Patents

Literature

98results about How to "Eliminate internal defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

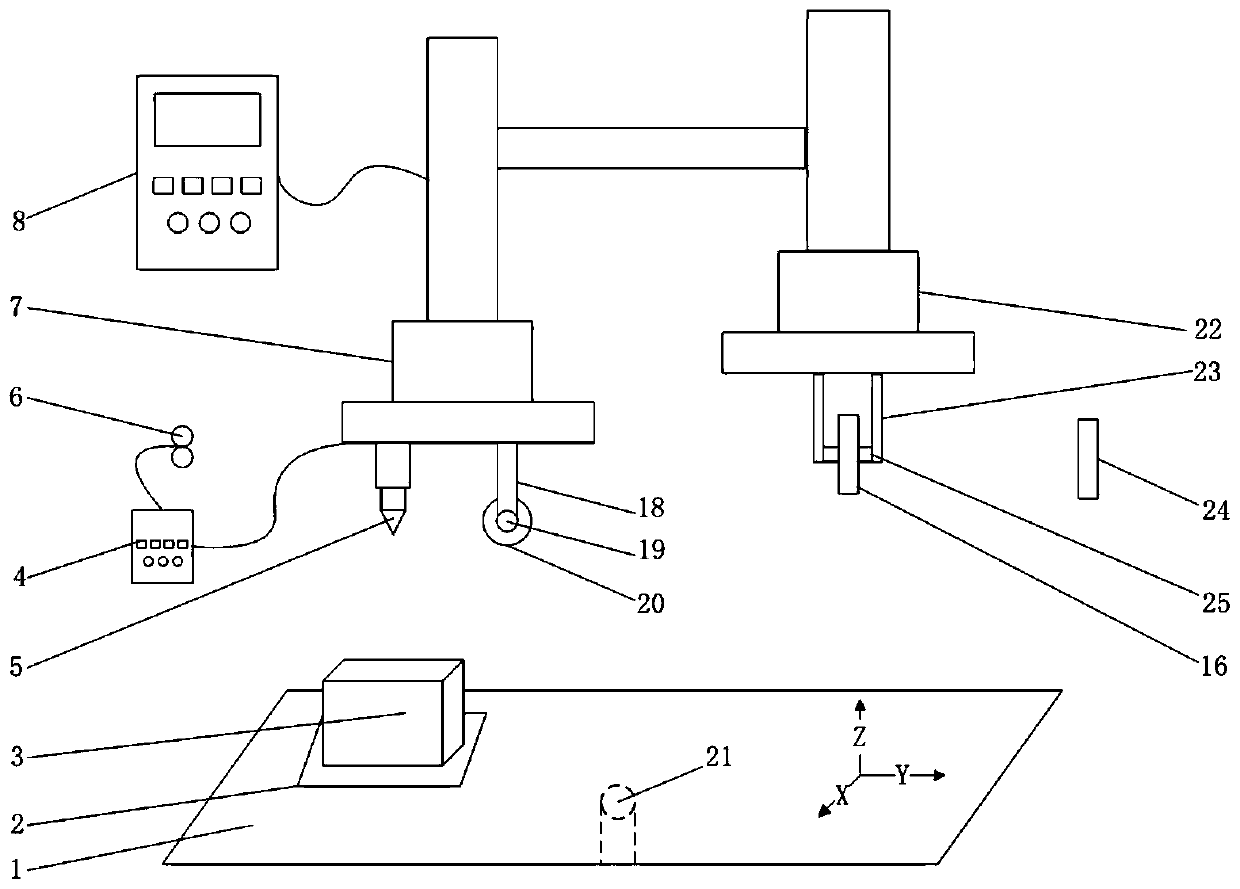

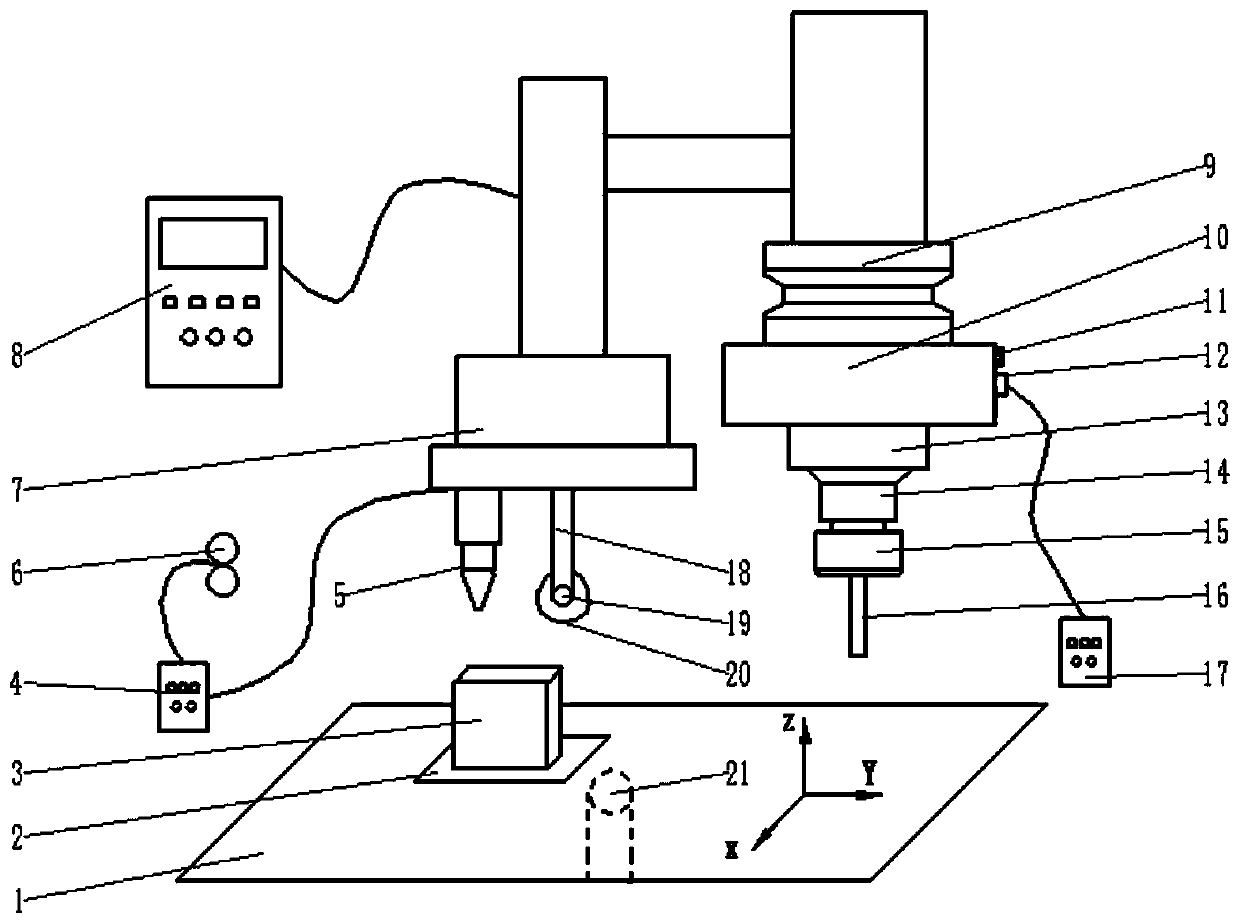

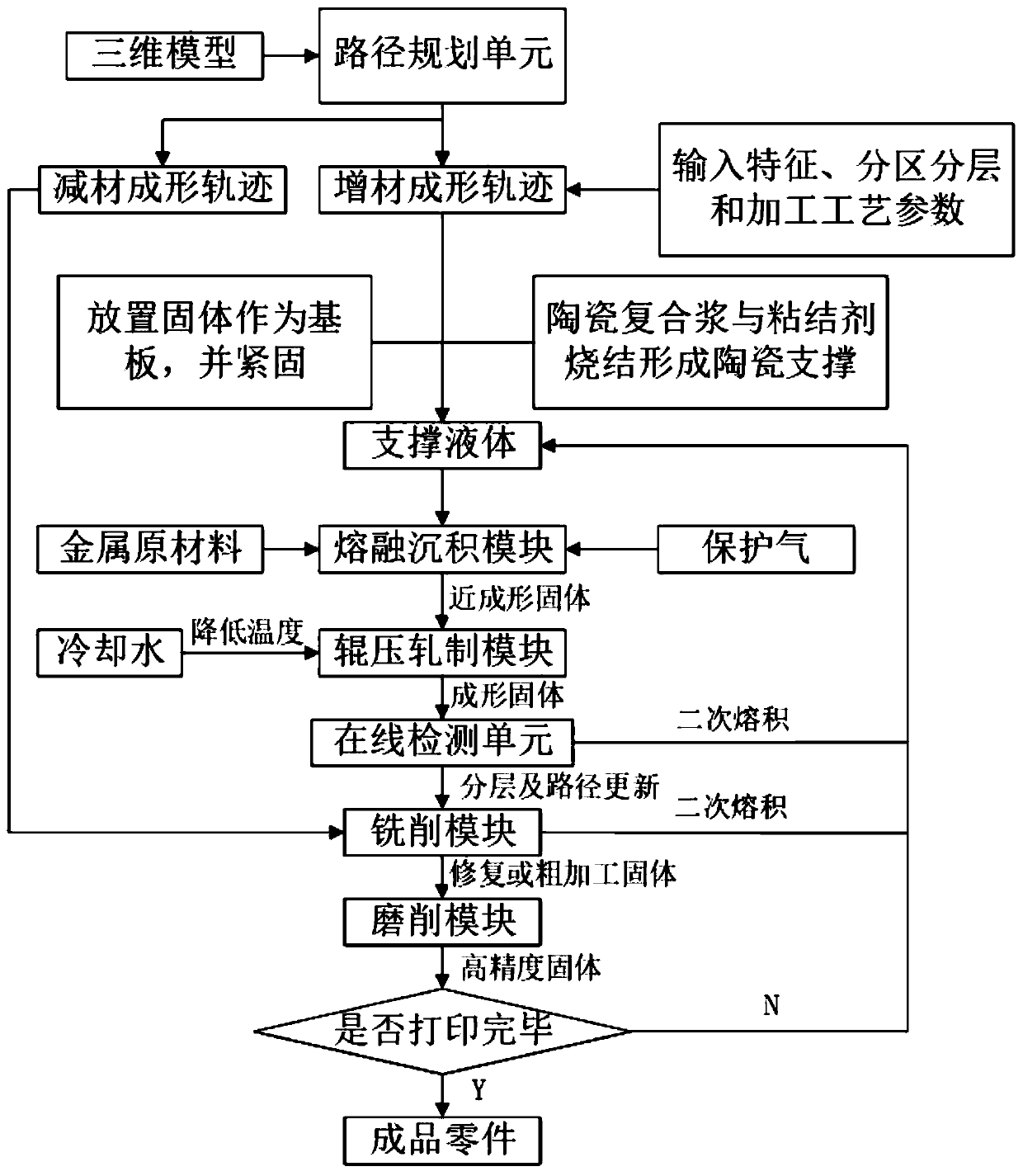

Metal part manufacturing system and method adopting micro-casting-forging and milling-grinding in-situ composite

InactiveCN110076566AImprove tissue mechanical propertiesImprove processing efficiencyAdditive manufacturing apparatusOther manufacturing equipments/toolsEngineeringManufacturing systems

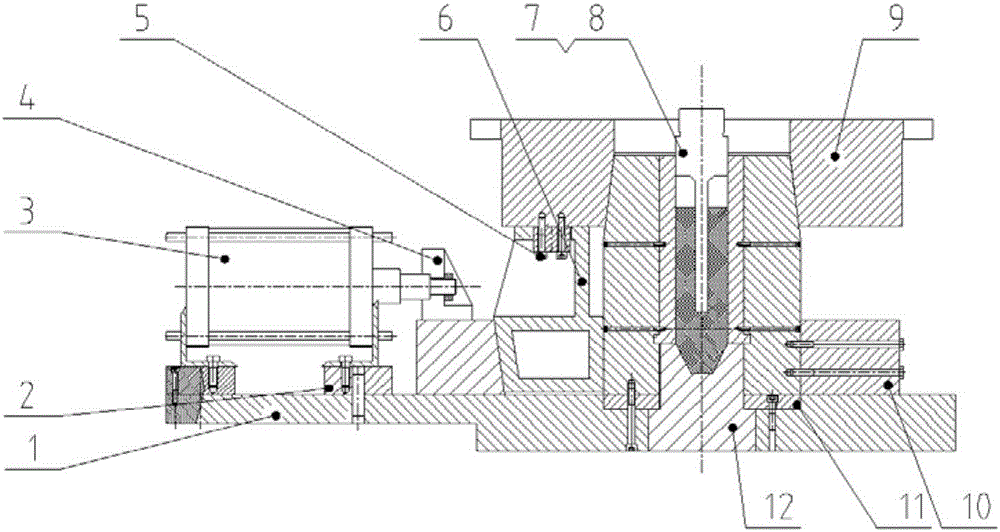

The invention belongs to the field of metal part manufacturing, and particularly discloses a metal part manufacturing system and method adopting the micro-casting-forging and milling-grinding in-situcomposite. The system involves a micro-casting-forging module, a milling module, a five-axis linkage workbench and a control device, wherein the micro-casting-forging module is connected with the milling module and comprises a fusion deposition sub-module and a roller-pressing rolling sub-module, the five-axis linkage workbench is positioned below the micro-casting-forging module and the milling module, and is used for containing metal parts to be formed, and the control device is connected with the fusion deposition sub-module, the roller-pressing rolling sub-module, the milling module and the five-axis linkage workbench. According to the system and method, micro-casting-forging and a milling process are composited to process and manufacture the metal parts, so that the problems that whenthe metal parts are made through the additive manufacturing, the structure is not uniform, the deformation is serious, the residual stress is large, the structure performance is poor, and the surfacequality is poor are solved, and the system and method is especially suitable for processing a high-performance complicated special-shaped element.

Owner:HUAZHONG UNIV OF SCI & TECH

Aluminum alloy workpiece additive manufacturing method implemented through friction stir welding

InactiveCN109108505AImprove mechanical propertiesElimination of internal tissue for refinementWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingVolumetric Mass Density

The invention discloses an aluminum alloy workpiece additive manufacturing method implemented through friction stir welding. On the basis of an existing electric arc additive manufacturing aluminum alloy workpiece, the characteristic that aluminum alloy is soft in property is combined, after an aluminum alloy workpiece is manufactured from electric arc additives layer by layer, friction stir welding intensification treatment is conducted on each layer, and therefore, defects such as pass gaps, interlayer incomplete fusion, air holes and the like can be eliminated through friction stir weldingwhen each layer is manufactured. Compared with the pure electric arc additive manufacturing aluminum alloy workpiece, by means of the method, the structural state of the aluminum alloy workpiece obtained through additive manufacturing can be improved; the grains can be finer; second-phase grains are finer and are distributed more uniformly; and the dislocation density achieved in the aluminum alloy additive manufacturing workpiece is increased. Compared with existing friction stir welding intensification, grain refining and defect elimination are conducted on each layer of the workpiece so that the strength of the whole workpiece can be improved rather than only surface modification, namely surface intensification, is conducted.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

