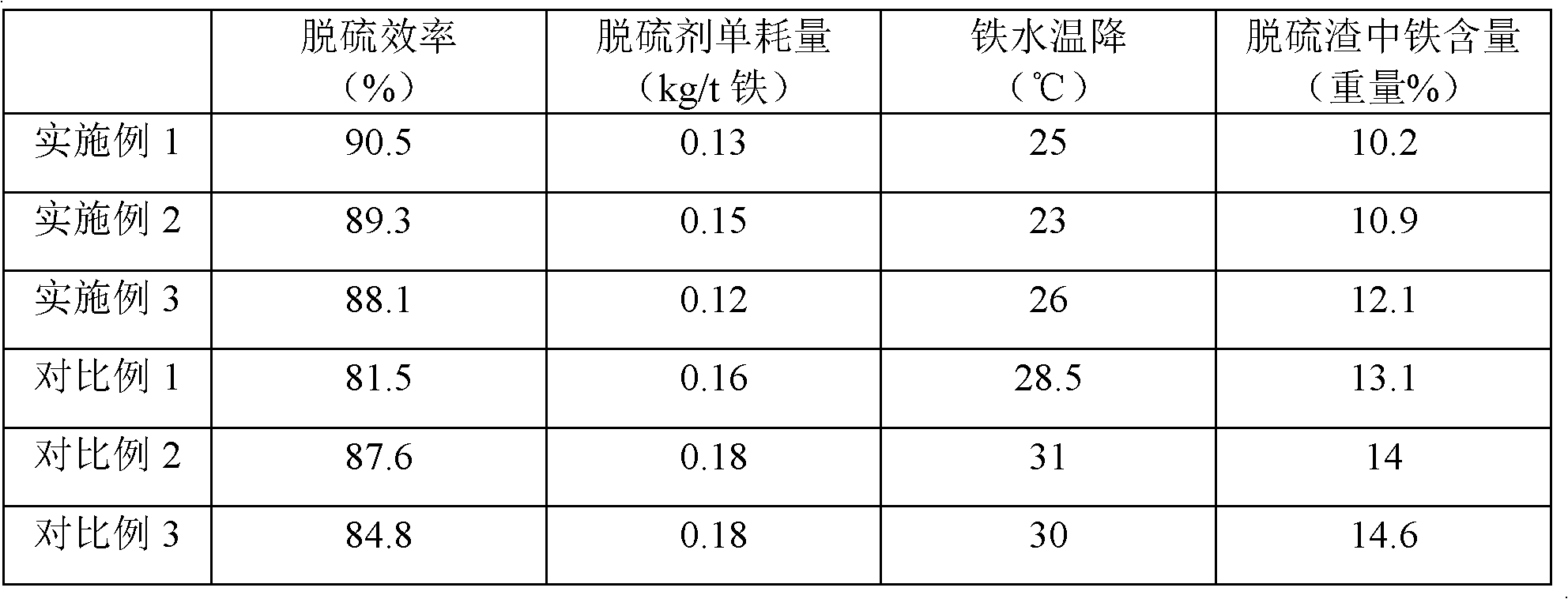

The invention discloses a blowing and stirring integrated type molten iron pretreatment desulphurization device and method. A powder-gas conveying pipe at the lower ends of weighing hoppers is in flexible connection with a powder spraying gun. The lower end of a fixed sleeve which is arranged outside the powder spraying gun in a sleeving mode is connected with a hollow transmission shaft through a bearing sleeve. A driven gear in which the bearing sleeve is embedded is engaged with a driving gear connected with a motor. A powder spraying pipe located at the lower end of the transmission shaft is buried in a stirring blade provided with a powder spraying channel. The stirring blade is inserted into a molten iron ladle cover. The method comprises the steps that the molten iron ladle cover is descended to the position above the edge of a molten iron ladle, the stirring blade enters the ladle cover to start a blowing system, and after the stirring blade conducts blowing in molten iron for 10-20 s, a stirring system is started for desulphurization; blowing and stirring are conducted for 8-20 min, and if the sulphur content in the molten iron reaches the standard, slagging-off operation is conducted; otherwise, desulphurization continues to be conducted till converting requirements are met; and the motor stops operating after the desulphurization, the blowing system is ascended, and blowing is stopped when the lower end of the stirring blade is flush with the edge of the molten iron ladle. According to the device and method, compared with a blowing method, the desulfurization rate is increased, and the consumption amount per ton of desulfurizing agents is reduced; compared with a KR stirring method, the temperature drop of the molten iron is reduced, and the service life of a stirring head is prolonged.

