Patents

Literature

66results about How to "Meet the stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal part manufacturing system and method adopting micro-casting-forging and milling-grinding in-situ composite

InactiveCN110076566AImprove tissue mechanical propertiesImprove processing efficiencyAdditive manufacturing apparatusOther manufacturing equipments/toolsEngineeringManufacturing systems

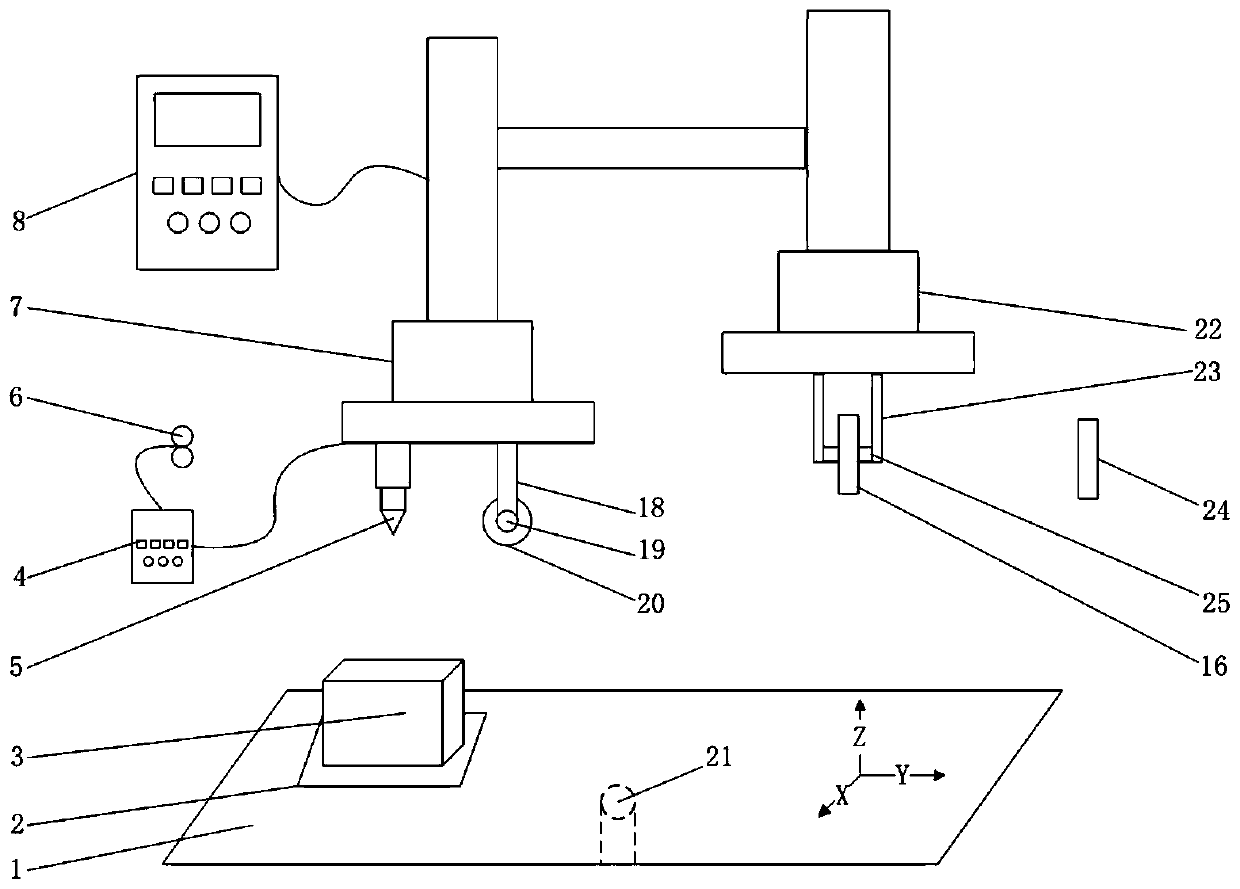

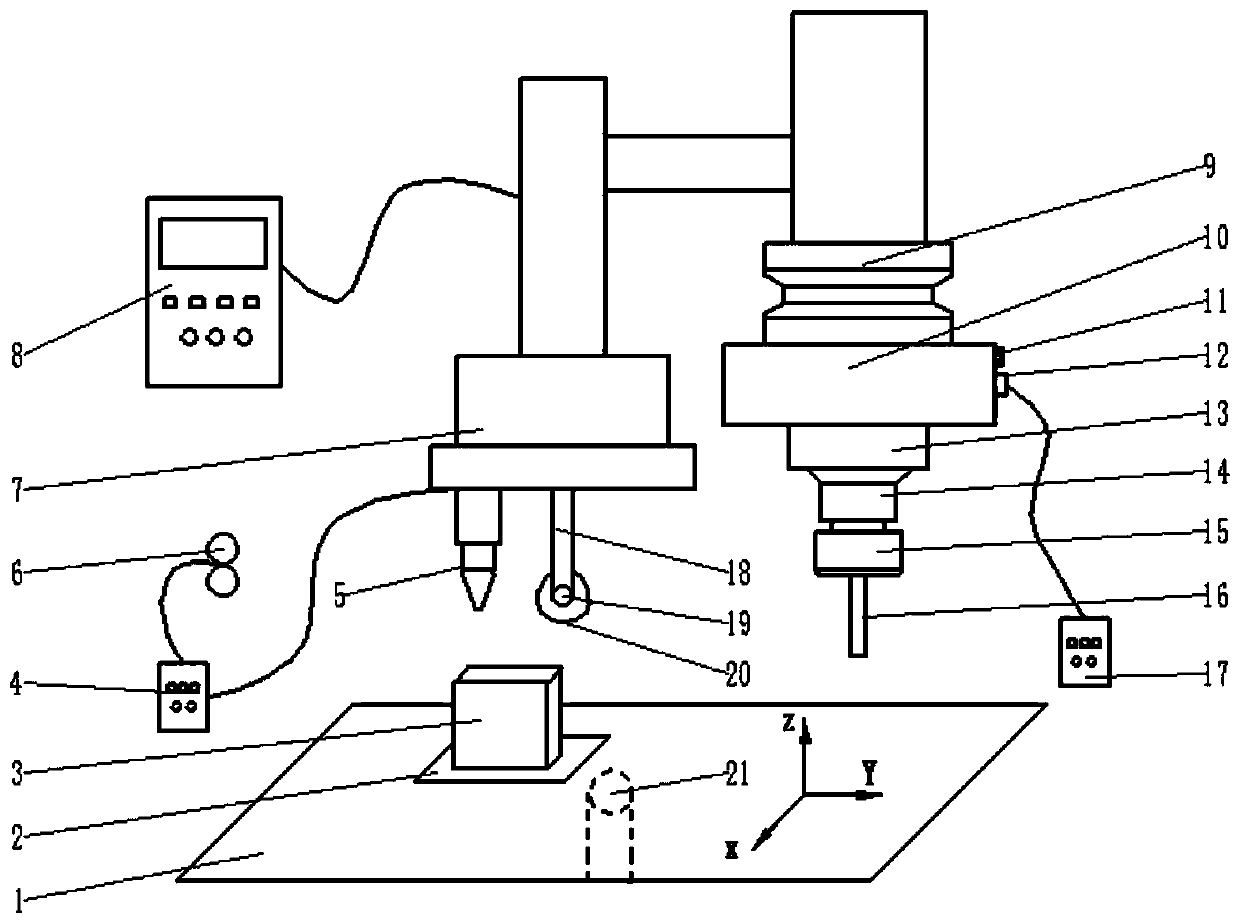

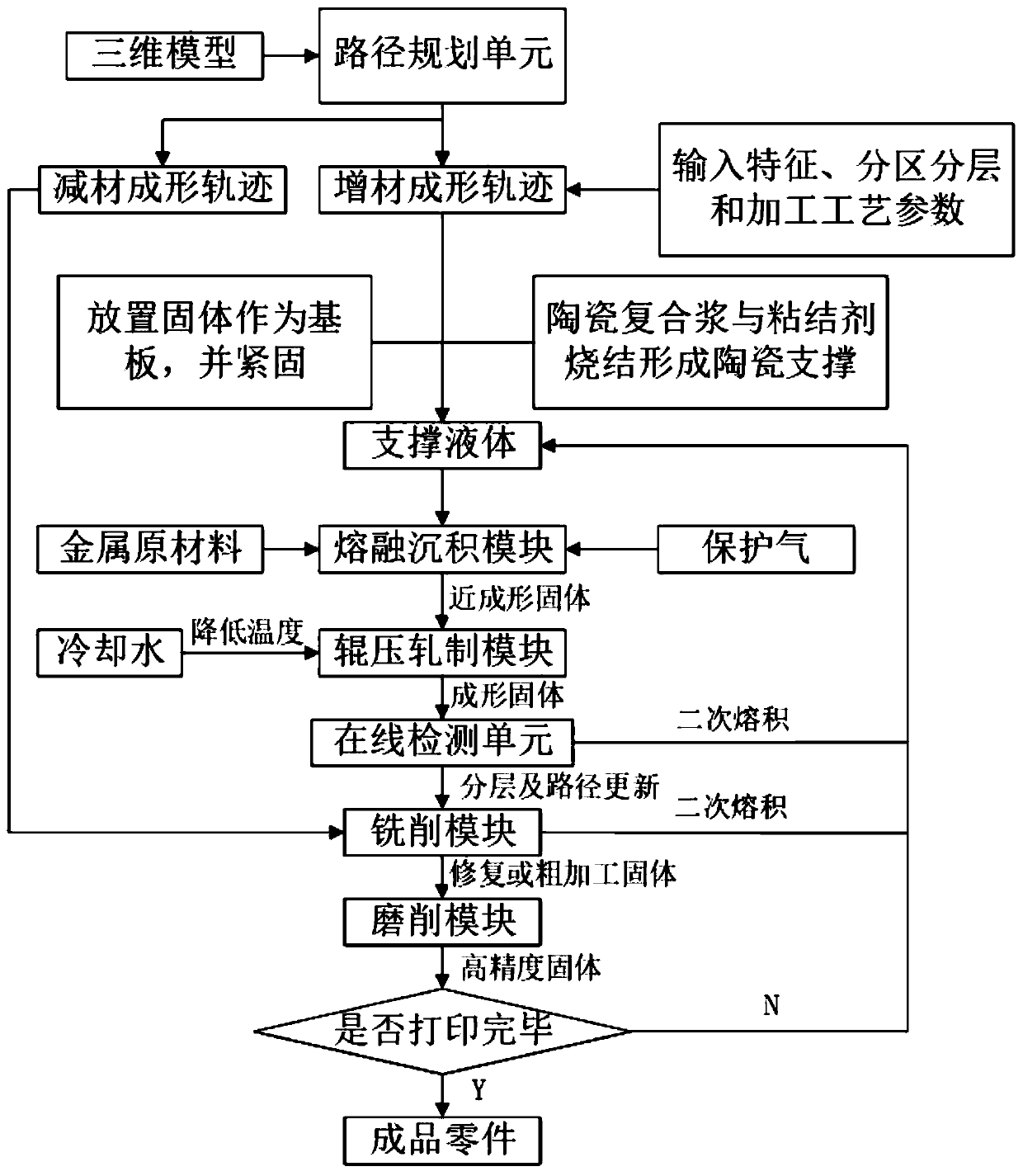

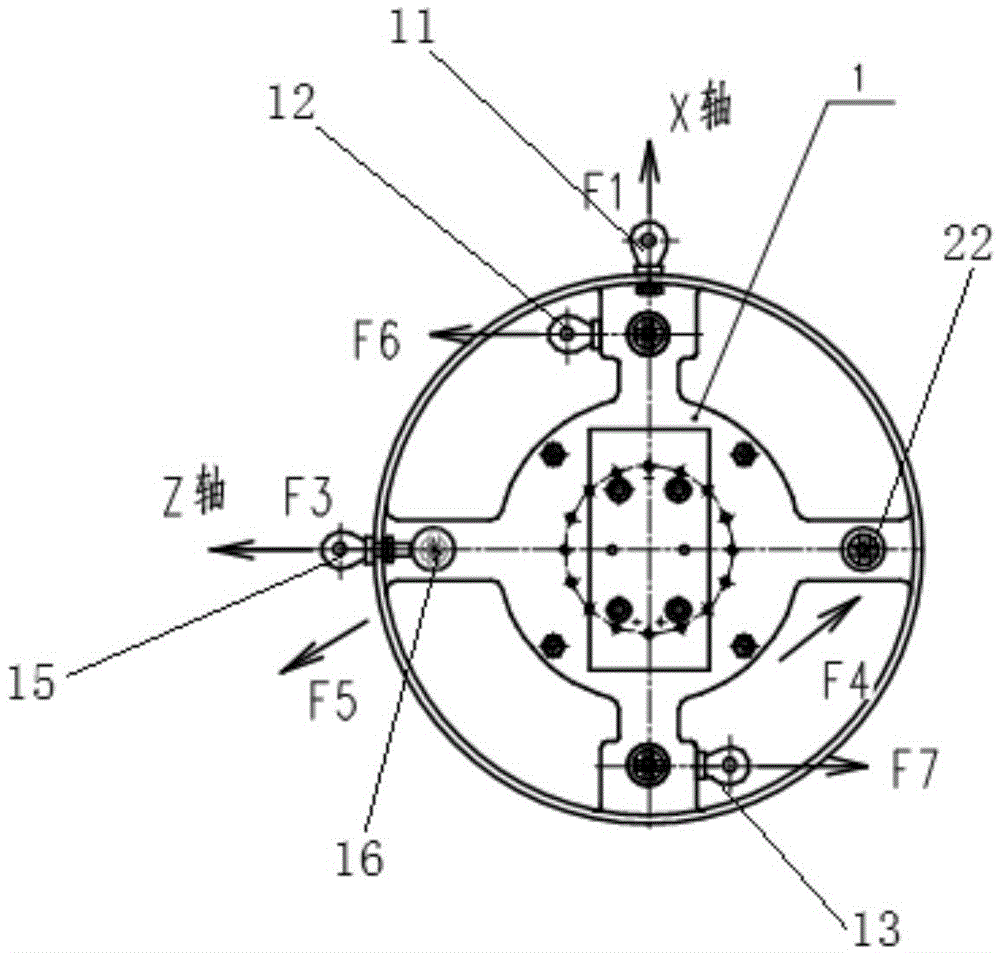

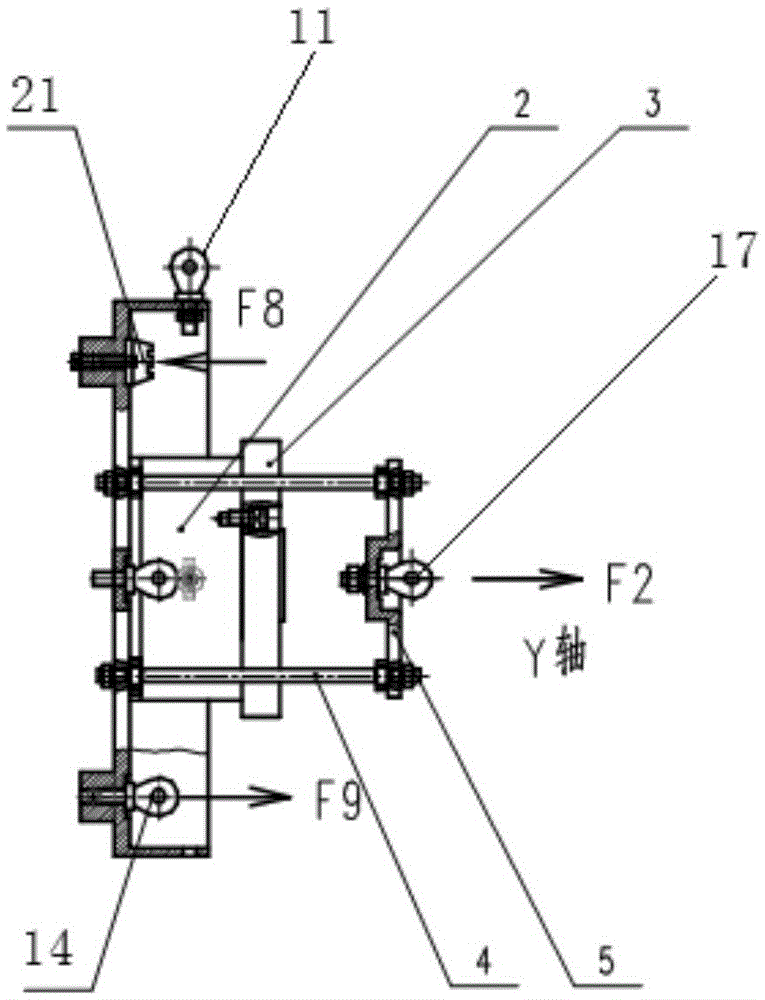

The invention belongs to the field of metal part manufacturing, and particularly discloses a metal part manufacturing system and method adopting the micro-casting-forging and milling-grinding in-situcomposite. The system involves a micro-casting-forging module, a milling module, a five-axis linkage workbench and a control device, wherein the micro-casting-forging module is connected with the milling module and comprises a fusion deposition sub-module and a roller-pressing rolling sub-module, the five-axis linkage workbench is positioned below the micro-casting-forging module and the milling module, and is used for containing metal parts to be formed, and the control device is connected with the fusion deposition sub-module, the roller-pressing rolling sub-module, the milling module and the five-axis linkage workbench. According to the system and method, micro-casting-forging and a milling process are composited to process and manufacture the metal parts, so that the problems that whenthe metal parts are made through the additive manufacturing, the structure is not uniform, the deformation is serious, the residual stress is large, the structure performance is poor, and the surfacequality is poor are solved, and the system and method is especially suitable for processing a high-performance complicated special-shaped element.

Owner:HUAZHONG UNIV OF SCI & TECH

Double-flexible-grinding-head magnetorheological polishing device

ActiveCN102632435AEfficient removalEffectively match processing efficiencyGrinding drivesGrinding feed controlMagnetic currentEngineering

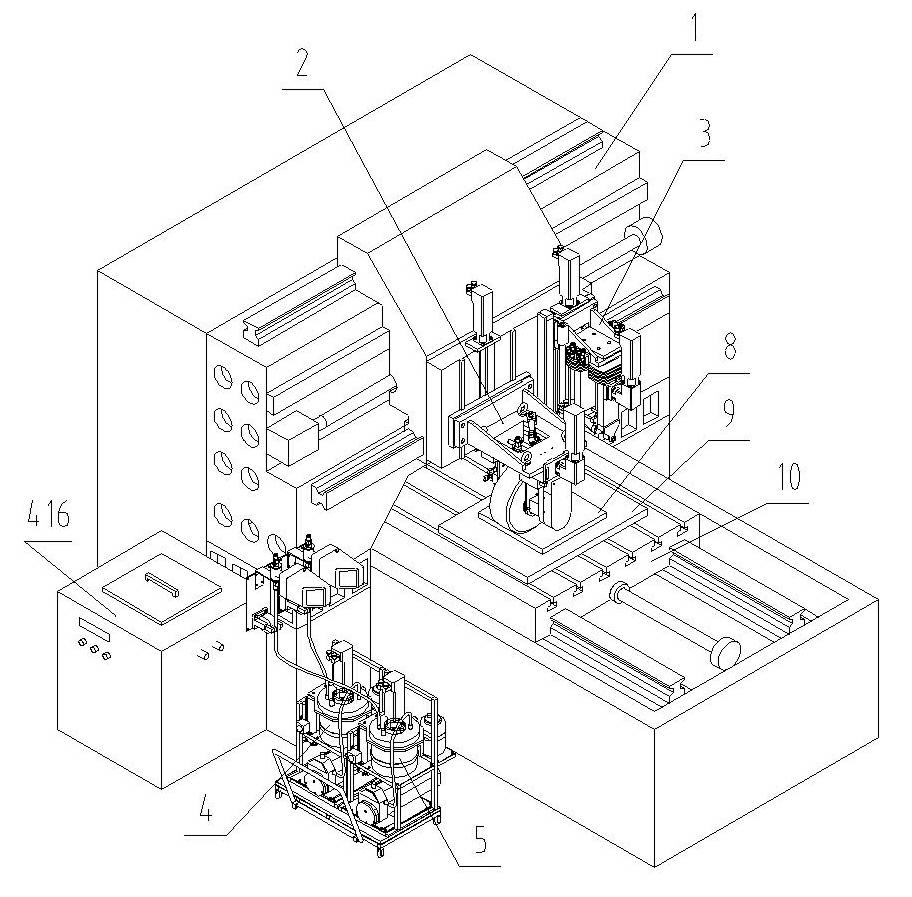

The invention discloses a double-flexible-grinding-head magnetorheological polishing device. In the device, a vertical gantry of a bed body and an X-axis are both fixed on a horizontal base; a worktable is fixed on a sliding block of the X-axis; a Y-axis is fixed on a horizontal beam of the vertical gantry; and a first Z-axis and a second Z-axis are arrangedon the Y-axis in parallel. A large flexible grinding head is installed on the first Z-axis; and a small flexible grinding head is arranged on the second Z-axis. A high-flow circulation system connected with the large flexible grinding head and a low-flow circulation system connected with the small flexible grinding head are arranged on a trolley. A control cabinet is arranged at the rear part of the vertical gantry; and a circulation system cabinet and a cleaning system are arranged at the side surface of the vertical gantry. The double-flexible-grinding-head magnetorheological polishing device provided by the invention has the advantages of high accuracy, high rigidness, high stability and high dynamic property. The double-flexible-grinding-head magnetorheological polishing device not only can be used for processing of large-caliber phase elements, but also can be used for high-accuracy processing of large-caliber planar optical elements within the range of full caliber. The optimal matching of the processing efficiency and the processing accuracy can be realized.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

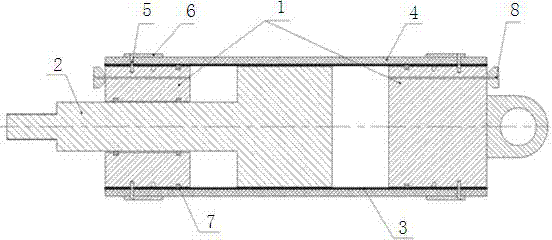

Vector thrust loading device for attitude control engine

ActiveCN105649817AGuaranteed positioning accuracyImprove machining accuracyRocket engine plantsAttitude controlEngineering

The invention relates to a vector thrust loading device for an attitude control engine. The vector thrust loading device comprises a loading head, a connecting rod, a sensor mounting flange and a rear flange, wherein one end of the loading head is connected to the engine; the other end of the loading head is connected to the rear flange through the connecting rod; the sensor mounting flange is arranged between the rear flange and the loading head and is fixed on a stationary foundation; one end of a vector force sensor is fixed on the sensor mounting flange, and the other end of the vector force sensor is fixed on the loading head; the central position of the loading head is set as an original point; six pull rings and two pressing seats are arranged on the loading head; a seventh pull ring is arranged on the rear flange; and the first to sixth pull rings and the two pressing seats realize the application of Fy, Fz, Mx, My and Mz standard forces in a combination manner. According to the invention, the problem of application of standard vector forces under the vector force sensor coordinate system in the in-situ calibration process of the vector force sensor on a testing site is solved.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

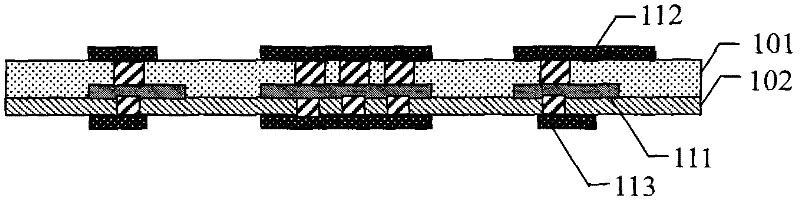

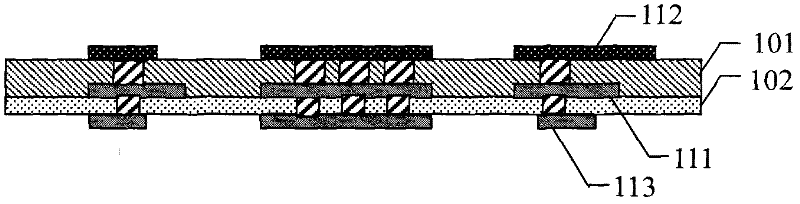

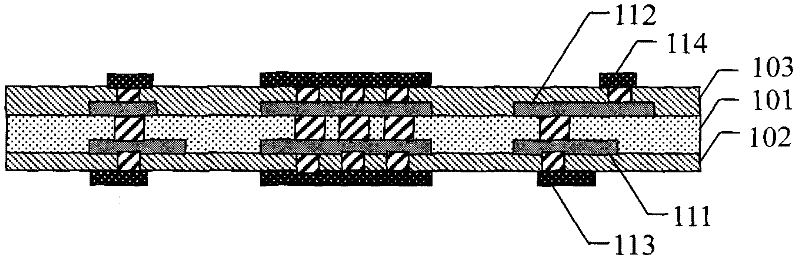

Multilayer circuit board and manufacturing method thereof

InactiveCN102548183AMeet the stiffnessFulfil requirementsInsulating substrate metal adhesion improvementPrinted circuit detailsGlass fiberElectrical and Electronics engineering

The invention discloses a multilayer circuit board and a manufacturing method thereof, relating to the technical field of multilayer circuit board manufacturing and aiming to improve the quality of multilayer circuit boards. The multilayer circuit board comprises multiple circuit layers overlapping with each other, wherein an insulating layer is arranged between two adjacent circuit layers; each circuit layer comprises a power wire layer, a ground wire layer and a signal wire layer; the insulating layers comprise at least a resin slice insulating layer and at least a prepreg insulating layer containing glass fiber cloths; the wiring density of the signal wire layer is greater than that of the power wire layer and / or the ground wire layer; and the resin slice insulating layer is arranged adjacent to the signal wire layer. The manufacturing method can be used for manufacturing the multilayer circuit board.