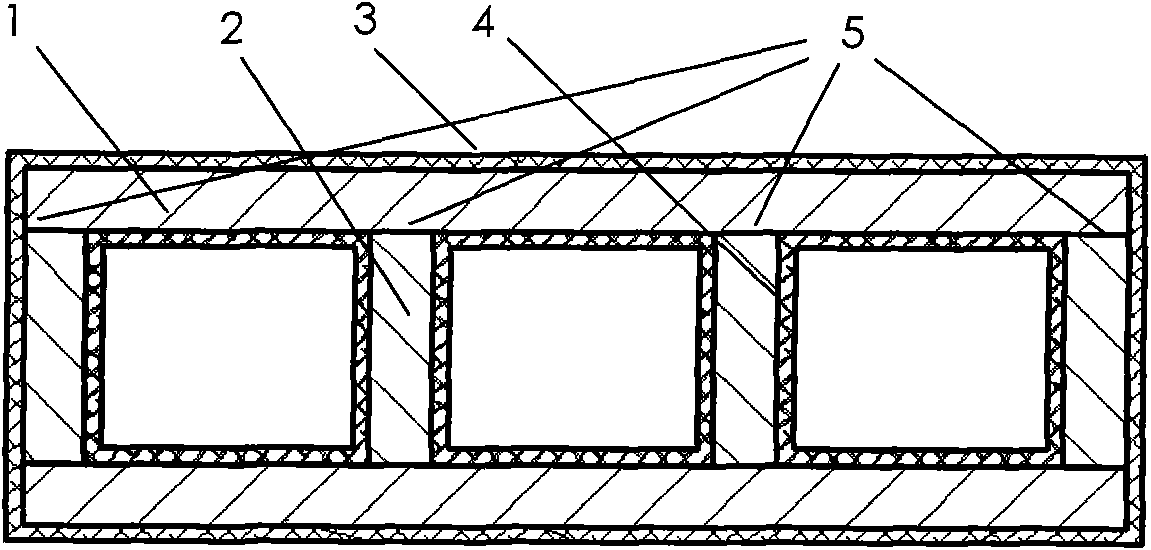

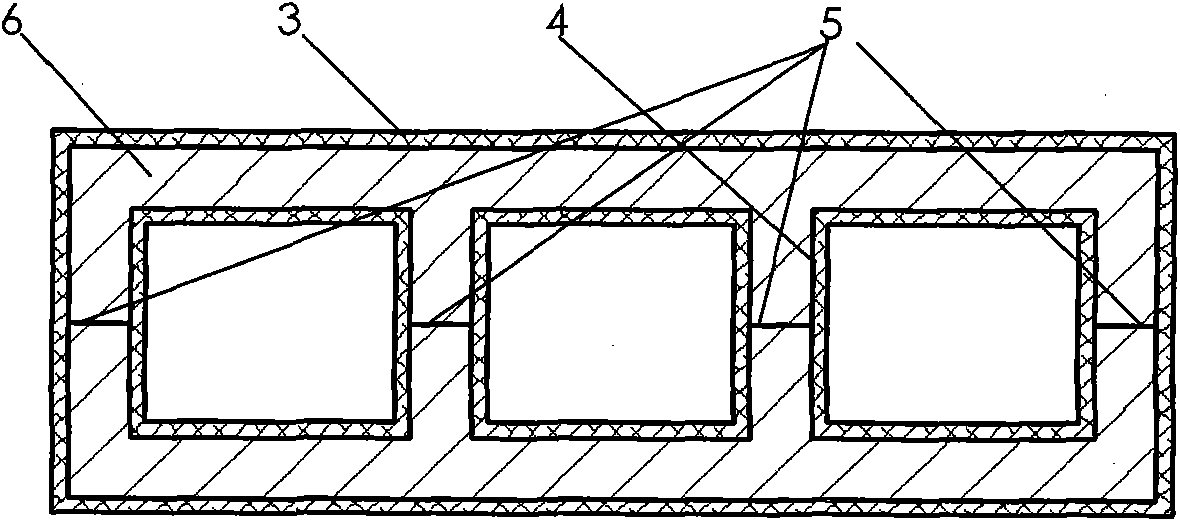

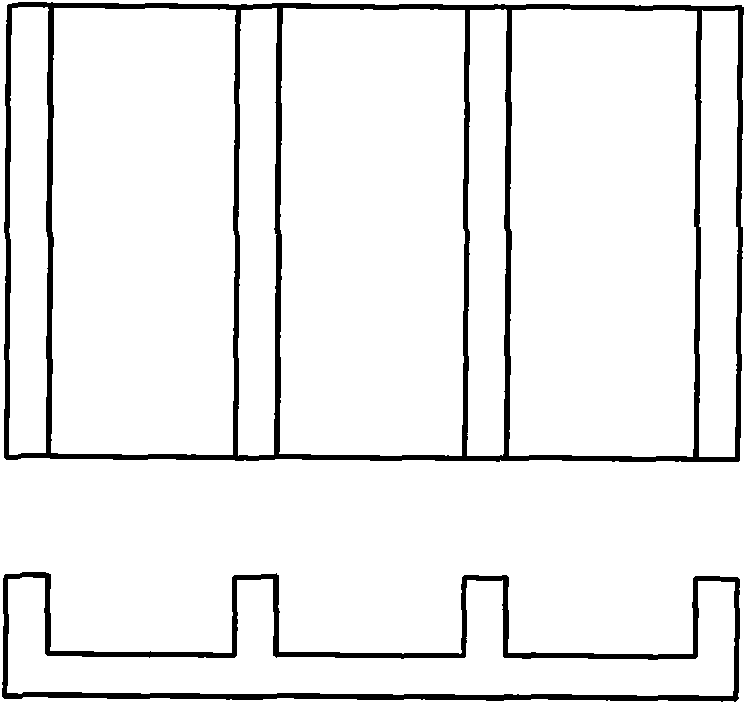

Manufacturing method of titanium alloy hollow component

ActiveCN101786223AIncrease productivityImprove efficiencyNon-electric welding apparatusTitanium alloyStressed skin

The invention relates to a manufacturing method of a titanium alloy thin-wall ribbed hollow component. The method comprises the following steps that: a. the titanium alloy hollow component is decomposed into a stressed-skin and ribbed structure form or a stressed-skin ribbed structure form according to the structure features of a hollow component, and an inner sheath and an outer sheath structure forms are determined according to a hollow part of the hollow component; b. the stressed-skin and ribbed or the stressed-skin ribbed structural part is processed or formed according to the decomposed structure forms; c. the inner and the outer sheaths are processed or formed; d. the stressed-skin and ribbed or the stressed-skin ribbed structural part being well processed is assembled with the inner and the outer sheaths, the inner and the outer sheaths are sealed in a welding way and are vacuum encapsulated, and the vacuum degree is 1.0 *10-3Pa; e. the dispersion connection of each structural part is realized through a hot isostatic pressing method; f. surface treatment on each prefabricated structural part is undertaken so as to prepare the hollow structural component. The manufacturing method has high production efficiency; a plurality of components can be prepared through one technical circulation; and the welding rate is more than 95 percent.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

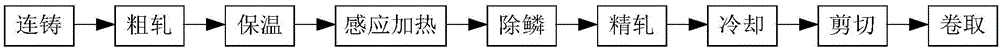

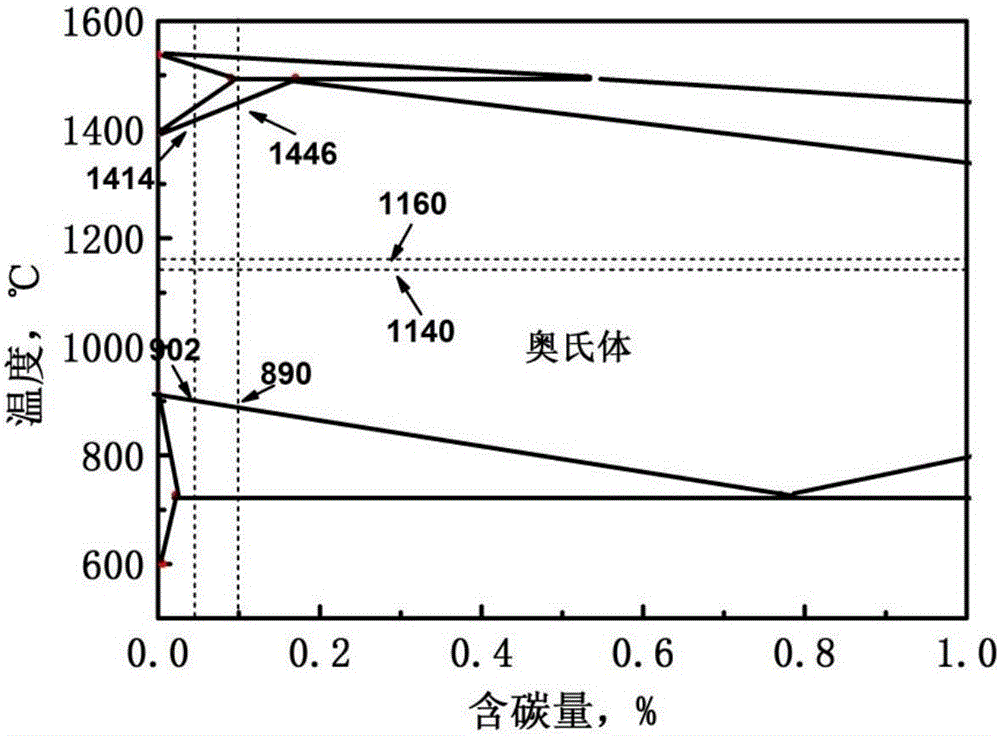

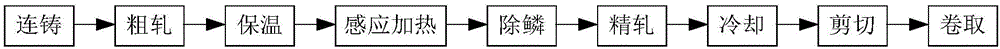

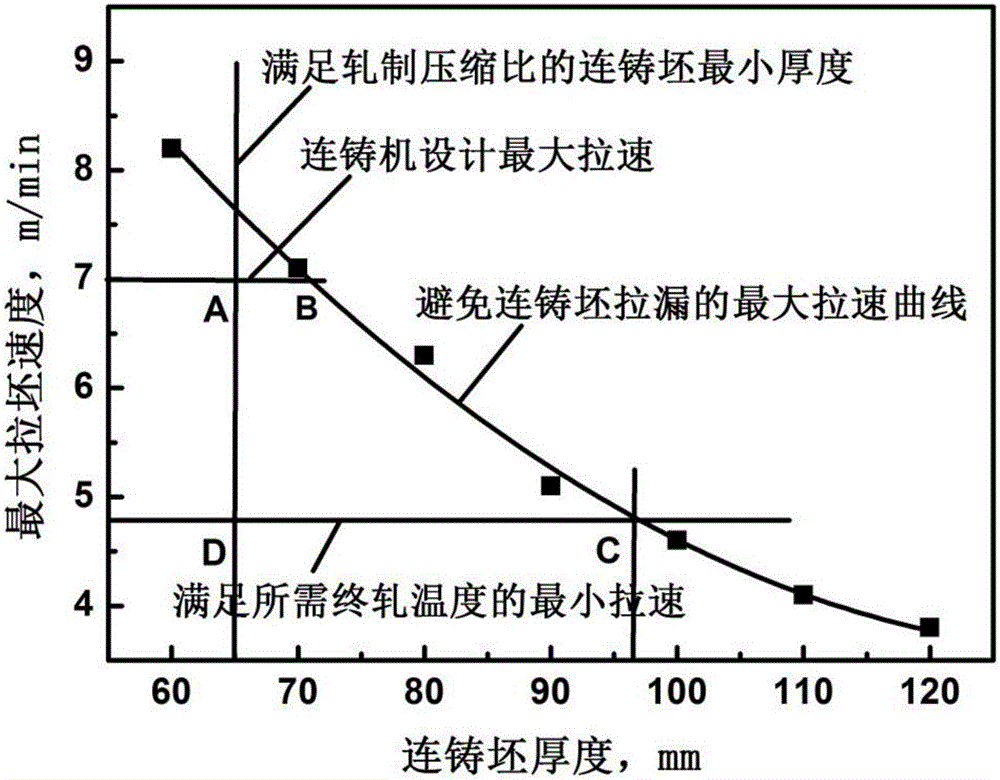

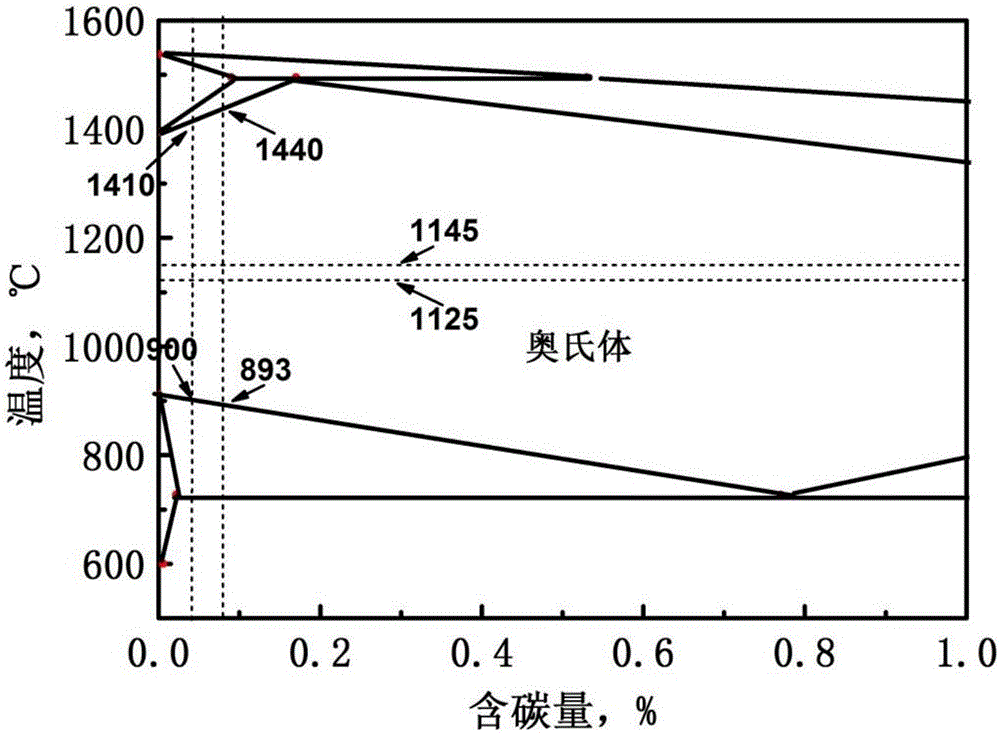

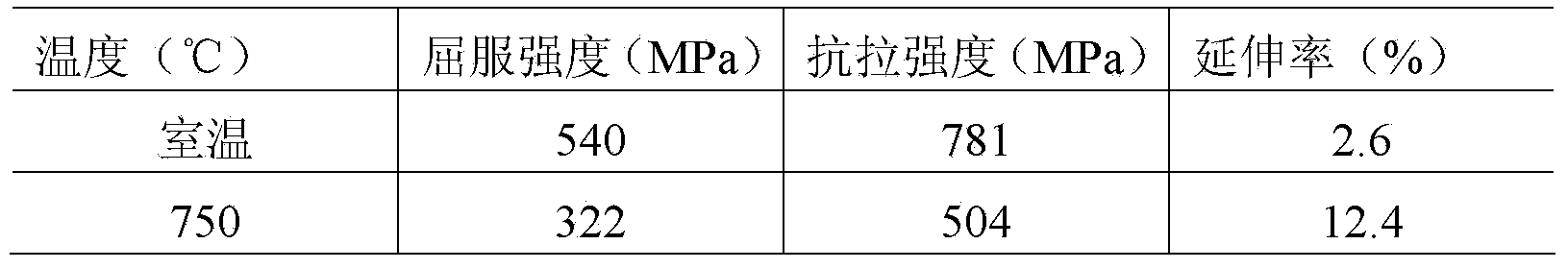

Method for producing thin-gauge dual-phase steel by applying thin slab continuous casting and rolling process