Owner:ANGANG STEEL CO LTD

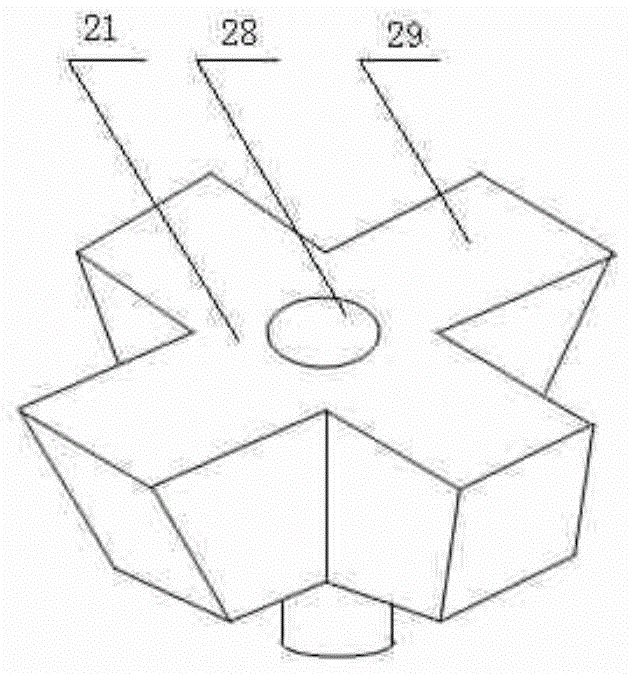

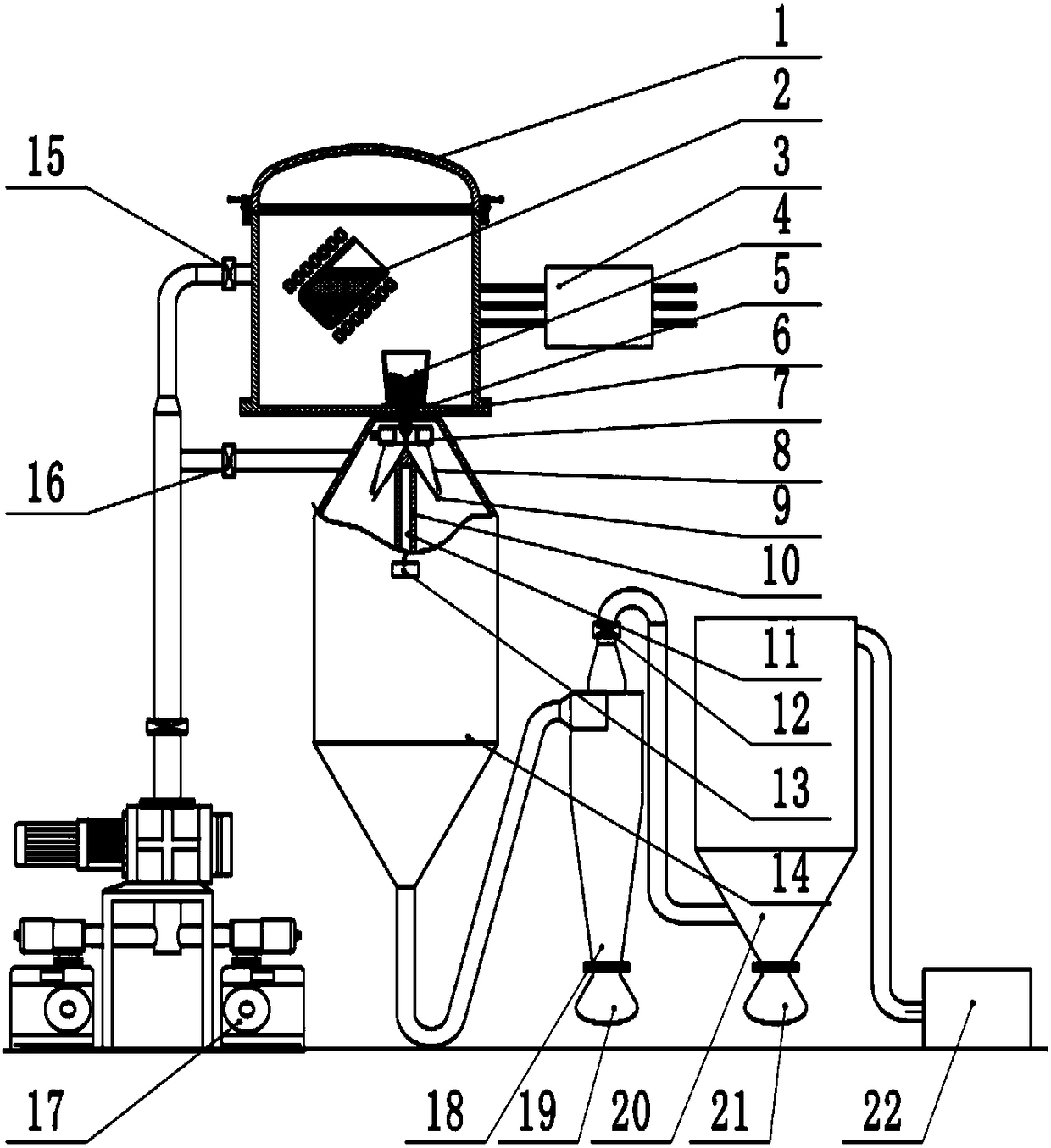

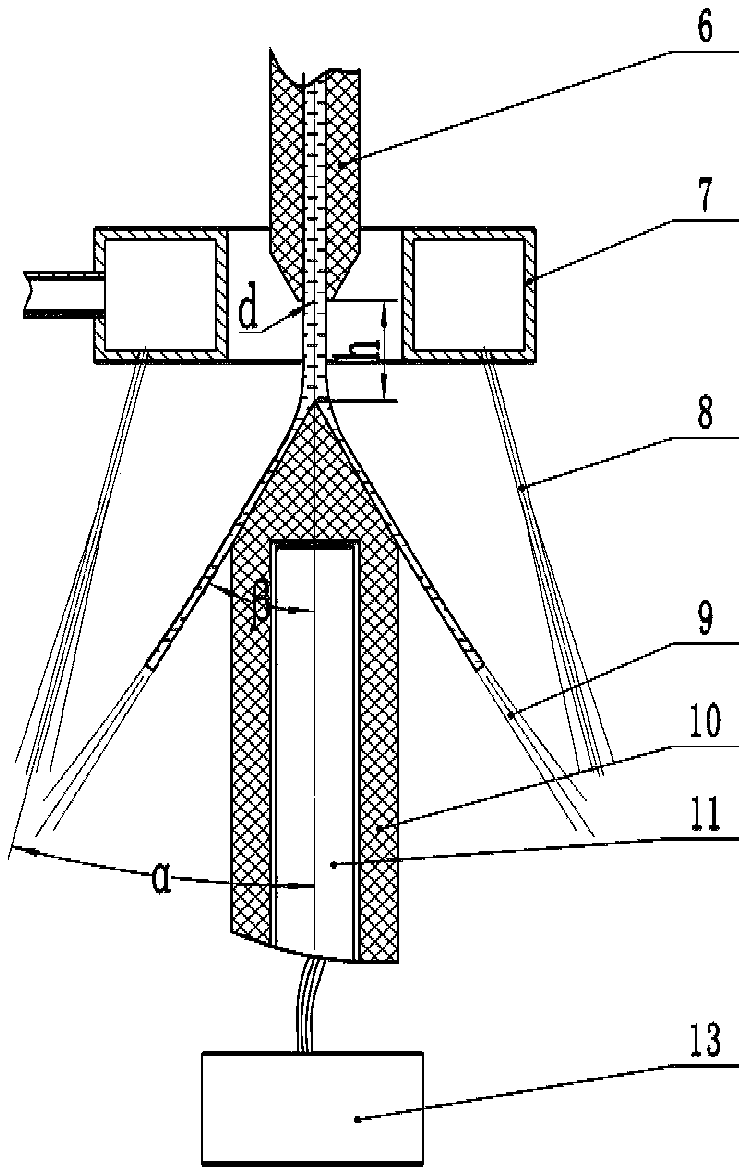

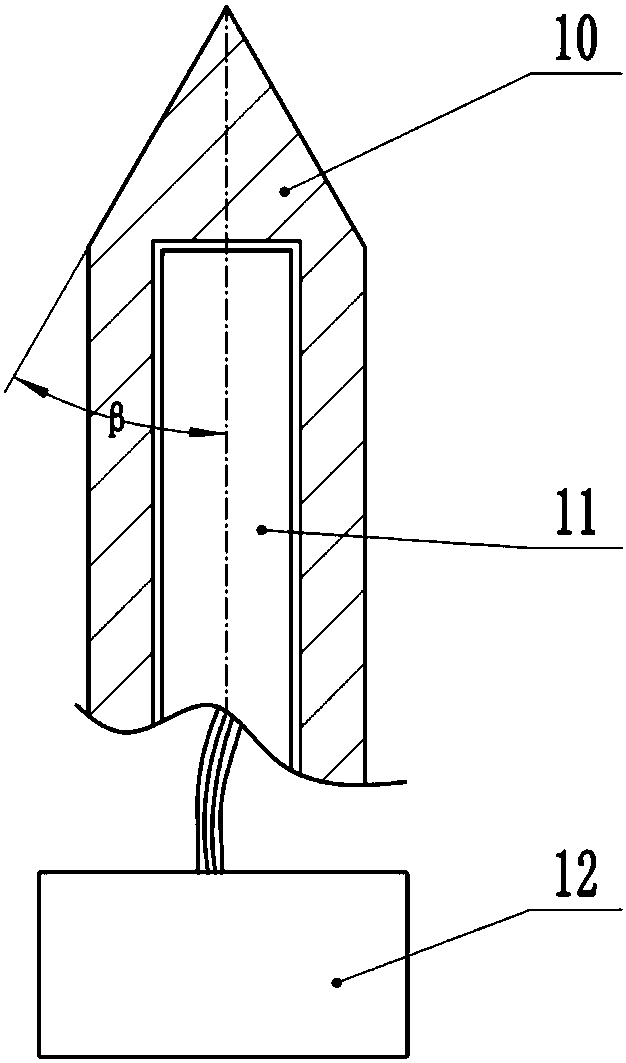

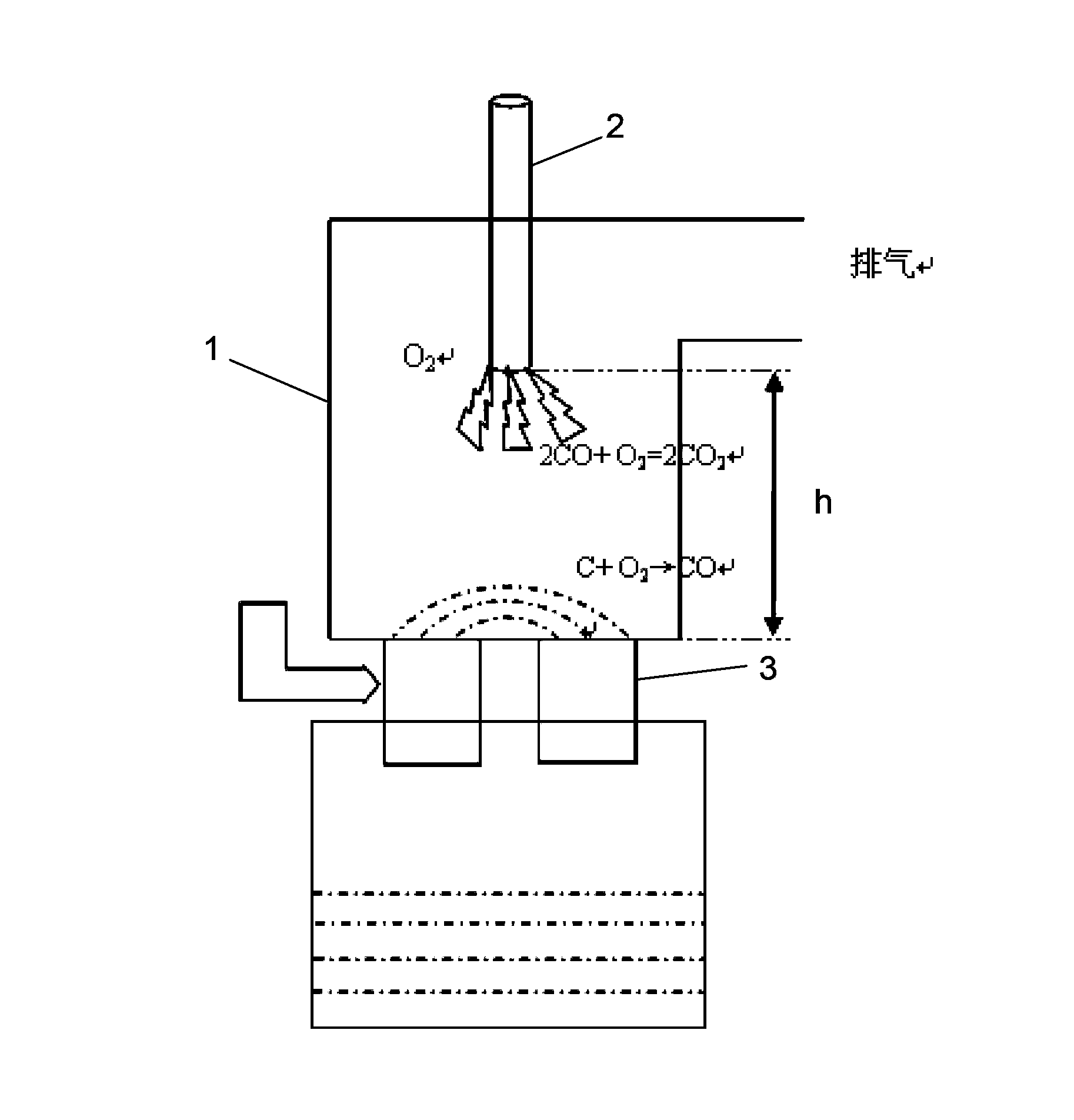

Metal powder preparation device and preparation method

InactiveCN108115145AGood particle size controllabilityNarrow particle size distributionControl systemSpray nozzle

The invention relates to a metal powder preparation device and method. The device consists of a control system, a smelting system, a vacuum system, an atomizing chamber, a pressure control system, a dust removing system and other parts. An atomizer in the atomizing chamber includes an atomizing nozzle, a flow nozzle and a melting body disperser; the atomizing nozzle and the flow nozzle are positioned above the melting body disperser, the central line of the atomizing nozzle is superposed with the central line of the melting body disperser and the central line of the flow nozzle, and the flow nozzle is installed at the bottom of a smelting chamber and stretches into the atomizing chamber. The method includes the steps that metal is fed into a furnace, heating and smelting are carried out onthe metal, melted bodies are ejected into the melting body disperser in the atomizing chamber under the action of the gravity and gas pressure and dispersed into liquid drops, the liquid drops are atomized into finer liquid drops, and then the finer liquid drops are cooled and solidified into metal powder. The metal powder preparation method has the advantages that the controllability of powder size is great, the powder size distribution is narrow, the furnace is not likely to be blocked, energy is saved, and the environment is protected.

Owner:BEIJING COMPO ADVANCED TECH

Compound iron melt desulfurizing agent and method of preparing the same

The invention relates to a composite type molten iron desulfurizer and a preparation method thereof, which relates to a novel desulfurizer used for desulfurizing of molten iron or molten steel and a manufacturing process thereof. The components and the weight percentage ratio of the composite type molten iron desulfurizer are: 70.0 to 75.0 percent of CaO, 2.0 to 3.0 percent of TMg, 10.0 to 12.0 percent of CaC2, 8.0 to 10.0 percent of NaHCO3, 0.5 to 1.5 percent of Al, C 1.0 to 4.0 percent of C, 0 to 5.0 percent of CaF2, less than and equal to 0.18 percent of S, less than and equal to 0.10 percent of P and the rest of impurities; the finished product of the desulfurizer is powdery. The preparation method of the sulfurizer is that lime, passivated magnesium powders, calcium carbide, alkali carbonate additives, aluminum powders, graphite or charcoal, fluorite, etc. are utilized as the raw materials and are mixed evenly according to a certain weight percentage, dried and pretreated; passivated liquid is prepared; then the passivated liquid is poured into the materials to be stirred till the materials are dried, and the materials are cooled naturally and ground to make into powdery finished product. Compared with the prior art, the composite type desulfurizer and the preparation method thereof of the invention have the following advantages: short time required by the desulfurizing treatment, small quantity of slags, small temperature drop and good desulfurizing effect; low comprehensive using cost; simple production process and wide resources of the raw materials; improvement of slag forms during molten iron desulfurizing and reduction of iron loss of the molten iron. The calcium carbide, especially the magnesium powders (particles) are the products of high energy consumption, the effect of energy saving is achieved because the composite type molten iron desulfurizer of the invention correspondingly lowers the using amount of CaC2 or Mg.

Owner:PANZHIHUA DONGPAN IND & TRADE

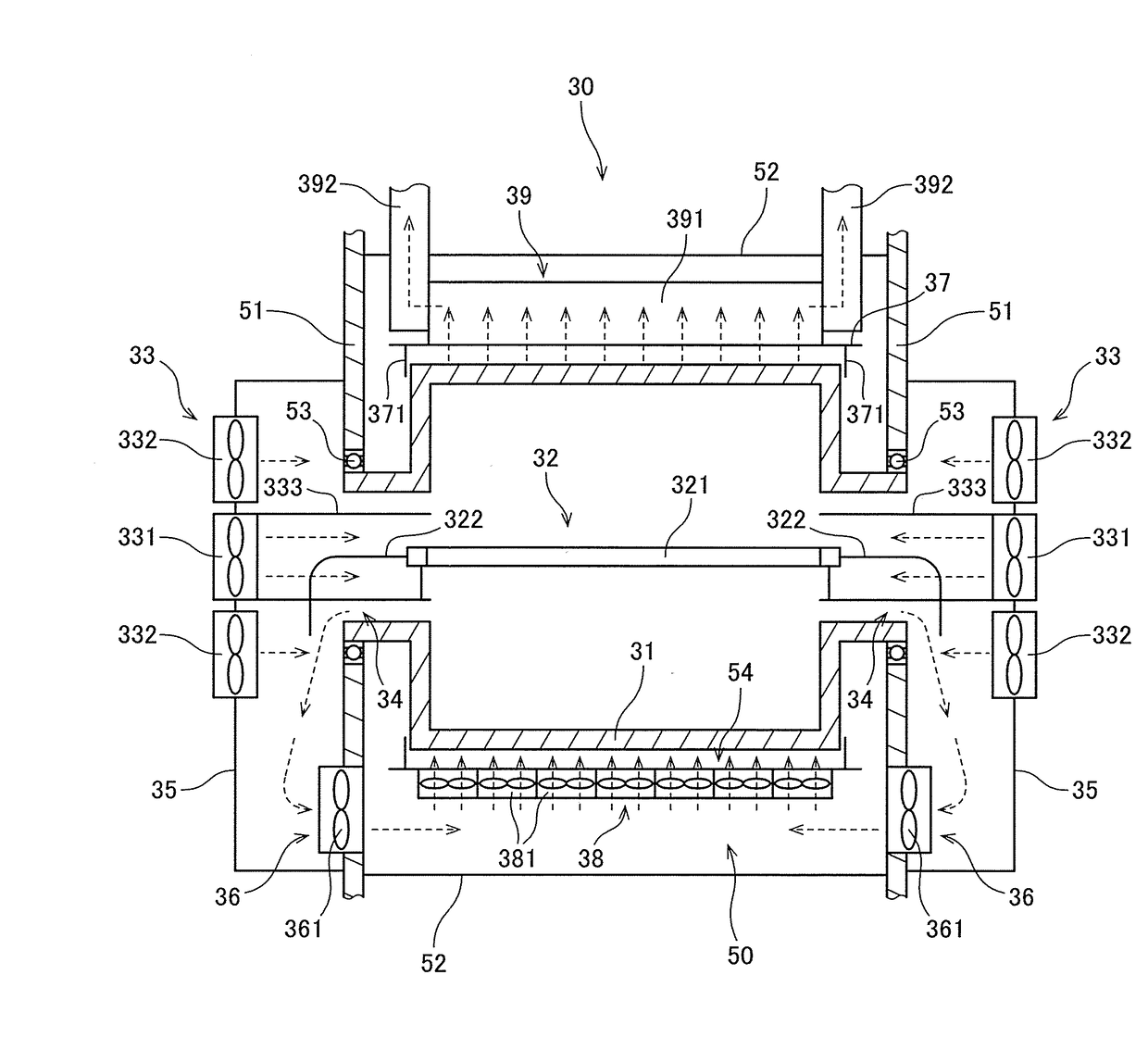

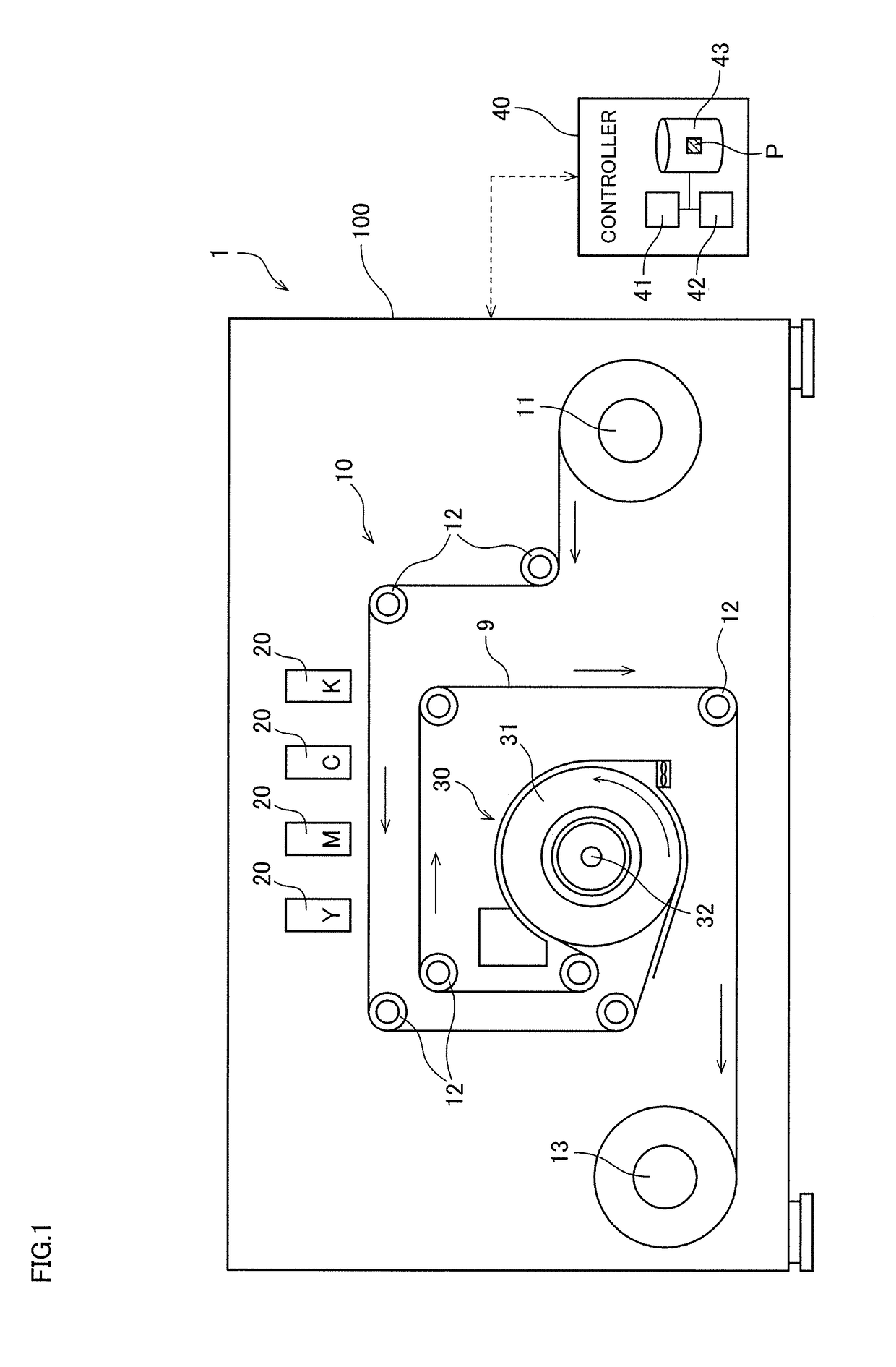

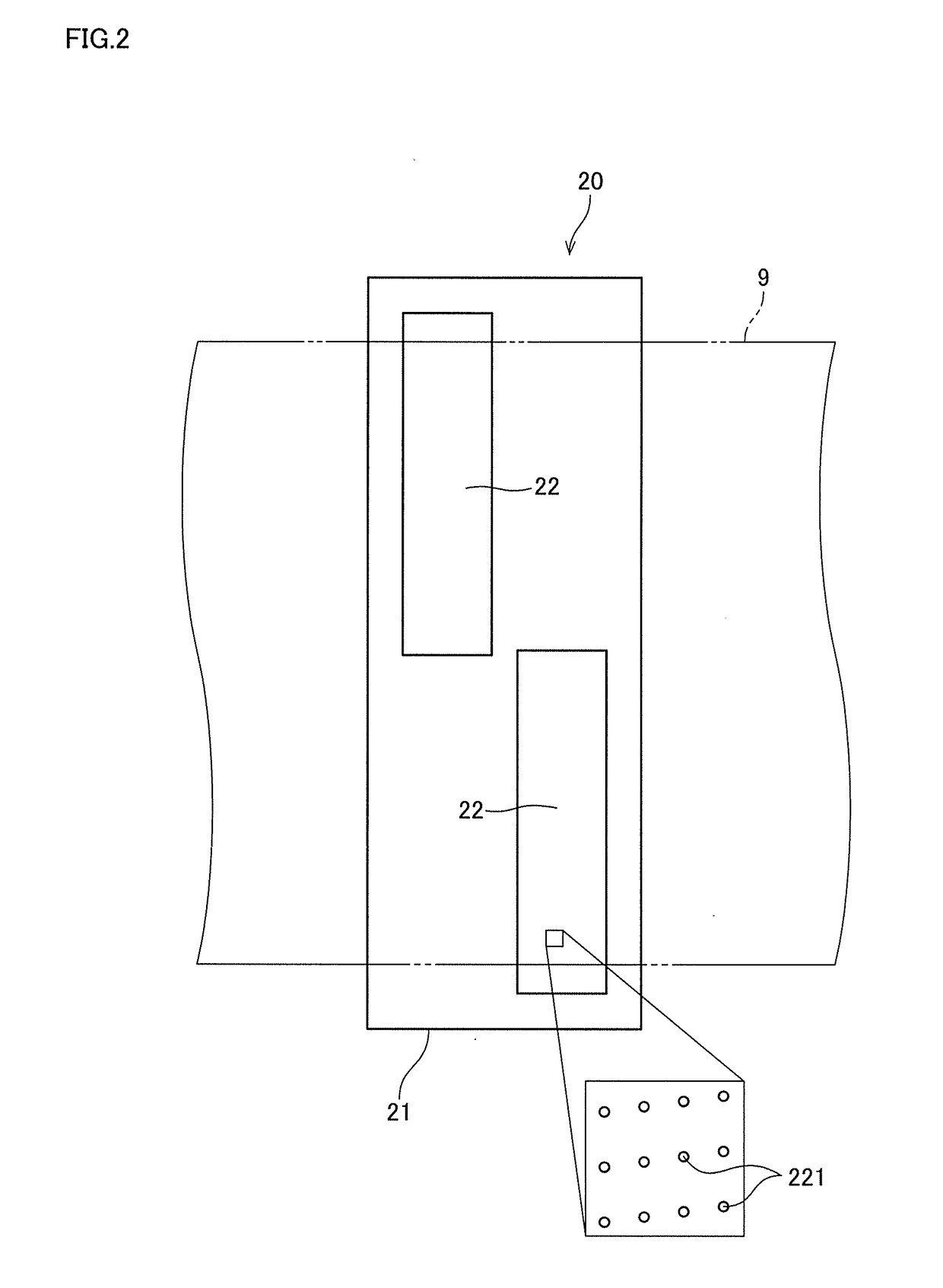

Drying device, printing apparatus, and drying method

ActiveUS20170173973A1Reduce humidityReduce temperature dropOther printing apparatusProcess engineeringGas supply

