Patents

Literature

754 results about "Cathodic protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cathodic protection (CP) is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. A simple method of protection connects the metal to be protected to a more easily corroded "sacrificial metal" to act as the anode. The sacrificial metal then corrodes instead of the protected metal. For structures such as long pipelines, where passive galvanic cathodic protection is not adequate, an external DC electrical power source is used to provide sufficient current.

Use of Cathodic Protection Compounds on Treated Metal Articles

A cathodic protection coating is disclosed that unexpectedly protects a treated metal substrate, notwithstanding the presence of a phosphate-containing conversion coating between the metal substrate and the cathodic protection compound. The cathodic protection coating includes sacrificial metallic particles less noble than metal in the metal substrate to be protected. The coating also includes inherently conductive polymer.

Owner:AVIENT CORP

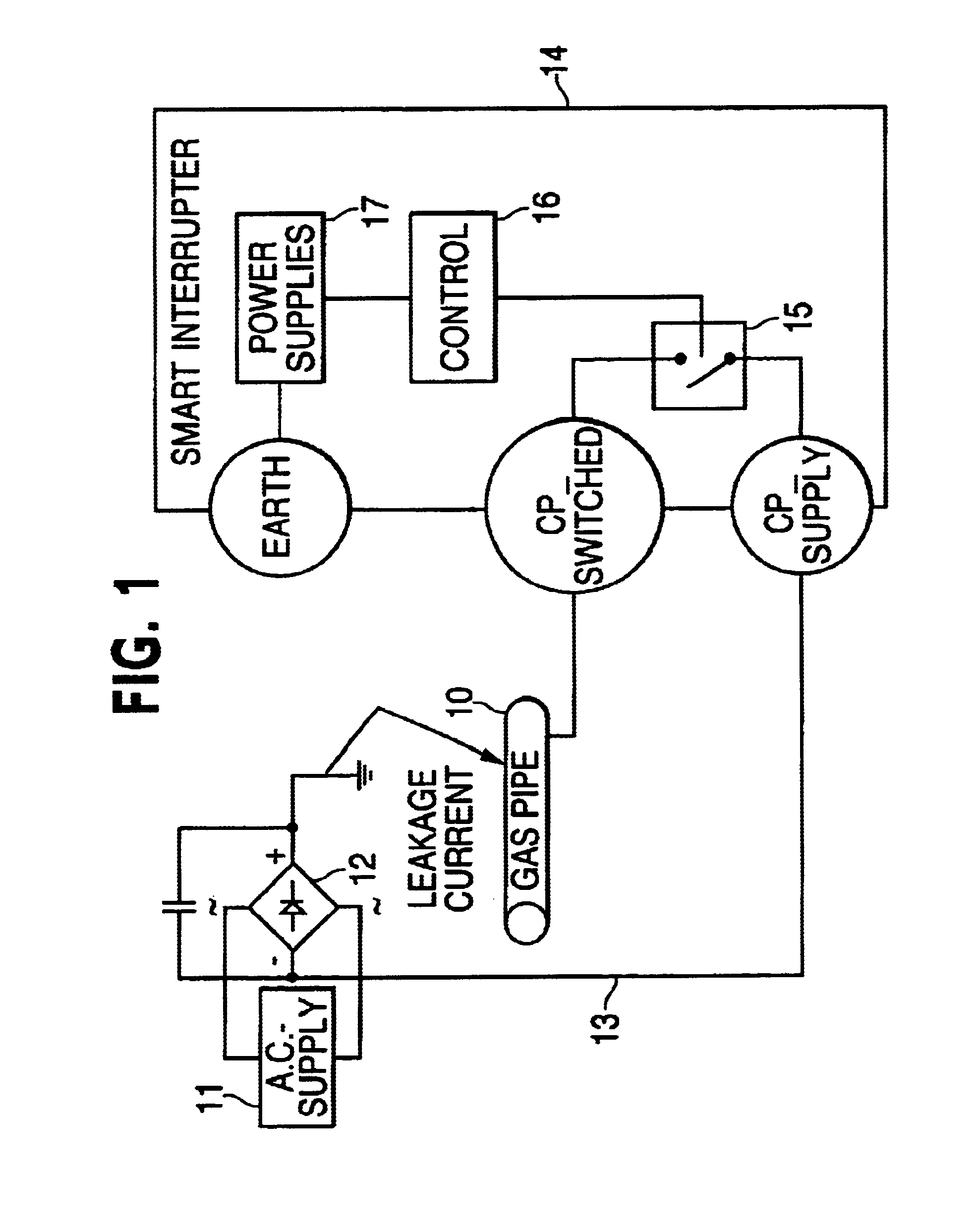

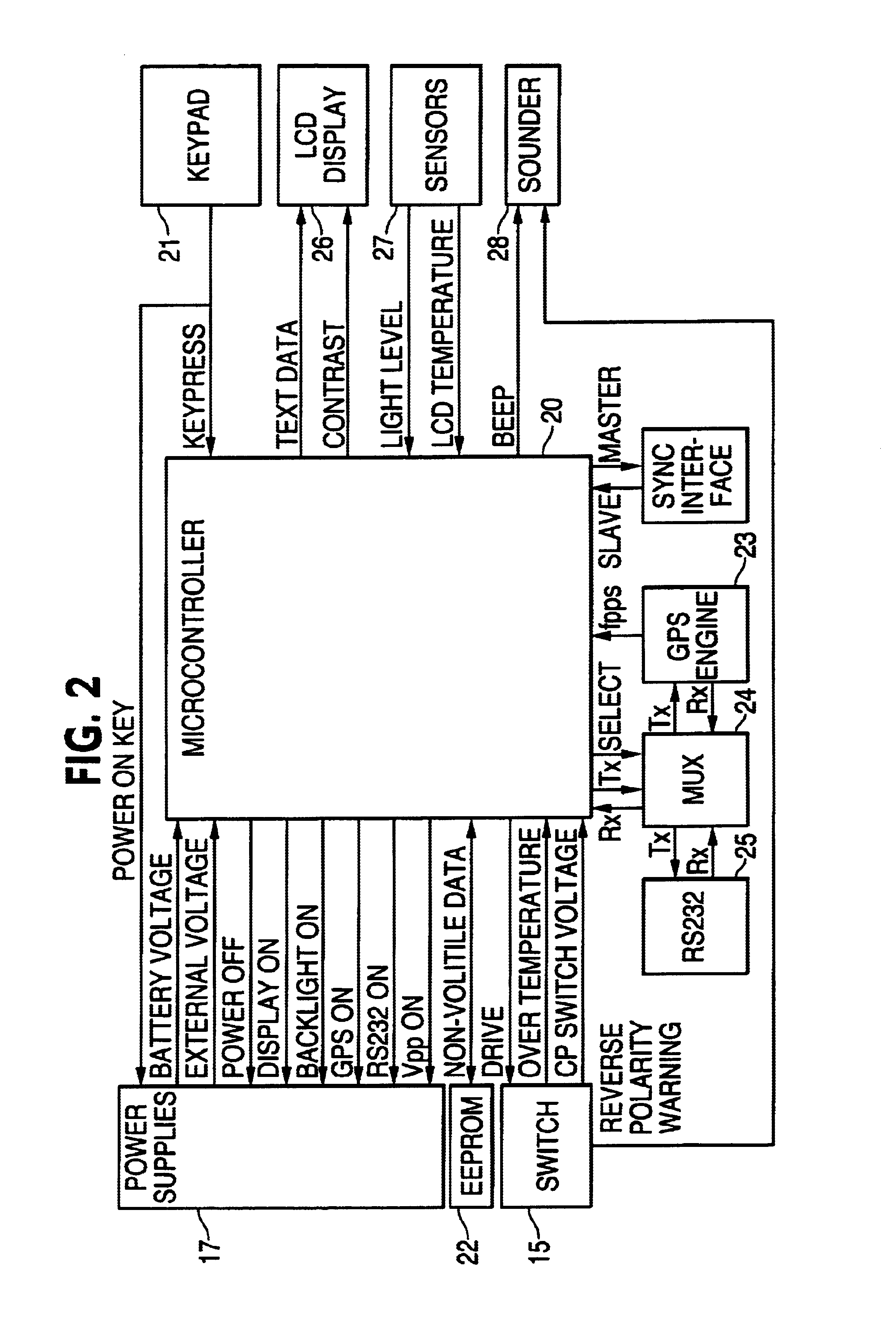

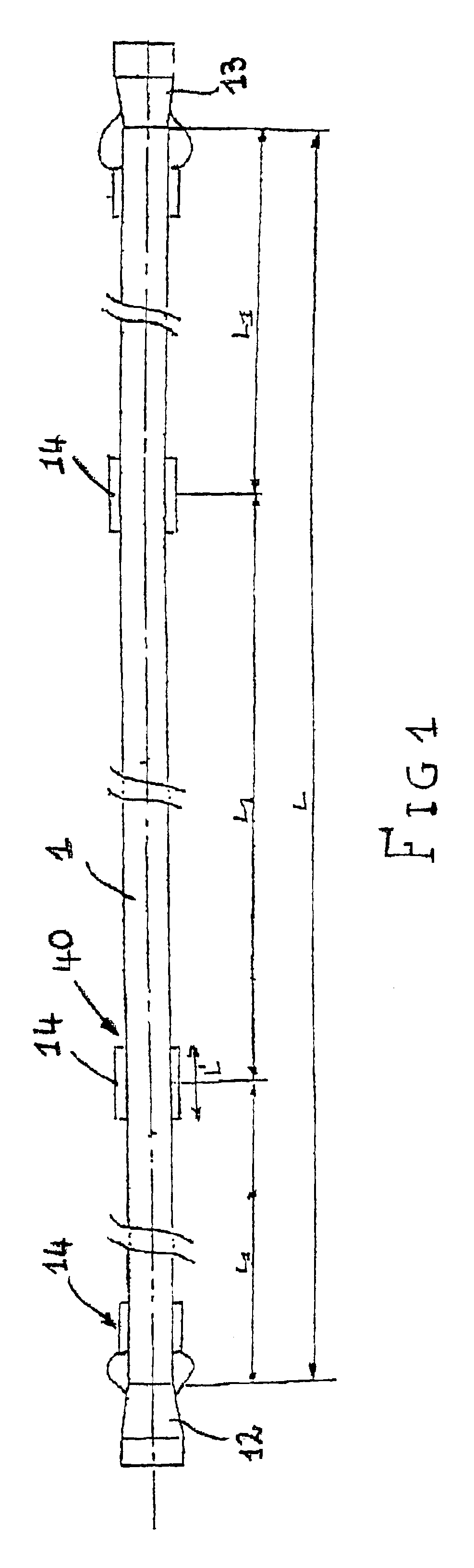

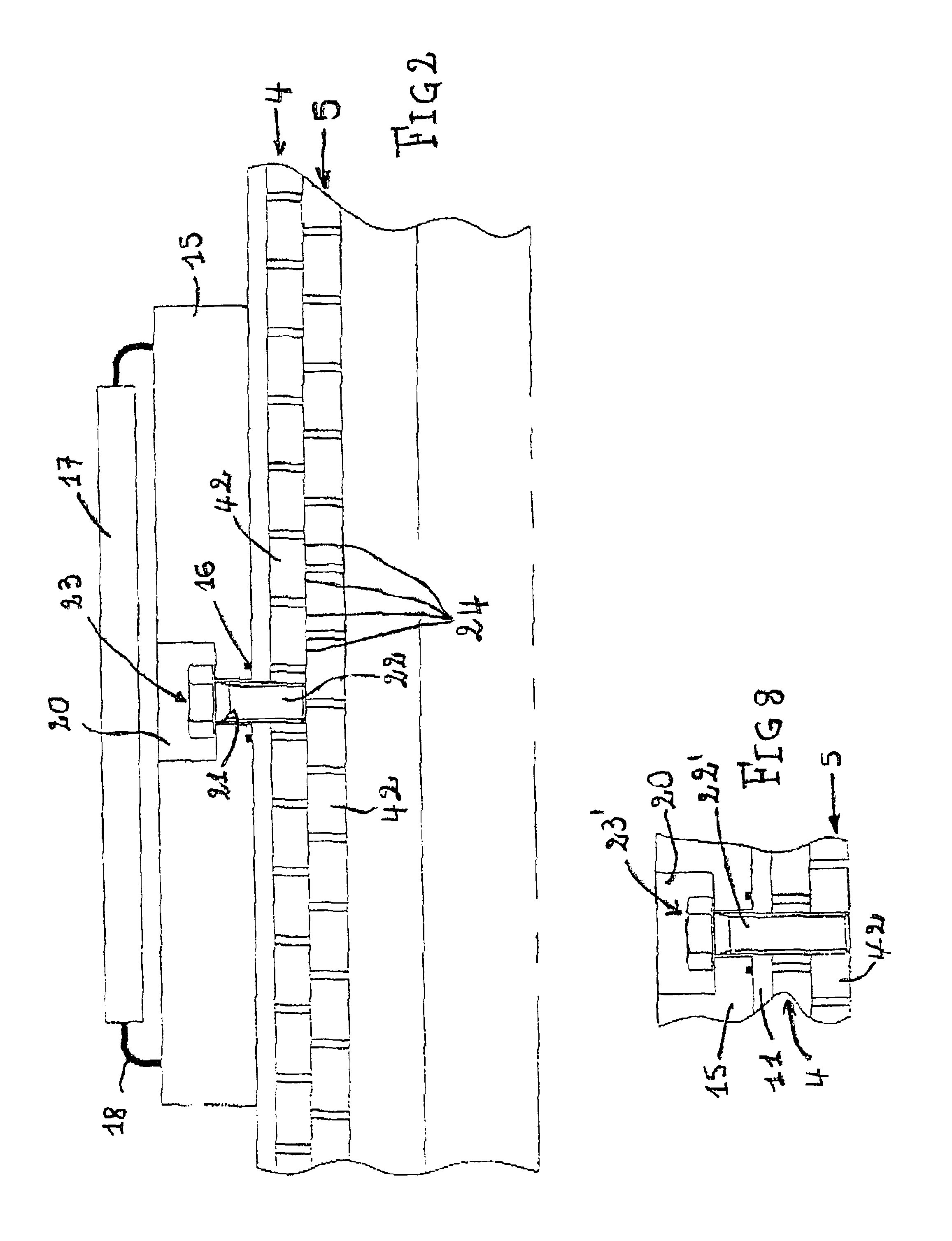

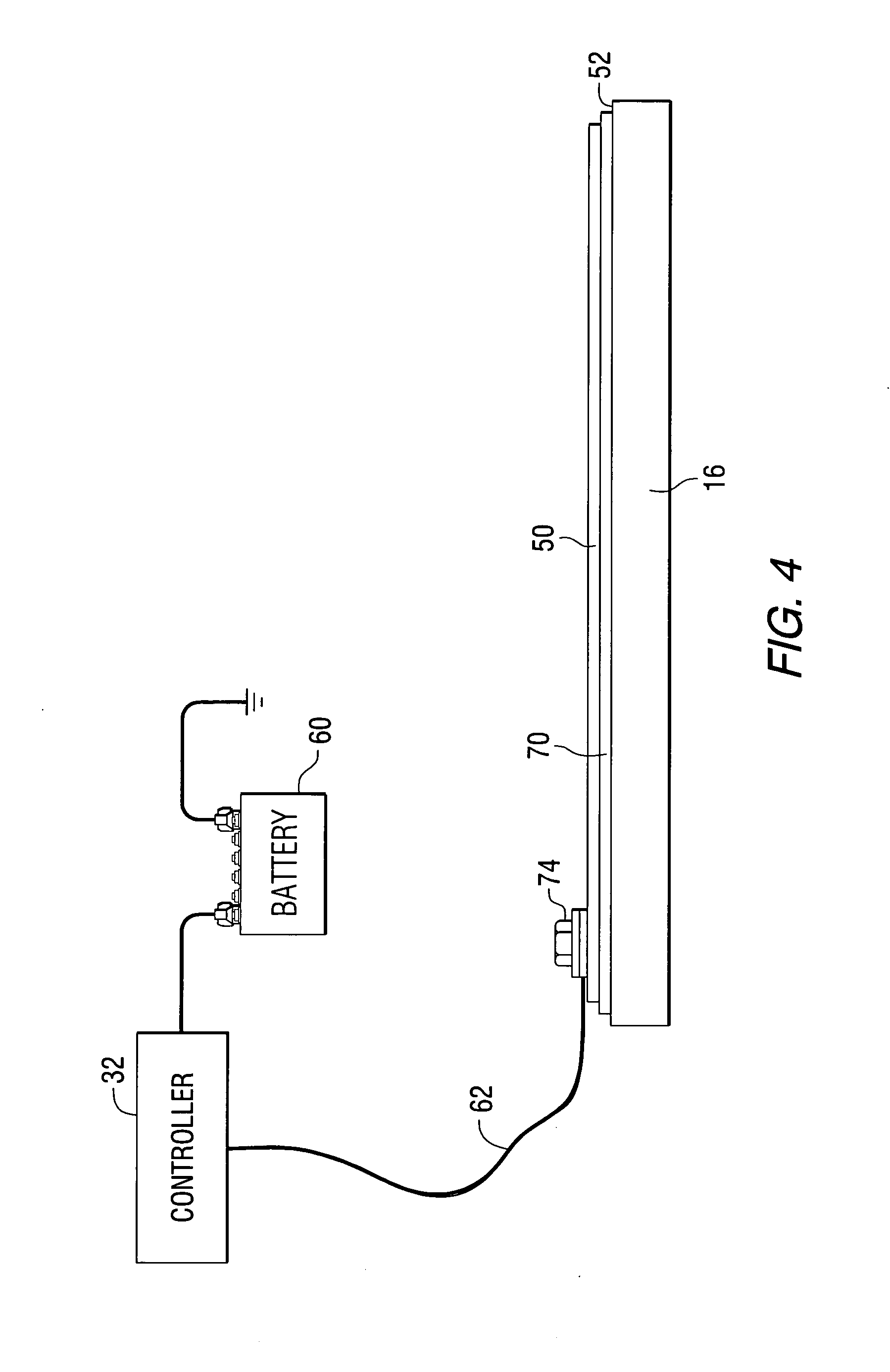

Pipeline mapping and interrupter therefor

InactiveUS6954071B2Convenient investigationEasy to identifyWeather/light/corrosion resistanceElectronic circuit testingElectrolysisEngineering

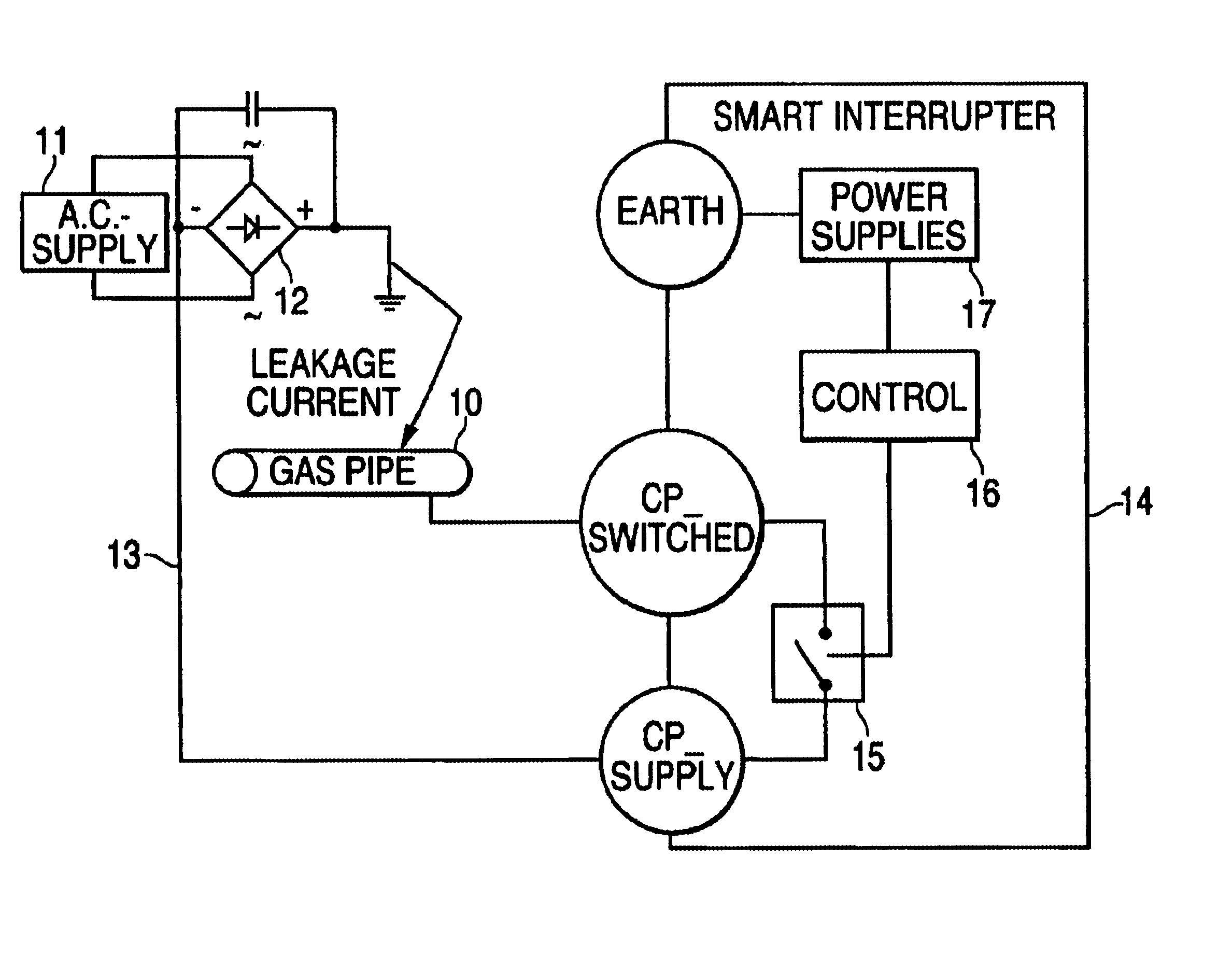

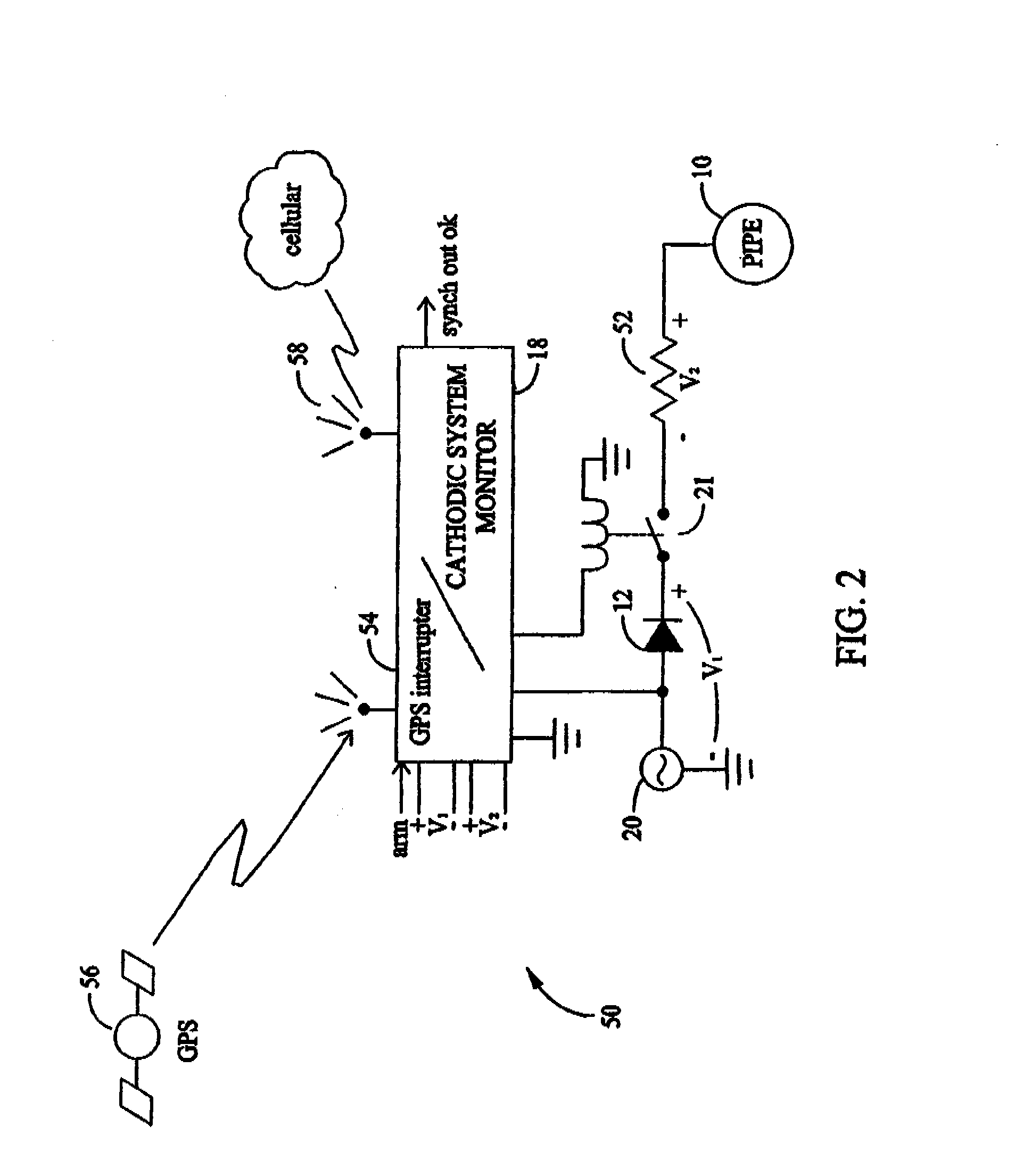

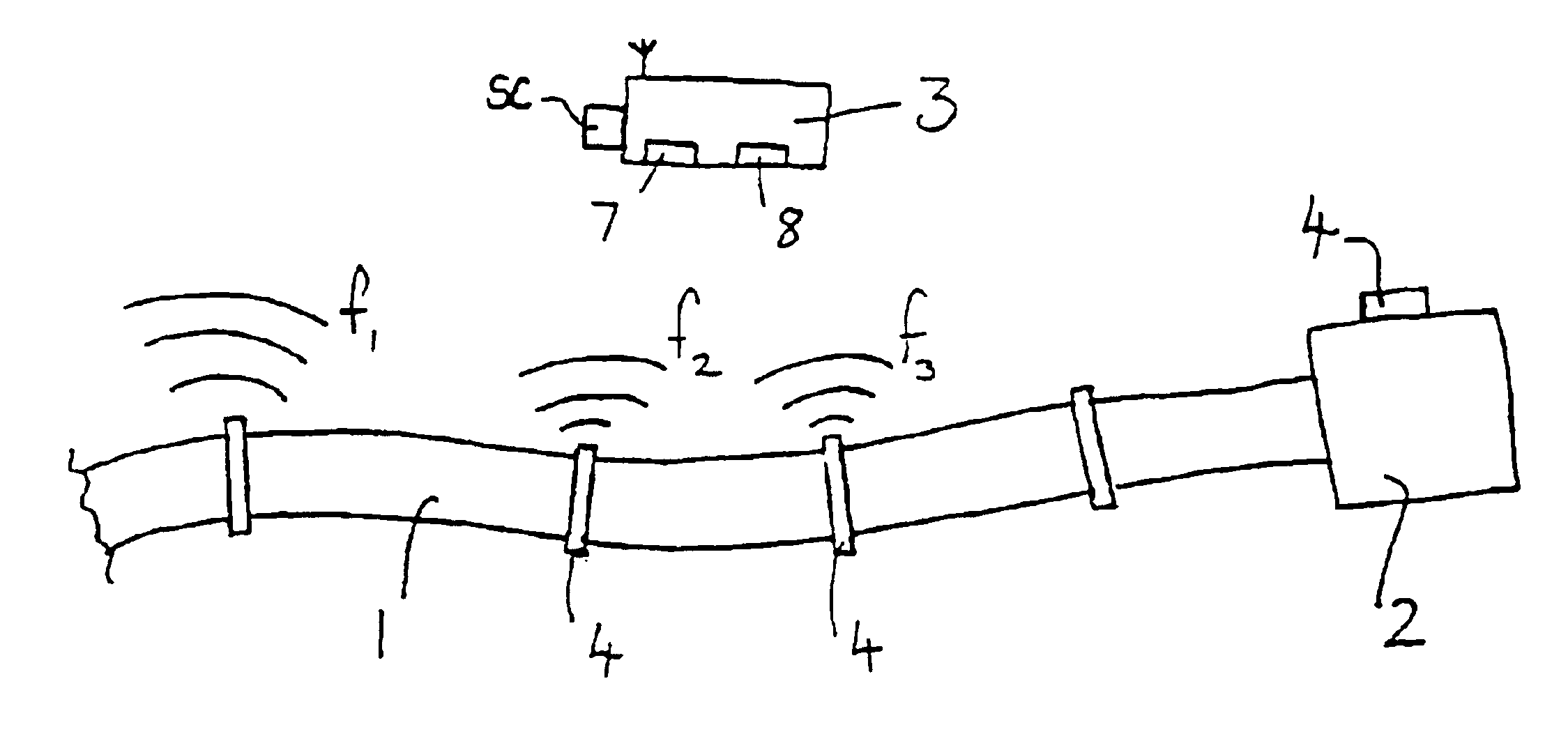

Cathodic protection voltages are used to resist the damage to pipes or cables from electrolytic effects. However, localized fields can lead to stray currents and may result in corrosion and it is therefore desirable to detect and analyse those stray currents. Frequently there are several pipes in the area of interest and so it is necessary to distinguish between those pipes. Therefore the cathodic voltage on the pipes is modulated, with different pipes having different modulations. This modulation may be applied using an interrupter. Orthogonal modulations with non-unitary aspect ratios improve the discrimination between the pipes while maximizing the energy content of the modulation pattern. The analysis is improved when the interrupters are synchronized with each other and so repeating on the same time-base. This synchronization may be achieved using an external time signal such as GPS. An interrupter which can be used in this regard is also proposed, and may be powered from the cathodic voltage itself.

