Patents

Literature

81results about How to "Costly and time-consume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

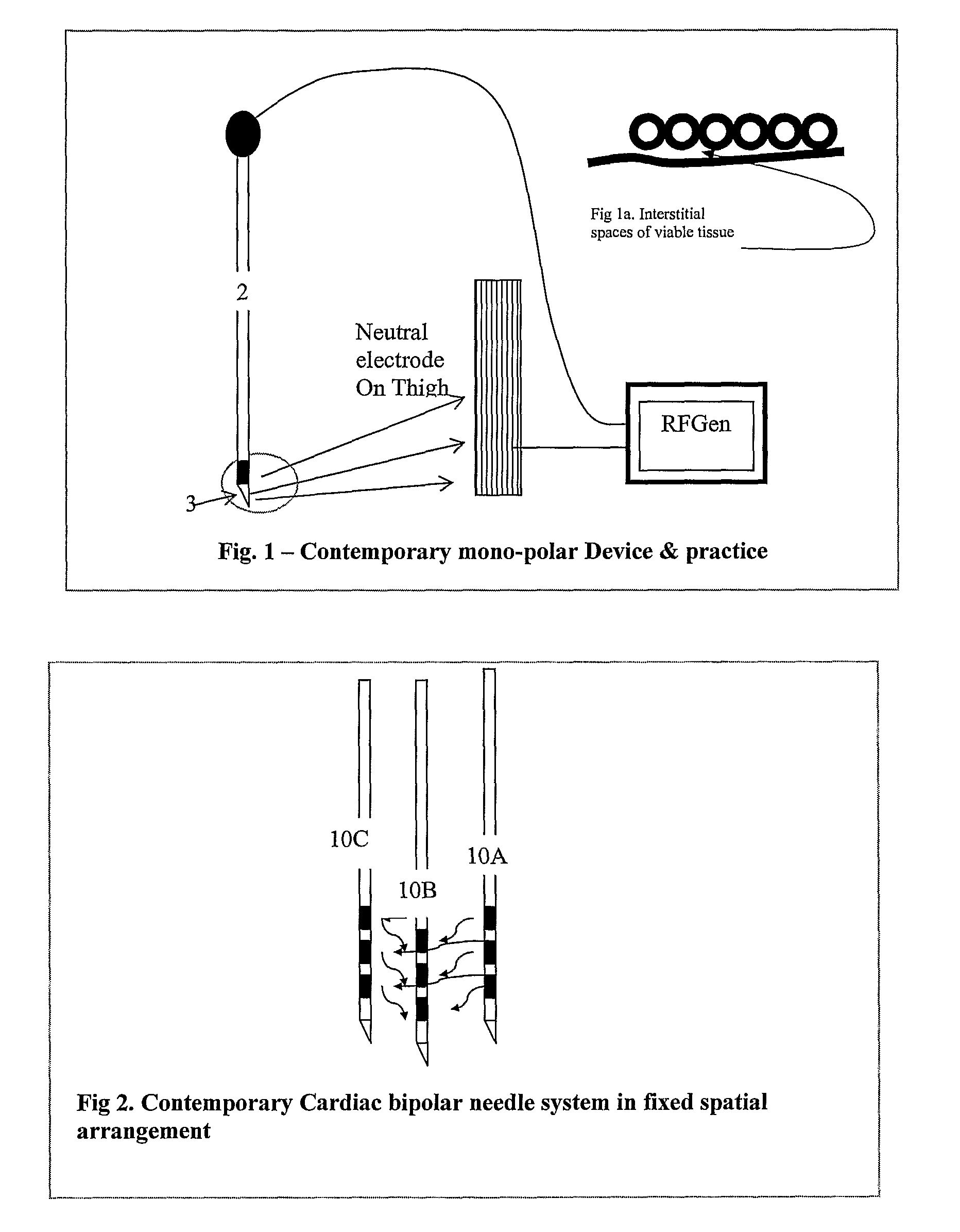

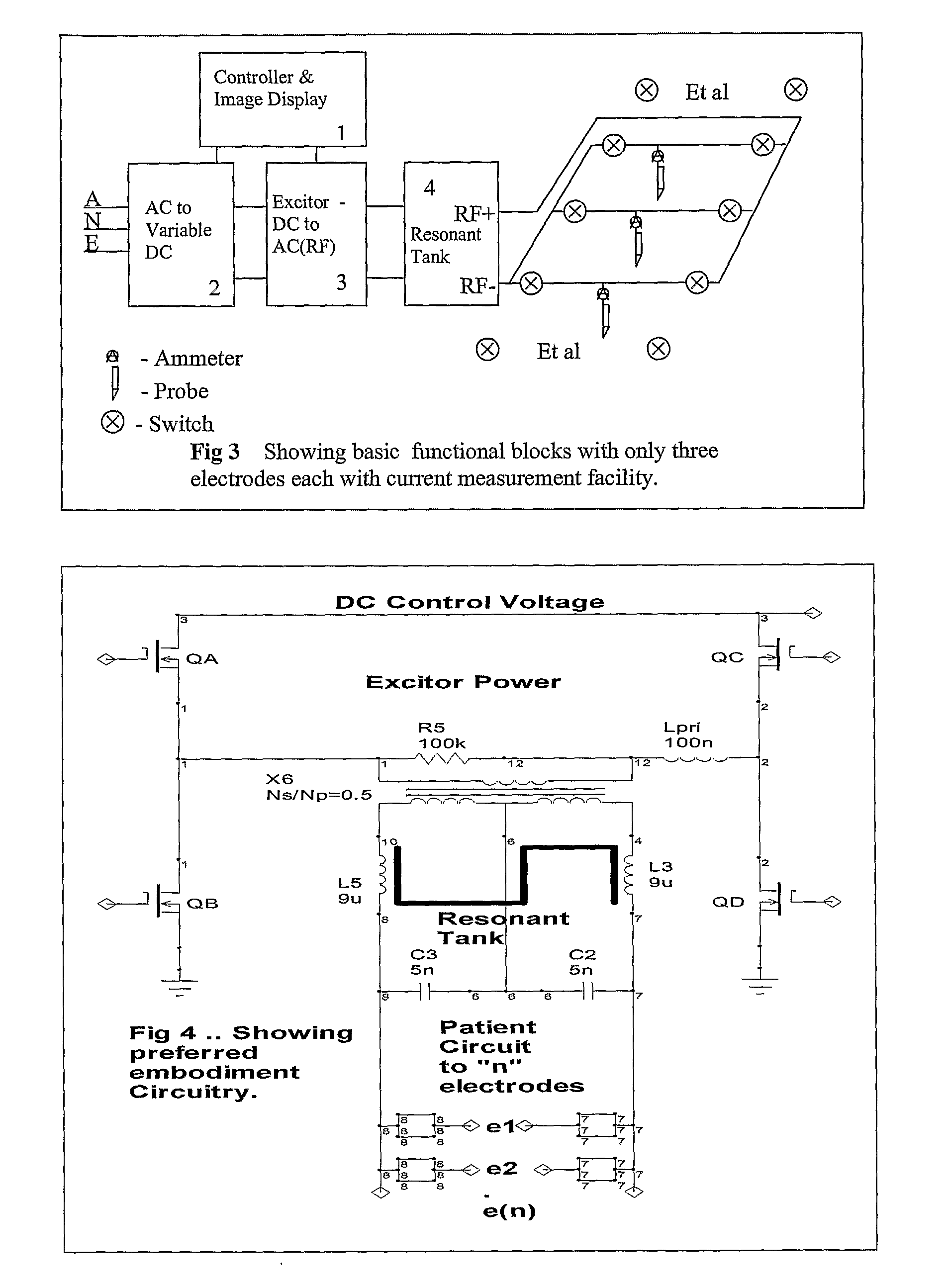

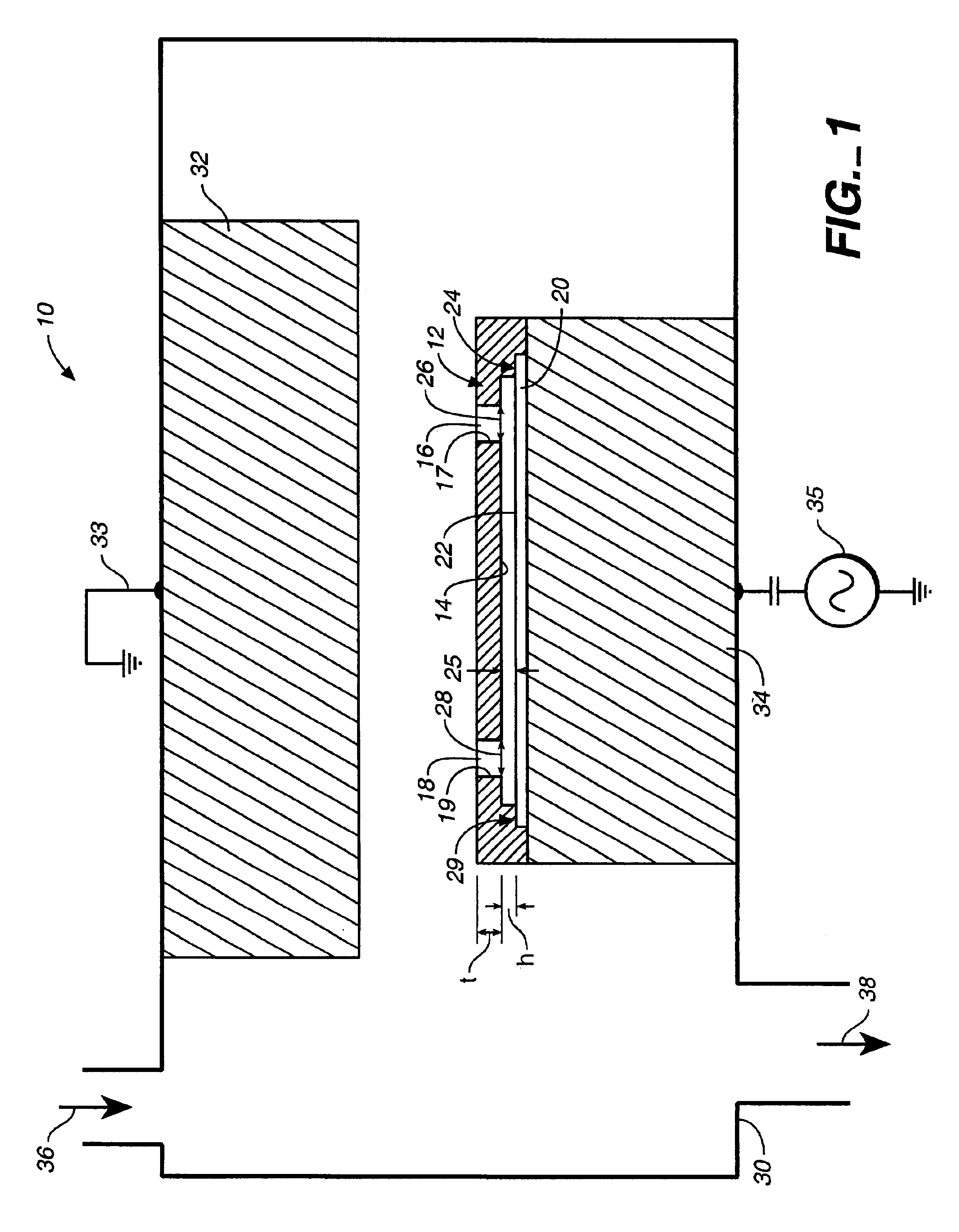

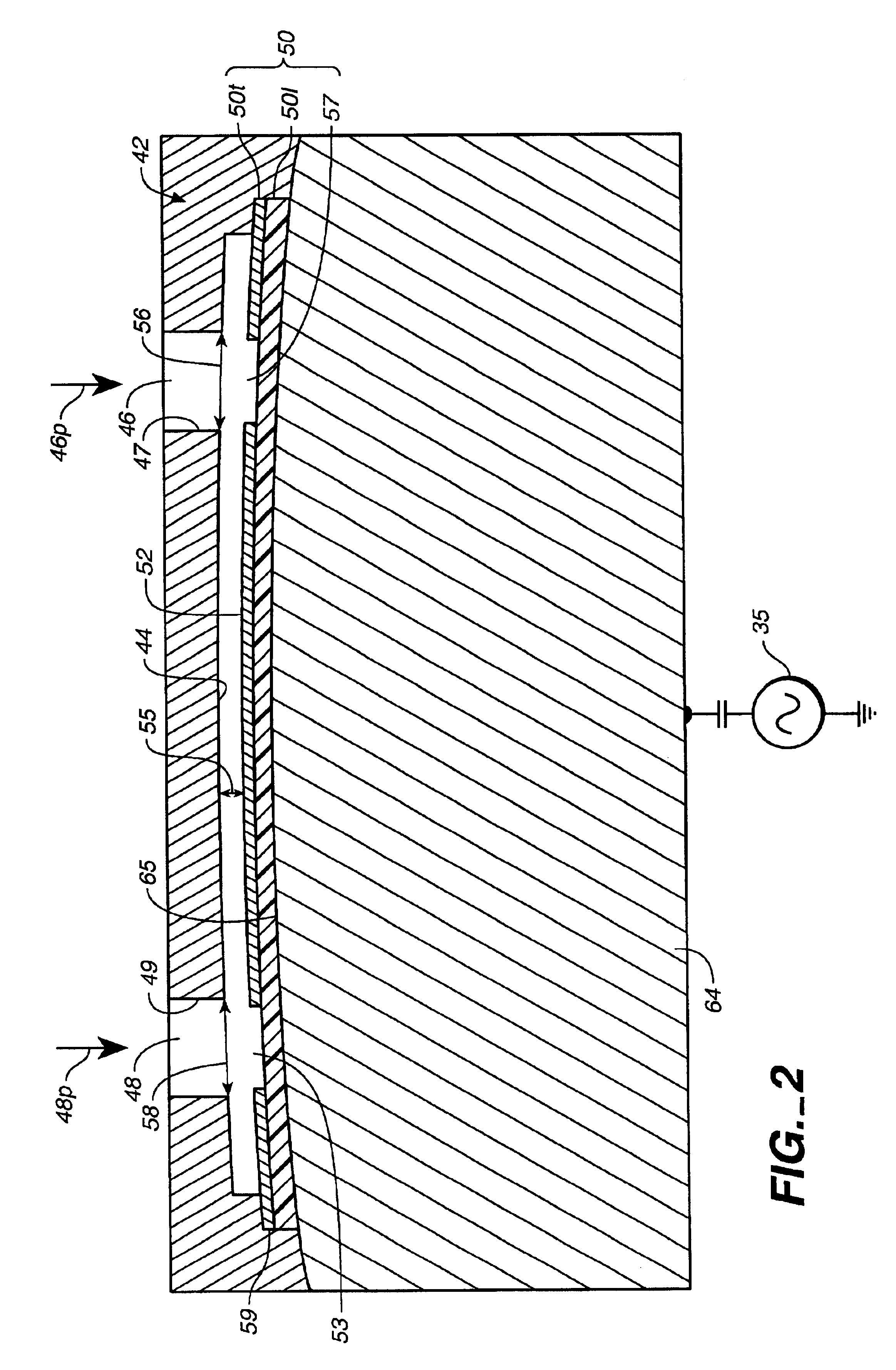

Minimal device and method for effecting hyperthermia derived anesthesia

InactiveUS9031667B2Improve comfortLess chance of physical damageElectrotherapySurgical needlesFiberMammal

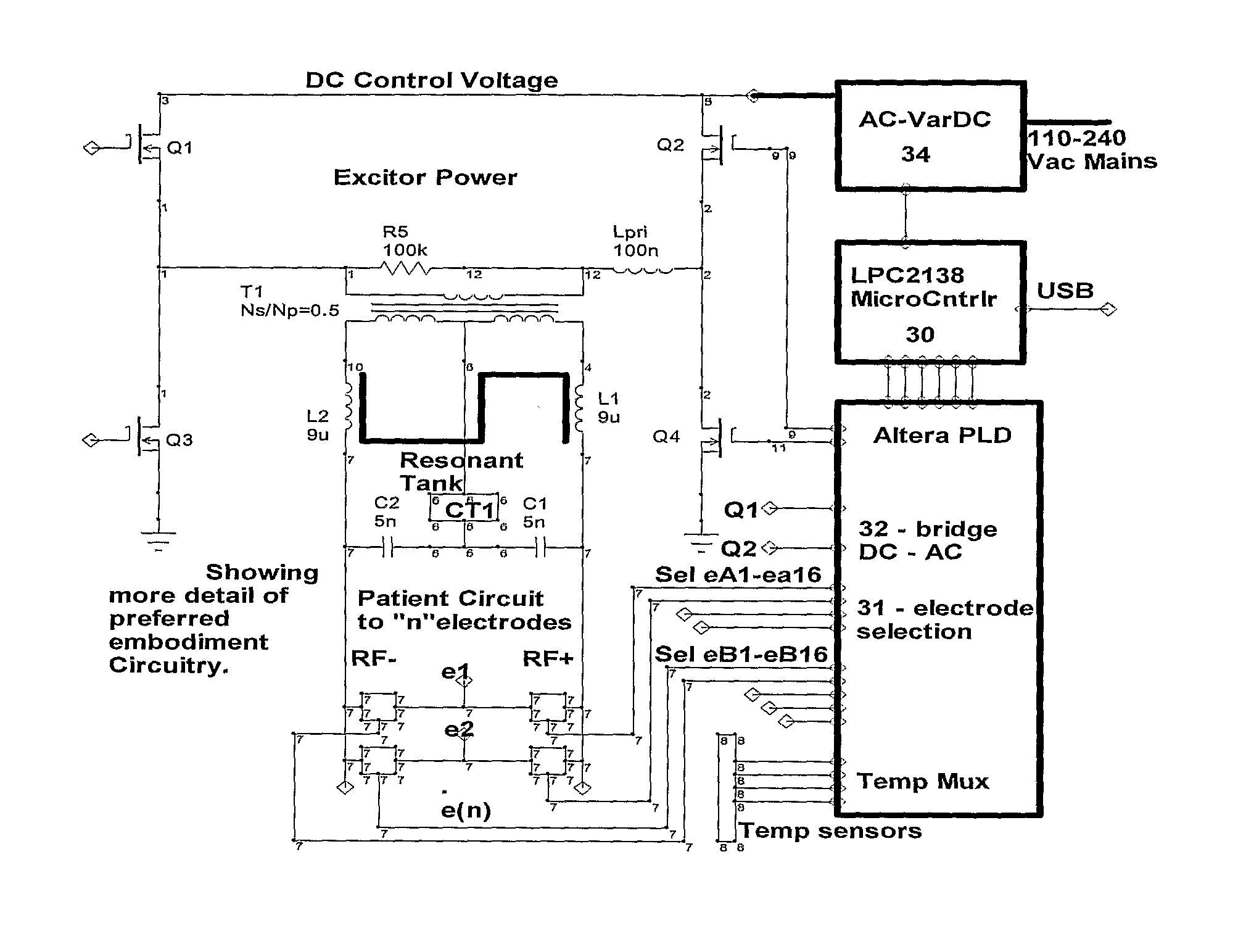

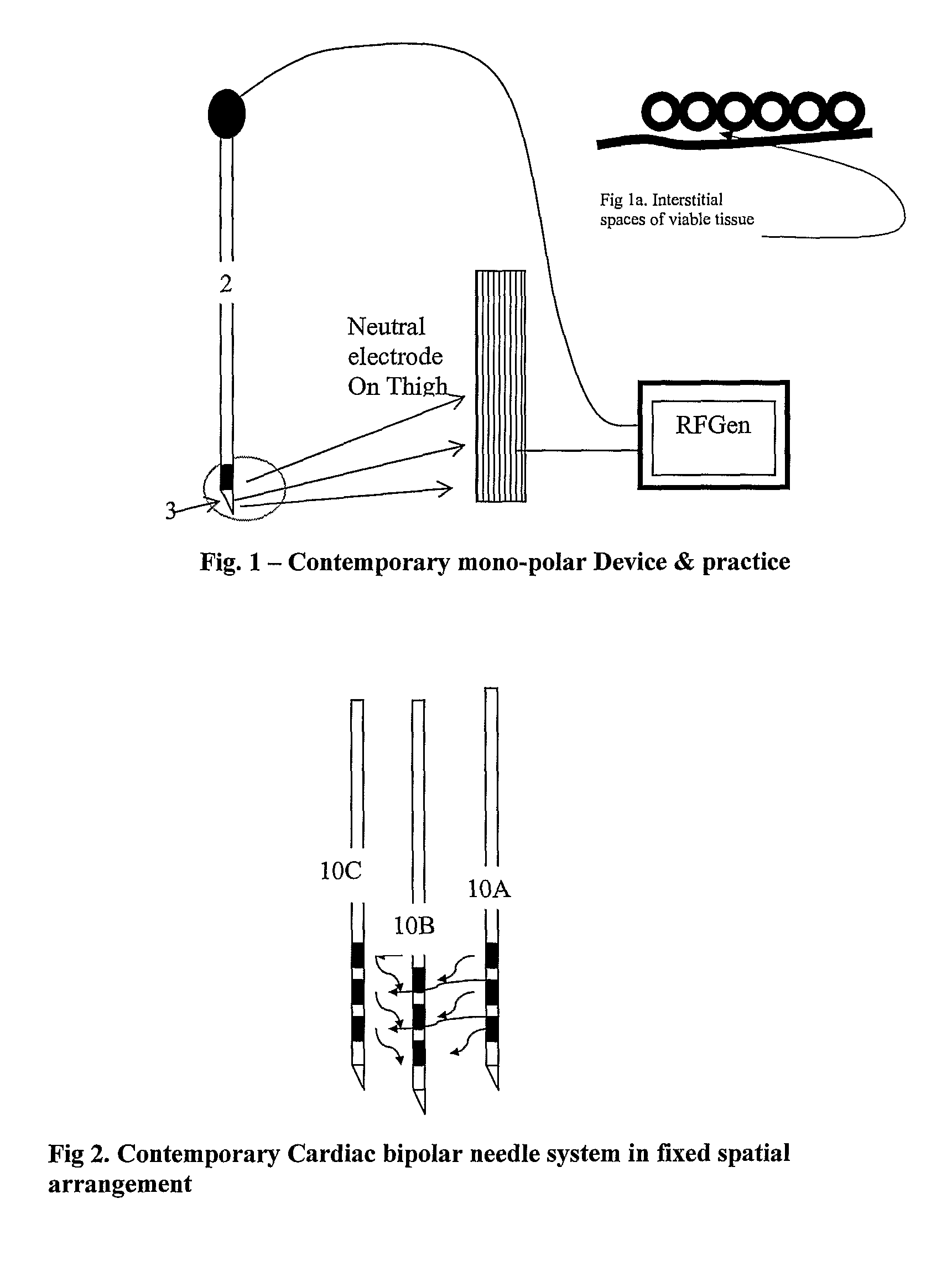

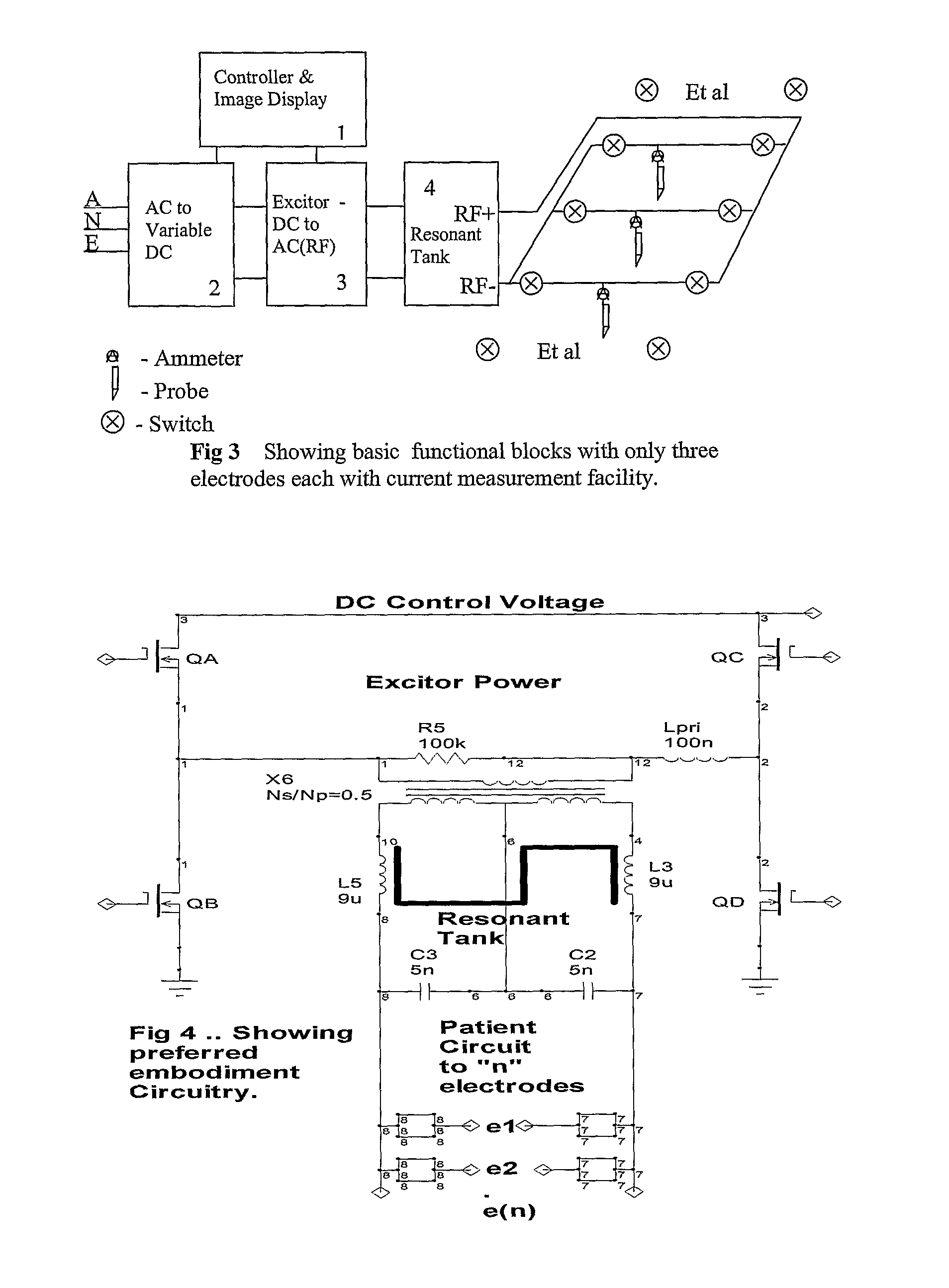

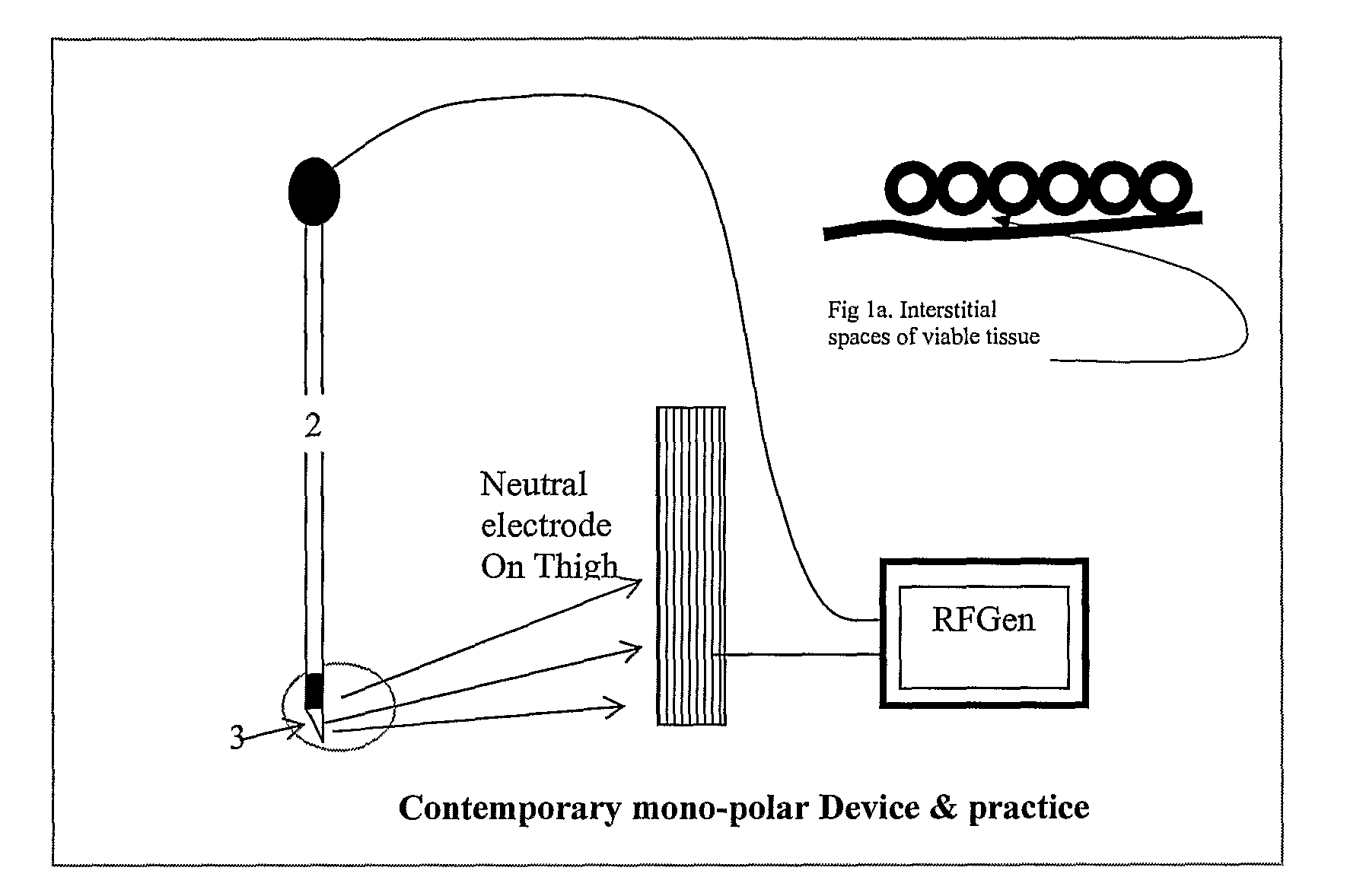

A method and device for inducing anaesthesia in mammals by the application of RF energy to create hyperthermia derived neural anaesthesia. An RF generator drives a plurality of electrodes placed in tissue surrounding the target nerve fiber to desiccate the desired length of nerve fiber to be desiccated in a single deployment. The device allows high-speed selection / de-selection of bipolar electrode pairs or sets under continuous RF excitation. Activation of electrode pairs is adapted in response to sensed current density and temperature (by electrodes not in the current discharge activation phase) in order to create lesions of complex and well defined shape necessary for the production of hyperthermia derived neural anaesthesia.

Owner:INTERVENTION TECH

Minimal Device and Method for Effecting Hyperthermia Derived Anesthesia

InactiveUS20080262490A1Improve comfortLess chance of physical damageElectrotherapySurgical needlesFiberMedicine

A method and device for inducing anaesthesia in mammals by the application of RF energy to create hyperthermia derived neural anaesthesia. An RF generator drives a plurality of electrodes placed in tissue surrounding the target nerve fibre to desiccate the desired length of nerve fibre to be desiccated in a single deployment. The device allows high-speed selection / de-selection of bipolar electrode pairs or sets under continuous RF excitation. Activation of electrode pairs is adapted in response to sensed current density and temperature (by electrodes not in the current discharge activation phase) in order to create lesions of complex and well defined shape necessary for the production of hyperthermia derived neural anaesthesia.