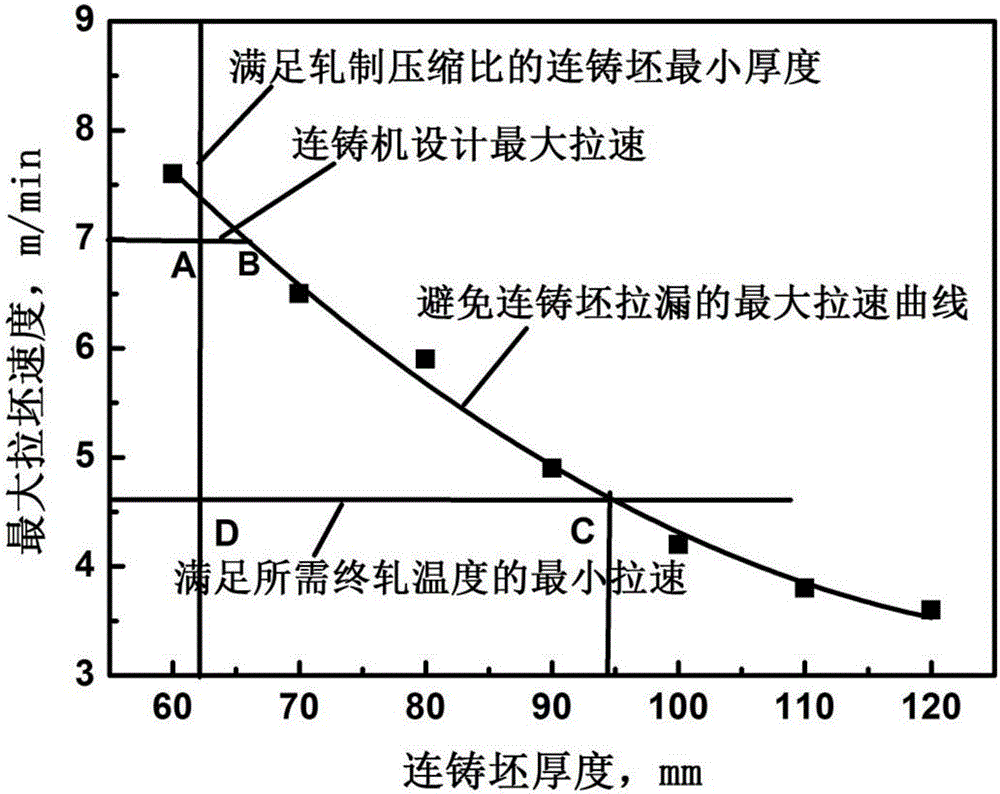

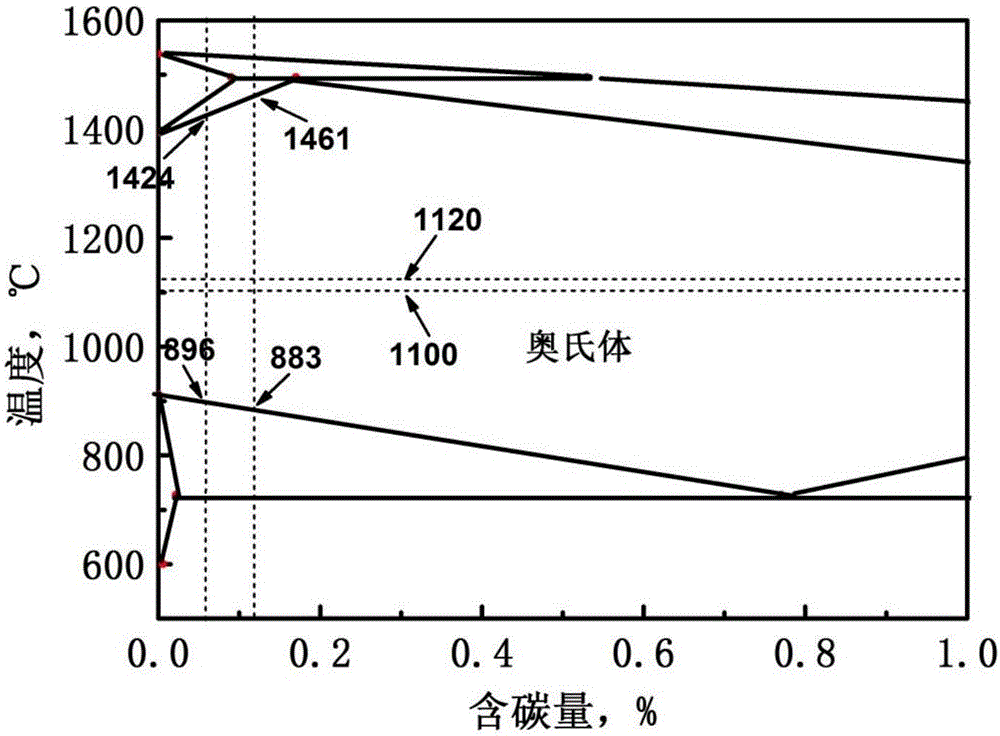

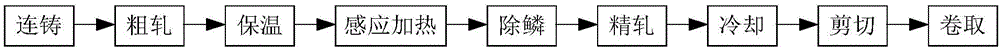

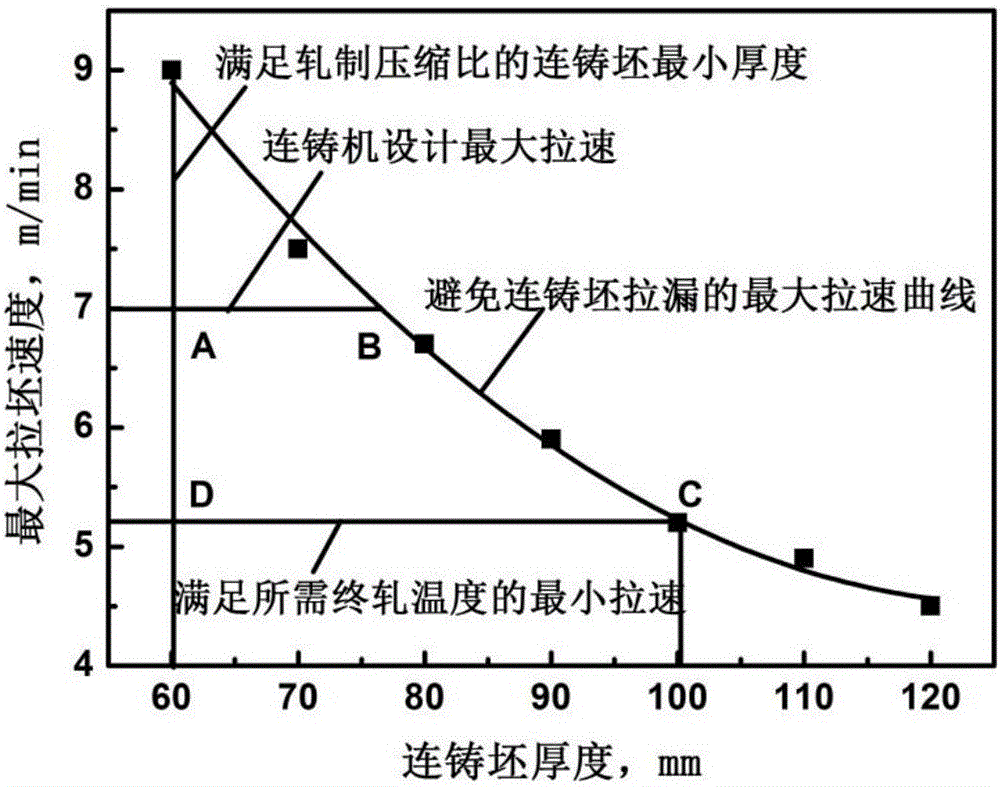

ActiveCN106734200ARealize the demand of "replacing cold with heat"Stable productionTemperature control deviceWork treatment devicesThin slabHigh pressure water

The invention relates to a method for producing thin-gauge dual-phase steel by applying a thin slab continuous casting and rolling process. The method comprises the steps: continuously casting molten steel to form a continuous casting slab with the width of 1300-1600mm and the thickness of 62-94mm; then, sequentially carrying out rough rolling, heat insulation by a heat insulation cover, induction heating, high-pressure water scale removal and finish rolling to obtain ultrathin strip steel with the width of 1300-1600mm and the thickness of 1.5-1.8mm; and finally, carrying out controlled cooling, coil-by-coil shearing and coil winding. A finished product of the thin-gauge dual-phase steel has the yield strength of 370-390MPa, the tensile strength of 590-630MPa and the elongation rate of larger than or equal to 15%. By using the method, hot-rolled thin-gauge dual-phase steel of which the size precision, slab shape precision and comprehensive mechanical property can meet requirements can be stably produced.

Owner:WISDRI ENG & RES INC LTD

Method for producing ultrathin low-carbon steel by use of thin slab casting and rolling process

ActiveCN106583453AStable productionRealize the demand of "replacing cold with heat"Roll force/gap control deviceTemperature control deviceThin slabHigh pressure water

The invention relates to a method for producing ultrathin low-carbon steel by use of a thin slab casting and rolling process. The method comprises the following steps: continuously casting molten steel into a continuous cast billet with the width of 1,300-1,600 mm and the thickness of 60-100 mm; then sequentially conducting rough rolling, heat preservation by a heat holding cover, induction heating, high-pressure water phosphorus removal and finish rolling to obtain ultrathin strip steel with the width of 1,300-1,600 mm and the thickness of 0.8-1 mm; and finally, performing controlled cooling, roll-dividing cutting and roll take-up. A produced ultrathin low-carbon steel end product has the yield strength of 250-310 MPa, the tensile strength of 350-400 MPa and the ductility of larger than or equal to 35%. By adoption of the method, stable production of hot-rolled ultrathin low-carbon steel with the thickness of 0.8-1 mm can be realized, the dimensional accuracy, the flatness accuracy and the comprehensive mechanical property can be improved, the demand for 'replacement of cold product by hot product' is met and the production cost is lowered.

Owner:WISDRI ENG & RES INC LTD

Method for using thin slab continuous casting and rolling technology for producing thin-specification, low-alloy and high-strength steel

ActiveCN106734201AIncreasing the thicknessIncrease pulling speedRoll force/gap control deviceTemperature control deviceDouble phaseThin slab

The invention relates to a method for using a thin slab continuous casting and rolling technology for producing thin-specification, low-alloy and high-strength steel. Molten steel is continuously cast into a continuous casting blank with the width being 1300 mm to 1600 mm and the thickness being 65 mm to 96 mm; then rough rolling, heat insulation cover heat insulation, induction heating, high-pressure water scale removing and finish rolling are conducted in sequence, and ultrathin strip steel with the width being 1300 mm to 1600 mm and the thickness being 1.3 mm to 1.6 mm is obtained; and finally the strip steel is controlled to be cooled, shorn in different rolled and are coiled into rolls. The yield strength of the thin-specification double-phase steel finished product ranges from 380 MPa to 430 MPa, the tensile strength ranges from 530 MPa to 610 MPa, and the elongation is larger than or equal to 25%. By means of the method, stable production of hot rolled thin-specification, low-alloy and high-strength steel with the thickness being 1.3 mm to 1.6 mm can be achieved, the size precision, the plate shape precision and the comprehensive mechanical performance are improved, the requirement for replacing cold with hot is met, and the production cost is reduced.

Owner:WISDRI ENG & RES INC LTD

Process for producing intermetallic compound

InactiveCN101219433ASimple designImprove performanceRoll force/gap control deviceFurnace typesBiological activationHeating temperature

The invention relates to a preparation method of intermetallic compound, which is characterized in that iron foil, nickel foil or titanium foil and aluminum foil are adopted as raw materials; the preparation method comprises the steps are that: selecting raw foil material with consideration of the thickness of the raw foil material; defatting, degreasing and surface activation treating; alternative lapping of the treated foil; making rolling blank; warm rolling under heating temperature of 100-180 DEG C and 40-70 percent of rolling draft; edge cutting and cold rolling with 10-20 percent of rolling draft; heat treating of solid-phase alloying under temperature of 400-680 DEG C for 1-5 hours. The invention has the advantages that: the prepared intermetallic compound has uniform fine texture; average grain size is 2-20 Mum; room temperature brittleness and high temperature obdurability of the intermetallic compounds have been greatly improved. The invention overcomes the problem that intermetallic compound is difficult formed and has extensive industrial application value.

Owner:NORTHEASTERN UNIV LIAONING

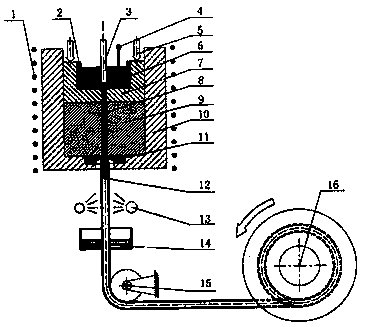

Production equipment and process of copper-clad aluminum bimetal composite wire rod

The invention relates to production equipment and process of a copper-clad aluminum bimetal composite wire rod, belonging to the technical field of metal material processing. The production equipment is composed of a heating element, a molten aluminum temperature control crucible, a core metal pouring stopper rod, a temperature measurement instrument, a pressure mechanism, an extrusion stem, a hollow hole forming pin, an extruding barrel, an extruding mold, a cooling device, a water tank, a tensioning mechanism and a winding machine. The production process comprises the following steps: a copper billet is placed in the extruding barrel and an aluminum ingot is placed in the temperature control crucible, heat is preserved after the heating element outside the extruding barrel is heated to be at the required temperature, the extrusion stem moves downwards under the action of the pressure mechanism to punch and extrude the copper billet in the extruding barrel to form a clad copper pipe; when the copper pipe is extruded out of a mold, the core metal molten aluminum pouring stopper rod is pulled, molten aluminum is sucked in the copper pipe under the action of the negative pressure in the pipe and solidified, is further cooled by the cooling device and the water tank, then passes through the tensioning mechanism, and finally is reeled and collected on the winding machine. The equipment is simple, the technological process is short, and both the equipment and the process are suitable for large-scale production; the prepared copper-clad aluminum wire rod has accurate boundary dimension, core metal has no casting defect, and the interface of outer layer metal copper and core metal aluminum is clean and free of pollution, and therefore, a good metallurgical bonding effect is achieved.

Owner:HUNAN UNIV

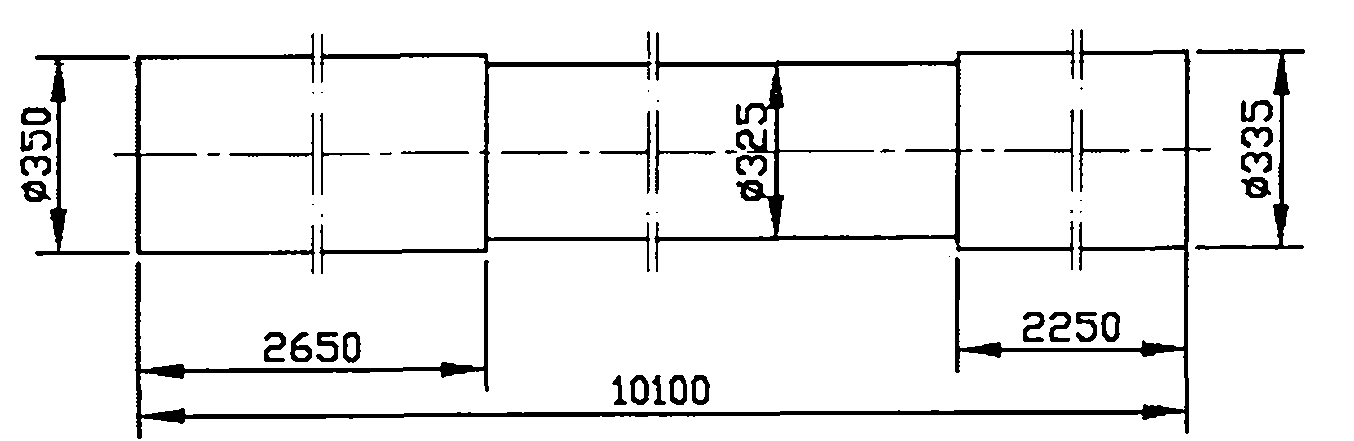

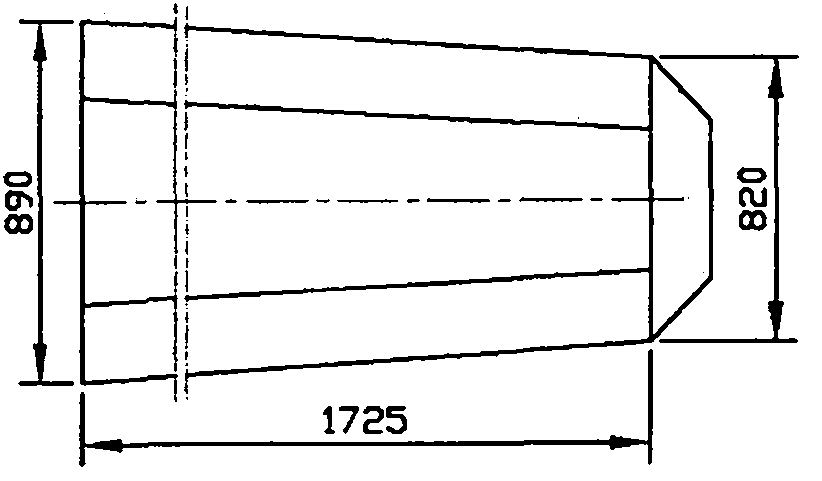

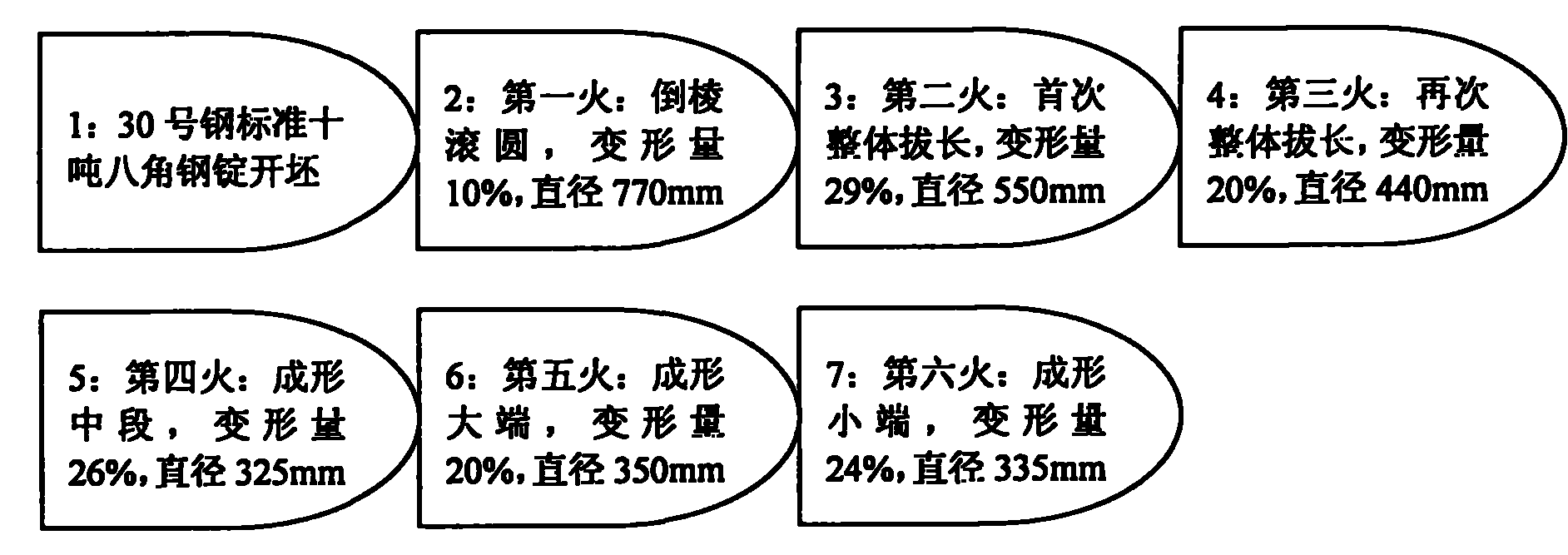

Method for forging large steel shaft forging

InactiveCN101920304AIncrease the amount of single deformationEliminate internal defectsEngine componentsSteel qualityCarbon steel

The invention discloses a method for forging a large steel shaft forging. The method comprises the following steps of: performing cogging, chamfered edge rounding, whole stretching for the first time, whole stretching again, section-by-section forging and the like on a medium carbon steel standard octagon ingot of which the carbon content is 0.3 to 0.4 percent. The step of whole stretching for the first time comprises the following steps of: heating a forged piece to a primary forging temperature; stretching on a forging hammer with a flat anvil; and reaching the deformation rate of 29 to 31 percent at the effective hole welding temperature of over 900 DEG C so as to overcome internal defects of the forged piece. The step of whole stretching again comprises the following steps of: heating the forged piece to the primary forging temperature; stretching on the forging hammer with the flat anvil; and reaching the deformation rate of 15 to 20 percent at the final forging temperature of 800 DEG C. And the single-time deformation rate of each section when the section-by-section forging is performed should not be less than 20 percent. The method of the invention effectively overcomes the internal defects of the material, reduces the material and working time waste, more reasonably distributes the deformation rate of each step, contributes to the reduction of the forging deforming force and realizes ideal material mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

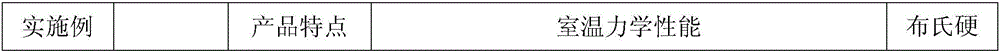

Liquid forging technology method for 6061 material commercial vehicle aluminum alloy shaft head

ActiveCN106319305AImprove metallographic structureEliminate shrinkageRare-earth elementSurface finishing

The invention discloses a liquid forging technology method for a 6061 material commercial vehicle aluminum alloy shaft head. The method mainly comprises the following steps of alloy component optimizing, smelting, melt purifying, liquid forging forming, demolding, trimming, hole tapping, heat treatment enhancing, machining and surface treatment. Firstly, components of elements in a 6061 alloy are optimized, a proper number of rare earth elements Gd and Sm and a proper number of elements Hf are added in a matched manner, and the vehicle shaft head is prepared through combination of the liquid forging technology; and through optimization of the chemical components of the alloy and the melt purifying technology, the metallographical structure of the alloy is improved, and shrinkage, loosening, air holes, cracks and other inner defects of products are greatly removed. The appearance quality of the shaft head product is obviously improved, the inner defects are obviously reduced, the production efficiency is high, the process is short, the technology cost is low, energy is saved, environment pollution is little, and economic benefits and social benefits are obvious.