Owner:RADIODETECTION

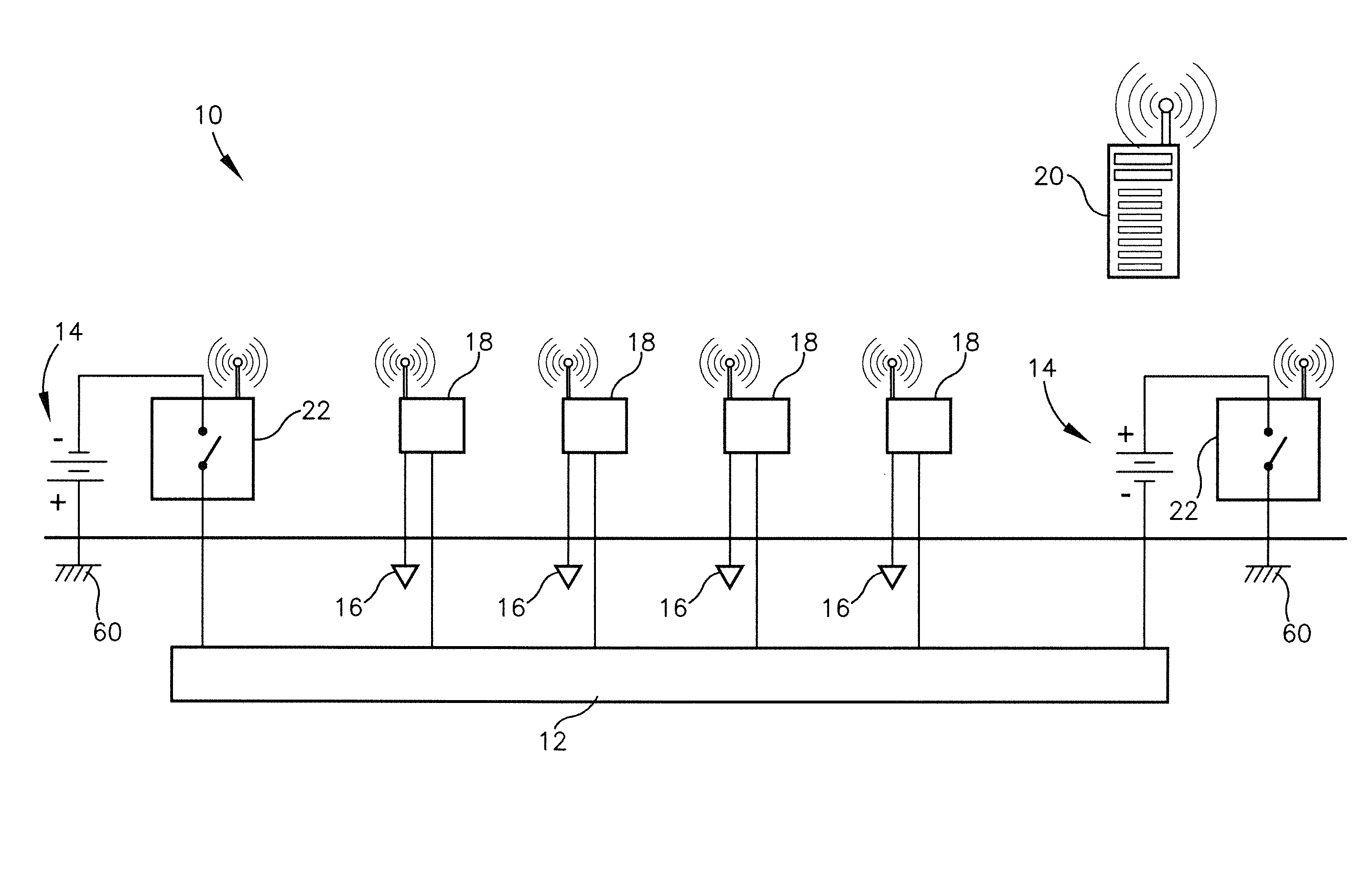

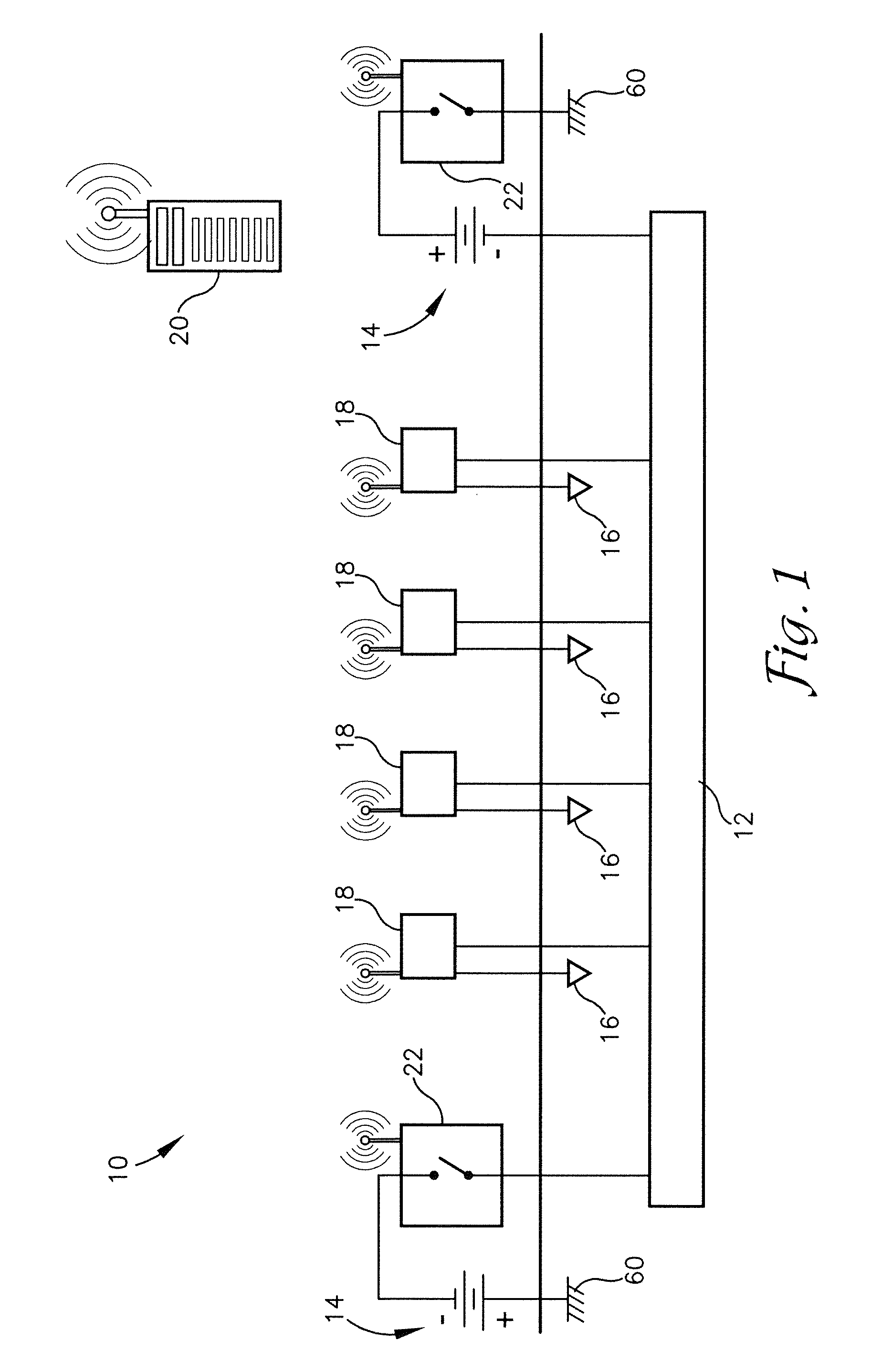

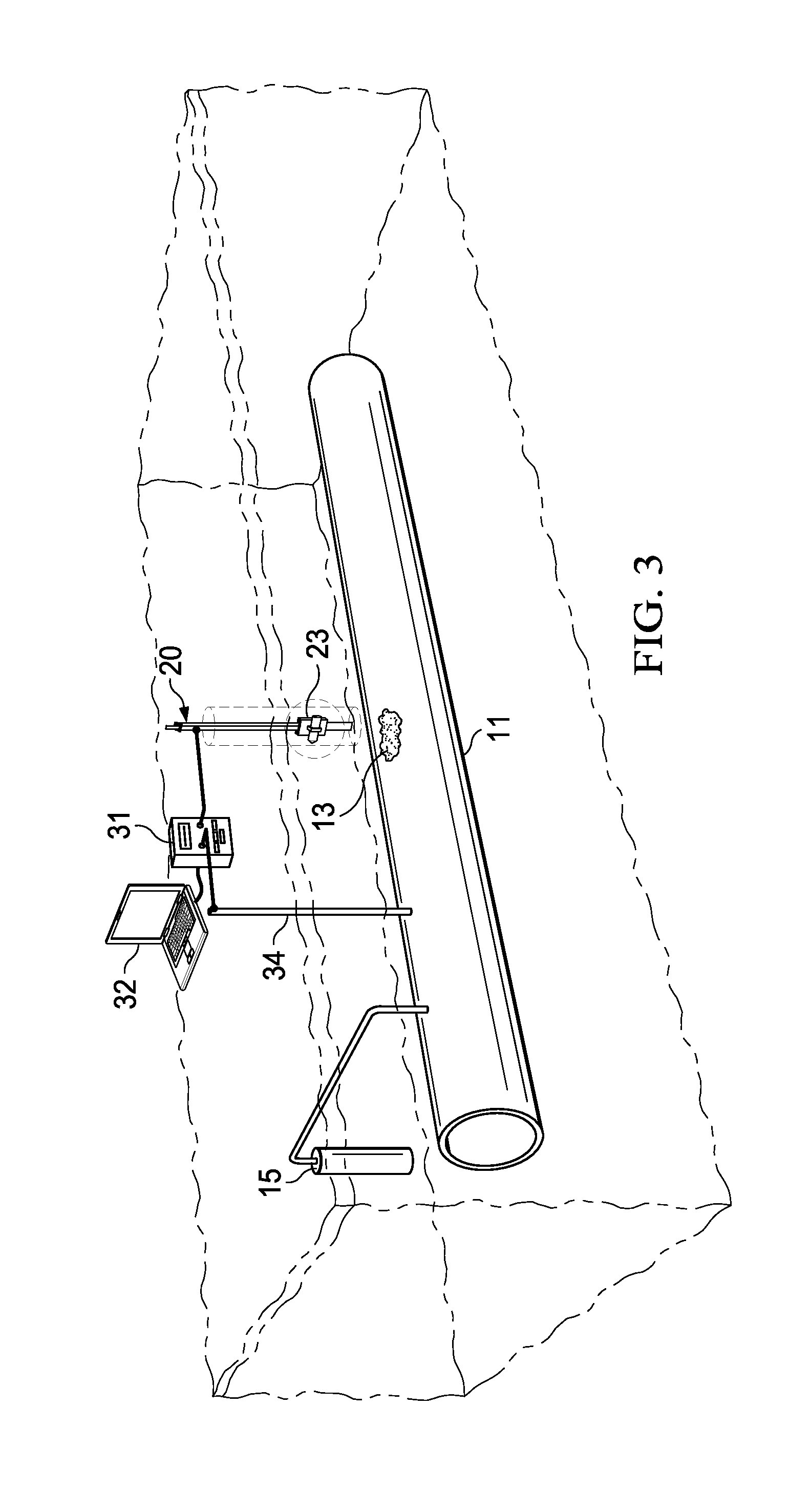

Apparatus and system for automated pipeline testing

InactiveUS20110238347A1Resistance/reactance/impedenceVoltage-current phase angleTransceiverWireless transceiver

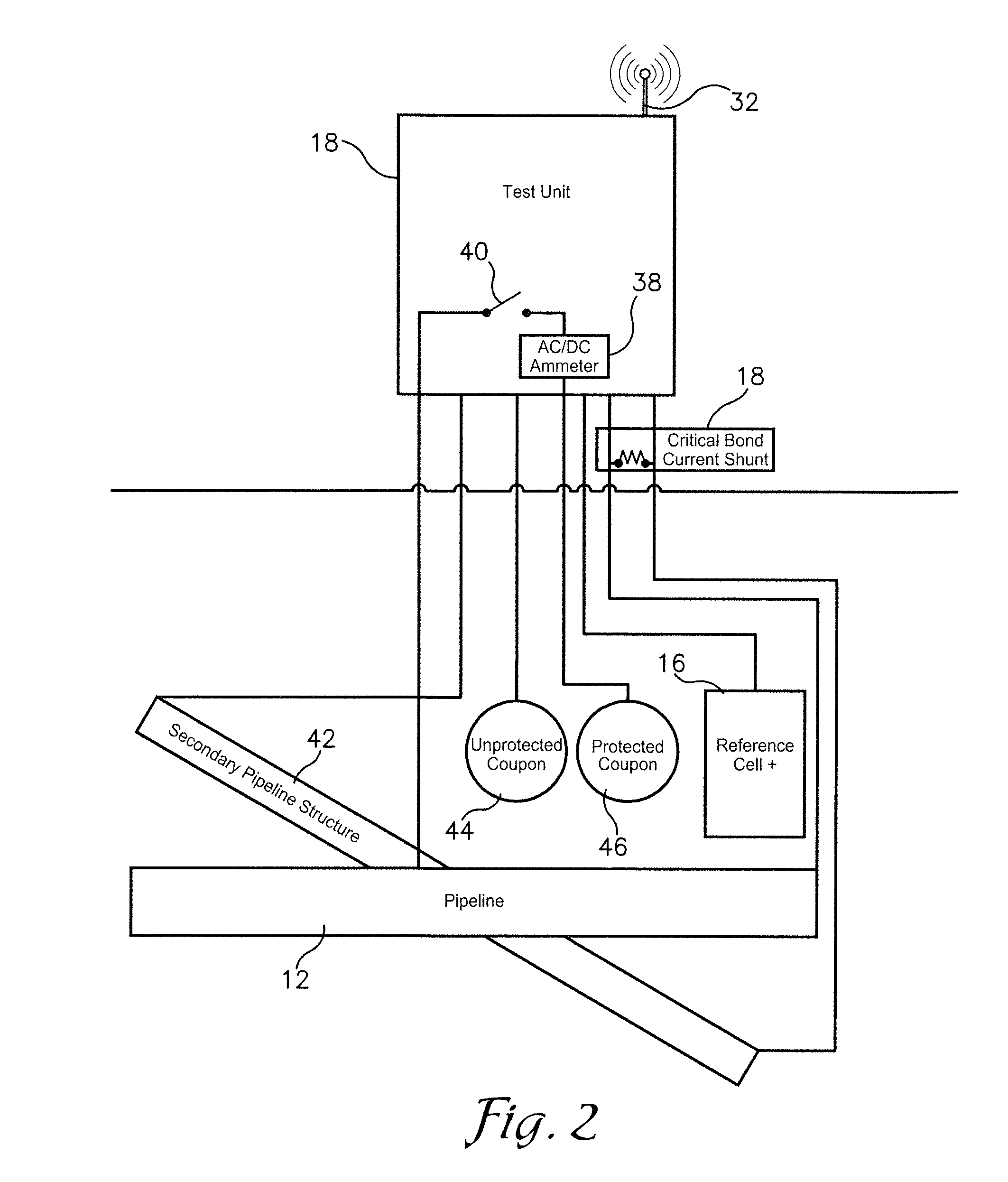

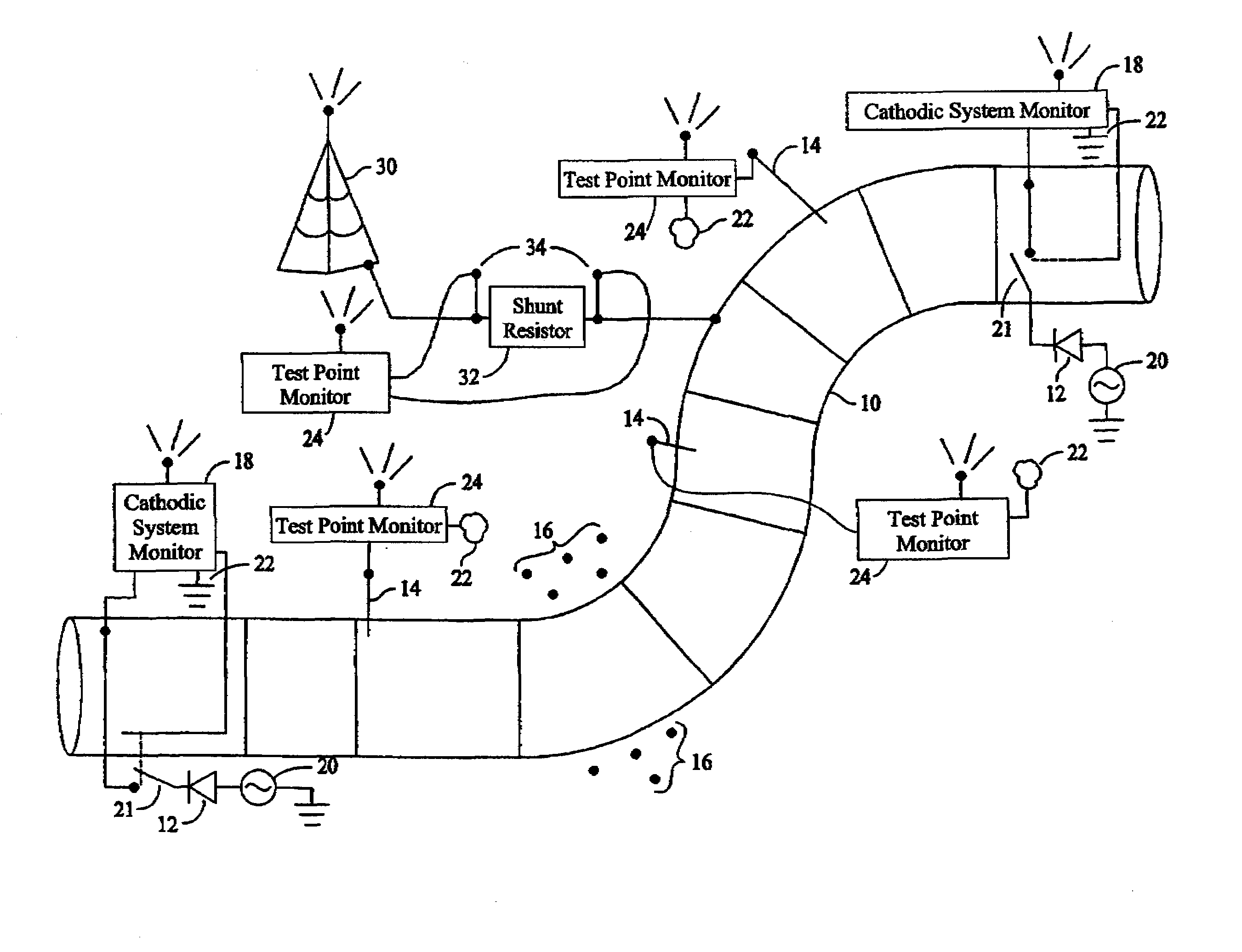

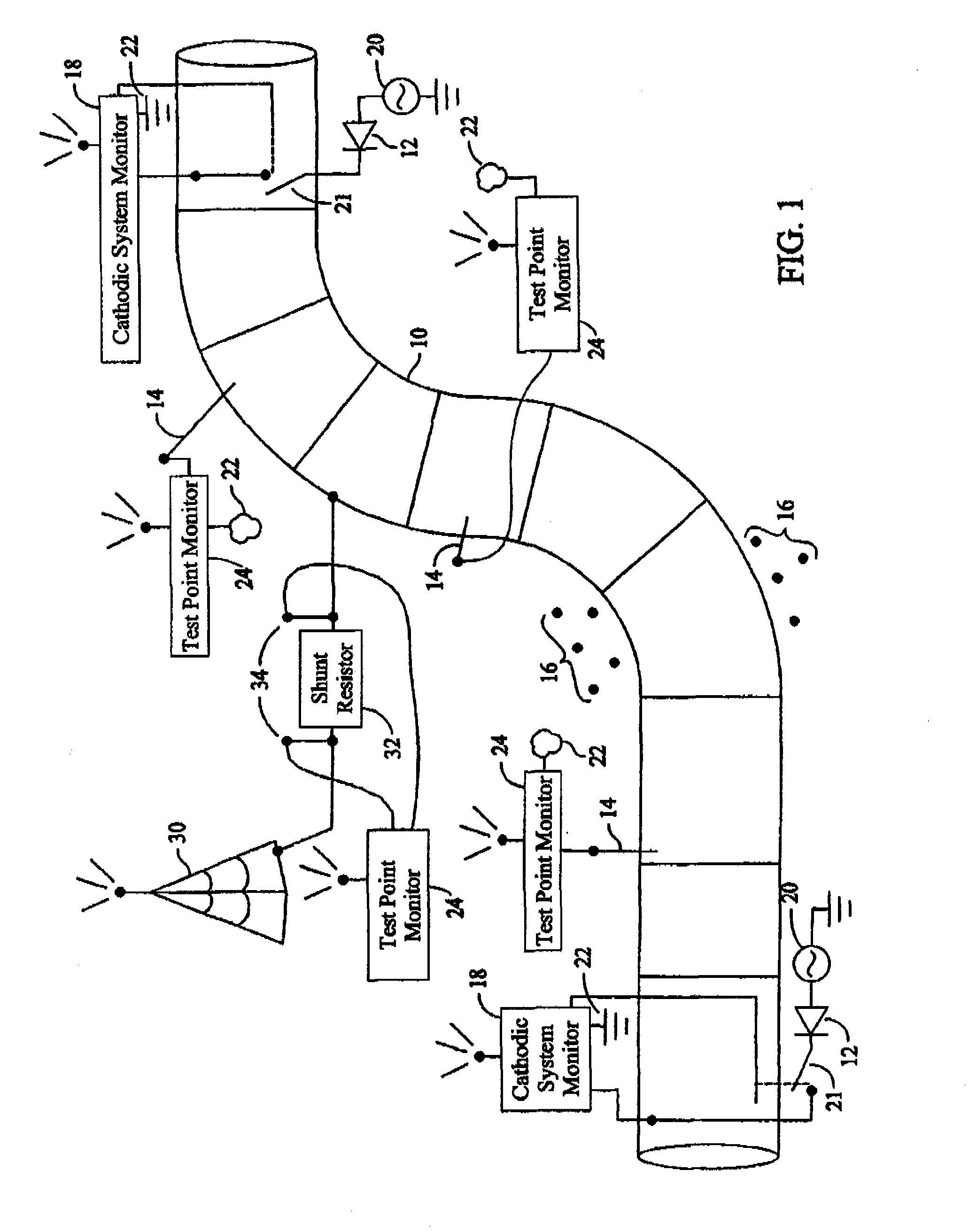

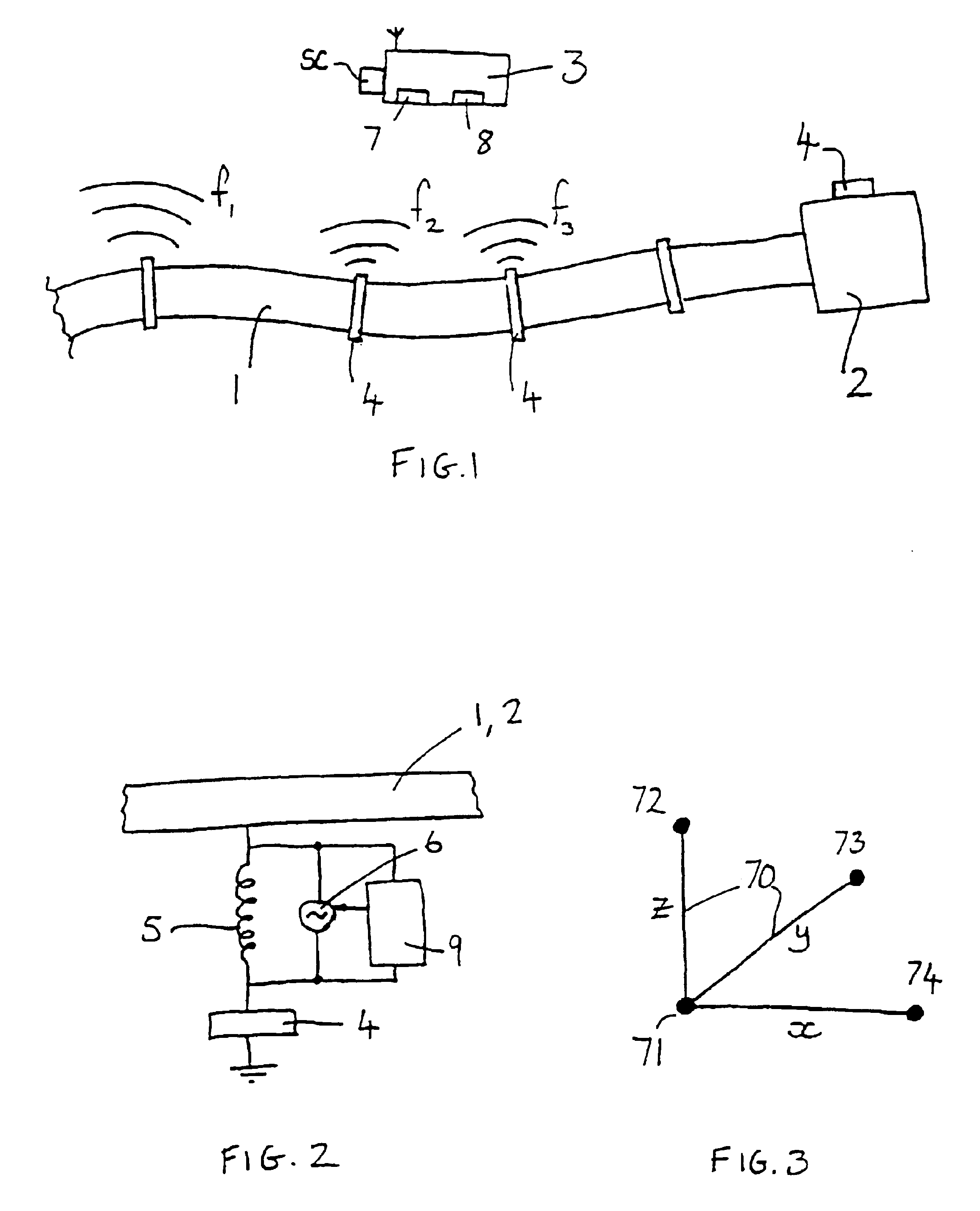

A cathodic protection system comprising remote test units for measuring various voltages and currents at remote locations on a cathodically-protected pipeline. The remote test units may comprise a processor configured to store measurements taken with the voltmeter and a wireless transceiver for communicating with other test units and / or a Web server or host computer in a daisy-chain or mesh radio configuration. The remote test units may comprise an instant-off switch which electrically connects the pipeline with a buried protected coupon of the same material as the pipeline, and a voltmeter configured to measure the instant-off potential of the protected coupon when the switch is opened. The test units may also comprise a millivoltmeter configured to measure a voltage across a critical bond current shunt resistor and an ammeter configured to measure AC and DC current flowing between the pipeline and the protected coupon with the instant-off switch is closed.

Owner:ELECSYS CORP

Cathodic protection monitor

ActiveUS20080204274A1Costly and time-consumeEfficient collectionElectric signal transmission systemsTelemetry/telecontrol selection arrangementsJet aeroplaneTransceiver

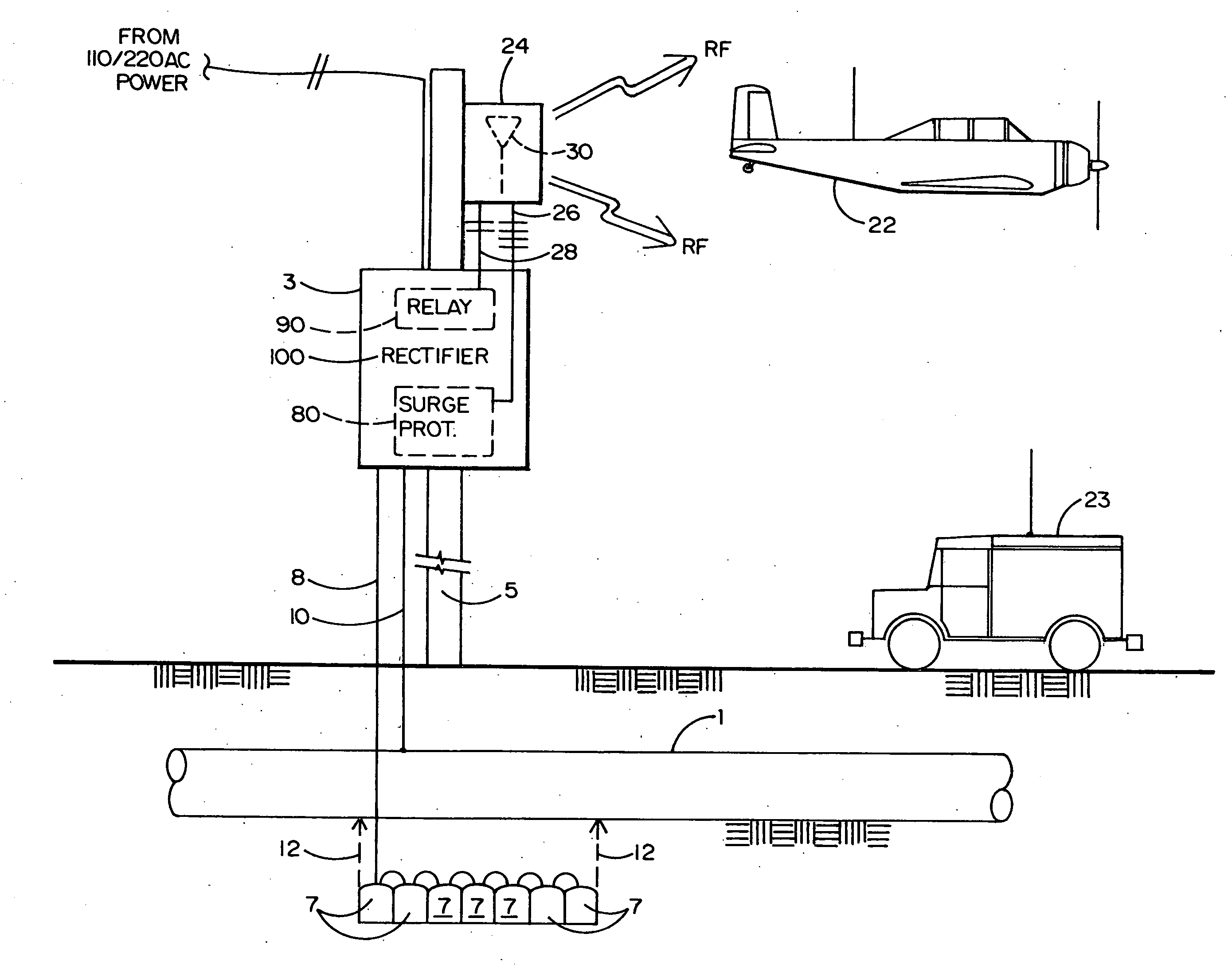

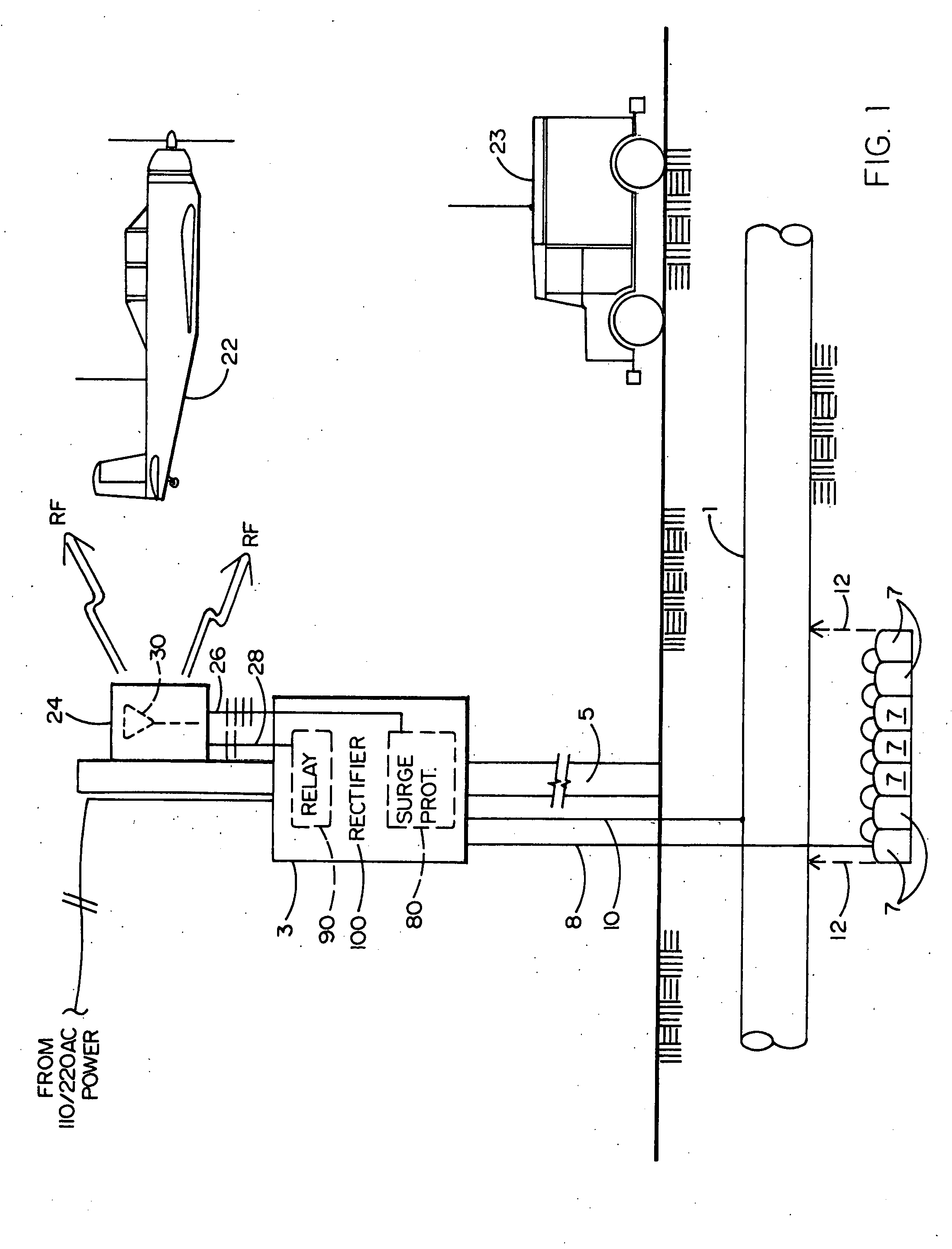

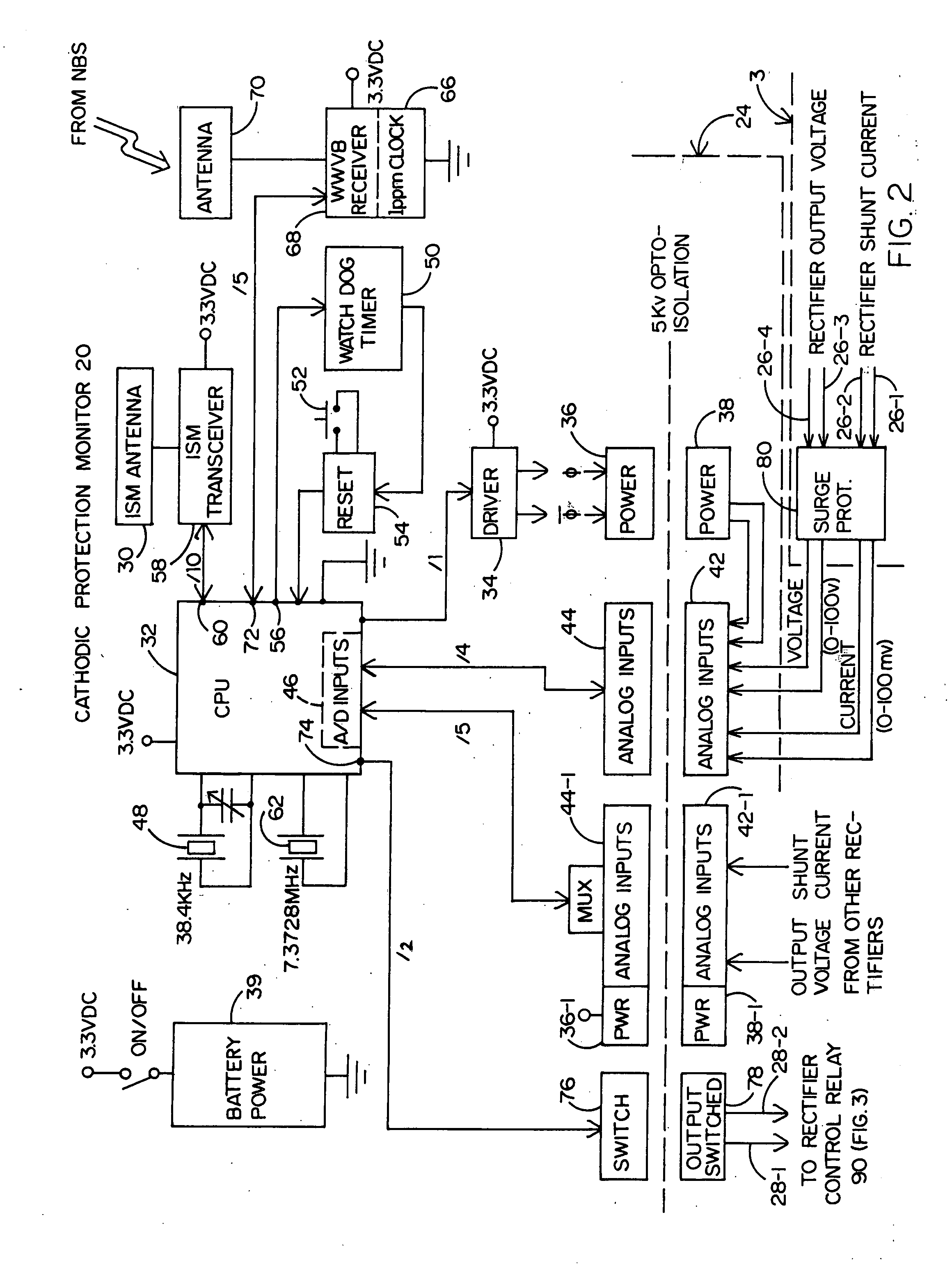

A cathodic protection monitor is disclosed to be electrically connected to a cathodic protection rectifier that is adapted to prevent rust, corrosion and possible leakage in an underground pipe or storage tank above which the rectifier is supported. The cathodic protection monitor includes a CPU that reads, digitizes and stores analog current and voltage signals which are supplied from the DC output of the rectifier and are indicative of the effectiveness thereof. The monitor includes an ISM band transceiver and antenna by which the CPU is polled and from which packets of stored data are transmitted to a data collector at an overhead airplane or nearby motor vehicle for retransmission and analysis by the pipe owner or maintenance crew. Synchronized timing signals are supplied (from the National Bureau of Standards) to a stable auxiliary clock by way of a WWVB transceiver and antenna. The auxiliary clock from each of a plurality of cathodic protection monitors along the pipeline provides a synchronized clock control signal to a respective CPU which, in turn, generates a switched relay control signal to a relay of the cathodic protection rectifier. Accordingly, the relays of all of the cathodic protection rectifiers can be simultaneously energized and de-energized during successive time periods so that all of the cathodic protection rectifiers can be turned on and off at the same time as may be required to compile ground voltage readings along the pipeline as part of a government-mandated survey.

