Patents

Literature

1044results about How to "Fast molding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Melt differential three-dimensional printer

ActiveCN103692653ABurn out preventionConvenient Quantitative ManagementManufacturing driving meansAdditive manufacturing with liquidsHot runnerMotor drive

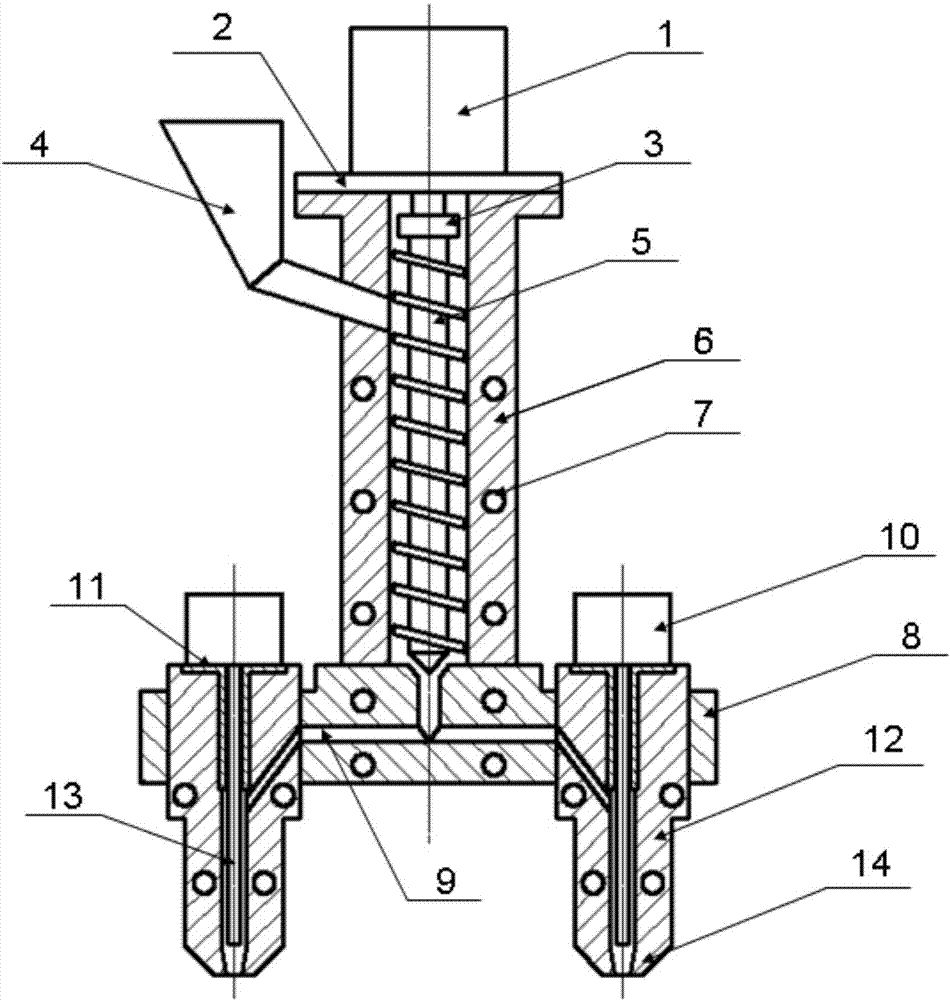

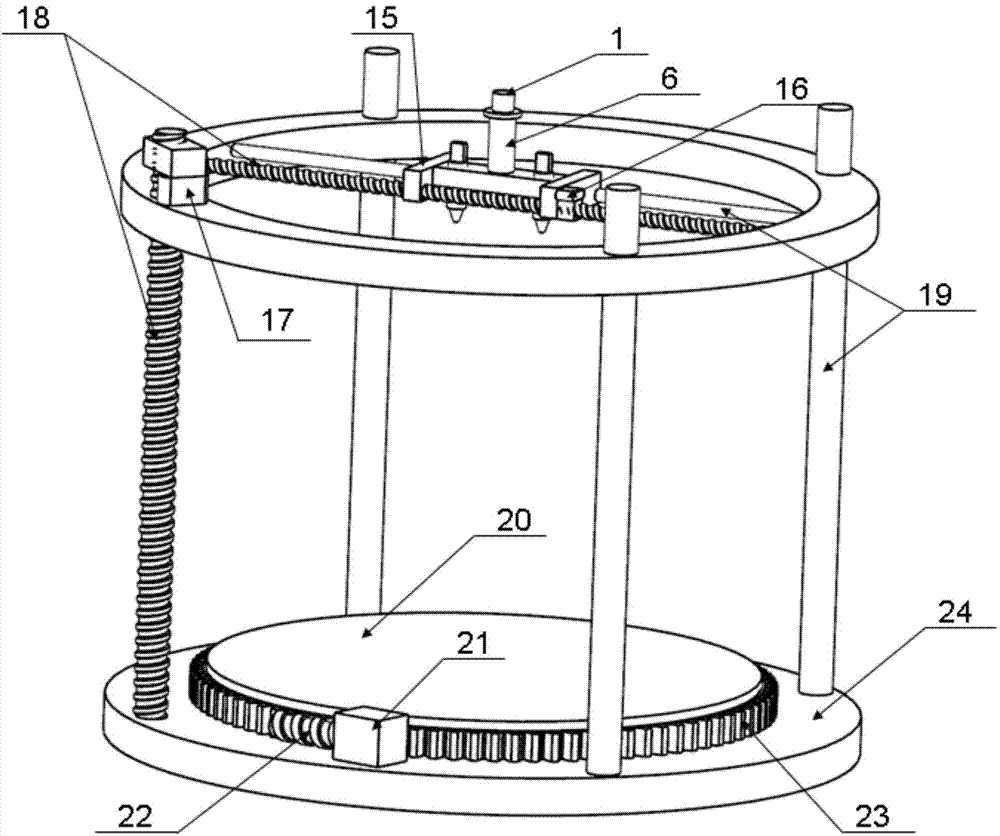

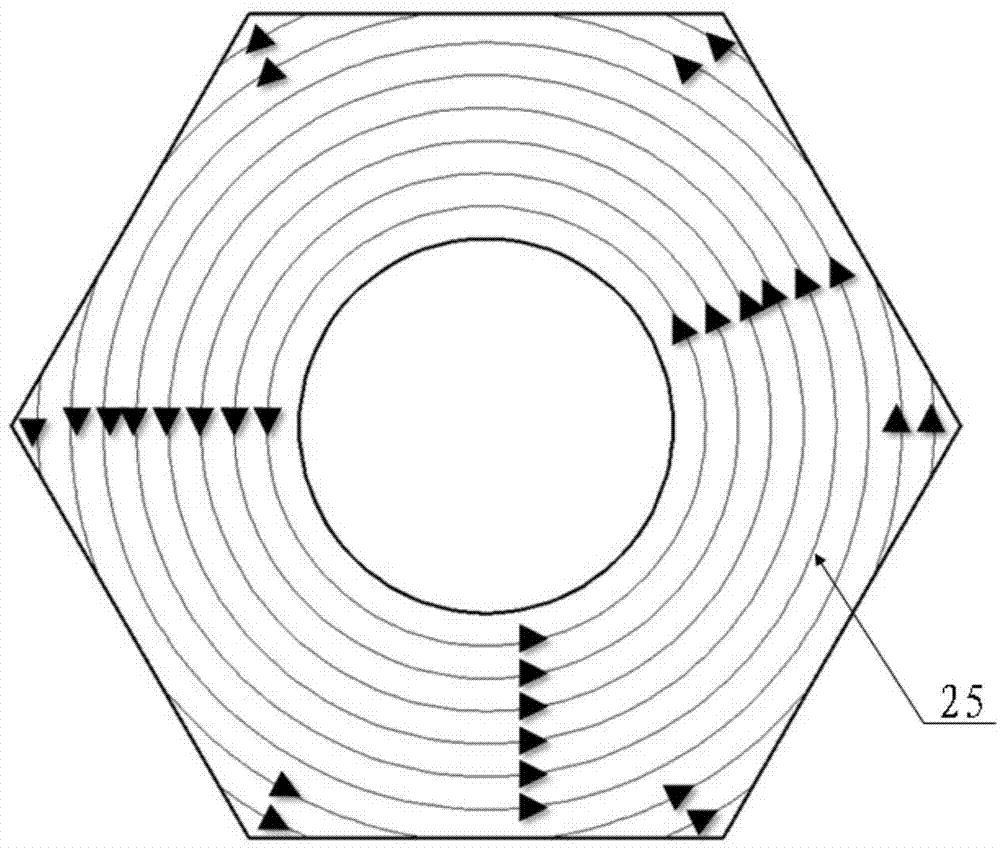

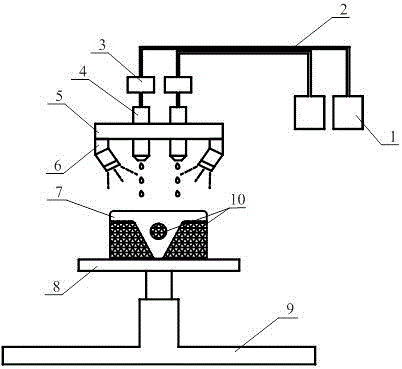

The invention discloses a melt differential three-dimensional printer. The melt differential three-dimensional printer mainly comprises a material melting unit, a micro-droplet jetting unit, a cylindrical-coordinate system molding unit and a rack, wherein a servo motor drives a screw rod to rotate in the material melting unit; a heater, which is fixedly arranged inside a machine cylinder, ensures that granules are entirely plastified through temperature regulation; a molten material is transmitted by the screw rod to the micro-droplet jetting unit; in the micro-droplet jetting unit, the molten material is transmitted into a valve body through a hot runner in a runner plate; a linear servo motor drives a valve needle to do reciprocating motion in the valve body so as to quantitatively and intermittently squeeze the molten material out of a nozzle to form melt micro-droplets; in the cylindrical-coordinate system molding unit, the molten micro-droplets are injected to a bearing table for cooling and deposition molding; the servo motors in the left-right direction and in the vertical direction are respectively engaged with the corresponding screw rod to rotate so as to drive the material melting unit and the micro-droplet jetting unit to move along the left-right direction and the vertical direction; a circumference servo motor drives the bearing table with a worm gear to rotate through a worm rod so as to realize three-dimensional movement under a cylindrical-coordinate system.

Owner:BEIJING UNIV OF CHEM TECH

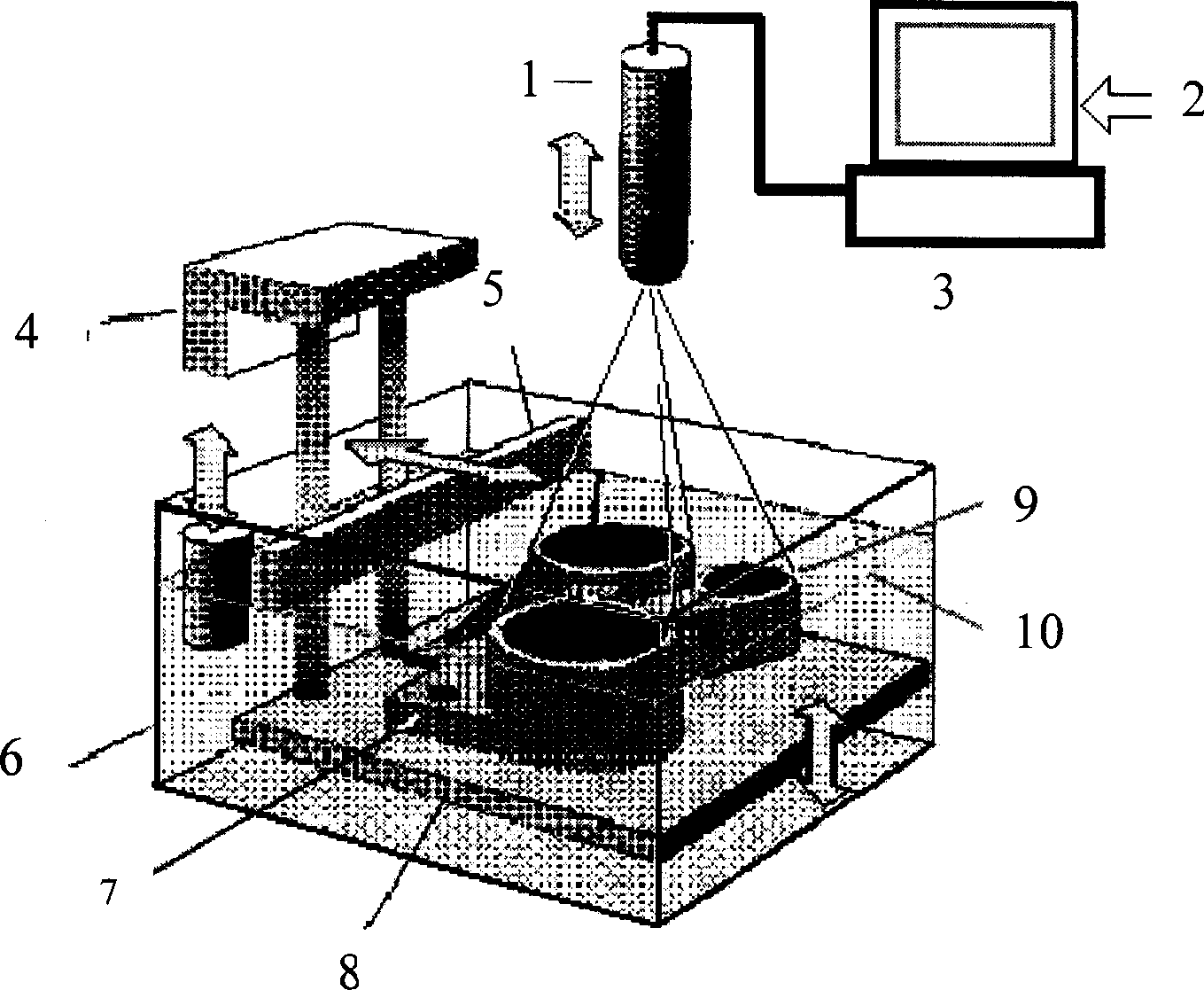

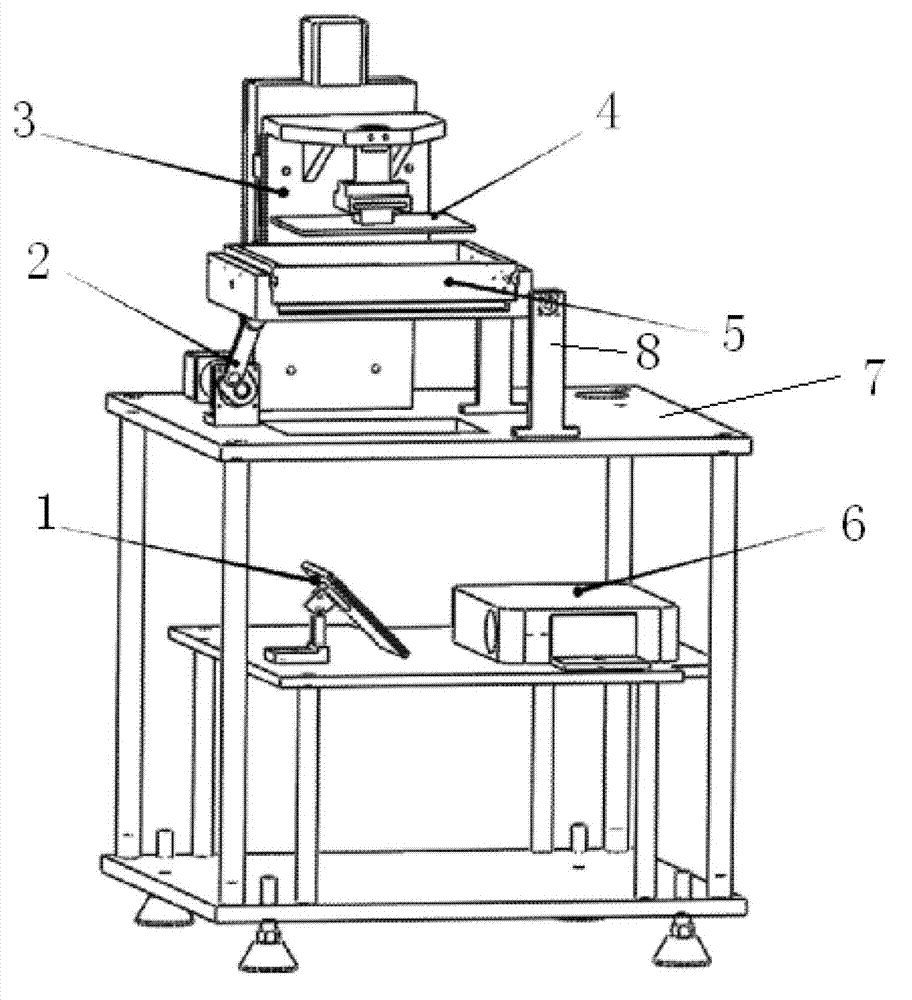

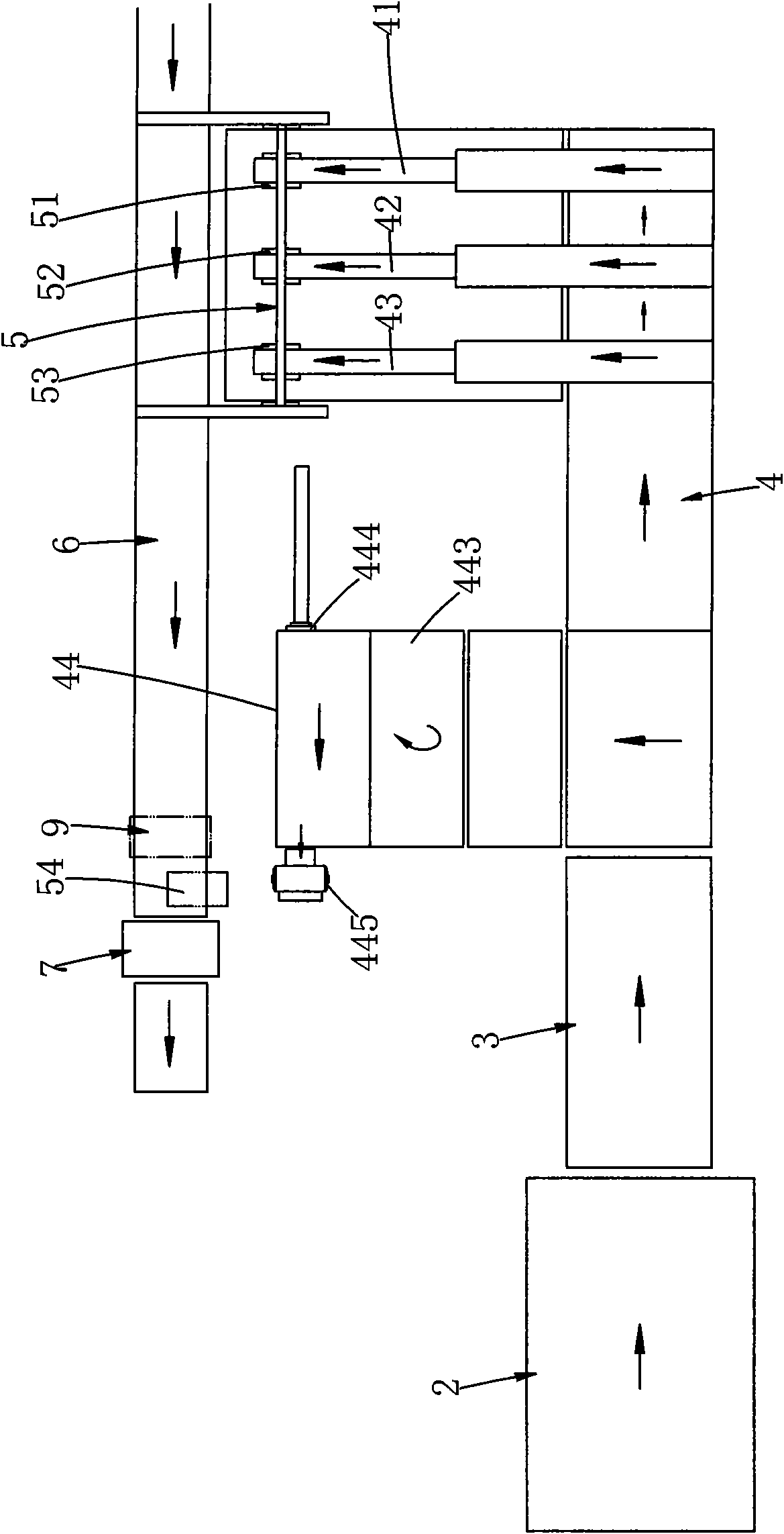

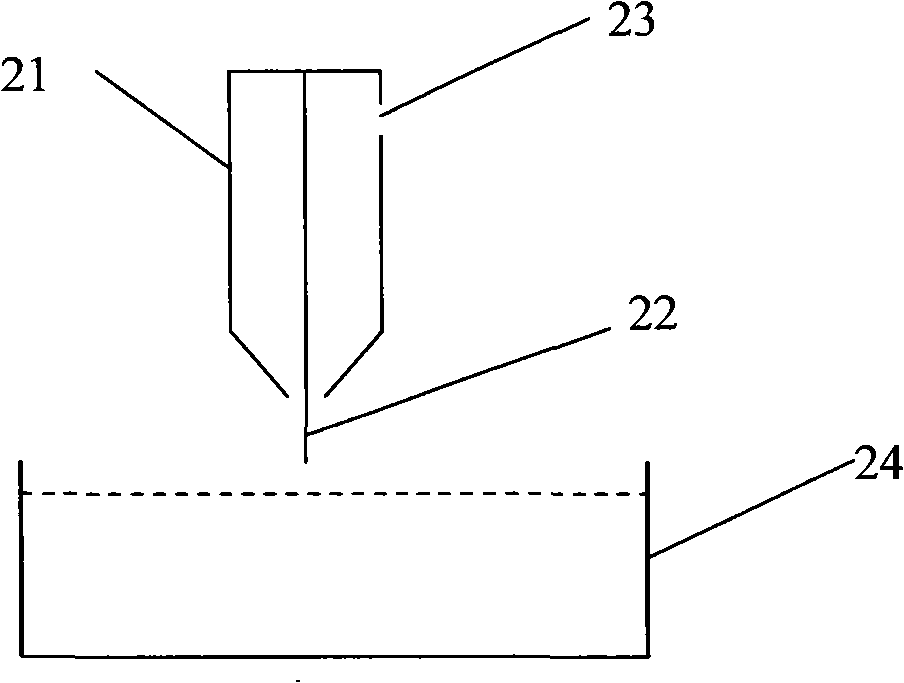

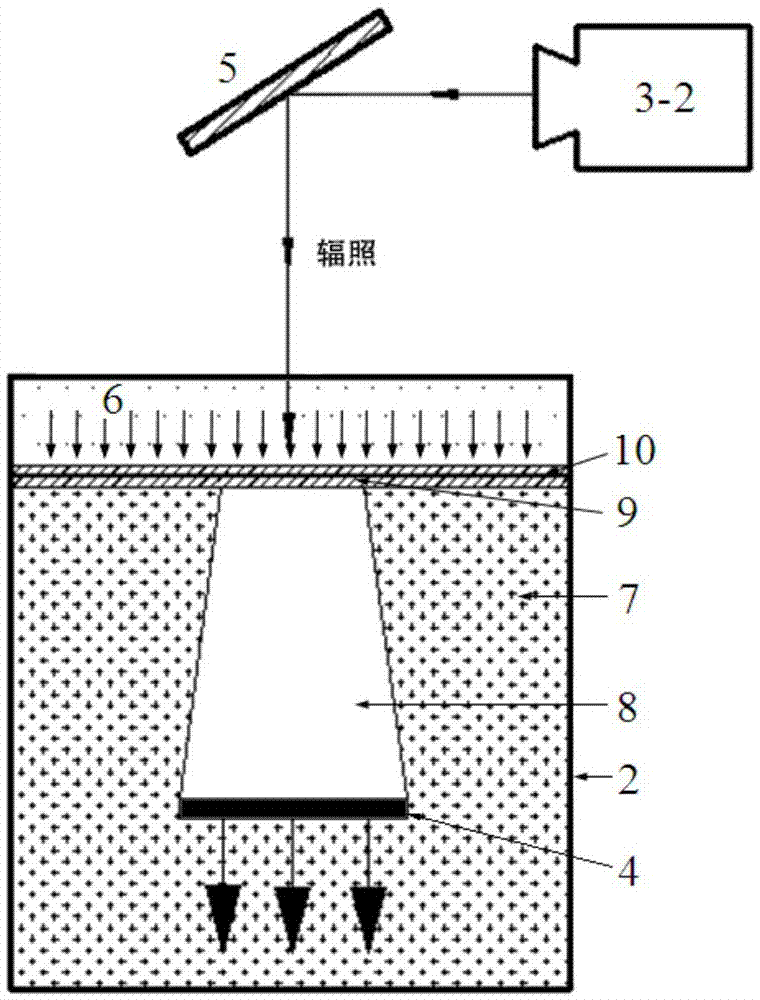

Light-curing three-dimensional printer based on digital light processing (DLP) projection