Owner:辽宁忠相铝业有限公司

Method for casting blade

ActiveCN103521704AMeet specific needsHigh strengthFoundry mouldsMoulding machinesAbrasive blastingMechanical engineering

The invention discloses a method for casting a blade, which is a method for casting blades by adopting precise casting. The method comprises the following steps: designing a die; manufacturing the die; melting raw materials; preparing blanking; centrifugally casting; cooling for the first time, molding for the second time, and cooling for the second time; trimming, and performing shot blasting; performing hot isostatic pressing. By virtue of the steps of the method, an excellent elimination factor of surface and internal defects of the blade of an engine can be guaranteed, and the internal microscopic tissues can be more uniform.

Owner:邯郸市峰峰海纳机械加工有限公司

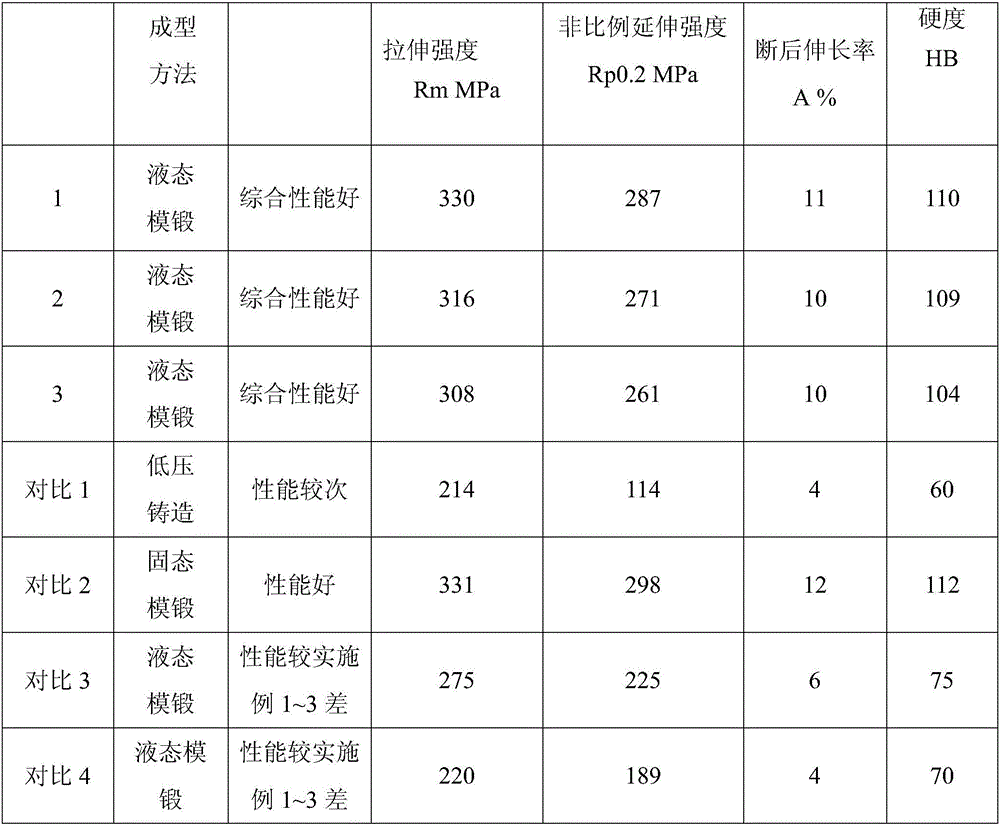

Method for preparing Ti2AlNb alloy by using vacuum pressure infiltration method

The invention discloses a method for preparing a Ti2AlNb alloy by using a vacuum pressure infiltration method and a method for preparing the Ti2AlNb alloy. The method disclosed by the invention is used for solving the problems of non-uniform distribution of elements such as Nb and Al and shrinkage cavity, pores and inclusion of the Ti2AlNb alloy in a conventional cast melting method for preparing the Ti2AlNb alloy are solved. The method comprises the following steps: 1, weighing 50.1-56.5 percent of pure Ti powder, 22.5-24.4 percent of Nb powder and 21.0-25.5 percent of Al-Y rare earth alloy block; 2, performing low-energy ball milling on pure titanium particles and niobium powder; 3, putting the rare earth aluminum alloy Al-Y block on the composite titanium and niobium powder, performing infiltration, so as to enable the melted Al-Y alloy to be fully penetrated into the composite titanium and niobium powder, reducing the pressure, performing heat preservation and pressure maintaining, and reacting and sintering to obtain the Ti2AlNb alloy. The method is simple in process, easy to operate, short in preparation period and low in manufacturing cost.

Owner:HARBIN INST OF TECH

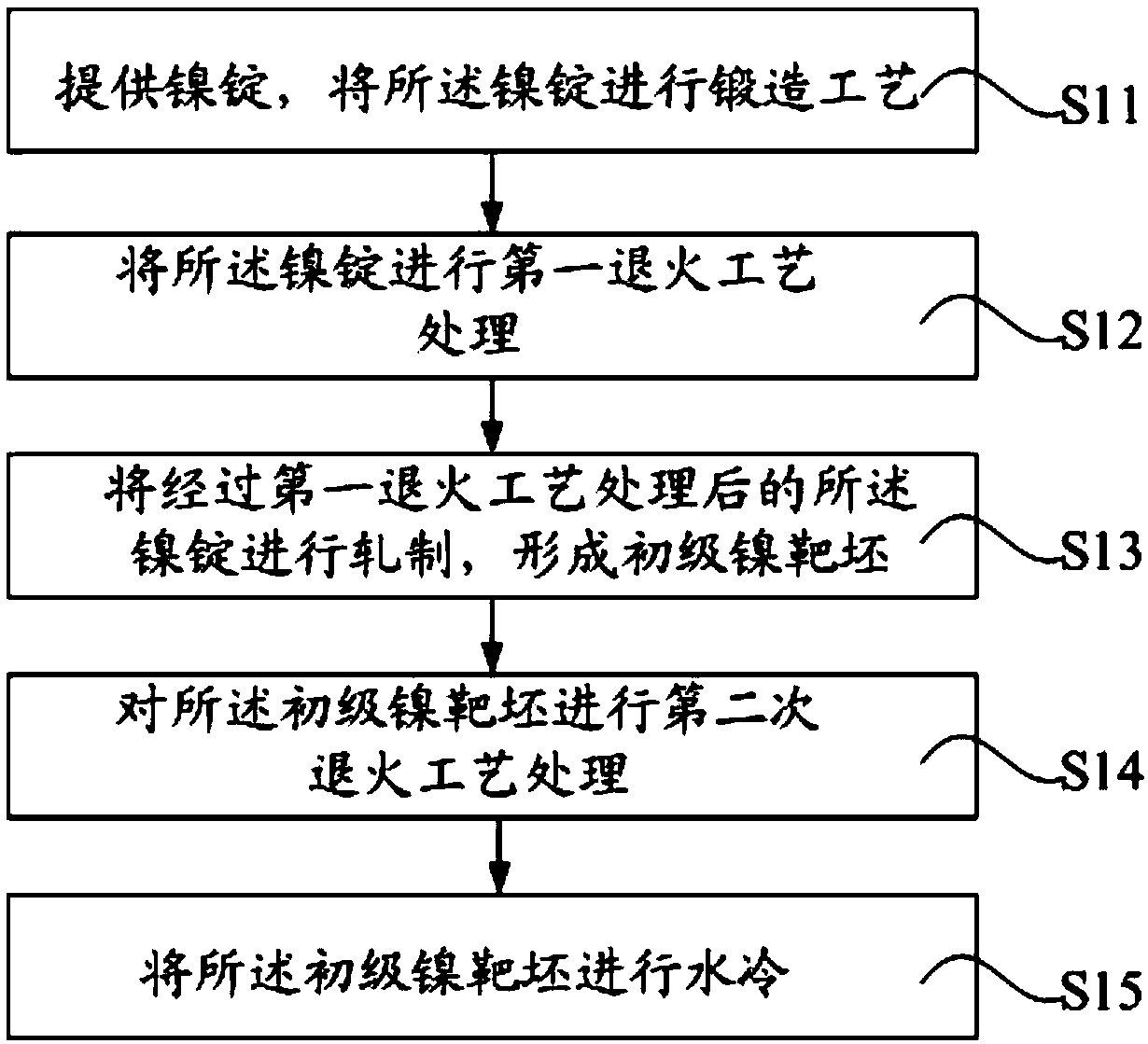

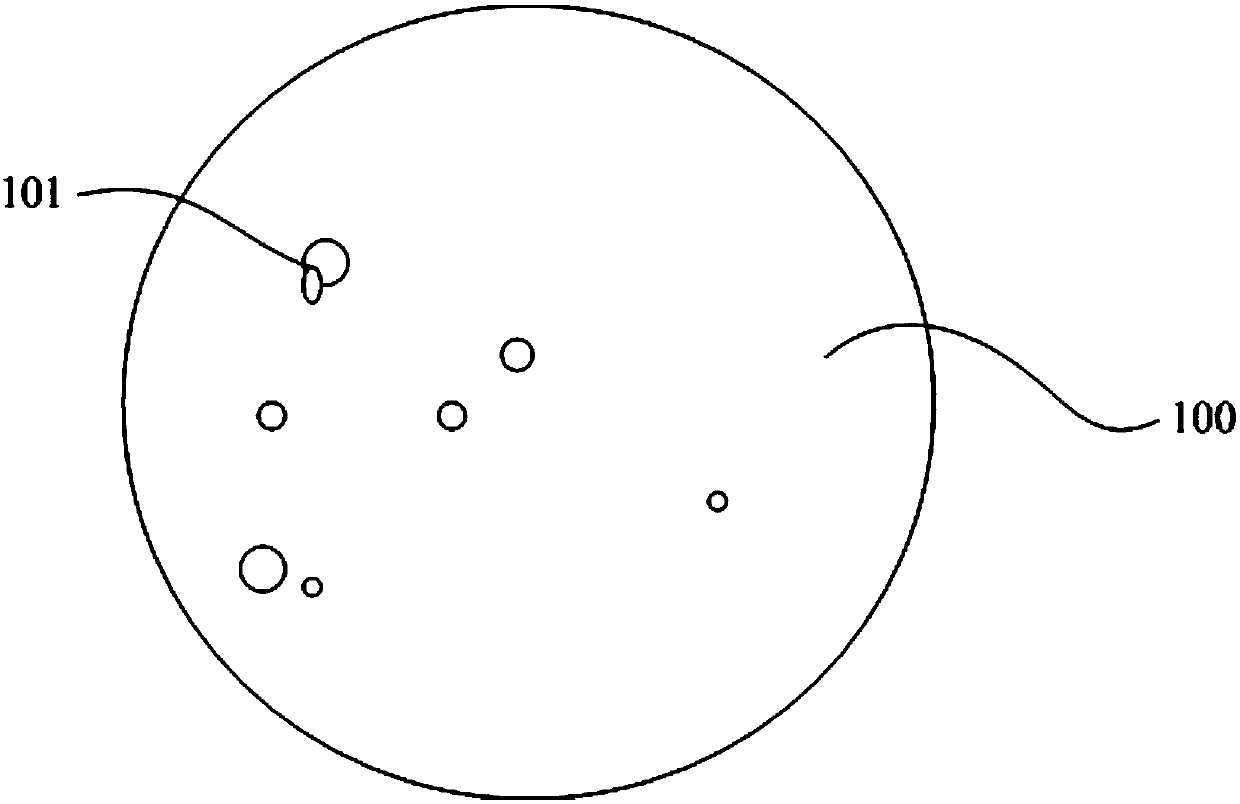

Nickel target blank and manufacturing method of target material

InactiveCN111088481AReduce hardnessReduce distortionVacuum evaporation coatingSputtering coatingIngotRoll forming

The invention discloses a nickel target blank and a manufacturing method of a target material. The manufacturing method of the nickel target blank comprises the following steps that a nickel ingot isprovided; the nickel ingot is subjected to first annealing process treatment, wherein the temperature of the first annealing process is 900-950 DEG C; and the nickel ingot treated by the first annealing process is rolled to form a primary nickel target blank. Before the nickel ingot is subjected to roll forming, the nickel ingot is subjected to primary annealing process treatment, so that the hardness of the nickel ingot material is reduced, so that the later cutting process is easier, residual stress in the nickel ingot is released, the deformation and cracking tendency of the material is reduced, and the effect of refining grains is achieved. The temperature of the first annealing process is controlled to be 900-950 DEG C, so that the interior of the rolled nickel target blank is free ofdefects, the nickel target material obtained after the nickel target blank is welded to a back plate is also free of defects, and the situation that the target material is scrapped due to the fact that the nickel target blank does not meet the requirement is reduced.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

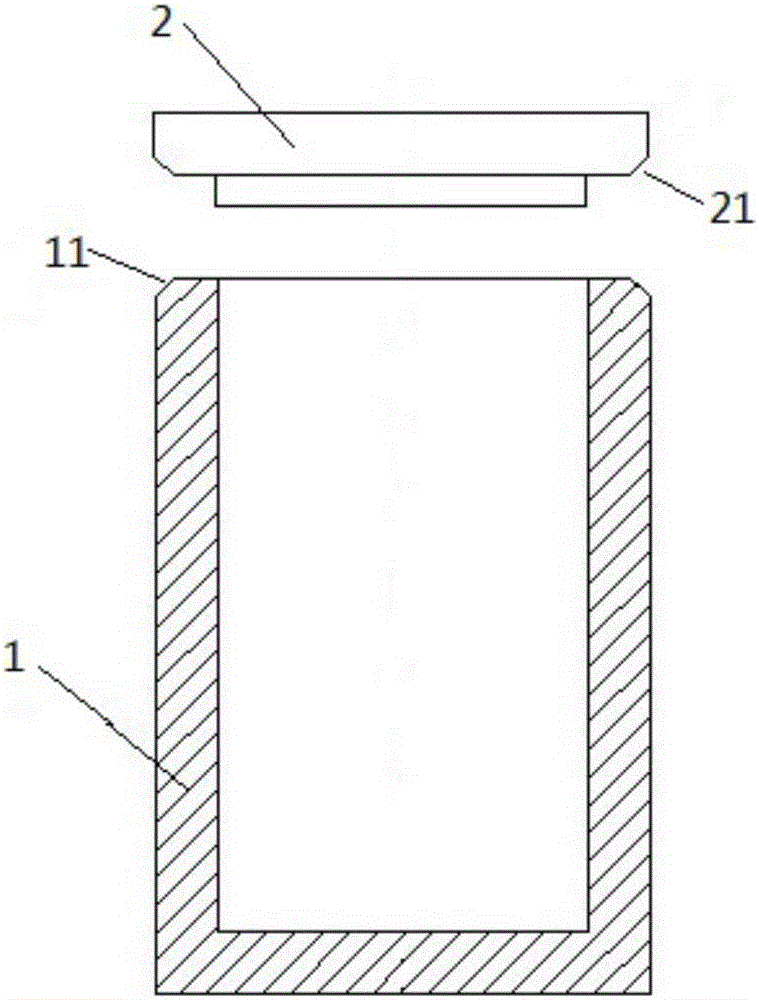

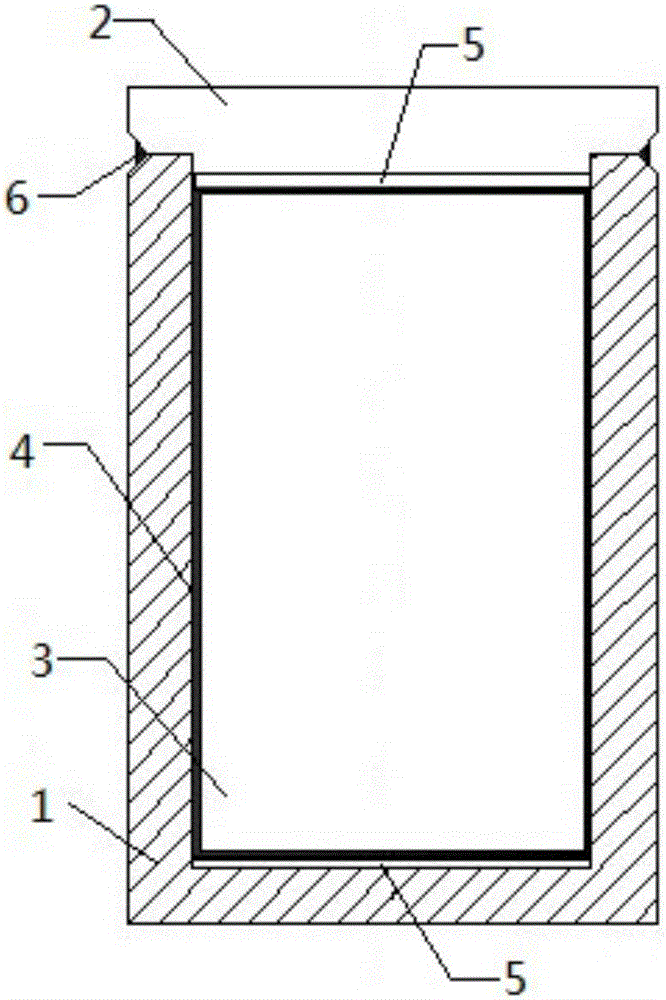

Wrapping cover method suitable for isothermal forging of Ti-Al-series intermetallic compound

The invention relates to a wrapping cover method suitable for isothermal forging of a Ti-Al-series intermetallic compound. The method comprises the following steps that firstly, wrapping cover pretreatment is conducted; secondly, the surface of a blank of the Ti-Al-series intermetallic compound is coated with a high-temperature anti-oxidization coating; thirdly, in the state that the high-temperature anti-oxidization coating is kept wet, the blank of the Ti-Al-series intermetallic compound is arranged in a wrapping cover, and a transition layer is arranged between the wrapping cover and the blank of the Ti-Al-series intermetallic compound; and fourthly, the wrapping cover is welded and sealed. Compared with the prior art, the wrapping cover method has the beneficial effects that the wrapping cover is simple and easy to use, the production efficiency is high, labor intensity is low, cracking and oxidizing in the Ti-Al-series intermetallic compound deforming process can be effectively prevented, and heat losses of the blank in the transferring process are reduced.