Owner:OLEUMTECH CORP

Reduction of the loss of zinc by its reaction with oxygen in galvanized steel and batteries

InactiveUS20070125644A1Improve Coulombic efficiencyMinimal porosityMachining electrodesFuel and primary cellsElectrochemical responseChemical reaction

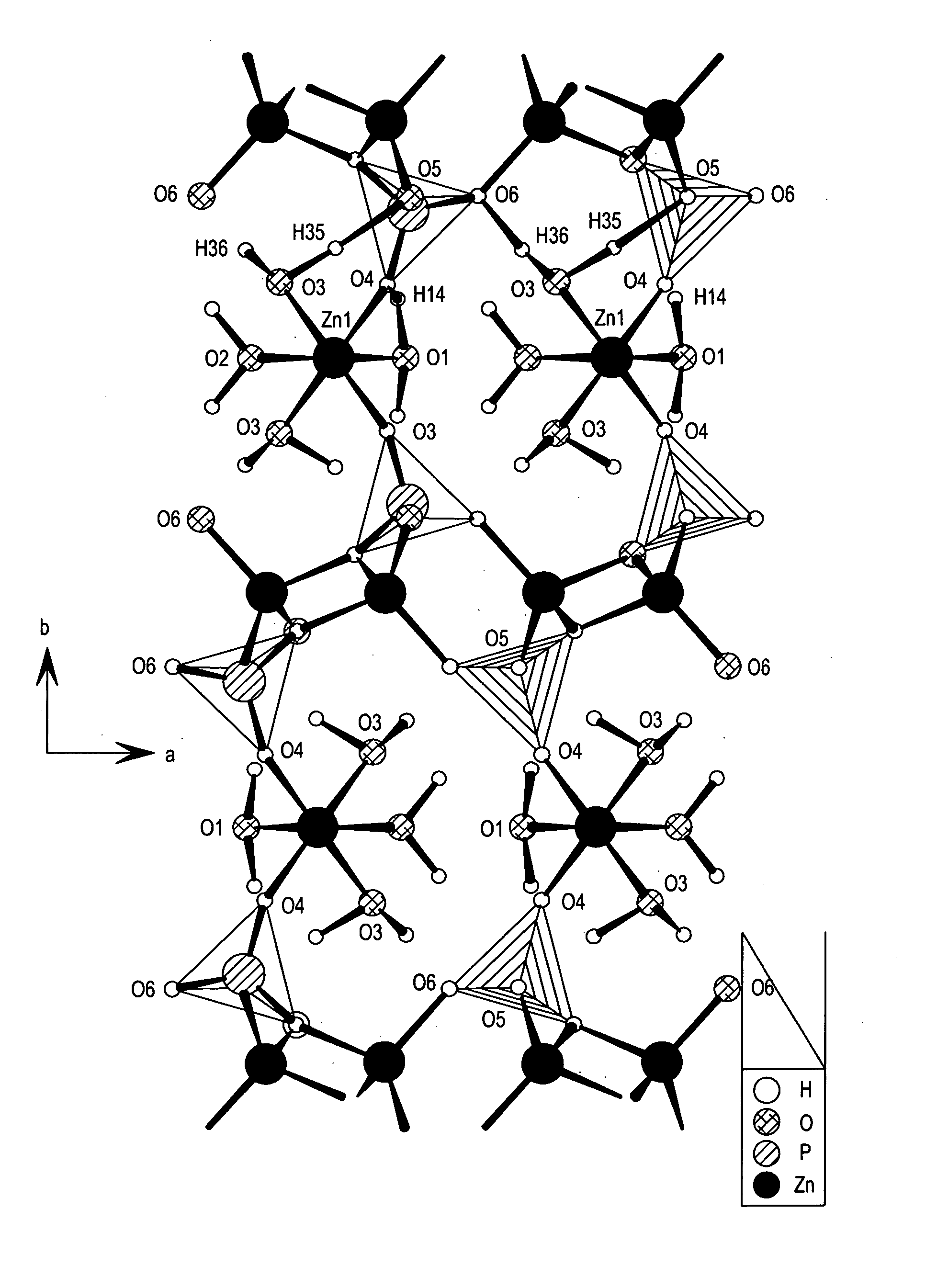

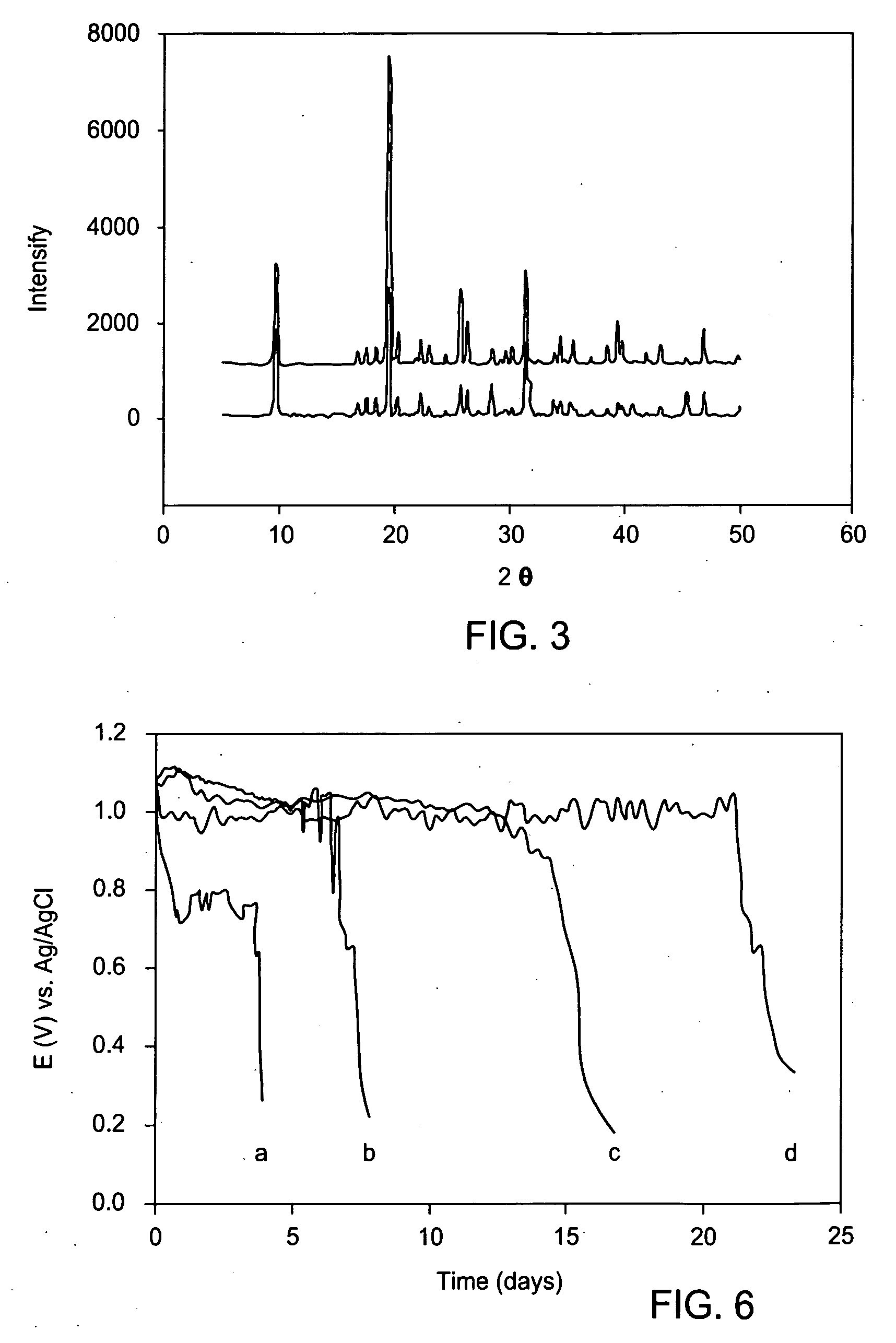

A non-porous Zn2+ conducting inorganic lamellar layer is formed on the zinc coating of galvanized steel or on a zinc anode of an electrochemical cell. The layer reduces the rate of the unwanted chemical reaction of zinc and oxygen but allows desired electrochemical reactions underlying the cathodic protection of the steel and the efficient utilization of zinc anodes in electrochemical cells, e.g., a physiological buffer solution or serum as their electrolytes. The ion conducting non-porous lamellar layer having a hopeite phase Zn3(PO4)2.4H2O may be formed spontaneously on, e.g., NAFION® coated zinc anodes discharged in neutral pH saline phosphate solutions.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Methods and systems for automated pipeline testing

InactiveUS20070035315A1Weather/light/corrosion resistanceResistance/reactance/impedenceElectricityProximate

A method for testing effectiveness of a cathodic protection device configured to apply at least one voltage across an underground structure and a reference point is described. The method includes providing a sample of the material from which the underground structure is fabricated, placing the sample proximate the underground structure, electrically connecting the sample to the underground structure through a switch, operating the switch at predetermined intervals, and measuring electrical characteristics of the sample at intervals based at least partially on the predetermined intervals and a position of the switch

Owner:ELECSYS INT CORP

Integrated ultrasonic testing and cathodic protection measurement probe

ActiveUS20180073975A1Material analysis using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceRobotic armUltrasonic attenuation

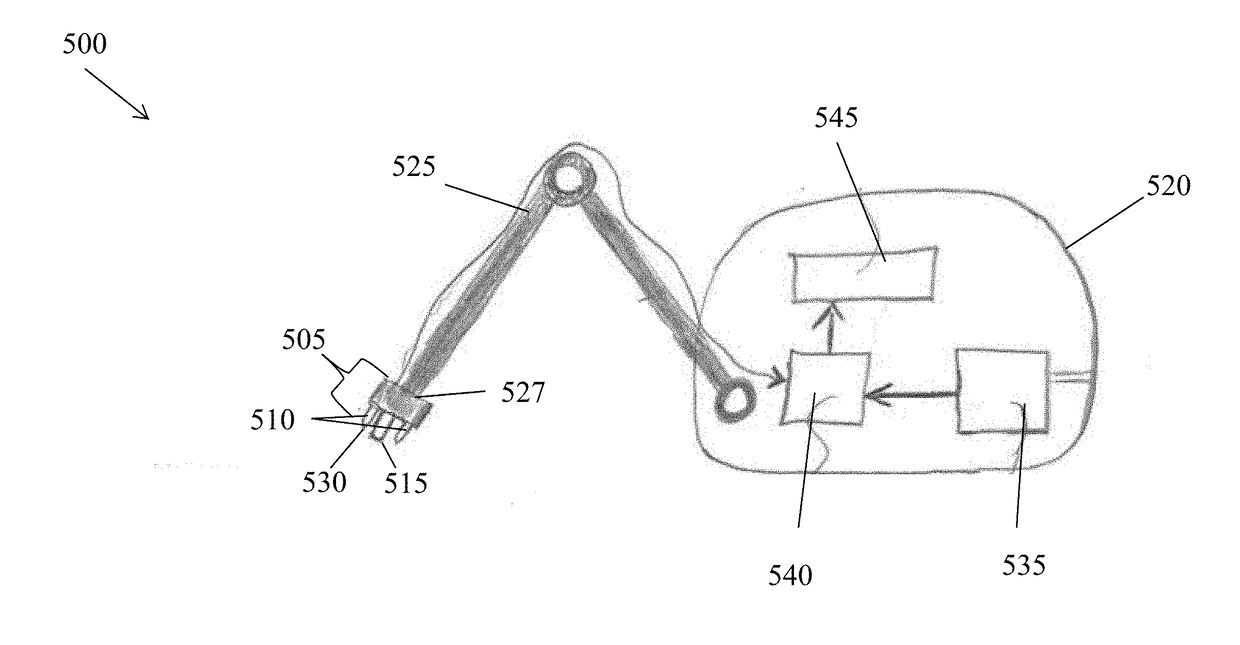

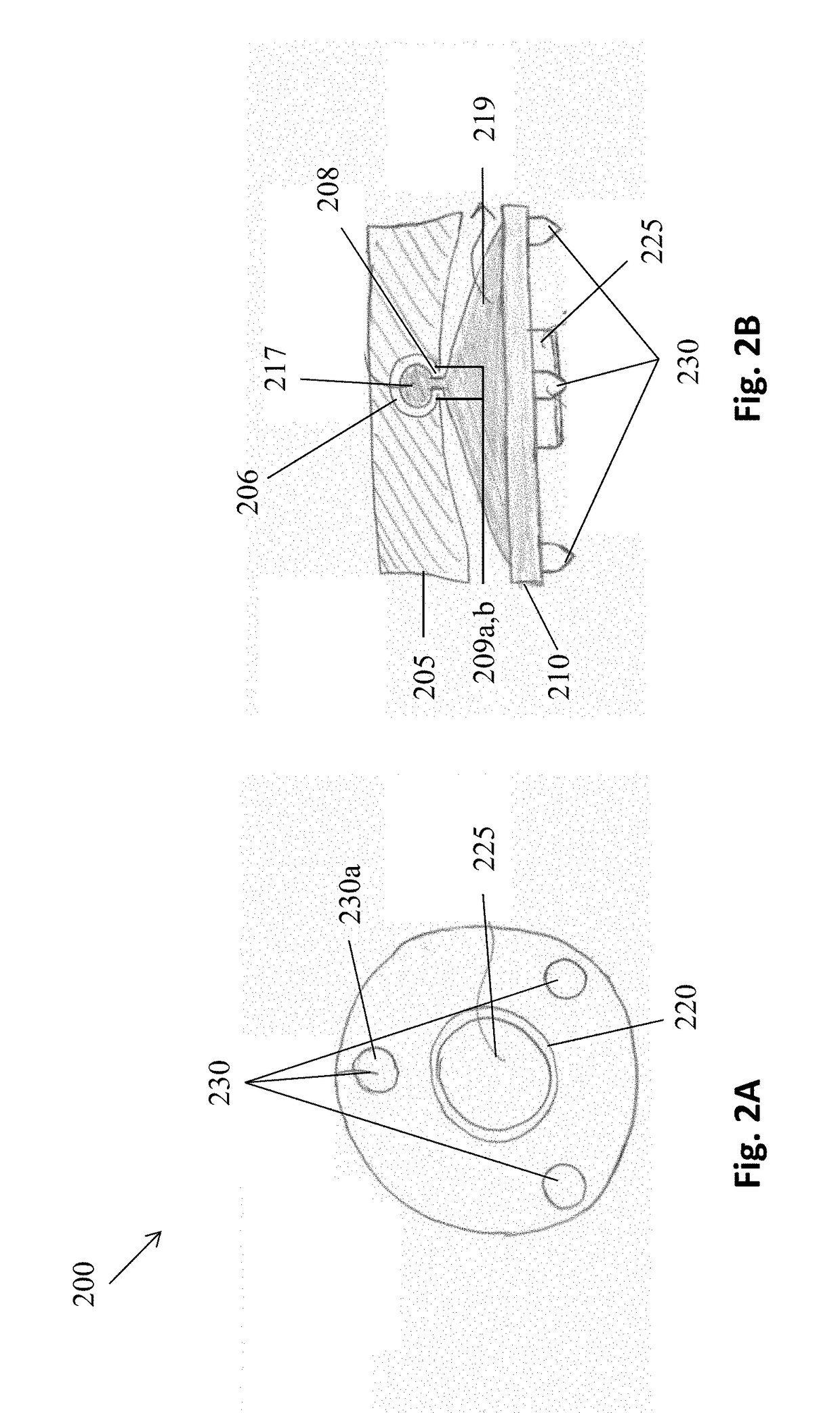

This application discloses integrated probes and probe systems, which can be attached to the robotic arms of a remotely operated vehicle to perform both cathodic protection (CP) voltage measurements and ultrasonic testing (UT) thickness measurements at an underwater surface. In some embodiments, the integrated probe system couples an inner and outer gimbal together such that one or more electrically conductive legs pass from the outer gimbal through the inner gimbal. These legs are arranged about an ultrasonic sensor which extends from the front surface of the inner gimbal. When the integrated probe contacts the underwater surface, both the ultrasonic sensor and at least one leg contact the surface, thereby providing substantially simultaneous CP and UT measurements.