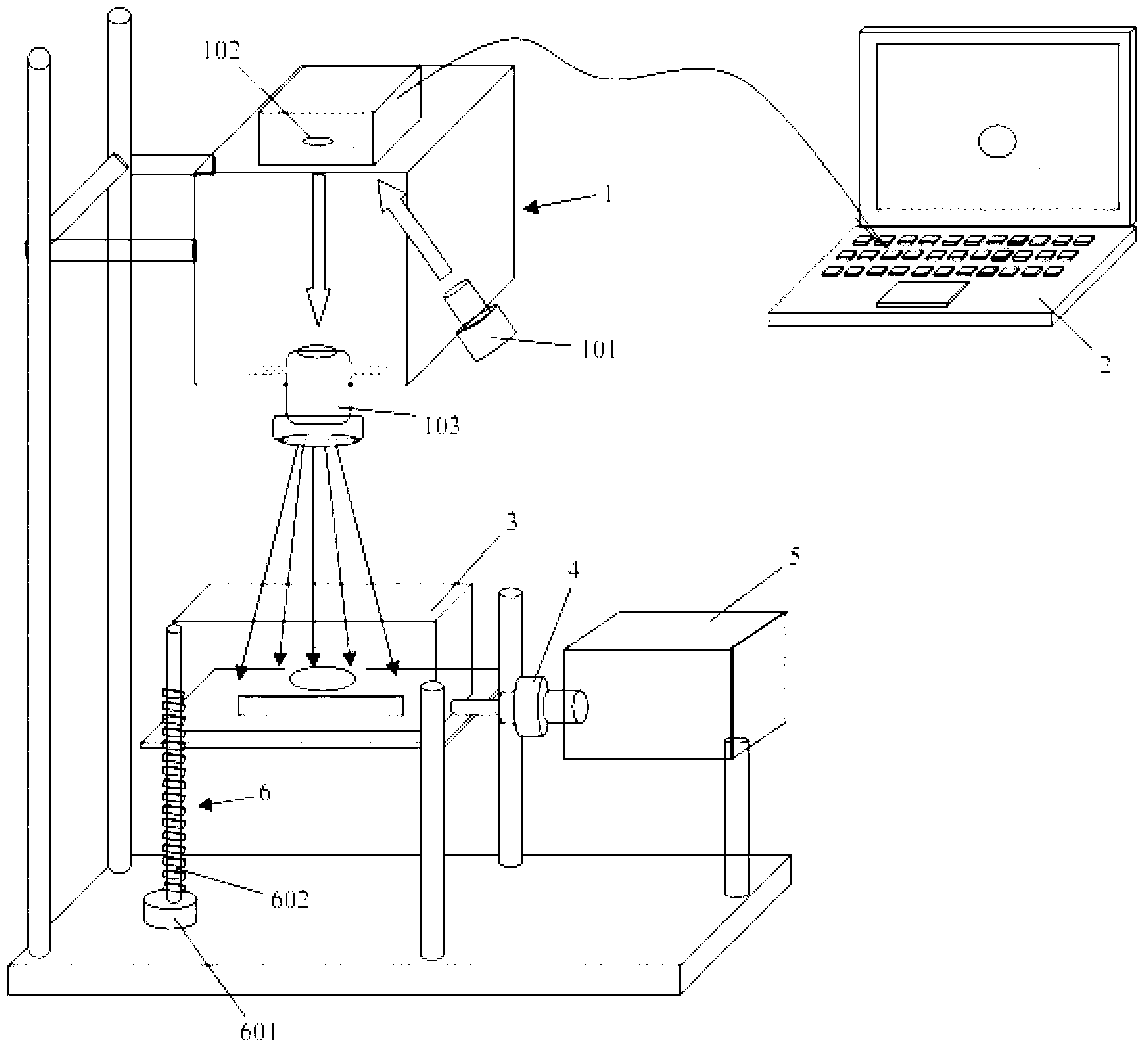

The invention discloses a light-curing three-dimensional printer based on digital light processing (DLP) projection, which comprises a computer system (2), an automatic control system, a DLP projection system (1), a molding work pool (3), a feeding system (4) and a lifting system. Compared with the three-dimensional printer in the prior art, the light-curing three-dimensional printer has the advantages of high molding speed and high printing precision, and the surface of a molded product is continuous and is not layered; moreover, the DLP projection-based light-curing three-dimensional printer can be applied to performing light curing on light-sensitive materials with various strengths and made from different raw materials.

Owner:王健犀

Three-dimensional color printing device and method

ActiveCN105500700AImprove printing accuracyFast molding speedAdditive manufacturing apparatusAutomatic controlControl system

The invention discloses a three-dimensional color printing device and method. The three-dimensional color printing device comprises a print area, a feeding system, a nozzle group, a moving mechanism and an automatic control system, wherein the print area is provided with a forming plate and a forming work pool, and the forming plate is provided with a lifting mechanism which is used for drawing a workpiece curing layer; the feeding system comprises a support material feeding box and a solid material feeding box and is used for supplying print raw materials for the nozzle group; the nozzle group comprises at least one solid material nozzle and a support material nozzle, the solid material nozzle is connected with the solid material feeding box of the feeding system through a premixer, and the support material nozzle is connected with the support material feeding box of the feeding system; andthe moving mechanism is provided with motors and guide posts / rods on the X-axis direction, the Y-axis direction and the Z-axis direction and is used for driving the nozzle group for performing mobile printing on the three-dimensional direction. The three-dimensional color printing device has the characteristics of being high in print accuracy and smooth and clean in surface of formed products and can realize color printing and printing of different photosensitive materials.

Owner:QINGDAO ACADEMY OF INTELLIGENT IND

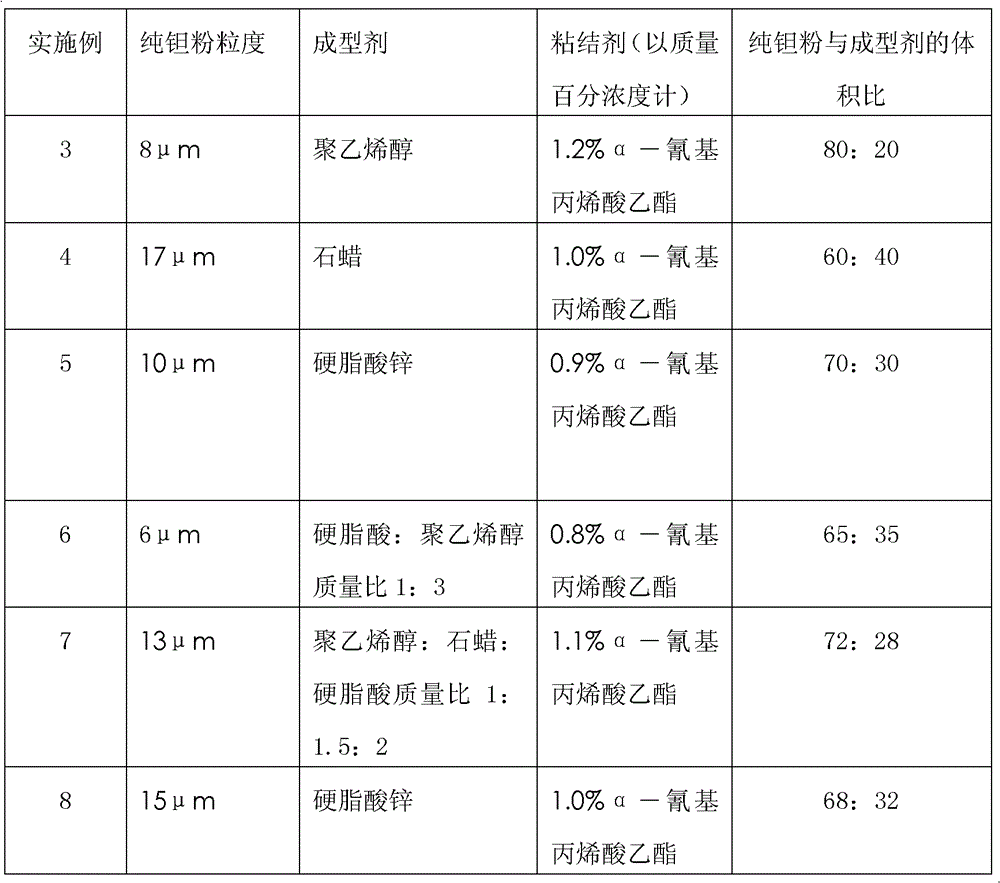

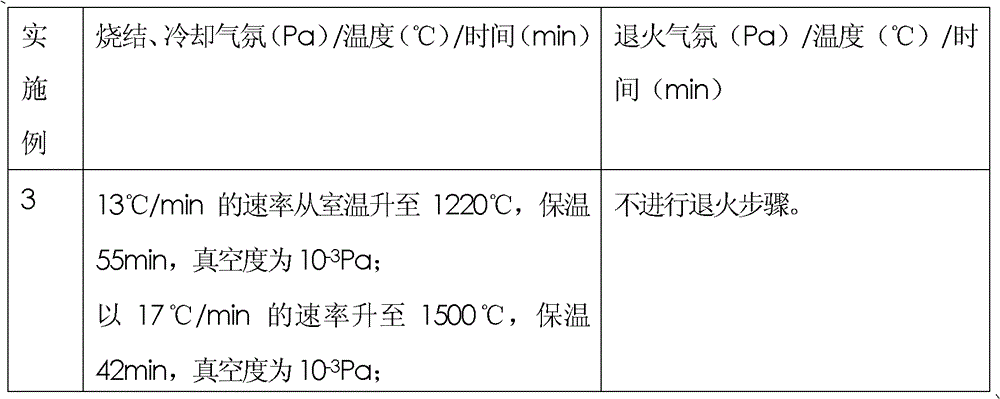

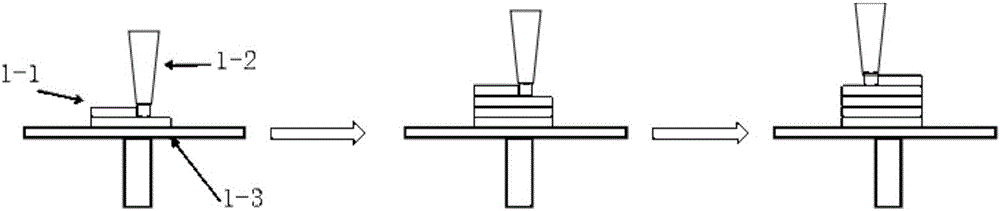

Method for preparing porous tantalum medical implant material through three-dimensional printing forming

ActiveCN102796909AFast molding speedHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyPorous tantalumBone tissue

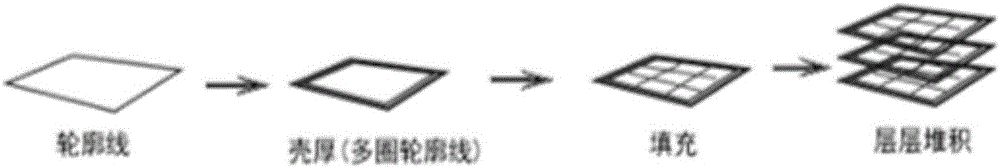

The invention discloses a method for preparing a porous tantalum medical implant material. The method comprises the following steps of: feeding mixed tantalum power formed by mixing pure tantalum powder and a forming agent into a printing platform of a three-dimensional printer, and rolling and paving; spraying an adhesion agent by a printing head of the three-dimensional printer to adhere the mixed tantalum powder so as to form a two-dimensional plane; descending a working table 80 to 100 mu m, and processing the next layer; accumulating and forming layer by layer; removing the tantalum powder particles which are not adhered to obtain an initially formed sample; and performing aftertreatment such as degreasing, vacuum sintering, cooling and the like to obtain the porous tantalum medical implant material, wherein the volume ratio of the pure tantalum powder to the forming agent is (60-80):(20-40), and the adhesion agent is 1 mass percent alpha-cyanoacrylate adhesive. The pores of the porous tantalum medical implant material prepared by the method are completely communicated in a three-dimensional mode; the porous tantalum medical implant material prepared by the method is high in biocompatibility; and meanwhile, the mechanical property of the porous tantalum medical implant material prepared by the method is consistent with that of loading bone tissues of a human body.

Owner:CHONGQING RUNZE PHARM CO LTD

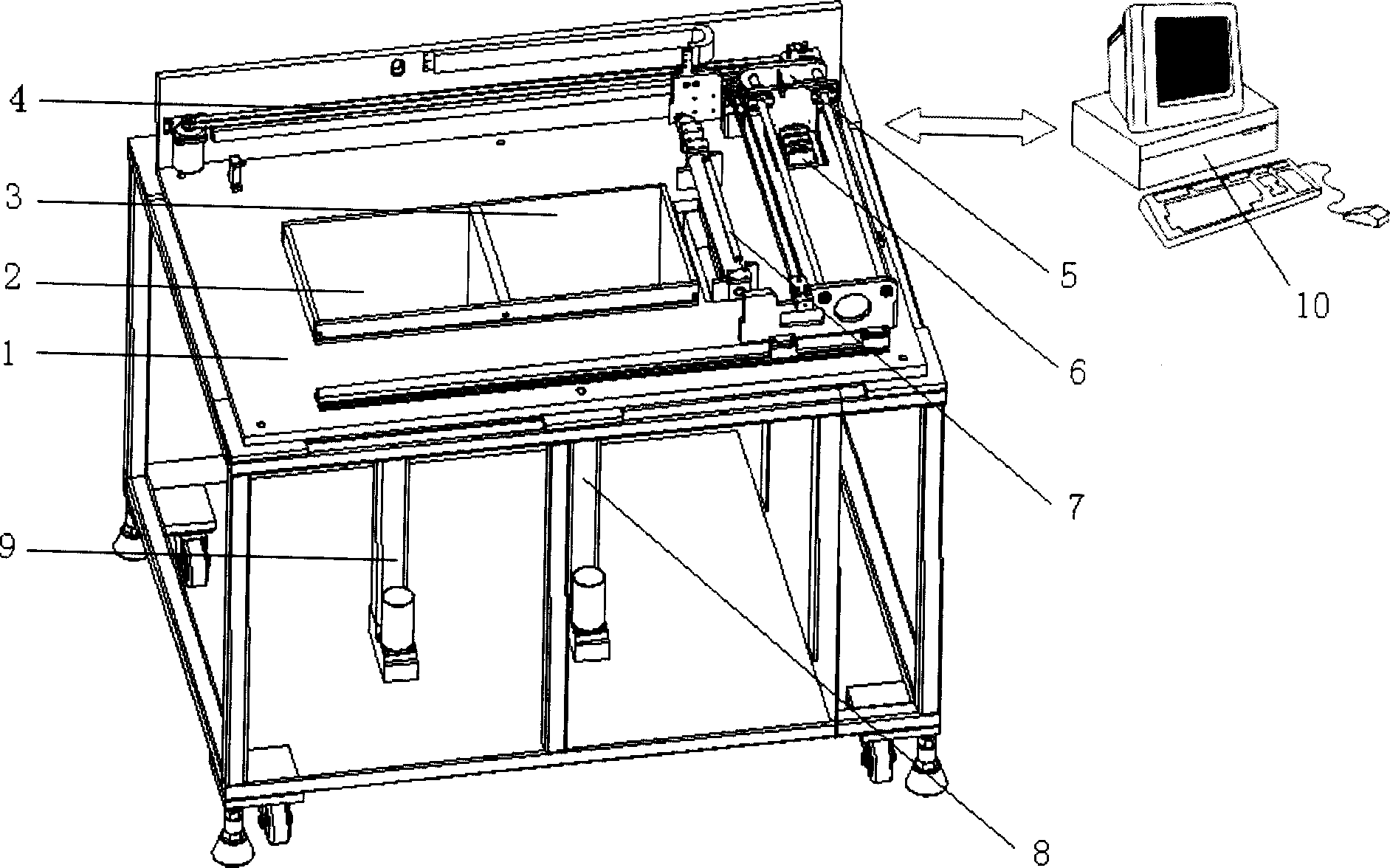

Three dimension color printing quick forming device and method

InactiveCN1857930ASimple processFast molding speedCeramic shaping apparatusPrintingColor printingLayer thickness

The present invention discloses a kind of 3D color printing and quick forming device and method. The 3D color printing and quick forming device includes an X-Y scanning platform and a Z motion mechanism. The X-Y scanning platform is provided with powder providing tank, forming tank, powder roller and printing head; and the Z motion mechanism includes pistons inside the powder providing tank and the forming tank. The quick forming process is one combination of quick forming technology and color printing technology and includes the following steps: jetting pigment of different colors with the precise printing head to the compact powder material inside the forming tank to form color cross section pattern, curing the powder material, lowering the powder material inside the forming tank by the height of one layer thickness while raising the powder material inside the powder providing tank by one layer thickness, forming one new powder material layer, and so on until forming the cured body.

Owner:XI AN JIAOTONG UNIV

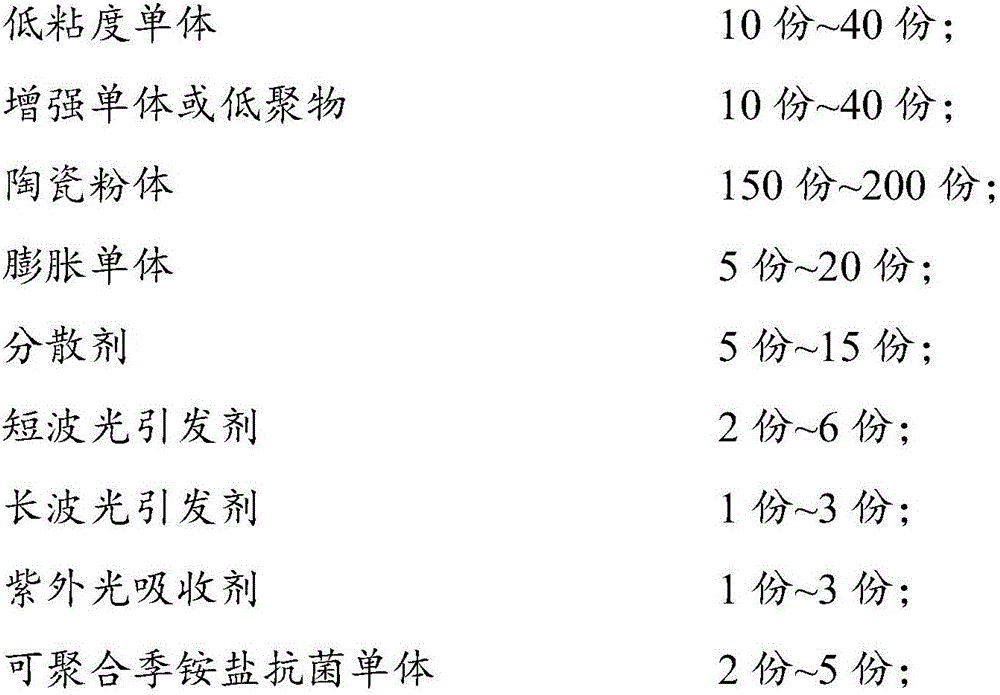

3D printing composite material for mouth rehabilitation and preparation and using method of 3D printing composite material

ActiveCN105943406AImprove completion efficiencySave time at workAdditive manufacturing apparatusImpression capsOral ProsthesisMaterials science

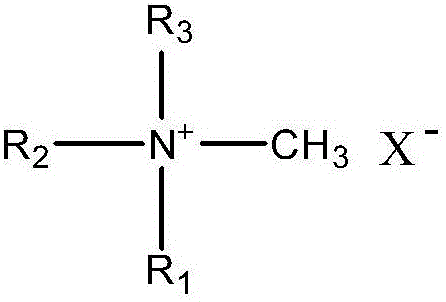

The invention relates to a 3D printing composite material for mouth rehabilitation and a preparation and using method of the 3D printing composite material. The 3D printing composite material for mouth rehabilitation is characterized by comprising the following components in parts by weight: 10-40 parts of low-viscosity monomer, 10-40 parts of enhanced monomer or low polymer, 150-200 parts of ceramic powder, 5-20 parts of expansion monomer, 5-15 parts of a dispersing agent, 2-6 parts of a short-wave photoinitiator, 1-3 parts of a long-wave photoinitiator, 1-3 parts of an ultraviolet absorber and 2-5 parts of polymerizable quaternary ammonium salt anti-bacterial monomer. The 3D printing composite material for mouth rehabilitation is small in curing shrinkage, short in curing time and high in anti-bacterial property, and is suitable for manufacturing a dental prosthesis.