Owner:TONGJI UNIV

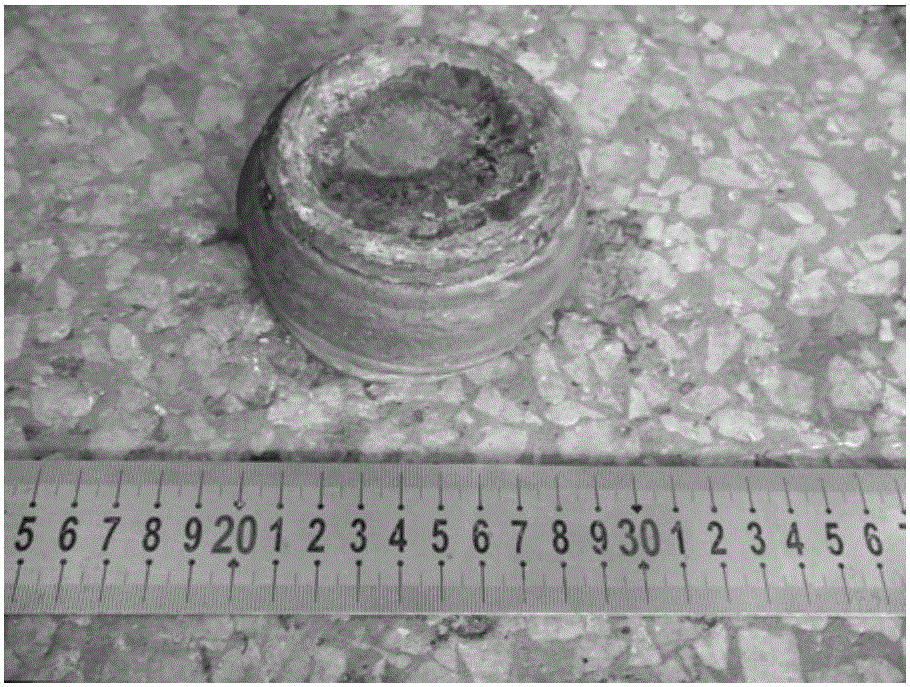

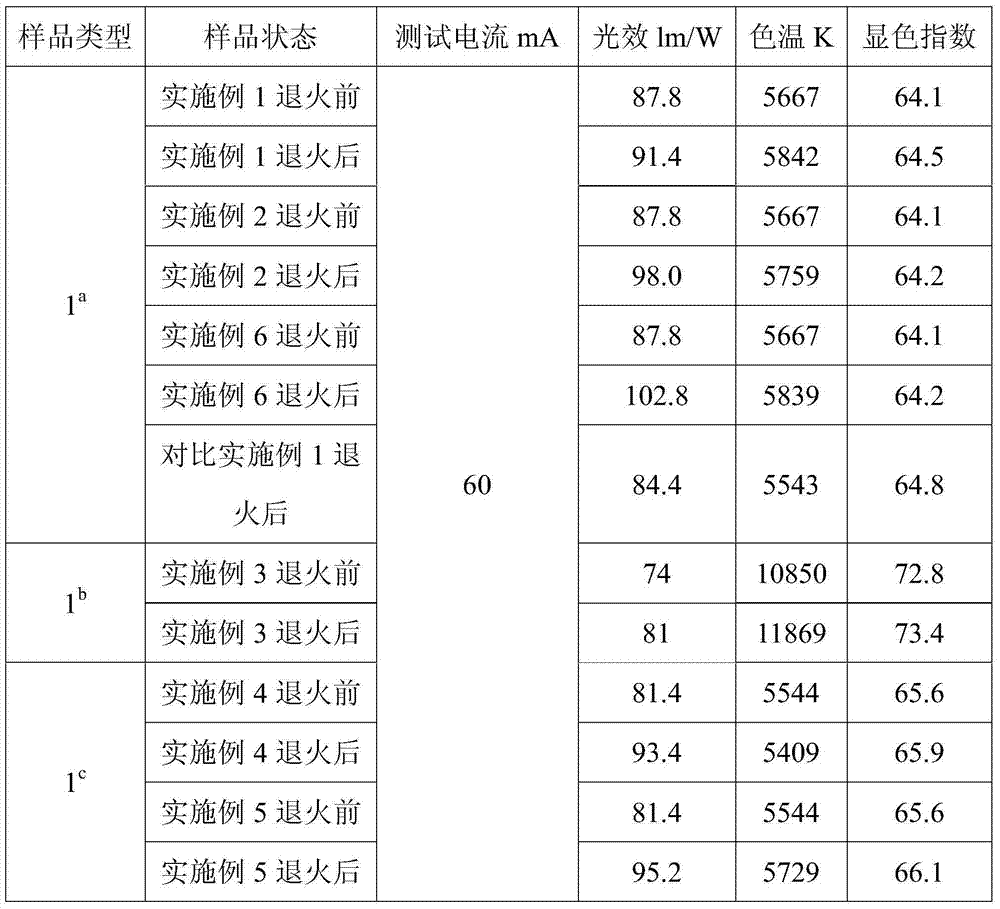

Annealing method of cerium-doped yttrium aluminium garnet wafer for white-light LED (Light Emitting Diode)

ActiveCN103590111AEliminate internal defectsEliminate oxygen vacanciesPolycrystalline material growthAfter-treatment detailsRoom temperatureCe element

The invention discloses an annealing method of a cerium-doped yttrium aluminium garnet wafer for a white-light LED (Light Emitting Diode). The annealing method comprises the following steps: (1) putting the cerium-doped yttrium aluminium garnet wafer in a porcelain boat, feeding the porcelain boat into a tubular annealing furnace, introducing annealing atmosphere and sealing, wherein the annealing atmosphere is a mixed gas A or oxygen, the mixed gas A is iH2+kL, the L stands for an inert protective gas, the i and the k respectively stand for the volume parts of the H2 and the L in the mixed gas A, and i / i+k is greater than or equal to 25% and less than or equal to 75%; (2) heating to 300 DEG C from a room temperature at the rate of 100-150 DEG C / h, and carrying out heat preservation for 3-8 hours; then heating to 900 DEG C at the rate of 150-200 DEG C / h, and carrying out heat preservation for 3-8 hours; heating to 1100-1500 DEG C at the rate of 100-150 DEG C / h, and annealing at a constant temperature for 30-72 hours; after annealing, cooling to 1100 DEG C at the rate of no greater than 50 DEG C / h, then cooling to 900 DEG C at the rate of 100 DEG C / h, finally cooling to a room temperature at the rate of 150-200 DEG C, wherein the time required in the total cooling stage is about 6.5-1.6 hours, and taking out so as to obtain the annealed wafer.

Owner:WENZHOU UNIVERSITY

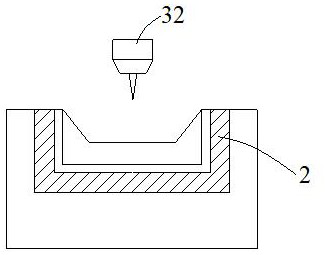

Precision casting method for engine vanes

ActiveCN103506594AMeet specific needsGood elimination rateFoundry moulding apparatusSand blastingPrecision casting

The invention discloses a precision casting method for engine vanes. The method comprises the steps of die designing, die manufacturing, raw material smelting, material preparing, centrifugal casting, primary cooling, post forming, secondary cooling, trimming, sand blasting and hot isostatic pressing. By means of the working procedures, the good elimination rate of defects of the surfaces and the interiors of the engine vanes can be ensured, and internal microstructures are more uniform.

Owner:浙江寰宇航空发动机有限公司

Device for preparing high-performance magnesium alloy through large plastic deformation and preparation method

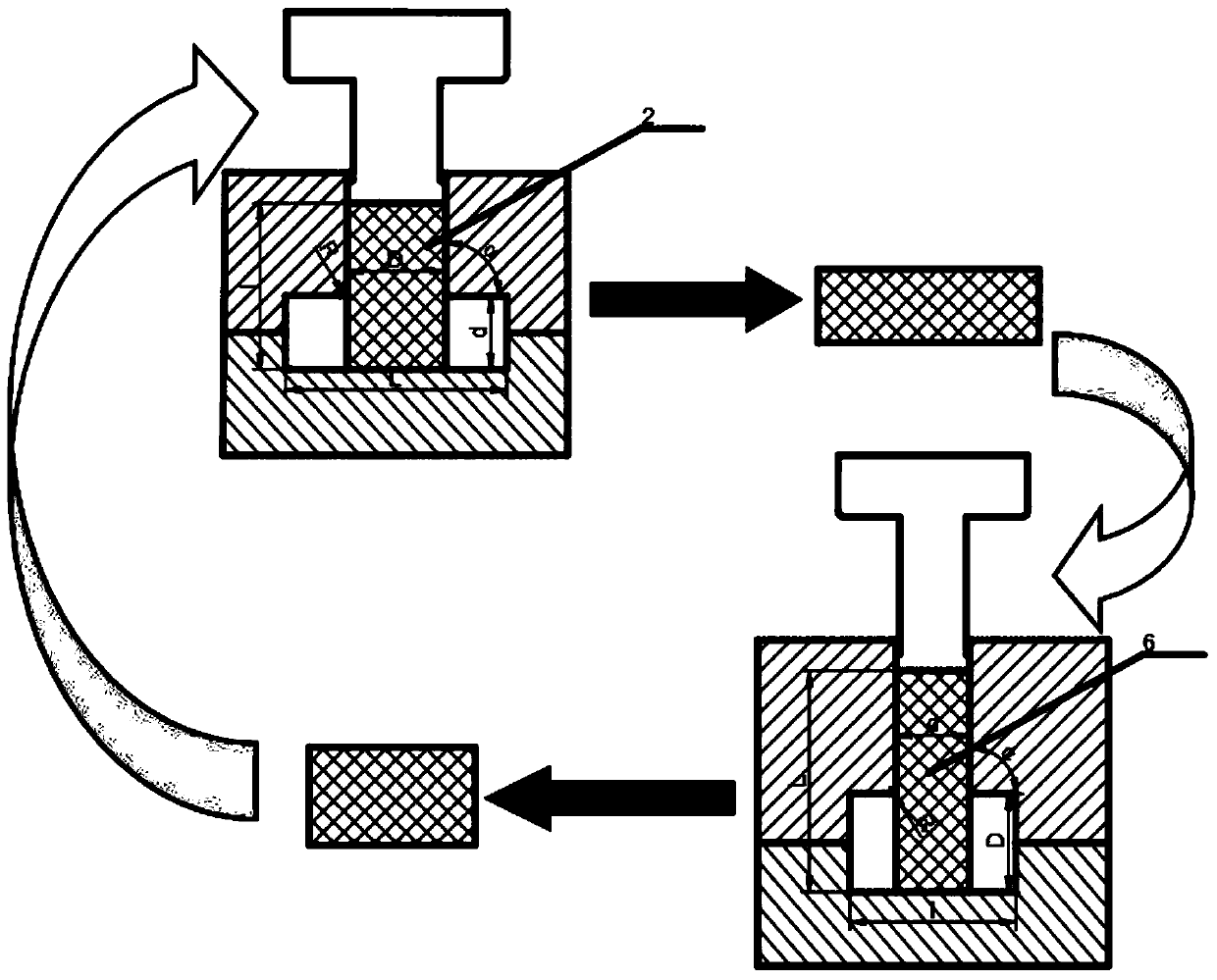

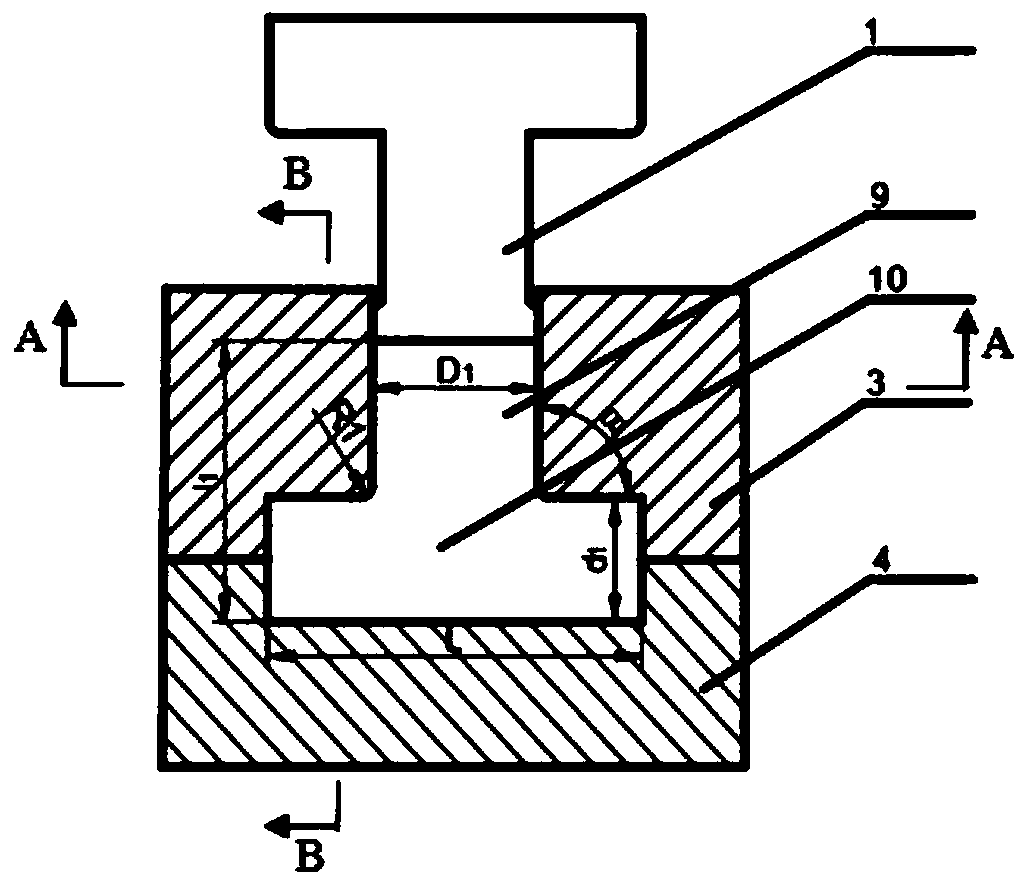

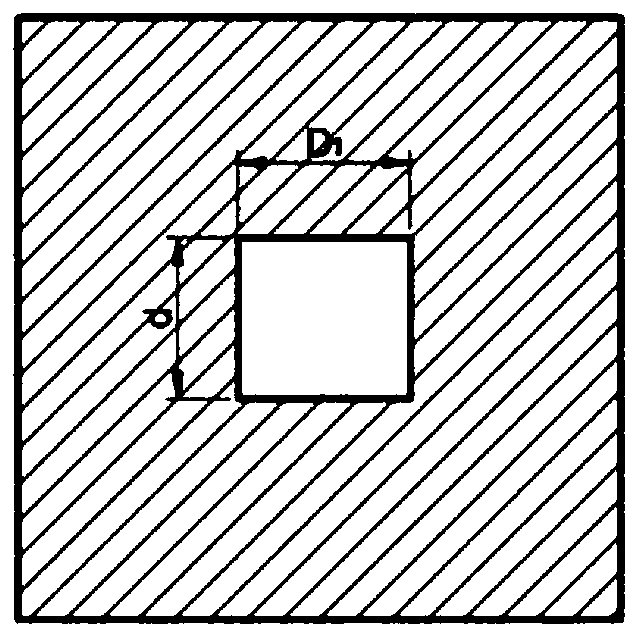

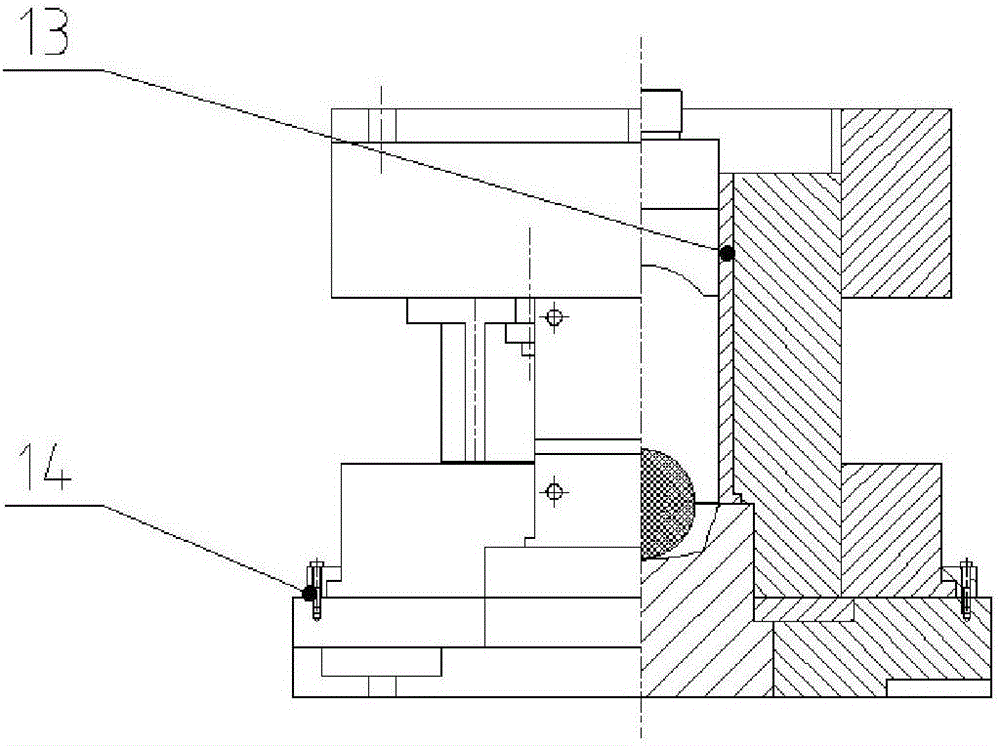

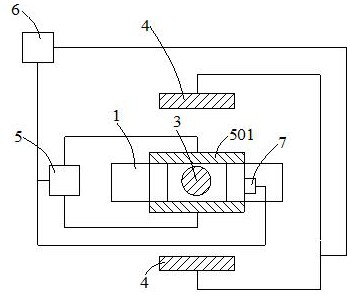

ActiveCN110000322AControl upsetting deformationSmall machining allowanceExtrusion diesForging/hammering/pressing machinesCrystal structurePlastic property