Owner:SAUDI ARABIAN OIL CO

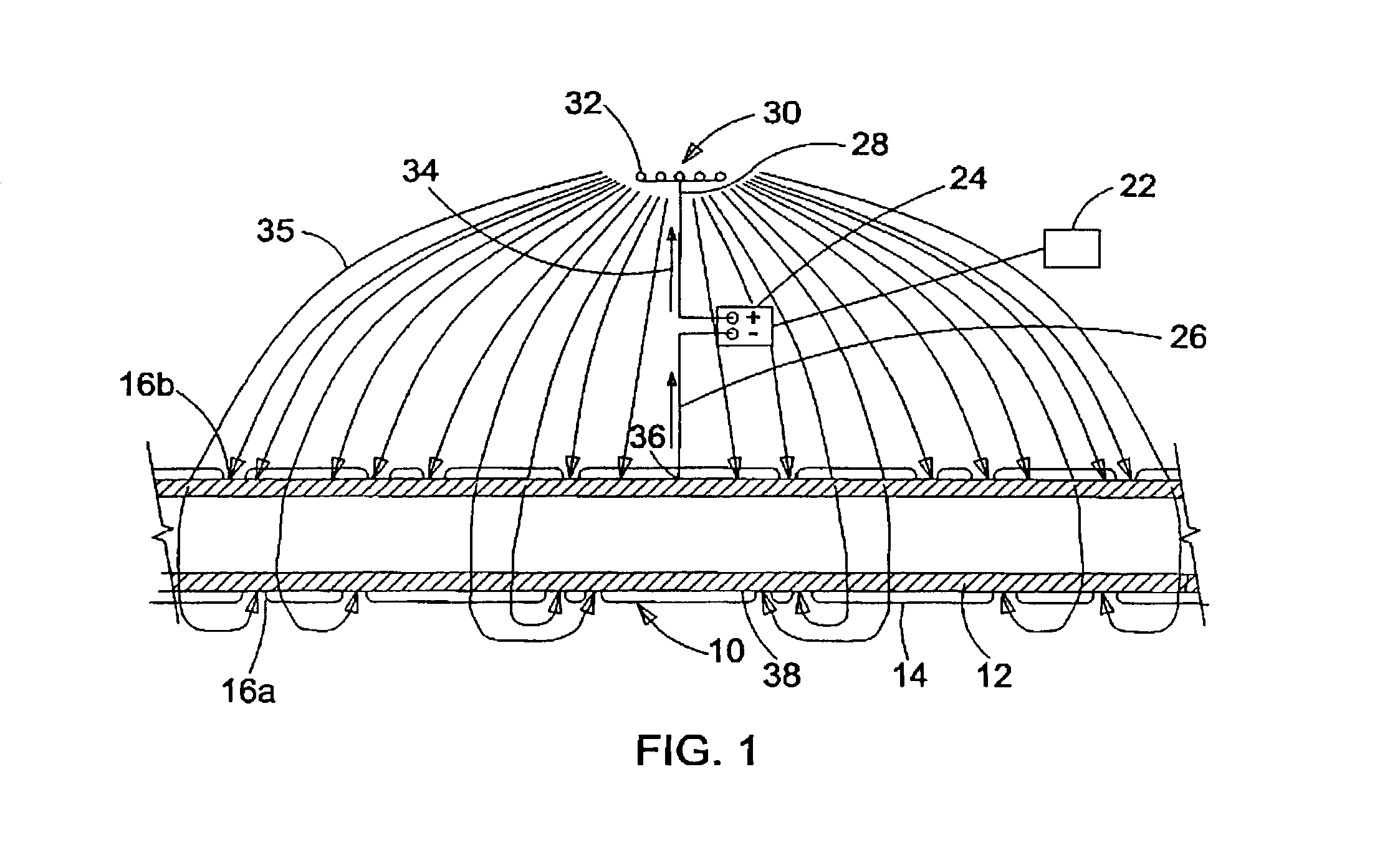

Cathodic protection system

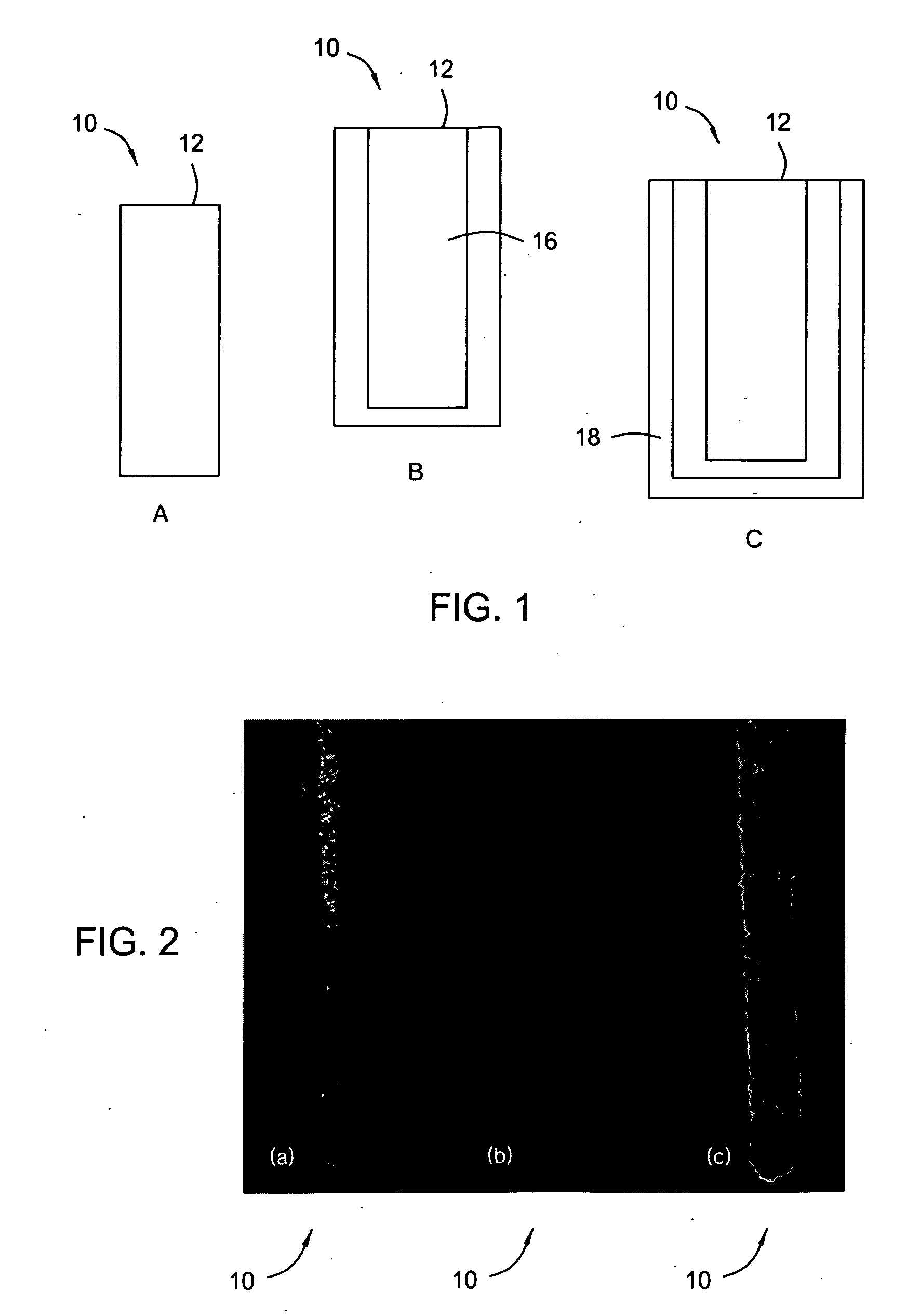

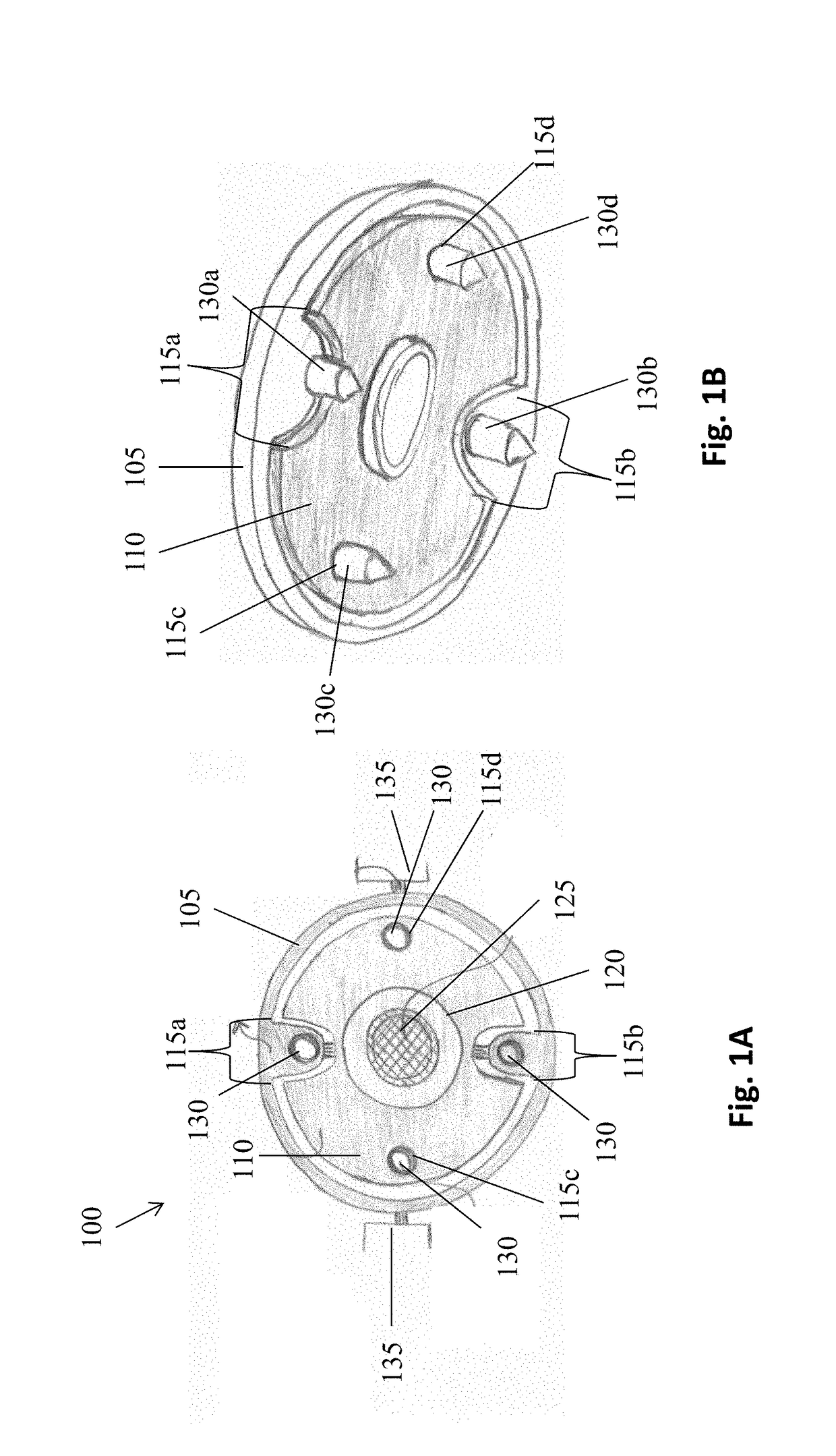

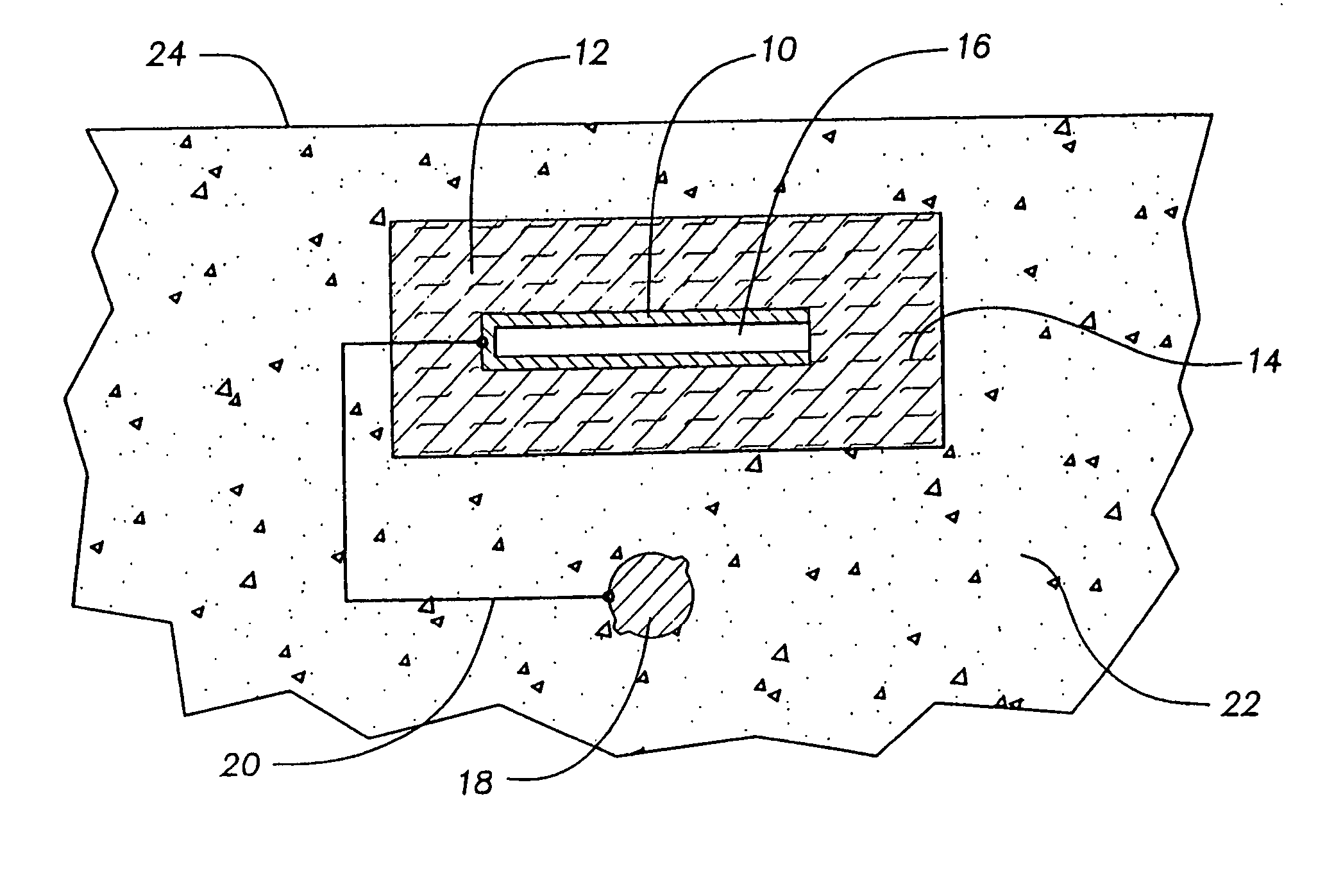

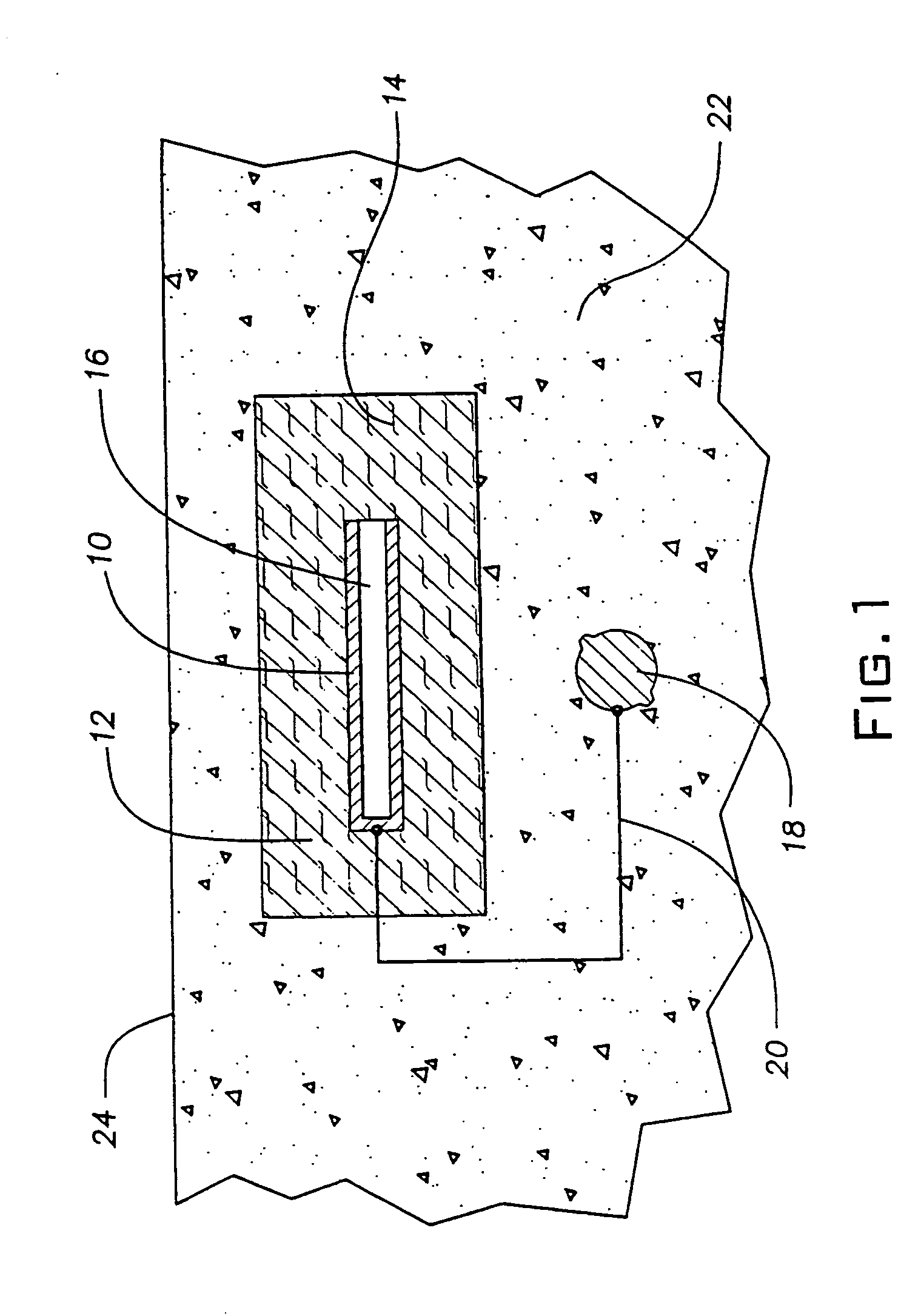

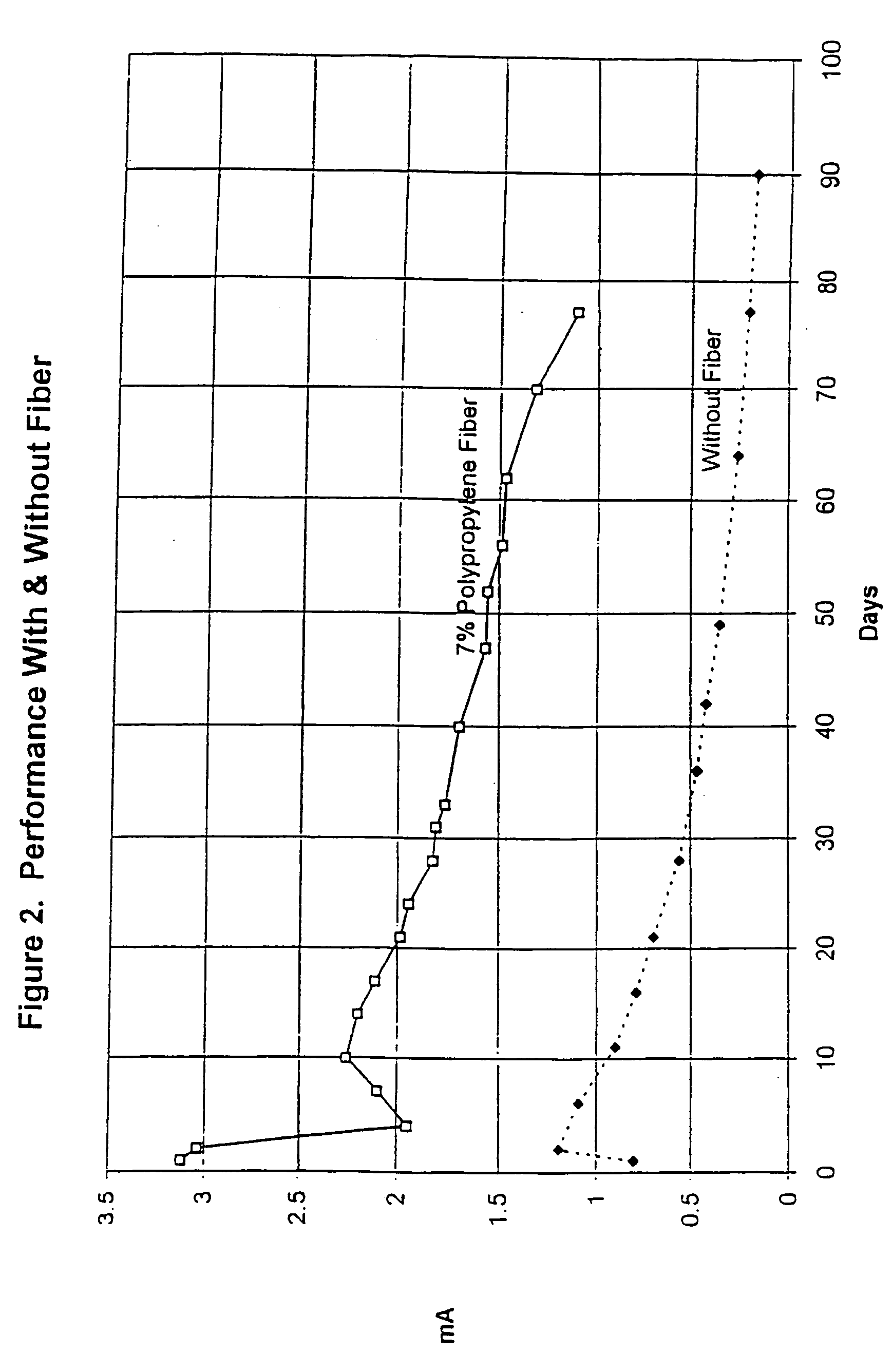

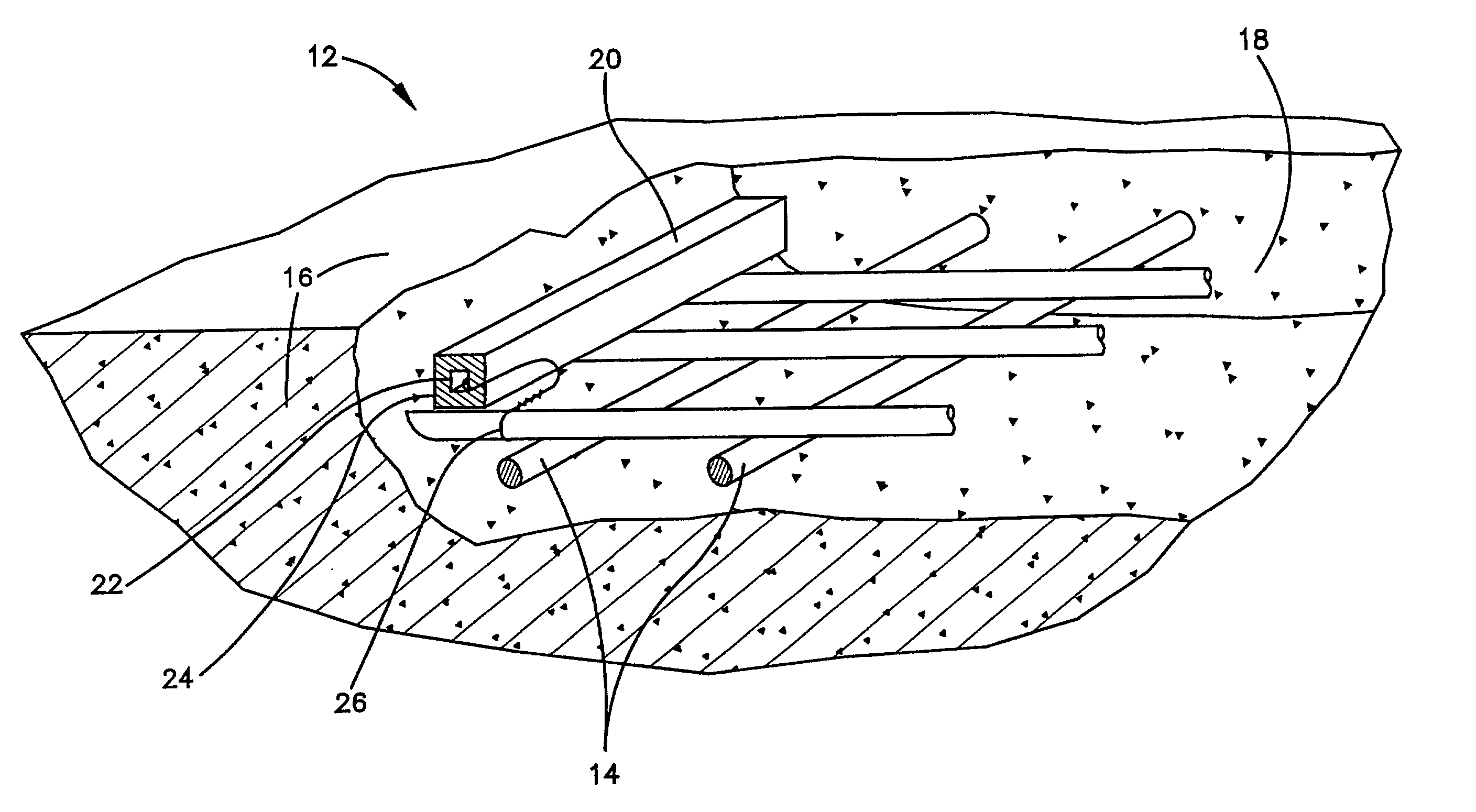

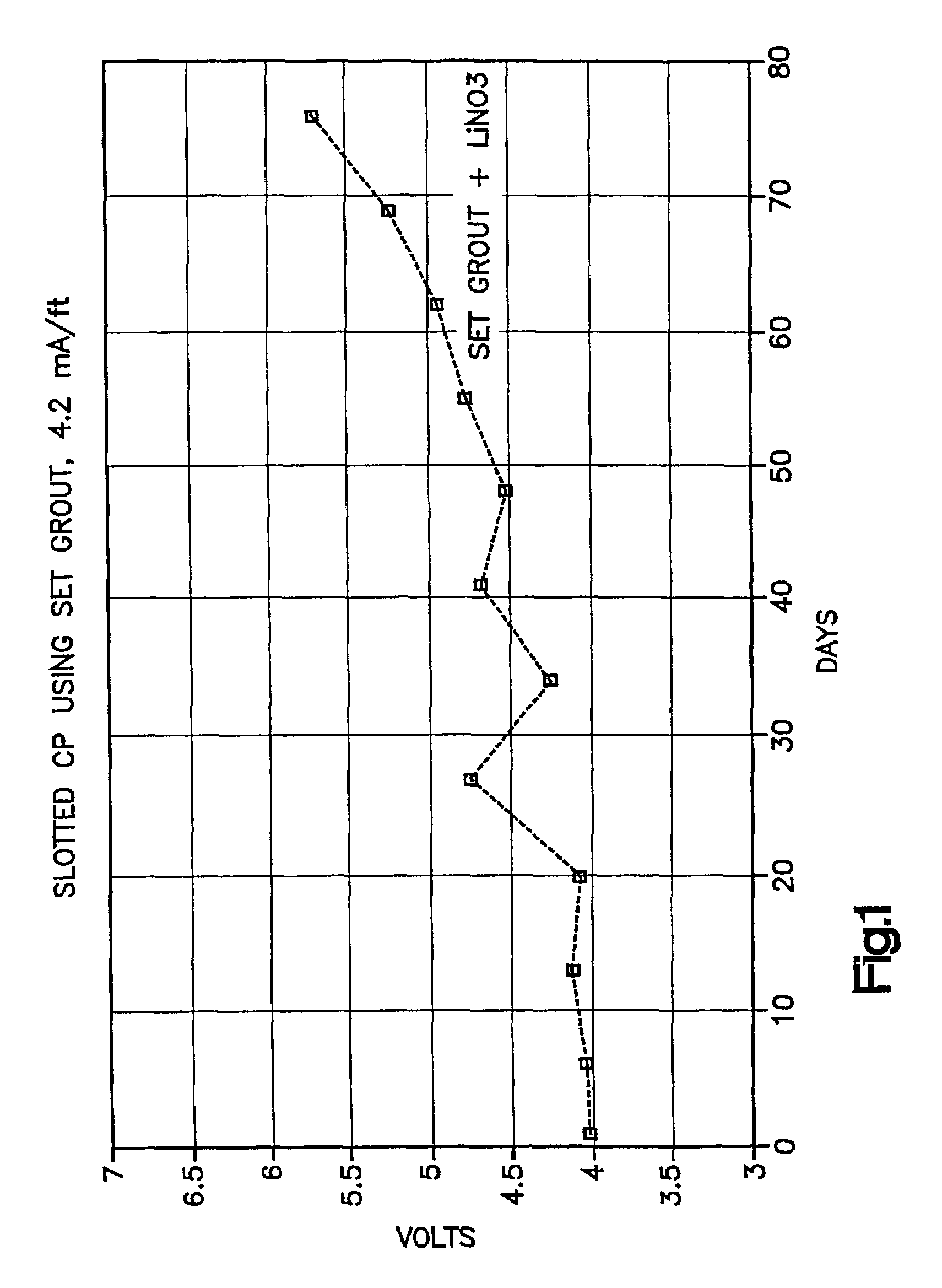

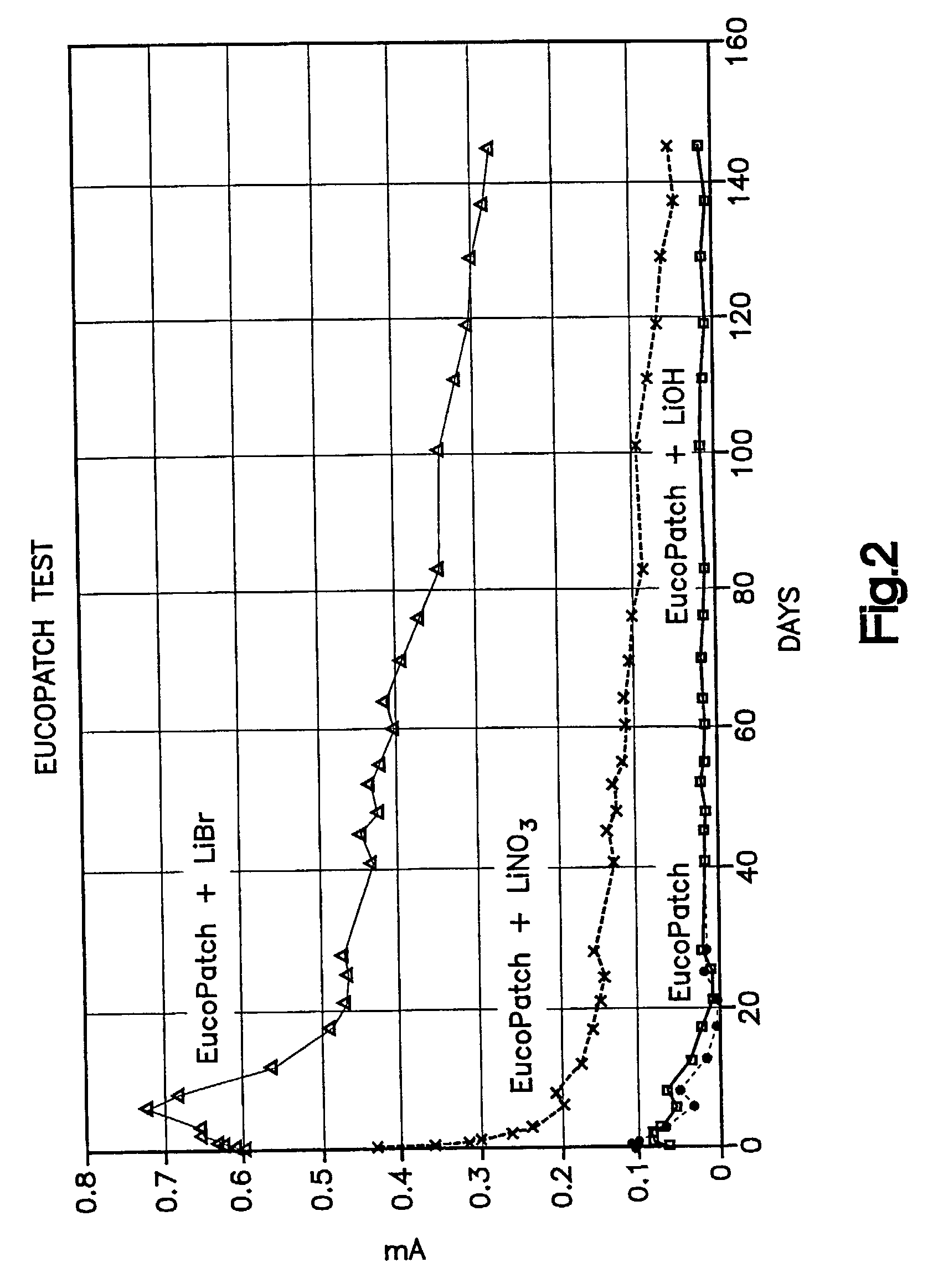

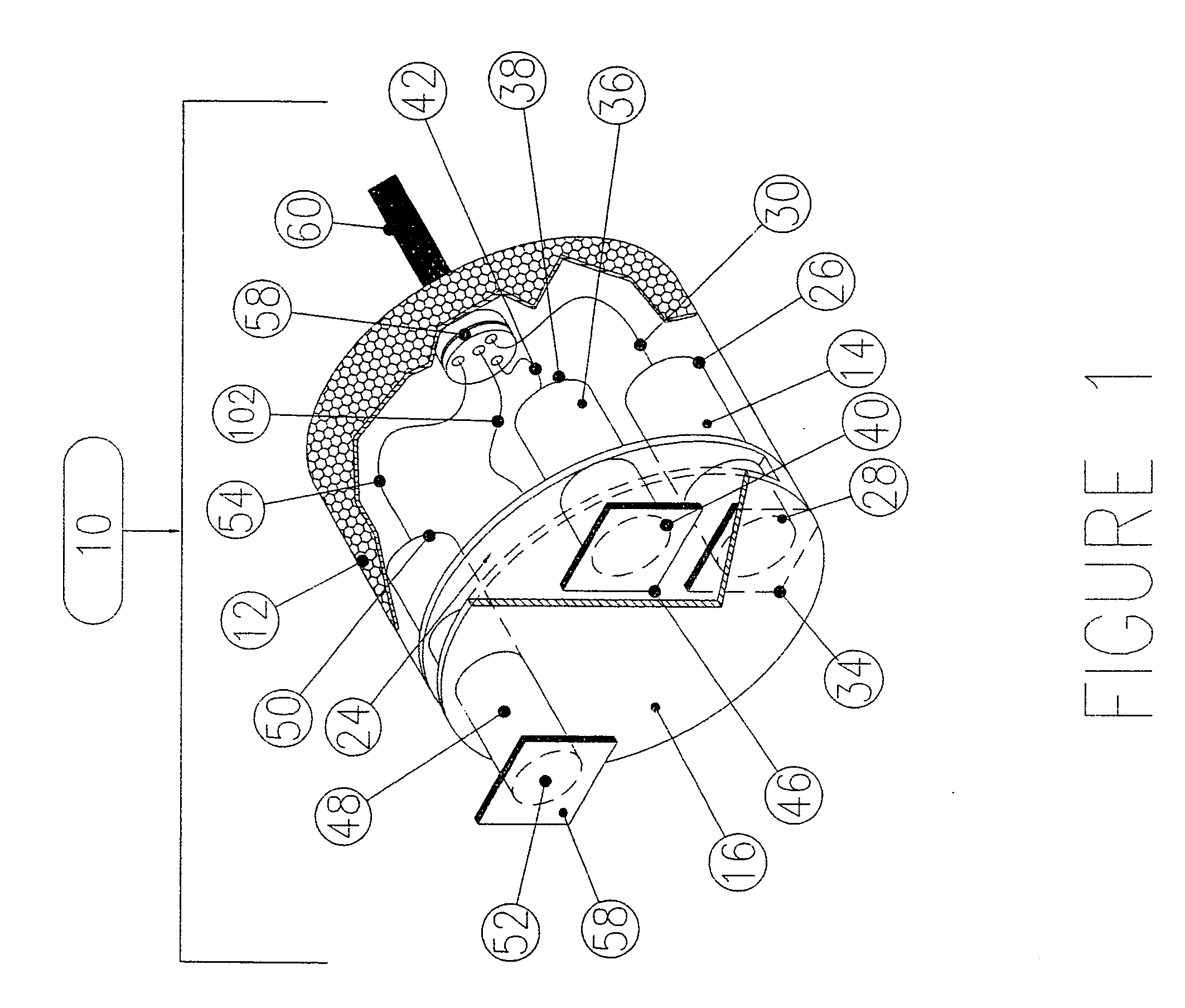

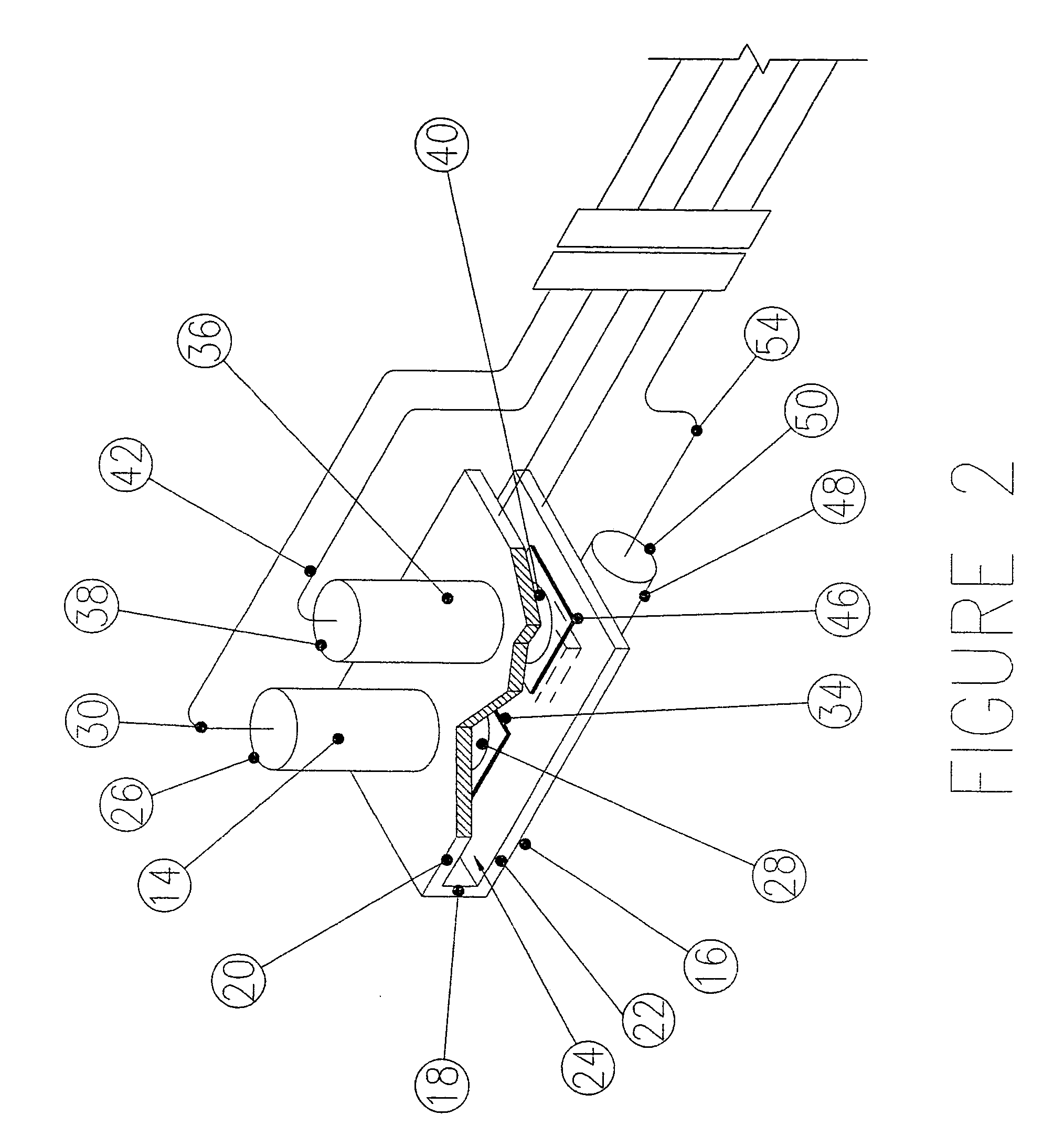

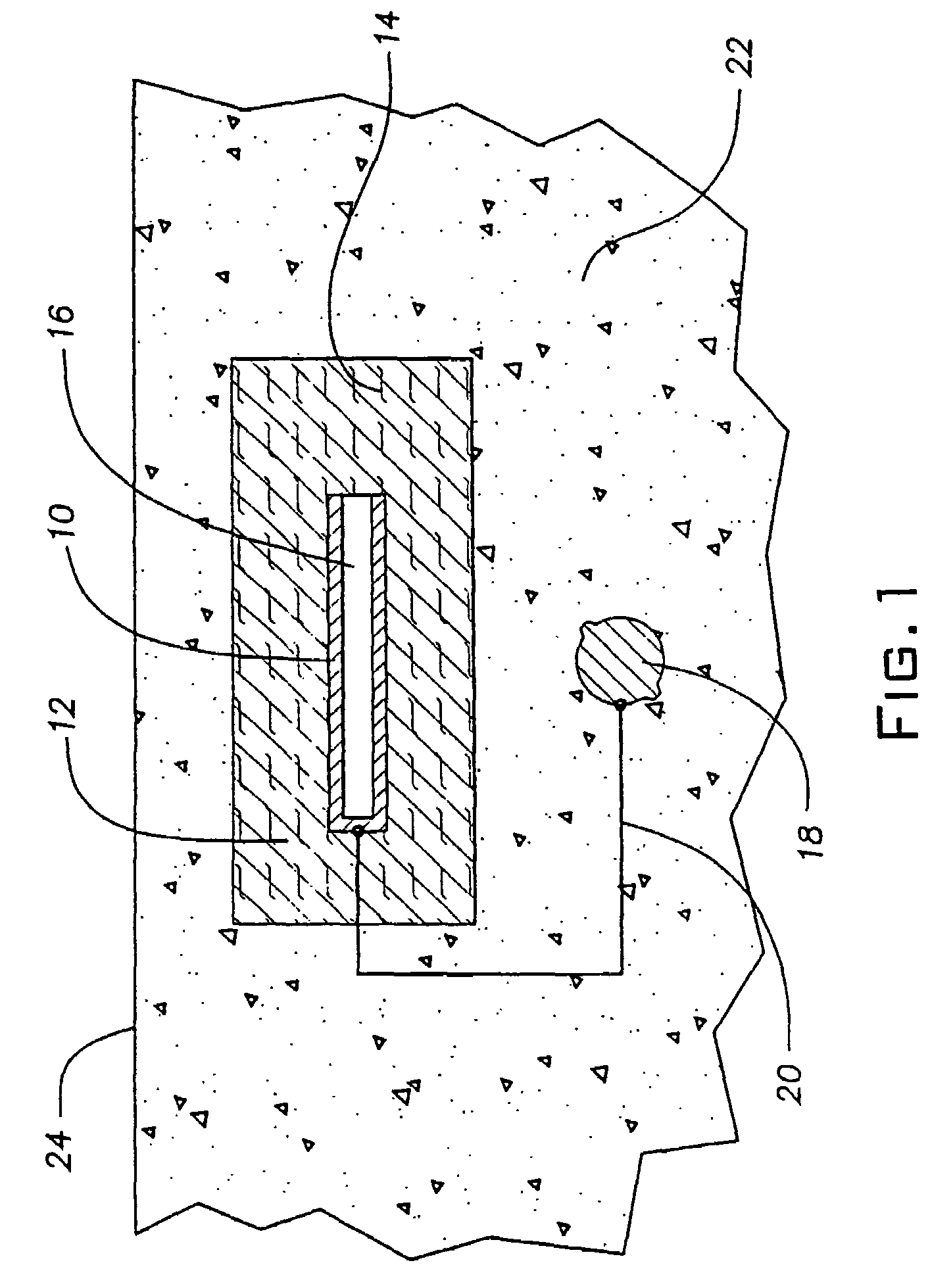

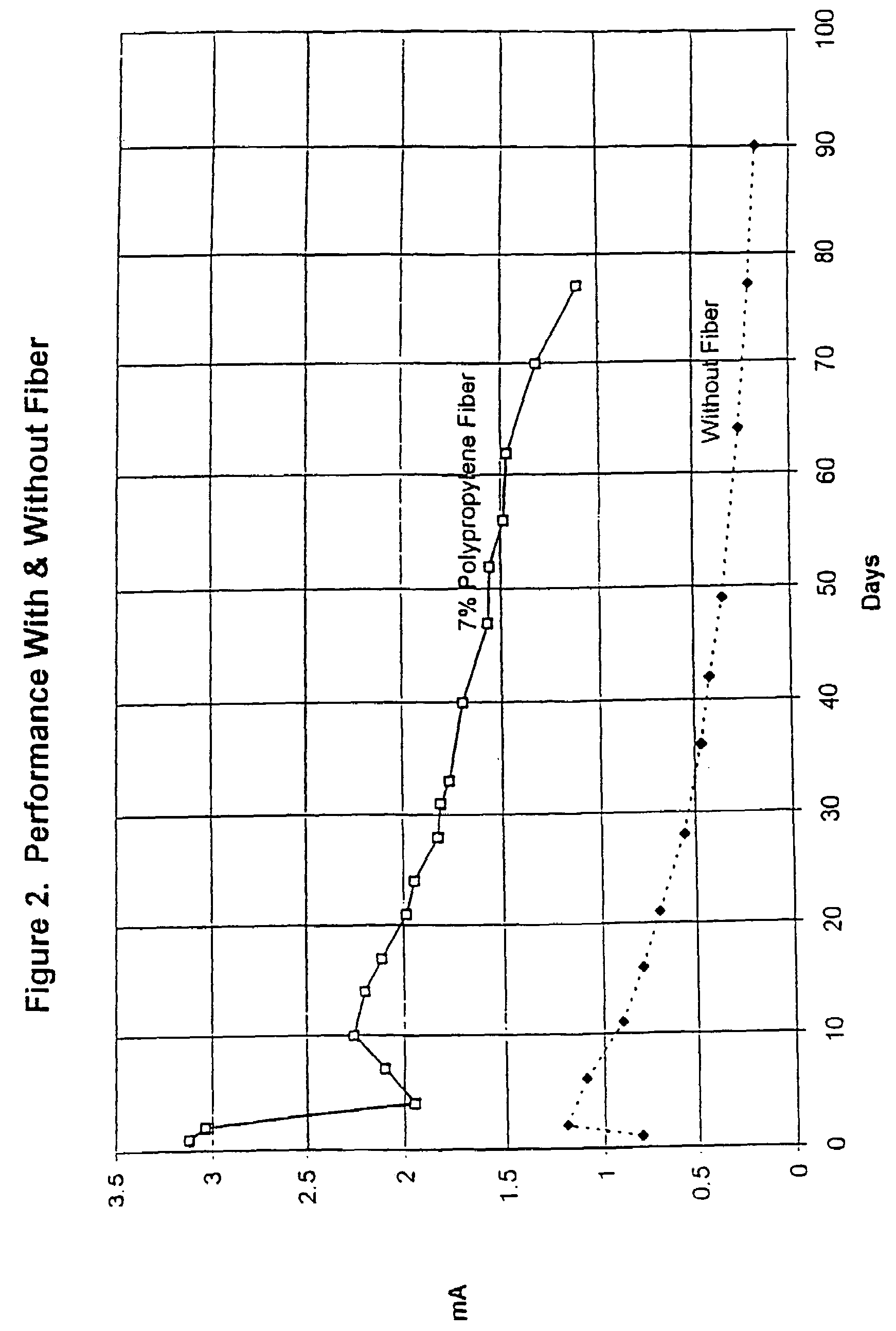

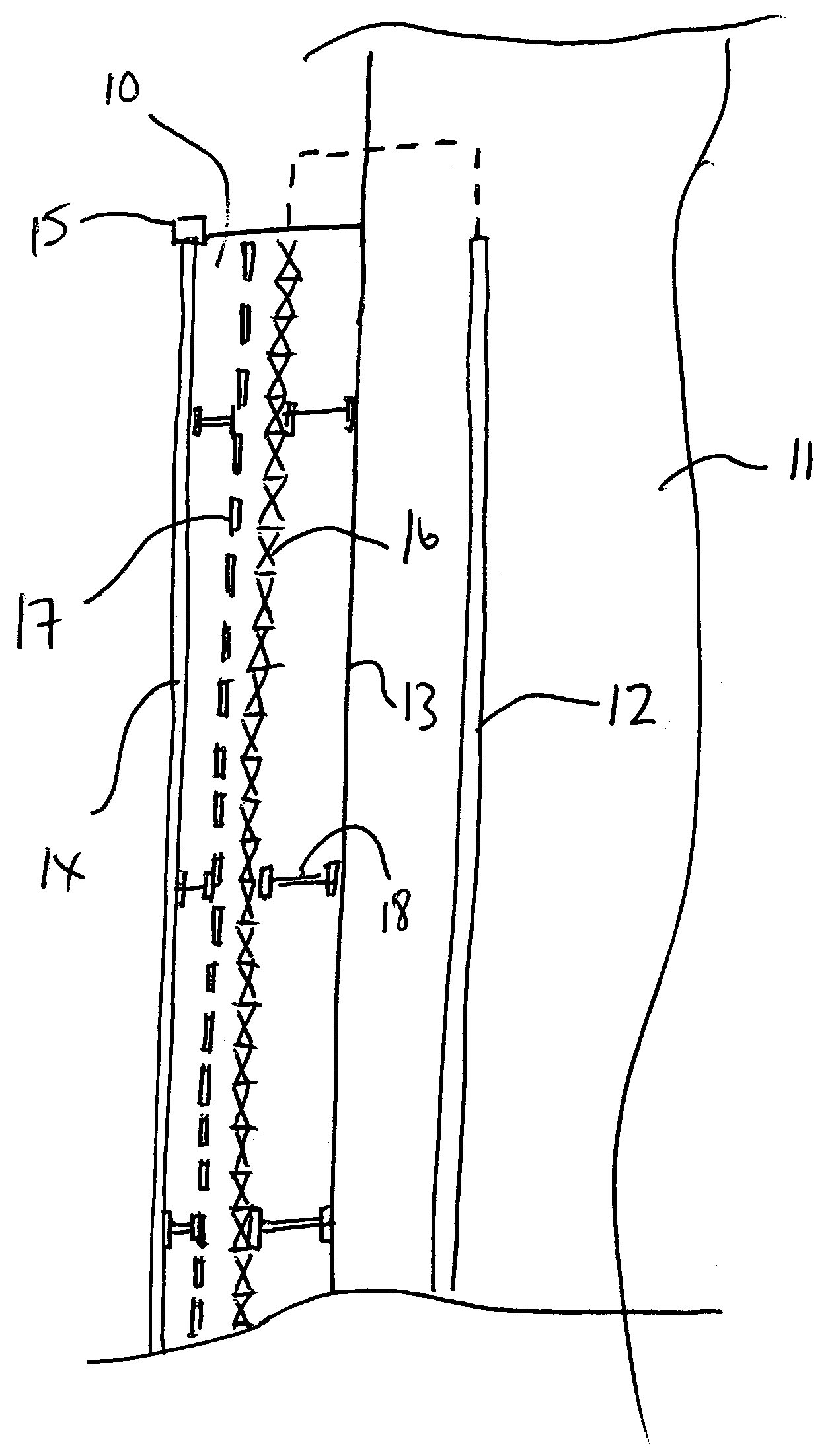

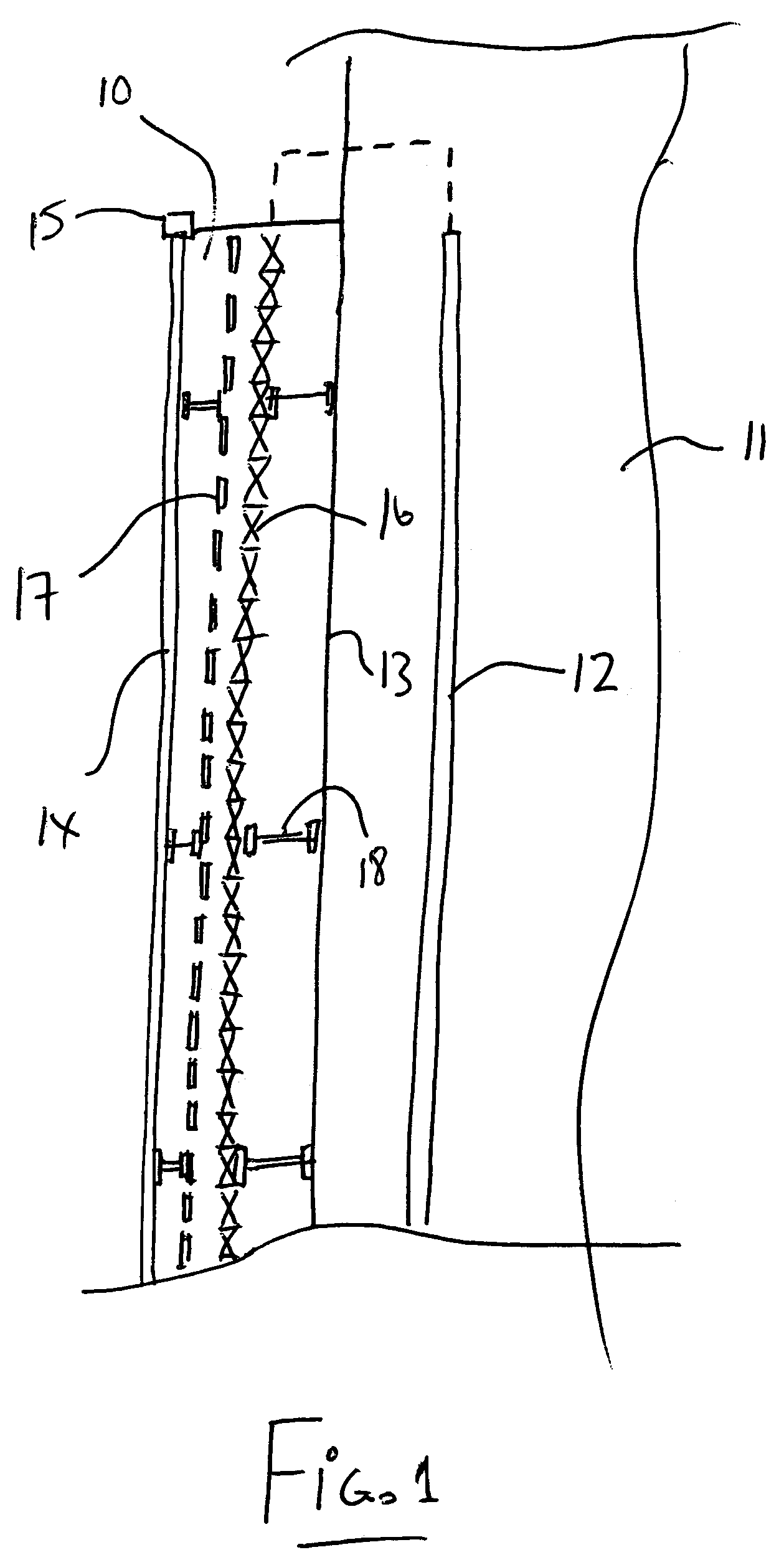

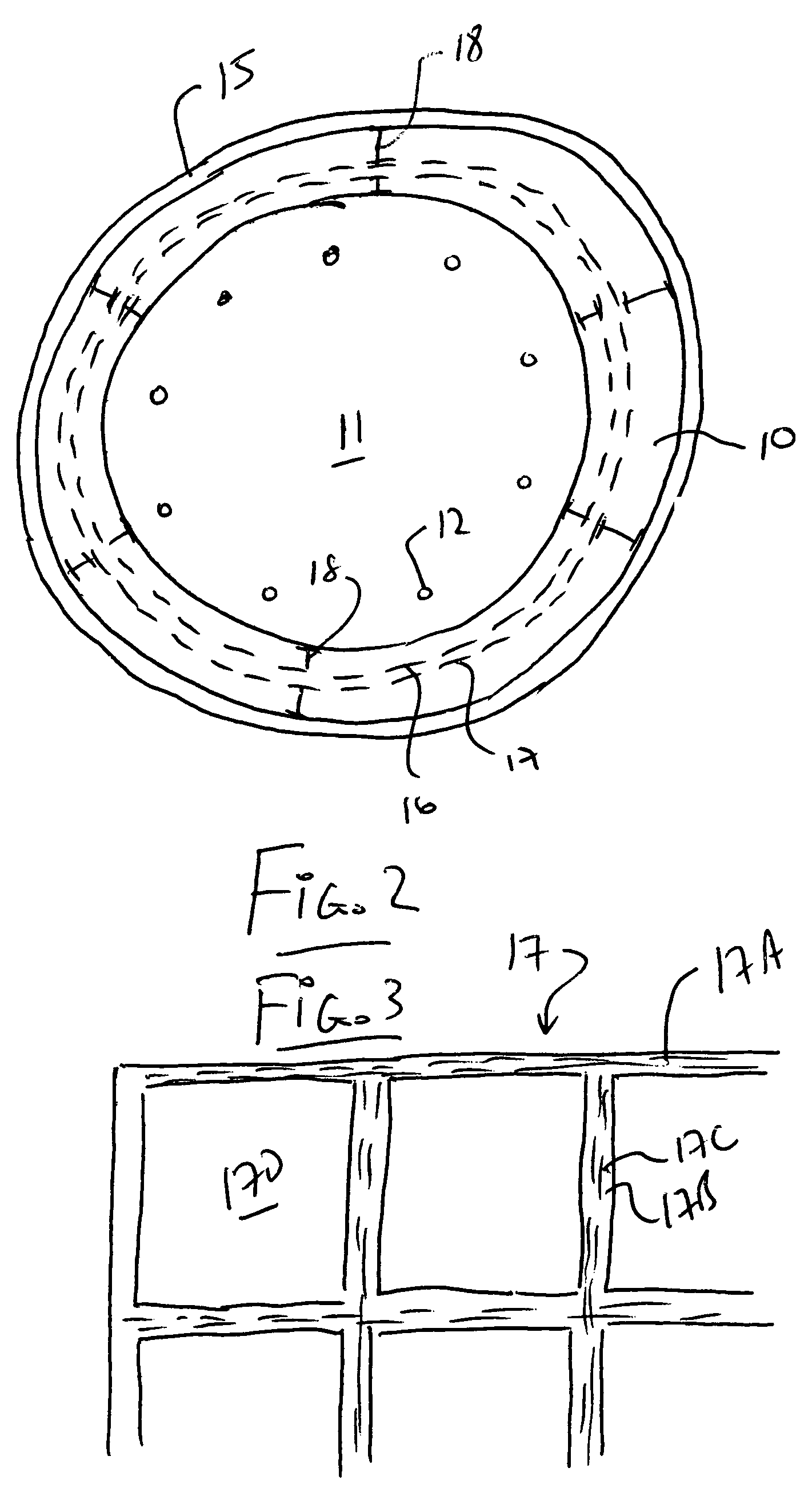

The cathodic protection system of a concrete structure (22) uses sacrificial anodes such as zinc, aluminum and alloys thereof embedded in mortar. A humectant is employed to impart high ionic conductivity to the mortar in which the anode is encapsulated. Lithium nitrate and lithium bromide and combinations thereof are preferred as the humectant. The anode (10) is surrounded by a compressive conductive matrix (12) incorporating a void volume between 15% and 50% to accommodate the sacrificial corrosion products of the anode. A void space of at least 5% of the total volume of the anode (12) may be provided opposite to the active face of the anode. Synthetic fibers such as polypropylene, polyethylene, cellulose, nylon and fiberglass have been found to be useful for forming the matrix. A tie wire is used to electrically connect the anode to the reinforcing bar.

Owner:THE EUCLID CHEM CO

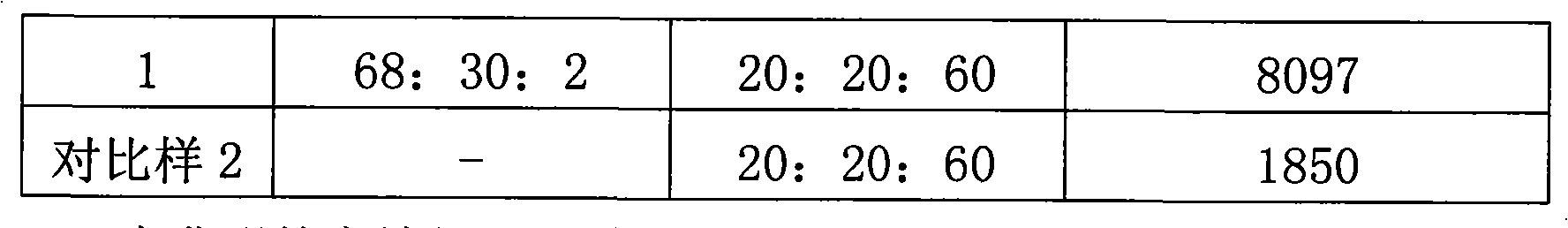

Cathodic protection system

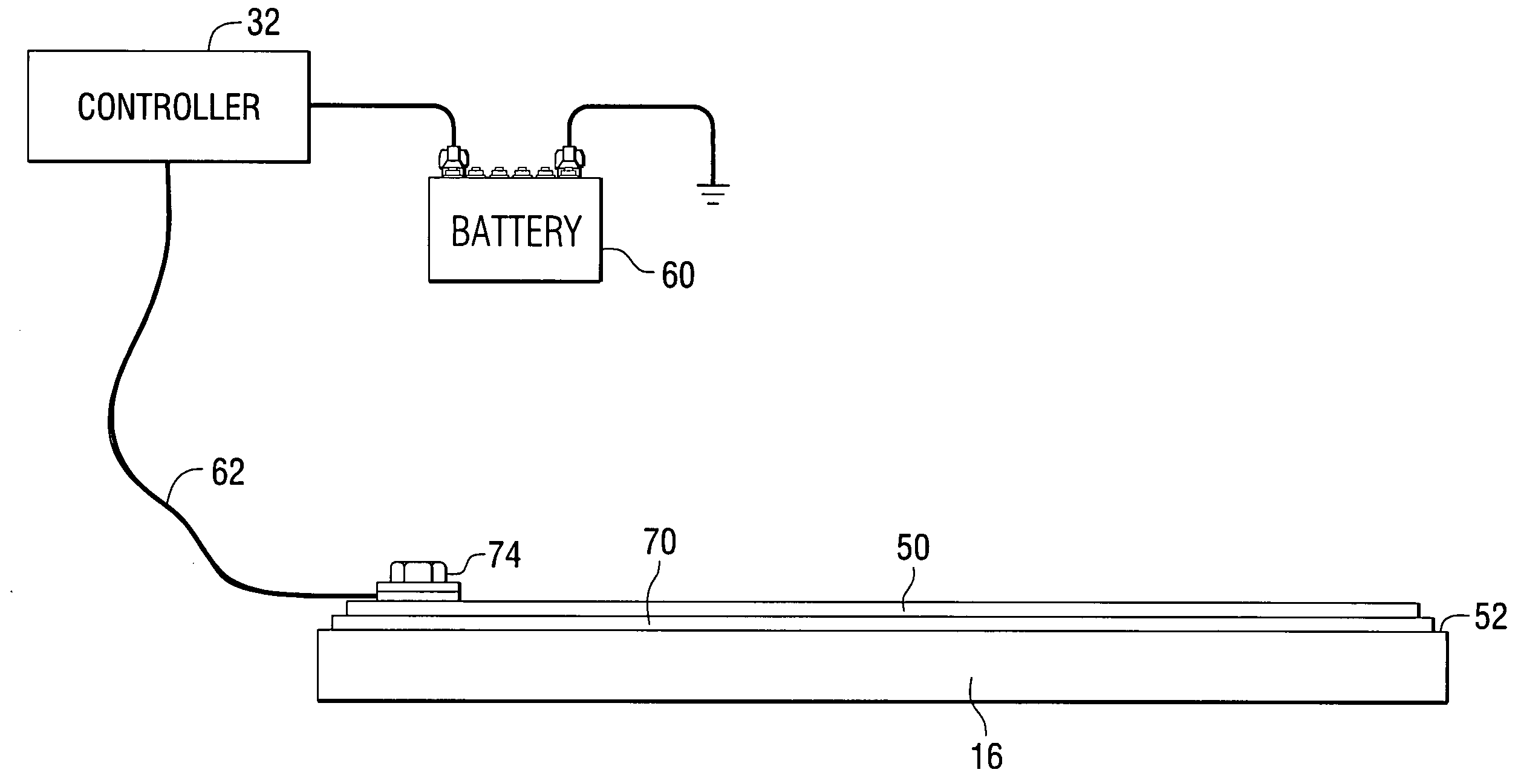

The present invention relates to a method of and an apparatus (20) for cathodic protection of reinforced concrete using discrete anodes (22) in or on the reinforced concrete member (14) to improve performance and service life of the discrete anodes. The discrete anode (22) is embedded in a cementitous grout or mortar (24) to encapsulate the anode (22) and provide contact to complete the cathodic protection circuit. A lithium salt is added to the cementitous grout or mortar (24) in an amount of at least about 0.05 gram per cubic centimeter. The lithium salt functions to enhance the performance of the cathodic protection system (20) by minimizing the deleterious effects of the anode reaction products on the grout or mortar adjacent to the anode and increasing the protective current delivered to the reinforcing steel.

Owner:THE EUCLID CHEM CO

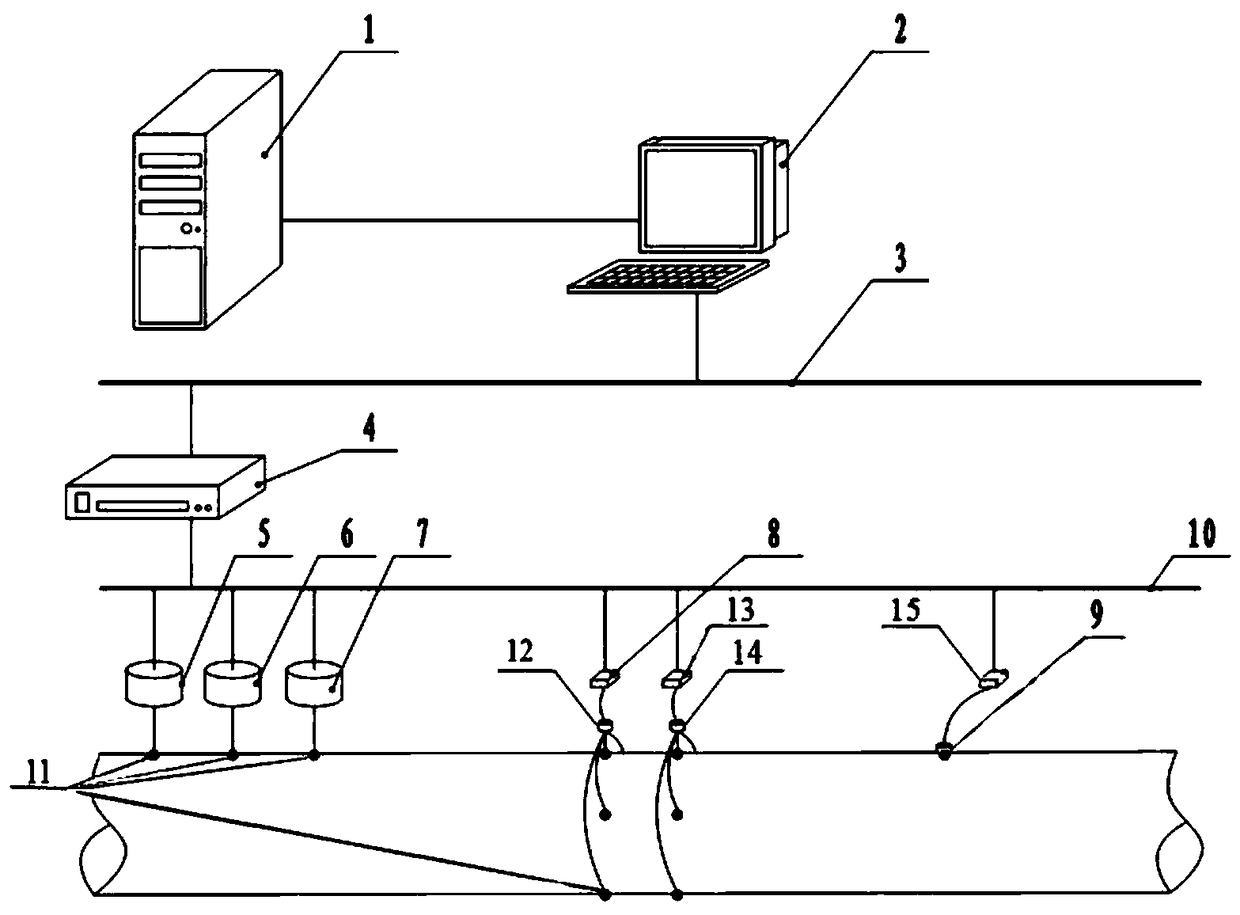

Online monitoring system and method of corrosion protection effect of oil well pipelines

PendingCN108918405AGuaranteed reliabilityReduce limitationsWeather/light/corrosion resistanceData acquisitionProtection layer

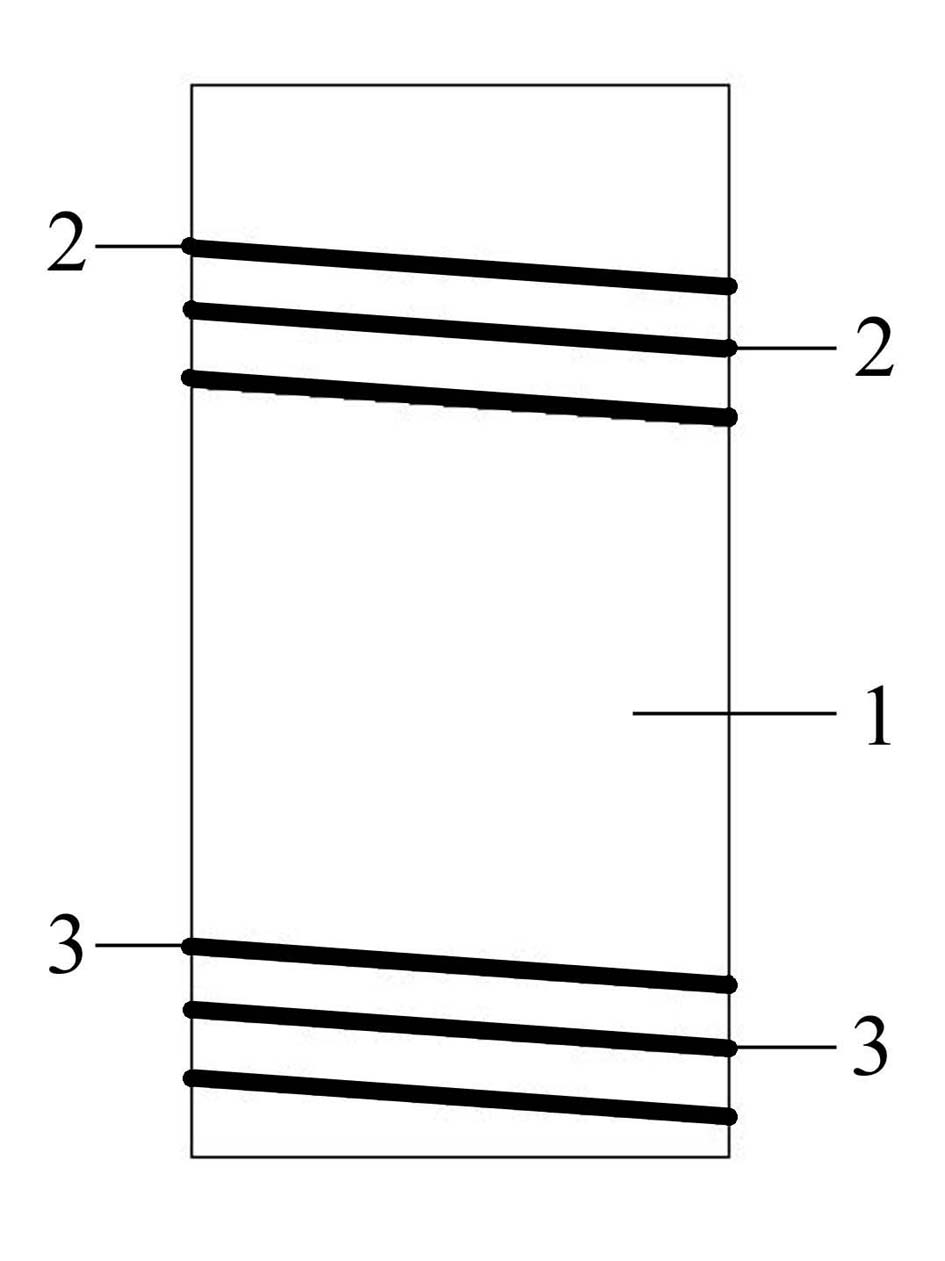

