Rotational molding plastic composite pipes with steel rings and manufacturing method thereof

A technology of rotomolding and composite pipes, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., which can solve the problem that the cost of pipe materials and ring stiffness have not reached an organic unity, the primary utilization rate of materials is not high, and the investment in production equipment High cost and other problems, to achieve the effect of high utilization rate of raw materials, satisfying anti-corrosion and low investment in production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

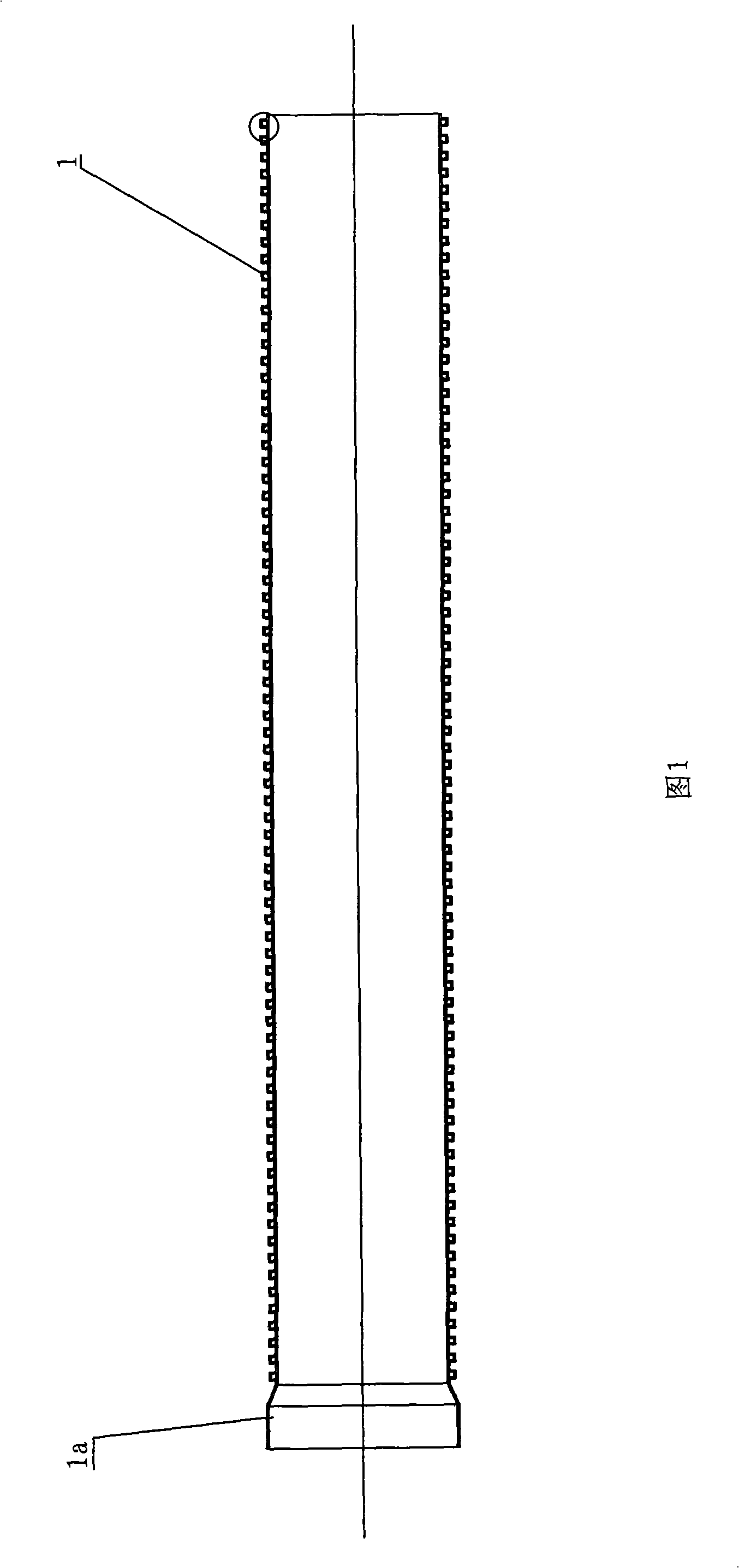

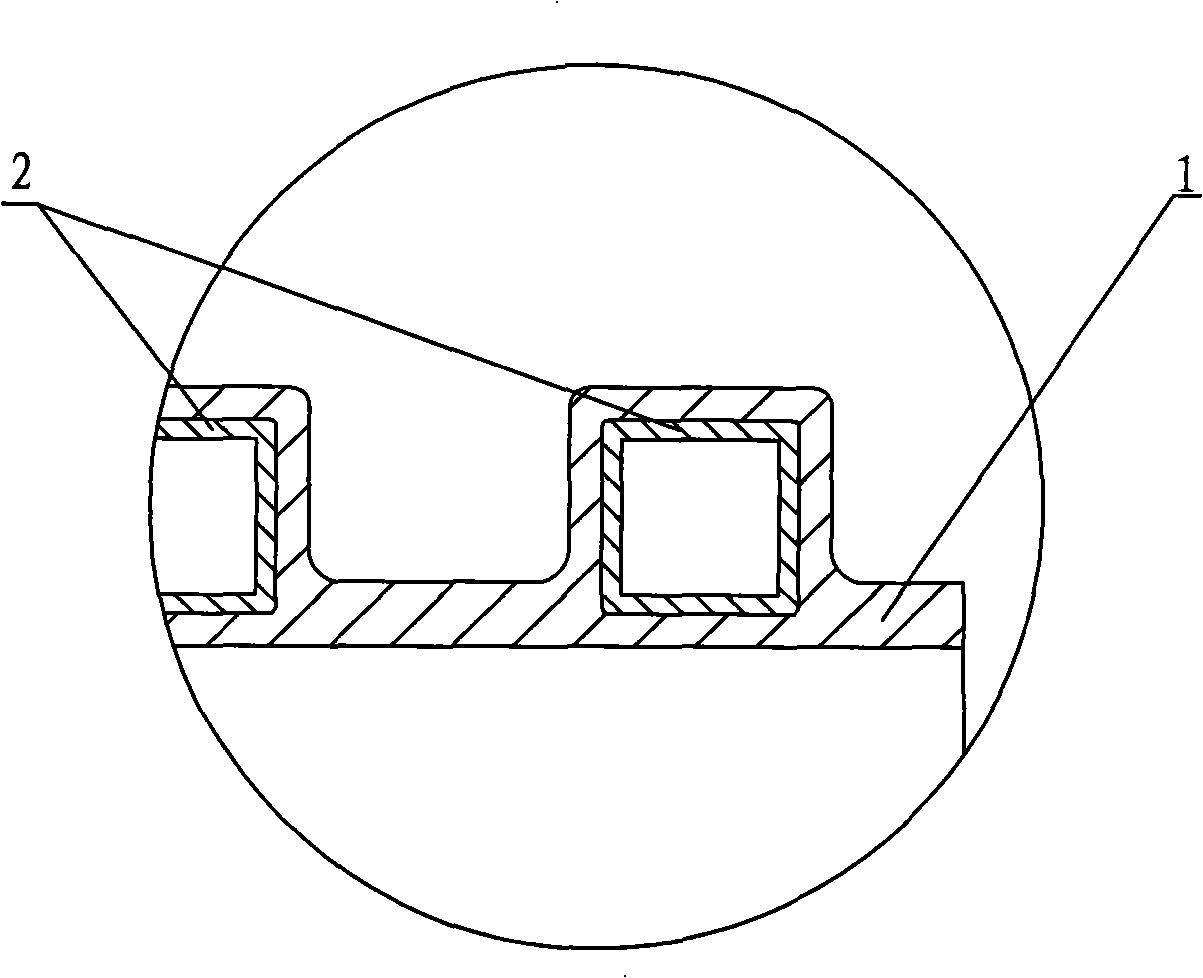

[0039] Figure 1, figure 2 As shown, the plastic composite pipe with steel ring is rotomolded, and the steel ring 2 is wrapped in the wave crest of the corrugated pipe body 1. The steel ring 2 coincides with the center line of the bellows body 1, and the steel ring is made of hollow rectangular steel. The bellows body 1 is provided with a socket 1a at one end.

[0040] The manufacturing method of rotomolding plastic composite pipe with steel ring consists of the following steps:

[0041] (1) Make mold 3, (see Figure 7, Figure 8 ) The inner cavity of the through pipe formed by the upper mold and the lower mold is provided with an annular groove 3a; one end of the mold 3 is also provided with upper and lower molds corresponding to the socket 1a.

[0042] (2) Cover the inner surface of the mold with release agent;

[0043] (3) Perform surface treatment on the steel ring, and set positioning nails on the outer surface and both sides of the steel ring;

[0044] (4) Calculate the volume...

