Patents

Literature

35results about How to "Improve anti-corrosion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

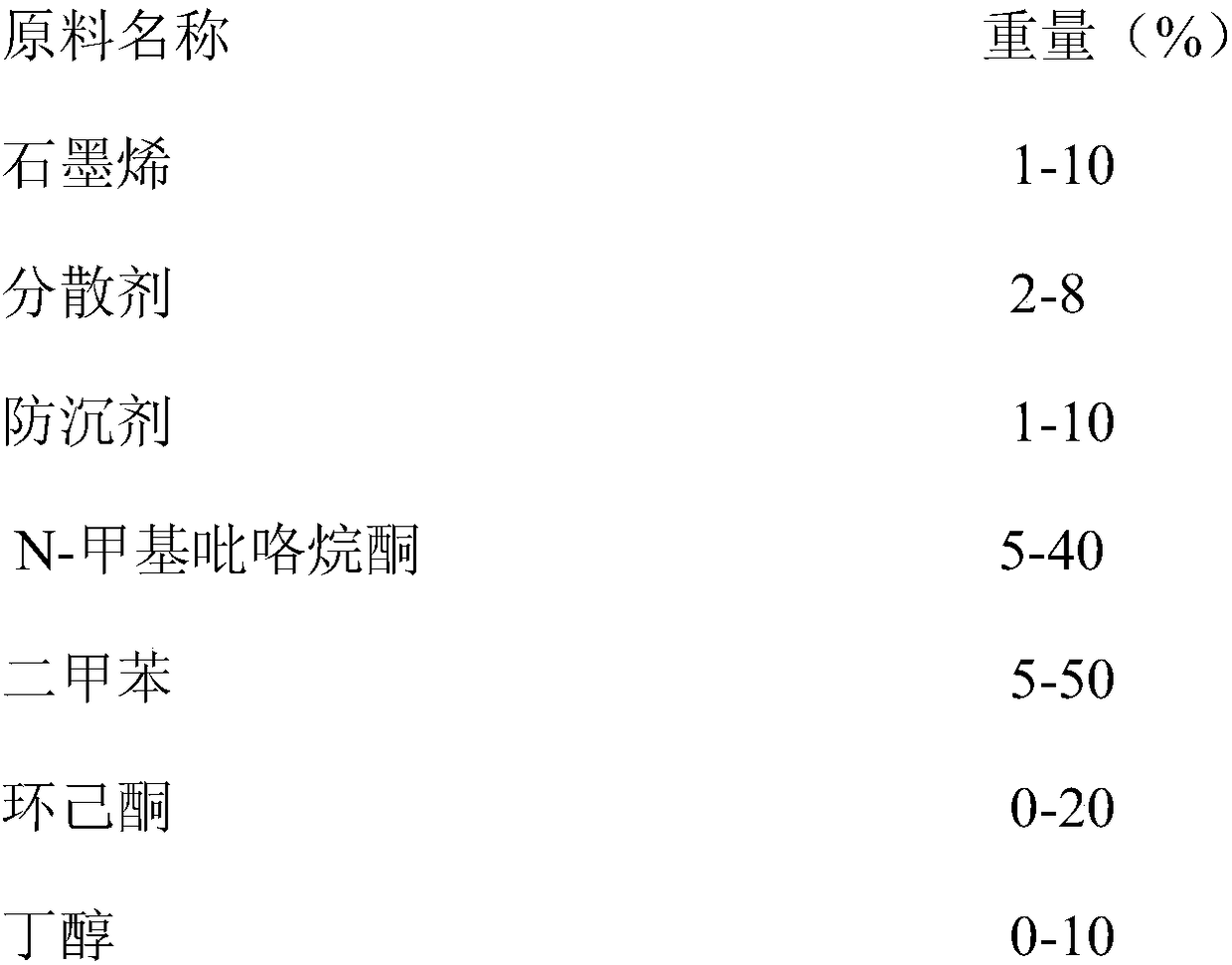

Thin-coating two-component anticorrosive coating for surface of precise steel structural part and preparation method thereof

InactiveCN108300146AImprove the effect of cathodic protectionImprove anti-corrosion efficiencyAnti-corrosive paintsEpoxy resin coatingsEpoxyCyclohexanone

The invention provides a thin-coating two-component anticorrosive coating for the surface of a precise steel structural part, wherein the two-component anticorrosive coating is composed of a componentA and a component B. The component A is composed of an epoxy resin liquid, graphene slurry, a zinc powder, flaky pigments and fillers, an auxiliary agent and a diluent. The component B is composed ofa polyamide curing agent and a mixture of xylene, n-butanol and cyclohexanone. The component A and the component B are evenly mixed according to the weight ratio of (5-15):1. The graphene slurry is prepared by adding powdery graphene and a dispersant into a mixed solvent under a stirring state, and dispersing in an ultrasonic oscillator to obtain the stable dispersed slurry. A coating layer has excellent cathodic protection effect, can be thin-coated to about 10-15 microns, still has good corrosion resistance, and can partly replace traditional phosphorization and oxidation processes.

Owner:MARINE CHEM RES INST +1

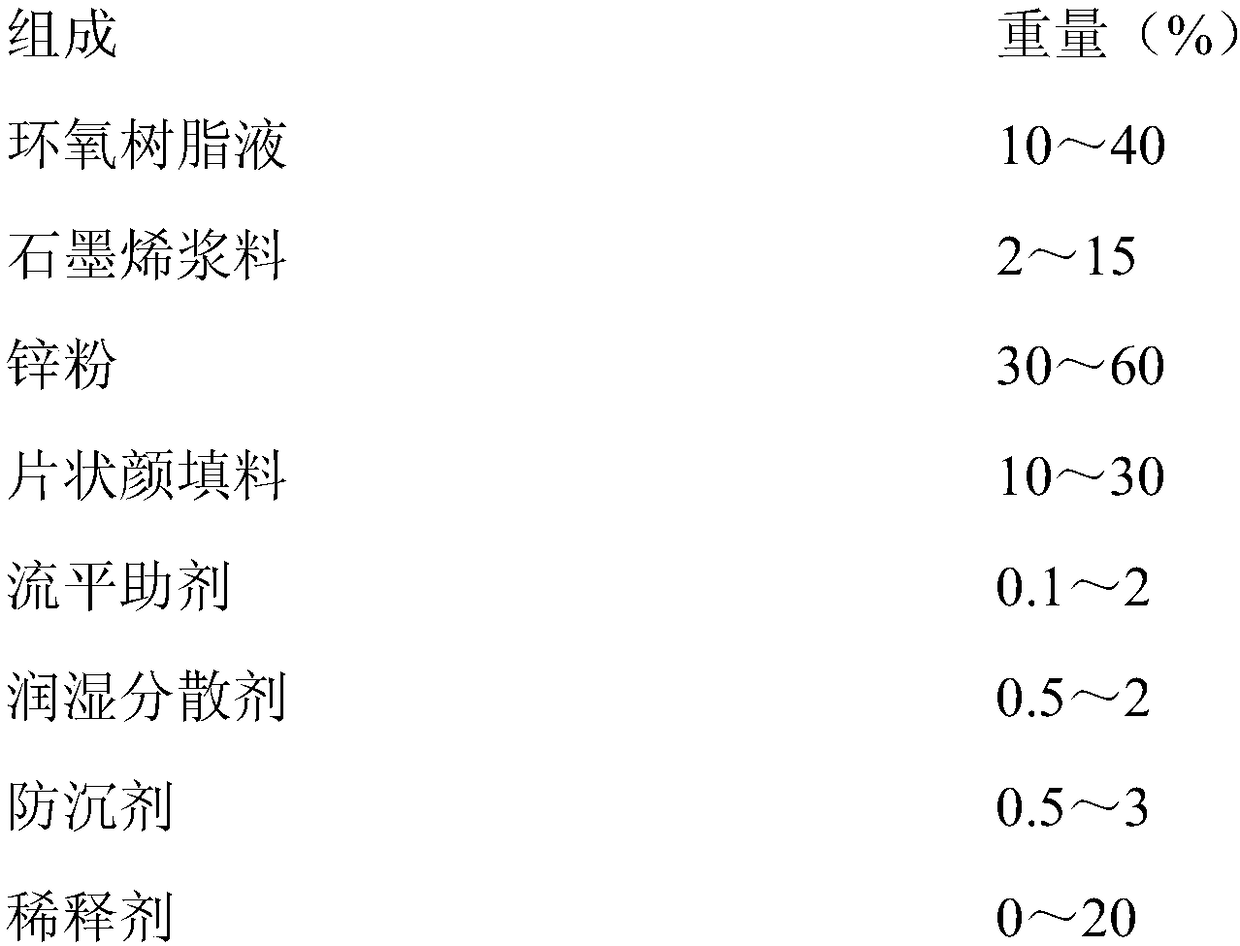

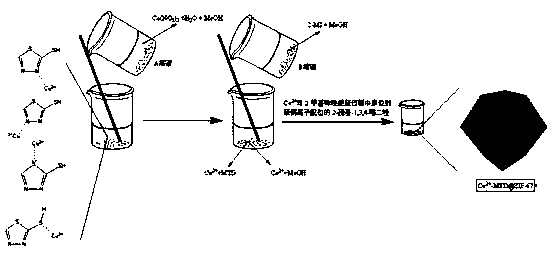

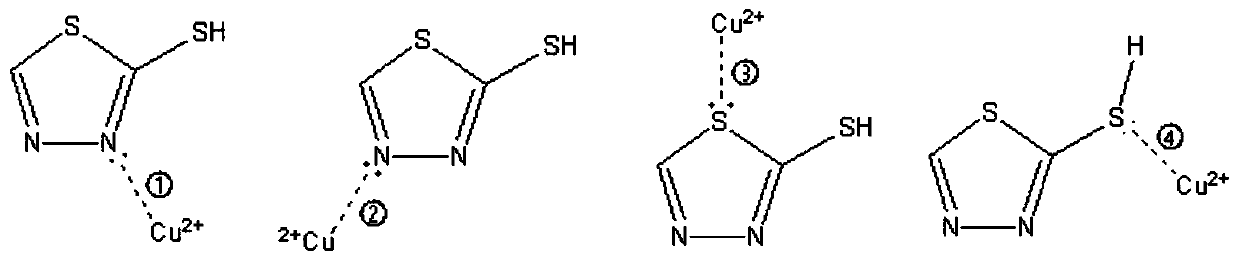

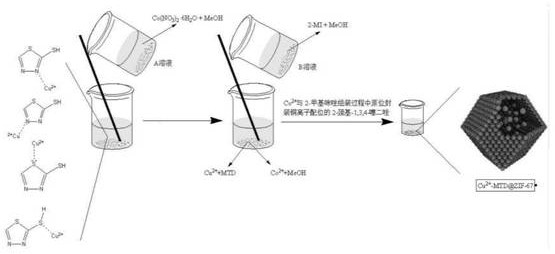

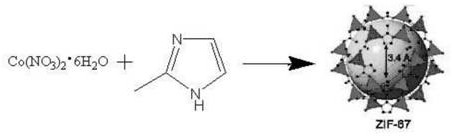

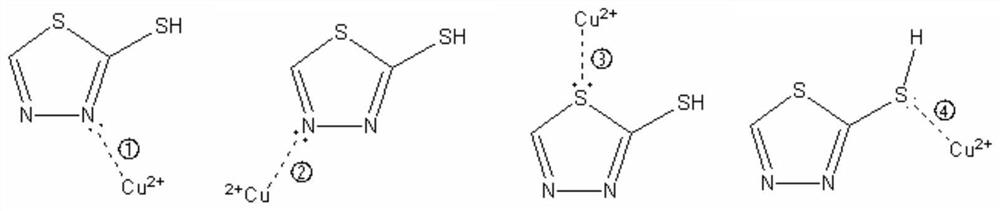

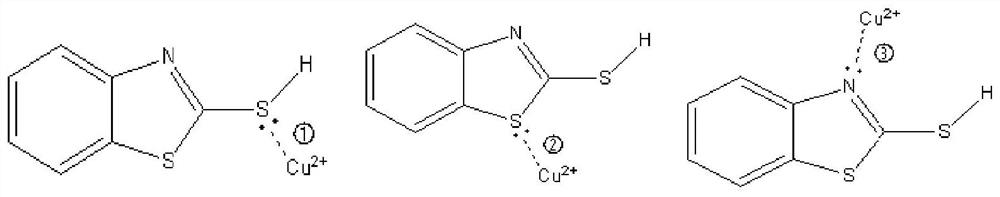

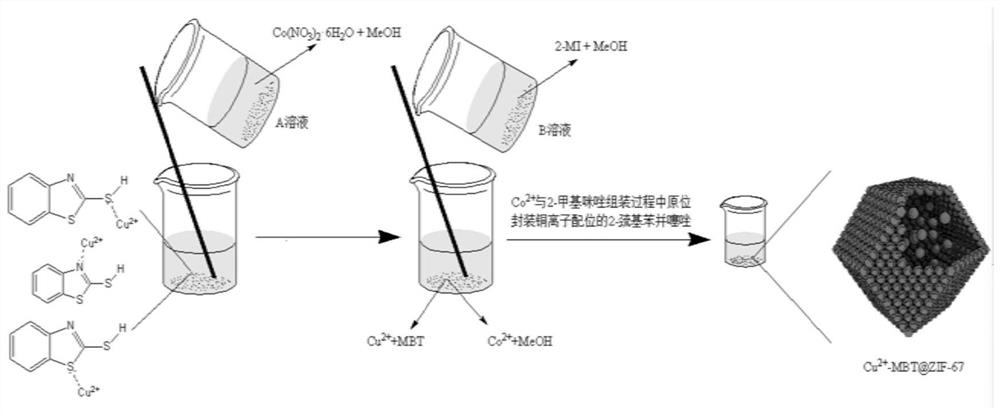

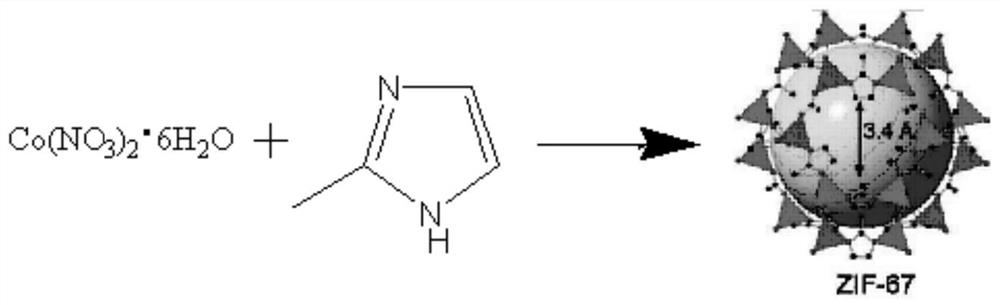

Compound of metal organic framework encapsulation corrosion inhibitor and preparation method and application thereof

ActiveCN110387548ARealization of sensitized anti-corrosion performanceAchieve self-healing effectSea wavesMicrobial corrosion

The invention discloses a compound of a metal organic framework encapsulation corrosion inhibitor and a preparation method and application thereof. The compound is composed of a ZIF metal organic framework material and the corrosion inhibitor encapsulated in the ZIF metal organic framework material. A composite material system is applied to a sea wave splashing zone, and carbon steel or a metal product make a metal organic framework generate defects due to the local acidic environment in the initial stage of dry-wet circulation alternating corrosion, so that the corrosion inhibitor is released, and targeted protection of a corrosion-induced region can be realized. Furthermore, the copper ion modified thiazole corrosion inhibitor is encapsulated in the metal organic framework so that highertransfer capacity can be obtained. Meanwhile, copper ions are desorbed from a pre-coordinated corrosion inhibitor shielding site under an acidic microenvironment, and microbial corrosion caused by growth of various aerobic bacteria on the surface of a substrate can be further inhibited. The corrosion inhibition system is high in targeting property, efficient, durable, high in cost performance, remarkable in application value and wide in market prospect.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