The invention discloses an online monitoring system and method of a corrosion protection effect of oil well pipelines. The system comprises a remote control center (1), an in-situ online corrosion monitoring unit (2), a transmission optical fiber (3), a corrosion data collector (4), a sensor and a network cable (10), wherein the remote control center (1) is connected with the in-situ online corrosion monitoring unit (2), the in-situ online corrosion monitoring unit (2) is connected with the corrosion data collector (4) through the transmission optical fiber (3), and the corrosion data collector (4) is connected with the sensor through the network cable (10). The online monitoring system disclosed by the invention can determine the corrosion damage states of buried oil well pipelines, locate damage points of corrosion layers, and evaluate the aging state of corrosion protection layers to serve as the basis for formulating a maintenance scheme, and can determine the corrosion condition and rate of the oil well pipelines, predict the safe service lives of the oil well pipelines, can avoid potential hazards due to corrosion leakage, can optimize the optimum injection amount of a corrosion inhibitor and can evaluate the forced impressed current cathodic protection effect of the oil well pipelines.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

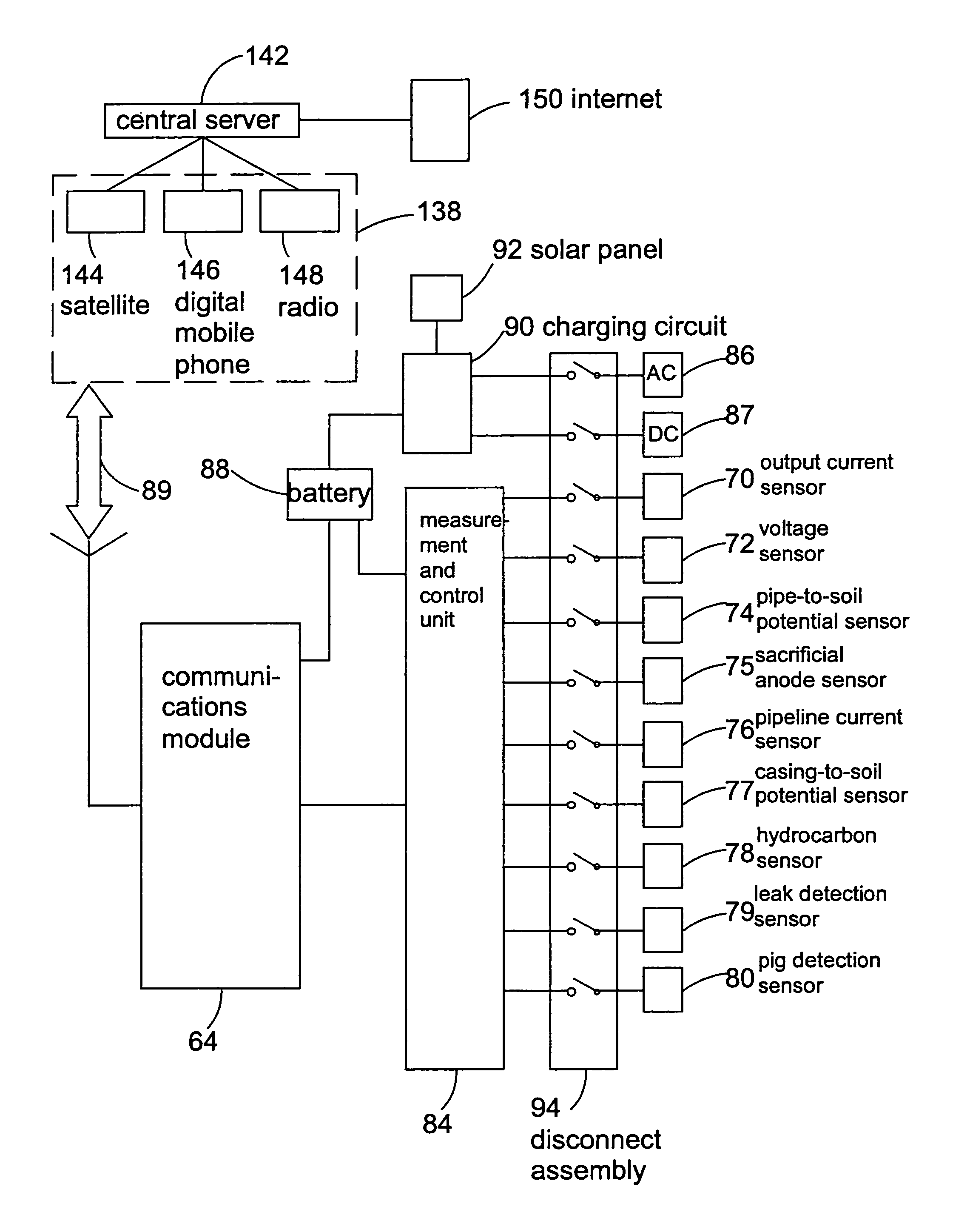

Method and apparatus for instrumental analysis in remote locations

InactiveUS20050006250A1Weather/light/corrosion resistanceVolume/mass flow measurementMeasurement deviceElectrolysis

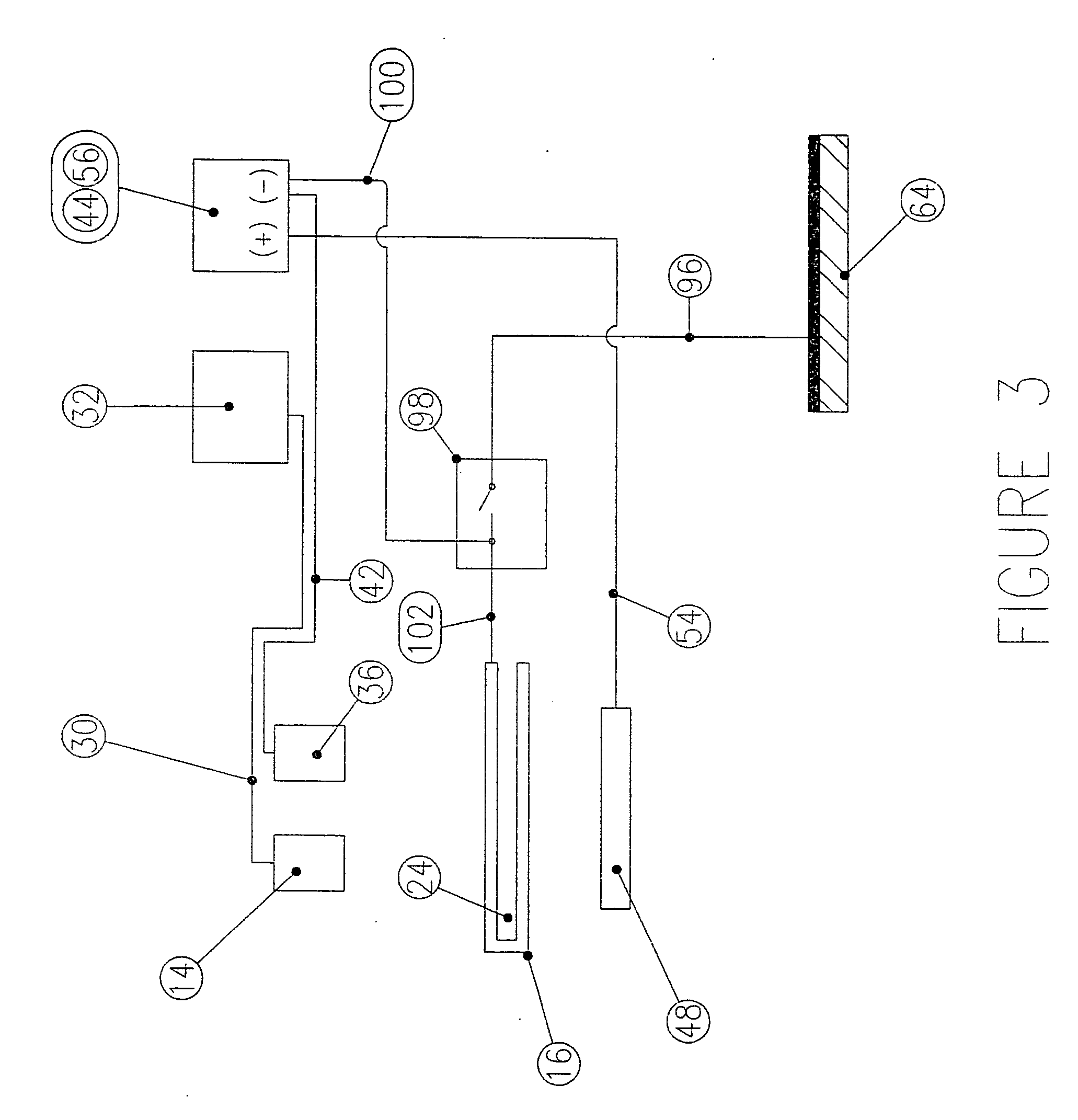

The present invention provides a method and apparatus for instrumental analysis in remote locations. In one embodiment, the present invention provides a method of controlling cathodic protection being applied to a metal structure having a surface disposed in an electrolytic environment comprising electrically connecting a metal coupon to the surface of the metal structure, positioning the metal coupon at a predetermined position relative to the surface of the metal structure and within the electrolytic environment, applying a cathodic protection agent to the surface of the metal structure to effect cathodic protection of the surface of the metal structure, measuring a cathodic protection indication proximate to the metal coupon, comparing the cathodic protection indication with a predetermined value, and adjusting the cathodic protection agent being applied to the surface of the metal structure in response to the comparison. In this respect, the present invention provides a system for controlling the efficacy of cathodic protection being applied to a metal structure disposed in an electrolytic environment comprising an electrical vintage and current source of applying an electrical current to the metal structure to effect cathodic protection of the metal structure, a measurement apparatus for measuring the efficacy of the cathodic protection, the measurement apparatus being electrically connected to the metal structure, and a passage for receiving movement of the means for measuring to effect positioning of the measurement apparatus at a predetermined position relative to the metal structure. The passage of the present invention could also be used to facilitate non-destructive testing at remote locations, as well as to mitigate or prevent stray current discharge.