Owner:PEKING UNIV FOUNDER GRP CO LTD

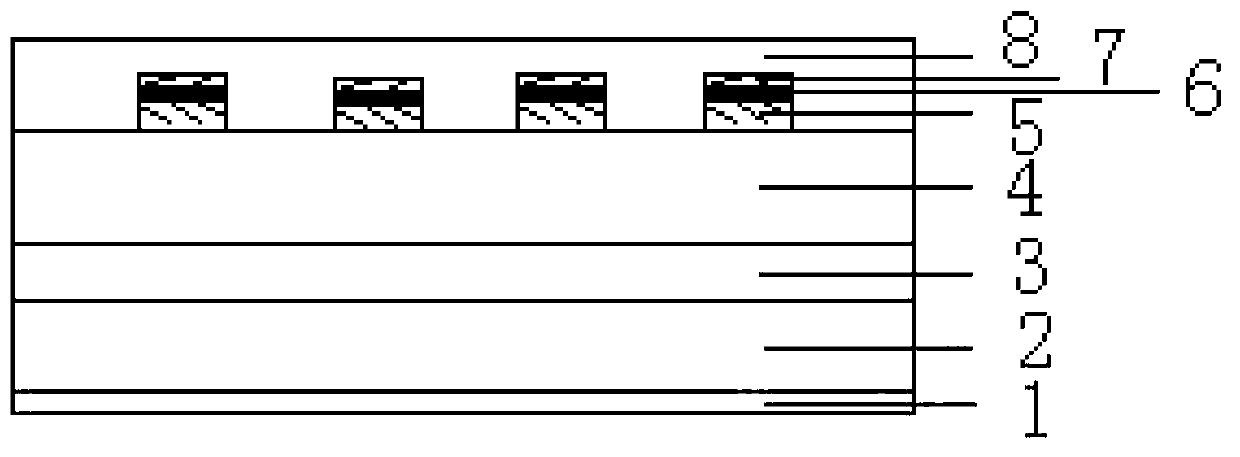

Positioning laser certificate anti-fake thin film for individually printing and preparation method thereof

ActiveCN103342064AMeet the stiffnessFulfil requirementsLamination ancillary operationsDuplicating/marking methodsInformation layerPolyethylene terephthalate glycol

The invention relates to the technical field of an anti-fake thin film and a preparation method thereof, and in particular relates to a positioning laser certificate anti-fake thin film for individually printing, wherein the thin film comprises an anti-static layer, a base material, a composite glue layer, a base material, a laser information layer, a reflecting medium layer, an anti-fake image-text layer and an adhesive layer, which are sequentially connected with one another from top to bottom. In order to obtain the anti-fake thin film with the structure, the laser anti-fake image text is prepared on the base in a positioning way at high precision, and is compounded with the base material, and a PVC (polyvinyl chloride) film is supported by the base material. The preparation method specifically comprises the following steps of: (1) preparing the laser information layer; (2) physically depositing the reflecting layer; (3) printing the anti-fake image text; (4) deionizing; (5) coating the adhesive layer; and (6) compositing. According to the thin film and the preparation method thereof provided by the invention, the position laser anti-fake function and the individual printing function are integrated onto the PVC film and a PETG (polyethylene terephthalate glycol) film to prepare a card in a layering way, the thin film and the preparation method thereof are unique in technical design and low in comprehensive cost, the certificate preparation equipment and technological process can be simplified, the manipulation resistance, the forgery resistance and the alteration resistance of the certificate can be preferably carried out, and the thin film can be widely used for the fake resistance of various legal certificates, certificate card tickets and the like.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

Tuned passive damper with two degrees of freedom

InactiveCN103867636AHigh quality and efficient processingInhibition first orderNon-rotating vibration suppressionMaintainance and safety accessoriesAngular degreesDamping ratio

The invention discloses a tuned passive damper with two degrees of freedom. The tuned passive damper with the two degrees of freedom comprises mass blocks, sliding blocks, elastic-damping units and rigidity adjusting bolts; grooves are formed in the two ends of each mass block, every two sliding blocks are arranged in one groove and are tightly attached to a thin plate in the corresponding elastic-damping unit, and each thin plate is provided with a sliding groove corresponding to the groove in the corresponding mass block. Each sliding block is located by the corresponding rigidity adjusting bolt penetrating through the corresponding groove and the corresponding sliding groove, so that the distance between the two sliding blocks on the same side of each mass block is adjusted through the corresponding bolts, and rigidity adjustment of the damper is achieved. Besides, a friction plate with the adjustable angle is arranged between the corresponding sliding blocks and the side wall of a base of the corresponding elastic-damping unit, the contact area between each friction plate and the corresponding mass block is changed by adjusting the angle of the corresponding friction plate, and therefore the damping ratio of the damper is adjusted. The tuned passive damper with the two degrees of freedom has the advantages of being simple in structure, convenient to implement and low in cost, having no pollution to the environment, being capable of effectively lowering vibration in a cutting process, and achieving high-efficiency and high-quality machining of parts.

Owner:BEIHANG UNIV

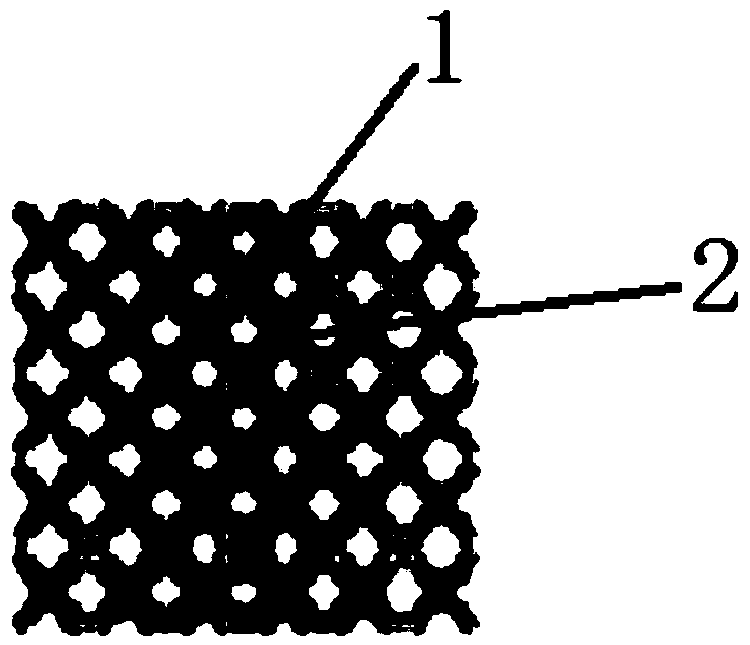

Metal bone trabecula and bone implant comprising metal bone trabecula

PendingCN107647941AMeet the stiffnessMeet the intensityBone implantJoint implantsHuman bodyBone Trabeculae

The invention discloses a metal bone trabecula. The metal bone trabecula comprises at least three crossed metal bone trabecula supports, a micro-topological grid structure is embedded into the metal bone trabecula, and at least three intersection points are formed between the micro-topological grid structure and the metal bone trabecula supports. The bone trabecula is formed by regularly or irregularly arranging hollowed-out unit structure bodies in a three-dimensional space, the weight reducing effect is obvious, meanwhile, the requirement of rigidity and strength of different areas of partscan be met at the same time, stress shielding is avoided, and good matching of high strength and high weight reduction ratio can be achieved; in addition, after growing into the bone trabecula structure comprising a micro-topological grid, human body sclerotin can be fused with bone, bone ingrow can be induced to the largest extent, and accordingly long-term biological fixation of a prosthesis canbe achieved. Meanwhile, the invention further discloses a bone implant comprising the metal bone trabecula. The bone implant can achieve personalized customization through 3D printing, the process issimplified, and the economic cost is greatly reduced.

Owner:GUANGZHOU HUATAI 3D MATERIAL MFG TECH CO LTD

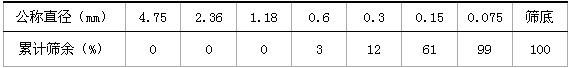

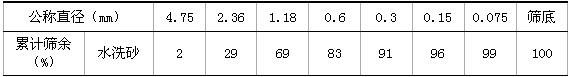

Large-flowability and high-strength concrete

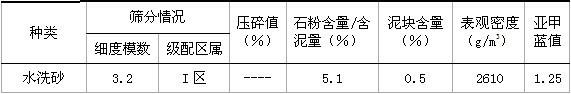

The invention discloses large-flowability and high-strength concrete, which comprises the following components in part by weight: 350 to 450 parts of cement, 30 to 60 parts of wollastonite, 40 to 90 parts of slag powder, 40 to 60 parts of coal ash, 650 to 700 parts of fine aggregates, 1,000 to 1,250 parts of coarse aggregates, 150 to 180 parts of water and 10 to 15 parts of pumping agent. The concrete particularly has high flowability while meeting requirements of performance of strength, rigidity, weight and the like of high-rise and mega-high-rise buildings, and the filling performance is improved obviously; the fine aggregates formed by mixing artificial machine-made sand and sand of Yangtze River can be distributed in the granularity from 0.075 to 4.72 millimeters, and after being mixed and filled into a template to form concrete members, the fine aggregates can be filled into gaps with various pore diameters among the coarse aggregates of a stressed skeleton, so that the strength can be improved; the performance of the fine aggregates is similar to that of natural medium sand, and the fine aggregates can be prepared from local materials, so the cost is reduced by half; and the coarse aggregates are limestone gravels with the diameters of between 5 and 10 millimeters and limestone gravels with the diameters of between 10 and 25 millimeters, and form the stressed skeleton in the concrete, so that the mechanical property of the stressed skeleton can be enhanced obviously, and the strength of the concrete can be improved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

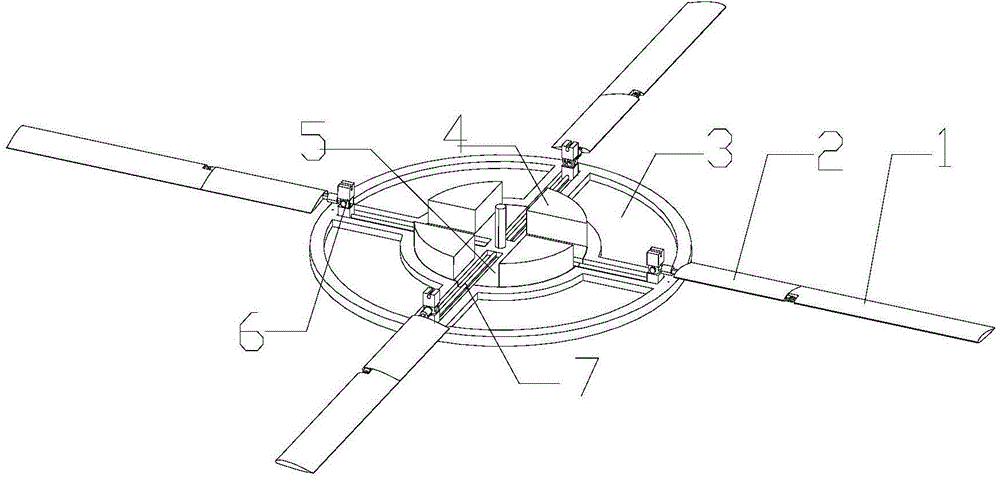

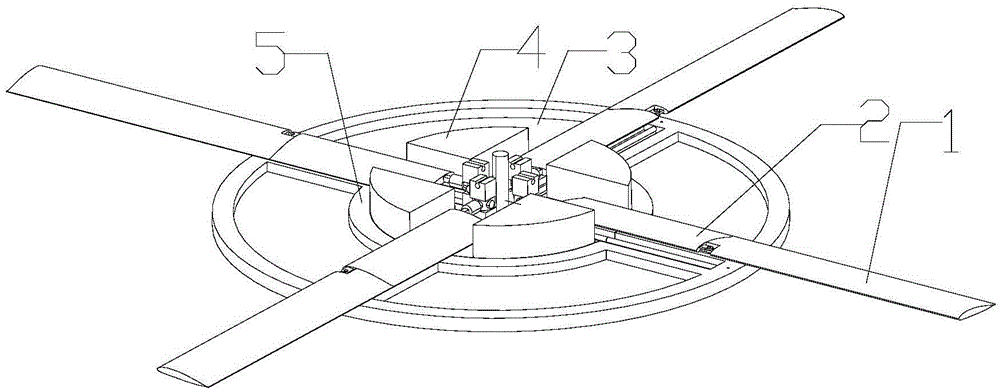

Telescopic foldable rotor wing

ActiveCN104816825ARealize the function of vertical take-off and landingShort timeRotocraftLevel flightPropeller

The invention discloses a telescopic foldable rotor wing. The telescopic foldable rotor wing comprises outer blade sections, inner blade sections, a big disc, internal stoppers of a small disc, the small disc, slide grooves, propeller hubs, sliding blocks, a main shaft, steering engines, a cowling, a motor, limit rollers and plug pins. According to the telescopic foldable rotor wing disclosed by the invention, the function of perpendicularly ascending and descending is well realized, the time for extending and retracting is short, the speed of level flight is high, and the big disc can generate ascending force during the level flight. The telescopic foldable rotor wing disclosed by the invention conforms to the requirements for the strength, the rigidness, the air operation, the weight, the fatigue life and the like of the structural design of an aircraft rotor wing, and does not generate negative influences on the use and the maintenance of aircrafts.

Owner:BEIHANG UNIV

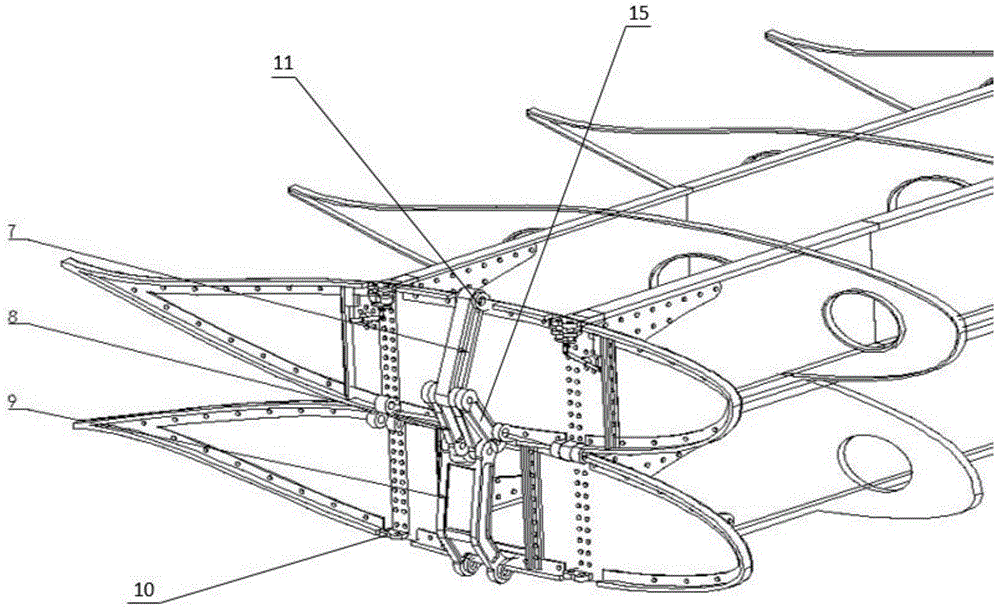

Novel folding wing and driving and deadlocking mechanism

ActiveCN105000169AImprove folding efficiencyPossibility of fully verifying engineering applicationsWing adjustmentsEngineeringActuator

The invention discloses a novel folding wing. The novel folding wing is overall divided into an inner segment, a middle segment and an outer segment. Folding positions comprise a 90-degree position and a 180-degree position. A folding manner is simple, easy to implement and high in efficiency. A hinge four-rod mechanism is selected as a body of a driving mechanism, and meanwhile a hydraulic actuator cylinder is selected as a power source. On the aspect of materials, high-strength alloy hardened and tempered steel is selected as materials of shaft pins, and strength titanium alloy materials are selected as materials of connecting rod structures and lug sheets. Rotating and locking structures are arranged on upper flanges and lower flanges of an upper beam and a rear beam, and it is guaranteed that unlocking and locking are reliably achieved. In the design process of the novel folding wing, the size is determined by meeting certain strength requirements.

Owner:BEIHANG UNIV

Lightweight high-strength carbon fiber composite hydrocylinder

InactiveCN103591078AIncrease productivityAvoid eccentricityFluid-pressure actuatorsResin matrixHigh intensity

The invention provides a lightweight high-strength carbon fiber composite hydrocylinder. The hydrocylinder comprises metal heads, a hydrocylinder piston, a metal liner formed by a hydrocylinder barrel, fixing parts, metal lantern rings and sealing rings, the metal liner is externally and integrally coated with a reinforcing layer formed by a carbon fiber composite, the metal lantern rings are sleeved outside the reinforcing layer which is formed by taking thermosetting resin as a matrix and carbon fiber as a reinforcement, and the thermosetting resin matrix accounts for 23-40% of the reinforcing layer by weight. Compared with all-metal hydrocylinders in the prior art, the lightweight high-strength carbon fiber composite hydrocylinder has the advantages that strength, rigidity and fatigue resistance of the hydrocylinder are all obviously improved under various working conditions, so that safety of the hydrocylinder is improved effectively, weight is reduced by 30-65%, and the objectives of mechanical pump truck weight reduction and complete truck cost reduction are achieved.