A drying device includes a cooling unit, a gas outward guide unit, a gas inward guide unit, a gas supply unit, and a gas exhaust unit. The cooling unit feeds cooling wind toward a part near a heat source. The gas outward guide unit guides gas outwardly from the part near the heat source. The gas inward guide unit guides the outwardly-guided gas inwardly into the drying chamber. The gas supply unit supplies the inwardly-guided gas in the drying chamber to a neighborhood of an outer peripheral surface of the heat roller. The gas exhaust unit releases gas from a surrounding of the heat roller to the outside of a printing apparatus. Thus, high-temperature gas with heat absorbed from the part near the heat source is fed to the surrounding of the heat roller. This reduces humidity increase in the surrounding of the heat roller and reduces temperature drop of the heat roller, compared to feeding gas at ordinary temperature. Further, diffusion of the high-temperature gas in the printing apparatus is prevented.

Owner:DAINIPPON SCREEN MTG CO LTD

Hot rolling method for wide and thin size high-strength cold-rolled base plate for automobile

InactiveCN105478472AGuaranteed MicrostructureGuaranteed mechanical propertiesMetal rolling arrangementsStructure propertySheet steel

The invention discloses a hot rolling method for a wide and thin size high-strength cold-rolled base plate for an automobile. After continuous casting billets are assembled in a heating furnace in a hot state, the Cu accumulation amount of iron oxide scales and steel substrates is reduced by adopting high-temperature preheating and high-temperature rapid heating technologies; after rough rolling, the thickness of an intermediate billet is reduced, a heat holding cover is used for reducing temperature drop and temperature differences of all parts, so that the finish rolling entry temperature of the intermediate billet is increased; and loads of all racks for finish rolling are reduced, and the stability of finish rolling is improved. In the process from finish rolling to steel belt coiling, a controlled rolling and controlled cooling technology is adopted, so that the cold-rolled base plate has excellent uniformity between the shape and the structure property. According to the method, the cold-rolled base plate with the thickness of 1.5-2.5 mm and the width of 1650-2000 mm can be obtained; the convexity degree of a steel belt is controlled to be in a range between 45-15 mu m and 45+15 mu m; the straightness is controlled to be 30I; the thickness accuracy is in a range between -30 mu m and +30 mu m; the structure property of different edges of the head, the middle, the tail of the steel belt is uniform; and the yield and the production efficiency of the wide and thin size high-strength cold-rolled base plate can be increased and improved, so that the cold-rolled base plate meeting the requirements of the actual product quality and the performance is provided for steel plates with the grade of 450-590 MPa for automobile covering parts.

Owner:ANGANG STEEL CO LTD

Micro fine-grained titanium-nickel-niobium shape memory alloy block material preparing method

The invention is a manufacturing method for a kind of micron tiny crystal titanium nickel-niobium shape memorizing alloy block materials, 45%-50% titanium, 40%-45% nickel, 5%-10% niobium are melted and produced into titanium nickel-niobium alloy cast ingot, and cuts the titanium nickel-niobium alloy block material into blank, and carries on surface finish process, and paints with glass lubricate, uses isometric curved squeezing mould with 90-120 degrees channel angle, the mould cavity surface is painted with black lead lubricate, the blank and mould are heated and carries on temperature reservation, and takes them out to be squeezed at the same time, finally gets the product. The invention solves the problem that the bad plastic property of titanium nickel-niobium shape memorizing alloy in room temperature, enhances the alloy mechanical performance, and lowers the cost.

Owner:SHANGHAI JIAO TONG UNIV

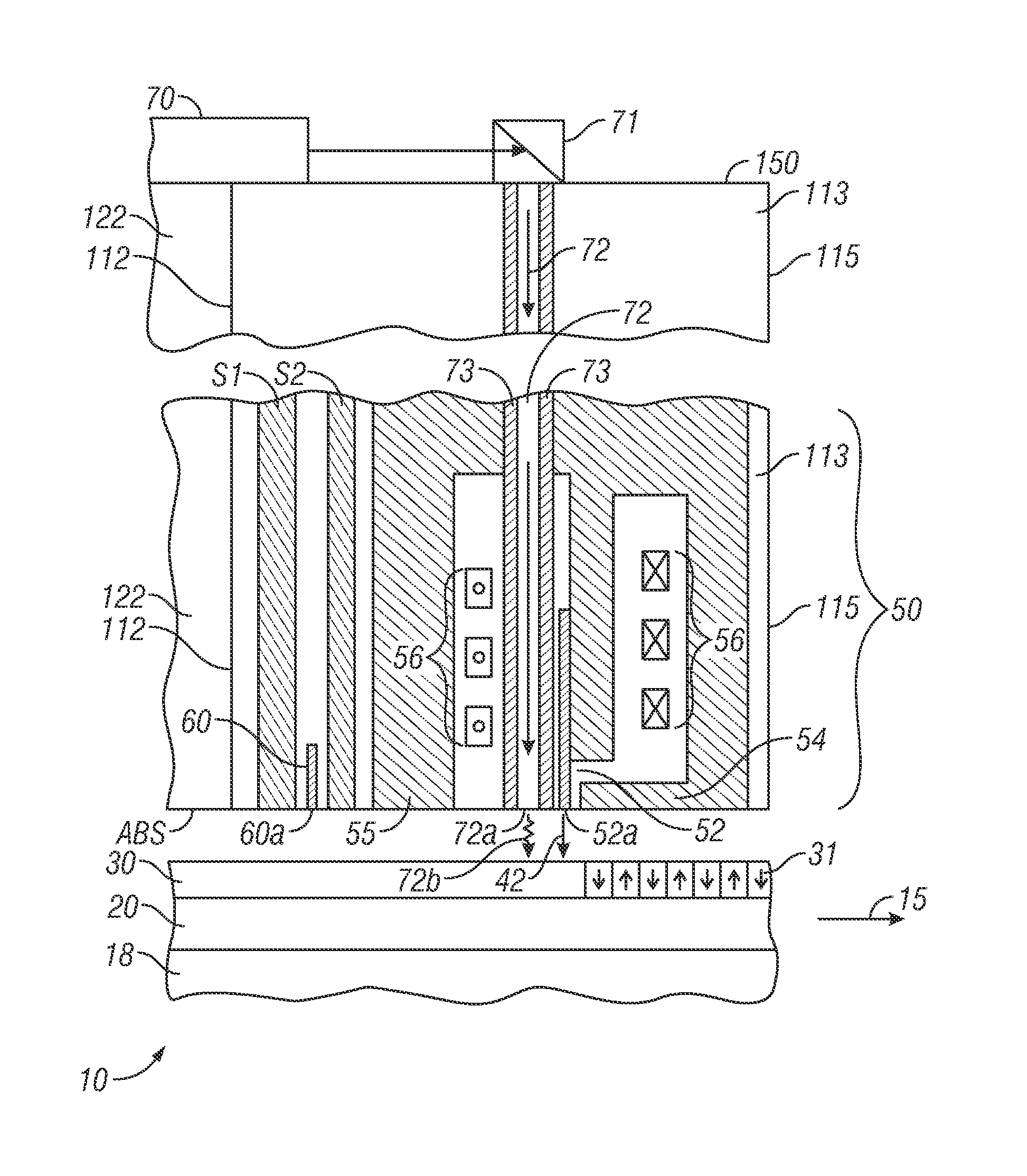

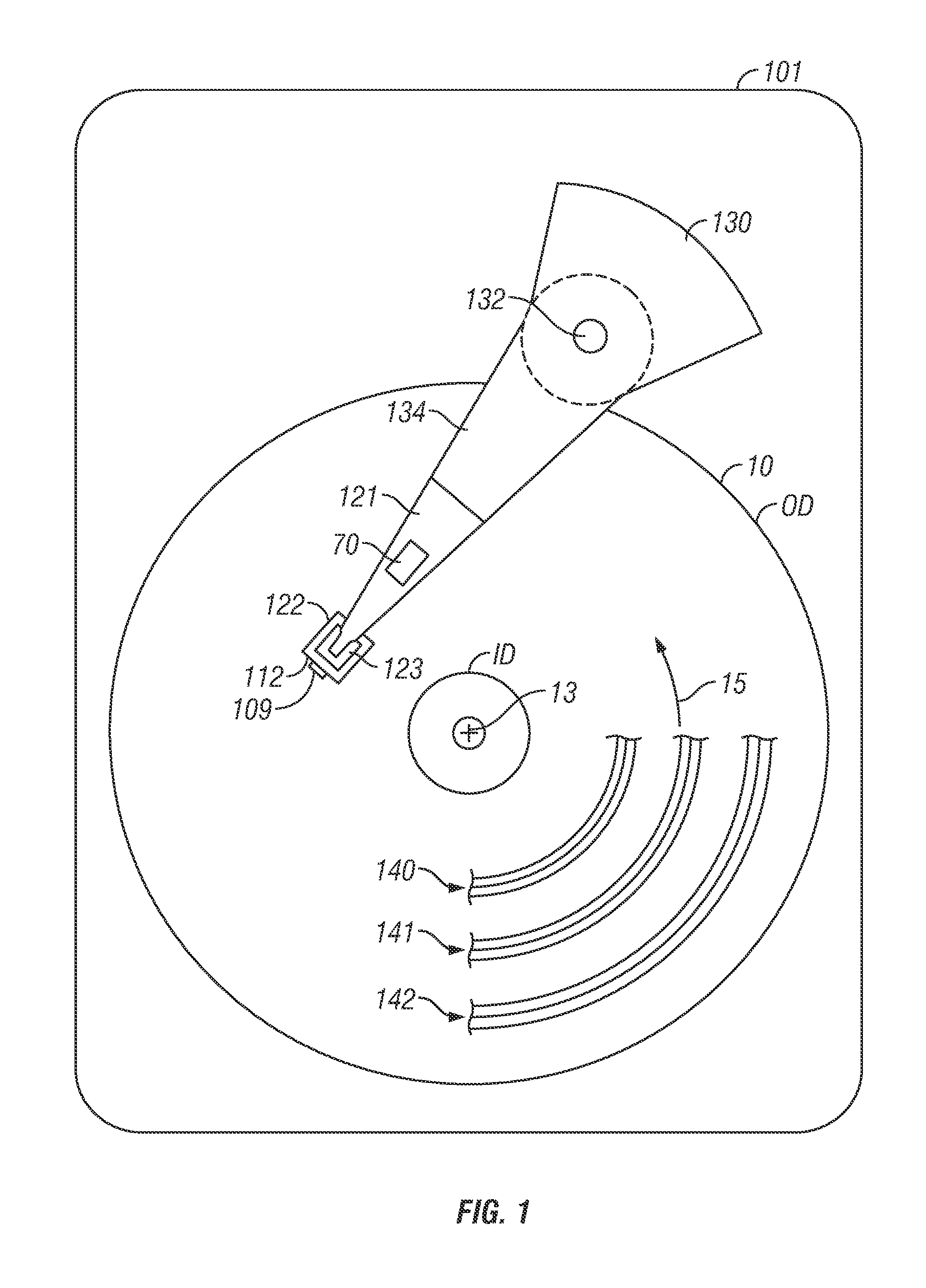

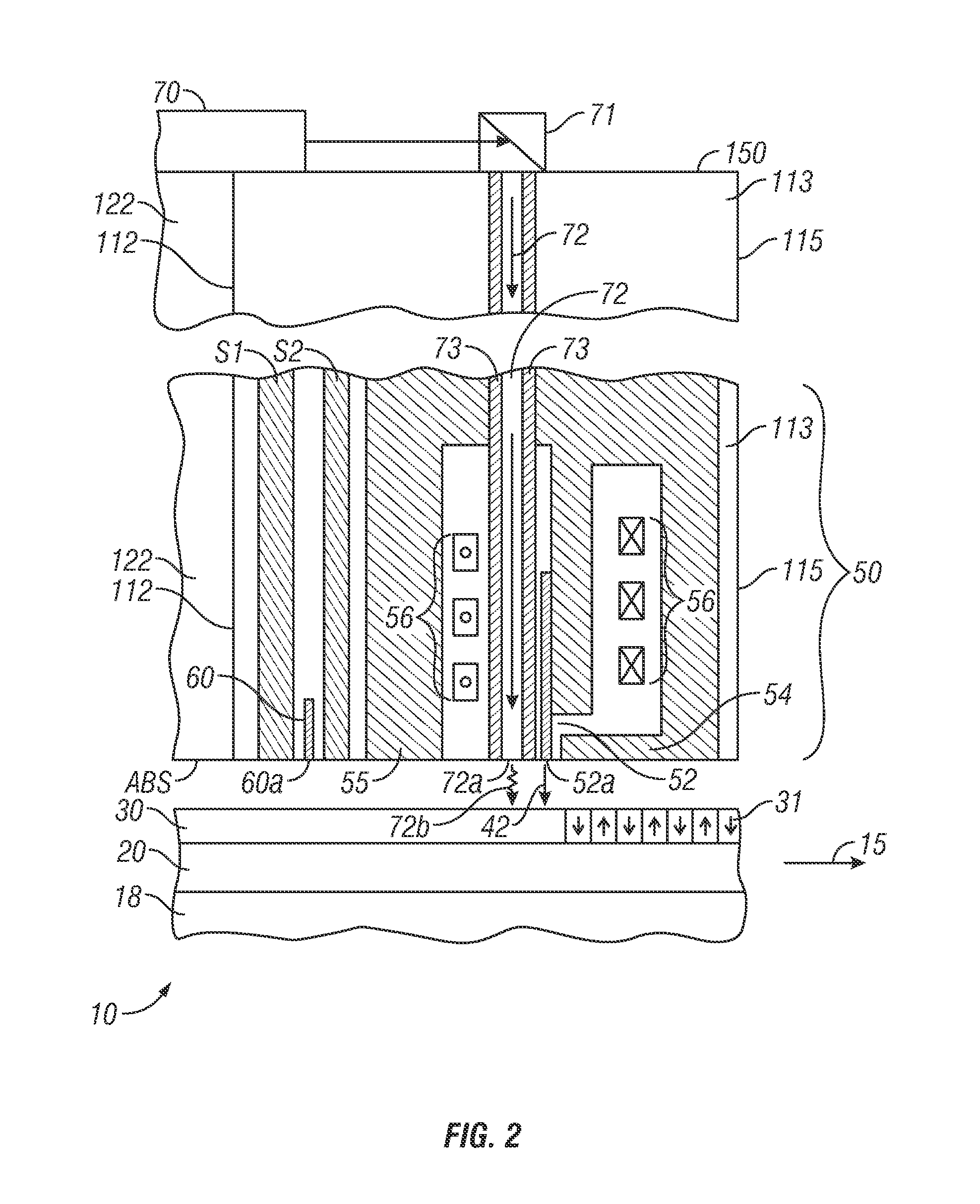

Magnetic recording disk drive with shingled writing and rectangular optical waveguide for wide-area thermal assistance

ActiveUS8416646B2Reduce cooling rateIncrease volumeCombination recordingRecord information storageTrailing edgeRecording layer

A thermally-assisted recording (TAR) disk drive uses “shingled” recording and a rectangular waveguide as a “wide-area” heat source. The waveguide generates a generally elliptically-shaped optical spot that heats an area of the recording layer extending across multiple data tracks. The waveguide core has an aspect ratio (cross-track width to along-the track thickness) that achieves the desired size of the heated area while locating the peak optical intensity close to the trailing edge of the write pole tip where writing occurs. The large cross-track width of the waveguide core increases the volume of recording layer heated by the optical spot, which reduces the rate of cooling. This moves the peak temperature point of the heated area closer to the write pole tip and reduces the temperature drop between the peak temperature and the temperature at the trailing edge of the write pole tip where writing occurs.

