Patents

Literature

61results about How to "High resin content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepreg applied for multi-layer board of printed electronic circuit

ActiveCN101220160ALow dielectricReduce residual stressSynthetic resin layered productsCircuit susbtrate materialsSolventFilling materials

The invention pertains to the technical field of the copper clad laminate, which more particularly relates to a prepreg applied to a printing circuit multilayer board. The prepreg comprises reinforced materials and resin composite, wherein, the reinforced materials is glass fiber paper, and according to part by weight, the formulation of the resin composite is as follows: 20 to 84 portions of resin, 0 to 35 portions of filling materials, 0.01 to 0.3 portions of curing accelerator and 10 to 45 portions of solvent; the resin composite solvent is soaked in the glass fiber paper for 1 to 5 minutes, and is put in a 140 to 200 DEG C oven for baking for 2 to 10 minutes; after the solvent is removed, the prepreg applied to multilayer PCB processing materials is obtained; white flake and spot problems of base materials during the manufacturing procedures of the multilayer PCB are prevented, problems of de-lamination, shrink resin, holes and crack of the resin and white flake, etc. that come up after the multilayer PCB goes through cold and hot impact are improved, and the prepreg has good reliability and low cost.

Owner:GUANGDONG SHENGYI SCI TECH

Separator for a fuel cell

InactiveUS6468685B1Improve flatnessAddressing Inadequate ContactCell seperators/membranes/diaphragms/spacersFinal product manufactureFuel cellsShell molding

In a separator for a fuel cell according to the invention, a separator is formed by a molding a bondcarbon compound in which a composition ratio of graphite powder is set to 60 to 90%, and a composition ratio of a thermosetting resin is set to 10 to 40%, and at least a top end face of each of a number of ribs contacting the surface of an anode or a cathode is coated with a conductive film made of a material which is lower in specific resistance than the bondcarbon compound. According to this configuration, while excellent moldability and high productivity are ensured by the use of the bondcarbon compound containing a larger content of a resin, the contact resistance with respect to an electrode is lowered so that the conductivity of the whole can be improved, and predetermined performance of a fuel cell can be surely exerted.

Owner:NIPPON PILLAR PACKING CO LTD

Through color high pressure decorative laminate and method of making same

InactiveUS20090155593A1Increase pressureAesthetically objectionableNon-fibrous pulp additionSpecial paperPolymer scienceFunctional monomer

A decorative laminate is provided and includes a core having a plurality of stacked paper sheets which are impregnated therein a melamine-formaldehyde resin and an internal plasticizer for the melamine-formaldehyde resin, the plasticizer comprising an amino-functional monomer; a decorative sheet overlying the core, the decorative sheet having impregnated therein a melamine-formaldehyde resin and an internal plasticizer for the melamine-formaldehyde resin; and, optionally, an overlay sheet on the decorative sheet. A combustion accelerant is also included in the resin.

Owner:THE DILLER

Synergistic filler compositions and low density sheet molding compounds therefrom

InactiveUS20060252869A1Improve efficiencyHigh resin contentMaterial nanotechnologySheet moulding compoundLow density

The present disclosure relates generally to resin formulations for sheet molding compounds. Particularly, but not by way of limitation, the disclosure relates to low-density thermosetting sheet molding compounds (SMC) comprising a treated inorganic clay, a thermosetting resin, a low profile agent, a reinforcing agent, a low-density filler, and substantially the absence of calcium carbonate. The thermosetting SMC are used to prepare exterior and structural thermoset articles, e.g. auto parts and panels, etc that have Class A Surface Quality.

Owner:ASHLAND LICENSING & INTPROP LLC

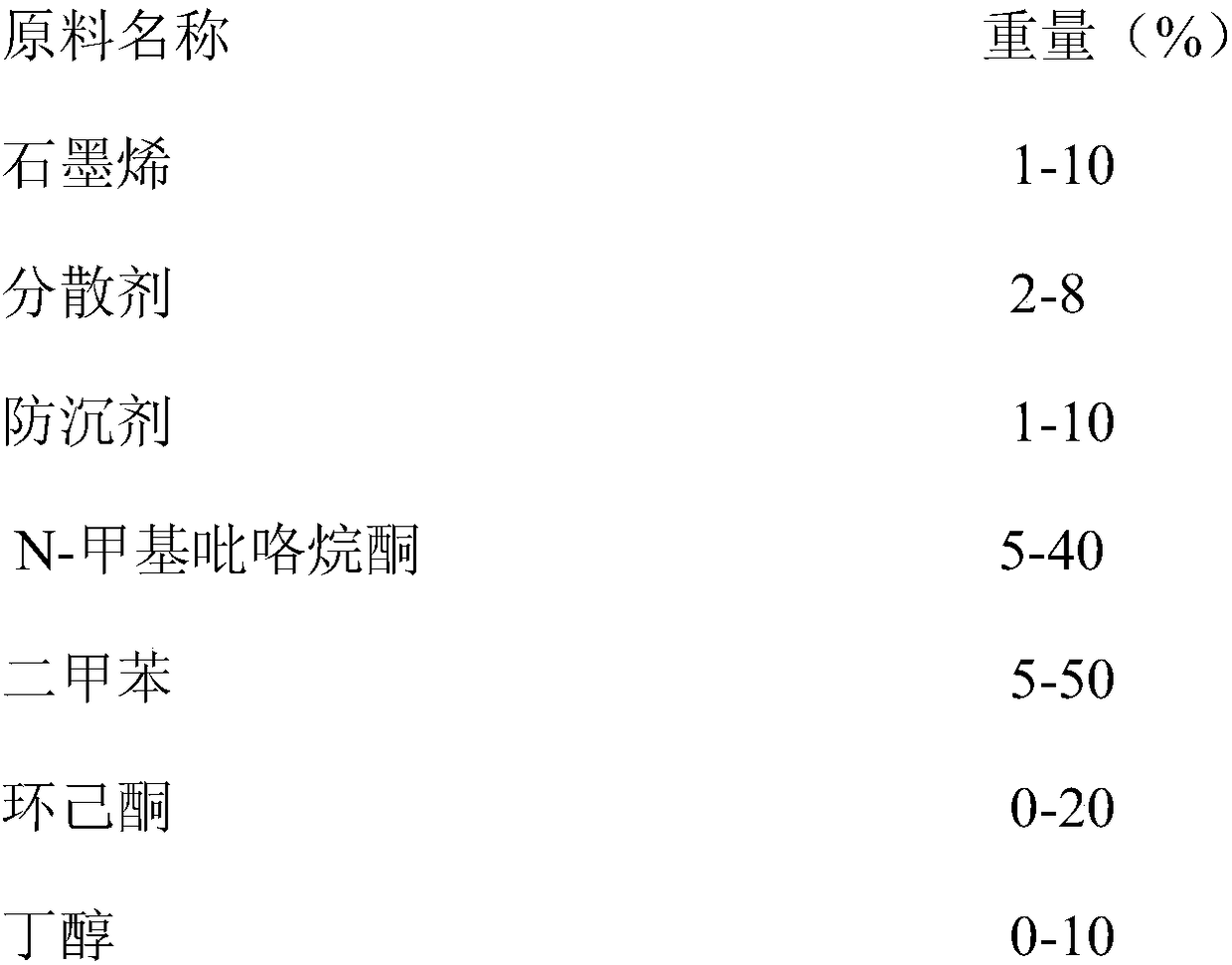

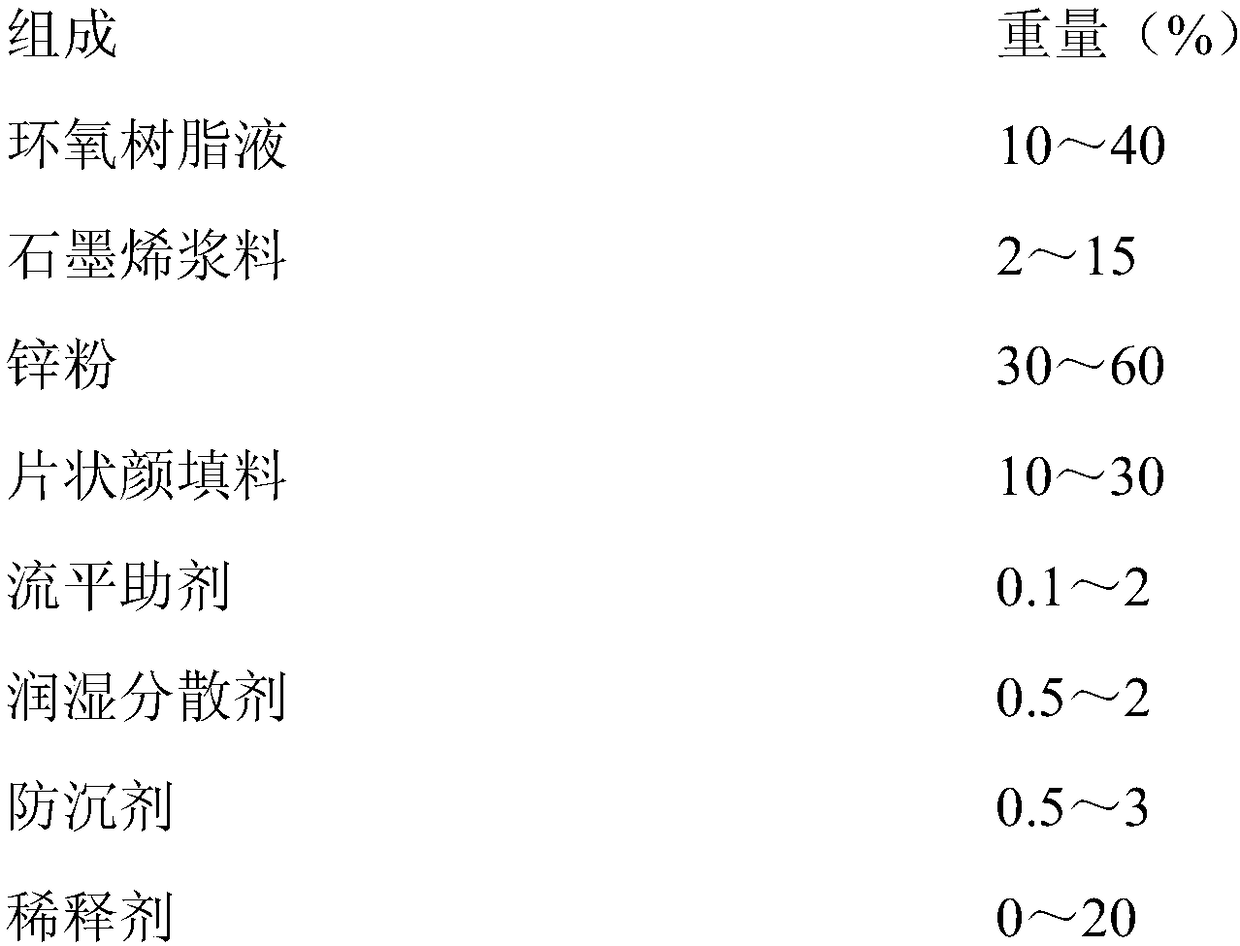

Thin-coating two-component anticorrosive coating for surface of precise steel structural part and preparation method thereof

InactiveCN108300146AImprove the effect of cathodic protectionImprove anti-corrosion efficiencyAnti-corrosive paintsEpoxy resin coatingsEpoxyCyclohexanone

The invention provides a thin-coating two-component anticorrosive coating for the surface of a precise steel structural part, wherein the two-component anticorrosive coating is composed of a componentA and a component B. The component A is composed of an epoxy resin liquid, graphene slurry, a zinc powder, flaky pigments and fillers, an auxiliary agent and a diluent. The component B is composed ofa polyamide curing agent and a mixture of xylene, n-butanol and cyclohexanone. The component A and the component B are evenly mixed according to the weight ratio of (5-15):1. The graphene slurry is prepared by adding powdery graphene and a dispersant into a mixed solvent under a stirring state, and dispersing in an ultrasonic oscillator to obtain the stable dispersed slurry. A coating layer has excellent cathodic protection effect, can be thin-coated to about 10-15 microns, still has good corrosion resistance, and can partly replace traditional phosphorization and oxidation processes.

Owner:MARINE CHEM RES INST +1

Synergistic filler compositions and low density sheet molding compounds therefrom

InactiveCN101213245ALow costSpeed up the flowMaterial nanotechnologyPolymer scienceSheet moulding compound

The present disclosure relates generally to resin formulations for sheet molding compounds. Particularly, but not by way of limitation, the disclosure relates to low-density thermosetting sheet molding compounds (SMC) comprising a treated inorganic clay, a thermosetting resin, a low profile agent, a reinforcing agent, a low-density filler, and substantially the absence of calcium carbonate. The thermosetting SMC are used to prepare exterior and structural thermoset articles, e.g. auto parts and panels, etc that have class A surface quality.

Owner:ASHLAND LICENSING & INTPROP LLC

Processing process of large-diameter anti-static fiber glass epoxy plastic pipeline

ActiveCN102490369ANo decline in physical strength indexAnti-static performance does not decreaseYarnEpoxy

The invention provides a processing process of a large-diameter anti-static fiber glass epoxy plastic pipeline. The process is characterized in that a carbon fiber felt is uniformly wound on a pipeline die, so that the carbon fiber felt is flatly coated on the outer wall of the pipeline die; after the carbon fiber felt is immersed by epoxy resin, fiber glass high-strength yarns and carbon fiber yarns are spirally wound on the pipeline die, and an anti-static high-strength fiber glass epoxy plastic pipeline produced by high-temperature cure heating after the winding is completed; and in the processing process, the carbon fiber inner felt, the high-strength carbon fiber, the fiber glass and imported epoxy resin are used as raw materials, and wounding formation, steam heating by stages and high-temperature inner die curing formation are adopted. The process comprises the following specific steps: preparing materials; winding the carbon fiber felt; adding carbon fibers; heating with steam by stages; curing and forming; and processing and finishing, thus obtaining a finished product pipeline. The pipeline provided by the invention has the advantages that the anti-static performance, the physical strength index of the material and the anti-corrosion index are not reduced at an environmental temperature of minus 40-120 DEG C, and the anti-static, anti-aging and anti-fatigue service life is not lower than 30 years under the condition that the pipeline is exposed in the sea.