Owner:INTERVENTION TECH

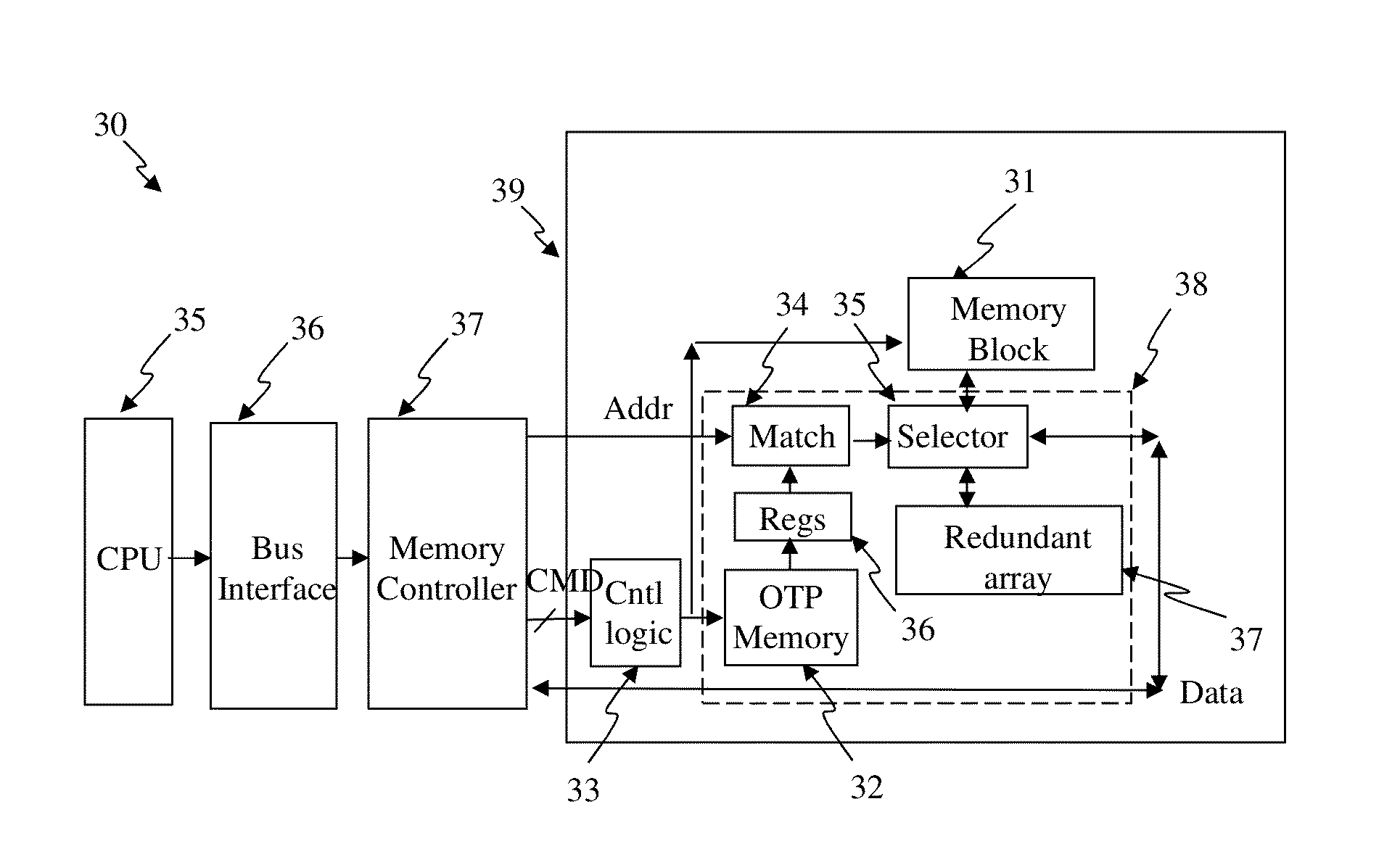

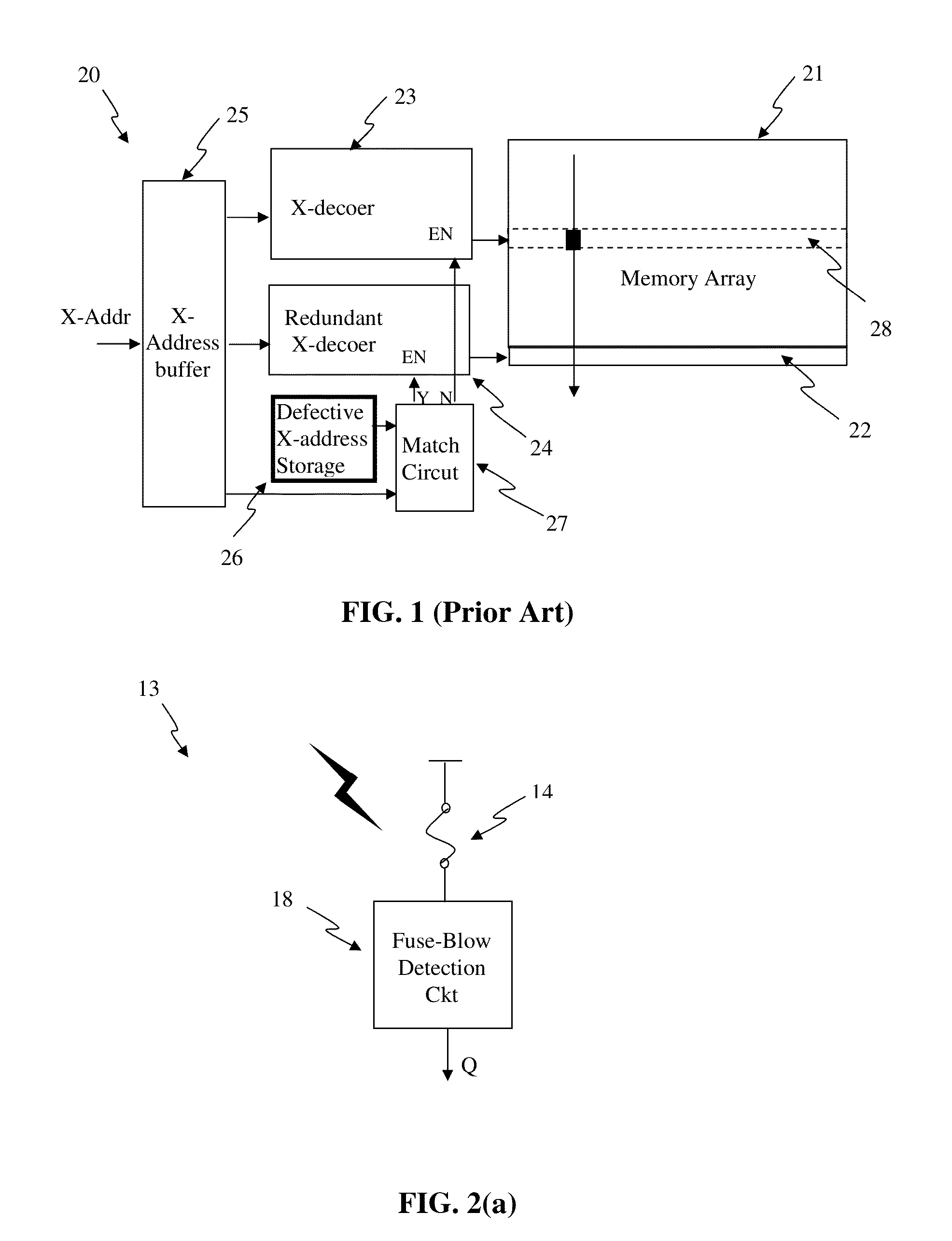

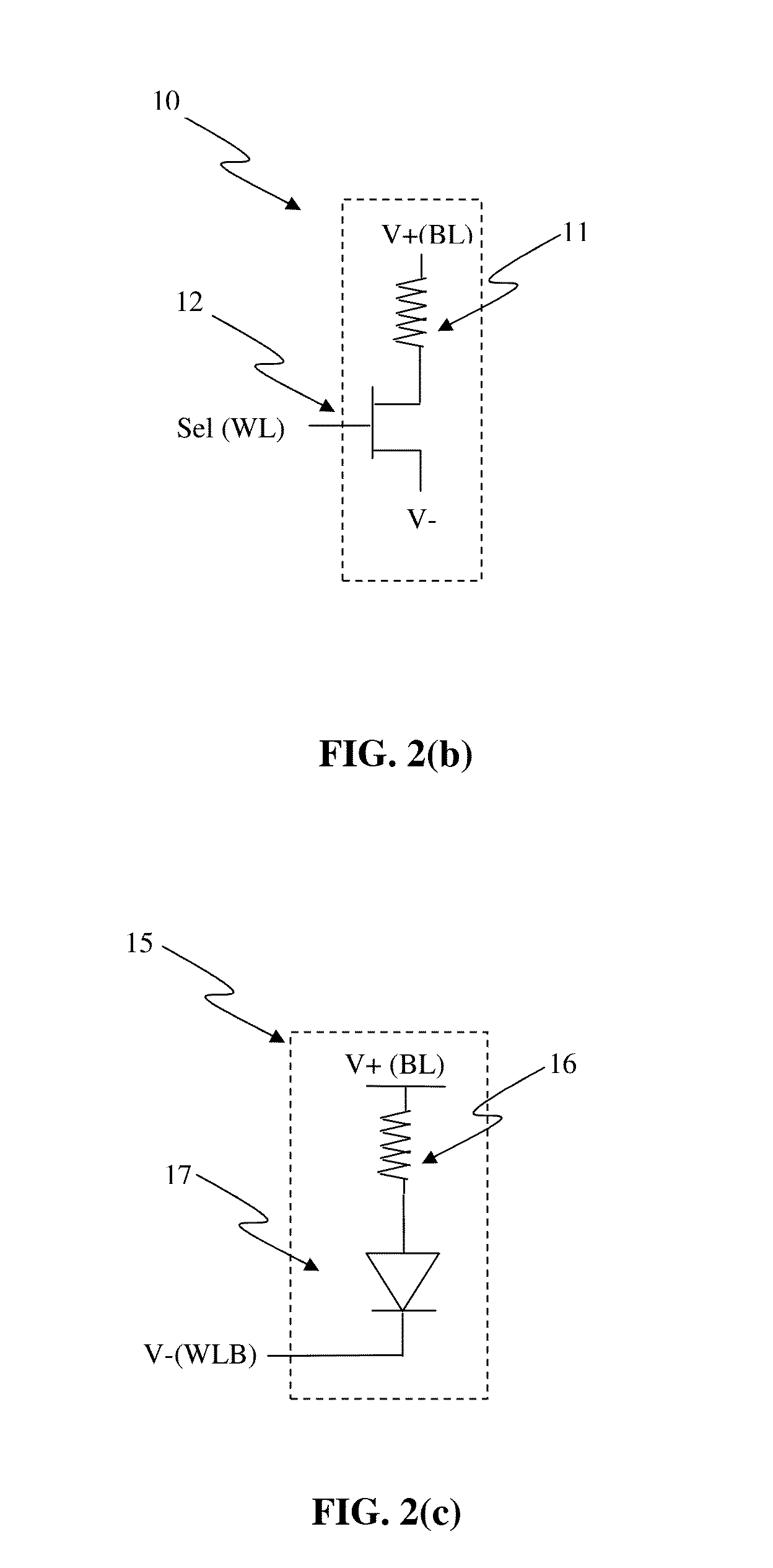

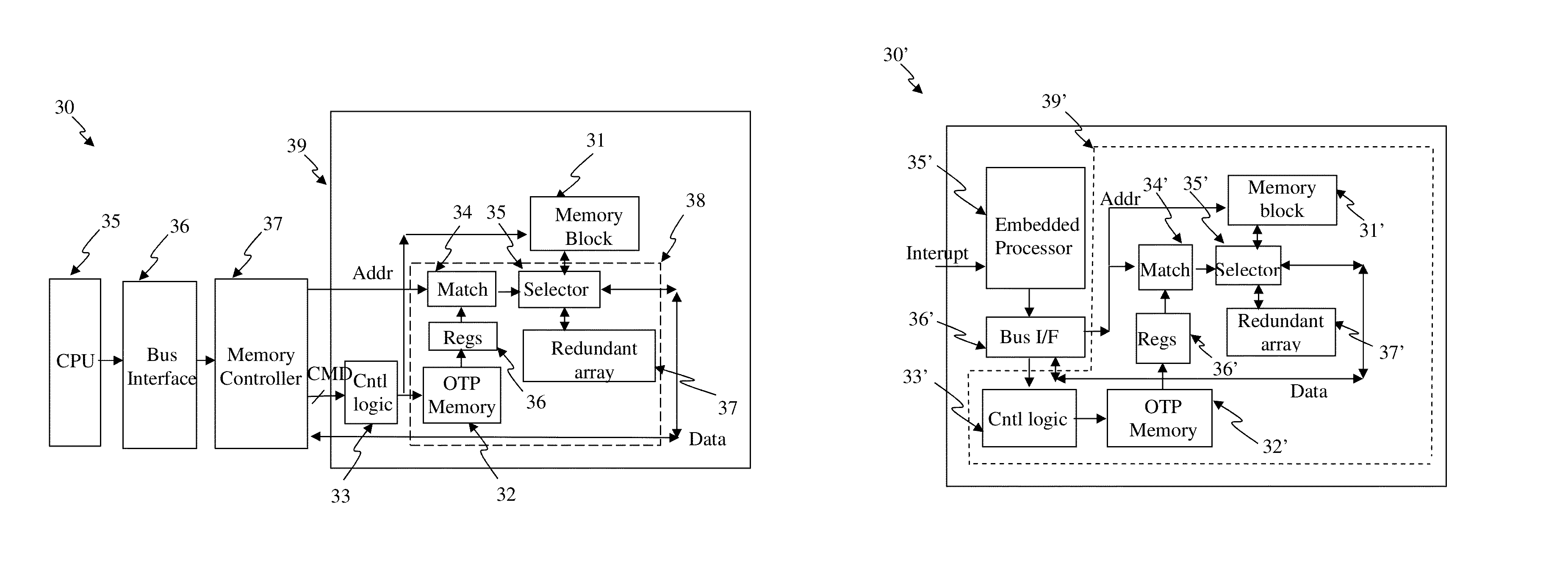

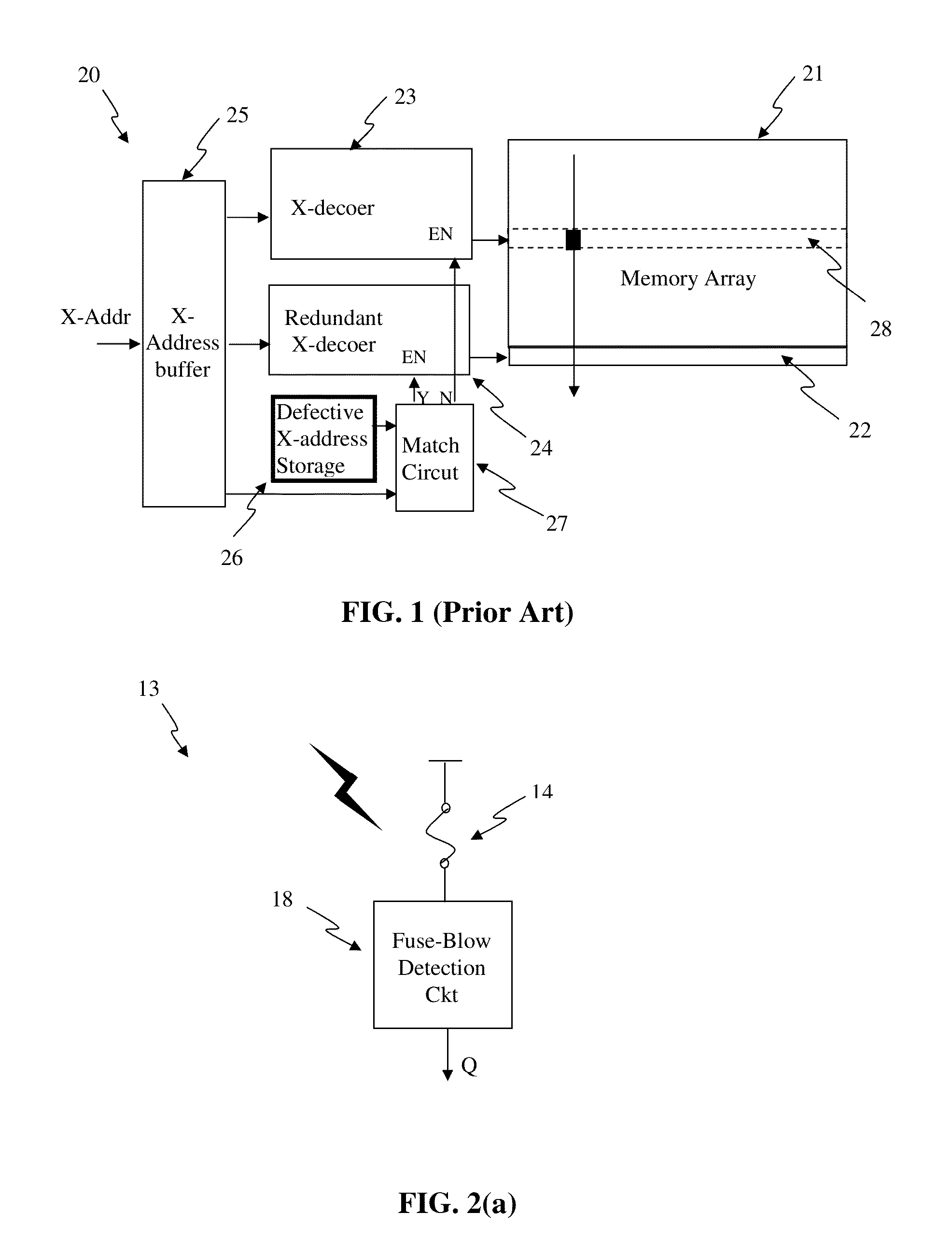

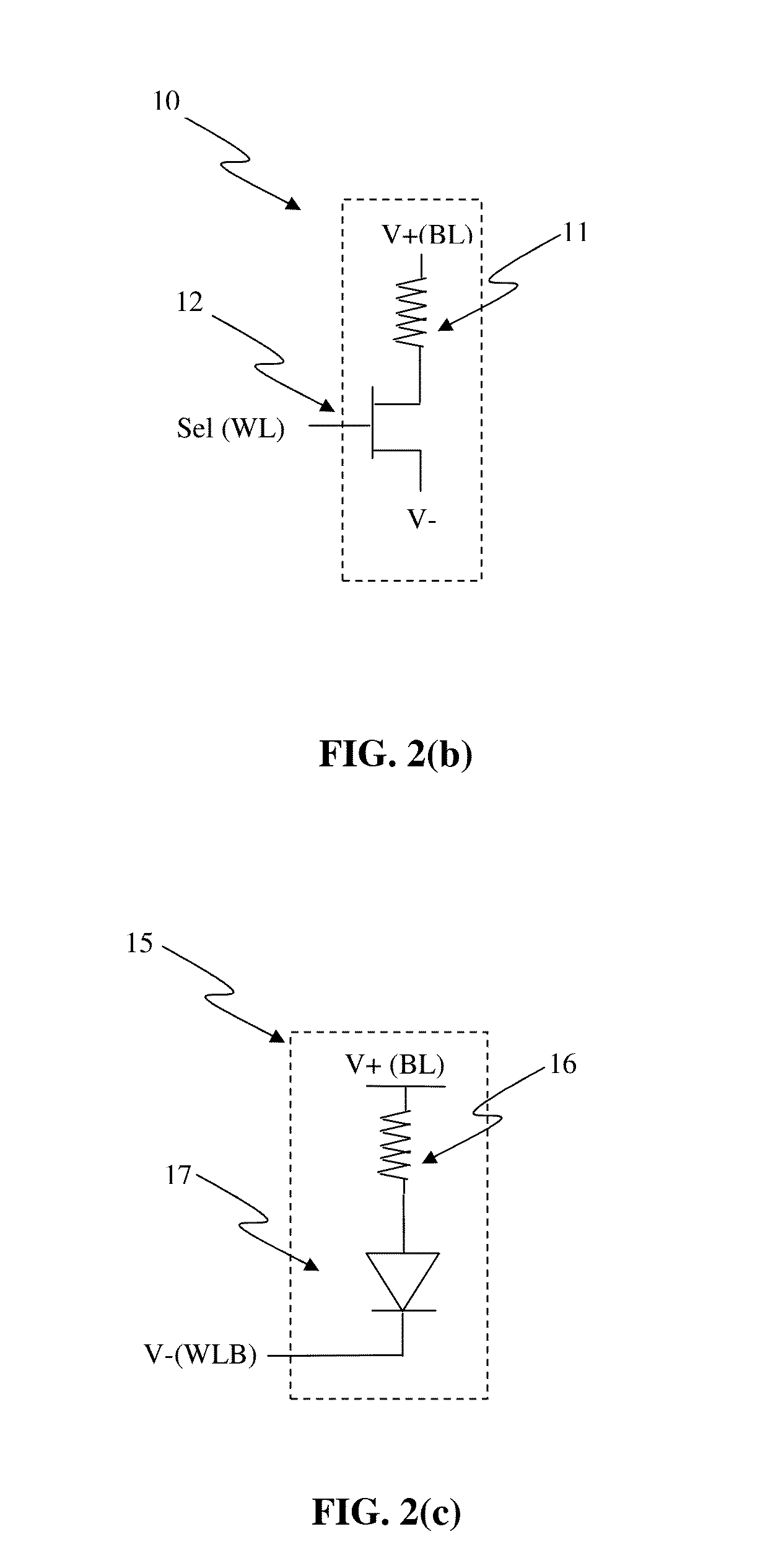

System and method of in-system repairs or configurations for memories

In-system repairing or configuring faulty memories after being used in a system are disclosed. In one embodiment, a memory chip can include at least one OTP memory to store defective addresses that are to be repaired. Advantageously, the OTP memory can operate without requiring additional I / O pins or high voltage supplies for reading or programming. The memory chip can also include control logic to control reading or programming of the OTP memory as needed.

Owner:ATTOPSEMI TECH CO LTD

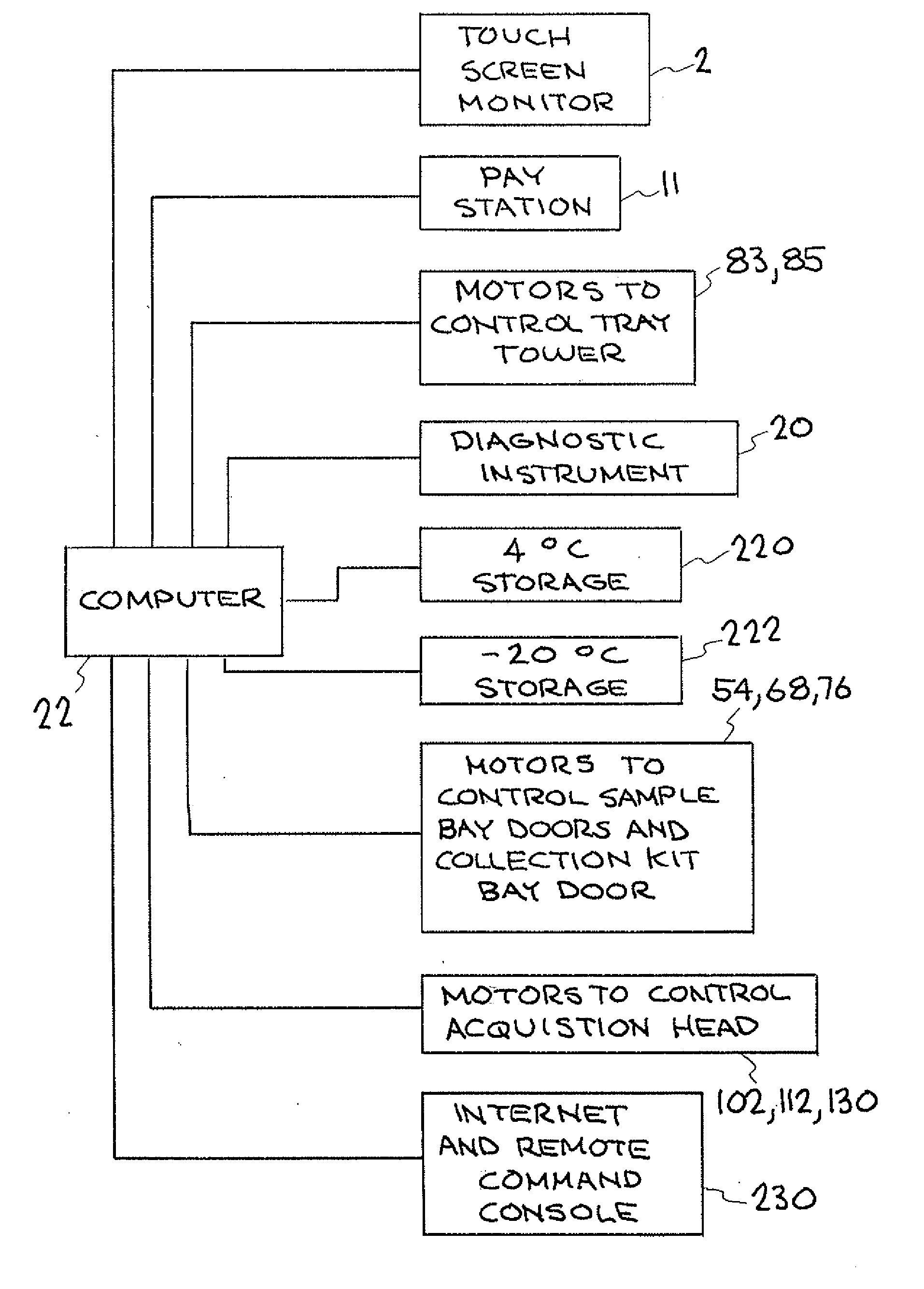

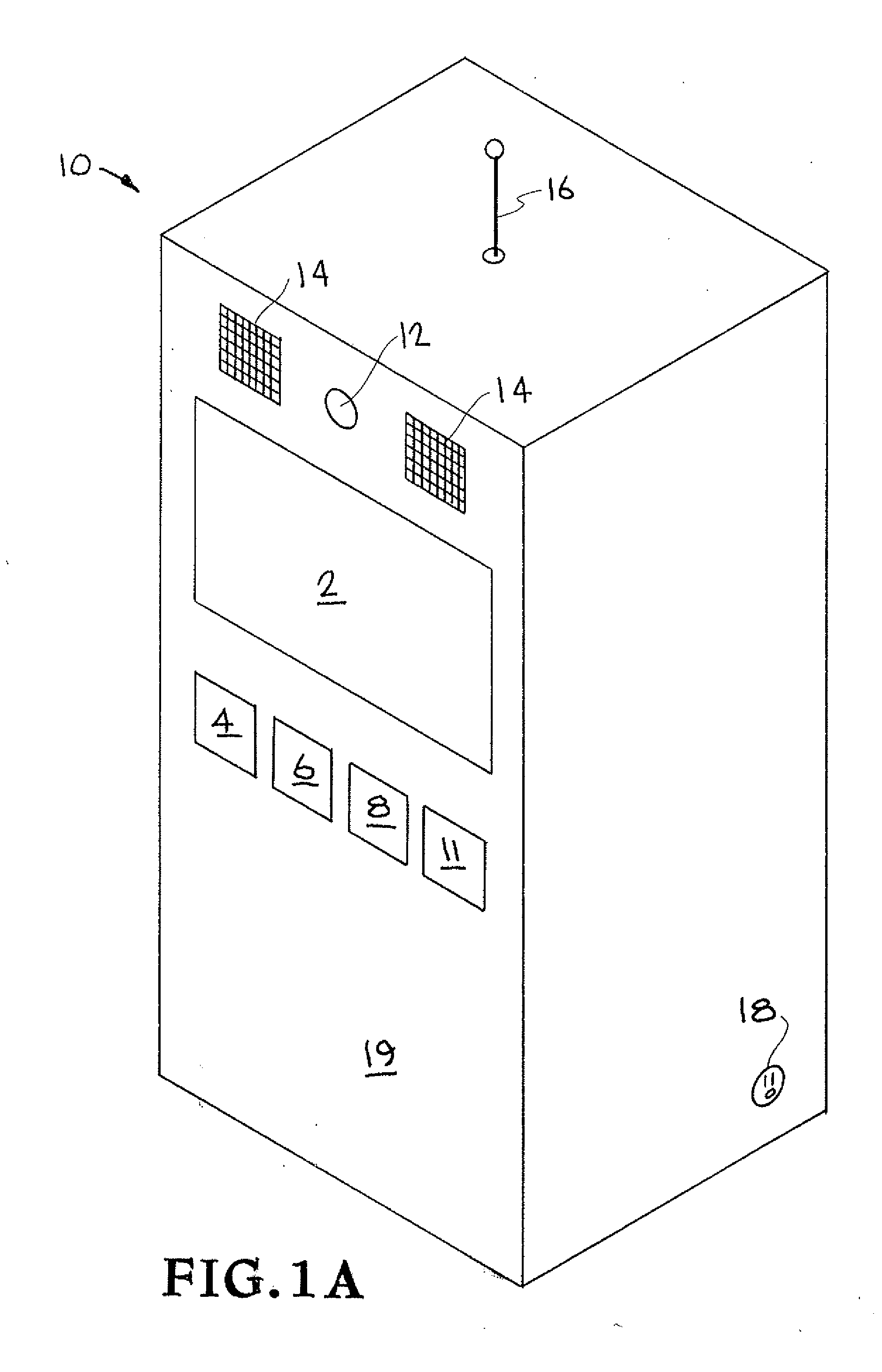

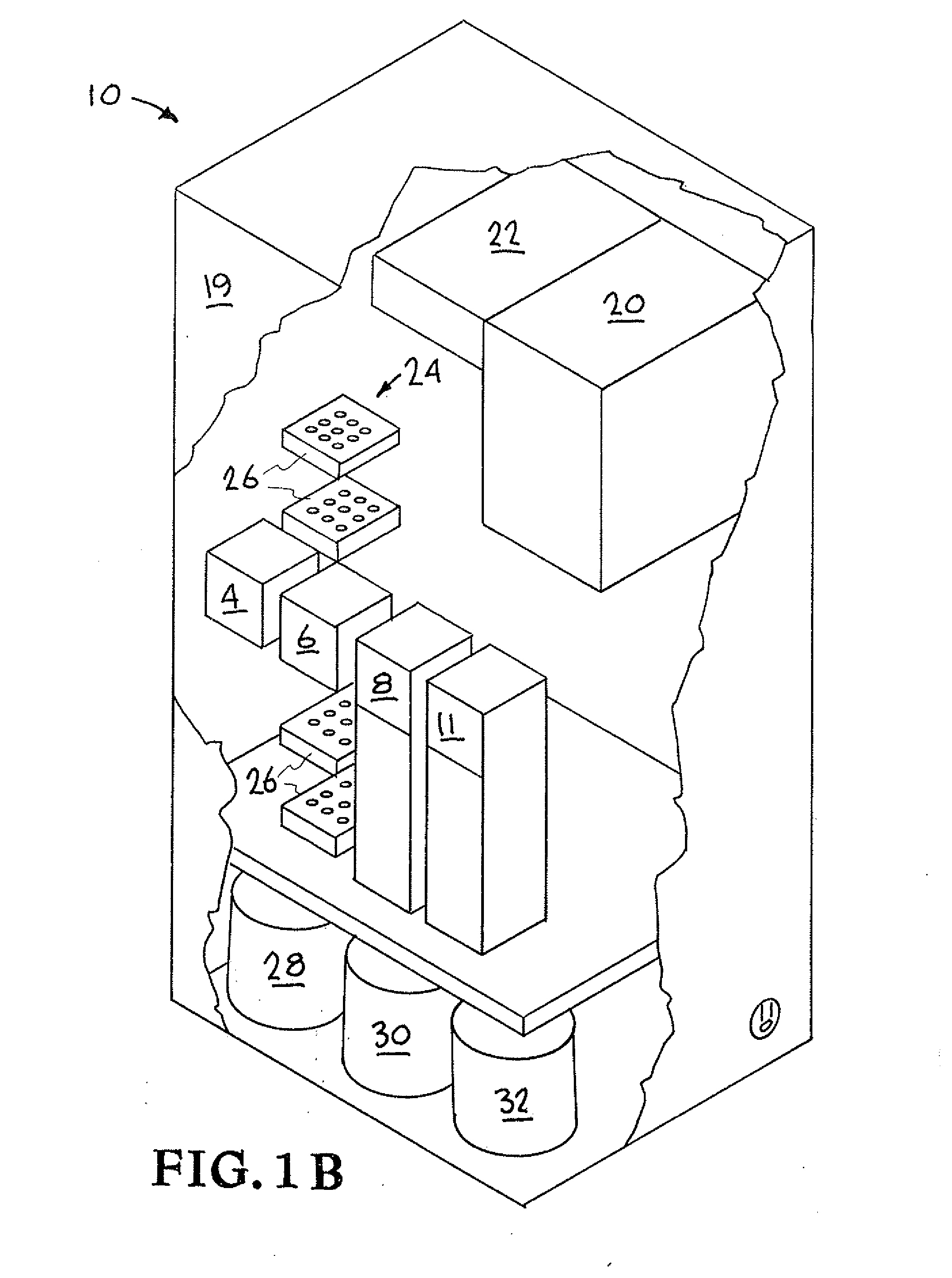

Automated diagnostic kiosk for diagnosing diseases

ActiveUS20100152885A1Costly and time-consumeReduce overcrowdingSamplingDigital data processing detailsPaymentMedicine

An automated and autonomous diagnostic apparatus that is capable of dispensing collection vials and collections kits to users interesting in collecting a biological sample and submitting their collected sample contained within a collection vial into the apparatus for automated diagnostic services. The user communicates with the apparatus through a touch-screen monitor. A user is able to enter personnel information into the apparatus including medical history, insurance information, co-payment, and answer a series of questions regarding their illness, which is used to determine the assay most likely to yield a positive result. Remotely-located physicians can communicate with users of the apparatus using video tele-medicine and request specific assays to be performed. The apparatus archives submitted samples for additional testing. Users may receive their assay results electronically. Users may allow the uploading of their diagnoses into a central databank for disease surveillance purposes.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

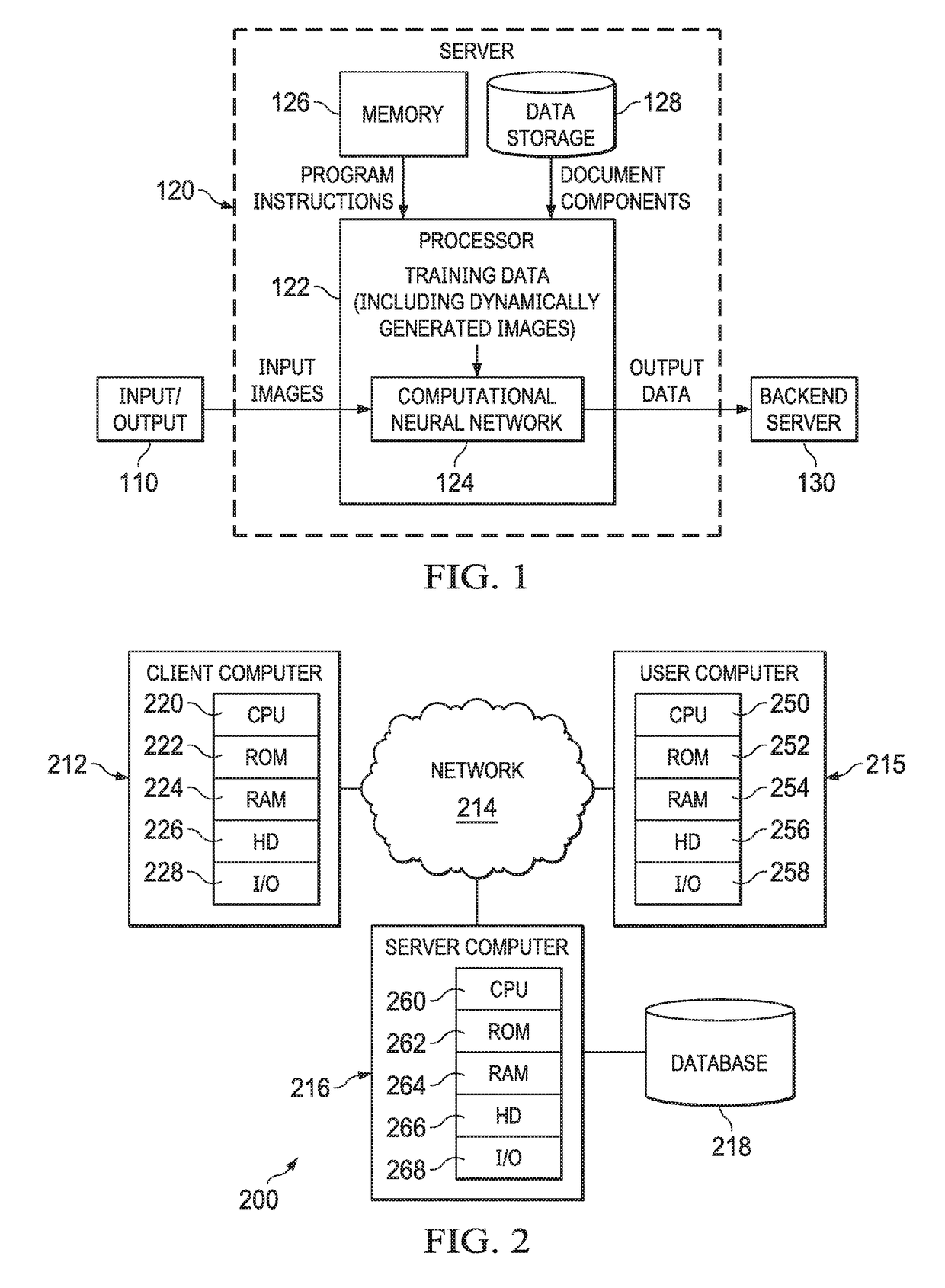

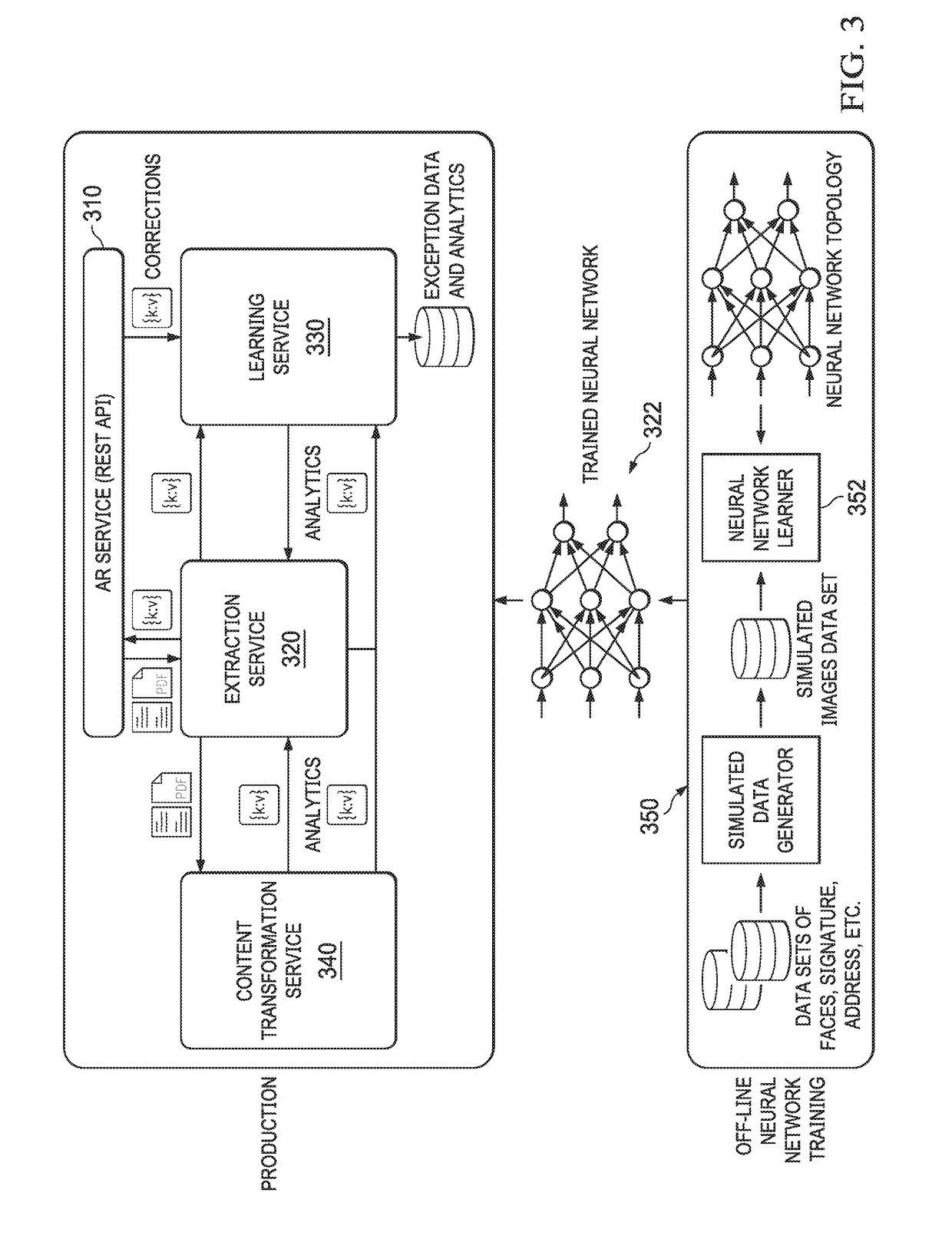

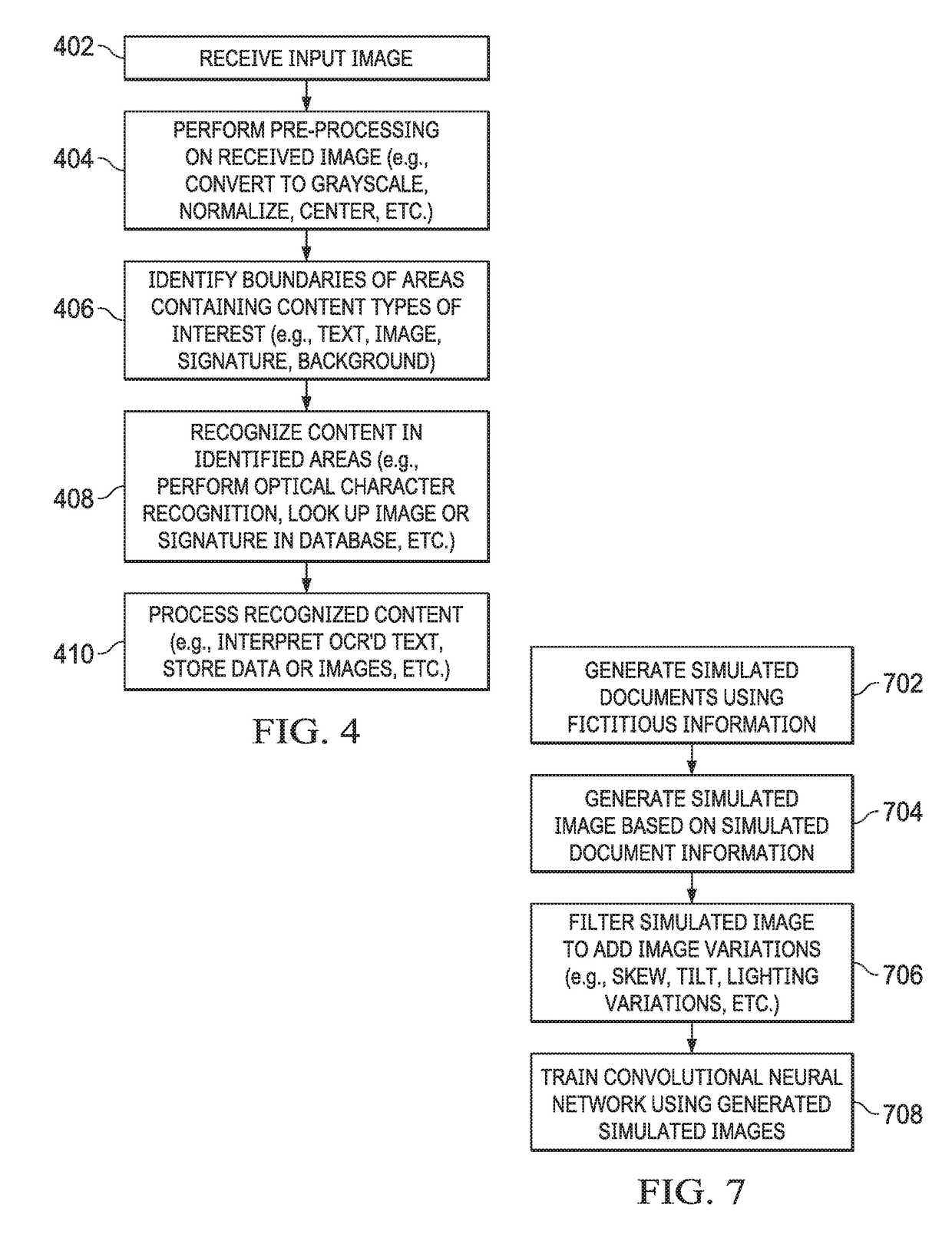

Systems and methods for image based content capture and extraction utilizing deep learning neural network and bounding box detection training techniques

ActiveUS20190019020A1Improve robustnessImprove efficiencyNeural learning methodsCharacter recognitionNerve networkDocumentation

Systems, methods and computer program products for image recognition in which instructions are executable by a processor to dynamically generate simulated documents and corresponding images, which are then used to train a fully convolutional neural network. A plurality of document components are provided, and the processor selects subsets of the document components. The document components in each subset are used to dynamically generate a corresponding simulated document and a simulated document image. The convolutional neural network processes the simulated document image to produce a recognition output. Information corresponding to the document components from which the image was generated is used as an expected output. The recognition output and expected output are compared, and weights of the convolutional neural network are adjusted based on the differences between them.

Owner:OPEN TEXT CORPORATION

System and method of in-system repairs or configurations for memories

ActiveUS8913449B2Low costCostly and time-consumeRead-only memoriesDigital storageMemory chipHigh pressure

In-system repairing or configuring faulty memories after being used in a system. In one embodiment, a memory chip can include at least one OTP memory to store defective addresses that are to be repaired. The OTP memory can operate without requiring additional I / O pins or high voltage supplies for reading or programming. The memory chip can also include control logic to control reading or programming of the OTP memory as needed.