Owner:WESTERN DIGITAL TECH INC

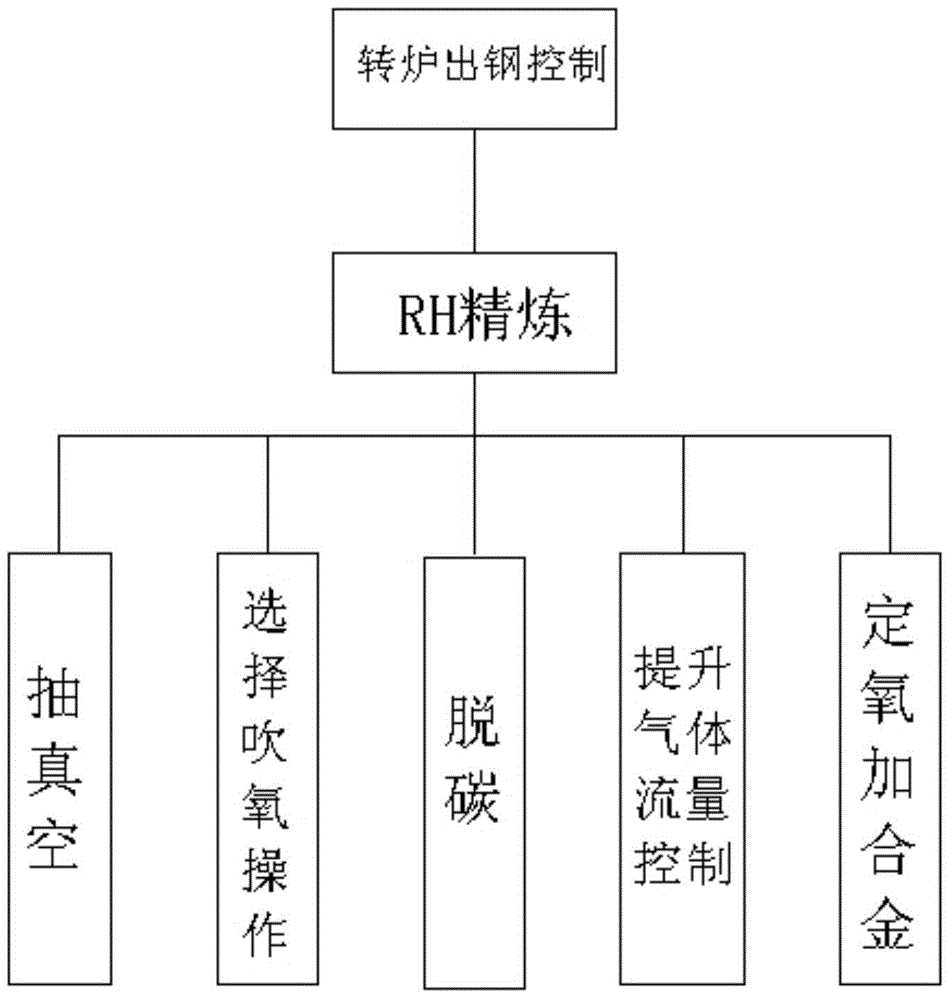

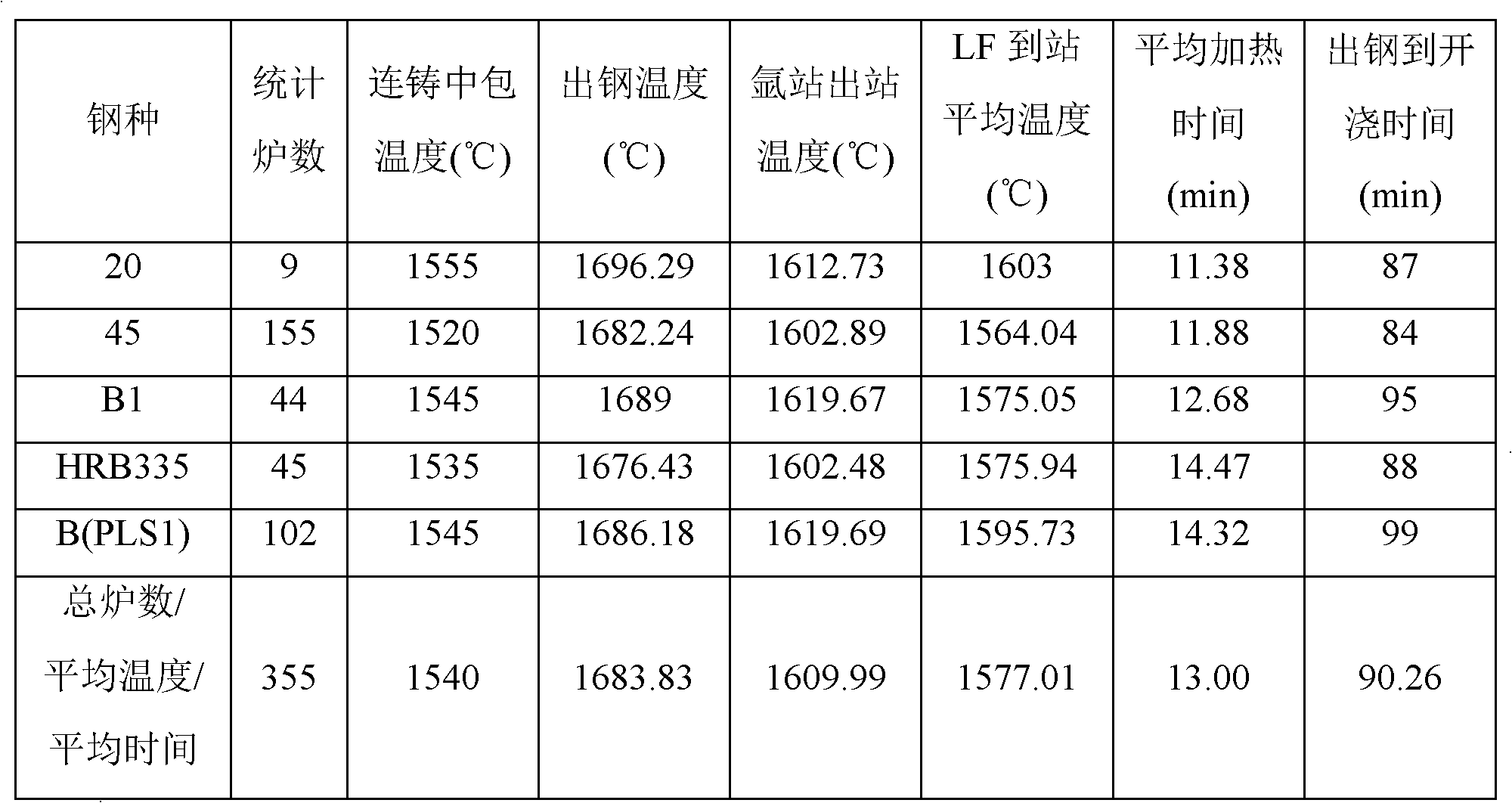

RH fast decarbonization method

ActiveCN104099445AShorten the refining cycleEfficient and fast decarbonizationMetallurgyOxygen content

The invention relates to an RH fast decarbonization method. The method comprises the following steps: the terminal control of a converter is performed; the temperature of the steel tapping terminal of the converter is controlled within 1675-1705 DEG C; by the mass percentage, the C content at the steel tapping terminal of the converter is controlled within 0.02-0.045%; by the mass percentage, the oxygen content is controlled within 900 ppm; after the steel tapping of the converter is finished, the RH refining is performed; the inlet temperature of molten steel is controlled within 1610-1640 DEG C; an RH judges if the oxygen blowing decarbonization is needed according to the inlet conditions and the carbon-oxygen relation, if so, the oxygen blowing should be performed within 4 min at the beginning of the vacuumizing, and the oxygen blowing quantity is not greater than 150 m3; and the gas flow is increased in the refining process. The method is suitable for the deep decarbonization process of ultralow carbon steel, and can decarbonize the molten steel C below 10*10-6 within 12 min, so that the efficient and fast decarbonization is realized, the RH refining period is shortened, and the temperature drop in the refining process is reduced.

Owner:SHOUGANG CORPORATION

Large-size mandril structure property control method

ActiveCN101787420AImprove purityImprove impact toughnessFurnace typesHeat treatment furnacesThighThermal fatigue

The invention relates to a large-size steel mandril structure thinning control method for improving the performance of a base body, belonging to the field of steel material manufacturing technique control technology. The method mainly comprises structure thinning treatment for mandril billet in the production process of a mandril by a thigh channel as well as quenching treatment-thinned and hardened structure of finished products of the mandril, namely, all performances of the mandril can be improved by technical way of double thinning structure. The large-size steel mandril manufactured by the method has higher impact toughness, better heat stability and higher thermal fatigue resistance.