Owner:山东欧森管道科技有限公司

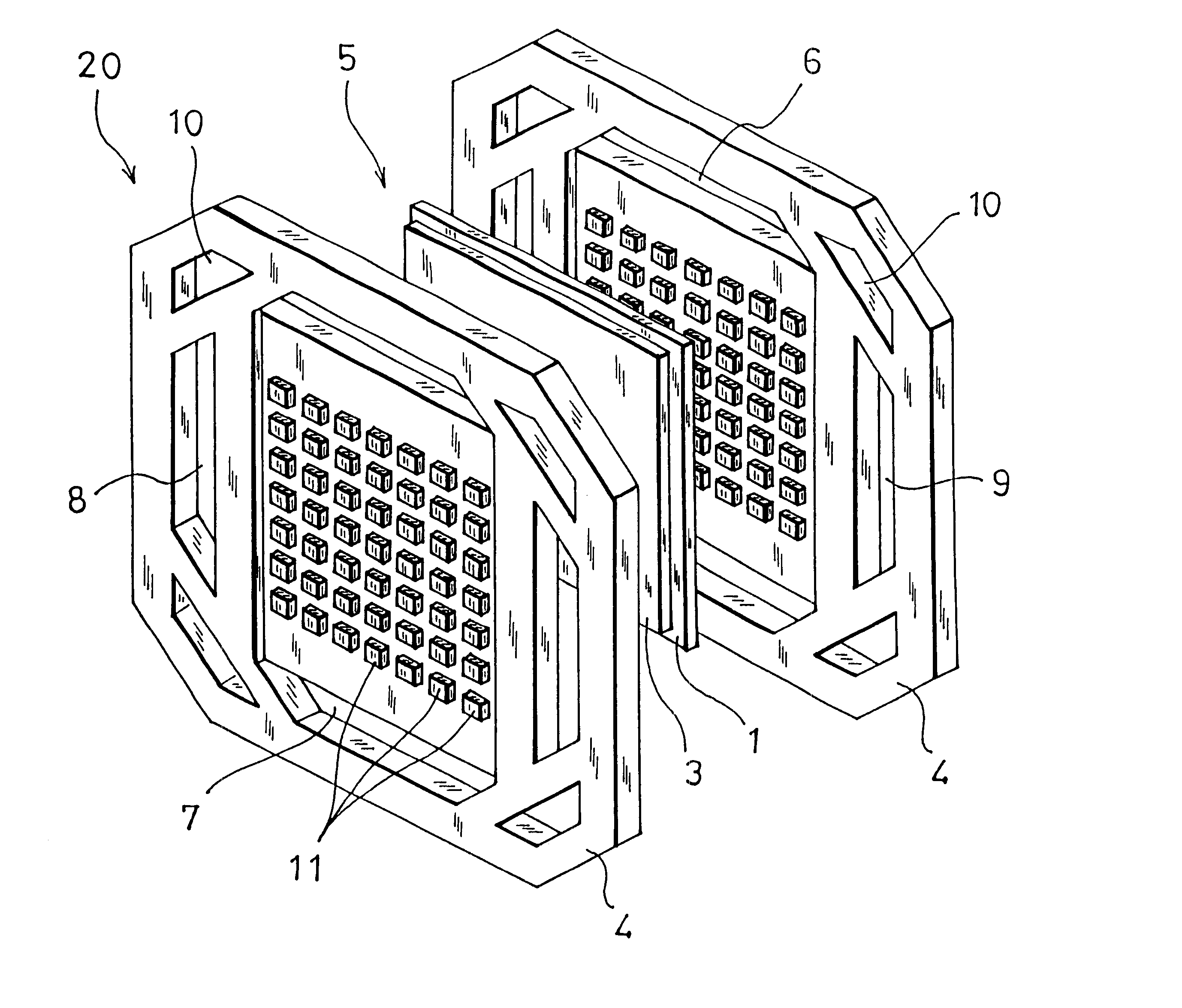

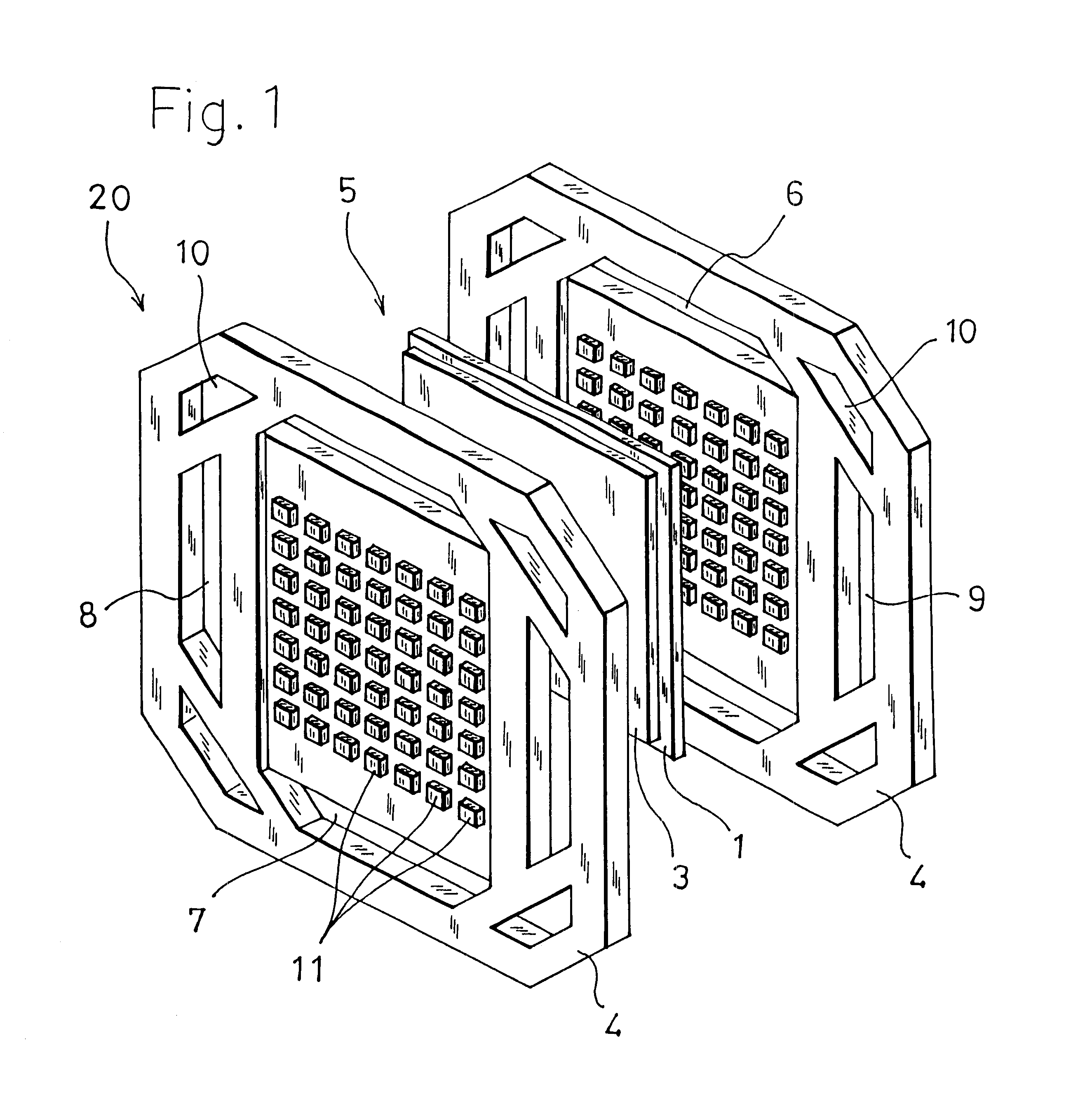

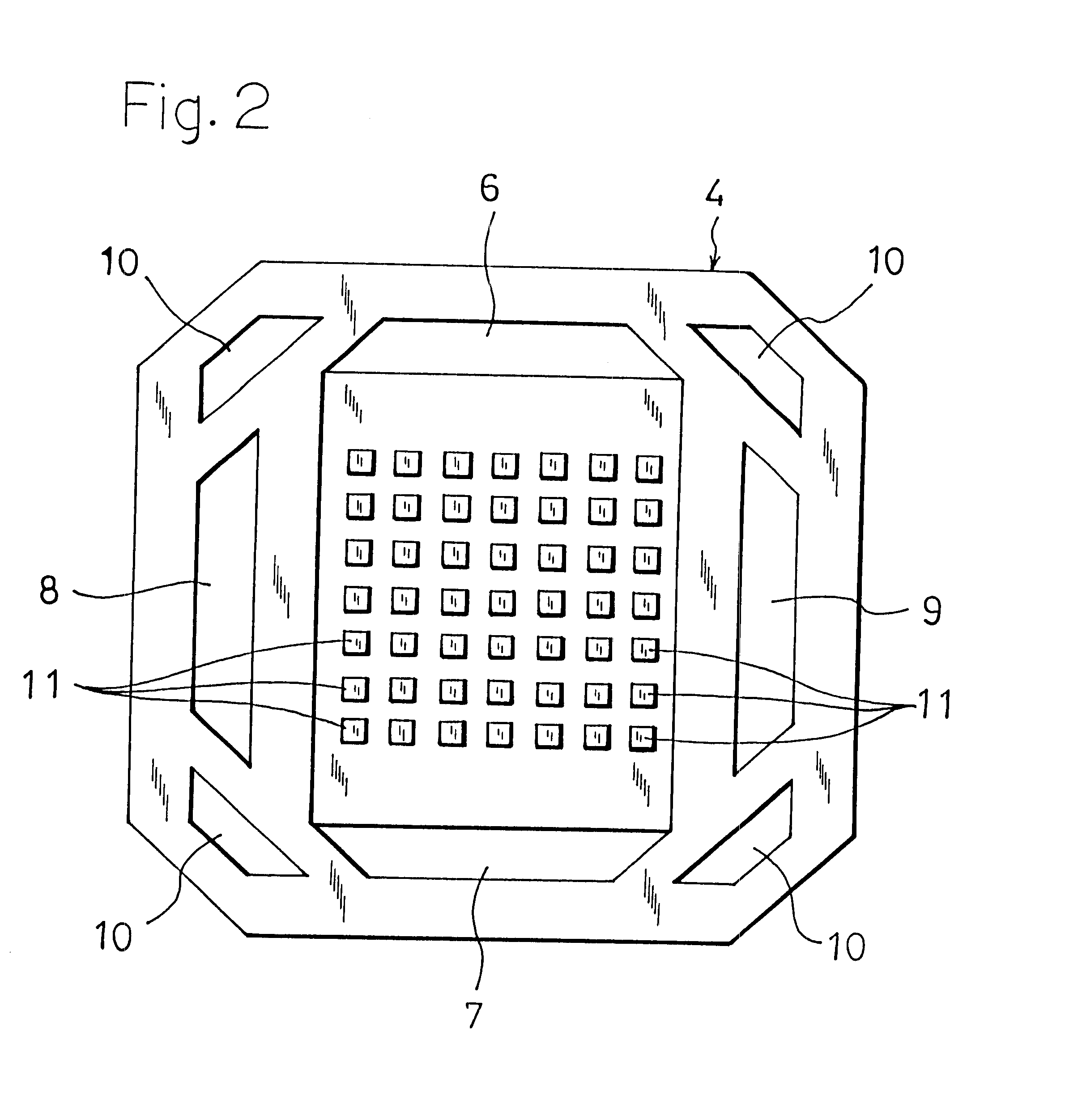

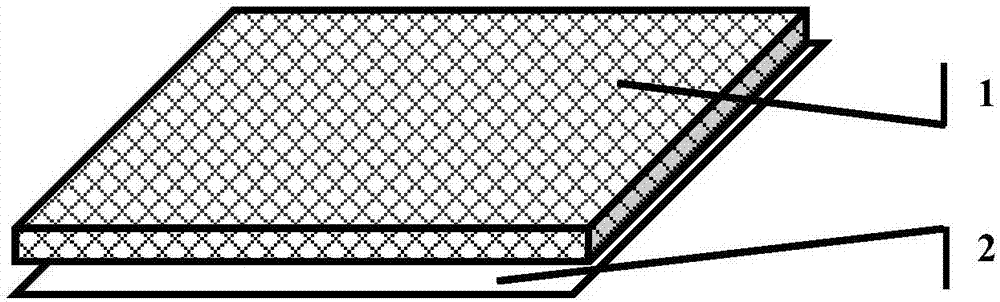

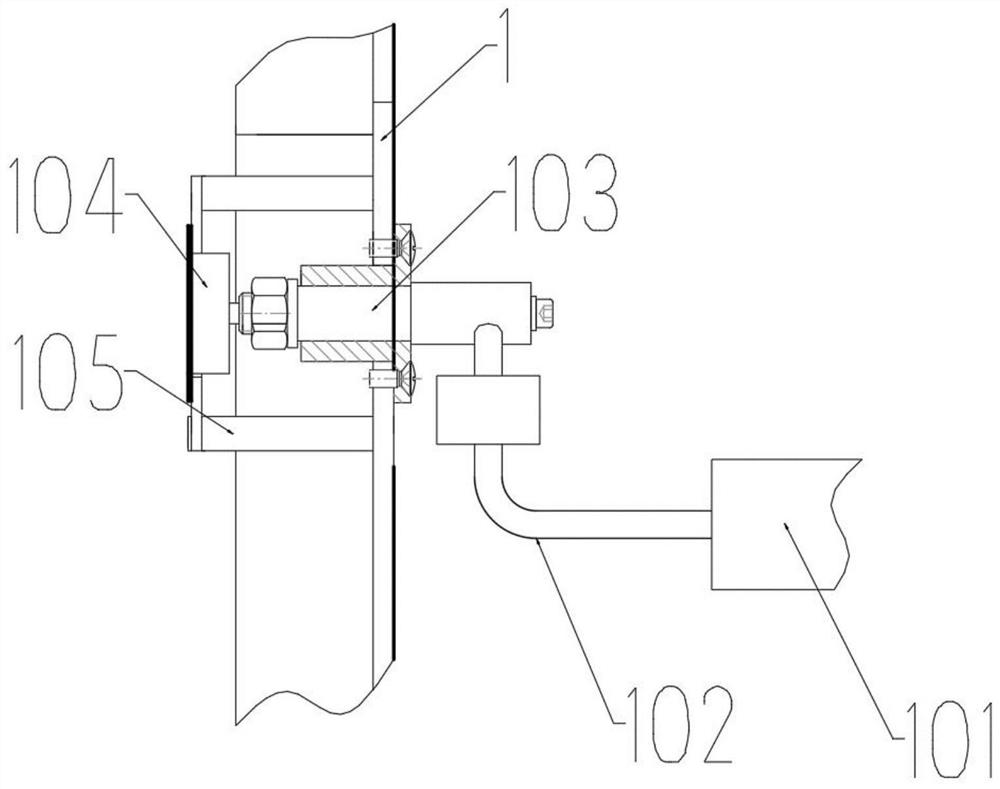

Manufacturing method of vehicle components, as well as vehicle components and vehicle

ActiveCN107053703AGood molding effectImprove layer performanceDomestic articlesFiberMarine engineering

The invention relates to manufacturing method of vehicle components, as well as vehicle components and a vehicle. The method comprises the following steps of: a, layering continuous-filament woven fabric to obtain a layering structure (1); b, laying a resin film (2) at the bottom of the layering structure (1), and then performing pre-cutting to obtain a fibrous preform (3); and c, placing the fibrous preform (3) in an injection mold with an injection molding space (8), after mold clamping, injecting an injection molding material (6) containing discontinuous fibers and thermoplastic resin into the injection mold, so that the injection molding space (8) is full of the injection molding material (6) through injection molding and the fibrous preform (3) is infiltrated with the injection molding material (6), and performing pressure maintaining and forming so as to obtain the vehicle components (7). The method belongs to revolutionary innovation of a conventional low-pressure injection molding process. The manufactured components can meet the requirements of mechanical properties and formability at the same time. The problems of difficult forming by the conventional laminating process and low mechanical performance of the conventional injection molding process are solved.

Owner:BEIJING AUTOMOTIVE IND CORP +1

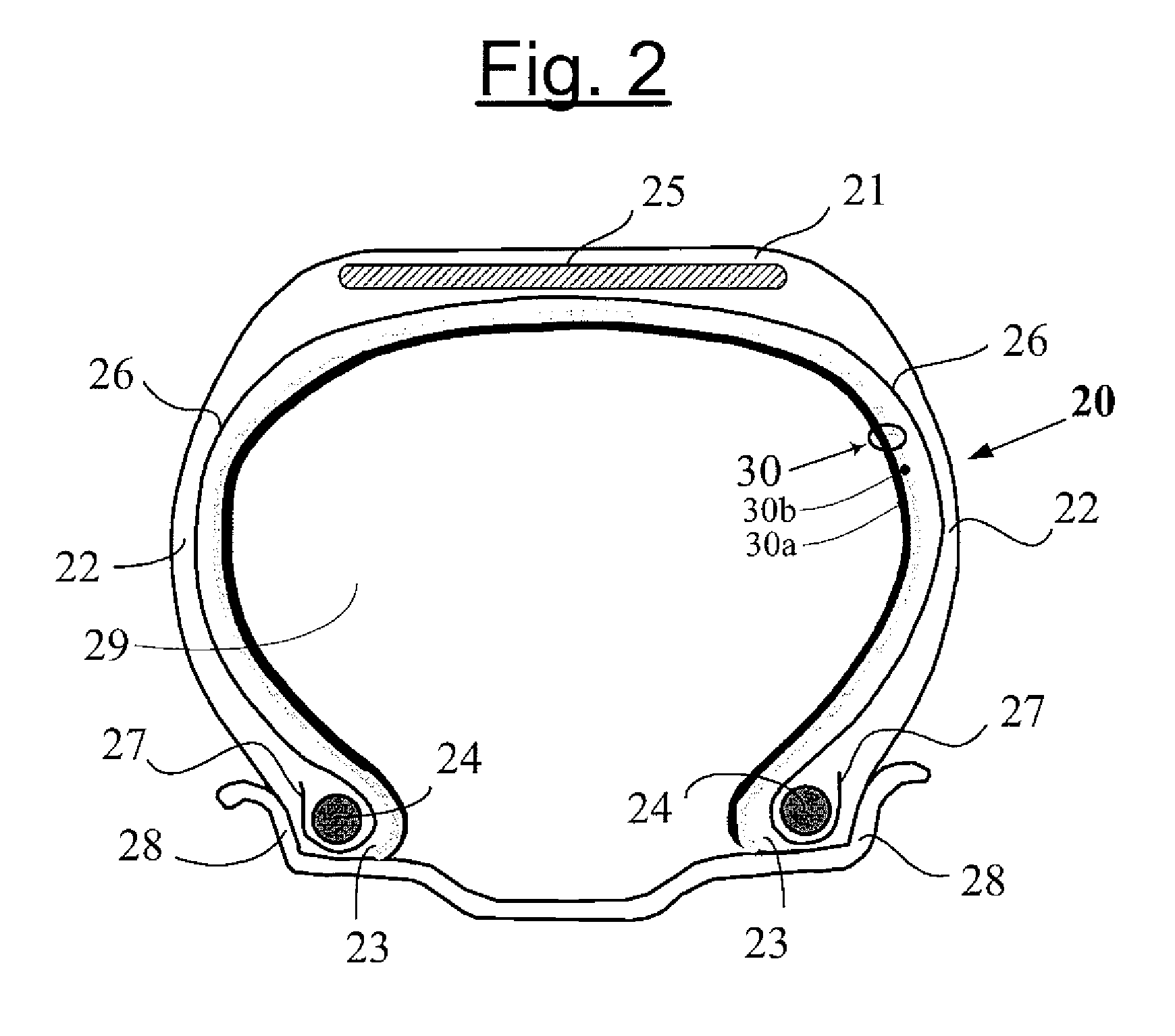

Process for manufacturing a self-sealing composition

Process for manufacturing a self-sealing elastomer composition, wherein the process comprises the following steps: firstly a masterbatch comprising at least one diene elastomer and a thermoplastic plasticizing hydrocarbon resin with a content greater than 30 phr is manufactured by compounding these various components in a mixer at a temperature or up to a temperature called the “hot compounding temperature” which is above the softening point of the hydrocarbon resin; and then at least one crosslinking system is incorporated into the masterbatch thus prepared, by compounding everything, in the same mixer or in a different mixer, at a temperature or up to a maximum temperature which is kept below 100° C., in order to obtain said self-sealing composition, and wherein at least one liquid plasticizer having a glass transition temperature (Tg) below −20° C. is furthermore incorporated in an amount of less than 60 phr into said masterbatch or into said composition.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