Owner:深圳长朗智能科技有限公司

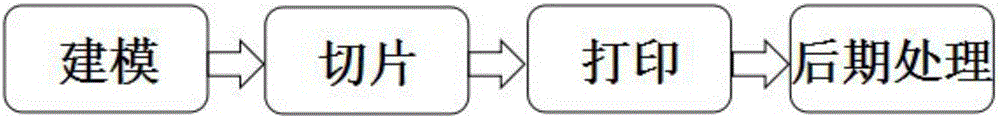

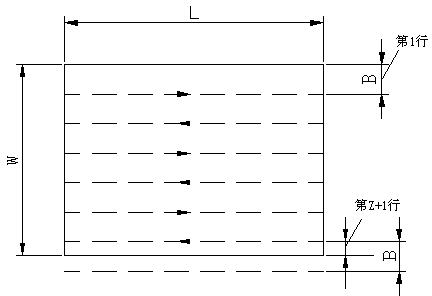

Model area change rate-based adaptive hierarchical processing method

InactiveCN106202687ASolve molding accuracySolve molding speedGeometric CADAdditive manufacturing apparatusRoundingLayer thickness

The invention discloses a model area change rate-based adaptive hierarchical processing method. The method comprises the following steps of importing an STL model and establishing a model topological structure; performing uniform hierarchical slicing on the model with the highest precision, obtaining a two-dimensional polygon contour layer and calculating an area of each layer of a polygon after slicing; performing derivation on the area of each layer of the polygon to obtain an area change rate of the model; comparing the calculated area change rate with a threshold according to a relationship between the area change rate of the model and the printing precision, and obtaining a printing precision distribution situation of the model in a printing direction; calculating hierarchical layer thickness data required for model printing, and performing processing by using a rounding-off method to generate adaptive hierarchical layer thickness data; and reading the hierarchical layer thickness data by a slicing engine, and performing adaptive layer thickness slicing on the model to obtain a gcode file required for printing. According to the method, while the detail characteristics of the model are ensured, the forming speed of the model is increased, and the printing time is effectively shortened.

Owner:HOHAI UNIV CHANGZHOU

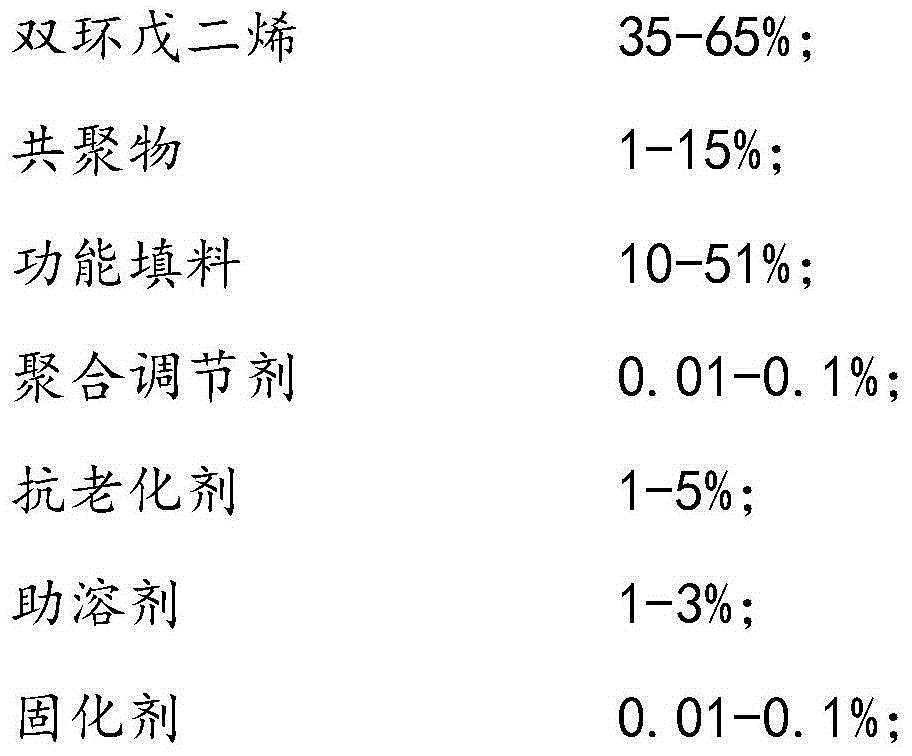

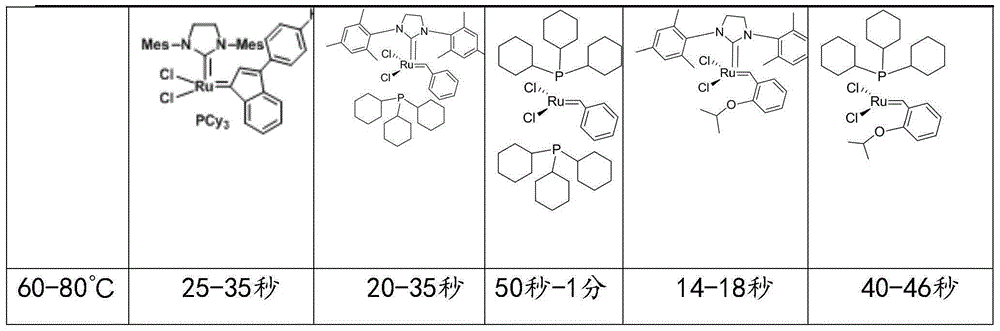

Polydicyclopentadiene composite material and single material reaction injection molding technology thereof

The invention discloses a formula of a polydicyclopentadiene (PDCPD) composite material and a single material reaction injection molding (RIM) technology thereof. The composite material is prepared from 35-65% of dicyclopentadiene, 1-15% of copolymers, 10-51% of functional filler, 0.01-0.1% of polymerization regulator, 1-5% of antiaging agents, 1-3% of cosolvent and 0.01-0.1% of curing agent, and the curing agent is a ruthenium-carbine catalyst. The single material reaction injection molding technological method includes the steps that the formula materials are mixed and evenly dispersed and form mixed slurry with a curing agent solution, and the mixed slurry is injected into a molding mold at the speed of 10-100 ml / s with the temperature kept below 30 DEG C; the mold is heated to 60 DEG C-80 DEG C, curing is carried out fast within one minute, and then demolding is carried out. The PDCPD composite material is good in mechanical property, the curing time is short, and the process is simple.

Owner:克琴新材料科技(上海)有限公司

Method for manufacturing tobacco sheet taking substrate as carrier through dry paper making method

A method for manufacturing tobacco sheet taking substrate as a carrier through a dry paper making method comprises the following steps: spraying slurry onto the right side of the substrate through a high pressure spraying method, and meanwhile carrying out negative pressure suction across a wire belt to the reverse side of the substrate; then sending the substrate into an oven and carrying out medium temperature baking and humidity discharging under the condition that the temperature of the substrate is 55 DEG to 70 DEG, and enabling hot air inside the oven to flow directional from the right surface of the substrate to the reverse surface of the substrate to carry out humidity discharging; sequentially, carrying out normal temperature humidity discharging treatment; setting medium temperature baking and humidity discharging time and the normal temperature baking and humidity discharging alternatively; and repeating the steps on the reverse side of the substrate, namely a tobacco sheet is prepared. The substrate is prepared by that scattered material is evenly paved and absorbed onto a formation fabric for dry paper making to form a fiber thin layer under the vacuumpumping of a vacuum air pumping device under the formation fabric, and carrying out antistatic-electricity treatment; and spraying adhesion agent onto a fiber thin layer, under the combination of mist spraying and vacuum take-off on sprayed back surface; and finally carrying out drying.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

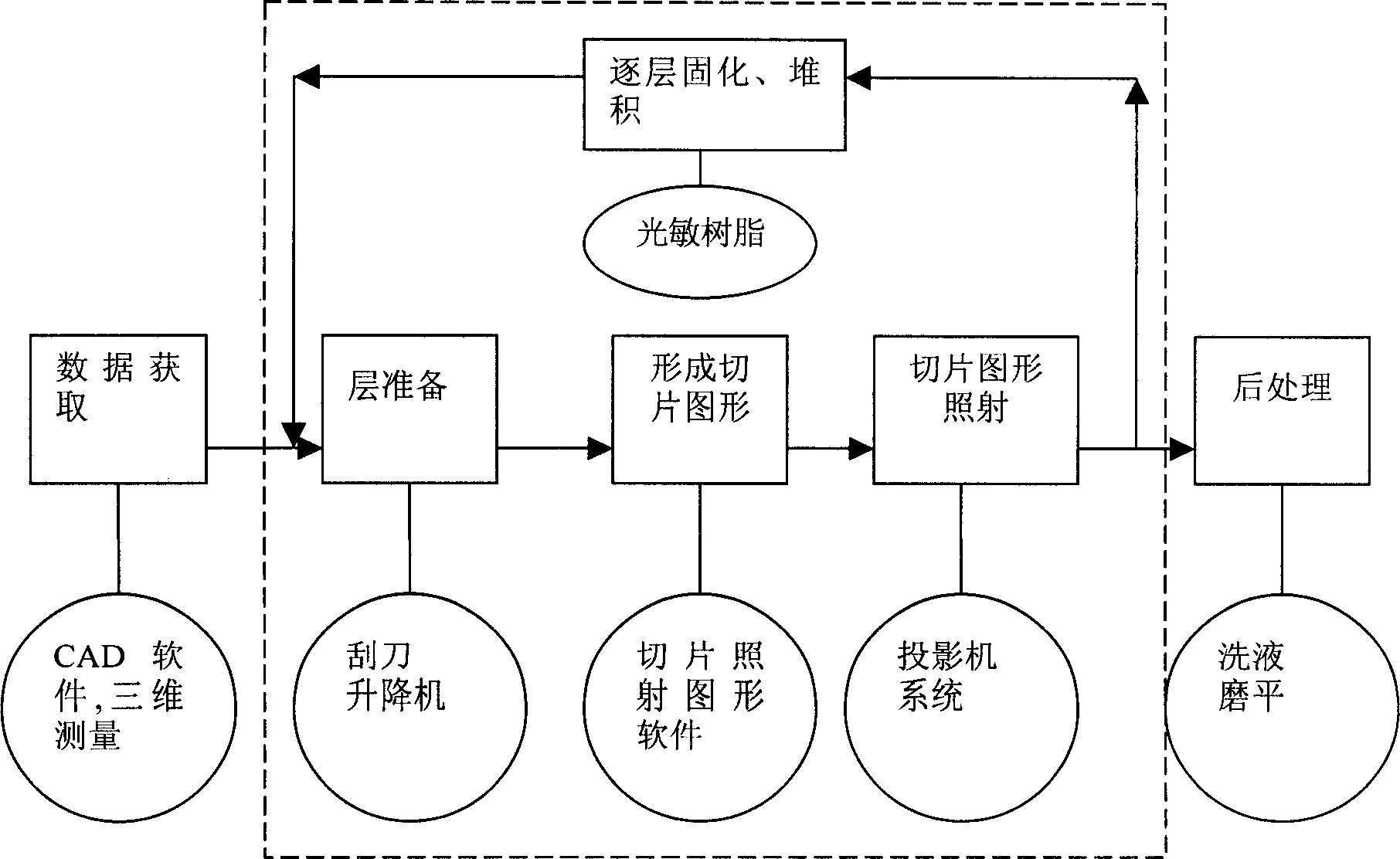

Quick forming method by adoption of projection technique

InactiveCN1769032ASimplified correspondenceControl and adjust sizeSpecial data processing applicationsDigital imageGraphics

The invention belongs to the producing area, which uses modern shadow casting technique and computer image processing technique to process the illumination solidification modeling on the surface of liquid photosensitive resin to form the three-dimensional solid quickly. The invention processes the sectional mould data of three-dimensional solid via the computer fast shaping processing technique to generate the digital grid image data which can be directly used in projection, to be transformed into digital optical signal via the digital image projector, and adjusted by different time and space patterns to be irradiated over the surface of photosensitive resin to solidify it.

Owner:谭昊涯 +1

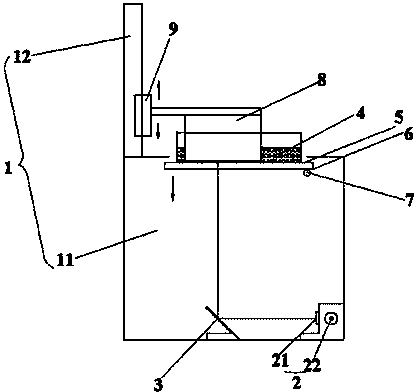

Rapid prototyping SLA 3D printer and printing method thereof

The invention relates to the technical field of 3D printers and printing methods, in particular to a rapid prototyping SLA 3D printer. The rapid prototyping SLA 3D printer comprises an SLA 3D printer body, wherein the SLA 3D printer body comprises a hollow cabinet body and a support which extends upwards along one side surface of the cabinet body, wherein a laser scanning device is arranged at the front end of the bottom surface of the cabinet body, a reflecting mirror is arranged at the center of the bottom surface of the cabinet body, a resin trough is arranged right above the reflecting mirror, the bottom surface of the resin trough is fixedly provided with a piece of high-transparency quartz glass, the high-transparency quartz glass is fixedly arranged on an iron plate, the iron plate is fixedly connected with a motor on the bottom surface of the cabinet body, a lifting platform is arranged right above the resin trough, the support is provided with a vertical slide rail, and the lifting platform can slide up and down along the vertical slide rail. The invention also discloses a printing method of the rapid prototyping SLA 3D printer. Compared with the prior art, the rapid prototyping SLA 3D printer has the advantages that the prototyping speed is high; since a downward-pulling mechanical structure for eliminating the vacuum force is arranged, the rate of finished products is greatly increased, the precision is high, and the printer is particularly suitable for producing a prototype with high precision requirement and a complicated structure; the structure is simple, the operation is convenient, and the production cost is greatly reduced; therefore, the rapid prototyping SLA 3D printer can be widely popularized and used.

Owner:DONGGUAN JINGJIZHE DIGITAL TECH

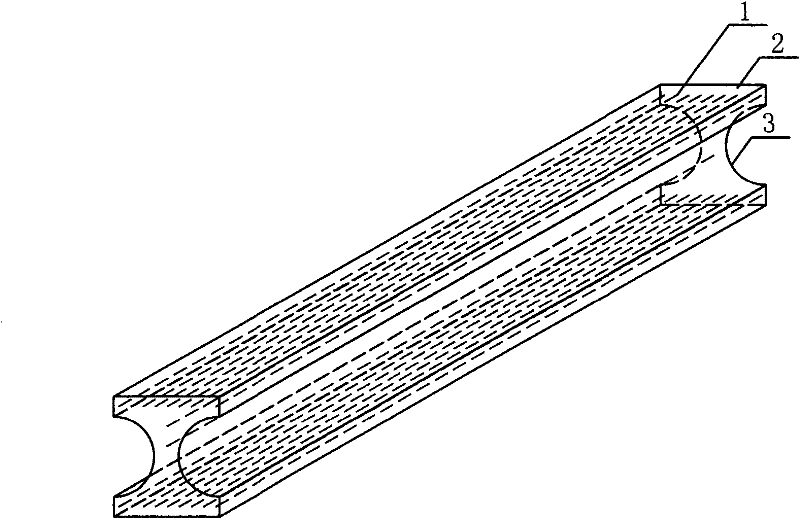

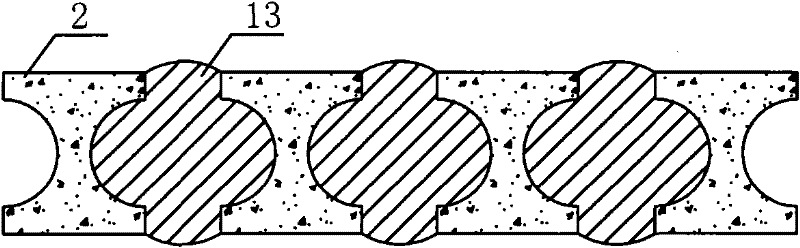

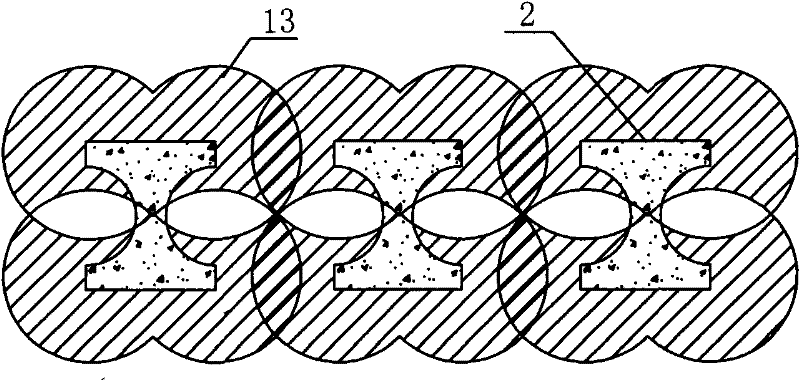

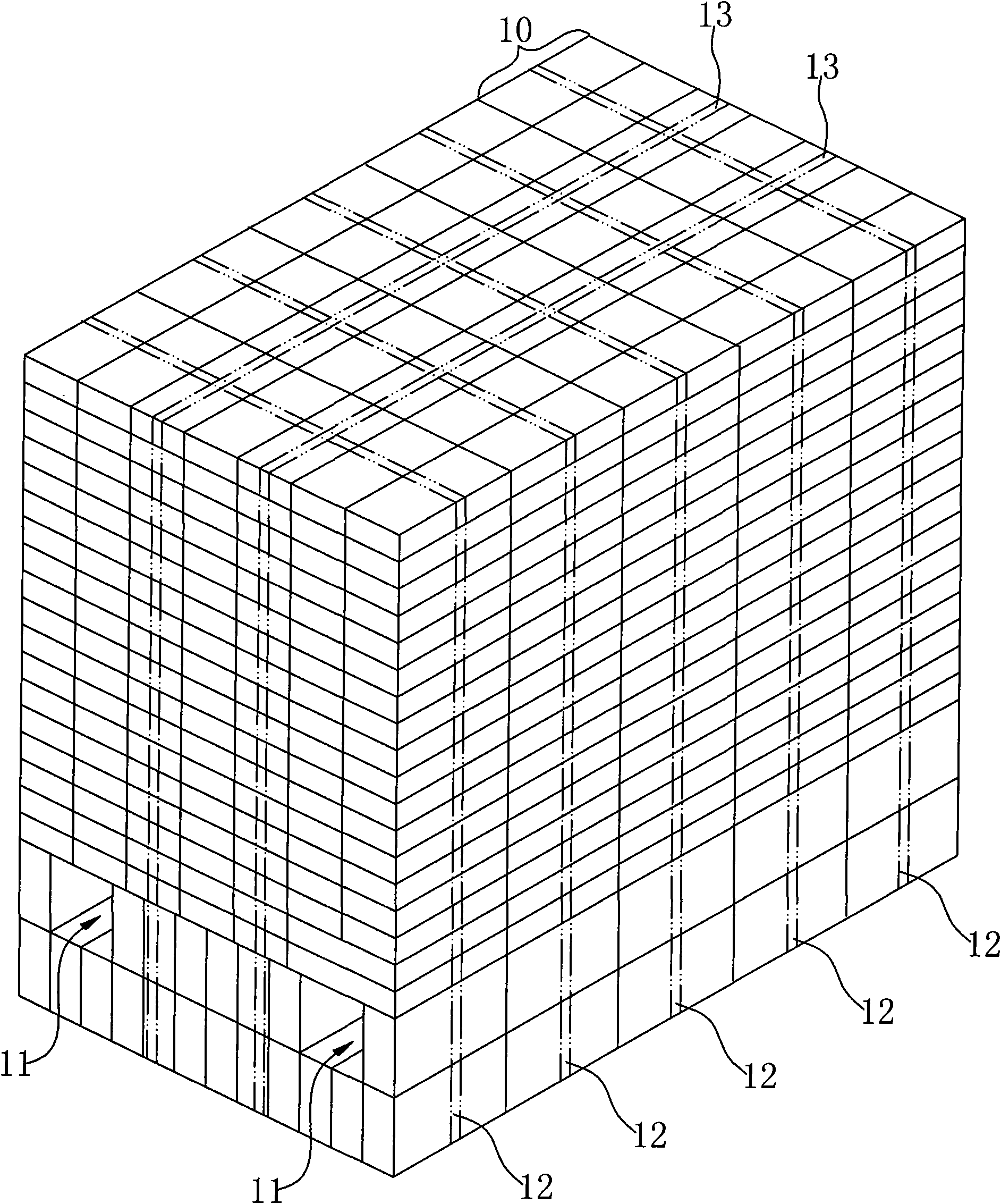

A kind of open high-strength concrete prefabricated pile and its pile form, centrifugal manufacturing method

InactiveCN102261065AImprove bearing capacityReduce the cross-sectional areaMouldsBulkheads/pilesHigh strength concreteCentrifugation

The invention relates to an open high-strength concrete prefabricated pile in the field of pile foundation engineering, a pile form thereof, and a centrifugal manufacturing method. 1) The outer high-strength concrete prefabricated pile body (2), and on the side of the high-strength concrete prefabricated pile body (2), there is a concave surface (3) with a centrifugally formed cross-section and an arc-shaped cross-section, depending on the shape of the cross-section. , proposed pile types such as H-type piles, groove piles, corner piles, open cylindrical piles, star piles, etc., and then put forward the pile mold and forming method of one-time centrifugal forming multi-section piles, and proposed open high-strength concrete precast piles and cement The structural composition and construction method of the PMW earth-retaining and water-stop pile combined with soil piles, the open high-strength concrete prefabricated pile of the present invention has high material strength, good flexural performance, small pile driving effect, and can greatly save the cost of pile foundation engineering. , the environmental protection benefits are outstanding.

Owner:张继红

Polystyrene microsphere modified photosensitive resin for 3D printing and preparation method thereof

The invention provides polystyrene microsphere modified photosensitive resin for 3D printing, which consists of the following raw materials in parts by mass: 30-70 parts of acrylic ester, 30-70 parts of epoxy resin, 5-60 parts of polystyrene microsphere, 0.1-5 parts of light stabilizer, 10-30 parts of diluent, 0.1-10 parts of antifoaming agent, 0.1-10 parts of leveling agent, 0.1-5 parts of antioxidant, 1-10 parts of cationic initiator and 1-10 parts of free radical type photopolymerization initiator. The polystyrene microsphere modified photosensitive resin provided by the invention has the advantages of fast formation, high mechanical strength, good dimensional stability and the like; moreover, the preparation process is simple and can be directly applied and popularized to the preparation of complicated-structure components in the field of 3D printing.