Owner:SHANGHAI UNIV

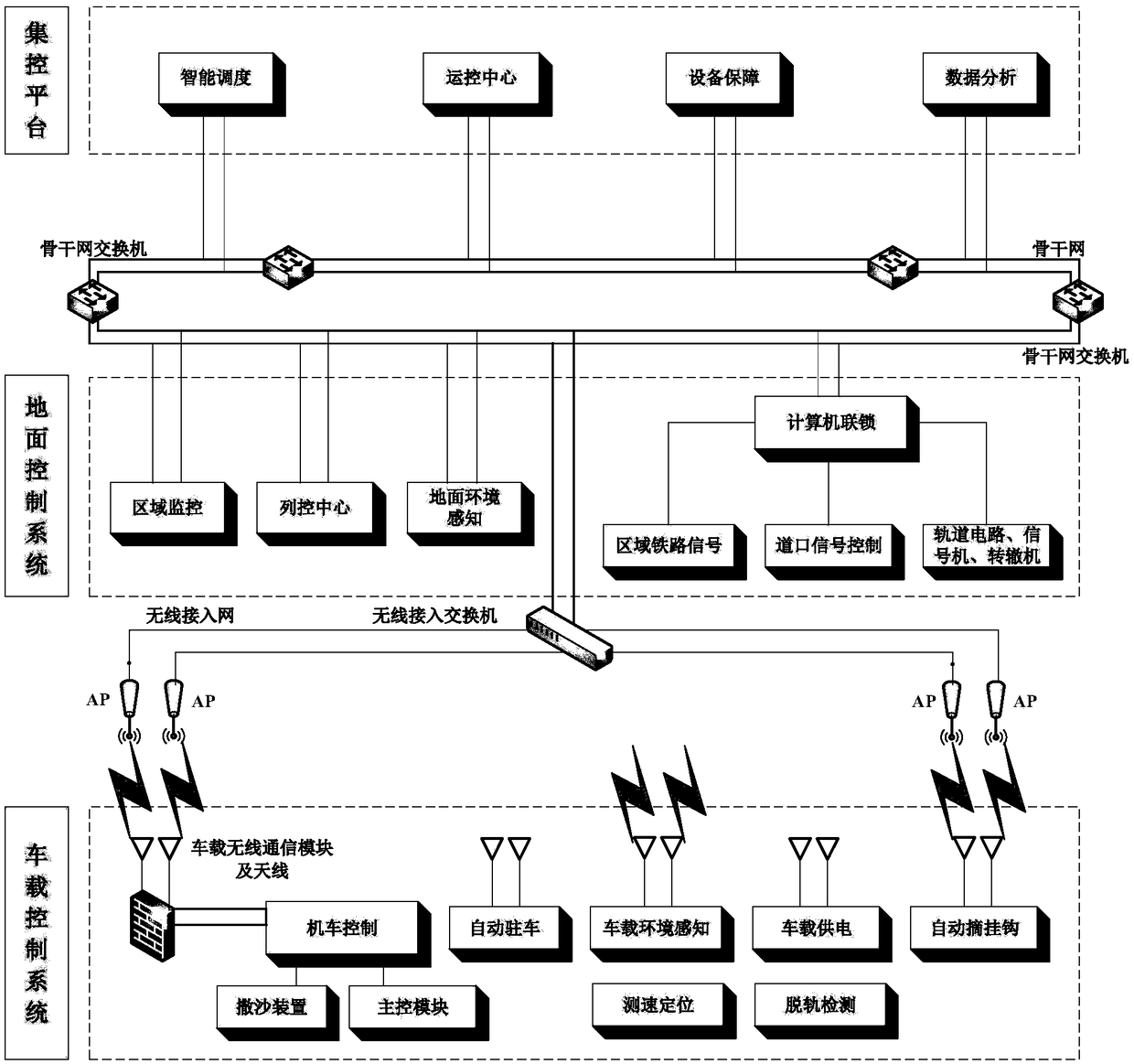

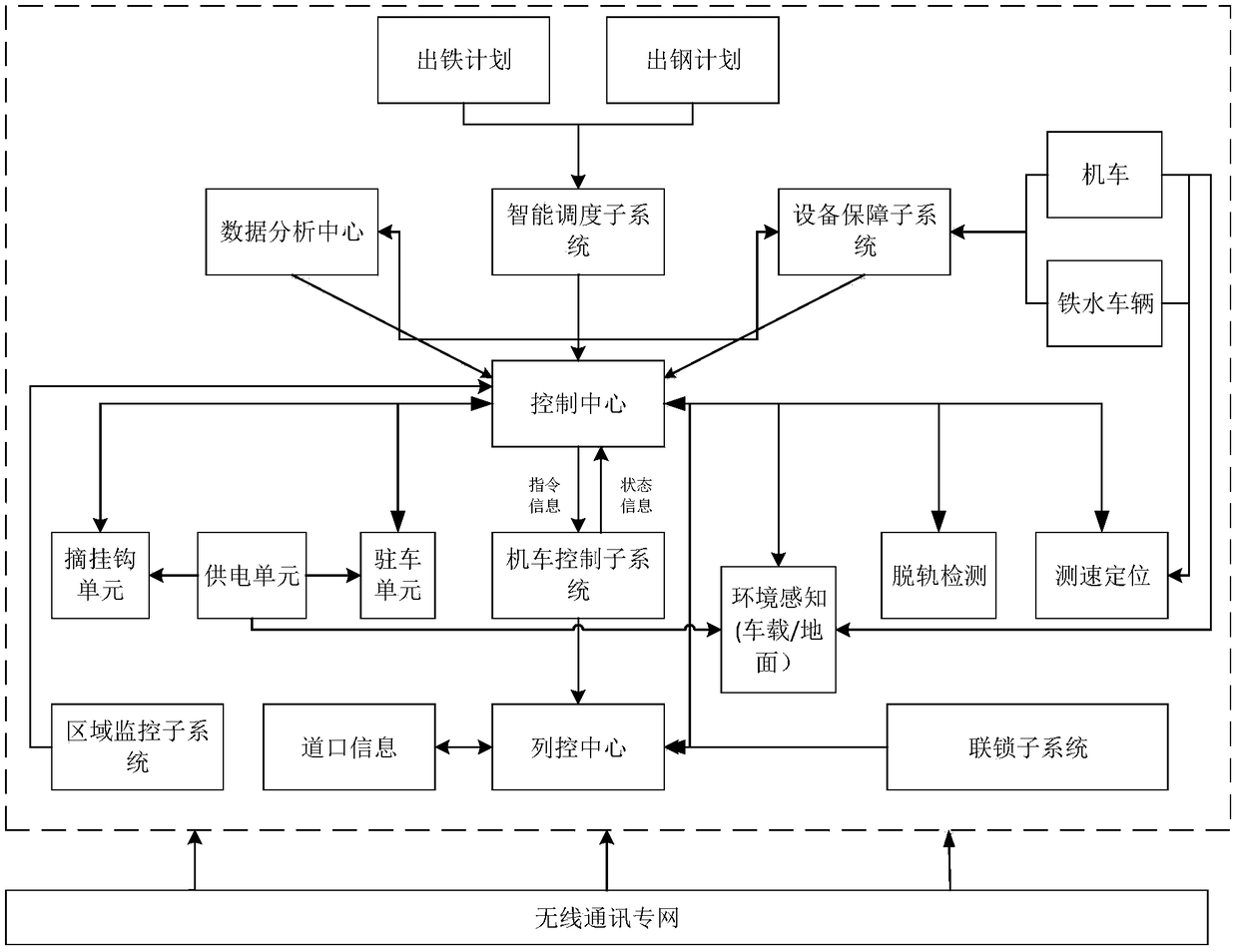

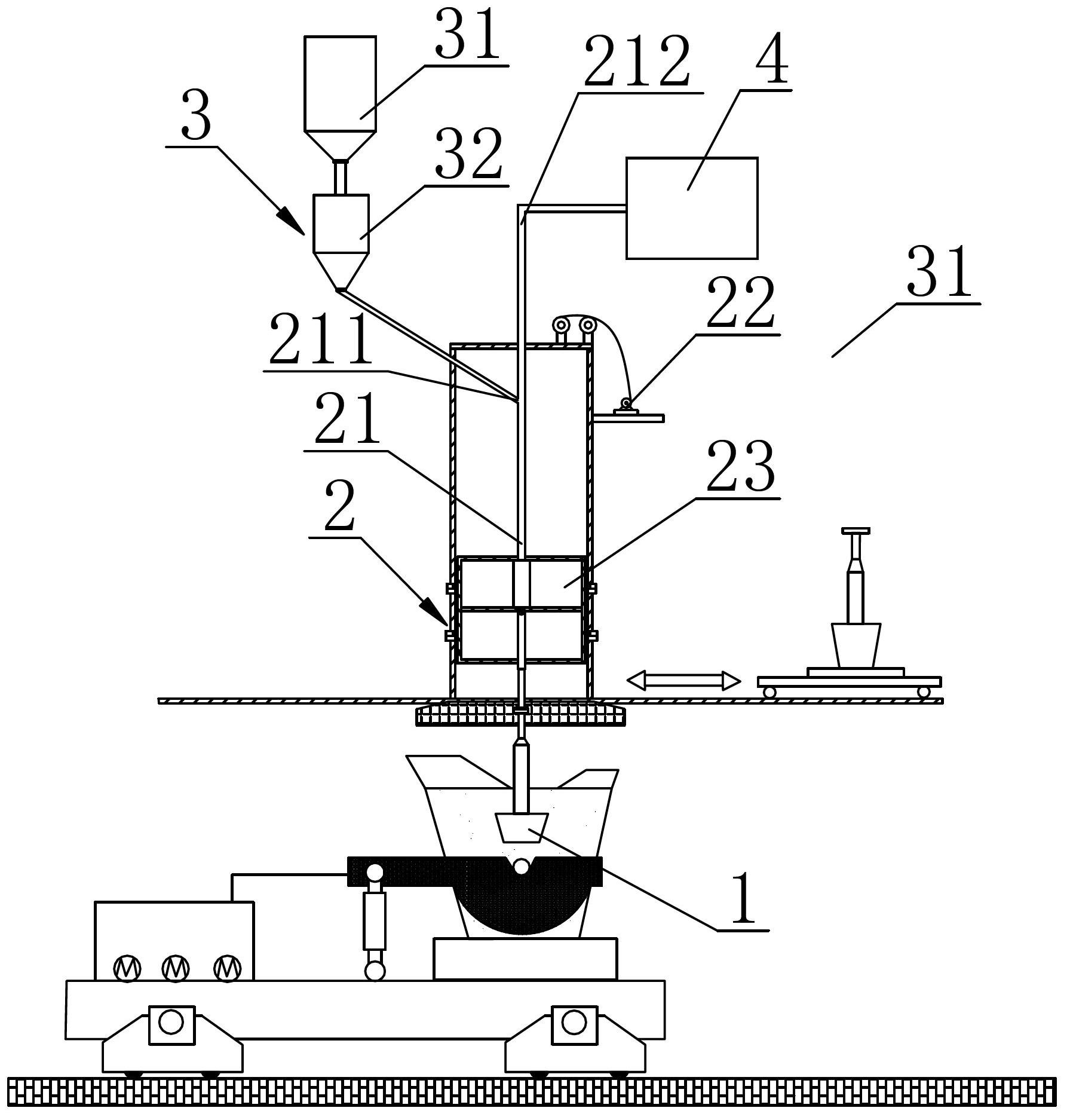

Intelligent molten iron conveying system

PendingCN109353359AReduce temperature dropAvoid temperature dropAutomatic systemsWagons/vansControl systemIron transport

The invention provides an intelligent molten iron conveying system. The system comprises a haulage motor body, a molten iron conveying vehicle body, a vehicle-mounted control system and a ground control system, wherein the vehicle-mounted control system is used for controlling motions of the haulage motor body and the molten iron conveying vehicle body according to a control instruction, the ground control system is used for collecting external environment information and controlling a ground advancing line of the haulage motor body and the molten iron conveying vehicle body according to the control instruction, and a centralized control platform is used for sending the control instruction to the vehicle-mounted control system and the ground control system. Automatic interaction of information and the control instruction is performed through the centralized control platform, a molten iron transporting vehicle achieves unmanned and organization scheduling intelligence in the whole molten iron transporting working process from a blast furnace casting field to a steel making transit station, the haulage motor operation efficiency is improved, the iron molten temperature drop is lowered, the road and haulage motor operation safety is improved, equipment damage and accidents caused by faults such as worker operation and judgment are completely eradicated, the operation risk is lowered, and personal safety of workers is ensured.