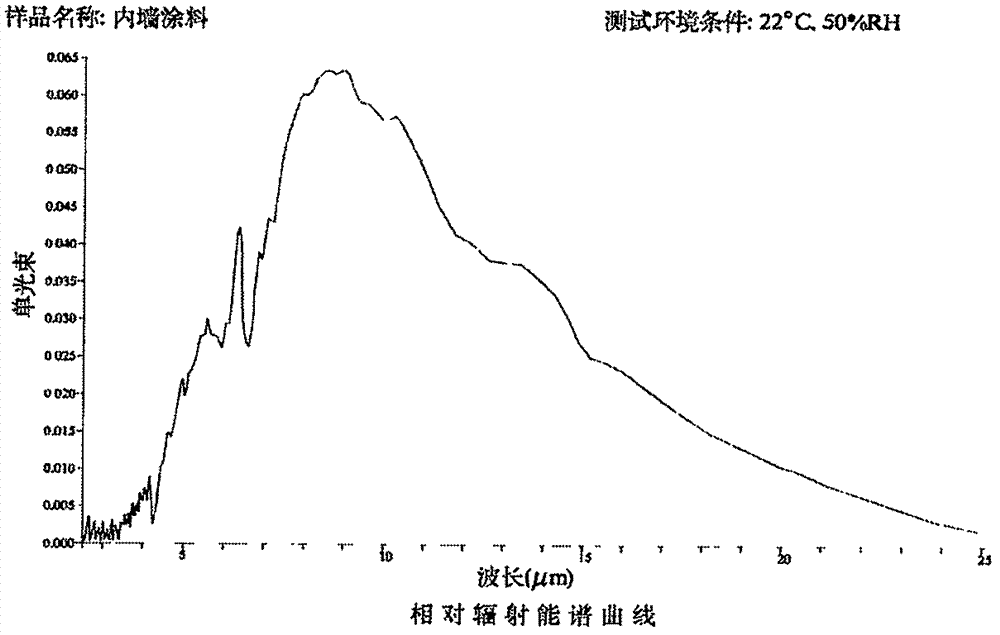

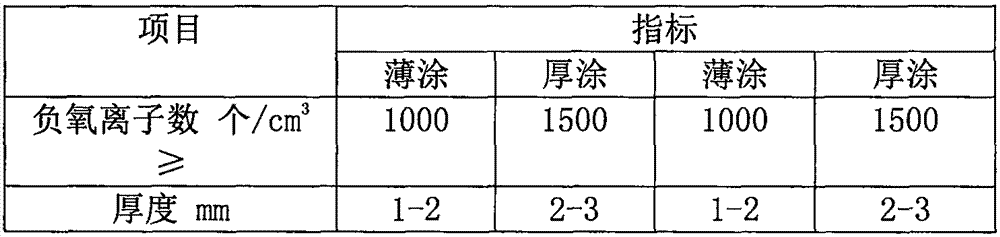

Environment-friendly functional paint capable of purifying indoor air

InactiveCN107057410AImprove thermal conductivityGood compatibilityAntifouling/underwater paintsPaints with biocidesDispersityProcess systems

The invention discloses an environment-friendly functional paint capable of purifying indoor air and an application. The environment-friendly functional paint adopts a tourmaline passive (hydroxyl) negative ion generation material as a main material, and adopts a processing method of a gas-flow crushing process system to prepare tourmaline powder. The environment-friendly functional paint disclosed by the invention has the advantages that TF-600 heat-conducting powder of a heat-conducting material is used as an additive of the tourmaline powder, not only is the heat conductivity coefficient increased, but also the processability is good, and the compatibility and the dispersity of the product are improved; graphene is used as the additive of the tourmaline powder, and is composited with the TF-600 heat-conducting powder for utilization, the complementation of advantages can be achieved, the heat resistance of infrared particles can be reduced, and the heat conductivity and the heat radiation coefficient are extremely high. After coating into the film, the environment-friendly functional paint not only has high strength, durable and wear-resistant effects and excellent decorative effect, but also can increase the concentration of negative ions in the air, has the effects of decomposing and eliminating toxic and harmful gases such as formaldehyde, ammonia, benzene and TVOC released by various indoor decorating and fitting materials and furniture and the like, and has the effects of humidifying, deodorizing and purifying indoor air.

Owner:郭文轩 +1

Anti-abrasive and anticorrosive paint for metal and preparation method of paint

InactiveCN105907191AExcellent metal corrosion resistancePromote environmental protectionWax coatingsConjugated diene hydrocarbon coatingsPhytic acidCarboxylic acid

The invention discloses an anti-abrasive and anticorrosive paint for metal and a preparation method of the paint. The paint is prepared from, by weight, 40-60 parts of copolymer of styrene and acrylic acid, 10-20 parts of styrene butadiene rubber, 10-15 parts of inorganic filler, 5-15 parts of EVA abrasion-resistant agent, 2-5 parts of wetting dispersant h-9040, 3-8 parts of petroleum resin modified wax emulsion, 2-10 parts of gaseous titanium dioxide, 1-4 parts of zinc oxide, 0.5-1 part of phosphonic carboxylic acid, 1-2 parts of 1.5% phytic acid, 0.5-1 part of lignosulfonate, 1-3 parts of anti-flash-rust agent, 2-6 parts of propylene glycol, 2-6 parts of film-forming agent, and 15-25 parts of water. The invention further discloses a preparation method of the anti-abrasive and anticorrosive paint for metal. The paint obtained according to the raw material formula and the preparation method has good metal anti-corrosion property, environmental friendliness, and abrasion resisting property; the service life and the anti-corrosion period of the paint are prolonged; therefore, the cost is reduced, the work intensity is lowered, and the anti-corrosion efficiency is improved.