Owner:滁州格美特科技有限公司

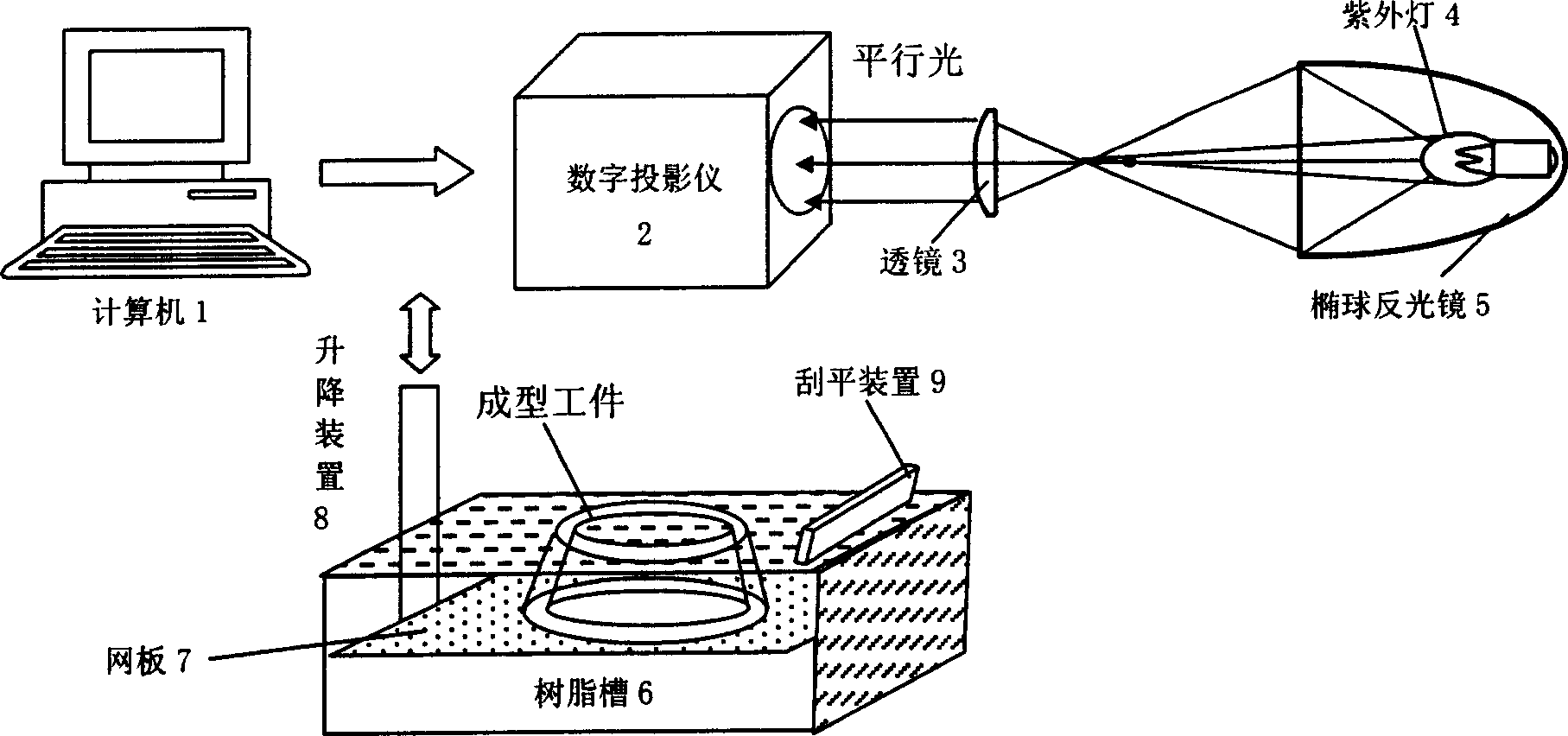

Digital projection photocurable rapid shaping apparatus and method

The invention discloses a digital projection photofixation quick molding device which includes the computer, the digital projecting apparatus, the lens, the ultraviolet light, the ellipsoidal reflector, the resin canal, the screen, the lifting motion and the striking device. It projects the figure of the CAD section on the surface of the liquid photosensitive resin by the digital projecting apparatus. When the forming layer reaches a solidified degree, the forming platform falls down to the height of a layer thickness, and the surface of the forming layer is covered with the liquid photosensitive resin, then to solidify the next layer. The invention has the high precision and simple process, so it can be used for the quick forming field.

Owner:XI AN JIAOTONG UNIV

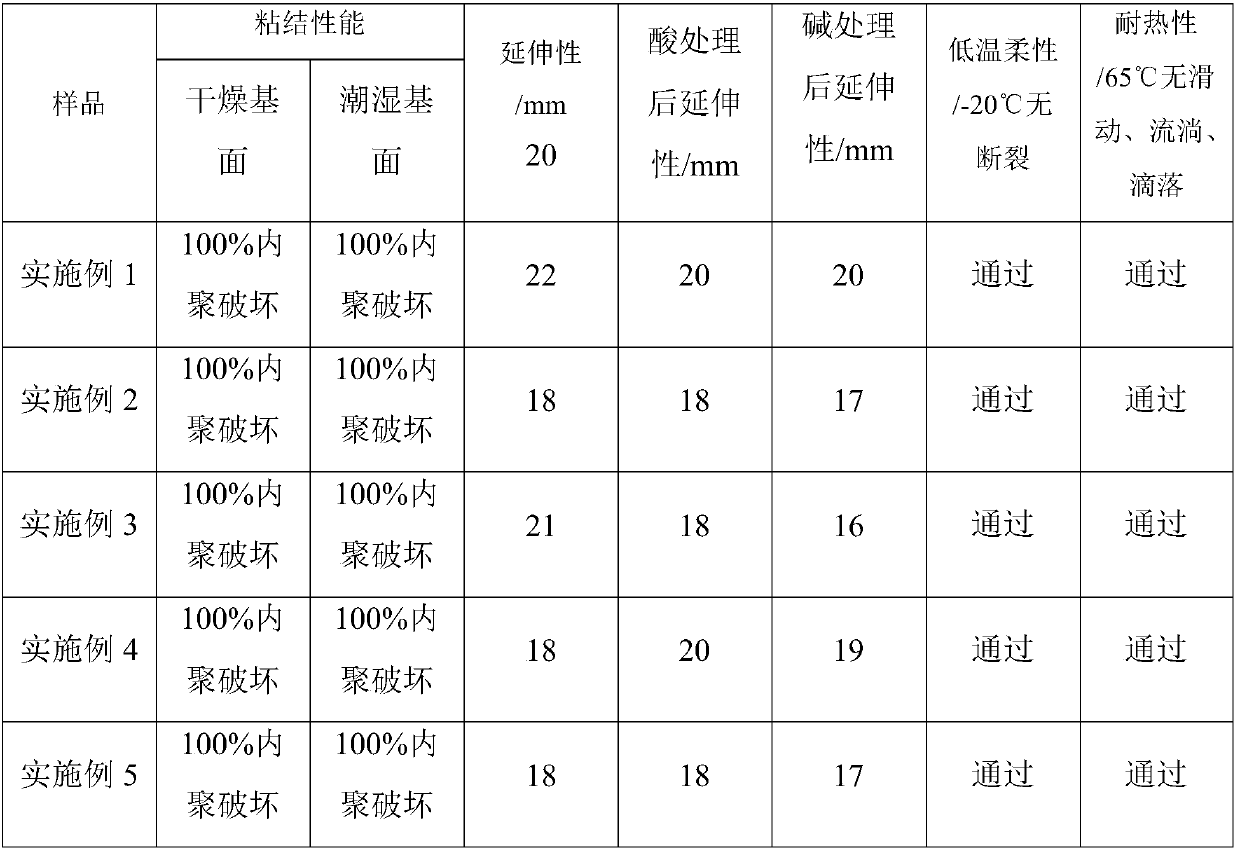

Anionic emulsified modified asphalt and preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating

ActiveCN109575310AGood dispersionHigh strengthConjugated diene hydrocarbon coatingsChloropene polymer coatingsFiberCarbon fibers

The invention discloses anionic emulsified modified asphalt and a preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating. The anionic emulsified modified asphalt is prepared from, by mass, 50-70 parts of matrix asphalt, 1-20 parts of a polymer modifier, 0.5-2 parts of nano carbon fibers, 2-5 parts of a surface modifier, 1-2 parts of an anionic surfactant, 0.1-0.8 part of a pH regulator and 20-40 parts of water. A film formed by the waterproof coating has excellent creep performance and extending performance and is capable of well sealing cracks of a baselayer to effectively resist cracking caused by base layer settlement, deformation and the like, water channeling is prevented, and reliability of an upper waterproof roll is improved.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Photosensitive resin and preparation method thereof

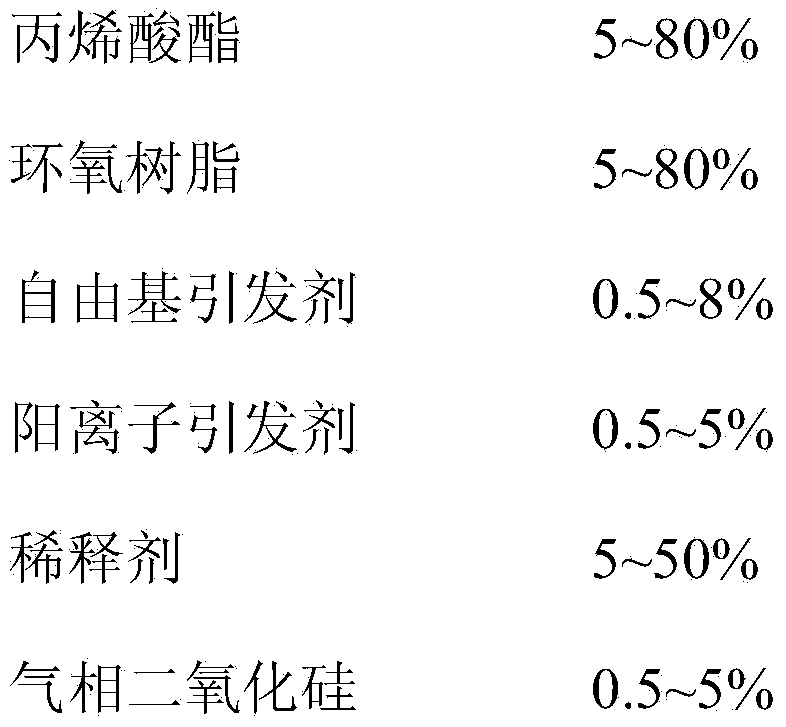

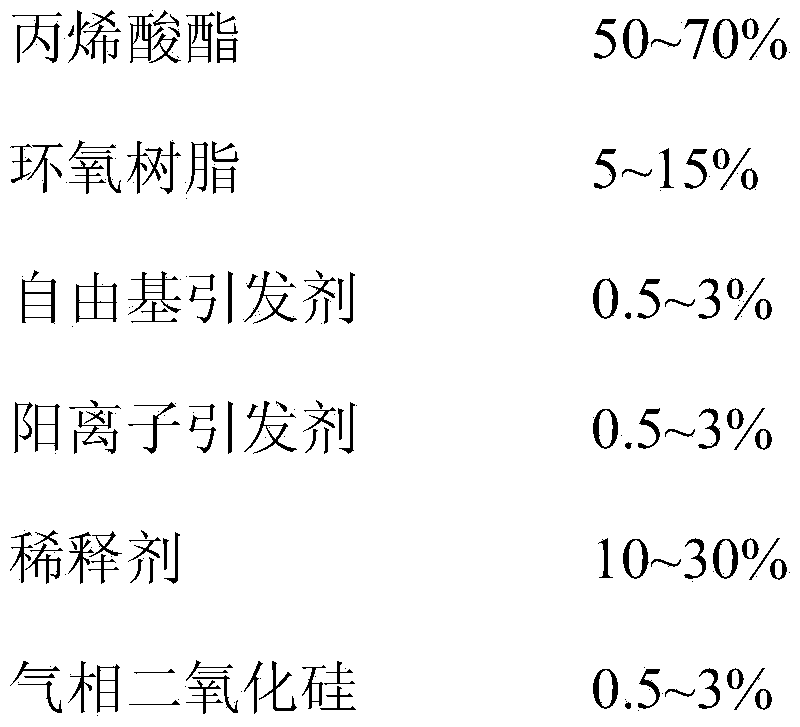

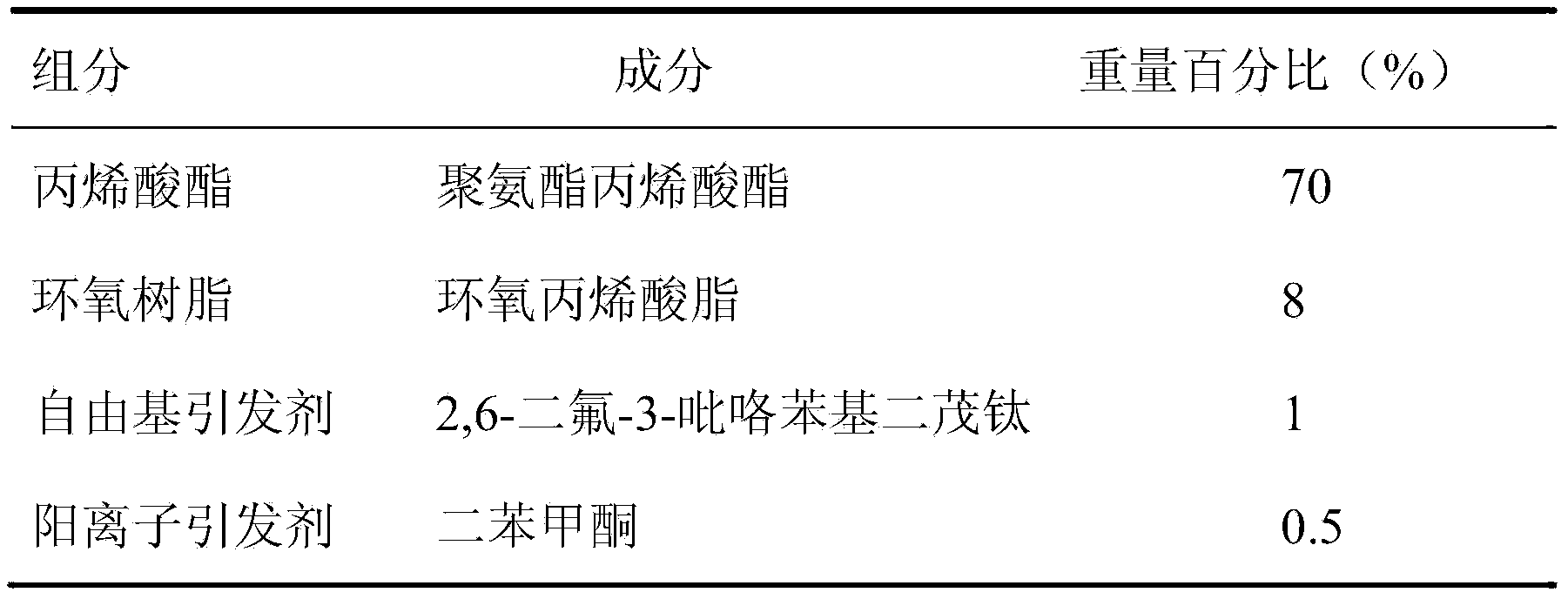

The invention belongs to the field of novel 3D printing materials and in particular belongs to the field of photosensitive resin. The photosensitive resin is prepared from the following components in percentage by weight: 5-80% of acrylic ester, 5-80% of epoxy resin, 0.5-8% of a radical initiator, 0.5-5% of a cationic initiator, 5-50% of a diluent and 0.5-5% of gas phase silicon dioxide. Flexural modulus and tensile modulus of the photosensitive resin reach over 2000Mpa; the photosensitive resin is high in capability of resisting bending deformation stress in an elastic limit, high in strength, low in possibility of deforming and high in mechanical strength; the service life is greatly prolonged; the volume shrinkage rate is about 1.0%; the ultralow volume shrinkage rate is achieved; the industrial use requirement can be met.