Owner:HENGSHEN

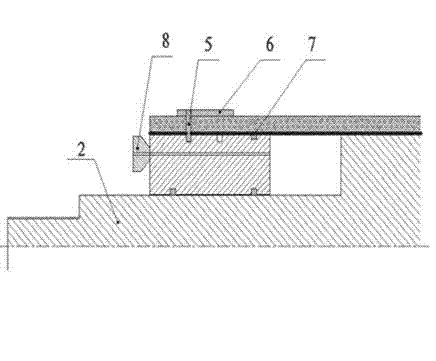

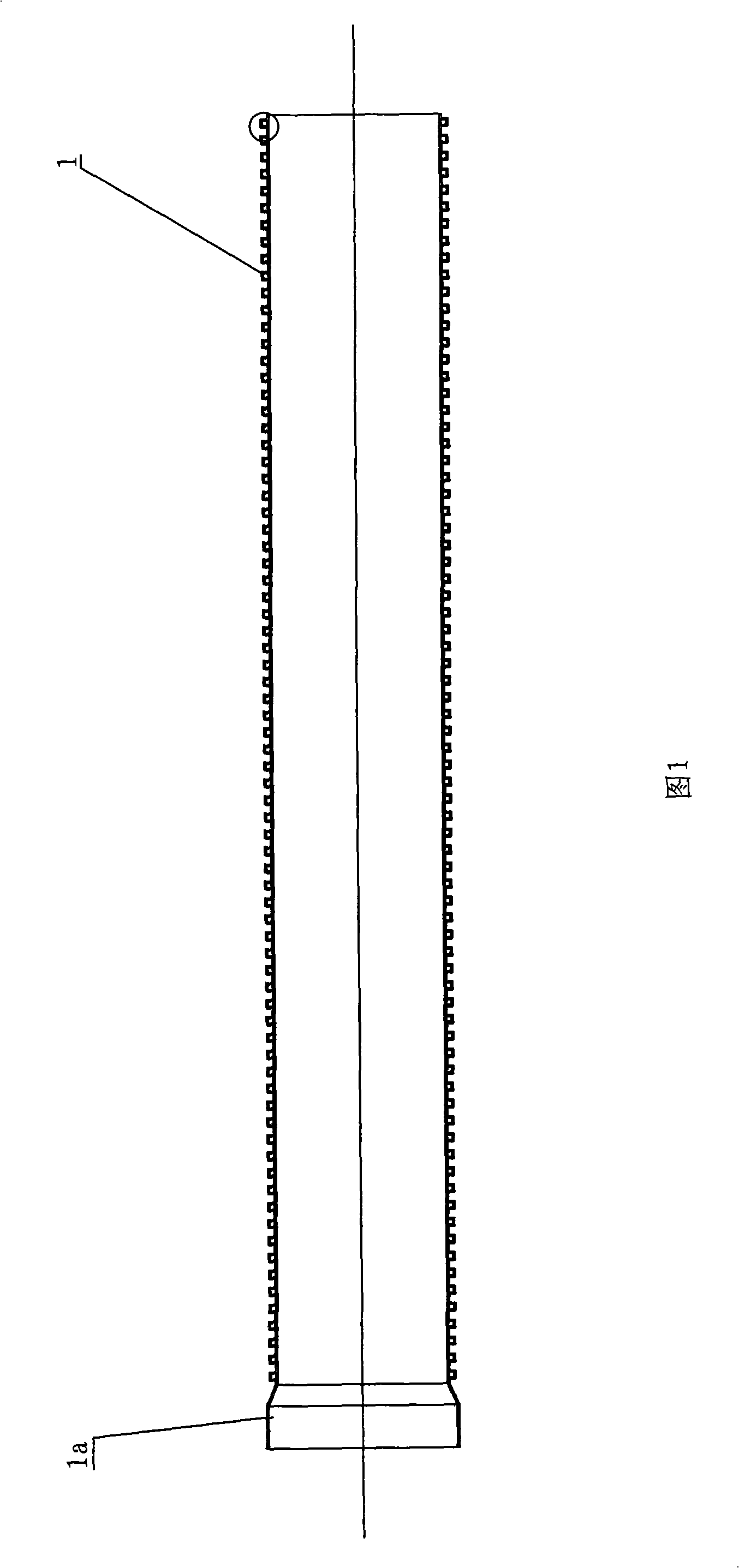

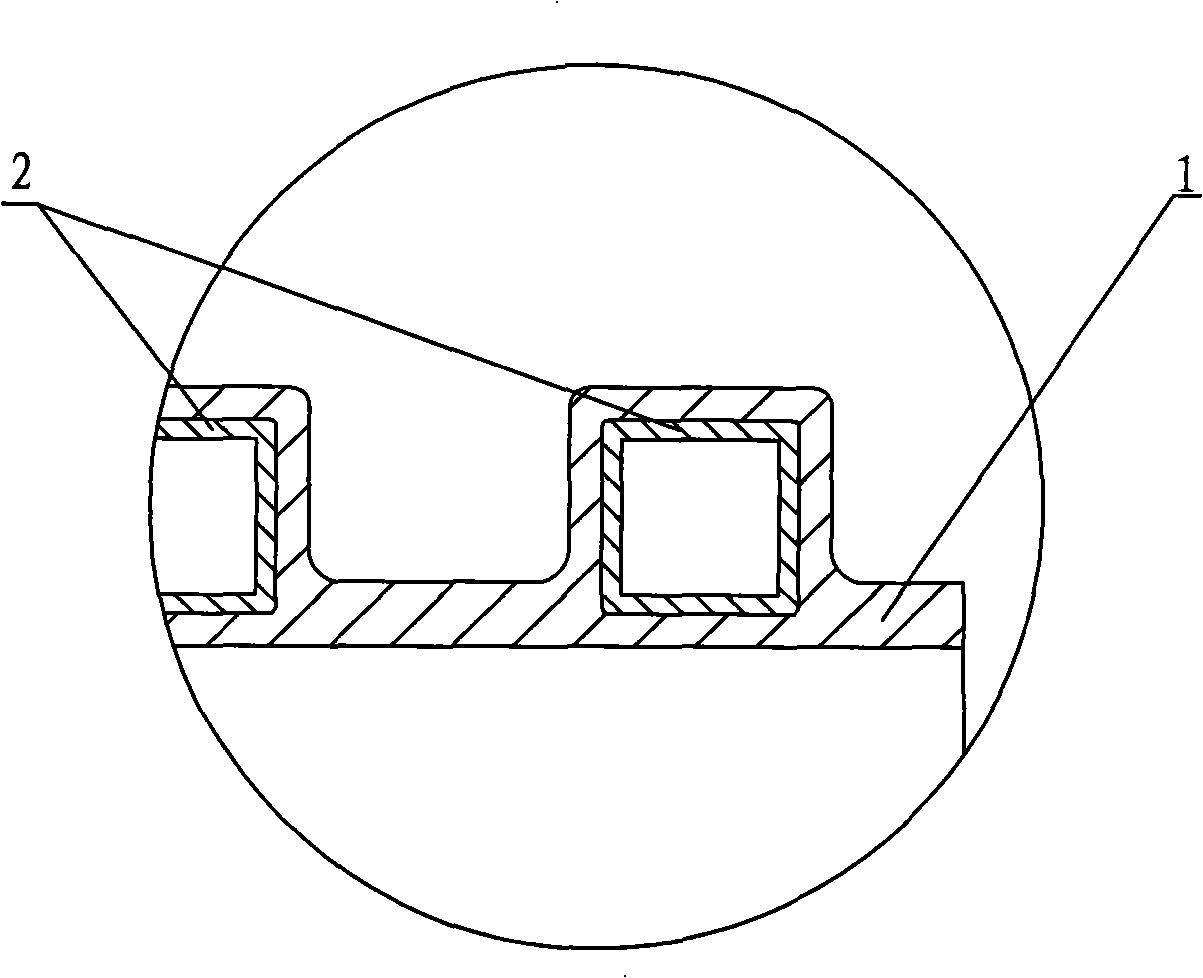

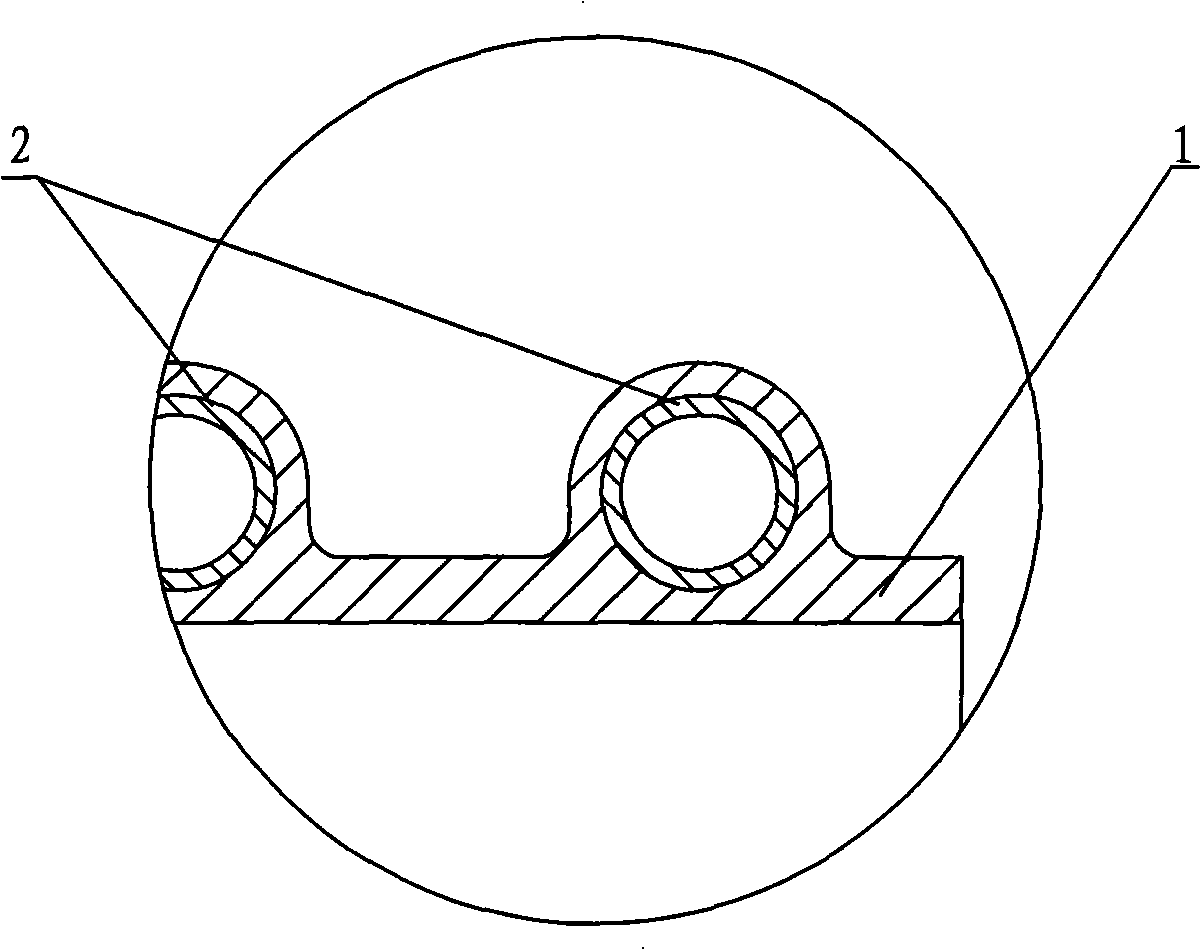

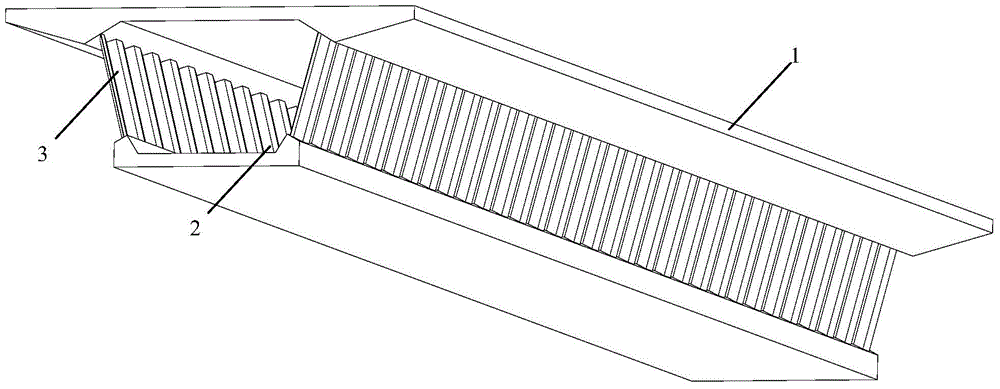

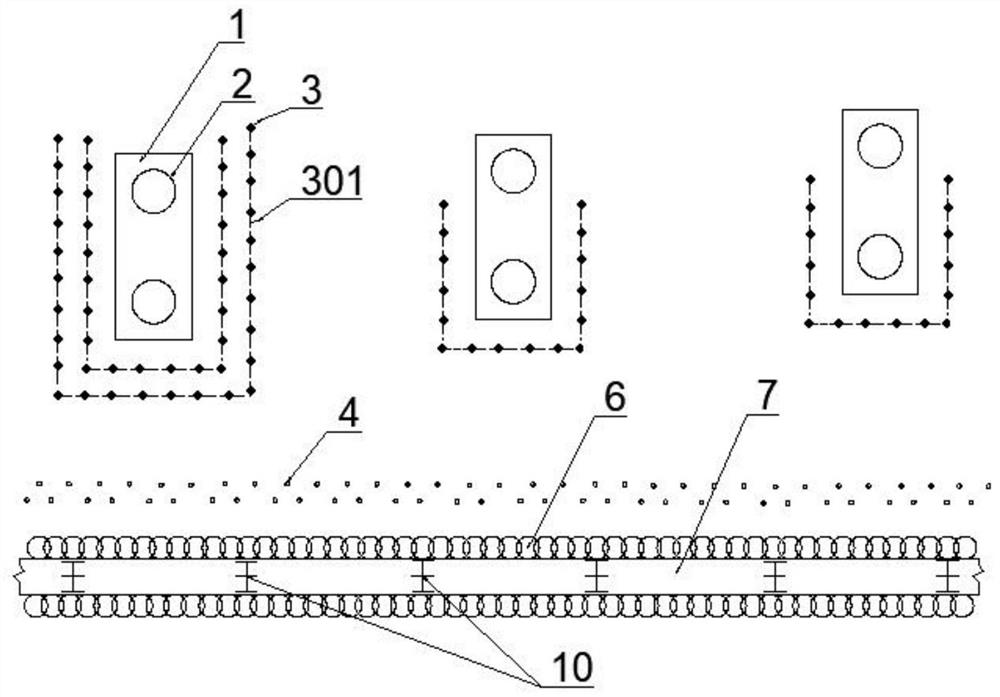

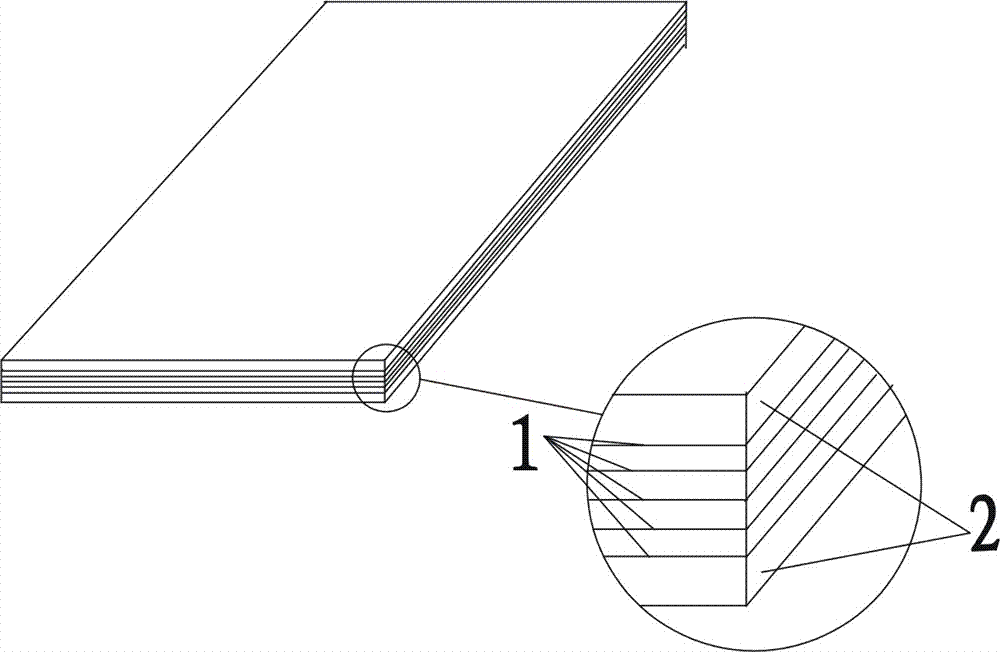

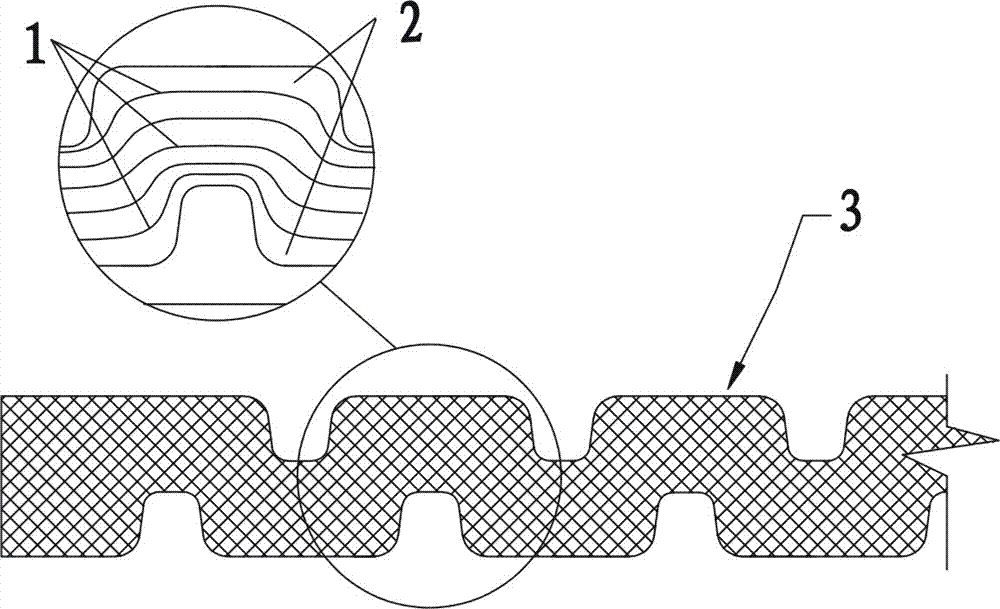

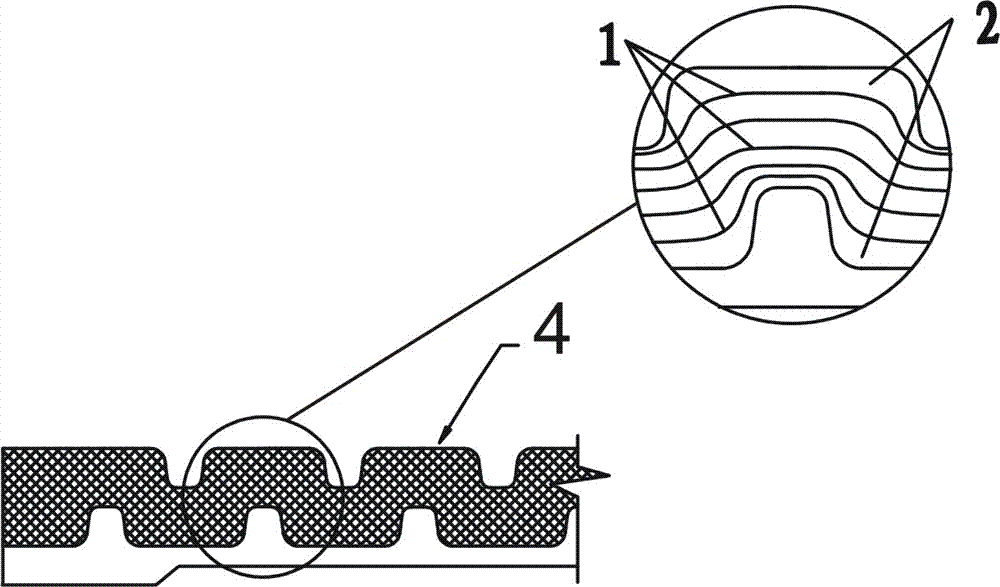

Rotational molding plastic composite pipes with steel rings and manufacturing method thereof

The invention discloses a rotational molding steel ring plastic composite pipe material and a manufacturing method thereof; the wave crest of a sylphon bellowss body (1) is packed with a steel ring (2); the manufacturing method is divided into the steps of mold (3) manufacture, coating mold release agent, steel ring surface treatment, raw material weight calculation, material filling and mold closing, rotating heating insulation, cooling, mold release, modification, inspection, finished products into warehouse, etc., so as to obtain the composite pipe material. The rotational molding steel ring plastic composite pipe material is combined with the steel ring; the plastic pipe body and the steel ring can be organically integrated into a whole, taking the advantage to make up for the deficiency so as to obtain double win, thereby not only meeting the needs of stiffness and strength of a large-caliber pipeline, but also meeting the needs of corrosion protection and service life prolonging, and manufacturing pipe material with arbitrary ring stiffness and diameter; the rotational molding steel ring plastic composite pipe material has small production equipment investment, easy equipment maintenance, high raw material using rate and almost no waste generation, reaches organic unification of pipe material cost and rigidity, and manufactures a buried pipe material with appropriate cost, arbitrary large caliber, self-taking mouthing and mouthing socket connection.