Owner:ATTOPSEMI TECH CO LTD

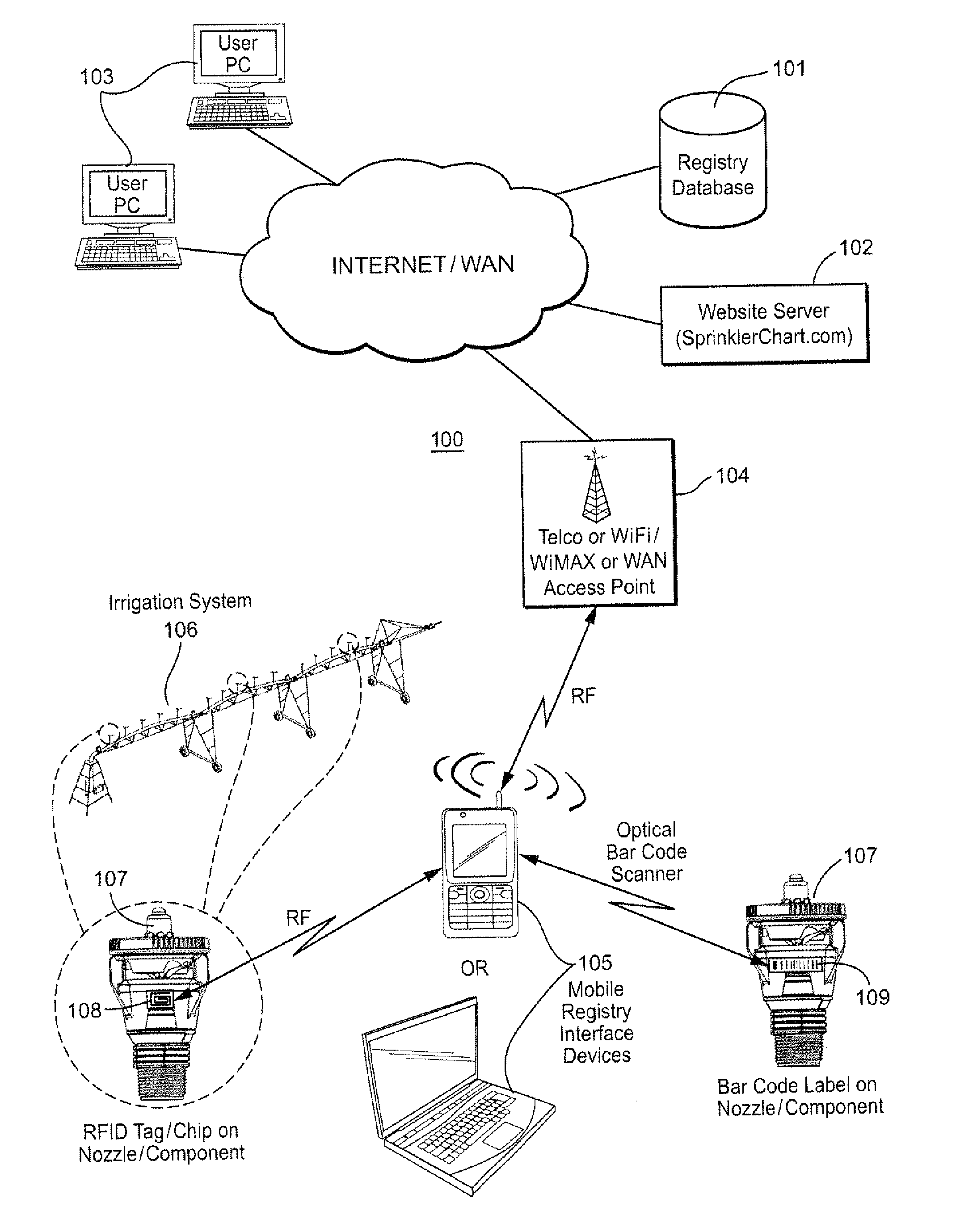

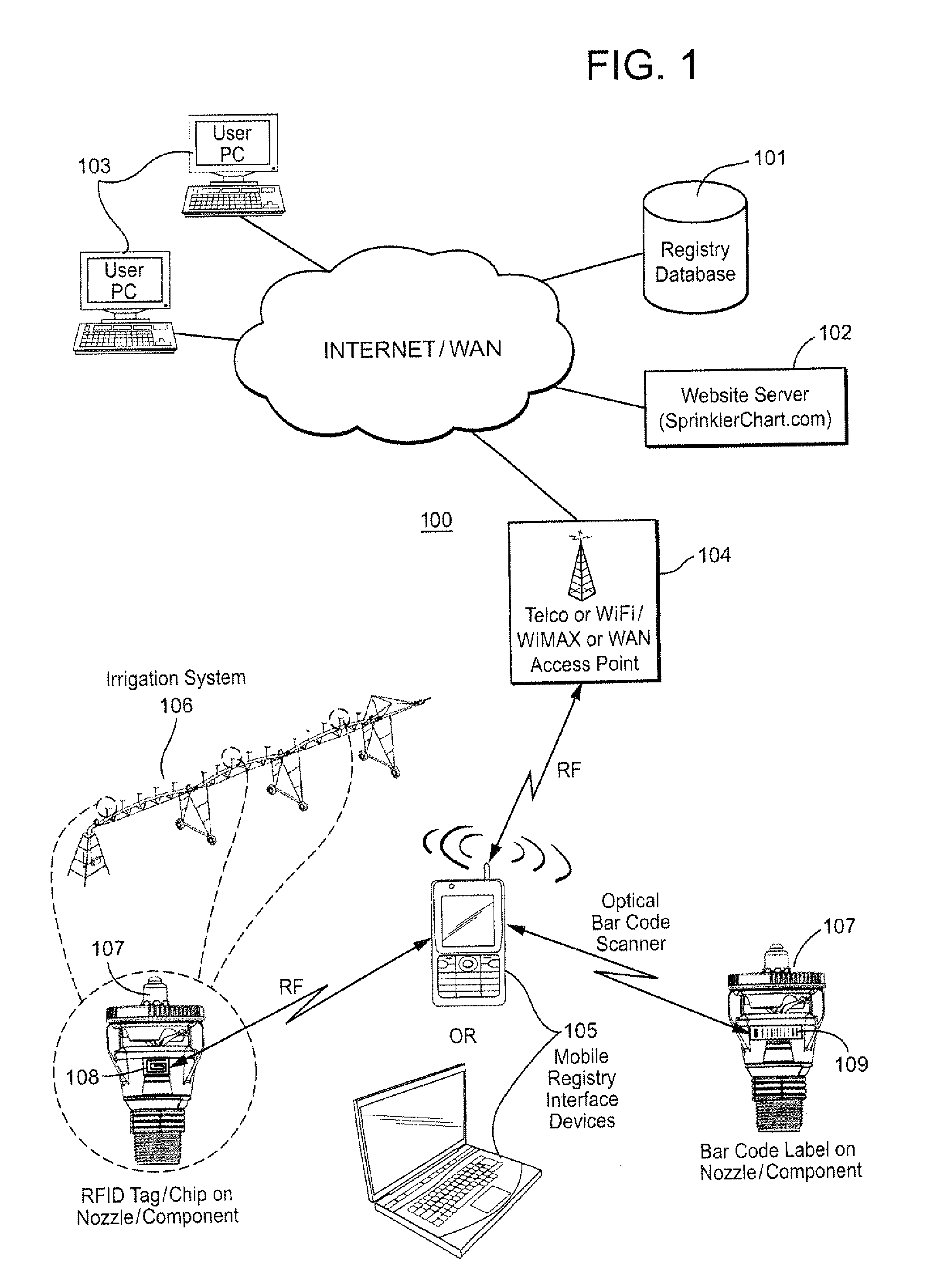

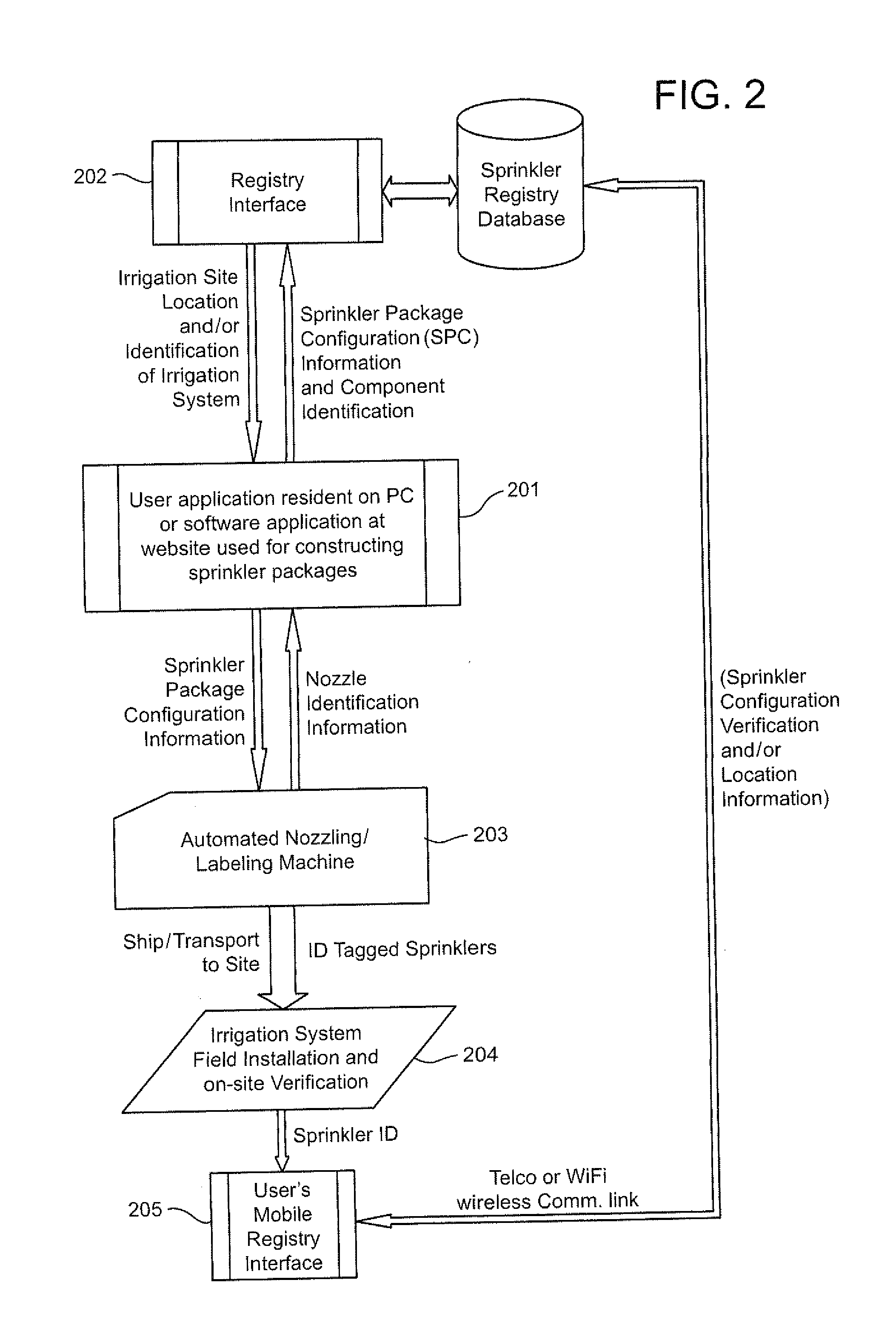

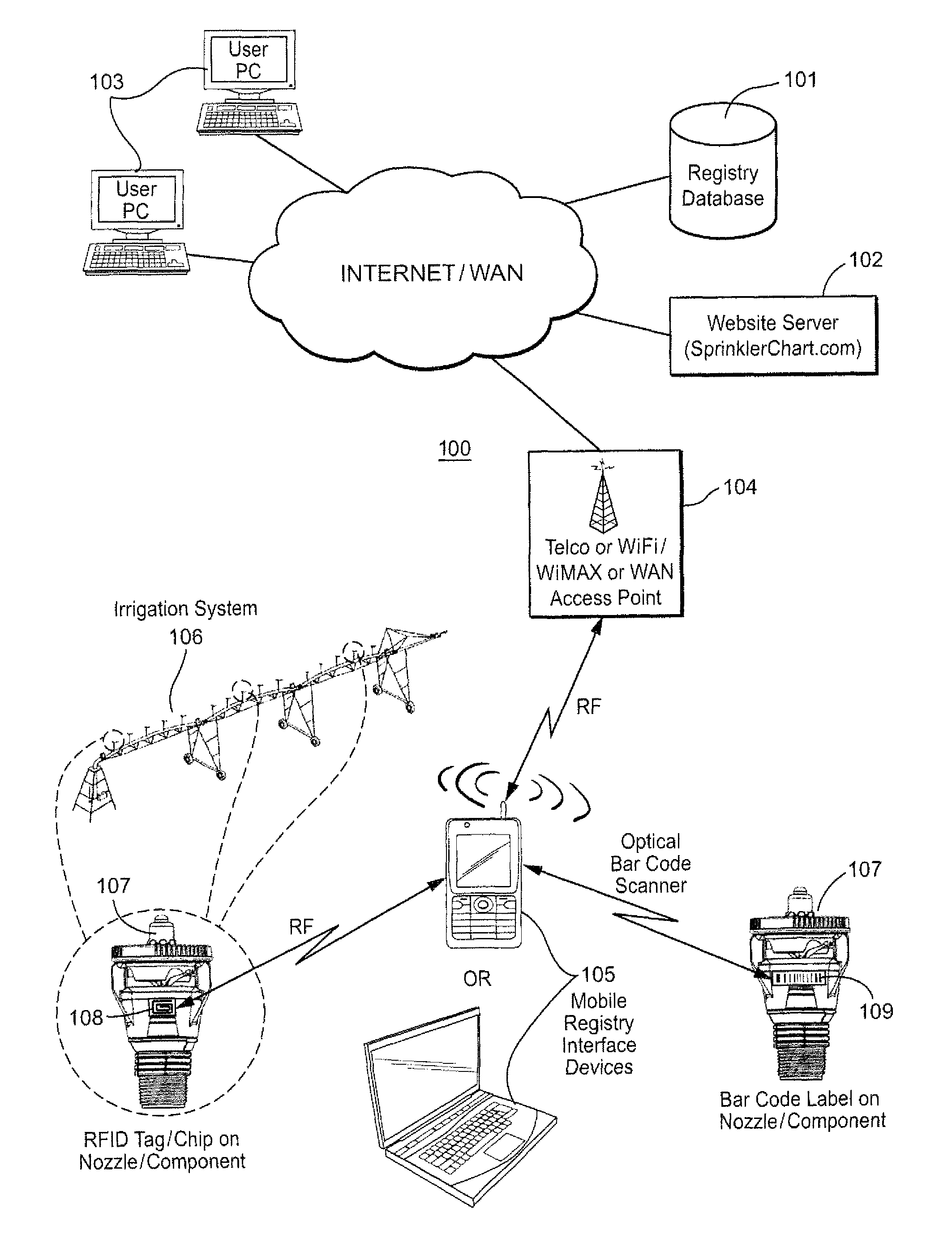

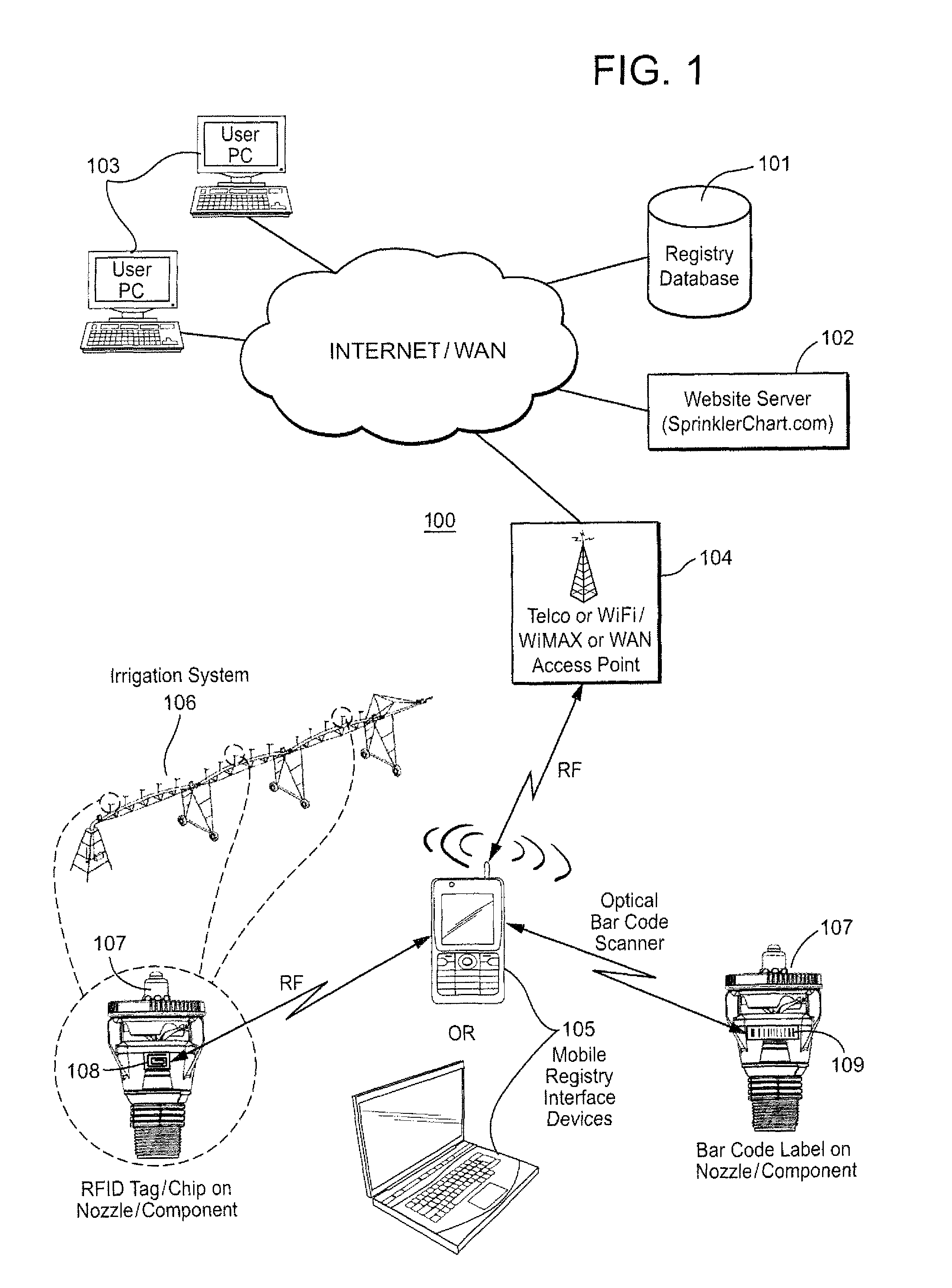

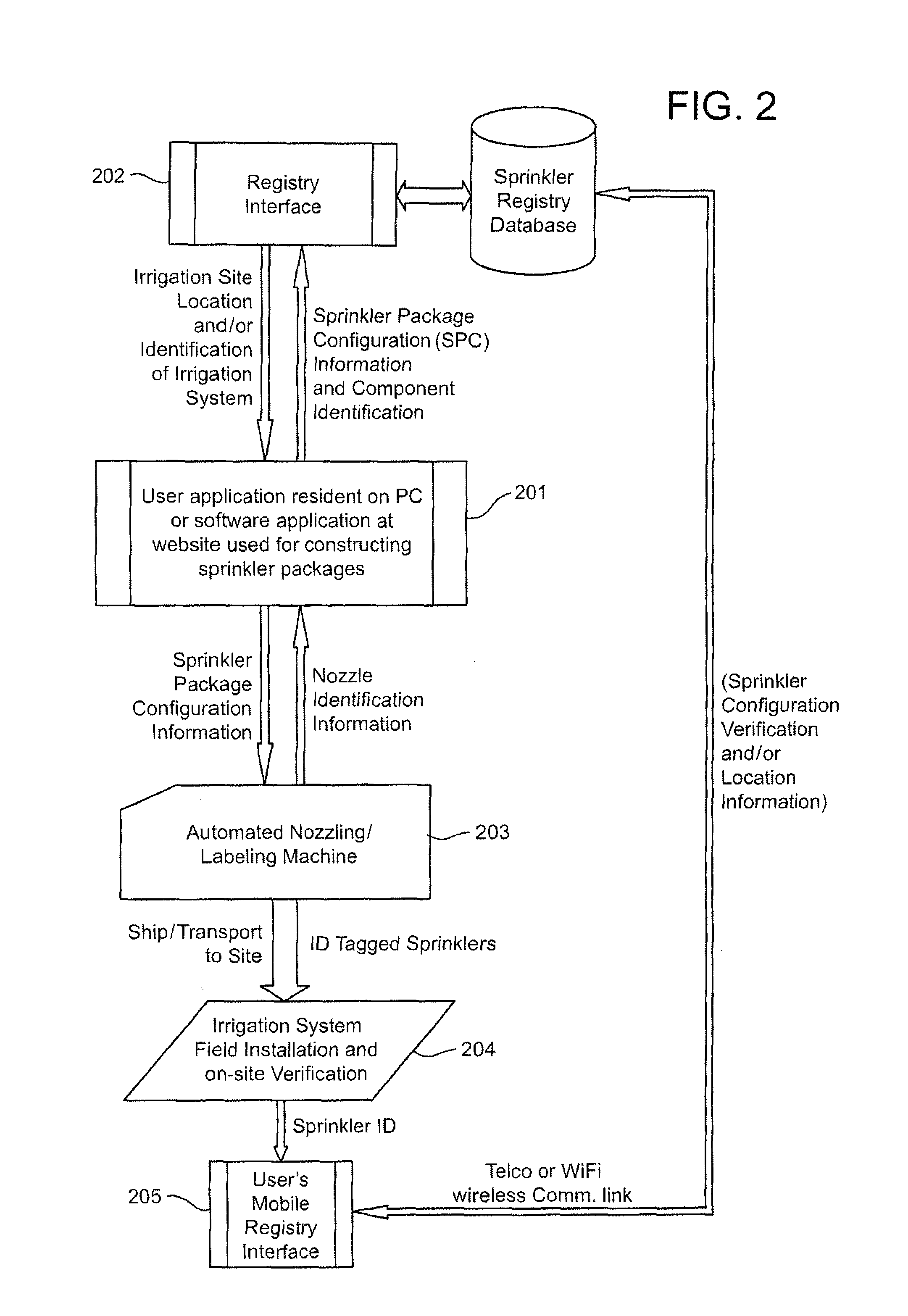

Method and apparatus for irrigation system design registration and on-site sprinkler package configuration verification

ActiveUS20120254784A1Convenient verificationMaximize efficiencyData processing applicationsInput/output processes for data processingSystems designLocation aware

Internet-accessible system and method for customized design and on-site verification of agriculture irrigation systems includes one or more of: 1) sprinkler package configuration software operable on a user's PC or accessible via an Internet website, 2) Internet-accessible proprietary irrigation system registry database and user interface, 3) computer-controlled automated component selection and labeling system for placing barcode or RFID information on components, and 4) portable wireless location-aware communication device operable at or near an irrigation site for accessing the registry database and obtaining sprinkler package configuration information specific to a particular irrigation system based on location and / or a particular irrigation system component detected in proximity to the portable communication device.

Owner:NELSON IRRIGATION

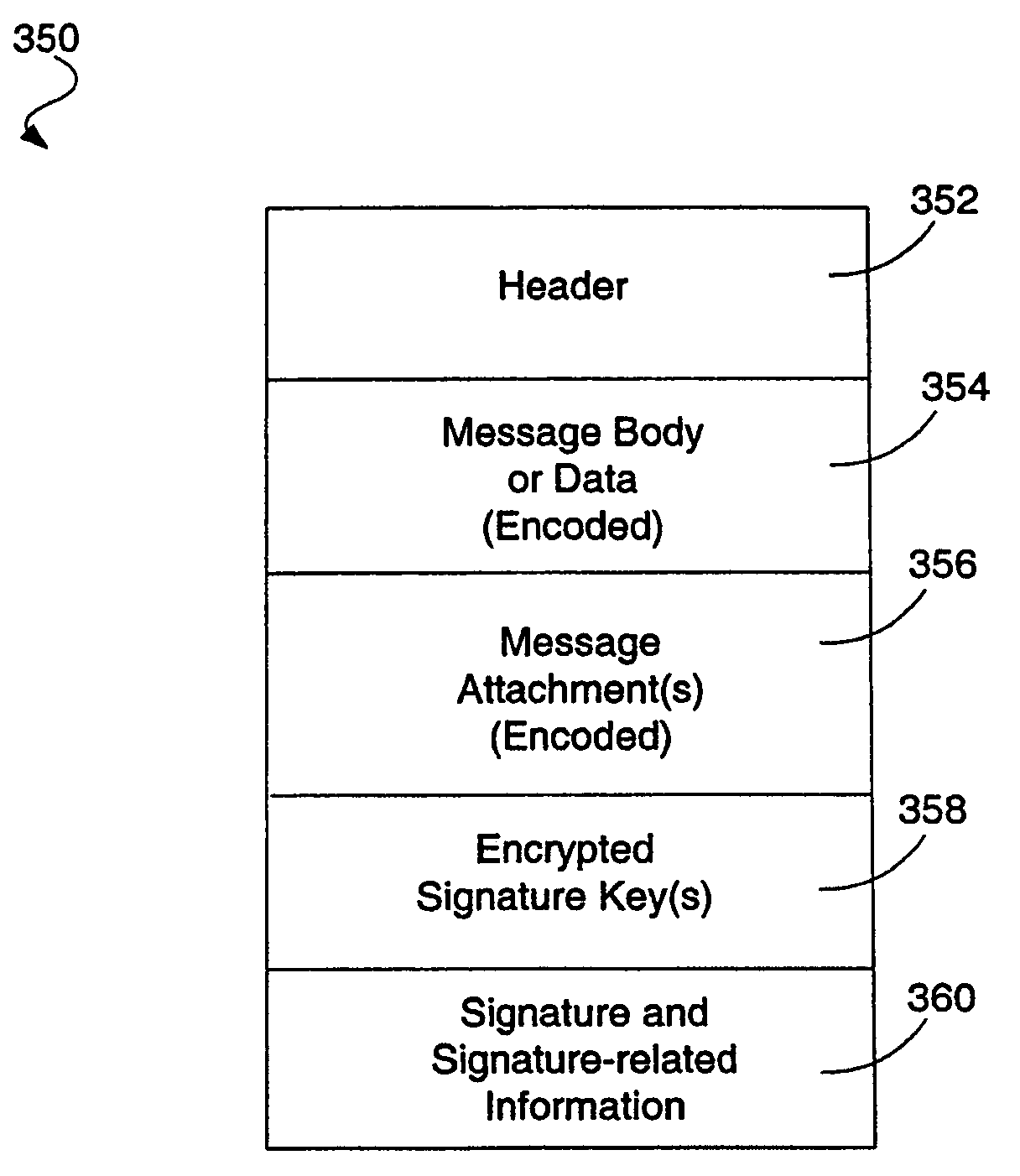

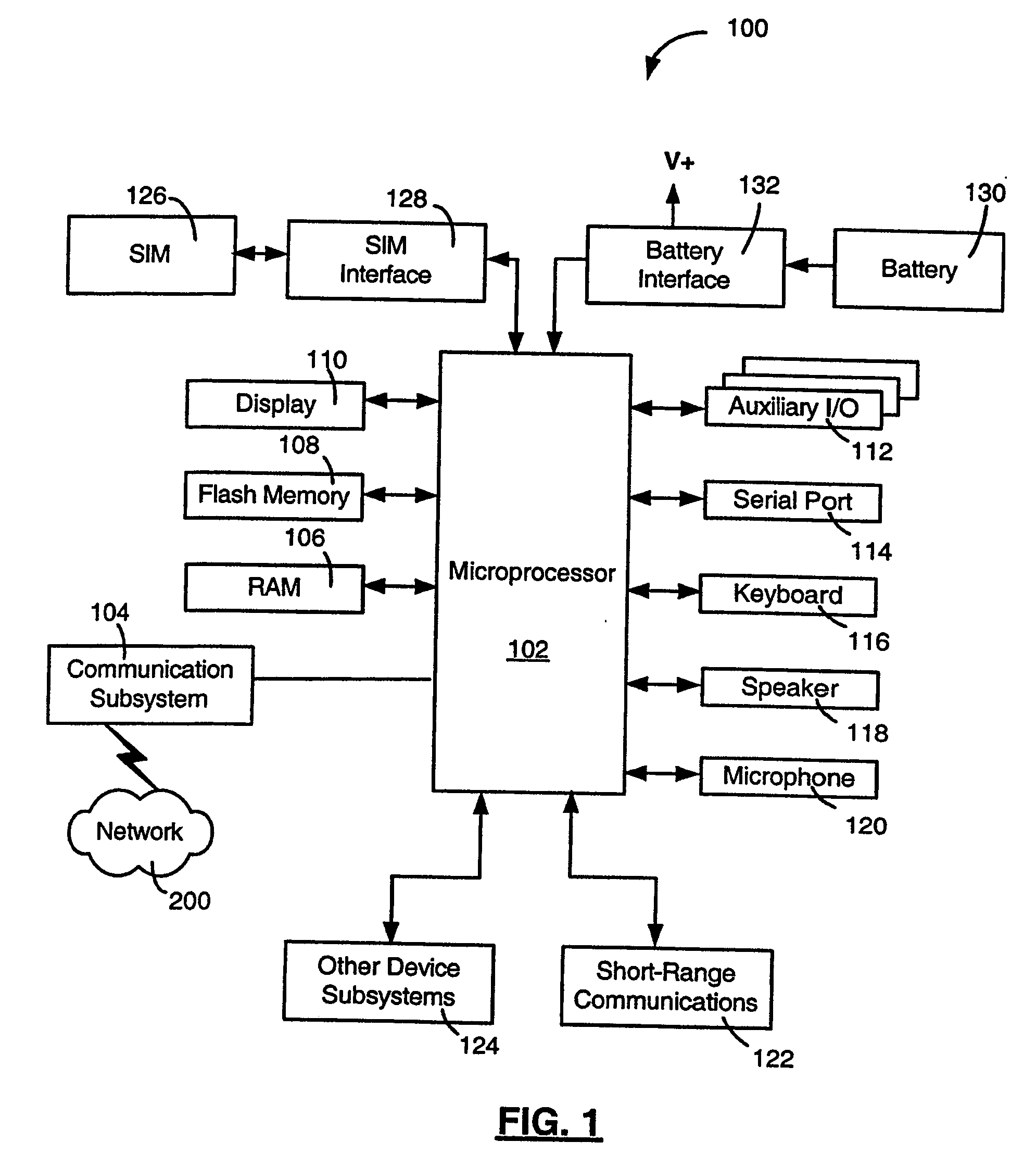

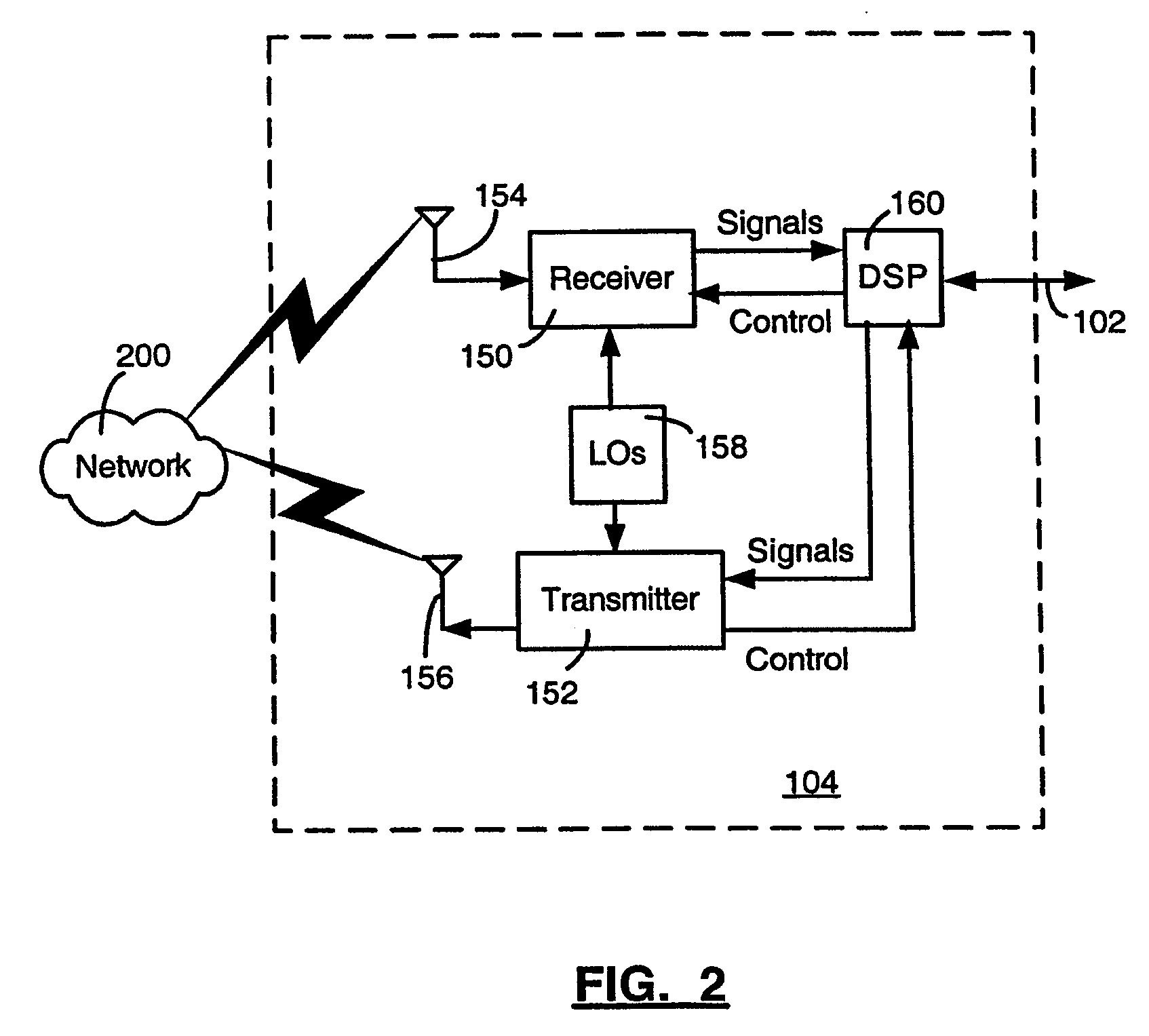

System and method for verifying digital signatures on certificates

ActiveUS20060095388A1Efficient verificationCostly and time-consumeUser identity/authority verificationElectronic credentialsDigital signatureDigital signature forgery

A system and method for verifying a digital signature on a certificate, which may be used in the processing of encoded messages. In one embodiment, when a digital signature is successfully verified in a signature verification operation, the public key used to verify that digital signature is cached. When a subsequent attempt to verify the digital signature is made, the public key to be used to verify the digital signature is compared to the cached key. If the keys match, the digital signature can be successfully verified without requiring that a signature verification operation in which some data is decoded using the public key be performed.

Owner:MALIKIE INNOVATIONS LTD

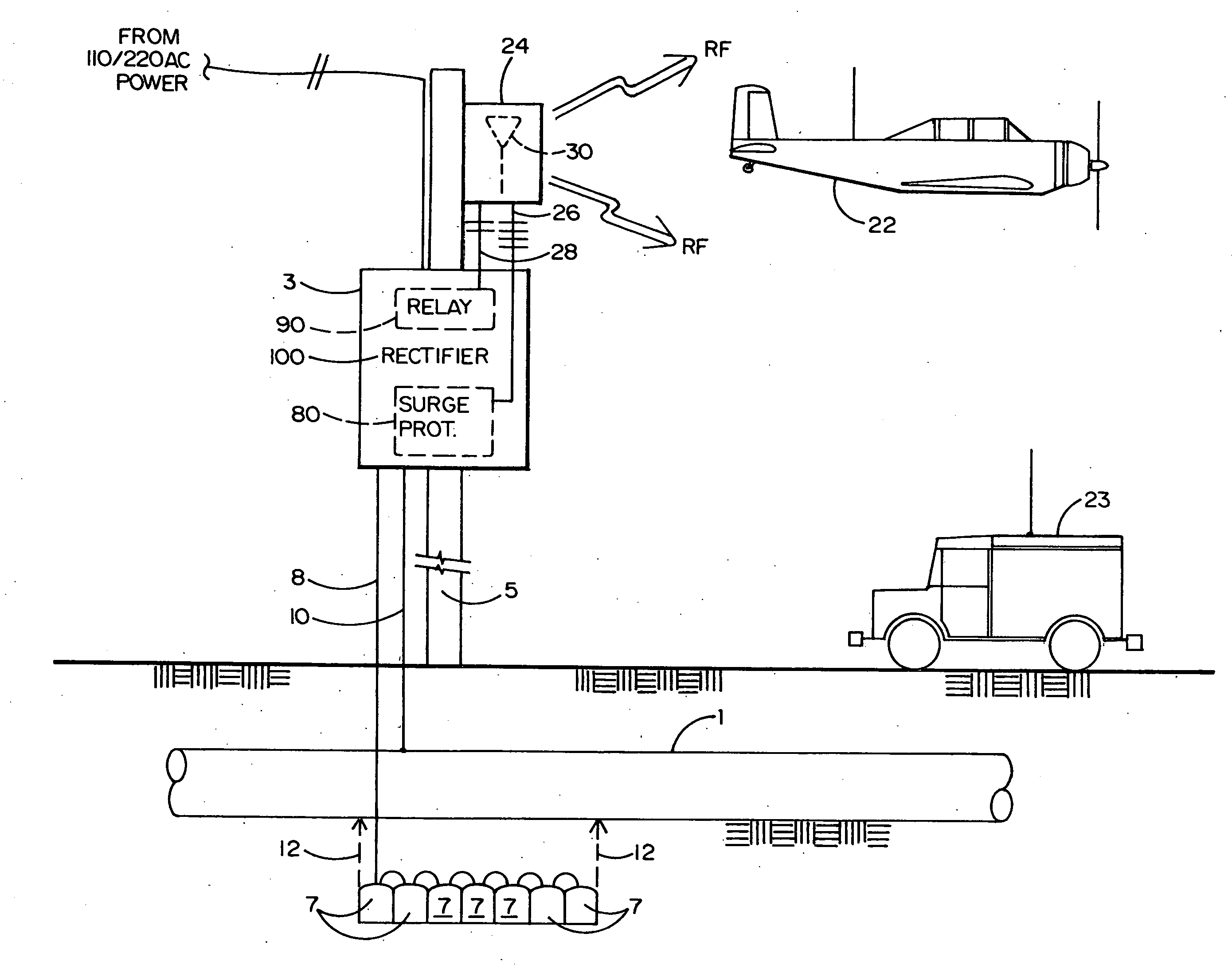

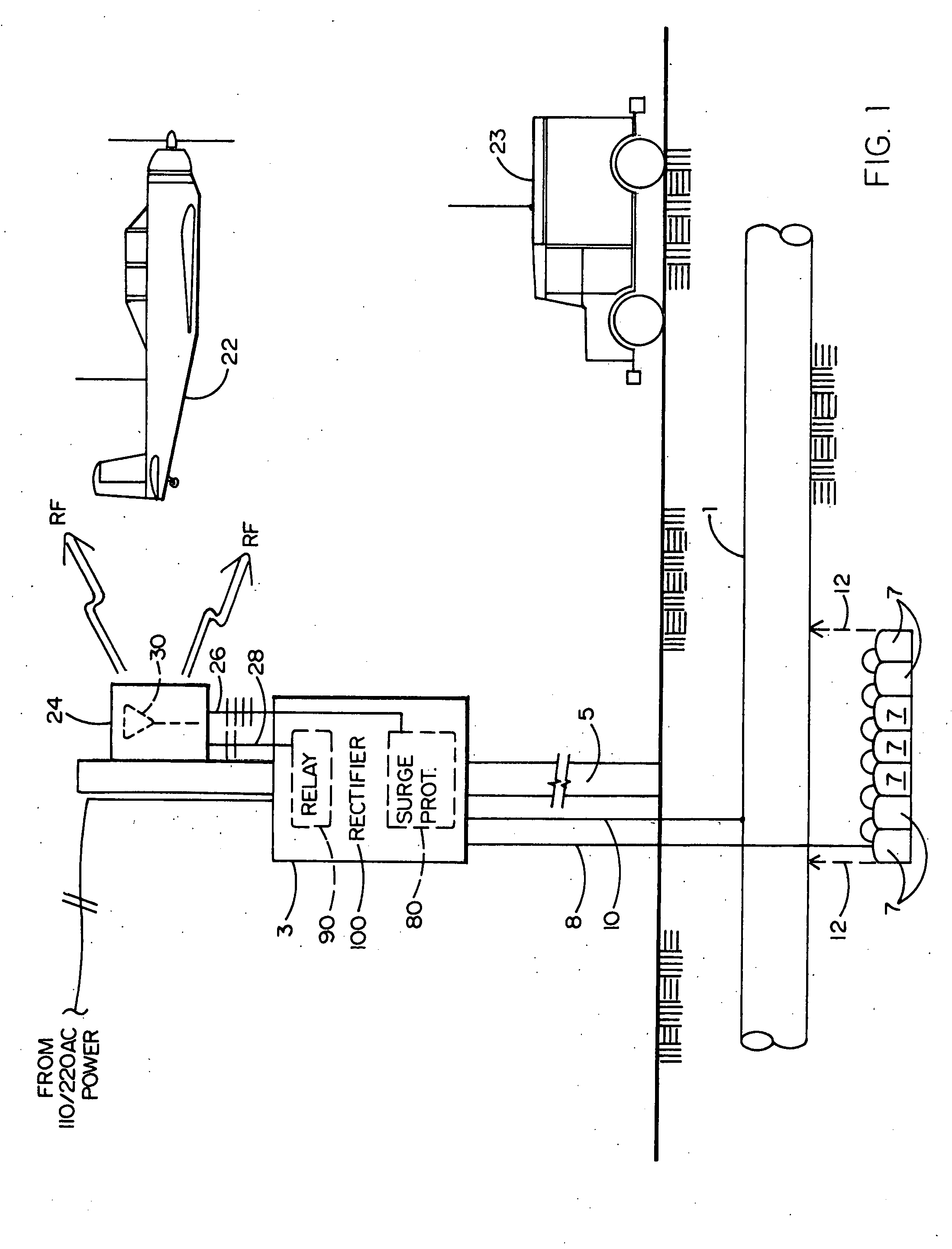

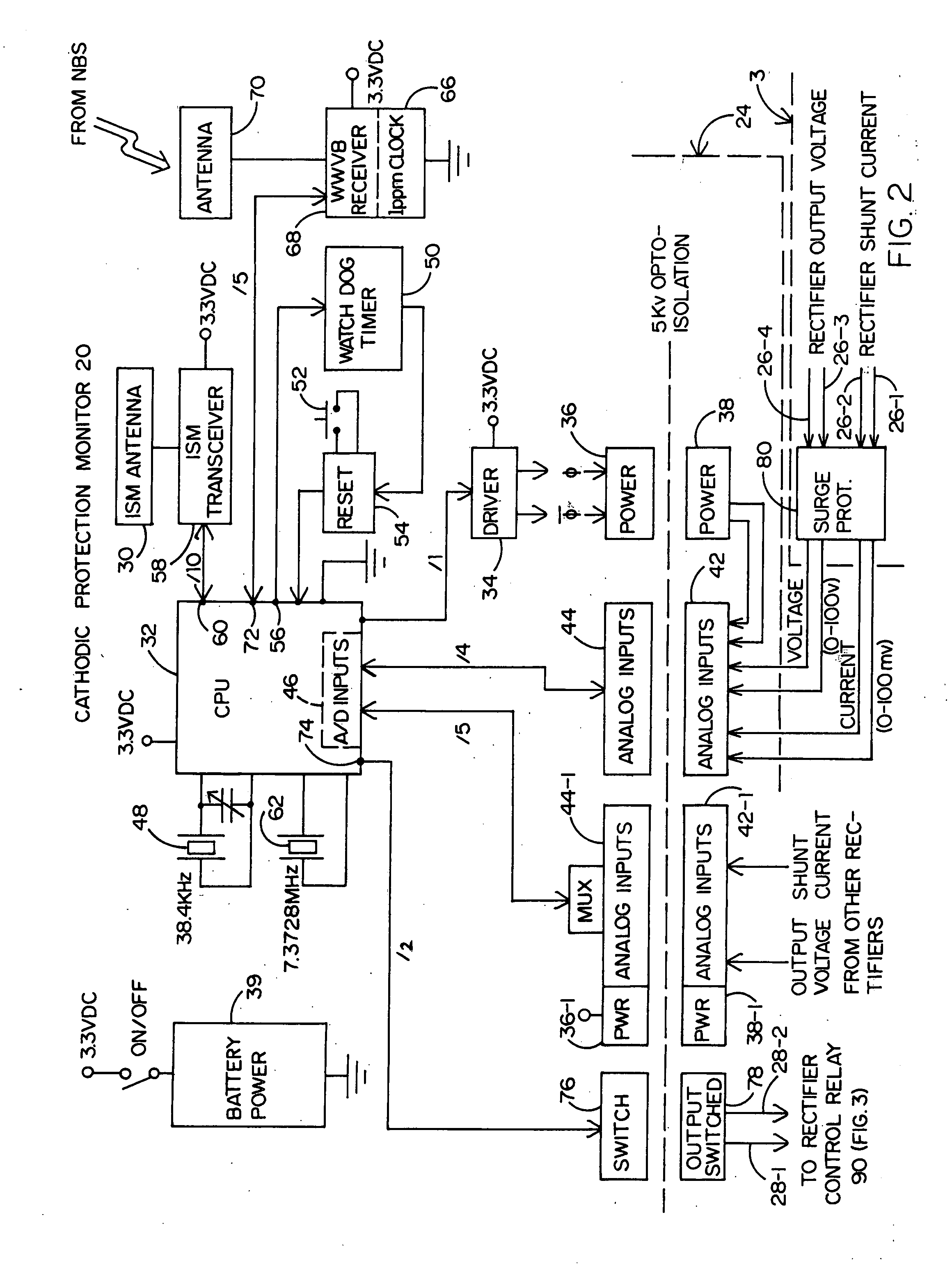

Cathodic protection monitor

ActiveUS20080204274A1Costly and time-consumeEfficient collectionElectric signal transmission systemsTelemetry/telecontrol selection arrangementsJet aeroplaneTransceiver

A cathodic protection monitor is disclosed to be electrically connected to a cathodic protection rectifier that is adapted to prevent rust, corrosion and possible leakage in an underground pipe or storage tank above which the rectifier is supported. The cathodic protection monitor includes a CPU that reads, digitizes and stores analog current and voltage signals which are supplied from the DC output of the rectifier and are indicative of the effectiveness thereof. The monitor includes an ISM band transceiver and antenna by which the CPU is polled and from which packets of stored data are transmitted to a data collector at an overhead airplane or nearby motor vehicle for retransmission and analysis by the pipe owner or maintenance crew. Synchronized timing signals are supplied (from the National Bureau of Standards) to a stable auxiliary clock by way of a WWVB transceiver and antenna. The auxiliary clock from each of a plurality of cathodic protection monitors along the pipeline provides a synchronized clock control signal to a respective CPU which, in turn, generates a switched relay control signal to a relay of the cathodic protection rectifier. Accordingly, the relays of all of the cathodic protection rectifiers can be simultaneously energized and de-energized during successive time periods so that all of the cathodic protection rectifiers can be turned on and off at the same time as may be required to compile ground voltage readings along the pipeline as part of a government-mandated survey.