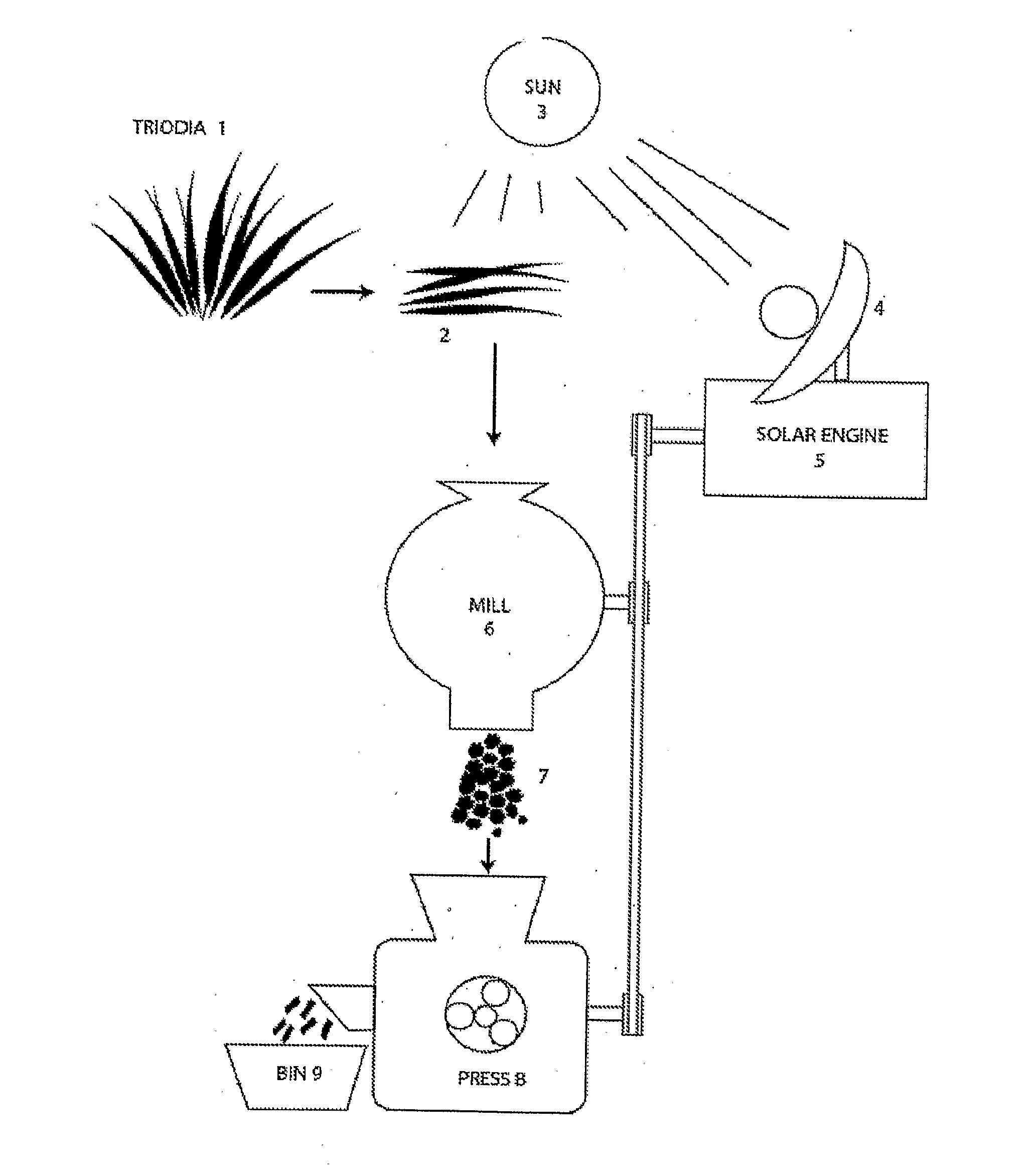

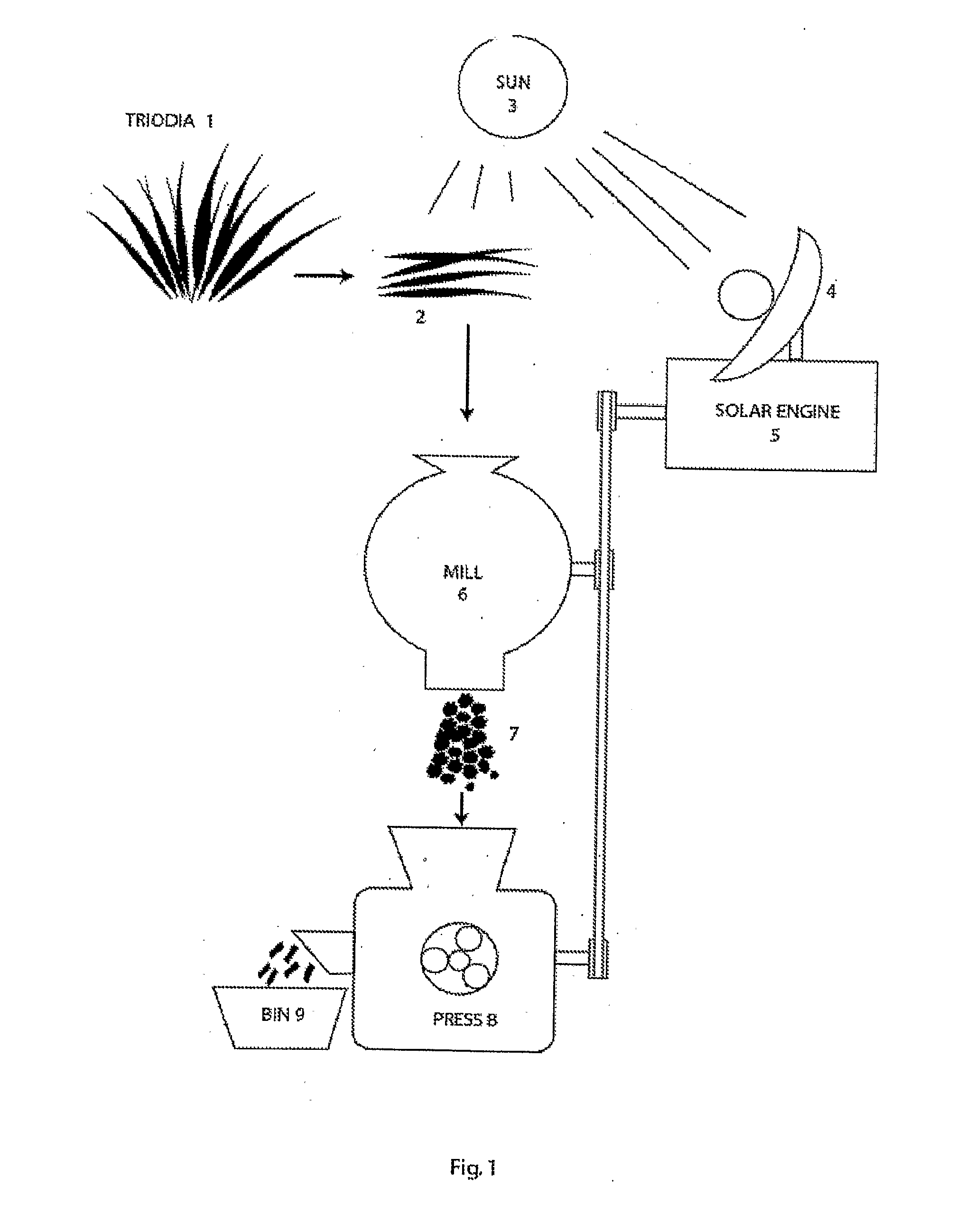

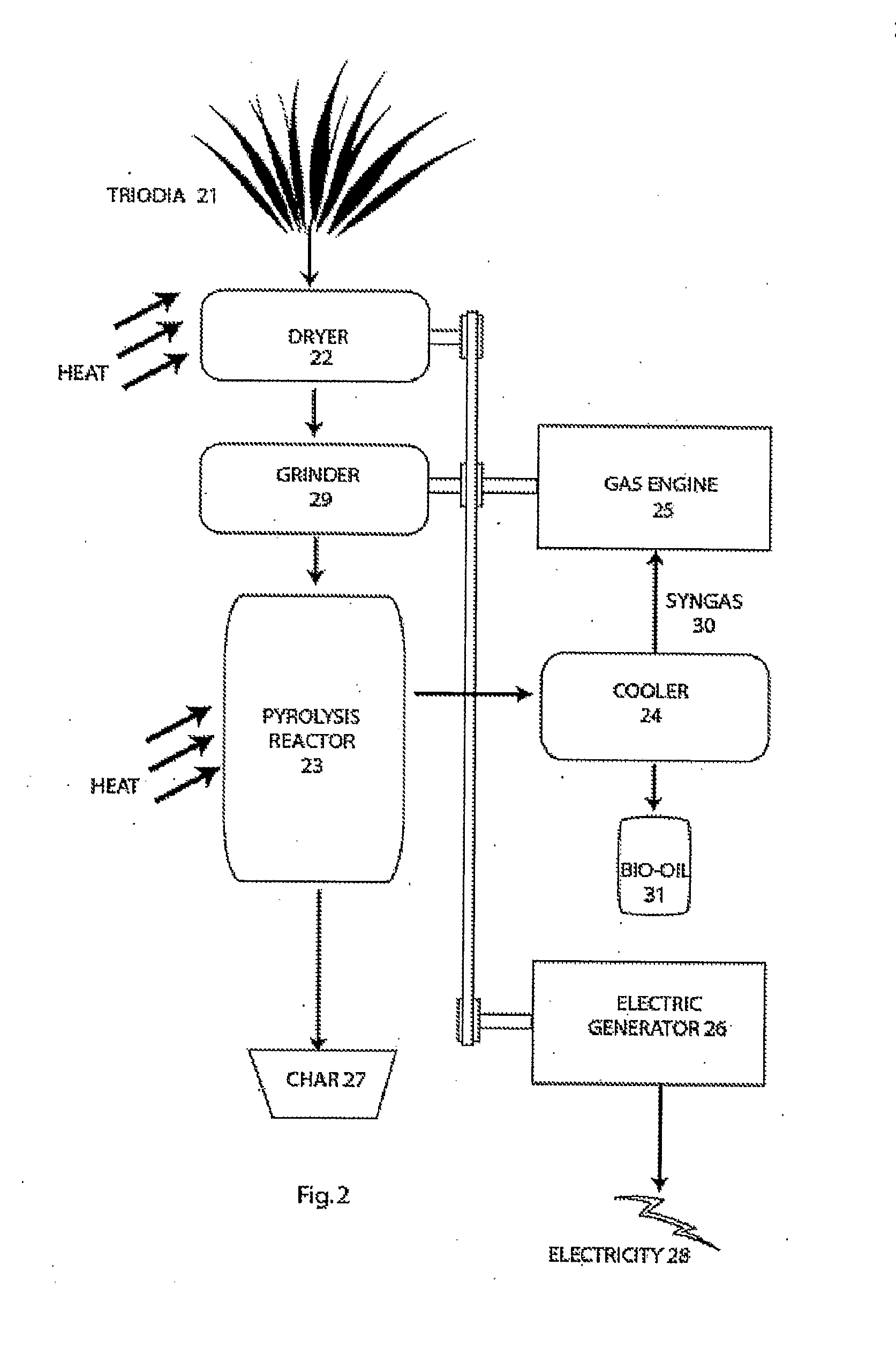

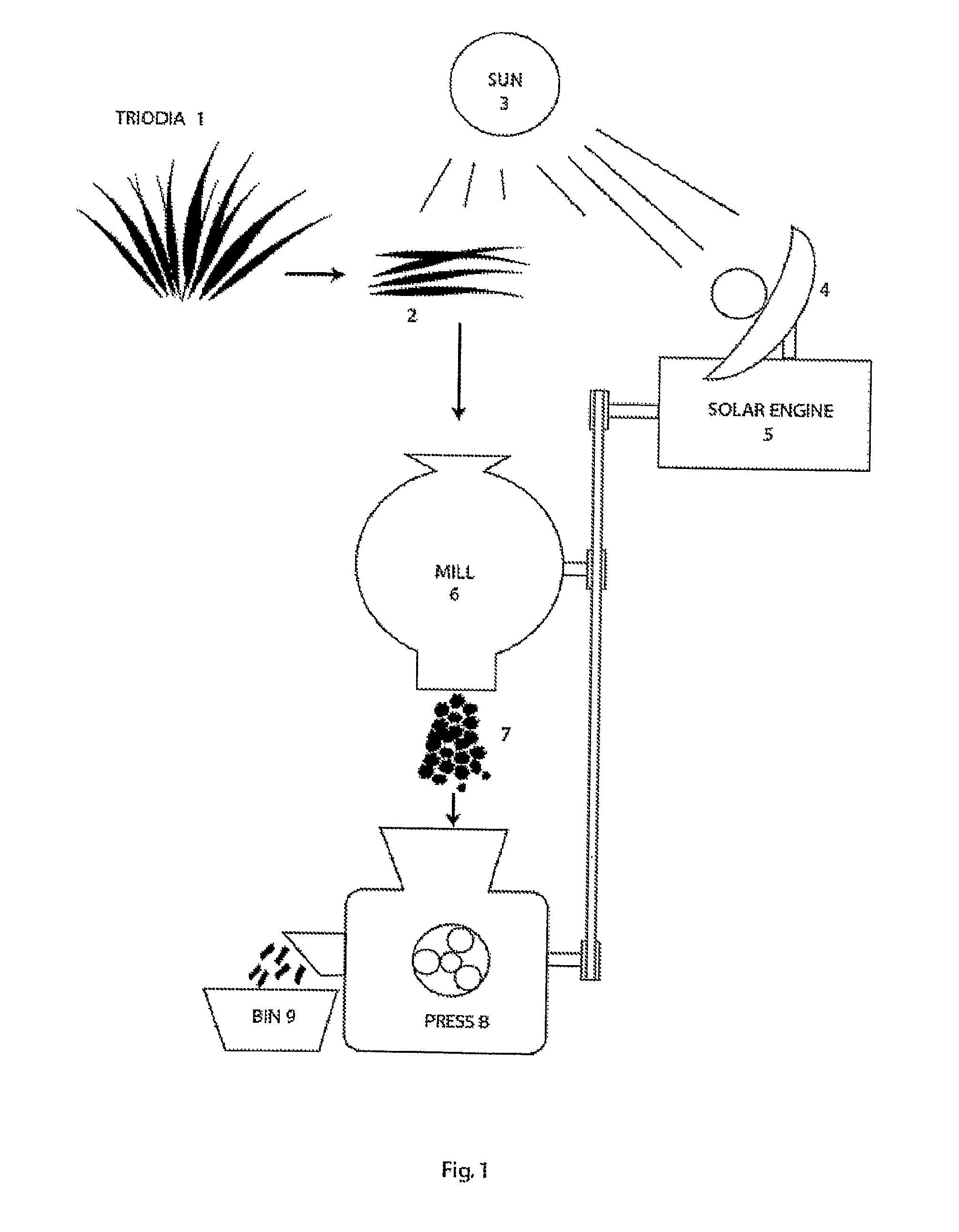

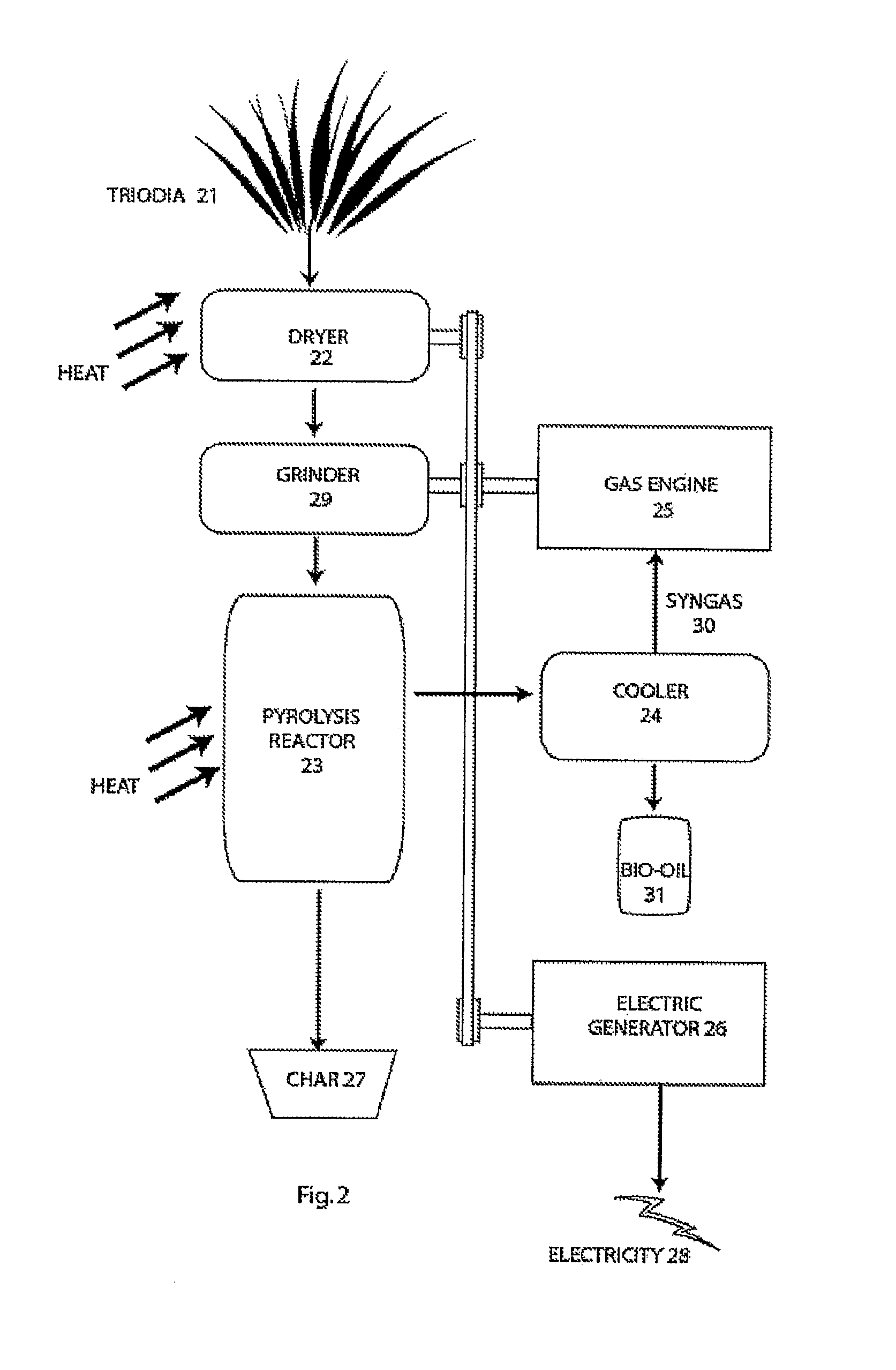

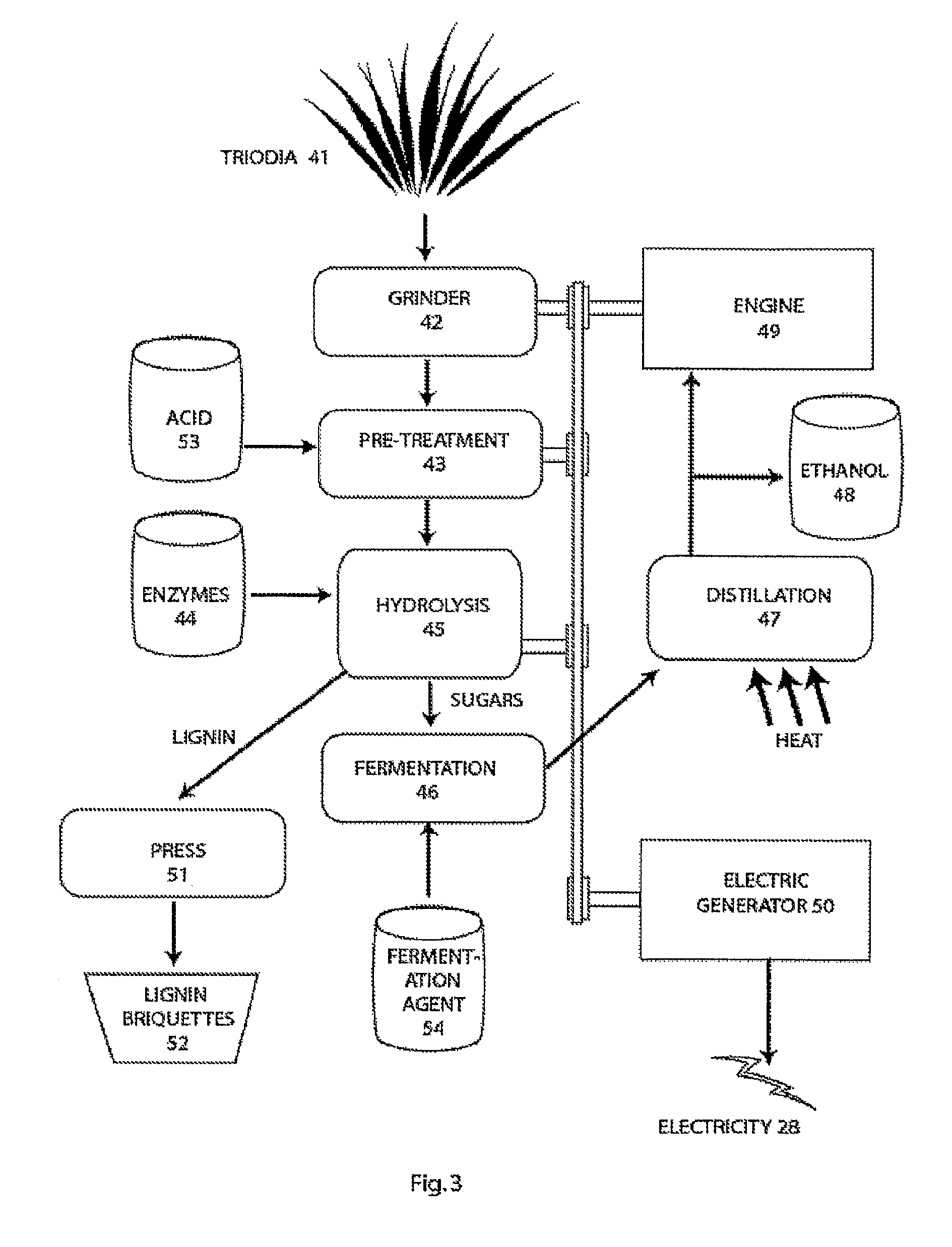

Methods and products using grass of the genus triodia

ActiveUS20120201913A1Improve energy efficiencyHigh resin contentAntibacterial agentsMowersAridBiofuel feedstock

According to this invention, plants of the genus Triodia are harvested for use as a renewable energy source or as a means of carbon sequestration. Triodia is a hummock-forming grass endemic to Australia, commonly known as spinifex. It is an abundant perennial plant which grows in semi-arid and arid regions. The novel use of Triodia as a biofuel feedstock has many advantages over the prior art. Being perennial, there is no need to plant and fertilise crops. The plants can be continuously harvested without damaging the soil. Triodia grows well with even small amounts of natural rainfall.

