Large-diameter feeding and drainage pipe provided with sacrificial anode and manufacturing method of large-diameter feeding and drainage pipe

A sacrificial anode and large-diameter technology, applied in the direction of pipe, rigid pipe, pipeline protection, etc., can solve the problems of short steel length, difficult implementation, and inability to protect construction, so as to reduce production costs, achieve good results, and simplify construction steps and difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

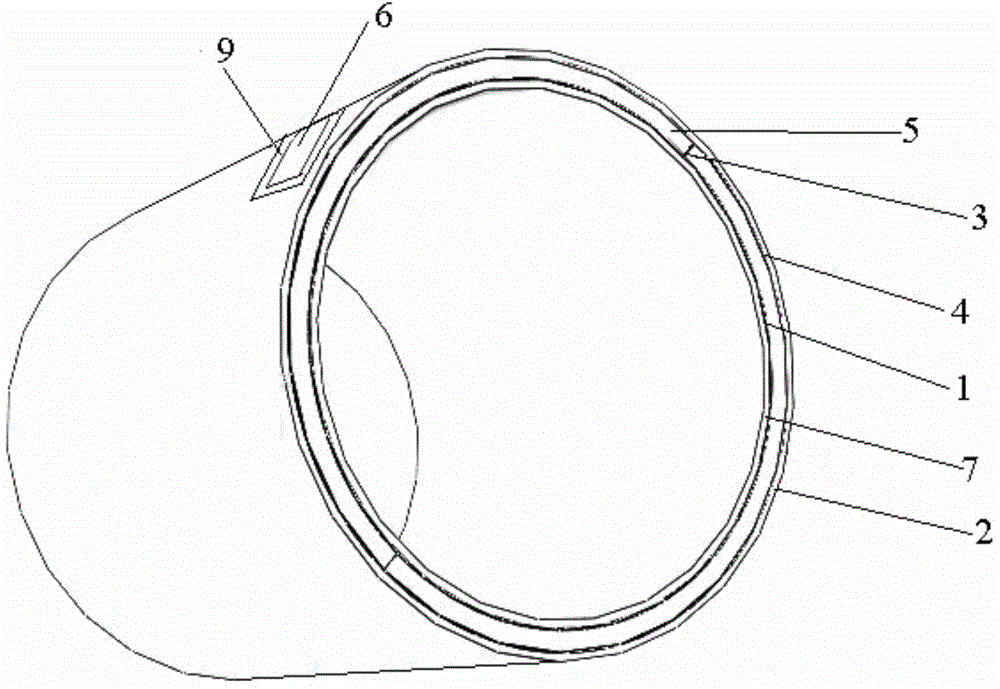

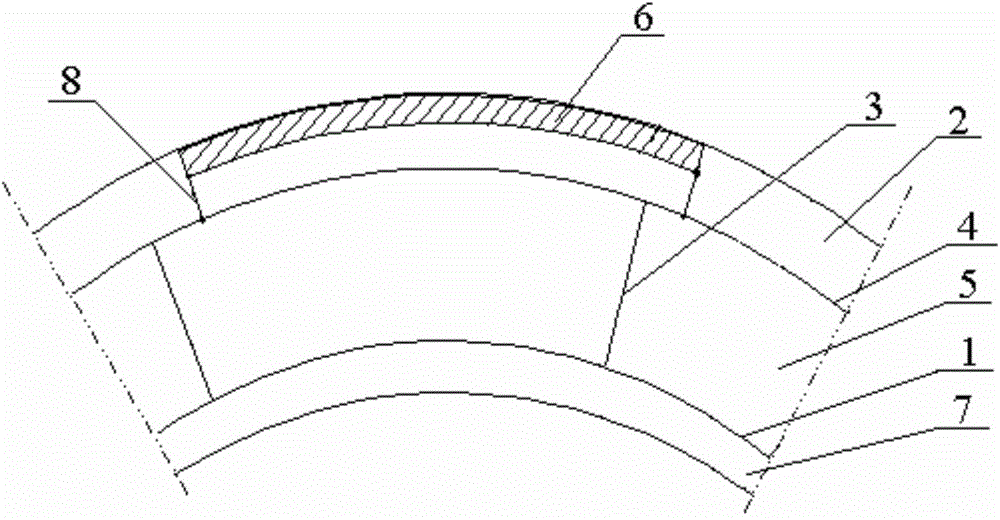

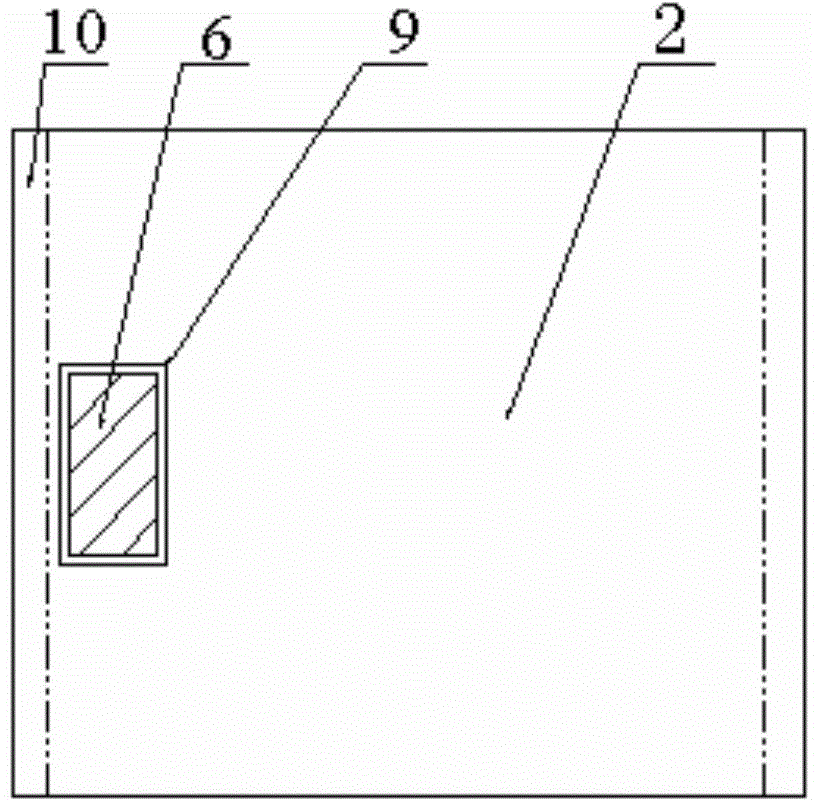

[0051] The large-diameter water supply and drainage pipe with sacrificial anode described in this embodiment is composed as follows: inner steel cylinder 1, outer concrete layer 2, reinforcement structure 3, outer steel cylinder 4, concrete filling structure 5 and sacrificial anode 6; The reinforcement structure 3 is wound and welded and fixed on the outside of the inner steel cylinder 1; the outer steel cylinder 4 is set on the outside of the reinforcement structure 3 and welded and fixedly connected with the reinforcement structure 3; the concrete filling structure 5 is located on the inner steel cylinder 1 , in the gap between the reinforced structure 3 and the outer steel cylinder 4; the outer concrete layer 2 is located outside the outer steel cylinder 4, the sacrificial anode 6 is located in the outer concrete layer 2, and the sacrificial anode 6 The outer surface and the outer surface of the outer concrete layer 2 are in the same curved surface.

[0052] The large-diame...

Embodiment 2