Owner:付志敏 +1

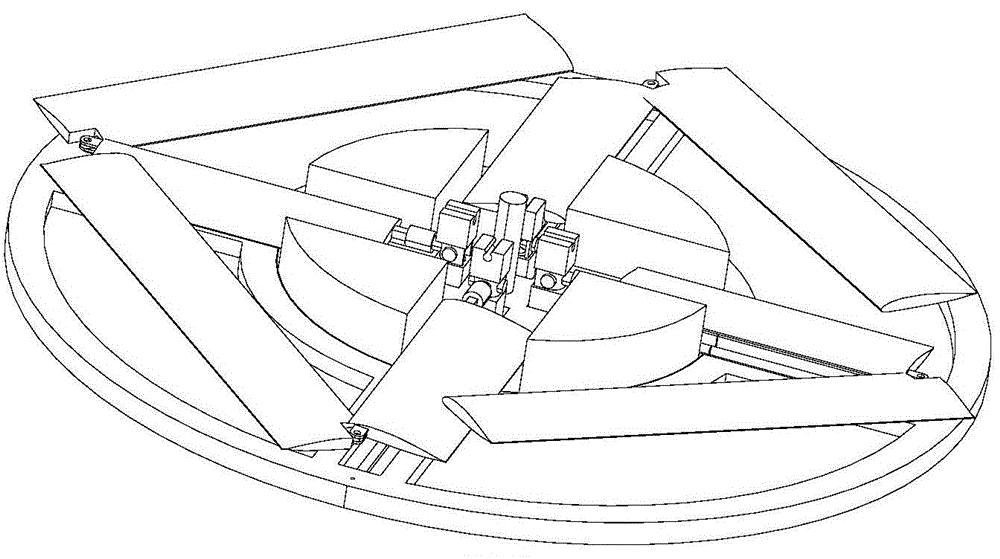

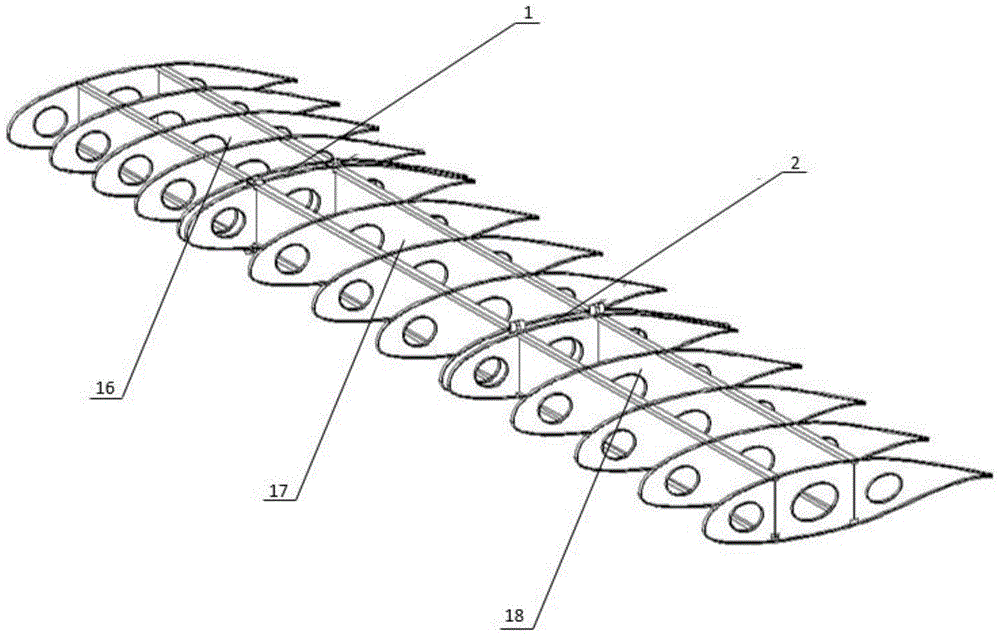

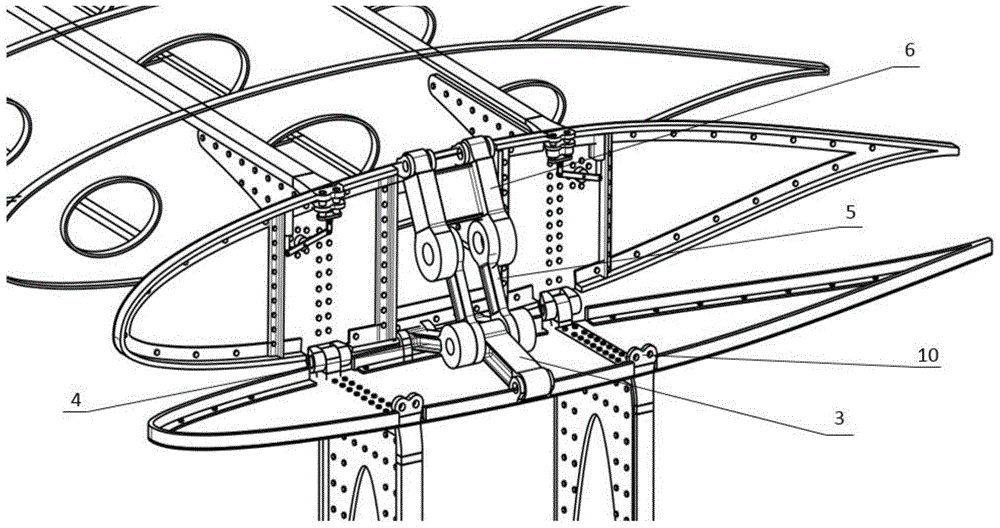

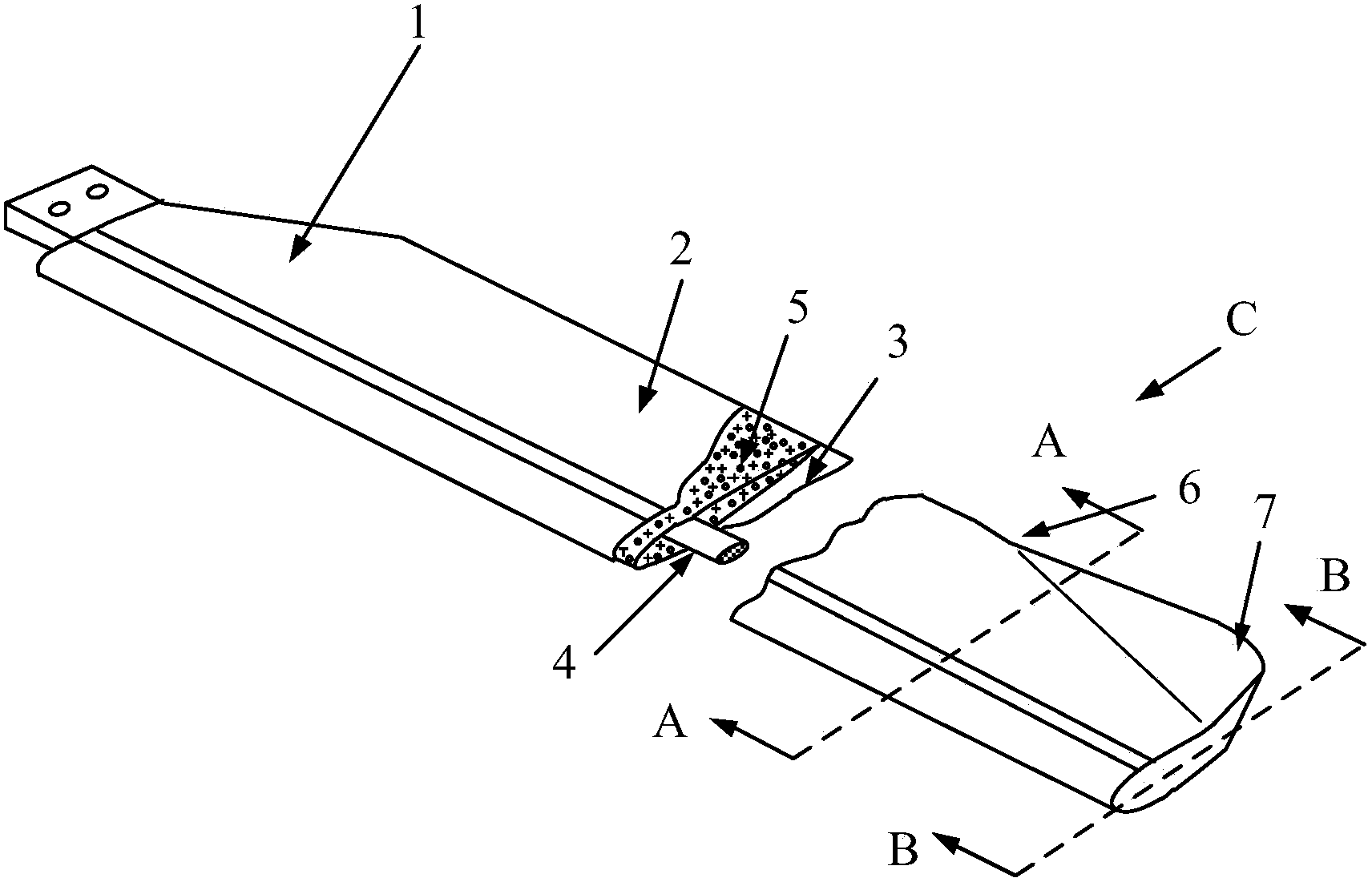

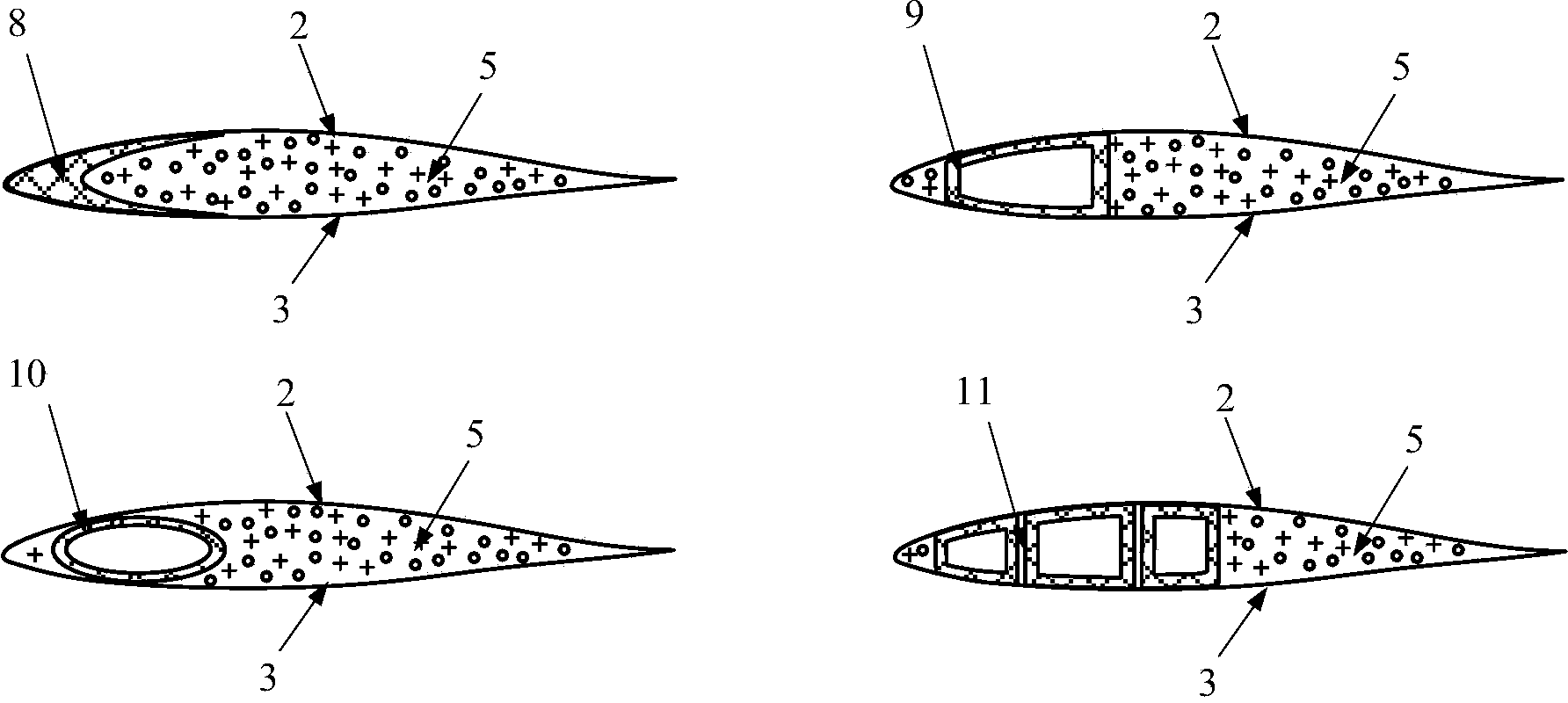

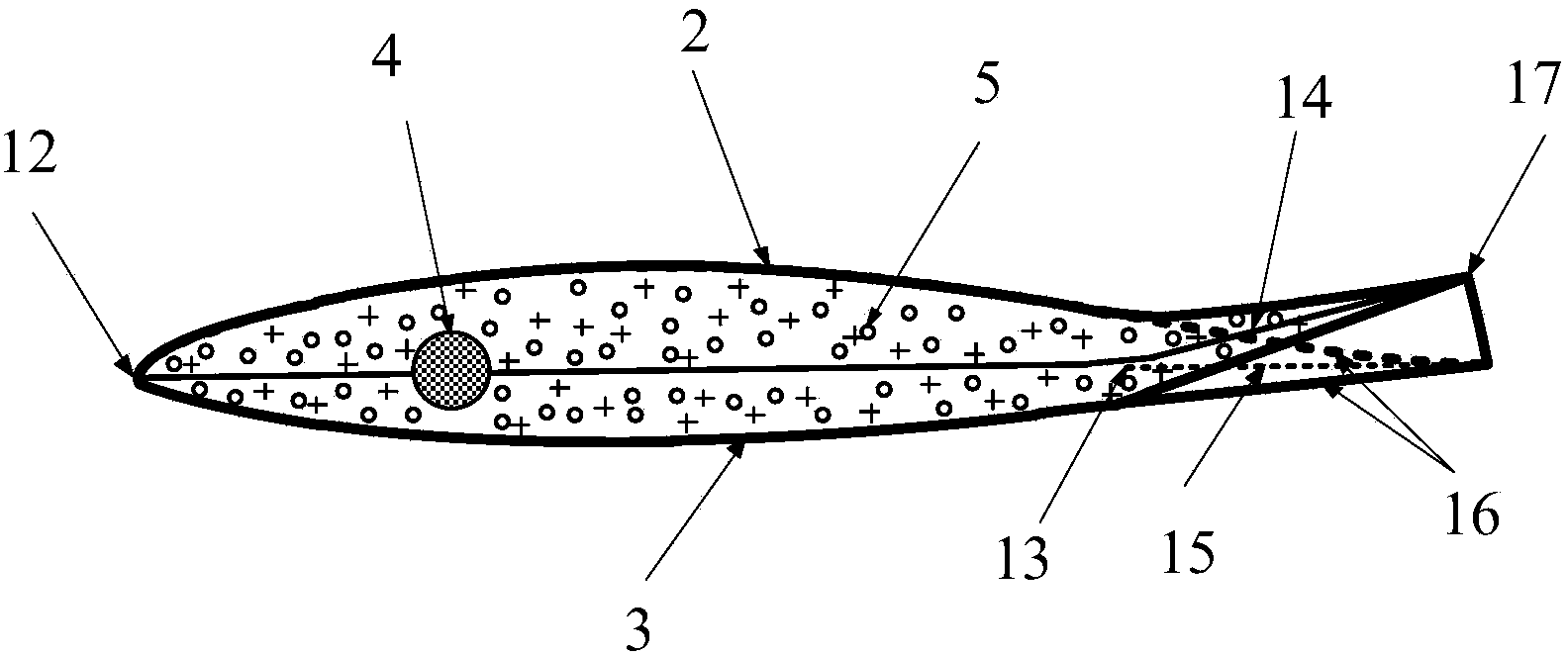

Rotor blade structure design capable of inhibiting rotation chattering of tilt rotor

InactiveCN104002966ASuppression of swing chatterIncreased rotational flutter speedRotocraftRadial positionFront edge

The invention discloses a rotor blade structure capable of inhibiting the rotation chattering of a tilt rotor, belonging to the technical field of tilt rotors. The rotor blade structure comprises a blade girder, a skin and a filler core; on the basis that the position of the girder, the wing shape of the blade and the torsion angle are maintained not to be changed, middle chord lines on all cross sections are bended upwards by a certain angle at the part which is a certain distance away from a front edge point from some radial position of a blade to the tip; meanwhile, the skin and the filler are bended upwards by the same angle; the lengths of the bended parts are linearly increased along with the increment of the radial position. After the rotor blade structure is used, the shearing gas power in a rotor wing shimmy surface can be effectively reduced, and the system damping is improved, so that the rotor blade structure has a good effect of inhibiting the rotation chattering and is capable of effectively accelerating the speed of the rotation chattering. The structure meets the basic performance requirement of the rotor blade structure of the tilt rotor and is simple in structure, and the weight of the blade is not increased.