Owner:ARCHER MICHAEL

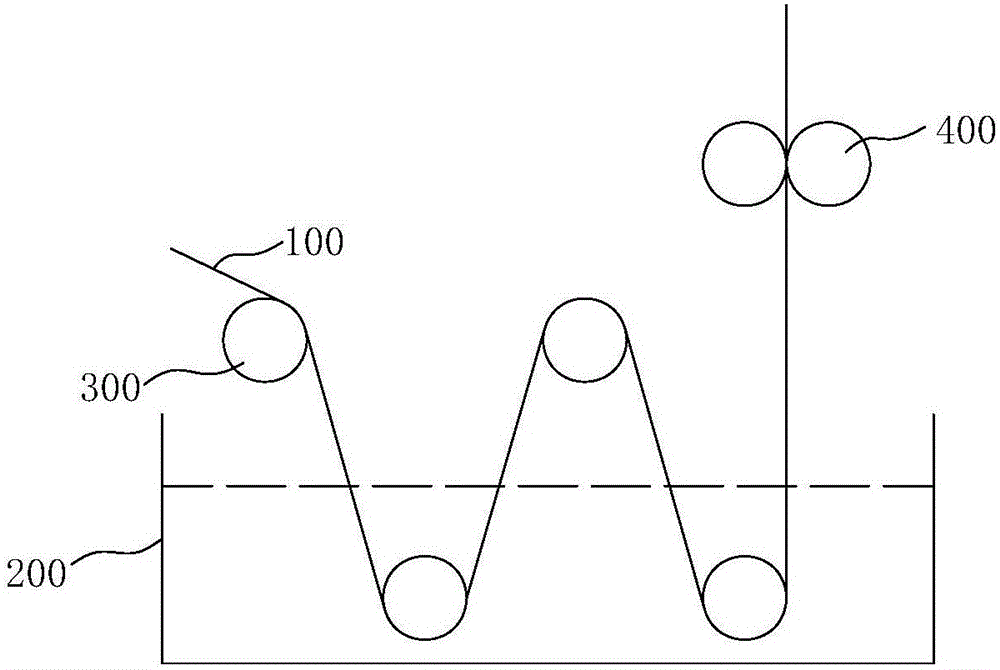

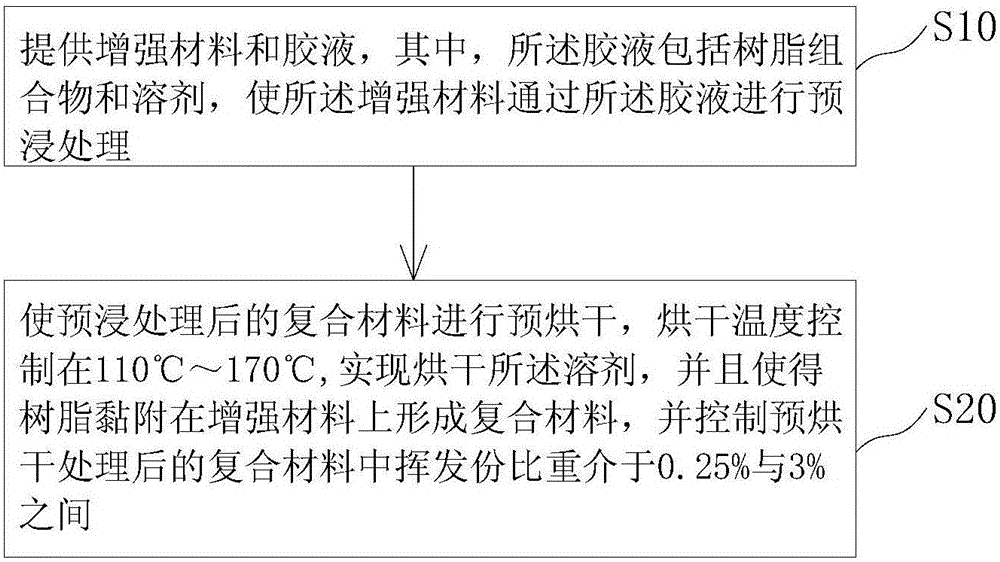

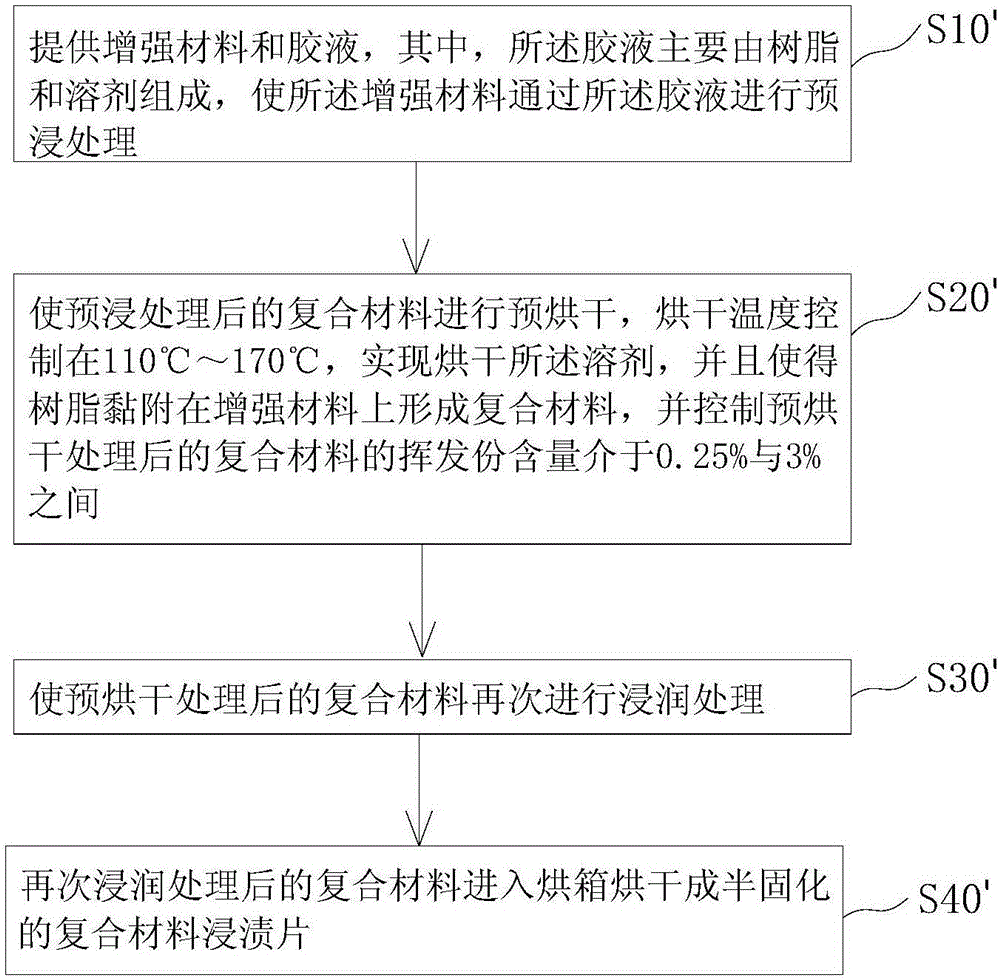

Dipping method, dipping piece and laminating plate

InactiveCN105153451AHigh resin contentImprove reliabilitySynthetic resin layered productsPosterior compositesSolvent

The invention discloses a dipping method. The method includes the steps of S10, conducting presoaking, wherein reinforcing materials and glue are provided, the glue comprises resin composite and solvent, and the reinforcing materials are presoaked in glue; S20, conducting pre-drying, wherein the presoaked composite is pre-dried, the drying temperature is controlled between 110 DEG C and 170 DEG C, solvent is dried away, resin is attached to the reinforcing materials to form the composite, and the proportion of volatile matter in the pre-dried composite is controlled between 0.25% and 3%. By strictly controlling the pre-drying temperature and controlling the content of volatile matter in the pre-dried composite between 0.25% and 3%, the reliability of a prepared dipping piece and a corresponding laminating plate is well kept, and good industrial application prospects are achieved.

Owner:GUANGDONG SHENGYI SCI TECH

Production method of large-scale heatproof corrosion-resistant glass fiber reinforced plastic cartridge

The invention relates the production method of large-scale corrosion resistant and heatproof glass fibre reinforced plastic barrel. The method comprises the following steps: sticking the demoulding film on the surface of die; then spraying bisphenol A unsaturated mylar and staple glass fiber mixture on the surface of die, solidifying to form barrel inner covering; the high strength glass fiber soaked with epoxide-resin glue winding around the surface of barrel inner covering, solidifying to form double layer barrel; spraying heatproof 191 resin and staple glass fiber mixture on the surface of high-intensity glass fiber, solidifying, demoulding, polishing, collating and forming barrel. The three-layer composite construction possesses the characters of fire resistant and corrosion resistant, forming above 5000m3 glass fibre reinforced plastic barrel.