Owner:SUZHOU HONGKE METAL PROD CO LTD

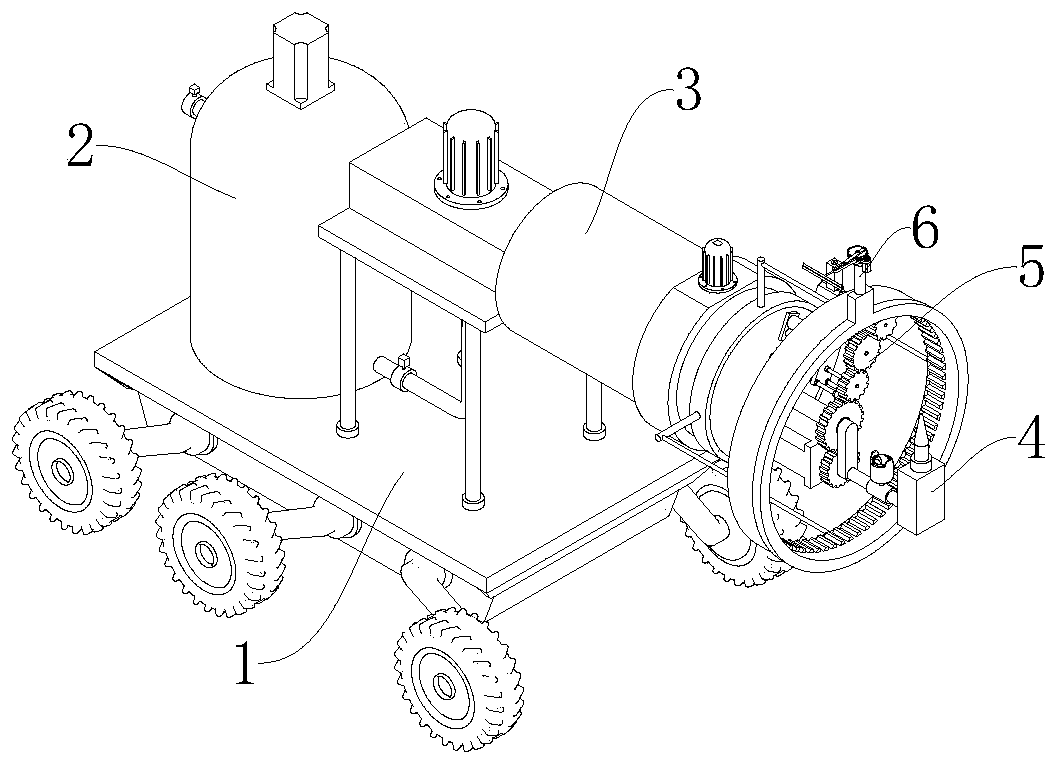

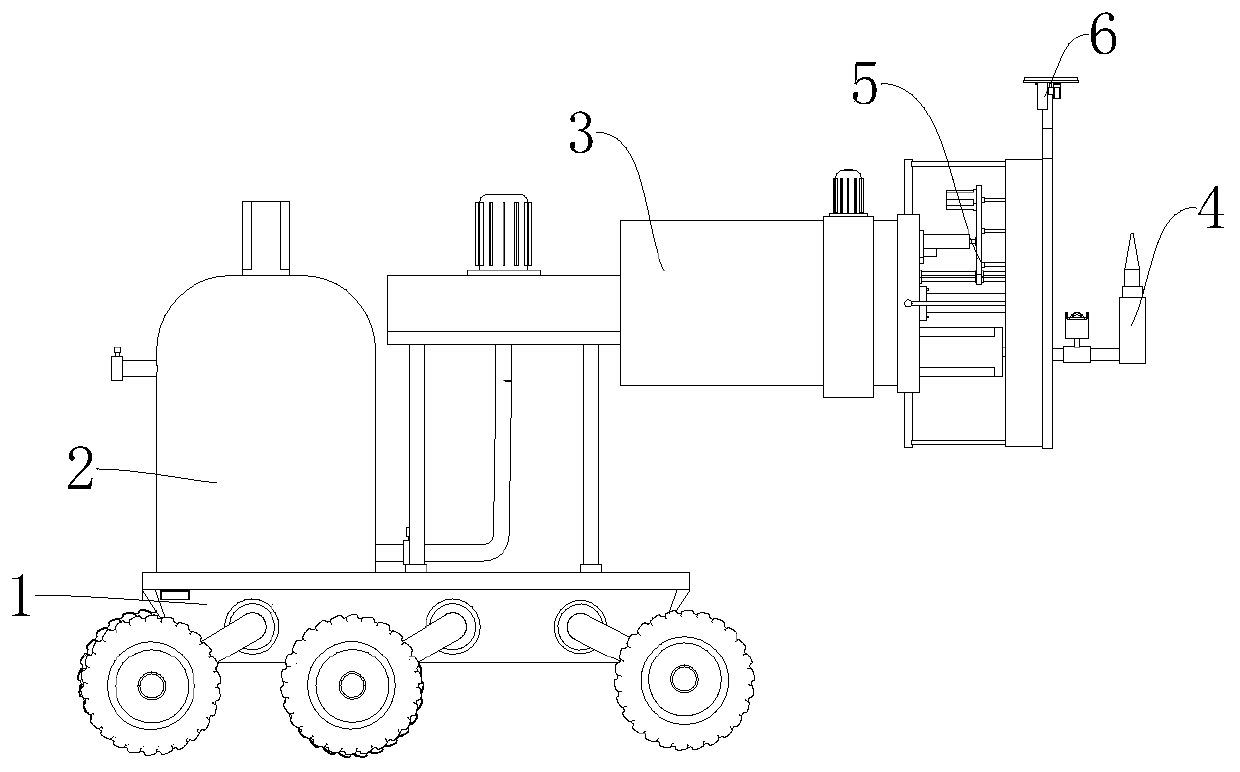

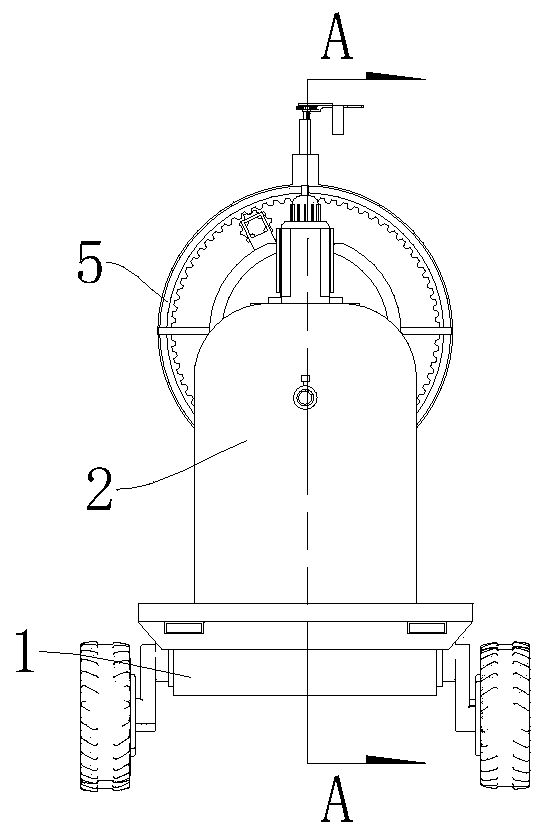

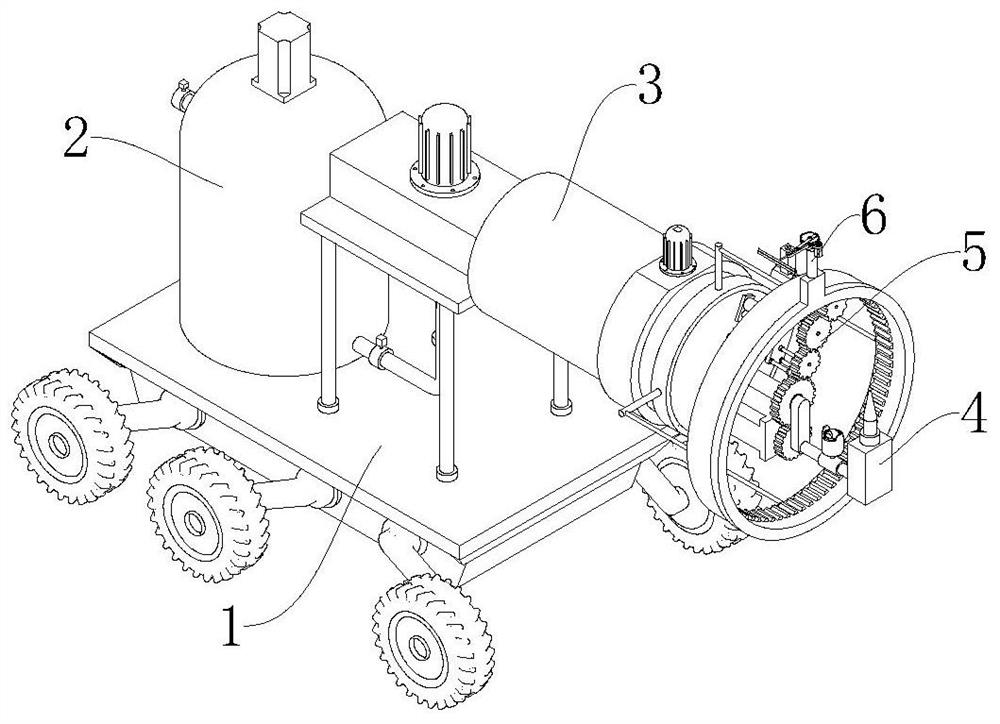

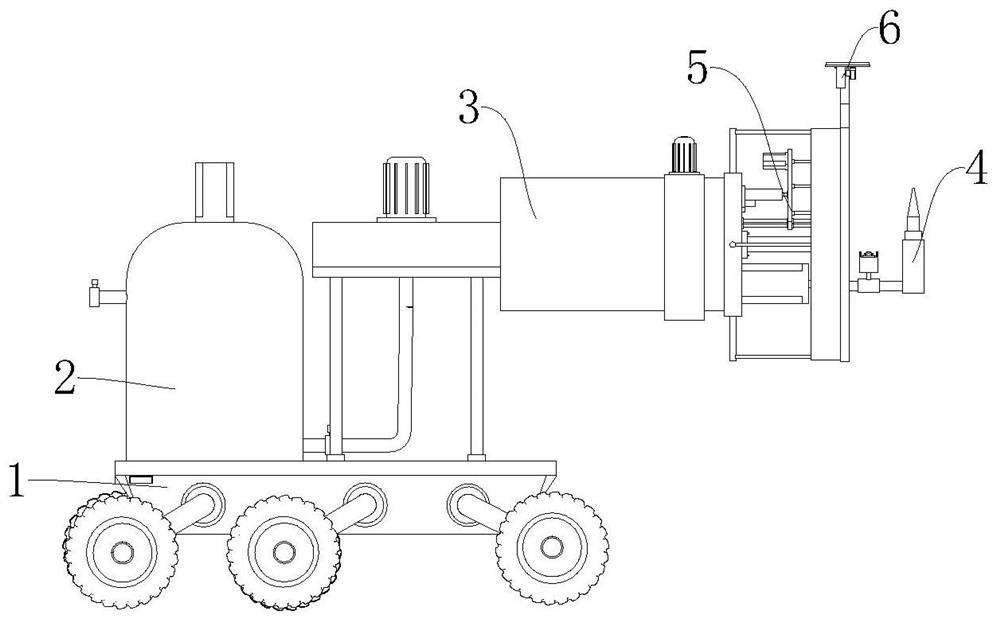

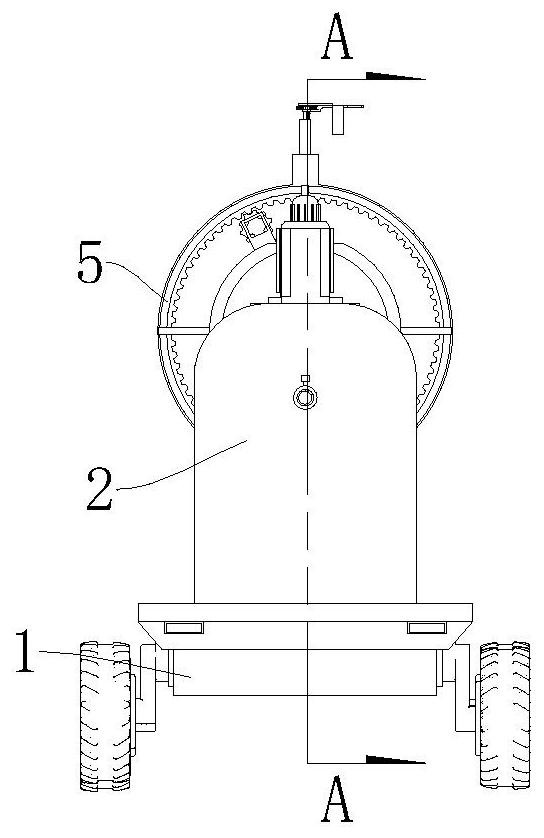

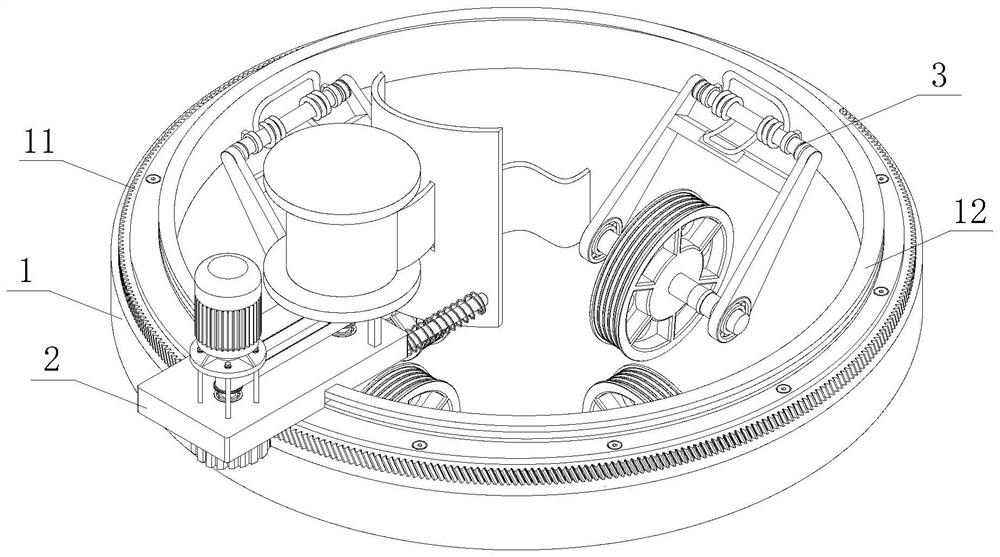

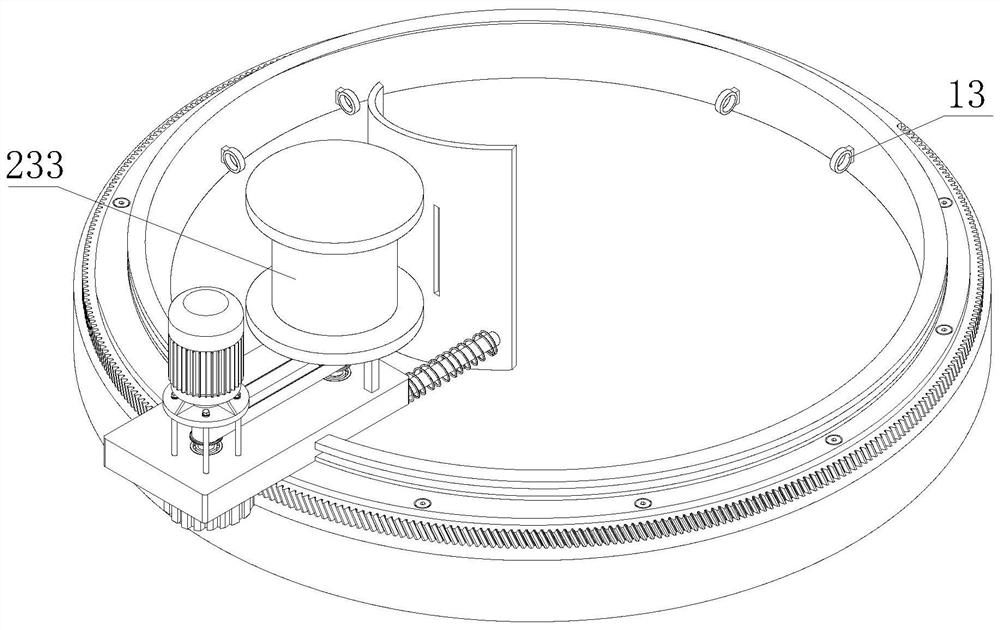

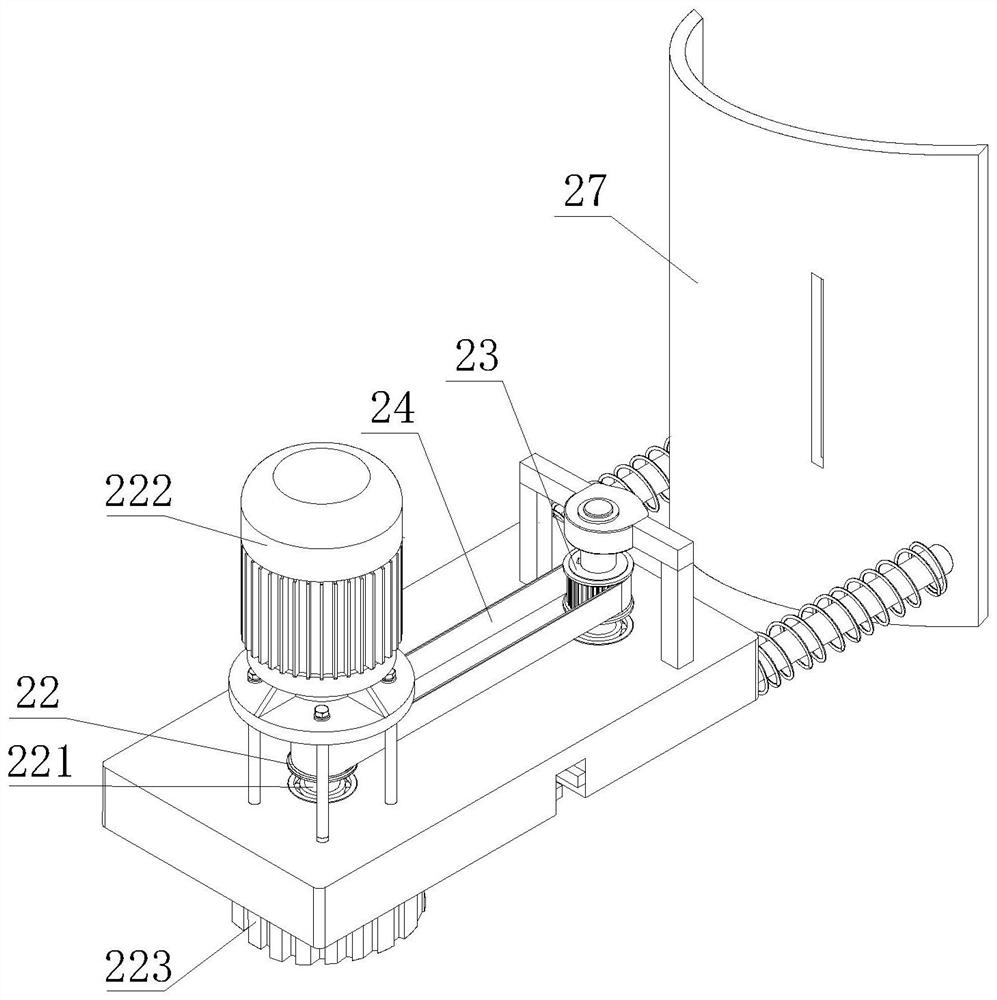

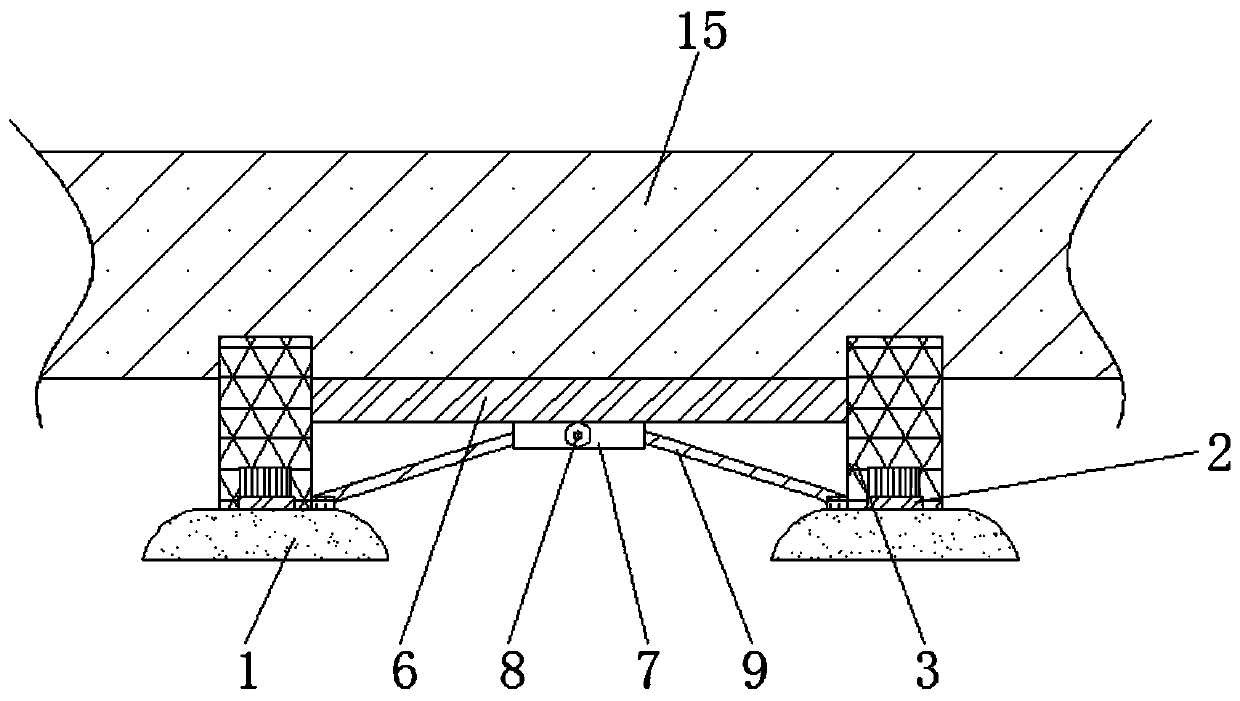

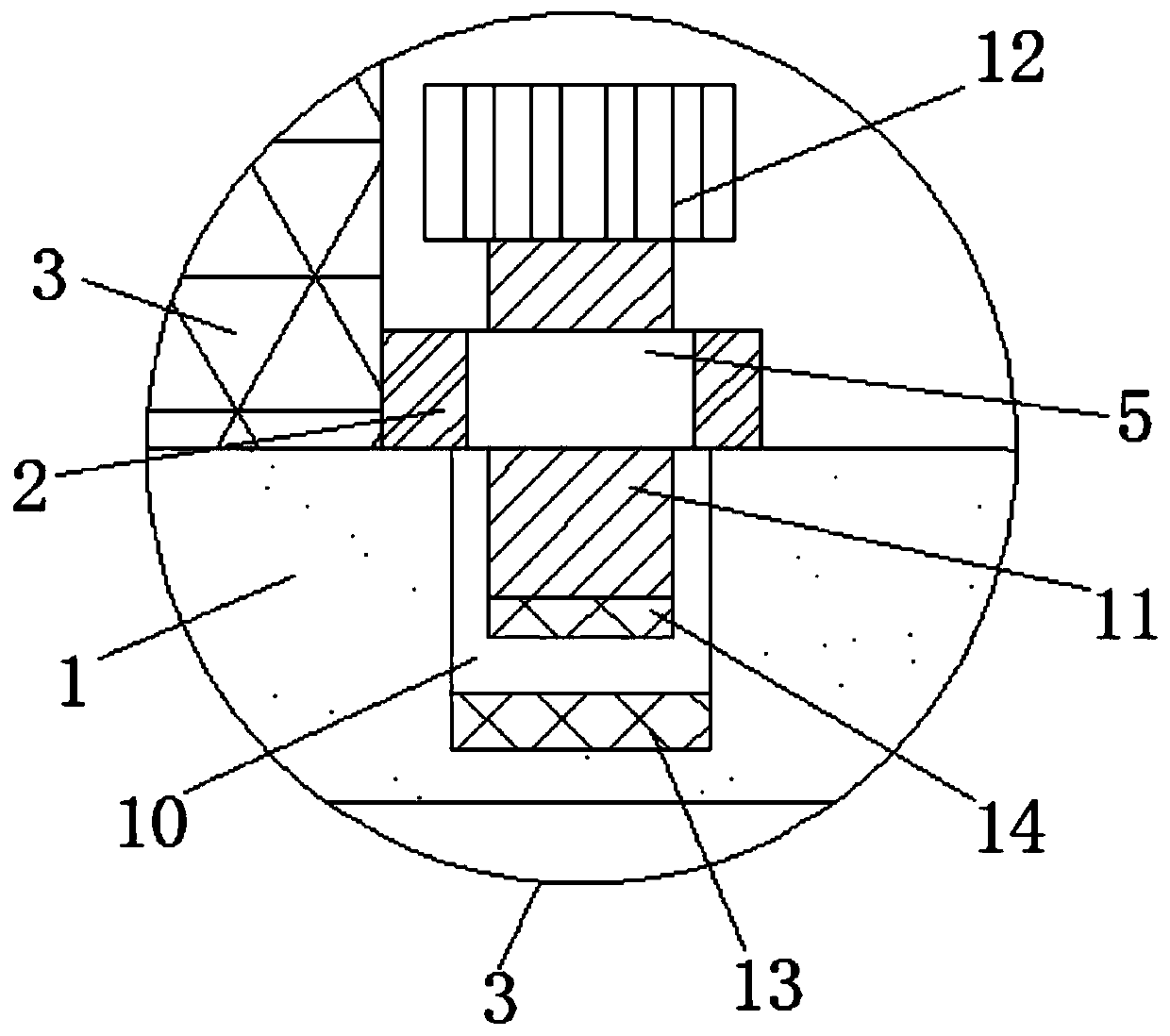

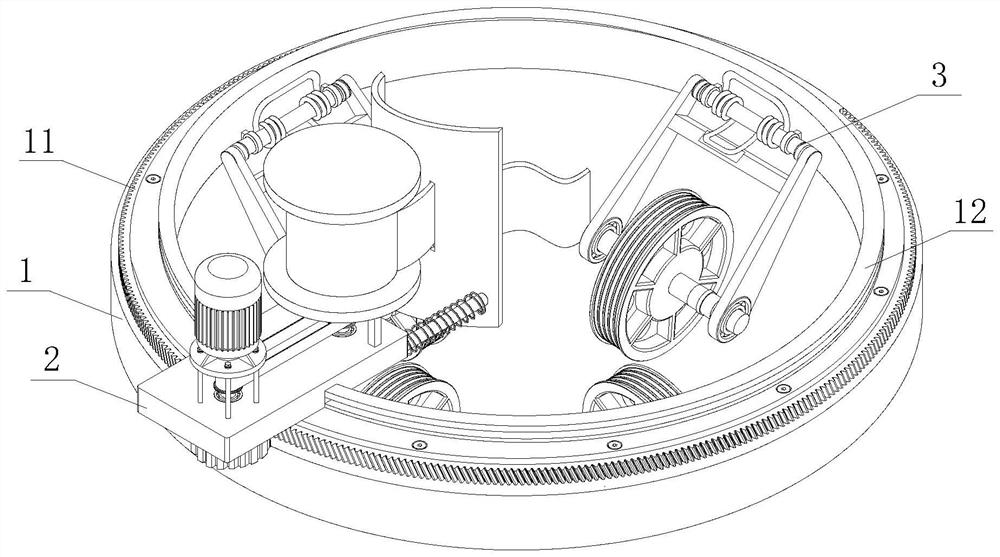

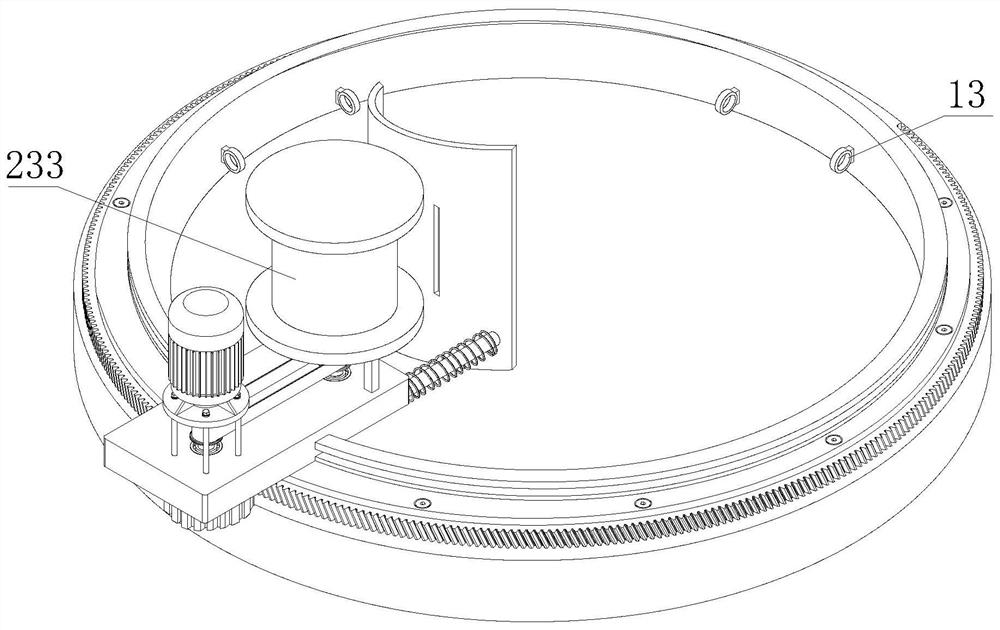

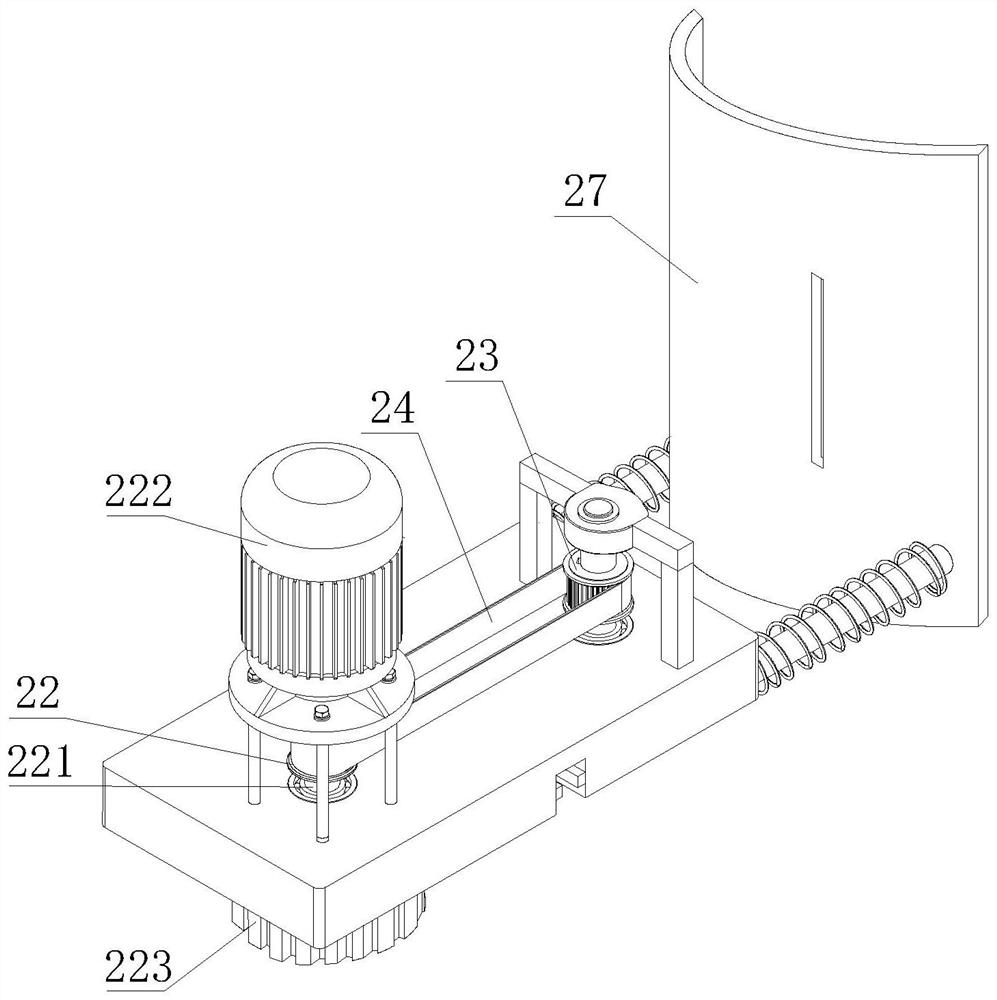

Pipeline internal anti-corrosion device

ActiveCN111589626AImprove anti-corrosion efficiencyAvoid shockPretreated surfacesCoatingsStructural engineeringMechanical engineering

The invention relates to the field of pipeline anti-corrosion, in particular to a pipeline internal anti-corrosion device which includes a carrying trolley for moving in the axial direction of a pipeline, a feeding mechanism arranged on the carrying trolley, a paint transfer mechanism, an automatic spraying mechanism, a rotating driving mechanism and an automatic screeding mechanism. Anti-corrosion paint is put in the feeding mechanism, the feeding mechanism is used for supplying the anti-corrosion paint and stirring the anti-corrosion paint evenly. The output end of the feeding mechanism is connected with the input end of the paint transfer mechanism, the output end of the paint transfer mechanism is connected with the input end of the automatic spraying mechanism which is used to executethe pipeline inner wall spraying work, the output end of the rotating driving mechanism is connected with the automatic spraying mechanism in a transmission mode, the rotating driving mechanism is used to drive the automatic spraying mechanism to rotate, and the automatic screeding mechanism rotates synchronously with the automatic spraying mechanism for screeding the paint sprayed on the inner wall of the pipeline. After the automatic spraying mechanism works, the automatic screeding mechanism is used to screed a coating immediately, the paint is evenly coated on the inner wall of the pipeline without spiral joints, and missing-spraying is avoided.

Owner:黄海军

High-efficient, environmentally-friendly, anti-corrosion and waterproof coating for subway shield segment and preparation method thereof

InactiveCN107964320AHigh antibacterial rateHas a synergistic antibacterial effectFireproof paintsAntifouling/underwater paintsEnvironmental resistanceSilicon dioxide

The invention provides a high-efficient, environmentally-friendly, anti-corrosion and waterproof coating for a subway shield segment and a preparation method thereof and relates to the technical fieldof coatings. The coating is prepared from a material A: 35 to 50 parts by weight of modified epoxy resin, 5 to 10 parts by weight of nano-zinc oxide, 5 to 8 parts by weight of chitosan, 15 to 20 parts by weight of nanometer light calcium carbonate, 10 to 15 parts by weight of nano-silica, 20 to 35 parts by weight of a styrene-acrylic emulsion, 15 to 25 parts by weight of titanium dioxide, 0.5 to1 part by weight of paraffin, 0.5 to 1 part of calcium stearate, 5 to 12 parts by weight of silicone oil, 3 to 5 parts by weight of polyacrylic acid, 5 to 8 parts by weight of texanol, 5 to 7 parts byweight of disodium EDTA, 3 to 5 parts by weight of sorbic acid, 5 to 10 parts by weight of cassia bark extract and 3 to 8 parts by weight of a flame retardant. The coating has the characteristics ofstrong weather resistance and low use cost and is waterproof, efficient, anticorrosion and environmentally friendly.

Owner:合肥卓立雅工程材料科技有限公司

Anti-corrosion spraying mechanism of pipeline internal anti-corrosion device