Owner:OLEUMTECH CORP

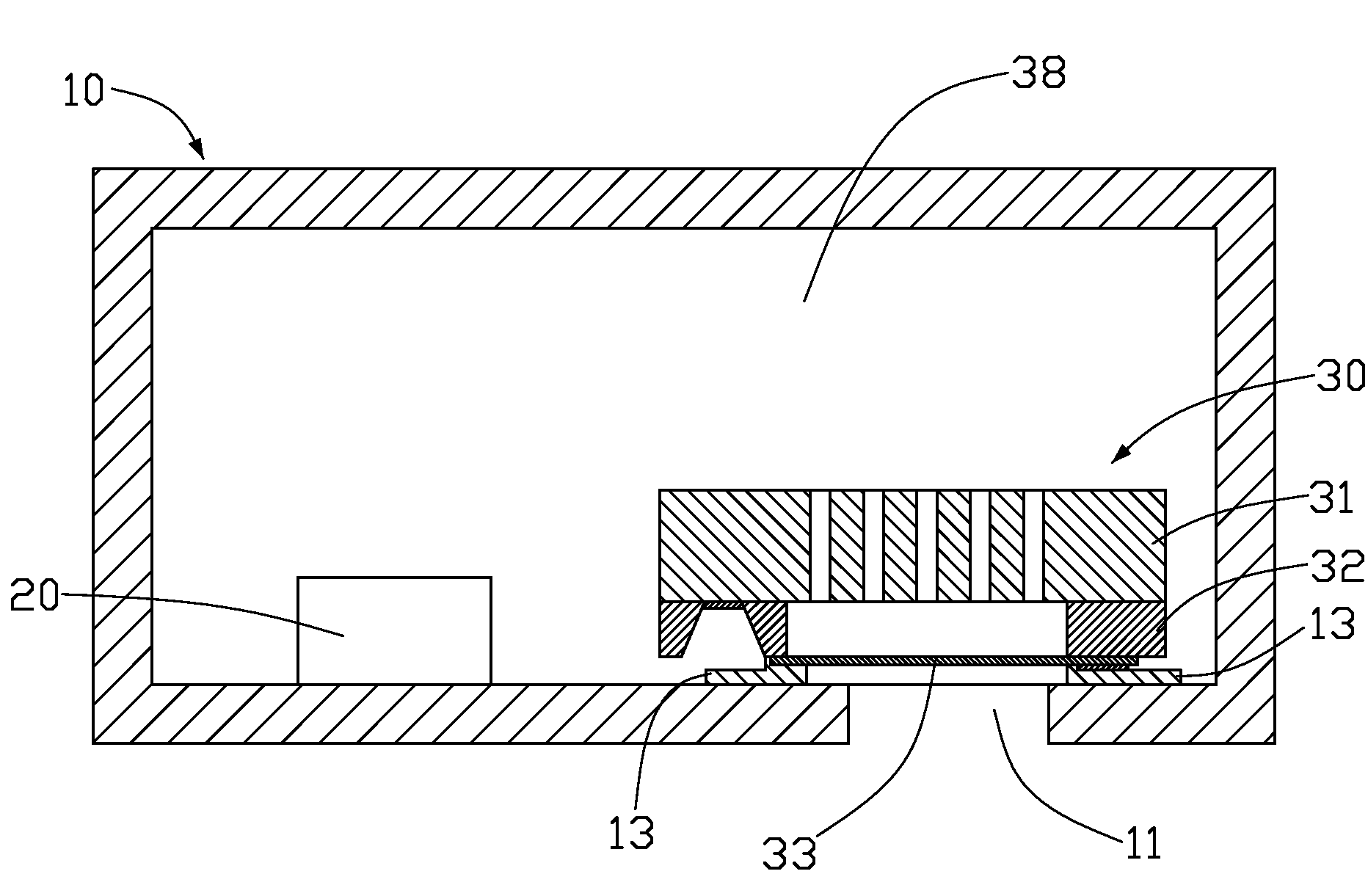

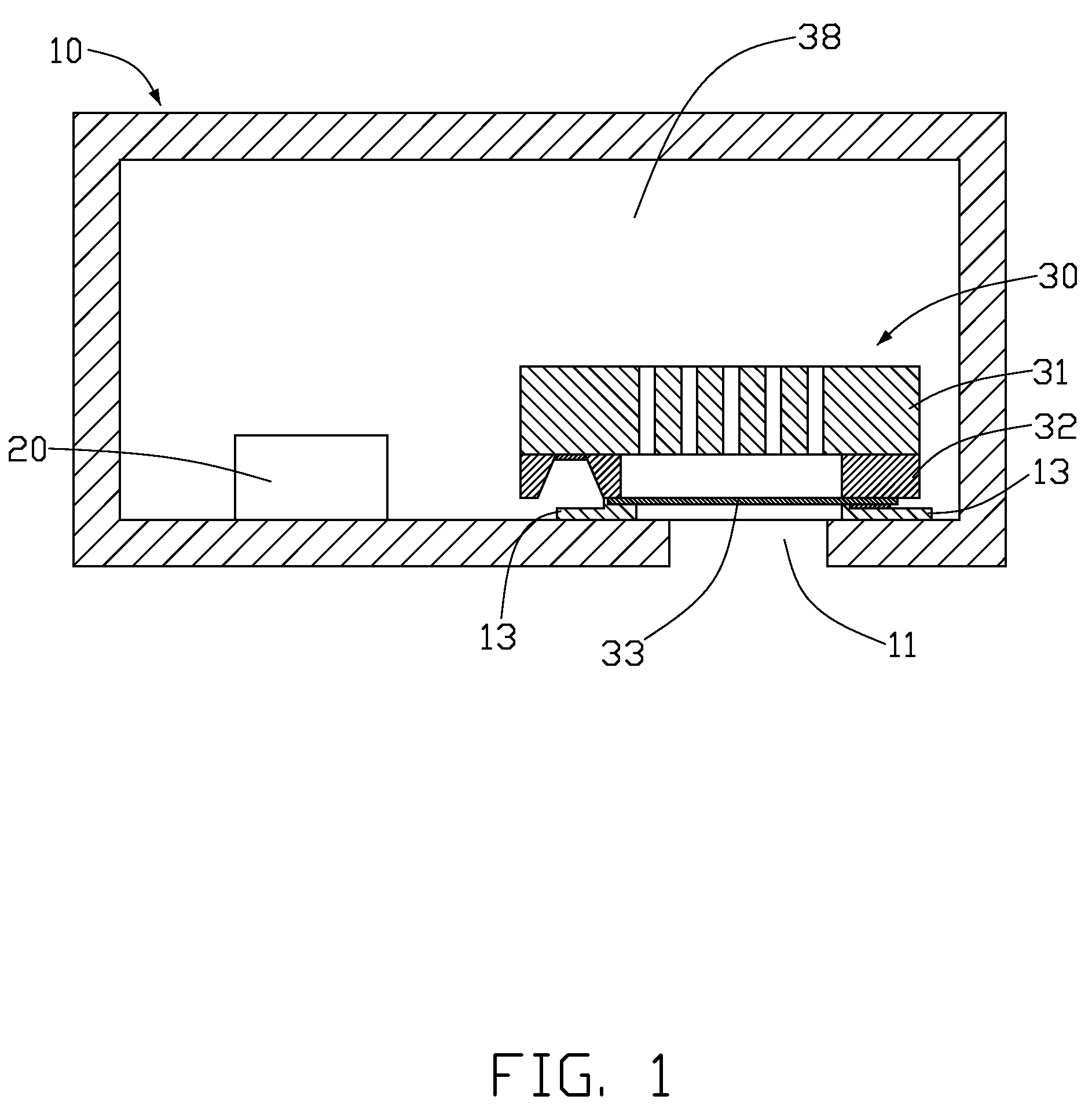

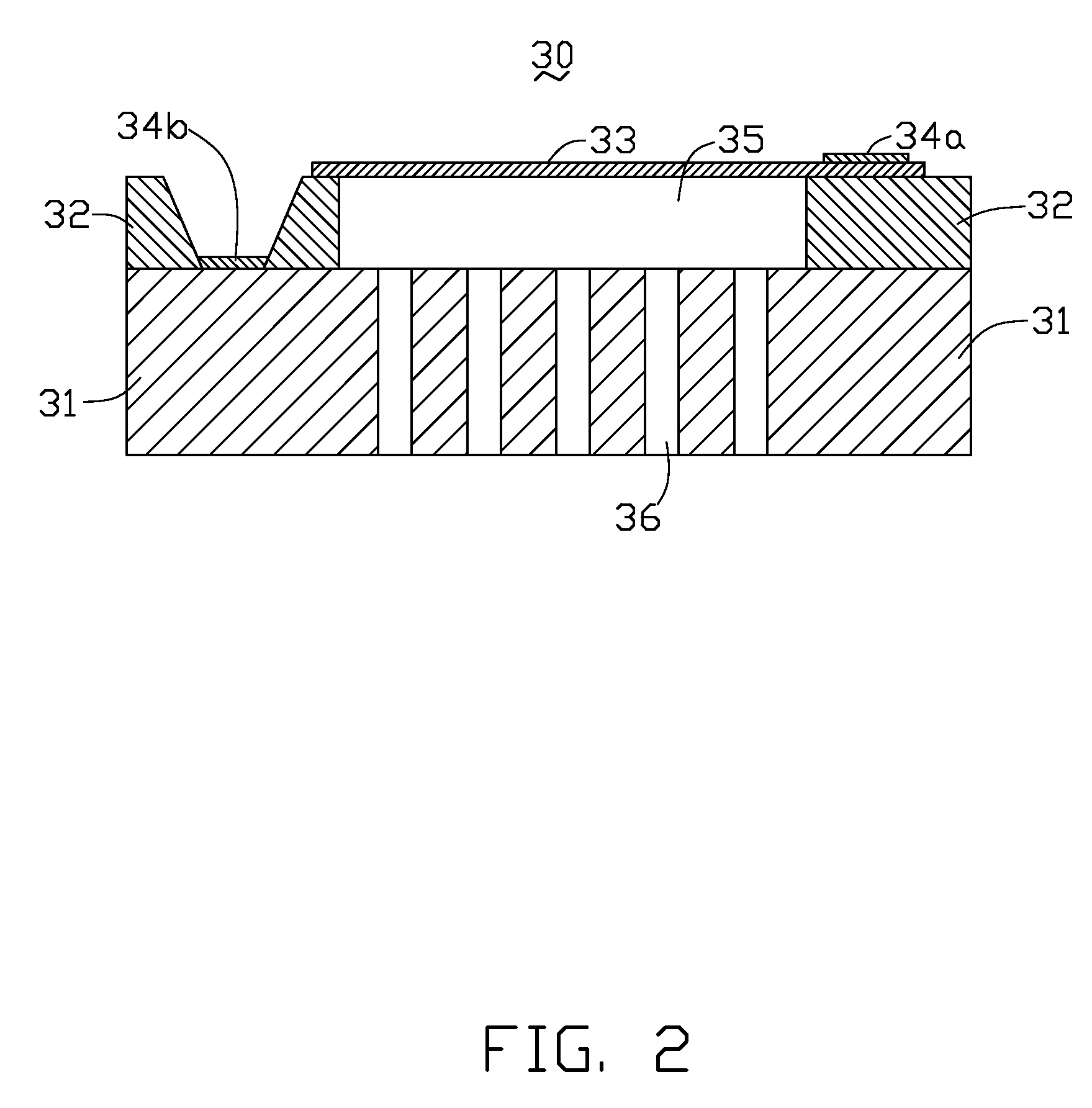

MEMS microphone and method for manufacturing the same

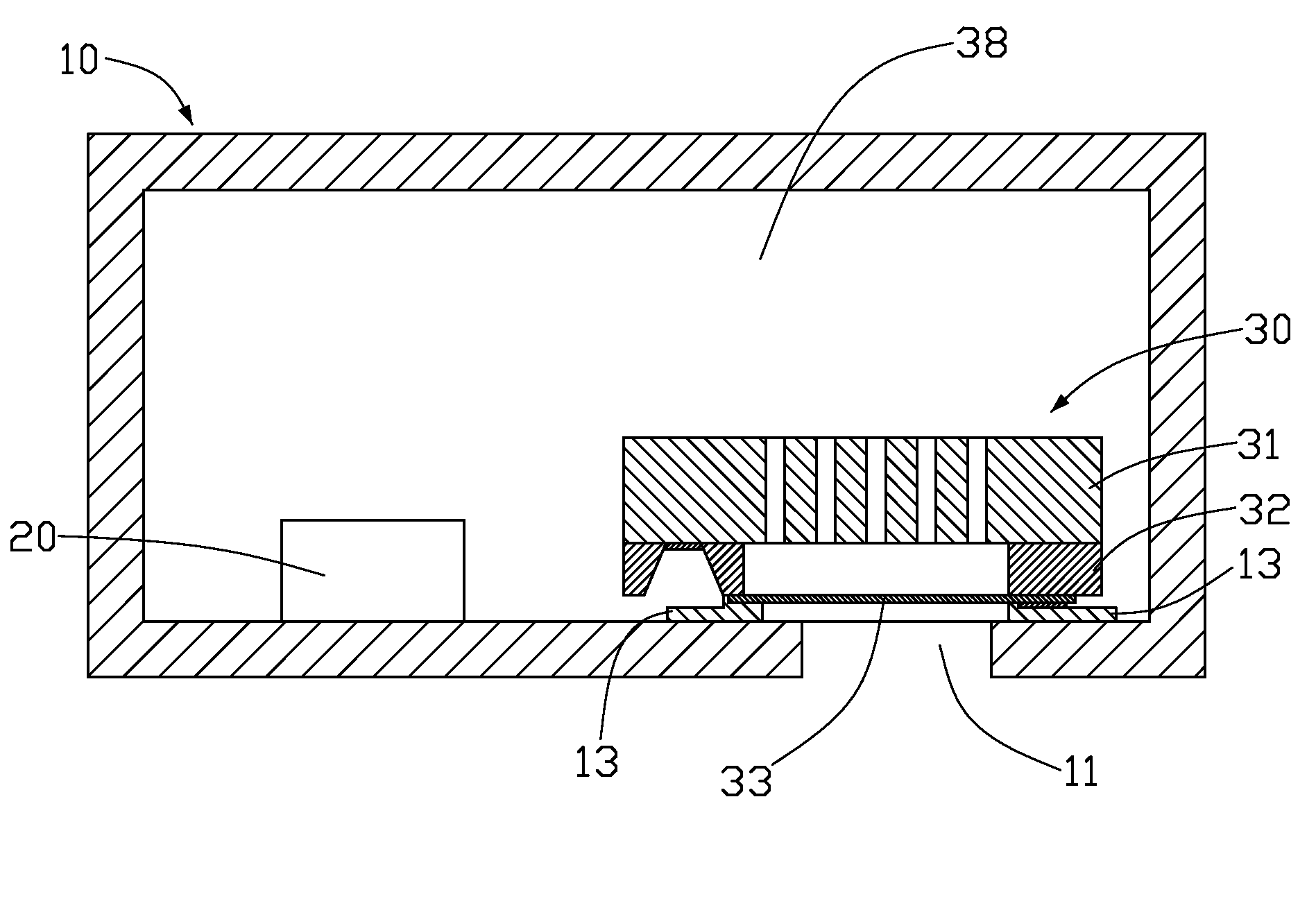

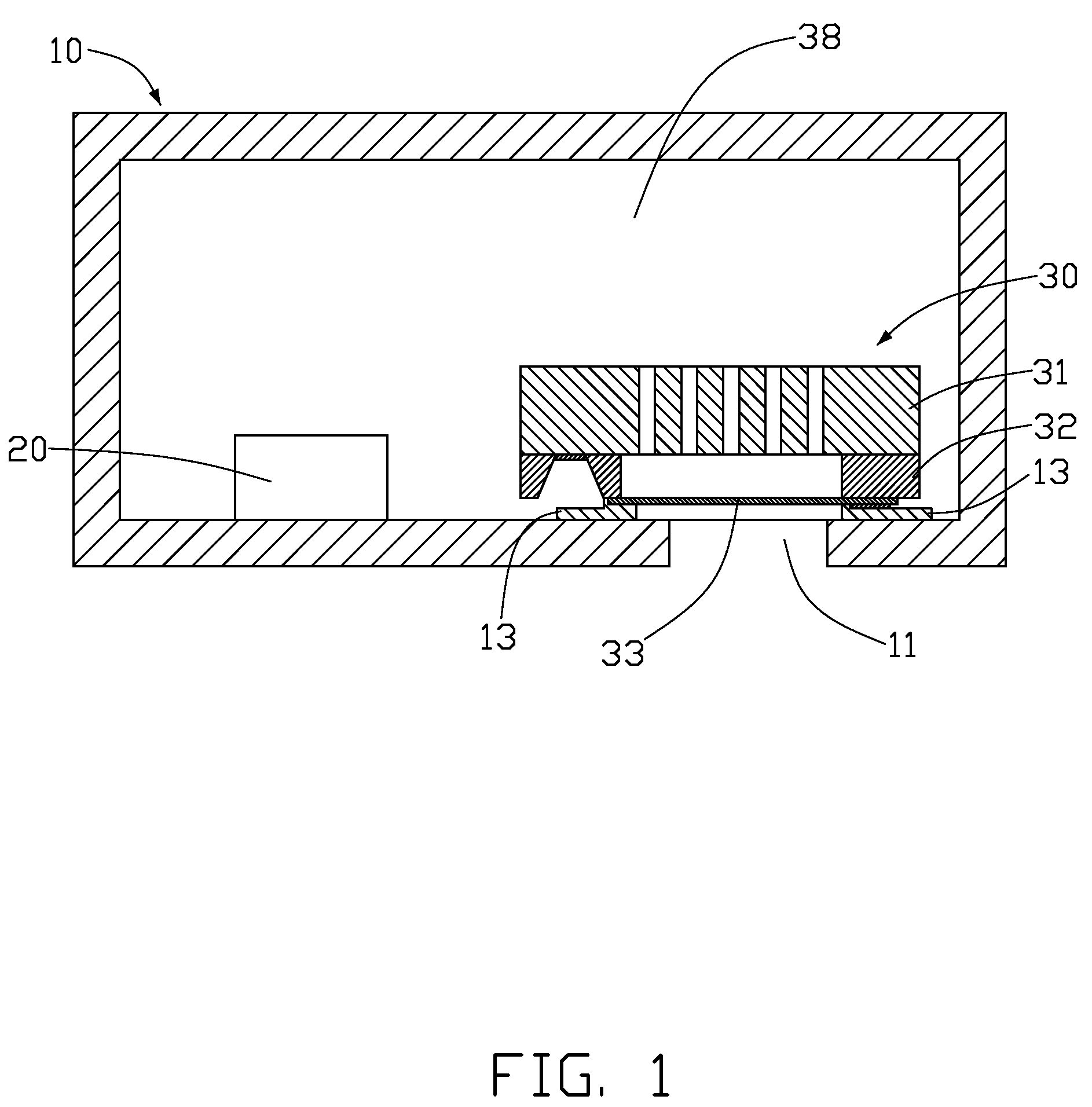

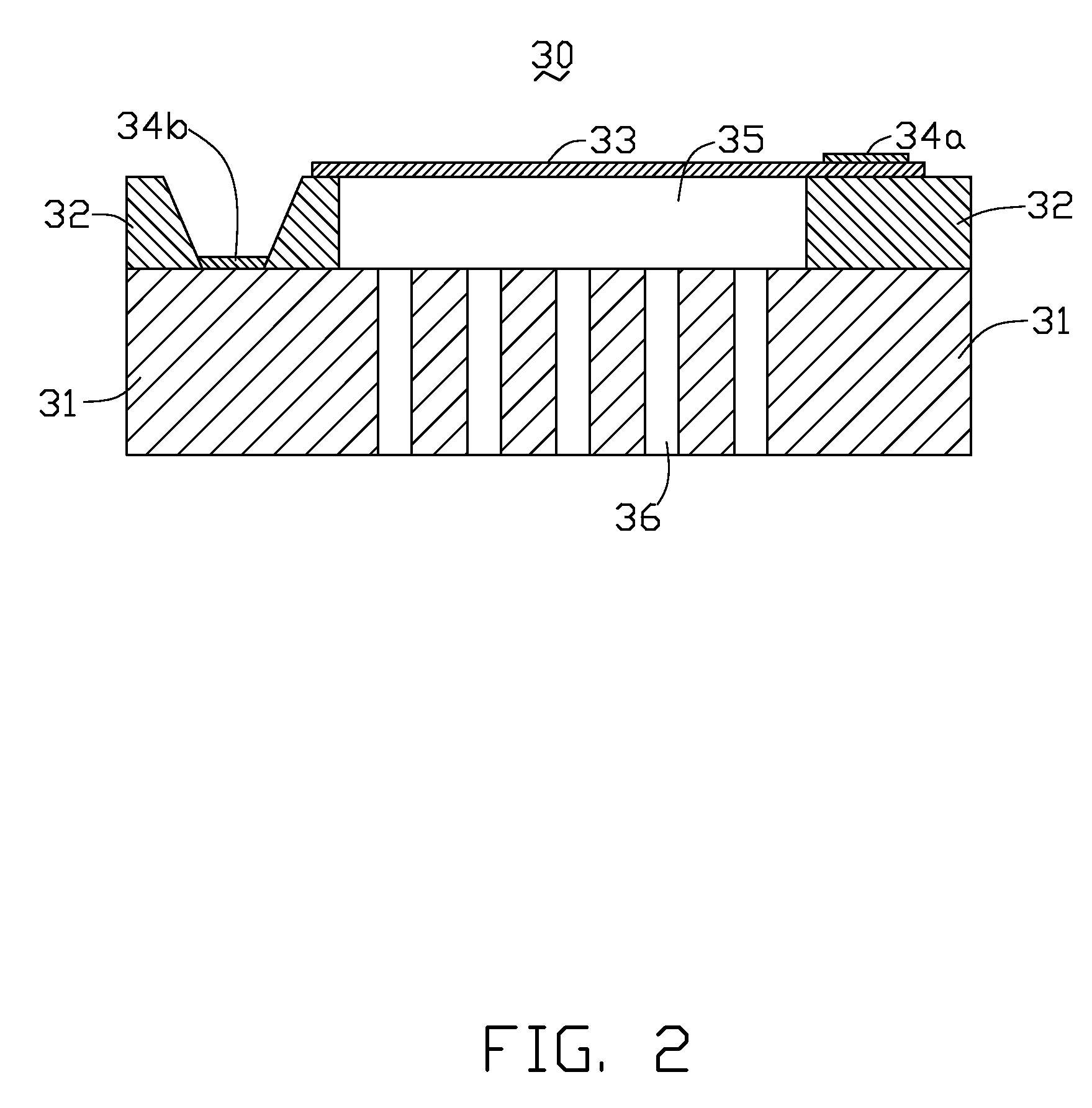

ActiveUS20090016550A1High sensitivityIncrease in sizePiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesEngineeringMicrophone

An MEMS microphone includes a casing (10) and a microphone chip (30) disposed in the casing. The casing defines a sound entrance (11) therein. The microphone chip includes a back plate (31), an isolation layer (32) and a diaphragm (33). The isolation layer separates the back plate from the diaphragm so as to form an air interstice (35) therebetween. The back plate and the diaphragm electrically connect with two electrodes (34a, 34b), respectively. The back plate defines a plurality of holes (36) therethrough. The holes communicate the air interstice with a sealed acoustic chamber (38) between the casing and the microphone chip. The diaphragm is adhered to an inner side of the casing at a position over the sound entrance.

Owner:TSINGHUA UNIV +1

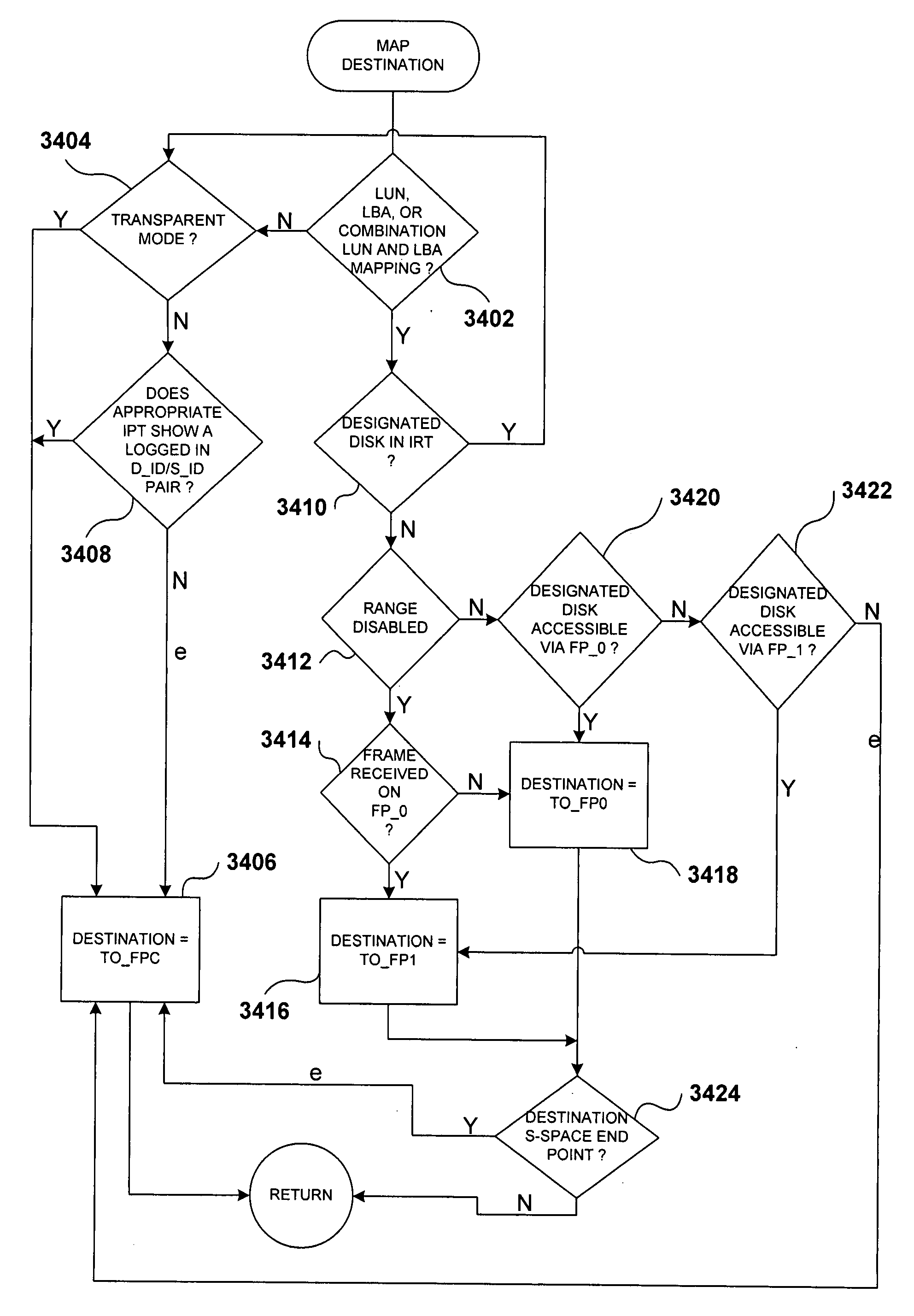

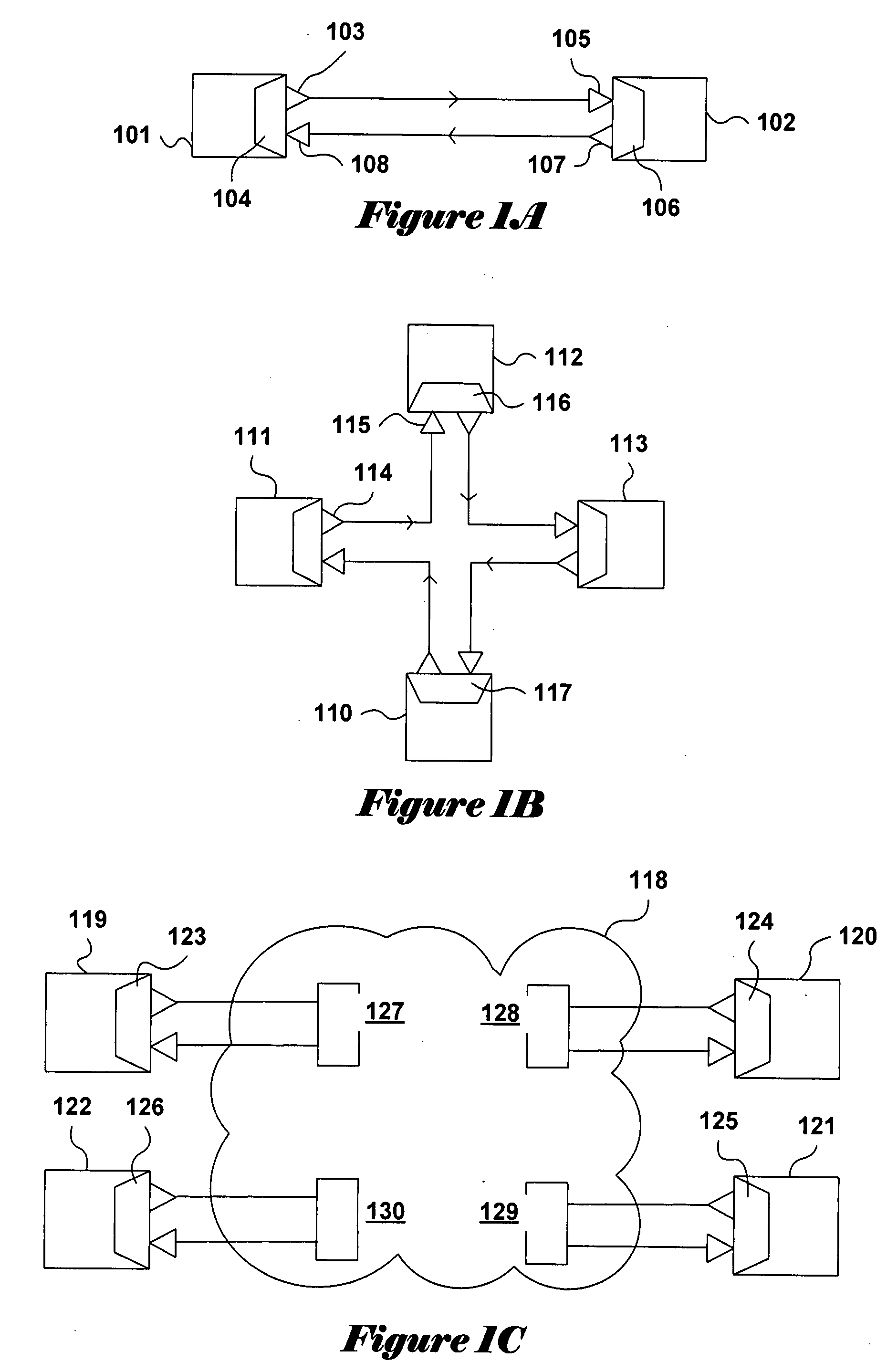

Allocation-unit-based virtual formatting methods and devices employing allocation-unit-based virtual formatting methods

ActiveUS20080016275A1Increase the number ofEasy reliable identificationMemory adressing/allocation/relocationData switching by path configurationDisk arrayDisk formatting

In various embodiments, the present invention provides virtual disk formatting by intermediate devices including: (1) a storage shelf router and the storage shelf in which the storage-shelf is included, to external computing entities, such as disk-array controllers and host computers; (2) an I / O controller; and (3) a storage-bridge device. The virtual-formatting methods of the present invention are based on allocation units, each allocation unit comprising a consecutive sequence of logical blocks and an additional pad region that together map to, and exactly align with, a corresponding consecutive sequence of device blocks.

Owner:EMULEX DESIGN & MFG

Rules-based system architecture and systems using the same

ActiveUS20060179028A1Simple processCostly and time-consumeDigital data information retrievalKnowledge representationRule-based systemData mining

Systems and methods for processing data. In one embodiments, a system for processing data can include a first rules engine configured to obtain the data, to obtain a first object including a rule identifier to contain the data, to generate an instance of a first rule based on the first object, and to execute the instance of the first rule passing the first object as input to the instance of the first rule, wherein the instance of the first rule configured to perform an action in order to process the data contained in the first object, and to modify the rule identifier included in the first object.