Owner:JIANGSU XINYANG NEW MATERIALS CO LTD

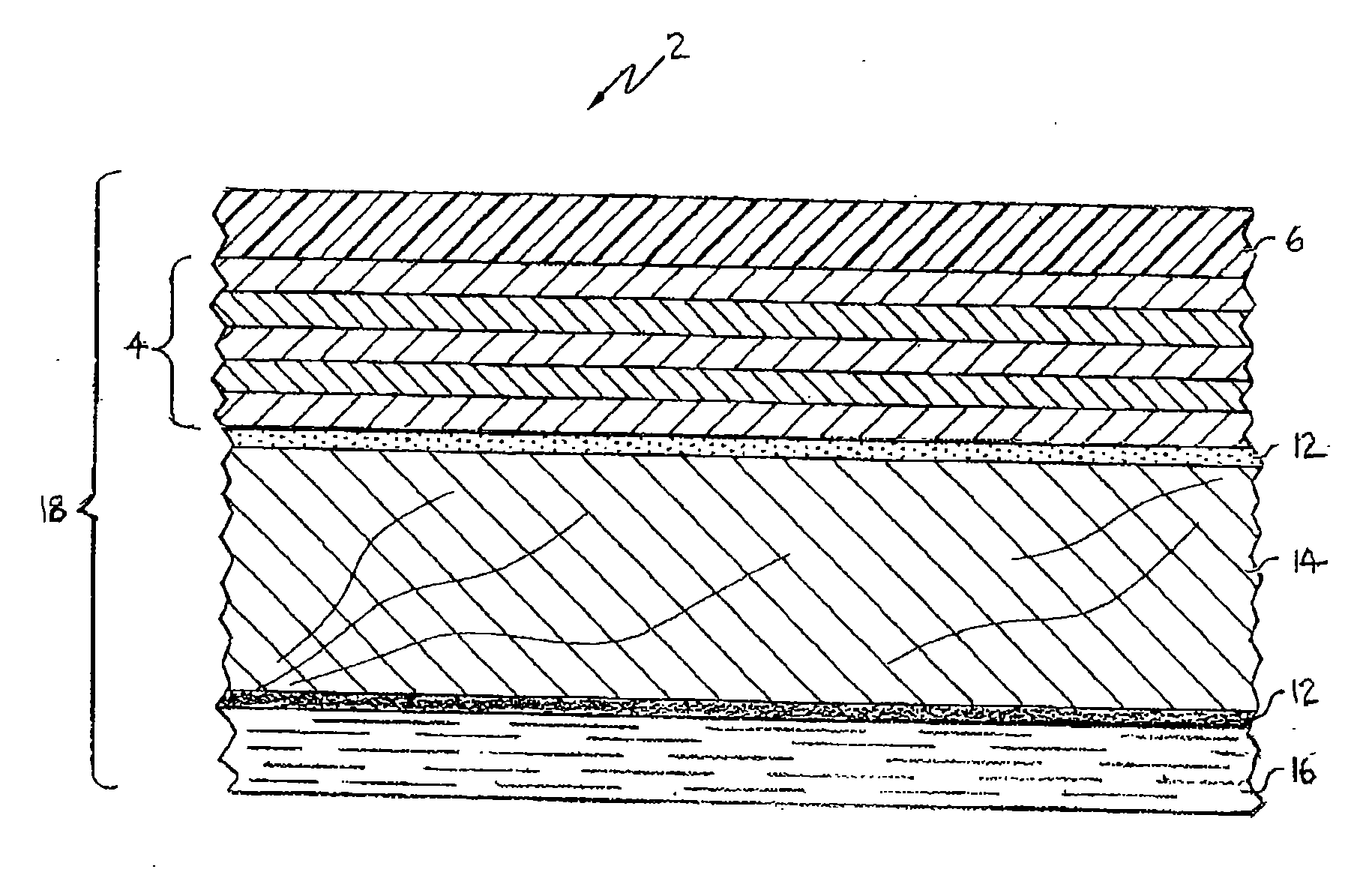

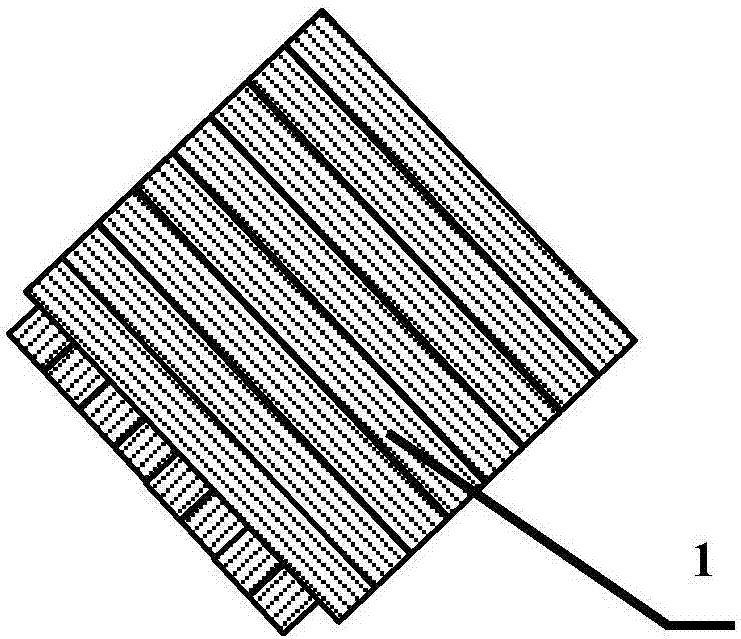

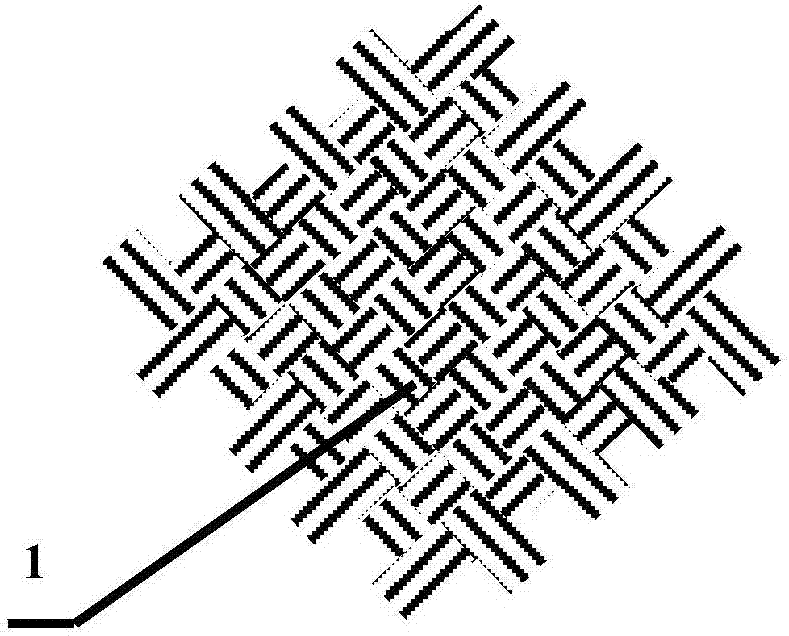

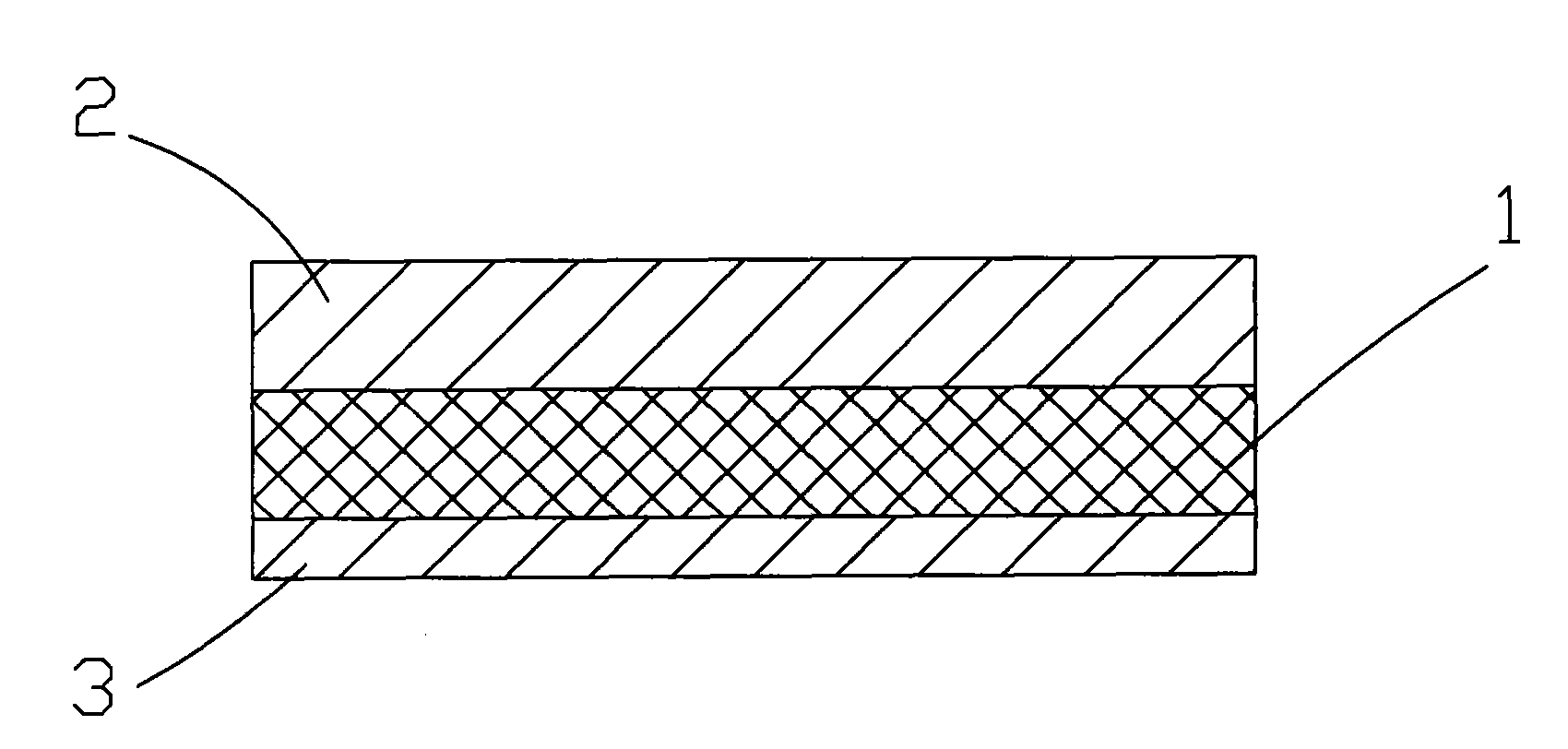

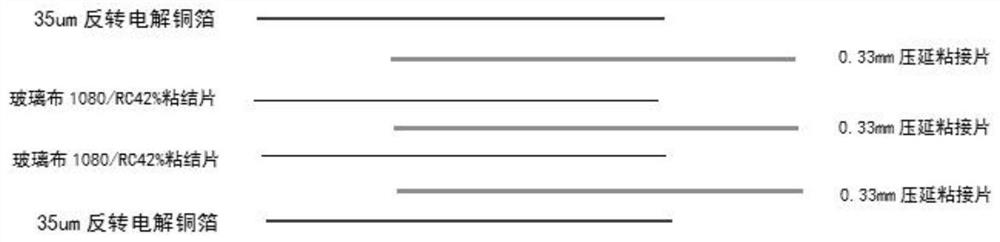

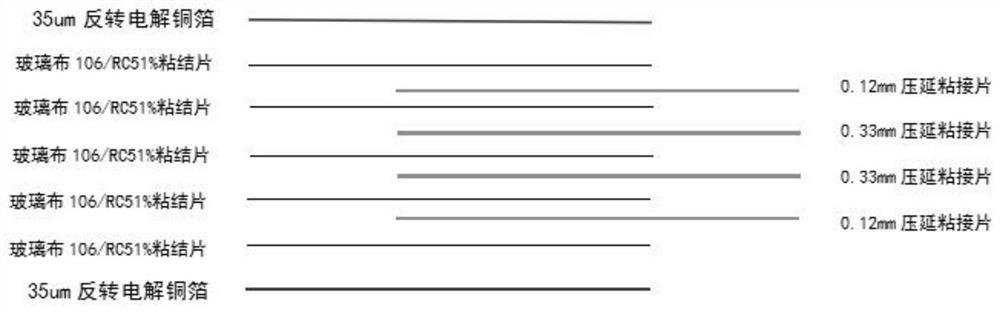

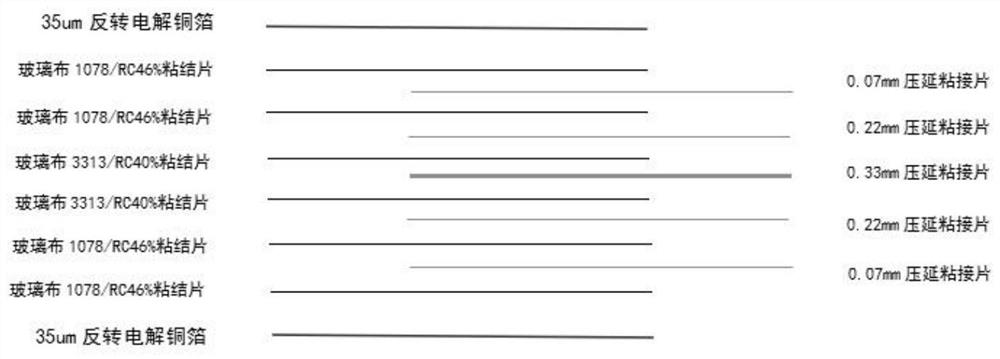

Prepreg having nonsymmetrical resin layer thickness and application thereof

ActiveCN101665017AHigh resin contentImprove or solve problems such as warpingSynthetic resin layered productsCircuit susbtrate materialsHigh densityLayer thickness

The invention relates to a prepreg having nonsymmetrical resin layer thickness and an application thereof. The prepreg having nonsymmetrical resin layer thickness comprises a reinforced material layer, a first resin layer and a second resin layer; the first resin layer and the second resin layer are respectively arranged at two opposite sides of the reinforced material layer; and the resin contentof the first resin layer and the second resin layer are different. The prepreg having nonsymmetrical resin layer thickness has different resin content of the resin layers at both sides of the reinforced material layer, and the thickness of the resin layers at both sides after plate pressing has a difference of 10-25 mu m; the invention adopts a subtractive process making technology, so that the problems that the copper clad laminate substrates have white spots, camber of single-sided plate and the like can be improved or solved under the condition of changing or not changing the thickness ofthe traditional prepreg substrate; the invention is applied to the field of printed circuit boards, can improve the defects of white spots of the substrates, resin filling of thick copper areas, resinfilling of high density interconnected circuit boards, line-to-line CAF and the like under the condition of certain thickness of a medium layer, so that the printed circuit boards reach the expectedrequirements of electric reliability, mechanical reliability, thermostabilization and the like.

Owner:GUANGDONG SHENGYI SCI TECH

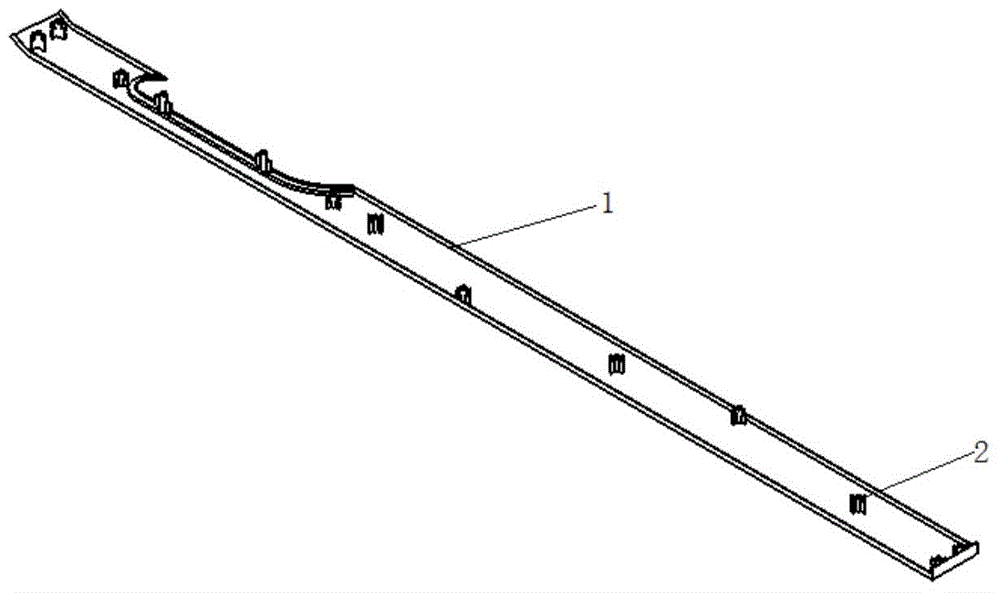

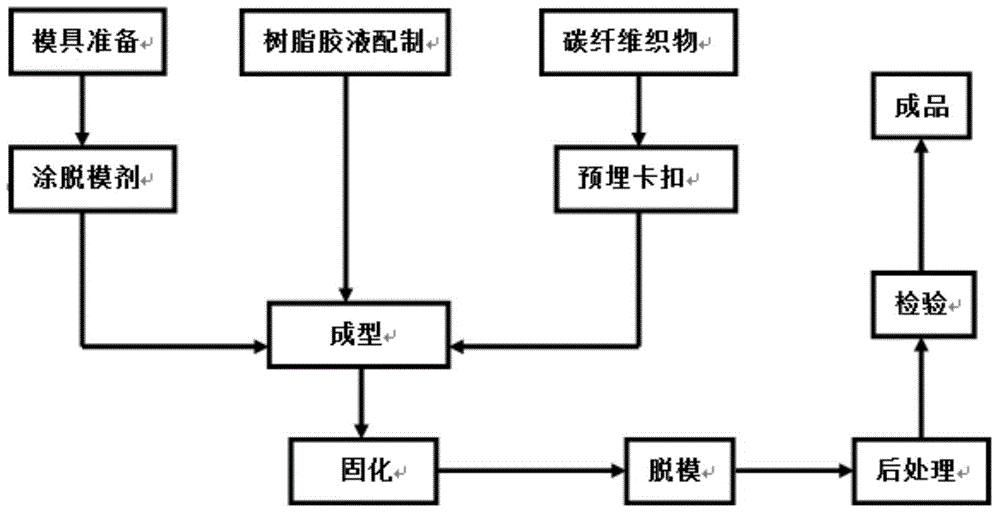

Preparation method of carbon fiber trim strip for automobile

InactiveCN104893252AImprove performanceRaise the gradeSynthetic resin layered productsFiberCarbon fibers

The invention provides a preparation method for a carbon fiber trim strip for an automobile. A carbon fiber fabric layer with excellent properties is obtained by optimizing the weight ratio of a curing agent to resin in a resin mixture containing the curing agent and the weight ratio of a carbon fiber fabric to the resin mixture containing the curing agent. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the process is simple, equipment investment is less, the resin content of products is high, and the products are good in corrosion resistance; the carbon fiber trim strip can completely replace a plastic interior trim strip; compared with a plastic product, the carbon fiber trim strip has the characteristic that the weight is reduced by about 50 to 60 percent; the grade of a complete automobile and the competitiveness of the products are improved, and the individualized demands are met.

Owner:CHERY AUTOMOBILE CO LTD

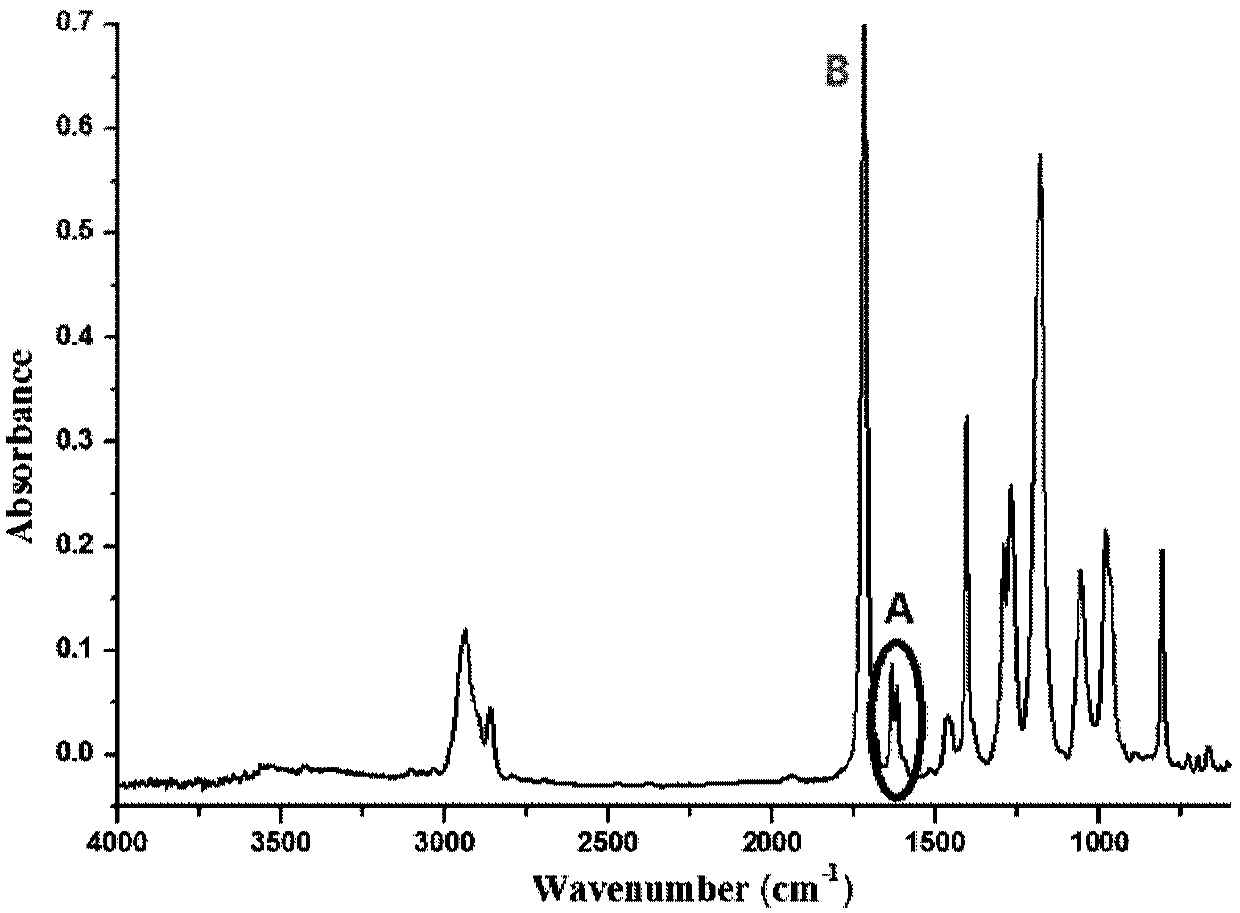

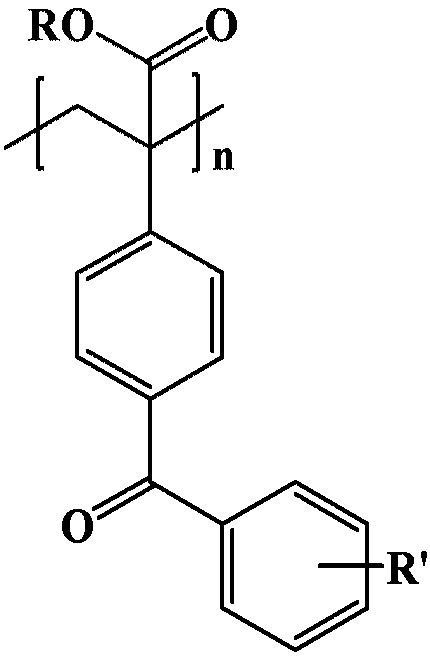

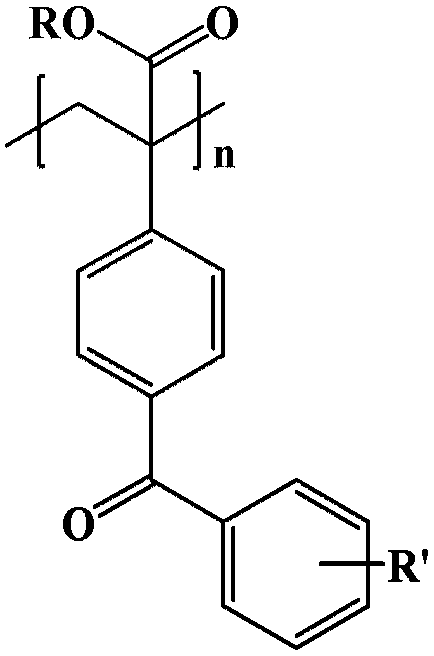

Macromolecular photoinitiator, preparation method and applications thereof

The invention relates to a macromolecular photoinitiator, wherein a hydrogen abstraction type photoinitiator benzophenone is used as a core, and a (methyl) acrylate group is introduced into one benzene ring of the core. According to the invention, by polymerizing a (methyl) acrylate group into a macromolecular photoinitiator with a specific molecular weight range, the macromolecular photoinitiatorhas high solubility and high compatibility in an ester solvent, and the benzophenone photosensitive group on the side chain can initiate polymerization of the active monomer in a colored glue under ultraviolet light; and if the other benzene ring of benzophenone as a side chain contains a hydrogen-donor group, the hydrogen-donor group can significantly improve the initiation efficiency of the photoinitiator and the polymerization speed of the system.

Owner:BEIJING ETERNAL MATERIAL TECH +1

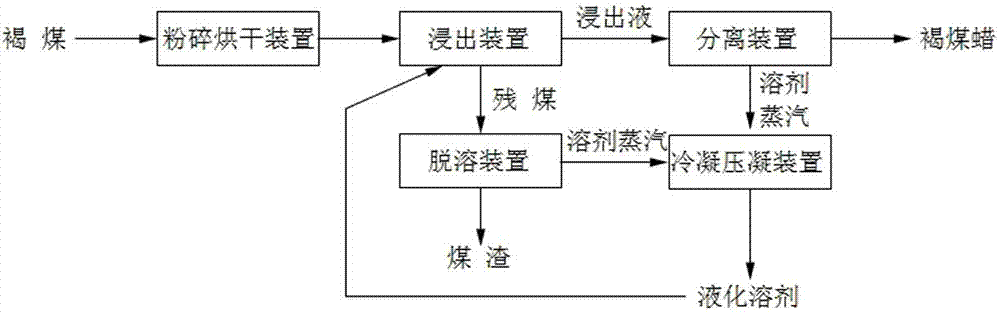

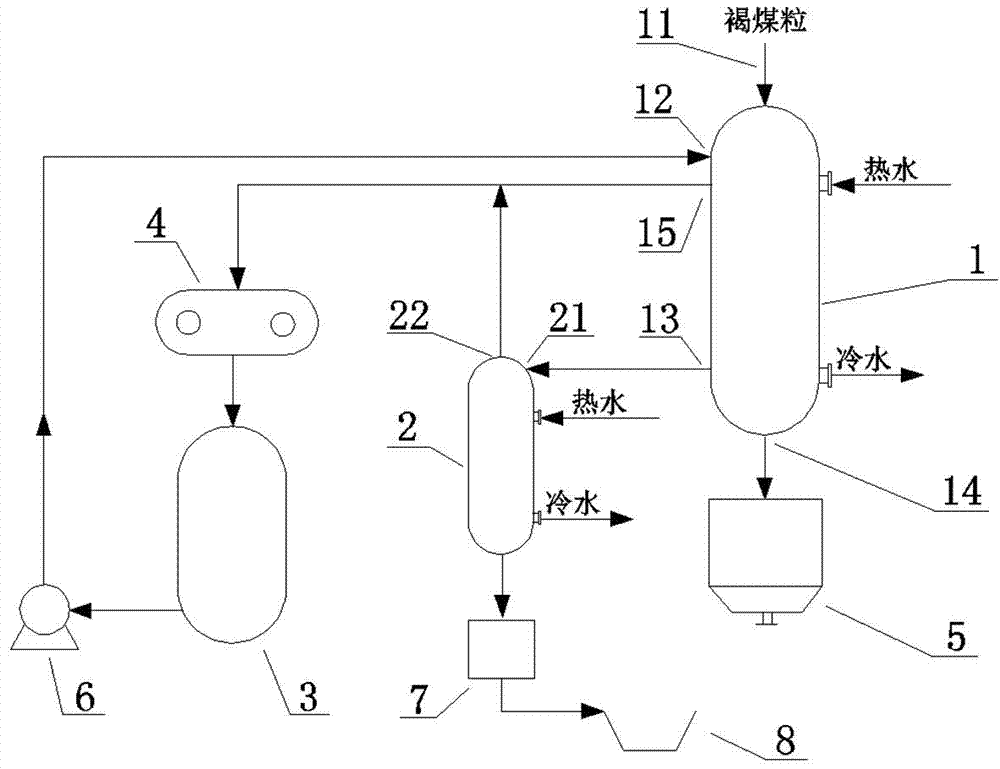

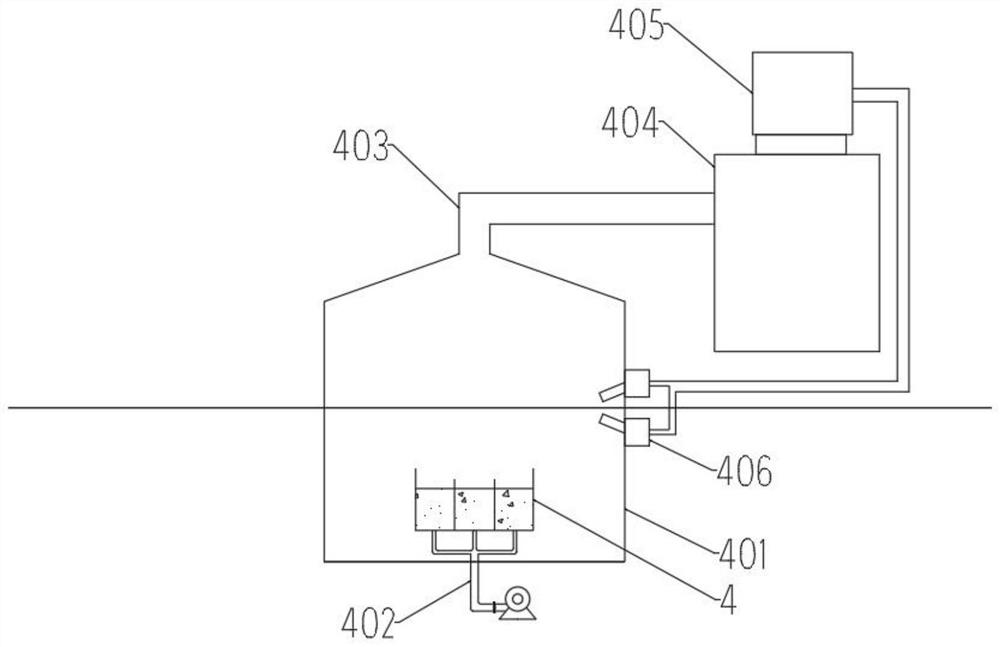

Method and device for leaching high-quality lignite wax

ActiveCN103881752AReduce resin contentHigh resin contentMineral wax recovery/refiningSolid solvent extractionPARAFFIN HYDROCARBONSResidual solvent