Embodiment 2

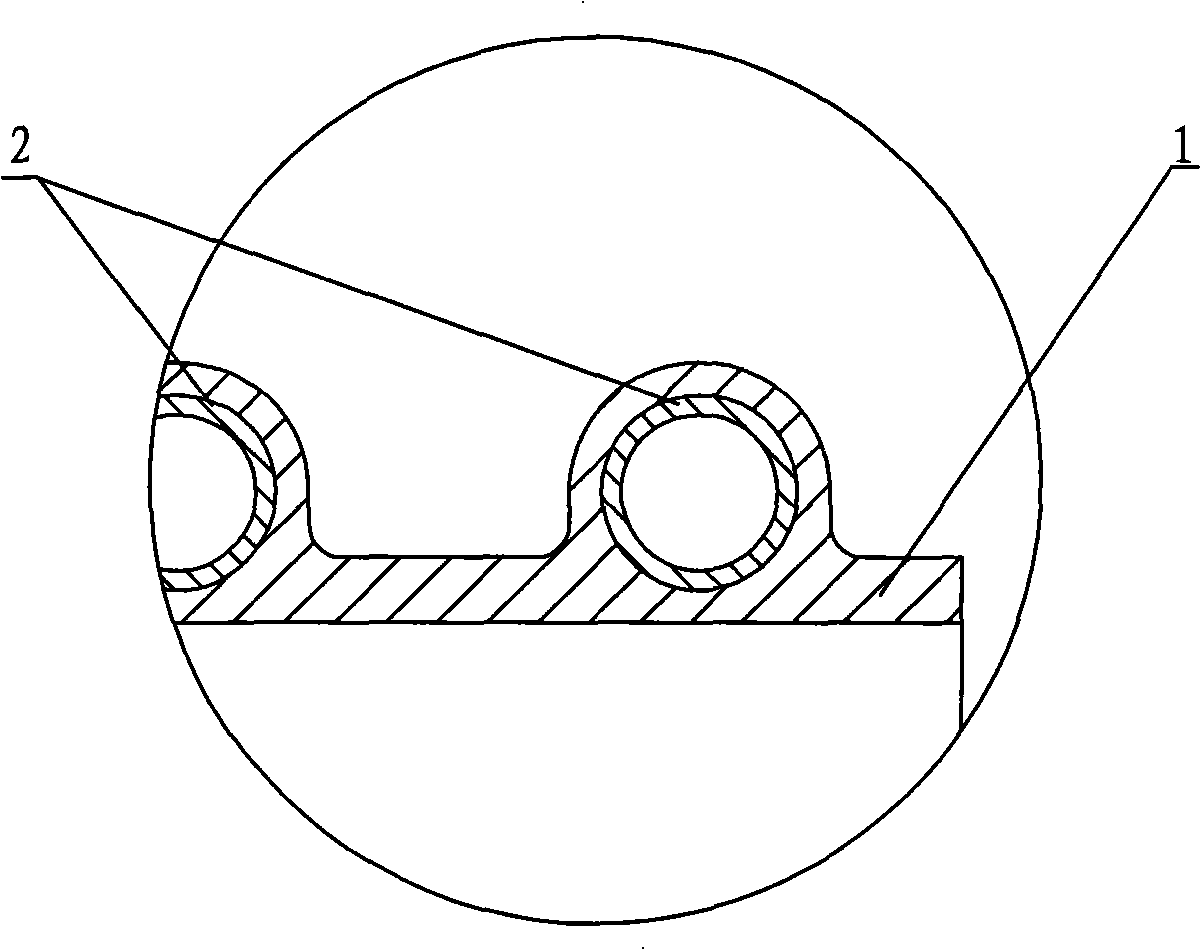

[0055] Figure 1, image 3 As shown, the plastic composite pipe steel ring with steel ring formed by rotational molding is made of hollow round steel, and the rest of the structure is the same as that of the first embodiment.

[0056] The manufacturing method of rotomolding plastic composite pipe with steel ring consists of the following steps:

[0057] (1) Make mold 3, (see Figure 7, Figure 8 1) An annular groove 3a is provided in the inner cavity of the through tube formed by the upper mold and the lower mold;

[0058] (2) Spread the release agent on the inner surface of the mold 3;

[0059] (3) Perform surface treatment on the steel ring, and set positioning nails on the outer surface and both sides of the steel ring;

[0060] (4) Calculate the volume of the plastic pipe wall according to the formula v=[πr 2 L-π(r-h) 2 L]×k

[0061] Where r- the outer diameter of the nozzle of the bellows body 1; L- the integral length of the bellows body 1 and the socket 1a;

[0062] h- the thi...

Embodiment 3

[0070] Figure 1, Figure 4 As shown, the plastic composite pipe steel ring with steel ring formed by rotational molding is made of "I" steel without a socket structure, and the rest of the structure is the same as that of the first embodiment.

[0071] The manufacturing method of rotomolding plastic composite pipe with steel ring consists of the following steps:

[0072] (1) Make mold 3, (see Figure 7, Figure 8 1) An annular groove 3a is provided in the inner cavity of the through tube formed by the upper mold and the lower mold;

[0073] (2) Spread the release agent on the inner surface of the mold 3;

[0074] (3) Perform surface treatment on the steel ring, and set positioning nails on the outer surface and both sides of the steel ring;

[0075] (4) Calculate the volume of the plastic pipe wall according to the formula v=[πr 2 L-π(r-h) 2 L]×k

[0076] Where r- the outer diameter of the nozzle of the bellows body 1; L- the integral length of the bellows body 1 and the socket 1a; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density ρ | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com