Owner:FIDELITY INFORMATION SERVICES LLC

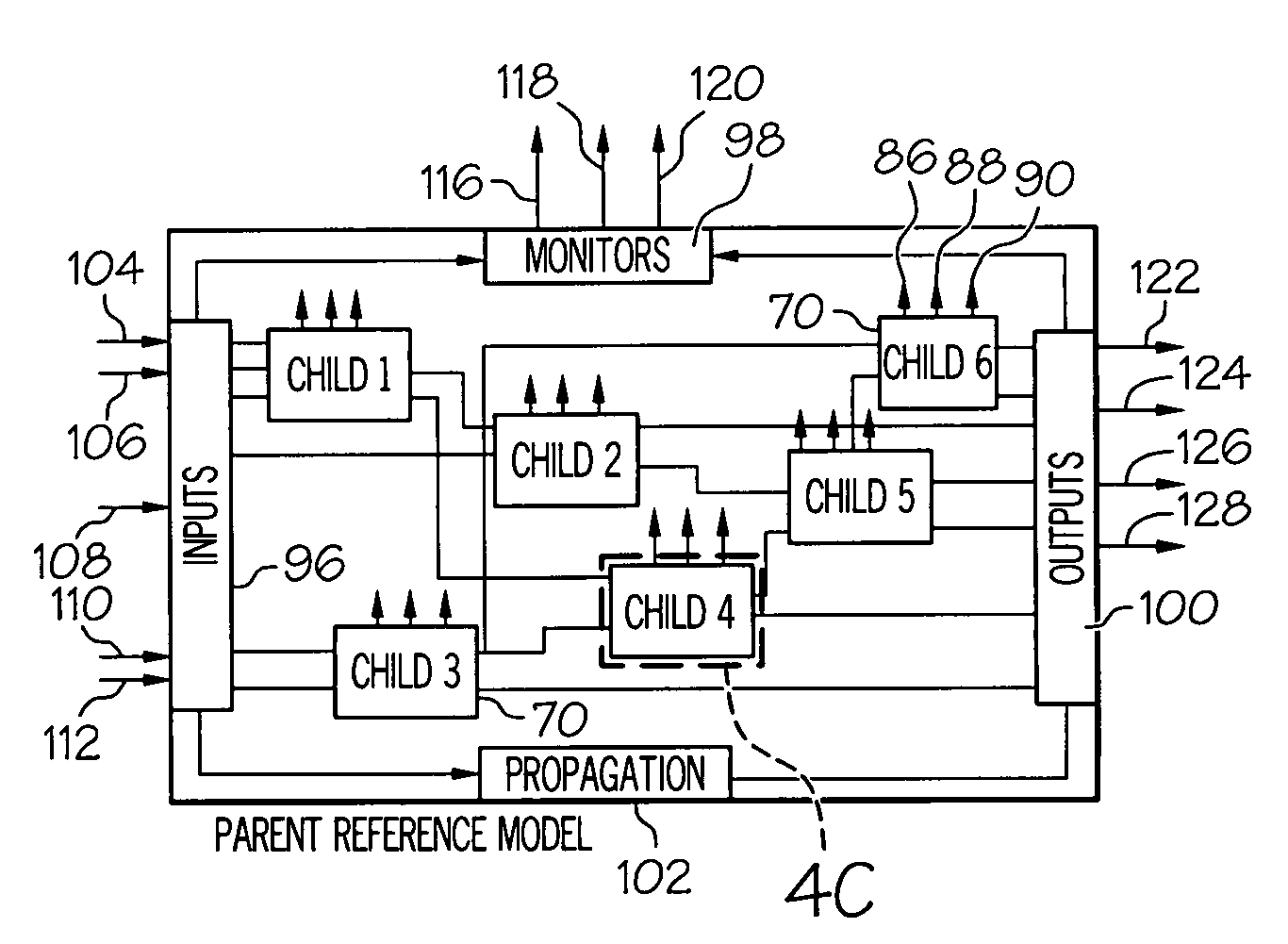

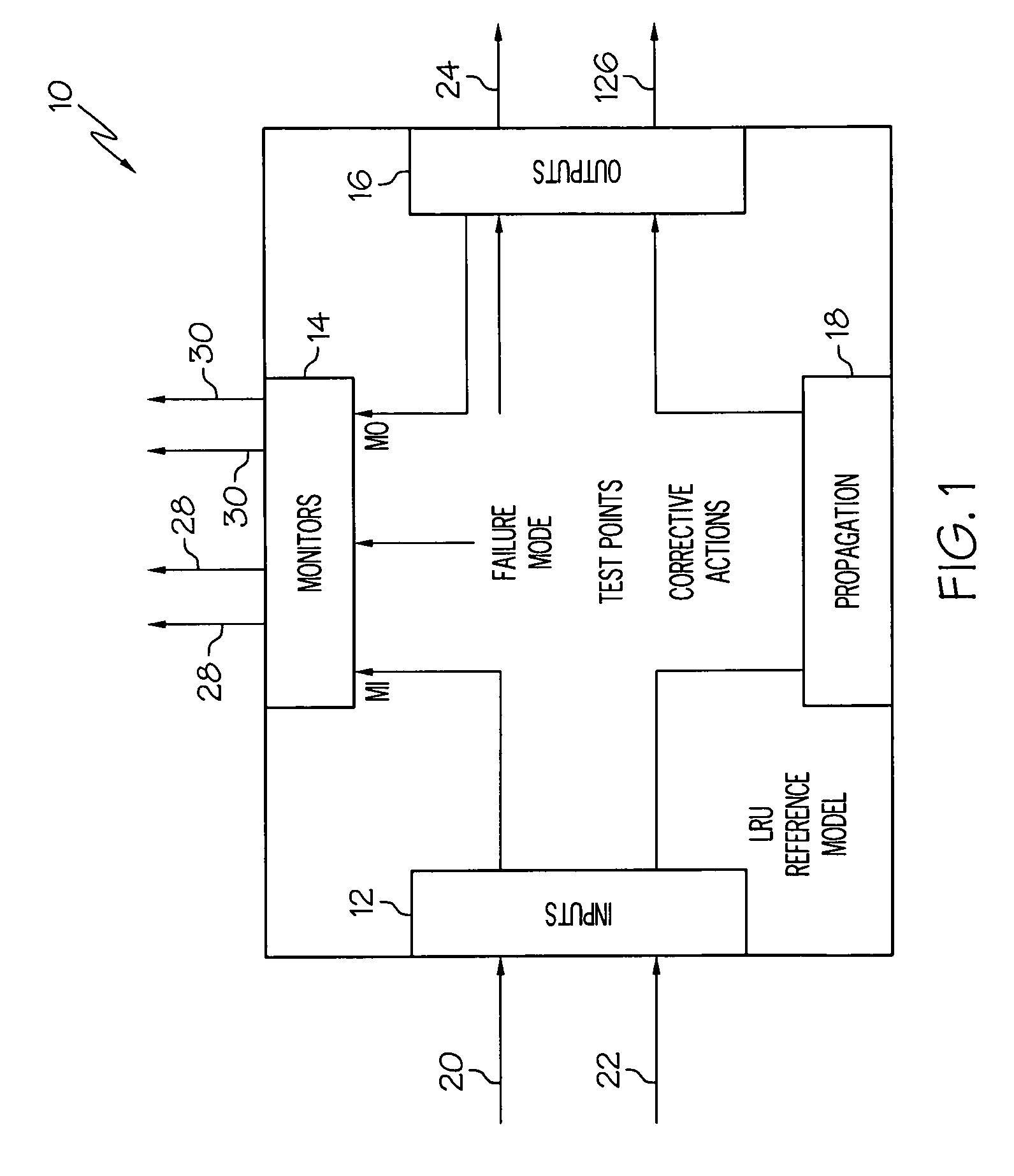

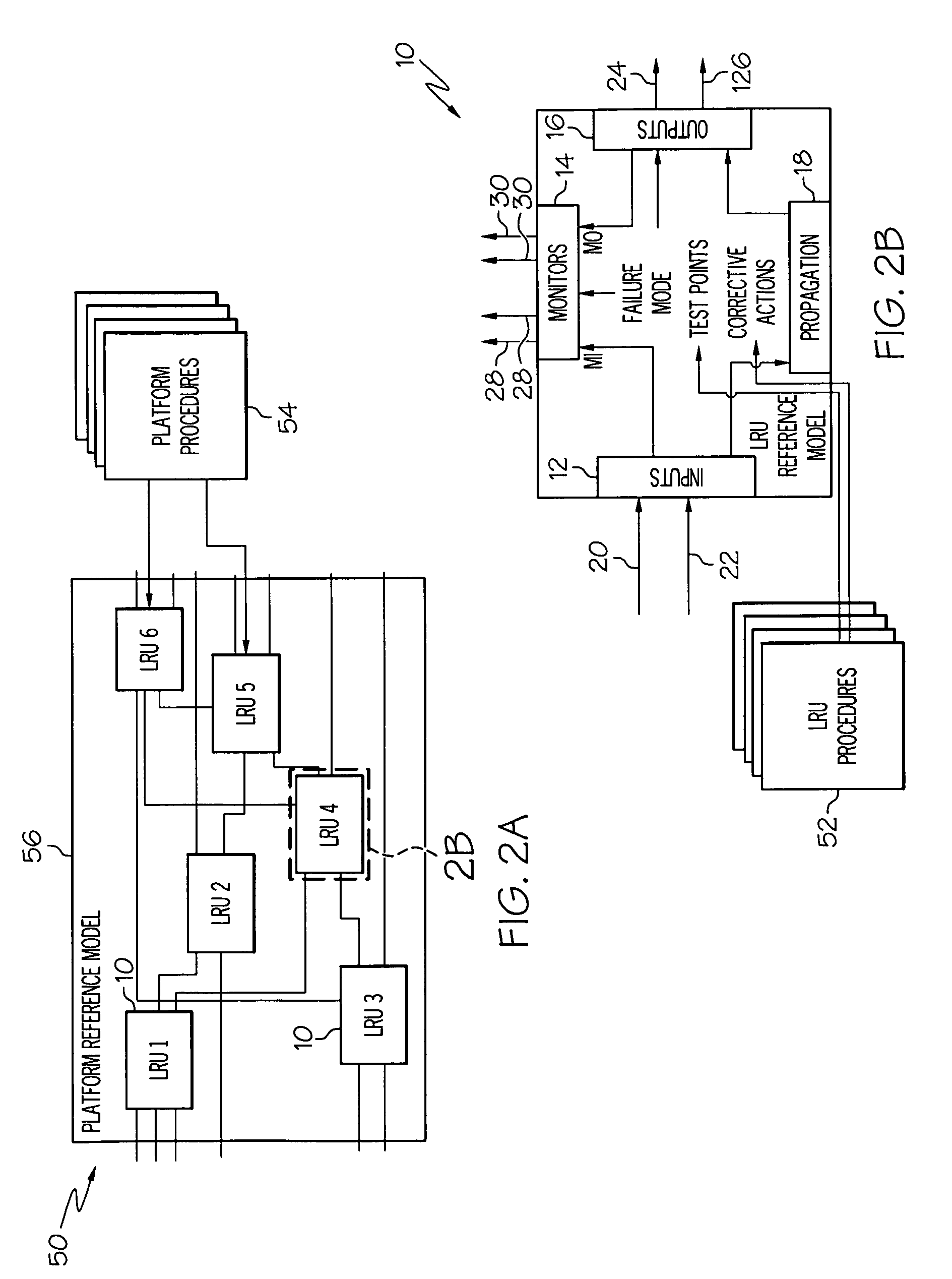

Recursive structure for diagnostic model

ActiveUS8170968B2Costly and time-consumeReduce complexityTesting/monitoring control systemsKnowledge representationComputer scienceDiagnostic model

A recursive mapping structure for diagnostic models is provided. A parent diagnostic model includes a first input module, a first output module, a first monitor module coupled to the first input and first output modules, and a first propagation module coupled between the first input and first output modules. A child diagnostic model includes a second input module, a second output module, a second monitor module coupled to the second input and second output modules, and a second propagation module coupled between the second input and second output modules, wherein the second monitor module is coupled to the first monitor module.

Owner:HONEYWELL INT INC

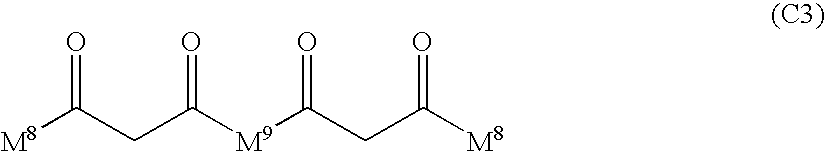

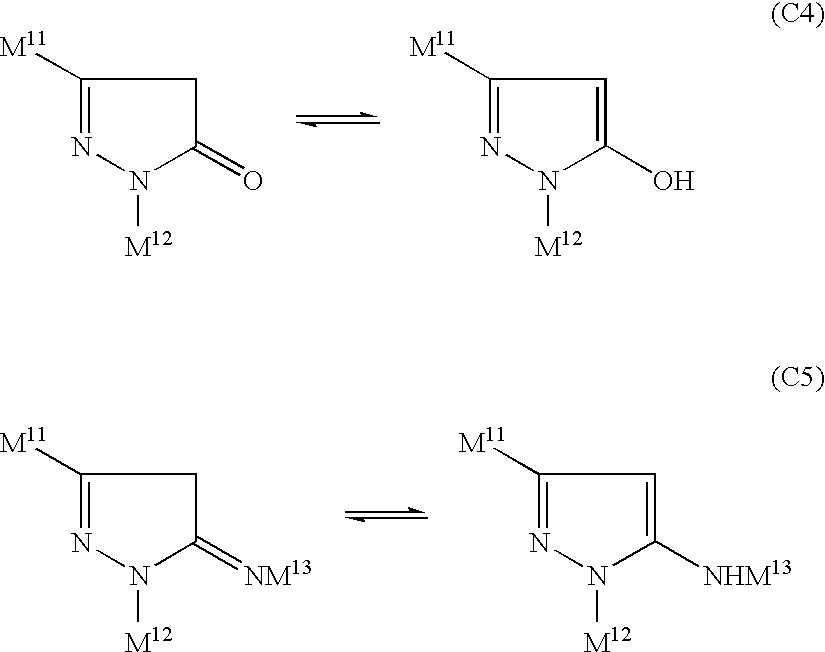

Agent for dyeing fibers containing keratin

InactiveUS20050262647A1Poor wash fastnessCostly and time-consumeCosmetic preparationsHair cosmeticsFiberPolymer science

An agent for dyeing keratin-containing fibers, in particular, human hair, to give the fibers fashionable bright colors. The agent comprises A) an oxidizing agent, B) a CH-acidic compound and C) a reactive carbonyl compound. The invention also includes a process for dyeing keratin-containing fibers with the agent.

Owner:HENKEL KGAA

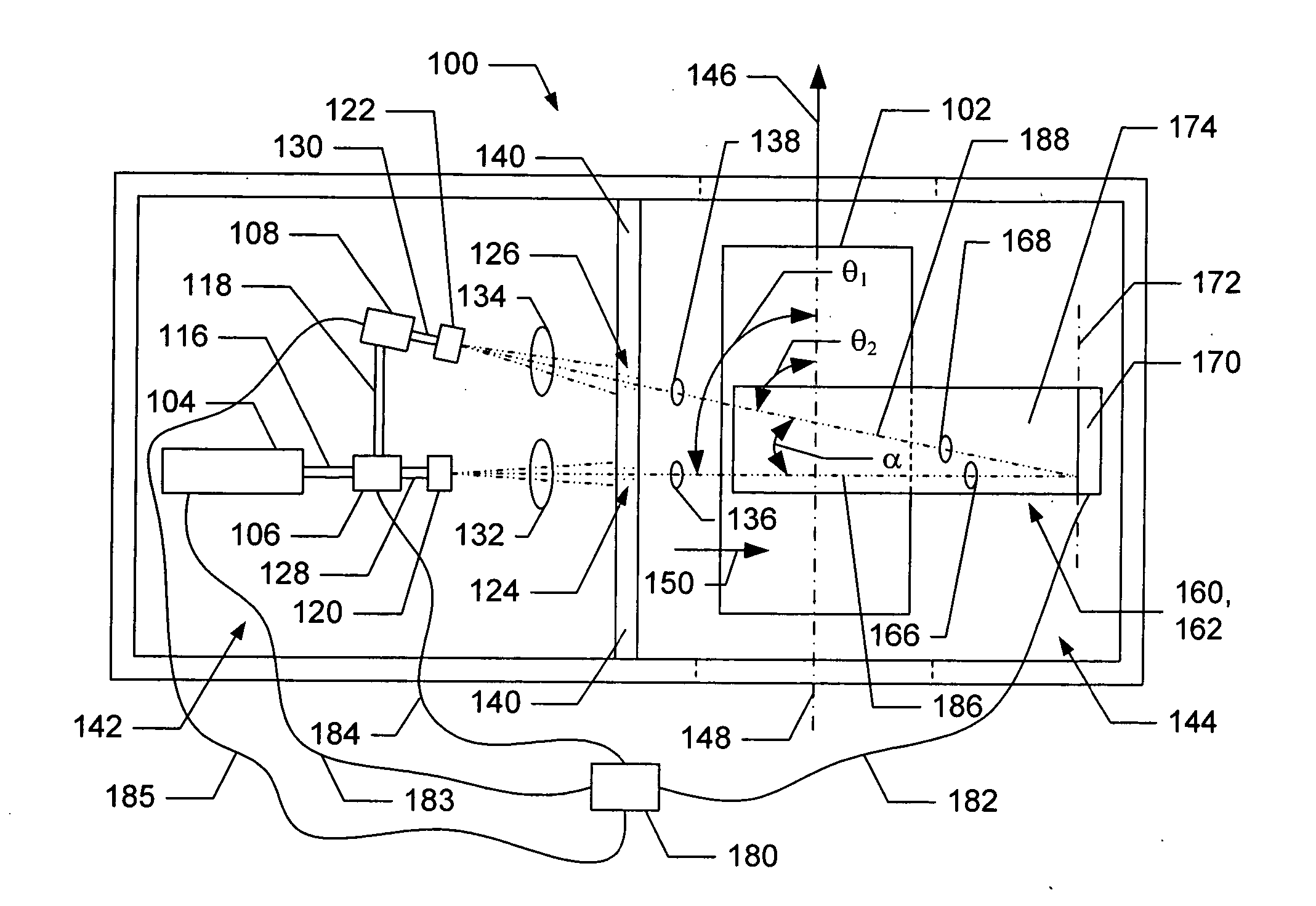

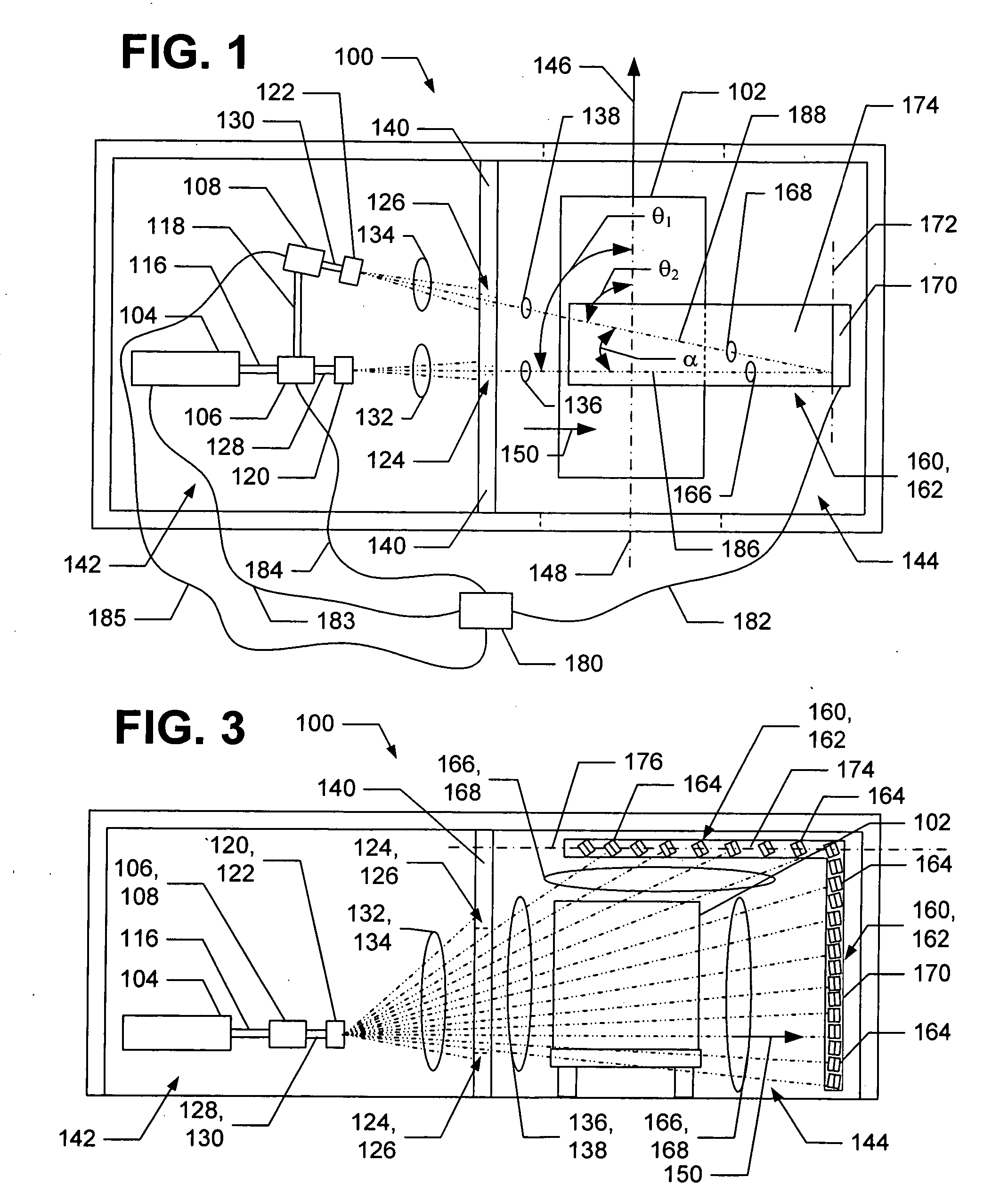

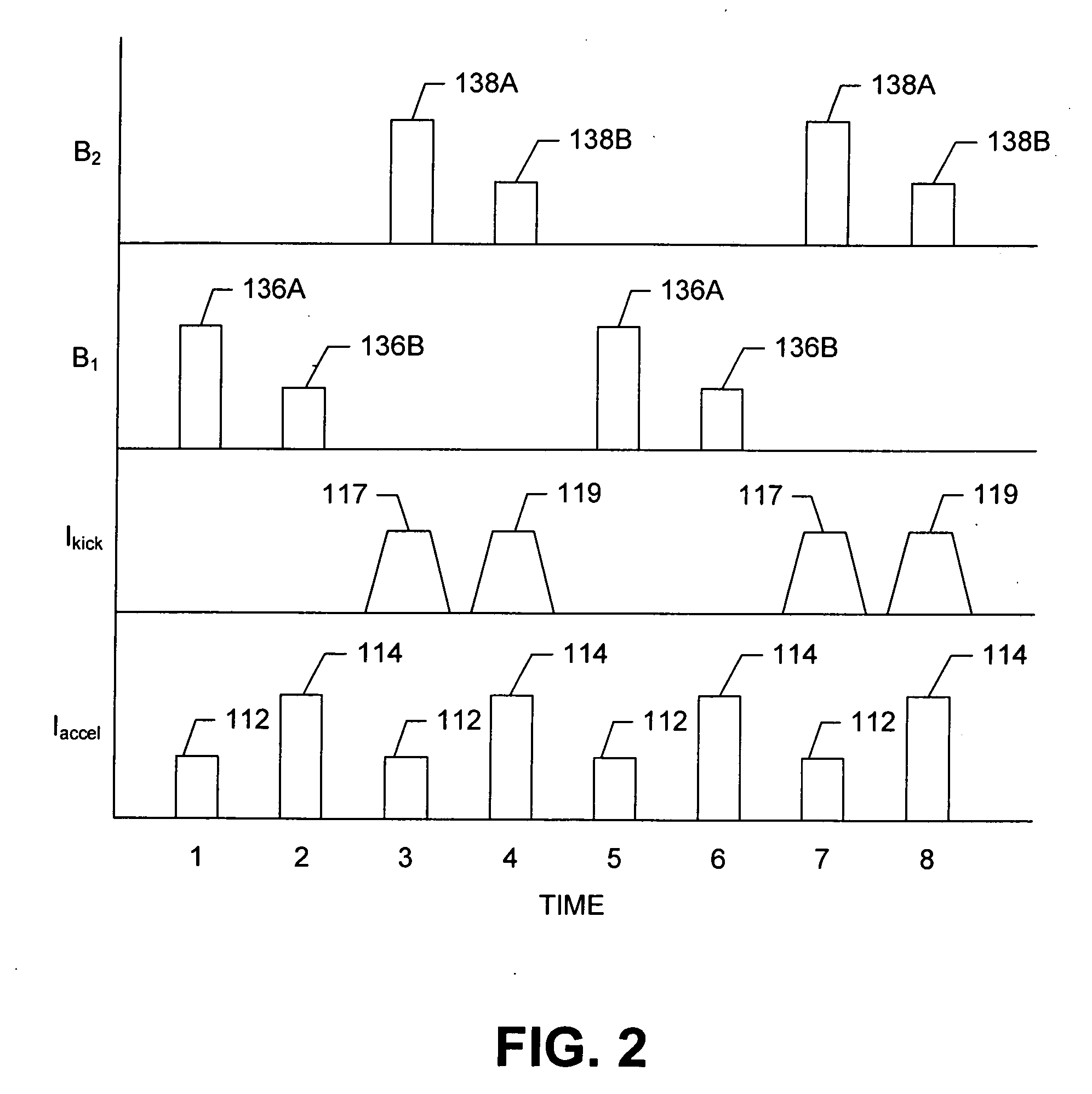

Angled-beam detection system for container inspection

InactiveUS20060233302A1Reduces number of orientation and geometryCostly and time-consumeRadiation/particle handlingStructural/machines measurementMulti materialHazardous substance

A non-intrusive inspection system, including apparatuses and methods, for non-intrusively inspecting containers such as, without limitation, those employed to transport items in international commerce. The non-intrusive inspection system is configured to generate and scan a container with multiple bremsstrahlung, or x-ray, beams having multiple spectra and directed at the container in multiple directions and planes separated by one or more angle(s). Using data collected from such scanning, software of the non-intrusive inspection system generates three-dimensional images of the items present in a container, calculates the volumes and densities of such items, computes effective “Z” numbers, and distinguishes between multiple materials, or elements, of such items. By employing multiple bremsstrahlung beams directed upon a container in multiple planes, the non-intrusive inspection system reduces the number of orientations and geometries of items within a container that might otherwise be employed to avoid the detection of harmful materials being transported within a container.

Owner:SCANTECH IDENTIFICATION BEAM SYST

Multifunctional compositions having combined insecticidal, mitacidal and fungicidal activity

InactiveUS20060008486A1Effective and controlling and preventingGuaranteed maximum utilizationBiocideCosmetic preparationsBiotechnologyAdditive ingredient

Particular aspects provide novel insecticide / miticide / fungicide compositions, and methods for using same for safe, environmentally friendly control of insects, mites and fungal pests in, e.g., gardening and commercial growing. Preferably, the compositions comprise organic or pure ingredients. Particular embodiments comprise: a fatty acid soap base (e.g., saponified soap with retained glycerin; or fatty acid salts with glycerin); at least one essential oil; an optional food oil; and a bicarbonate reagent, along with water. Additional embodiments comprise: a soap base, and / or glycerin or other suitable base; at least one organic or pure plant essential oil; an organic or pure food oil; and a bicarbonate reagent, along with water as diluent and carrier, and methods for using same. Further aspects provide a method for controlling mite and fungal pests with a single composition comprising, along with an aqueous carrier or diluent: a non-petroleum-based food oil; and a bicarbonate agent.

Owner:LEWIS SUSAN E

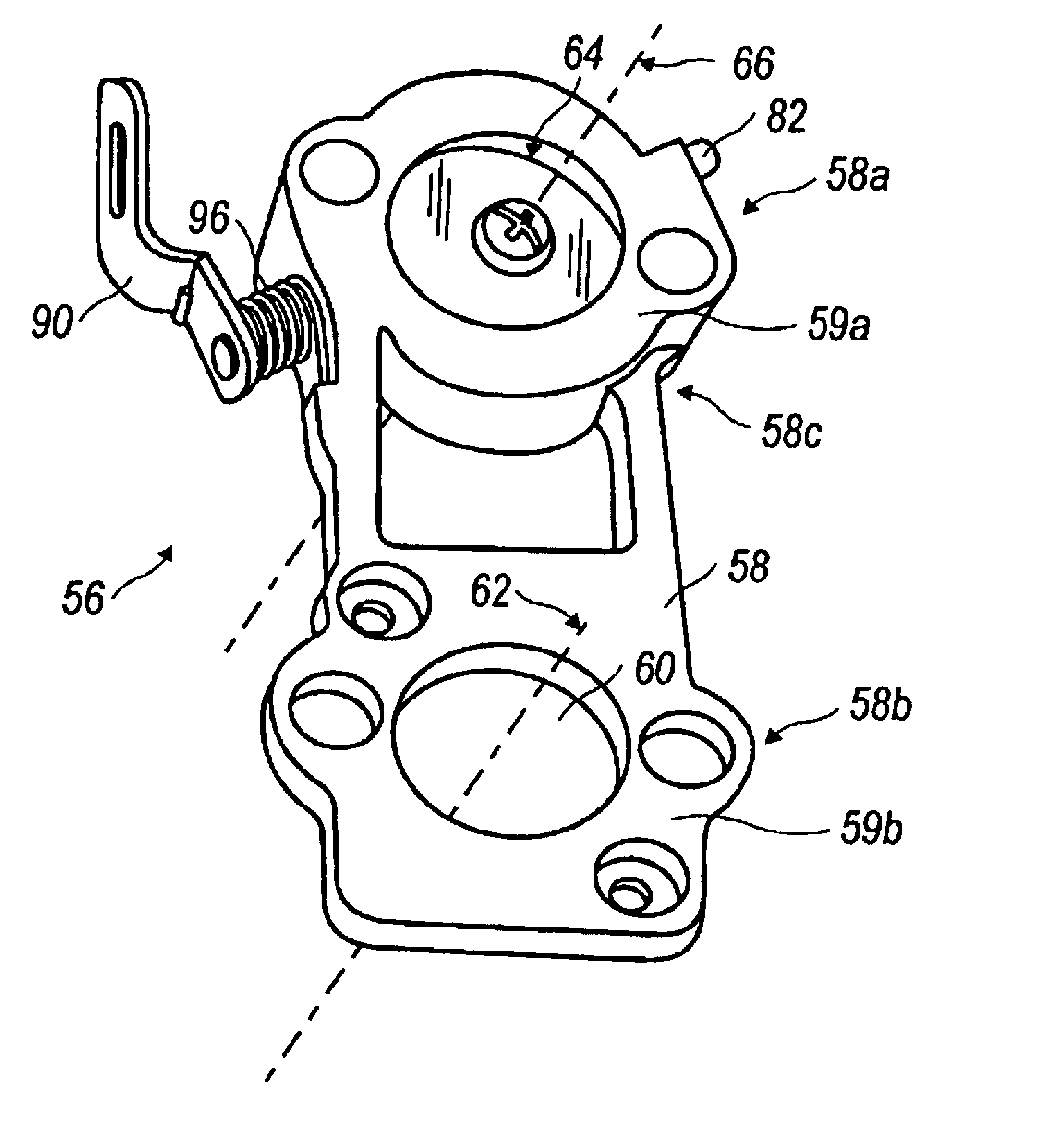

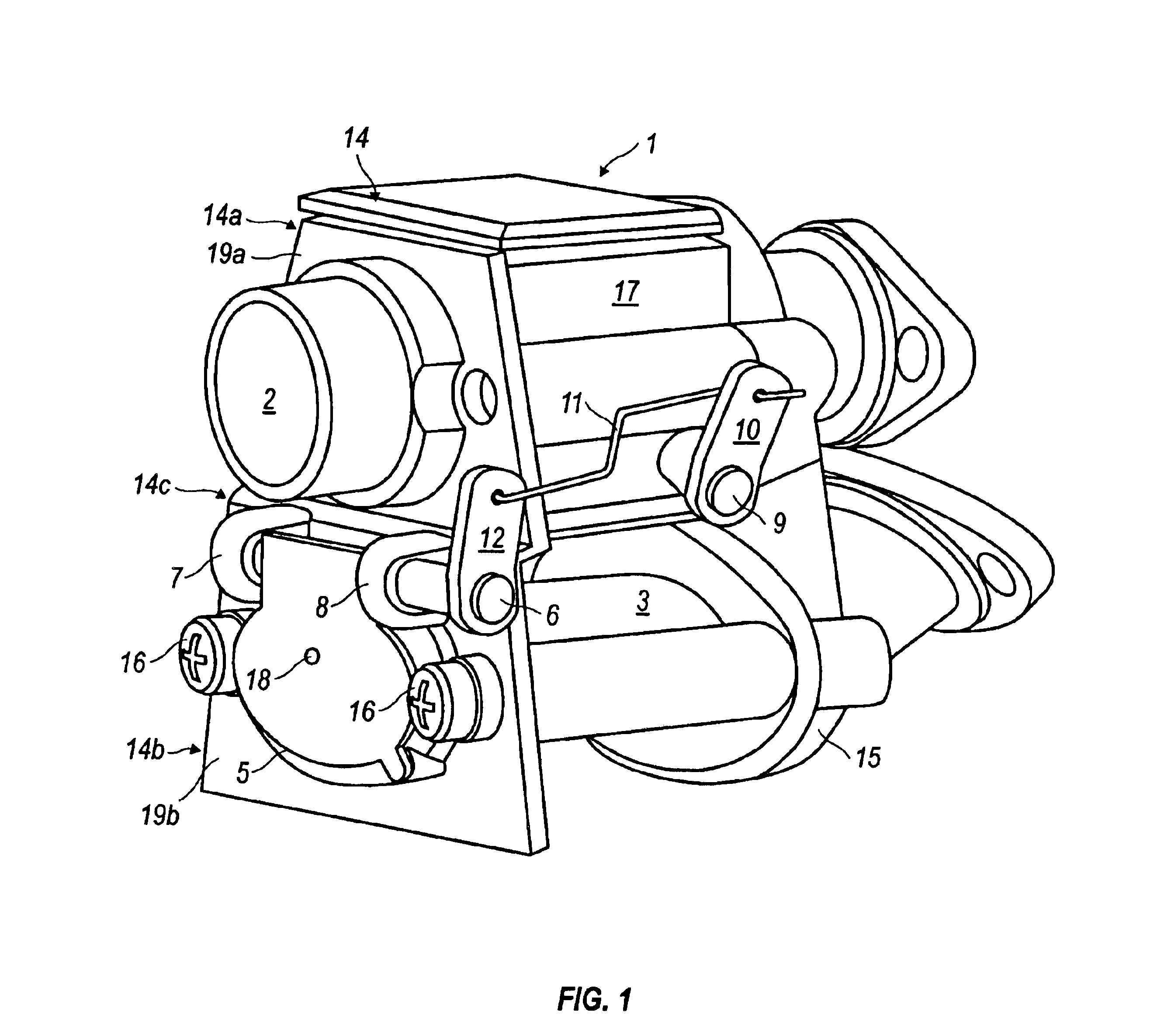

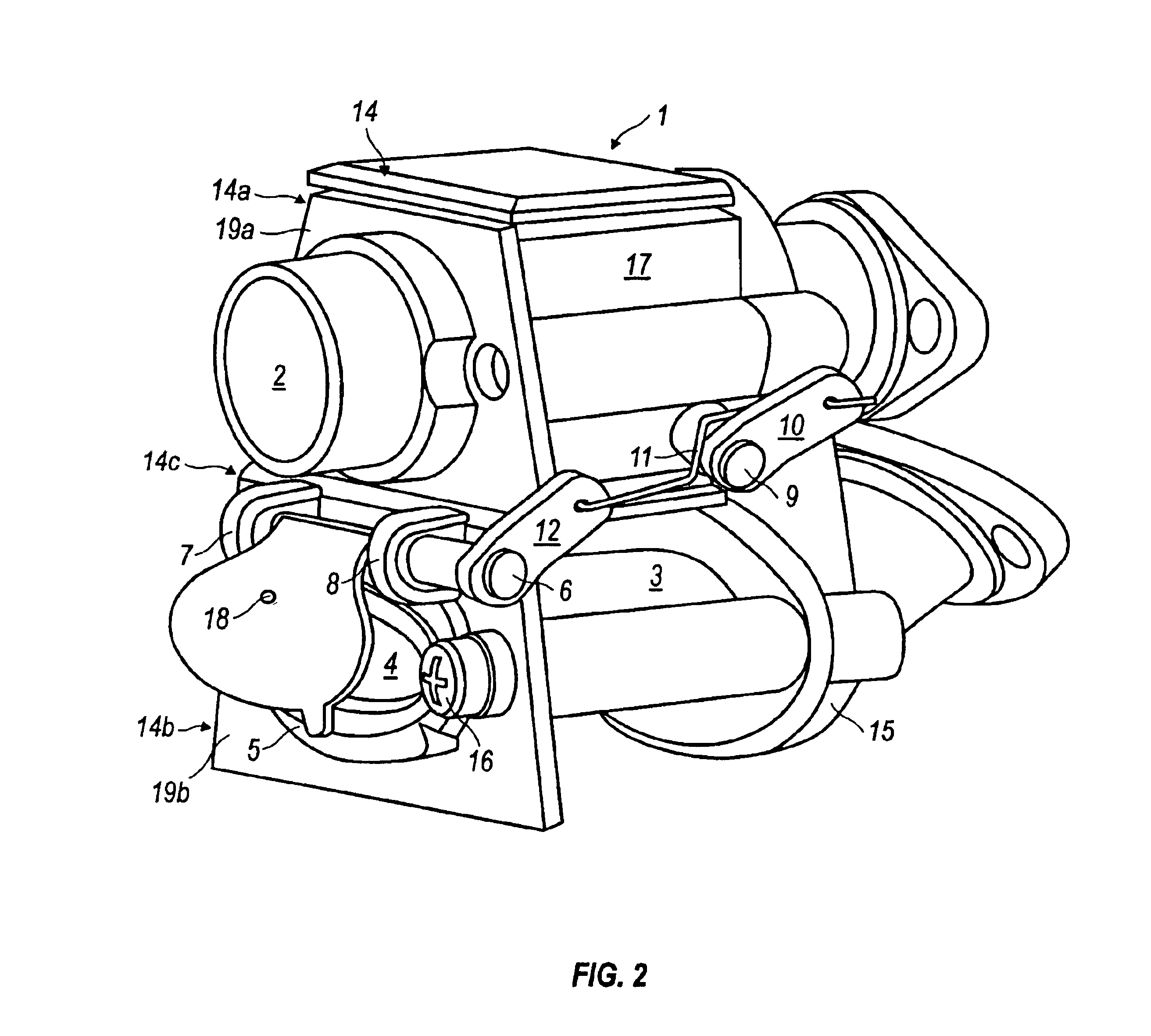

Valve for control of additional air for a two-stroke engine

InactiveUS6877723B2Easy to modifySimple and elegant constructionInternal combustion piston enginesLighting and heating apparatusFour-stroke engineCarburetor

Flange assembly for supporting a structure that provides scavenging air supply to an internal combustion engine at the carburetor to the engine. The assembly includes a thin-body flange that is configured to be abuttingly installed upon an end surface of the carburetor. The carburetor has its combustion air intake or port exposed at an outer surface for intaking air for the combustion process. The thin construction of the flange enables advantageous positioning of the adaptive flange. The relative dimensioning of the thin-body flange also contributes to its low-impact as a modification to air inlet arrangement. A combustion air aperture is provided that extends through the thin-body flange. The combustion air aperture is located in the flange for alignment with the combustion air intake. By this alignment, fluid communication is established across the flange and into the carburetor when the flange is abuttingly installed upon the carburetor. A scavenging air aperture also extends through the thin-body flange and is spaced apart from the combustion air aperture. A valve assembly is operatively coupled to the thin-body flange and has a valve element positioned at the scavenging air aperture for opening and closing the scavenging air aperture.

Owner:HUSQVARNA AB

Method and apparatus for irrigation system design registration and on-site sprinkler package configuration verification

Internet-accessible system and method for customized design and on-site verification of agriculture irrigation systems includes one or more of: 1) sprinkler package configuration software operable on a user's PC or accessible via an Internet website, 2) Internet-accessible proprietary irrigation system registry database and user interface, 3) computer-controlled automated component selection and labeling system for placing barcode or RFID information on components, and 4) portable wireless location-aware communication device operable at or near an irrigation site for accessing the registry database and obtaining sprinkler package configuration information specific to a particular irrigation system based on location and / or a particular irrigation system component detected in proximity to the portable communication device.