The invention discloses a method and a device for leaching high-quality lignite wax. The leaching method comprises the followings steps: smashing lignite, sieving by use of a sieve with the hole size of 1.0-8.0 millimeters, and drying until the water content is 15-25 percent; loading the dried lignite and a straight-chain paraffin solvent into a leaching device at a temperature of 0.5-1.5MPa at a material-liquid ratio of (1:2)-(1:5) (kg / L), soaking at the temperature of 10-40 DEG C for 3-6 hours, and performing material-liquid separation to obtain leach liquor and residual lignite; putting the leach liquor into a separating device, and heating to 30-60 DEG C or reducing the pressure to 30-60KPa for evaporating the solvent to obtain lignite wax and a solvent; putting the leached residual lignite into a desolventizer, and heating or evaporating the residual solvent under reduced pressure under the conditions of the step C to obtain lignite residues and the solvent. The leaching device comprises a leacher, a fluid wax evaporation-separation tank and a solvent storage tank. According to the method, low-toxicity straight-chain paraffin is taken as a leaching solvent, and a leaching process is performed at the room temperature or a temperature higher than the room temperature, so that energy conservation and environmental protection are facilitated, and the resin content and asphalt content of the wax are low.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Dispersion type waterborne epoxy zinc-alkene rusty, anti-rust and heavy anti-corrosion primer

ActiveCN108531033AEvenly dispersedFull and effective integrationAnti-corrosive paintsEpoxy resin coatingsEpoxyWater dispersible

The invention discloses a dispersion type waterborne epoxy zinc-alkene rusty, anti-rust and heavy anti-corrosion primer. The dispersion type waterborne epoxy zinc-alkene rusty, anti-rust and heavy anti-corrosion primer is a waterborne heavy anti-corrosion primer composed of three components, wherein a component A is composed of waterborne epoxy dispersion, dispersant, defoamer, zinc oxide, rust converter, water dispersible graphene, graphene-specialized dispersant, flash rust inhibiting auxiliaries, waterborne rheological auxiliaries and water; a component B is zinc powder; a component C is composed of waterborne epoxy curing agent and water. The dispersion type waterborne epoxy zinc-alkene rusty, anti-rust and heavy anti-corrosion primer has no volatilization of organic solvent, and by taking water as dispersion medium, can convert rust on steel into stable substance, give play to anti-corrosion capability of the graphene, the zinc oxide and epoxy resin and provide continuous negativeelectrode protecting ability for the surface of base materials.

Owner:湖北铁神新材料有限公司

Low-dielectric polyperfluorinated ethylene propylene copper-clad plate and preparation method thereof

ActiveCN110228239AMeet the requirements of high frequencyShorten the timeSynthetic resin layered productsLaminationPolymer scienceCopper foil

The invention discloses a low-dielectric polyperfluorinated ethylene propylene copper-clad plate and a preparation method thereof. The preparation method comprises the following steps: performing pretreatment on chopped glass fibers, performing modification with a silane coupling agent, adding a dispersing agent to perform fluffing by a fluffer, and enabling the glass fibers to be uniformly dispersed; drying the dispersed glass fibers to remove water, adding polyperfluorinated ethylene propylene emulsion, uniformly mixing the polyperfluorinated ethylene propylene emulsion and the glass fibers,and performing dehydration and concentration; coating a high temperature resistant film with a concentrated solution uniformly by using an automatic coater; performing vacuum drying, and taking out the materials after cooling so as to prepare a polyperfluorinated ethylene propylene prepreg; and attaching the prepreg onto a copper foil, and performing pressing by a hot press so as to obtain the copper-clad plate. The copper-clad plate is prepared by selecting a polyperfluorinated ethylene propylene resin, and has a dielectric constant value up to 2-2.5, a dielectric loss value up to 0.0008-0.0015 and the water absorption rate of 0.02-0.05%. The copper-clad plate disclosed by the invention is excellent in dielectric property, low in water absorption rate, good in cohesive property and highin machinability.

Owner:SOUTH CHINA UNIV OF TECH

Adhesive compositions with amorphous polyolefins

InactiveUS20160101209A1Reasonable creep resistanceReasonable hot melt sprayabilityPersonal careFilm/foil adhesivesPolyolefinOligomer

The invention relates to a hot melt adhesive composition that, when used as an elastic attachment adhesive (EAA), provides elastic laminates having an initial creep performance of less than 25%. The composition comprises a selectively hydrogenated, high vinyl block copolymer having the structure SEBS or (SEB)nX amorphous polyolefin such as polyethylene, polypropylene, butylene homopolymers and copolymers, or a mixture of two or more of these, tackifier, and maleated polypropylene oligomer or maleated SEBS.

Owner:KRATON POLYMERS US LLC

Water-based ink for tipping paper

The invention relates to water-based ink for tipping paper. The water-based ink is characterized by comprising the following components in parts by weight: 20-50 parts of water-soluble polyvinyl butyral, 0.1-15 parts of water-soluble modified rosin resin, 0.1-45 parts of a pigment, 0.1-50 parts of a filler, 0.1-1 part of wax powder, 50-95 parts of ethanol, 0.1-95 parts of water and 0.1-1 part of adispersant, wherein the water-soluble modified rosin resin consists of water-soluble maleic acid, pentaerythritol abietate and triethanolamine according to a weight ratio of 1:2:5:2. The water-basedink provided by the invention has the advantages of small odor, low viscosity and good stability.

Owner:WENZHOU LIKEDA PRINTING

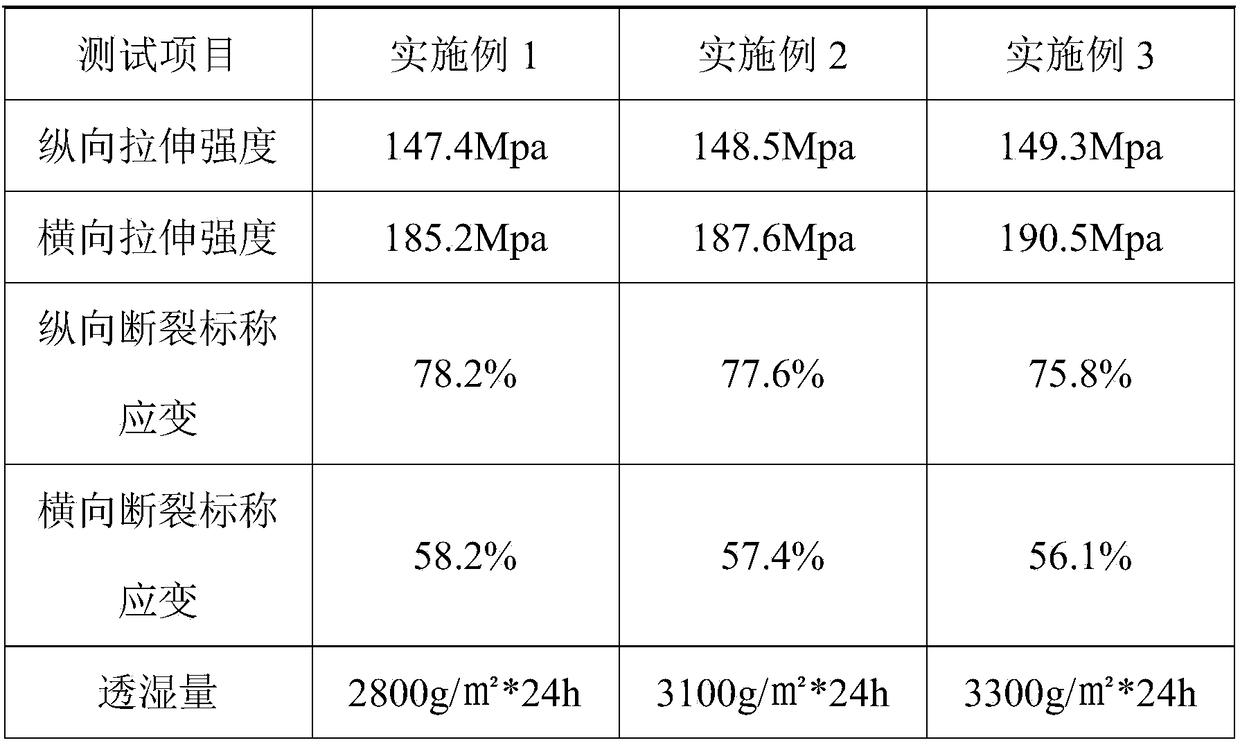

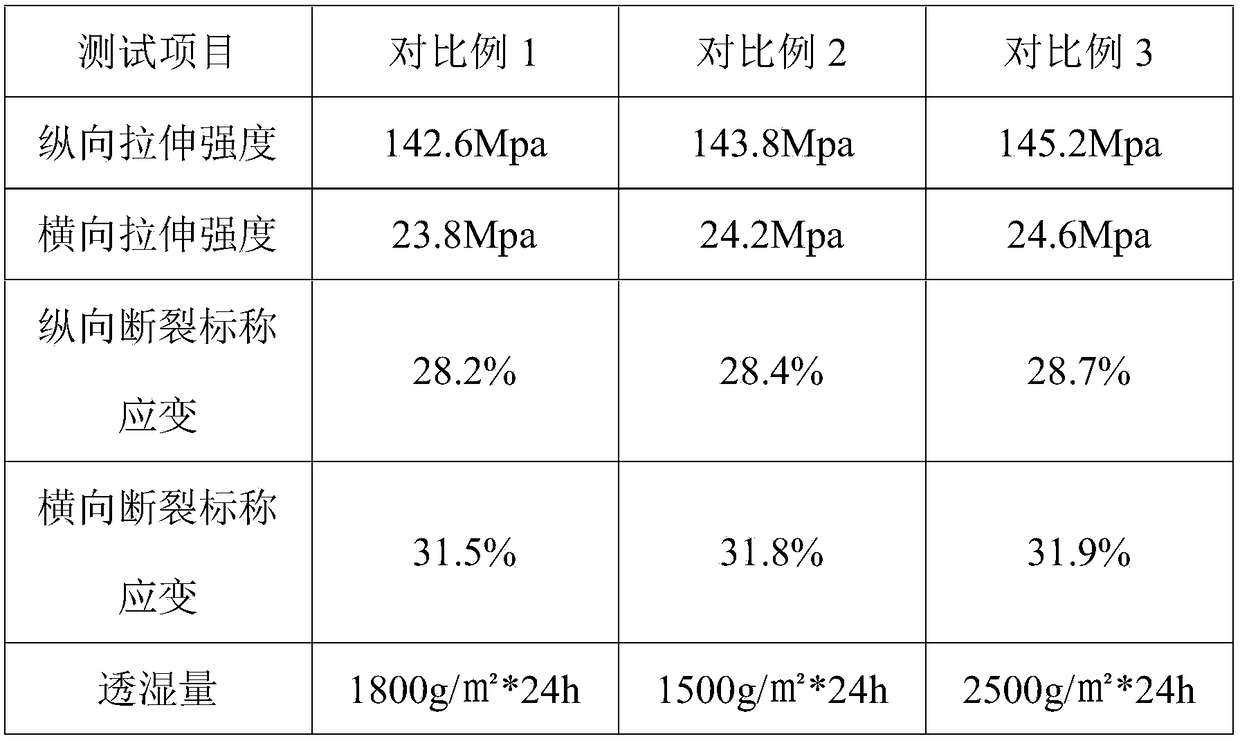

Biaxially oriented polypropylene waterproof breathable film and preparation method thereof

InactiveCN109294056AEasy to shapeImprove mechanical propertiesFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a biaxially oriented polypropylene waterproof breathable film and a preparation method thereof. The waterproof breathable film is composed of the following components in partsby weight: 30-32 parts of homo-polypropylene resin, 50-52 parts of heavy calcium carbonate powder, 1-2 parts of a coupling agent, 5-10 parts of linear low-density polyethylene resin and 6-12 parts oflow-density polyethylene. The biaxially oriented polypropylene waterproof and breathable film prepared according to the formula and the method disclosed by the invention is more excellent in mechanical property and better in toughness, has more uniform and stable longitudinal and transverse properties, has moisture permeability obviously superior to moisture permeability of a similar product prepared by a tape casting method, can be applied to medical sanitary product packaging, food packaging, daily-use products and the like, and has a wide application prospect.