The invention discloses a device for preparing a high-performance magnesium alloy through large plastic deformation and a preparation method. The device comprises a die I and a die II which have the same structure; each die comprises a male die, an upper female die and a lower female die; a cuboid-shaped extrusion channel is horizontally formed between each upper female die and the corresponding lower female die; the upper female die is vertically penetrated to be provided with a male die channel; the male die channel communicates with the extrusion channel and is matched with the male die; the width of the male die channel of the die I is equal to the height of the extrusion channel of the die II, and the width of the male die channel of the die II is equal to the height of the extrusionchannel of the die I; and the thicknesses of the male die channels and the extrusion channels are equal. According to the device for preparing the high-performance magnesium alloy through the large plastic deformation and the preparation method, the magnesium alloy is repeatedly upset and extruded by replacing the dies to continuously accumulate strain, so that mass points of the magnesium alloy are expected to uniformly generate corner shearing, expansion and upsetting deformation, and finally a texture is weakened while forming a uniform fine crystal structure so as to prepare the high-performance magnesium alloy.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method of thermal power generation carburization wear-resisting ball

InactiveCN105855516AEliminate internal defectsEasy access to raw materialsSolid state diffusion coatingFurnace typesFerromanganeseSlag

The invention discloses a preparation method of a thermal power generation carburization wear-resisting ball. The preparation method comprises the following process steps: firstly, casting a wear-resisting ball body casting, selecting the following raw materials in parts by weight: 2.2 to 2.6 parts of ferromanganese, 25 to 30 parts of scrap iron blocks, 0.4 to 0.7 part of a waste copper plate and 0.3 to 0.5 part of a slag forming constituent, putting the raw materials into a smelting furnace for desulfuration, transferring smelted liquid subjected to desulfuration into a medium-frequency induction furnace for continuous smelting and heat insulation, adding a spheroidizing agent which is 0.5 to 1.2 percent of the weight of the smelted liquid into the medium-frequency induction furnace for spheroidizing at the temperature of 900 to 960 DEG C, and pouring in a die to obtain the wear-resisting ball body casting. According to the preparation method, the wear-resisting ball body and a wear-resisting layer are respectively obtained by pouring twice, so that the wear-resisting ball is high in mechanical property and impact toughness; furthermore, most components in the thermal power generation carburization wear-resisting ball are conventional elements, so that the production cost is low, and the preparation method is convenient to popularize.

Owner:MAANSHAN YIFENG INDAL GROUP

Production process of high-performance 6061 aluminum alloy for cell phone card slot and key materials

InactiveCN109536792AImprove metallographic structureImprove the ratio of ingredientsSolution treatmentMetal machining

The invention belongs to the technical field of aluminum alloy metal machining and discloses a production process of a high-performance 6061 aluminum alloy for cell phone card slot and key materials.According to the production process, a high-performance 6061 aluminum alloy plate is obtained through the steps of smelting and casting, homogenization treatment, machining face-milling, hot rolling,cold rolling to the finished product thickness, solution treatment and quenching at a continuous quenching line, manual aging treatment and the like, the tensile strength Rm of the high-performance 6061 aluminum alloy plate reaches 300 MPa or above, the hardness HV of the high-performance 6061 aluminum alloy plate reaches 90 or above, and on the one hand, the high-performance 6061 aluminum alloy plate has good machining performance and can be suitable for early CNC machining of the cell phone card slot and key materials; and on the other hand, the high-performance 6061 aluminum alloy plate hasgood anodic oxidation performance, can be oxidized into various bright colors and thus is quite attractive, a layer of uniform and luster-consistent protecting film is formed on the surfaces of the materials after oxidation, the hardness and abrasion resistance of a cell phone card slot and keys are greatly improved, and the service life of a product is prolonged.