InactiveCN111744708AImprove anti-corrosion efficiencyAvoid shockSpraying apparatusStructural engineeringMechanical engineering

The invention discloses an anti-corrosion spraying mechanism of a pipeline internal anti-corrosion device. The anti-corrosion spraying mechanism comprises an automatic spraying mechanism, a rotating drive mechanism, an automatic smoothing mechanism and an automatic spraying mechanism. The automatic spraying mechanism comprises a spraying head. The automatic spraying mechanism is arranged on the rotating drive mechanism. The rotating drive mechanism drives the automatic spraying mechanism to rotate. The automatic smoothing mechanism is arranged on the rotating drive mechanism, and the rotatingdrive mechanism drives the automatic smoothing mechanism to rotate. The automatic smoothing mechanism is provided with a detachable smoothing scraper and a vibrating wheel and can automatically smoothanti-corrosion materials on the inner wall of a pipeline, and the smoothing efficiency is greatly improved.

Owner:隋广林

Preparation method of ultraviolet-curable nano aluminum phosphate and graphene oxide anticorrosive paint

InactiveCN112552799AImprove anti-corrosion efficiencyImprove surface propertiesAnti-corrosive paintsEpoxy resin coatingsEpoxyOxide composite

The invention relates to a preparation method of an ultraviolet-curable nano aluminum phosphate and graphene oxide anticorrosive paint. The ultraviolet-curable nano aluminum phosphate and graphene oxide anticorrosive paint is characterized by comprising a nano aluminum phosphate / graphene oxide composite pigment, epoxy resin, epoxy acrylate and a photoinitiator in a weight ratio of 1-20: 100: 1-30:1-10, the preparation method comprises the following steps: a, loading nano aluminum phosphate with graphene oxide; b, pre-dispersing the composite pigment into epoxy resin; and c, preparing the ultraviolet curable pain according to the formula.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

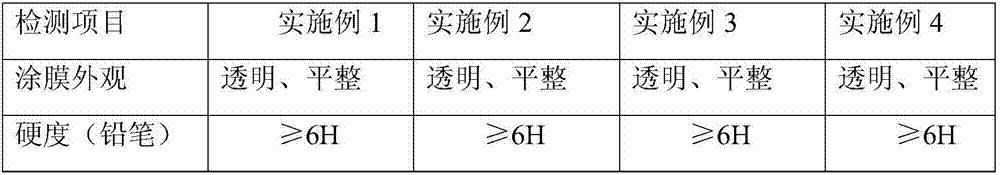

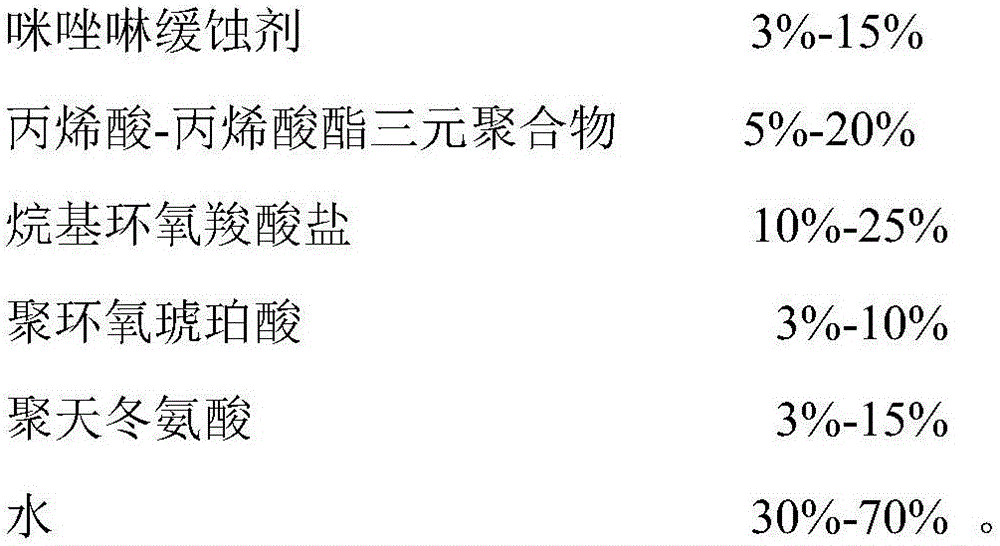

Anti-aging and antibacterial nano-paint

InactiveCN107474652AImprove densification performanceImprove microstructureAntifouling/underwater paintsPaints with biocidesCalcium silicateTert butyl

The invention provides anti-aging and antibacterial nano-paint. The nano-paint is prepared from, by weight, 45-55 parts of nanometer aqueous fluorocarbon emulsion, 10-15 parts of propylene glycol, 8-10 parts of texanol, 7.5-9 parts of hydroxyethyl cellulose, 10-12 parts of nanoscale amphoteric polyacrylamide, 2-3 parts of sodium benzoate, 2-3 parts of aspartame, 2-3 parts of sodium methyl parahydroxybenzoate, 3-5 parts of paraffin, 2-3 parts of calcium stearate, 20-30 parts of nano titanium dioxide, 2-3 parts of calcium silicate, 2-3 parts of N-cyclohexyl-N'-phenyl p-phenylenediamine, 3-5 parts of 2,6-di-tert-butyl-4-methylphenol, 1-5 parts of nano zinc oxide powder, 1-5 parts of lauric acid, 0.3-0.5 part of difenoconazole, 0.5-1.5 parts of silver ionic antibacterial agent, 3-5 parts of inorganic thickening agent, 0.5-1.5 parts of antifoaming agent and 0.03-0.05 part of pH regulator. The anti-aging and antibacterial nano-paint is high in heat reflectivity and also good in heat insulation performance and further has the advantages of being good in sterilization effect and resistant to corrosion and aging.

Owner:NANJING XIANCAOTANG BIOLOGICAL TECH CO LTD

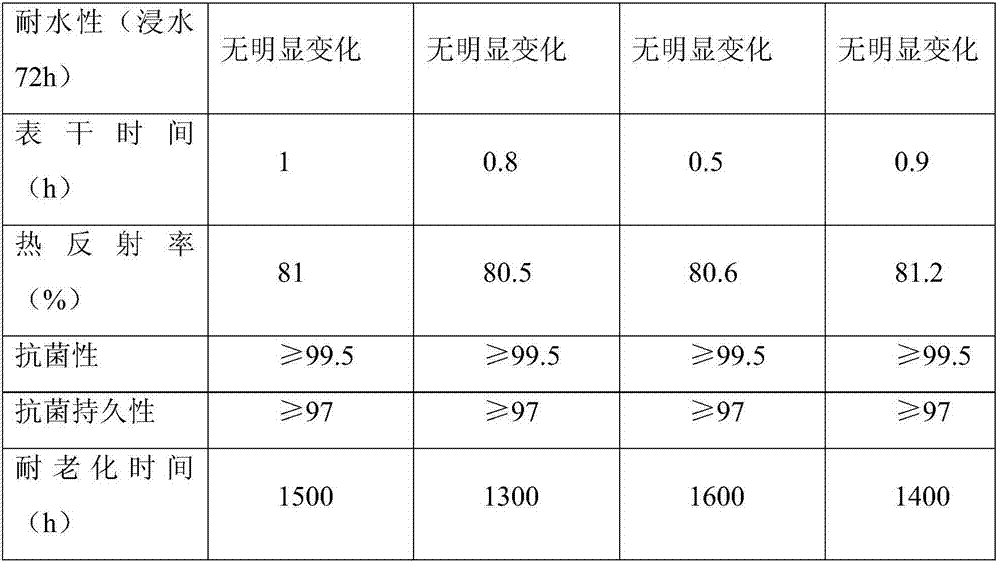

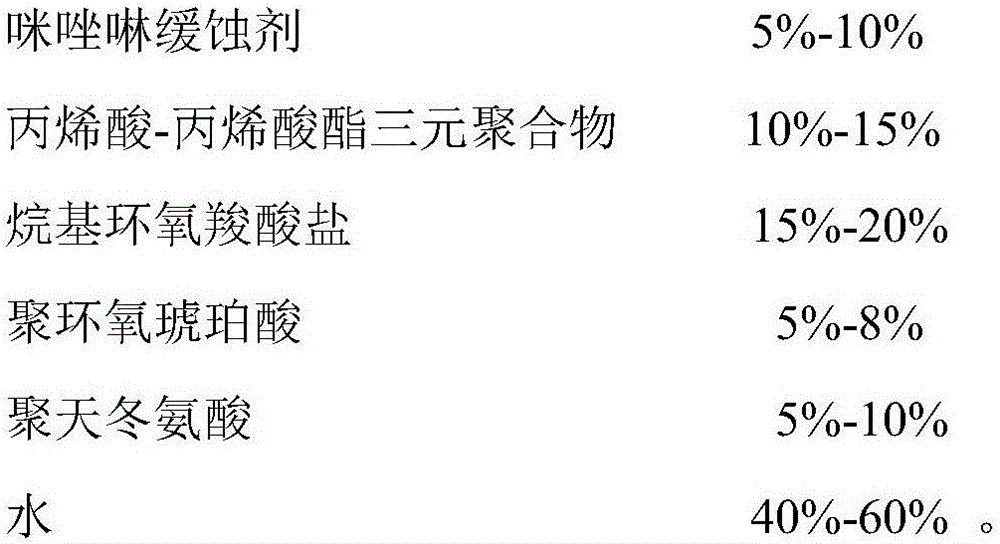

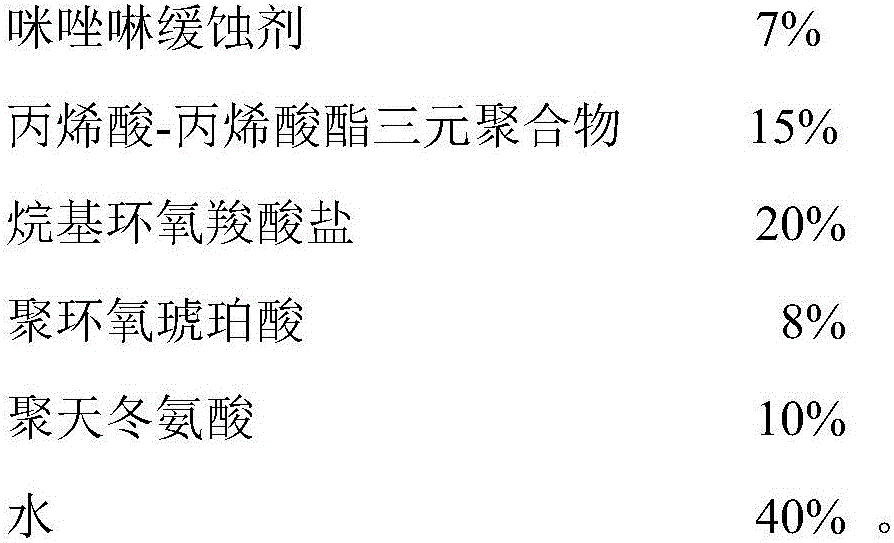

Novel multifunctional scale inhibitor for leachate deep treatment

InactiveCN106673215ANo irritating smellImprove thermal stabilityScale removal and water softeningContaminated groundwater/leachate treatmentEpoxyCarboxylic salt