[0084] The large-diameter water supply and drainage pipe with sacrificial anode described in this embodiment is composed as follows: inner steel cylinder 1, outer concrete layer 2, reinforcement structure 3, outer steel cylinder 4, concrete filling structure 5 and sacrificial anode 6; The reinforcement structure 3 is wound and welded and fixed on the outside of the inner steel cylinder 1; the outer steel cylinder 4 is set on the outside of the reinforcement structure 3 and welded and fixedly connected with the reinforcement structure 3; the concrete filling structure 5 is located on the inner steel cylinder 1 , in the gap between the reinforced structure 3 and the outer steel cylinder 4; the outer concrete layer 2 is located outside the outer steel cylinder 4, the sacrificial anode 6 is located in the outer concrete layer 2, and the sacrificial anode 6 The outer surface and the outer surface of the outer concrete layer 2 are in the same curved surface.

[0085] The size of the...

Embodiment 3

[0090] The large-diameter water supply and drainage pipe with sacrificial anode described in this embodiment is composed as follows: inner steel cylinder 1, outer concrete layer 2, reinforcement structure 3, outer steel cylinder 4, concrete filling structure 5 and sacrificial anode 6; The reinforcement structure 3 is wound and welded and fixed on the outside of the inner steel cylinder 1; the outer steel cylinder 4 is set on the outside of the reinforcement structure 3 and welded and fixedly connected with the reinforcement structure 3; the concrete filling structure 5 is located on the inner steel cylinder 1 , in the gap between the reinforced structure 3 and the outer steel cylinder 4; the outer concrete layer 2 is located outside the outer steel cylinder 4, the sacrificial anode 6 is located in the outer concrete layer 2, and the sacrificial anode 6 The outer surface and the outer surface of the outer concrete layer 2 are in the same curved surface.

[0091] The diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com