Owner:G I RUSSELL

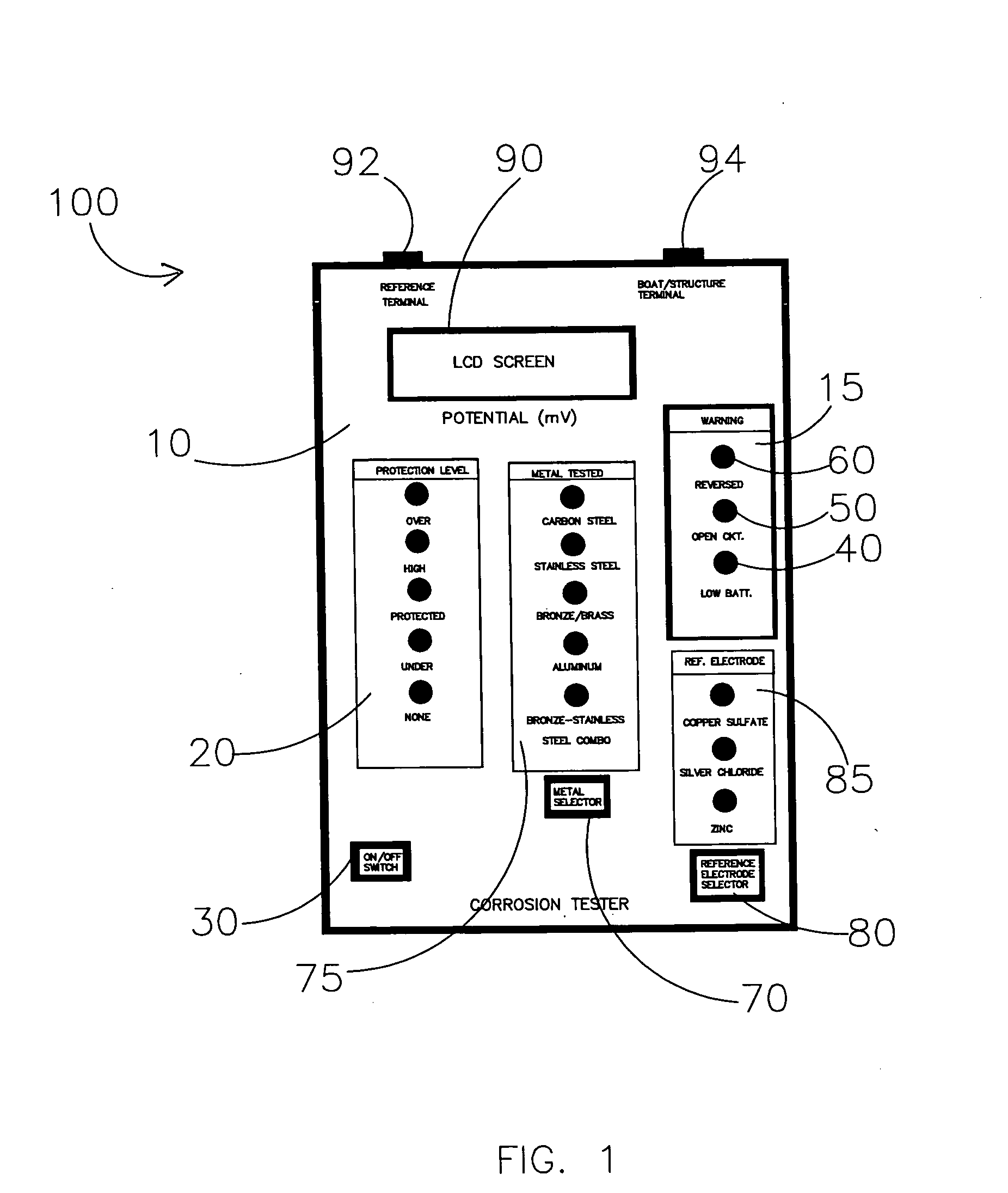

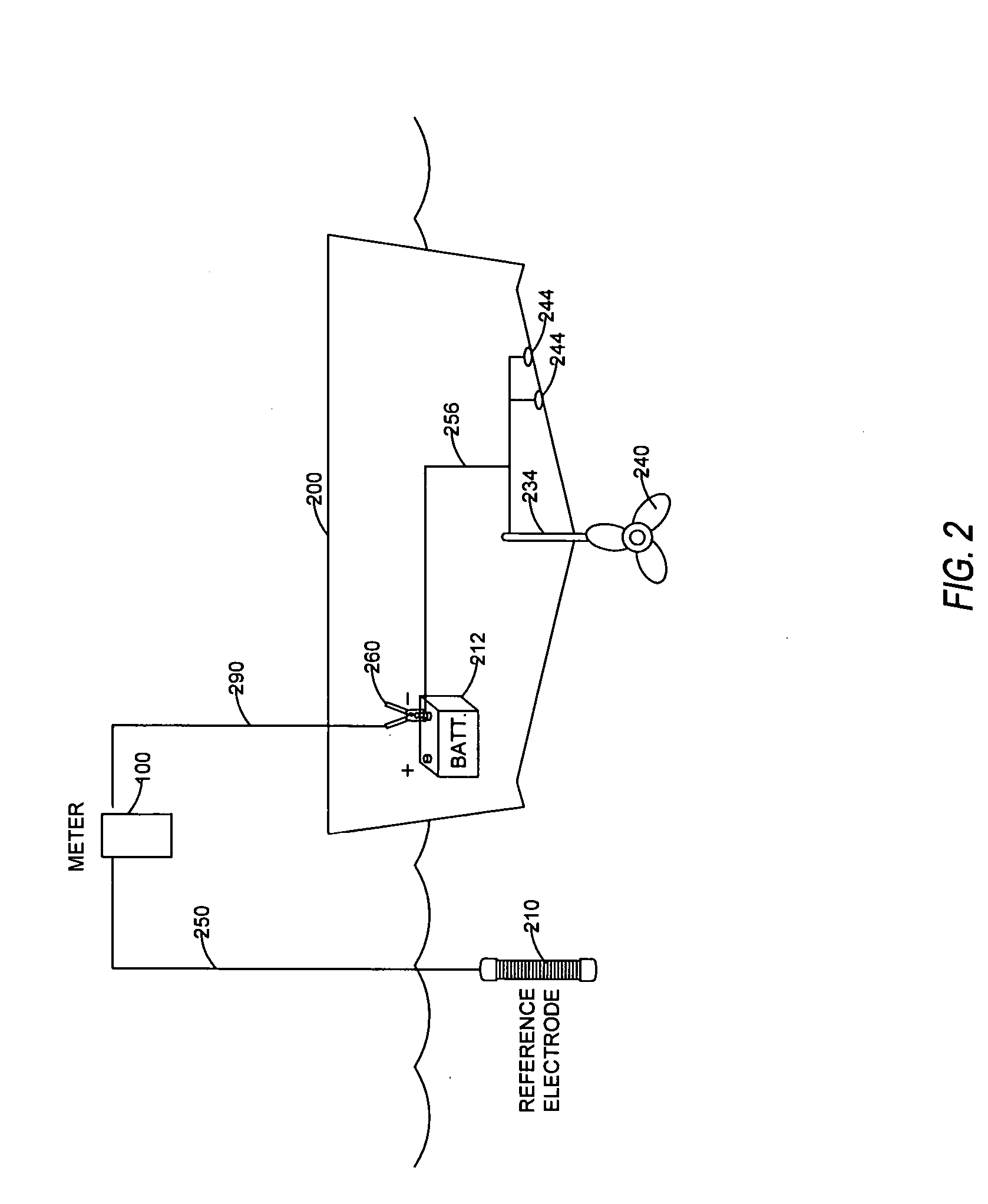

Corrosion tester

InactiveUS20060065551A1Easy to useErroneous readingWeather/light/corrosion resistanceMaterial analysis by electric/magnetic meansPower flowVoltage drop

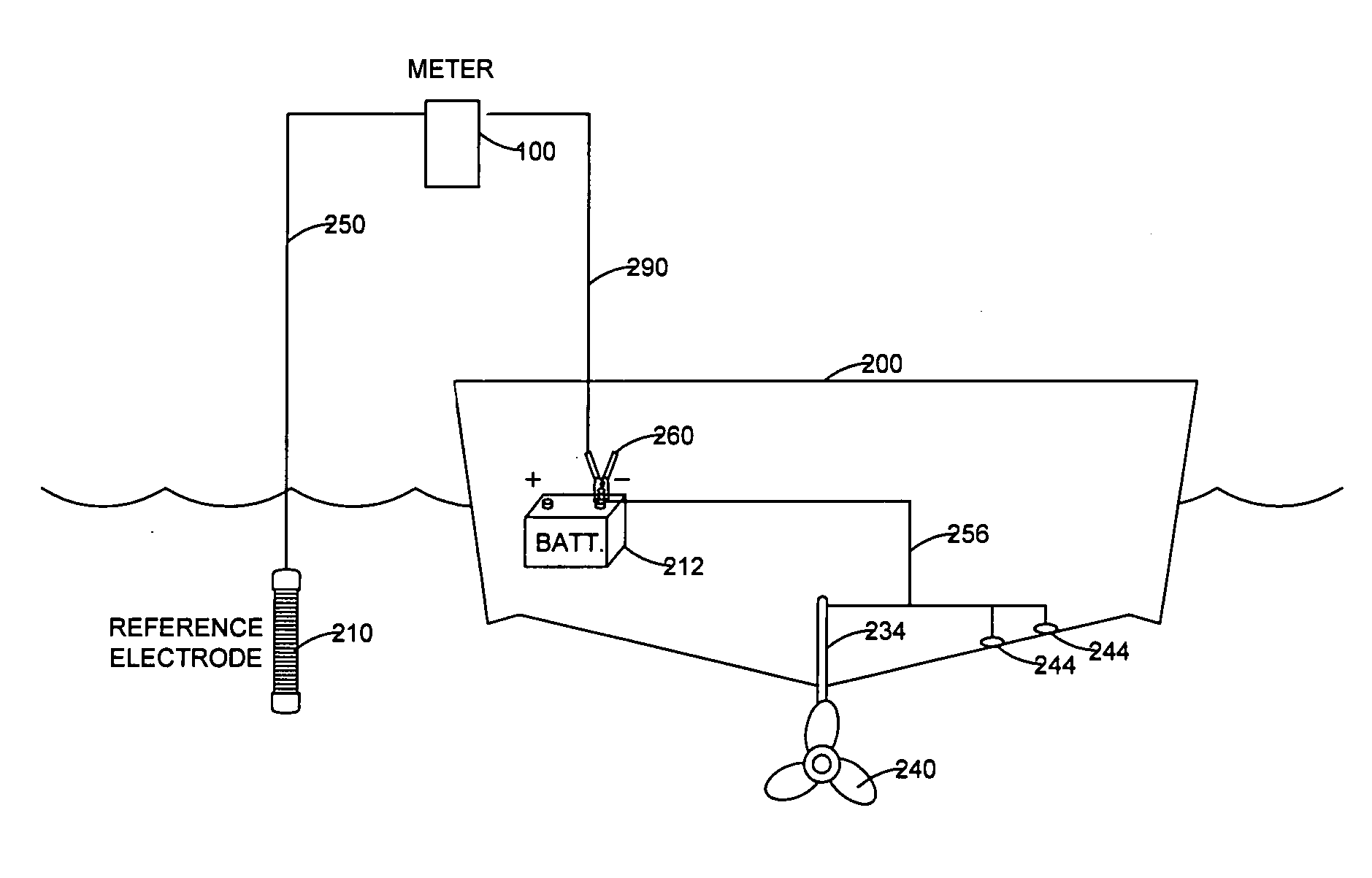

A portable, handheld, automatic protection level interpreting cathodic protection meter for testing the level of protection being afforded to metallic structures protected by either sacrificial anode or impressed current cathodic protection systems, or both. The meter is suitable over a variety of environments including salt water, freshwater, and soil. The operator can select both the type of metal to be tested as well as the type of reference electrode that is being used. The meter automatically calibrates data interpretation of the level of protection based on the operator's selections and eliminates any voltage drop error existing between a reference electrode and the structure being protected.

Owner:CALIFORNIA CORROSION CONCEPTS

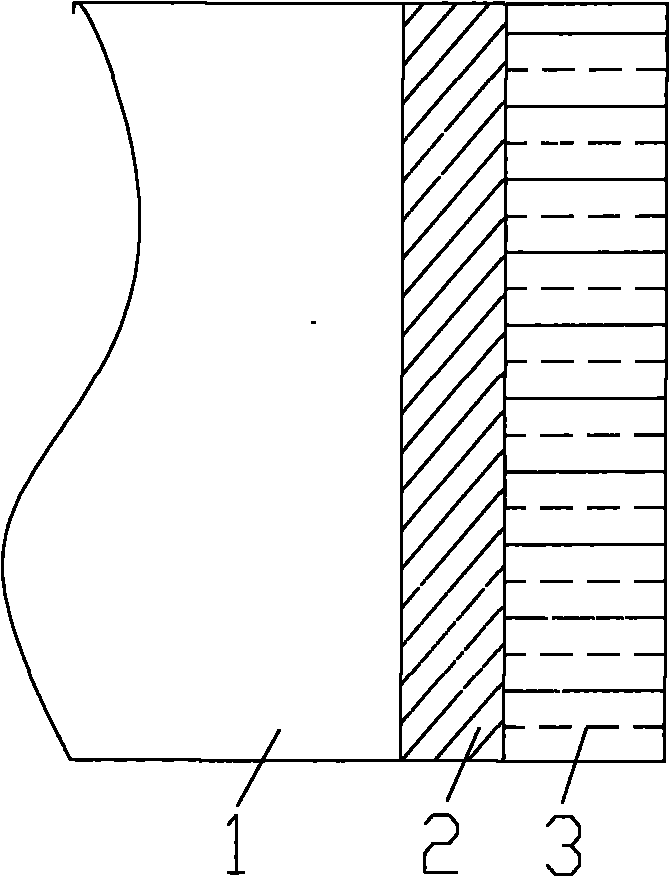

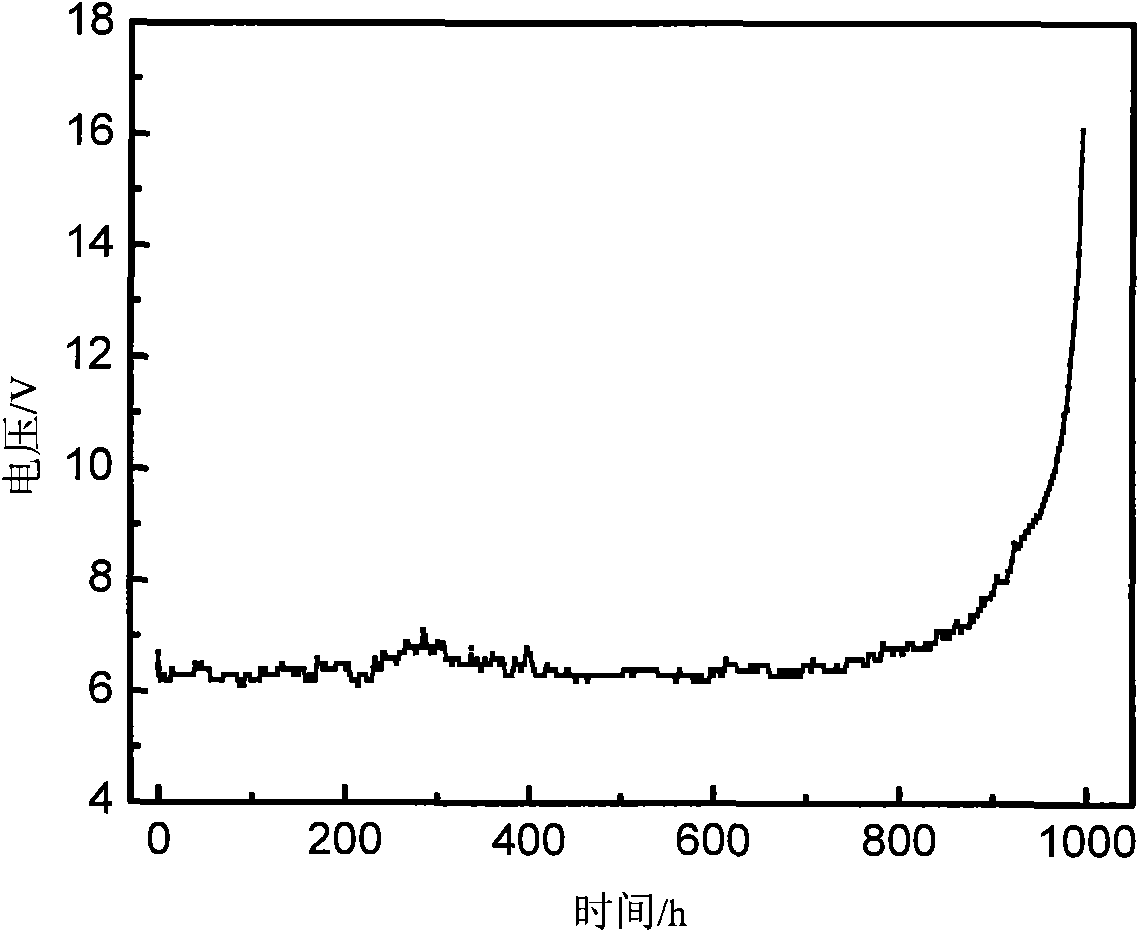

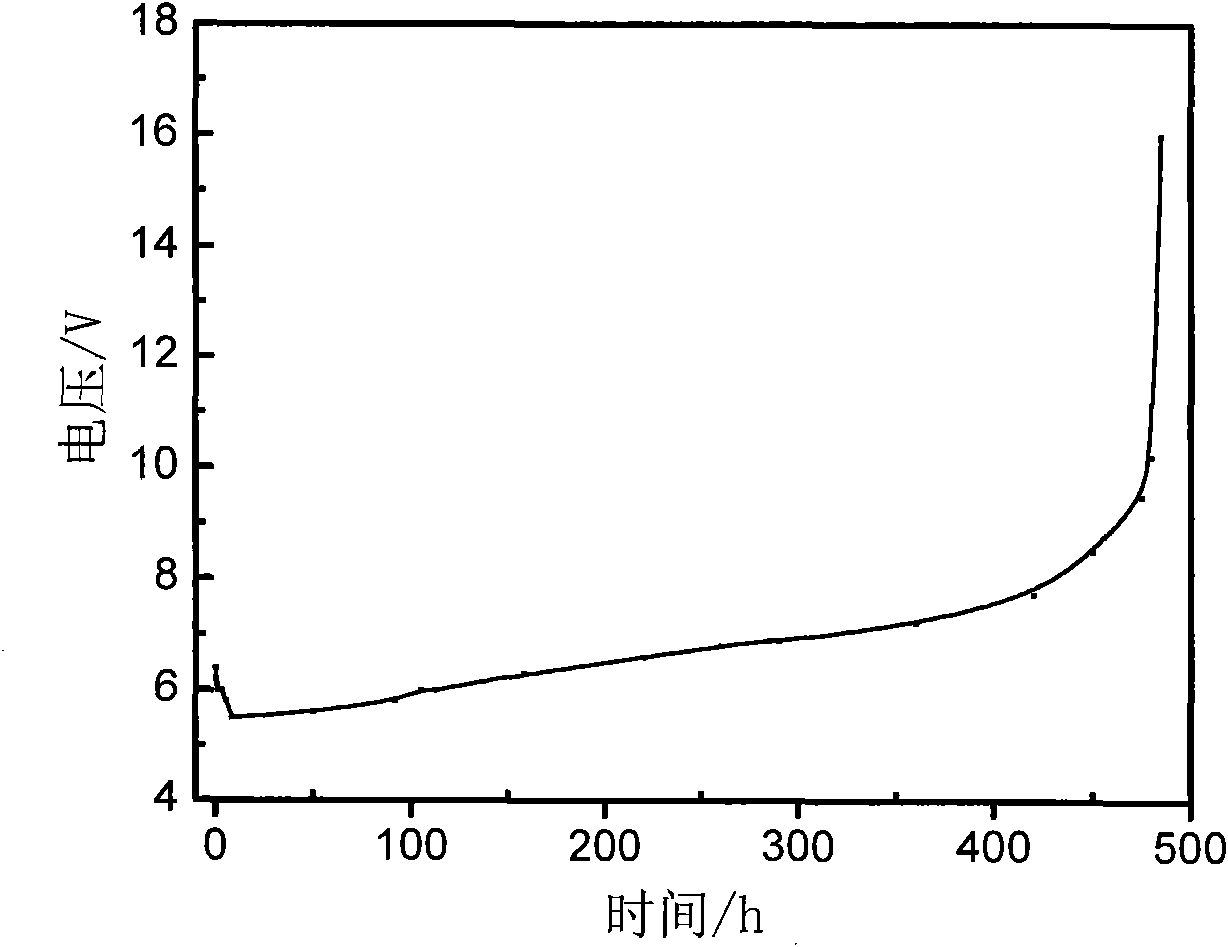

High-stability DSA anode for preparing chlorine by electrolysis and preparation method thereof

The invention relates to a high-stability DSA anode for preparing chlorine by electrolysis and a preparation method thereof. The anode comprises a titanium substrate, a middle layer and a surface active layer, wherein the IrxM (1-x) O2 middle layer is arranged between the titanium substrate and the surface layer, and M is Co, Mn or a CoTa mixture; and the components of the surface active layer are RuO2, IrO2, TiO2 and SnO2. The preparation method comprises the following steps: dissolving the components of the middle layer in proportion in isopropanol or n-butanol and other organic solvents, evenly coating on the pretreated substrate, and drying under an infrared lamp or in a drying box; then placing in a muffle furnace for thermal oxidation, and repeating the step for 1 to 10 times; and then coating the blended surface layer solution on the middle layer, repeating the preparation steps for 10 to 20 times, and holding in the muffle furnace. The service life of the anode is greatly prolonged based on the existing industry standards (20h), and the anode can be widely used in electrolyzing seawater antifouling, chlor-alkali industry and cathodic protection and other fields.

Owner:DALIAN UNIV OF TECH

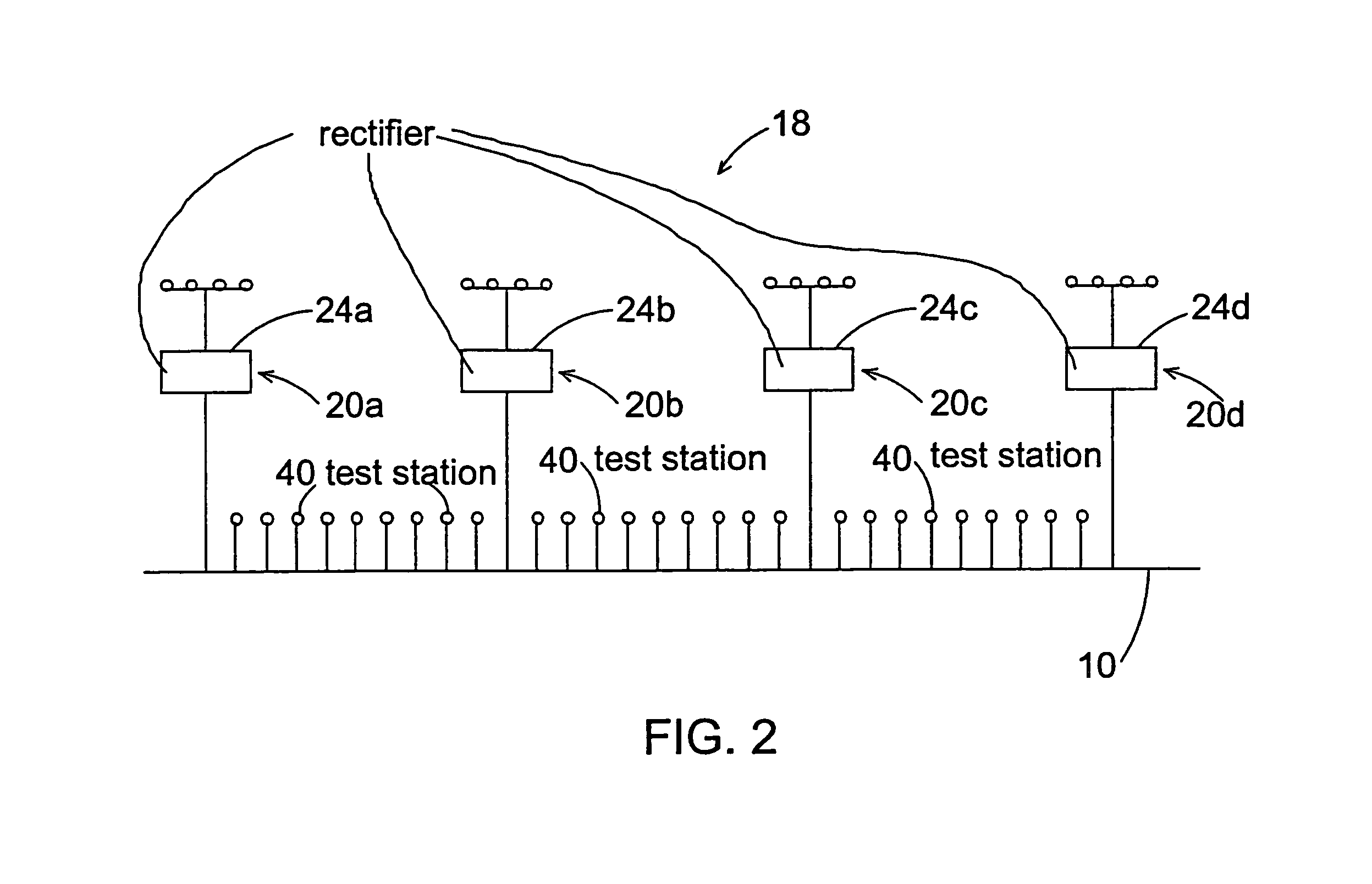

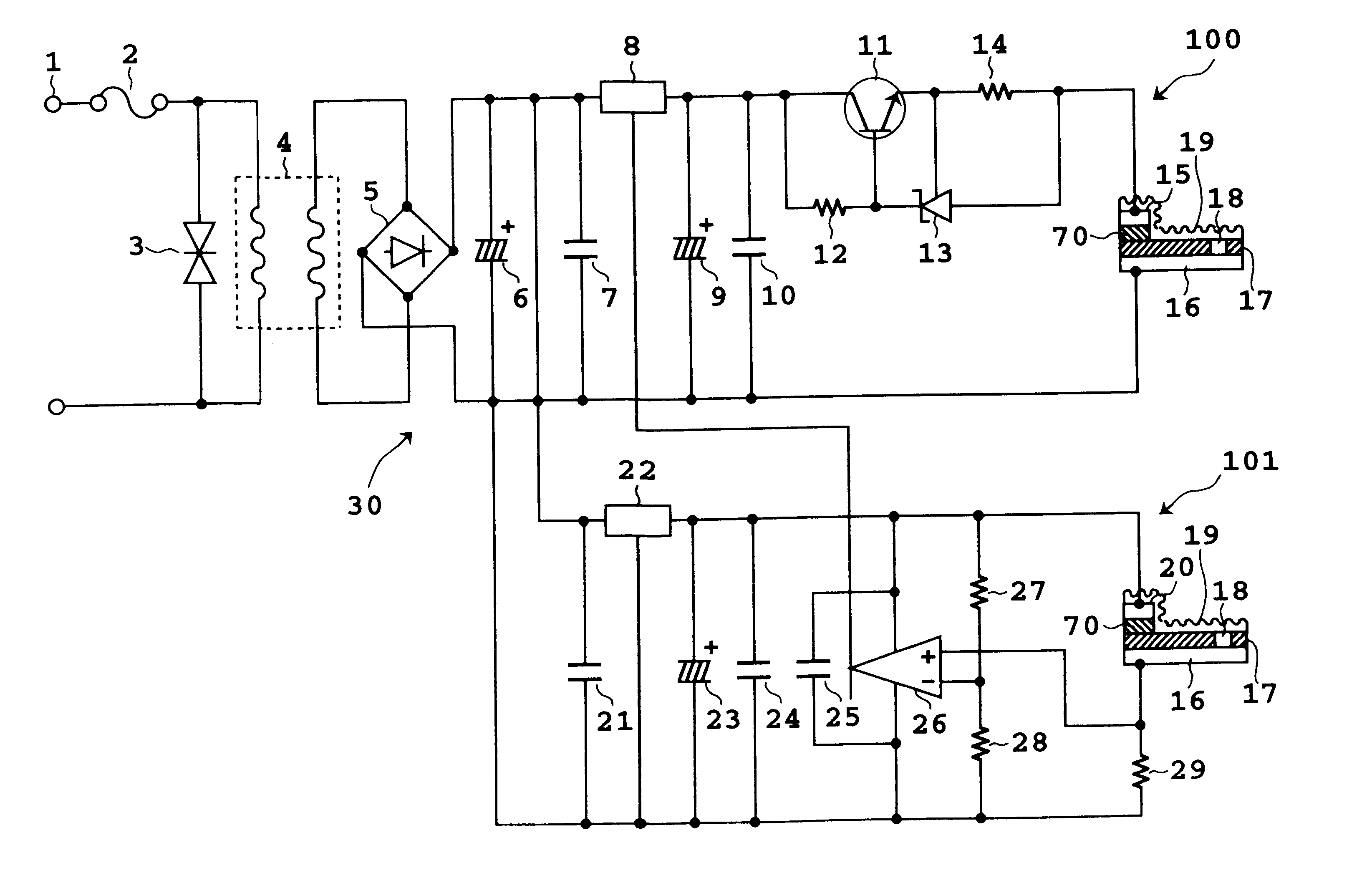

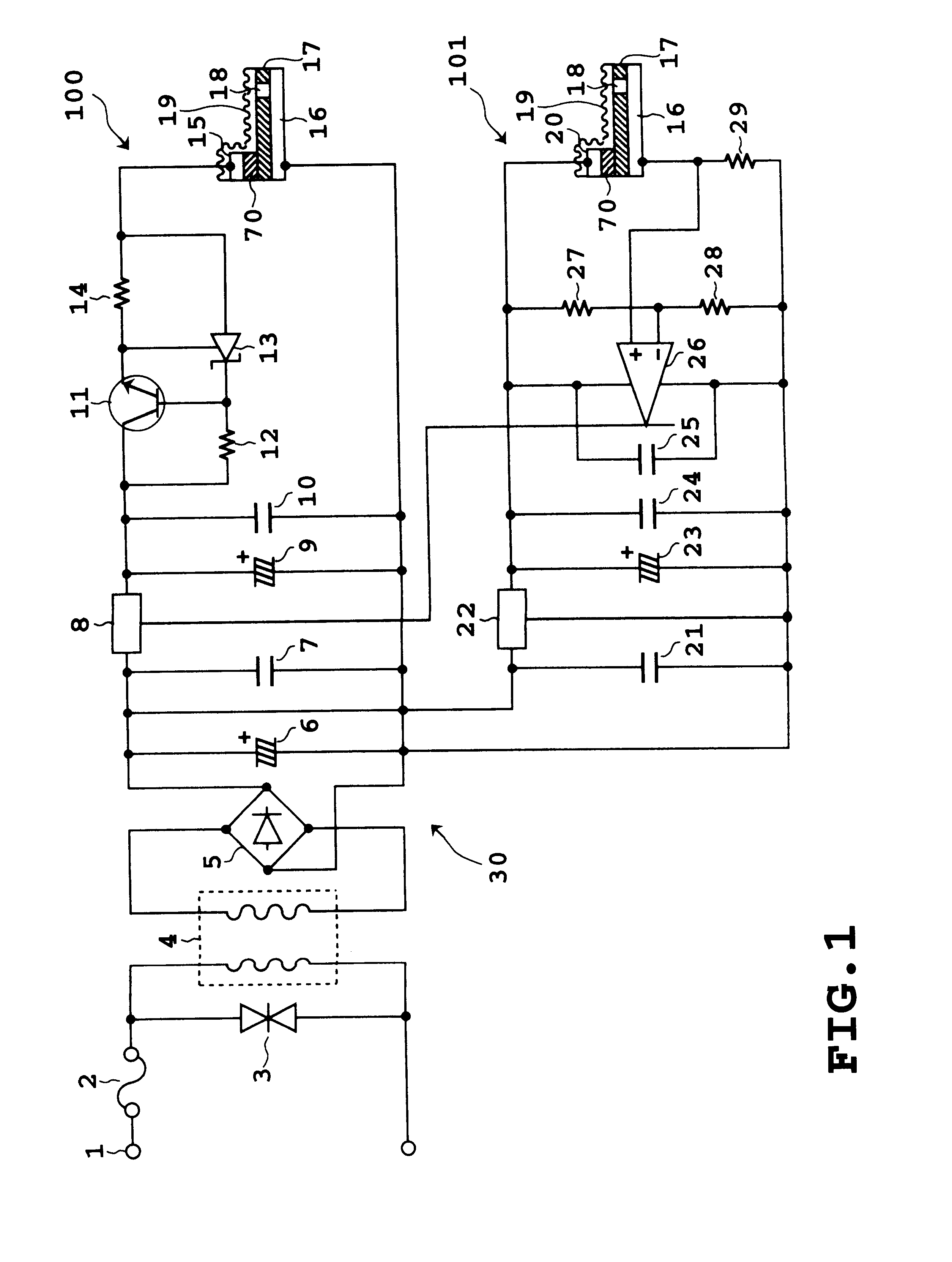

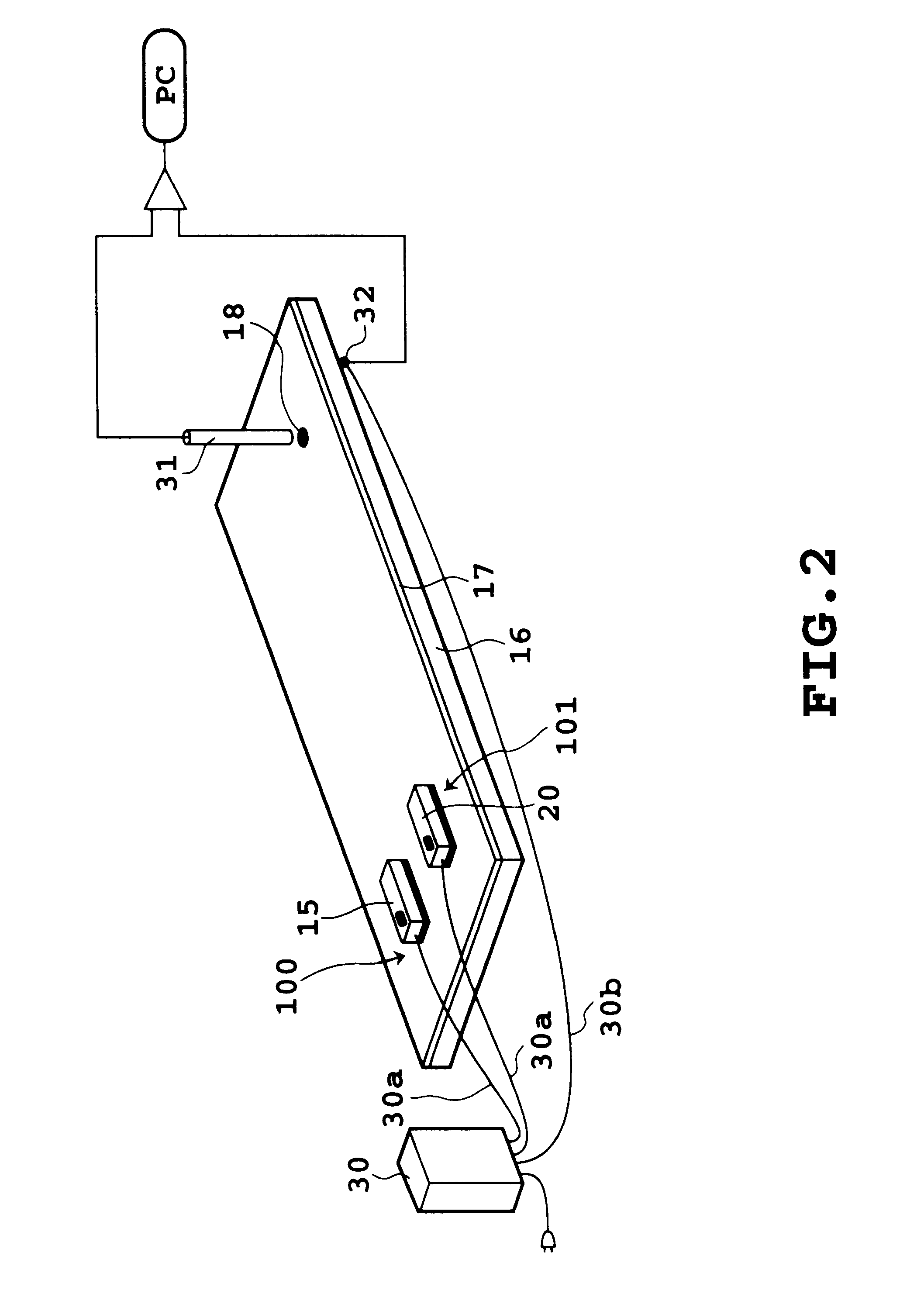

Current interrupter assembly

InactiveUS7027957B2Extended service lifeAvoid failureTesting dielectric strengthError detection/correctionPotential measurementEngineering

A method for determining the influence of one of a plurality of cathodic protection circuits along a pipeline includes switching one of a plurality of cathodic protection circuits off, while the remainder of the plurality of cathodic protection circuits are left on, with a portable pipe-to-soil potential measurement unit measuring the pipe-to-soil potential along the pipeline. From these measurements, a calibration curve is generated and an apparatus for monitoring the cathodic protection circuits is strategically positioned on the pipeline. The apparatus includes a remote monitoring unit having a pipe-to-soil potential measurement unit for measuring the potential between the ground bed and pipeline. The remote monitoring unit is off except while making measurements. The remote monitoring unit may optionally include a pipeline current measurement unit connected at a second connection point on the pipeline for measuring the current passing through the pipeline between the first and second connection points.