The invention discloses a novel multifunctional scale inhibitor for leachate deep treatment. The novel multifunctional scale inhibitor comprises the following ingredients in percentage by mass: 3 to 15 percent of imidazoline corrosion inhibitors, 5 to 20 percent of acrylic acid- acrylic ester ternary polymers, 10 to 25 percent of alkyl epoxy carboxylate, 3 to 10 percent of polyepoxysuccinic acid, 3 to 15 percent of polyaspartic acid and 30 to 70 percent of water. The novel multifunctional scale inhibitor is invented by specially aiming at the characteristics of high hardness, high alkalinity, high heavy metal pollution concentration of the landfill leachate wastewater; ingredients with certain scale inhibition, dispersion and corrosion inhibition effects are compounded; the synergistic interaction effect is achieved. The novel multifunctional scale inhibitor has the advantages that the price is low; the cost is low; the good effects are achieved on the corrosion inhibition of the metal pipeline in the leachate deep treatment and the scale inhibition of a reverse osmosis membrane.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

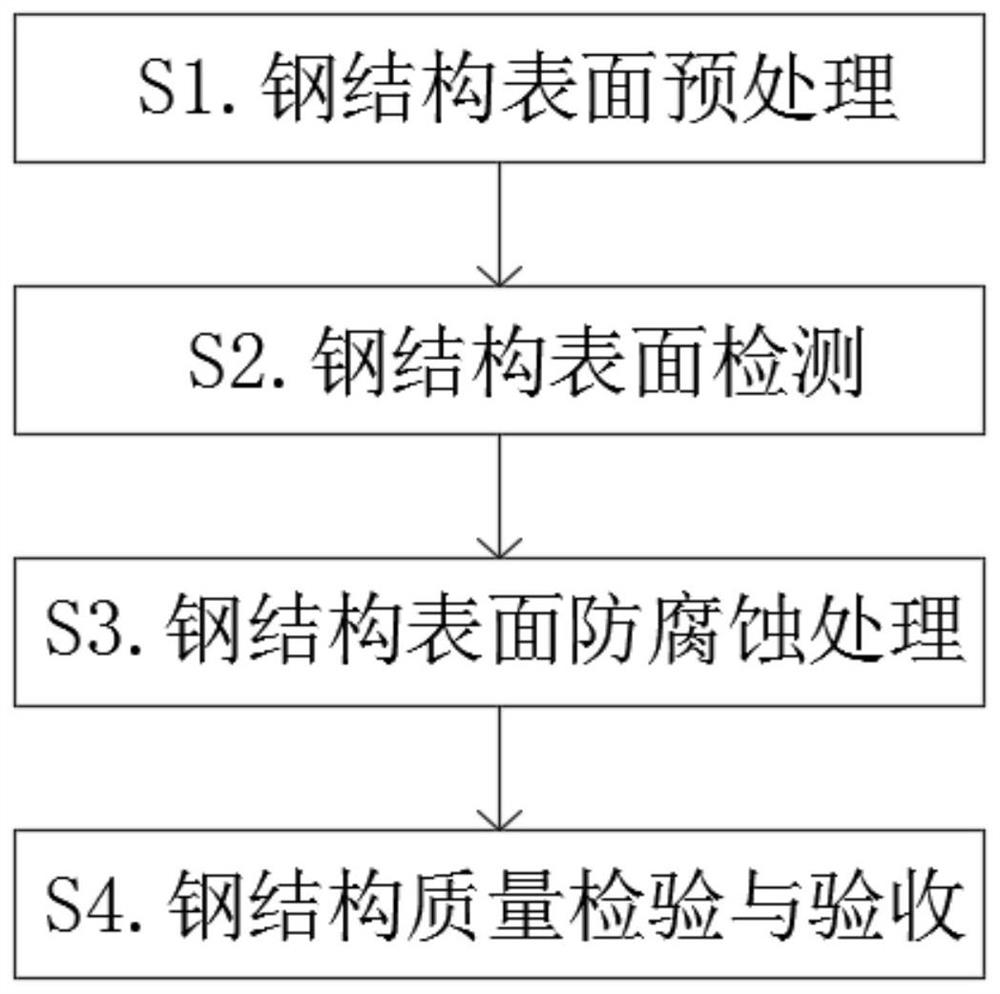

Steel structure anti-corrosion treatment method

InactiveCN112275592AImprove cleanlinessConvenient anti-corrosion treatmentRubber derivative coatingsPretreated surfacesMetallurgySteel structures

Owner:扬州市骏茂机械有限公司

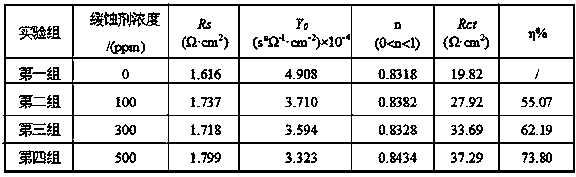

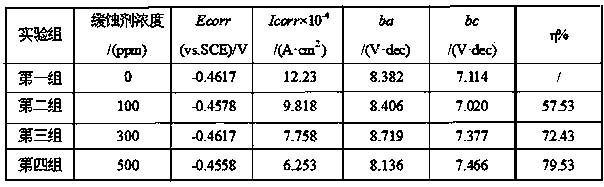

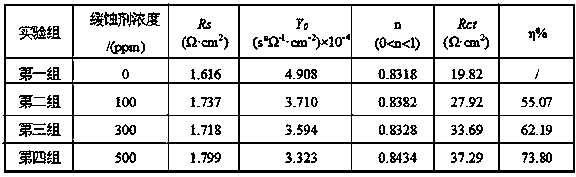

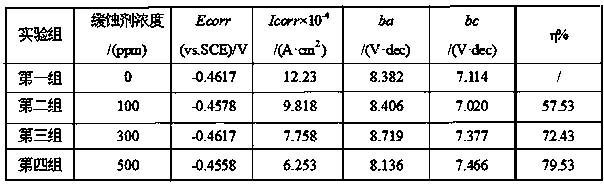

Preparation method for polyaniline/salicylaldehyde modified chitosan corrosion inhibitor

ActiveCN108048853ASolve the shortcomings of poor water solubilityImprove anti-corrosion efficiencySalicylaldehydeSulfamic acid

The invention discloses a preparation method for a polyaniline / salicylaldehyde modified chitosan corrosion inhibitor. The method comprises the steps that a certain amount of chitosan is dissolved in an acetic acid solution firstly, then a certain amount of a salicylaldehyde ethanol solution is added into the mixed solution, and under the condition that heating and stirring are carried out, reacting is carried out for a certain time to obtain the salicylaldehyde modified chitosan; and then a certain amount of aniline and a certain amount of sulfamic acid are sequentially added into the mixture,after the mixed solution is uniformly stirred, a certain amount of an acetic acid solution with an ammonium persulfate is added into the mixed solution, and after the reaction is finished, filtering,washing and filter cake drying are carried out to obtain the polyaniline / salicylaldehyde modified chitosan corrosion inhibitor.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Metal rust preventive emulsion and preparation method thereof

InactiveCN108531057AImprove rust resistanceImprove anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEmulsionSURFACTANT BLEND

The invention discloses a metal anti-rust emulsion including the following raw materials: phthaloyl amidoacetic acid alcoholamine salt, acetyl triethyl citrate, tetrabutylammonium acetate, an antifoaming agent, a surfactant, methyl hydroxyethyl cellulose, aqueous resin and water. The invention also provides a preparation method of the metal anti-rust emulsion, and the method comprising the steps of: adding the phthaloyl amidoacetic acid alcoholamine salt, the acetyl triethyl citrate and the tetrabutylammonium acetate into the water, heating and stirring uniformly to prepare a prefabrication material A; adjusting the pH of the aqueous resin to 7.5 to 9, adding the prefabrication material A, then adding the antifoaming agent, the surfactant and the methyl hydroxyethyl cellulose, and uniformly stirring to obtain the metal anti-rust emulsion. The metal anti-rust emulsion is good in film forming property, strong in adhesive force, high in anti-corrosion efficiency, green and environmentally-friendly.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

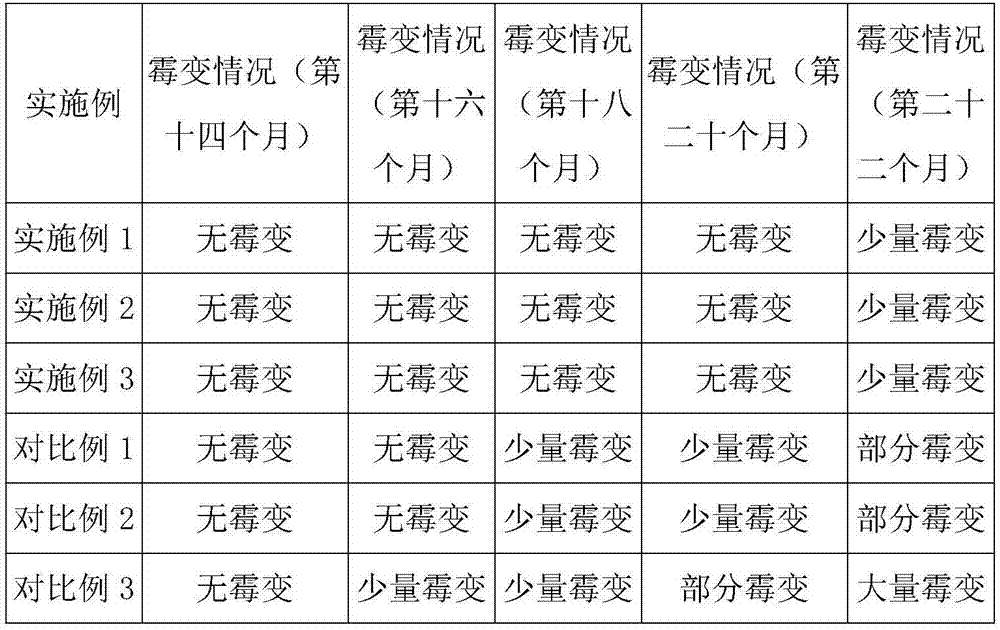

Preservative for preserving oat and preparation method of preservative

InactiveCN107439683AAnti-corrosion safetyHas therapeutic effectEdible seed preservationMugwort Essential OilPreservative

A preservative for oat preservation and a preparation method thereof. According to the percentage by weight, the formula is as follows: Artemisia argyi essential oil 1-5%, tea tree leaf extract 1-3%, Panax notoginseng extract 2-3%, toluene Sodium sulfonate 0.8-1.2%, triethanolamine 1.5-2%, sodium citrate 0.2-0.6%, gibberellin 0.012-0.015%, sodium acrylate 0.7-1.0%, isopropanol 0.3-0.5%, pyridine 0.2-0.4 %, the rest is water. The preservative provided by the invention can effectively prevent mildew during the oat preservation process and prolong the shelf life of the oat, and the extract prepared by the preparation method can greatly preserve the active ingredients of the oat and improve the antiseptic efficiency.

Owner:ANHUI KEJIE LIANGBAO STORAGE EQUIP

Preparation method of polyaniline/salicylaldehyde modified chitosan corrosion inhibitor

ActiveCN108048853BSolve the shortcomings of poor water solubilityImprove anti-corrosion efficiencySalicylaldehydeSulfamic acid

The invention discloses a preparation method for a polyaniline / salicylaldehyde modified chitosan corrosion inhibitor. The method comprises the steps that a certain amount of chitosan is dissolved in an acetic acid solution firstly, then a certain amount of a salicylaldehyde ethanol solution is added into the mixed solution, and under the condition that heating and stirring are carried out, reacting is carried out for a certain time to obtain the salicylaldehyde modified chitosan; and then a certain amount of aniline and a certain amount of sulfamic acid are sequentially added into the mixture,after the mixed solution is uniformly stirred, a certain amount of an acetic acid solution with an ammonium persulfate is added into the mixed solution, and after the reaction is finished, filtering,washing and filter cake drying are carried out to obtain the polyaniline / salicylaldehyde modified chitosan corrosion inhibitor.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

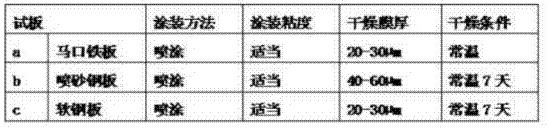

A kind of waterborne epoxy anticorrosion primer for container

ActiveCN110540790BMade with reasonable collocationKeep dryAnti-corrosive paintsEpoxy resin coatingsEpoxyFirming agent

The invention provides a water-based epoxy anti-corrosion primer for containers and a preparation method thereof. The water-based epoxy anti-corrosion primer is composed of component A and component B with a ratio of 12:1 by weight. Parts include epoxy resin emulsion, water-based functional emulsion, functional barrier filler, talc powder, anti-rust pigment, coloring pigment, dispersant, wetting agent, film-forming aid, thickener, defoamer and purified water; Component B includes water-soluble modified amine curing agent, anti-flash rust agent and purified water. The epoxy emulsion is modified by water-based functional emulsion, which not only improves the adhesion to the substrate, but also improves the drying and water resistance of the paint film. The addition of functional shielding fillers enhances the shielding effect of the paint film and significantly improves the anti-corrosion performance of the paint film. The water-based epoxy anti-corrosion primer of the present invention is a water-based paint product with low VOC content, can be diluted with water, is healthy and environmentally friendly, and at the same time, the paint film dries quickly, has good adhesion and excellent anti-corrosion performance.