Owner:CISDI ENG CO LTD

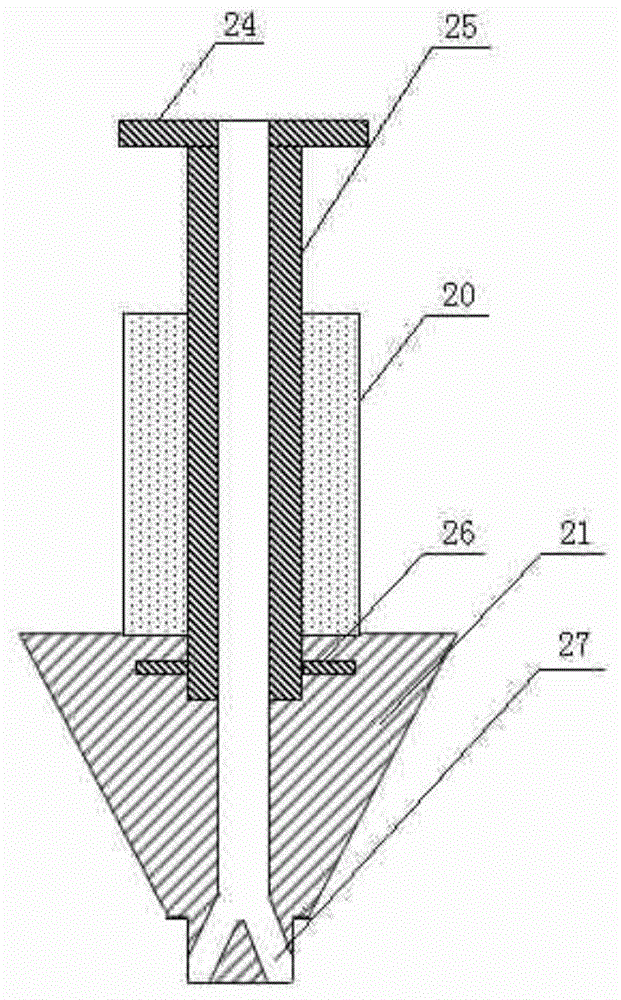

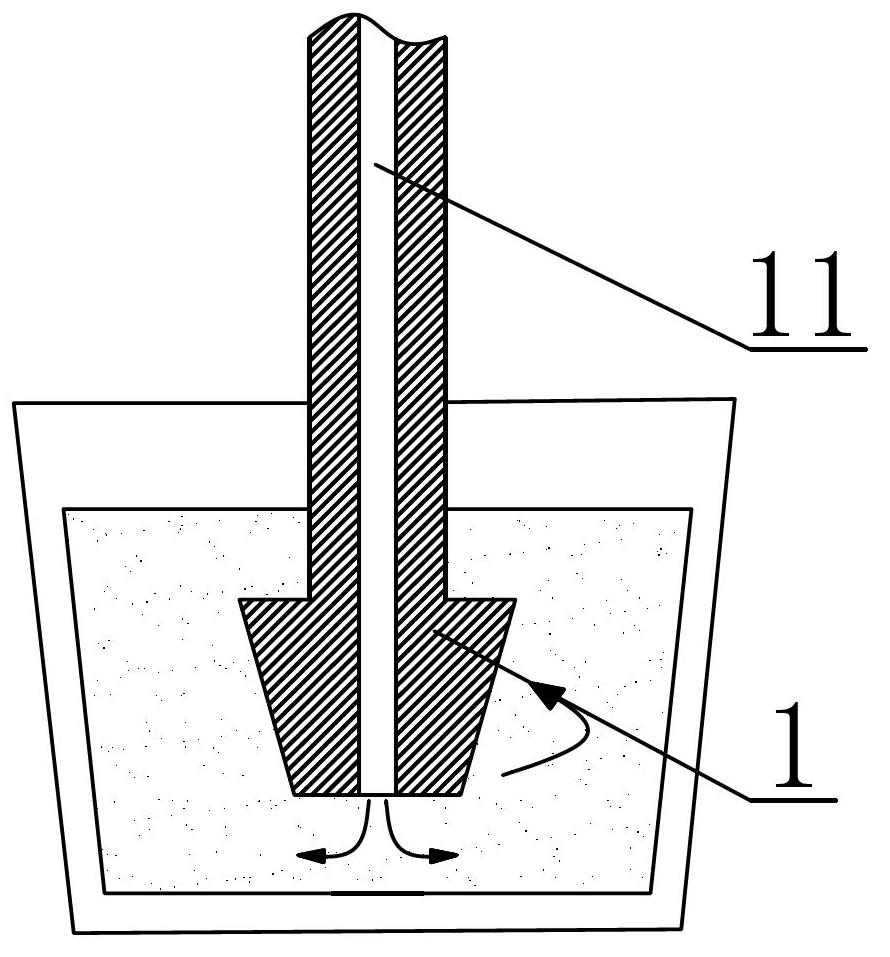

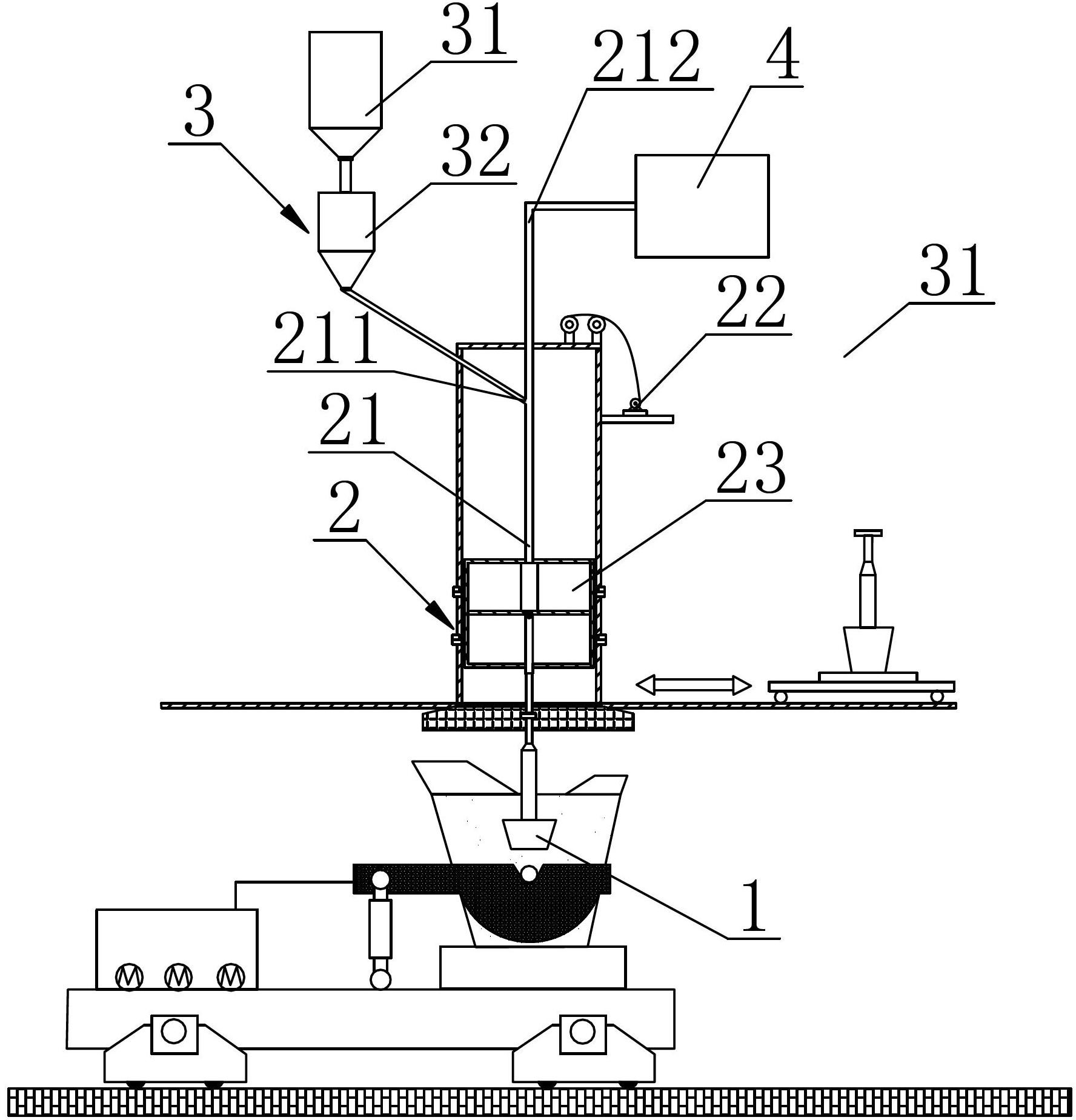

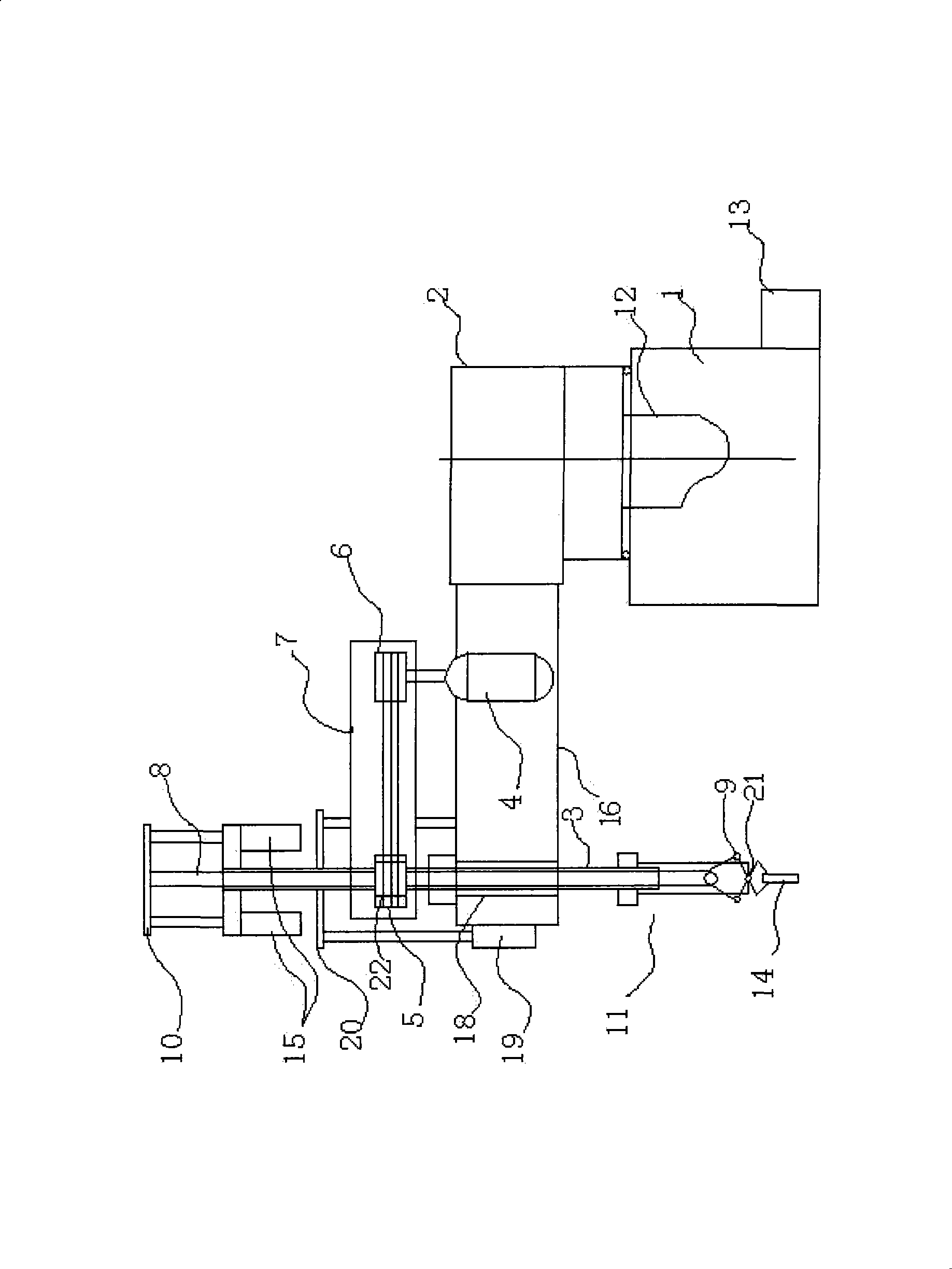

KR (knotted reactor) powder spraying, stirring and desulfurizing device and method

InactiveCN102676741AThe desulfurization cycle is shortenedReduced desulfurization working timeGranularityEngineering

The invention relates to a KR (knotted reactor) powder spraying, stirring and desulfurizing device. The KR powder spraying, stirring and desulfurizing device comprises a stirring head and a driving device for controlling the stirring head to act, wherein the driving device comprises a connecting rod linked with the stirring head, a lifting device for driving the connecting rod to move up and down and a stirring motor for driving the connecting rod to rotate. The KR powder spraying, stirring and desulfurizing device is characterized by further comprising a feeding system and a high-pressure gas source, wherein a through hole for introducing high-pressure inert gas and desulfurizing agents is formed on the stirring head, and an inlet of the through hole is communicated with a desulfurizing agent outlet and a high-pressure gas source outlet of the feeding system. The invention further relates to a method for desulfurizing molten iron by using the KR powder spraying, stirring and desulfurizing device. By using the device, efficient, fast and precise desulfurization can be realized, and the effects of reducing the requirements for granularity of desulfurizing agents, reducing the temperature drop and reducing the loss of the stirring head can be achieved.

Owner:ZENITH STEEL GROUP CORP

Laminar flow width-offset-adjusting cooling device and control method thereof

ActiveCN101837379AEnsure shapeGuaranteed mechanical propertiesSpray nozzlesRoll mill control devicesStrip steelEngineering

The invention provides a laminar flow width-offset-adjusting cooling device and a control method thereof. The laminar flow width-offset-adjusting cooling device comprises a plurality of groups of spray pipe devices, and each group of spray pipe device comprises a collecting pipe, two screw rods, two pistons and two motors, wherein the collecting pipe is provided with a plurality of evenly distributed spray pipes and a water inlet pipe; the two screw rods are respectively arranged at the two ends of the collecting pipe along the central axis of the collecting pipe, and can move inside the collecting pipe along the central axis of the collecting pipe; the two pistons are respectively positioned at the two adjacent ends of the screw rods, the external diameters of the pistons are matched with the internal diameter of the collecting pipe, the sides of the pistons are respectively provided with at least one locating key along the axial direction, and the at least one locating key is meshedwith at least one locating groove arranged on the inner wall of the collecting pipe along the axial direction; the two motors are respectively used for driving the screw rods; and the water inlet pipe is positioned in the middle of the collecting pipe. According to the requirements of the cooling technique of the strip steel with different widths, the invention can be used for adjusting the area of cooling water along the width direction of a channel, thus reducing the temperature reduction of the side of the strip steel, and ensuring the uniformity of the profile shape, the mechanical performance, the temperature and the phase change of the strip steel along the width direction.

Owner:BAOSHAN IRON & STEEL CO LTD +2

Ladle top slag deoxidation modifier for ultralow carbon steel, and use method thereof

The invention relates to a ladle top slag deoxidation modifier for ultralow carbon steel, and a use method thereof. The technical problems of complex preparation process, high production cost and easyenvironment pollution during use of existing ladle top slag modifiers for ultralow carbon steel are mainly solved. The ladle top slag deoxidation modifier for ultralow carbon steel comprises 18-28 wt% of Al, 20-30 wt% of CaCO3, 3-7 wt% of CaO, 5-10 wt% of Al2O3, 5-9 wt% of CaF2, 5-8 wt% of MgO, 6 wt% or less of Na2CO3, and the balance of inevitable impurities; and the particle size of all components in the ladle top slag deoxidation modifier is less than or equal to 1 mm. The modifier can significantly improve the slag crusting problem of the ladle and improve the fluidity of molten steel.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Steel-making method and application thereof and continuous casting method

InactiveCN103160634AShort processing timeReduce temperature dropManufacturing convertersSlagAdditive ingredient

The invention discloses a steel-making method and an application thereof and a continuous casting method, wherein the method comprising the following steps: firstly, a converter can be used for an primary making and then molten steel obtained from the primary making can be tapped in a steel ladle; secondly, in a steel tapping process, before steel is alloyed, the molten steel can be in recarburization and in selective deoxidization so as to regard total weight of the molten steel as a basic standard and activated oxygen contents of the molten steel is less than or equal to 100 parts per million (ppm); a slag foaming agent can be added to absorb impurities in the molten steel and gas evolution of the slag foaming agent is larger and equal to 90 liters per kilogram; thirdly, after the steel tapping argon can be blew into the molten steel of the steel ladle so that the molten steel can be in thermoregulation process; an selective feeding aluminum and a selective feeding carbon can be carried out according to ingredients of the molten steel so as to regard the total weight of the molten steel as the basic standard and the activated oxygen contents of the molten steel is less than and equal to the 50 ppm and carbon content of the molten steel can be adjusted as a middle limitation of ingredient demands of steel types. According to steel-making method and the application and the continuous casting method, the steel-making method which is provided can be used for accurately controlling the ingredients of the molten steel and regulating rhythms of making steel. The steel-making method is short in process time, small in temperature fall degree and low in energy consumption.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Desulfurizing agent and application thereof as well as molten iron krypton (KR) desulfurization method

The invention discloses a desulfurizing agent, which is characterized by consisting of the following components in percentage by weight: 25-31% of calcium oxide, 10-20% of calcium fluoride, 10-25% of calcium carbide, 4.5-15% of calcium carbide, 3-6% of alumium and 5-8% of aluminium oxide, wherein the particle diameter of the desulfurizing agent is not greater than 2mm. In addition, the invention discloses an application of the desulfurizing agent in vanadium-containing molten ion krypton (KR) desulfurization and a molten iron KR desulfurization method. The desulfurizing agent disclosed by the invention is applicable to the desulfurization of the vanadium-containing molten ion.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