Owner:NELSON IRRIGATION

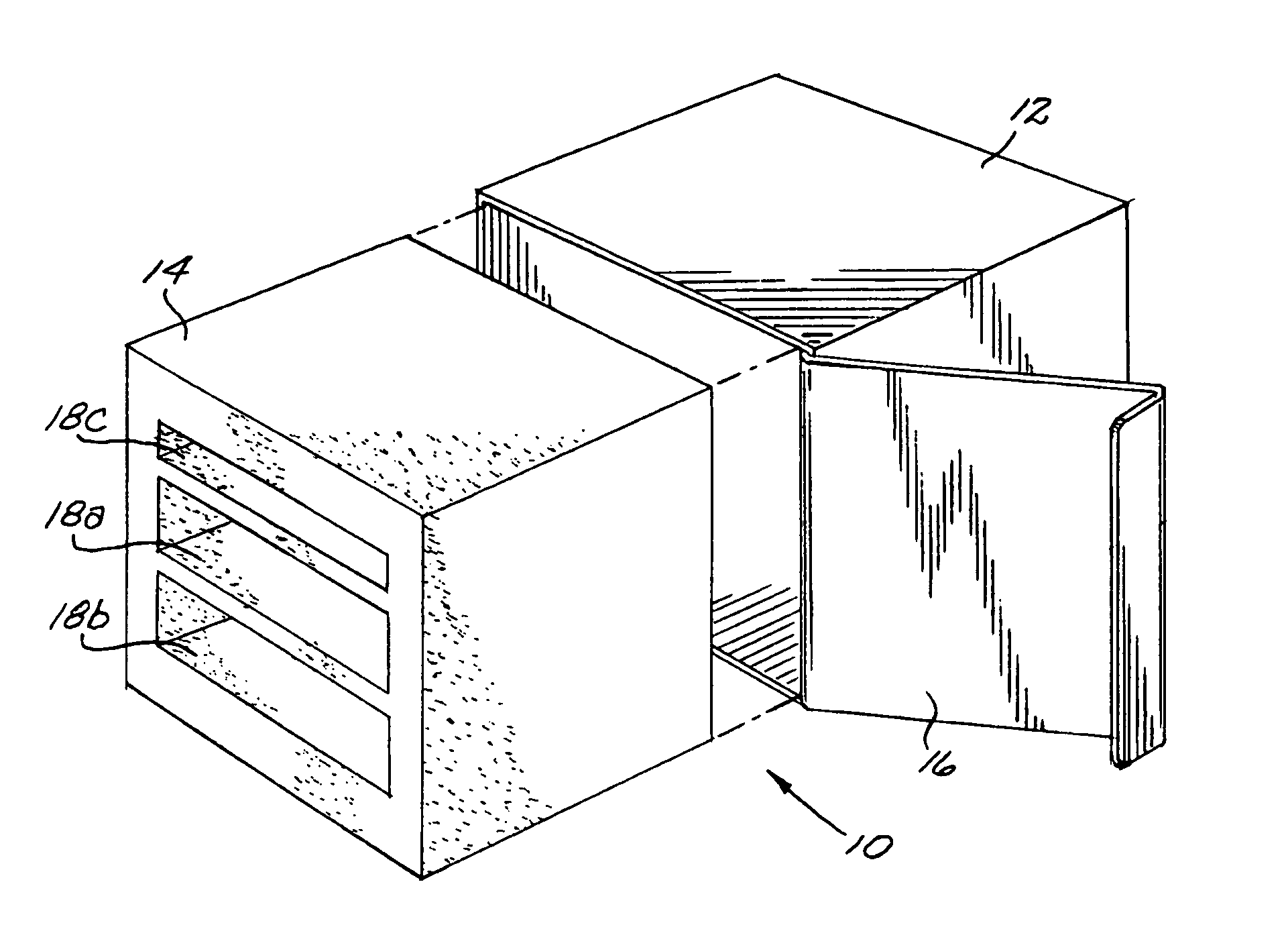

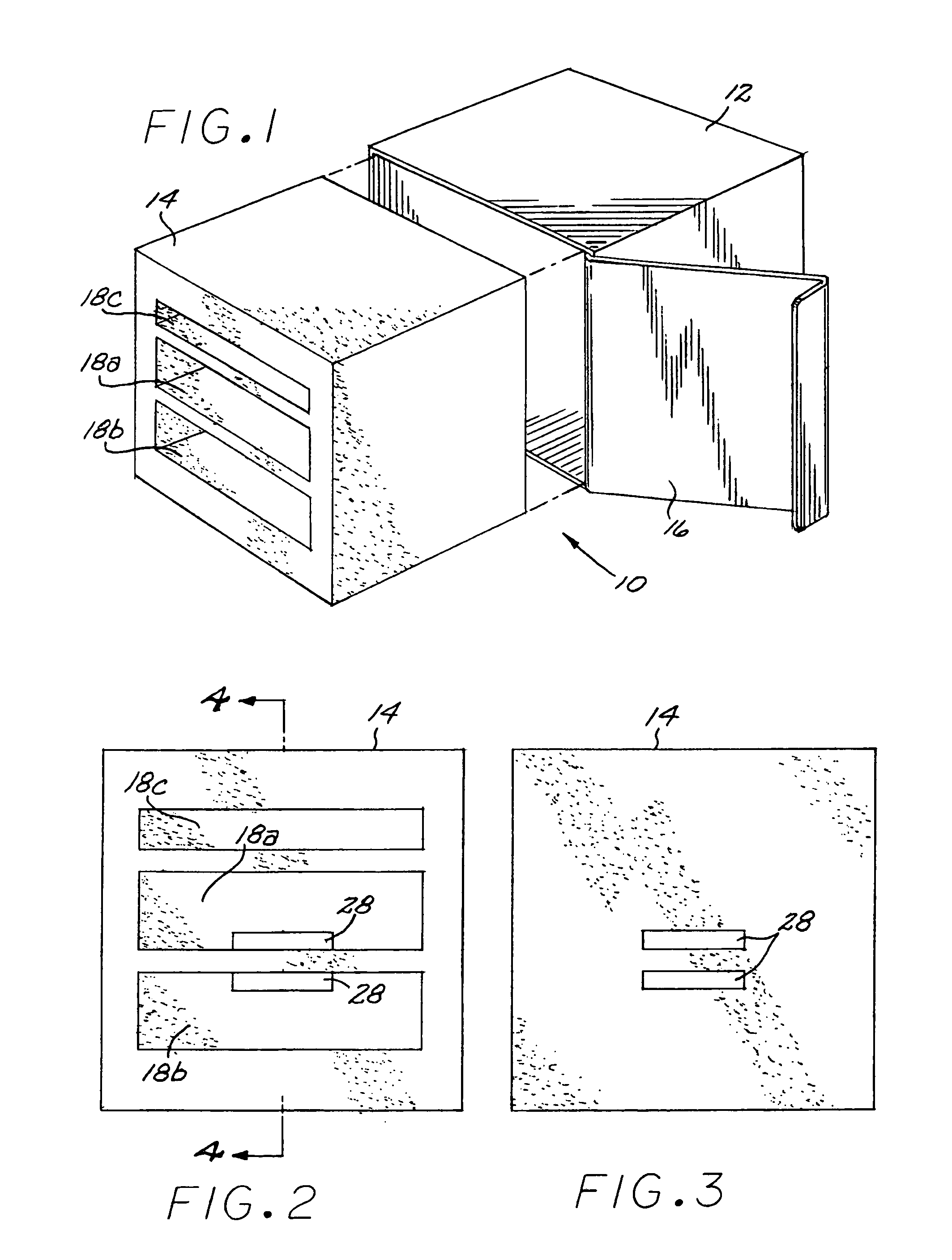

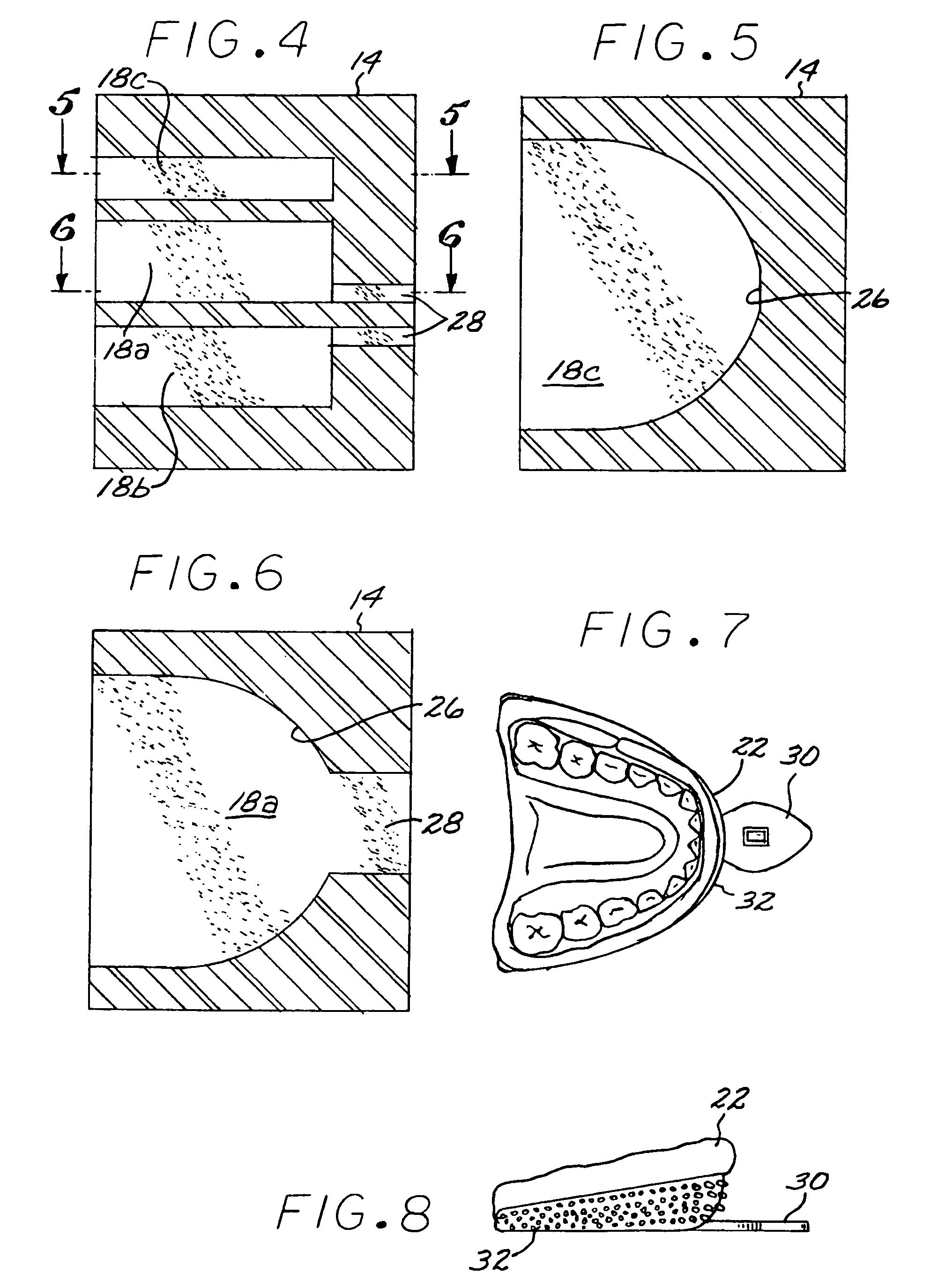

Container for transporting and processing three-dimensional dentition models

A method of transporting and processing a set of three-dimensional dentition models includes (a) providing a container having an outer shell containing a shock-absorbing core, wherein the core defines a plurality of compartments each configured to hold one model in the set of three-dimensional dentition models; (b) loading each of the dentition models into its respective compartment; (c) transporting the container to a processing site; and (d) processing the dentition models while they are in the container.

Owner:ALIGN TECH

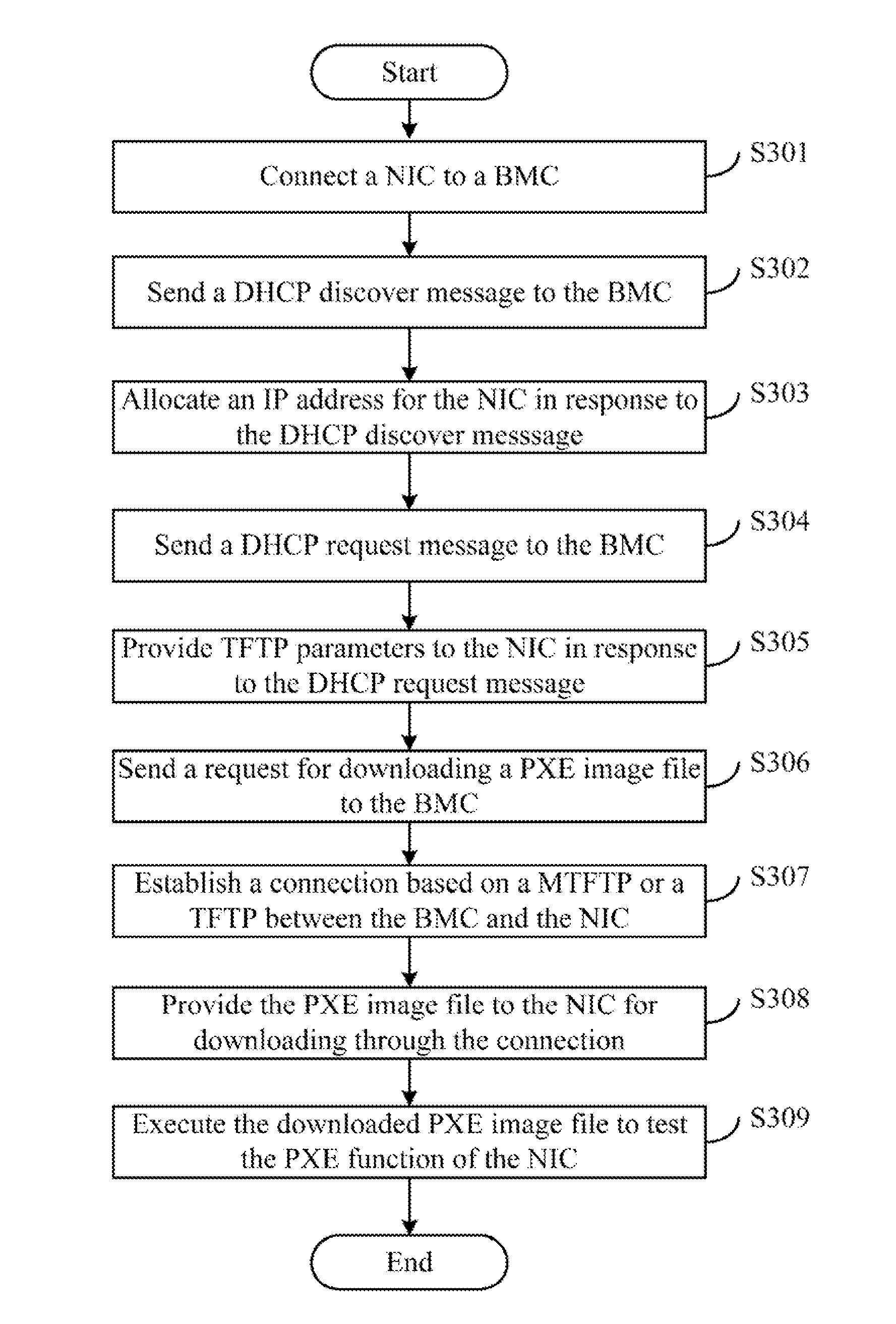

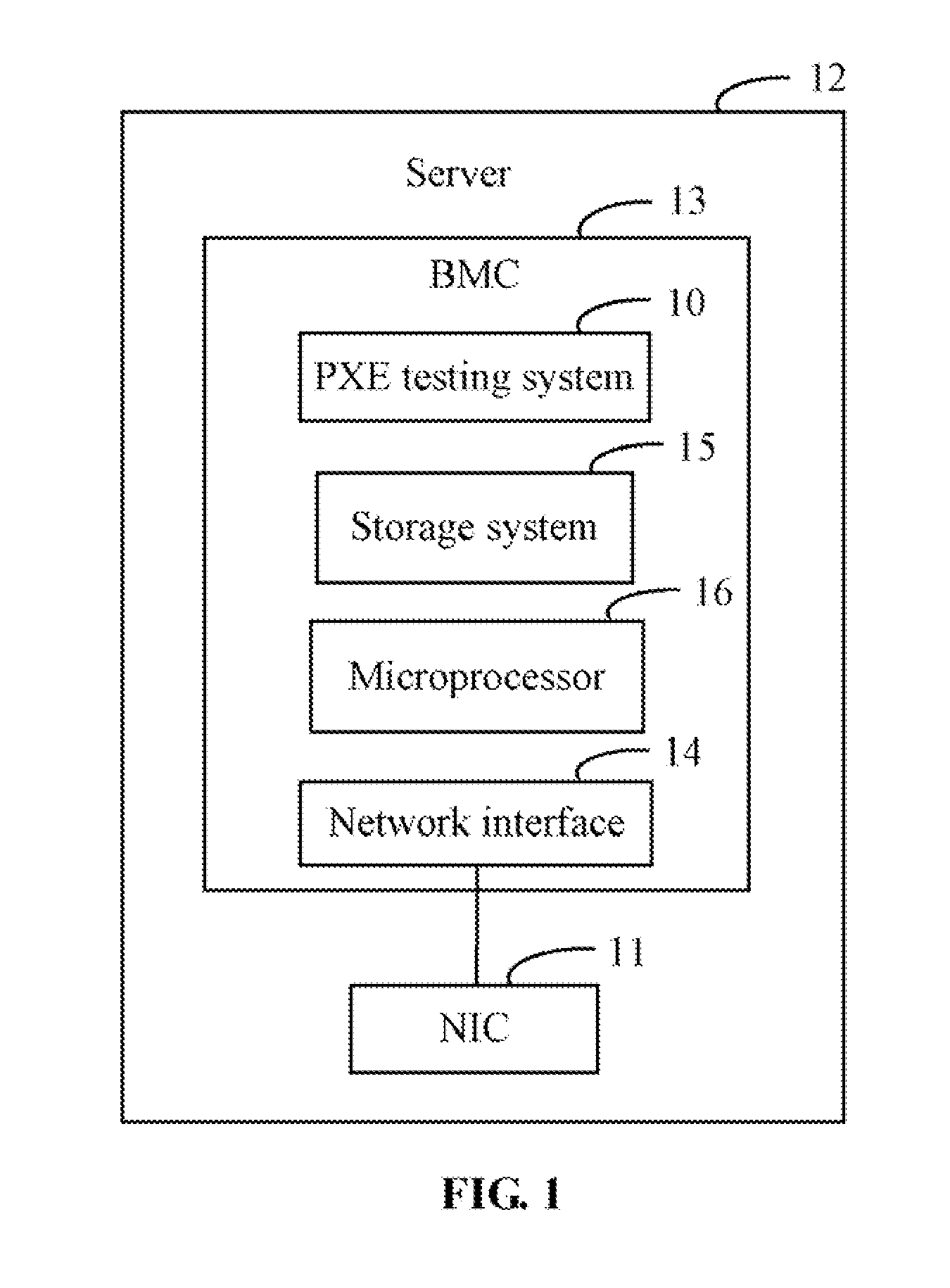

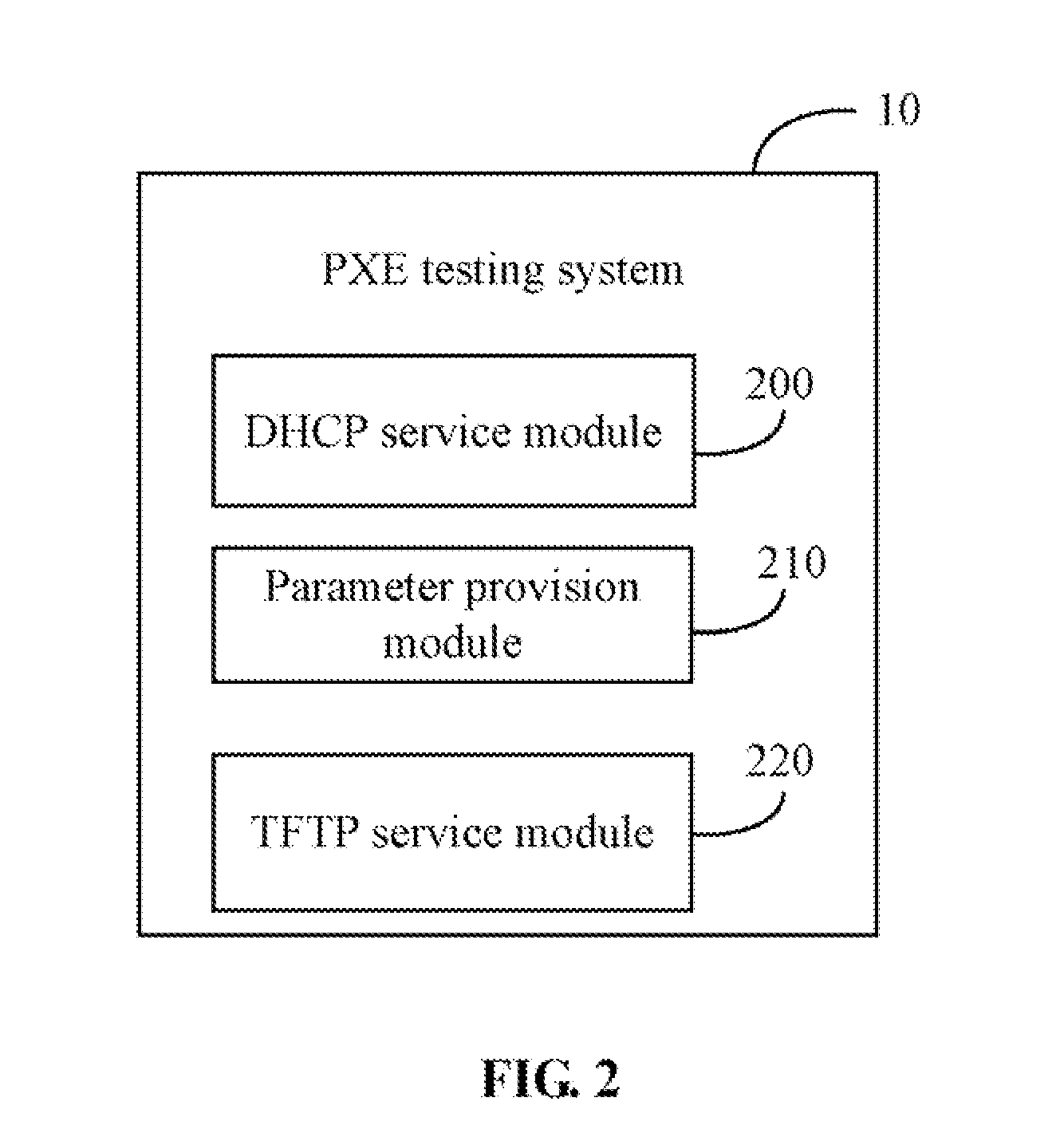

Server and method for testing pxe function of network interface card

InactiveUS20120124242A1Costly and time-consumeMultiple digital computer combinationsTransmissionIp addressNetwork interface

In a method for testing a preboot execution environment (PXE) function of a NIC of a server, an IP address is allocated for the NIC by sending a DHCP offer message to the NIC in response to receiving a DHCP discover message from the NIC. TFTP parameters are provided to the NIC by sending a DHCP ACK message to the NIC in response to receiving a DHCP request message from the NIC. A connection based on a MTFTP or a TFTP between the BMC and the NIC is established according to the TFTP parameters. A PXE image file is provided to the NIC for downloading through the connection in response to receiving a request for downloading the PXE image file from the NIC, and the downloaded PXE image file is executed to test whether the PXE function of the NIC is normal.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

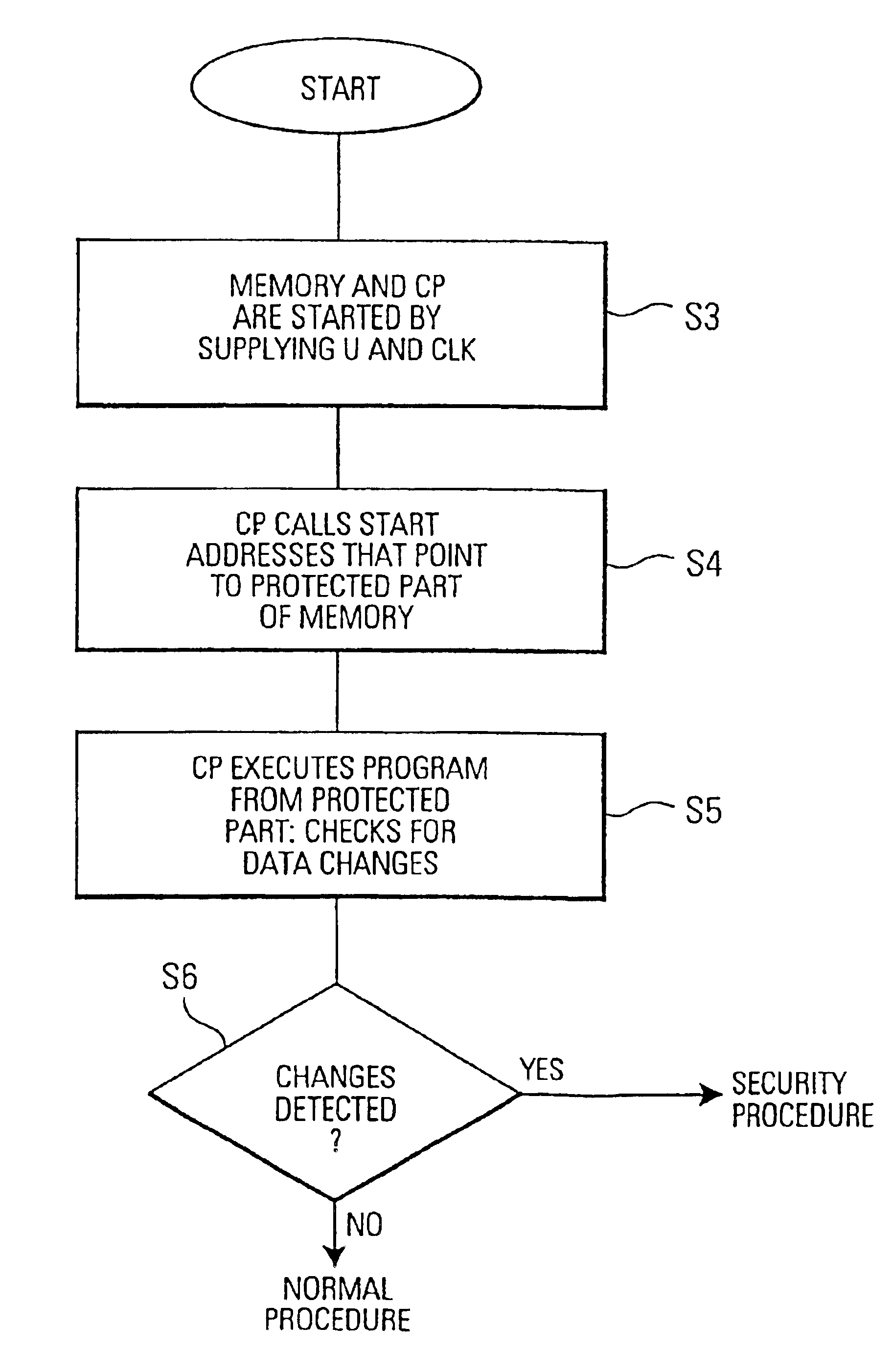

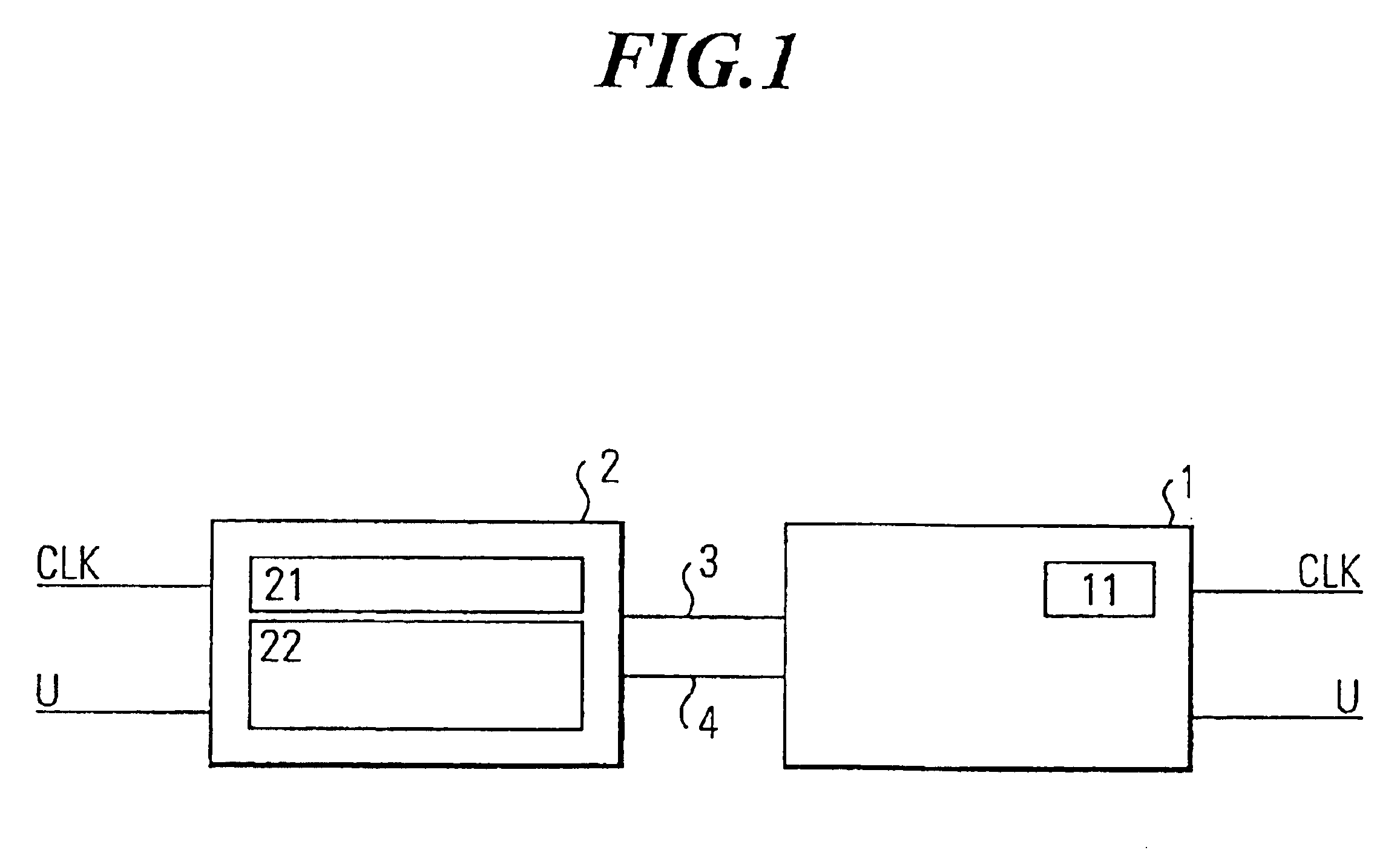

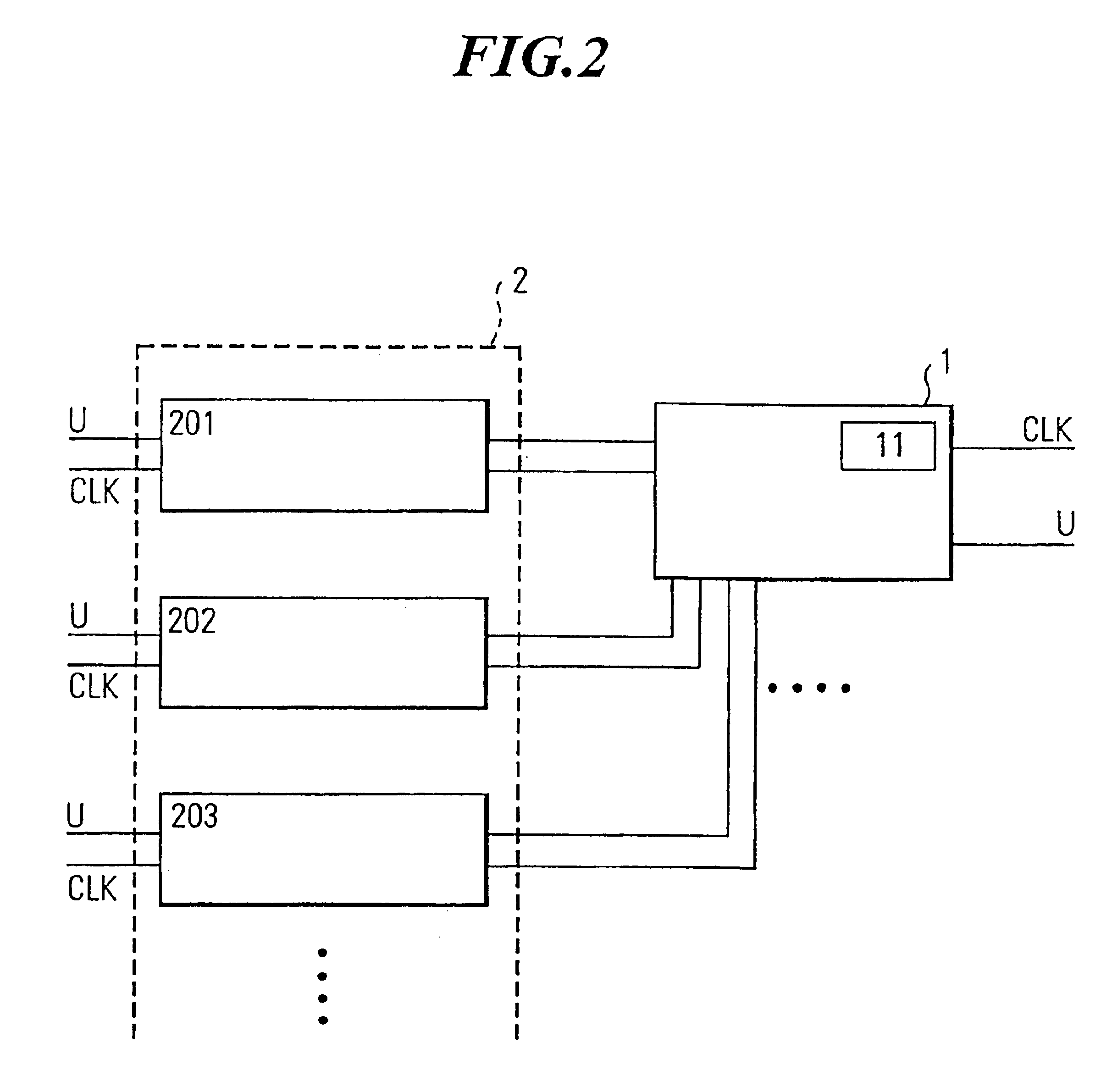

System and method for data processing by executing a security program routine initially stored in a protected part of irreversibly blocked memory upon start-up

InactiveUS6857068B1Easy to implementCostly and time-consumeSpecific access rightsInternal/peripheral component protectionComputer hardwareStart up

Device for processing data includes a processor for executing program routines, and a memory for storing program routines to be executed by the processor. Part of the memory includes a protected part from which data can be read but which is protected against being written into. The processor is arranged to necessarily execute a program routine stored in the protected part of the memory upon start-up.

Owner:TELEFON AB LM ERICSSON (PUBL)

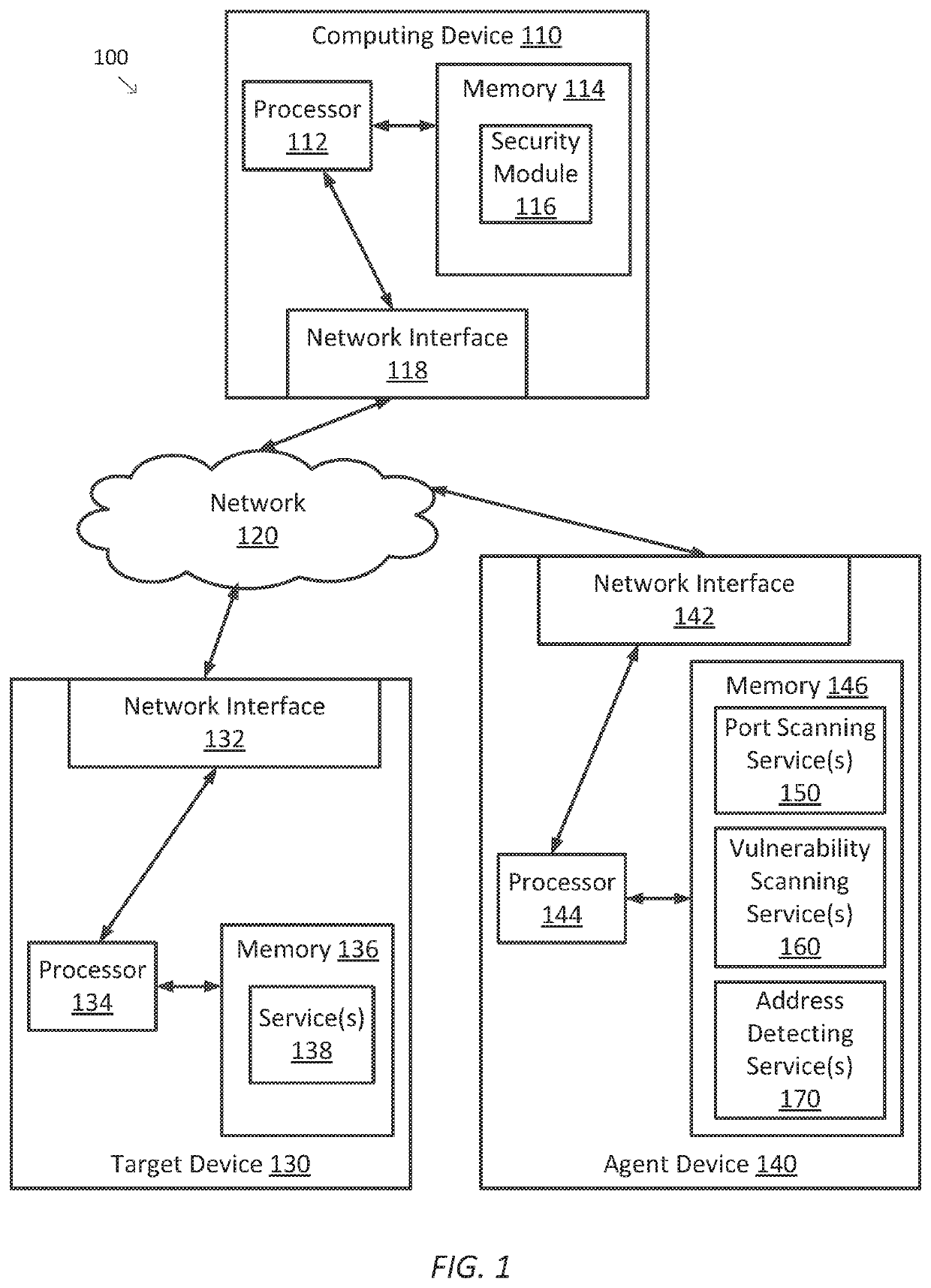

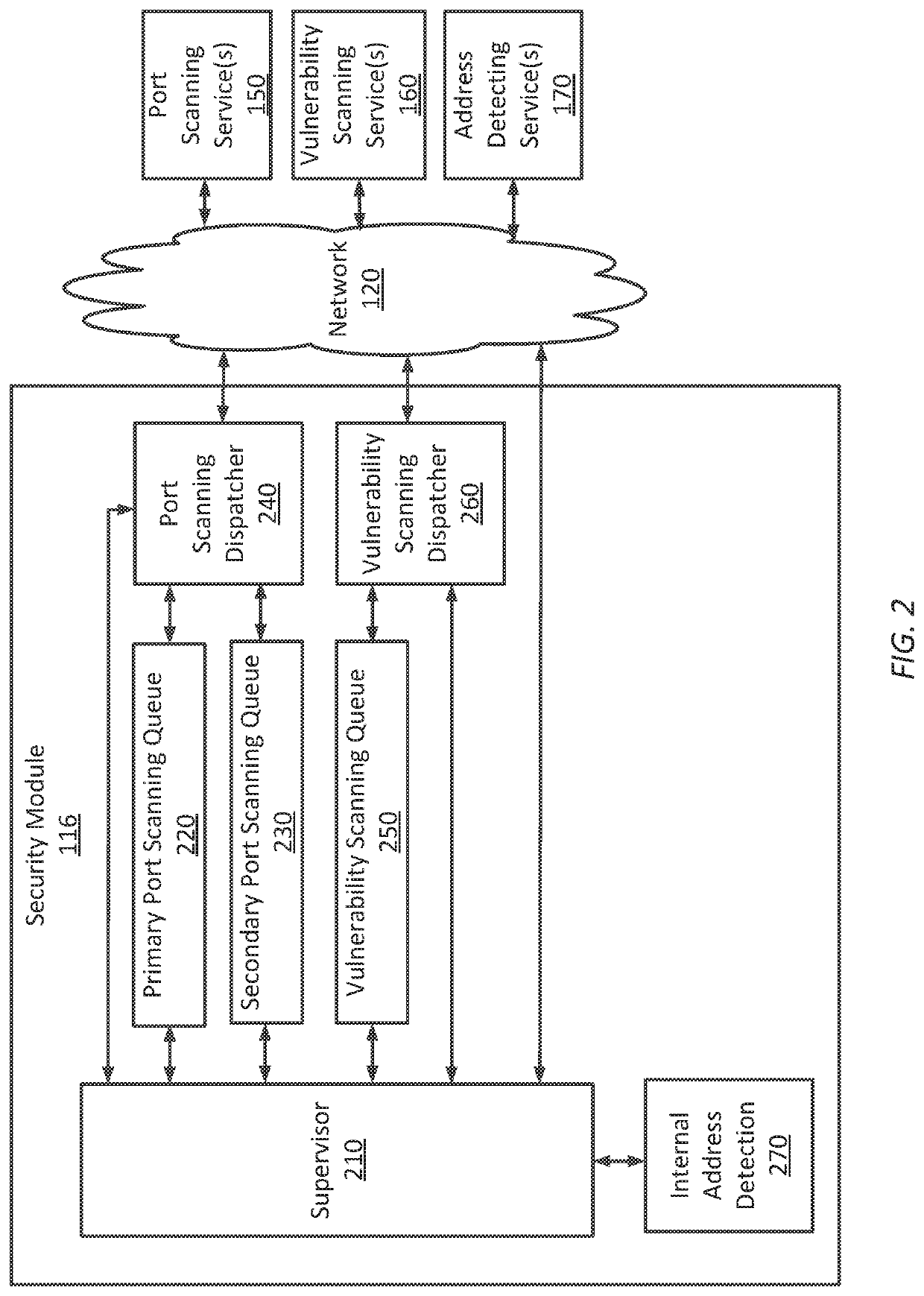

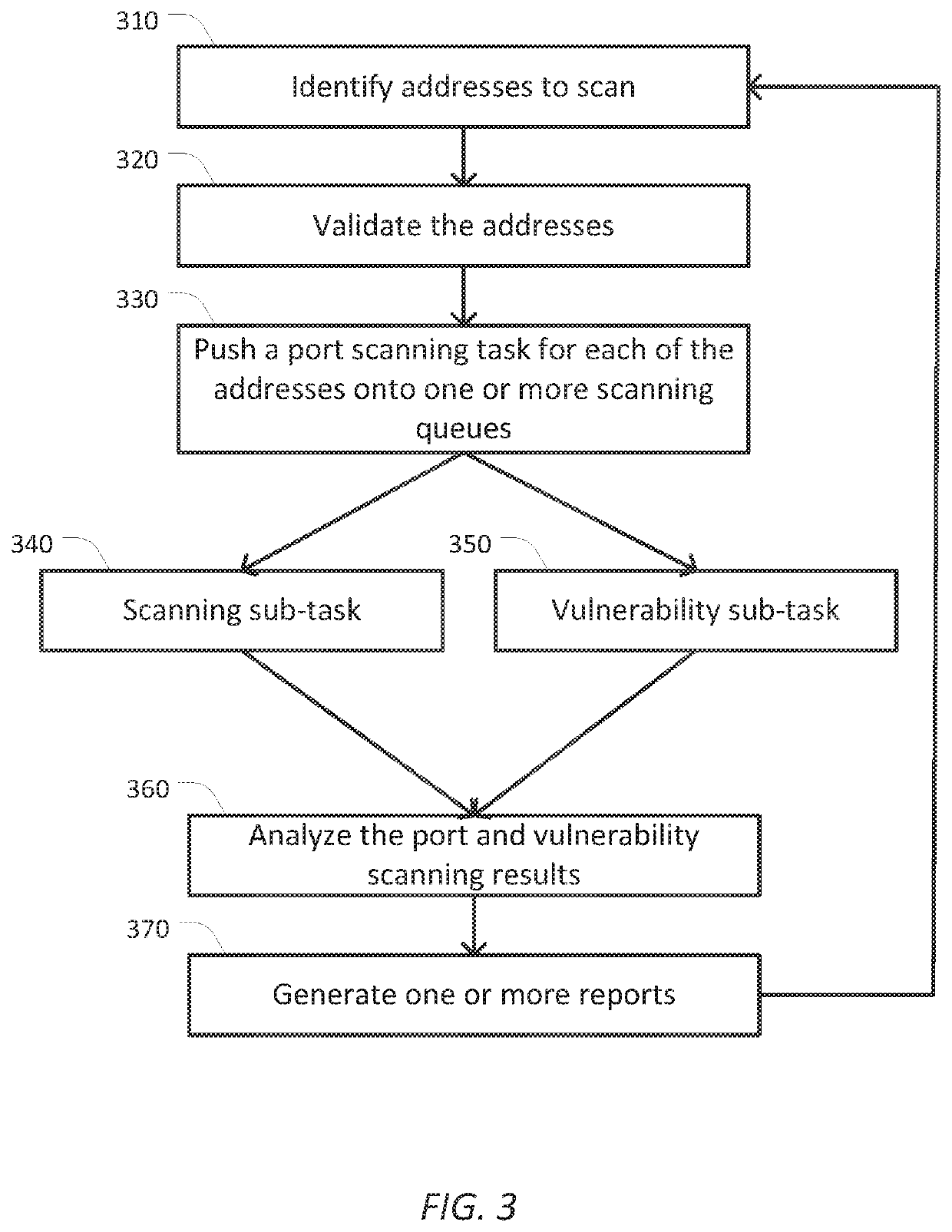

Techniques for analyzing network vulnerabilities

One embodiment of the present disclosure sets forth a technique for analyzing network vulnerabilities. The technique includes determining an address for each target device included in a plurality of target devices; for each target device, assigning a port scanning task to an associated port scanning service, the port scanning task being associated with the target device via the address of the target device; for each port scanning task, receiving a port scanning result from the port scanning service assigned to the port scanning task, the port scanning result including a list of open ports for the target device associated with the port scanning task; for each open port included in each port scanning result, assigning a vulnerability scanning task to an associated vulnerability service; receiving a vulnerability scanning result for each vulnerability scanning task; and generating a report based on the port scanning results or the vulnerability scanning results.