Owner:江苏德威涂料有限公司

A compound of metal-organic framework encapsulating corrosion inhibitor and its preparation method and application

The invention discloses a metal-organic framework encapsulating a corrosion inhibitor compound and a preparation method and application thereof. The compound is composed of a ZIF metal-organic framework material and a corrosion inhibitor encapsulated therein. The composite material system is applied in the splash area of seawater waves. Due to the local acidic environment in the early stage of the alternating dry-wet cycle corrosion of carbon steel or metal products, the metal-organic framework is defective and the corrosion inhibitor is released, which can realize the targeting of the corrosion-induced area. protection. Further encapsulation of copper ion-modified thiazole corrosion inhibitors in metal-organic frameworks can obtain higher reprinting capacity. To inhibit the microbial corrosion caused by the growth of various aerobic bacteria on the surface of the substrate. Adopting the corrosion inhibition system of the present invention has strong targeting, high efficiency and durability, high cost performance, and has remarkable application value and broad market prospect.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Rust-proof treatment liquid and preparation method thereof

InactiveCN108410562AAvoid contactImprove anti-corrosion efficiencyLubricant compositionPhytic acidSurface-active agents

The invention discloses rust-proof treatment liquid which comprises phthaloyl imino pentanoic acid, citric acid, tetrabutyl acetic acid, phytic acid, pentaerythritol, sodium molybdate, defoaming agents, surface active agents and water. The invention further provides a preparation method of the rust-proof treatment liquid. The preparation method includes the steps: uniformly mixing the phthaloyl imino pentanoic acid, the citric acid, the tetrabutyl acetic acid, the phytic acid, pentaerythritol and methylbenzene, and removing the methylbenzene and the water after reflux reaction to prepare a prefabricated material A; heating and uniformly stirring the prefabricated material A, the sodium molybdate, the defoaming agents, the surface active agents and the water to prepare the rust-proof treatment liquid. The rust-proof treatment liquid is high in metal corrosion protection efficiency, safe and environmentally friendly.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

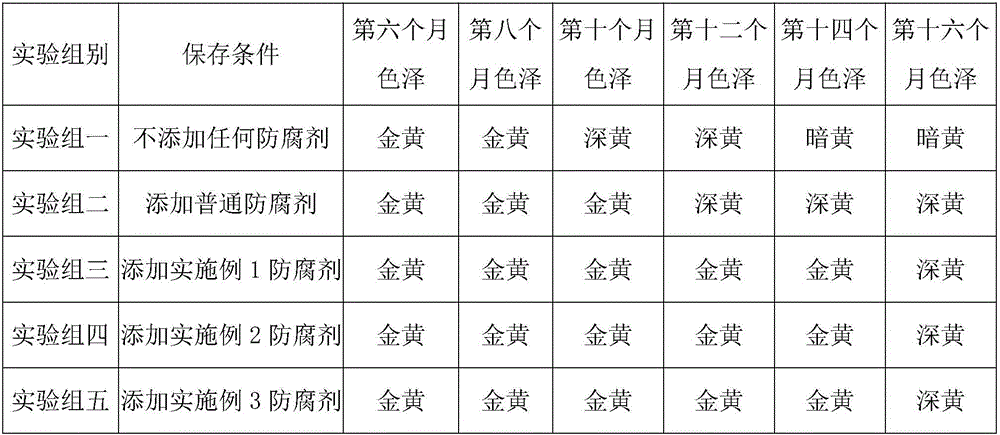

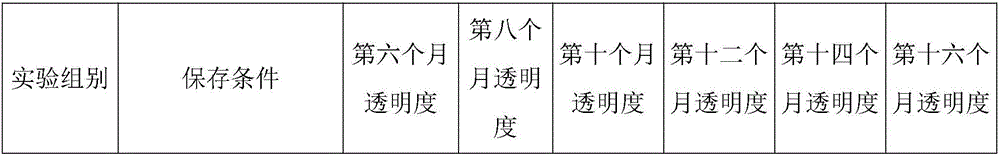

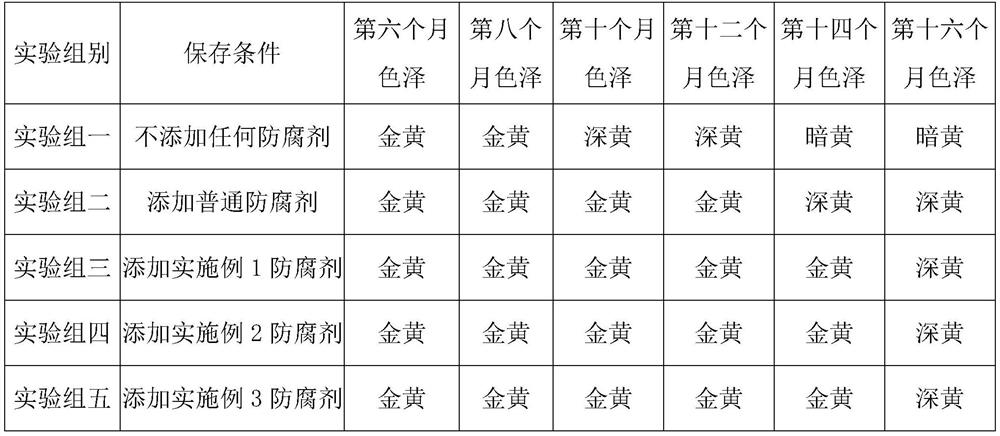

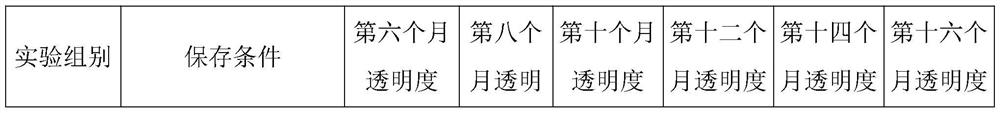

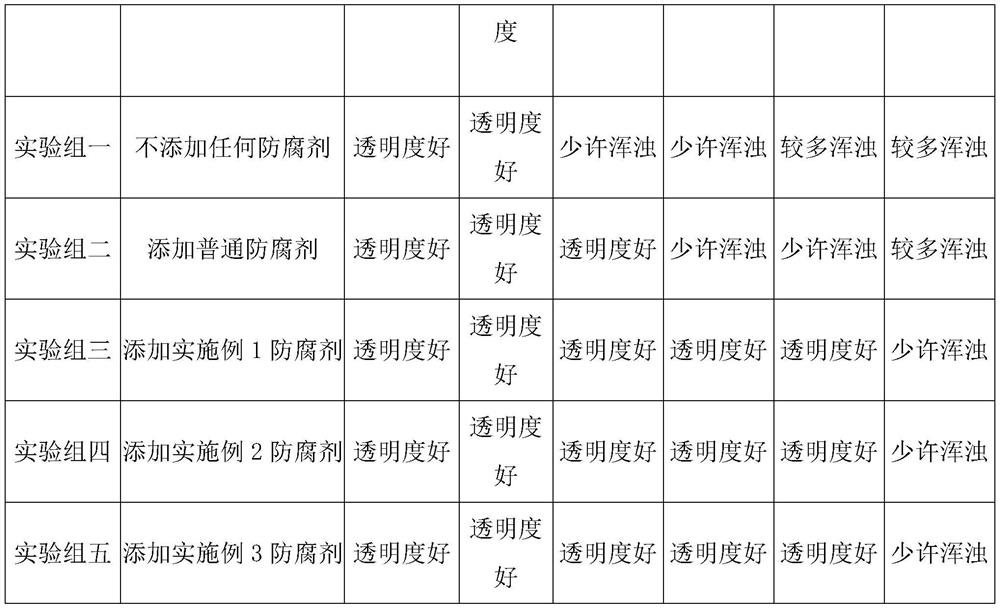

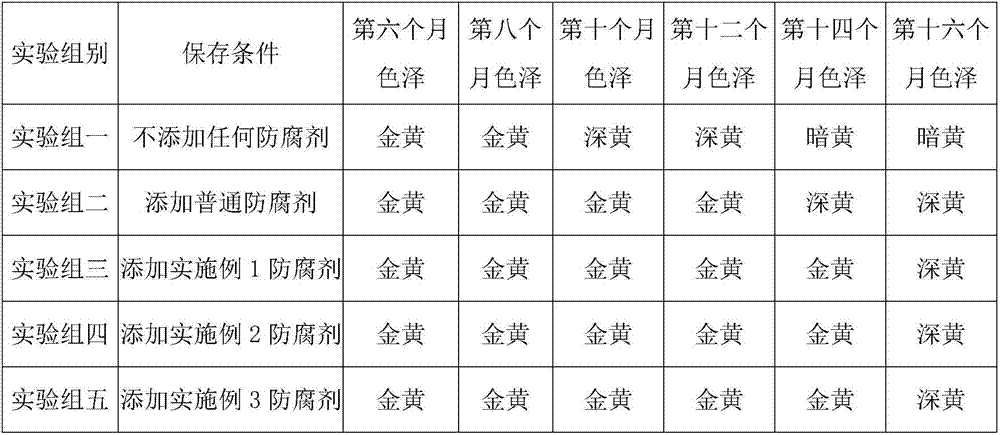

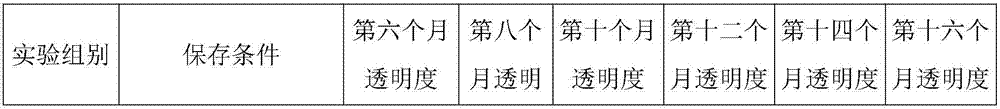

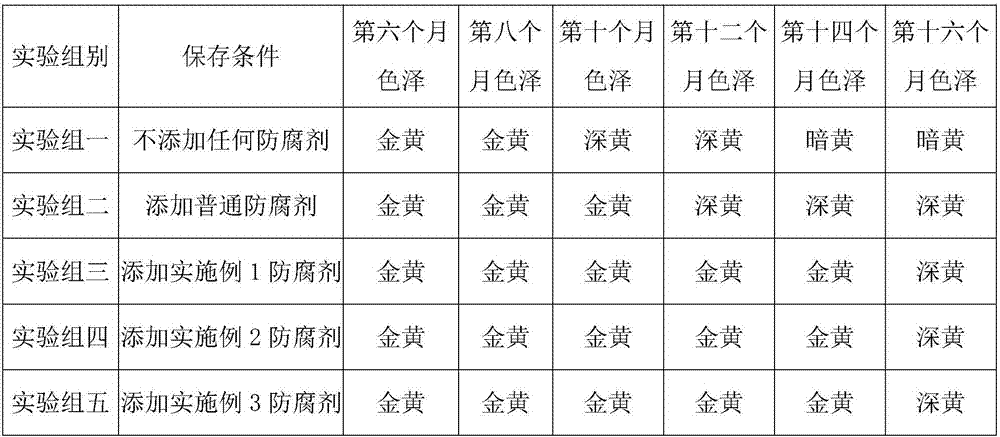

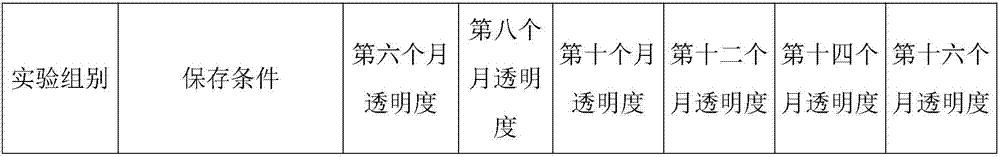

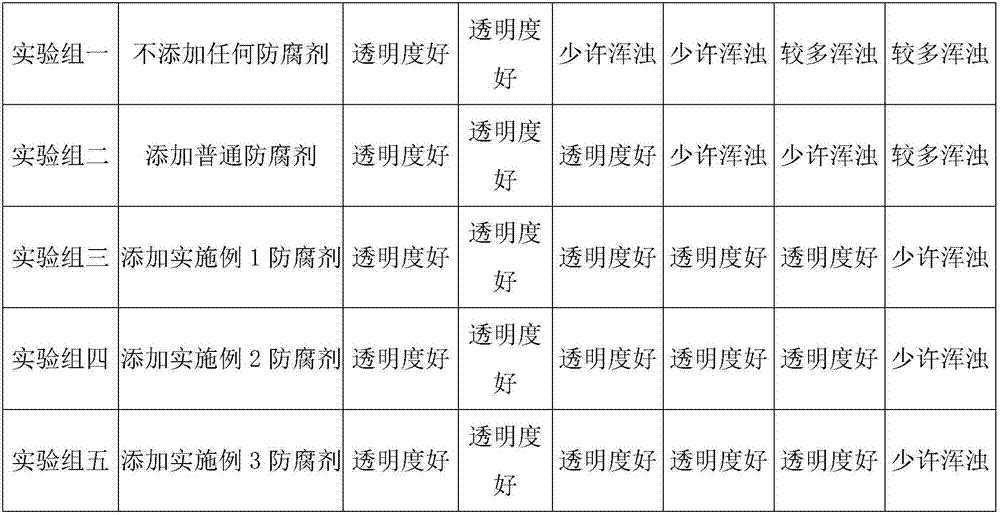

Chinese chestnut canned food preservative and preparation method thereof

The invention relates to a Chinese chestnut canned food preservative and a preparation method thereof. The formula of the Chinese chestnut canned food preservative comprises the following components in percentage by weight: 3-5% of catechin, 0.1-0.3% of isoflavones, 0.3-0.5% of potassium sorbate, 2-4% of a chestnut shell extract, 0.6-0.8% of honey, 1.2-1.5% of propylgallate, 0.8-1.2% of anthocyan and the balance of water. The preparation method comprises the following steps of preparing the chestnut shell extract and preparing the preservative. After the prepared preservative disclosed by the invention is used for preserving Chinese chestnut canned foods, the preservation time can be effectively prolonged, the color, the transparency, the lamination phenomenon and the smell of the Chinese chestnut canned foods can be better than those of the Chinese chestnut canned foods without addition of the preservative or with addition of ordinary preservatives, no corrupt components are detected through relevant chemical detection, and no untoward reactions or discomfort symptoms appear after follow-up investigation on eaters.

Owner:金寨县果兴果业农业科技开发有限公司

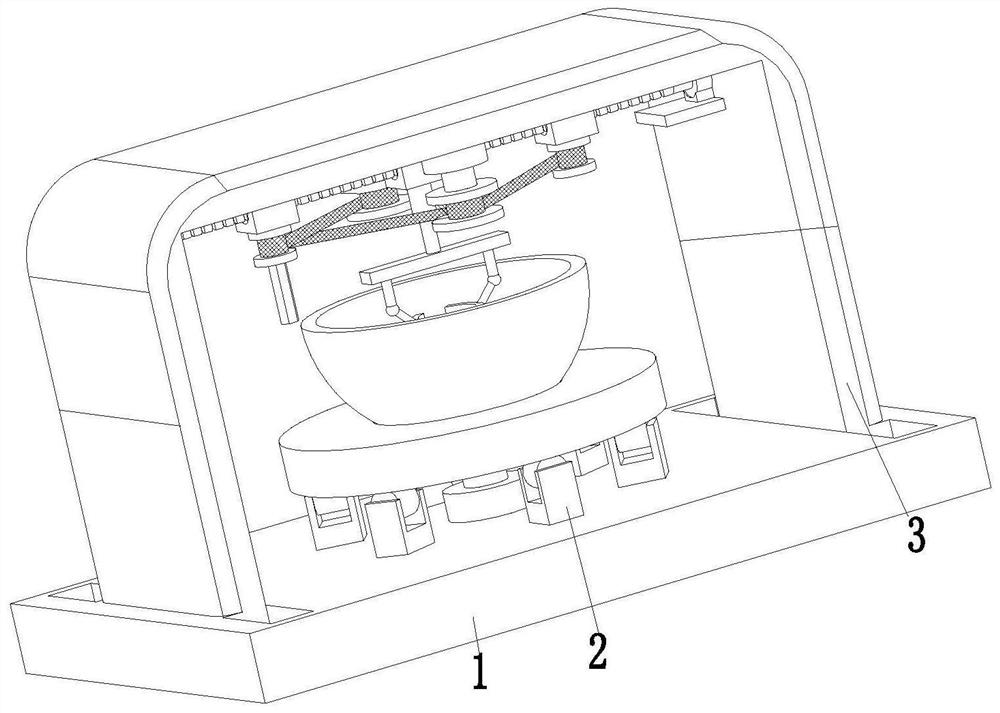

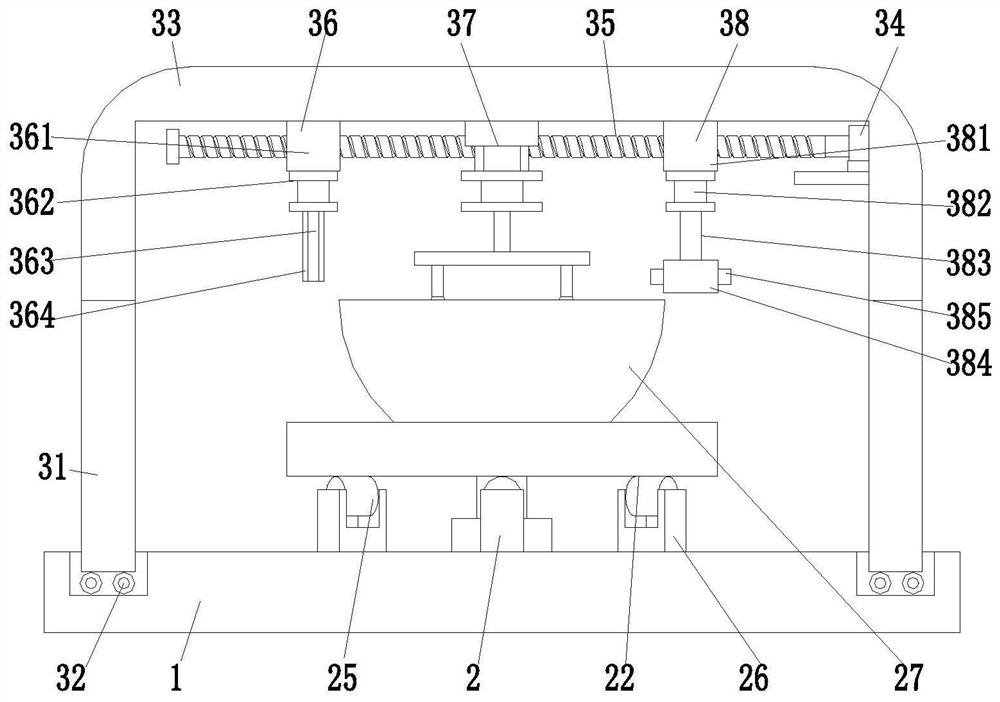

An automatic control platform for a pipeline anticorrosion and heat preservation glass fiber laying device

ActiveCN112718329BImprove anti-corrosion efficiencyLow costHollow article cleaningPackagingGlass fiberAutomatic control

Owner:浙江壹点设计咨询有限公司

A compound of metal-organic framework encapsulating corrosion inhibitor and its preparation method and application

The invention discloses a metal-organic framework encapsulating a corrosion inhibitor compound and a preparation method and application thereof. The compound is composed of a ZIF metal-organic framework material and a corrosion inhibitor encapsulated therein. The composite material system is applied in the splash area of seawater waves. Due to the local acidic environment at the initial stage of the alternating dry-wet cycle corrosion of carbon steel or metal products, the metal-organic framework is defective and the corrosion inhibitor is released, which can realize the targeting of the corrosion-induced area. protection. Further encapsulation of copper ion-modified thiazole corrosion inhibitors in metal-organic frameworks can obtain higher reprinting capacity. To inhibit the microbial corrosion caused by the growth of various aerobic bacteria on the surface of the substrate. Adopting the corrosion inhibition system of the present invention has strong targeting, high efficiency and durability, high cost performance, and has remarkable application value and broad market prospect.