Owner:郑州明泰实业有限公司

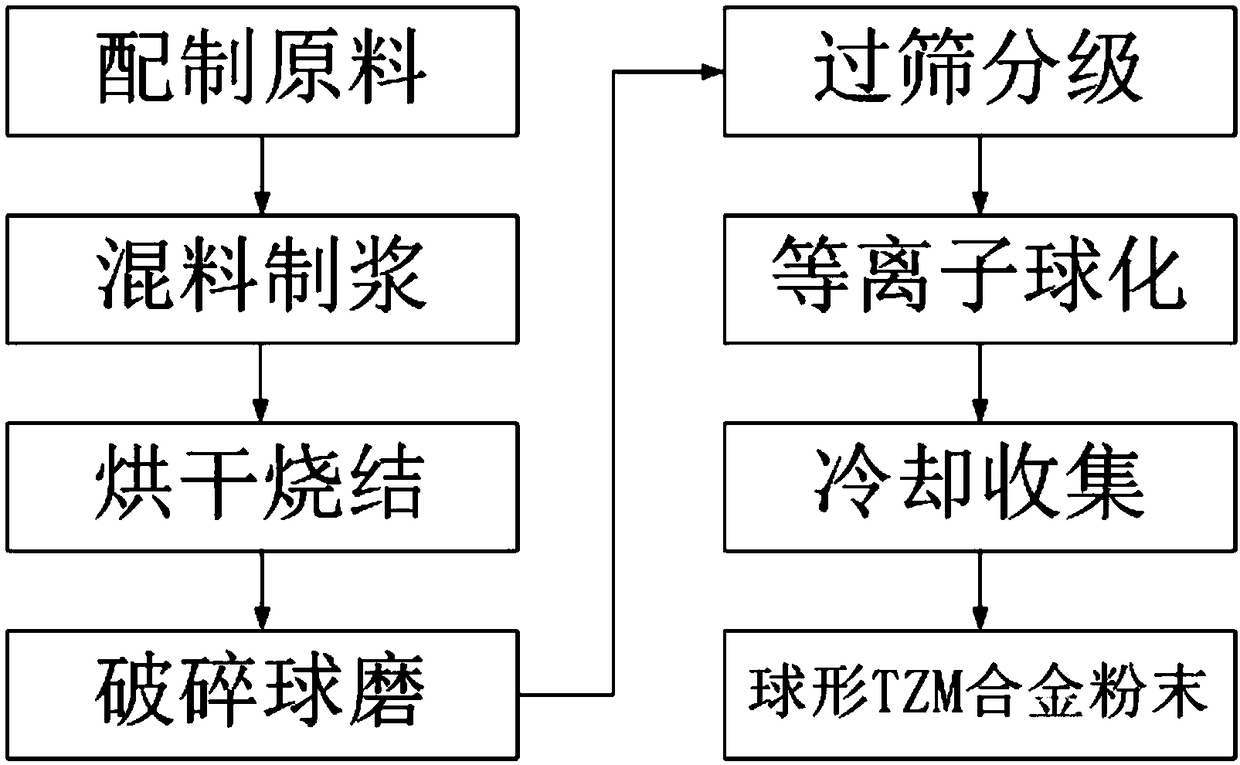

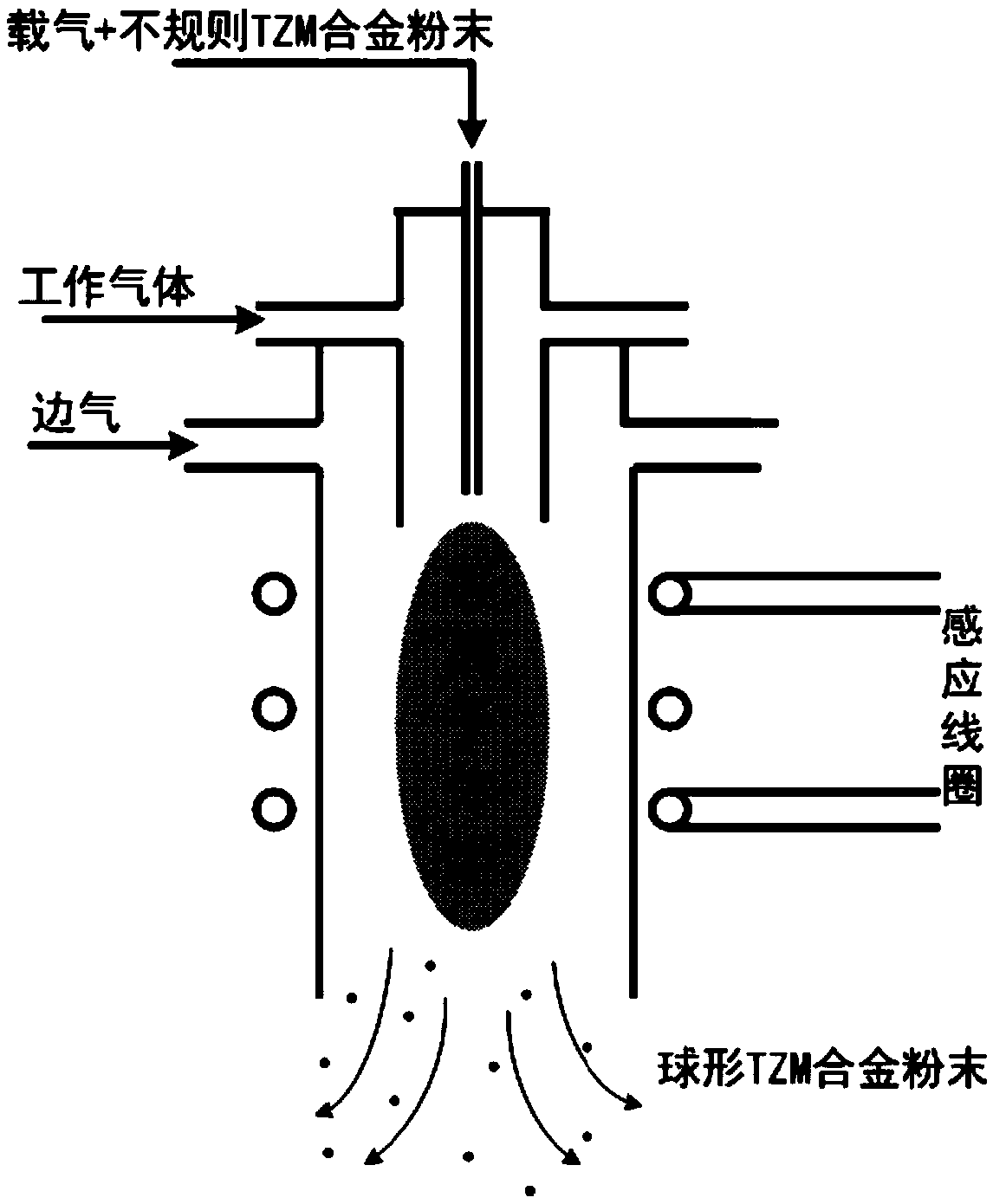

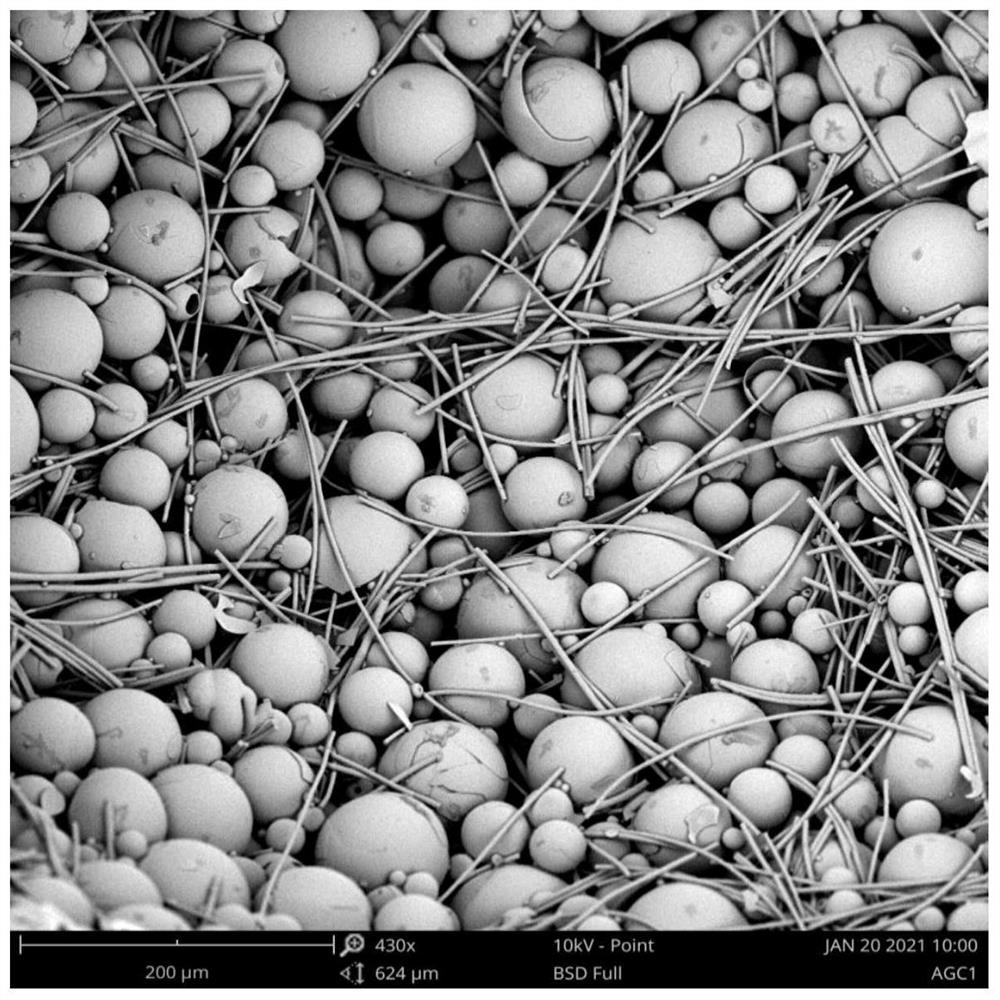

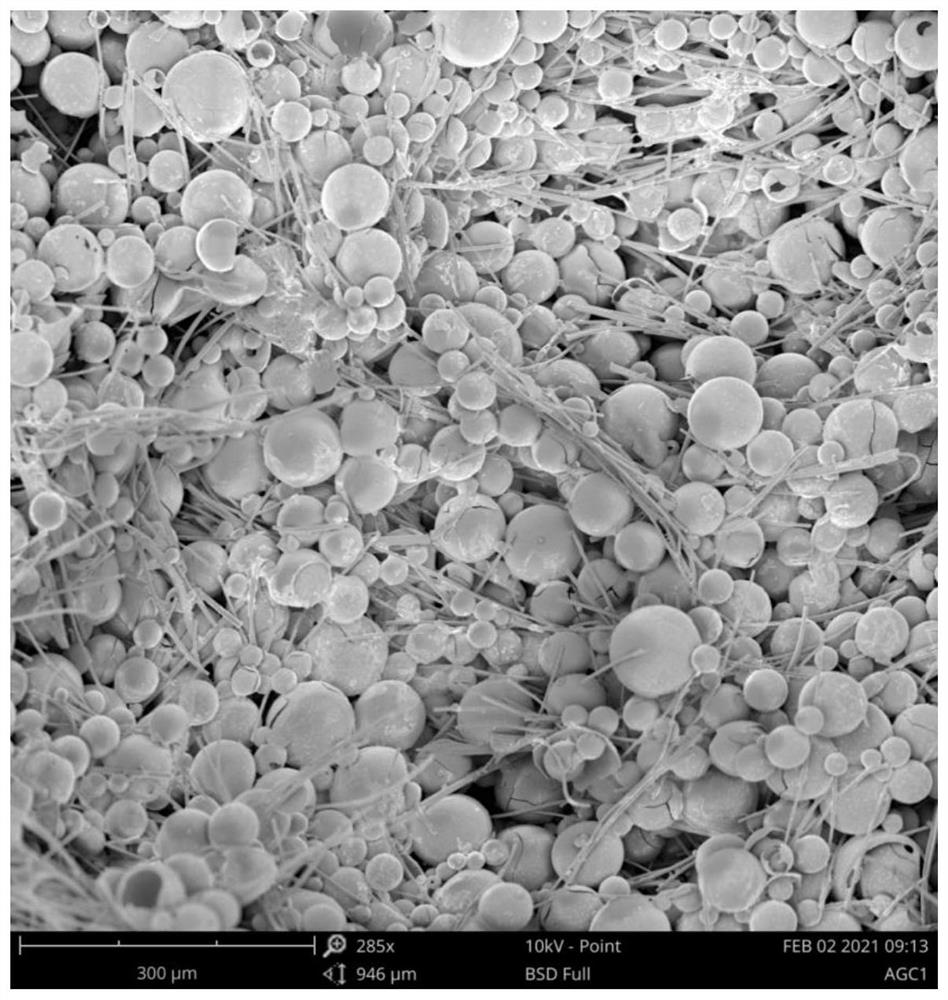

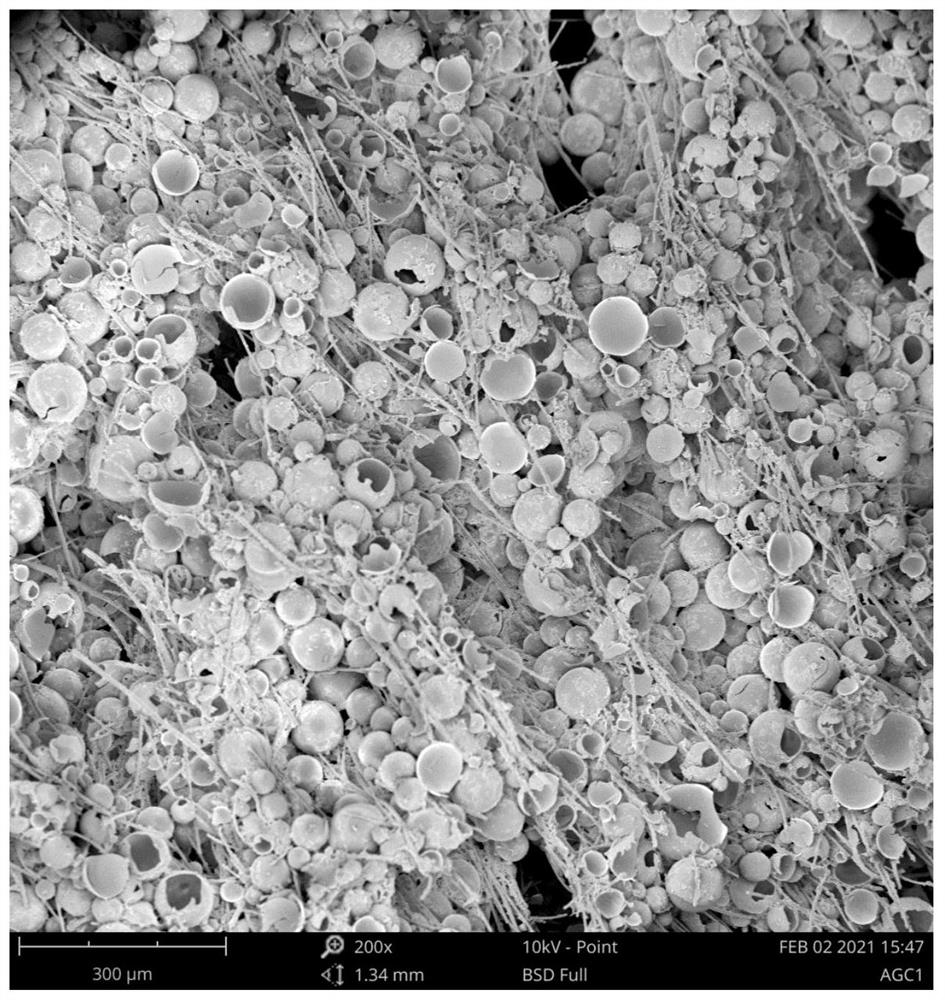

Method for preparing spherical Titanium-Zirconium-Molybdenum alloy powder

ActiveCN109332717ASpeed up meltingPowder state optimizationTransportation and packagingMetal-working apparatusZirconium hydrideTitanium zirconium

The invention provides a method for preparing spherical Titanium-Zirconium-Molybdenum (TZM) alloy powder, and belongs to the technical field of metal powder material preparation. The method for preparing the spherical Titanium-Zirconium-Molybdenum (TZM) alloy powder comprises the steps that reduced molybdenum (Mo) powder, titanium hydride (TiH2) powder, zirconium hydride (ZrH2) powder and graphitepowder are adopted as basic raw materials to prepare raw powder which conforms to the alloy stoichiometry; absolute ethyl alcohol is added into the raw powder to prepare slurry, and thorough stirringis carried out for uniform mixing; the slurry is subjected to vacuum drying, and powder is sintered under a reducing atmosphere; the alloy powder sintered blank is subjected to ball-milling to be sufficiently broken; the ball-milled alloy powder is sieved and irregular TZM alloy powder within a certain particle size range is selected out; the irregular TZM alloy powder is fed into an inductivelycoupled plasma torch, the TZM alloy powder is rapidly melted under a high temperature, and molten alloy droplets form a spherical shape under the action of surface tension; and the molten spherical TZM alloy droplets are separated from a high temperature region of plasma and rapidly cooled under the protection of inert gas to form the spherical TZM alloy powder.

Owner:云航时代(重庆)科技有限公司

Preparation method of wear-resistant ball for cement

InactiveCN106086611AEliminate internal defectsImprove wear resistanceAnti-corrosive paintsAdditivesWear resistantAlloy

The invention discloses a preparation method of a wear-resistant ball for cement. The preparation method comprises the following step that a wear-resistant ball workblank is obtained through pouring, wherein a wear-resistant ball workblank alloy comprises, by weight percentage, 3.2-3.4% of C, 0.9-1.2% of Si, 0.4-0.8% of Mn, 0.002-0.01% of P, 0.005-0.013% of S, 1.4-1.7% of Cr, 0.14-0.18% of RE, 0.15-0.35% of W, 0.04-0.12% of V, 1.25-1.45% of Ni, 0.03-0.06% of Te, 0.02-0.08% of Cu and the balance iron. According to the preparation method of the wear-resistant ball, internal defects of a material are effectively eliminated; wear resistance and fatigue strength of the wear-resistant ball are improved; meanwhile, the preparation method has the beneficial effects of being free of oxidation, free of decarburization, free of element depletion and the like; and heat treatment deformation of the wear-resistant ball can be reduced.

Owner:MAANSHAN YIFENG INDAL GROUP

Light super-strong aerogel heat insulation coating and preparation method thereof

InactiveCN113248950AExcellent high temperature resistanceGood stabilityFireproof paintsAlkali metal silicate coatingsUltrasonic assistedFiber

The invention discloses a light super-strong aerogel heat-insulating coating and a preparation method thereof, and belongs to the technical field of high-temperature-resistant heat-insulating coatings, and the light super-strong aerogel heat-insulating coating comprises the following components: an inorganic binder, aerogel powder, a hollow heat-insulating filler, reinforced fibers, a thickener, a surfactant, a dispersant and deionized water. The coating prepared by the invention has the characteristics of good dispersion performance, good stability and the like; an aerogel coating formed after curing and drying has the characteristics of high temperature resistance, light weight, good heat insulation performance, high crack resistance and the like; ultrasonic-assisted preparation is adopted, large bubbles in the coating are eliminated, micron-sized bubbles are formed, the porosity of the coating is increased, and the heat insulation capacity of the coating is improved; and the preparation method is simple, convenient and suitable for industrial production.

Owner:NAVAL UNIV OF ENG PLA

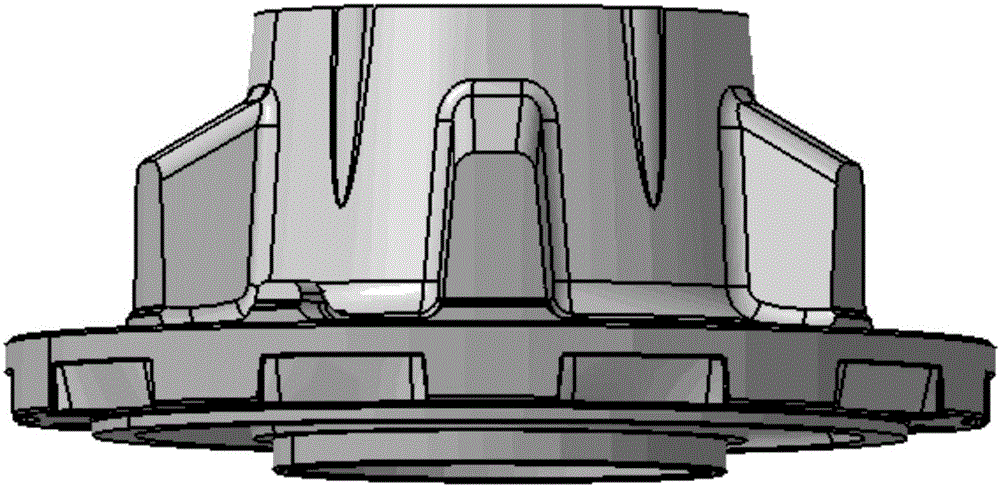

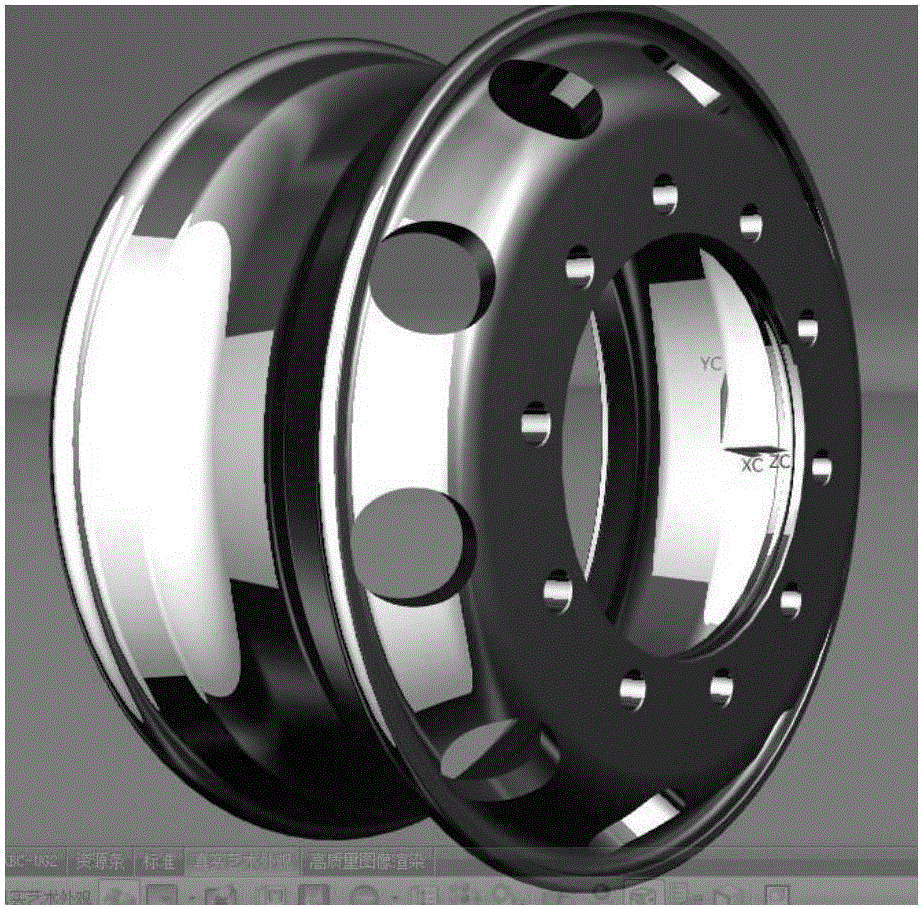

Liquid forging process method for 6061-material commercial vehicle aluminium alloy hub

ActiveCN106636798AImprove metallographic structureImprove appearance qualitySocial benefitsChemical composition

The invention discloses a liquid forging process method for a 6061-material commercial vehicle aluminium alloy hub. The liquid forging process method mainly comprises the following steps: alloy component optimizing, smelting, melt purifying, liquid forging moulding, de-moulding, trimming and forming holes, performing heat-treatment strengthening, machining and performing surface treatment. According to the liquid forging process method for the 6061-material commercial vehicle aluminium alloy hub, a vehicle hub is prepared by optimizing the components of various elements in a 6061-alloy first, then matching and adding suitable amounts of rare elements Gd and Sm and element Hf, and combining a liquid forging process; by optimizing the chemical components of the alloy and a melt purifying technology, the metallographical structure of the alloy is improved, and internal defects, such as hole shrinkage, hole loosening, air holes, cracks and the like in a product are greatly eliminated. The hub product appearance quality is obviously improved; the internal defects are obviously reduced; the liquid forging process method is high in production efficiency, short in process flow, low in process cost, energy-saving, low in environmental pollution and obvious in economic benefit and social benefit.

Owner:辽宁忠相铝业有限公司

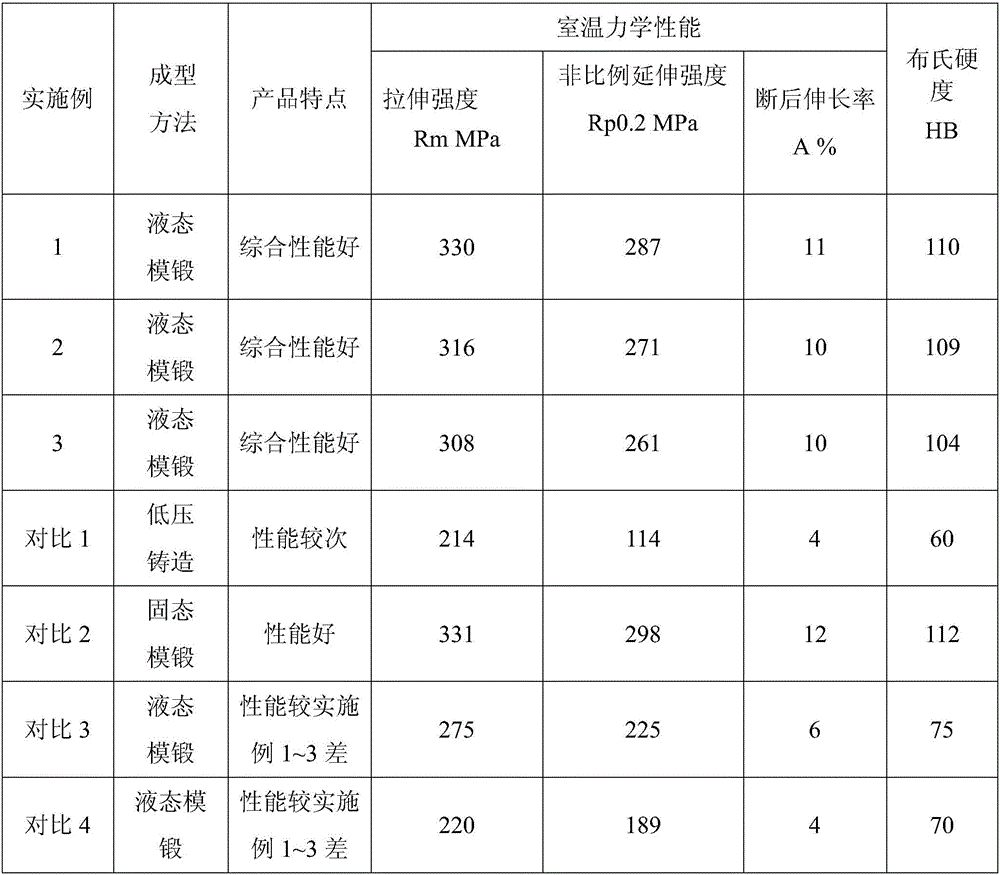

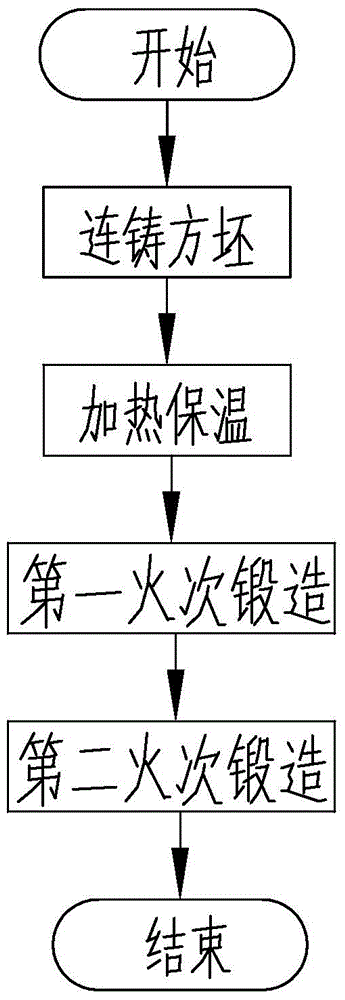

Blank making method for 42CrMoA axial forging

ActiveCN104525808AEliminate internal defectsImprove fatigue lifeMetal-working apparatusNon-metallic inclusionsStretch ratio

The invention discloses a blank making method for a 42CrMoA axial forging. The method comprises the following steps: continuous casting of a billet: casting the billet continuously, wherein 42CrMoA pour steel is obtained by combining a ladle refining method and a vacuum degassing method, and the gas content and the nonmetallic inclusion content in the billet meet related requirements; heating and heat preservation: heating the billet stepwise at 750 plus or minus 10 DEG C and 1,250 plus or minus 10 DEG C while the heat preservation time is set; first firing forging: forging the billet by upsetting and stretching in sequence, wherein the upsetting ratio is greater than or equal to 2.5, and the stretching ratio is greater than or equal to 3.0; and second firing forging: heating the billet in a furnace to 1,250 plus or minus 10 DEG C, preserving heat, and forging the billet again by upsetting and stretching to form a blank, wherein the final forging temperature is controlled within 850-900 DEG C. The method provided by the invention has the benefits that the internal defects of the billet are eliminated, the metallographic structure is qualified, the fatigue life of the forging is long and the manufacturing cost is low.