Owner:DISNEY ENTERPRISES INC

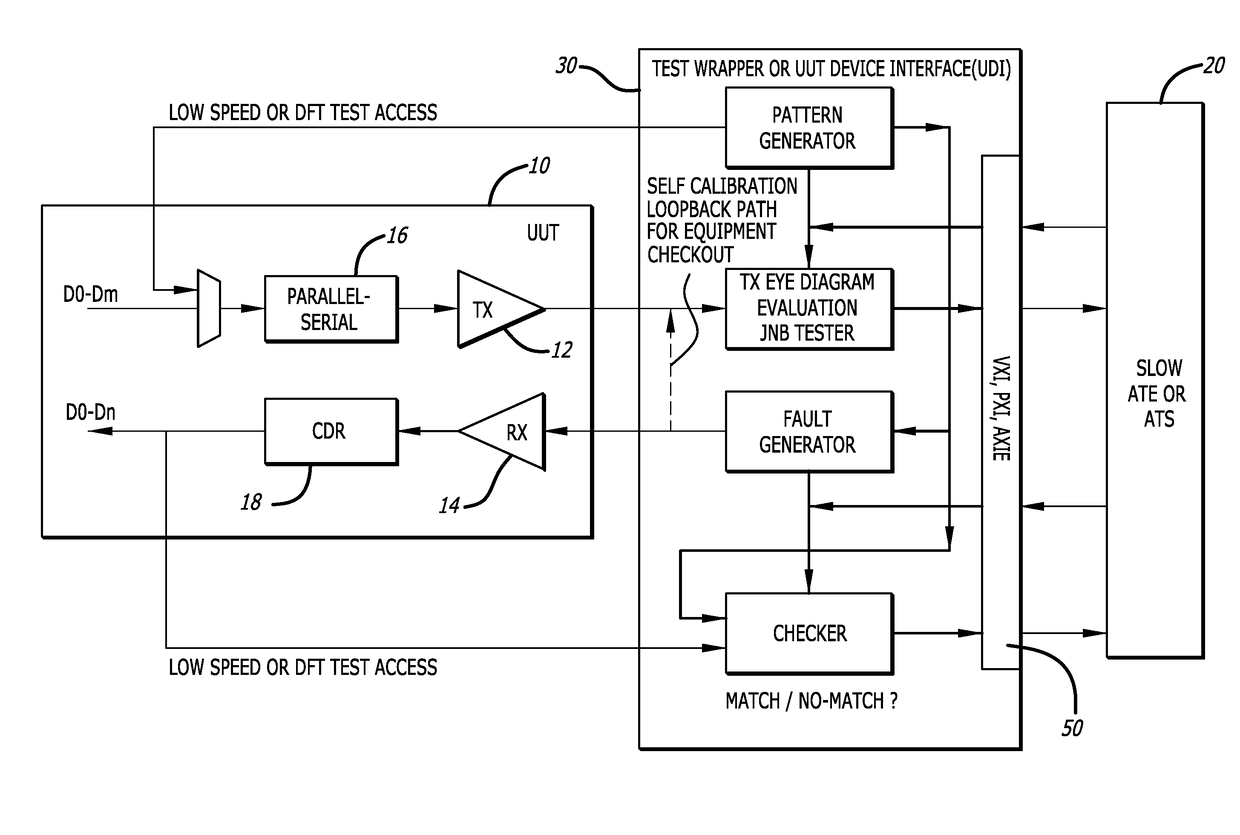

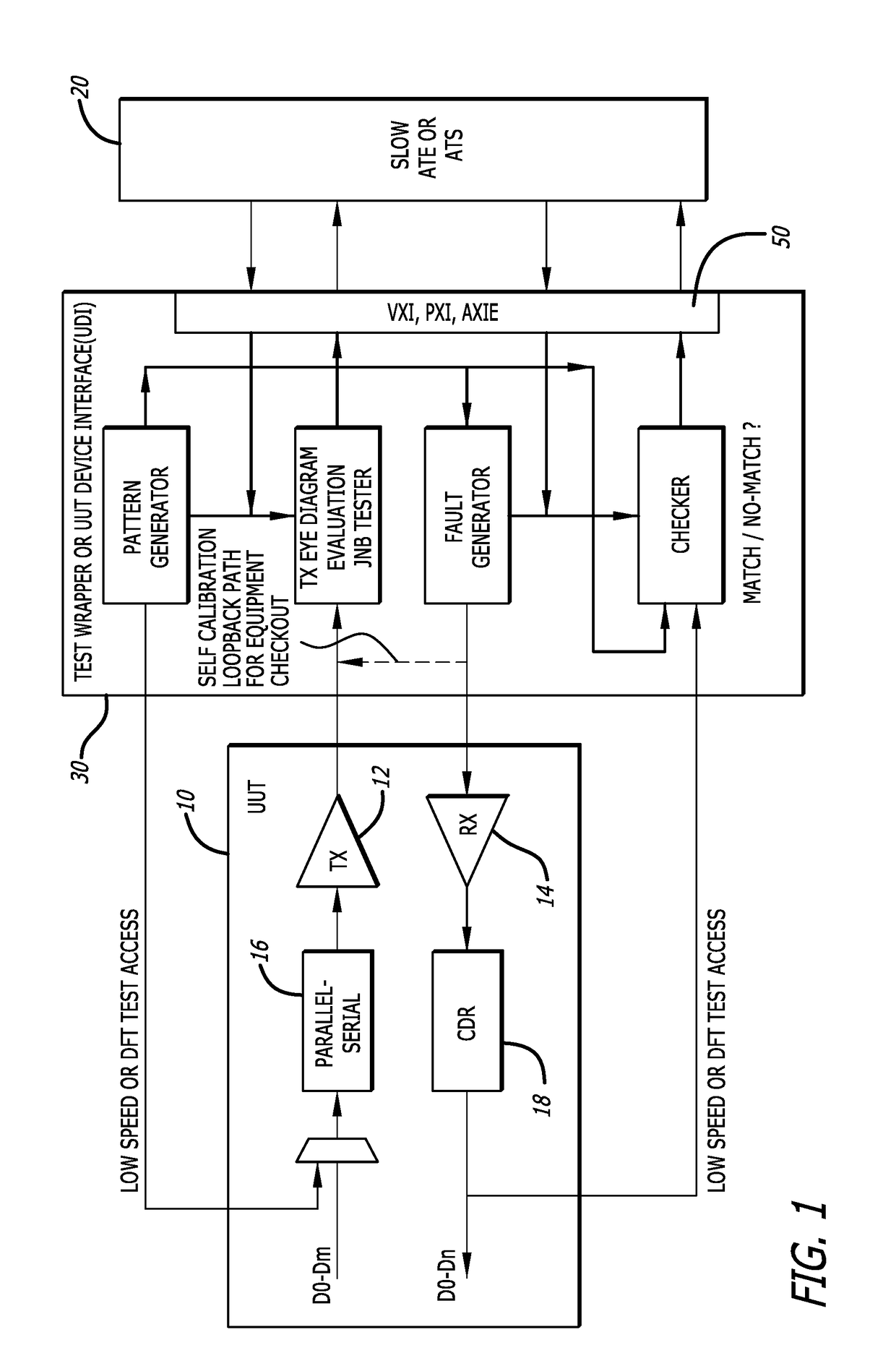

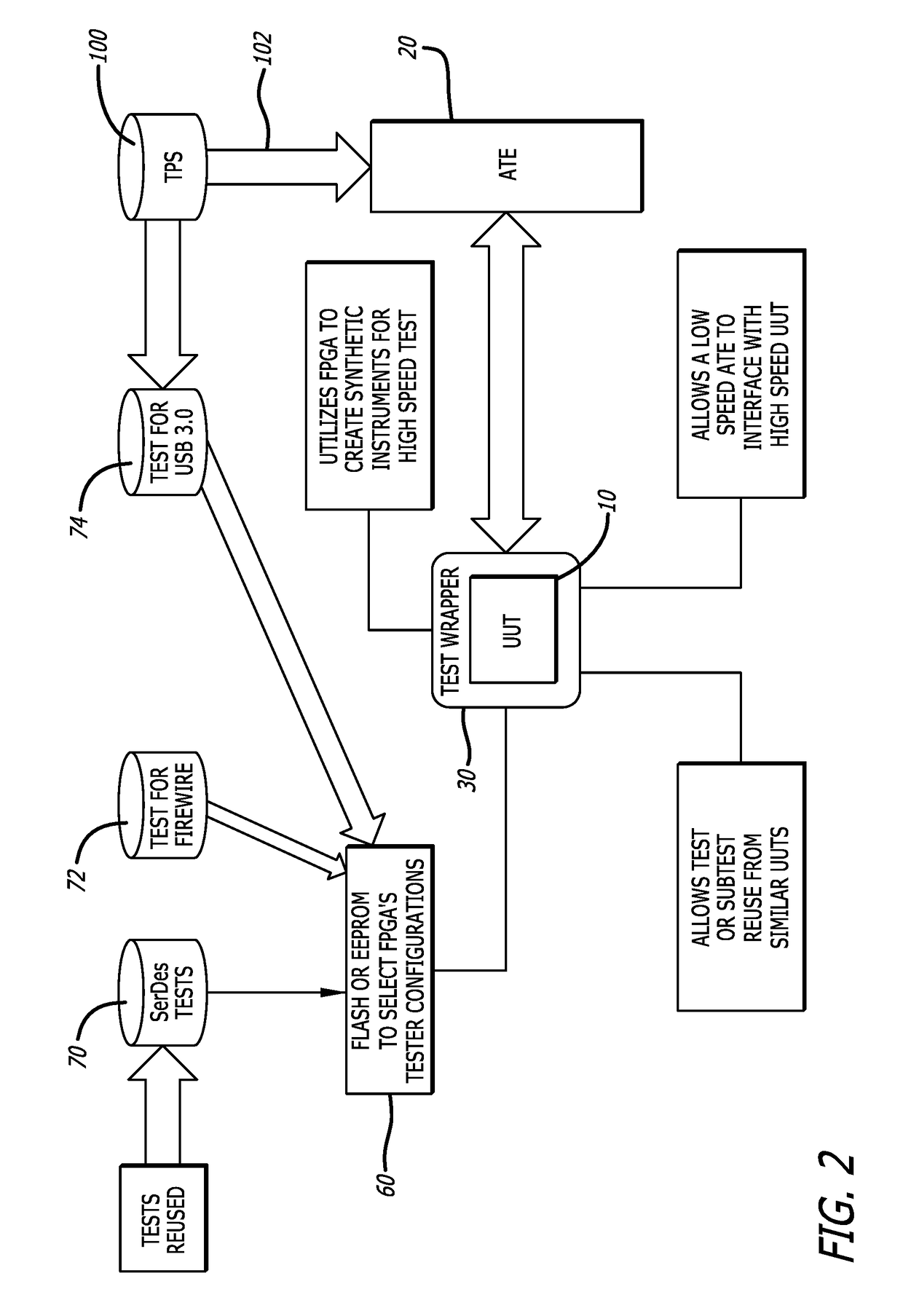

Systems and methods for dynamically reconfiguring automatic test equipment

ActiveUS20180205621A1Testing is superfluousImprove signal integrityDetecting faulty computer hardwareElectrical testingSynthetic instrumentAutomatic test equipment

A dynamically reconfigurable interface for an automatic test equipment is disclosed where one or more synthetic instruments transmit the high speed signals as well as receive the high speed signals from a device under test so that testing can be performed at speeds higher than the ATE was originally designed to accommodate. Synthetic instruments are implemented on a field programmable gate array (FPGA) that operate at higher speeds than COTS instruments and can reach the frequencies that high speed I / O buses use. SIs can be created by configuring the FPGA, with different configurations creating different SIs. A single FPGA can house a number of SIs.

Owner:A T E SOLUTIONS

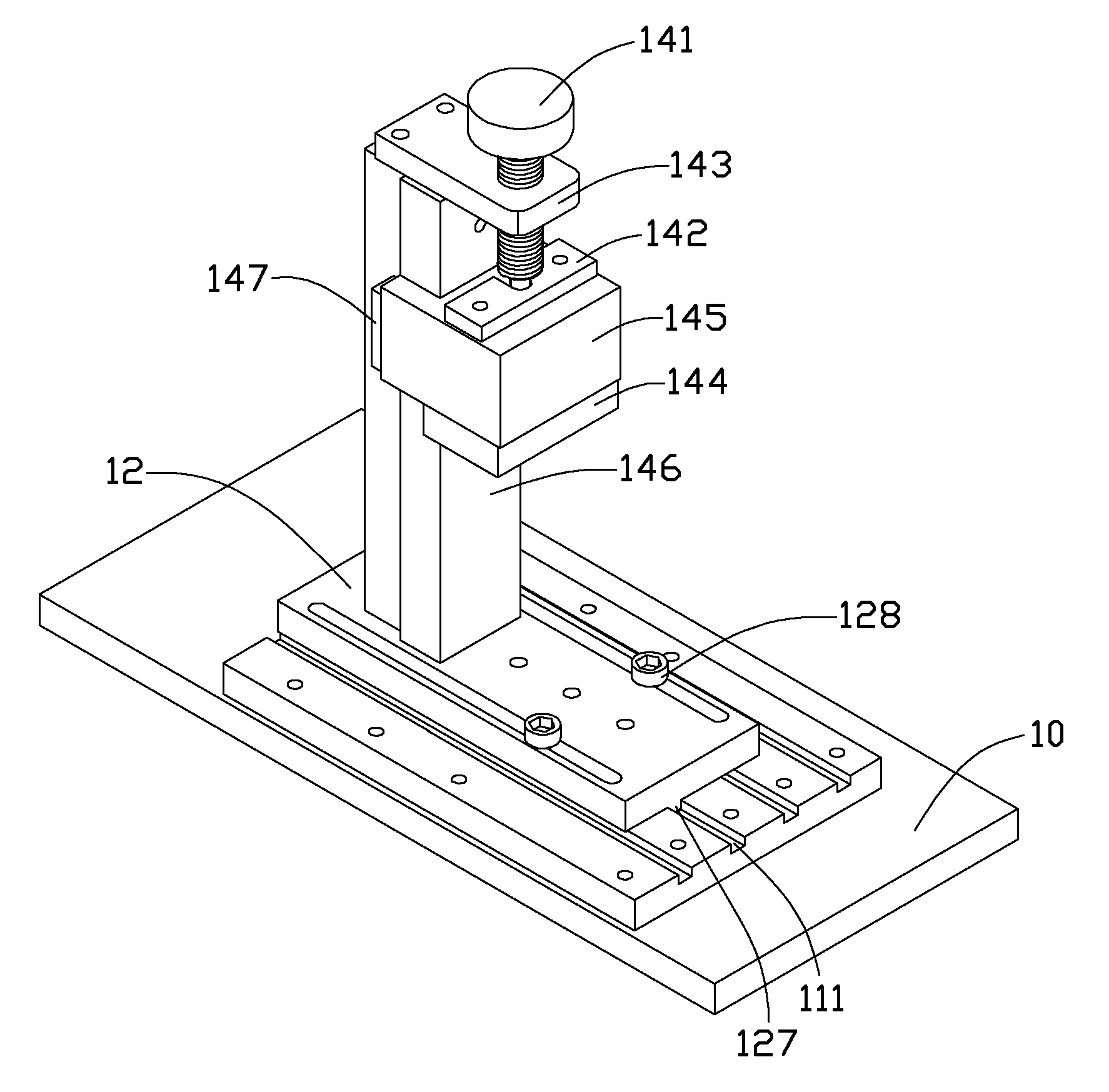

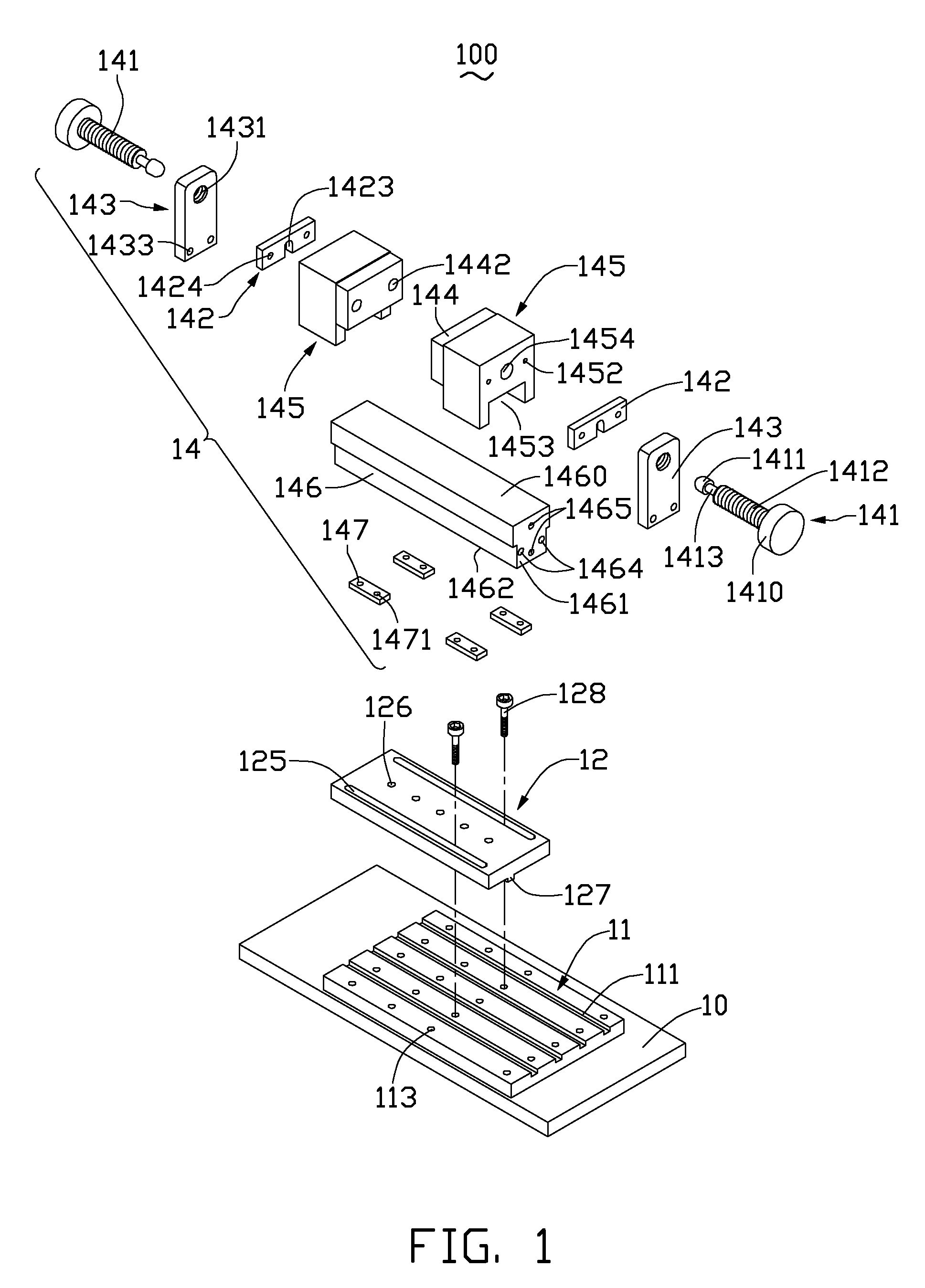

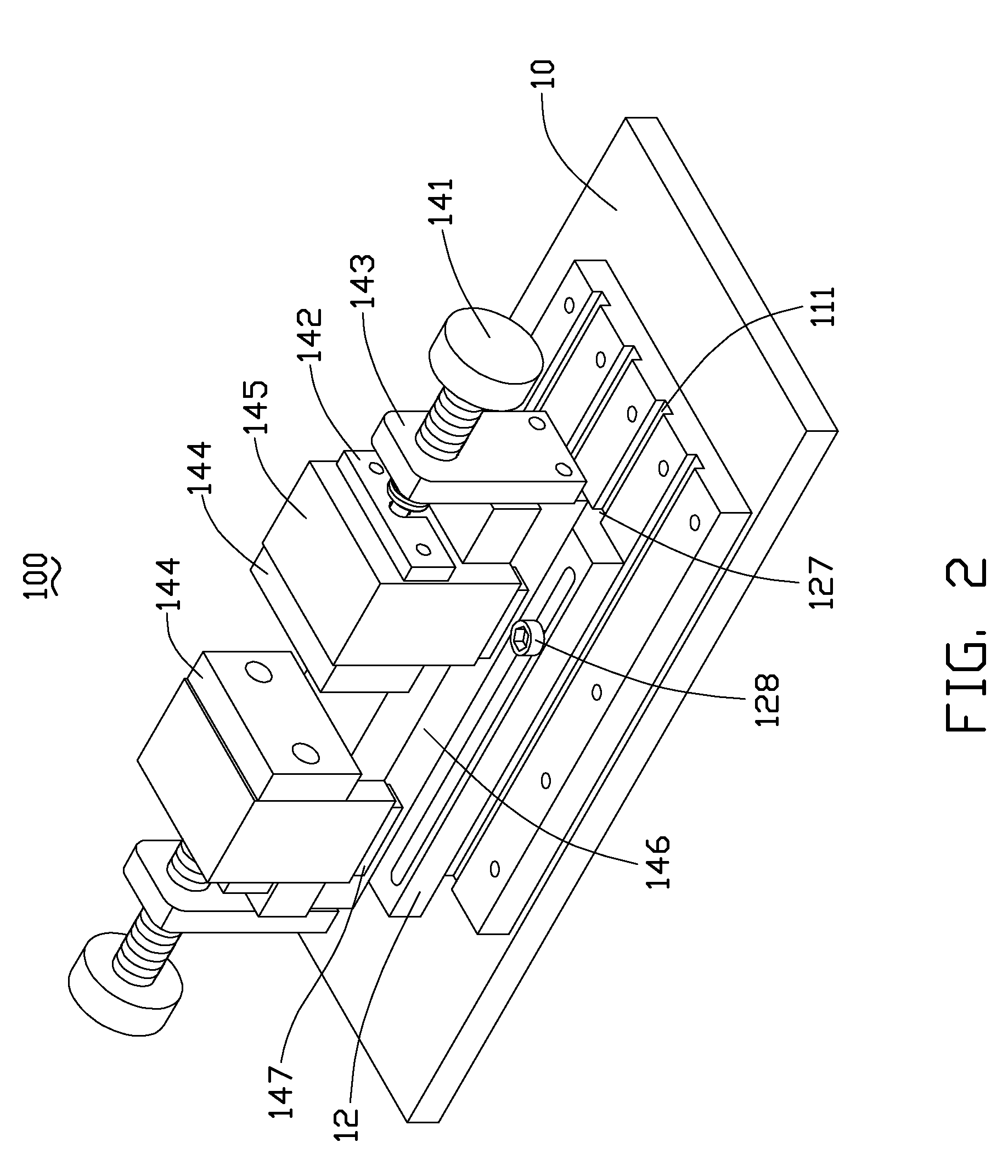

Clamping device for portable electronic device

InactiveUS20100107377A1Low testing efficiencyCostly and time-consumeSnap fastenersClothes buttonsElectric equipmentElectron device

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

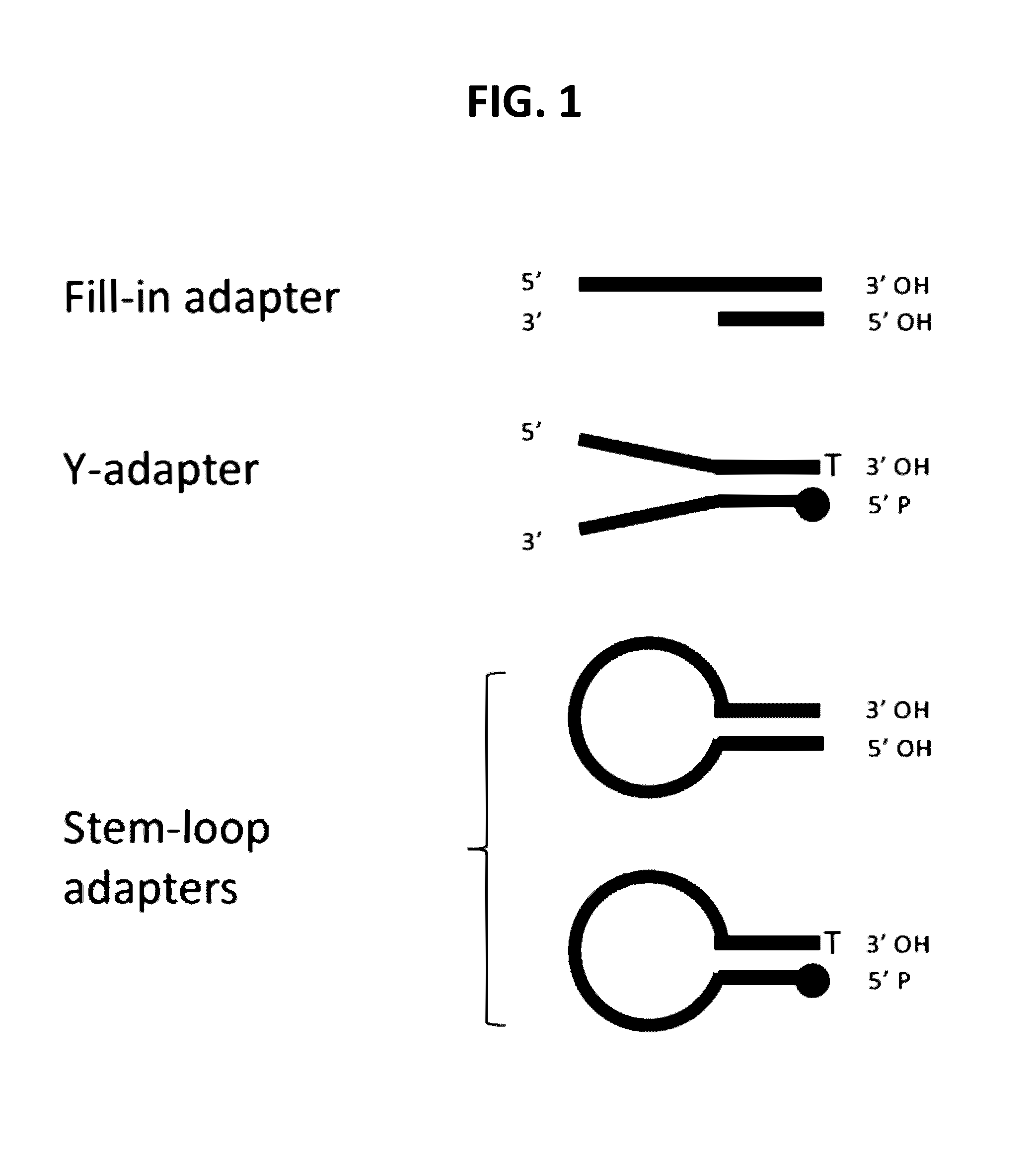

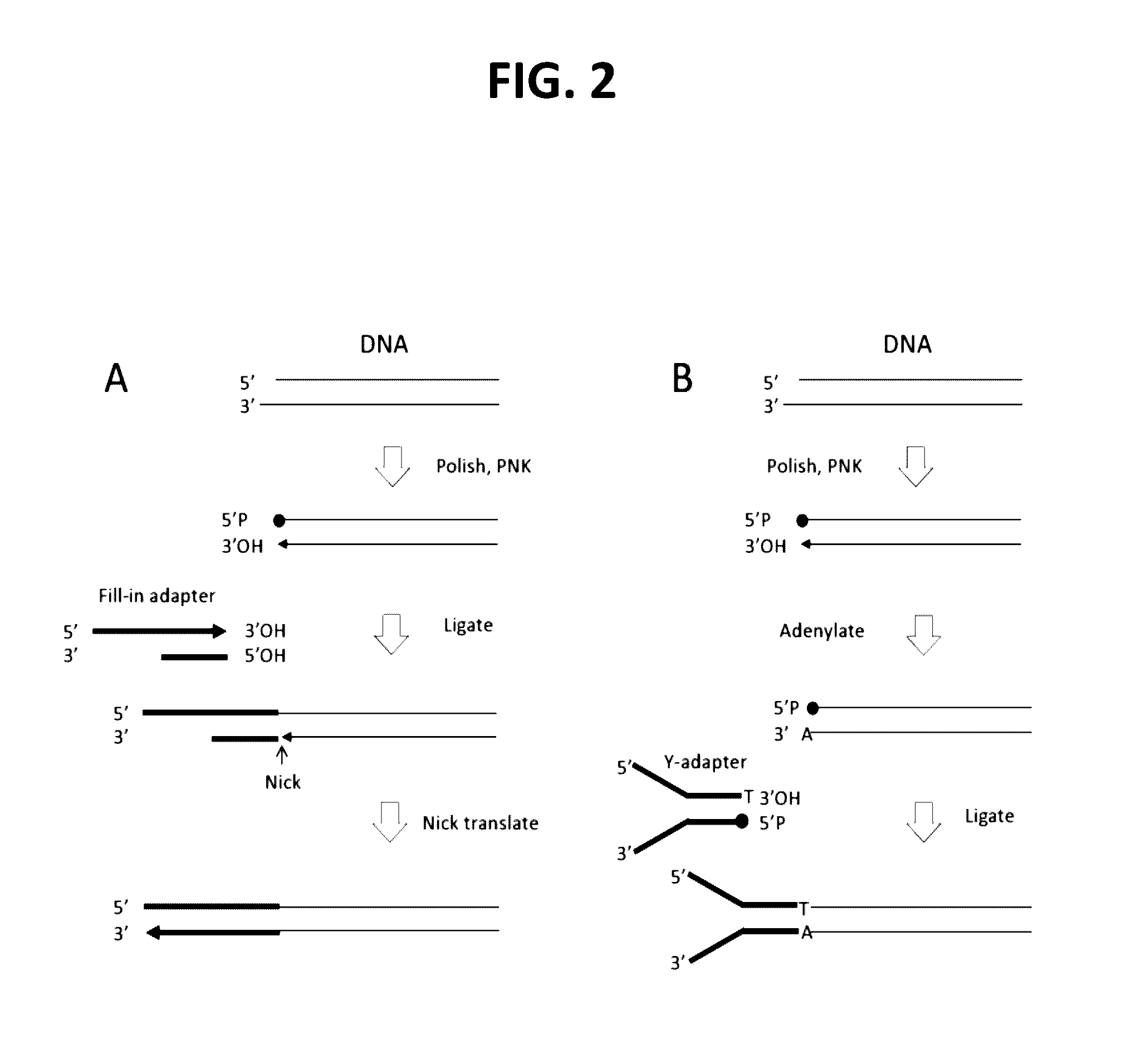

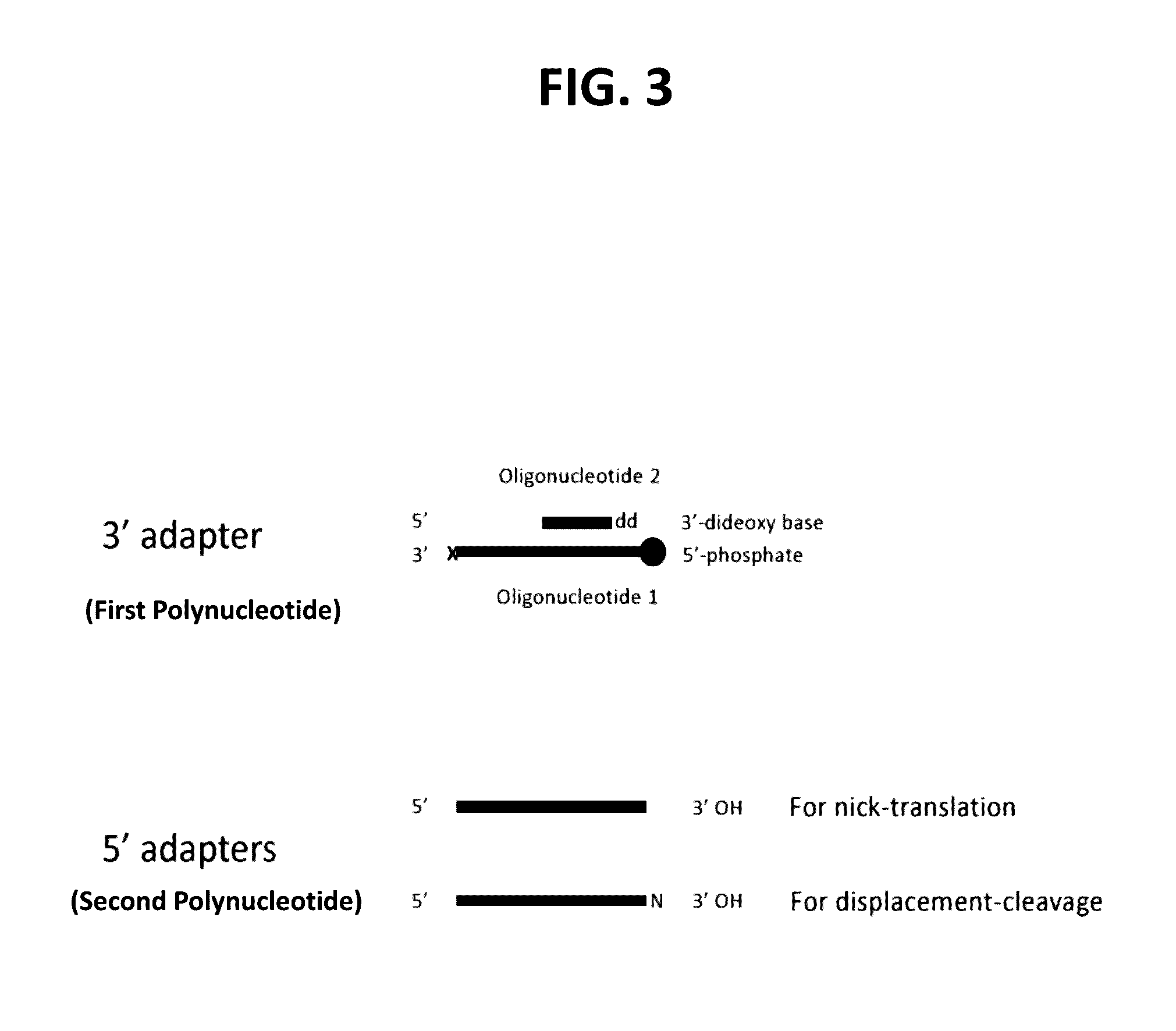

Methods for processing DNA substrates

ActiveUS20160340746A1Increase in library yieldHigh library preparation yieldMicrobiological testing/measurementVector-based foreign material introductionDouble strandedDouble strand dna