Owner:SUN YAT SEN UNIV

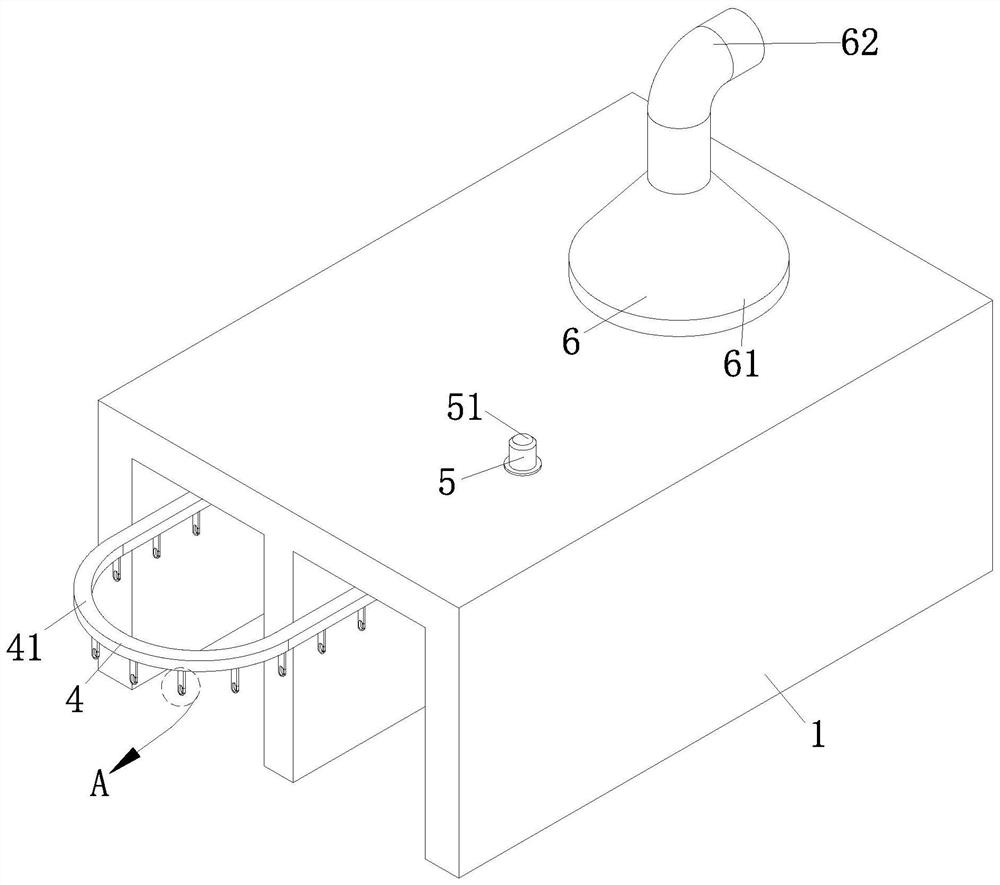

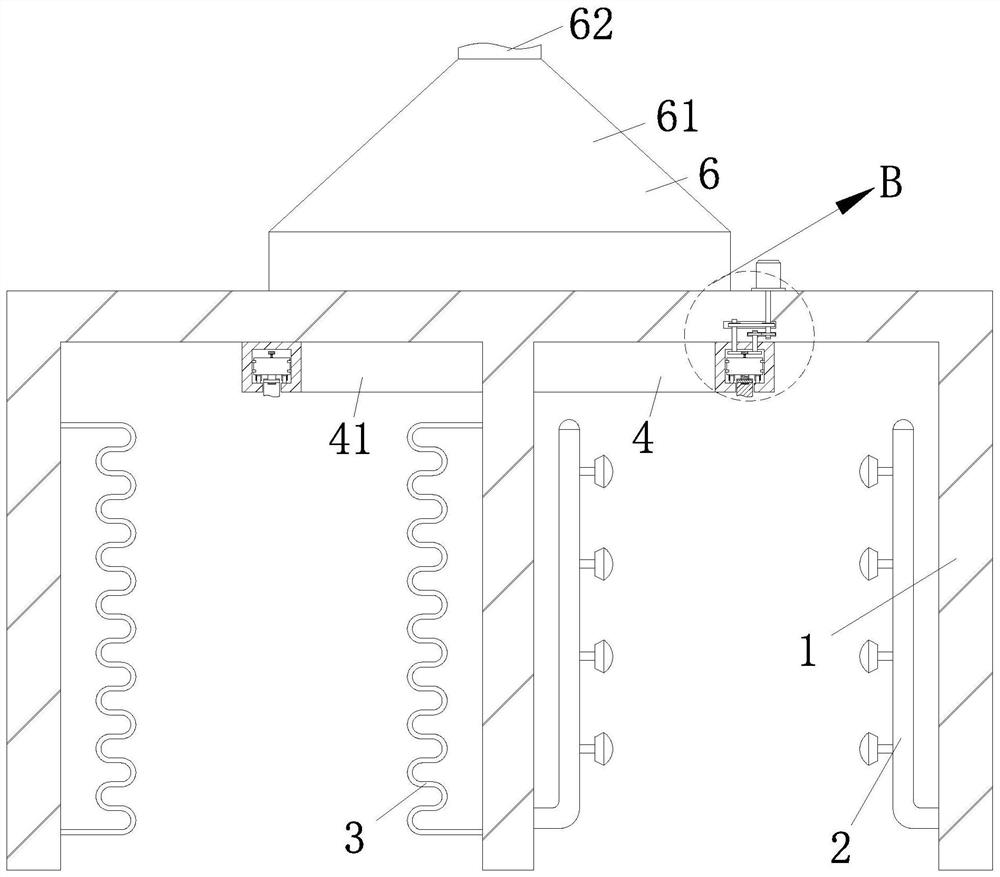

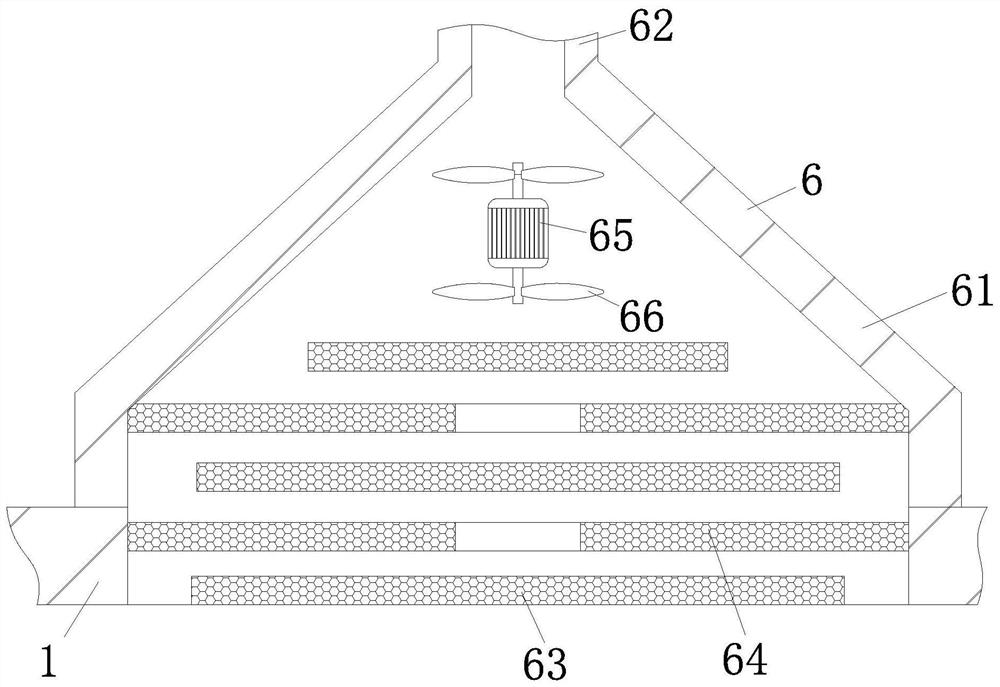

Preservative treatment device for rice noodle processing equipment

InactiveCN112704175AAvoid direct contactReduce frictionFood preservationProcess engineeringChain link

The invention discloses a preservative treatment device for rice noodle processing equipment. The preservative treatment device comprises a main body, a moving mechanism, a guide rail, movable blocks, pulleys, rollers, hooks, a first chain, connecting rods, a circulating mechanism and an exhaust mechanism. The preservative treatment device has the beneficial effects that a power part in the circulating mechanism drives the first chain to move in the guide rails, a plurality of movable blocks are rotationally connected to the first chain through a plurality of connecting rods, and the movable blocks are connected to the interiors of the guide rails through a plurality of pulleys and a plurality of rollers in a rolling mode. By arranging the pulleys and the rollers, the friction force between the movable blocks and the guide rails can be reduced, the load of the power part in the circulating mechanism is reduced, and when parts constituting the equipment need to be sprayed, the parts are hung in the hooks at the bottom ends of the movable blocks, then under driving of the first chain, the parts pass through spraying and heating areas in the main body one by one, so that the preservative efficiency is improved, and workers are prevented from directly making contact with preservative materials harmful to body health.

Owner:湖南彭述林粉业有限公司

Preservative for peony seed oil preservation and preparation method thereof

ActiveCN107354006BAnti-corrosion safetyHas therapeutic effectFatty substance preservation using additivesEdible oils/fatsBiotechnologyBenzoic acid

Owner:三门峡牡仙生物科技有限公司

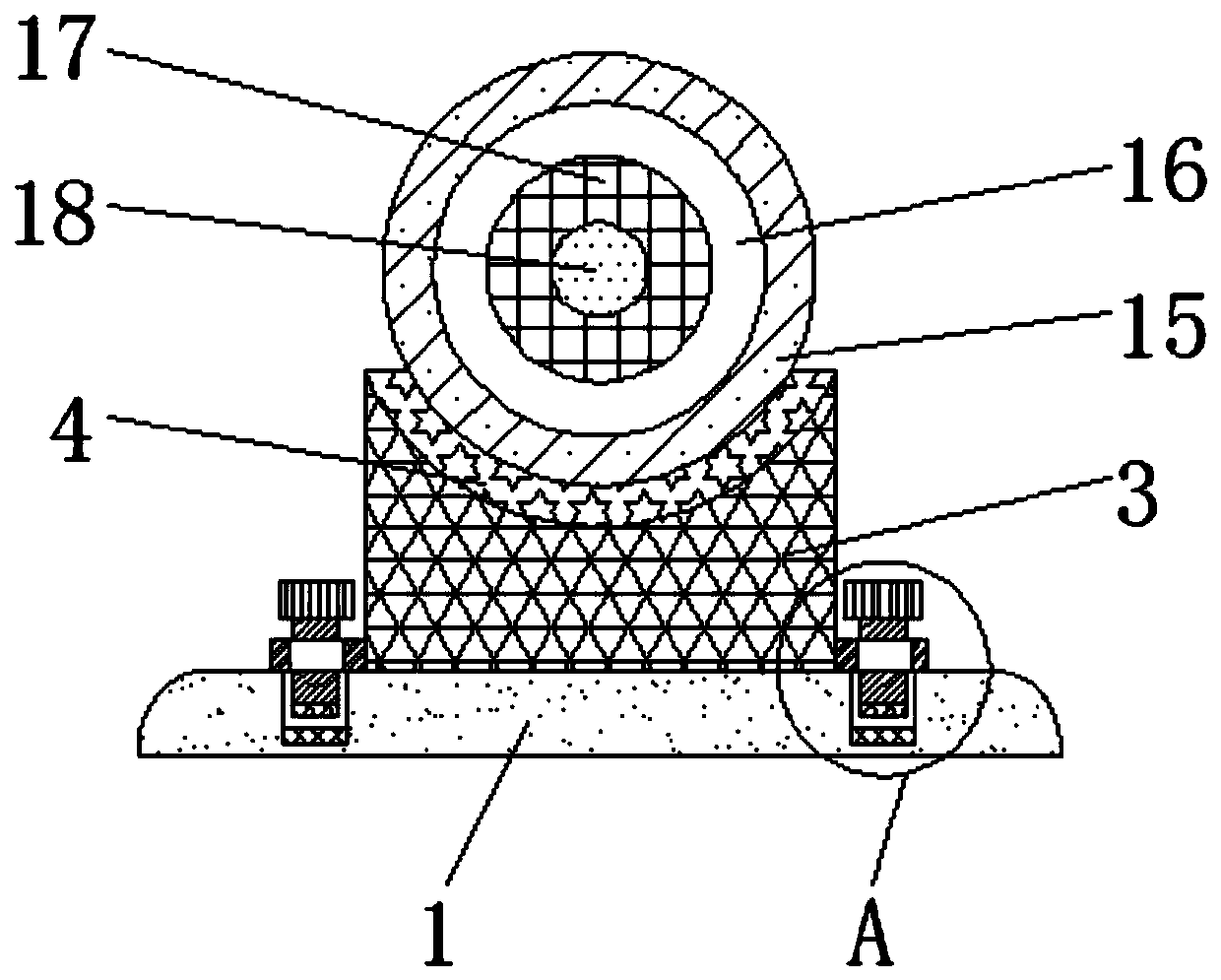

Neodymium iron boron magnet with good corrosion resistance

InactiveCN109887704AImprove anti-corrosion efficiencyImprove work efficiencyPermanent magnetsNeodymium iron boronEngineering

The invention discloses a neodymium iron boron magnet with good corrosion resistance, comprising a base, wherein a supporting column is fixedly connected to an upper surface of the base, fixing platesare fixedly connected to left and right side faces of the supporting column, through holes are formed in the upper surfaces of the fixing plates, a fixing hole is formed in the upper surface of the base, a fixing rod is arranged in the fixing hole, the fixing rod is clamped in the fixing hole, the fixing rod passes through the through holes and extends into the fixing hole, a first magnet block is fixedly connected to an inner bottom wall of the fixing hole, a second magnet block is fixedly connected to a bottom surface of the fixing rod, a neodymium iron boron magnet is placed on the upper surface of the supporting column, and a galvanized layer is arranged on an outer surface of the neodymium iron boron magnet. The neodymium iron boron magnet disclosed by the invention has a reasonabledesign structure, an anti-corrosion effect of the neodymium iron boron magnet can be achieved by electroplating a nickeled layer and the galvanized layer, so that the protectiveness of the neodymium iron boron magnet is improved, and the galvanized layer improves the corrosion resistance of the neodymium iron boron magnet.