Owner:NANJING BAICHUAN XINGYUAN LASER TECH

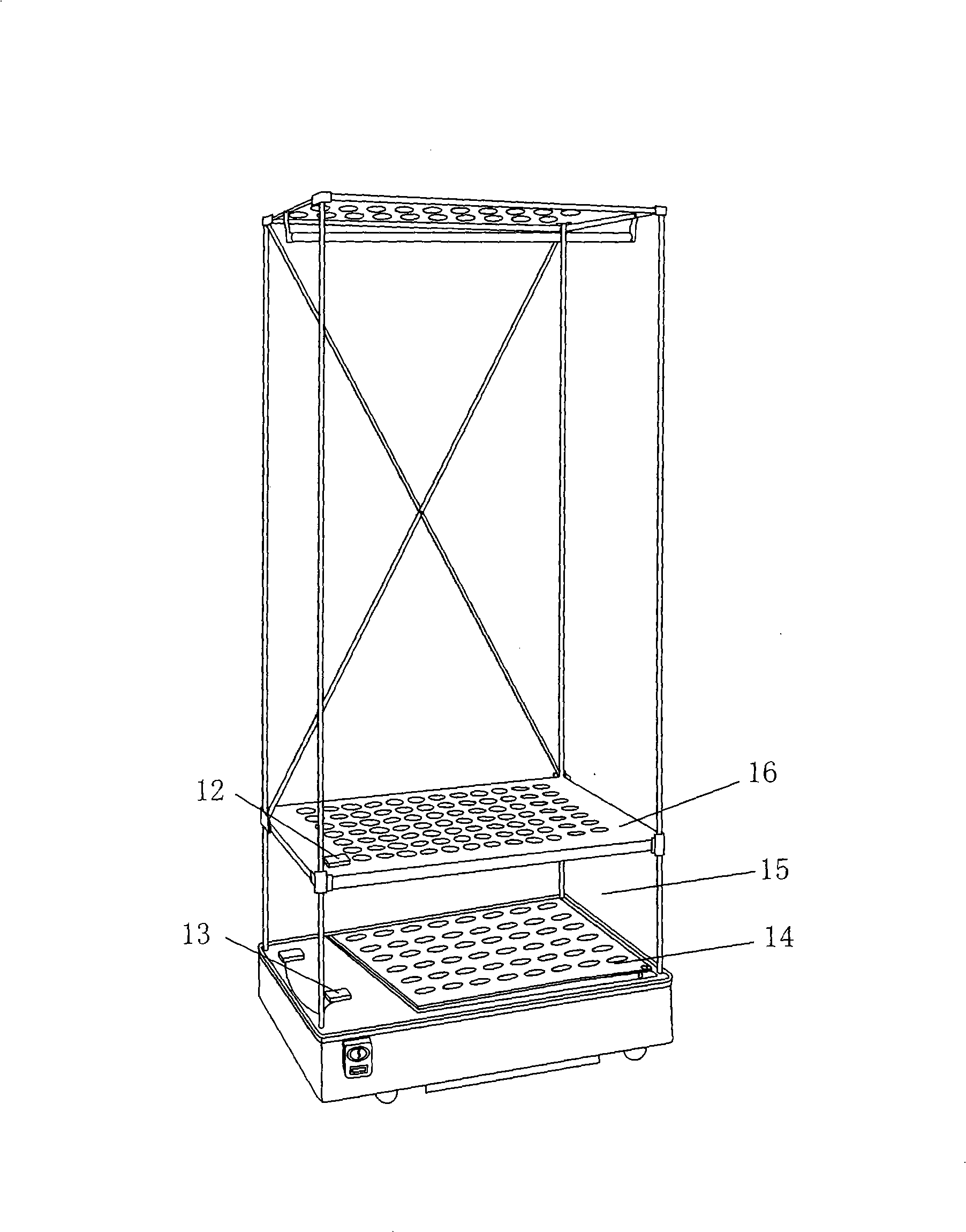

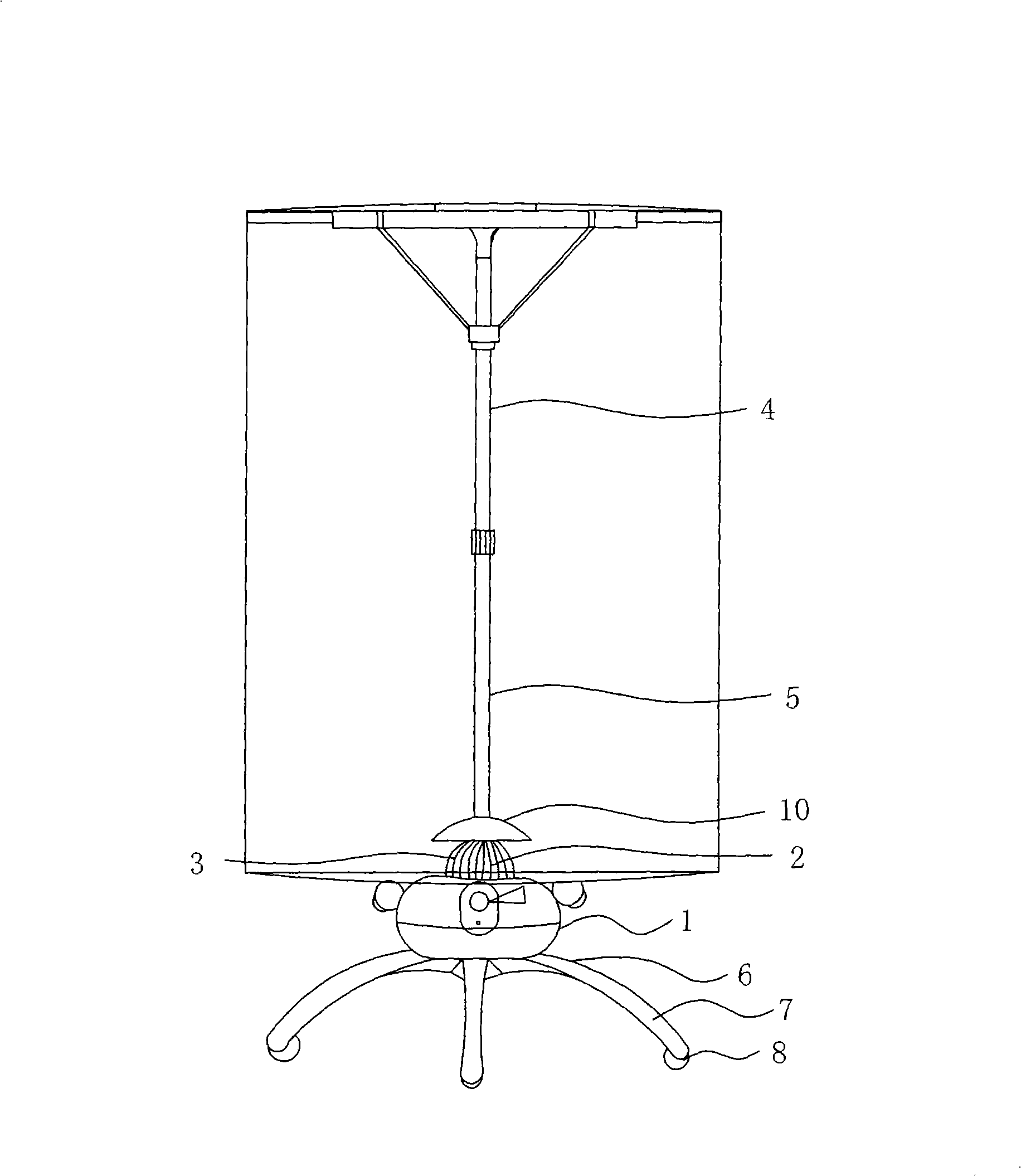

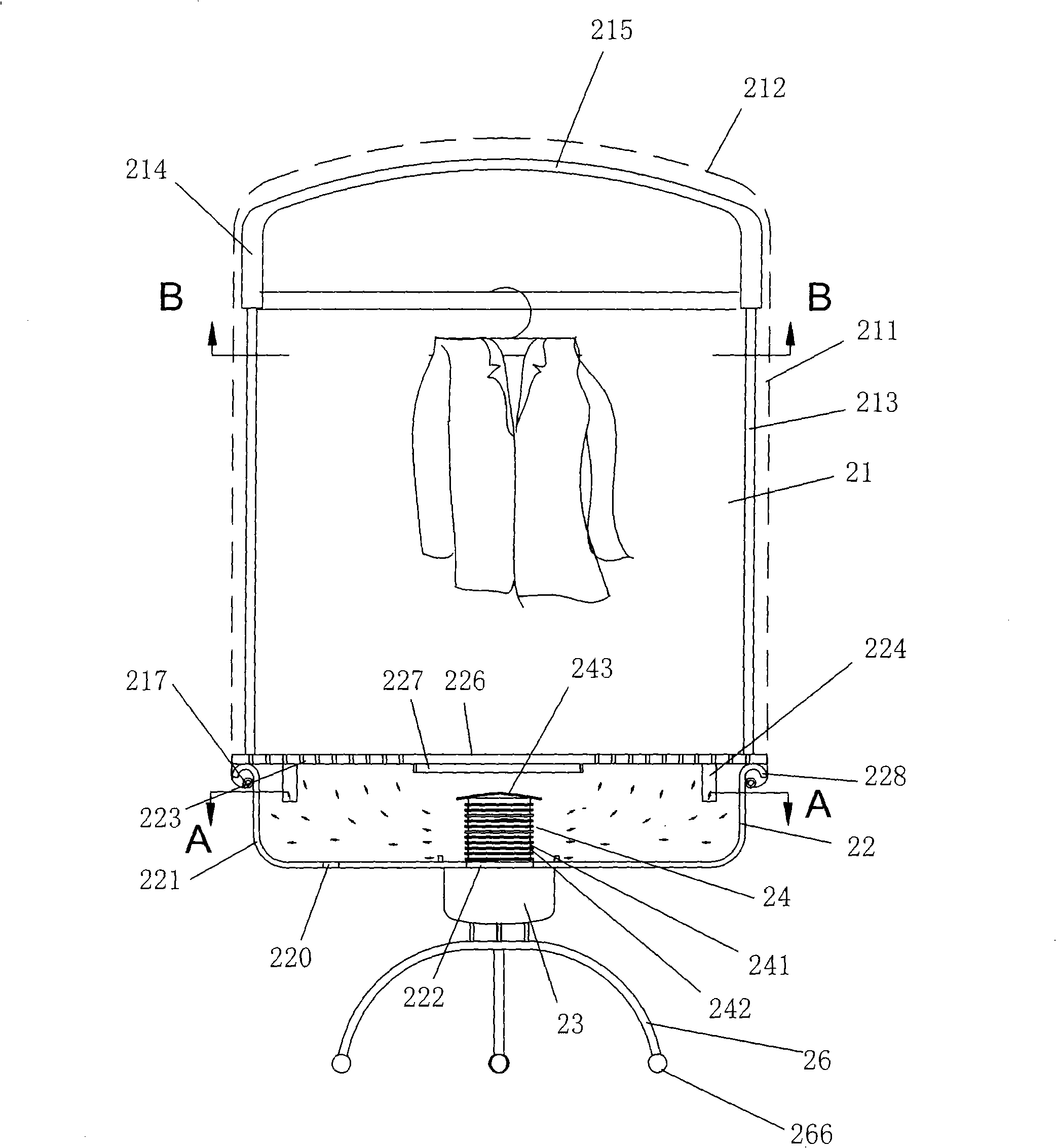

Safe clothes dryer having large spatial structure

ActiveCN101280510ASimple structureEasy to disassembleTextiles and paperLaundry driersEngineeringMechanical engineering

The invention relates to a clothes dryer, in particular to a safety clothes dryer with large-space structure , which comprises a clothes drying room, a hot air abating room, a hot air making room and a controller, wherein the clothes drying room, the hot air abating room and the hot air making room are respectively an independent part and are assembled in sequence from top to bottom. The hot air abating room is arranged below the clothes drying room and is a basin-shaped box with top opening, the bottom of the basin-shaped box is provided with an air intake connected with the hot air making room, an air-guiding safety cover is arranged at the top opening of the basin-shaped box and a clothes drying room installation device is arranged at the top opening of the basin-shaped box. The clothes drying room is composed of a bucket-shaped cloth cover, a support rack for supporting the bucket-shaped cloth cover, a basin-shaped box for forming the hot air abating room, a support member that is inserted connectively at the peripheries of the basin-shaped box and the support rack, a hot air making room, and bottom support feet. The clothes dryer has the advantages of large space, safety use, simple structure, convenient assembly / disassembly, transportation and installation, and that consumer can finish installation only in short time.

Owner:胡杰波

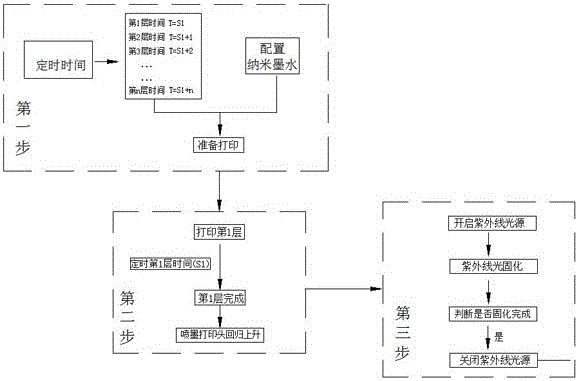

Composite material 3d printing method realized by photocuring-jetting nano ink and printer

InactiveCN106634208AHigh precisionLarge forming sizeAdditive manufacturing apparatusInksGraphicsNarrow range

The invention discloses a composite material 3d printing method realized by photocuring-jetting nano ink, and the method comprises the following steps: preparing the nano ink; by means of micro-droplet jetting, jetting the nano-ink by an ink-jet print head; dividing three-dimension modeling into a plurality of two-dimension graphs, and calculating the print time for each graph; according to the print time for each graph, turning on an ultraviolet light source in a fixed time, monitoring the temperature of curing regions in real time by a temperature sensor, monitoring the curing moulding status of nano-particle ink in printing regions, and turning off the ultraviolet light source after curing is finished; and performing printing layer by layer, and performing curing layer by layer, so as to finish product printing. The method is suitable for printing ceramics, glass, nylon or plastic products; by using the ultraviolet light for curing moulding, the technical problems in an existing 3D printing technology on narrow range of material choice, poor moulding precision, small moulding size, slow moulding speed and the like are solved. The invention also discloses a micro-droplet-jetting 3d printer which is suitable for 3D printing in the above method.

Owner:安徽泰尔控股集团有限公司

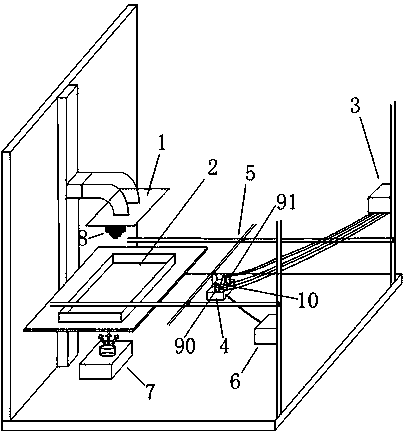

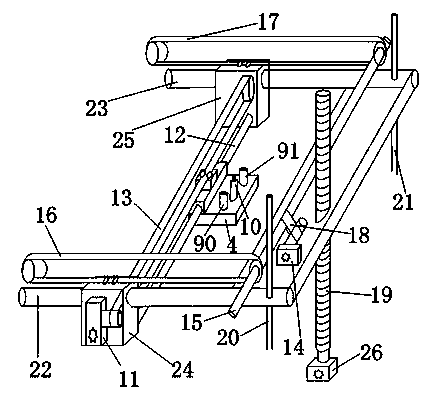

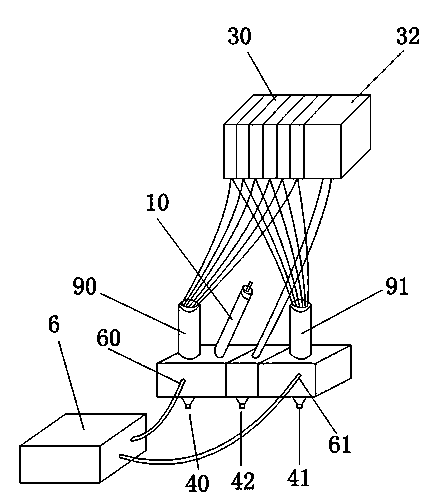

Micro-nano three-dimensional printing nozzle device

ActiveCN103407163AFast molding speedHigh forming precisionElectrostatic spraying apparatus3D object support structuresMicro nanoEngineering

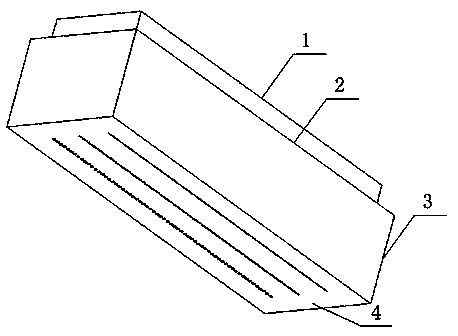

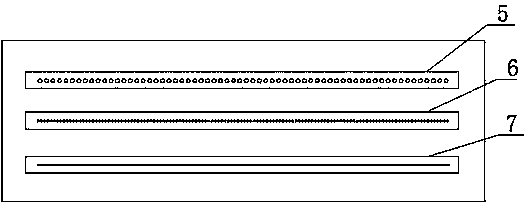

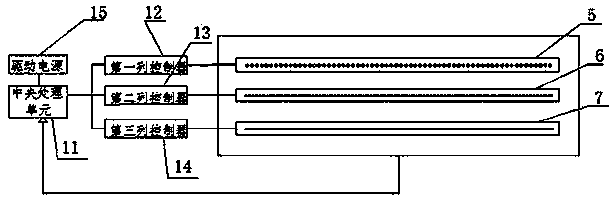

The invention discloses a micro-nano three-dimensional printing nozzle device. The three-dimensional printing nozzle device comprises a controller, a storage bin and a nozzle main body part. The nozzle main body part comprises three groups of spray orifice arrays with different diameters, and the spray orifice arrays are respectively an A group spray orifice array, a B group spray orifice array and a C group spray orifice array. The three groups of the spray orifice arrays with the different diameters are connected to three nozzles respectively. The controller comprises a central processing unit, a controller for the first spray orifice array, a controller for the second spray orifice array, a controller for the third spray orifice array and a driving power source. The central processing unit controls and switches working of the controller for the first spray orifice array, the controller for the second spray orifice array and the controller for the third spray orifice array by outputting different pulse signals. The controller for the first spray orifice array, the controller for the second spray orifice array and the controller for the third spray orifice array respectively control a working state of each spray orifice in each of the three groups of the spray orifice arrays with the different diameters. According to the three-dimensional printing nozzle device, rapid rough machining is performed by utilization of the work of the large-diameter spray orifices and slow finish machining is performed by utilization of small-diameter spray orifices, thus achieving macro-micro composited three-dimensional rapid moulding.

Owner:GUANGDONG RATIONAL PRECISION INSTR

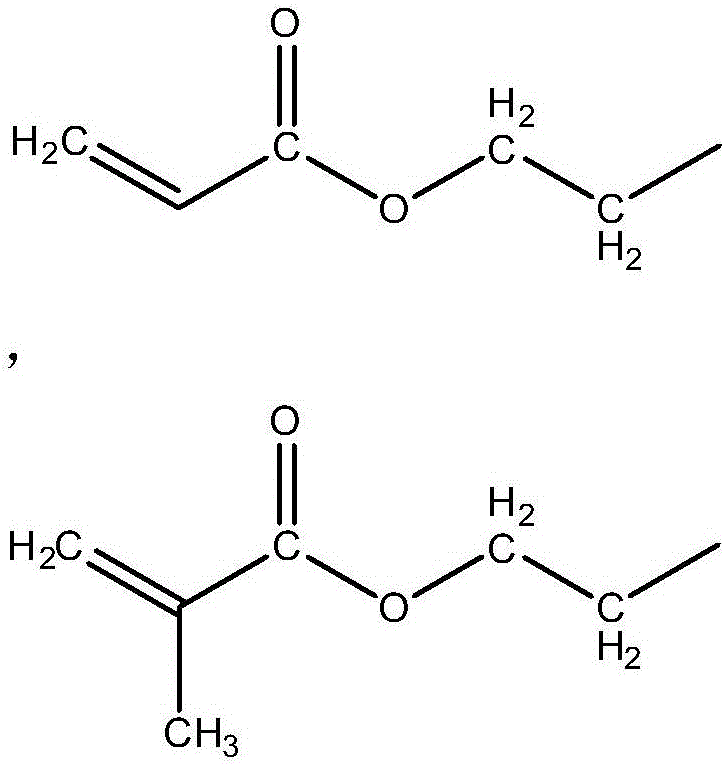

Elastic photosensitive resin for 3D printing of digital light processing (DLP) and preparation method of elastic photosensitive resin

The invention belongs to the field of a high molecular material, and particularly relates to photo-cured elastic photosensitive resin with wavelength being 405 nanometers for 3D printing of digital light processing (DLP). The elastic photosensitive resin comprises the following raw materials based on parts by weight: 10-50 parts of elastic acrylate, 30-70 parts of active diluents, 1-10 parts of photoinitiator, 0.01-0.05 part of flatting agent, 0.01-0.05 part of dispersning agent and 0.01-0.05 part of polymerization inhibitor. The elastic photosensitive resin can be directly used for 3D printing of DLP or can be mixed with other existing photosensitive resin, a product with a complicated structure and certain elasticity can be printed, meanwhile, the elastic photosensitive resin has the characteristics of small volatile odor, rapid formation speed, small product shrinkage rate, high formation accuracy and the like.

Owner:广州谱睿汀新材料科技有限公司 +1

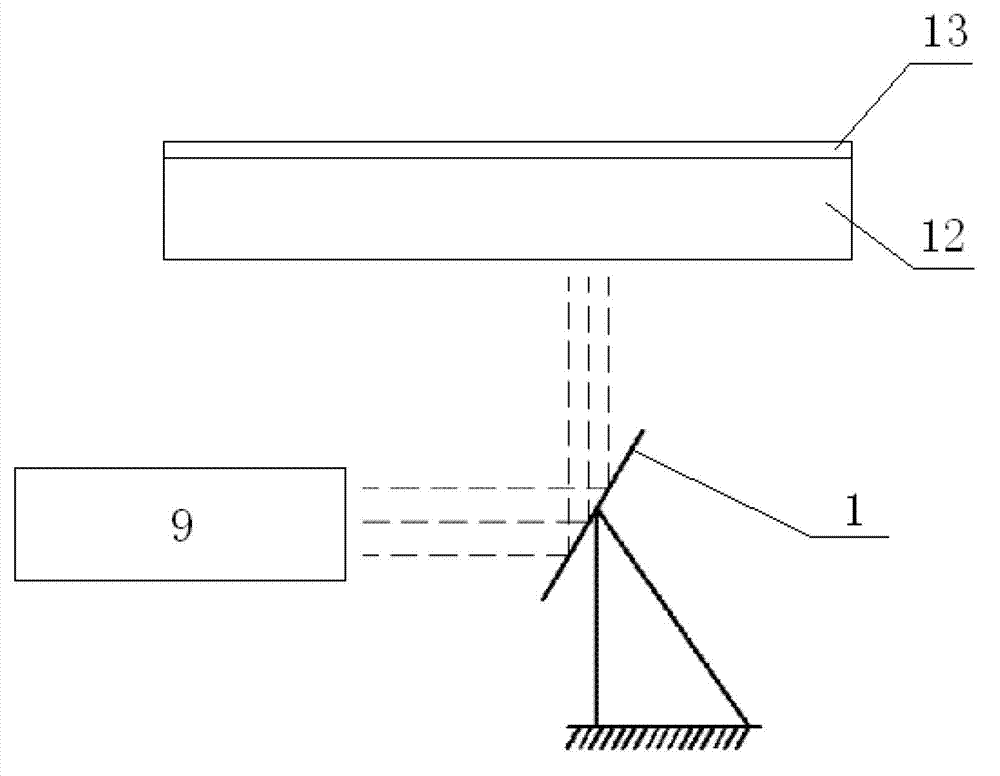

Planar stereo lithography apparatus and method

ActiveCN103203875AFast molding speedEquipment structure and process simplificationEngineeringLithography

The invention provides a planar stereo lithography apparatus and method. The apparatus comprises an ultraviolet light digital projector, a resin storage tank and a workbench, wherein the bottom of the resin storage tank is prepared from glass which allows ultraviolet light to be transmitted, and a gap used for filling resin liquid is arranged between the lower end face of the workbench and the bottom of the resin storage tank. The resin liquid is injected into the gap located between the resin storage tank and the workbench; the contour of an ultraviolet light layer of an entity part generated by using a digital projection method forms an image on the resin liquid through a base plate of the resin storage tank so as to obtain a solidified layer with the contour of a corresponding layer; the workbench is lifted a layer higher, then the resin liquid is injected into a gap between the lower end face of the solidified layer and the resin storage tank, and exposure and solidification of a next layer are carried out. According to the invention, the problem of buckling deformation after stereo lithography is overcome, and the advantages of high molding precision, a fast molding speed, a simple process and low cost are obtained.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