Owner:ANHUI GUOFENG PLASTIC

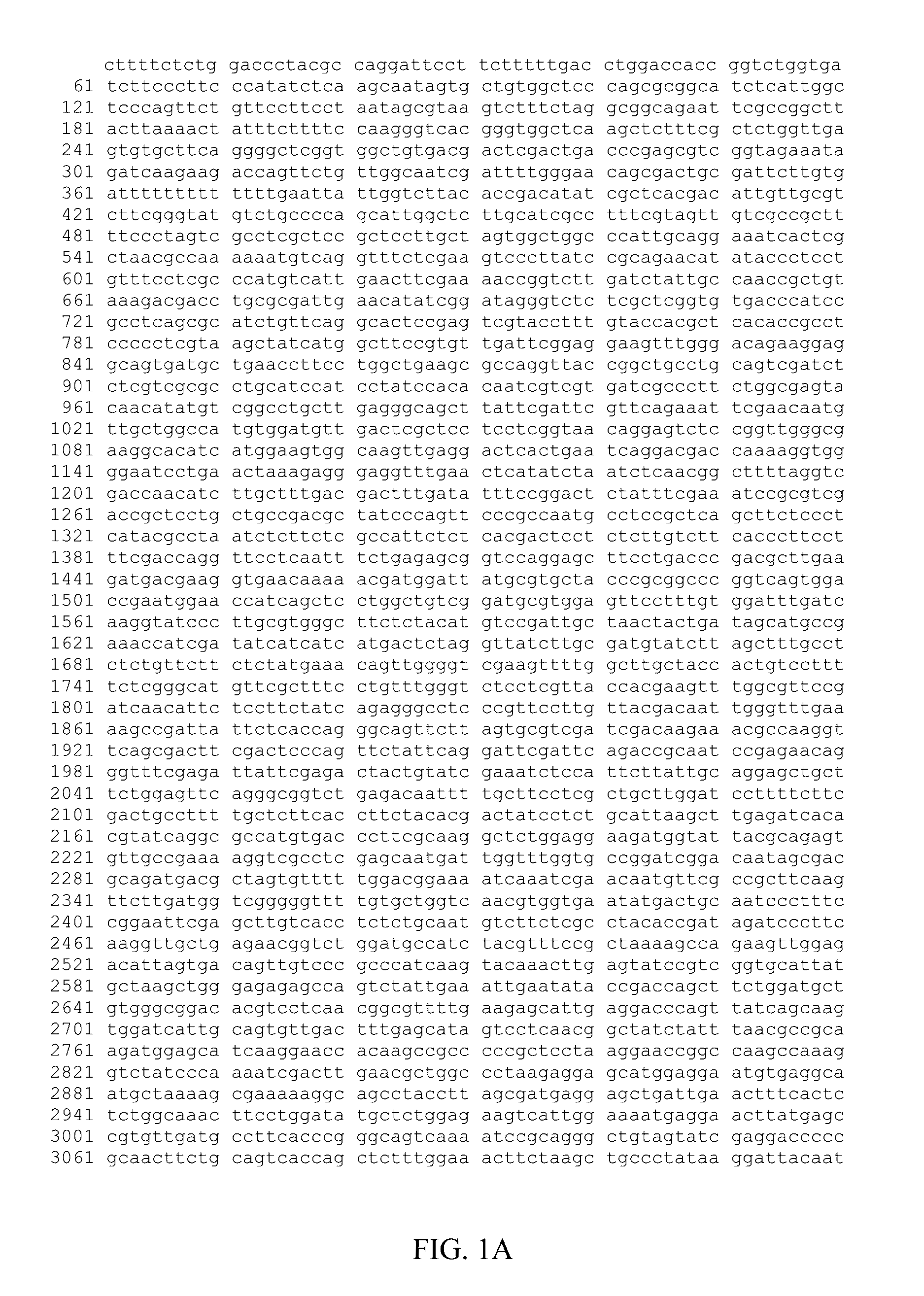

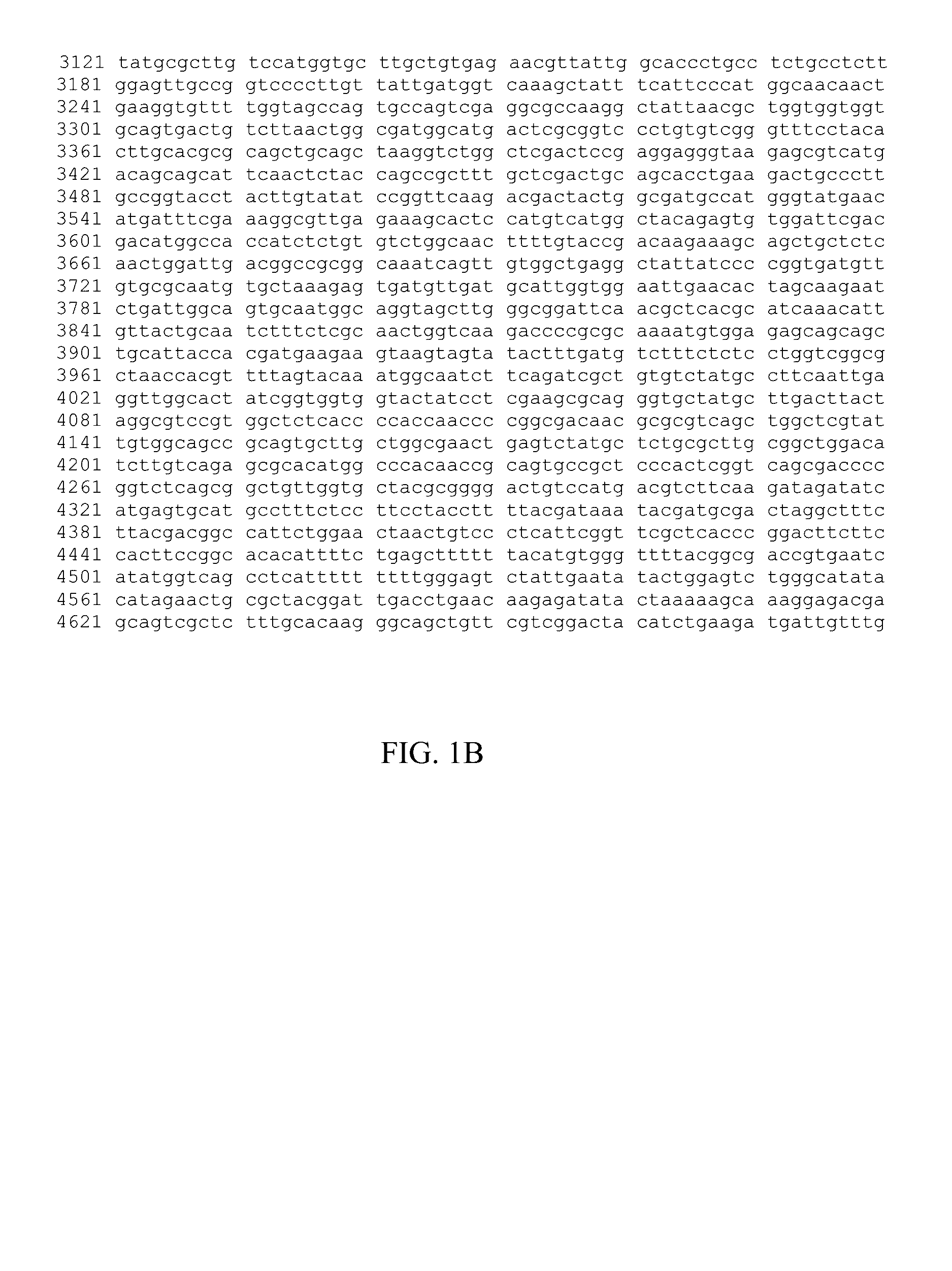

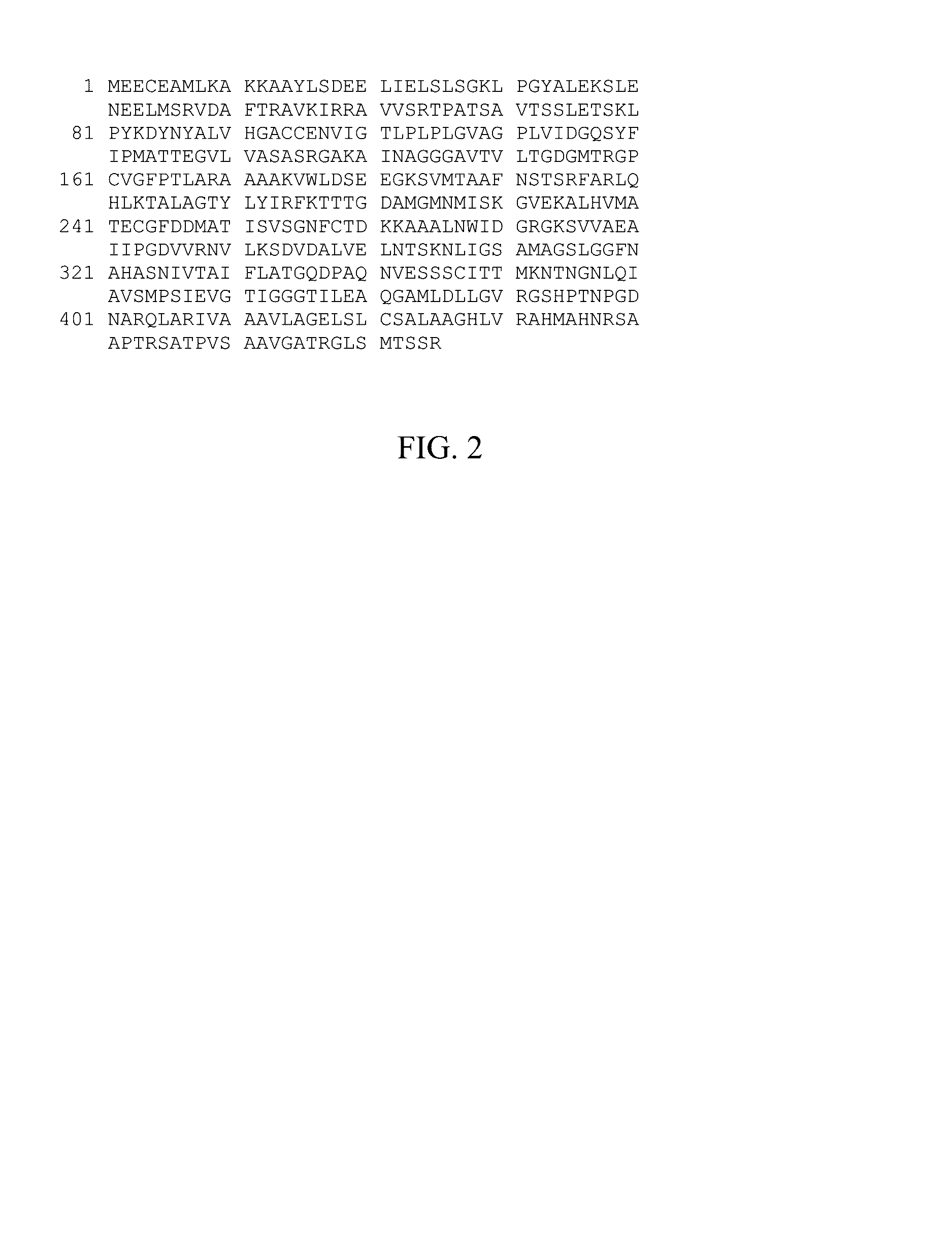

Transgenic guayule for enhanced isoprenoid production

ActiveUS9574203B1Reduce the amount of solutionHigh resin contentOxidoreductasesVector-based foreign material introductionIsopreneBotany

Owner:US SEC AGRI

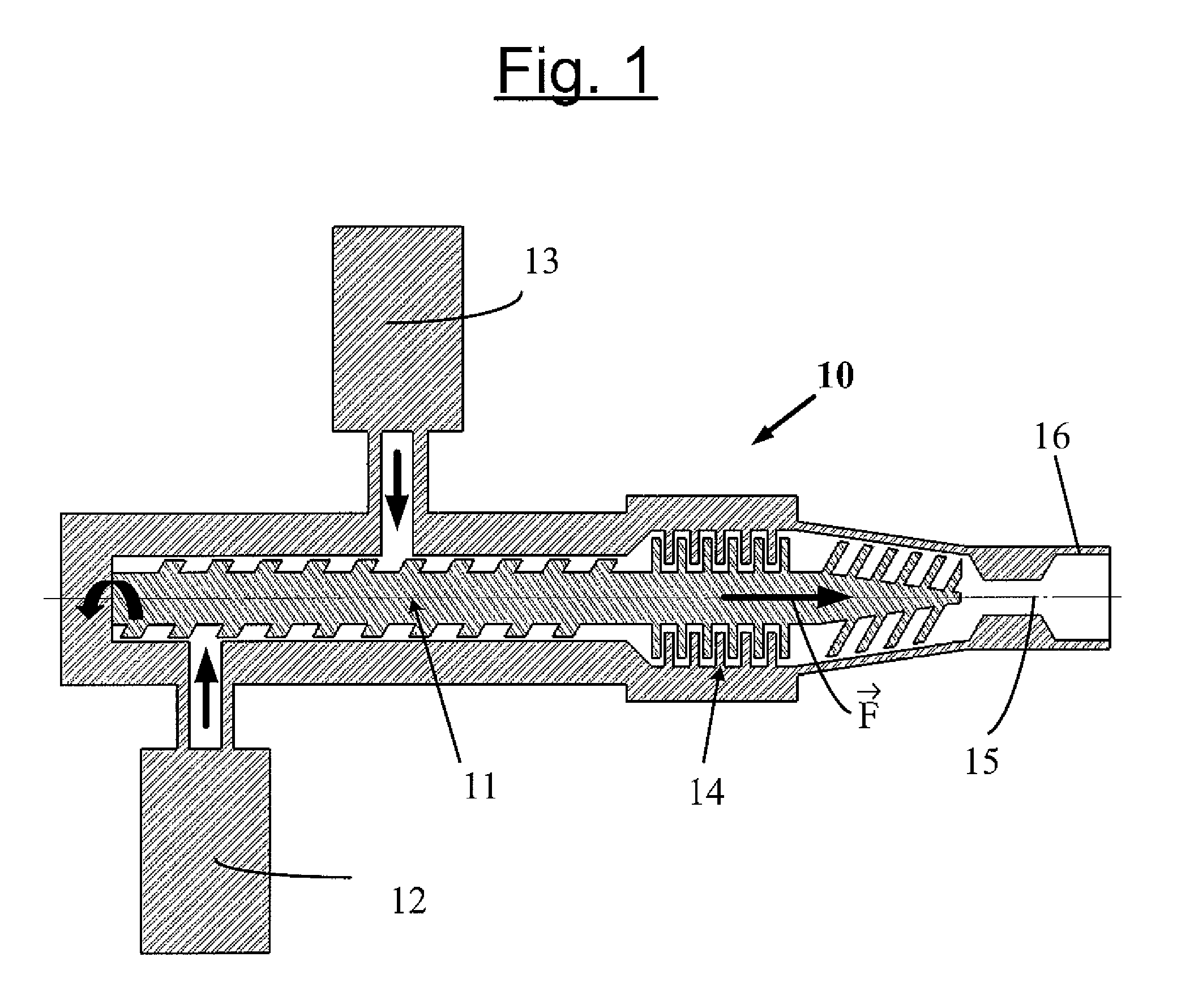

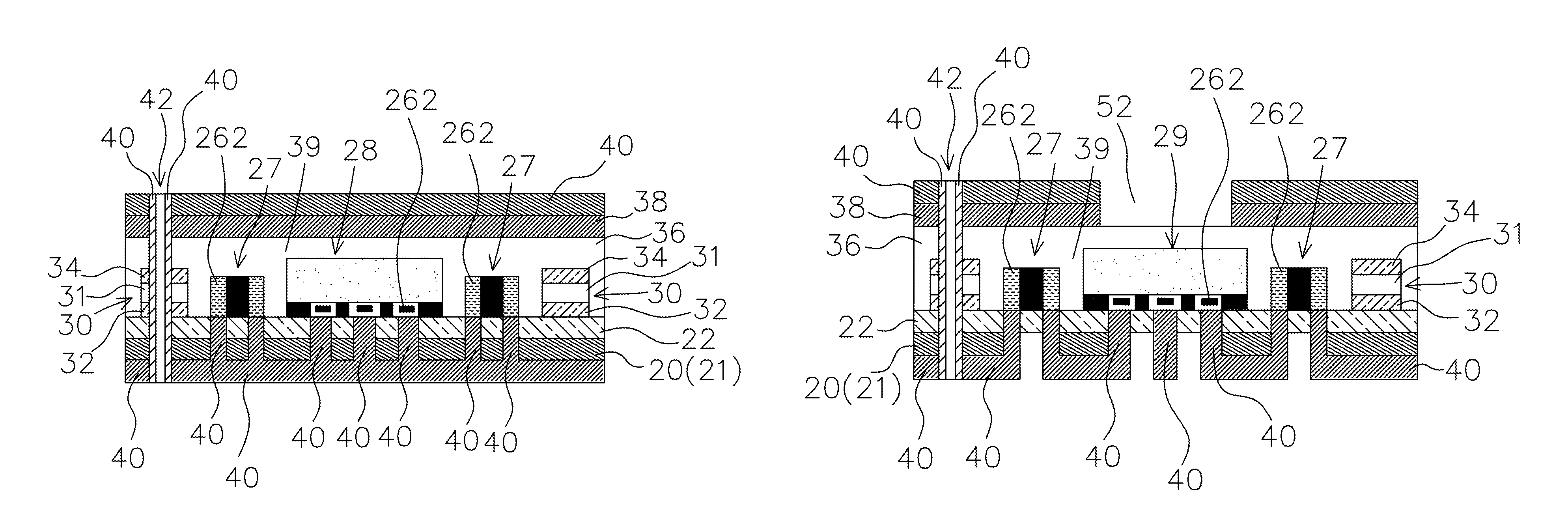

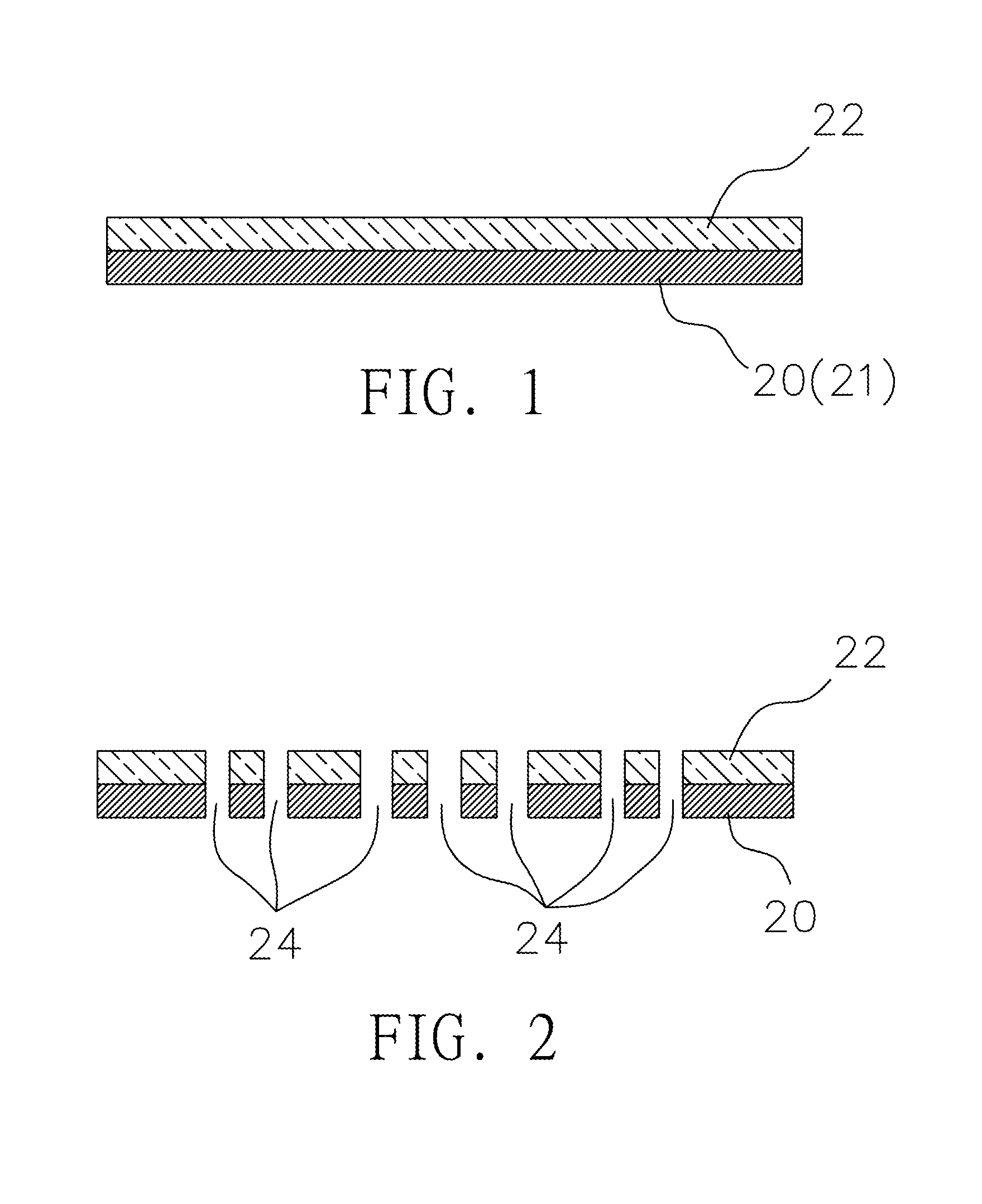

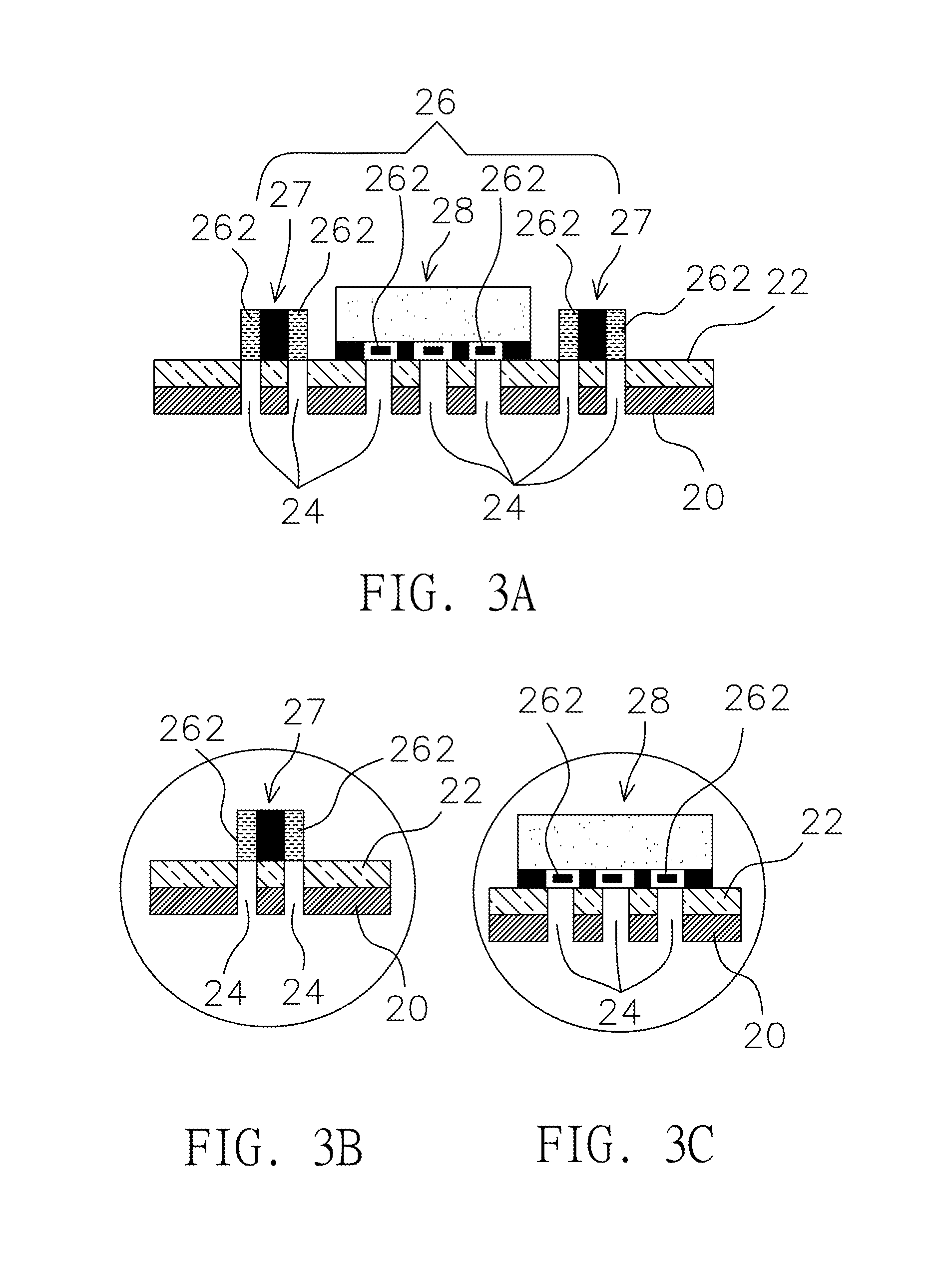

Method for directly attaching dielectric to circuit board with embedded electronic devices

ActiveUS9443743B1High resin contentPrecise positioningFinal product manufactureSemiconductor/solid-state device detailsElectricityEmbedded electronics

A method for directly attaching dielectric to a circuit board with embedded electronic devices is provided. That is, a plurality of through holes are produced before embedding an electronic device, wherein plural through holes are corresponding to a plurality of electrodes of the electronic device. So that the plural electrodes of the electronic device is accurately positioned with the through holes if the electronic device is being embedded. On the other hand, since the first dielectric layer is adhesive, the electronic device is directly stuck on the first dielectric layer in order to save cost of adhesive material or metal conductive paste in prior arts.