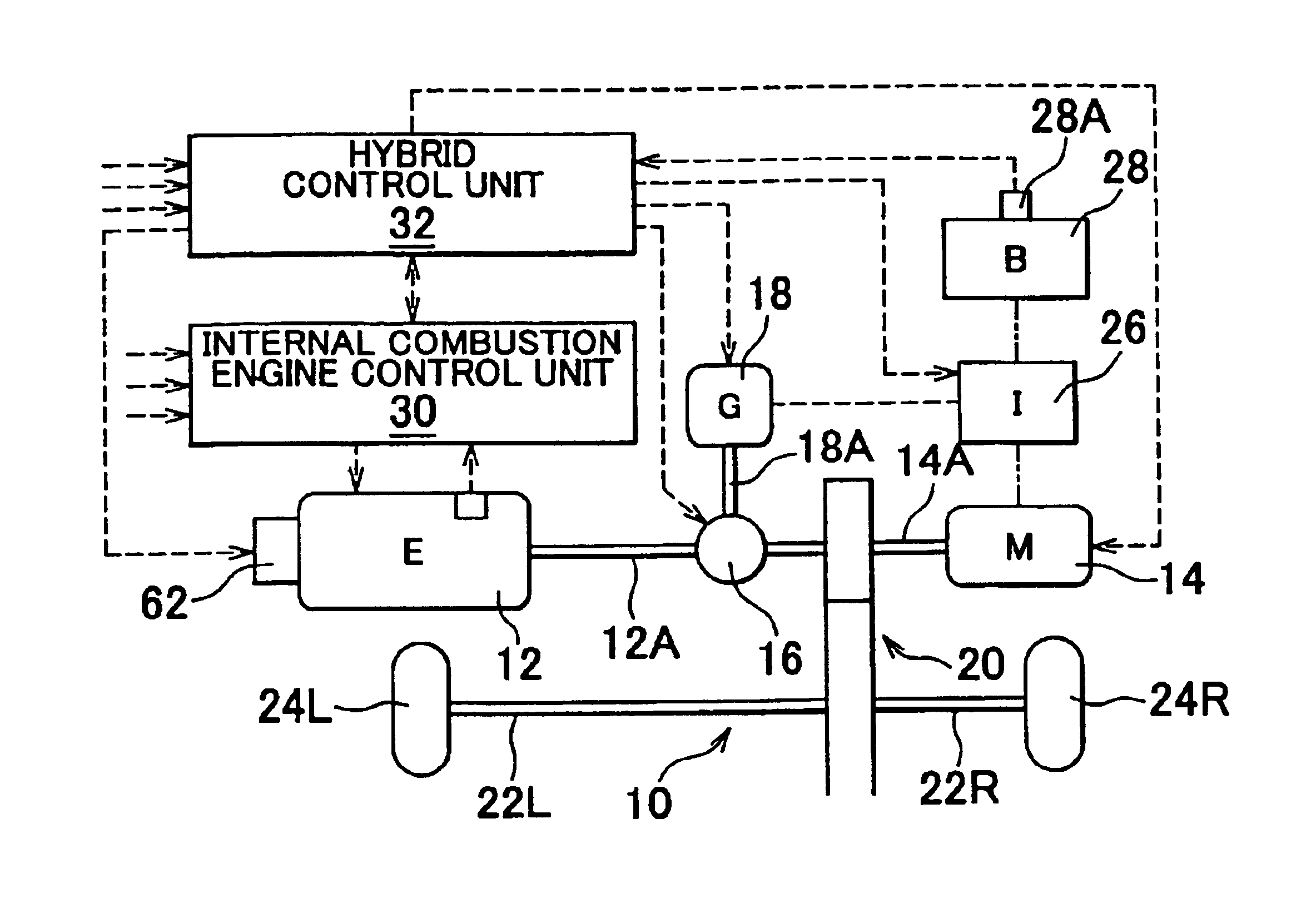

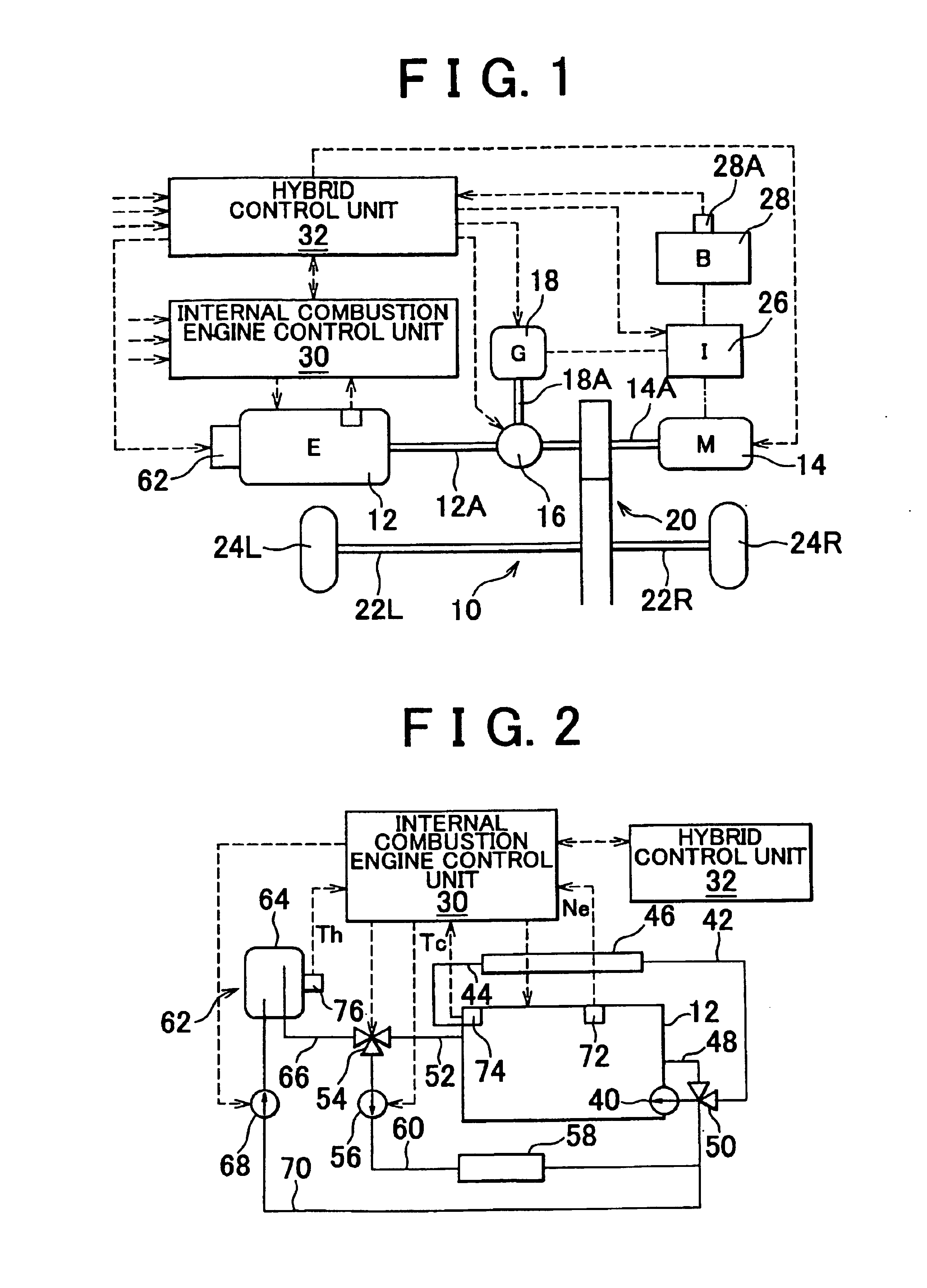

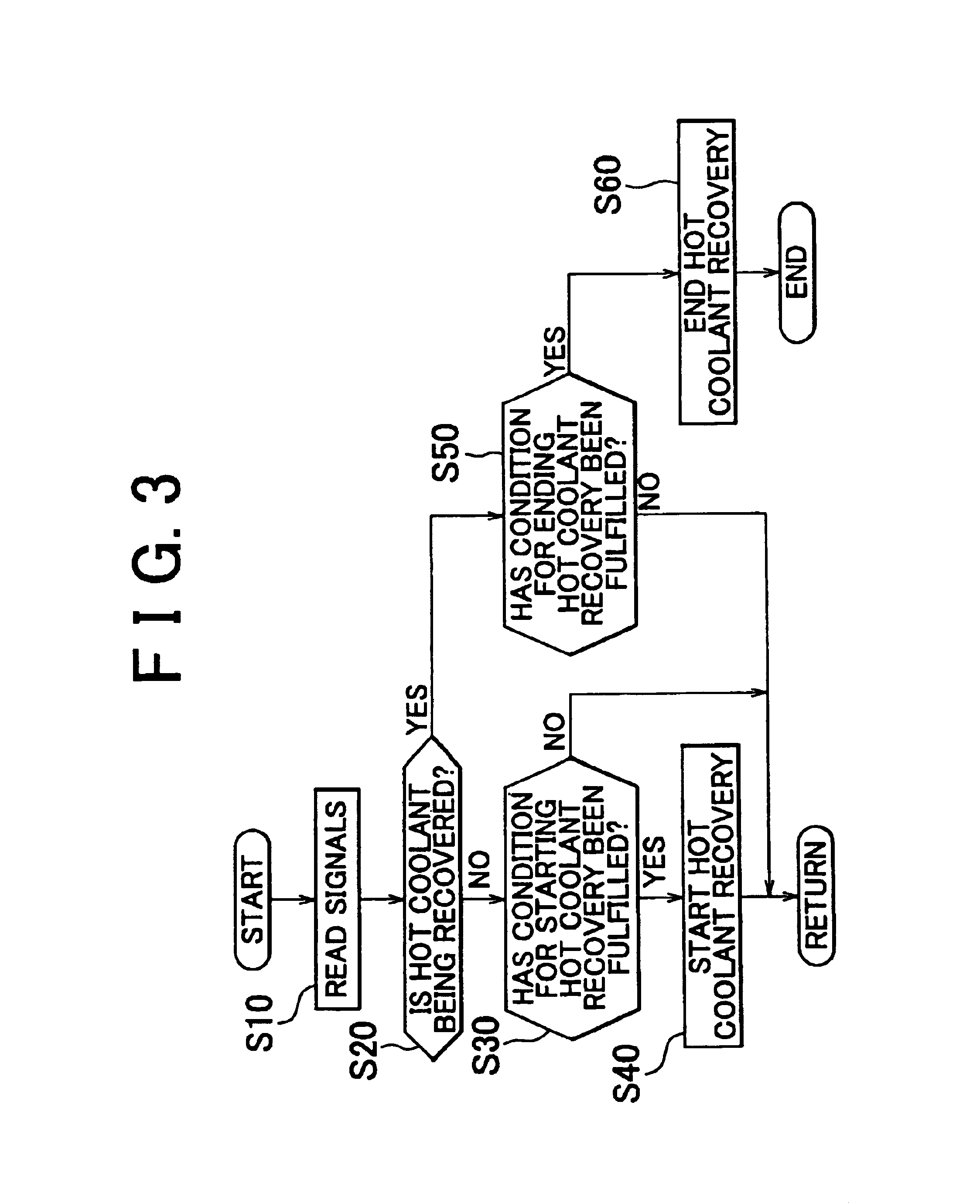

Hot coolant type heat accumulating apparatus for a hybrid vehicle and heat accumulating method thereof

InactiveUS6928962B2Improve cold start performanceReduce exhaust emissionsHybrid vehiclesInternal combustion piston enginesInternal combustion engineHybrid vehicle

A hot coolant type heat accumulating apparatus for a hybrid vehicle is provided that includes an internal combustion engine having first and second coolant circulation systems through which a coolant is circulated using power from the engine, a heat accumulation tank that recovers, via part of the second coolant circulation system, some of the coolant that has been heated by the internal combustion engine, and stores that heated coolant, and a controller. This controller automatically shuts off the internal combustion engine when a predetermined shutoff condition has been fulfilled, circulates the coolant through the second coolant circulation system while the internal combustion engine is shutoff, and inhibits recovery of the hot coolant while the internal combustion engine is shutoff by automatic shutoff.

Owner:TOYOTA JIDOSHA KK

Technique for rolling figured steel for magnetic suspension train rail

ActiveCN101214494ALow costIncrease productivityRoll force/gap control deviceTemperature control deviceProduction lineThermal treatment

The invention belongs to the technology field of metal thermal treatment, which relates to the rolling technology of deformed steel used for a maglev train rail. The invention comprises the procedures in turn of rough rolling, finishing rolling, coolant-controlling and straightening, which is characterized in that two reversible mills rolling is adopted for rough rolling and the maximum rolling force of a two reversible mill is 8000 to 10000KN. And the rolling deformation should account for 60 to 90 per cent of total deformation. Three-stand universal continuous rolling line with high rolling force and high accuracy is adopted for finishing rolling to realize mixing roll under universal mode. The invention can merely use large H-shaped hot- rolling production line to produce finished products and does not require thermal treatment and machining process, with the result that the cost can be greatly reduced and the requirement of mass production can be fully satisfied.

Owner:LAIWU IRON & STEEL GRP

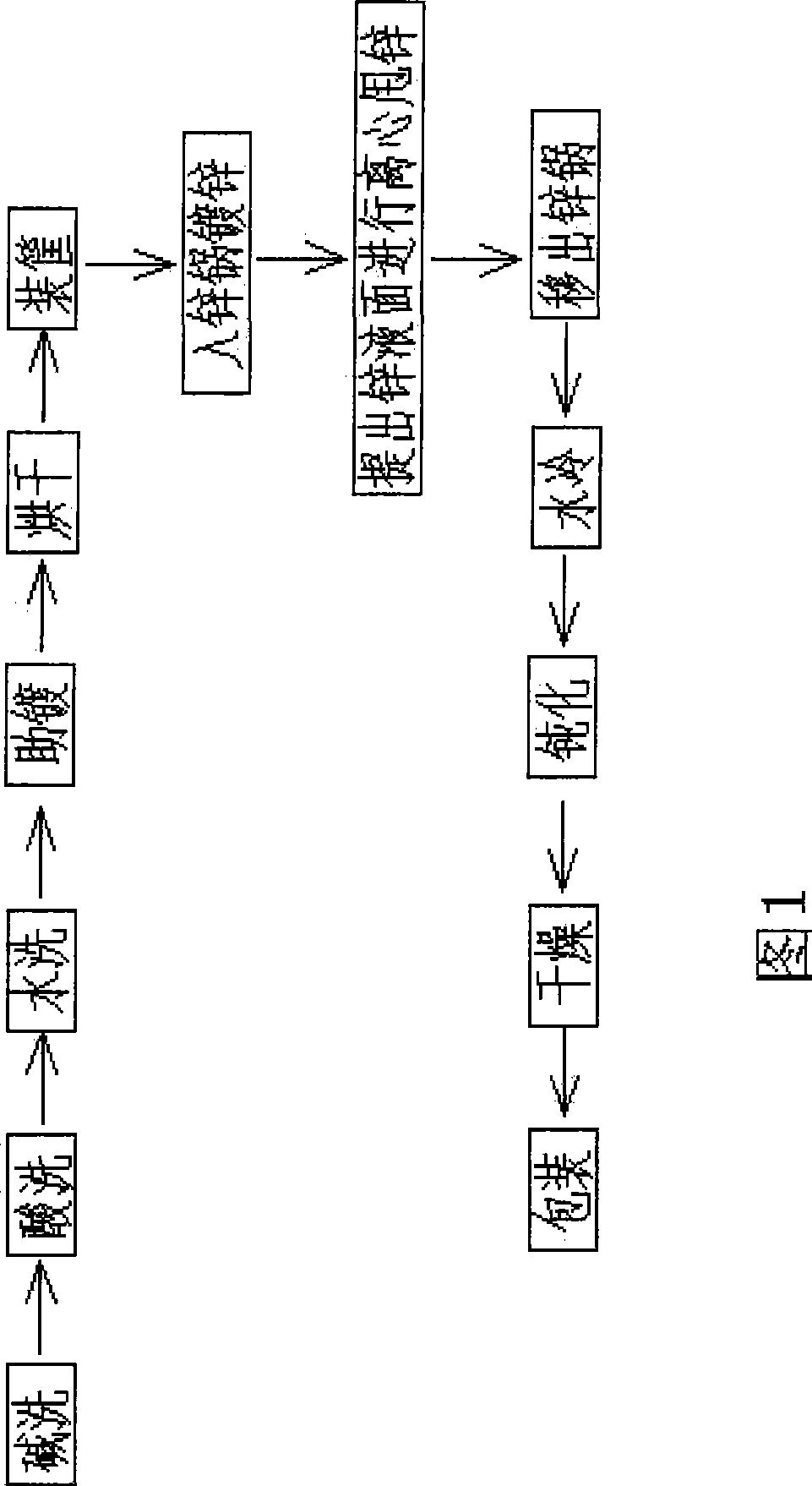

Automatic hot galvanizing technique for steel fastener

InactiveCN101368253AGuaranteed accuracyGuaranteed StrengthHot-dipping/immersion processesAutomatic controlAcid washing

The invention discloses an automatic pot galvanizing technique of a steel fastener which orderly includes the working procedures like caustic washing, acid washing, water washing, assistant plating, drying, crating, galvanizing, centrifugal zinc throwing, water cooling, passivating, drying, packaging, and the like. The galvanizing temperature is between 450 and 480 DEG C; the working procedures of galvanizing and centrifugal zinc throwing are automatically controlled; the centrifugal zinc throwing is to hoist a galvanized workpiece out of a galvanized surface with a galvanizing material basket and lead the galvanized workpiece to horizontally rotate with the galvanizing material basket to make centrifugal movement. The technique leads the galvanized workpiece to instantly carry out zinc throwing without pouring the basket; the temperature drop of the workpiece is small; the galvanizing temperature can be reduced below 480 DEG C; energy is saved; the coherence for the intensity, the precision and the quality of the fastener is ensured; the service life of a zinc boiler is prolonged; the production cost is reduced; the processes for galvanizing and zinc throwing are automatic, safe and effective; besides, the working intensity is low. The technique provided by the invention can be used for carrying out pot galvanizing on the steel fasteners like bolts, nuts, nails, and the like.