Owner:INTEGRATED DNA TECHNOLOGIES

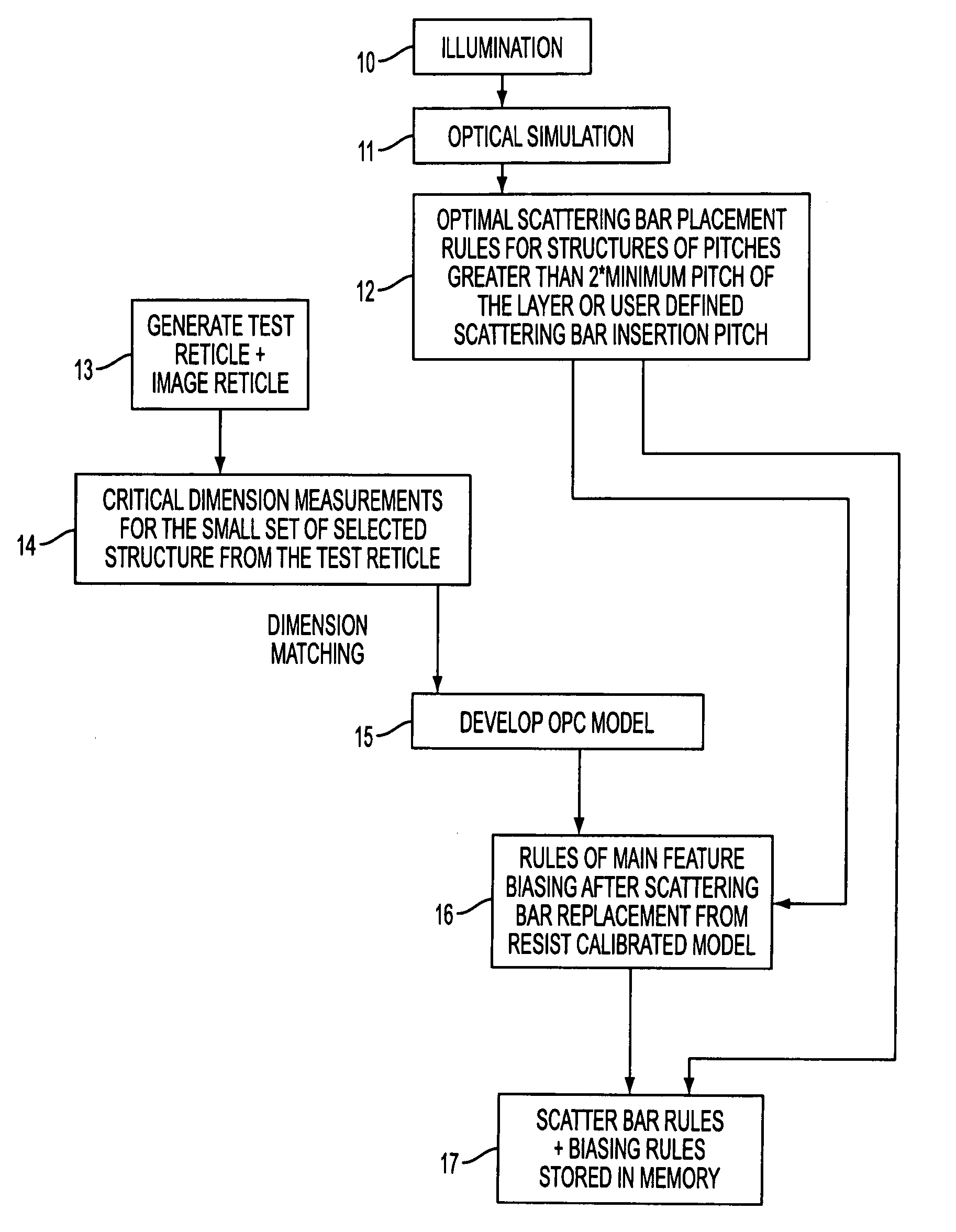

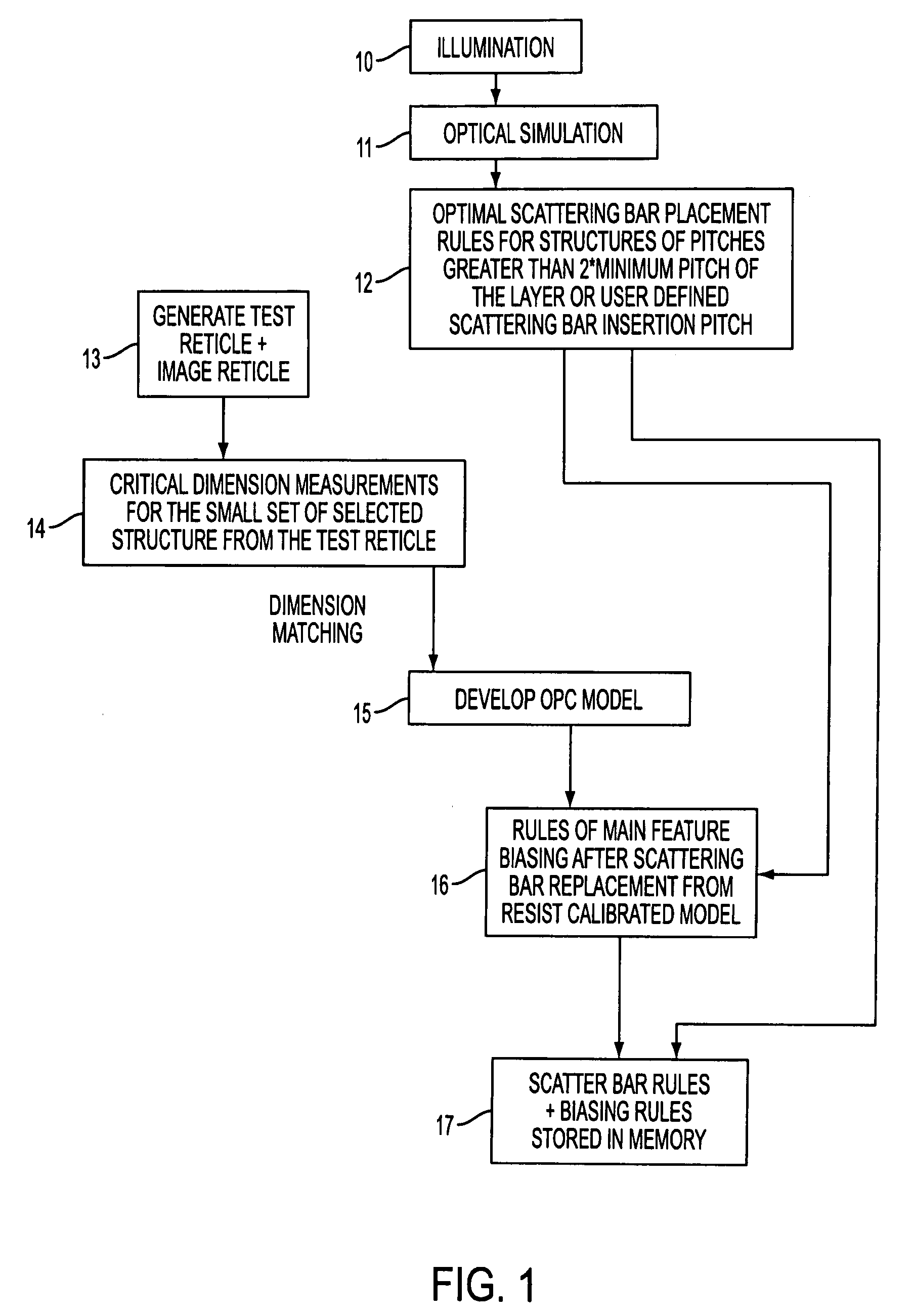

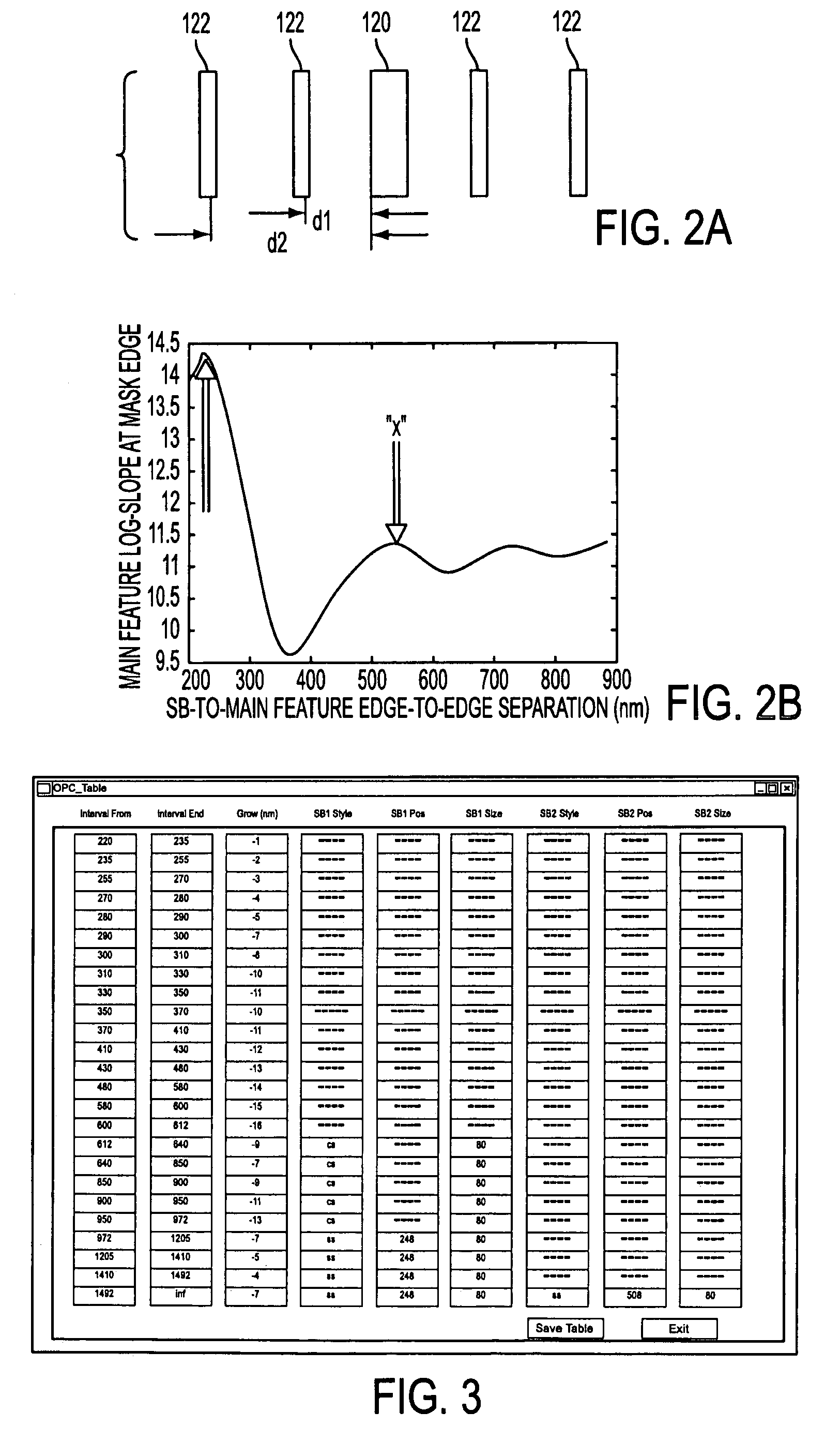

Automatic optical proximity correction (OPC) rule generation

ActiveUS7124395B2Eliminate needCostly and time-consumeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusAlgorithmReticle

A method of automatically applying optical proximity correction techniques to a reticle design containing a plurality of features. The method comprises the steps of: (1) generating a first set of rules for applying scatter bar assist features to the plurality of features for a given illumination setting; (2) generating a second set of rules for applying biasing to the plurality of features for said given illumination setting; (3) forming a look-up table containing the first set of rules and the second set of rules; and (4) analyzing each of the plurality of features with the first set of rules and the second set of rules contained in the look-up table to determine if either the first set of rules or the second set of rules is applicable to a given feature. If either the first set of rules or the second set of rules is applicable to the given feature, the given feature is modified in accordance with the applicable rule.

Owner:ASML NETHERLANDS BV

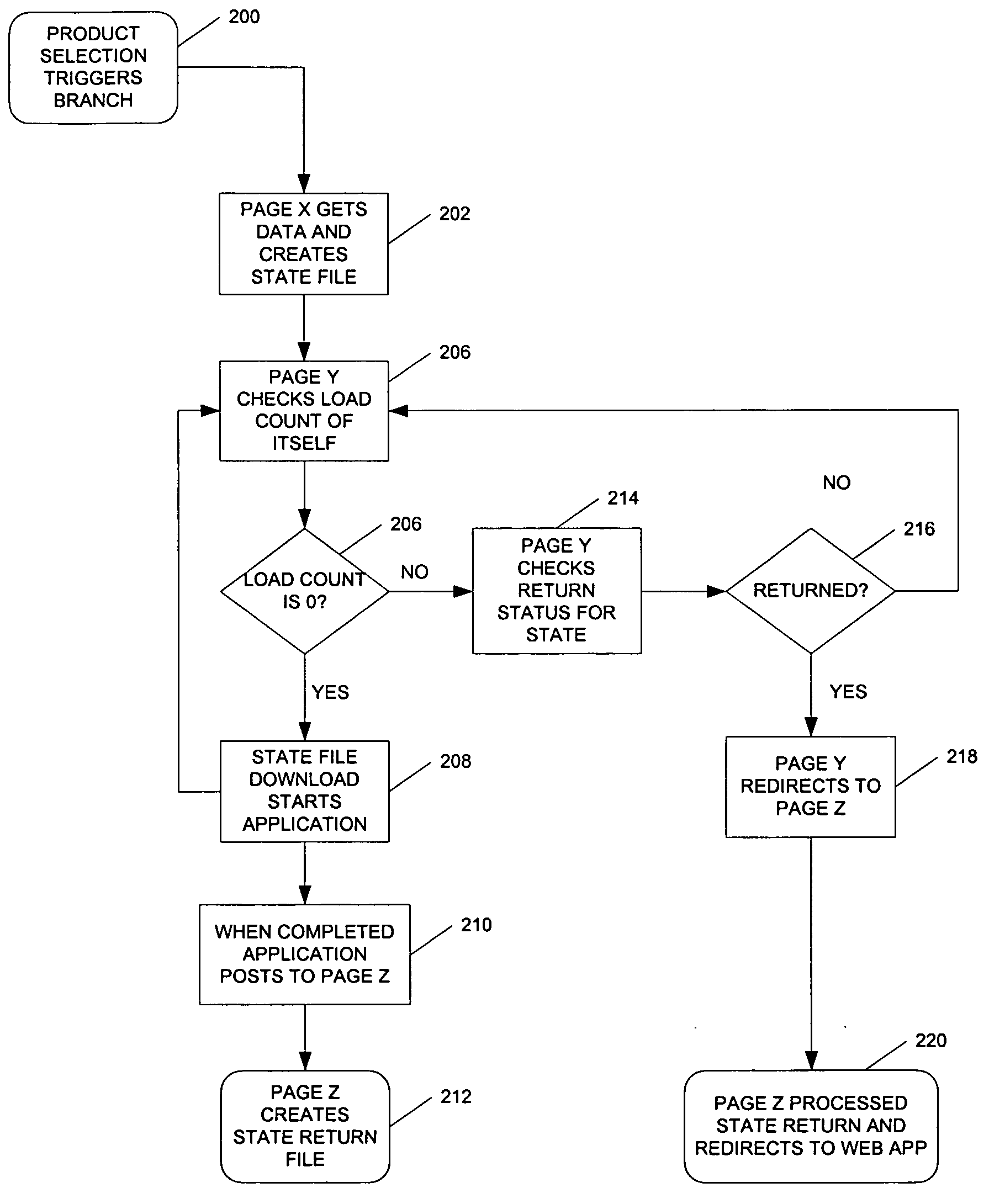

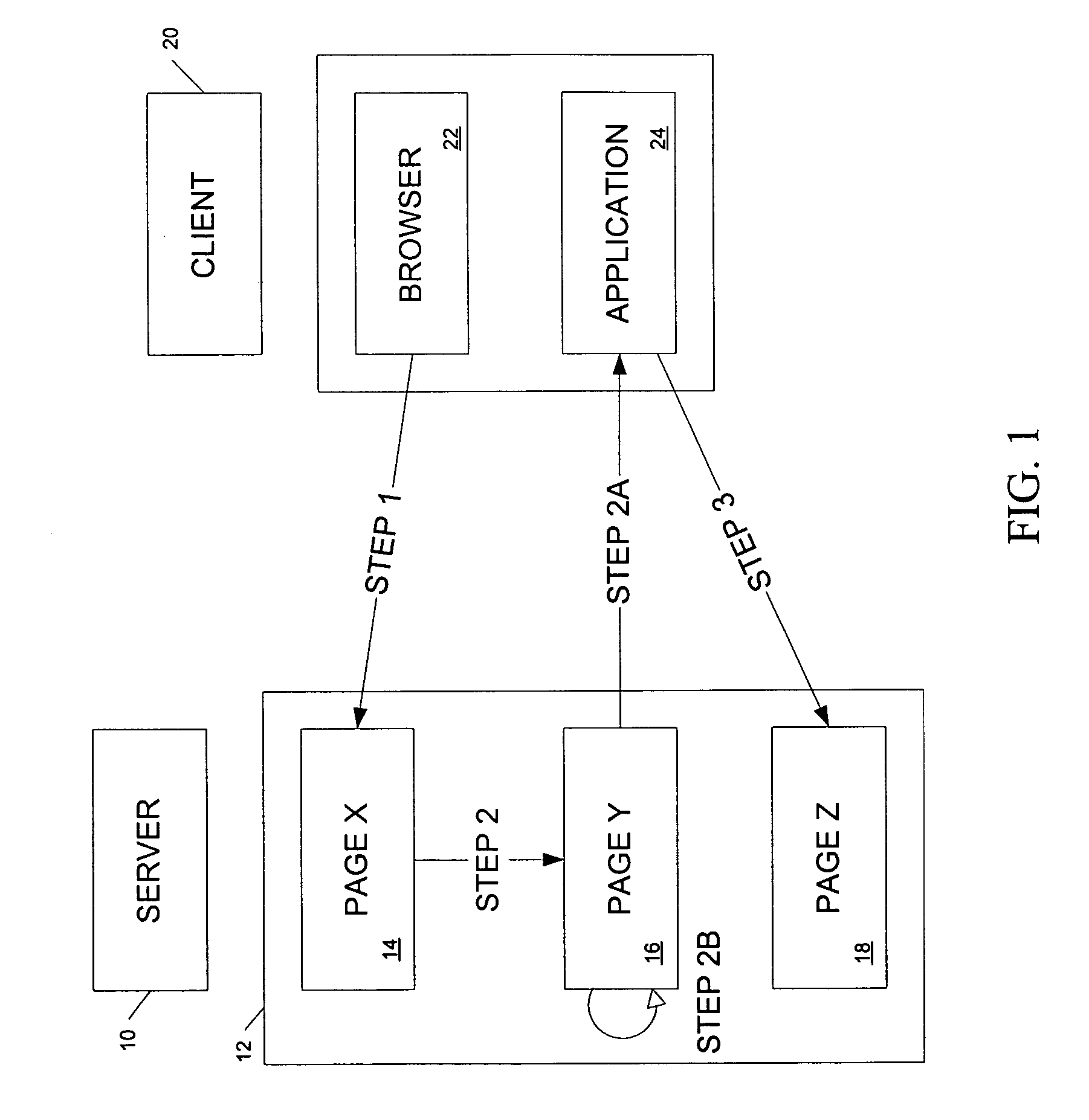

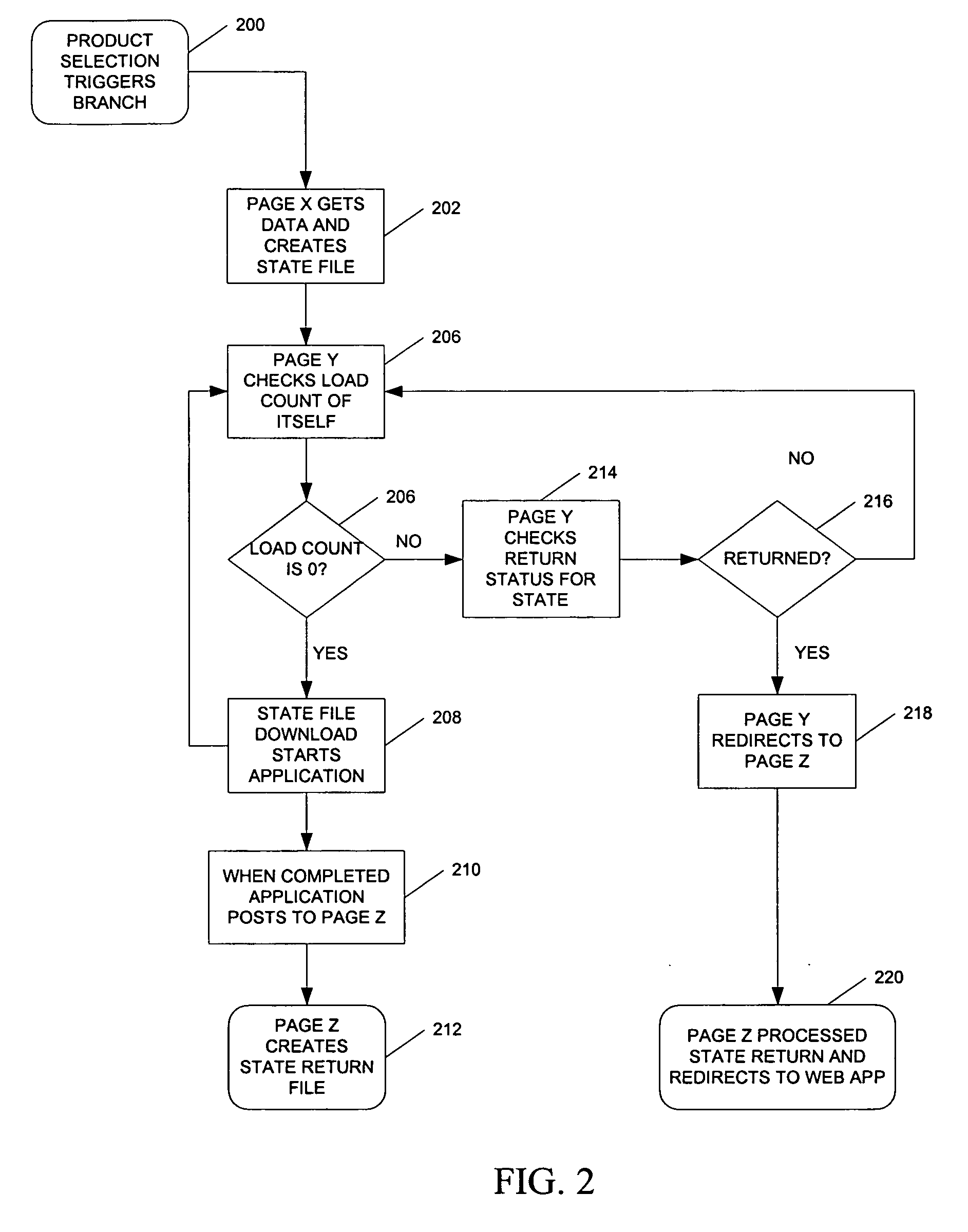

Method of communicating between web applications and local client application while maintaining remote user session

InactiveUS20060026260A1Costly and time-consumeLow modification costMultiple digital computer combinationsProgram controlWeb applicationWeb browser

A method for non-browser based client applications to be integrated into a user's web session and allowed to transfer information from the non-browser applications to the user's session on the web server. The method provides communications between a web-based application and a client application while maintaining a unique client session with a web server. The web browser requests a web page containing data or any other information needed by the non-browser based client application. When the web server receives the client request, it redirects the client web browser to a second web page which is reloaded on a regular basis in order to prevent the client session with the web server from expiring. The second web page generates a web form that includes a link to a file stored on the web server containing the data or other information for use by the client application. When the second web page is finished loading the first time, it downloads the file to the client device and automatically starts execution of the non-browser based client application. The client application uses the data or other information contained in the downloaded file when the non-browser client application executes. The client application returns the results of its processing to the web server which stores the data or other information to preserve session information. The second web page detects a return criterion that is returned with the results and processes the server file containing the stored results from the non-browser based client application.

Owner:ABB RES LTD

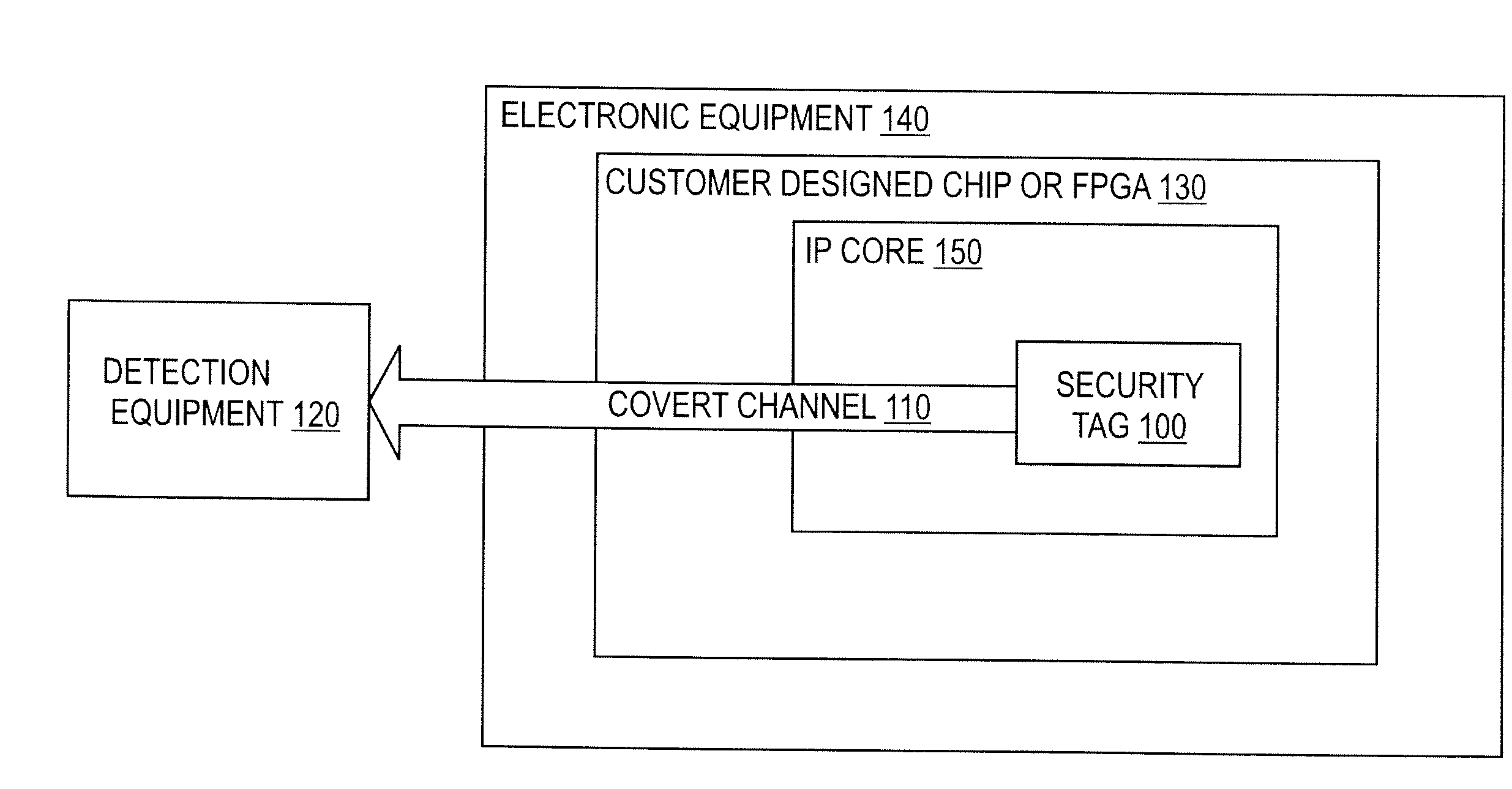

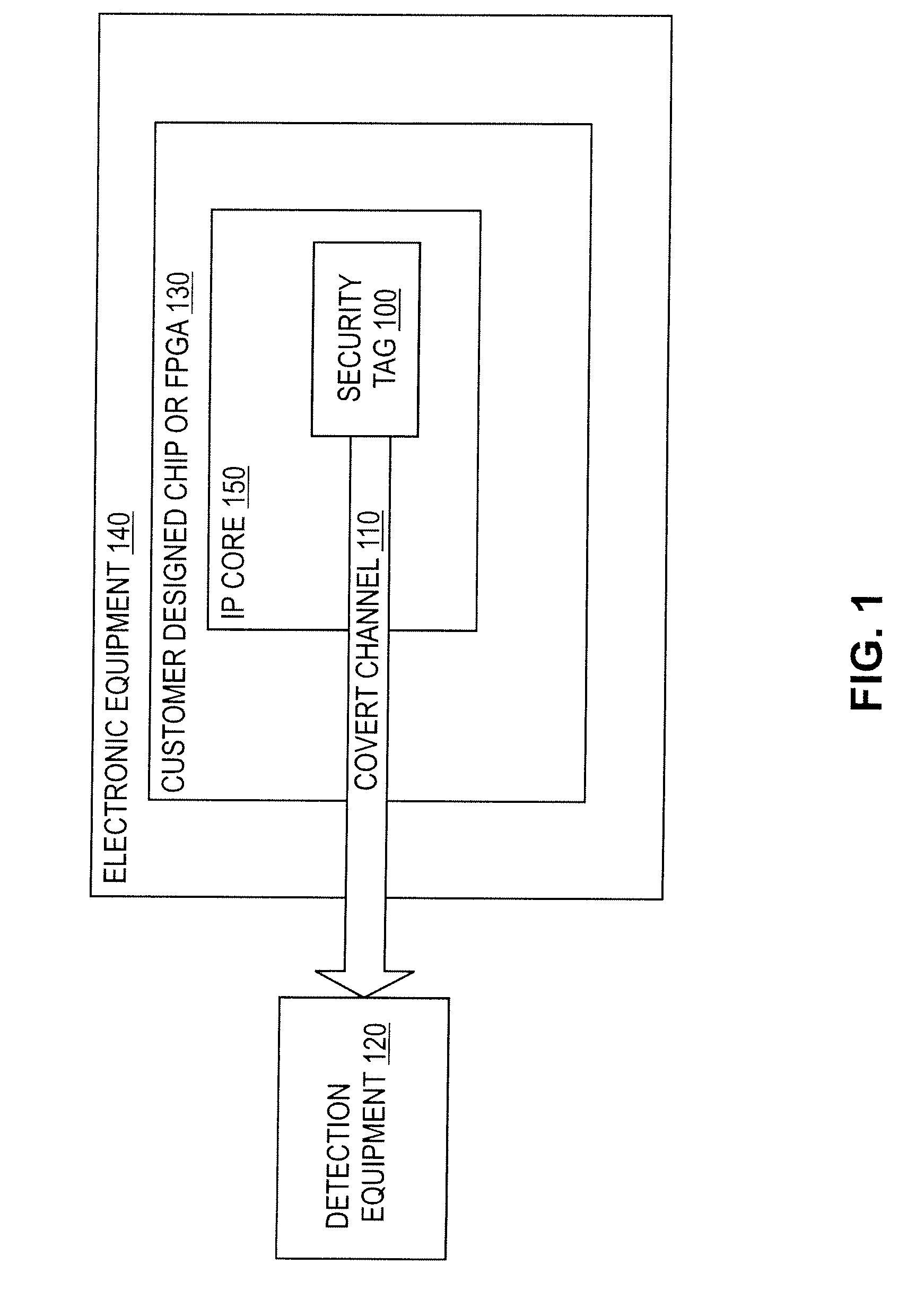

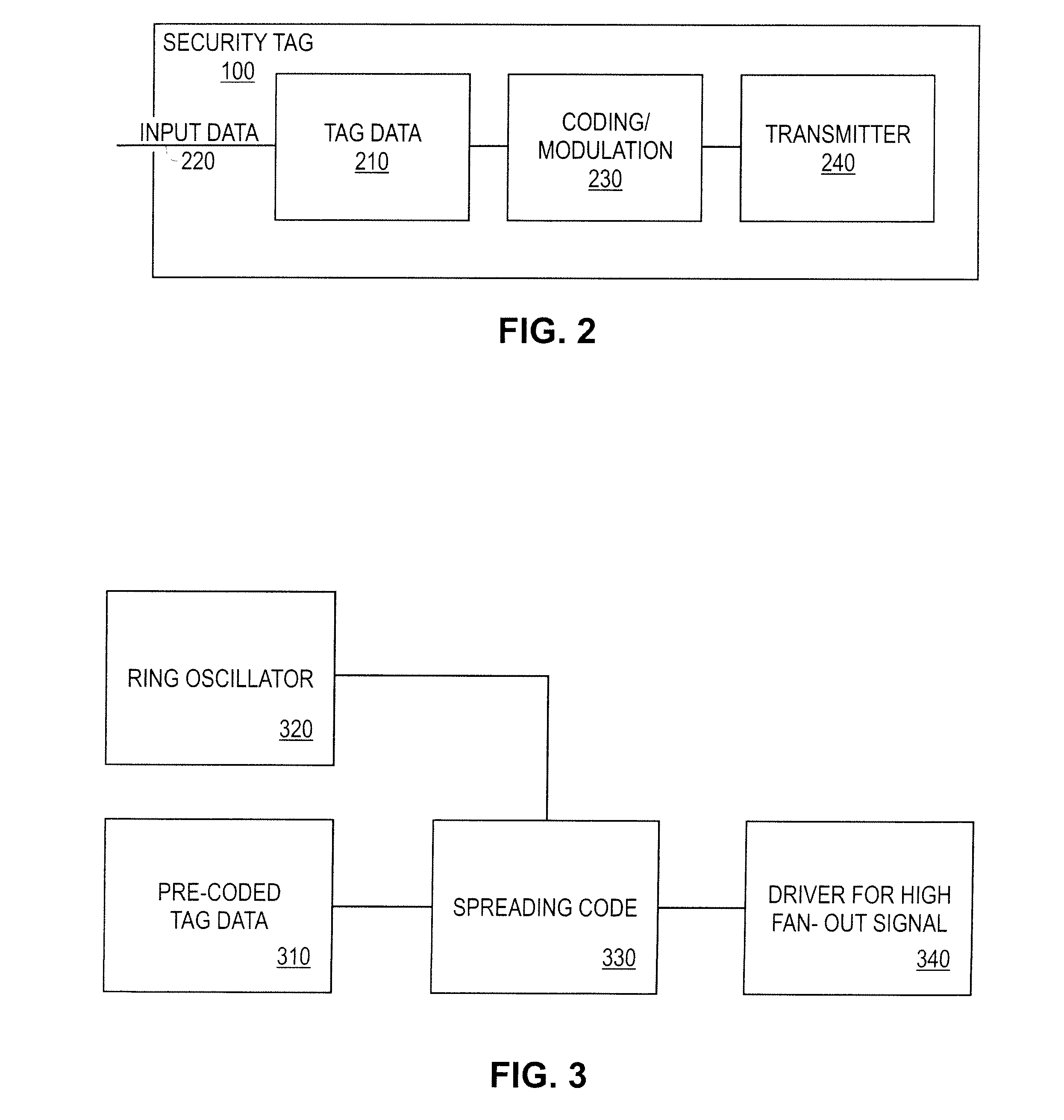

Method of Actively Tagging Electronic Designs and Intellectual Property Cores

InactiveUS20080061980A1Costly and time-consumeSemiconductor/solid-state device detailsInternal/peripheral component protectionComputer hardwareIntellectual property

In an embodiment of the invention, an active security tag is e bedded within the digital logic of an electronic design for logic destined for an integrated circuit such as an FPGA. The security tag includes security tag data which permits identification of the electronic design, and facilitates efforts to enforce copyrights in the designs. The security tag also includes a transmitter designed to covertly transmit security tag data to a receiver. Other information, such as error information and status information about the integrated circuit may also be transmitted. The transmitted information is concealed from detection by being hidden within background noise signals or other signals created by normal usage of the integrated circuit.

Owner:ALGOTRONIX

MEMS microphone and method for manufacturing the same

ActiveUS8243962B2High sensitivityIncrease in sizePiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesIsolation layerEngineering

An MEMS microphone includes a casing (10) and a microphone chip (30) disposed in the casing. The casing defines a sound entrance (11) therein. The microphone chip includes a back plate (31), an isolation layer (32) and a diaphragm (33). The isolation layer separates the back plate from the diaphragm so as to form an air interstice (35) therebetween. The back plate and the diaphragm electrically connect with two electrodes (34a, 34b), respectively. The back plate defines a plurality of holes (36) therethrough. The holes communicate the air interstice with a sealed acoustic chamber (38) between the casing and the microphone chip. The diaphragm is adhered to an inner side of the casing at a position over the sound entrance.

Owner:TSINGHUA UNIV +1

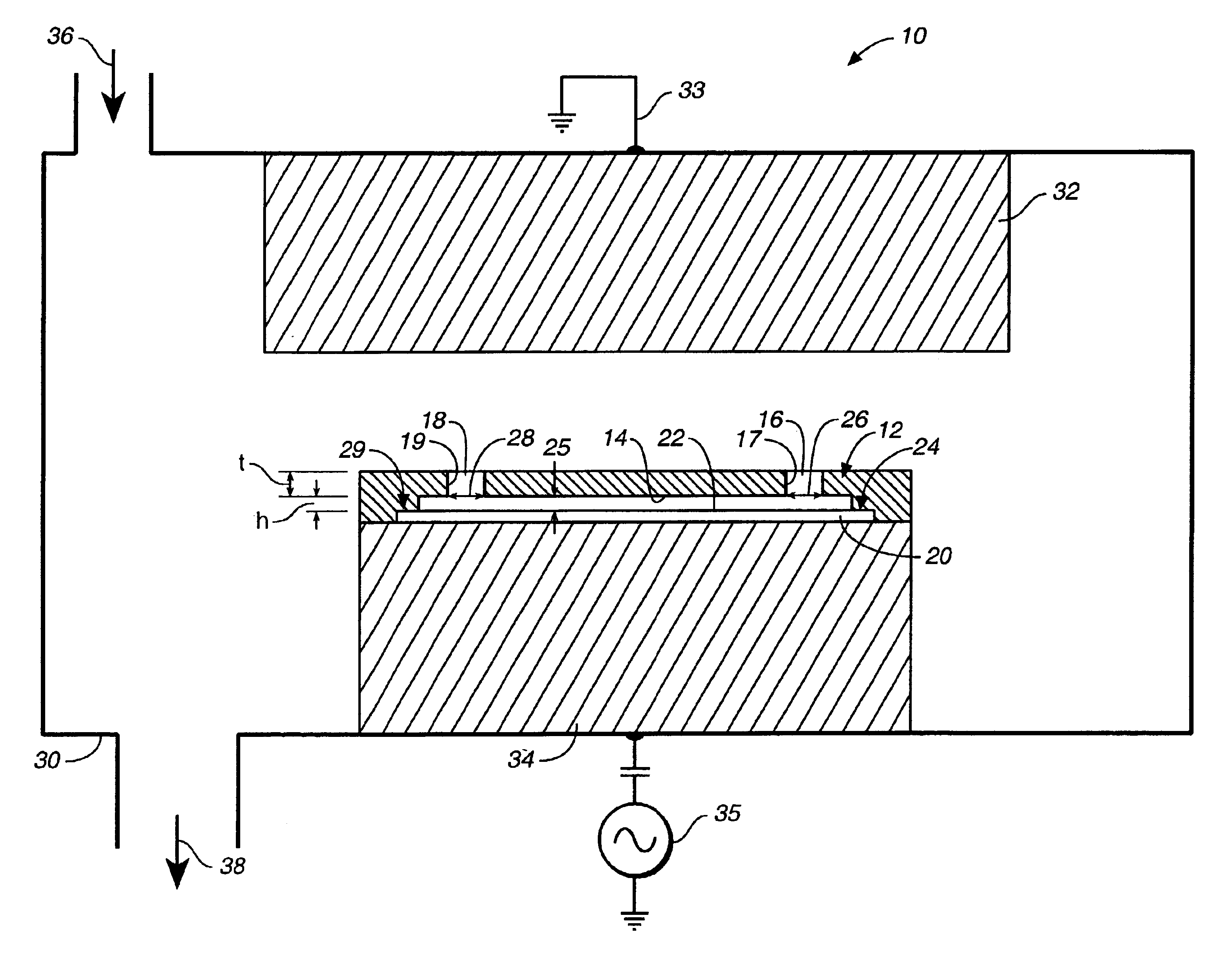

Confinement device for use in dry etching of substrate surface and method of dry etching a wafer surface

InactiveUS6852243B2Costly and time-consumeEfficient and more-effectiveElectric discharge tubesDecorative surface effectsWaferingMicrowave

A confinement device for operative arrangement within a substrate etching chamber, having a lower surface of the device generally arranged over a substrate outer top surface such that a gap-spacing therebetween is generally equidistant. This spacing is less than a sheath thickness for the plasma, preferably less than ⅓rd of an inner width of an aperture through the lower surface of the device. The aperture, sized preferably greater than 3 times the sheath thickness, is in communication with a channel of the device in which an etchant gas can be confined for reaction to selectively etch a localized area in the substrate outer top surface generally below the aperture. A system for dry etching an IC wafer includes a substrate etching chamber and a confinement device. The etchant gas may be a plasma induced and sustained by RF energy, a microwave source, or other source, as designed. And, a method is included for selectively etching a localized area in a substrate outer top surface, having the steps of: arranging a lower surface of a confinement device over the outer top surface, leaving a spacing therebetween, so that an aperture through said lower surface is located generally above the localized area (the spacing may cover the whole of the outer top surface, an area on which microcircuits are fabricated, or some other portion of the outer top surface); and providing an etchant gas to a channel in the device that is in communication with the aperture.

Owner:BELL SEMICON LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com