Owner:UNITECH PRINTED CIRCUIT BOARD CORP

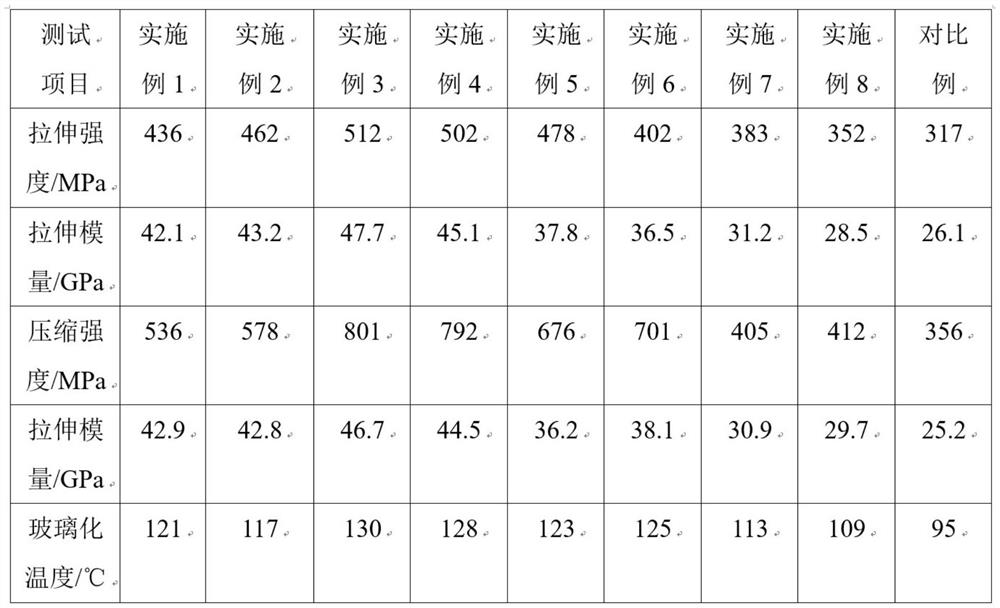

Epoxy resin composition capable of being rapidly cured at medium and low temperatures, epoxy resin-based composite material and preparation method thereof

ActiveCN113292819AFast medium and low temperature curing speedHigh glass transition temperaturePolymer scienceFirming agent

The invention provides an epoxy resin composition capable of being rapidly cured at medium and low temperatures, an epoxy resin-based composite material and a preparation method thereof. The epoxy resin composition capable of being rapidly cured at medium and low temperatures comprises the following components in parts by weight: 100 parts of epoxy resin, 0.1-5 parts of an imidazole accelerant, 2-40 parts of filler, 30-200 parts of an anhydride curing agent, 1-40 parts of a toughening agent and 0.5-10 parts of a release agent. According to the epoxy resin composition capable of being rapidly cured at medium and low temperatures, the epoxy resin-based composite material and the preparation method of the epoxy resin-based composite material, the medium and low temperature curing time of the epoxy resin-based composite material can be obviously shortened through cooperation of the anhydride curing agent, the imidazole accelerant and other raw materials in the epoxy resin composition; meanwhile, the pultrusion speed of the composite material in a pultrusion process is remarkably improved, and the composite material is excellent in mechanical property and high in glass transition temperature.

Owner:北玻院(滕州)复合材料有限公司

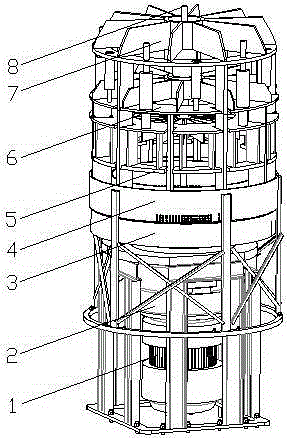

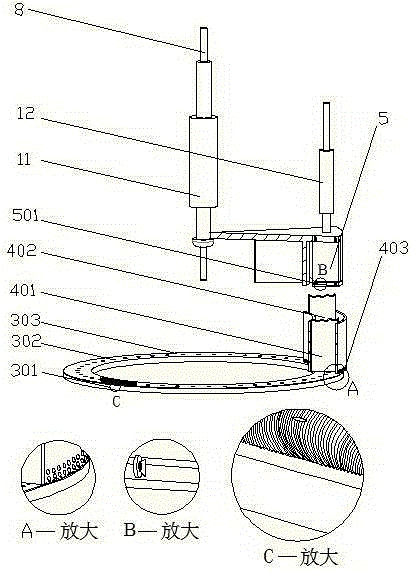

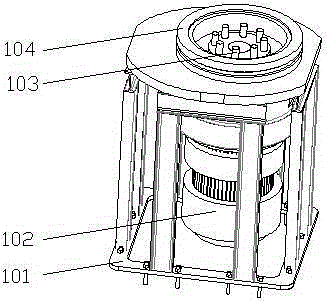

Direct pulverzing mill of glass fiber reinforced plastic wastes

The invention belongs to the technical field of pulverzing mills and particularly relates to a direct pulverzing mill of glass fiber reinforced plastic wastes. The direct pulverzing mill comprises a main motor, a speed reducer, a milling disc, a clamping frame, a pressing head and a rapid going-forward / going-backward disc, which are mounted in a rack, wherein the main motor is connected with the speed reducer; the main motor and the speed reducer are mounted at the lower part of the rack; the speed reducer drives the milling disc; a milling piece is mounted in the milling disc; the clamping frame is arranged above the milling piece; the pressing head is mounted on the clamping frame; the rapid going-forward / going-backward disc drives the pressing head; the pressing head can move in the clamping frame; and the direct pulverzing mill is characterized in that the milling piece is a steel-based milling piece plated with carborundum and spiral convex edges are fully distributed on the milling piece; and the milling disc is internally provided with a cooling water pipe, is provided with a main motor cooling water jacket and is equipped with a dust separation cover. The direct pulverzing mill of the glass fiber reinforced plastic wastes has a large milling region and has a good milling effect on the glass fiber reinforced plastic wastes.

Owner:江西铜业集团(贵溪)防腐工程有限公司

Processing technology of PCB plug hole board

ActiveCN109429432AWill not lead to scrappingHigh resin contentPrinted circuit aspectsPrinted element electric connection formationPetroleum engineeringScrap

The invention relates to a processing technology of a PCB plug hole board. The processing technology is used for manufacturing a PCB. During green-oil printing of the PCB, green oil is formed by mixing special plug hole oil and welding surface-resistant oil according to a mass ratio being 1:1, the special plug hole oil is high in content and does not have developing performance, the saturation ofink in a hole can be ensured by a plug hole, the welding surface-resistant oil is high in developing performance and low in resin content, rework can be ensured when the plug hole is unfavorable, theresin content of the ink of a new plug hole can be ensured when the special plug hole oil and the welding surface-resistant oil are matched to form the plug hole according to a proportion being 1:1, meanwhile, the oil developing performance of the new plug hole is also satisfied, the saturation condition of the plug hole is ensured, rework also can be performed when unfavorable condition occurs, and the scrap of a PCB cannot be caused.

Owner:LONGTENG ELECTRONICS TECH CO LTD

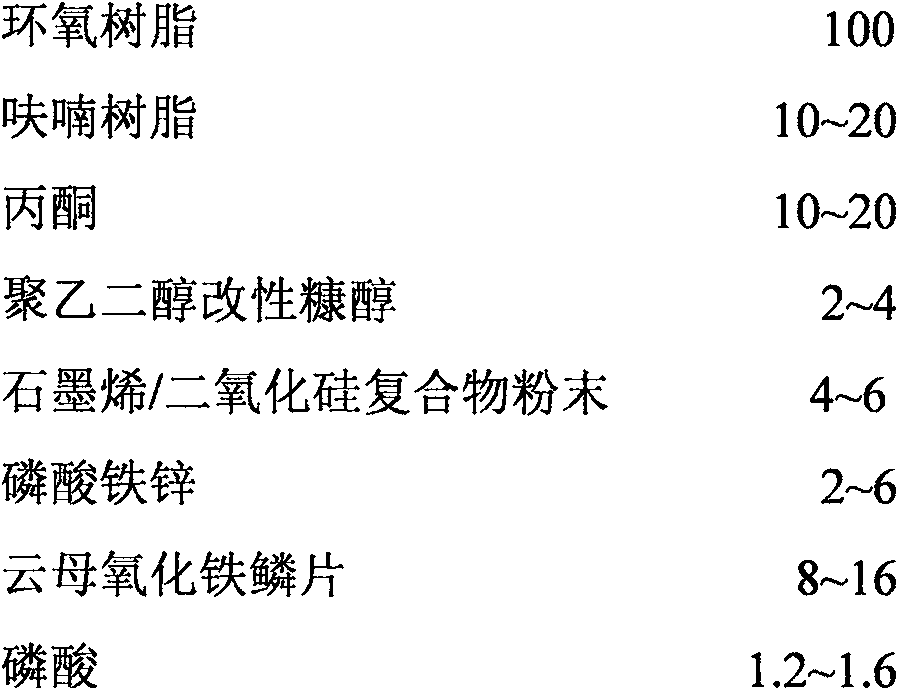

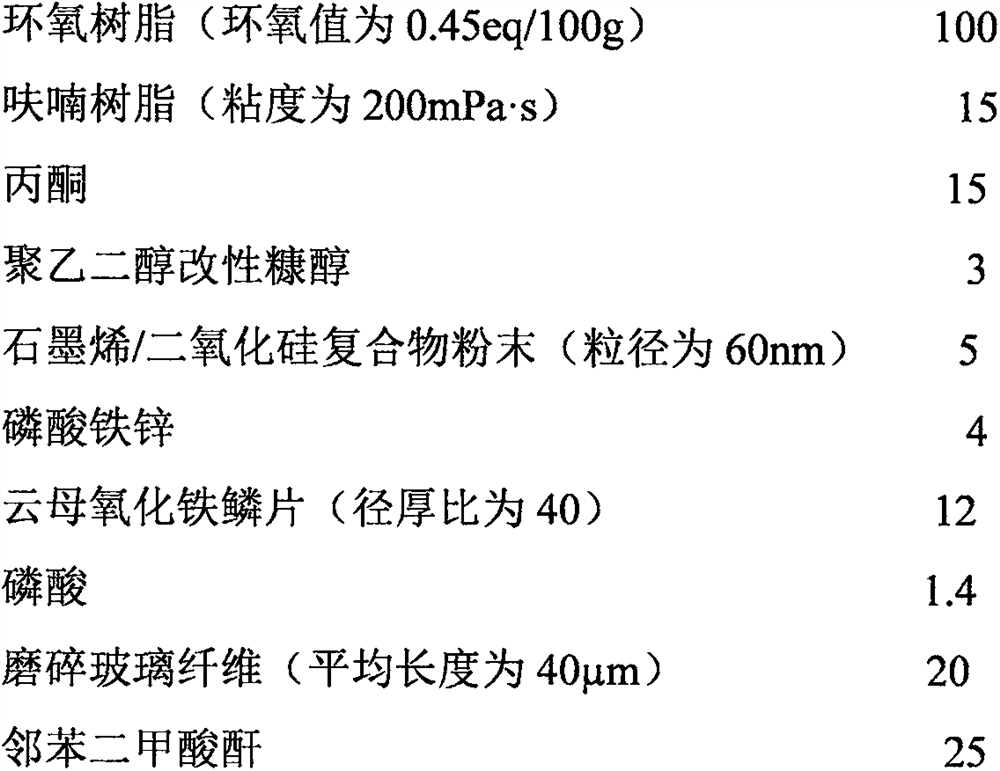

A kind of anticorrosion material for sewage pool and its preparation method and construction technology

ActiveCN109401194BHigh strengthIncrease production capacityCesspoolsGeneral water supply conservationO-Phosphoric AcidPolyethylene glycol

The invention discloses an anti-corrosion material for a sewage pool and a preparation method and construction technology of the anti-corrosion material for the sewage pool, and relates to a chemicalengineering anti-corrosion material and a preparation method and construction technology thereof. The chemical engineering anti-corrosion material and the preparation method and construction technology thereof can be used for sewage pool anti-corrosion treatment. The anti-corrosion material is formed by compoundingof epoxy resin, furane resin, acetone, polyethylene glycol modified furfuryl alcohol, graphene / silicon dioxide composite powder, zinc iron phosphate, mica iron oxide flake, phosphoric acid andmilled glass fiber, and an adoptedcuring agent is phthalic anhydride. According to the anti-corrosion material for thesewage pool and the preparation method and construction technology of the anti-corrosion material for the sewage pool, production and construction are convenient, the anti-corrosion performance is good, compared with other anti-corrosion coatings, the application is broader, the anti-corrosion range is wider, the use of the milled glass fiber improves the intensity of theanti-corrosion material after solidification, and the condition that an anti-corrosion layer is thicker compared with a traditional anti-corrosion coating, and is not prone to cracking and falling off is ensured. Compared with glass fiber reinforced plastics anti-corrosion, the technology is simple, the operation is simple and convenient, the content of the resin is higher, and the anti-corrosioneffect is better.

Owner:无锡市中舶远航环保科技有限公司

Methods and products using grass of the genus Triodia

ActiveUS8557307B2High resin contentAmount of resin is minimisedAntibacterial agentsBioreactor/fermenter combinationsBiotechnologyBiofuel feedstock

Owner:ARCHER MICHAEL

Preparation method of high-performance polytetrafluoroethylene copper-clad plate

PendingCN113386418AHigh resin contentImprove consistencyLamination ancillary operationsSynthetic resin layered productsCopper foilFilm material

The invention discloses a preparation method of a high-performance polytetrafluoroethylene copper-clad plate. The preparation method comprises the following steps: firstly, dipping electronic-grade glass fabric into polytetrafluoroethylene emulsion to obtain a polytetrafluoroethylene glass fabric-based bonding sheet; extruding and calendering a wide base film by using polytetrafluoroethylene dispersion resin powder to obtain a pure polytetrafluoroethylene adhesive film material; and performing double-sided copper foil coating on a polytetrafluoroethylene glass fabric-based bonding sheet with the weight ratio of 15-80% and a polytetrafluoroethylene extrusion calendering bonding film material with the weight ratio of 20-85%, and performing high-temperature vacuum lamination molding to prepare the high-performance polytetrafluoroethylene copper-clad plate. The dielectric constant [epsilon]r of the prepared copper-clad plate at the frequency of 1 G / 10 G ranges from 2.10 to 3.50 and is adjustable. The process provided by the invention can be used for large-scale industrial production, and the prepared combination can improve the RC of the bonding sheet to the maximum extent and reduce the cost.

Owner:CHENZHOU GONGTIAN ELECTRONICS CERAMICS TECH

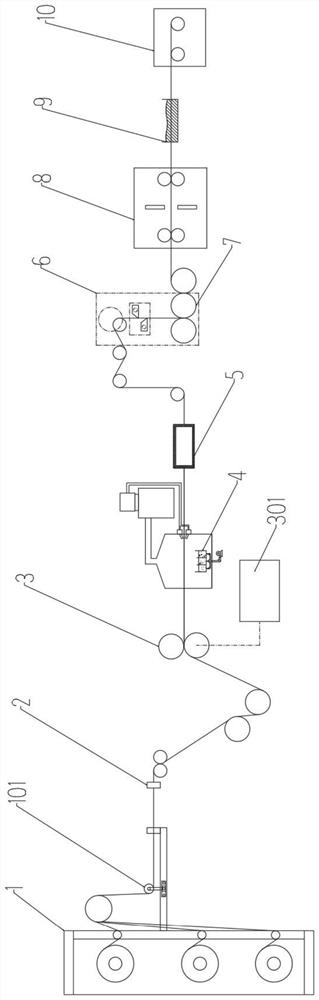

Full-automatic production line for PEEK production

The invention discloses a full-automatic production line for PEEK production. The full-automatic production line comprises a creel, a yarn collecting plate, a yarn spreading roller, a powder trough, a hot drying machine, a melting and dipping module, a three-roller calender, a cooling traction machine, a cooling pool and a winding machine which are sequentially arranged in the advancing direction of carbon fiber yarns. According to the production line disclosed by the invention, the overall production line is optimized, and powder impregnation of electrostatic feeding, first-layer impregnation of a hot drying machine and second-layer impregnation of a melting impregnating module are adopted, so that the uniformity of a matrix is effectively improved, and the resin content and apparent quality of the prepreg are remarkably improved. The powder impregnation adopts a recovery tube, a pulse dust filter and an electrostatic spraying gun, so that the adhesion rate of the carbon fiber yarns can be effectively improved, and meanwhile, the waste of resin powder is avoided.

Owner:江苏亨博复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com