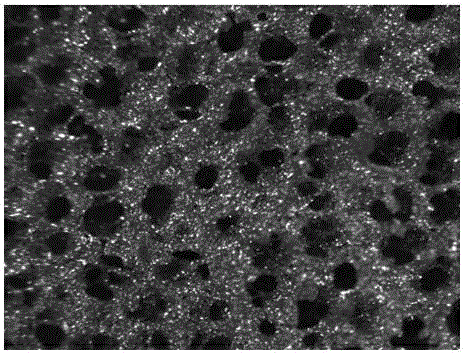

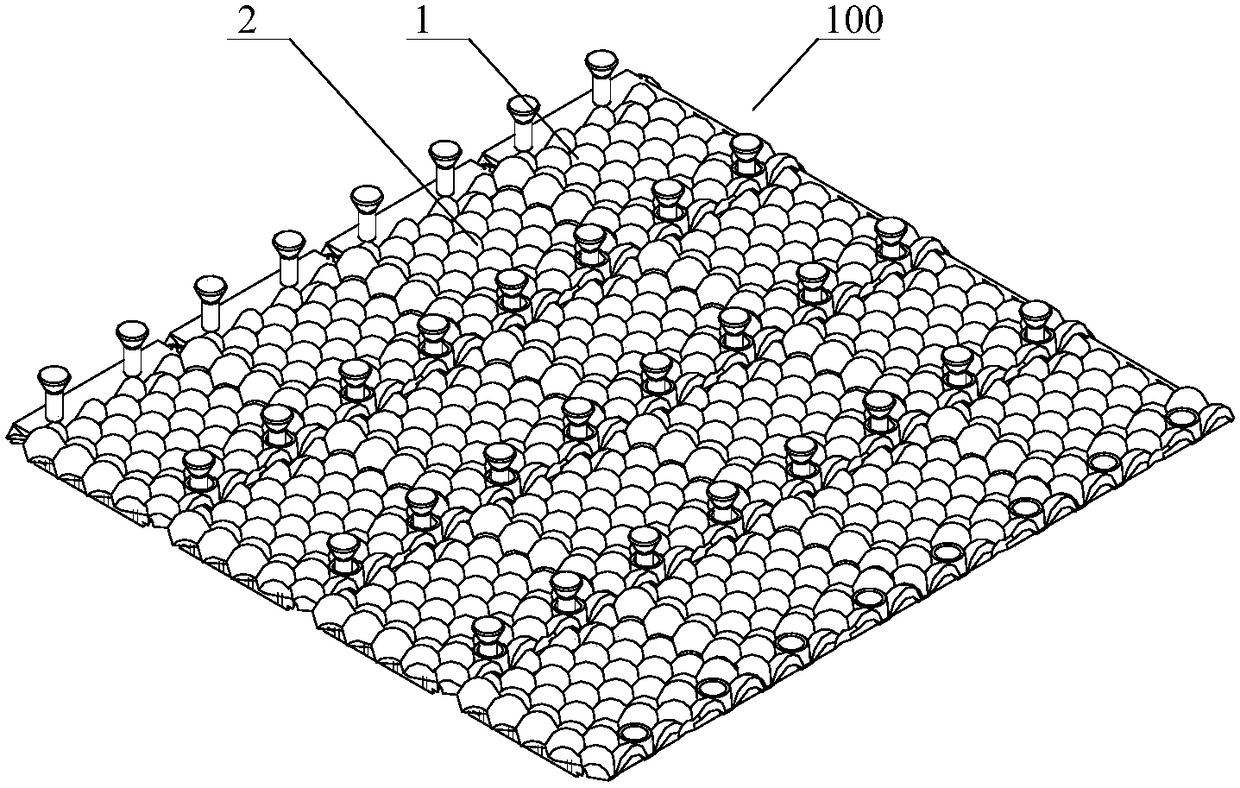

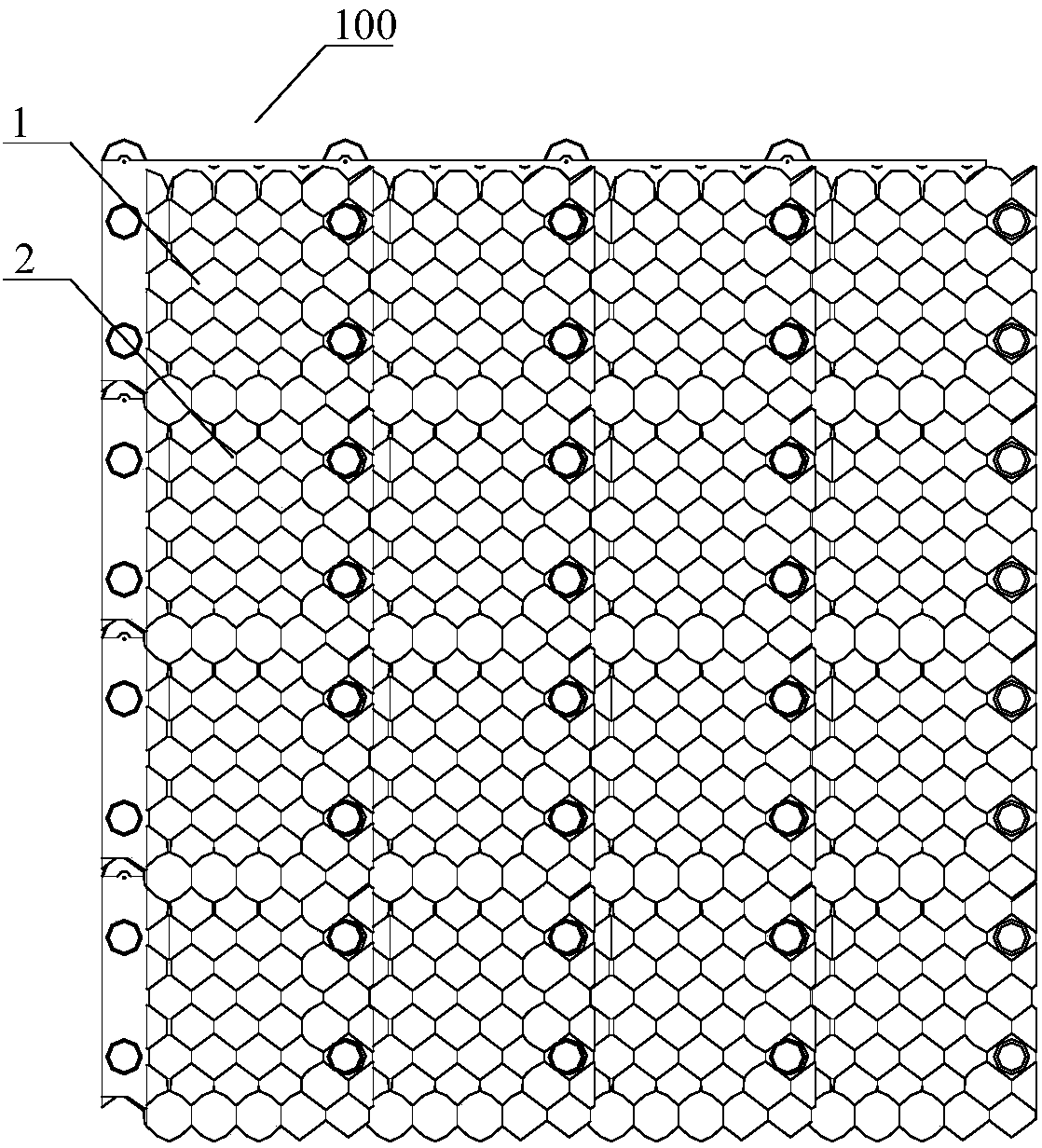

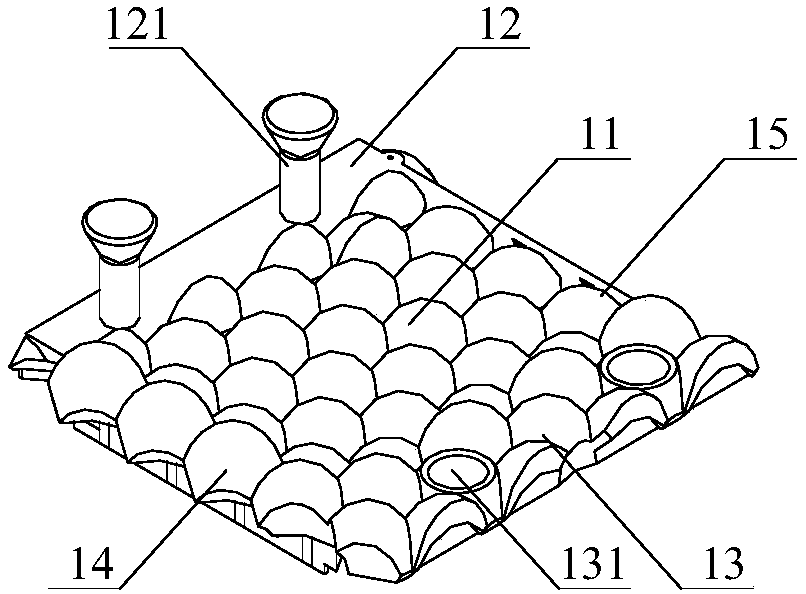

Armour splicing-type stab-proof vest based on hollow micro-egg shell structure

PendingCN108095222AIncrease flexibilityReduce heat and moisture resistanceProtective garmentPlastic materialsMoisture permeability

The invention discloses an armour splicing-type stab-proof vest based on a hollow micro-egg shell structure. The stab-proof vest comprises a plurality of stab-proof sheet sets, each stab-proof sheet set comprises a first stab-proof base plate and a second stab-proof base plate connected with the first stab-proof base plate, the first stab-proof base plate and the second stab-proof base plate are made of a plastic material by means of a 3D printing-laser sintering technology, and the first stab-proof base plate in each stab-proof sheet set is connected with the first stab-proof base plate and the second stab-proof base plate in adjacent stab-proof sheet set. Compared with an existing stab-proof vest, the armour splicing-type stab-proof vest uses an arrangement mode of hierarchical overlapping of animal scales and shells for reference, all the stab-proof base plates are horizontally arranged according to the arrangement of upper-lower layering, overall surface density is reduced, overallcomfort and flexibility are improved, and diathermanous effects and moisture permeability effects are improved; a plurality of hollow semi-ellipsoidal shells are sequentially arranged in a staggeredmanner to effectively disperse the impact force of sword stabbing, and the stab-proof performance of the stab-proof base plates can be enhanced; the stab-proof vest has the advantages of simple production process, high efficiency, light weight, raw materials savings, low cost and good market competitiveness.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

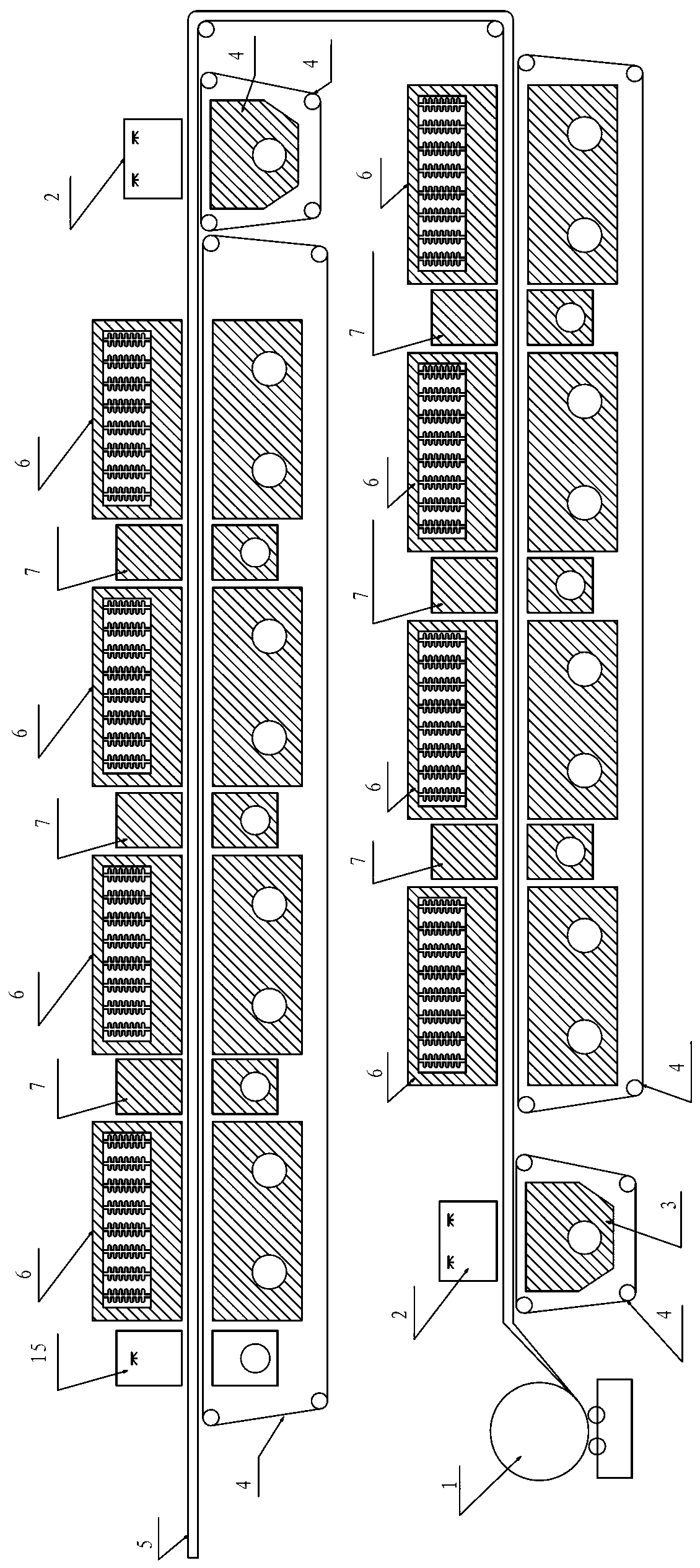

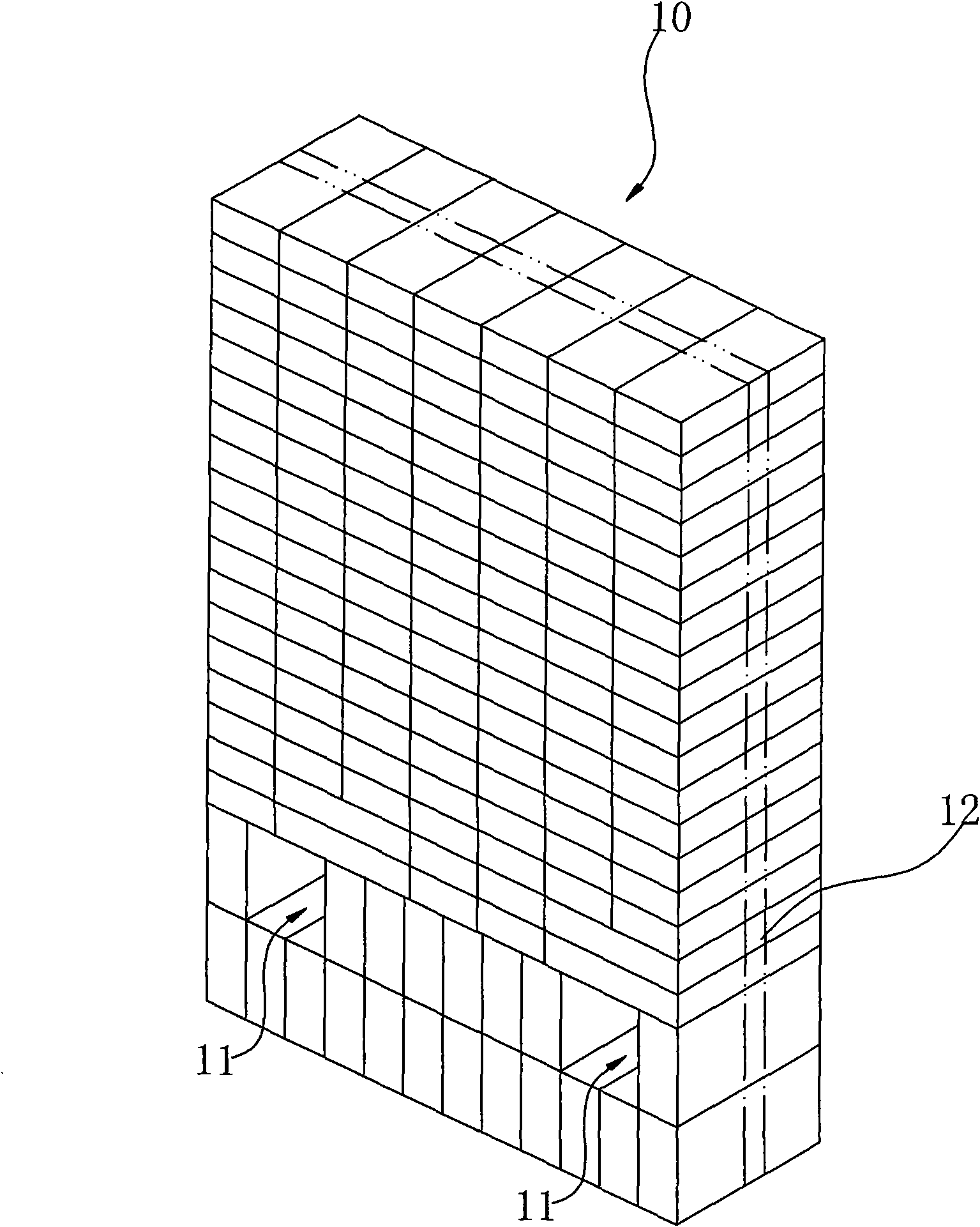

Device and method for automatically stacking and packaging bricks

InactiveCN101870369AFast molding speedReduce wasteBuilding material packagingBrickMechanical equipment

The invention relates to a device and a method for automatically stacking and packaging bricks, in particular to bricks for building and a series of automatic machinery. The device comprises an accepting device, an aligning device, a line conveying stacking device group, a hanging clip hook device group, a conveying belt, and the like. The device can automatically stack pre-determined number of bricks with required volume through the one-by-one conveying operation of the conveying belt and the corresponding one-by-one capturing shifting operation of the hanging clip hook devices of the hanging clip hook device group; and with cooperation of a packaging machine, the device can perform automatic packaging operation; and two long rectangular grooves are reserved on the second layer of bricks and are used for inserting two inserted links of a fork lift truck. The device stacks and packages the bricks according to the required number and volume layer by layer by using automatic mechanical equipment and has the advantages of reducing labor waste, increasing the forming speed of brick stacking and packaging and increasing the use value in industry.

Owner:陈有福

High grade highway pavement double-layer micro-surfacing and construction method thereof

InactiveCN1667194AImprove shear resistanceImprove adhesionIn situ pavingsPolymer modifiedPortland cement

The invention relates to a high grade road surface double layer micro-process and the construction method. The construction water proof layer is laid on the road surface, and a skid resistance wearing coat is laid on the construction water proof layer. The amounts by weight or volume of water proof layer is that: aggregate is 100; polymer modification positive ion emulsified asphalt is 8 to 16; water is 6 to 11; Portland cement or slaked lime is 1 to 4; and additive is 0.1 to 0.5. The amounts by weight of skid resistance wearing coat is that: aggregate is 100; polymer modification positive ion emulsified asphalt is 6 to 11; water is 7 to 13; Portland cement or slaked lime is 1 to 3; and additive is 0.1 to 0.5. The construction process is the following steps: cleaning the road surface, laying out, laying water proof layer, laying skid resistance wearing coat, early days conserving and quality checking out. The invention is reasonable designed, good performance of water proof, and fast moulding.