Owner:BEIHANG UNIV

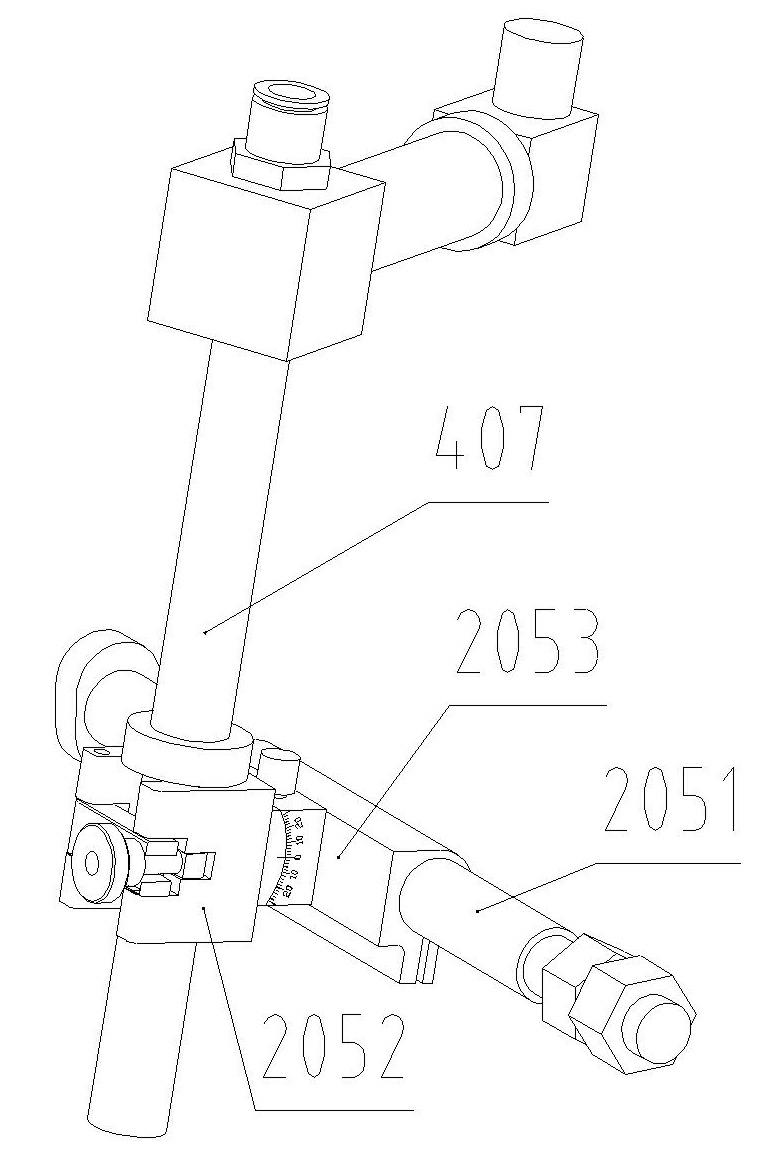

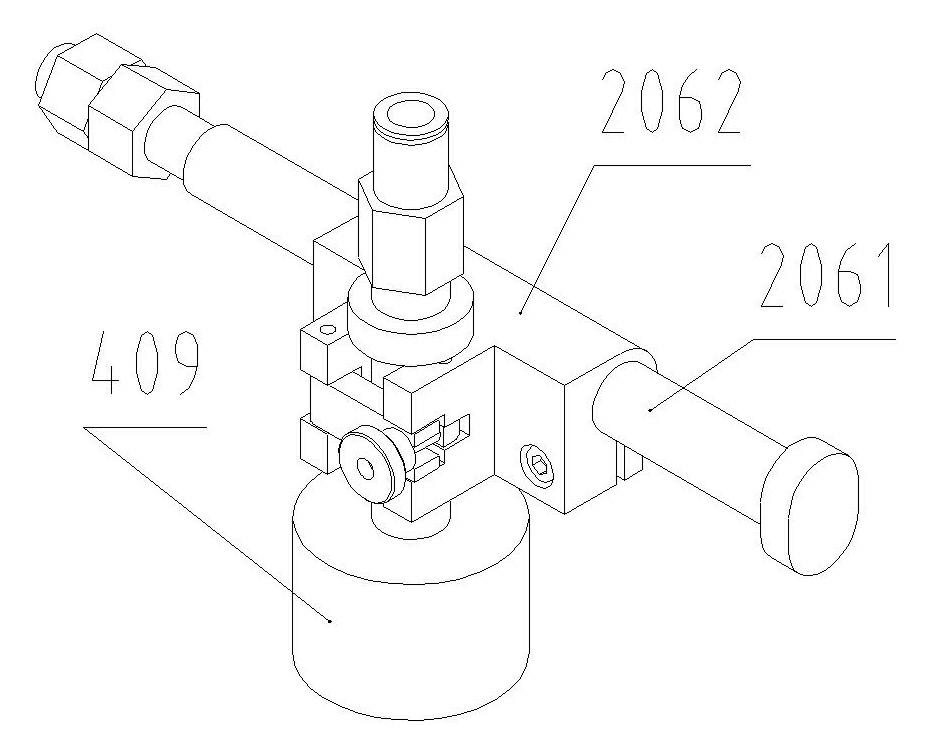

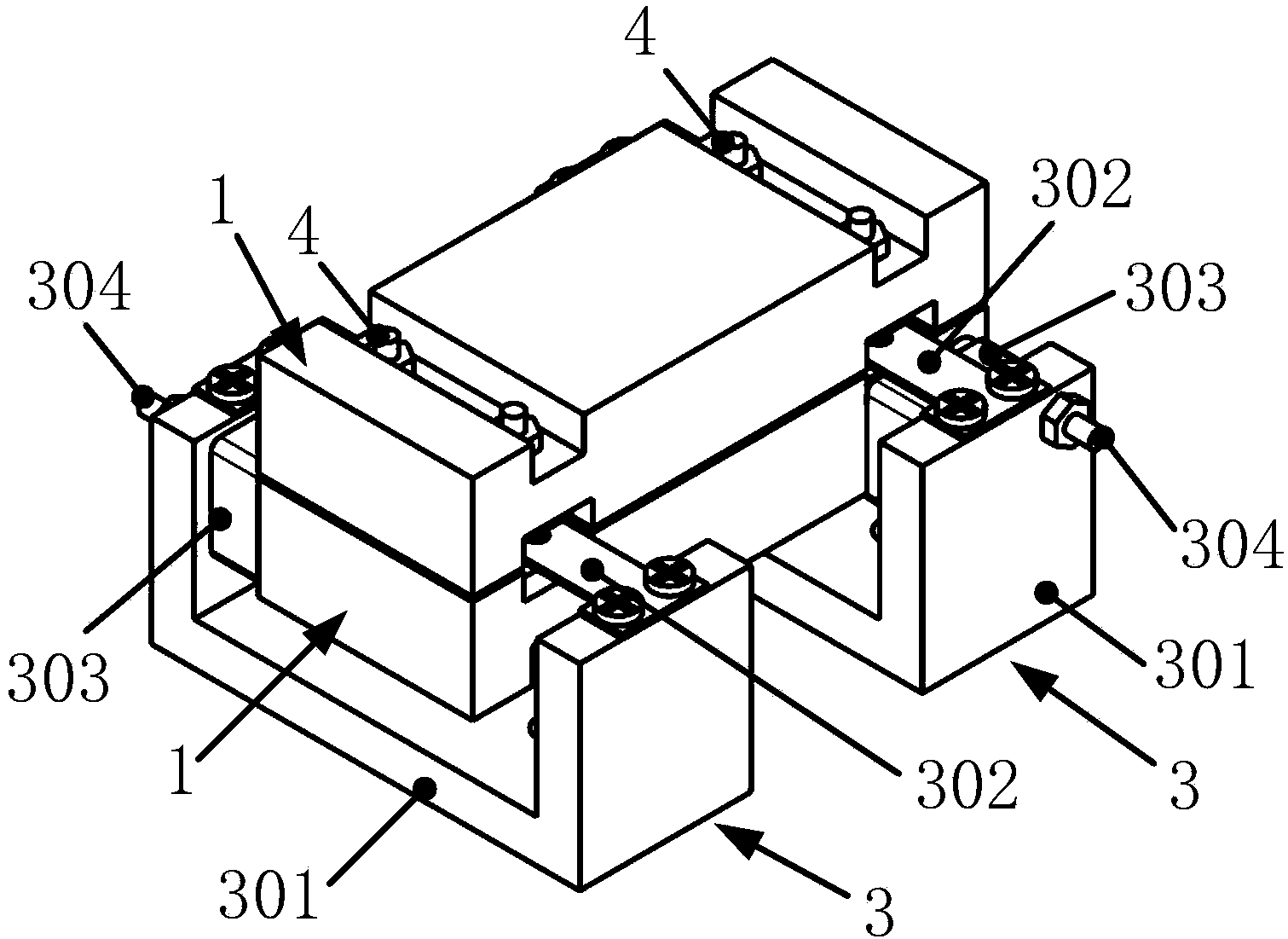

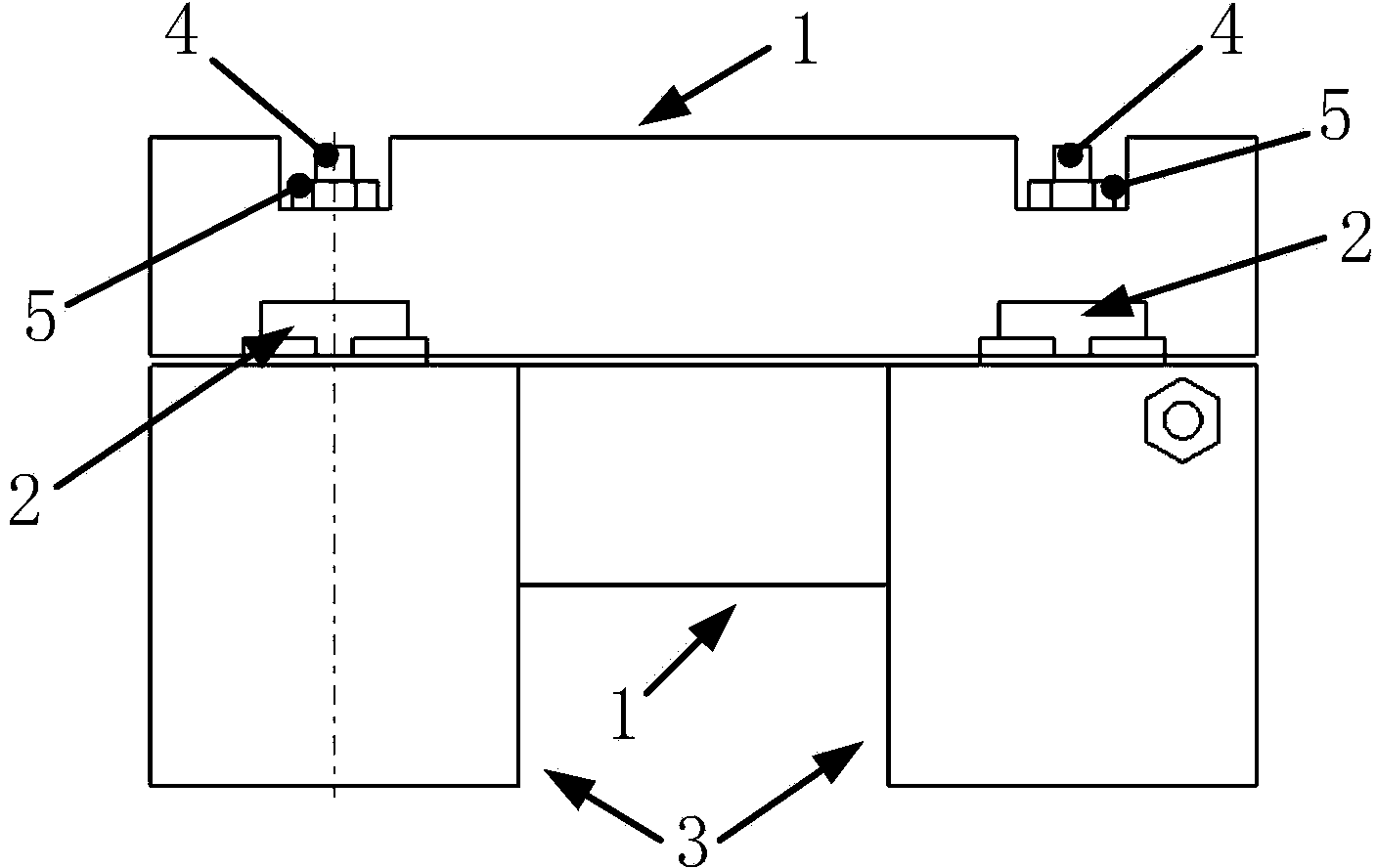

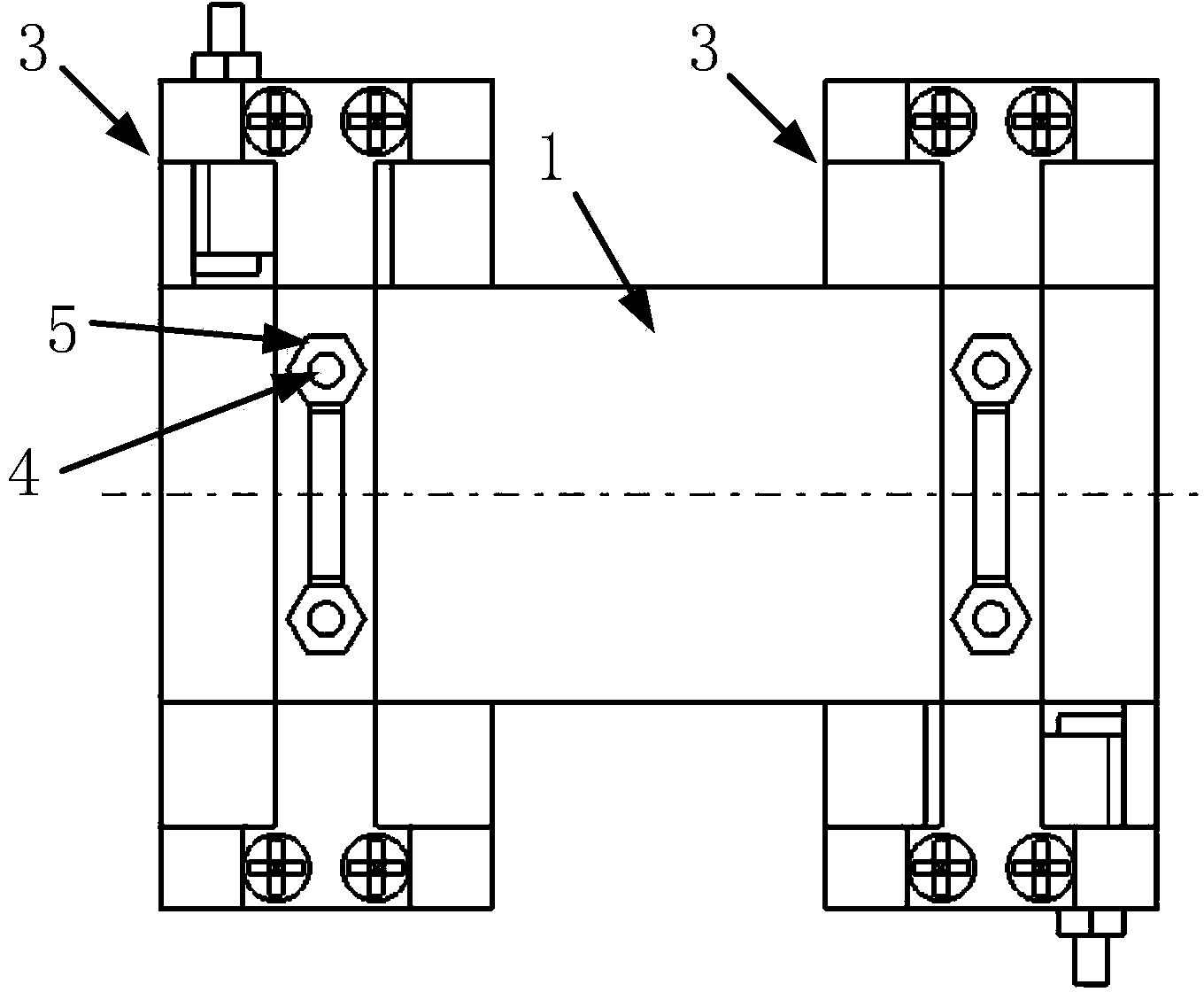

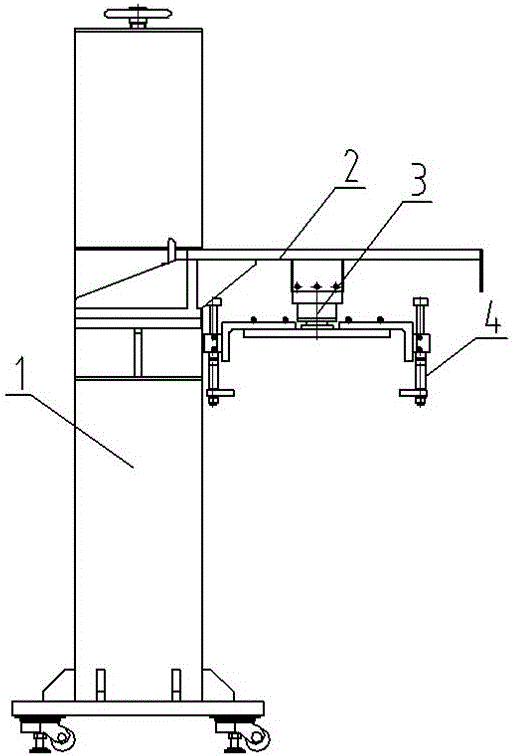

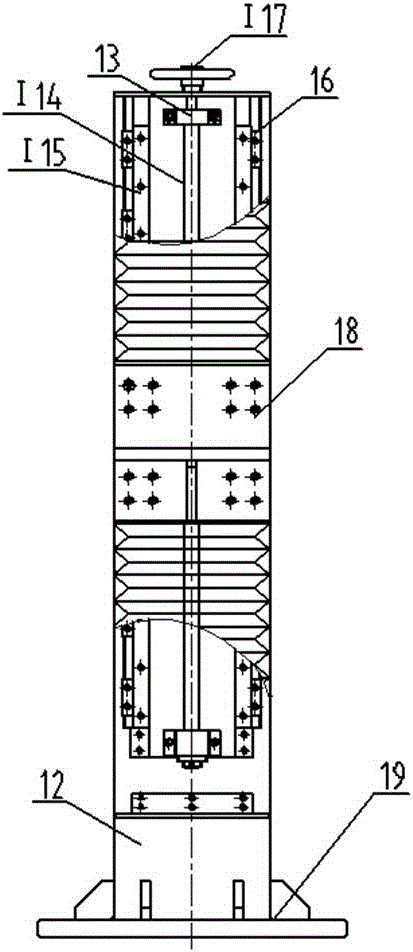

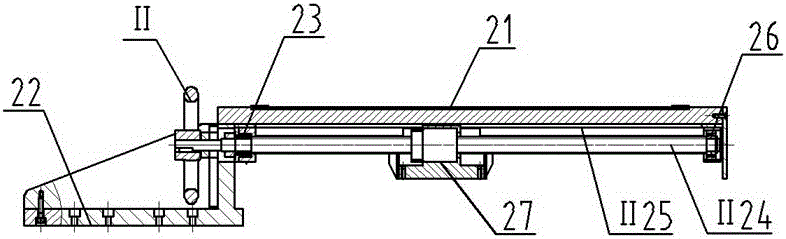

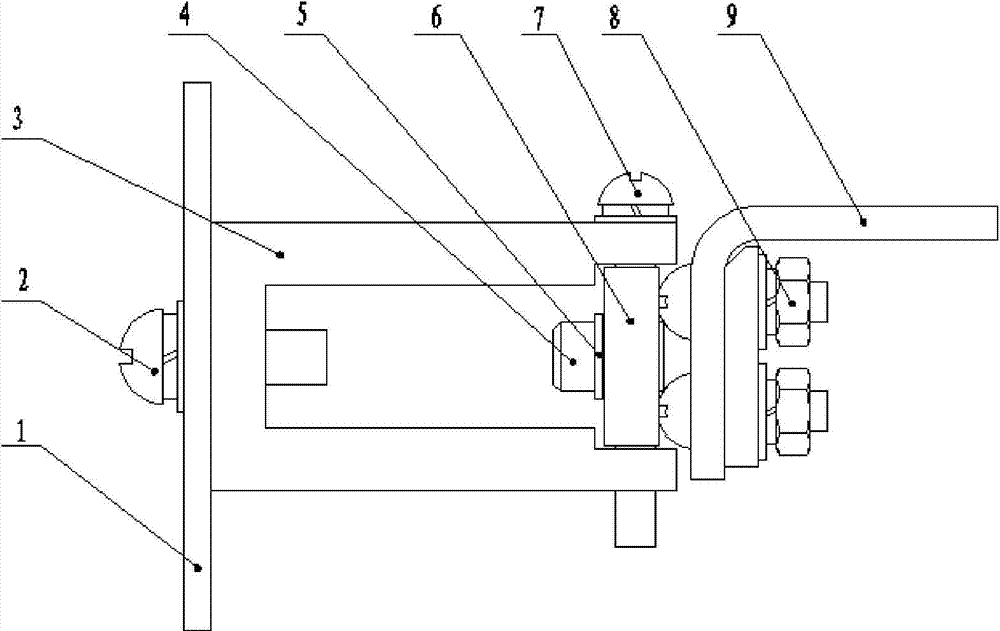

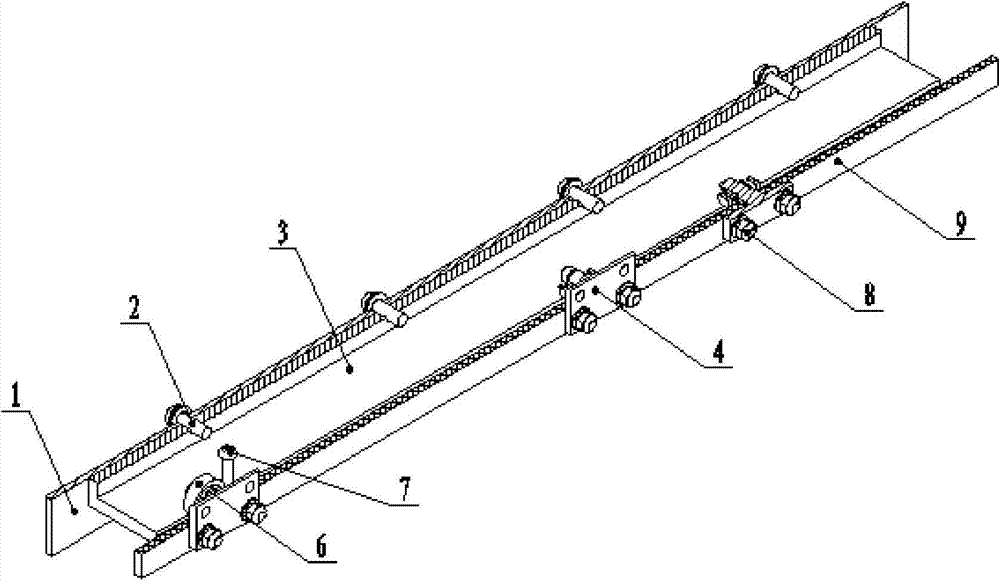

Loading mechanism for testing rigidity of hydrostatic guide rail

ActiveCN106441752AEasy to adjustMeet the stiffnessElasticity measurementBall screwMechanical engineering

The invention discloses a loading mechanism for testing the rigidity of a hydrostatic guide rail. In the loading mechanism, a stand column of a vertical guide rail unit is fixed on a base; a transverse guide rail mounting plate is mounted on a ball screw I in the stand column; a horizontal guide rail unit is mounted on the transverse guide rail mounting plate; a worktable in the horizontal guide rail unit is mounted on a ball screw II; a connecting bearing seat in an indexing unit is mounted on the worktable; and a fixed seat in a loading force applying unit is mounted on an upper adjusting plate in the indexing unit. The horizontal guide rail unit, the vertical guide rail unit and the indexing unit are arranged so that the adjustment of a space position of a loading force applying mechanism is realized and the loading force applying mechanism is adaptive to different guide rails; a differential nut in the loading force applying unit realizes slow feeding of a screw in the vertical direction, so that accurate application of a loading force is realized; and meanwhile, the loading force applying unit is internally connected with a sensor so that the loading force can be measured in real time. According to the loading mechanism disclosed by the invention, loss-free application of the loading force and the adjustment of positions, directions and sizes in a relative large range can be realized.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

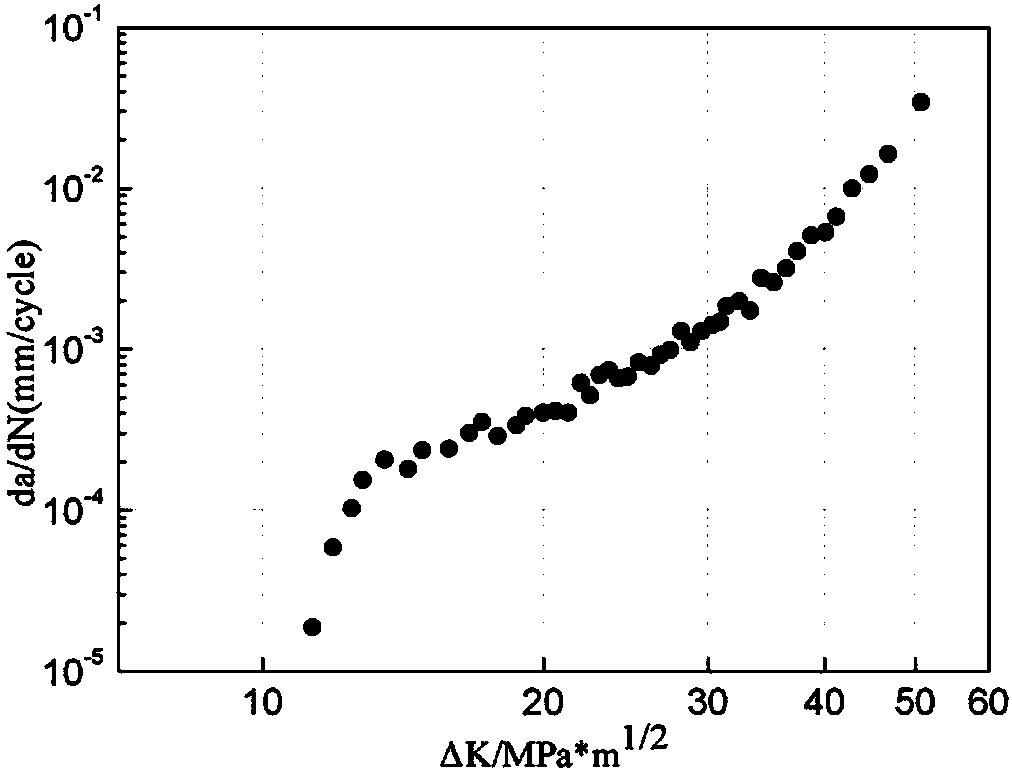

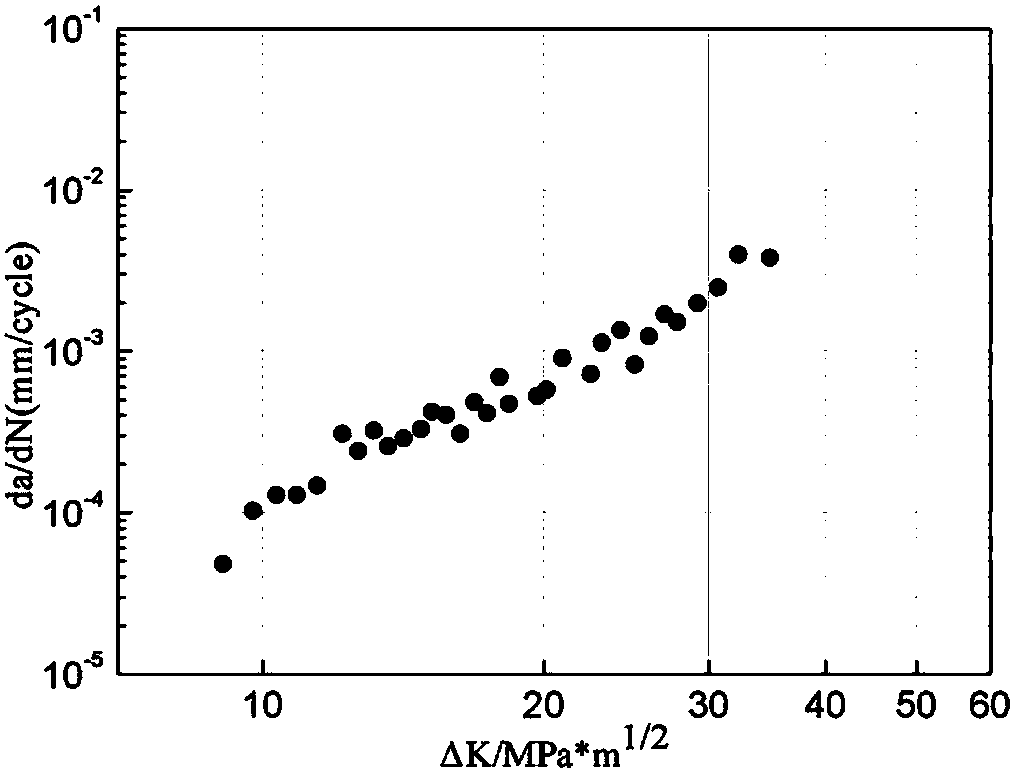

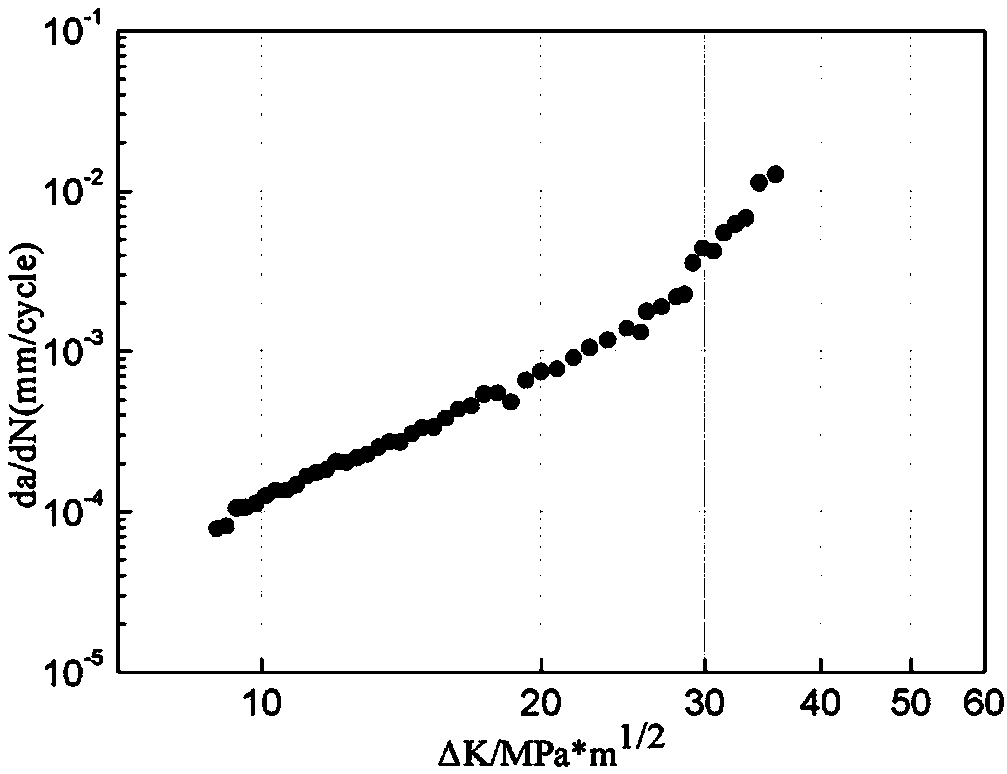

Medium and high strength damage resistant aluminum lithium alloy material and preparation method and application thereof

The invention discloses a medium and high strength damage resistant aluminum lithium alloy material and a preparation method of the medium and high strength damage resistant aluminum lithium alloy material. The medium and high strength damage resistant aluminum lithium alloy material is prepared from, by mass, 0.5-2% of lithium, 2-5% of copper, 0.2-0.7% of magnesium, 0.1-0.5% of silver, 0.1-0.6% of manganese, 0.01-0.15% of titanium, 0.08-0.15% of zirconium, 0.05-0.6% of ruthenium, 0-0.15% of erbium and the balance aluminum. Since a small amount of rare and precious metal element ruthenium withthe higher melt purifying ability is added into the alloy, the prepared aluminum lithium alloy has the high specific strength, high molding performance, high tenacity and excellent corrosion resistance, and the comprehensive mechanical properties of the alloy are greatly improved.