Owner:CHONGQING CHANGZHENG HEAVY IND

Asynchronous cold rolling forming process of aluminum alloy stainless steel composite plate

ActiveCN110883093AIncrease rolling capacityImprove rolling precisionTemperature control deviceWork cooling devicesComposite plateLine heating

The invention discloses an asynchronous cold rolling forming process of an aluminum alloy stainless steel composite plate. The process comprises the following process steps: 1, rolling and compoundinga stainless steel plate and an aluminum alloy plate in an asynchronous rolling mode, and 2, after asynchronous rolling, diffusing and annealing the composite plate, specifically, in the step 1, online heating is carried out on the opposite surface of the composite plate surface of the stainless steel plate, online cooling is carried out on the opposite surface of the composite plate surface of the aluminum alloy plate online, and the heating temperature is 350 DEG C-850 DEG C; the temperature of the composite plate surface of the stainless steel plate from which the composite plate is rolledis lower than 650 DEG C, and the temperature of the composite plate surface of the aluminum alloy plate from which the composite plate is rolled is lower than 300 DEG C; the rolling reduction rate is20%-90%; the different speed ratio of a roller for asynchronous cold rolling is 1.05-1.50; the thickness ratio of the aluminum alloy plate to the stainless steel plate is 1.5-4.0; and in the step 2, the annealing temperature is 250 DEG C-500 DEG C and the annealing time is 15-120 min. The single-side online heating process for rolling the composite plate is creatively provided so as to improve theinterface bonding strength of the composite plate and realize rolling compounding in an interface semi-melting state.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

Method for preparing abrasion-resistant balls for flue gas desulfurization ball mills

InactiveCN105886726AEliminate internal defectsImprove wear resistanceSolid state diffusion coatingFurnace typesAlloyUltimate tensile strength

The invention discloses a method for preparing abrasion-resistant balls for flue gas desulfurization ball mills. The method includes a technological step that cast molten iron comprises, by weight, 2.1-2.5% of C, 0.5-0.9% of Si, 0.6-0.9% of Mn, 0.3-0.5% of Mo, 0.004-0.012% of S, 2.1-2.4% of Cr, 0.04-0.08% of Ni, 0.15-0.25% of Ti, 0.05-0.11% of W, 0.15-0.25% of Ni and the balance iron. The method has the advantages that internal defect of materials can be effectively eliminated, the abrasion resistance and the fatigue strength of the abrasion-resistant balls can be improved, the method is free of oxidation, decarburization and element dilution, heat treatment deformation of the abrasion-resistant balls can be reduced, and the like.

Owner:MAANSHAN YIFENG INDAL GROUP

Tool and method for forging crank throw on double-action hydraulic press

InactiveCN107520394ASimple structureEasy PickupForging/hammering/pressing machinesForging press drivesFiberEngineering

The invention discloses a tool and method for forging a crank throw on a double-action hydraulic press. The tool comprises an upper die-closing plate, a U-shaped die cavity, a platy die cavity and a lower die-closing plate. The method comprises the steps that on the double-action hydraulic press, a punch in the vertical direction is connected with a compacting die firstly, the compacting process is conducted on a blank; then the hydraulic press is adjusted back to the initial position, and the compacting die is detached and replaced with a male die; the blank is subjected to forming; and after the crank throw is formed, the equipment is started to lift up the upper die-closing die and a die-closing supporting frame, an air cylinder in the horizontal direction is started, the die is opened, and a forged piece is taken out. The characteristics of low energy consumption and high efficiency of the double-action hydraulic press are given to full play; through the designed tool, the die closing time and the die opening time are greatly shortened, and the production efficiency is improved; the tool is simple in structure, reliable in work, easy to machine and convenient to detach; and meanwhile, according to the method, it can be guaranteed that the fiber flow direction of the forged piece is not cut off, thus the forming quality of the crank throw is high, in addition, the utilization rate of the crank throw material is improved, and the production cost of the crank throw is reduced.

Owner:YANSHAN UNIV

Device for repairing aircraft thin-walled beam through laser deposition and repairing method thereof

ActiveCN111733416ARealize the repair effectGood restorativeMetallic material coating processesEngineeringMechanical engineering

The invention relates to a device for repairing an aircraft thin-walled beam through laser deposition and a repairing method thereof. The device comprises a heating plate, a laser deposition platform,an alternating magnetic field auxiliary platform and a liquid nitrogen forced cooling device, wherein the heating plate is used for carrying the aircraft thin-walled beam to be repaired; the laser deposition platform is used for repairing the aircraft thin-walled beam to be repaired; the alternating magnetic field auxiliary platform is used for providing a magnetic field with the variable direction and intensity, and the alternating magnetic field auxiliary platform is fixed to the laser deposition platform; and the liquid nitrogen forced cooling device is used for cooling the repaired aircraft thin-walled beam. The aircraft thin-walled beam to be repaired is carried on the heating plate for heating and repaired through the laser deposition platform under the magnetic environment providedby the alternating magnetic field auxiliary platform, and then the repaired aircraft thin-walled beam is cooled under the action of the liquid nitrogen forced cooling device. The device for repairingthe aircraft thin-walled beam through laser deposition is good in overall repairing effect, high in efficiency, and low in cost.

Owner:常州江苏大学工程技术研究院 +1

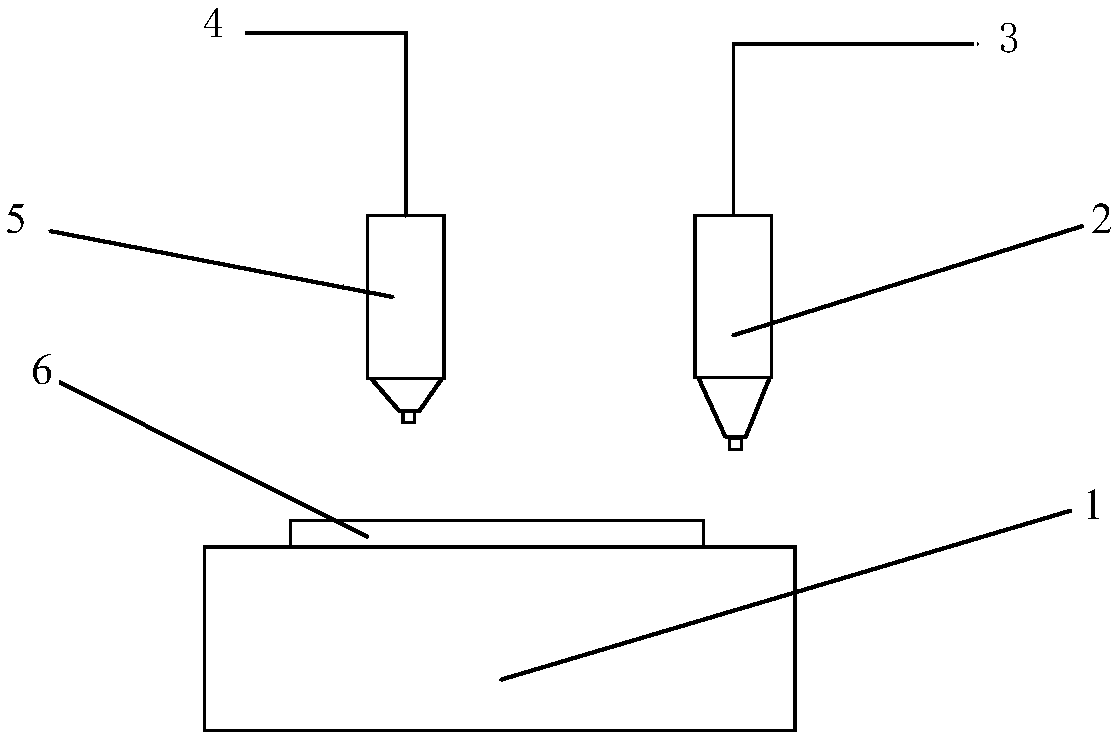

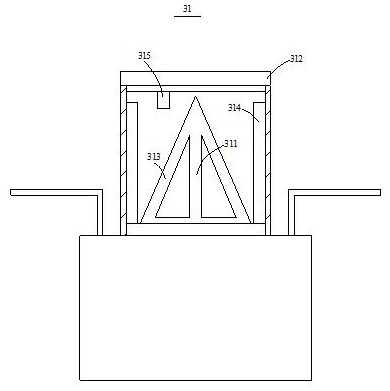

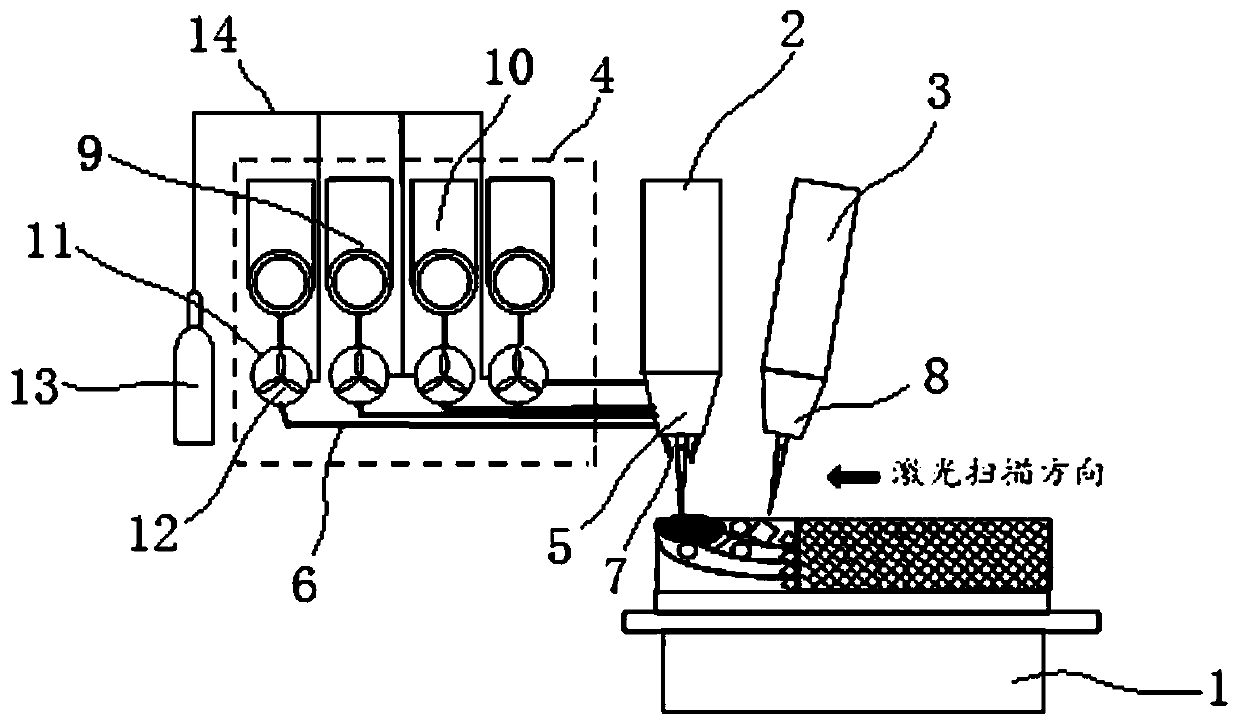

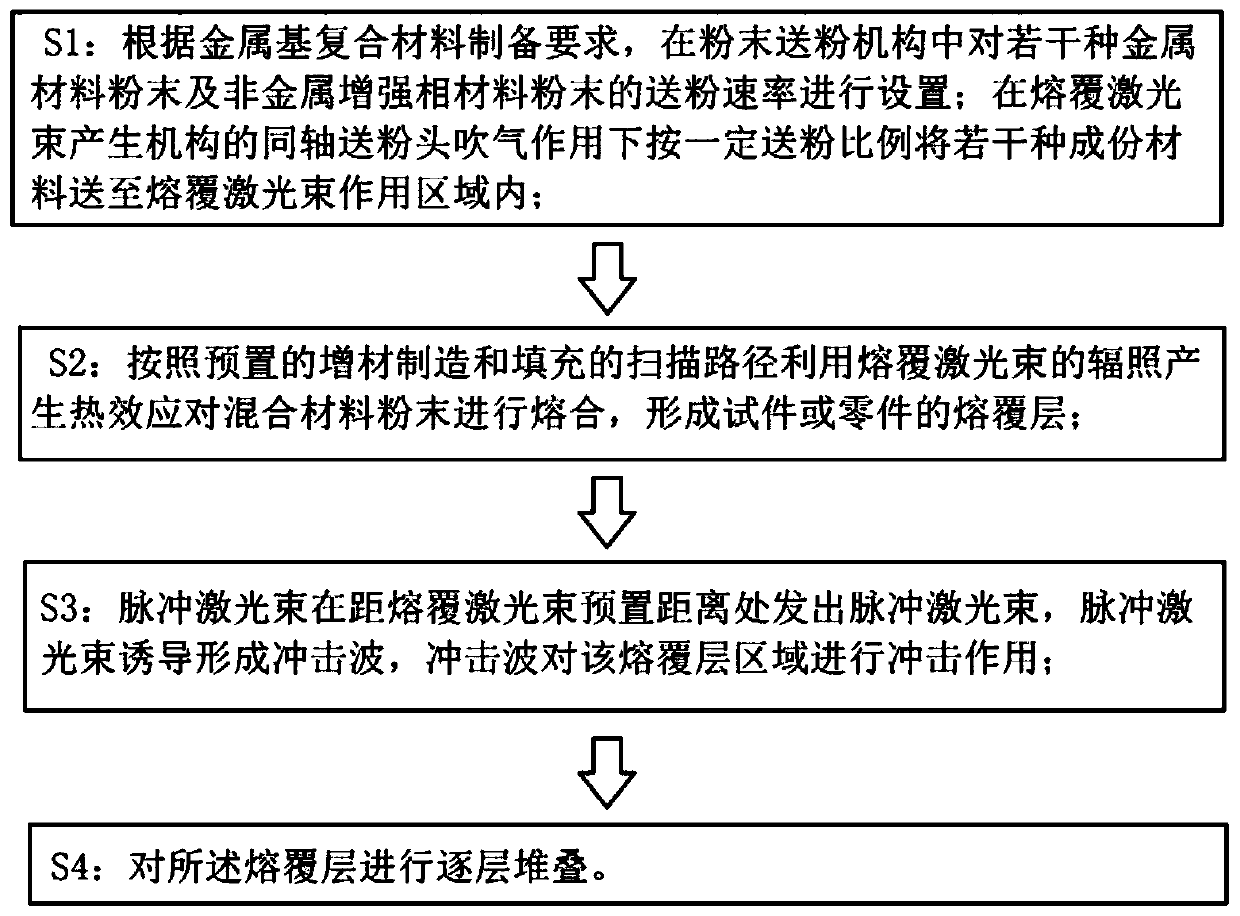

Metal matrix composite material composite additive manufacturing device and manufacturing method

ActiveCN111468723AQuality improvementImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyMixed materialsMetal matrix composite

The invention discloses a metal matrix composite material composite additive manufacturing device and manufacturing method. The manufacturing method comprises the following steps of S1: setting powderfeeding rates of a plurality of kinds of metal powder and nonmetal powder in a powder feeding mechanism according to preparation requirements of a metal matrix composite material, and feeding a plurality of component materials into a cladding laser beam action area according to a certain powder feeding proportion under the action of blowing of a coaxial powder feeding head; S2: fusing mixed material powder by utilizing a thermal effect generated by irradiation of a cladding laser beam according to a preset scanning path for additive manufacturing and filling to form a cladding layer of a testpiece or a part; S3: emitting a pulse laser beam at a preset distance from the cladding laser beam, inducing the pulse laser beam to form a shock wave, and impacting the cladding layer area by the shock wave; and S4: stacking cladding layers layer by layer. According to the metal matrix composite material composite additive manufacturing device and manufacturing method, metal matrix composite material test pieces and parts can be prepared with high efficiency, low cost and strong controllability.

Owner:GUANGDONG UNIV OF TECH

Preparation method of fatigue-resistant alloy lining plate for ball mill

InactiveCN106636974AImprove wear resistanceImprove fatigue strengthFurnace typesGrain treatmentsIngotUltimate tensile strength

The invention discloses a preparation method of a fatigue-resistant alloy lining plate for a ball mill. The preparation method comprises the following process steps that a steel ingot is cast, wherein the steel ingot contains, by weight, 1.3-1.5% of C, 1.5-1.9% of Si, 2.6-2.9% of Mn, 0.7%-1.1% of Mo, 0.004%-0.01% of S, 2.2-2.4% of Cr, 0.3-0.5% of Ni, 0.15-0.21% of Ti, 0.2-0.4% of W, 0.12-0.22% of Al, 0.02-0.09% of Re and the balance iron, The internal defects of the alloy lining plate material are effectively eliminated, the abrasion resistance and fatigue strength of the alloy lining plate are improved, and meanwhile the preparation method has the advantages of being free of oxidation, decarburization and element vaporizing and the like and can effectively improve the ball milling efficiency.

Owner:马鞍山市银鼎机械制造股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com