Owner:西安高远公路养护技术有限公司

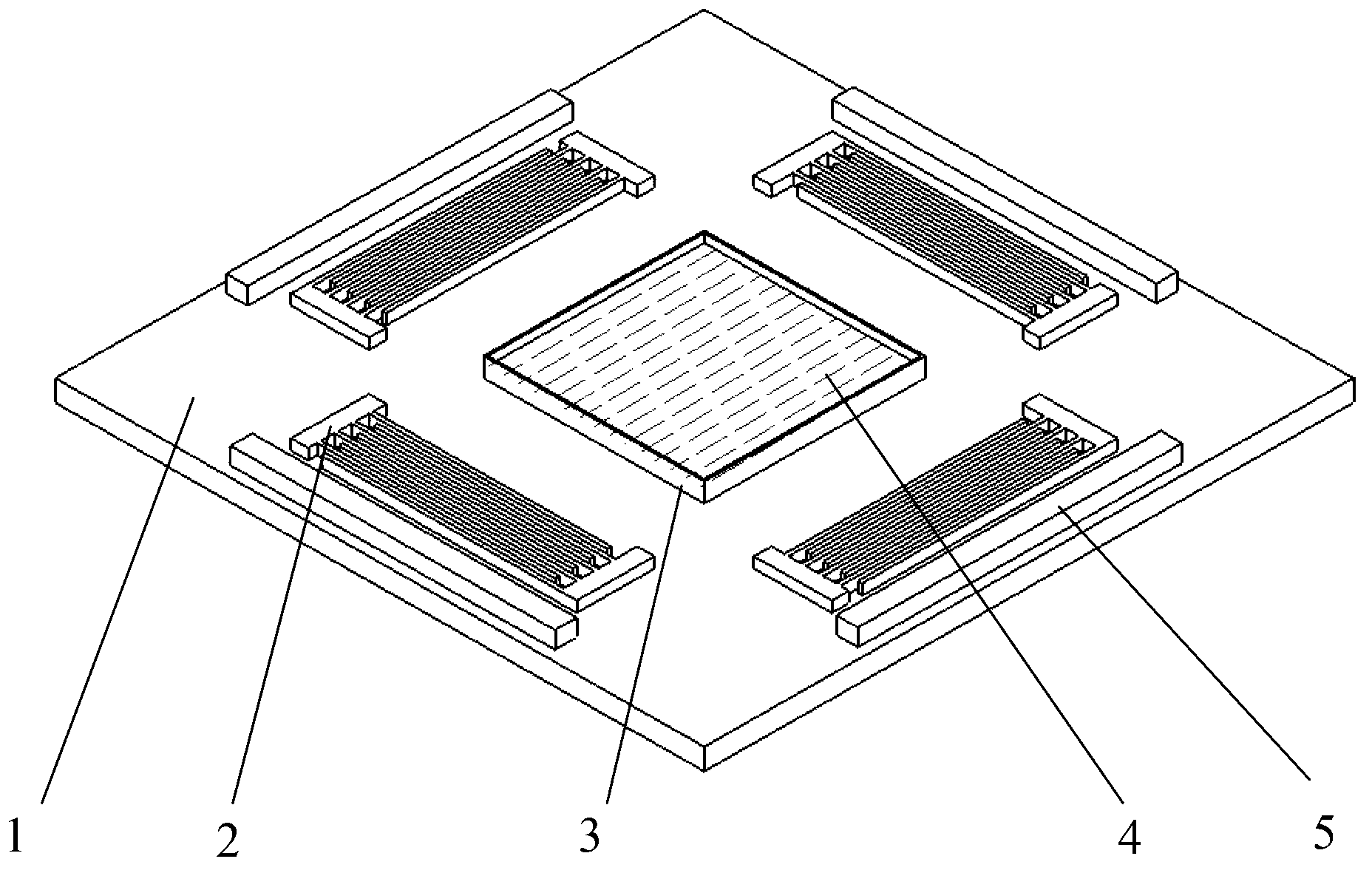

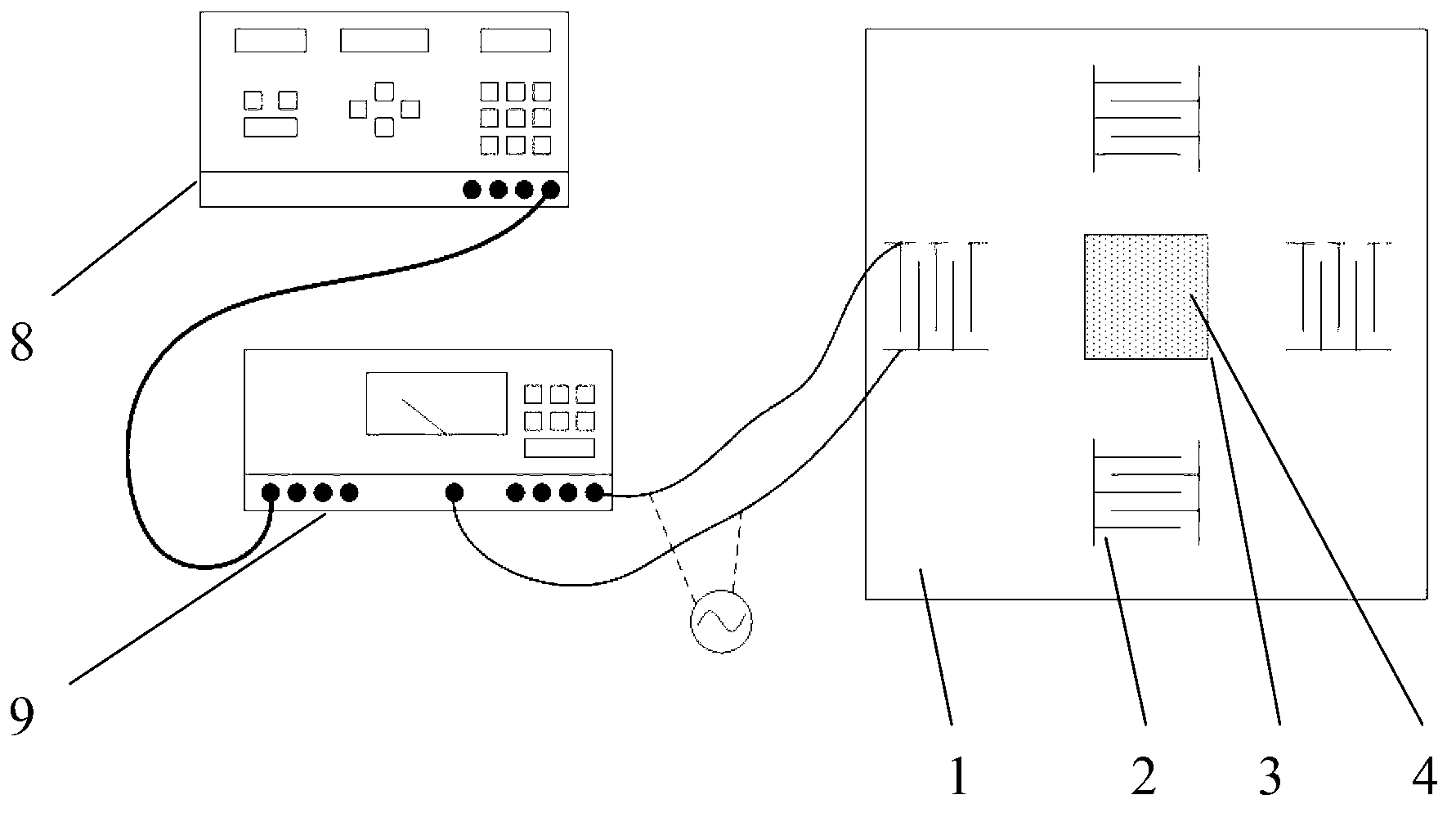

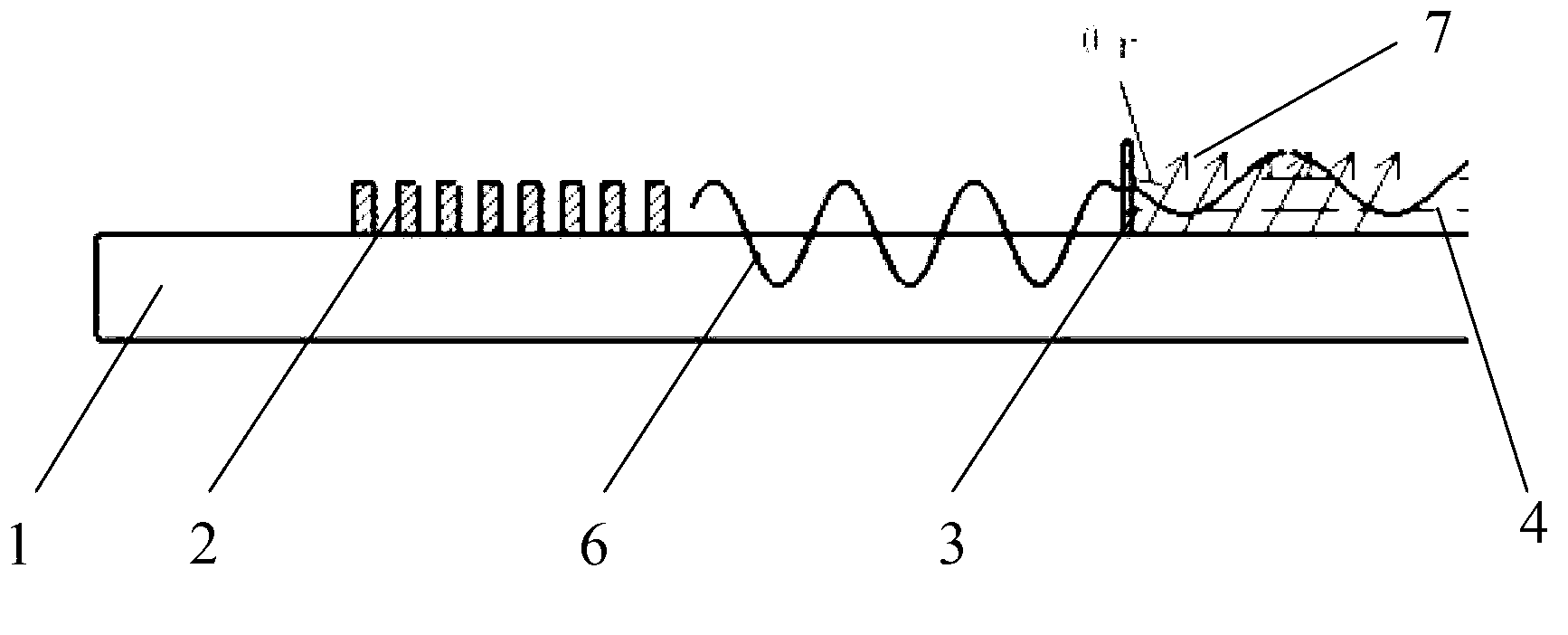

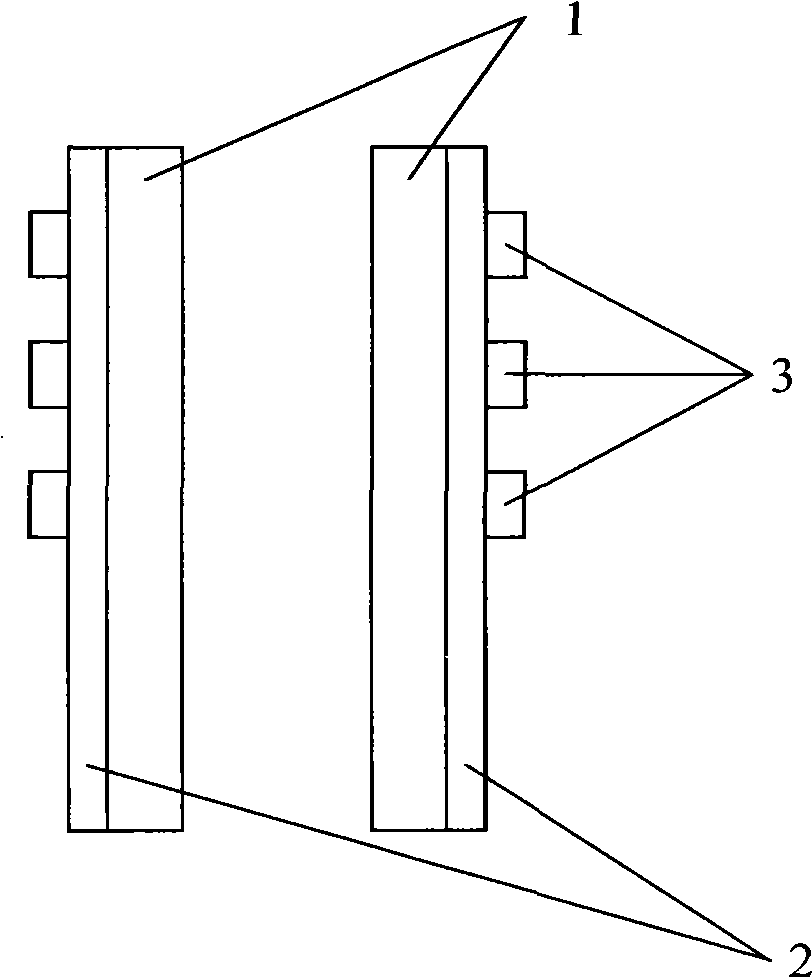

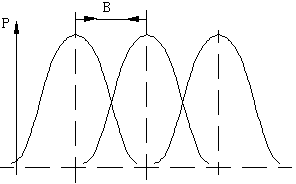

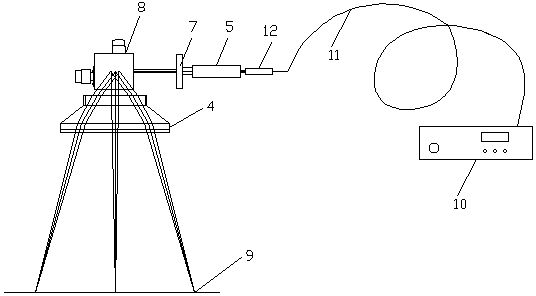

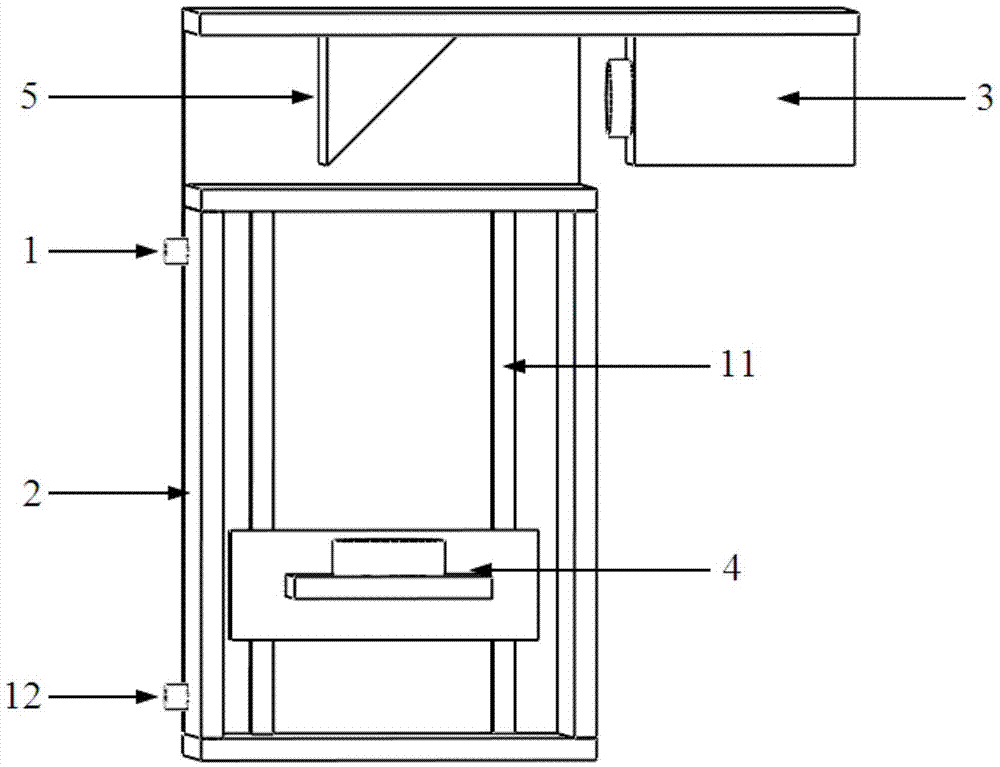

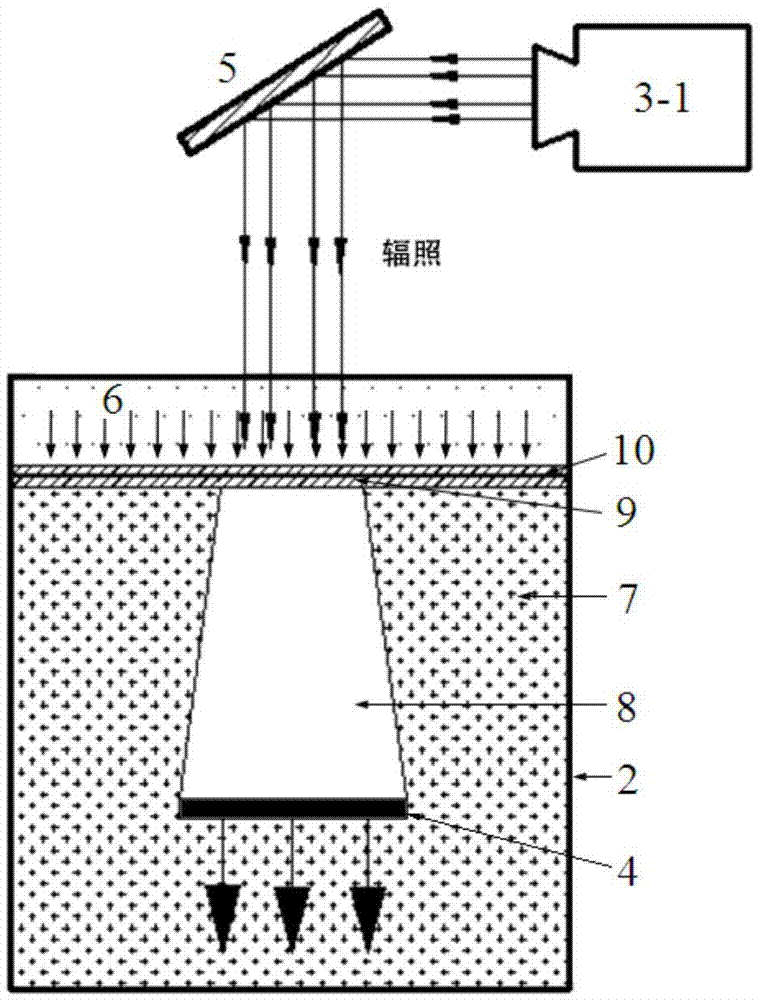

Microarray die-free forming device based on surface acoustic wave and forming method

The invention discloses a microarray die-free forming device based on a surface acoustic wave and a forming method. The technical scheme is that a square piezoelectric matrix plate is provided with two pairs of interdigital transducers in a photoetching manner, each pair of interdigital transducers is symmetrically arranged with a center shaft of the square piezoelectric matrix plate as an axis, a square glass fluid tank is placed in the middle of the piezoelectric matrix plate and adhered to the piezoelectric matrix plate, and a formed liquid-state material is accommodated in the glass fluid tank. An ultrasonic surface wave is transmitted in the piezoelectric matrix plate, the energy of the ultrasonic surface wave is leaked into the formed liquid-state material within a certain angles to form a sound field, a signal generator and a power amplifier are adjusted to change amplitude values, frequency and phases of the ultrasonic surface wave, so that a required stable microarray structure is formed on the surface of the formed liquid-state material, and the microarray structure is cured and formed through ultraviolet irradiation. The microarray die-free forming device based on the surface acoustic wave and the forming method have the advantages that the sound field is adopted to manufacture the surface microarray structure through rapid forming in the liquid-state material, the die is not required, the manufacturing process is simple, the equipment requirement is low, the operation is simple and convenient, the production cost is low, and the material usage rate and the production efficiency are high.

Owner:ZHEJIANG UNIV

Method for preparing porous ceramic support

The invention discloses a method for making a porous ceramic support body. The method comprises the following steps that: (1) a step of ceramic powder pretreatment, during which, ceramic powder and a pore-forming material are evenly ground with the weight of the pore-forming material is 5 to 30 percent of that of the ceramic powder; (2) a step of slurry preparing, during which, a forming agent is dissolved in a solvent and then is added in the pretreated ceramic powder so as to be ground evenly; the forming agent is polysulfone or polyethersulfone and the solvent can dissolve the forming agent; moreover, the weight percent of the forming agent, the solvent and the pretreated ceramic powder is 1 to 15 percent : 2 to 30 percent : 55 to 97 percent; (3) a step of making green compact, during which, slurry is made into green compact and then is dipped in pure water so as to carry out forming; and (4) a step of high-temperature sintering. The method has high rate of finished products and quick making speed and can be used in the solid oxide fuel cell field.