Owner:TIANJIN NIBBOH MAGNETS

Production method of SMA high-elastic modified asphalt for steel bridge deck

PendingCN114774001AImprove anti-corrosion efficiencyImprove attachment efficiencyAntifouling/underwater paintsConjugated diene hydrocarbon coatingsFirming agentBridge deck

The invention relates to the technical field of petroleum asphalt preparation, and discloses a production method of SMA high-elastic modified asphalt for a steel bridge deck, which comprises the following working steps: 1, preparing a component A raw material; 2, preparing a component B raw material; and 3, mixing the component A raw material and the component B raw material according to a weight ratio of 1: (0.4-1.2). According to the production method of the SMA high-elastic modified asphalt for the steel bridge deck, anticorrosive petroleum asphalt is prepared by mixing a component A raw material and a component B raw material, and the component A raw material is prepared from 70 # asphalt, rosin soap, an emulsifier, sodium hydroxide, a defoaming agent, a thickening agent, water, bentonite, an epoxy curing agent, glass flakes and the like; the component B is prepared from the following raw materials: acrylic emulsion, styrene-butadiene latex, a defoaming agent, a coalescing agent, a flatting agent, an anti-flash-rust agent, a thickening agent, a solvent, a processing agent and the like, so that not only is the corrosion prevention efficiency of the petroleum asphalt improved, but also the adhesion efficiency of the petroleum asphalt is improved.

Owner:云南瑞三控股集团有限公司

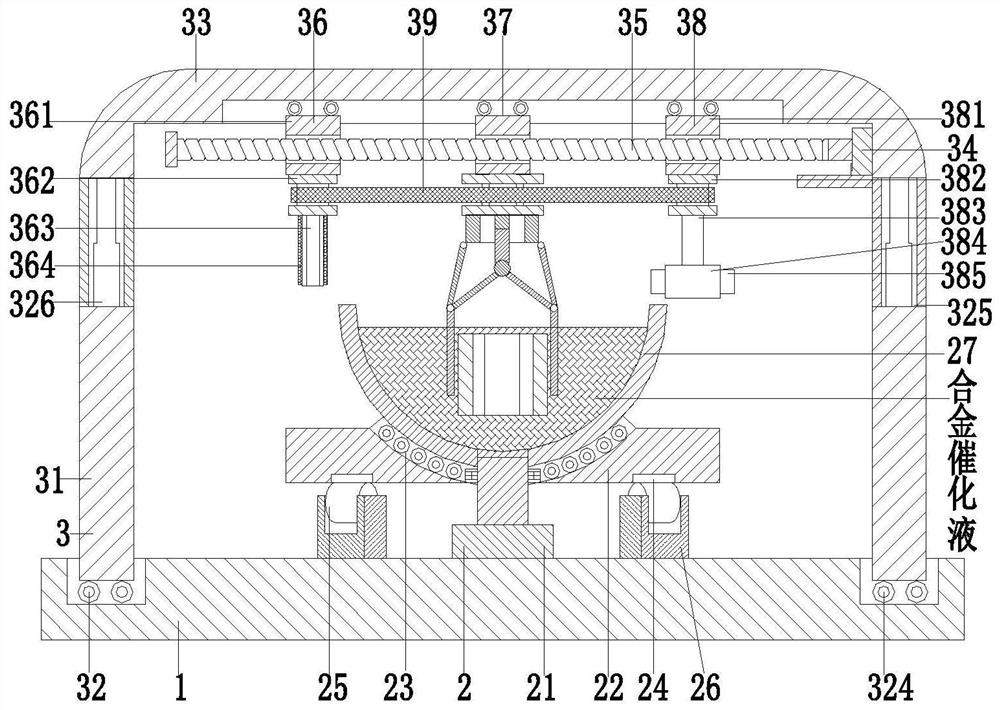

Surface treatment device for hardware tool after forming

InactiveCN111850525AEven contactImprove anti-corrosion performanceLiquid/solution decomposition chemical coatingCorrosion preventionMetallurgy

The invention relates to a surface treatment device for a hardware tool after forming. The surface treatment device comprises a bottom plate, a soaking device and clamping devices, wherein the soakingdevice is arranged in the middle of the bottom plate; sliding grooves are formed in the two ends of the bottom plate; the clamping devices are arranged in the sliding grooves in a sliding fit mode; and the clamping devices are positioned above the soaking device. According to the surface treatment device, the problems that according to existing sleeve surface anti-corrosion treatment device, a sleeve is thrown into an alloy catalyst liquid pool, so that all surfaces of the sleeve cannot be in contact with alloy catalyst liquid, all the surfaces of the sleeve cannot be in uniform contact withthe alloy catalyst liquid through rotation, the anti-corrosion treatment effect of the sleeve is influenced, the sleeve cannot be quickly clamped out when the sleeve soaking anti-corrosion treatment is completed, the sleeve cannot be well supported aiming at the hexagonal structure in the sleeve, so that the alloy catalyst liquid cannot flow to soak all the surfaces of the sleeve, the anti-corrosion treatment efficiency is low, and the anti-corrosion effect is poor can be solved.

Owner:张秋鹏

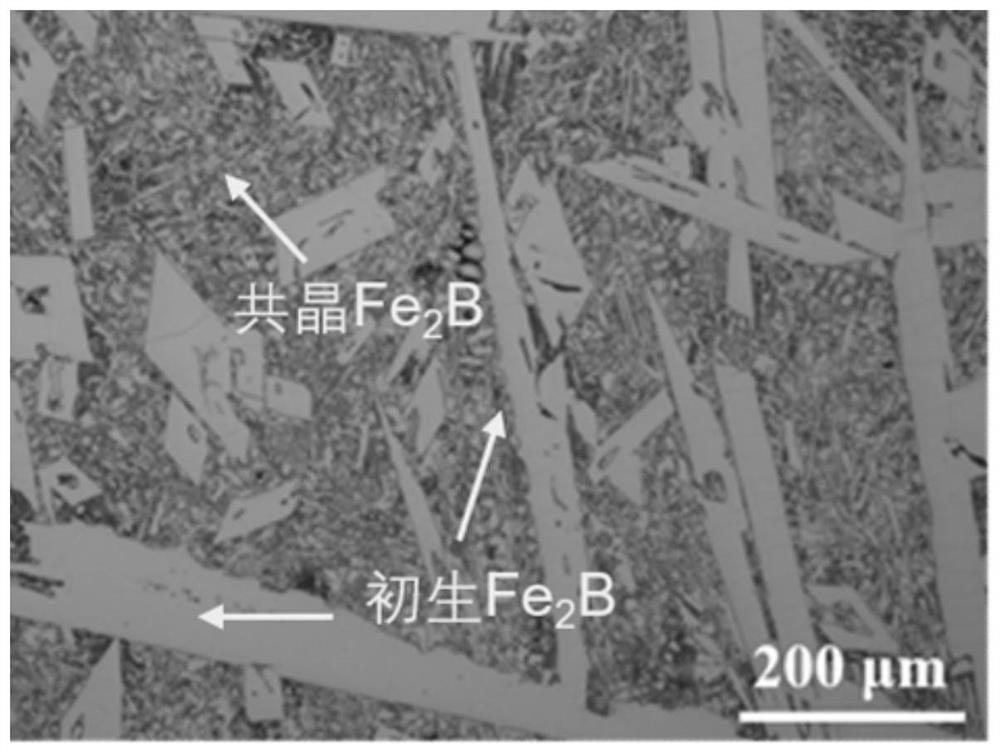

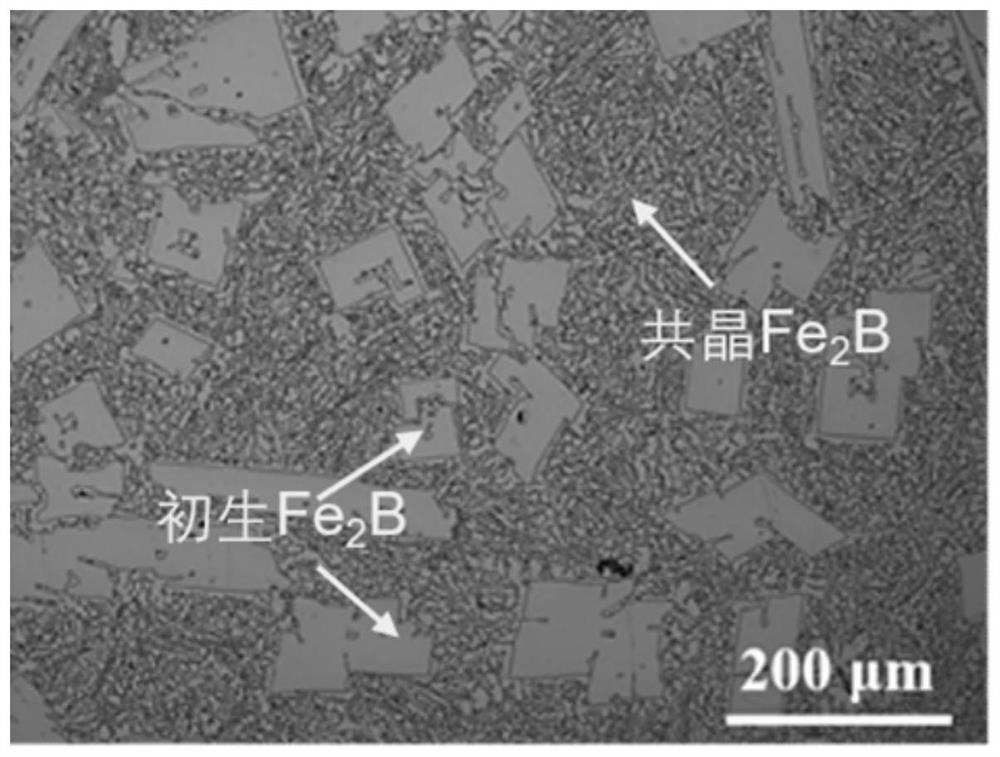

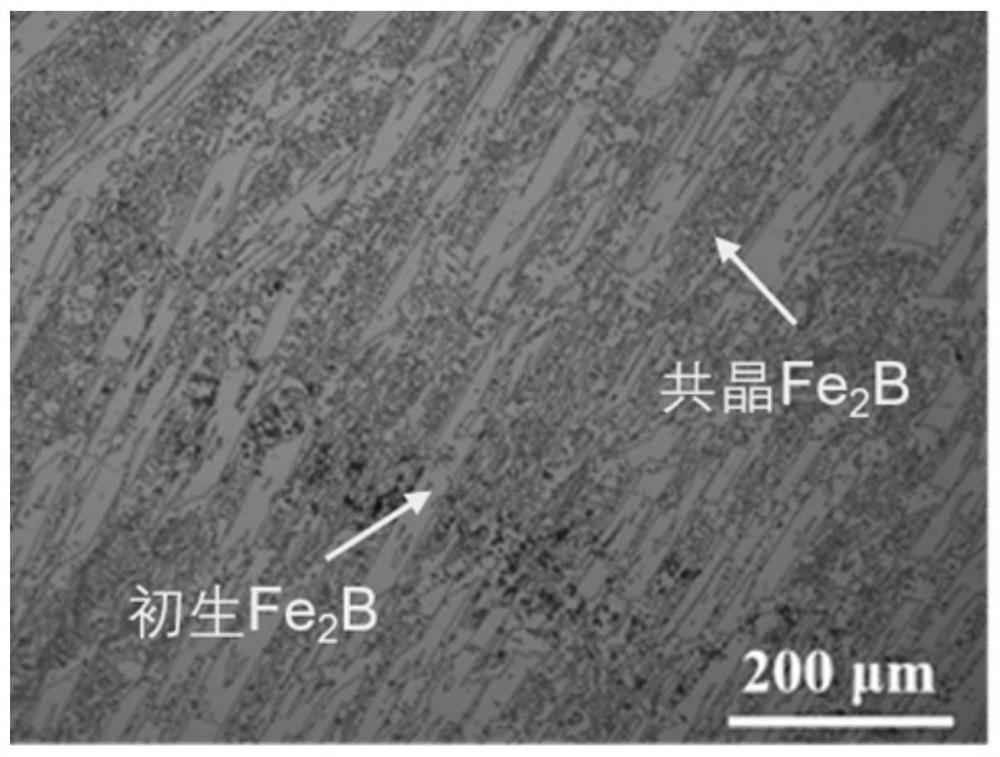

Iron-based composite material and its preparation method and application

ActiveCN110923552BStrengthen the corrosion resistance of molten aluminumMake up for the short board that is easily corroded by molten aluminumAlloyTitanium

The invention provides an iron-based composite material and its preparation method and application. The composite material includes 0.2-0.5wt% carbon, 2.0-4.0wt% boron, 8.0-16.0wt% chromium, 0.7-2.0wt% titanium, 0.4 ‑0.6wt% nickel, 1.0‑3.0wt% silicon, sulfur<0.05wt%, phosphorus<0.05wt%, the balance is iron, the invention adds a specific content of titanium element, and the in-situ reaction generates micron and nanometer Class ceramic particles, these ceramic particles can not only regulate the Fe in the iron-boron alloy 2 The shape and size of the B phase can further strengthen the corrosion resistance of the iron matrix and make up for the short plate that the iron matrix is easily corroded by the aluminum liquid; 2 Under the coordinated action of these multi-scale compounds in the B phase, it effectively hinders the diffusion of aluminum atoms into the iron matrix during the corrosion process, thereby greatly improving the corrosion resistance efficiency.

Owner:SHANGHAI JIAO TONG UNIV

Preservative for preserving peony seed oil and preparation method of preservative

ActiveCN107354006AAnti-corrosion safetyHas therapeutic effectFatty substance preservation using additivesEdible oils/fatsBenzoic acidPreservative

Disclosed are a preservative for preserving peony seed oil and a preparation method thereof. The preservative comprises the following components in percentage by weight: 3-7% of artemisia argyi volatile oil, 1-3% of a peony juice extract, 2-3% of a peony seed shell extract, 0.8-1.2% of benzoic acid, 1.5-2% of glycerol, 0.2-0.6% of citric acid, 0.012-0.015% of gibberellin, 0.7-1.0% of sodium dehydroacetate and the balance of water. The preparation method comprises the steps of preparing the artemisia argyi volatile oil, the peony juice extract and the peony seed shell extract respectively, mixing the volatile oil and the extracts with the benzoic acid, glycerol, citric acid, gibberellins and sodium dehydroacetate, and dissolving the mixture in water. The provided preservative can effectively prolong the preservation time, and keep the color, transparency, demixing phenomenon and odor superior to those not added with a preservative or added with a common preservative; any corrupt component is not detected in relevant chemical detection, and eaters of the preservative do not have any adverse response or discomfort symptoms in a tracking survey.

Owner:三门峡牡仙生物科技有限公司

Automatic control platform of pipeline anti-corrosion heat-preservation glass fiber laying device

ActiveCN112718329AImprove anti-corrosion efficiencyLow costHollow article cleaningPackagingGlass fiberAutomatic control

The invention discloses an automatic control platform of a pipeline anti-corrosion heat-preservation glass fiber laying device. The automatic control platform comprises a fixing base, a first fixing frame, a second fixing frame, a driving module and a control machine body, wherein the first fixing frame and the second fixing frame are separately and fixedly arranged on the fixing base, the driving module is arranged between the first fixing frame and the second fixing frame, the first fixing frame is provided with a first supporting shaft capable of sliding in a telescopic mode, the second fixing frame is provided with a second supporting shaft capable of sliding in a telescopic mode, the first supporting shaft and the second supporting shaft are connected together in a butt joint mode after sliding, the control machine body slides on the first supporting shaft and the second supporting shaft, the interior of a pipeline can be cleaned and painted through sliding of the control machine body, then anti-corrosion operation is completed, the anti-corrosion efficiency of the pipeline is greatly improved, and the anti-corrosion cost is reduced.

Owner:浙江壹点设计咨询有限公司

Preservative for canned yellow peaches and preparation method of preservative

InactiveCN107079986AFor long-term storageNo side effectsFood ingredient as antioxidantClimate change adaptationBenzoic acidPreservative

The invention relates to a preservative for canned yellow peaches and a preparation method of the preservative. The preservative adopting the formula consists of the following components in percentage by weight: 2-5% of diacetate, 1-3% of a yellow peach leaf extract, 3-5% of lysozyme, 0.5-1.0% of benzoic acid, 1.2-1.5% of cassia oil, 0.2-0.6% of citric acid, 0.8-1.2% of gibberellin, 0.7-1.0% of nisin and the balance of water. The preparation method comprises the following steps of preparing the yellow peach leaf extract, preparing the cassia oil, and preparing the preservative. The preservative prepared by the method disclosed by the invention is used for preserving canned yellow peaches, so that the preservation time can be effectively prolonged, the transparency, the stratification and the smell of the canned yellow peaches preserved by using the preservative are better than those of canned yellow peaches free from addition of preservatives or being preserved by using a common preservative, any corruption components are not detected through relevant chemical detection, and the preservative cannot cause any adverse reactions or discomfort symptoms for eaters through follow-up investigation.

Owner:金寨县果兴果业农业科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com