Owner:CENT SOUTH UNIV

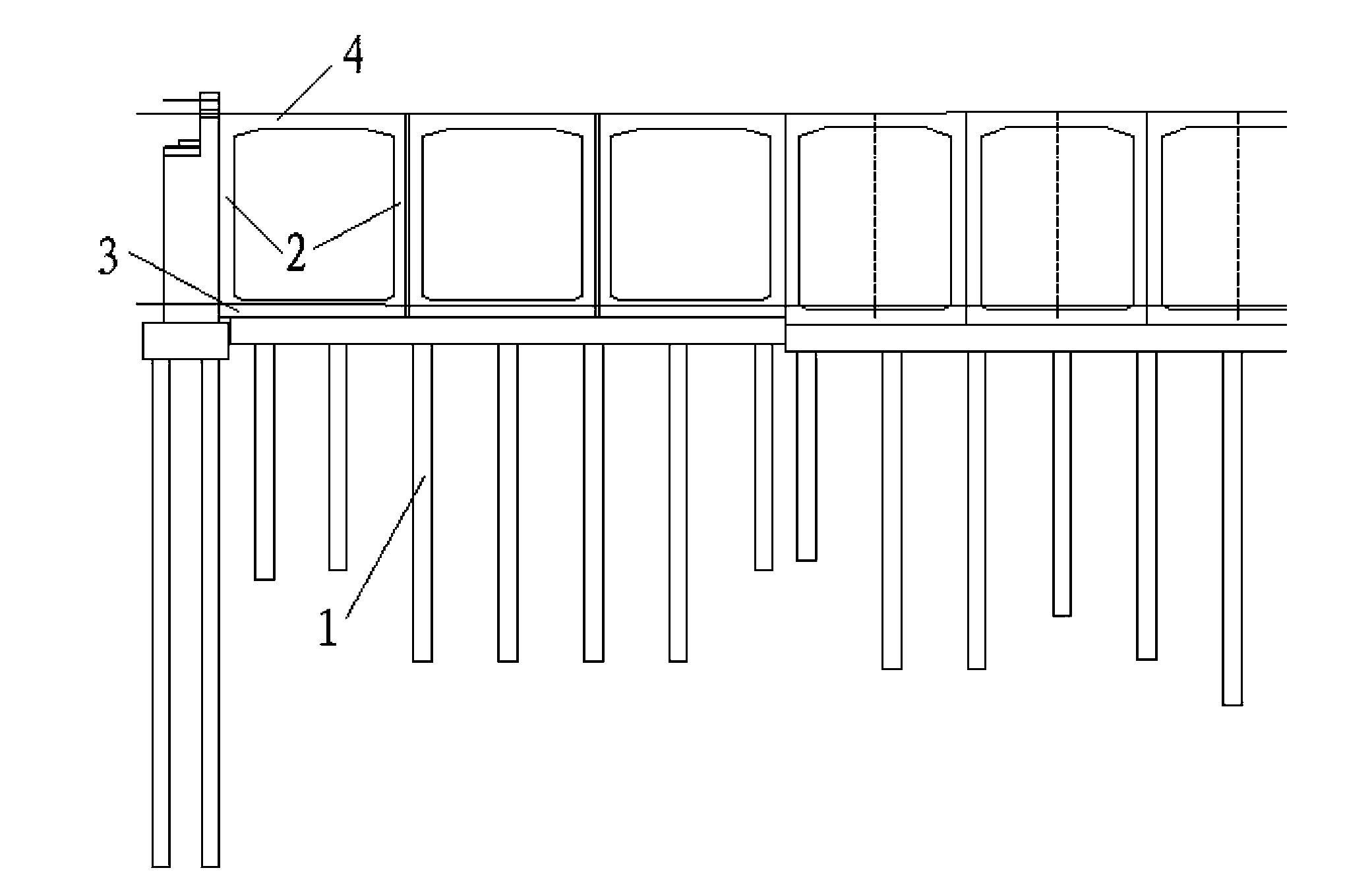

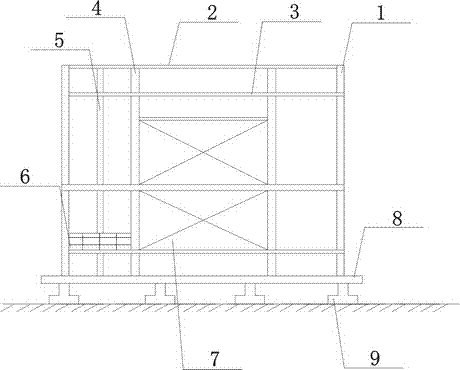

Closely arranged frame bridge structure of high speed railway switch area

InactiveCN103835221AMeet the stiffnessFulfil requirementsBridge applicationsBridge structural detailsTransverse stiffnessBuilding construction

The invention belongs to the technical field of bridge structures, and particularly relates to a closely arranged frame bridge structure of a high speed railway switch area. The bridge structure comprises a base plate located on a foundation, a side wall and a train walking roof. A plurality of closely arranged frames are formed by the base plate, the side wall and the train walking roof, the aperture of the frames which are perpendicular to the switch area ranges from 8 m to10-m, and a gap among the frames in the train driving direction is 2cm. The closely arranged frame bridge structure of the high speed railway switch area has the advantages that stress is clear, the structure is reasonable and the economy is good, requirements on a bridge longitudinal stiffness, a transverse stiffness and a displacement of the high speed railway switch are met, construction is convenient and fast, the construction process can move fast, service life of the structure is assured, traffic of a road under the frames can be also assured, the frames without interchange can be developed for business purposes, and that is to say, one bridge has three functions.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

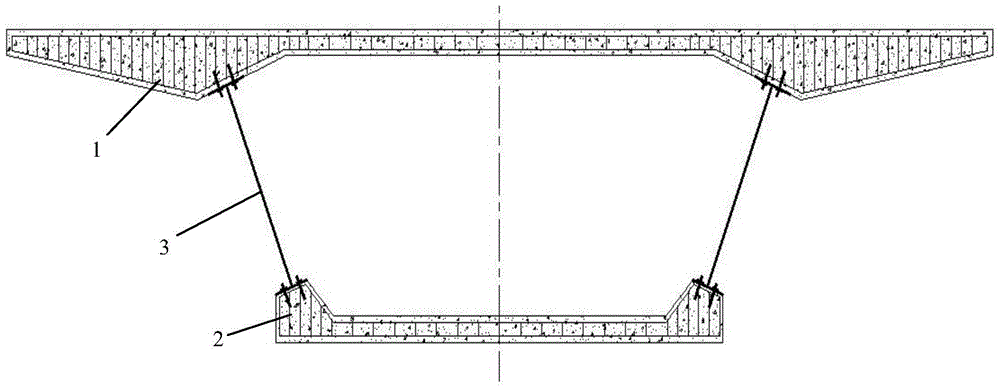

Emergency repair method for concrete box girders

ActiveCN104088232AEmergency repair is effectiveQuickly resume operationsBridge erection/assemblyBridge strengtheningBox girderPrecast concrete

The invention relates to an emergency repair method for concrete box girders. Emergency repair and fast line recovery of the concrete box girders of urban transportation facilities such as railways and roads are achieved by assembling and splicing prefabricated concrete roofs, concrete bottom plates and corrugated steel webs. Fast and effective emergency repair of the concrete box girders is achieved through the method, dependence on large transportation and hoisting equipment is reduced, the area and the scale of an emergency girder storage field are reduced, emergency repair cost is reduced, and the requirement that girder bodies repaired in emergency are high in rigidity, small in deformation and vibration and low in noise is met, and traffic lines can be recovered fast.

Owner:BEIJING JIAOTONG UNIV

Anti-crack and anti-seepage steel slag pavement base mixture and preparation method thereof

The invention relates to the technical field of roadbed materials and preparation thereof, in particular to an anti-crack and anti-seepage steel slag pavement base mixture and a preparation method thereof. The anti-crack and anti-seepage steel slag pavement base mixture is prepared from steel slag, common sand, bentonite, fly ash, fibers, cement and water according to the following steps of: fullystirring the steel slag, the common sand, the bentonite and the fibers to obtain a mixture; adding water into the mixture, fully mixing, sealing and standing to obtain a mixture; and adding cement, fly ash and the remaining water into the mixture to obtain the anti-crack and anti-seepage steel slag pavement base mixture. The raw materials are easy to obtain, the preparation method is simple and convenient, the obtained anti-crack and anti-seepage steel slag pavement base mixture meets the strength, rigidity and water stability of a pavement base structure, the crack resistance and seepage resistance can be improved, cracks caused by temperature stress and shrinkage can be reduced, and meanwhile, the erosion resistance, wear resistance and durability can be improved.

Owner:XINJIANG AGRI UNIV

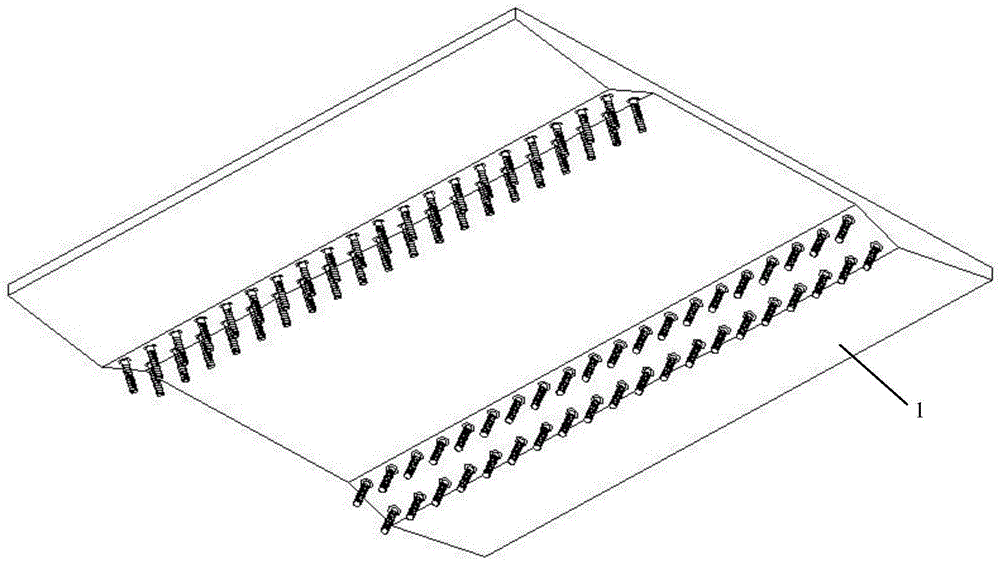

Reinforcing steel bar formwork frame

InactiveCN103806648AReliable frameEasy to get materialsForms/shuttering/falseworksSurface mountingSteel bar

The invention discloses a reinforcing steel bar formwork frame. The reinforcing steel bar formwork frame comprises two stand columns, the upper ends of the stand columns are connected through a cross beam, the cross beam and the stand columns are detachable, a steel beam flange is arranged at the lower ends of the stand columns, the stand columns are arranged to be close to the steel beam flange, more than one bearing base is arranged on the lower surface of the steel beam flange, the bearing bases are evenly arranged on the lower surface of the steel beam flange, sleeve pipes and thin steel pipes are connected between the cross beam and the steel beam flange respectively, the top ends of the thin steel pipes are connected with the cross beam, the bottom ends of the thin steel pipes are connected with a gate type frame body, a horizontal connecting beam is arranged between the two stand columns, the horizontal connecting beam respectively penetrates through the sleeve pipes and the thin steel pipes and is in rigid connection with the stand columns, the lower portion of the gate type frame body is connected with the horizontal connecting beam, and an operation platform is mounted between the two sleeve pipes. The reinforcing steel bar formwork frame is reliable, material taking is convenient, construction is flexible, the requirements of structural design on strength, rigidity and stability of a large-span formwork system can be met, and the construction cost can be saved to a certain degree.

Owner:CHENGDU JIAMEIJIA SCI & TECH

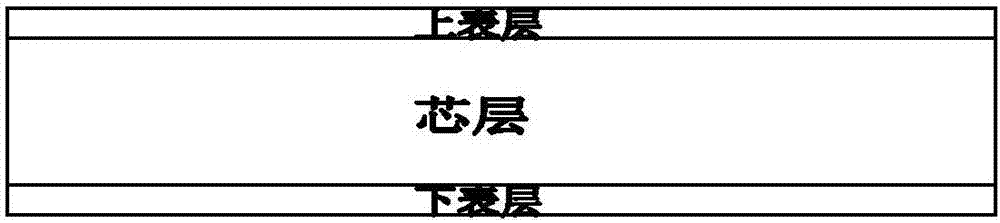

BOPP (Biaxially-oriented Polypropylene) thin film for soft-pack stiff-casement cigarette with wrinkle resistance and wear resistance and preparation method of BOPP thin film

InactiveCN107139561AMeet the stiffnessMeet shrinkageSynthetic resin layered productsFlat articlesWrinklePolypropylene

The invention relates to a BOPP (Biaxially-oriented Polypropylene) thin film for a soft-pack stiff-casement cigarette with wrinkle resistance and wear resistance and a preparation method of the BOPP thin film. The BOPP thin film is characterized by being prepared by a direct coextrusion laminating mode of a structure comprising an upper surface layer, a core layer and a lower surface layer, wherein a main component of the upper surface layer is a polypropylene copolymer; a main component of the core layer is a polypropylene homopolymer and a main component of the lower surface layer is a polypropylene copolymer. Counted by 100 parts by weight, the upper surface layer is prepared from the following material components in parts by weight: 79 to 91 parts of copolymer polypropylene, 6 to 20 parts of slipping agent masterbatch and 3 to 9 parts of anti-sticking agent masterbatch; the core layer is prepared from the following material components: 79 to 91 parts of homopolymer polypropylene, 10 to 20 parts of stiffening agent masterbatch and 2 to 4 parts of electrostatic agent masterbatch; the lower surface layer is prepared from the following material component in parts by weight: 100 parts of copolymer polypropylene. The BOPP thin film disclosed by the invention has the characteristics and the beneficial effects that special requirements of high-grade cigarettes on stiffness, shrinkage rate, transparency and the like of the BOPP thin film are met.

Owner:ZHANJIANG PACKAGING MATERIAL ENTERPRISES

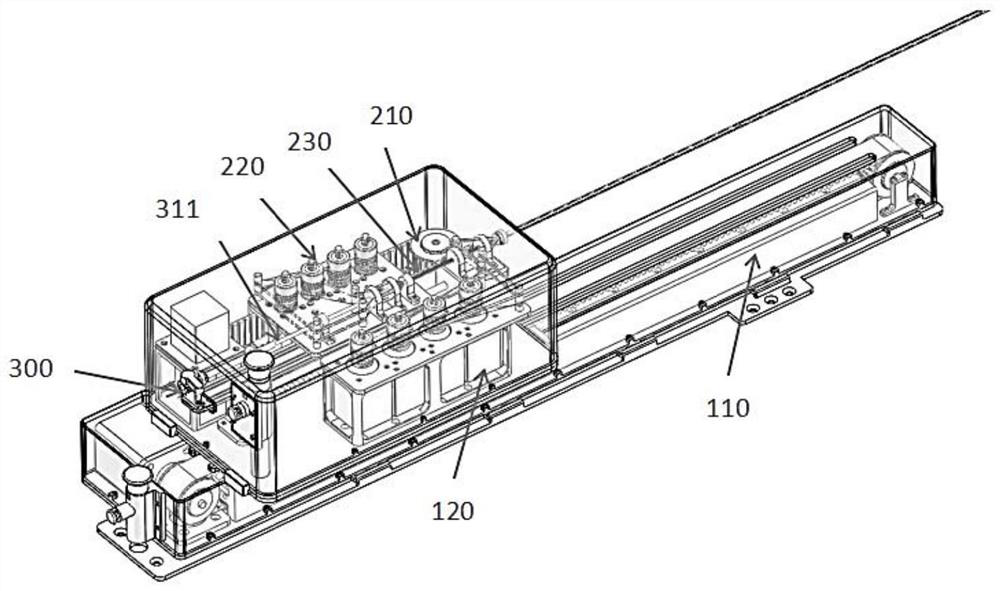

Bronchial intervention continuum robot for lung micro nodules

ActiveCN113243947AIncrease the lengthSmall outer diameterBronchoscopesLaryngoscopesPhysical medicine and rehabilitationExternal catheter

The invention provides a general bronchial intervention continuum robot for lung micro nodules. The robot comprises a concentric continuum outer catheter and a driving structure thereof, a concentric continuum inner catheter and a driving structure thereof, and a medical instrument channel and a driving structure thereof. The concentric continuum outer catheter can realize front-back feeding single-degree-of-freedom and bending double-degree-of-freedom movement through a motor set module thereof; the concentric continuum inner catheter can realize extension single-degree-of-freedom and bending double-degree-of-freedom movement relative to the outer catheter through a motor set module thereof; and the lung global flexible active navigation can be realized through the movement of the concentric continuum inner and outer catheters, so that the robot can reach the peripheries of the lung micro nodules. The concentric continuum inner catheter is provided with an endoscopic camera for providing images of lung bronchi. A medical instrument delivery module can realize delivery and fixation of medical instruments to finish the extraction work of diagnosis samples of the lung micro nodules. A disassembly button is provided; and a quick disassembly function can support preoperative disinfection and sterilization operations.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

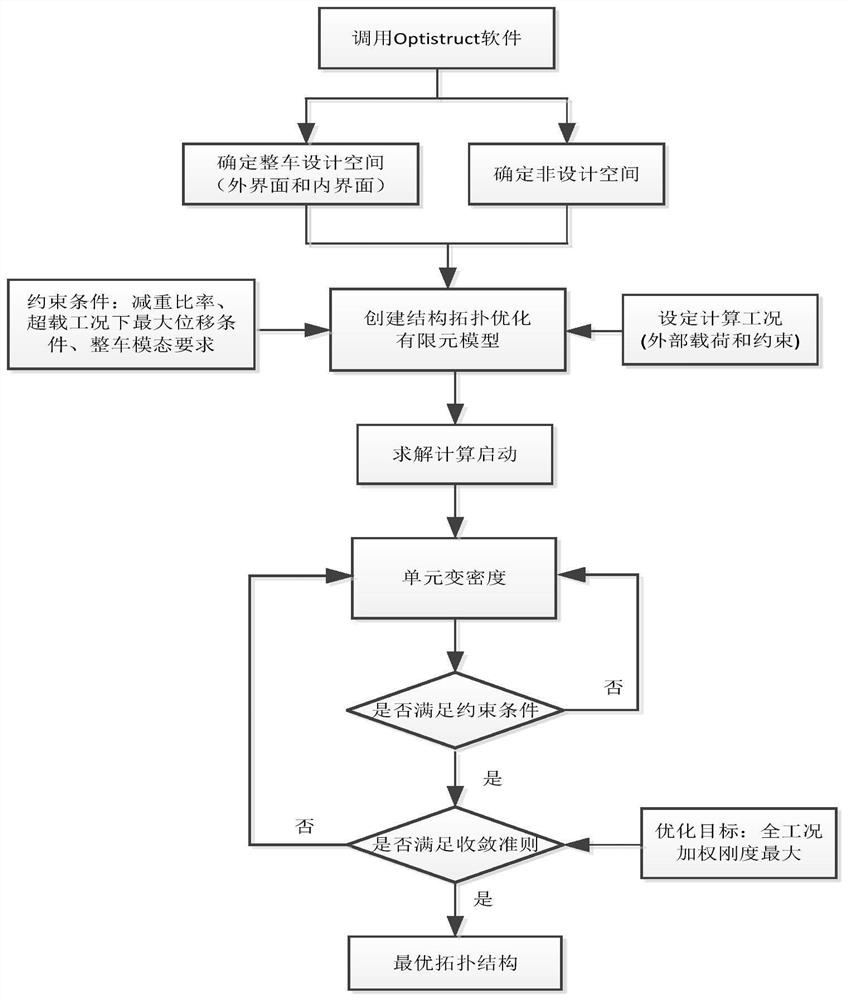

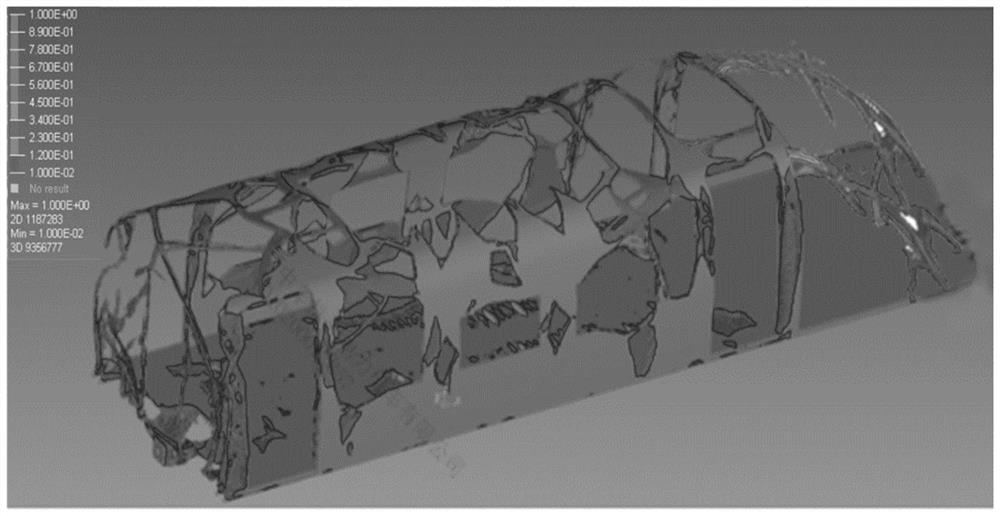

Carbon fiber composite vehicle body structure and design method thereof

PendingCN114329773AImprove Simulation EfficiencyImprove simulation accuracyGeometric CADInternal combustion piston enginesStructural engineeringDesign space