Owner:SOUTH CHINA UNIV OF TECH

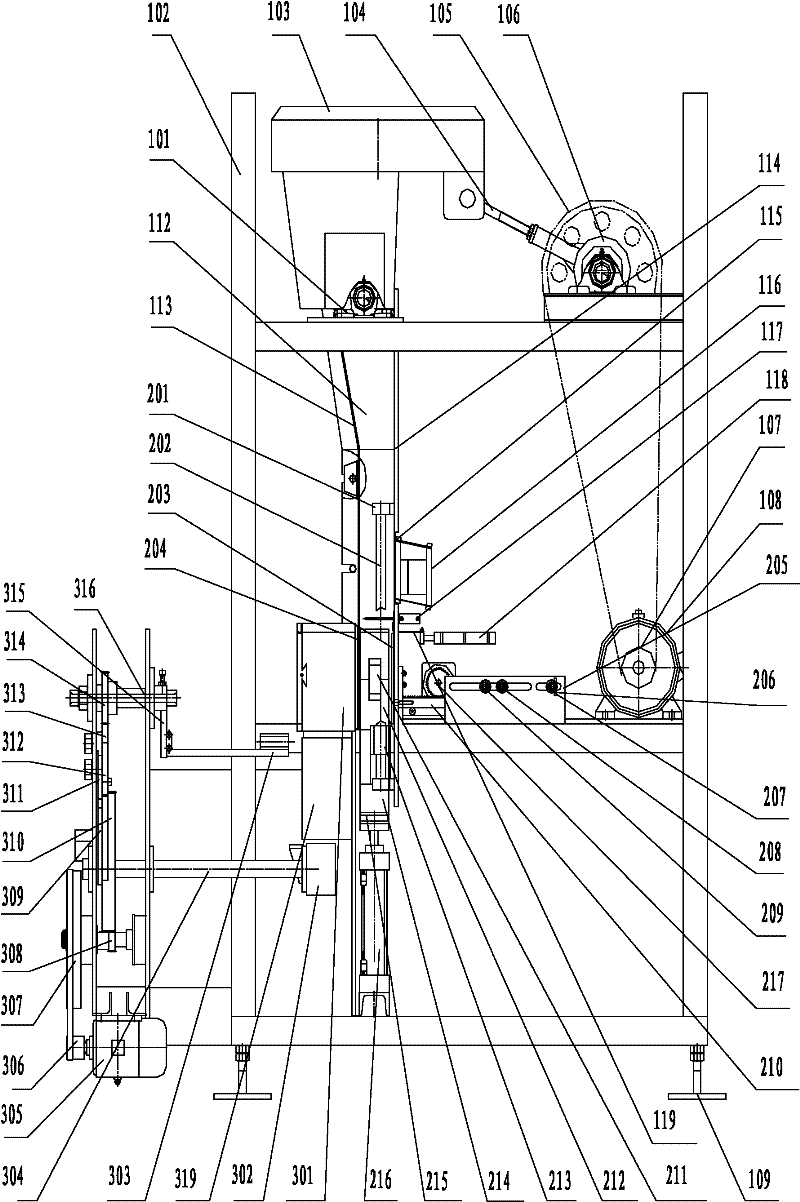

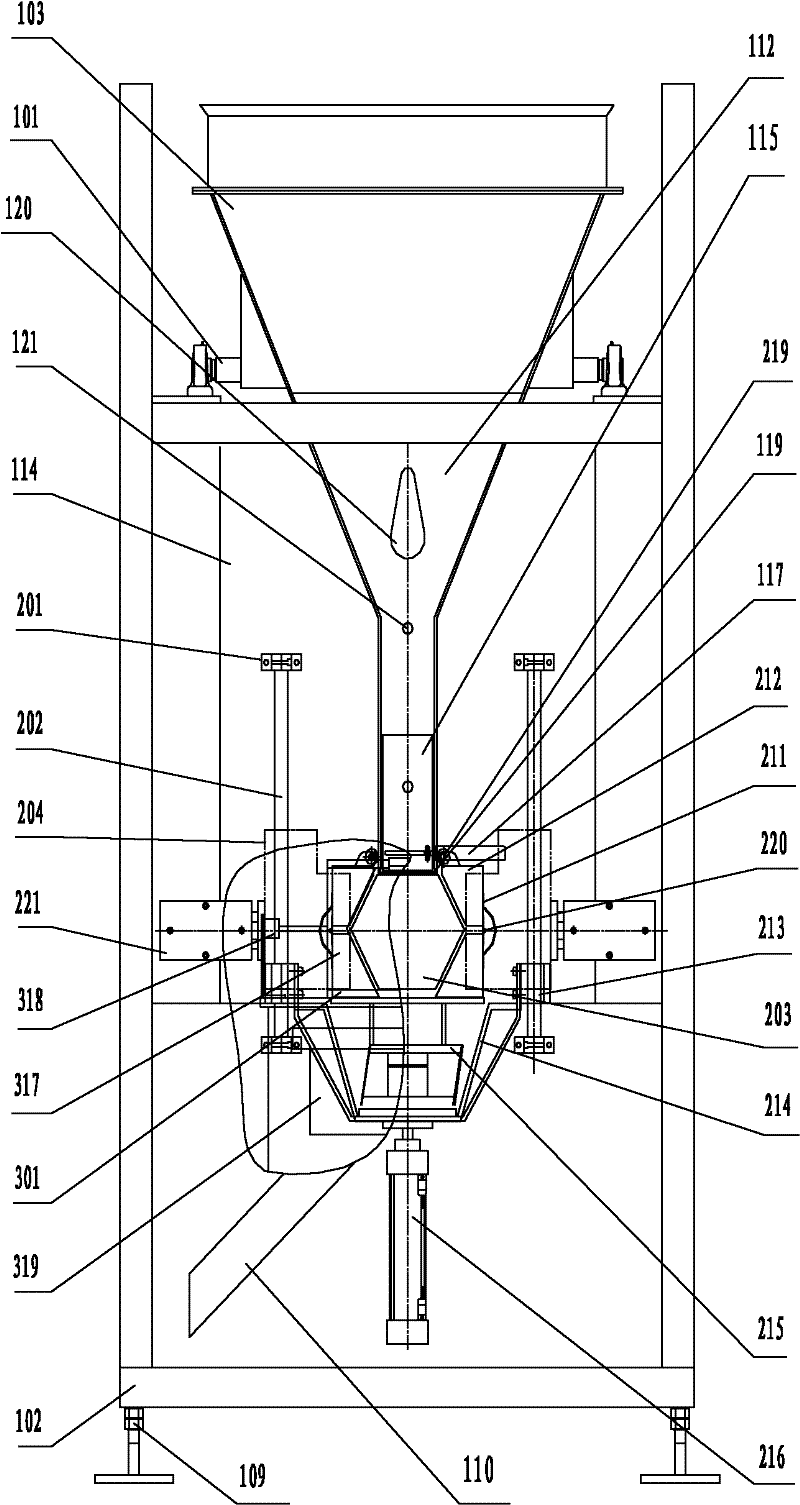

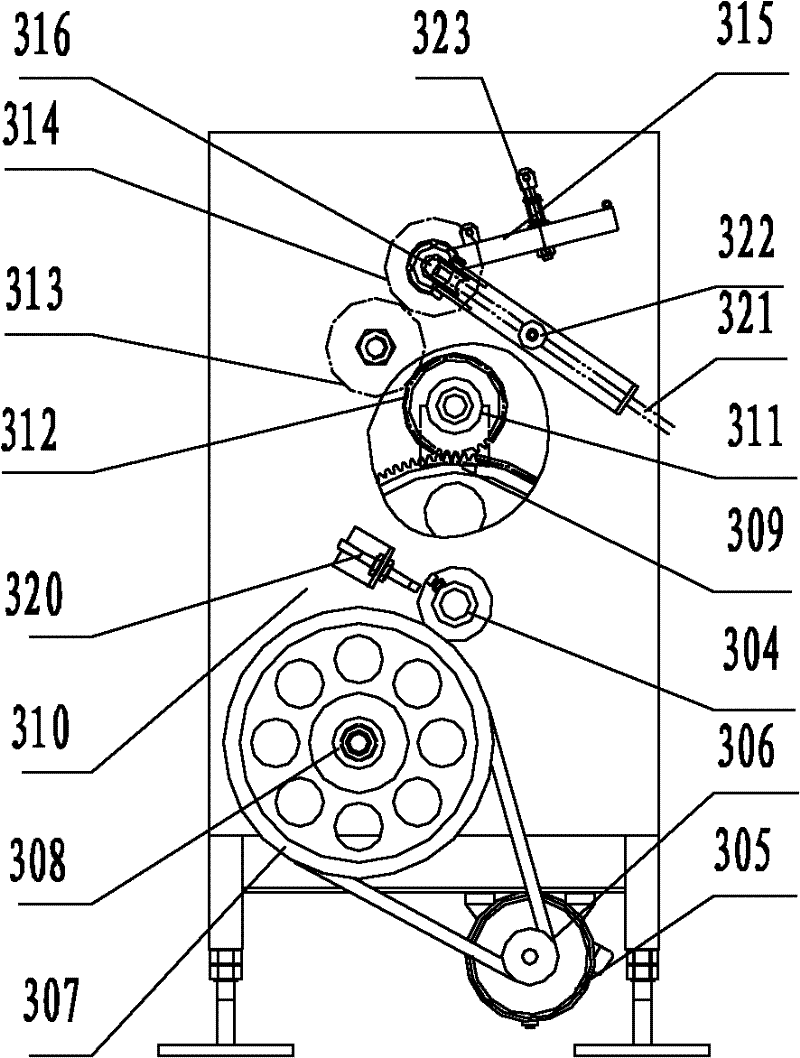

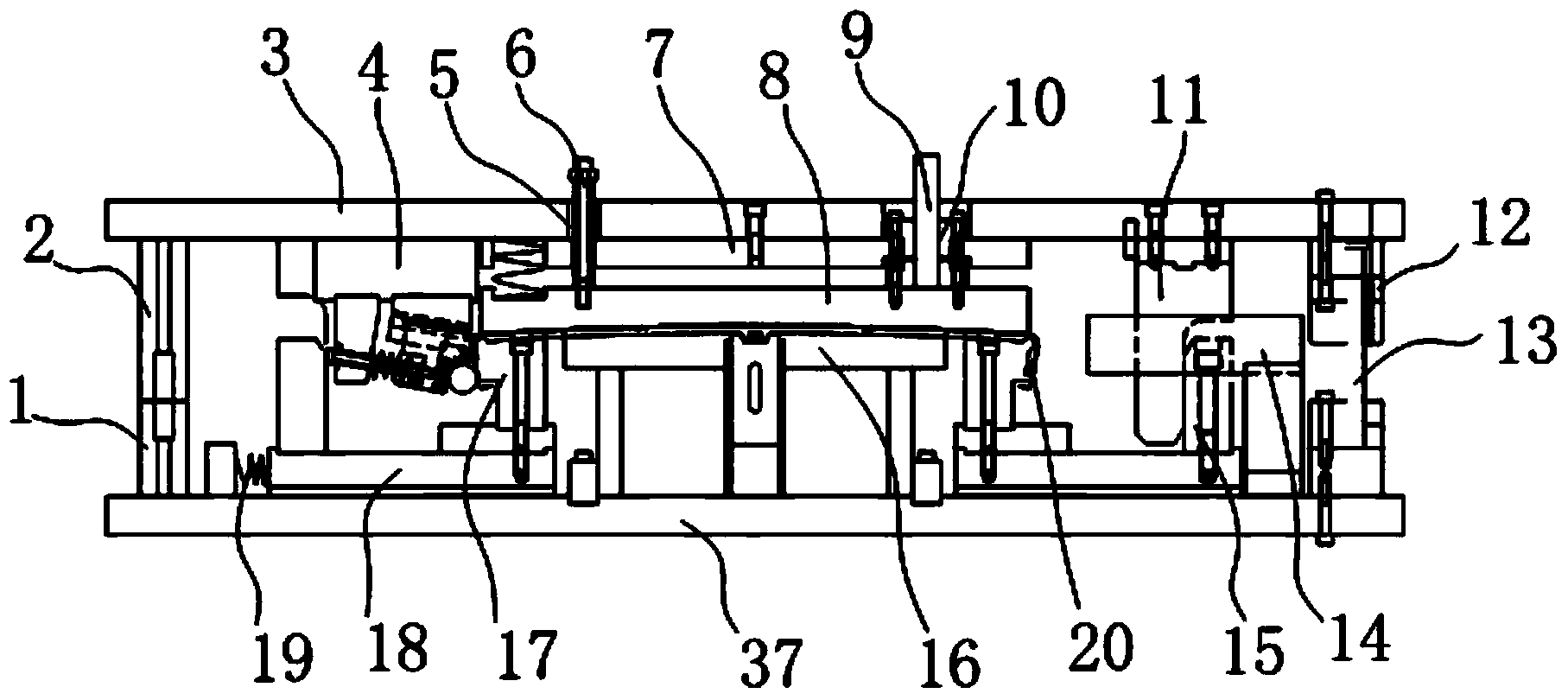

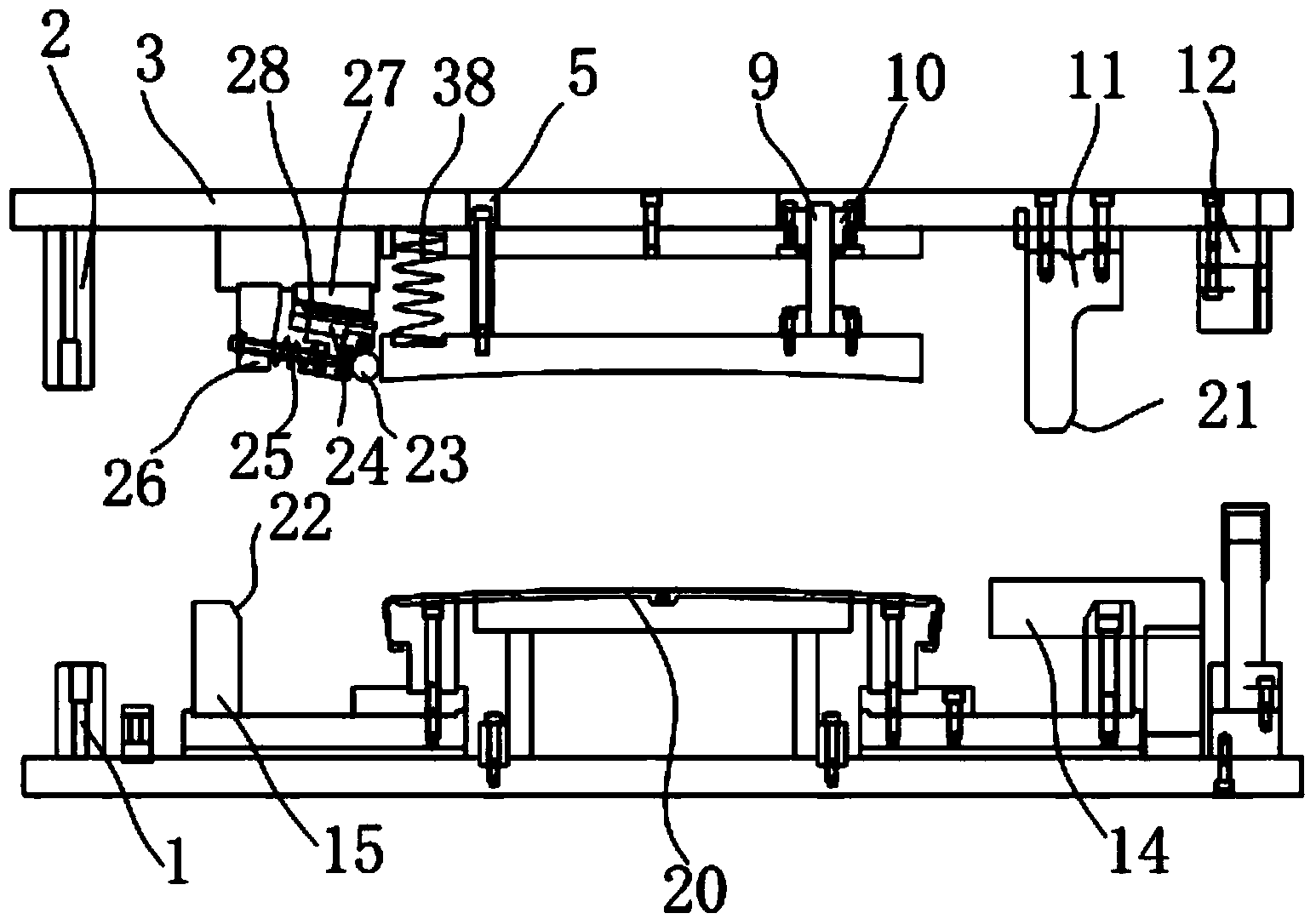

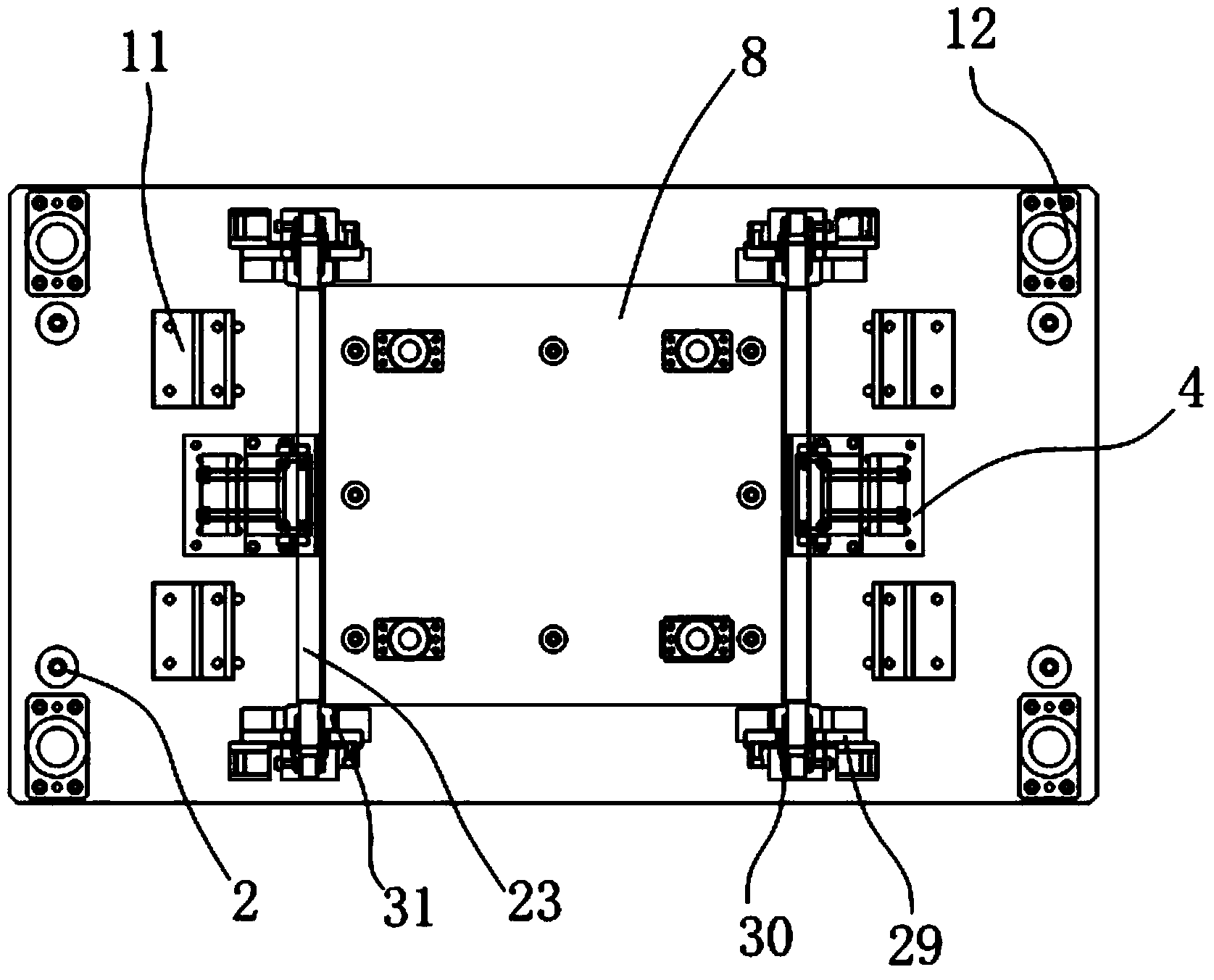

A molding binding device of firecrackers tube cake

The invention discloses a molding binding device of firecrackers tube cake, comprising a vertical feeding system, a loading molding system, a binding system and a control system. The beneficial effects of the molding binding device of firecrackers tube cake are lie in that(1) the arrangement, combination molding and binding of the firecrackers tube cake are completed in full-automation, the molding speed is fast, the binding is tight and the shape of the firecrackers tube cake is regular and beautiful; more than 300 firecrackers tube cakes can be finished per hour, which saves the human resources significantly, improves the work efficiency and solves the problem of labor shortage; (2) each part of the molding binding device is modular designed and installed, the size can be adjusted in accordance with the product, and the operation is convenient and the maintenance is fast; the abrasion of the contact site is low by employing a pneumatic roller structure, so that the device can be used for a long time without worrying about the precision to be effected.

Owner:浏阳市鸿隆综合贸易有限公司

Edging and bending die for refrigerator door panel

ActiveCN103831358ASmooth cornersAvoid deformationShaping toolsRolling resistanceRefrigerated temperature

The invention discloses an edging and bending die for a refrigerator door panel. The edging and bending die comprises an upper die plate and a lower die plate. A material pressing plate is arranged in the middle of the upper die plate and provided with a discharging mechanism. A material supporting plate is arranged on the lower die plate, and two bending mechanisms are fixed to the positions, at the two sides of the material pressing plate, of the upper die plate. According to the edging and bending die for the refrigerator door panel, due to the fact that shaping wheels used for fast bending a refrigerator door and a rolling shaping shaft are adopted, the surface of the refrigerator door panel is prevented from being pulled to be damaged in the bending process, the shaping wheels at the two sides of the shaping shaft enable the bevel ends of the refrigerator door to form flat wrap angles, and therefore the wrap corners of the refrigerator door panel are flat and the wrap corners can prevent the refrigerator door from deforming after being shaped. Due to the fact that a pressure assembly exerts pressure on the shaping shaft, the forming speed of the die is improved, and meanwhile the shaping shaft is prevented from being scrapped due to bending and deforming after long-time use. The matching position of the pressure mechanism and the shaping shaft is provided with a rolling pressure rolling shaft, the sliding friction between the shaping shaft and the pressure assembly is converted into rolling friction, abrasion of the shaping shaft is further reduced, and the quality of the formed refrigerator door panel is further improved.

Owner:昆山市三建模具机械有限公司

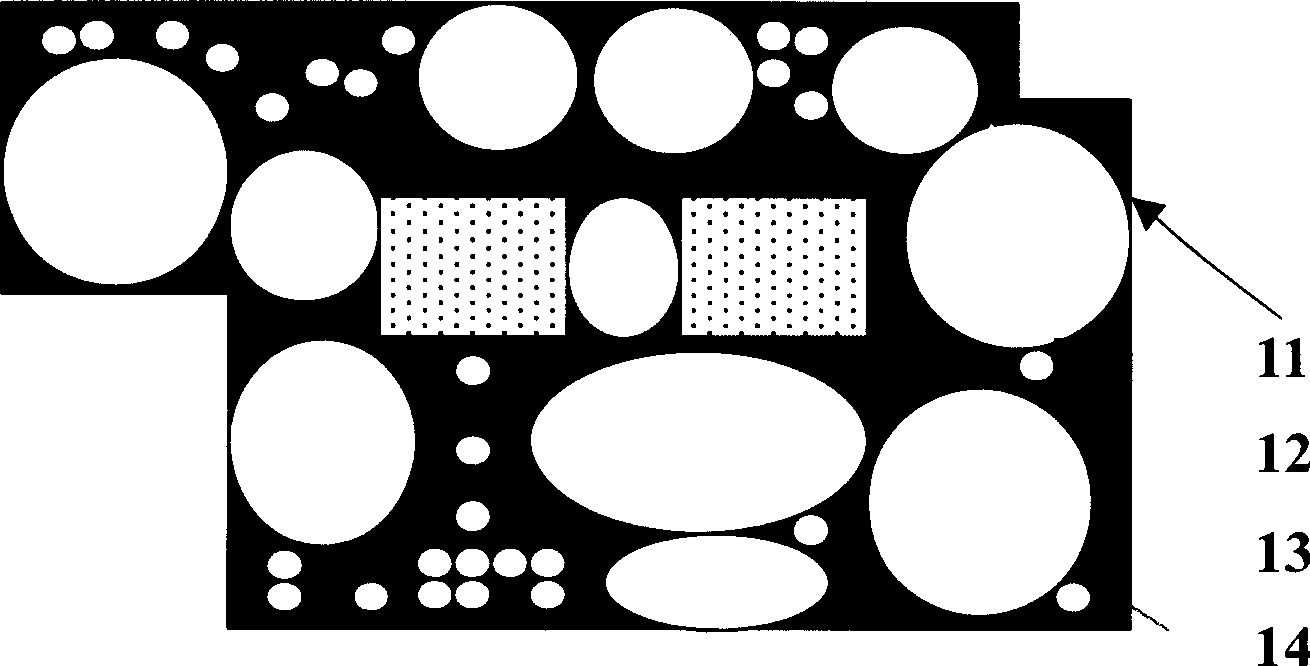

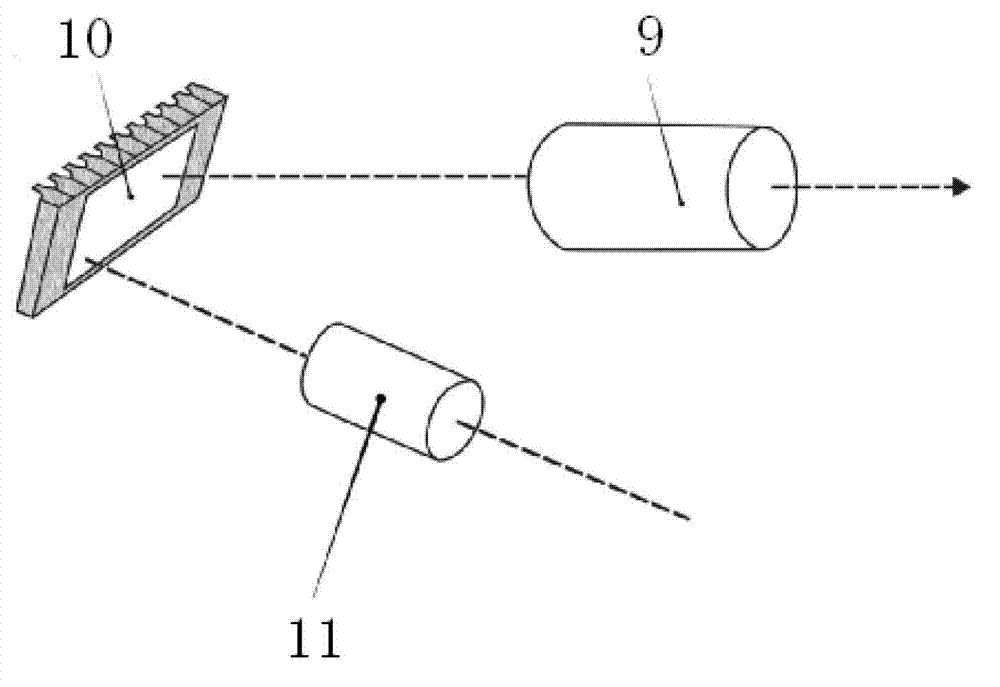

Laser scanning device and method for making three-dimensional object

InactiveCN104142574AGuaranteed accuracyFast molding speedOptical elementsControl systemLaser scanning

The invention provides a laser scanning device and method for making a three-dimensional object. The laser scanning device comprises a laser device, a galvanometer system, a control system and a beam adjustment system. The control system divides spots to be scanned on each section of a workpiece into an outline region and a filling region; when the outline region is scanned, the control system controls the laser device through the galvanometer system and controls the beam adjustment system at the same time to select first light spots with a smaller size for scanning; when the filling region is scanned, the control system controls the laser device through the galvanometer system and controls the beam adjustment system at the same time to select second light spots with a larger size for scanning. According to the laser scanning device and method for making the three-dimensional object, by the adoption of a regional scanning mode, the forming speed of the three-dimensional object is increased on the premise of guaranteeing the accuracy of the made three-dimensional object.

Owner:HUNAN FARSOON HIGH TECH CO LTD

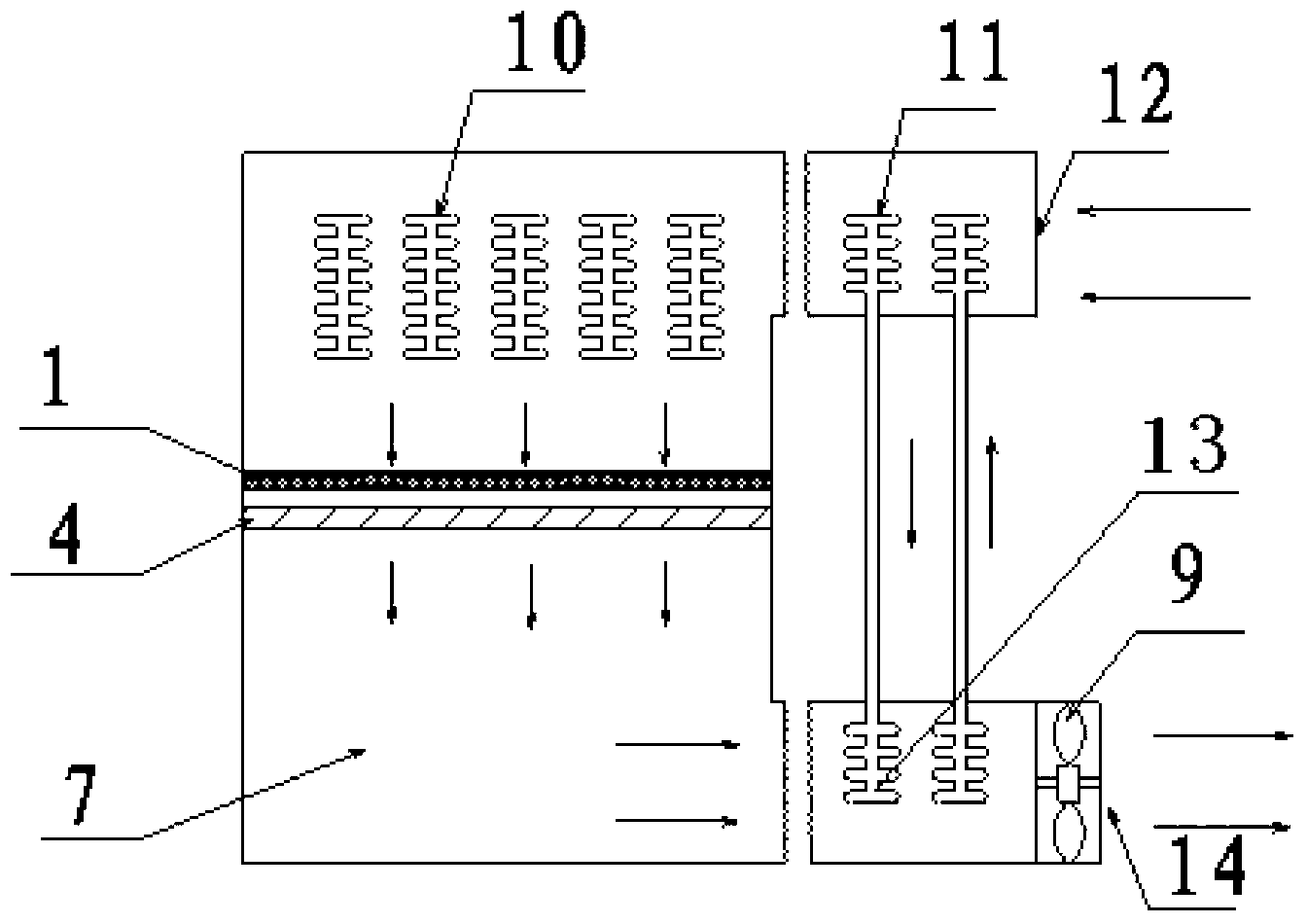

Continuous sinking-mode efficient 3D printing method and equipment

ActiveCN105437547AAvoid influenceFast molding speedAdditive manufacturing apparatusEquilibrium pointChemistry

The invention discloses a continuous sinking-mode efficient 3D printing method and equipment. The continuous sinking-mode efficient 3D printing method comprises the following steps: by utilizing the principle that after oxygen is applied to the liquid level of resin, oxygen molecules can form an oxygen molecule concentration equilibrium point in the resin and projecting or focusing a light source at the equilibrium point and a region below the equilibrium point, curing of photosensitive resin is initiated, a printing table adhered to a cured product is driven by a motor to continuously move downwards, meanwhile, the photosensitive resin supplements the cured region with the equilibrium point, and changed light of the light source is projected onto the equilibrium point to carry out continuous curing under the control of a program, so that 3D printing is finished. In the printing process, the concentration gradient of the oxygen molecules which permeate into the resin can be controlled by regulating an input parameter of applied oxygen. The continuous sinking-mode efficient 3D printing method and the equipment can dramatically increase the forming speed of the traditional 3D printing, are suitable for large 3D printing products and are simple in mechanism, convenient to operate, high in accuracy of the printed products and excellent in performance.

Owner:陕西普立通复材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com