Owner:陈冬

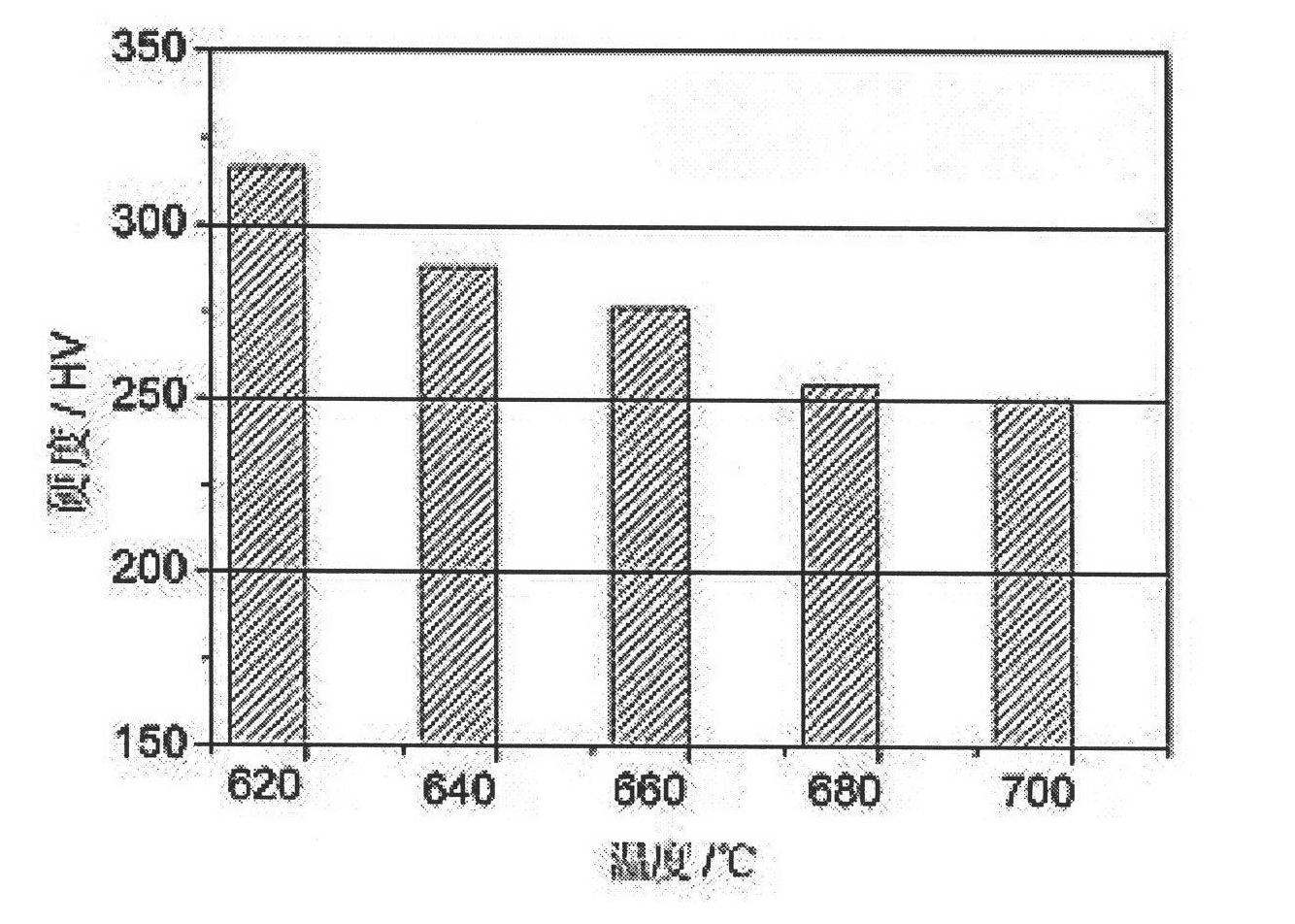

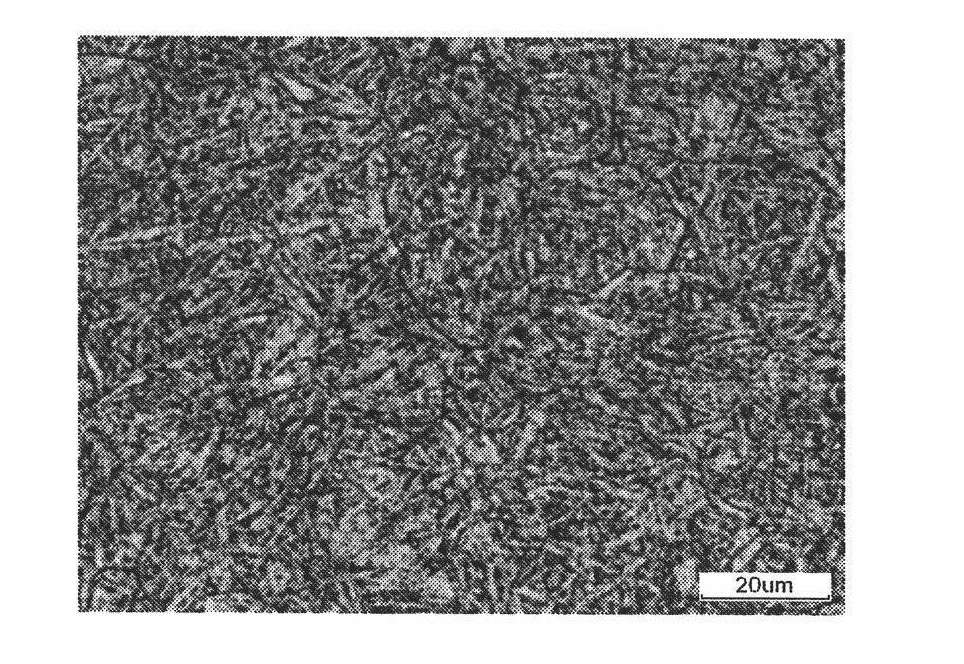

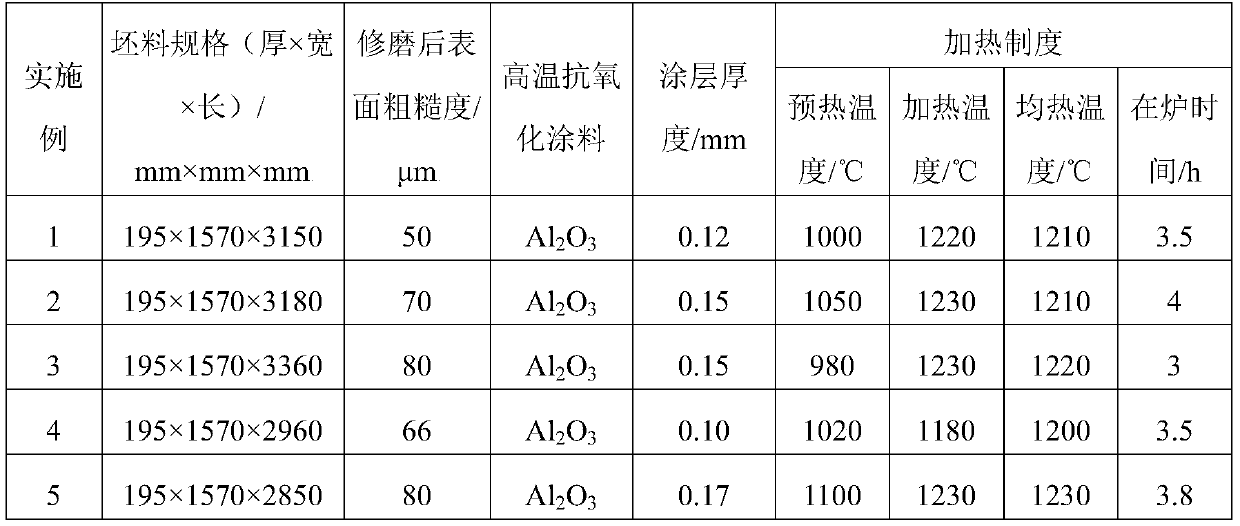

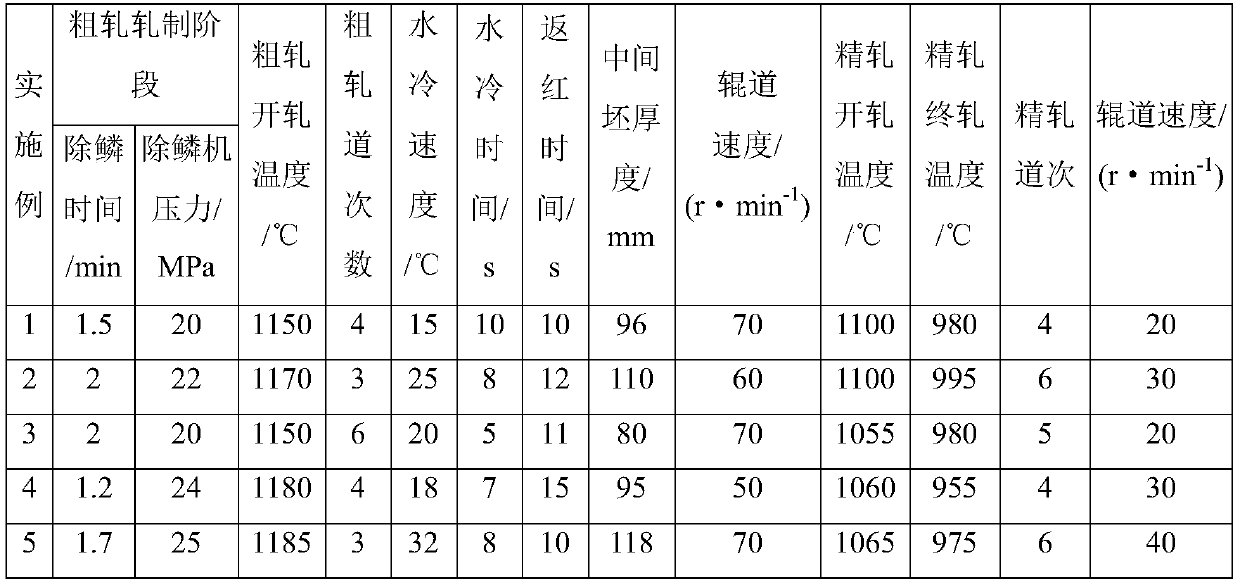

Excellent-performance high-N austenitic stainless steel medium-thick plate and manufacturing method thereof

ActiveCN110499448AIncrease the axial grain rateQuality improvementProcess efficiency improvementReduction rateThick plate

The invention discloses an excellent-performance high-N austenitic stainless steel medium-thick plate and a manufacturing method thereof. The continuous casting slab medium axialite ratio is higher than or equal to 80%; the casting blank surface roughness is smaller than or equal to 100 microns; the casting blank preheating section temperature is 980 DEG C to 1100 DEG C, the heating section temperature is 1160 DEG C to 1230 DEG C, the soaking section temperature is 1200 DEG C to 1230 DEG C, and the in-furnace time is 3 h-4 h; the rough rolling starting temperature is higher than or equal to 1150 DEG C, the first-two gate rolling reduction rate is higher than or equal to 20%, the rough rolling follow-up gate reduction rate is smaller than or equal to 15%, and the intermediate blank thickness is 80 mm to 120 mm; the finish rolling start temperature is higher than or equal to 1050 DEG C, the final rolling temperature is higher than or equal to 950 DEG C, and the rolling reduction rate issmaller than or equal to 20%; and the solution temperature is 980 DEG C to 1050 DEG C, and the in-furnace time is 2 min / mm to 5 min / mm. The product width is 2200 mm to 4000 mm, and the product thickness is 30 mm to 60 mm. The -196 DEG C yield strength is larger than or equal to 350 MPa, the tensile strength is larger than or equal to 1250 MPa, the elongation is larger than or equal to 40%, and thesurface crack rejection rate drops from more than 15% to less than 5%.

Owner:ANGANG STEEL CO LTD

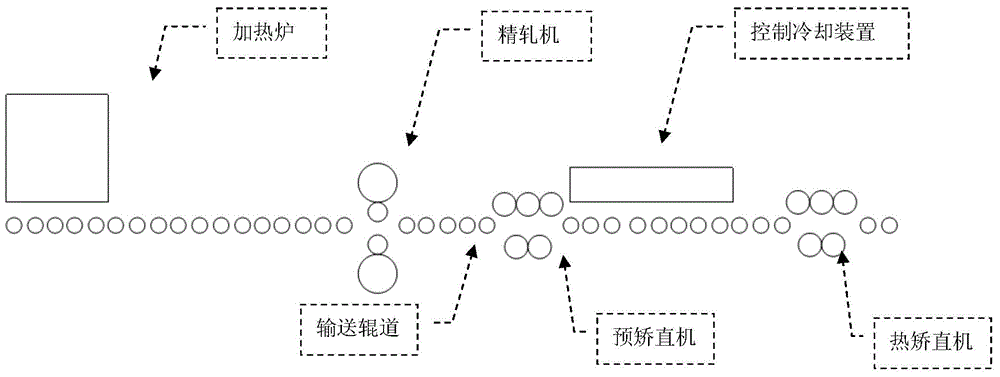

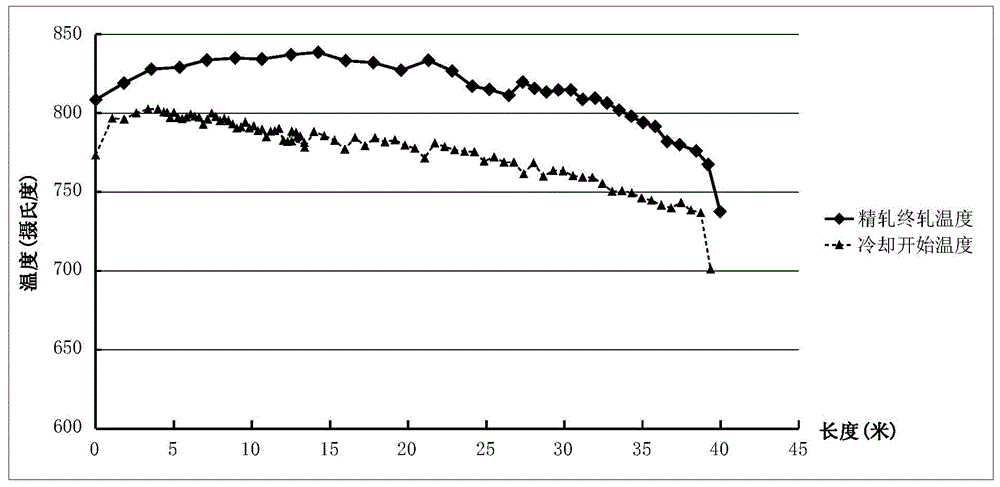

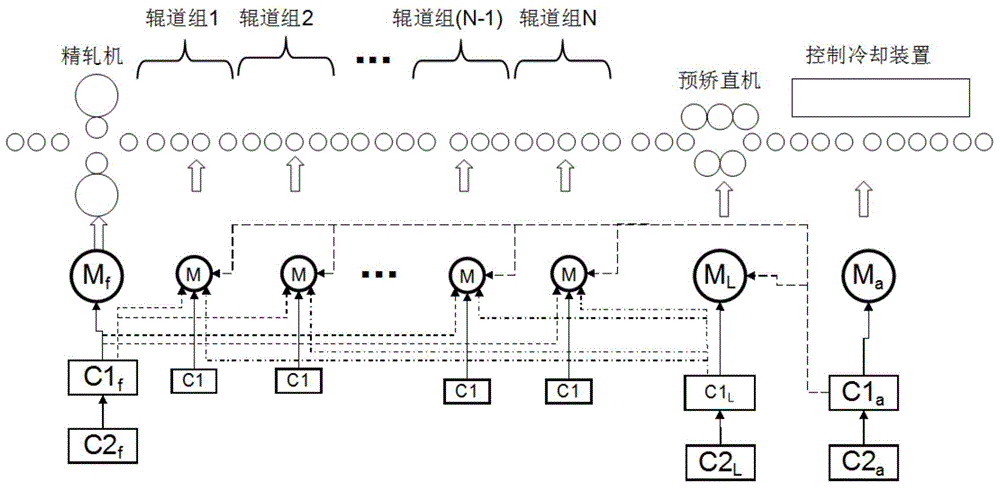

Control method of medium-thickness plate rolling and conveying speed

ActiveCN105215057AReduced risk of overloadingReduce scratchesRoll speed control deviceProduction lineAutomatic control

The invention relates to an automatic speed control method in a final rolling process of a rolling mill, in a roller way conveying process of steel plates from a finish rolling mill to a control cooling device and in a pre-straightening process, and aims to satisfy the TMCP process parameter requirements of smaller difference between the final rolling temperature of finish rolling and the cooling beginning temperature of some products. The technical scheme of the invention is suitable for a modern medium-thickness plate production line arranged by a finish rolling mill, a pre-straightener and a control cooling device and having an automatic control system. The technical scheme of the invention gives a velocity diagram (10) of integrated steel plate operation satisfying the seamless speed joint between the steel polishing process and the steel plate transportation process in final rolling considering the final rolling temperature and cooling beginning temperature process requirements; and the technical scheme newly adds a speed control module for global coordinative calculation of parameters of the velocity diagram for realizing the velocity diagram of integrated steel plate operation, and improves new speed control schemes of speed control modules of traditional all units.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for controlling temperature rise in secondary combustion of vacuum refining exhaust gas

The invention discloses a method for controlling temperature rise in secondary combustion of vacuum refining exhaust gas. According to the method, at the early stage of RH decarburization, only when the vacuum degree reaches 0.6kpa, an oxygen lance is controlled to go down for blowing oxygen, the blowing oxygen flow is reduced along with the increase of time; at the middle and later periods of RH decarburization, the blowing oxygen flow is reduced continuously, the temperature rise amplitude in the secondary combustion reaches 15-20 DEG C, so that formation of cool steel in a hot bending pipe is greatly lowered, the temperature in a groove is improved, temperature drop in RH processing is reduced, and the purity and components of molten steel are not affected.

Owner:BAOSHAN IRON & STEEL CO LTD

Production method for duplex stainless steel hot-rolled coils

ActiveCN104032108AEliminate edge cracksImprove thermoplasticitySS - Stainless steelHigh pressure water

The invention relates to a production method for duplex stainless steel hot-rolled coils. The production method comprises such steps as smelting, continuous casting, slab polishing, tandem type slab heating, high-pressure water scale removal, rough rolling, rolling by a steekle mill and coiling; the content of S in steel is controlled below 0.0007%; Creq / Nieq is controlled within 1.92-1.97; the slab isometric crystal rate is controlled above 80%; the reasonable slab length and slab heating temperature are actually determined by combining with the scene; the process of slab high-pressure water scale removal one-gate and rough rolling frame non-scale removal is adopted; in particular, the rolling temperature of the hot rolling steekle mill is controlled; the produced stainless steel hot-rolled coils have no edge cracks, so that the yield is prominently improved; the problem of the edge crack defect generated by rolling the steel coils through the steekle mill in the rolling process is solved; and the edge quality of the hot-rolled steel coils is guaranteed.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com