Owner:AMERICAN INNOVATIONS MINNESOTA

Preparation method of chemical nickeling phosphorus alloy film

InactiveCN1912180AUniform and dense thicknessNo porosityLiquid/solution decomposition chemical coatingPhosphorous acidChemical plating

The invention relate to a chemical plating nickel phosphor alloy coating manufacturing method. It includes oil removing, rust removing, activating, chemical plating, and post treatment. Its bath uses secondary phosphorous acid as reducer, nickel sulfate as main salt, adds complexing agent, buffering agent, stabilizing agent, etc. It optimizes bath constituent and chemical plating technological parameter by homogeneous design and single factor test method to form active surface, reduce nickel phosphor alloy coating at certain chemical plating condition. The invention has the advantages of safe, reliable, even coating, long useful life, cathodic protection function for copper alloy screw propeller, lowering marine life defilement.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

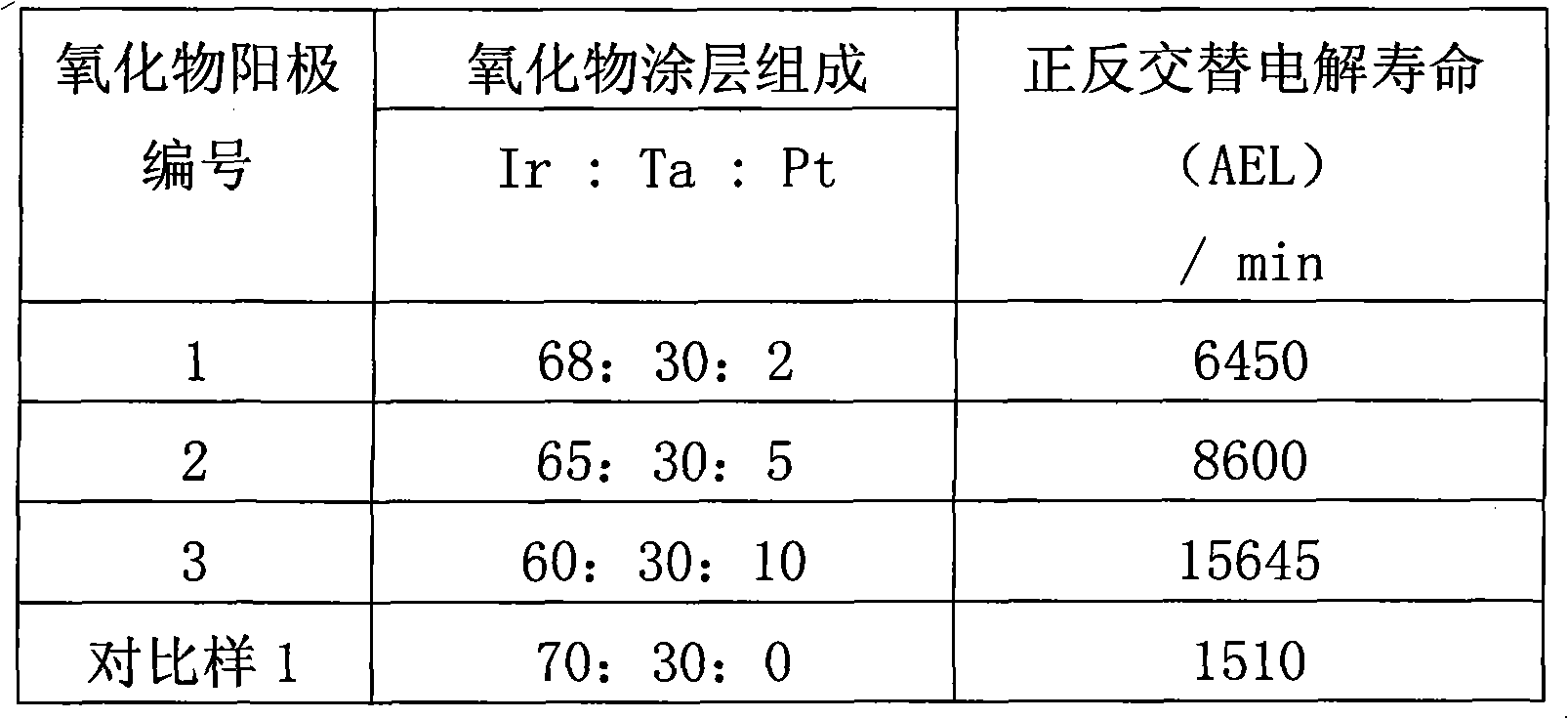

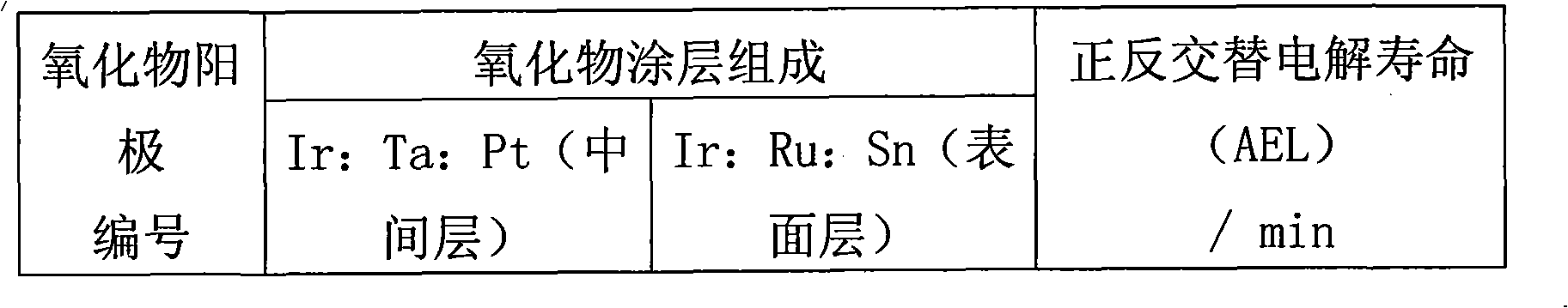

Positive and negative alternate electrolysis-resistance metal oxide electrode

ActiveCN101565833AExcellent resistance to positive and negative alternating electrolytic performanceImprove protectionWater/sewage treatment by electrochemical methodsLiquid/solution decomposition chemical coatingElectrolysisMechanical property

The invention relates to a positive and negative alternate electrolysis-resistance metal oxide electrode, which is suitable to be used in the field of electrochemical industry, such as high-speed steel plate plating, sea water electrolysis marine biofouling-resistance devices, sodium hypochlorite electrolysis production devices, sewage treatment, cathodic protection and other technical fields of electrochemistry. The positive and negative alternate electrolysis-resistance metal oxide electrode consists of a titanium substrate and a platinum-containing multielement mixed metal oxide coating formed on the titanium substrate by a pyrolytic process or a sol-gel method, wherein the mass percentage purity of the metal titanium substrate is over 99 percent; valve metal titanium has excellent mechanical property and machinability and is suitable for making electrode substrates, and the electrode titanium substrate is netty, platy, tubular or bar structural shapes; the platinum-containing multielement mixed metal oxide coating is IrO2-Ta2O5-PtOx, wherein the mole ratio of the Ir to Ta to Pt is (40-70):(20-40):(1-20); and the metal oxide electrode is obviously improved in positive and negative alternate electrolysis resistance and comprehensive performance, and is simple in structure and long in service life.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Cathodic protection device for flexible pipes

The flexible pipe comprises a plastic sealing sheath and an inner plastic sheath which define an annular space in which structural elements are placed. The structural elements comprising at least one armor ply consisting of metal wires wound helically with a long pitch are in the space. An end fitting is fitted at each end of the flexible pipe. At least one external anode electronically connected to at least one armor ply. The anode is placed in an intermediate region of the flexible pipe distal from the end fittings. A connection means connects the anode to at least one of the metal wires of the said armor ply in the intermediate region.

Owner:COFLEXIP

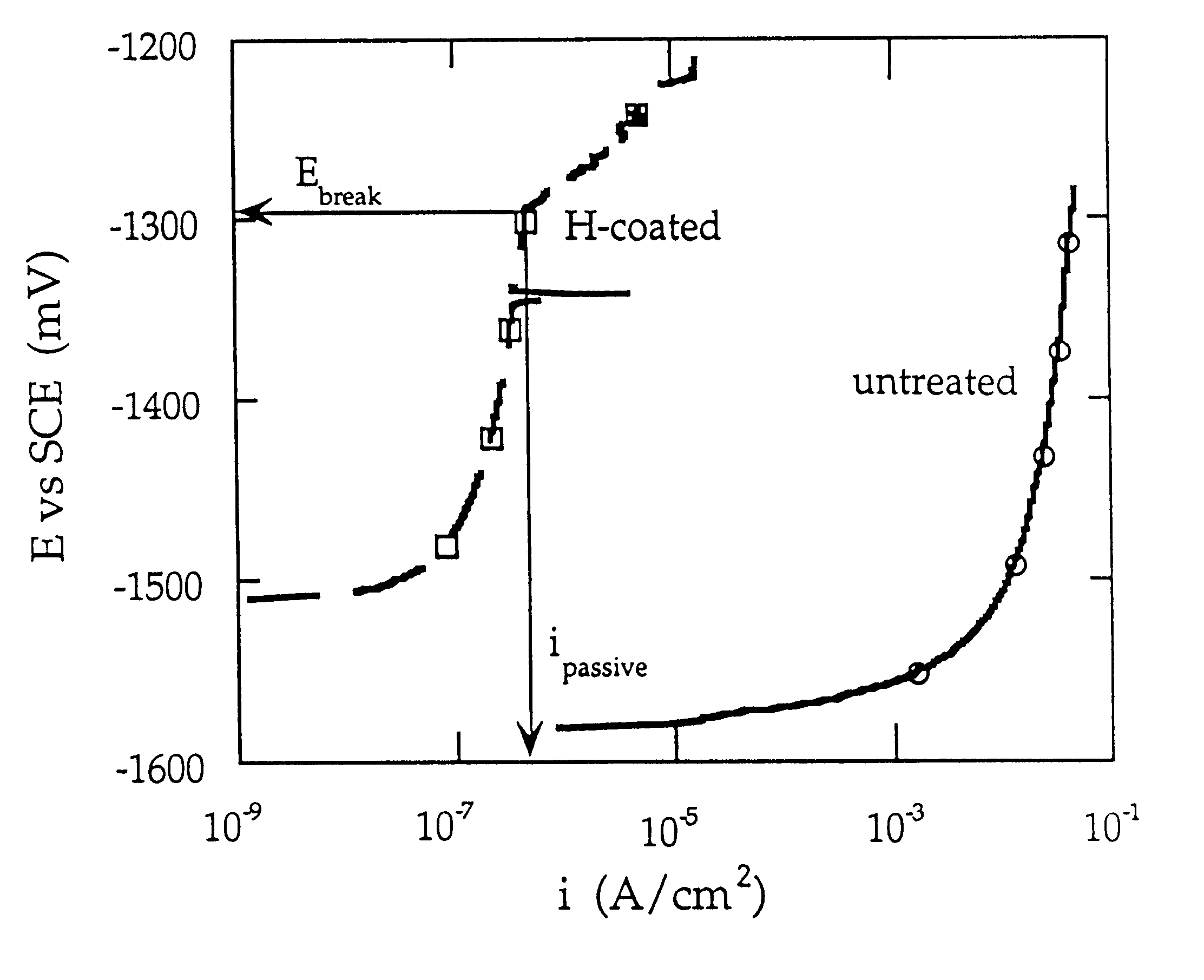

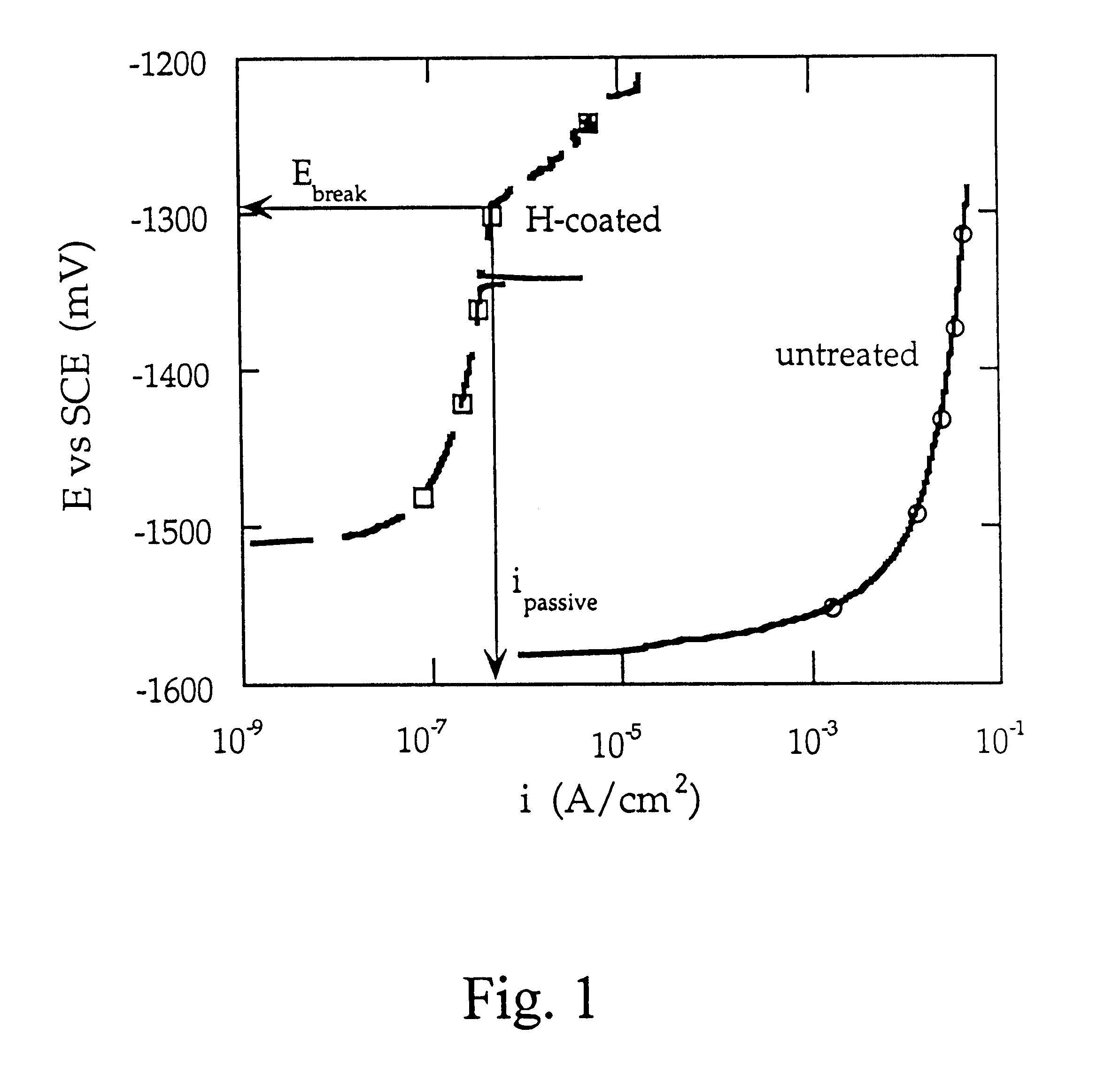

Cathodic protective coating on magnesium or its alloys

InactiveUS6291076B1Simple and efficientConvenient and economical solutionAnodisationNatural mineral layered productsHydrogenAlloy

A method is provided for treating a magnesium-containing article to form a cathodic protective coating on such article. This is done by electrochemically treating the article, acting as a cathode, in an alkaline solution, preferably at a temperature of between 40 and 80° C., with a cathodic current density of 5-200 mA / cm2. The treatment produces a magnesium-containing article having a protective coating of magnesium hydride of predetermined thickness with a high count of hydrogen particles.

Owner:INTERMAG MODELEX

Cathodic protection system

Owner:THE EUCLID CHEM CO

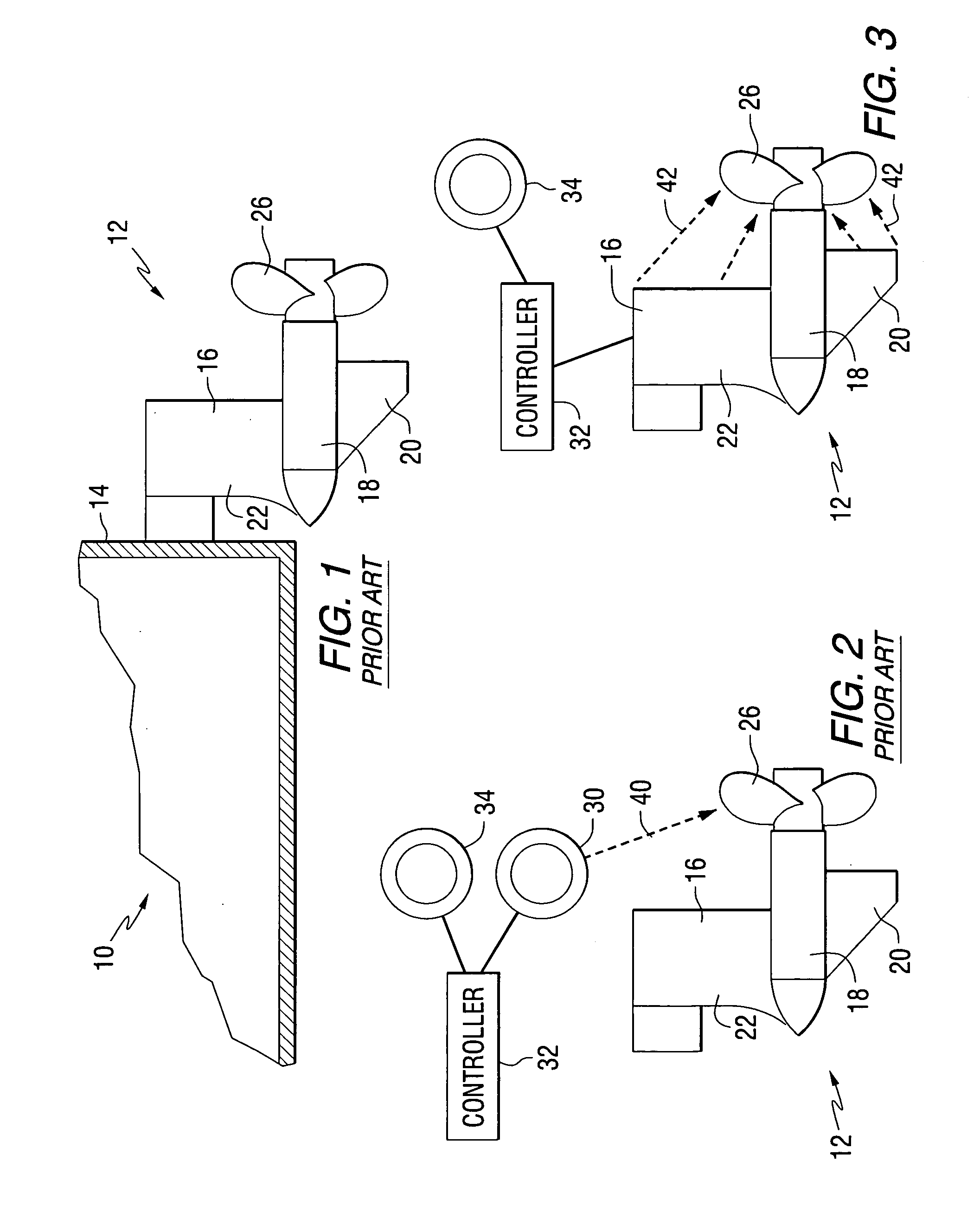

Method for protecting a marine propulsion system

An electrically conductive coating is provided on a housing structure of a marine propulsion system. By impressing a current on the electrically conductive coating, which can be a polymer material, the housing structure is used as an anode in a cathodic protection system. In addition, the use of the electrically conductive coating on the housing structure as an anode inhibits the growth of marine fouling on the outer surface of the housing structure by forming chlorine gas in a saltwater environment and by forming an acidic water layer near the surface in a non-saltwater environment.

Owner:BRUNSWICK CORPORATION

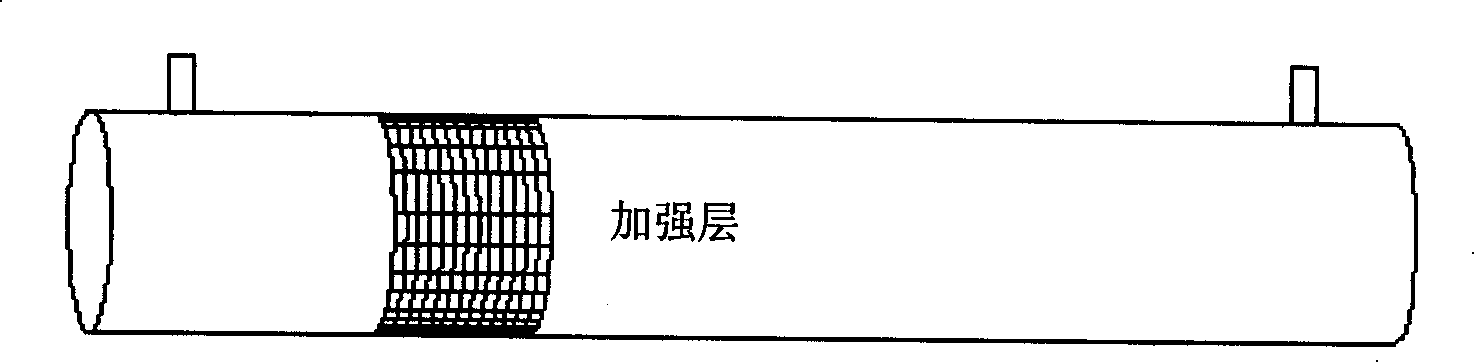

Method for renovation and reinforcement of pipe using basalt fibre complex material

The invention relate to a method applicable to pipeline, in particular to a method of repairing reinforcing or strengthening a metallic pipe. The main materials used in the invention are basalt fiber reinforcing material and resin basis material. According to the invention, as the strength and the modulus of reinforcing or strengthening materials are similar with those of the metallic pipe body material, the materials used in the invention can be integrated with the pipe body into a whole to bear pressure in the pipe together and finally form a bearing capacity of a composite repairing layer reaching or exceeding the bearing capacity of the original pipe; as the basalt fiber material is insulating, the compatibility between the pipe and cathodic protection and the electrochemical corrosion resistant capacity of the pipe are greatly improved. The method provided by the invention which has simple construction not only facilitates the close attaching between the reinforcing material and the pipe body and between reinforcing layers, but also enables repairing reinforcing and strengthening operations on pipelines in active service.

Owner:BEIJING SAFETECH PIPELINE

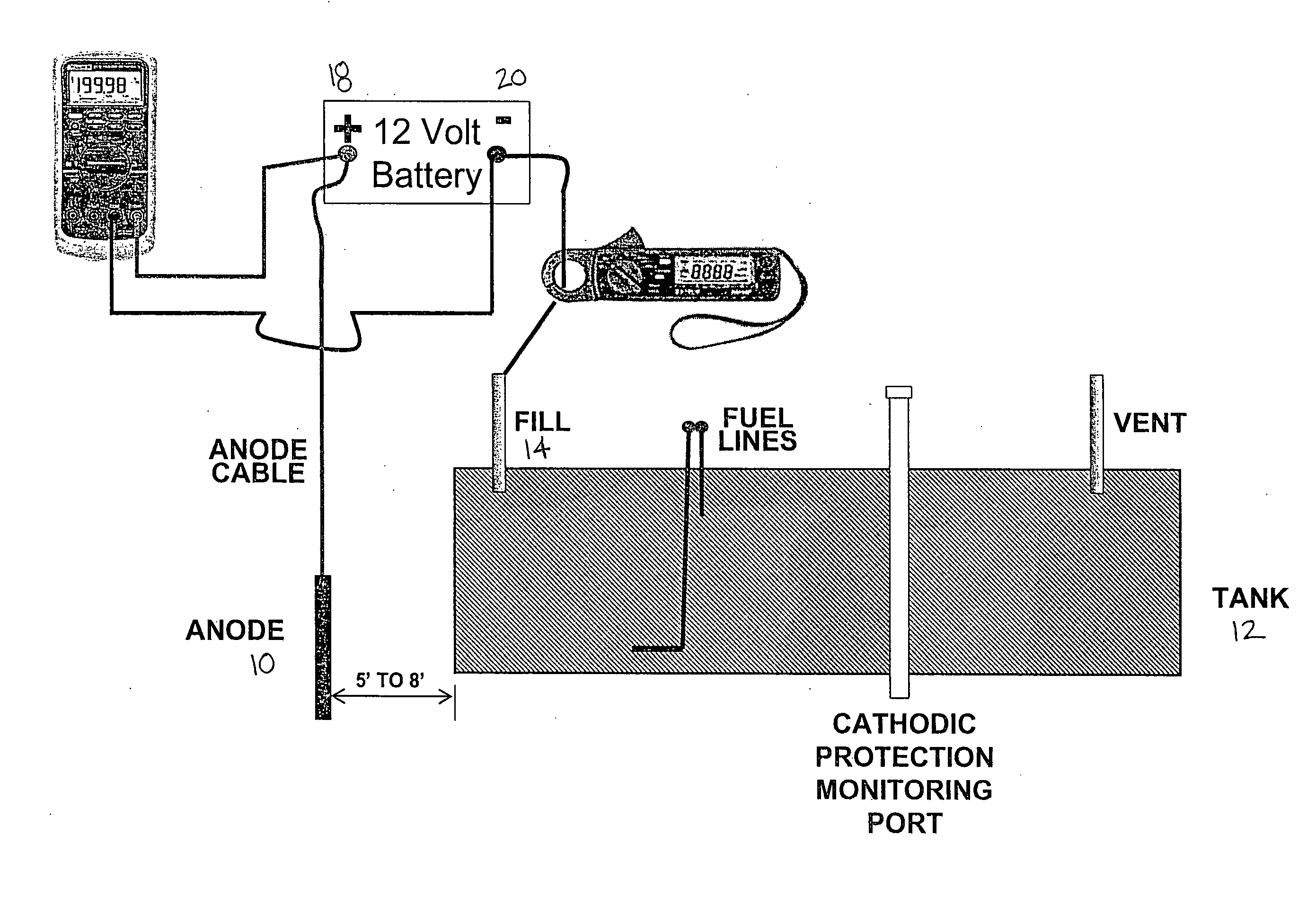

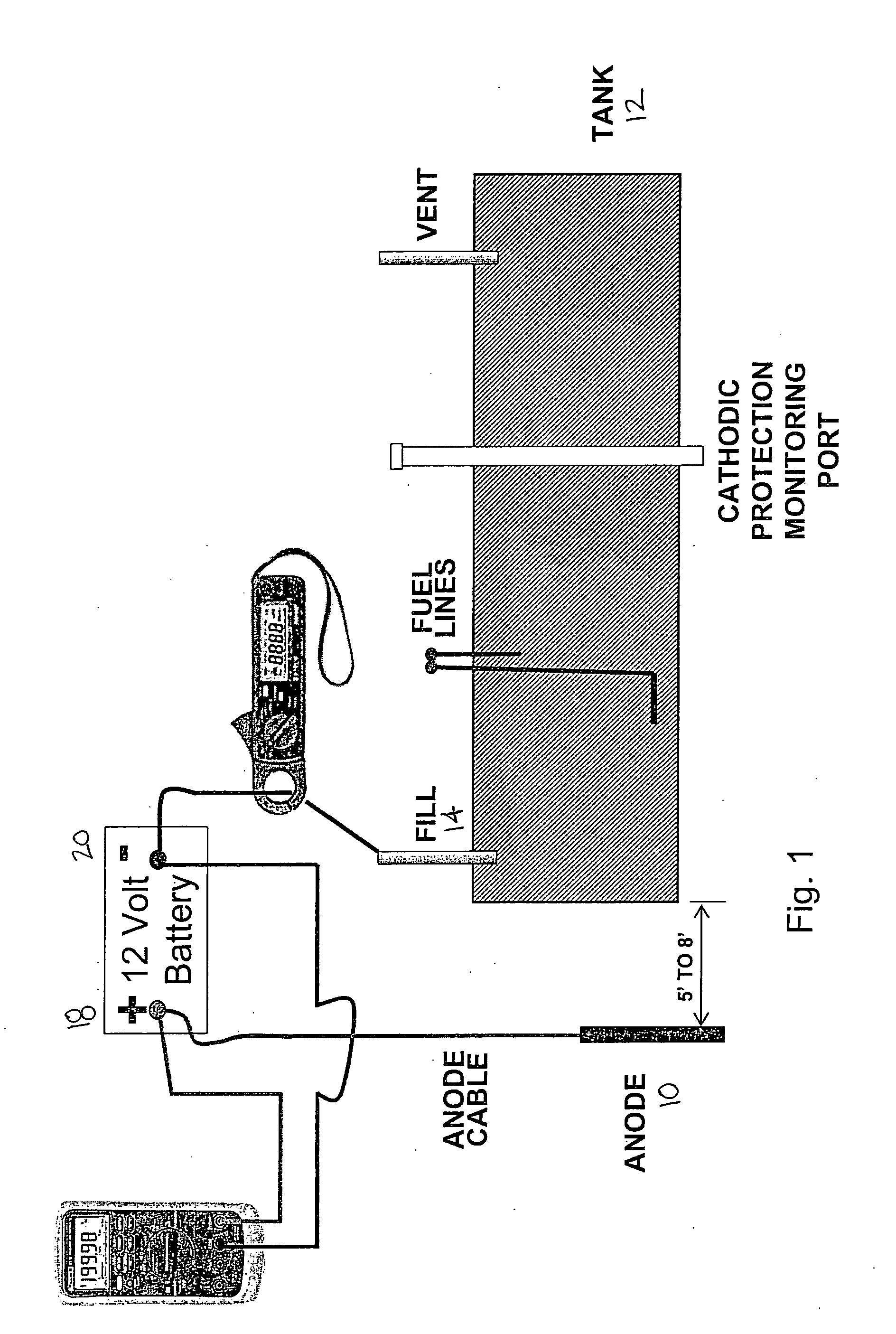

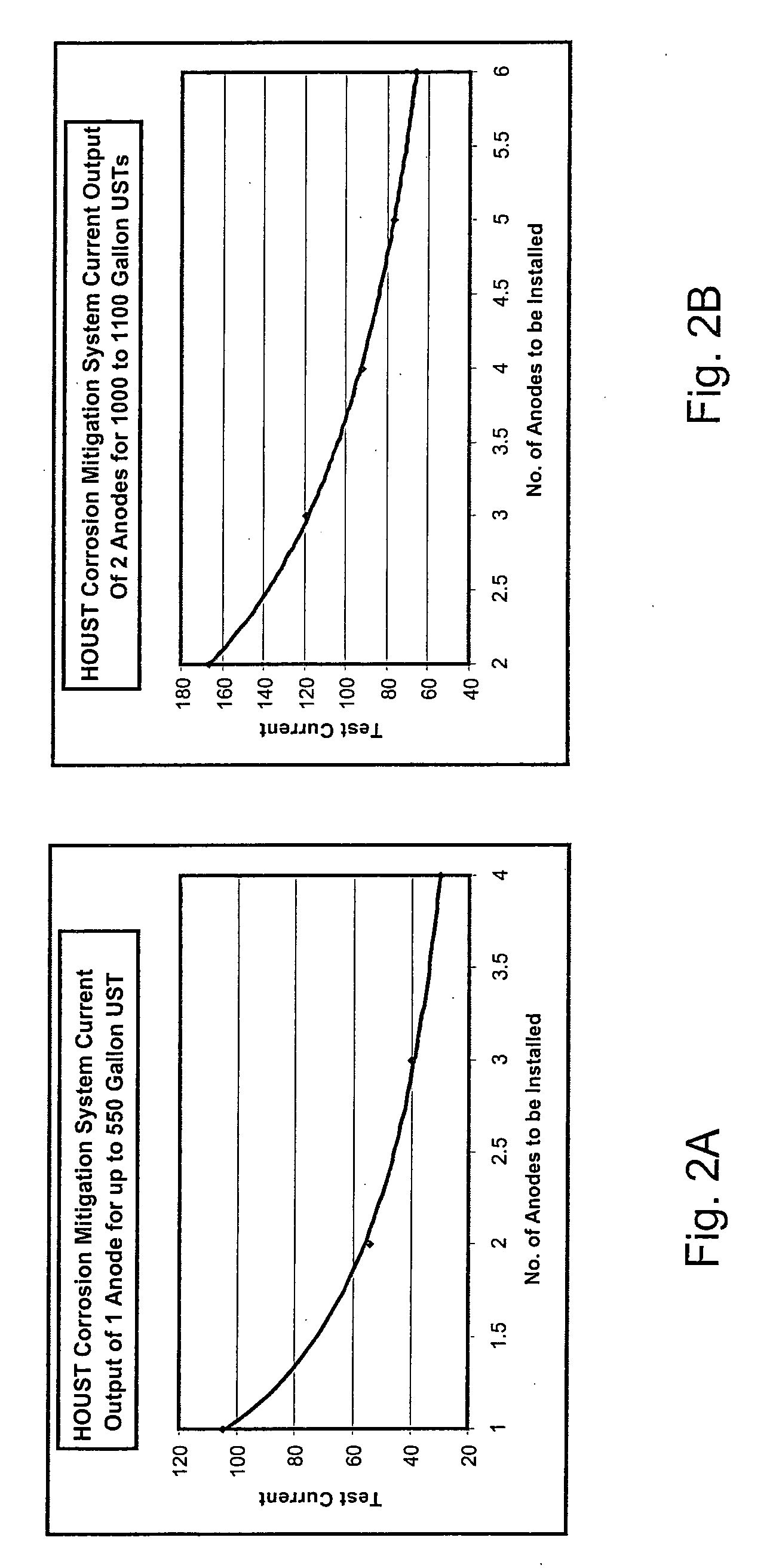

Cathodic protection system for underground storage tank

There is provided a method for implementing a cathodic protection system for an underground storage tank. A DC voltage source provides a test current between the installed anode and storage tank resulting in the flow of electrical current. If the output is above a defined value, an automatic control DC power supply has sufficient voltage capacity to deliver the required current. If the anode test currents fall below the required minimum current, additional anode(s) are installed as set forth in a pre-engineered table. The method allows for the installation of a cathodic protection system by technicians and other non-experts.

