Manufacturing method of vehicle components, as well as vehicle components and vehicle

A technology for parts and vehicles, applied in the field of vehicle parts and vehicles, manufacturing vehicle parts, can solve the problems of low mechanical properties and difficult molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment is used to illustrate the method of manufacturing vehicle parts of the present disclosure.

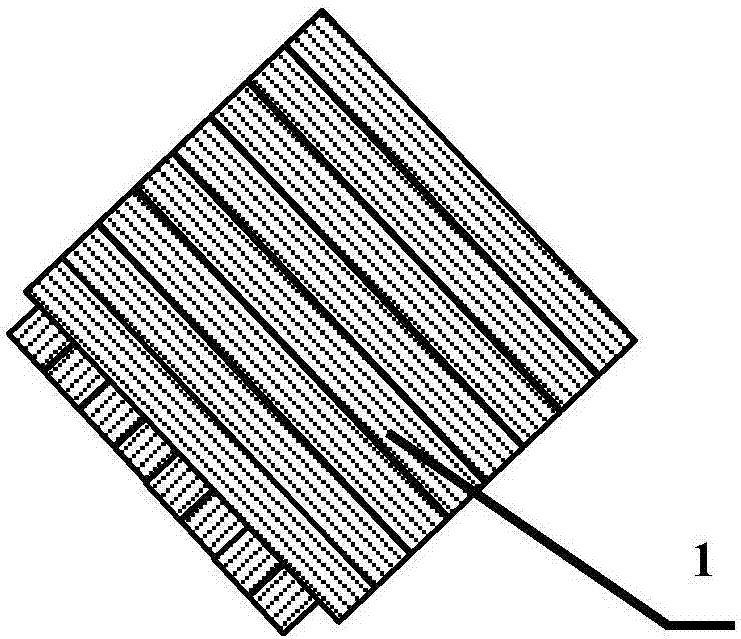

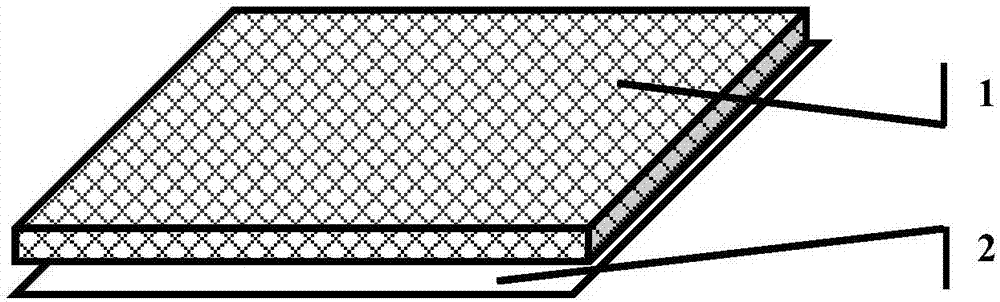

[0064] Lay up the biaxial cloth (purchased from Kefanle Special Textile Co., Ltd., made of T700 carbon fiber, the product number is BX300), the laying angle of the biaxial cloth layer is 90°, two adjacent layers of biaxial The laying angle of the cloth is 0°, and the number of layers is 13, such as figure 1 Laminate structure 1 shown. Nylon 6 resin (purchased from China Petrochemical Corporation, product number BL2340-H, melting point 220°C) was stretched to obtain a nylon 6 resin film, and the resin film was laid on the bottom of the laminated structure 1, according to The requirements of the target vehicle parts for the required prefabricated body structure are simulated by the FiberSim analysis software to obtain the cut shape, and then the laminated structure covered with the resin film is pre-cut by laser equipment to obtain the fiber prefabricated body 3, ...

Embodiment 2

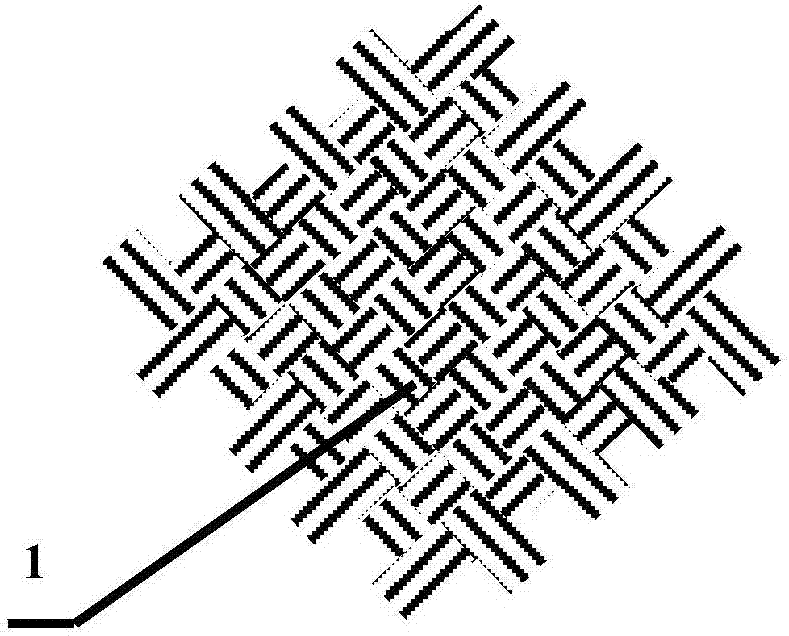

[0069] Manufacture vehicle components according to the method of embodiment 1, the difference is that the lay-up structure in the present embodiment adopts such as figure 2 The woven fabric shown (purchased from Toray Company, made of T700 carbon fiber, product number CK6244) is laminated. The laying angle of two adjacent layers of woven fabric is 90°, and the number of layers of the laminated structure is 19 layers.

Embodiment 3

[0071] Manufacture vehicle parts according to the method for embodiment 1, the difference is that the thermoplastic resin in the resin film and the injection molding compound in the present embodiment is polypropylene resin (purchased from China Petrochemical Corporation, commodity number is PPB-M02, fusing point is 170°C), the injection molding temperature is 220°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com