The invention discloses a carbon fiber composite vehicle body structure and a design method thereof, and the method comprises the steps: taking a design space, a non-design space, a constraint condition, a calculation condition and an optimization target as the input of simulation software, and creating a vehicle body topological optimization structure model; and performing iterative calculation on the vehicle body topological optimization structure model by using a variable density method to obtain a vehicle body structure force transmission path meeting constraint conditions and working condition requirements under different material utilization degrees, and obtaining an optimal vehicle body structure configuration according to the force transmission path. The design method of the input parameters is given, it is ensured that the needed structural configuration can be obtained, and the simulation efficiency and the simulation precision are improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

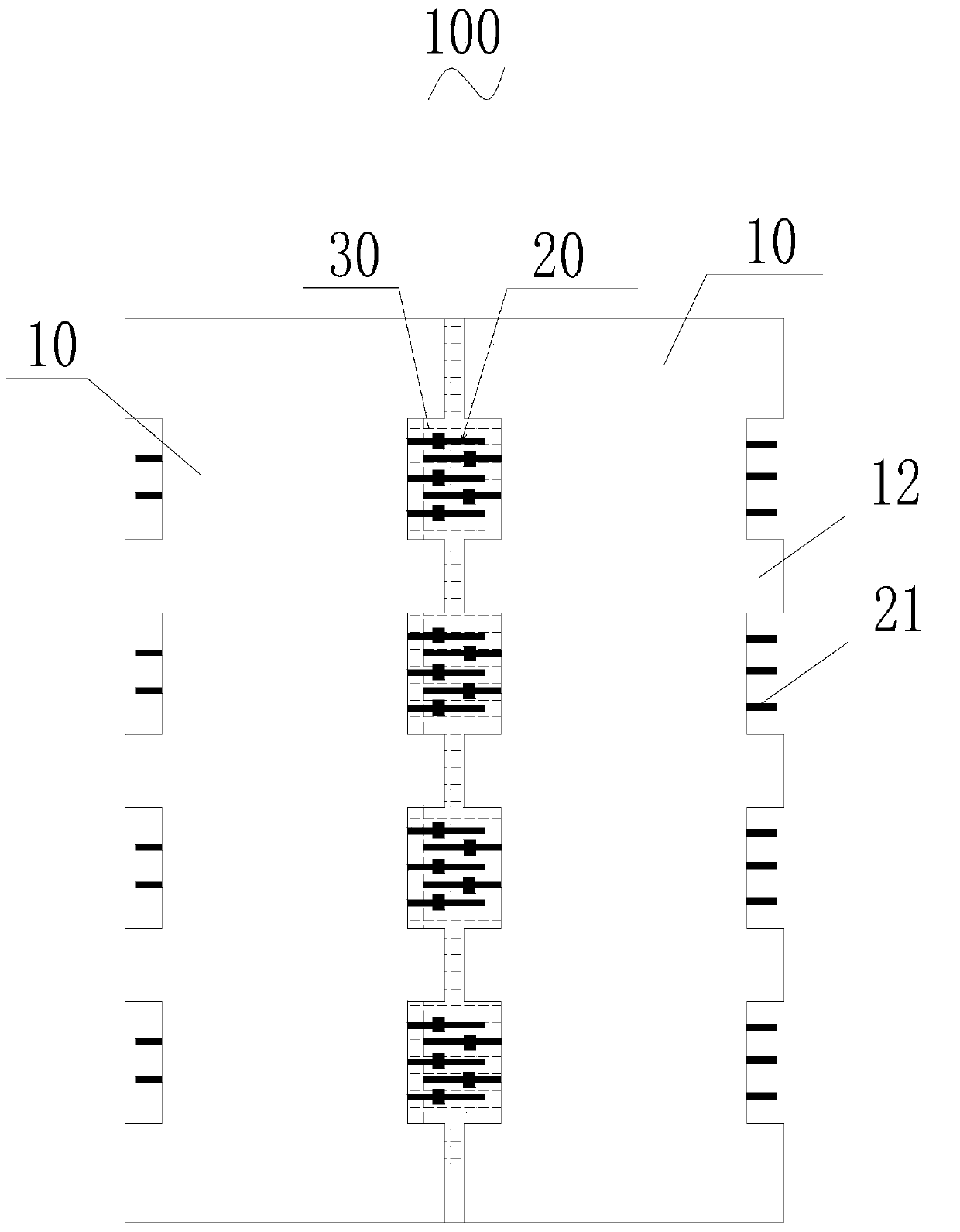

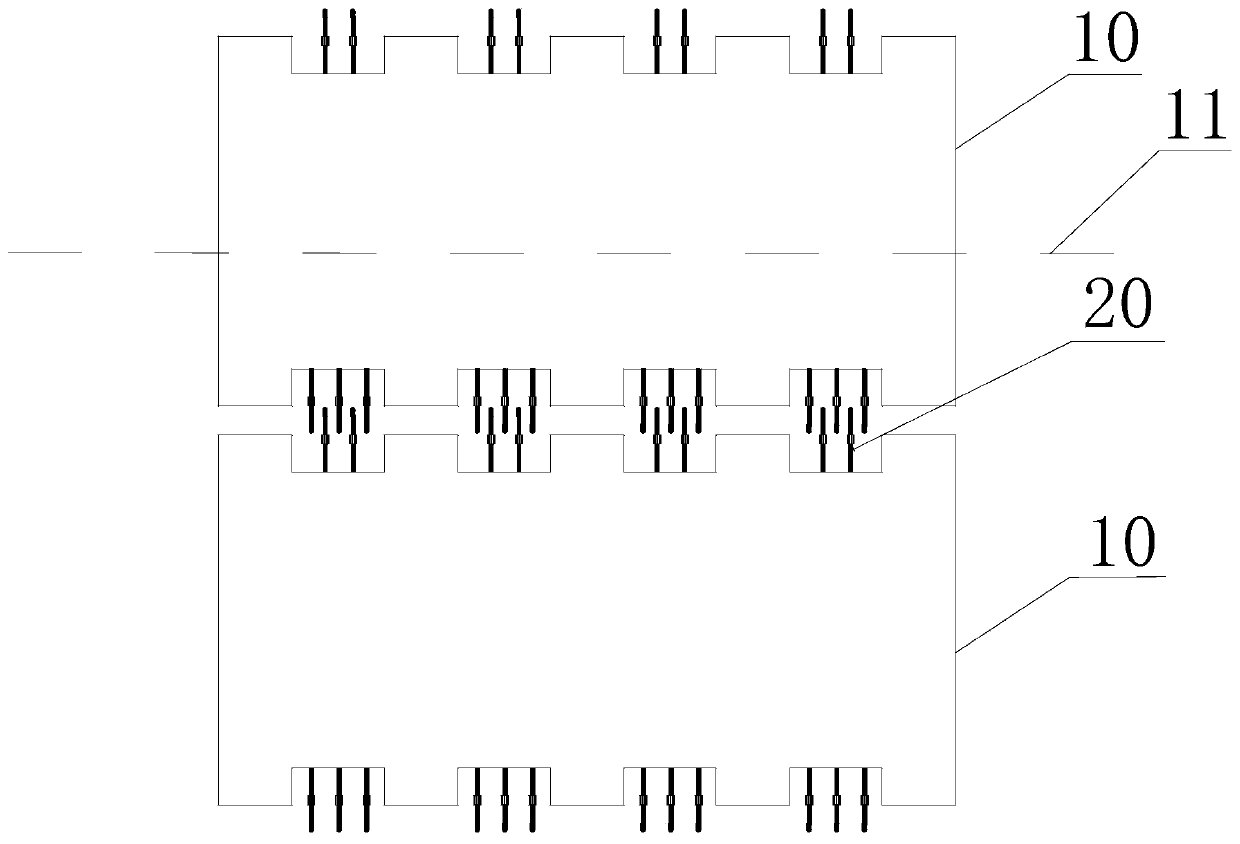

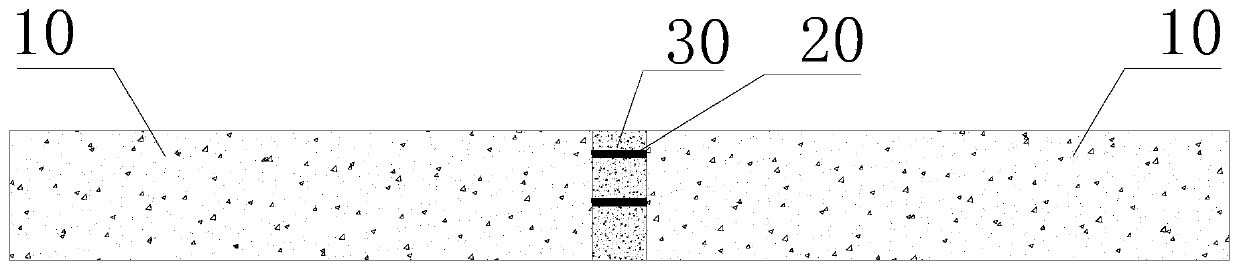

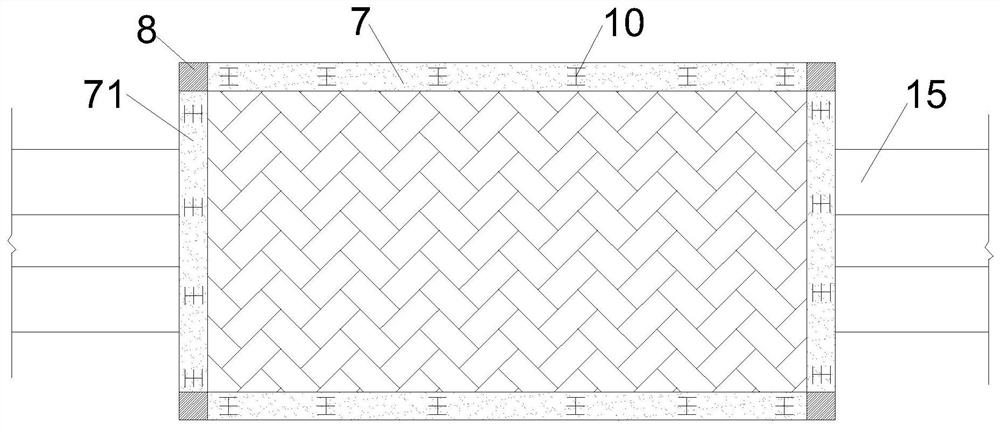

Prefabricated lane board

PendingCN111118997ASimple structureClear forceSingle unit pavingsPaving detailsArchitectural engineeringRebar

The invention relates to a prefabricated lane board. The prefabricated lane board comprises a prefabricated lane plate body, a steel reinforcement framework and a joint area cast-in-place material. Aplurality of protrusions are arranged on the edges of the two sides of each prefabricated lane plate body respectively, a steel reinforcement framework extending out of the prefabricated lane plate body is arranged between every two adjacent protrusions, the adjacent prefabricated lane plate bodies are arranged oppositely at intervals, and the adjacent prefabricated lane plate bodies are integrated through the steel reinforcement frameworks and joint area cast-in-place materials. The joint area cast-in-place material is made of a fiber cement-based composite material, on the premise that the requirements for strength, waterproofness and the like are met, the joint area cast-in-place material can be dismantled when needing to be dismantled, and the prefabricated lane plate is recycled. A force transmission path is clear, factory-like and standardized production is easy, and on-site assembly is convenient and rapid; the prefabricated lane board has the characteristics of the small on-site pouring amount, high construction efficiency, convenience in later cyclic utilization, replacement and renewal and the like.

Owner:TONGJI UNIV

Method for forming grid structure composite material component

The invention discloses a method for forming a grid structure composite material component, which comprises the following steps: 1, forming the grid structure based on various areas, and separately forming a plurality of frames and a side wall plate independently by an autoclave process; 2, bonding the plurality of frames and the side wall plate into a whole through a bonding tool; 3, detecting the position relation among the frames after the bonding, and confirming that the sizes of the frames meet the requirements of a drawing; 4, performing R corner filling on the frames and between the frames and the side wall plate by a mold pressing process; 5 wrapping the plurality of frames and the side wall plate together by a wrapping material; 6, placing the wrapped frames and side wall plate into an RTM glue injection mold for glue injection; 7, placing the mold subjected to glue injection into a baking oven for curing; and 8, demolding to obtain the grid structure composite material component. The method ensures the size of a product by an RTM mould cavity, basically does not need machining, and achieves high size precision. The surface of the product is a film attaching surface, so that while the product strength and rigidity are met, the weight of the product is obviously reduced, and the cost is reduced.

Owner:JIANGSU XINYANG NEW MATERIALS CO LTD

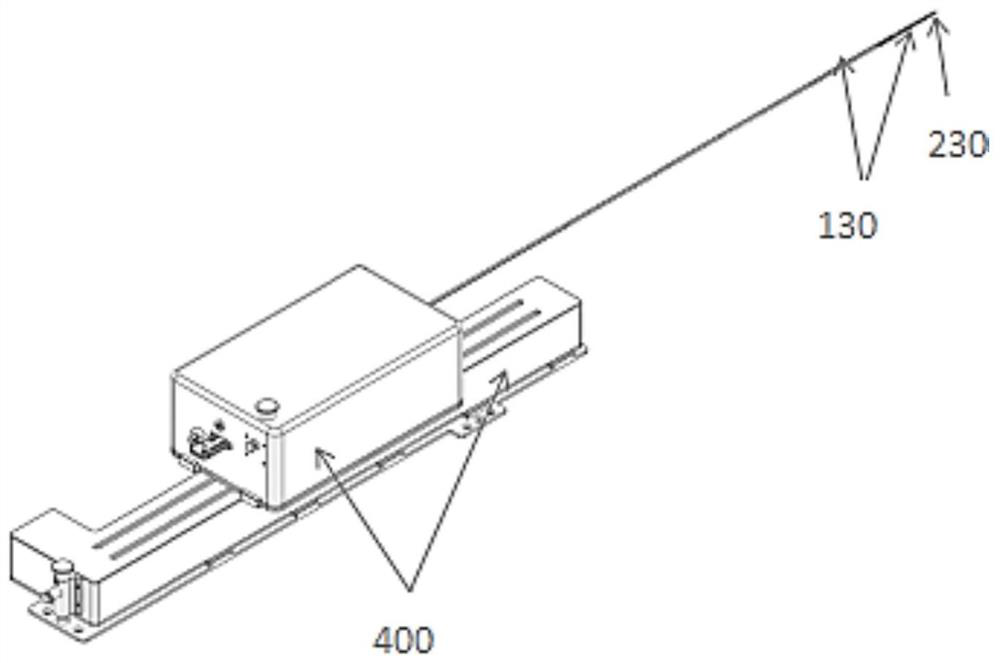

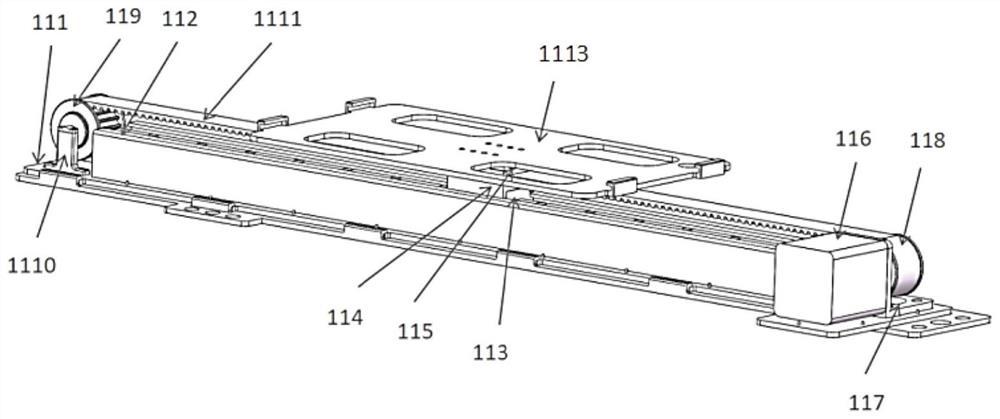

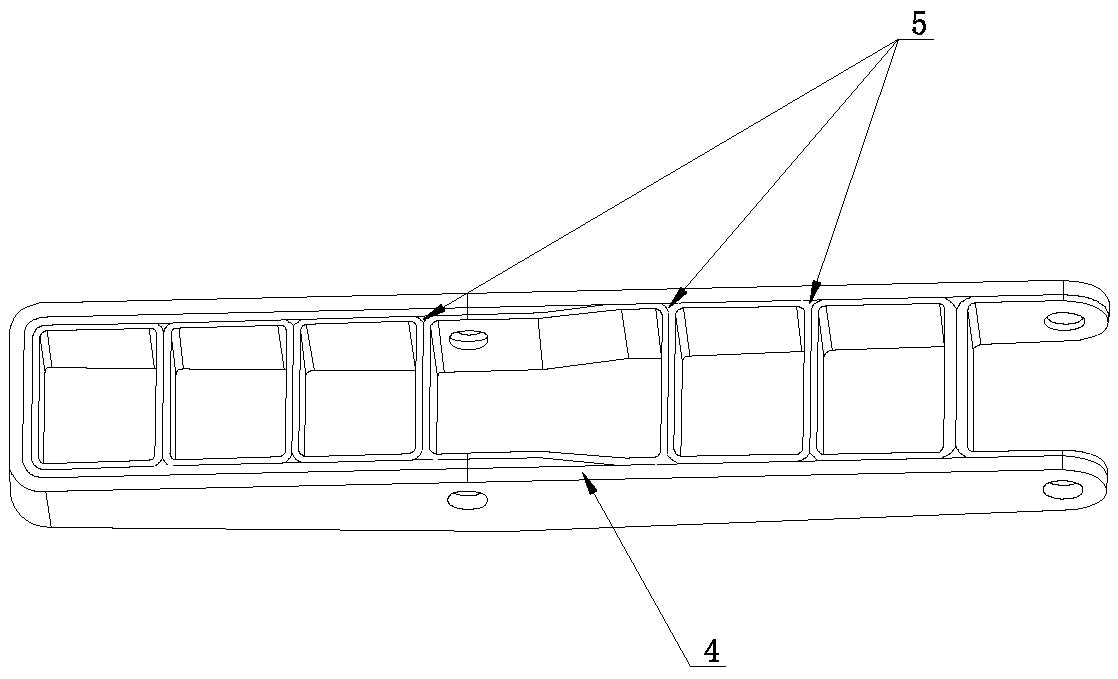

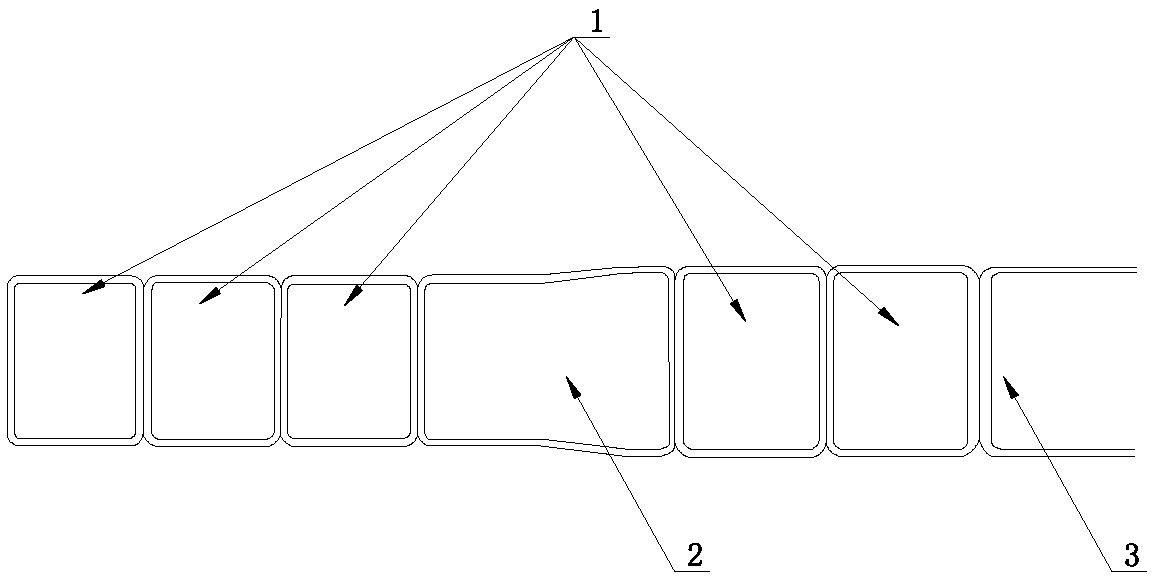

Machine box sliding rail

The invention discloses a machine box sliding rail. The machine box sliding rail comprises a first sliding rail body and a plurality of sets of second sliding rail bodies, wherein the first sliding rail body is installed on a machine box supporting frame through first fastening pieces and provided with a limiting screw, and the second sliding rail bodies can slide inside the first sliding rail body. The second sliding rail bodies are installed on the side face of a supporting plate through second fastening pieces. Each second sliding rail body is composed of a shaft, a bearing and a shaft check ring. The first sliding rail body is of a U-shaped structure, and is used for providing sliding ways for the second sliding rail bodies and limiting the transverse line displacement of the second sliding rail bodies. The number of the sets of the second sliding rail bodies is at least three. One end of each shaft is in a square shape and is used for being connected with an installing supporting plate, and the other end of each shaft is in a cylindrical shape and is used for installing the corresponding bearing and providing limiting for the corresponding bearing. The first sliding rail body is made of steel materials, the requirement for the rigidity of the sliding rail is met, and the appearance of the first sliding rail body can be changed according to the installing position of a machine box. The limiting screw is installed on the first sliding rail body to prevent the installing supporting plate from sliding out of the machine box during the sliding process. The integral stability of the sliding rail can be effectively enhanced, and the deformation, caused by vibration when the machine box is transported, of the machine box sliding rail is eliminated.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

High-alloy steel cobalt-containing ejecting head

The invention discloses a high-alloy steel cobalt-containing ejecting head mainly comprising carbon, iron, chromium and molybdenum. The high-alloy steel cobalt-containing ejecting head comprises the following elements in percentage by weight: 0.19-0.39% of C, 0.2-1.4% of Cr, 0.35-2.0% of Ni, 0.3-1.8% of Co, 0.1-1.0% of Si, 0.1-0.9% of Mn, 0.3-2.3% of Mo, 0.5-4% of W, 0.1-1.3% of Nb and the balance of Fe and a small amount of other elements. Alloy elements are added into the high-alloy steel cobalt-containing ejecting head disclosed by the invention, so that the strength of a punching ejecting head is greatly improved, and the punching ejecting head can meet the necessary rigidity for punching and has good temperature resistance at the same time; when the ejecting head is used for punching a stainless steel seamless steel tube, the service life of the ejecting head is two to three times that of a foreign product of the same type, so that the production cost is greatly reduced.