Owner:HOUST

Cathodic protection of steel within a covering material

Cathodic protection of an existing concrete structure, including a steel member at least partly buried, such as steel rebar, in the concrete structure, is provided by embedding anodes into a fresh concrete layer applied over an excavated patch and / or as a covering overlay. The anodes are embedded at spaced positions or as an array in the layer and connected to the rebar. A reinforcing layer is applied to the anode or adjacent the anode to resist expansion of the anode body tending to cause cracking of the concrete caused by the larger volume of the corrosion products relative to the anode material. Pores are provided in the anode body so as to take up the corrosion products. The reinforcing layer can be provided in the actual anode body as a closed surface surrounding the anode material inside or may be provided in the concrete as a layer on top of the anode in an array form at or near the outer surface of the concrete.

Owner:WHITMORE DAVID W

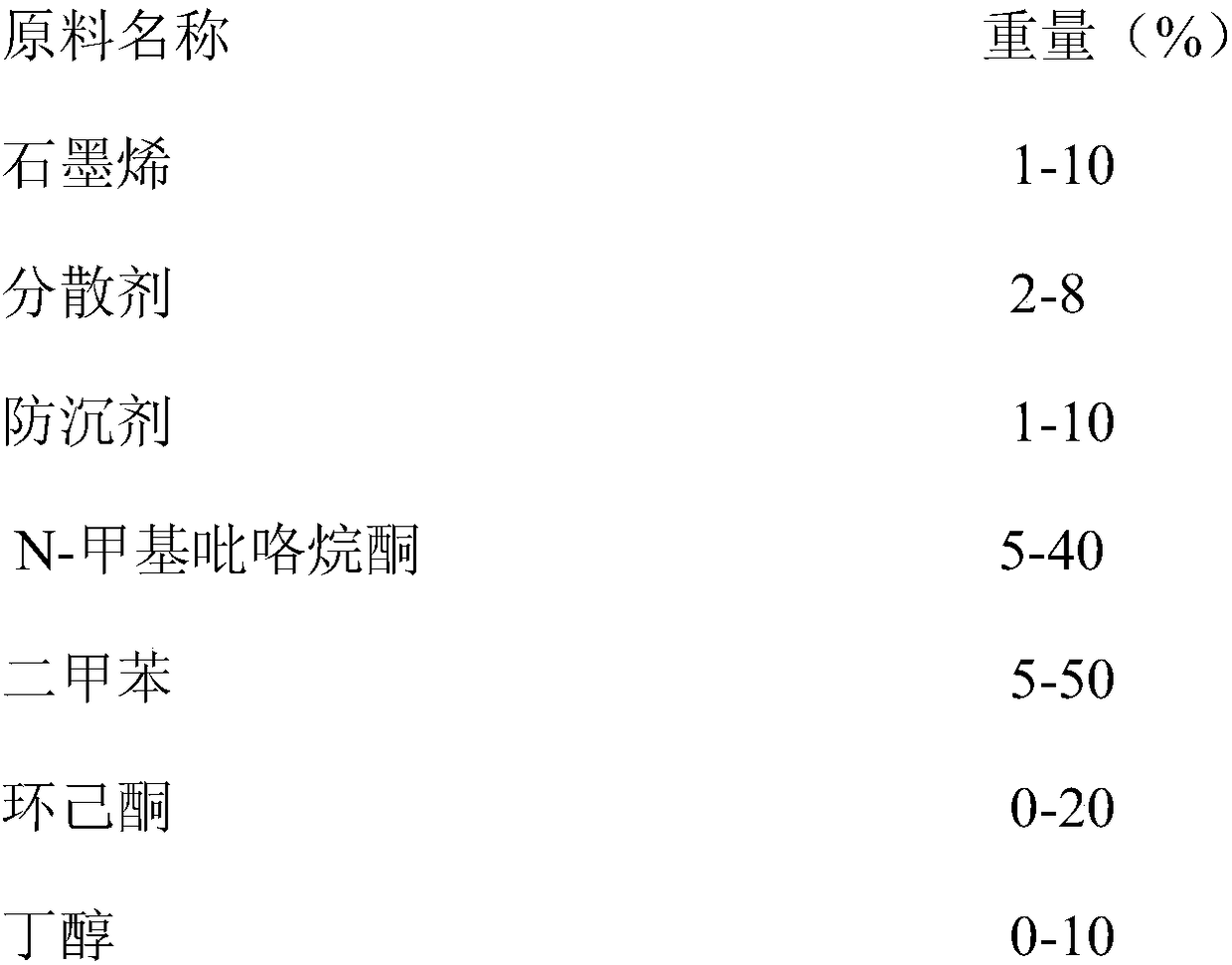

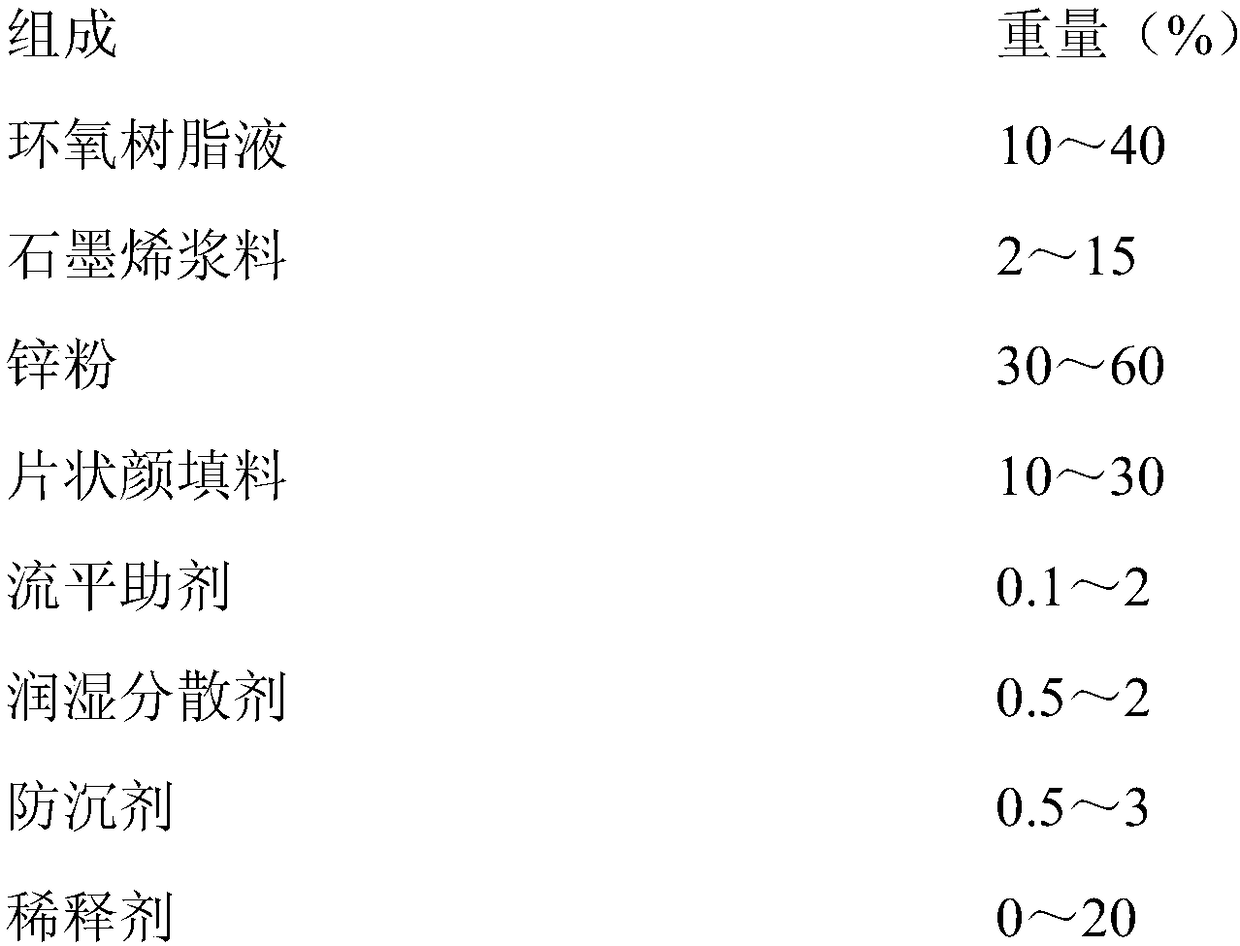

Thin-coating two-component anticorrosive coating for surface of precise steel structural part and preparation method thereof

InactiveCN108300146AImprove the effect of cathodic protectionImprove anti-corrosion efficiencyAnti-corrosive paintsEpoxy resin coatingsEpoxyCyclohexanone

The invention provides a thin-coating two-component anticorrosive coating for the surface of a precise steel structural part, wherein the two-component anticorrosive coating is composed of a componentA and a component B. The component A is composed of an epoxy resin liquid, graphene slurry, a zinc powder, flaky pigments and fillers, an auxiliary agent and a diluent. The component B is composed ofa polyamide curing agent and a mixture of xylene, n-butanol and cyclohexanone. The component A and the component B are evenly mixed according to the weight ratio of (5-15):1. The graphene slurry is prepared by adding powdery graphene and a dispersant into a mixed solvent under a stirring state, and dispersing in an ultrasonic oscillator to obtain the stable dispersed slurry. A coating layer has excellent cathodic protection effect, can be thin-coated to about 10-15 microns, still has good corrosion resistance, and can partly replace traditional phosphorization and oxidation processes.

Owner:MARINE CHEM RES INST +1

Subsea navigation and survey

InactiveUS6865139B2Optimize spaceUse is attractiveSonic/ultrasonic/infrasonic transmissionSeismology for water-covered areasOcean bottomMarine engineering

A subsea navigation system comprising a plurality of spaced antenna means provided on a subsea structure arranged to emit electromagnetic radiation. A detection means is provided on a subsea vehicle for receiving and analyzing the electromagnetic radiation transmitted by the antenna means allowing the subsea vehicle to navigate relative to the subsea structure. Each of the antenna means comprises a cathodic protection anode provided on the subsea structure.

Owner:EXPRO NORTH SEA

Detection of Corrosion Defects in Buried Pipelines Using Vertically Measured Pipe-To-Soil Potential

ActiveUS20150204775A1Weather/light/corrosion resistanceElectrical measurementsPotential measurementMaterials science

A method for in-situ measuring the corrosion rate of a corroding site on an underground metal structure buried in soil, the structure being under cathodic protection. The structure-to-soil potential at varying depths above the pipeline is measured to a depth above, but not reaching the structure. These measurements are extrapolated to obtain data representing the structure-to-soil potential at the surface of the structure under the probe. The gradient of the electrical potential at this surface is used to calculate the corrosion rate of the defect. A special probe may be used to obtain the potential measurement data.

Owner:SOUTHWEST RES INST

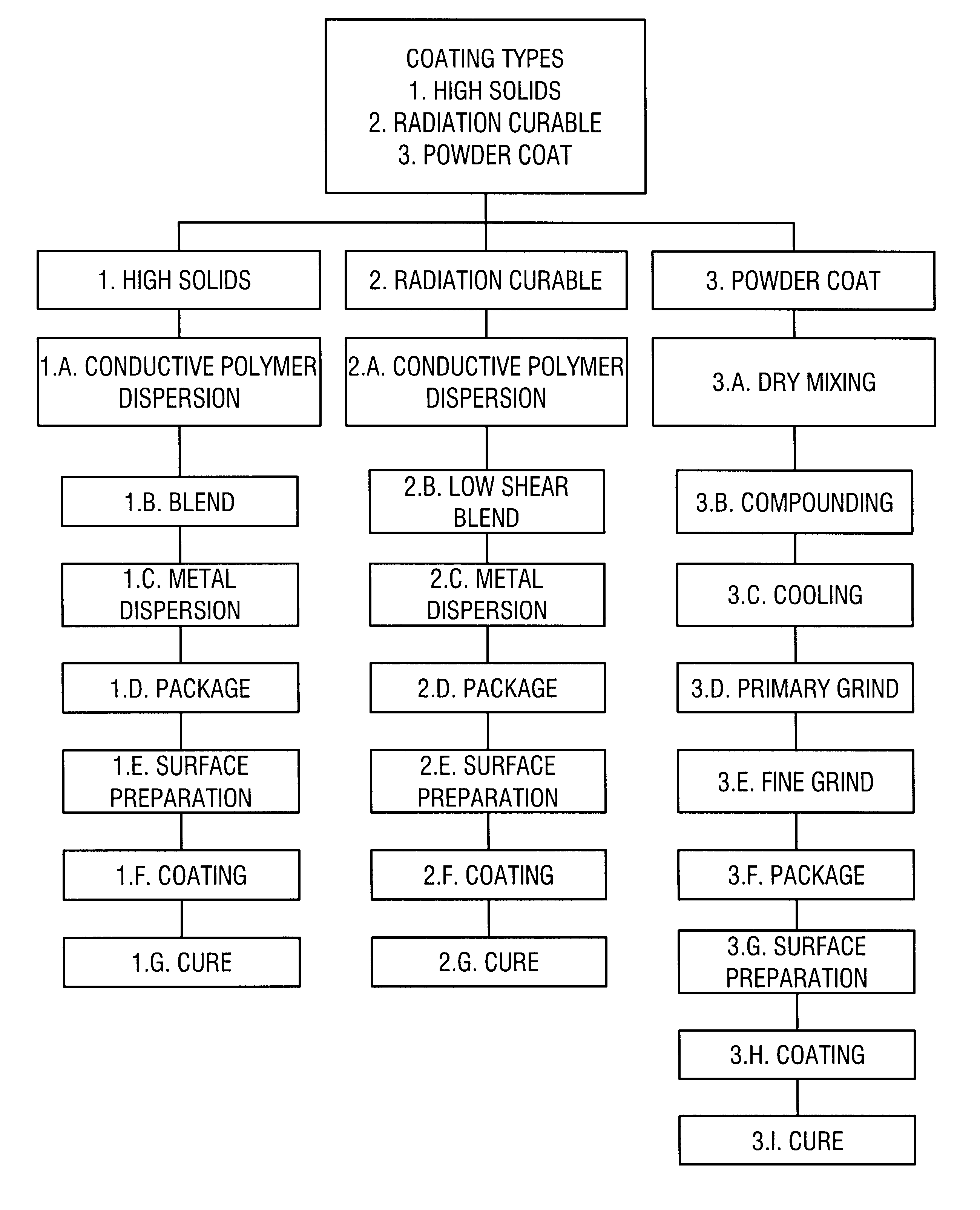

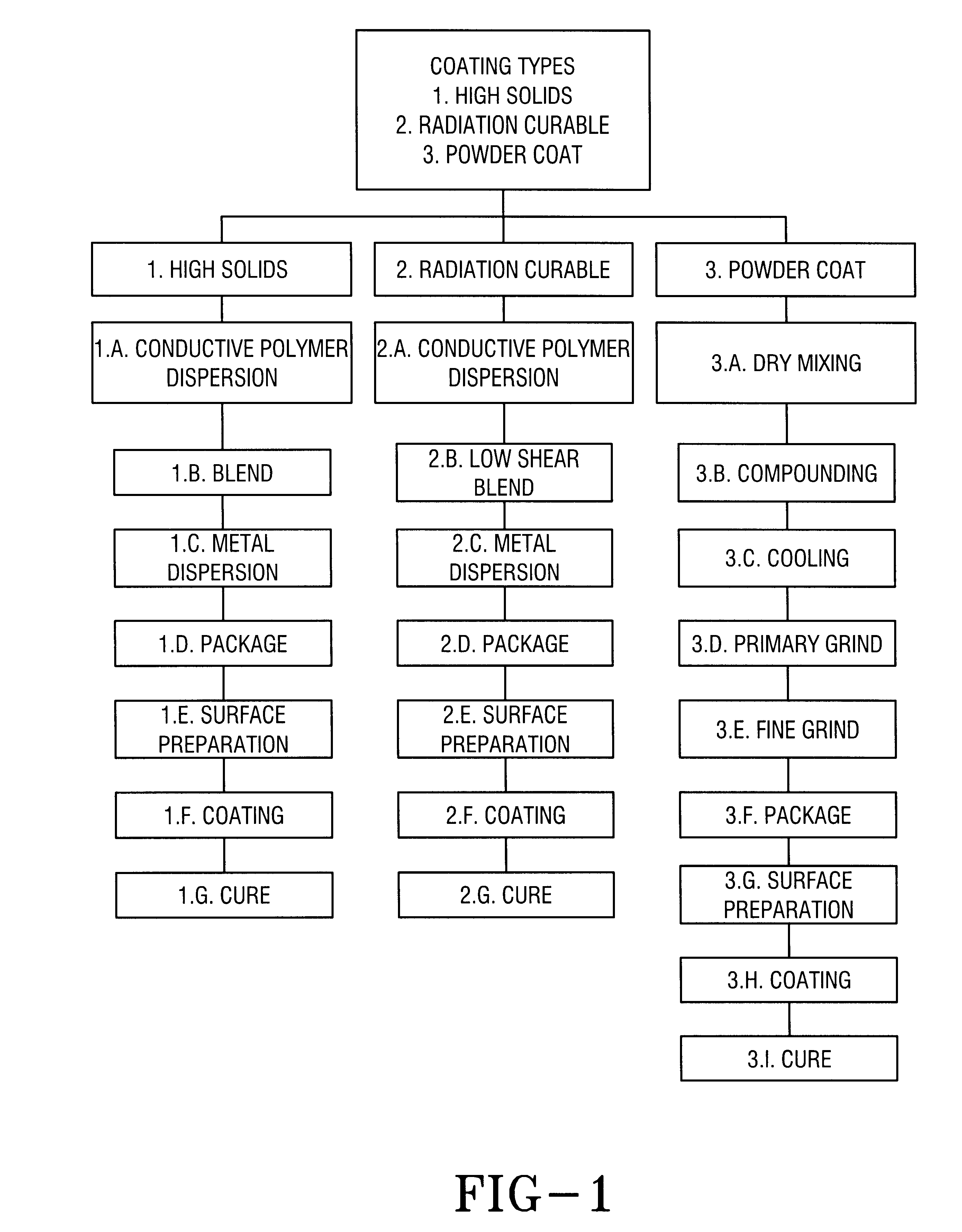

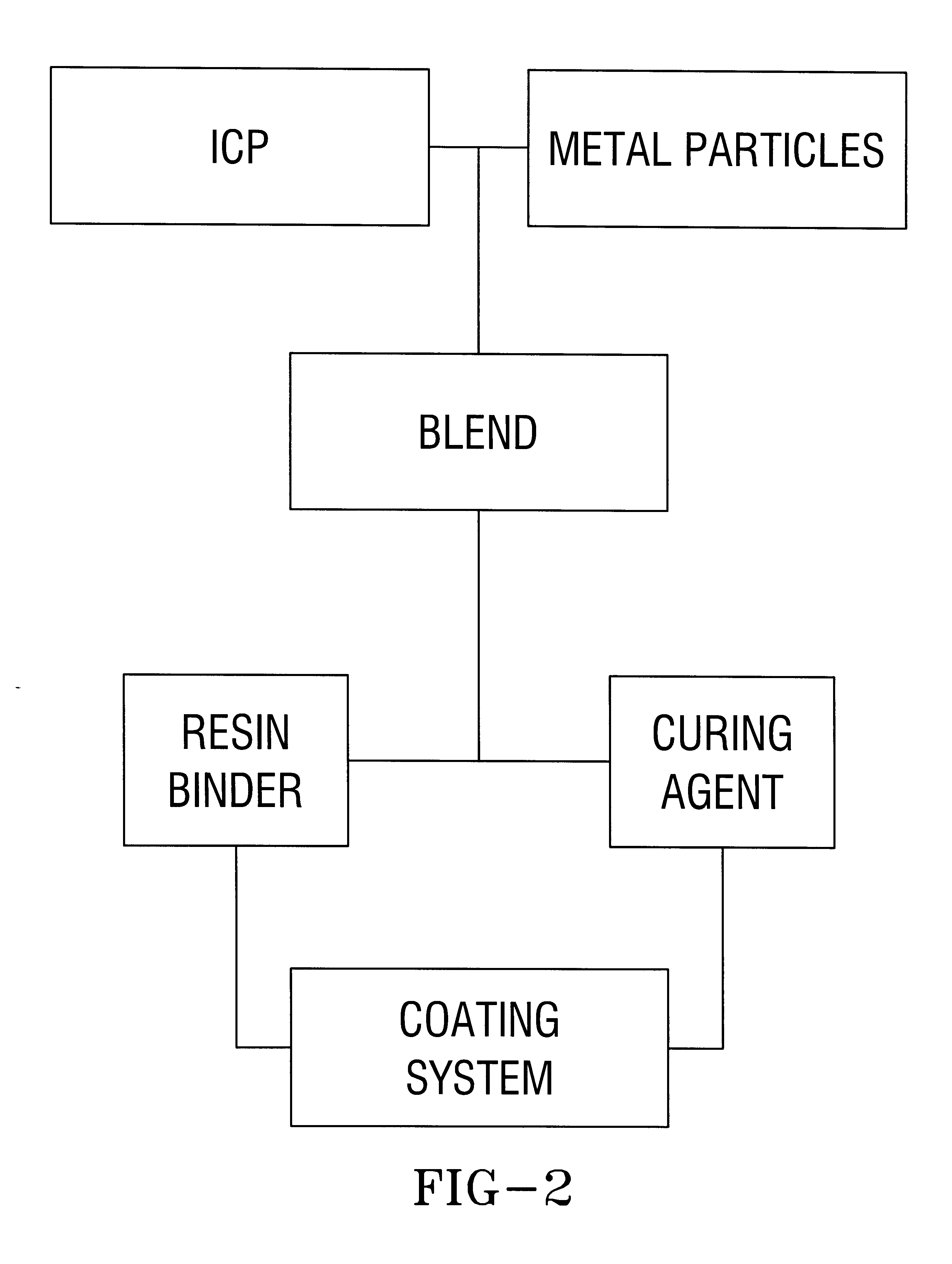

Method for applying a coating that acts as an electrolytic barrier and a cathodic corrosion prevention system

InactiveUS6627117B2Improve performanceConductive materialPretreated surfacesElectrolysisCoating system

A coating system for ferrous and nonferrous metal substrates that provides cathodic protection from corrosion by coating with inherently conductive polymers and sacrificial anodic metal particles. The coating system is formed by a process that includes premixing of the inherently conductive polymer with the anodic metal particles to form a inherently conductive polymer / metal particle complex.

Owner:LUMIGEN +1

Cathodic protection compounds

ActiveUS7794626B2Improve the effect of cathodic protectionLess expensiveMaterial nanotechnologyConductive materialCompound aMetallurgy

A cathodic protection compound is disclosed. The coating includes sacrificial metallic particles less noble than metal in the metal substrate to be protected. The coating also includes inherently conductive polymer in an amount of less than 1 weight percent of total solids of the coating. A concentrate of the metallic particles and inherently conductive polymer can also be prepared.

Owner:AVIENT CORP

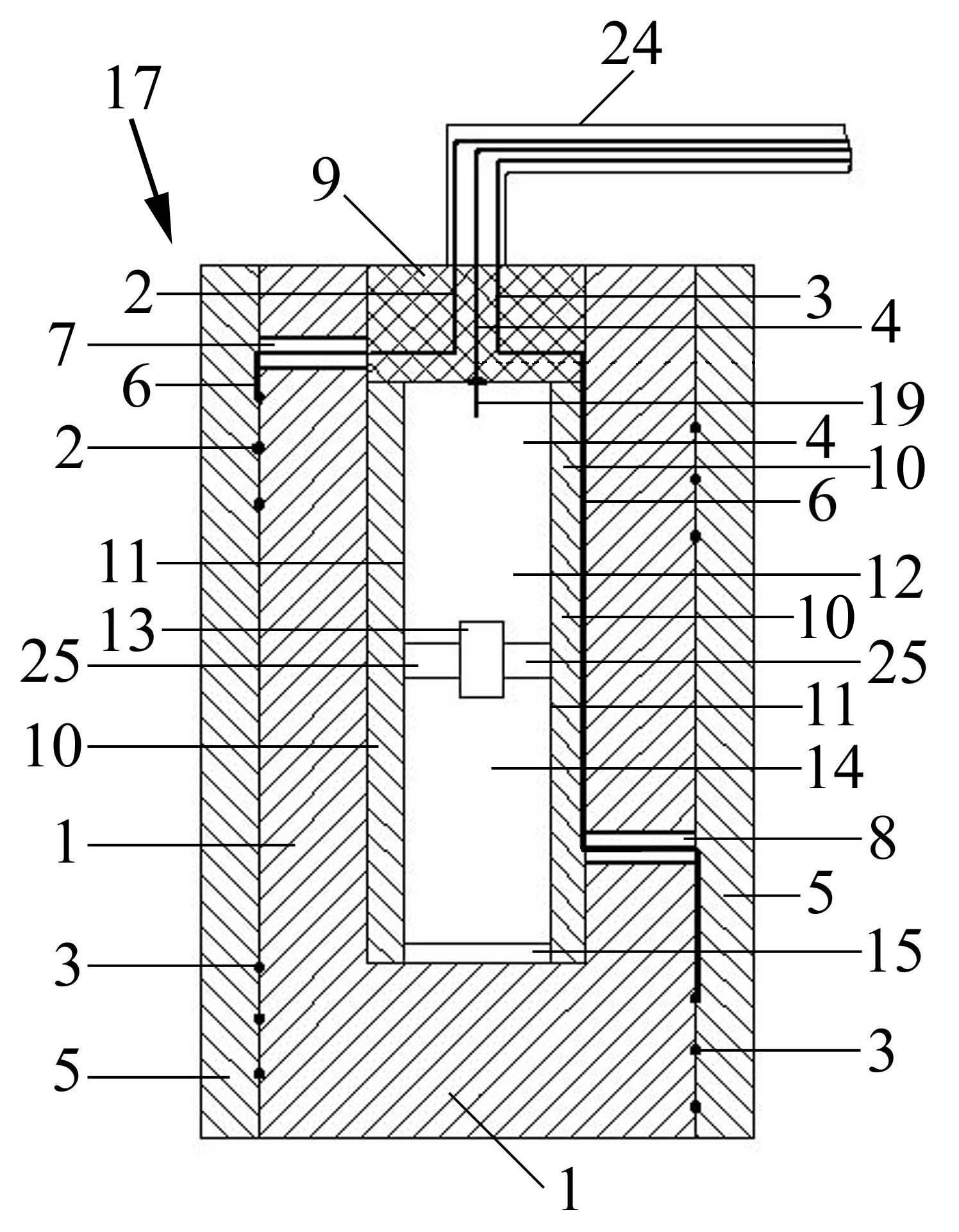

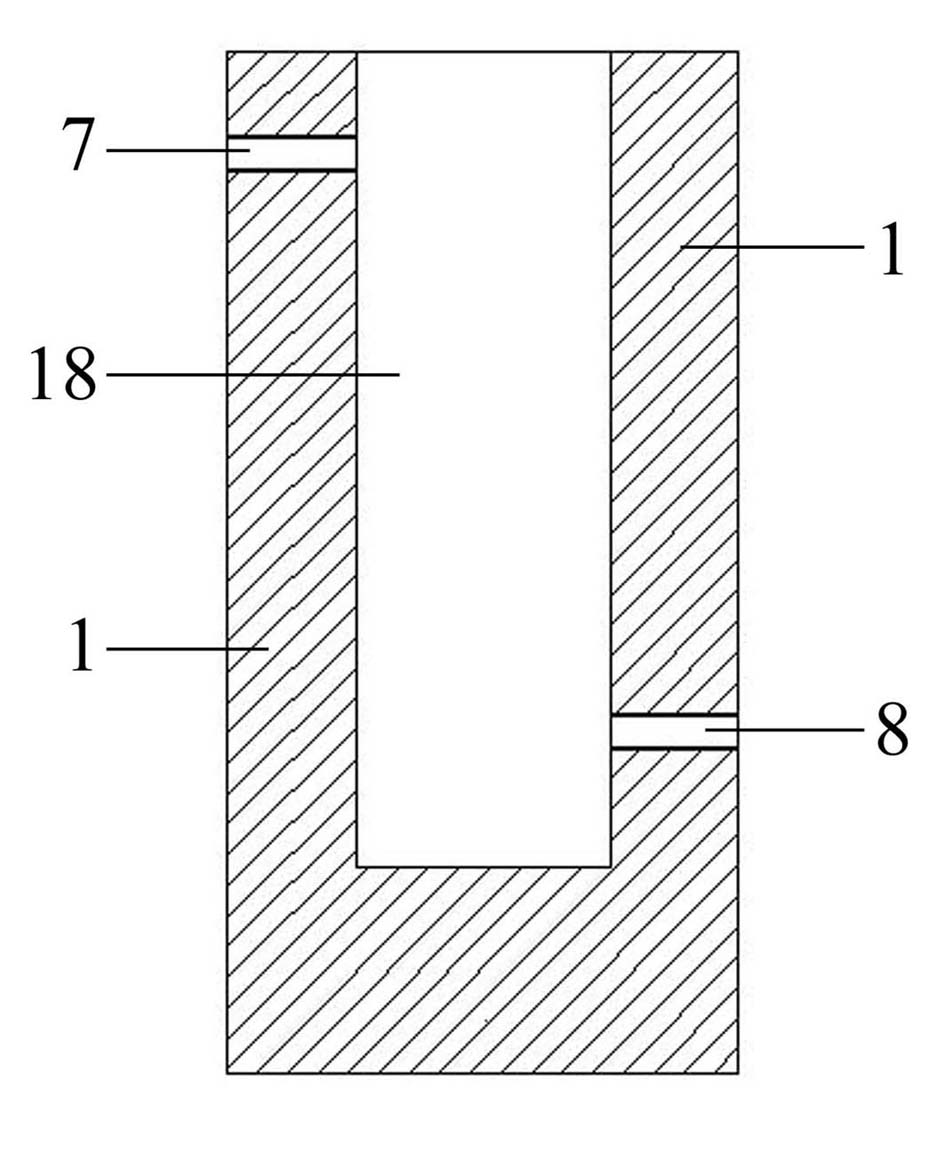

Cathodic protection method and device for metal structure

A main anode and a pilot anode are mounted on a coating film of a metal structure, a cathode is mounted on a metal based material of the metal structure, a predetermined voltage is applied from the pilot anode to the metal structure, a magnitude of corrosion protection current of the metal structure is read from a current value of the pilot anode varying with variation of corrosion environment of the metal structure, the application voltage of the main anode is increased or decreased in accordance with the current value, whereby providing a cathodic protection method and apparatus for a metal structure capable of expanding protectable area by a single anode to a maximum without causing over-corrosion protection.

Owner:KINAN

Cathodic protection monitoring probe, cathodic protection monitoring probe monitoring system, and manufacturing method and monitoring method thereof

The invention discloses a cathodic protection monitoring probe, a cathodic protection monitoring probe monitoring system, and a manufacturing method and a monitoring method thereof. The probe main body is integrally cylindrical; the probe core is integrally cylindrical and is provided with a hollow blind hole; the hollow hole is a probe core cavity; the upper part of the probe core is provided with an electrode threaded hole which passes through the cylindrical wall of the probe core and is communicated with the probe core cavity; the probe core cavity is provided with a reference electrode; and a fixing layer is arranged between the reference electrode and the cylindrical wall of the probe core so as to fix the reference electrode in the probe core. The cathodic protection monitoring probe has the advantages of scientific design, reasonable structure, reliable performance, wide application range, high stability, strong polarization resistance, and stable quality, and is used for pipeline transportation of various fluid materials such as crude oil, natural gas, running water, urban liquefied gas and the like in the fields such as highways, railways, water transportation, aviation, agriculture and industry and the like.

Owner:TIANJIN WATER RESOURCES RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com