Owner:江苏优泽科技有限公司

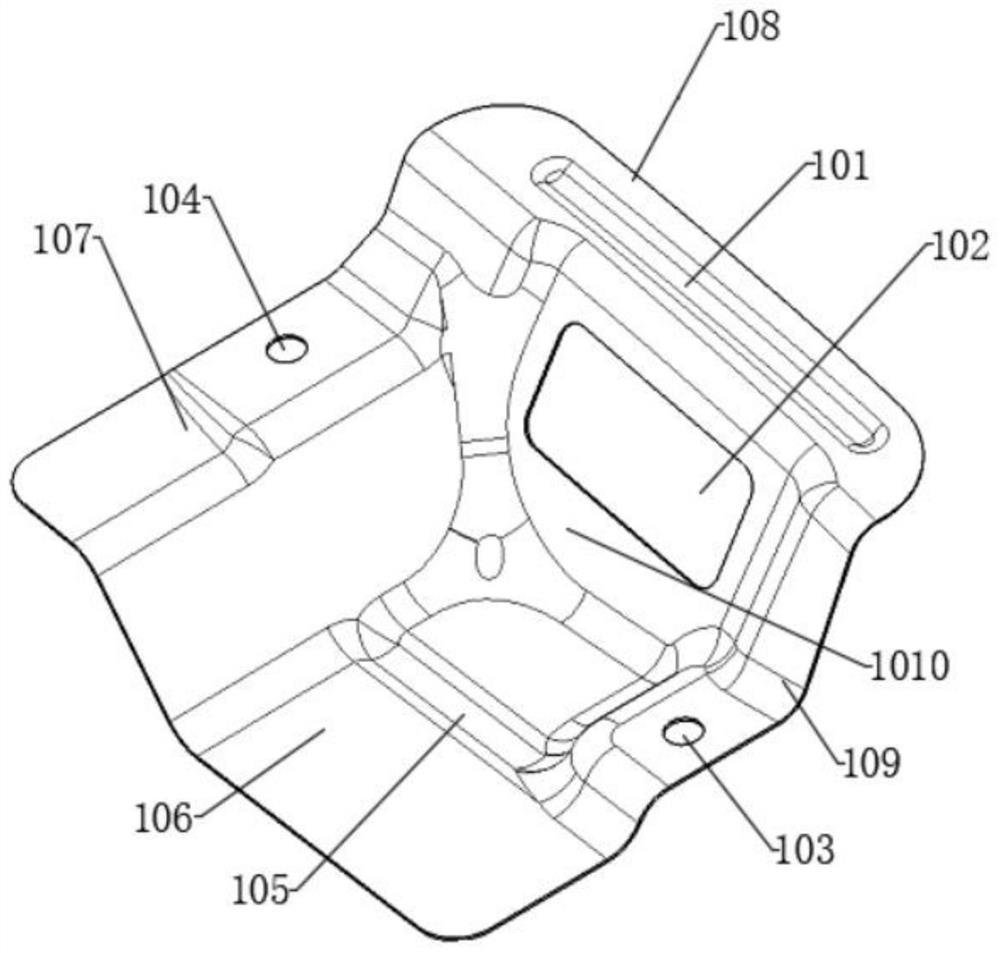

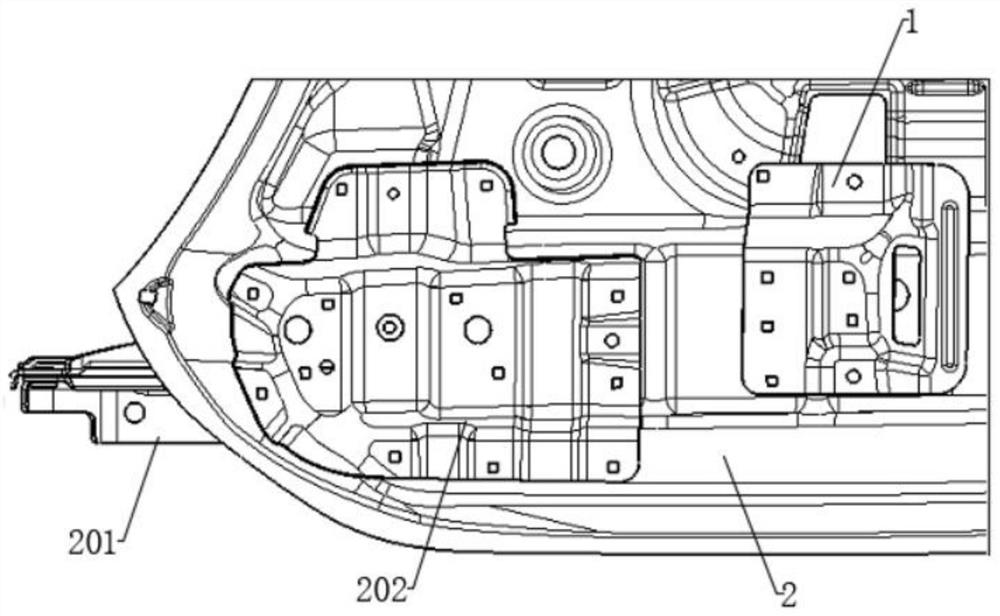

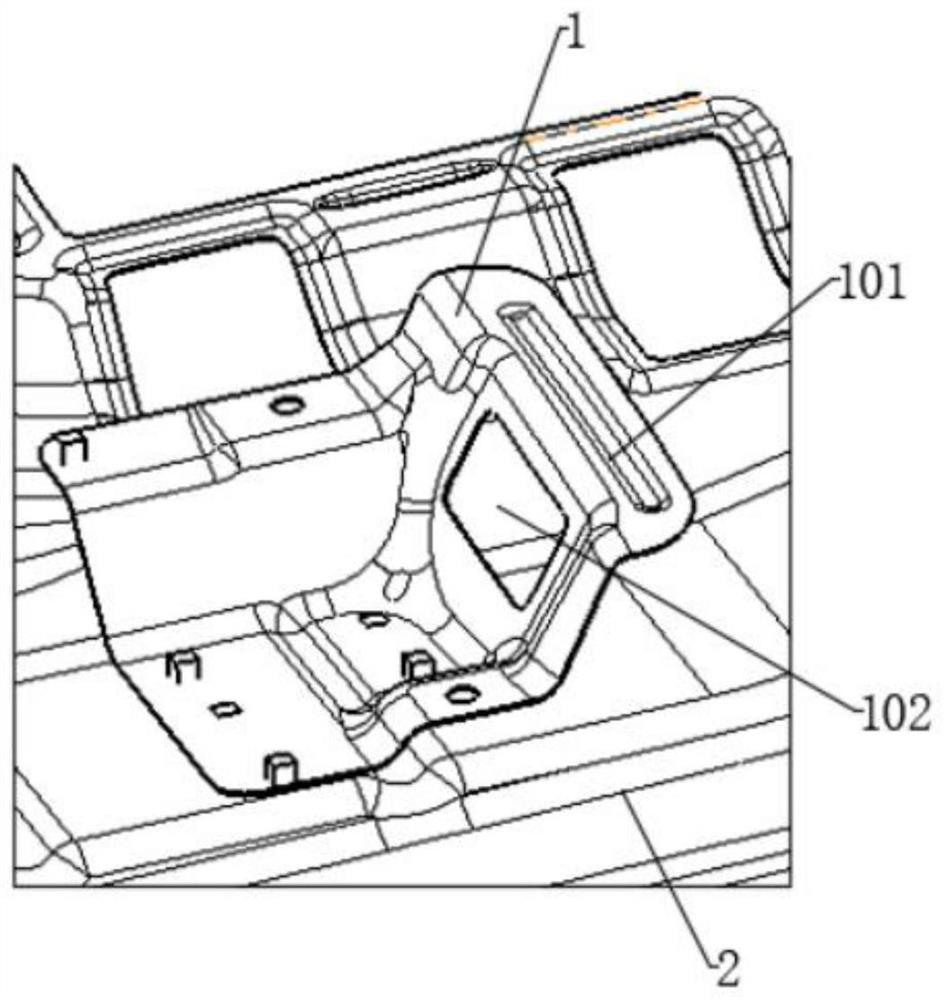

Engine cover outer plate side edge supporting plate structure

PendingCN111717293AMeet the stiffnessSatisfy anti-dentPedestrian/occupant safety arrangementSuperstructure subunitsAutomotive engineeringLightening holes

The invention discloses an engine cover outer plate side edge supporting plate structure. The supporting plate structure comprises an engine cover inner plate and a supporting plate body; engine coverhinges are fixedly mounted on the two sides of the engine cover inner plate correspondingly; an engine cover hinge reinforcing plate is fixedly mounted at the upper part of the engine cover inner plate; the supporting plate body is fixedly welded to the engine cover inner plate; a first positioning hole and a second positioning hole are formed in the two sides of the upper portion of the supporting plate body respectively; a gluing groove is formed in one side of the supporting plate body; lightening holes are formed in one side of the supporting plate body; and weakening ribs are fixedly welded to the upper portion of the bottom of the supporting plate body. The weakening ribs are fixedly welded to the fixing plate of the structure, so that the engine cover is vertically weakened, the requirements for rigidity, sinking resistance, modality, pedestrian protection and process performance of the engine cover can be met, the lightening holes are formed in the inclined part of the structure, the weight of the engine cover is reduced through the lightening holes, and light weight of the whole vehicle is facilitated.

Owner:HANTENG AUTOMOBILE CO LTD

Deformation control construction method for building close to foundation pit

PendingCN113737774AReduce stress transferReduce distortionProtective foundationTunnelsDeformation controlLarge deformation

The invention discloses a deformation control construction method for a building close to a foundation pit. The method comprises the steps: I, conducting deformation protection on the building close to the foundation pit; II, reinforcing isobathic groove walls of a diaphragm wall; III, enclosing the underground diaphragm wall and controlling deformation of adjacent buildings; and VI, reinforcing the pit bottom and the end. According to the construction method, deformation of adjacent buildings can be effectively reduced, safety and normal use of surrounding pipelines and adjacent buildings can be guaranteed, stability of groove walls and smooth construction are guaranteed in the enclosure structure construction process, perfection and smooth tunneling of a shield tunneling machine are guaranteed in the shield station-crossing process, stability of a foundation pit is guaranteed in the foundation pit excavation process, the diaphragm wall has no large deformation, and joints have no water seepage.

Owner:中铁二十局集团第五工程有限公司 +1

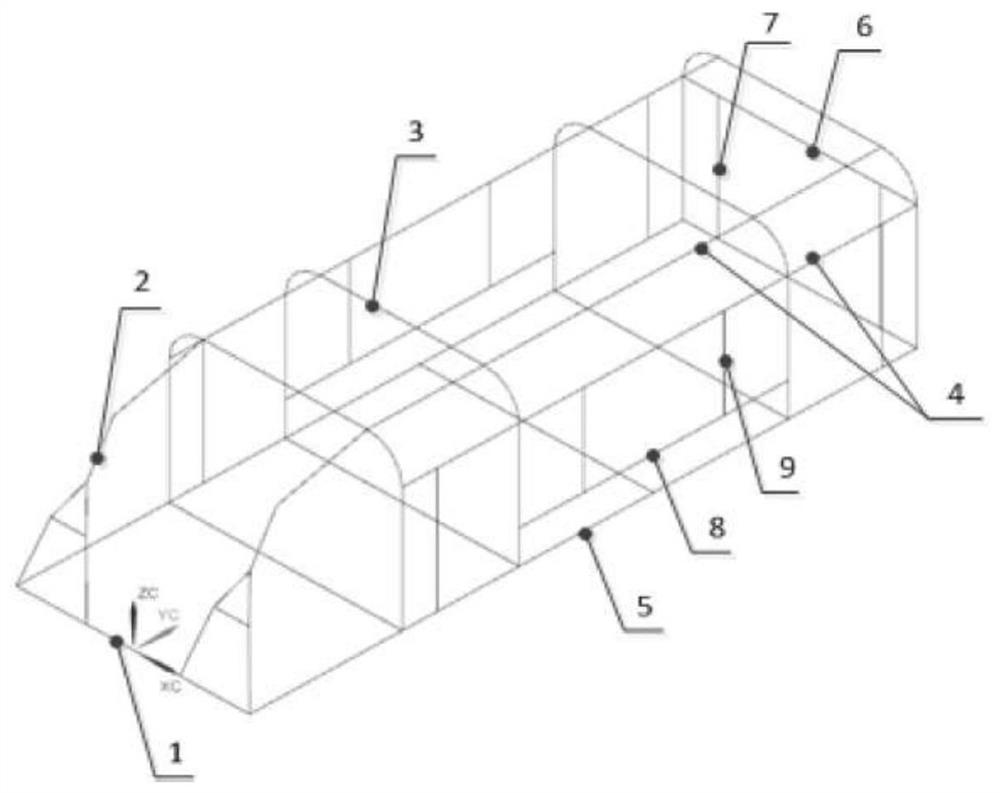

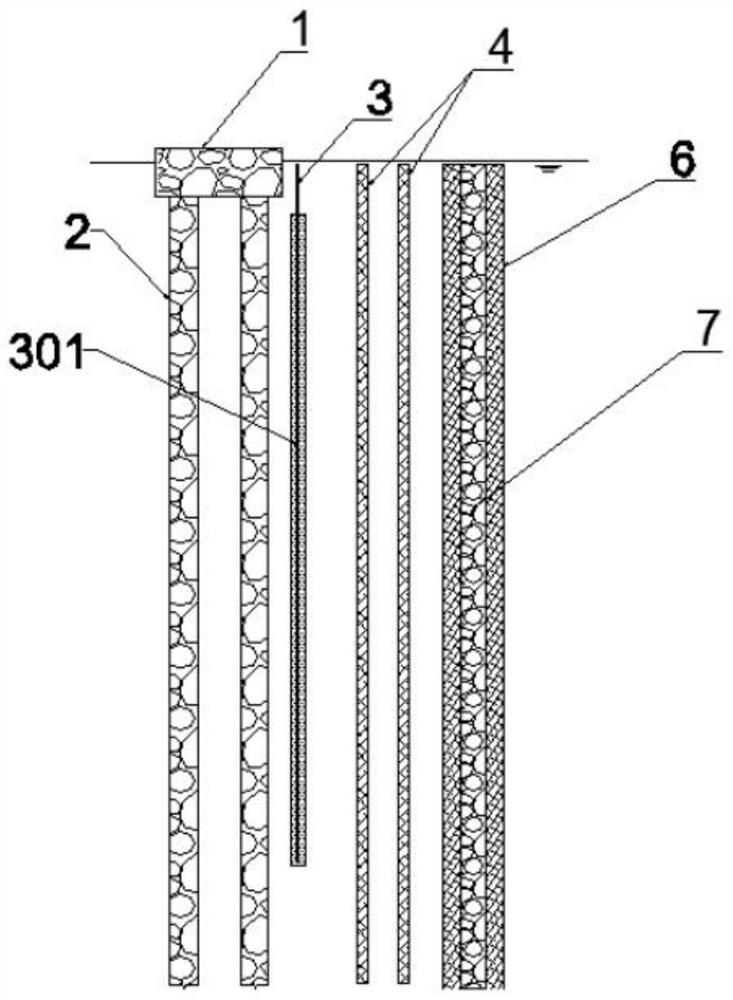

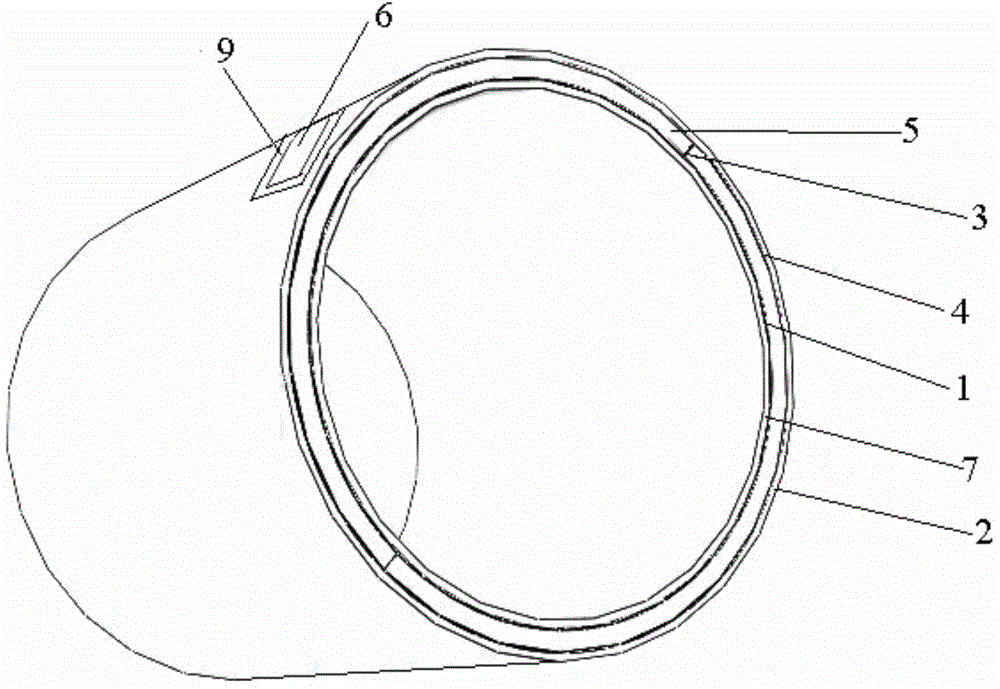

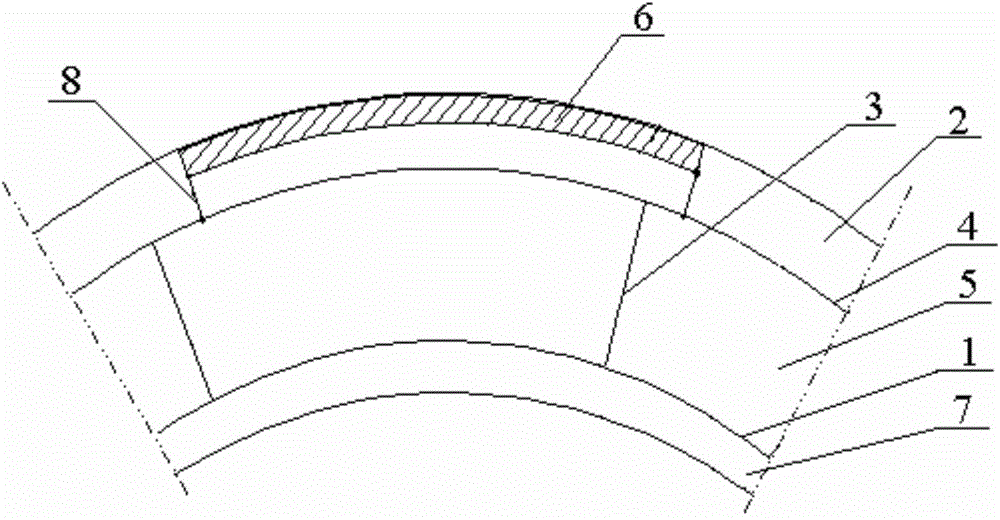

Large-diameter feeding and drainage pipe provided with sacrificial anode and manufacturing method of large-diameter feeding and drainage pipe

ActiveCN104089107AIncrease jacking thrustPromote sheddingCorrosion preventionPipe protection against corrosion/incrustationUltimate tensile strengthMaterials science

The invention discloses a large-diameter feeding and drainage pipe provided with a sacrificial anode and a manufacturing method of the large-diameter feeding and drainage pipe. The large-diameter feeding and drainage pipe comprises an inner-layer steel cylinder (1), an outer-layer concrete layer (2), a reinforcing structure (3), an outer-layer steel cylinder (4), a concrete filling structure (5) and the sacrificial anode (6), wherein the reinforcing structure (3) winds round and is welded and fixed on the outer side of the inner-layer steel cylinder (1); the outer side of the reinforcing structure (3) is sleeved with the outer-layer steel cylinder (4), and the outer-layer steel cylinder (4) is welded and fixedly connected with the reinforcing structure (3); the concrete filling structure (5) is located in a gap among the inner-layer steel cylinder(1), the reinforcing structure (3) and the outer-layer steel cylinder (4); the outer-layer concrete layer (2) is located on the outer side of the outer-layer steel cylinder (4); the sacrificial anode (6) is located in the outer-layer concrete layer (2). The large-diameter feeding and drainage pipe provided with the sacrificial anode is good in anti-corrosion effect, durable, simple in manufacturing process and capable of reducing the production cost while meeting requirements for the rigidity and the strength and has higher social and economic values.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Complex rubber pad board, preparation method thereof and combined mold machine of pad board blank

ActiveCN102734366AReduce distortionMeet the stiffnessMultiple spring combinationsRailway tracksReinforced rubberLoad carrying

The invention relates to a complex rubber pad board, a preparation method thereof and a combined mold machine of a complex rubber pad board blank, and particularly relates to complex rubber pad boards between a railway track and a concrete sleeper under a bad work environment, and preparation methods thereof and special devices for preparing the complex rubber pad boards. The complex rubber pad board is composed of a surface glue layer and a core layer, wherein the core layer is of a main load-carrying structure of the pad board, and is a compound layer laminated by cloth-both-sides composed of twill fabric or bead cloth woven by high-strength and high-toughness fiber and rubber compound. According to the complex rubber pad board, the preparation method thereof and the combined mold machine, a pure rubber product is replaced by composite reinforced rubber; the compressive strength, the abrasive resistance and the creep resistance of a rubber product are obviously improved; the service life is prolonged; the maintenance cost of the railway is reduced; the ambient temperature range and the application field of the complex rubber pad board are expanded. Secondly, the invention also provides selection of a reinforced material and a reinforced mode suitable for large-scale industrial production, and a matched process route, and the quality reliability and the homogeneity of products are ensured.

Owner:北京唐研铭诚科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com